Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

286 results about "Vertical deflection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

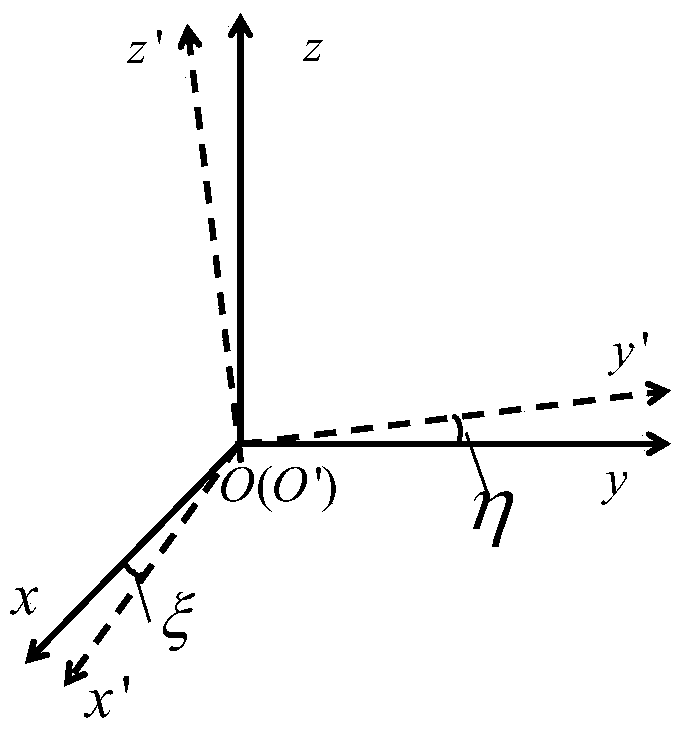

The vertical deflection (VD; also known as deflection of the plumb line and astro-geodetic deflection) at a point on the Earth is a measure of how far the gravity direction has been shifted by local anomalies such as nearby mountains. They are widely used in geodesy, for surveying networks and for geophysical purposes.

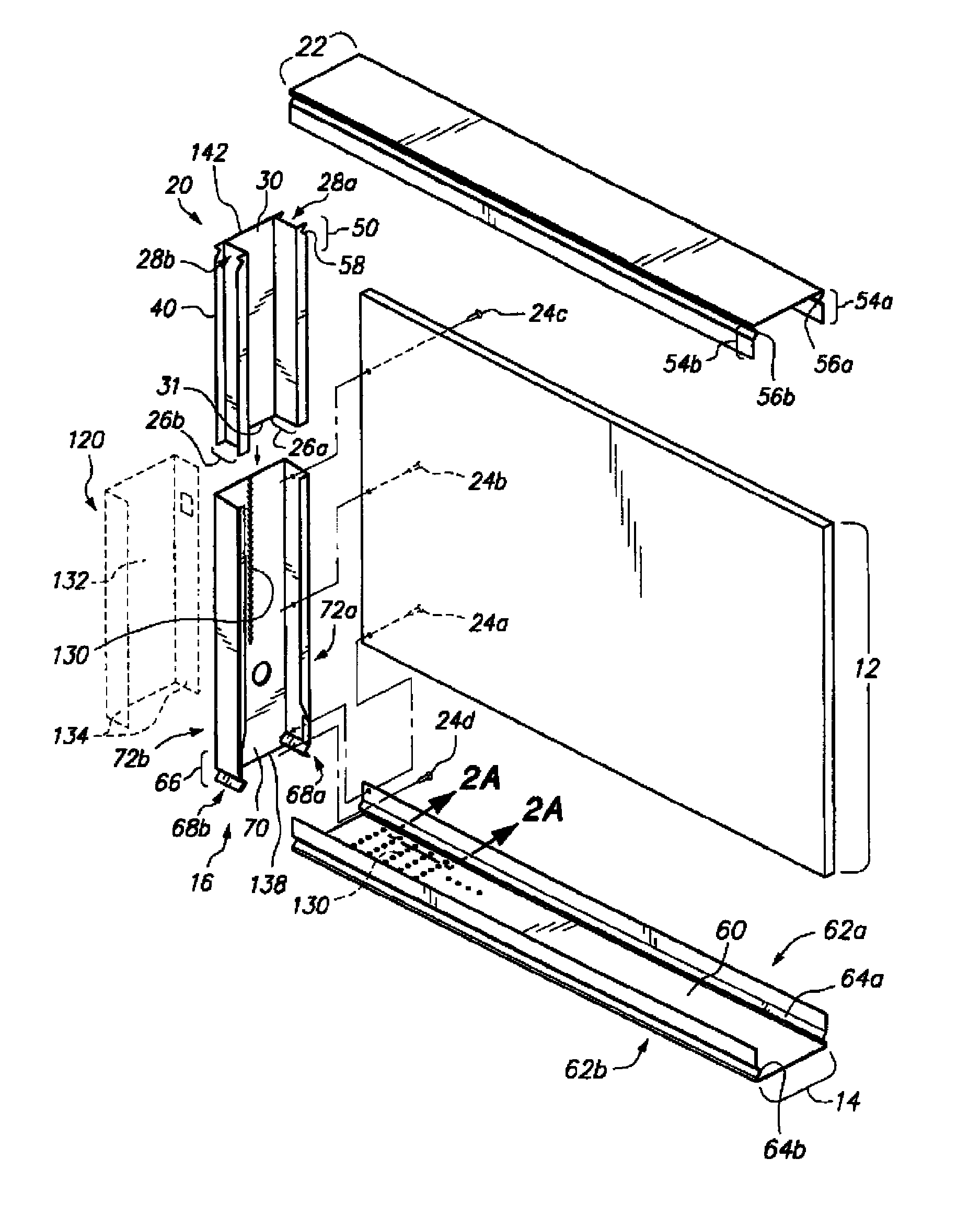

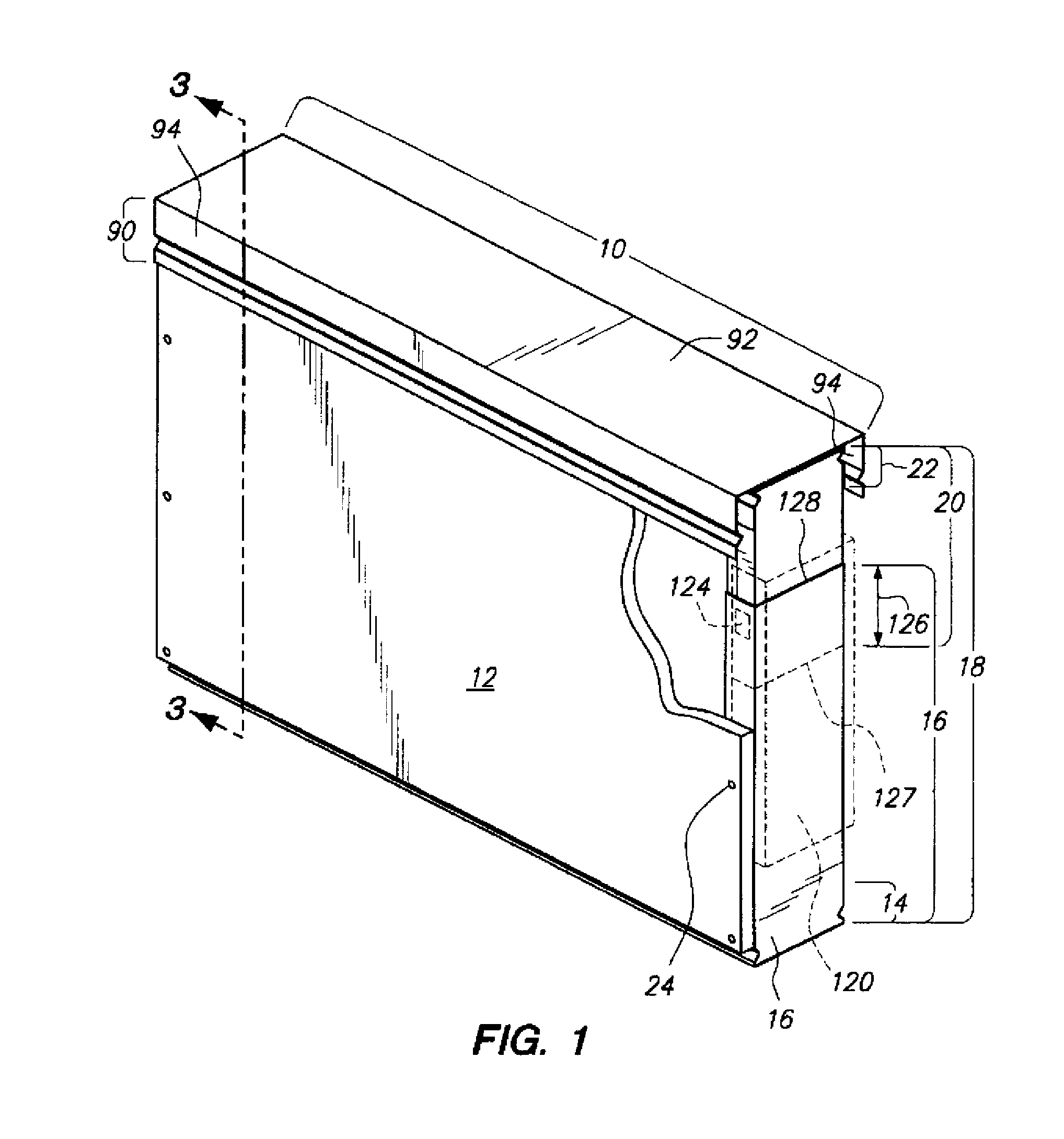

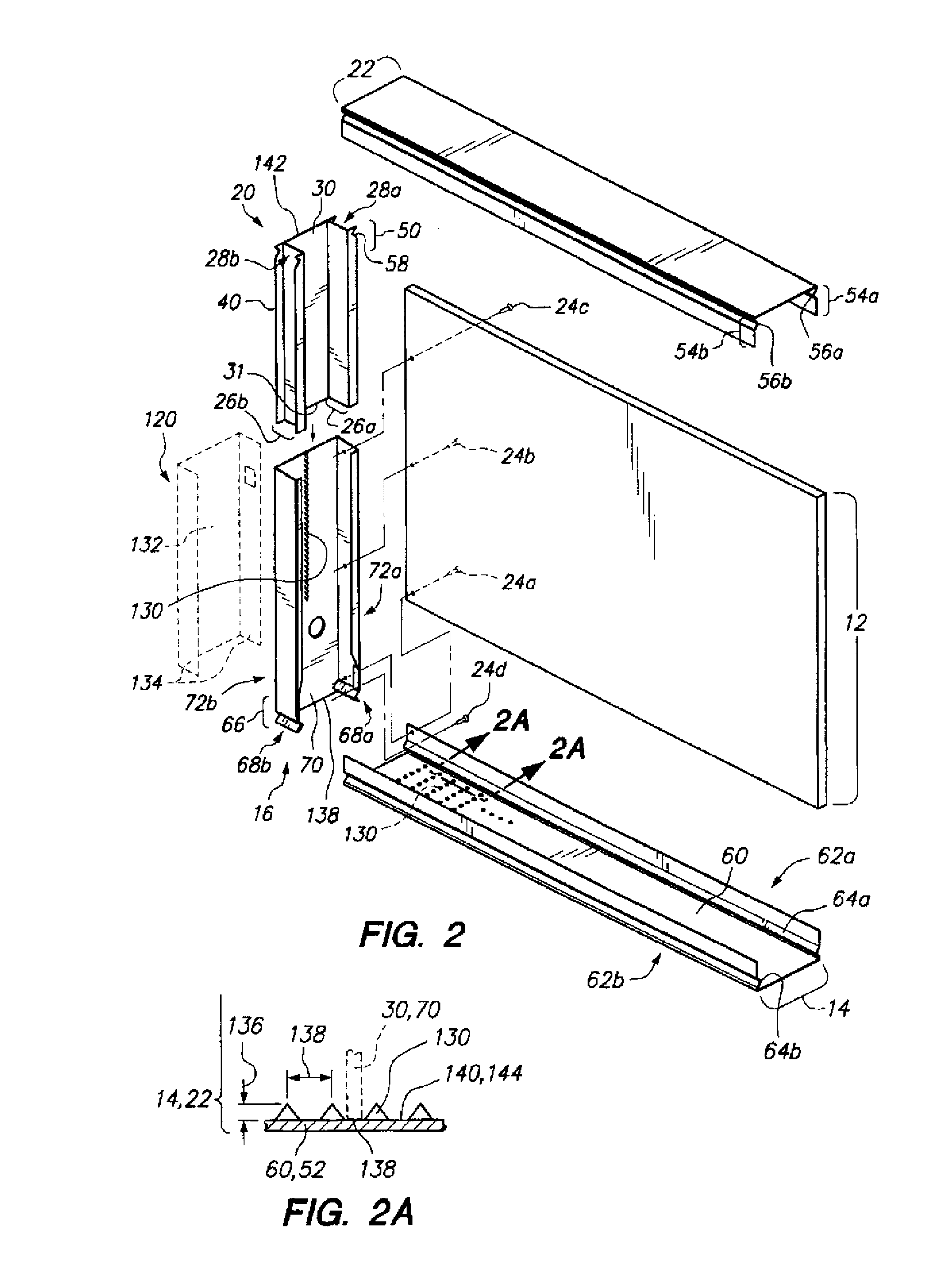

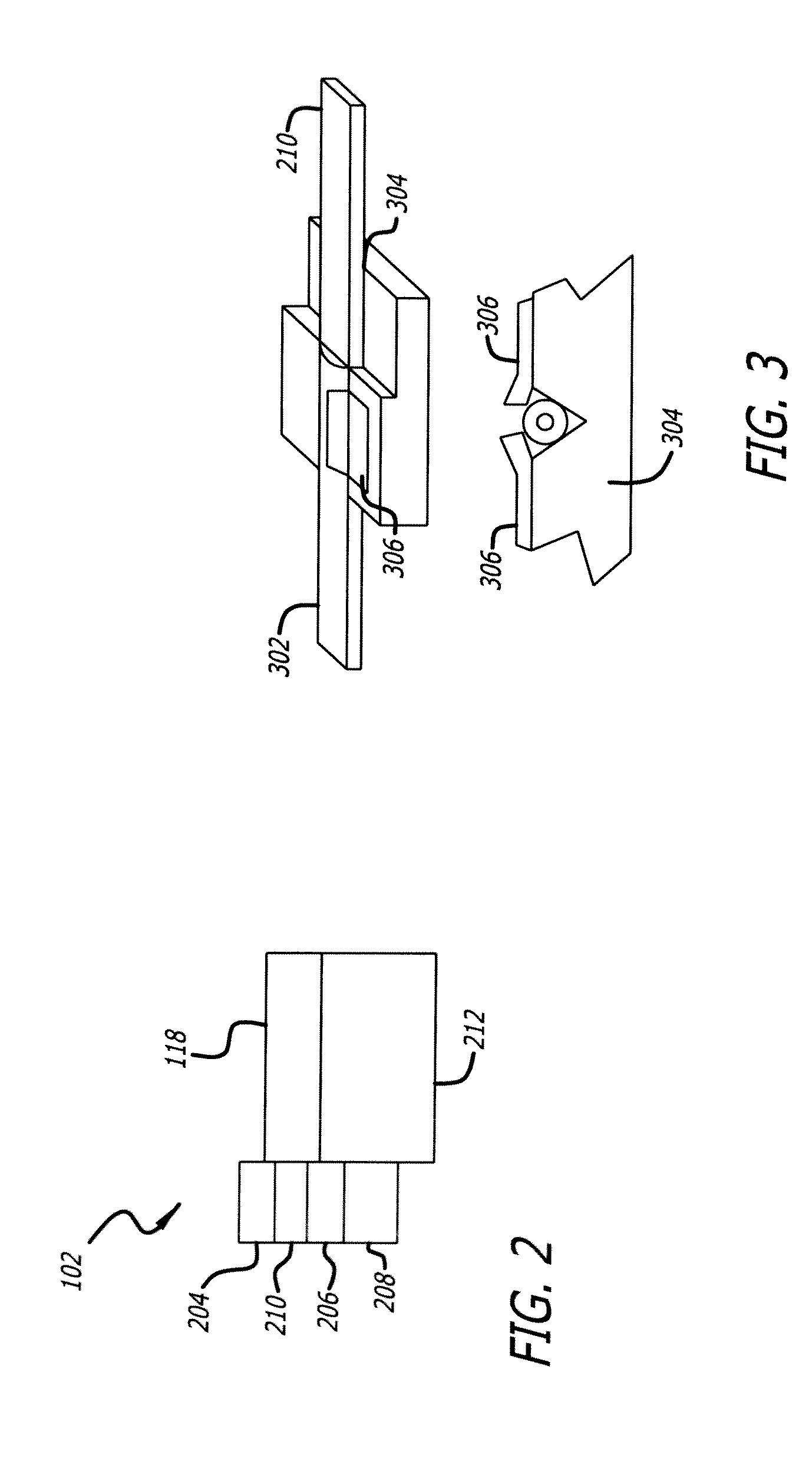

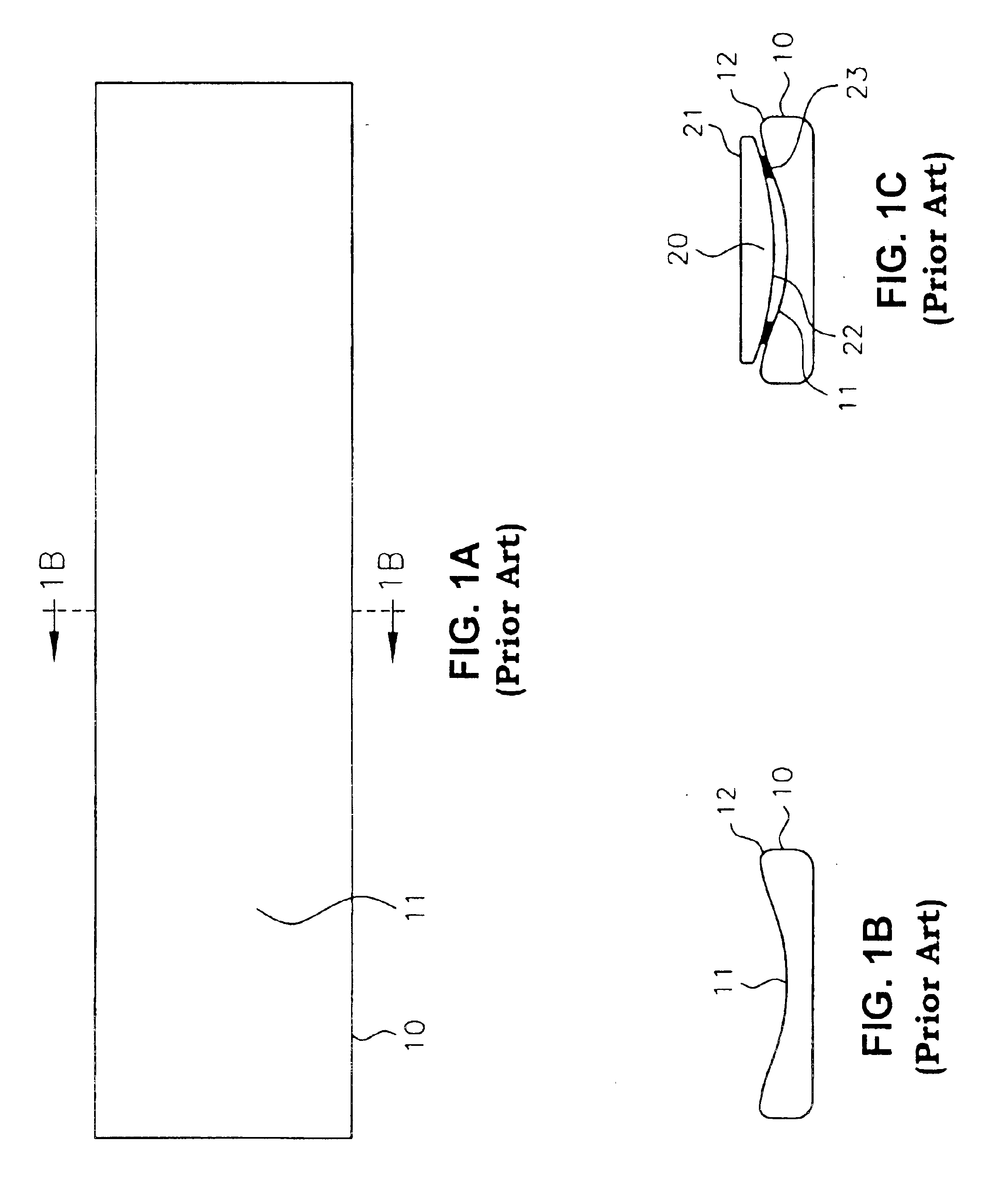

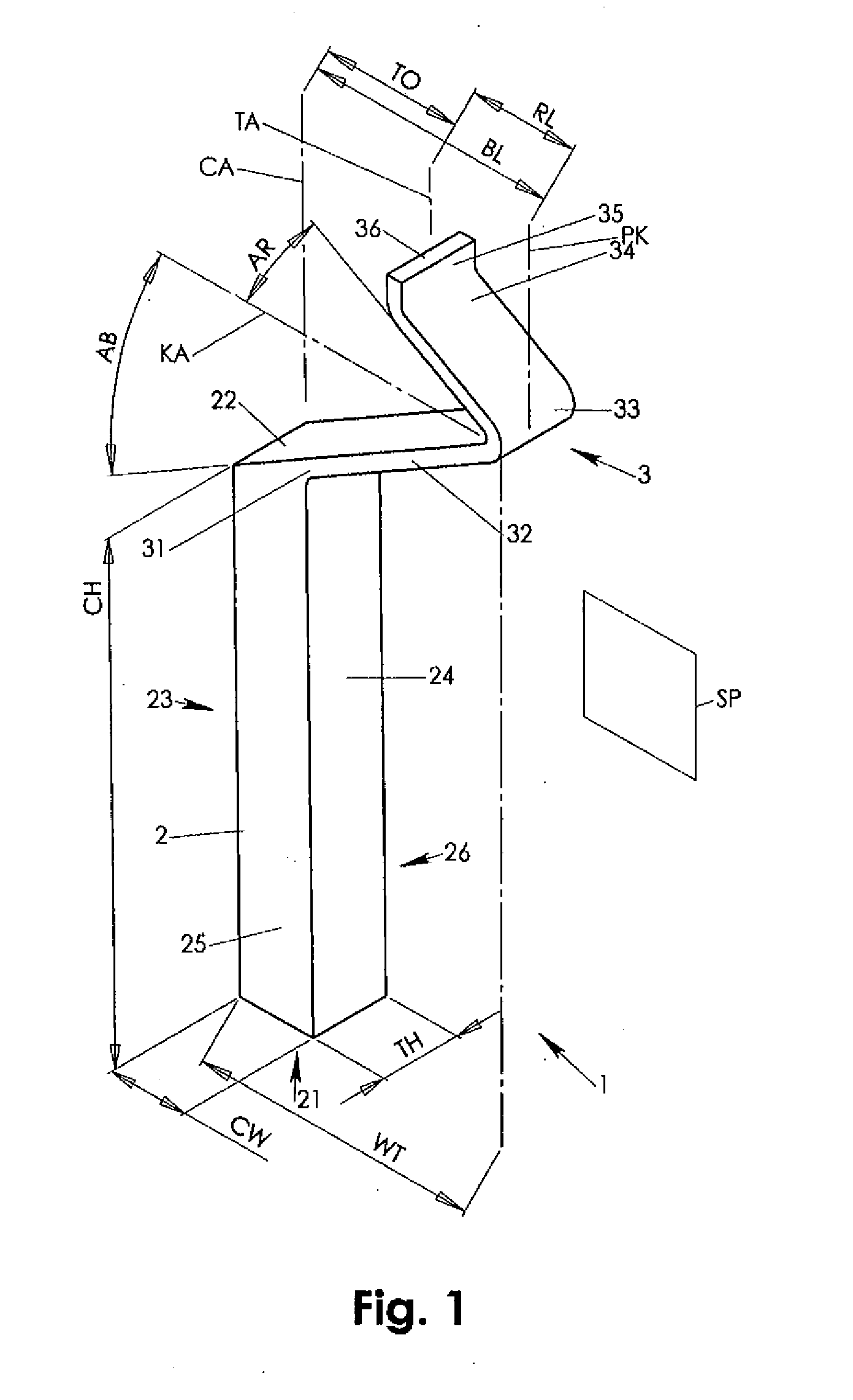

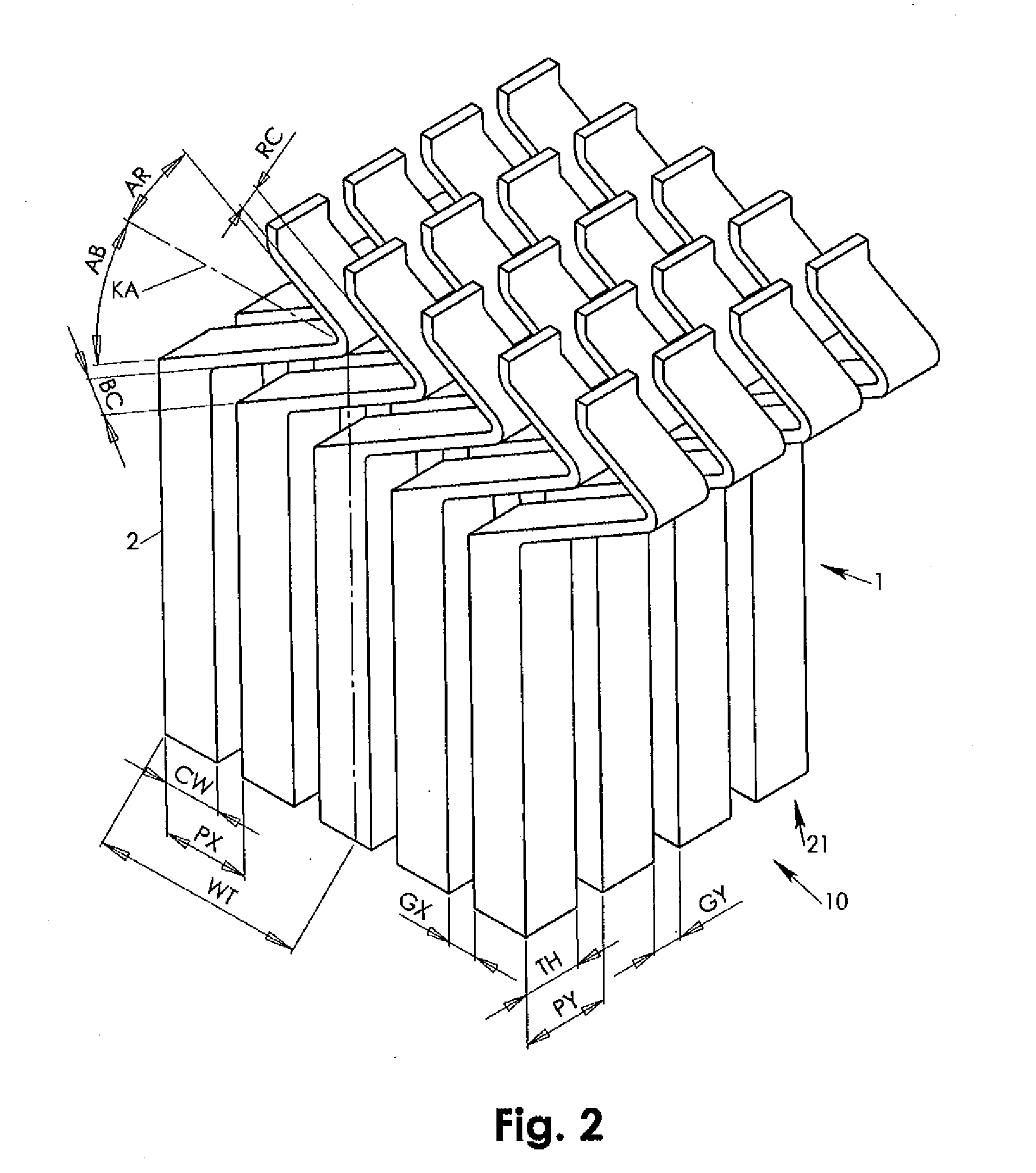

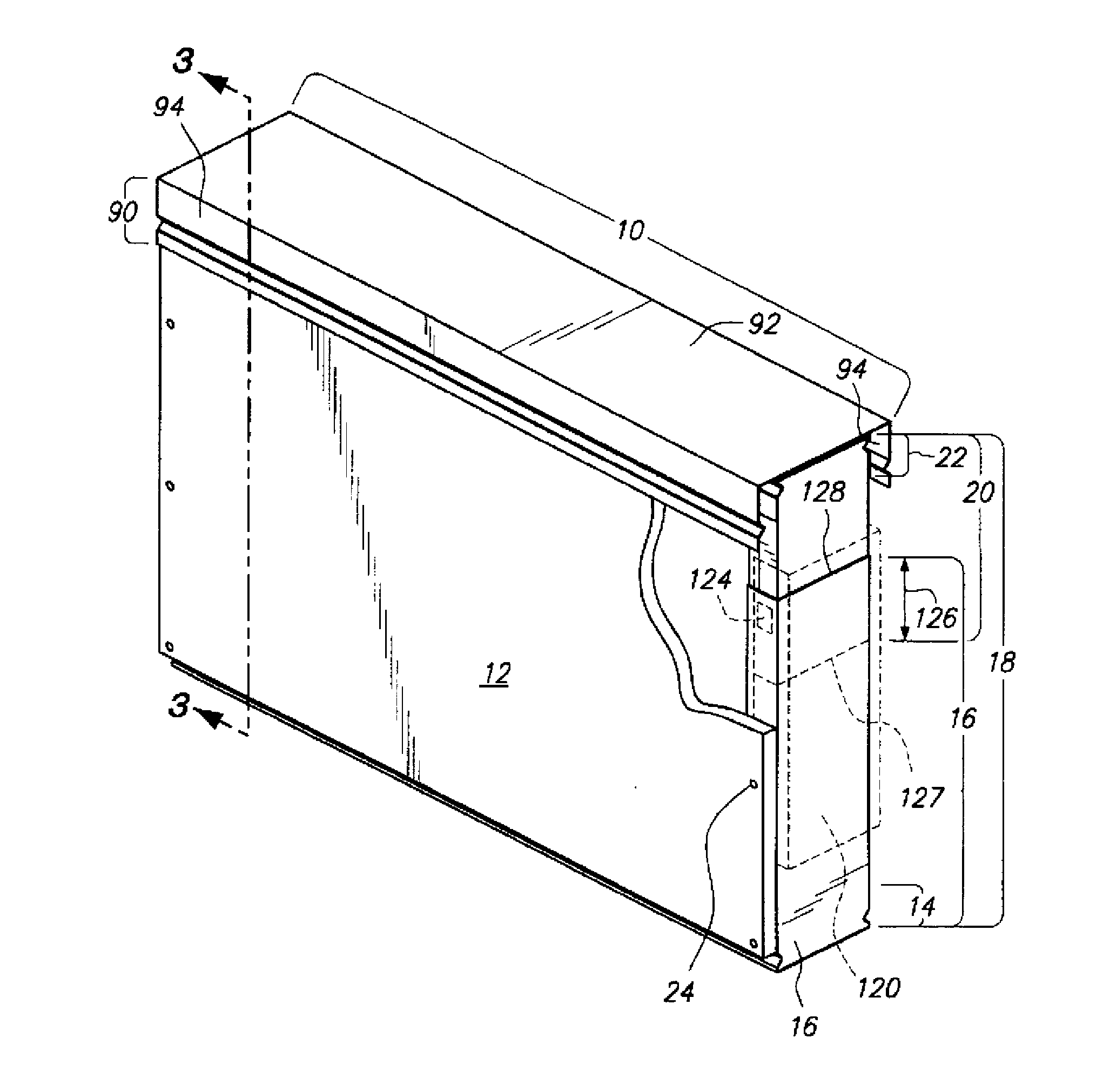

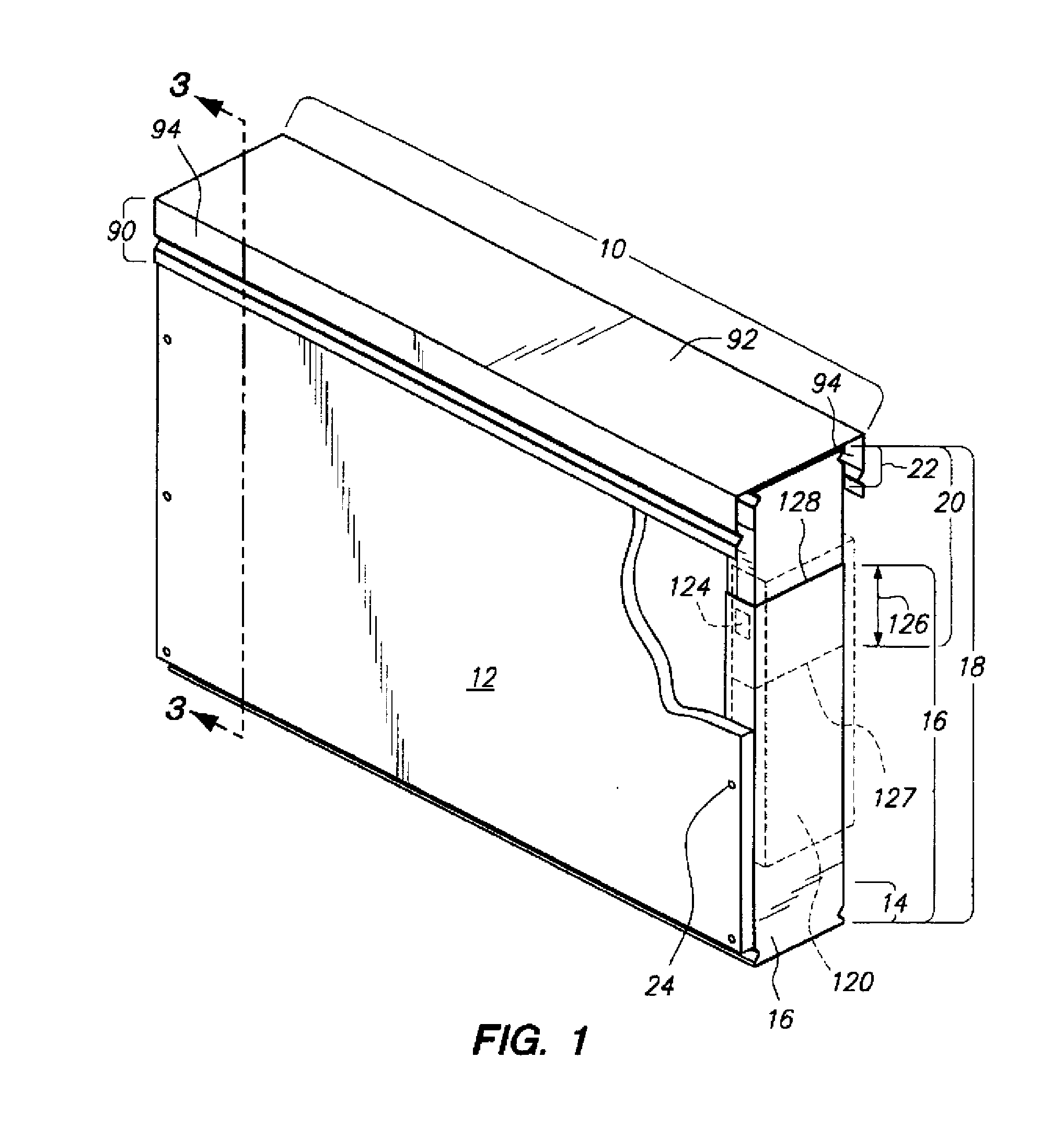

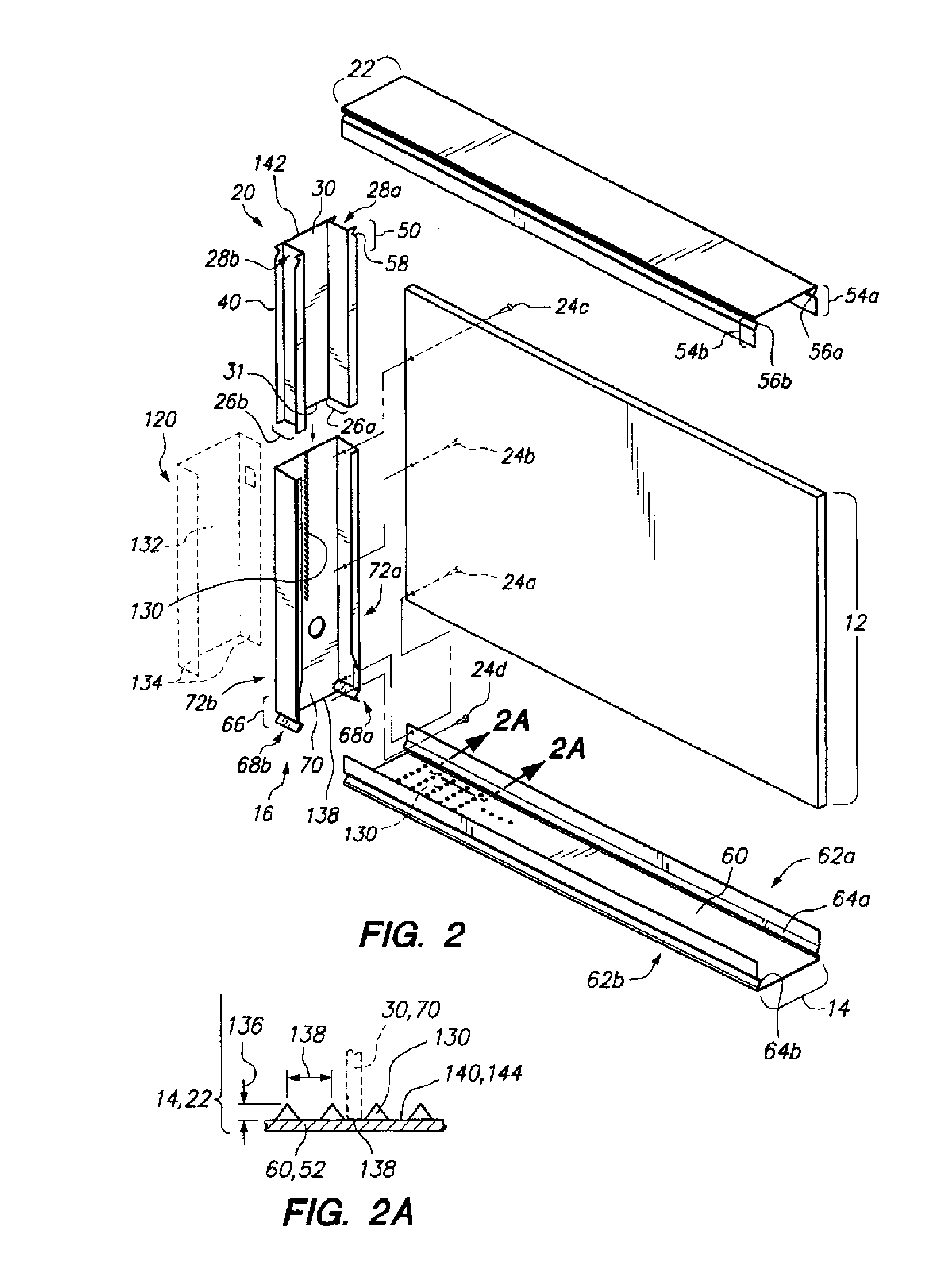

Vertical deflection extension end member

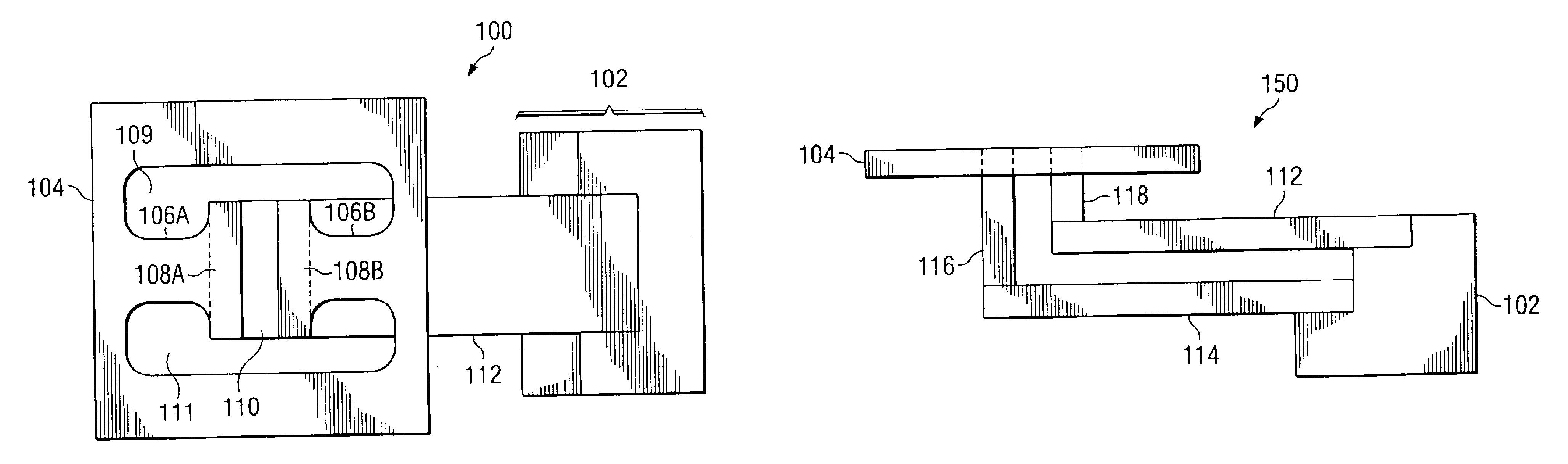

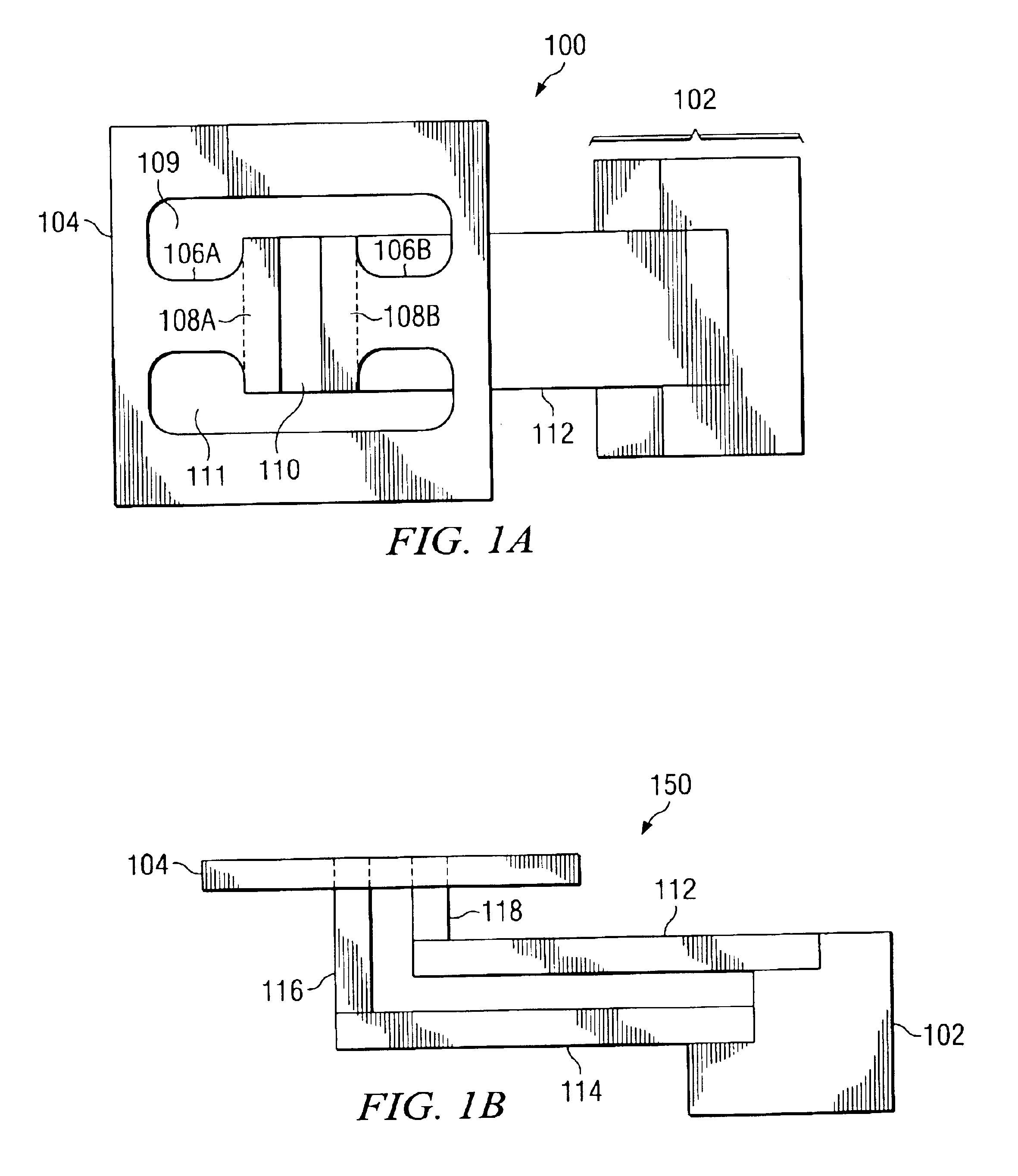

ActiveUS8061099B2Infinite vertical range of movementPrevent disengagementWallsPublic buildingsVertical deflectionDrywall

A wall structure has a telescoping portion and a stationary portion. An overlapping section of the telescoping portion has a recess to allow dry wall to be fastened to the stationary portion at the overlapping section without being attached to the telescoping portion. The fastener pierces through the drywall and a sidewall of the stationary portion. However, a tip of the fastener does not engage a sidewall of the telescoping portion. Rather, the tip of the fastener stops within the recess of the telescoping portion.

Owner:TSF SYST

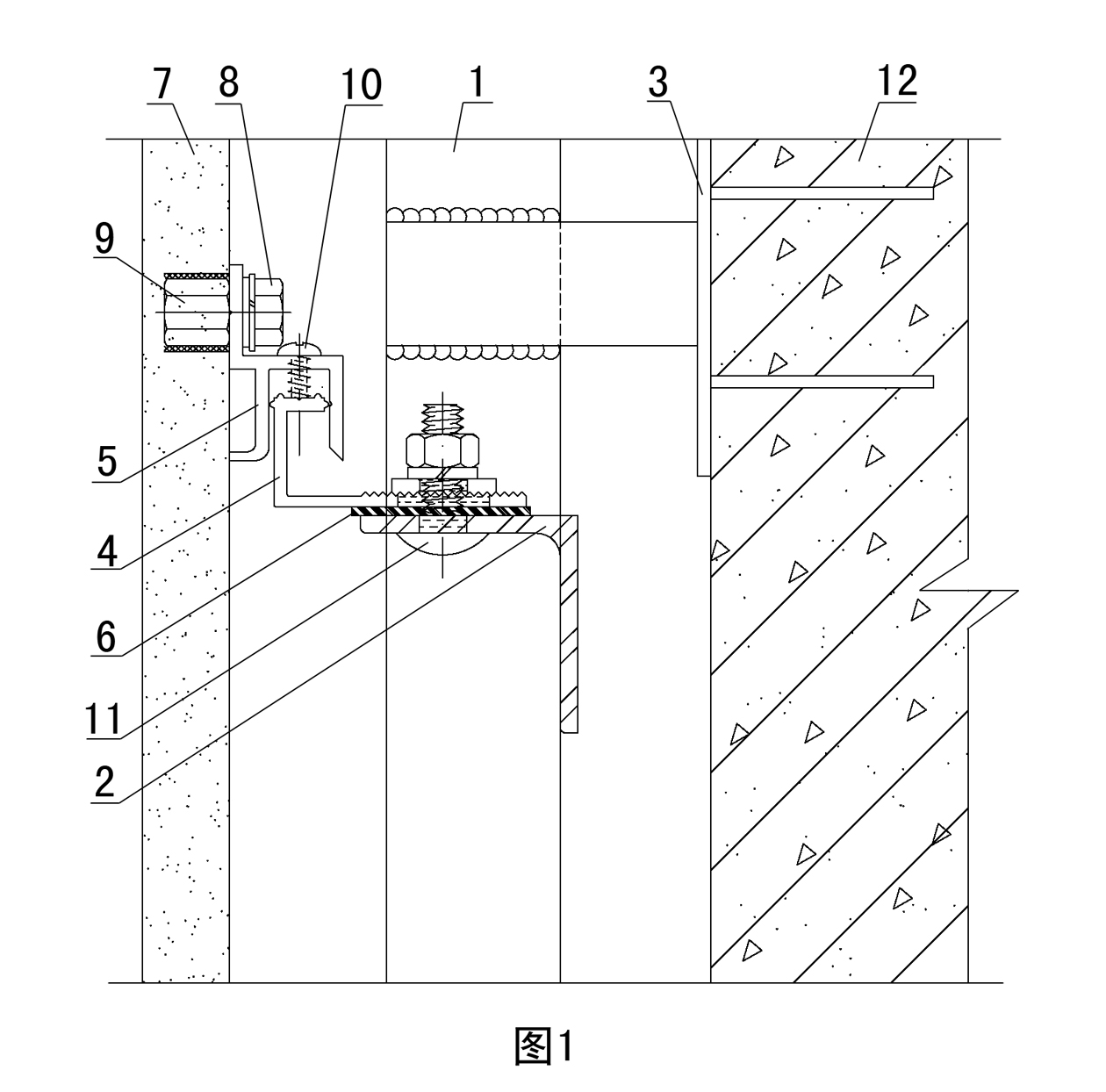

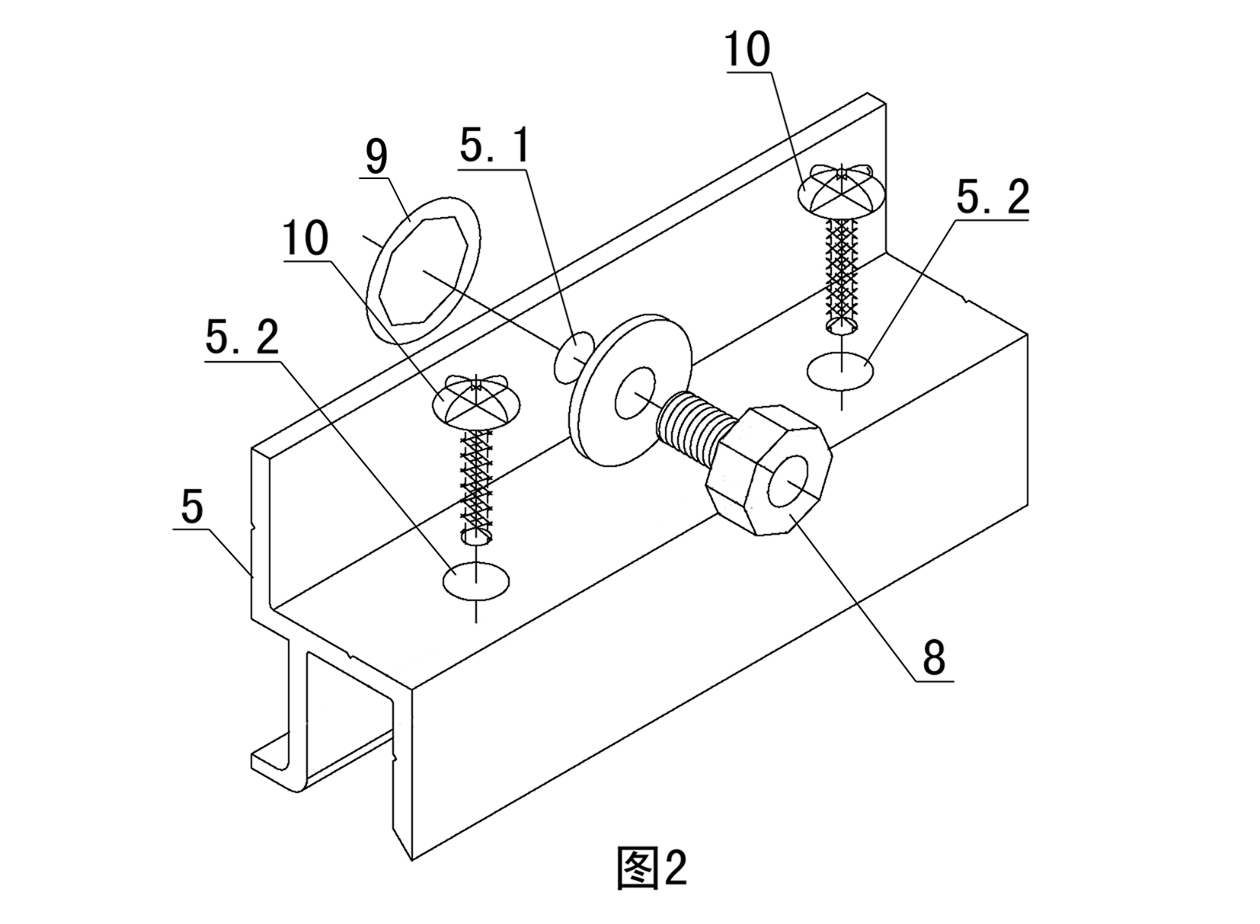

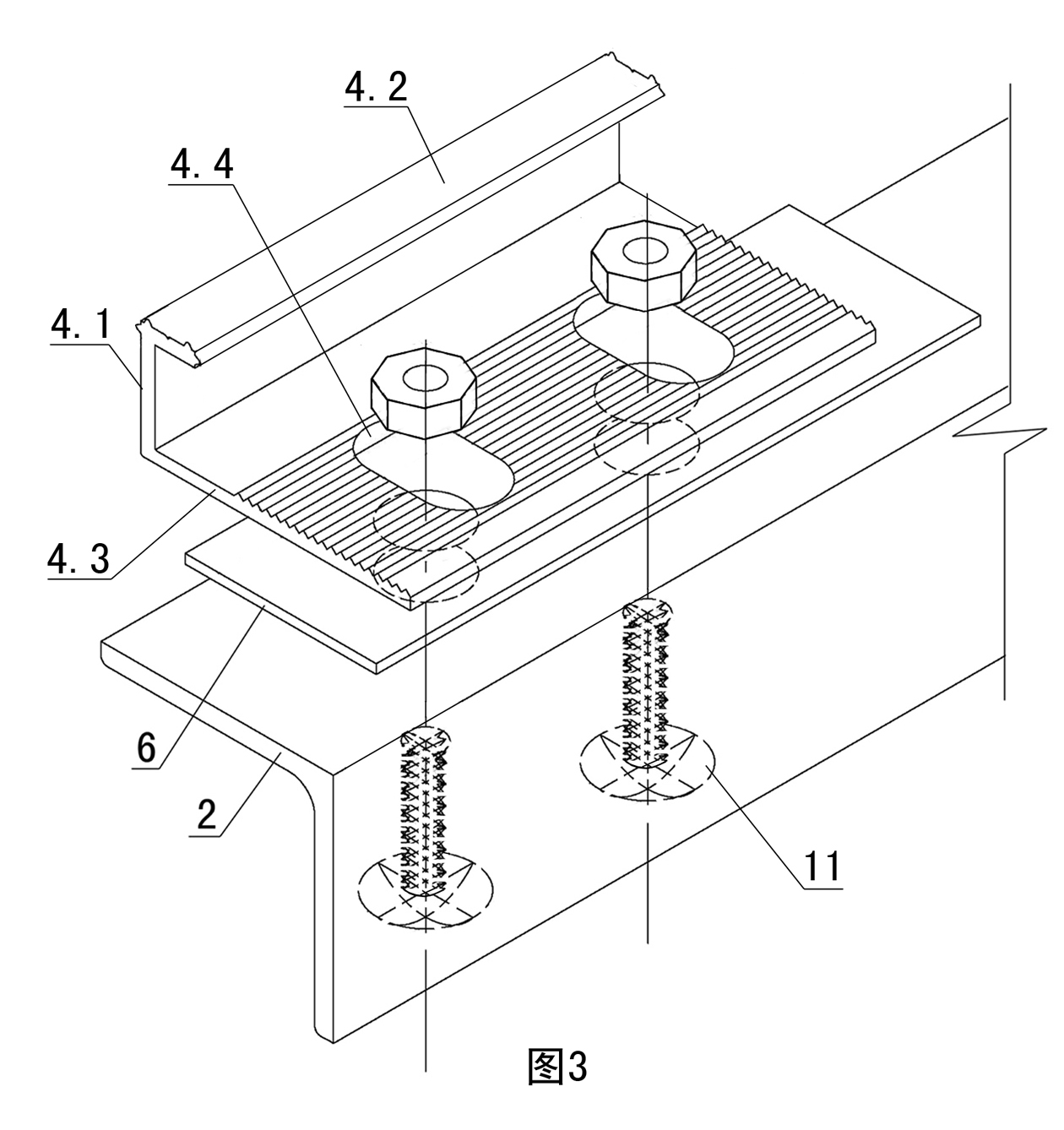

Three-dimensionally adjustable disconnectable curtain wall connecting device and construction method thereof

ActiveCN101956438ASolve the adjustmentSolve the different size of the board seamCovering/liningsWallsVertical deflectionKeel

The invention relates to a three-dimensionally adjustable disconnectable curtain wall connecting device. In the three-dimensionally adjustable disconnectable curtain wall connecting device, the section of a back pendant has a chair shape; a back bolt hole is formed at the back of the chair and is in threaded connection with an embedded nut at the back of each curtain wall plate through a back bolt; the back chair legs have L shapes and are propped against the back of each curtain wall plate; a jackscrew bolt hole is formed on the chair surface and is connected with an adjustable supporting piece of which the upper end is embedded between the front and back chair legs through a jackscrew bolt; the adjustable supporting piece is formed by connecting a supporting plate, a vertical plate and an adjusting plate to be a whole; the supporting plate is in top contact connection with the jackscrew bolt; the thread height of the jackscrew bolt is more than the longitudinally adjusting distance of each curtain wall plate; and a long round hole vertical to the wall body is formed on the adjusting plate. The device solves the problems that the position of each curtain wall plate cannot be adjusted, the plate gaps are different in sizes, the curtain wall plates are staggered with one another and the like so as to guarantee the appearance of the curtain wall and overcomes the defect that the installation of the traditional curtain wall plates completely depends on the control level and the vertical deflection of keels at the same time, so that the construction quality can be controlled easily.

Owner:泛华建设集团有限公司

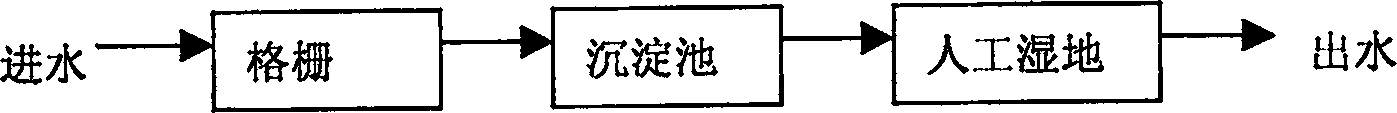

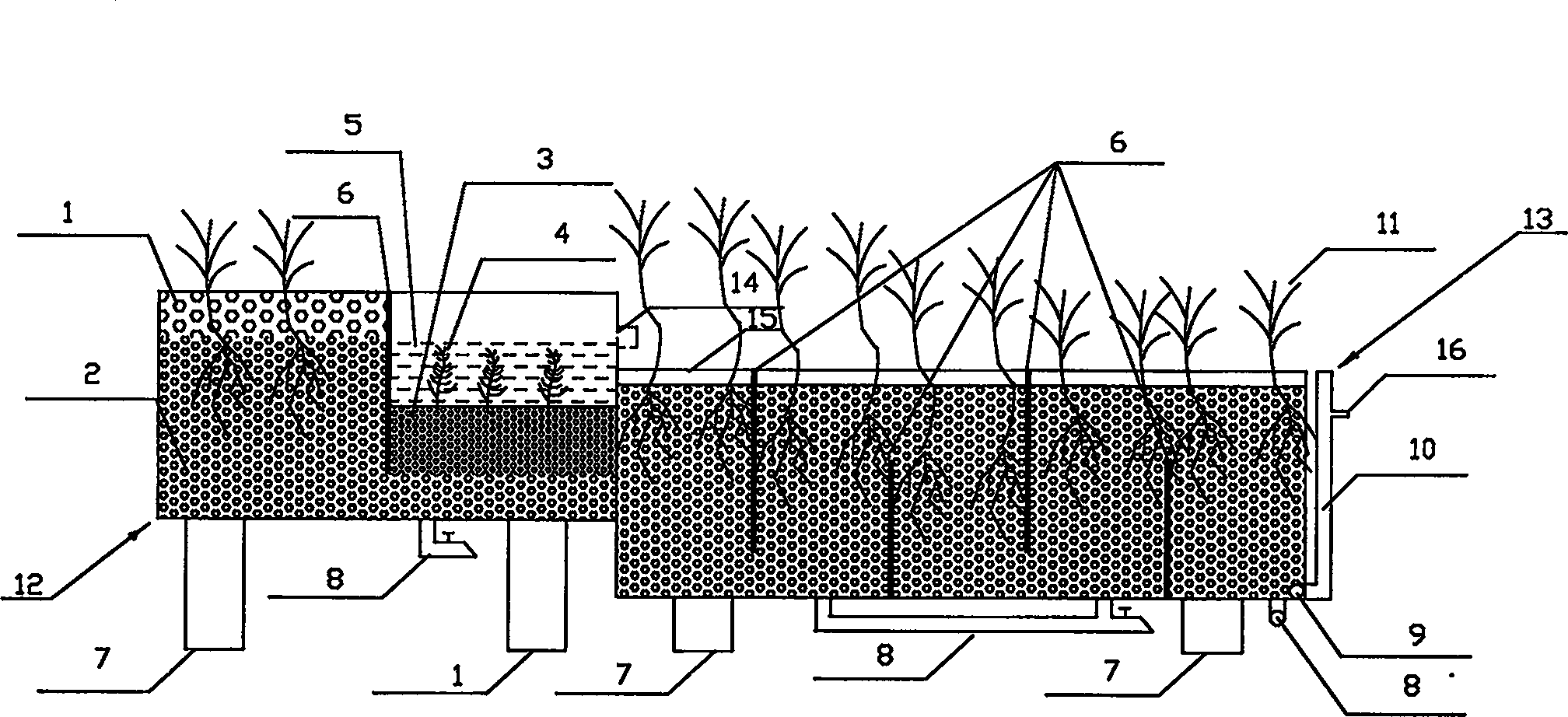

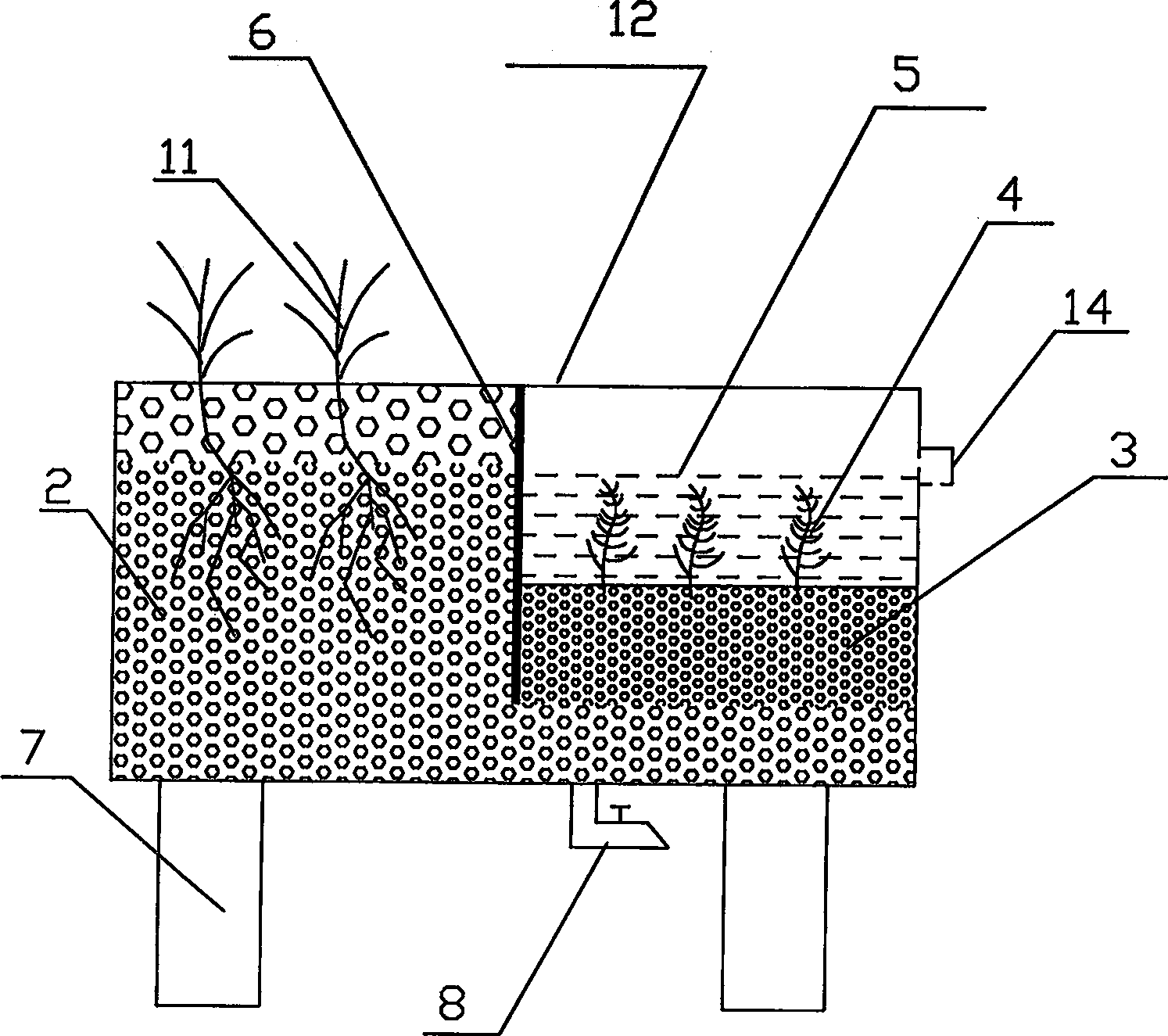

Method and installation for treating domestic sewage by using artificial wetland

InactiveCN1872738AIncrease dissolved oxygen contentPromote nitrificationSustainable biological treatmentBiological water/sewage treatmentConstructed wetlandVertical deflection

This invention relates to a combined vertical flow-vertical deflection wet land treatment technique for domestic wastewater. The technique comprises a pretreatment system and an artificial wet land system. The pretreatment system is mainly aim to removing the floating matters and precipitable suspended matters in domestic wastewater. The artificial wet land system is composed of combined vertical flow-vertical deflection in series. The invention has high removing rate on COD, N and P in domestic wastewater.

Owner:NANJING UNIV

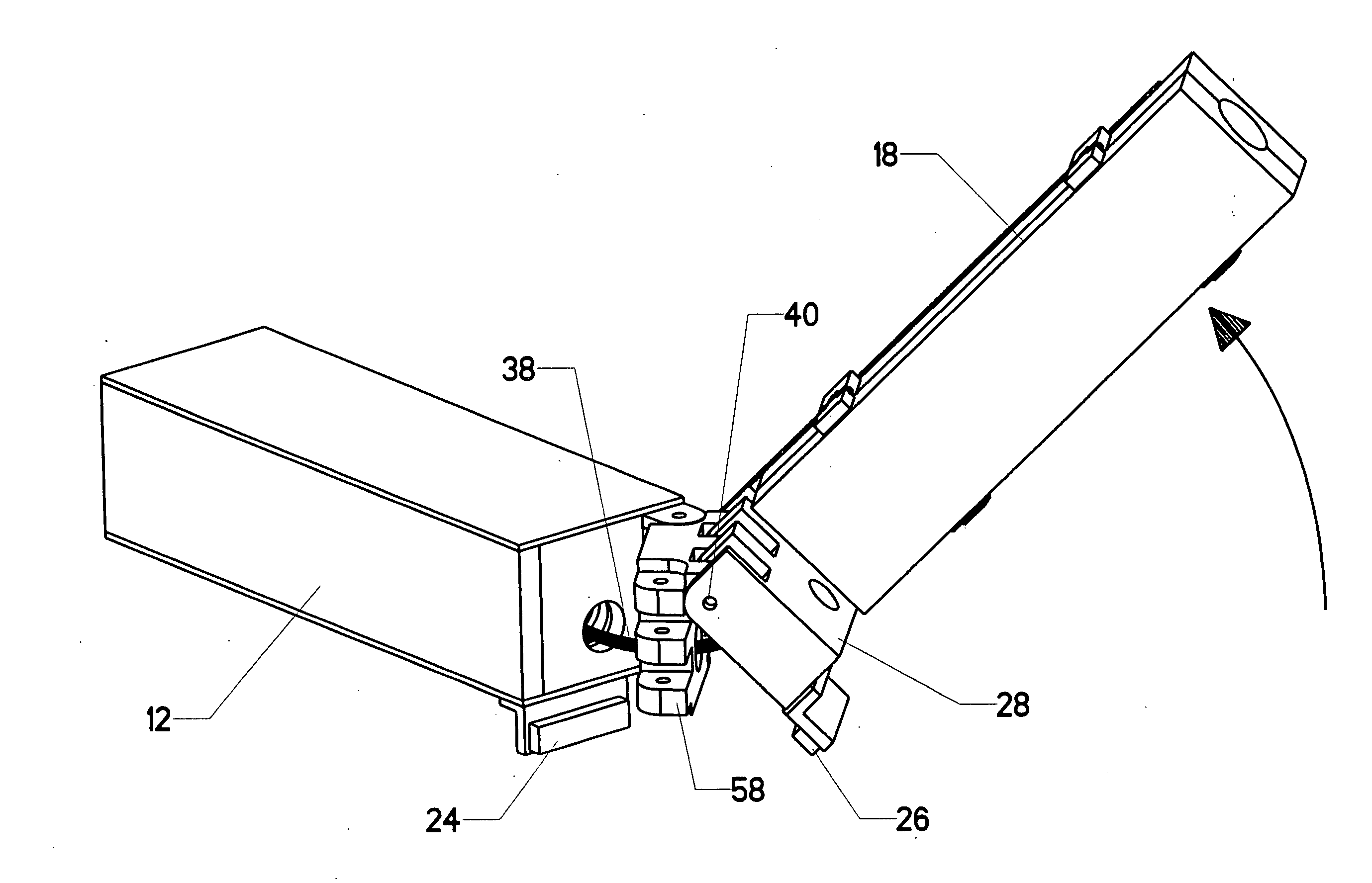

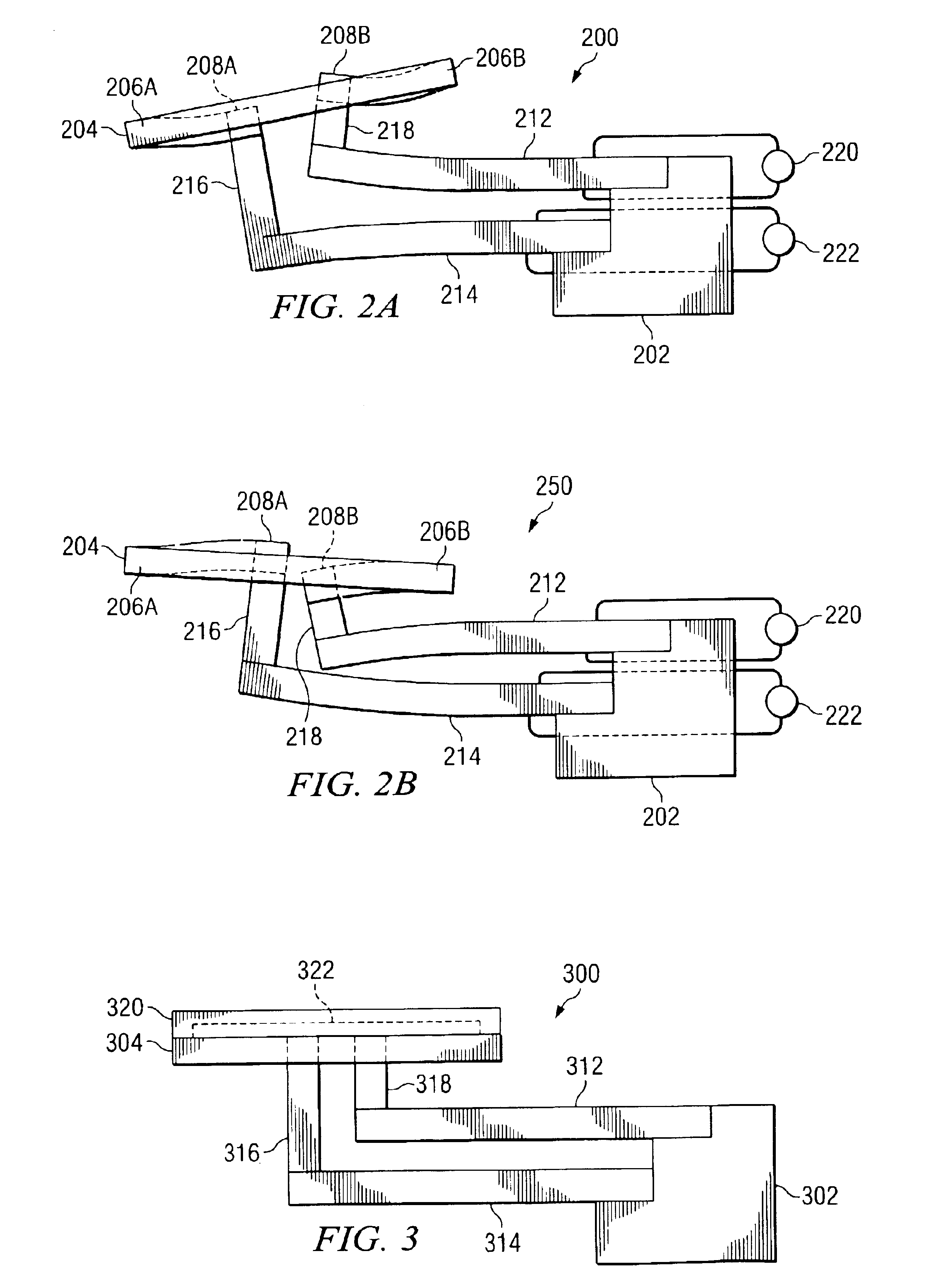

Dual-action breakaway gate safety system

A safety system for use with a boom gate. The boom gate includes a boom and a boom moving means for moving the boom between a down position and an up position. The safety system also has a boom deflection detector for detecting deflection of the boom, such as deflection caused by collision of the boom with a vehicle. A control system is provided for actuating the boom moving means to move the boom to the up position whenever deflection is detected.In the preferred embodiment a combination hinge is used to permit the boom to deflect in both a horizontal and vertical direction. The combination hinge includes a horizontal pivot joint and a vertical pivot joint. The combination hinge joint is spring biased to retain the boom in a normal, undeflected position. The spring also acts to return the boom to the normal, undeflected position after the boom has been deflected. In the preferred embodiment the boom deflection detector is configured to detect both horizontal deflection and vertical deflection of the boom.

Owner:FLORIDA DEPT OF TRANSPORTATION

Composite joist floor system

The composite joist floor system includes joists supported by supporting members. Corrugated steel decking is positioned over the joists such that the corrugations are substantially perpendicular to the joists. Self-drilling, self-tapping, stand-off screws are spaced along the length of the joist, aligned with the deck corrugations. These stand-off screws provide the required shear transfer between the joist and concrete slab to form a composite floor system. The placed concrete encapsulates the upper non-threaded shank portions of the stand-off screws and the end of the joists. After the concrete has cured, the resultant system comprised of steel joists, steel decking, stand-off screws, and concrete, act together to form a composite system with greater load carrying capacity and less vertical deflection. The stand-off screws connect the joist upper chords to the concrete slab allowing the joist and concrete slab to act as a unit, by transferring shear between the two joined components.

Owner:NUCOR CORP

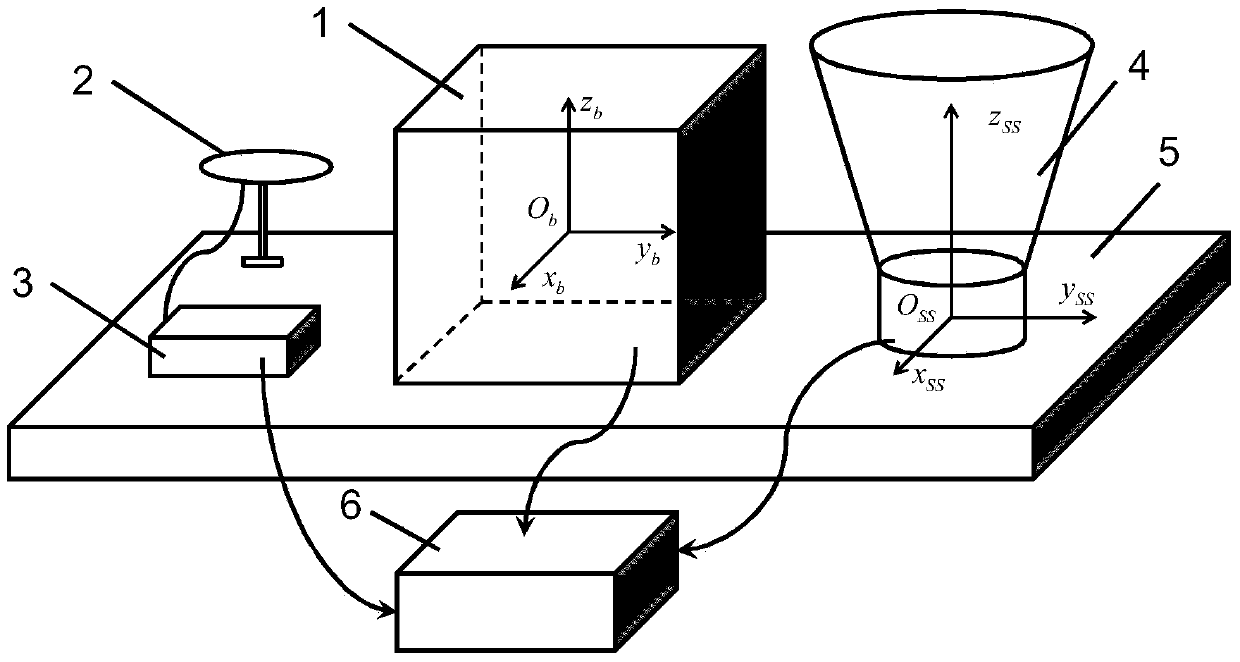

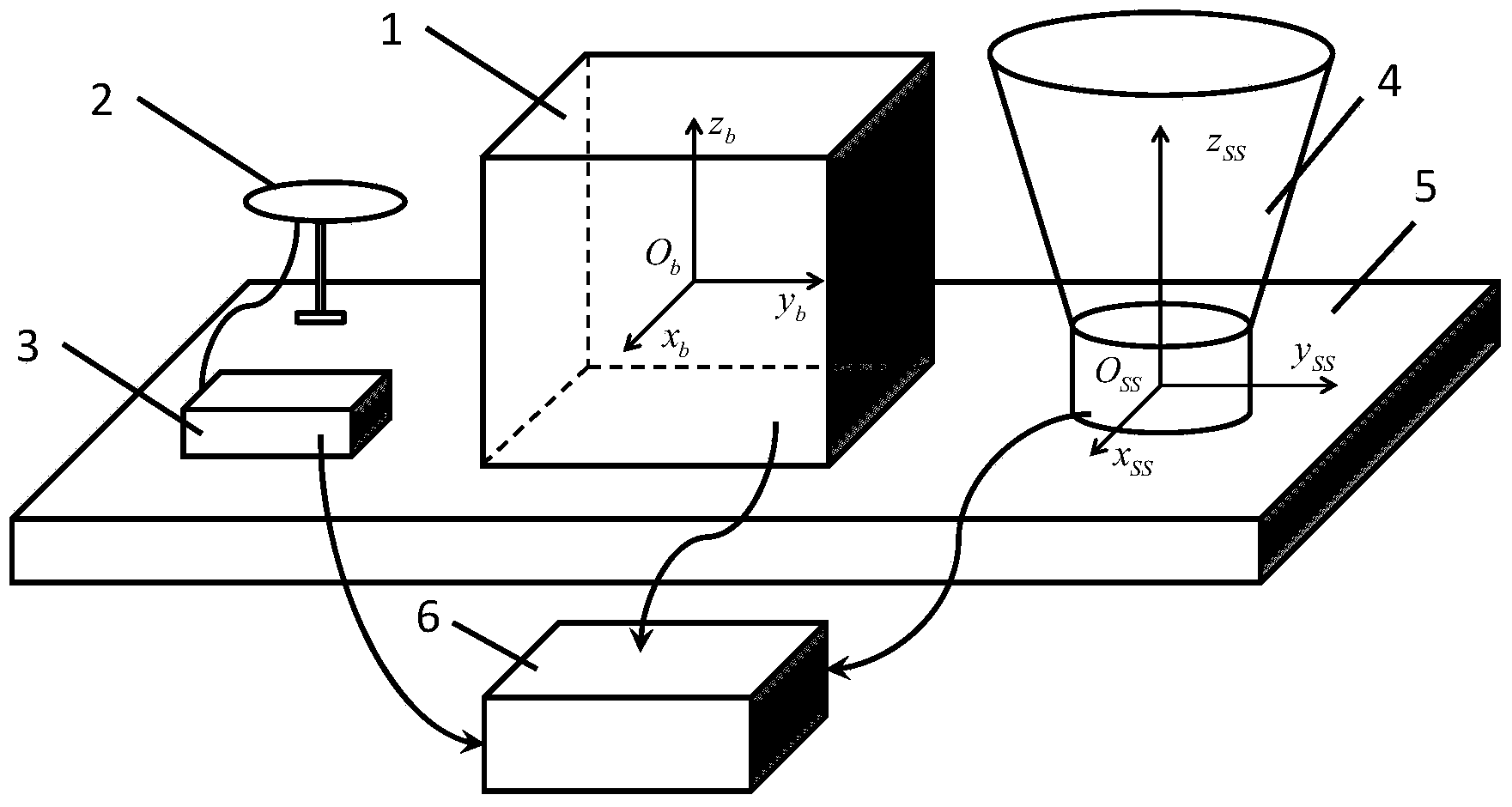

Dynamic measuring device and method for plumb line deviation kept on basis of astronomical attitude reference

ActiveCN103674030AReduced precision requirementsImprove navigation solution accuracyNavigational calculation instrumentsNavigation by astronomical meansAviationMeasurement device

The invention discloses a dynamic measuring device and method for plumb line deviation kept on the basis of an astronomical attitude reference. An INS / GPS attitude measurement subsystem and an LGU / GPS attitude measurement subsystem are built, wherein an initial value adopted for attitude updating by the LGU / GPS attitude measurement subsystem is provided by attitude information output by a star sensor. The difference between the attitude output by the LGU / GPS attitude measurement subsystem and the attitude output by the INS / GPS attitude measurement subsystem is obtained, and further the plumb line deviation is calculated. Finally, jump errors in the measuring values of the plumb line deviation are finally corrected, and low frequency errors in the measuring values of the plumb line deviation are corrected by utilizing global gravity model data. The systems in the invention are simple; the method provided by the invention is strong in robustness, and the measuring results are stable; requirements to GPS accuracy are lowered; compared with a traditional vector airborne gravitometer which relies on high precision difference GPS, the dynamic measuring device provided by the invention only requires common GPS single point positioning to meet accuracy requirements. Therefore, the application scope of the measuring method is expanded.

Owner:NAT UNIV OF DEFENSE TECH

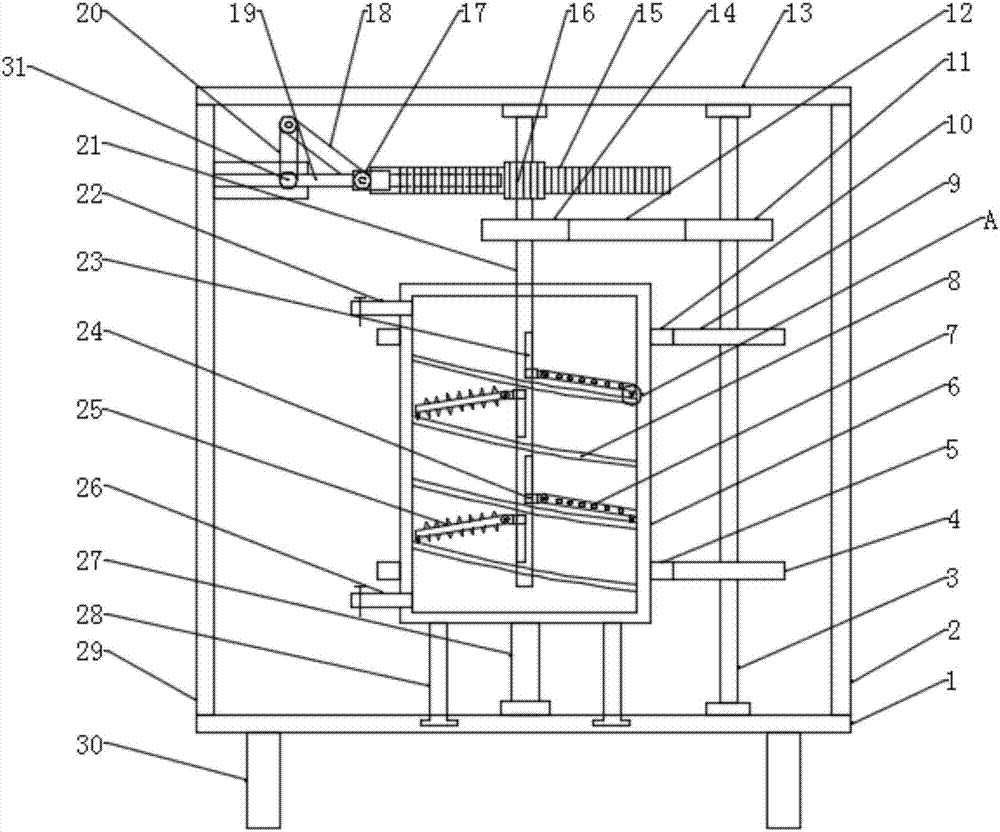

Efficient paint stirring equipment for building decoration

InactiveCN107115813AReduce resistanceAvoid breakingRotating receptacle mixersTransportation and packagingVertical deflectionGear wheel

The invention discloses efficient paint stirring equipment for building decoration. The equipment comprises a bottom plate, a first connecting rod, a second connecting rod, a sliding sleeve, a rack, a first gear, a first rotating shaft, a stirring tube, a chute, a slide block, a first stirring rod, a second stirring rod, a universal rolling wheel, a spiral rail, a first belt wheel, a second belt wheel, a third rotating shaft, a second gear and a third gear. The efficient paint stirring equipment for building decoration is provided with the first connecting rod, the second connecting rod, the sliding sleeve, the rack and the first gear; through the matching of the components, the first stirring rod and the second stirring rod are driven to do positive and reverse rotation, so that the stirring efficiency is improved; the chute, the slide block, the universal rolling wheel and the spiral rail are installed; through the matching of the components, the first stirring rod and the second stirring rod realize the vertical deflection during the rotation; the stirring efficiency is improved; the first belt wheel, the belt, the second belt wheel, the third rotating shaft, the second gear and the third gear are installed, so that the rotating directions of the stirring tube and the first rotating shaft are opposite; and the stirring efficiency is improved.

Owner:王佳宝

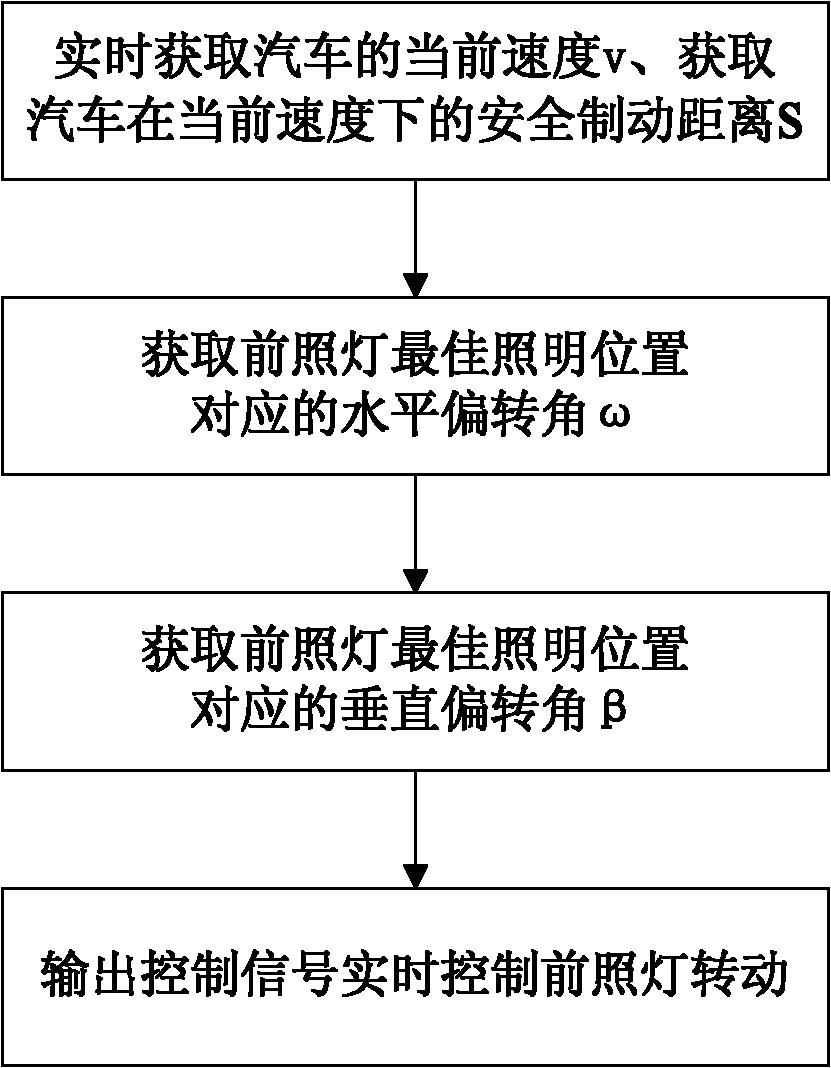

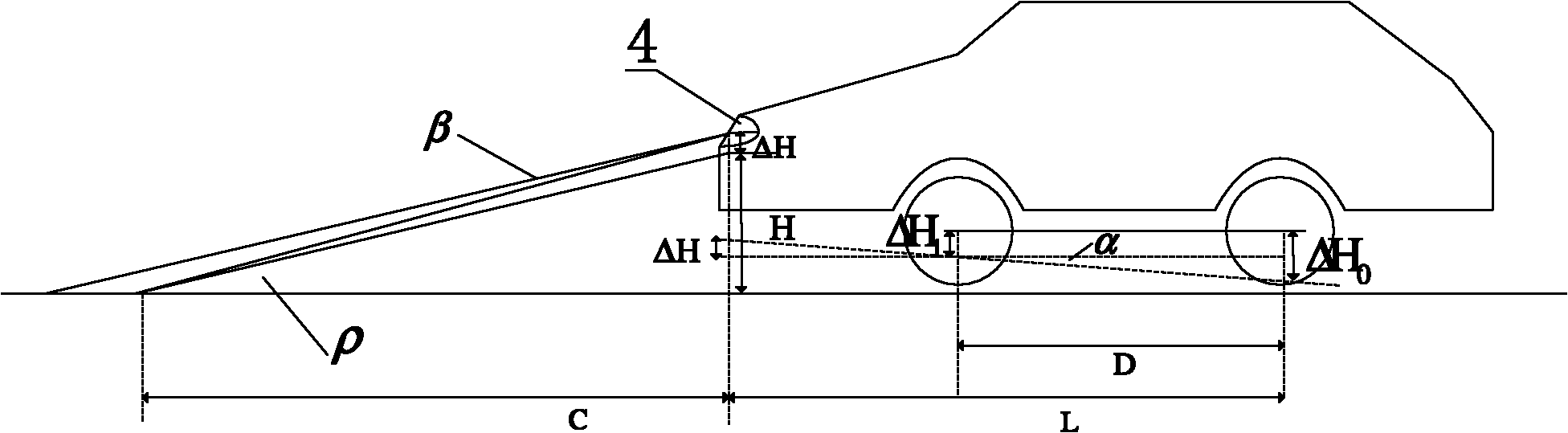

Headlamp adaptive control method and device

InactiveCN102029941AIncrease viewing distanceIncrease visual rangeOptical signallingRide heightControl signal

The invention discloses headlamp adaptive control method and device. The method comprises the steps of: (1) acquiring the current speed v of an automobile in real time, and acquiring the safe stopping distance S of the automobile at the current speed; (2) acquiring a horizontal deflection angle omega corresponding to the optimum lighting position of the headlamp; (3) acquiring a vertical deflection angle beta corresponding to the optimum lighting position of the headlamp; and (4) outputting control signals to control the turning of the headlamp in real time. The device comprises a control unit (1), and a detection unit (2) and a driving mechanism (3) which are respectively connected with the control unit (1), wherein the detection unit (2) comprises a speed sensor (21), a steering wheel angel sensor (22), a front ride height sensor (23), a rear ride height sensor (24), a sunshine and rain sensor (25) and an acceleration sensor (26). The invention has the advantages of large lighting range, good lighting effect, no reflected glare, simple structure, accurate control, good environmental suitability, safety, reliability and comfortable drive.

Owner:HUNAN UNIV

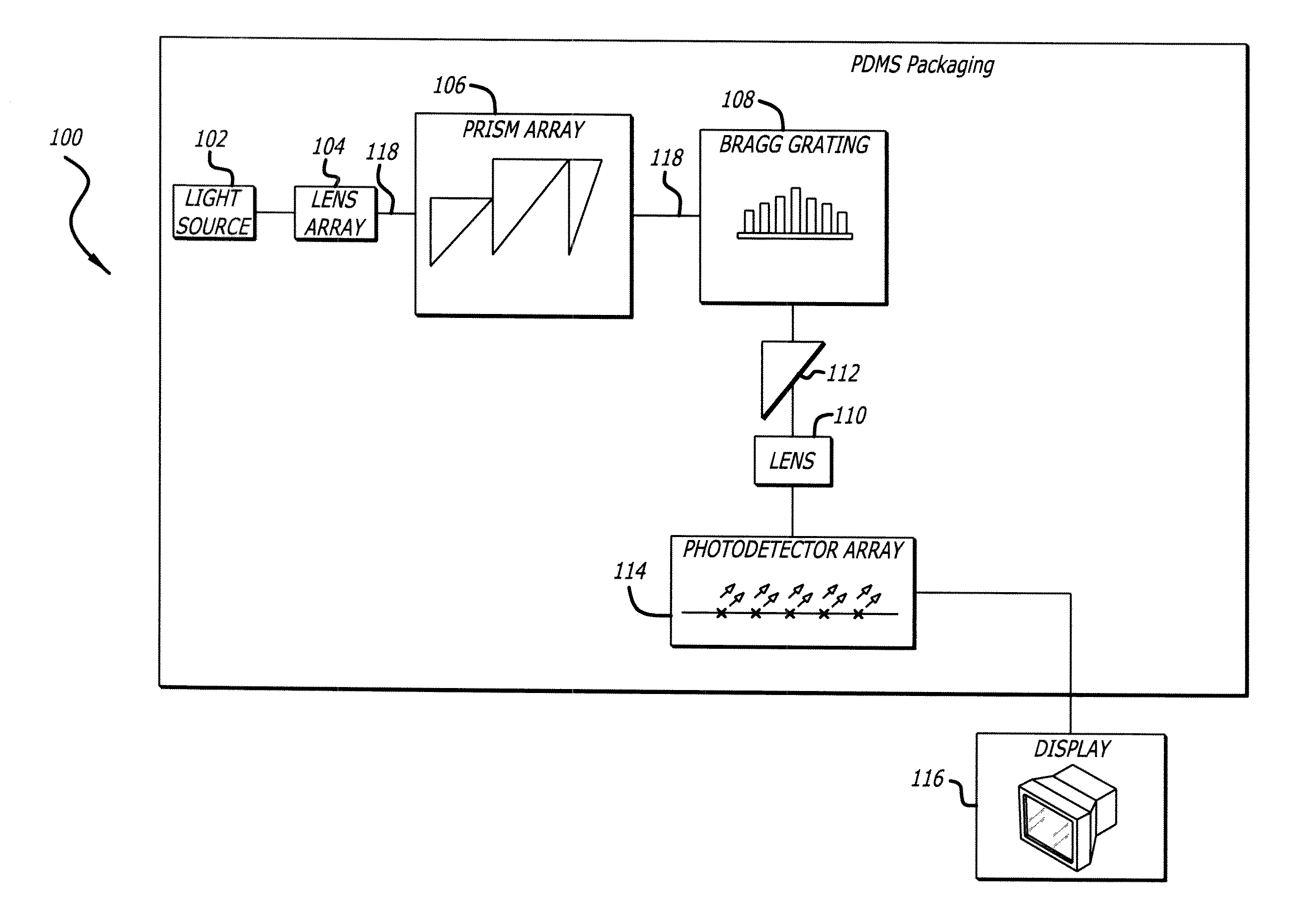

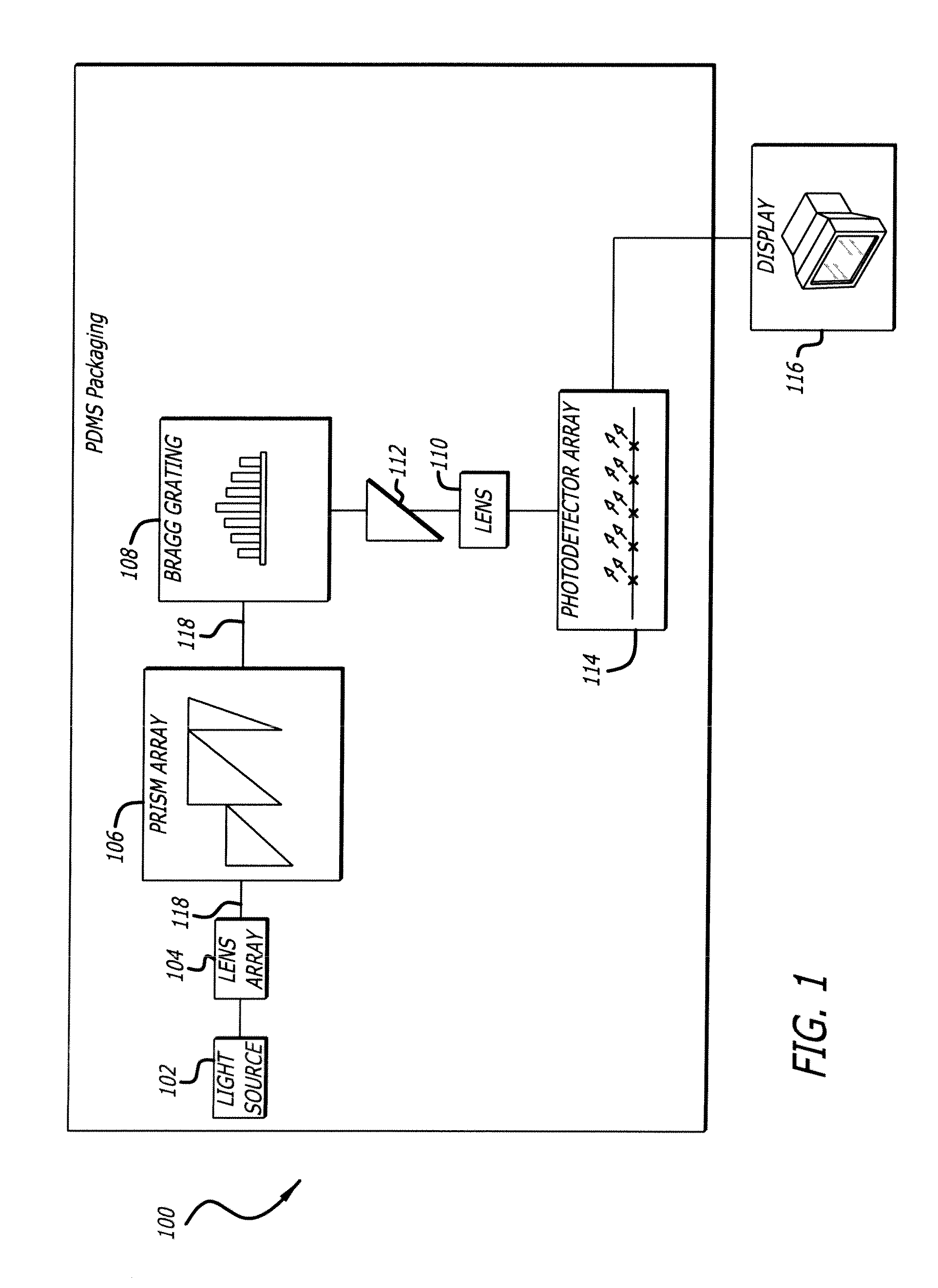

Two dimensional optical scanning image system

InactiveUS20080304123A1Drawback can be obviatedReduced collateral damagePrismsBeam/ray focussing/reflecting arrangementsGratingPhotodetector

An ultra high speed miniature two dimensional electro-optic image acquisition system uses prisms of varying geometries to control the amount of horizontal deflection and a Bragg grating to control the amount of vertical deflection. A collimating lens array and a Gaussian profile Bragg grating help confine the beam diameter of the deflected light beam. A separate prism further bends light into the vertical direction. A spherical lens focuses light onto a photodetector array for display.

Owner:UNIV OF WASHINGTON

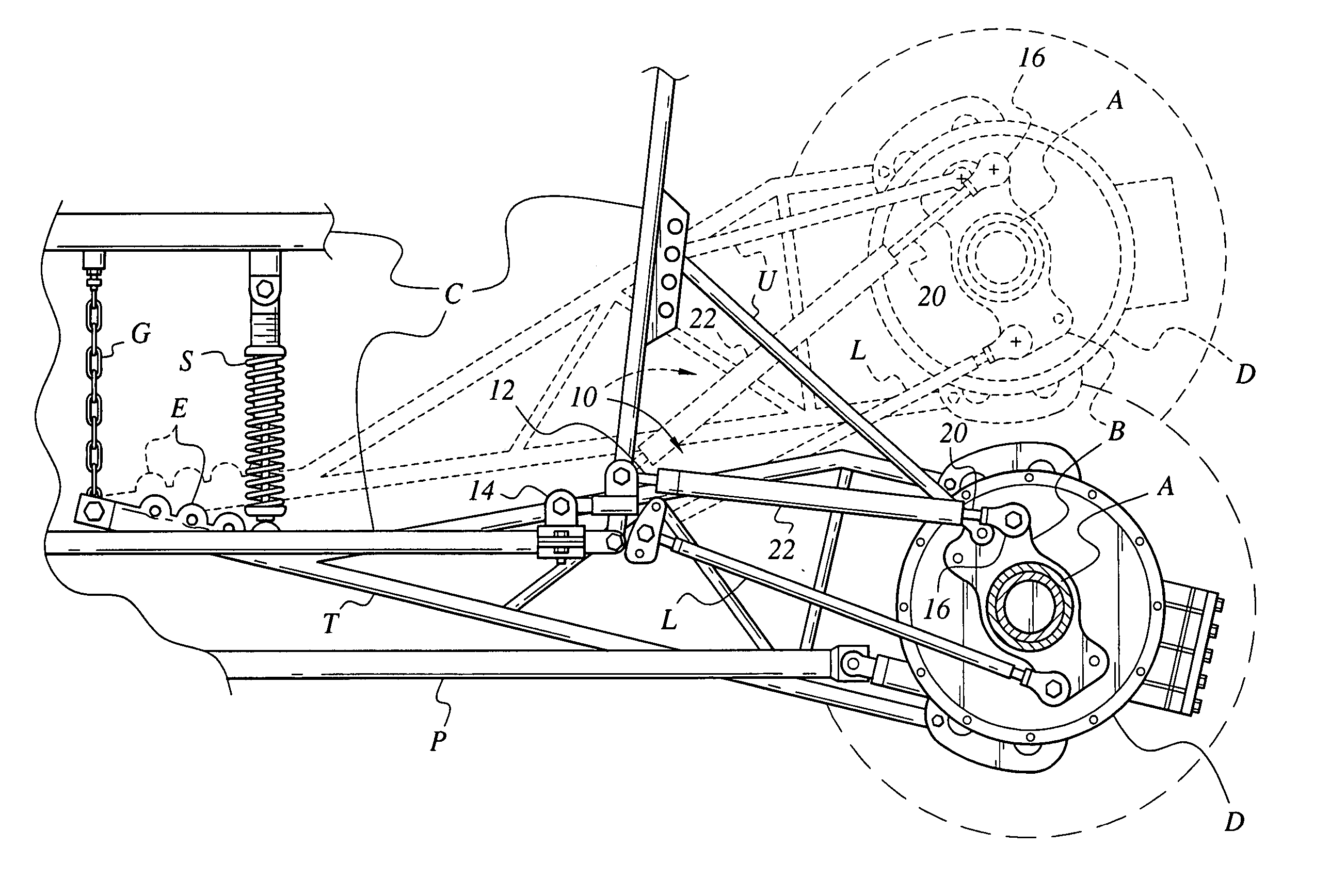

Torque reaction damper for a drive axle

The present torque reaction damper for a drive axle is a series of embodiments of installations and attachment bracketry for use in dirt track late model (DTLM) racing vehicles. Such cars are set up to provide relatively large vertical deflections of the solid rear drive axle, to drive the inboard wheel downwardly against the track surface for better traction and to shift the axle angularly to promote oversteer through the turns when the throttle is applied. The present torque reaction damper solves the problem of sudden “chassis drop” and its destabilizing effect, when the throttle is suddenly closed at the end of a straight before entering a turn. The present damper comprises a shock absorber installed either forwardly or rearwardly between the “bird cage” axle bracket and the chassis and serves to cushion the movement of the chassis when the throttle is closed, thereby facilitating car stability and control.

Owner:HUPPERICH HERBERT L JR

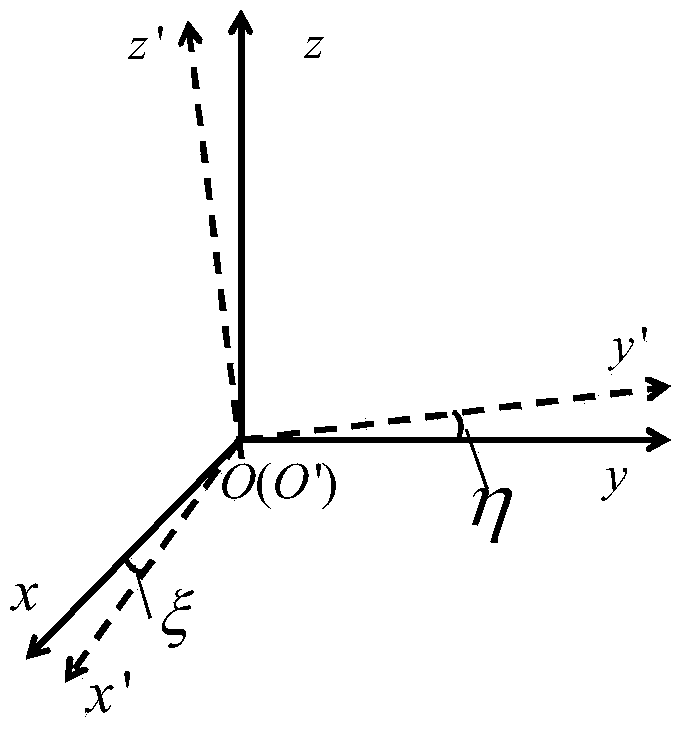

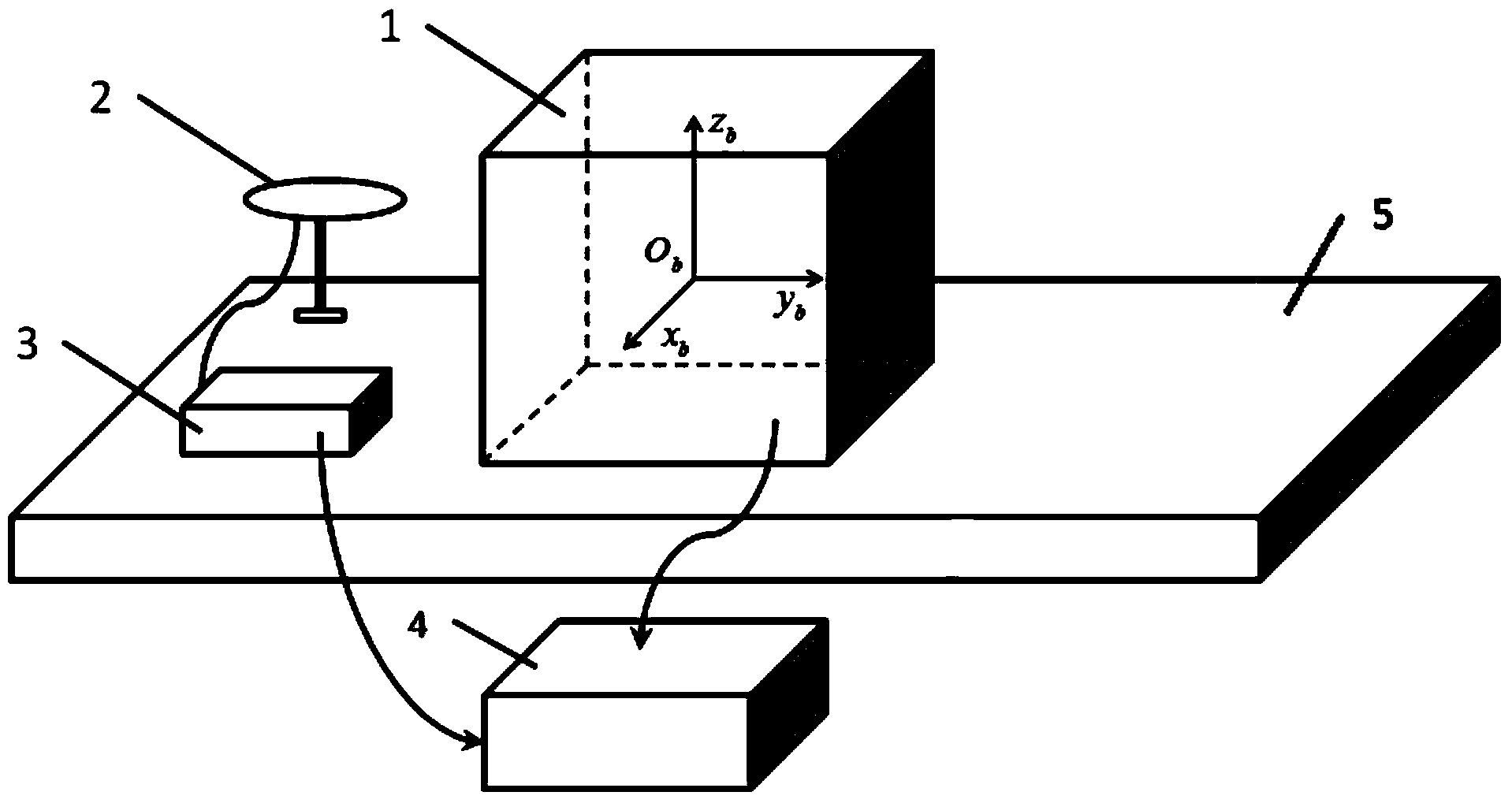

Plumb line deviation dynamic measurement device and method based on combination of INS and GPS

ActiveCN104061945AEliminate dependenciesLow costNavigational calculation instrumentsSatellite radio beaconingVertical deflectionMeasurement device

The invention discloses a plumb line deviation dynamic measurement device and method based on combination of an INS and a GPS. The method comprises the steps that firstly, an INS / GPS attitude measurement subsystem and an LGU / GPS attitude measurement subsystem are built, and an attitude matrix output by the INS / GPS is utilized to initialize the LGU / GPS attitude measurement subsystem at the moment when measurement is started; secondly, the LGU / GPS and the INS / GPS are used for conducting attitude calculating respectively, and the difference between the attitude angle output by the LGU / GPS and the attitude angle output by the INS / GPS is calculated; finally, an optimal estimated value of plumb line deviation is obtained through a Kalman filtering method by the aid of a global gravity model by establishing an observation equation and a state equation for plumb line deviation measurement with the difference between the attitude angle output by the LGU / GPS and the attitude angle output by the INS / GPS as the observed quantity. The plumb line deviation dynamic measurement device and method based on combination of the INS and the GPS can effectively reduce the complexity and cost of a system, improve the measurement accuracy and reliability, and are independent of the measurement environment, high in operability and convenient to implement.

Owner:NAT UNIV OF DEFENSE TECH

Accurate and rapid calculation method for global and local ocean disturbing gravity

The invention discloses an accurate and rapid calculation method for global and local ocean disturbing gravity, which belongs to the technical field of geodetic surveying. The method is used for global ocean disturbing gravity calculation, FFT calculation is carried out on each latitude circle by supplementing observation data in a global area, and then summation calculation is carried out in a longitude direction, and the processing method ensures the consistency of the result after the FFT calculation and the result of the original analysis algorithm. With respect to local ocean disturbing gravity calculation, a kernel function forms a cyclic matrix by supplementing a certain amount of data in the kernel function and the observation data, and then the consistency of the result and the result of the original analysis algorithm is ensured by virtue of FFT calculation. According to the method disclosed by the invention, a calculation formula is provided for calculating disturbing gravity by virtue of ocean height measurement satellite data, and an accurate and rapid method is given simultaneously. The method disclosed by the invention can also be applied to resolution for most of integral problems in physical geodesy, for example, resolution for geoidal surface, the deviation of plumb line, terrain correction and the like.

Owner:西安测绘研究所

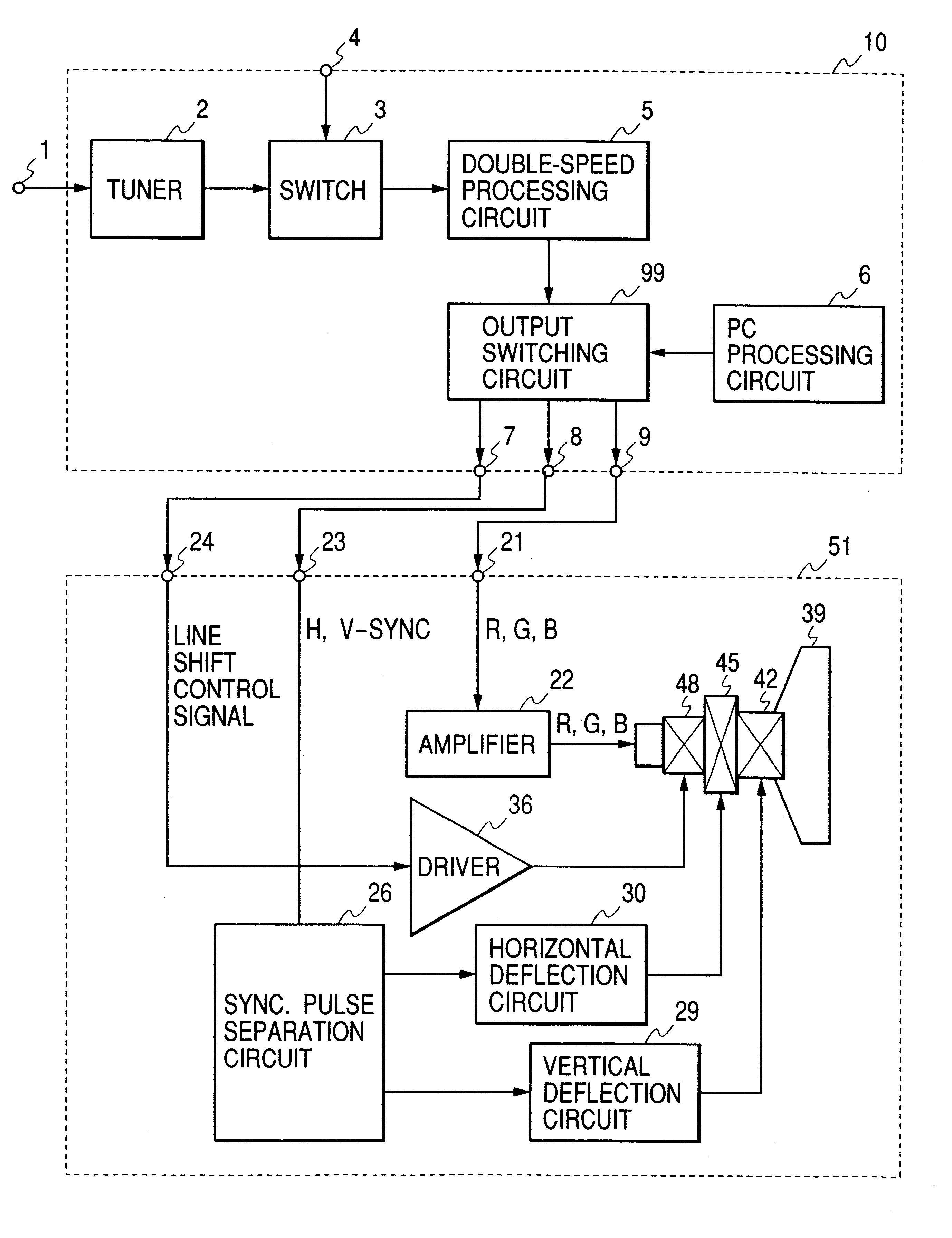

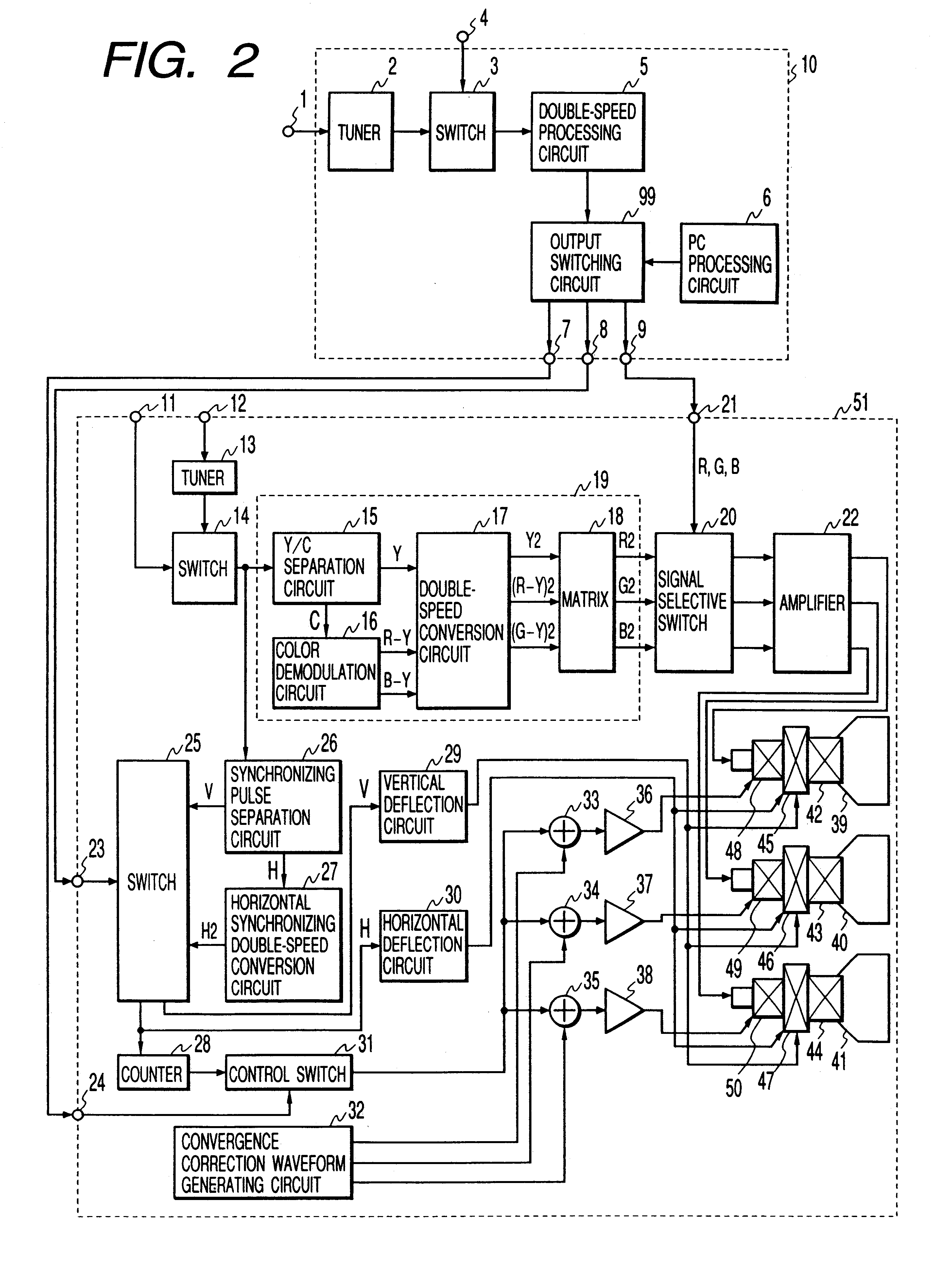

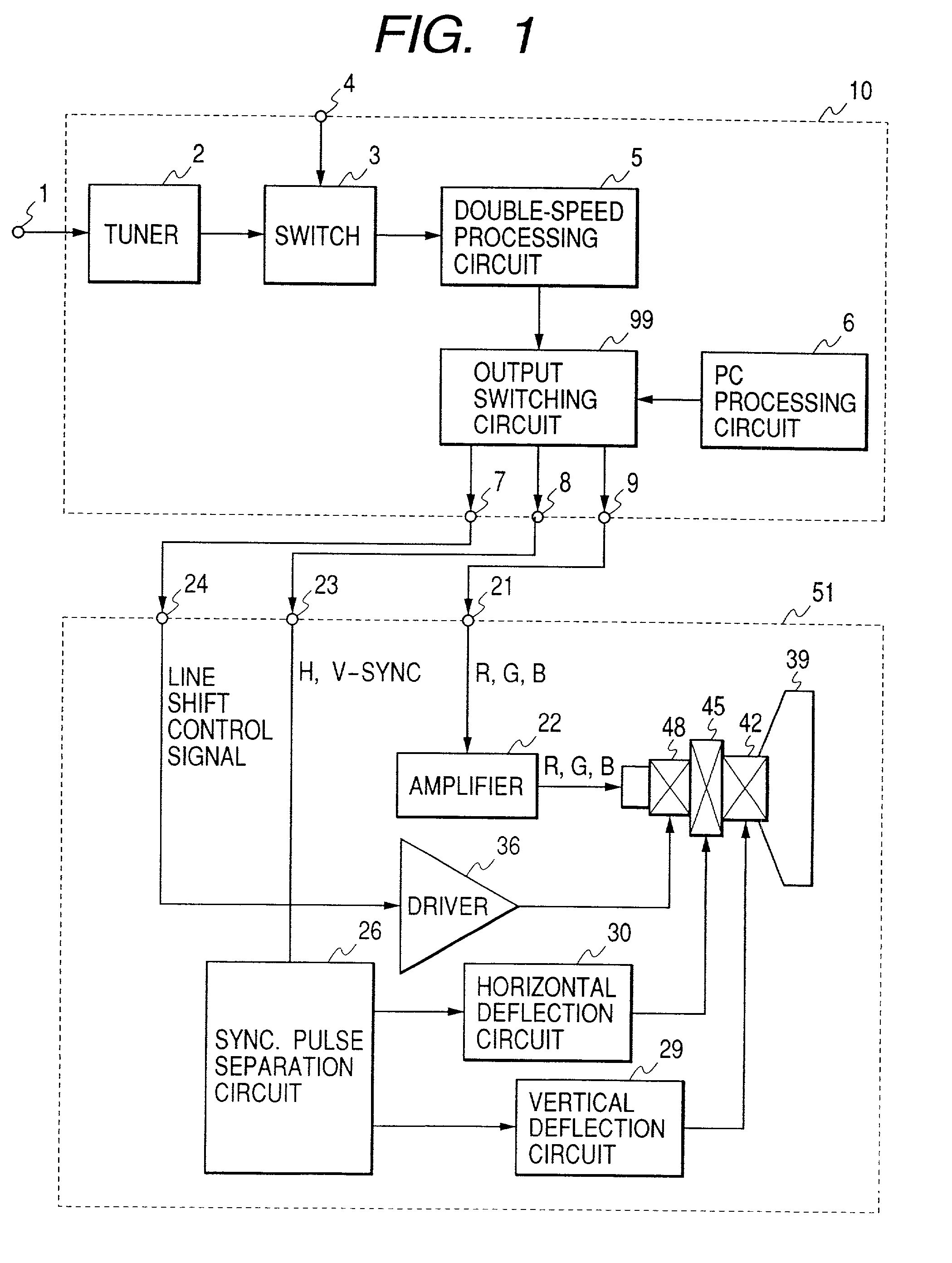

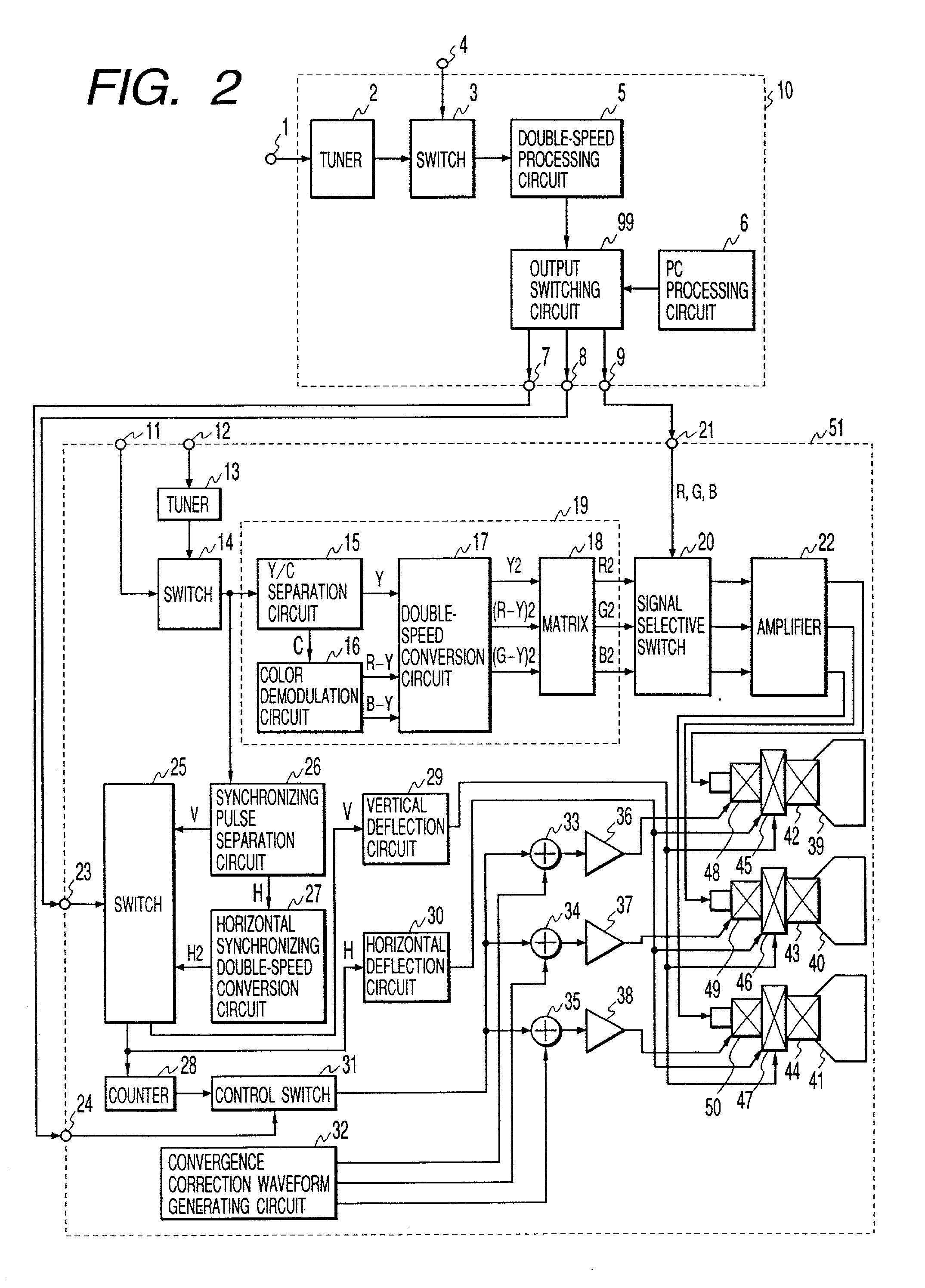

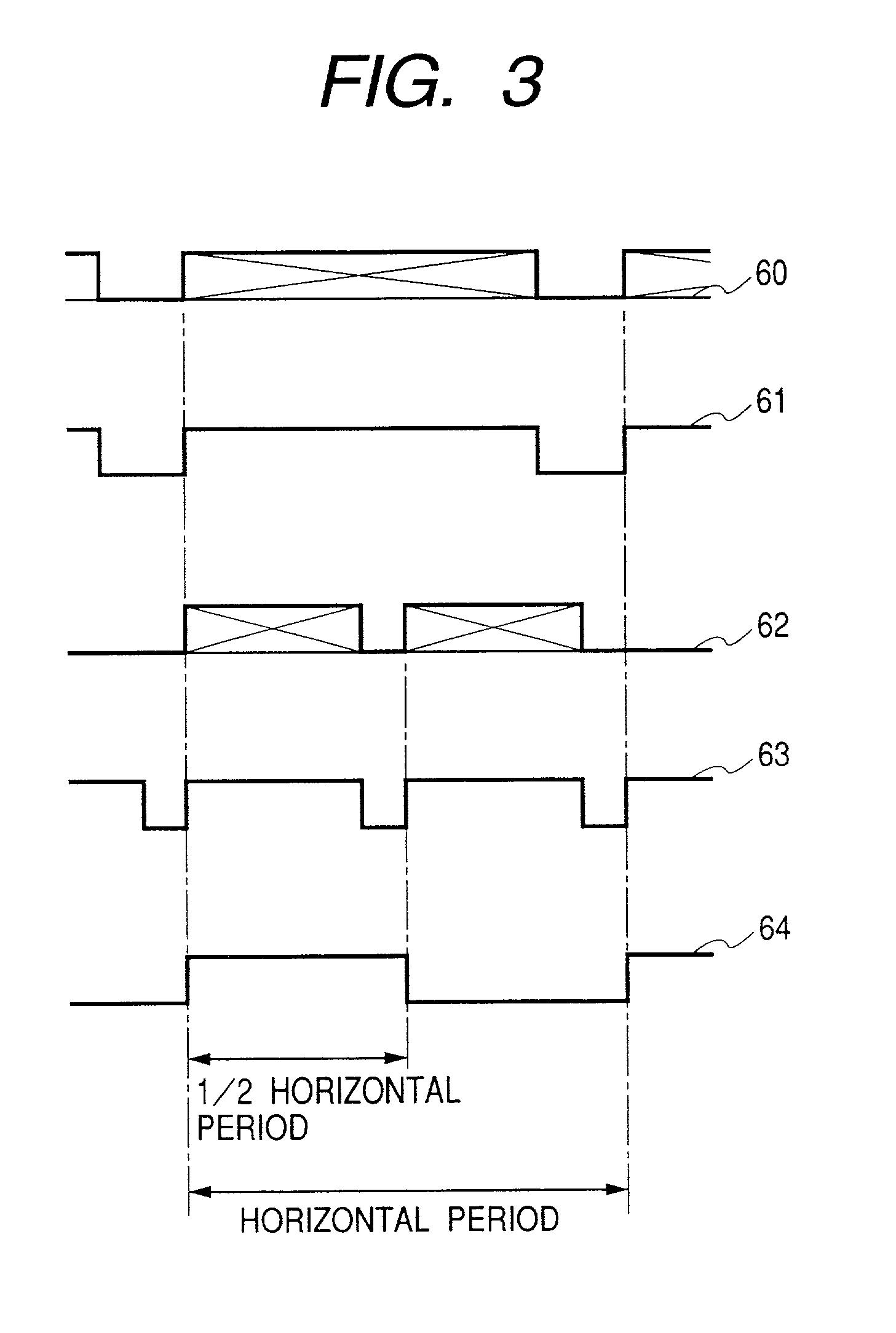

Image display apparatus and personal computer for displaying personal computer signals and broadcast signals

InactiveUS6268887B1High resolutionLow costTelevision system detailsColor signal processing circuitsVertical deflectionInterlaced video

When a video signal is double-speed processed by the first device, a slight vertical deflection process is performed for redundant similar scan lines by the second device, and any slight deflection in the second device is controlled by the first device to thereby enable setting so as to always display images with excellent resolution. More particularly, a discrimination signal is generated by the first device to designate interlaced scanning and flag a need for vertical scan-line deflection, and such discrimination signal is provided to the second device such that the second device can always appropriately determine the need for vertical scan-line deflection. Through monitoring for the discrimination signal, an image display apparatus is capable of preventing vertical resolution from being deteriorated when video signals possibly requiring vertical line-shifting are inputted from an external source. Further, an image display apparatus is capable of preventing the vertical resolution from being deteriorated when images of video signals having different systems are displayed within different areas on a same screen.

Owner:HITACHI LTD

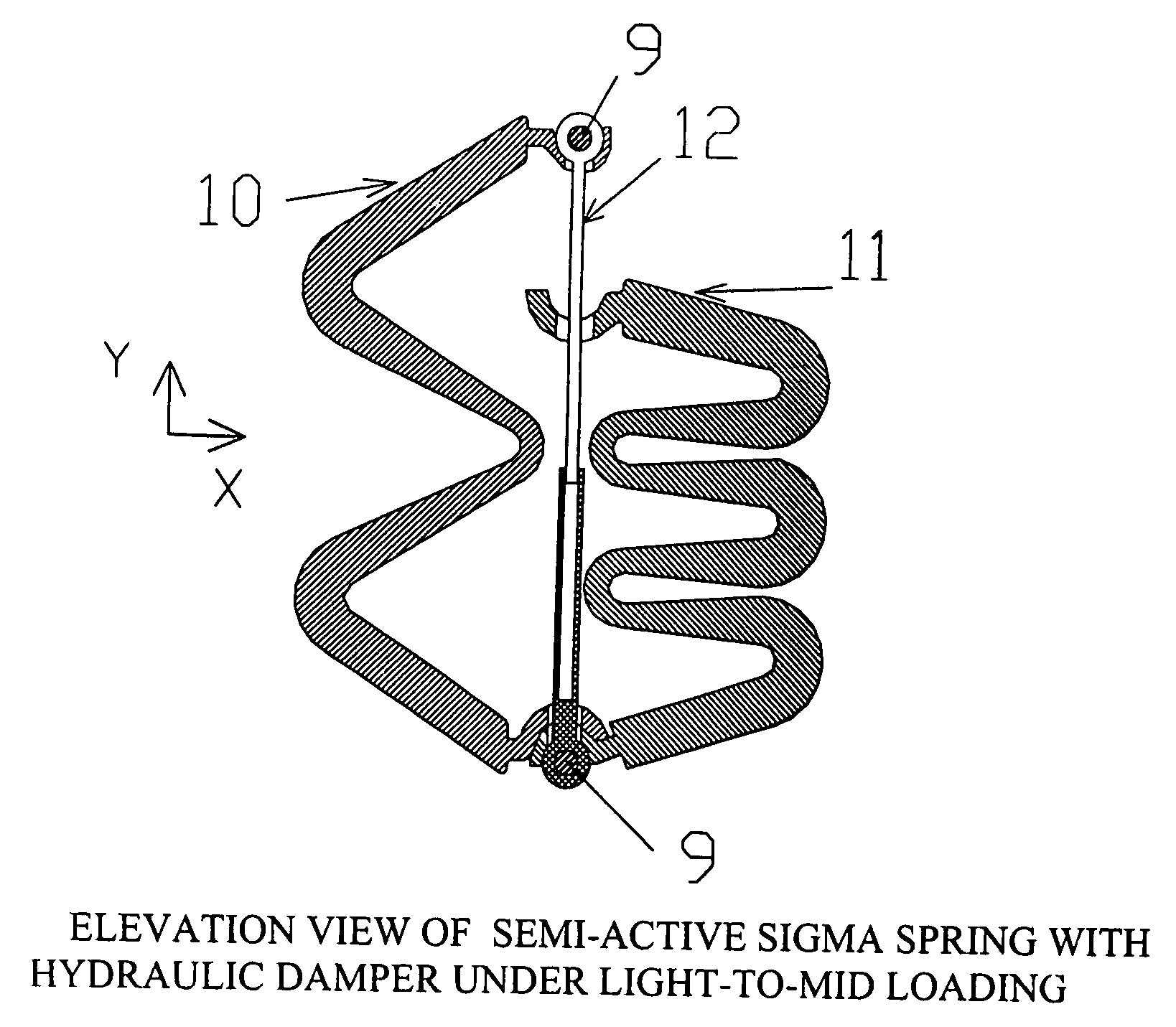

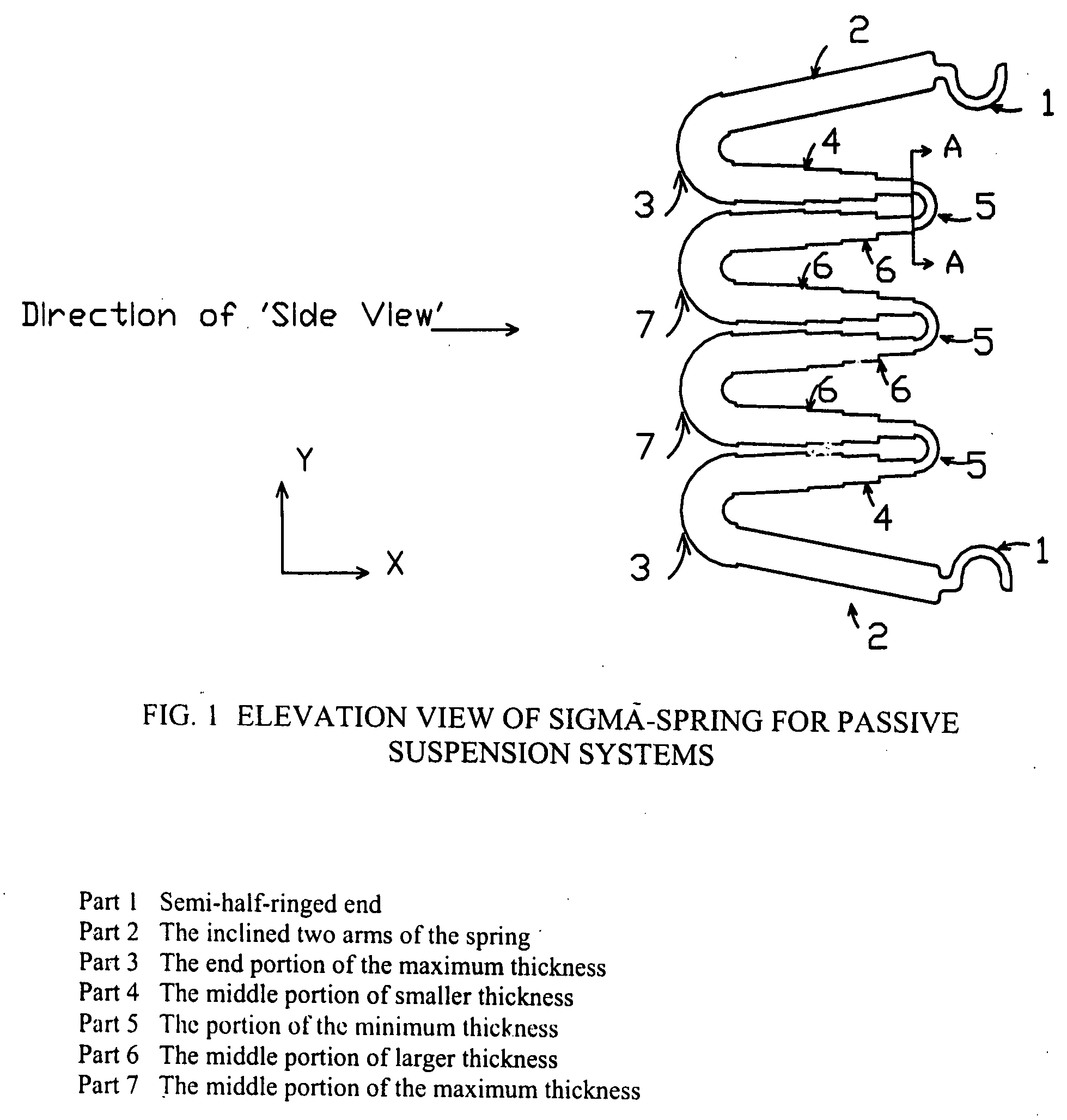

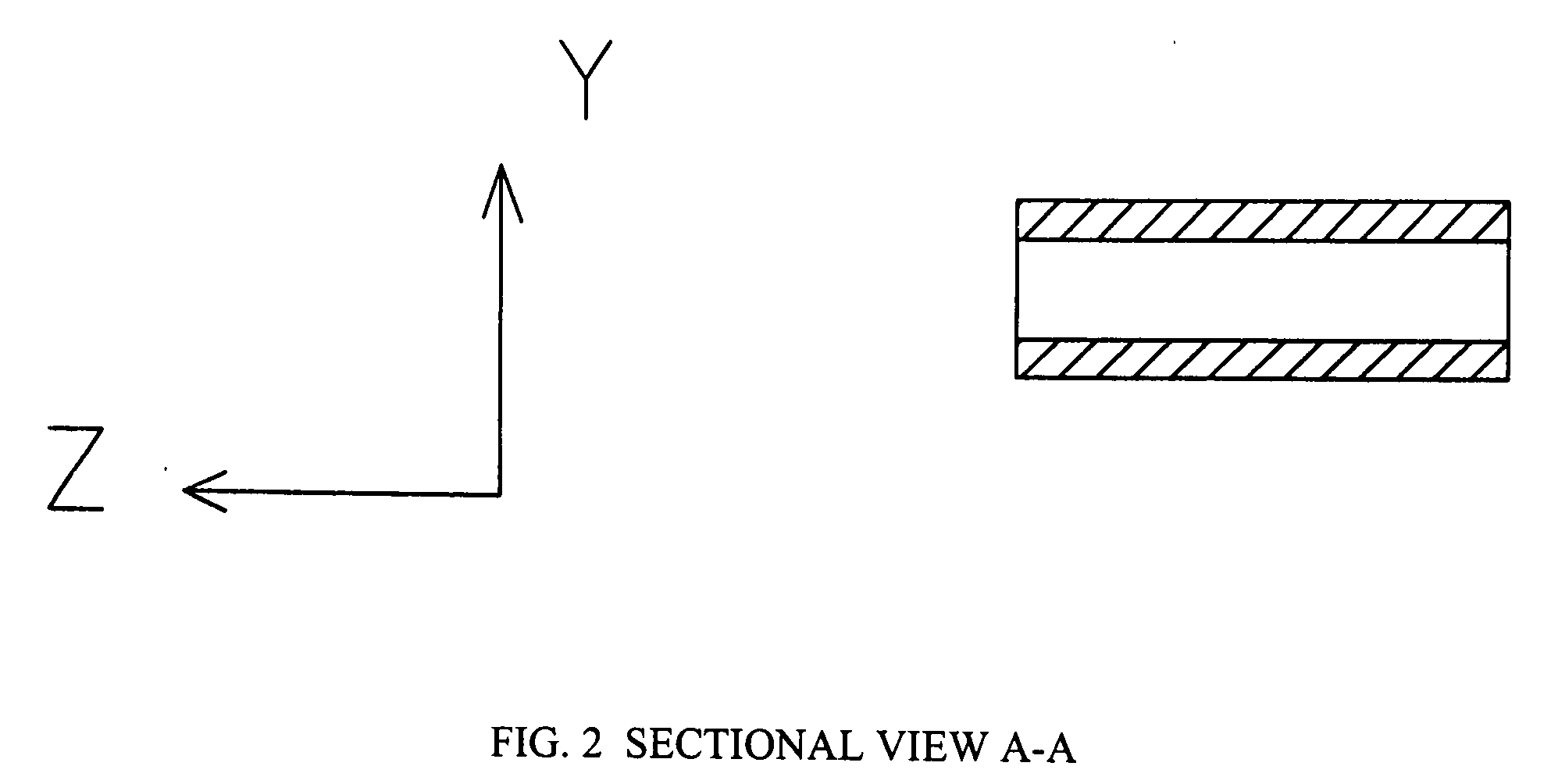

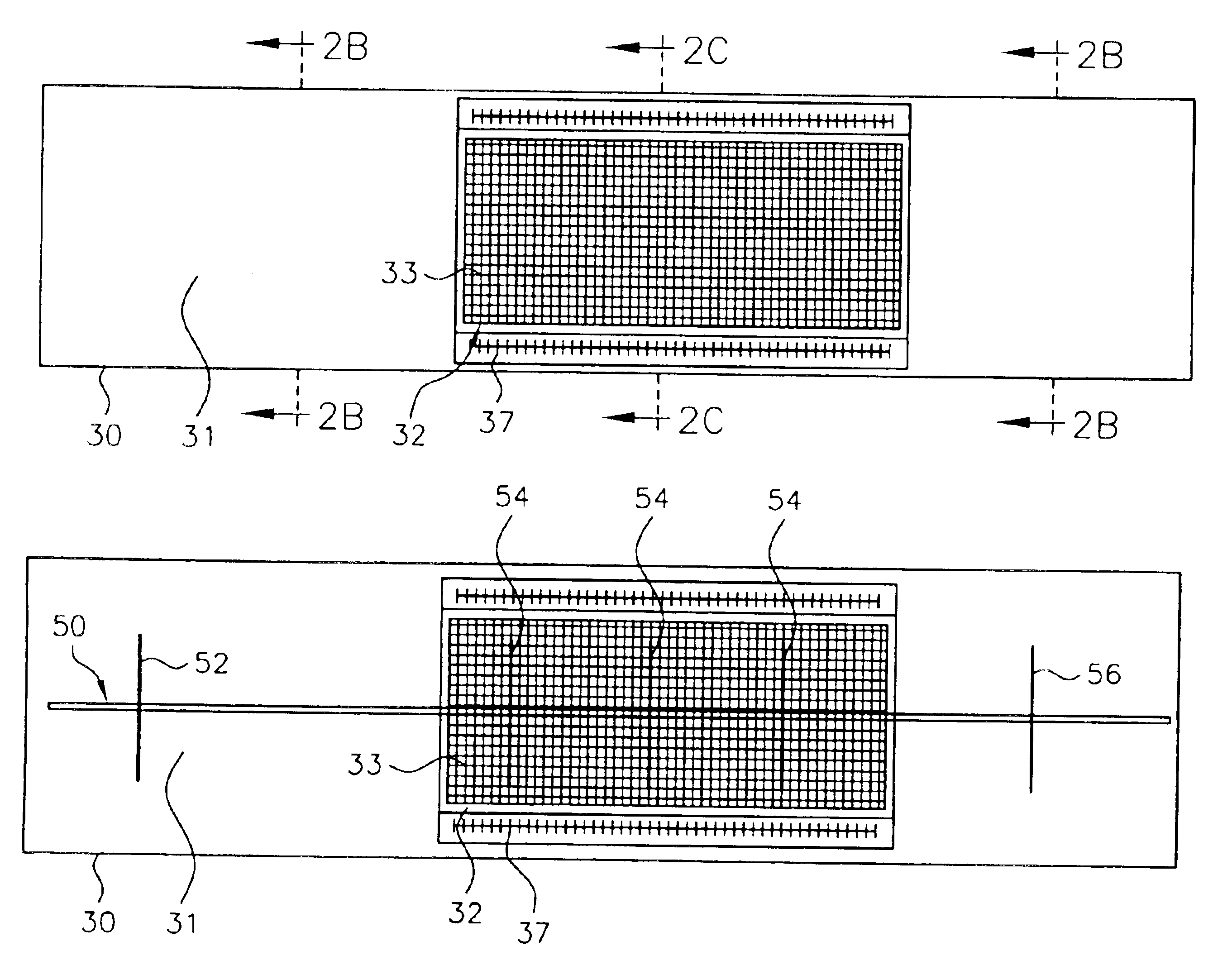

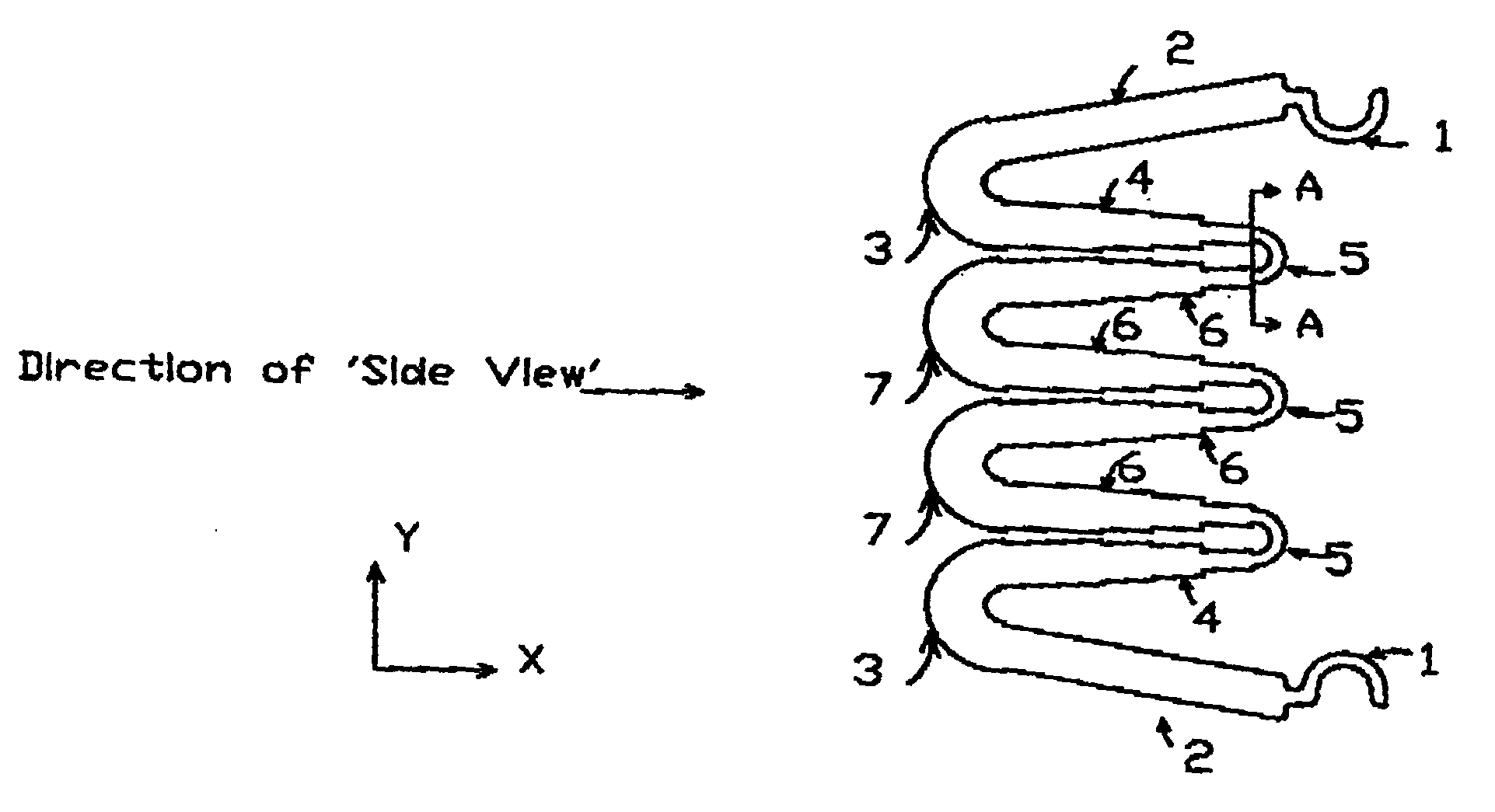

Sigma-springs for suspension systems

InactiveUS20070267792A1Improve rendering capabilitiesQuality improvementLeaf springsResilient suspensionsGlass fiberSemi active

Sigma-spring can be used as a passive vehicle suspension system of built-in damping, a passive vehicle suspension system with hydraulic damper, a semi-active vehicle suspension system of two opposite Sigma-springs (10,11) of built-in damping, or a semi-active vehicle suspension system of two opposite Sigma-springs (10,11) penetrated at line of external loading by hydraulic damper (12). The Sigma-spring is a spring of a special Sigma-shape above which mass can be suspended vertically while under static or dynamic loading conditions. The outer two arms of the Sigma-shape of the spring are inclined such that to be horizontal while fully loaded ensuring safe compression pattern. The Sigma-shape has two opposite sets of turns of different sizes one of small radius of curvature at the side of line of the applied external load and the opposite one has large radius of curvature in order to maximize spring vertical deflection capability. Thickness throughout the Sigma-spring developed length is graduated in order to minimize induced stresses, weight, and cost. Stiffness of the Sigma-spring can be nonlinear in order to provide improved vibration isolation and can be adjusted for same compact space allowance through increasing or decreasing its number of turns. The Sigma-spring can be made of Polymeric Matrix Composite of resin strengthened at nano-scale by nanometer-sized powder E-glass fibers. Moreover, the Sigma-spring can be made of Metallic Matrix Composite or of whole metallic monolithic material.

Owner:ELMOSELHY SALAH AHMED MOHAMED

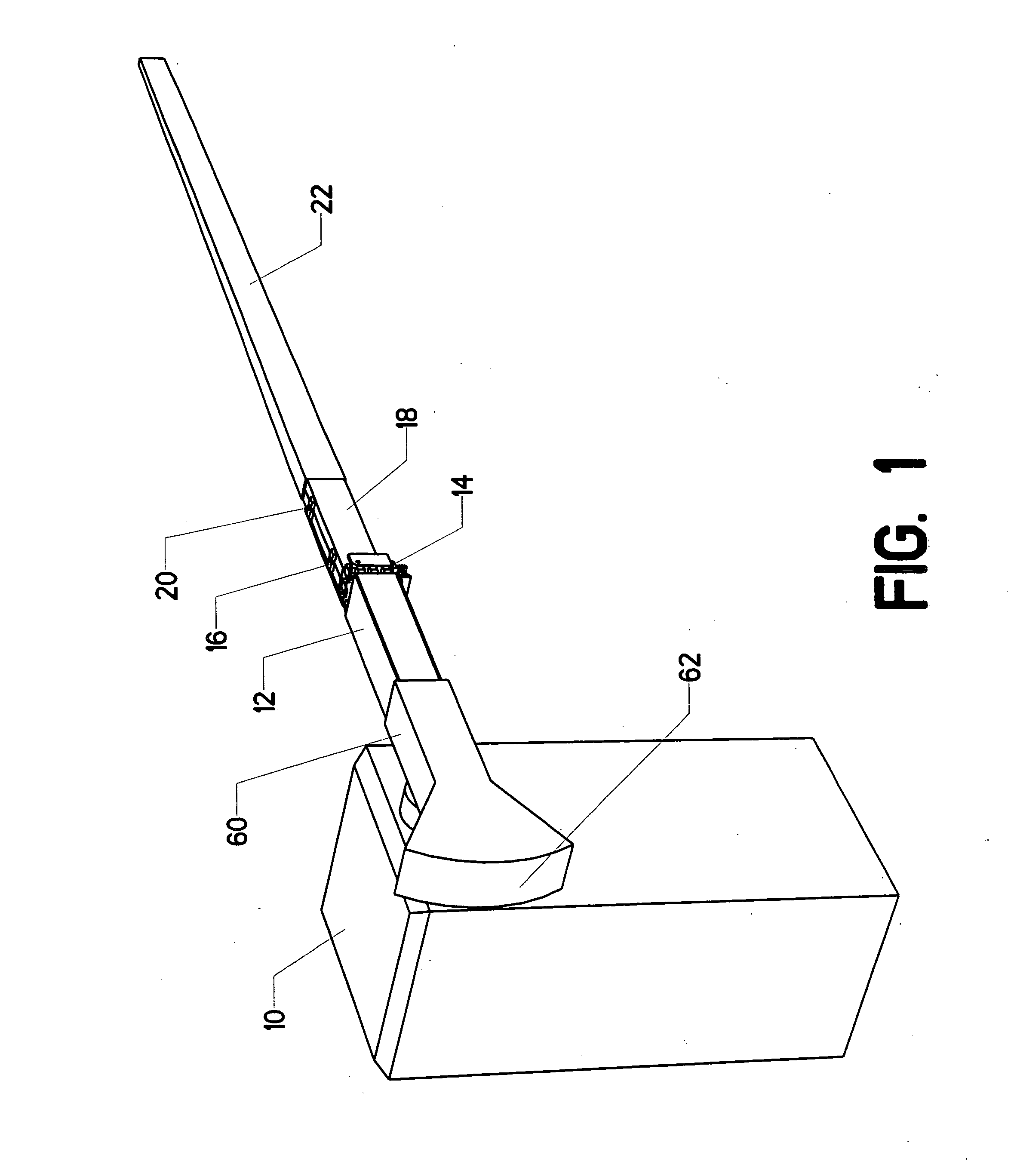

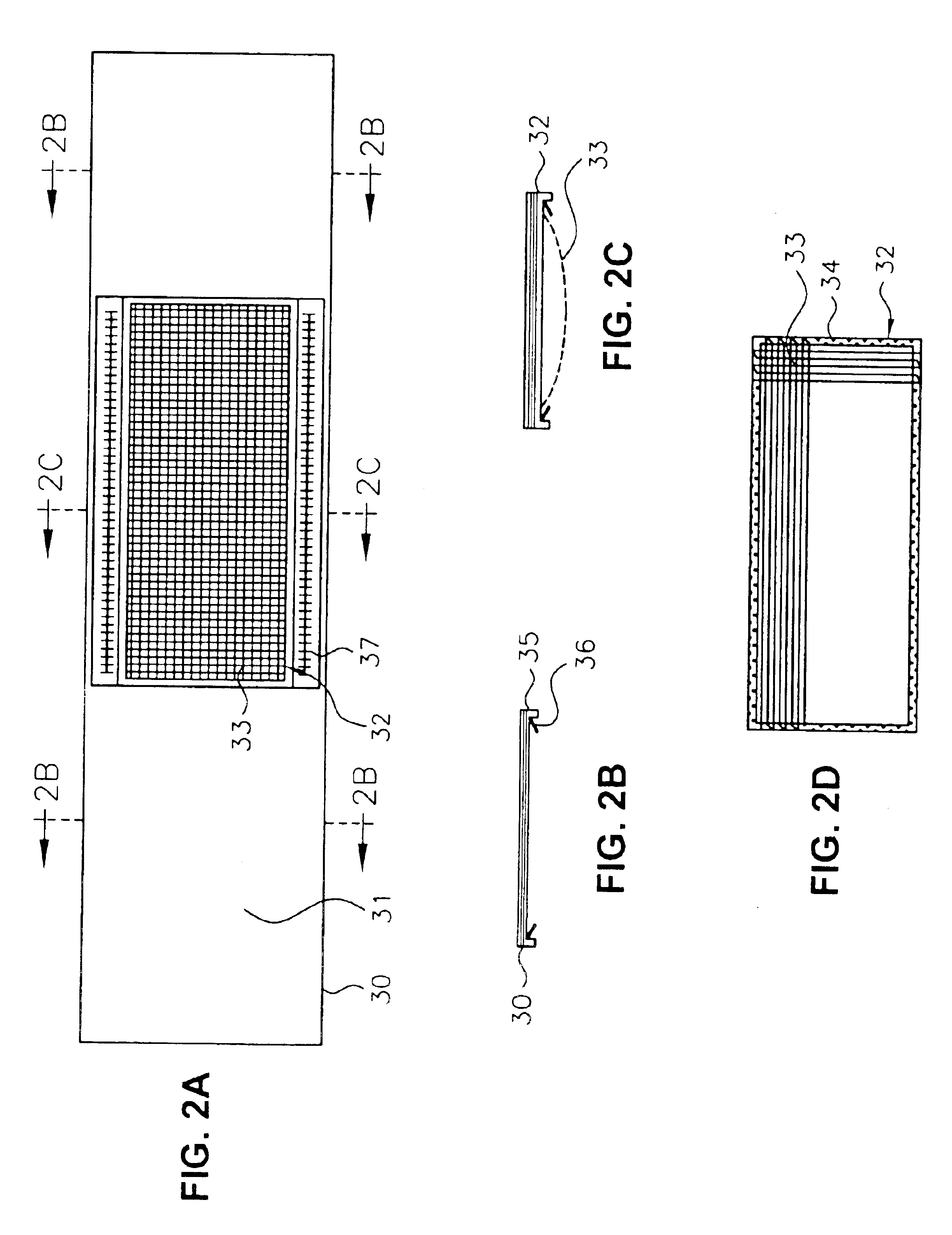

Diagnostic imaging tabletop

A tabletop useful for accurate positioning of a patient for imaging and diagnosis, so that patient positioning in subsequent medical treatments, such as radiation therapy, accurately and precisely correlates with the imaging data. The tabletop of the present invention is a solid flat tabletop adapted to fit over or as an insert in a conventional CT imaging or scan table and provides a flexible support section in which the flexible support material is tensioned to provide a vertical deflection corresponding to the vertical deflection of a flexible patient support of a treatment simulator or linear accelerator. In a preferred embodiment, the flexible support section may be removed and inserted into the treatment table to provide an exact correlation in vertical deflection during treatment.

Owner:DIACOR

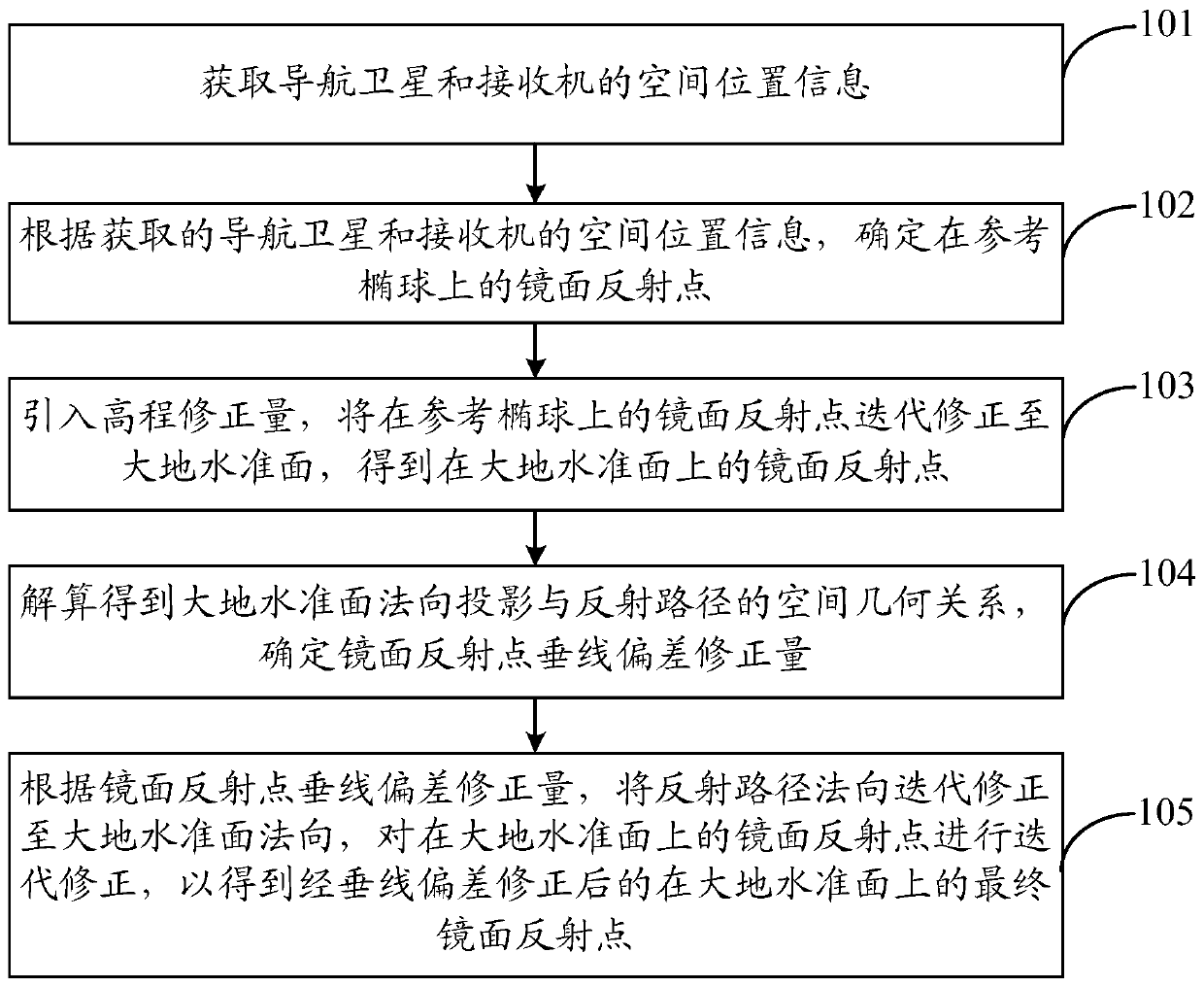

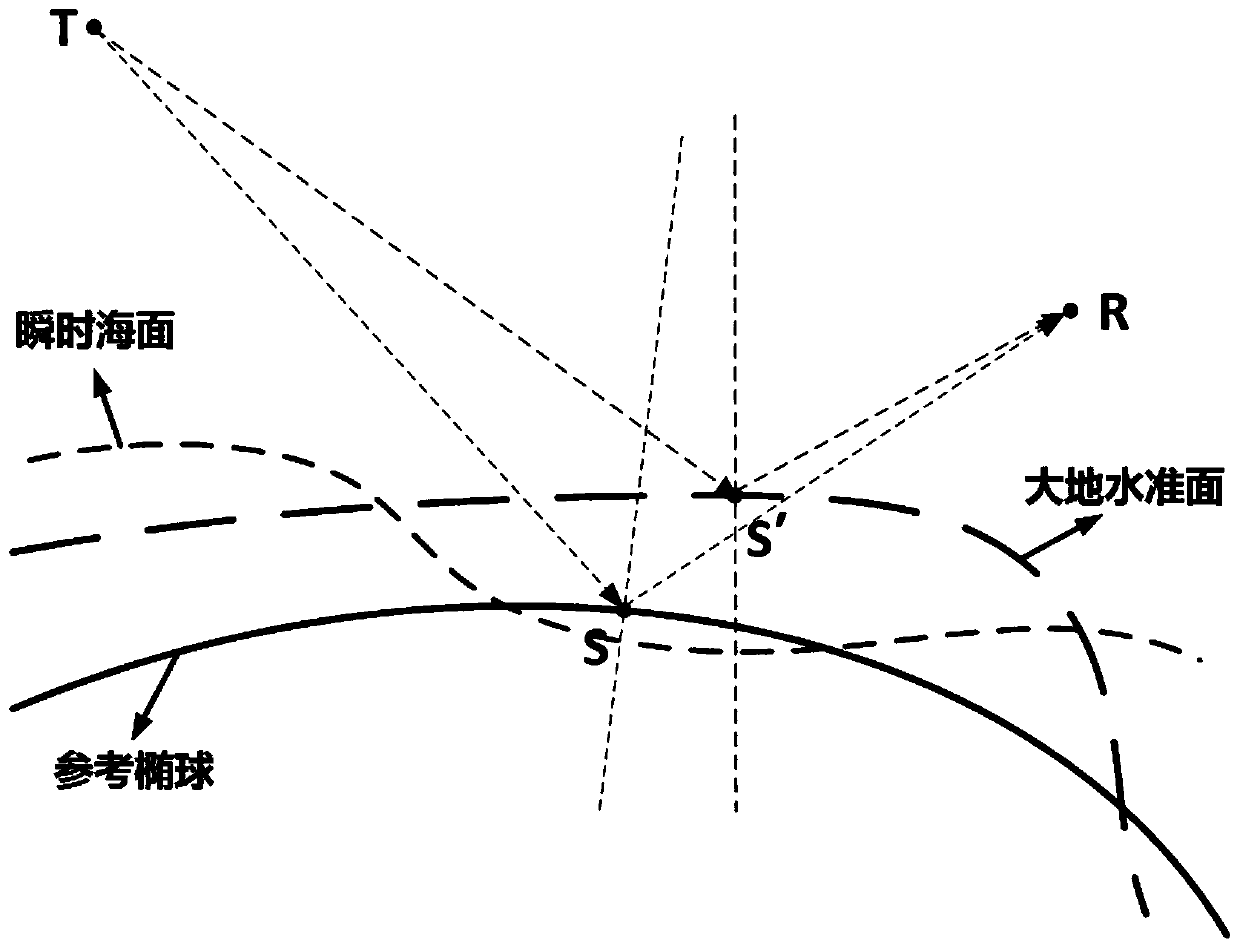

Geoid-vertical line deviation correction method and system for GNSS-R specular reflection point

InactiveCN109696697AAdvantages of high spatial resolution observationHigh measurement accuracySatellite radio beaconingVertical deflectionImage resolution

The invention discloses a geoid-vertical line deviation correction method and system for a GNSS-R specular reflection point. The method comprises the steps of acquiring spatial position information ofnavigation satellites and a receiver; determining a specular reflection point on the reference ellipsoid according to the spatial position information of the navigation satellites and the receiver; introducing the elevation correction amount, iteratively correcting the specular reflection point on the reference ellipsoid to the geoid to obtain a specular reflection point on the geoid; calculatingthe spatial geometric relationship between the normal projection of the geoid and the reflection path, determining the vertical line deviation correction amount of the specular reflection point, anditeratively correcting the normal direction of the reflection path to the normal direction of the geoid, and carrying out iterative correction on the specular reflection point on the geoid to obtain afinal specular reflection point corrected by the vertical line deviation on the geoid. The geoid-vertical line deviation correction method and system improve the positioning accuracy of the specularreflection point and provide support for acquiring a marine gravity field with high spatial resolution and high precision.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

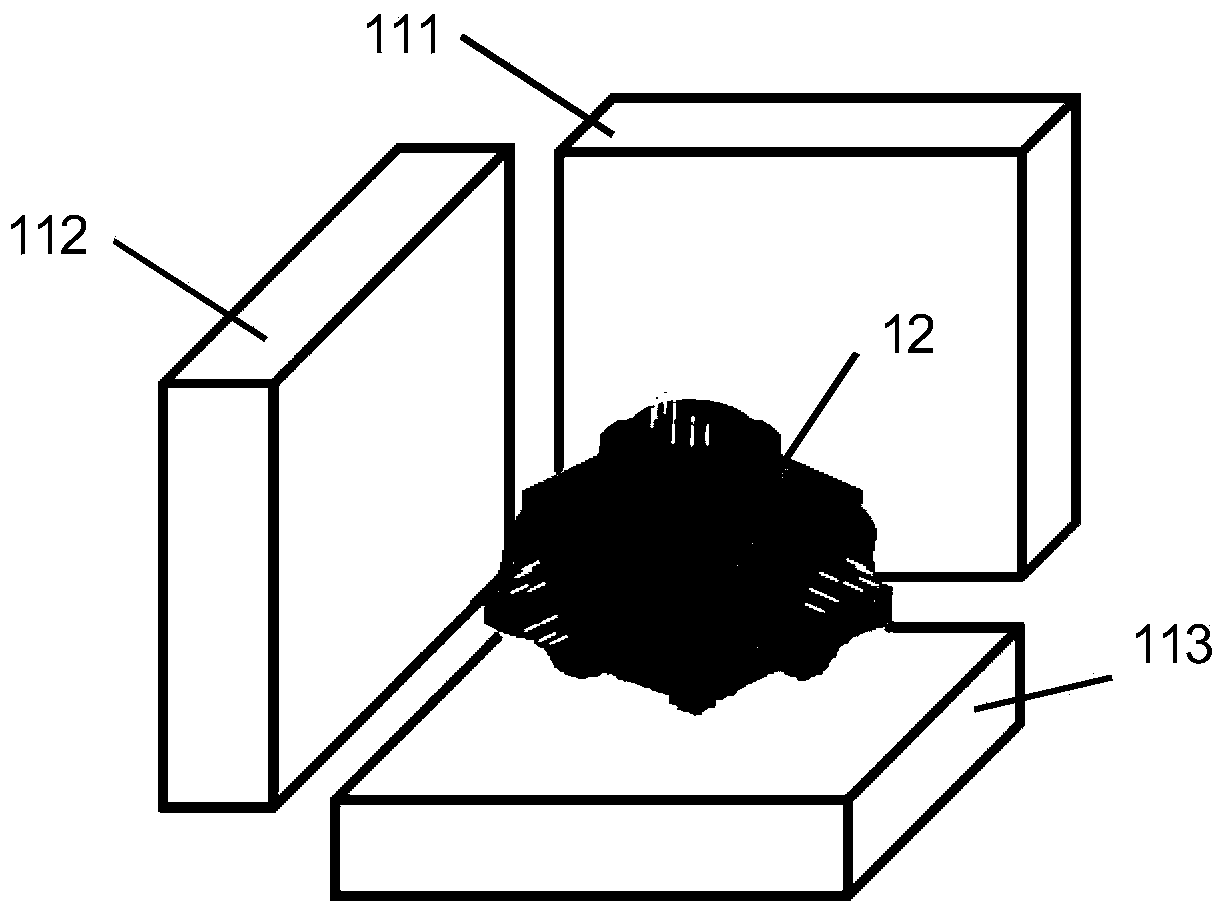

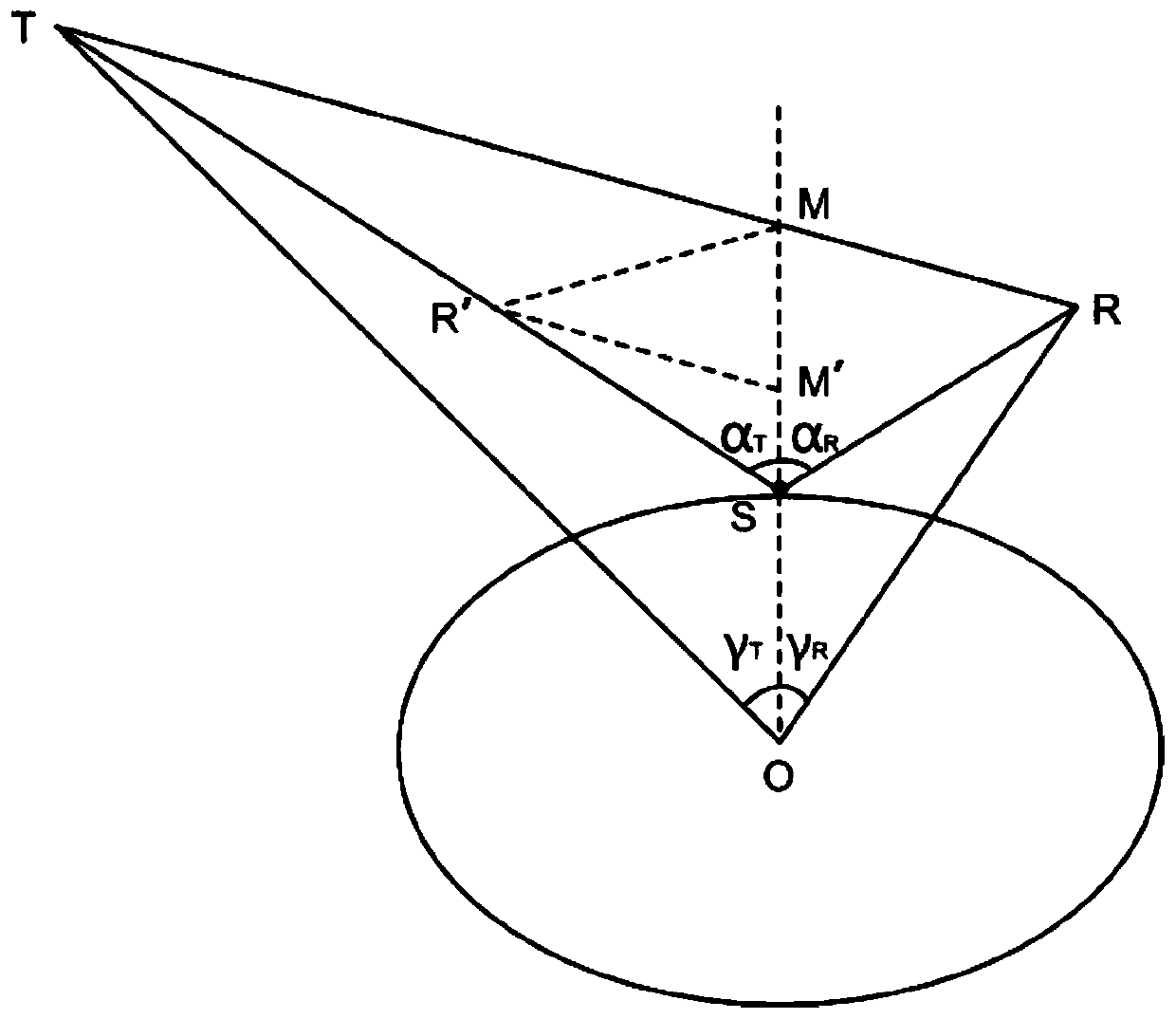

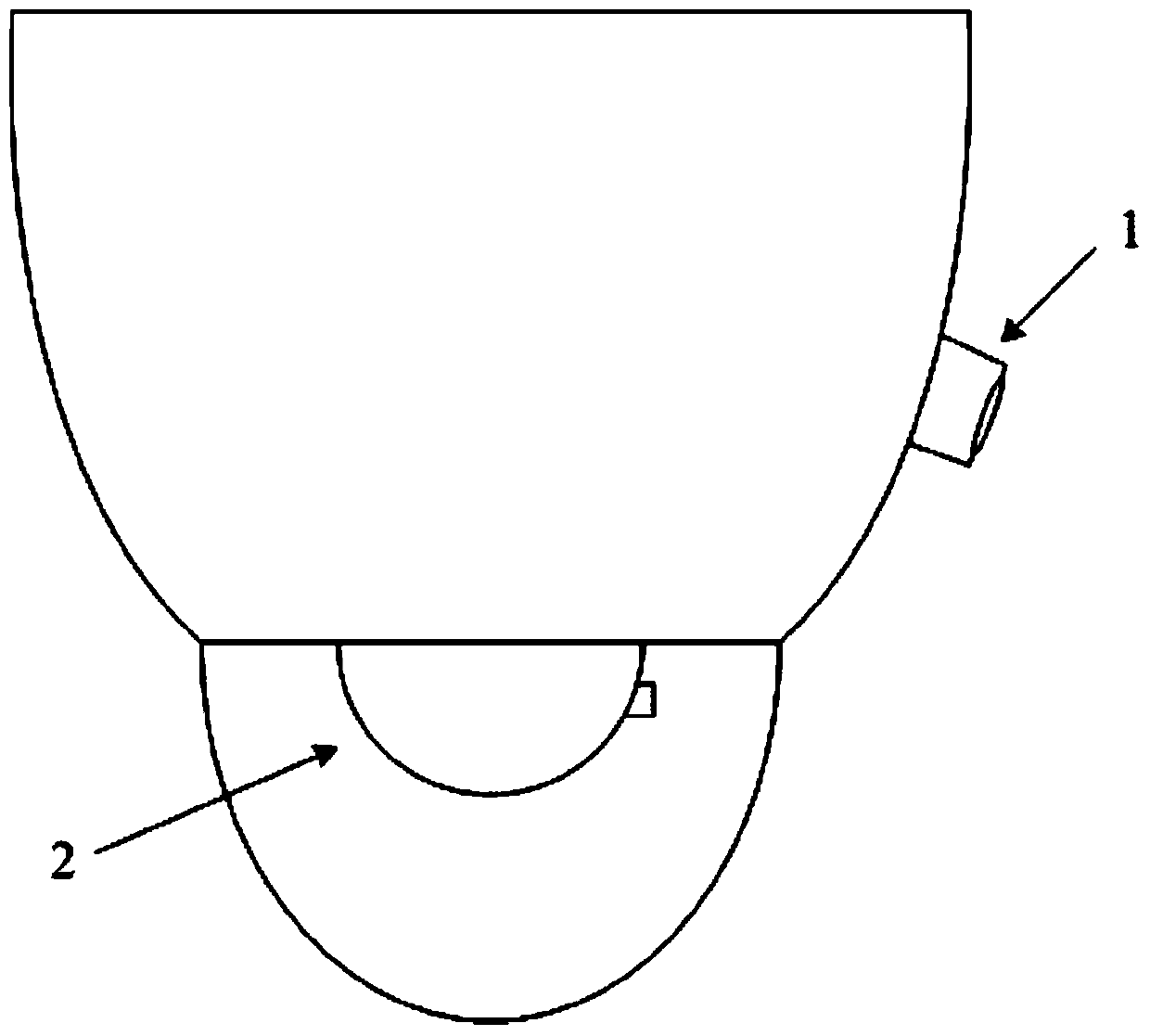

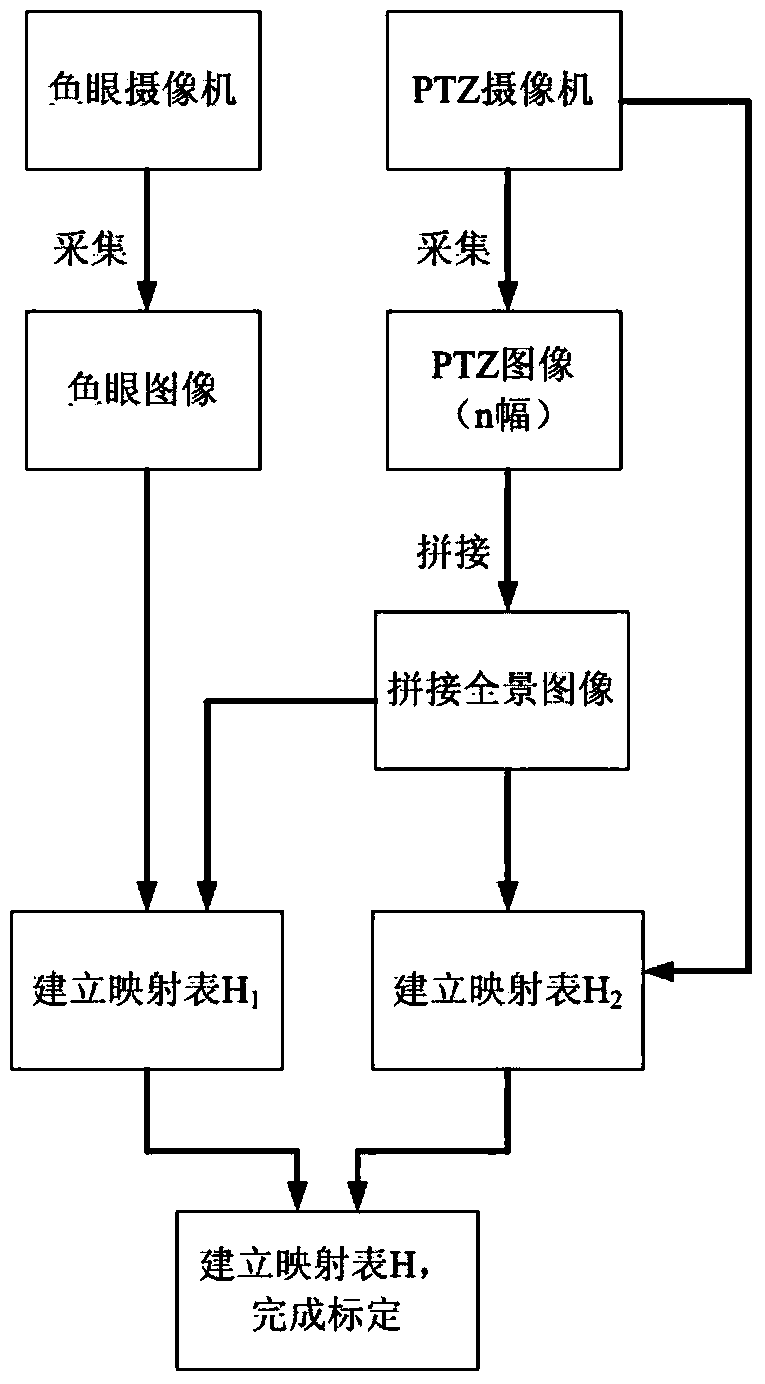

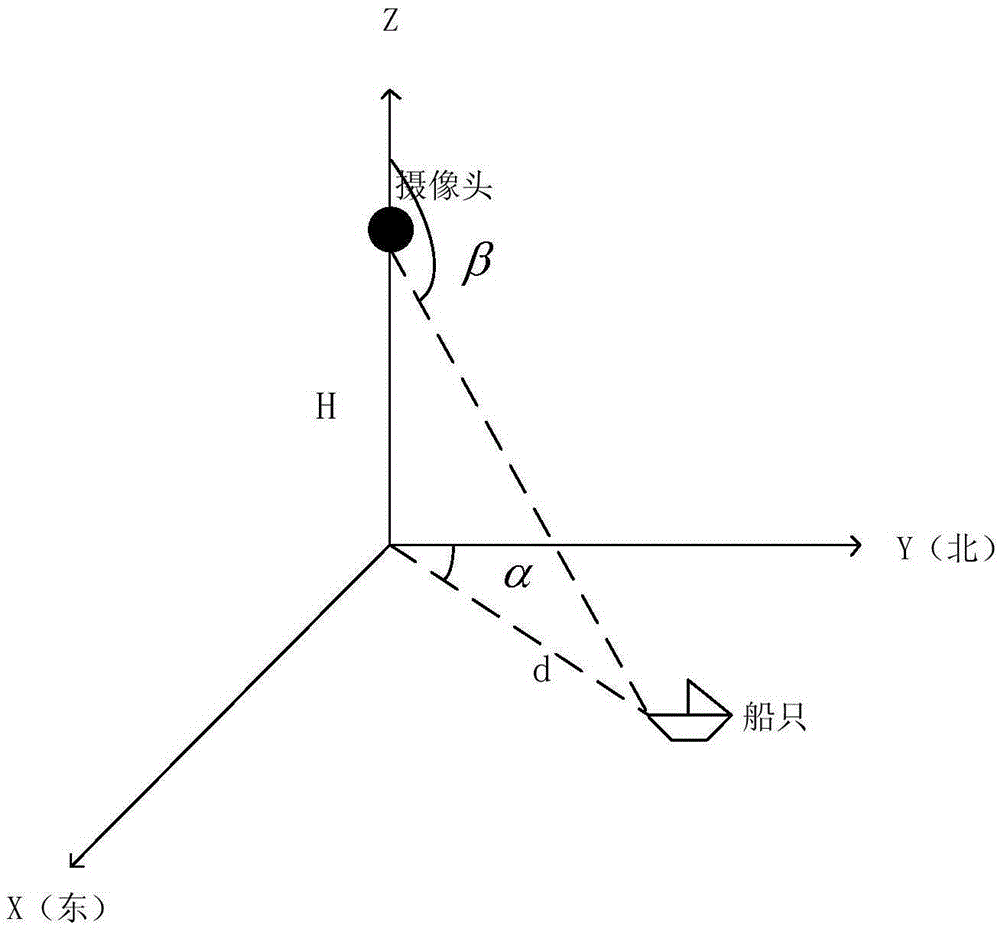

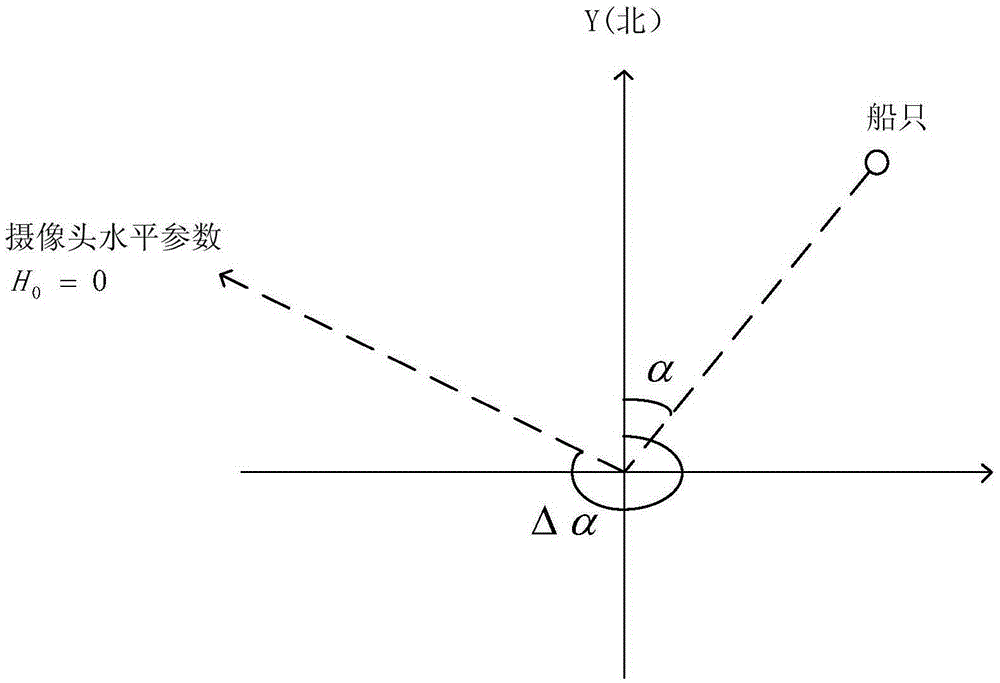

Panoramic gaze camera space calibration method based on image splicing

ActiveCN103971375AAchieving Spatial CalibrationAccurate control of horizontal deflection angleImage enhancementImage analysisVertical deflectionMotion parameter

The invention discloses a panoramic gaze camera space calibration method based on image splicing. The method includes the steps that firstly, a rotation model of a PTZ camera in a panoramic speed dome is built; secondly, multiple PTZ images shot by the PTZ camera and including all information of scenes are spliced to acquire a panoramic image; thirdly, based on the panoramic image, a mapping relation H2 between pixel points of the panoramic image and motion parameters of the PTZ camera and a mapping relation H1 between the pixel points of the panoramic image and pixel points in a fisheye image are built; fourthly, based on the mapping relation H1 and the mapping relation H2, a mapping relation H between the pixel points of the fisheye image and the motion parameters of the PTZ camera is built, and then panoramic gaze camera space calibration is achieved. By the adoption of the method, a horizontal deflection angle and a vertical deflection angle of the PIZ camera in the panoramic gaze camera can be accurately controlled, the monitoring position of a region of interest of the fisheye image shot by a selected fisheye camera is made to be at the center of the image shot by the PTZ camera, and then accurate positioning monitoring is achieved.

Owner:NAT UNIV OF DEFENSE TECH

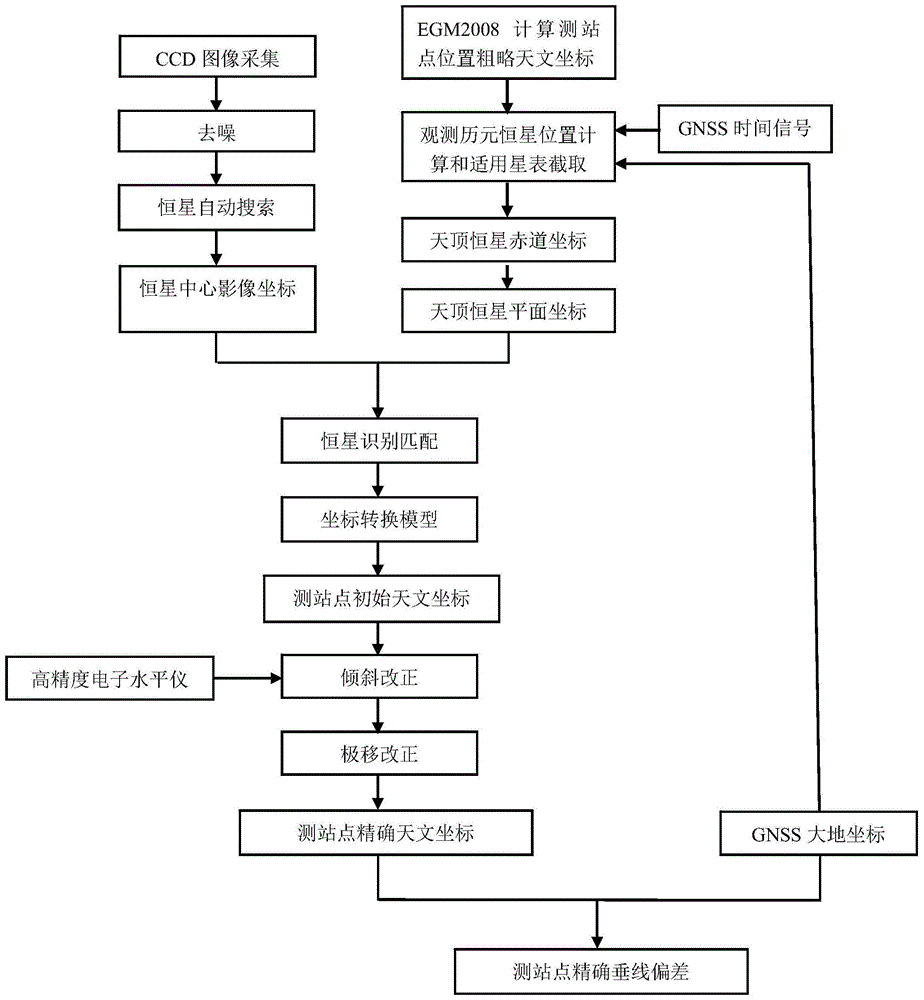

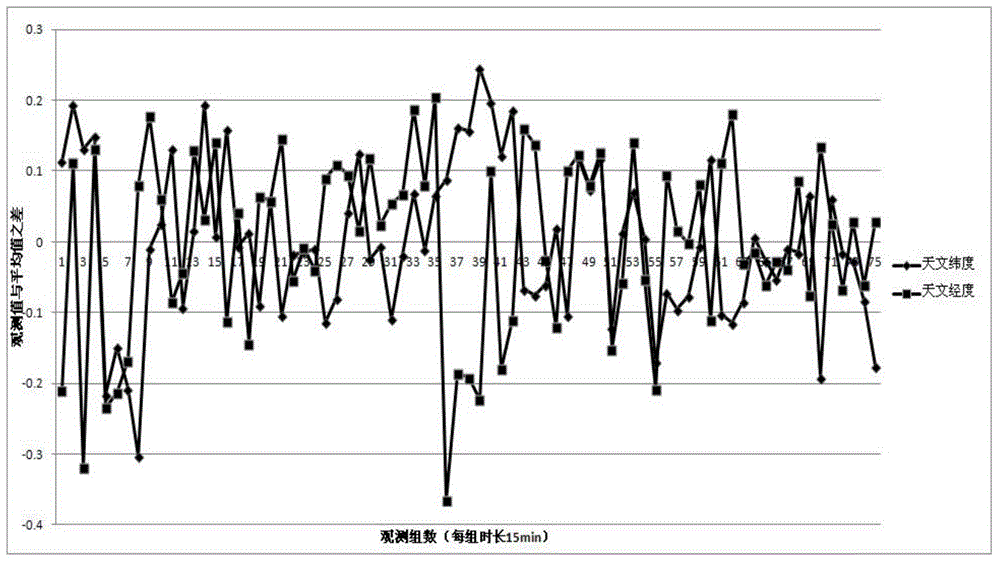

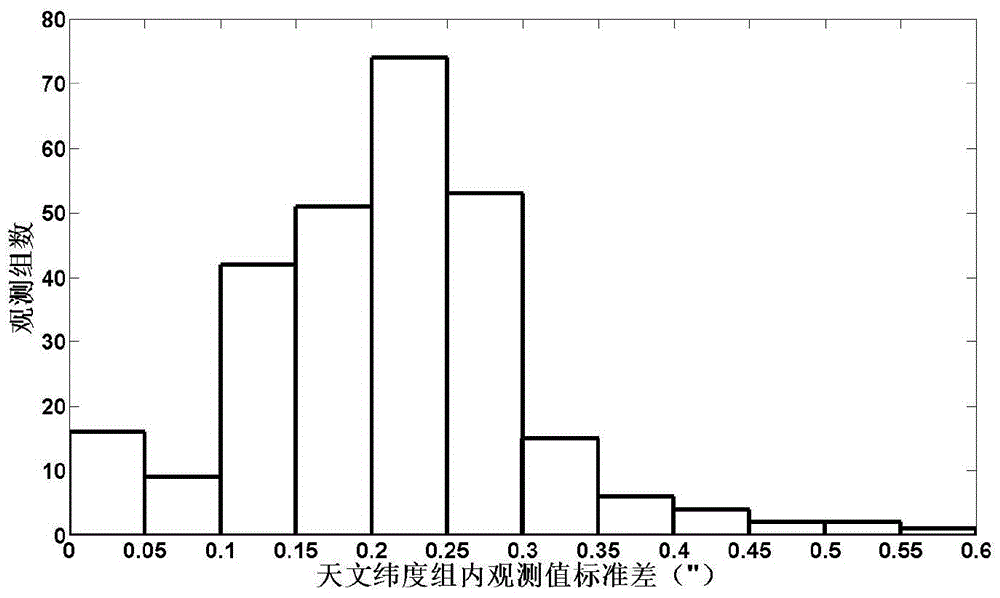

GNSS-CCD-integrated zenith telescope high-precision vertical deflection fast measurement method

ActiveCN104913780AShorten the timeMeasurement accuracyNavigational calculation instrumentsInformaticsFixed starsStar catalogue

The invention discloses a GNSS-CCD-integrated zenith telescope high-precision vertical deflection fast measurement method. At a measurement station, the optical axis of a zenith telescope faces to the zenith and takes a picture of a zenith zone so that a CCD fixed star image is obtained, fixed star image coordinates are calculated, exposure epoch is controlled by geodetic coordinates and a GNSS time signal measured by GNSS, fixed star information in the zenith zone is acquired in an appropriate star catalogue according to the measurement station vertical deflection calculated by an EGM2008 geopotential model, coupling identification of fixed stars in a zenith tangent plane zone of a celestial sphere in the star catalogue and in the CCD fixed star image is realized, zenith astronomical coordinates are calculated by least spuare iterative computation, and vertical deflection of the observed point is calculated according to geodetic coordinates. Compared with the prior art, the method provided by the invention has the characteristics of simple operation, time and labor saving and high measurement precision and is suitable for high-precision vertical deflection fast measurement.

Owner:SHANDONG UNIV OF SCI & TECH

Knee Probe Having Reduced Thickness Section for Control of Scrub Motion

ActiveUS20100182030A1Easy to manufactureDegraded contactMeasurement leads/probesContactless circuit testingVertical deflectionElectrical devices

An improved knee probe for probing electrical devices and circuits is provided. The improved knee probe has a reduced thickness section to alter the mechanical behavior of the probe when contact is made. The reduced thickness section of the probe makes it easier to deflect the probe vertically when contact is made. This increased ease of vertical deflection tends to reduce the horizontal contact force component responsible for the scrub motion, thereby decreasing scrub length. Here “thickness” is the probe thickness in the deflection plane of the probe (i.e., the plane in which the probe knee lies). The reduced thickness probe section provides increased design flexibility for controlling scrub motion, especially in combination with other probe parameters affecting the scrub motion.

Owner:MICRO PROBE

Sigma Sigma-springs for suspension systems

InactiveUS20060033252A1High strength-to-weight ratioImprove carrying capacityLeaf springsLow internal friction springsVertical deflectionPre stress

Sigma Σ-spring is a spring of a Sigma Σ-shape resembles the capital Sigma Σ letter, above which mass can be suspended vertically while under static or dynamic loading conditions. The outer two arms of the Σ-shape of the spring are inclined such mat to be horizontal while fully loaded ensuring safe compression pattern and providing pre-stressed condition that reduces stress at critically stressed sections. The Σ-shape has two opposite sets of turns of different sizes one of small radius of curvature at the side of line of loading of the mass that can be suspended vertically and the opposite one has large radius of curvature in order to maximize spring vertical deflection capability. Thickness throughout the Σ-spring developed length is graduated in order to minimize induced stresses, weight, and cost. Stiffness of the Σ-spring can be adjusted in compact space condition through increasing or decreasing number of turns of the Σ-spring. The Σ-spring is made of Polymeric Matrix Composite of resin strengthened by mineral clay powder providing built-in damping in addition to springing. Σ-spring of built-in damping can suspend mass passively as a stand-alone spring providing both of springing and damping, or semi-actively through two opposite Σ-springs of built-in damping providing both of springing and damping.

Owner:ELMOSELHY SALAH AHMED MOHAMED

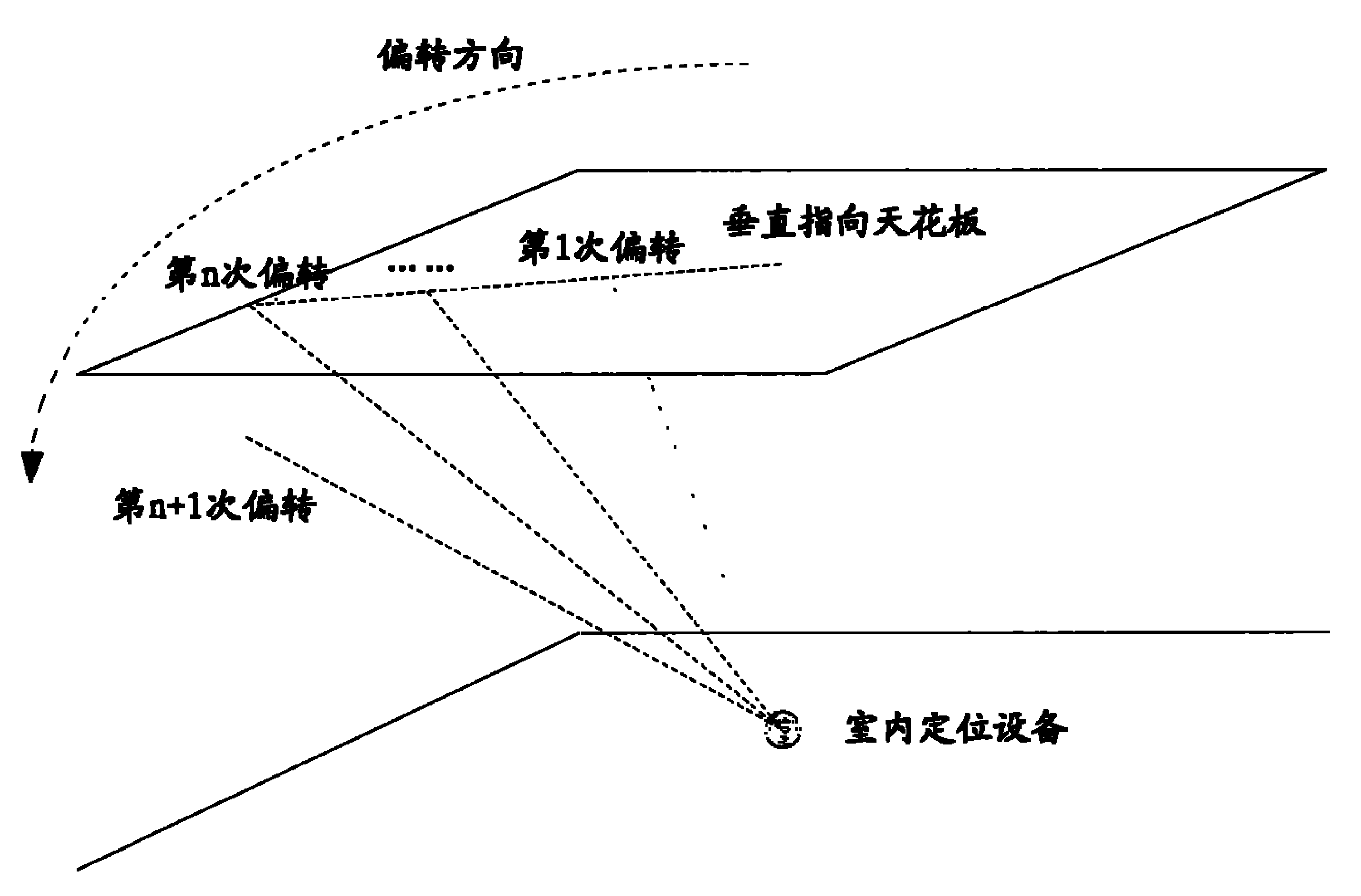

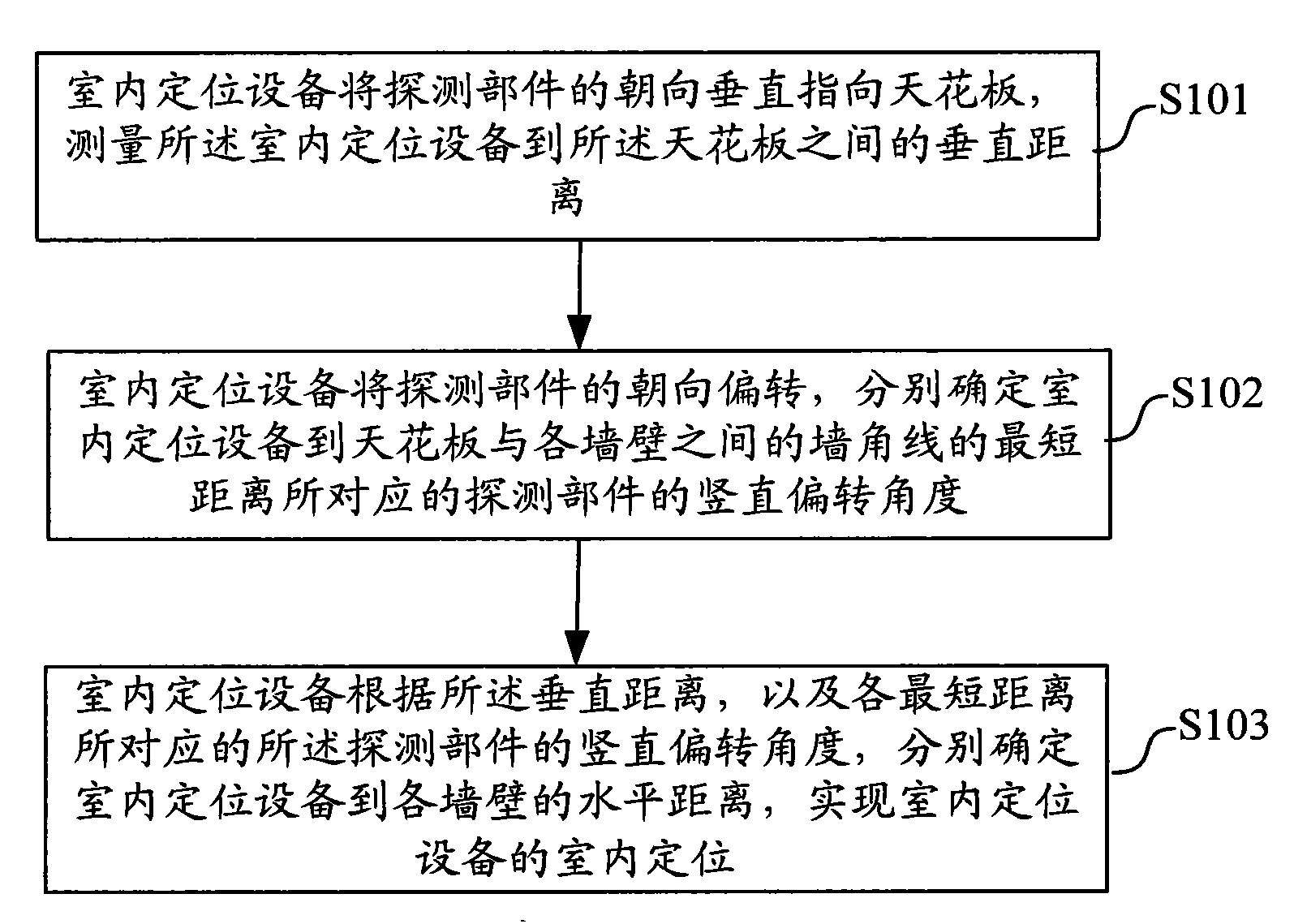

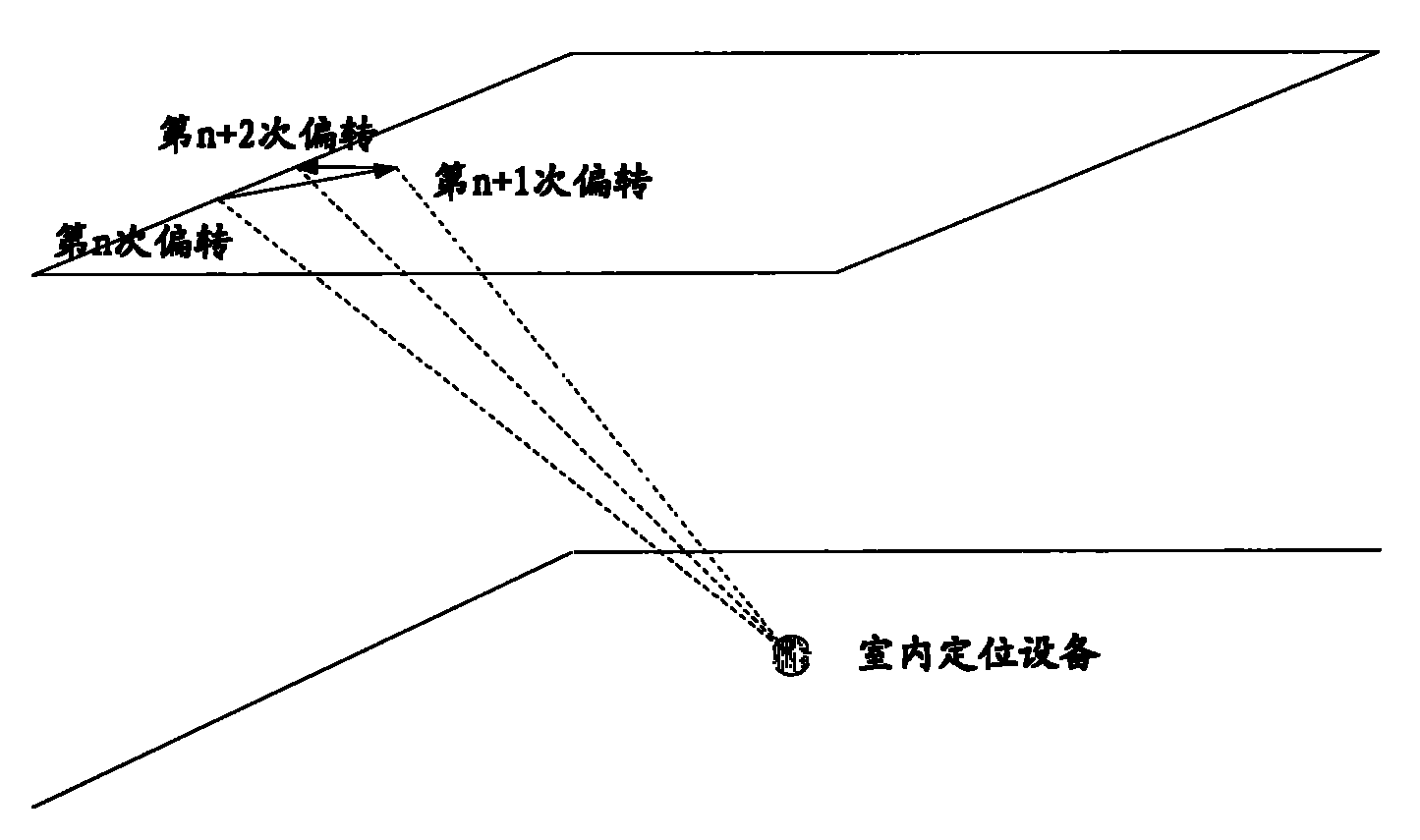

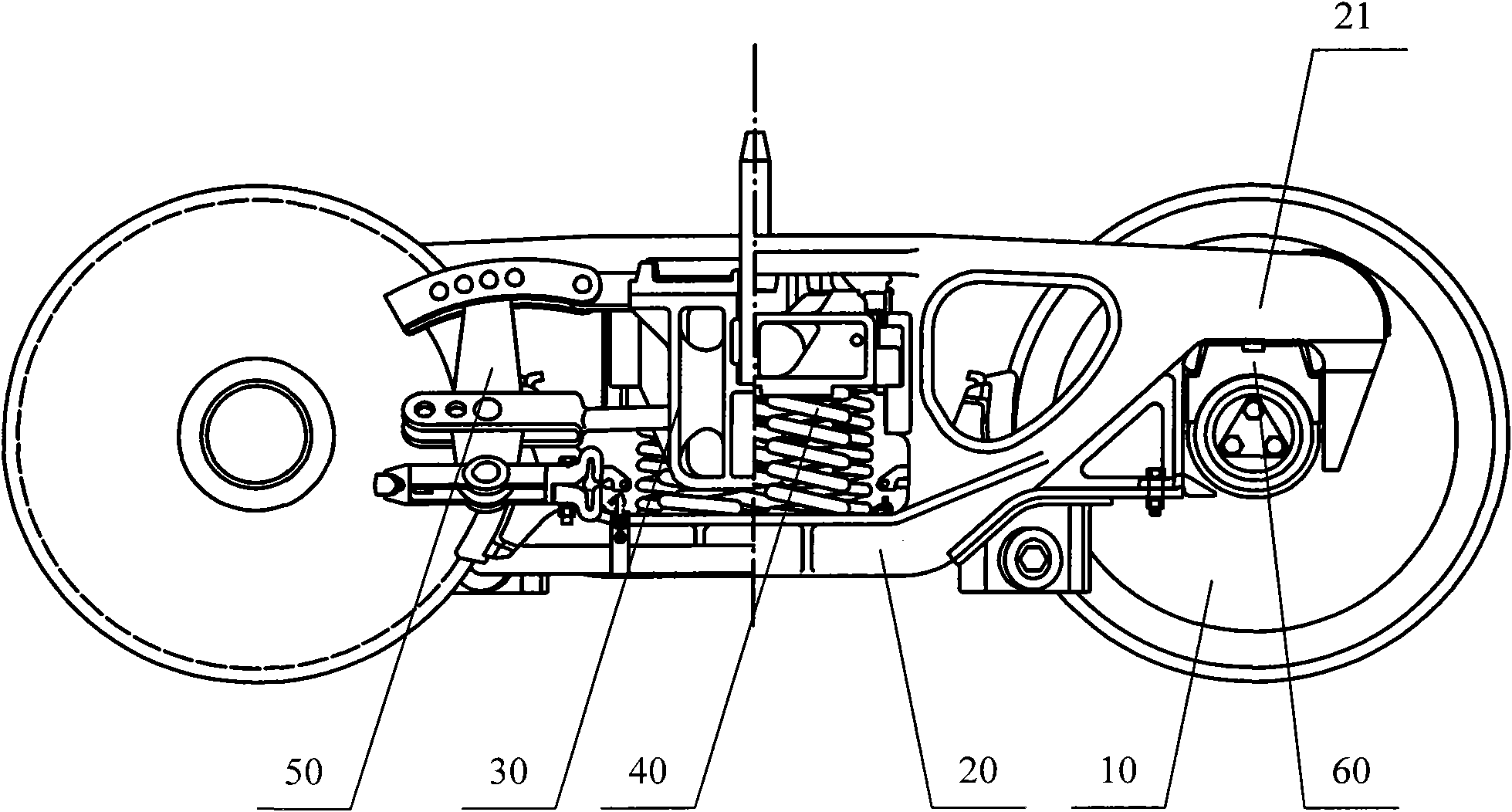

Indoor positioning method and indoor positioning device

InactiveCN104062626AAvoid interferenceHigh precisionBeacon systems using ultrasonic/sonic/infrasonic wavesBeacon systems using electromagnetic wavesVertical deflectionShortest distance

The embodiment of the present invention discloses an indoor positioning method and an indoor positioning device. By applying the technical scheme provided by the embodiment of the present invention, the horizontal distances between the indoor positioning device and the walls are determined according to the vertical distance between the indoor positioning device itself and a ceiling, and a vertical deflection angle corresponding to a corner line having the shortest distance of the corner lines between the indoor positioning device itself and the ceiling, and between the indoor positioning device itself and the walls, thereby realizing the indoor positioning, avoiding the interference of the ground barriers to the indoor positioning, improving the precision and operation efficiency of the indoor positioning and the universality of an indoor positioning technology, and reducing the requirements for an indoor environment and the cost of the indoor positioning.

Owner:吴晓栋

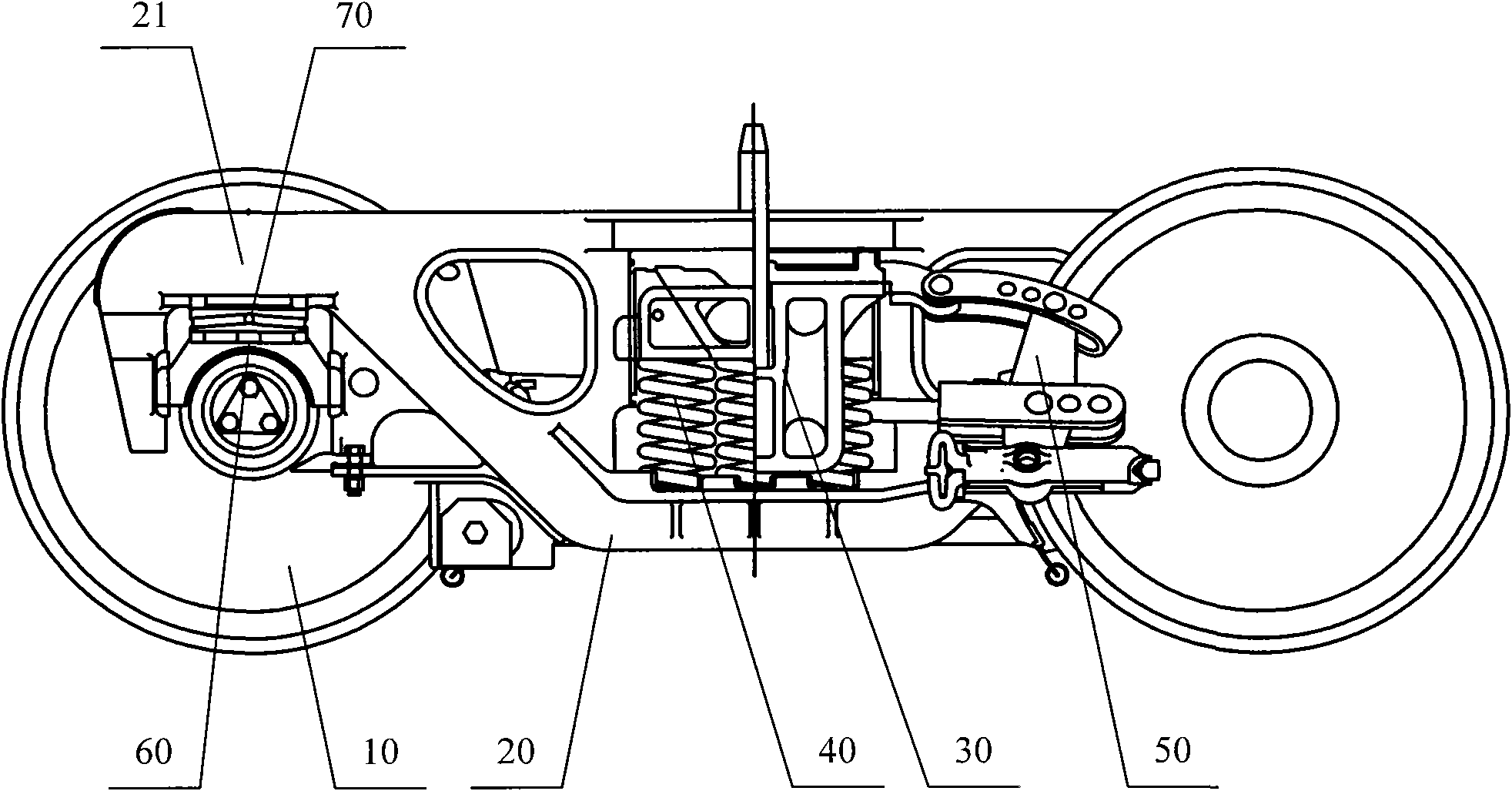

Elastic side bearing for bogie and bogie

InactiveCN101962021AImproved axle loadImproved low power performanceBogie-underframe connectionsBogieVertical deflection

The invention discloses an elastic side bearing for a bogie and the bogie. The bogie comprises a wheel set assembly, a side frame assembly, a swing bolster assembly, a basic braking device and a vibration damper, wherein the swing bolster assembly is provided with the elastic side bearing; and the elastic side bearing at least comprises a side bearing body, the side bearing body comprises a rubber body, and a spring is arranged in the rubber body. The rigidity of a bearing body can be effectively reduced and the vertical deflection can be increased by improving the structure of the elastic bearing so as to improve the axle load and the low power performance of the bogie.

Owner:CRRC QIQIHAR ROLLING CO LTD

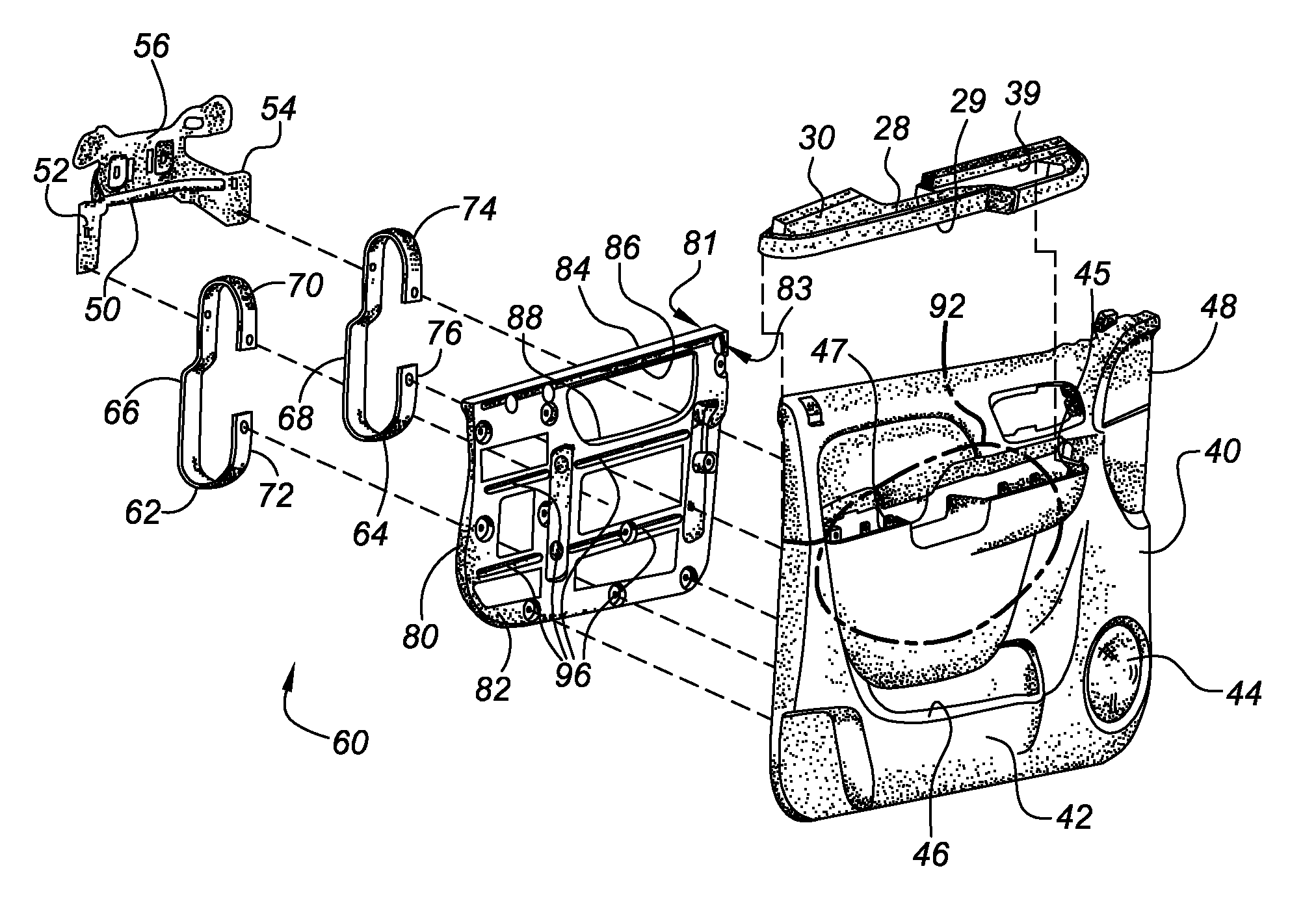

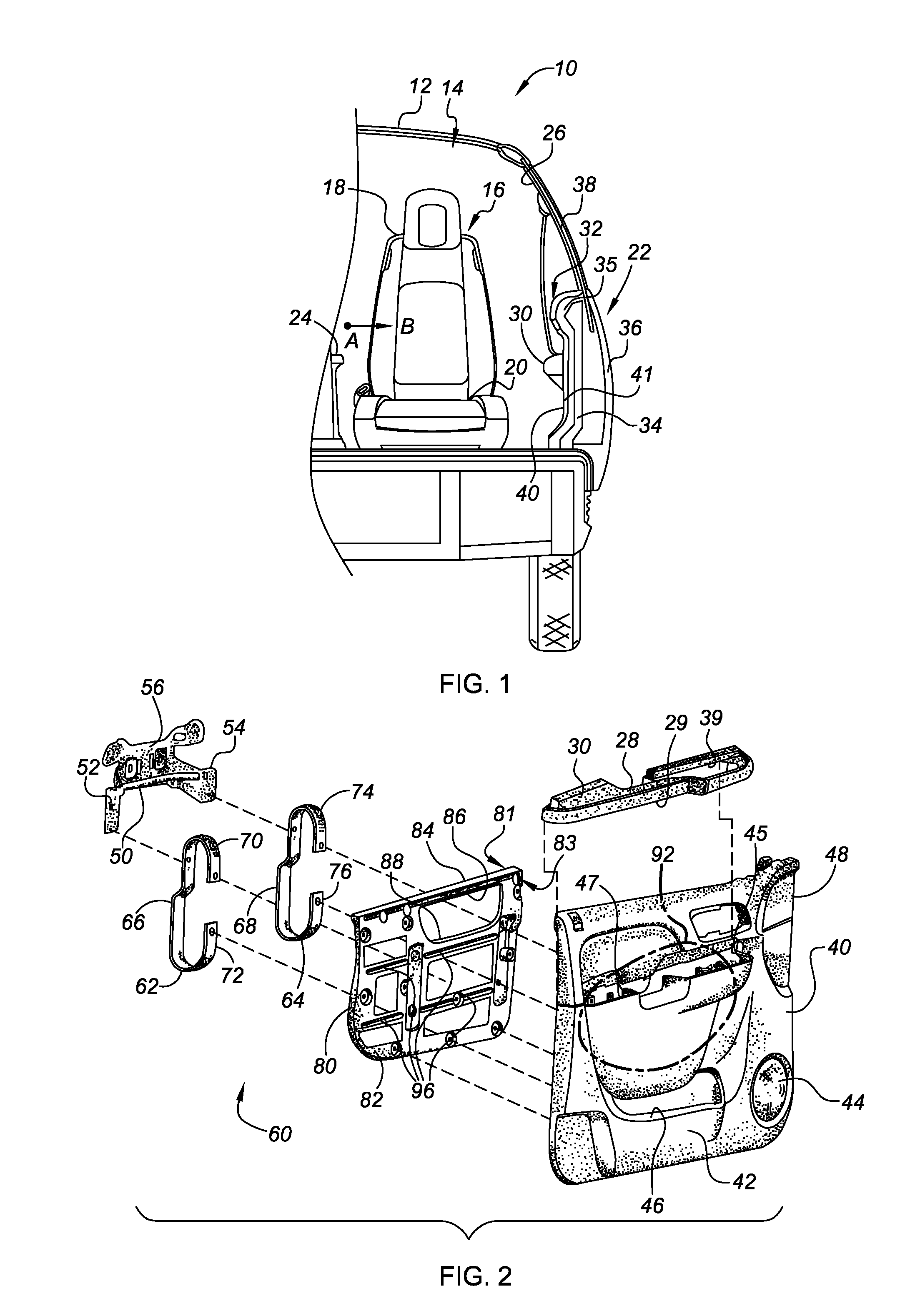

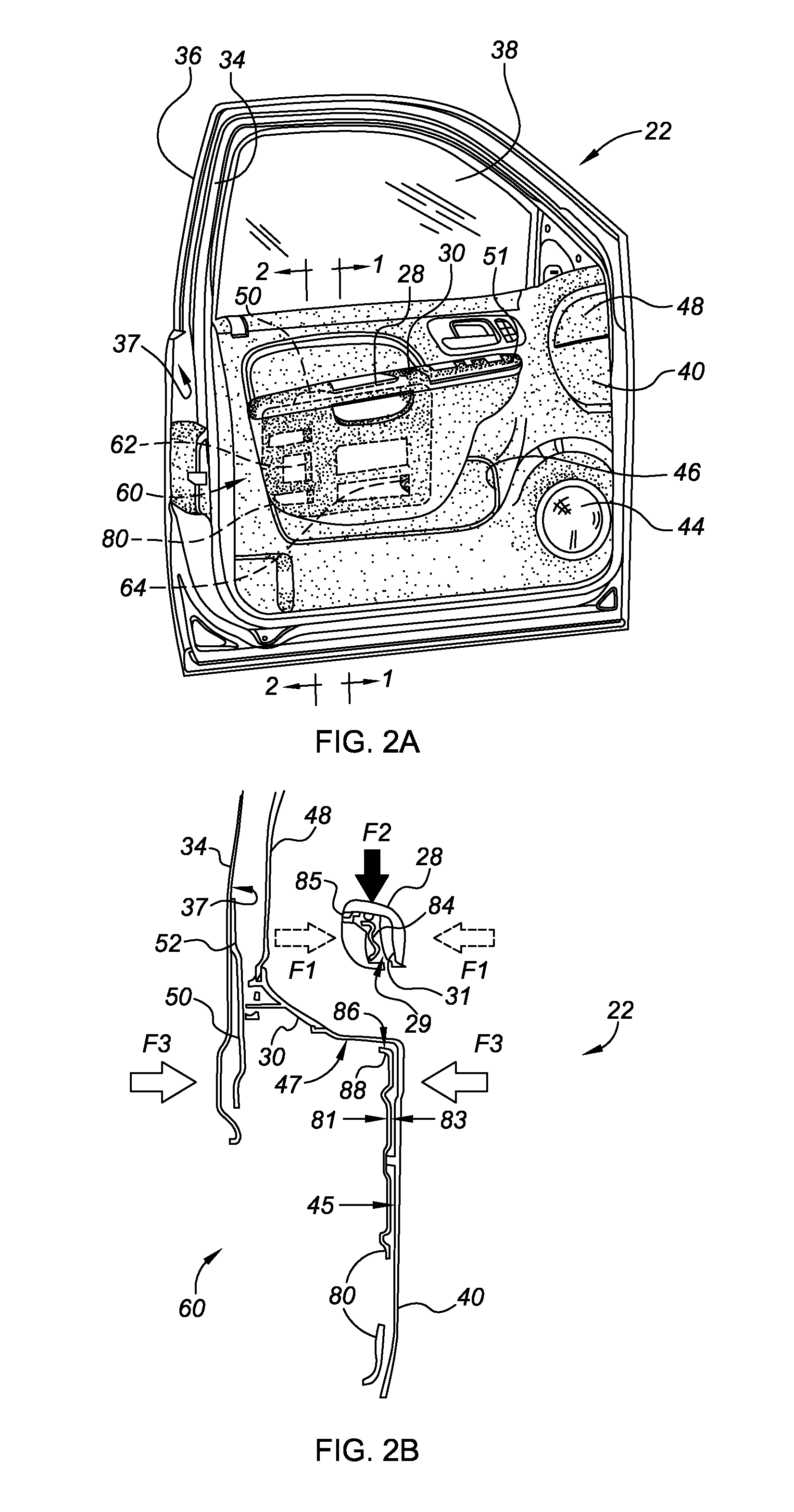

Energy-absorbing system for vehicle door assembly

InactiveUS7726726B2Control deflectionLimits of assemblyVehicle seatsPedestrian/occupant safety arrangementVertical deflectionEnergy absorption

An energy-absorbing system for vehicle door assemblies is provided, including first and second brackets and a reaction plate. Each bracket attaches to an inner support panel of the door assembly via a mounting portion having leg members extending inward from opposing ends thereof. The reaction plate includes a generally planar portion with a flange portion extending from an upper edge thereof. One side of the reaction plate is attached to an inner surface of a trim panel, whereas the other side is attached to the leg members of the first and second brackets. One section of the flange portion abuts against an underside surface of an armrest assembly, and another section abuts against a b-side surface of a pull-handle. Both brackets are configured to sustain a minimum vertical loading condition (limit vertical deflection), and controllably deform under a threshold lateral loading condition to absorb and attenuate kinetic energy resulting therefrom.

Owner:GM GLOBAL TECH OPERATIONS LLC

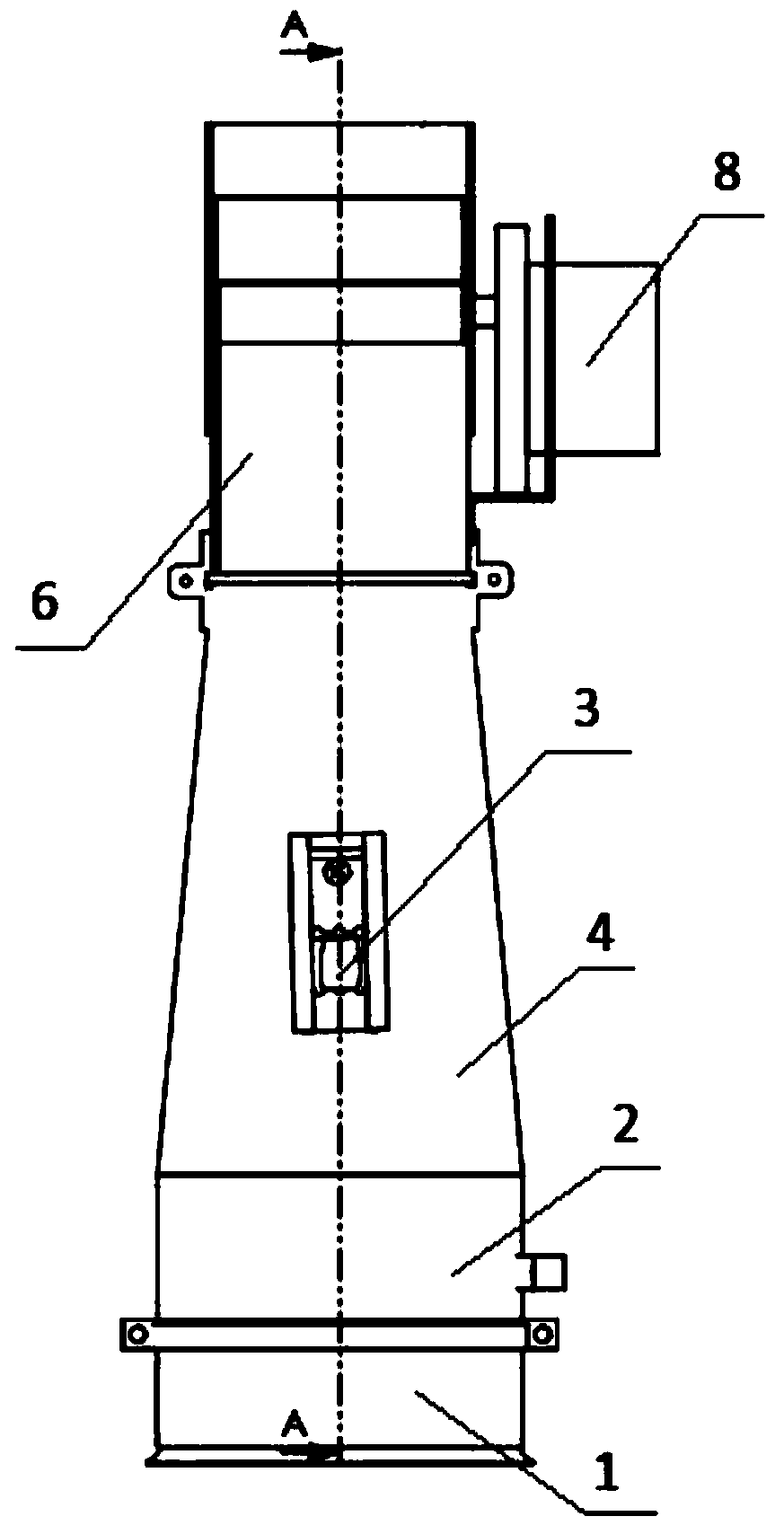

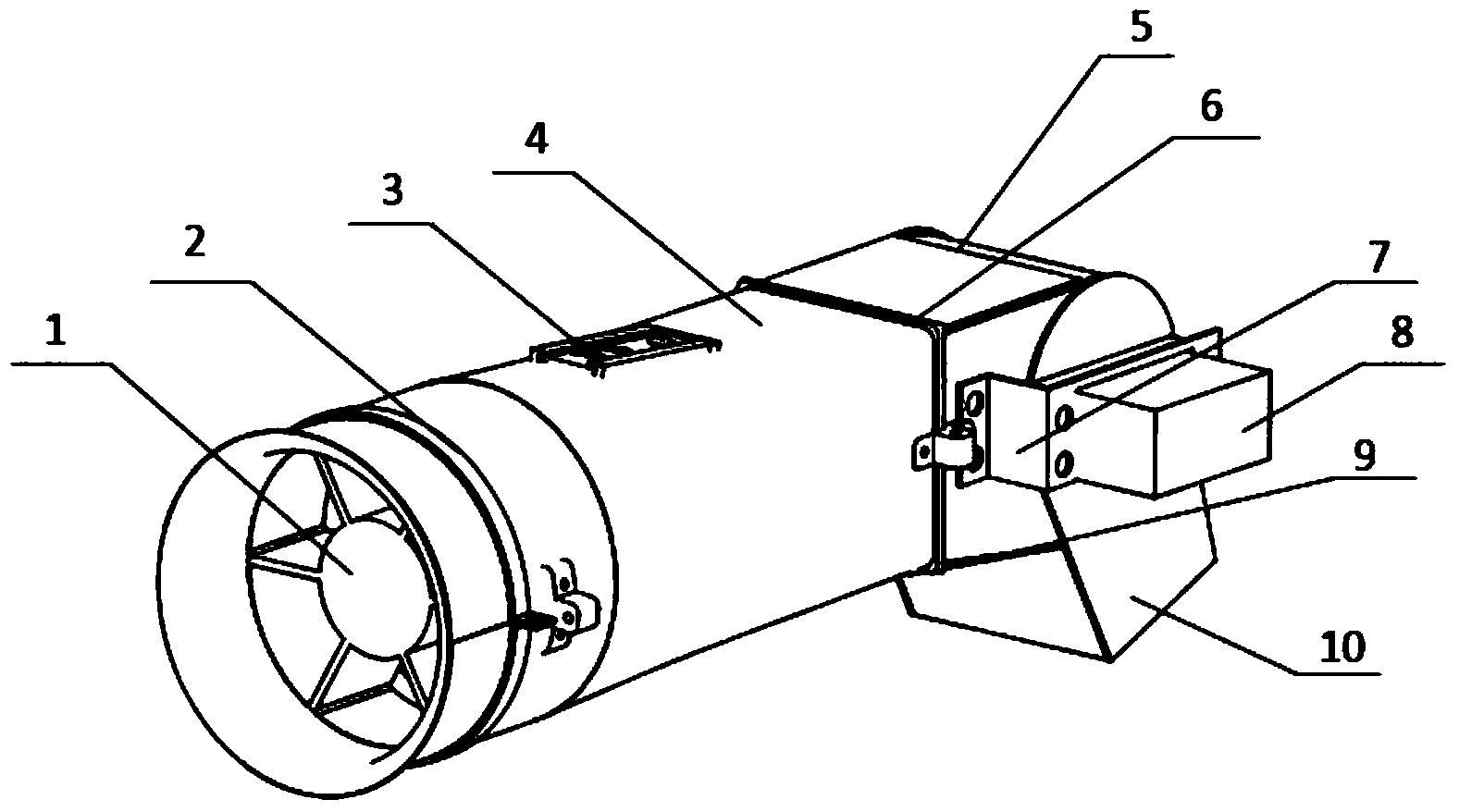

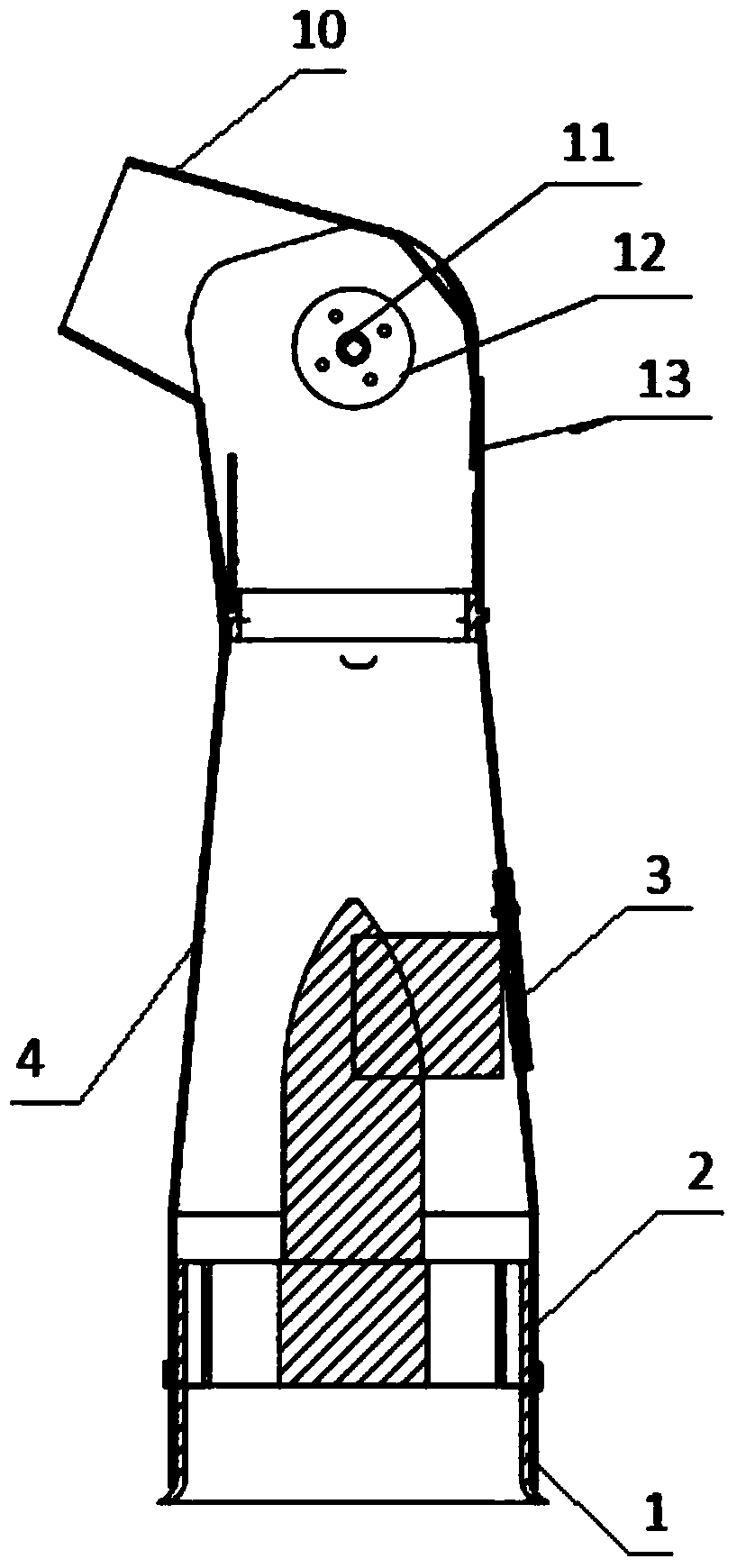

Bypass type vector thrust device suitable for small unmanned aerial vehicle

ActiveCN104044742AControl normal flightRealize up and down deflectionAircraft power plant componentsLow speedVertical deflection

The invention relates to a vector thrust device, in particular to a bypass type vector thrust device. The bypass type vector thrust device is suitable for small unmanned aerial vehicles, and adopts the technical scheme that the bypass type vector thrust device comprises a thrust generation device, a vector nozzle assembly and a flow guide device, wherein the thrust generation device is used for generating air flow, the vector nozzle assembly is used for changing the direction of the air flow, the thrust generation device is a bypass fan (1), the flow guide device comprises a pipeline (4), circular fixing rings (2) and square fixing rings (6), the circular fixing rings (2) and the square fixing rings (6) are arranged at the front and back ends of the pipeline (4), and the vector nozzle assembly comprises a rudder (8), a turntable (12) and a tail nozzle port (10). The bypass type vector thrust device has the advantages that the vertical deflection of the tail nozzle port is realized by controlling a steering device to rotate, the vertical landing and takeoff and the hovering of the small unmanned aerial vehicle are realized, and the unmanned aerial vehicle is guaranteed to realize maneuvering flight at low speed and large angle of attack, and is controlled to normally fly by utilizing the vector thrust to provide additional operation torque when the operation of rudder surface nearly fails.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Image display apparatus and personal computer for displaying personal computer signals and broadcast signals

InactiveUS20010028409A1Television system detailsTelevision system scanning detailsVertical deflectionInterlaced video

When a video signal is double-speed processed by the first device, a slight vertical deflection process is performed for redundant similar scan lines by the second device, and any slight deflection in the second device is controlled by the first device to thereby enable setting so as to always display images with excellent resolution. More particularly, a discrimination signal is generated by the first device to designate interlaced scanning and flag a need for vertical scan-line deflection, and such discrimination signal is provided to the second device such that the second device can always appropriately determine the need for vertical scan-line deflection. Through monitoring for the discrimination signal, an image display apparatus is capable of preventing vertical resolution from being deteriorated when video signals possibly requiring vertical line-shifting are inputted from an external source. Further, an image display apparatus is capable of preventing the vertical resolution from being deteriorated when images of video signals having different systems are displayed within different areas on a same screen.

Owner:HITACHI LTD +1

Pivoting platform having a piezoelectric drive

A pivoted platform has two flexible arms having rigid end zones which are attached by means of spacers to piezoelectric elements. The piezoelectric elements are made to deflect in opposite directions upon the application of the electrical signal to cause the platform to pivot. Applying voltages of the opposite polarity causes the platform to pivot in the opposite direction. A mirror may be attached to the platform to produce a scanning mirror for the vertical deflection of a television image.

Owner:TEXAS INSTR INC

Vertical deflection extension end member

ActiveUS20100293888A1Infinite vertical range of movementPrevent disengagementWallsPublic buildingsVertical deflectionBiomedical engineering

A wall structure has a telescoping portion and a stationary portion. An overlapping section of the telescoping portion has a recess to allow dry wall to be fastened to the stationary portion at the overlapping section without being attached to the telescoping portion. The fastener pierces through the drywall and a sidewall of the stationary portion. However, a tip of the fastener does not engage a sidewall of the telescoping portion. Rather, the tip of the fastener stops within the recess of the telescoping portion.

Owner:TSF SYST

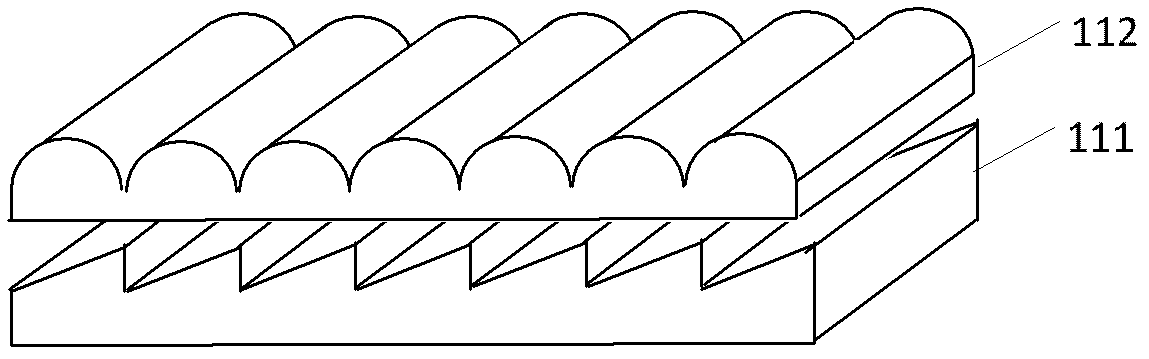

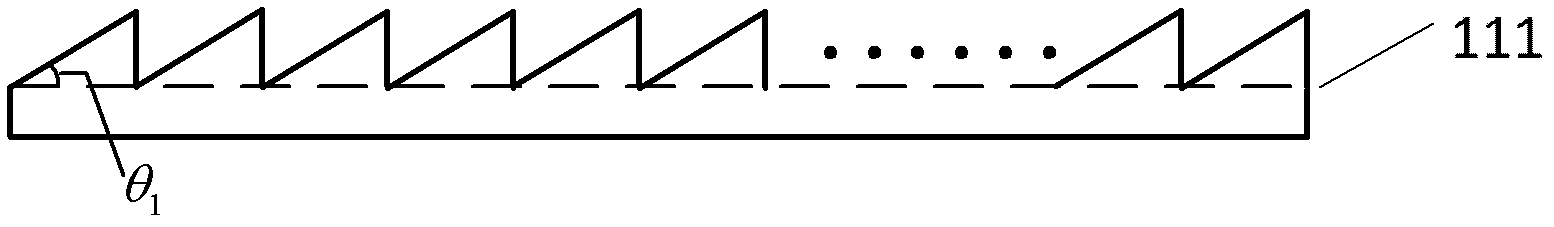

Pitching multi-view floating panoramic space 3D display device based on combined screen

InactiveCN102279514AIn line with the physiological habit of perceiving real objectsProjectorsCathode-ray tube indicatorsViewpointsVertical deflection

The invention discloses a pitching multi-view angle suspension type panoramic space three-dimensional display device based on a combined screen. The pitching multi-view angle suspension type panoramic space three-dimensional display device comprises a combined deviation diffuser screen, a high speed projector, an image control module, a rotation detection module, a motor and a transmission mechanism, wherein the high speed projector projects level 360-degree view field combined images at different pitching view angles of different three-dimensional objects into different regions on the combined deviation diffuser screen; each region of the combined deviation diffuser screen can control vertical deflection and divergence angles and horizontal divergence angles of incident light rays at different angles, so that observers watching around in different heights can observe three-dimensional images in accordance with viewpoint positions by two eyes; and reproduced three-dimensional scenes are suspended above the combined deviation diffuser screen. The pitching multi-view angle suspension type panoramic space three-dimensional display device has the characteristic that: a plurality of people can watch a horizontal 360-degree full view field from a plurality of view angles by naked eyes, along with space shading and blanking, touch interaction and the like.

Owner:ZHEJIANG UNIV

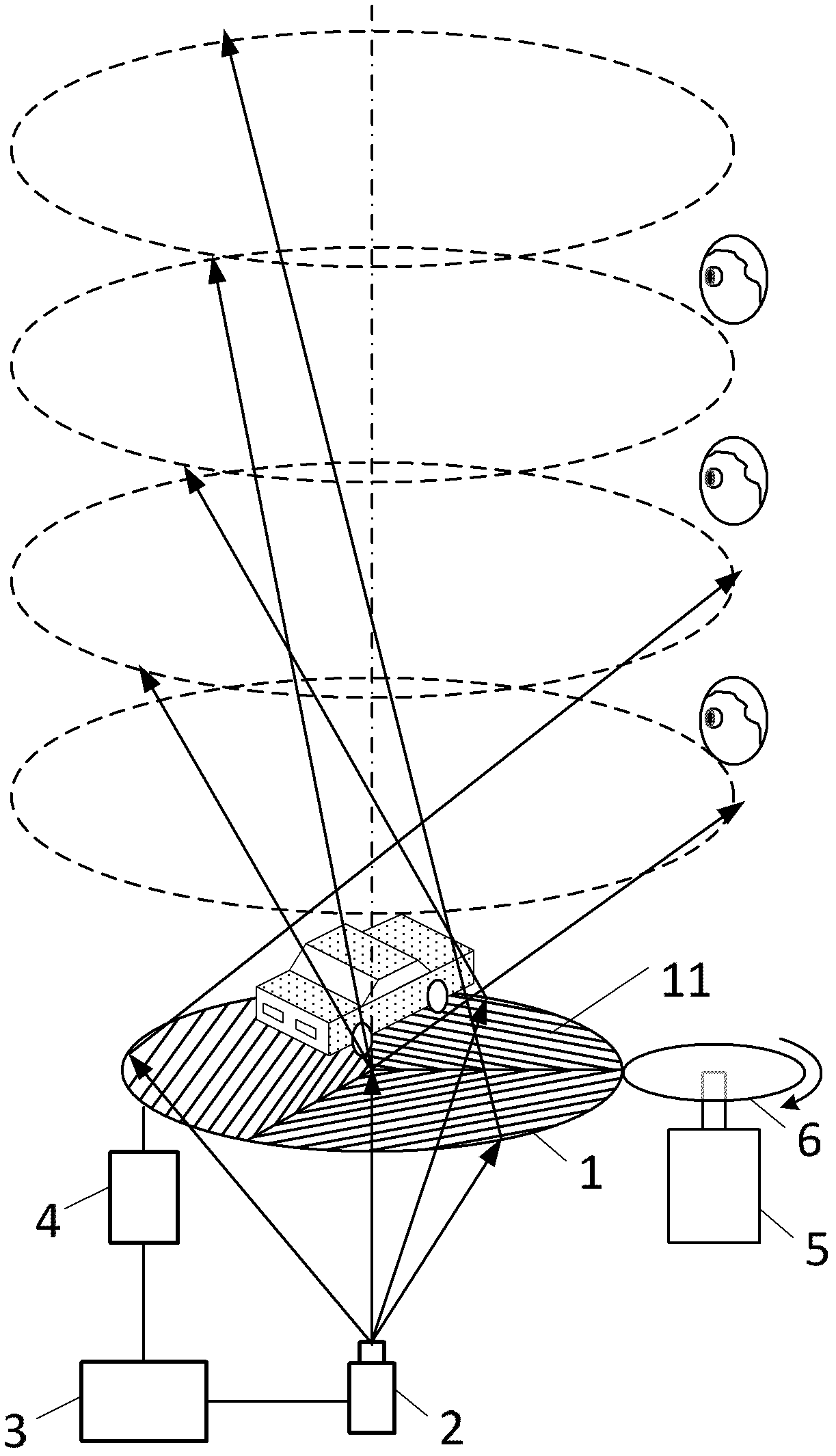

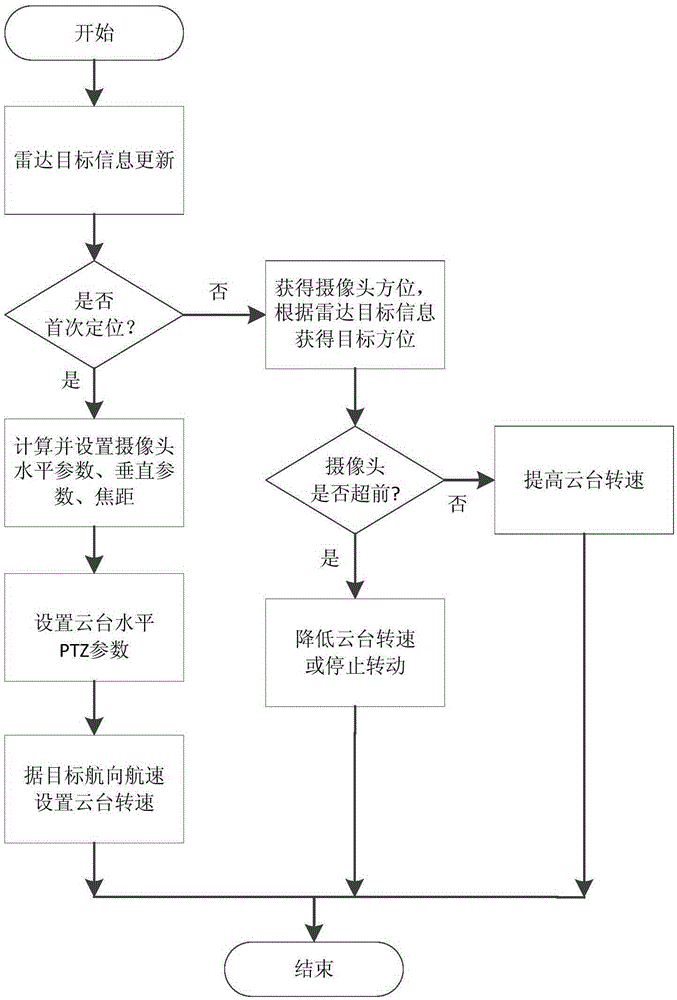

Smooth CCTV (Closed Circuit Television System) ship video tracking method

The invention discloses a smooth CCTV ship video tracking method. Information including the latitude and longitude, the course, the speed, the length and the height of a monitored ship is obtained, the horizontal deflection angle, the vertical deflection angle and the focal length of a camera holder are calculated via the installation latitude and longitude, the height to the water surface and the zero azimuth of a CCTV camera, and the holder is rotated at a proper speed along the projection direction of the ship course. The position of the camera relative to the monitored ship is detected when AIS or radar data arrives, the holder is decelerated or stopped when the camera is ahead of the ship, and the holder is accelerated when the camera is behind the ship. The continuous rotation scheme enables the holder to rotate continuously in the same direction in the monitoring process, jittering of monitoring frames is reduced, and a close rapid target is prevented from loss. The CCTV monitoring camera can thus track the ship, the proportion of the ship in the monitoring frames is kept the same, and the smooth jittering of tracking frames is lower.

Owner:THE 28TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

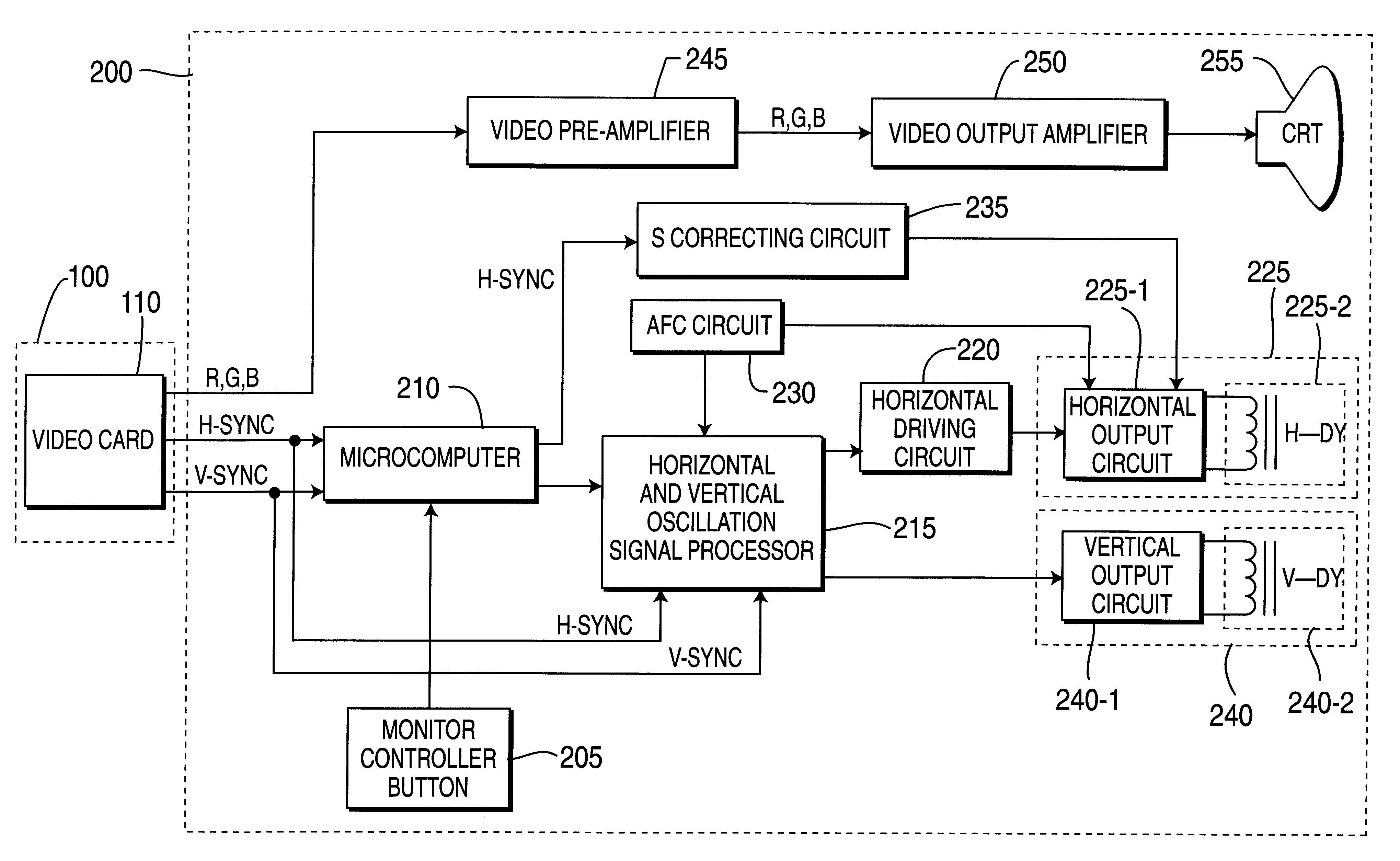

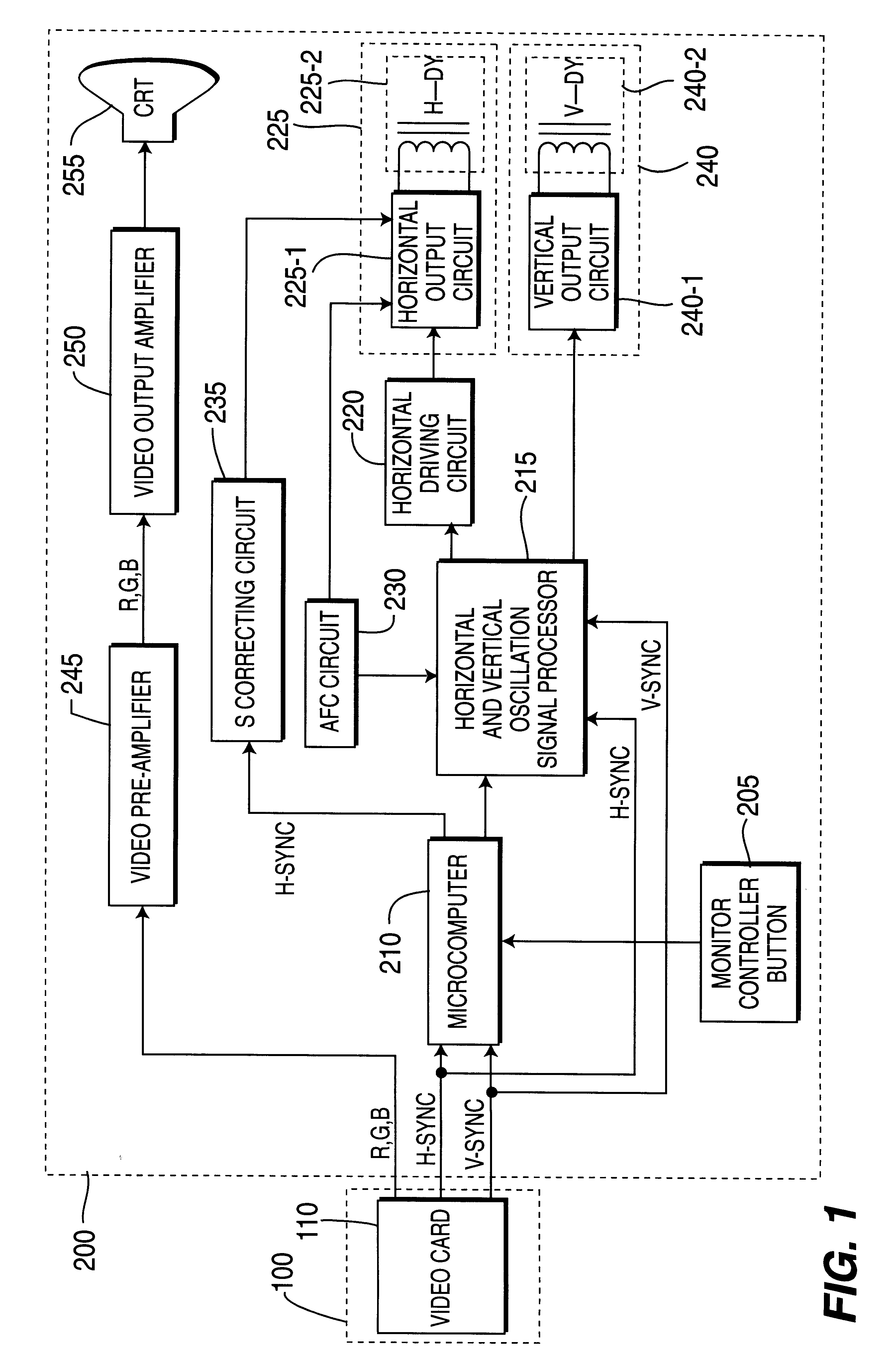

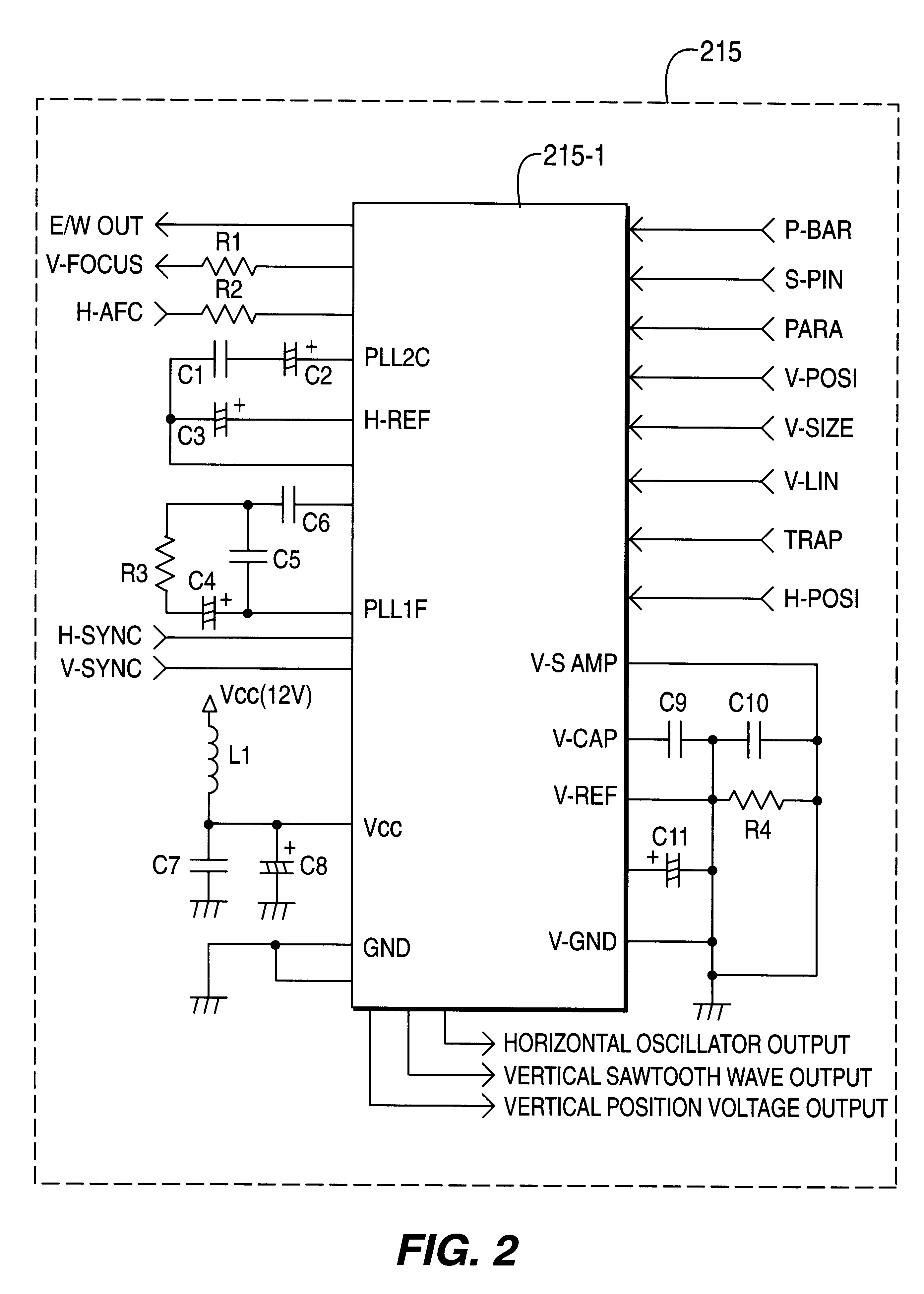

Technique for controlling screen size of monitor adapted to GUI environment

InactiveUS6211855B1Television system detailsTelevision system scanning detailsMicrocomputerVertical deflection

A circuit for controlling a partial magnification of a monitor screen, includes: a microcomputer having a program for controlling the size of the monitor screen which receives the horizontal and vertical synchronization signals H-SYNC and V-SYNC and generates horizontal and vertical control signals by using those synchronization signals, and thus controlling the magnification of the monitor screen; a horizontal and vertical signal processor for receiving a voltage control signal according to a vertical size magnification of the monitor screen output from the microcomputer, and outputting a control voltage according to the voltage control signal; an S-shaped correcting and switching circuit for receiving an S-shaped correcting signal and a switching control signal output from the microcomputer, and for controlling the horizontal size of the screen; and a vertical deflection IC for receiving the control voltage according to the voltage control signal for magnifying the vertical size of the monitor screen output from the horizontal and vertical signal processor, and for transferring the sawtooth wave current to a vertical deflection yoke circuit with the supplied voltage control signal.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com