Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "Olefiant gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

This group also discovered that ethylene could be combined with chlorine to produce the oil of the Dutch chemists, 1,2-dichloroethane; this discovery gave ethylene the name used for it at that time, olefiant gas (oil-making gas.)

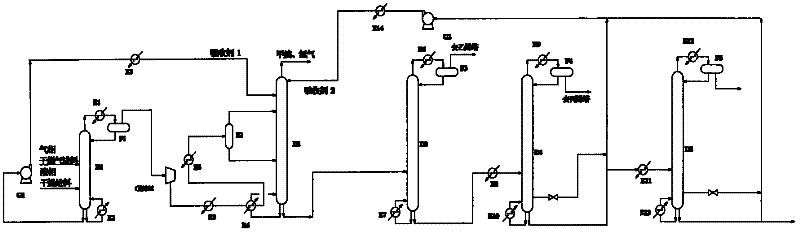

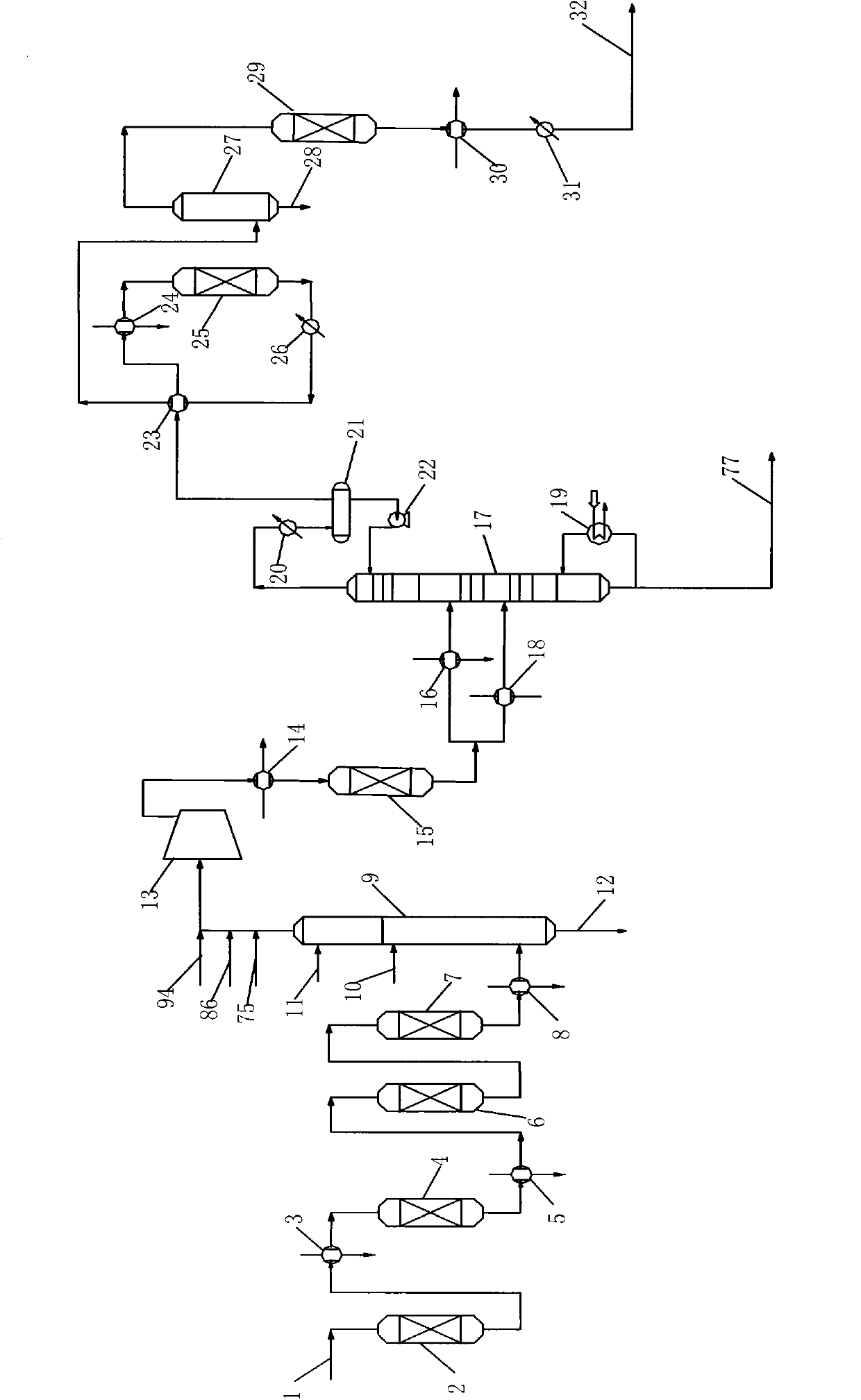

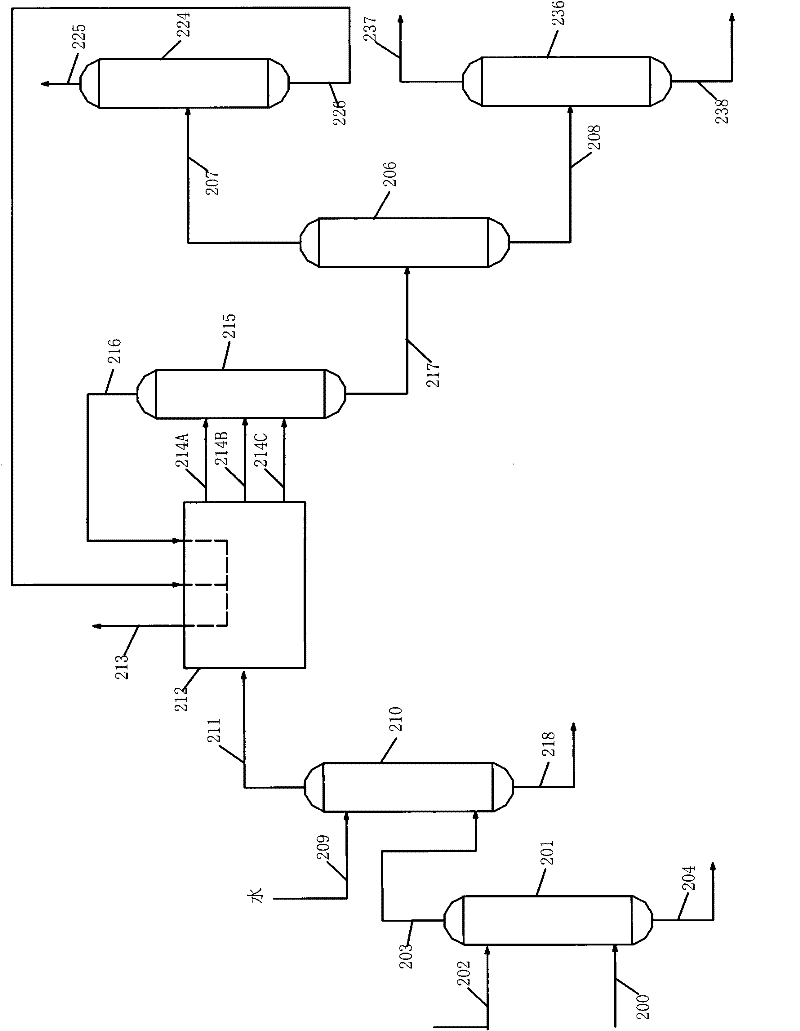

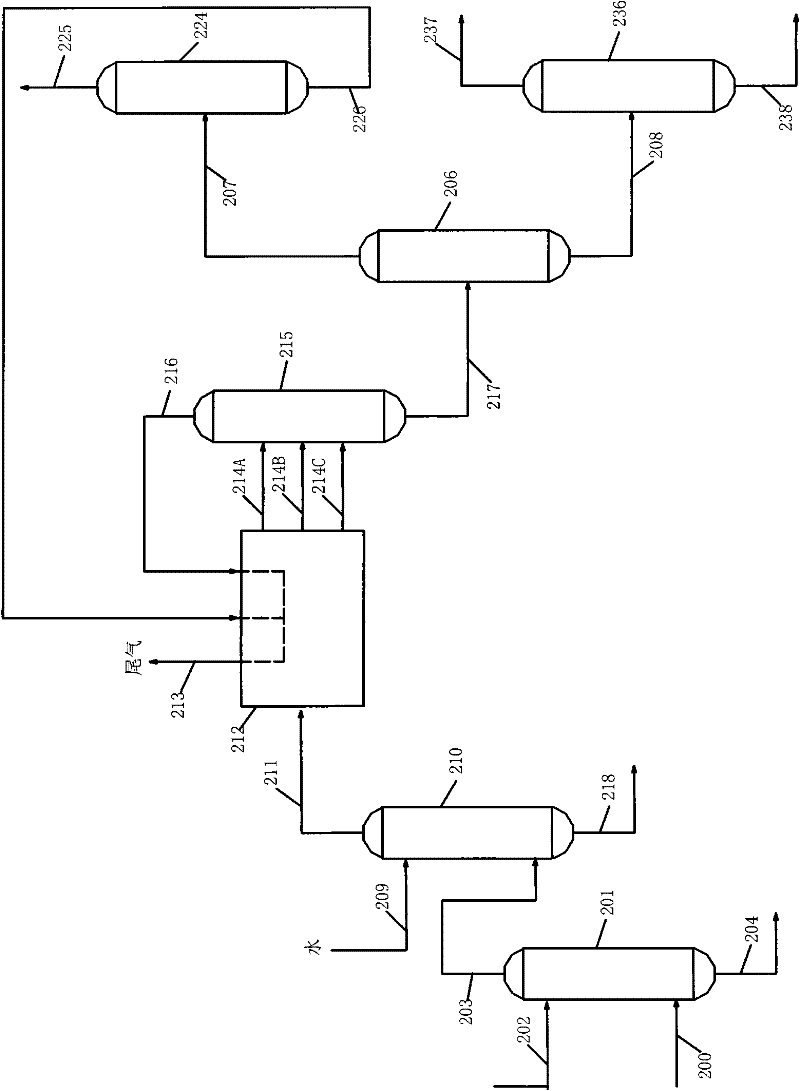

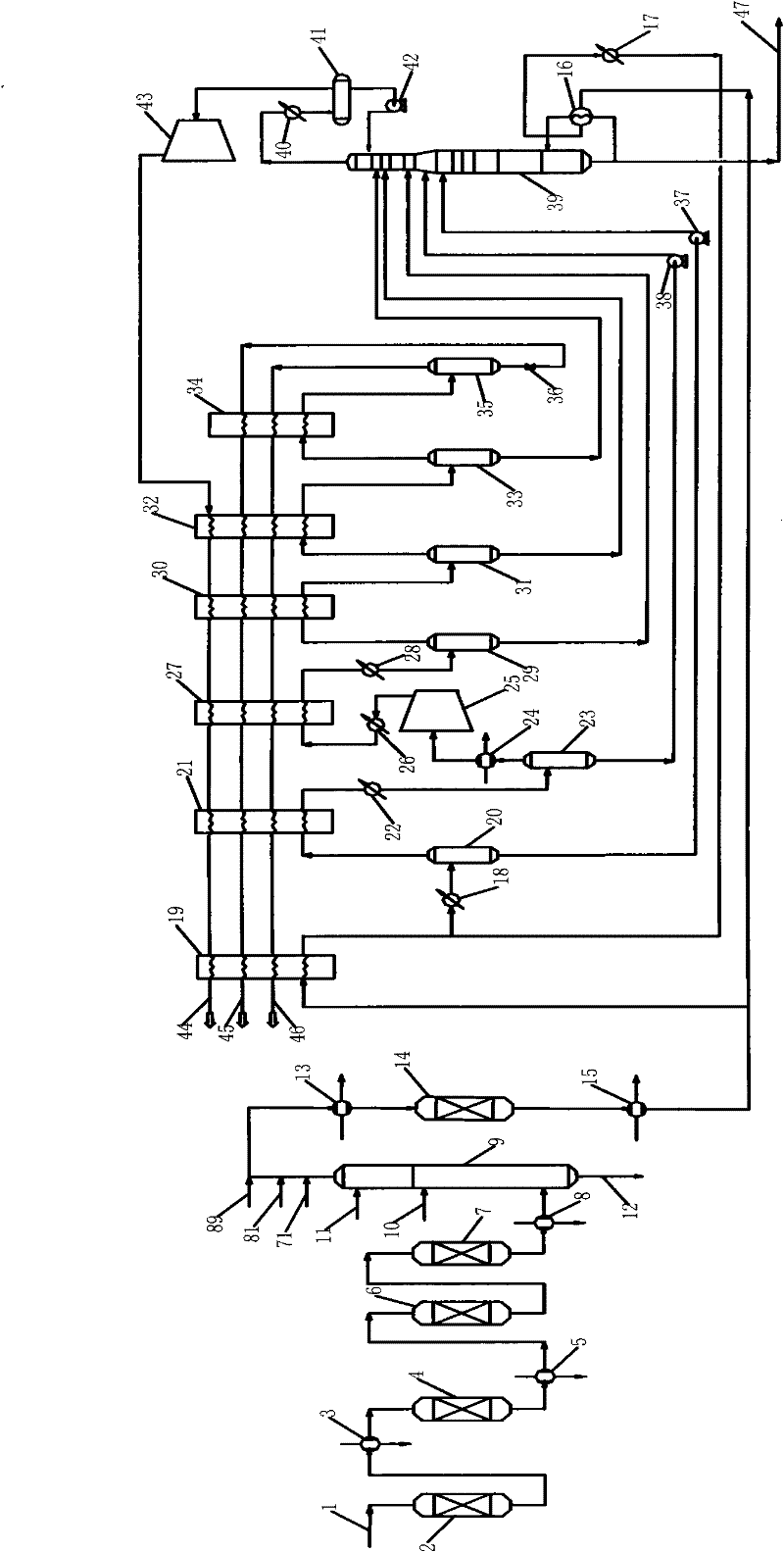

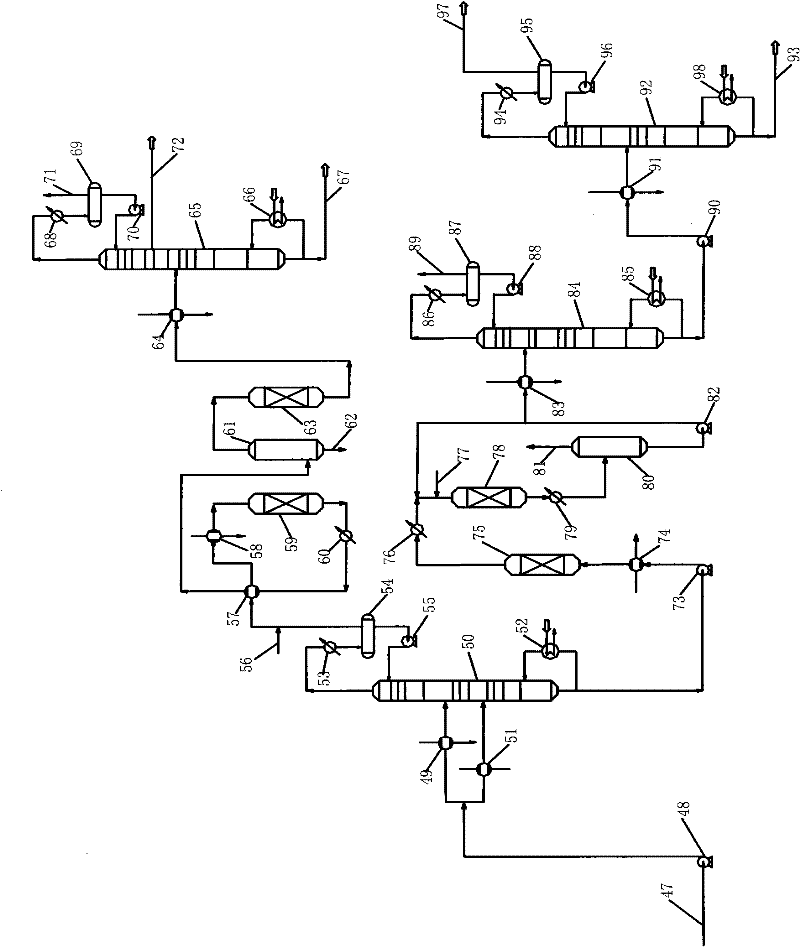

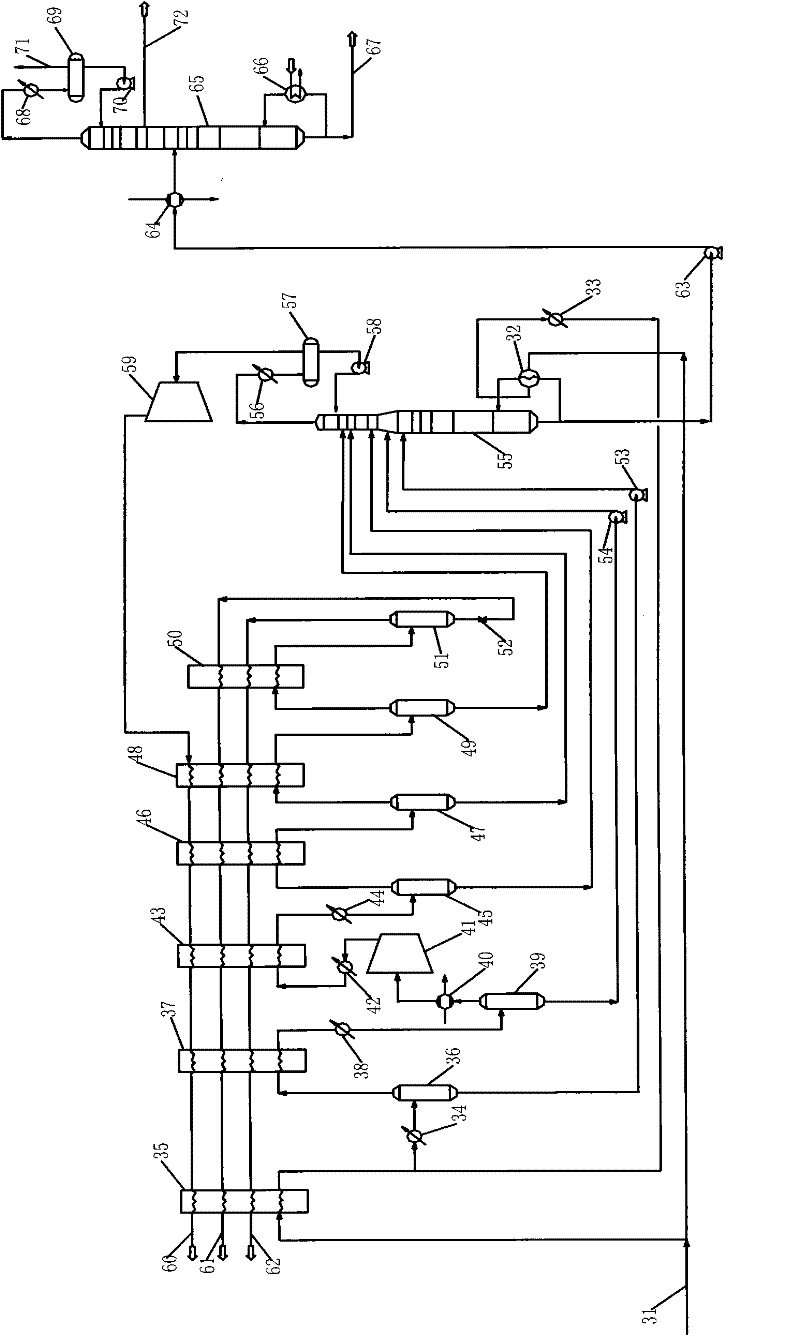

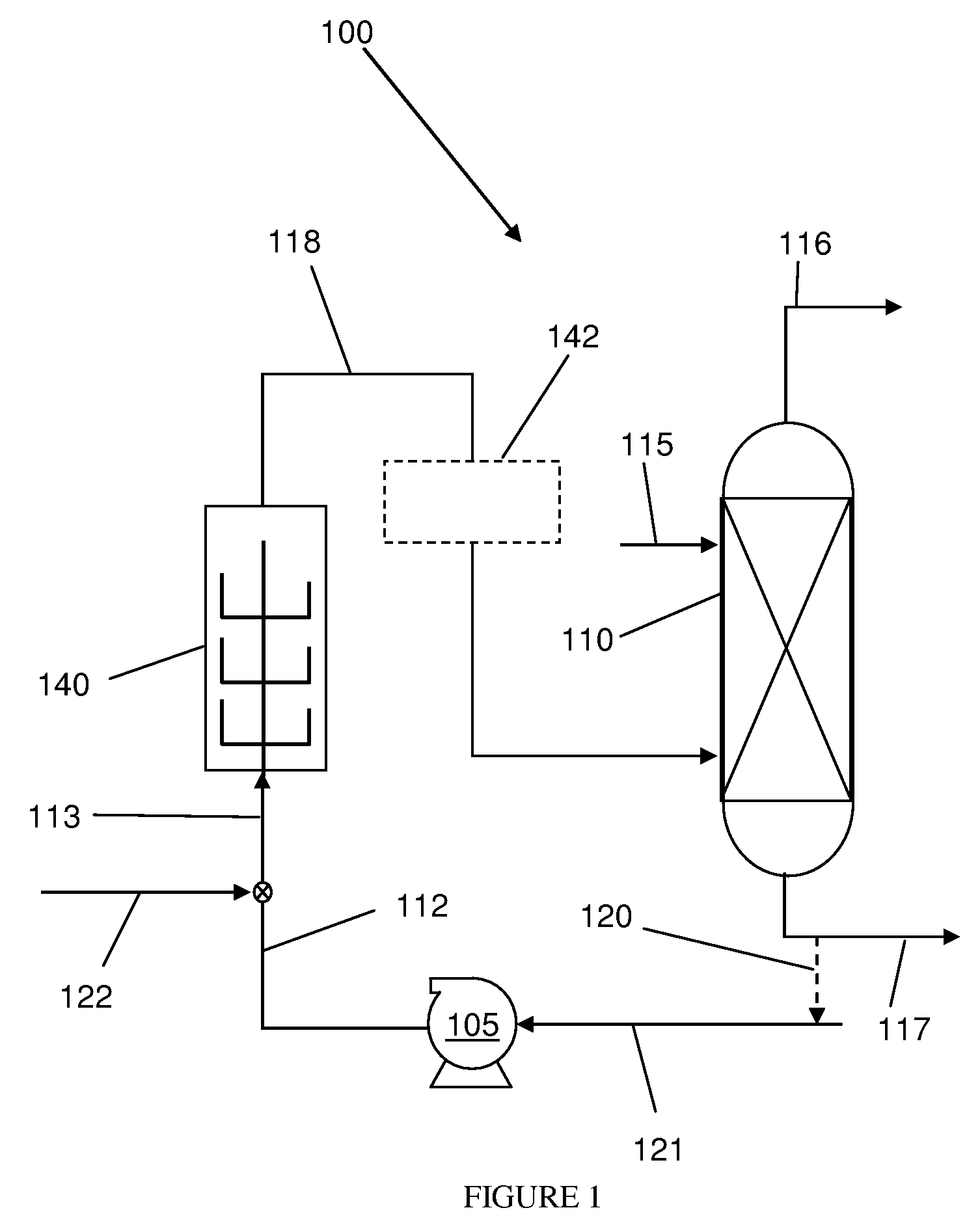

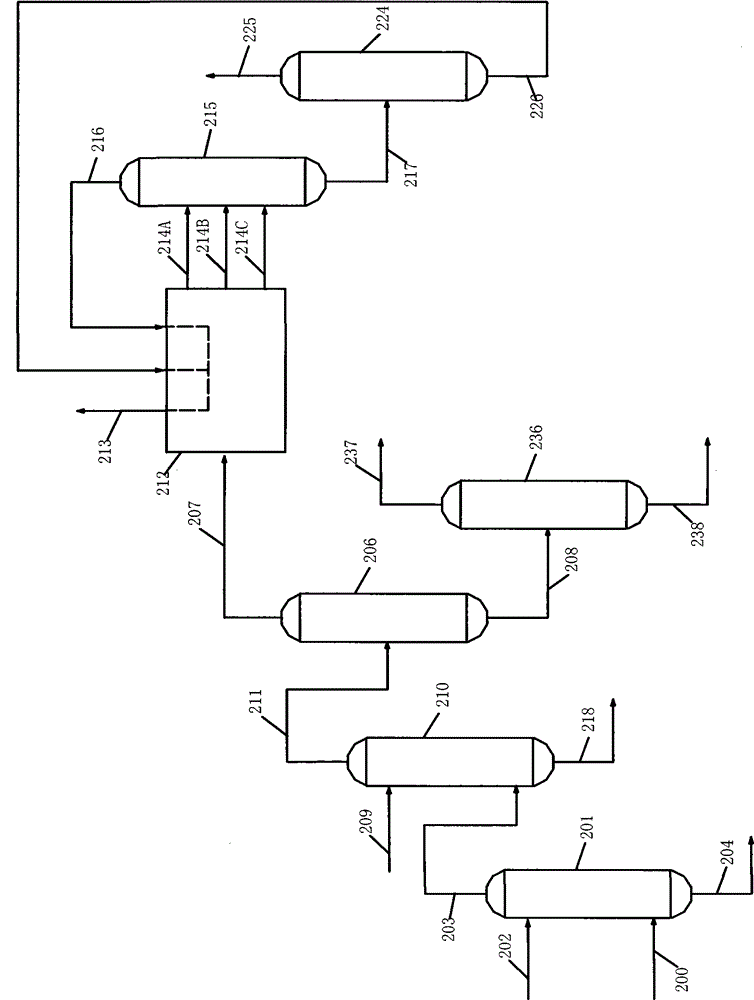

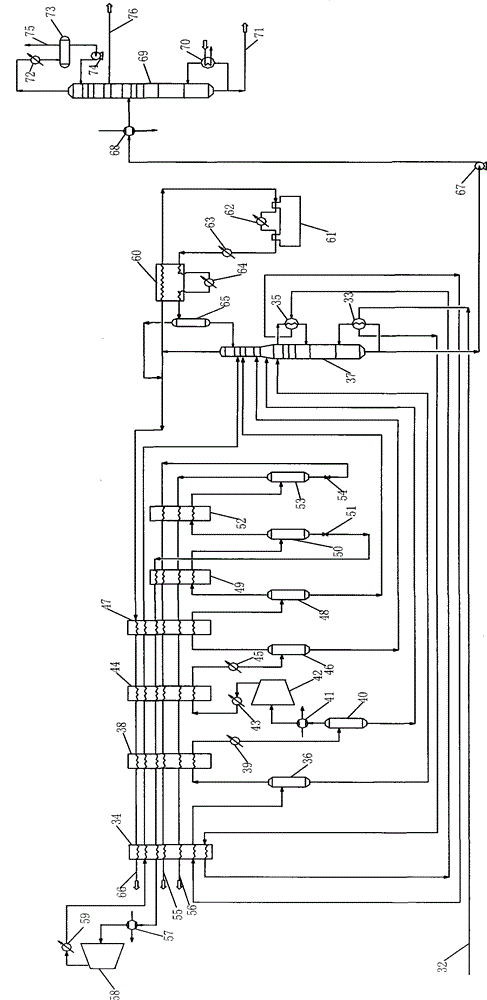

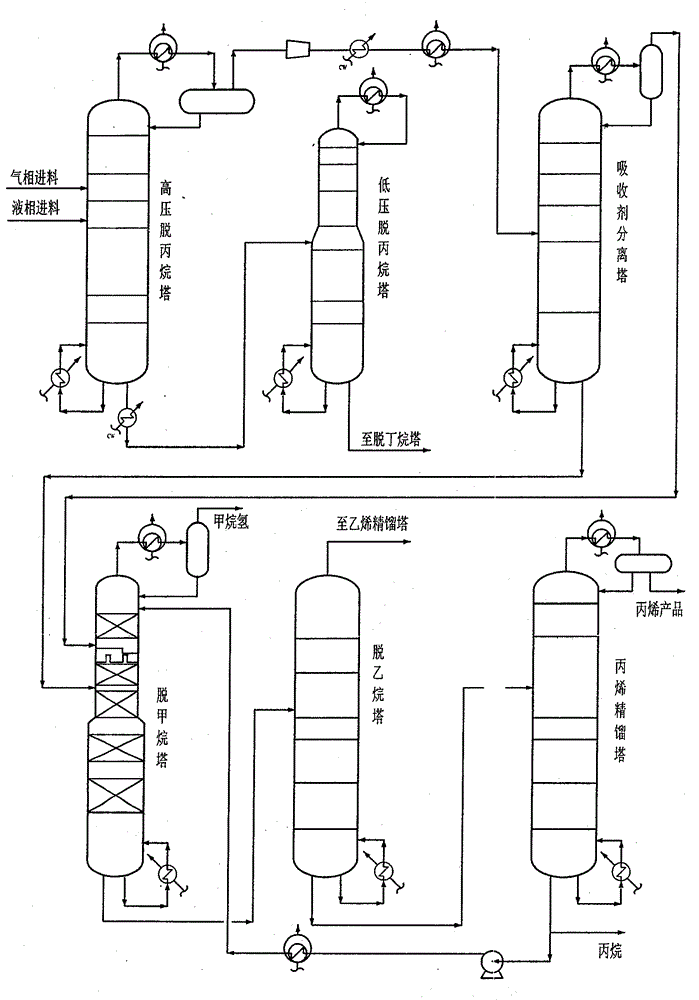

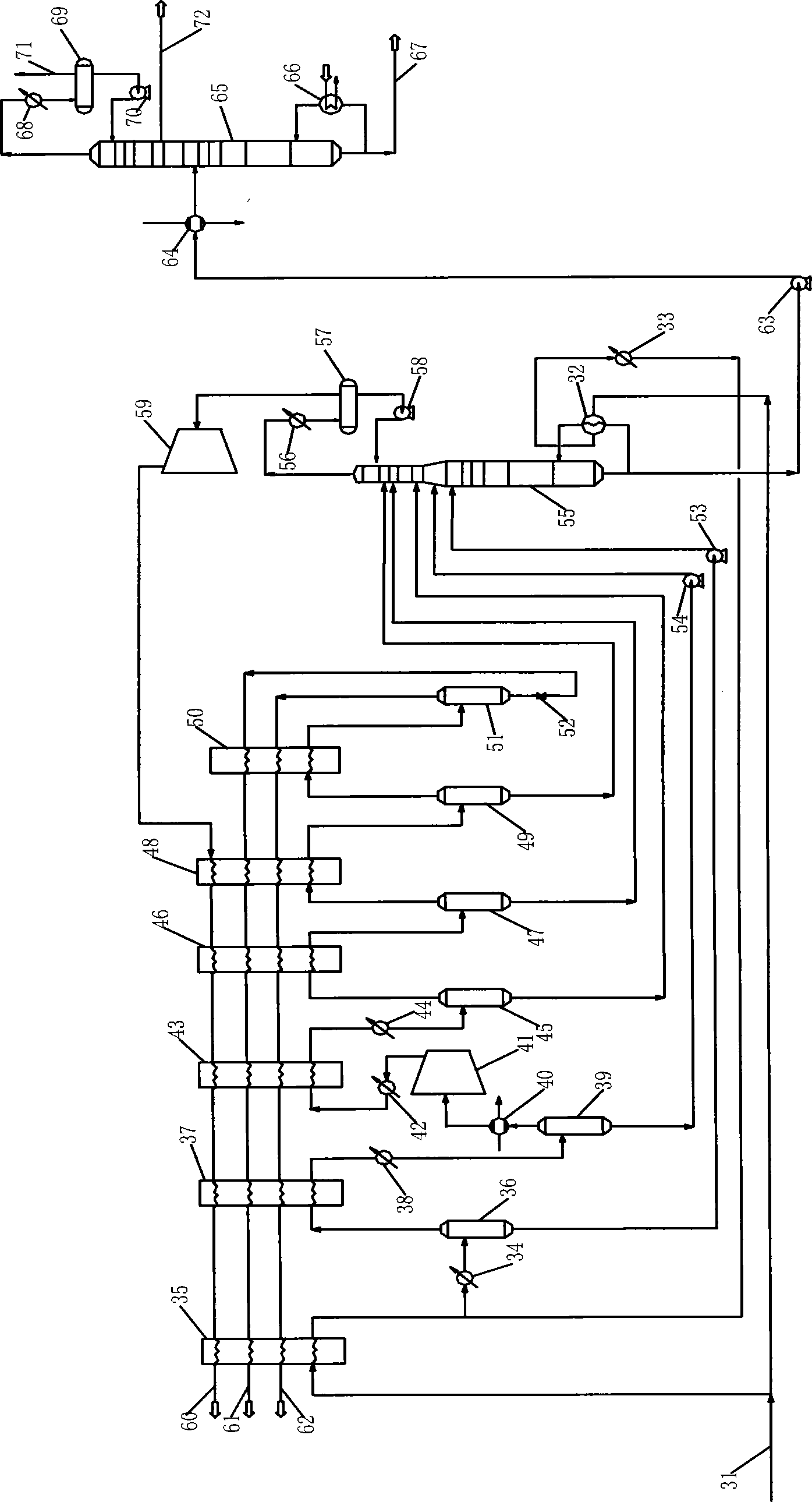

Process flow for separating low-carbon hydrocarbons and separating gas during production of olefins (M-OS/MTO) from methanol

ActiveCN102503757ALess investmentReduce energy consumptionDistillation purification/separationEthylene productionOlefiant gasAbsorption effect

The invention provides a non-cryogenic oil absorption separation method for a mixture of low-carbon hydrocarbons, which is used for separating the mixture of the hydrocarbons from gas during production of olefins from methanol. Methane / hydrogen can be separated from heavy components, namely C2 and above by absorbing fractions of the C2 and above by adopting two or more strands of absorbing agents. According to the method disclosed by the invention, an absorbing agent separating tower is increased before a demethanization tower, one strand of material flow, which is separated from the tower is taken as a main absorbing agent of the demethanization tower for absorbing the C2 and C3, the strand of the absorbing agent is the mixture of the fractions, which is from the former system and needs to be separated, and circulation is not required. The second strand of the absorbing agent of the demethanization tower is from a system including a depropanization tower and a debutanization tower, and the absorption effect is further enhanced. Compared with the prior art, the method can greatly reduce the using quantity of the circulating absorbing agents; moreover, the multiple strands of the absorbing agents are adopted, equipment investment and energy consumption are significantly reduced, the recovery rate of ethylene and propylene is further improved; and furthermore, the flow is simple, the operation cost is low, and the operation is safe and reliable.

Owner:SINOPEC SHANGHAI ENG +1

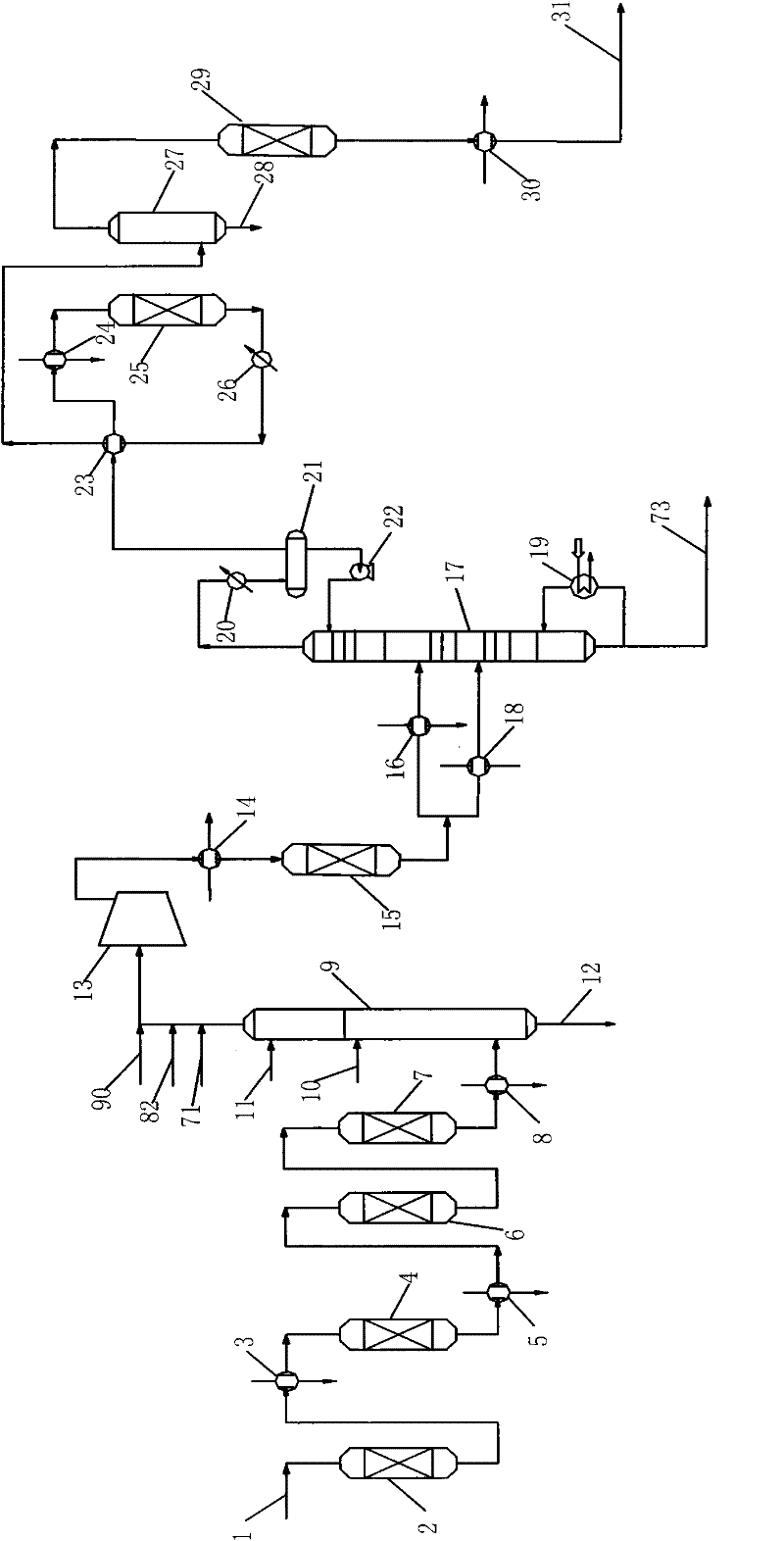

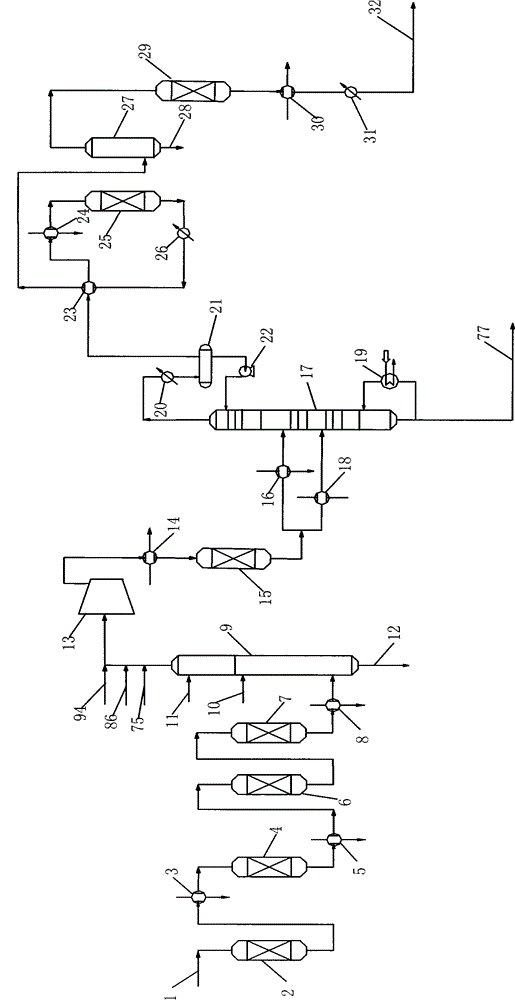

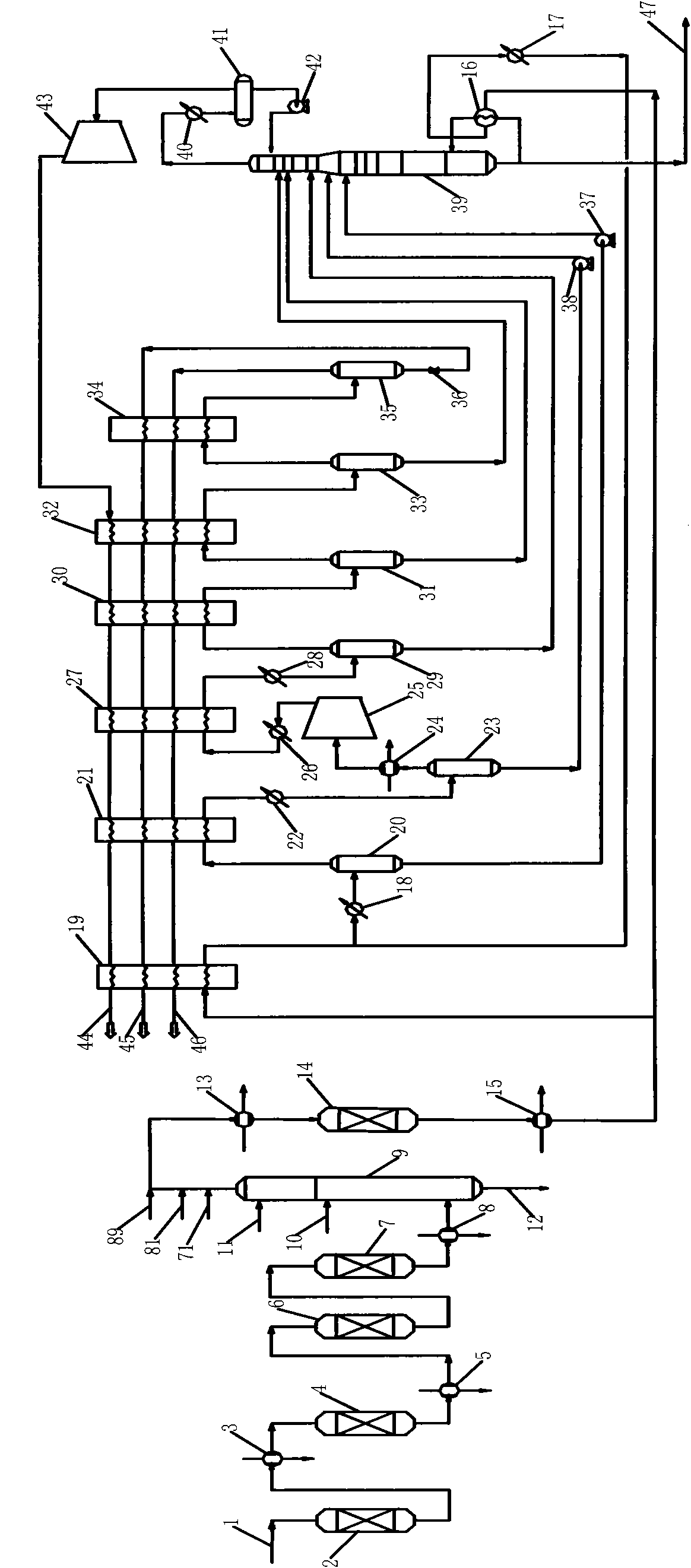

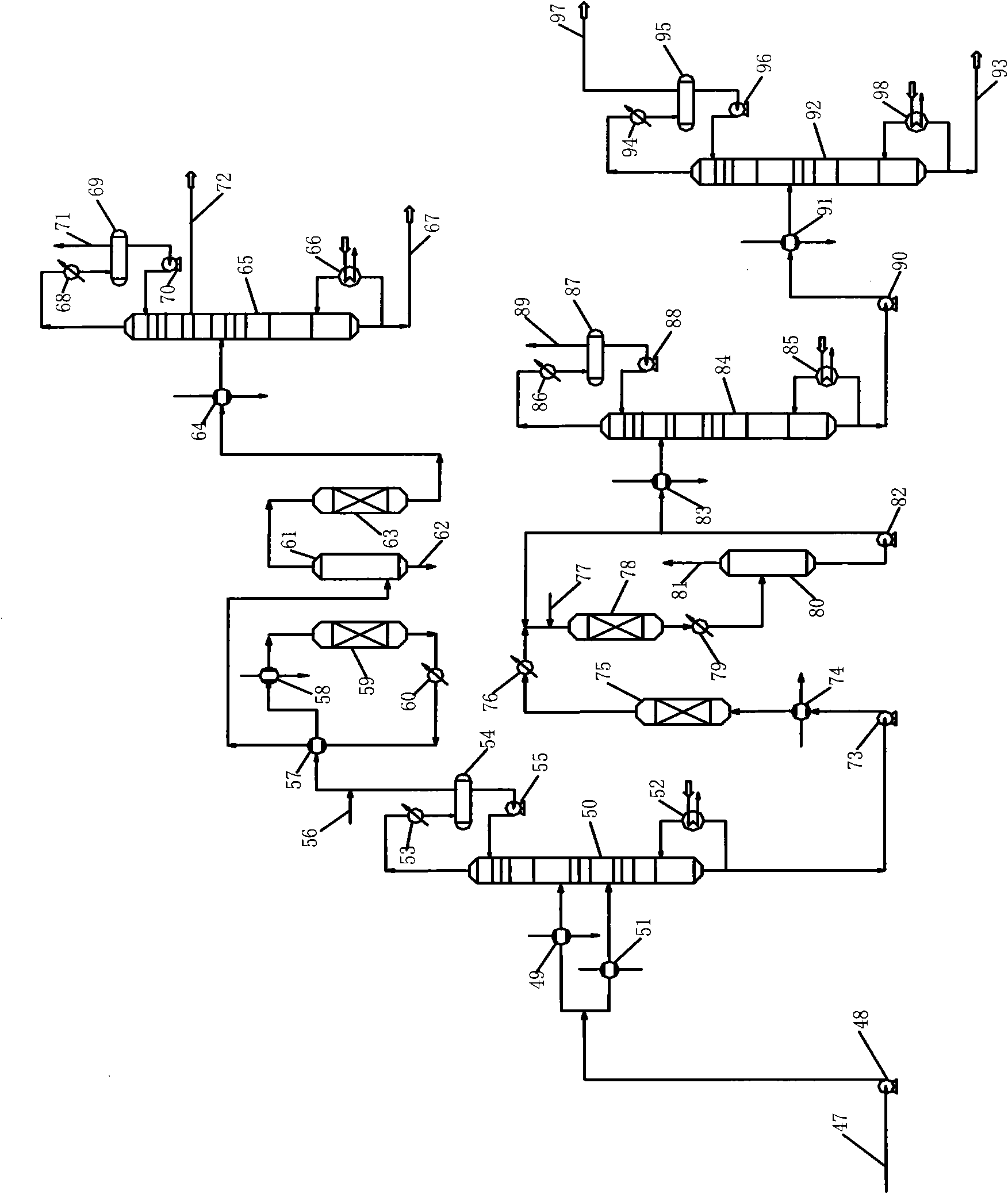

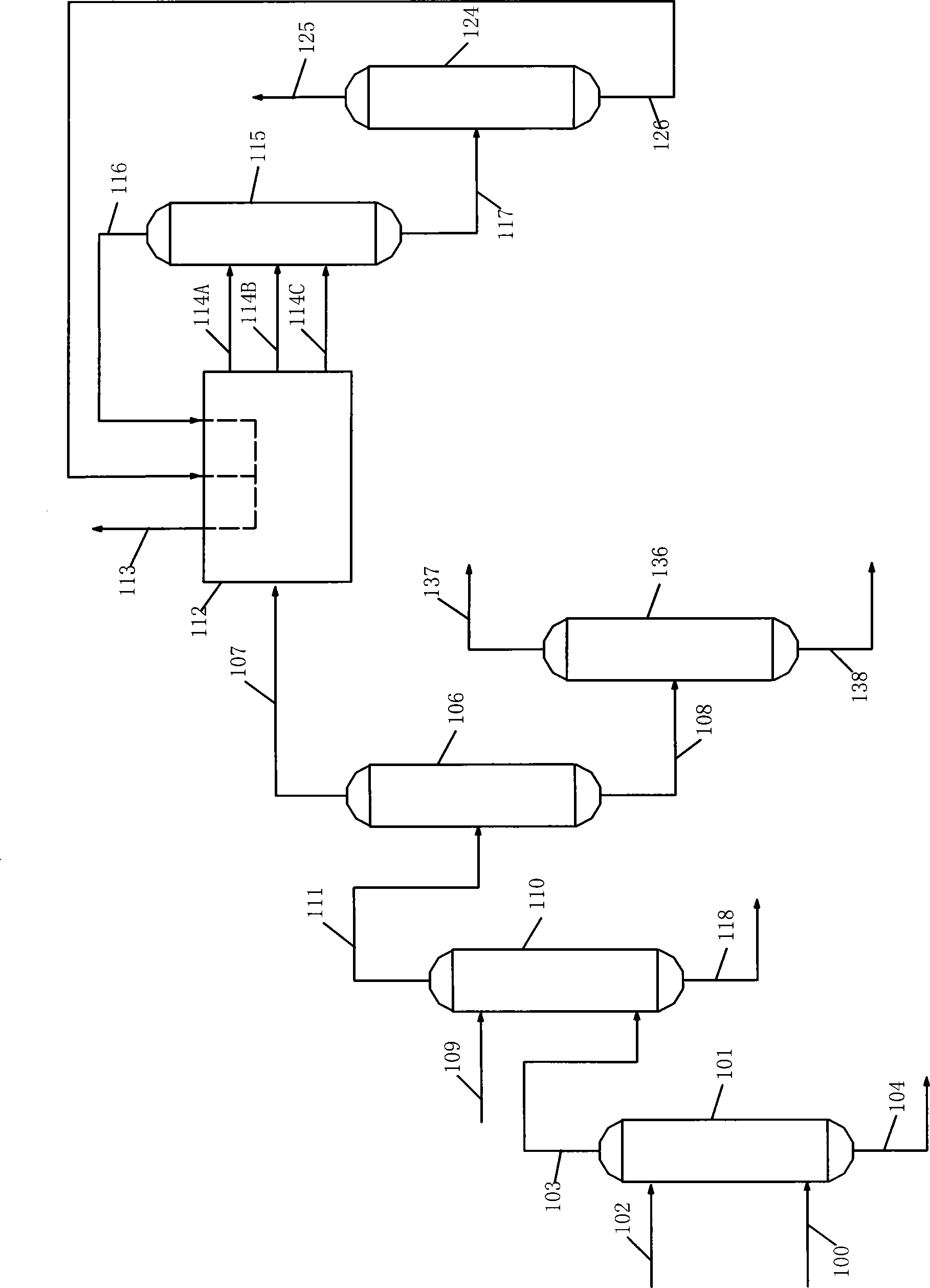

Technology for separating low carbon olefin gases

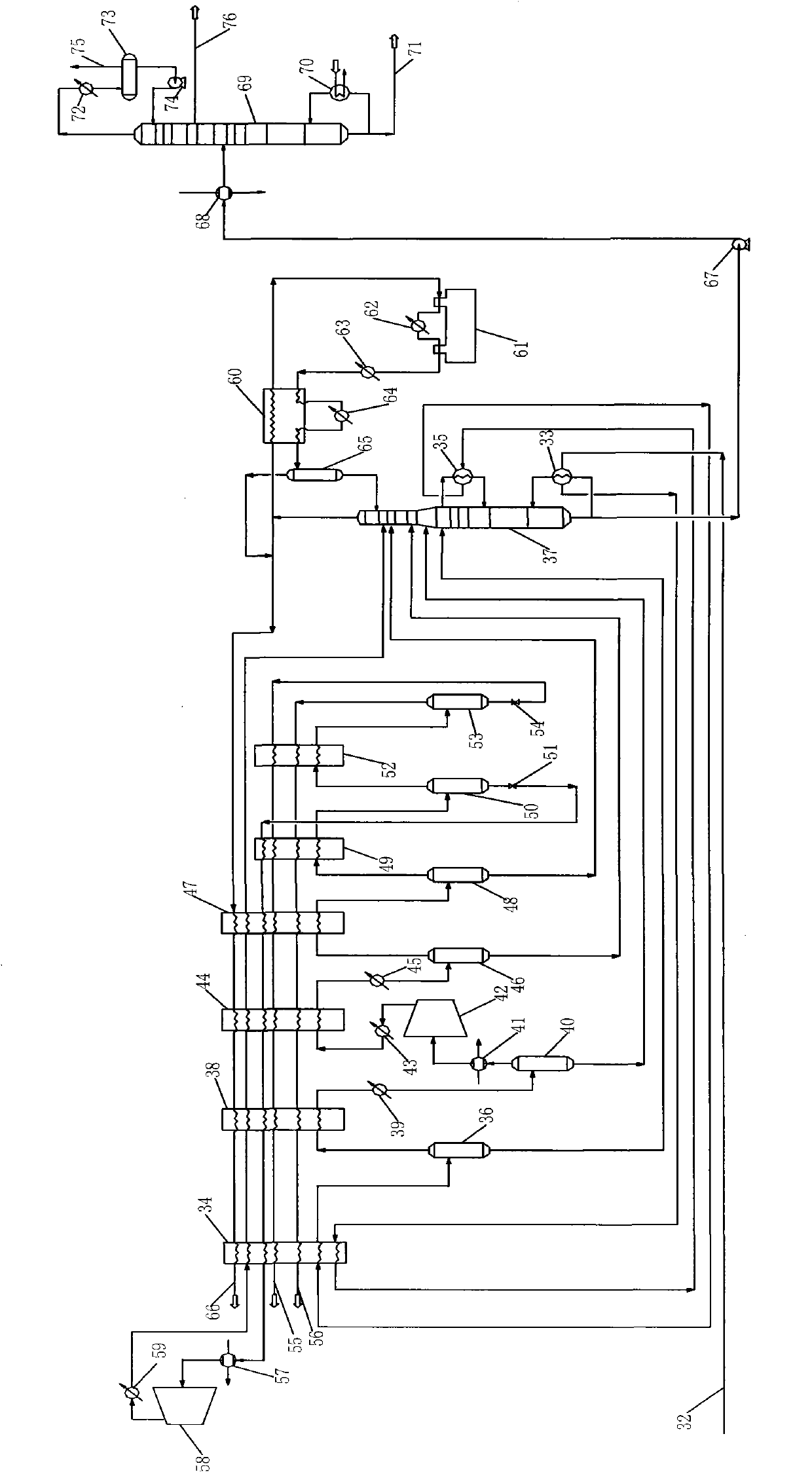

The invention discloses a technology for separating low carbon olefin gases, for solving the problems that hydrogen, methane, ethane and propane and other products with high purity can not be acquired and dimethyl ether and oxygen and carbon monoxide in impurities are not removed efficiently, etc. in the prior art. The technology is characterized in that a step of removing carbon monoxide and oxygen is added, methanol-to-olefin gas streams processed by removing carbon monoxide and oxygen enter into a deethanizing column, deethanizing column overhead streams successively pass through an ethene hydrogenation reactor, six separation pots, a low pressure demethanizing column and an ethene rectification column, etc. to separate to obtain ethene and ethane products, and deethanizing column bottom streams successively pass through a propyne hydrogenation reactor, a methane stripper and a propylene rectification column, etc. to separate to obtain propylene and propane products. According to the invention, polymer grade ethene and propylene products can be obtained, and hydrogen, methane, ethane and propane products, etc. with high purity can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of high-isotacticity polybutene-1 powder

ActiveCN104193870AImprove the problem of long period of crystal transformationSimple processPolymer scienceOlefiant gas

The invention relates to a preparation method of high-isotacticity polybutene-1 powder. The method comprises the following steps: sequentially adding a cocatalyst solution, an outer electron donor, a main catalyst, an assistant compound and a liquid-phase alpha-olefin into a tank reactor, prepolymerizing at 10-90 DEG C for 10-120 minutes, evacuating olefin gas, charging butylene-1 monomer and molecular weight regulator hydrogen gas, polymerizing at -10-90 DEG C for 1-20 hours, and carrying out flash evaporation on the unreacted monomer to obtain the high-isotacticity polybutene-1 powder. The polymerization method for synthesizing high-isotacticity polybutene-1 and powder thereof is simple in technique and easy to operate. The prepolymerization method solves the problem of difficulty in controlling the form of the polybutene-1 in the common catalytic polymerization method, and improves the problem of long crystal form transition period of the polybutene-1.

Owner:HEBEI UNIV OF TECH

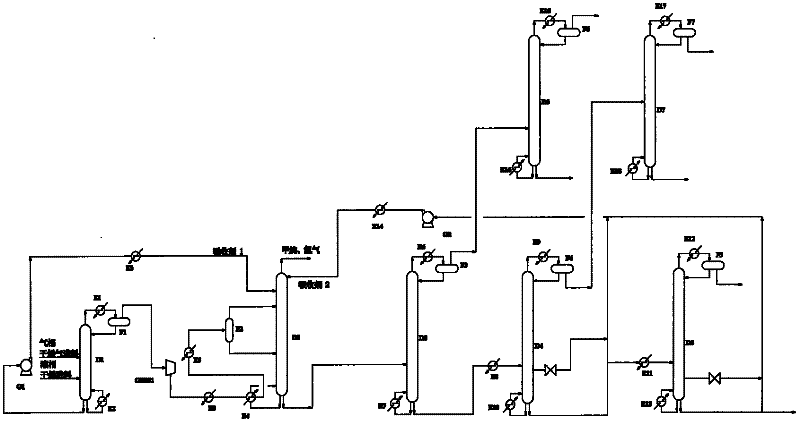

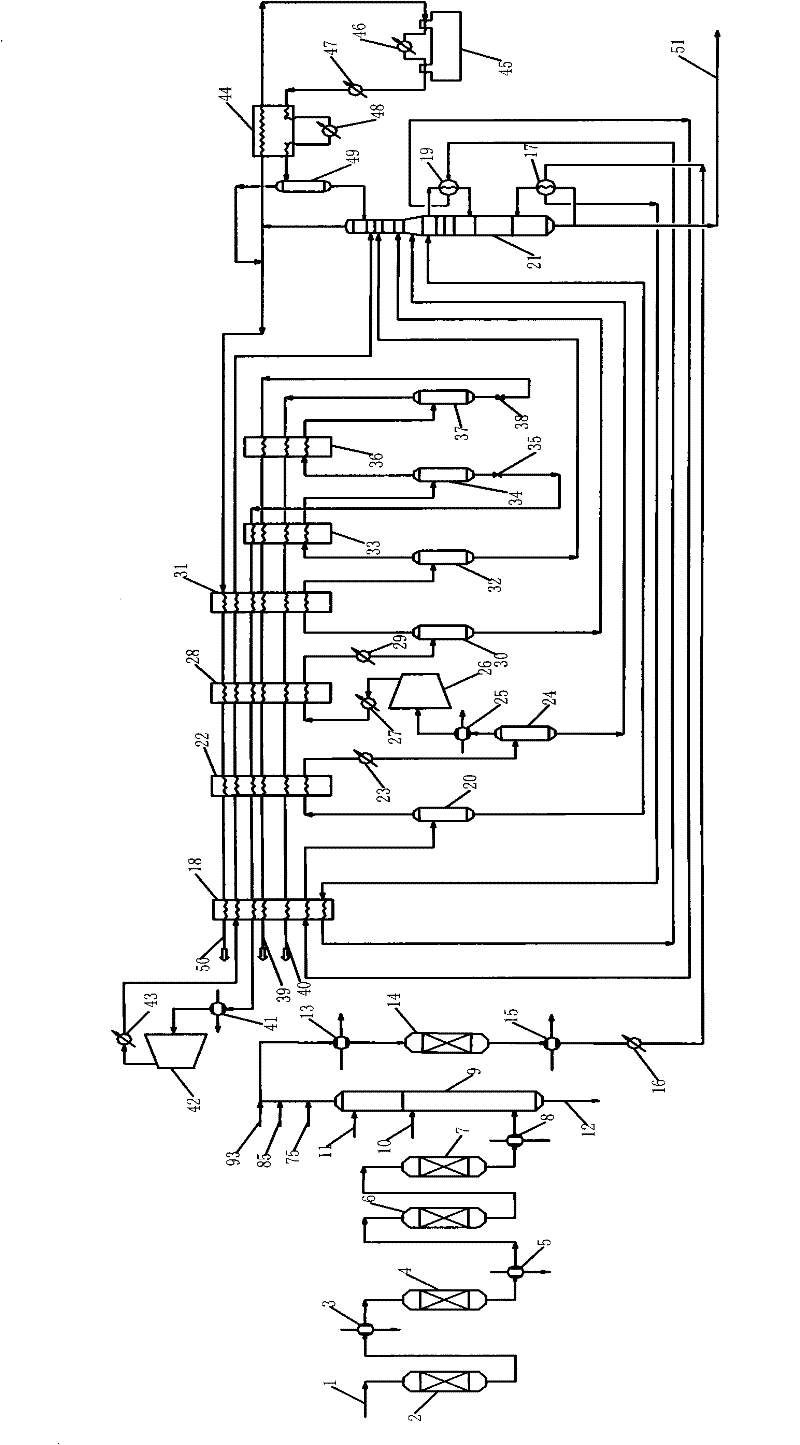

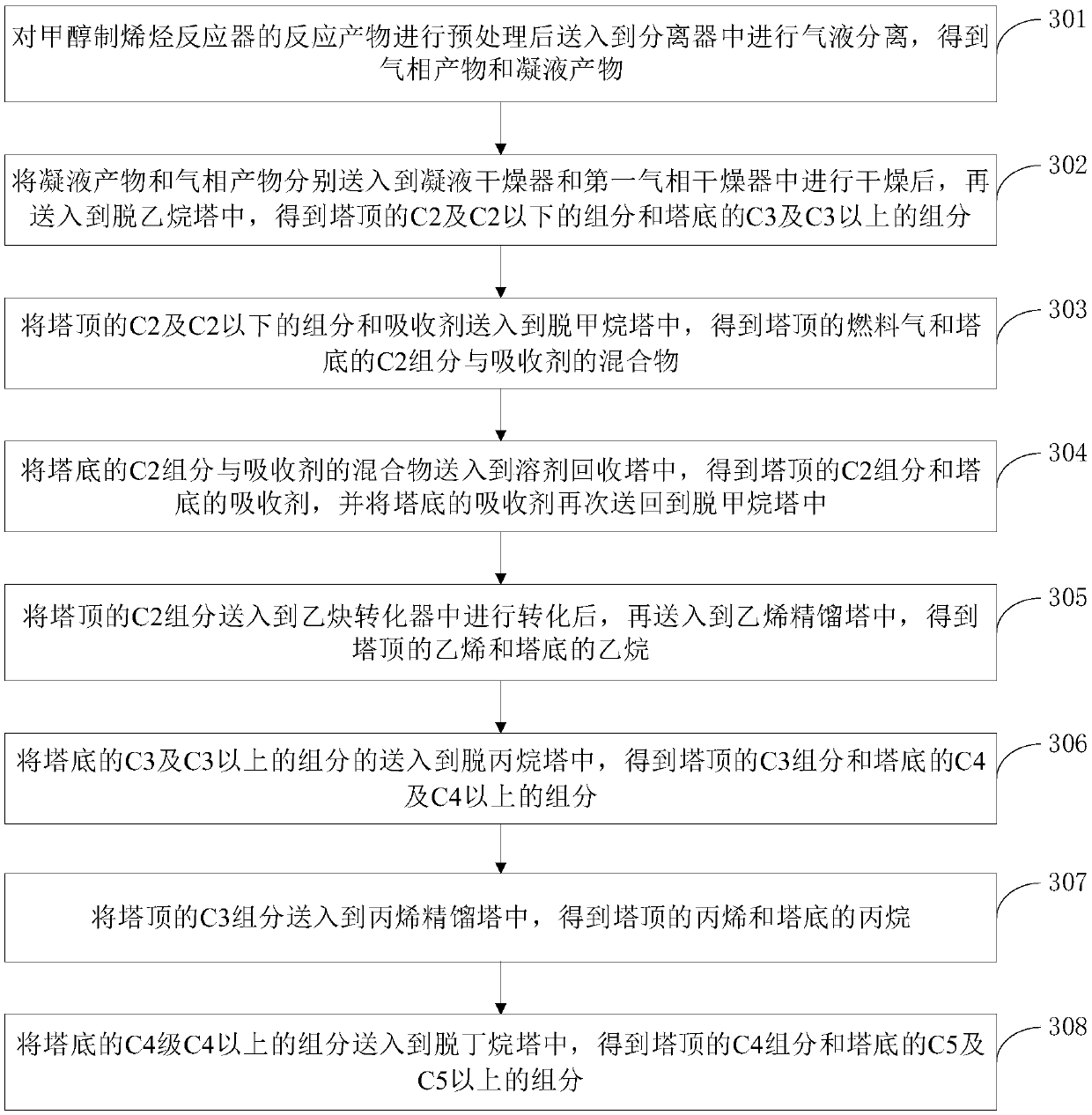

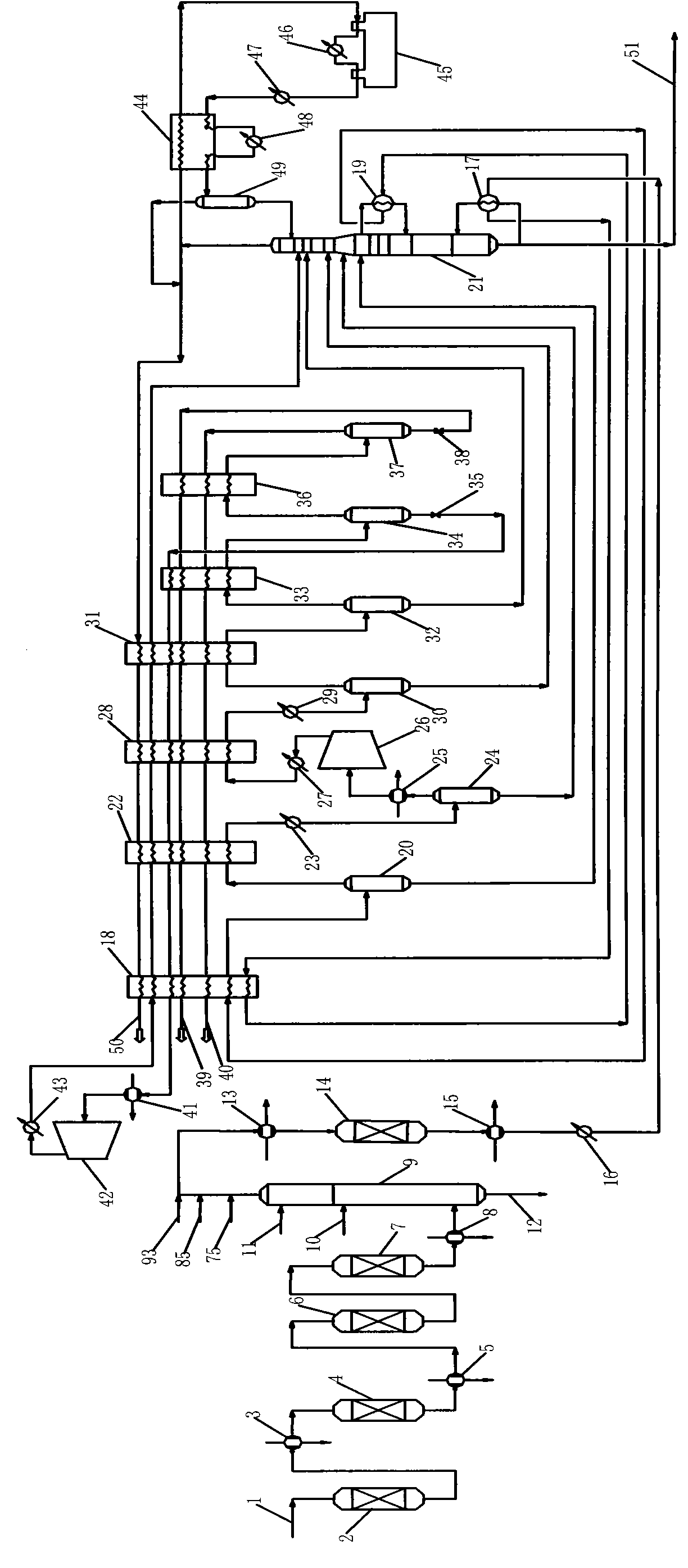

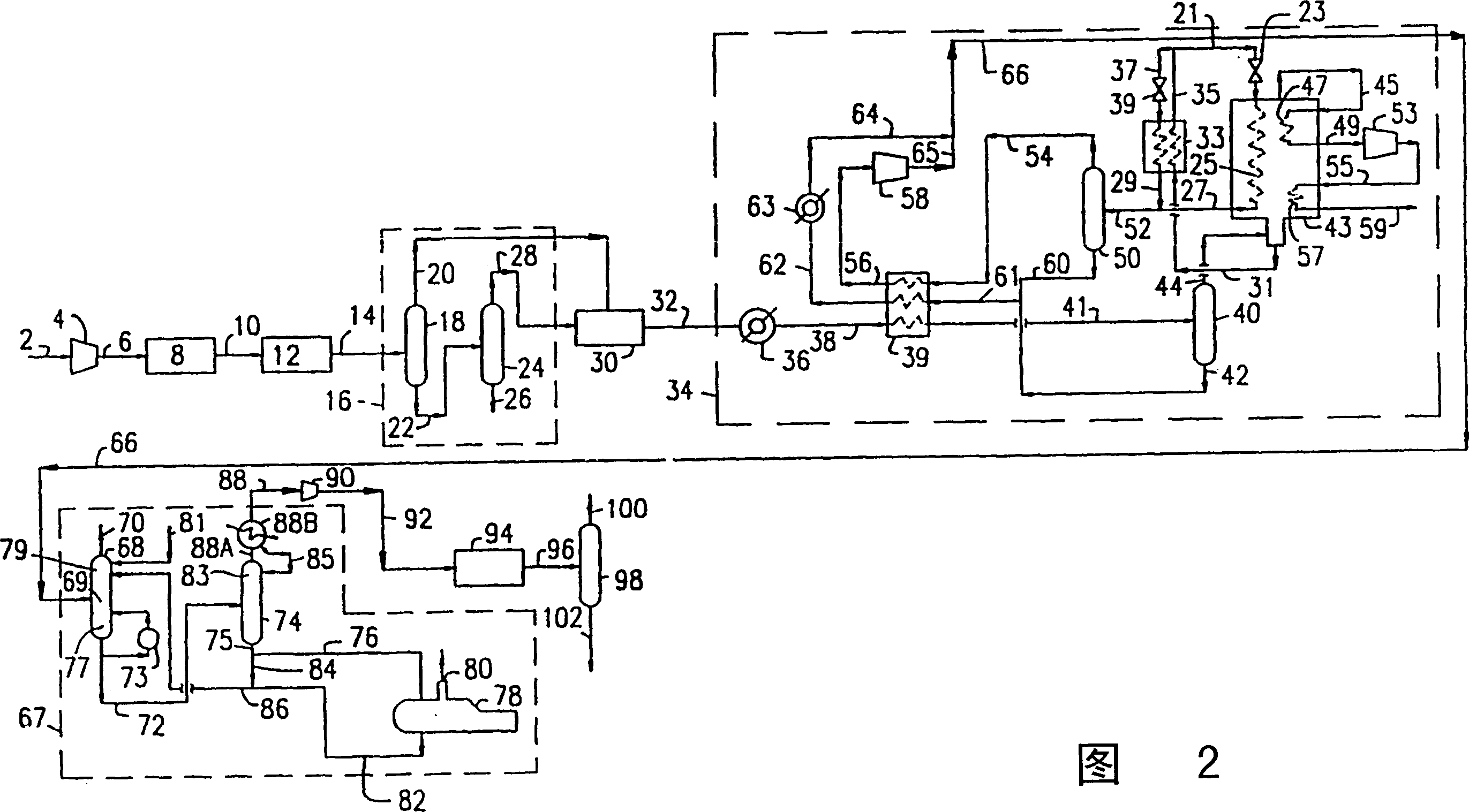

Separation process for preparing low-carbon alkene gases through conversion of methanol

The invention discloses a separation process for preparing low-carbon alkene gases through conversion of methanol and aims to solve the problems that high-purity products such as hydrogen, methane, ethane and propane cannot be obtained and oxygen and carbon monoxide in dimethyl ether and gas impurities cannot be effectively eliminated in the prior art. According to the alkene gas streams through conversion of methanol, eliminating steps of oxygen and carbon monoxide are added, the alkene gas streams through conversion of methanol after elimination of oxygen and carbon monoxide sequentially passes six knockout drums and then enters a low-pressure demethanizer, a deethenizer, an acetylene hydrogenation reactor, an ethylene rectification tower, an allylene hydrogenation reactor and a propylene rectification tower for separation, the liquid from the bottoms of the first four knockout drums sequentially enter the middle-upper portion of the demethanizer, and the liquid from the bottom of the fifth knockout drum enters the upper portion of the demethanizer or returns to a section of a compressor. The separation process for preparing the low-carbon alkene gases through conversion of methanol can obtain products such as polymer grade ethylene, propylene, and the high-purity products such as hydrogen, methane, ethane and propane.

Owner:CHINA PETROLEUM & CHEM CORP +1

Separation process for preparing low-carbon olefin gas through methanol conversion

The invention discloses a separation process for preparing low-carbon olefin gas through methanol conversion, aiming at overcoming the defects that products such as high-purity hydrogen, methane, ethane and propane cannot be obtained, dimethyl ether and oxygen and carbon monoxide in flue gas impurities are not effectively removed and the like in the prior art. A carbon monoxide and oxygen removal step is added in the process. Methanol-to-olefin gas with the carbon monoxide and the oxygen being removed passes through six separation tanks and then enters a high-pressure demethanation tower, a deethanization tower, an acetylene hydrogenation reactor, an ethylene rectifying tower, an allylene hydrogenation reactor, a propylene rectifying tower and the like for separation, wherein liquid which comes out from the bottoms of the first five separation tanks sequentially enters the middle-to-upper part of the demethanation tower. By adopting the separation process, polymer-grade ethylene and propylene products can be obtained and products such as high-purity hydrogen, methane, ethane and propane can also be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Separation method for preparing low-carbon olefin gas through methanol conversion

ActiveCN102675025AHigh purityReduce usageLiquid hydrocarbon mixture productionAbsorption purification/separationOlefiant gasOxygen

The invention discloses a separation method for preparing low-carbon olefin gas through methanol conversion, and aims to solve the problems that products with high purity such as hydrogen, methane, ethane and propane which cannot be obtained in the prior art and oxygen, carbon oxide and the like in dimethyl enther and gas impurities cannot be effectively removed. According to the method, a step of removing the carbon oxide and the oxygen is increased, a methanol prepared olefin gas material flow from which the carbon oxide and the oxygen are removed enters a deethanizing column; the material flow on the top of the deethanizing column flows through an acetylene hydrogenation reactor, six separation tanks, a demethanizing column, an ethylene rectifying column and the like in sequence to separate to obtain ethylene and ethane products; and the material flow at the bottom of the deethanizing column flows through a propyne hydrogenation reactor, a methane stripping column, a propylene rectifying column and the like in sequence to separate to obtain propene and propane products. By using the separation method, polymer grade ethylene and propene products can be obtained, and products with high purity such as hydrogen, methane, ethane and propane can also be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

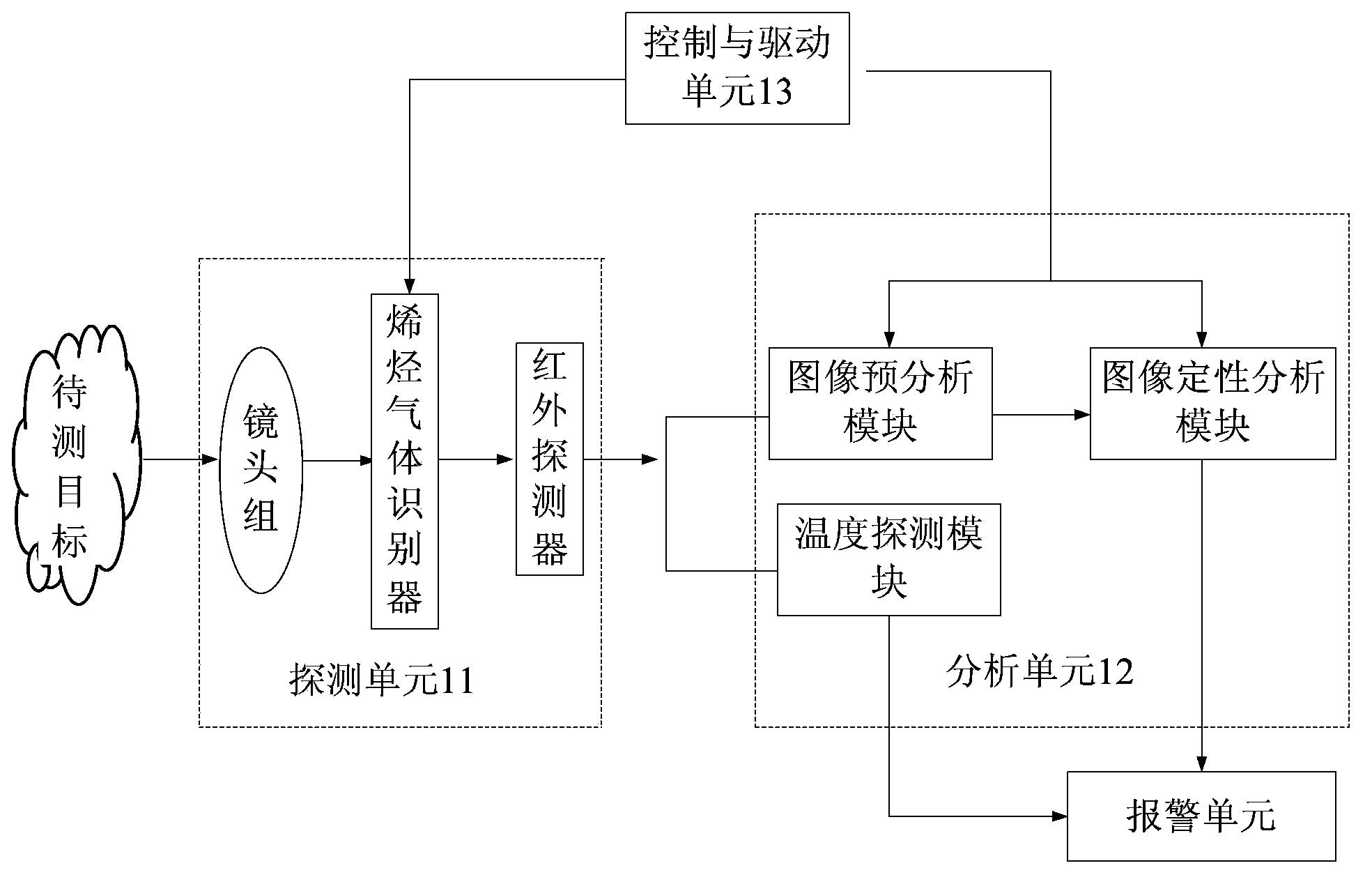

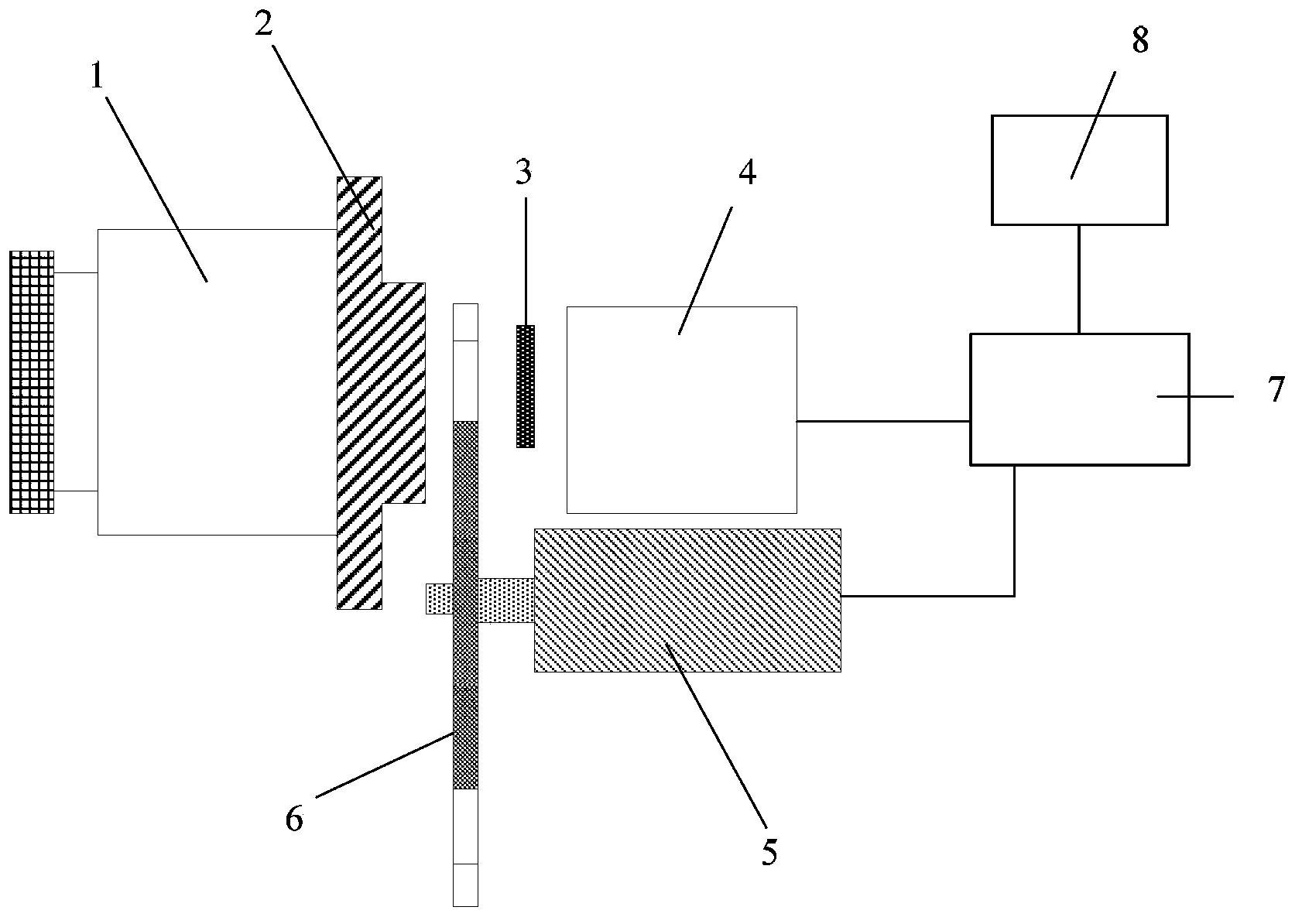

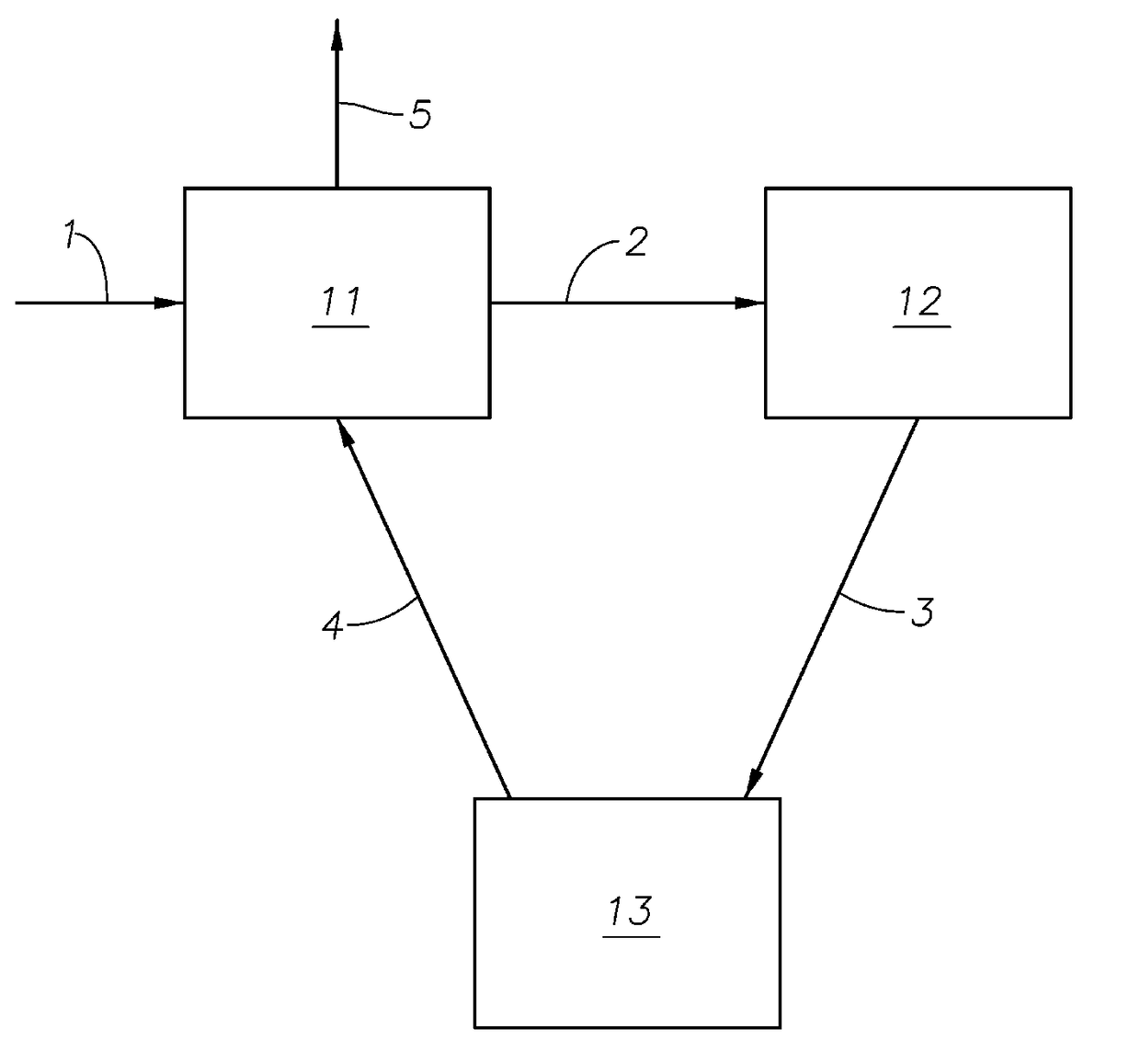

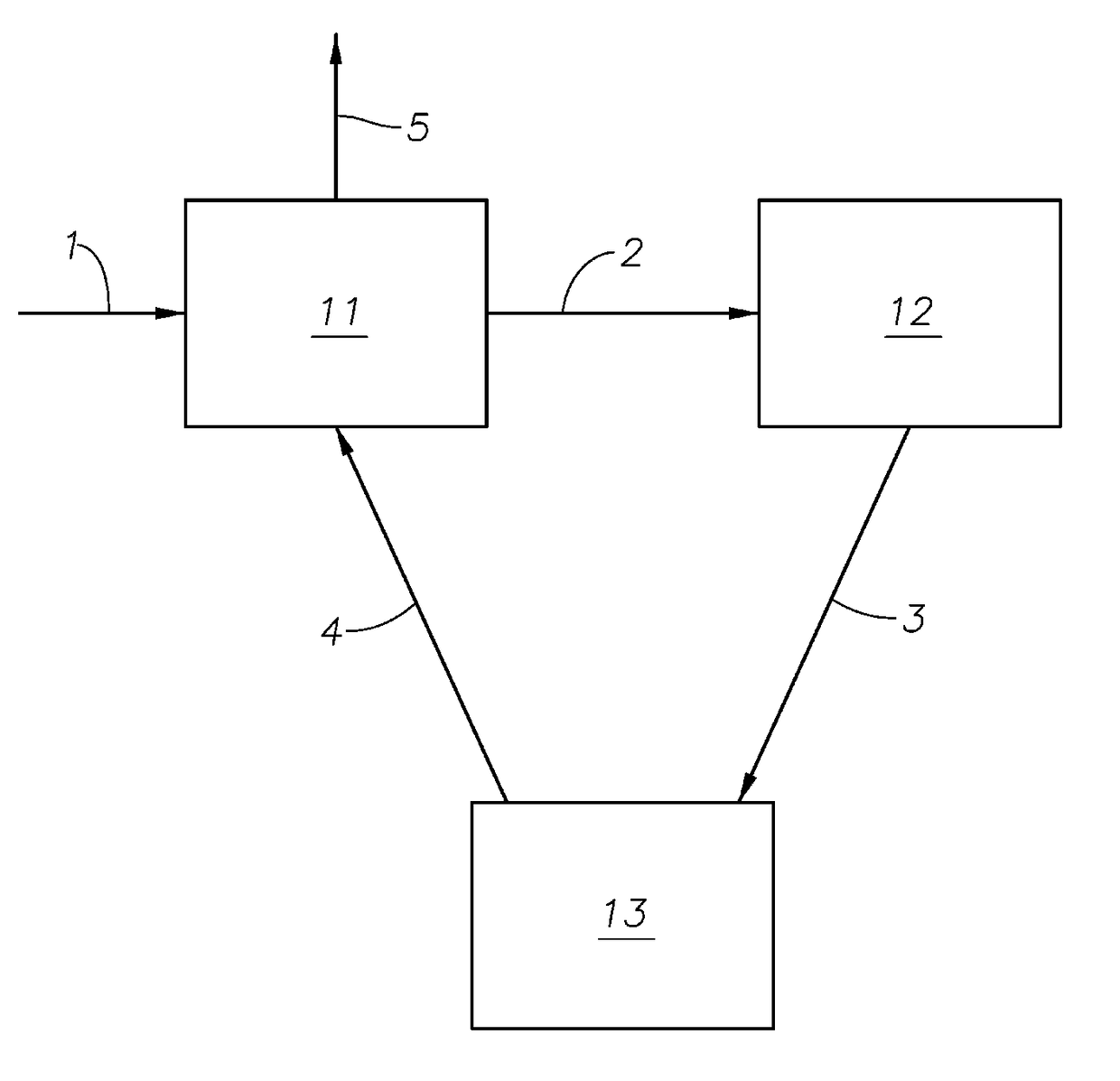

Olefin gas leakage monitoring system and method thereof

InactiveCN104122039AAccurate detectionEnsure safetyMaterial analysis by optical meansFluid-tightness measurement using fluid/vacuumOlefiant gasMonitoring system

An olefin gas leakage monitoring system and a method thereof. The monitoring system contains a detection unit for detecting and imaging an area to be detected, an analytical unit, a control and drive unit and an alarm unit. The detection unit contains an infrared thermal imager which contains an olefin gas recognizer. The analytical unit contains an image preanalysis module and an image qualitative analysis module, wherein the image preanalysis module is used for analyzing an image detected by the detection unit before the olefin gas recognizer is started and judging whether it is a gas; and the image qualitative analysis module is used for recognizing and analyzing the image detected by the detection unit after the olefin gas recognizer is started and judging whether it is an olefin gas. The control and drive unit is connected with the detection unit and the analytical unit and is used for controlling and driving the olefin gas recognizer according to an analysis result of the analytical unit. The monitoring system and the method disclosed in the invention are used for online monitoring of olefin gas leakage. By the system and the method, olefin gas leakage can be detected timely and accurately, and safety and continuity of the production can be guaranteed.

Owner:GR APPL TECH

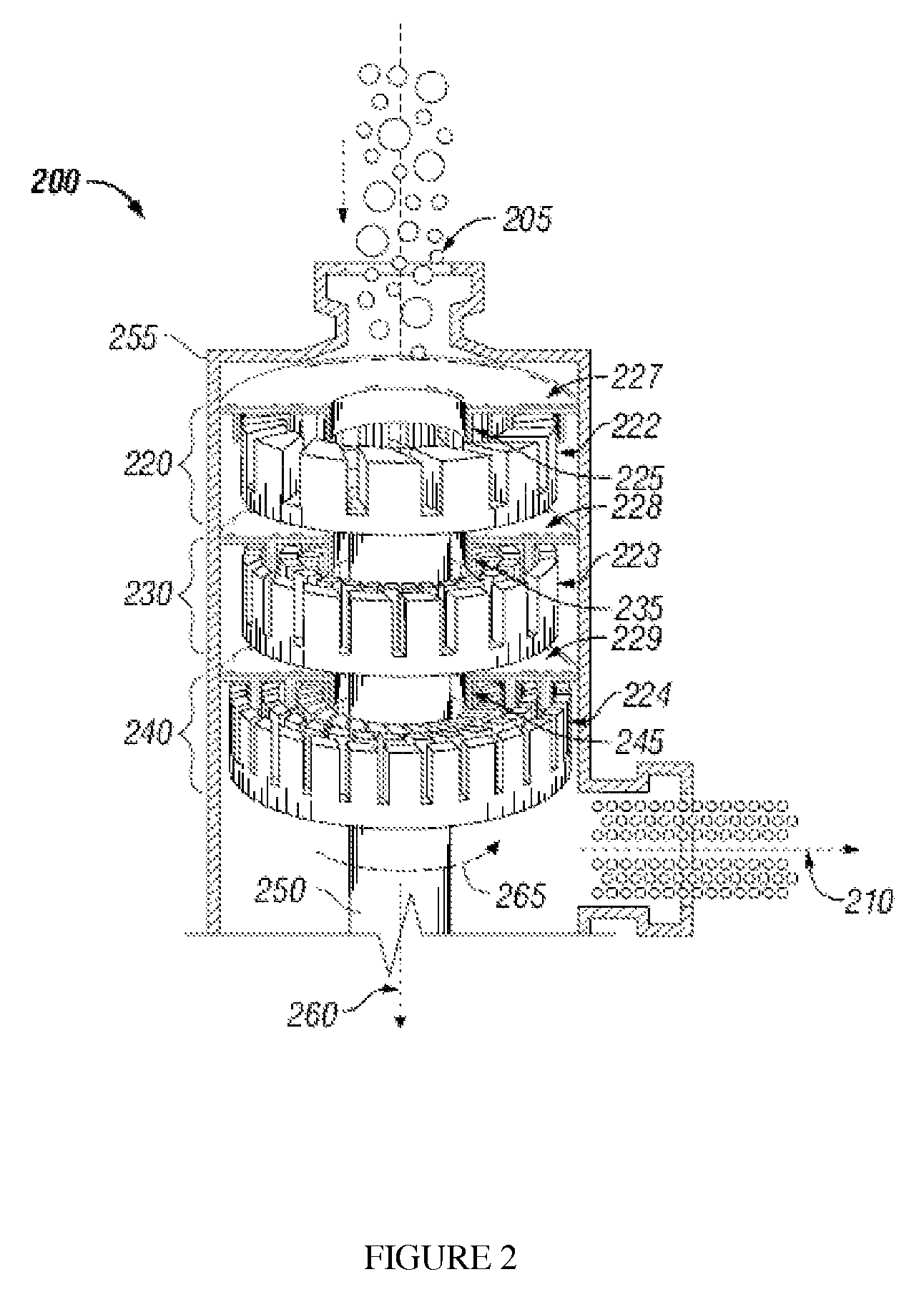

Method of making alcohols

InactiveUS7482497B2Good dispersionImprove solubilityOrganic compound preparationRotary stirring mixersMean diameterSolubility

Owner:HRD CORP

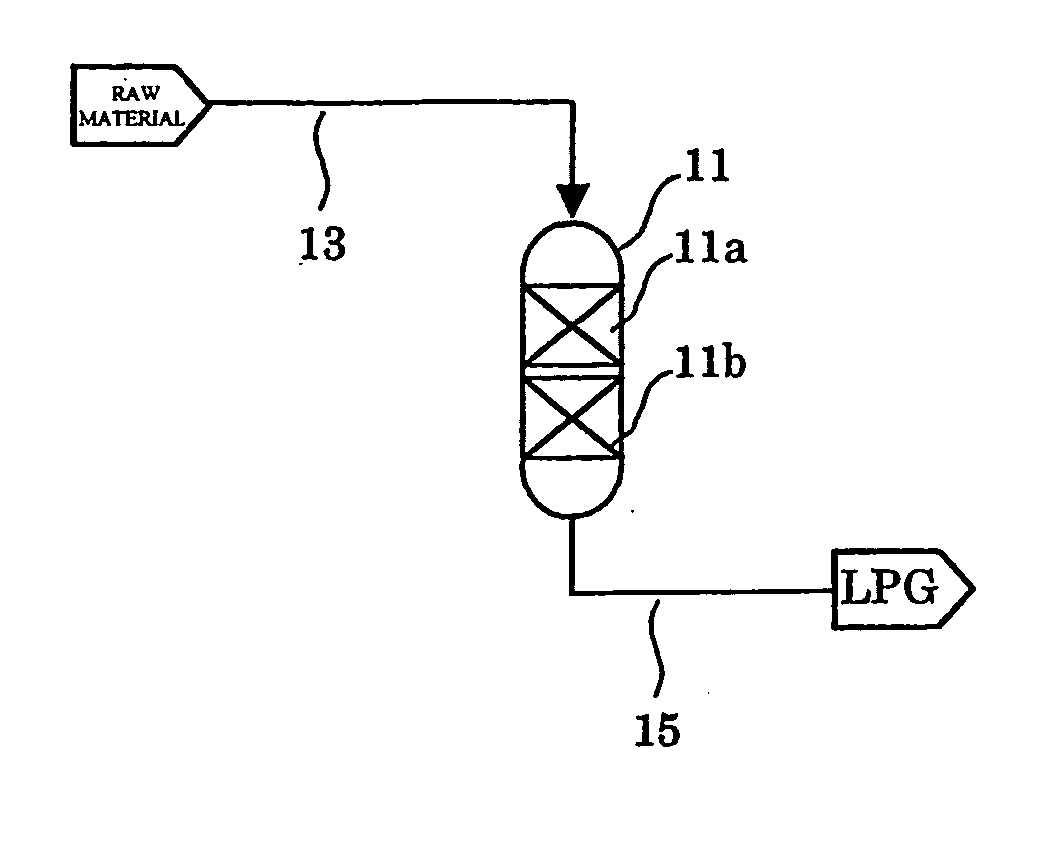

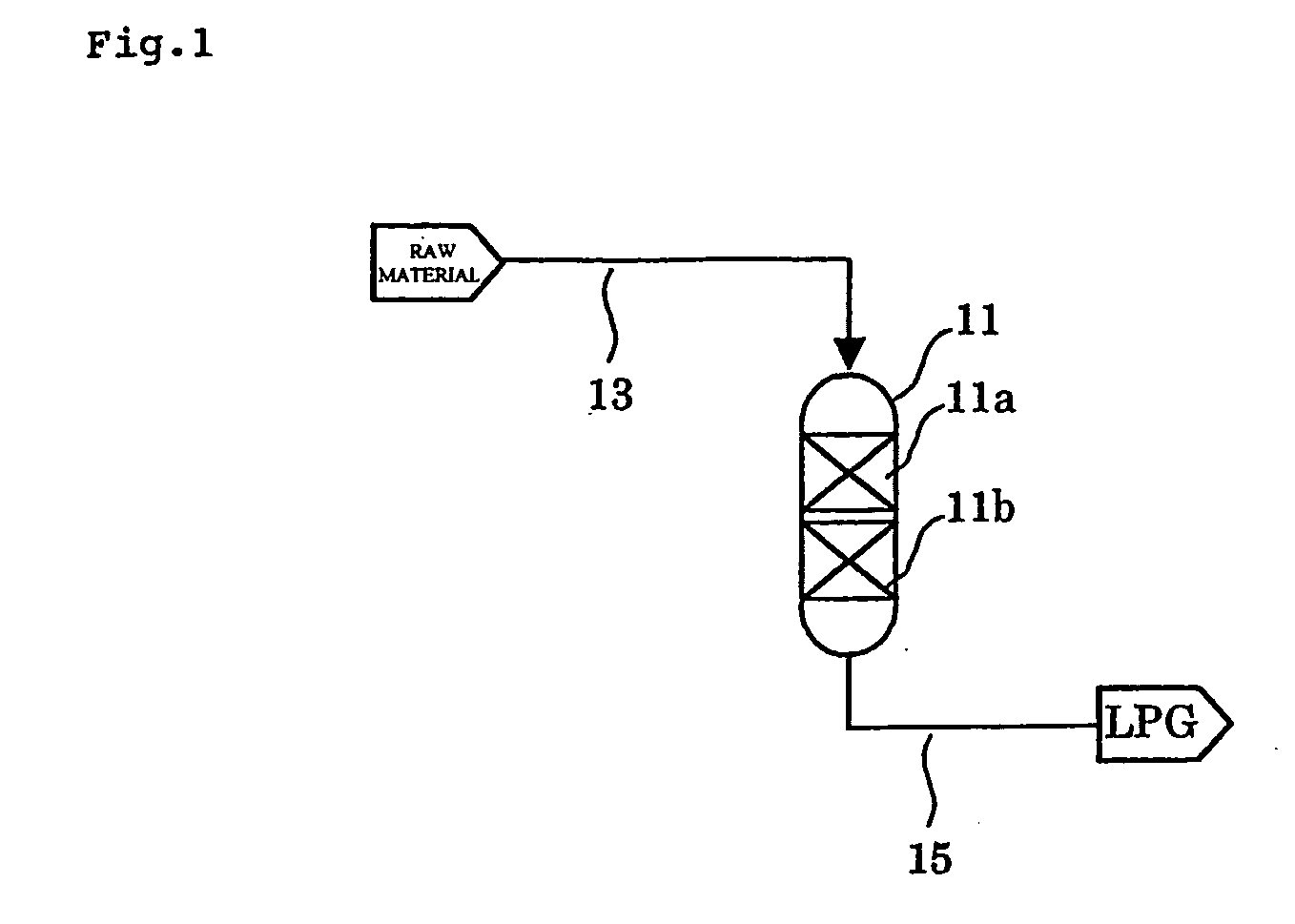

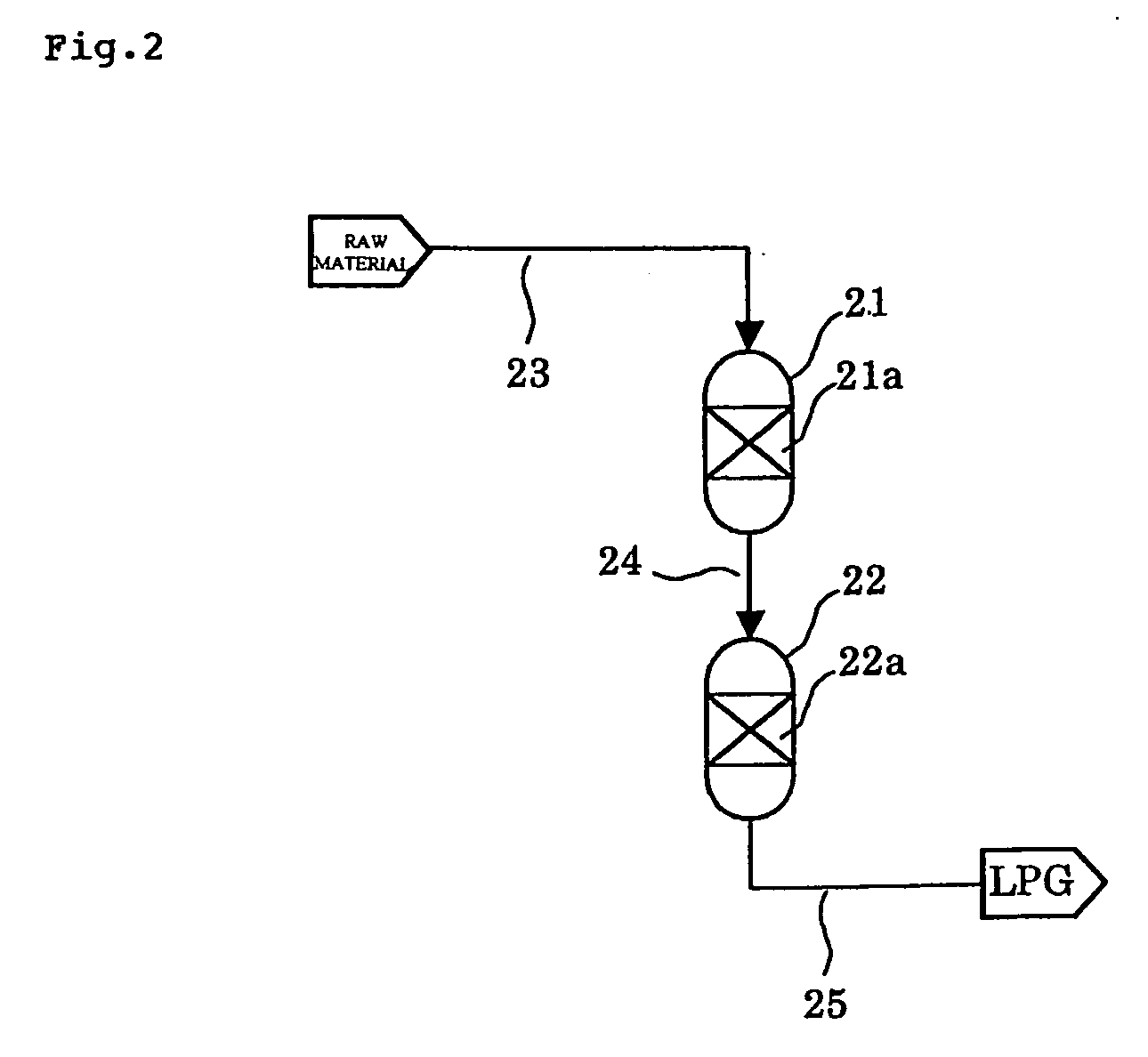

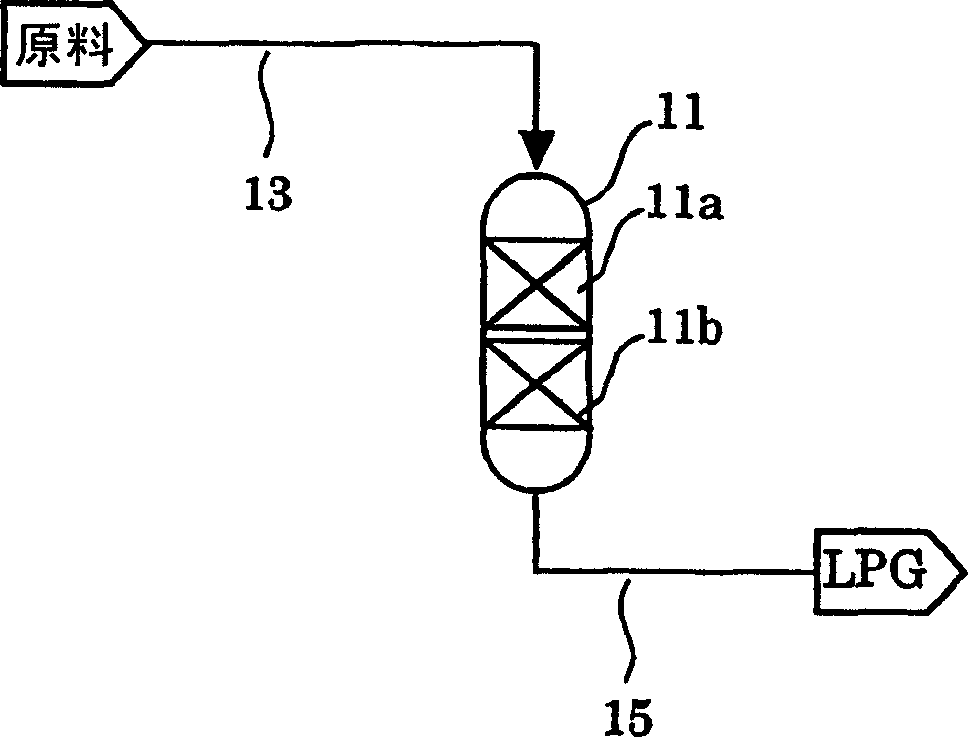

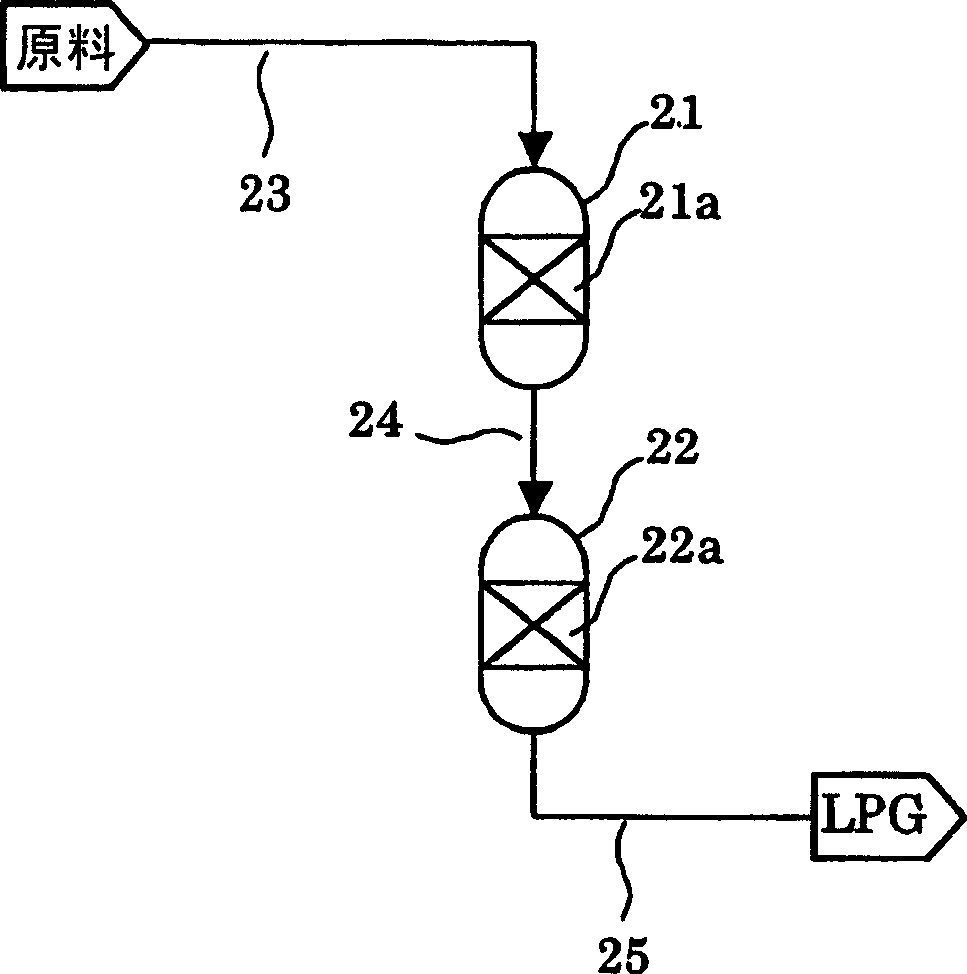

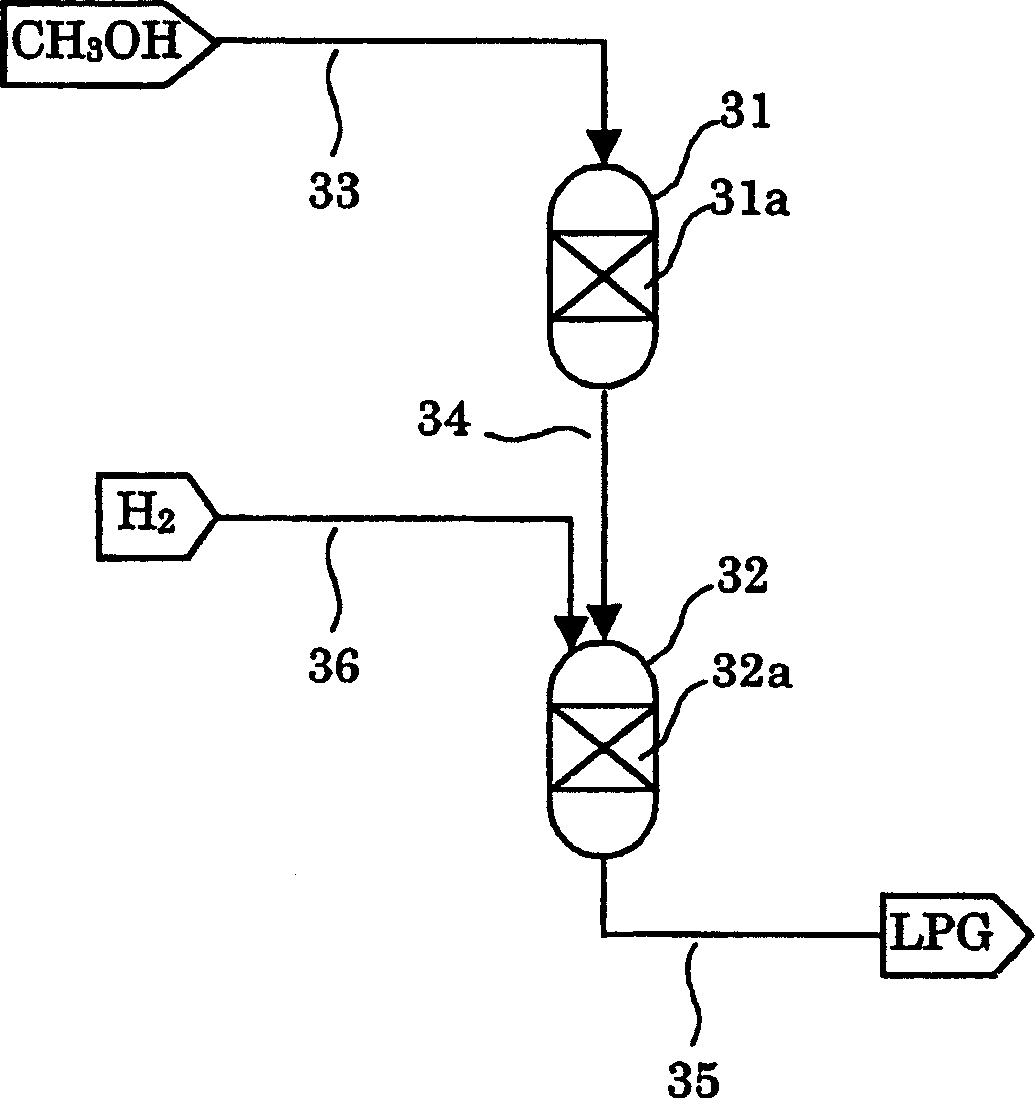

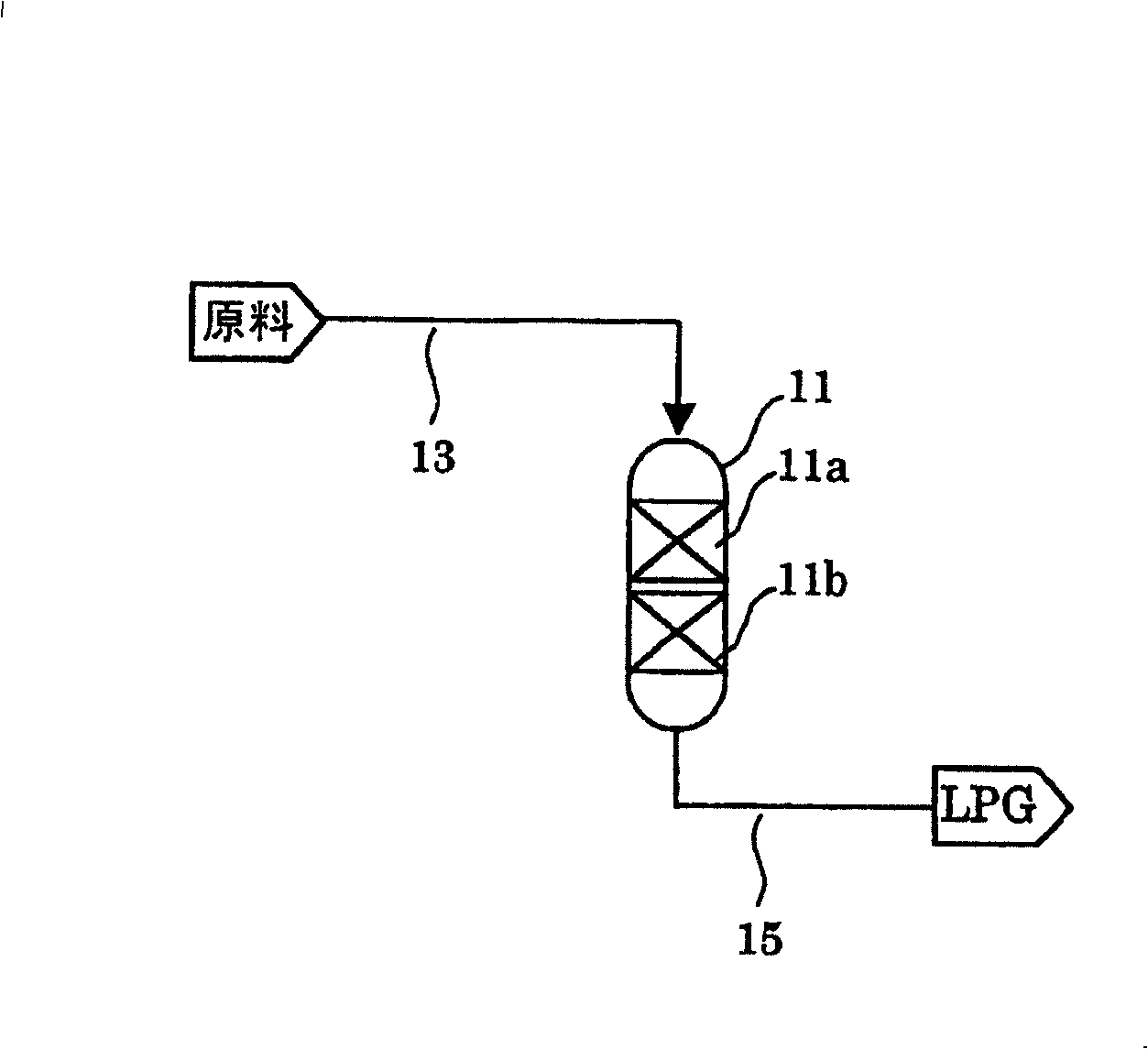

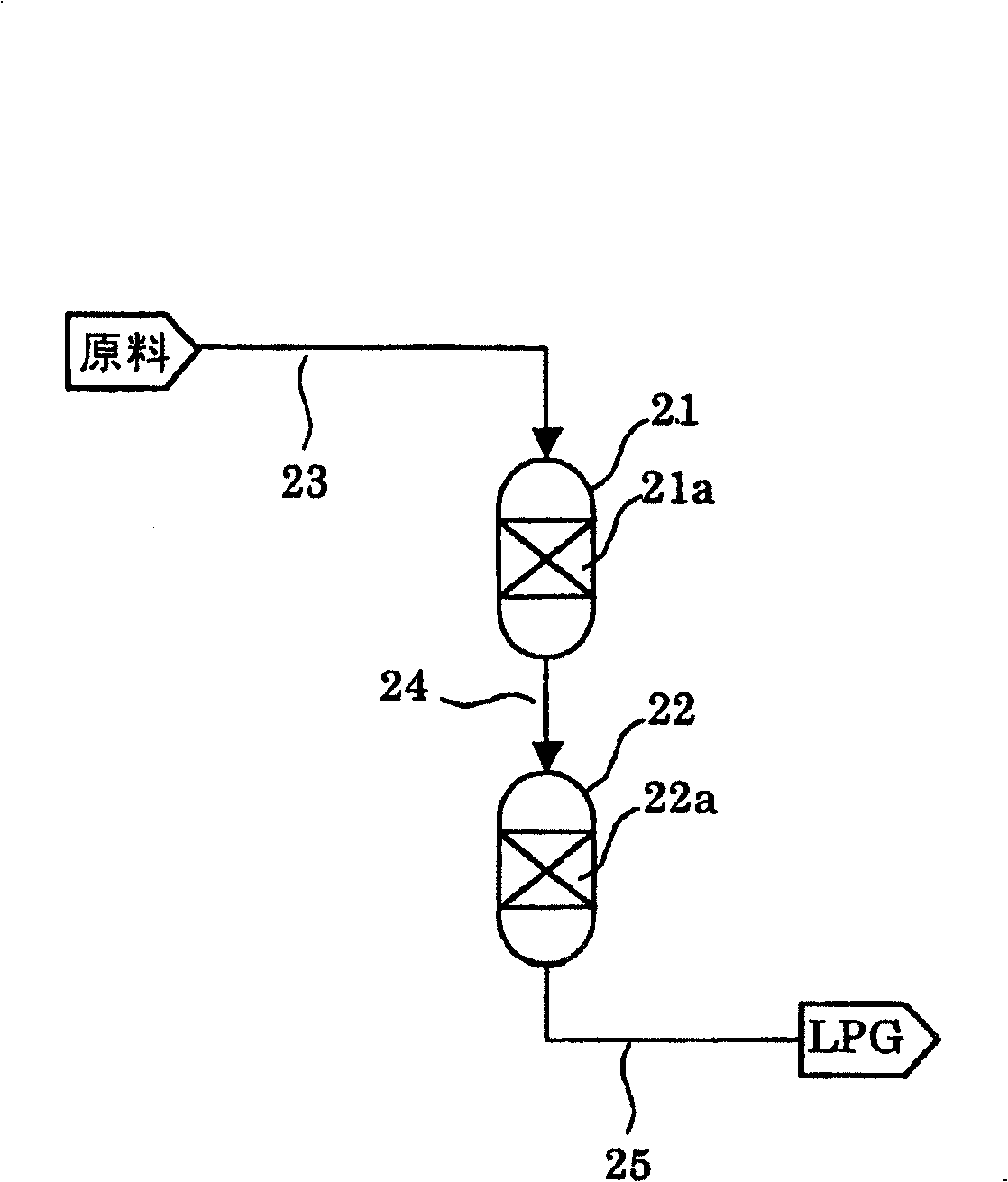

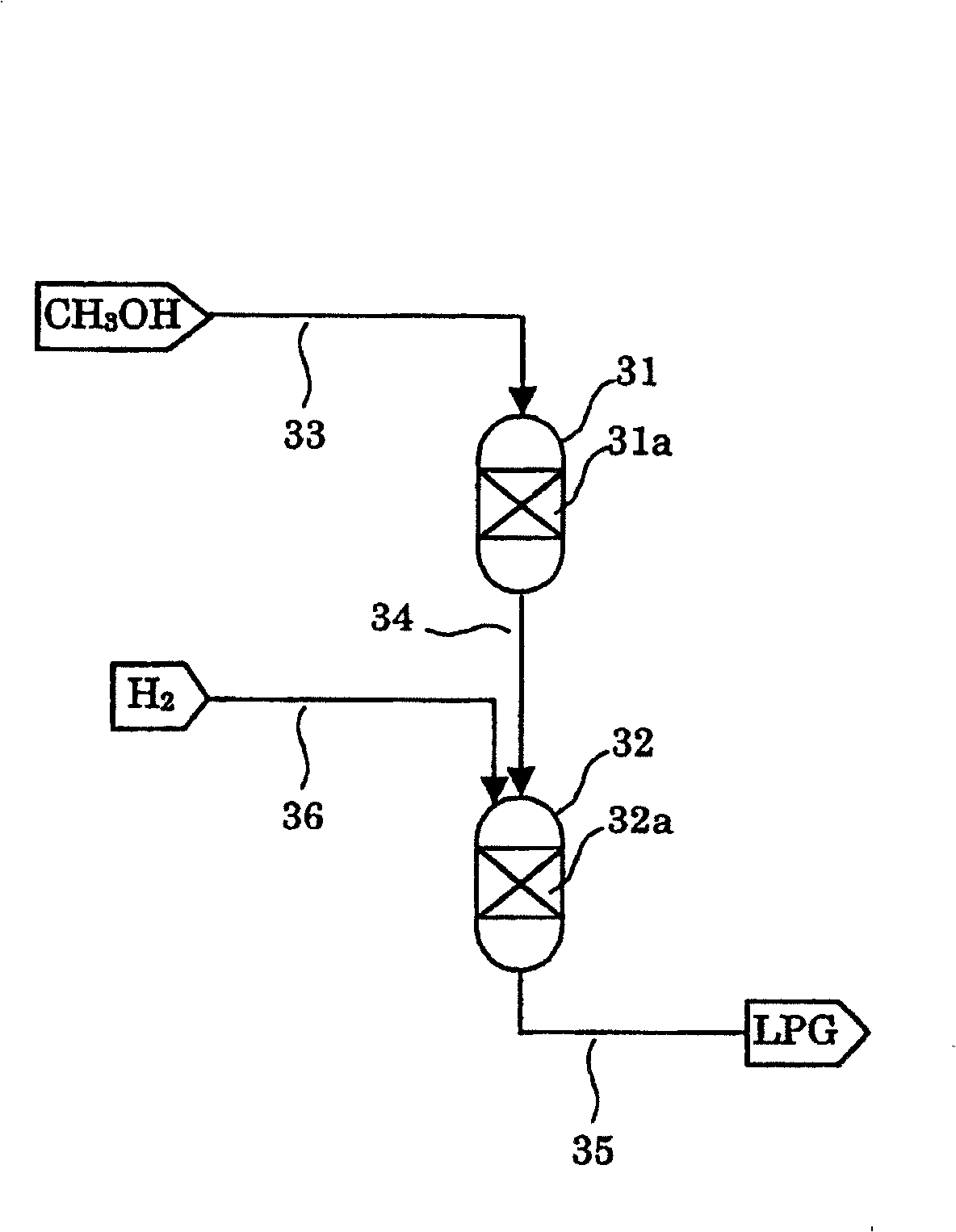

Method for producing liquefied petroleum gas

InactiveUS20070004954A1High yieldImprove propylene yieldGaseous fuelsHydrocarbonsHydrogenOlefiant gas

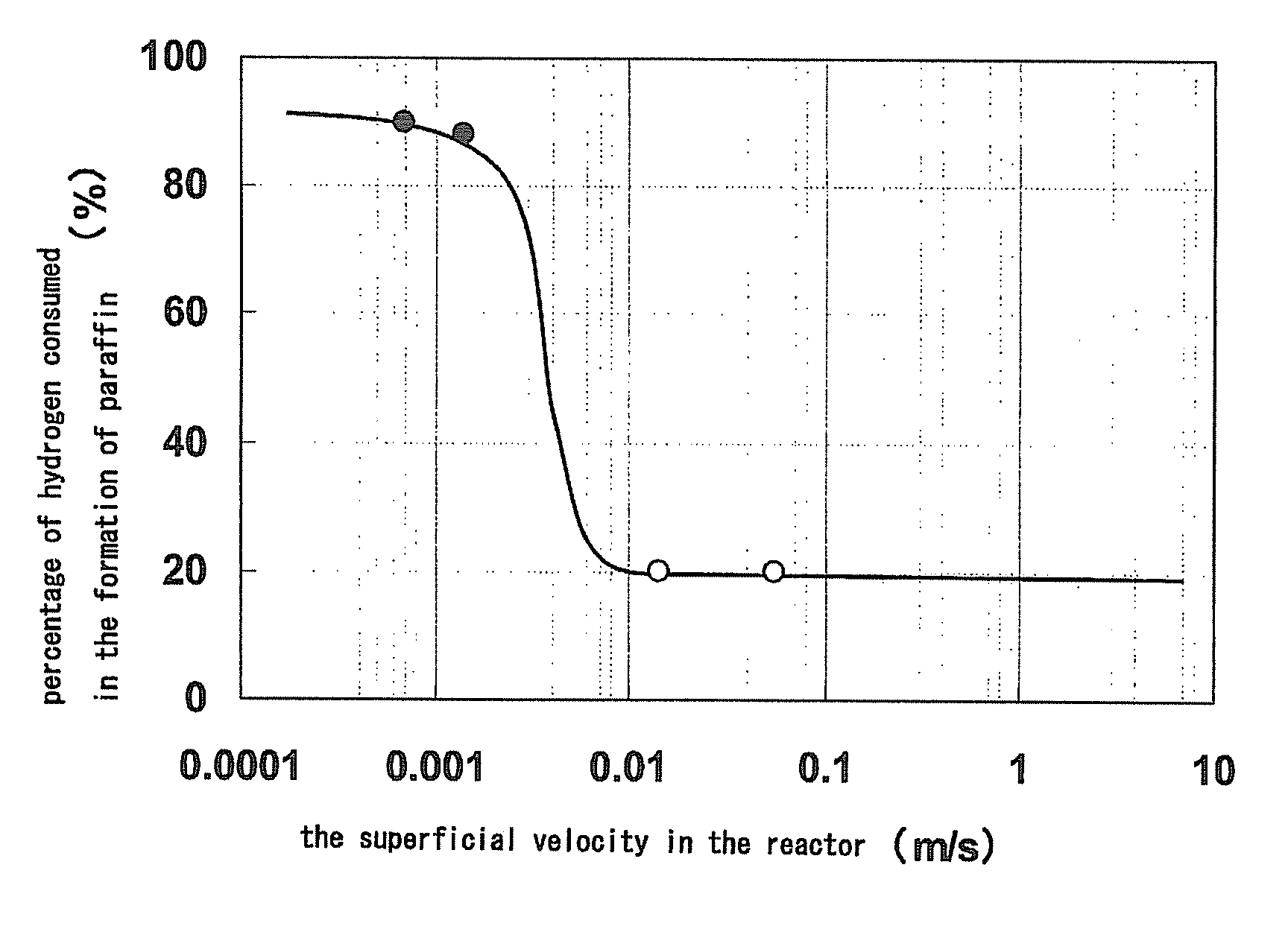

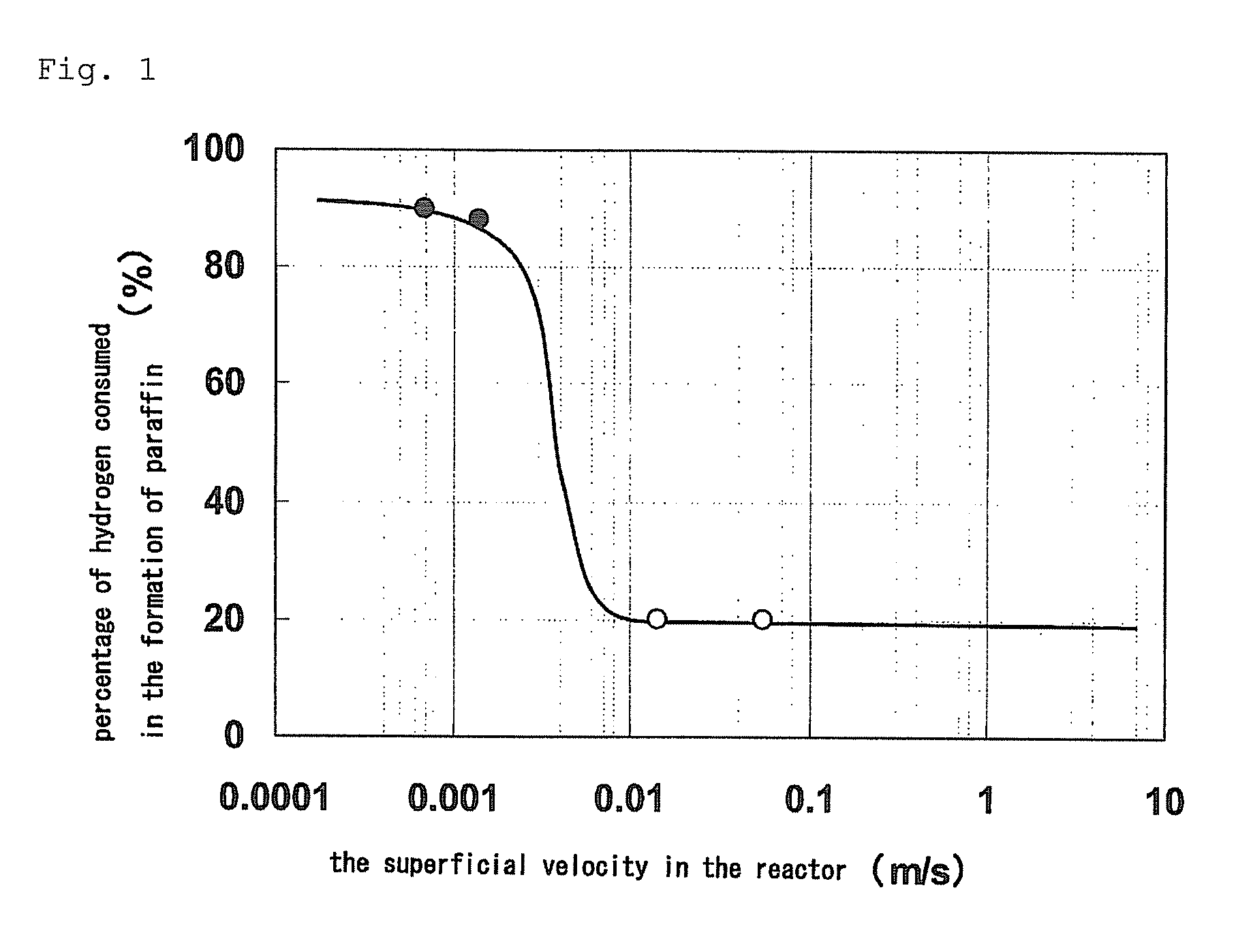

A liquefied petroleum gas containing propane or butane as a main component is produced by passing a raw material gas comprising hydrogen and at least one selected from the group consisting of methanol and dimethyl ether through a catalyst layer comprising, in the direction of flowing of the raw material gas, a former catalyst layer comprising a catalyst for synthesizing an olefin-containing gas which is used when producing an olefin-containing gas from at least one selected from the group consisting of methanol and dimethyl ether, and a latter catalyst layer comprising a catalyst for hydrogenating an olefin-containing gas which is used when an olefin is hydrogenated to produce a paraffin.

Owner:JAPAN GAS SYNTHESIZE

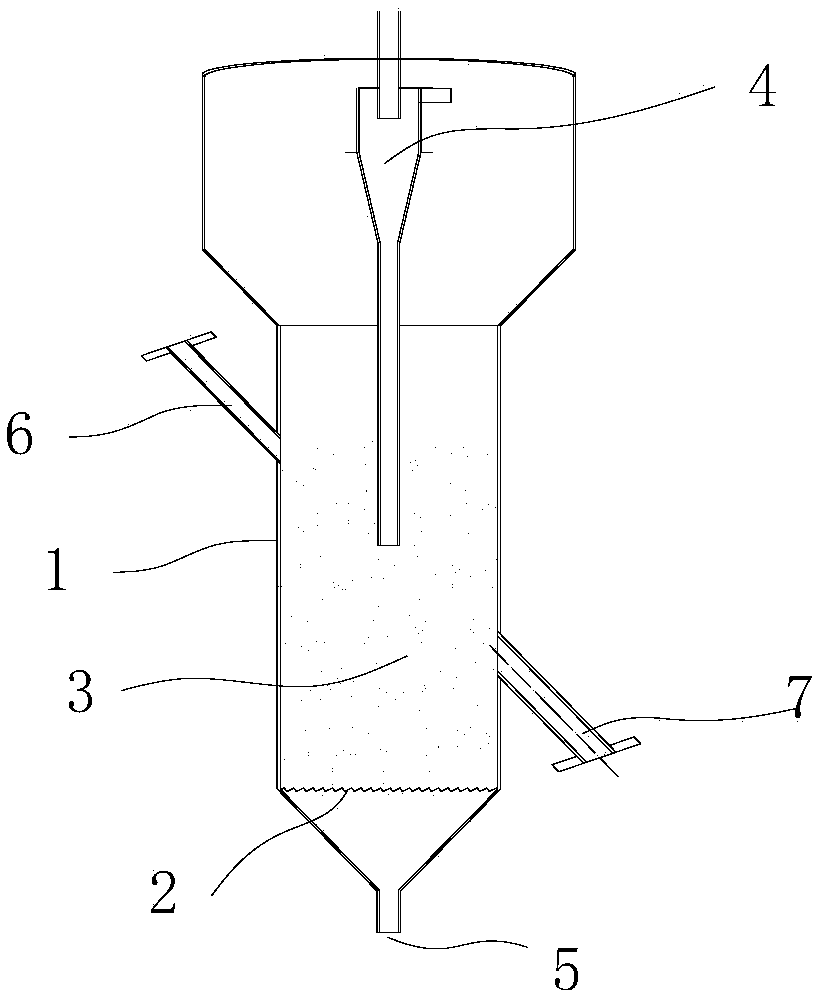

Equipment for production of carbon nanotubes with fluidized bed and preparation method thereof

The invention provides equipment for production of carbon nanotubes with a fluidized bed and a preparation method thereof. The equipment consists of a main reaction furnace, a gas distributor, a fluidized bed and a gas-solid separator. The bottom of the main reaction furnace is equipped with a carbon source gas inlet, and the gas distributor is arranged at the upper side of a carbon source gas inlet and is mounted at the bottom end of the fluidized bed. A catalyst inlet is disposed at an obliquely upward part on the outer wall of the main reaction furnace at the fluidized bed top, and a carbonnanotube outlet is arranged at an obliquely downward part on the outer wall of the main reaction furnace at the lower-middle part of the fluidized bed. The preparation method comprises the steps of:sending a prepared mixed metal oxide catalyst directly into the fluidized bed in the main reaction furnace; and introducing olefin gas of 4 or less than 4 carbon into the fluidized bed at 600-1000DEGC to obtain carbon nanotubes with a diameter of 4-80nm and a length of 0.5-200micrometer, and then performing discharge from the outlet. The equipment has the advantages of simple structure, easy operation and low energy consumption, and is suitable for continuous production of carbon nanotubes with kiloton annual output.

Owner:허난구오안일렉트릭머터리얼컴퍼니리미티드 +1

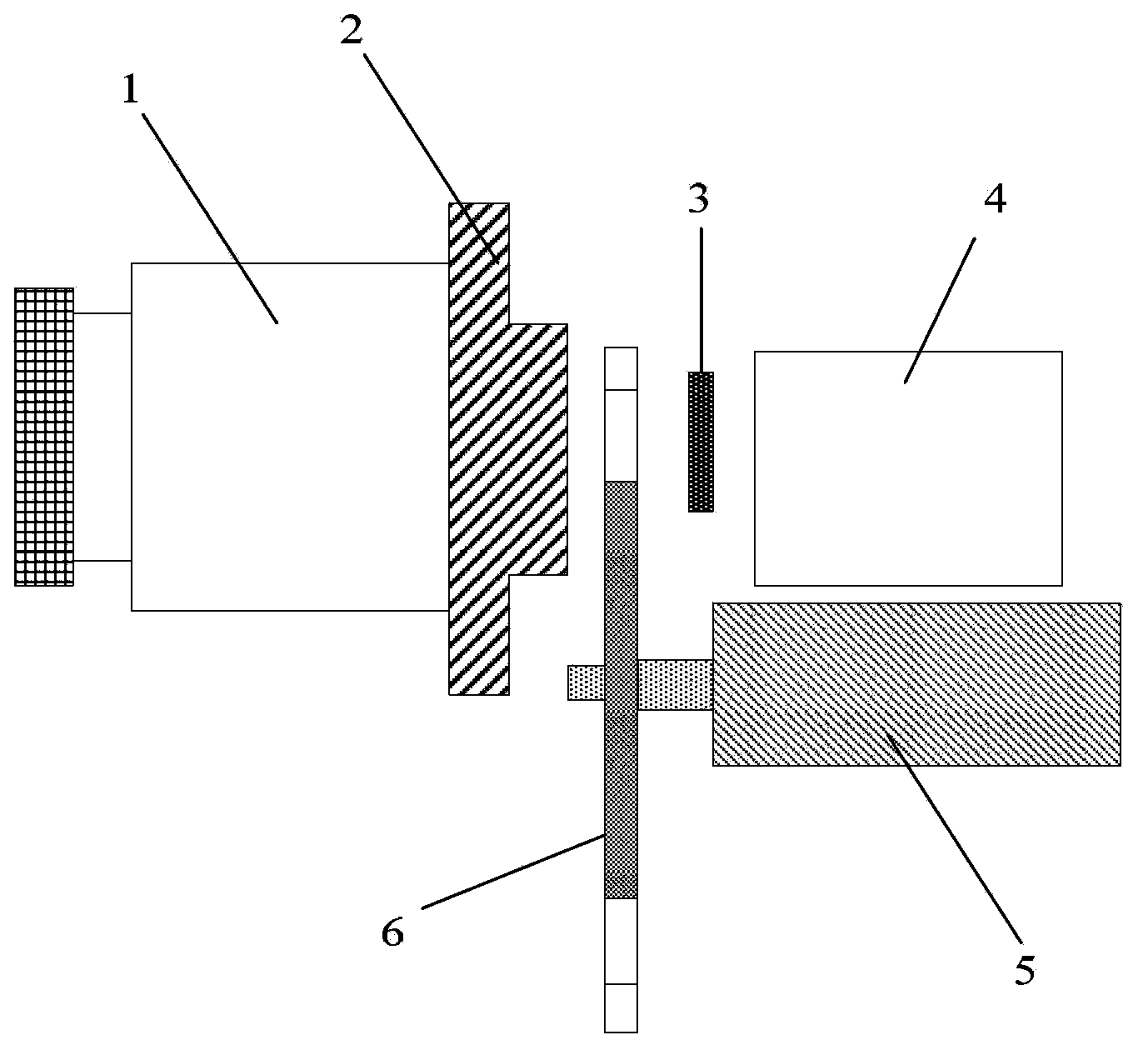

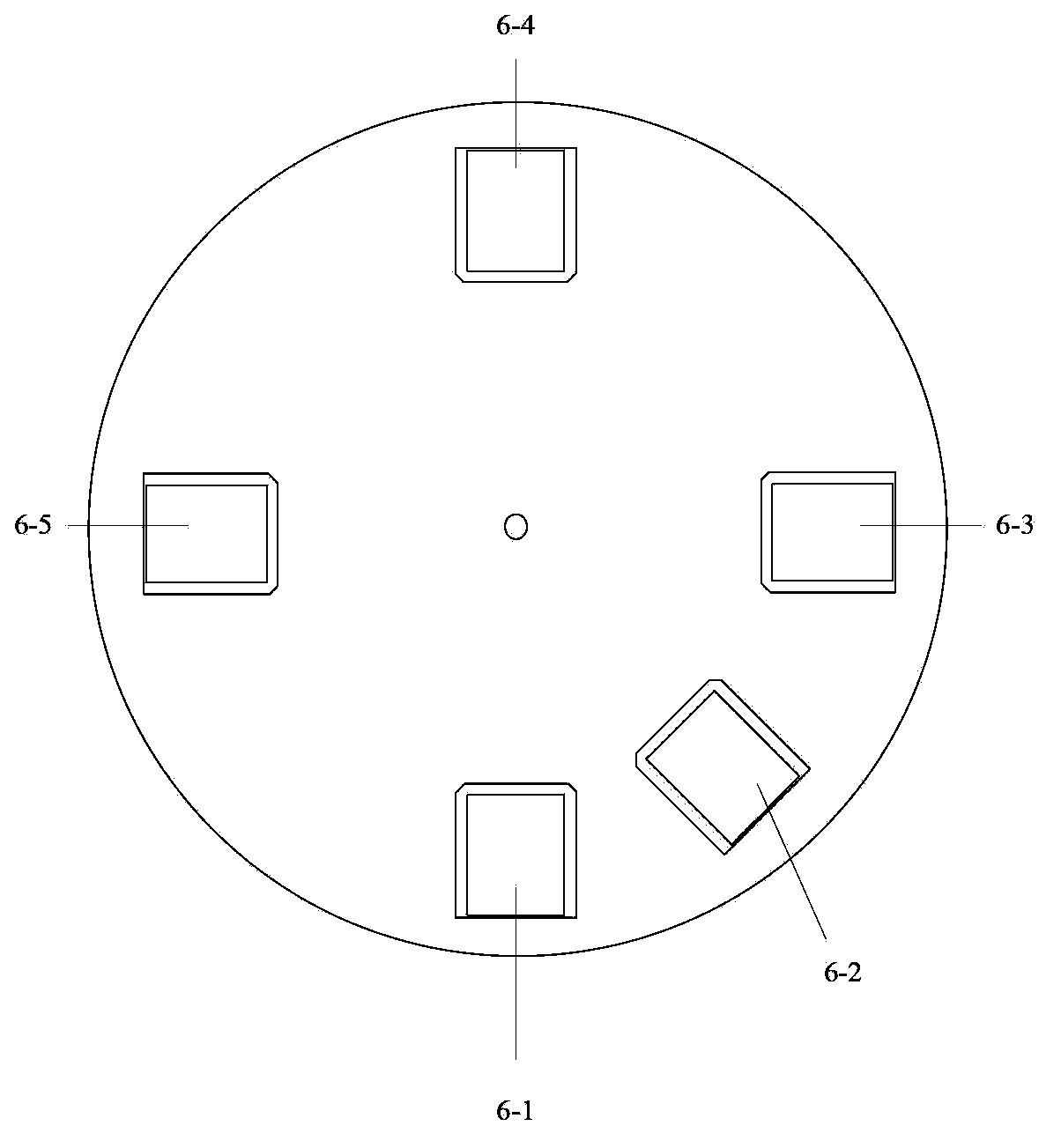

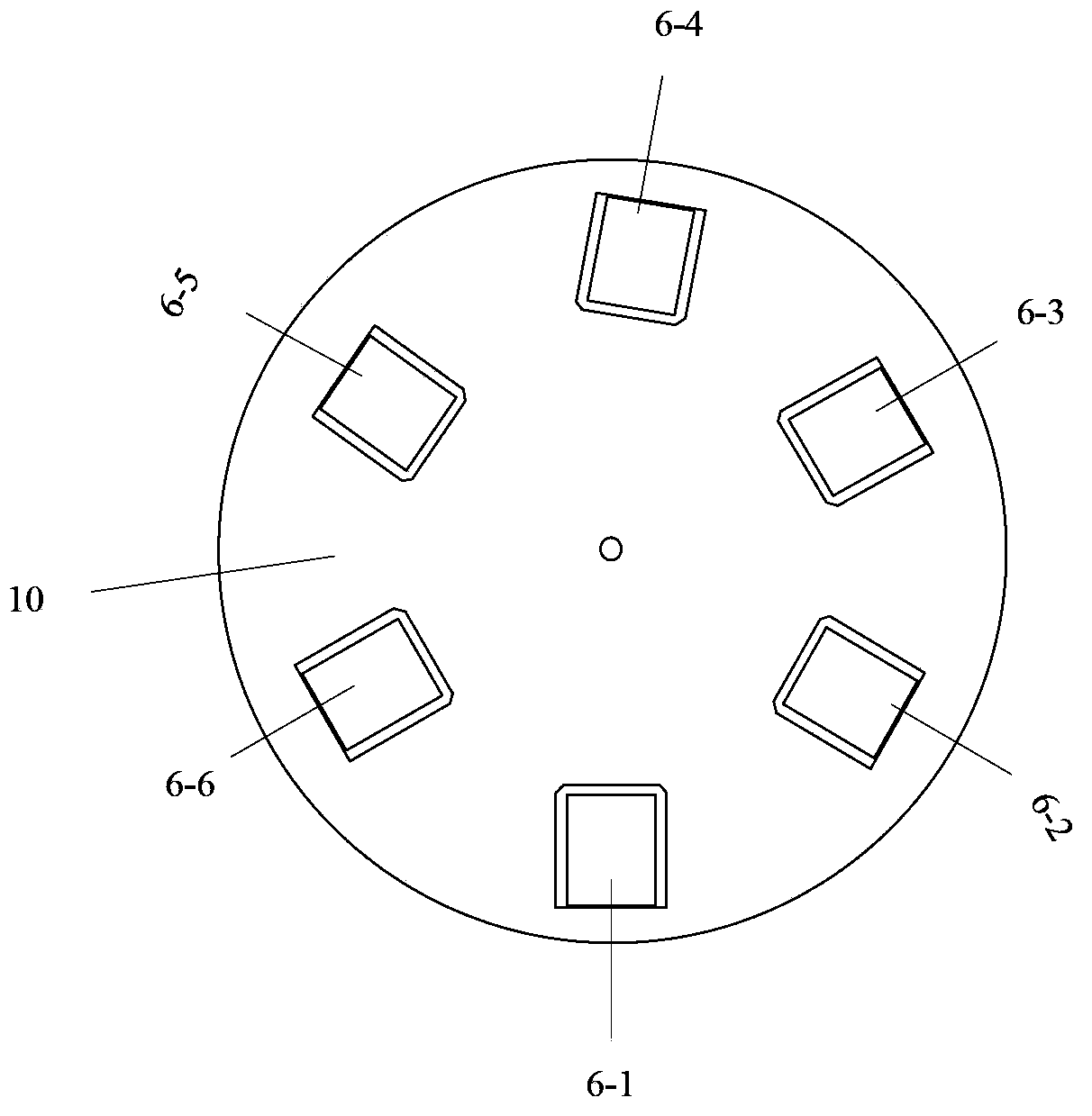

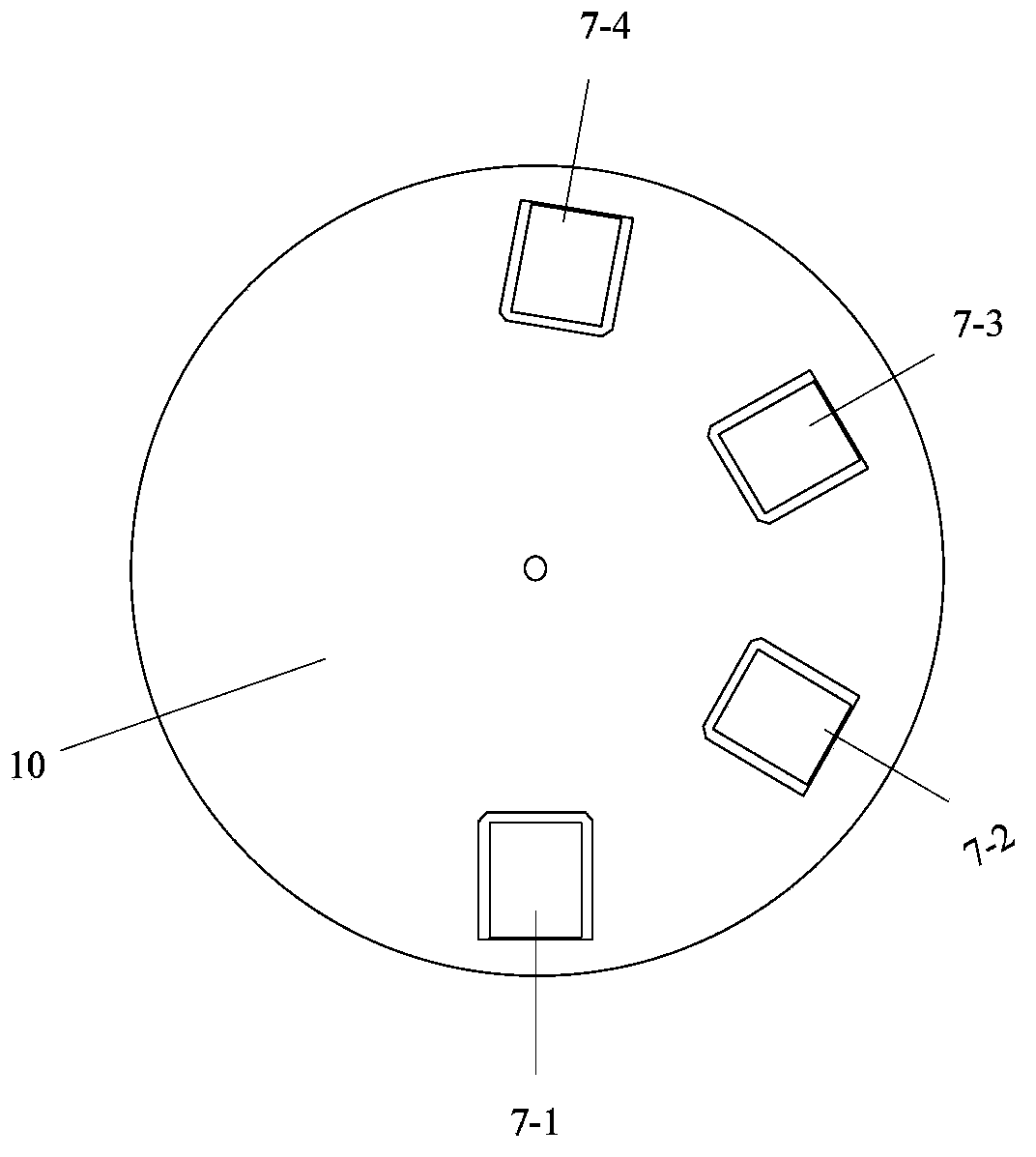

Detection device and method for olefin gas

InactiveCN104122235AVisual judgmentQuick judgmentTransmissivity measurementsOlefiant gasBand-pass filter

The invention provides a detection device and method for an olefin gas. The detection device includes: an infrared optical lens, which is used for focusing infrared radiation signals; an olefin gas recognizer, which includes a turntable and at least one olefin band pass filter plate disposed on the turntable; an infrared detector, which is used for converting infrared radiation signals passing through the olefin band pass filter plate into voltage signals so as to form an infrared image; a monitoring and analysis unit, which is used for acquiring and analyzing the infrared image, outputting the analysis result, and controlling the turntable of the olefin gas recognizer according to the analysis result; and a display, which is connected to the output end of the monitoring and analysis unit and is used for displaying the output result. Compared with the prior art, the olefin gas detection device and method provided by the invention are based on an infrared imaging technology, and can visually judge whether a to-be-detected target is an olefin gas accurately and quickly.

Owner:GR APPL TECH

Method for producing liquefied petroleum gas

A liquefied petroleum gas containing propane or butane as a main component is produced by passing a raw material gas comprising hydrogen and at least one selected from the group consisting of methanol and dimethyl ether through a catalyst layer comprising, in the direction of flowing of the raw material gas, a former catalyst layer comprising a catalyst for synthesizing an olefin-containing gas which is used when producing an olefin-containing gas from at least one selected from the group consisting of methanol and dimethyl ether, and a latter catalyst layer comprising a catalyst for hydrogenating an olefin-containing gas which is used when an olefin is hydrogenated to produce a paraffin.

Owner:TOKAI

Process for producing olefins

InactiveUS8013200B2Inhibition formationShort timeCatalystsHydrocarbon preparation catalystsAlkaneRhenium

Owner:MITSUI CHEM INC

A kind of preparation method of high regularity polybutene-1 powder

ActiveCN104193870BImprove the problem of long period of crystal transformationSimple processOlefiant gasPolymer science

The invention relates to a preparation method of high-isotacticity polybutene-1 powder. The method comprises the following steps: sequentially adding a cocatalyst solution, an outer electron donor, a main catalyst, an assistant compound and a liquid-phase alpha-olefin into a tank reactor, prepolymerizing at 10-90 DEG C for 10-120 minutes, evacuating olefin gas, charging butylene-1 monomer and molecular weight regulator hydrogen gas, polymerizing at -10-90 DEG C for 1-20 hours, and carrying out flash evaporation on the unreacted monomer to obtain the high-isotacticity polybutene-1 powder. The polymerization method for synthesizing high-isotacticity polybutene-1 and powder thereof is simple in technique and easy to operate. The prepolymerization method solves the problem of difficulty in controlling the form of the polybutene-1 in the common catalytic polymerization method, and improves the problem of long crystal form transition period of the polybutene-1.

Owner:HEBEI UNIV OF TECH

A kind of method that prepares 1,3-dibasic alcohol by prins condensation reaction

ActiveCN105315130BHigh activityHigh selectivityOrganic compound preparationHydroxy compound preparationOlefiant gasReaction temperature

The invention relates to a method for preparing 1,3-dihydric alcohols through Prins condensation reaction. The method adopts olefin and formaldehyde aqueous solution as reaction substrates, and directly prepares 1,3-diol under the catalysis of an acidic composite metal oxide. The reaction process is as follows: After mixing the formaldehyde aqueous solution with the catalyst, put it into a pressure vessel and seal it, pour in olefin gas, stir, the reaction temperature is higher than 80°C, and the reaction time is longer than 2h. After the reaction, the catalyst and the reaction system are easy to separate and can be reused. The yield of 1,3-diol can reach up to 90% in the second cycle.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

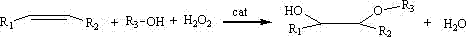

Green synthesis method for preparing alcohol ether by using olefin in one step

The invention belongs to the field of organic chemical industry, and provides a green synthesis method for preparing alcohol ether by using olefin in one step. The green synthesis method is characterized in that a jet type reactor is used for continuously jetting alcohol, hydrogen peroxide and a cyclization-alcoholysis catalyst into a pressured reaction kettle filled with olefin gas, so that continuous epoxidation and alcoholysis reaction is carried out; after being separated by a ceramic membrane, reaction liquid enters to an olefin and alcohol removal tower; after olefin and alcohol are removed, the reaction liquid directly and continuously enters to a rectifying tower, and the alcohol ether product is obtained by rectifying; the effective utilization rate of the hydrogen peroxide is more than or equal to 98%, the alcohol ether selectively is greater than or equal to 99%, and the product purity is higher than or equal to 99.5%. The green synthesis method can be used for preparing the alcohol ether in one step and is suitable for industrial large-scale production.

Owner:SHANDONG UNIV OF TECH

Process of Producing Paraxylene by The Methylation of Toluene and/or Benzene

InactiveUS20180155255A1Increase profitIncrease volumeMolecular sieve catalystCatalystsAlkyl transferOlefiant gas

A process for producing paraxylene by the catalytic alkylation of benzene and / or toluene with methanol. In prior art processes, water is typically co-injected with the methanol to improve the utilization of methanol, increase the amount of methanol that reacts with the benzene and / or toluene, and decrease the amount of methanol that decomposes to undesirable carbon monoxide, carbon dioxide, or water or reacts with itself to produce unwanted light olefinic gases. Rather than using purified methanol and co-feeding water as is taught in the prior art, crude, or unpurified, methanol that contains at least 5 wt %, such as between 5 and 35 wt %, water, based on the total amount of water and methanol feed, can be used as the alkylating agent, reducing the need to co-inject water at least partially, if not completely.

Owner:EXXONMOBIL CHEM PAT INC

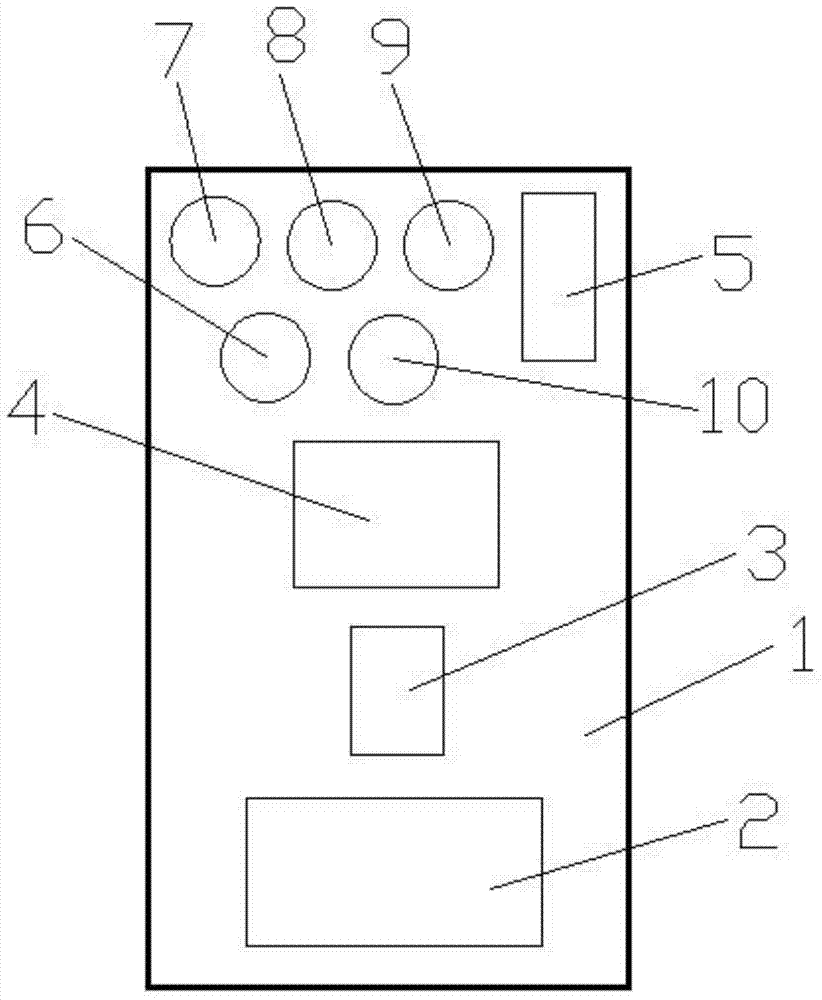

Mobile phone device capable of measuring concentration of inflammable gases

InactiveCN104270511AImplement basic functionsReasonable designSubstation equipmentMaterial analysisAlkaneOlefiant gas

The invention belongs to the technical field of communication and relates to a mobile phone device capable of measuring the concentration of inflammable gases. The mobile phone device comprises a mobile phone body, a battery, a user identity recognition card, a data processing system, a wireless signal receiving and transmitting system, an alkane gas concentration measuring device, an olefin gas concentration measuring device, an alkyne gas concentration measuring device, a hydrogen sulfide gas concentration measuring device and a hydrogen concentration measuring device, wherein the battery, the user identity recognition card, the data processing system, the wireless signal receiving and transmitting system and the inflammable gas concentration measuring devices are arranged on the mobile phone body. The mobile phone device achieves the basic functions of calling and short messages, and meanwhile the concentration of the inflammable gases in the environment where a user is located can be synchronously measured. The mobile phone device is reasonable in design, simple in structure and capable of achieving multiple measuring functions.

Owner:魏庆玉

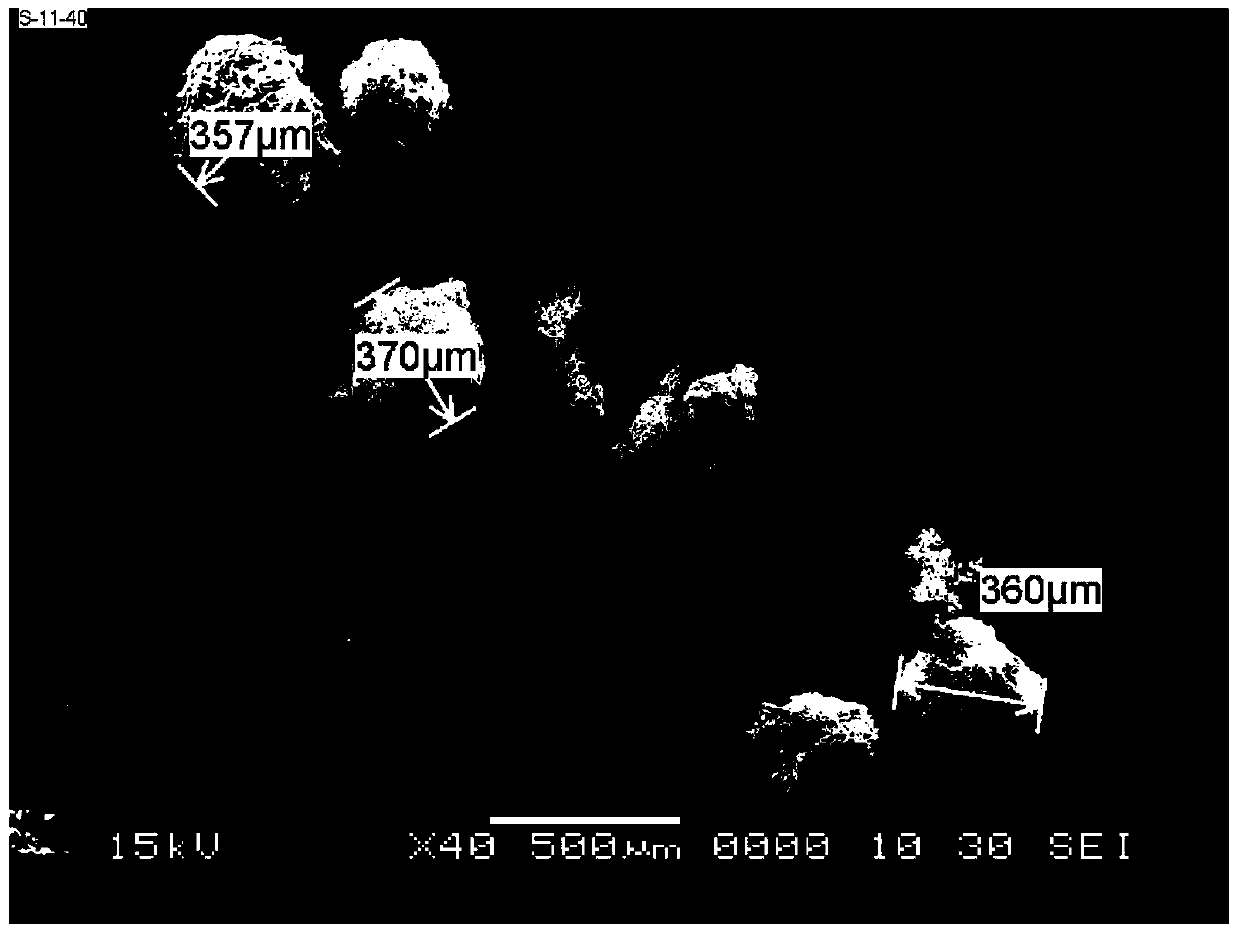

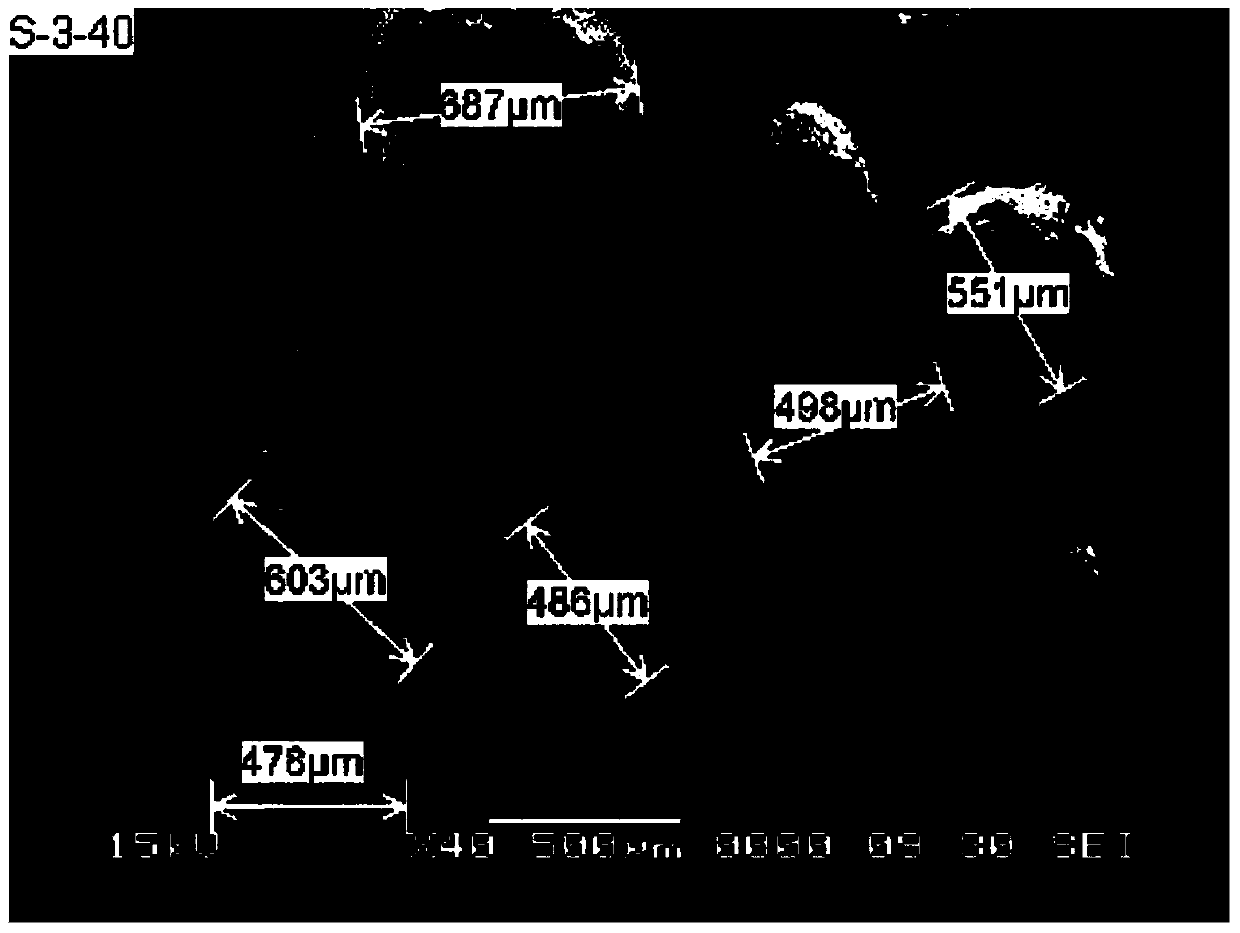

Method for producing polyolefin

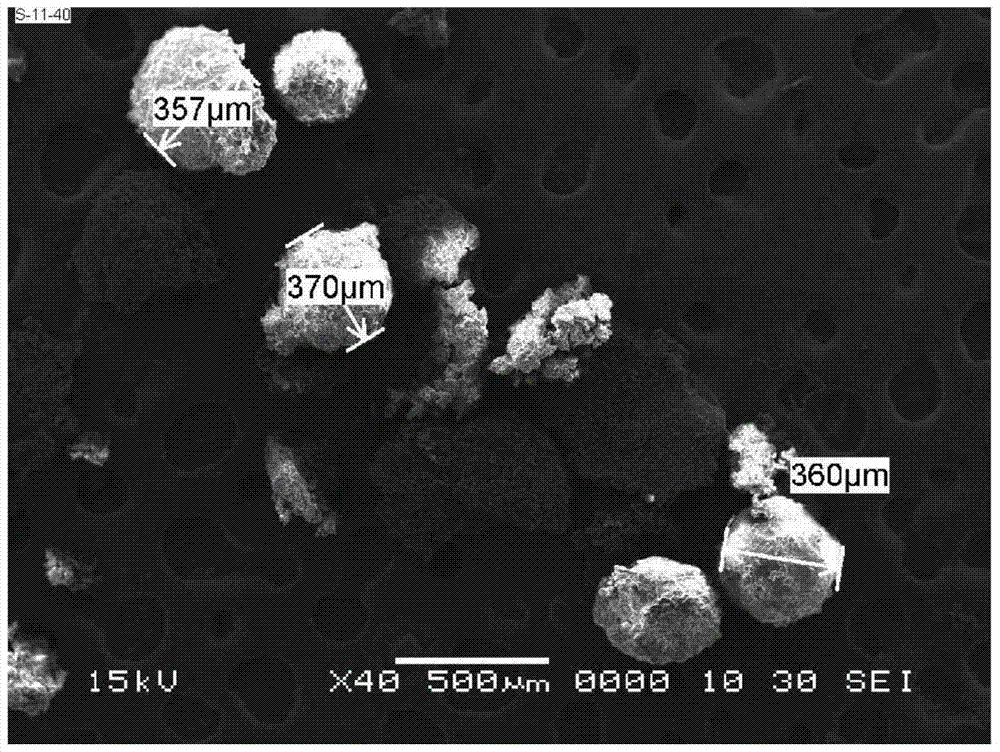

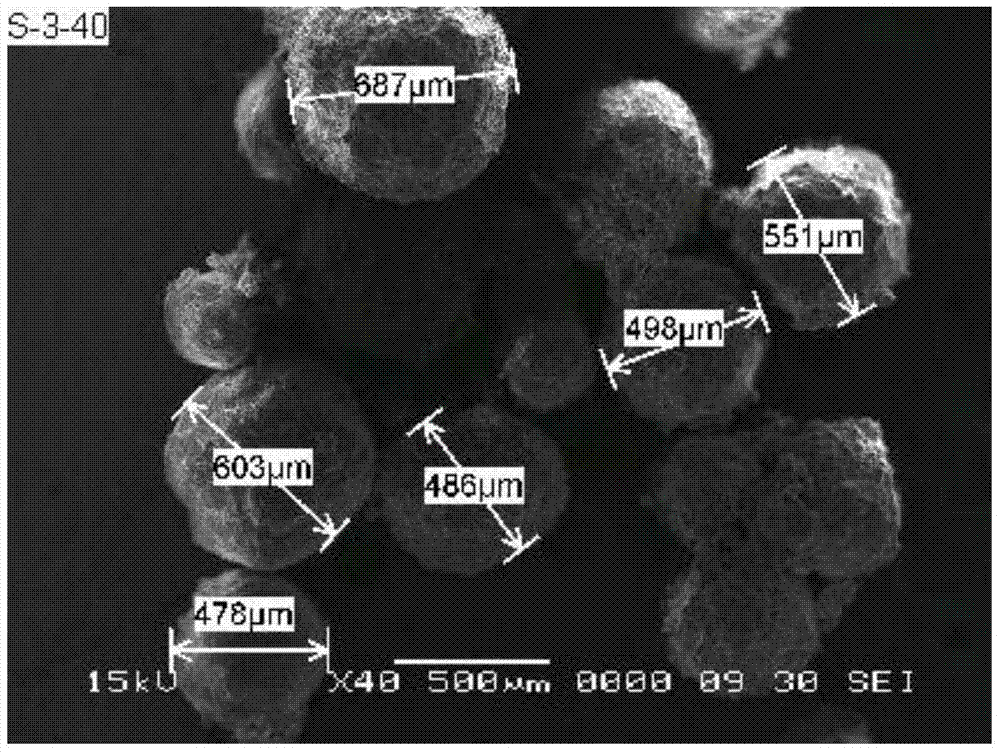

A method for producing a polyolefin is provided. The method includes a step of feeding a polyolefin powder having a catalytic activity into a gas phase polymerization vessel in which there is a polyolefin powder and through which a gas comprising an olefin is being circulated, thereby commencing polymerization of an olefin. The following formula (1) is satisfied:0.5<β / (αB)<24.0 (1)In formula (1), α represents the median diameter (μm) of the catalytically active polyolefin powder to be fed into the vapor phase polymerization vessel, β represents the median diameter (μm) of the polyolefin powder that is contained in the vapor phase polymerization vessel before the feeding of the catalytically active polyolefin powder into the vapor phase polymerization vessel, and B represents the linear gas velocity (m / sec) of the gas containing an olefin within the vapor phase polymerization vessel.

Owner:SUMITOMO CHEM CO LTD

Method for producing liquefied petroleum gas

InactiveCN100455643CIncrease productionHydrocarbon from carbon oxidesGaseous fuelsAlkaneOlefiant gas

A liquefied petroleum gas containing propane or butane as a main component is produced by passing a raw material gas comprising hydrogen and at least one selected from the group consisting of methanol and dimethyl ether through a catalyst layer comprising, in the direction of flowing of the raw material gas, a former catalyst layer comprising a catalyst for synthesizing an olefin-containing gas which is used when producing an olefin-containing gas from at least one selected from the group consisting of methanol and dimethyl ether, and a latter catalyst layer comprising a catalyst for hydrogenating an olefin-containing gas which is used when an olefin is hydrogenated to produce a paraffin.

Owner:TOKAI

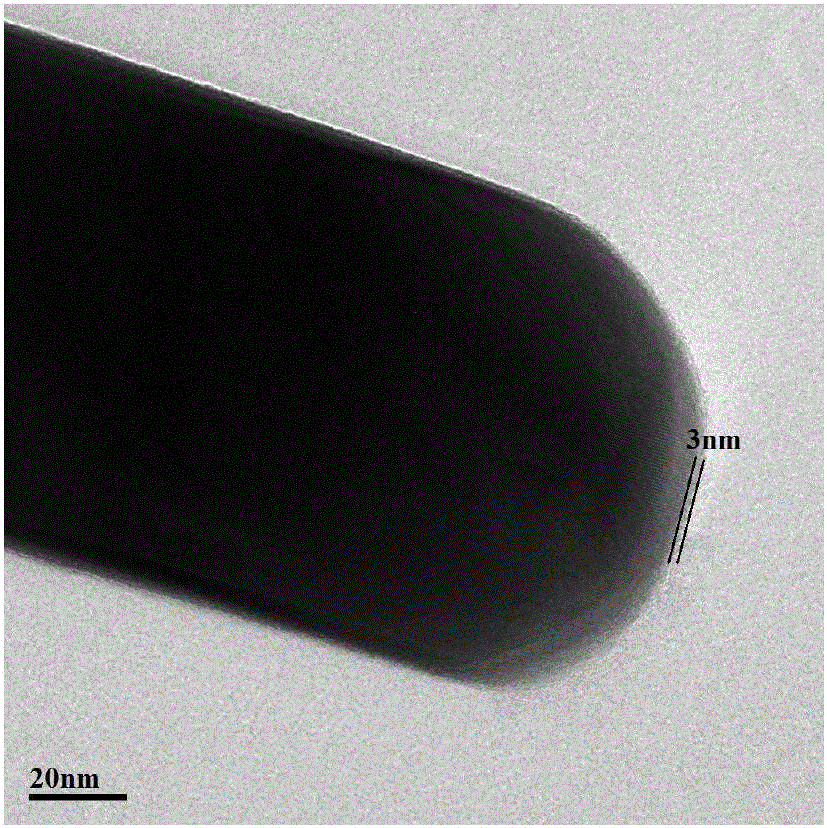

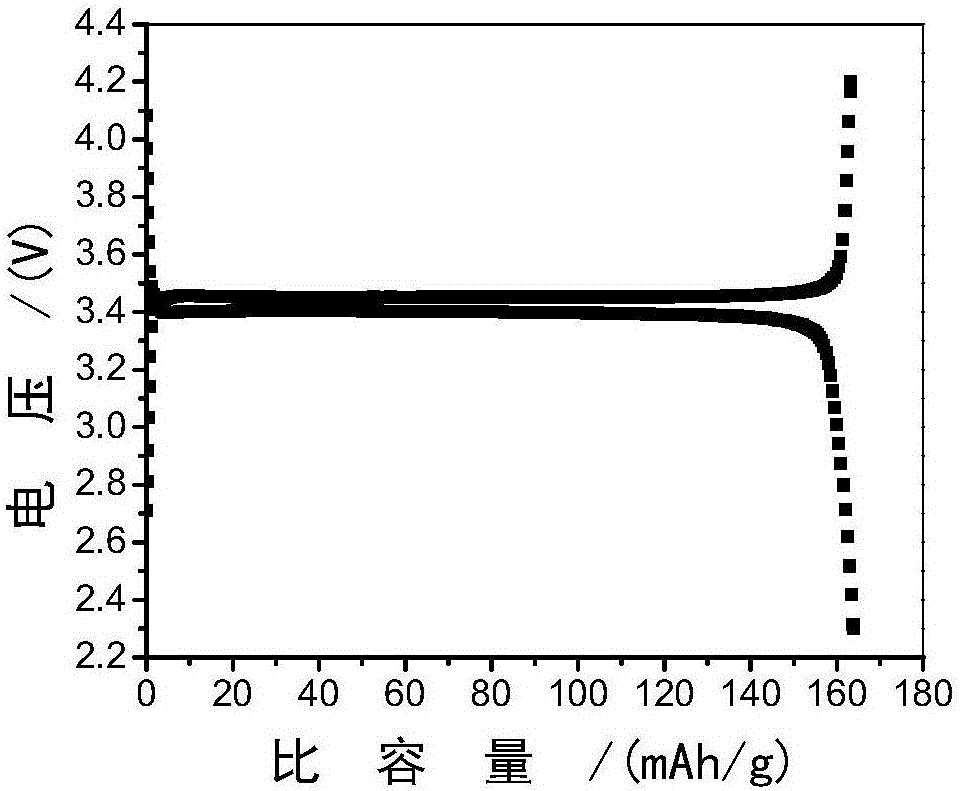

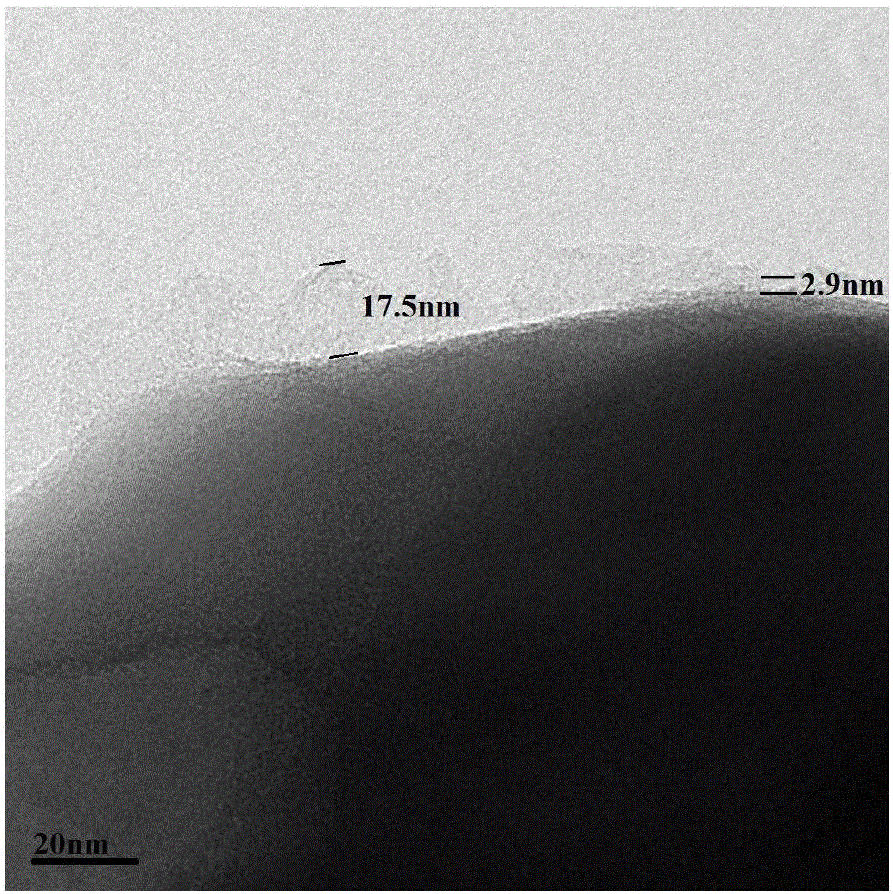

Hydrothermal lithium iron phosphate carbon coating method

ActiveCN106207251ADo not change element ratioCrystal structure unchangedCell electrodesSecondary cellsAir atmosphereCarbon coating

The invention discloses a hydrothermal lithium iron phosphate carbon coating method which includes the steps: first, placing lithium iron phosphate prepared by a hydrothermal method in air atmosphere and heating and drying the lithium iron phosphate for 1-3 hours; second, placing the dried lithium iron phosphate in a high-temperature furnace, keeping the temperature of 570-600 DEG C for 1-2 hours in protective gas atmosphere, leading reaction gas at the temperature of 600-650 DEG C, performing reaction for 4-6 hours, switching the reaction gas into protective gas and cooling the lithium iron phosphate to below 100 DEG C to obtain a LiFePO4 / C composite material. The reaction gas is prepared by mixing olefin gas with the protective gas. A carbon coating layer with uniform components, controllable thickness and good conductivity can be obtained under the catalytic action of Fe3+ on the surface of LiFePO4 for olefin carbonization. The material has excellent electrochemical performance, and tap density can be improved.

Owner:HEBEI UNIV OF TECH

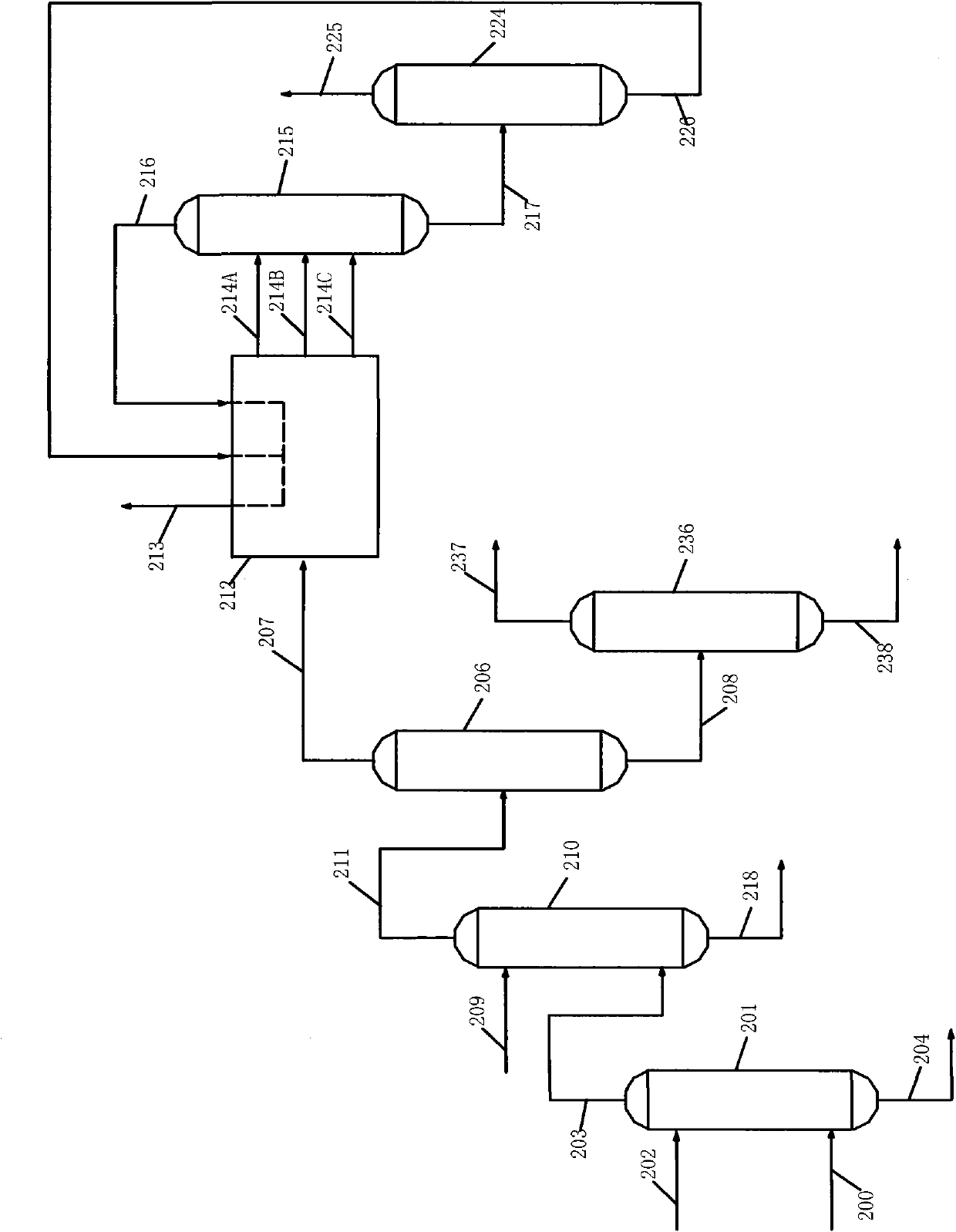

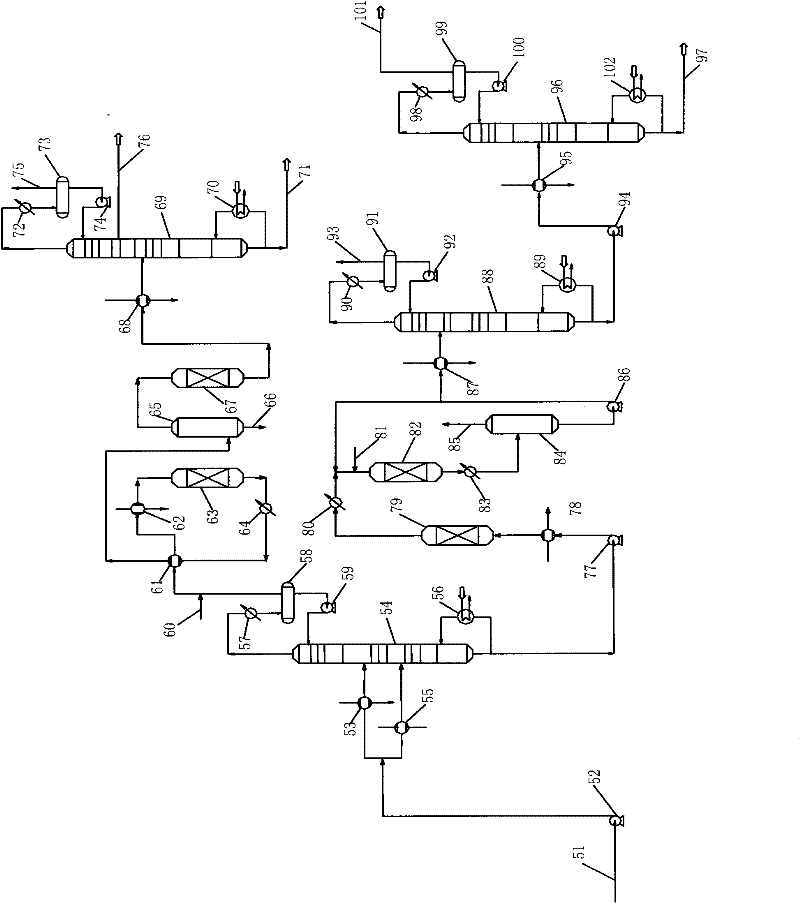

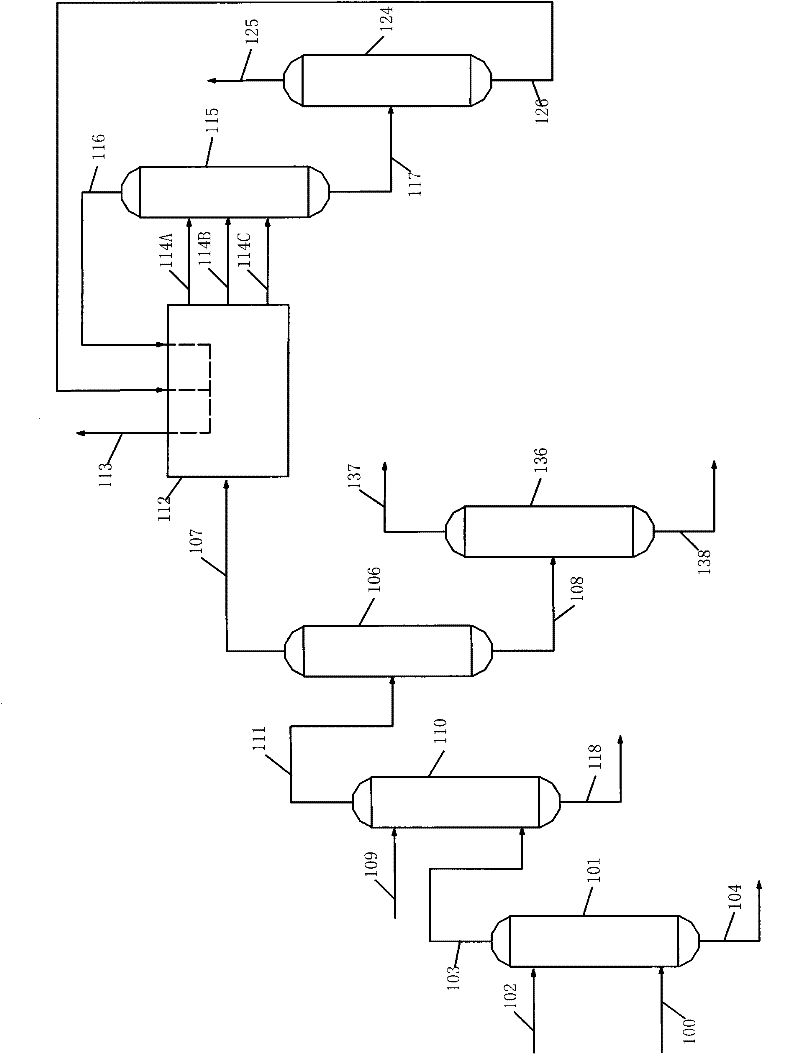

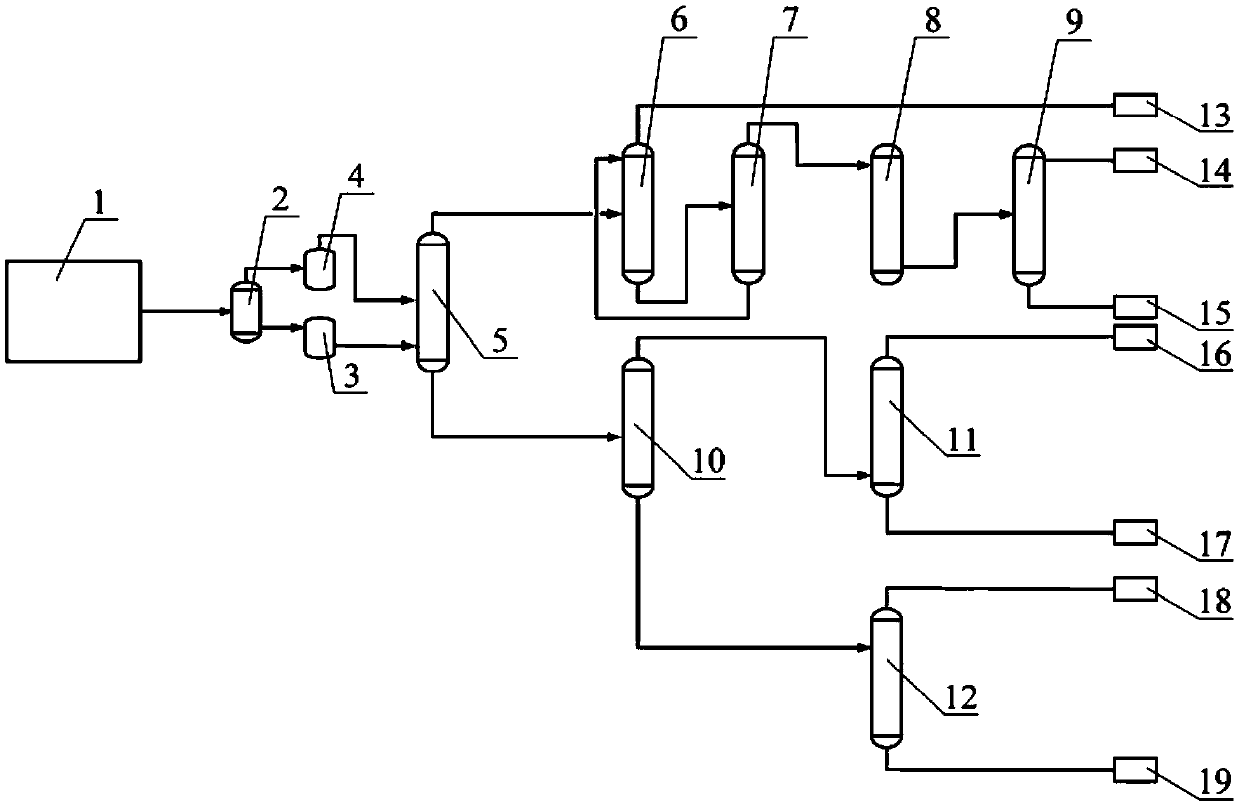

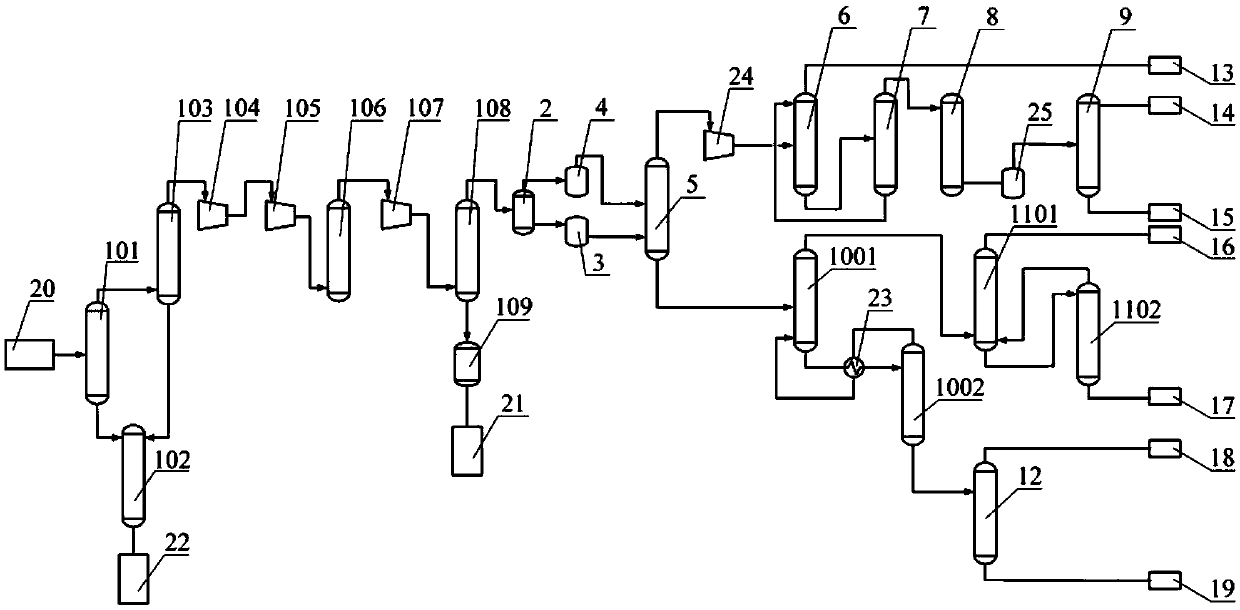

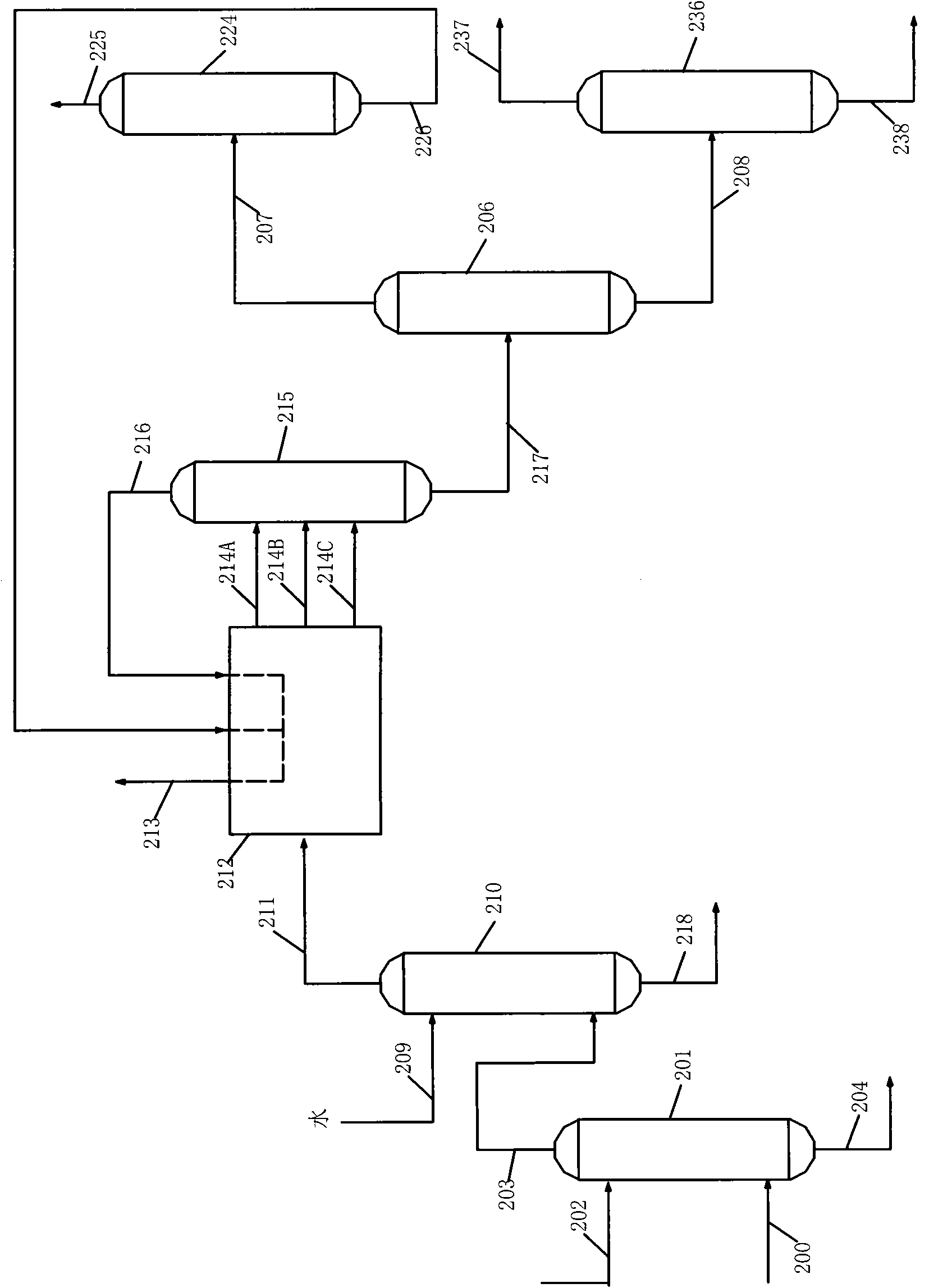

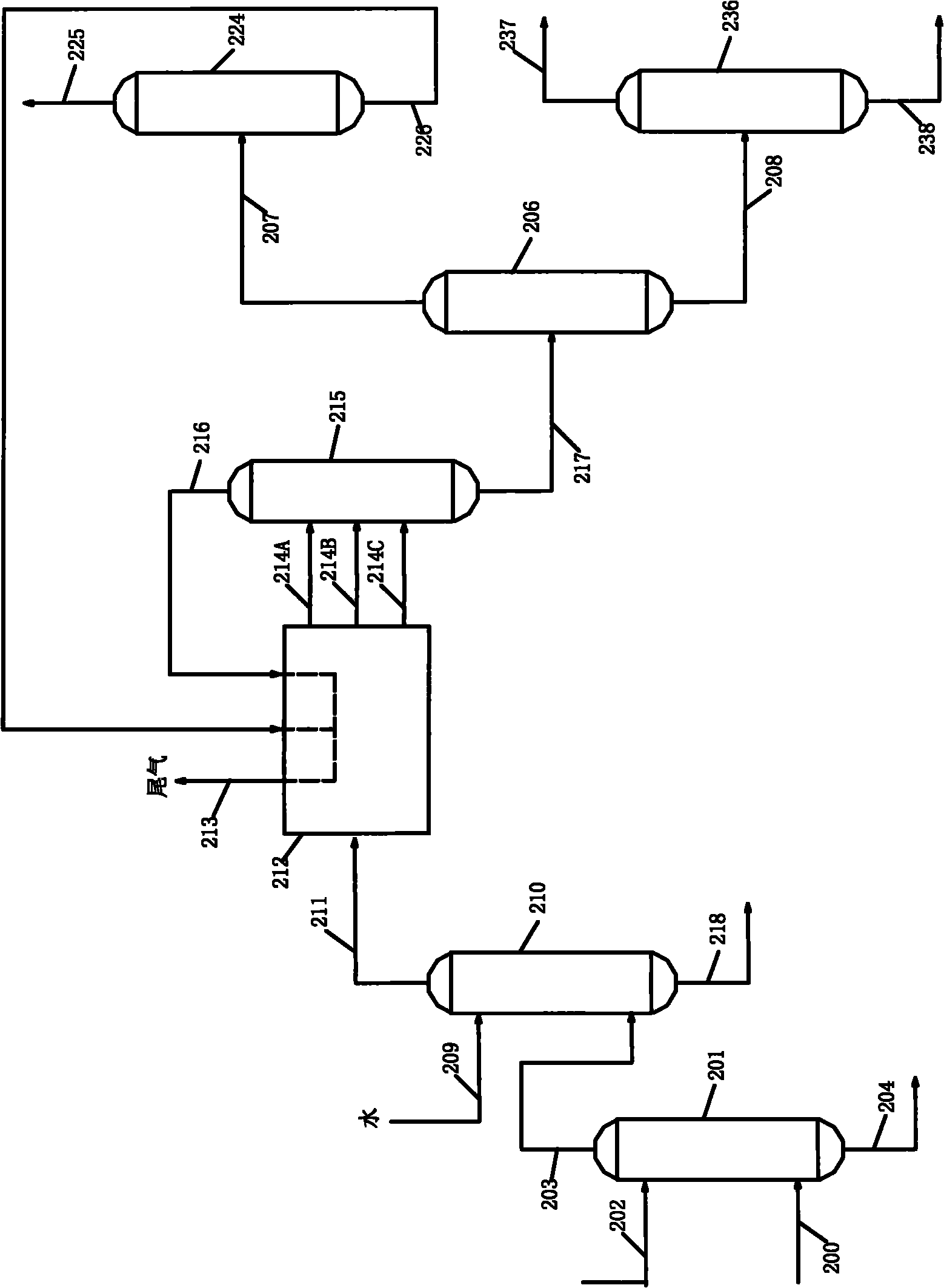

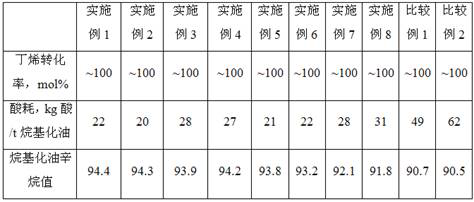

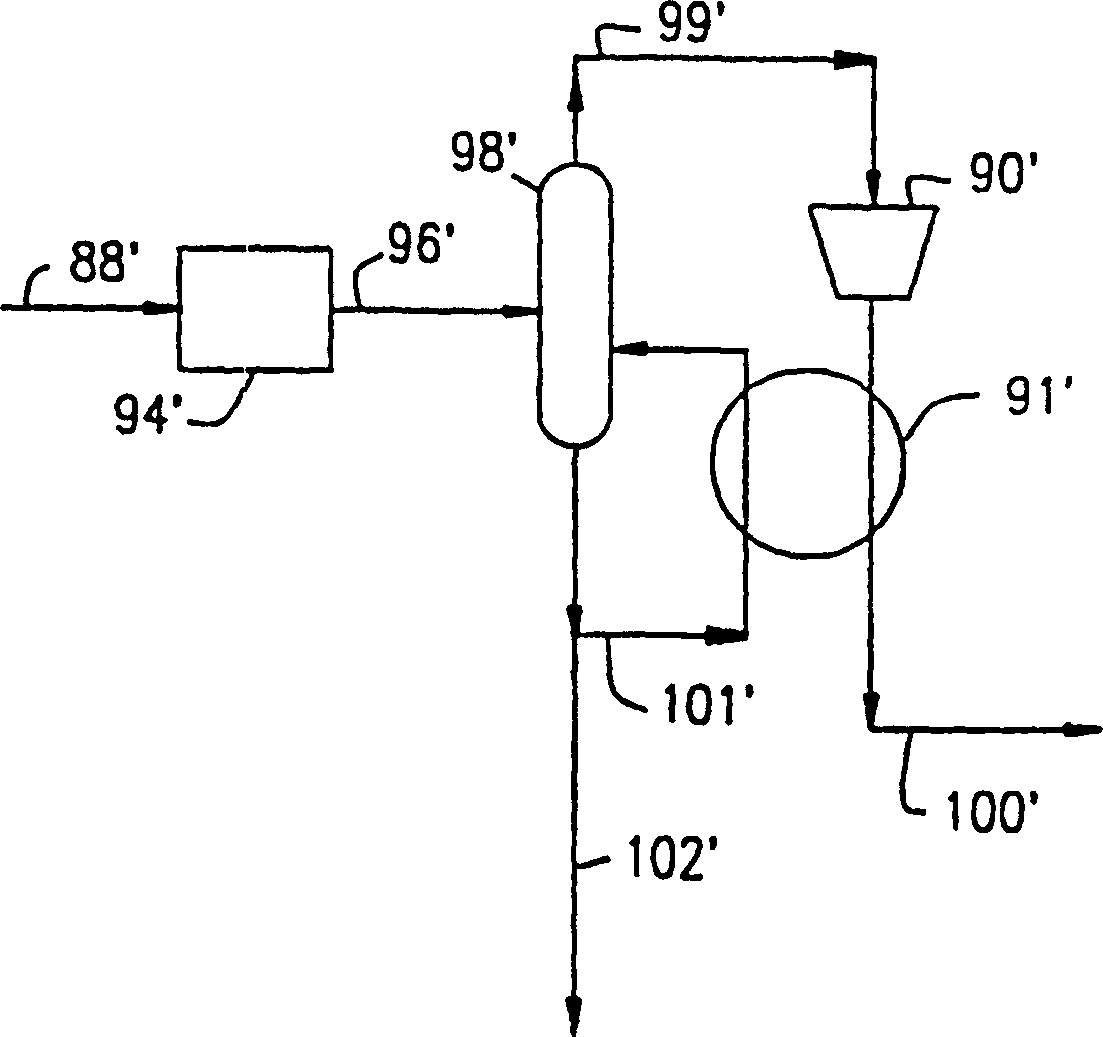

Separation device and separation method for methanol-to-olefin gas

PendingCN110950733AAchieve recyclingReduce loadDistillation purification/separationEthylene productionOlefiant gasPhysical chemistry

The invention discloses a separation device and a separation method for methanol-to-olefin gas. According to the method, methanol-to-olefin gas is pretreated through a pretreatment assembly (1); phaseseparation is carried out in a separator (2); the condensate is conveyed to a condensate dryer (3); the gas phase is conveyed to a first gas phase dryer (4), and is dried, and the dried material is conveyed to an ethane removal tower (5); the tower top gas phase of the ethane removal tower (5) passes through a methanol removal tower (6), a solvent recovery tower (7), an acetylene converter (8) and an ethylene rectifying tower (9) to separate ethylene; and the tower bottom of the ethane removal tower (5) passes through a propane removal tower (10) and a propylene rectifying tower (11) to separate propylene. According to the method, the circulation loop of the absorbent comprises a methanol removal tower (6), a solvent recovery tower (7) and a methanol removal tower (6), so that the circulation loop is short, does not uses an ethane removal tower (5) and a propylene rectifying tower (11), and effectively reduces the load, the energy consumption and the equipment investment of the ethaneremoval tower (5) and the propylene rectifying tower (11).

Owner:PETROCHINA CO LTD +1

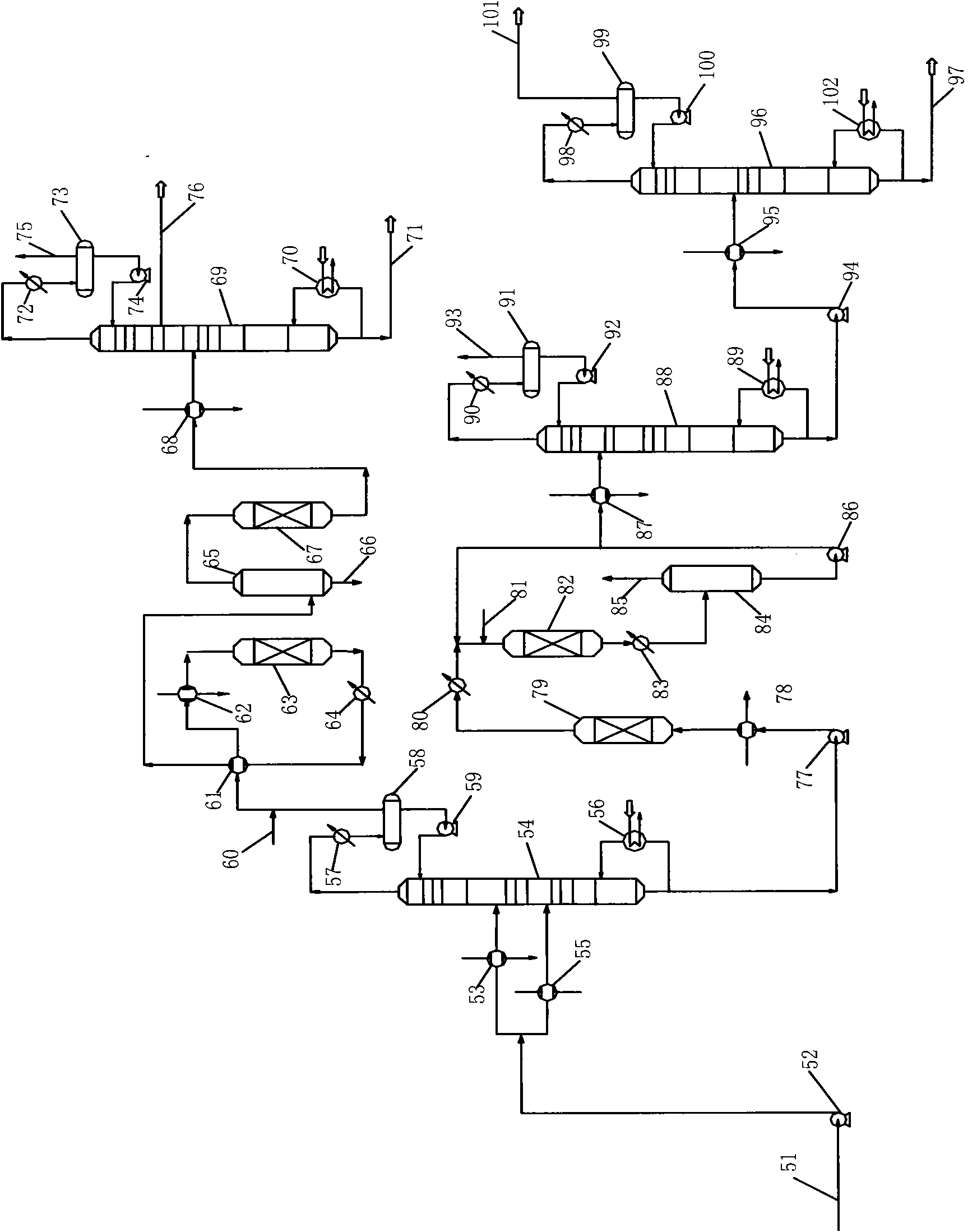

Technology for separating low carbon olefin gases

The invention discloses a technology for separating low carbon olefin gases, for solving the problems that hydrogen, methane, ethane and propane and other products with high purity can not be acquired and dimethyl ether and oxygen and carbon monoxide in impurities are not removed efficiently, etc. in the prior art. The technology is characterized in that a step of removing carbon monoxide and oxygen is added, methanol-to-olefin gas streams processed by removing carbon monoxide and oxygen enter into a deethanizing column, deethanizing column overhead streams successively pass through an ethene hydrogenation reactor, six separation pots, a low pressure demethanizing column and an ethene rectification column, etc. to separate to obtain ethene and ethane products, and deethanizing column bottom streams successively pass through a propyne hydrogenation reactor, a methane stripper and a propylene rectification column, etc. to separate to obtain propylene and propane products. According to the invention, polymer grade ethene and propylene products can be obtained, and hydrogen, methane, ethane and propane products, etc. with high purity can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Separation process for preparing low-carbon alkene gases through conversion of methanol

The invention discloses a separation process for methanol conversion to produce low-carbon olefin gas, in order to solve the problem that the prior art cannot obtain products such as hydrogen, methane, ethane and propane with high purity and cannot effectively remove dimethyl ether and flue gas impurities Defects such as oxygen and carbon monoxide in the air. The methanol-to-olefins gas stream in this process adds carbon monoxide and oxygen removal steps, and the methanol-to-olefins gas stream that removes carbon monoxide and oxygen passes through six separation tanks in sequence and then enters the low-pressure demethanizer, deethanizer, and acetylene hydrogenation reactor , ethylene rectification tower, propyne hydrogenation reactor and propylene rectification tower, etc., in which the liquid from the bottom of the first four separation tanks enters the middle and upper part of the demethanizer in turn, and the liquid from the bottom of the fifth separation tank enters the demethanizer The upper part of the tower or return to the compressor section. By using the present invention, polymer grade ethylene and propylene products can be obtained, and products such as hydrogen, methane, ethane and propane with higher purity can also be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

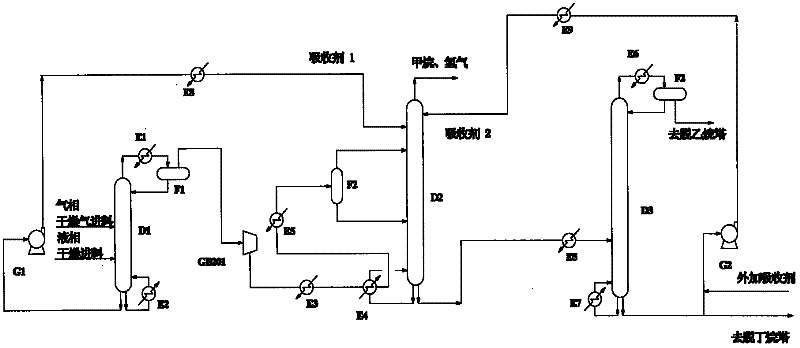

Methanol-to-olefin preparation gas separation process

InactiveCN104926585APromote absorptionReduce investmentDistillation purification/separationHydrocarbonsOlefiant gasHydrocarbon mixtures

The invention discloses a methanol-to-olefin preparation gas separation process. According to the invention, a pre-C3-removing process is adopted, and an absorbent separation tower is arranged before a methane-removing tower, such that a material is preliminarily separated. Two streams of different absorbents are adopted in the methane-removing tower, and enter the tower from different positions on the upper part. A main absorbent is a tower kettle material from the absorbent separation tower, and the other stream of absorbent is C2, C3 or a mixture of hydrocarbons thereof from subsequent systems. Compared to prior arts, the process has the advantages of low investment, low energy consumption, high material recovery rate, simple operation, and the like.

Owner:SINOPEC SHANGHAI ENG +1

Ex-situ presulfuration method for hydrogenation catalyst

InactiveCN109833919AImprove the activation effectHigh activityCatalyst activation/preparationVitamin COlefiant gas

The invention belongs to the field of catalysts, and especially relates to an ex-situ presulfuration method for a hydrogenation catalyst. The method concretely comprises the following steps: immersingthe hydrogenation catalyst in an organic solvent containing industrial vitamin C, and carrying out reduction pretreatment at 80-100 DEG C for 5-10 h; adding sulfur and ammonia water having a concentration of 23-25% into a reactor, heating the added substances to 120-140 DEG C, and carrying out a reaction for 3-4 h to generate ammonium polysulfide; introducing an olefin gas into the reactor, carrying out heat insulation treatment under a pressure of 5-10 MPa for 24-36 h; cooling the reactor to room temperature after the reaction is finished in order to obtain a sulfuration agent; and adding the pretreated catalyst to the sulfuration agent, adding the olefin gas, carrying out heat treatment to sufficiently sulfurate the catalyst, passivating the sulfurated catalyst in a container filled aninert gas, and carrying out constant temperature treatment for 10-12 h. The method has the advantages of simplicity in process operation, low cost and small in environmental pollution, and is suitablefor industrial production.

Owner:沈阳益泰科信息技术有限公司

Separation process for preparing low-carbon olefin gas through methanol conversion

The invention discloses a separation process for preparing low-carbon olefin gas through methanol conversion, aiming at overcoming the defects that products such as high-purity hydrogen, methane, ethane and propane cannot be obtained, dimethyl ether and oxygen and carbon monoxide in flue gas impurities are not effectively removed and the like in the prior art. A carbon monoxide and oxygen removal step is added in the process. Methanol-to-olefin gas with the carbon monoxide and the oxygen being removed passes through six separation tanks and then enters a high-pressure demethanation tower, a deethanization tower, an acetylene hydrogenation reactor, an ethylene rectifying tower, an allylene hydrogenation reactor, a propylene rectifying tower and the like for separation, wherein liquid which comes out from the bottoms of the first five separation tanks sequentially enters the middle-to-upper part of the demethanation tower. By adopting the separation process, polymer-grade ethylene and propylene products can be obtained and products such as high-purity hydrogen, methane, ethane and propane can also be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

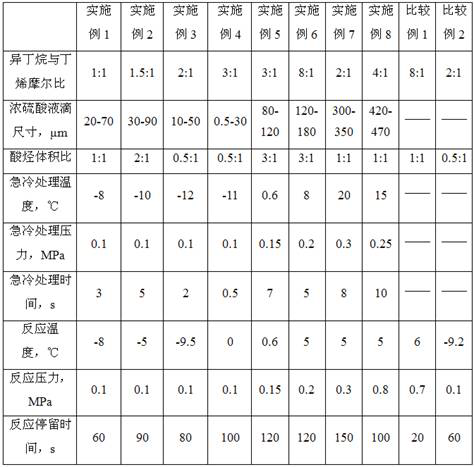

Alkylation method

PendingCN112745898AReduce acid consumptionLess side effectsLiquid hydrocarbon mixtures productionHydrocarbon oils treatmentAlkanePtru catalyst

The invention relates to an alkylation method, which comprises the following steps: mixing isobutane and C3-C5 olefin gas to form mixed raw material gas, dispersing concentrated sulfuric acid into liquid drops with the size of 0.001-500 [mu]m, mixing the mixed raw material gas with the concentrated sulfuric acid liquid drops, and then carrying out quenching treatment under the conditions that the temperature is -20 to 20 DEG C and the pressure is 0.1-1 MPa, so that the mixed raw material gas is subjected to phase change condensation and is kept for 0.1-10 seconds; and the reaction temperature is adjusted to -20 DEG C to 10 DEG C, the reaction pressure is kept to be 0.1-1 MPa, and the materials are subjected to an alkylation reaction. The method comprises the following steps: mixing a mixed raw material gas with finely dispersed sulfuric acid liquid drops, condensing the raw material gas on the surface of the sulfuric acid liquid drops under a quenching condition to form reaction liquid drops, further controlling the reaction conditions, taking sulfuric acid as a catalyst, enabling the condensed raw material gas to quickly generate alkylation reaction, and enabling olefin and alkane to react according to a molecular ratio close to 1:1, so that side reactions are reduced, and the alkylation reaction efficiency is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Separation method for preparing low-carbon olefin gas through methanol conversion

ActiveCN102675025BHigh purityReduce usageLiquid hydrocarbon mixture productionAbsorption purification/separationOlefiant gasOxygen

Owner:CHINA PETROLEUM & CHEM CORP +1

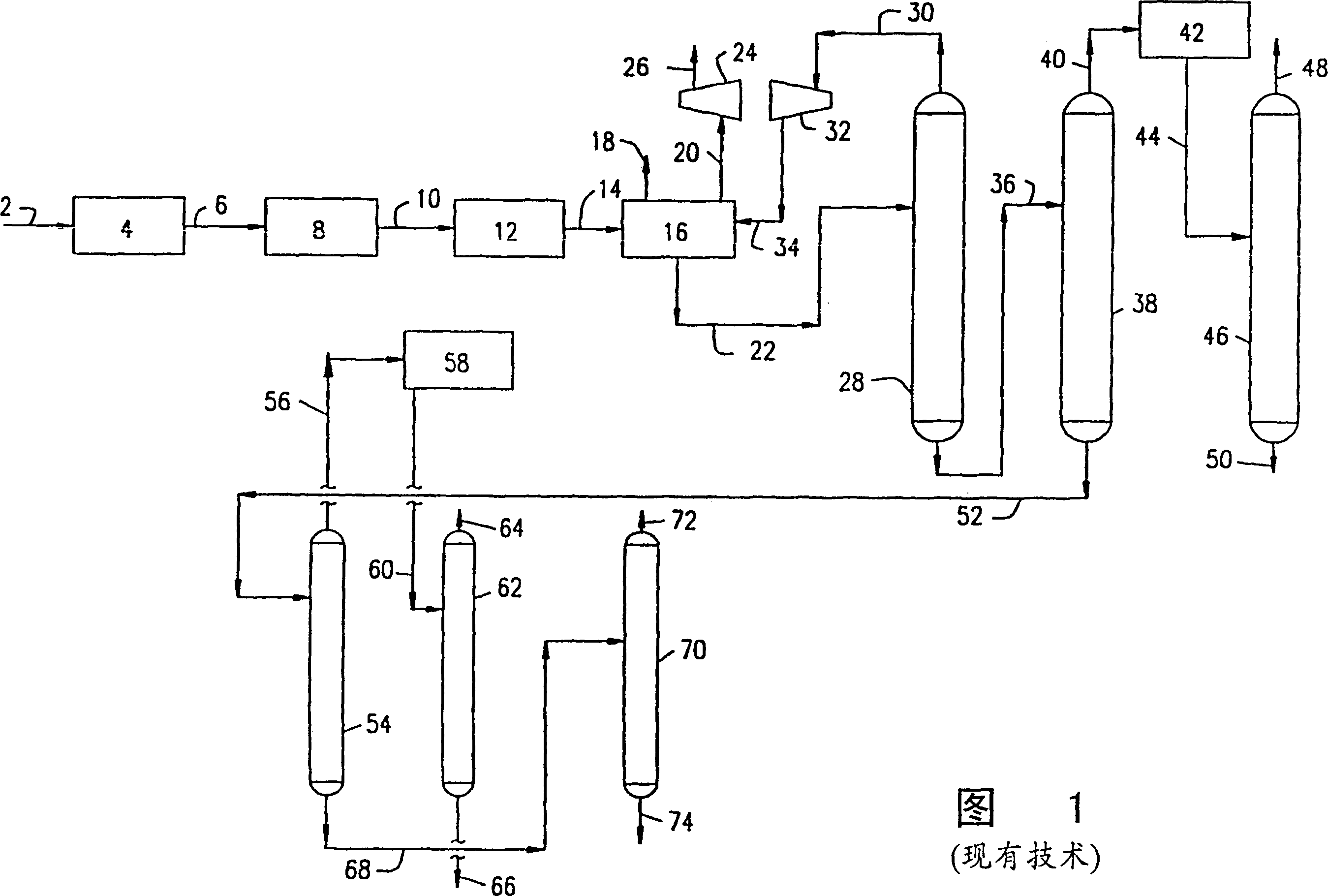

Improved chemical absorption process for recovering olefins from cracked gases

The present invention relates to an improved process for the recovery of high purity olefins from cracked gas effluents or other paraffin / olefin gas mixtures by chemical absorption.

Owner:STONE WEBSTER ENG

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com