Improved chemical absorption process for recovering olefins from cracked gases

A technology of olefins and gases, applied in chemical instruments and methods, purification/separation of hydrocarbons, organic chemistry, etc., can solve problems such as large solution circulation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

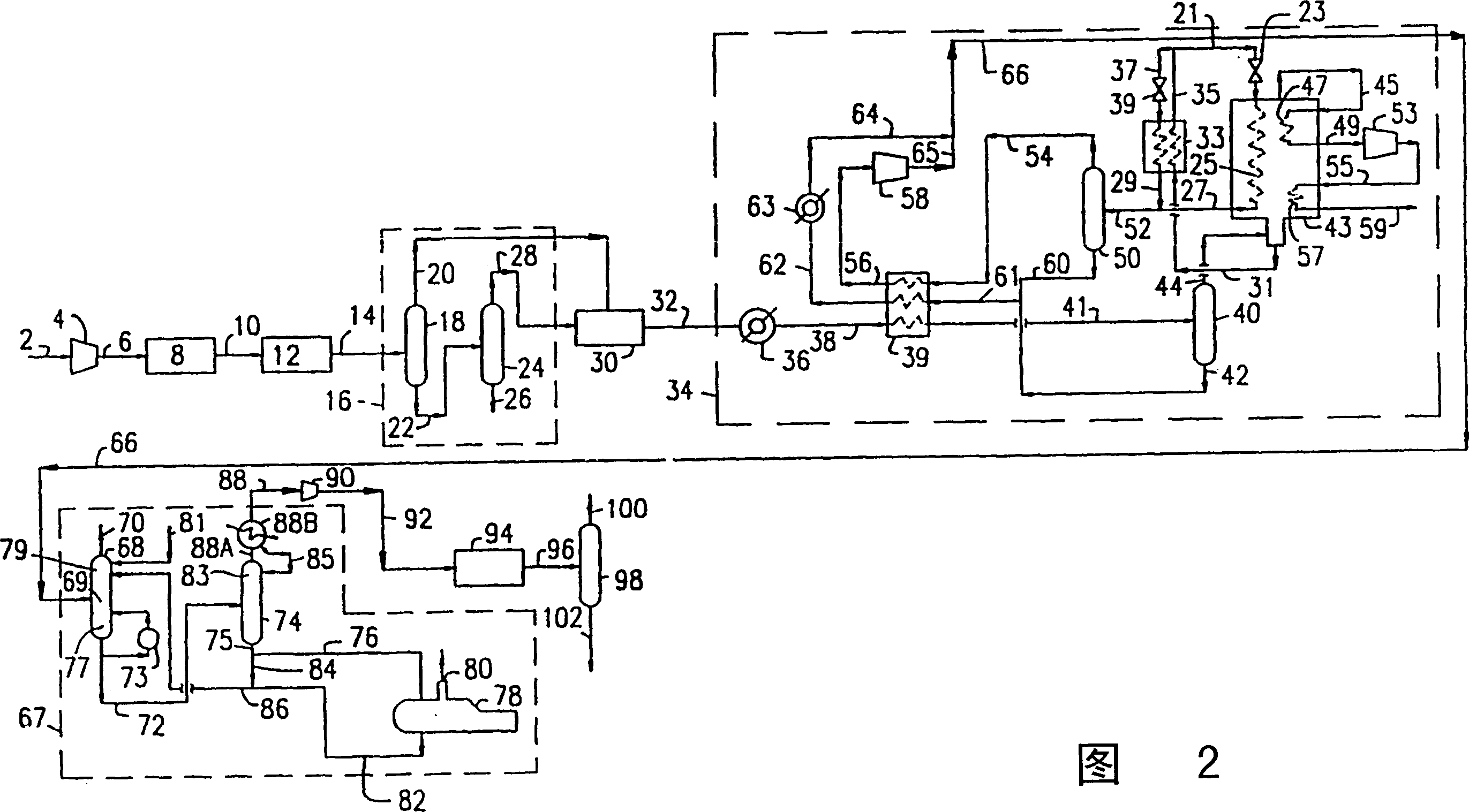

[0028] The present invention proposes a new method for recovering olefins from cracked gas. The method includes the following steps: (a) Demethanization of cracked gas stream removes at least part of methane and almost all hydrogen from the cracked gas stream to generate a partially demethanized gas stream; b) The partially demethanized gas stream is contacted with a metal solution capable of selectively chemically absorbing ethylene and propylene to generate a separate paraffin-enriched gas stream and a chemically adsorbed olefin-enriched stream; and (c) from the chemical absorbent The olefin is recovered from the solution.

[0029] In the method of the present invention, demethanization includes the following steps:

[0030] (I) The depropanized gas stream is quenched to -30℃--60℃, so that C 2 +Partial condensation of components;

[0031] (II) The condensed C 2 +The components are separated from the quenched gas stream;

[0032] (III) Demethanization of the quench gas stream to pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com