Method for producing liquefied petroleum gas

A technology of liquefied petroleum gas and manufacturing method, which is applied in the petroleum industry, producing hydrocarbons from carbon oxides, gas fuel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

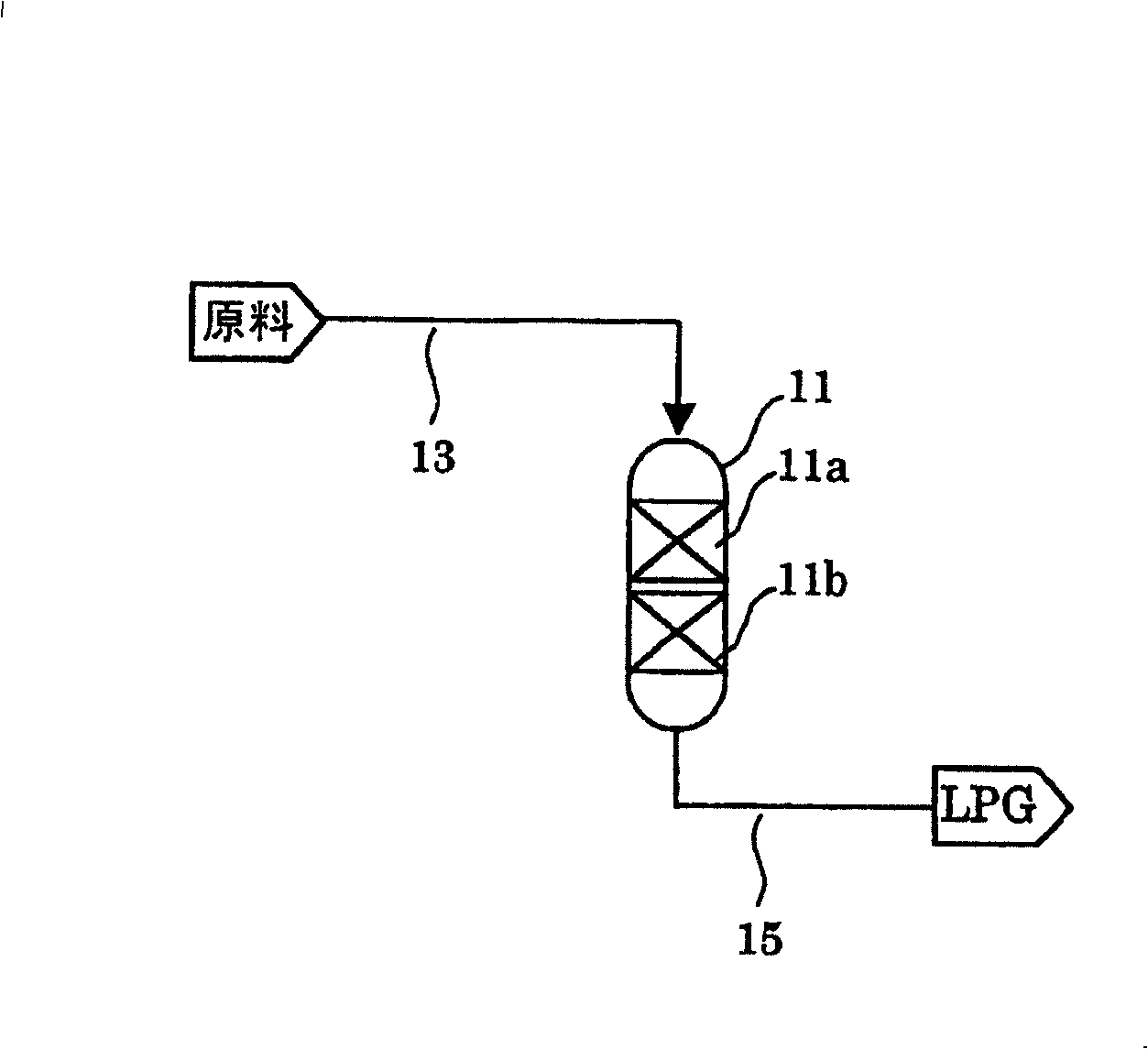

[0208] use figure 1 The LPG manufacturing apparatus shown produces LPG. As a catalyst for olefin-containing gas synthesis, a dry standard 73.5% by weight of H-ZSM-5 having a Si / Al ratio (atomic ratio) of 25.0 and a dry standard 26.5% by weight of alumina viscosity were used. A catalyst prepared by mixing, wet-forming, drying, and calcining a mixture (Catalyzed Chemical Industry Co., Ltd., Kataroide AP). As the catalyst for the hydrogenation of the olefin-containing gas, a 2.0% by weight Pt / C (manufactured by N.E. CHEMCAT (Epi-Tech Co., Ltd.)) was used. Both the catalyst for olefin-containing gas synthesis and the catalyst for olefin-containing gas hydrogenation were extruded molded articles having the same shape as 1 / 32-inch cylinders.

[0209] The raw material gas with the composition of methanol 50% (mol) and hydrogen 50% (mol) was passed through the first catalyst layer in the first stage (50% of the reactor volume) composed of the above-mentioned catalyst for synthesizin...

Embodiment 2

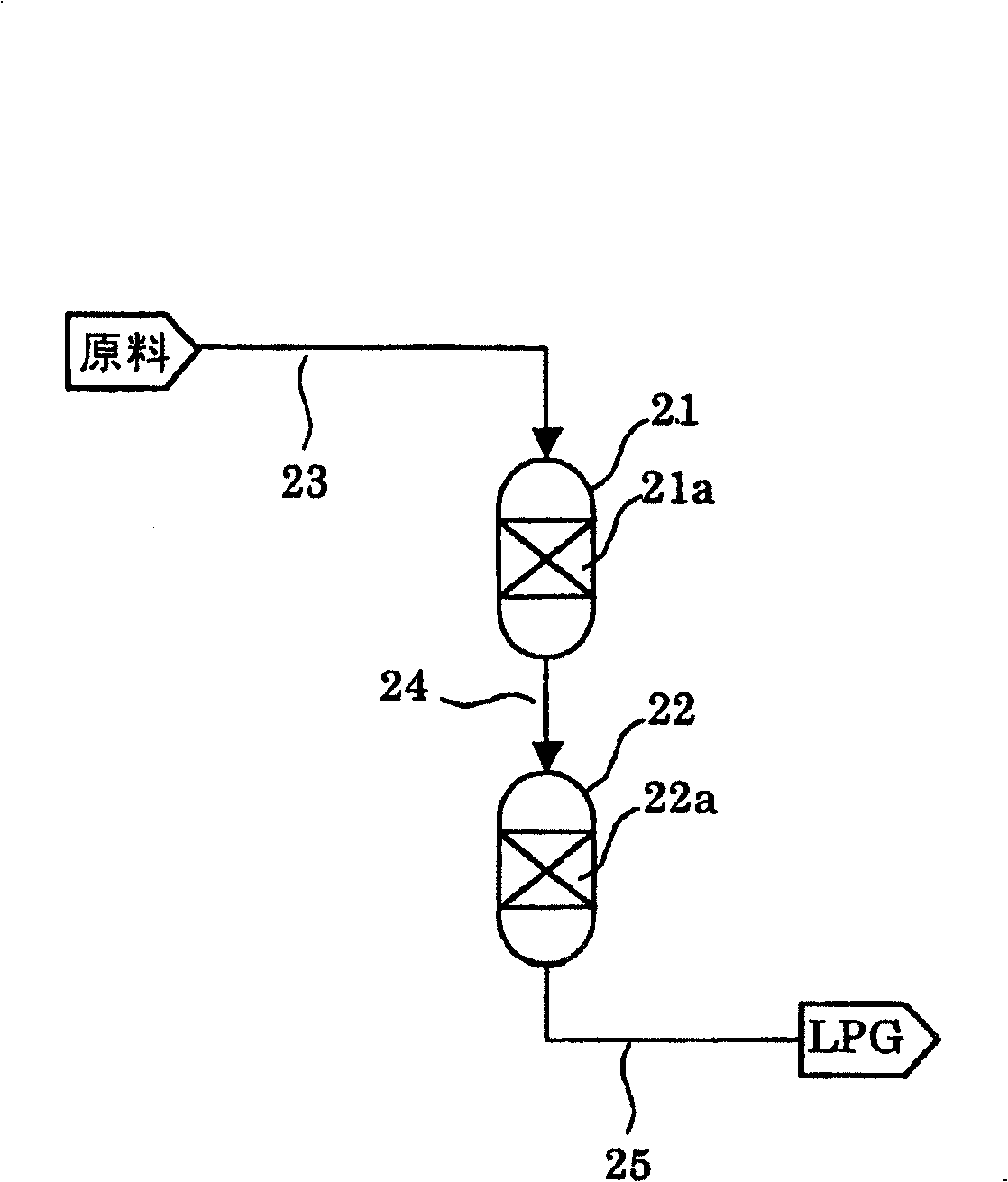

[0212] use figure 2 The LPG manufacturing apparatus shown produces LPG. As the catalyst for synthesizing olefin-containing gas, the same catalyst for synthesizing olefin-containing gas as in Example 1, and the same catalyst for synthesizing olefin-containing gas as in Example 1 were used to support 0.2% by weight of Pt (hereinafter referred to as Catalysts for the isomerization and hydrogenation of olefin-containing gases). In addition, the same catalyst for hydrogenation of olefin-containing gas as in Example 1 was used as the catalyst for hydrogenation of olefin-containing gas. Further, the catalyst for isomerization and hydrogenation of olefin-containing gas is a catalyst for olefin-containing gas synthesis having the function of a catalyst for hydrogenation of olefin-containing gas.

[0213] The raw material gas having the same composition as in Example 1, the part that passes through the reactor inlet by volume 2 / 3 is the above-mentioned catalyst for olefin-containing ...

Embodiment 3

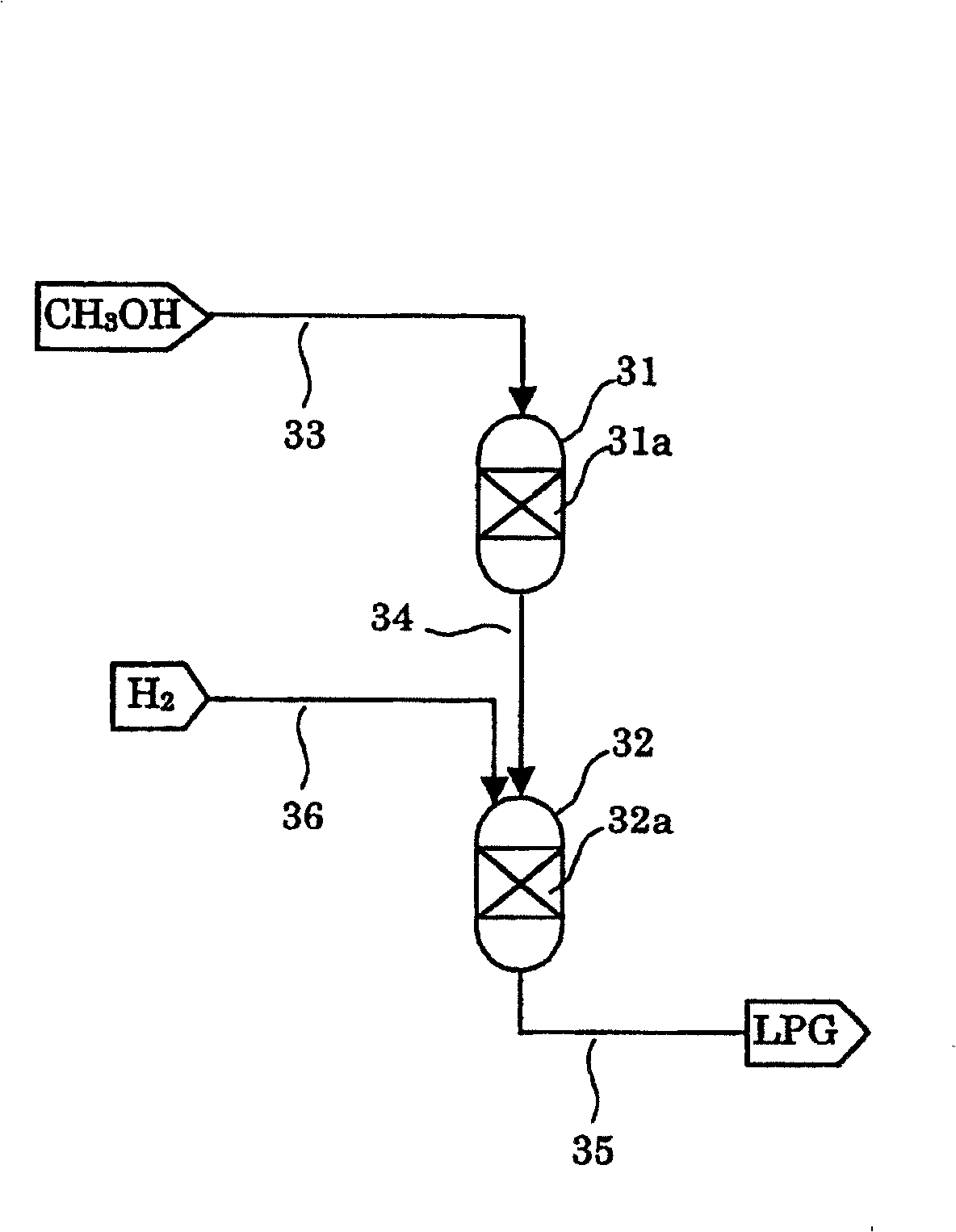

[0217] use image 3 The LPG manufacturing apparatus shown produces LPG. As the catalyst for synthesizing an olefin-containing gas, the same catalyst for synthesizing an olefin-containing gas as in Example 1 was used. As the catalyst for hydrogenation of olefin-containing gas, the same catalyst for hydrogenation of olefin-containing gas as in Example 1, and the same catalyst for isomerization and hydrogenation of olefin-containing gas as in Example 2 were used.

[0218] A raw material gas having a composition of 50 mol% of methanol and 50 mol% of steam was passed through the first catalyst layer composed of the above-mentioned catalyst for synthesizing an olefin-containing gas. The reaction conditions are: the reaction temperature: the control temperature of the reactor inlet is 330°C, the maximum temperature of the catalyst layer is 365°C; the reaction pressure: the partial pressure of methanol is 70kPa, and the space-time velocity of methanol liquid is 40H relative to the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com