Shaft end device for bogie of high-speed train

A high-speed EMU and bogie shaft technology, applied in bogie, axle box installation, transportation and packaging, etc., can solve problems such as hidden dangers in safe operation, breaking and falling off, inability to adapt to driving speed signal communication, etc., to achieve enhanced reliability, The effect of increasing the strength of bolted joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

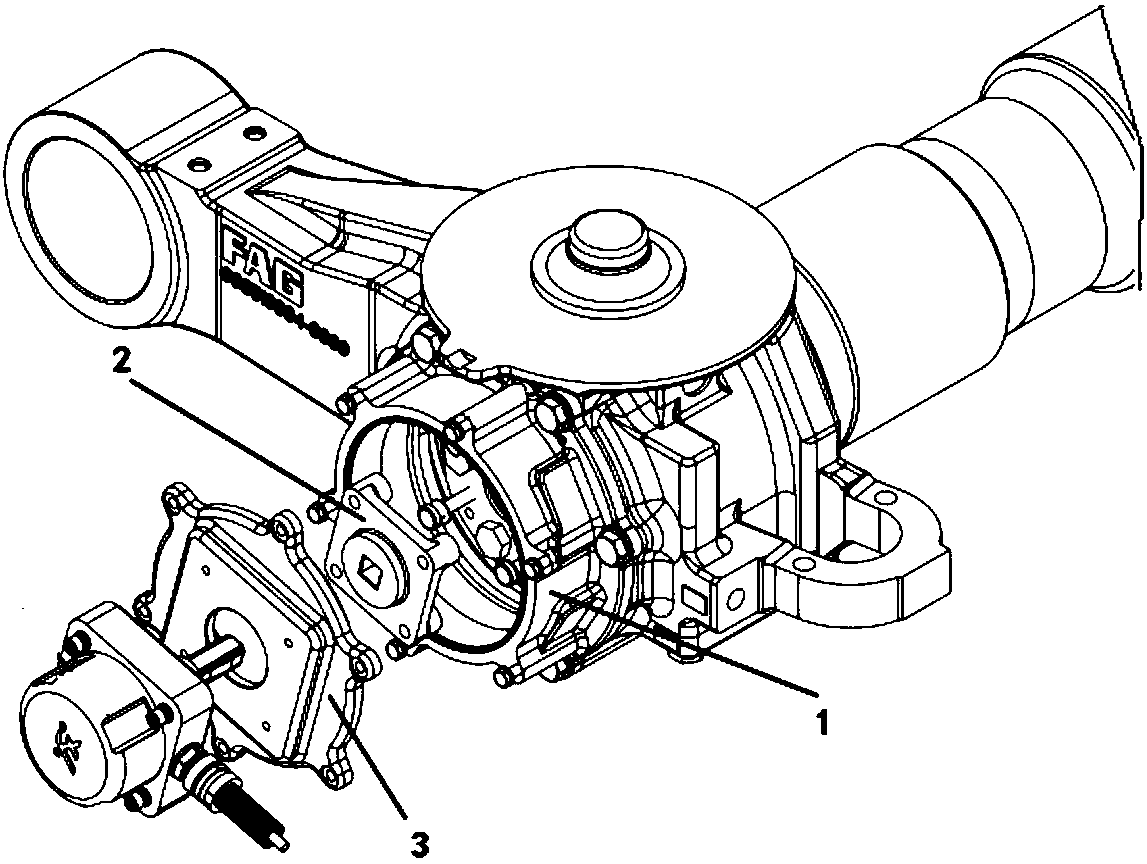

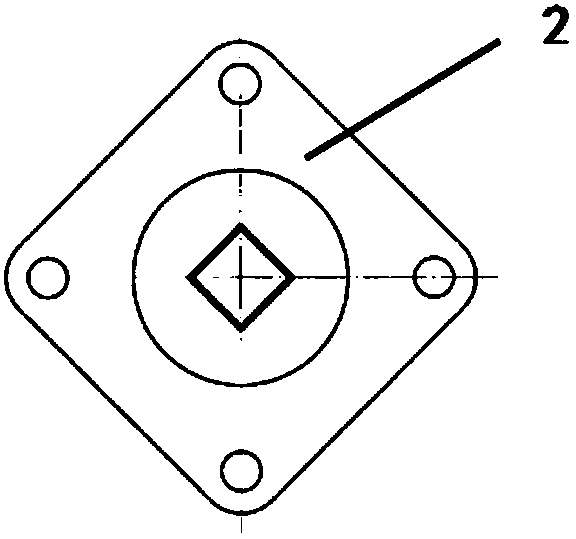

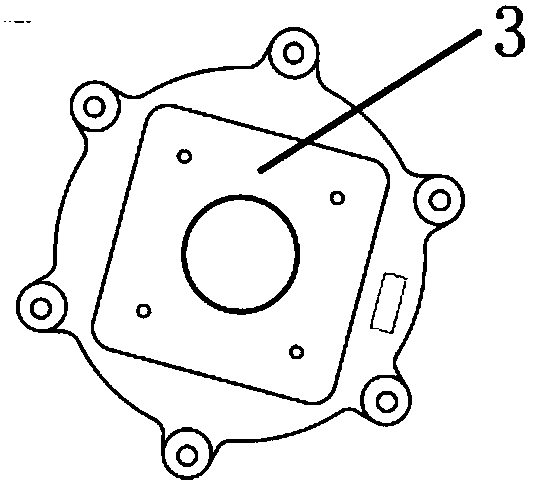

[0012] Such as figure 1 , figure 2 , image 3 As shown, the axle end transition cover 1 and the axle box end front cover 3 are fastened and veneer connected by M10 bolts, which effectively improves the strength of the bolt connection and enhances the reliability of the connection and fastening of the axle box end front cover. An ATP / LKJ driving speed sensor is installed on the front cover 3 of the axle box end, and a movable plate 2 adopting a four-hole installation structure is arranged in cooperation with the ATP / LKJ driving speed sensor.

[0013] The dynamic board is designed to be used in conjunction with the ATP / LKJ speed sensor to adapt to the speed signal of the existing line and ensure the normal operation requirements of the existing line of the high-speed EMU.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com