Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

71 results about "Back burns" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

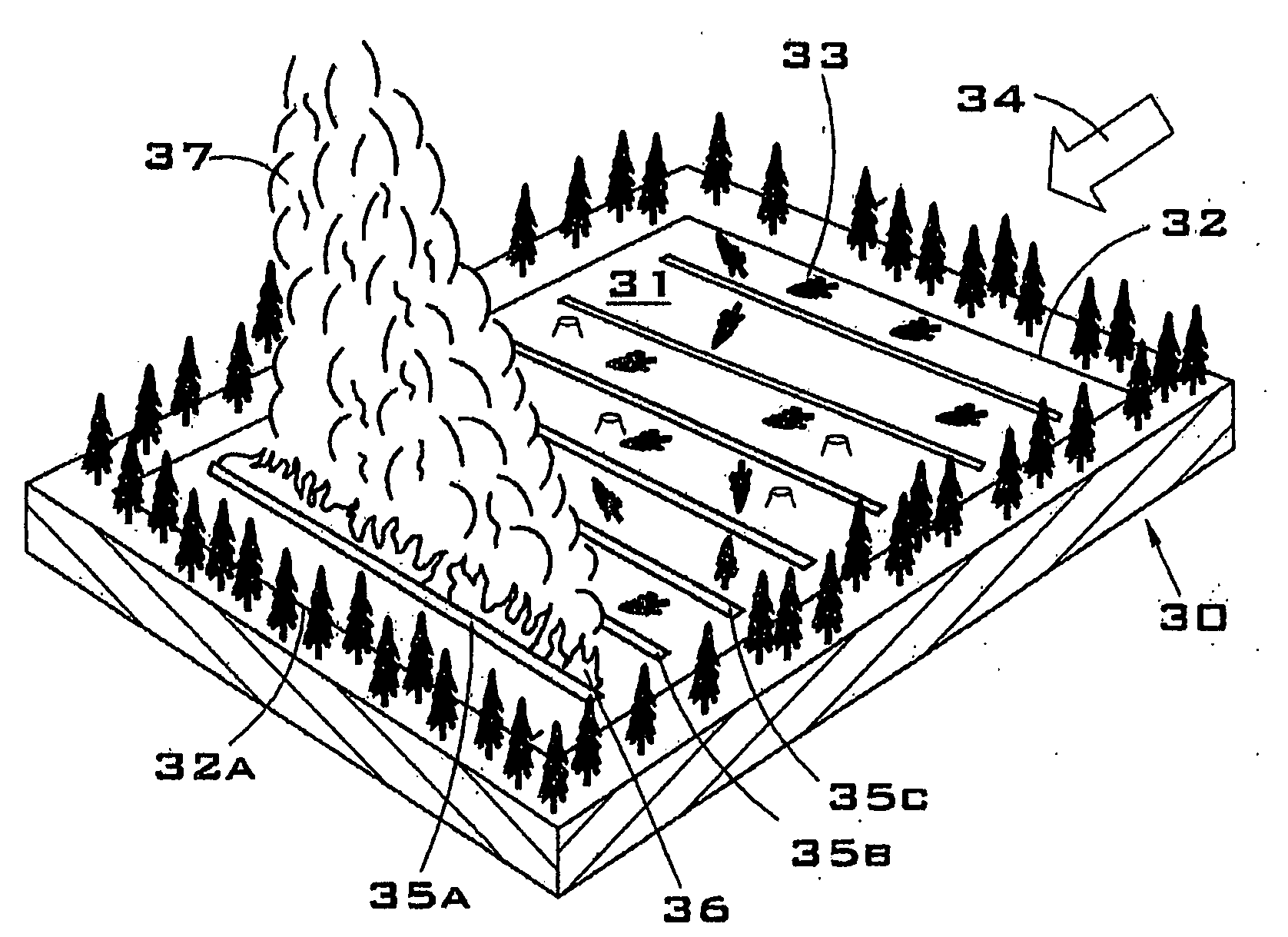

Back burning involves starting small fires along a man-made or natural firebreak in front of a main fire front. Back burning reduces the amount of fuel that's available to the main fire by the time that it reaches the burnt area. Back burning is utilized in controlled burning and during wildfire events.

Processed solid burnable fuel composition

A solid burnable fuel composition which contains a major proportion of spent dried coffee grounds is described. The fuel composition includes at least 50% dried spent coffee grounds and a combustible wax which are mixed together and compressed into a suitable shape for combustion. The fuel composition may further include a small amount, 10% or less, of a coking agent useful to control burn rate and to prevent cracking of compressed fuel during combustion. Small amounts of cellulosic material may also be incorporated to improve the structural properties of the composition. Due to its superior heat and flame production, dried spent coffee grounds are an excellent fuel source for processed fuel products such as fire-logs and fuel pellets. The advantage is a hotter, cleaner burn which produces less soot and smoke, releases fewer harmful pollutants and provides a brighter flame over a longer period of time.

Owner:ROYAL OAK ENTERPRISES

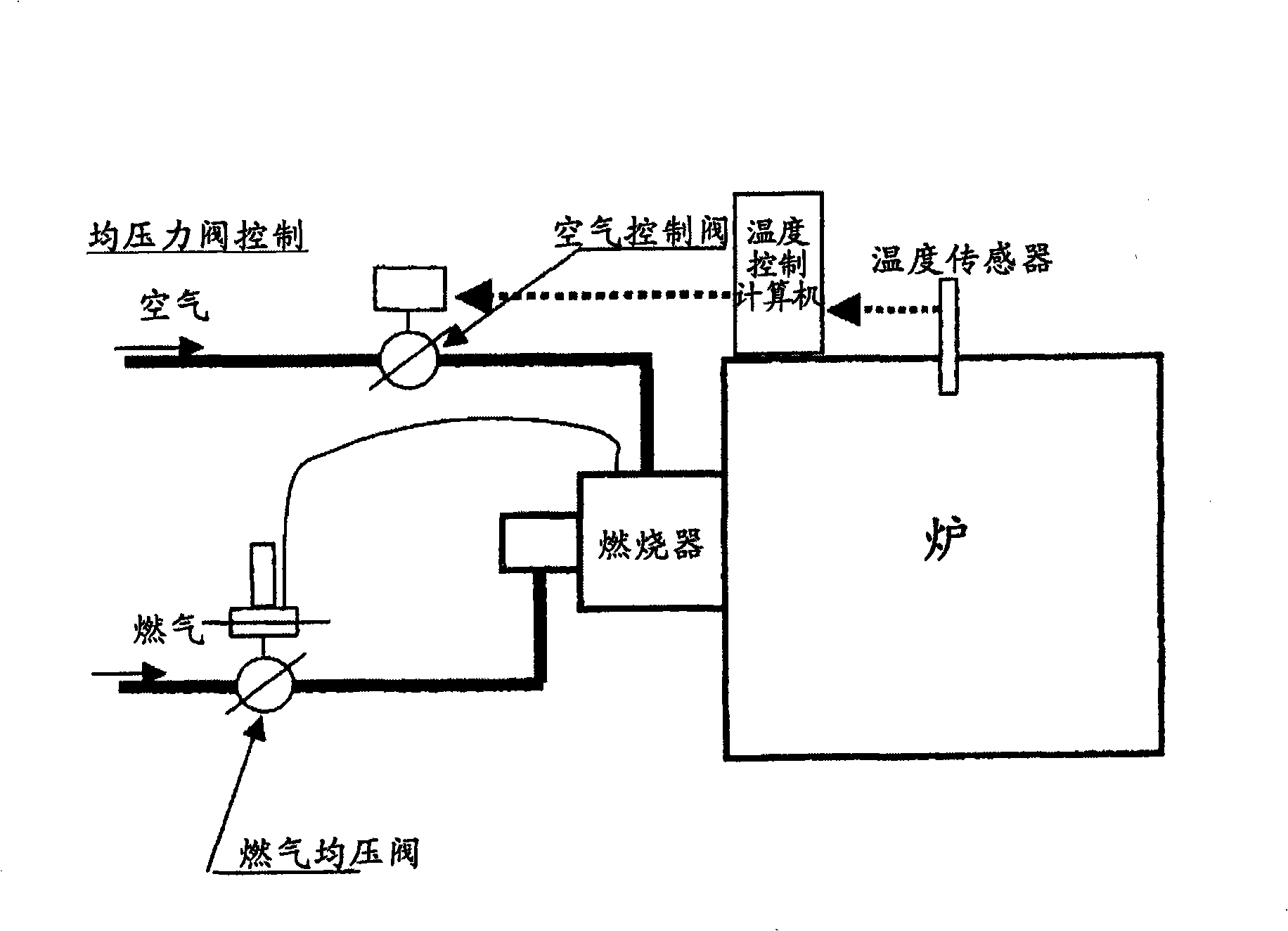

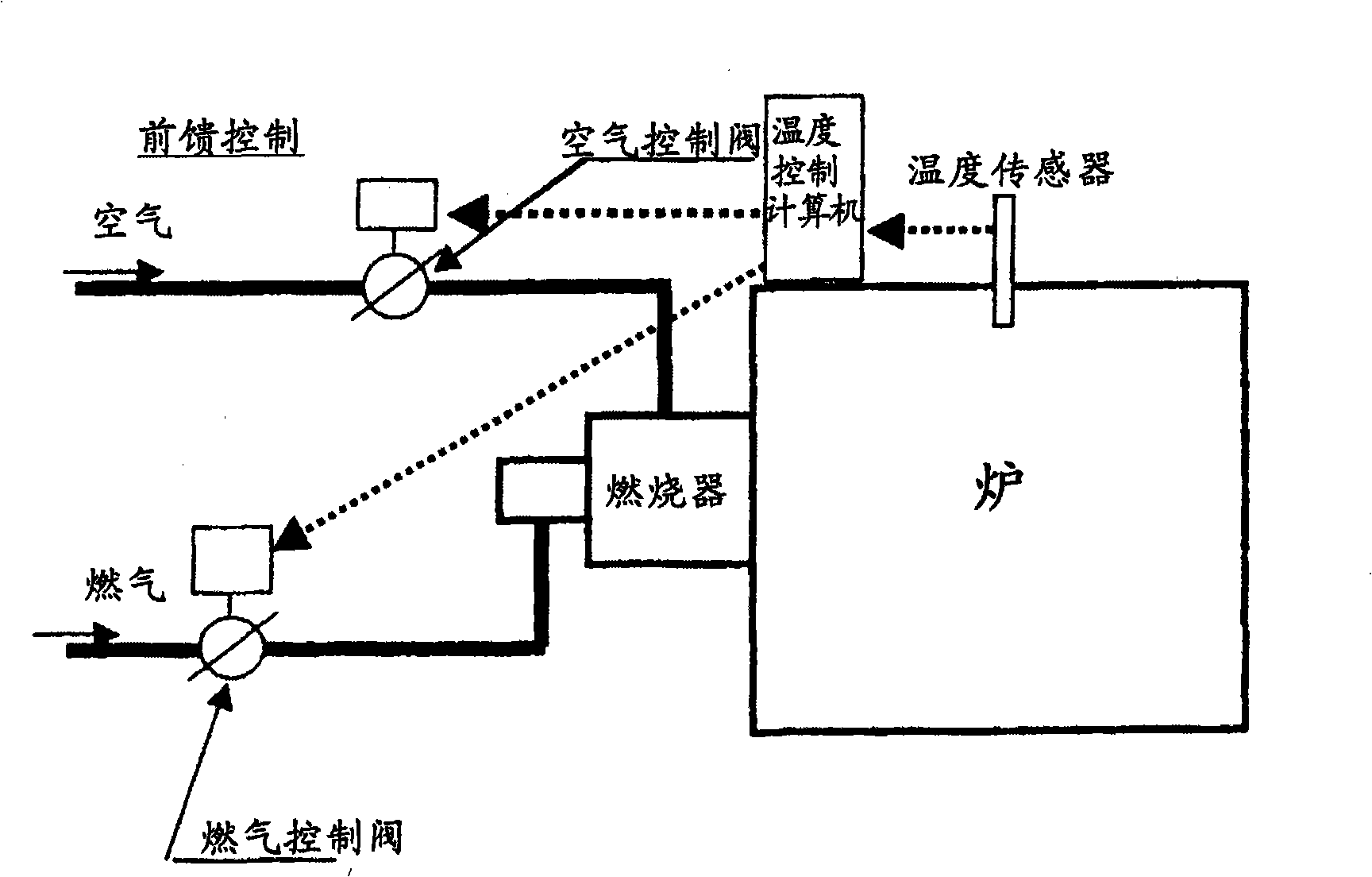

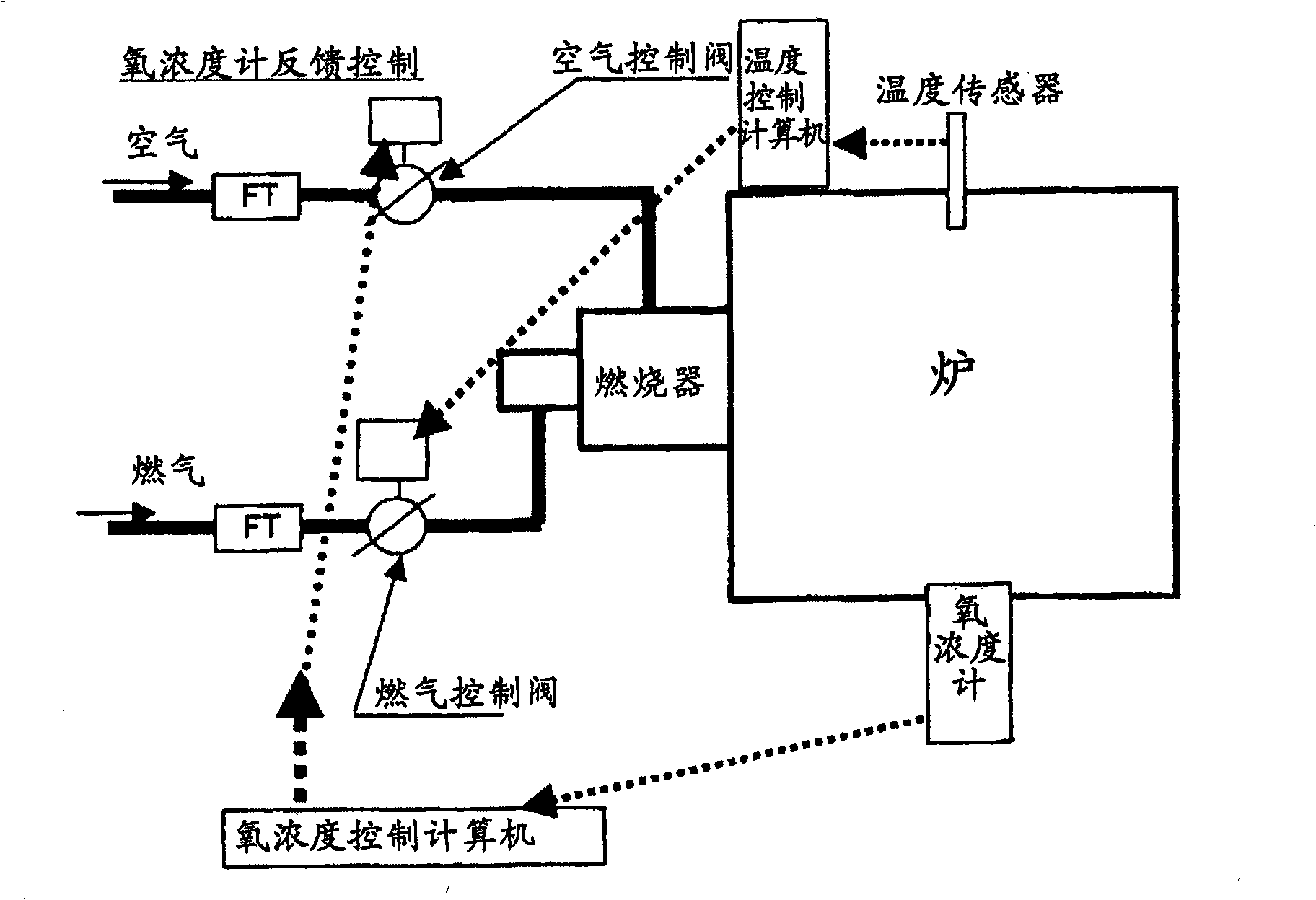

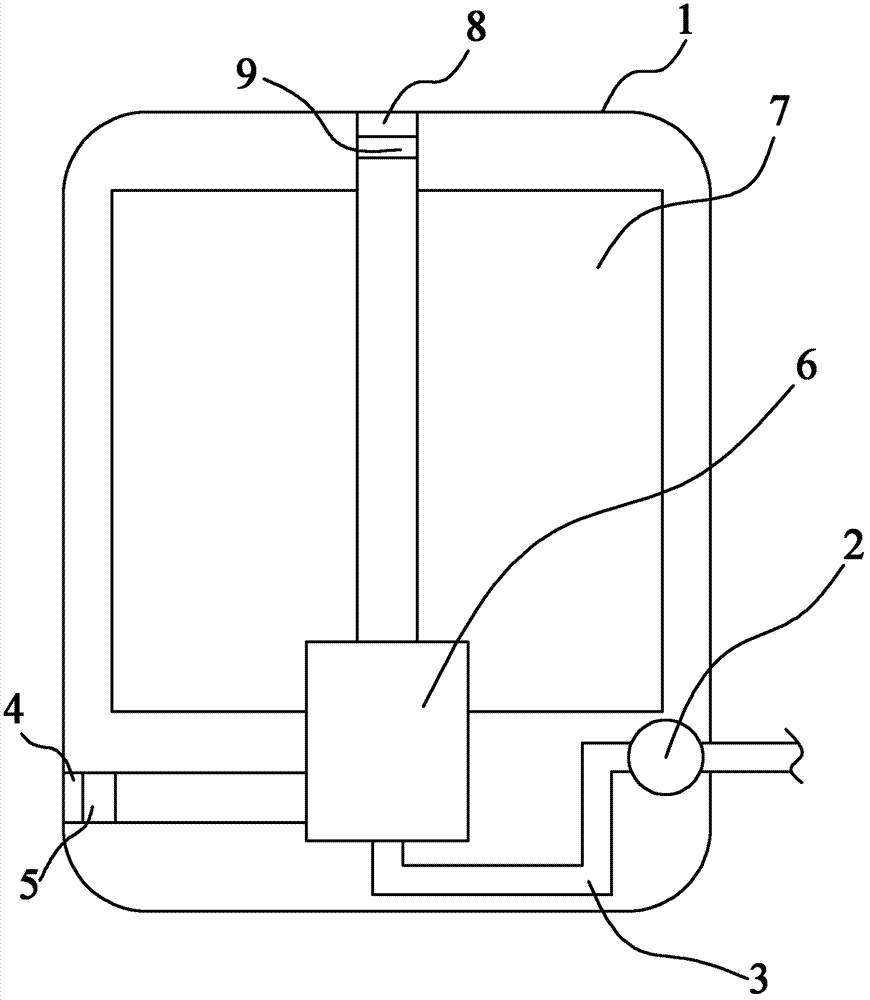

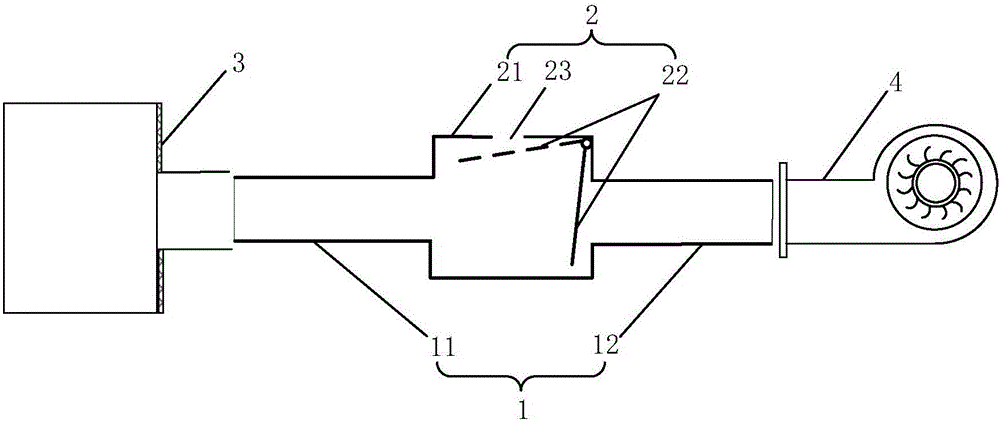

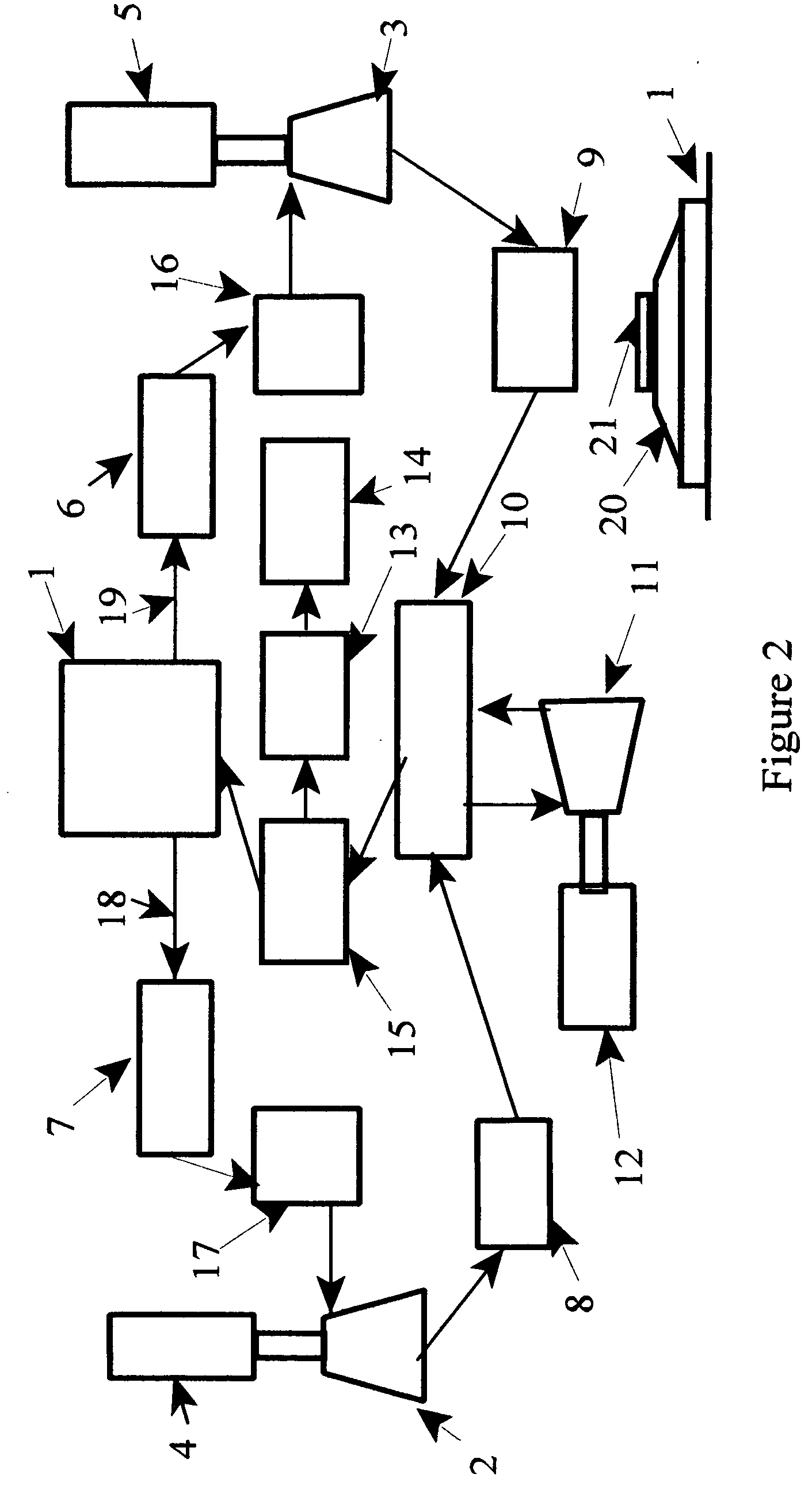

Air-fuel ratio control system of combustion heating furnace

ActiveCN101270880AEnsure the amount of circulating gasPrevent uneven firing qualityFuel supply regulationBack burnsOxygen

The invention provides an air fuel ratio control system of a burning heating furnace capable of controlling burning widely from oxidation burning to restoring burning and of determining oxygen concentration simply lacking of operators with technical knowledge. The system includes a burner (2) arranged in the burning heating furnace, a fuel supply pipe (3) supplying fuel gas to the burner (2), an air supply pipe (4) supplying air for burn to the burner (2) and a temperature control computer (10). The temperature control computer (10) pre-remembers a first formula (burning air amount=fuel gas flow*theoretical air amount*air fuel ratio) and a second formula (air fuel ratio=20.6 / 20.6-oxygen concentration) and automatically controls burning air amount according to the gas flow based on the formula when inputting the oxygen concentration.

Owner:NGK INSULATORS LTD

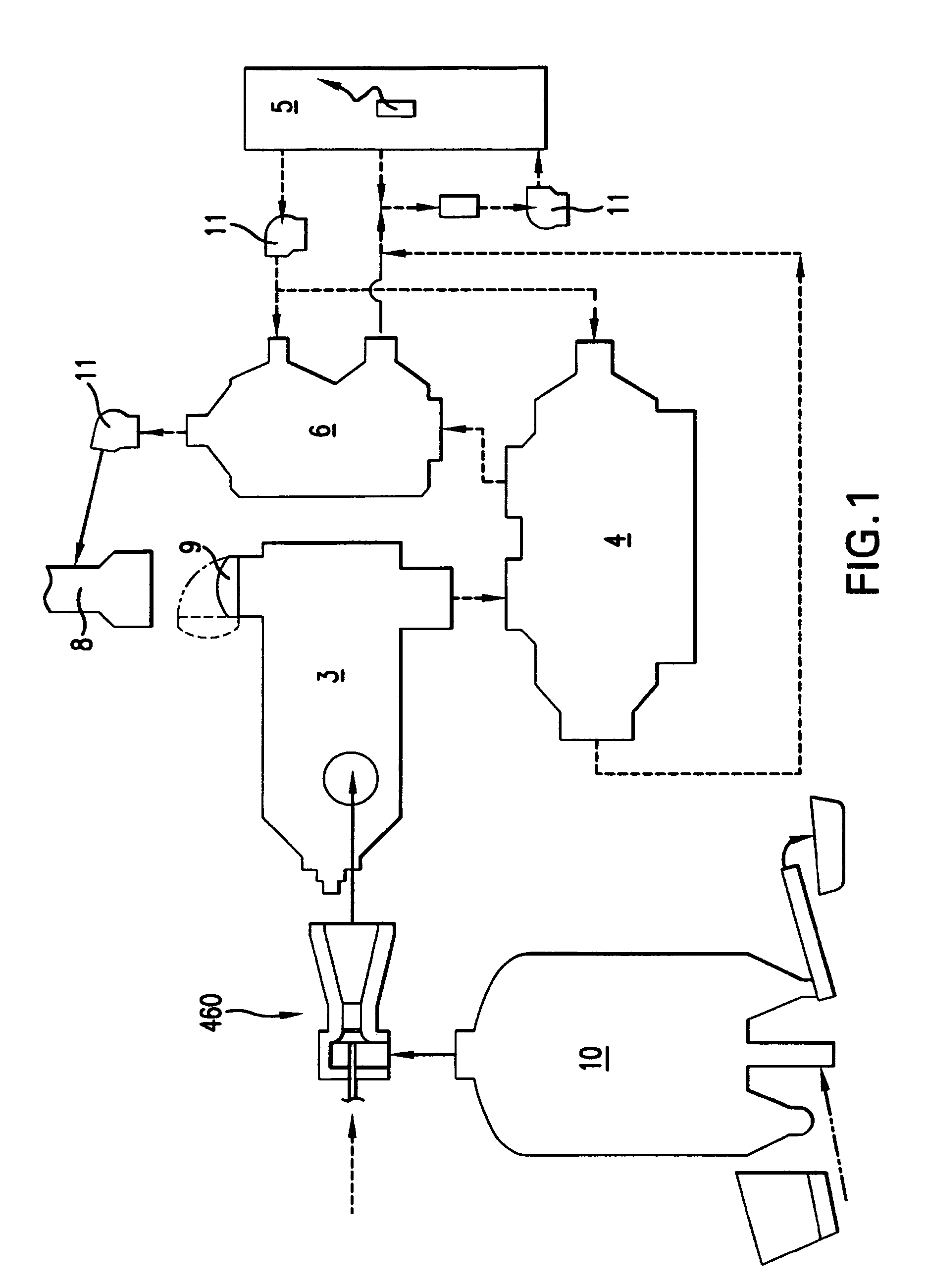

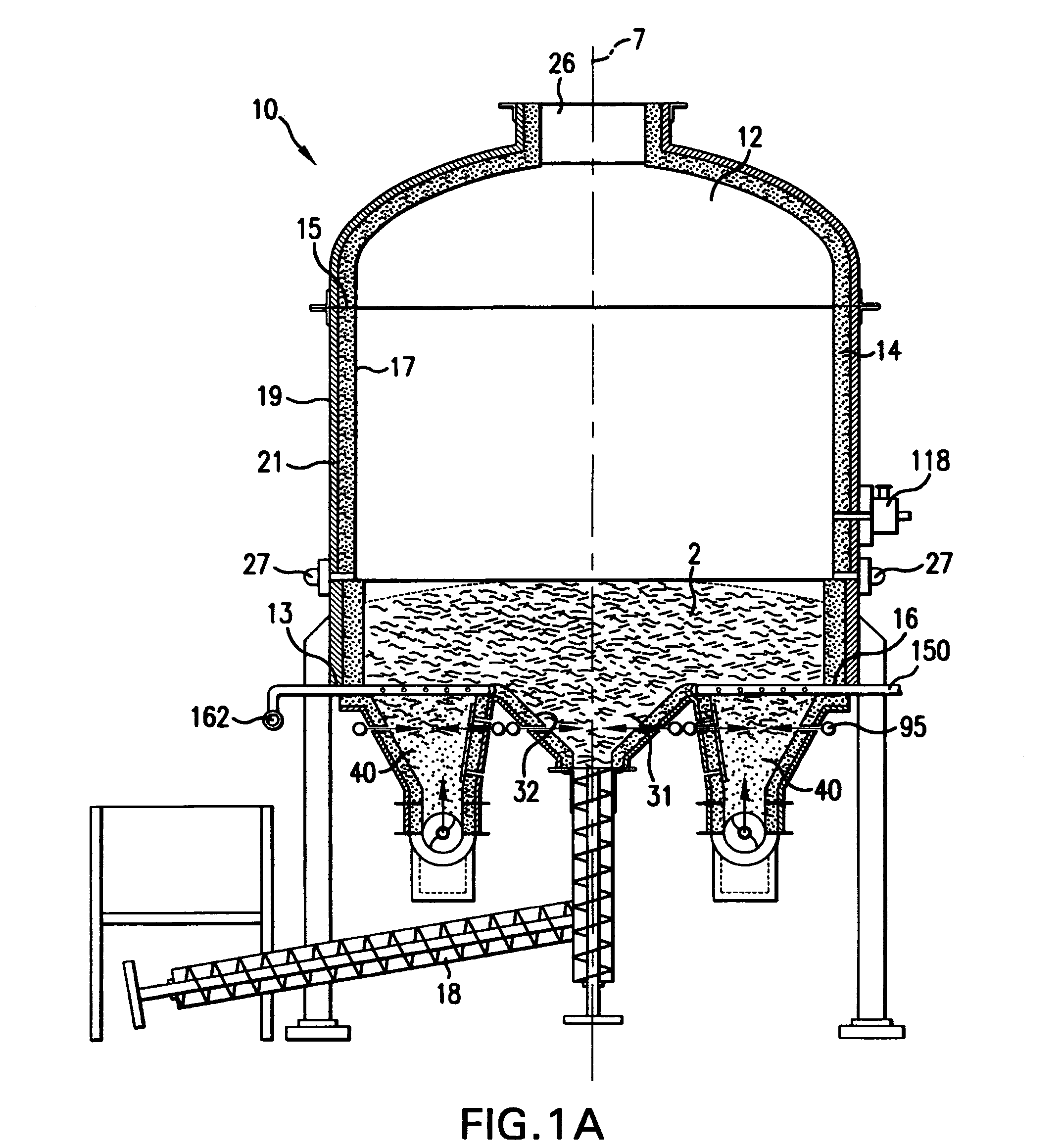

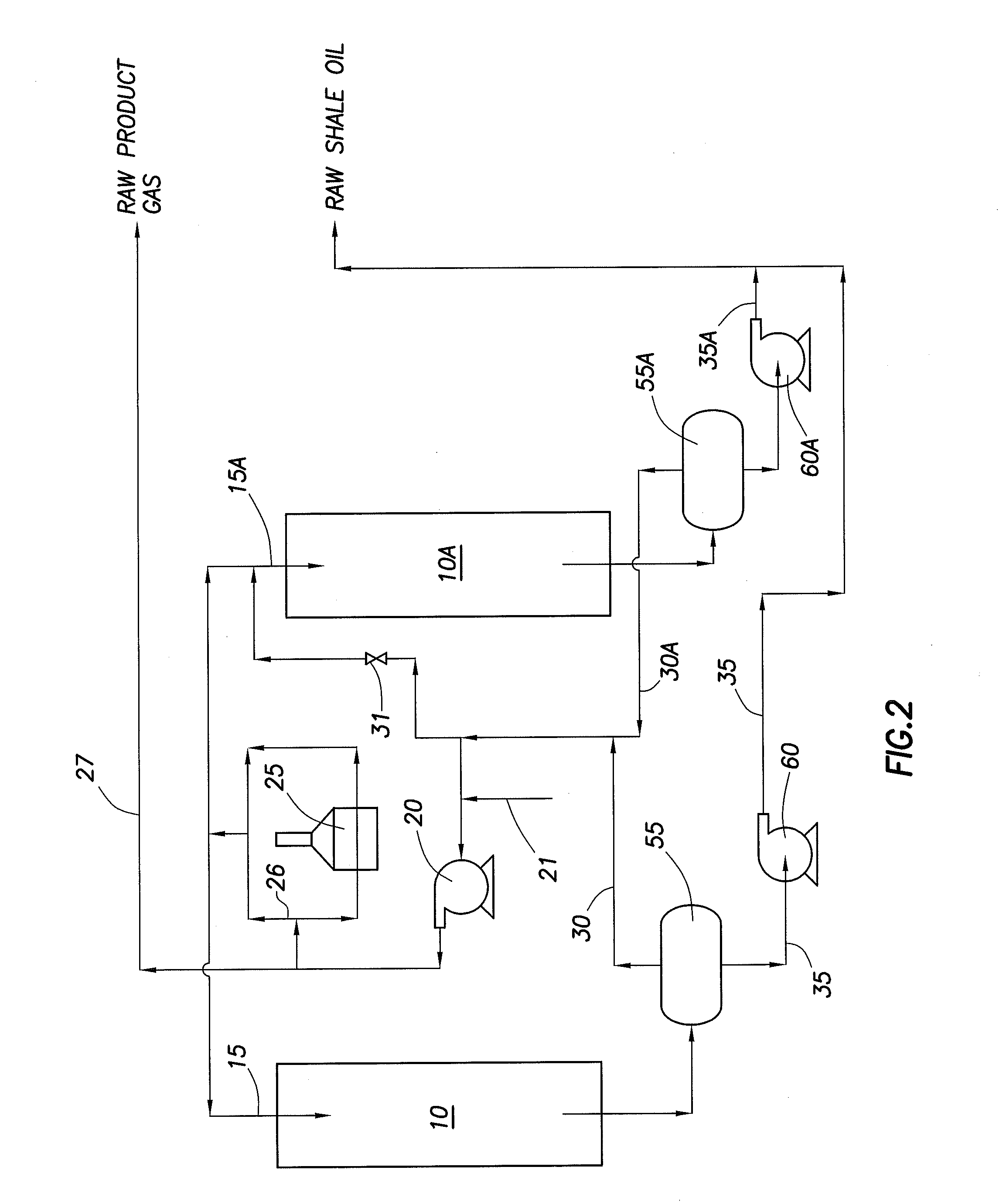

Pyrolyzing gasification system and method of use

InactiveUS7241322B2Reduce formationLarge volumeGasifier mechanical detailsBiofuelsBack burnsProcess engineering

The gasifier includes a furnace bed segmented into individual cells, each cell is independently monitored using a ramp temperature probe, and provided with controlled air injection to provide individually controlled burn regions within the gasifier. Gasifier air injection includes tuyere arrays, lances, or both.

Owner:HEAT TRANSFER INT

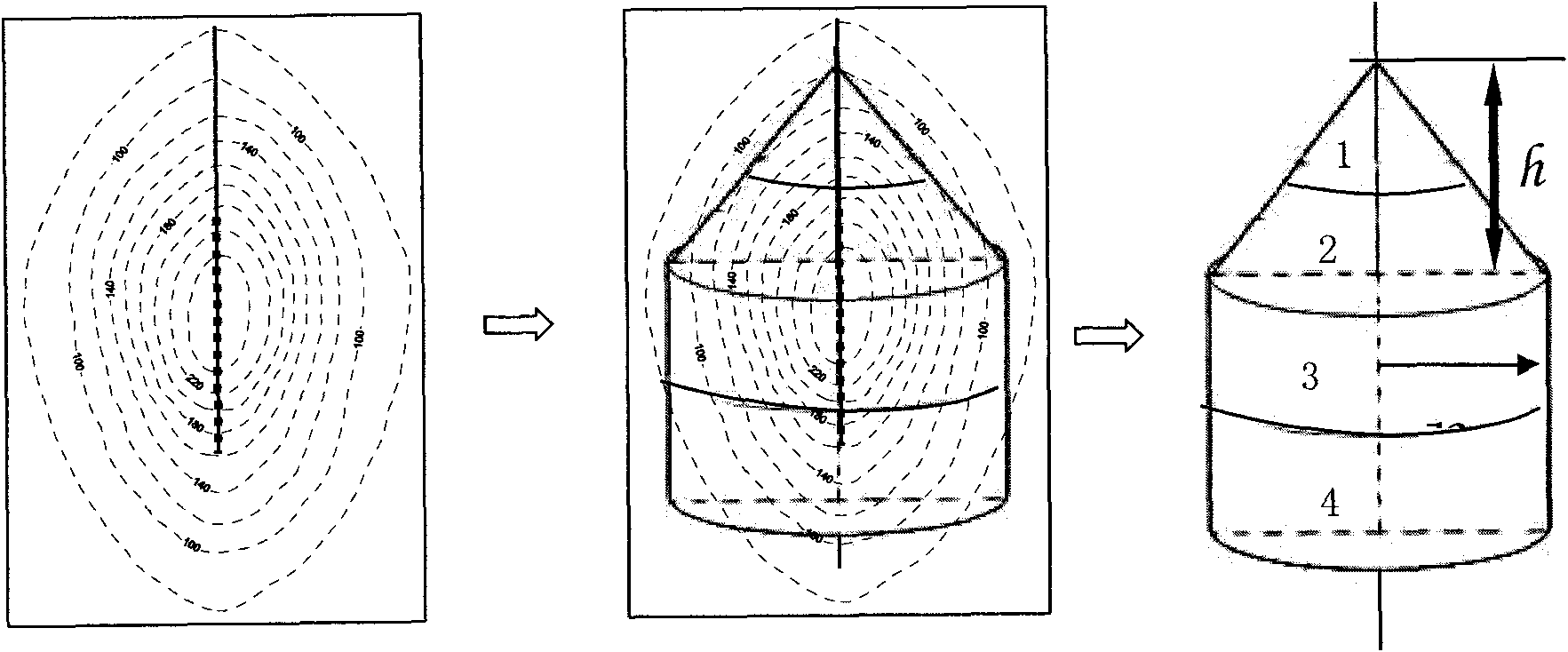

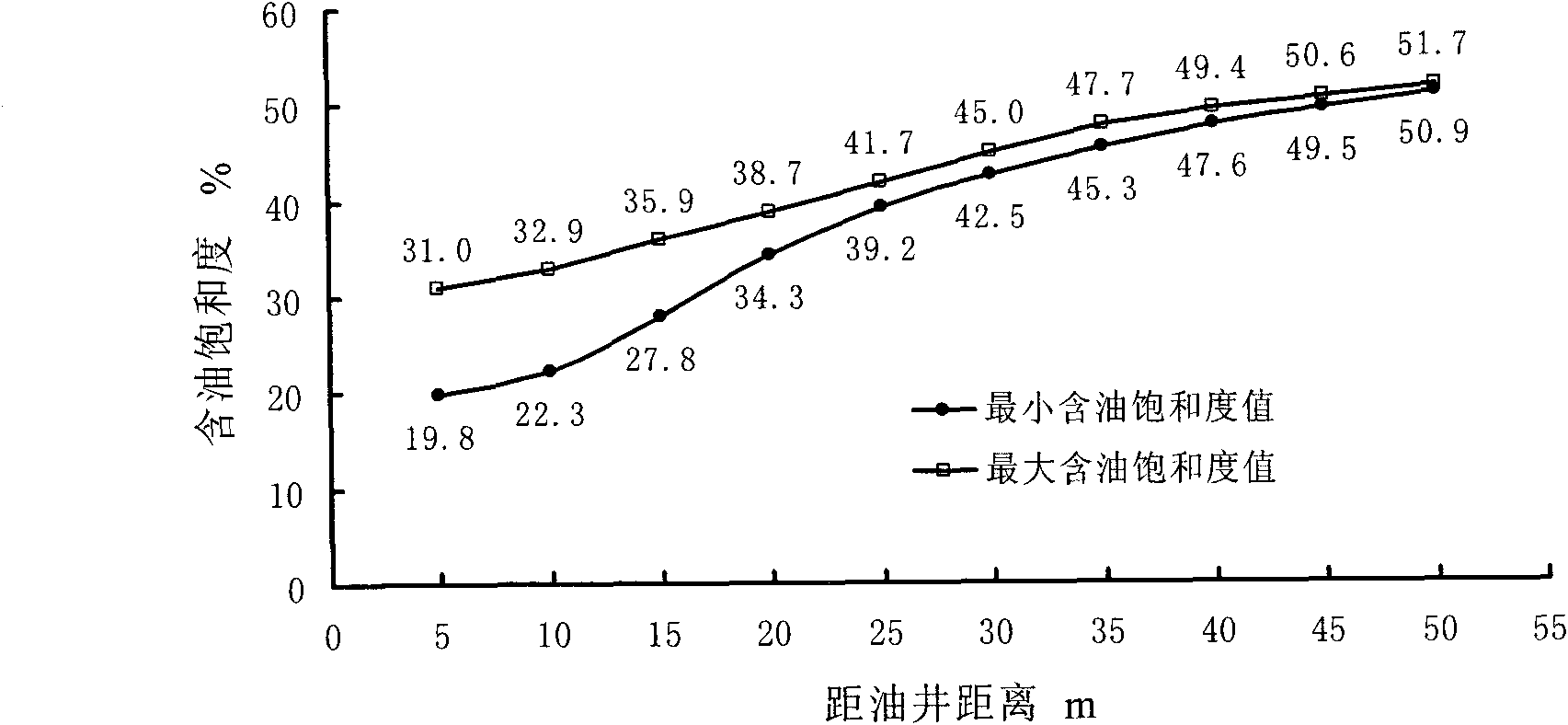

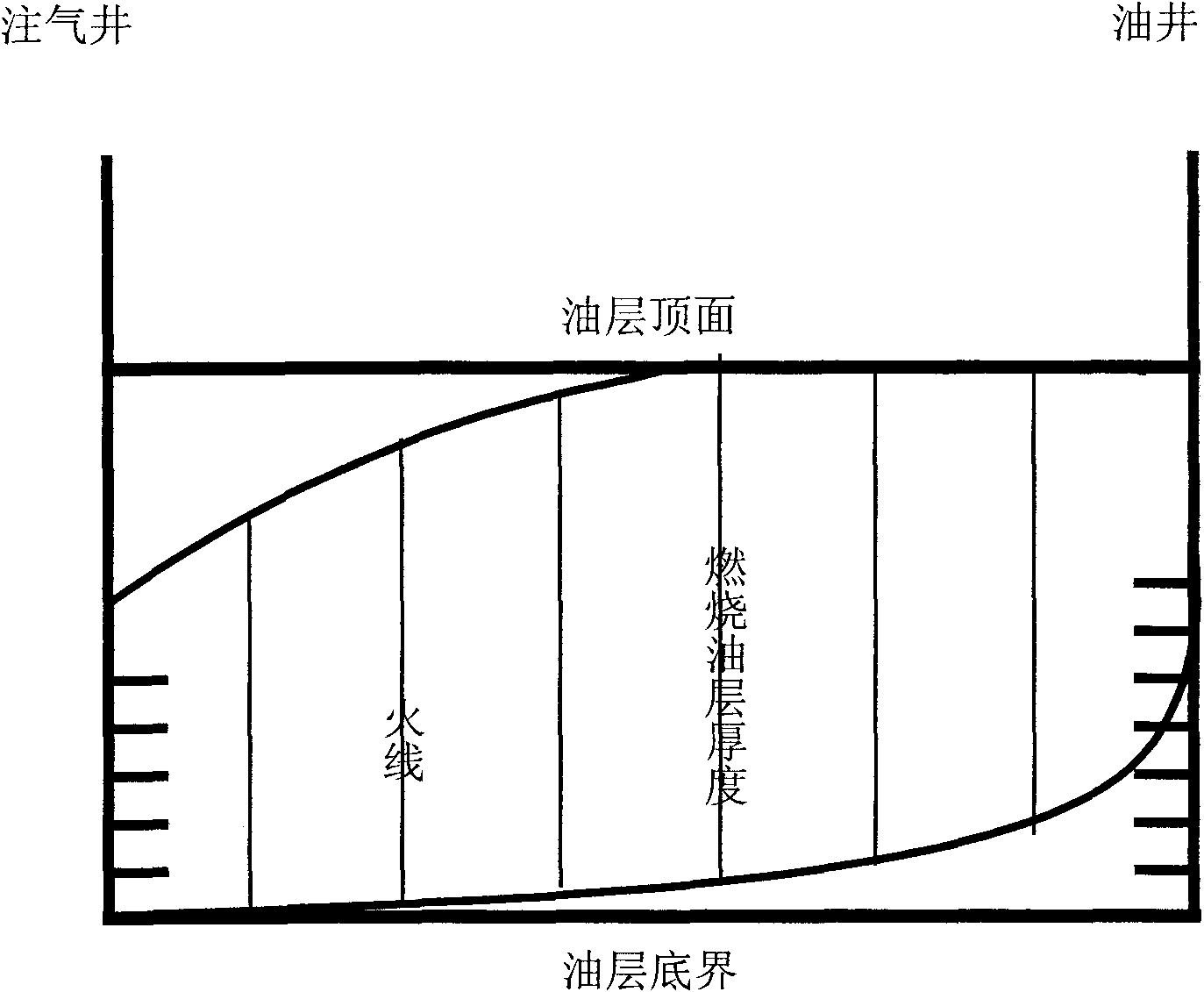

Method for improving recovery rate of thick massive viscous oil reservoir by controlling burning gas injection speed

The invention relates to a method for improving recovery rate of a thick massive viscous oil reservoir by controlling burning gas injection speed, which mainly comprises the following steps of: determining the thickness and residual oil saturation of an oil layer at the burning front edge by stages according to the condition and rule of fire-flooding live wire wave by combining fine research results of double analogs in a massive oil reservoir chamber; then determining planar residual oil saturation and residual oil at different positions apart from a gas injection well, and predicting the burned section area of the burning front edge, the non-homogeneity of the reservoir and the optimal configuration relationship between the residual oil and the gas injection speed; and finally, dynamically adjusting the single-well gas injection speed by stages, and selecting a variable and lower burning gas injection speed to maintain stable and normal burning on the premise of ensuring combustion. The method can fulfill the purposes of improving the burning wave and volume of the massive oil reservoir, the development effect of the burning oil layer and the final recovery rate.

Owner:PETROCHINA CO LTD

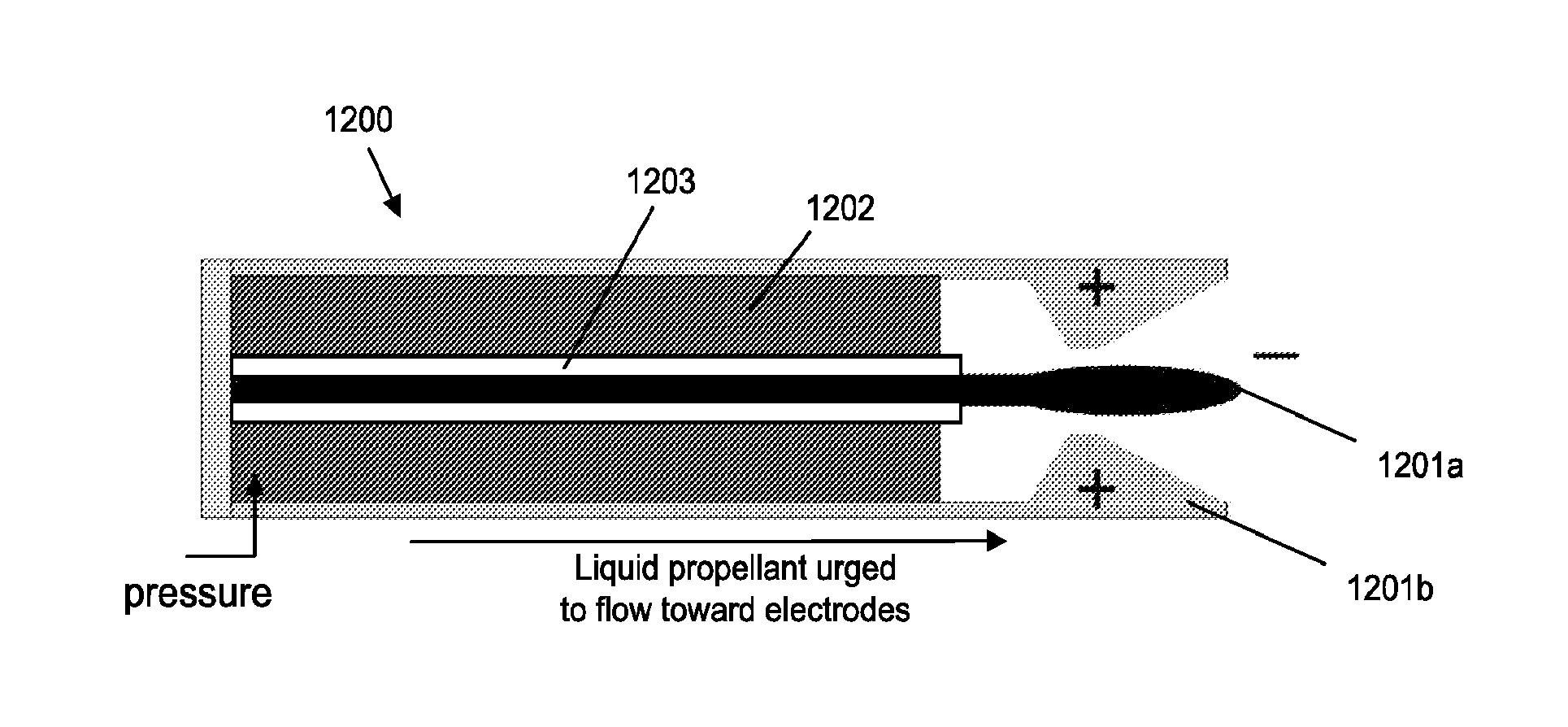

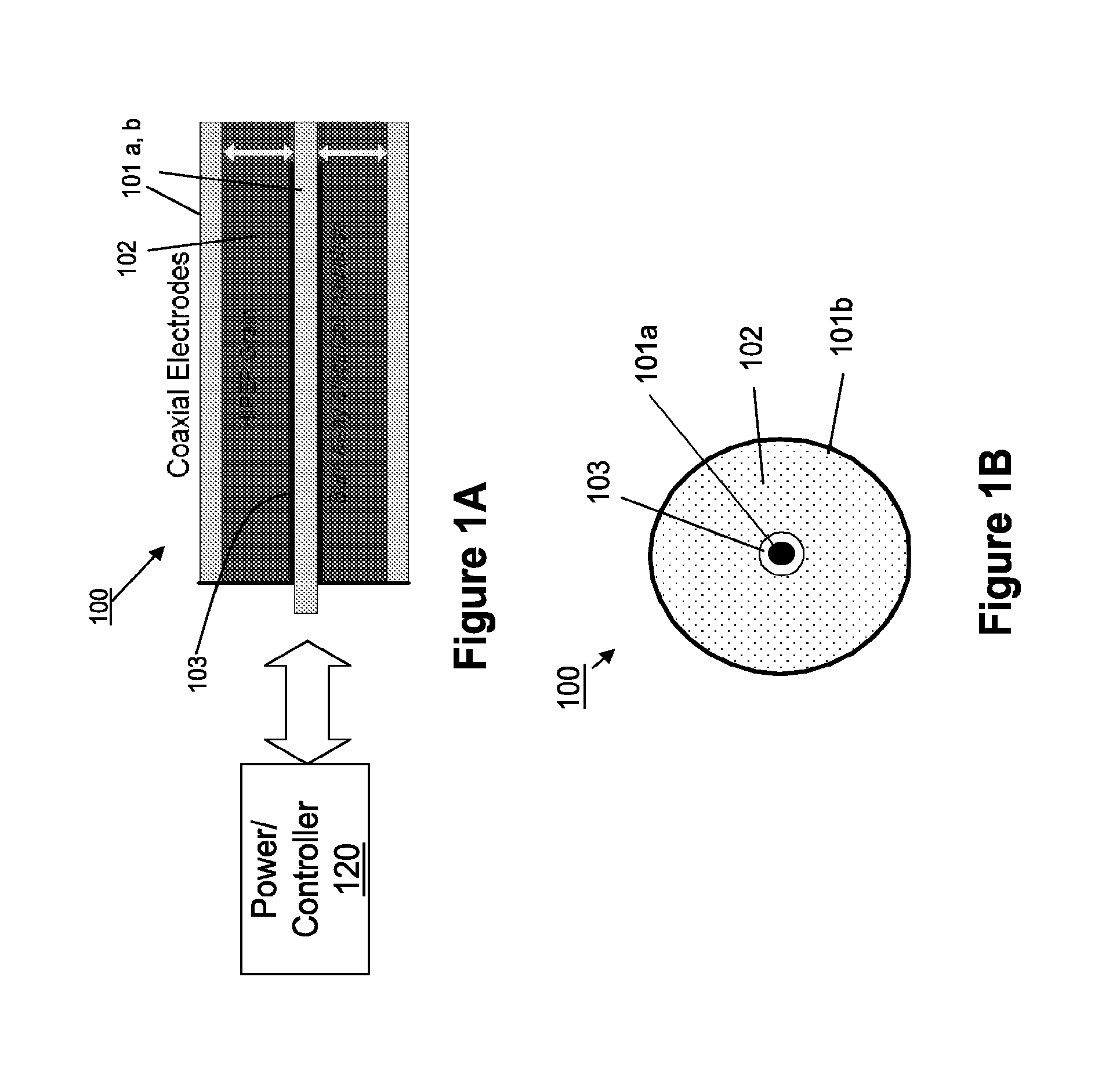

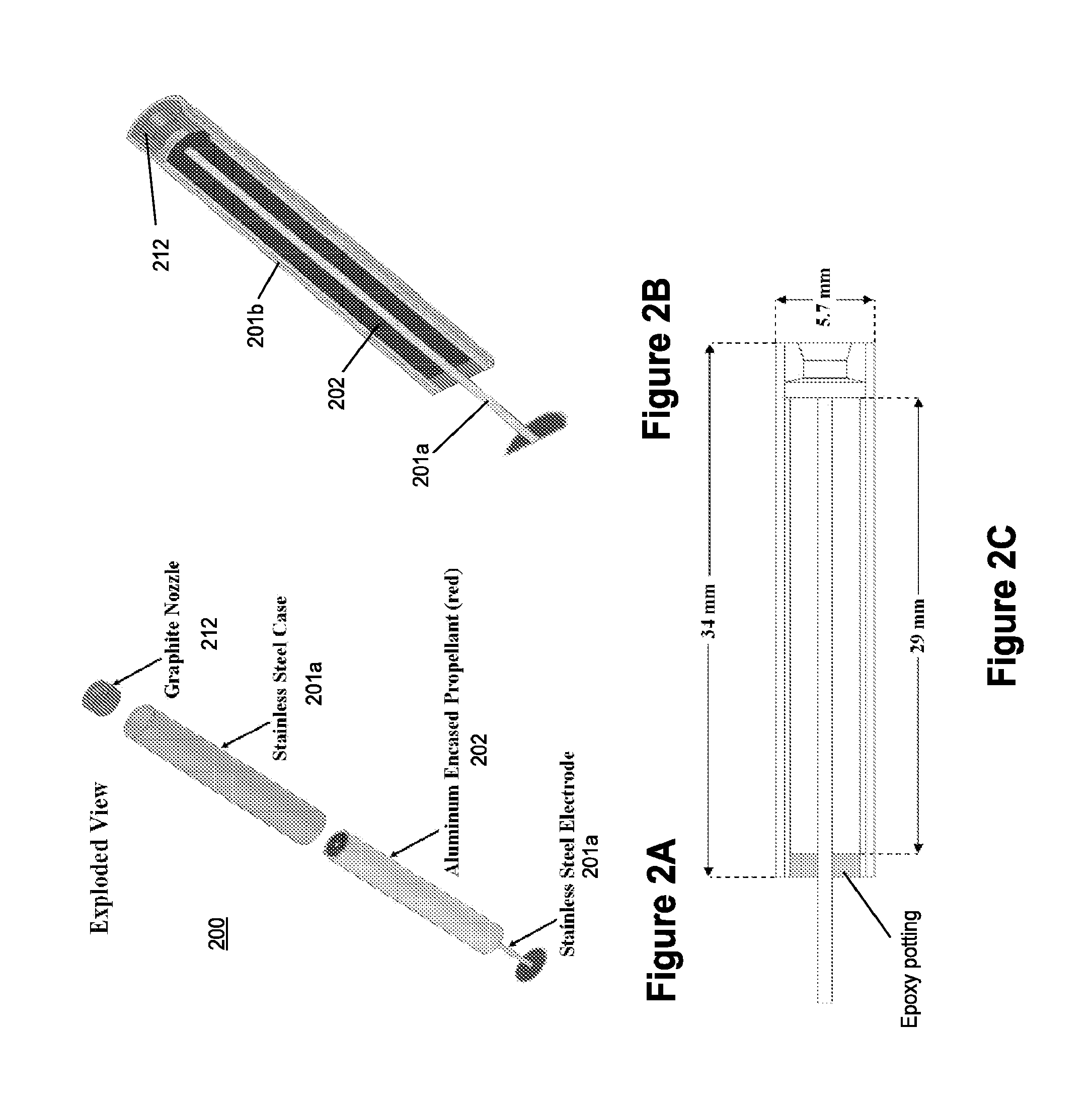

Electrode ignition and control of electrically ignitable materials

Apparatus for providing electrically initiated and / or controlled combustion of electrically ignitable propellants is provided. In one example, the apparatus includes a volume of electrically ignitable propellant (liquid and / or gas) capable of self sustaining combustion, and electrodes operable to ignite the propellant. The apparatus may further include a power supply and controller in electrical communication with the electrodes for supplying a potential across the electrodes to initiate combustion of the propellant and / or control the rate of combustion of the propellant. Various configurations and geometries of the propellant, electrodes, and apparatus are possible. In one example, the electrodes are supplied a direct current, which causes combustion of the propellant at the positive electrode. In another example, the electrodes are supplied an alternating current, which initiates combustion of the propellant at both electrodes.

Owner:DIGITAL SOLID STATE PROPULSION

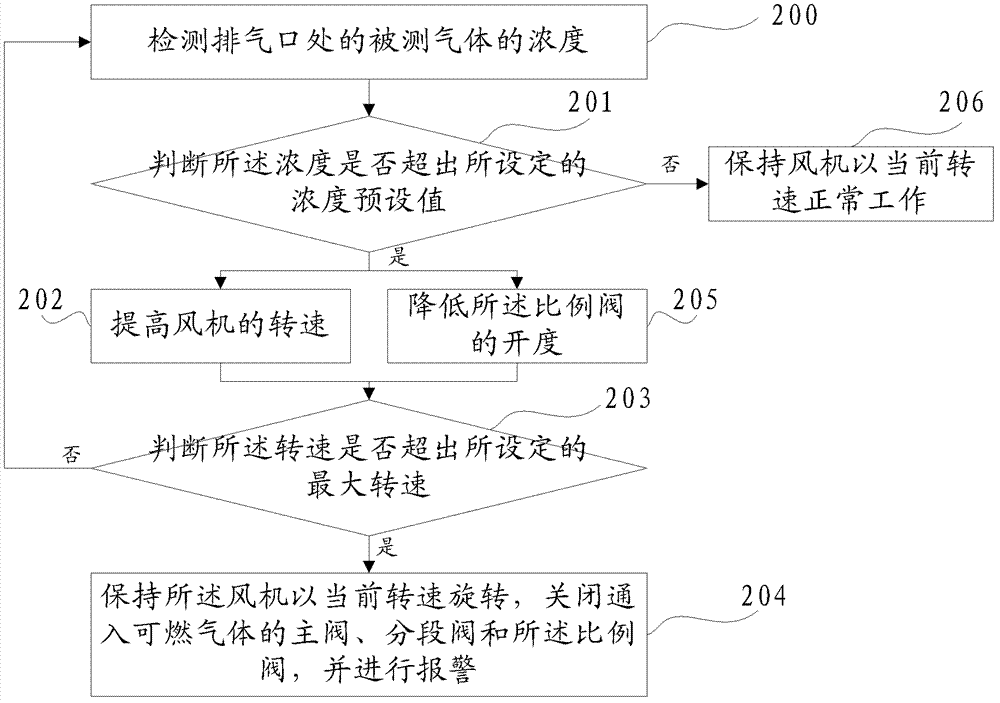

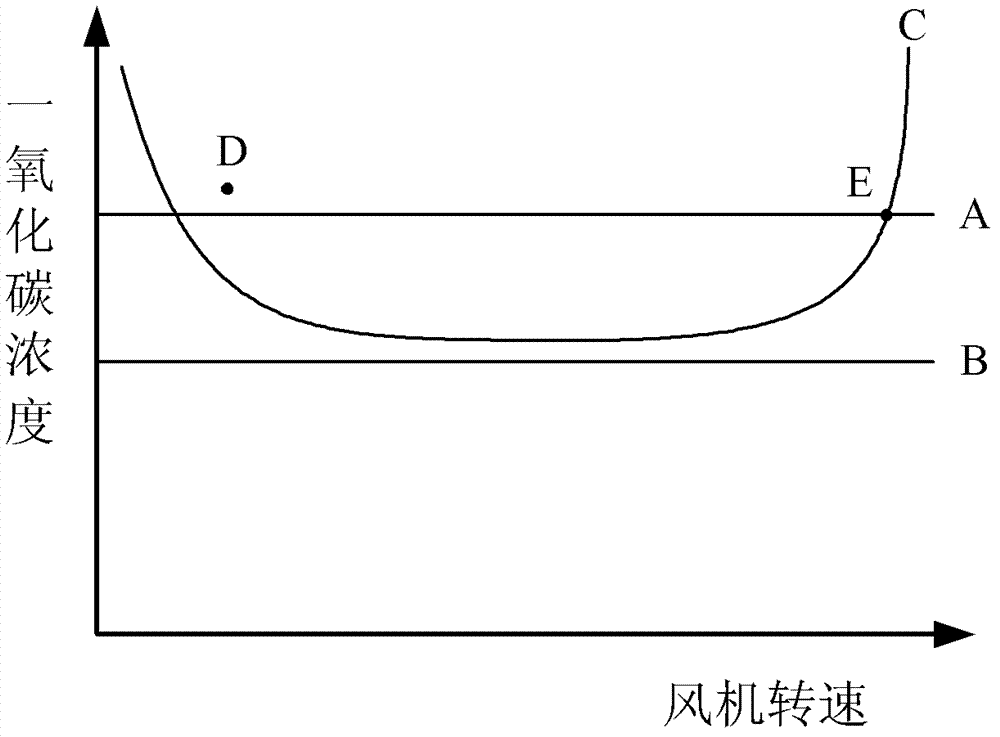

Method and device for controlling burning efficiency

ActiveCN102767842AImprove combustion efficiencyEnsure safetyFluid heatersFuel supply regulationBack burnsCombustible gas

The invention discloses a method and a device for controlling burning efficiency. The method and the device for controlling burning efficiency belong to the field of burning equipment and are designed for solving the problem that effective controlling of burning efficiency cannot be realized in the prior art. The method for controlling burning efficiency includes detecting concentration of gas to be tested at an exhaust port; judging whether the concentration exceeds the preset concentration value or not; improving rotation speed of a fan if the concentration exceeds the preset concentration value; keeping the fan working normally at the constant rotation speed if the concentration is within the preset concentration value; judging whether the rotation speed exceeds the preset maximum rotation speed or not; keeping the fan rotating at the current speed and switching off a main valve, a sectional valve and a proportional valve for inputting combustible gas if the rotation speed exceeds the preset maximum rotation speed; and detecting the concentration of the gas to be tested at the exhaust portion if the rotation speed is within the preset maximum rotation speed.

Owner:WUHAN HAIER WATER HEATER +2

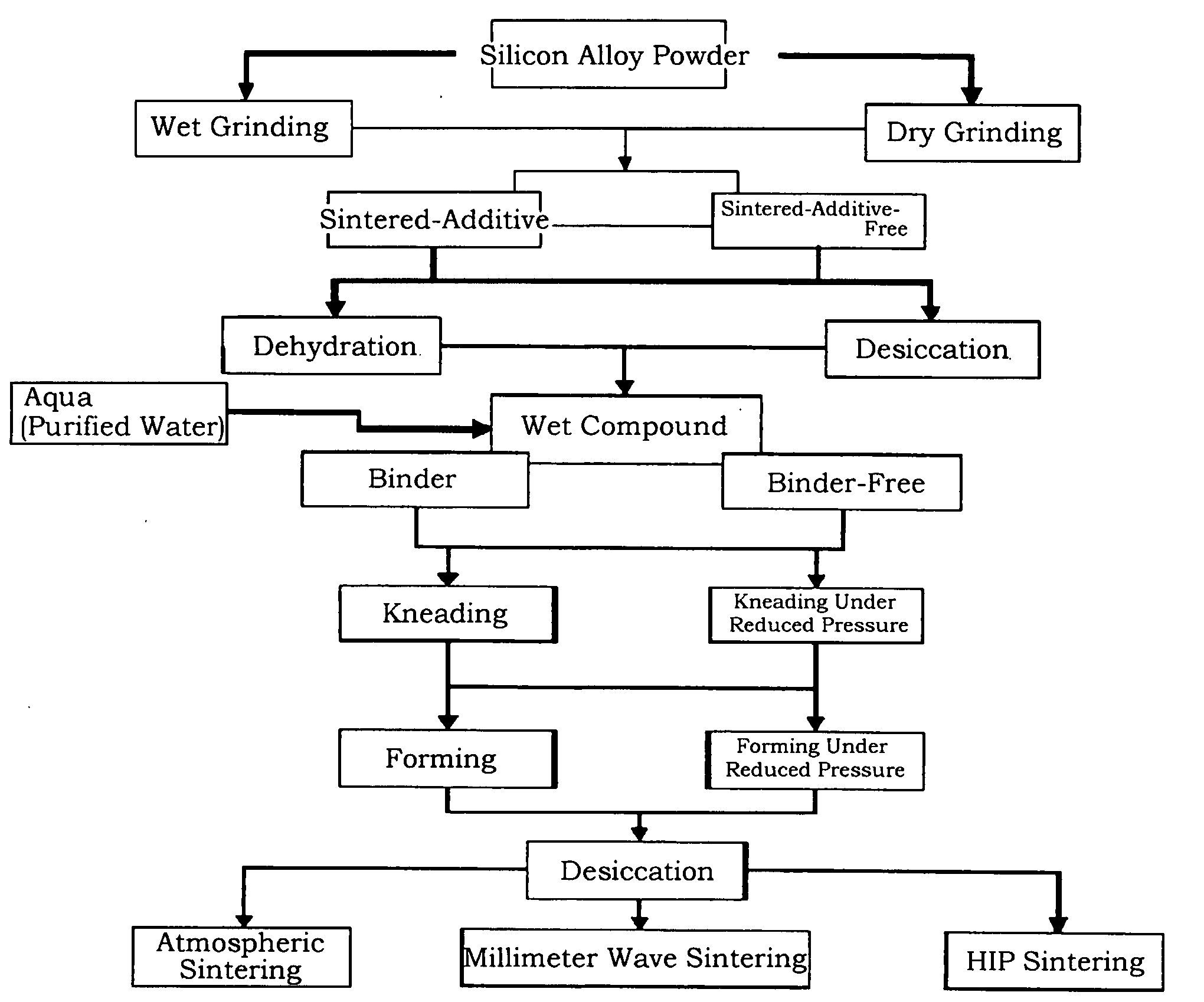

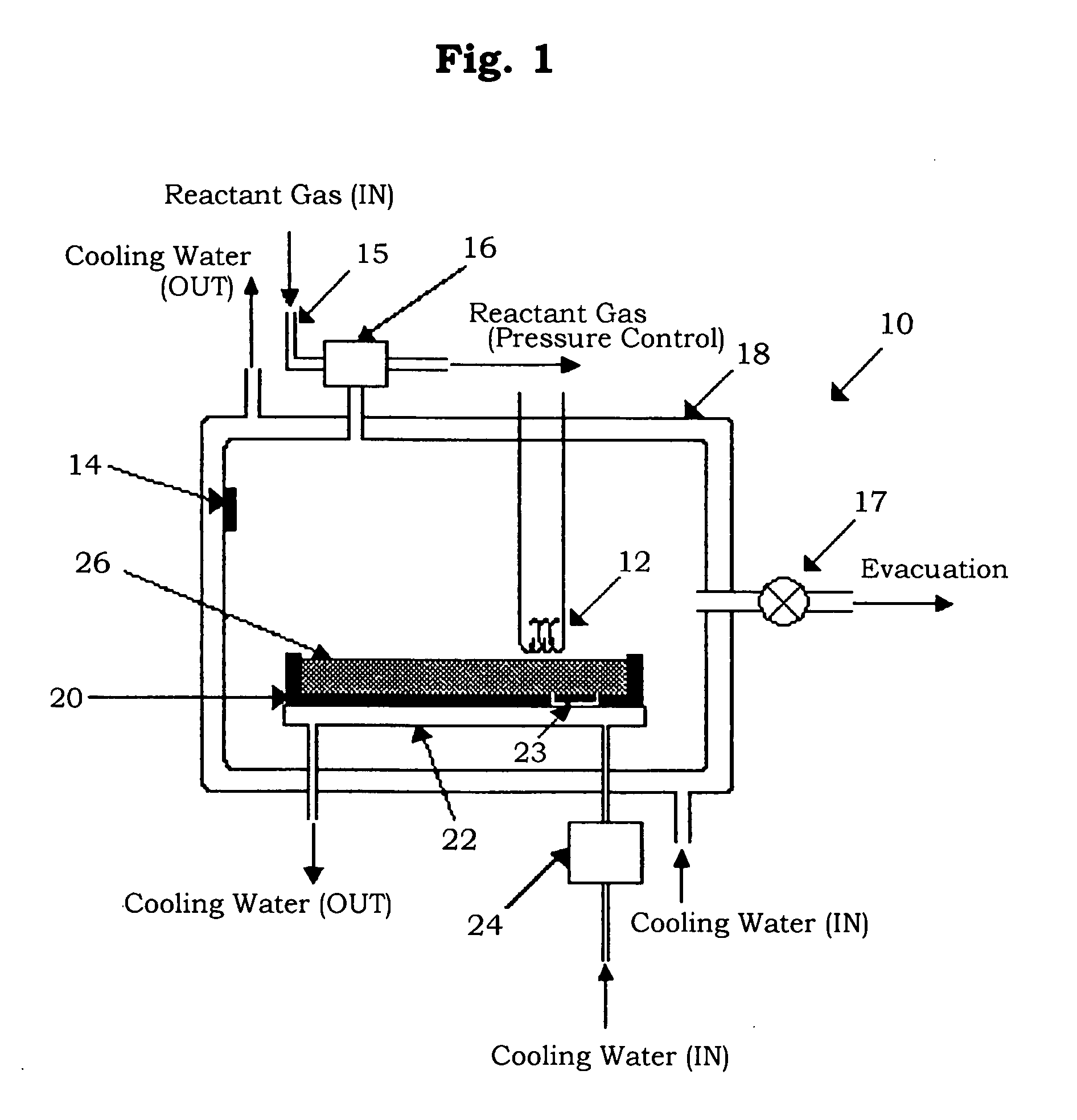

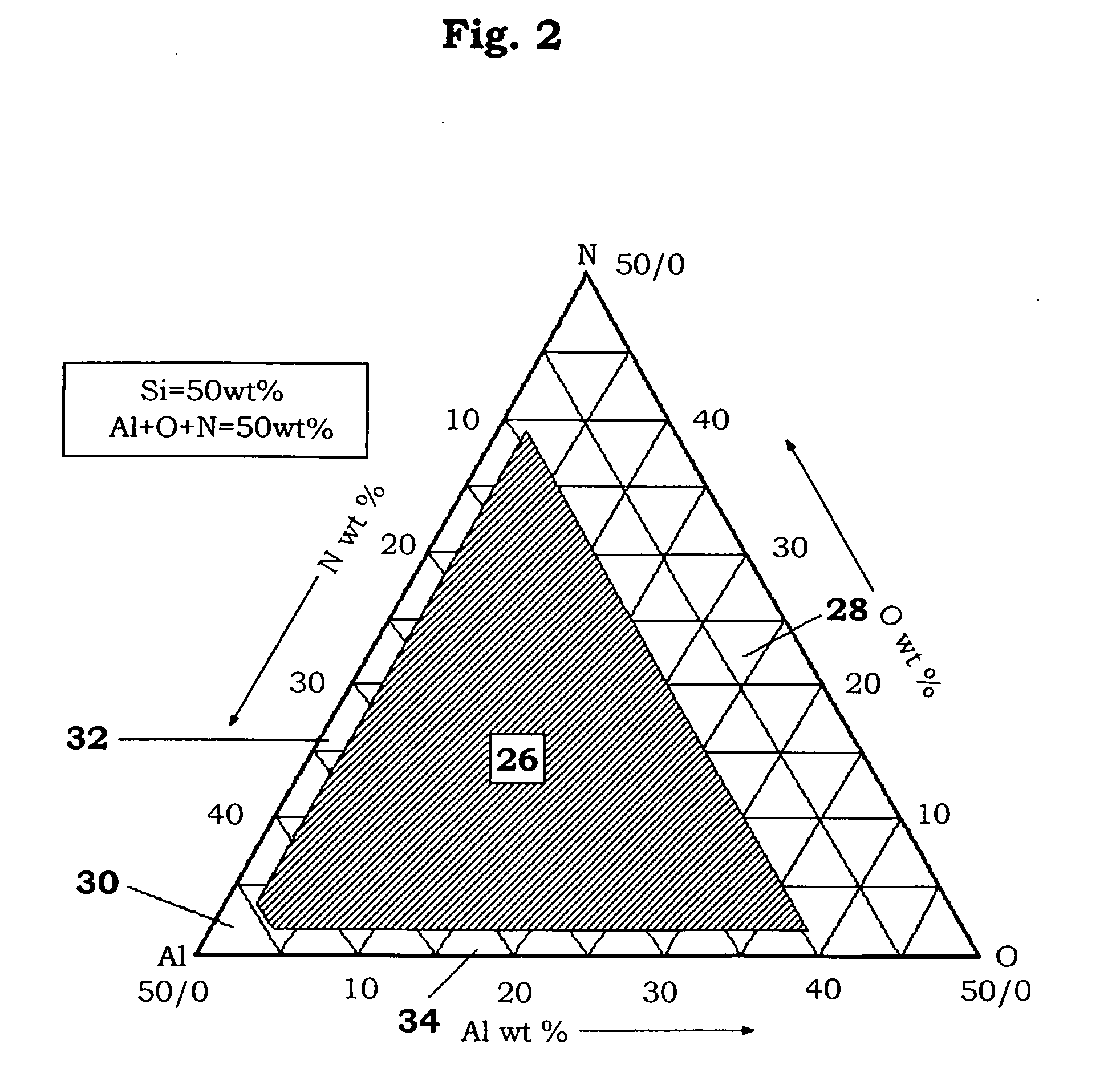

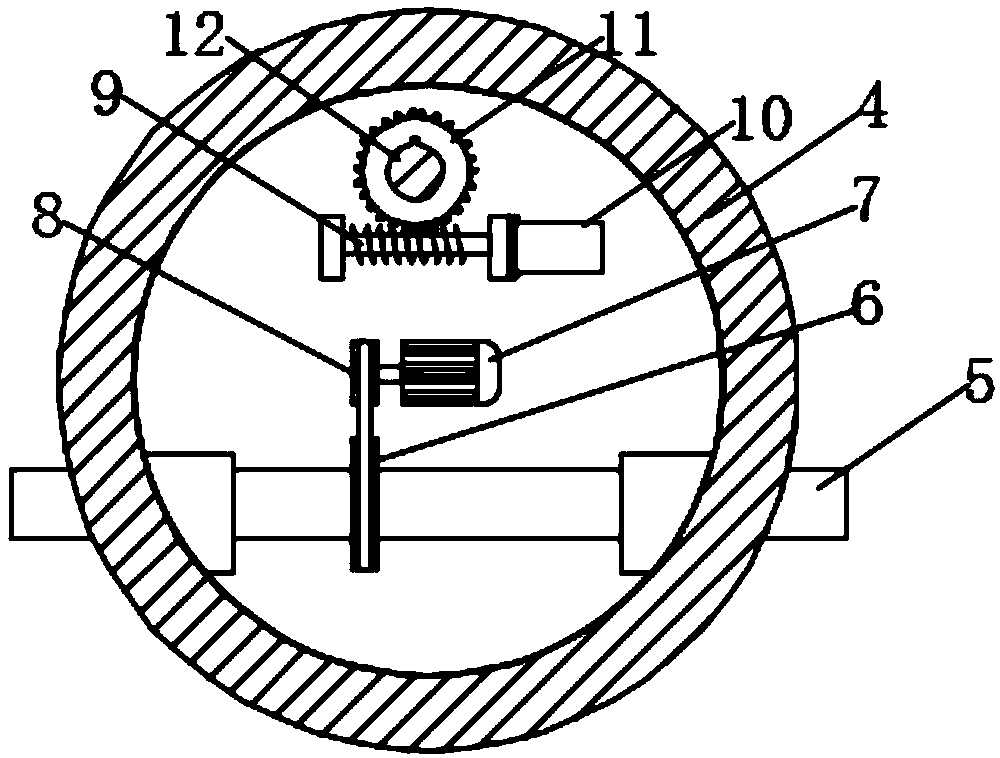

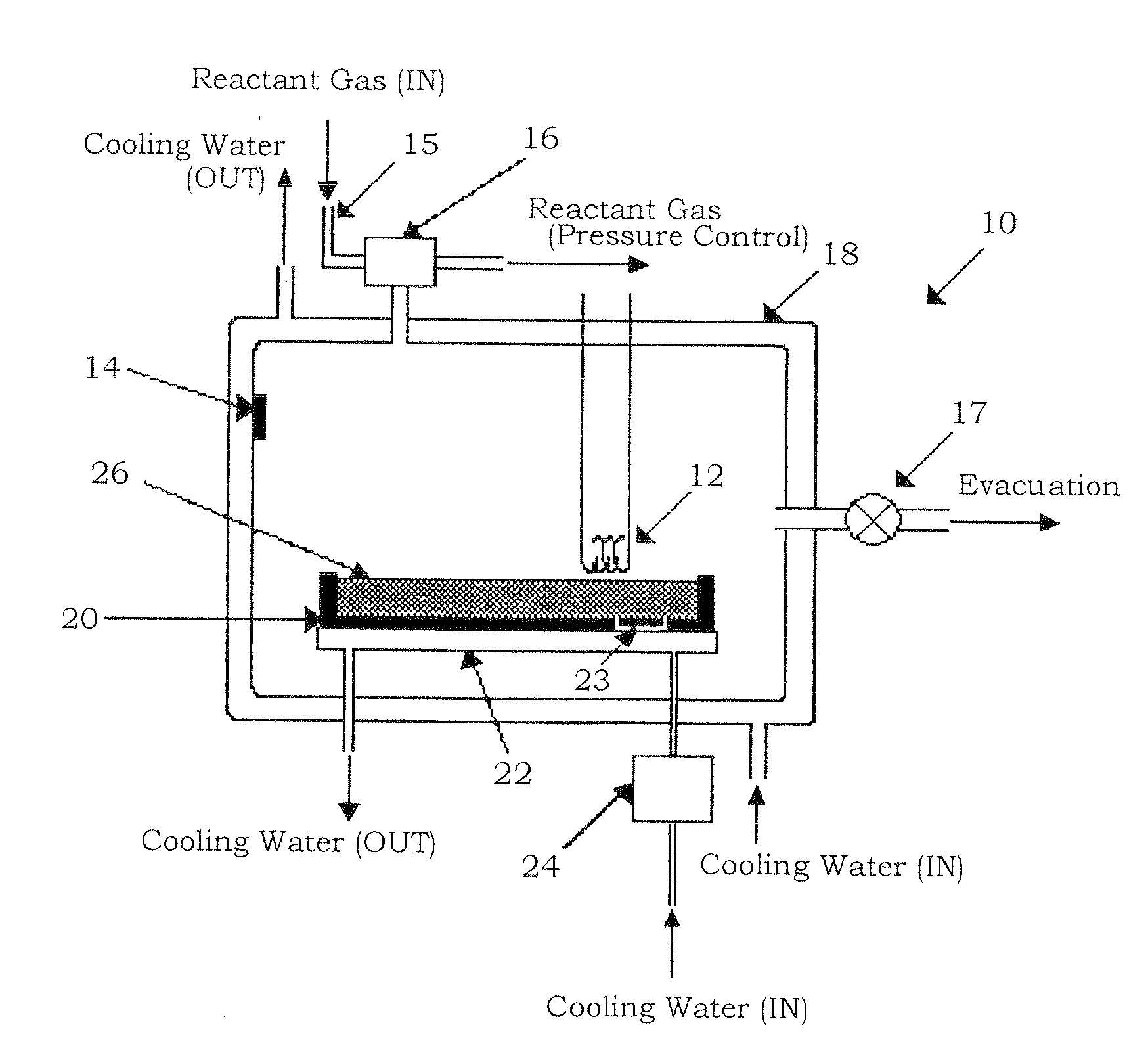

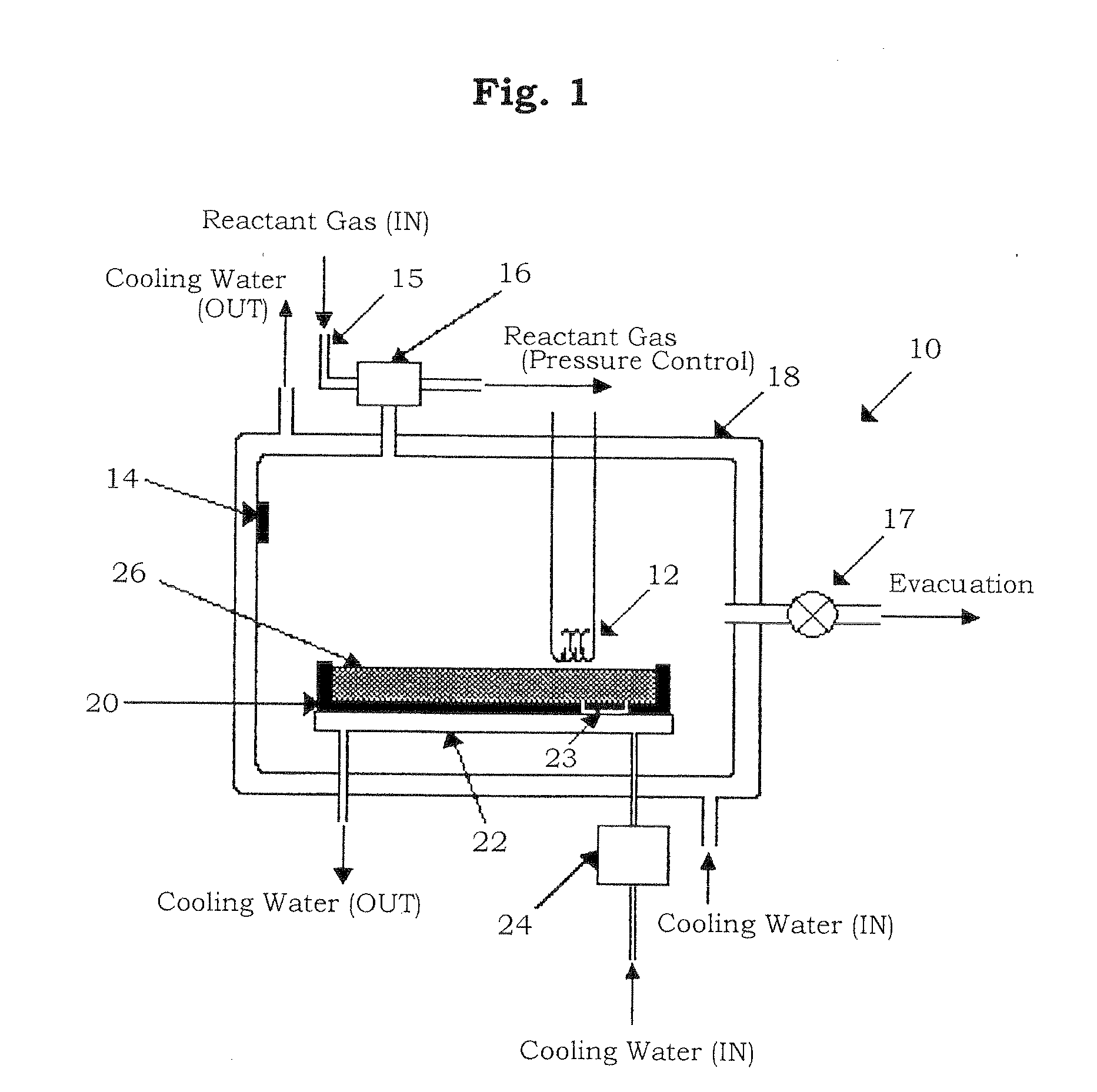

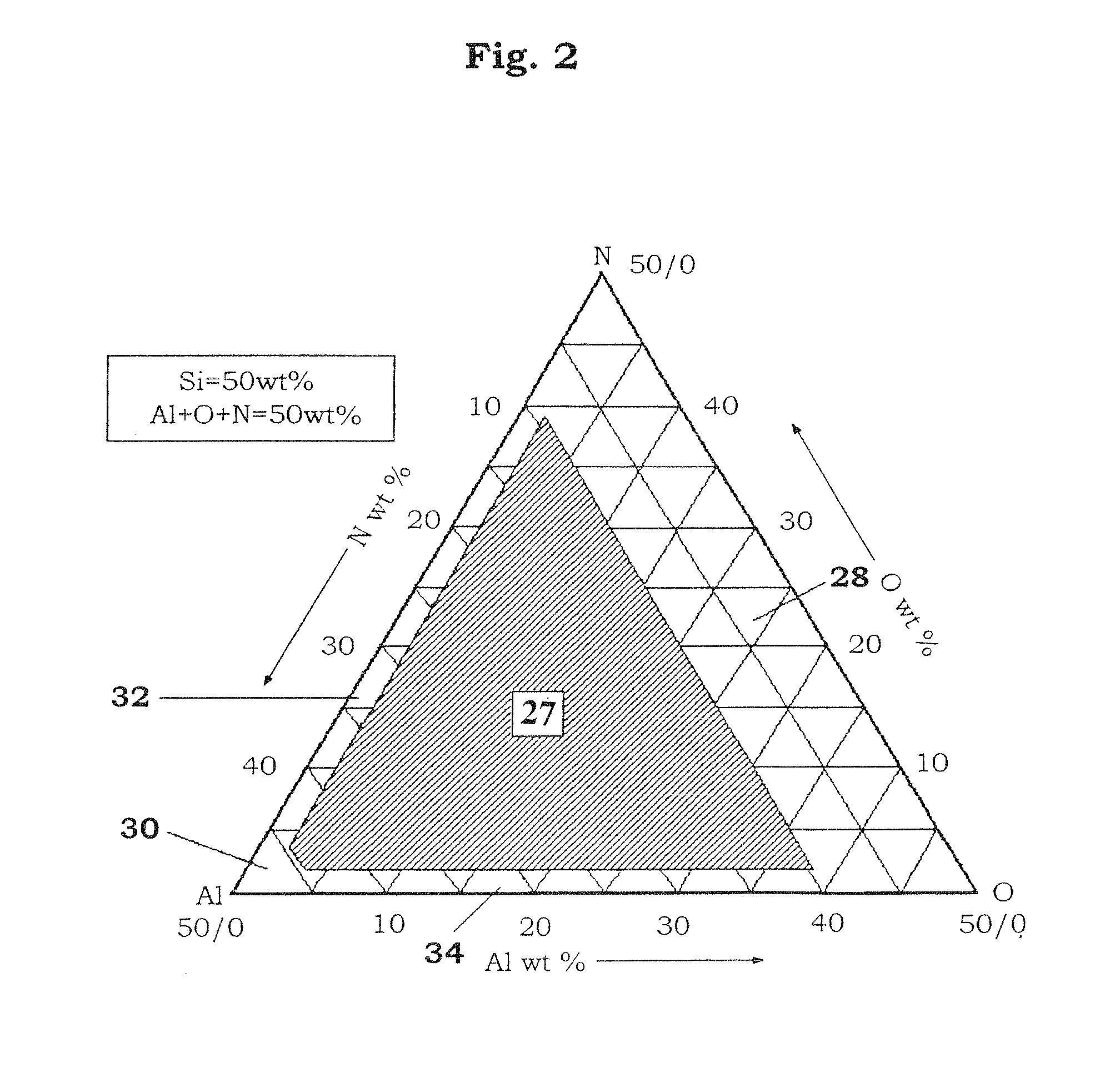

Silicon alloy, alloy powder thereof, manufacturing apparatus, manufacturing process and sintered alloy thereof

InactiveUS20080159905A1Heat treatment process controlNitrogen and non-metal compoundsBack burnsSilicon alloy

A controlled combustion synthesis apparatus comprises an ignition system, a pressure sensor for detecting internal pressure, a nitrogen supply, a gas pressure control valve for feeding nitrogen and exhausting reaction gas, means for detecting the internal temperature of the reaction container, a water cooled jacket, and a cooling plate. A temperature control system controls the temperature of the reaction container by controlling the flow of cooling water supplied to the jacket and the cooling plate in response to the detected temperature. By combustion synthesizing, while controlling the internal pressure and temperature, the apparatus can synthesize a silicon alloy including 30-70 wt. % silicon, 10-45 wt. % nitrogen, 1-40 wt. % aluminum, and 1-40 wt % oxygen.

Owner:ISMAN J CORP

Coal firing method with low discharged nitrous oxides

ActiveCN101097060AReduce generationSuppress generationFluidized bed combustionAir supply regulationBack burnsCombustion chamber

The invention discloses a fire coal method to discharge low nitrogen oxide, which is characterized by the following: adopting high temperature oxygen-enriched smoke gas from circulating fluidized bed burner as high temperature low oxygen twice wind of pulverized coal fired boiler; burning coal dust in high temperature low oxygen coordinating wind with temperature at 800-950 deg. c; decreasing generated quantity of nitrogen oxide (NOx)greatly; controlling circulating fluidized bed burner and main combustion area of coal dust burner fire box at reducing atmosphere; controlling burning temperature; inhibiting the generation of NOx; keeping stability and complete burning property of burning; realizing low NOx discharge of boiler; decreasing the discharging quantity of NOx below 130mg / Nm3.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

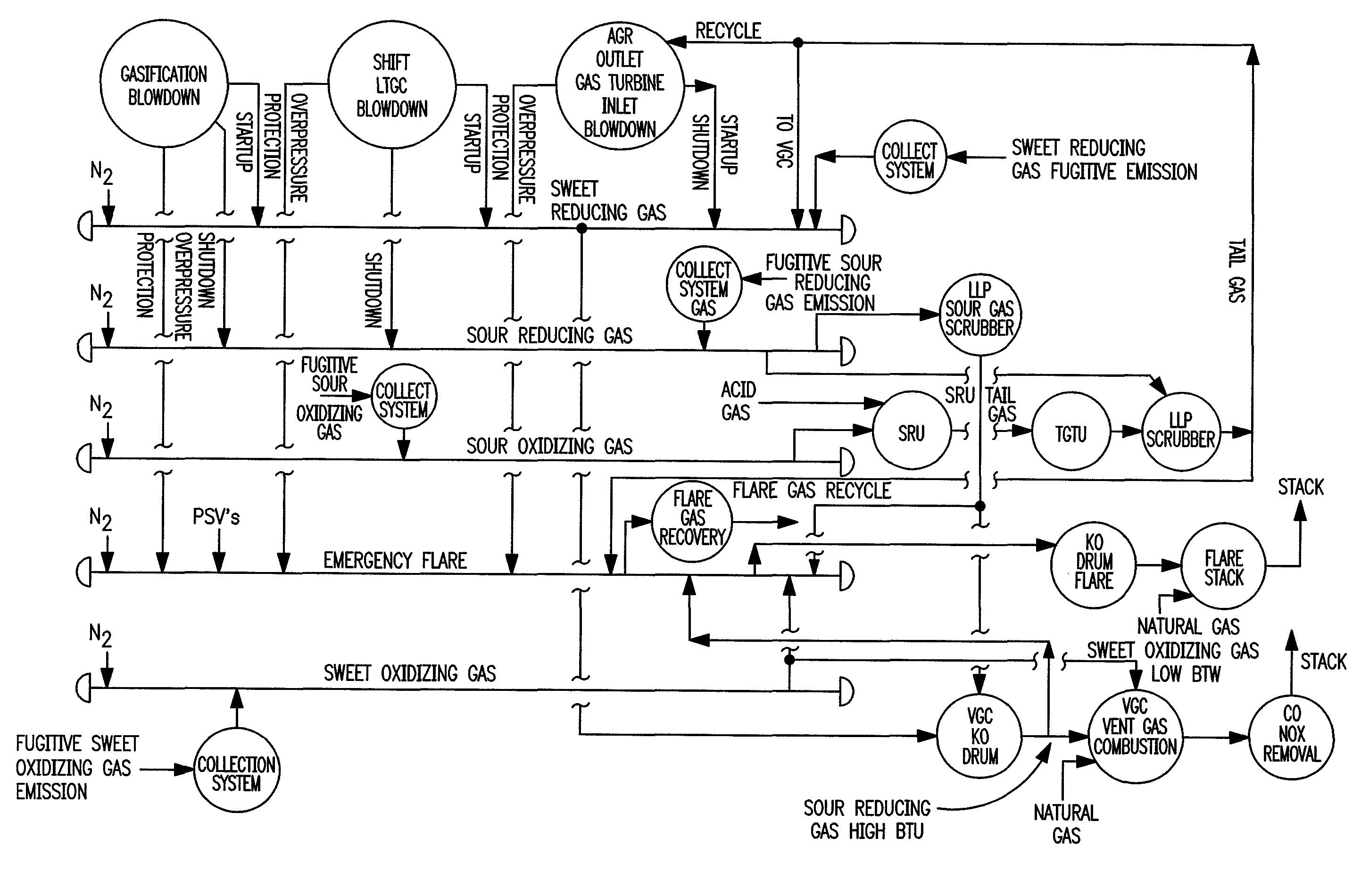

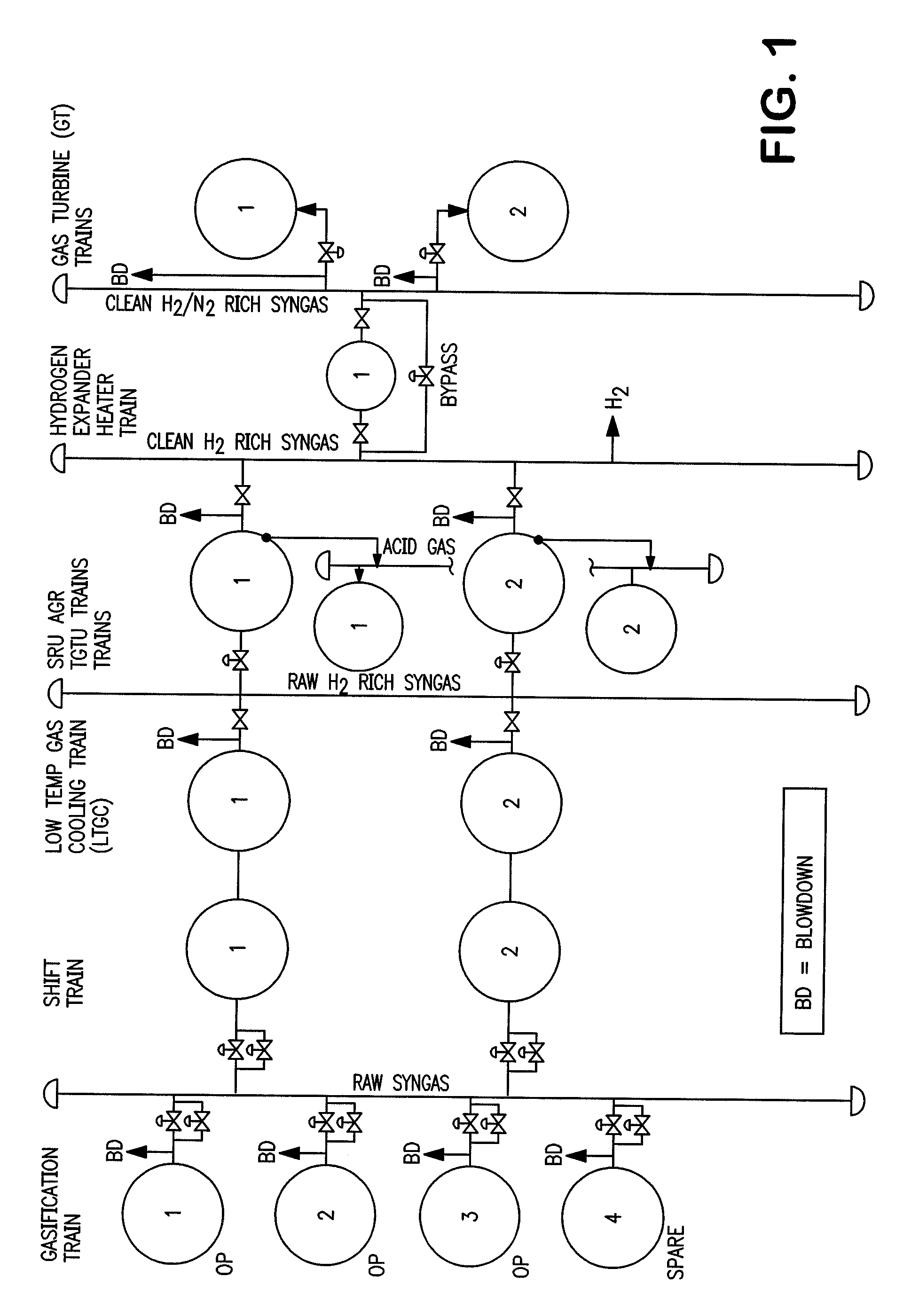

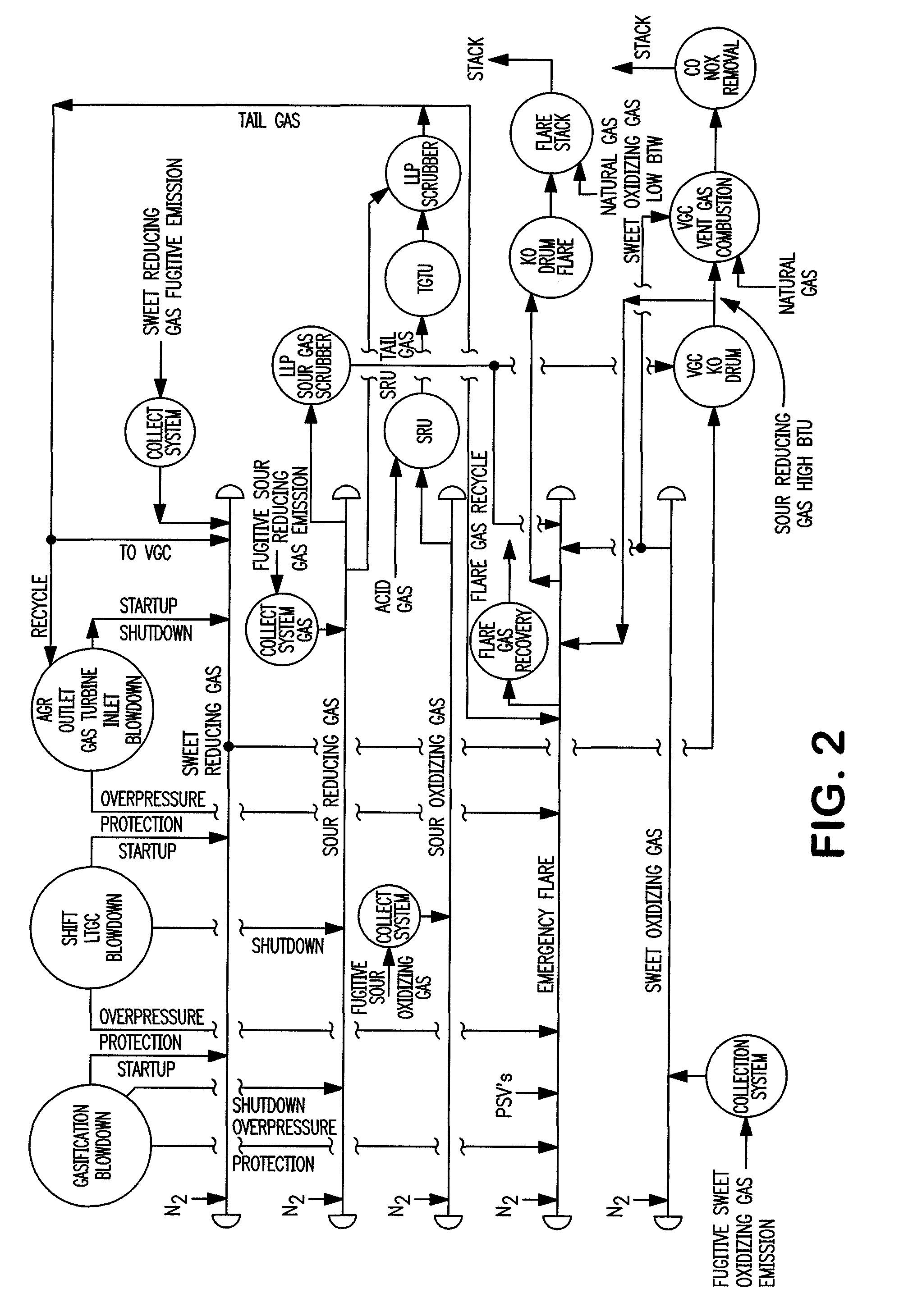

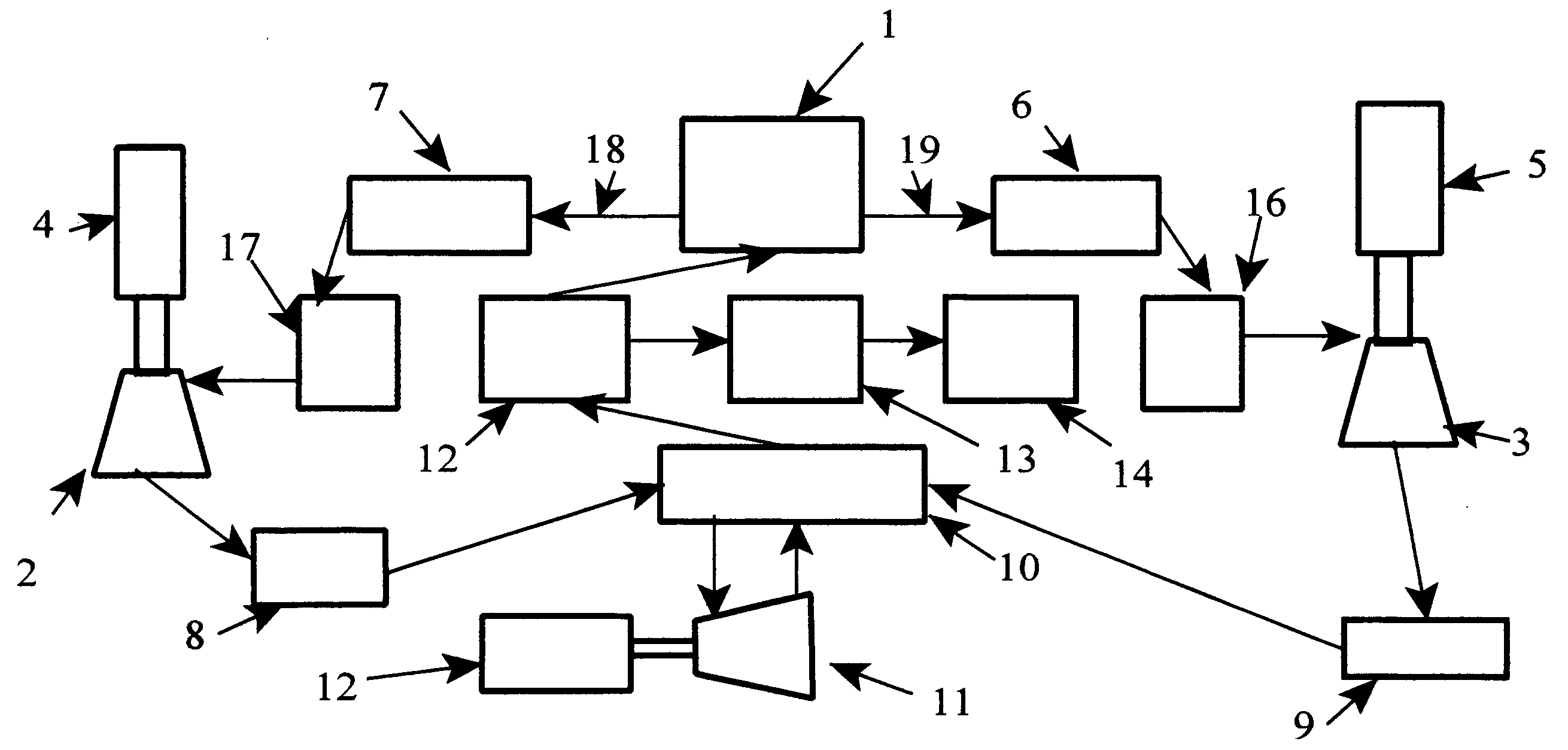

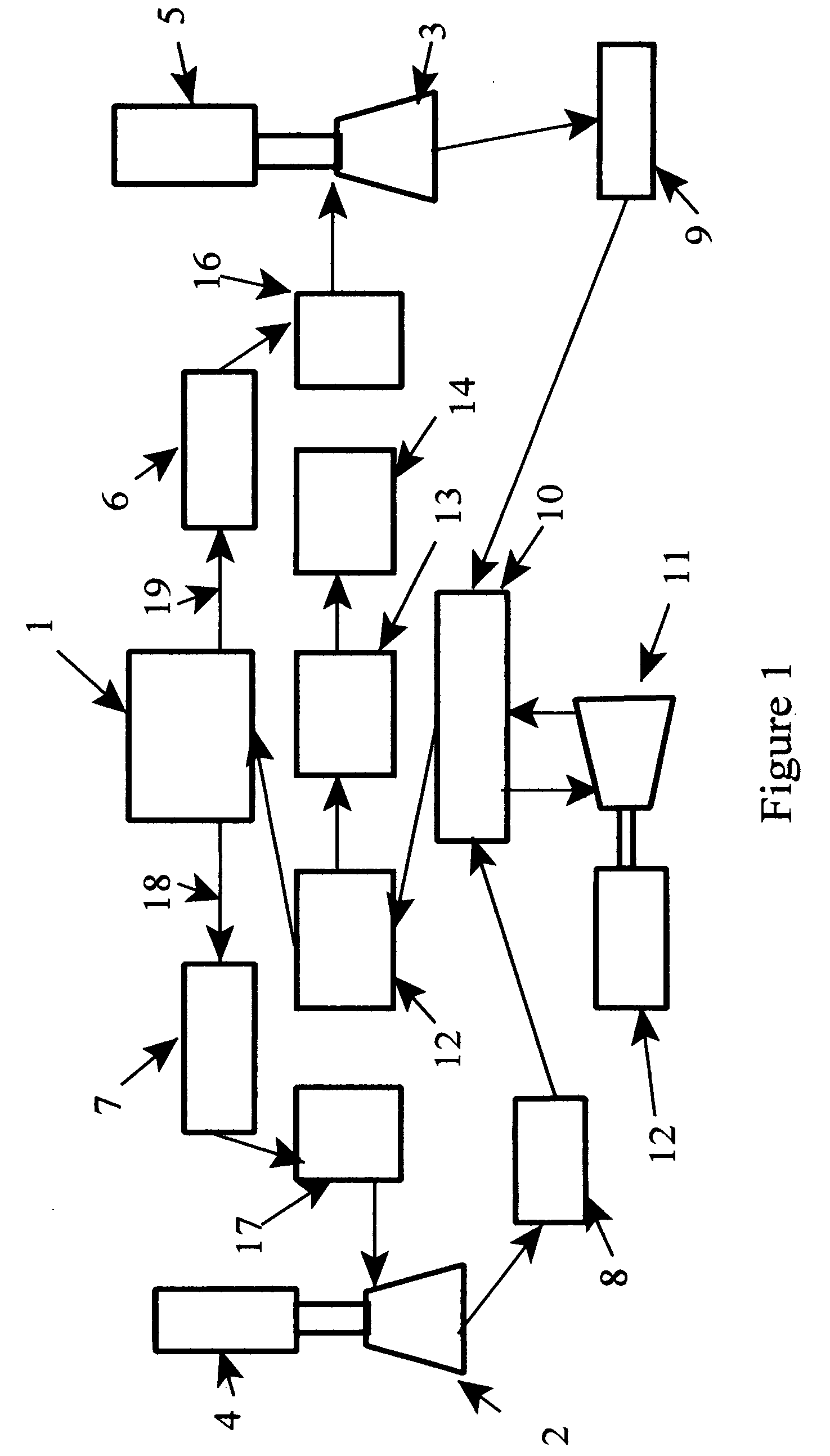

Emission free integrated gasification combined cycle

InactiveUS20100077767A1Improve efficiencyEmission reductionHydrogen separation using liquid contactGaseous fuelsBack burnsAtmospheric air

Disclosed is a process to start-up, operate, and shut down a gasifier and an integrated gasification combined cycle complex without flaring while additionally reducing the release of contaminants such as carbon monoxide, hydrogen sulfide, and nitrogen oxides. The process is accomplished by scrubbing ventable sour gases and passing scrubbed sour gases and ventable sweet gases to a vent gas combustor for controlled combustion prior to release of any such gases to the atmosphere. Additionally, the gases are subjected to a CO oxidation treatment and selective catalytic reduction treatment prior to release to the atmosphere.

Owner:HYDROGEN ENERGY INT

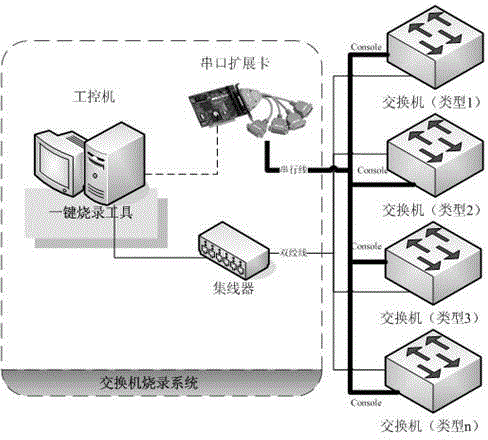

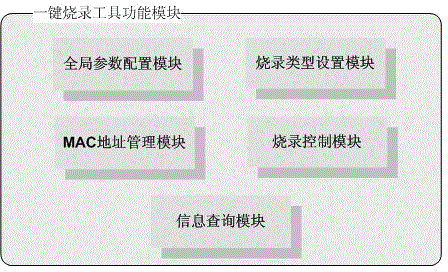

System for simultaneously burning multiple switches, method thereof and corresponding switches

InactiveCN104425001AImprove programming productivityReduce duplicationDigital storageData switching networksBack burnsThe Internet

The invention relates to a system for simultaneously realizing one-button burning on multiple switches, a method thereof and the corresponding switches. The system comprises a computer arranged with a one-button burning tool, at least a serial port expansion member and a bench common exchange apparatus. The system can simultaneously sent correlation operation instructions to multiple switches to be burned through the serial port expansion member and read the return content; and then is simultaneously connected to the internet access of multiple switches to be burned through the common exchange apparatus, and then simultaneously transmits the upgrade files to the multiple switches to be burned; the one-button burning tool arranged on the computer can be used for starting several tasks and control burning operation on multiple switches. The system can greatly increase the production efficiency of switch burning, by management of MAC address and batch number, faults such as repetition and omission due to artificial operation can be reduced.

Owner:TRANSCEND COMM BEIJING

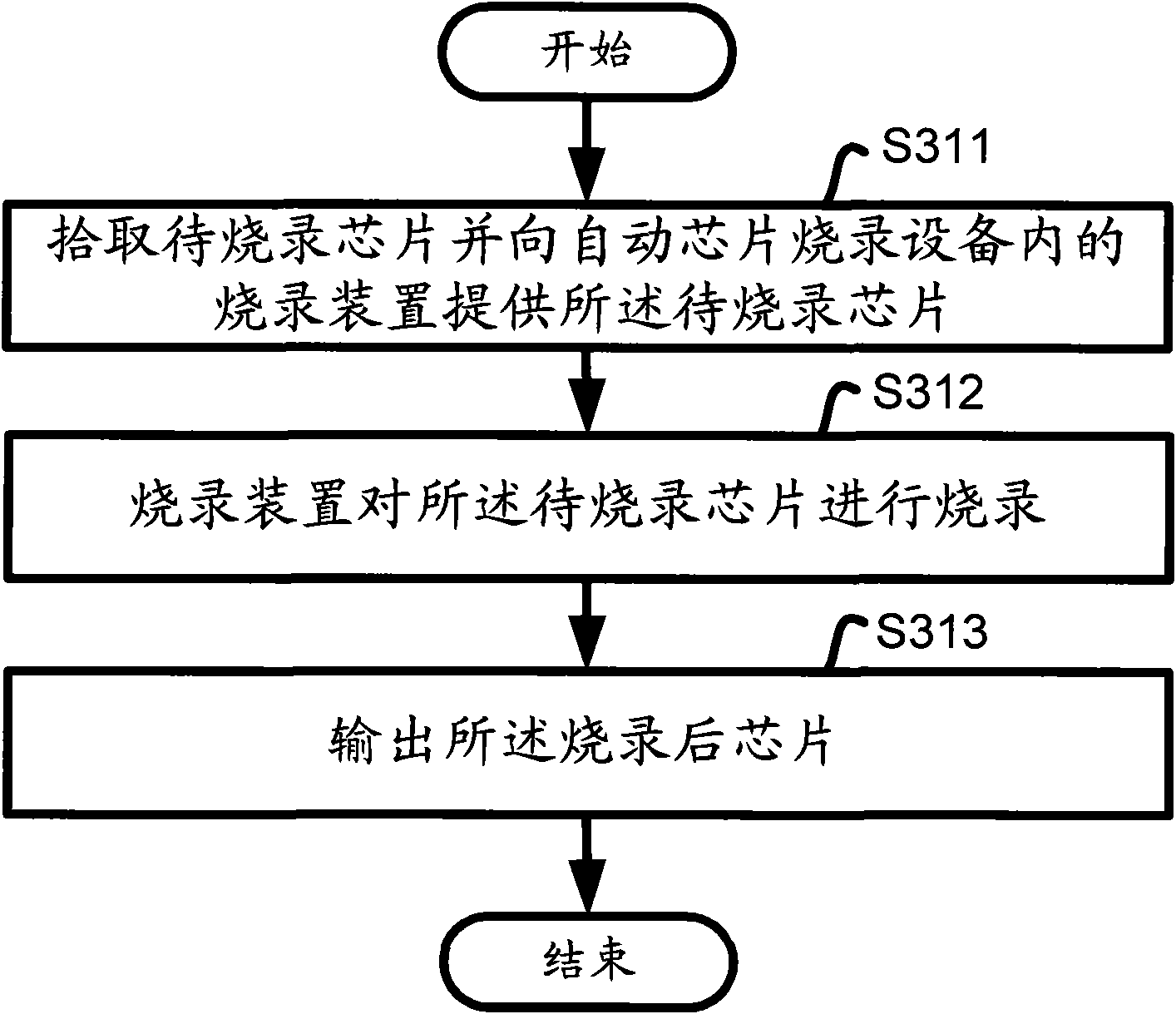

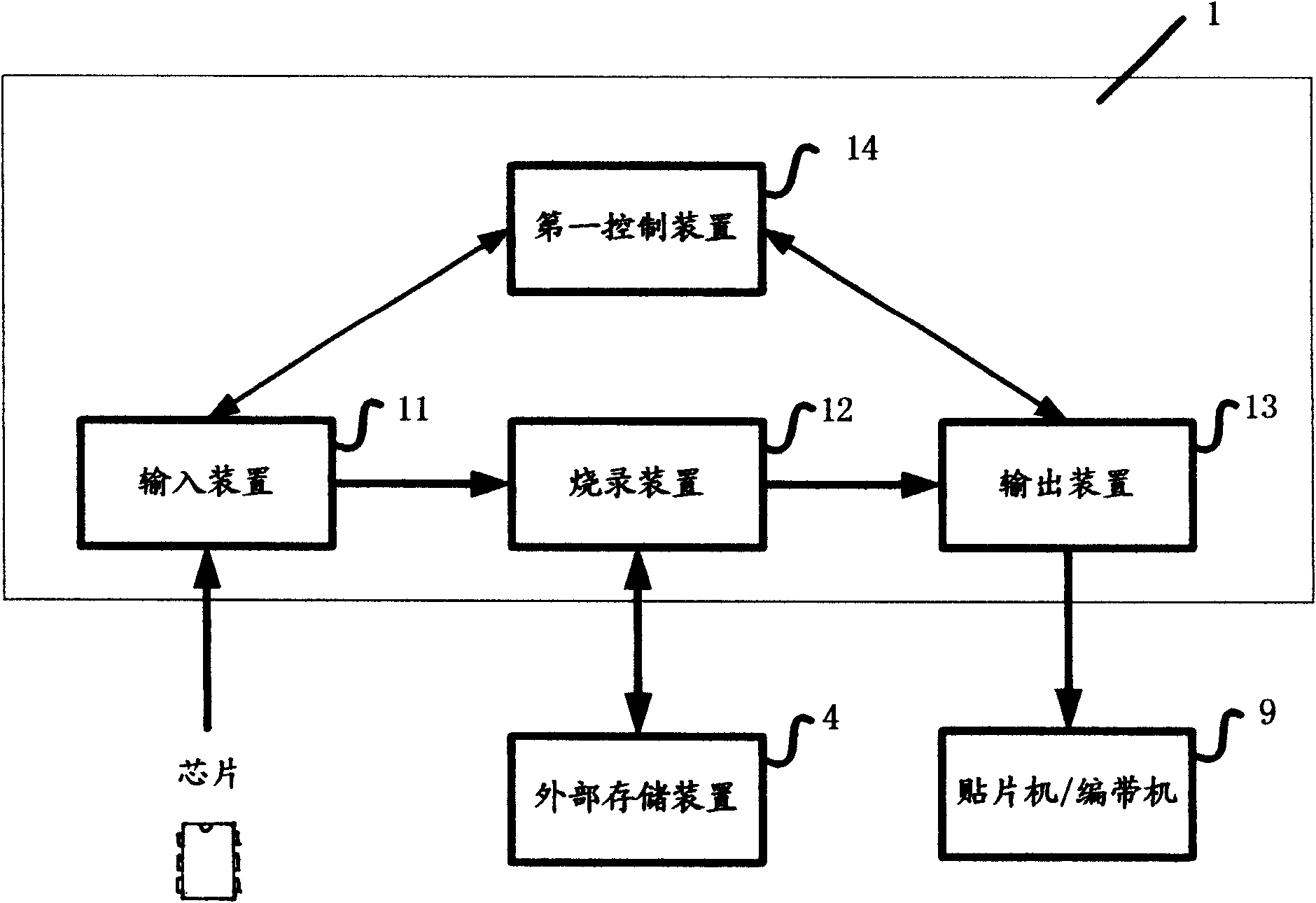

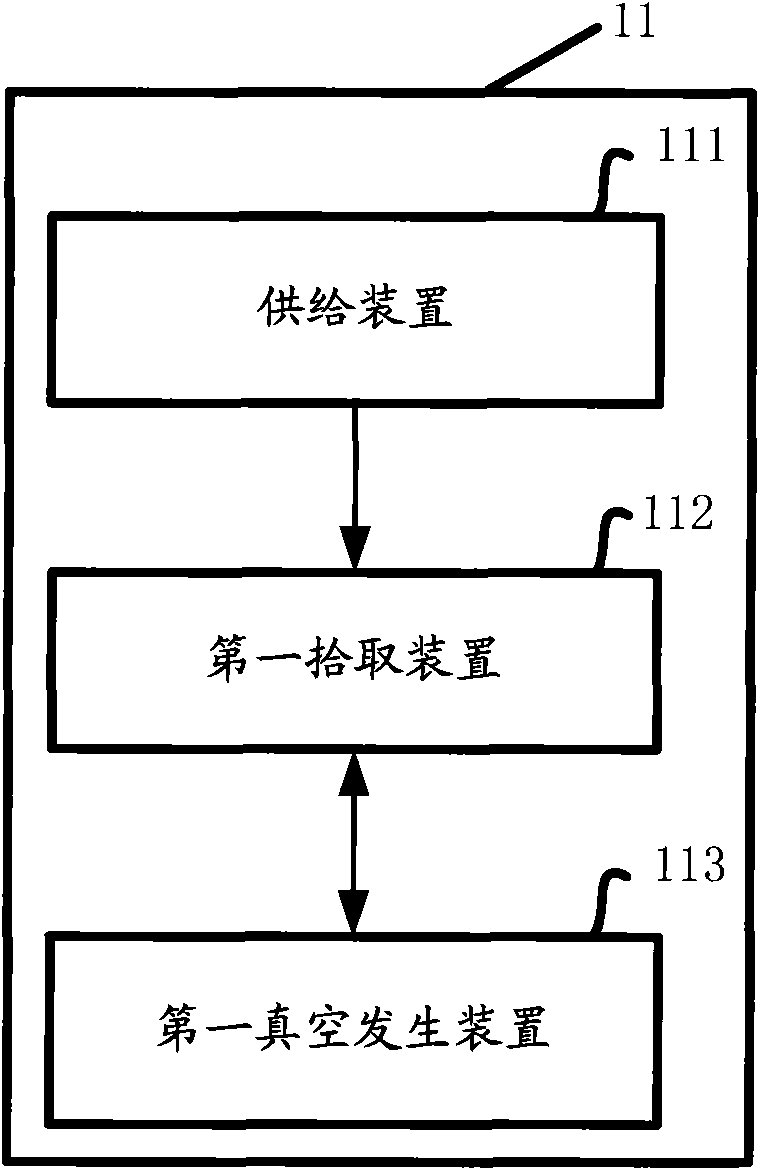

Control method for controlling burning and corresponding automatic chip burning equipment

InactiveCN101620887AEasy inventory managementImprove supply chain effectivenessRead-only memoriesProduction lineBack burns

The invention provides a control method for controlling burned-chip transmission of automatic chip burning equipment, and automatic chip burning equipment. The burning equipment comprises an input device, a first control device, a burning device and an output device. The burning equipment is characterized in that the output device comprises a transmission connecting device which is at least used for being adaptively connected with a surface mounted device or a taping machine respectively. By improving the output device of the prior chip automatic online burning equipment and correspondingly improving the control method for controlling burned-chip transmission, the invention provides a control method for supporting two burning functions of automatic online burning and offline burning on burning equipment, and corresponding automatic chip burning equipment, thus the equipment can be directly used on production lines of surface mounted devices and taping machines, the chip inventory management can be simplified and the effect of the supply chain can be improved. The control method and corresponding automatic chip burning equipment are characterized in low cost, high yield, high speed, high quality, high efficiency and the like.

Owner:刘佐毅

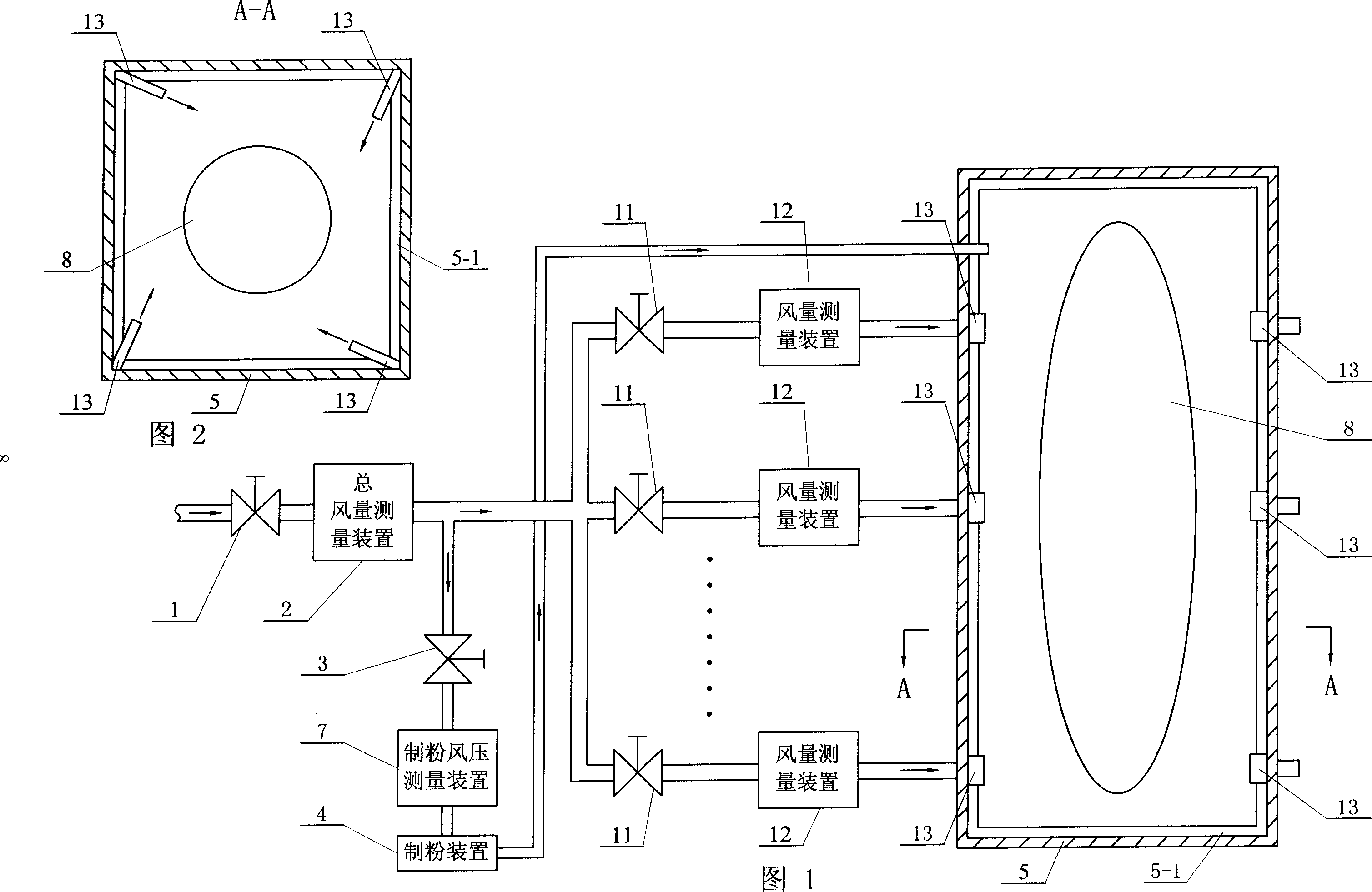

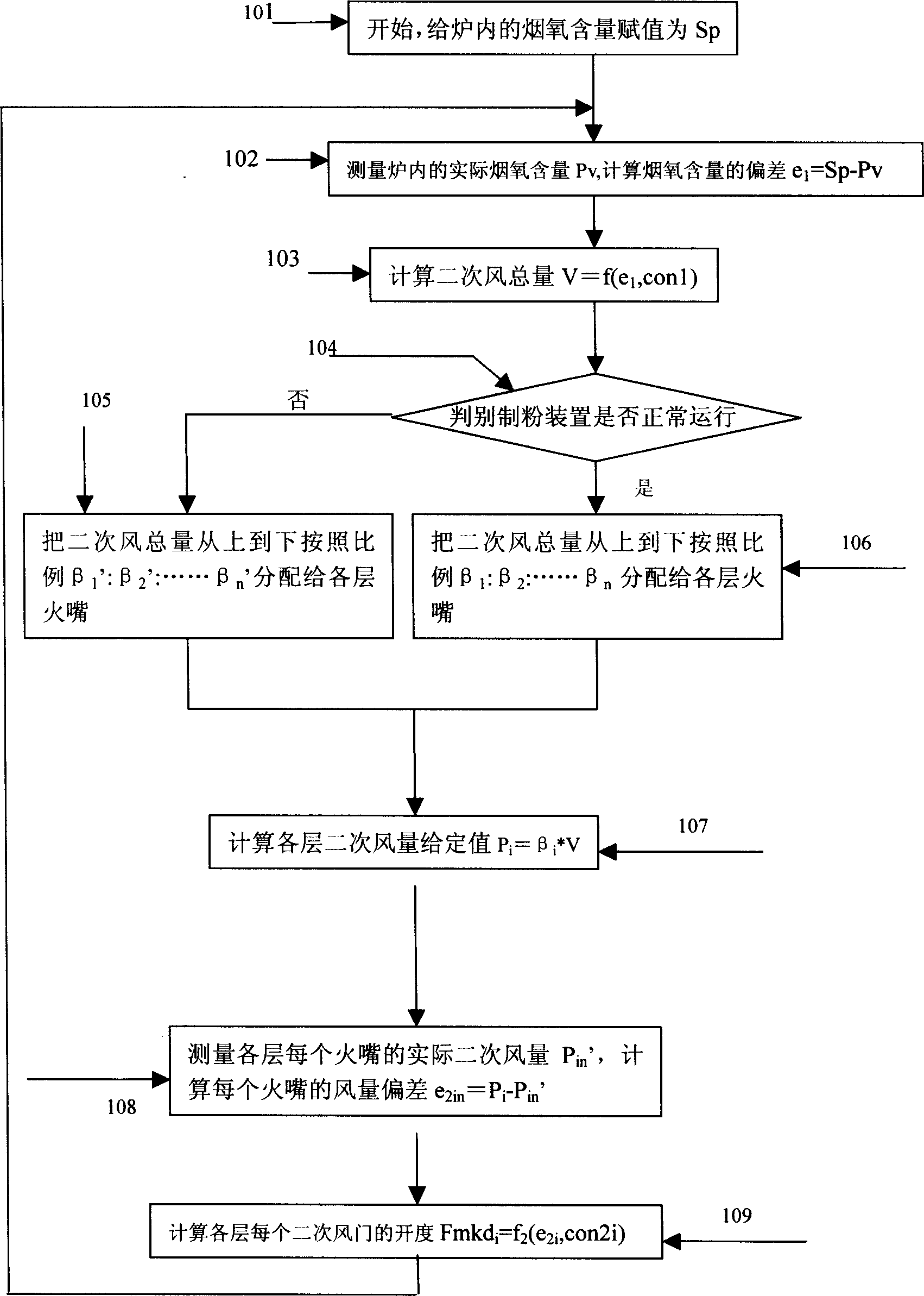

Method for controlling burning state of coal powder boiler fire

InactiveCN1683832AImprove securityImprove heat transfer efficiencyAir supply regulationAir volumeBack burns

The control method of burning state in coal powder boiler includes the following steps: setting the value Sp of oxygen content in boiler fume exhaust; measuring the practical oxygen content Pv in furnace fume, calculating the deviation E1 between Sp and Pv, and calculating the given value of total secondary blast based on the outer loop controller; judging whether the powder making apparatus is running; if 'yes', distributing the total secondary blast value to the fire nozzles in the first proportion; if 'no', distributing the total secondary blast value to the fire nozzles in the second proportion; and regulating the secondary blast gates to track the given blast amount. The method can distribute blast accurately, fast and automatically.

Owner:柴庆宣

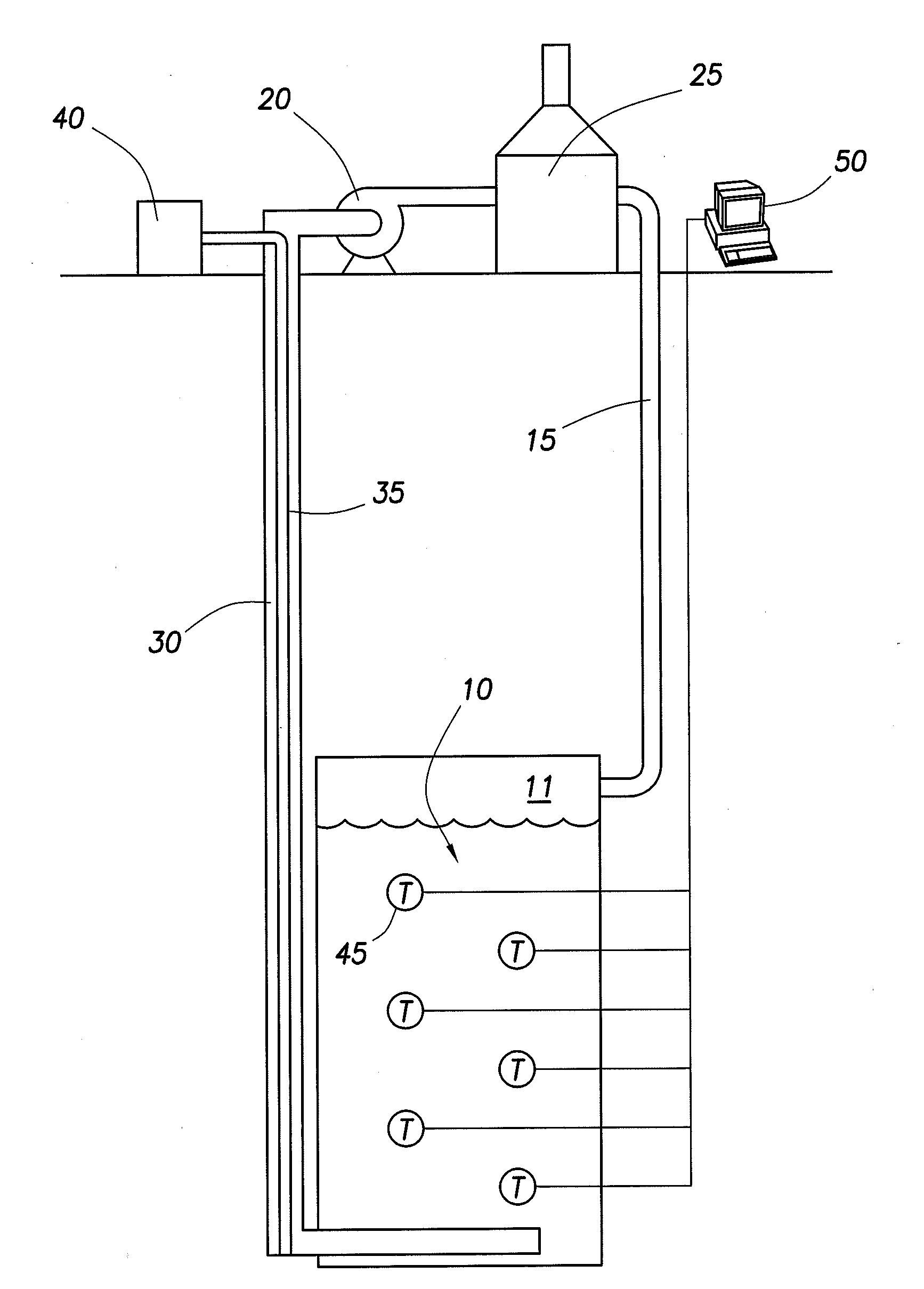

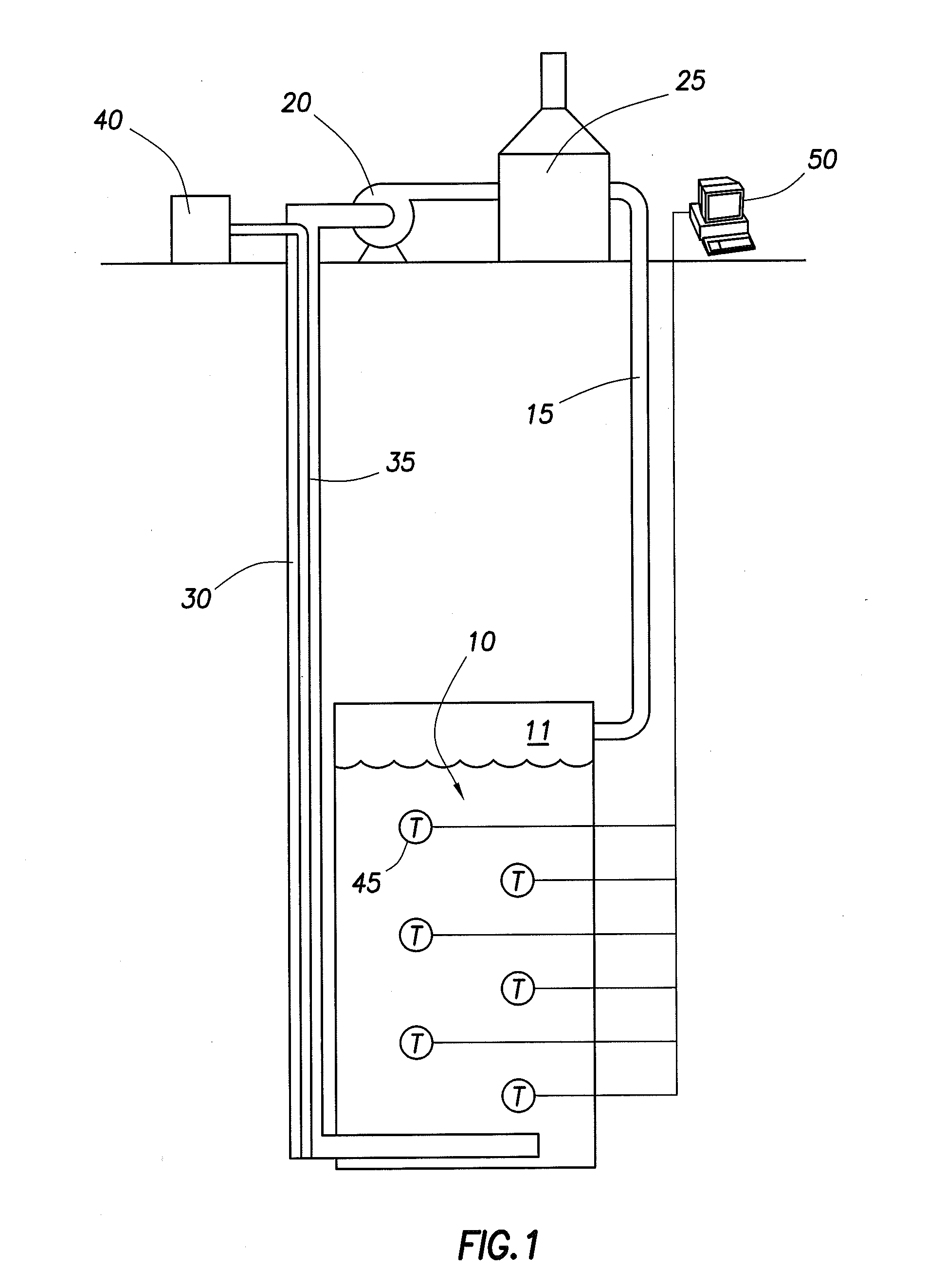

Recovery of Hydrocarbons From Oil Shale Deposits

This invention relates to recovering hydrocarbons from oil shale preferably in-situ where the temperature of the oil shale deposit is controlled to maximize recovery of hydrocarbons and minimize decomposition of carbonate minerals into carbon dioxide that might be released into the atmosphere. The process includes generating heat from hydrocarbon gases recovered from the oil shale and then later performing a controlled burn of the char that is left in the spent shale after the kerogens have been thermally cracked and the most of the recoverable hydrocarbons have been recovered. The burning of the char is also controlled based on the temperature of the oil shale in-situ, the temperature of the gases retuning to the surface from the oil shale and the carbon dioxide in the gases returning to the surface.

Owner:CONOCOPHILLIPS CO

Burner monitoring and control systems

Systems and methods for monitoring and controlling burning operations are provided. A method of one embodiment includes igniting oil or gas with a burner (282) during a burning operation and monitoring the burning operation with a camera (290). This monitoring of the burning operation can include acquiring image data for a flame (290) of the burner via the camera and analyzing the acquired image data to detect image features indicative of combustion of the oil or gas via the burner. Additional systems, methods, and devices are also disclosed.

Owner:SCHLUMBERGER TECH CORP

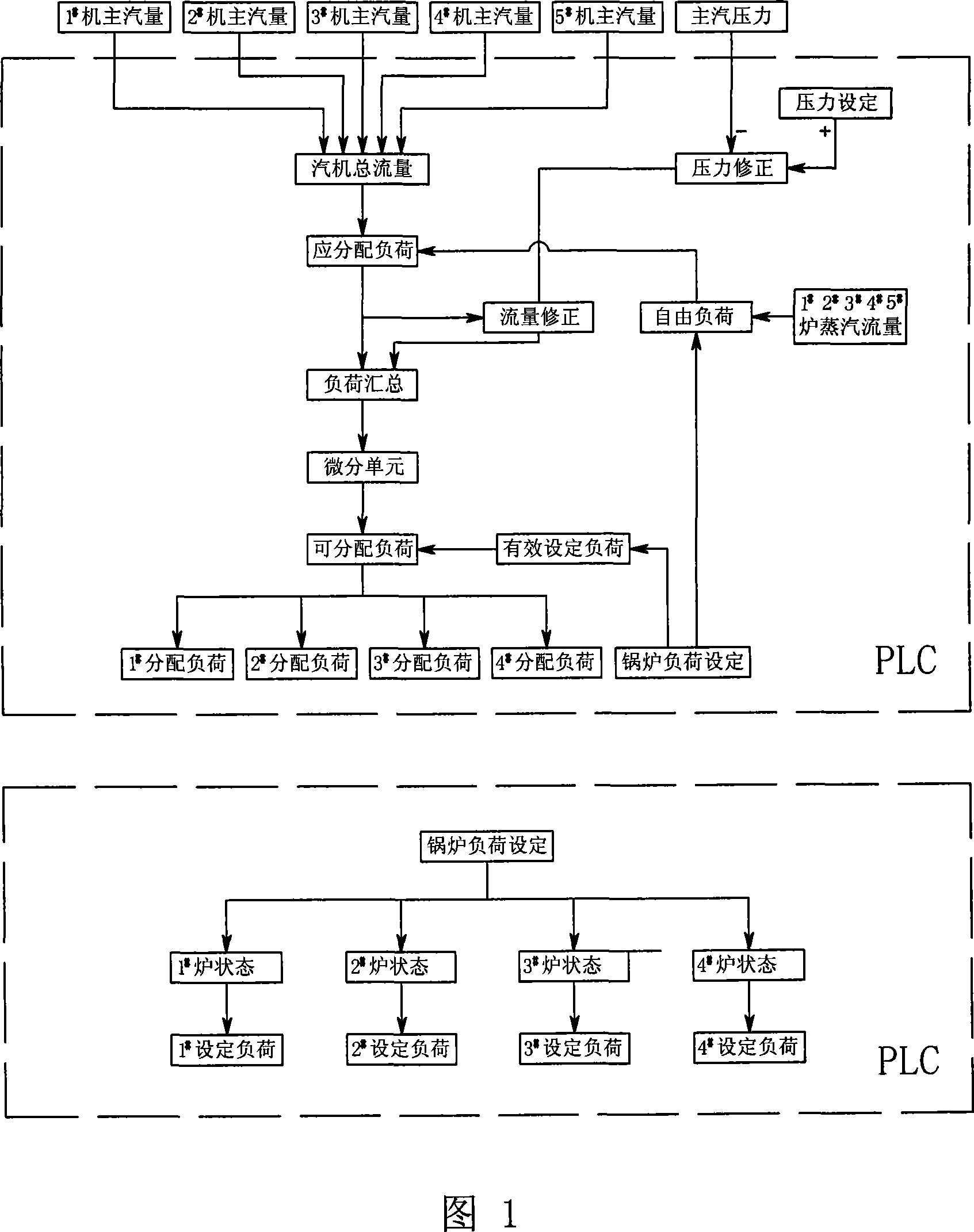

Distribution control method for automatic balancing pressures in mother pipes of boilers run parallelly

InactiveCN101093075ASolve the technical problem that the pressure is unstable and can only be controlled manuallyGuaranteed uptimeBoiler controlAuto regulationBack burns

This invention discloses an automatic balance and distribution method for pressure of master pipes of parallel operating boilers, which collects and computes volumes of steam equipment and output volume after PID adjustment according to the pressure of a master pipe then sends them to a boiler load distributing module to distribute them to the boilers in terms of a rule, which control burning according to the distributed flow and control the actual flow equal to the distributed ones, when the steam volume or the pressure of a master pipe is changed, the load distributed to the boiler is changed and the actual one is changed too so as to stabilize pressure of master piles and realize automatic adjustment.

Owner:周振华 +1

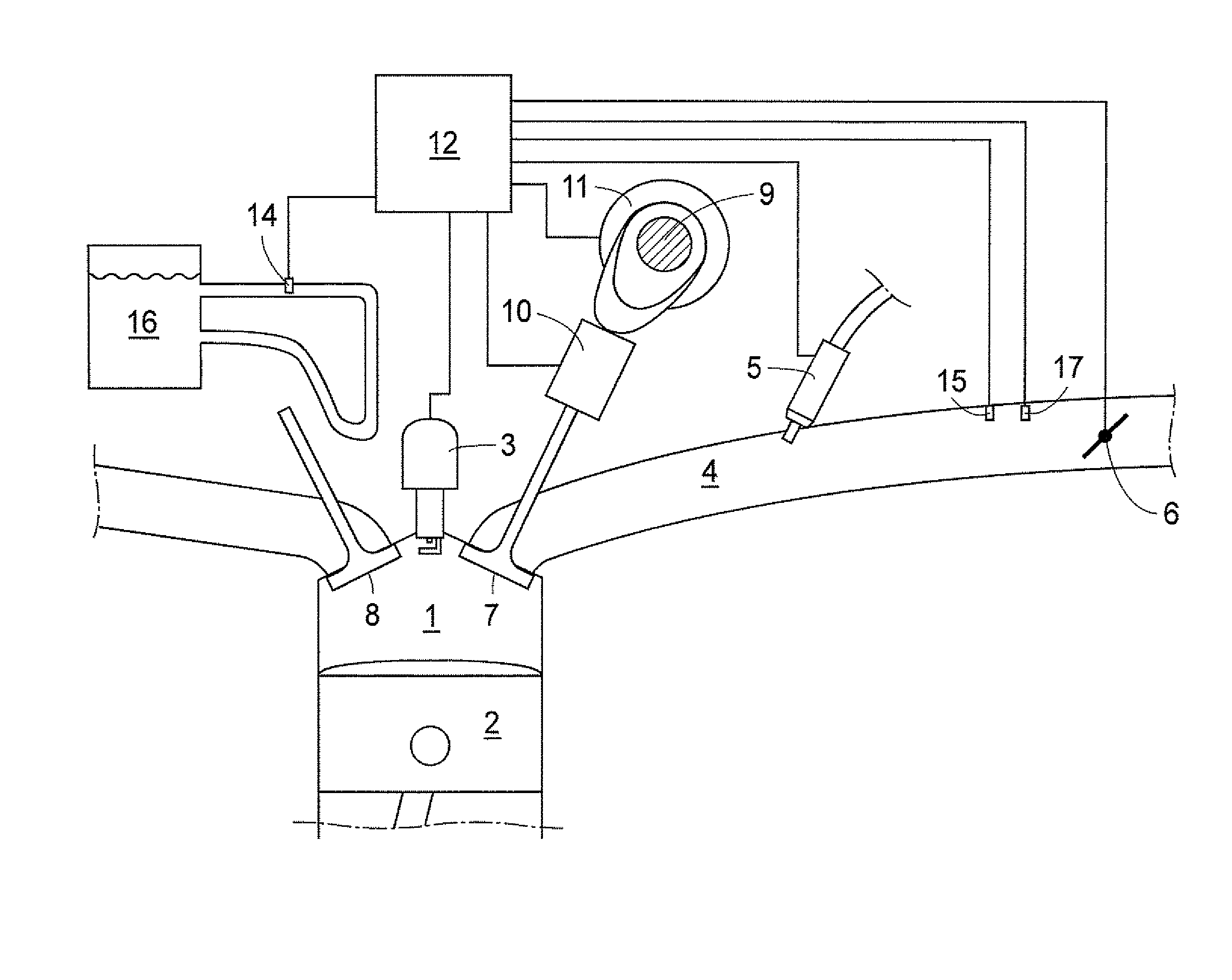

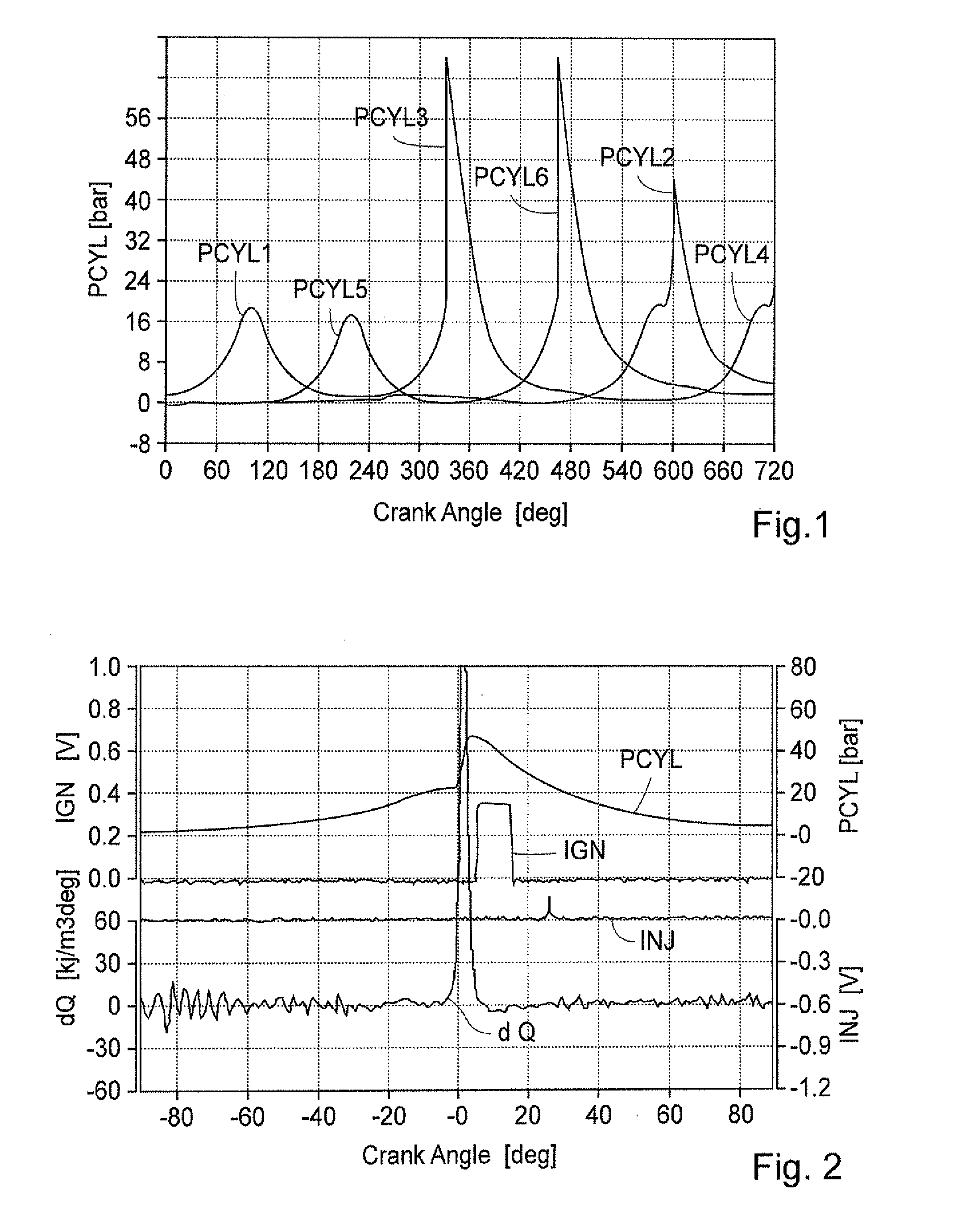

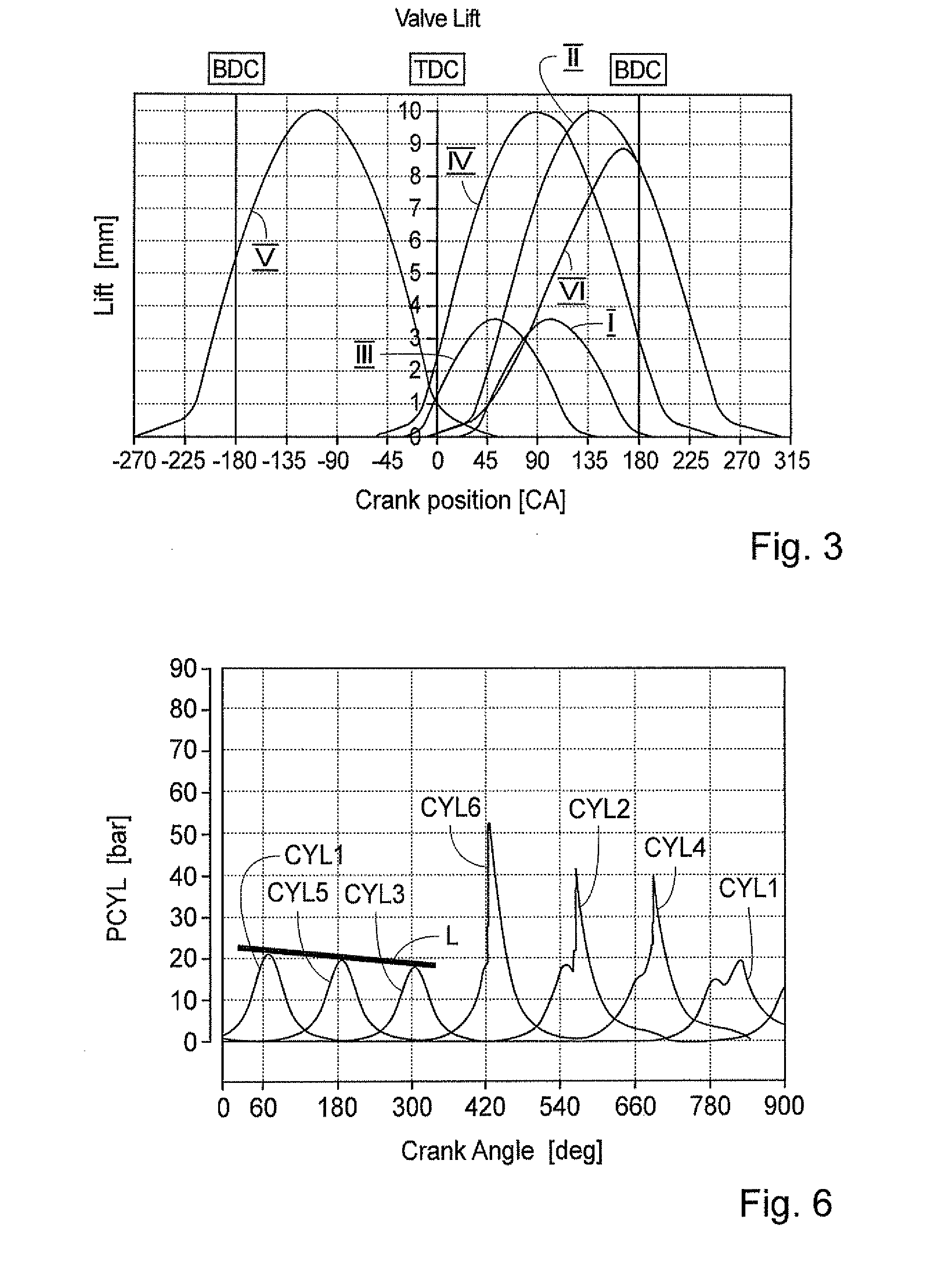

Method For an Internal Combustion Engine, and an Internal Combustion Engine

ActiveUS20070215120A1Avoid low air temperatureLow engine speedElectrical controlInternal combustion piston enginesBack burnsHot start

The invention relates to an internal combustion engine, and a method for an internal combustion engine with at least one cylinder, at each of which at least one spark providing device for ignition being provided. The engine is operated, in connection to a start procedure of the engine, in a controlled self-ignition mode comprising at least one controlled combustion without spark ignition. The controlled combustion without spark ignition can comprise homogeneous charge compression ignition (HCCI). The invention will significantly reduce the risk of engine knocking at a hot start of the engine.

Owner:FORD GLOBAL TECH LLC

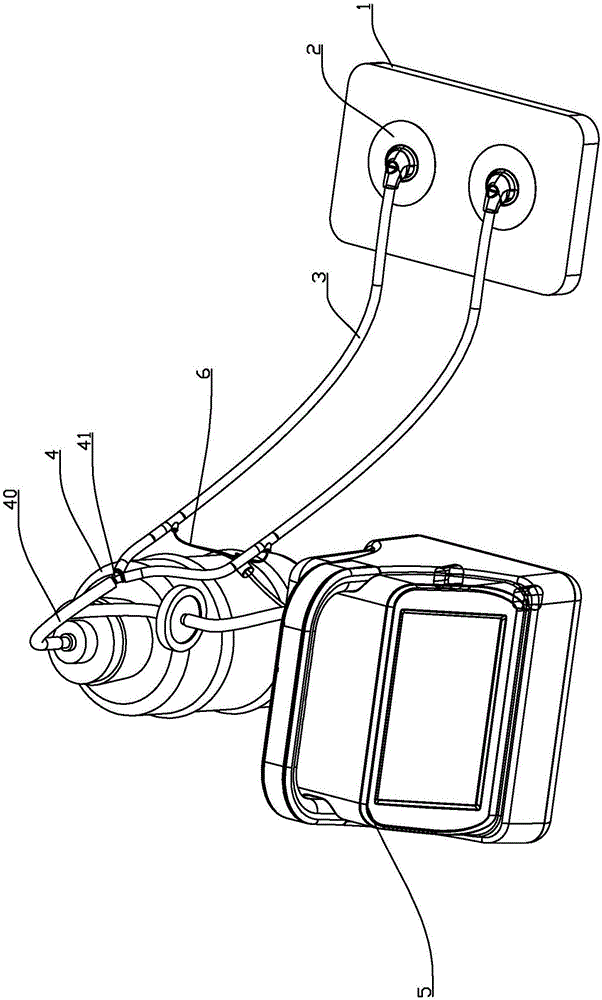

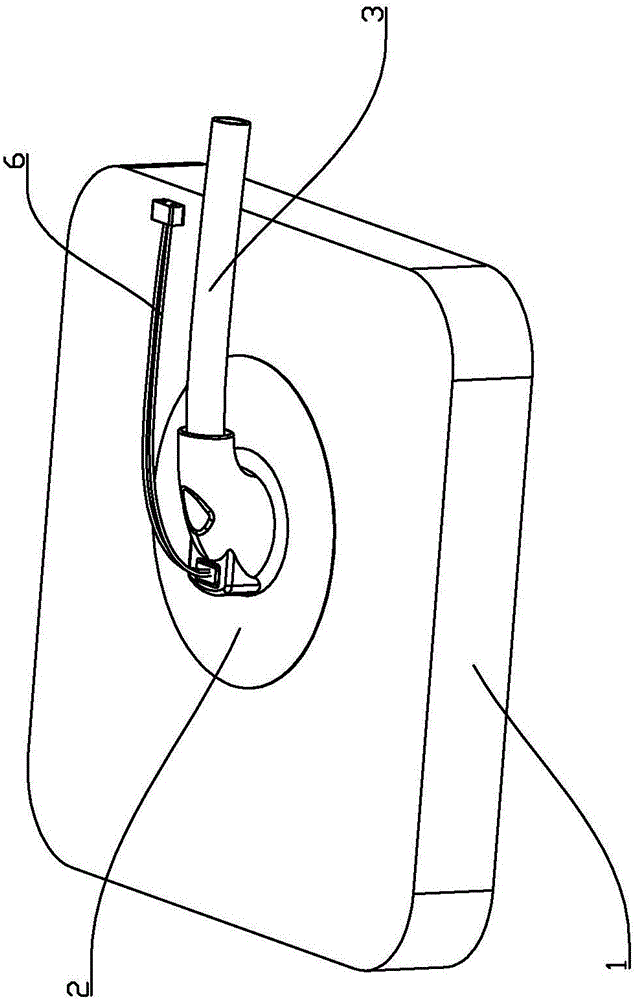

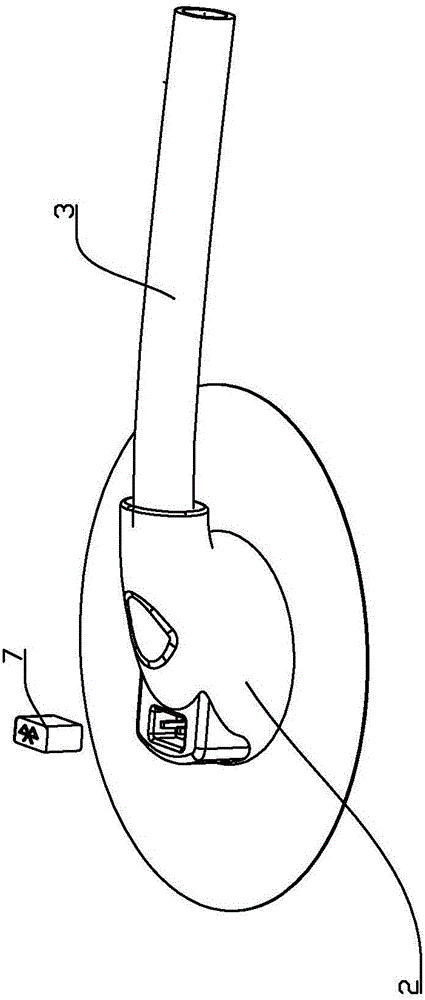

Protector for combustion fan of bulk curing barn

InactiveCN105831790ASolve technical problems that are easy to burnPromote combustionTobacco preparationPump componentsCombustionBack burns

The invention provides a protector for a combustion-supporting fan in a dense barn, which includes a hollow protector body and a box body. The protector body includes a heating chamber end and a combustion-supporting fan end; Between, and a square box connected to the two; the box also includes a heat insulation baffle, which can block the airflow passage of the protector main body when the combustion fan is shut down, and open the airflow passage of the protector main body during operation. When the combustion-supporting fan stops running, the wind force on the heat insulation baffle disappears, and the heat insulation baffle is attached to the side wall of the main body of the box under its own gravity. Since the box is a square box, the heat insulation baffle can be connected with the box body Close fit, the flame in the heating chamber is completely blocked at the heat insulation baffle, which effectively prevents the flame from entering the combustion fan. The protector can control the burning rate of the combustion-supporting fan within 2.4%, effectively solving the technical problem that the combustion-supporting fan is easy to burn out in the prior art.

Owner:LIUYANG BRANCH OF CHANGSHA COMPANY OF HUNAN TOBACCO

Light acid-proof brick and preparation thereof

InactiveCN101274839AReduce weightLight heat retentionCeramic materials productionClaywaresBack burnsBrick

The invention relates to a light weight acid resistant brick which is characterized in that: the components of the light weight acid resistant brick comprise by weight percentage 35 to 45 percent of diatomite, 30 to 40 percent of pottery clay aggregate and 25 to 30 percent of pulverized fuel ash. The granularity of the diatomite is 120 to 150 meshes, the granularity of the pottery clay aggregate is 8 to 10 meshes and the pulverized fuel ash is screened by a 12-mesh sieve. The preparation method of the light weight acid resistant brick is characterized in that the raw materials are smashed, screened and added with water to make pug which is then milled, molded, dried (under temperature of 60 to 100 DEG C) and burned under temperature of 1100 plus or minus 10 DEG C to obtain finished products. The light weight acid resistant brick of the invention has reasonable and uniform proportioning, strictly controlled burning temperature and beautiful color of the finished products, light weight (the bulk density is 0.8 to 1.0 g / m <3>) and good heat insulating property (the heat conductivity coefficient is 0.3 to 0.4 W / m question mark k), the cost of which is lowered by 30 percent, compared with the prior art.

Owner:吕则文

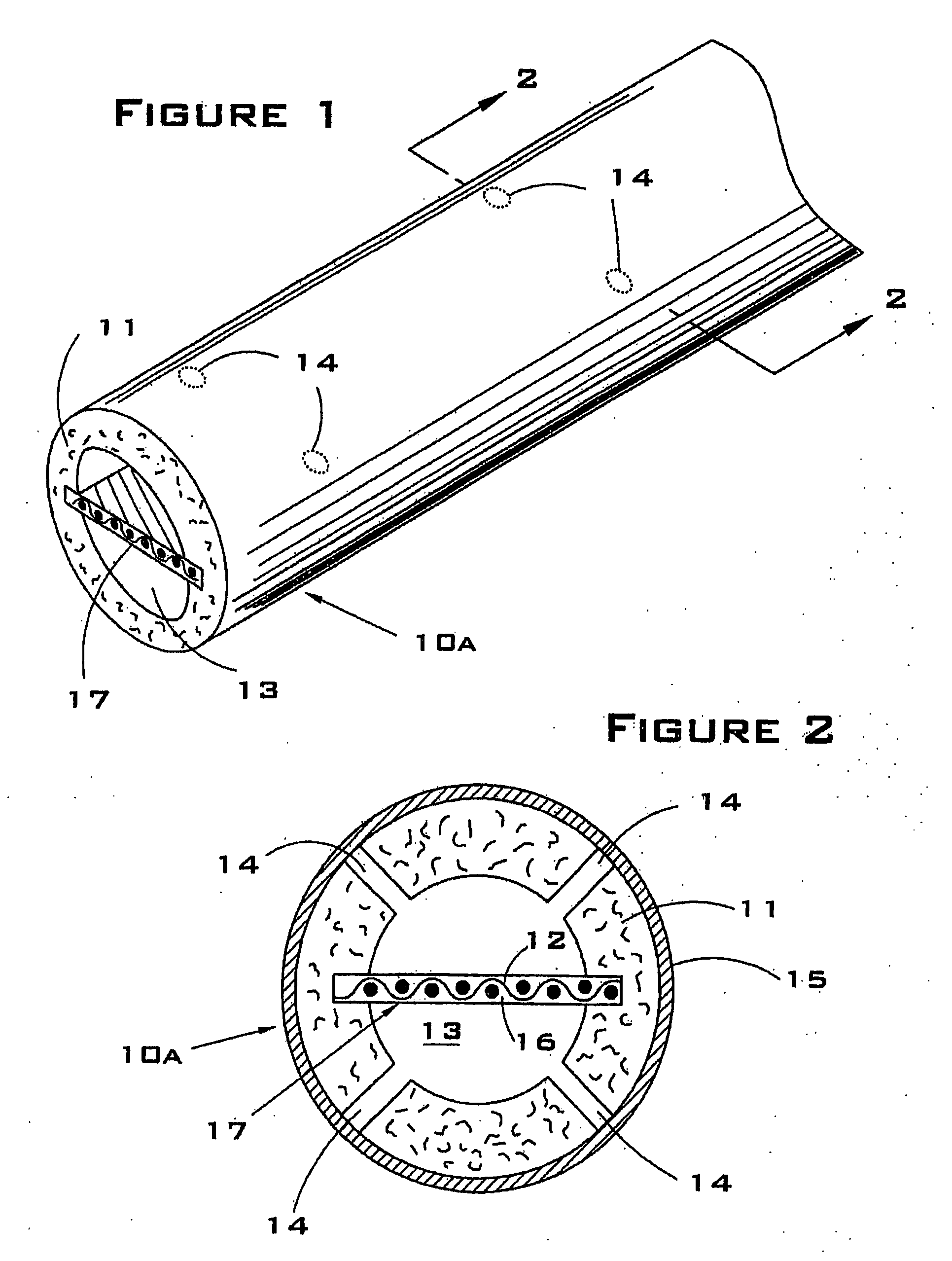

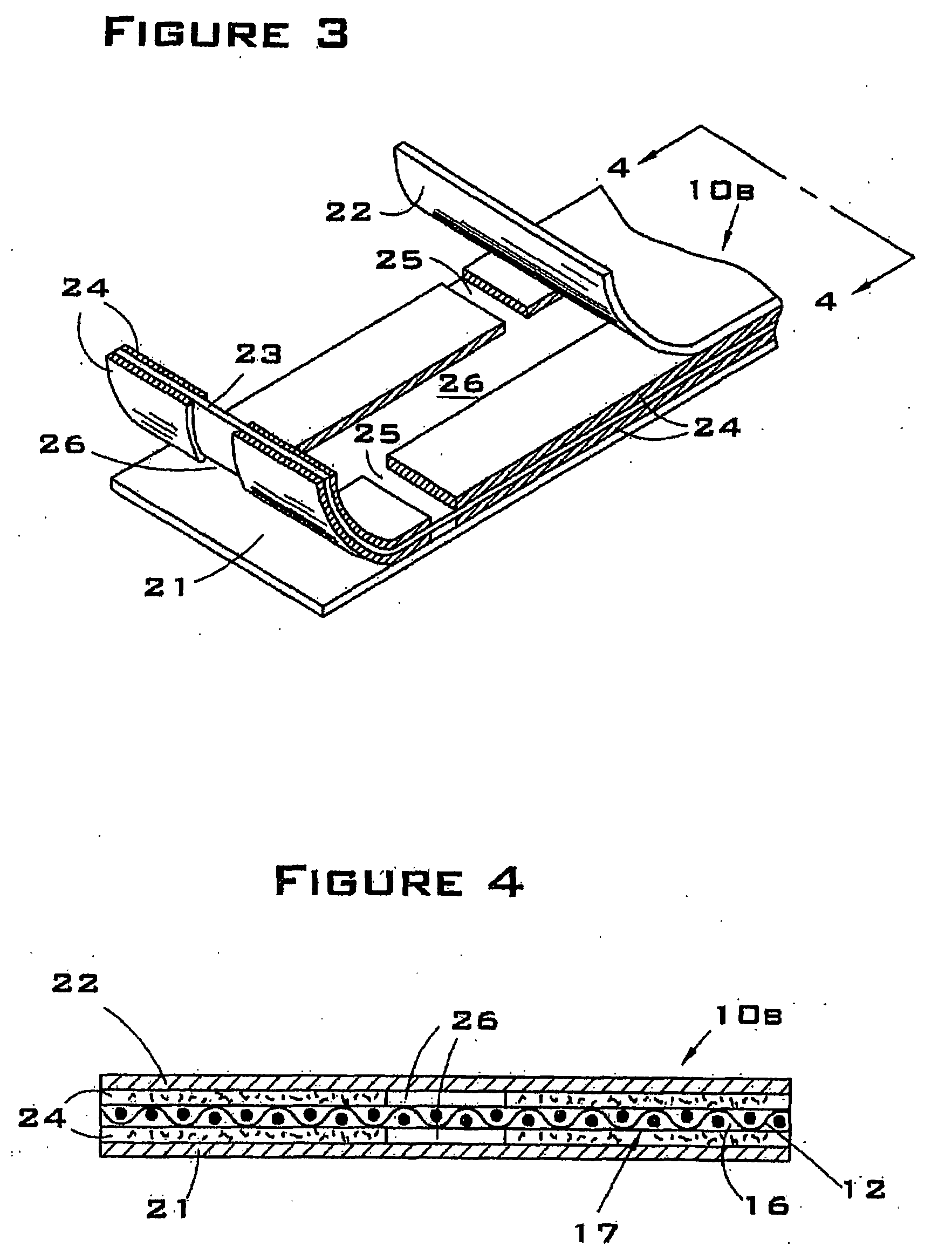

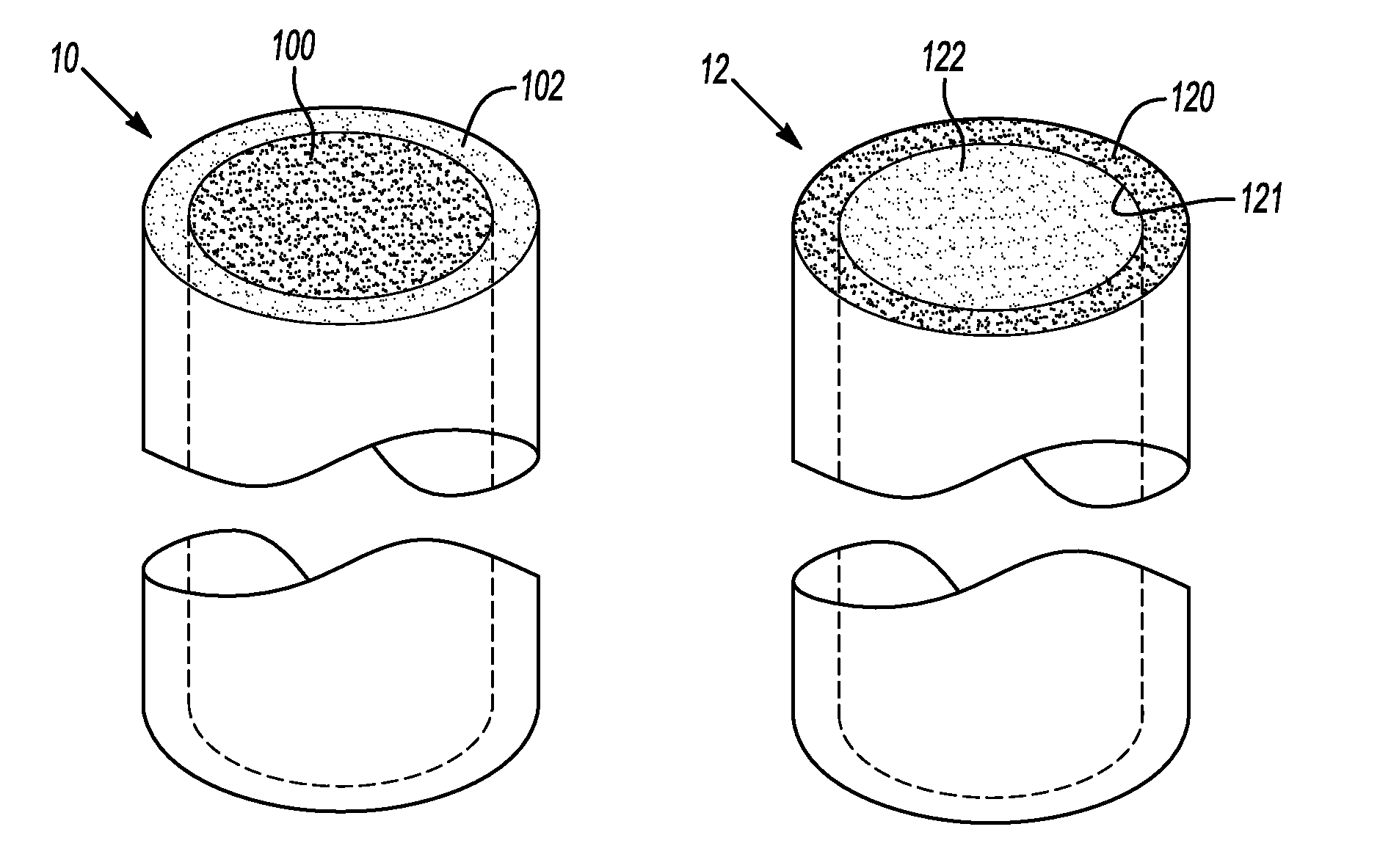

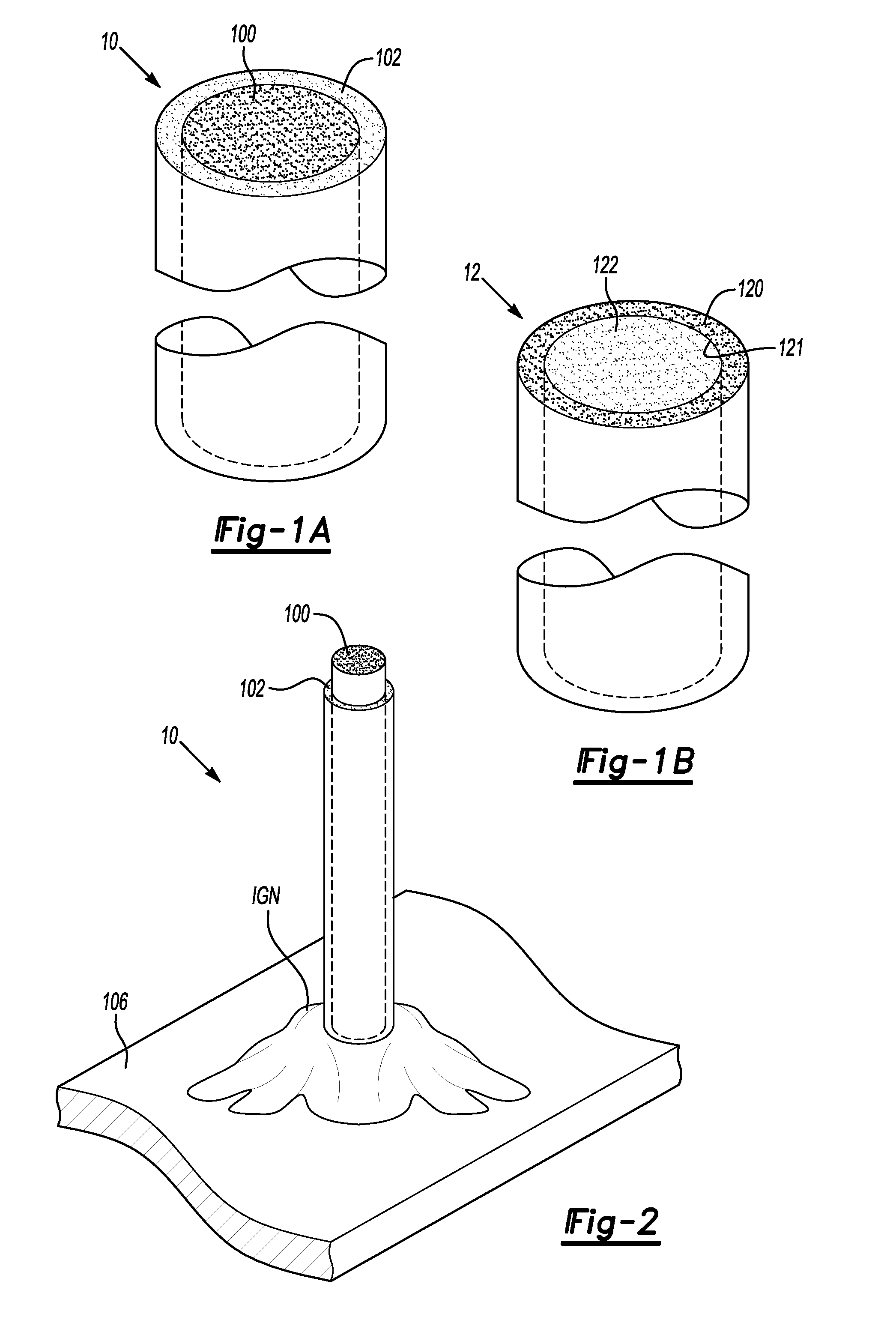

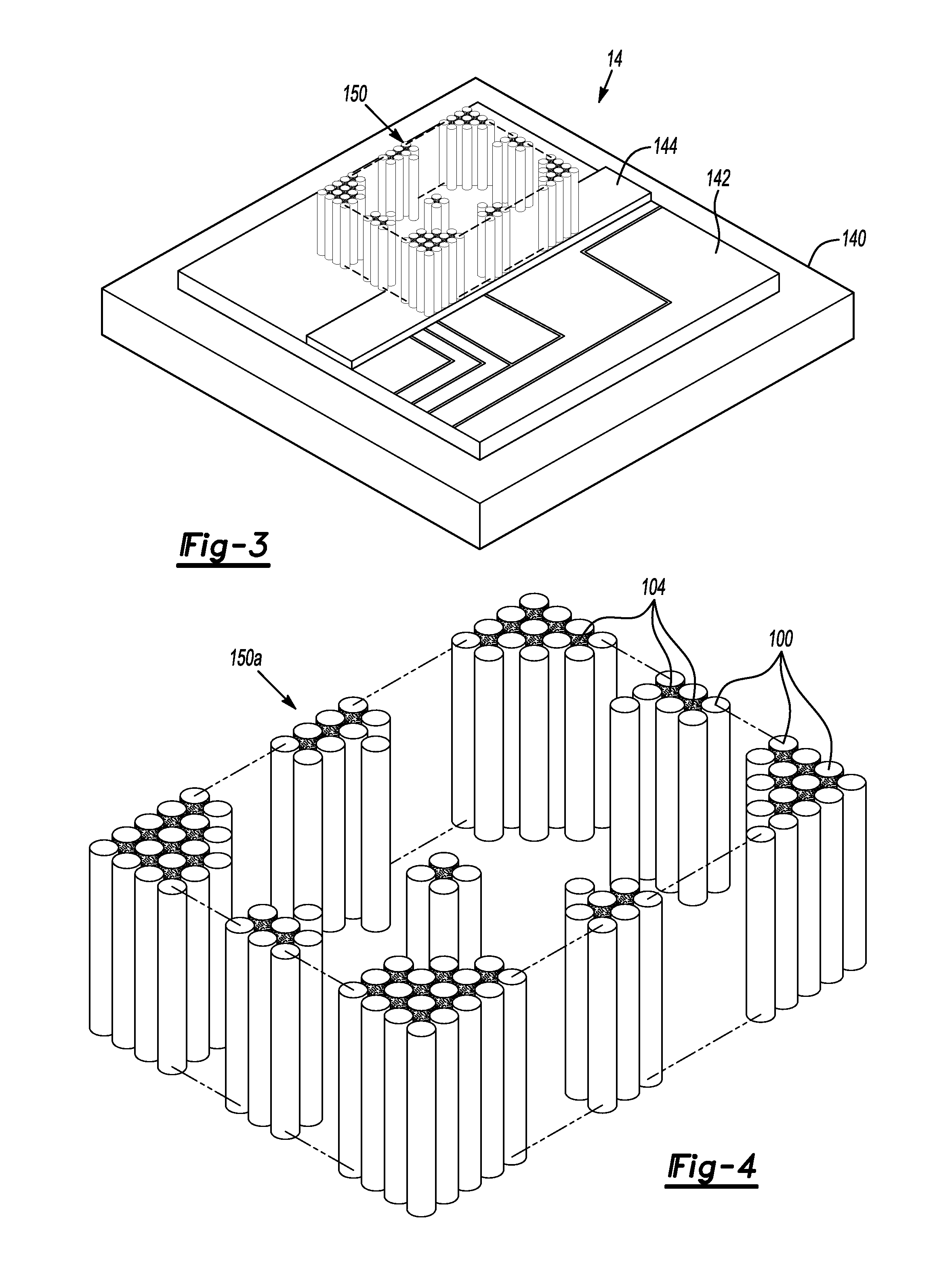

Linear incendiary strand and method for prescribed fire ignition

ActiveUS20090272288A1Easy to controlImproved to manipulate fire behaviorAmmunition projectilesFuse ignition meansBack burnsCombustion

An elongate, flexible, incendiary device for producing a nearly instantaneous source of flaming combustion along a linear pathway of indeterminate length. The incendiary device is provided in the form of a solid, continuous strand, such as, for example, a ribbon, tape, cord, filament, rope or tube. The device is comprised of means for rapid ignition along the longitudinal axis of the strand in co-linear arrangement with a solid or semi-solid combustible fuel composition. Upon ignition, the device produces flames from its exterior surface for a duration of time suitable for igniting nearby combustible matter. The incendiary device provides a nearly instantaneous line of fire for igniting prescribed fires, controlled burns, and backfires. A method for igniting vegetative matter over an area of land using one or more indeterminate lengths of a rapidly igniting linear incendiary strand.

Owner:ARCTOS RES

Gramineae plant detergent and its preparing process

InactiveCN1664089AEasy to useExcellent cleaning and decontamination functionDetergent compounding agentsBack burnsSurface-active agents

An agrostological washing agent and the preparing method. The washing agent is produced by the following steps: employing straw or wheat straw as stock, geting the straw ash by controlling burning, taking the extract from the straw ash with water as main component and adding findings and getting the product. The findings comprises enzyme agent, surface activator, thickening agent and common salt. For hand-washing dinner set the enzyme agent added for washing agent is alkaline lipase; for cloth the enzyme agent comprises alkaline lipase, alkaline prolease, alkaline cellulase; the surface activator is alkyl heteroside in general, the thickening agent is carboxymethyl cellulose and common salt in general. The method for making is: preparing extract firstly, modifying the pH value of the extract to be 8~9, adding enzyme agent, surface activator, thickening agent according to the formula proportion and getting the washing agent. The product is characterized by the unique formula, non-contamination, good washing effect, simple production device, short process, low investment and energy consumption and adaptable for washing dinner set and cloth.

Owner:陈志中

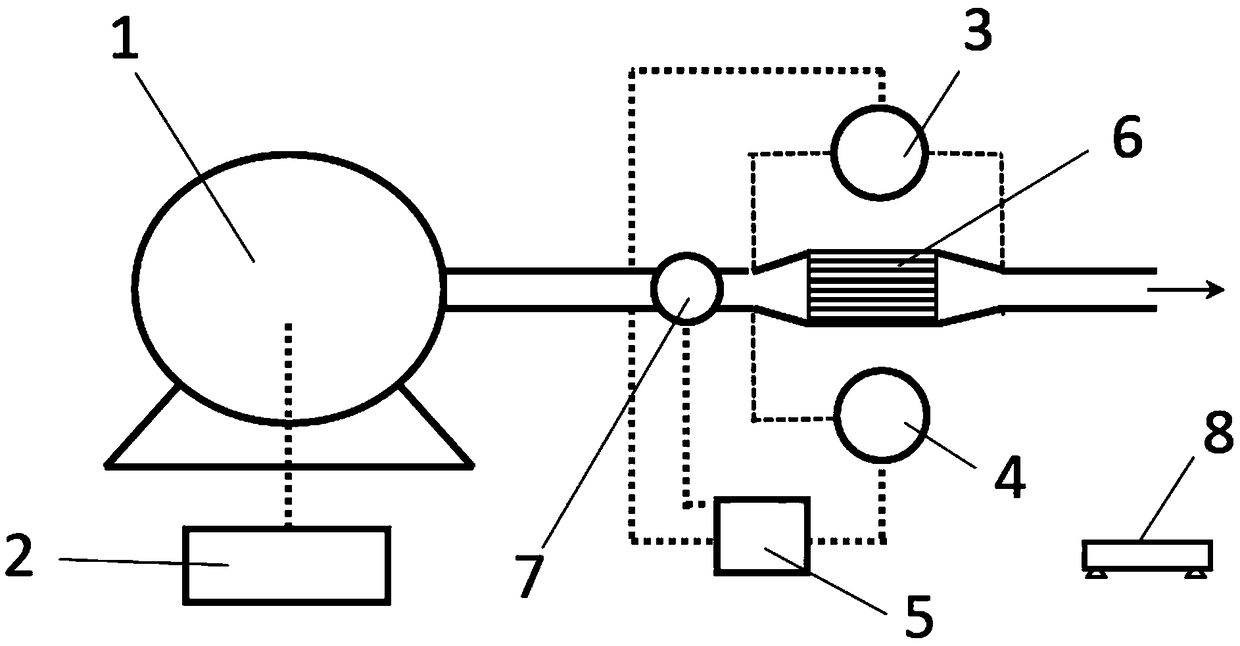

Fast ash accumulation device for gasoline engine particulate filter as well as application method thereof

The invention relates to a fast ash accumulation device for a gasoline engine particulate filter as well as an application method thereof. The fast ash accumulation device comprises a burner, a burnercontrol system, a differential pressure sensor, a temperature sensor, a data acquisition system, a gasoline engine particulate filter and a weighing system. The burner is connected with the gasolineengine particulate filter by virtue of a pipeline, the differential pressure sensor is arranged on the gasoline engine particulate filter, the temperature sensor is arranged at an air inlet end of thegasoline engine particulate filter, a flowmeter is arranged at the air inlet end of the gasoline engine particulate filter, the burner is connected with the burner control system, and the burner control system can control burning working condition of the burner. During test, burning of the burner is controlled, an ash component is dispersed in exhaust airflow of the burner, the ash in the exhaustairflow is filtered by the gasoline engine particulate filter when flowing through the gasoline engine particulate filter, and then an ash accumulation process is completed. The fast ash accumulationdevice provided by the invention is simple in method, steps are easy to operate, ash accumulation rate is high, and process controllability is strong.

Owner:WUXI WEIFU ENVIRONMENT PROTECTION CATALYST

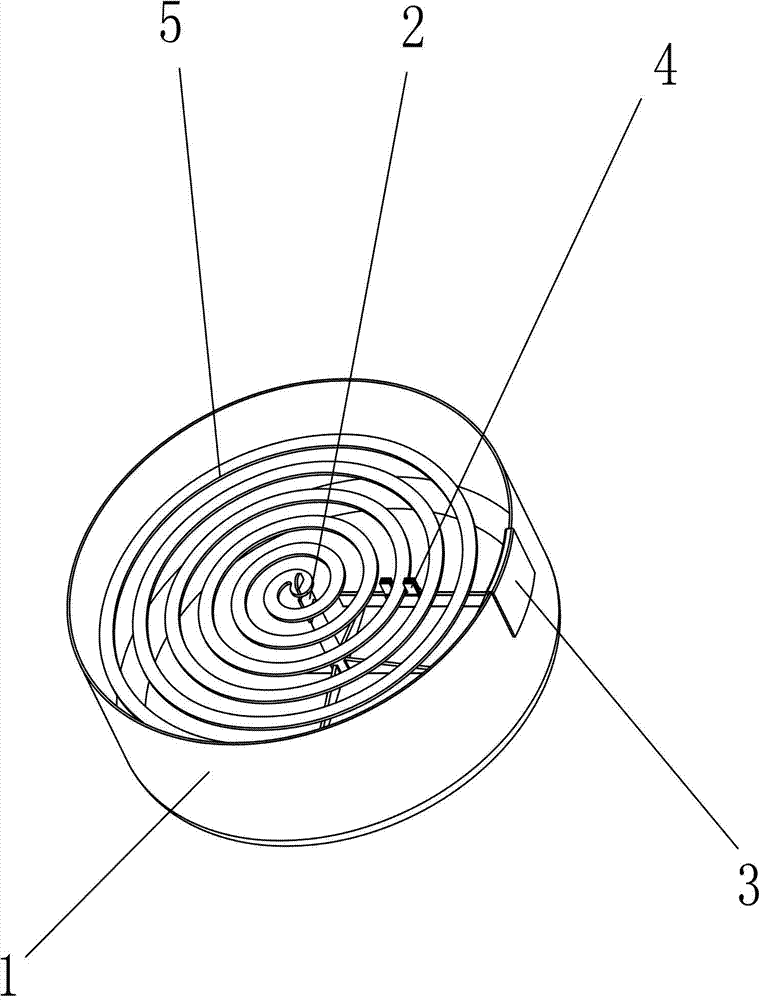

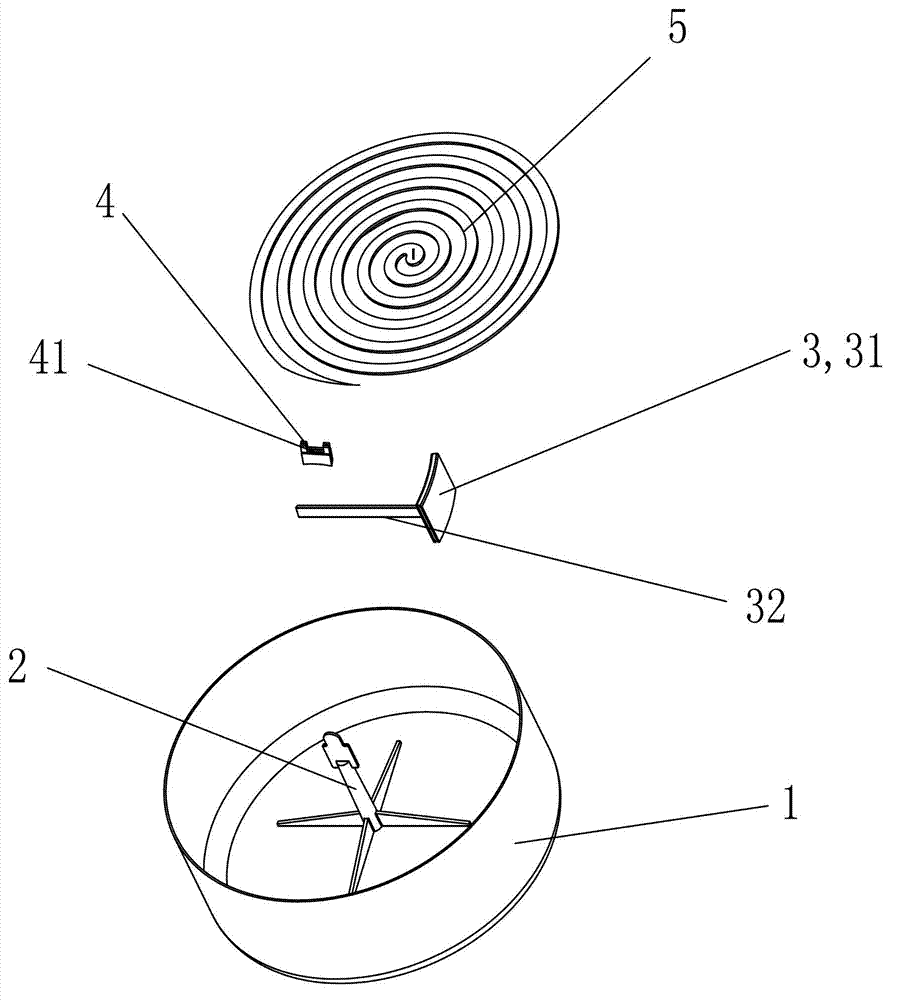

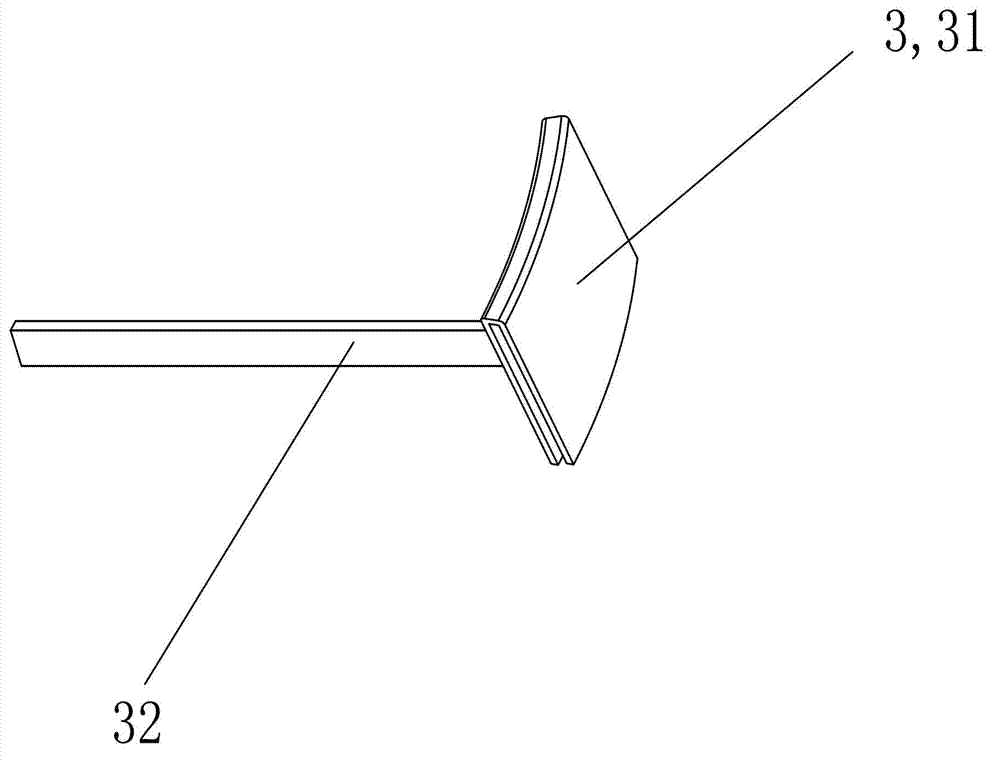

Device for controlling burning time of mosquito-repellent incense

Owner:ZHONGSHAN FLASHLIGHT POLYTECHNIC +1

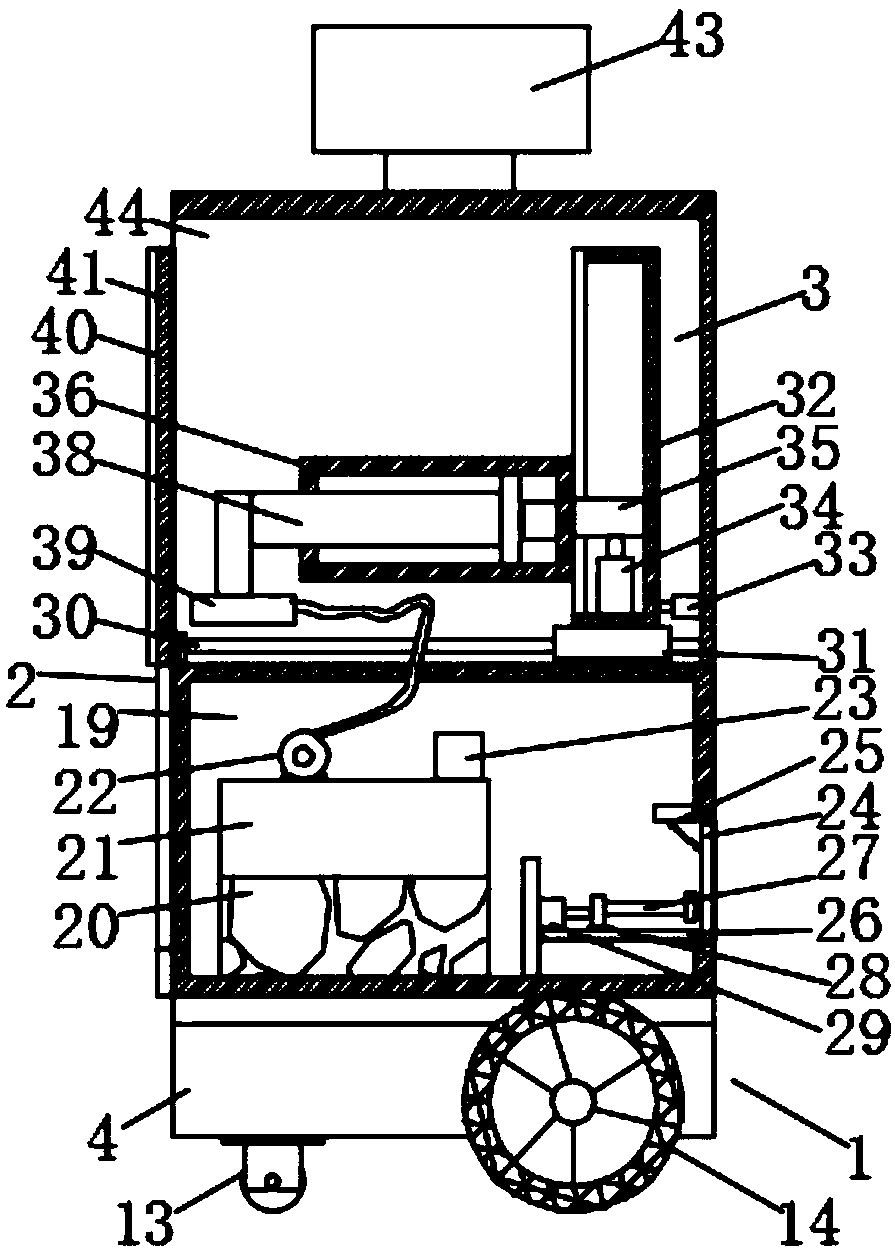

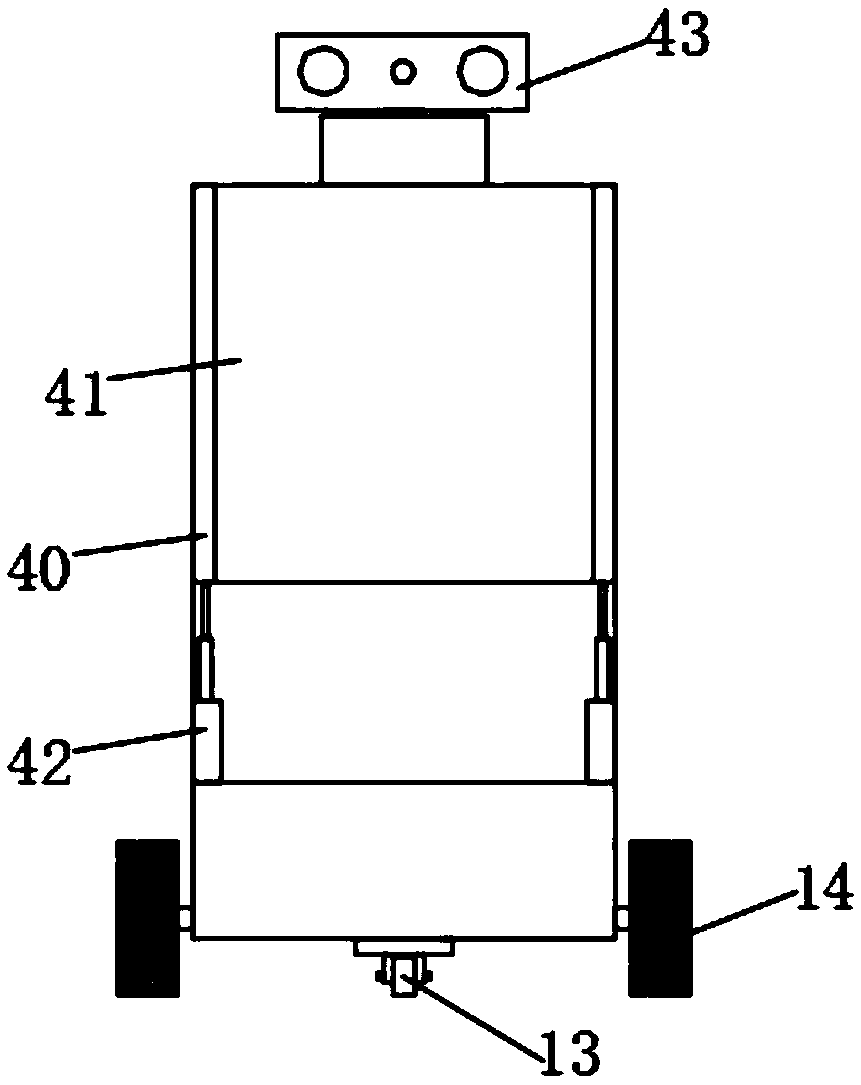

Intelligent robot that can return to charge

ActiveCN108972588AEasy to moveEasy to self-applyMedical atomisersManipulatorSteering wheelBack burns

Owner:付小芹

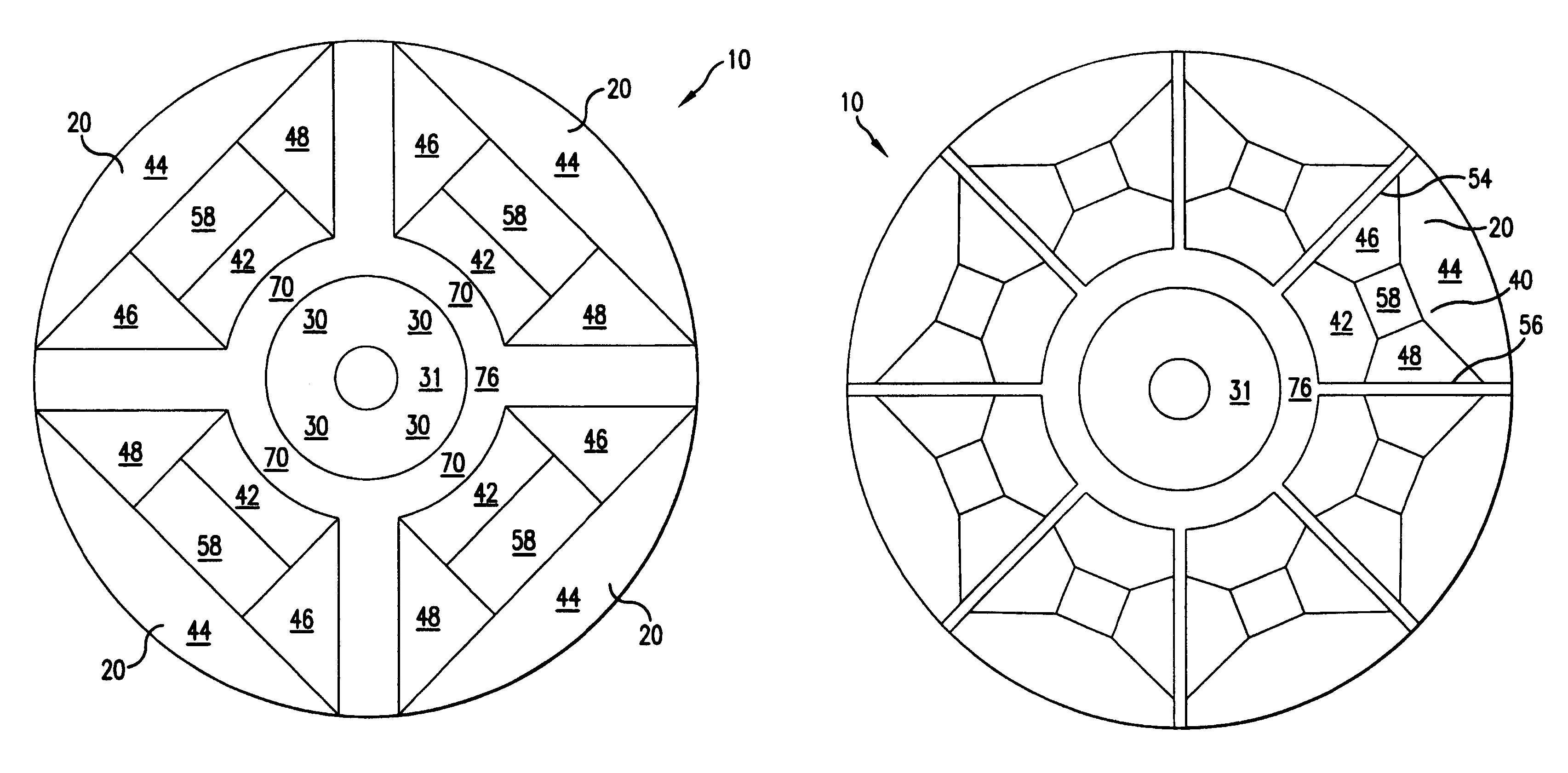

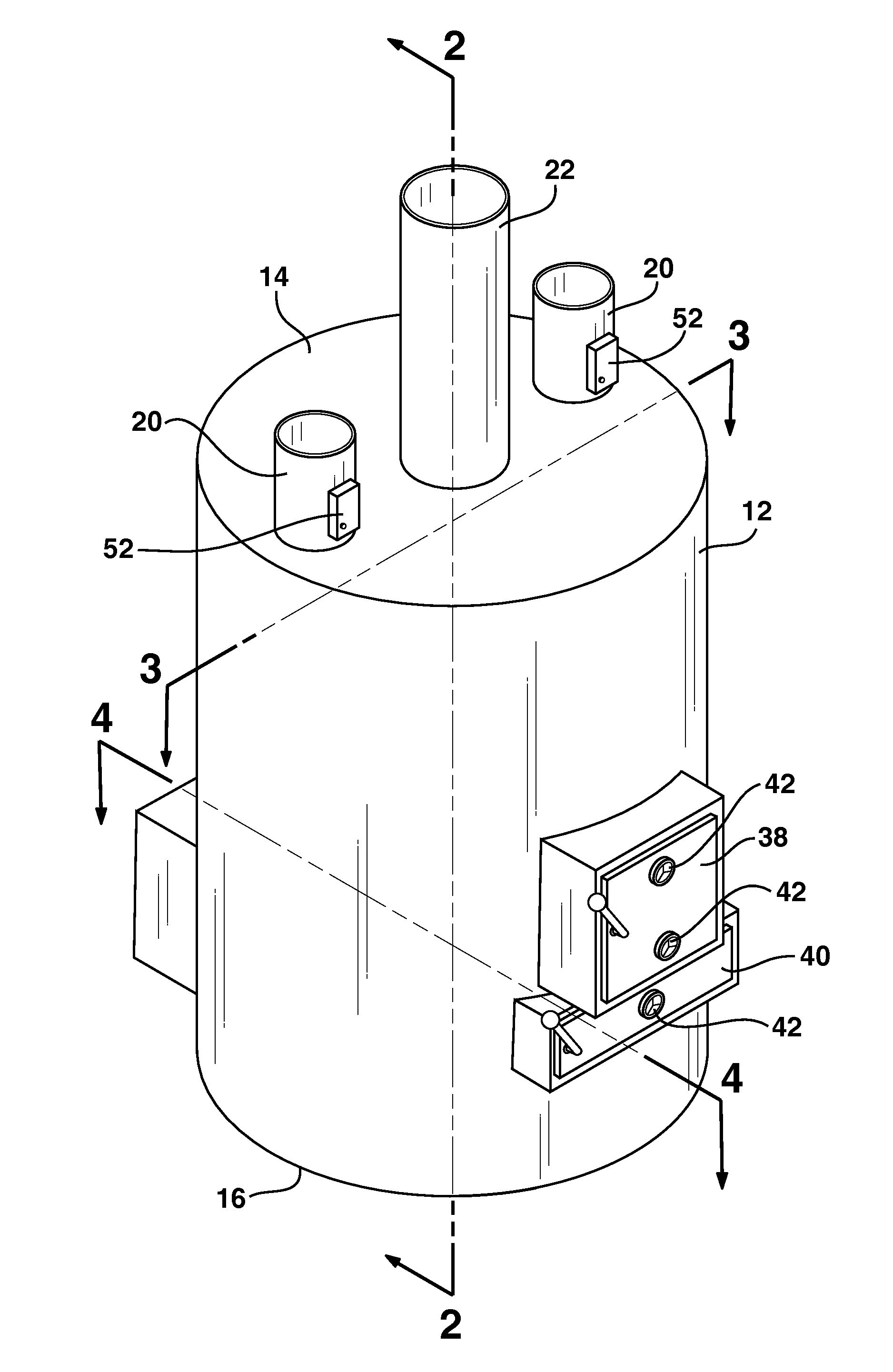

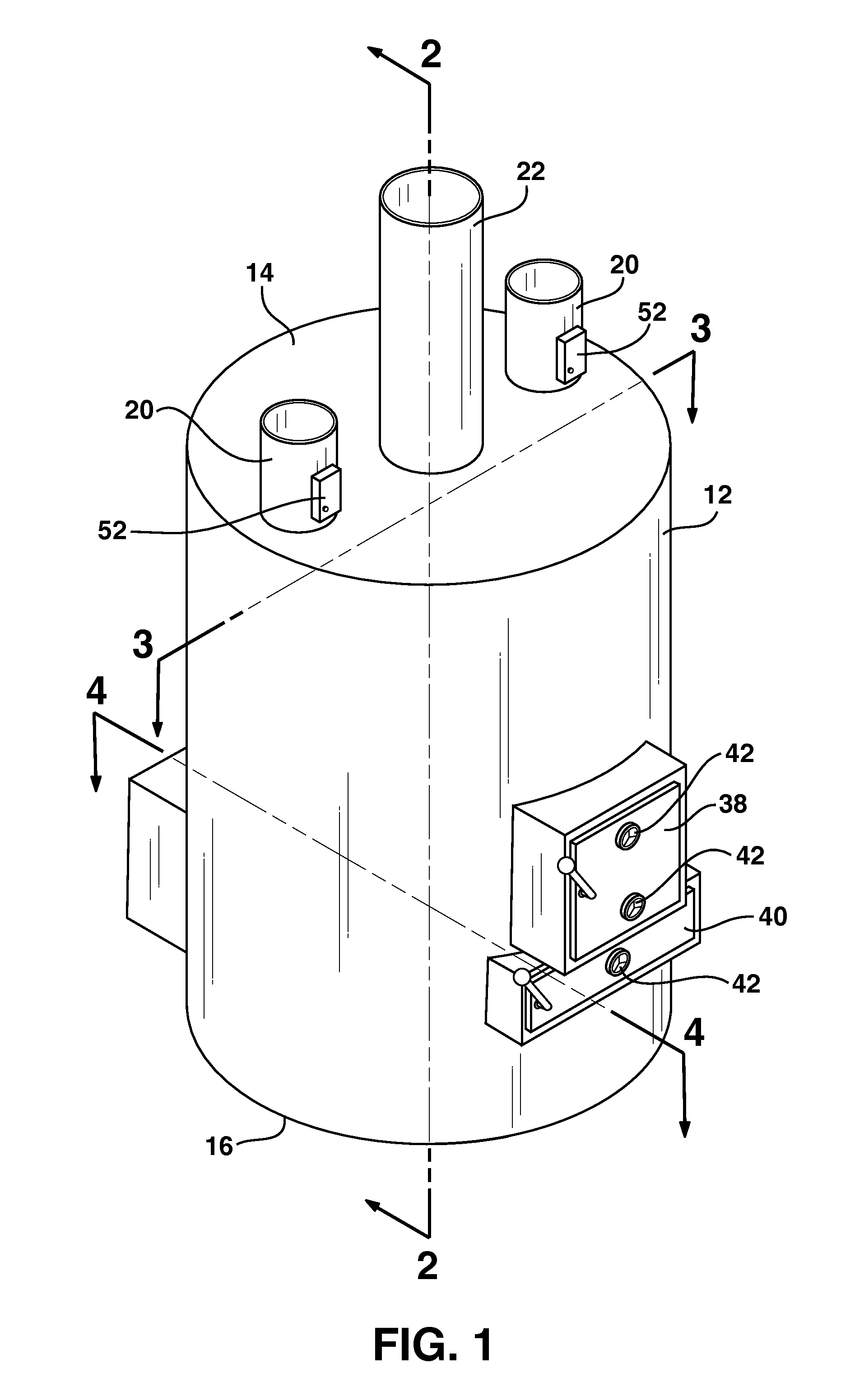

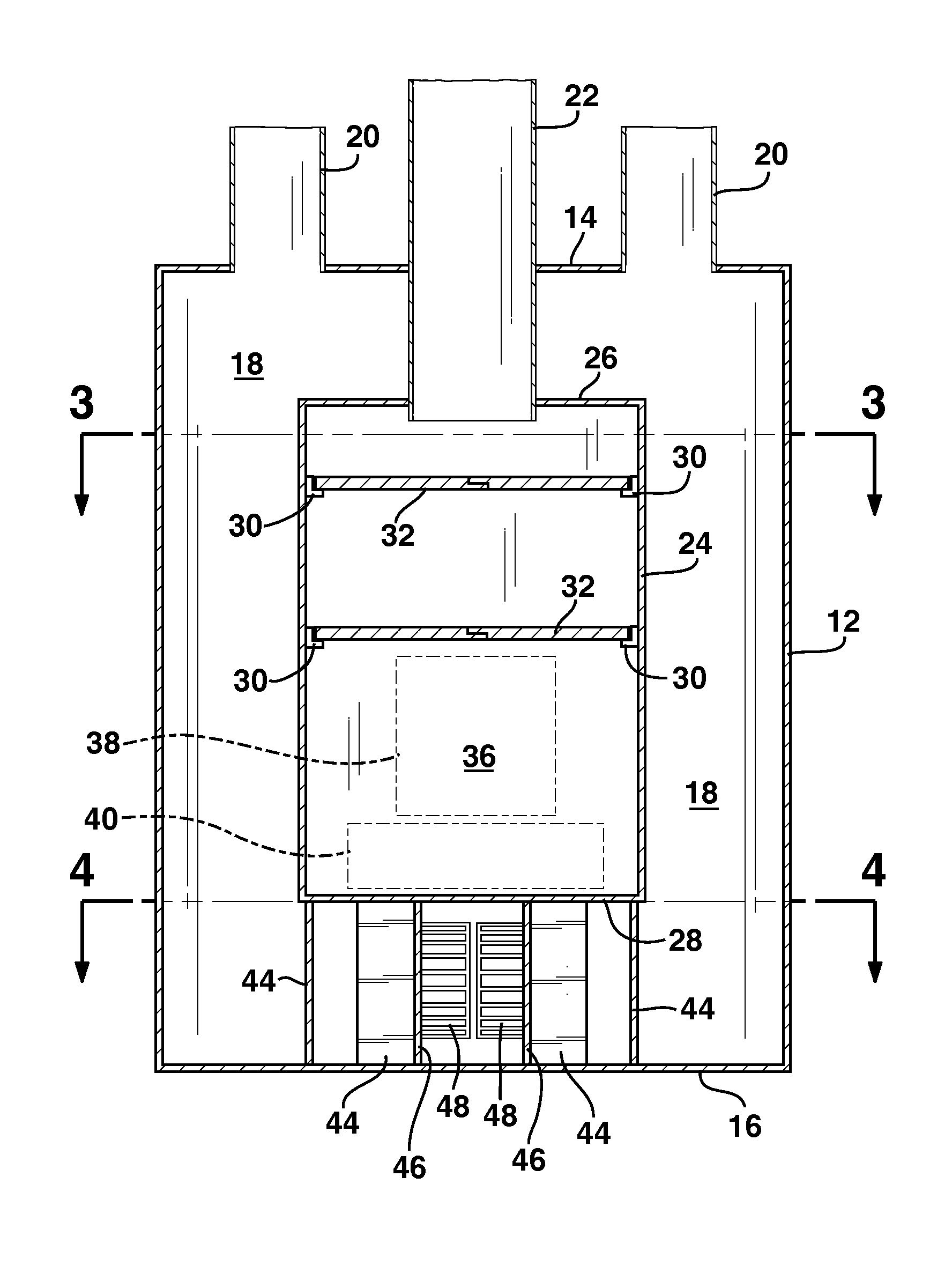

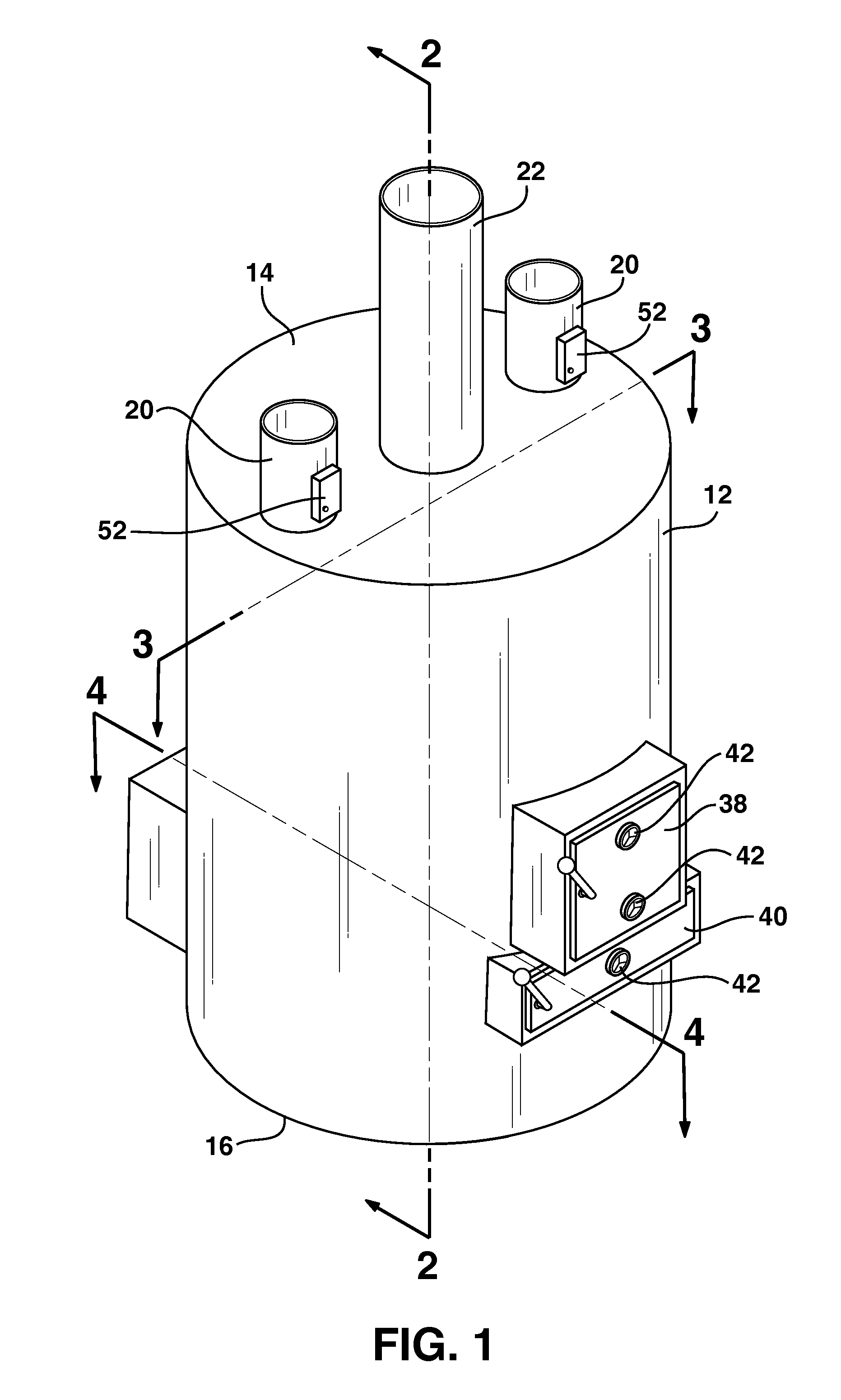

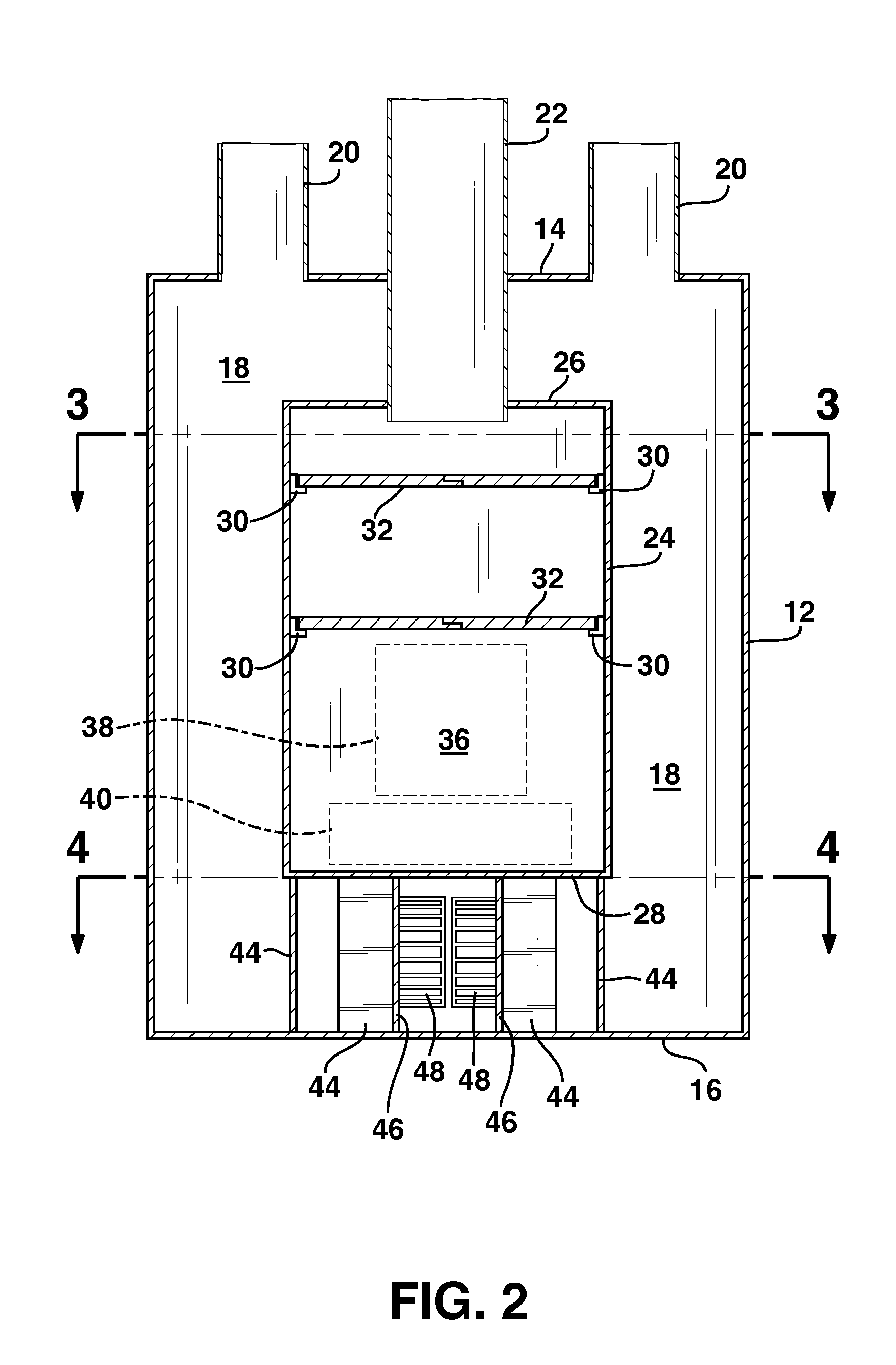

Efficient solid fuel burning appliance

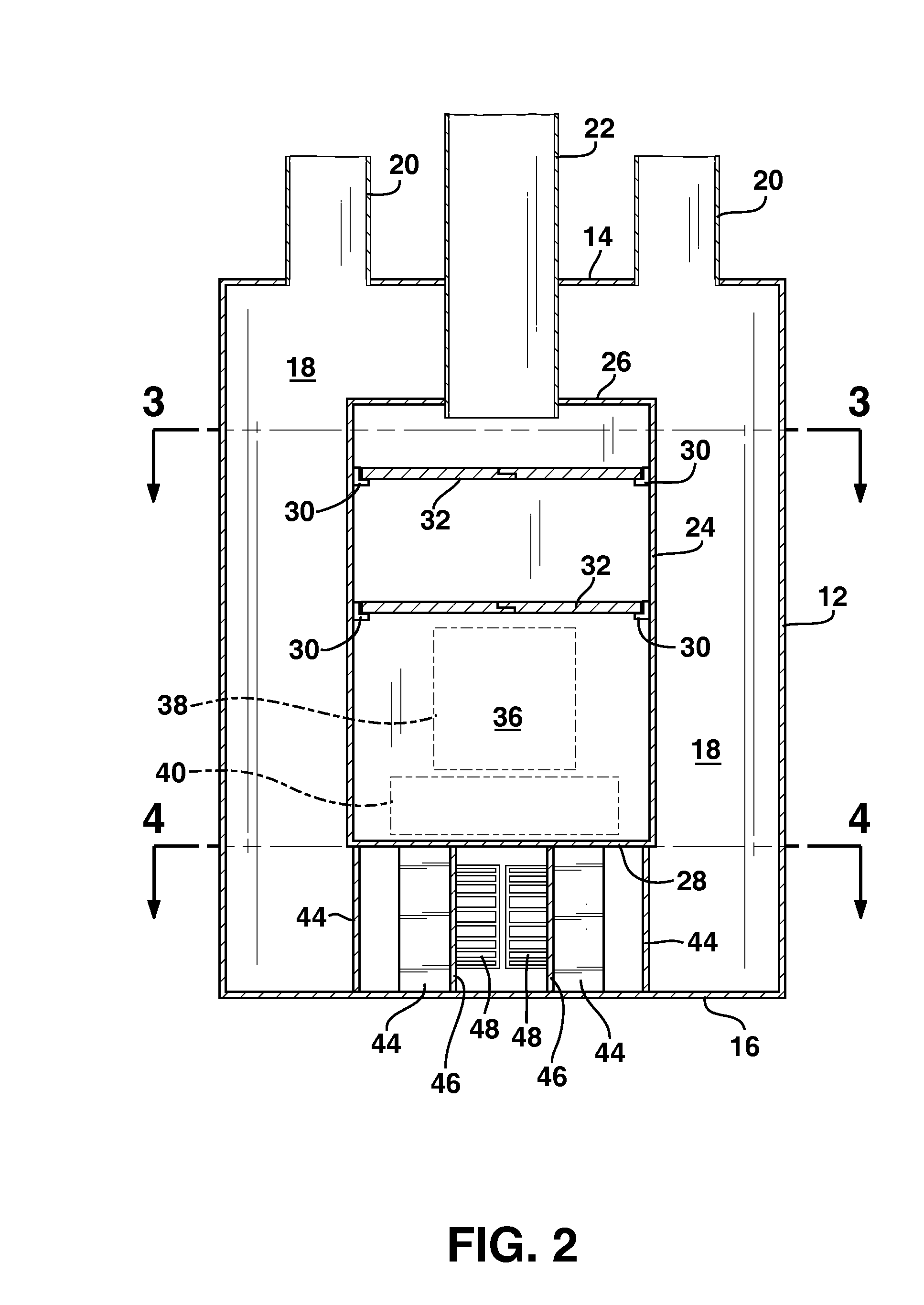

ActiveUS20100313798A1Efficient heat distributionCheap constructionGratesDamper arrangementBack burnsSolid fuel

A wood or other bio mass fueled appliance is disclosed for maximum efficiency and low cost construction for home, garage, workshop, and barn. Comprised of a vertical cylindrical outside shell (12) outside bottom (16) and outside top (14) enclosing an inside shell (24) inside bottom (28) and inside top (26). Inside shell (24) forming a vertical cylindrical chamber (36) accessed by load door (38) and ash door (40), through which disassembled baffles (32) may pass. A suitable means for igniting fuel in chamber (36) and controlling burn rate by draft regulators (42) and fan limit switches (52). Whereby circular baffles (32) elevated by 90° angle shaped supports (30) suppress the flow of flame and exhaust gases from entering flue (22). Exhaust gases and flame pass by gap (50), directing energy toward the inside surface of inside shell (24) inside bottom (28) and inside top (26). Thus maximizing the efficiency of heat transferred from chamber (36) to the air or fluid in space (18) circulated through ducts (20) by blowers / pumps (48) and directed by air deflectors (46) producing economizing results.

Owner:MURRAY ANDREW

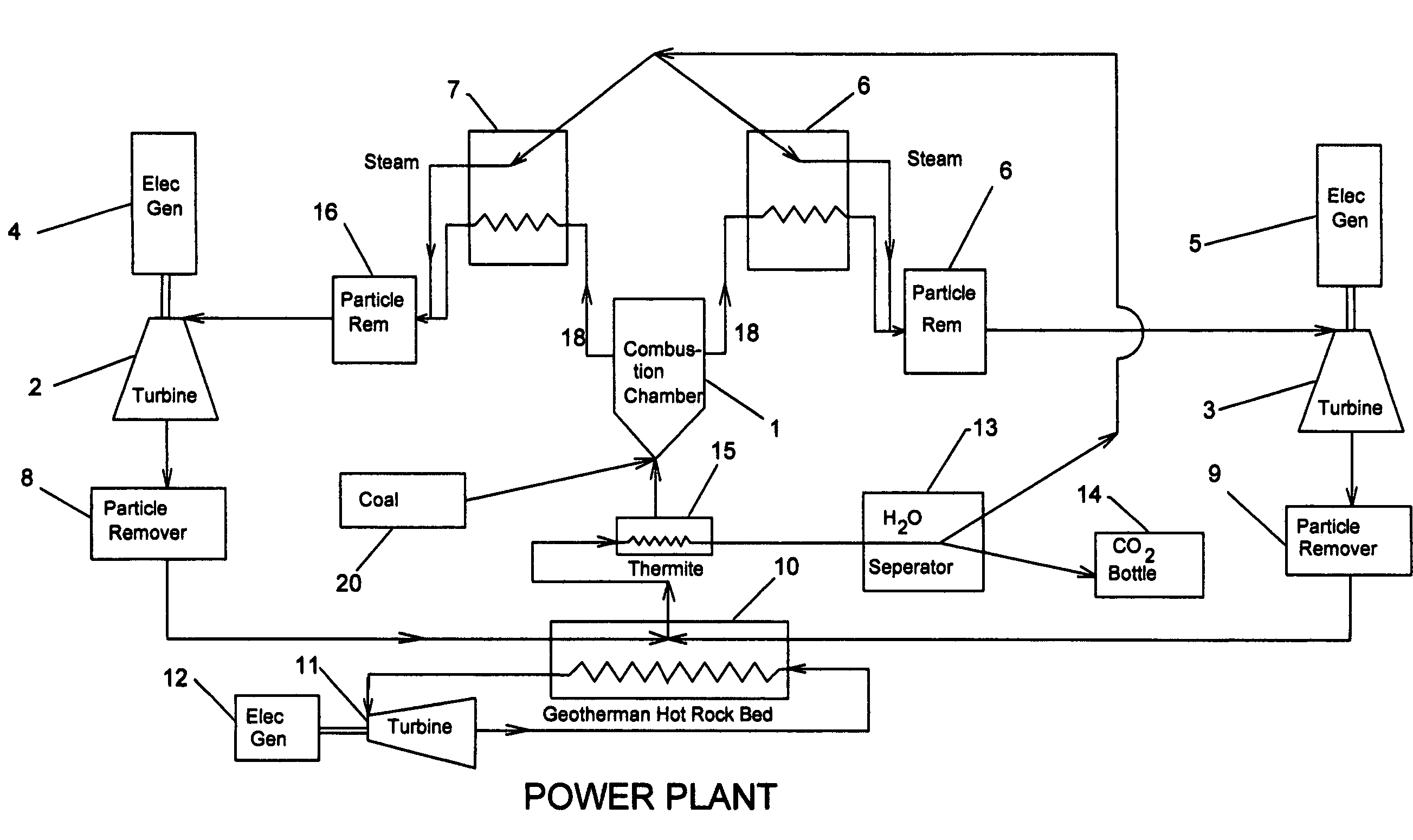

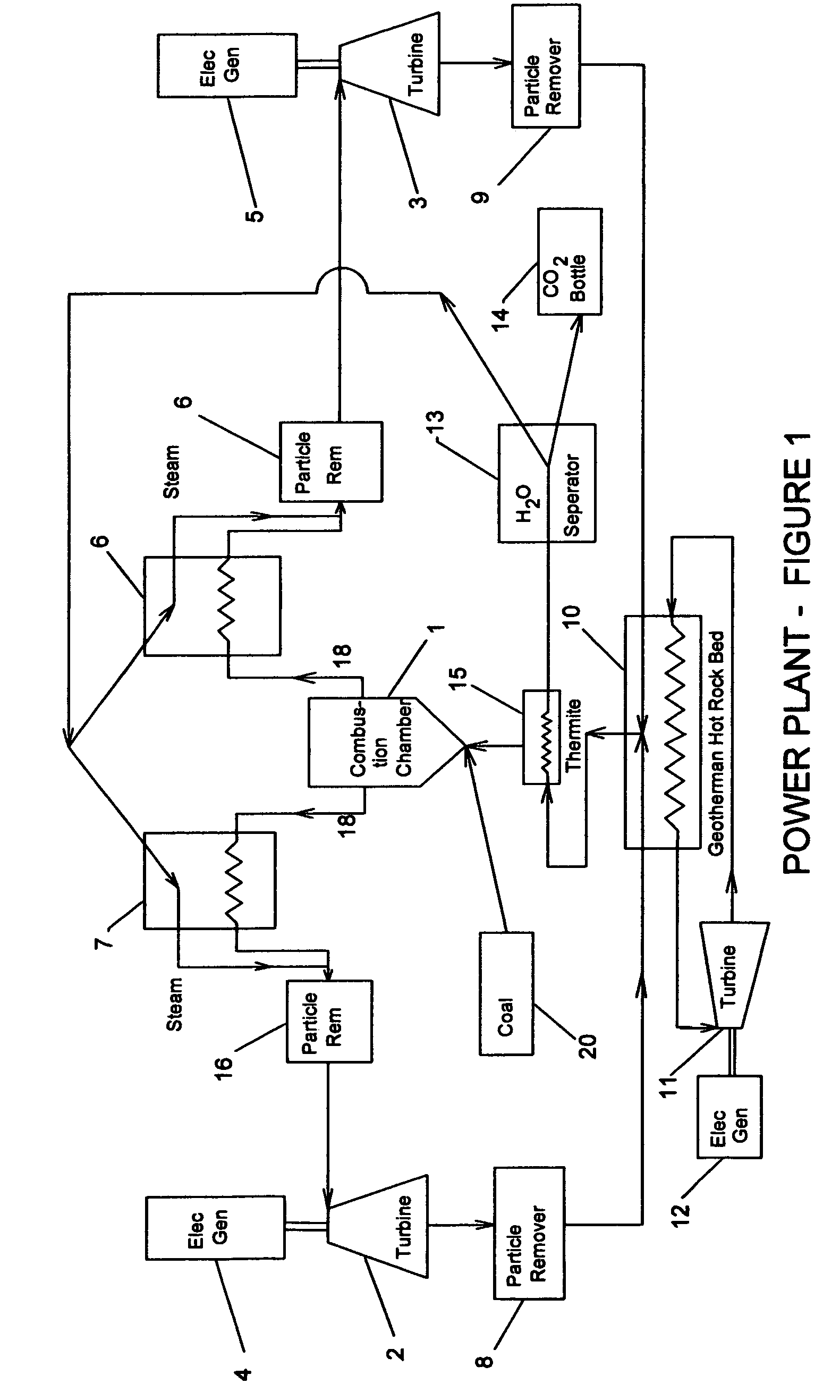

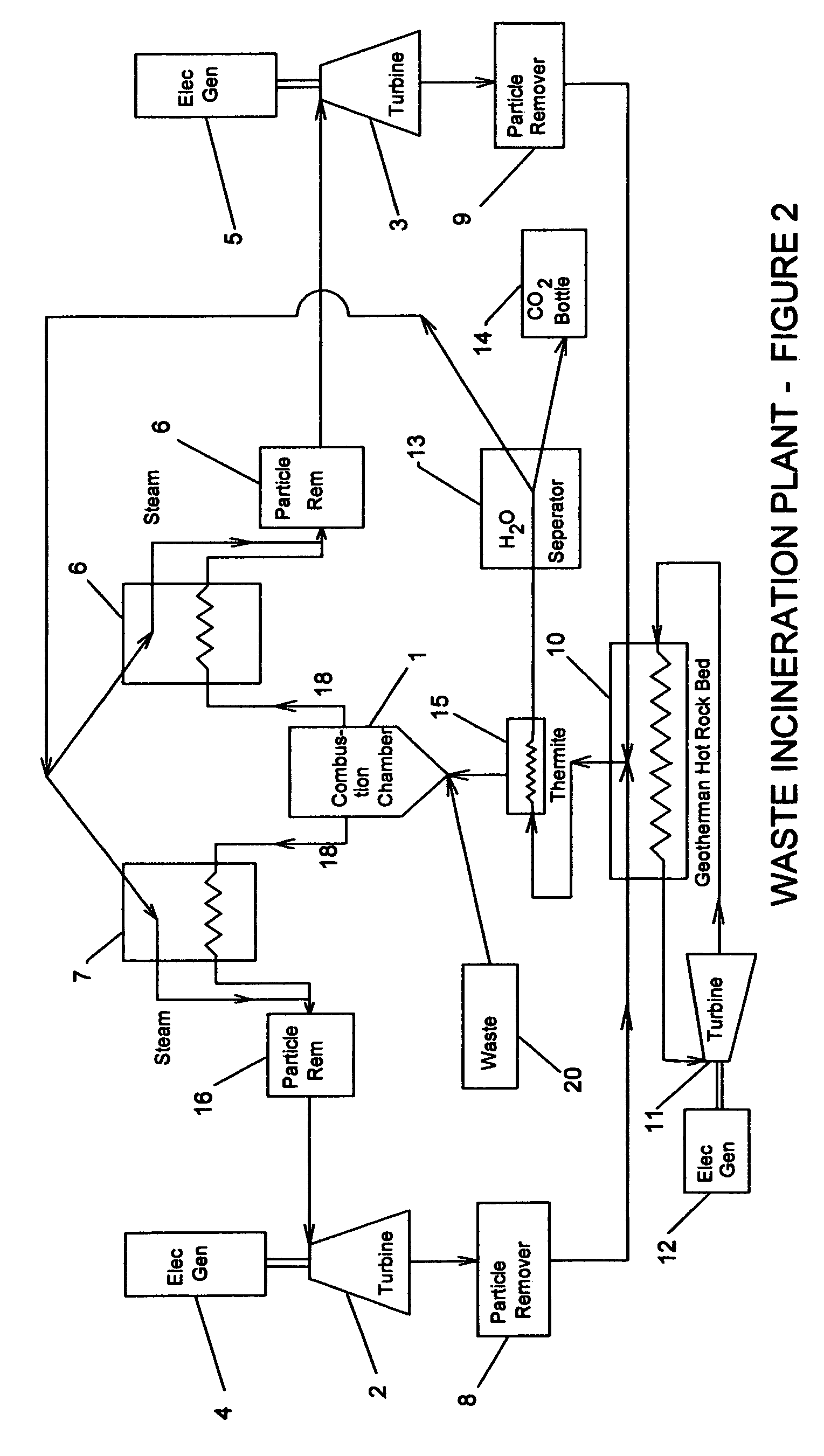

Non-polluting high temperature combustion system

Disclosed is a non-polluting high temperature combustion system which comprises in combination a graphite-lined combustion chamber fueled by a controlled-burn thermite fuel, wherein the fuel burns a temperature of up to 6000 degrees Fahrenheit, wherein the resulting gases are essentially pollution free; the system also include a means of passing a substrate into and out of the combustion chamber and / or a turbine powered by gases from the combustion products, means of injecting a working fluid into the combustion gases upstream of the turbine, a heat recovery means that comprises a geo-thermal hot rock bed, a steam generator utilizing heat from the geo-thermal hot rock bed, a working fluid separation means which comprises a condenser, and means of liquefying the remaining gases for commercial use.

Owner:CARTER JR GREG +1

Intelligent humidity control burn and scald treatment system

ActiveCN105999440AImprove pathophysiological stateExcessive wound exudatePlastersMedical devicesBack burnsControl system

The invention discloses an intelligent humidity control burn and scald treatment system, which comprises an intelligent humidity control host computer, a vacuum pump, a temperature sensor of the intelligent humidity control host computer, a liquid storage bottle, a suction catheter, a drainage dressing layer and a medical membrane, wherein the other end of the suction catheter is communicated with a three-dimensional intercommunication structure of the drainage dressing layer; the humidity sensor is arranged in the drainage dressing layer. A drainage material liquid suction cavity is formed below the medical membrane after an attachment fin is attached to the surface of skin on the outer side of the edge of a burned part of a patient, humidity in the liquid suction cavity is sensed by the humidity sensor, a signal is fed back to a chip humidity control system in the intelligent humidity control host computer, and after the humidity concentration in the liquid suction cavity exceeds a preset value, the vacuum pump works to provide suction powder to suck away liquid in the liquid suction cavity to keep the humidity in the liquid suction cavity at the stable level of 80 to 90 percent by virtue of the liquid storage bottle, the suction catheter, the drainage dressing layer and suckers.

Owner:GUANGDONG MEIJI BIOTECH

Efficient solid fuel burning appliance

ActiveUS9182116B2Effective distributionCheap constructionGratesDamper arrangementBack burnsBurn rate

Owner:MURRAY ANDREW

Non-polluting high temperature combustion system

InactiveUS20050098073A1Efficient disposalSolid fuel combustionExplosivesCombustion chamberBack burns

Disclosed is a non-polluting high temperature combustion system which comprises in combination a graphite-lined combustion chamber fueled by a controlled-burn thermite fuel, wherein the fuel burns a temperature of up to 6000 degrees Fahrenheit, wherein the resulting gases are essentially pollution free; the system also include a means of passing a substrate into and out of the combustion chamber and / or a turbine powered by gases from the combustion products, means of injecting a working fluid into the combustion gases upstream of the turbine, a heat recovery means that comprises a geo-thermal hot rock bed, a steam generator utilizing heat from the geo-thermal hot rock bed, a working fluid separation means which comprises a condenser, and means of liquefying the remaining gases for commercial use.

Owner:CARTER JR GREG +1

Silicon alloy, alloy powder thereof, manufacturing apparatus, manufacturing process and sintered alloy thereof

A controlled combustion synthesis apparatus comprises an ignition system, a pressure sensor for detecting internal pressure, a nitrogen supply, a gas pressure control valve for feeding nitrogen and exhausting reaction gas, means for detecting the internal temperature of the reaction container, a water cooled jacket, and a cooling plate. A temperature control system controls the temperature of the reaction container by controlling the flow of cooling water supplied to the jacket and the cooling plate in response to the detected temperature. By combustion synthesizing, while controlling the internal pressure and temperature, the apparatus can synthesize a silicon alloy including 30-70 wt. % silicon, 10-45 wt. % nitrogen, 1-40 wt. % aluminum, and 1-40 wt % oxygen.

Owner:NIPPON STEEL & SUMIKIN BUSSAN CORP

Carbon nanotube explosives

Owner:ARMY US SEC THE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com