Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89 results about "Sour gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sour gas is natural gas or any other gas containing significant amounts of hydrogen sulfide (H₂S). Natural gas is usually considered sour if there are more than 5.7 milligrams of H₂S per cubic meter of natural gas, which is equivalent to approximately 4 ppm by volume under standard temperature and pressure. However, this threshold varies by country, state, or even agency or application. For instance, the Texas Railroad Commission considers a sour gas pipeline one that carries gas over 100 ppm by volume of H₂S. However, the Texas Commission on Environmental Quality has historically defined sour gas for upstream operations – which requires permitting, reporting, and possibly additional emission controls – as gas that contains more than 24 ppm by volume. Natural gas that does not contain significant amounts of hydrogen sulfide is called "sweet gas".

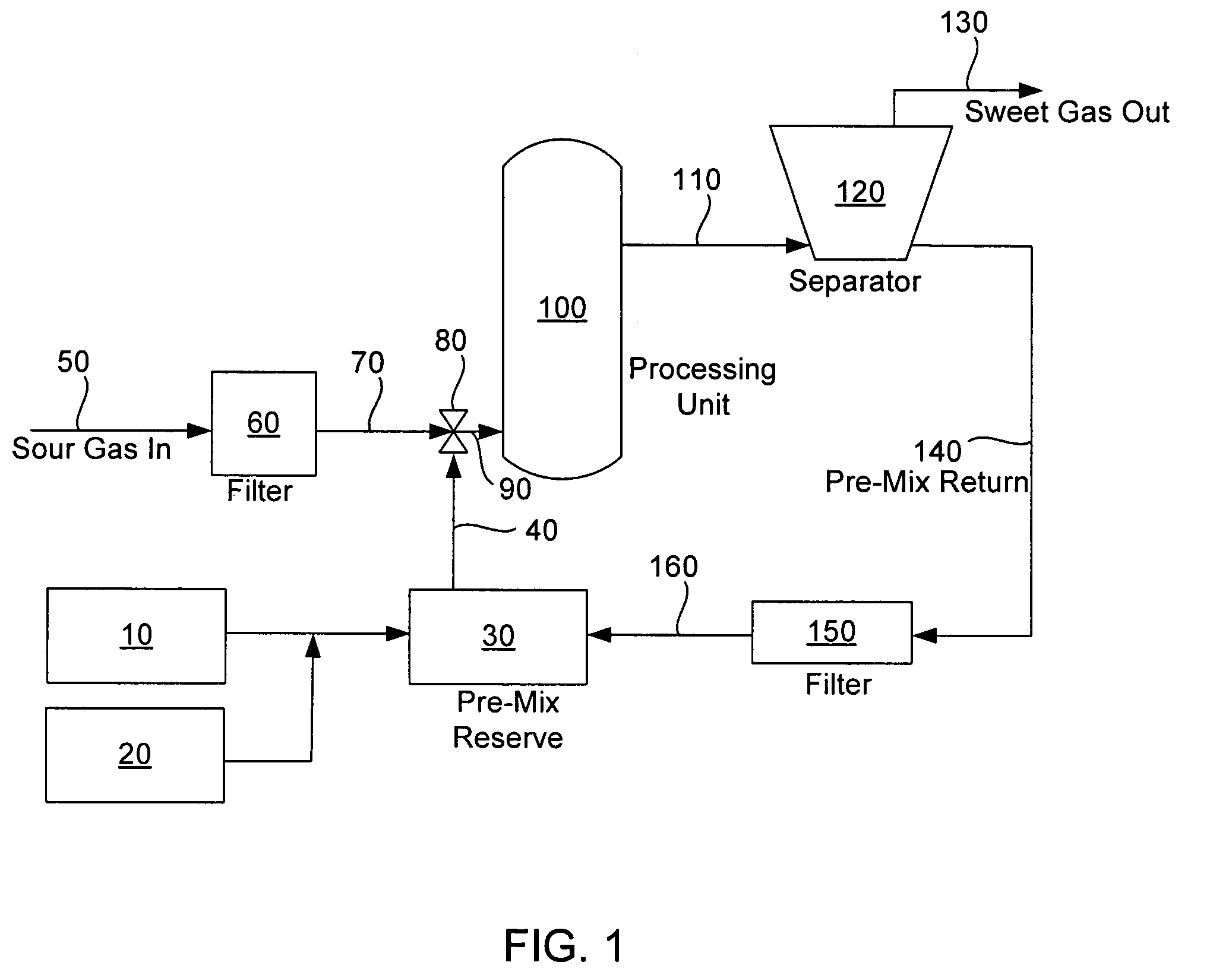

Method and apparatus for treating a sour gas

Owner:AIR PROD & CHEM INC

Removal of methyl mercaptan from gas streams

InactiveUS20050287056A1Efficient productionGas treatmentDispersed particle separationHigh concentrationThiol

The invention described herein is a method for selectively removing mercaptans such as methyl mercaptan from dry gas mixtures containing high concentrations of carbon dioxide. In the method, the carbon dioxide-rich gas (sour gas) is passed through an absorption vessel or distillation column in which it is contacted with an absorbent such as liquid carbon dioxide in order to selectively absorb the mercaptans. The treated gas, which is now free of mercaptans, leaves the top of the vessel as a sales gas suitable for use in enhanced oil recovery applications. Preferably, a portion of the carbon dioxide in the sales gas is condensed and the liquid is returned to the absorber or distillation column as the scrubbing agent. At least part of this scrubbing agent leaves the bottom of the absorber or distillation column enriched in methyl mercaptan and other sulfur compounds. The stream from the absorption vessel containing the mercaptans can be incinerated or otherwise processed to utilize or dispose of the methyl mercaptan.

Owner:DAKOTA GASIFICATION COMPANY

Integrated separation and purification process

InactiveUS7637984B2Improved arrangementSimple processGas treatmentCarbon compoundsMostly TrueSelexol

Increasing the economic and environmental compatibility in treatment processes in sour gas production. For 25 yr, Mobil Erdgas Erdoel GmbH (MEEG) has been treating considerable amounts of sour gas in N. Germany. In 9 fields with different gas qualities, there are ca 30 producing wells. The main processes of the sour gas production and treatment are described. The gas is dried at the well site and if the reservoir pressure is not sufficient, compressed for transportation to the central processing facility. In most cases the use of sulfur solvents is necessary at the wells. Natural gas scrubbers for the total removal of hydrogen sulfide and Claus units with downstream units to obtain sulfur are utilized. To increase the environmental compatibility and economics, a number of secondary processes have been introduced for emission control; glycol stripping; and the Purisol, Selexol, Sulfinol, and Claus processes.

Owner:UOP LLC

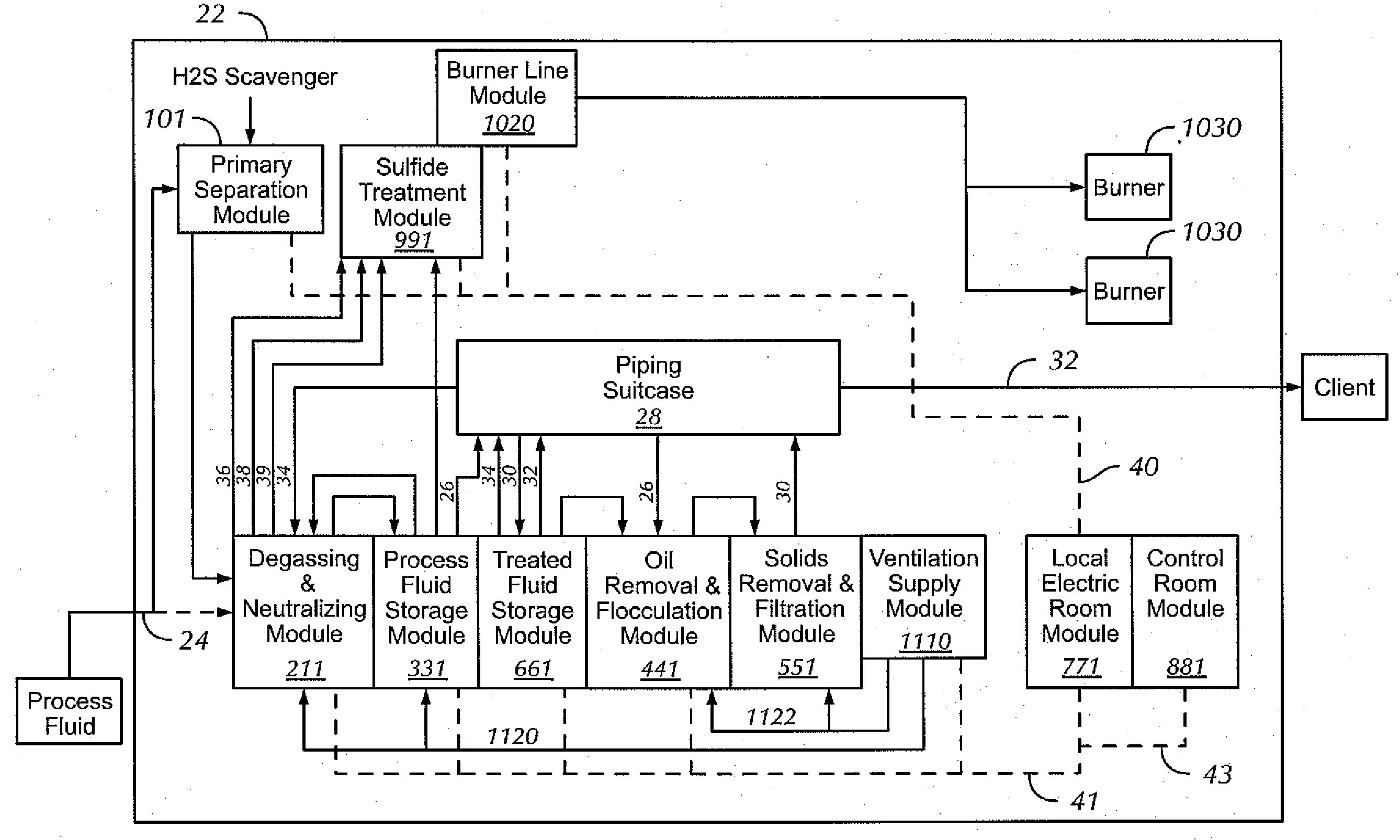

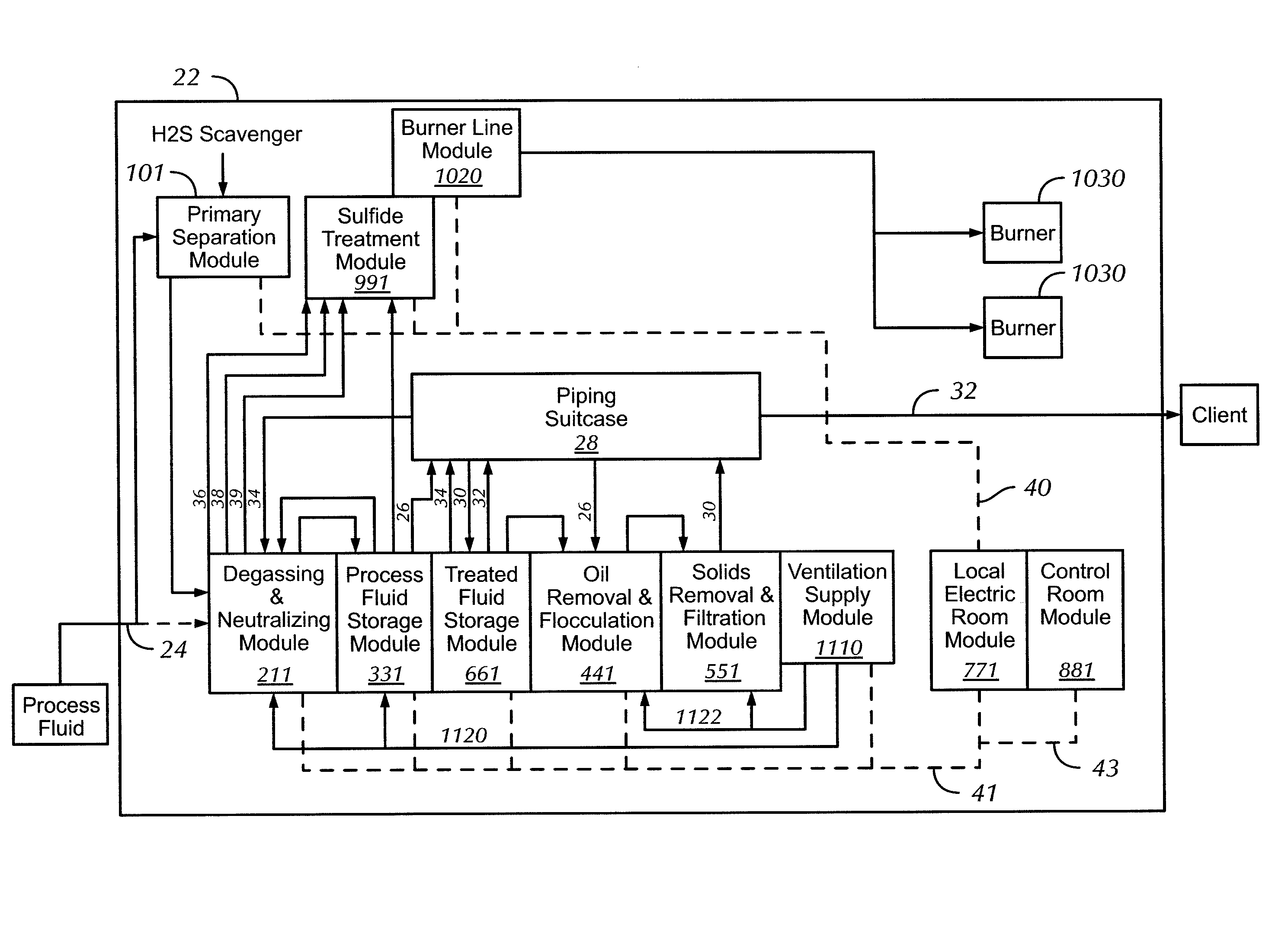

Hydrogen sulfide treatment system

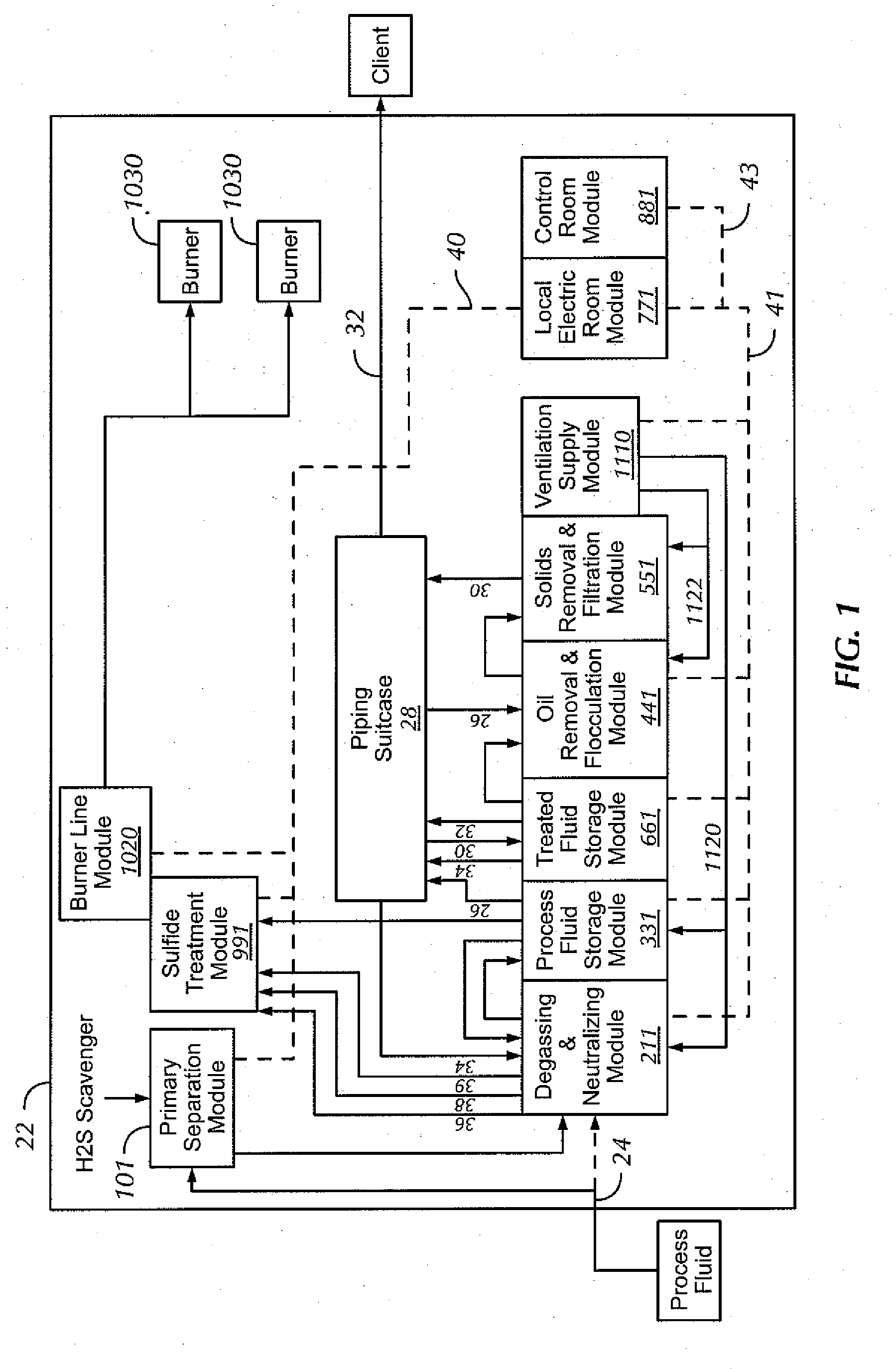

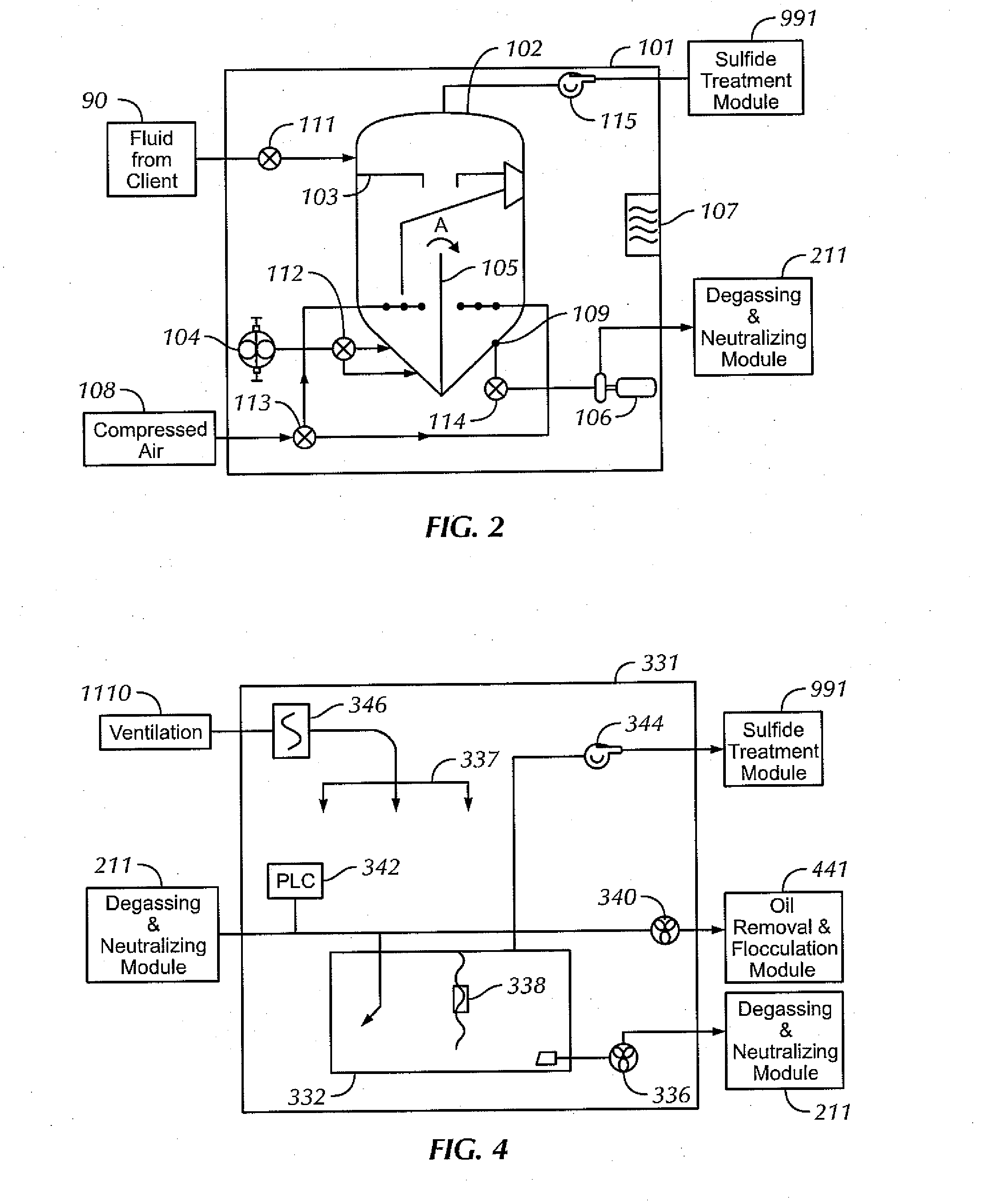

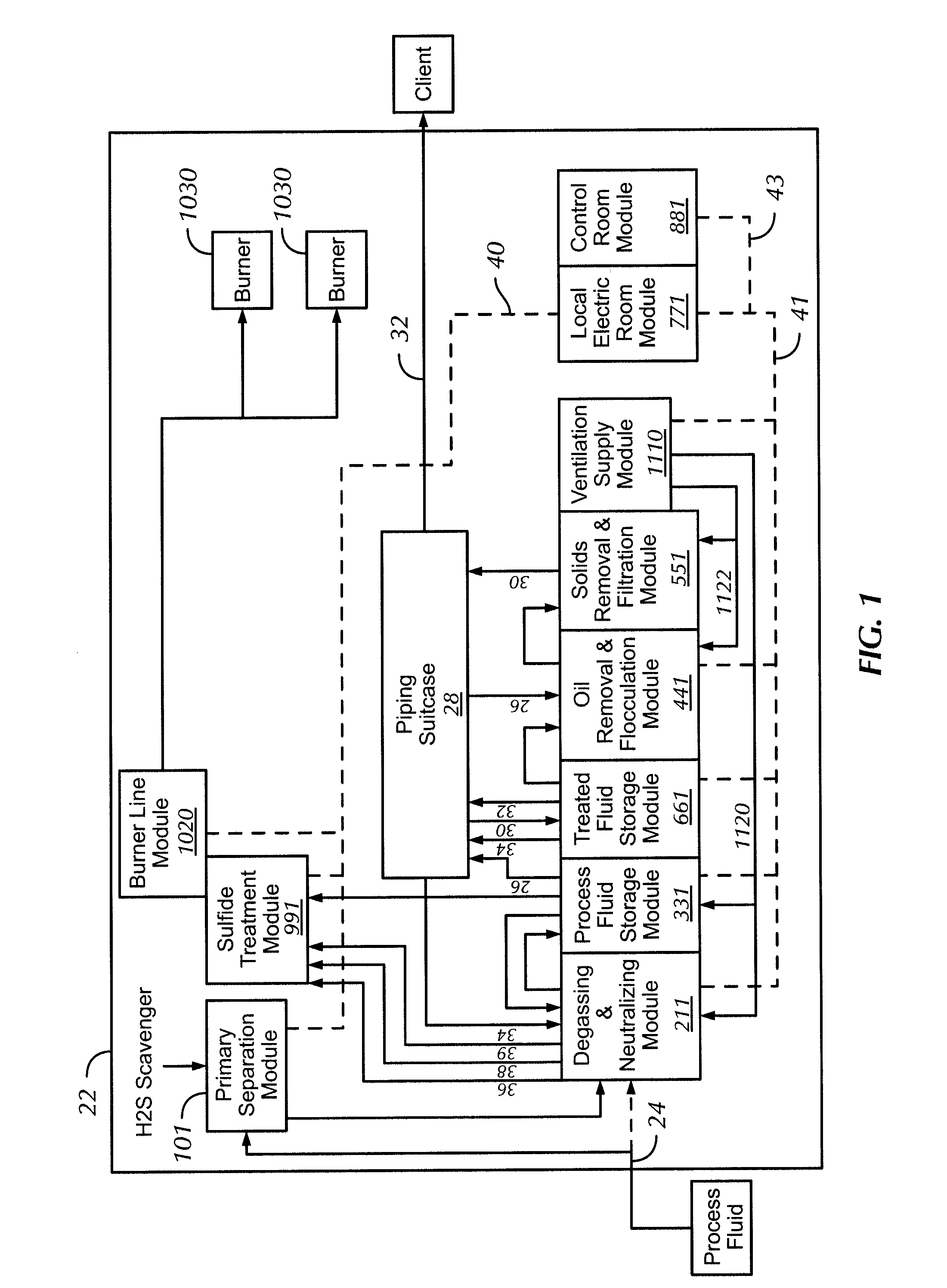

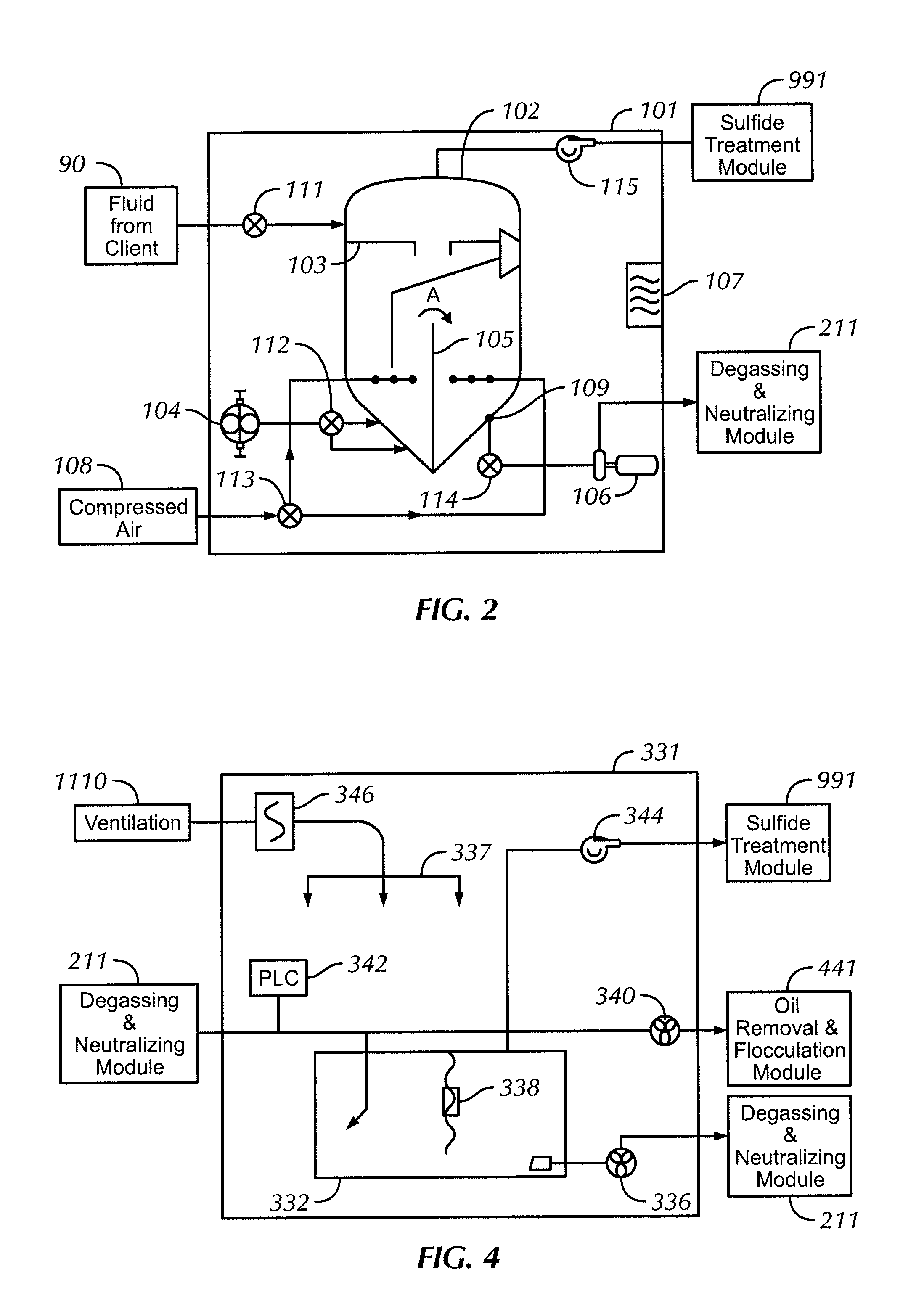

InactiveUS20070199872A1Waste water treatment from quariesLiquid degasificationCombustorControl system

The present invention provides a system for treating a process fluid. The system includes a modular arrangement that includes ten modules for; reducing the amount of dissolved and entrained hydrogen sulfide gas in the process fluid; monitoring the pH of the process fluid; storing the process fluid; reducing an amount of oil from the process fluid; and flocculating the process fluid; measuring the amount of oil in the process fluid; providing ventilation supply air to at least one of the modules; removing hydrogen sulfide gas from a sour gas; delivering gases to a burner system; and controlling the processes of the system.

Owner:MI

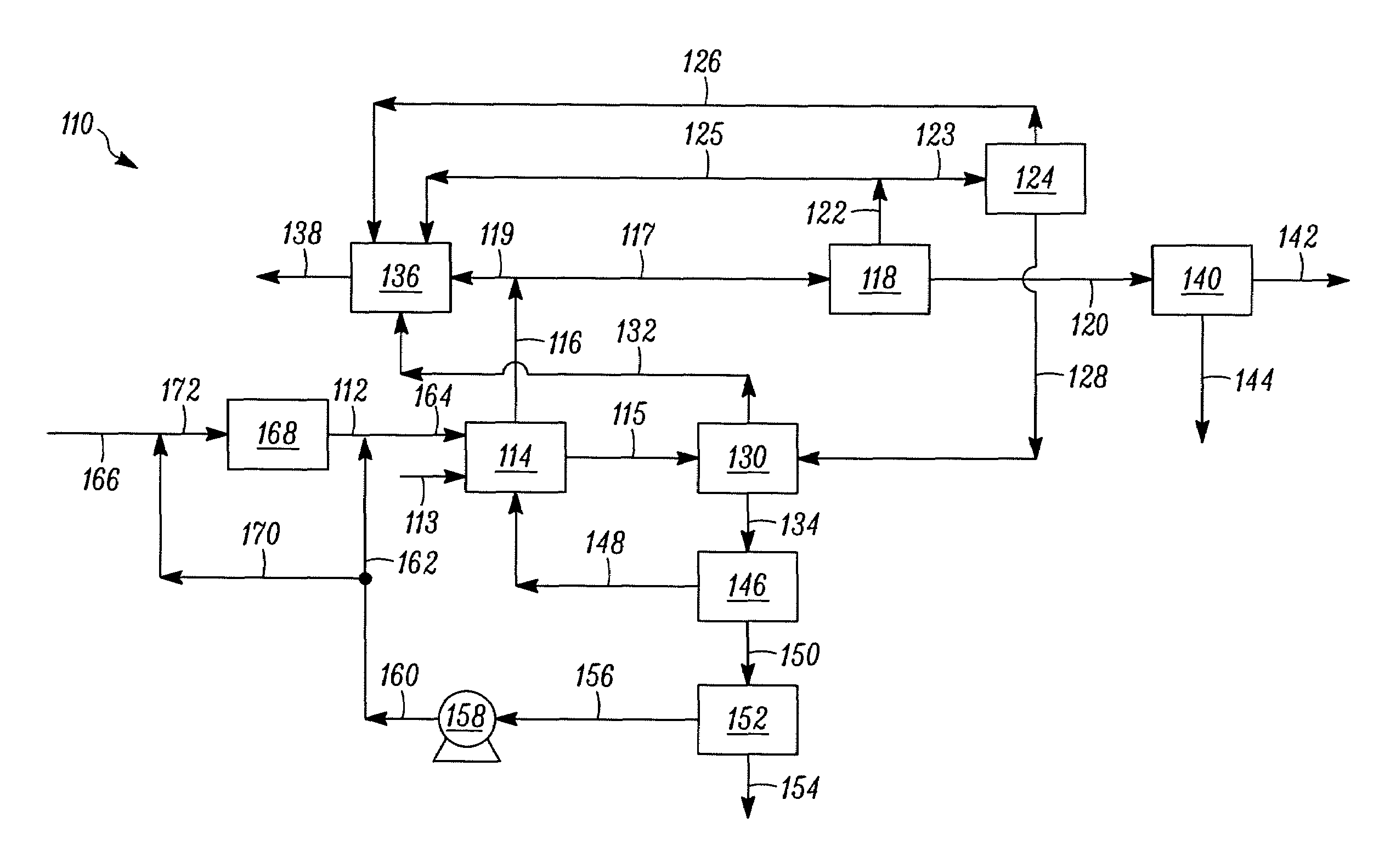

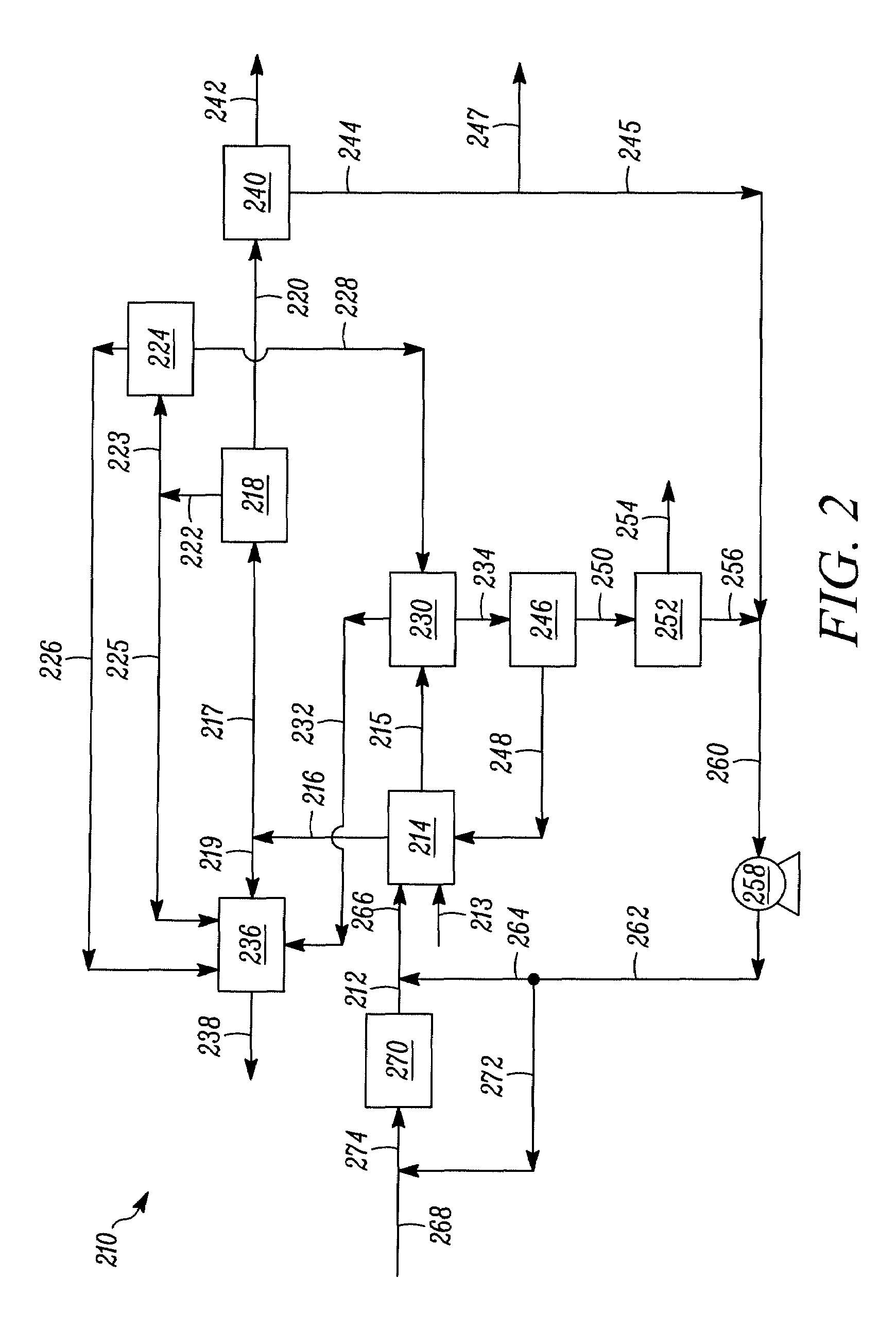

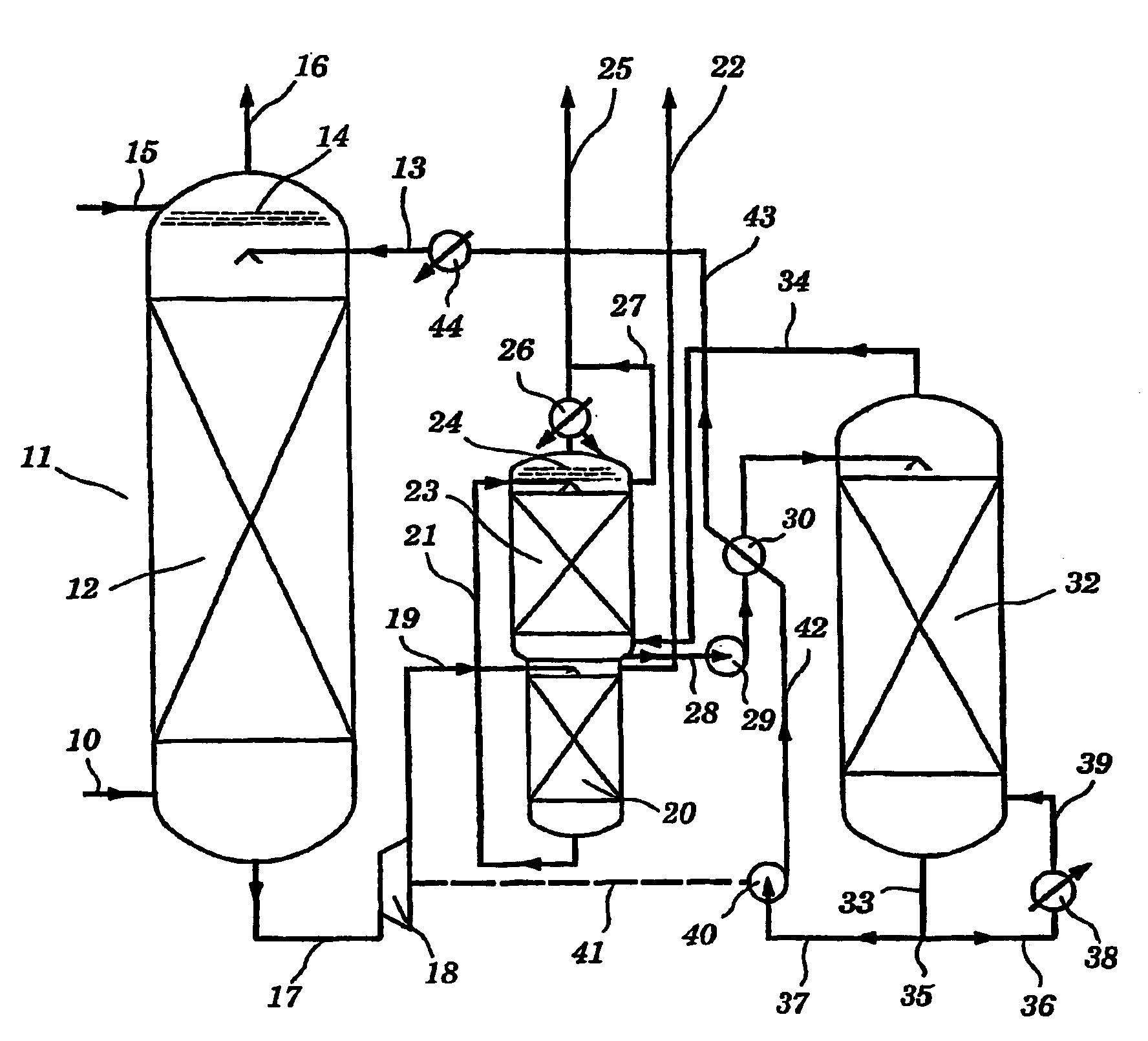

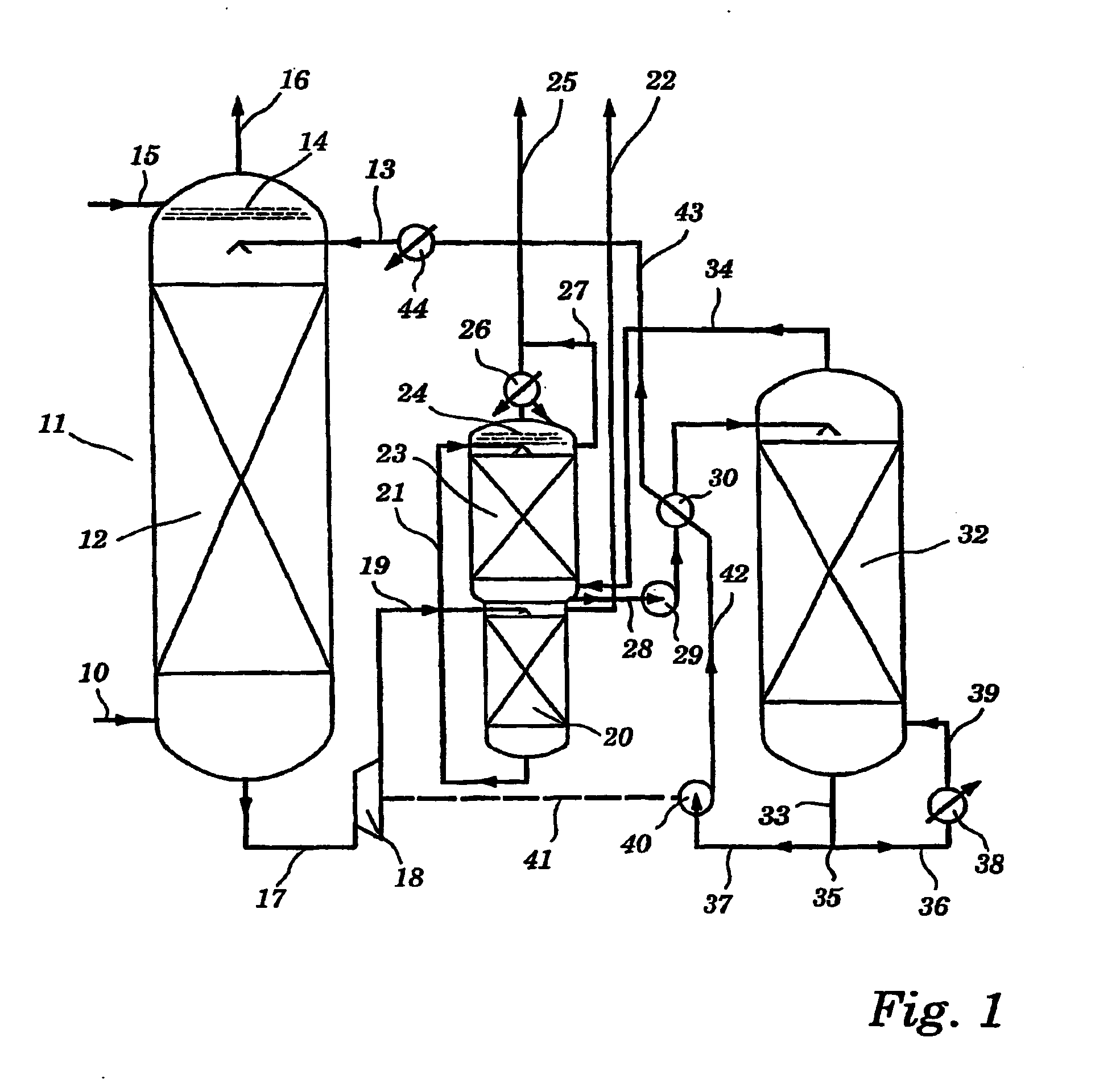

Apparatus and method for exclusively removing VOC from regeneratable solvent in a gas sweetening system

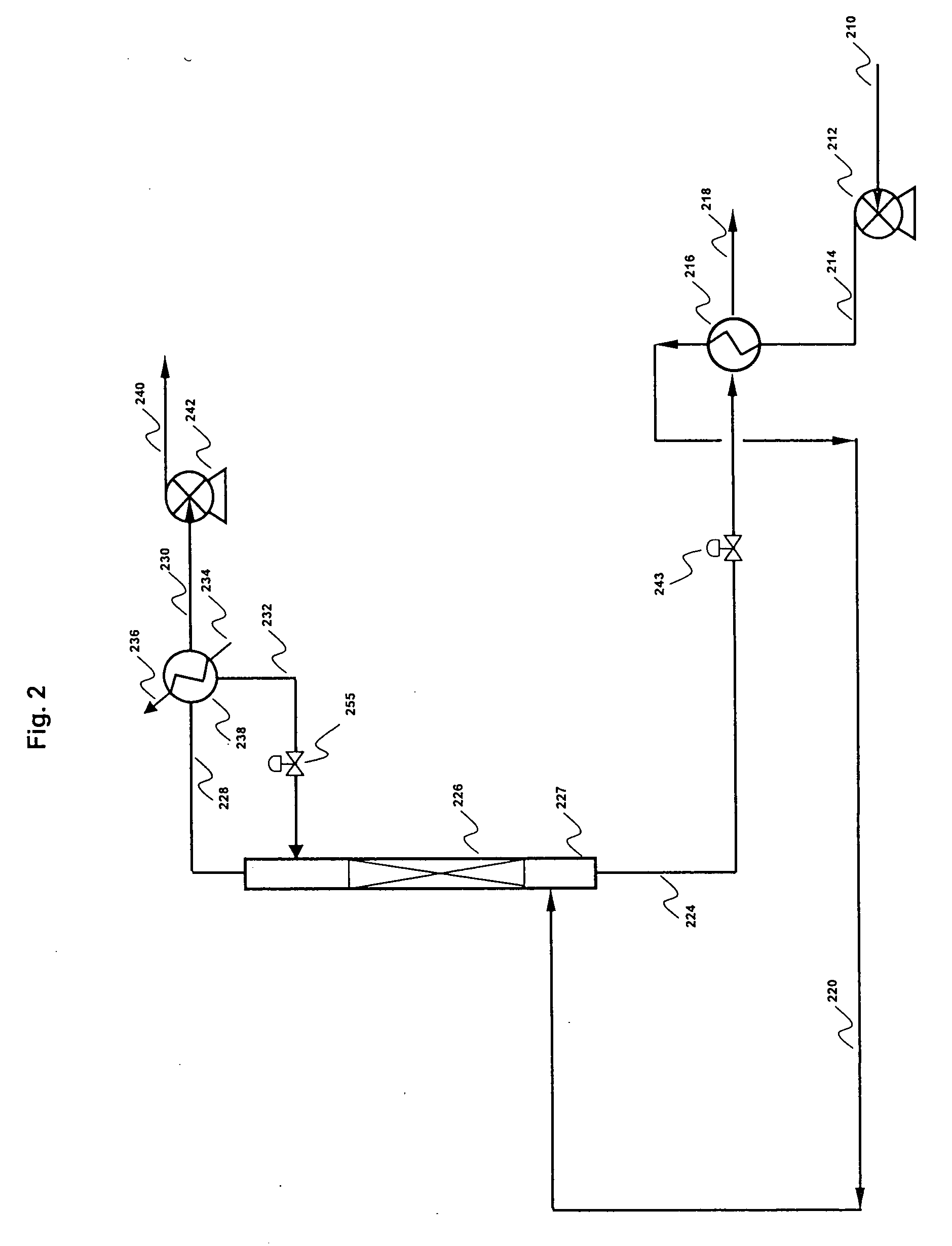

A method for removing residual VOC components from a fluid stream used in the sweetening of sour gas at gas processing plants. In a retrofit configuration, the method includes interposing a supplemental VOC removal station after a primary VOC removal station in an absorbent fluid stream. The absorbent fluid stream incorporates fluid into which sour gas components and VOC have been absorbed from a treated gas stream such as produced natural gas. The primary VOC removal station is configured to remove an initial portion of the absorbed VOC from the absorbent fluid stream. The supplemental VOC removal station is configured to liberate a portion of residual absorbed VOC remaining in the absorbent fluid stream downstream from the primary VOC removal station. Further, the supplemental VOC removal station is configured to avoid liberating absorbed sour gas components from the absorbent fluid stream. Alternatively, a single, but enhanced performance VOC removal station is utilized to liberate a sufficient proportion of the absorbed VOC from the absorbent fluid stream.

Owner:FRONDORF MATTHEW T

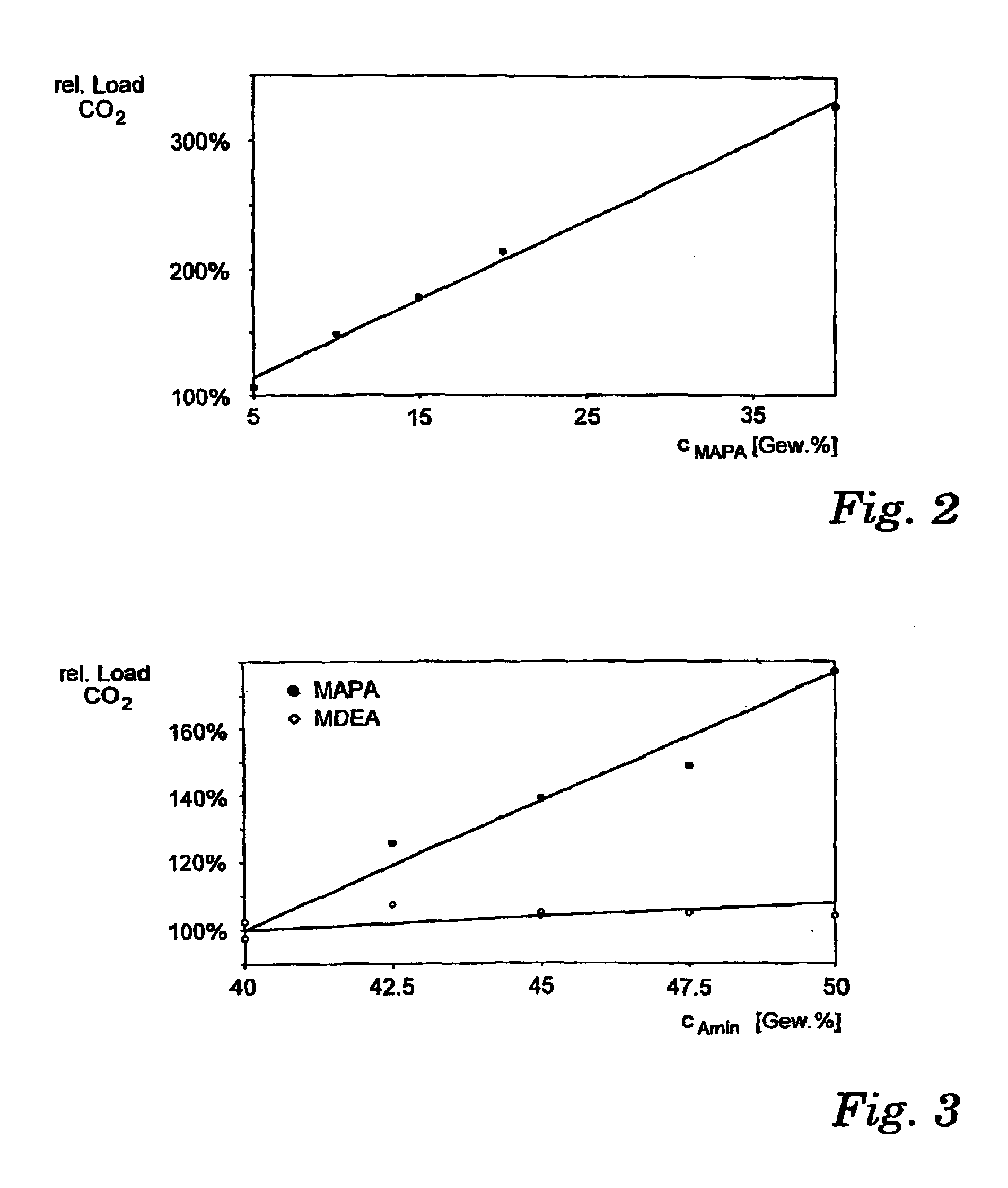

Method for neutralizing a stream of fluid, and washing liquid for use in one such method

InactiveUS6939393B2Improve load effectPromote absorptionUsing liquid separation agentScale removal and water softeningHydrogenProduct gas

A description is given of the use of an alkylenediamine of the type R1HN—X—NHR2, where X is an alkylene radical having from 2 to 9 carbons, R1 is a hydrocarbon radical having from 1 to 6 carbons and R2 is a hydrocarbon radical having from 1 to 6 carbons or is hydrogen (H) for removing sour gases from a sour-gas-containing fluid stream, and of a process for deacidifying a fluid stream of this type and a wash liquid or absorption liquid for use in such a process. According to the invention, in at least one absorption step, the fluid stream is brought into intimate contact with a wash liquid, the wash liquid comprising an aqueous amine solution which comprises at least one tertiary aliphatic alkanolamine having from 2 to 12 carbons and an activator of the above type R1HN—X—NHR2. The fluid stream which is substantially freed from sour gases and the sour-gas-loaded wash liquid are then separated from one another.

Owner:BASF AG

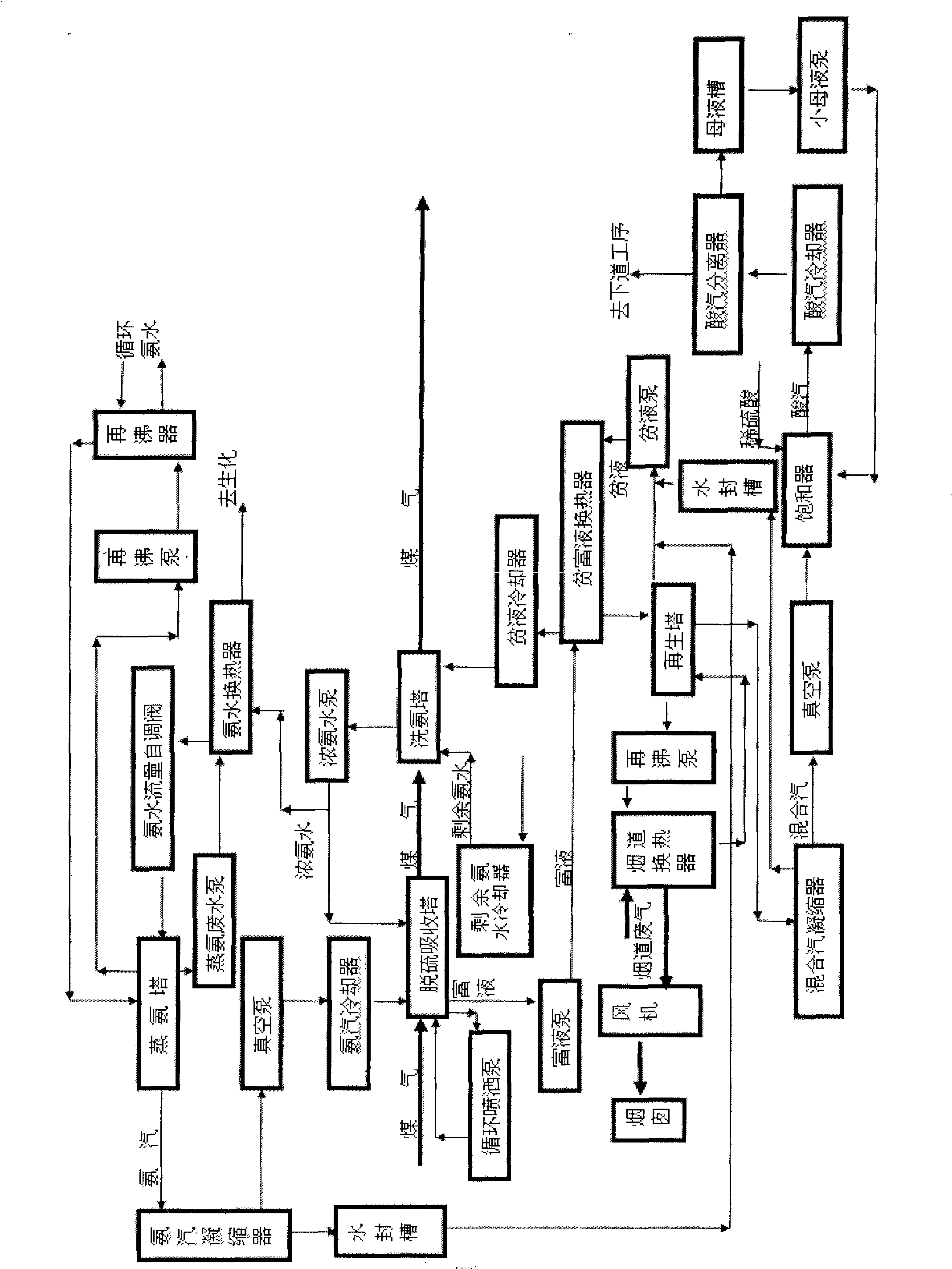

Desulphurization process by vacuum ammonia method

The invention provides a novel process for removing ammonia, H2S and HCN in coke-oven gas in the coking industry, comprising: taking ammonia in coke-oven gas and the residual ammonia water as an alkali source to have reaction with H2S and HCN in the coke-oven gas, then carrying out the resolution in a regeneration tower, removing ammonia in the obtained mixed gas by a saturex firstly, and producing elemental sulfur by the residual sour gas in a Claus furnace. The process is characterized in that: a rich liquid is obtained by utilizing the strong ammonia water obtained by ammonia in the coal gas to have reaction with H2S and HCN in the coal gas under the vacuum state, the tower bottom takes the sensible heat of flue waste gas as a heat source, the resolution is implemented in the regeneration tower under the negative pressure, and the obtained barren solution on the tower bottom is used for rewashing the ammonia. The process has advantages of simple technique, low running cost, investment saving, and high ammonia, H2S and HCN removal efficiency, and is an innovation of ammonia, H2S and HCN removing process in coal gas for coke plants.

Owner:马永伟 +1

Sour Gas and Acid Natural Gas Separation Membrane Process by Pre Removal of Dissolved Elemental Sulfur for Plugging Prevention

ActiveUS20120103185A1Avoid production lossImprove life expectancyCombination devicesGas treatmentTowerChemistry

Methods for removing sulfur from a gas stream prior to sending the gas stream to a gas separation membrane system are provided. Two schemes are available. When the sulfur content is high or flow is relatively high, a scheme including two columns where one tower is regenerated if the sulfur concentration exceeds a preset value can be used. When the sulfur content is low or flow is relatively low, a scheme including one column and an absorption bed.

Owner:SAUDI ARABIAN OIL CO

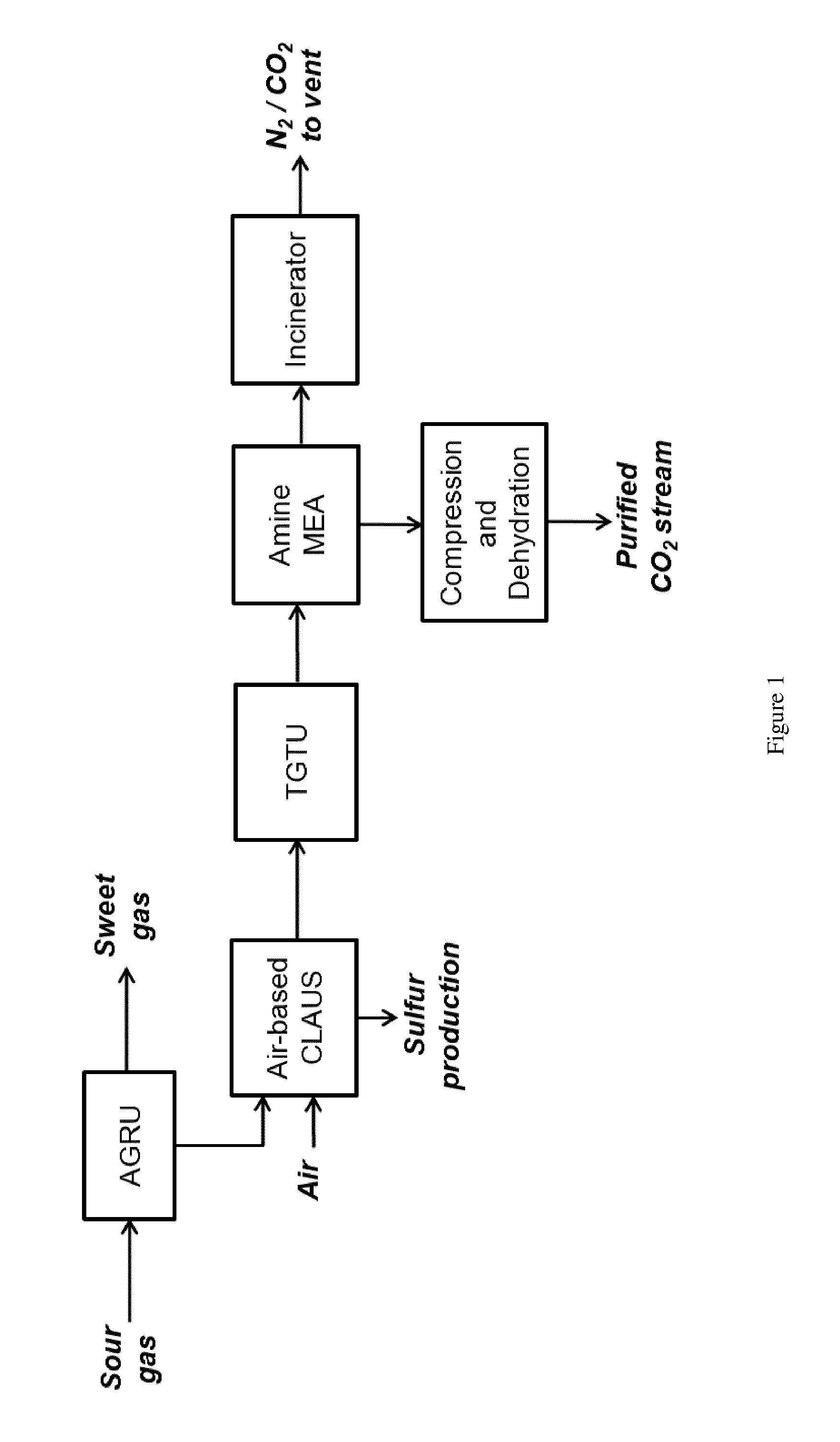

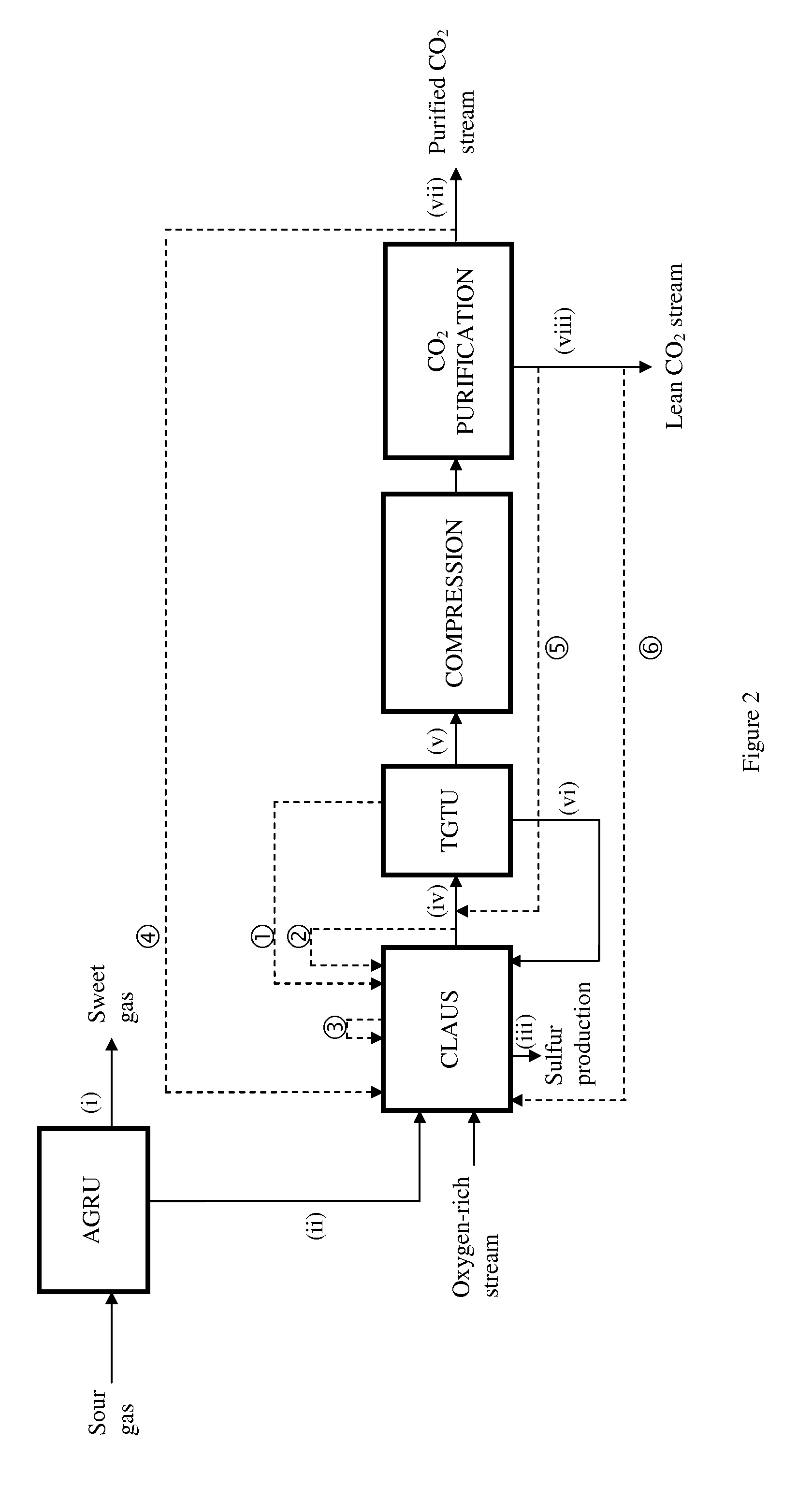

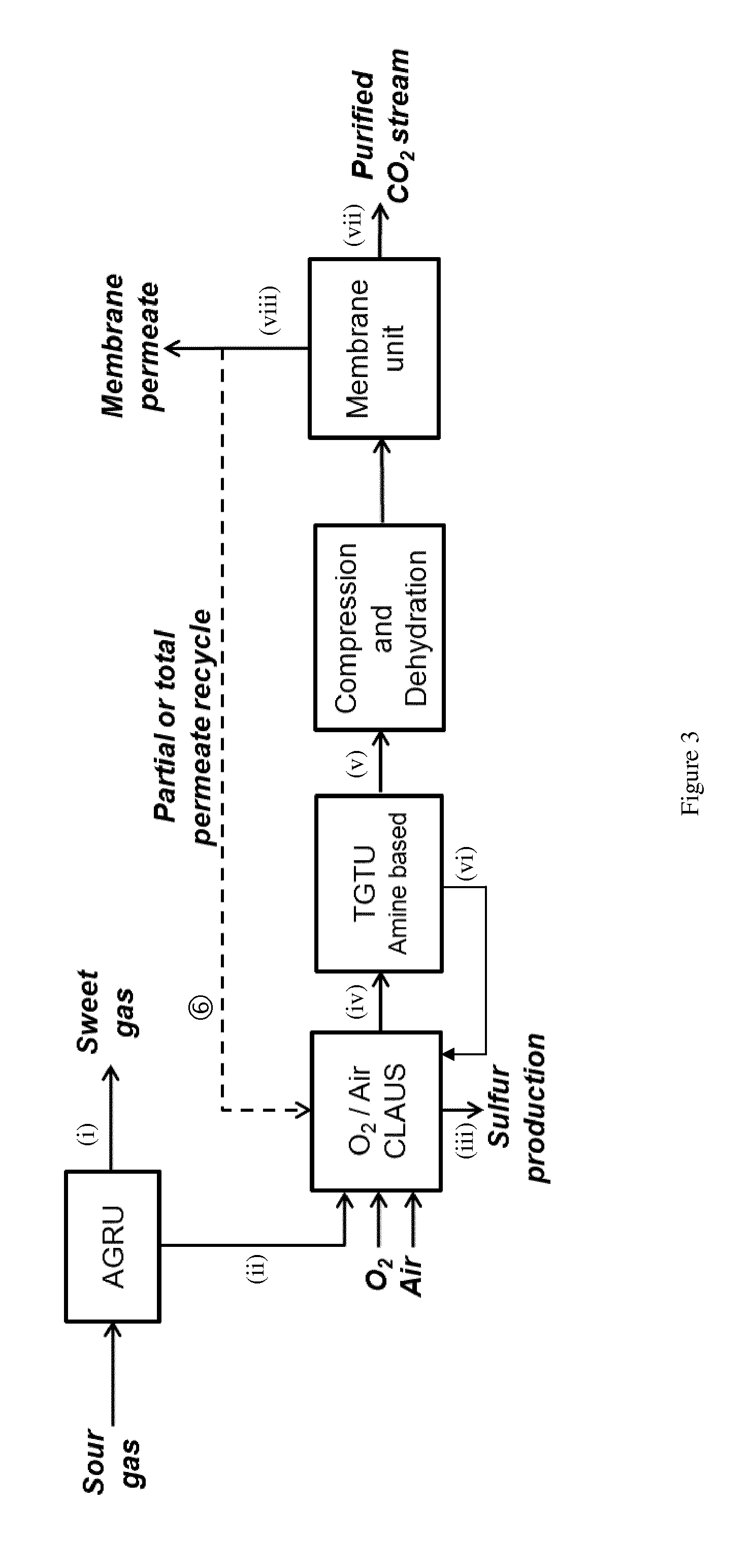

Integrated process for native co2 recovery from a sour gas comprising h2s and co2

The invention relates to a method for treating a hydrocarbon feed gas stream containing CO2 and H2S to recover a purified CO2 gas stream (vii), comprising: a. Separating said feed gas stream into a sweetened gas stream (i), and an acid gas stream (ii); b. Introducing stream (ii) into a Claus unit wherein an oxygen-rich stream is used as a combustive agent in the Claus furnace, thereby recovering a liquid stream of elemental sulfur (iii) and a tail gas stream (iv); c. Introducing the stream (iv) into a Tail Gas Treatment Unit (TGTU) thereby separating said tail gas stream into a CO2 enriched gas stream (v), and a stream enriched in sulfur compounds (vi); d. Compressing stream (v) exiting the TGTU; e. Passing the compressed CO2 enriched gas through a CO2 purification unit thereby recovering a purified CO2 gas stream (vii), and the device for carrying out said method.

Owner:TOTAL PUTEAUX FR +1

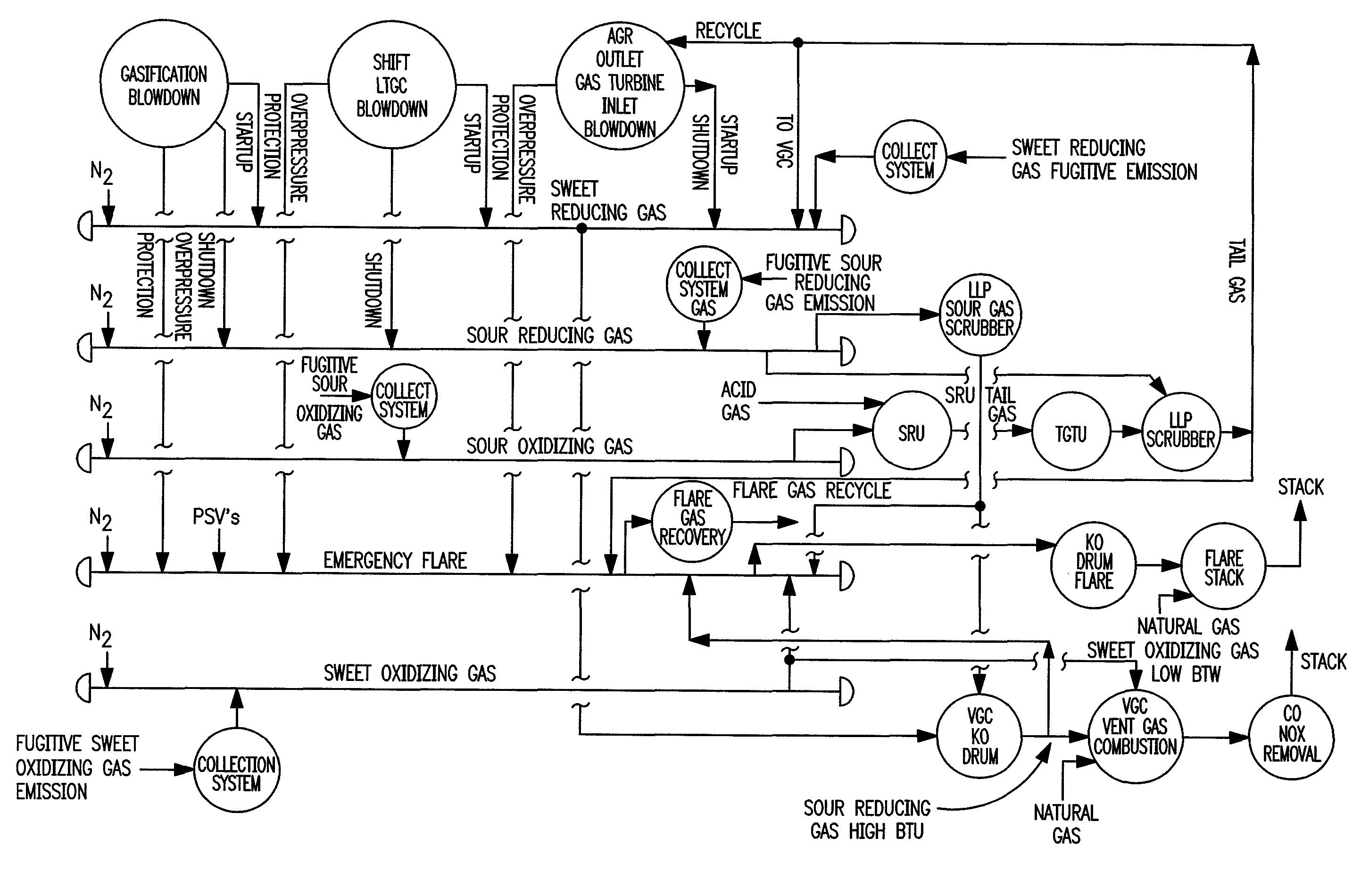

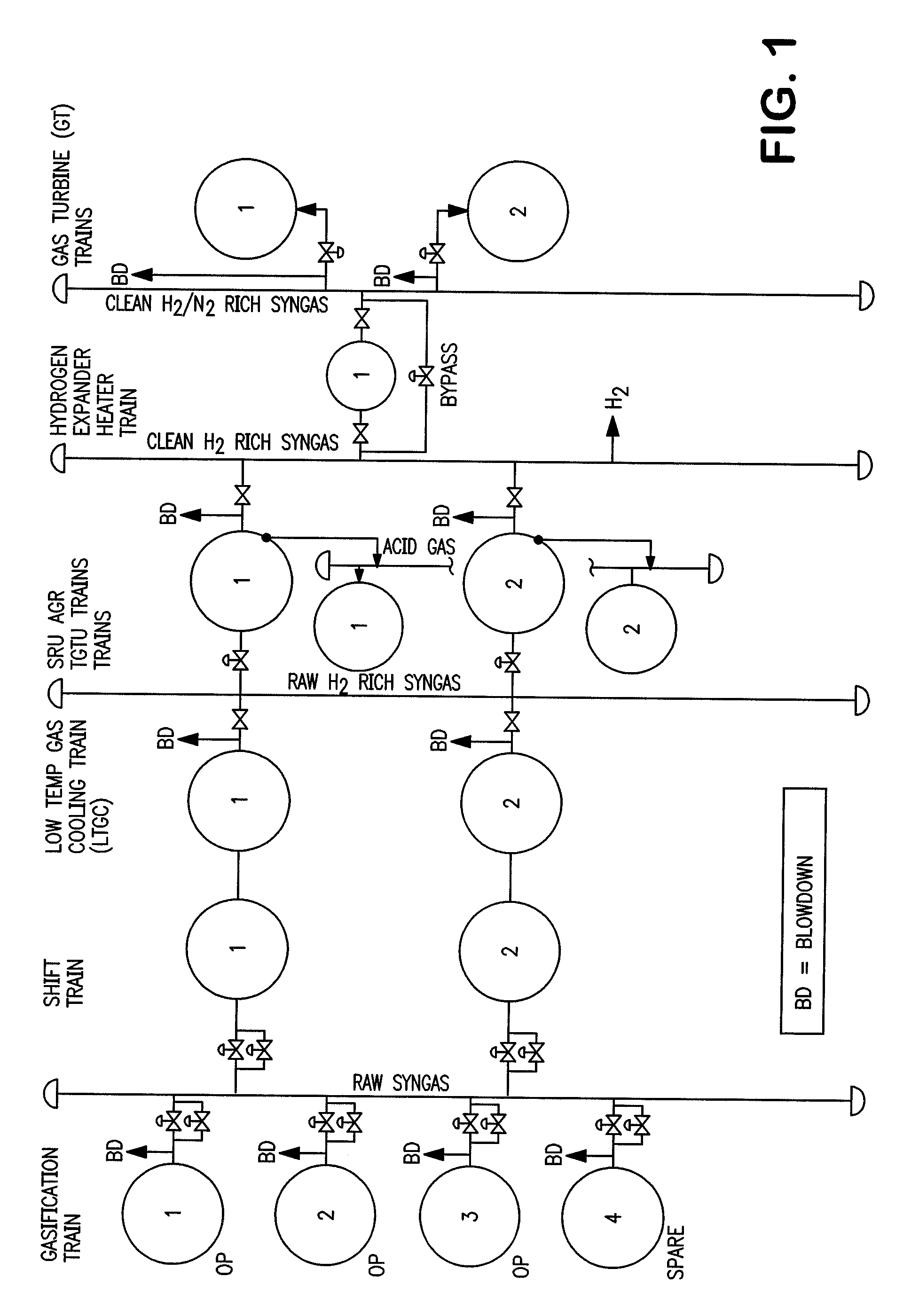

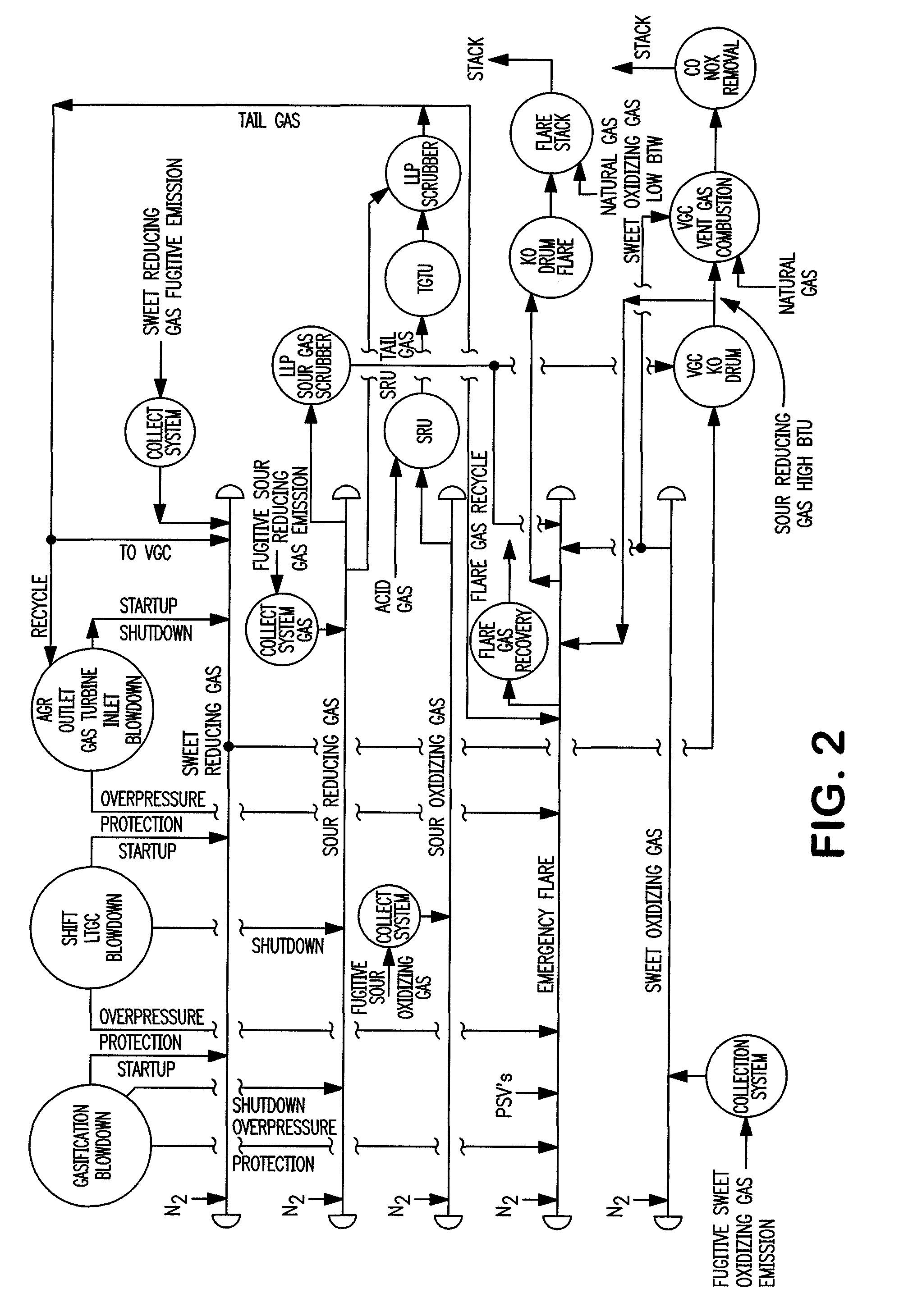

Emission free integrated gasification combined cycle

InactiveUS20100077767A1Improve efficiencyEmission reductionHydrogen separation using liquid contactGaseous fuelsBack burnsAtmospheric air

Disclosed is a process to start-up, operate, and shut down a gasifier and an integrated gasification combined cycle complex without flaring while additionally reducing the release of contaminants such as carbon monoxide, hydrogen sulfide, and nitrogen oxides. The process is accomplished by scrubbing ventable sour gases and passing scrubbed sour gases and ventable sweet gases to a vent gas combustor for controlled combustion prior to release of any such gases to the atmosphere. Additionally, the gases are subjected to a CO oxidation treatment and selective catalytic reduction treatment prior to release to the atmosphere.

Owner:HYDROGEN ENERGY INT

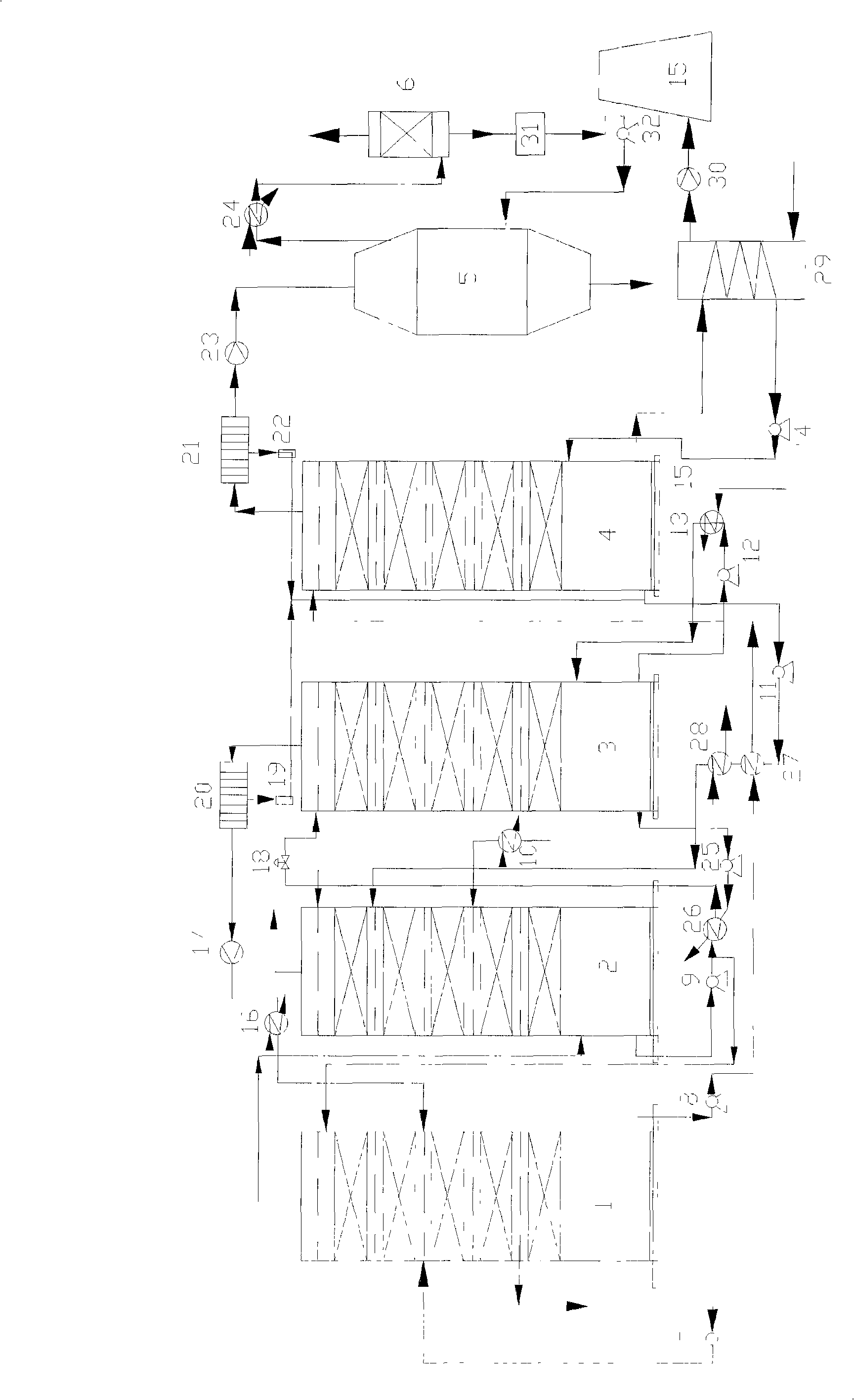

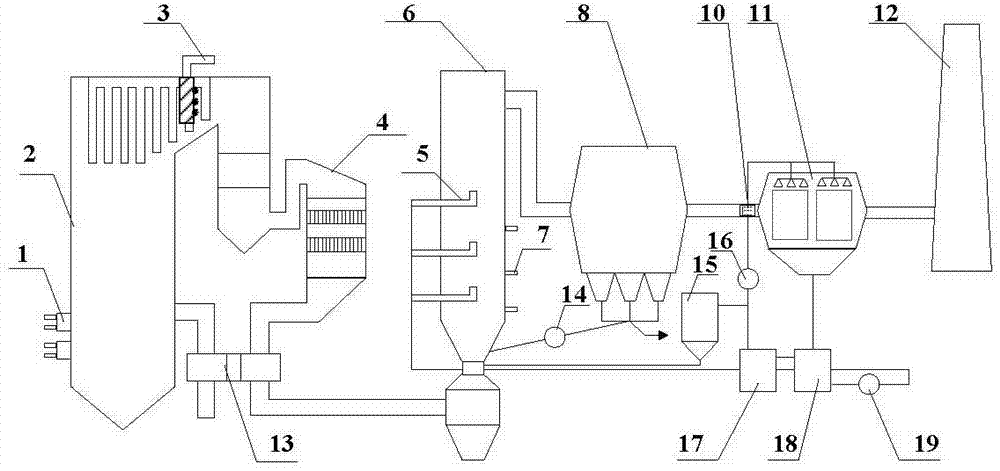

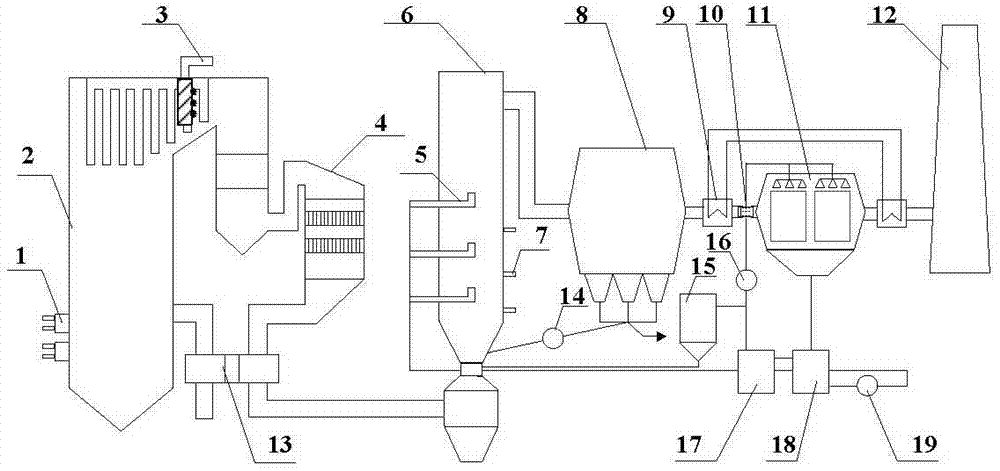

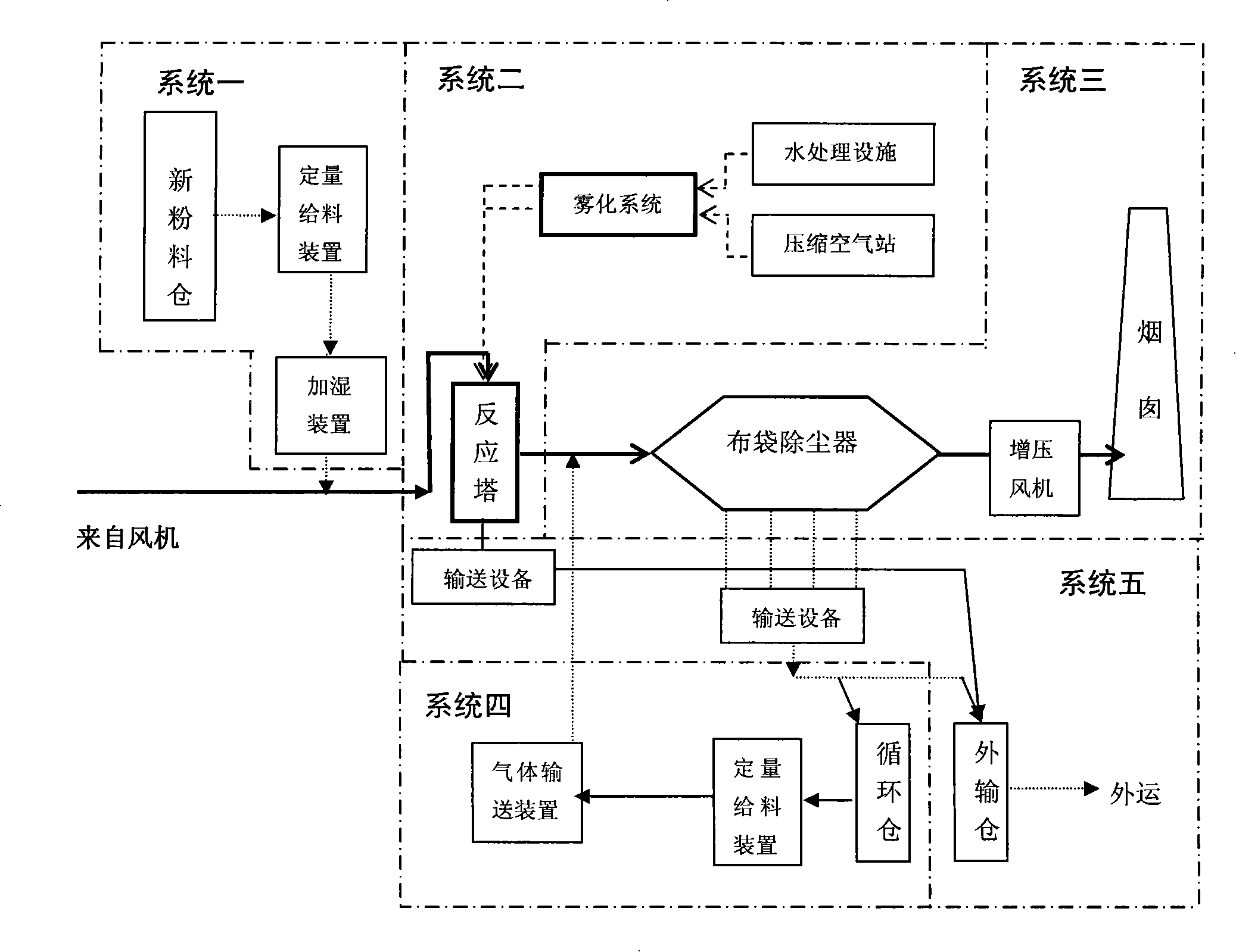

Low-cost coal-fired flue gas various pollutant ultralow emission system and low-cost coal-fired flue gas various pollutant ultralow emission method

InactiveCN104759192AReduce consumptionSmall and portableCombustion using gaseous and pulverulent fuelCombination devicesControl systemMulti pollutant

The invention relates to a low-cost coal-fired flue gas various pollutant ultralow emission system and a low-cost coal-fired flue gas various pollutant ultralow emission method. The system mainly includes a nitrogen oxide gradient control system, a semidry flue gas purifying system and a wet-type static deep purification system. In the invention, by means of the nitrogen oxide gradient control system, the emitted NOx is less than 50 mg / Nm3 in concentration; by means of the semidry flue gas purifying system, the removal efficiency of SO2 can be reach not less than 90%, the removal efficiency of SO3 can be reach not less than 90%, the removal efficiency of acidic gas can be reach not less than 95% and the dust is less than 30 mg / Nm3; and by means of the wet-type static deep purification system, the PM is less than 5 mg / Nm3 and the removal efficiency of SO2 can be reach not less than 50%. The dust-containing waste water in the wet-type static deep purification system is used for slaking limestone and moistening and activating an absorbent in the semidry flue gas purifying system, so that near-zero emission of the waste water in the system is achieved and finally it is achieved that the pollutant emission concentrations of PM is less than 5 mg / Nm3, the emission concentration of SO2 is less than 35 mg / Nm3 and the emission concentration of SO2 is less than 50 mg / Nm3 in a coal-fired power plant, thereby achieving an ultralow emission requirement of the main pollutant under a condition of the near-zero emission of the waste water.

Owner:ZHEJIANG UNIV

Fe-Ni alloy pipe stock and method for manufacturing the same

ActiveUS20070175547A1Improve mechanical propertiesEasy to manufactureMetal rolling arrangementsChemical compositionAlloy

An Fe—Ni alloy pipe stock having a chemical composition comprising, by mass %, C≦0.04%, Si≦0.50%, Mn: 0.01 to 6.0%, P≦0.03%, S≦0.01%, Cr: 20 to 30%, Ni: 30 to 45%, Mo: 0 to 10%, W: 0 to 20%, with Mo(%)+0.5W(%): more than 1.5% to not more than 10%, Cu: 0.01 to 1.5%, Al≦0.01% and N: 0.0005 to 0.20%, and the balance substantially being Fe, with 1440−6000P−100S−2000C≧1300, Ni+10(Mo+0.5W)+100N≦120, (Ni−35)+10(N−0.1)−2(Cr−25)−5(Mo+0.5W−3)+8≧0, can be manufactured into a seamless pipe by use of a Mannesmann piercing and rolling mill because of its excellent inner surface properties. The resulting seamless pipe has excellent mechanical properties and moreover has excellent corrosion resistance in a sour gas environment, and thus, the Fe—Ni alloy pipe stock can be used as a pipe stock for oil country tubular goods and line pipes and further as a pipe stock for various structural members of nuclear power plants and chemical industrial plants.

Owner:NIPPON STEEL CORP

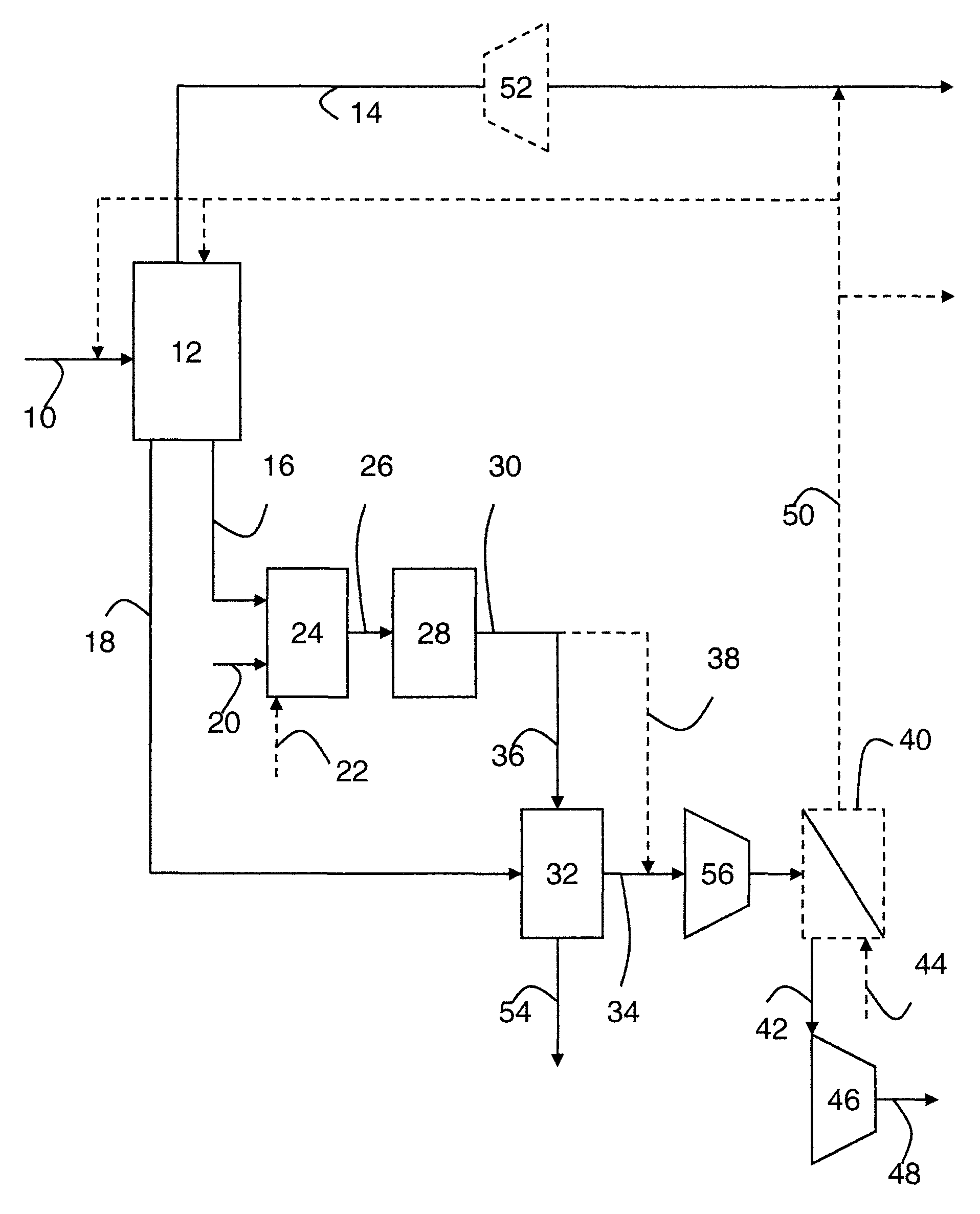

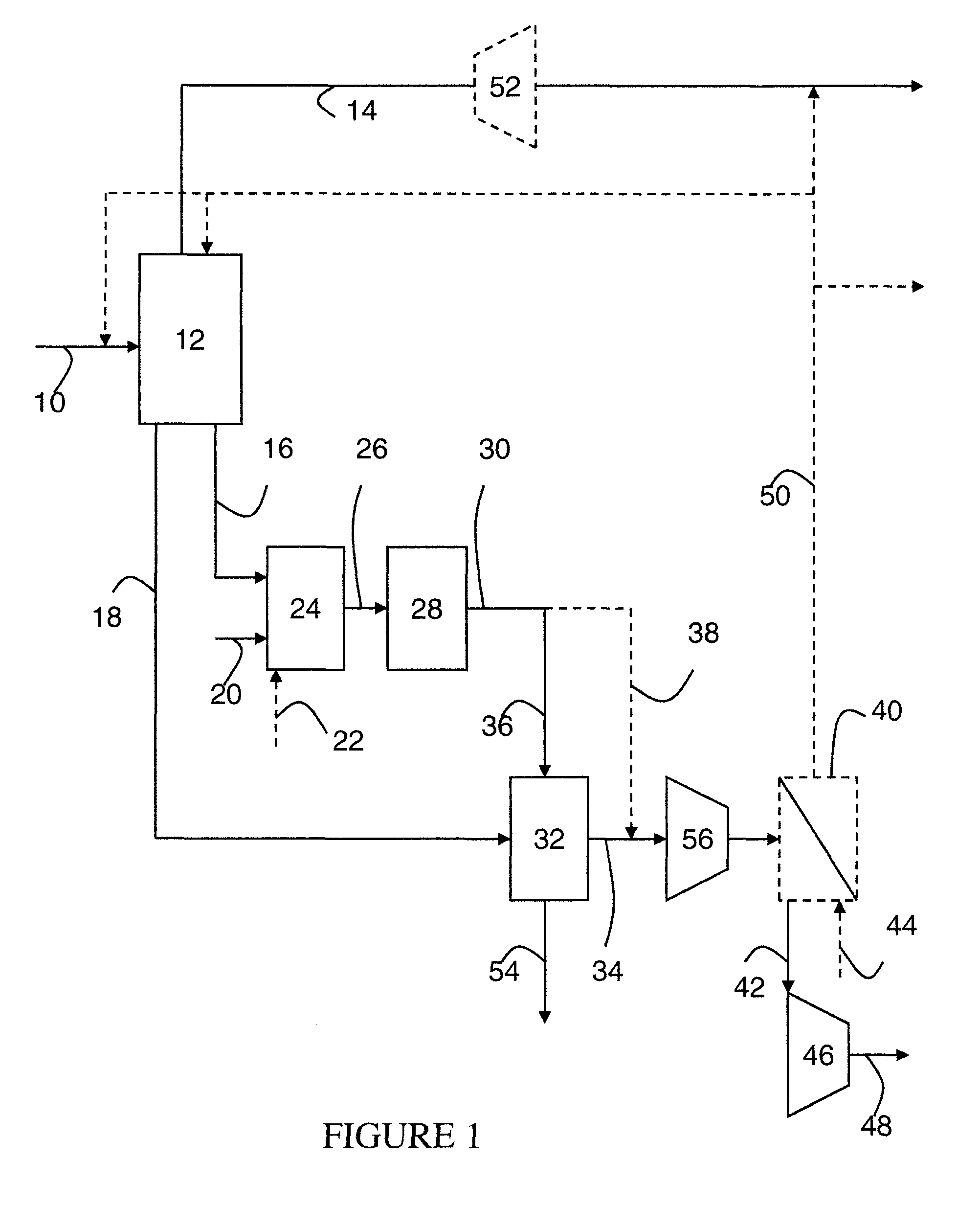

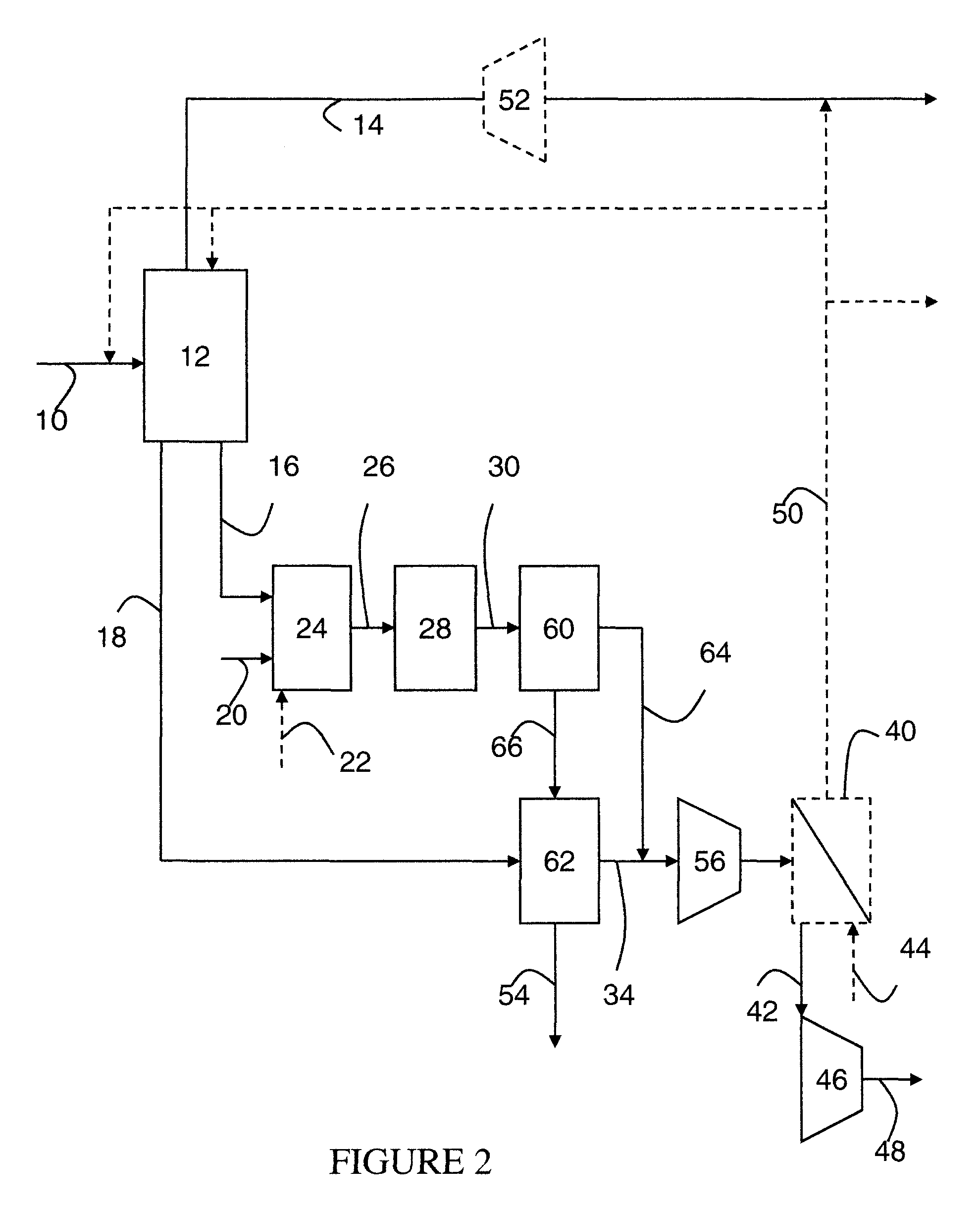

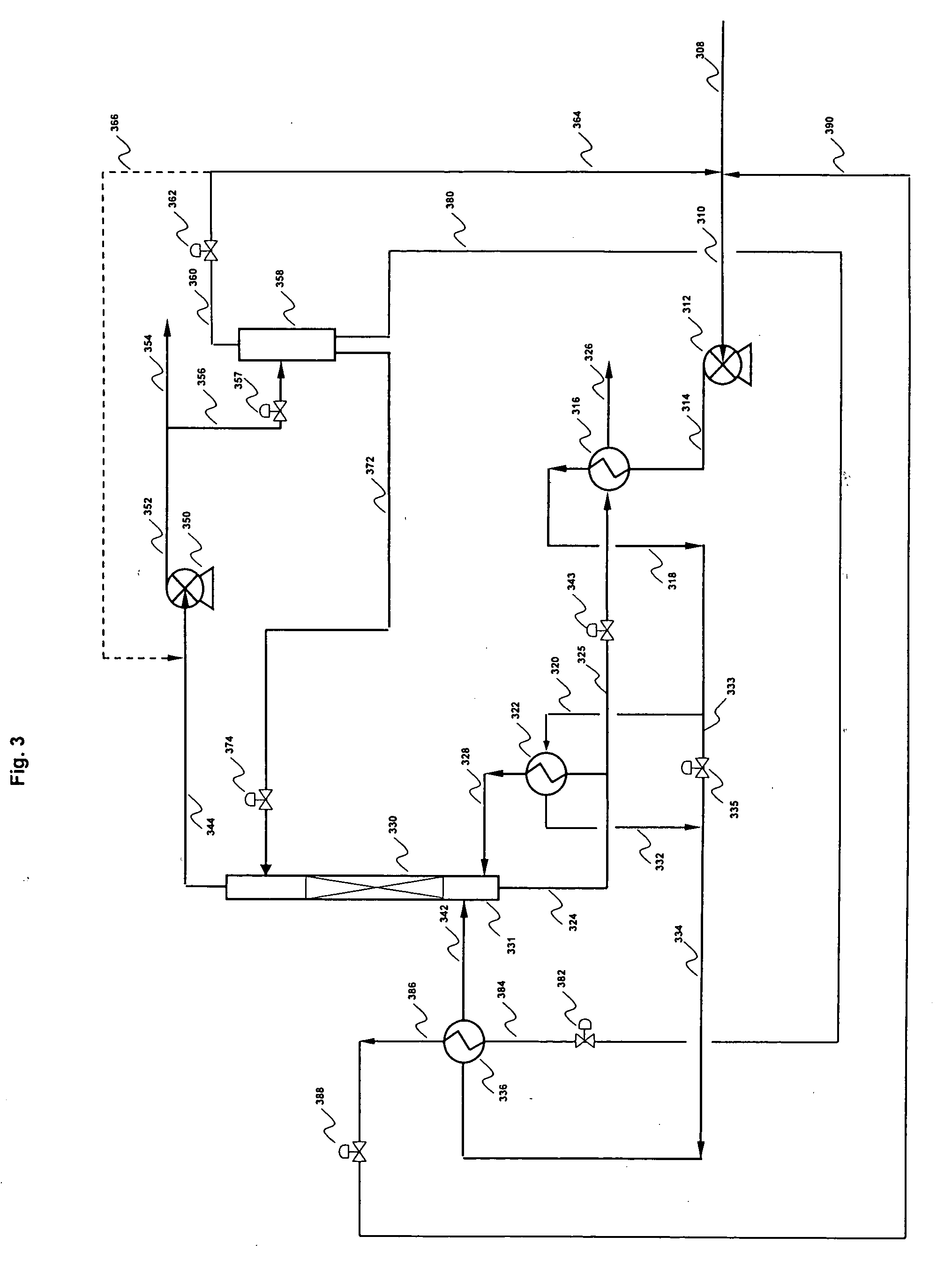

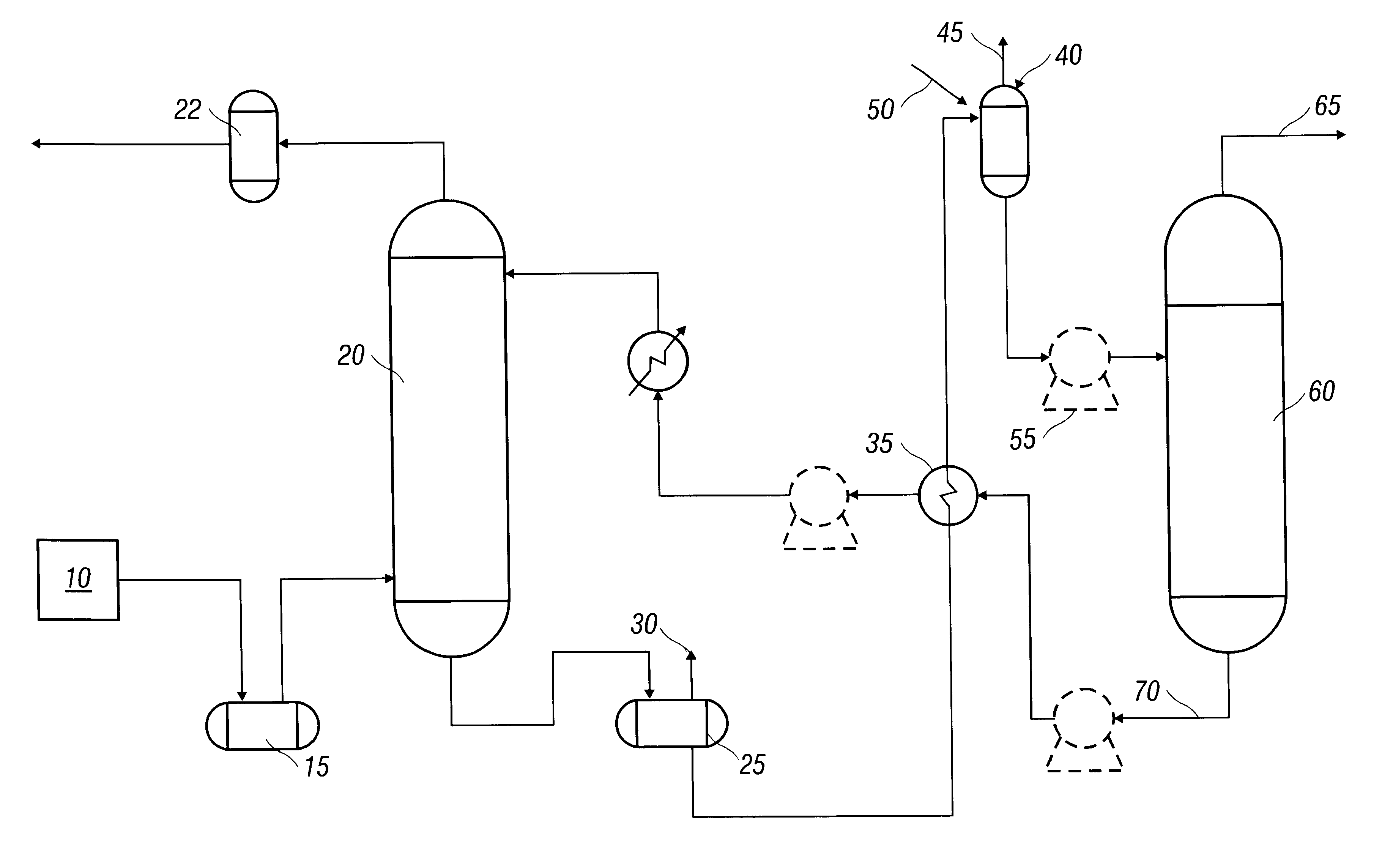

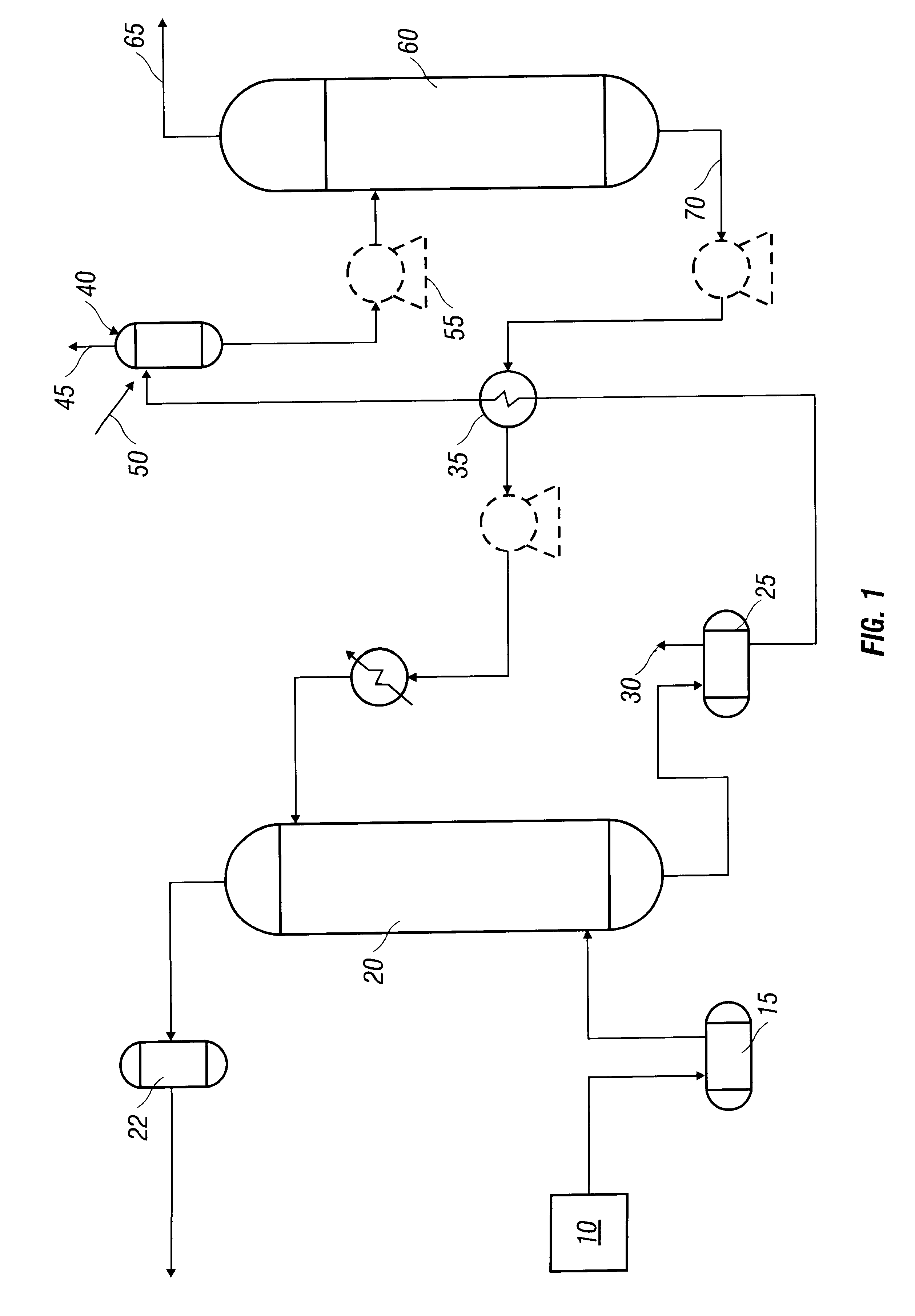

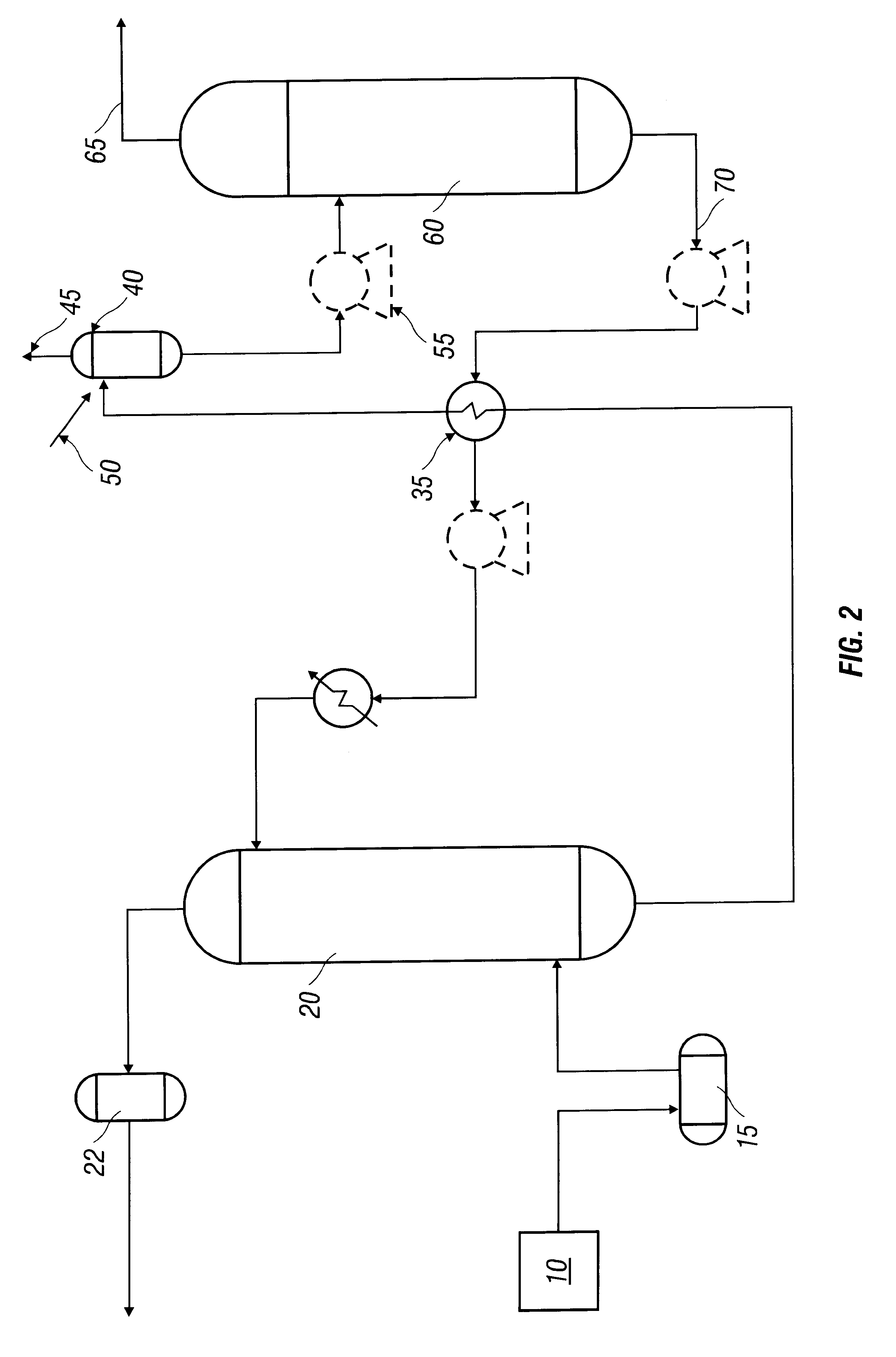

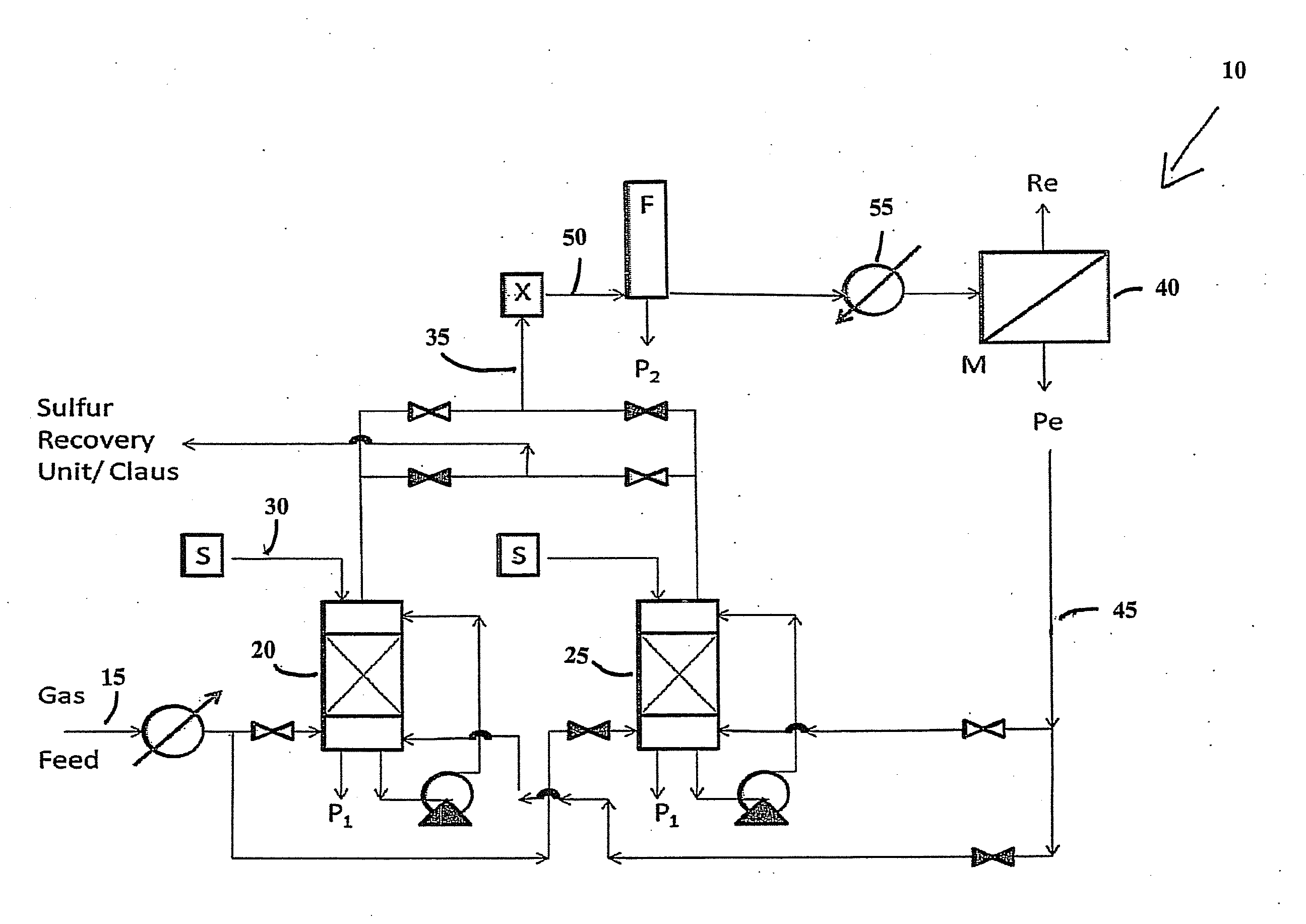

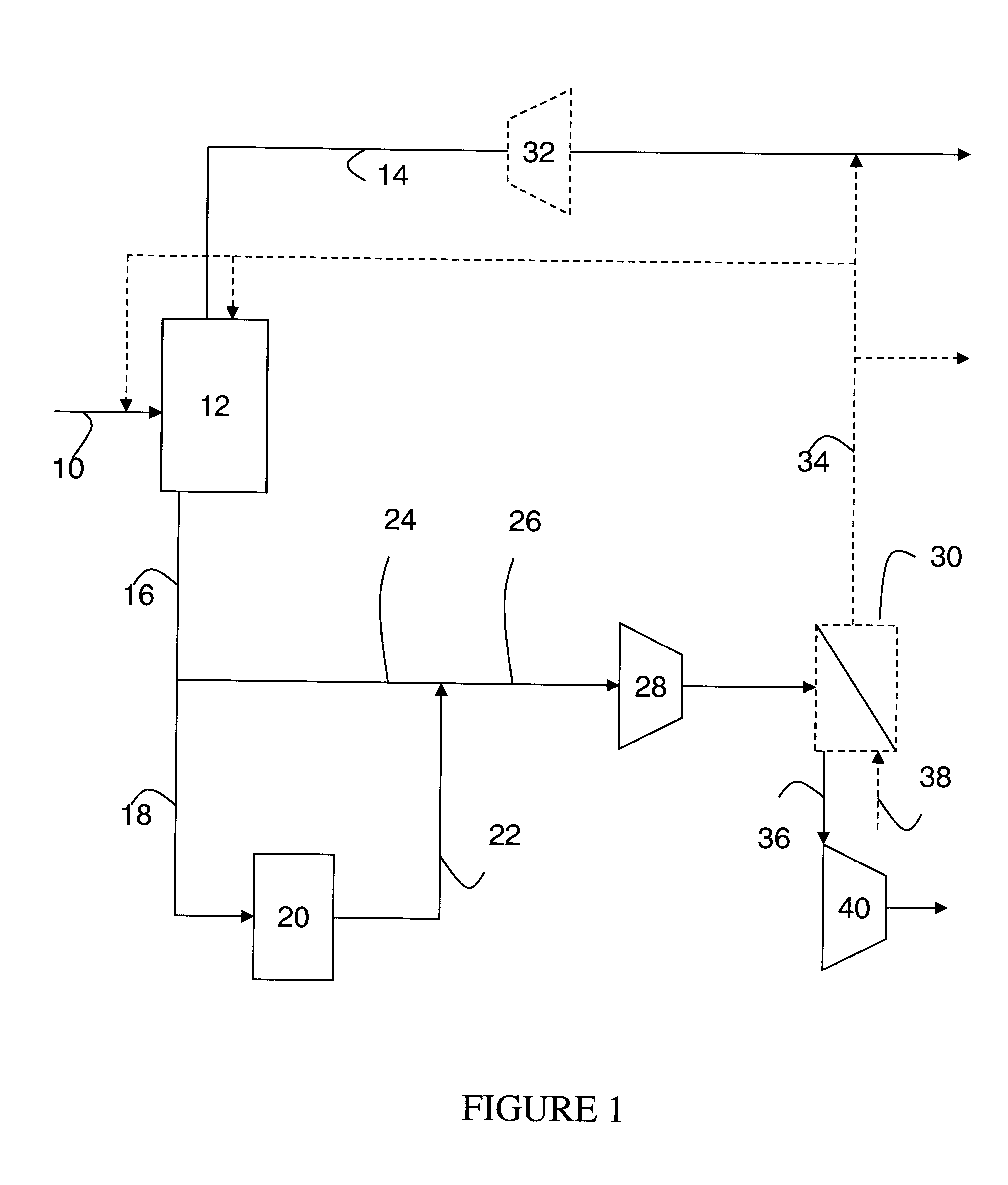

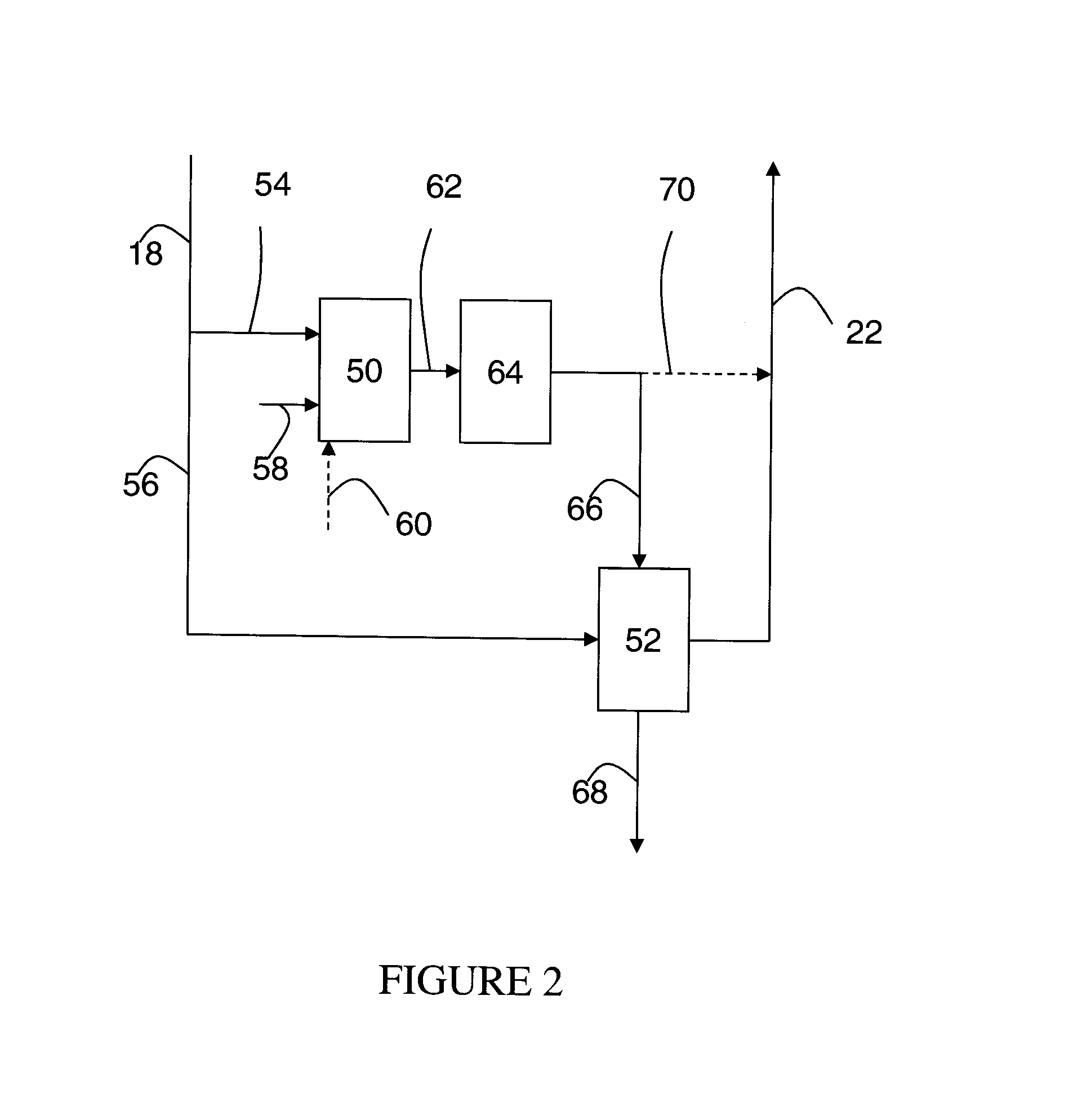

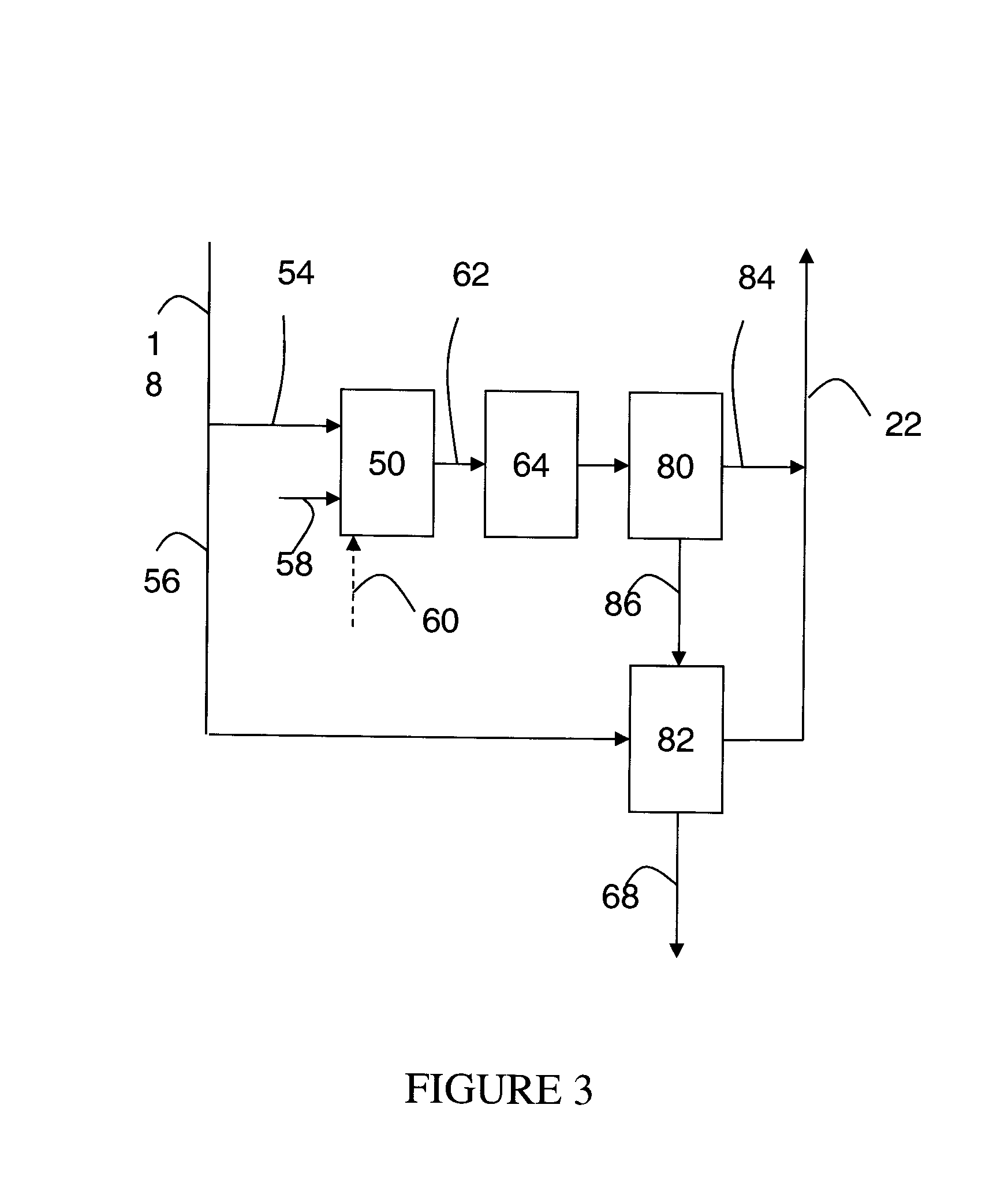

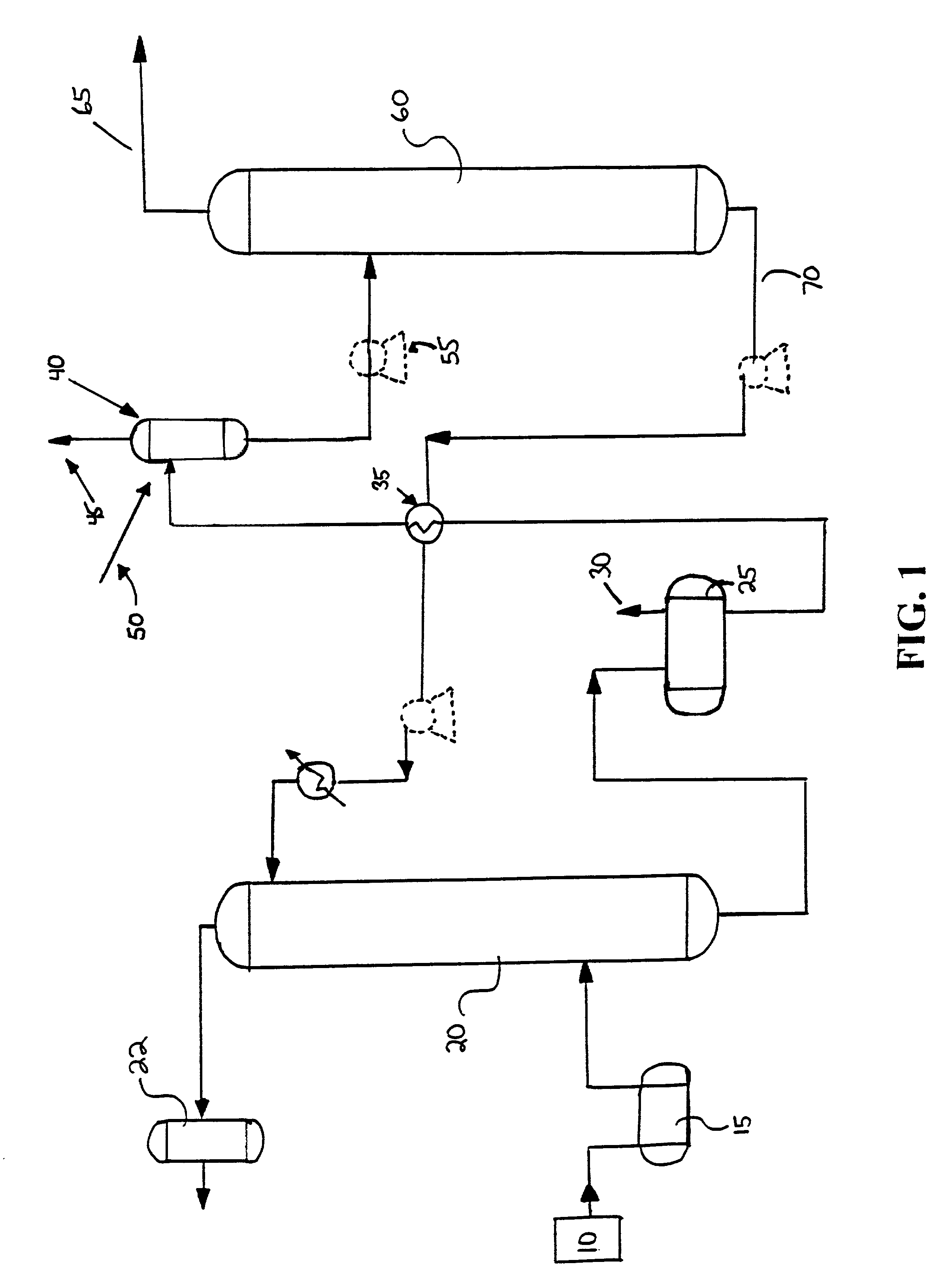

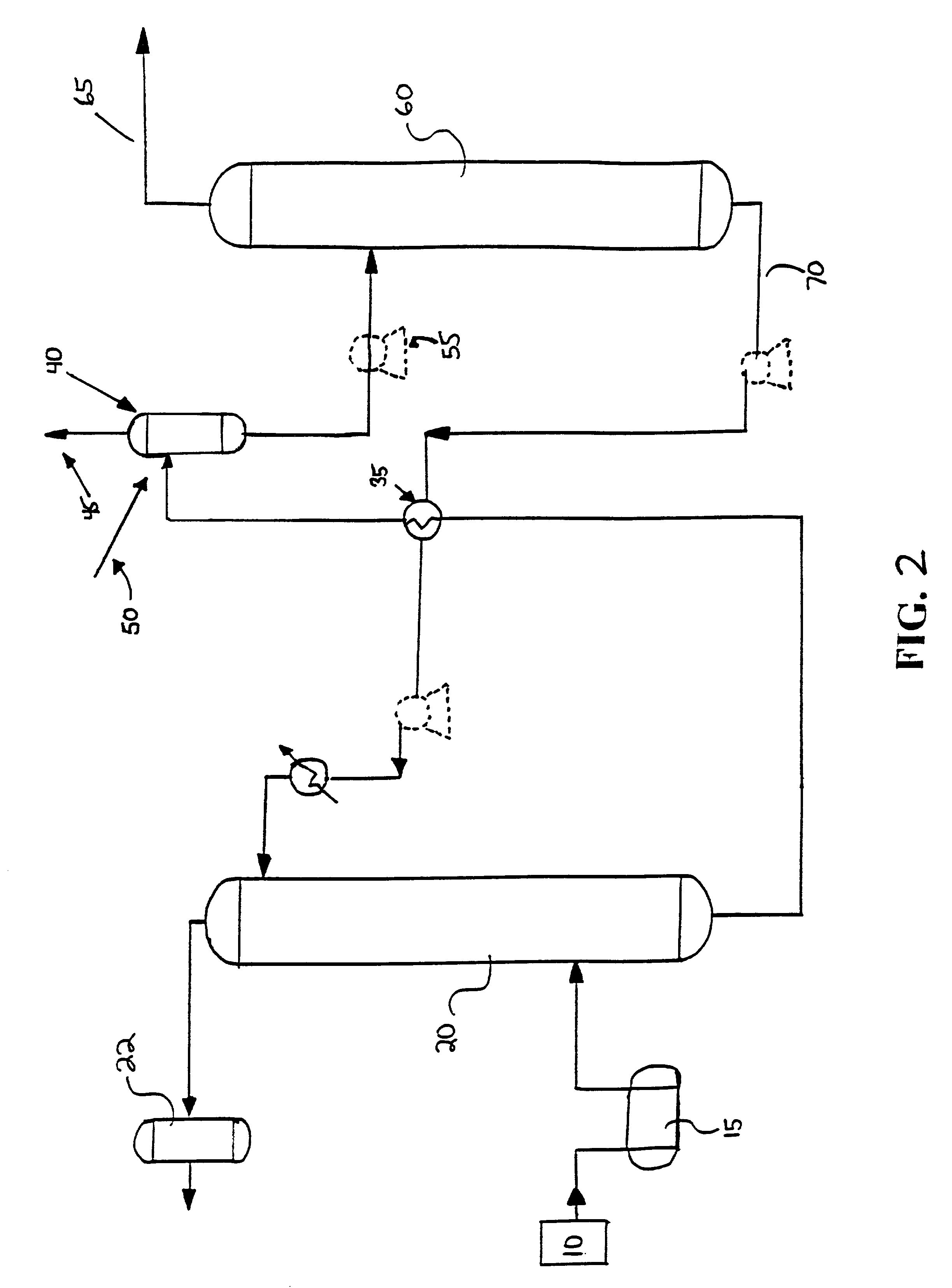

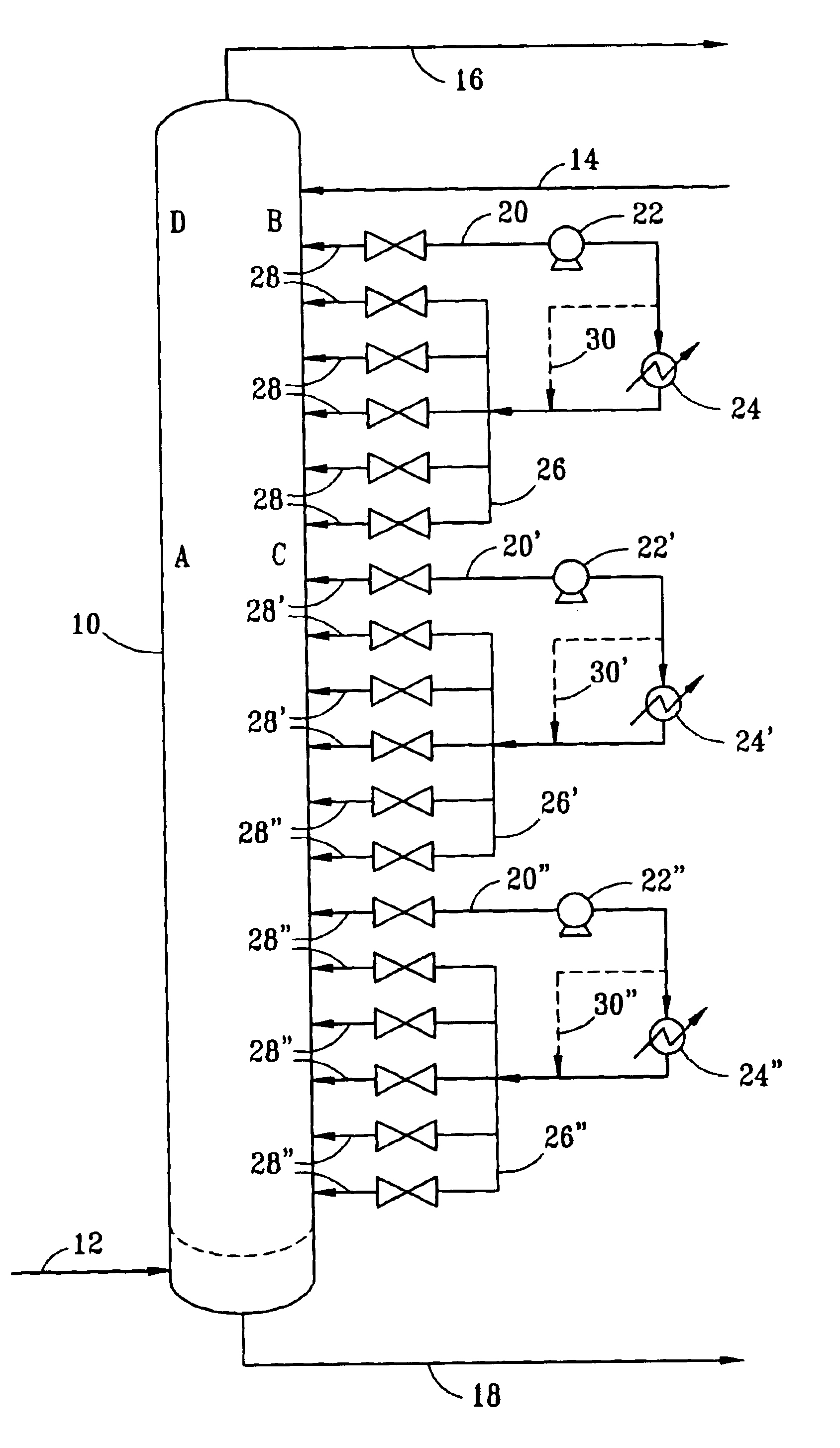

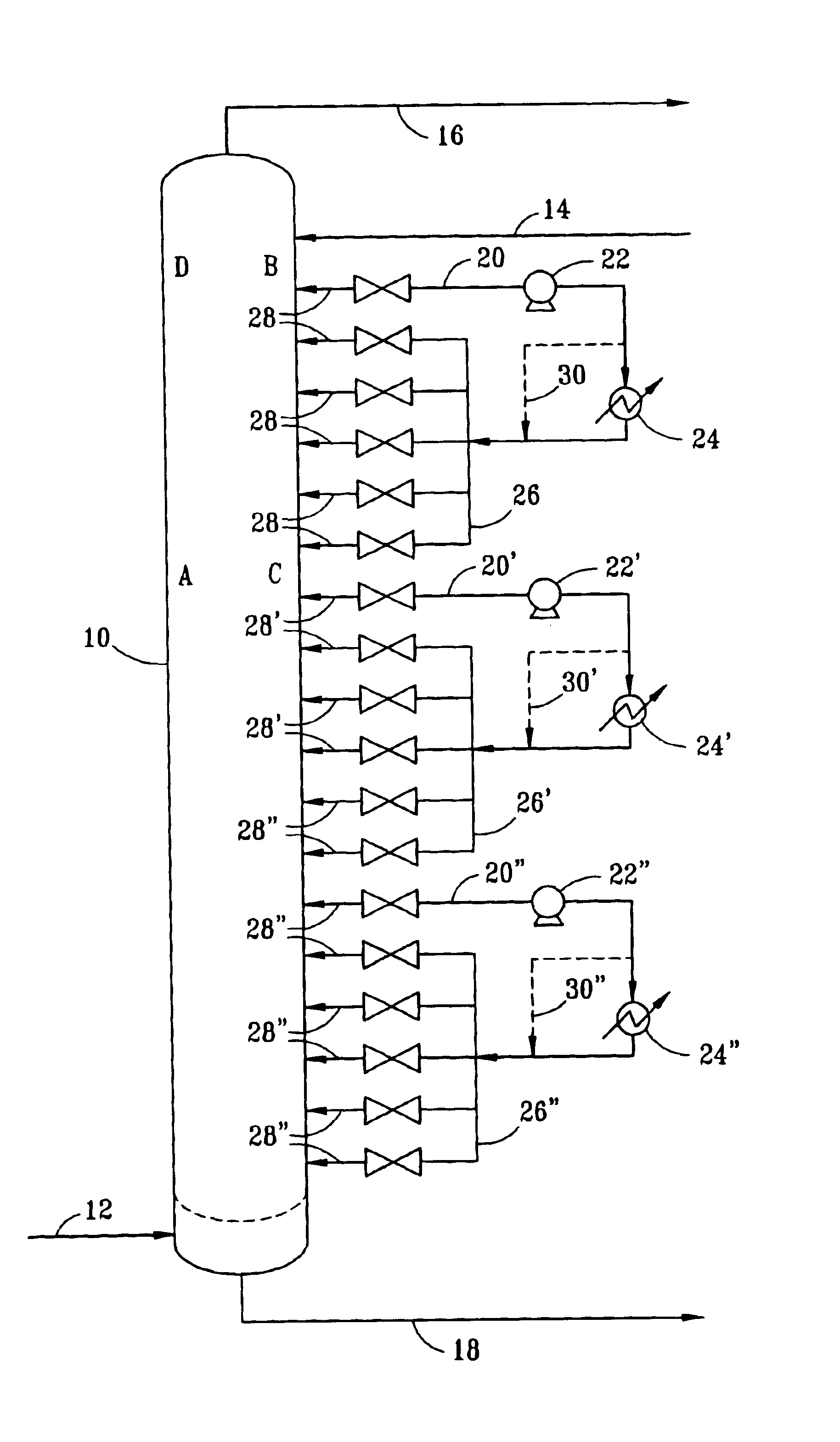

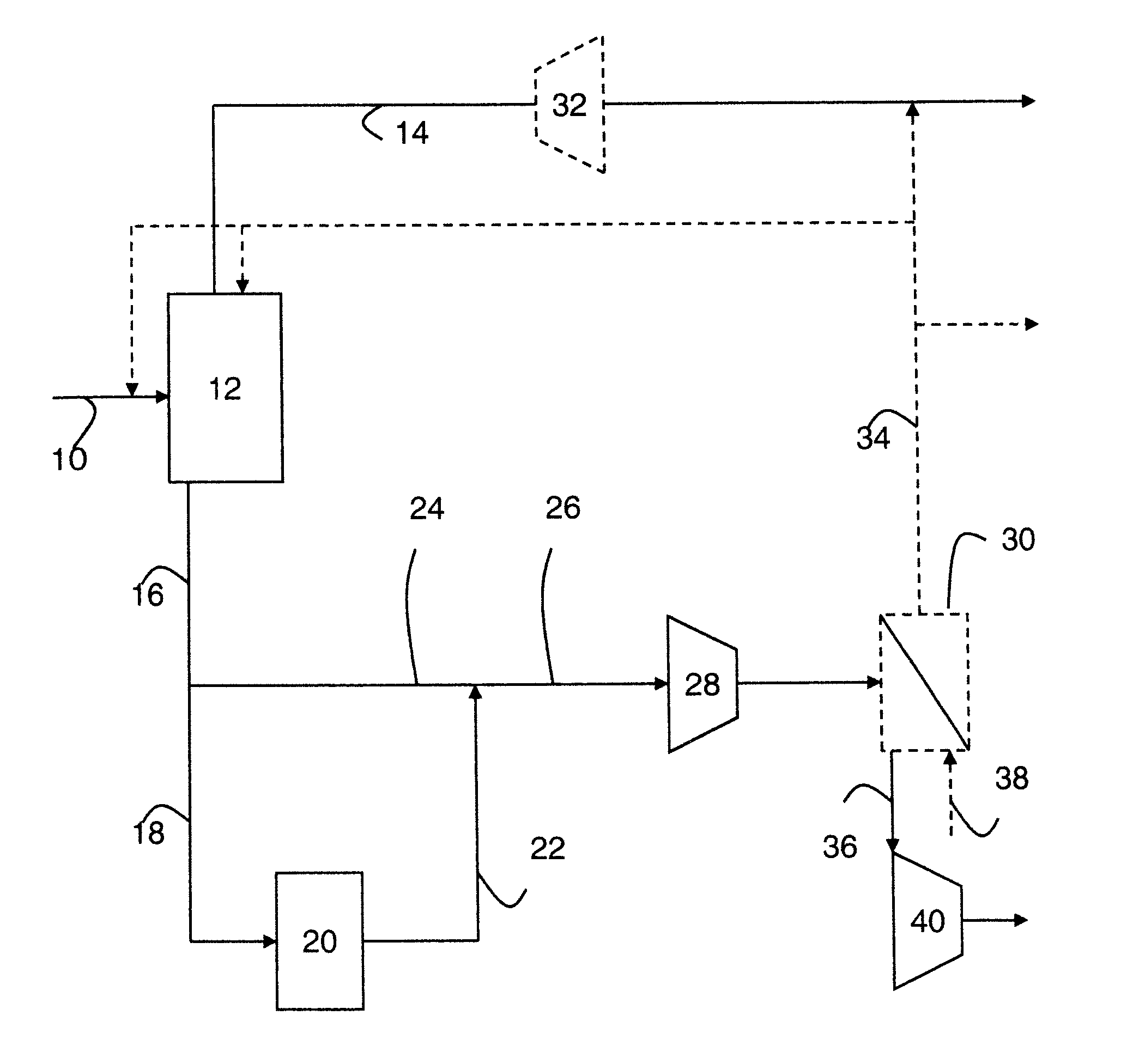

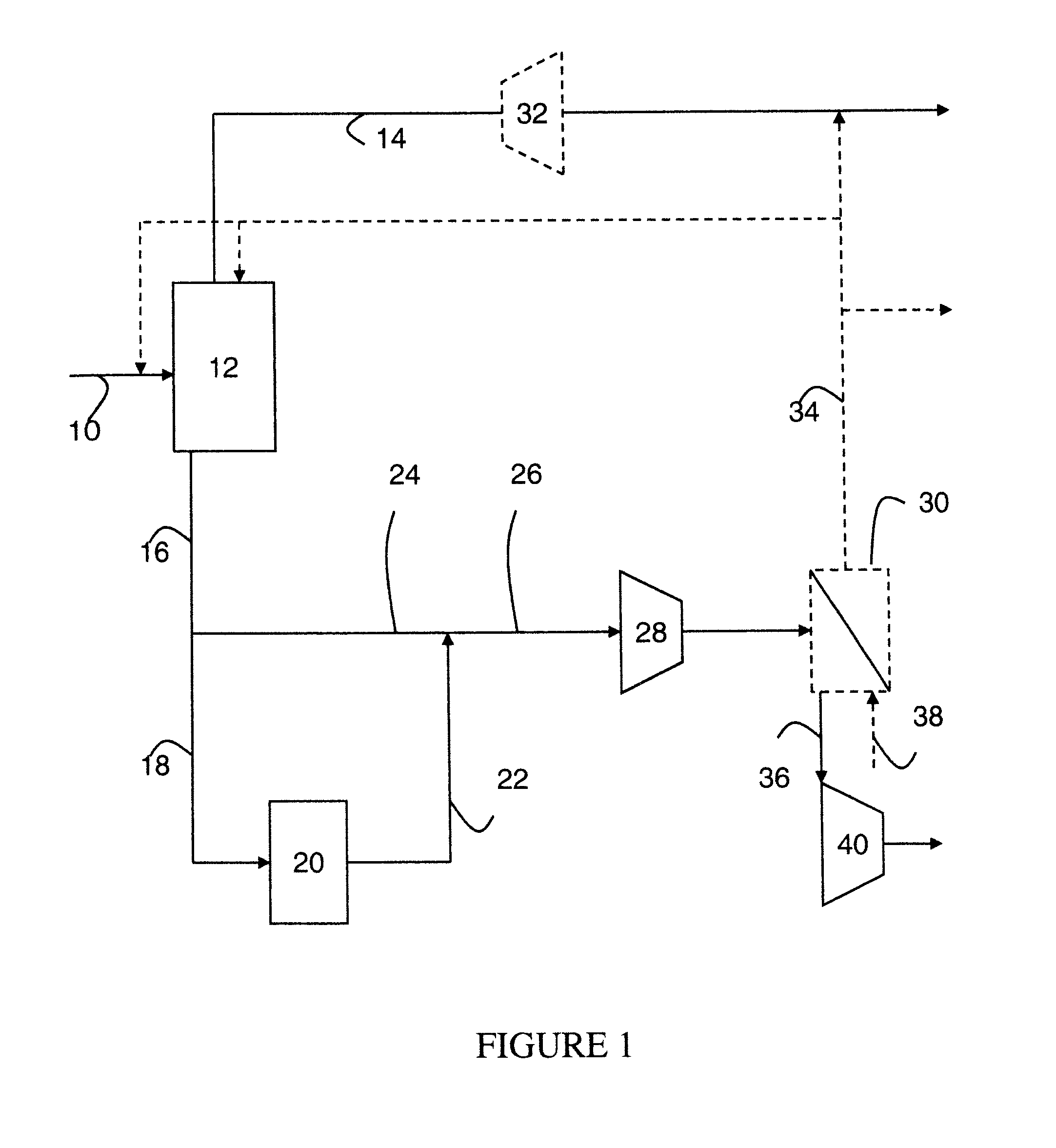

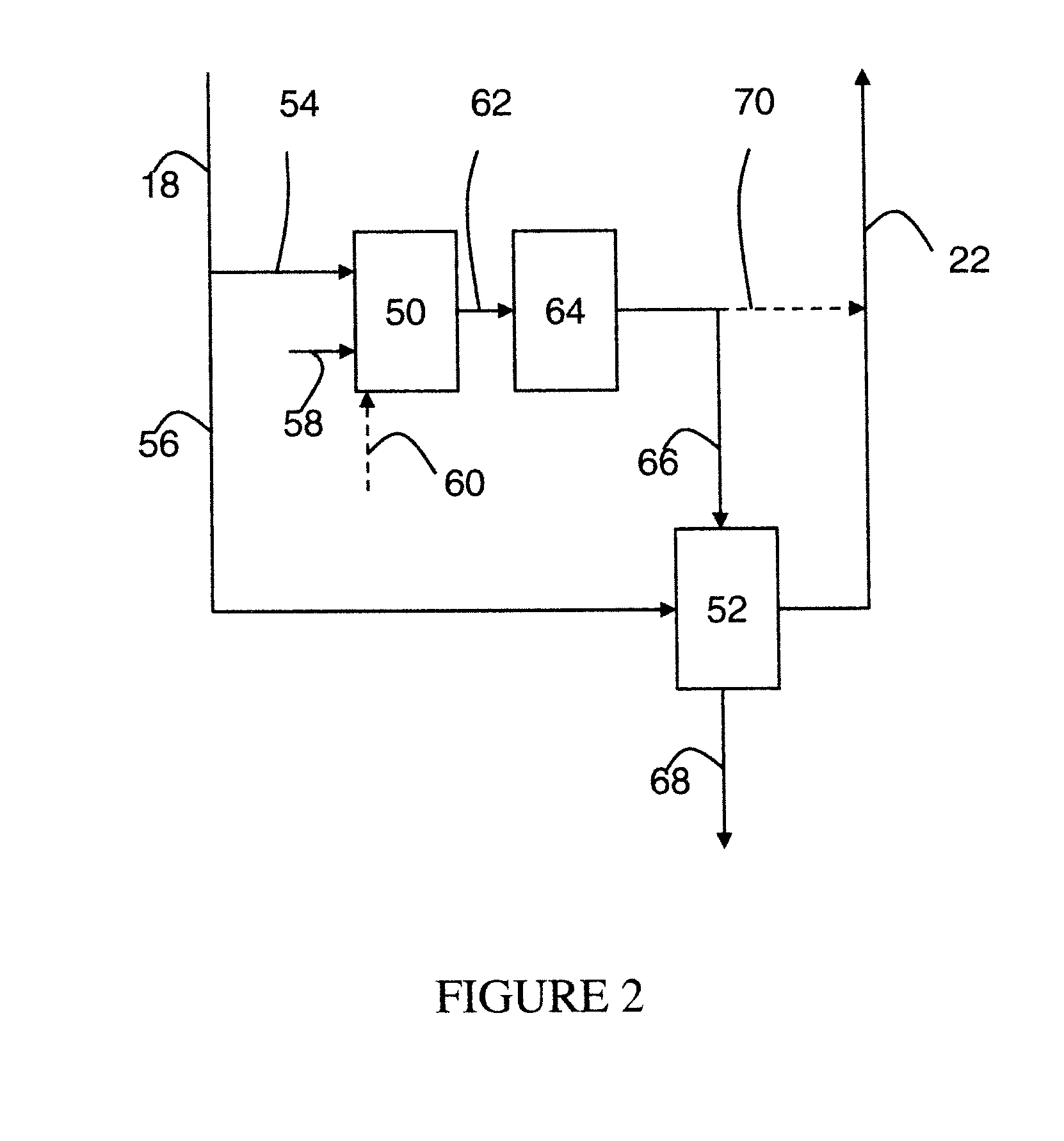

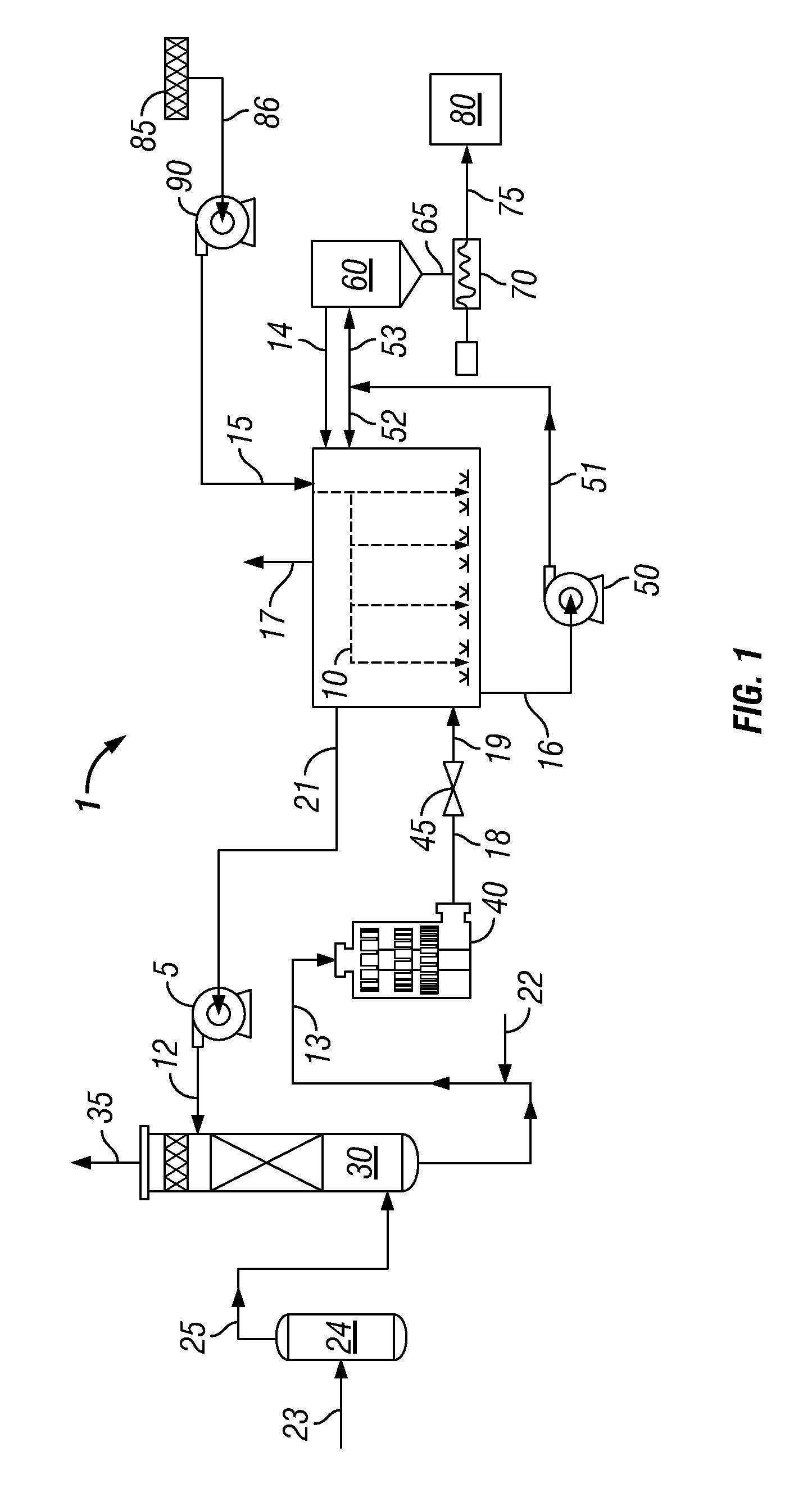

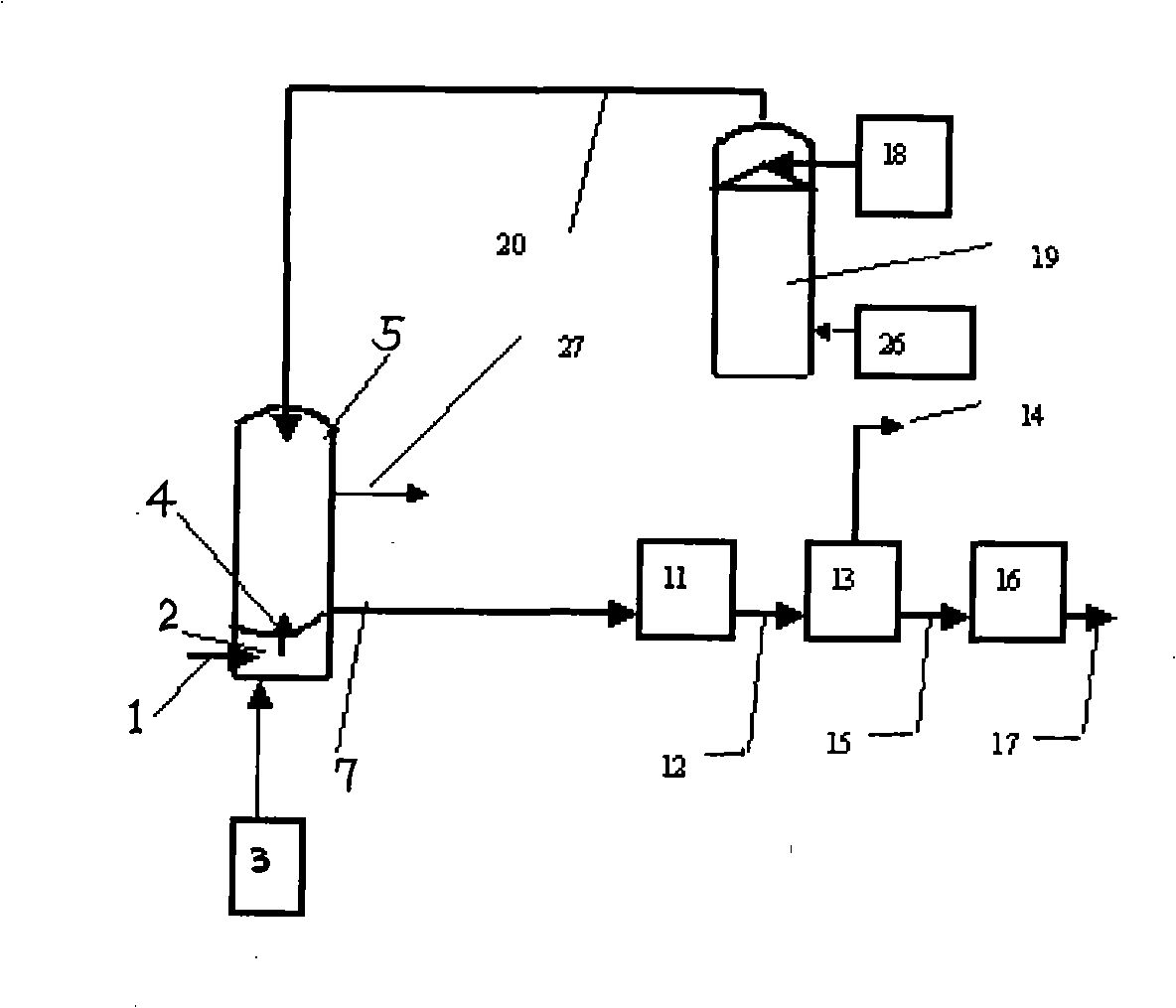

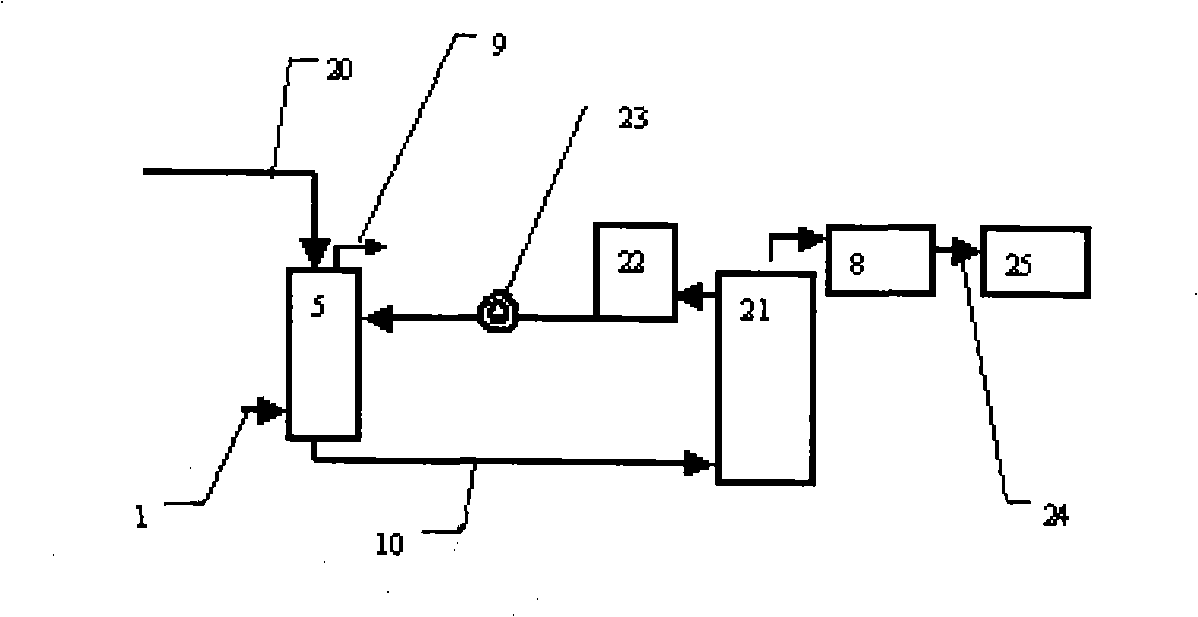

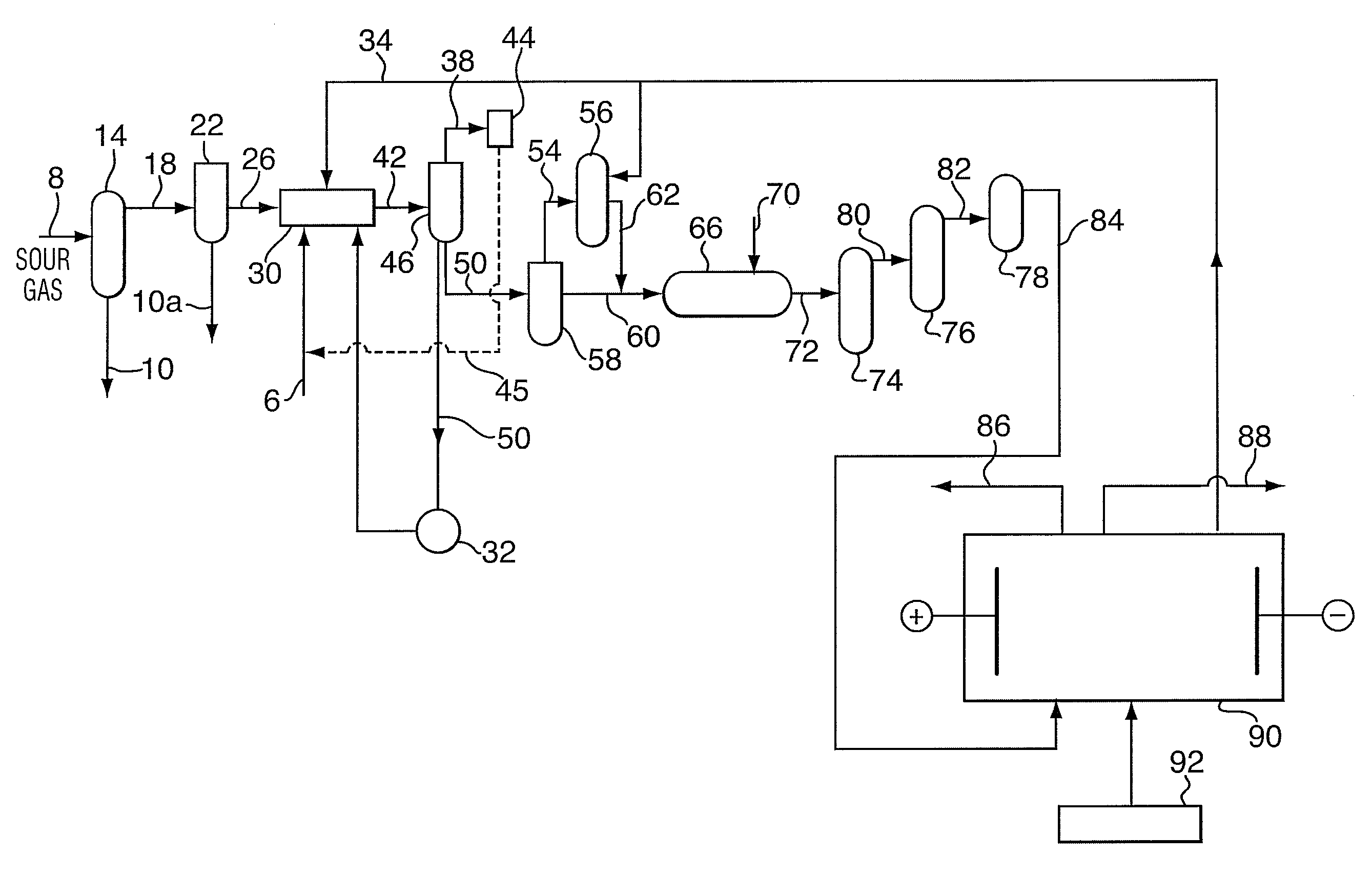

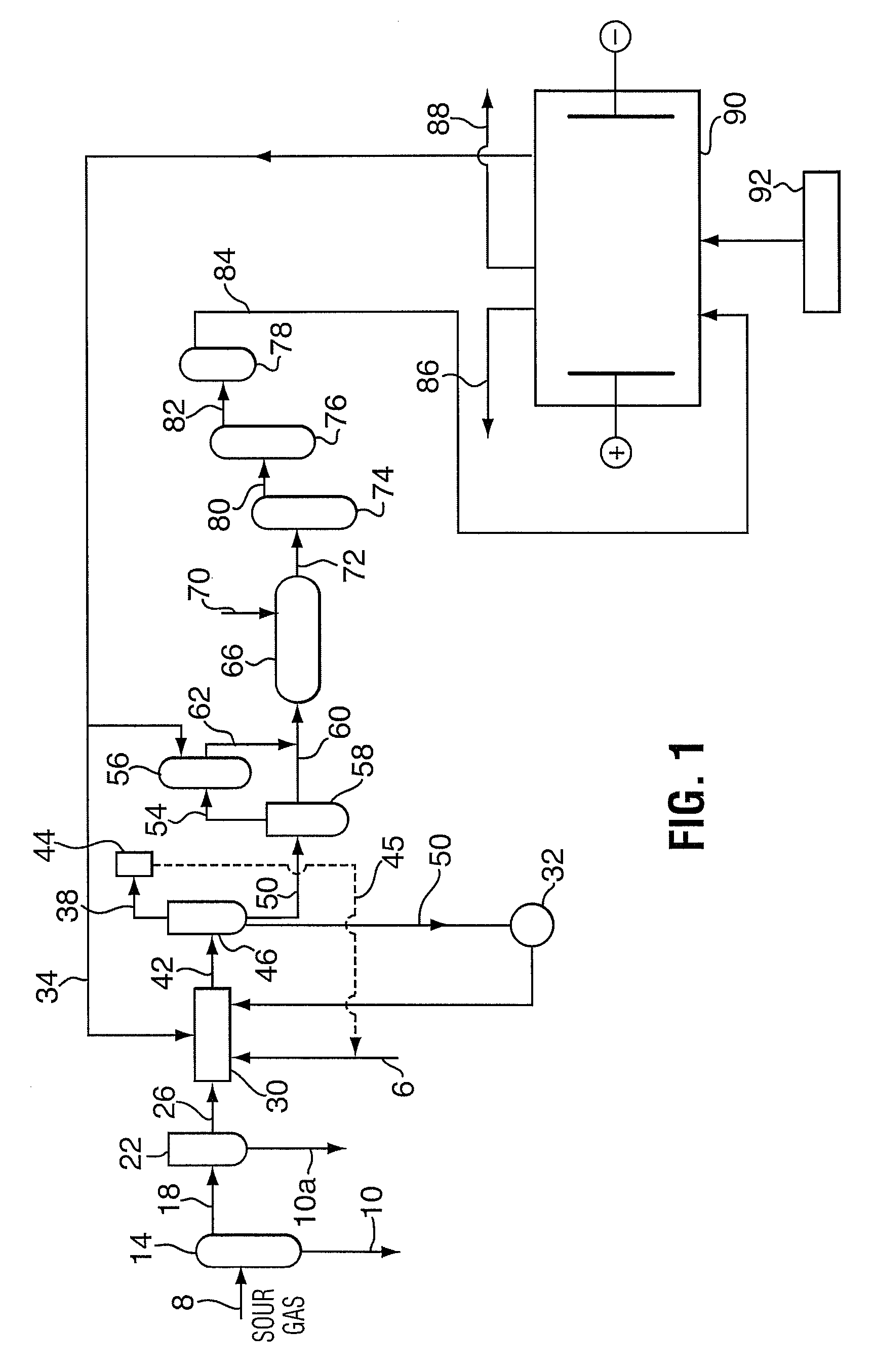

Method and Apparatus for Adjustably Treating a Sour Gas

A feed gas comprising CO2, H2S and H2 is treated to produce an H2-enriched product and an H2S-lean, CO2 product. The feed gas is separated to provide the H2-enriched product and a stream of sour gas. The stream of sour gas is divided into two parts, one of which is processed in an H2S removal system to form one or more streams of sweetened gas, and the other of which bypasses the H2S removal system, the stream(s) of sweetened gas and the sour gas bypassing the H2S removal system then being recombined to form the H2S-lean, CO2 product gas. The division of the sour gas between being sent to and bypassing the H2S removal system is adjusted responsive to changes in the H2S content of the sour gas, so as to dampen or cancel the effects of said changes on the H2S content of the H2S-lean, CO2 product gas.

Owner:AIR PROD & CHEM INC

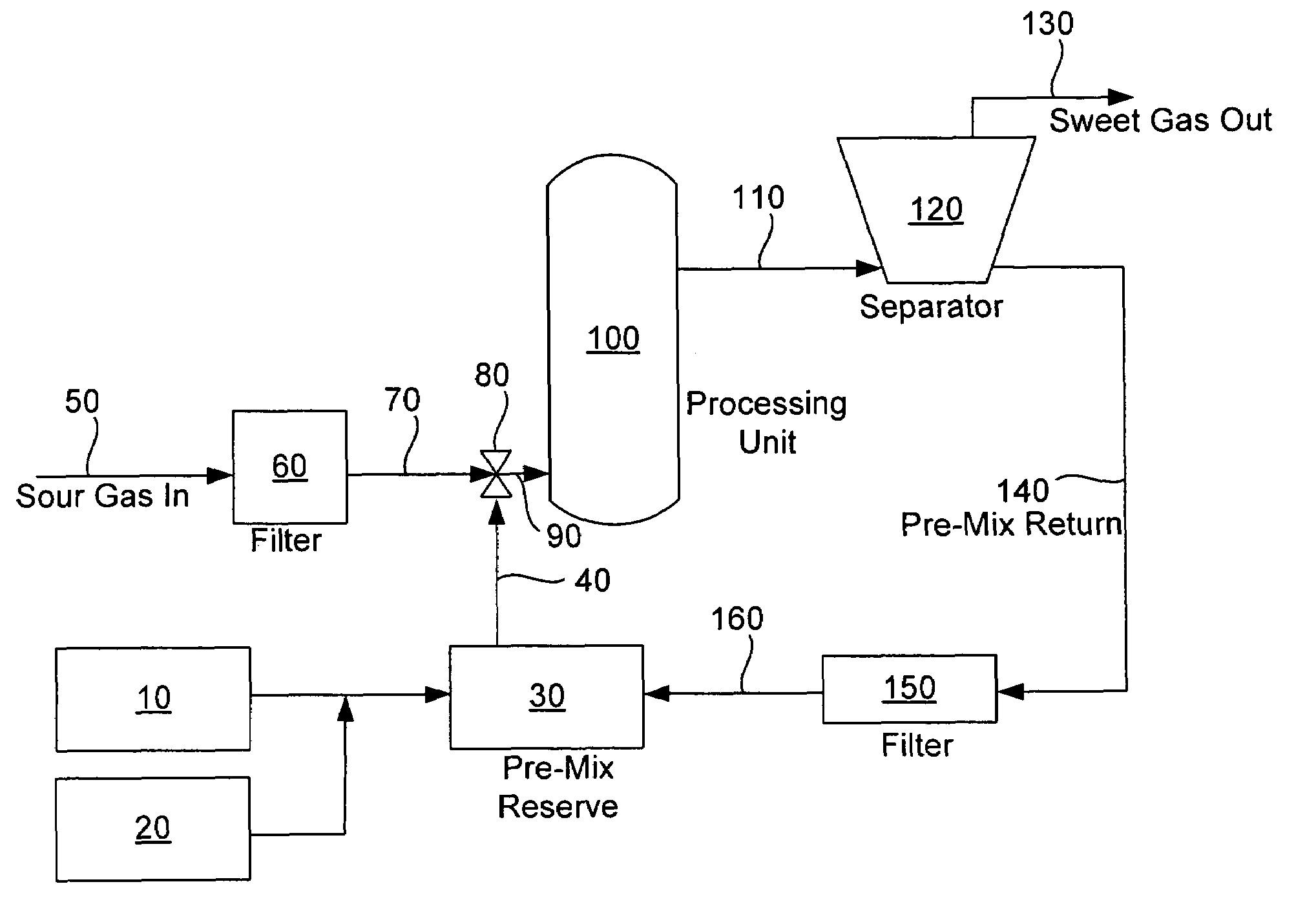

Hydrogen sulfide removal method and system for treating gaseous process streams

A method and system for removing hydrogen sulfide from gaseous process streams, such as sour gas streams are disclosed and described. A gaseous stream containing hydrogen sulfide can be contacted with an aqueous silicon-containing composition under high shear conditions to form a sweetened gaseous product. The gaseous product has significantly reduced hydrogen sulfide content and recovered liquid and solid filtrates are generally non-toxic.

Owner:NESTCO

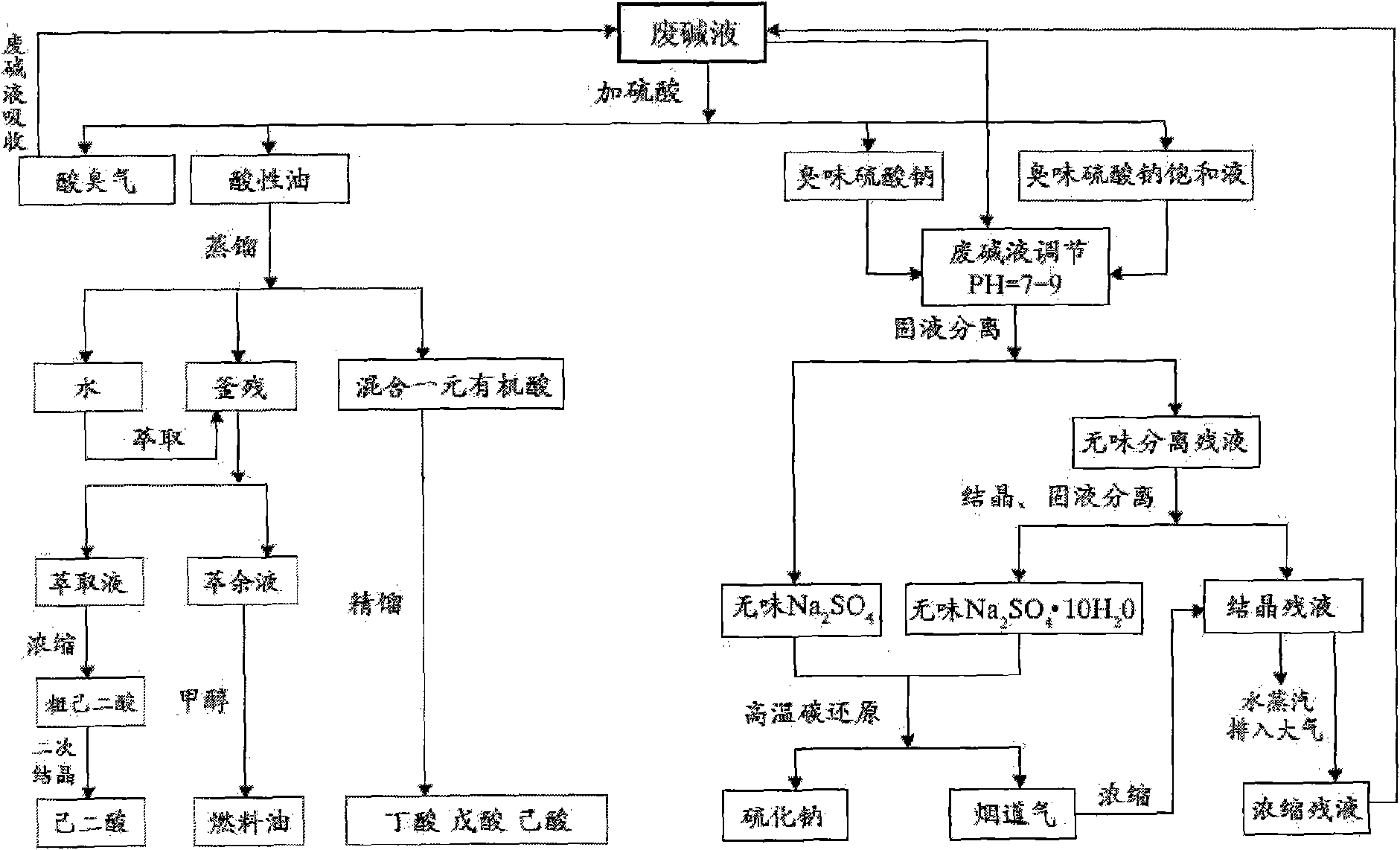

Method of recycling cyclohexanone waste lye

InactiveCN101560011AEliminate secondary pollutionGood social and environmental benefitsAlkali metal sulfides/polysulfidesNature of treatment waterCogenerationChemical products

The invention relates to a method of recycling cyclohexanone waste lye. The method comprises the following steps: 1) acid is used for neutralizing waste lye to extract acid oil, anhydrous sodium sulphate and sodium sulphate with water; acidulated sewage is processed; 2) acidic sour gas is processed; 3) anhydrous sodium sulphate and sodium sulphate with water are used for cogeneration of sodium sulfide; 4) acid oil is used for cogeneration of monocarboxylie acid, adipate and fuel oil. The technical route is reasonable and has the advantages that waste lye is used for processing the sewage acidulated by sodium sulfate solution immediately after neutralization with acid to eliminate acidic sour gas, so as to radically treat secondary pollution of acid neutralization method, achieve zero emission and improve environmental benefits obviously; sodium sulfide, monocarboxylie acid, adipate, clean fuel oil and other chemical products with high added-value are obtained, so that economic benefits are obvious; The method recycles waste resource, has low energy consumption and simple technique, which is applicable to scale treatment of cyclohexanone waste lye as well as industrial production of resource recovery.

Owner:赵志军

Apparatus and method for exclusively removing VOC from regeneratable solvent in a gas sweetening system

InactiveUS20020012622A1Mitigate such drawbackImprove performanceLiquid degasificationOther chemical processesProduct gasSolvent

A method for removing residual VOC components from a fluid stream used in the sweetening of sour gas at gas processing plants. In a retrofit configuration, the method includes interposing a supplemental VOC removal station after a primary VOC removal station in an absorbent fluid stream. The absorbent fluid stream incorporates fluid into which sour gas components and VOC have been absorbed from a treated gas stream such as produced natural gas. The primary VOC removal station is configured to remove an initial portion of the absorbed VOC from the absorbent fluid stream. The supplemental VOC removal station is configured to liberate a portion of residual absorbed VOC remaining in the absorbent fluid stream downstream from the primary VOC removal station. Further, the supplemental VOC removal station is configured to avoid liberating absorbed sour gas components from the absorbent fluid stream. Alternatively, a single, but enhanced performance VOC removal station is utilized to liberate a sufficient proportion of the absorbed VOC from the absorbent fluid stream.

Owner:FRONDORF MATTHEW T

Hydrogen sulfide treatment system

The present invention provides a system for treating a process fluid. The system includes a modular arrangement that includes ten modules for; reducing the amount of dissolved and entrained hydrogen sulfide gas in the process fluid; monitoring the pH of the process fluid; storing the process fluid; reducing an amount of oil from the process fluid; and flocculating the process fluid; measuring the amount of oil in the process fluid; providing ventilation supply air to at least one of the modules; removing hydrogen sulfide gas from a sour gas; delivering gases to a burner system; and controlling the processes of the system.

Owner:MI

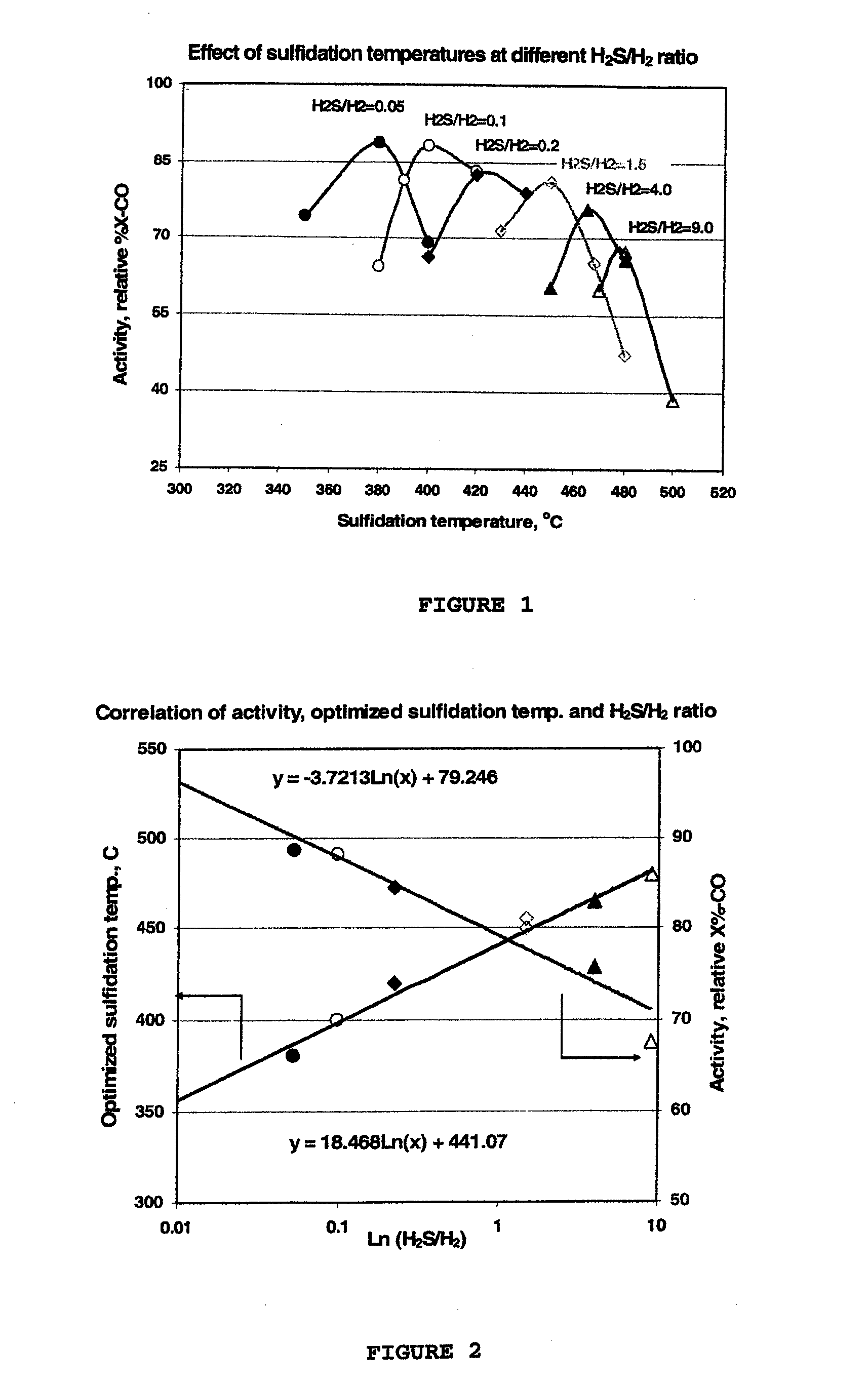

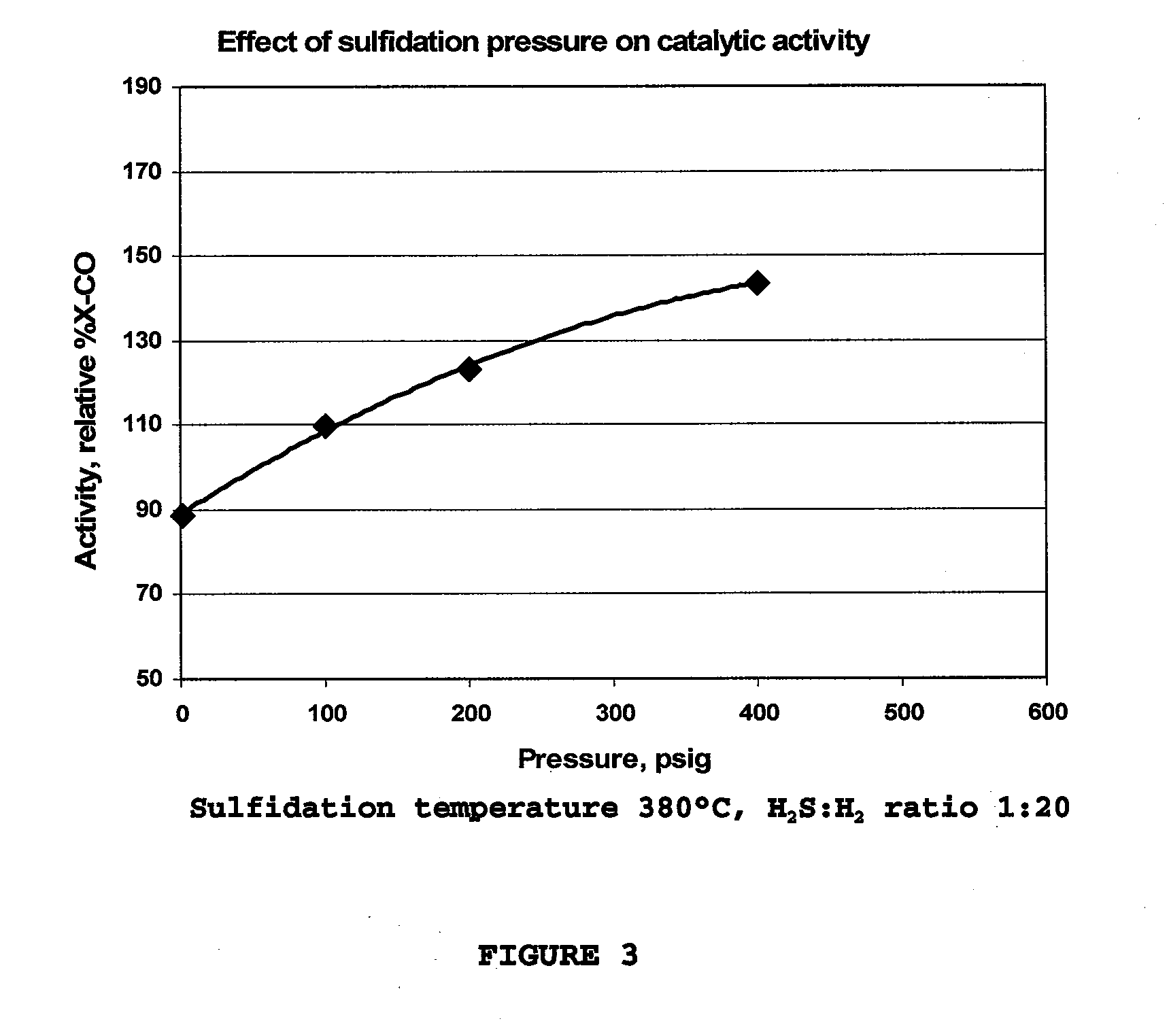

Process for sulfiding catalysts for a sour gas shift process

A process for the sulfidation of a sour gas shift catalyst, wherein the temperature of the sulfidation feed stream is coordinated with the sulfur / hydrogen molar ratio in that feed stream to obtain enhanced performance of the sour gas shift catalyst. In the sulfidation process to produce a sour gas shift catalyst, the lower the sulfur to hydrogen molar ratio of the sulfidation feed stream, the lower the required temperature of the sulfidation feed stream. The sulfidation reaction can be further enhanced by increasing the pressure on the sulfidation feed stream.

Owner:CLARIANT INT LTD

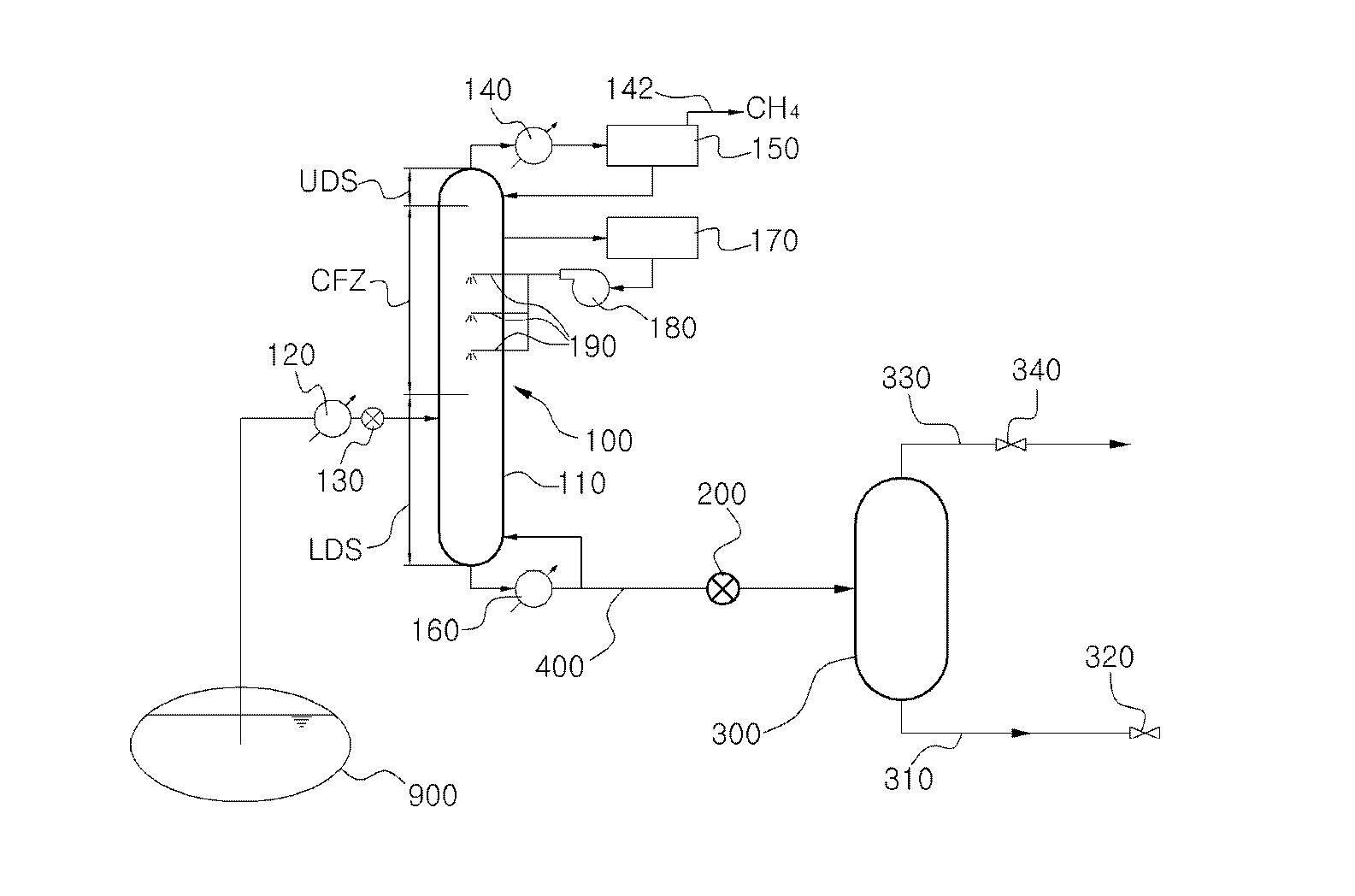

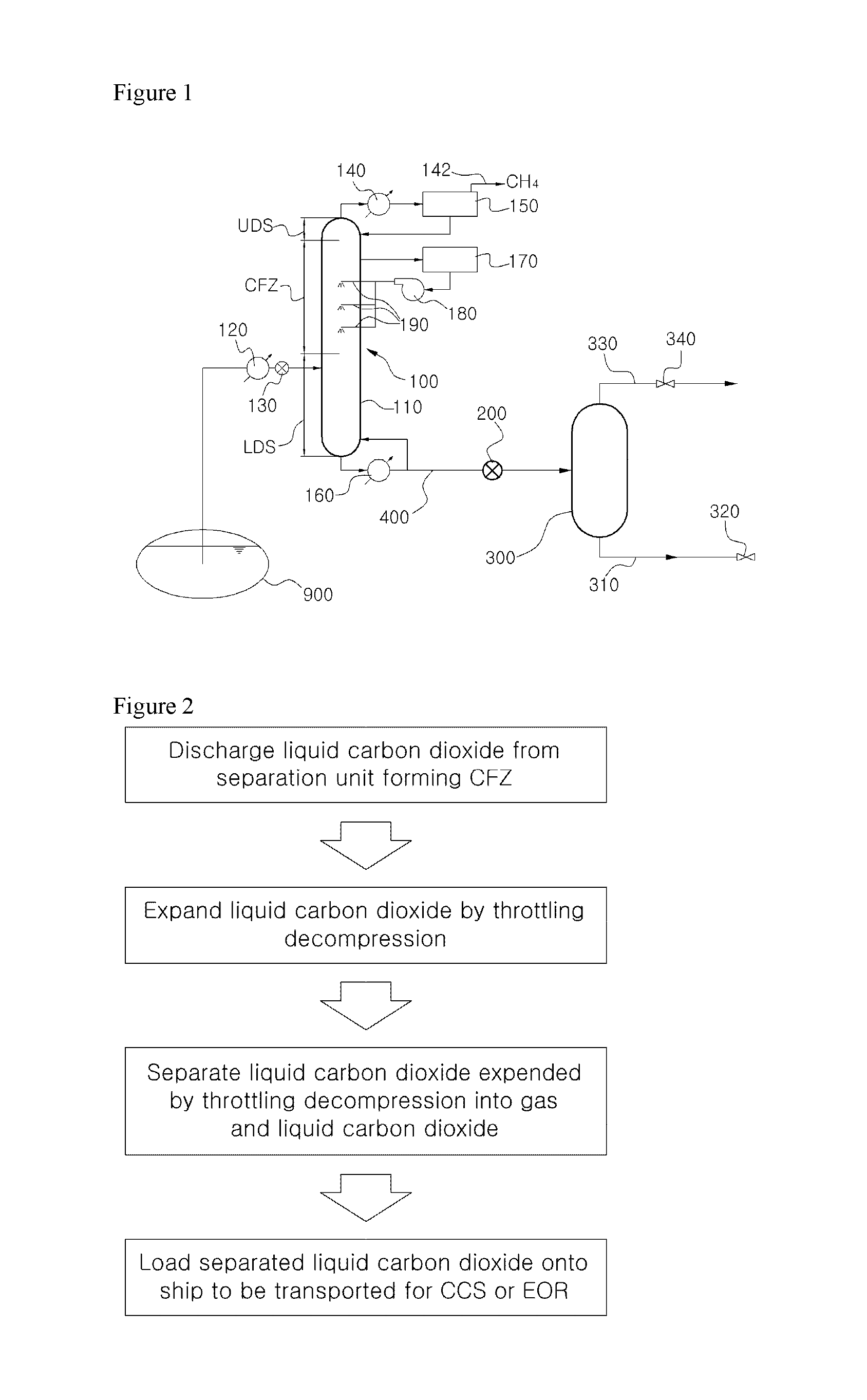

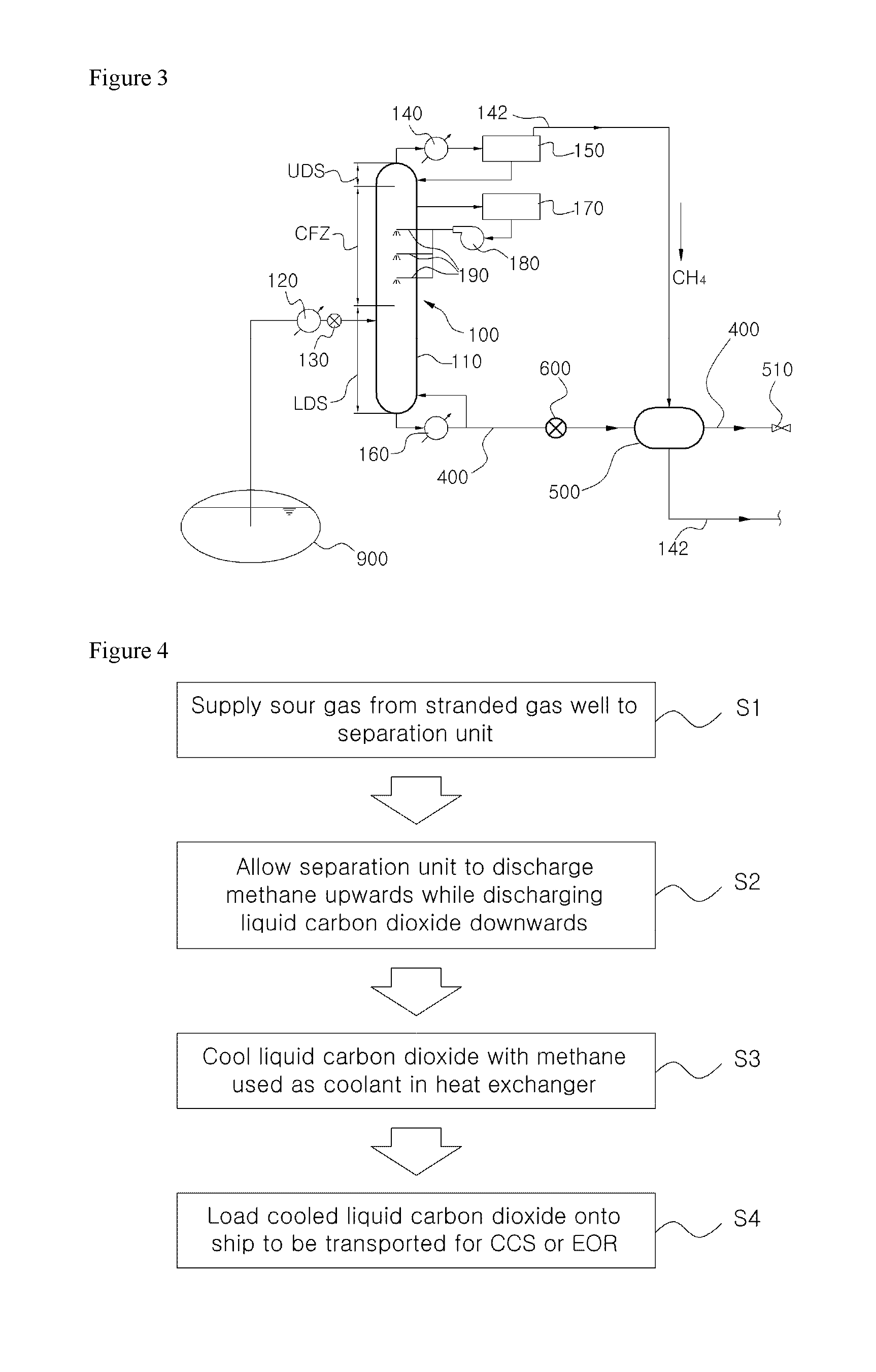

Module for treatment of carbon dioxide and treatment method thereof

InactiveUS20140360226A1Easy to transportReduce loadSolidificationLiquefactionLiquid carbonProduct gas

Liquid carbon dioxide separated from sour gas is expanded by throttling decompression and is gas-liquid separated at a low temperature so as to be supplied for shipping or the improvement of petroleum recovery. Methane generated from a stranded gas well is allowed to pass as a coolant through liquid carbon dioxide separated and discharged from sour gas generated from the stranded gas well so as to cool liquid carbon dioxide. Disclosed is a module for treating carbon dioxide, and a treatment method thereof for supplying liquid carbon dioxide at a proper temperature and state conditions when there is a need for liquid carbon dioxide of very low temperature for the storage or collection of carbon dioxide, the improvement of petroleum recovery, or the like by cooling carbon dioxide using a material separated from sour gas of a stranded gas well as a coolant.

Owner:DAEWOO SHIPBUILDING & MARINE ENG CO LTD

Semi-dry method flue gas desulfurization technique

InactiveCN101249380AFacilitate smooth transportationImprove efficiencyDispersed particle separationSulfateAdditive ingredient

The invention provides a novel stack gas desulphurization process adopting the semi-dry process, which is characterized in that: (1) powdered neutralizer is uniformly wetted; (2) the powdered neutralizer is separately put into a fume conduit, forms mixed gas flow with fume and enters a reaction tower; (3) in the reaction tower, atomized water is adopted to further wet the neutralizer and the fume so that SO2 and other acidic gases in the fume react with the powdered neutralizer to generate solid salt; after the reaction, the fume gets out of the reaction tower and enters a dust catcher; the dust catcher is used to remove the solid salt before the fume is discharged. By adopting the process, acid injurious ingredients in the fume such as SO2 and so on react with the neutralizer to generate vitriol and so on, so that the acid ingredients in the gas become solid salt, and are removed from the gas, thus purifying the gas which can be discharged according to the state emission standard.

Owner:BEIJING KEDA LIANCHUANG METALLURGICAL TECH

Method and system for increasing the absorption selectivity of H2S from a gas containing CO2 and H2S

ActiveUS6884282B2High selectivityMixing methodsUsing liquid separation agentAbsorption columnProduct gas

A system and a method for increasing the selectivity of H2S absorption in an aqueous amine treating processes for streams containing high CO2:H2S ratio mixtures in an absorption column by maintaining the temperature in the absorption column by withdrawing, cooling and returning cooled aqueous amine to the column at at least one location intermediate the sour gas inlet to the column and the lean gas outlet from the column.

Owner:BLACK & VEATCH HLDG

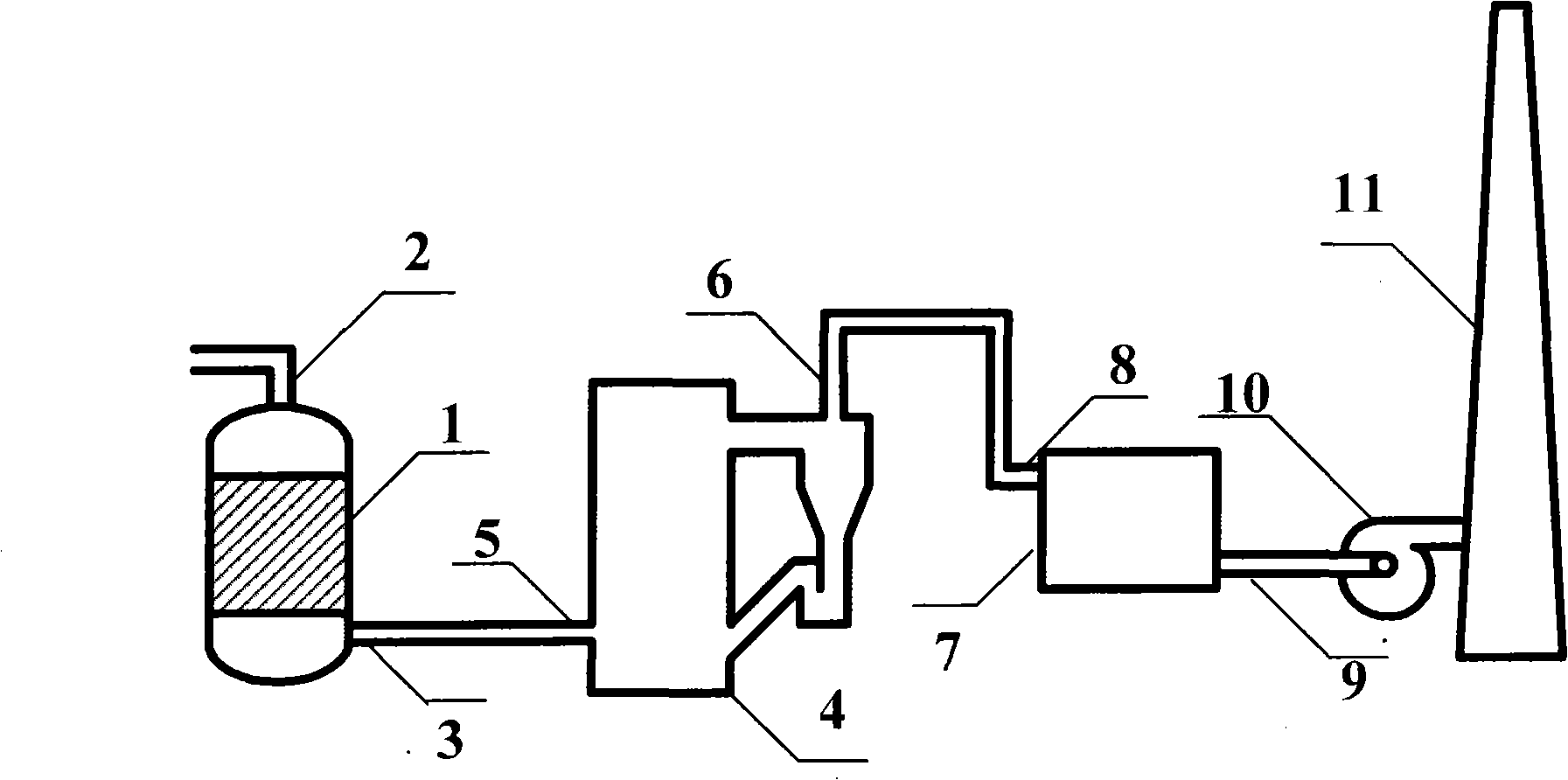

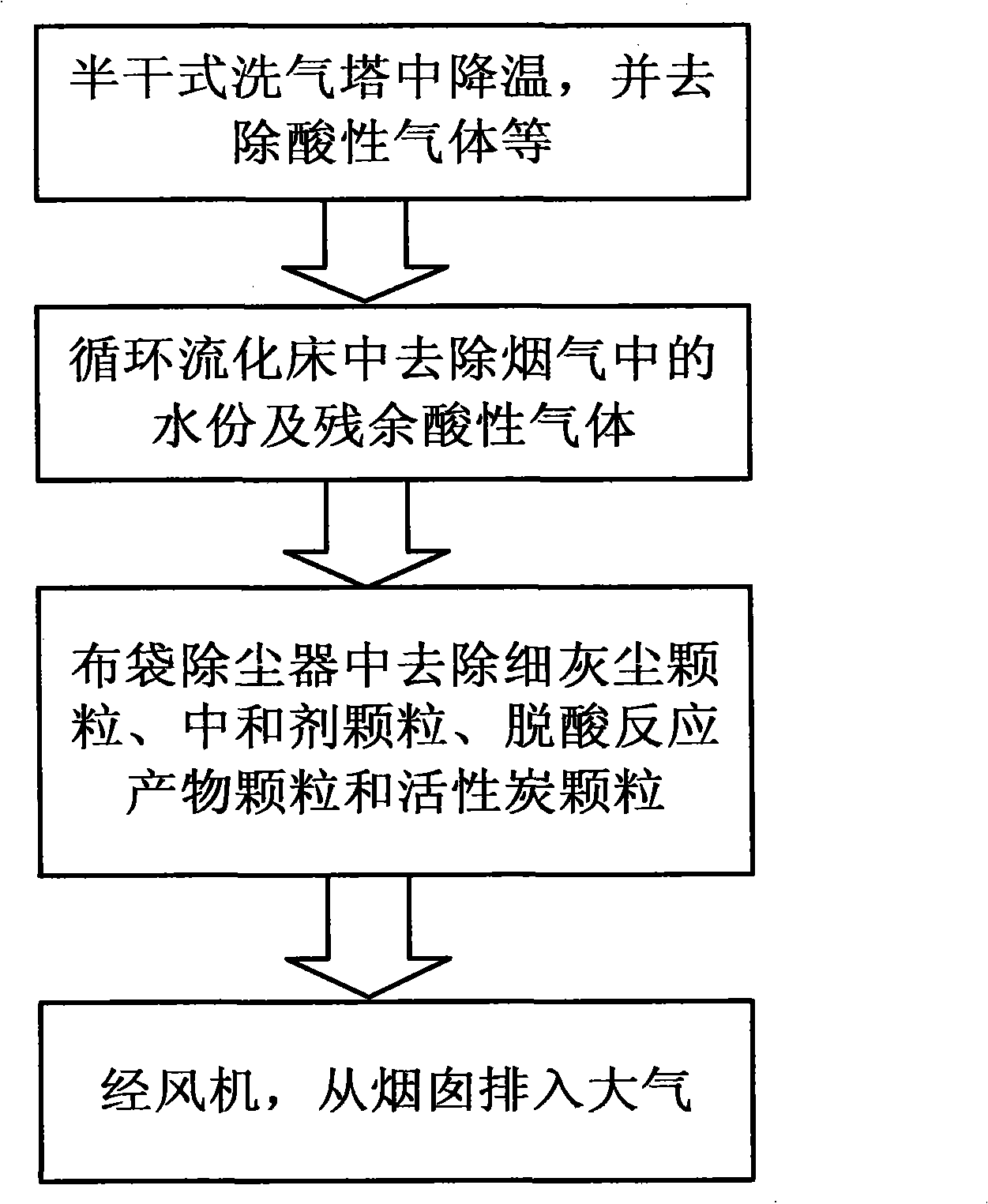

Novel wastes incineration flue gas purification system and process thereof

InactiveCN101275746AImprove purification effectPurify thoroughlyCombination devicesIncinerator apparatusBaghouseExhaust fumes

The invention belongs to the waste gas handling technical field, particularly a novel waste burning gas cleaning system and the cleaning technology, wherein the system includes a dump dry type gas washing tower, a circulating fluid bed, a bag dust collector and a fan, and the cleaning technology is: the gas enters the dump dry type gas washing tower through the gas entry, which removes the sour gas in the gas; the cleaned gas enters the circulating fluid bed through the tower gas outlet, which removes the water and the residue sour gas, and enters the bag dust collector through the gas outlet of the circulating fluid bed; the bag dust collector filters the fine dust particles, the neutralizer particles, the deacidification reaction product particles and the active carbon particles in the gas, the cleaned gas is discharged into the air through the fan and the chimney. The system and the technology of the invention can greatly advance the cleaning capacity to the gas with wide accommodation limit and regulating range, low cost.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method and Apparatus for Adjustably Treating a Sour Gas

A feed gas comprising CO2, H2S and H2 is treated to produce an H2-enriched product and an H2S-lean, CO2 product. The feed gas is separated to provide the H2-enriched product and a stream of sour gas. The stream of sour gas is divided into two parts, one of which is processed in an H2S removal system to form one or more streams of sweetened gas, and the other of which bypasses the H2S removal system, the stream(s) of sweetened gas and the sour gas bypassing the H2S removal system then being recombined to form the H2S-lean, CO2 product gas. The division of the sour gas between being sent to and bypassing the H2S removal system is adjusted responsive to changes in the H2S content of the sour gas, so as to dampen or cancel the effects of said changes on the H2S content of the H2S-lean, CO2 product gas.

Owner:AIR PROD & CHEM INC

Hydrogen sulfide removal method and system for treating gaseous process streams

A method and system for removing hydrogen sulfide from gaseous process streams, such as sour gas streams are disclosed and described. A gaseous stream containing hydrogen sulfide can be contacted with an aqueous silicon-containing composition under high shear conditions to form a sweetened gaseous product. The gaseous product has significantly reduced hydrogen sulfide content and recovered liquid and solid filtrates are generally non-toxic.

Owner:NESTCO

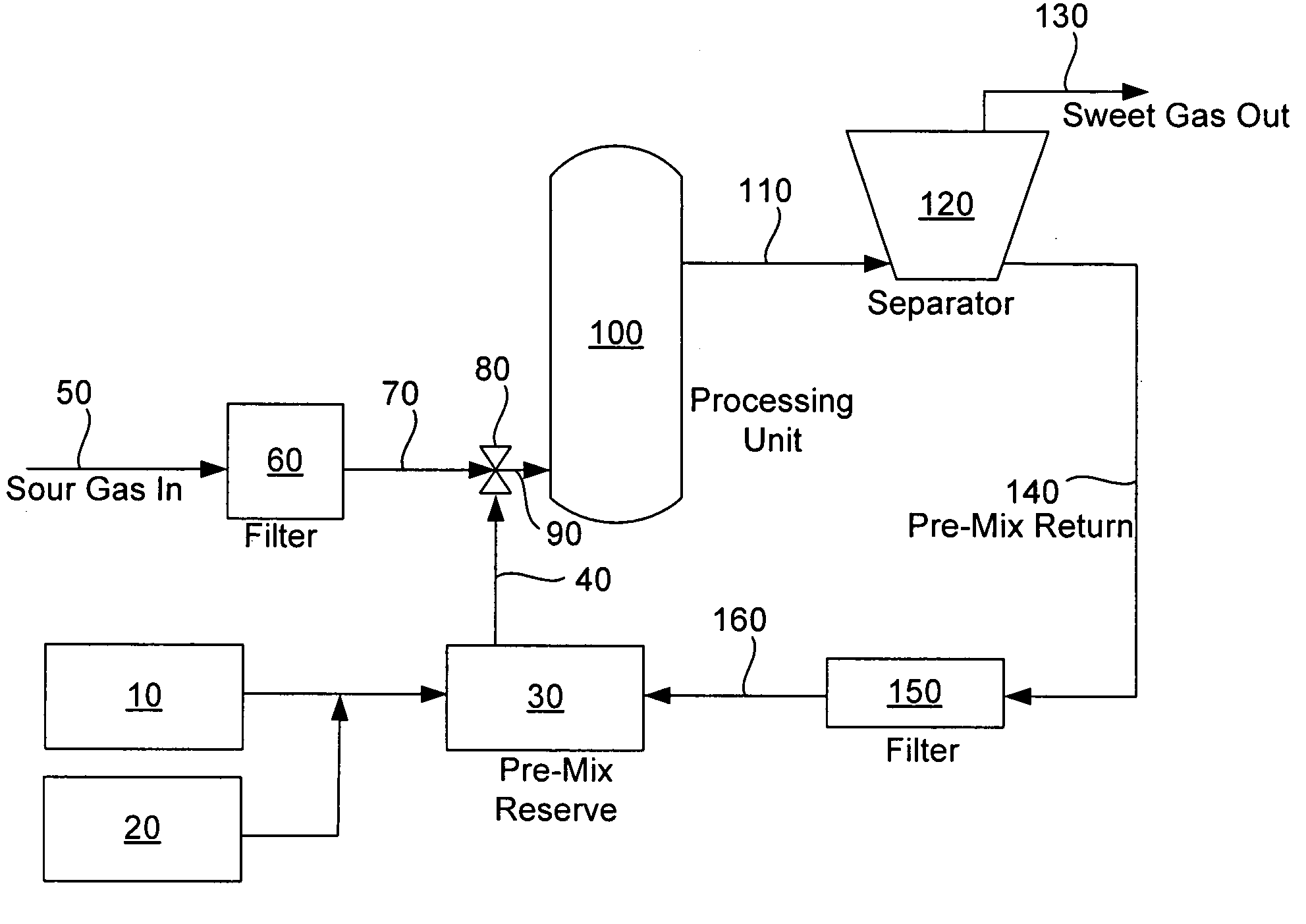

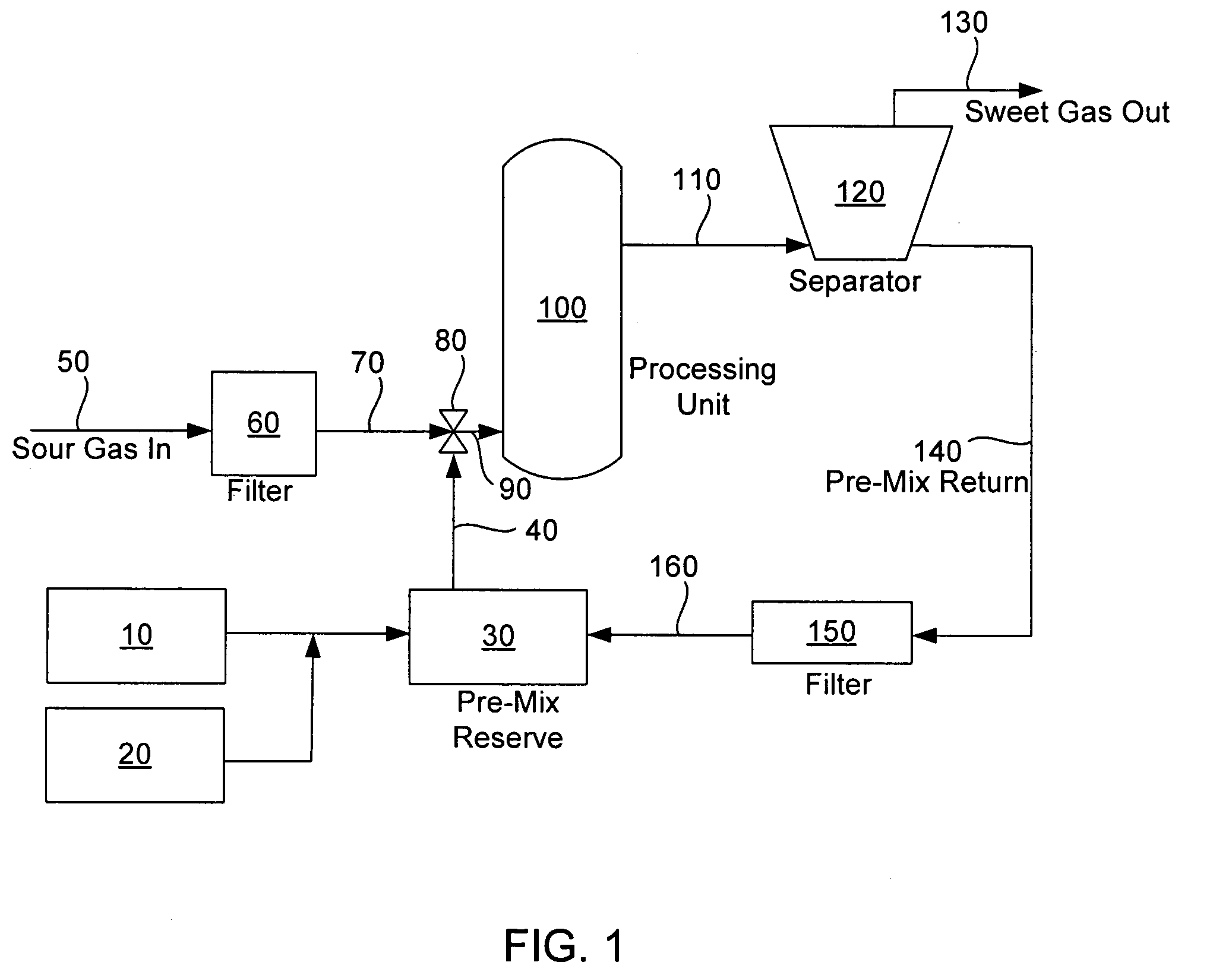

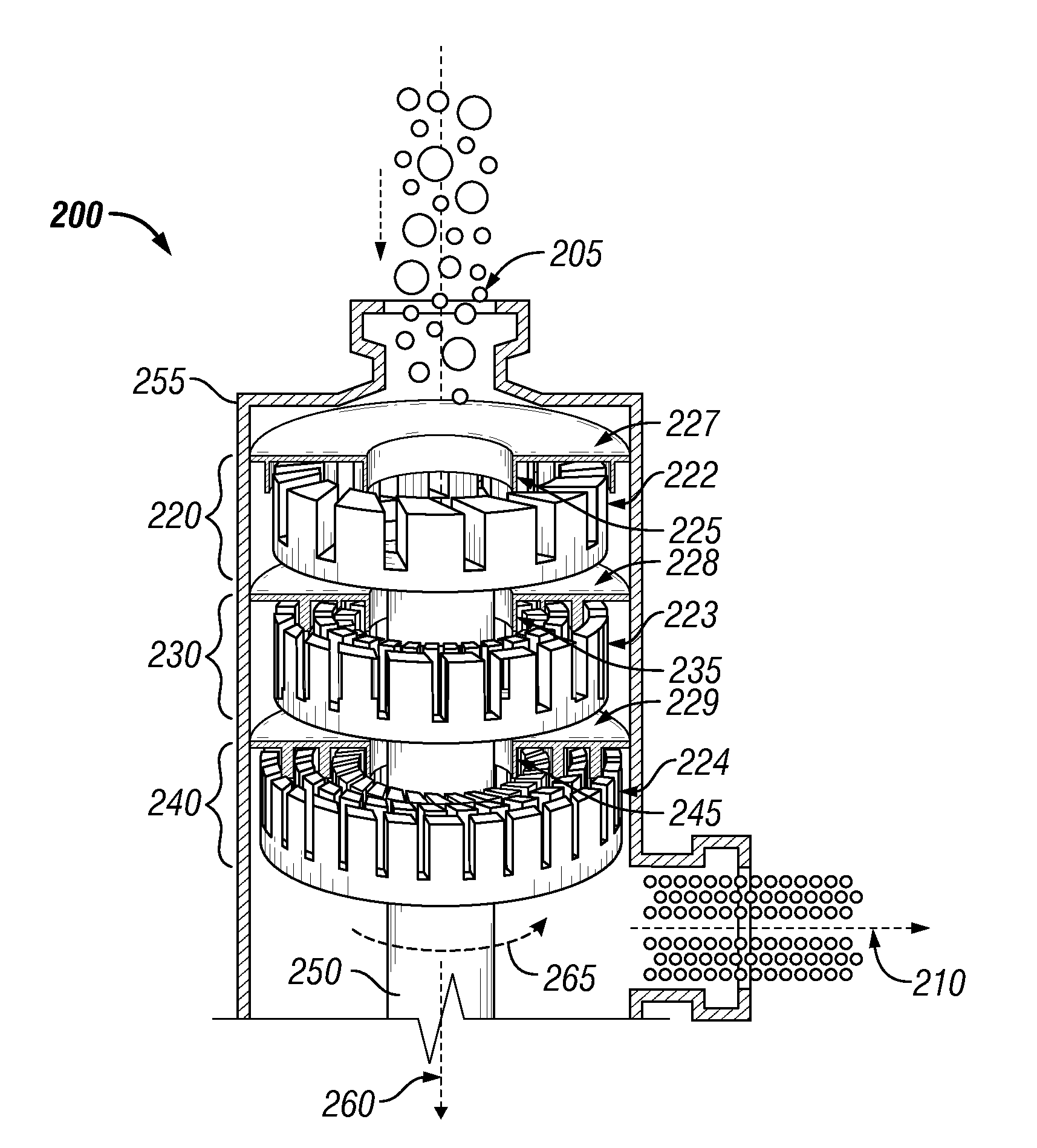

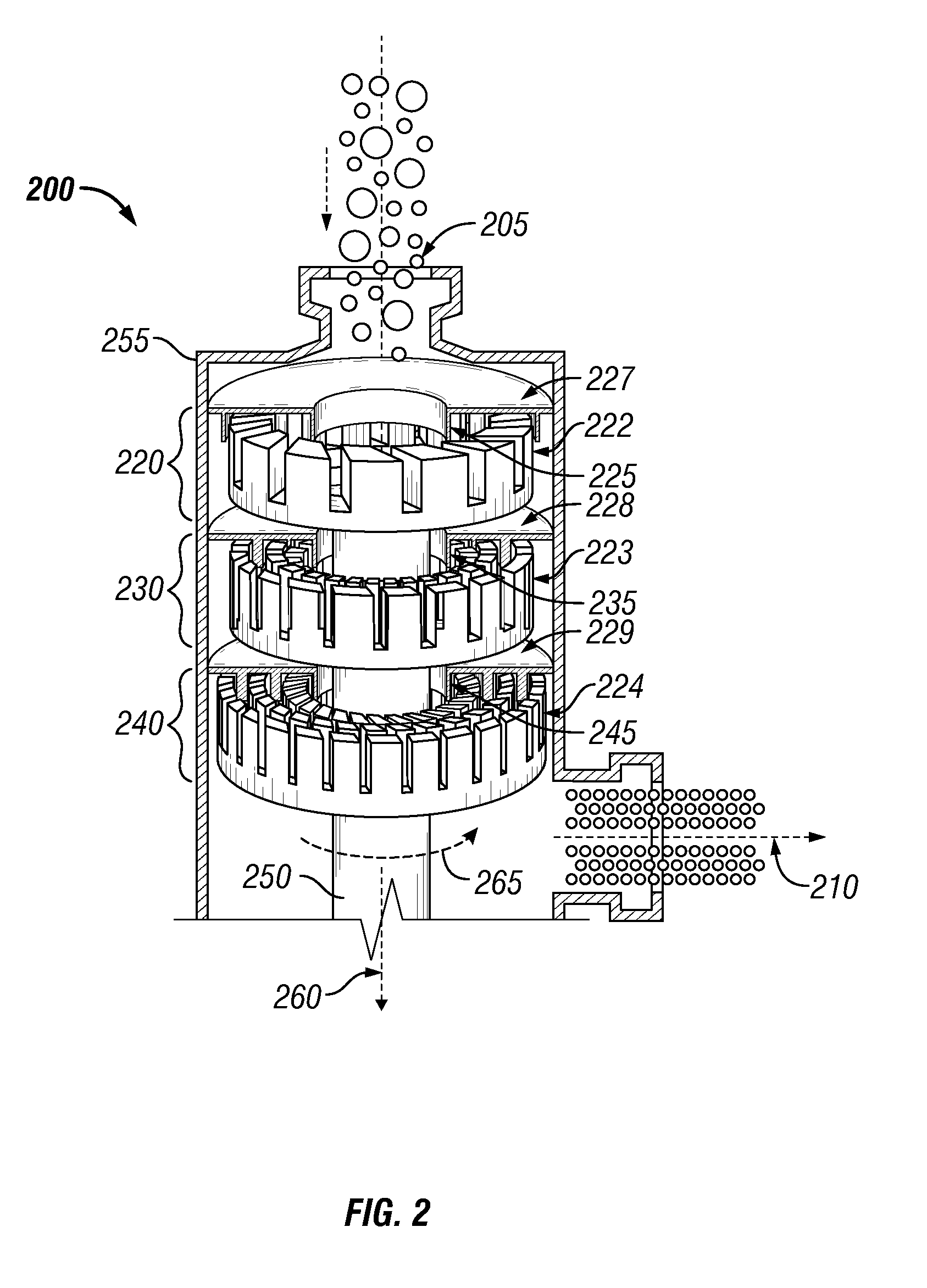

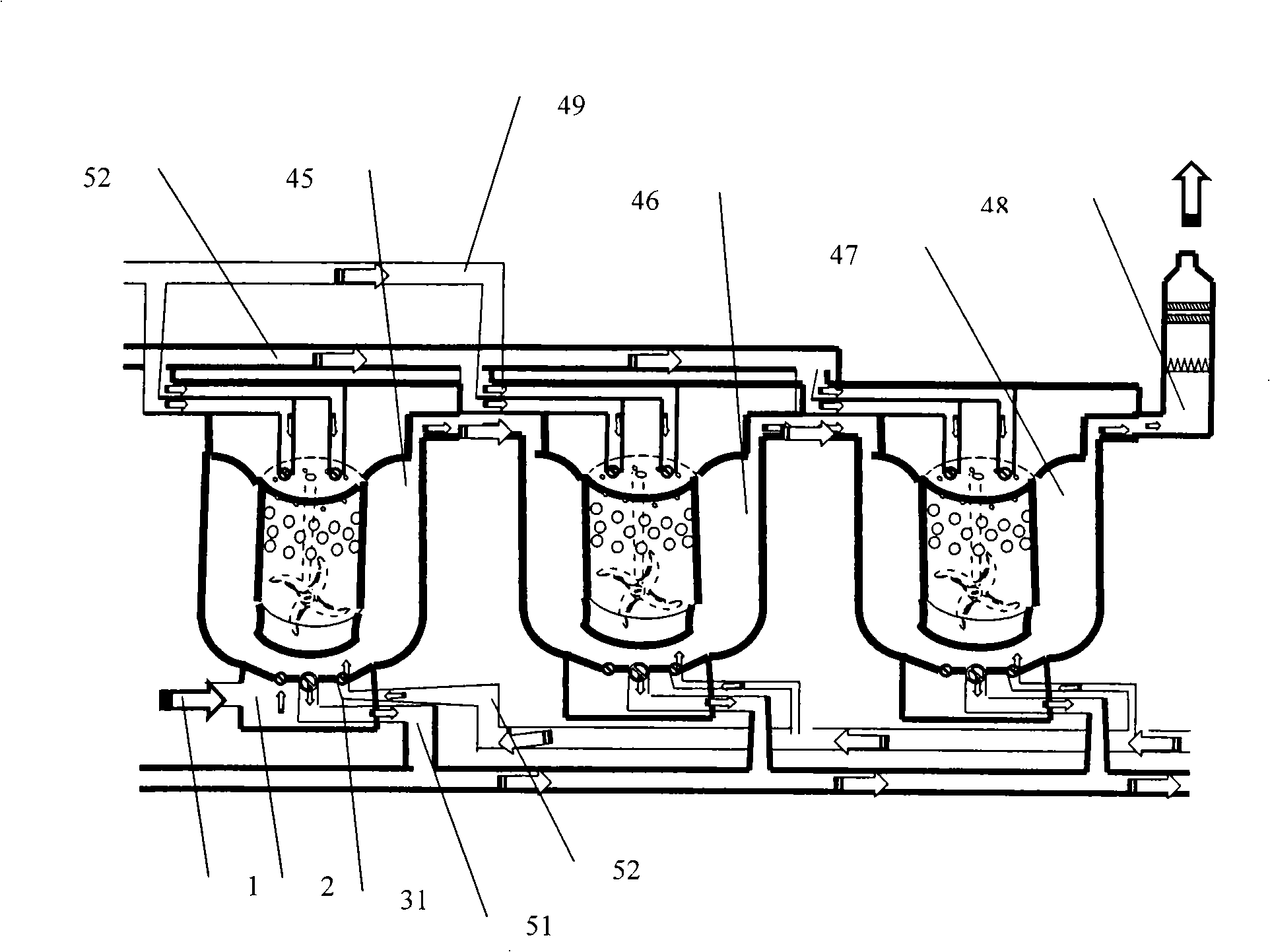

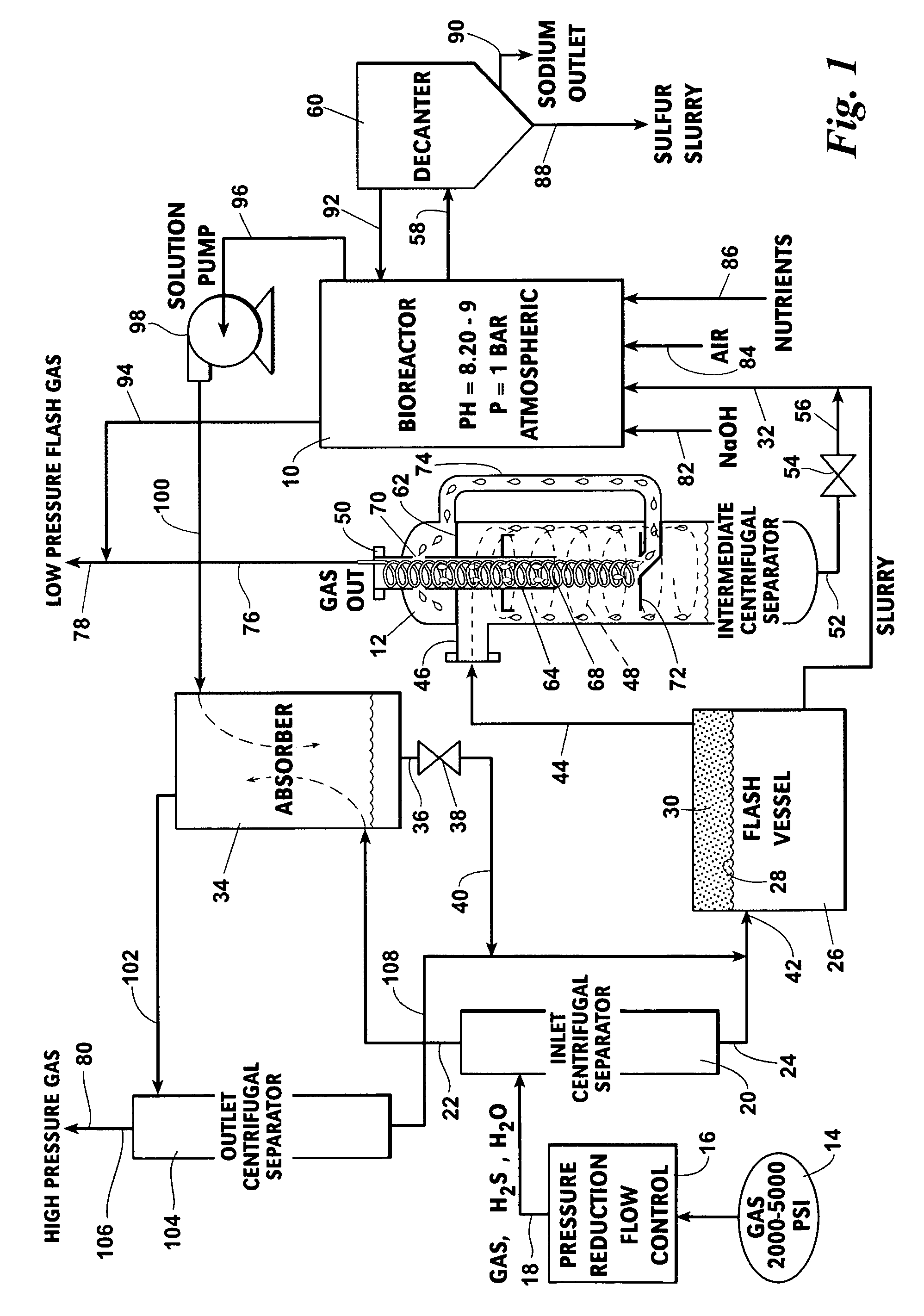

System and process for gas sweetening

ActiveUS20100018118A1Increase ratingsLow costDispersed particle separationGaseous fuelsPtru catalystAqueous solution

A method for removing hydrogen sulfide from a sour gas stream comprising hydrogen sulfide by oxidizing hydrogen sulfide in a converter by contacting the sour gas stream with an aqueous catalytic solution, thereby producing a desulfurized gas stream and a liquid stream comprising reduced catalyst and elemental sulfur, introducing an oxidant and the liquid stream comprising reduced catalyst and elemental sulfur into a high shear device and producing a dispersion wherein the mean bubble diameter of the oxidant gas in the dispersion is less than about 5 μm, introducing the dispersion into a vessel from which a sulfur-containing slurry is removed and a regenerated catalyst stream is removed, wherein the sulfur slurry comprises elemental sulfur and aqueous liquid, and recycling at least a portion of the regenerated catalyst stream to the converter. A system of apparatus for carrying out the method is also provided.

Owner:HRD CORP

Process and equipment for preparing biological energy source

InactiveCN101307288AIncrease profitReduce consumptionBioreactor/fermenter combinationsBiological substance pretreatmentsOperational costsAtmospheric air

The invention relates to a method for preparing a biological energy source and a device for carrying out the same. Carbon element captured through absorption / separation is used for cultivating microalgae in a form of a liquid carbon containing compound. And simultaneously components which are contained in exhaust air and pollute the atmosphere are eliminated. In the prior art for capturing carbon, after CO2 is absorbed / separated, the carbon is regenerated in a form of CO2 and is compressed and canned for storage, transportation and reconversion. The invention saves a CO2 regenerating link to a certain degree, thereby saving a CO2 micropore pipe link and a CO2 compression, canning, storage and transportation link accounting for 1 / 3 of the total microalgae cultivation cost, and consequently reducing operating cost and improving the carbon utilization ratio of microalgae when cultivating microalgae. The device comprises three parts, namely an absorption / separation device, a biological cultivation vessel and a conversion device for biological cultivation products. When CO2 is captured, dusty gases such as oxysulfide, nitric oxide, sour gas (HCl), fluoride (HF), etc. are also captured from the exhaust air.

Owner:朱洪

Cardo-Type Co-Polyimide Membranes For Sour Gas Feed Separations From Natural Gas

ActiveUS20180345229A1Less footprintFlexible operationSemi-permeable membranesGas treatmentPolyimide membraneMethyl group

Co-polyimide membranes for separating components of sour natural gas where embodiments can include at least three distinct moieties polymerized together, the moieties including a 2,2′-bis(3,4-dicarboxyphenyl)hexafluoropropane dianhydride (6FDA) based moiety; a 9,9-bis(4-aminophenyl) fluorene (CARDO) based moiety; and 2,3,5,6-tetramethyl-1,4-phenylenediamine (durene diamine) based moiety.

Owner:SAUDI ARABIAN OIL CO

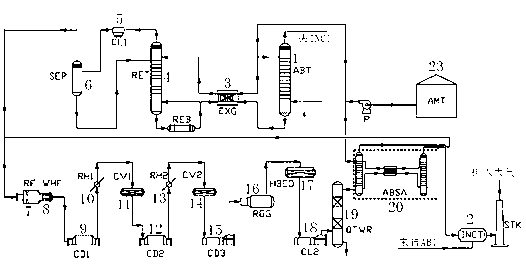

Integrated sour gas treating process

ActiveCN102838088AEasy to recycleHigh recovery rateHydrogen sulfidesSulfur preparation/purificationProcess engineeringEnvironmental engineering

The invention discloses an integrated sour gas treating process, and aims at the sour gas which contains light concentration H2S and is generated in a desulfuration decarburization device. The integrated sour gas treating process comprises the following steps of: adding a sour gas concentrating segment before a two-level Claus sulfur recovery segment, concentrating the H2S concentration in sour gas to more than 50%, and enabling the sour gas after concentrating to enter the two-level Claus sulfur recovery segment to carry out reaction, wherein the sulphur recovery rate of a sour gas concentrating + sulfur recovery segment is improved by 1%-2% compared with the general two-level Claus sulfur recovery segment, thereby being beneficial for sulfur recovery to obtain high sulfur recovery ratio. The integration sour gas treating process provided by the invention has the advantages that the technological operation is flexible and reliable, the investment is saved, the energy consumption is low, the total sulfur recovery ratio can achieve more than 99.8%, and the strict environmental standard requirements are met.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

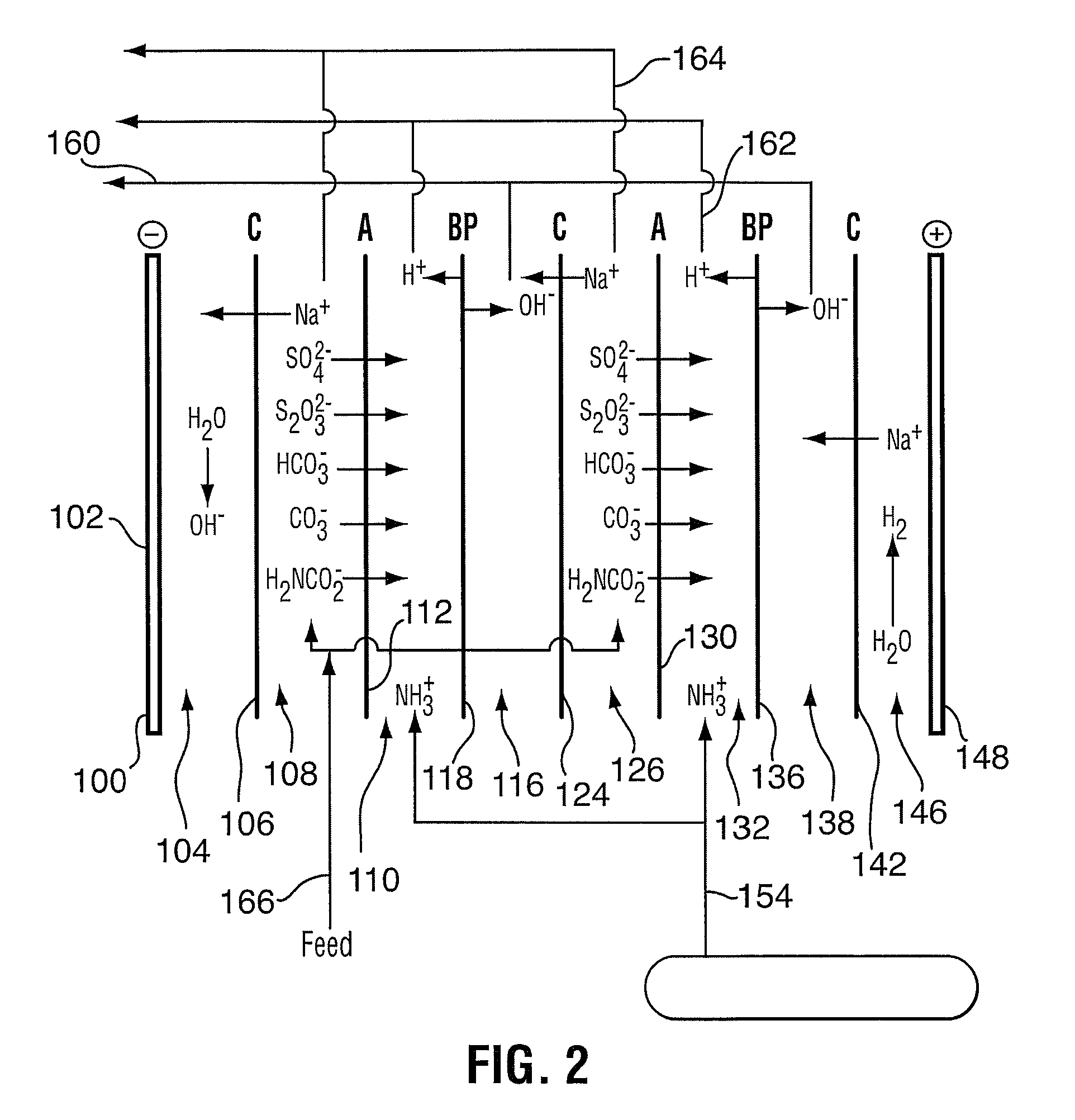

Method for sour gas treatment

A method for selectively removing hydrogen sulfide and carbon dioxide from sour gas by reacting the hydrogen sulfide and carbon dioxide in the sour gas with sodium hydroxide is disclosed. Also disclosed is a process for the production of a salt product from a sour gas stream. The reaction with sodium hydroxide creates a scrubber solution comprising water, hydrocarbons, contaminants and salts. The scrubber solution may be oxidized, filtered and can then be subjected to electrodialysis. Ammonia is introduced into the acid compartments of the cell. Sodium hydroxide and a salt product comprising ammonium sulfate or ammonium thiosulfate with ammonium bicarbonate, ammonium carbonate, ammonium carbamate may be produced. The regenerated sodium hydroxide may be used to sweeten further sour gas. The salt product may be used as a fertilizer.

Owner:ARISTOS ENERGY

Method for extracting H2S from sour gas

This invention teaches a process that includes extraction of gas in which the presence of foam results in the carry over in the outlet gas stream of excessive liquids and / or solids, including the steps of injecting the foam laden gas stream tangentially into a cyclonic separator having an axial gas outlet and a liquid outlet, under conditions in which the inlet stream is subjected to at least about 150 G's, the outlet gas being substantially liquids / solids free and the outlet liquid stream being conveyed for disposal or further processing.

Owner:NAT TANK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com