Fast ash accumulation device for gasoline engine particulate filter as well as application method thereof

A particle trap and accumulation device technology, applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problems of high equipment damage rate and long time consumption, reduce damage, shorten test time, Improvement of controllability and effect of ash accumulation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific drawings.

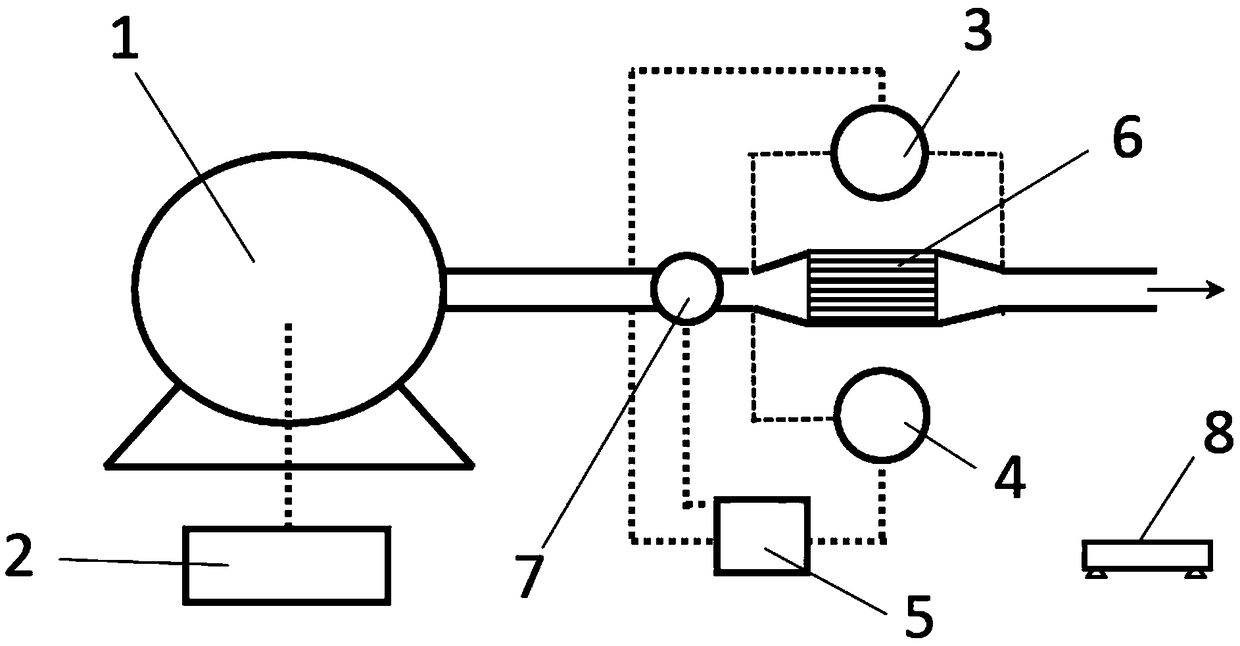

[0027] Such as figure 1 Shown: A fast ash accumulation device for a gasoline engine particulate filter, including a burner, a burner control system, a differential pressure sensor, a temperature sensor, a data acquisition system, a gasoline engine particulate filter, a flow meter and a weighing system, and a burner A gasoline engine particulate filter is connected through a pipeline, a differential pressure sensor is arranged on the gasoline engine particulate filter, a temperature sensor is installed at the intake end of the gasoline engine particulate filter, and a flow meter is arranged at the intake end of the gasoline engine particulate filter. The burner is connected with a burner control system, the burner control system can control the combustion conditions of the burner, the weighing system is used to measure the weight change of the gasoline engine particle filter, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com