Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2421 results about "Fill device" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A fill device or key loader is a module used to load cryptographic keys into electronic encryption machines. Fill devices are usually hand held and electronic ones are battery operated. Older mechanical encryption systems, such as rotor machines, were keyed by setting the positions of wheels and plugs from a printed keying list. Electronic systems required some way to load the necessary cryptovariable data. In the 1950s and 1960s, systems such as the U.S. National Security Agency KW-26 and the Soviet Union's Fialka used punched cards for this purpose. Later NSA encryption systems incorporated a serial port fill connector and developed several common fill devices (CFDs) that could be used with multiple systems. A CFD was plugged in when new keys were to be loaded. Newer NSA systems allow "over the air rekeying" (OTAR), but a master key often must still be loaded using a fill device.

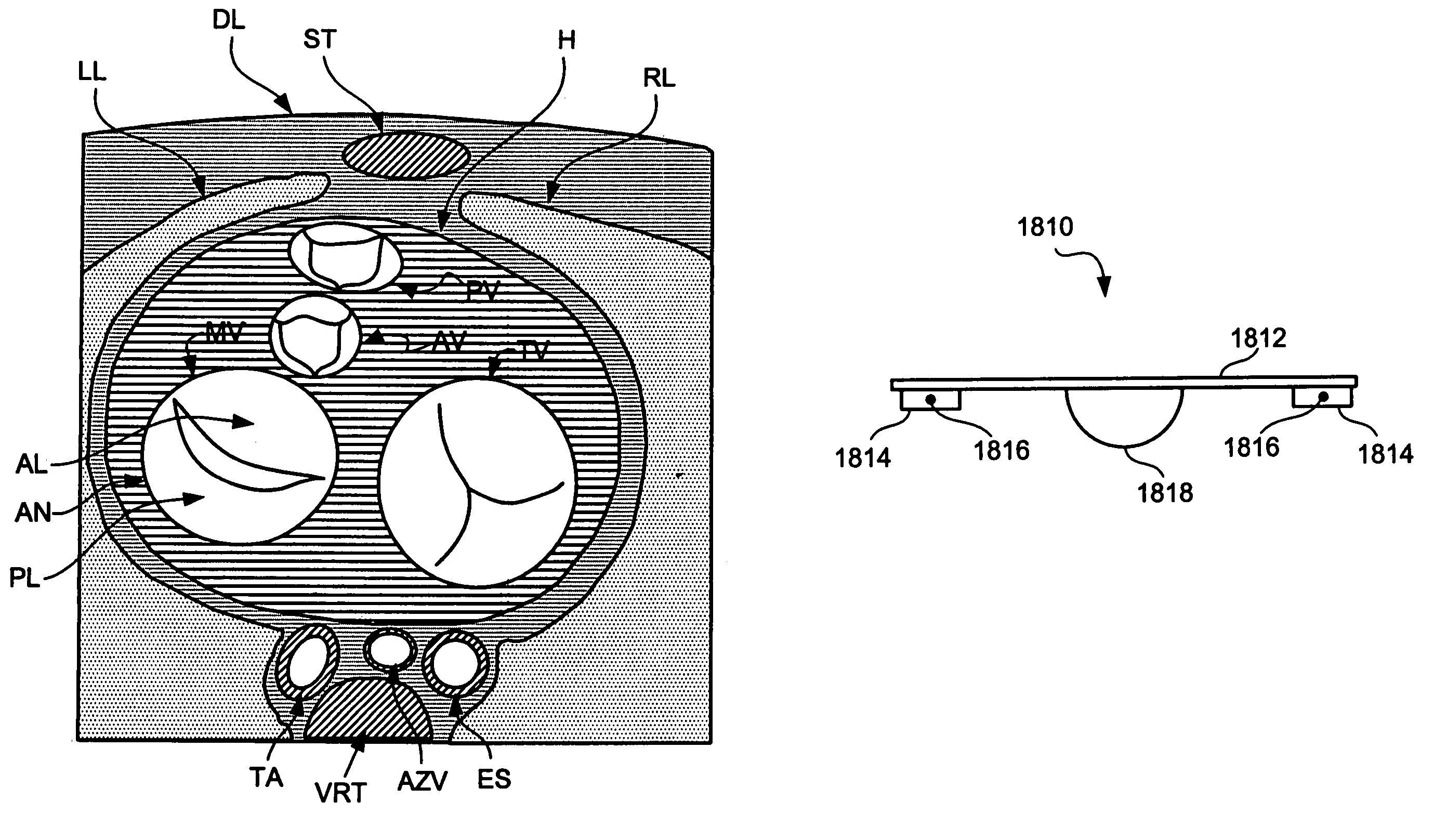

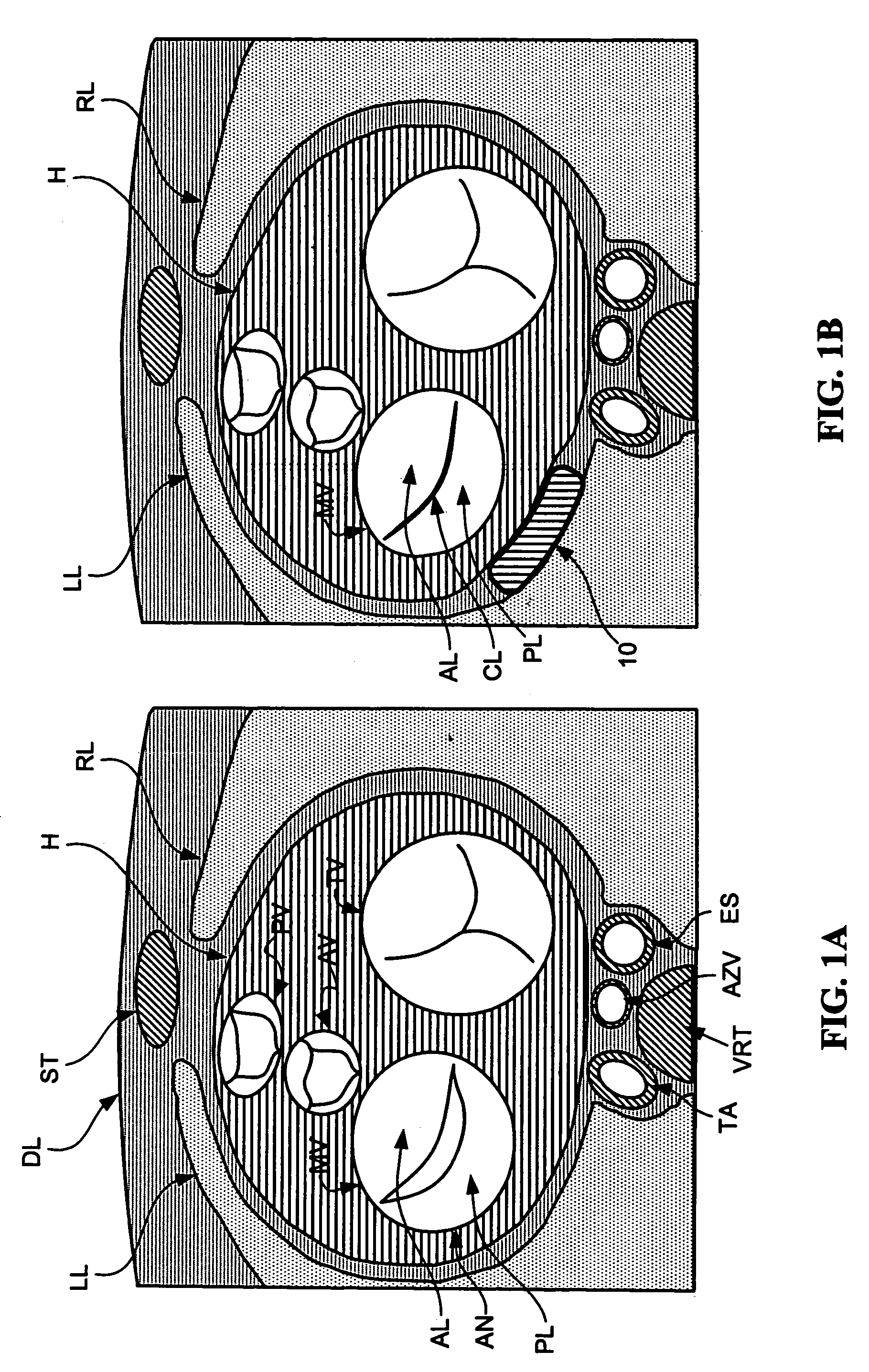

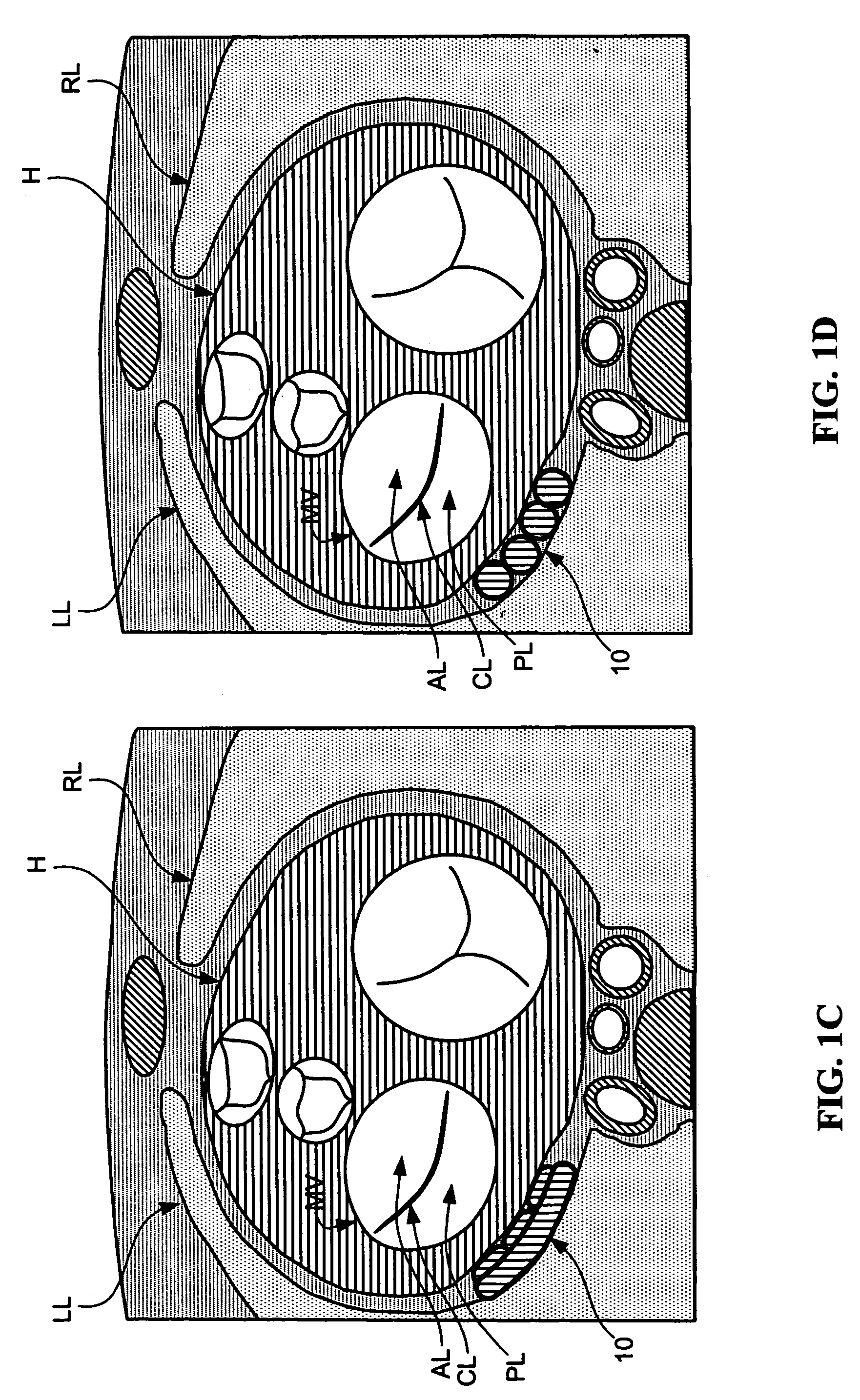

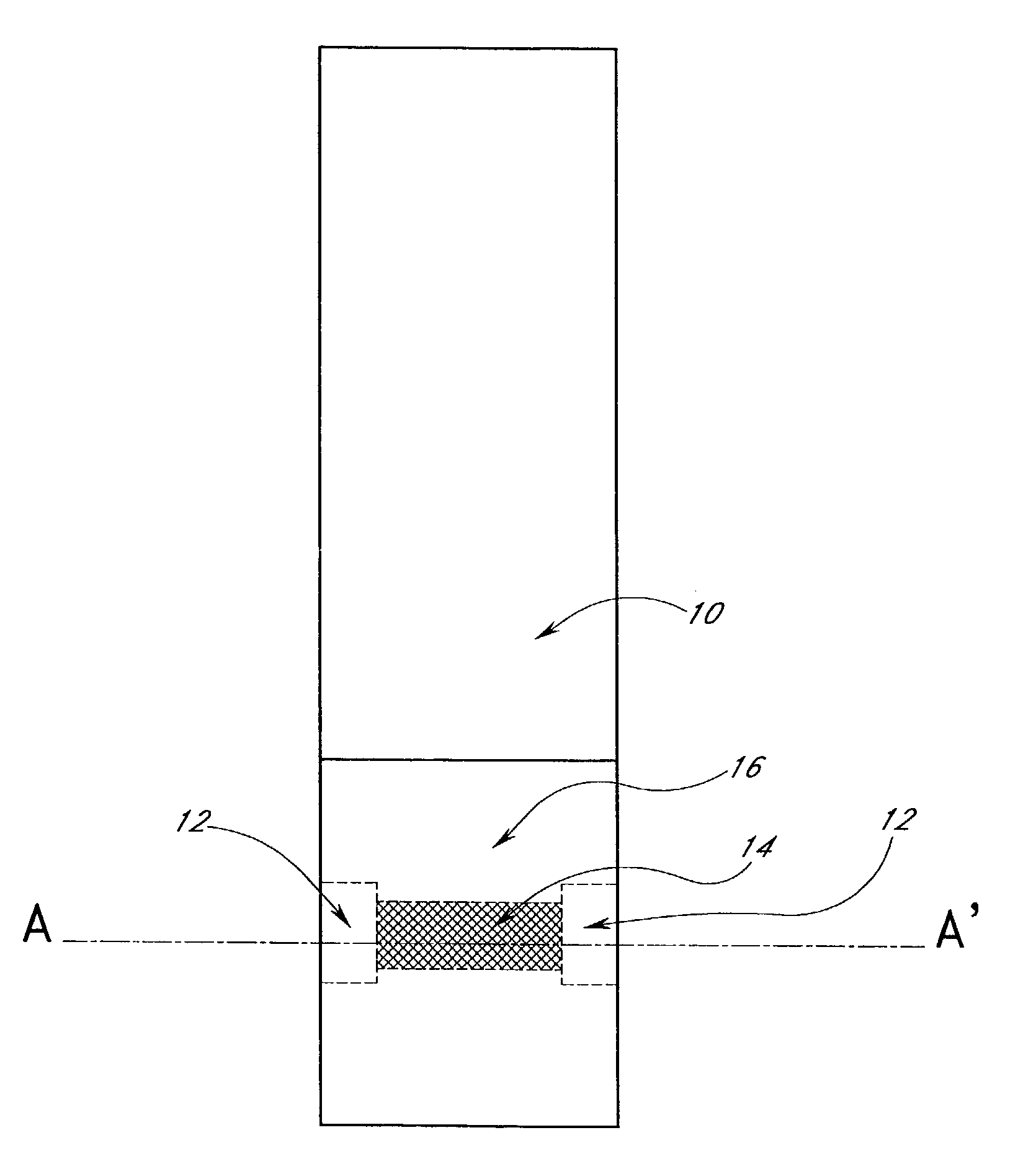

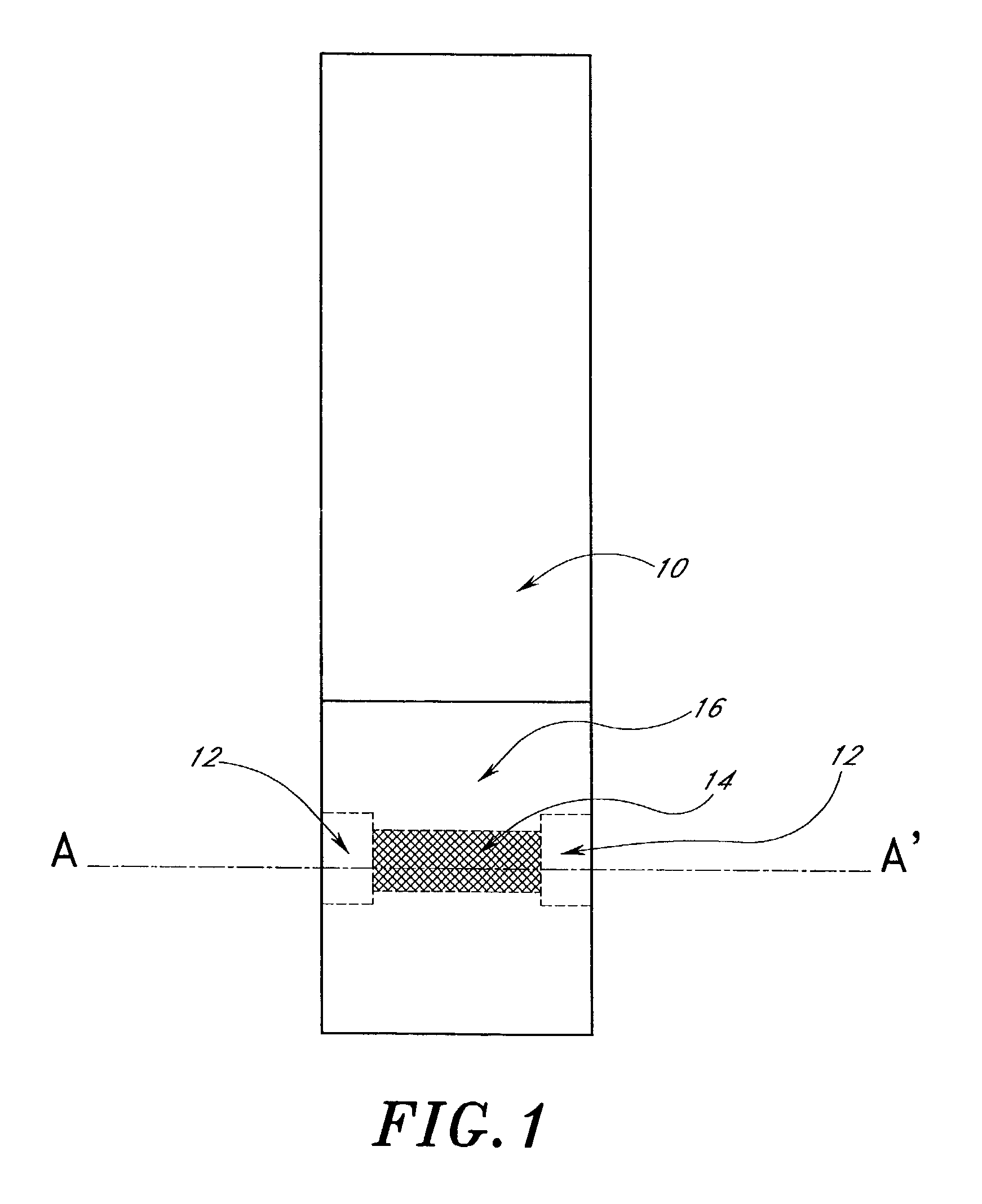

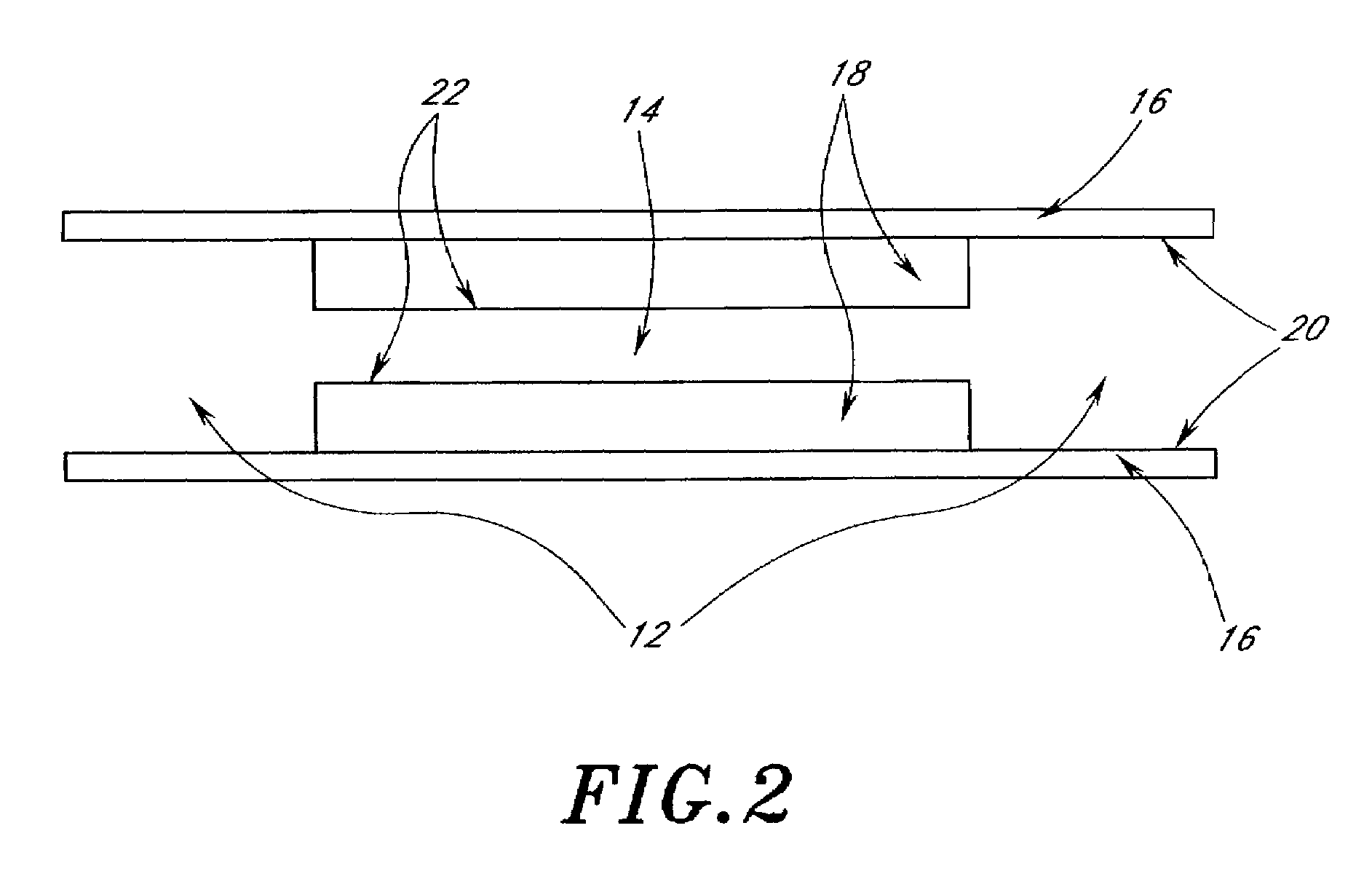

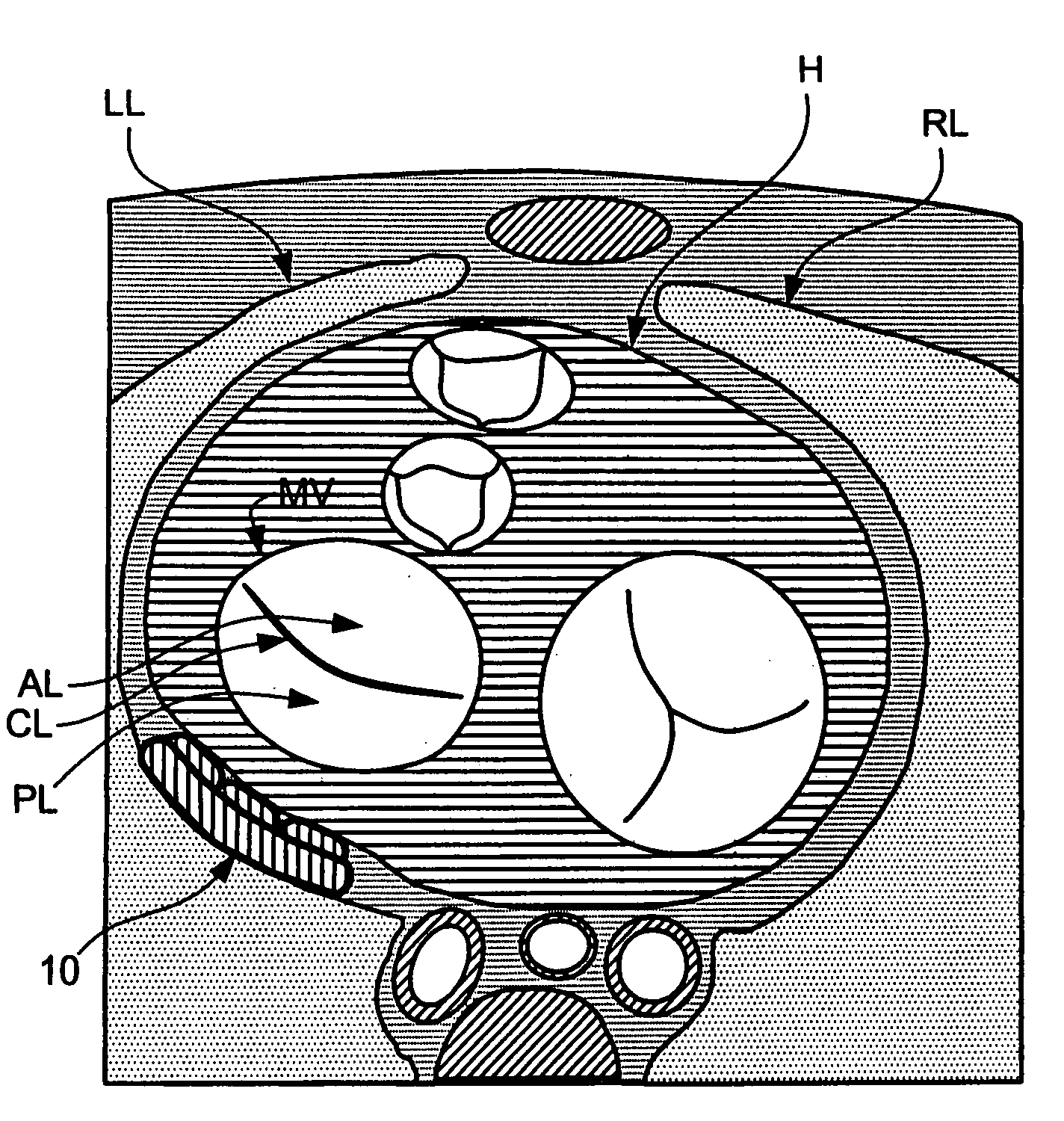

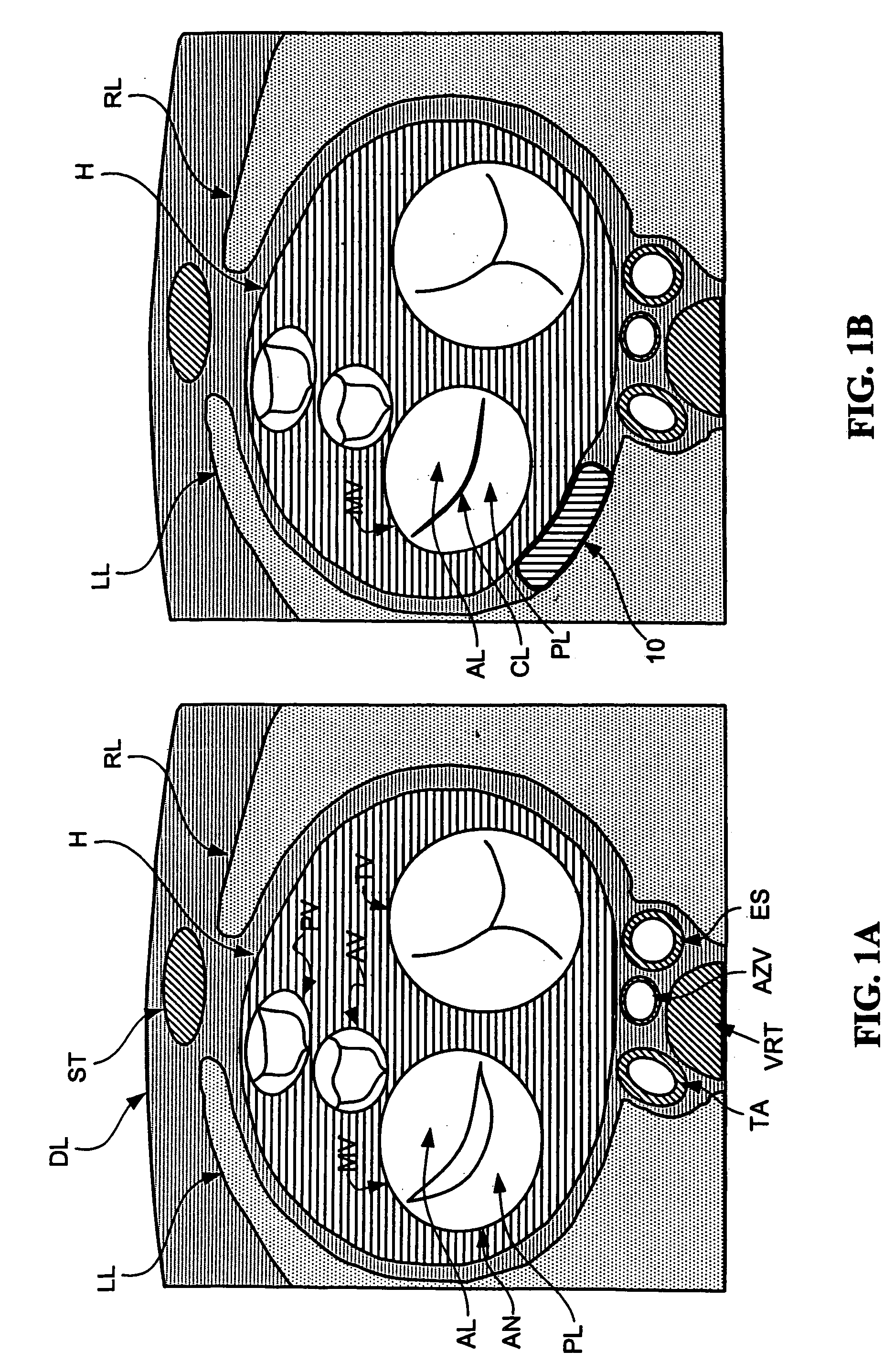

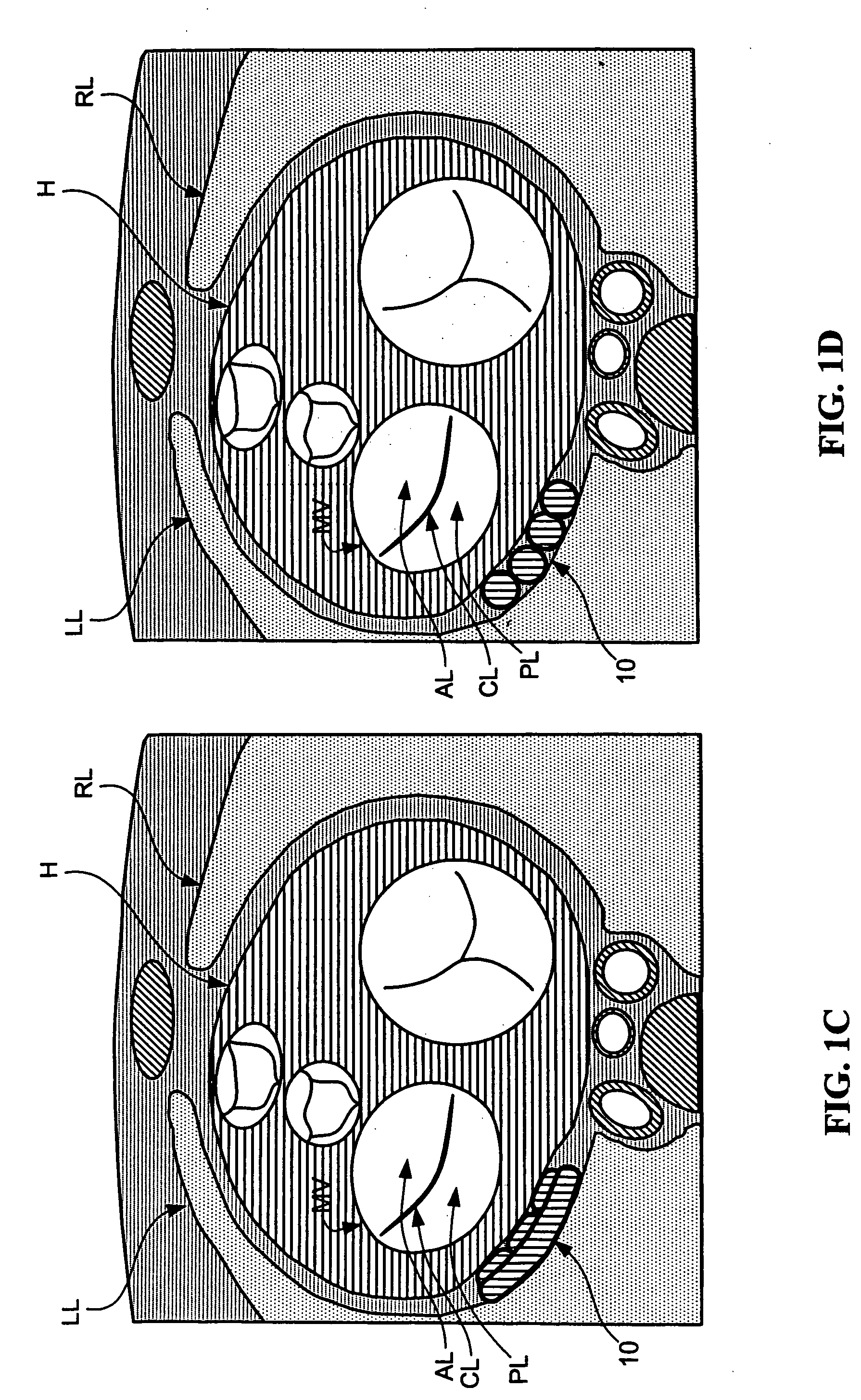

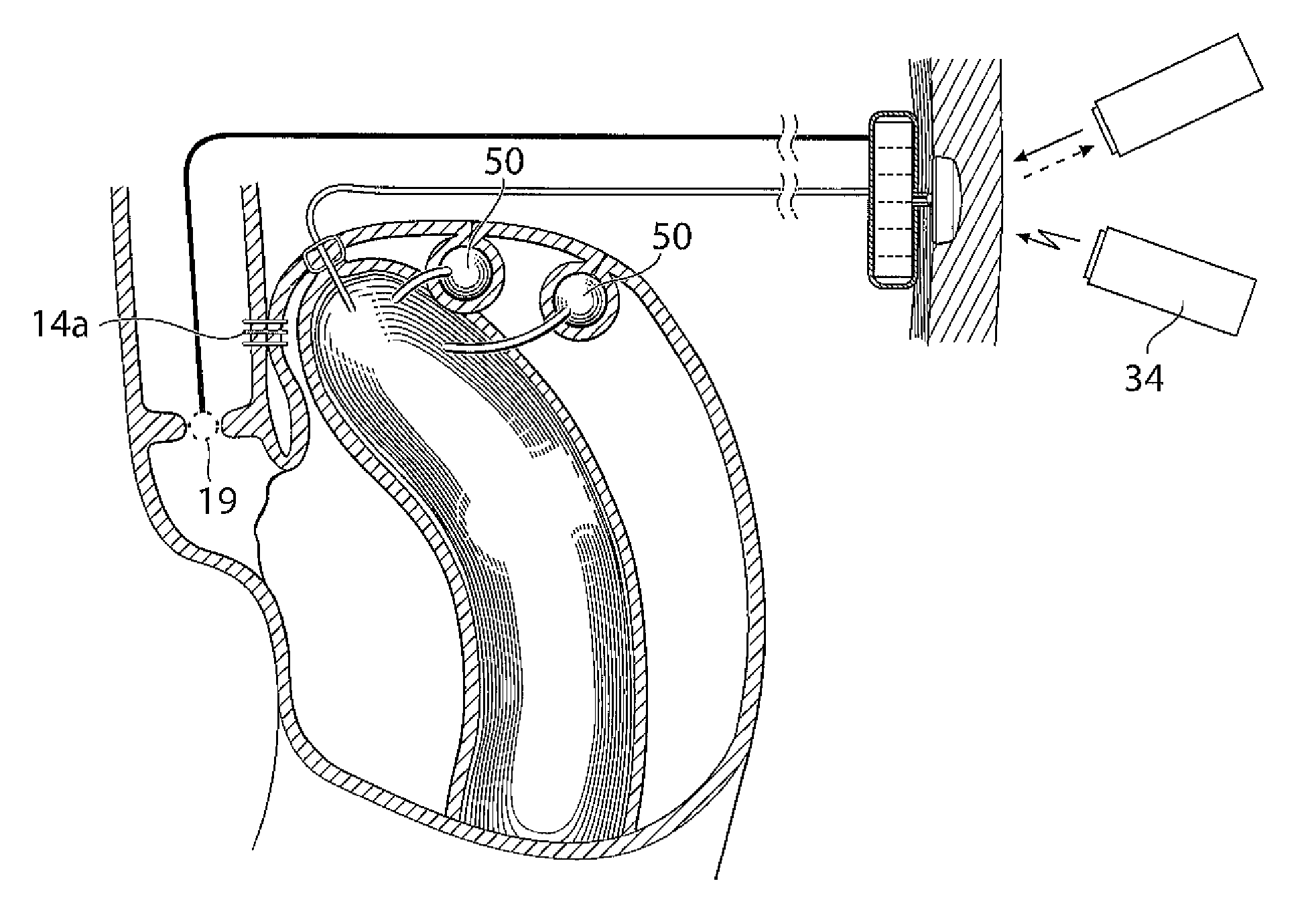

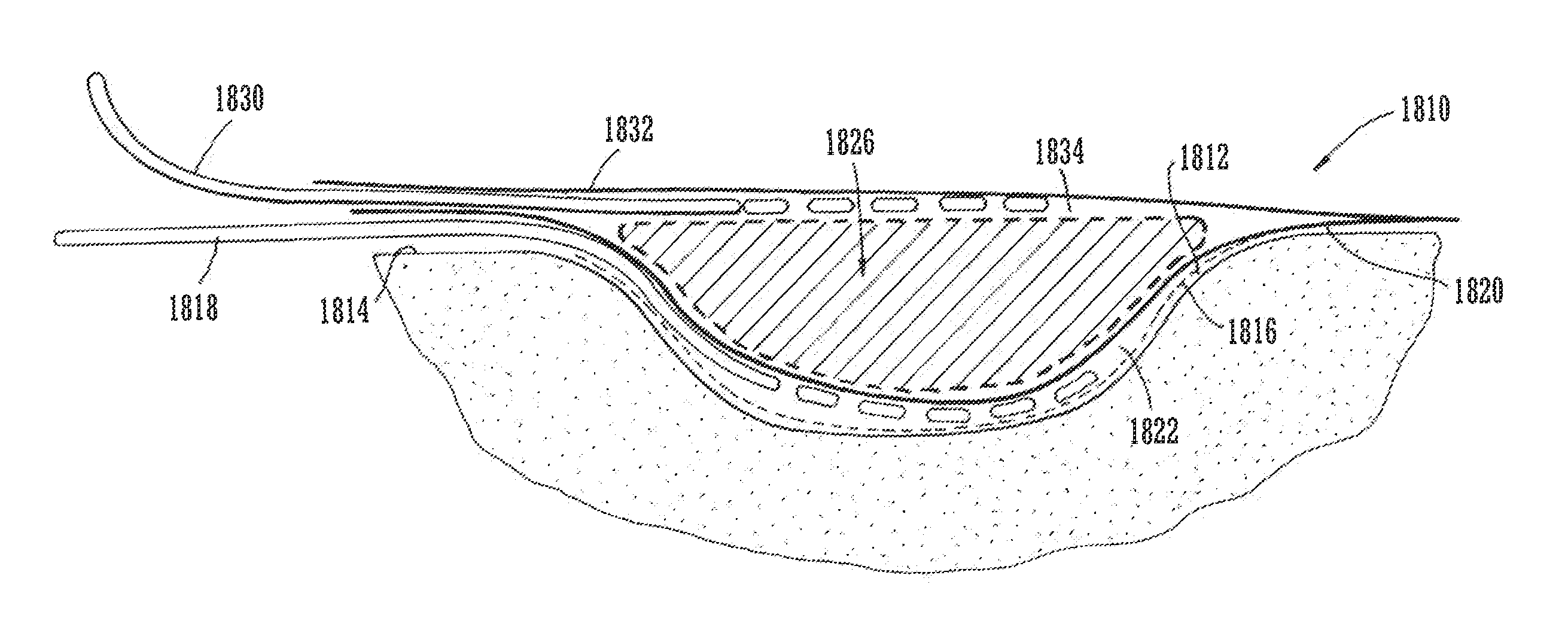

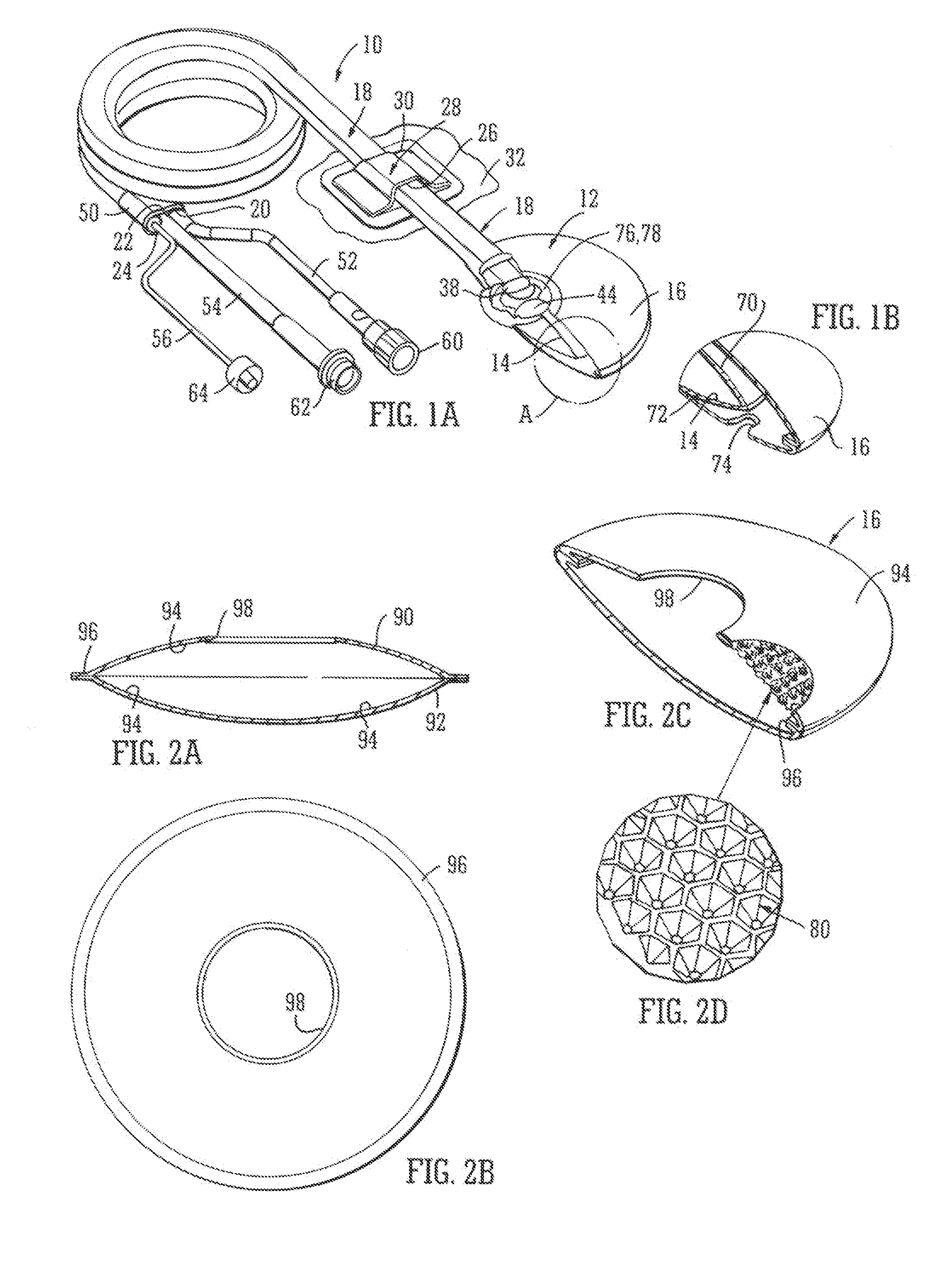

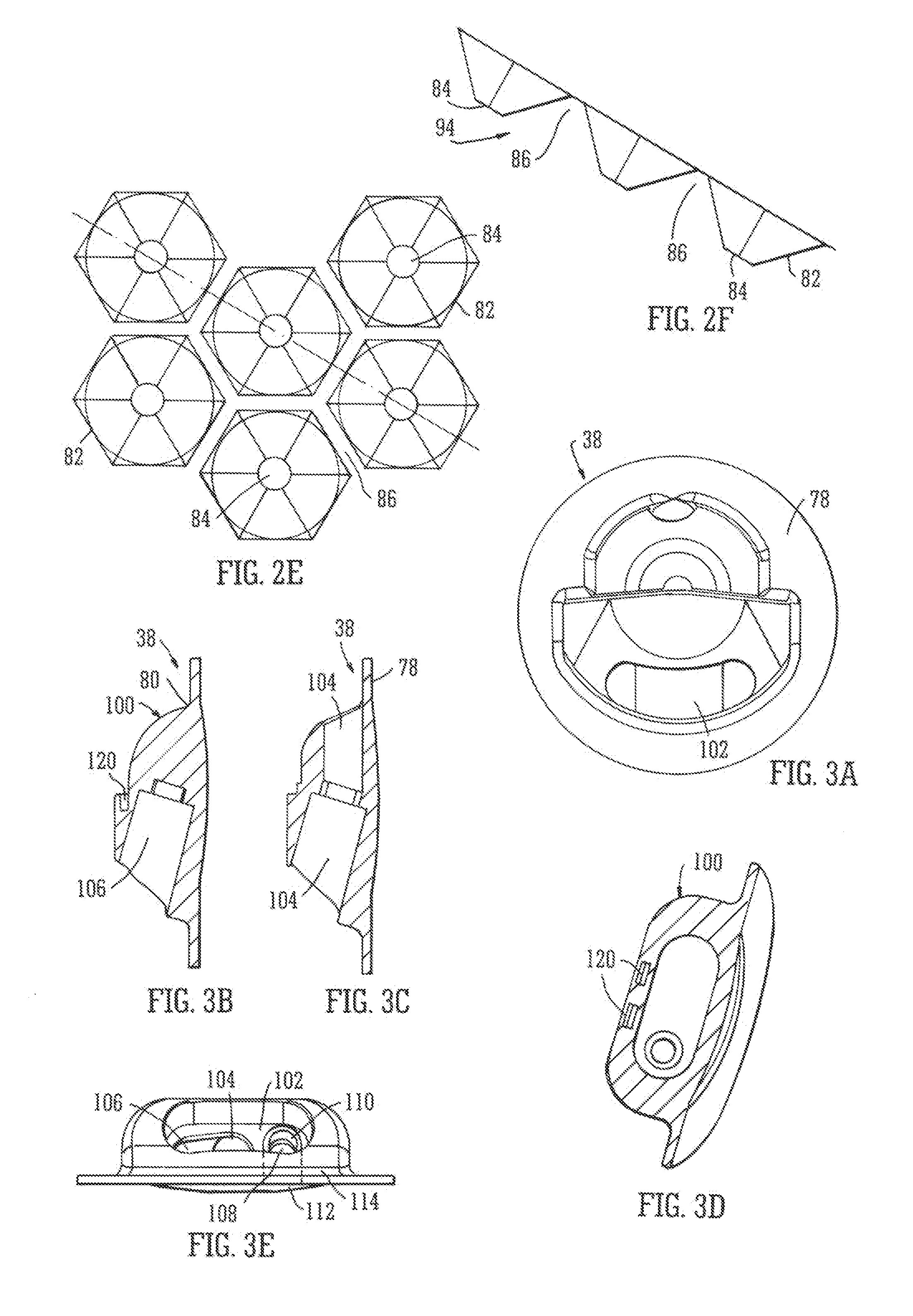

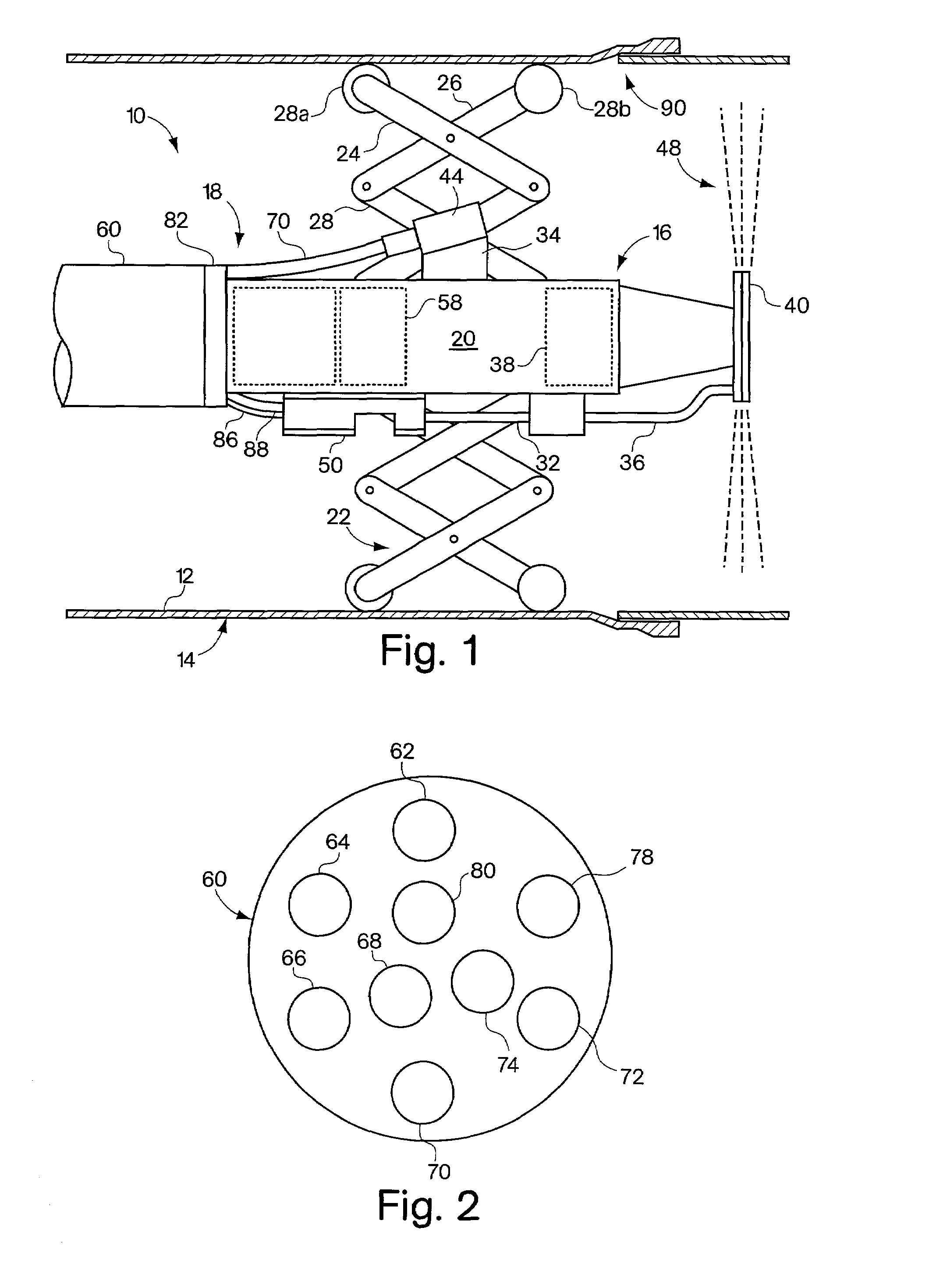

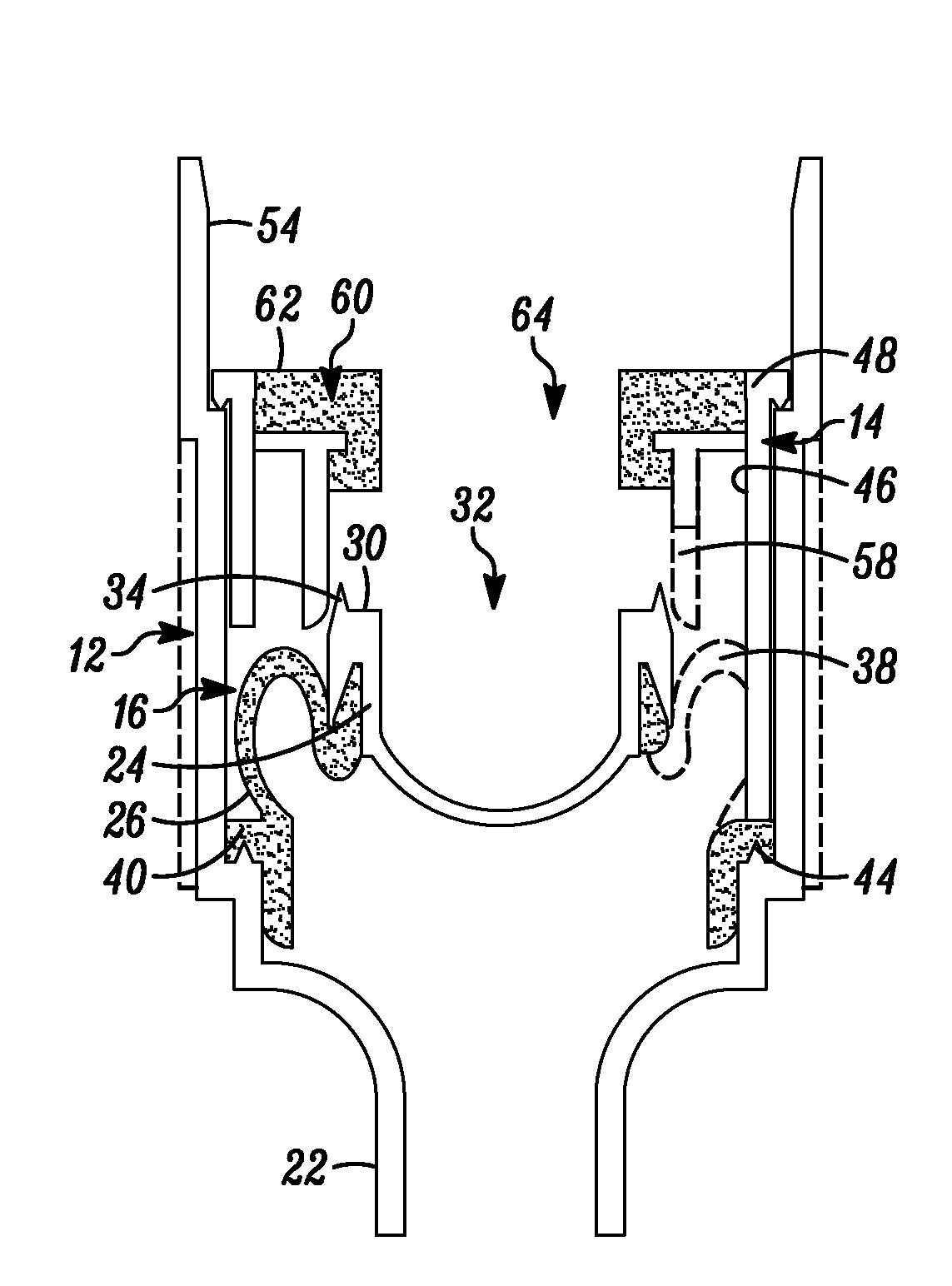

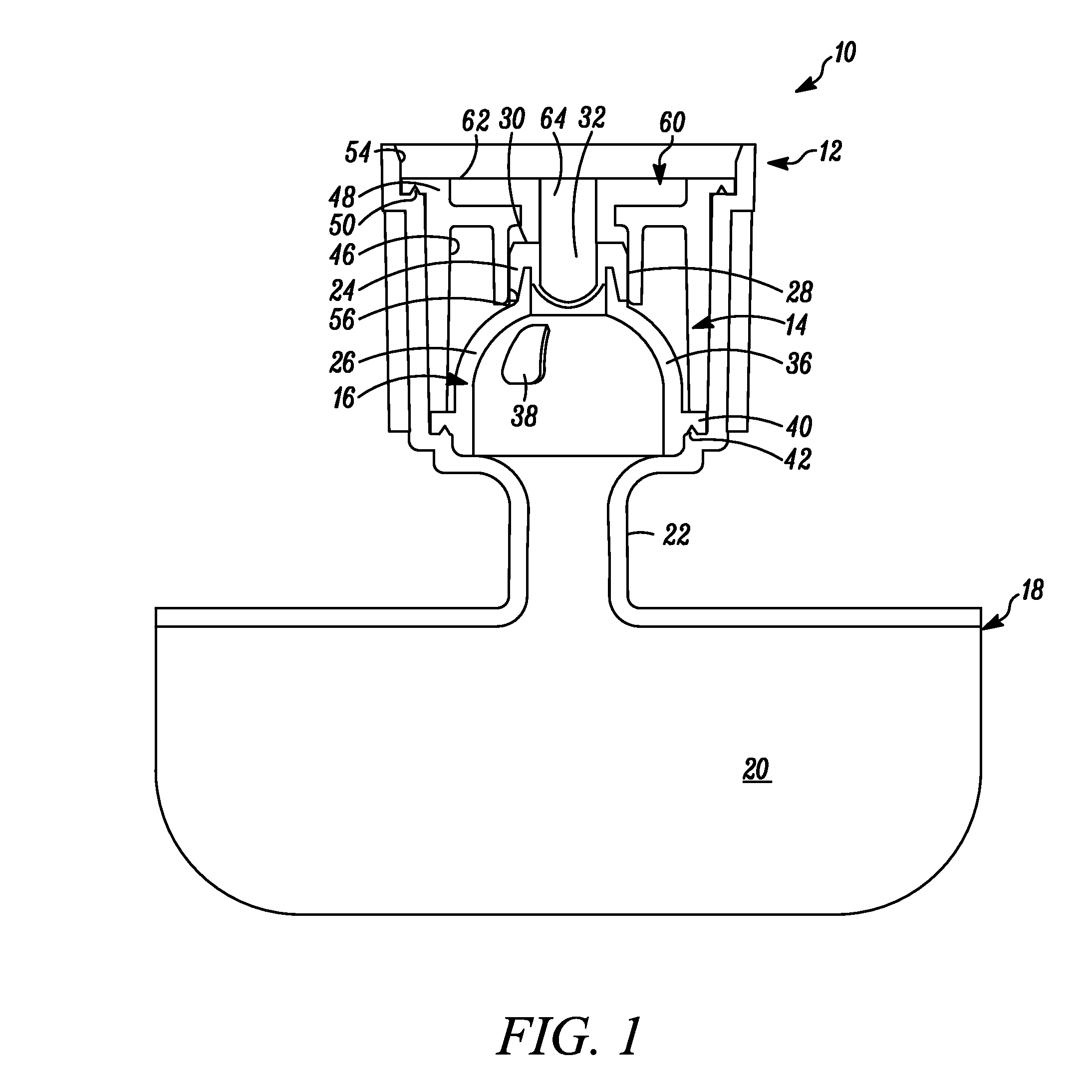

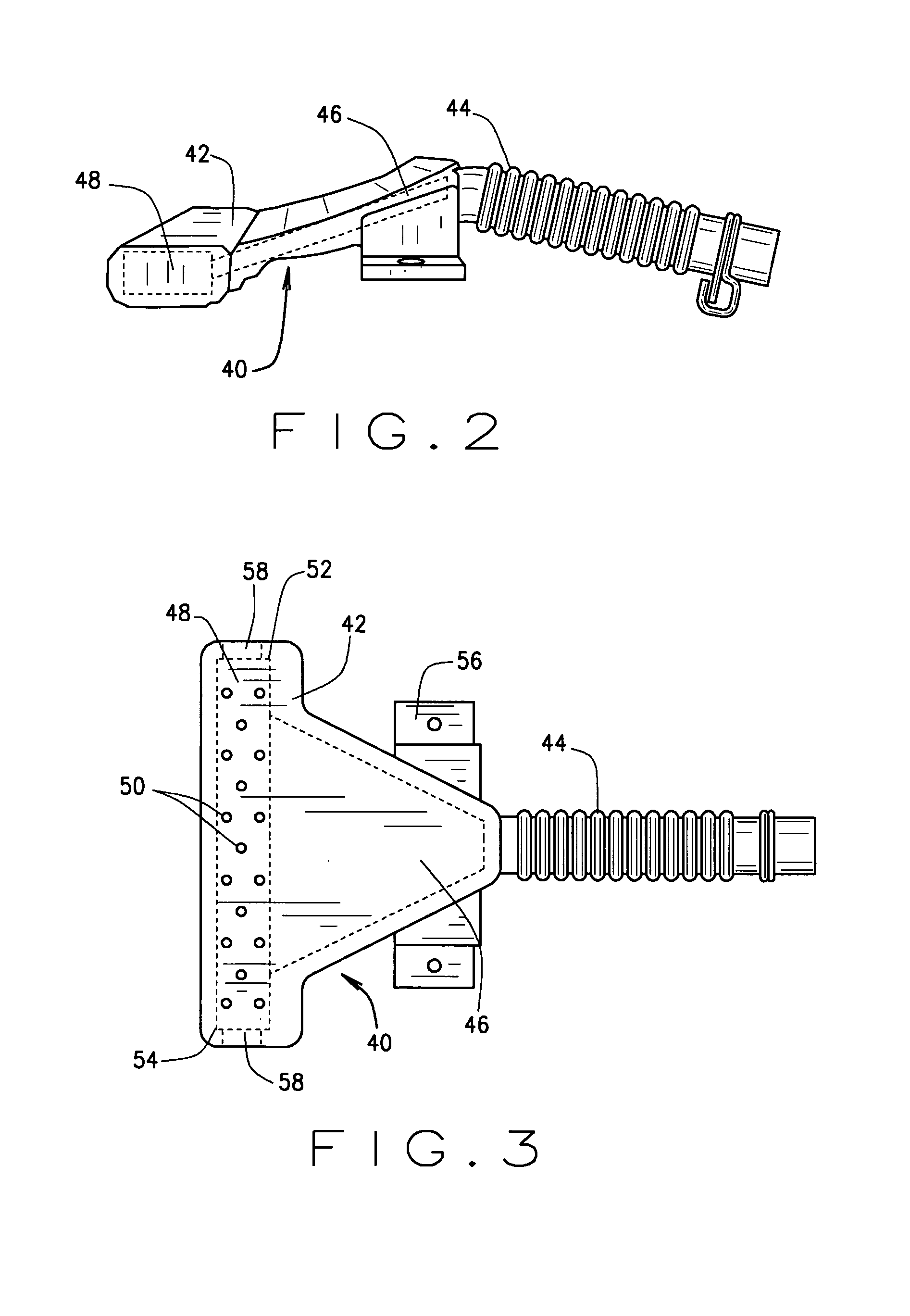

Devices and methods for heart valve treatment

ActiveUS7112219B2Function increaseGood jointSuture equipmentsAnnuloplasty ringsAnatomical structuresSurgical approach

Devices and methods for improving the function of a valve (e.g., mitral valve) by positioning a spacing filling device outside and adjacent the heart wall such that the device applies an inward force against the heart wall acting on the valve. A substantially equal and opposite force may be provided by securing the device to the heart wall, and / or a substantially equal and opposite outward force may be applied against anatomical structure outside the heart wall. The inward force is sufficient to change the function of the valve, and may increase coaptation of the leaflets, for example. The space filling device may be implanted by a surgical approach, a transthoracic approach, or a transluminal approach, for example. The space filling portion may be delivered utilizing a delivery catheter navigated via the selected approach, and the space filling portion may be expandable between a smaller delivery configuration and a larger deployed configuration.

Owner:EDWARDS LIFESCIENCES LLC

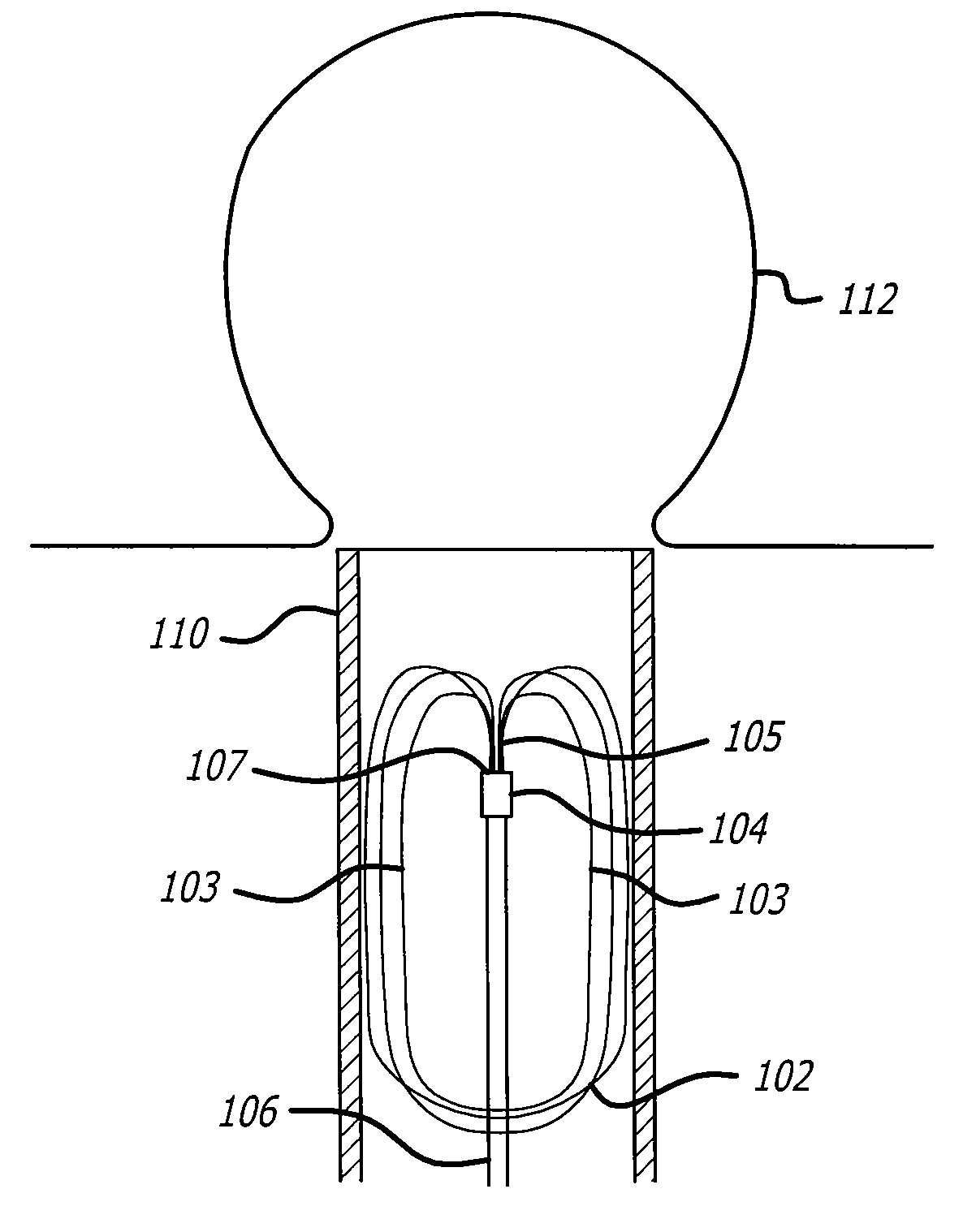

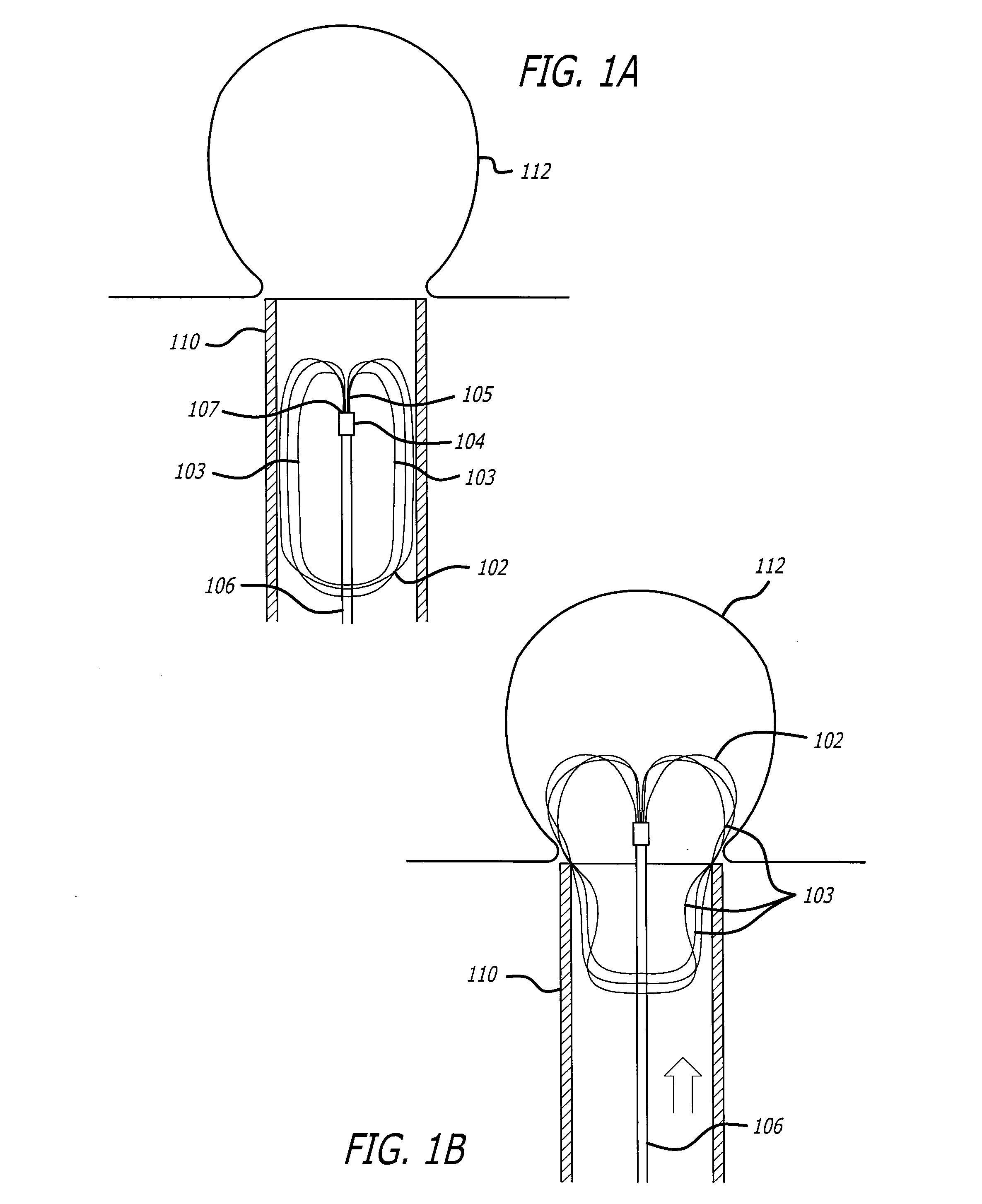

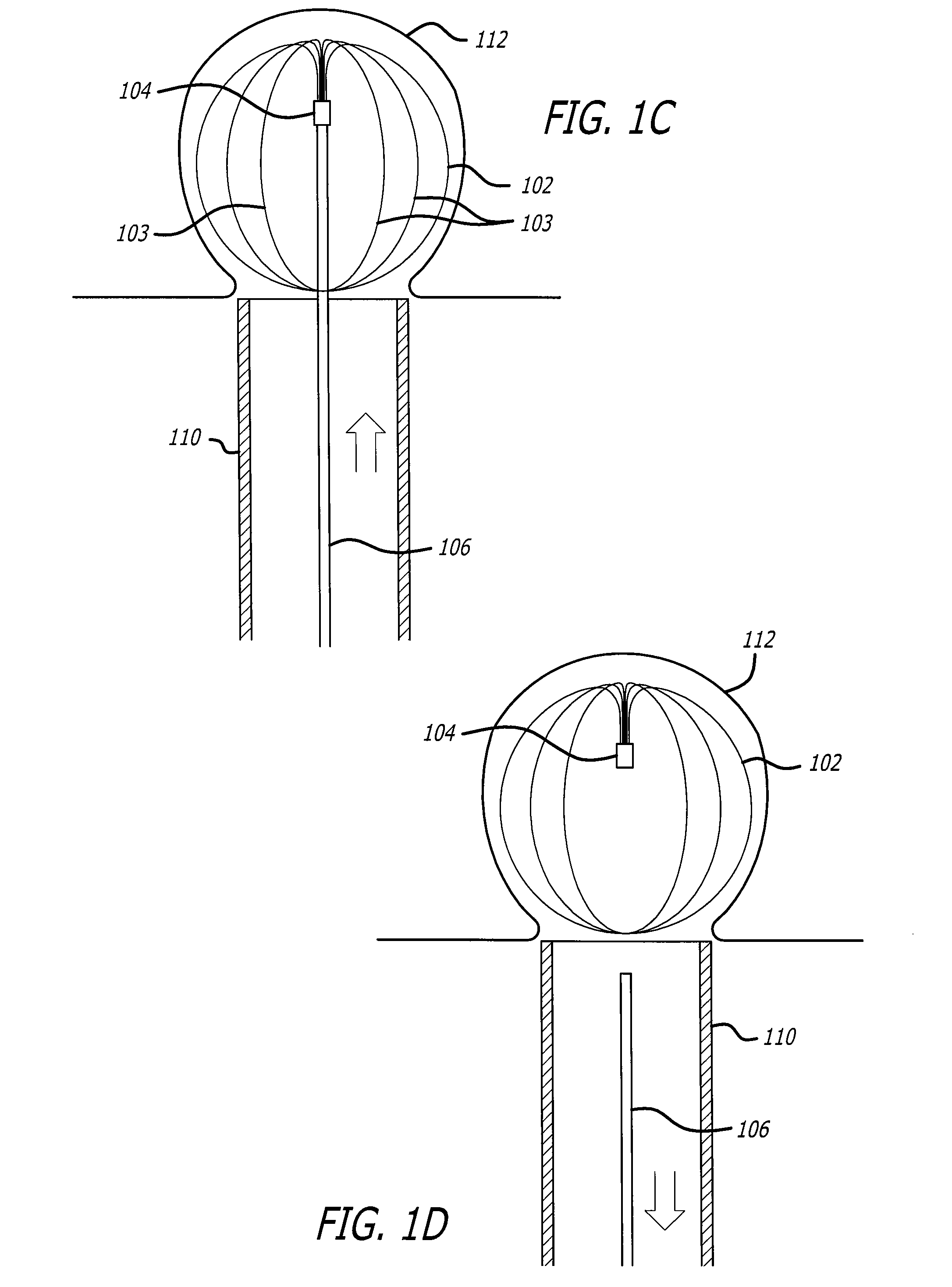

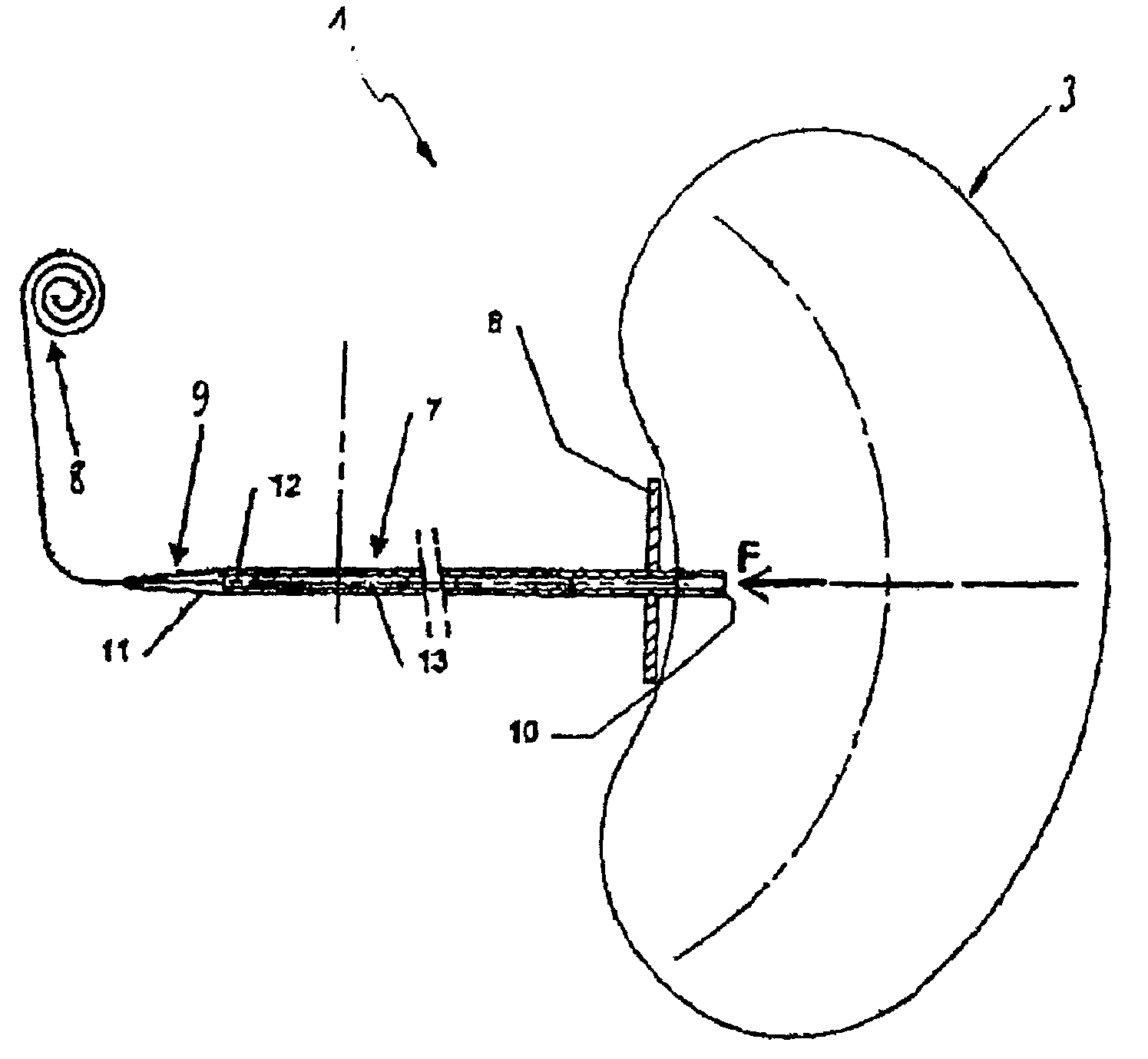

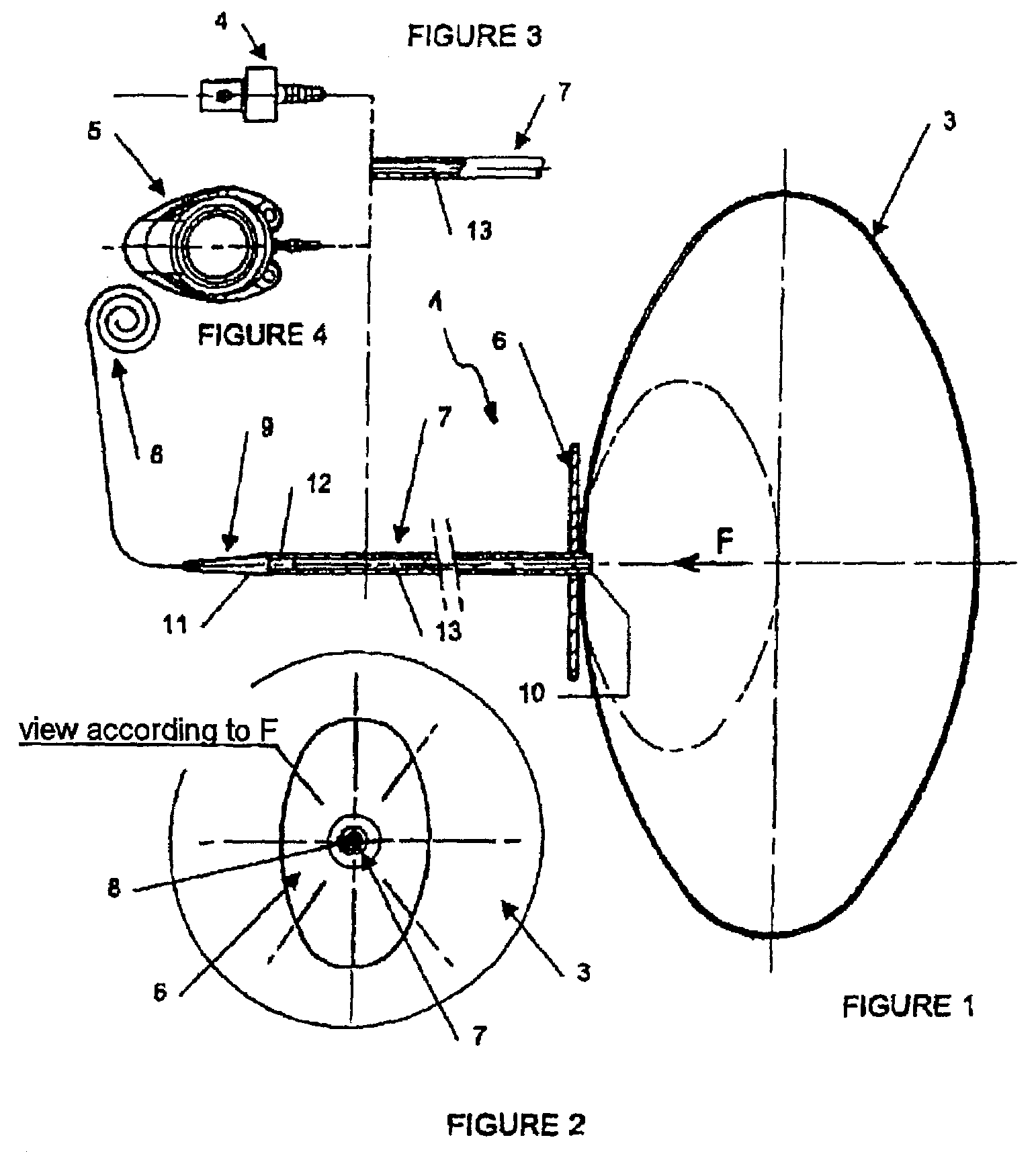

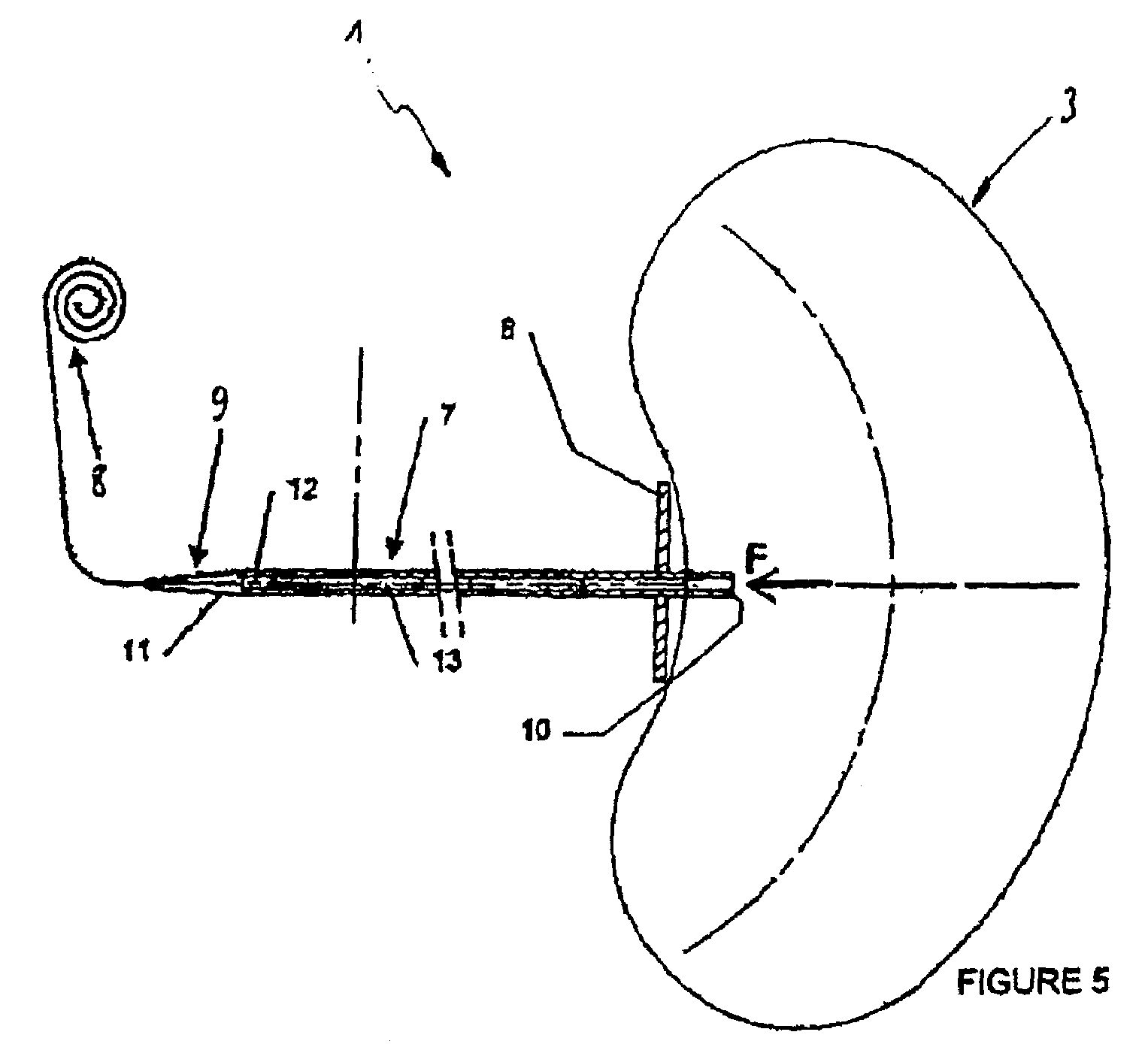

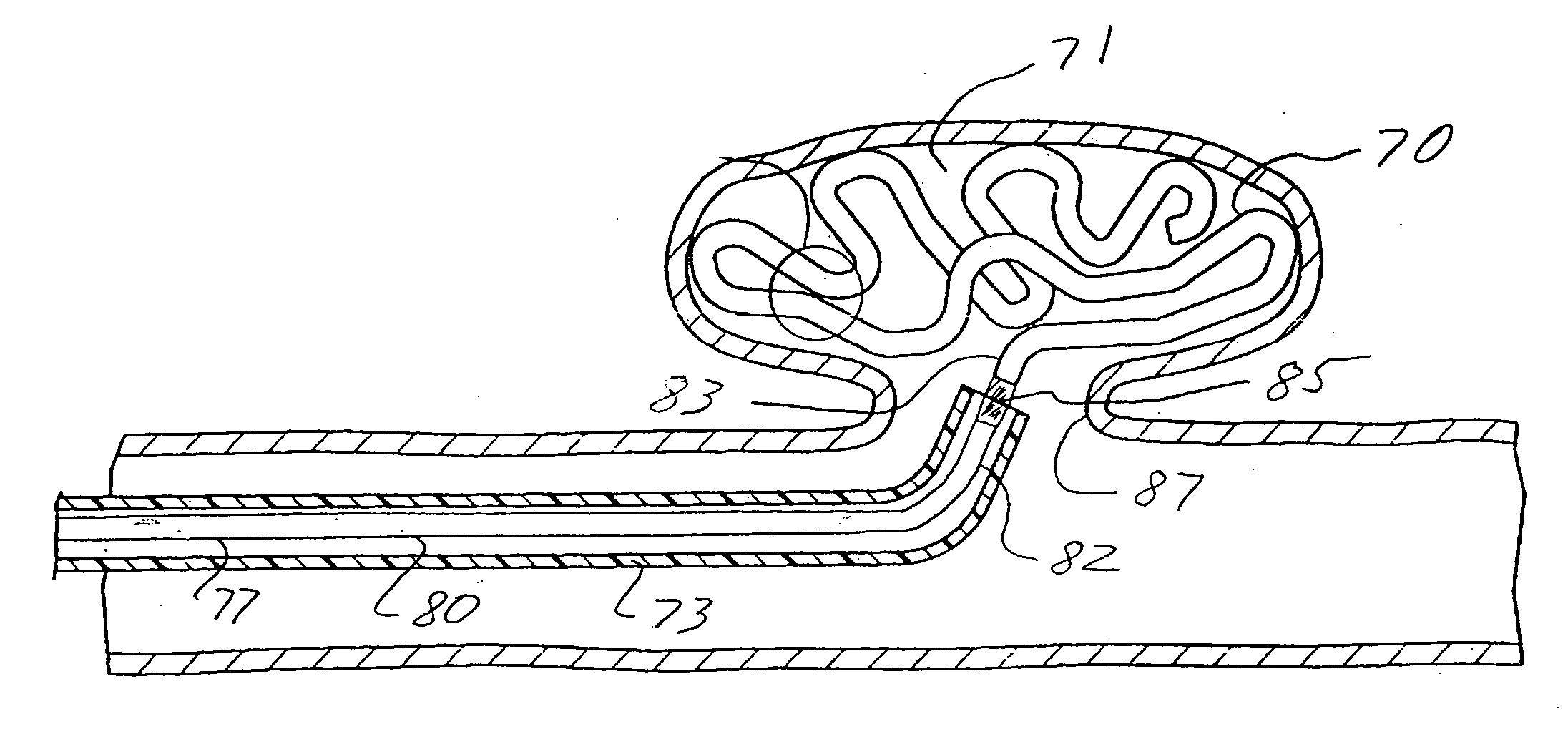

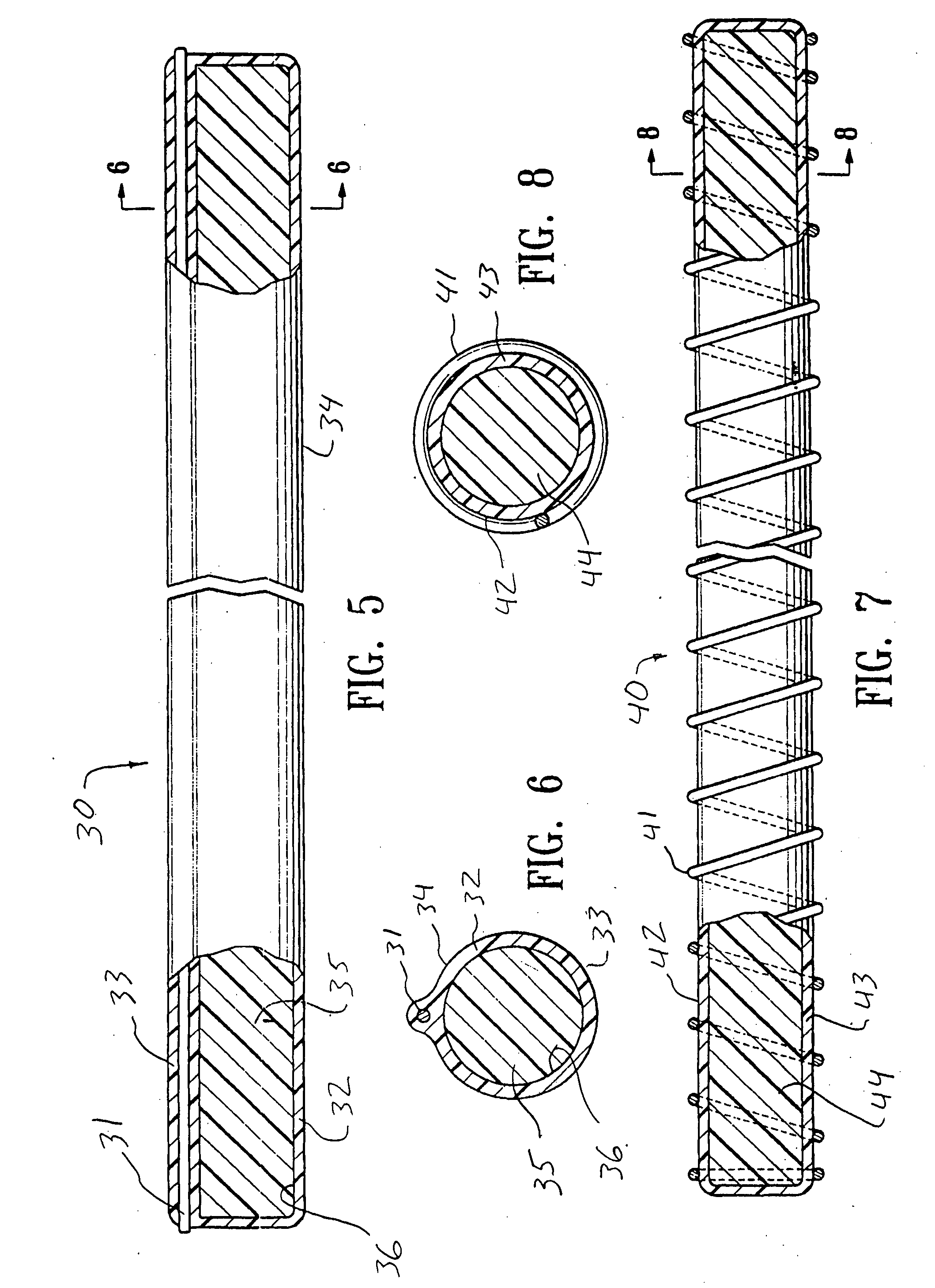

Self-expandable aneurysm filling device, system and method of placement

The self-expandable aneurysm filling device, system and method provide for placement of the stent into an aneurysm to at least partially fill and stabilize the aneurysm. The self-expandable aneurysm filling device has a compressed undeployed configuration and an expanded three-dimensional deployed configuration, and a severable deployment junction releasably connects the self-expandable aneurysm filling device to a pusher wire. The severable deployment junction can be mechanically, electrolytically, or thermally severed to separate the self-expandable aneurysm filling device from the pusher wire.

Owner:PENUMBRA

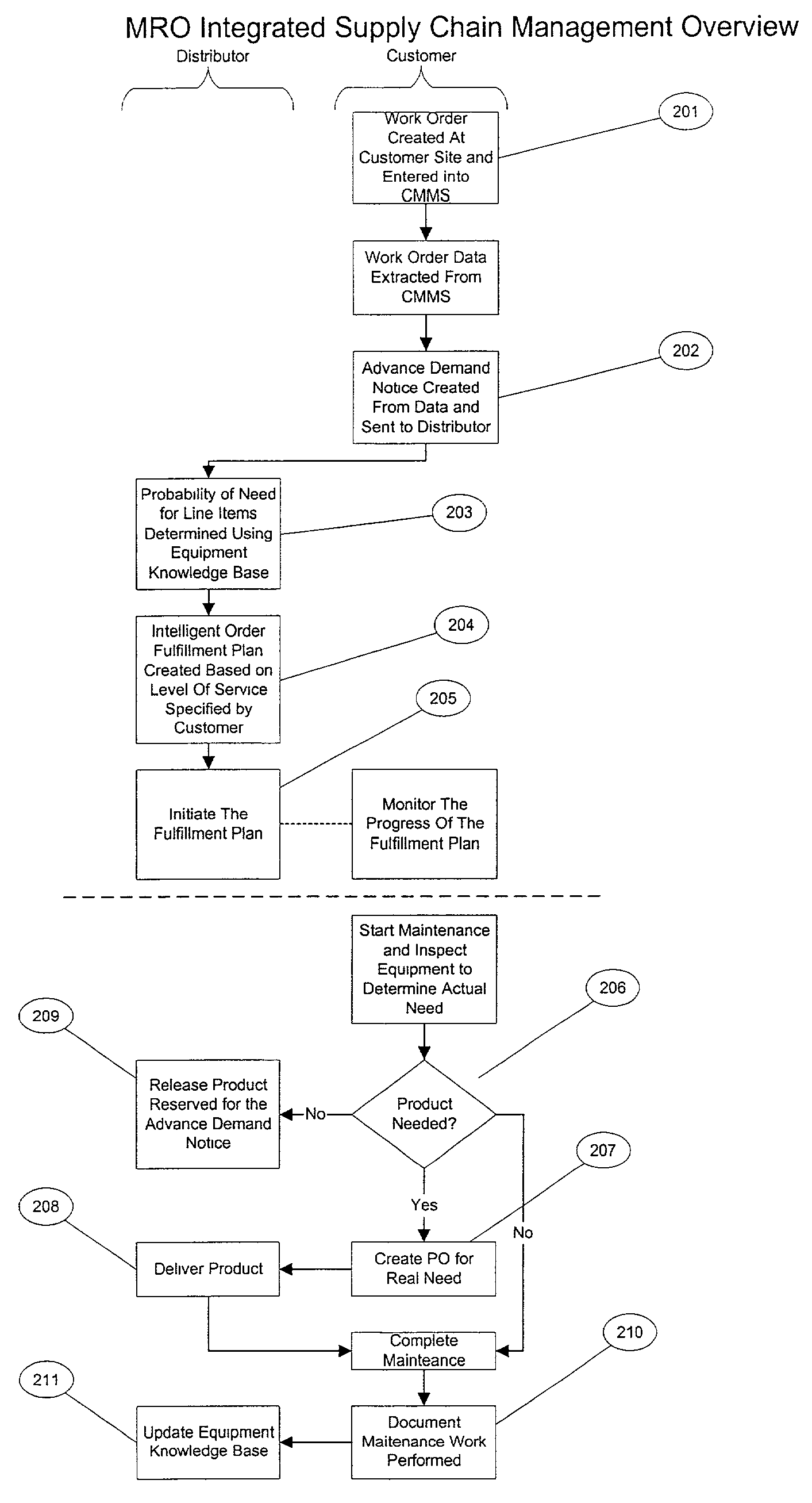

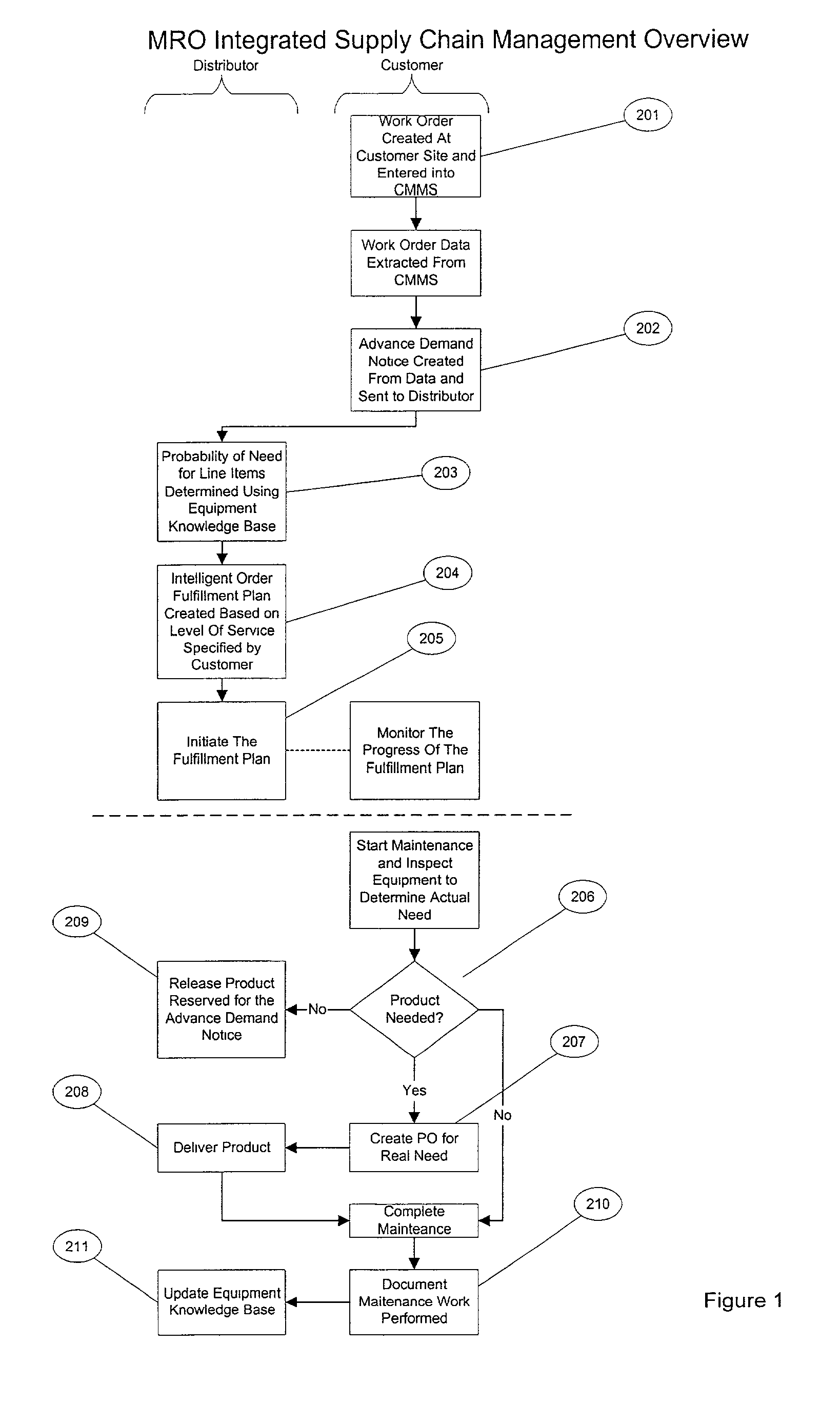

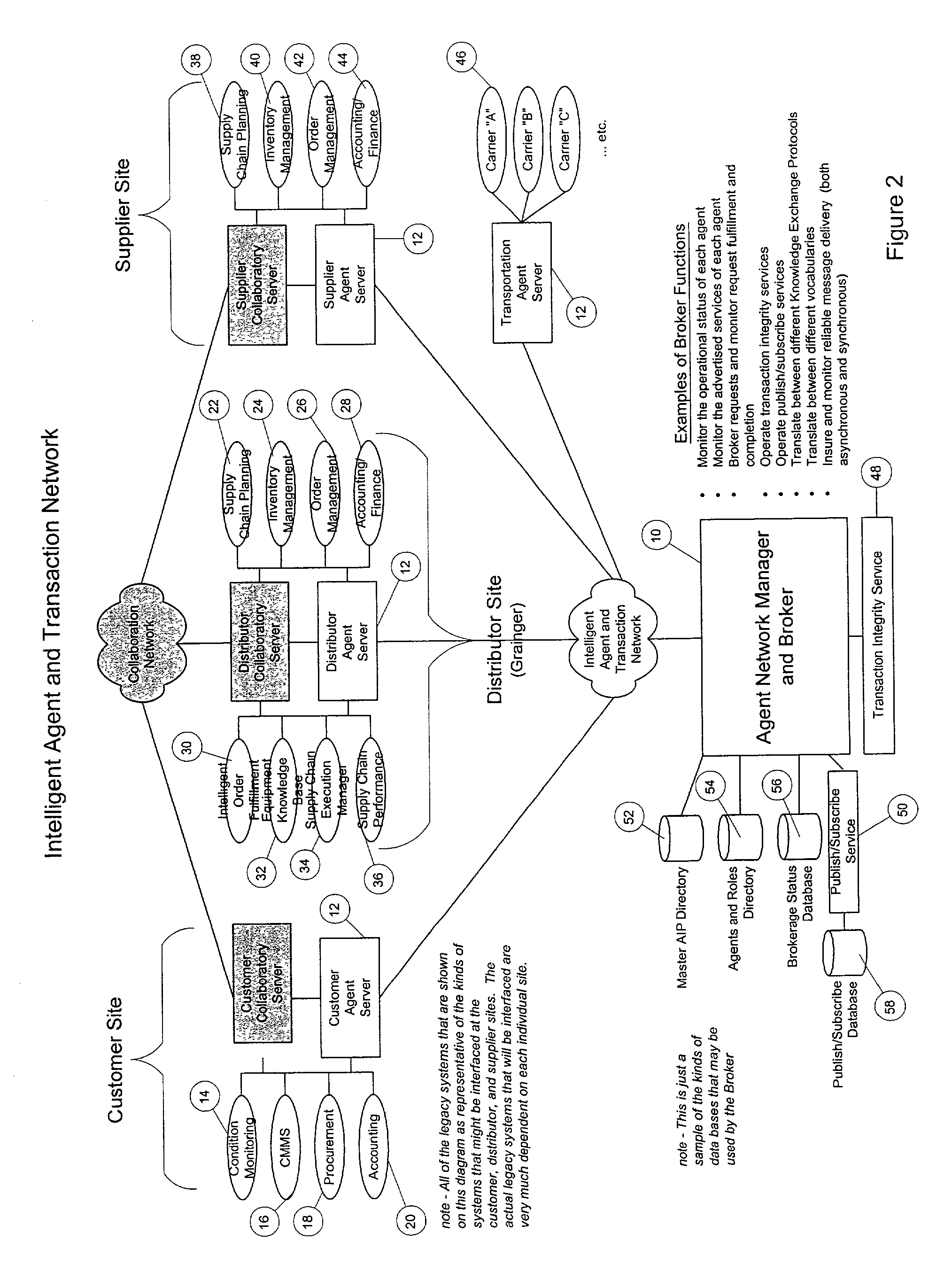

Method for fulfilling an order in an integrated supply chain management system

A method for fulfilling an order in a supply chain. The method is performed by extracting from a customer system information pertaining to the work order that specifies a piece of equipment to be repaired and items expected to be used during the repair procedure, determining, using an equipment knowledge base, a probability that each of the items will be needed to effect the repair procedure, and using the determined probability to stage the items within the supply chain whereby the items are made ready for use in the repair procedure. Further steps can include extracting from the customer system information pertaining to a completion of the repair procedure and using the information pertaining to the completion of the repair procedure to populate the equipment knowledge base for use in future probability of need calculations.

Owner:W W GRAINGER

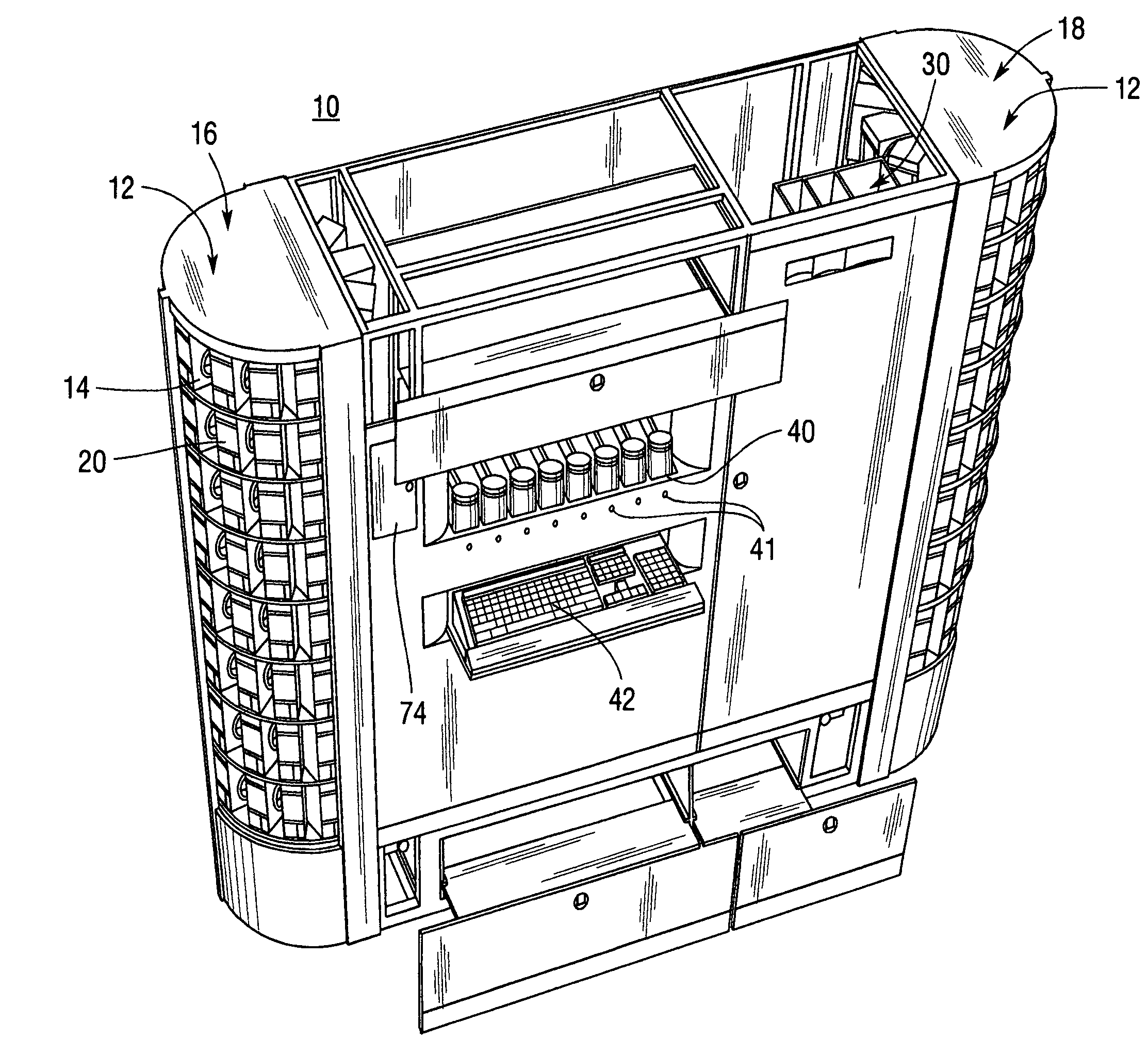

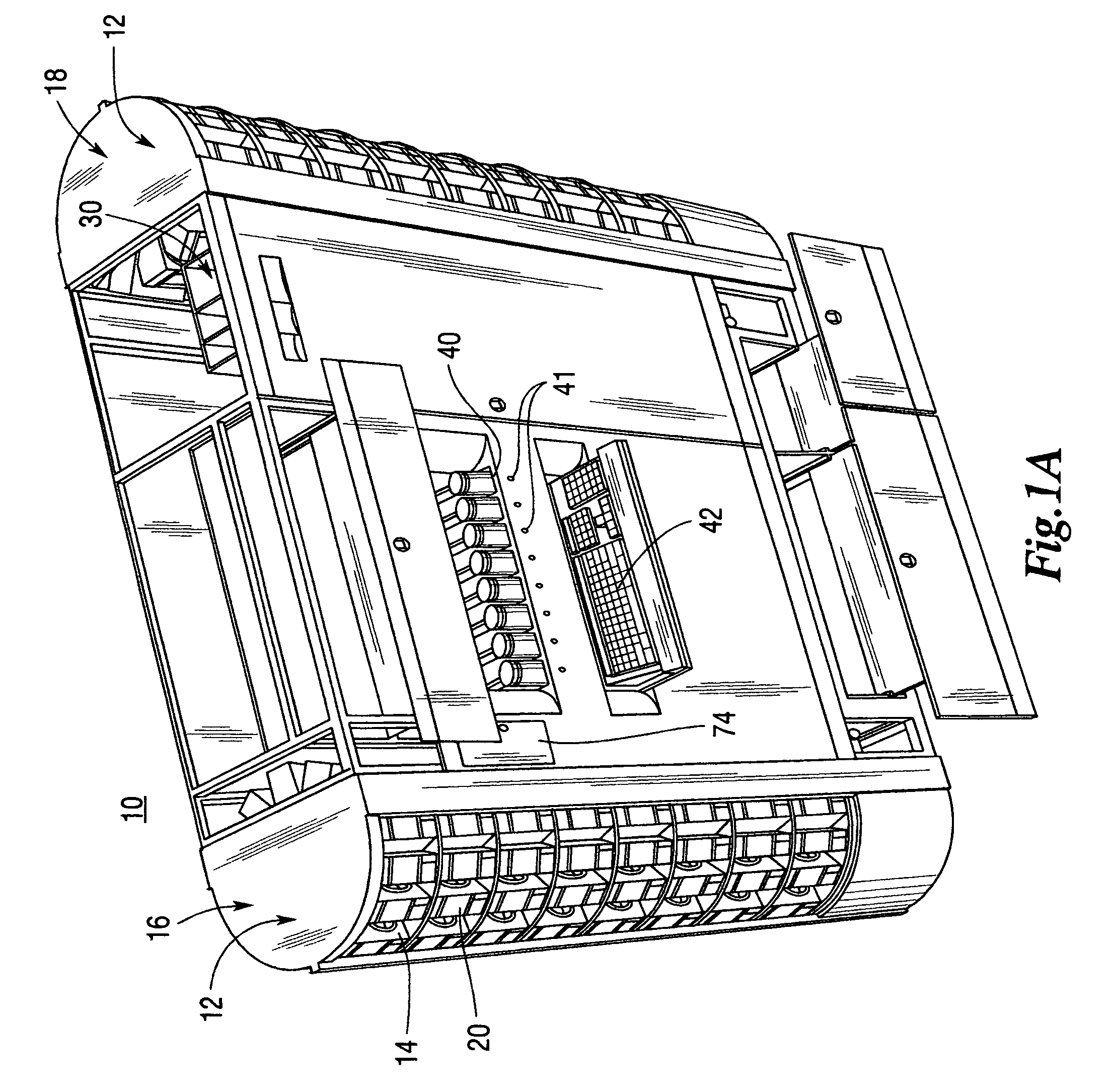

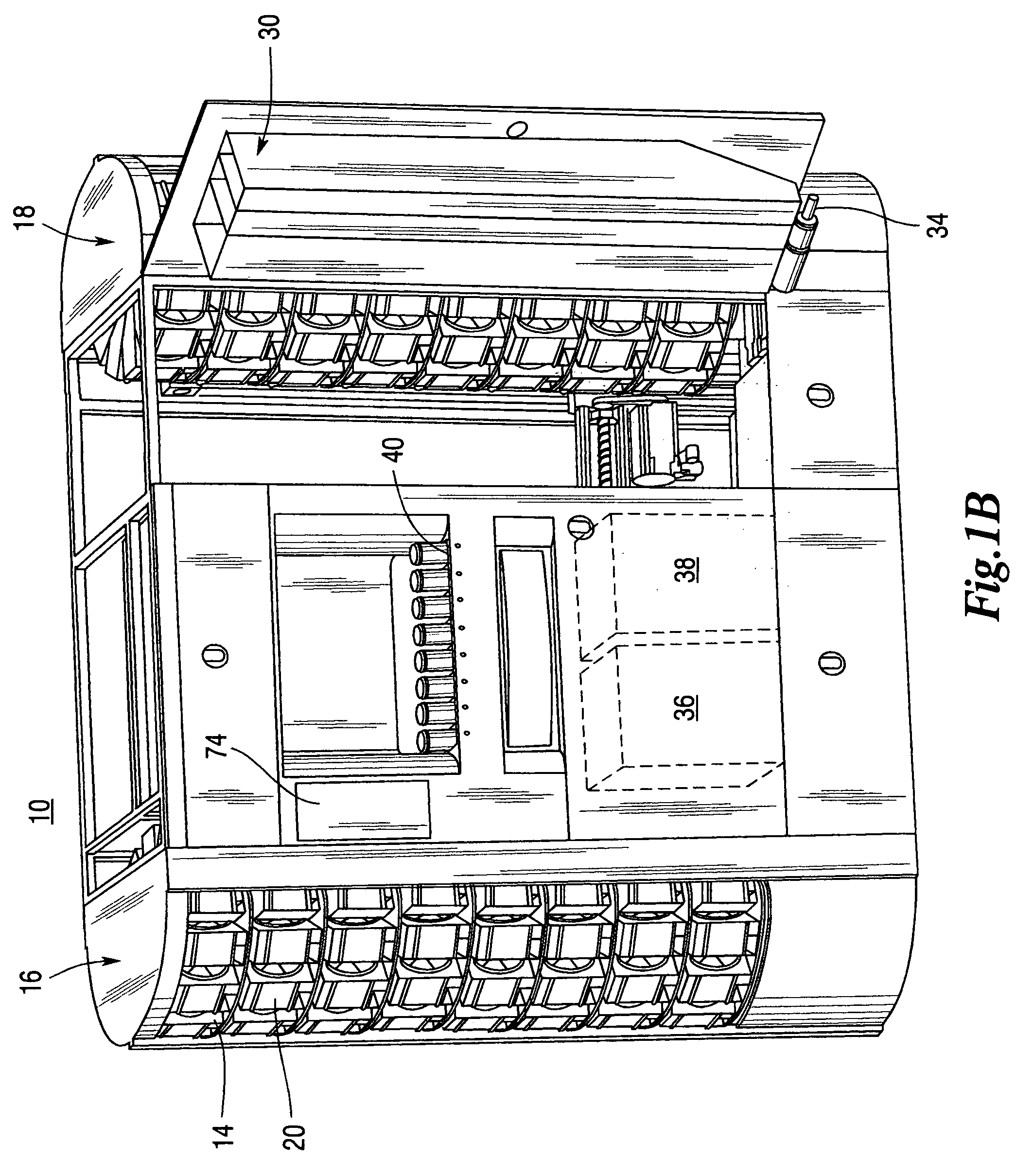

Prescription filling apparatus implementing a pick and place method

ActiveUS7228198B2Easy to scaleSmall footprintDigital data processing detailsSolid materialComputer control systemOutput device

An apparatus for filling vials comprises a shelving unit defining an array of storage locations. The shelving unit may be an array in an XY plane or one or more carousels. A plurality of storage containers are provided, each removably carried by one of the storage locations. A counting and dispensing unit, a source of vials, a label printer and application unit or units, and an output device are also provided. The output device may take a variety of forms such as an output chute, which is preferably used when a capping unit is provided, an output conveyor, a plurality of output lanes, and an output carousel, which may be a dedicated carousel or a portion of the carousel providing the plurality of storage locations. A computer controlled engagement device provides motion in a Z direction. The engagement device may be comprised of a first stage for engaging the storage containers and a second stage for engaging the vials. A computer controlled system carries the engagement device and moves the engagement device in XY directions among the plurality of storage locations, counting and dispensing unit, source of vials, label printer and application unit, and output device. Methods of operating and refilling the vial filling apparatus are also disclosed.

Owner:MCKESSON AUTOMATION SYST

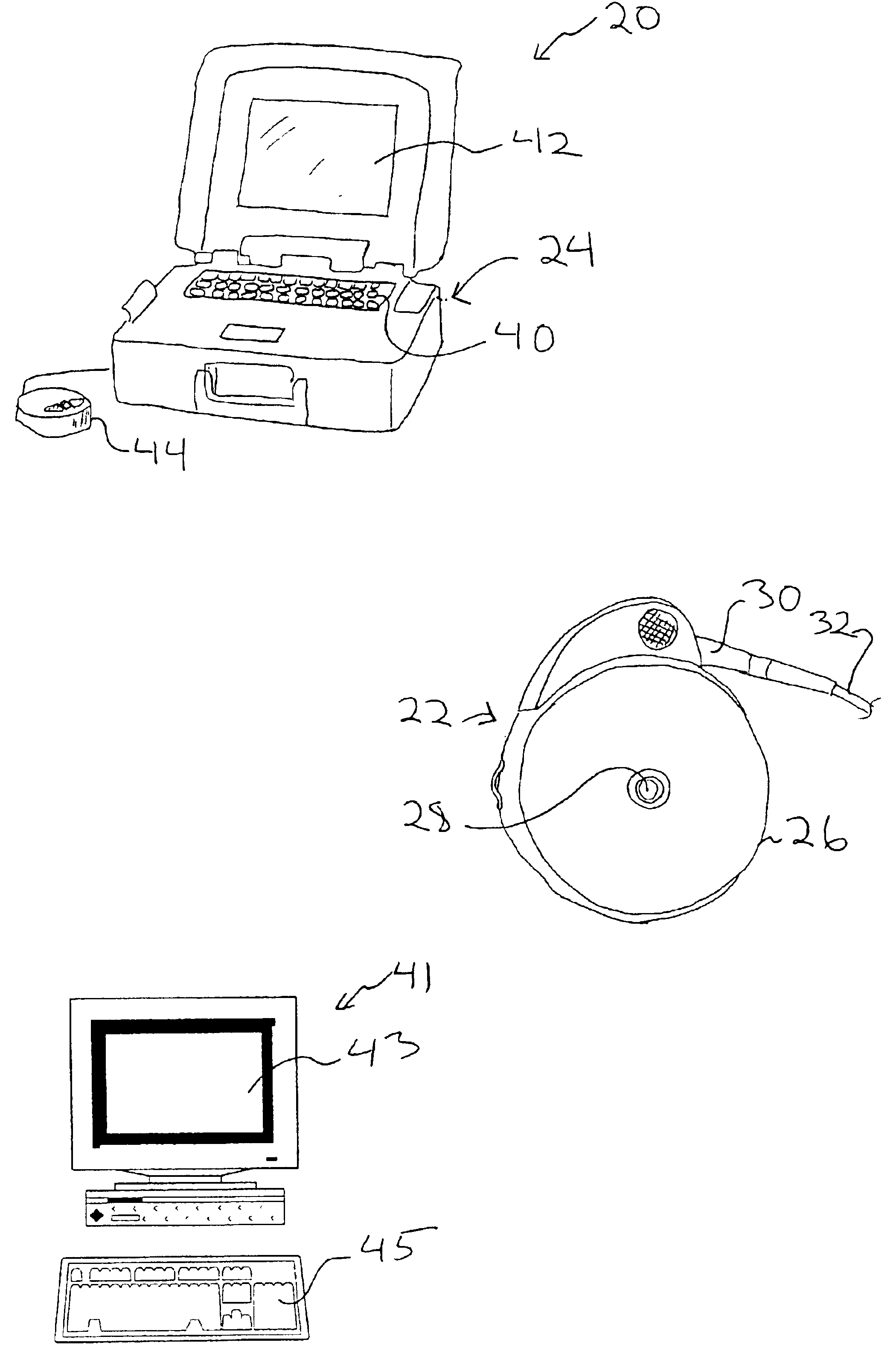

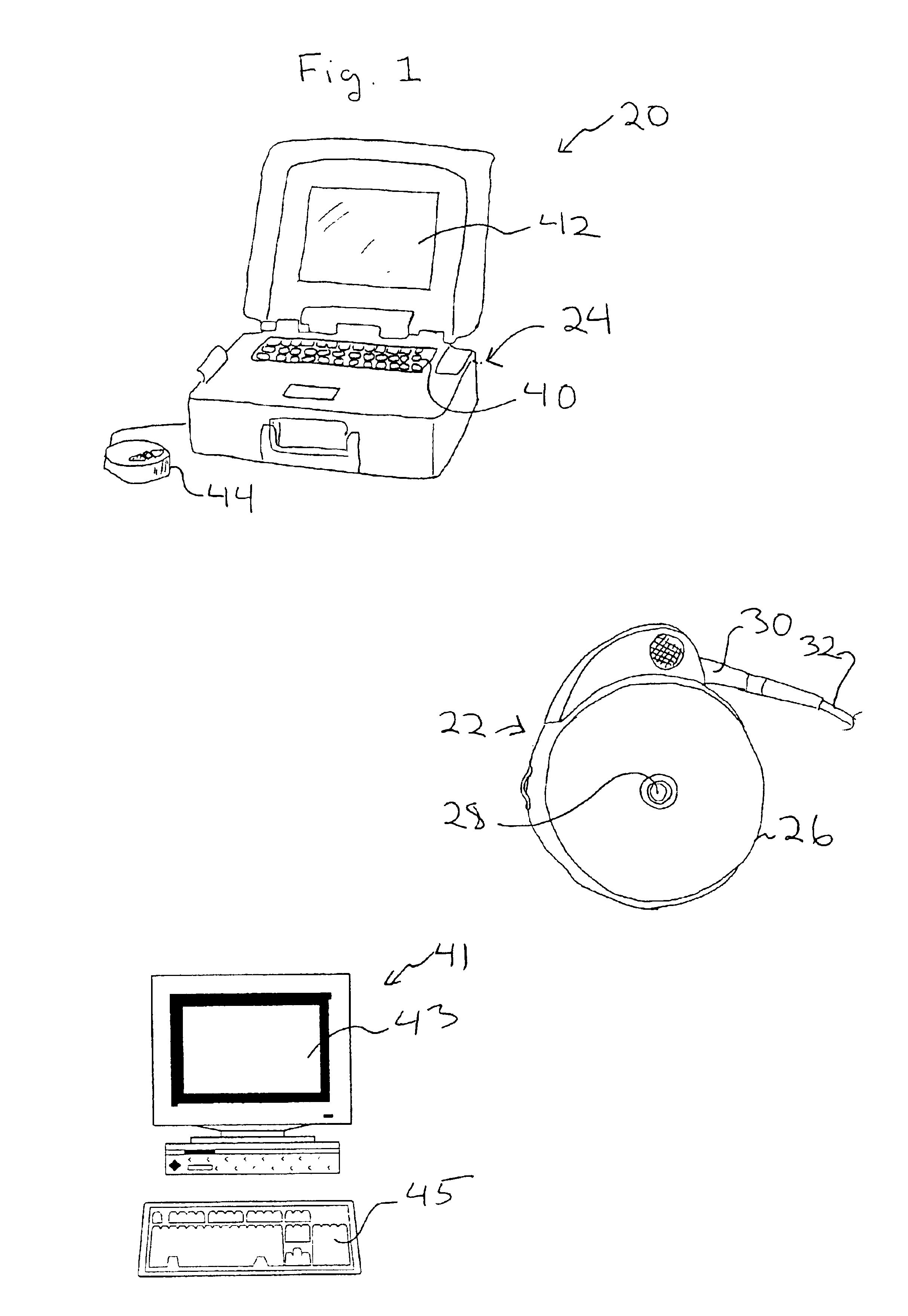

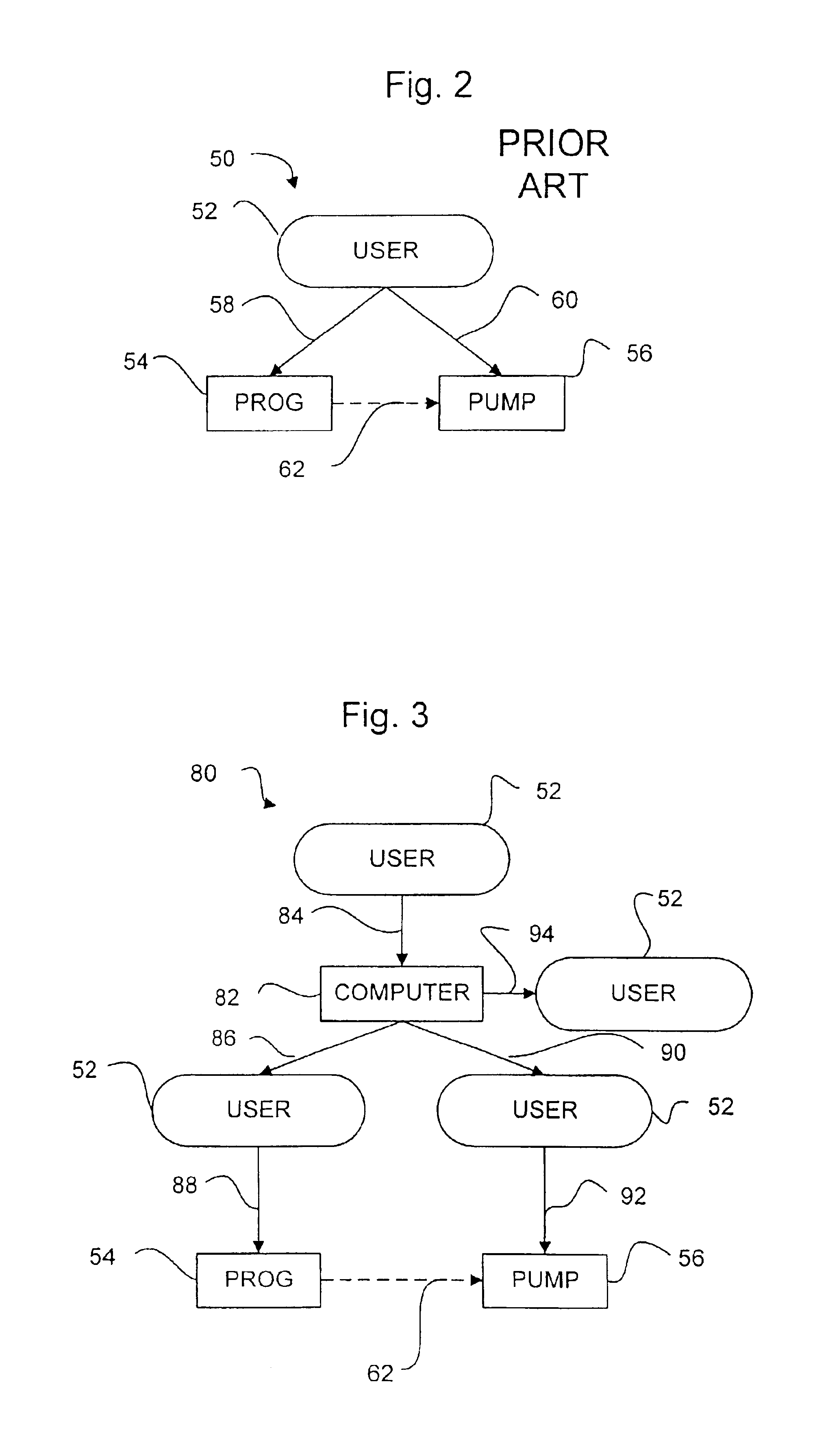

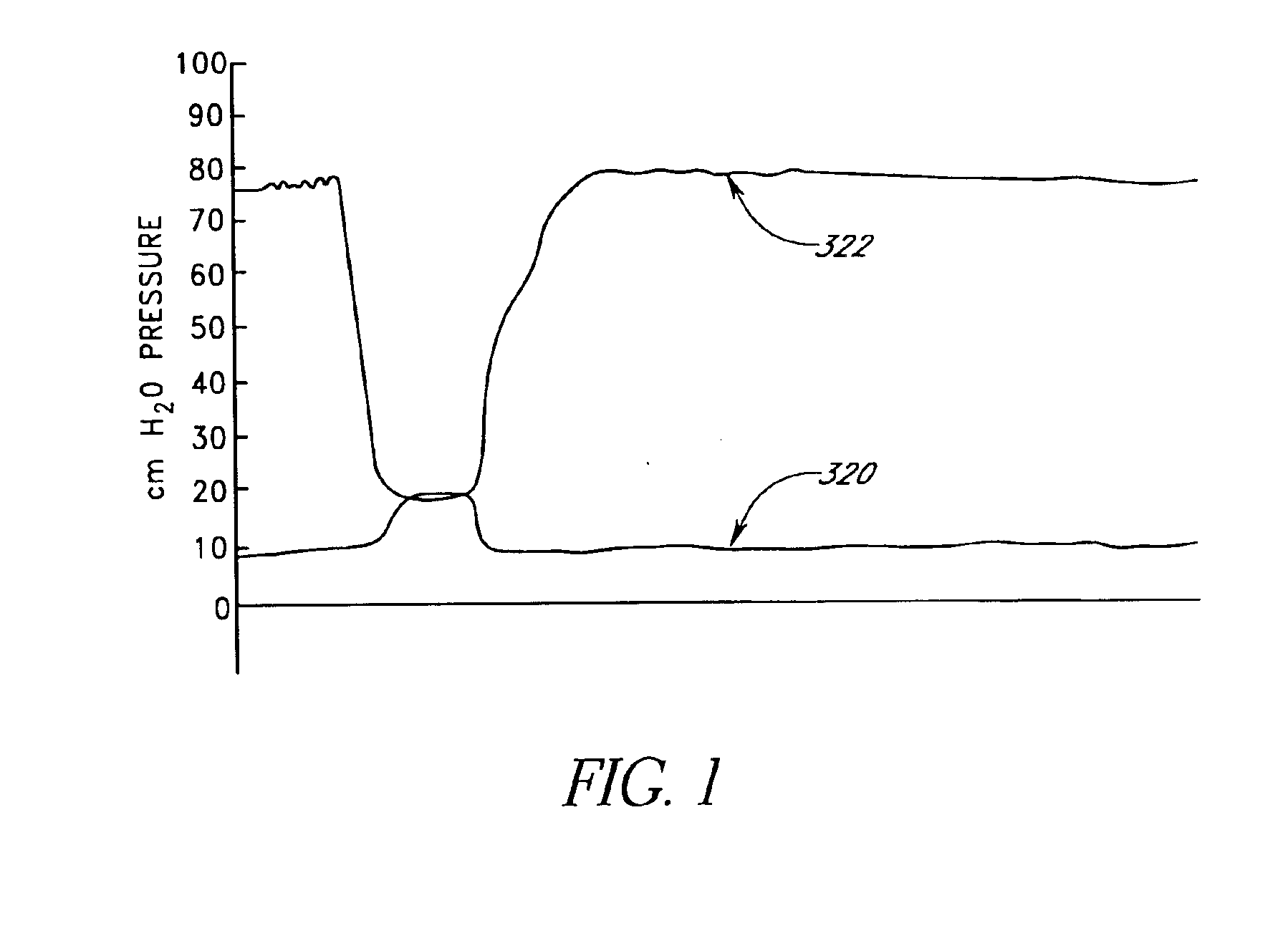

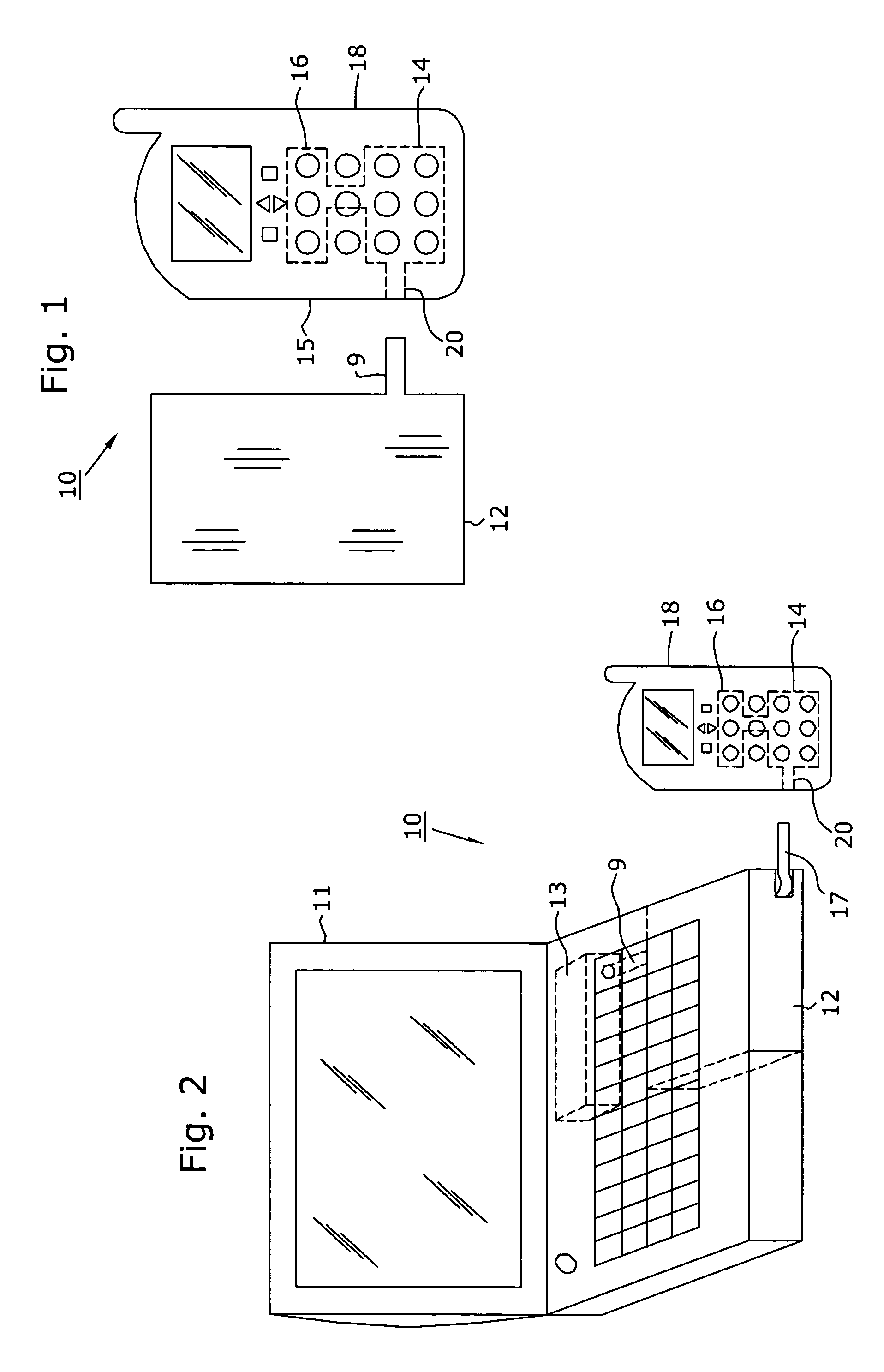

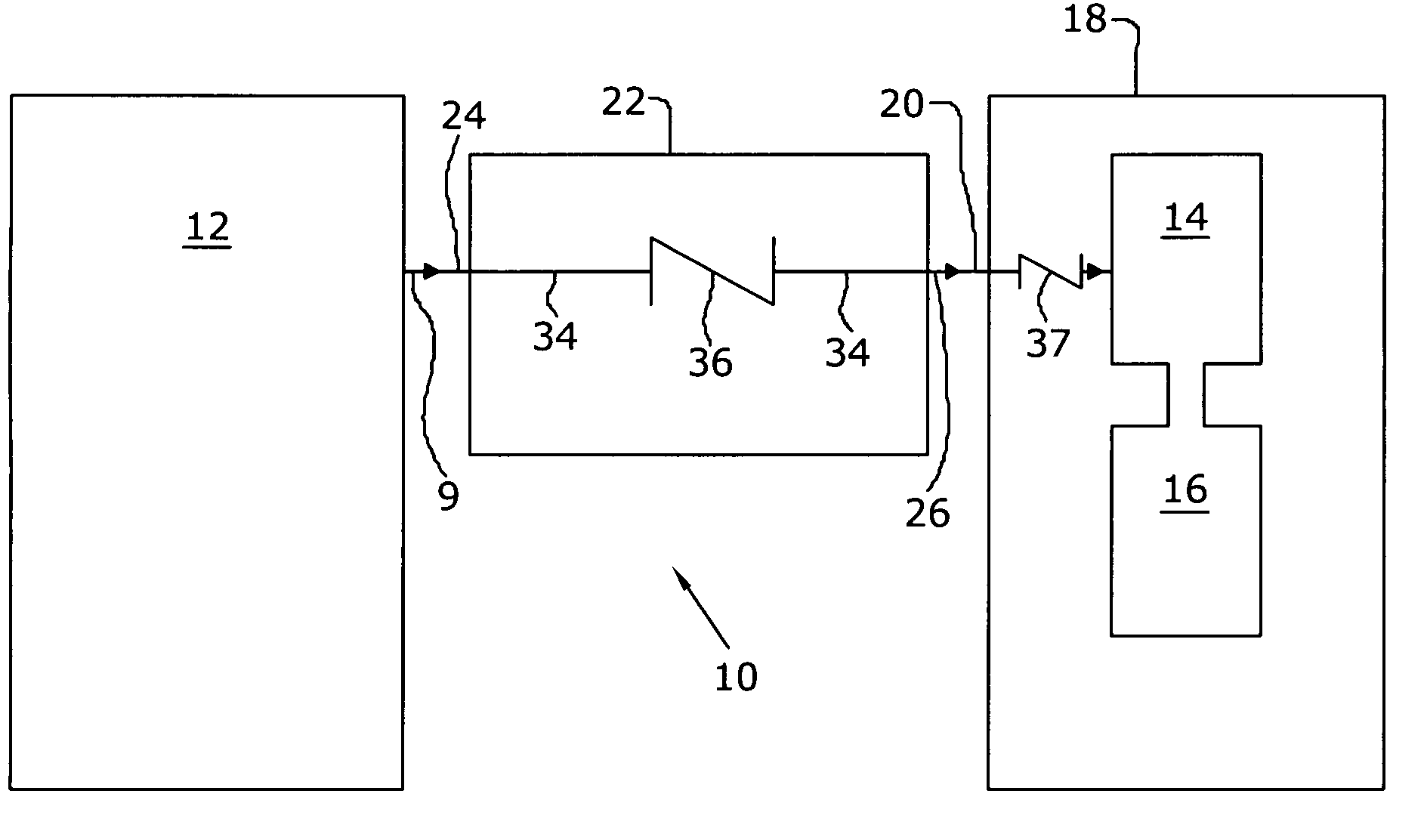

Decision information system for drug delivery devices

ActiveUS6928338B1Sampled-variable control systemsControlling ratio of multiple fluid flowsDoses rateGeneral purpose computer

Decision information systems, methods, and computer programs for better informing decisions to use multiple drugs in drug delivery devices, including implantable devices, for drug administration. Executable computer programs and logic embodying methods of the invention can calculate consistent multiple drug mixture amounts and drug delivery flow rates. One program accepts user input indicating a desired first drug dose rate, an initial first drug concentration, a desired second drug dose rate, an initial second drug concentration, and the reservoir size of the drug delivery device. The program method calculates a first drug amount and a second drug amount to combine in a mixture as well as a first drug true concentration in the mixture. The drugs can be mixed consistent with the physician's instructions using the program output. The first drug true concentration can be entered into a programmer device as the only drug concentration entered. Another program calculates a consistent first drug, second drug, and diluent amount to be added to a mixture for injection into a fixed flow rate, implantable drug delivery device. Methods preferably output true concentrations and dose rates for all drugs to be added and most preferably show all calculations used to arrive at the flow rate and mixture amount calculations. Yet another program receives a new desired drug dose rate for a previously filled device. The program accepts the existing mixture volume and true drug concentrations for a partially depleted device and calculates a new mixture flow rate to achieve the desired dose rate using the existing mixture. The methods can be implemented as executable computer programs in programmer devices, general purpose computers, servers, handheld computers, and personal digital assistants.

Owner:MEDTRONIC INC

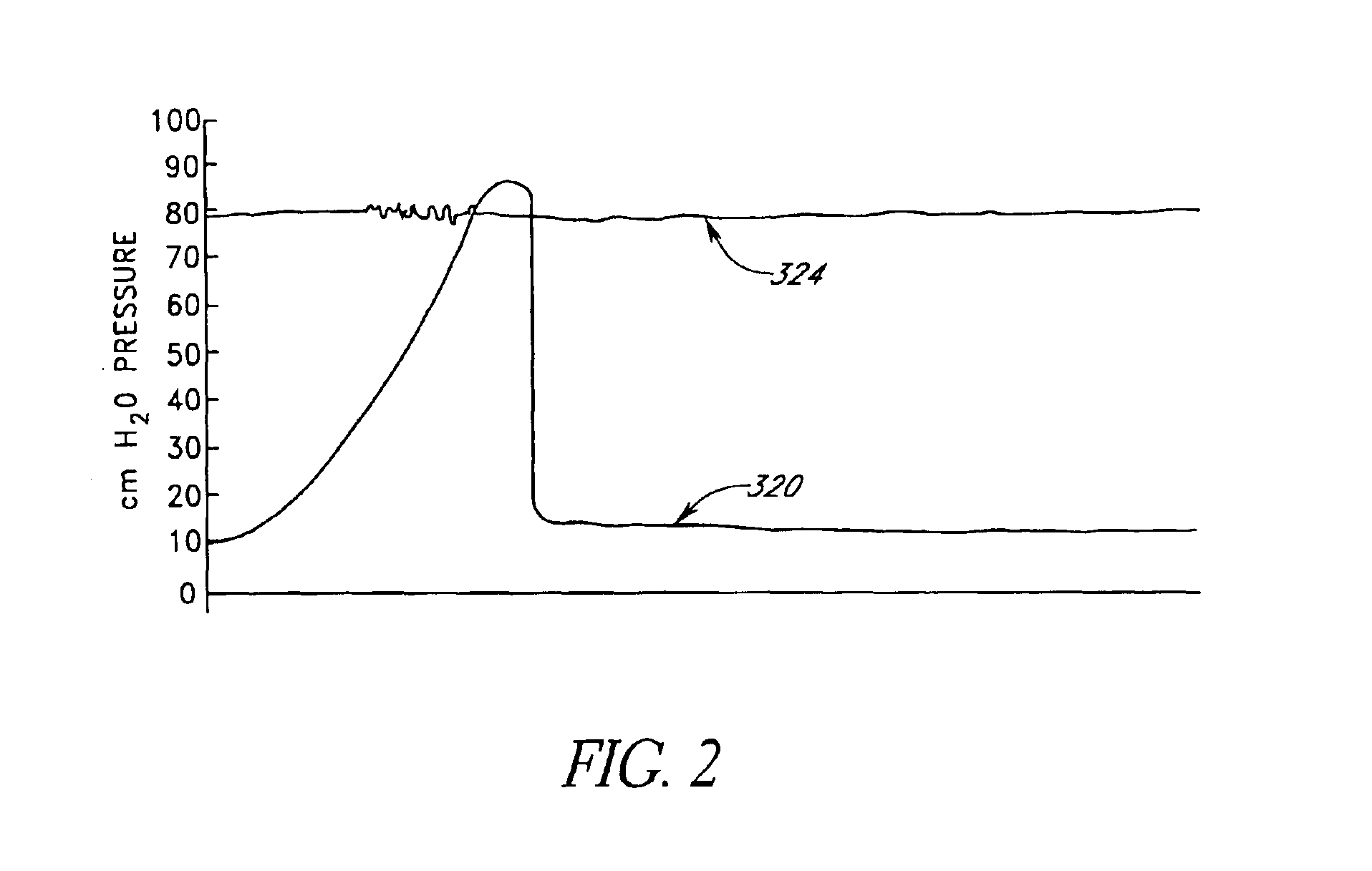

Implantable valved pressure attenuation device

InactiveUS6976950B2Increase pressureLower the volumeUrinary bladderStentsUltrasound attenuationSurgery

Owner:SOLACE THERAPEUTICS

Method of preventing short sampling of a capillary or wicking fill device

InactiveUS7043821B2Line/current collector detailsElectrical transducersMedicineBiomedical engineering

Owner:LIFESCAN INC

Decives and methods for heart valve treatment

ActiveUS20060036317A1Improve valve functionGood jointSuture equipmentsAnnuloplasty ringsAnatomical structuresSurgical approach

Devices and methods for improving the function of a valve (e.g., mitral valve) by positioning a spacing filling device outside and adjacent the heart wall such that the device applies an inward force against the heart wall acting on the valve. A substantially equal and opposite force may be provided by securing the device to the heart wall, and / or a substantially equal and opposite outward force may be applied against anatomical structure outside the heart wall. The inward force is sufficient to change the function of the valve, and may increase coaptation of the leaflets, for example. The space filling device may be implanted by a surgical approach, a transthoracic approach, or a transluminal approach, for example. The space filling portion may be delivered utilizing a delivery catheter navigated via the selected approach, and the space filling portion may be expandable between a smaller delivery configuration and a larger deployed configuration.

Owner:EDWARDS LIFESCIENCES LLC

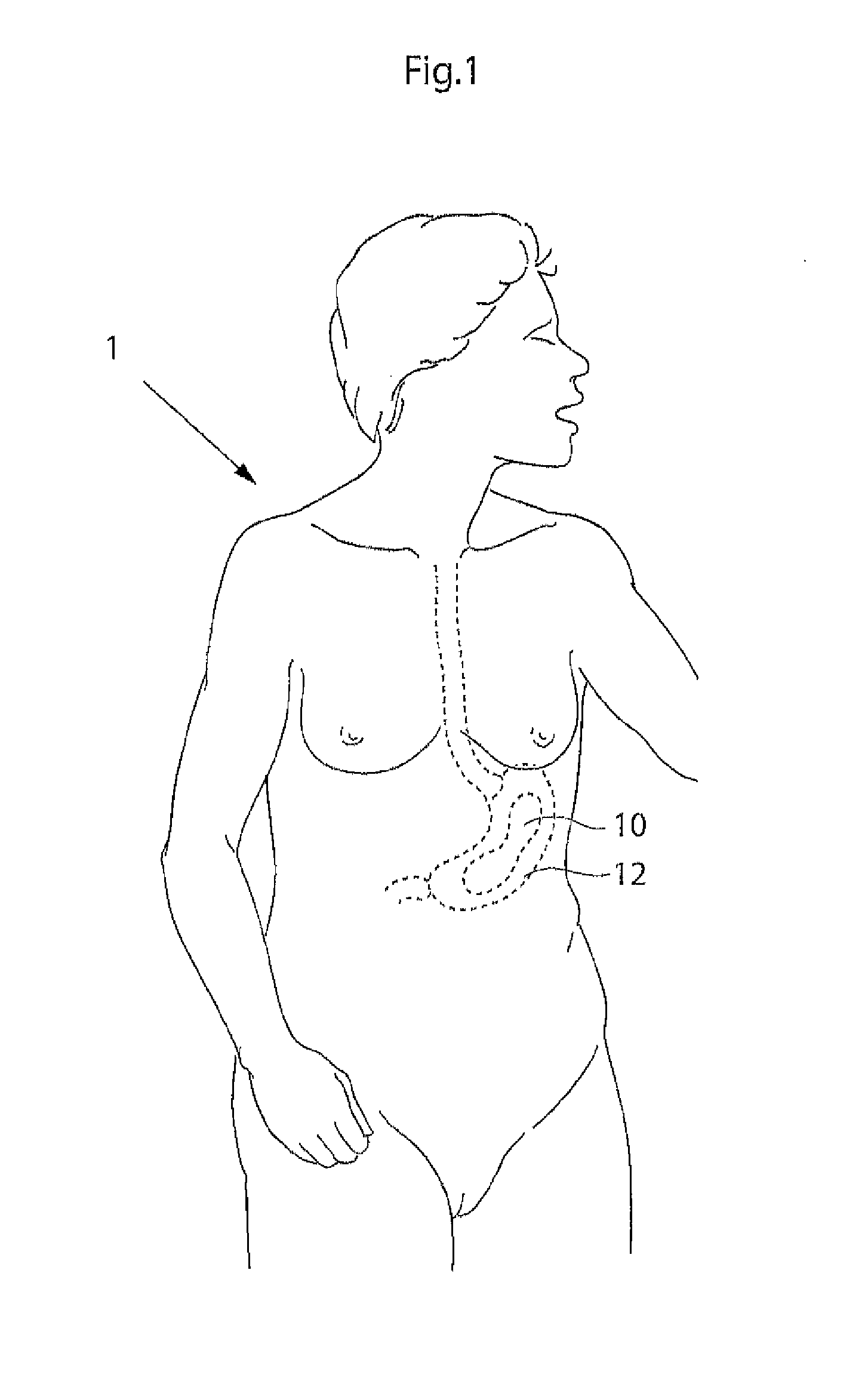

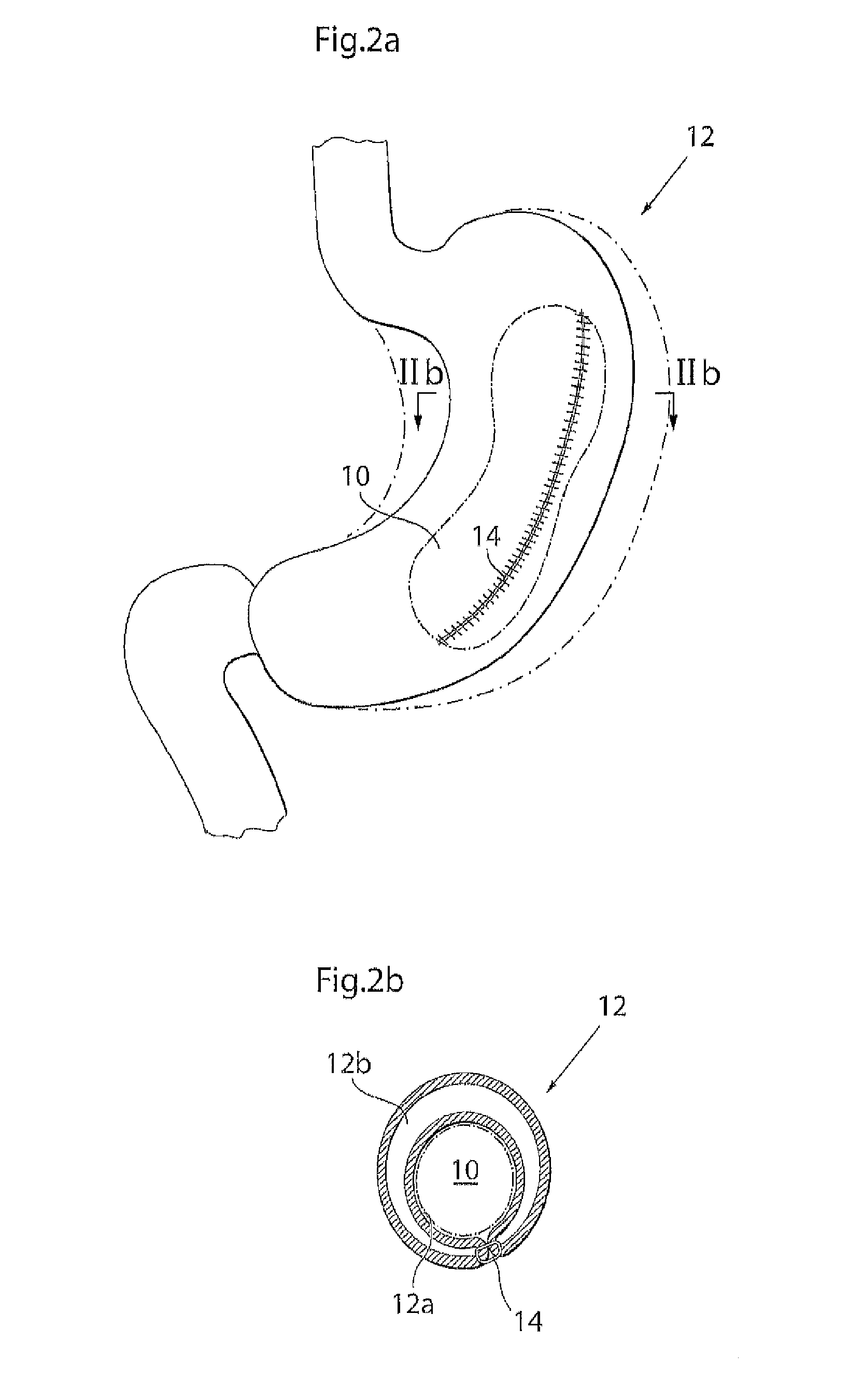

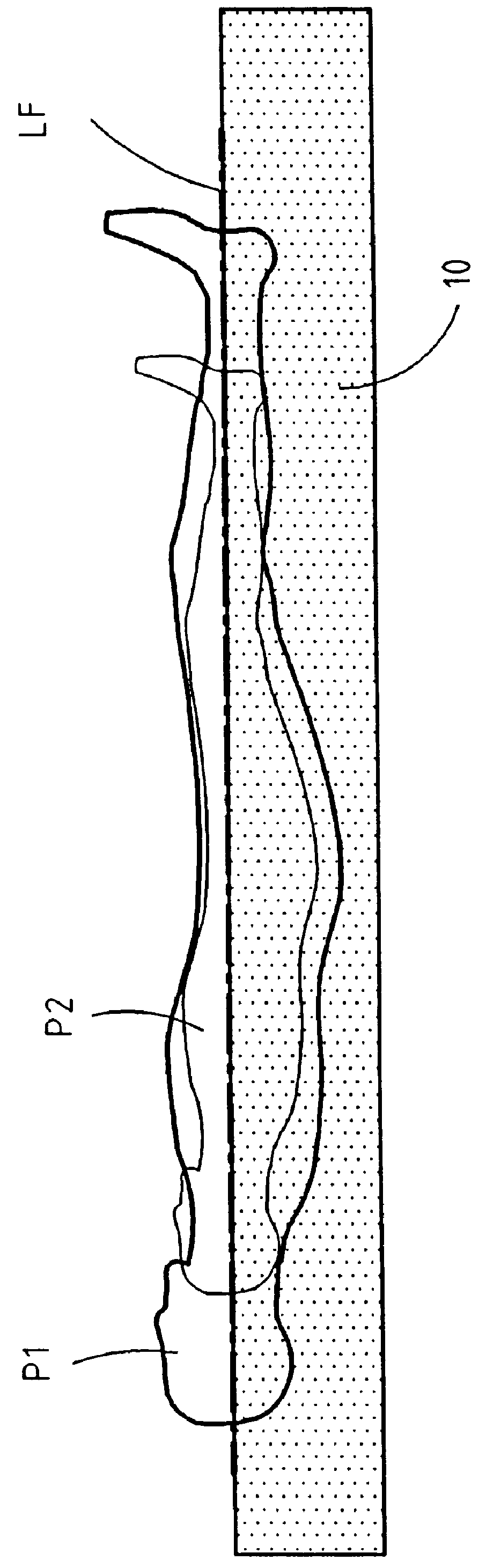

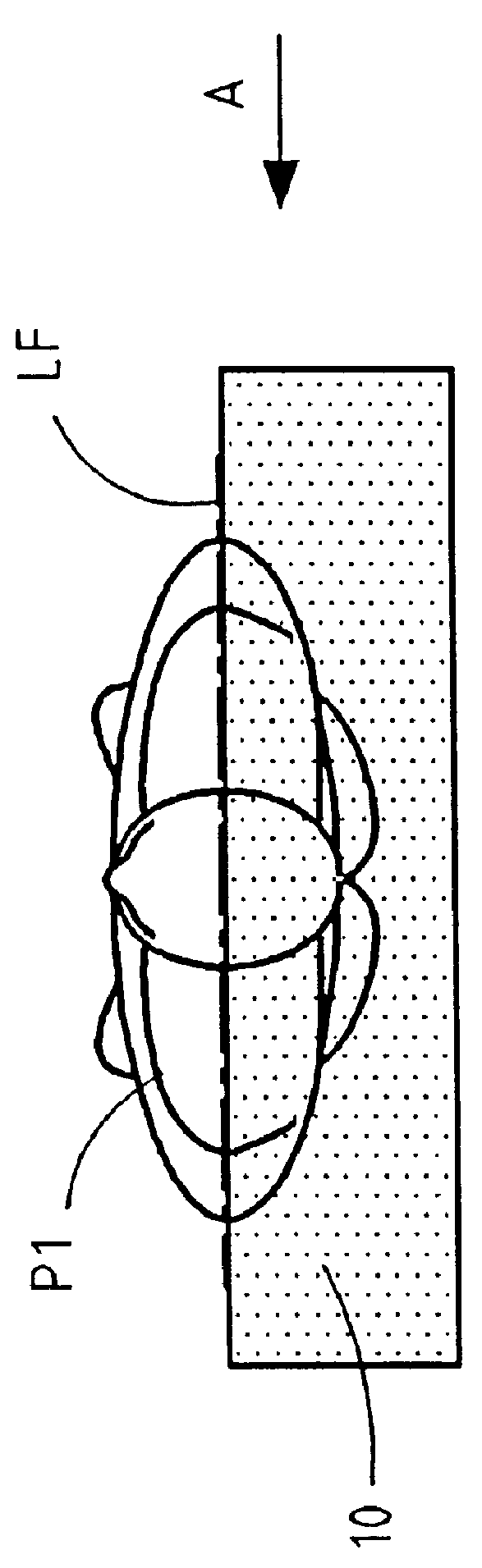

Intragastric device for treating morbid obesity

An intragastric device inserted by endoscopic path into a patient's stomach. The device includes a balloon or envelope having a specific nominal volume. The balloon is sealingly connected to connecting elements consisting of a disc forming a support base for the balloon against an inner wall of the stomach. The device also includes a flexible tube or catheter for connecting the balloon to a filling device and catching element integral with the tube or catheter. The connection elements enable a doctor to set and / or remove the balloon and to fix, either inside the patient's body, or subcutaneously the filling device and to be able to bring the balloon or envelope to its predetermined nominal volume.

Owner:DISTRICLASS MEDICAL

Obesity treatment

ActiveUS20120029550A1Improved long-term propertyLower the volumeSuture equipmentsBatteries circuit arrangementsStomach wallsVolume filling

An apparatus for treating obesity comprises a volume filling device formed by at least two segments and is provided and following implantation, the device is placed resting against the stomach wall of the patient to reduce the inner volume of the stomach, thereby affecting the patients appetite.

Owner:FORSELL PETER

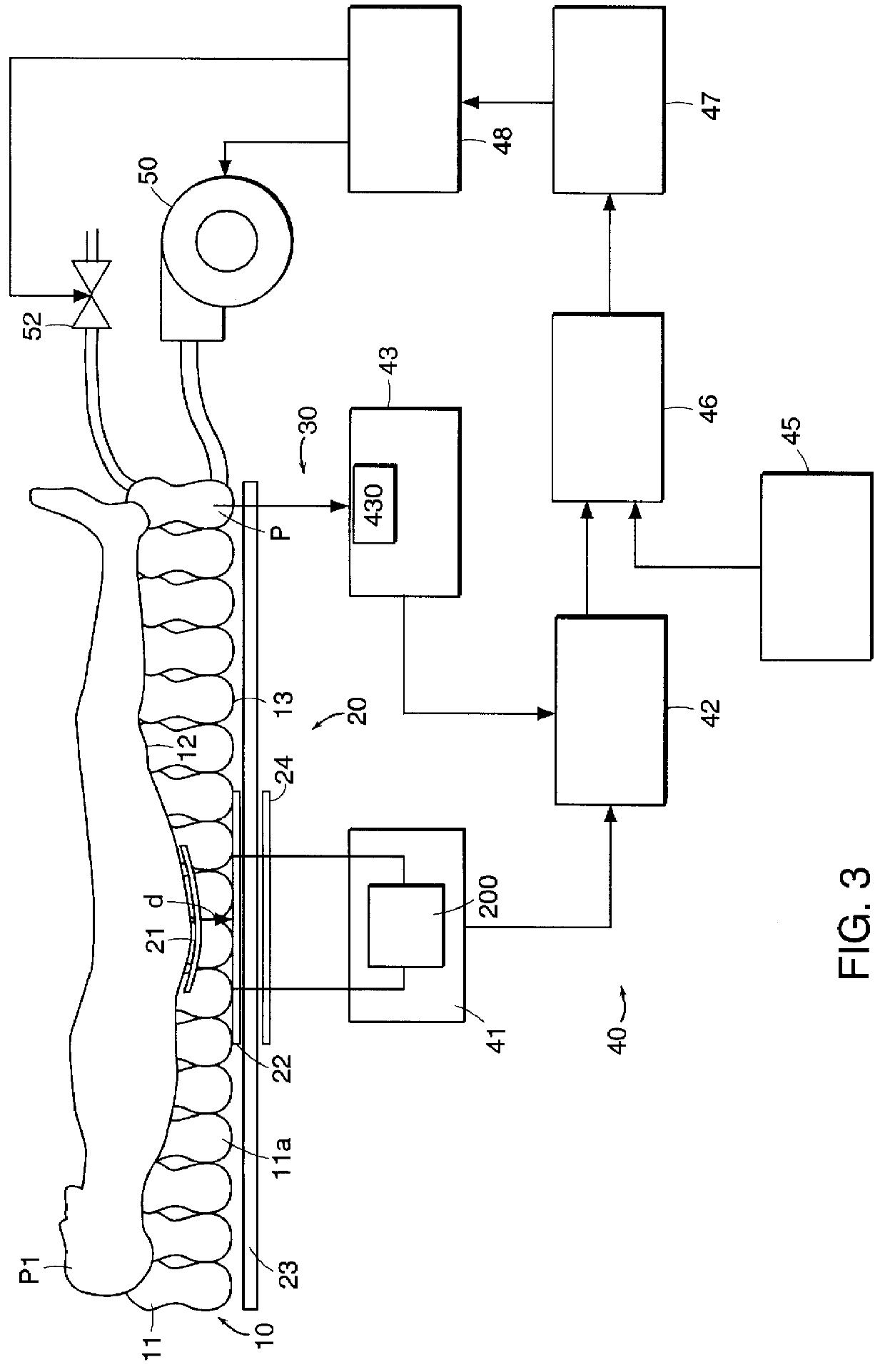

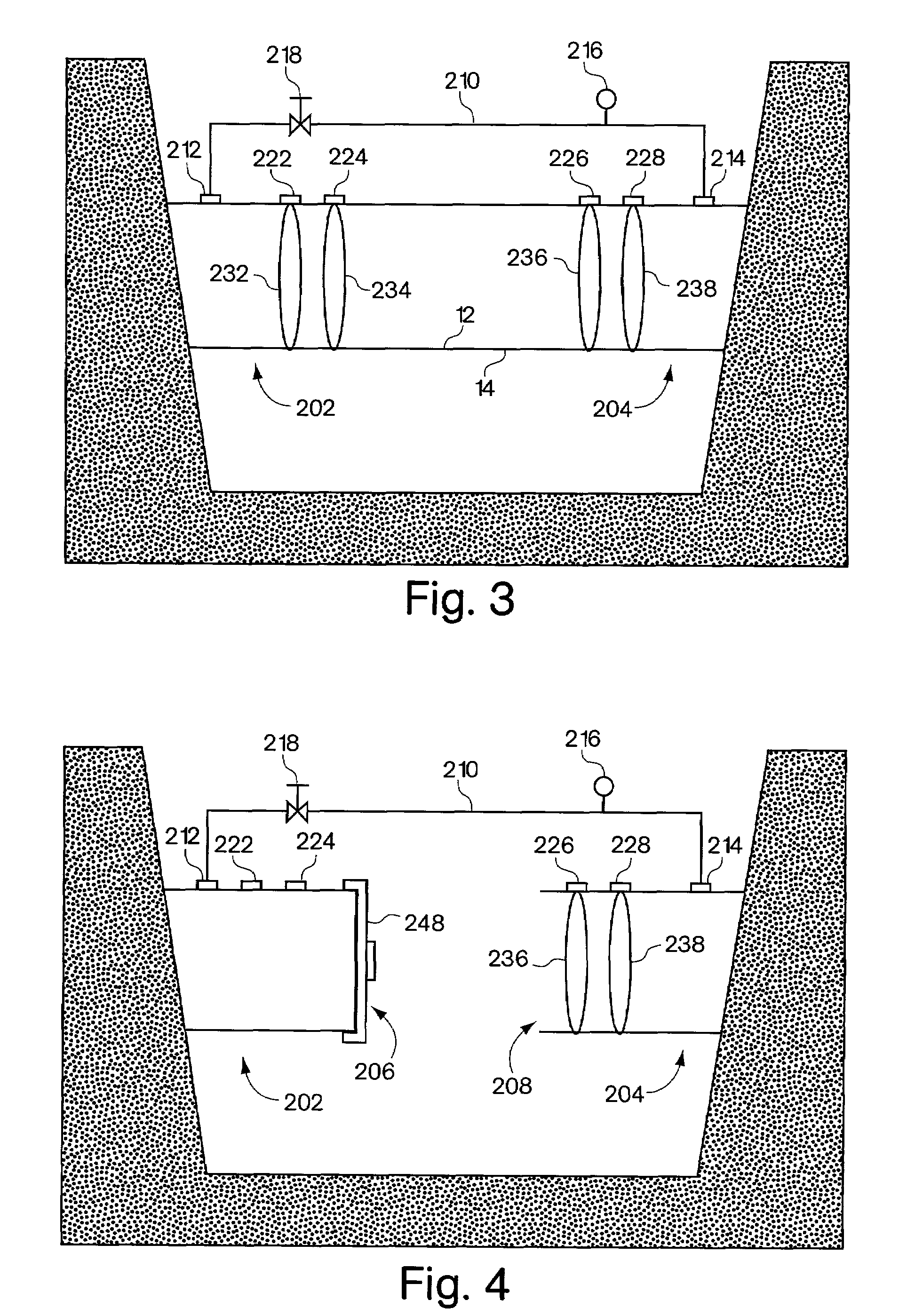

Method and apparatus for supporting an element to be supported, in particular the body of a patient, making it possible to support said element at a predetermined float line

InactiveUS6009580AHigh pressureStuffed mattressesSpring mattressesControlled releaseMeasurement device

The present invention relates to a method and apparatus for supporting a body element. The apparatus includes at least one support device with at least one closed or controlled-release chamber, a filling device and an emptying means device for filling said chamber with a filling fluid and emptying the fluid from the chamber, and a distance-measurement device for measuring the distance between a top face and a bottom face of the chamber. The apparatus further includes a reaction-measurement device for measuring the reaction of the support device relative to the morphological data of the body element to be supported, and a control system including a combination device for combining the measurement of the penetration distance d provided by the distance-measurement device and the measurement of the reaction provided by the reaction-measurement device. This combination is advantageously constituted by summing the two obtained measurements. The invention makes it possible to support the element to be supported substantially in a position of equilibrium corresponding substantially to a predetermined float line.

Owner:HILL ROM INDS

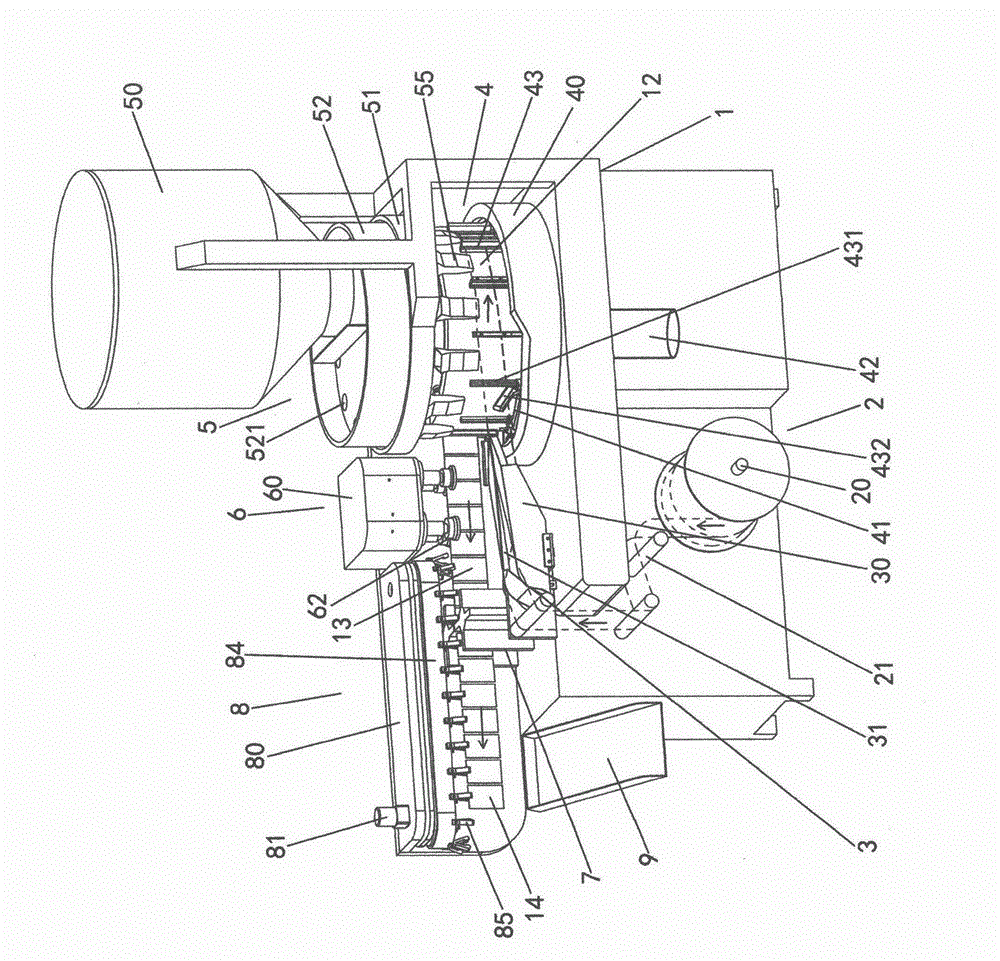

Opening-sealing apparatus for honeycomb molded body, opening-sealing apparatus for honeycomb fired body, method of filling plug material paste, and method of manufacturing honeycomb structured body

ActiveUS20070199643A1Small diameterSmall openingInternal combustion piston enginesSilencing apparatusCell basedPosition error

An opening-sealing apparatus for a honeycomb molded body comprising:a paste filling device equipped with a paste filling unit having an opening-sealing mask in which a number of openings are formed at predetermined positions and a paste supplying unit;an image pickup device for picking up an image of the end face of the honeycomb molded body; andan image analyzing device for analyzing the image obtained by the image pickup device, whereinthe image analyzing device analyzes the positions of the cells based upon the image of the end face picked up by the image pickup device; the opening-sealing mask is made in contact with the end face of the honeycomb molded body in such a manner that the positional error between the openings of the opening-sealing mask and the cells of the honeycomb molded body is reduced to a minimal level; and the plug material paste, which has been supplied from the paste supplying unit to the paste filling unit, is injected through the opening-sealing mask and filled in the end portion of the cells.

Owner:IBIDEN CO LTD

Wound filling apparatuses and methods

InactiveUS20130096518A1Large apertureEasy to controlMedical devicesAdhesive dressingsEngineeringCatheter

Many embodiments of wound filling devices and methods of their use in systems for the application of negative pressure therapy are described herein. In one embodiment, a wound filling device comprises: an inflatable bag member having at least one fluid carrying conduit operably connected thereto to inflate / deflate said bag member; a separate textured covering sock member at least partially covering the inflatable bag member. Another embodiment comprises a three-dimensional wound packing member, and may optionally comprise a plurality of such members linked together. Certain embodiments of wound packing members may comprise a porous bag member adapted to be non-adherent to the wound. Yet other embodiments may comprise a non-porous bag member provided with means to connect a fluid supply to the interior.

Owner:SMITH & NEPHEW INC

Intracorporeal occlusive device and method

InactiveUS20050267511A1Fit closelyRigid and stable space filling massBalloon catheterDilatorsCatheterBiomedical engineering

An intracorporeal space filling device and a delivery system and method for using the device is disclosed. The space filling device is preferably configured for percutaneous delivery from a peripheral conduit of a patient. The space filling device has an elongated tubular or interconnected bead structure which may have a transmutable material disposed within it. The transmutable material can be altered from a non-rigid state to a rigid state by the application of various types of energy or by other suitable means. The space filling device can be positioned by a delivery system and detached from the delivery system after desired positioning is achieved.

Owner:MARKS MICHAEL P

Method and apparatus for filling a fuel container

A filling device for use to manually or automatically refill a fuel cartridge using a separate fuel container or a second fuel cartridge is disclosed. The filling device provides for the sharing or fuel among numerous fuel containers and fuel cartridges in various consumer electronic devices. Fuel cartridges can be filled in-situ using an adapter for connecting the fuel container to the fuel cartridge. The adapter includes an input connector and an output connector arranged to adapt various fuel containers and fuel cartridges together. The adapter can be arranged as a passive device or as an active device and can include pumps, valves, power sources and control units as desired.

Owner:INTELLIGENT ENERGY LTD

Dispensing device for drinks

InactiveUS7353850B2Avoid soilUniform qualityBarrels/casks fillingBeverage vesselsEngineeringIdentification device

A dispensing device dispenses drinks or similar dosable liquid foodstuffs, especially coffee, milk, soft drinks or soups. The dispensing device includes an identification device for identifying a vertical height of a container for receiving the foodstuff and for emitting a height signal, a filling device which can be arranged in such a way that the height thereof can be adjusted in relation to the container, and a control device which sets the filling device to a pre-controllable filling level in relation to the container, on the basis of the height signal, before the foodstuff is introduced into the container. In this way, a container can be filled in an optimum manner without spilling.

Owner:FRANKE TECH & TRADEMARK LTD

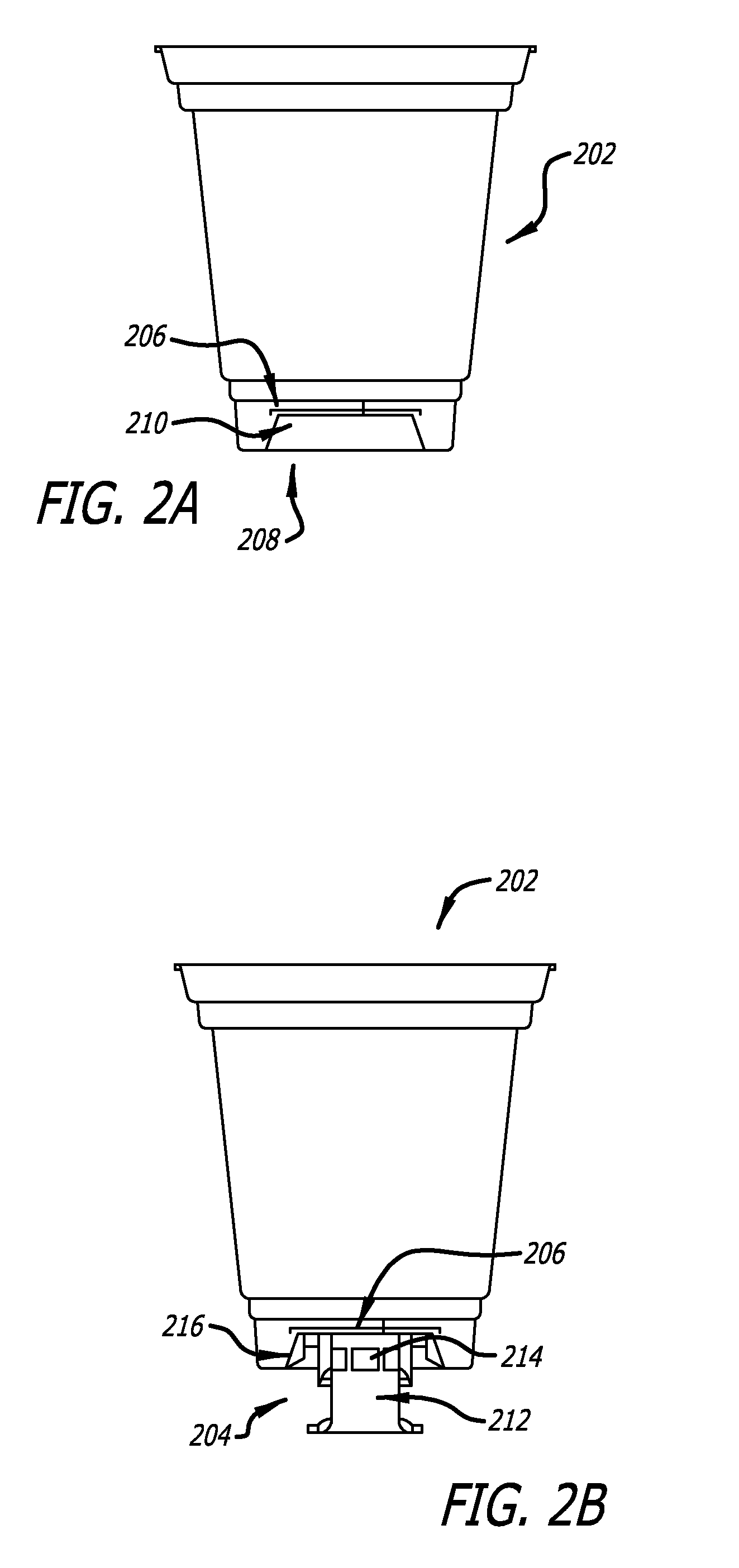

Fluid transfer assembly and methods of fluid transfer

ActiveUS20110061764A1Drain fastEasy to removeOperating means/releasing devices for valvesLiquid fillingEngineeringFill device

A fluid transfer assembly and methods of fluid transfer is described. In one aspect, the fluid transfer assembly includes a fluid container having an opening in a bottom, a coupling device attached to the fluid container at the opening, and a filling device. The coupling device may include a valve biasing the coupling device in a closed fluid-tight position via magnetic attraction of opposing first and second components, each of the opposing first and second components including a magnetic material. The filling device may include a rigid member with a perimeter smaller than a perimeter of the fluid container opening, the rigid member including a passage along a longitudinal axis and one or more apertures through a sidewall in fluid communication with the passage, such that the coupling device is transitioned from the closed fluid-tight position to an open position by pressing the rigid member against one of the opposing first and second components, thereby placing the apertures in fluid communication with an interior of the fluid container.

Owner:GRINON INDS

Method and apparatus for filling a fuel container

A filling device for use to manually or automatically refill a fuel cartridge using a separate fuel container or a second fuel cartridge is disclosed. The filling device provides for the sharing or fuel among numerous fuel containers and fuel cartridges in various consumer electronic devices. Fuel cartridges can be filled in-situ using an adapter for connecting the fuel container to the fuel cartridge. The adapter includes an input connector and an output connector arranged to adapt various fuel containers and fuel cartridges together. The adapter can be arranged as a passive device or as an active device and can include pumps, valves, power sources and control units as desired.

Owner:INTELLIGENT ENERGY LTD

Dispensing device for drinks

ActiveUS20060108023A1Uniform qualityAvoid soilBarrels/casks fillingBeverage vesselsIdentification deviceEngineering

The invention relates to a dispensing device for drinks or similar dosable liquid foodstuffs, especially coffee, milk, soft drinks or soups. Said dispensing device comprises an identification device for identifying a vertical height of a container for receiving the foodstuff and for emitting a height signal, a filling device which can be arranged in such a way that the height thereof can be adjusted in relation to the container, and a control device which sets the filling device to a pre-controllable filling level in relation to the container, on the basis of the height signal, before the foodstuff is introduced into the container. In this way, a container can be filled in an optimum manner without spilling.

Owner:FRANKE TECH & TRADEMARK LTD

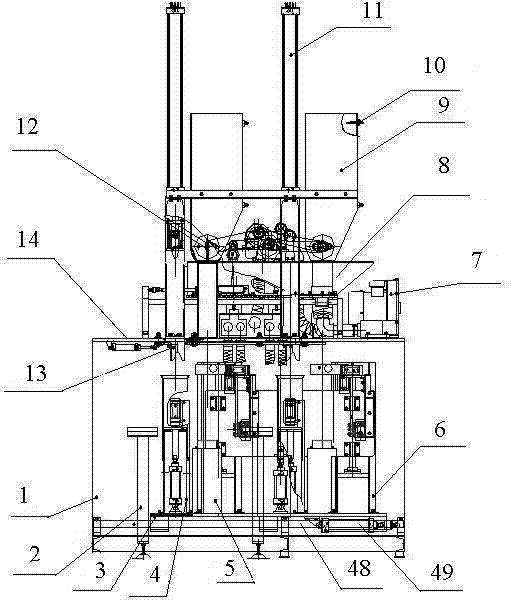

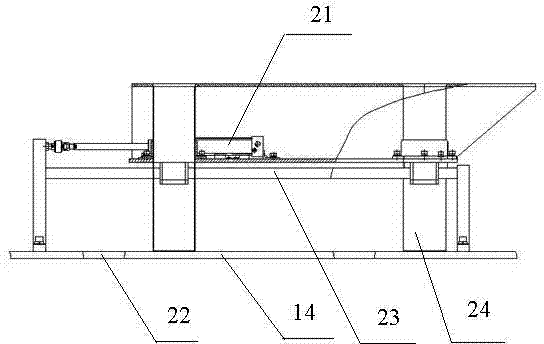

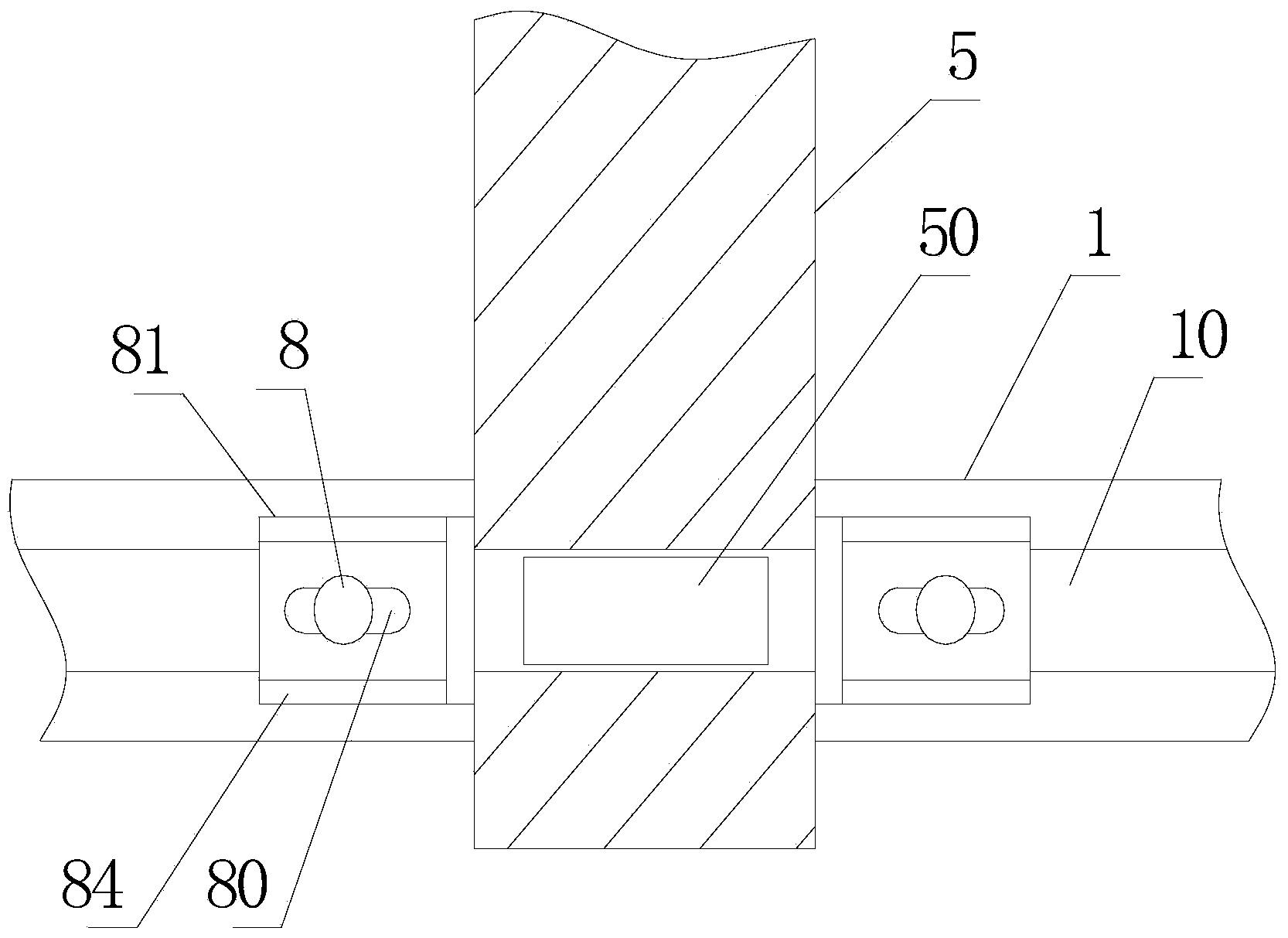

Automatic edible fungi bag filler

InactiveCN102396344AImprove uniformityImprove compactnessPackagingHorticultureEngineeringFill device

The invention relates to an automatic edible fungi bag filler, which is characterized by comprising a stander which is provided with an upper crown plate and a base, wherein a base guiding rod is arranged below the base, the base is also connected with a base air cylinder, and the base is connected with the base guiding rod through a slide block, a holing device and a storage hopper are arranged above the upper crown plate, and a blender is arranged in the bottom part of the storage hopper; a movable barrel device is arranged below the storage hopper, and the base is provided with at least one set of bag taking and filling device; and the bag taking and filling device consists of a bag taking device, a bag filling device and a bag pushing device. Due to the adoption of the automatic edible fungi bag filler, the manual bagging industrial difficulty is thoroughly solved, the labor intensity is alleviated, operators can be released, and multiple machines can be operated by one person; the labor efficiency can be improved; and the maneuverability is strong, and the automatic edible fungi bag filler is simple to operate and is easy to control.

Owner:徐寿海 +1

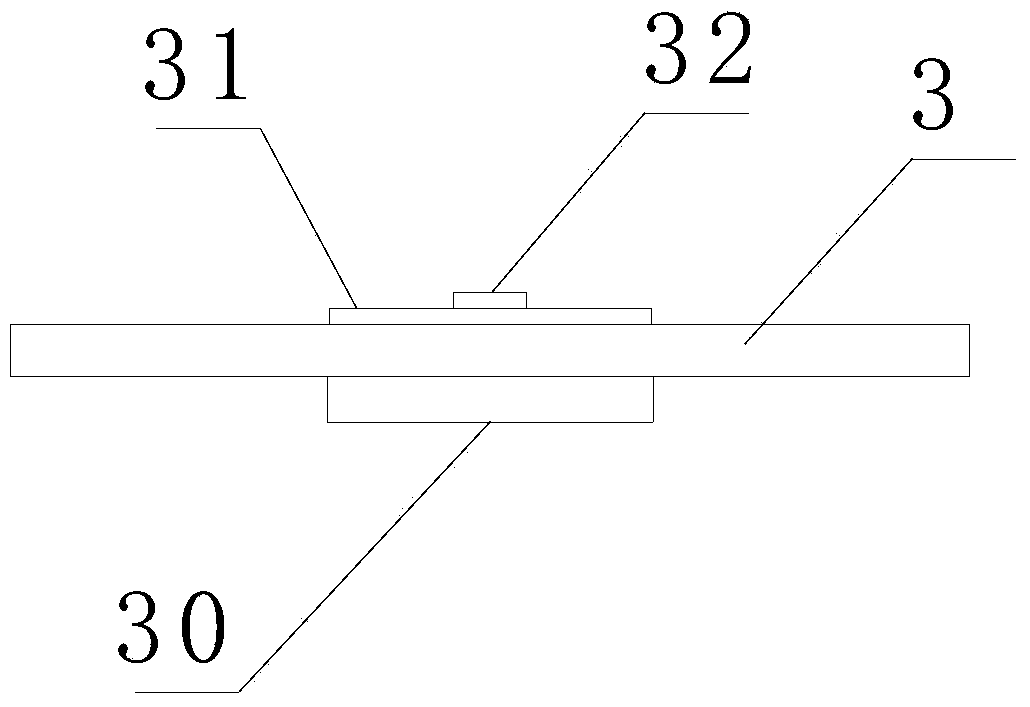

Method and apparatus for treating underground pipeline

InactiveUS6966950B2Operational securityConvenient lengthSpraying apparatusLiquid/solution decomposition chemical coatingFilling materialsUnderground pipeline

A system for internally filling a joint or other discontinuity in a pipeline. The system includes a flexible conduit, a fill device removably connected to said flexible conduit, wherein the fill device is constructed and arranged to apply a fill material to an interior surface of said pipeline to fill one or more gaps in the pipeline, and a propulsion unit connected to at least one of the flexible conduit and the fill device that propels the flexible conduit through said pipeline.

Owner:NEUCO INC

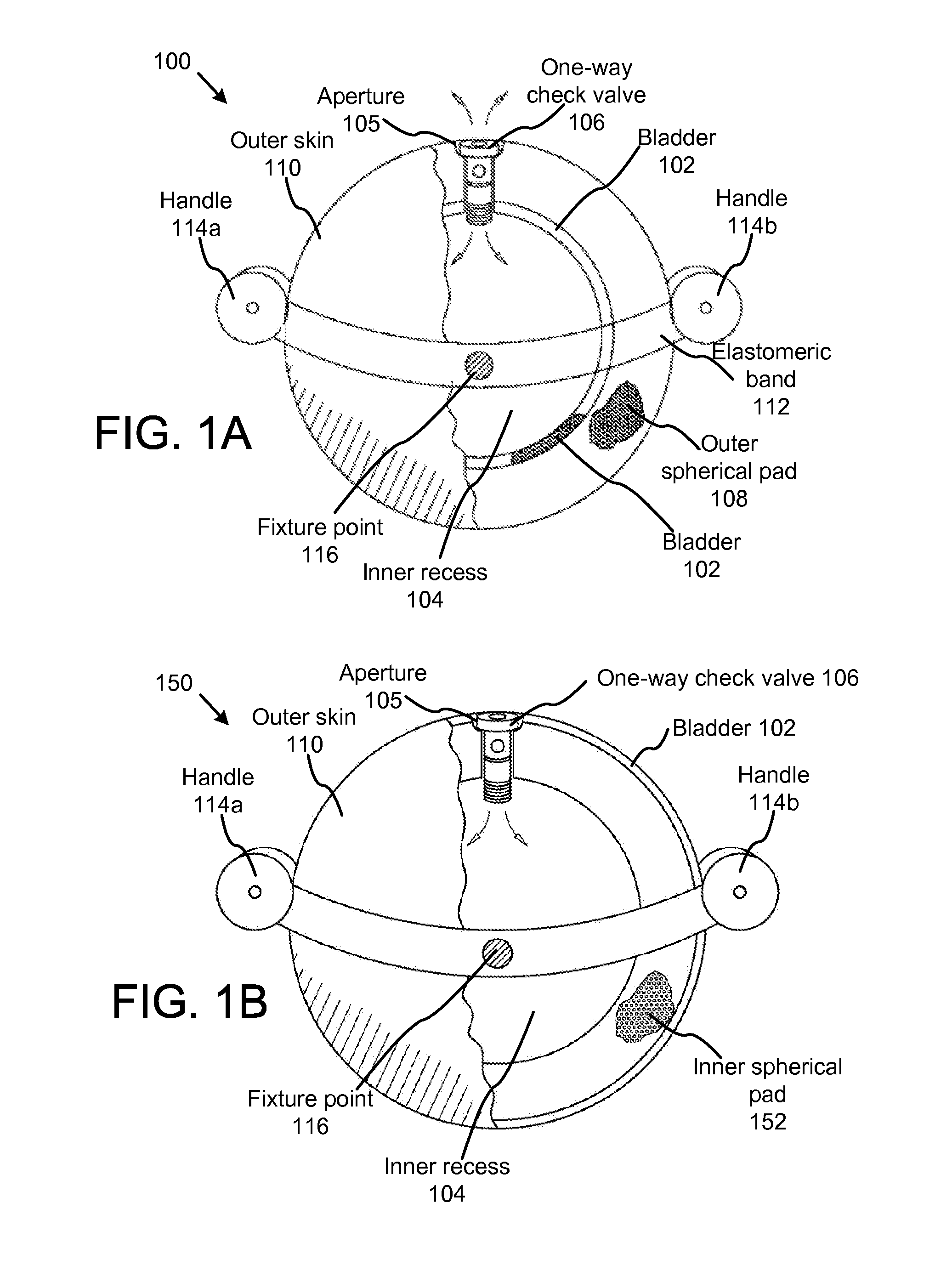

Multi-function isotonic exercise ball

A portable isotonic compression-expansion exercise device is disclosed which can also function as a recreational object, therapy tool, and strength measurement apparatus. One embodiment comprises of an elastomeric, resilient ball with a detachable removable and interchangeable exterior resistance band with two opposing handles. Some embodiments include a pneumatic airflow control valve, which valve reaches into the hollow core of an internal foam center. Resistance from the device during these exercises comes from static pneumatic resistance from within the sealed elastic object, changing pneumatic resistance as air flows in and out of the foam-filled device through the airflow control valve. Internal springs, internal foam resistance, external band(s) on the device's surface, and / or internal apparatus can create multiple forms of resistance. The disclosed device, in some embodiments, further comprises a strength measurement gauge in the form of an air pressure gauge.

Owner:WILSON DANIEL VAUGHAN

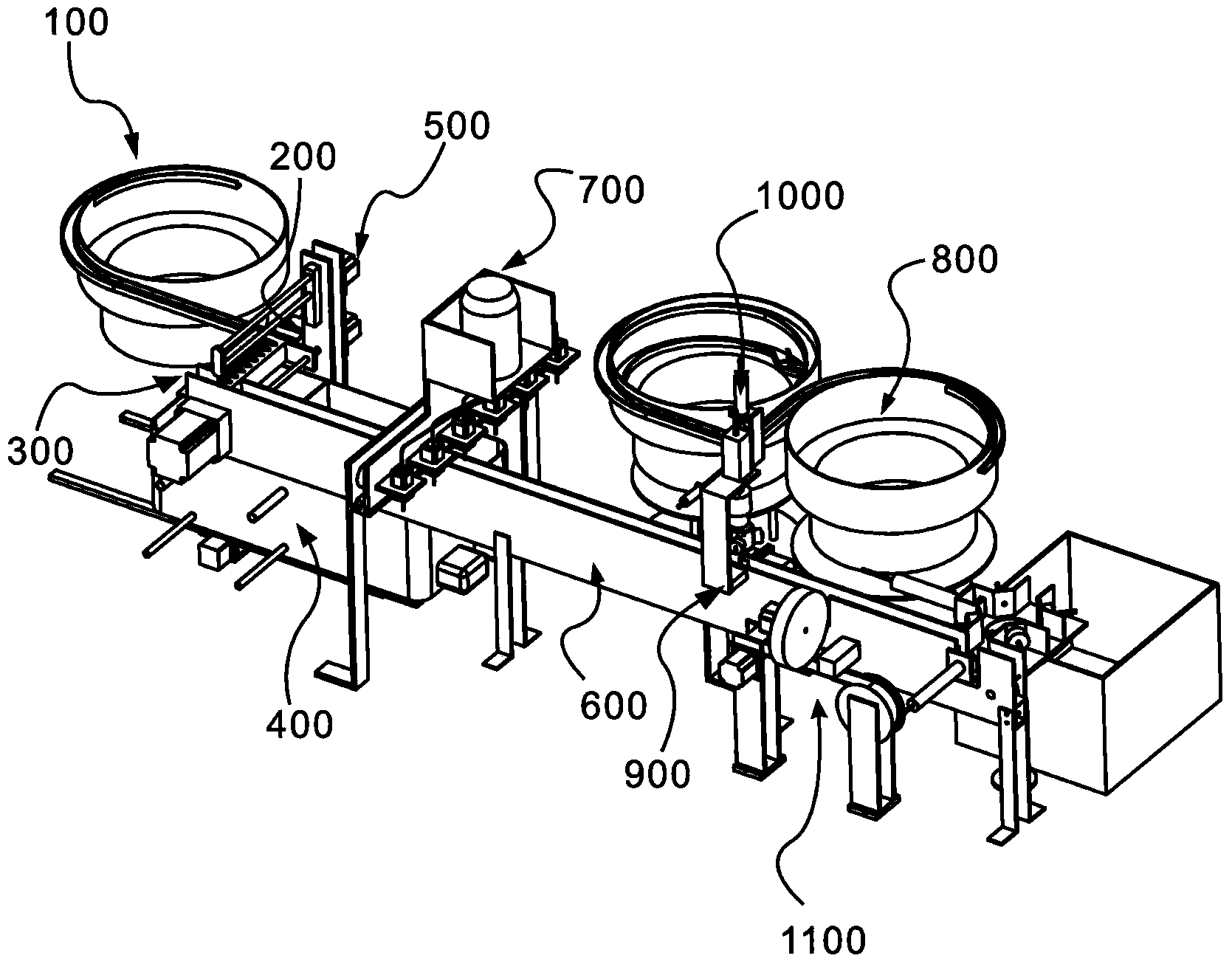

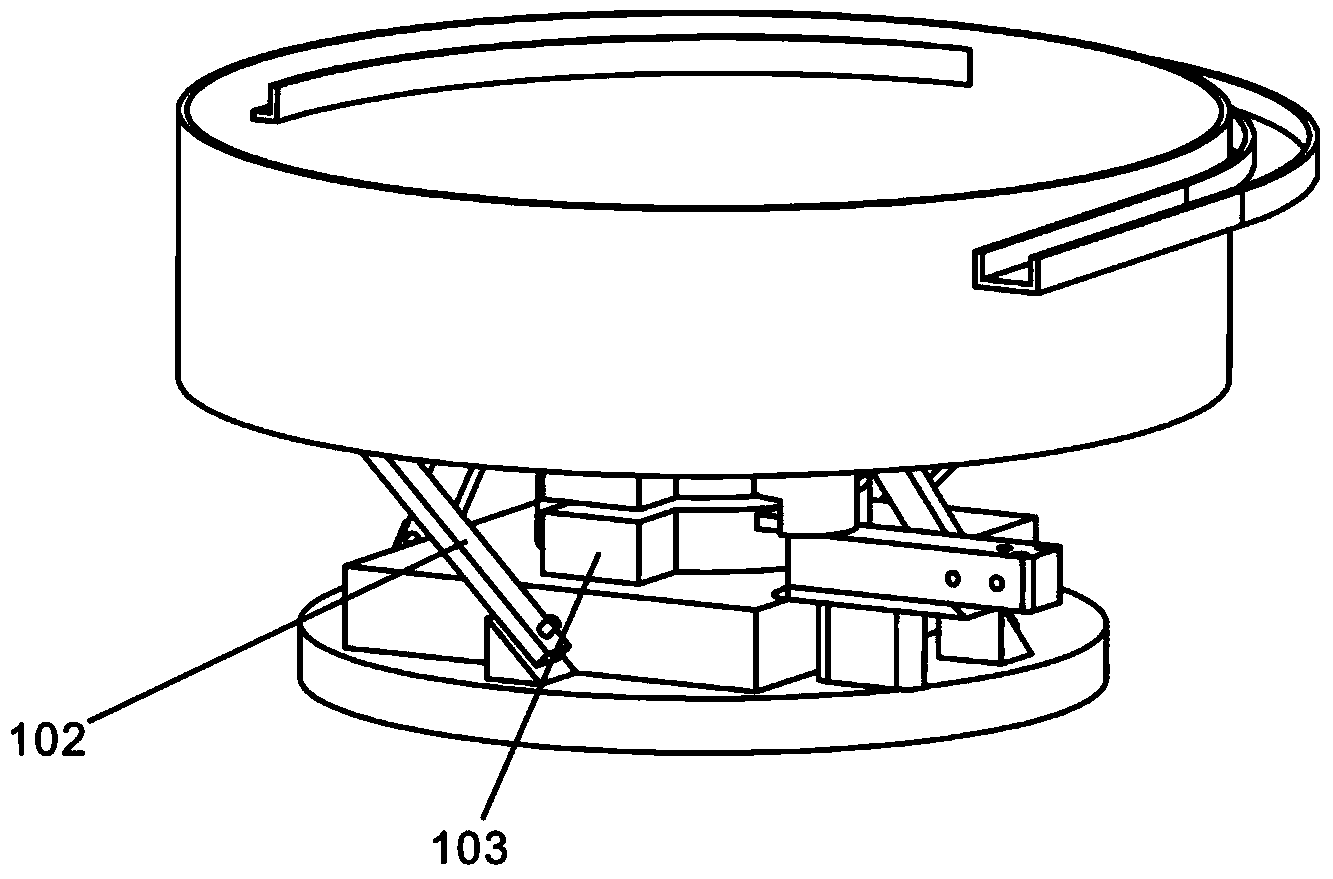

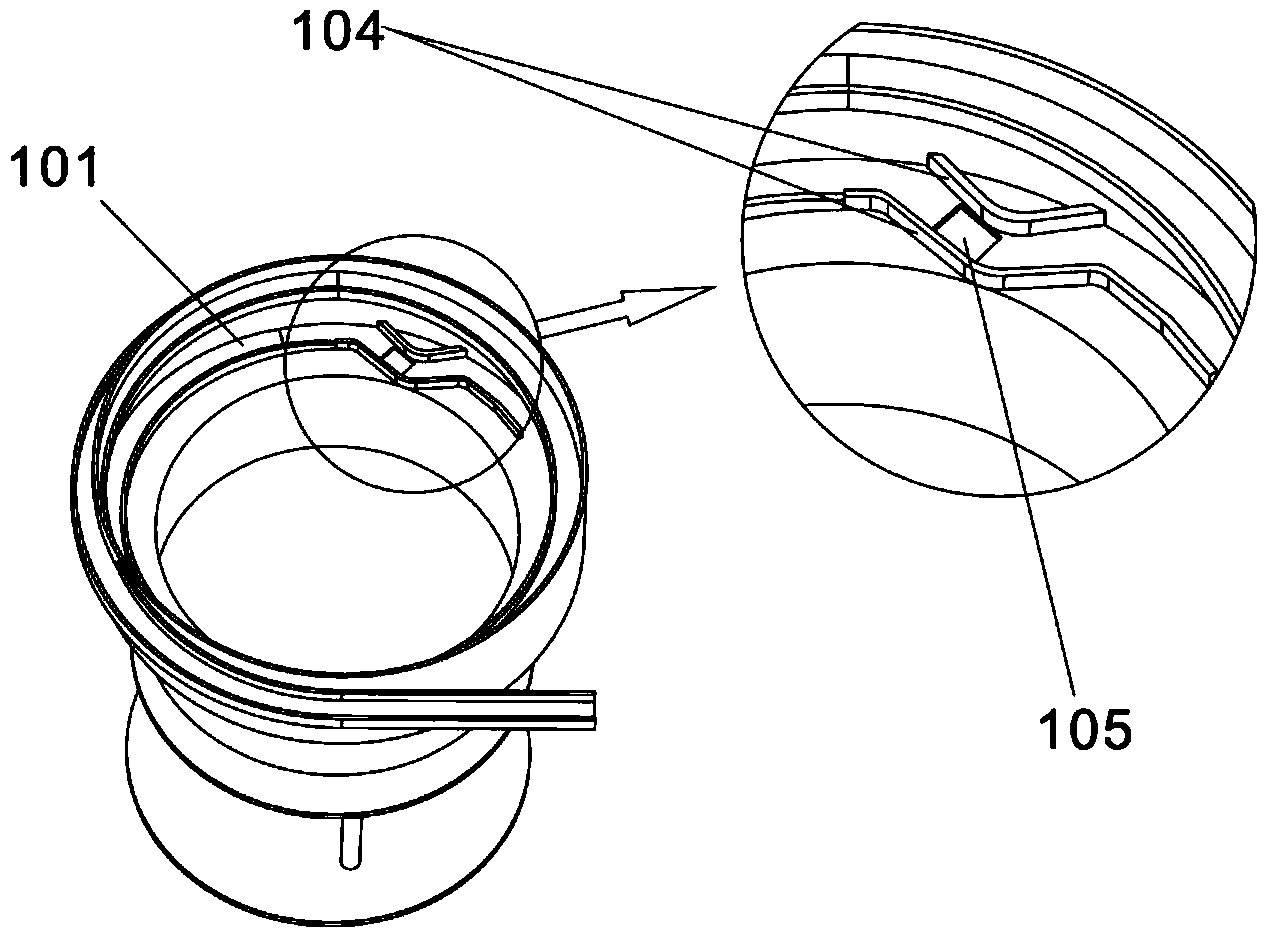

Filling bottle correcting, pushing, rinsing, conveying, filling, cover conveying and screwing labeling and coding system

ActiveCN104326431ASolve the problem of directional transportCapsThreaded caps applicationEngineeringBottle

The invention discloses a filling bottle correcting, pushing, rinsing, conveying, filling, cover conveying and screwing labeling and coding system which comprises a correcting device and a pushing device and also comprises a carrying device, a rinsing device, a progressive device, a conveying device, a filling device, a cover conveying device, an impact extrusion device, a cover screwing device and a labeling device, wherein the correcting device is a cavity of which one end is open; a material channel which spirally ascends is formed in the inner side wall of the cavity; and the pushing device comprises a pushing cylinder and a pushing platform. According to the system disclosed by the invention, the problem that the filling bottles cannot be directionally transported can be solved, and the problems that the filling bottles cannot be subjected to automatic progressive rinsing, conveying and filling, cover conveying, filling bottle cover impact extrusion and fixation, cover screwing and labeling and coding also can be solved.

Owner:NANTONG SNT PACKING MACHINERY

Device for connecting or filling and method

Owner:INTACT CLOSED TRANSFER CONNECTORS LLC

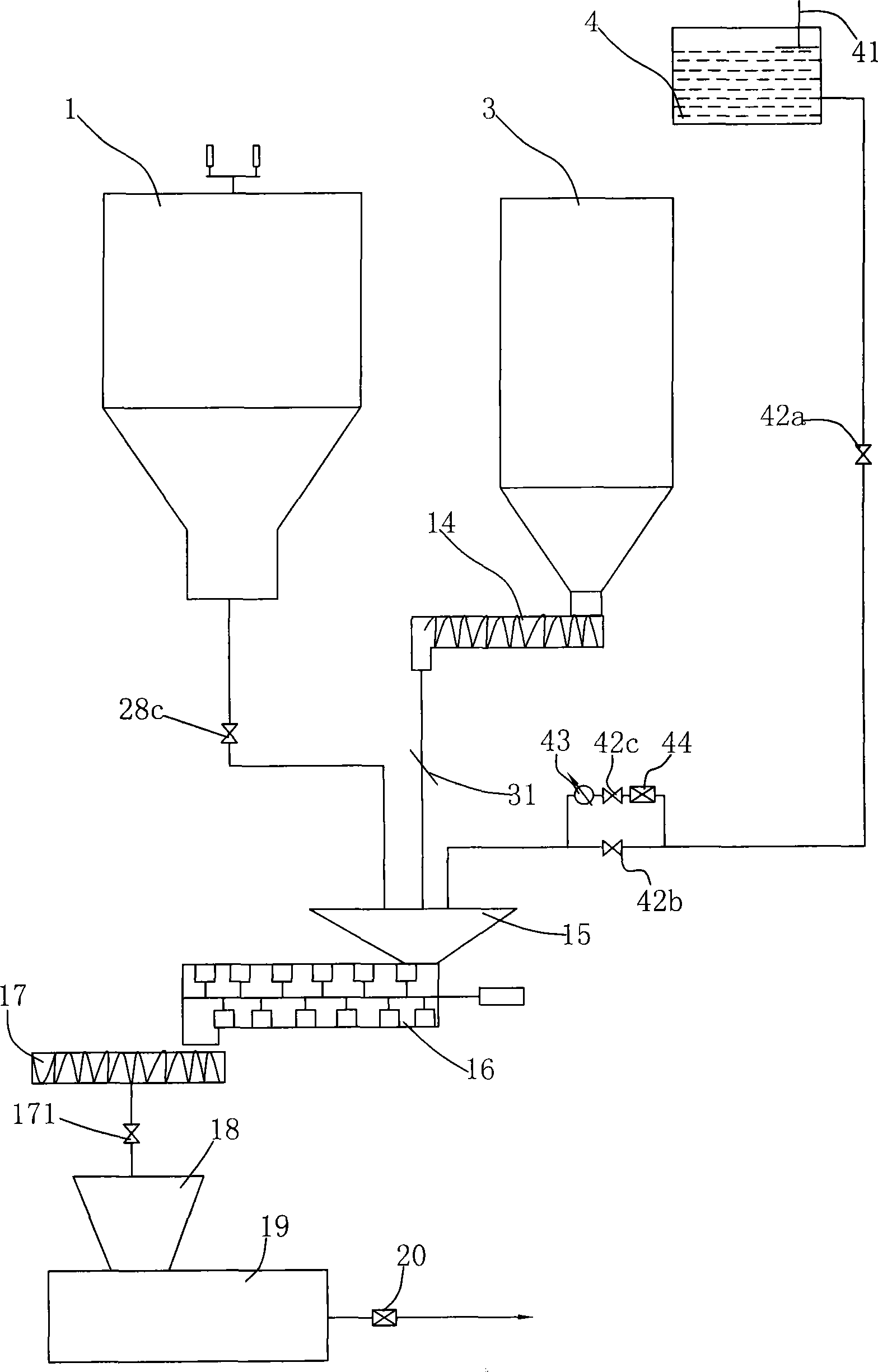

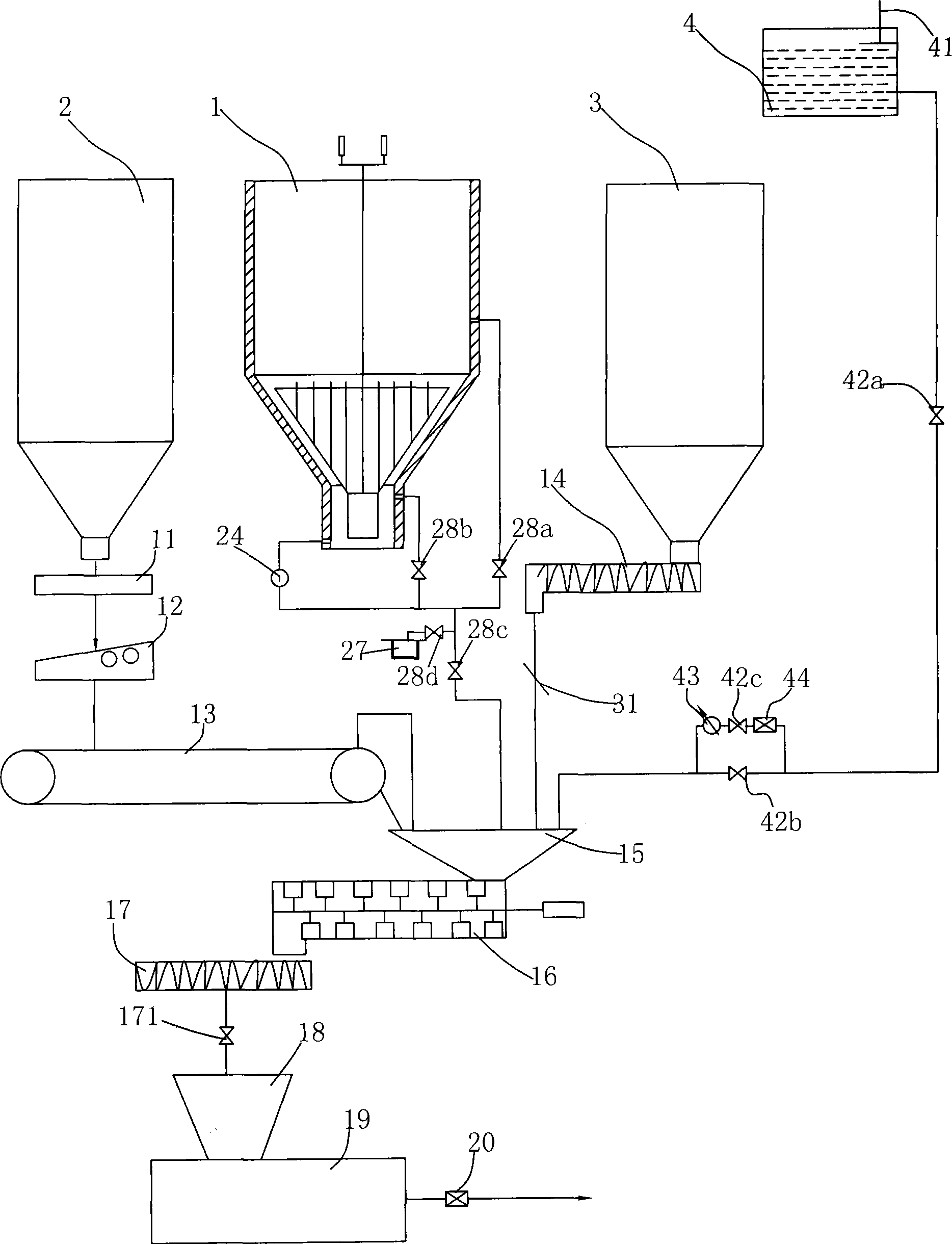

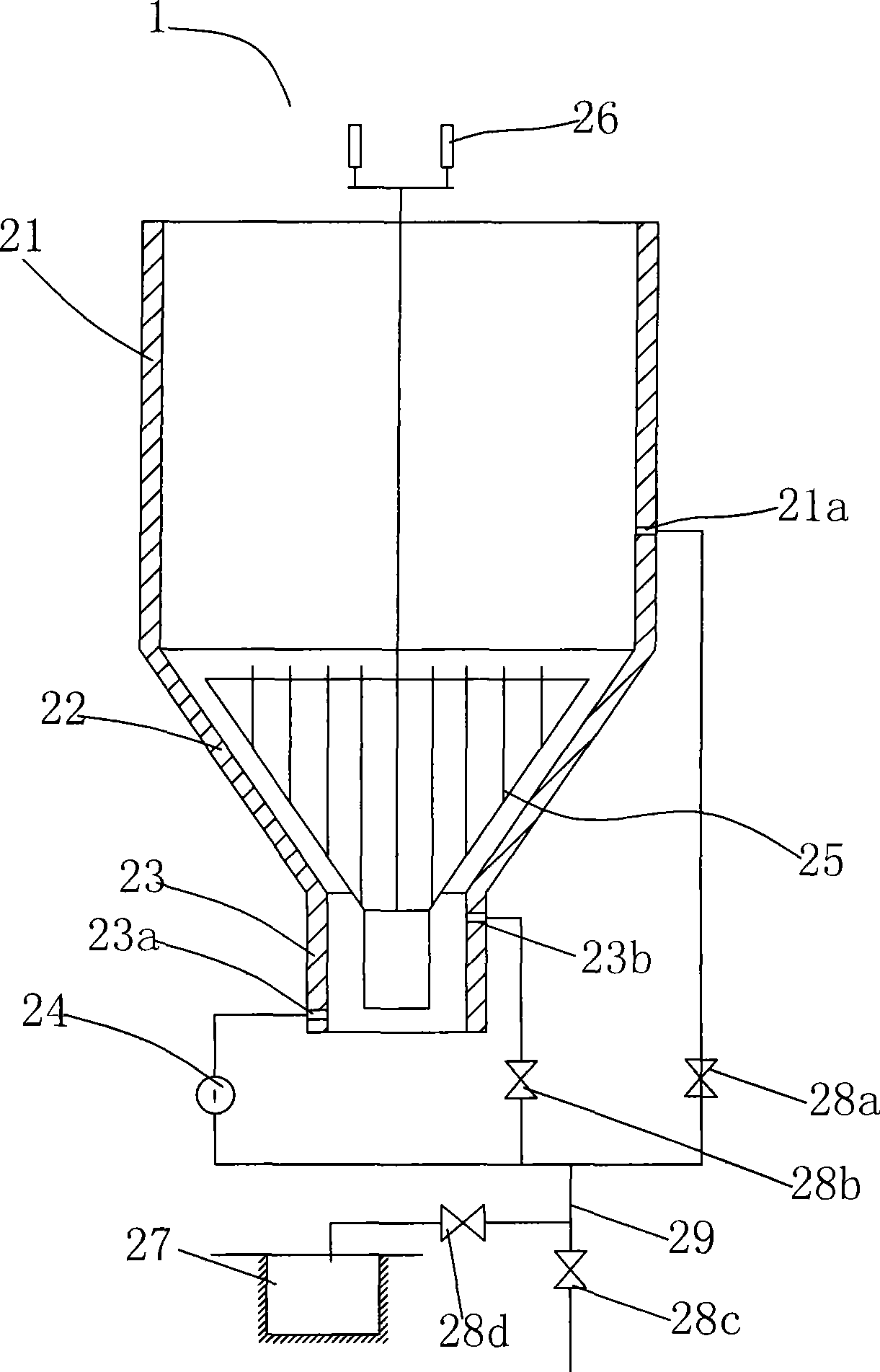

Filling apparatus and filling technique

ActiveCN101469614AGood concentration efficiencyHigh concentrationMaterial fill-upEngineeringMoisture

The present invention discloses a filling device and filling process, wherein the filling device includes: a deep cone thickener used for storing and concentrating tailing paste; a cementing material storehouse used for store cementing material; a stirring device used to receive concentrated tailing paste and cementing material from the deep cone thickener and the cementing material storehouse to mix them and stir to obtain filling paste; and a conveyer used for receiving filling paste from the stirring device and conveying the filling paste to mine goaf. By using deep cone thickener, the filling device through the invention has better concentrating efficiency, higher concentrating degree without using a filter for moisture abstraction operation to concentrated tail paste, hence the device is simple and cost low.

Owner:CHINA ENFI ENGINEERING CORPORATION

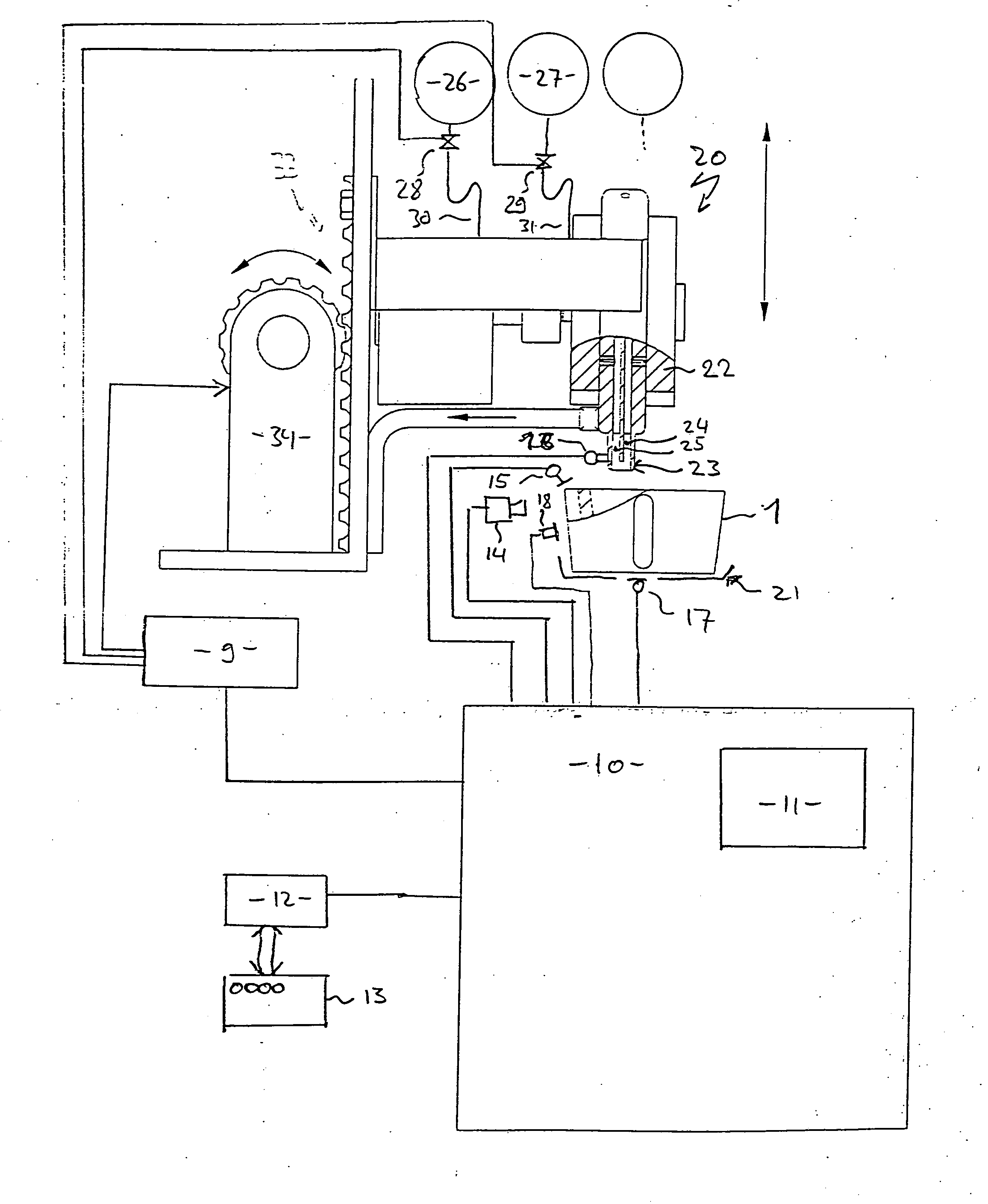

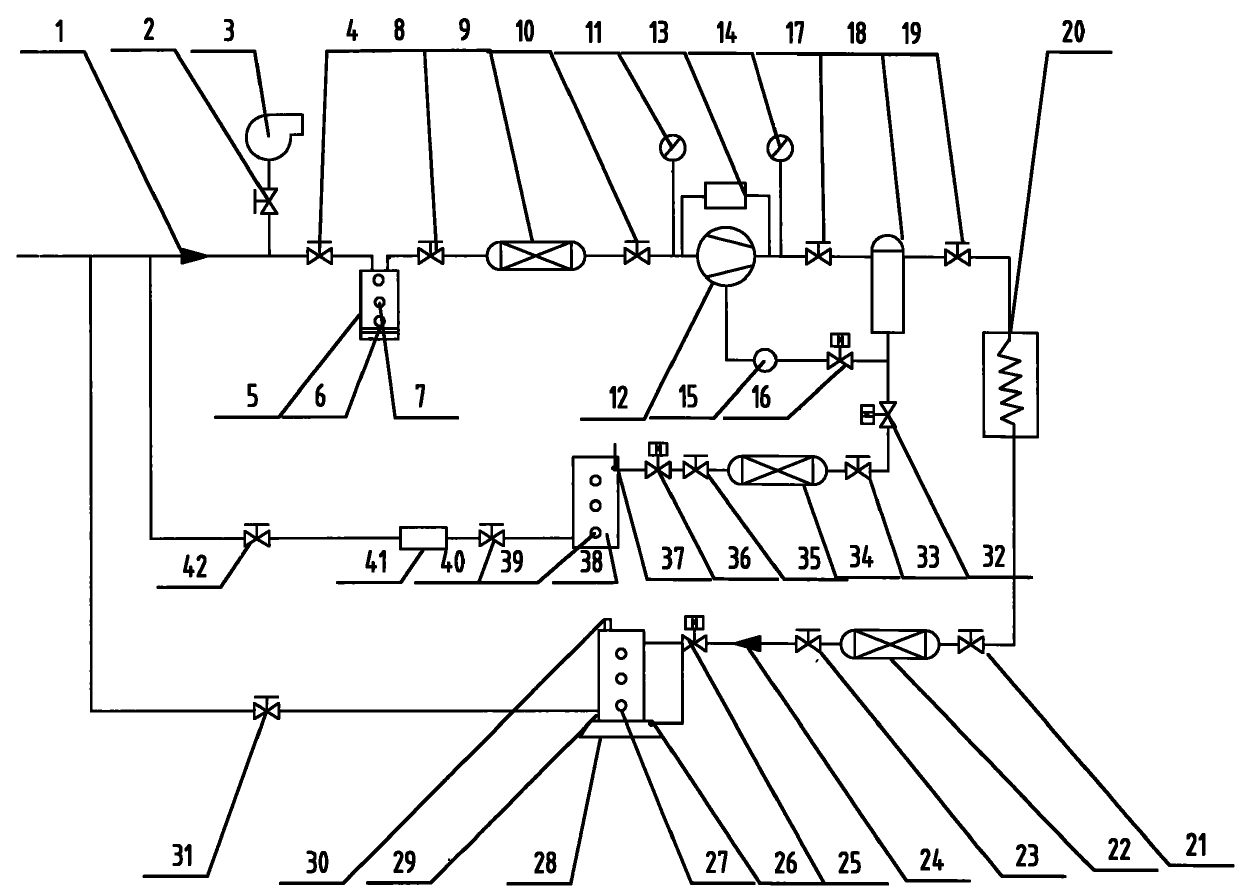

Automatic recovery and fill system of refrigeration system

InactiveCN101769655APlay the role of energy saving and environmental protectionAvoid damageCompressorVacuum extractorRefrigerant reclamation

The invention discloses an automatic recovery and fill system of a refrigeration system, comprising a refrigerant recovery and fill device, a vacuum extractor and a refrigeration oil recovery and fill device, wherein, the refrigerant recovery and fill device comprises a gas-liquid separation evaporating drum, a compressor, an oil separator, a condenser and a fluid reservoir; the refrigeration oil recovery and fill device comprises an oilway filter, an oil reservoir and an oil flowmeter. As an outlet of the oil separator of the system additionally has the refrigeration oil recovery and fill device, both refrigerant recovery and refrigeration oil recovery are realized, also, the refrigeration oil can be filled into the refrigeration system and the compressor. The gas-liquid separation evaporating drum of the invention can separate gas and liquid fully, while a heating strip under the drum enables liquid refrigerant in the drum to evaporate at every moment, which prevents the return liquid damaging the compressor. The system has the effects of energy saving and environmental protection.

Owner:DALIAN SANYO COMPRESSOR

High-speed full-automatic packing machine

ActiveCN102874423AReduce packaging costsReduce labor intensityWrapping material feeding apparatusWrapper twisting/gatheringPack materialEngineering

A high-speed full-automatic packing machine is characterized by comprising a frame, and a membrane placing device, a packing bag shaping device, a longitudinal sealing device, a filling device, a sealing device, a cutting device, a bag sending device and a finished product delivery device which are arranged on the frame respectively, wherein the membrane placing device, the packing bag shaping device, the longitudinal sealing device, the sealing device, the bag sending device and the finished product delivery device are arranged sequentially along the conveying direction of a packing material; the filling device is positioned above the longitudinal sealing device; and the finished product delivery device is positioned below the bag sending device. Therefore, the high-speed full-automatic packing machine is capable of manufacturing a packing membrane into a packing bag and packing the packing bag in a filling manner, so that the full-automatic packing with high speed is realized. As a result, the packing cost and the labor intensity are lowered, and the production efficiency is improved.

Owner:广东宏川环宇科技有限公司

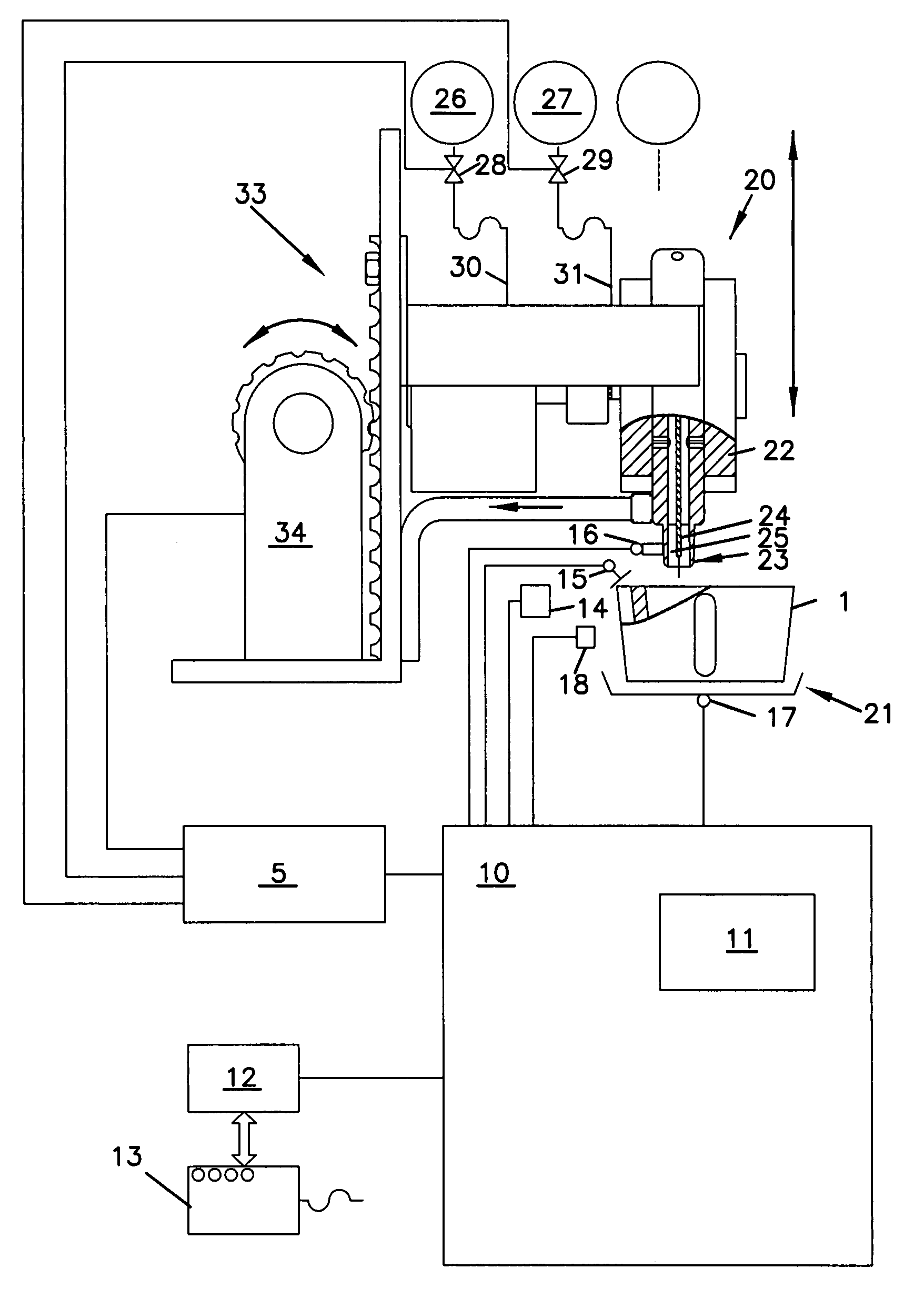

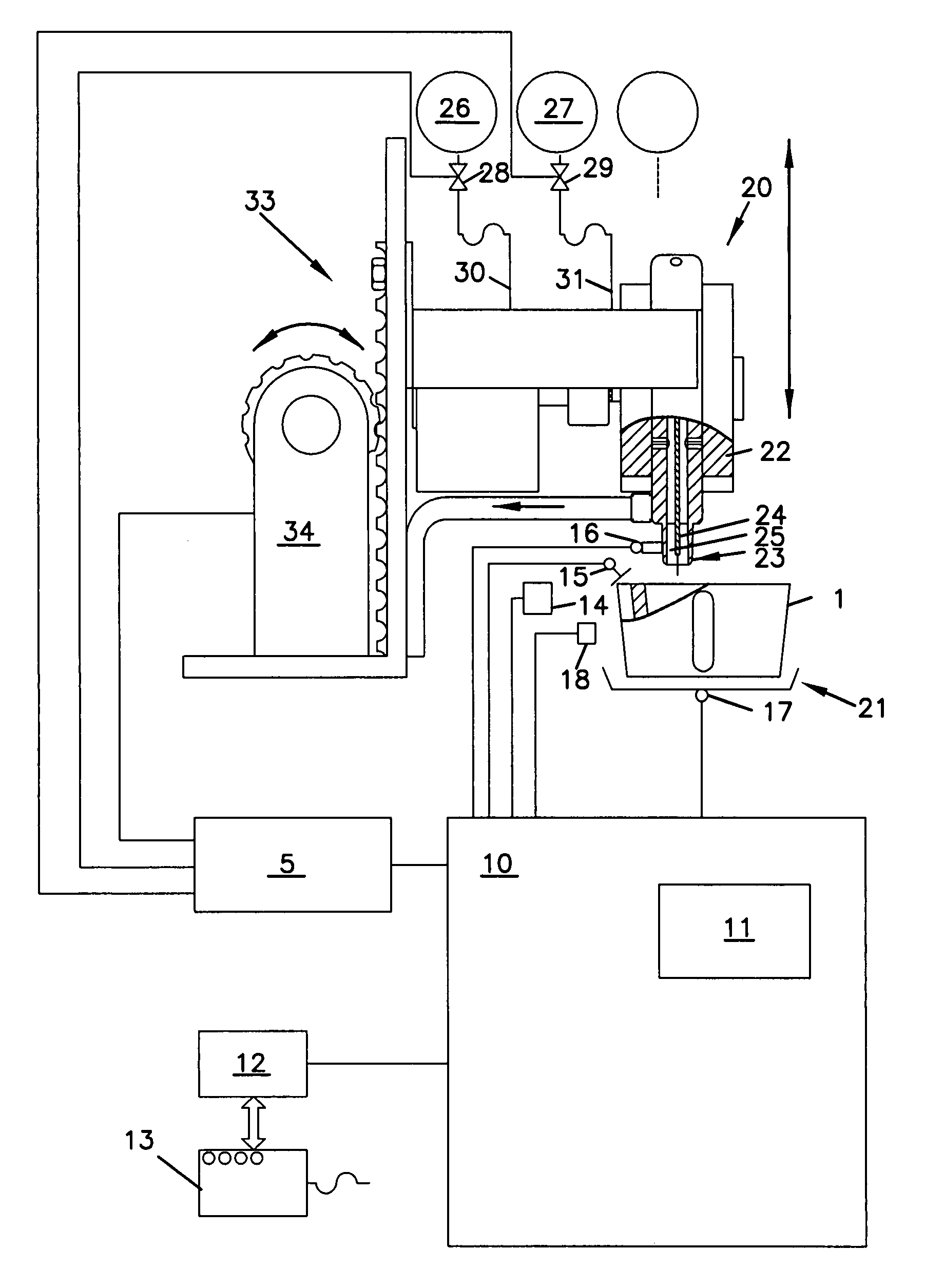

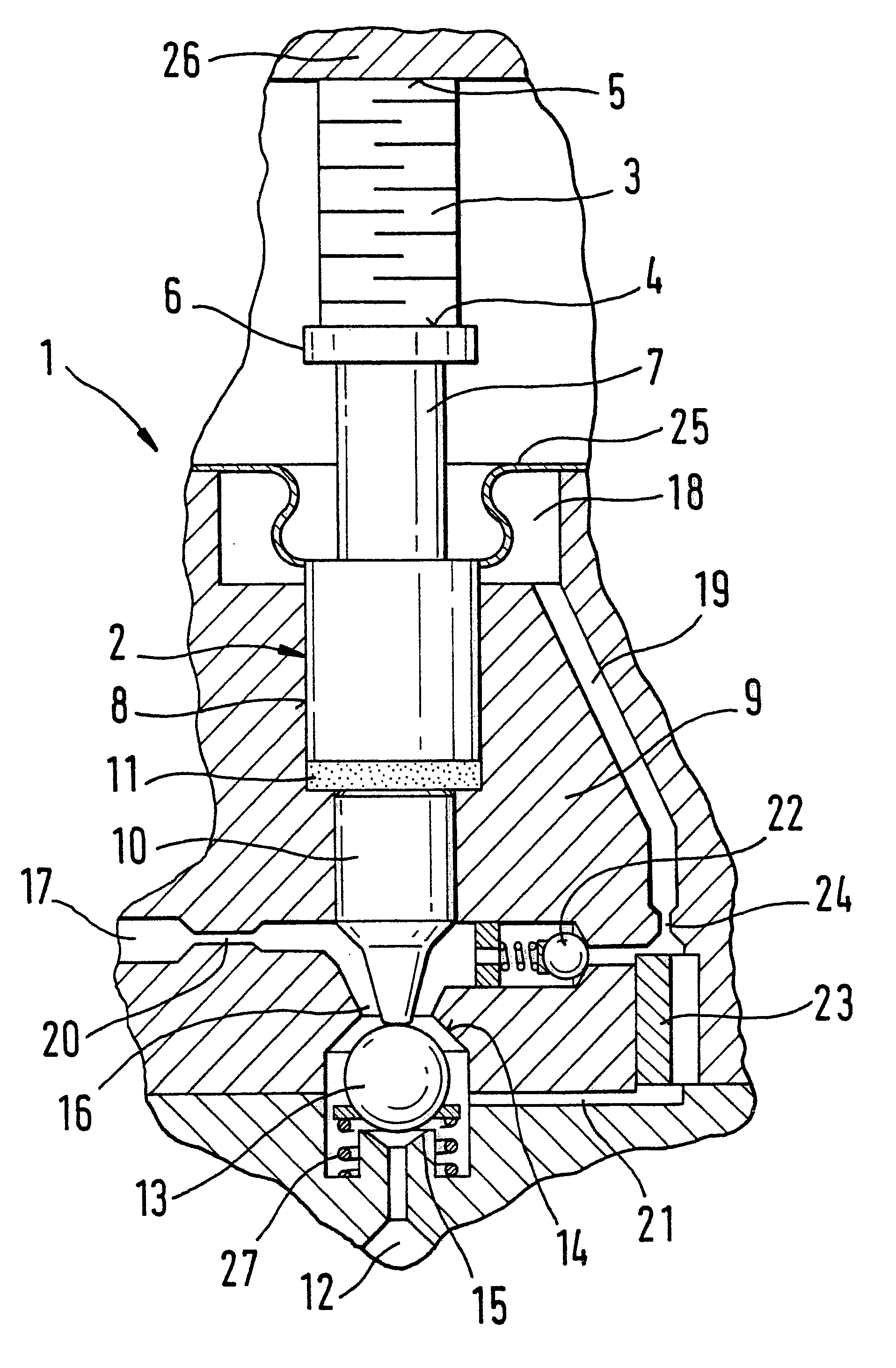

Valve for controlling fluids

InactiveUS6427968B1Low production costOperating means/releasing devices for valvesPiezoelectric/electrostriction/magnetostriction machinesSystem pressureEngineering

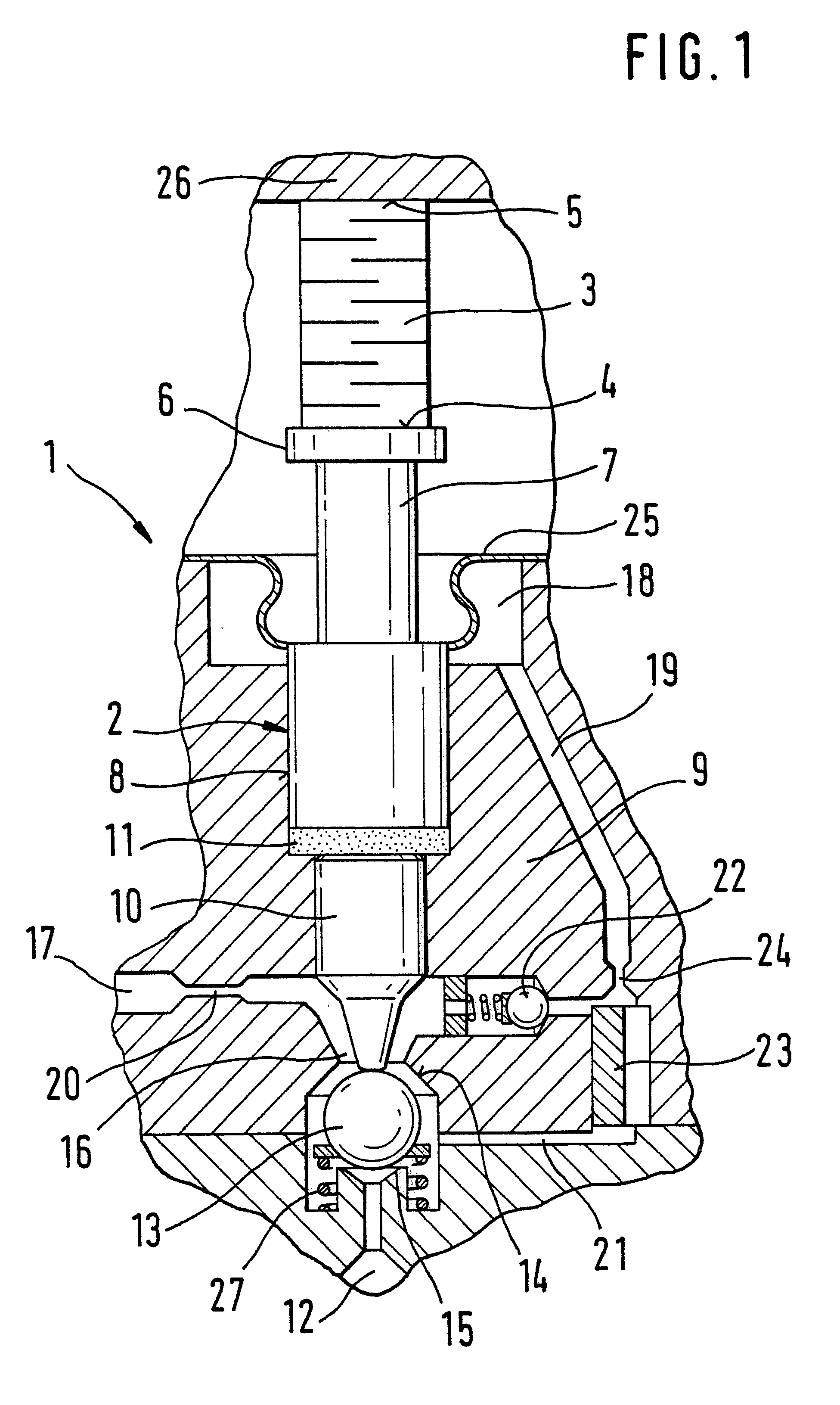

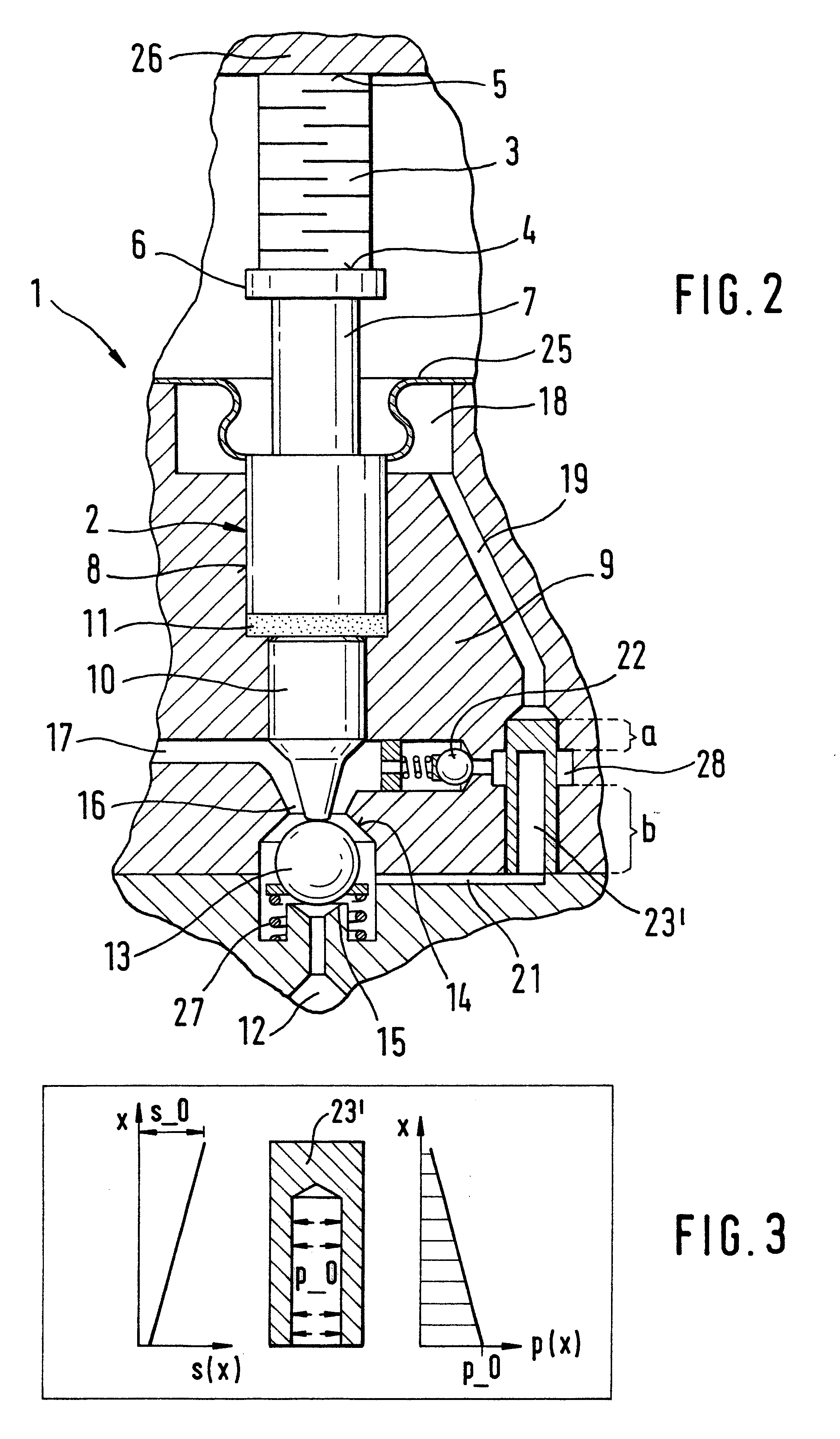

A valve (1) for controlling liquids is embodied with a piezoelectric unit (3) for actuating a valve member (2) that is axially displaceable in a bore (8) of a valve body (9). One end of the bore (8) adjoins a valve system pressure chamber (18) defined by a sealing element (25), and its other end adjoins a valve low-pressure chamber (16), which has a leak drainage conduit (17) and which communicates with the valve system pressure chamber (18) via a compensation conduit (19), which has a pressure limiting device (20, 23') and a filling device (23, 23'). The valve member (2) is assigned a valve closing member (13), which cooperates in such a way with at least two valve seats (14, 15), disposed in the valve low-pressure chamber (16), for opening and closing the valve (1) that in a closing position it separates the valve low-pressure chamber (16) from a valve control chamber (12), which is at high pressure, and in an intermediate position between the valve seats (14, 15) it fluidically connects the valve low-pressure chamber (16) to the valve control chamber (12); at least one damping device (20, 23', 24) for damping the control motions of the valve member (2) is provided and briefly generates hydraulic counterforces (Fig.).

Owner:ROBERT BOSCH GMBH

Spray fill device and method for using the same

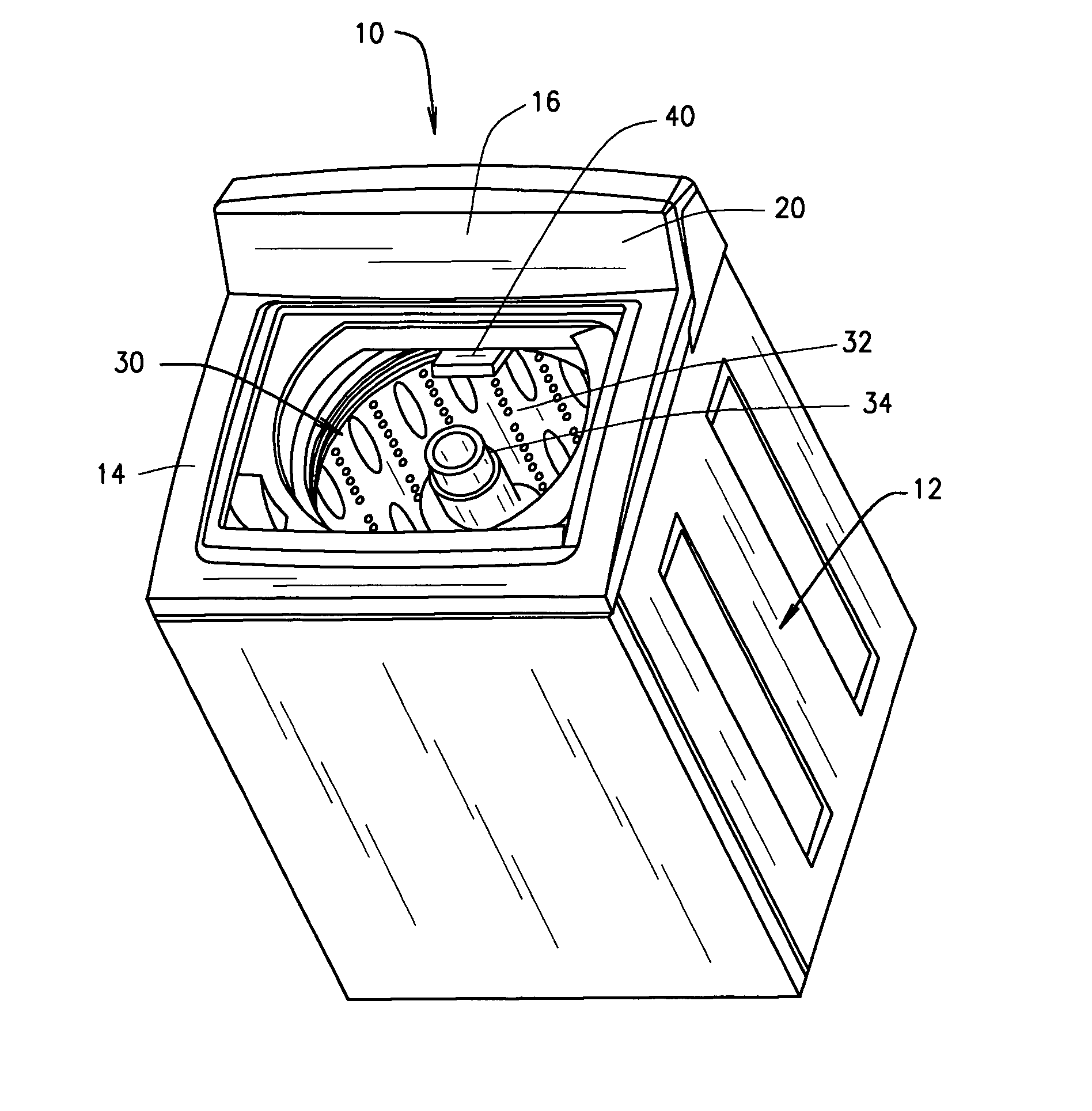

A spray fill device for delivering water to a washing machine is provided. The spray fill device includes a body defining an inlet, an outlet port, a mounting port, and a plurality of outlet apertures in flow communication with the inlet. The spray fill device also includes a first valve coupled to the inlet, the valve configured to control a flow rate of water into the inlet. The spray fill device also includes a pressure relief mechanism coupled to the mounting port, the pressure relief mechanism inhibiting flow through the outlet port when a pressure within the body is less than a predetermined pressure.

Owner:HAIER US APPLIANCE SOLUTIONS INC

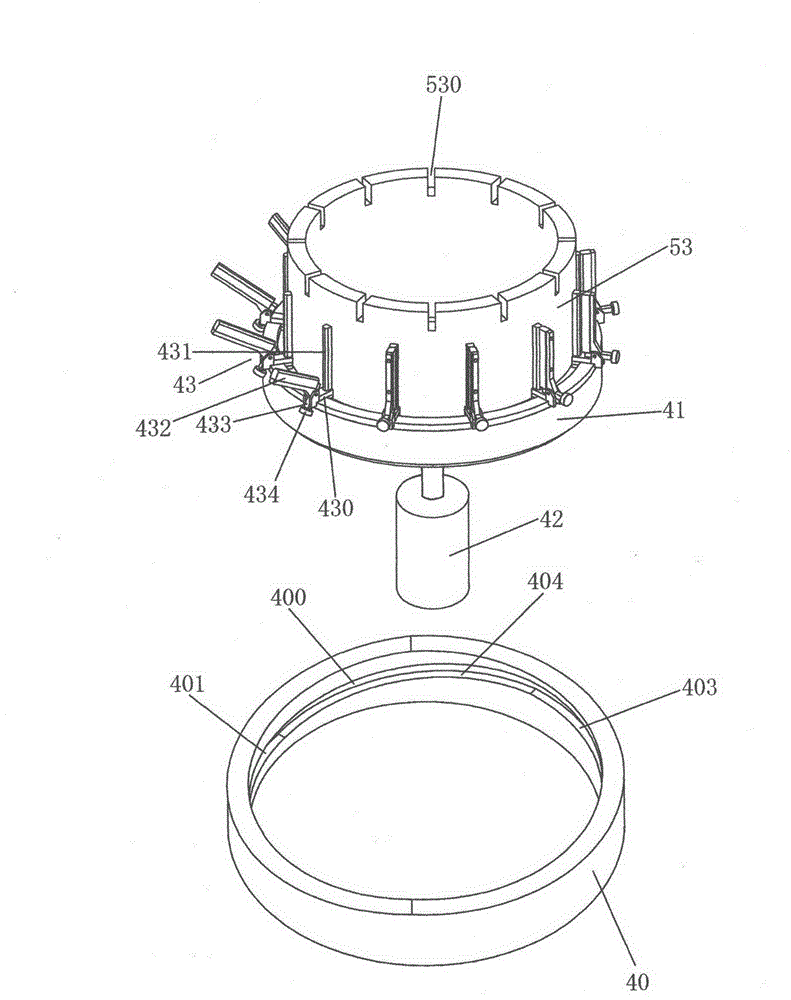

Glue filling device with high-speed rotation working platform

ActiveCN104209231AGuaranteed uniformityNo air gapLiquid surface applicatorsWrapper twisting/gatheringEngineeringWorkload

The invention relates to a glue filling device with a high-speed rotation working platform. The glue filling device comprises a frame, a baseplate, a turntable, a fixed component and a sealing component, wherein the sealing component comprises a cylinder and a pressing block; the pressing block is connected with an air pump; a motor is arranged on the baseplate; and a shaft sleeve is arranged on the cylinder. The glue filling device has the following advantages: glue is accommodated in a glue filing product, and is sealed in the glue filling product through the pressing block arranged on the sealing component; the motor is driven to rotate the turntable; the glue gradually moves to the center after splashing all around under the effect of centrifugal force generated in the rotation of the turntable; the adjustment can be performed according to the customer demands; the air pump sucks or blows air into the glue filling product, so that the glue filling vacuum degree is guaranteed, and the stability of the centrifugal force is guaranteed; one person is needed to operate, so that the workload is relieved, and the labor cost is reduced; and meanwhile, the working efficiency is improved, the product yield is high, and the potential safety hazard is not occurred.

Owner:湖州倍格曼新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com