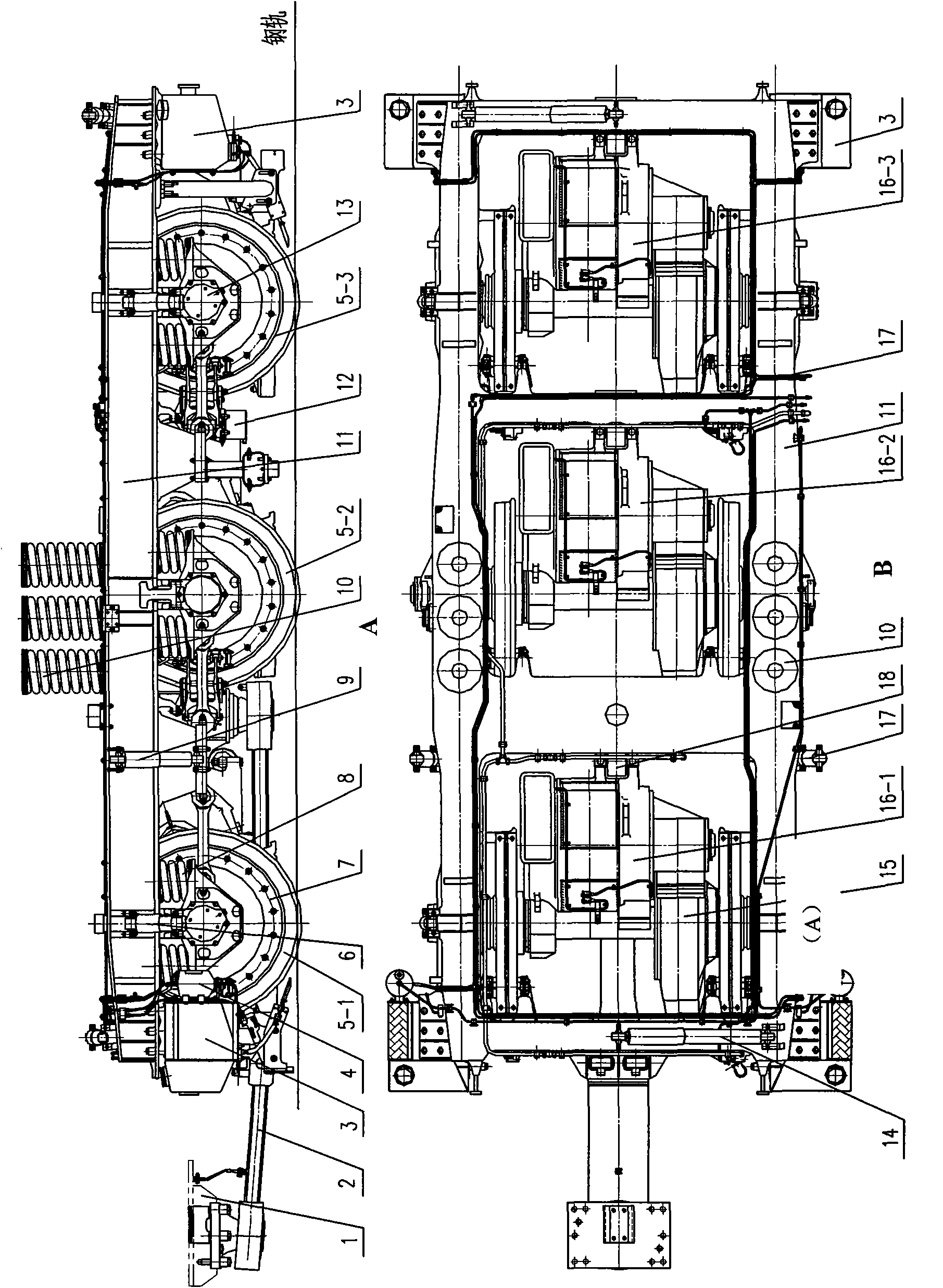

Co bogie for high-adherence heavy-load freight locomotive

A bogie and frame technology, applied in the field of bogies, can solve the problems of limited locomotive traction, low locomotive power, poor locomotive running stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] like figure 1 As shown, a locomotive high-adhesion heavy-duty freight Co bogie provided by the embodiment of the present invention includes three wheel pairs 5, and two sets of axle box devices 13, a set of drive unit 15, and a large wheel set are installed on each wheel pair. Power AC traction motor 16, they form the wheel pair driving device. Each axle box 13 is equipped with two primary springs 8, and the wheel set 5-1, 2 is equipped with a vertical primary vertical shock absorber 6. The frame 11 is installed on the primary spring 8, and the primary vertical vibration damper The device 6 connects the frame 11 and the axle box 13. Three secondary springs 10 are installed on each side of the frame 11. The car body 1 falls on the secondary springs 10. Each side of the bogie is equipped with a secondary vertical shock absorber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com