Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2491 results about "Baghouse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A baghouse,also known as a baghouse filter, bag filter, or fabric filter is an air pollution control device and dust collector that removes particulates or gas released from commercial processes out of the air. Power plants, steel mills, pharmaceutical producers, food manufacturers, chemical producers and other industrial companies often use baghouses to control emission of air pollutants. Baghouses came into widespread use in the late 1970s after the invention of high-temperature fabrics (for use in the filter media) capable of withstanding temperatures over 350 °F (177 °C).

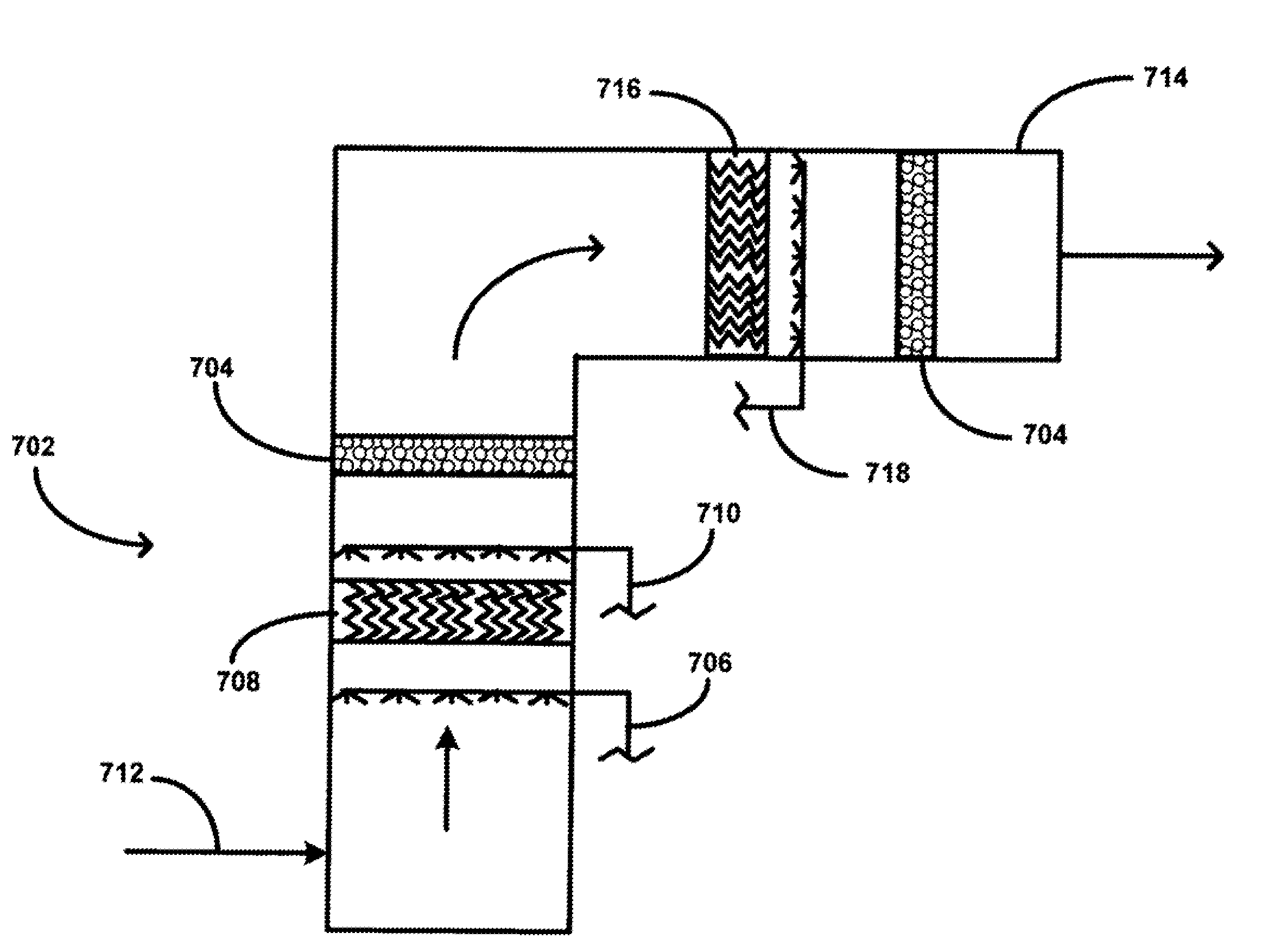

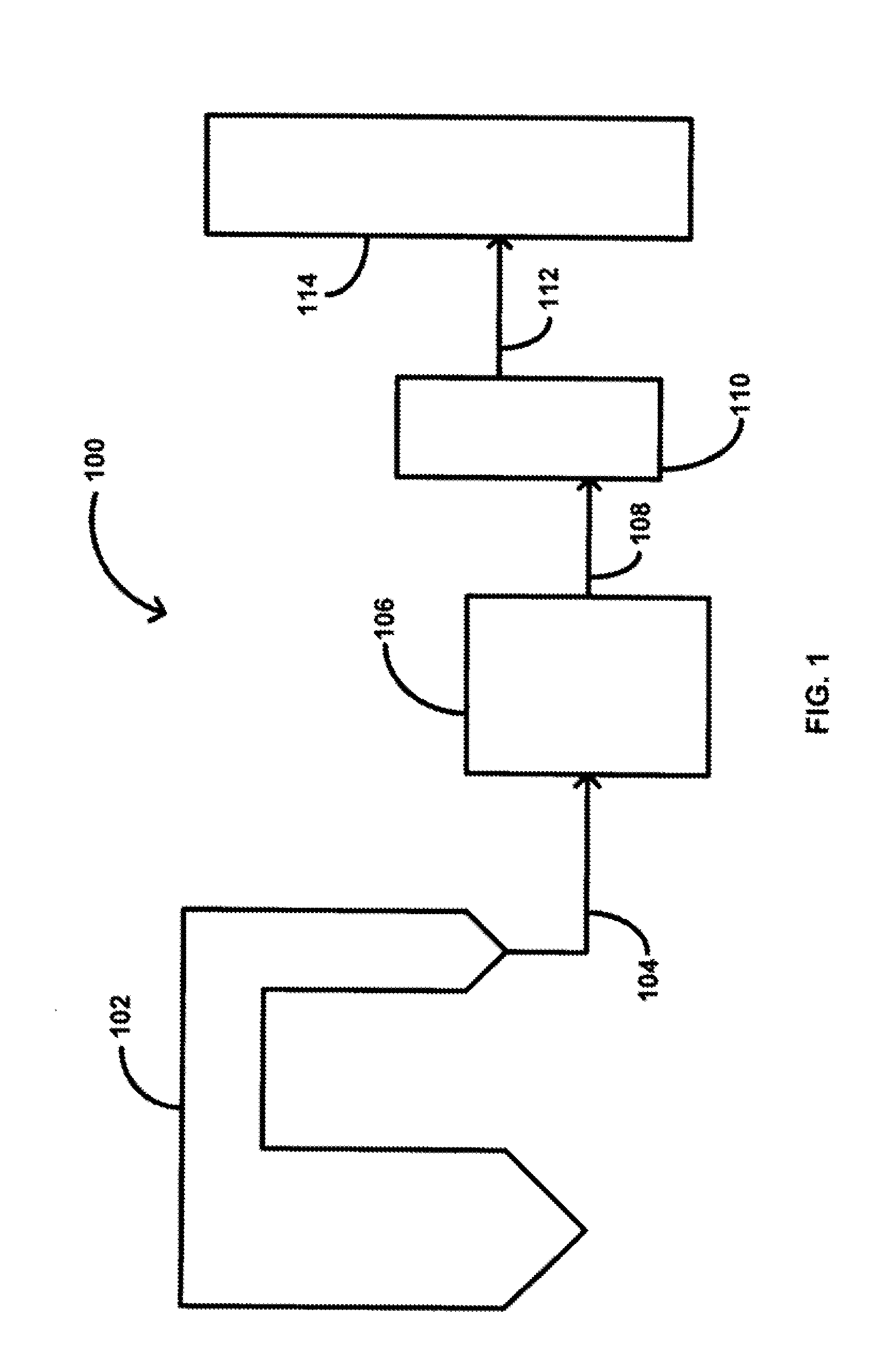

Sorbent Filter for the Removal of Vapor Phase Contaminants

Methods and apparatuses are described for removing a contaminant, such as a vaporous trace metal contaminant like mercury, from a gas stream. In one embodiment, a primary particulate collection device that removes particulate matter is used. In this embodiment, a sorbent filter is placed within the housing of the primary particulate collection device, such as an electrostatic precipitator or a baghouse, to adsorb the contaminant of interest. In another embodiment, a sorbent filter is placed within or after a scrubber, such as a wet scrubber, to adsorb the contaminant of interest. In some embodiments, the invention provides methods and apparatuses that can advantageously be retrofit into existing particulate collection equipment. In some embodiments, the invention provides methods and apparatuses that in addition to removal of a contaminant additionally remove particulate matter from a gas stream.

Owner:ELECTRIC POWER RES INST INC

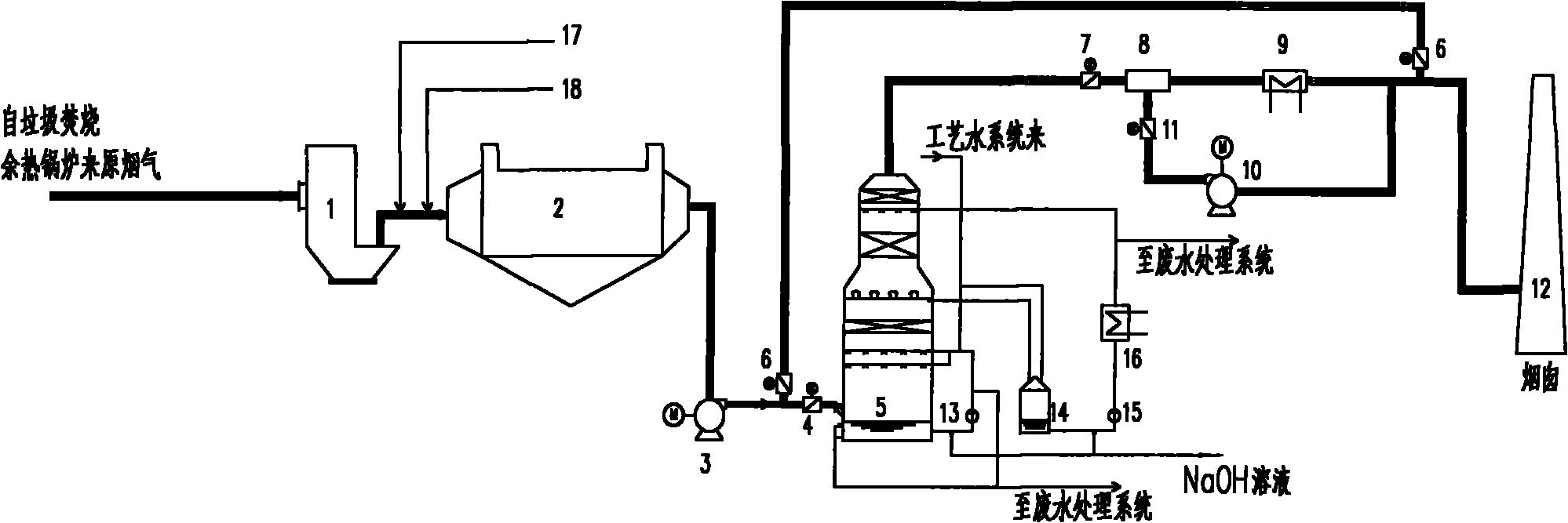

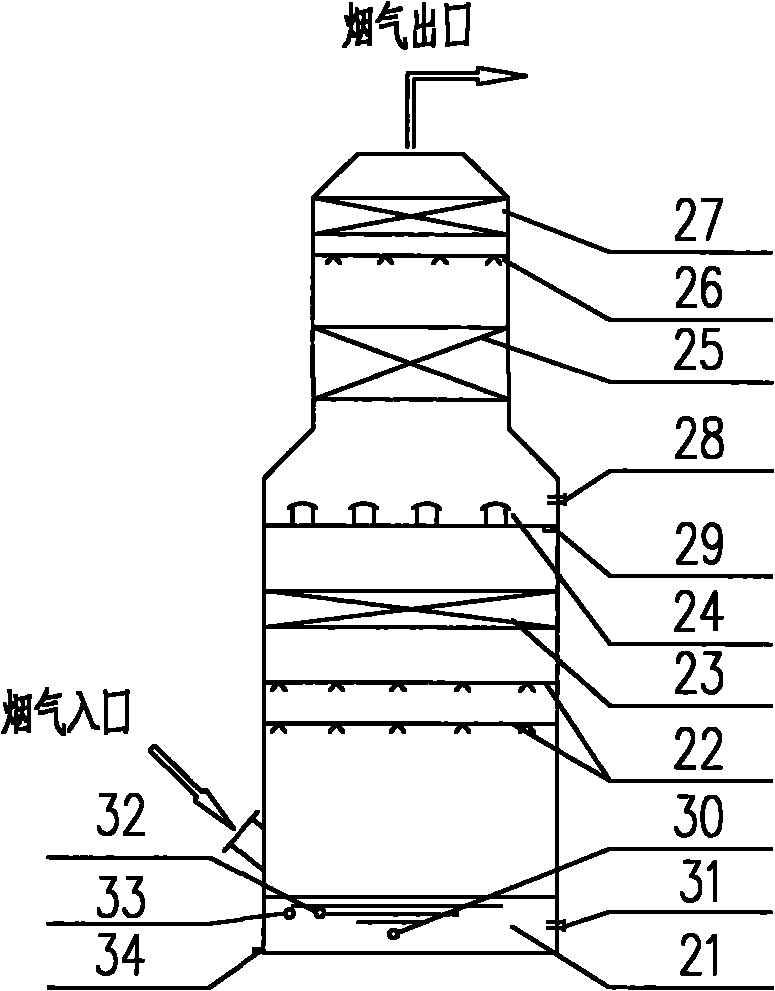

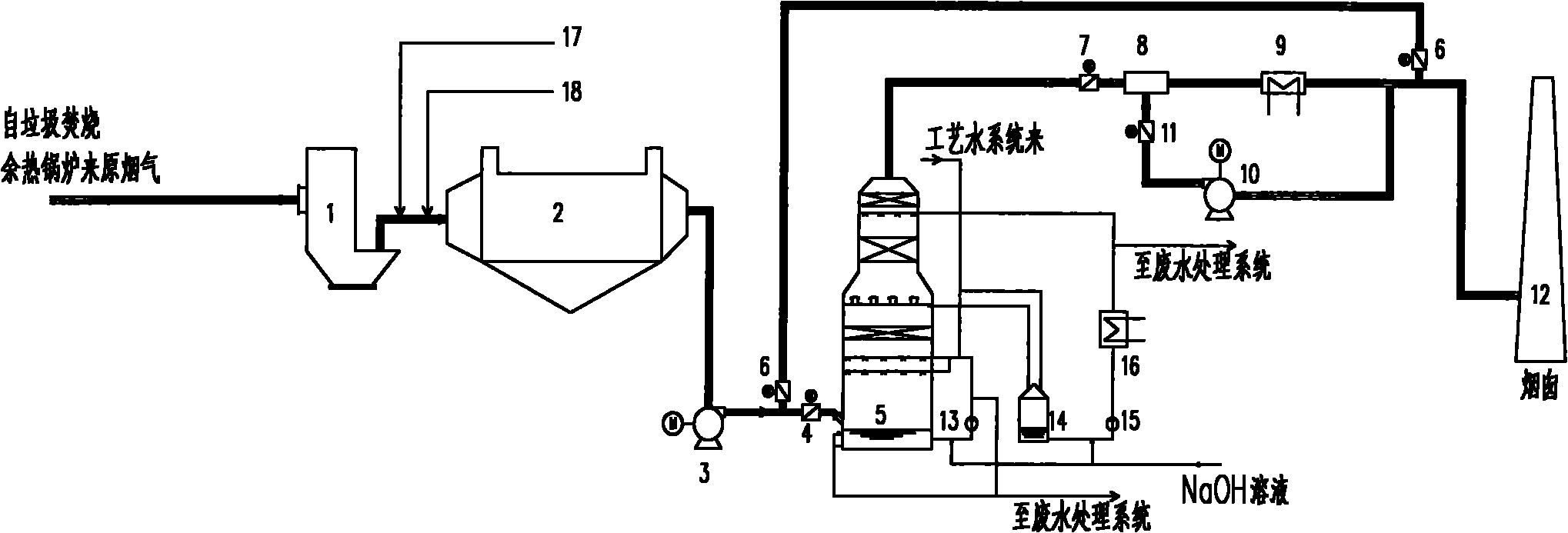

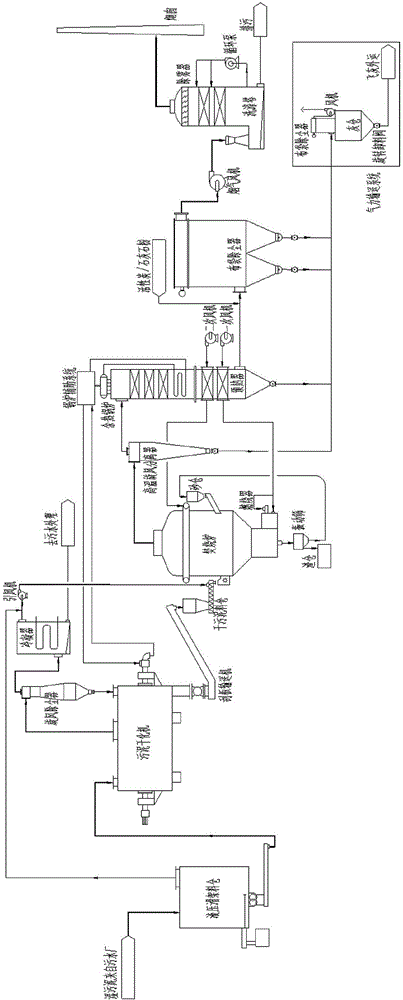

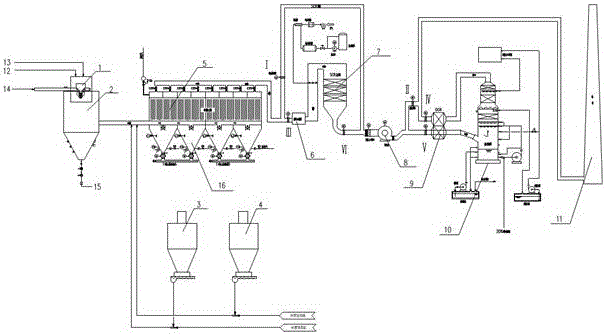

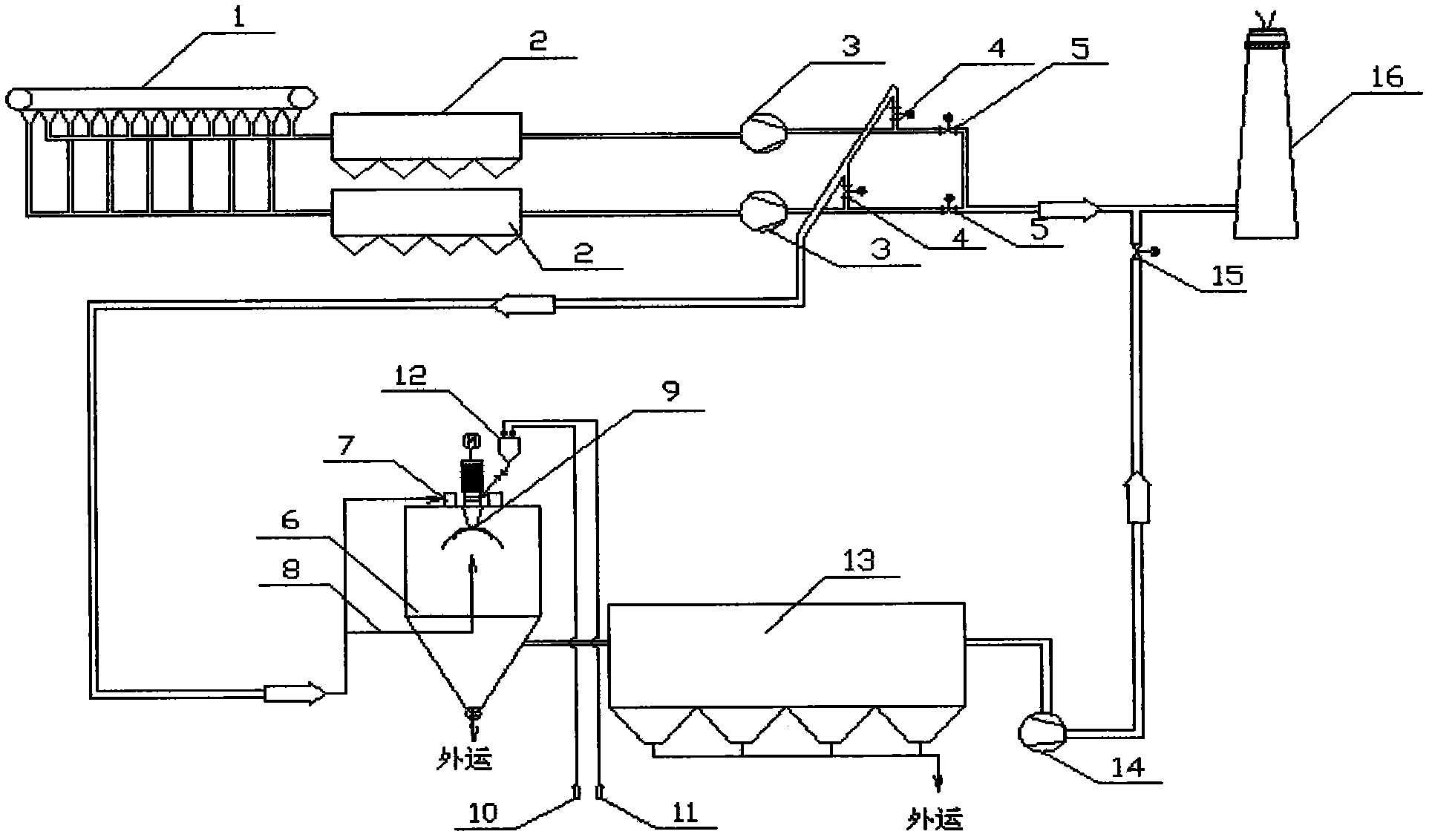

Flue-gas cleaning method and system for waste incineration

InactiveCN101829468AImprove removal efficiencyLarge load concentrationCombination devicesLighting and heating apparatusCooling towerHazardous substance

The invention discloses a flue-gas cleaning method for waste incineration, which comprises a dry process and a wet process. In the dry process, harmful substance in the flue gas is adsorbed by utilizing an adsorbent, and acid gas is neutralized by utilizing an alkaline absorbent, and in the wet process, a wet spray scrubber is utilized to purify the flu gas with higher efficiency. In addition, the invention also discloses a flue-gas cleaning system for waste incineration, which comprises a cooling tower, a bag-type dust collector, a wet washing tower and a glue-gas reheater. Flue gas from an exhaust-heat boiler enters the bag-type dust collector after being cooled by the cooling tower. Activated carbon and slaked lime powder are sprayed into the flue gas before the flue gas enters the bag-type dust collector to carry out preliminary purification on the flue gas; the purified flue gas is introduced to the wet washing tower through a draught fan for further processing; and the purified flue gas is discharged into the atomosphere by a chimney after the two-stage heating. The invention can effectively remove pollutant in flue gas and the quality of the purified flue gas can achieve the EU 2000 effluent standard.

Owner:山东三融环保工程有限公司

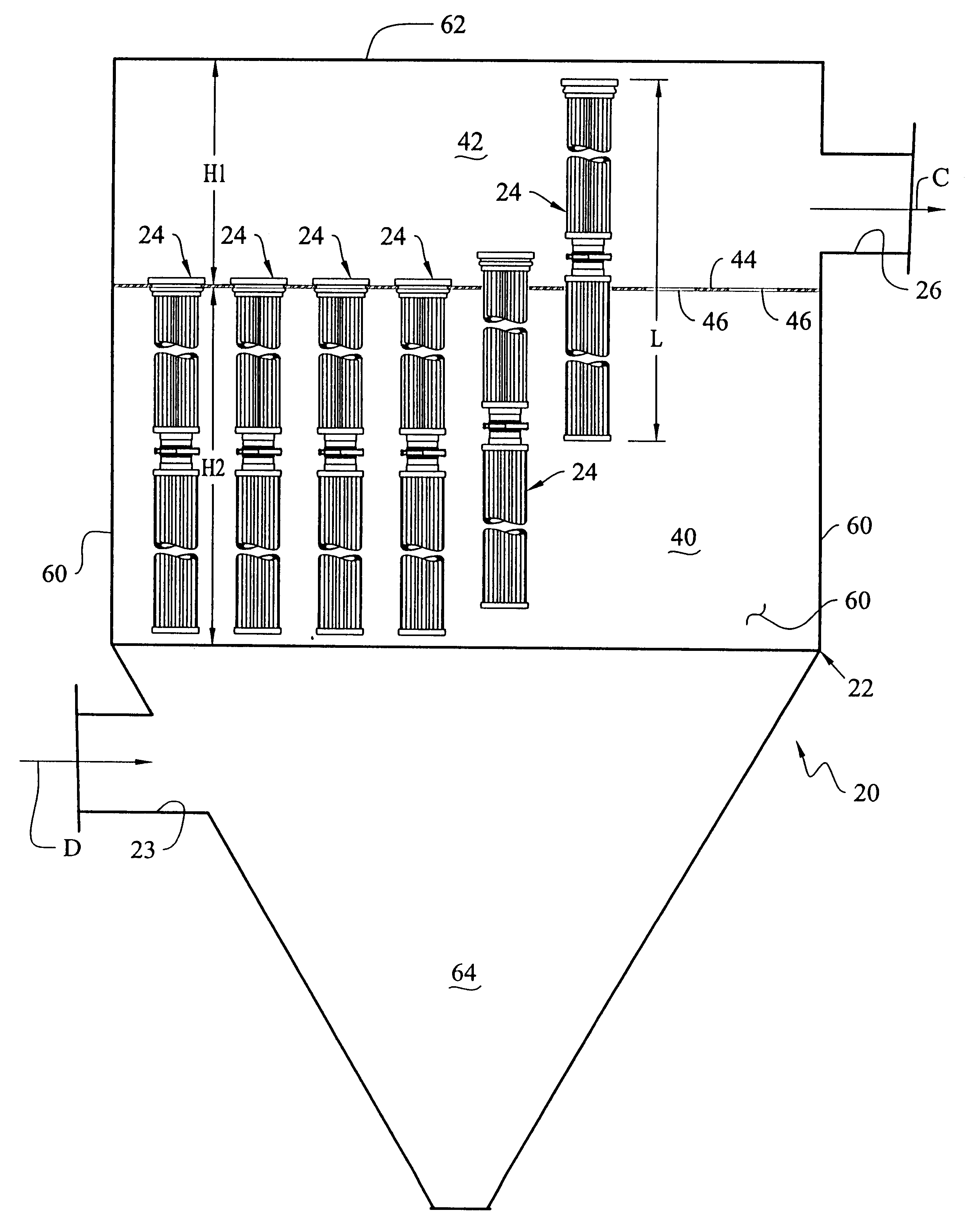

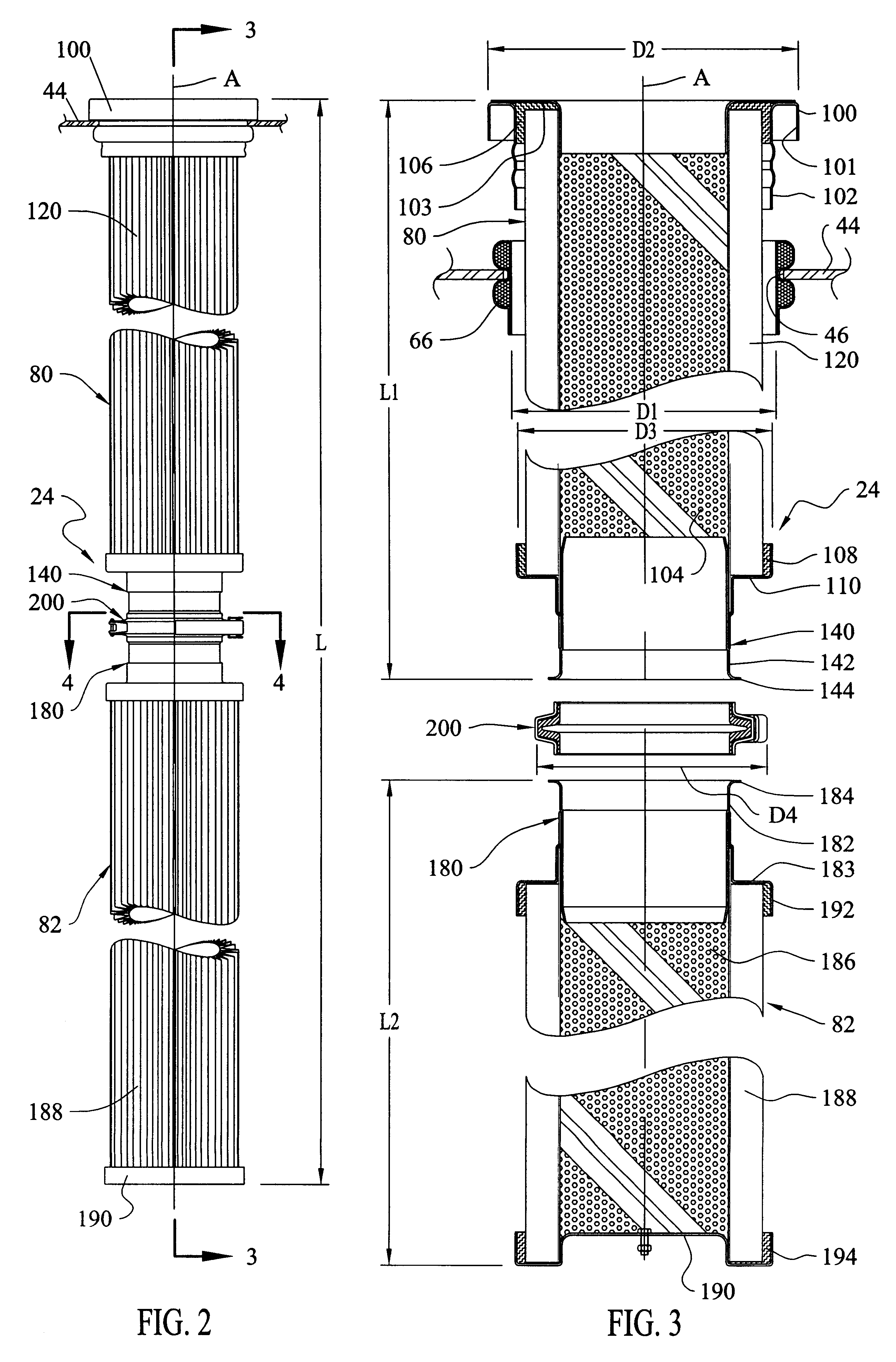

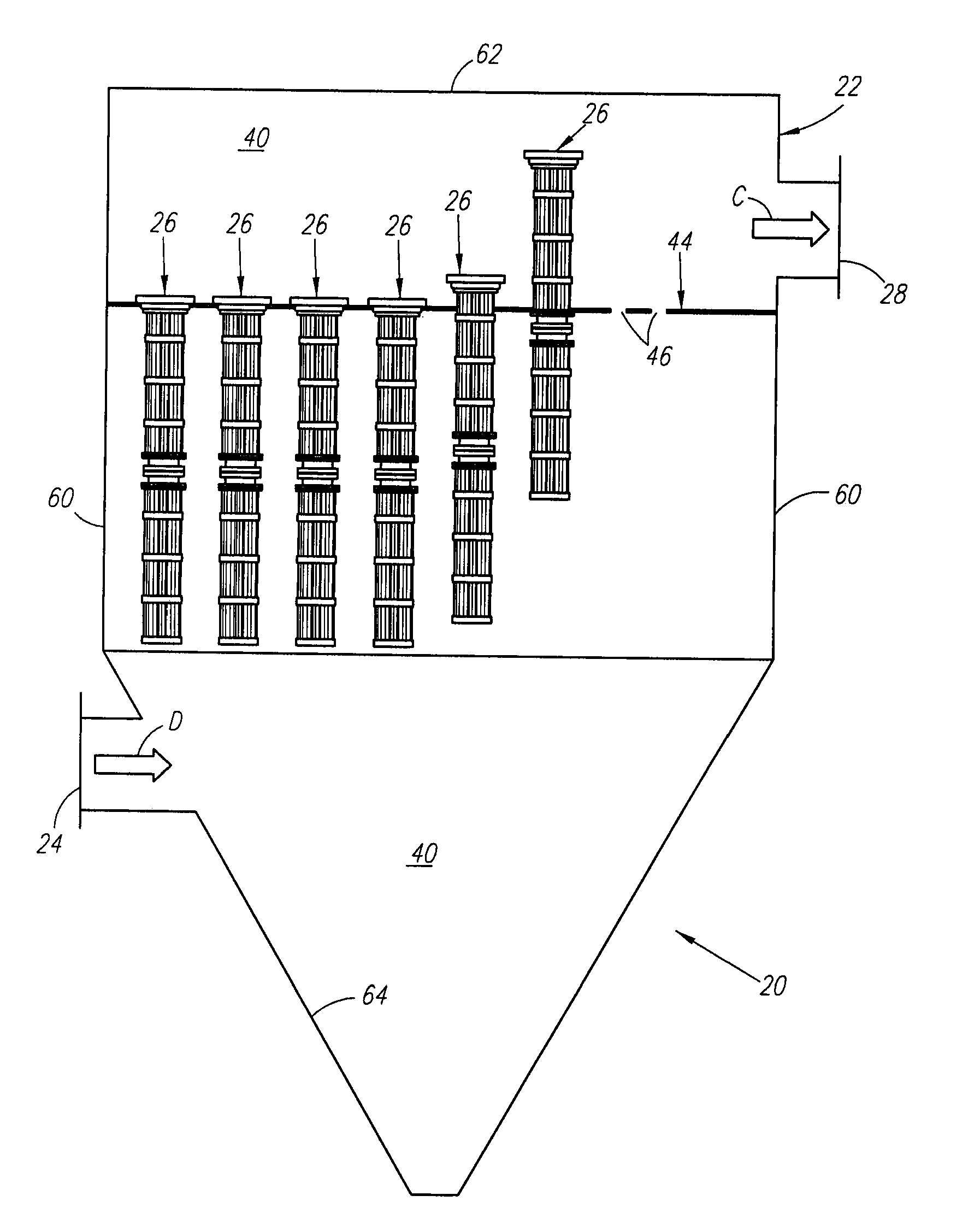

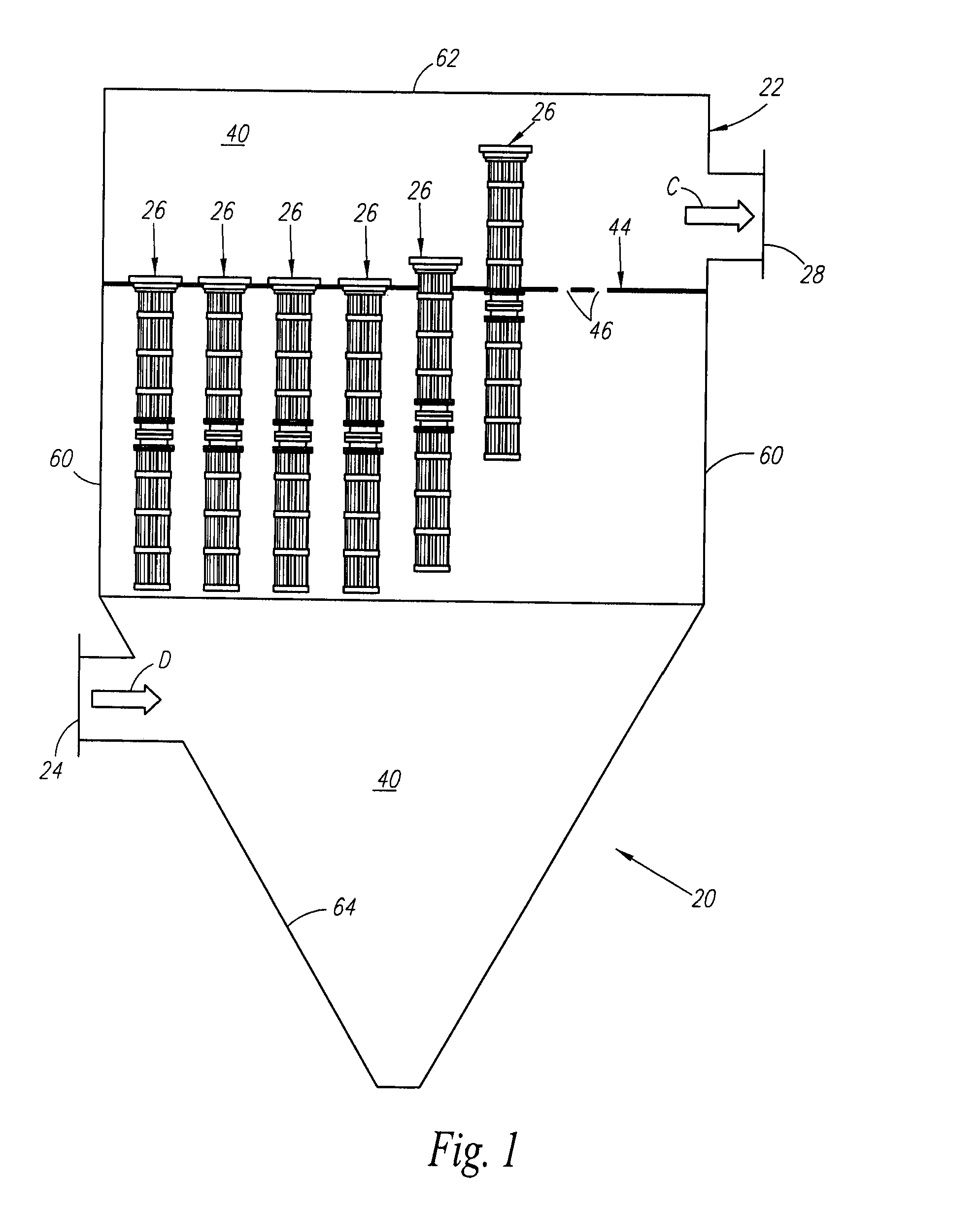

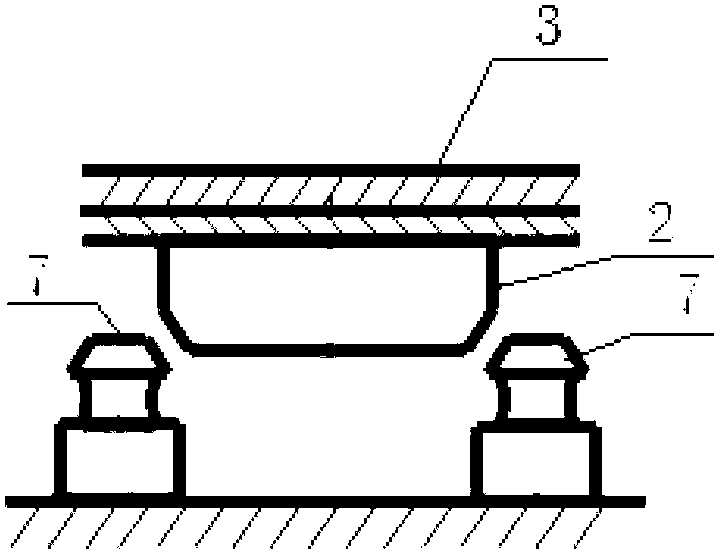

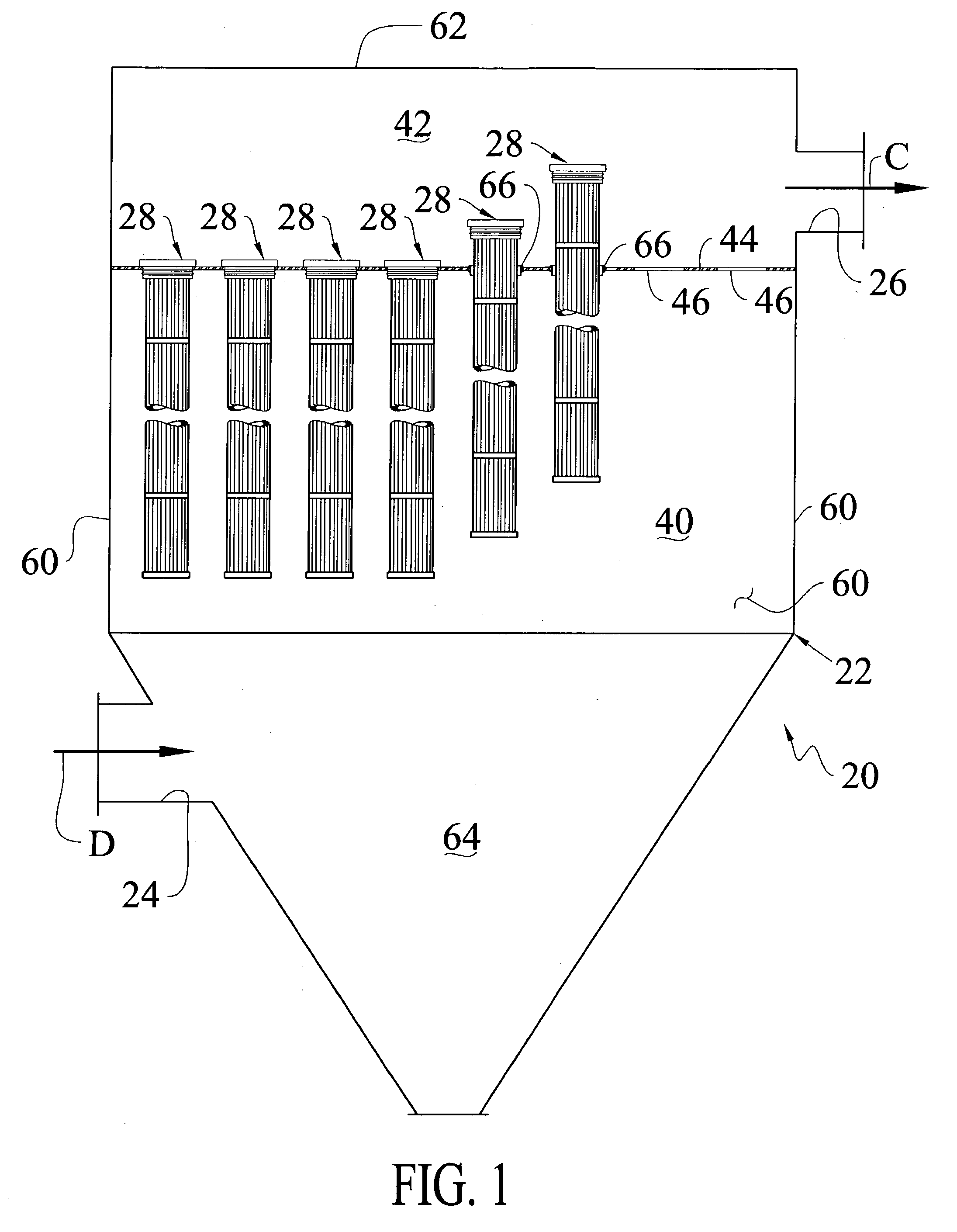

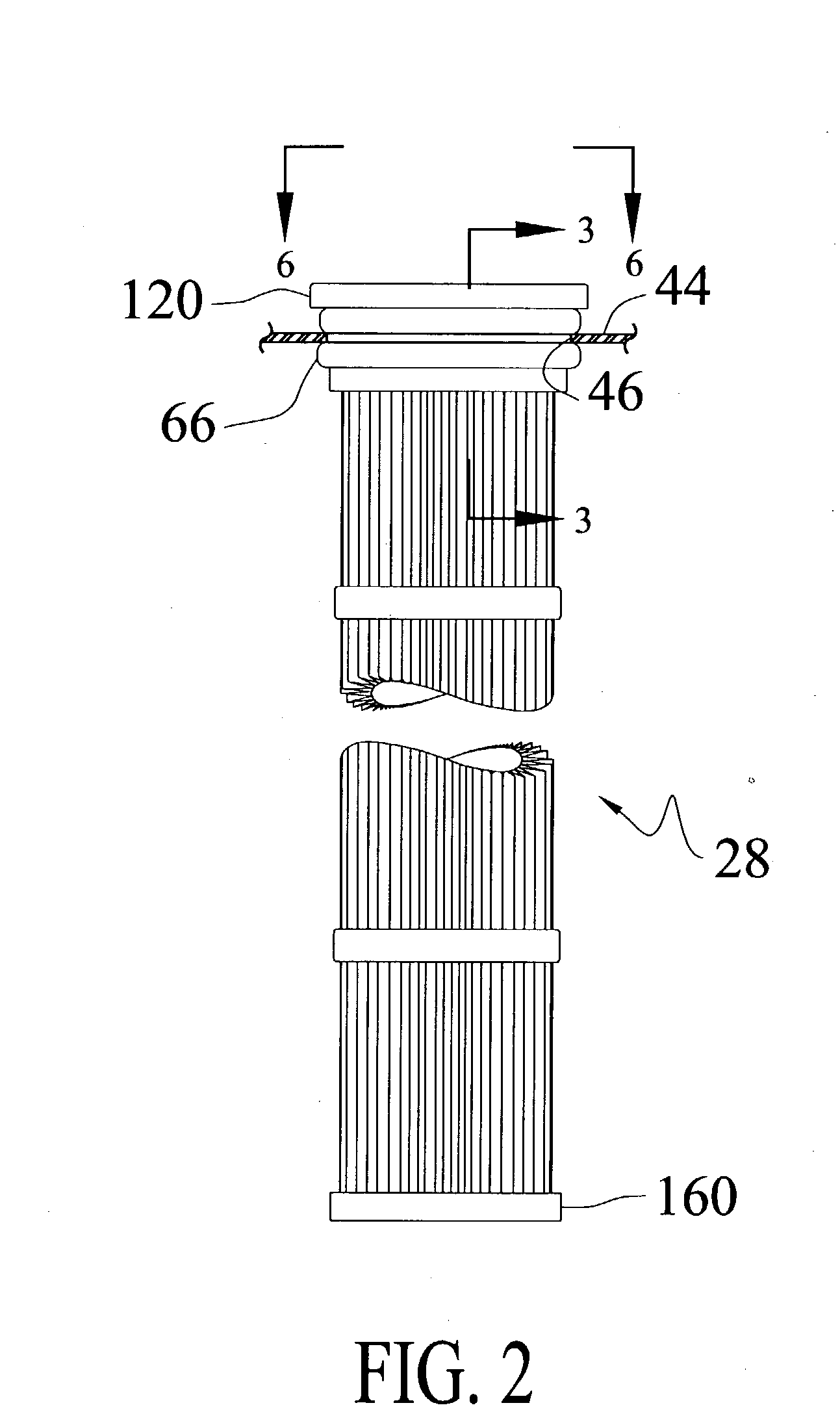

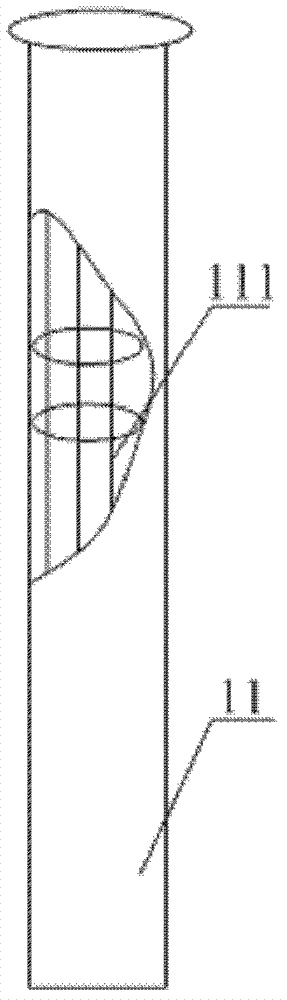

Baghouse, long filter assembly and method of installation

A filter assembly (24) includes a first filter portion (80) with a first attachment (100) adapted to attach to a tubesheet (44) to support at least a portion of the first filter portion in a second plenum (40) and to permit fluid communication between the first filter portion and a first plenum (42). A tubular member (104) is fixed to and extends from the first attachment (100). A pleated filter element (120) is disposed adjacent to the tubular member (104) for support. A second attachment (140) is fixed to the tubular member (104) at a second end of the first filter portion (80) and defines an opening through which fluid may flow. The tubular member (104) is fixed to the first and second attachments (100, 140) with sufficient strength to support the weight of at least one other filter portion. A second filter portion (82) includes a third attachment (180) at a first end and defines an opening through which fluid may flow. A tubular member (186) is fixed to and extends from the third attachment (180). A pleated filter element (188) is disposed adjacent to the tubular member (186) for support. A plate (190) closes a second end of the second filter portion (82). A clamping mechanism (200, 240) sealingly connects the second attachment (140) of the first filter portion (80) with the third attachment (180) of the second filter portion (82) and permits fluid communication between the first and second filter portions. The clamping mechanism (200, 240) has sufficient strength to support eh weight of filter portions located on the side of the clamping mechanism opposite the first attachment (100) of the first filter portion (80).

Owner:BHA GROUP HLDG

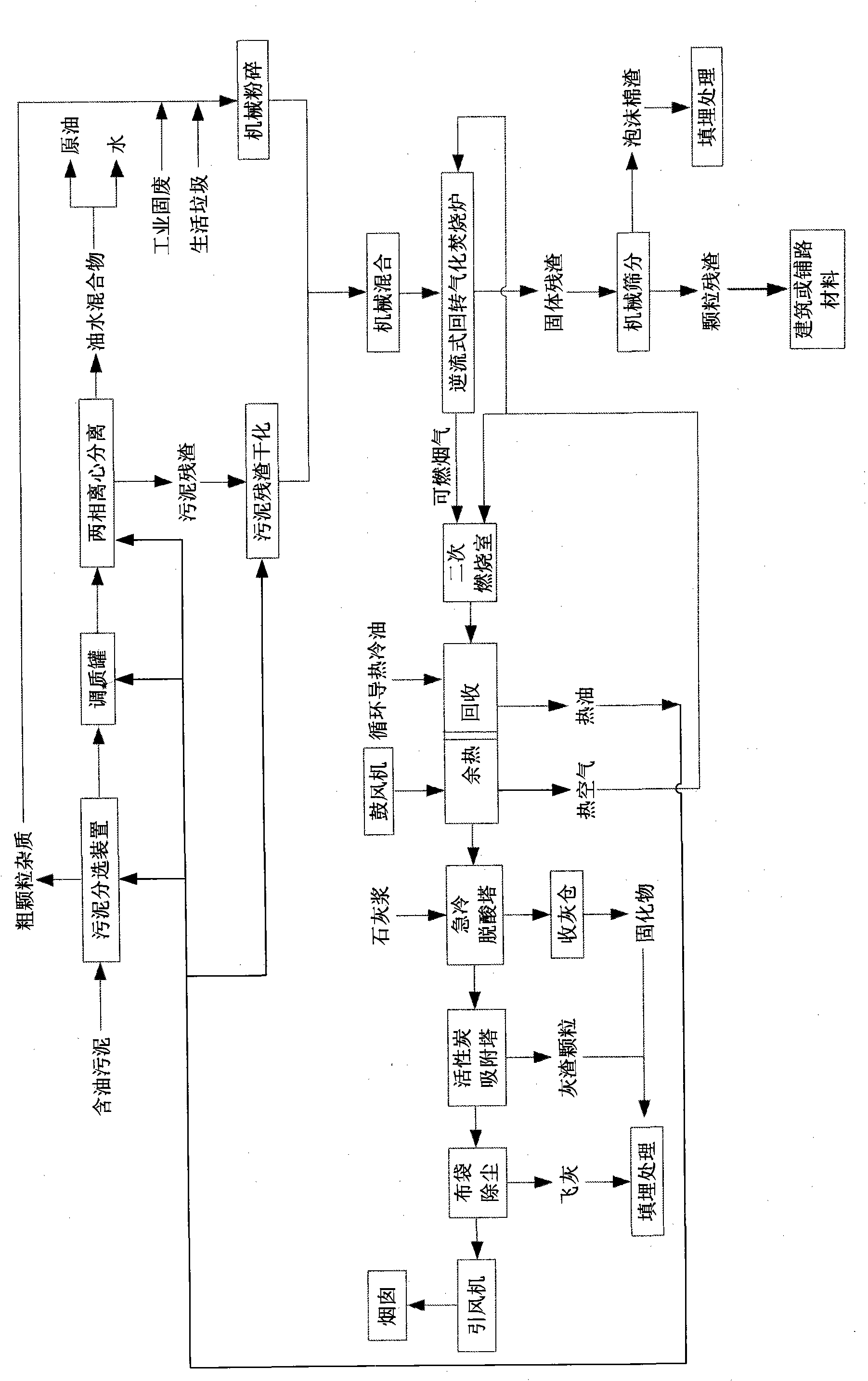

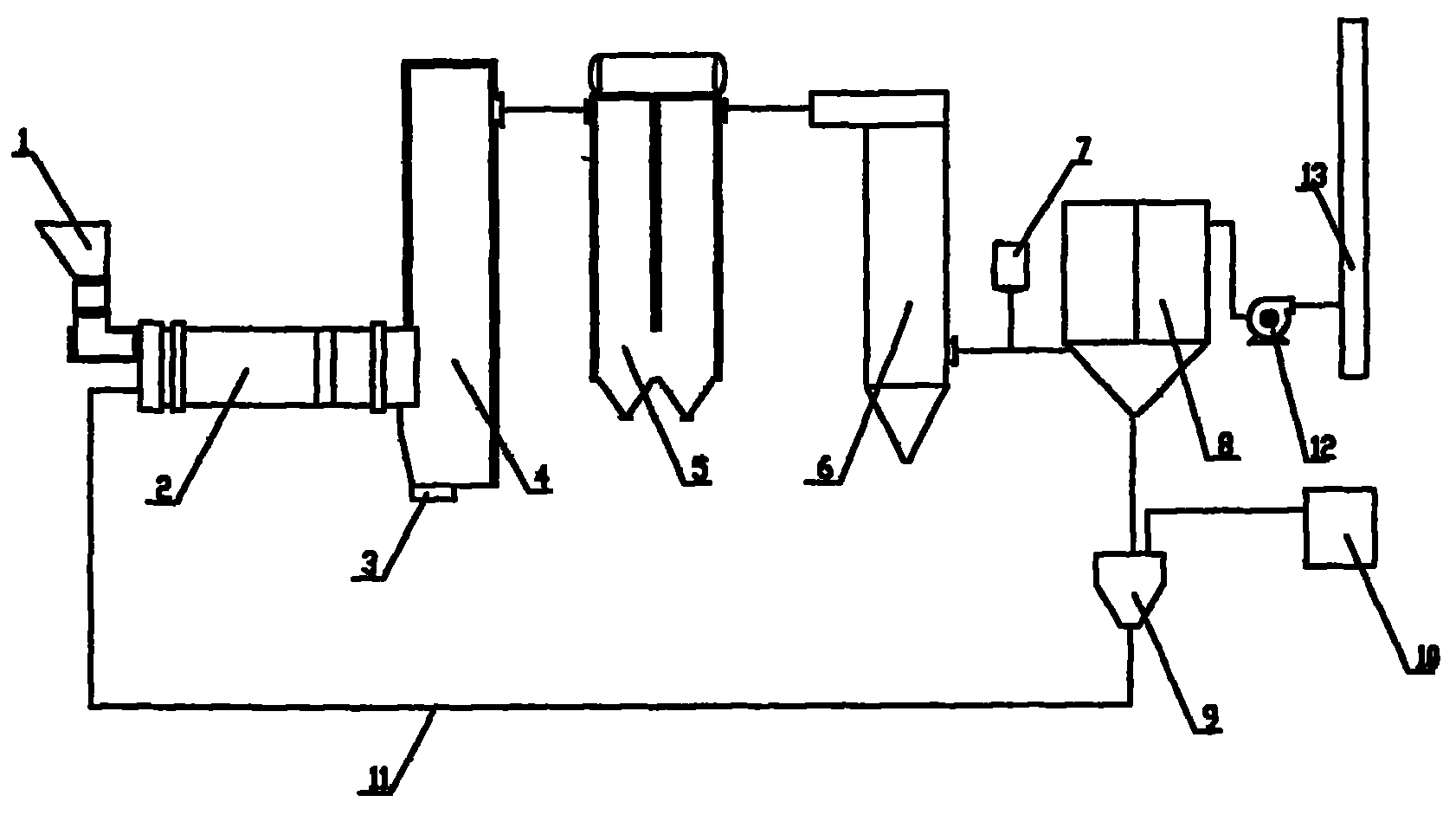

Combined treatment method for oilfield solid waste

InactiveCN101963358AHigh recovery rateLess investmentIncinerator apparatusCombustion chamberOil sludge

The invention provides a new combined treatment process for oilfield solid waste (oil sludge, industrial solid waste and household garbage). In the process, liquid-solid separation is performed on the oil sludge of an oilfield by adopting a conditioning-centrifugal separation process; the separated liquid enters oil-water separation equipment constructed on the oilfield for recovering crude oil; the oil recovery rate is up to 65 to 90 percent; after drying separated solid residue, the separated solid residue and pre-crushed industrial solid waste and household garbage are mixed and enter a countercurrent-type rotary gasification incinerator; combustible components in the oilfield solid waste are decomposed and gasified into combustible gases which are combusted partially in the incinerator; the combustible gases are combusted completely in a secondary combustion chamber; high-temperature smoke gas afterheat is recovered by a conduction oil afterheat boiler and air preheating equipment; and low-temperature smoke gas of which the afterheat is recovered is harmlessly exhausted after being treated by a sharp-quenching deacidification tower, an activated carbon adsorption tower and a bag-type dust remover. The process realizes the purposes of decrement, harmlessness and resources of oilfield solid waste treatment.

Owner:KUNMING UNIV OF SCI & TECH

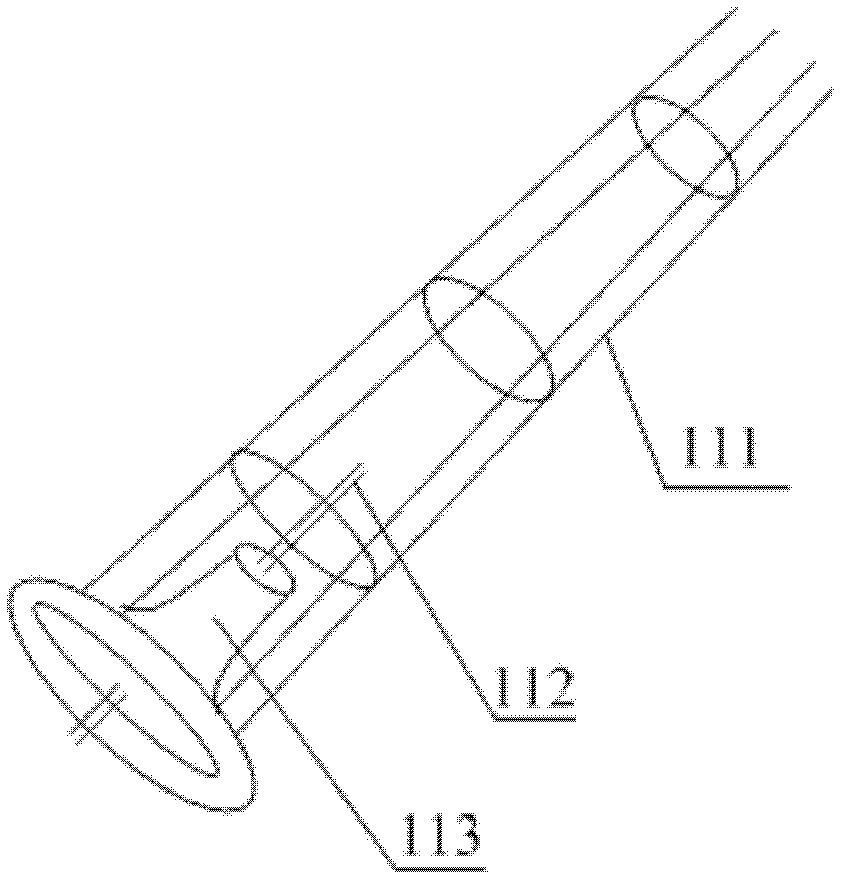

Twist and lock connection for pleated filter element with flange-to-flange locking means

ActiveUS20100101195A1Well formedDispersed particle filtrationTransportation and packagingCouplingBaghouse

A baghouse and filter assembly are provided for at least partially removing particulate matter from a gas stream. The filter assembly includes first and second filter portions to be coupled together by a coupler for establishing fluid communication between the first and second filter portions when connected. The coupler includes a first coupling portion including a side wall defining an interior passage through which the gas stream can pass in an axial direction between the first and second filter portions, and one or more flanges projecting from said side wall, the one or more flanges supporting a plurality of male studs. The coupler further includes a second coupling portion including a plurality of female keyhole-shaped receivers spaced apart for receiving at least a portion of the male studs and coupling the first coupling portion to the second coupling portion.

Owner:PARKER INTANGIBLES LLC

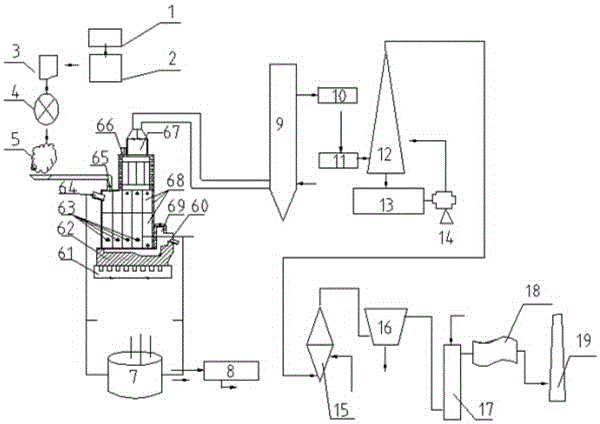

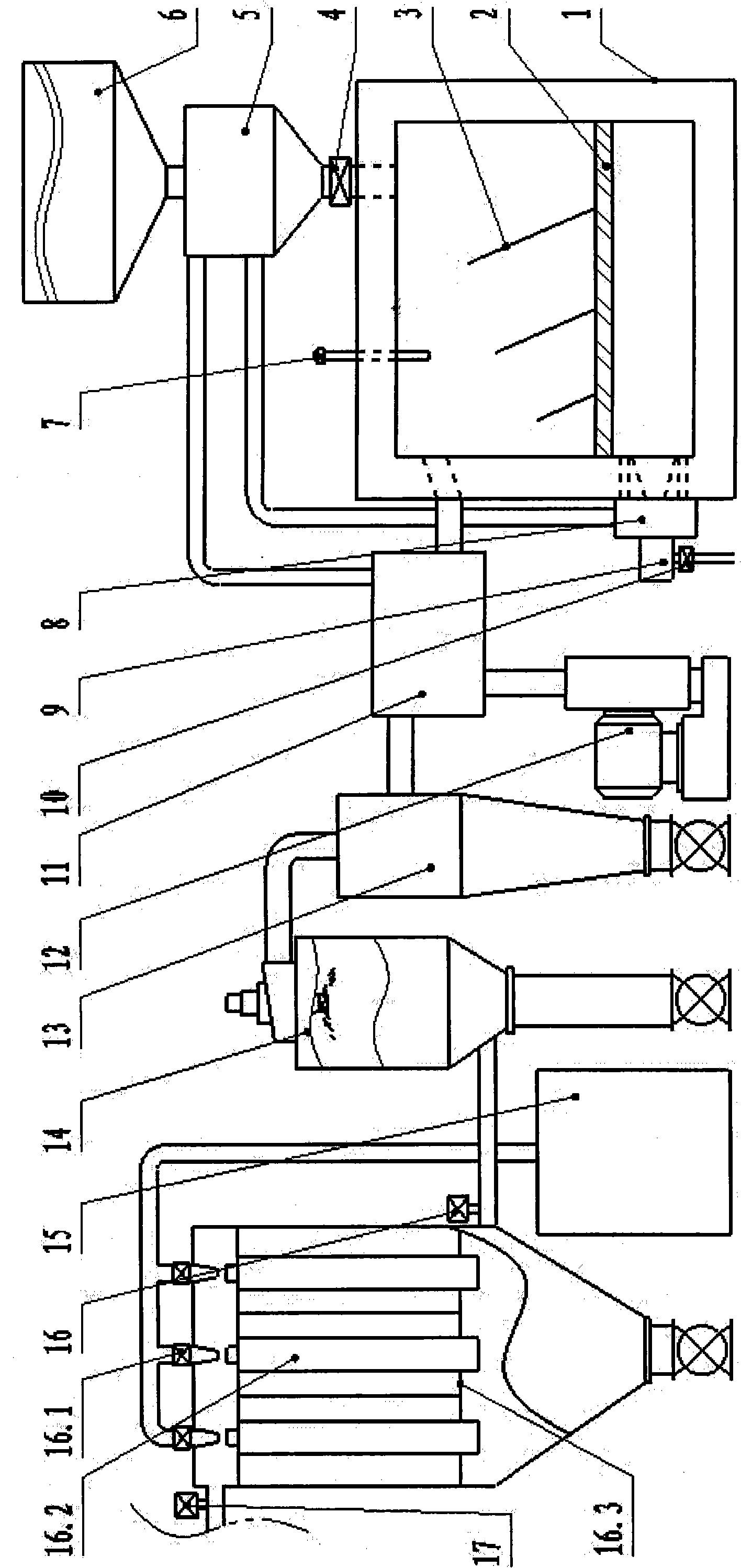

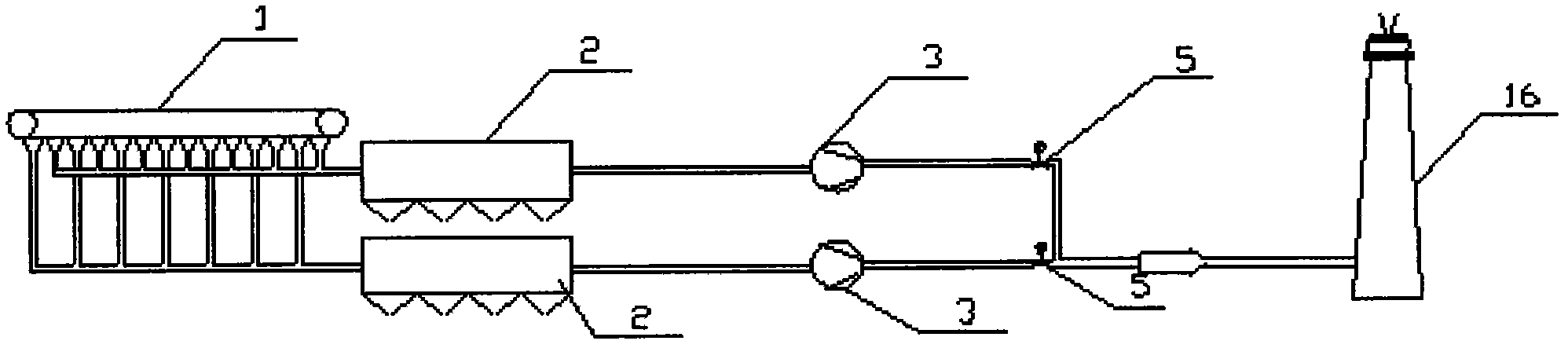

Dry-method dust collection and surplus energy recovery device for steel-smelting converter flue gas

InactiveCN1962884AExtended service lifeEnsure safetyManufacturing convertersProcess efficiency improvementCycloneBaghouse

The invention discloses a recycling device of residual heat to dedust through drying method, which is composed of steel-smelting rotary furnace, high-temperature rapid valve, mobile petticoat pipe, combusting device, vaporization cooling flue, high-temperature cyclone duster, shell-and-tube exchanger, cloth duster (or electric duster), three-way switching valve, dedusting fan, gas thruster device and gas box, wherein the gas combusting supplementing device is set in the flue after mobile smoke bell; the high-temperature vortex deduster is set behind the evaporation cooling flue; the shell-and-tube exchanger is behind the high-temperature vortex deduster, which possesses cloth deduster.

Owner:云南阳光基业能源管控技术股份有限公司

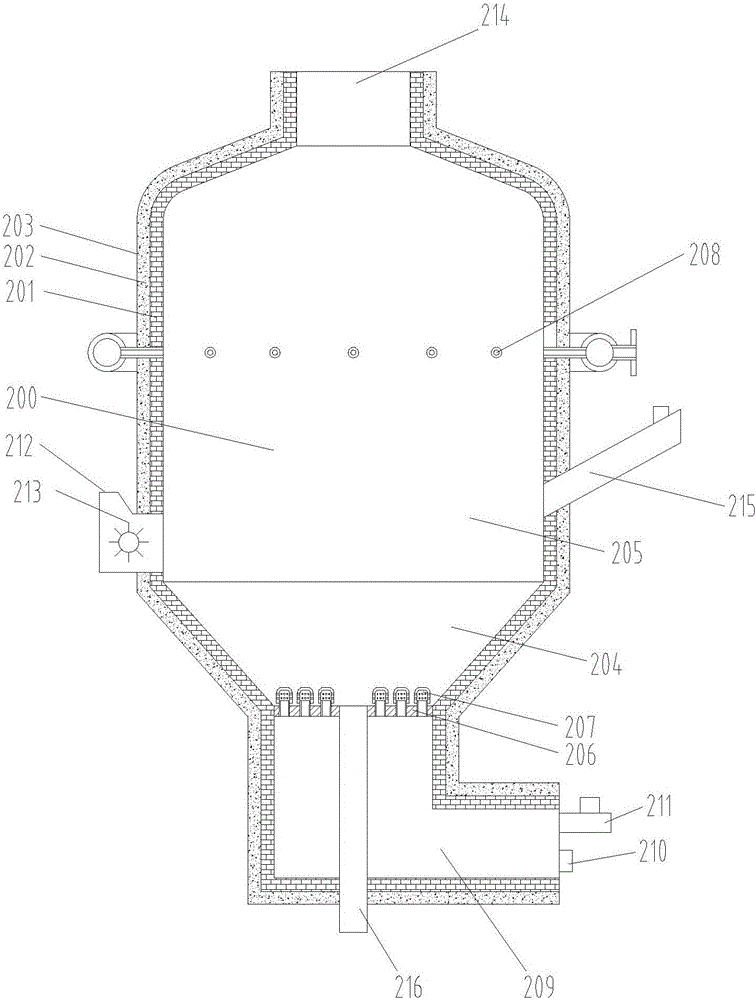

High-temperature melting treatment system and method for sludge

ActiveCN102537980ALow running costEmission reductionCombination devicesSludge treatment by pyrolysisAir preheaterCooling tower

The invention discloses a high-temperature melting treatment system and a method for sludge, and relates to a sludge treatment system and a sludge treatment method. The system and the method solve the problem that dioxine exists in sludge incineration methods in prior arts. A first device comprises a melting chamber with a furnace body integrally manufactured from a lower side to an upper side, a shrinking section smoke outlet and a secondary combustor, high temperature and low temperature superheaters arranged in a smoke duct, high temperature and low temperature coal economizers, high temperature and low temperature air preheaters, and an SCR (selective catalytic reduction) denitration system, wherein the smoke duct is communicated with a smoke fast cooling tower, the smoke fast cooling tower is communicated with a bag-type dust collector, and the bag-type dust collector is communicated with a chimney by a smoke wet desulphurization system and a draught fan. The first method comprises the steps of feeding dry sludge powder into the melting chamber for burning to a high-temperature melting state, recycling liquid-state slag and reusing, treating high-temperature smoke after entering the smoke duct, and discharging. The differences between a system in a second scheme and the first device are as follows: the high temperature and low temperature superheaters and the high temperature and low temperature coal economizers are not arranged, and a steam heat exchanger is additionally arranged. A difference between a system in the third scheme and the second scheme is as follows: a multistage sludge dryer is additionally arranged. The high-temperature melting treatment system and method for the sludge are used for high-temperature melting treatment of the sludge.

Owner:HARBIN INST OF TECH

System and method for repairing organic material polluted soil

ActiveCN103008337AClear division of laborGive full play to the advantages of technologyContaminated soil reclamationAir preheaterEngineering

The invention discloses a system for repairing organic material polluted soil, which comprises a chimney and a rotary kiln reactor, wherein the smoke exhaust port of the rotary kiln reactor is connected with a furnace chamber; the furnace chamber is connected with a cyclone separator; one end of the cyclone separator is connected with a preheating passage; the other end of the cyclone separator is connected with a refeeder; the refeeder is connected with the furnace chamber; the preheating passage is connected with the chimney after passing through a flue gas desulfurization denitration purifier and a bag-type dust remover; an air preheating device is arranged in the preheating passage; one end of the air preheating device is connected with a first blower; the other end of the air preheating device is connected with the rotary kiln reactor and the furnace chamber respectively; and a rotary kiln repaired soil outlet is arranged on the rotary kiln reactor. The invention further discloses a method for repairing organic material polluted soil. According to the invention, the advantages of the thermal desorption technology in the organic material polluted soil repairing process are fully played; and organic material polluted soil, which is difficult to repair, can be repaired fast through the combination of new rotary kiln thermal desorption technology and the circulatory fluidized bed incineration technology.

Owner:HUAZHONG AGRI UNIV

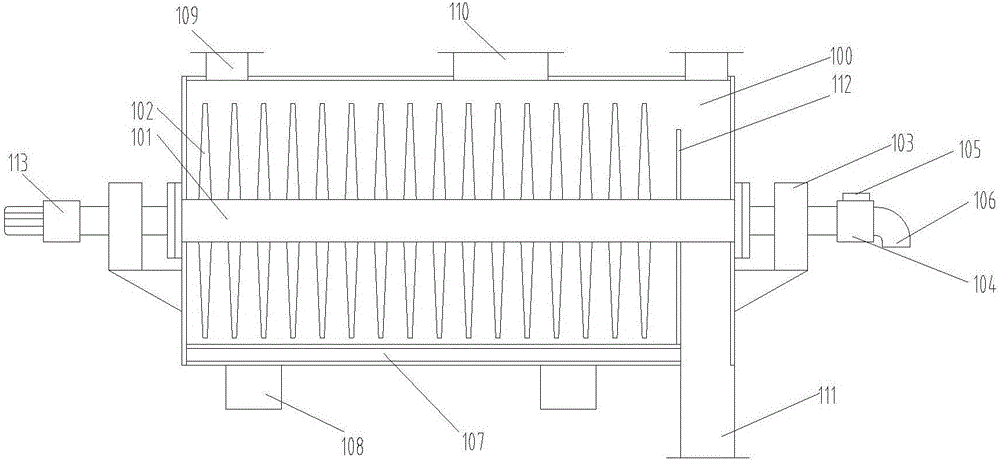

Method using drying and incineration to treat sludge

InactiveCN105948459AEfficient removalImprove thermal efficiencySludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesThermal energyMoisture recycling

The invention discloses a method using drying and incineration to treat sludge. The method includes: the pre-dewatered sludge of a sewage treatment plant is conveyed into a sludge bin, with an arch breaking function, of a system, then the sludge is conveyed to a horizontal stirring sludge drying machine through a sludge pump, and the sludge is subjected to stirring and indirect heat exchange to remove moisture and increase heat value and conveyed into a fluidized bed incinerator for incineration; smoke generated by the incineration is subjected to pre-dust-removing by a high-temperature separator and conveyed into a waste heat boiler system so as to recycle heat serving as the heat source of the drying machine, the processed smoke is conveyed into a preheater to preheat air entering the fluidized bed incinerator, and then the smoke enters a cloth-bag dust remover and is processed by a washing tower and discharged in a standard-reaching manner through a chimney; the tail gas generated by the drying machine is subjected to moisture recycling by a condenser and dust removing and then conveyed into the fluidized bed incinerator; fly ash is collected by a pneumatic conveying system to serve as a construction raw material. The method has the advantages that stable, harmless and recycling type sludge treatment can be achieved by the incineration of the dried sludge, the system effectively utilizes the incineration heat to serve as the heat source of the drying machine, and the smoke generated by the incineration is effectively treated and discharged in a standard-reaching manner.

Owner:SHANDONG QISHENG ELECTRICAL & MECHANICAL ENG

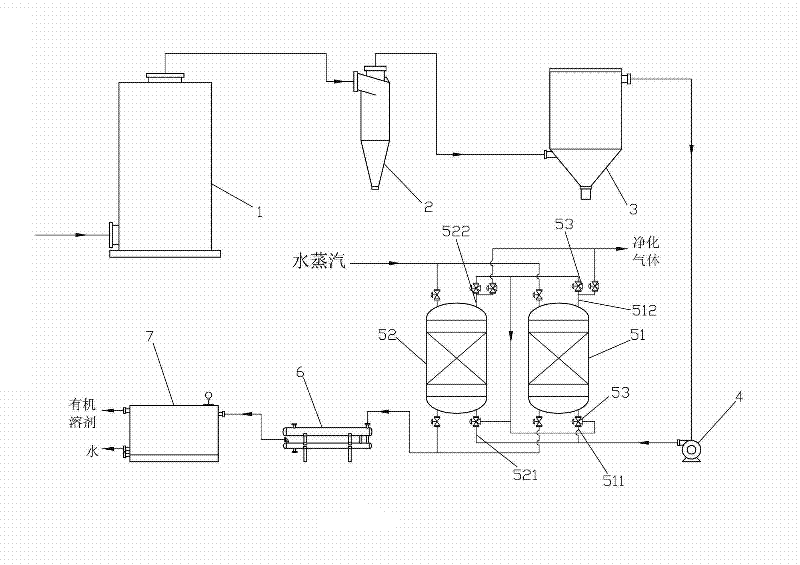

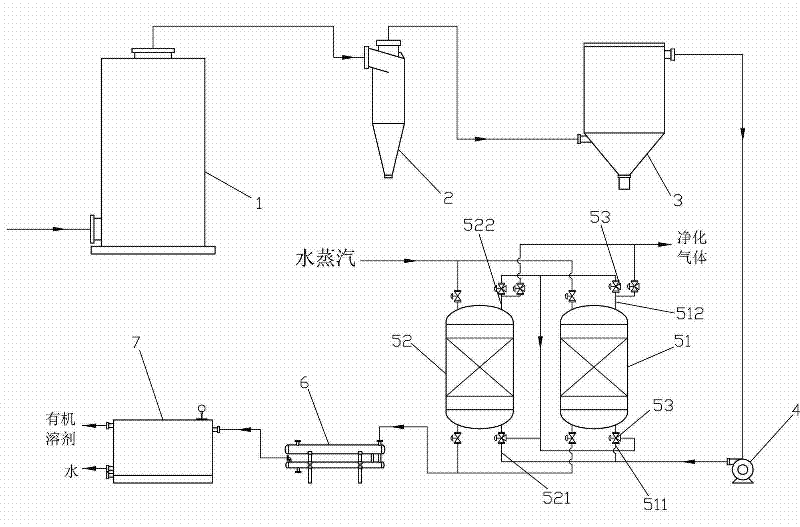

Recycling device for exhaust gas of painted organic solvent and method for recycling organic solvent

The invention discloses a recycling device for an exhaust gas of a painted organic solvent. The recycling device comprises a painting fog removing device, a fan, an absorbing jar, a condenser and an oil-water separator which are connected in turn, wherein the painting fog removing device comprises a gas collecting tank, a cyclone dust collector and a bag type dust collector; the gas collecting tank is used for temporarily storing the exhaust gas of the organic solvent; and the gas collecting tank, the cyclone dust collector and the bag type dust collector are connected in turn. All componentsof the recycling device are reasonably and compactly jointed; collection efficiency is high; and the painting fog is efficiently removed while a trouble in frequently exchanging filter cotton is avoided. The invention also discloses a method for utilizing the recycling device for the exhaust gas of the painted organic solvent to recycle the organic solvent. The method comprises the following steps: removing the painting fog; absorbing; desorbing steam; condensing; and separating oil from water, wherein the step of removing the painting fog is carried out by changing the painting fog into painting powder and then efficiently removing the painting fog. Compared with a traditional process, the method is more reasonable, compact and labor-saving.

Owner:中科天龙(厦门)环保股份有限公司

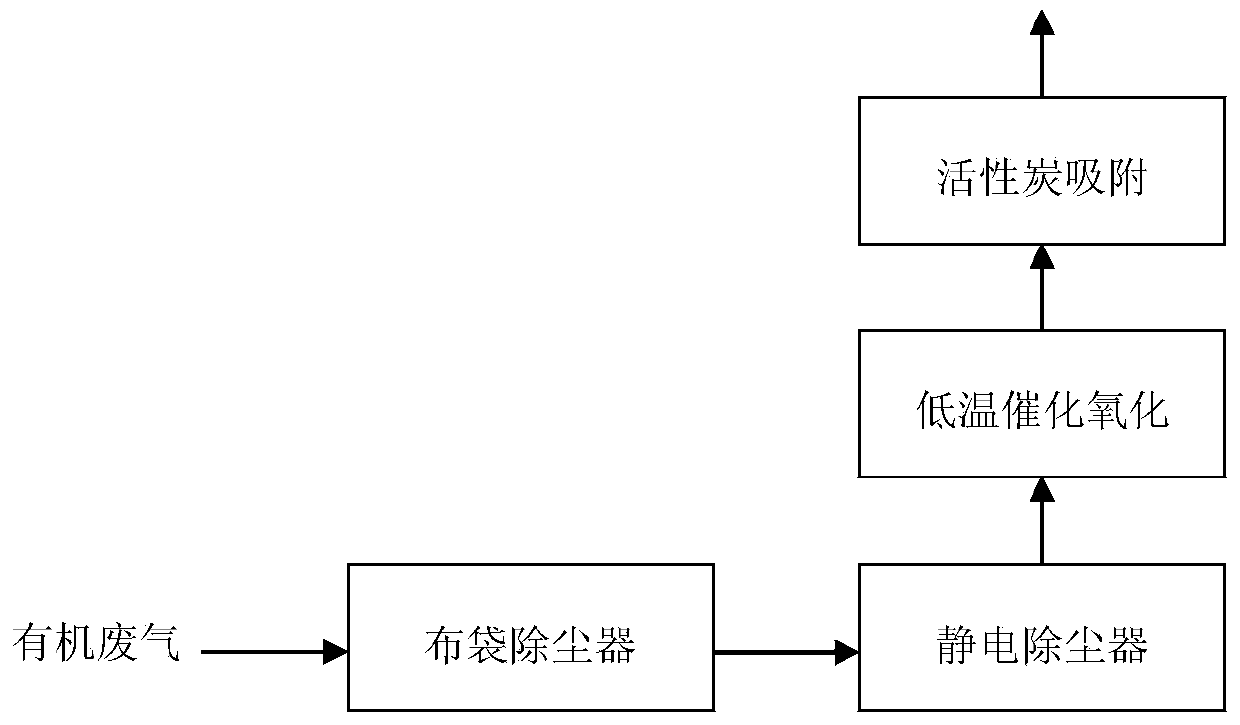

VOCs high-efficiency processing method

InactiveCN103721510AEasy to recycleGood emission concentrationCombination devicesHigh concentrationAdditive ingredient

The invention relates to a VOCs (Volatile Organic Compounds) high-efficiency processing method. In the method, dust removal processing, odor removal processing and tail gas processing are carried out on waste gas. Firstly, a bag-type dust collector is adopted to carry out preprocessing on the waste gas, parts of materials are recovered and then an electrostatic dust collector is introduced to further recovery the materials; then the waste gas is subjected to low-temperature catalytic oxidation processing; the waste gas is subjected to adsorption processing. According to the invention, the petrochemical industrial organic waste gas is processed by utilizing the combination of catalytic oxidation and adsorption processes, so that the materials can be well recovered, odor of the organic waste gas is eliminated and the problem of emission of petrochemical industrial tail gas is solved. The method disclosed by the invention has a good purifying effect and low consumption and is low in engineering cost; the materials can be recovered; flue gas emission concentration is lower than the emission standard by over 30 percent; the VOCs high-efficiency processing method has obvious economic benefits and social benefits and can be used for processing the petrochemical industrial organic waste gas with high concentration, high flow and complex ingredients.

Owner:JIANGSU ZHONGKE RUISAI POLLUTION CONTROL ENG +1

Filter cartridge mounting structure

A filter cartridge for use in a baghouse having a tubesheet with a plurality of opening. A flexible snapband is biased towards engagement with a surface defining one of the openings in the tubesheet and is adapted to receive a portion of the filter cartridge. The snapband has a first surface and a second surface with a pair of protrusions separated by a groove adapted to receive a peripheral edge of one of the tubesheet openingd. The pair of protrusions sealingly engage surfaces of the tubesheet. The filter cartridge includes filter media. Structure supports the filter media. A rigid non-metallic tubular collar is integrally formed with the filter media and the structure to secure this filter media and the structure to said collar. The collar includes a pair of longitudinally spaced continuous projections extending radially from the collar. The collar further includes an annular surface extending from the collar for establishing the position of the filter cartridge relative to the tubesheet The collar is adapted to be positioned within the snapband and engage the first surface of the snapband to effect sealing engagement of the snapband against a portion of the opening in the tubesheet. The first projection extends radially the said collar to further force a portion of the snapband into sealing engagement with a surface of the tubesheet. The second projection further forces another portion of the snapband into sealing engagement with another surface of the tubesheet.

Owner:BHA ALTAIR

Melting solidification integrated method and system for incineration of hazardous wastes and incinerated fly ash

The invention discloses a melting solidification integrated method and a melting solidification integrated system for the incineration of hazardous wastes and incinerated fly ash. The method comprises the following steps of: incinerating and melting the hazardous wastes by using a multi-section incinerator which consists of a slag rotary kiln and a secondary combustion chamber; recovering the heat of smoke generated during incineration by using an afterheat boiler; conveying fly ash collected by a bag-type dust collector to the slag rotary kiln by using a silo pump and a fly ash return pipeline; performing compatibility on the fly ash and medical wastes, so that the fly ash is melted at a high temperature in the slag rotary kiln; and performing water quenching to form vitreous slag, and wrapping heavy metal by using the slag to realize the stable solidification of the metal. In the method, heat energy generated by combusting the hazardous wastes is utilized fully to provide energy for the melting solidification of the fly ash, the problem of high cost of stabilization treatment of the fly ash is solved while the innocent treatment of the hazardous wastes is realized, running cost is reduced, and the important effects of energy conservation, emission reduction and waste control by the wastes are achieved; and due to the adoption of an integrated design, the integrated system is reasonably and compactly connected and has a mature equipment structure and higher economy.

Owner:ZHEJIANG UNIV

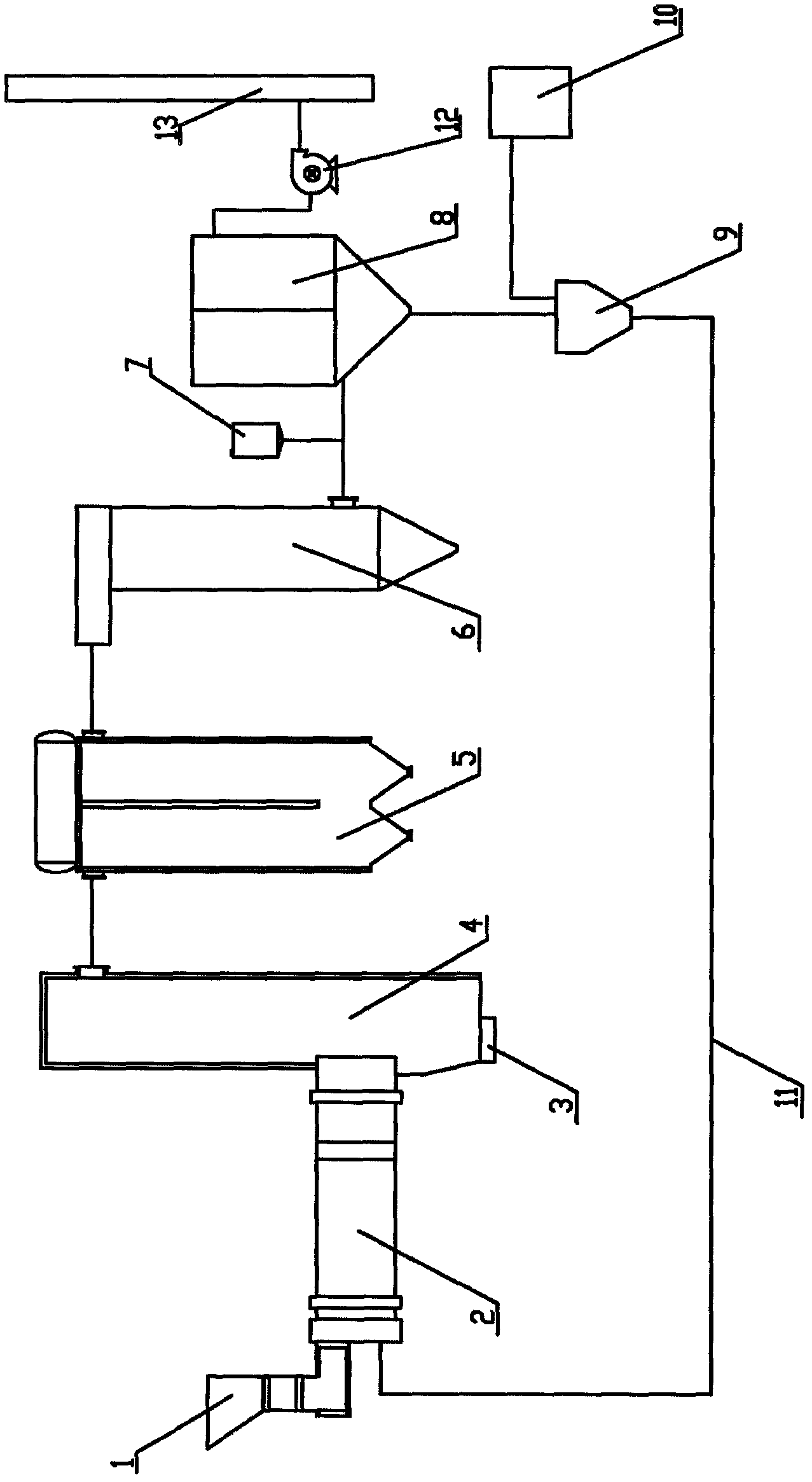

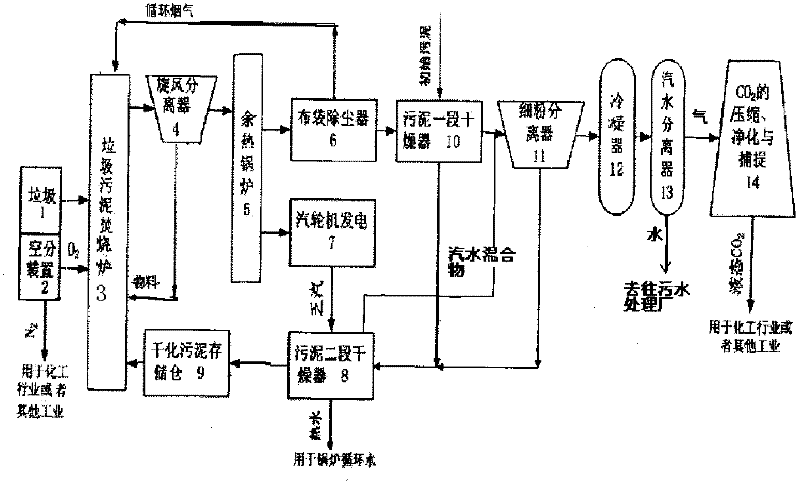

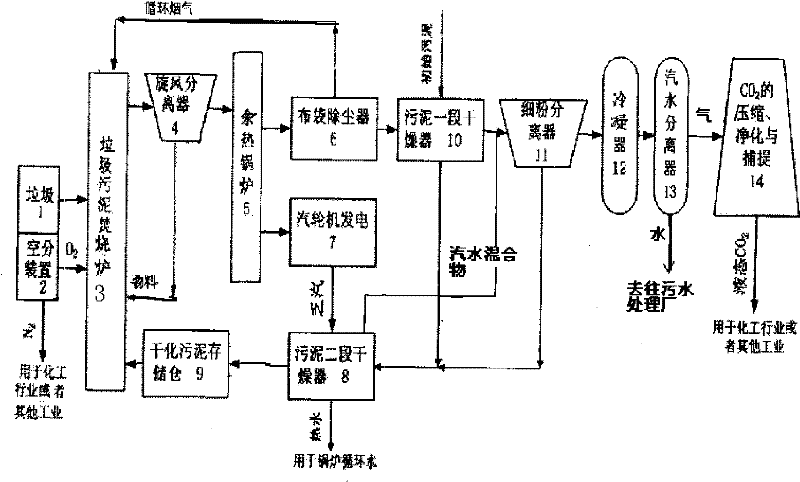

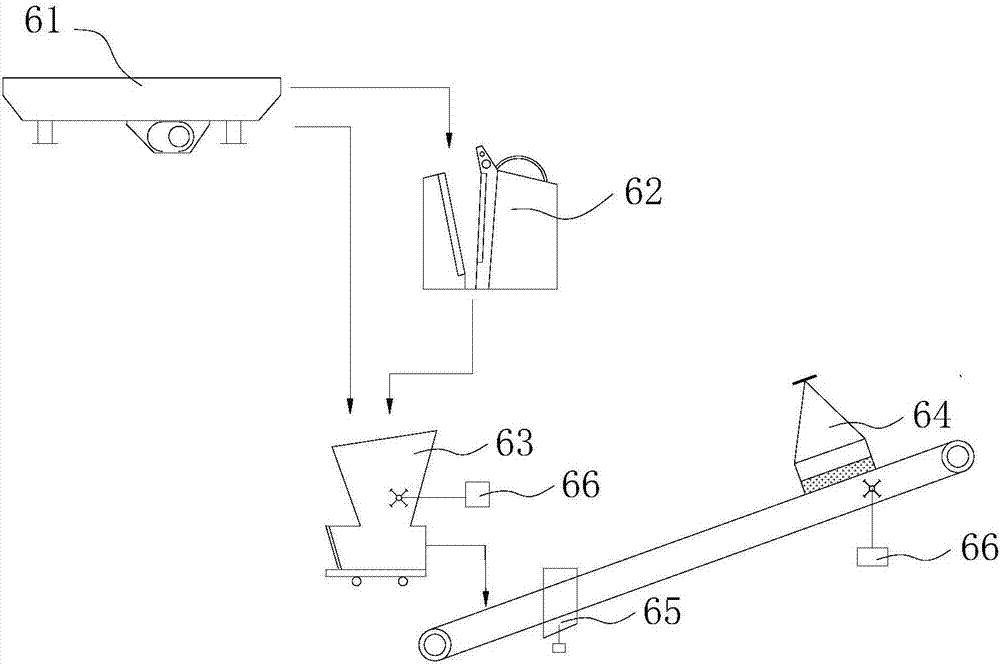

Sludge drying and incinerating integrated zero-discharge treatment system and treatment process

InactiveCN102531318AGood effectLow running costSludge treatment by de-watering/drying/thickeningIndirect carbon-dioxide mitigationSludgeToxic material

The invention discloses a sludge drying and incinerating integrated zero-discharge treatment system and treatment process, belonging to the technical field of harmless treatment of sludge. The treatment system is composed of a garbage storage pit, an air separation device, a garbage-sludge incinerator, a cyclone separator, a waste heat boiler, a bag-type dust remover, a turbo-generator set, a two-stage drier, a dried sludge storage bin, a fine powder separator, a condenser, a steam-water separator, and a carbon dioxide purifying and catching system. According to the invention, the dried sludge burns sufficiently in oxygen-rich atmosphere, the auxiliary fuel is saved, the incinerating waste heat is efficiently recovered and utilized, CO2 in discharged flue gas is cooled, purified, compressed and liquefied to ultimately obtain high-purity CO2 which can be used for industrial application, other impurities are recovered, dioxin and other extremely toxic substances are collected separately and conveyed to qualified divisions for unitized treatment, the purposes of treating a waste with another waste and promoting harmless treatment with resource treatment are realized, the waste treatment cost is lowered and the energy utilization rate is improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

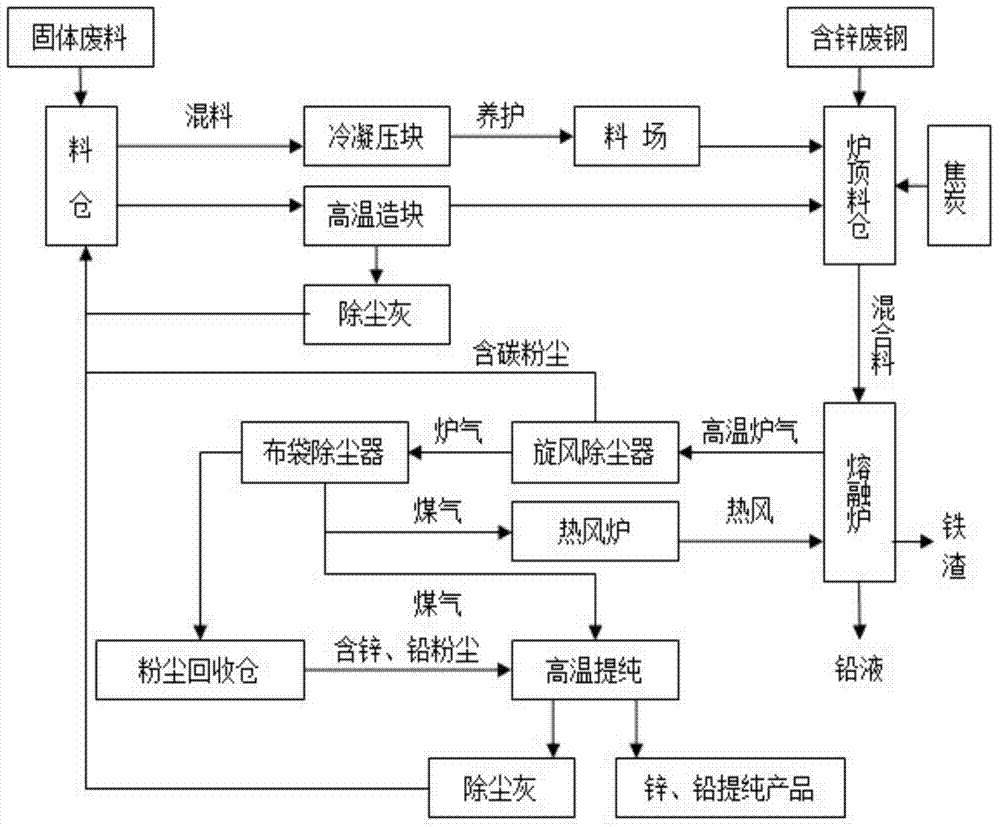

Process method for processing solid waste of steelworks by utilizing smelting furnace

The invention relates to a process method for processing iron-containing solid waste of steelworks by utilizing a smelting furnace. The process method comprises the following steps: with blast furnace dust containing zinc and lead, revolving furnace sludge, electric furnace fly ash, slag metal, waste metal and the like as principal raw materials, carrying out condensation agglomeration and high-temperature agglomeration, and carrying out operations such as maintaining or cooling and granulation so as to obtain finished agglomerates; after mixing the finished agglomerates with coke, sending the mixture into the smelting furnace to be subjected to high-temperature smelting, simultaneously adding the waste such as zinc-containing waste into the smelting furnace in a certain proportion to finally generate high-temperature mixed gas, separating elements such as carbon from the mixed gas by utilizing a cyclone dust collector at the top of the furnace, recycling carbon-containing dust again, further separating the residual mixed gas by utilizing a bag-type dust collector so as to obtain zinc-rich and lead-rich dust, and recycling the zinc-rich and lead-rich dust and applying the zinc-rich and lead-rich dust to the high-temperature agglomeration, the hot air preheating of the smelting furnace and a smelting furnace purification process; then purifying the collected zinc-rich and lead-rich dust, so as to obtain high-purity zinc and lead products; regularly opening a lead discharging hole in the bottom of the smelting furnace, and collecting lead liquid so as to simultaneously obtain wet lead and products such as molten iron and furnace slag.

Owner:卢龙宏赫废料综合利用有限公司

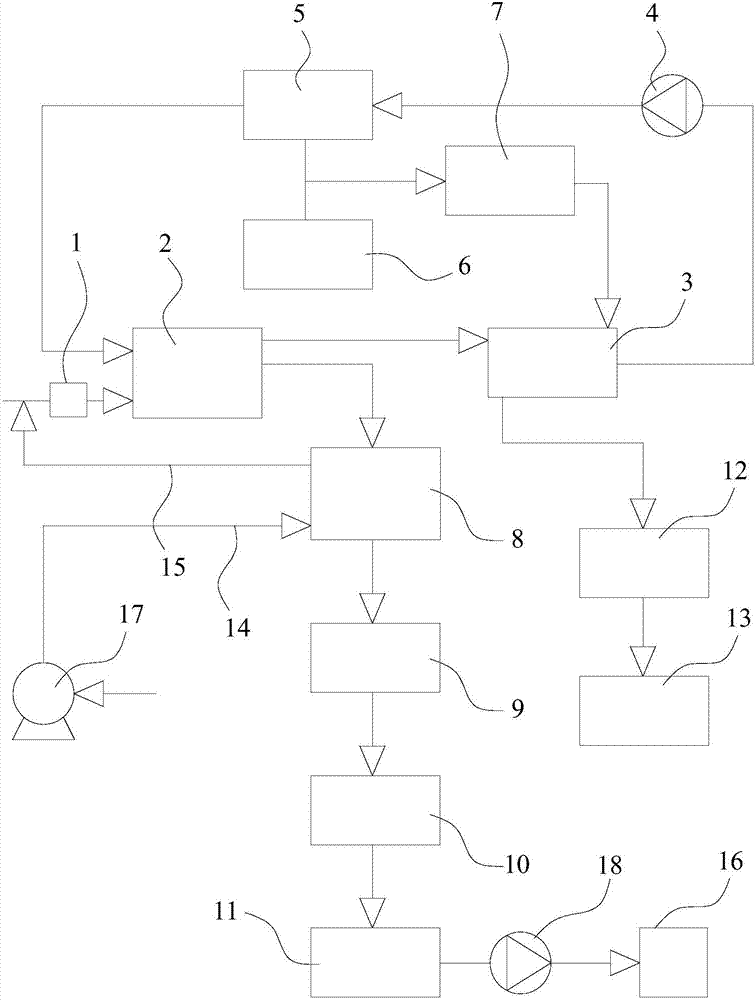

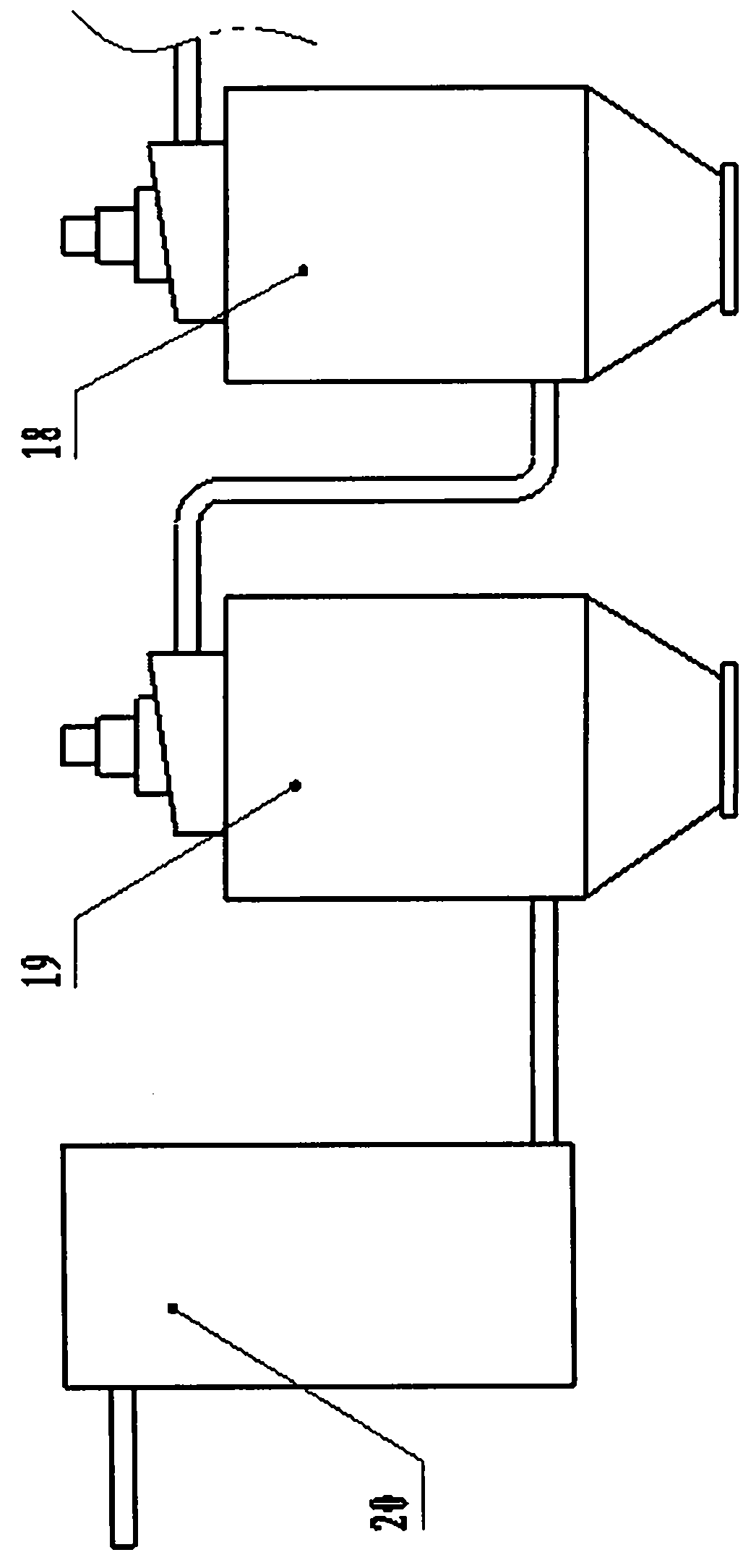

Multistage spray and fluidized drying equipment

ActiveCN103277985AReduce hanging phenomenonLarge specific surface areaDrying solid materials with heatHearth type furnacesBaghouseFluidized bed

The invention discloses multistage spray and fluidized drying equipment and relates to multistage spray and fluidized drying equipment with upward air exhausting. The multistage spray and fluidized drying equipment is satisfactory drying equipment applicable to various materials with different features, such as dairy products, mirco-encapsulated essence, coffee mate, yolk powder and fruit and vegetable powder. The multistage spray and fluidized drying equipment comprises a multistage spray drying tower, an in-tower fluidized bed, a cyclone separator, a bag-type dust collector, an external fluidized bed, a main tower air supply fan, a main tower air supply filter, a main tower air supply heater, an in-tower fluidized bed air supply fan, an in-tower fluidized bed air supply heater, an internal fluidized bed air supply filter, an external fluidized bed air supply fan, an external fluidized bed air supply heater, an external fluidized bed air supply filter, a bag-type dust collector off-gas exhausting machine, a bag-type dust collector fine-powder air supply fan, a bag-type dust collector fine-powder air supply filter, a main tower star-shaped discharging valve, a bag-type dust collector star-shaped discharging valve, a product powder distributor, a feed feeding and metering pump, a feed solution buffer tank and a waste heat recoverer.

Owner:WUXI SUNSHINE DRYNESS EQUIP

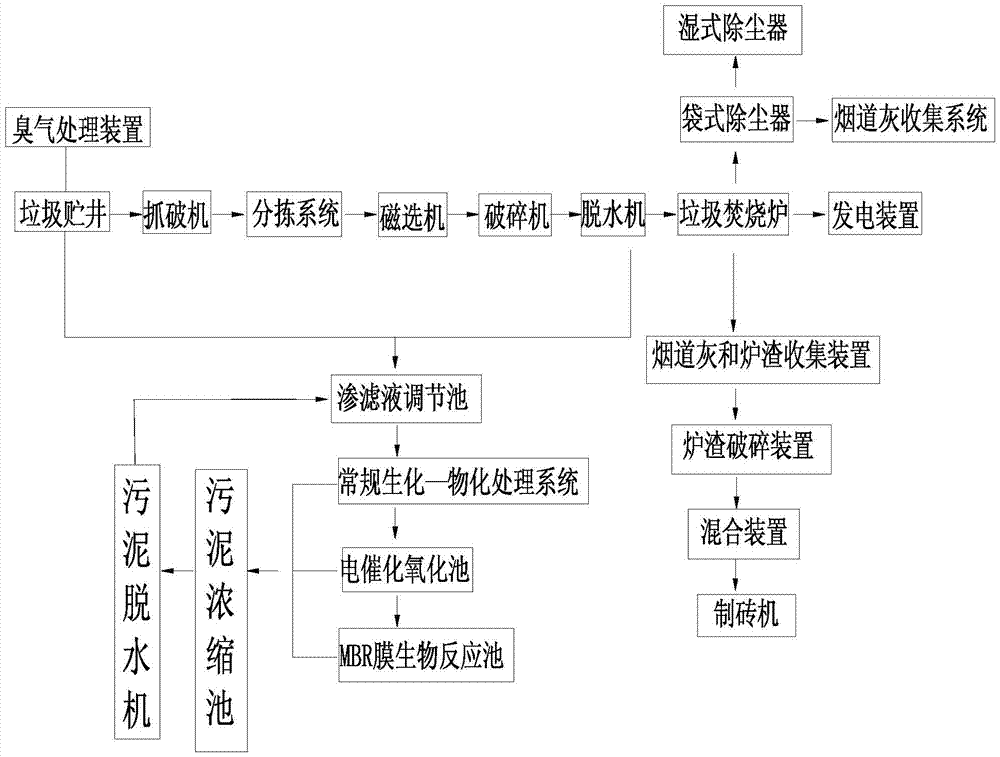

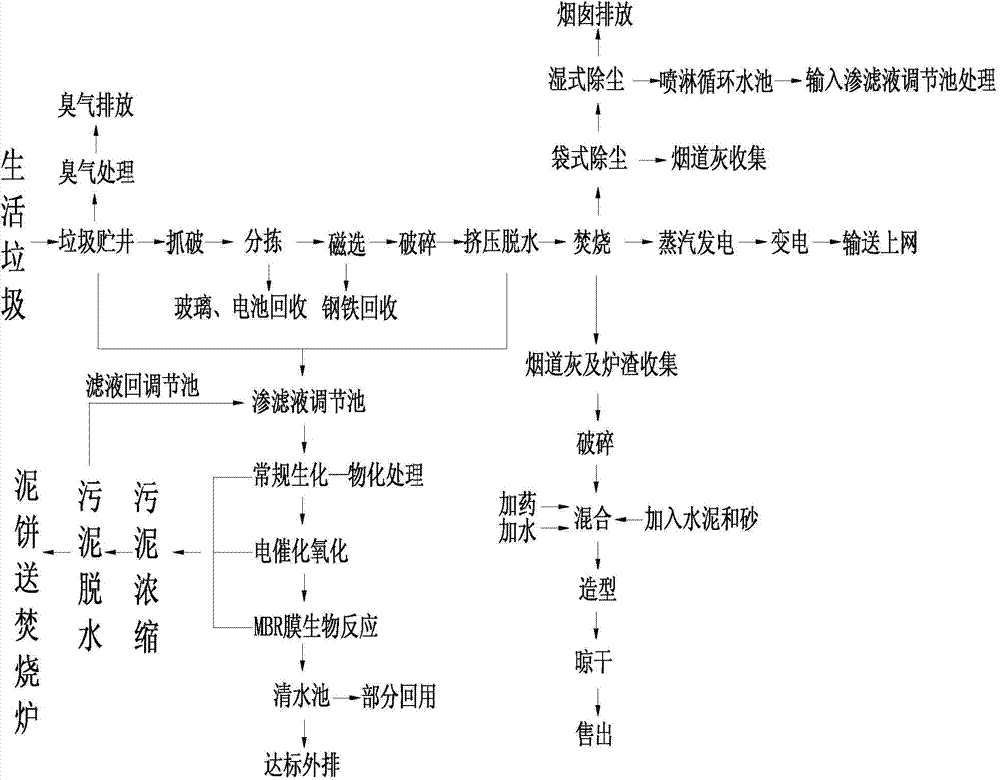

Environment-friendly device matched with efficient and pollution-free refuse incineration power generation and using technology thereof

ActiveCN103900090AGuaranteed normal processingReduce pollutionCombination devicesMultistage water/sewage treatmentSlagCollection system

The invention relates to the technical field of refuse incineration power generation and particularly discloses an environment-friendly device matched with efficient and pollution-free refuse incineration power generation and a using technology of the environment-friendly device matched with efficient and pollution-free refuse incineration power generation. On the basis of an existing refuse incineration power generation system, a pre-treatment system, a flue gas treatment system and a leachate treatment system are additionally arranged. The pre-treatment system comprises a scratching machine, a sorting system, a magnetic separator, a crusher and a dehydrator. The flue gas treatment system comprises a bag type dust collector and a wet type dust collector, and a slag outlet of the bag type dust collector is provided with a flue dust collecting system. A leachate adjusting pool is sequentially connected with a convectional biochemical-physicochemical treatment system, an electrocatalytic oxidation pool and a membrane biological reaction pool. Through the environment-friendly device matched with efficient and pollution-free refuse incineration power generation and the using technology of the environment-friendly device matched with efficient and pollution-free refuse incineration power generation, generation of dioxin precursors is greatly reduced or even eliminated, and therefore first, pollution is reduced, and second, waste treatment cost is reduced and the national emission standard can be reached. The environment-friendly device matched with efficient and pollution-free refuse incineration power generation has prominent innovation, the generating capacity is improved by more than 1.5 times, and the tough problem of environmental pollution is solved comprehensively and thoroughly.

Owner:深圳市宇力科技有限公司

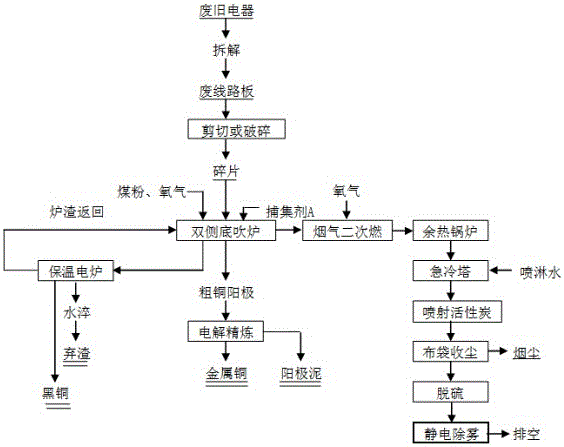

Complete equipment and method for extracting and purifying precious metals from waste circuit boards

ActiveCN106086415AComponent adaptabilitySimple preparationProcess efficiency improvementPrinted circuit boardQuenching

The invention discloses complete equipment and a method for extracting and purifying precious metals from waste circuit boards. The complete equipment comprises a bottom-blowing furnace, a secondary smoke combustion furnace, an absorption tower, a pulsed jet cloth filter, a wet desulfurization device and an electrostatic precipitation defogging device, and is characterized in that smoke generated by the bottom-blowing furnace is discharged through a flue arranged on the top of the bottom-blowing furnace; the flue communicates with an inlet of the secondary smoke combustion furnace; the secondary smoke combustion furnace communicates with a spraying quenching tower through a smoke waste heat boiler; an outlet of the spraying quenching tower communicates with the pulsed jet cloth filter through the absorption tower; an activated carbon spraying device is arranged inside the absorption tower; the pulsed jet cloth filter communicates with the wet desulfurization device; and the wet desulfurization device communicated with a chimney through the electrostatic precipitation defogging device. Effective separation and respective enrichment and recycle of various metals are achieved, organic substances are used as fuel, and no secondary pollution is generated for the environment. The process procedure is short, and the remarkable economic, environment-friendly and social benefits are achieved.

Owner:江西自立环保科技有限公司

Efficient waste heat using organic contaminated soil displacement thermal desorption repairing system and method

ActiveCN107971330AReduce consumptionEmission reductionCombination devicesDispersed particle filtrationAir preheaterThermal desorption

The invention relates to an efficient waste heat using organic contaminated soil displacement thermal desorption repairing system and method. A burner is communicated with a high temperature oxidizingchamber, a high temperature smoke pipe of the high temperature oxidizing chamber is communicated with a rotary kiln heating processing system and an air heat exchanger, a high temperature air outletof the air heat exchanger is communicated with the burner, a smoke pipe of the air preheater is communicated with an inlet of a quench tower, an outlet of the quench tower is communicated with an inlet of a bag-type dust collector, an outlet of the bag-type dust collector is communicated with an inlet of a deacidification tower, an outlet of the deacidification tower is communicated with an air inlet of a second induced draft fan, and an outlet of the second induced draft fan is communicated with a chimney. A part of high temperature flue gas generated by the burner enters a rotary kiln thermal desorption reactor to achieve desorption of organic pollutant and soil drying pretreatment, organic matter enters the high temperature oxidizing chamber through a backflow pipe for burning treatment, and thorough oxidative degradation removal is achieved; and the other part of high temperature flue gas is used for increasing the temperature of combustion air through the air heat exchanger.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

Equipment for deeply treating superfine classifiable garbage waste material particles

ActiveCN106807529ACrushed fullySolve the disadvantages of hasty dischargeGrain treatmentsBaghouseAmbient air

The invention discloses equipment for deeply treating superfine classifiable garbage waste material particles. The equipment comprises a top screening and filtering barrel. The lower portion of the top screening and filtering barrel communicates with a primary pulverization chamber. A deep pulverization chamber is formed below the primary pulverization chamber. A first filtering screen, a second filtering screen and a third filtering screen are each arranged in an inclined manner with the left portion being high and the right portion being low, and multiple screen holes different in size and diameter are formed in a screen body of each filtering screen. A top outlet of a material elevator returns into the top screening and filtering barrel through a material conveying pipe. A cooling sleeve is arranged on the outer side wall of a chamber body of the deep pulverization chamber. The end of a dust collection pipe is connected to a bag-type dust collector. By means of the equipment for deeply treating the superfine classifiable garbage waste material particles, deep pulverization can be conducted on waste materials; the waste material particles different in diameter size can be collected in a classified manner, and classified collection is conducted more definitely; and in addition, by means of the cooling sleeve, the temperature of the chamber body can be lowered rapidly, and the situation that ambient air is polluted due to dust scattering is prevented.

Owner:NINGXIA RUISHENG MINGJIE INTPROP CONSULTING CO LTD

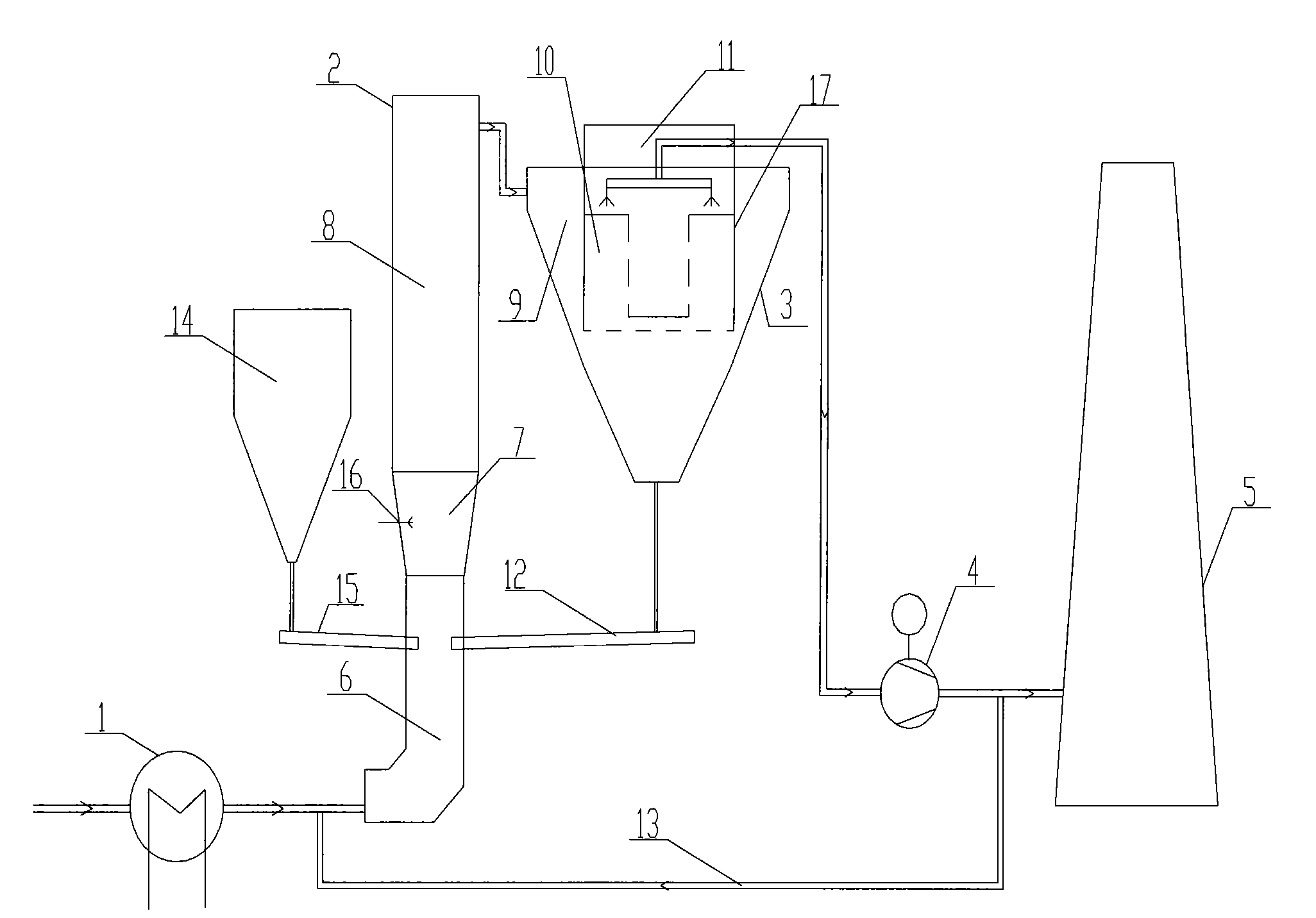

Clearing device for smoke pollutants of glass kiln and clearing method thereof

InactiveCN101628201ASolution to short lifeReduce loadCombination devicesGlass furnace apparatusSmall footprintEngineering

The invention relates to smoke treatment, in particular provides a clearing device for smoke pollutants of a glass kiln and a clearing method thereof. The clearing device is suitable for the glass kiln with high smoke temperature, smaller smoke amount, high clearing efficiency, stable system operation, simple structure and small floor area and is provided with an afterheat recovery boiler, a reaction tower, a bag dust collector, a circulating fluidization flume, a clean smoke recirculating flue, an absorbent bin and a feeding air flume which are sequentially connected. The clearing method comprises the following steps: smoke emitted by the glass kiln enters the afterheat recovery boiler; original smoke emitted by the afterheat recovery boiler enters a high-temperature reaction region of the reaction tower for premixing treatment with an absorbent, is accelerated by a Venturi accelerating region before entering a circulating fluidization reaction region and is cooled and purified before entering the bag dust collector; the purified smoke emitted from the reaction tower firstly enters the bag dust collector to remove particles and is emitted to a chimney by a draft fan in a purification chamber; and reaction dust emitted by the reaction tower is collected by the bag dust collector and is returned to the high-temperature reaction region.

Owner:FUJIAN LONGKING DSDN ENGINEERING CO LTD

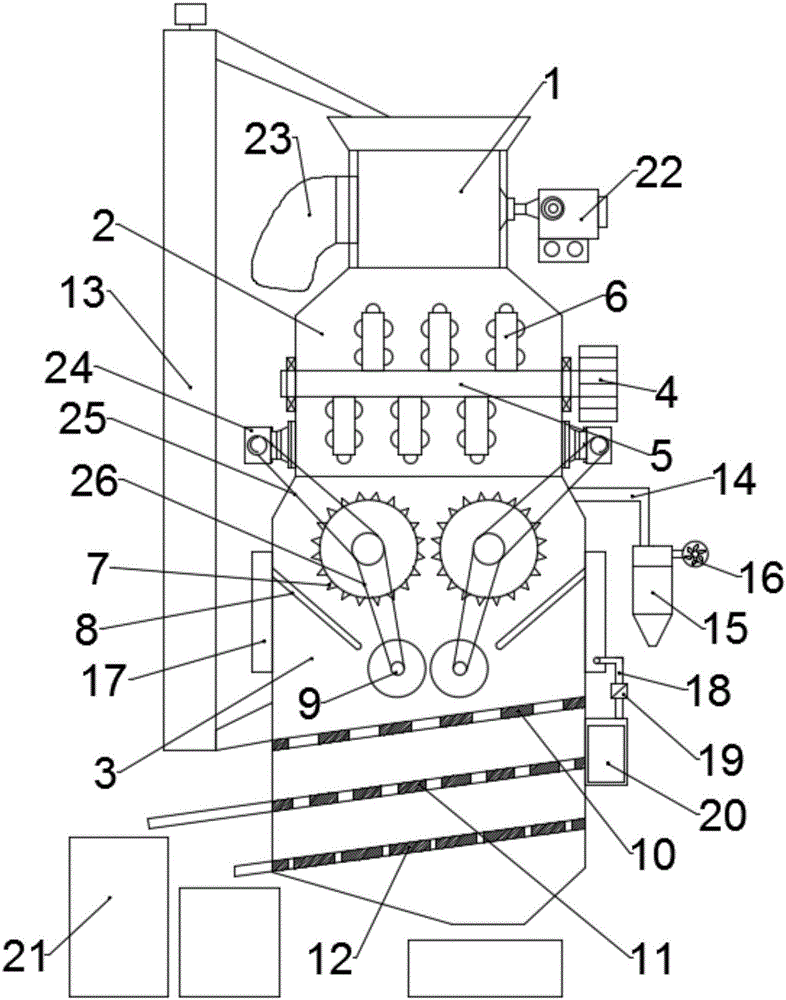

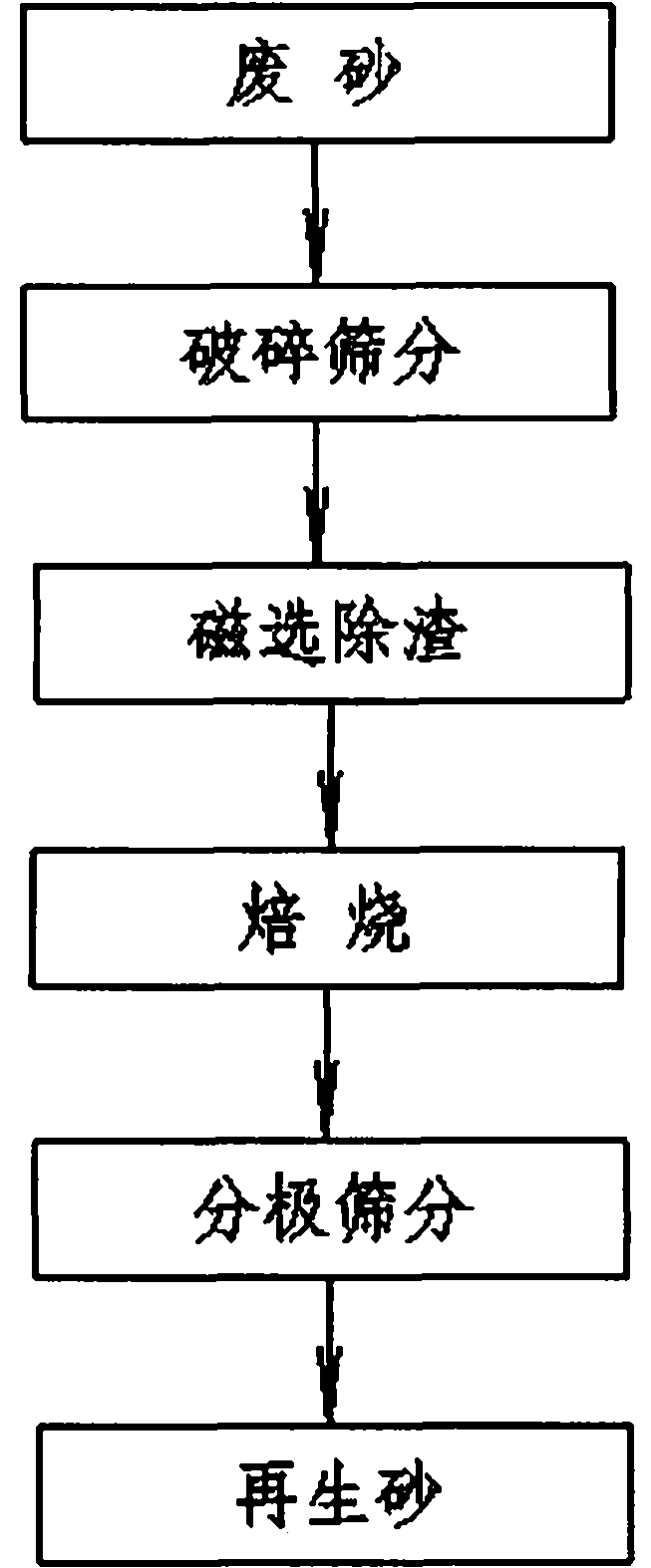

Waste foundry sand regenerating process method

InactiveCN102009122AReduce roasting energy consumptionMould handling/dressing devicesFoundryCombustor

The invention discloses a waste foundry sand regenerating process method, which comprises the processes of crashing and screening, magnetic separation, roasting and graded screening. The roasting process particular comprises the following steps of: preheating waste sand which does not enter a furnace and air for combustion by using the heat of hot sand which is discharged from the furnace; controlling the roasting temperature of a roasting furnace to be between 780 and 850 DEG C by controlling a roasting furnace burner and the flow of the waste sand entering the furnace; separating roasted waste sand from waste gas by using a cyclone dust collector, a spraying dust collector and a bag type dust collector; and exhausting the separated waste gas to the atmosphere after passing through an alkali liquor washing tank and an adsorption tank, wherein the bag type dust collector has a high-pressure air flow blowback control bag dust-removing structure; and the dust-removing process and the normal operation of a system are maintained by controlling the bag dust-removing cycle of the bag type dust collector. Compared with the conventional method, the waste foundry sand regenerating process method has the advantages of greatly reducing energy consumption and guaranteeing the cleaness of the exhausted waste gas.

Owner:LIUZHOU AOKAI ENG MACHINERY

Soil thermal desorption repair process and apparatus

ActiveCN106180169AHigh removal rateWill not cause secondary pollutionCombination devicesGas treatmentAtmospheric airPollution

The invention discloses a soil thermal desorption process and apparatus. The apparatus comprises a soil pretreatment system, a rotary kiln thermal desorption system and a rotary kiln tail gas treatment system. During treatment, to-be-repaired soil is fed into an inflation shed pretreatment field to be subjected to crushing, screening and dehydration pretreatment, and the water content of the soil is controlled to be 20% or less; the soil is conveyed into a thermal desorption rotary kiln to be subjected to thermal desorption treatment under the closed environment, and the treated material is subjected to spraying humidification treatment and then fed into an inspection waiting area to be inspected; and waste gas produced by the rotary kiln is fed into a condensing tower to be condensed, the flue gas temperature is controlled to be 180 DEG C or lower, most dust is removed through a bag dust remover, the waste gas is then fed into an activated carbon absorber so that pollutants in the waste gas can be further removed and is fed into a NOx chemical absorption system so that NOx produced in the combustion process can be purified, and finally, the waste gas is extracted through an induced draft fan and exhausted into the atmosphere through a chimney after the standard is reached. According to the soil thermal desorption process, the pollutant treatment range is wide, the pollutant removal rate is high, and secondary pollution cannot be caused.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

Garbage incineration fume ultralow emission purifying system

PendingCN106621754AImprove removal efficiencyAchieve cleanupCombination devicesGas treatmentActivated carbonPlate heat exchanger

The invention discloses a garbage incineration fume ultralow emission system. A garbage incineration fume purifying treatment device comprises an SNCR (selective non-catalytic reduction) device, a semi-dry type reaction tower, a slaked lime spraying device, an activated carbon spraying device, a bag type deduster, a steam heater, an SCR (selective catalytic reduction) reaction tower, a fume / fume heat exchanger, a wet type scrubbing tower, an induced draft fan and a chimney. The low-temperature fume after washing is performed with heat exchange in the fume / fume heat exchanger, heated, and exhausted out of the chimney. The garbage incineration fume purifying treatment device has the advantage that the emission of the fume is superior to the European Union 2000 standard.

Owner:SHANGHAI SUS ENVIRONMENT

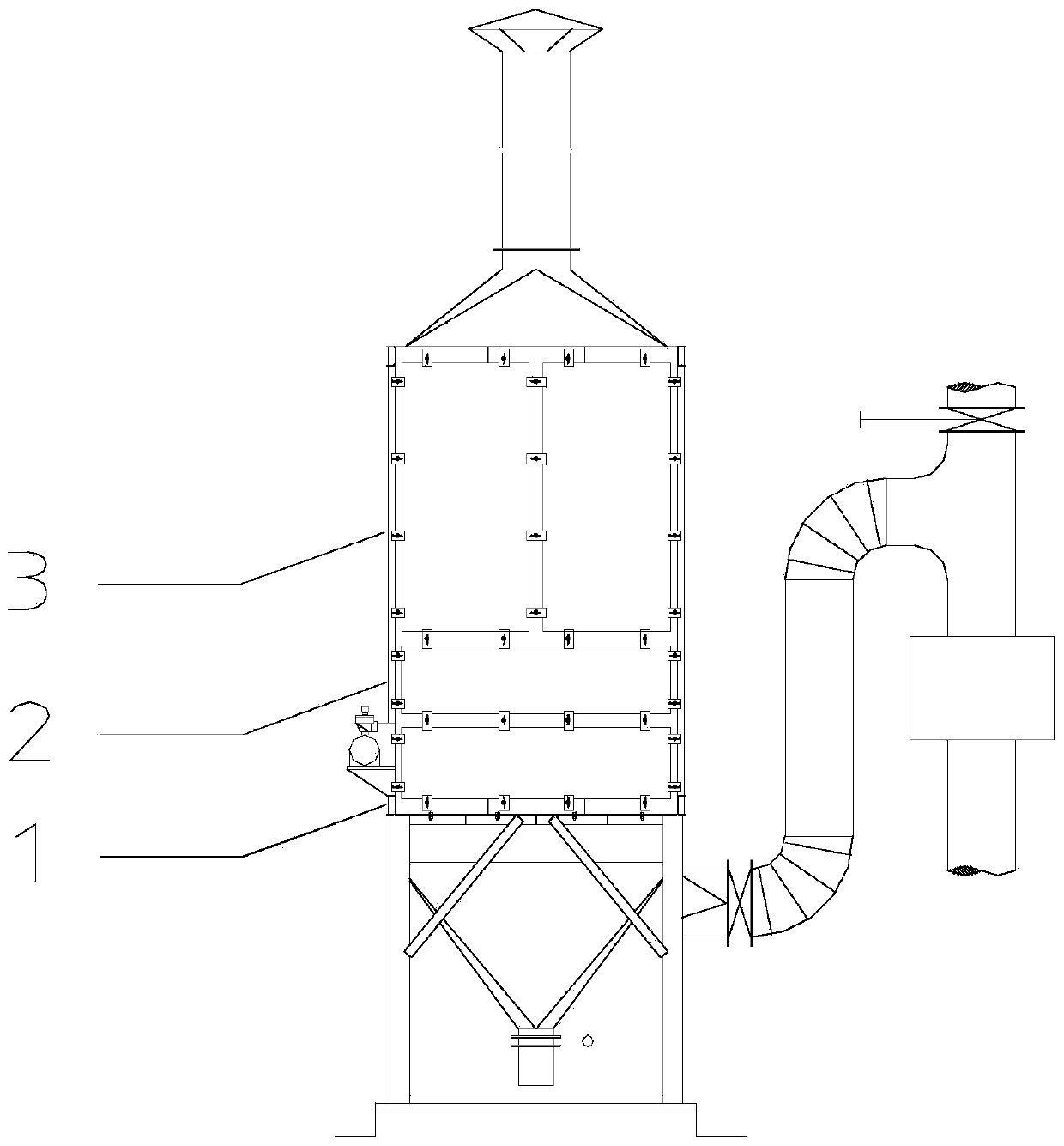

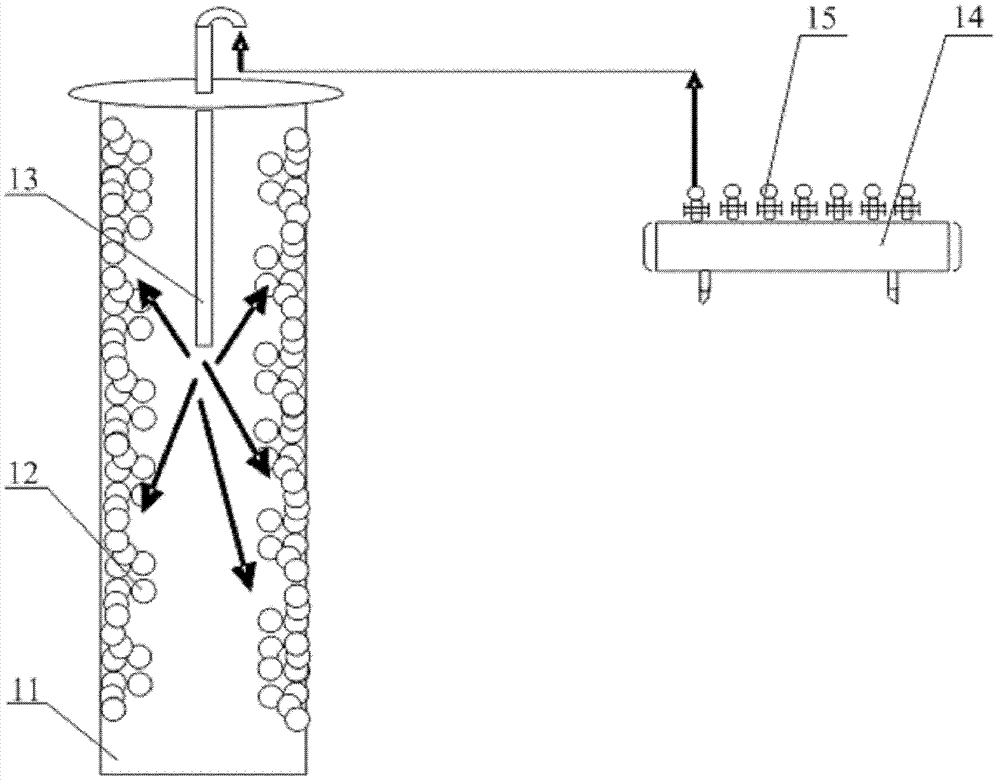

Bag dust remover

InactiveCN102784526ASimple structureReduce manufacturing costDispersed particle filtrationBaghouseEngineering

Owner:SHANDONG RUIYU BATTERY

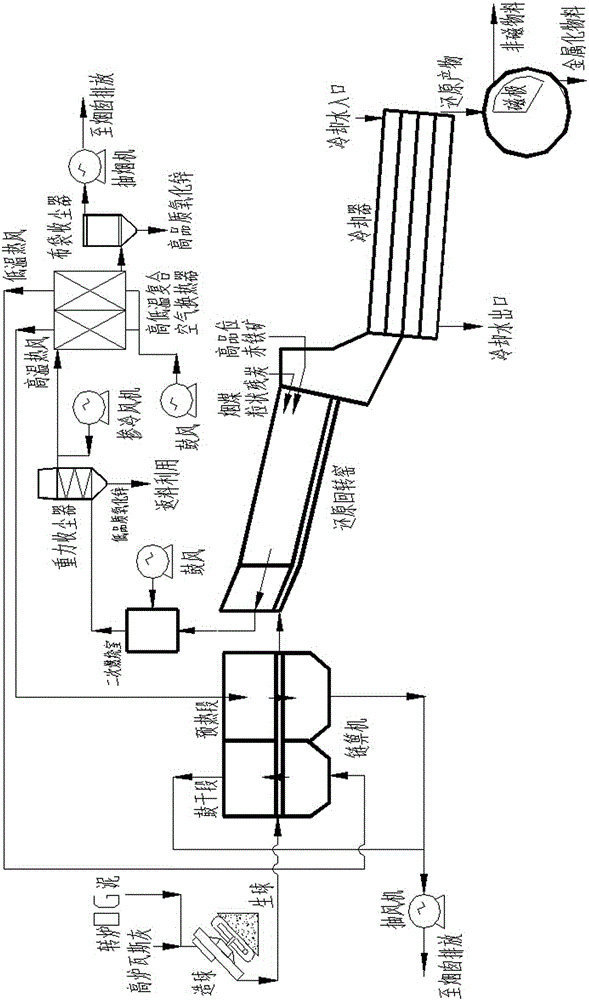

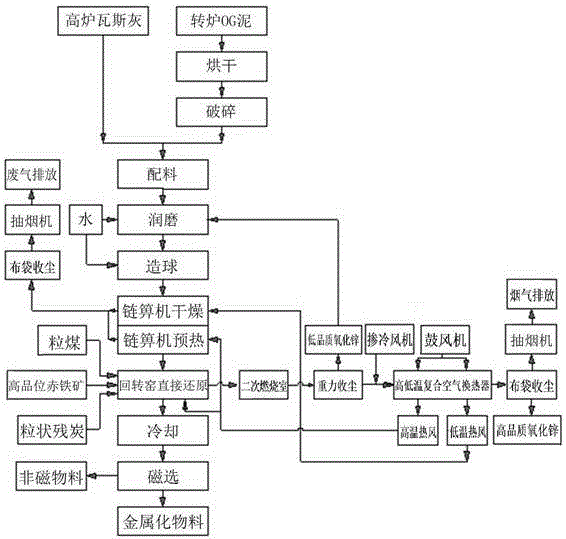

Method for treating high-zinc iron-containing slime through utilizing rotary kiln

ActiveCN106367600AEfficient use ofReduce loadRotary drum furnacesProcess efficiency improvementLarge particleMagnetic separation

The invention relates to a method for treating high-zinc iron-containing slime through utilizing a rotary kiln. The method comprises the steps that blast furnace gas ash and converter OG mud are mixed and pelletized; wet pellets are dried and preheated, and a drying and preheating heat source is hot air generated by high-temperature flue gas of the rotary kiln after passing through a high-low temperature composite air heat exchanger; a pea coal spray gun, a carbon residue spray gun and an ore grain spray gun are arranged at a kiln head of the rotary kiln, and high-volatile matter coal, residual carbon and high-grade iron ore are sprayed into the kiln; the dried pellets are fed into the rotary kiln, and high-temperature metallized pellets are obtained after the dried pellets are subjected to direct reduction and high-temperature solidification in the rotary kiln; after being cooled to the normal temperature, materials like the metallized pellets and excess carbon residue are subjected to magnetic separation, and metallized pellets are obtained; and large-particle dust is removed from the high-temperature flue gas of the rotary kiln, the high-temperature flue gas enters the high-low temperature composite air heat exchanger to be cooled, the cooled flue gas enters a bag-type dust collector, and zinc oxide powder is recycled. According to the method, the high-zinc iron-containing slime generated by iron and steel enterprises is efficiently utilized, and environmental pollution caused by stacking of the high-zinc iron-containing slime is solved.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

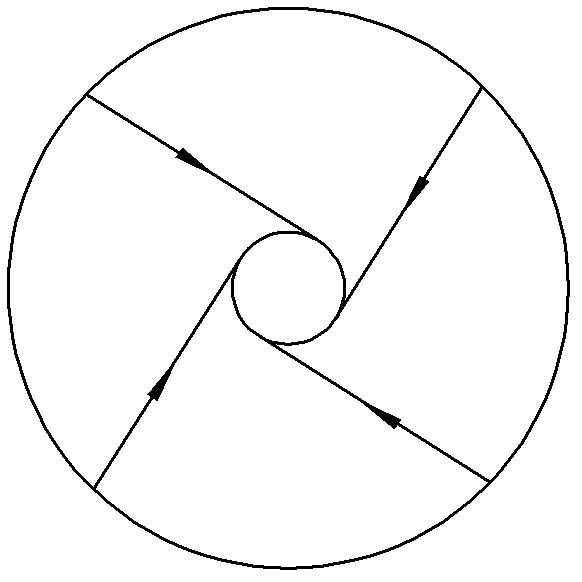

Sintering flue gas desulfurization and purification method and equipment

InactiveCN102380308ASmall running resistanceEasy maintenance and operationCombination devicesPurification methodsFlue gas

The invention discloses a sintering flue gas desulfurization and purification method and equipment, which are characterized by adopting a rotation atomizing semidry method to desulfurize, and the technological process is: sintering flue gas-electrostatic precipitator- main suction fan-desulfurizing tower-pulse bag type dust remover-booster fan-chimney -exhaust, the flue gas is distributed according to a proportion and then enters the desulfurizing tower through a flue gas distributer, the proportion of the flue gas which enters the top part is 55%-65%, the proportion of the flue gas which enters the center is 35%-45%, and a circumferential inlet mode is adopted. Lime slurry is atomized into fog drips of 30-80mum through a high speed revolution atomizer, and is fully contacted with the sintering flue gas which is uniformly distributed by the flue gas distributer at the top part and the flue gas distributer at the center, so the efficient desulfuration purpose is realized. The sintering flue gas desulfurization and purification method and the equipment disclosed by the invention have the advantages of high desulfuration efficiency, automatic regulation of the serous fluid flow, low water consumption, simple system, small operation resistance, convenience in operation maintenance, strong adaptability of sintering conditions, low requirement on desulfurizer quality, comprehensive utilization of byproducts and the like.

Owner:鞍钢集团工程技术有限公司

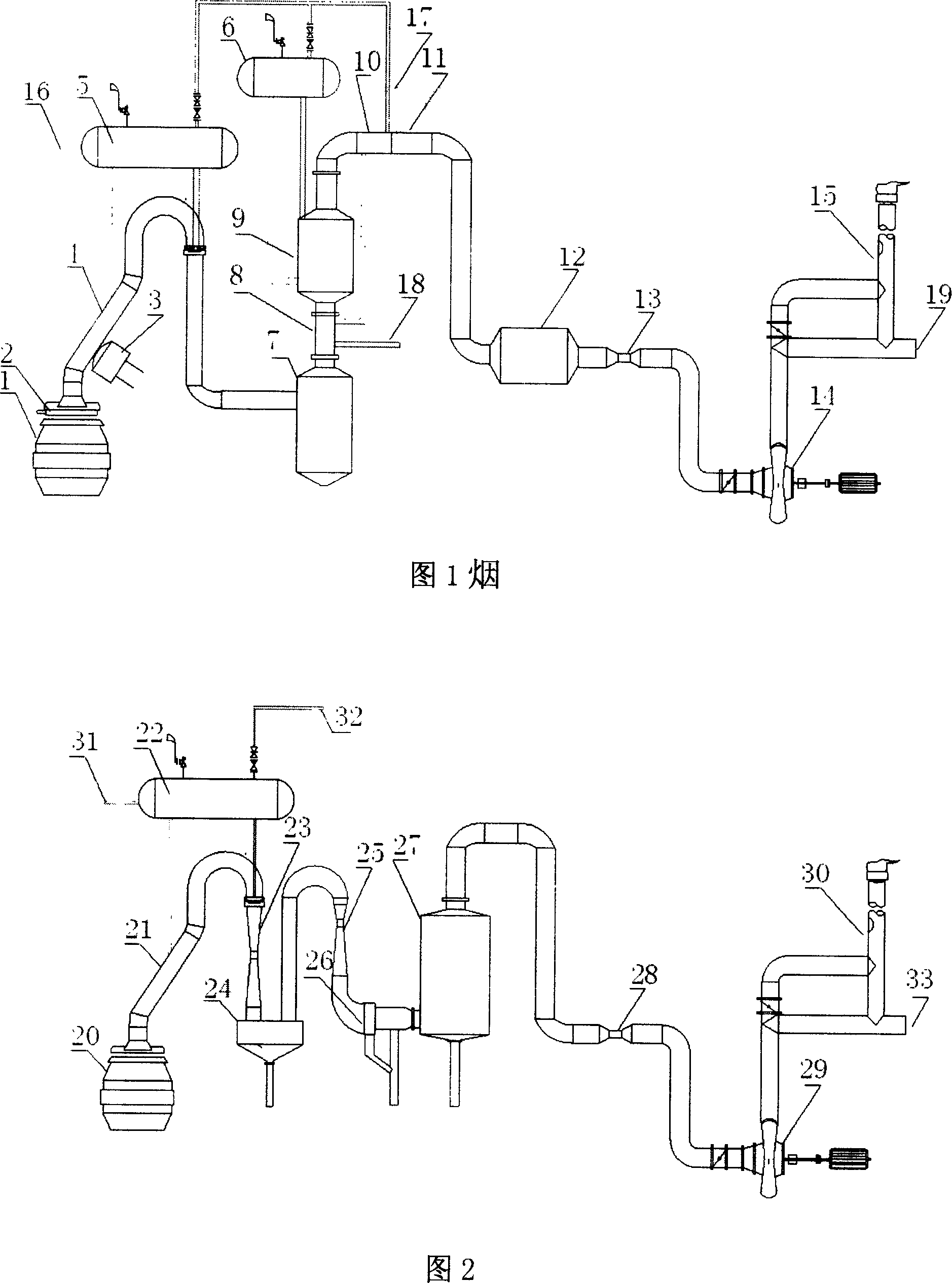

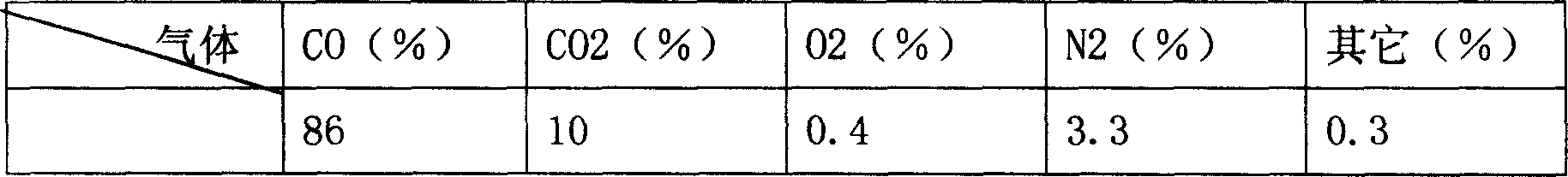

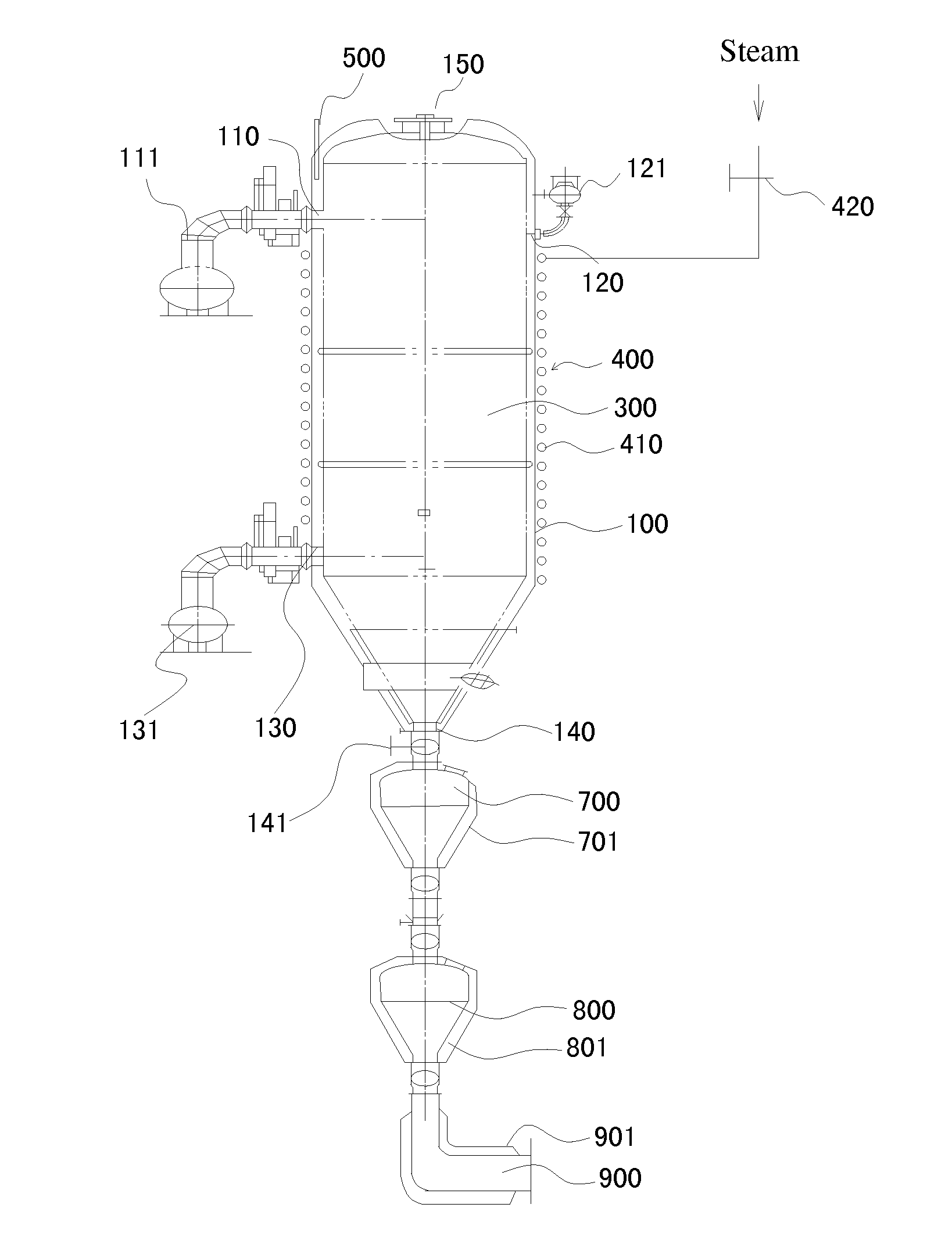

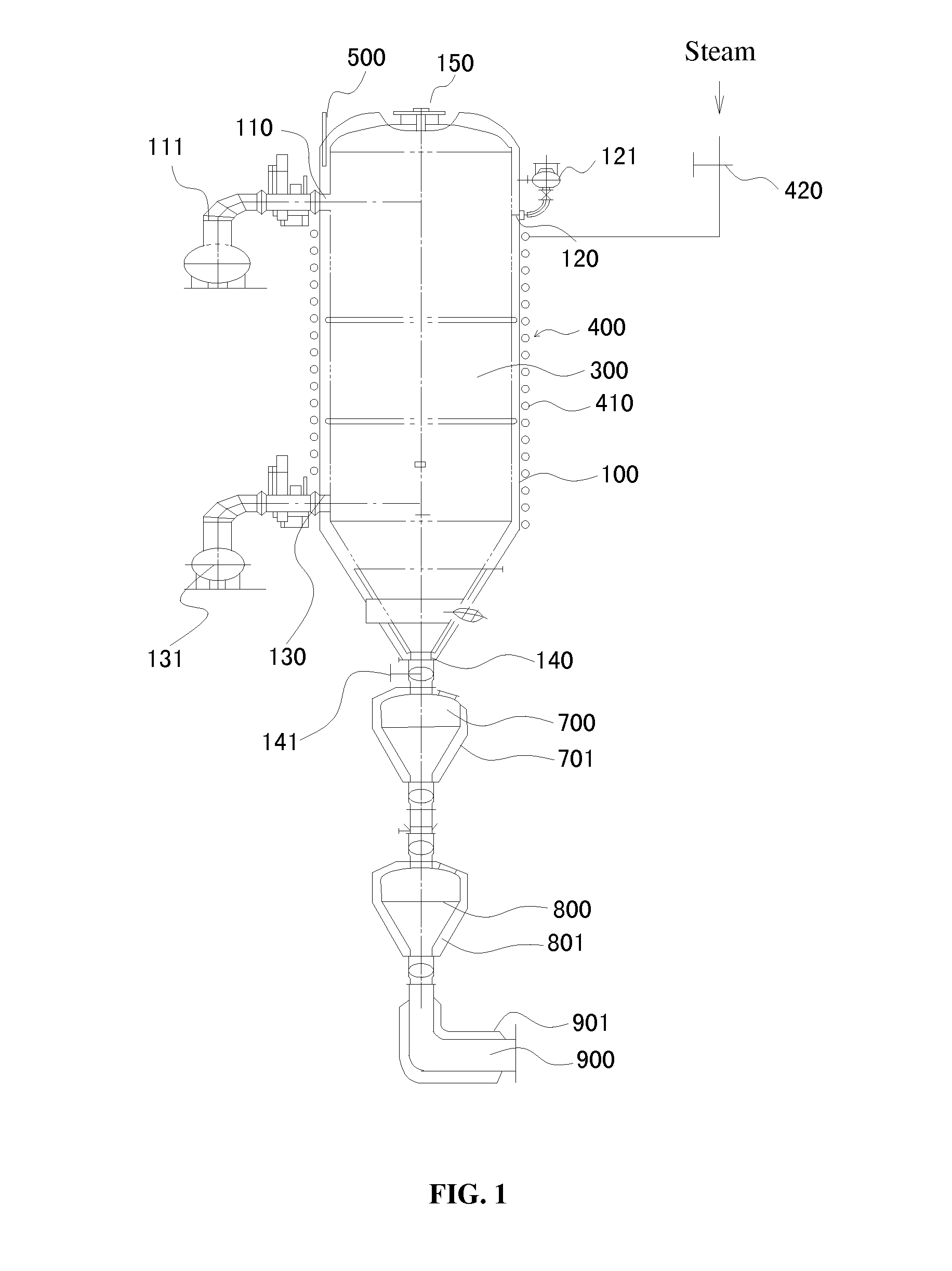

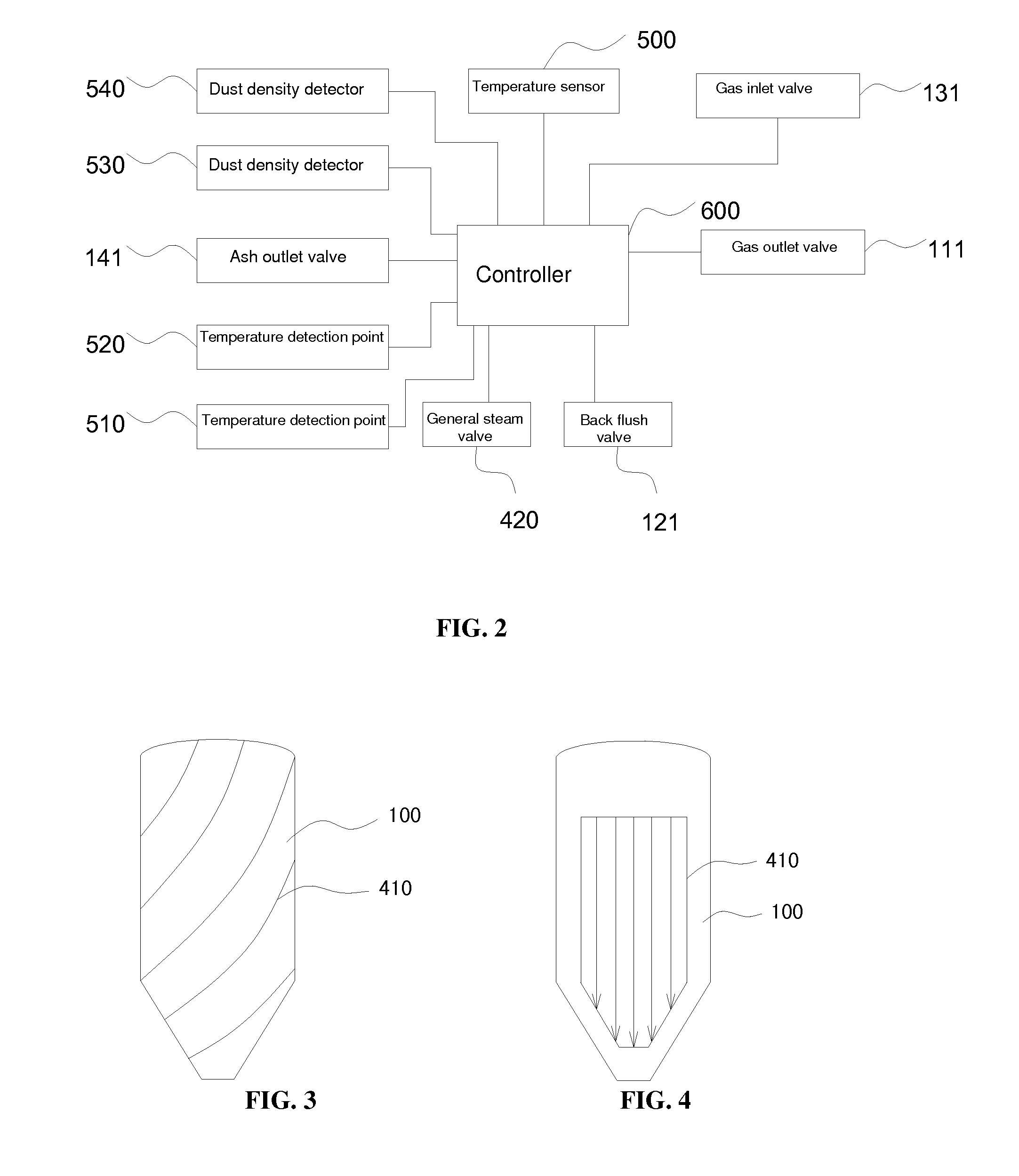

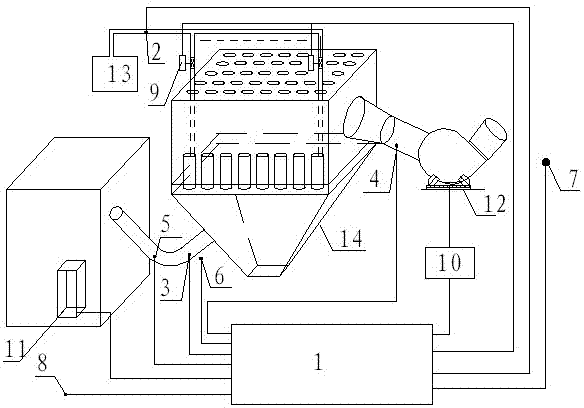

Dust Removal Method Using Baghouse Filters And Dust Removal Apparatus Therefor

ActiveUS20110265652A1Reduce in quantityImprove air tightnessCombination devicesAuxillary pretreatmentPresent methodFluidized bed

A dust removal method using baghouse filter to process raw syngas from fluidized bed coal gasifier, wherein temperature in the baghouse (300) is maintained at 180° C.-250° C., pressure difference between the gas inlet (130) of the baghouse (300) and the gas outlet (110) of the baghouse (300) is controlled at 1000-5000 Pa, the raw syngas from the fluidized bed coal gasifier enters the gas inlet under the pressure of 0.2-3.0 Mpa. The present method effectively solves the technical problems of condensation and baghouse block due to high steam and ash content in the raw syngas from the fluidized bed coal gasifier and the present method is also applicable to remove dusts from the raw syngas produced by the fluidized bed coal gasifier under the conditions of high water-gas ratio (the water-gas ratio is up to 37%), high dust content (15-100 g / Nm3 dusts) and 0.2-3.0 Mpa pressure. The present invention also discloses a baghouse dust collector and a dense phase pneumatic conveying apparatus for the method.

Owner:GAS TECH INST

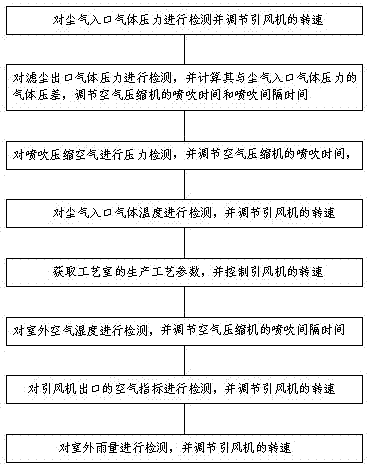

Optimization energy-saving dedusting control method and system of cloth bag pulse dust collector

InactiveCN103521008AExtended service lifeRealize the purpose of energy savingDispersed particle filtrationFrequency changerClosed loop

The invention provides an optimization energy-saving dedusting control method and system of a cloth bag pulse dust collector. The system comprises a main control system electrically connected with a control system of a craft room, a first pressure sensor, a second pressure sensor, a third pressure sensor, a temperature sensor, a humidity sensor, an air detector, a rain sensor, a pulse control valve and a frequency converter, wherein the first pressure sensor, the second pressure sensor, the third pressure sensor, the temperature sensor, the humidity sensor, the air detector, the rain sensor, the pulse control valve and the frequency converter are respectively connected with the main control system. The pulse control valve is arranged in a compressed air pipeline, and the frequency converter is respectively connected with the main control system and an induced draft fan. According to the optimization energy-saving dedusting control method and system, gas temperature and pressure of dust gases at the inlet of the cloth bag dust collector, gas pressure at the outlet of the cloth bag dust collector, pressure of blown compressed air, production process parameters and other data are detected, on the basis of the data, the main control system controls the frequency converter according to set values to control the rotation speed of the induced draft fan, additionally, the main control system is connected with an air detection instrument to achieve closed-loop control of the air speed, the energy-saving purpose is achieved through an optimization control mode, and the optimization energy-saving dedusting control method and system have the advantages of being high in dedusting efficiency and environmentally friendly, saving energy and prolonging the service life of a dedusting cloth bag.

Owner:山东开泰工业科技有限公司

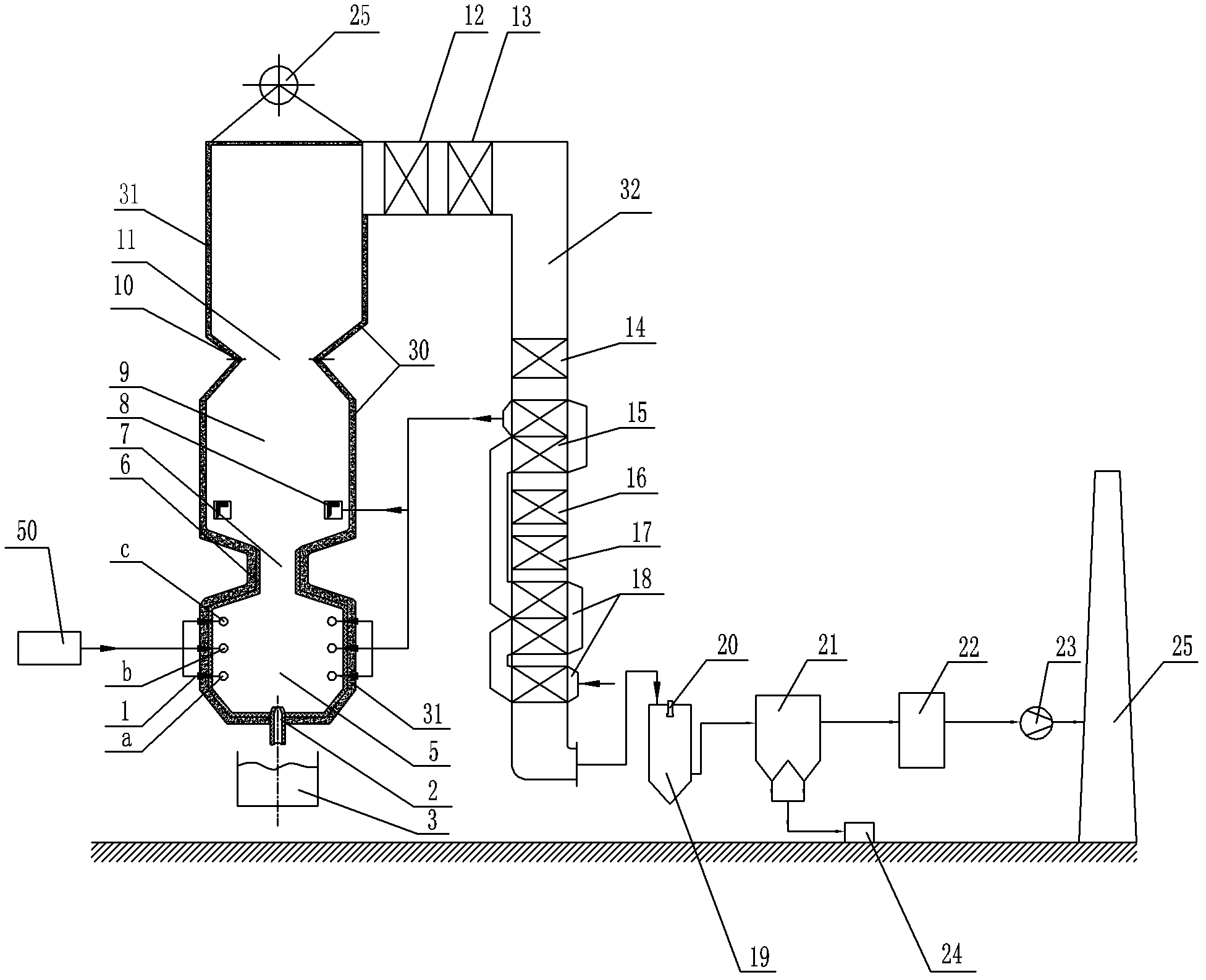

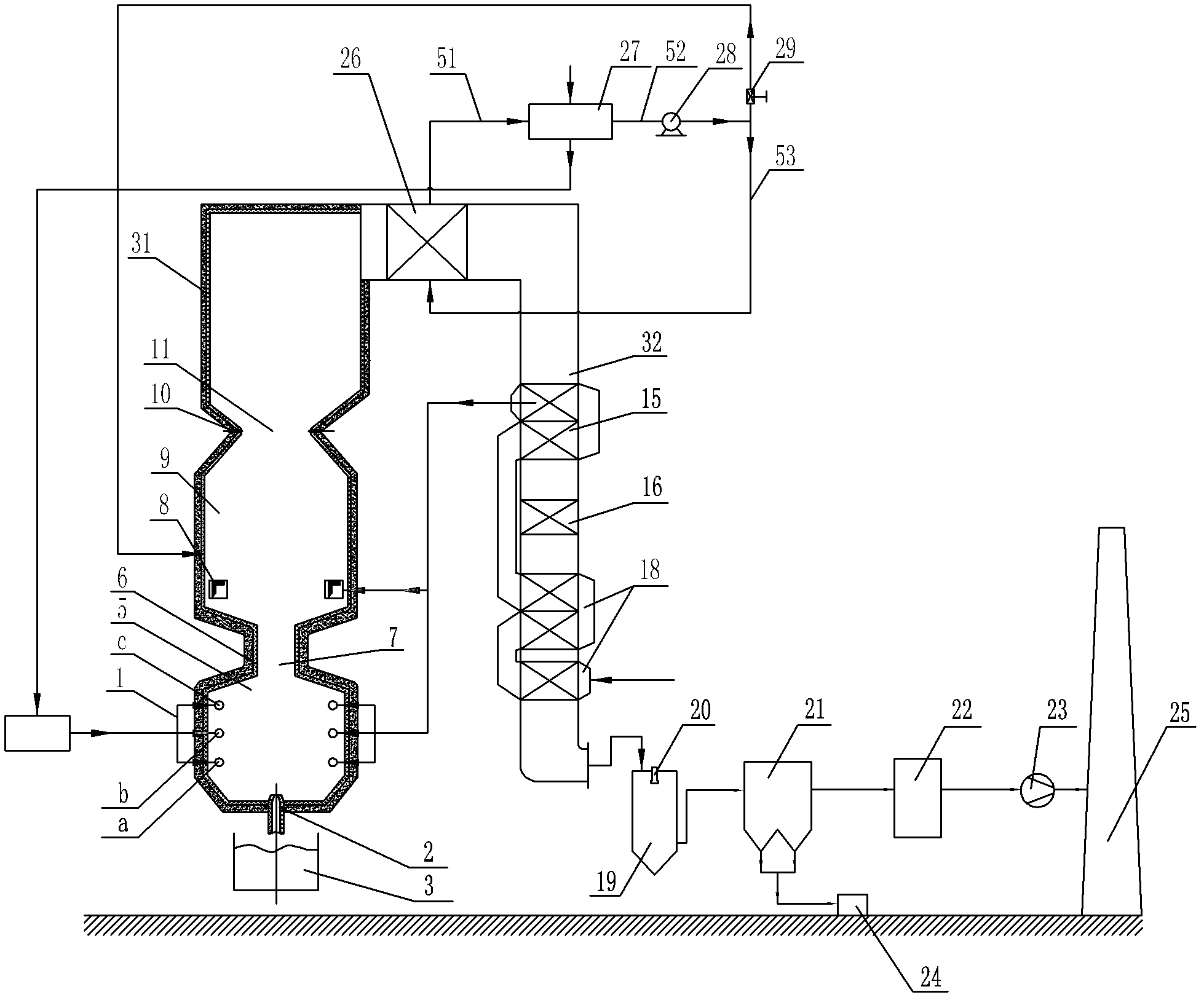

Circulating fluidized bed garbage incineration boiler and pollution control system with same

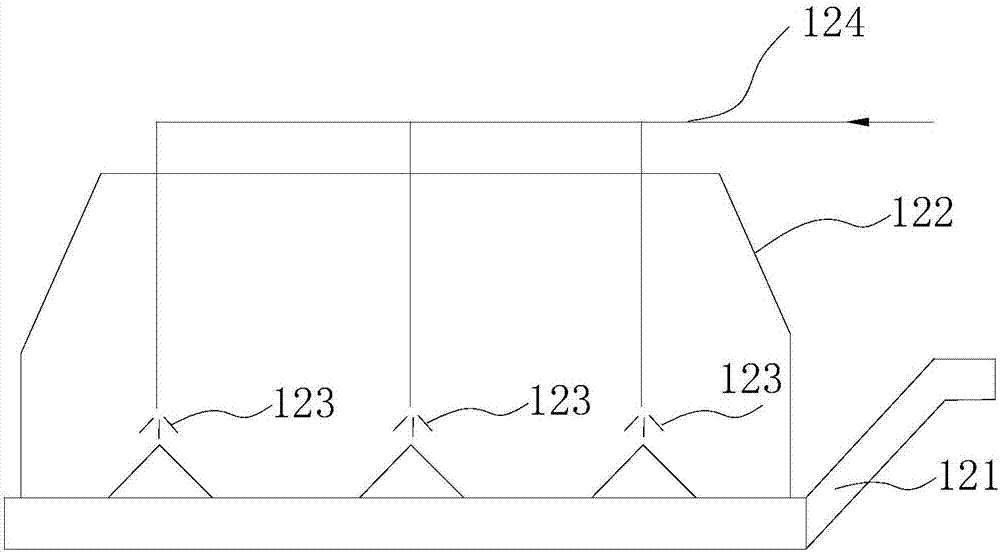

The invention discloses a circulating fluidized bed garbage incineration boiler and a pollution control system with the same, which relate to a garbage incineration boiler and a pollution control system with the same, and aim to solve the problems that the conventional circulating fluidized bed garbage incineration furnace difficultly discharges slag and is required to be stopped regularly to remove the slag and the economy of a garbage incineration plant is influenced. According to the scheme I, a circulating fluidized bed and double V-shaped wind distributing plates are arranged in a boiler body, the boiler body, a separator, a flue gas cooling chamber and a tail flue are communicated in sequence, an upper level low-temperature superheater, a lower level low-temperature superheater, a primary wind air preheater, a secondary wind air preheater, an upper level primary wind economizer, a lower level primary wind economizer, an upper level secondary wind economizer and a lower level secondary wind economizer are arranged in the tail flue, and the separator is communicated with the boiler body by a U-shaped valve; different from the scheme I, the scheme III is characterized in that: double inverted V-shaped wind distributing plates are adopted; different from the scheme III, the scheme V is characterized in that: an inverted V-shaped wind distributing plate is adopted; and according to the scheme II, the scheme IV and the scheme VI, a semidry reaction tower, a bag-type dust collector, an induced draft fan, a chimney, a fly ash cabin, a lime slurry preparation system, a rotary atomizer and an active carbon injecting device are added on the basis of the scheme I, the scheme III and the scheme V. The circulating fluidized bed garbage incineration boiler and the pollution control system with the same are used for incinerating garbage, and pollutant emission can be controlled.

Owner:无锡光核新能源建设有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com