Olefin gas leakage monitoring system and method thereof

A technology of gas leakage and monitoring system, which is used in liquid/vacuum measurement for liquid tightness, measurement device, material analysis by optical means, etc. The overall system, the problem of the leakage location and diffusion status of olefin gas cannot be found intuitively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

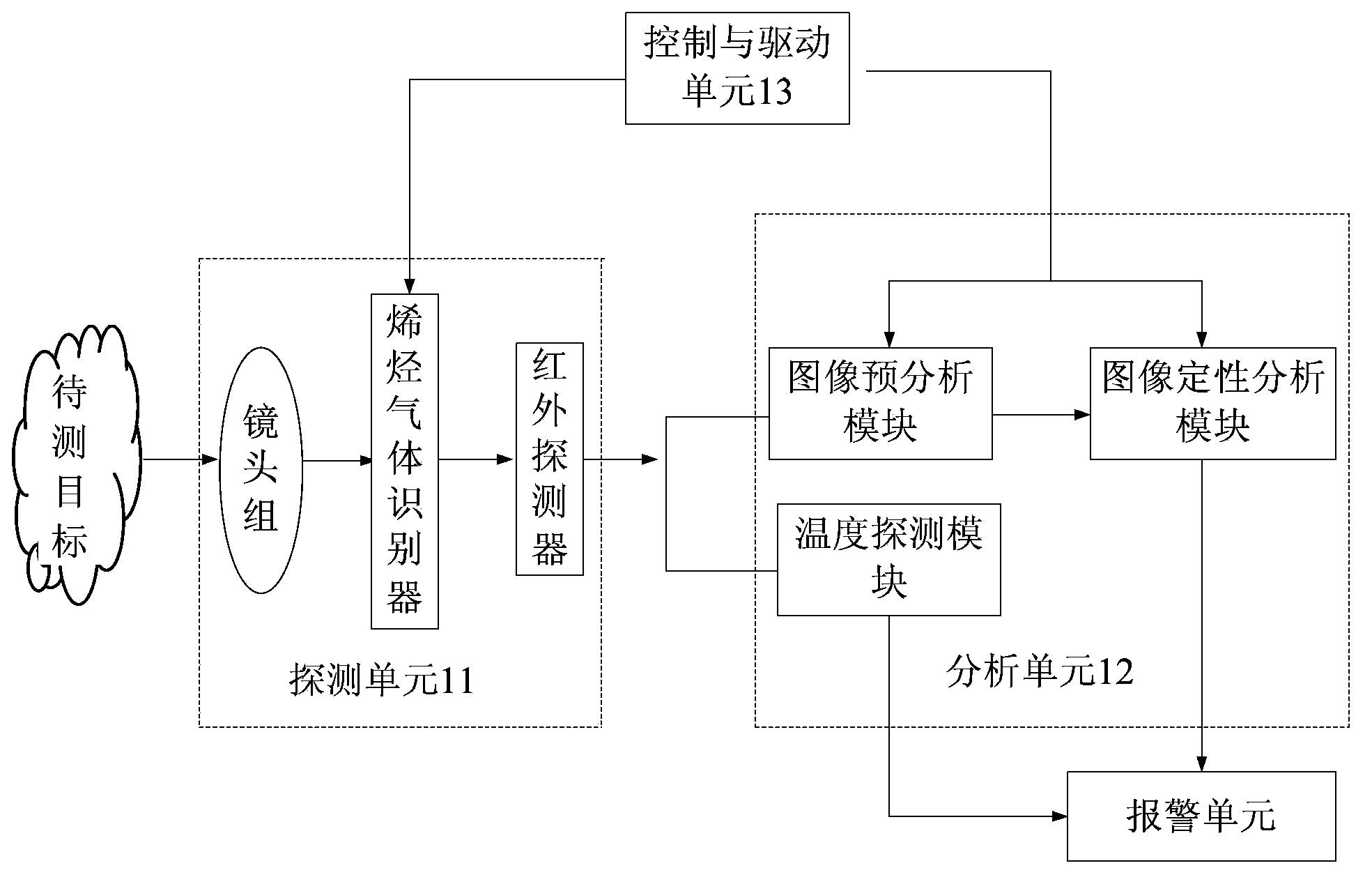

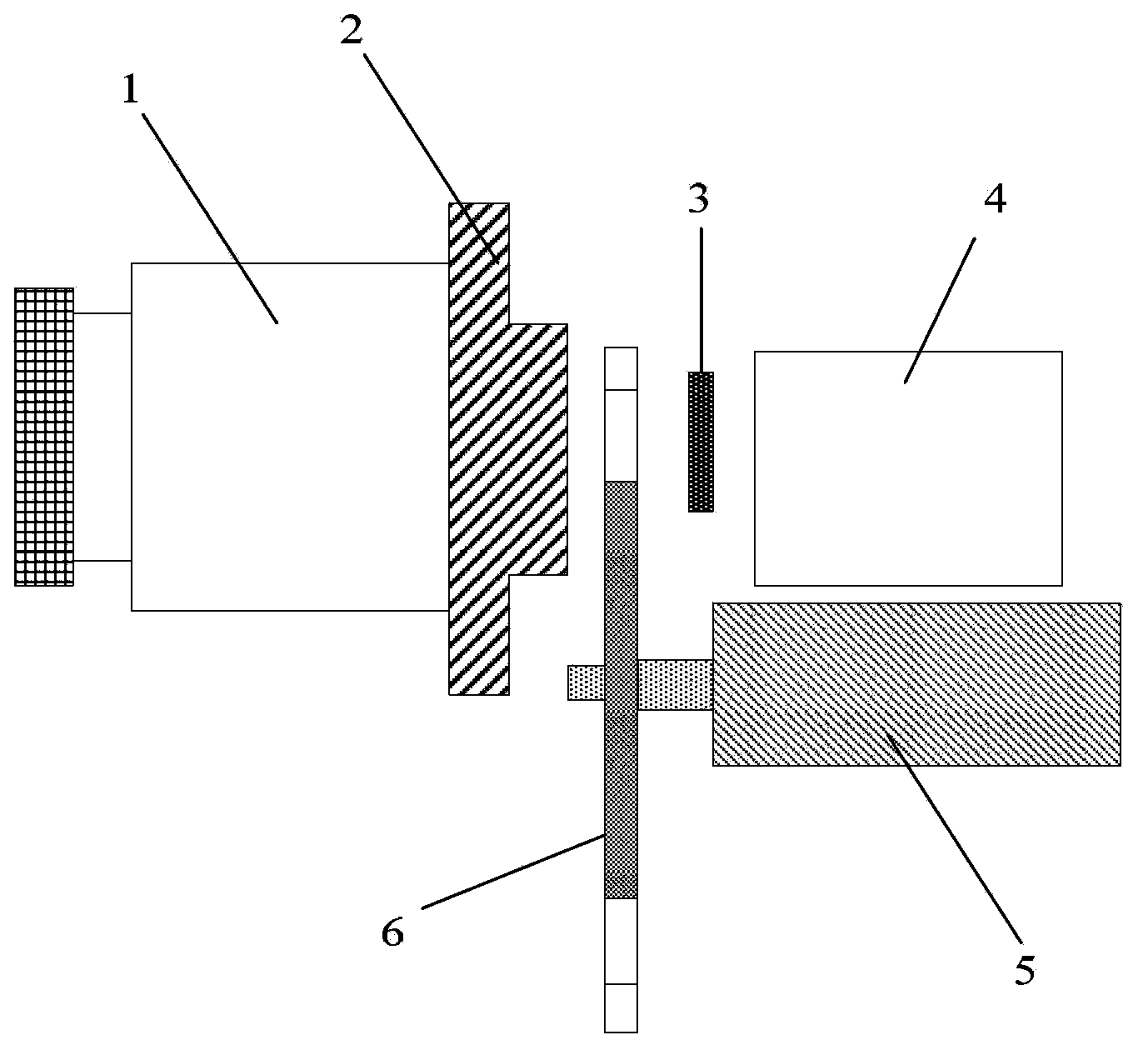

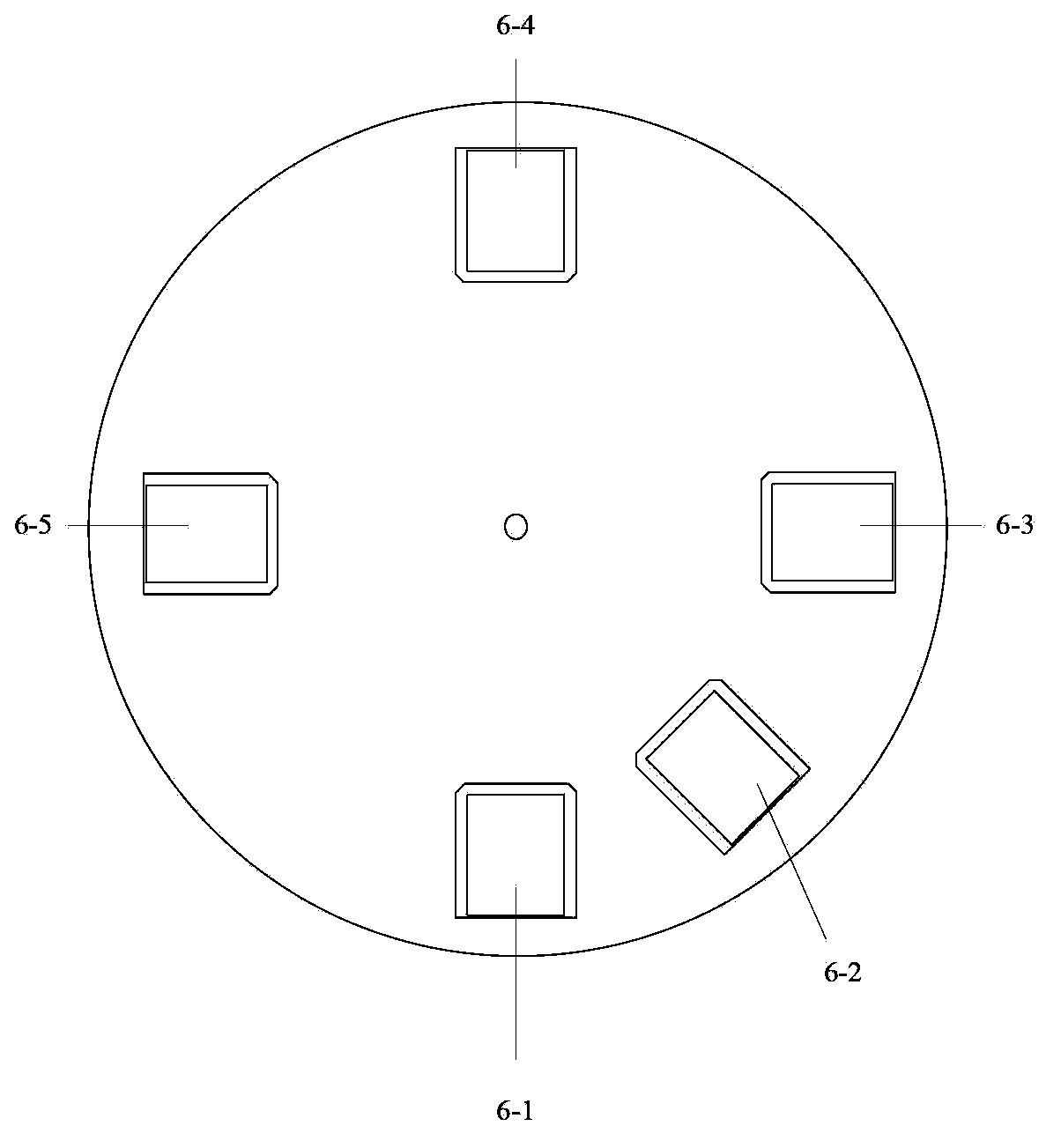

[0040] This embodiment discloses a monitoring system for olefin leakage, figure 1 It is a schematic structural diagram of the monitoring system in this embodiment. Such as figure 1 As shown, the monitoring system includes a detection unit 11, which includes an infrared thermal imager, figure 2 It is a structural schematic diagram of the infrared thermal imager, and the infrared thermal imager includes a lens 1 , a lens interface 2 , an olefin gas identifier 6 , an infrared detector 3 and a processing circuit 4 , and an encoding motor 5 . image 3 It is a top view structure schematic diagram of the olefin gas identifier 6 . Such as image 3 As shown, the olefin gas identifier 6 includes an empty window 6-1, a black body 6-2, and bandpass filters 6-3, 6-4 and 6-5 arranged on the turntable. image 3 Only the case where the olefin gas identifier includes three band-pass filters is shown in , in practice, the olefin gas identifier may include 1-5 band-pass filters. And those ...

Embodiment 2

[0056] This example describes in detail the monitoring method for olefin leakage using the monitoring system in Example 1. Figure 4 A flowchart of the method is shown. First, the thermal imaging camera does not activate the olefin gas identifier, that is, the band-pass filter of the olefin gas identifier is not on the imaging optical path, and the empty window 6-1 of the turntable of the olefin gas identifier faces the infrared detector 3 to detect The target (the target here takes the production site of a chemical industry as an example, but the present invention is not limited thereto) to obtain an infrared image. The advantage of doing this is that the infrared heat radiation energy collected by the lens group is collected as much as possible, and it is unlikely that a single Blocked by the band-pass filter at the beginning, the infrared thermal radiation energy is converted into an electrical signal by the focal plane array, and a clear infrared image is displayed on the ...

Embodiment 3

[0062] This embodiment discloses another monitoring system for olefin leakage. Image 6 A schematic structural diagram of the monitoring system is shown. The monitoring system includes a detection unit, and the detection unit includes an infrared thermal imager, and the infrared thermal imager has the same structure as the infrared thermal imager in Embodiment 1. Including lens, lens interface, olefin gas detector, infrared detector and processing circuit, encoding motor. Under normal conditions, the empty window 6-1 is facing the infrared detector 3, and the olefin gas identifier is not started at this time, that is, the bandpass filter of the olefin gas identifier is not on the optical path of imaging, and the detection target (the target here Taking the production site of a chemical industry as an example, but the present invention is not limited thereto) to obtain infrared images, the advantage of this is that the infrared heat radiation energy collected by the lens group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com