Assembly type wood frame structure beam-column joint with sleeve

A technology of beam-column joints and wood frames, which is applied in the field of beam-column connections of wood frame structures in the construction field, can solve the problems of rare wood frame structure joint forms, limited research and application, etc., and achieve convenient construction, clear force, and The effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

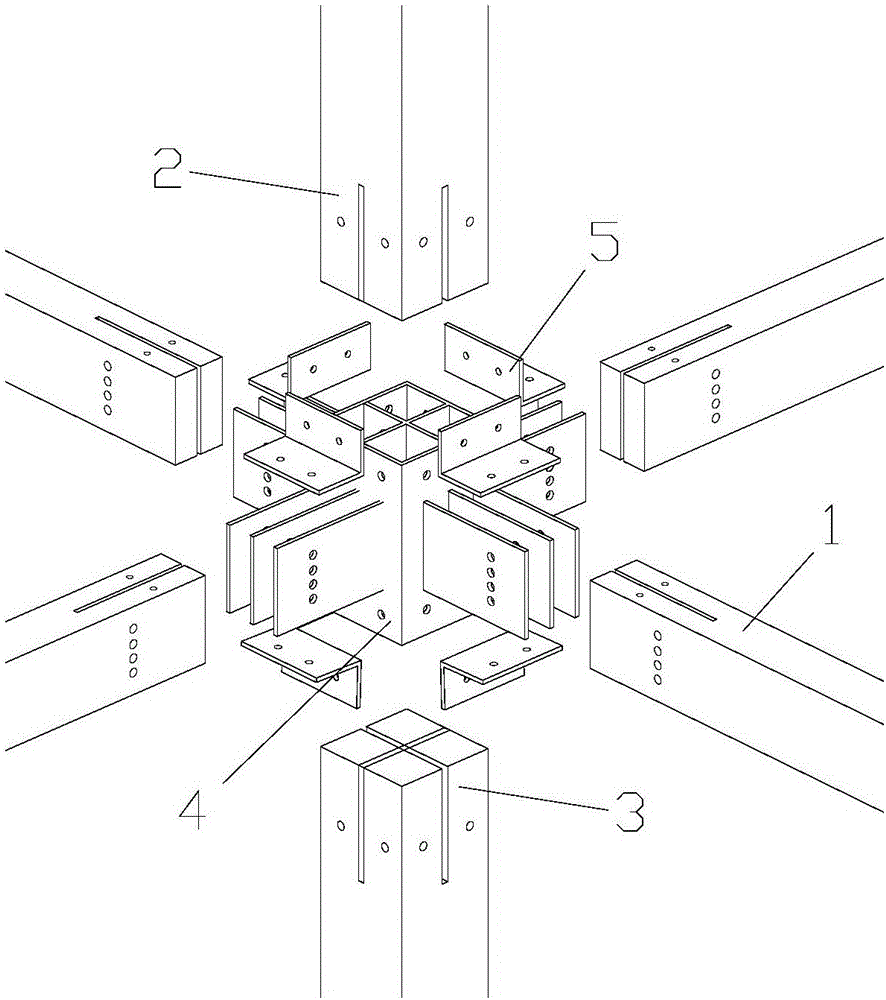

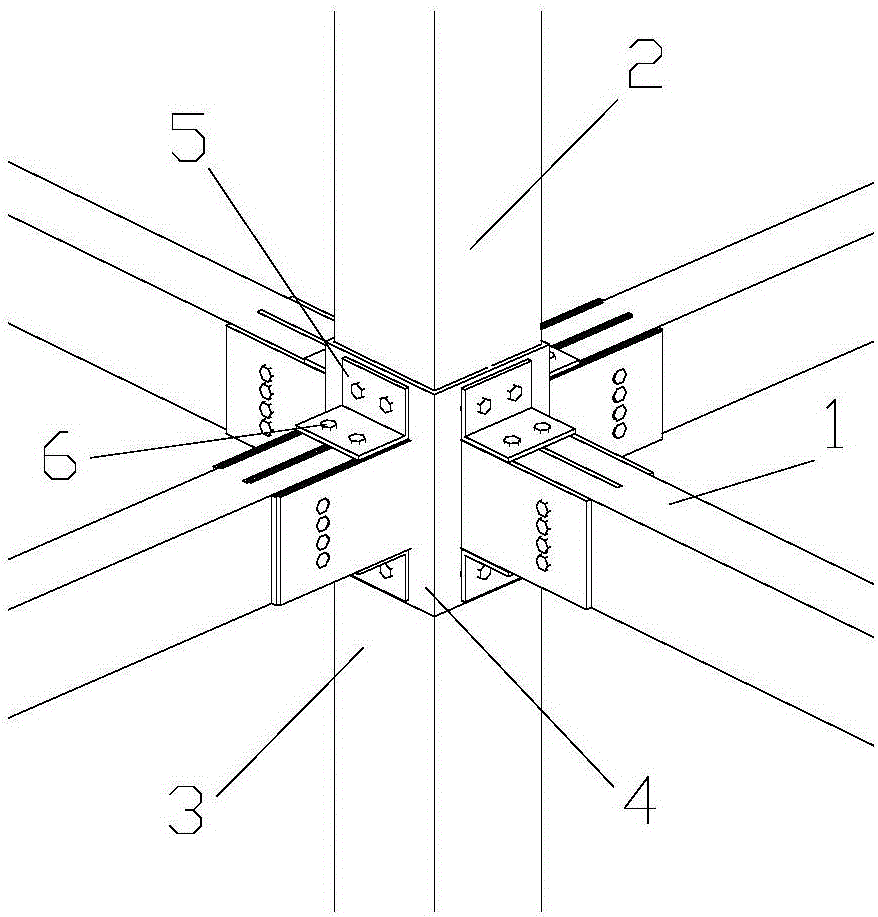

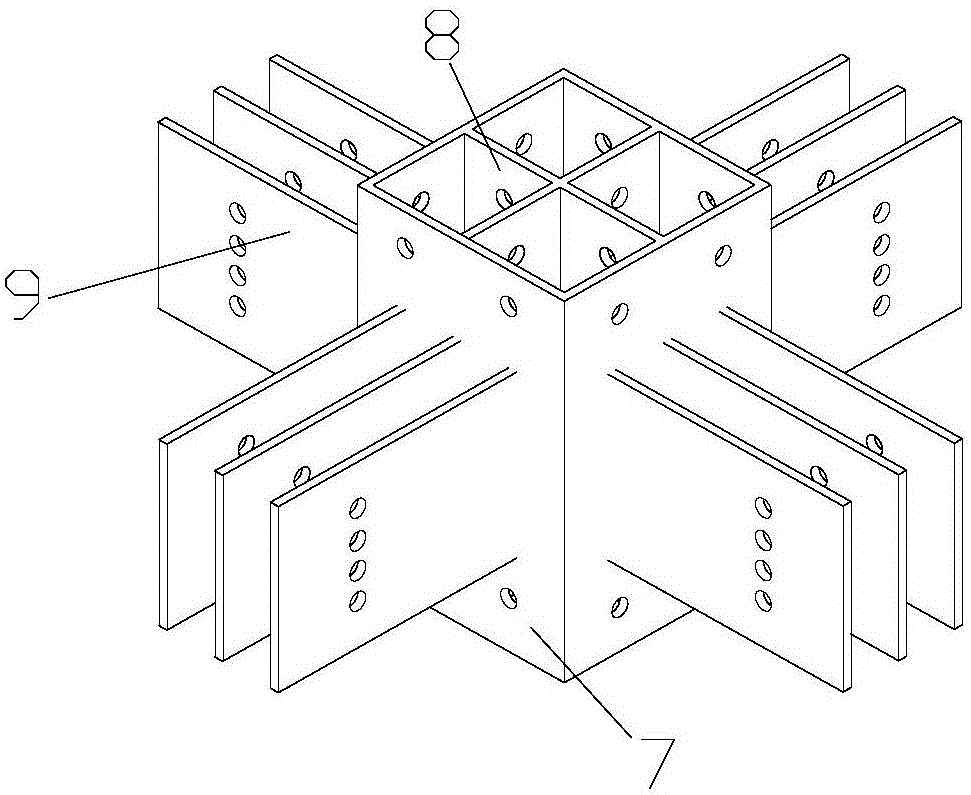

[0016] see Figure 1 to Figure 4 , an assembled beam-column joint of a wood frame structure with a sleeve, comprising a wooden beam 1, an upper wooden column 2, a lower wooden column 3, a sleeve joint 4 and a reinforcing corner piece 5; at the end of the wooden beam 1 There is a middle vertical slot extending along its entire height; a "ten"-shaped slot is provided at the upper end of the lower wooden column 3; a "ten"-shaped slot is provided at the lower end of the upper wooden column 2 The sleeve node 4 is provided with a column sleeve 7, and a "ten"-shaped sleeve longitudinal rib 8 and a sleeve middle diaphragm 10 are arranged in the column sleeve 7, and in the column sleeve The outer middle part of 7 is vertically provided with three fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com