Air-fuel ratio control system of combustion heating furnace

An air-fuel ratio and control system technology, which is applied in the combustion method, combustion control, and fuel supply adjustment, etc., can solve the problems of less usage, uneven temperature distribution, and uneven firing quality, and achieves the goal of preventing unevenness. Qi effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

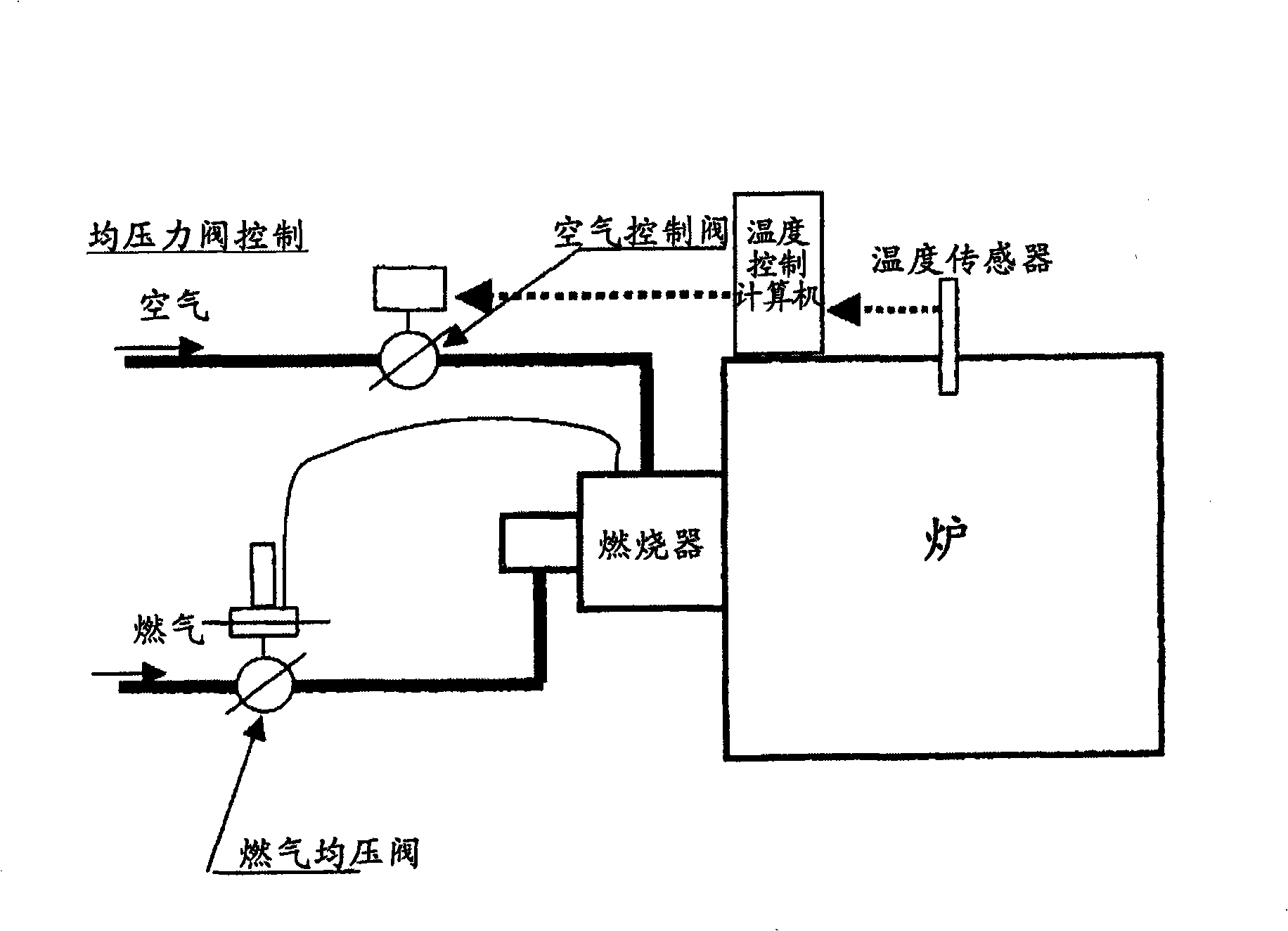

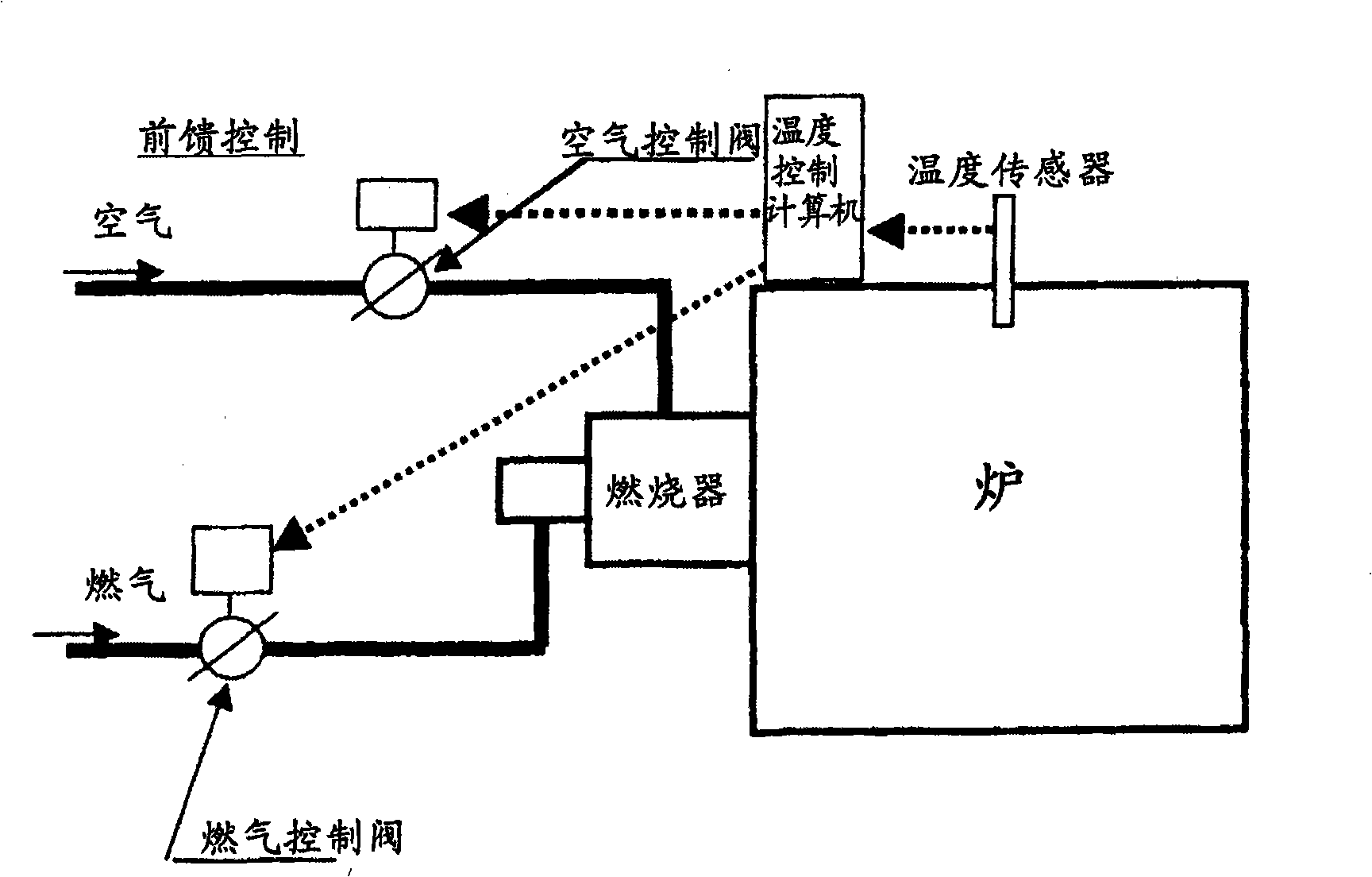

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will be described below.

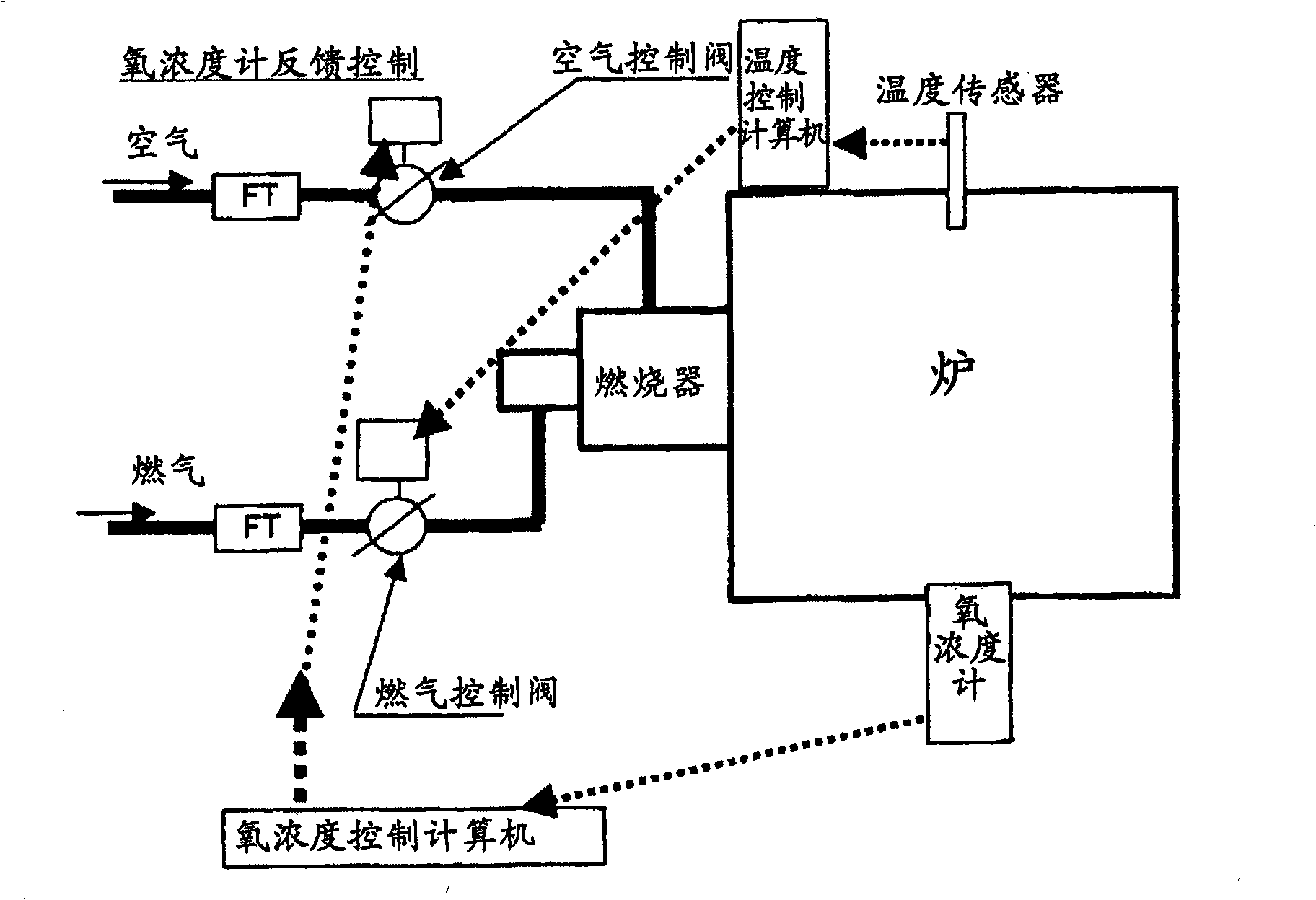

[0034] exist Figure 4 Among them, 1 is a furnace body of a combustion heating furnace used for heating and firing of various kiln products and ceramic products, and 2 is a burner installed in the furnace body 1 . In this figure, only one burner 2 is illustrated for explanation, but it goes without saying that a plurality of burners 2 are actually installed. Burner 2 is a gas burner, 3 is a gas supply pipe, and 4 is an air supply pipe. The furnace body 1 of this embodiment is a batch furnace, preferably a shuttle kiln.

[0035] A gas flow meter 5 and a gas flow control valve 6 are provided in the gas supply pipe 3 , and an air flow meter 7 and an air flow control valve 8 are provided in the air supply pipe 4 . In addition, a temperature sensor 9 is installed in the furnace body 1 .

[0036] 10 is a computer for temperature control. This temperature control computer 10 has a temperature control function...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com