Flue-gas cleaning method and system for waste incineration

A flue gas purification system and waste incineration technology, which is applied in the field of waste incineration flue gas purification and waste incineration flue gas purification system, and can solve problems such as auxiliary machine failure, dust accumulation on the tower wall, wear of the disc and nozzle of the rotary sprayer, etc. , to achieve the effect of facilitating the diffusion of flue gas and high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment the present invention will be described in further detail:

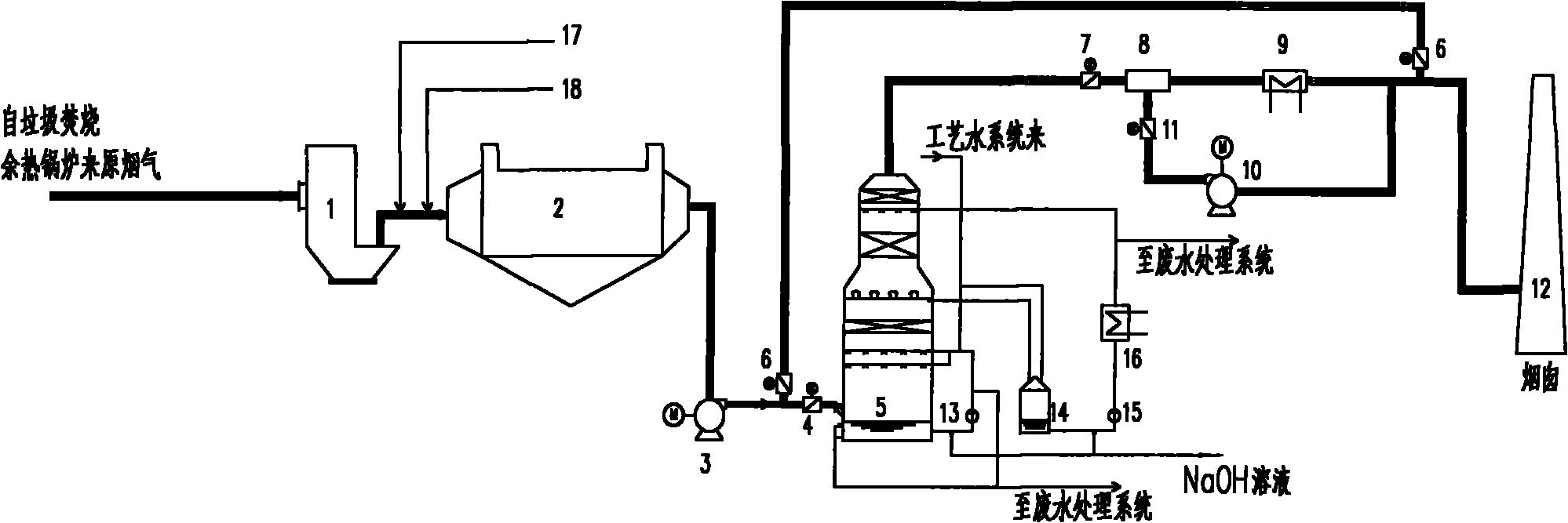

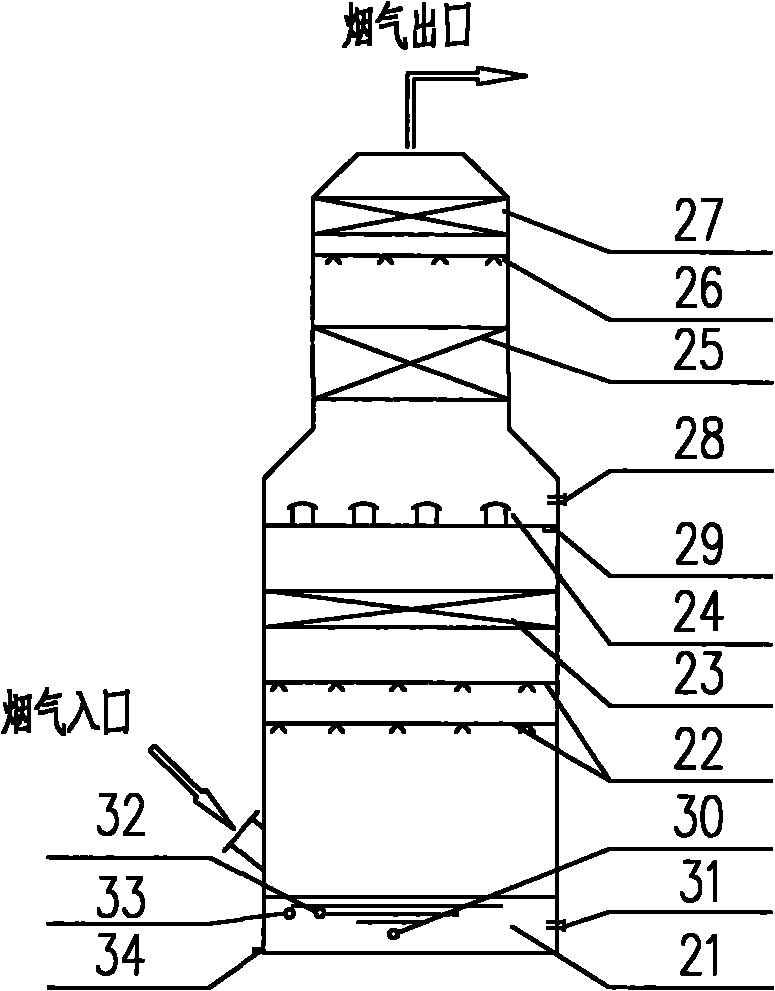

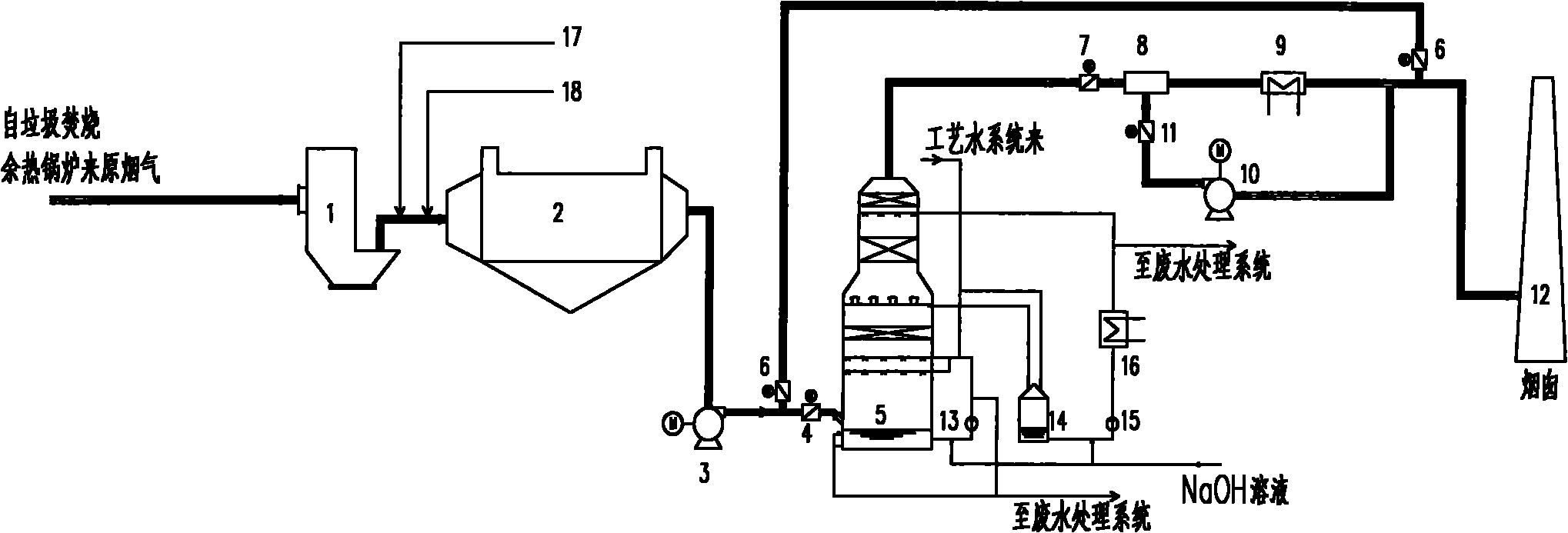

[0026] Such as figure 1 As shown, the process flow of the waste incineration wet flue gas purification process method of the present invention is divided into the following steps:

[0027] (1) Flue gas cooling

[0028] The temperature of the flue gas produced after garbage incineration is relatively high, and a cooling tower 1 is installed between the waste heat boiler and the bag filter 2 to spray water to reduce the temperature of the flue gas. The cooling water and the compressed air pass into the nozzle at the top of the cooling tower 1. The compressed air atomizes the cooling water, and the temperature of the flue gas is reduced from 190°C to about 150°C through the volatilization of moisture. This temperature is suitable for Ca(OH) 2 The temperature at which the adsorption neutralizes the reaction of HCl gas. The cooling effect of this cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com