Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

515 results about "Axle load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The axle load of a wheeled vehicle is the total weight bearing on the roadway for all wheels connected to a given axle. Axle load is an important design consideration in the engineering of roadways and railways, as both are designed to tolerate a maximum weight-per-axle (axle load); exceeding the maximum rated axle load will cause damage to the roadway or rail tracks.

Electronic braking system and method for drawbar trailers

ActiveUS8267485B2Overcome disadvantagesReduce probabilityBraking action transmissionAutomatic initiationsAxle loadBraking system

A system and method for braking a drawbar trailer having a front axle and one or more further axles, each axle having at least two wheels, includes first sensors which sense the axle load of at least one axle, and second sensors which sense the rotational wheel speeds. Brakes actuatable with a pneumatic brake pressure brake the trailer. Brake signals generated in the towing vehicle are transmitted between the towing vehicle and the trailer. A control unit receives these brake signals and the sensor signals, and determines the axle load. The operating pressure is adapted to the brake pressure which is fed to the brakes. The control unit detects the brake pressure value as a function of (i) the specific axle loads of the front axle and the other axles and (ii) the received brake signals, and actuates the brakes such that the detected brake pressure is made available.

Owner:WABCO EURO BVBA SPRL

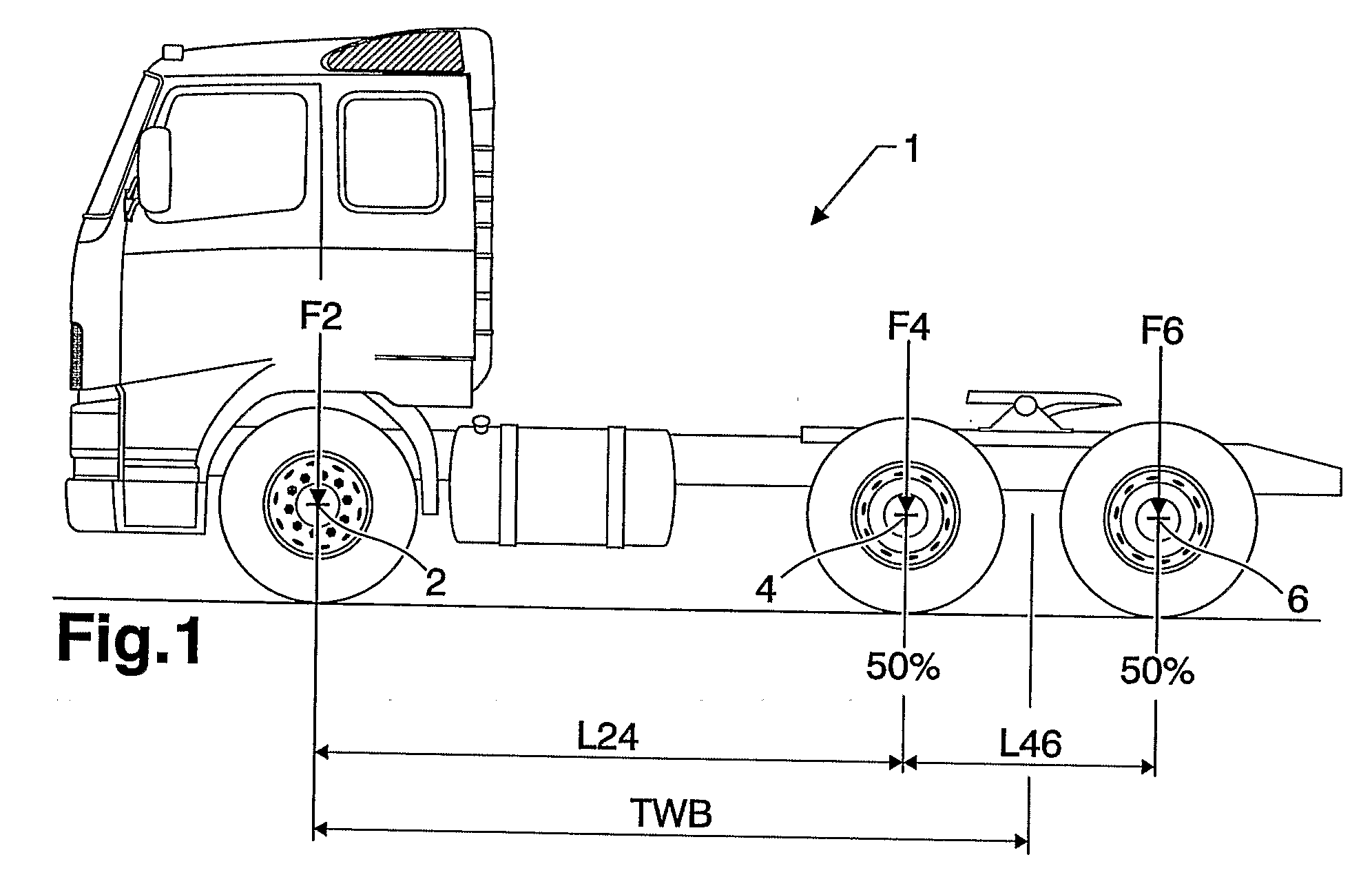

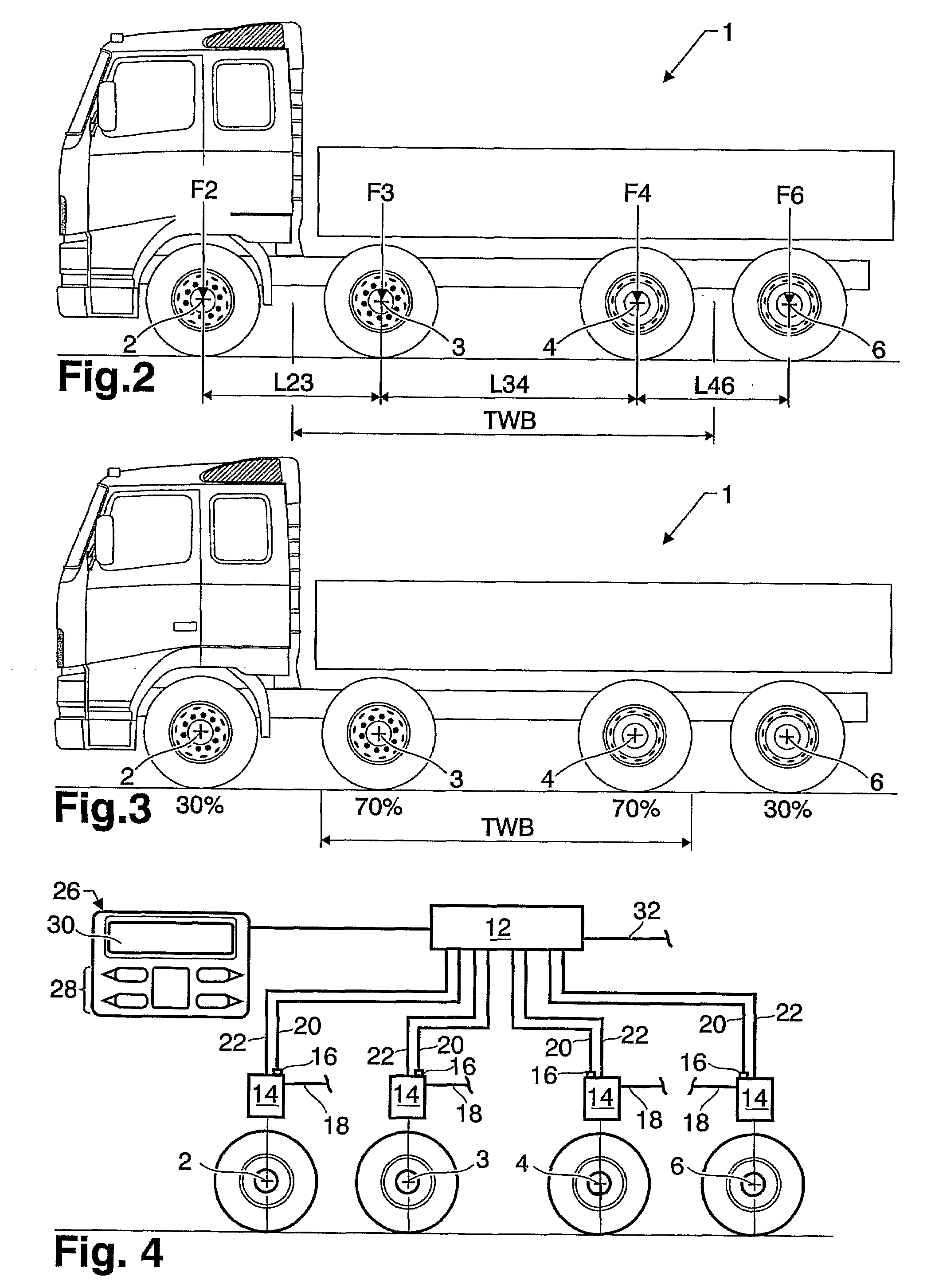

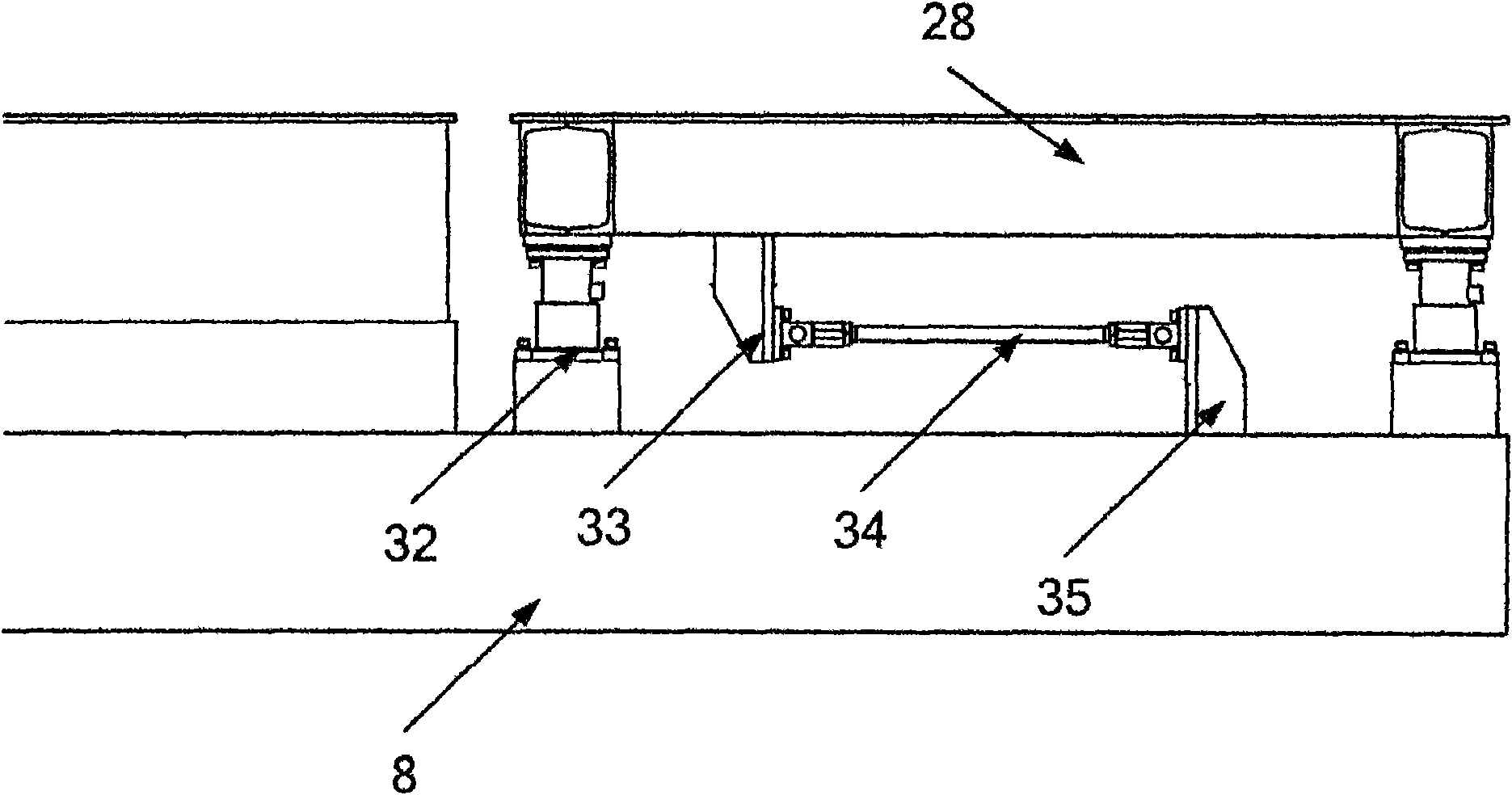

System and Method for Controlling the Axle Load Split Ratio on a Vehicle With Two Front Axles

InactiveUS20080269986A1Risk minimizationImprove vehicle handlingDigital data processing detailsAnimal undercarriagesMobile vehicleAdjustable stiffness

A system is provided for controlling the load split between the axles and thereby the theoretical wheelbase of a vehicle having two front axles being suspended in suspension units at least some of which have springs with adjustable stiffness. A method for controlling the load split between the axles and to a motor vehicle including such a system and / or by use of such a method is also disclosed.

Owner:VOLVO LASTVAGNAR AB

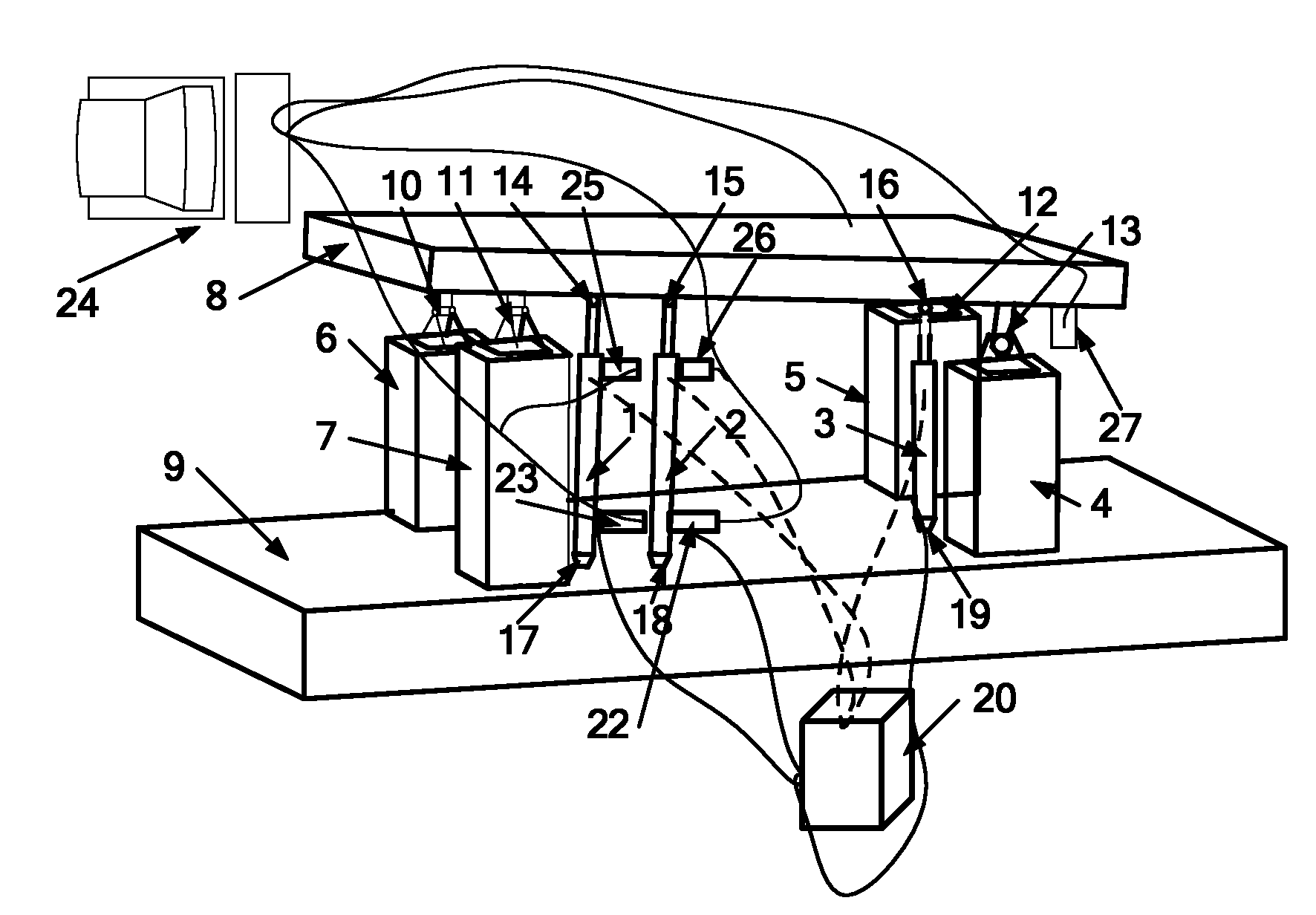

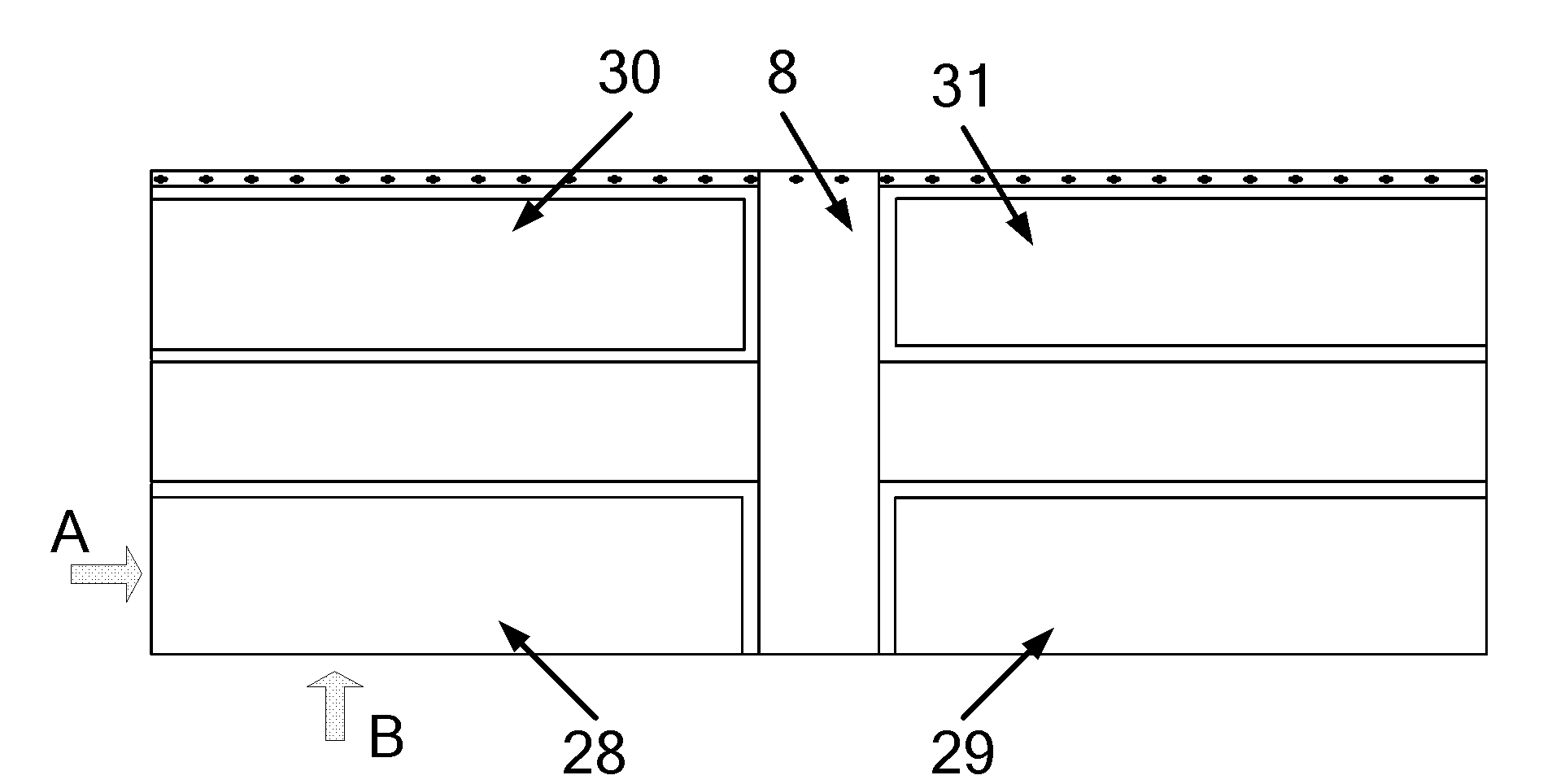

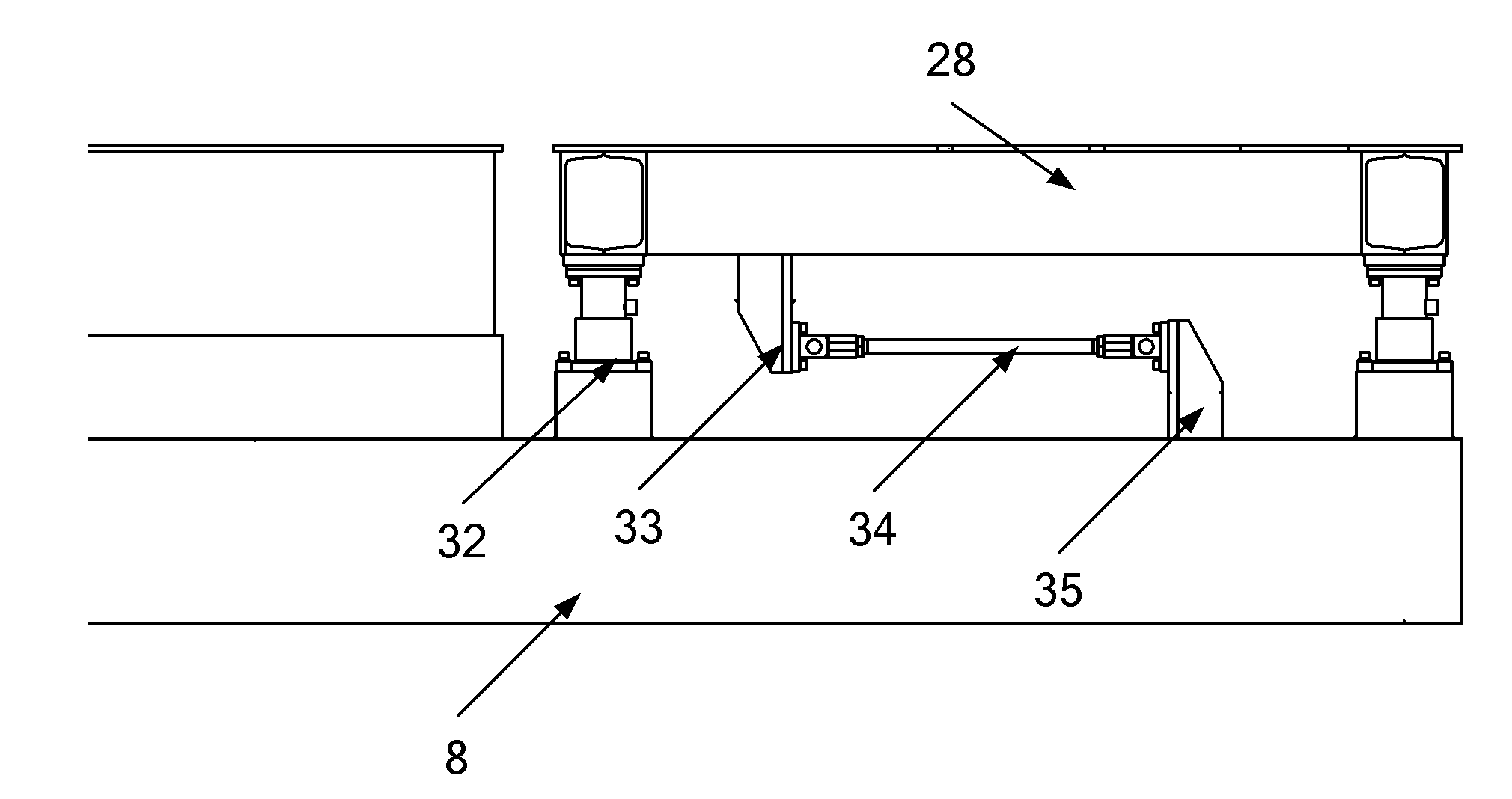

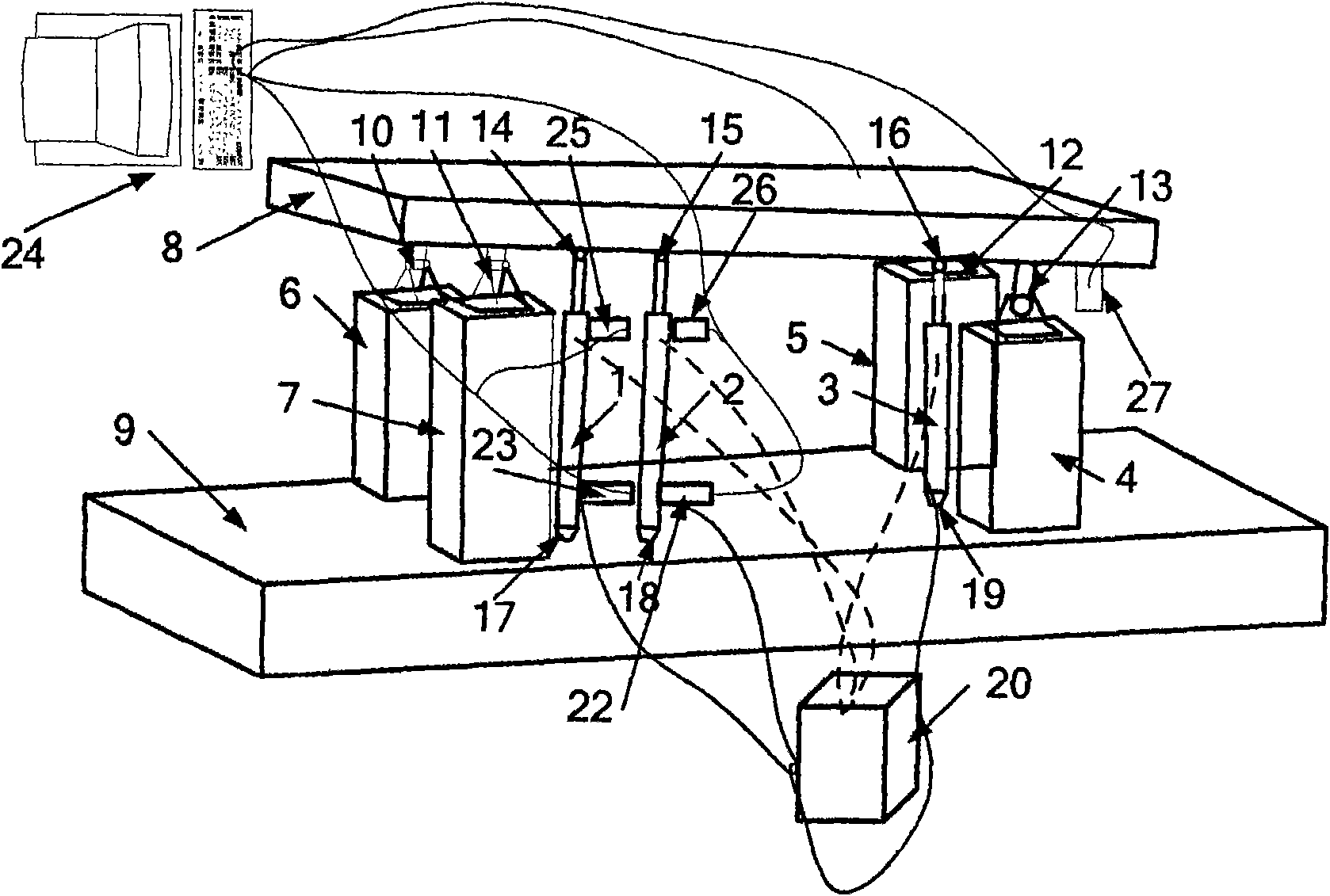

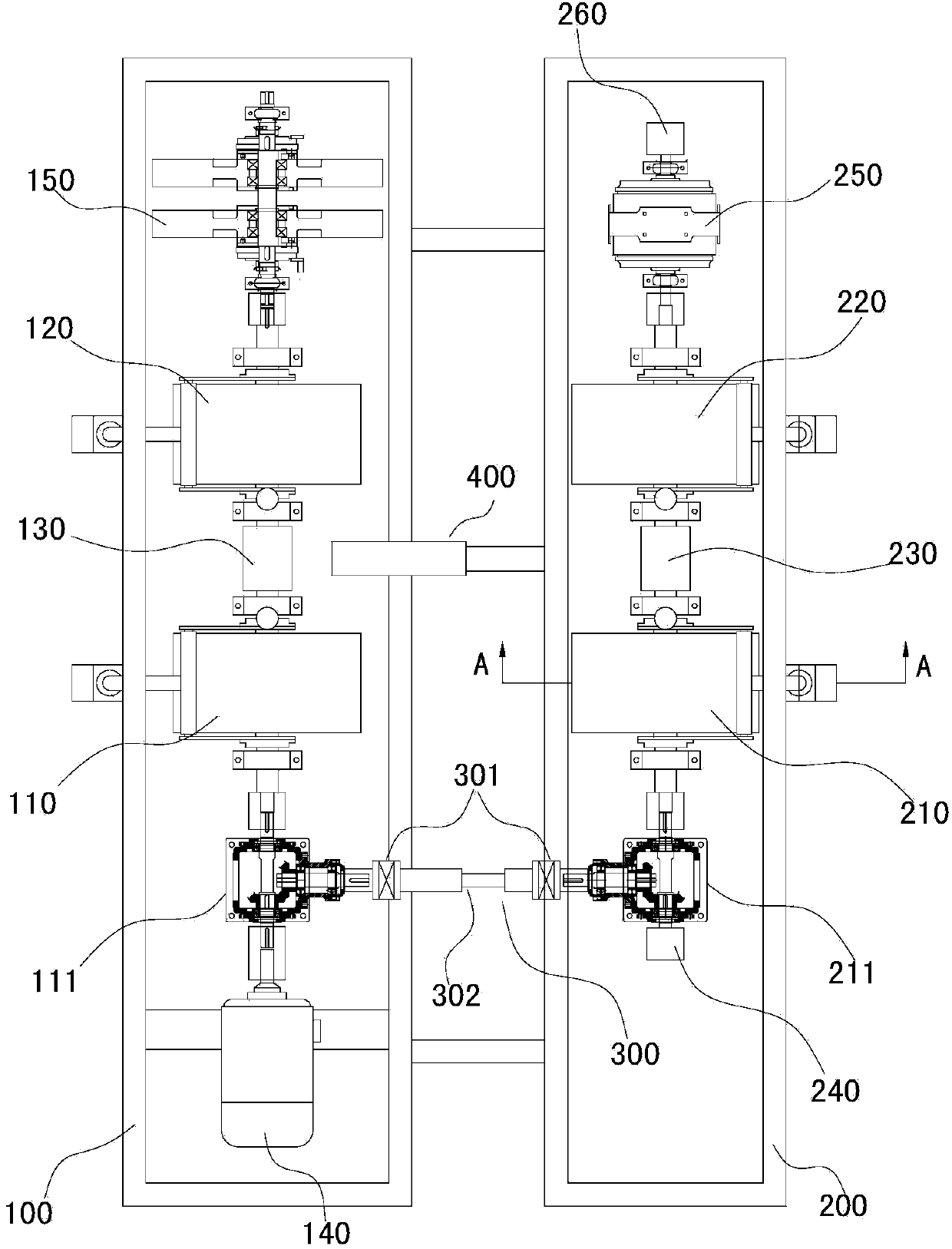

Automobile stability parameter test bench and test method using same

InactiveCN101893517ARealize measurementReduce testing workloadVehicle testingStatic/dynamic balance measurementStability parameterMeasurement device

The invention relates to an automobile stability parameter test bench and a test method using the same, which are used for integrally testing automobile mass parameters, centroid position parameters and anti-tipping angle parameters. The automobile stability parameter test bench of the invention comprises a measuring platform, four platform balances, platform supporting columns, a foundation, three hydraulic cylinders, an inclination angle measuring device, hydraulic sensors, a pump station and a computer, wherein the four platform balances are installed on the measuring platform and are supported by a weighting sensor; the supporting points of the platform supporting columns are distributed in rectangular peaks; the foundation is used for bearing the supporting columns and the platform; the three hydraulic cylinders are arranged between the platform and the foundation and can enable the platform to incline longitudinally or laterally; the inclination angle measuring device is fixed on the platform; the hydraulic sensors are installed in the positions of the upper cavity and the lower cavity of the two hydraulic cylinders which enable the platform to incline longitudinally; the pump station is connected with the hydraulic cylinders; and the computer is used for acquiring and calculating the data of the weighing sensor, the oil pressure of the hydraulic cylinders and the inclination angle data of the platform. Compared with the existing test equipment, the invention can finish tests of automobile total mass, axle loads, wheel loads, centroid positions, anti-tipping angles and the like, so that the test workload and the test cost of the parameter tests are greatly reduced.

Owner:JILIN UNIV

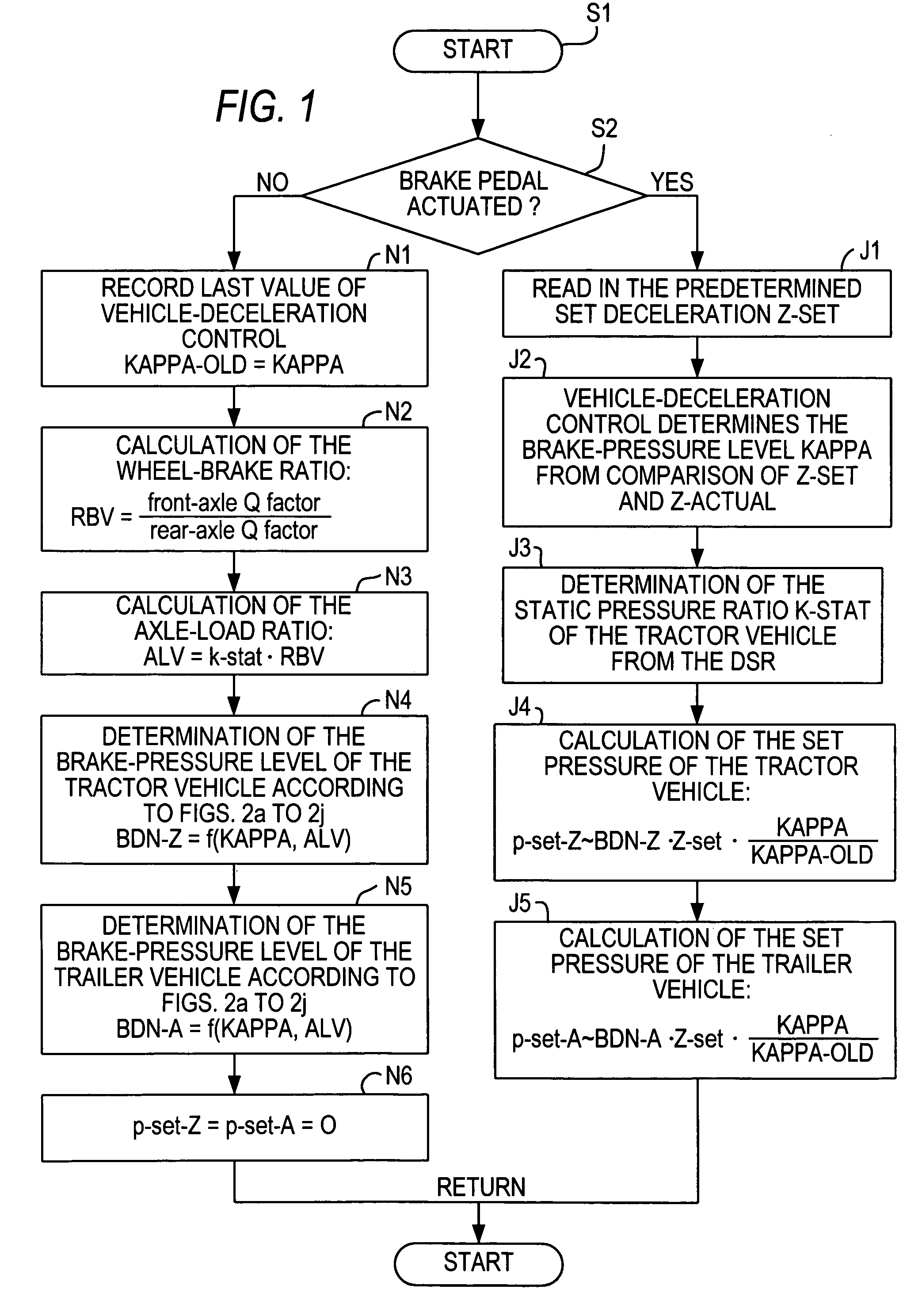

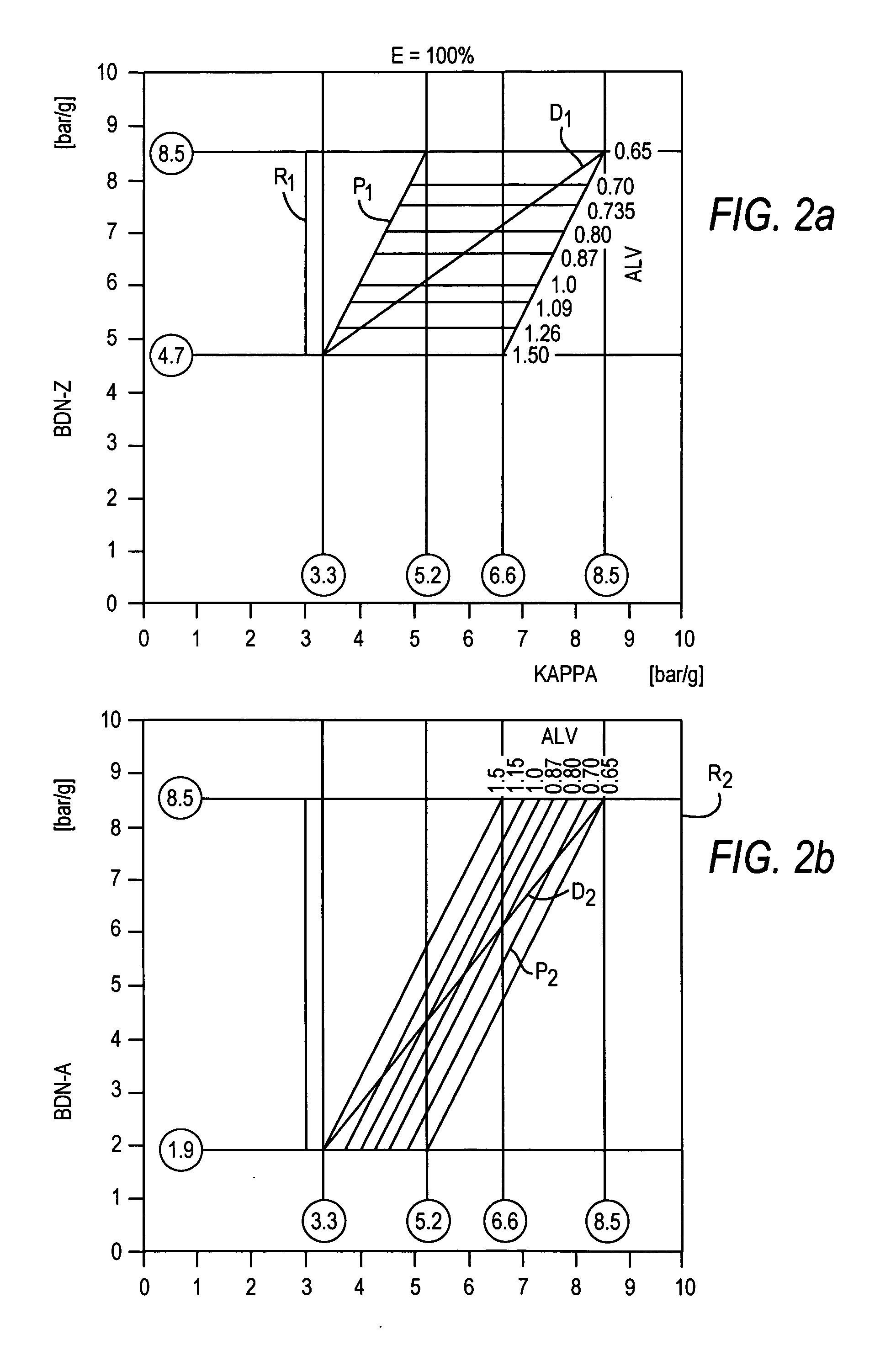

Method and system for controlling brake-application energy in a vehicle combination

ActiveUS20050017577A1Adapt quicklyGreater braking comfortAnalogue computers for trafficBraking action transmissionControl systemEngineering

A method and system for controlling brake-application energy in a tractor-trailer vehicle combination, the tractor vehicle having an electronic braking system (EBS), wherein, during braking, a set deceleration value is determined and compared with an actual deceleration value, and a current brake-application energy reference value (kappa) is determined from the comparison. To effect automatic load-dependent brake-force control for the trailer vehicle and to realize rapid adaptation of the control system to driving and load conditions, set brake-application energy values for each of the tractor and trailer vehicles are determined from the set deceleration value, from a value depending on kappa, and from brake-application energy levels for each of the tractor and trailer vehicles, using sets of performance characteristics resident in the EBS to describe the dependencies of the brake-application energy levels for the tractor and trailer vehicles on kappa and / or on the axle-load ratio of the tractor vehicle.

Owner:WABCO GMBH

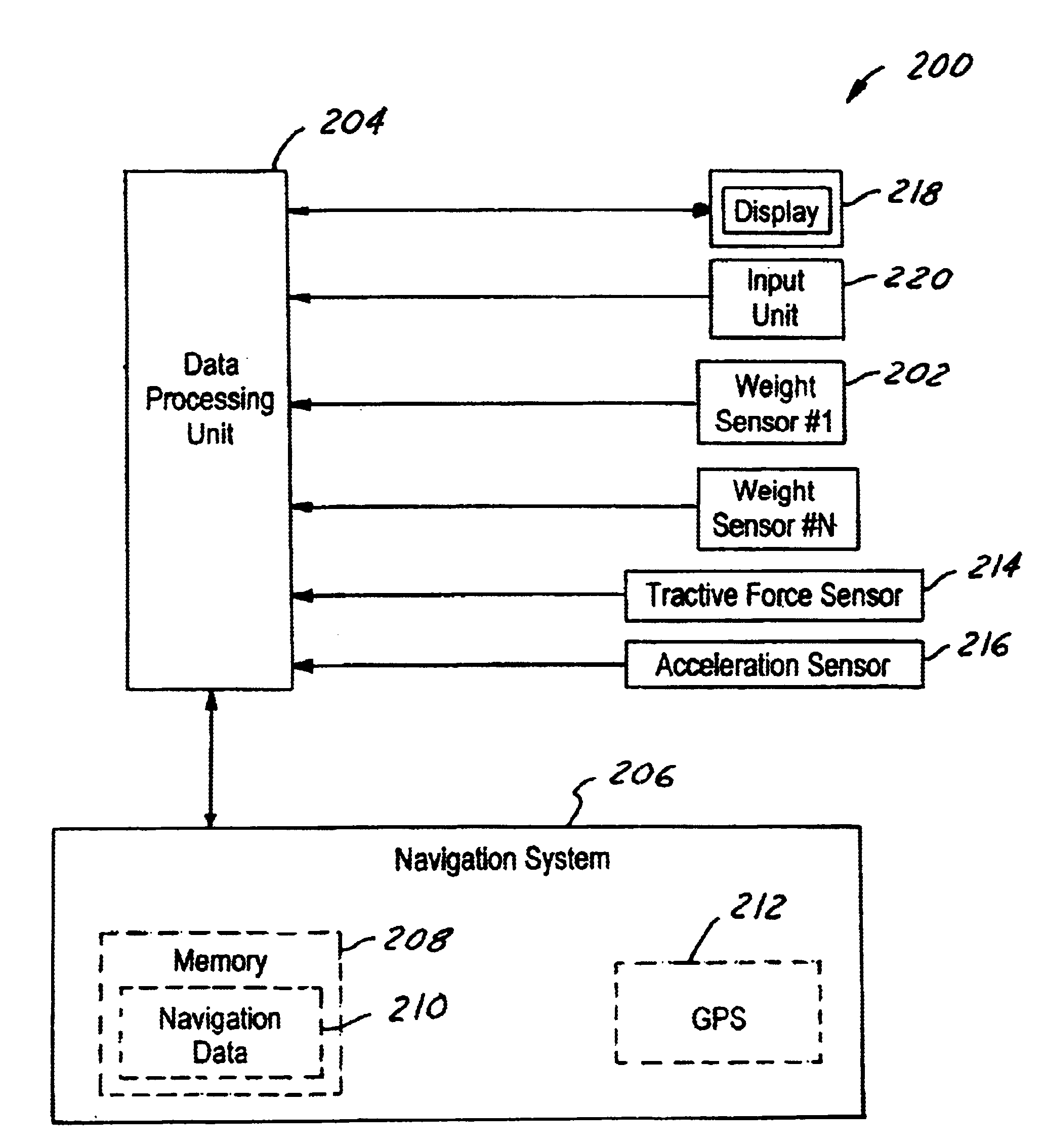

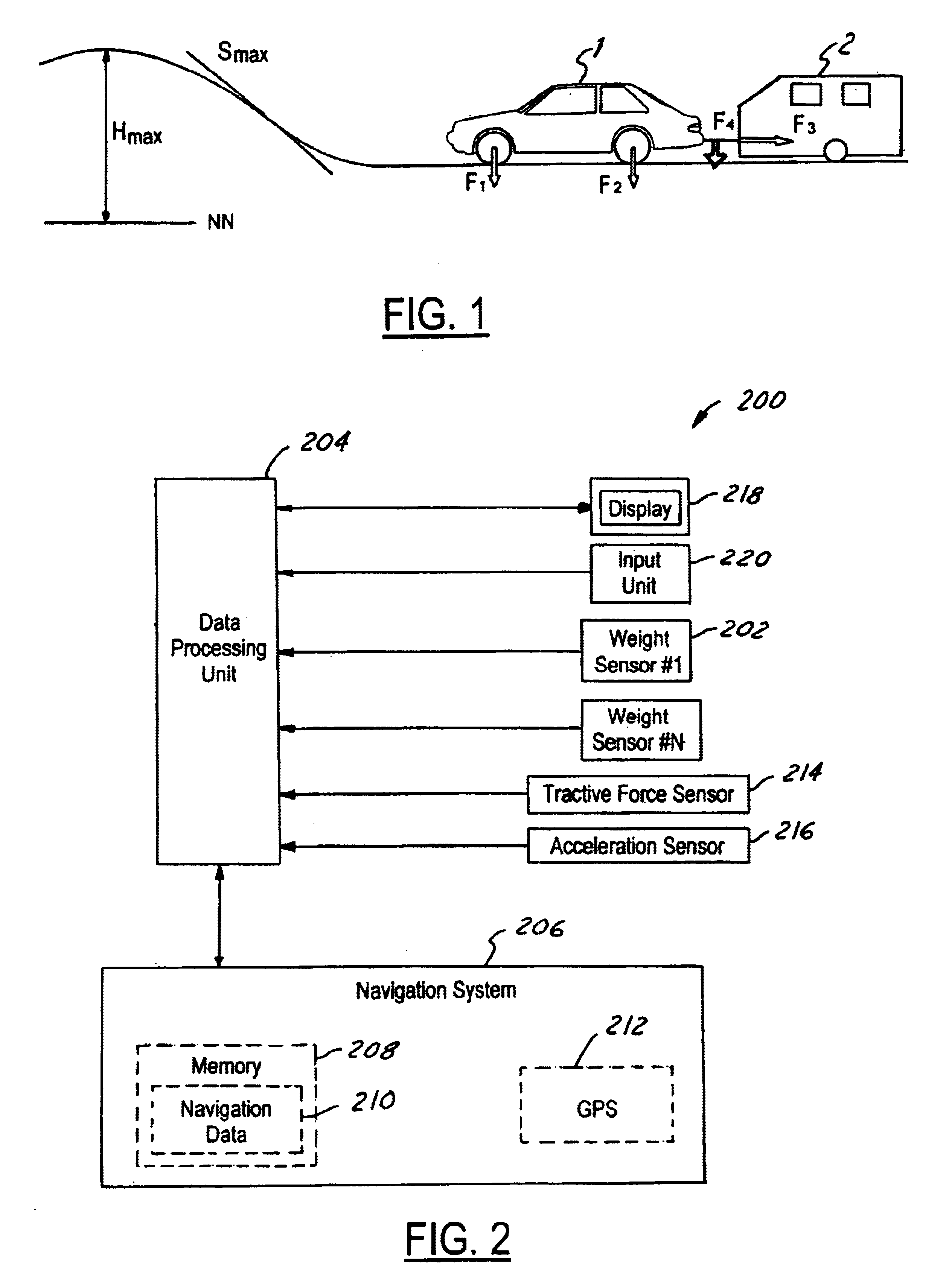

Vehicle weight observation system

InactiveUS6829943B2Improve protectionInstruments for road network navigationForce measurement by permanent gauge deformationDriver/operatorWeight monitoring

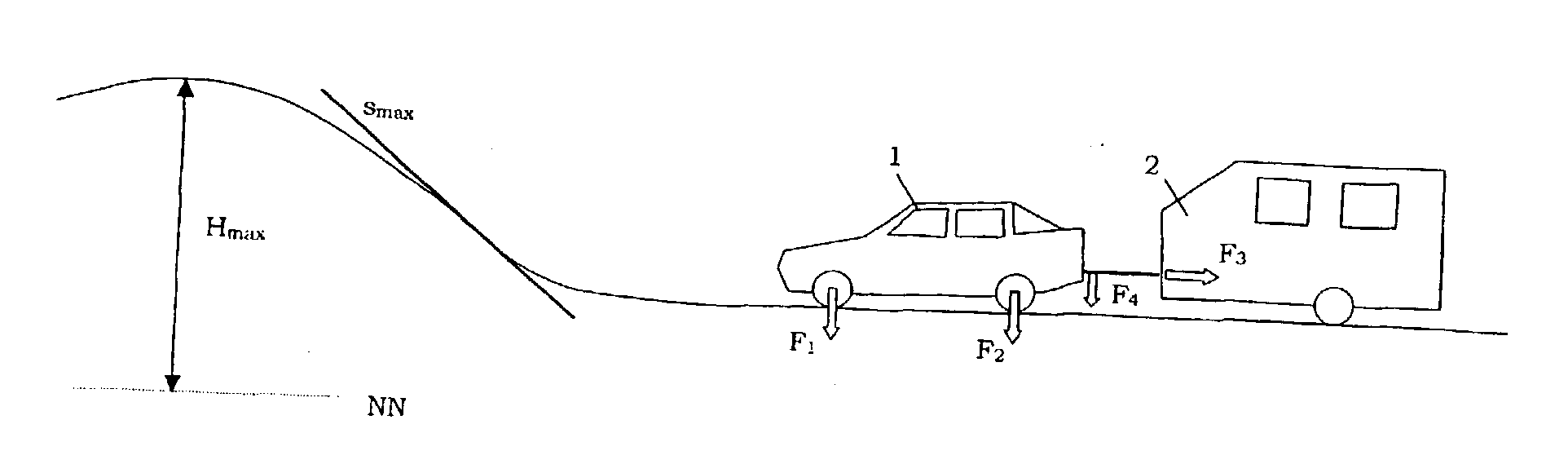

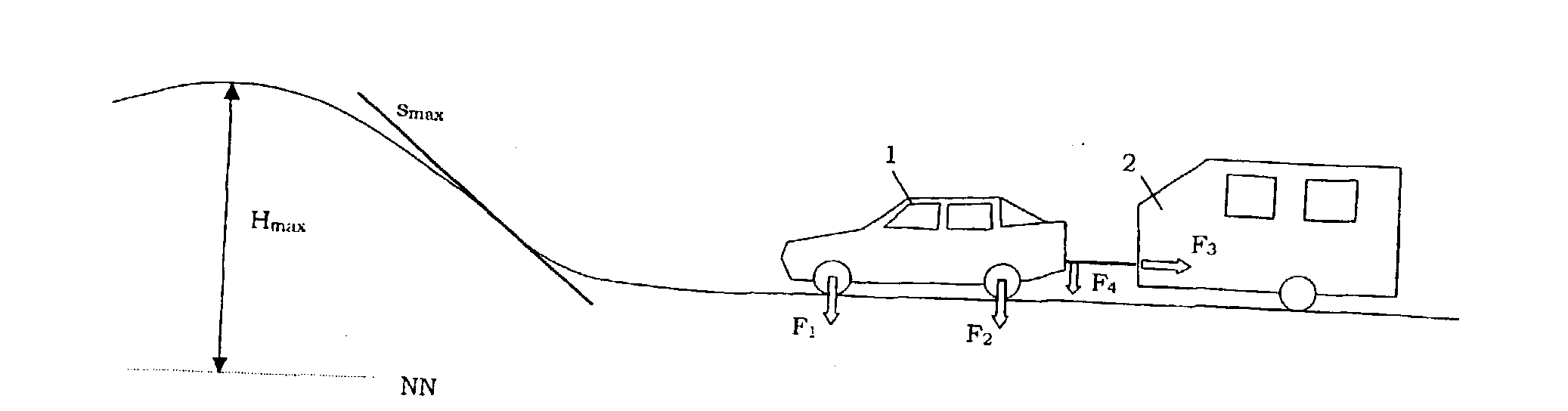

The invention relates to a weight monitoring system for a motor vehicle (1) which can, if appropriate, be connected to a trailer (2). The system uses weight sensors to determine the weights (F1, F2) acting on the axles of the motor vehicle, in order to calculate from them the overall weight of the vehicle, and the axle loads. In addition, a tractive force sensor may be provided in the trailer hitch so that the mass of the trailer (2) can be determined by means of the tractive force (F3) and the acceleration of the vehicle. The weight monitoring system calculates various weight variables from the measured values and monitors to determine whether they remain within defined limits. In this context, it is possible, in particular, to take into account a planned route in such a way that the limiting values of the charge are adapted with respect to the maximum altitude (Hmax) above sea level and / or the maximum gradient (smax) of the route. In addition, the system can be configured in such a way that it provides the driver with proposals for a different distribution of the payload which leads to a permissible axle load.

Owner:FORD GLOBAL TECH LLC

Stability parameter test board for automobile

ActiveCN101788385AAchieving rollover resistanceReduce testing workloadVehicle testingStatic/dynamic balance measurementRolloverStability parameter

The invention discloses a stability parameter test board for an automobile and belongs to the technical field of measurement. The test board is used for integrally testing a quality parameter, a mass center position parameter and an anti-rollover angle parameter of the automobile. The stability parameter test board consists of a measuring table board, four platform scales, a table board pillar, a foundation, three hydraulic cylinders, an inclination angle measuring device, hydraulic sensors, a pumping station and a computer, wherein the platform scales are arranged on the measuring table board and supported by a weighing sensor; supporting points of the table board pillar are distributed in a form of rectangular top points; the foundation is used for supporting the pillar and the table board; the three hydraulic cylinders are arranged between the table board and the foundation and can make the table board incline longitudinally or laterally; the inclination angle measuring device is fixed on the table board; the hydraulic sensors are arranged at upper and lower cavity positions of two hydraulic cylinders which make the table board incline longitudinally; the pumping station is connected with the hydraulic cylinders; and the computer is used for acquiring data of the weighing sensor, oil pressures of the hydraulic cylinders and the inclination angle of the table board and performing an operation. The table board has the advantage that: compared with a conventional test device, the device can complete tests on the total mass, the axle load, the wheel load, the mass center position, the anti-overturn angle and the like of the automobile, so the test workload and the test cost of the parameter test are lowered.

Owner:武汉元丰汽车电控系统股份有限公司

Electronic height control

InactiveUS6959932B2Vehicle cleaning apparatusLoading/unloading vehicle arrangmentRide heightAir spring

A method for controlling the ride height in a suspension of an over the highway truck or tractor based on rear axle load. A load on the rear axle is measured. An optimum ride height is calculated at core response to correct drive lighted angles based on the rear axle load. The actual ride height is measured. The difference between the optimum ride height and the actual ride height is calculated. A component of the suspension, such as an air spring, is adjusted to adjust the actual ride height to a height closer to the optimum ride height.

Owner:VOLVO TRUCKS NORTH AMERICA

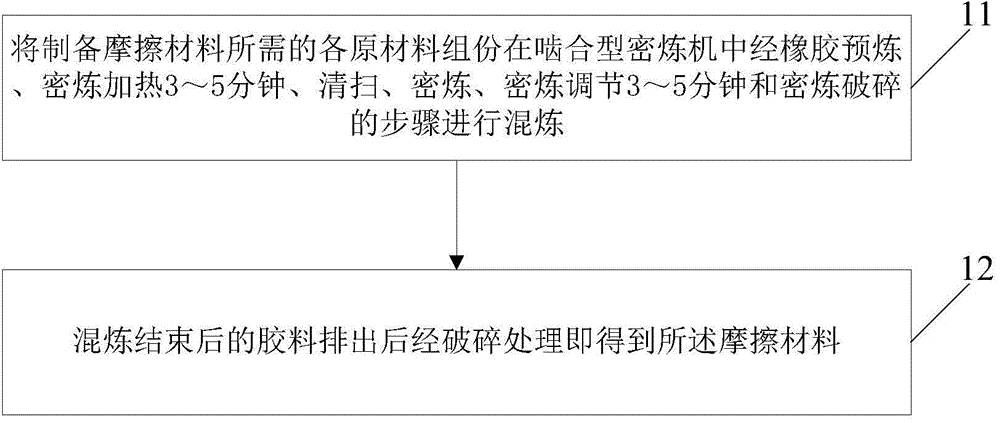

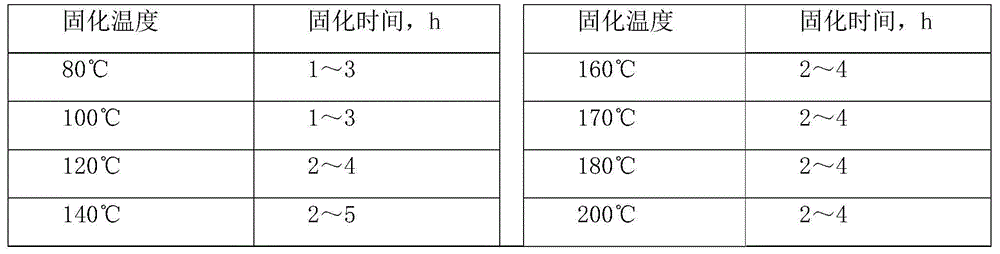

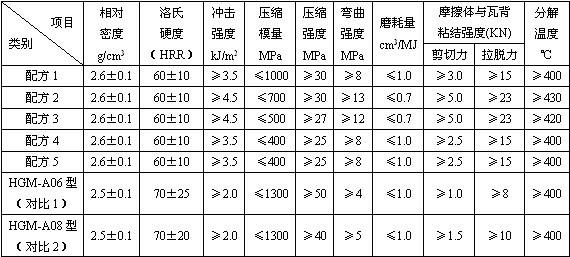

Friction material for brake-shoe of heavy axle-load wagon and preparation method of friction material

InactiveCN104087245AMeet the friction performanceMeet the mechanicsOther chemical processesFiberKyanite

The invention discloses a friction material for a brake-shoe of a heavy axle-load wagon. The friction material is prepared from the following components in percentage by mass: 6-12 percent of nitrile rubber, 1-4 percent of butadiene styrene rubber, 3-8 percent of A-stage phenolic resin, 0.4-1 percent of insoluble sulfur, 0.1-0.6 percent of an accelerant, 0.1-0.6 part of a curing agent, 2-6 percent of carbon black, 8-18 percent of barite, 1-4 percent of kyanite, 17-40 percent of hybrid fibers, 7-14 percent of magnesium oxide, 2-6 percent of petroleum coke, 2-8 percent of calcium sulfate crystal whiskers, 1-4 percent of molybdenum disulfide, 1-5 percent of crystalline flake graphite, 1-4 percent of artificial graphite, 1-4 percent of mica iron oxide and 1-3 percent of antimony sulfide. The friction material can satisfy the friction performance and mechanical property required by the brake-shoe of the heavy axle-load wagon and can meet the high speed operating requirement on heavy load of the wagon.

Owner:BEIJING RAILWAY STAR FORTUNE HIGH TECH

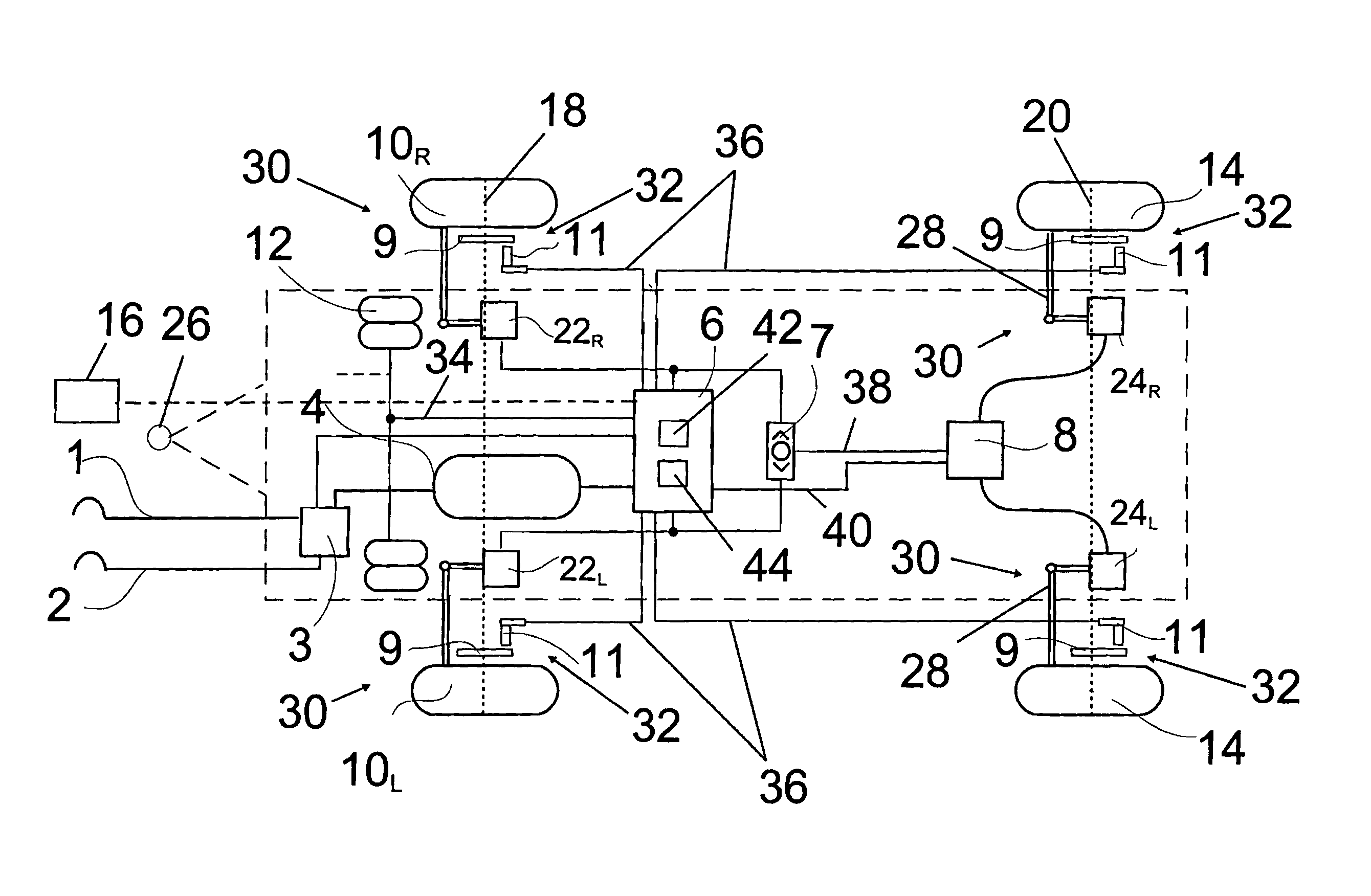

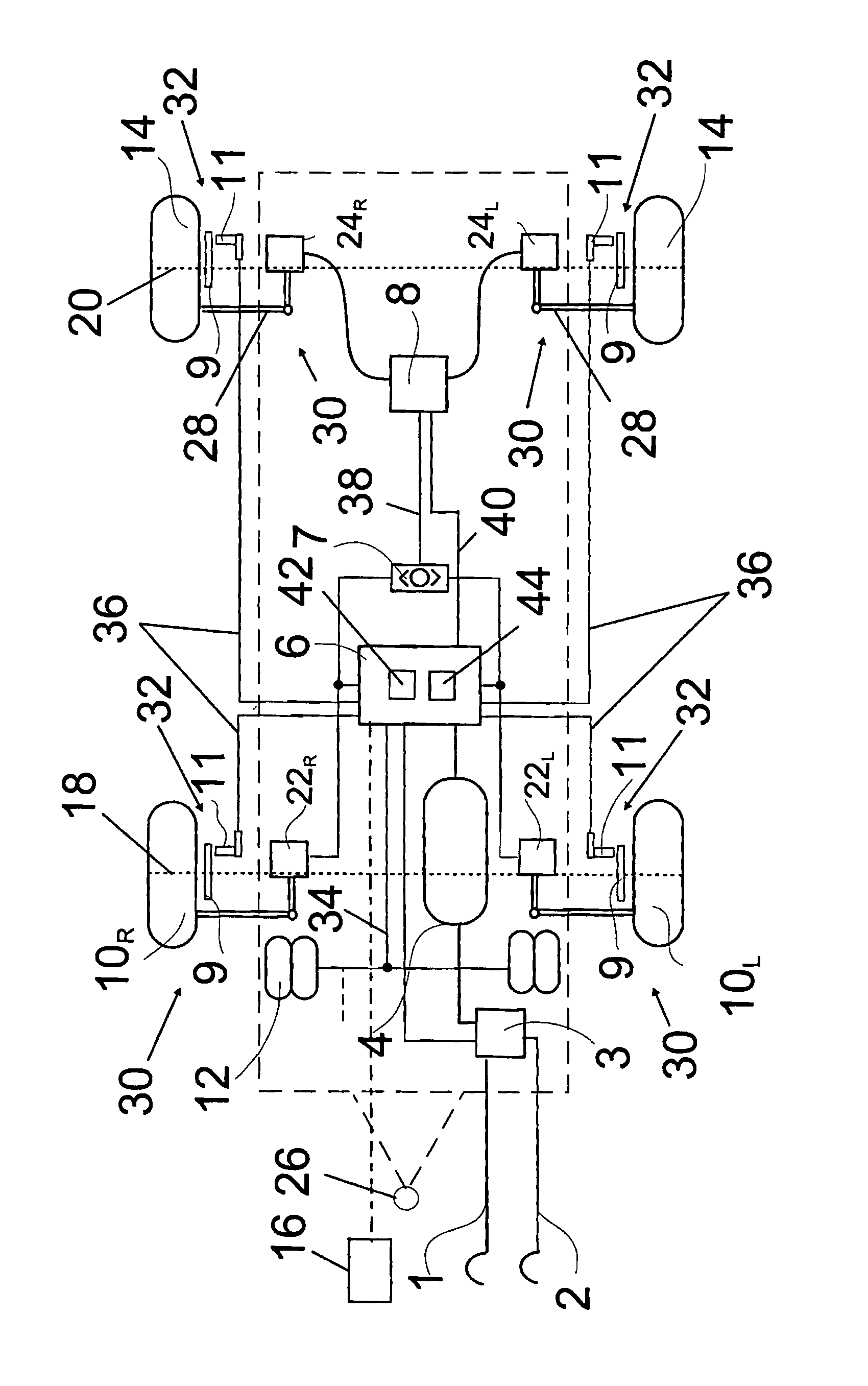

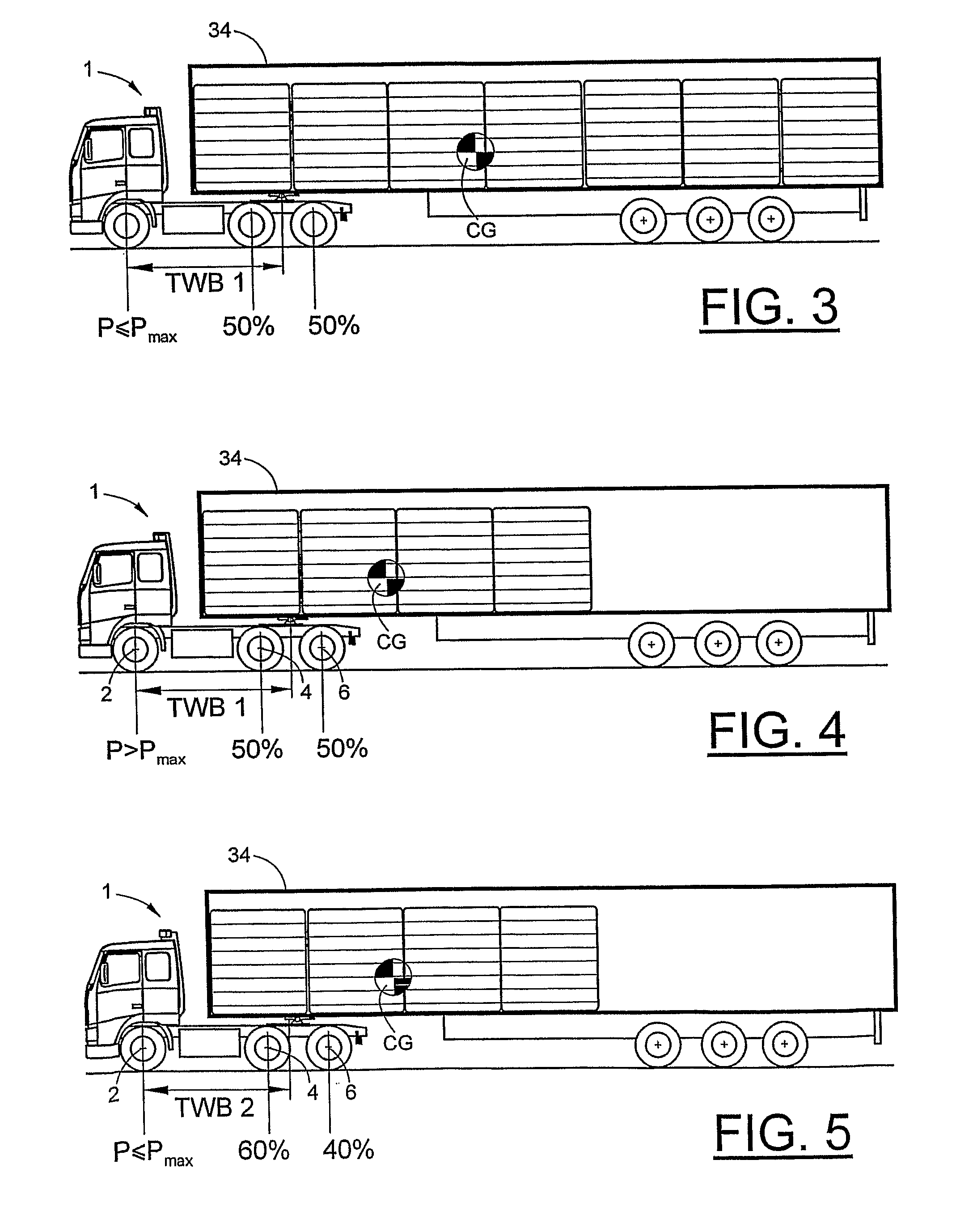

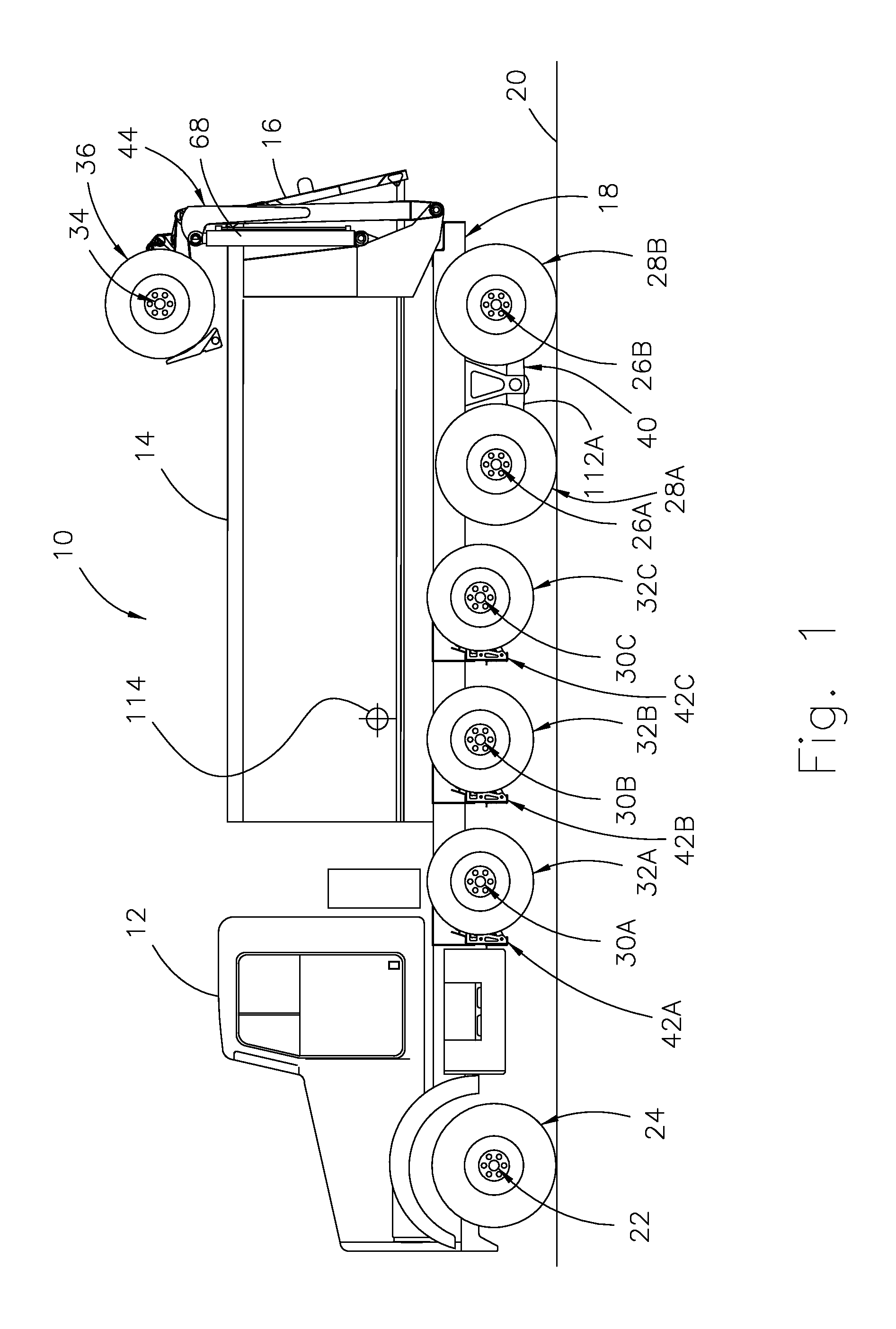

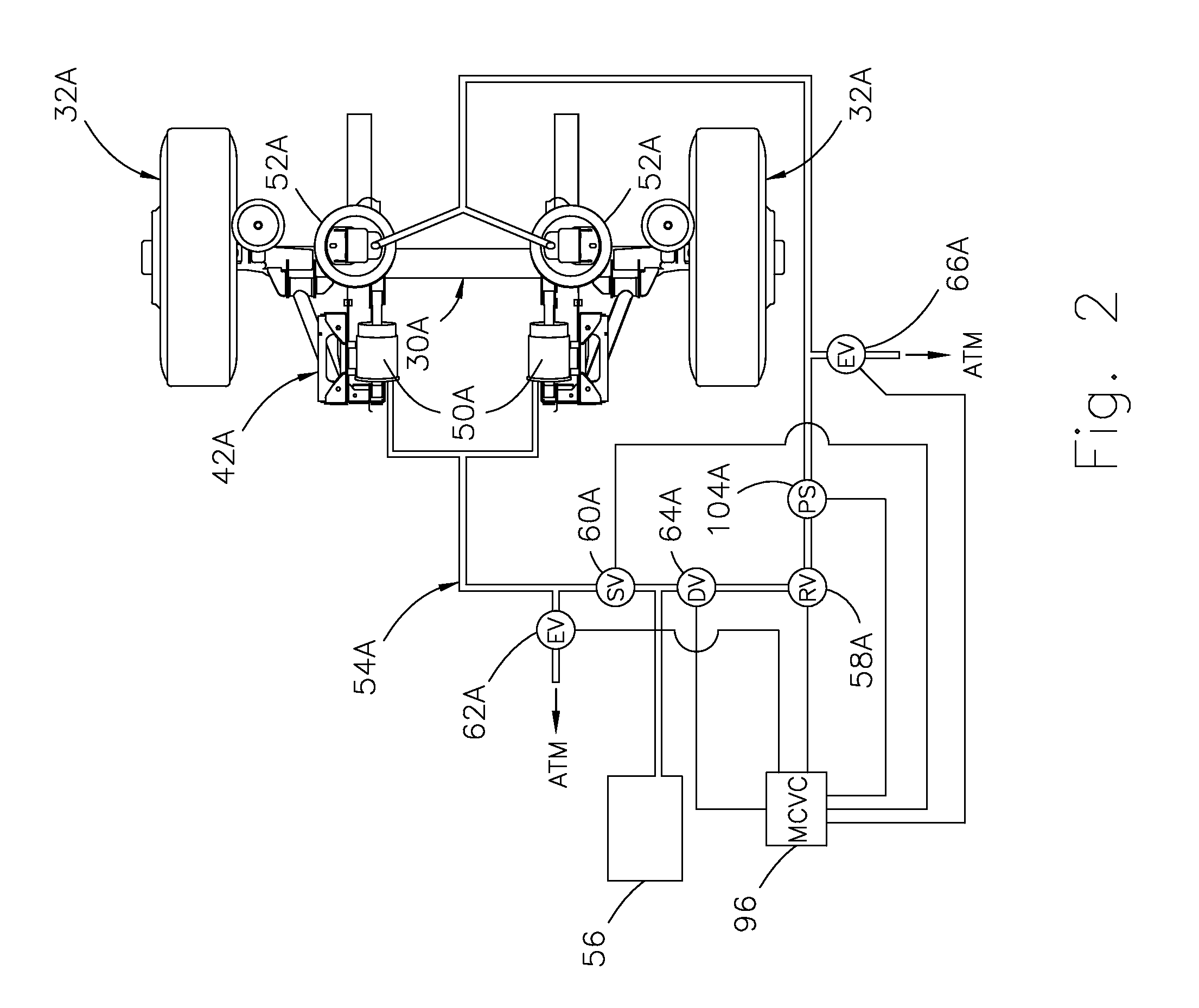

Axle load control system and a wheel base adjustment system

InactiveUS20070296173A1Tractor-trailer combinationsResilient suspensionsDriver/operatorControl system

An axle load control system and method for a load-carrying truck having a front axle and two or more rear axles is provided. The system includes a wheel suspension system with a suspension control processor, a load sensor arranged at each of the axles for detecting one or more load indication parameters, the load sensor providing the parameters to the suspension control processor which translates the parameters into actual axle load values for the individual axles. The control processor is arranged to compare the actual axle load values with a predefined maximum allowable axle load value for each axle, and to control—or indicate to a driver the need to control—the wheel suspension system so as to effect an individual adjustment of the suspension characteristics for each axle in such a way that excess axle load on an overloaded axle is transferred to one or more of the remaining axles, thereby adjusting the theoretical wheelbase of the truck.

Owner:VOLVO LASTVAGNAR AB

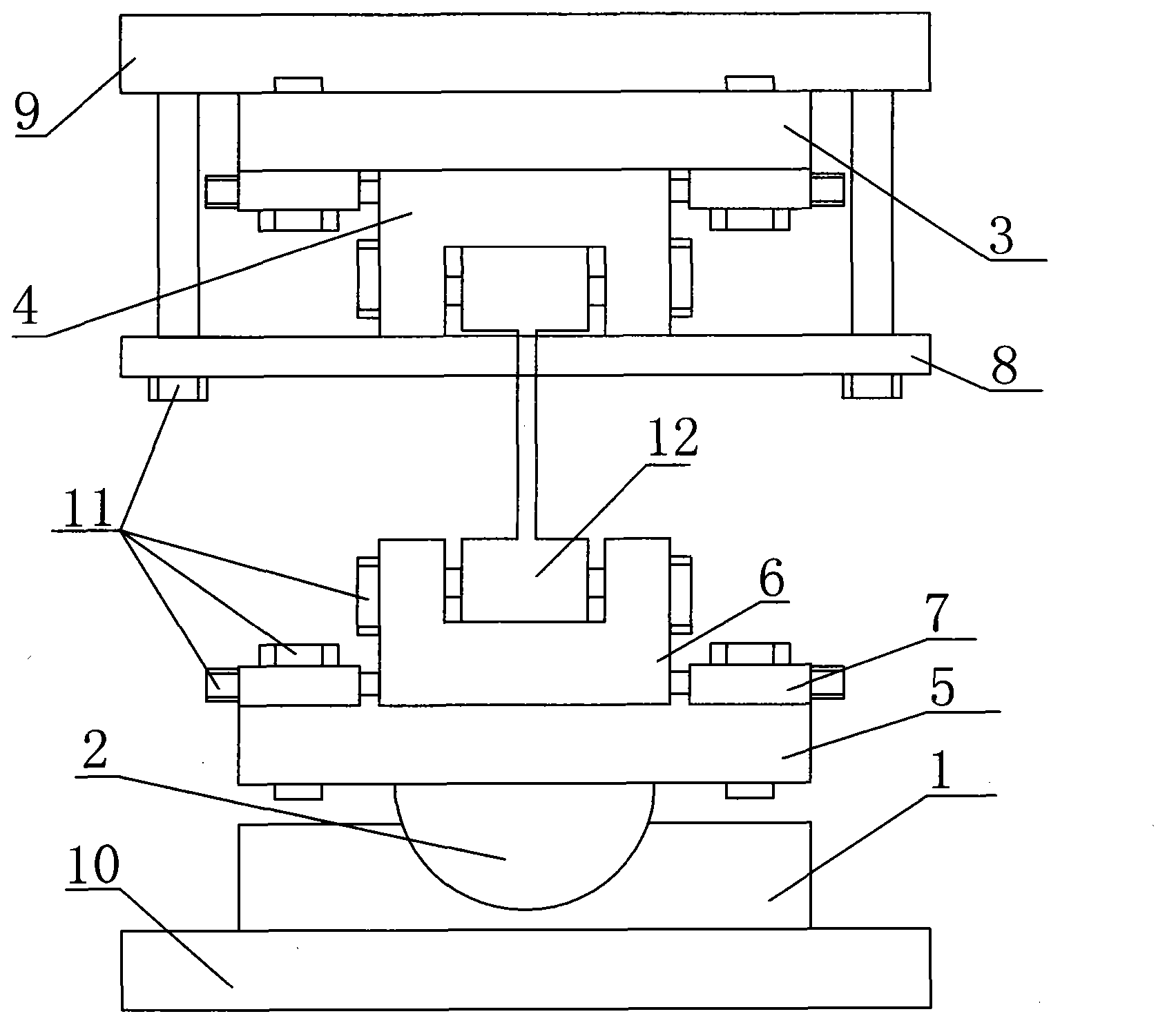

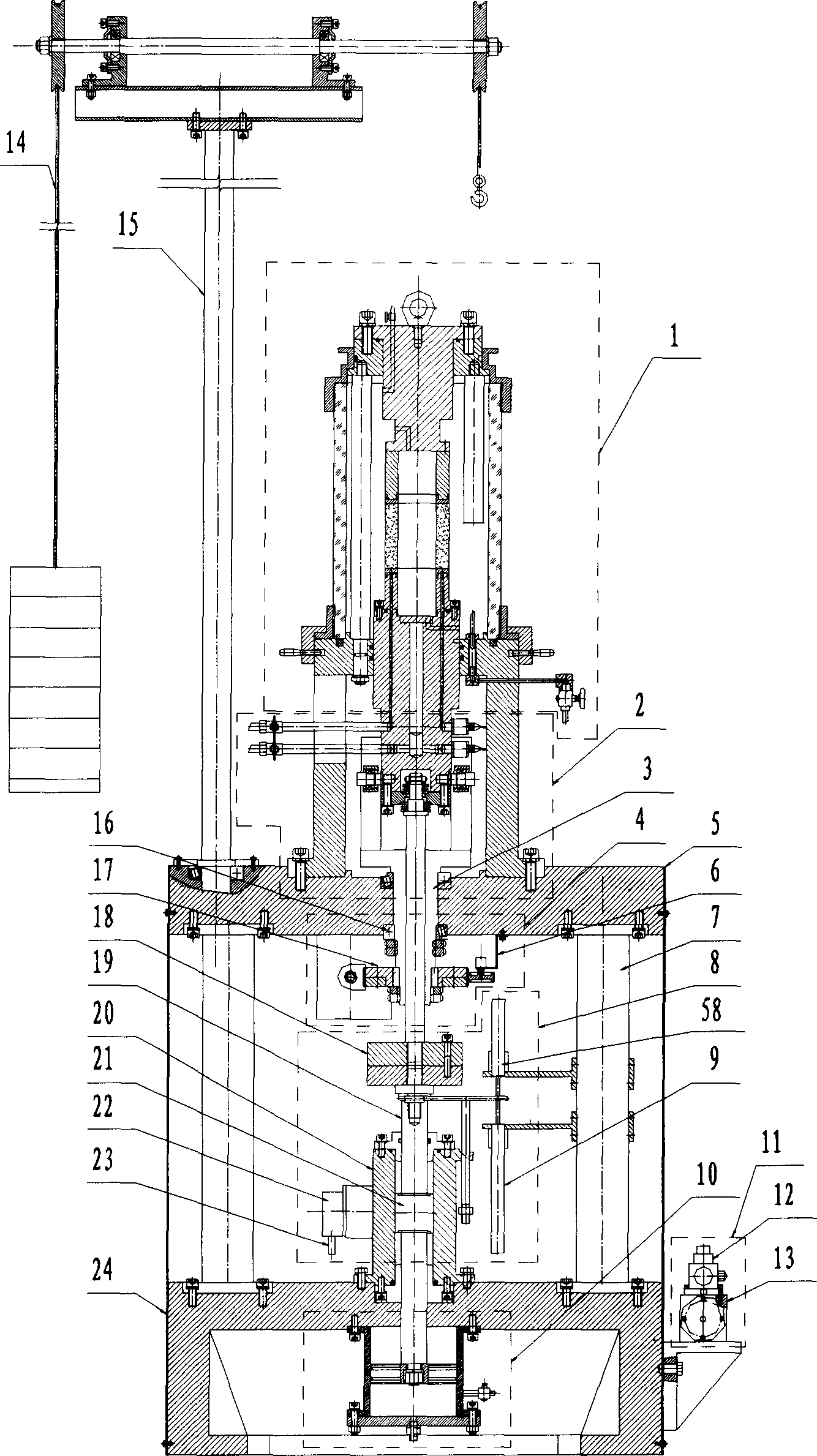

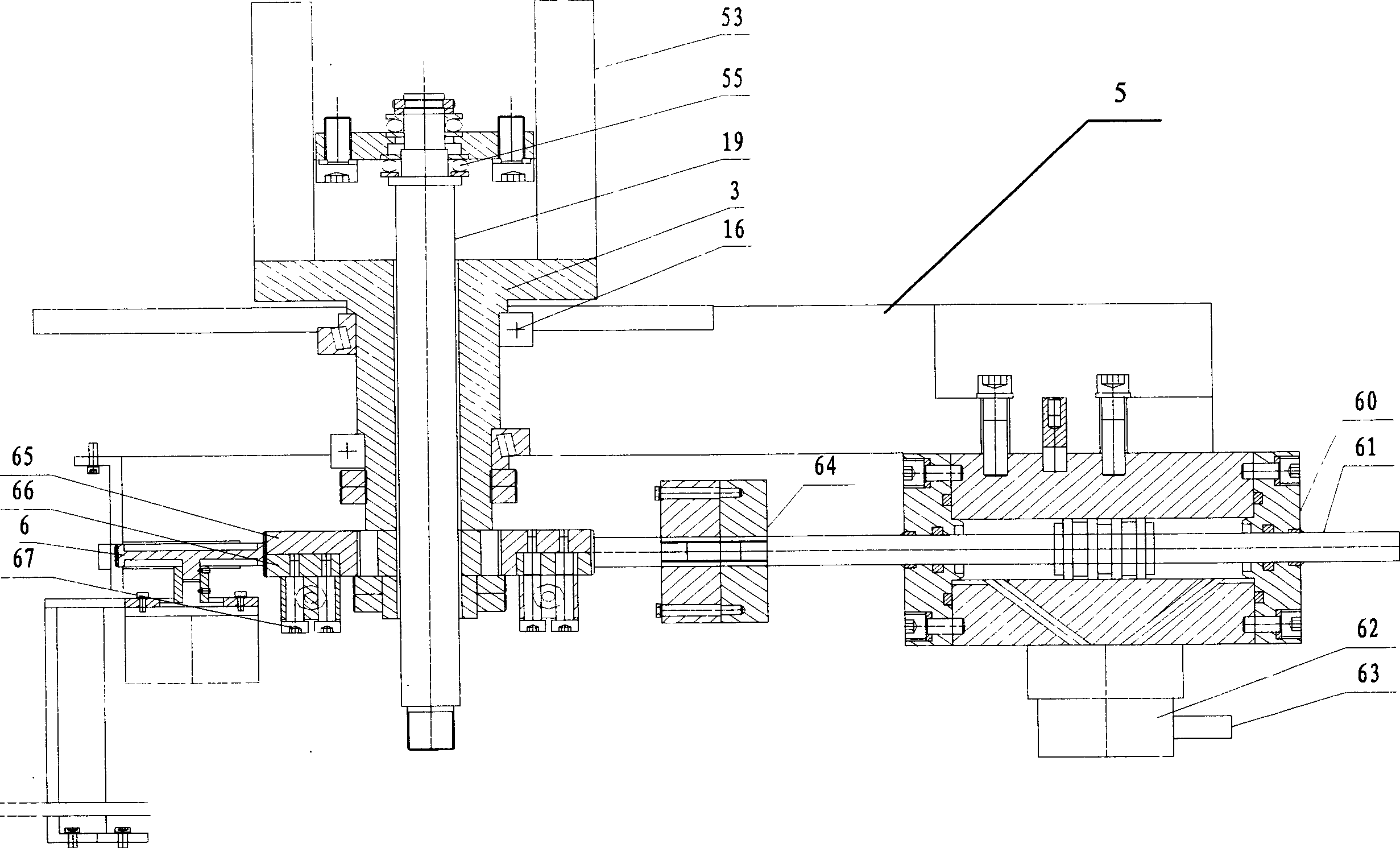

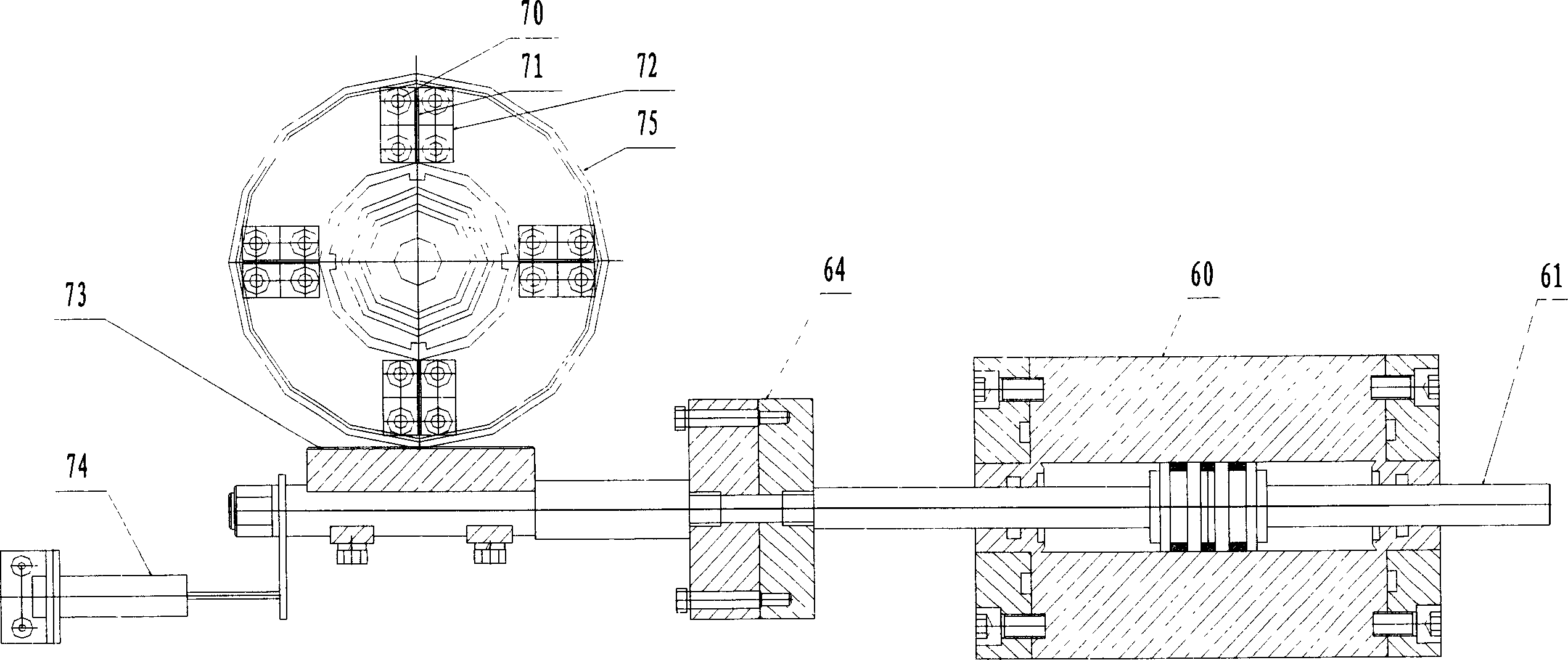

Stiffened plate structure axial compression stability test clamp and method

InactiveCN103293056AGuaranteed validityAchieve symmetryStrength propertiesAxial compressionTest analysis

The invention discloses a stiffened plate structure axial compression stability test clamp and method, and the stiffened plate structure axial direction compression stability test clamp comprises a semicircle ball seat (1) and a semicircle bulb (2) which can be moved in the semicircle ball seat (1); the semicircle ball seat (1) is fixed in the middle of the lower loading plate (10) of the testing machine, and the lower loading plate (10) is connected to a loading actuated cylinder of the testing machine; the inner part of the semicircle ball seat (1) is uniformly smeared with lubricating oil, and the semicircle bulb (2) is uniformly smeared with lubricating oil and is placed in the semicircle tee (1), and the semicircle bulb (2) can be moved in the semicircle tee (1) when bearing compressive load; an end portion support coefficient determination and adjusting method provided by the invention is used, and can effectively determine and adjust the end portion support state during the stiffened plate axle load stability test, and provide basis for the test analysis.

Owner:空军工程大学

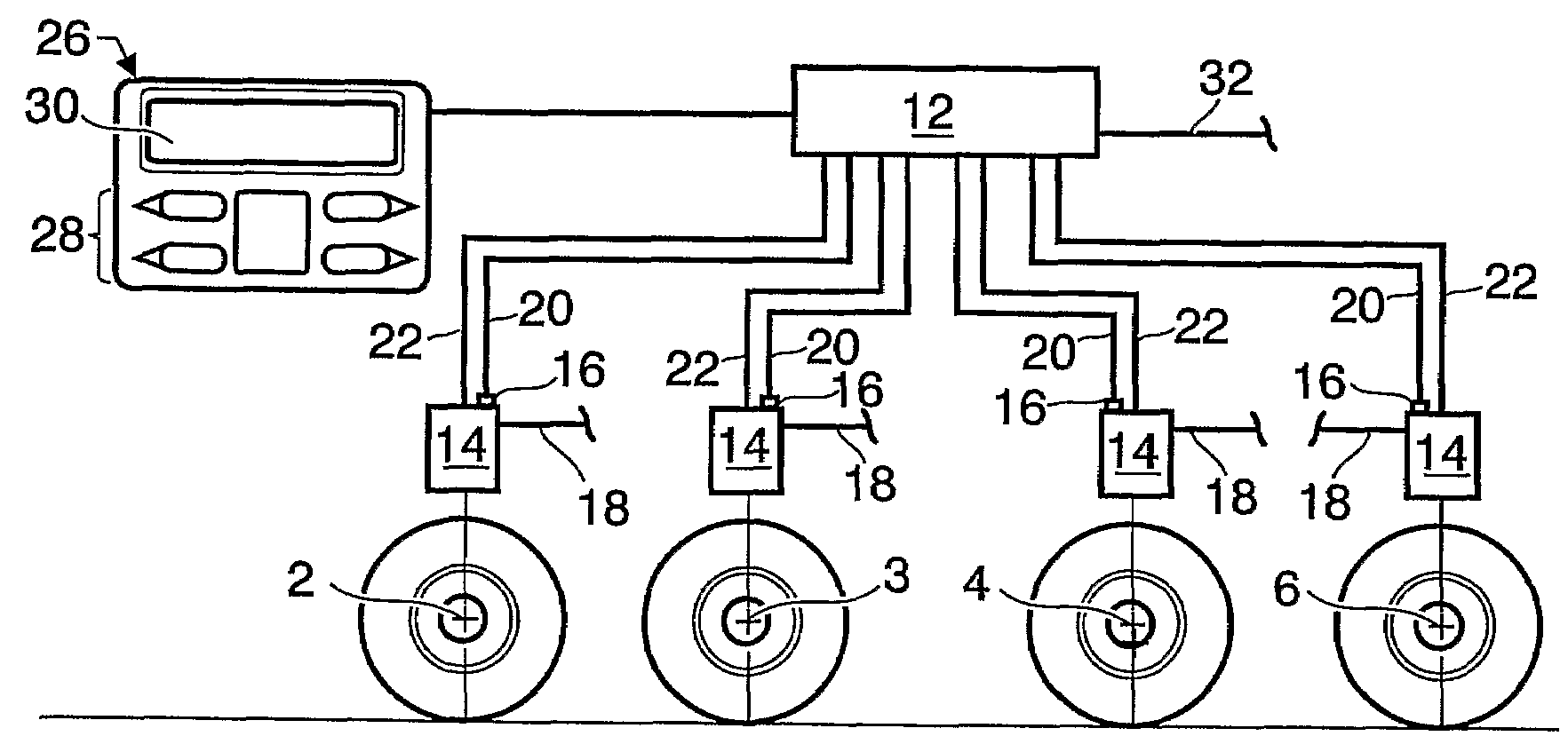

Vehicle weight observation system

InactiveUS20030154798A1Improve protectionImprove securityInstruments for road network navigationForce measurement by permanent gauge deformationDriver/operatorWeight monitoring

The invention relates to a weight monitoring system for a motor vehicle (1) which can, if appropriate, be connected to a trailer (2). The system uses weight sensors to determine the weights (F1, F2) acting on the axles of the motor vehicle, in order to calculate from them the overall weight of the vehicle, and the axle loads. In addition, a tractive force sensor may be provided in the trailer hitch so that the mass of the trailer (2) can be determined by means of the tractive force (F3) and the acceleration of the vehicle. The weight monitoring system calculates various weight variables from the measured values and monitors to determine whether they remain within defined limits. In this context, it is possible, in particular, to take into account a planned route in such a way that the limiting values of the charge are adapted with respect to the maximum altitude (Hmax) above sea level and / or the maximum gradient (smax) of the route. In addition, the system can be configured in such a way that it provides the driver with proposals for a different distribution of the payload which leads to a permissible axle load.

Owner:FORD GLOBAL TECH LLC

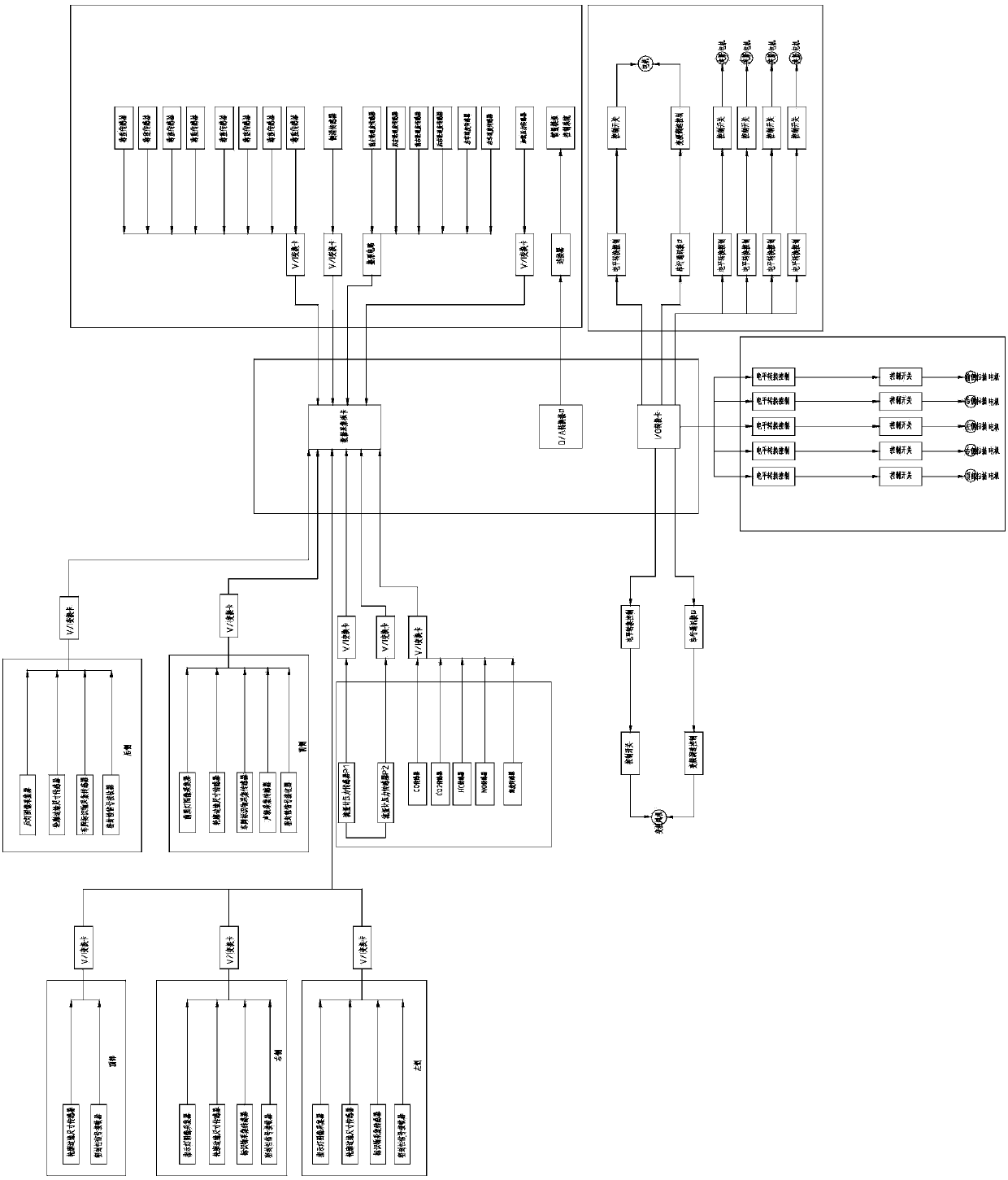

Dynamic intelligent detecting platform and method for motor vehicle external characteristics

The invention provides a dynamic intelligent detecting platform and method for motor vehicle external characteristics. A motor vehicle is made to simulate various speed and load changes in actual driving through the detecting platform, all external characteristic indexes such as axle loads, side sliding, high-speed and low-speed braking, power, oil consumption, waste gas exhaust, sealing performance, headlamps, steering lamps, a fog lamp, a marker and contours are fast completed at a time under different road surface butt joint and half-to-half separation conditions, and a chart curve is formed and uploaded to a network to become public data sources for social share. Because the inner source factors of an automobile are not taken into consideration, measurement of an ABS, an EBD, an ESP and a cruise control system becomes possible, a uniform standard for evaluating the motor vehicle external characteristics is enacted and provided for the automobile industry chain, external characteristic detection is provided for the links of research and development, delivery inspection, automobile using detection and maintenance, and a historical breakthrough is made in site, time, mode and management. A standard is provided for the Internet of things, public safety and energy conservation and environmental protection of automobiles worldwide.

Owner:庞抗美

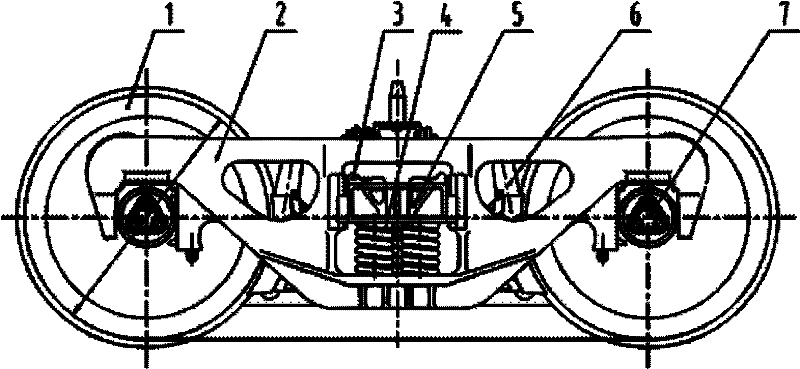

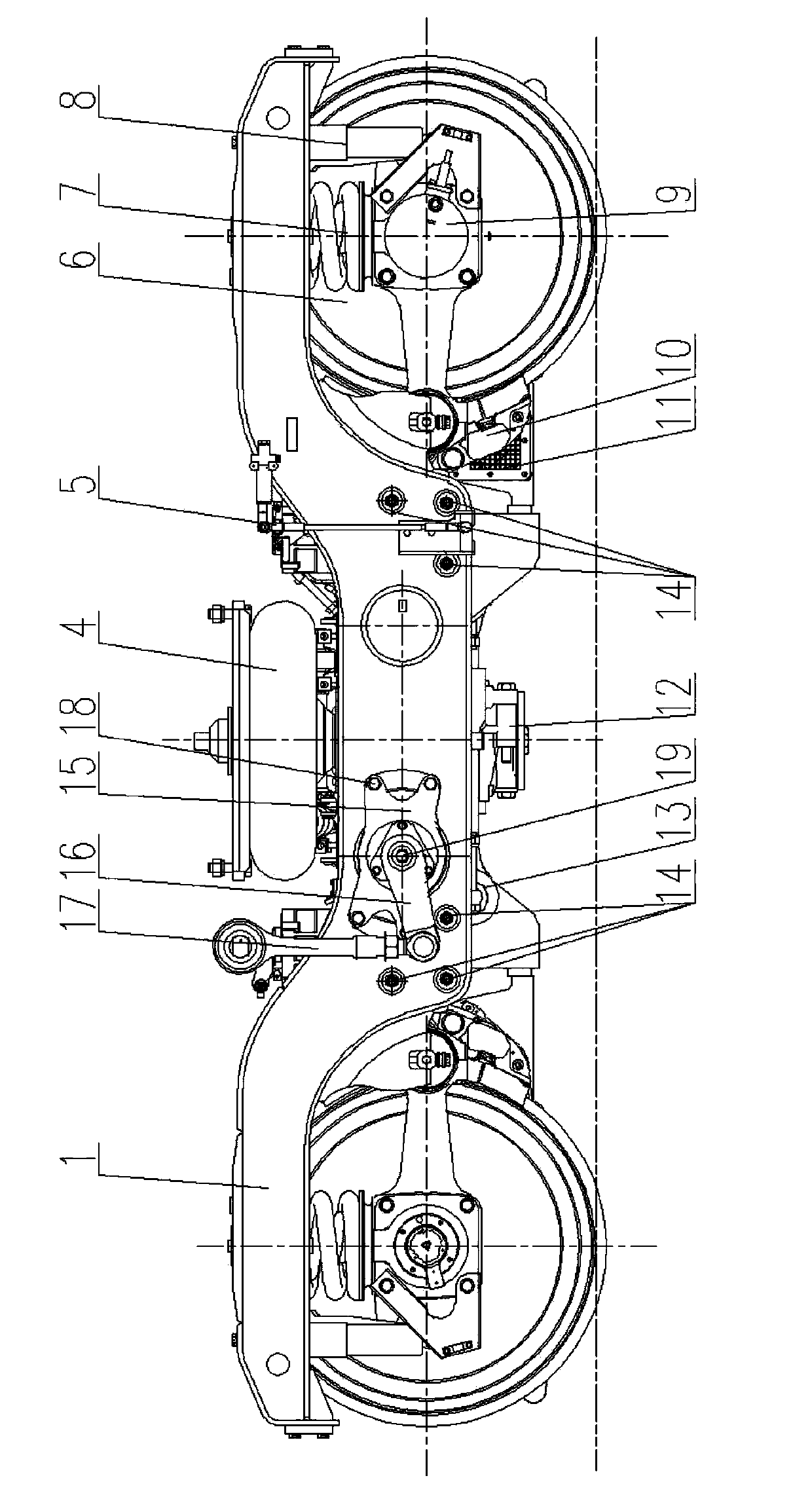

Bogie of narrow gauge railway vehicle

InactiveCN102514584AImprove diamond stiffnessIncrease static deflectionBogiesBogie-underframe connectionsVariable stiffnessBogie

The invention discloses a bogie of narrow gauge railway vehicle, which comprises a wheel pair, a side frame, a vibration absorber, a swing bolster and a braking device. The wheel pair is connected with the side frame in a rolling way through a rolling bearing device; the side frame and the swing bolster form a bogie body structure through central mounting; a dual-acting elastic side bearer is laid in a swing bolster side bearer box; and the swing bolster side bearer box and the swing bolster are cast into a whole body. The invention optimizes structures of the wheel pair, a vehicle axle, the swing bolster and the side frame, and ensures that the wheel pair meets running requirements of narrow gauge (especially 1067mm gauge), and the structural strength of main bearing structures, such as the swing bolster and the side frame, meets bearing requirements of an 18t axle load bogie. The central mounting adopts a dual-stage variable stiffness spring, increases the empty natural bow, and meets different requirements on the central mounting in different operating conditions. By adopting the frictional vibration absorber of the control type bogie, the diamond resistant rigidity of the bogie is improved. By adopting the dual-acting elastic side bearer, stable turning drag torque is provided for the running of a vehicle, and the running speed of the vehicle is increased.

Owner:CRRC MEISHAN

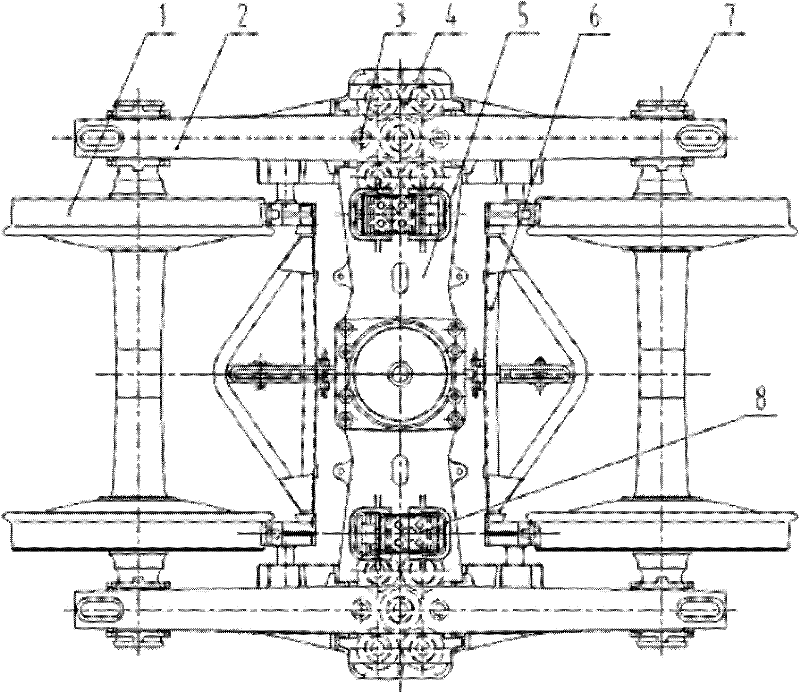

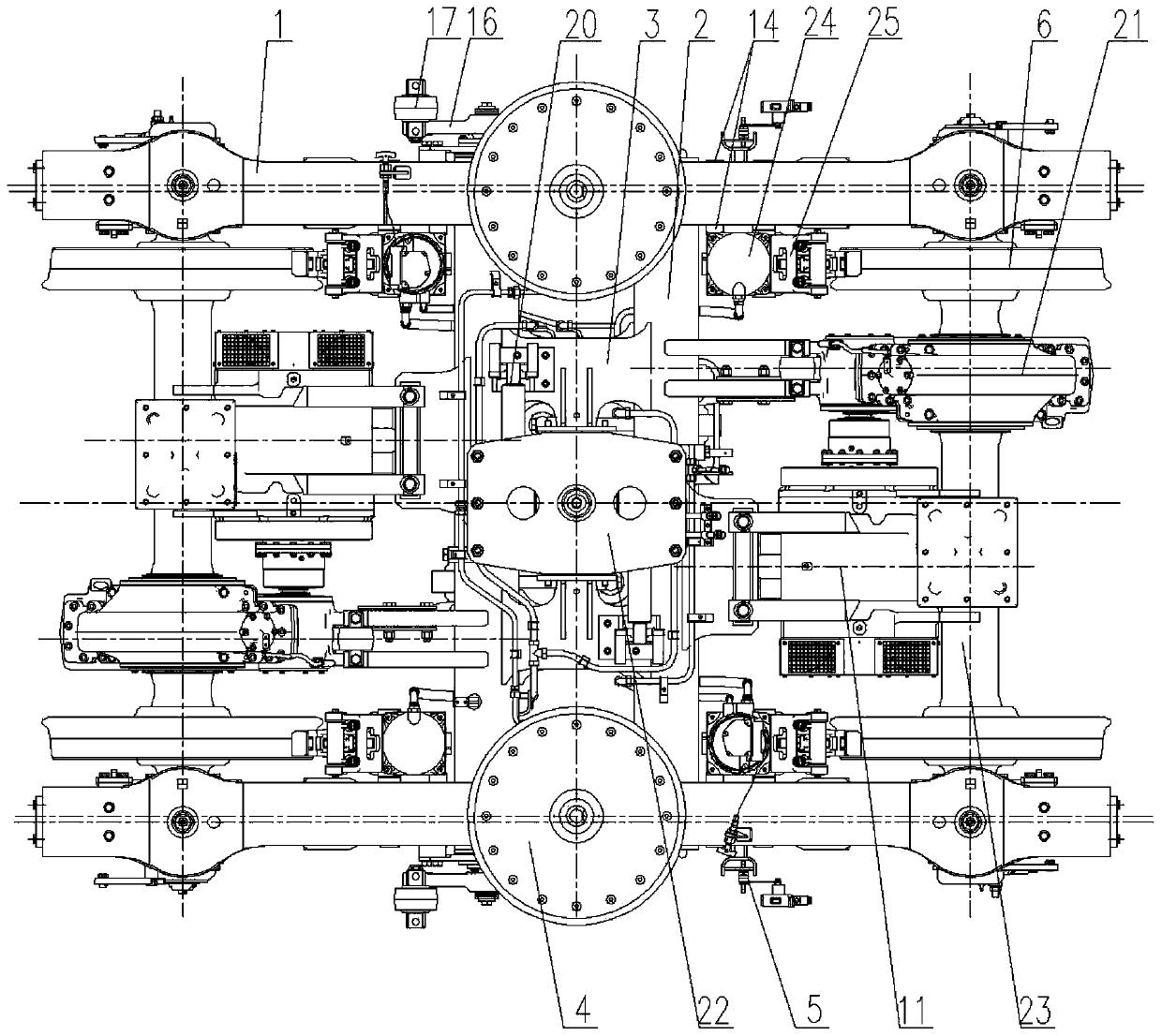

Co bogie for high-adherence heavy-load freight locomotive

ActiveCN101823493AMeet the application requirementsMeet application requirementsBogiesBogieEngineering

The invention relates to a Co bogie for a heavy-load alternating-current transmission power freight locomotive on a railway, in particular to a Co bogie for a high-adherence heavy-load freight locomotive, comprising wheel pair driving systems, a framework, a two-series suspension device, a traction device, a motor suspension device and a braking device. Three wheel pair driving systems are installed on each bogie and adopt integrated axial suspension drives with flexible axle couplers and alternating-current traction motors; gear boxes are in load bearing structures; a first-axle wheel pair axle box device and a third-axle wheel pair axle box device are provided with integrated conical bearings with small axial clearances, and a second-axle wheel pair axle box device is provided with an integrated cylindrical bearing with a large axial clearance. The bogie structure provided in the invention can satisfy the adoption requirements of 25-ton axle-load electric locomotives.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

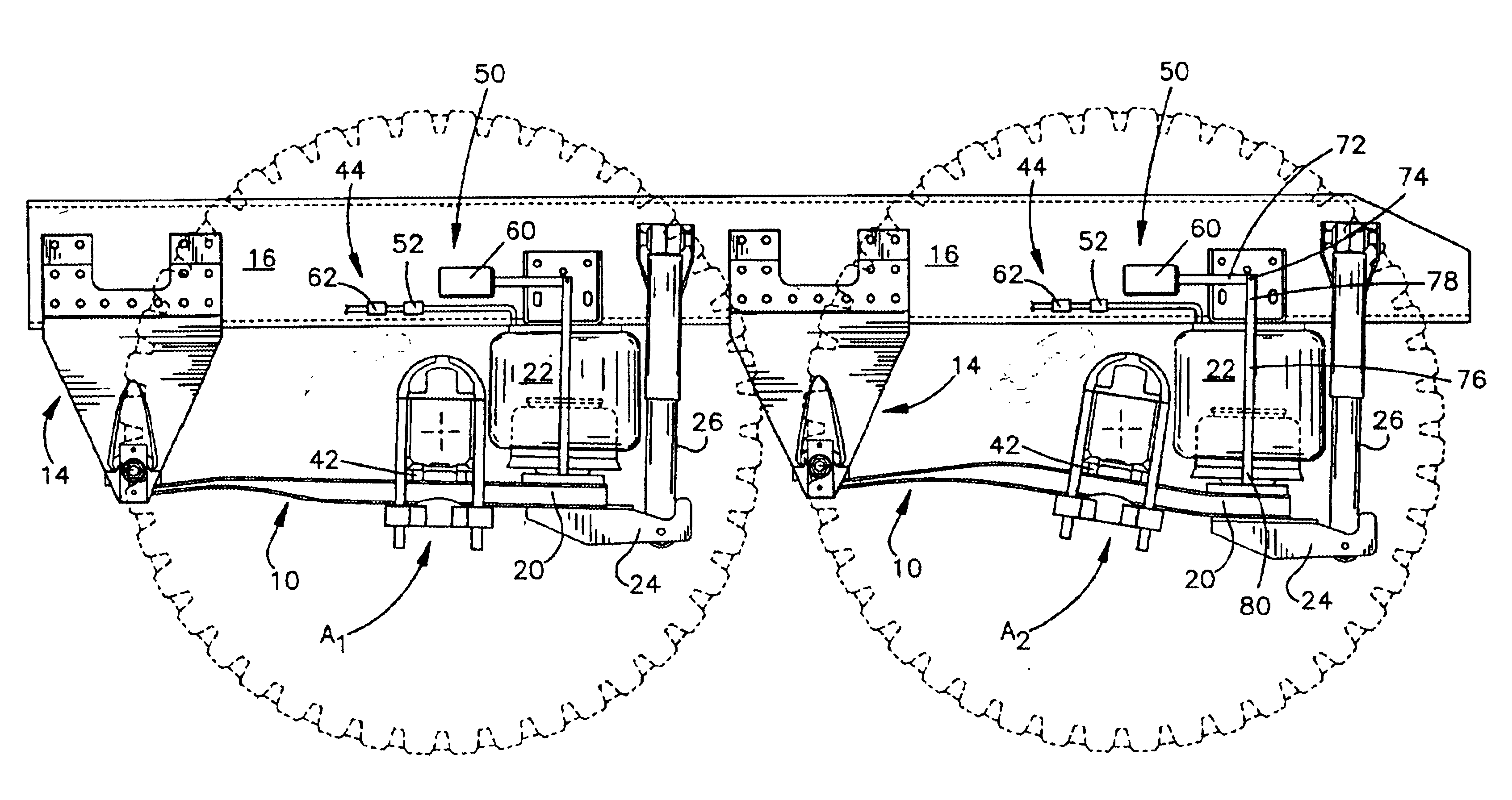

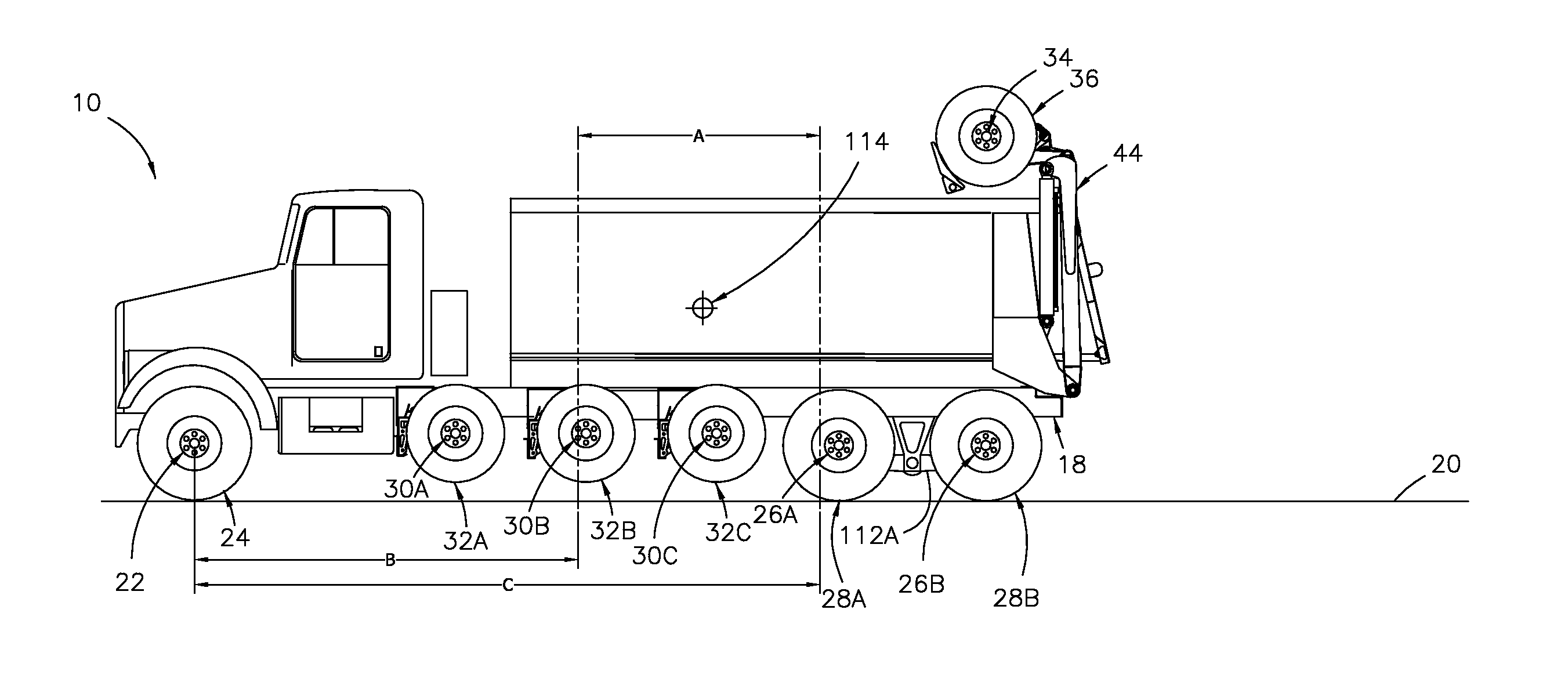

Axle Load Monitoring System

InactiveUS20170016757A1Resilient suspensionsSpecial purpose weighing apparatusMonitoring systemMotorized vehicle

An axle load monitoring system is disclosed for a load-transporting motor vehicle having two or more primary axles and one or more auxiliary axles wherein the monitoring system detects a noncompliant axle carrying weight condition when the weight of the vehicle acting on any primary axle exceeds a prescribed maximum allowable axle carrying weight assigned to that axle and also when the weight acting on any group of the axles arranged consecutively exceeds a prescribed maximum allowable axle group carrying weight assigned to that axle group. And on such detection, the monitoring system recommends auxiliary axle usage that would result in no maximum allowable axle carrying weight and maximum allowable axle group carrying weight being exceeded provided the current gross vehicle weight does not exceed a prescribed maximum allowable gross vehicle weight determined by all of the axles and the current center of gravity of the vehicle is located within a certain compliance-manageable range. And with the monitoring system also recommending optimal auxiliary axle usage in other situations where full compliance may not be possible for various reasons.

Owner:STRONG BROOKS +1

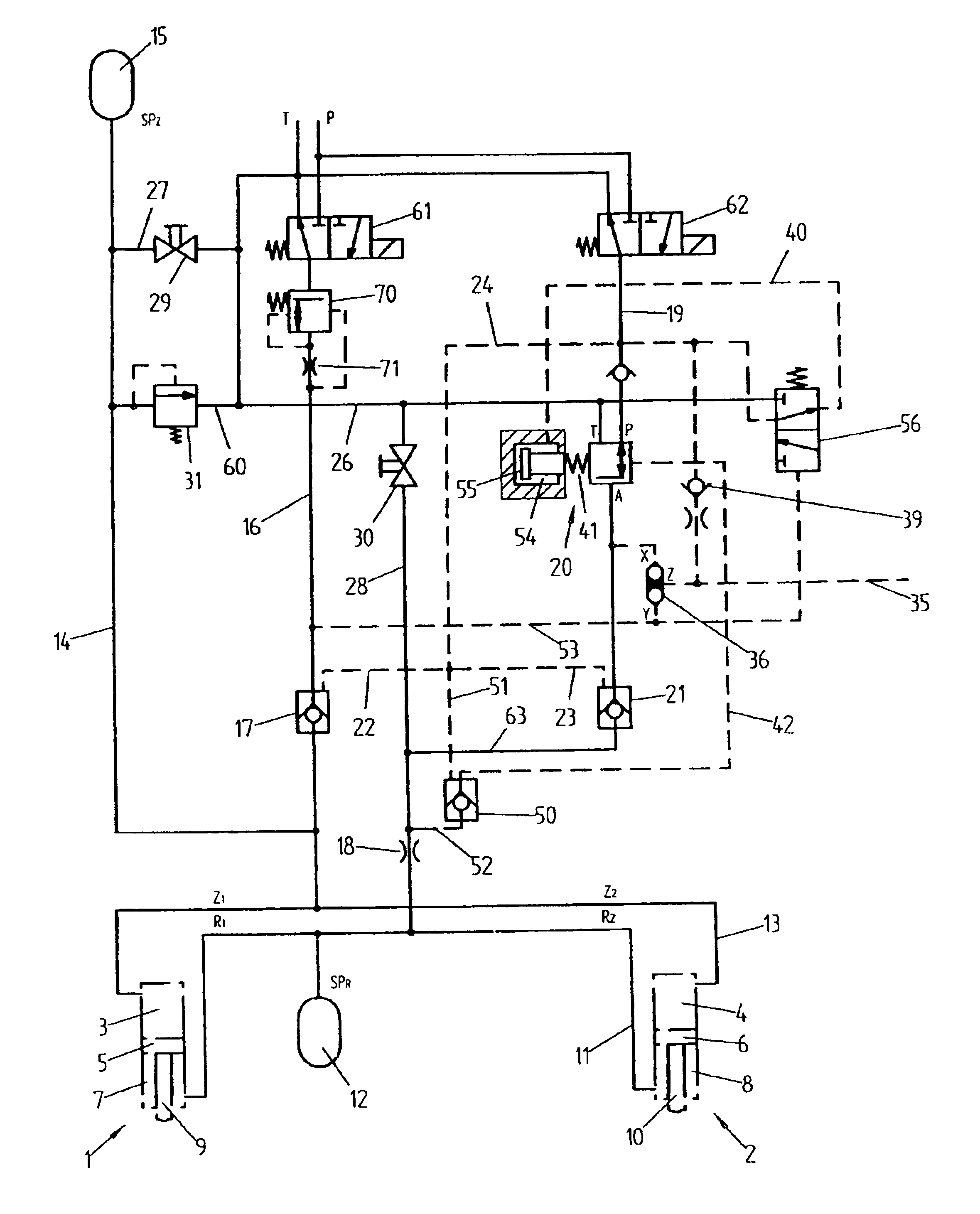

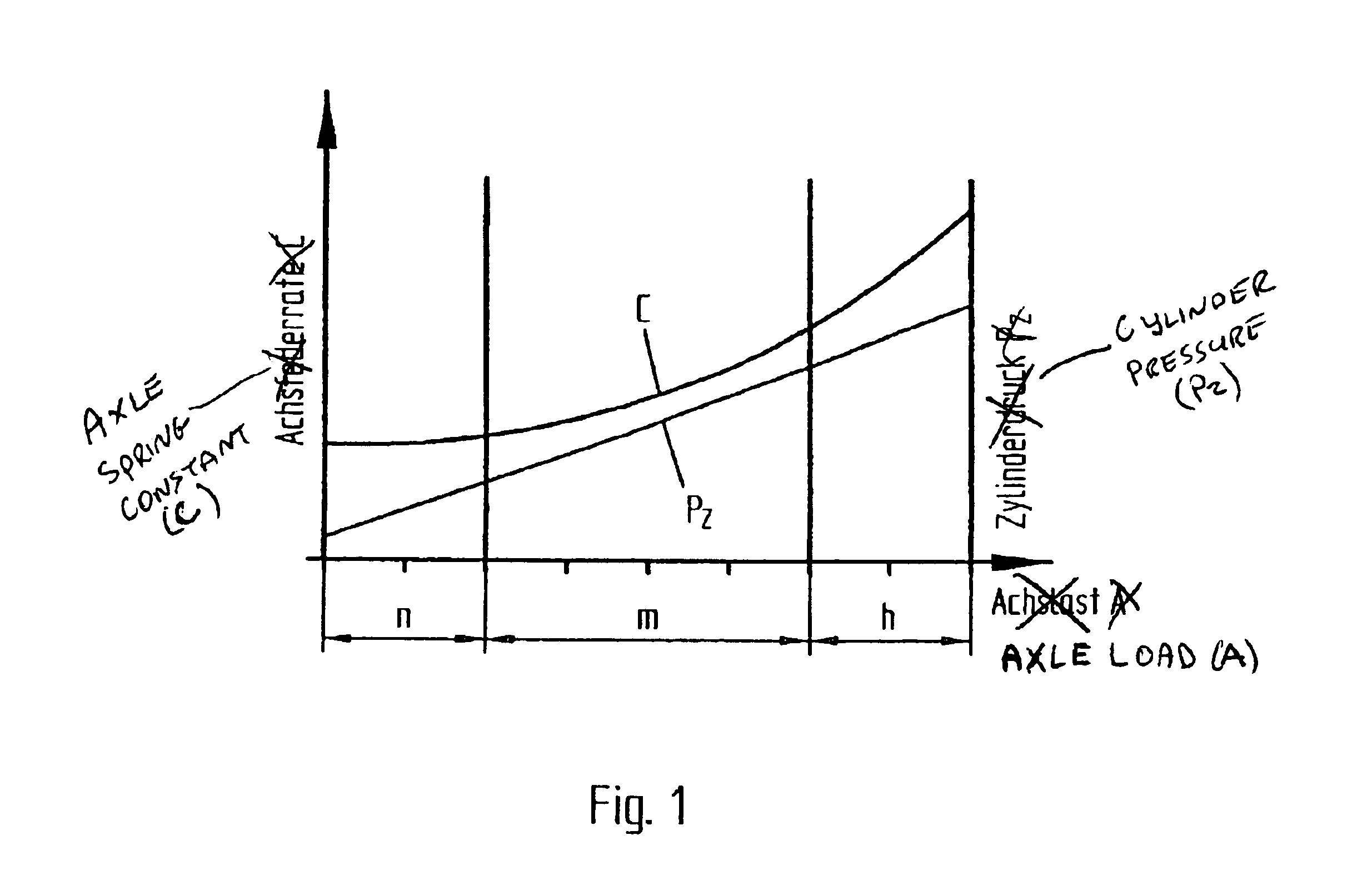

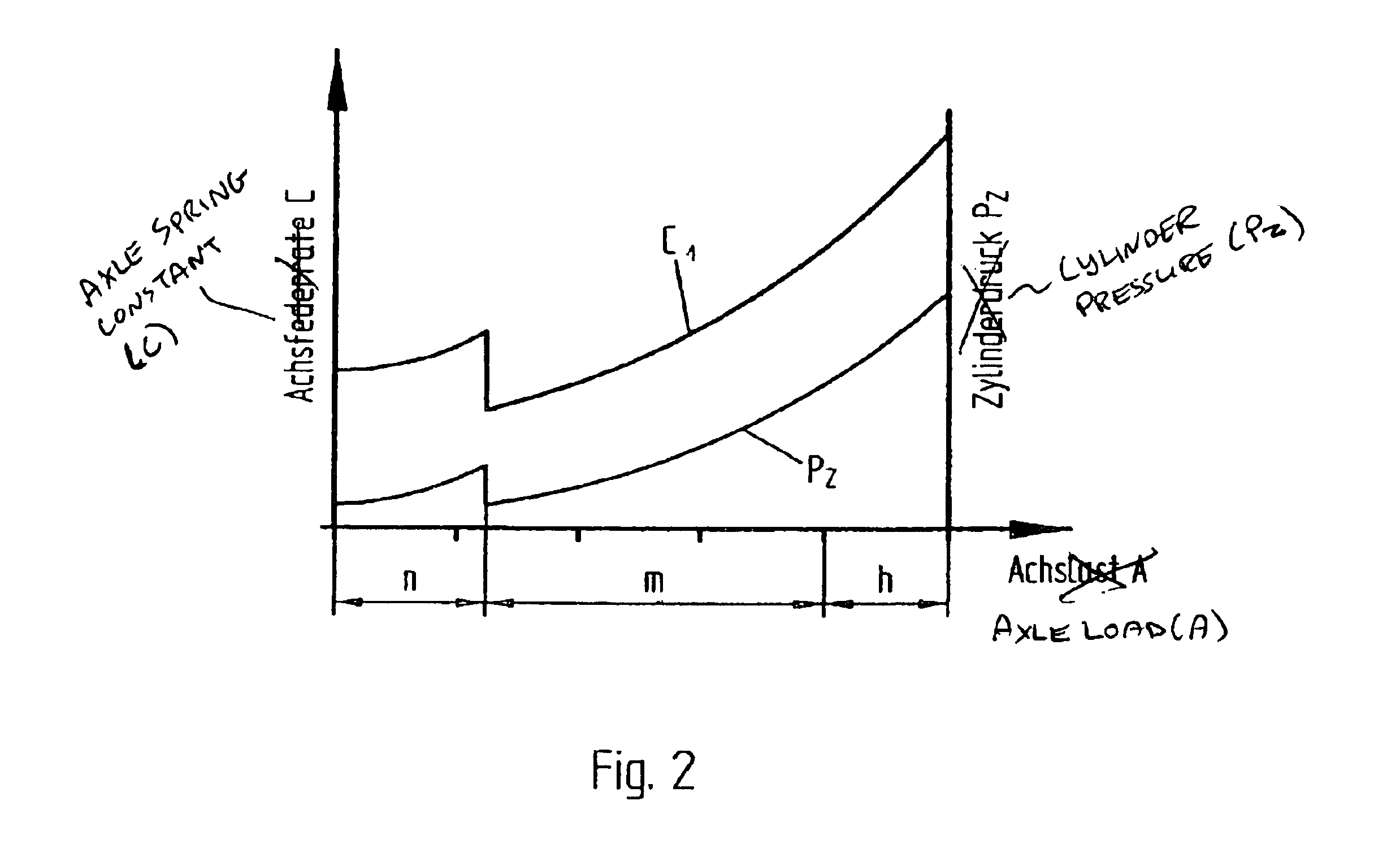

Method and device for controlling the suspension performance in vehicles having hydropneumatic suspension devices and highly variable axle-load ratios

InactiveUS6786492B2Small installation volumeQuick pressure adjustmentVehicle cleaning apparatusLoading/unloading vehicle arrangmentHydraulic cylinderHydropneumatic suspension

A method of controlling suspension performance in vehicles having hydropneumatic suspension devices between suspended masses and unsuspended masses and extremely variable axle load ratios, in particular on vehicles in which the front axle is subjected to a low, medium or high static load range, depending on the application of the vehicle, and the suspension device has double-action hydraulic cylinders between the suspended masses and unsuspended masses, their pressure spaces being connectable to a pump over pressure lines, a pressure-regulating valve being installed in the pressure line to the annular spaces, the pressure-regulating valve constantly correcting the pressure in the annular spaces to the pressure in the piston spaces in a predefined ratio, with the pressure (PR) in the annular spaces (7, 8) of the spring cylinders (1, 2) being increased in the low load range (n) on the front axle.

Owner:CARL FREUDENBERG KG

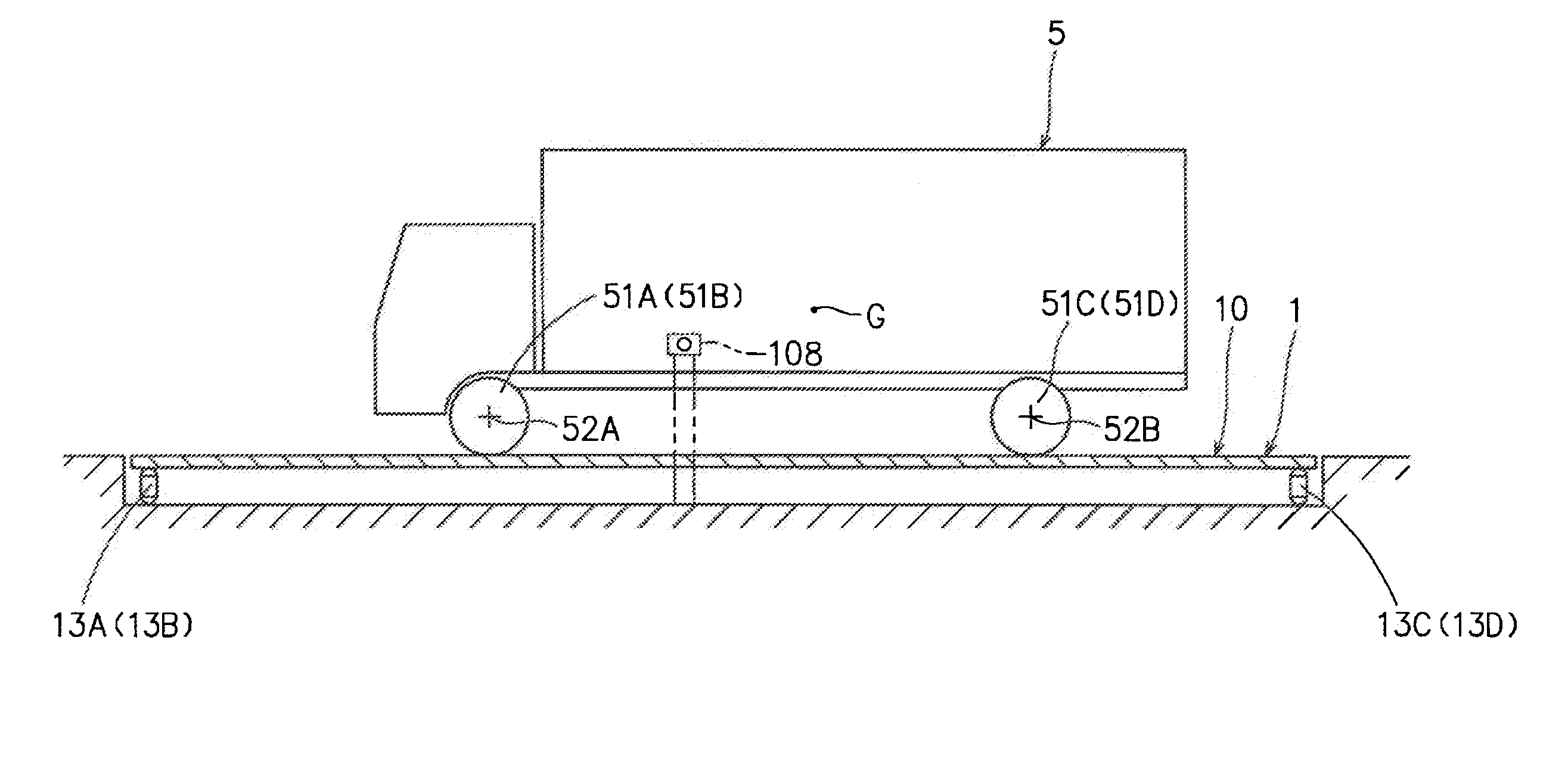

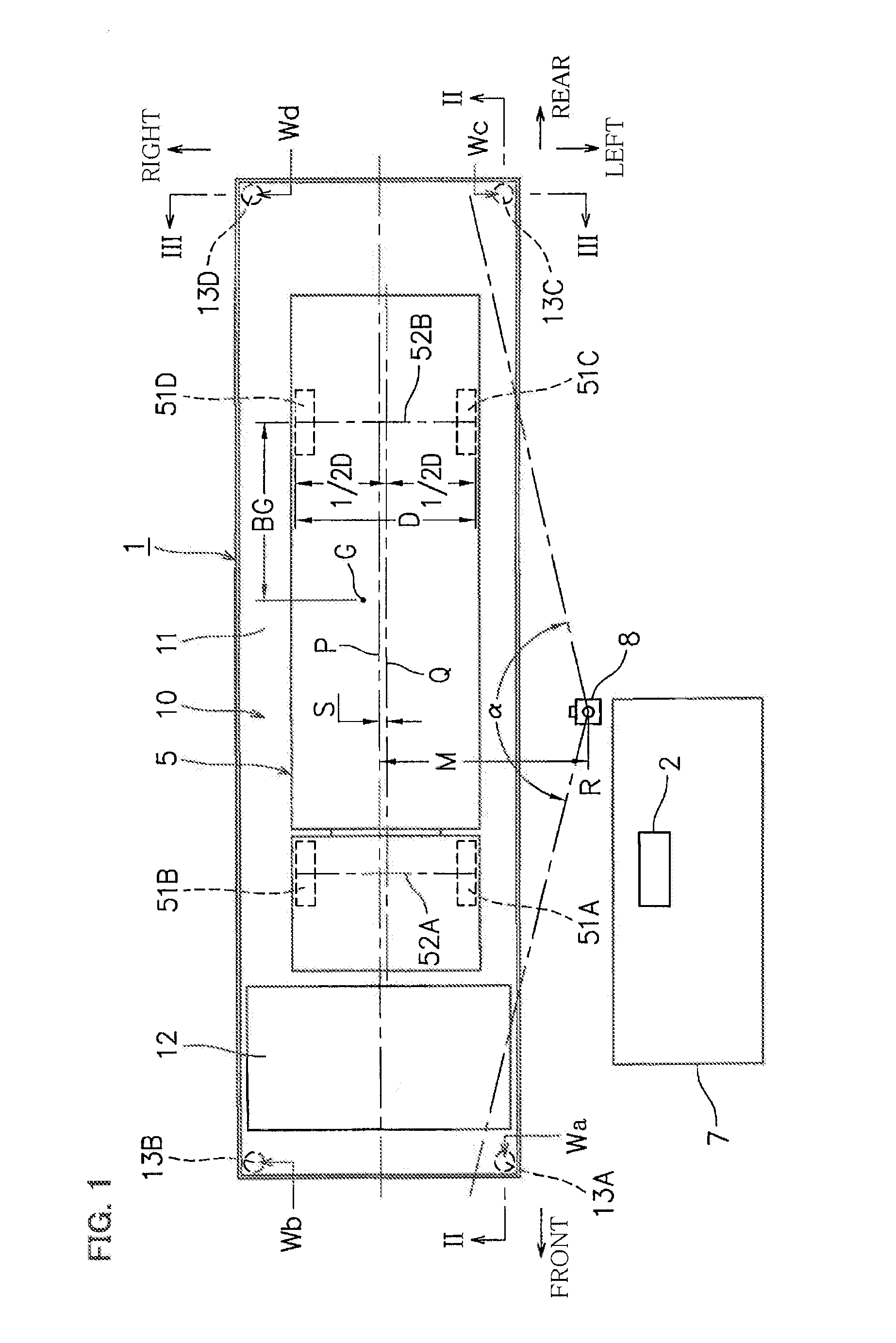

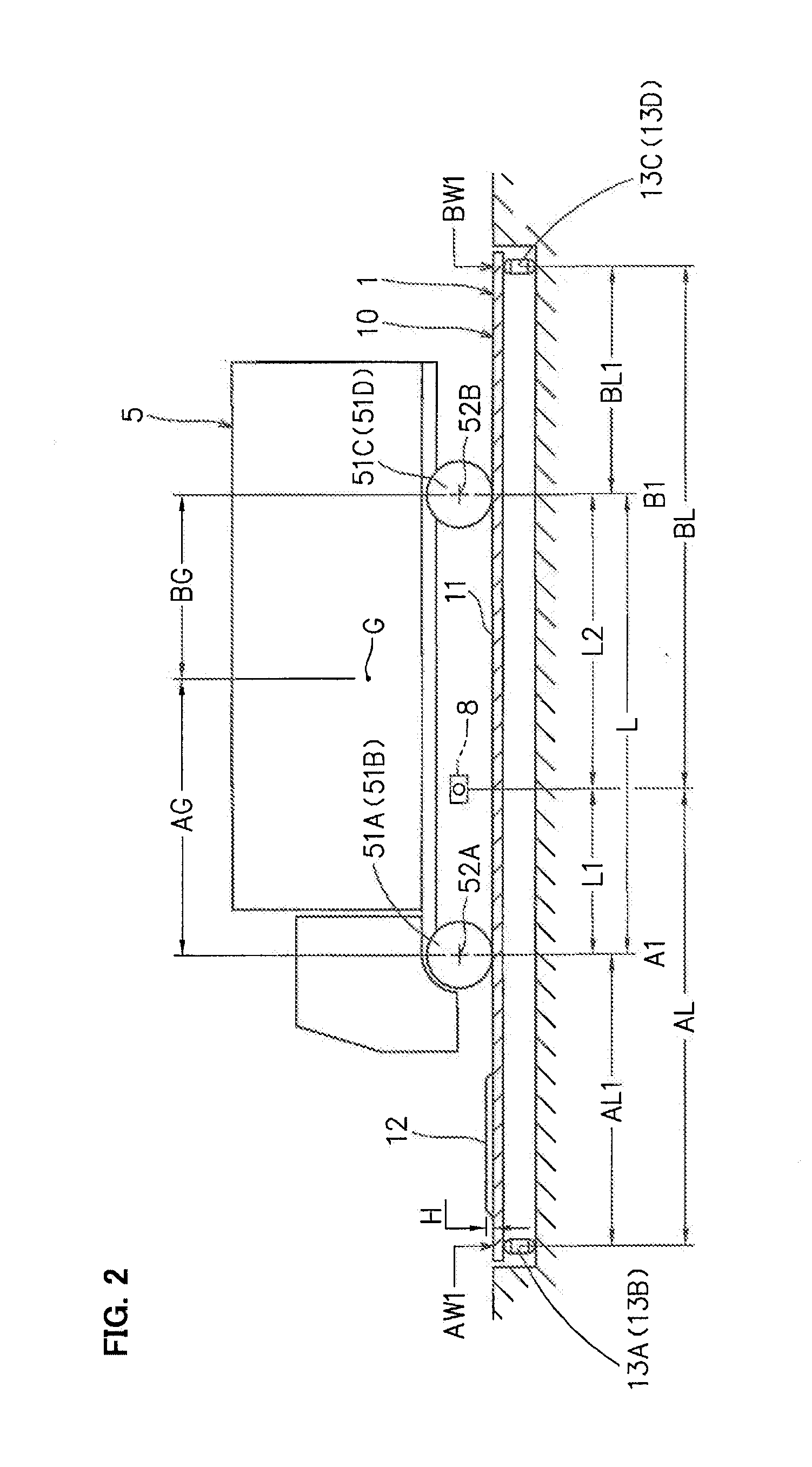

Measurement Device of Position of Center of Gravity of Vehicle to be Measured on Truck Scale and Truck Scale

ActiveUS20130081451A1Stable center of gravityHigh riskVehicle testingStatic/dynamic balance measurementGravity centerControl theory

As a measurement table (10), an object provided with a flat surface (11) having an area on which all wheels of a vehicle can be mounted at the same time and a front wheel mounting table (12) which is disposed in front of the flat surface (11) and is lifted by a step of a predetermined height is used, a wheel position detector (8) which is capable of detecting a front wheel position and a rear wheel position of a vehicle to be measured is provided, a computation processing device (3) is provided with anterior-posterior displacement calculation means, an inter-axle distance calculation means (21), a vehicle inclination calculation means (22), a front wheel axle load calculation means (23A), a rear wheel axle load calculation means (23B), an anterior-posterior gravity center position calculation means (24), a storage means (32), an anterior-posterior gravity center displacement calculation means (25), and a vehicle gravity center height position calculation means (26), and from a gravity center displacement which is calculated from anterior-posterior gravity center position information calculated on the flat surface (11) and anterior-posterior gravity center position information in the state in which front wheels are mounted on the front wheel mounting table (12) and a vehicle inclination which is calculated by the vehicle inclination calculation means (22), the position of the height of the center of gravity of the vehicle to be measured is calculated.

Owner:KAMACHO SCALE

Hydropneumatic, level-regulated axle suspension on vehicles, in particular for full-suspension vehicles

InactiveUS7055831B2Increase driving speedImprove securityInterconnection systemsResilient suspensionsAxle loadHydraulic pressure

A hydropneumatic, level-regulated axle suspension for the front wheel axle and rear wheel axle on vehicles, in particular vehicles whose large axle load spread is large, having two double-acting hydraulic suspension cylinders, whose cylinder spaces are each connected to a first accumulator and whose annuli on the piston side are connected to a second accumulator, the axle suspension for the front axle (39) and the rear axle (40) being designed as a reversible double-function axle suspension, so that each axle (39, 40) is switchable both as an oscillating axle (in the cylinder transverse combination) and as a stabilizing axle (in the cross combination).

Owner:CARL FREUDENBERG KG

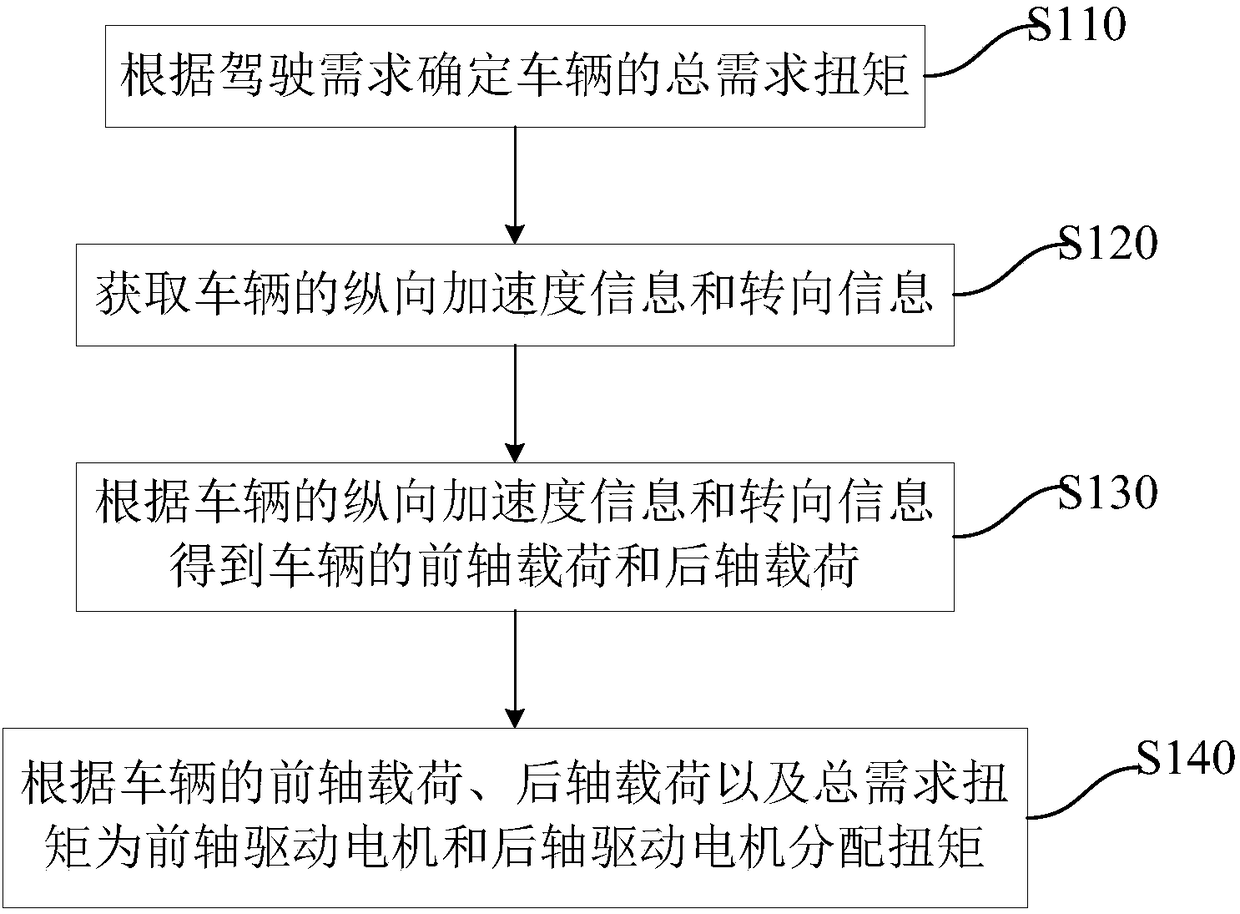

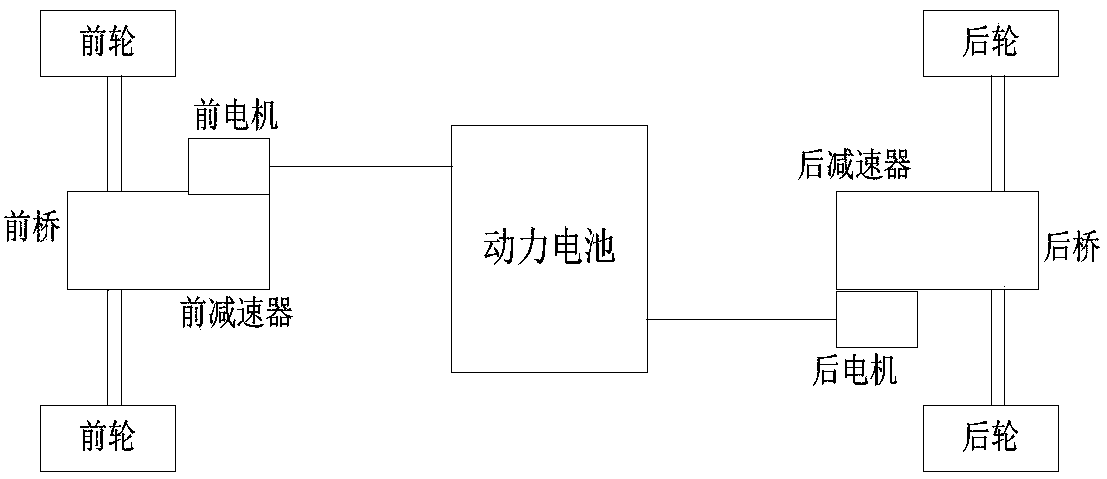

Control method and system of vehicle, and vehicle

ActiveCN108237950AGuaranteed stabilityEnsure safetySpeed controllerElectric energy managementPower batteryDrive motor

The invention discloses a control method and system of a vehicle, and the vehicle. The vehicle comprises a power battery, a front-axle driving motor and a rear-axle driving motor. The control method comprises the steps that according to the driving need, the total demand torque of the vehicle is determined; longitudinal acceleration information and steering information of the vehicle are obtained;according to the longitudinal acceleration information and the steering information of the vehicle, the front-axle load and the rear-axle load of the vehicle are obtained; and according to the front-axle load, the rear-axle load and the total demand torque of the vehicle, the torque is distributed for the front-axle driving motor and the rear-axle driving motor. The longitudinal acceleration information and the steering information of the vehicle are comprehensively considered, the obtained total demand torque is distributed to the front-axle driving motor and the rear-axle driving motor of the vehicle reasonably, and the stability, safety and power performance of the vehicle are guaranteed.

Owner:BEIQI FOTON MOTOR CO LTD

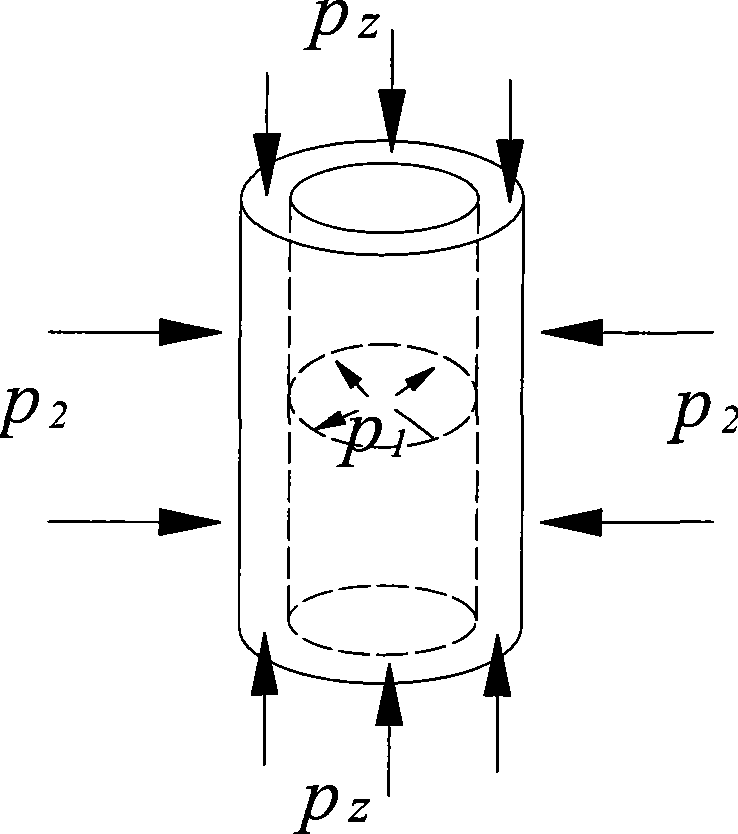

Three-way confining pressure and temperature combined loading device for Hopkinson compression bar impact test

InactiveCN103852373AConstant temperature fieldApplicable dynamic mechanical parametersStrength propertiesCylinder blockMechanical engineering

The invention discloses a three-way confining pressure and temperature combined loading device for a Hopkinson compression bar impact test. The three-way confining pressure temperature combined loading device comprises an axle load loading device consisting of an incident rod and a transmitting rod and an annular pressure temperature combined loading device, wherein the annular pressure temperature combined loading device comprises a cylinder of which two ends are provided with cylinder covers; a shaft hole through which the incident rod and the transmitting rod penetrate is reserved in the middle of the cylinder cover; a test piece is coaxially arranged between the incident rod and the transmitting rod; an oil-resistant rubber sleeve is arranged on the test piece and at the periphery of the incident rod and the transmitting rod in the cylinder; a test piece positioning sleeve with a hole is arranged on the outer side of the oil-resistant rubber sleeve; an exhaust hole is formed above the cylinder, and an oil injection hole is formed below the cylinder; a heating device is arranged on the outer side of the test piece positioning sleeve; a temperature measurement device is arranged on the surface of the test piece. By adoption of the combined loading device, the Hopkinson compression bar impact test loading of three-way confining pressure and temperature coaction can be realized, and material dynamic parameters under the three-way confining pressure and temperature coaction are provided for scientific calculation and engineering application.

Owner:PLA UNIV OF SCI & TECH

Test methods for acquiring thick wall cylinder sample ring fracture

InactiveCN101509852AImprove the simulation effectGreat practicabilityMaterial strength using tensile/compressive forcesInternal pressureTest sample

The invention relates to a test method for obtaining ring fracture of a cylinder sample with thick wall. The method comprises the following steps: firstly, sampling is carried out to testing rock mass objects; the rock mass which is obtained by sampling is made into the cylinder sample with thick wall; a certain axle load is applied to the cylinder sample with thick wall so as to lead the sample and an upper rigid loading end part and a lower rigid loading end part to contact closely; oil is filled into inner holes of the cylinder sample with thick wall, and into gaps between the cylinder sample and a load chamber; three axles of inner pressure, confining pressure and axle pressure of the cylinder sample with thick wall are loaded to a designed pressure value so as to lead the top, the bottom, the inner hole wall and the outer wall of the cylinder sample with thick wall are respectively in pressure state; the axial loading of three-directional loading is kept to be constant; and unloading is carried out to the cylinder sample with thick wall till the test sample is damaged. Three axles test is carried out to the cylinder sample with thick wall by loading and unloading so as to obtain the ring fracture results of the cylinder sample with thick wall, which is similar with the subarea fracture phenomenon occurring when the deep rock mass is excavated, therefore, the subarea fracture research is carried out, and corresponding measures need to be adopted for solving the problem that the subarea fracture phenomenon occurs when the deep rock is excavated.

Owner:CHINA UNIV OF MINING & TECH

Tractor-trailer axle center height control method and apparatus

ActiveUS8002065B2Low costDigital data processing detailsAnimal undercarriagesAltitude controlAxle load

A tractor-trailer combination includes a semitrailer tractor having a front axle and at least one drive axle having a predefined nominal axle load, a semitrailer having a first axle and at least one second axle, and an axle load adjusting device, which has an axle center height drive for the first axle enabling the axle load acting on the drive axle to be changed by adjusting a center height of the first axle, that can automatically switch into a starting assistance mode in which the second-axle axle load is increased to a starting-assistance axle load that is always below a predefined maximum axle load. An axle center height controller is adapted to automatically detect actuation of an off-road starting sensing device, and increase the second-axle axle load to an off-road starting axle load that is greater than the maximum axle load if the off-road starting sensing device is actuated.

Owner:WABCO EURO BVBA SPRL

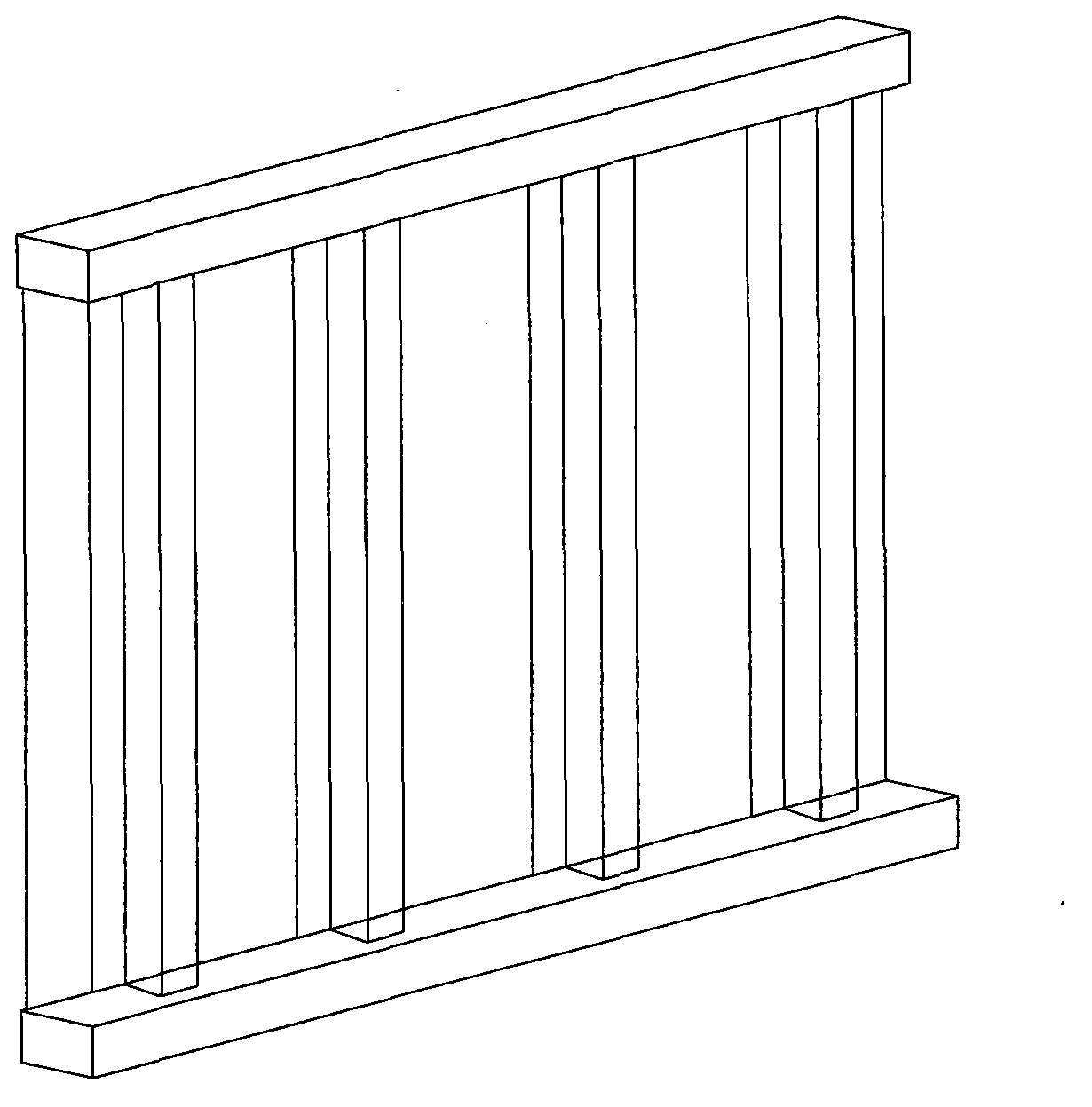

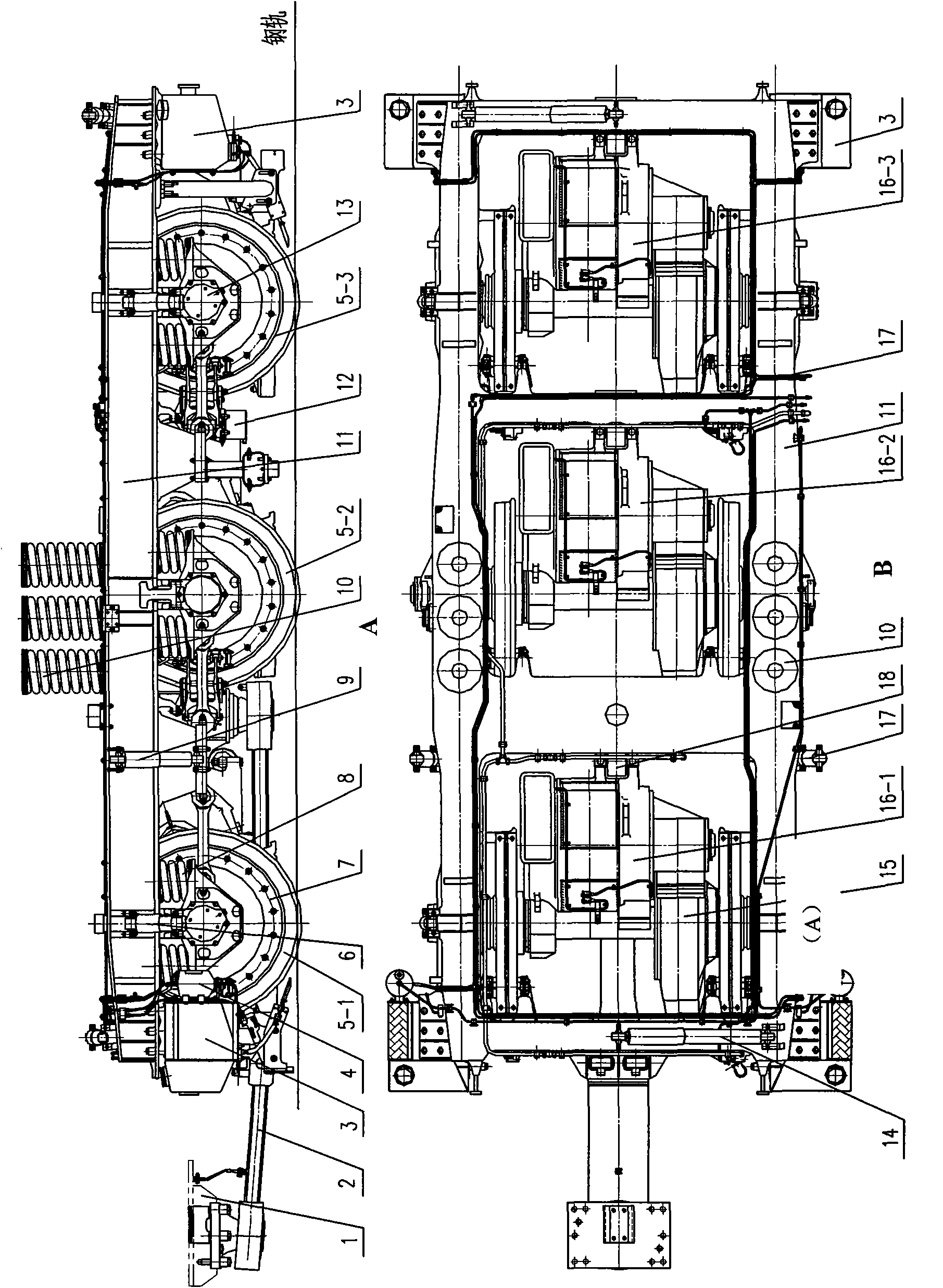

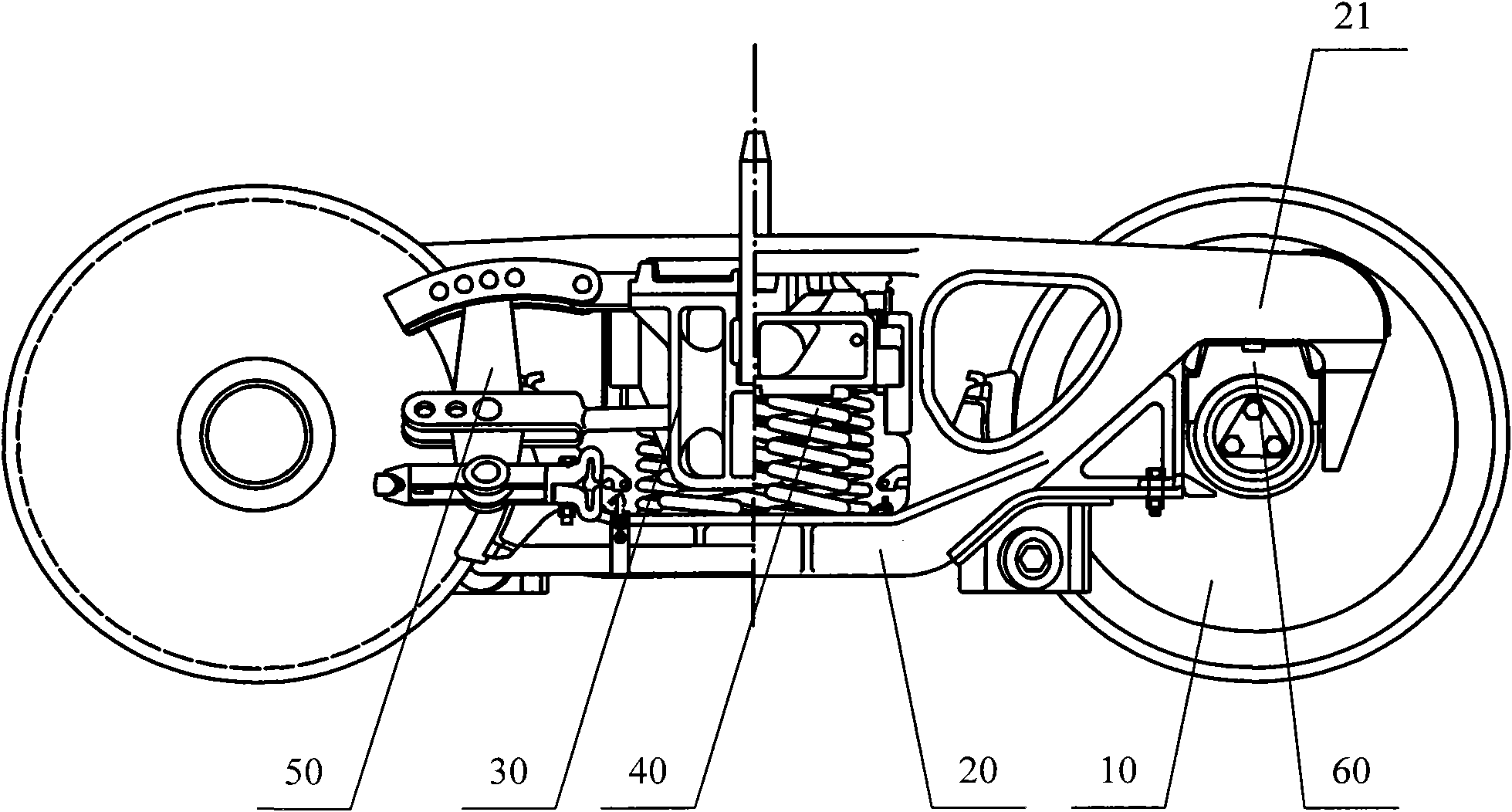

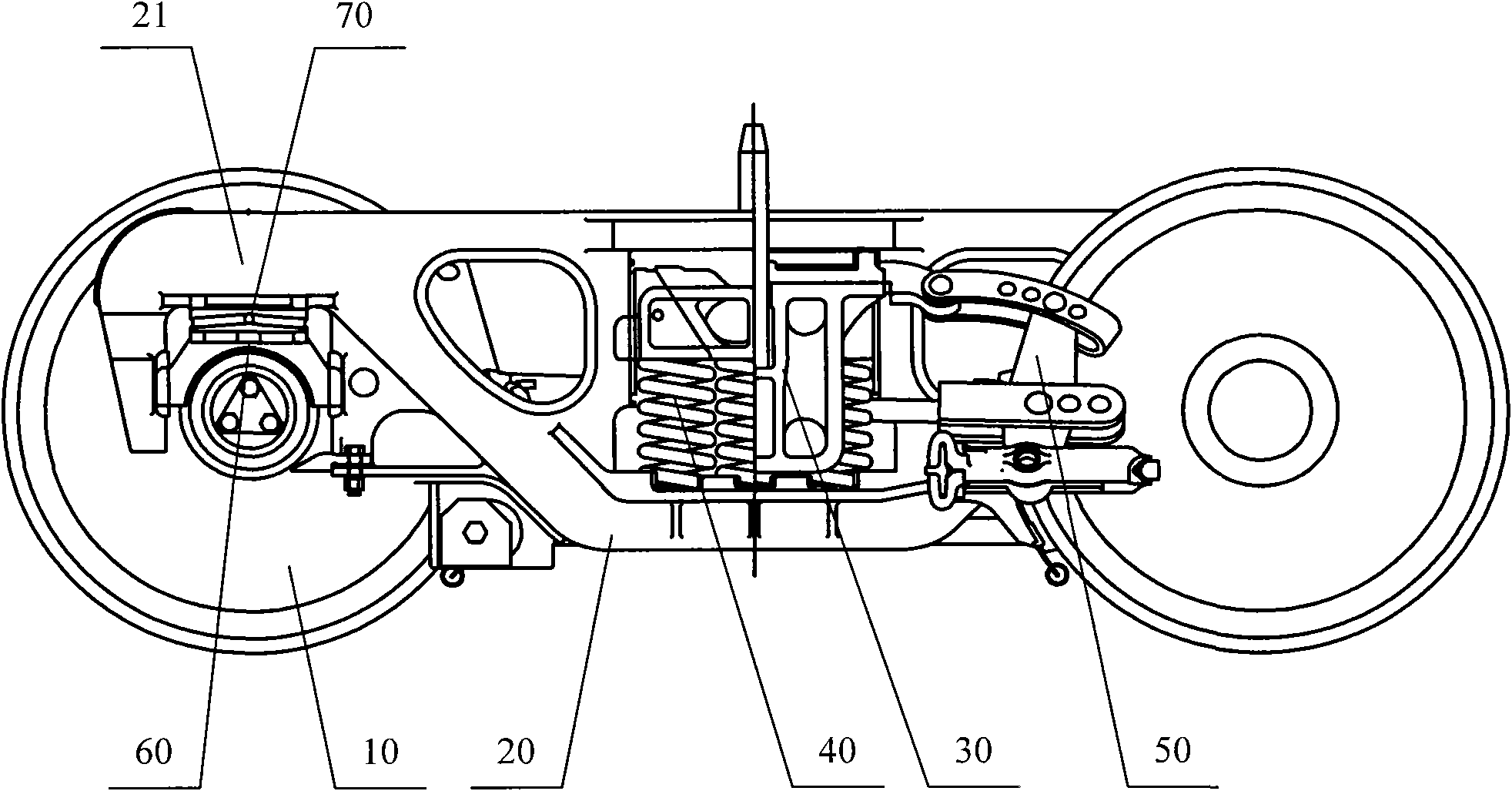

Large-axle-load railway vehicle bogie

ActiveCN103625493AImprove flexural strengthIncreased torsional strengthBogiesBogie-underframe connectionsBogieAir spring

The invention relates to a large-axle-load railway vehicle bogie which comprises a framework. The framework is composed of side beams, a cross beam, an auxiliary beam, two wheel pairs, a primary suspension device, a secondary suspension, a traction device, a foundation brake device, a traction motor and a gearbox. The primary suspension device is composed of a steel spring and a rotating arm shaft box, and the rotating arm shaft box is connected with the framework through the steel spring. The wheel pairs comprise wheel shafts and wheels fixed at the two ends of each wheel shaft, and the wheel shafts are connected with the rotating arm shaft box. The secondary suspension device comprises an air spring, a side-rolling preventing torsion bar and a height control device which all are arranged on the framework. The height of side beam vertical plates and the outer radius and the thickness of the cross beam are increased, the overall bending strength and the torsional strength of the bogie are greatly improved, the load bearing ability of a motor lifting seat and a gearbox lifting seat is greatly improved, the vertical load bearing ability of the side beams is greatly improved, and 17 tons of axle load can be met.

Owner:CRRC QINGDAO SIFANG CO LTD

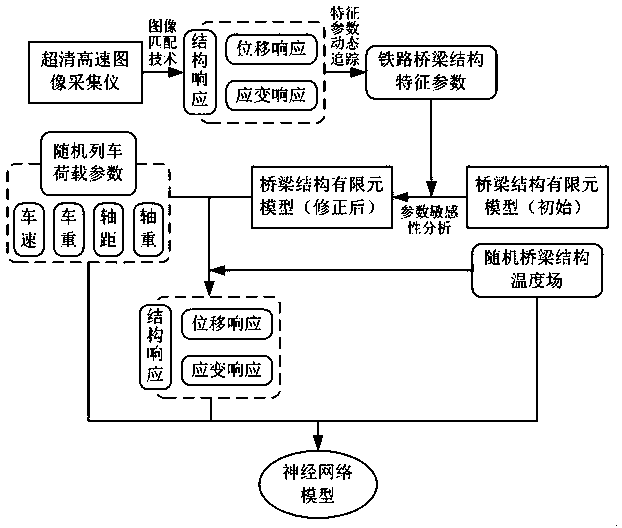

Train dynamic weighing system and weighing method based on deep learning

ActiveCN111144039AAdequate sampleReduce in quantityDesign optimisation/simulationNeural architecturesElement modelSimulation

The invention discloses a train dynamic weighing system and a weighing method based on deep learning. The method comprises the steps of correcting a bridge finite element model in real time based on actually measured bridge structure response information; considering the train-rail-bridge coupling effect and the bridge temperature field, and calculating bridge structure response data under different train load effects; then, training a neural network model by taking the response data and the vehicle speed as input data and taking the train weight, the axle load and the axle distance as outputdata, and verifying the accuracy of a training result based on the bridge structure response data under the known train load effect; and finally, according to the image acquisition instruments at thetwo ends of the bridge, based on a multi-target tracking algorithm, identifying the train speed and the structural response in real time, inputting the train speed and the structural response into theneural network model, and calculating other train load parameters. According to the method, the train load parameters can be quickly and effectively identified, and reference is provided for railroadbridge operation management.

Owner:SOUTHEAST UNIV

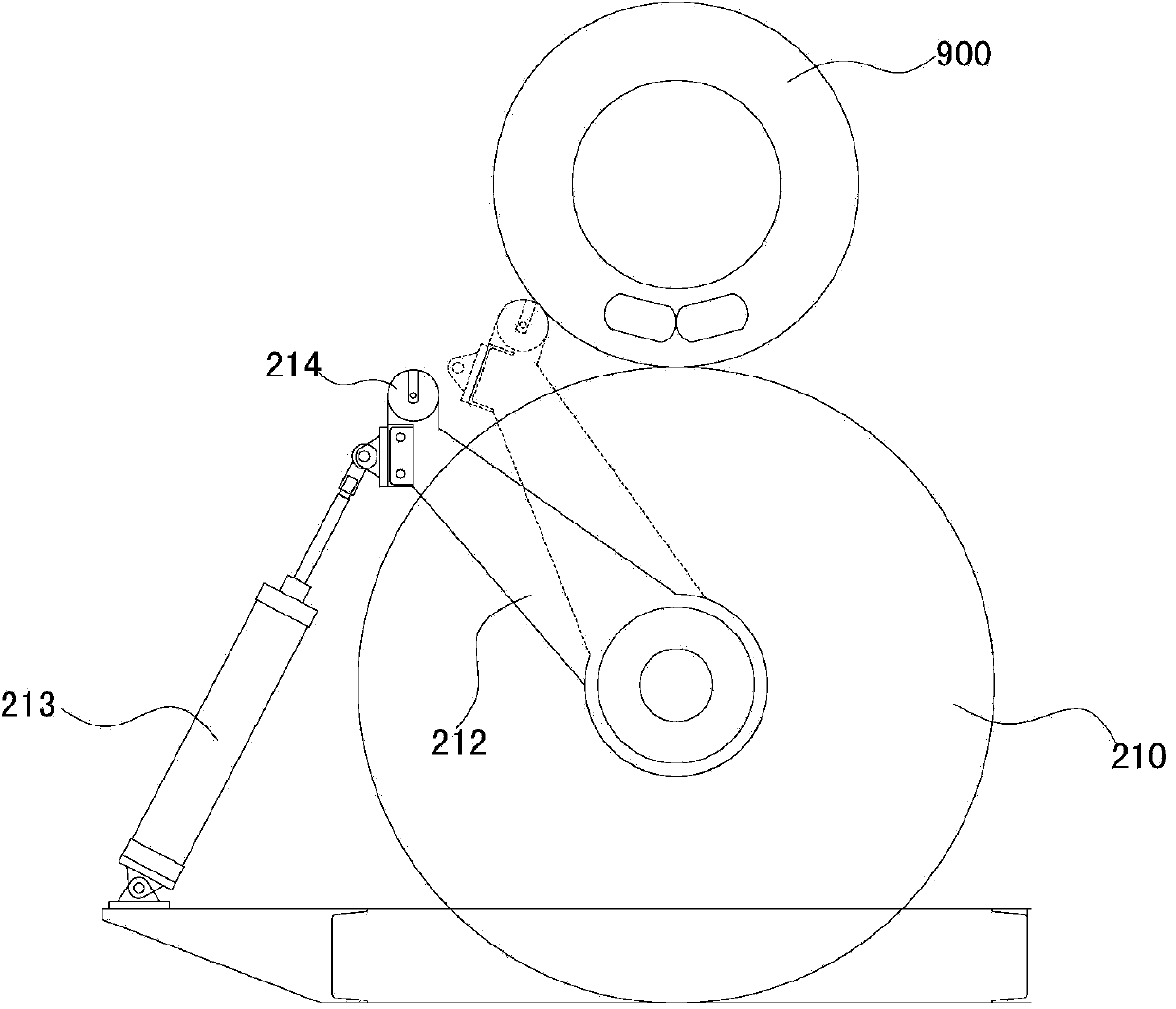

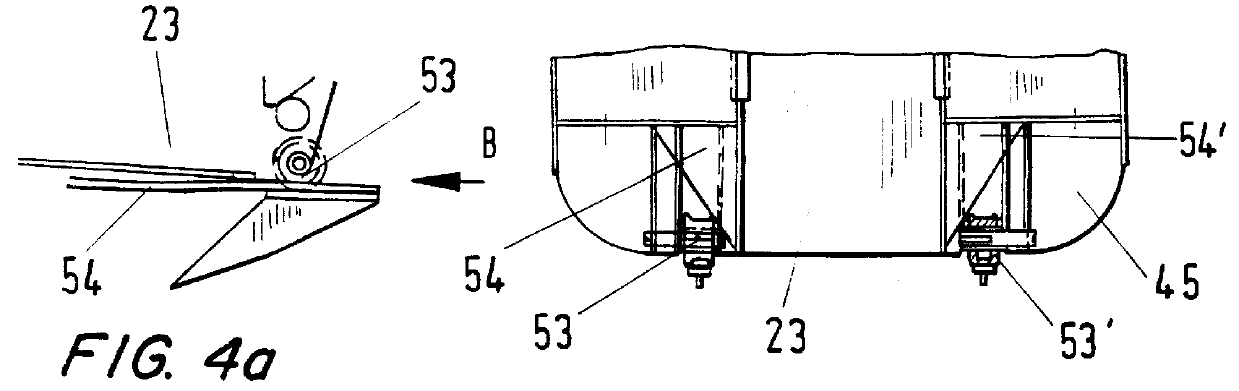

Apparatus for reducing the axle load of a multiaxle movable telescopic crane

An apparatus for reducing the axle load of a multiaxle movable crane which includes a truck; a superstructure rotatably mounted on the truck; a main jib including a basic jib and at least one telescopic section, the basic jib having a plurality of rollers fastened in operative connection, the main jib being releasably fastened to the superstructure; and a semitrailer having a front end and a back end with a loading area, a first ramp-like beam and a second ramp-like beam arranged in a longitudinal direction of the semitrailer in the loading area so as to be parallel to and at a distance from one another, each ramp-like beam having a top edge and a contoured runway disposed along the top edge, the rollers being configured to the contour of the runway and operable to transport the main jib from the superstructure to the semitrailer.

Owner:TEREX GLOBAL GMBH

Composition brake shoe for railway freight car, and method for manufacturing same

ActiveCN102661340AHigh bonding strengthReduce wearOther chemical processesBraking membersCrazingSlag

The invention discloses a composition brake shoe for a railway freight car, and a method for manufacturing the same. A friction piece of the composition brake shoe for the railway freight car is synthetised by using following materials by weight parts: 6-10 parts of nitrile rubber, 2-8 parts of modified phenolic resin, 3-6 parts of steel wool fibers, 9-16 parts of sepiolite fibers, 2-16 parts of composite mineral fibers, 5-13 parts of graphite, 0.4-2 parts of calcined bauxite, 20-24 parts of barium sulfate, 8-12 parts of potassium feldspar powder, 10-20 parts of iron powder, and 1-3 parts of additives. The friction piece of the composition brake shoe is formed through the steps of dosing, banburying or mixing, crashing, hot press molding and curing forming, and thermal processing. The composition brake shoe is capable of well satisfying various performance indexes requested in PRC (People's Republic of China) railway industrial standard TB / T2403-2010, and can be applied to railway freight cars traveling at the highest speed of 120km / h and axle load of the composition brake shoe is not greater than 25 tons; besides, the composition brake shoe has stable friction properties and excellent friction resistance, and is low in attrition to wheels and low in braking noise; and as a result, potential quality hazards ( such as brake shoe body breakage, slag and block dropping, metal inlaying and hot cracks) endangering traveling safety are fundamentally solved.

Owner:CHONGQING YUHONG RAIL CAR ACCESSORIES CO LTD

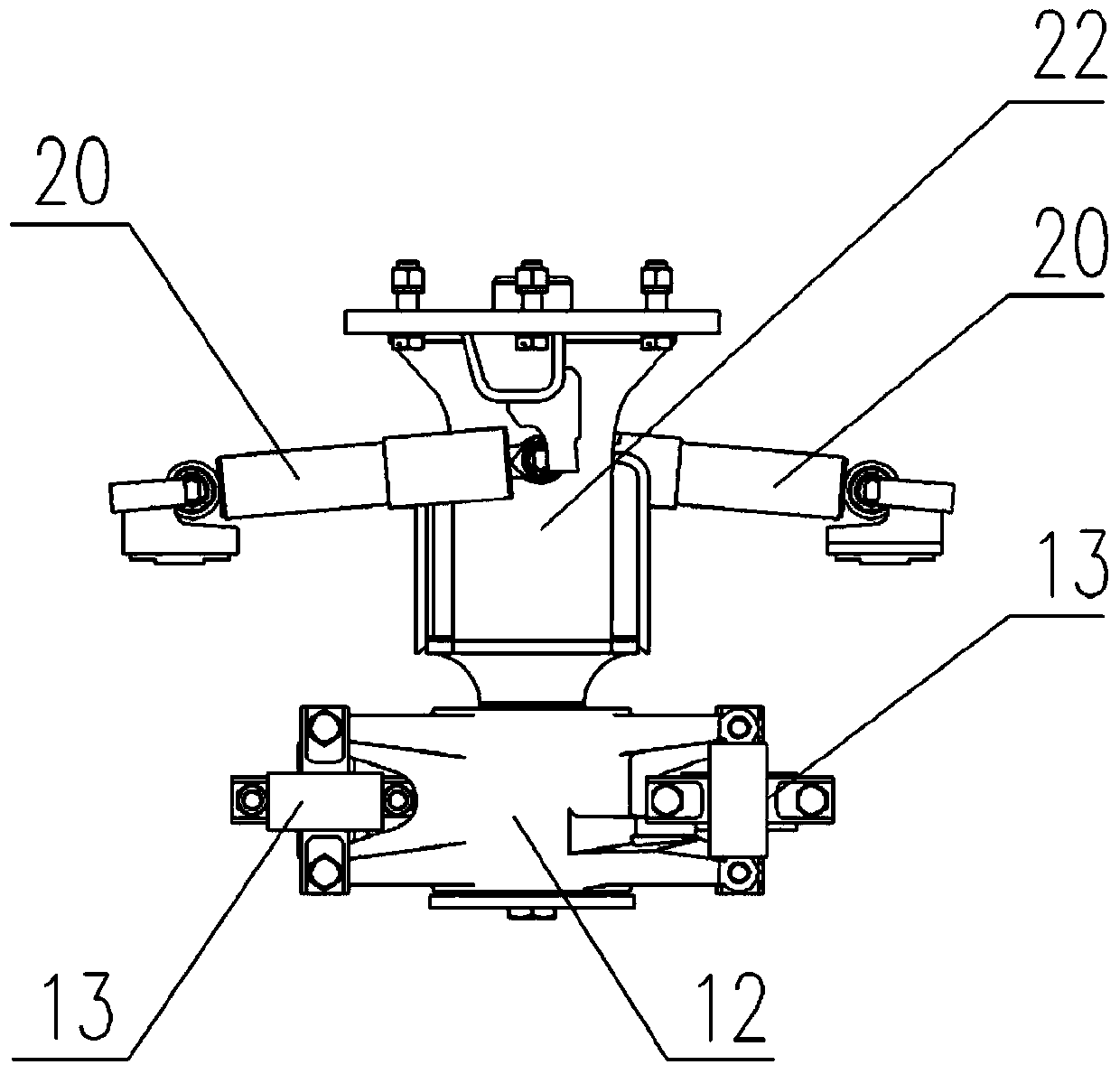

Elastic side bearing for bogie and bogie

InactiveCN101962021AImproved axle loadImproved low power performanceBogie-underframe connectionsBogieVertical deflection

The invention discloses an elastic side bearing for a bogie and the bogie. The bogie comprises a wheel set assembly, a side frame assembly, a swing bolster assembly, a basic braking device and a vibration damper, wherein the swing bolster assembly is provided with the elastic side bearing; and the elastic side bearing at least comprises a side bearing body, the side bearing body comprises a rubber body, and a spring is arranged in the rubber body. The rigidity of a bearing body can be effectively reduced and the vertical deflection can be increased by improving the structure of the elastic bearing so as to improve the axle load and the low power performance of the bogie.

Owner:CRRC QIQIHAR ROLLING CO LTD

Transversal leaf spring type front independent suspension mechanism with sliding blocks at two ends

The invention relates to a front independent suspension mechanism of a vehicle, in particular to a front axle independent suspension mechanism mainly used on a commercial vehicle such as lorry and passenger car. In the mechanism, one, two or mainly leaf springs are used in place of an elastic element of the conventional independent suspension such as spiral spring independent suspension or torsion bar independent suspension, plate-end sliding blocks are used to connect a common independent suspension and leaf springs together perfectly, structures such as I-beam are not used, parts such as leaf springs are hidden in a cross beam of a secondary vehicle frame, and the advantages of the common independent suspension and the advantages of the leaf spring suspension are fully combined. In the mechanism, the loading capacity is high with many elastic elements are used, and the difference between equivalent averages of idle-load comfort and load comfort is small; and compared with the conventional axle load commercial vehicle, the commercial vehicle using the mechanism is more comfortable, takes up a smaller space and is lower in cost.

Owner:合肥金辉机械制造有限公司

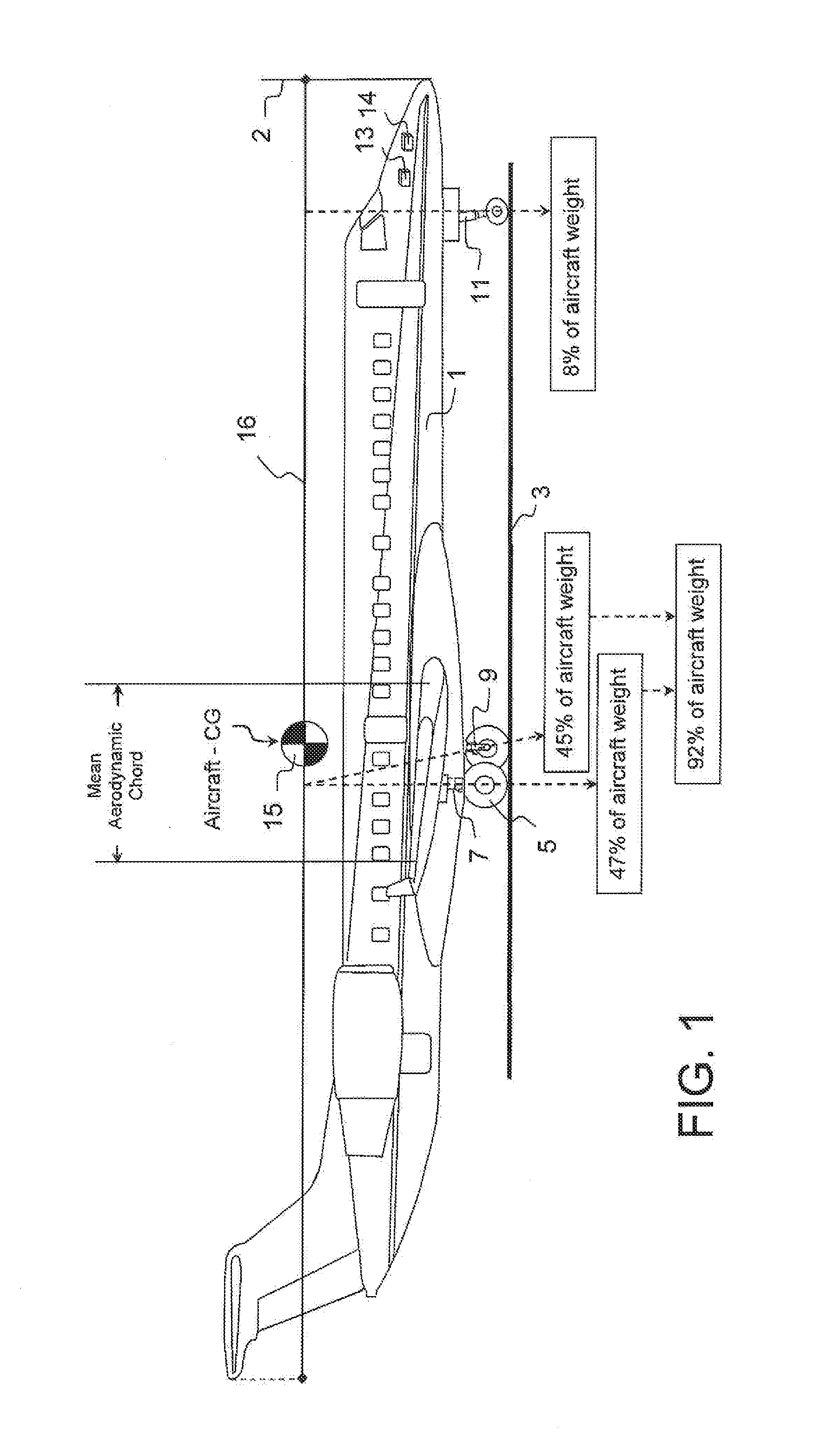

Method for determining aircraft center of gravity independent of measuring the aircraft weight

ActiveUS20150316438A1Digital data processing detailsStatic/dynamic balance measurementReduced sizeAircraft landing

A method which determines aircraft Center of Gravity independent of measuring the aircraft weight. The method is used in monitoring, measuring and computing the Center of Gravity of an aircraft utilizing pressurized, telescopic landing gear struts with axles. Pressure sensors are mounted in relation to each of the landing gear struts to monitor, measure and record aircraft landing gear strut loads by way of pressure. Axle deflection sensors are mounted in relation to each of the landing gear axles to monitor, measure and record aircraft landing gear axle loads by way of deflection. Nose landing gear strut pressure and corresponding values from axle deflection sensors may be adjusted in correlation to the reduced size of the nose landing gear, as compared to the size of the main landing gear, allowing aircraft Center of Gravity to be determined from the combined measured main landing gear pressures in relation to a nose landing gear strut pressure measurements, or combined main landing gear axle deflection sensor in relation to a nose landing gear axle deflection sensor; without any determination of the aircraft weight.

Owner:NANCE C KIRK

Electrohydraulic servo pressure-torque coupling three-way vibration loading tree-axis instrument

InactiveCN1776402AImprove mutual interferenceIncrease smoothnessUsing mechanical meansStrength propertiesAutomatic controlControl system

The triaxial apparatus includes three portions: host; hydraulic power source connected to servo valve for loading electrohydraulic in three directions in host through pipe; automatic control system connected to the input signal measured by sensor as well as connected to electrical signal output from servo valve. The host includes pressure chamber, axle load mechanism, twist mechanism connected to the axle load mechanism in coaxial coupling, pressing-twisting mechanism between the pressure chamber and twist mechanism, balance-cylinder and side pressure mechanism. The balance-cylinder, side pressure mechanism and pressure chamber are connected through pipe so as to constitute self-balanced mechanism of hydraulic pressure. The invention overcomes interactional movement between axle load mechanism and twist mechanism of current triaxial apparatus of vibration and torison shear as well as overcomes disadvantages of side pressure mechanism. Features are: smooth waveform of load, and low cost.

Owner:XIAN UNIV OF TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com