Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

796results about "Barrels/casks filling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

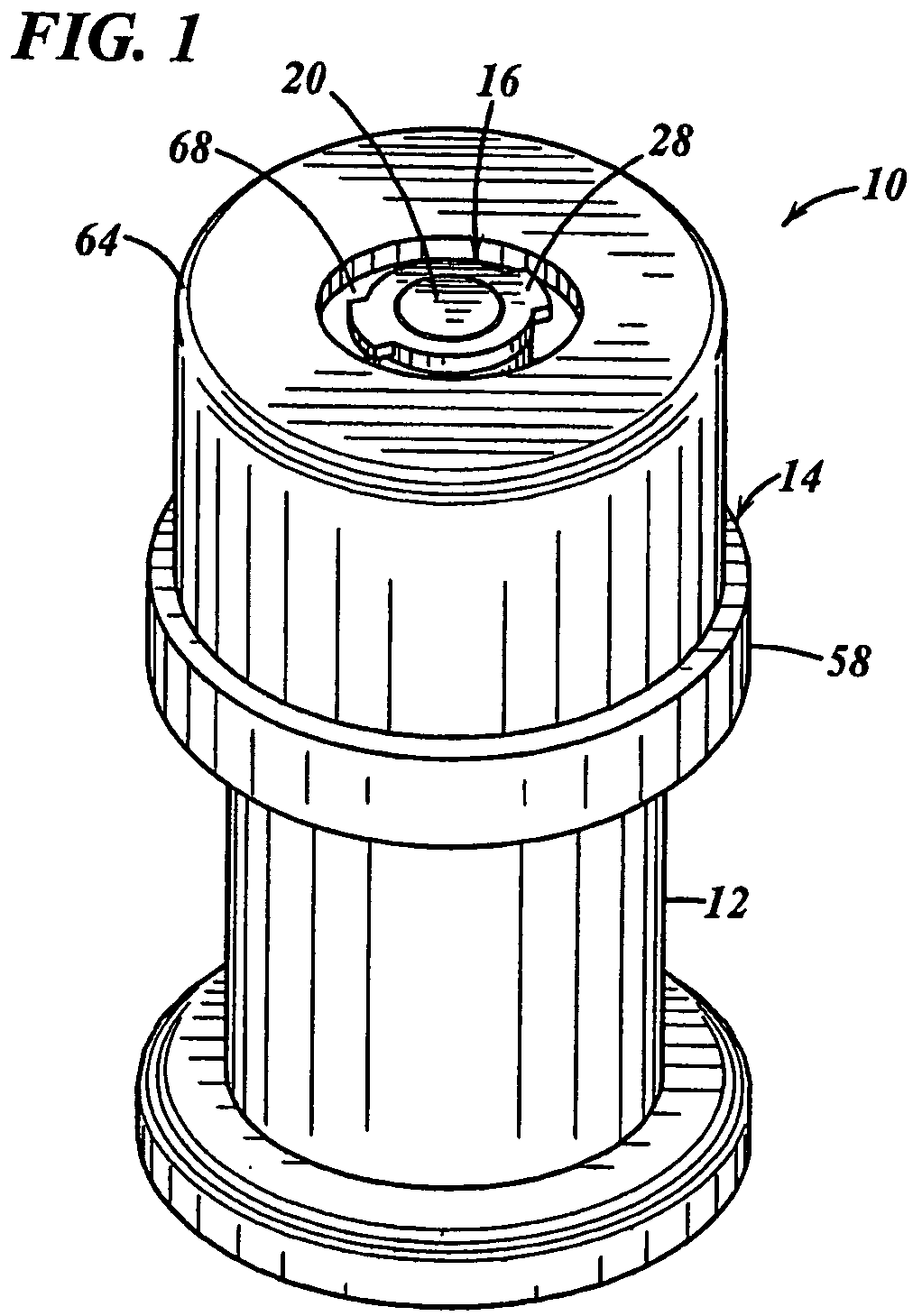

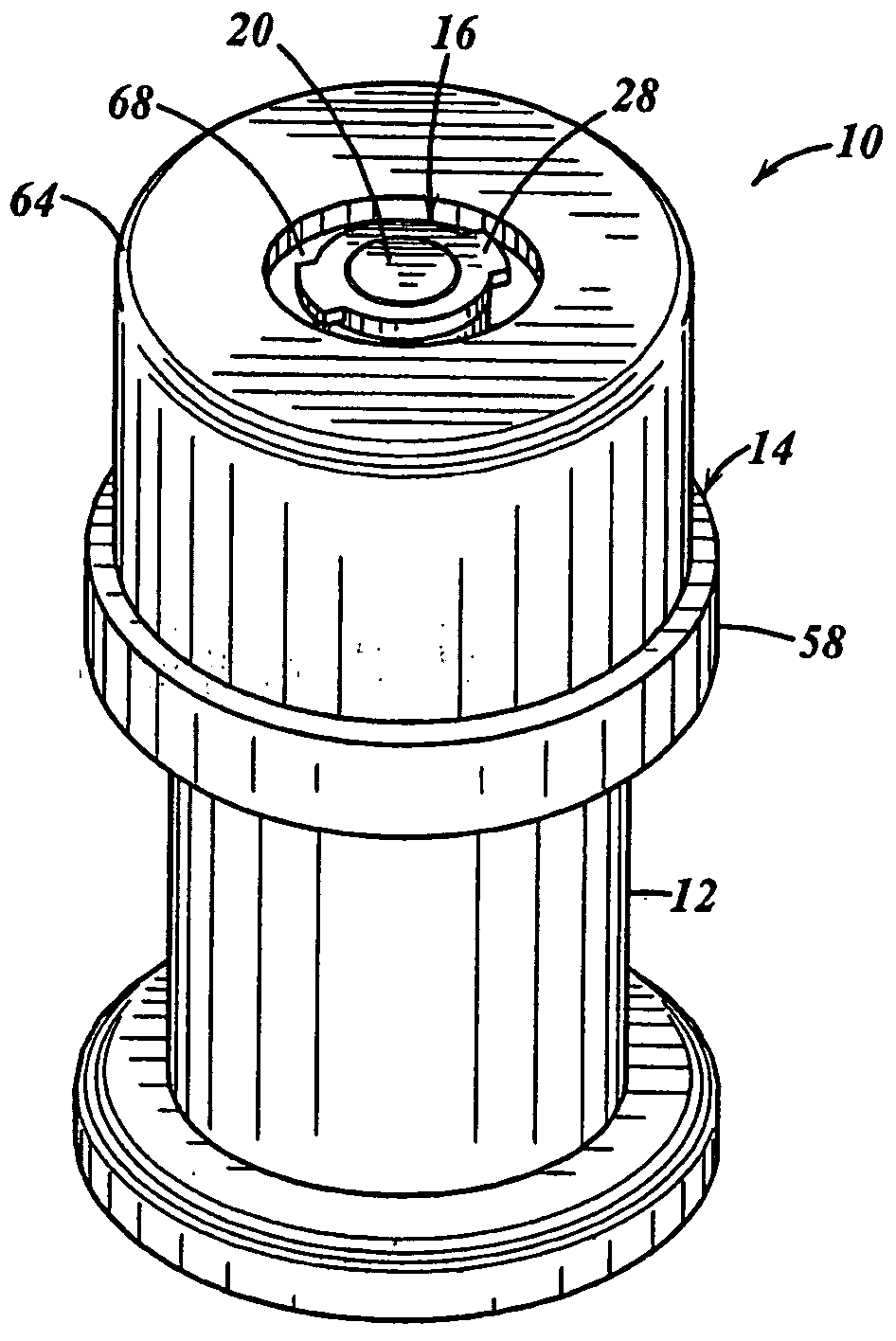

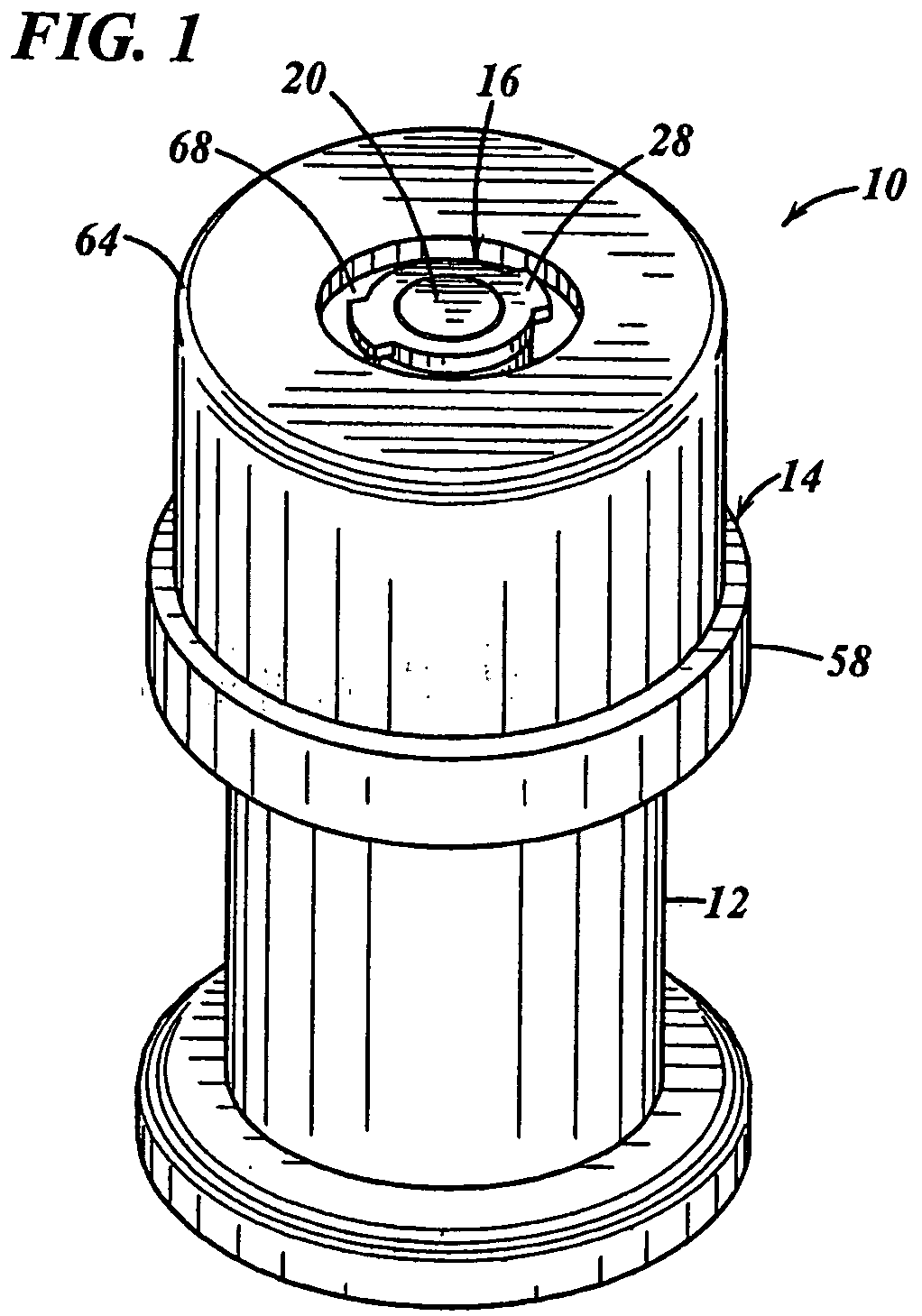

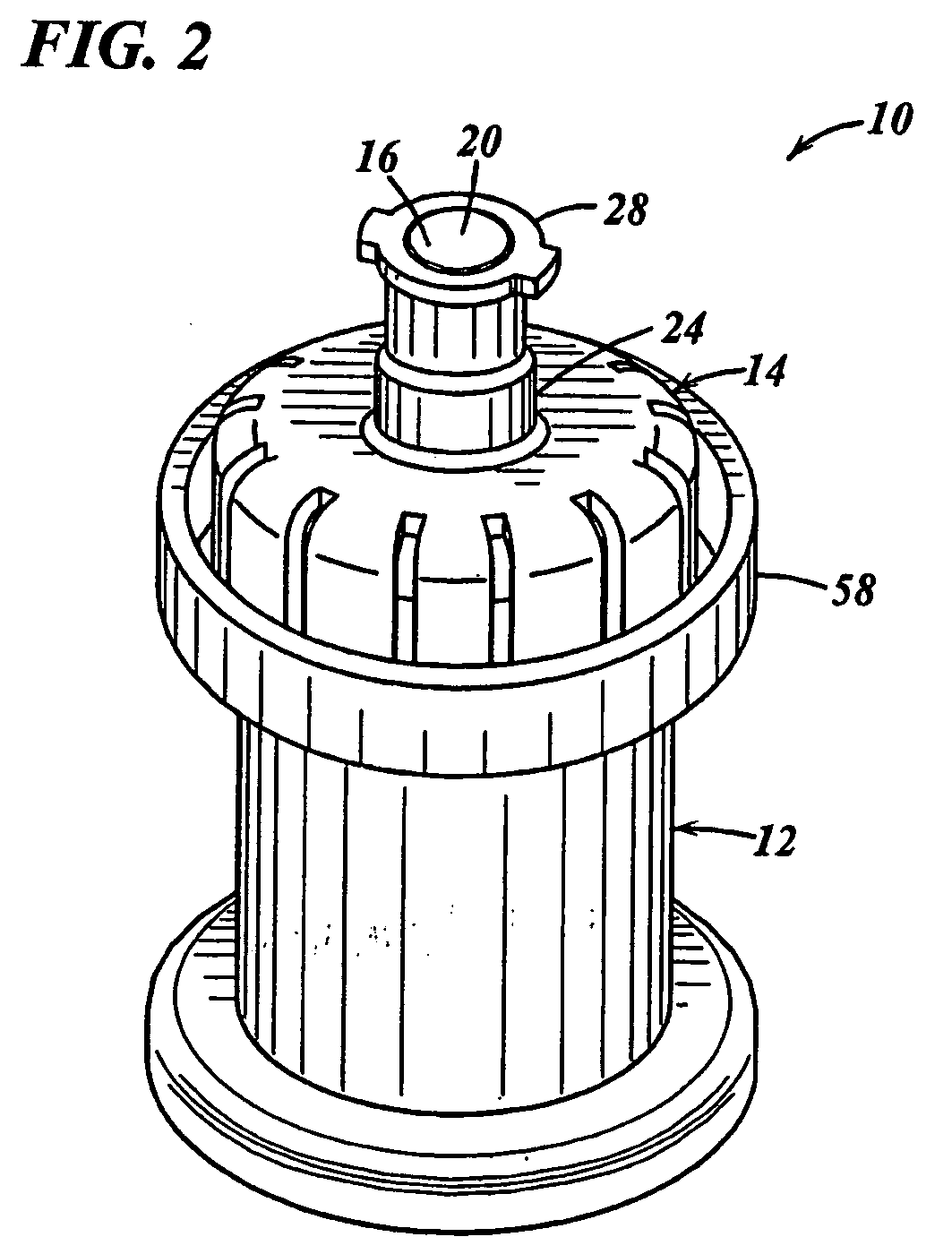

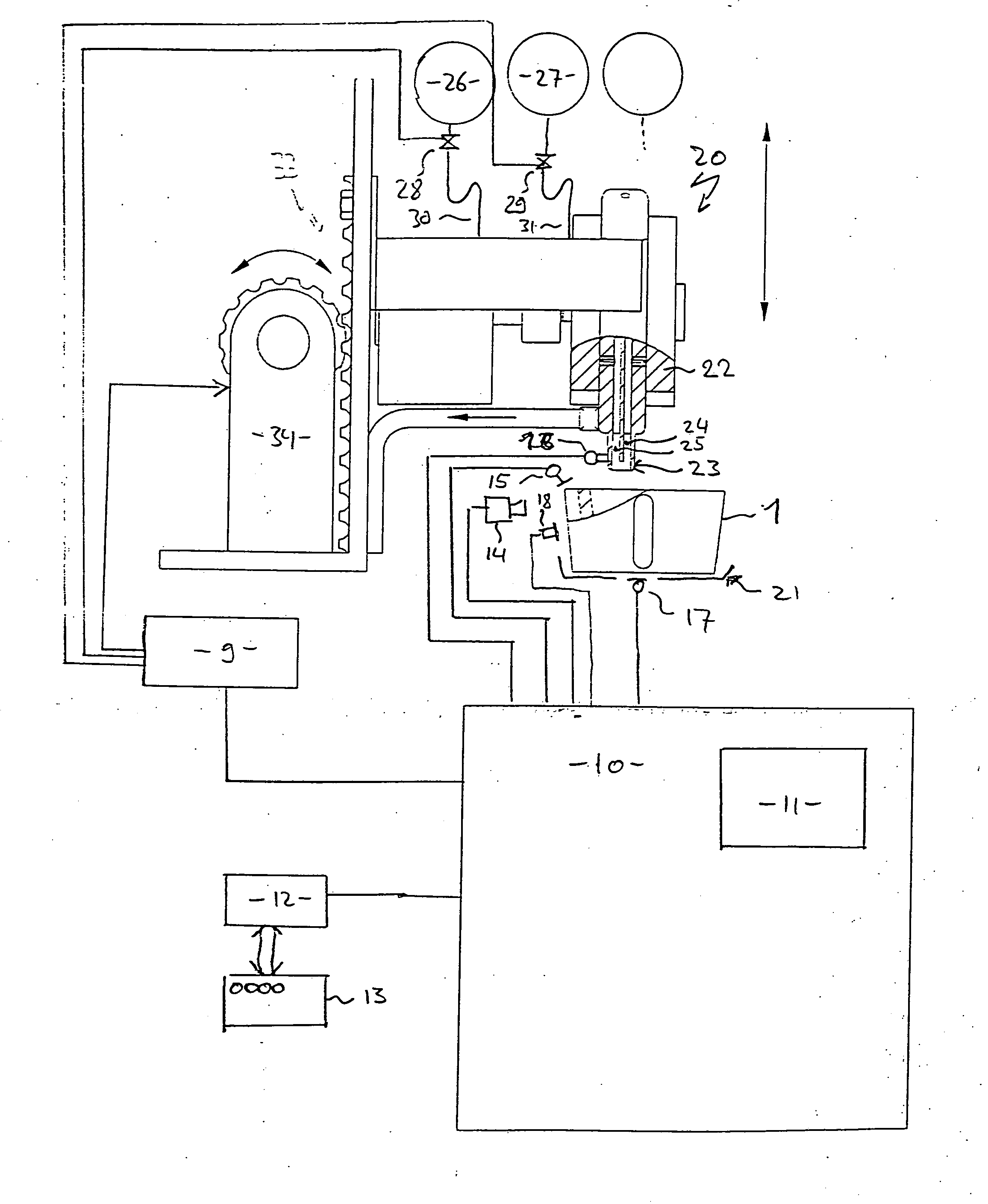

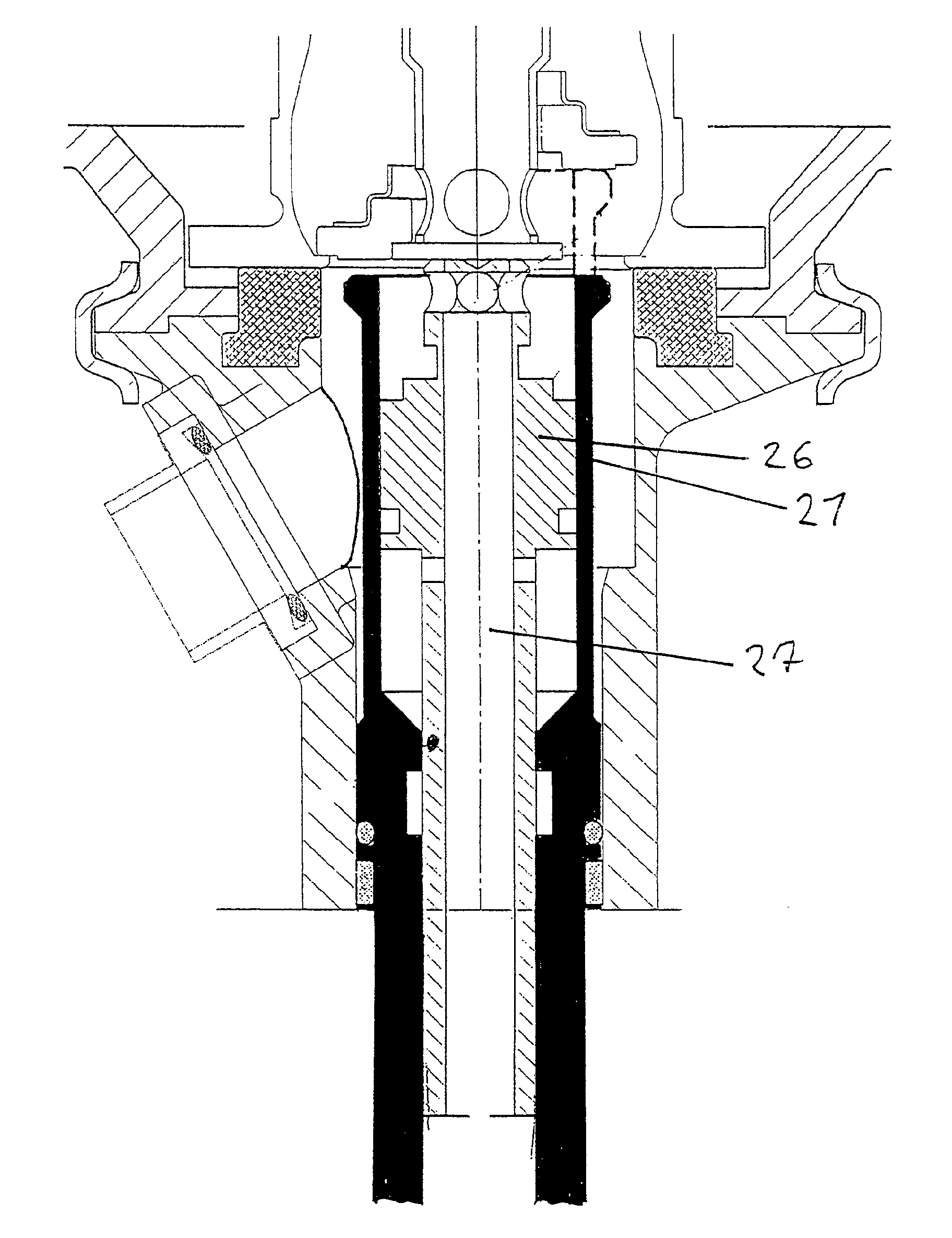

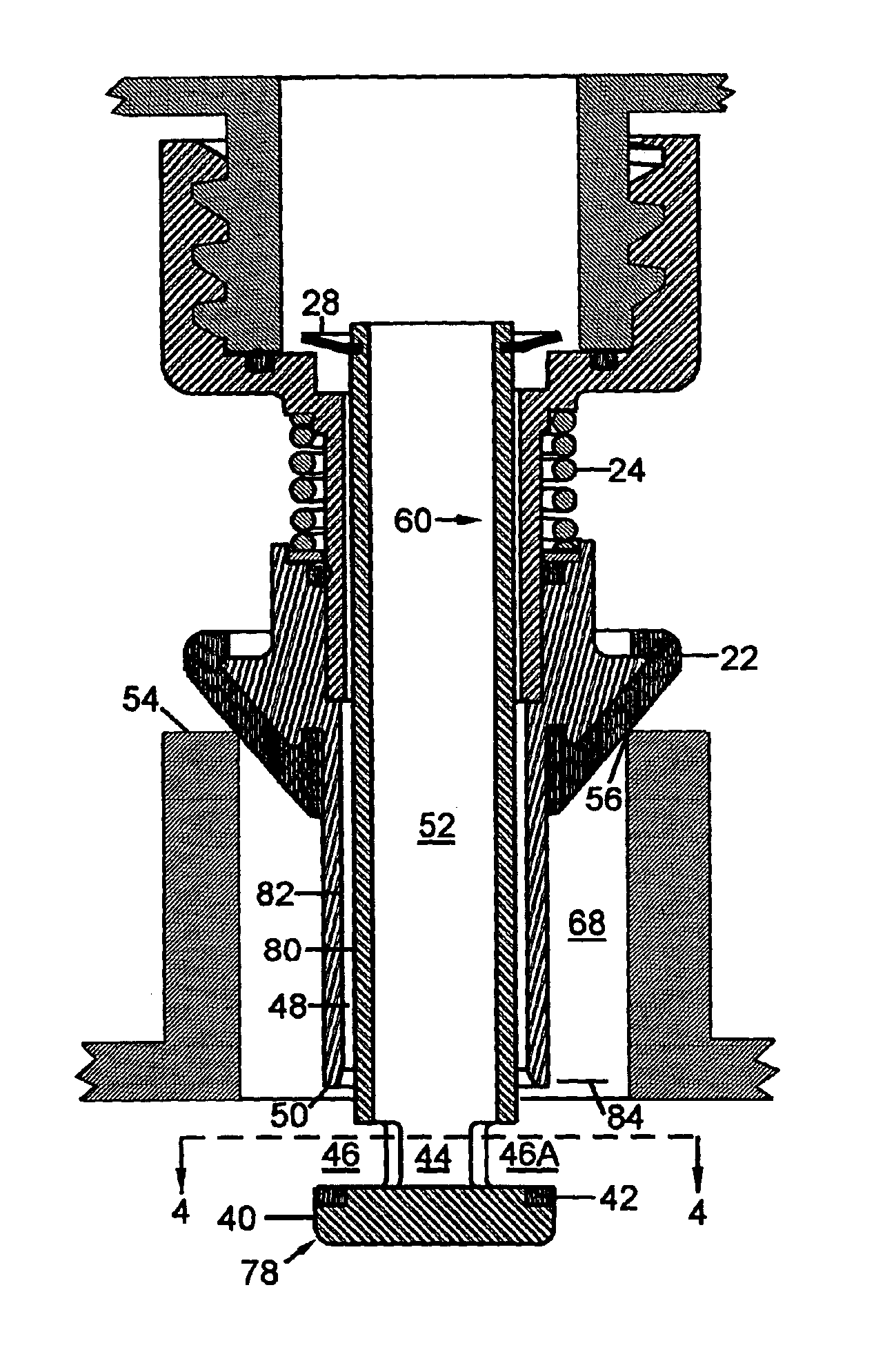

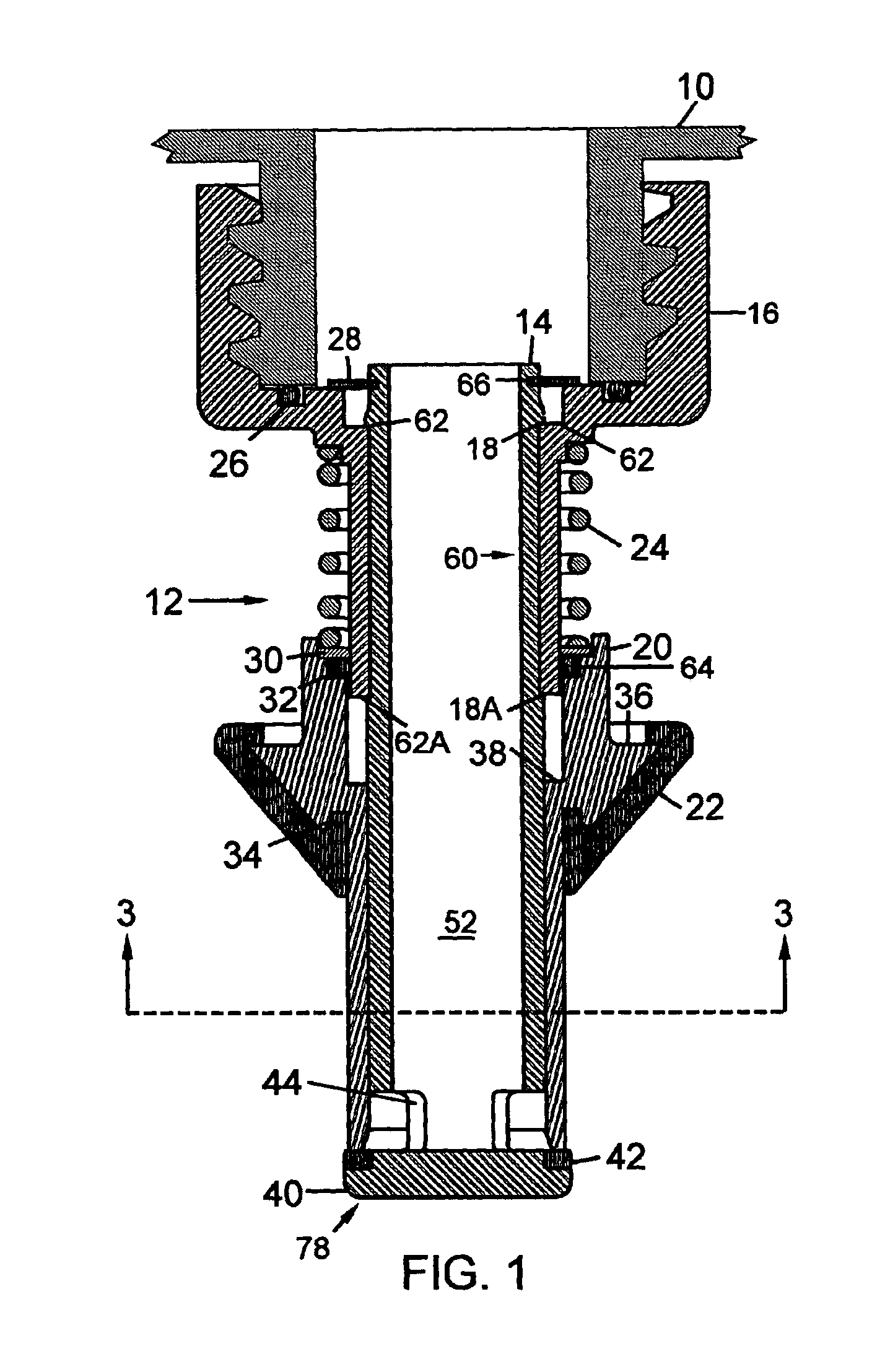

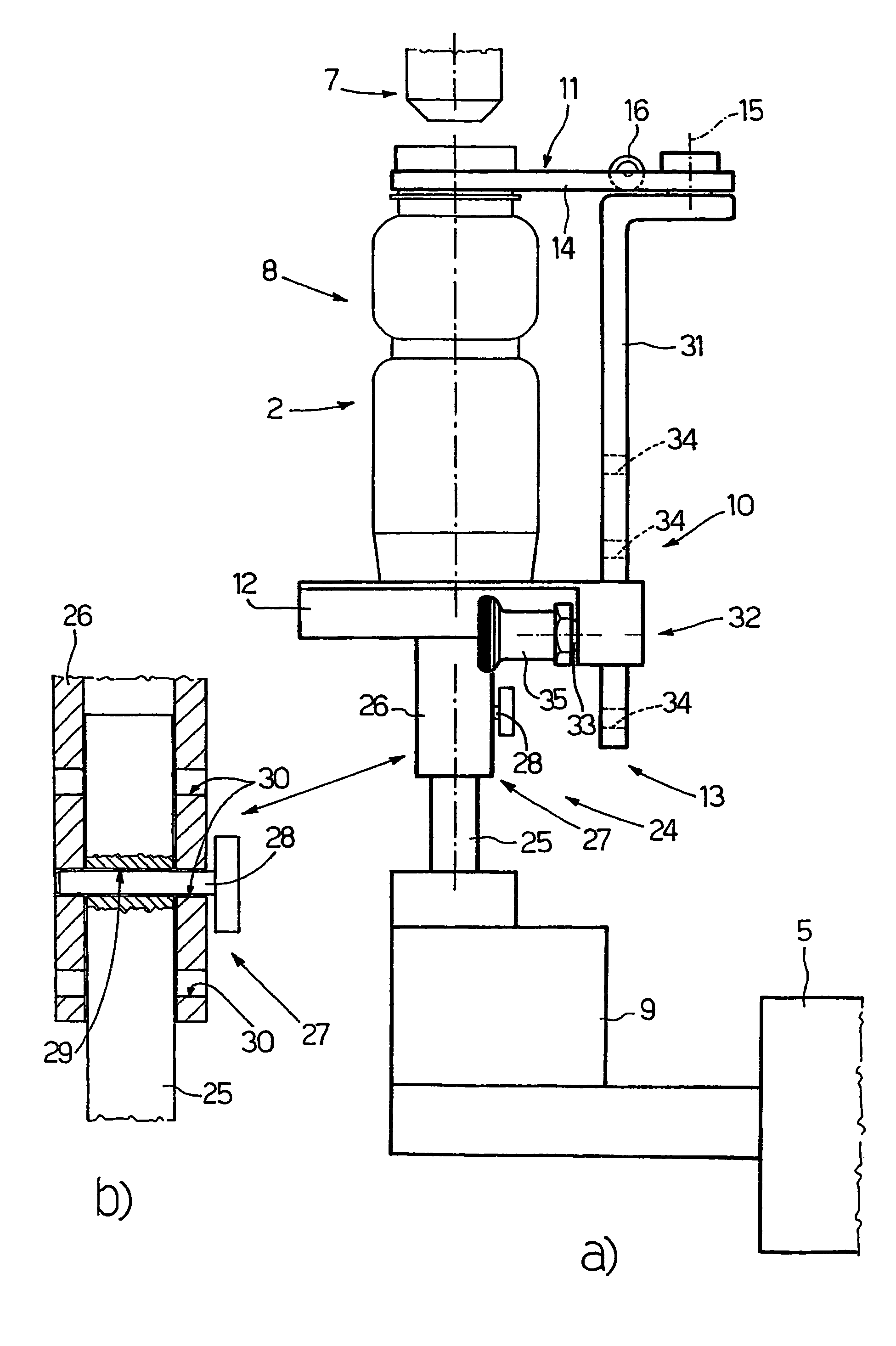

Container with valve assembly for filling and dispensing substances, and apparatus and method for filling

ActiveUS7077176B2Low costImprove the level ofValve arrangementsClosuresEngineeringBiomedical engineering

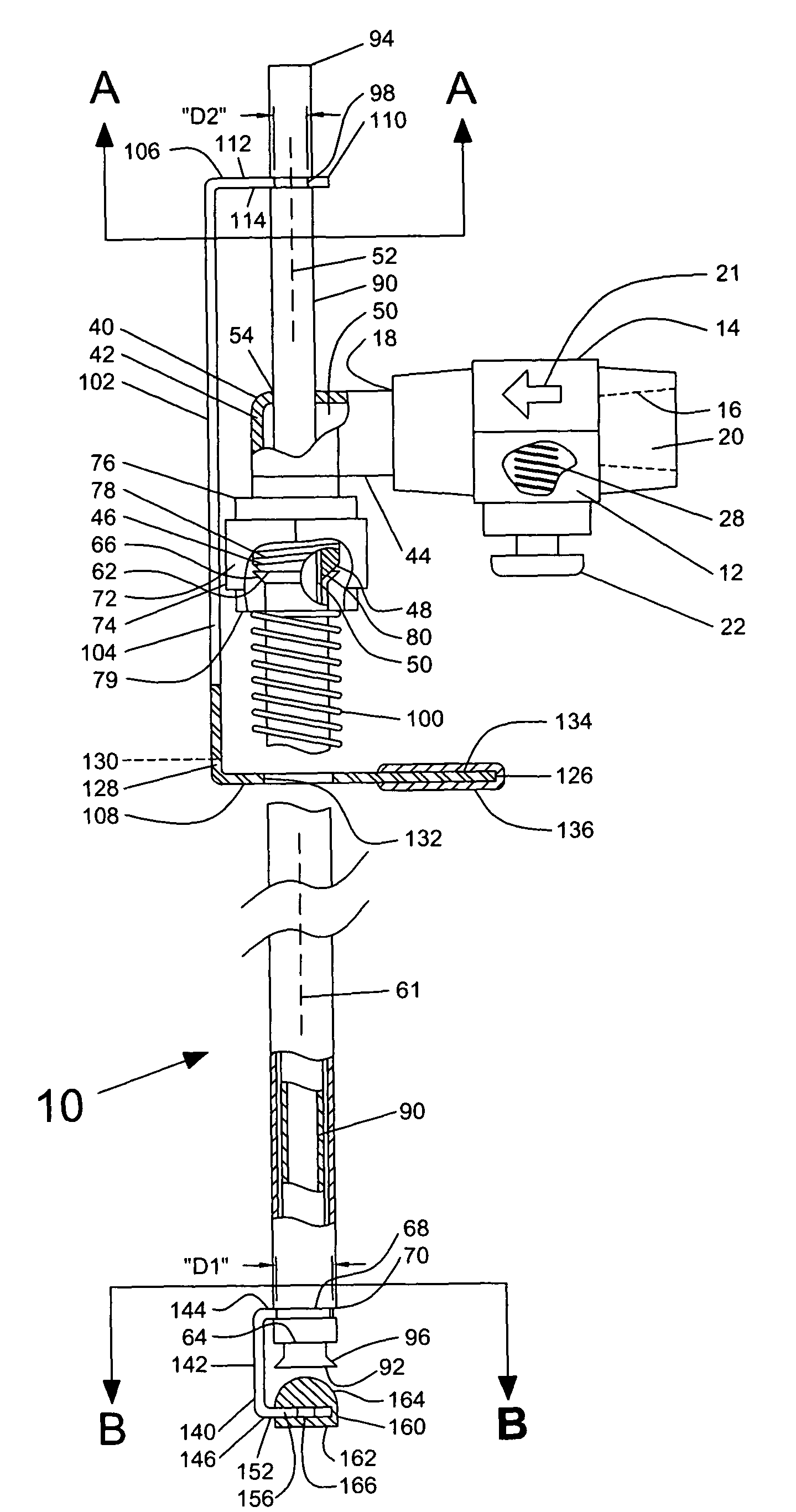

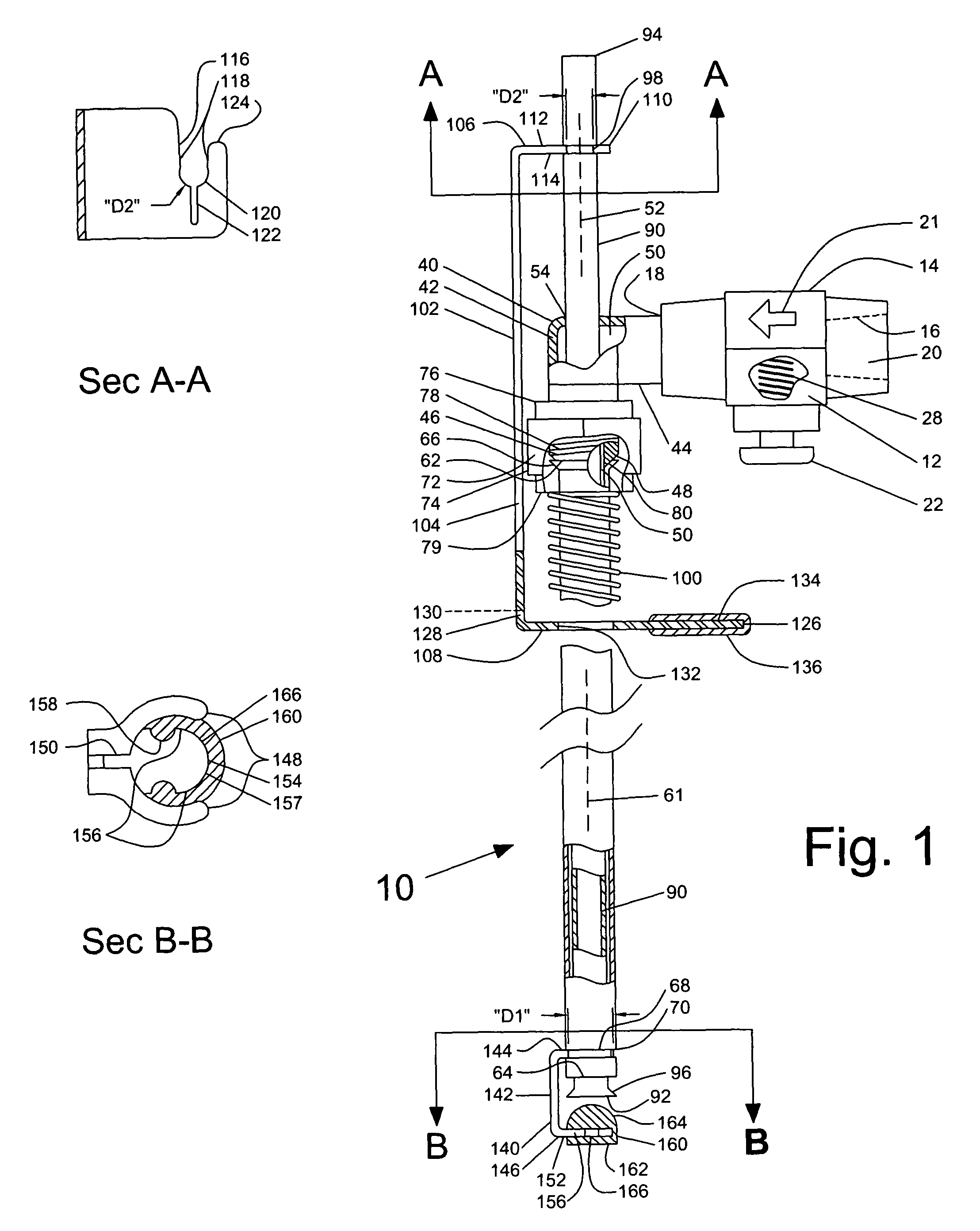

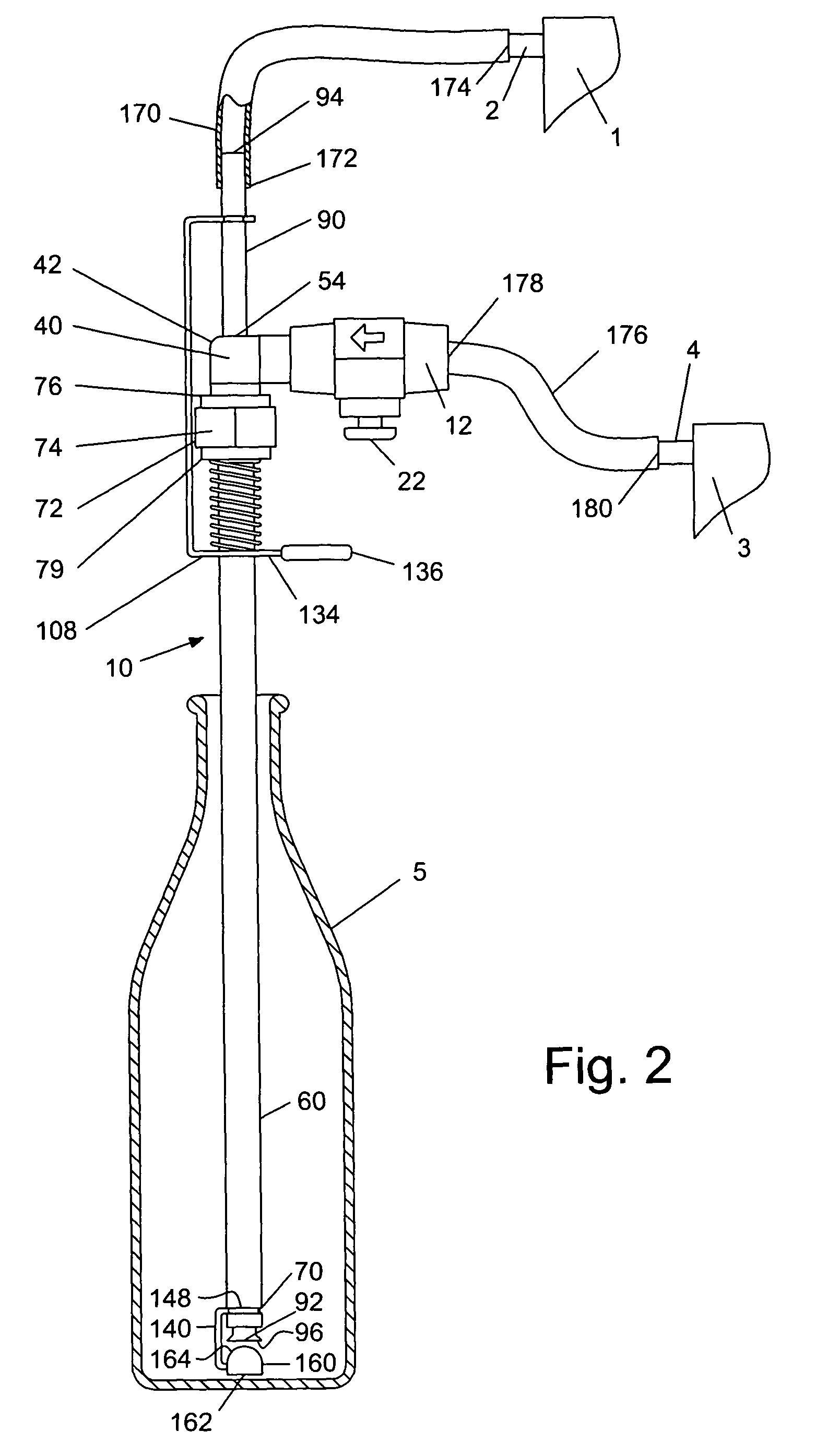

A vial has a body defining a chamber for receiving a substance therein; and a valve assembly coupled in fluid communication with the chamber and defining (i) an open position permitting at least one of (a) passage of the substance through the valve assembly and into the chamber for storing the substance in the chamber, and (b) passage of the substance out of the chamber for dispensing the substance therefrom; and (ii) a closed position forming a fluid-tight seal between the chamber and exterior of the container. A filling member engages a flexible valve member of the valve assembly to move the valve member between the closed and open positions to fill and seal the vial, respectively. A syringe is connectable to the vial. The valve assembly opens upon connecting the syringe to the vial to allow the substance within the vial to be withdrawn from the vial and into the syringe by actuating a plunger of the syringe, and the valve assembly closes upon disconnecting the vial and syringe to hermetically seal and store the substance remaining in the syringe for later use.

Owner:DR PY INST LLC

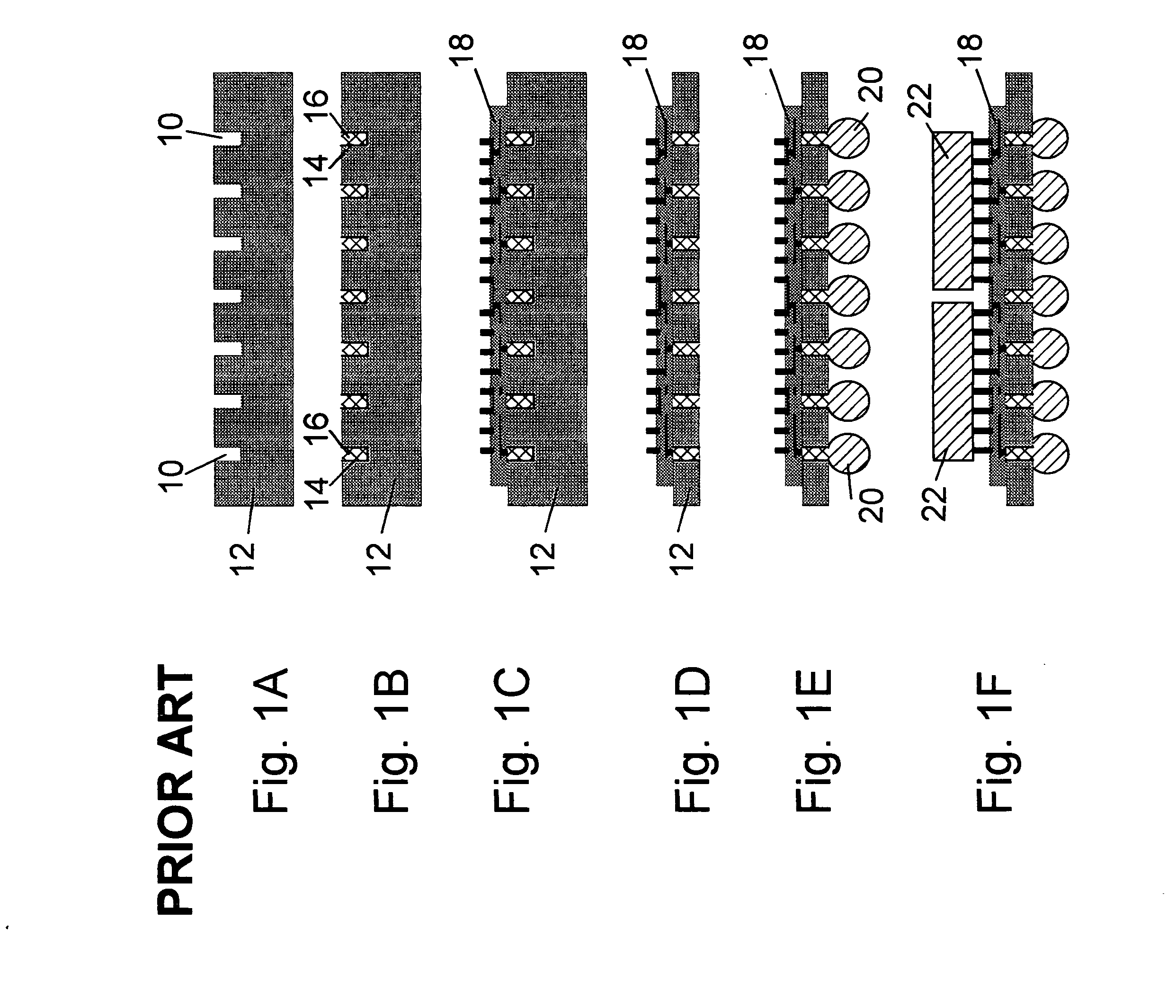

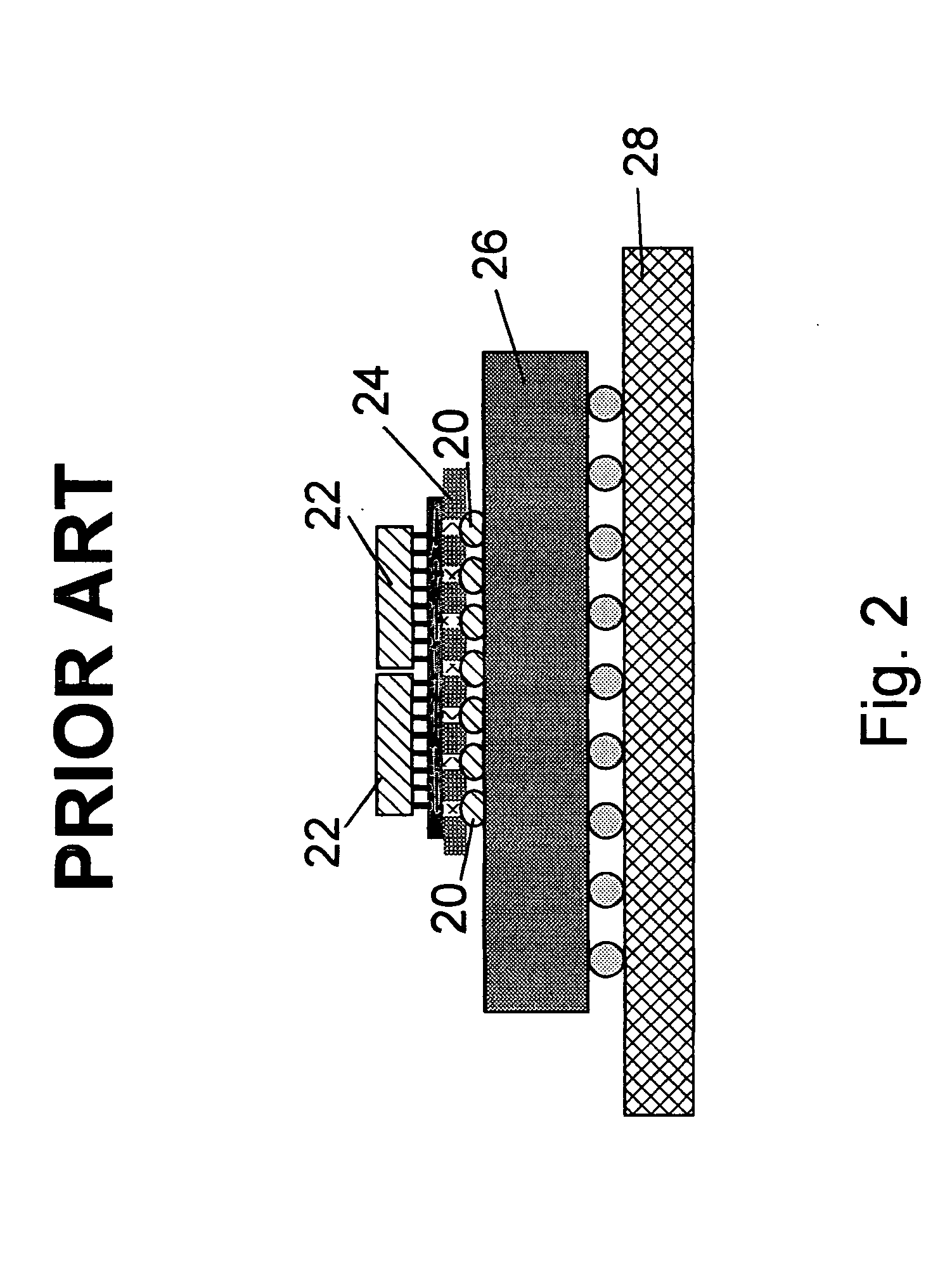

Method and apparatus for filling vias

ActiveUS20050106834A1Reliable fillingPrinted circuit assemblingLiquid surface applicatorsMechanical engineering

A method for filling vias, and in particular initially blind vias, in a wafer, and various apparatus for performing the method, comprising evacuating air from the vias; trapping at least a portion of the wafer and a paste for filling the vias between two surfaces; and pressurizing the paste to fill the vias.

Owner:GLOBALFOUNDRIES US INC

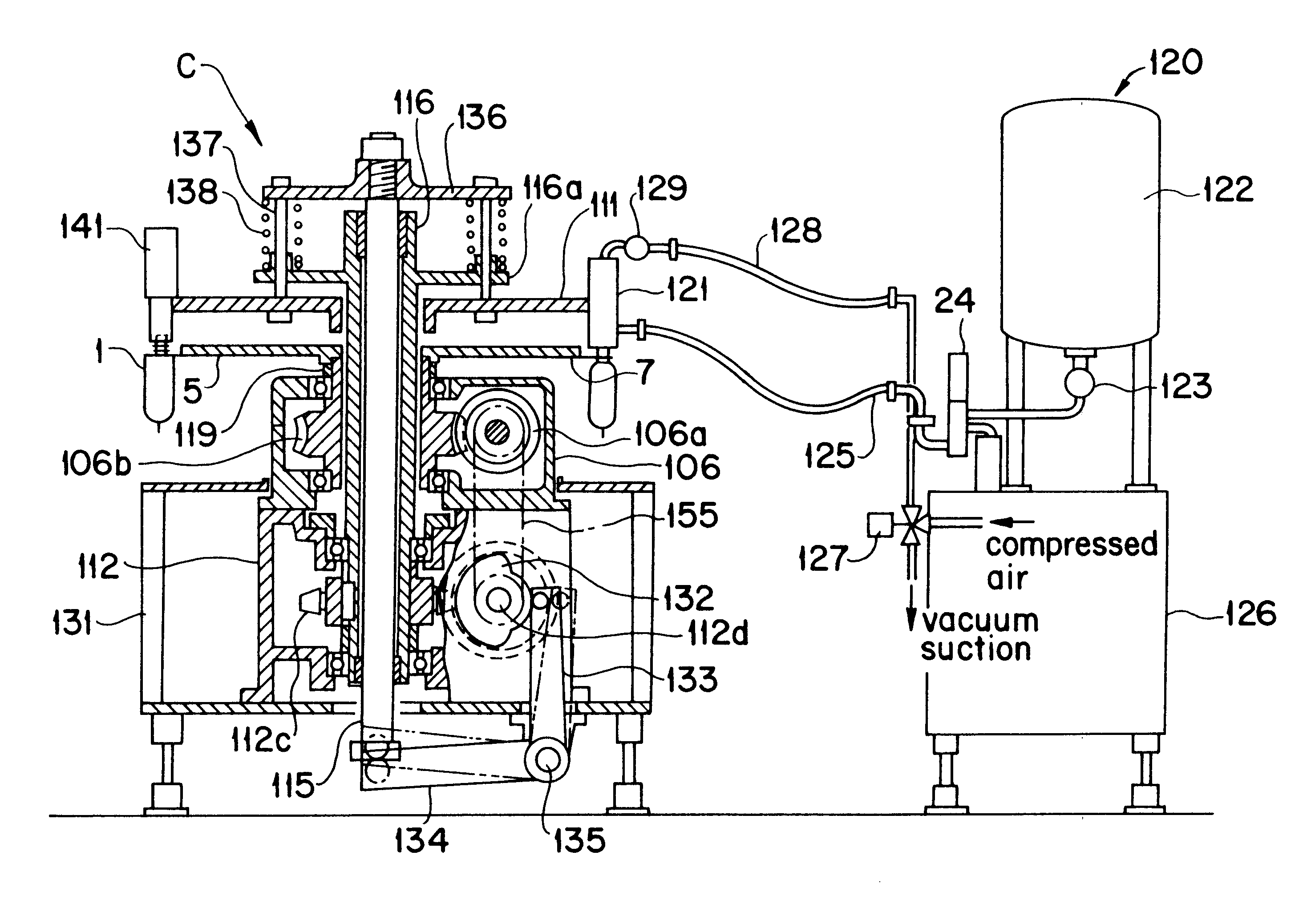

Apparatus for conveying, supplying, and filling unshaped containers, and method for conveying and supplying the same

InactiveUS6338371B1Reduce the numberEnvelopes/bags making machineryWrapping material feeding apparatusEngineeringContinuous rotation

A filling apparatus of irregular-formed vessels having an intermittent swinging table (111) disposed above a continuous rotation table (5) and having a plurality of filling nozzles (121) at a same pitch as the vessel holding pitch, filling means for pushing out the liquid from the filling nozzles (121), vertical moving means for vertically moving the filling nozzles (121), a continuously rotating outside hollow shaft (119) to which the continuous rotation table (5) is mounted, a hollow shaft (116) disposed concentrically with the outside hollow shaft (119) for reciprocally rotating the intermittent swinging table (111).

Owner:MITSUBISHI HEAVY IND LTD

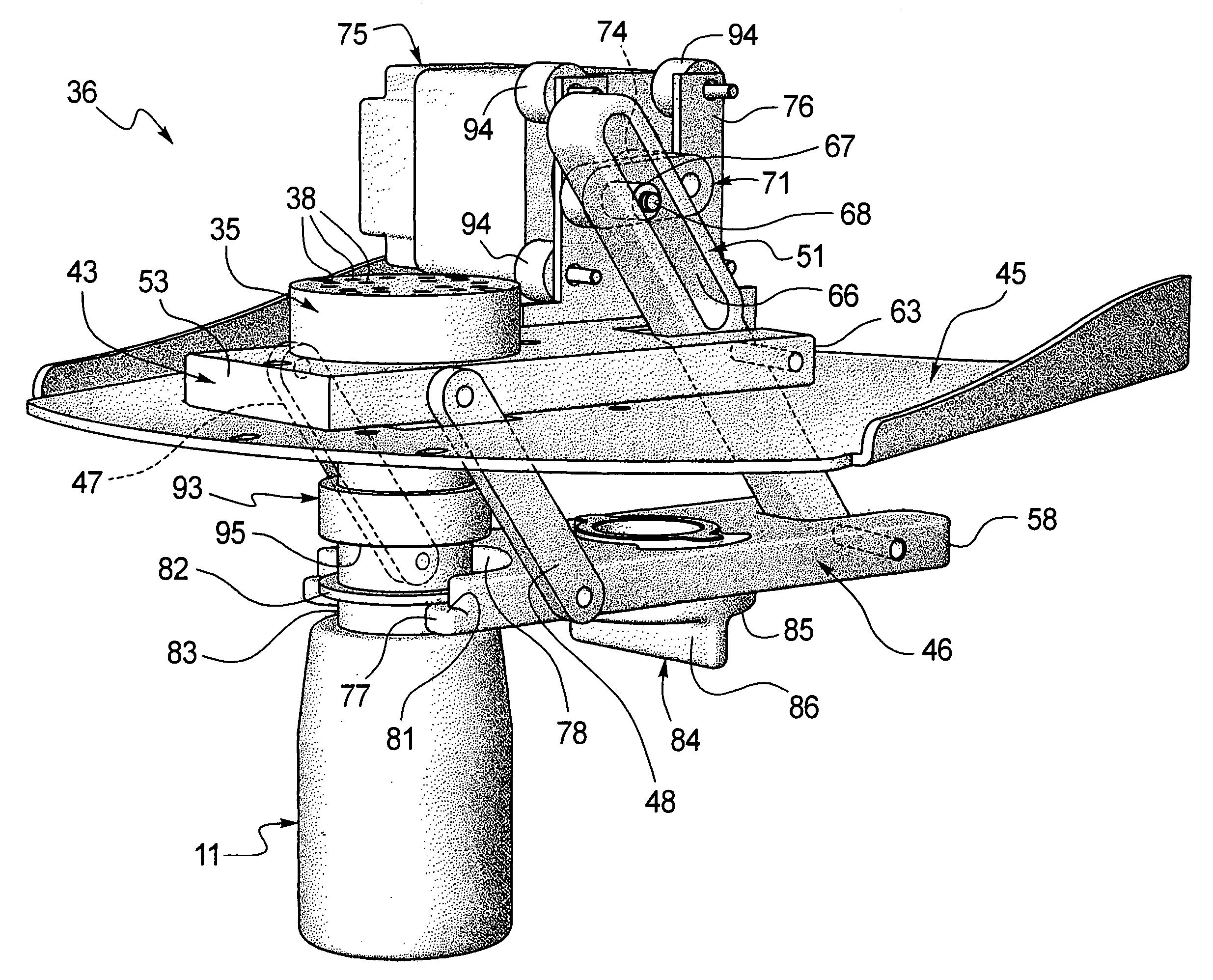

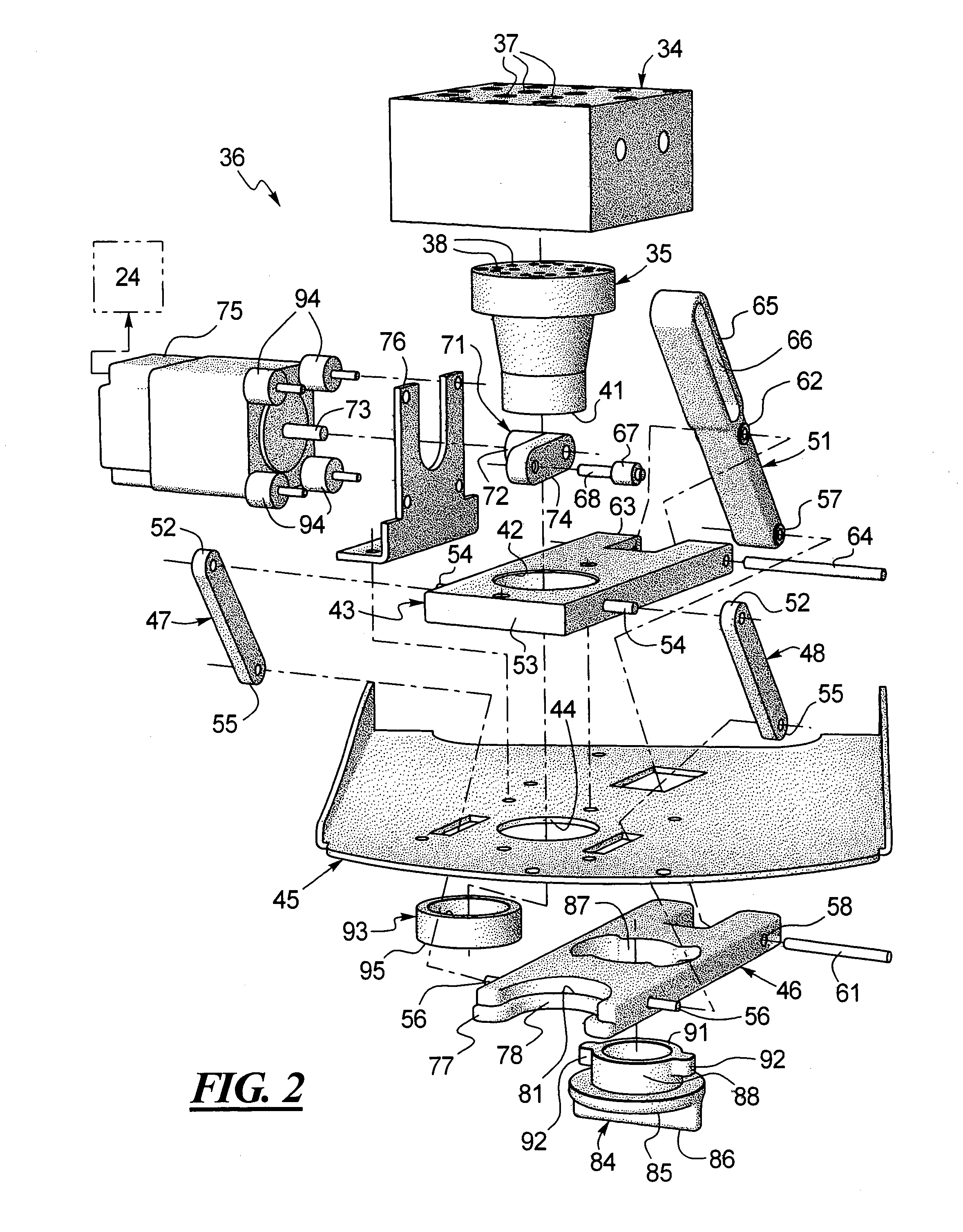

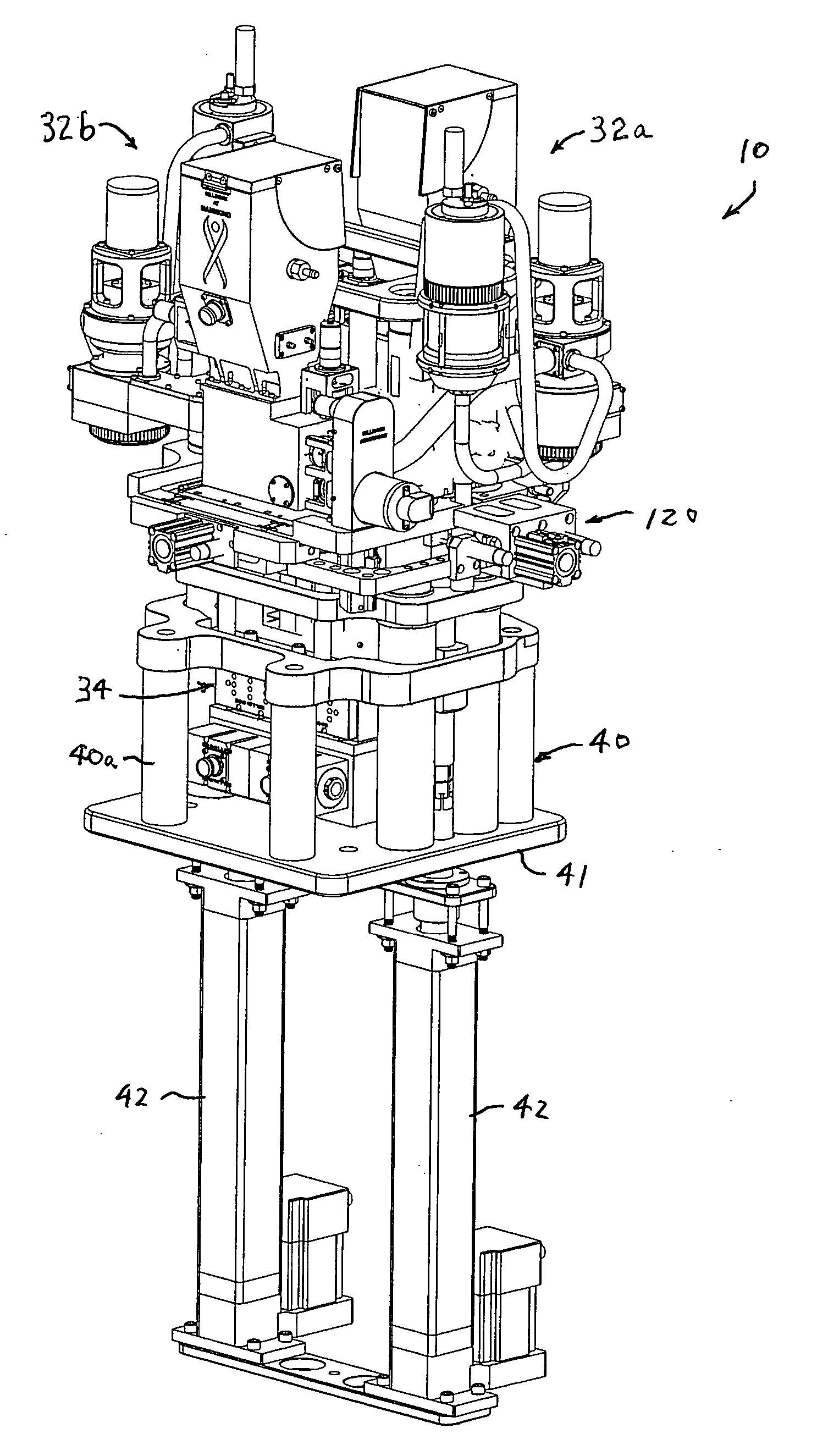

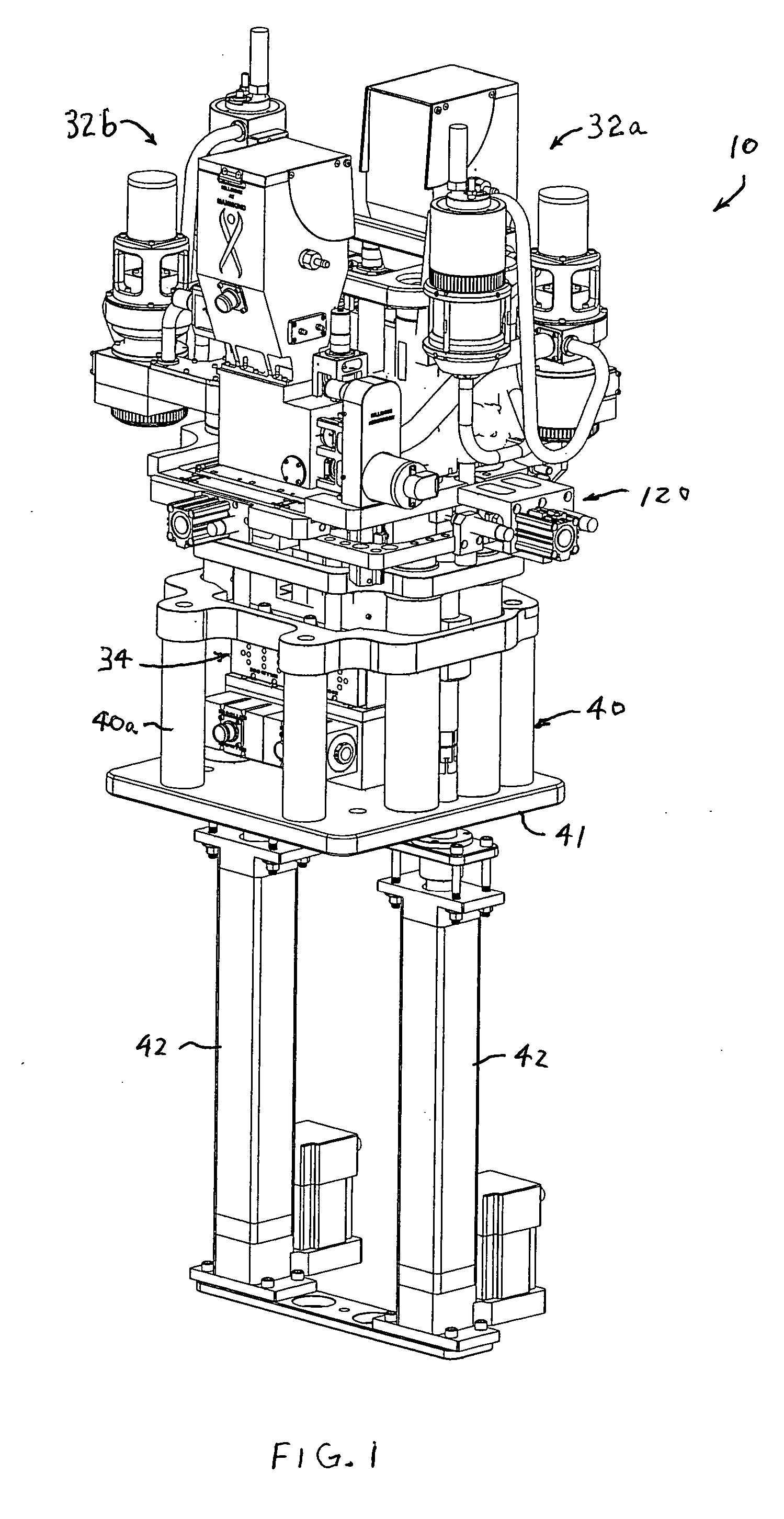

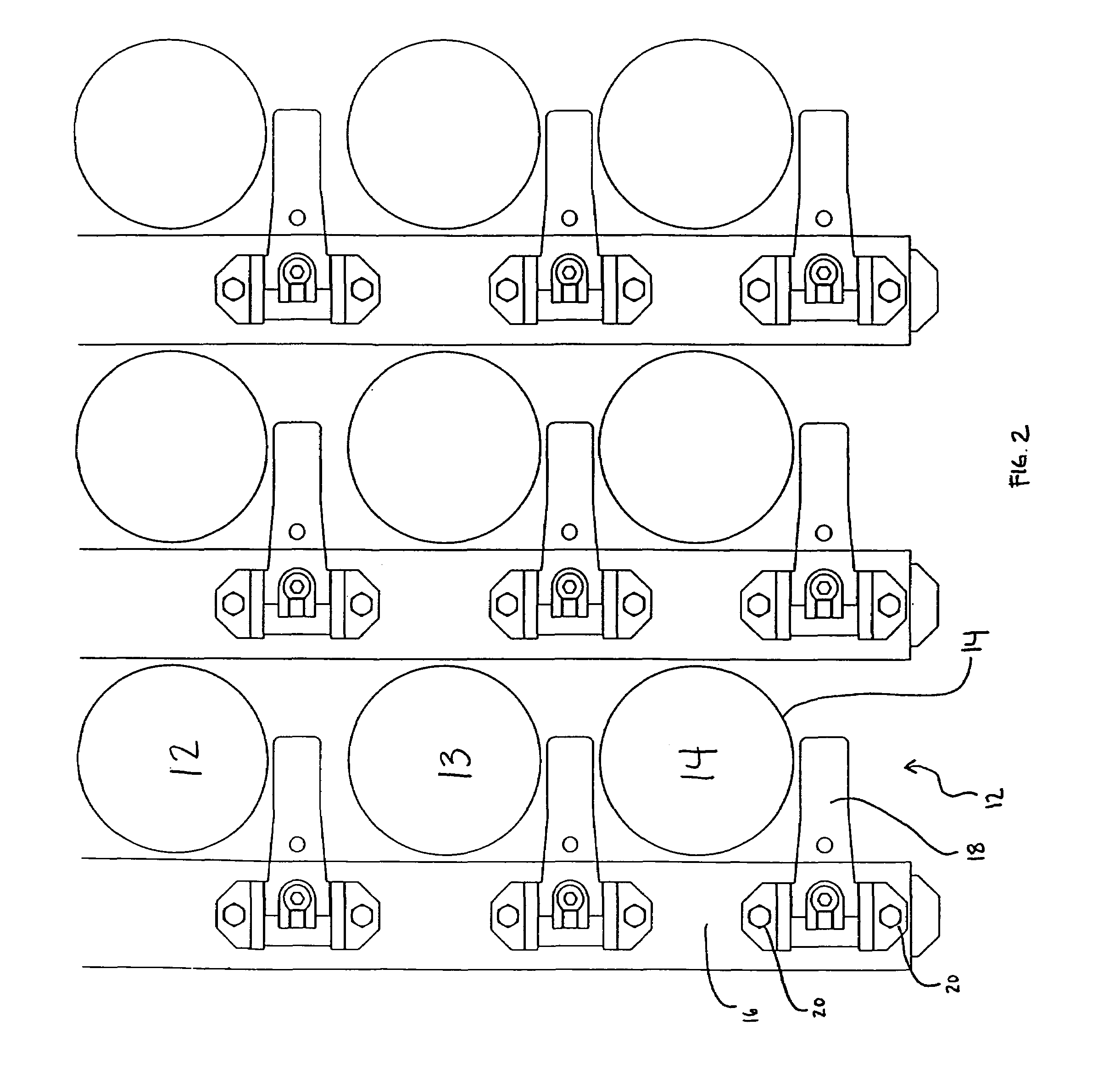

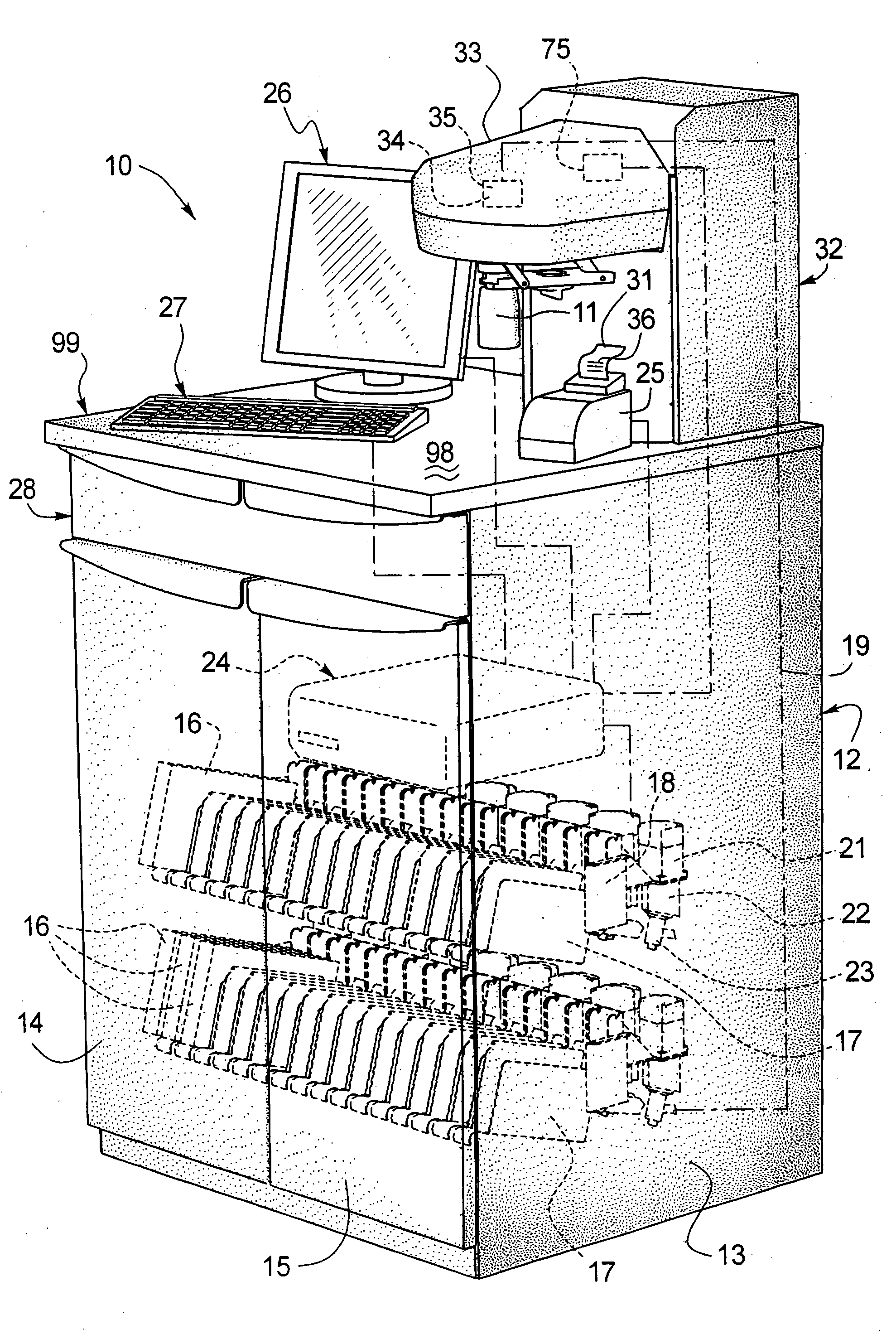

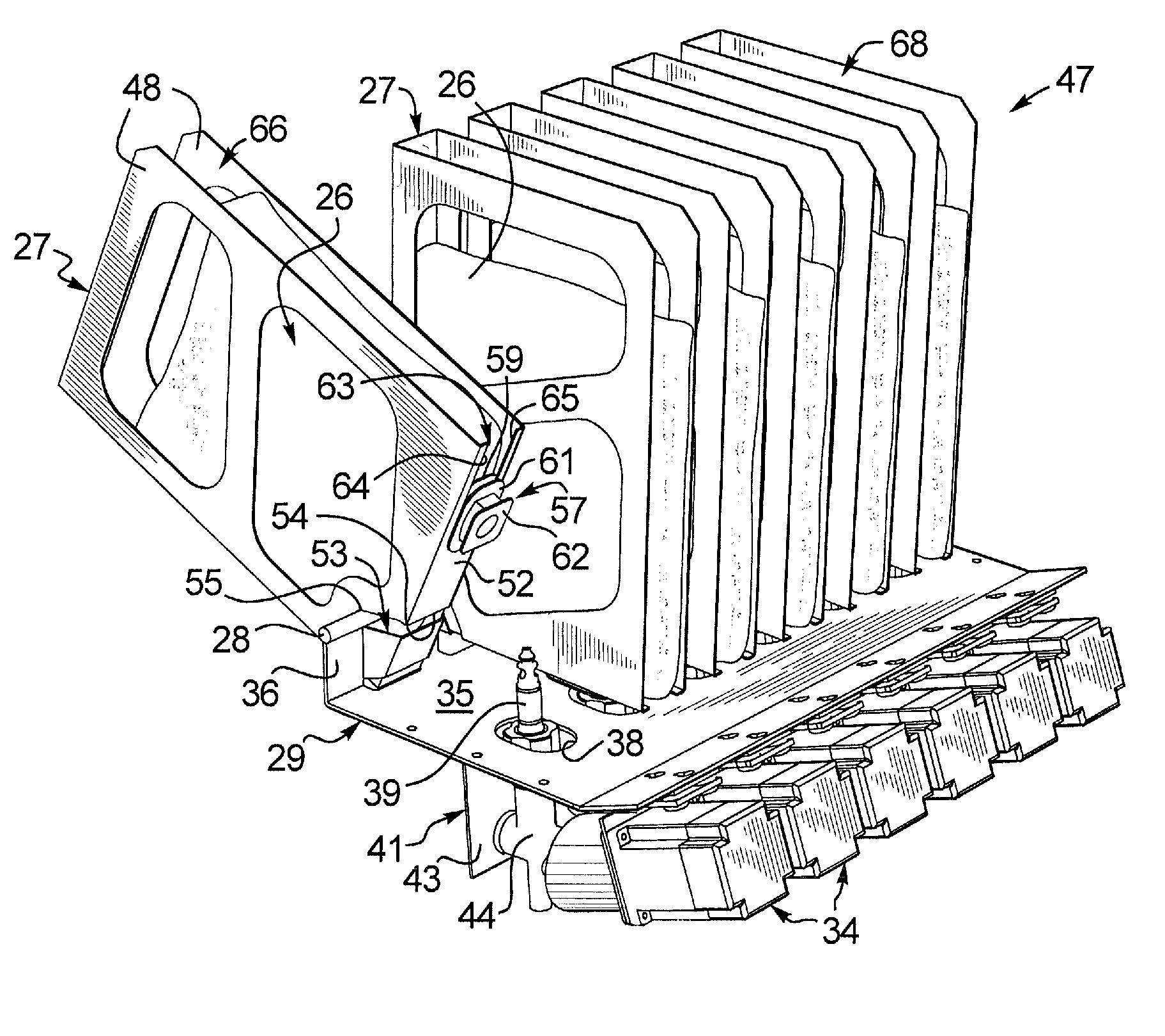

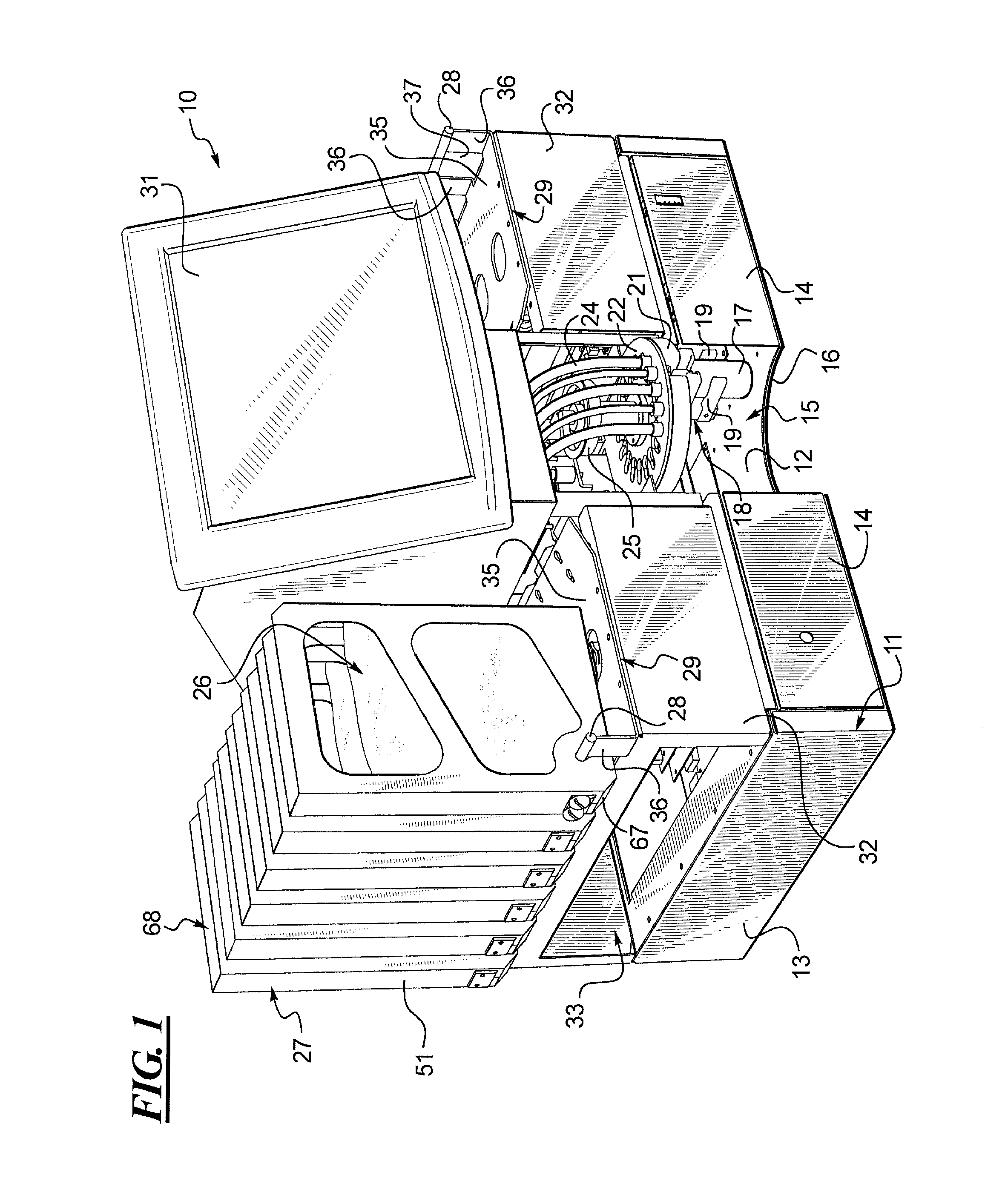

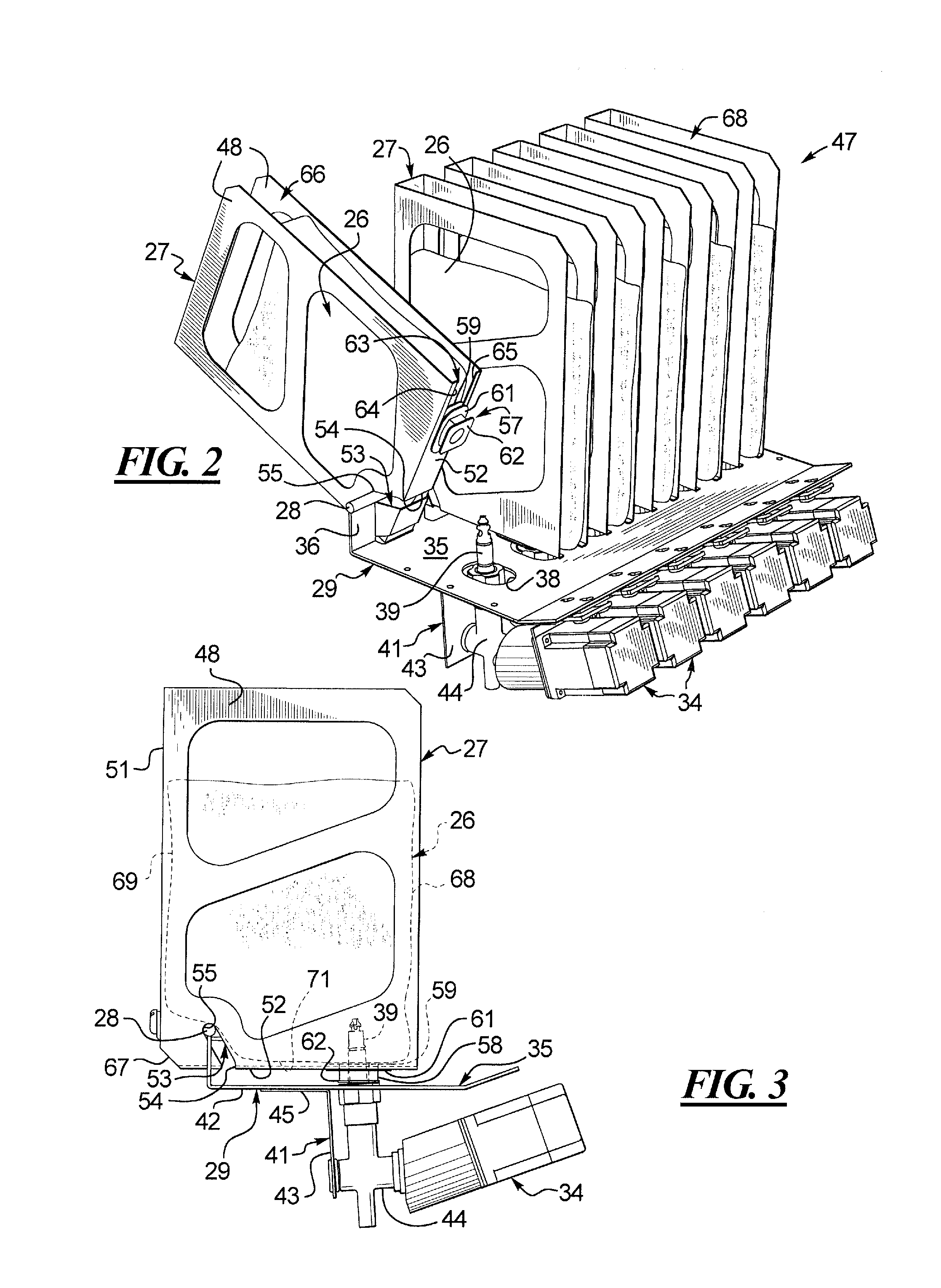

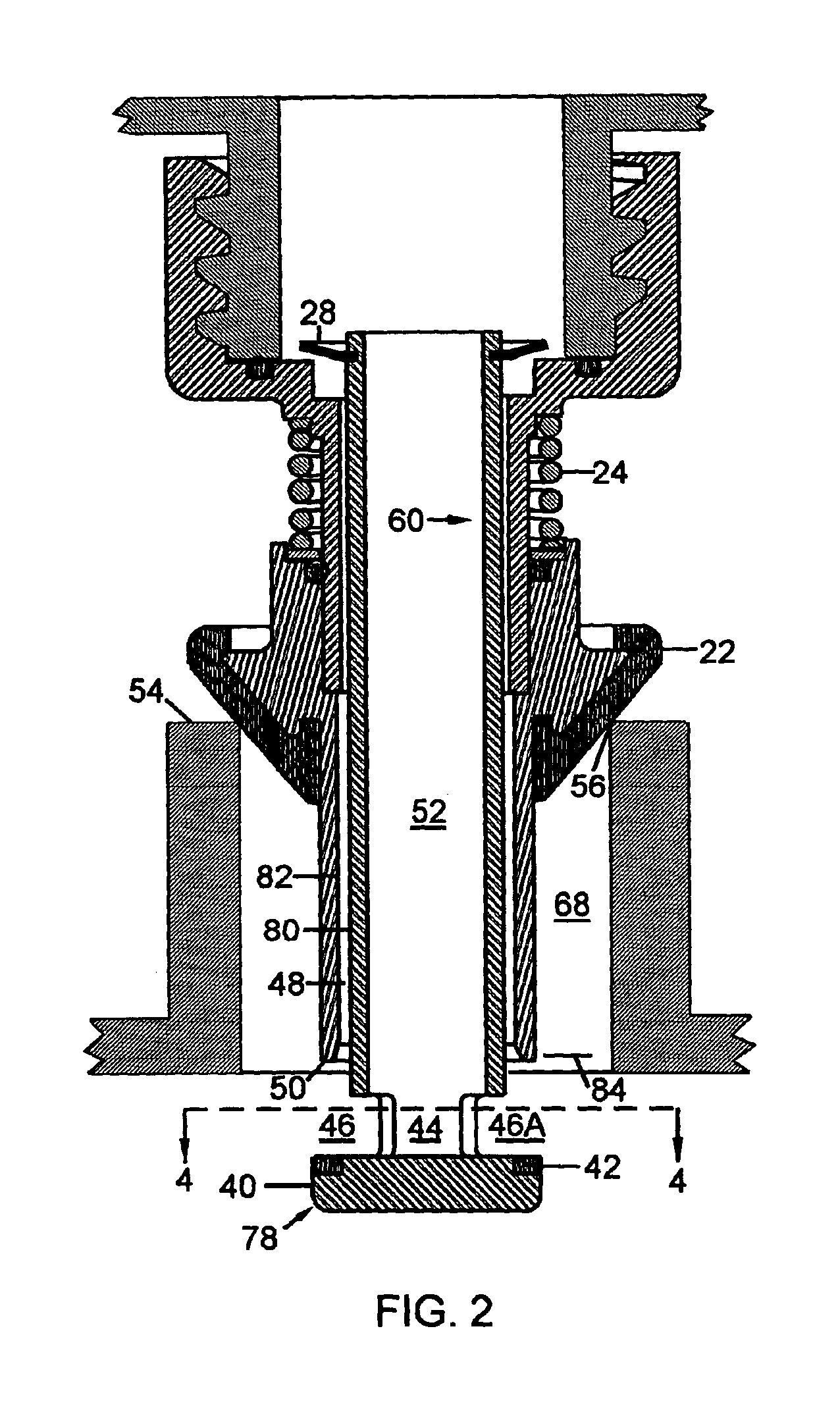

Apparatus for dispensing paint and stain samples and methods of dispensing paint and stain samples

ActiveUS7228879B2Eliminate needReduce and eliminate possibilityClosuresBarrels/casks fillingEngineeringNozzle

An improved fluid dispenser specially adapted to provide sample-size amounts of a fluid mixture is shown and described. An automated closure and seal system is provided for the manifold that moves, on command from a controller, from a closed or sealed position thereby limiting exposure of the manifold and fluid outlet nozzles from the ambient atmosphere, to a dispense system where a sample-size container is held up against and engaging a lower end of the manifold for a sealing element disposed on a lower portion of the manifold. When the dispense is complete, the system automatically moves back toward a closed position where the filled container is held open and ready to be removed by a technician before it is capped and labeled.

Owner:FLUID MANAGEMENT LLC

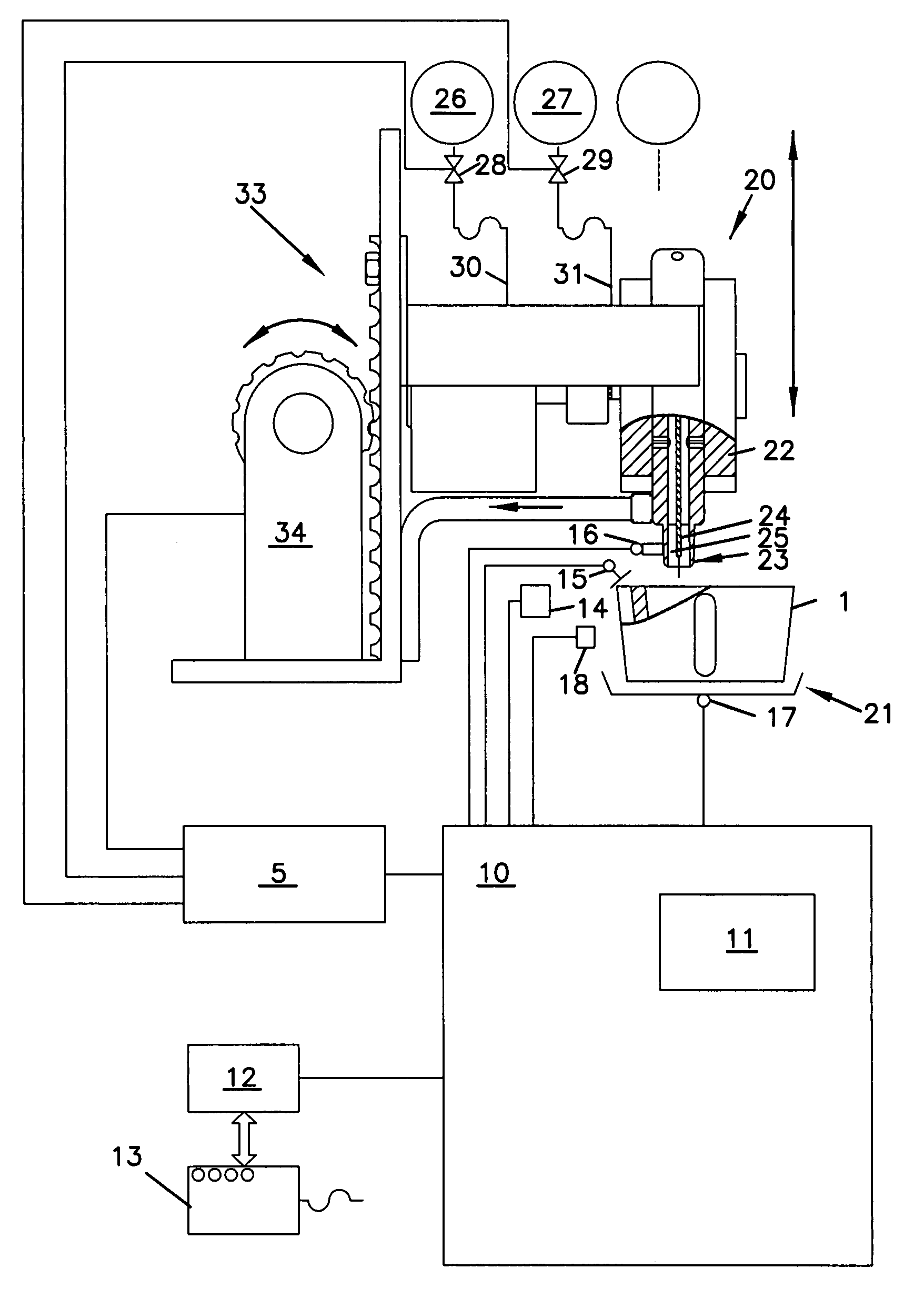

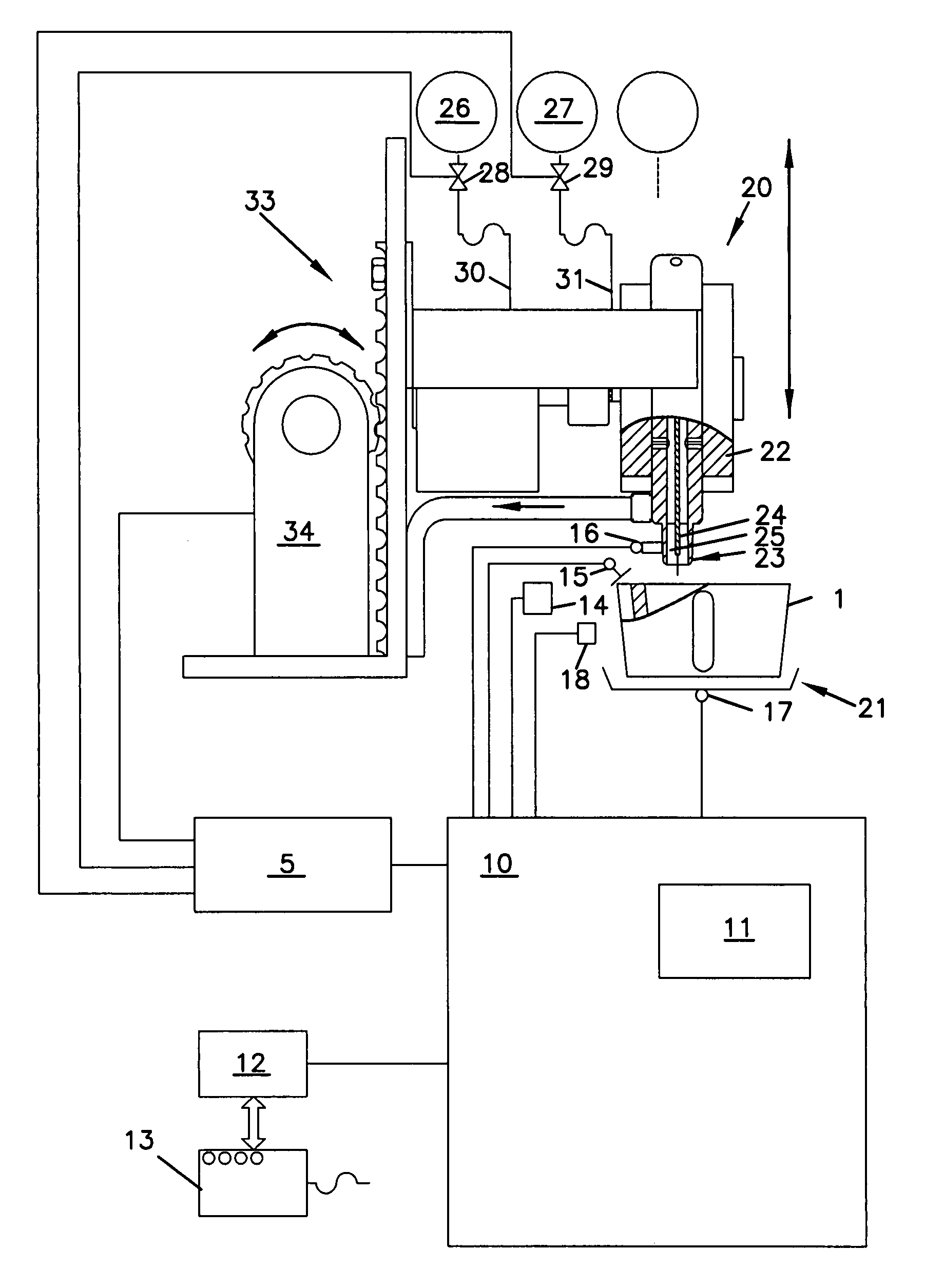

Dispensing device for drinks

InactiveUS7353850B2Avoid soilUniform qualityBarrels/casks fillingBeverage vesselsEngineeringIdentification device

A dispensing device dispenses drinks or similar dosable liquid foodstuffs, especially coffee, milk, soft drinks or soups. The dispensing device includes an identification device for identifying a vertical height of a container for receiving the foodstuff and for emitting a height signal, a filling device which can be arranged in such a way that the height thereof can be adjusted in relation to the container, and a control device which sets the filling device to a pre-controllable filling level in relation to the container, on the basis of the height signal, before the foodstuff is introduced into the container. In this way, a container can be filled in an optimum manner without spilling.

Owner:FRANKE TECH & TRADEMARK LTD

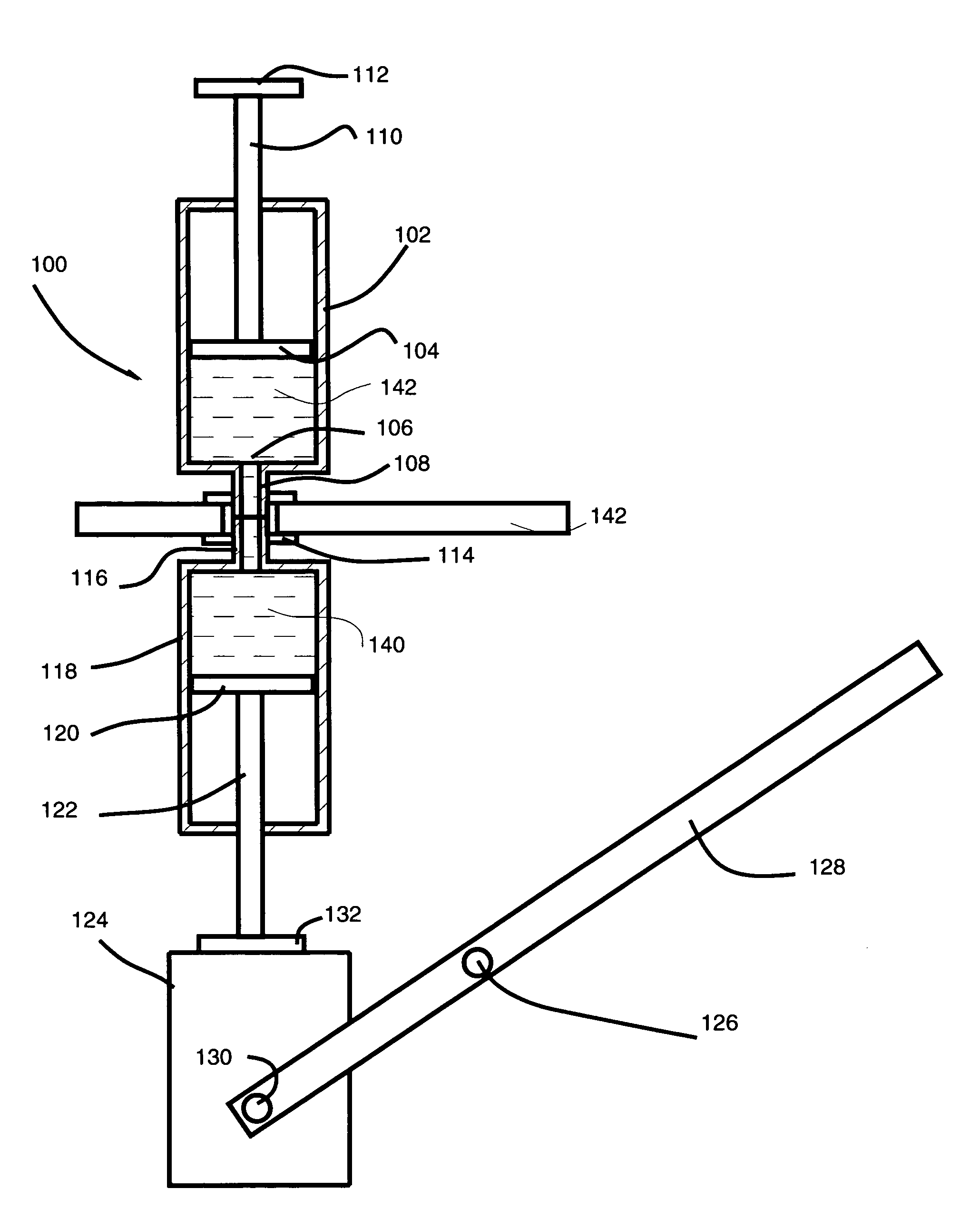

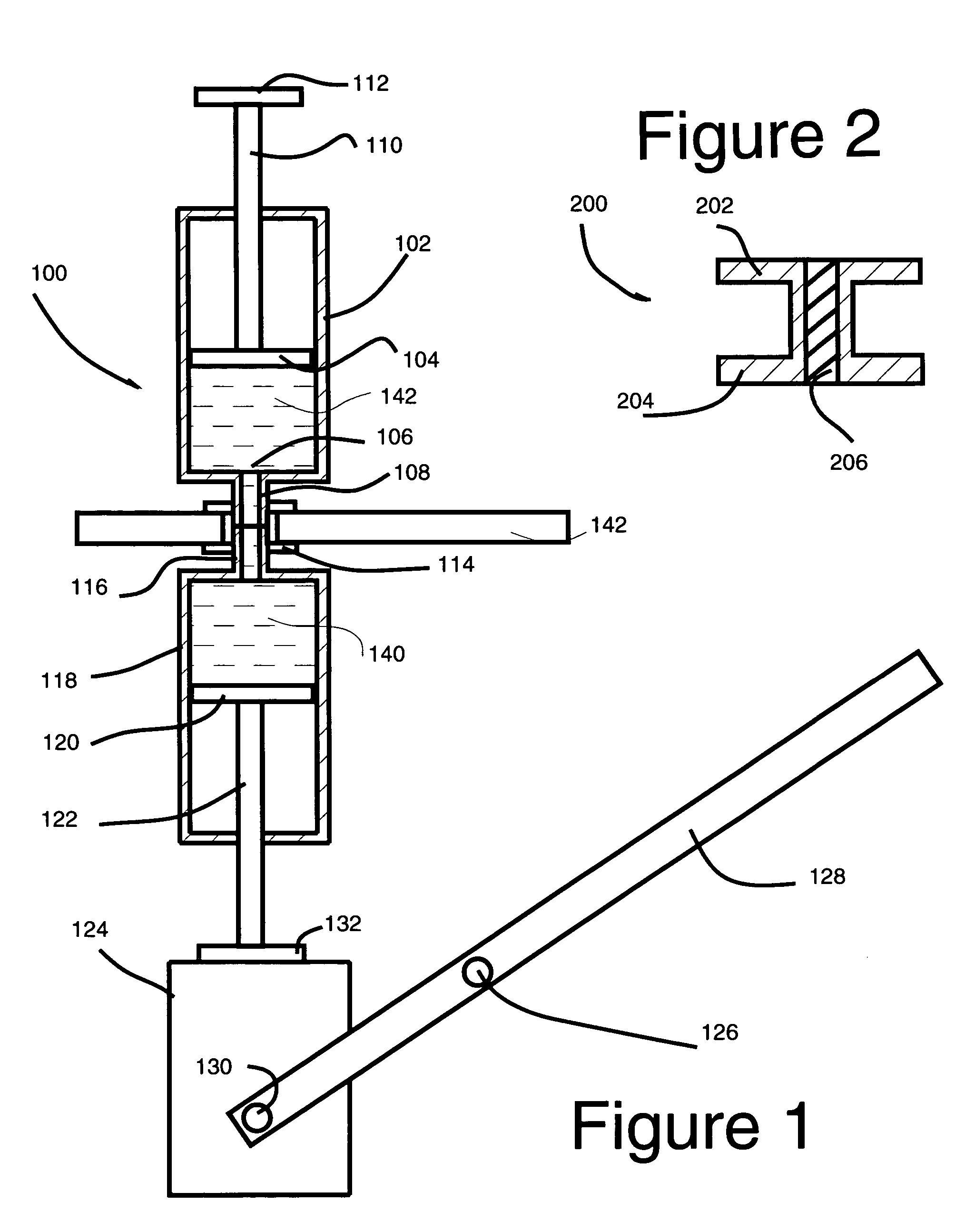

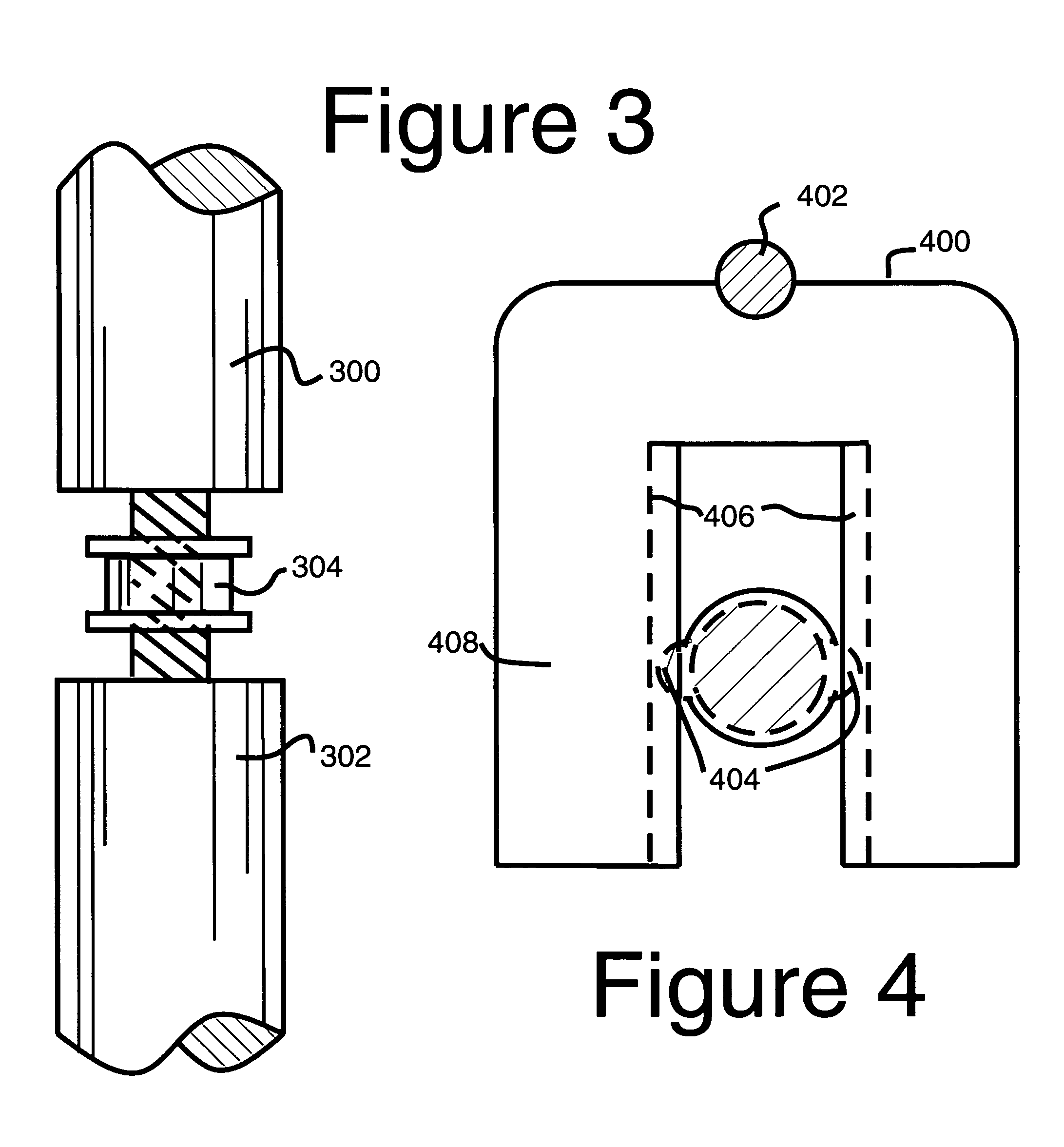

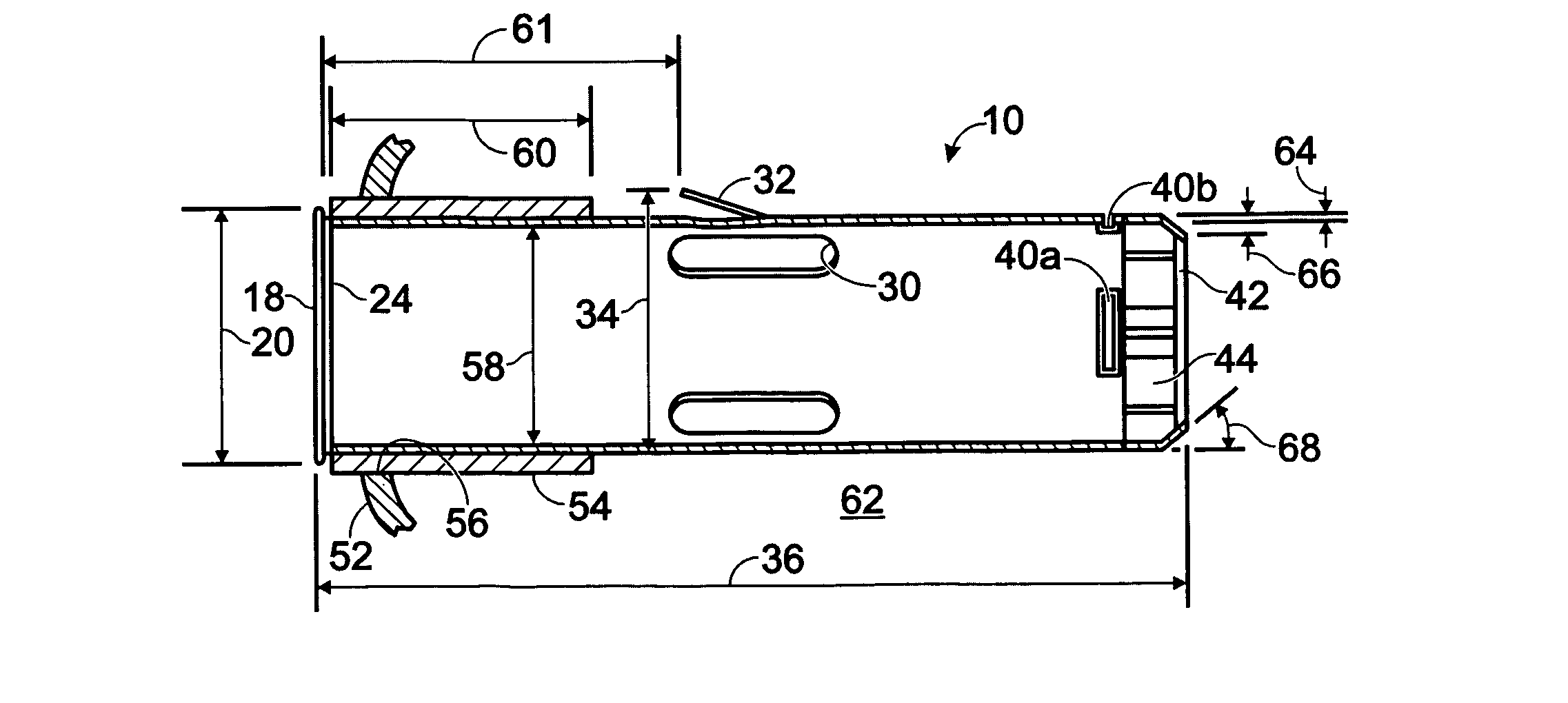

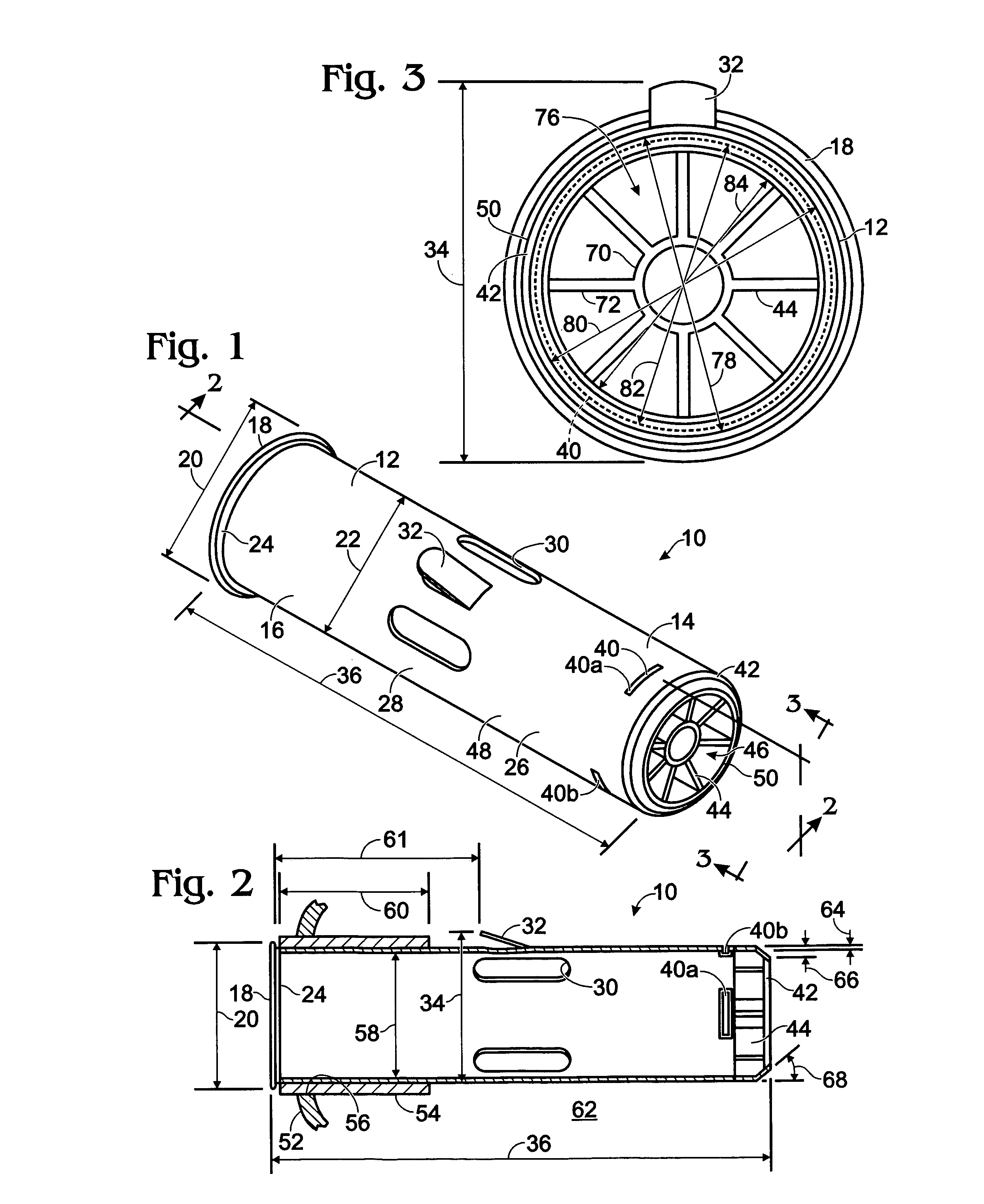

Container with valve assembly for filling and dispensing substances, and apparatus and method for filling

ActiveUS20050178462A1Low costImprove the level ofValve arrangementsBarrels/casks fillingHermetic sealBiomedical engineering

A vial has a body defining a chamber for receiving a substance therein; and a valve assembly coupled in fluid communication with the chamber and defining (i) an open position permitting at least one of (a) passage of the substance through the valve assembly and into the chamber for storing the substance in the chamber, and (b) passage of the substance out of the chamber for dispensing the substance therefrom; and (ii) a closed position forming a fluid-tight seal between the chamber and exterior of the container. A filling member engages a flexible valve member of the valve assembly to move the valve member between the closed and open positions to fill and seal the vial, respectively. A syringe is connectable to the vial. The valve assembly opens upon connecting the syringe to the vial to allow the substance within the vial to be withdrawn from the vial and into the syringe by actuating a plunger of the syringe, and the valve assembly closes upon disconnecting the vial and syringe to hermetically seal and store the substance remaining in the syringe for later use.

Owner:DR PY INST LLC

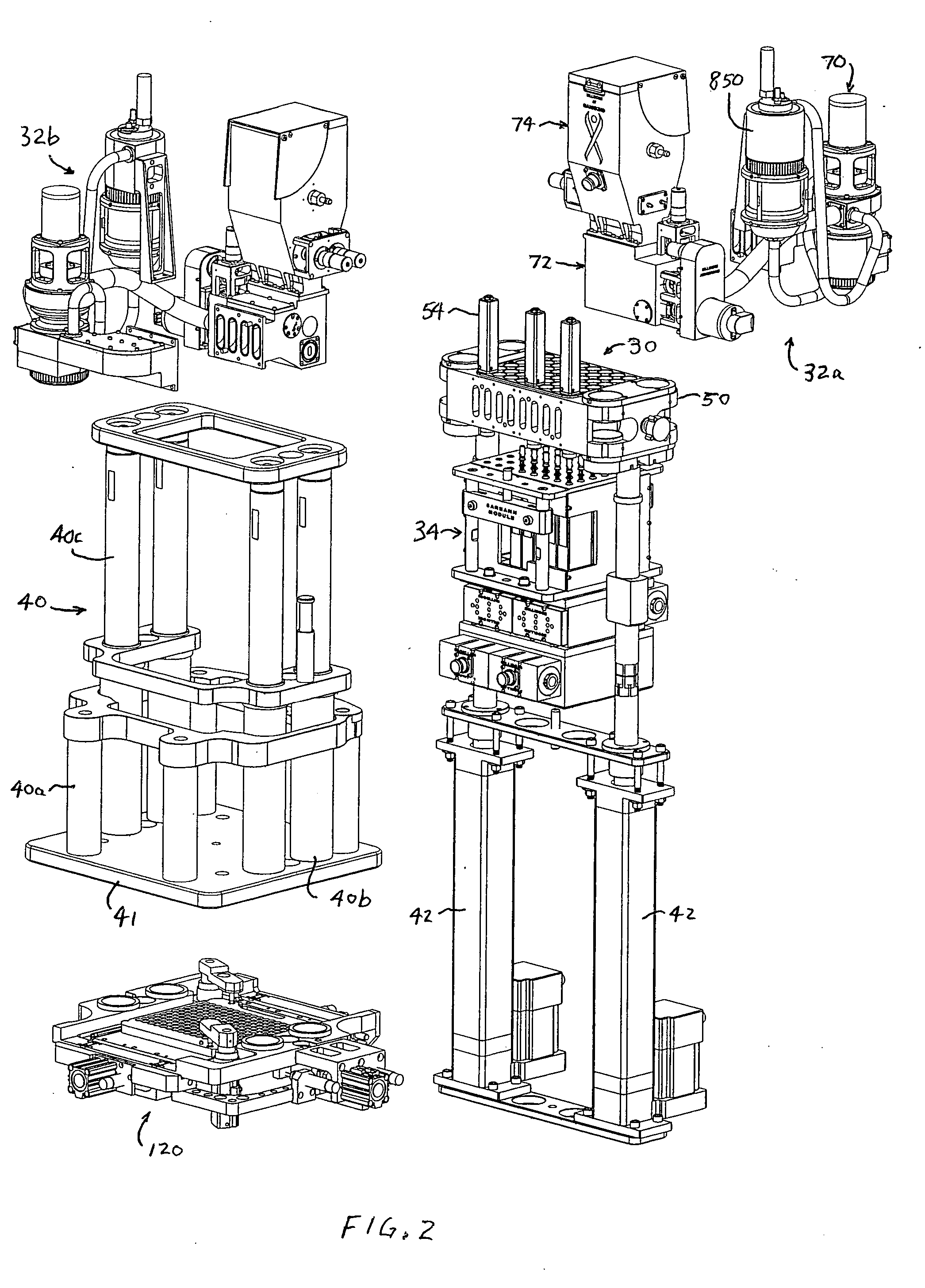

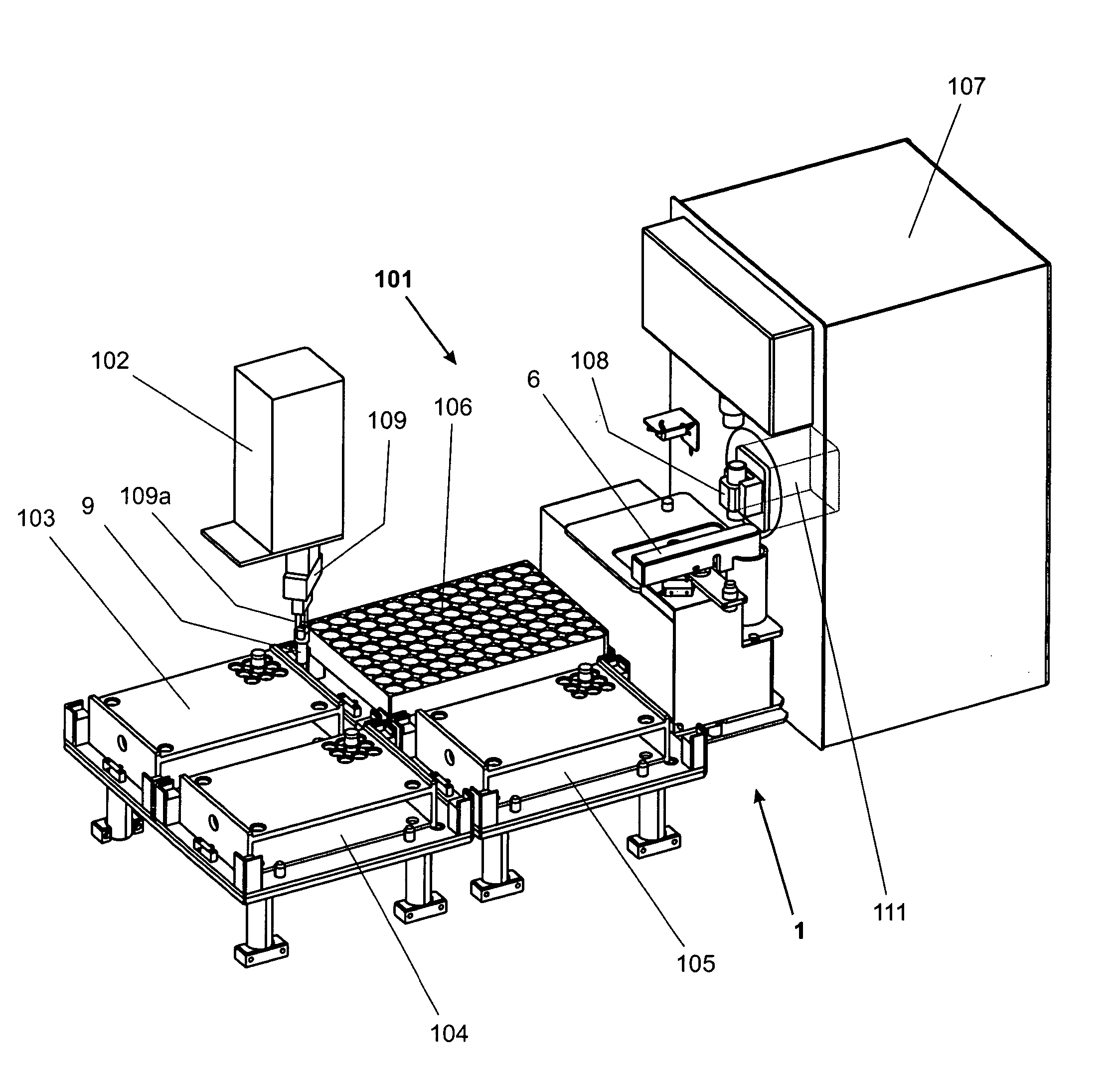

Powder dispenser modules and powder dispensing methods

InactiveUS20070131707A1Facilitates regulatory approvalImprove compactnessBarrels/casks fillingMovable measuring chambersTransport systemControl system

Powder dispensing and sensing apparatus and methods are provided. The powder dispensing and sensing apparatus includes a tray support structure to receive a cartridge tray holding cartridges, a powder dispenser assembly including powder dispenser modules to dispense powder into respective cartridges of a batch of cartridges in the cartridge tray, a powder transport system to deliver powder to the powder dispenser modules, a sensor module including sensor cells to sense respective fill states, such as the weights, of each of the cartridges in the batch of cartridges, and a control system to control the powder dispenser modules in response to the respective sensed fill states of each of the cartridges of the batch of cartridges.

Owner:MANNKIND CORP

Method and apparatus for compounding medications

InactiveUS7748892B2Cosmetic preparationsShaking/oscillating/vibrating mixersEngineeringBULK ACTIVE INGREDIENT

Owner:MCCOY WILLIAM

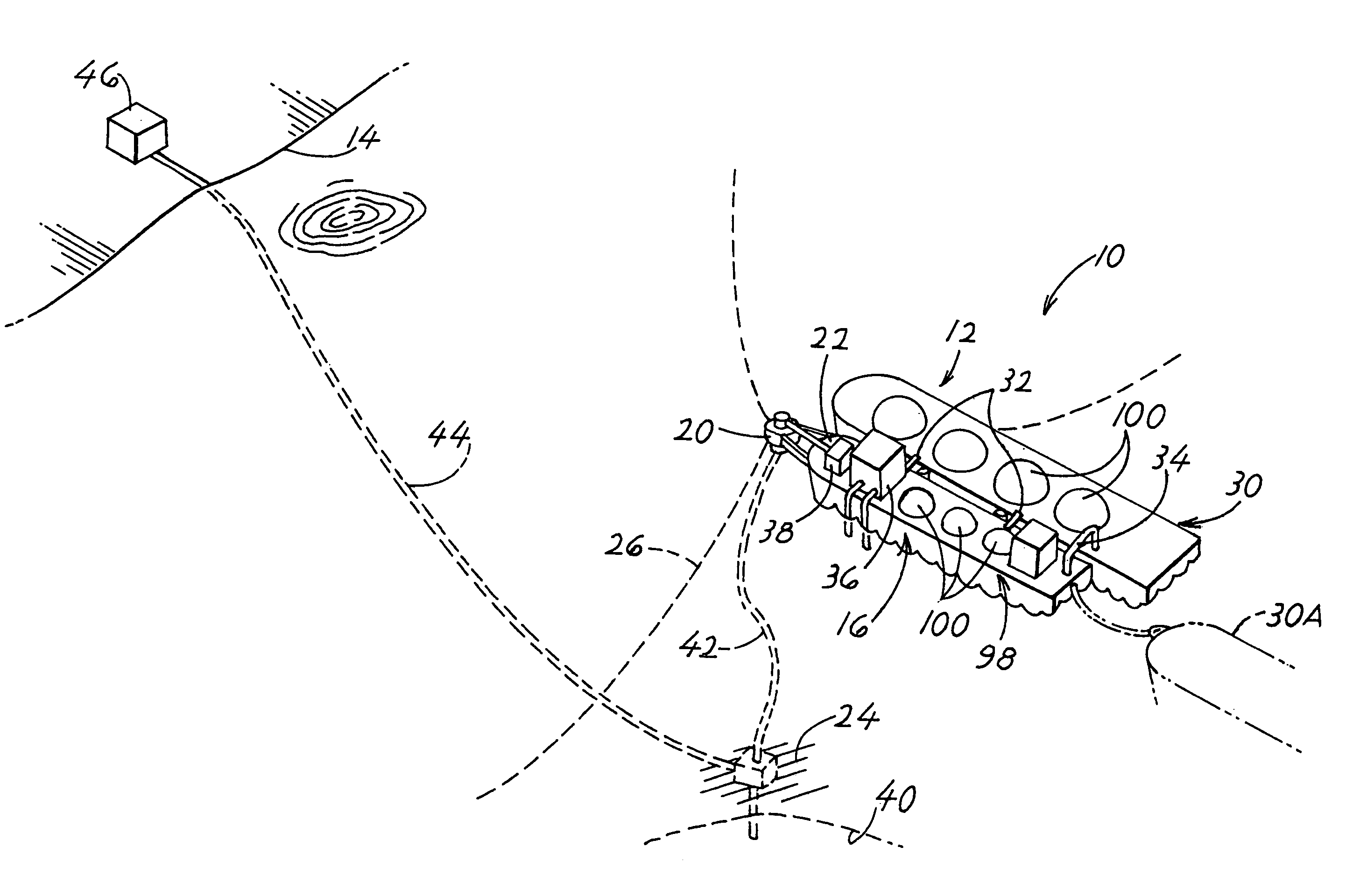

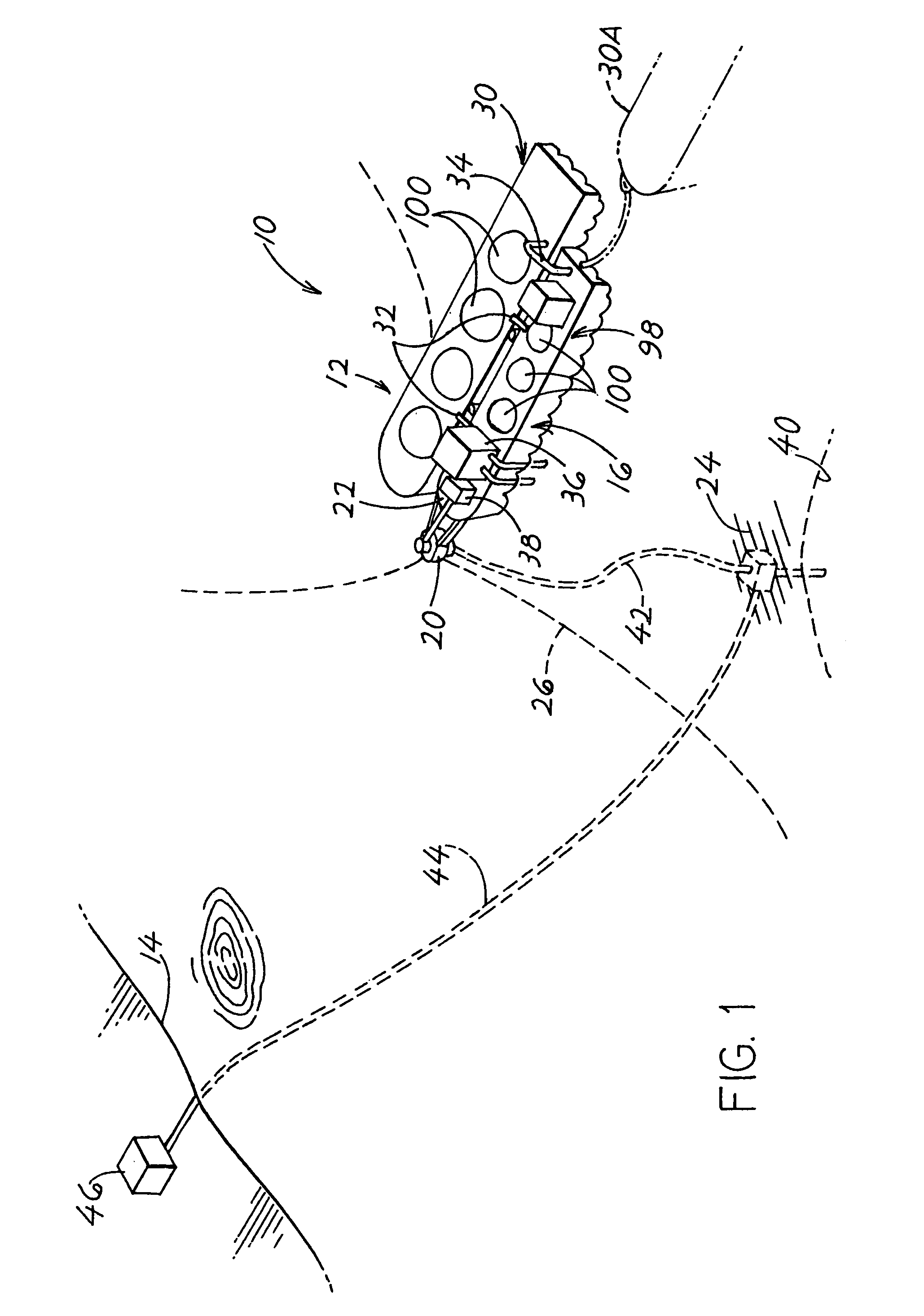

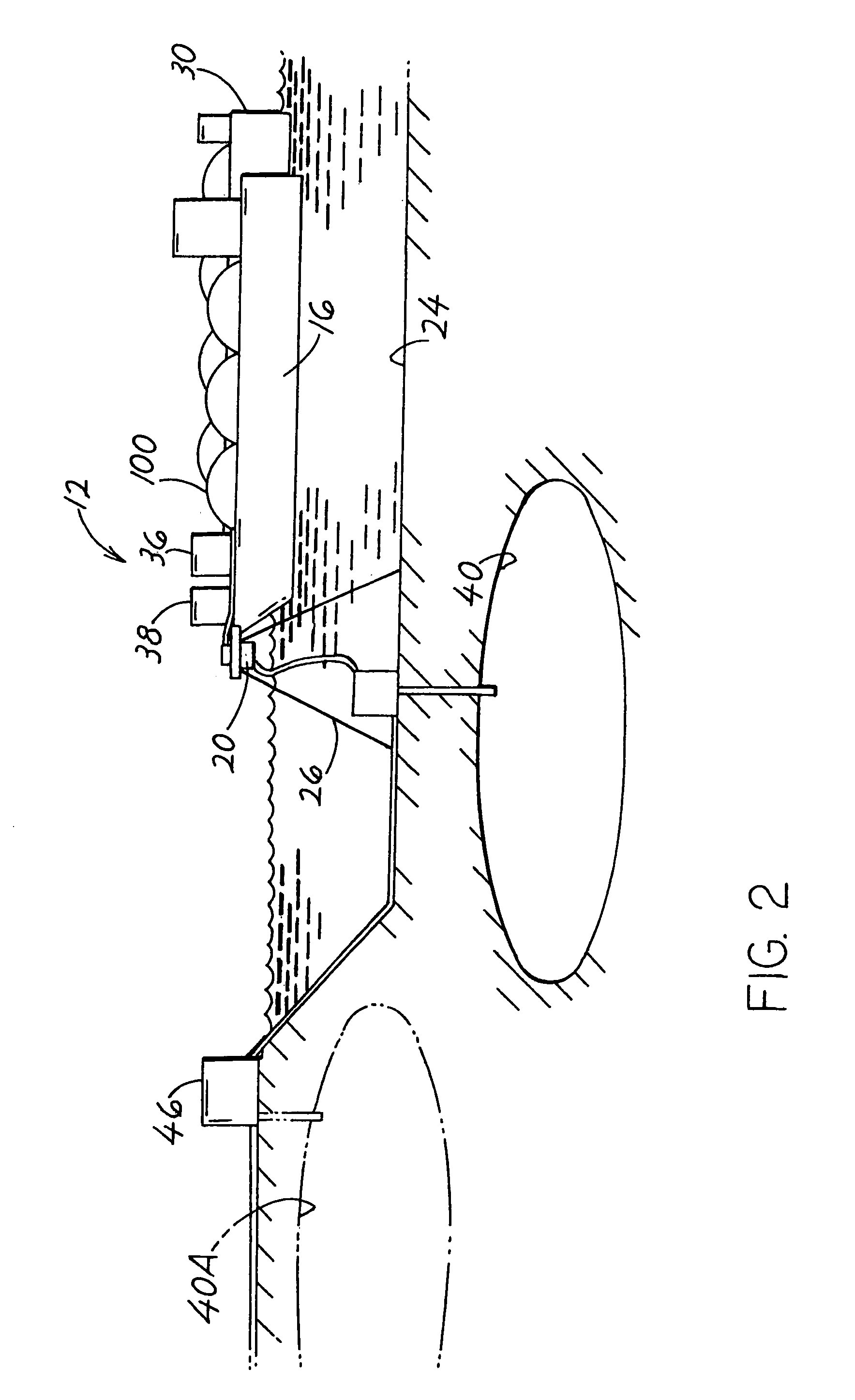

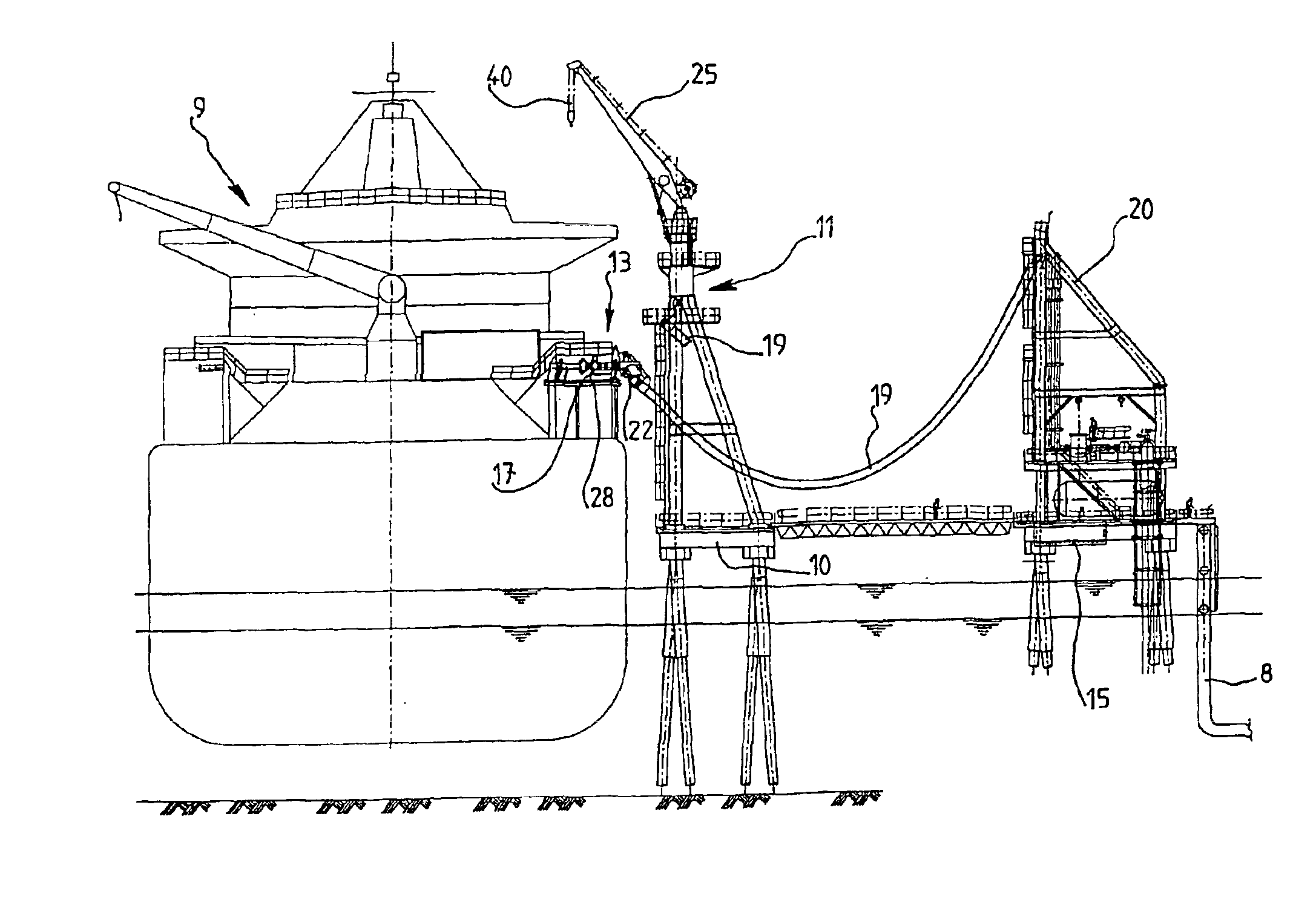

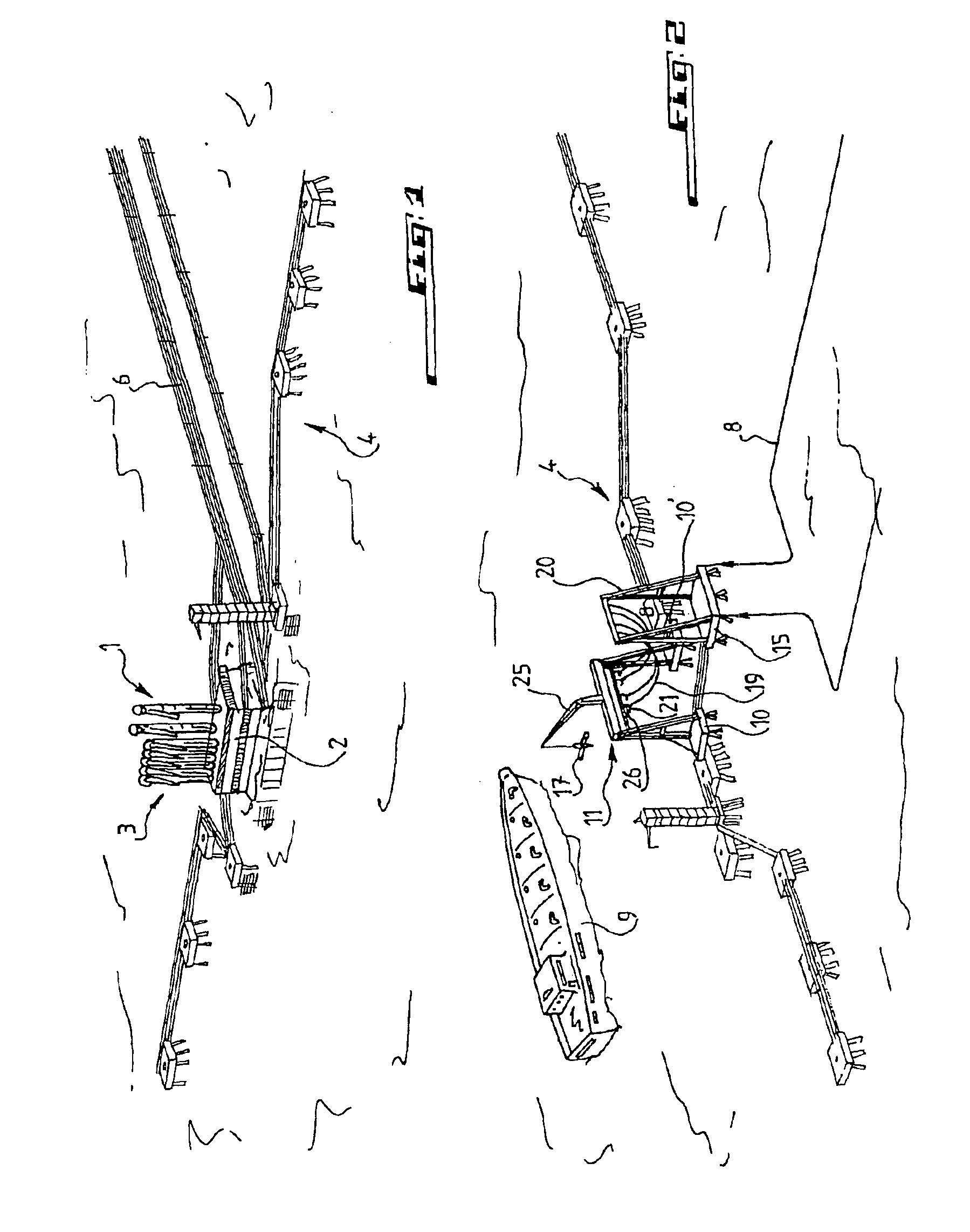

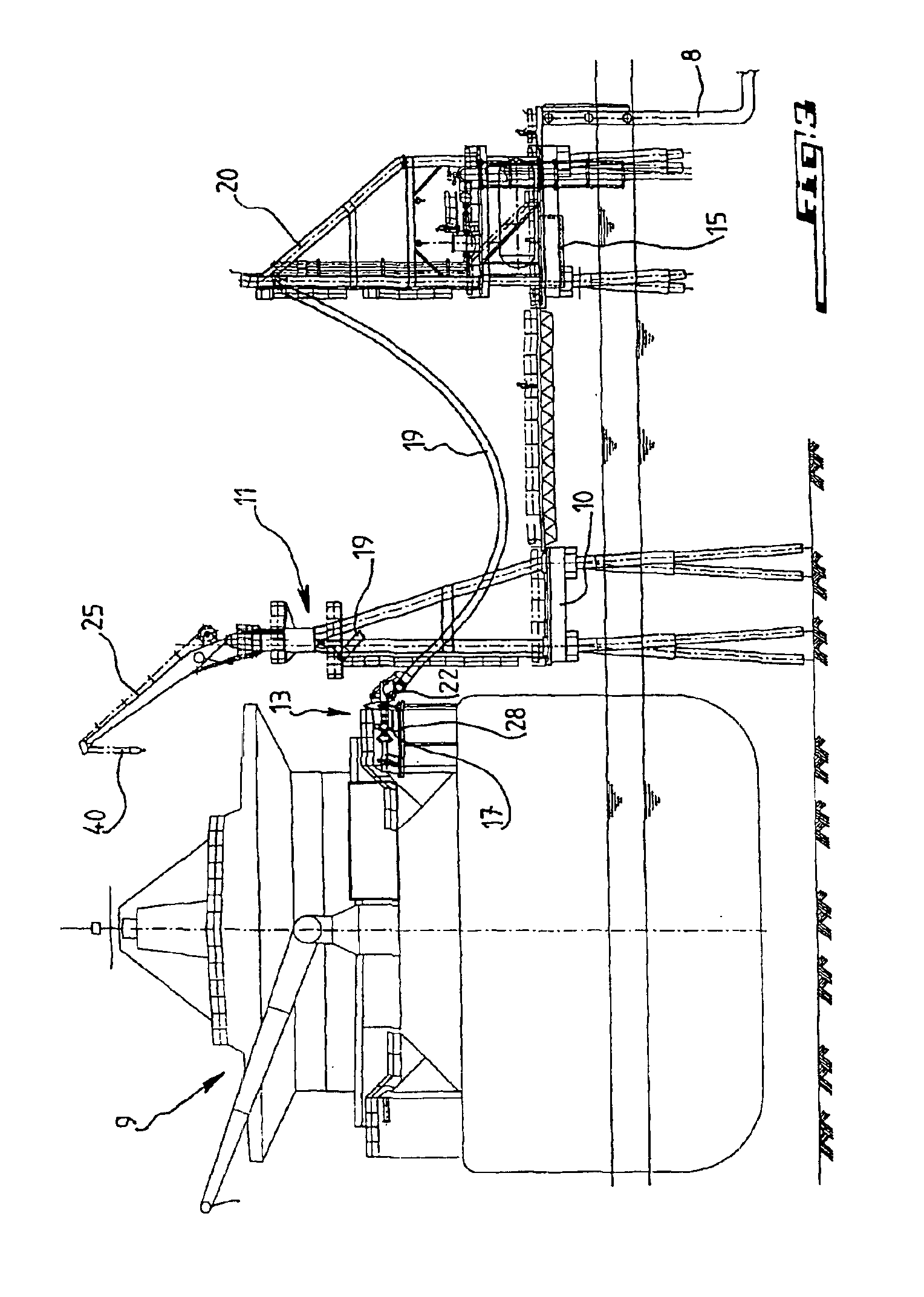

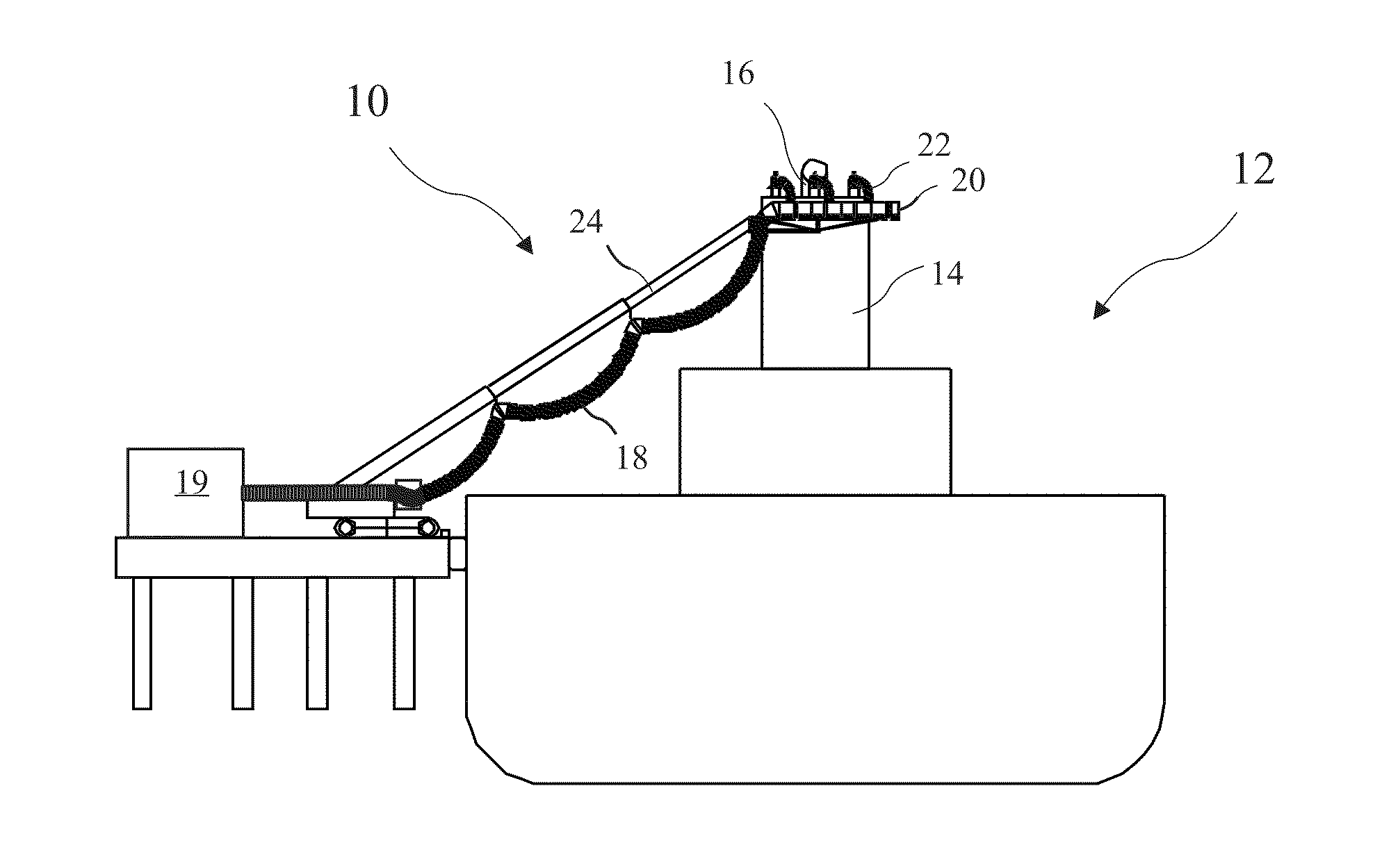

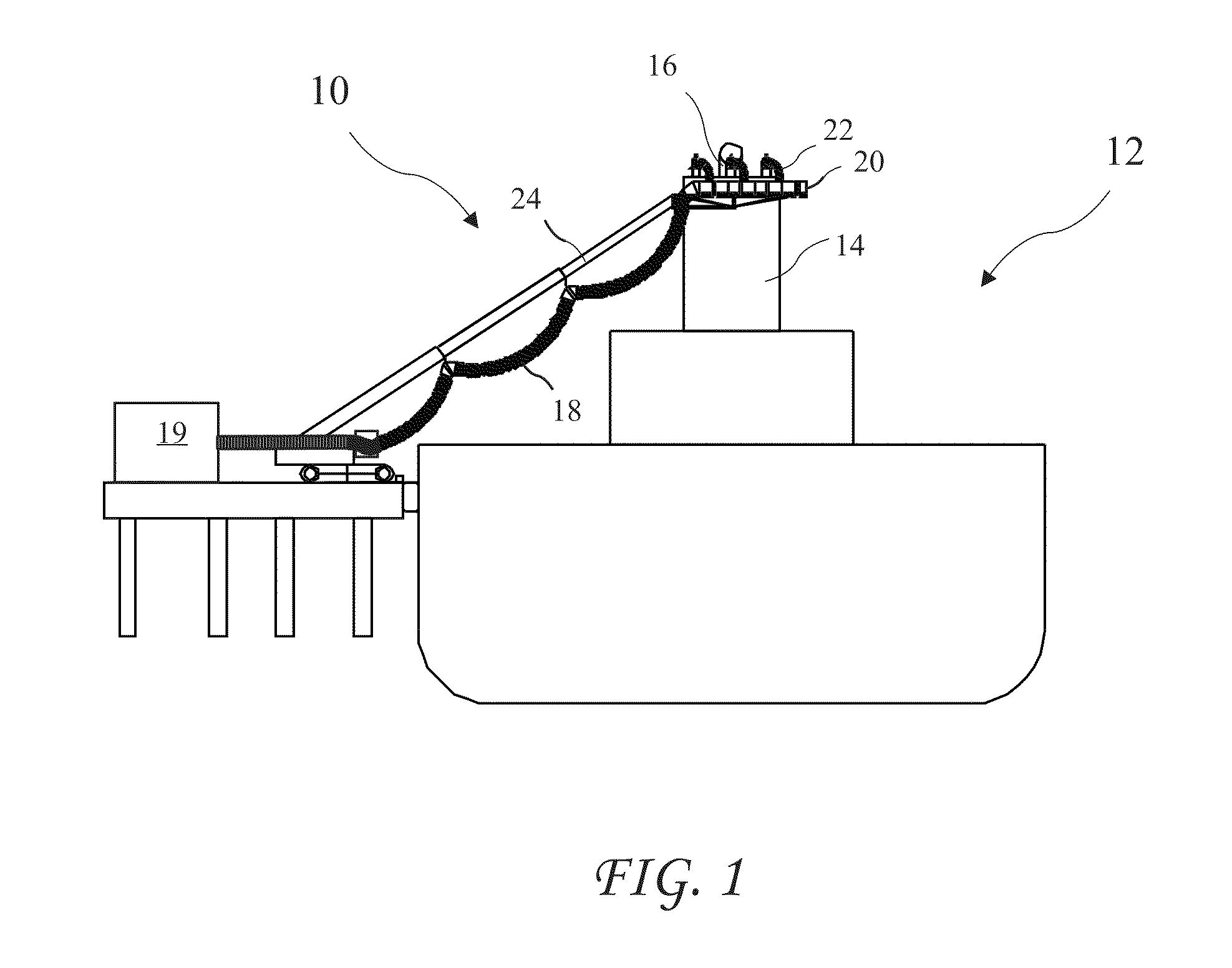

Quick LNG offloading

ActiveUS7080673B2Low costReceive quicklyGas handling applicationsGas handling/storage effectsProduct gasEngineering

A system of the type wherein LNG from a tanker (30) is offloaded to a moored vessel (16), which has a regas unit (36) which heats the LNG to transform it into gaseous hydrocarbons, and which has a pump unit (38) that pumps the gaseous hydrocarbons to a consumer (46) such as an onshore gas distribution facility. The system is constructed to enable more rapid tanker unloading so the tanker is released earlier to sail back to a pickup location. The moored vessel has a thermally insulated LNG storage facility such as LNG tanks (100), with a capacity to store all LNG not regassed during offloading of the tanker. The regas unit has sufficient capacity to regas all LNG received in one tanker load, before the tanker returns with another load of LNG.

Owner:SINGLE BUOY MOORINGS INC

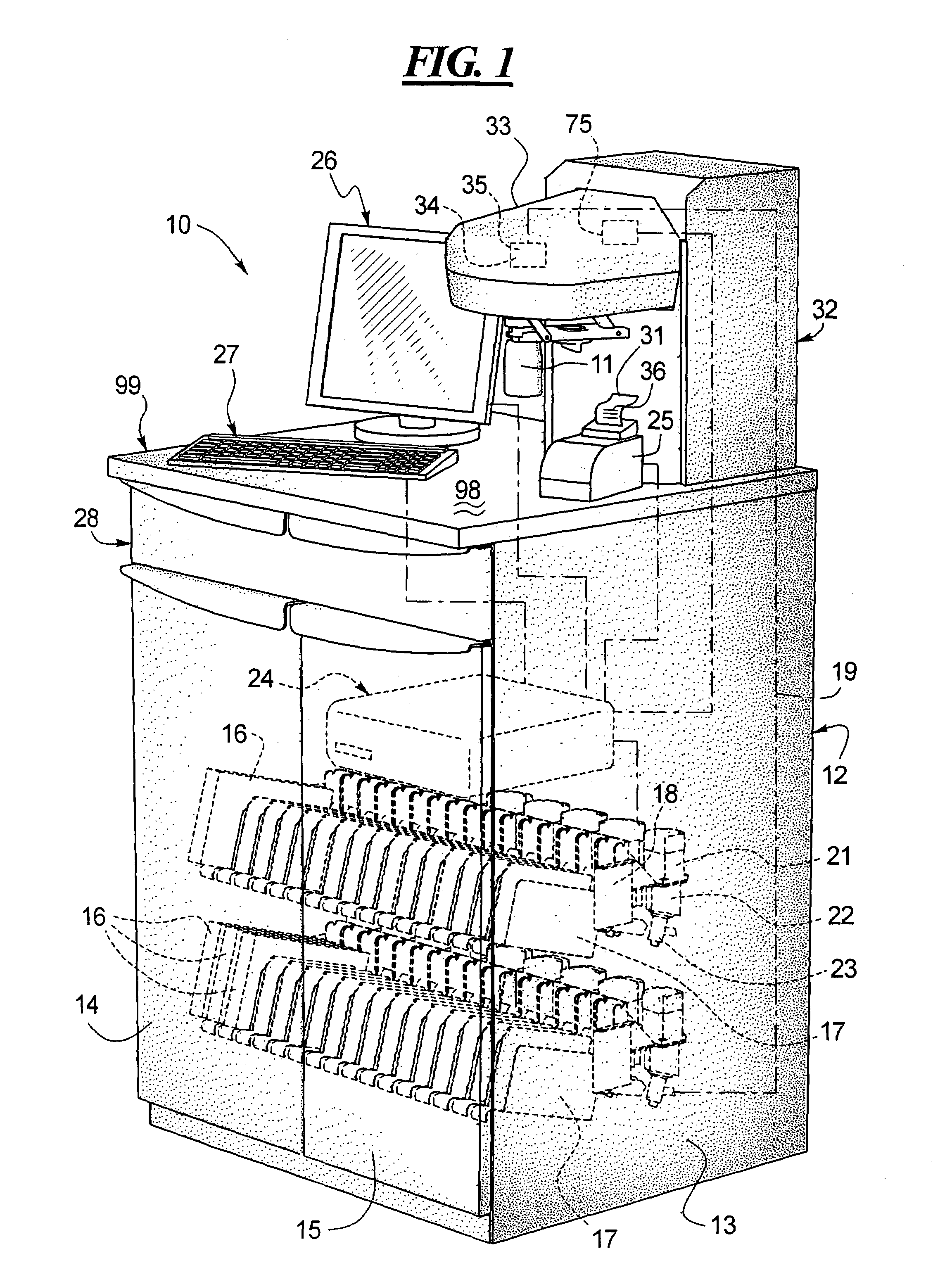

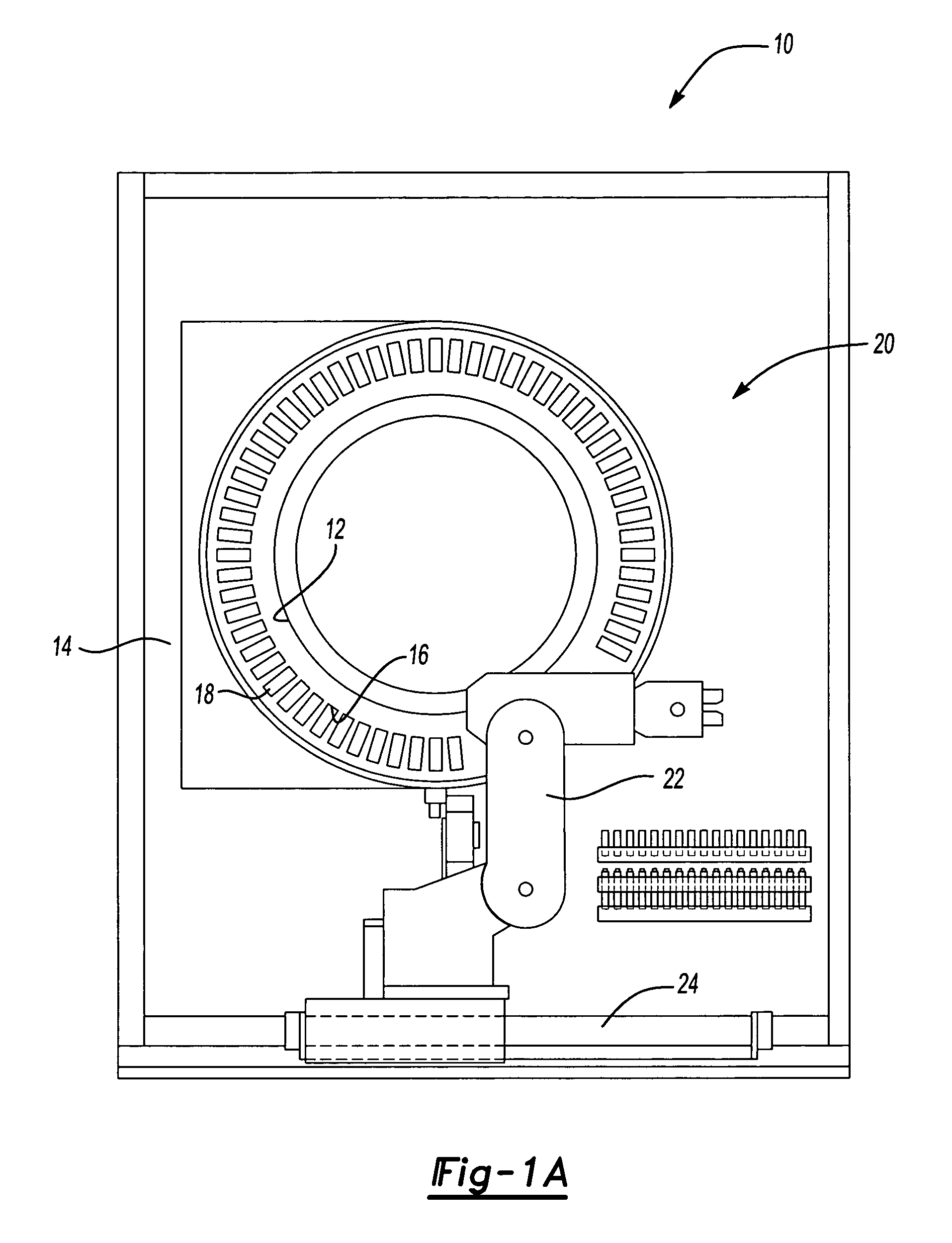

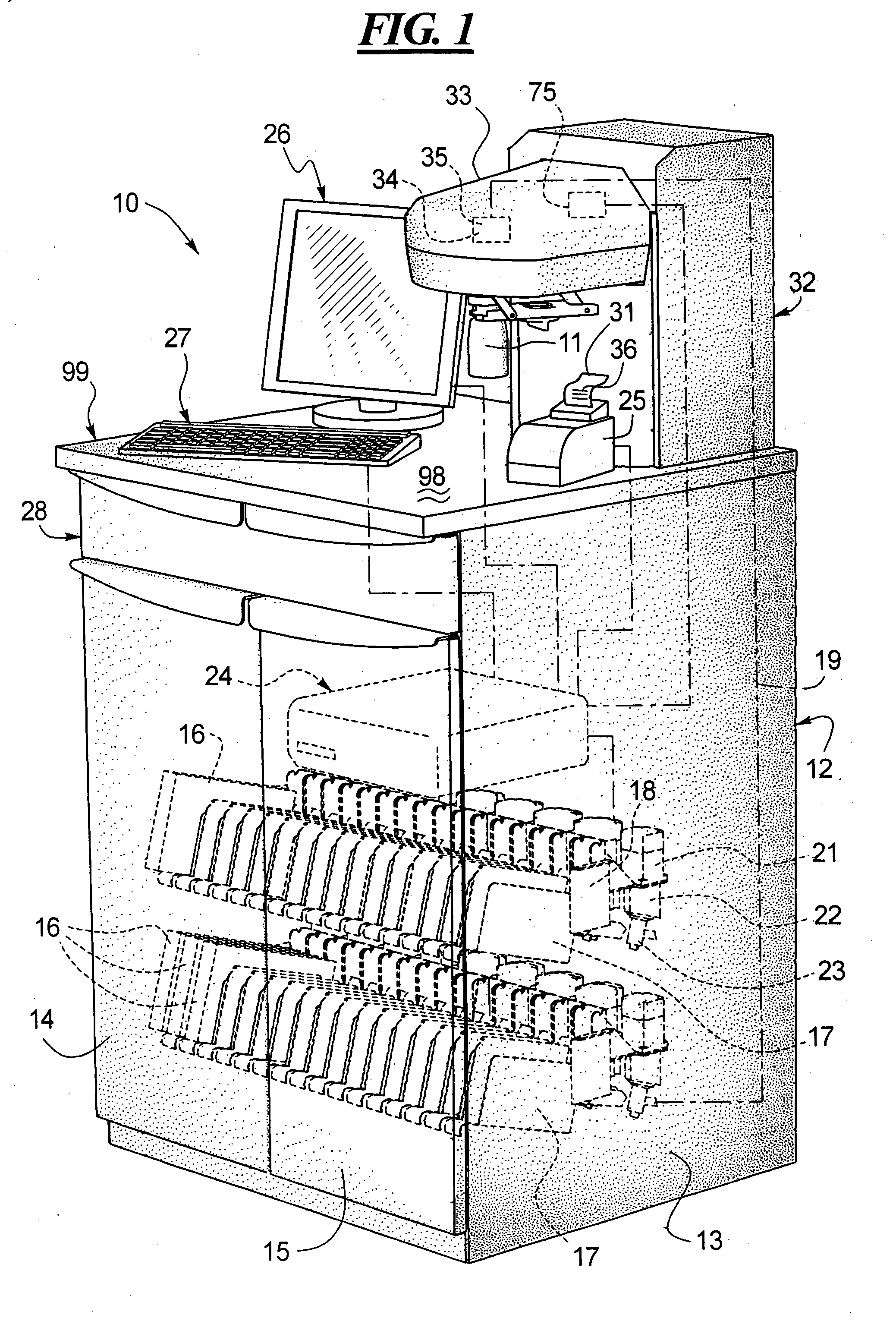

Automated customized cosmetic dispenser

ActiveUS7624769B2Enhanced customer involvementEnhancing product salesShaking/oscillating/vibrating mixersMixer accessoriesBiomedical engineeringPoint of sale

The present invention provides a method and apparatus for the creation and dispensing of a custom formulation within a package at a retail point of sale. In one aspect, the invention includes an automated dispensing apparatus including at least a two-axis robot arm. In another aspect, the invention includes an automated mixer adapted to mix the dispensed custom formulation within the package.

Owner:COSMETIC TECH L L C

Fingerboard with pneumatically actuated finger latches

Owner:VARCO I P INC

Beverage dispensing apparatus

InactiveUS7040359B2Low manufacturing and maintenance costsReduce the cross-sectional areaBarrels/casks fillingLiquid flow controllersEngineeringNozzle

A removable nozzle for attachment to a conventional faucet of a beverage dispensing device to permit the dispensing of a pressurized beverages at a high flow rate without producing excessive foaming comprising a streamlined valve assembly and a downward extending nozzle assembly which permits a range of containers to be filled from the bottom.

Owner:LAMINAR TECH

Process for Making Non-Uniform Patterns of Multiphase Compositions

A method of filling a container with a liquid composition, which comprises at least two visually distinct phases, comprising the steps of: a.) transferring said liquid composition to a container using a dispenser which has an initial fill rate; b.) rotating said container during said step a. at an initial speed of rotation and in an initial direction of rotation; c.) changing a feature selected from the group consisting of: the speed of rotation of said container, the fill rate of the dispenser, and the direction of rotation of said container; and mixtures of said features, each independently from the geometry of said container; and d.) completing the transfer of said liquid composition to said container.

Owner:THE PROCTER & GAMBLE COMPANY

System for transferring a fluid product between a carrying vessel and a shore installation

A system for transferring a fluid product between a carrier, such as a vessel, and an installation, in particular a fixed installation, for processing and storing the product. The system includes a tubular structure for conveying the product between the vessel and the installation, a device for connection to a manifold of the vessel and a flexible transfer pipe connected to the installation. The connection device and the pipe are connectable to each other at free ends for transferring the fluid product between the vessel and the installation. At least the free end of the flexible transfer pipe includes a product handler for displacing the free end between a position for connection to the connection device and a disengaged position for storage. The invention enables the transfer of cryogenic liquefied natural gas.

Owner:SOC EURO DINGENIERIE MECANIQUE EURODIM SA

System and method for filling, removing and transporting containers

InactiveUS7304260B2Increase the level of automationEasy to handleBarrels/casks fillingSeparation devicesShipping container

The present invention relates to a system and method for automatically transporting receiving containers for sorted products. The containers are filled with the sorted products along a sorting stretch at individual, similar target stations, and automatically transported by means of a transport device after being filled. A full receiving container for sorted products is thus lowered, after a transport command has been triggered, by means of a transport device beneath a target station. The container is then placed on the transport device, if the device is not already occupied by a receiving container. The receiving container is then transported away from the target station by means of the transport device.

Owner:SIEMENS SWITZERLAND

Dispensing device for drinks

ActiveUS20060108023A1Uniform qualityAvoid soilBarrels/casks fillingBeverage vesselsIdentification deviceEngineering

The invention relates to a dispensing device for drinks or similar dosable liquid foodstuffs, especially coffee, milk, soft drinks or soups. Said dispensing device comprises an identification device for identifying a vertical height of a container for receiving the foodstuff and for emitting a height signal, a filling device which can be arranged in such a way that the height thereof can be adjusted in relation to the container, and a control device which sets the filling device to a pre-controllable filling level in relation to the container, on the basis of the height signal, before the foodstuff is introduced into the container. In this way, a container can be filled in an optimum manner without spilling.

Owner:FRANKE TECH & TRADEMARK LTD

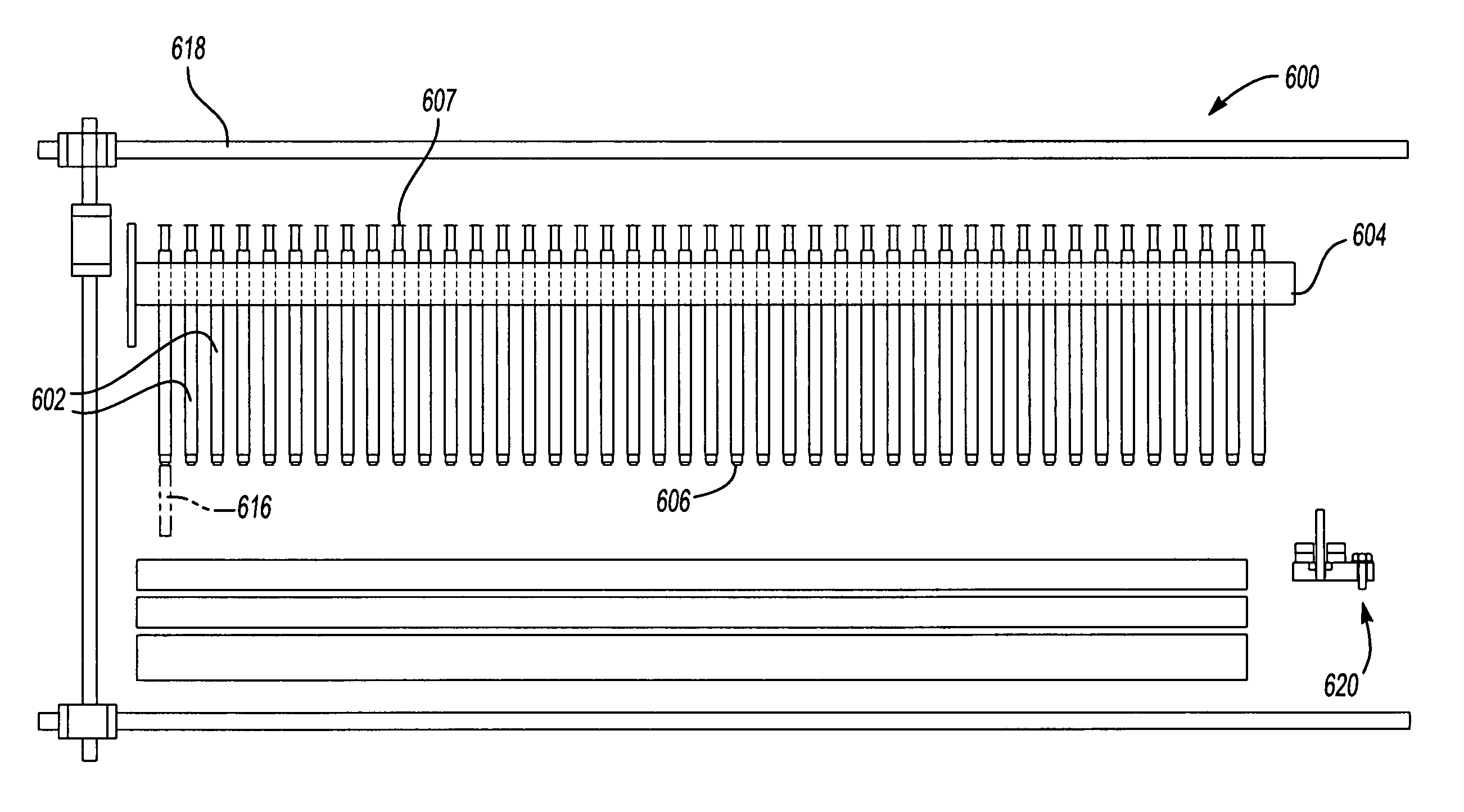

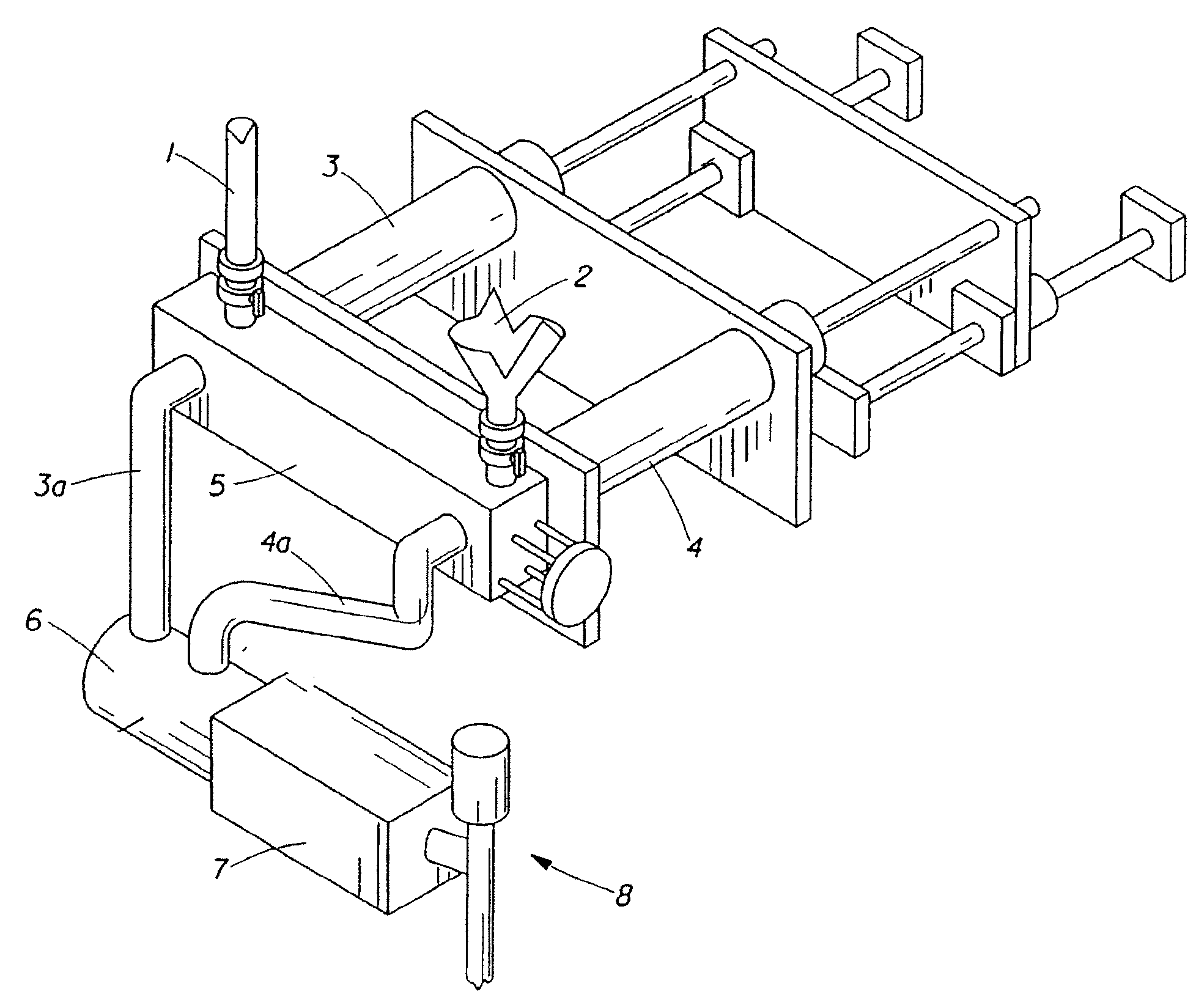

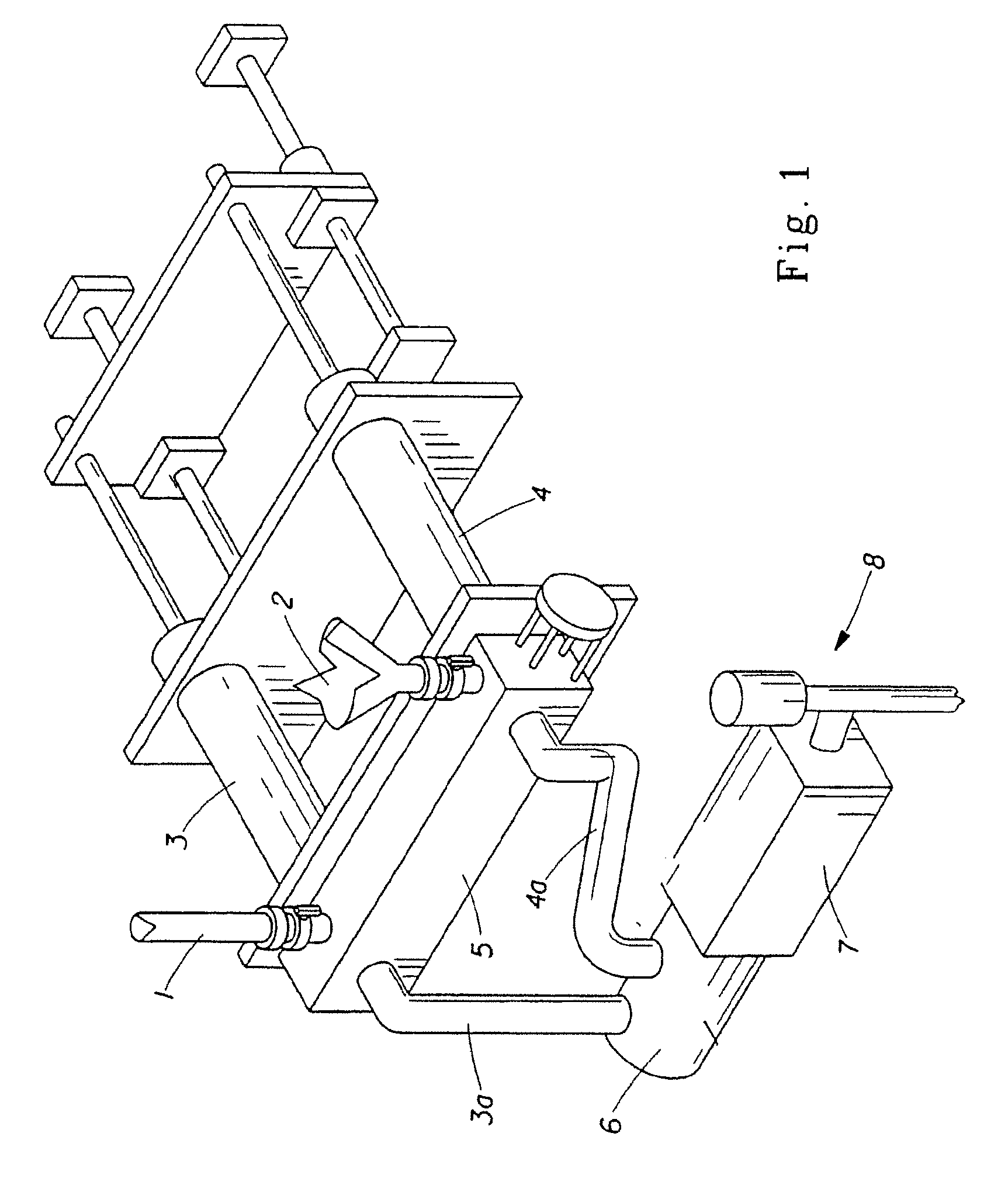

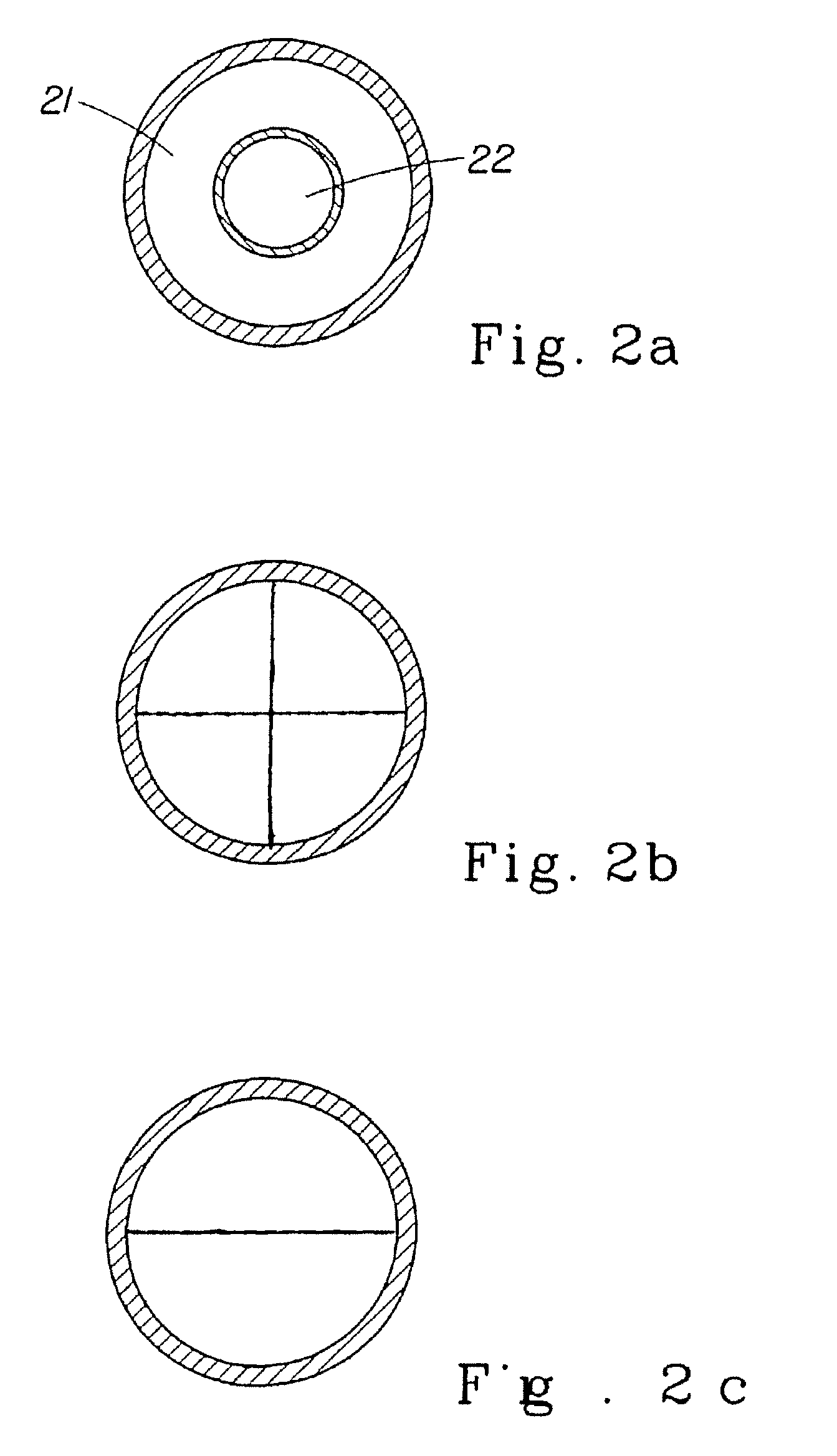

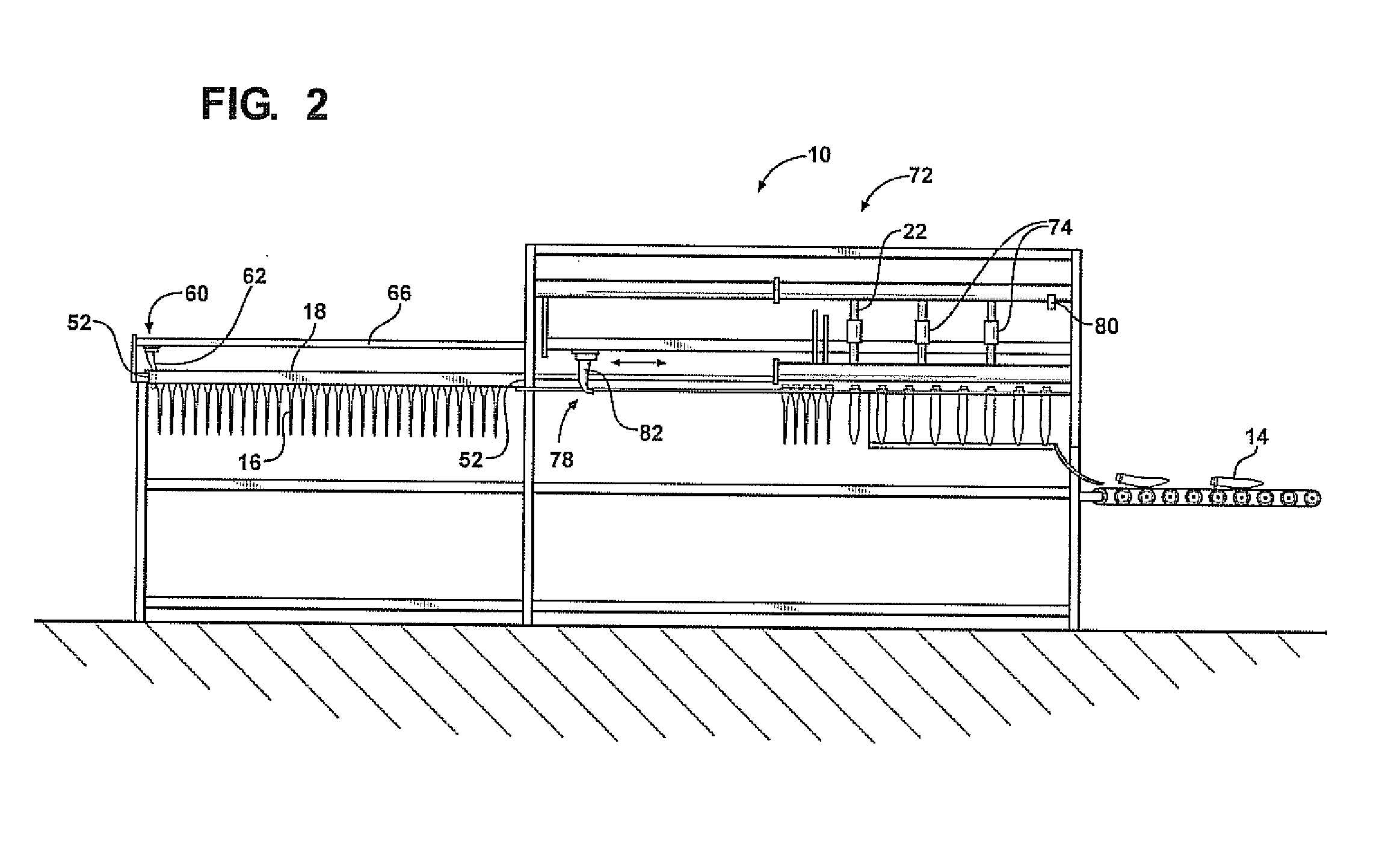

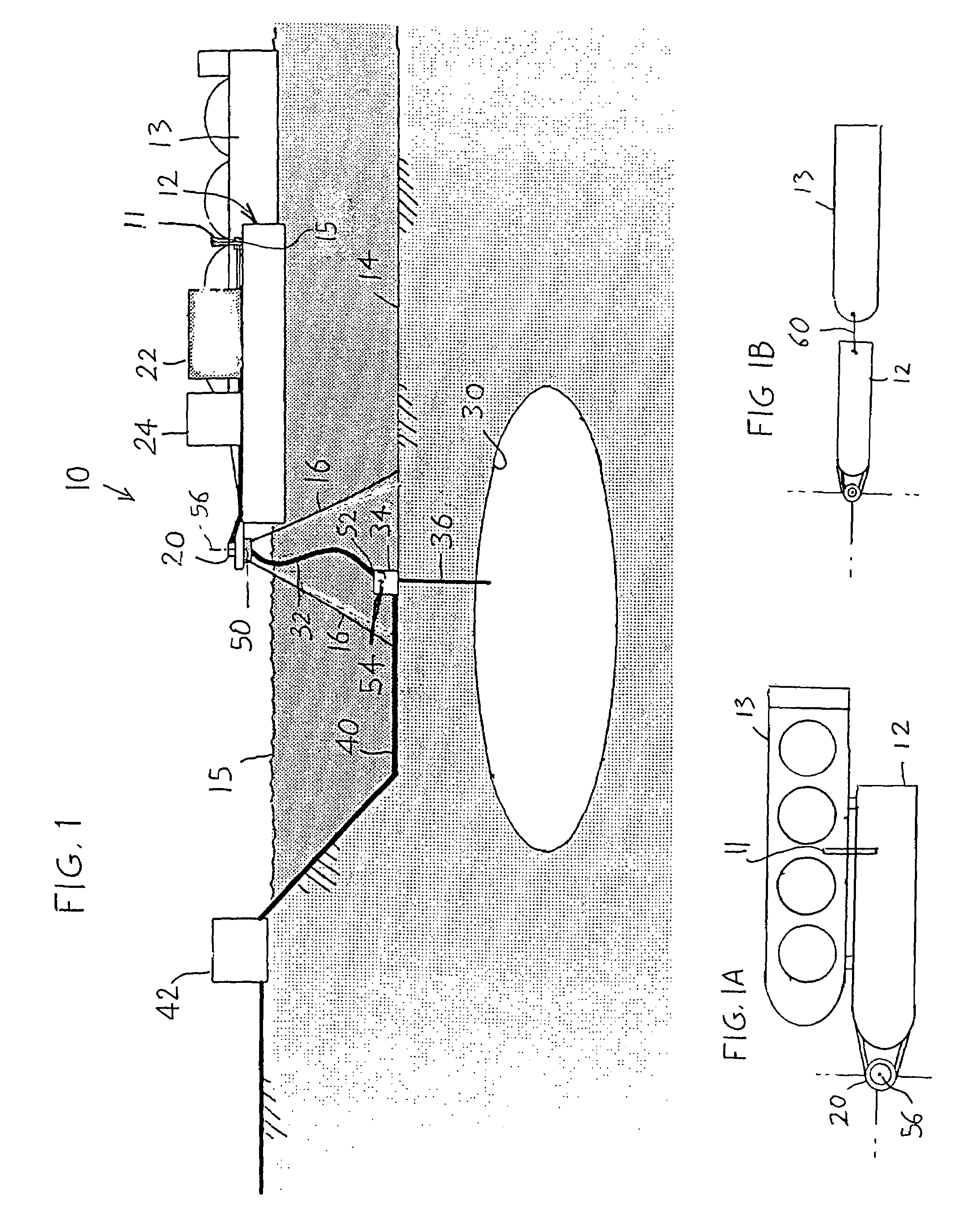

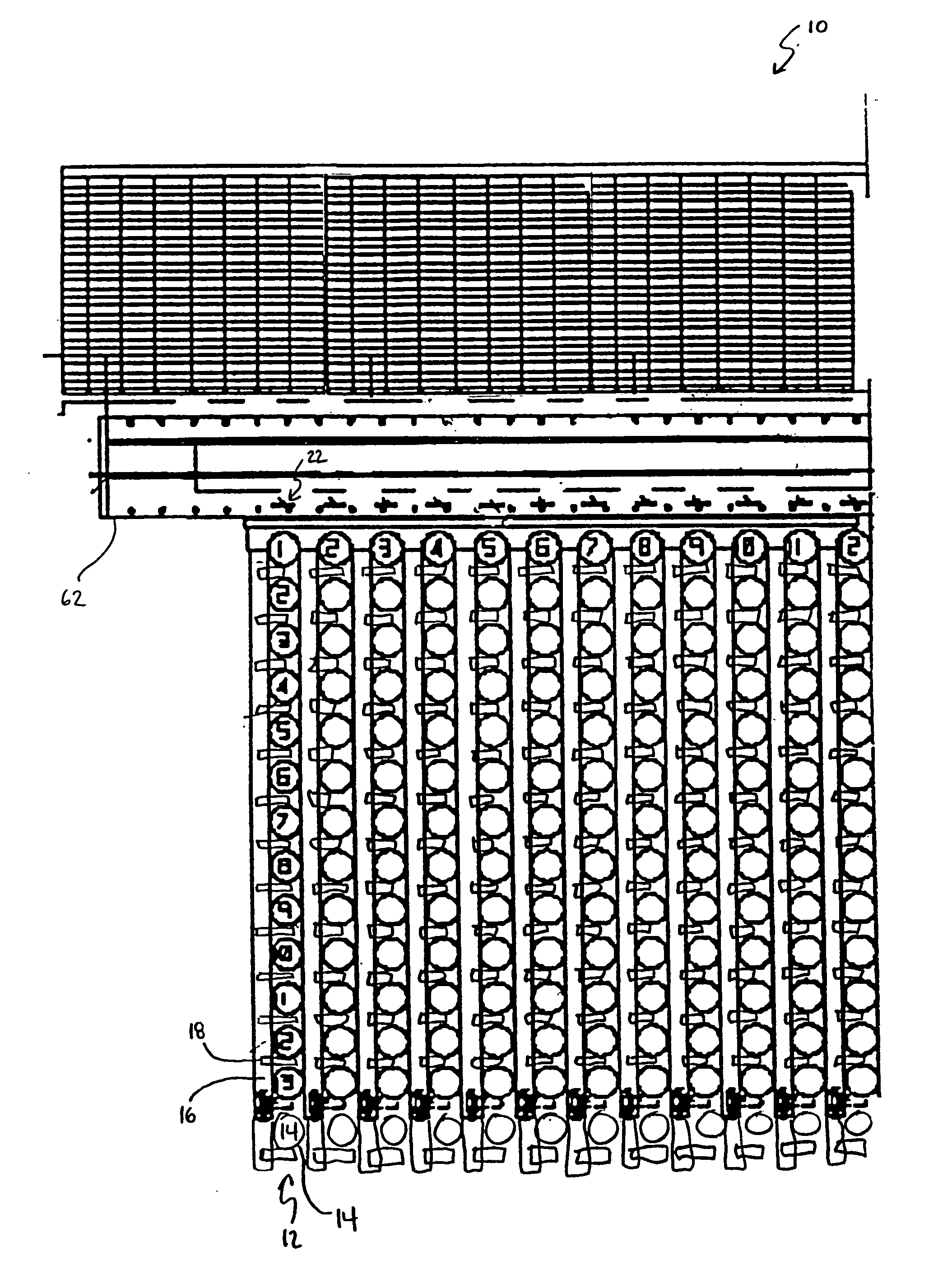

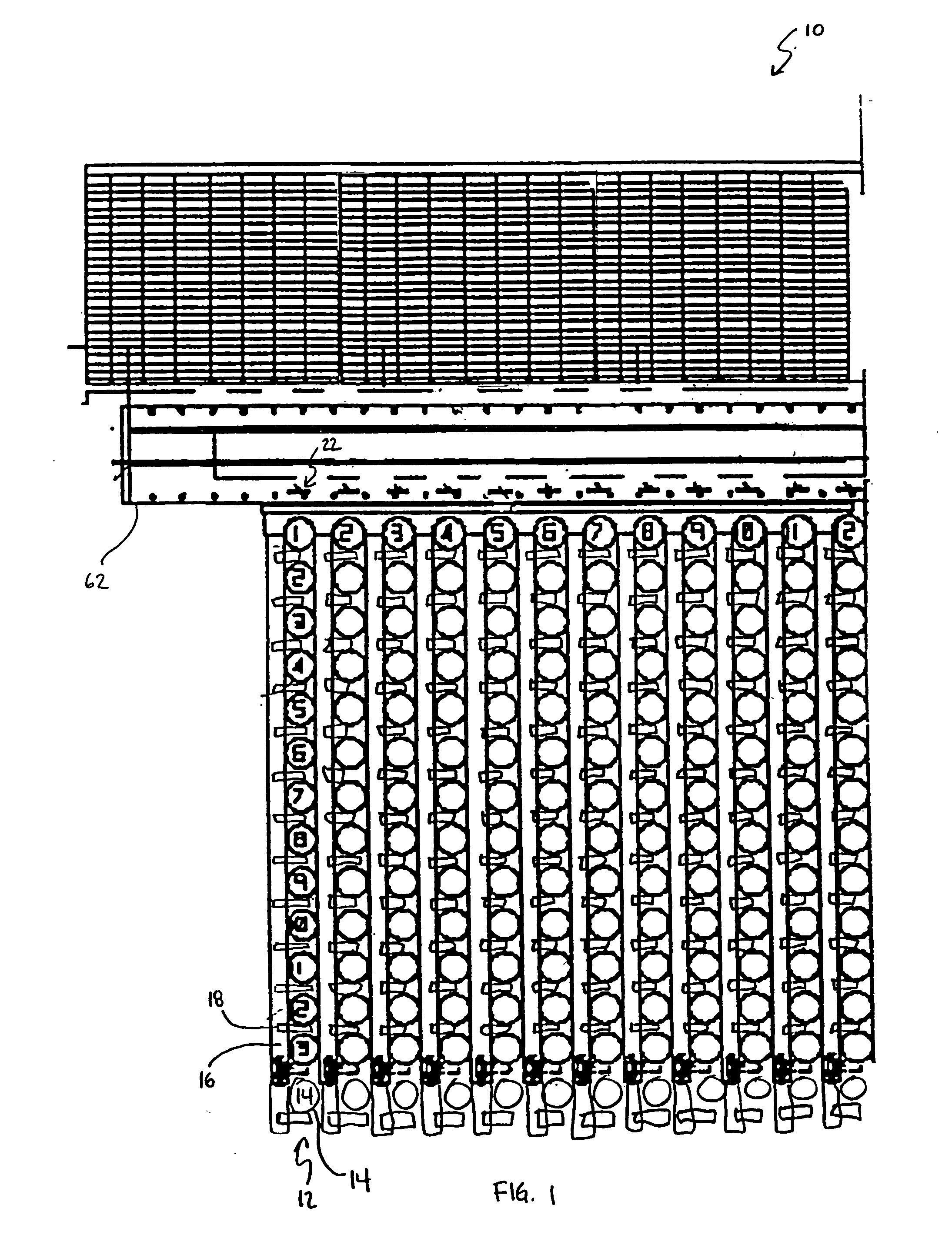

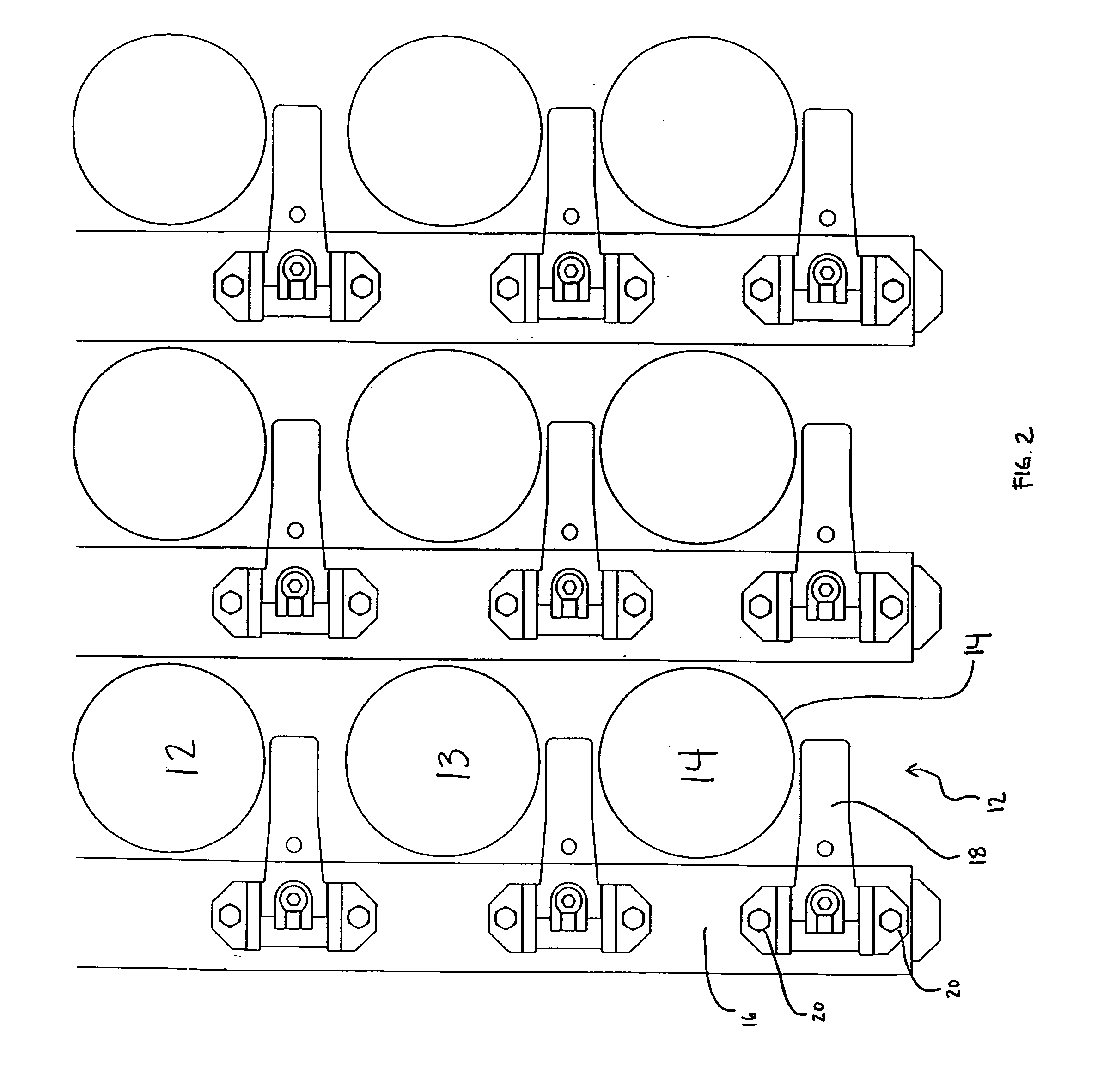

Exhaust Gas Capture System for Ocean Going Vessels

ActiveUS20110265449A1Reduce and eliminate leakage of gasSmall sizeBarrels/casks fillingExhaust apparatusGreenhouseExhaust fumes

An exhaust gas capture system for capturing the exhaust gas emitted by auxiliary engines, auxiliary boilers, and other sources on an Ocean Going Vessel (OGV) while at berth or at anchor so that these gases may be carried to an emissions treatment system for removal of air pollutants and or greenhouse gases. The exhaust gas capture system includes a manifold and a family of parallel-flow flexible ducts for connecting directly to individual OGV exhaust pipes. The exhaust gas capture system further includes apparatus for connecting the parallel-flow flexible ducts to the OGV exhaust pipes.

Owner:ADVANCED CLEANUP TECH +1

Apparatus for dispensing paint and stain samples and methods of dispensing paint and stain samples

ActiveUS20050252934A1Improve recallEliminate needClosuresBarrels/casks fillingAdditive ingredientEngineering

An improved fluid dispenser specially adapted to provide sample-size amounts of a fluid mixture is shown and described. An automated closure and seal system is provided for the manifold that moves, on command from a controller, from a closed or sealed position thereby limiting exposure of the manifold and fluid outlet nozzles from the ambient atmosphere, to a dispense system where a sample-size container is held up against and engaging a lower end of the manifold for a sealing element disposed on a lower portion of the manifold. When the dispense is complete, the system automatically moves back toward a closed position where the filled container is held open and ready to be removed by a technician before it is capped and labeled. An improved shelving system is also provided for housing a large quantity of different ingredients conveniently within a relatively compact cabinet thereby making the system suitable for a retail environment. An improved method of preparing a sample quantity of a fluid mixture is also disclosed.

Owner:FLUID MANAGEMENT LLC

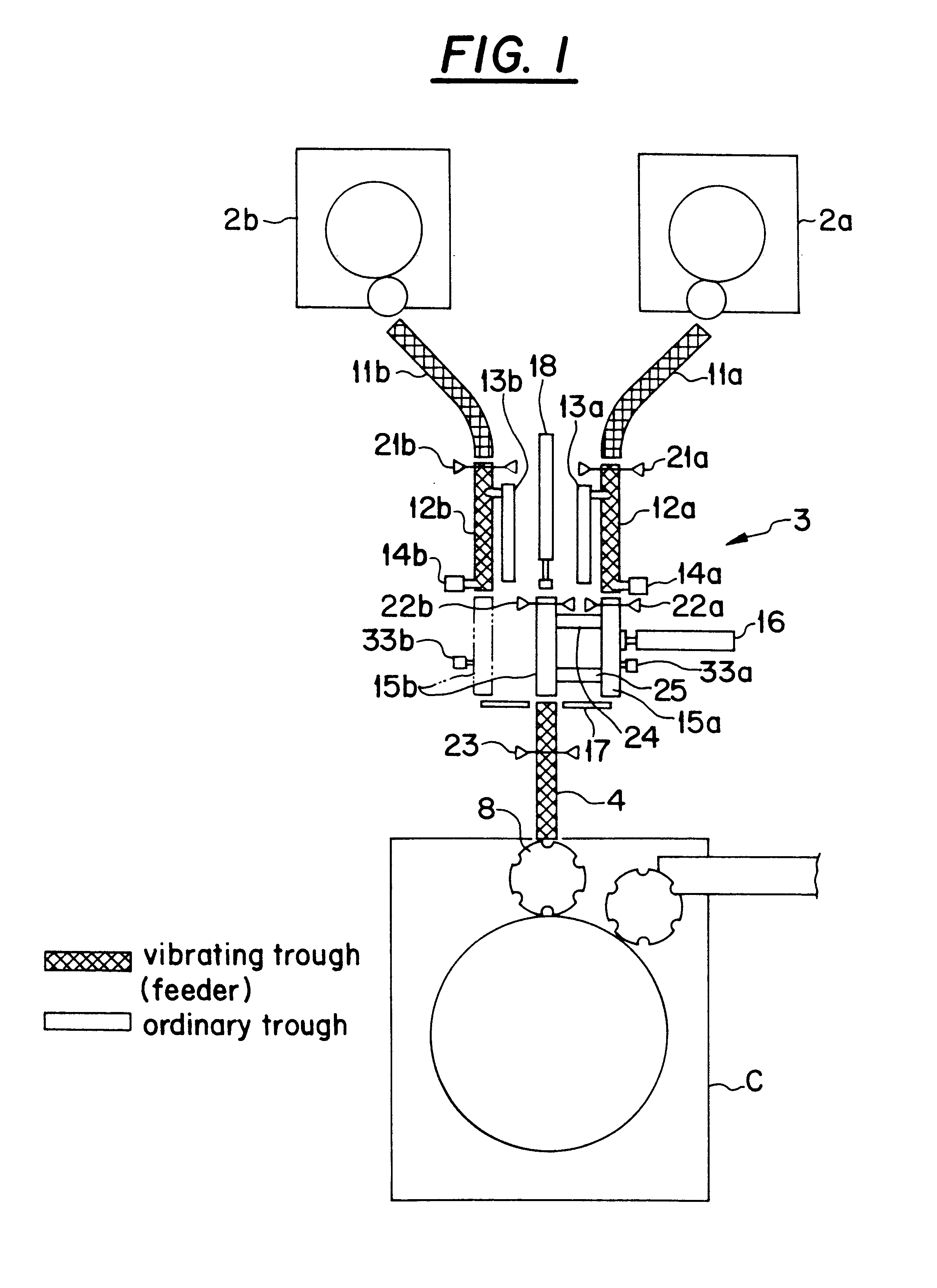

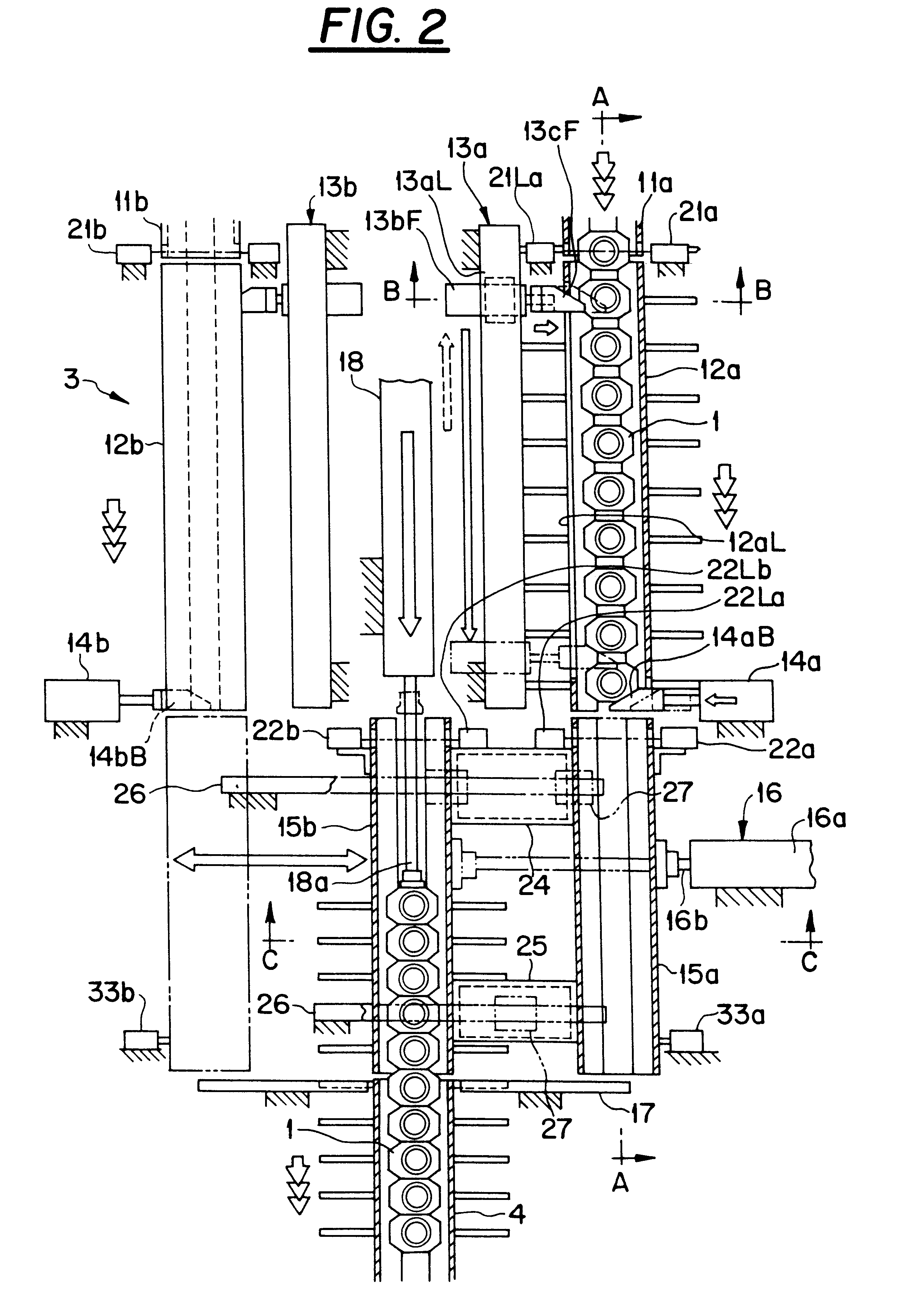

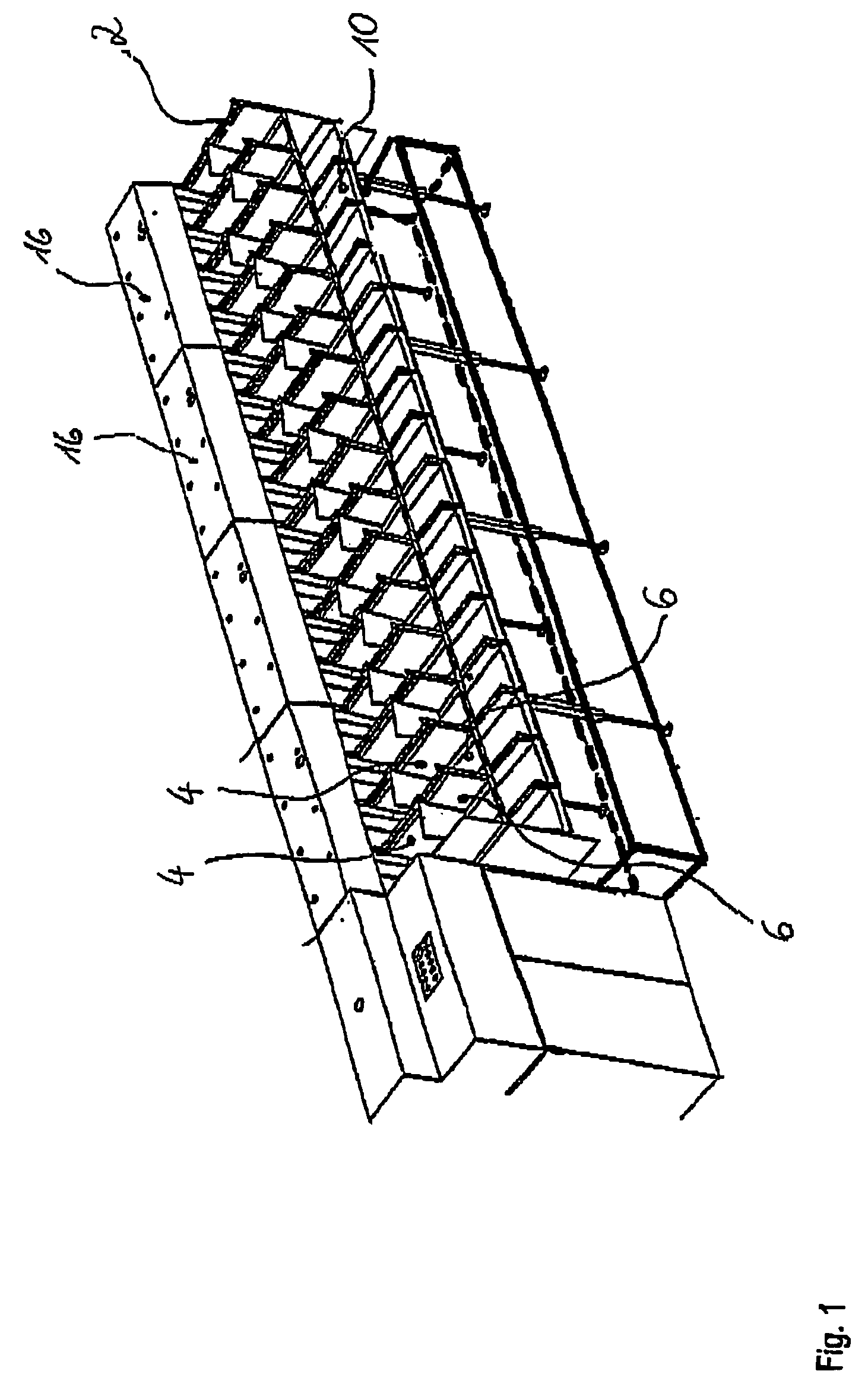

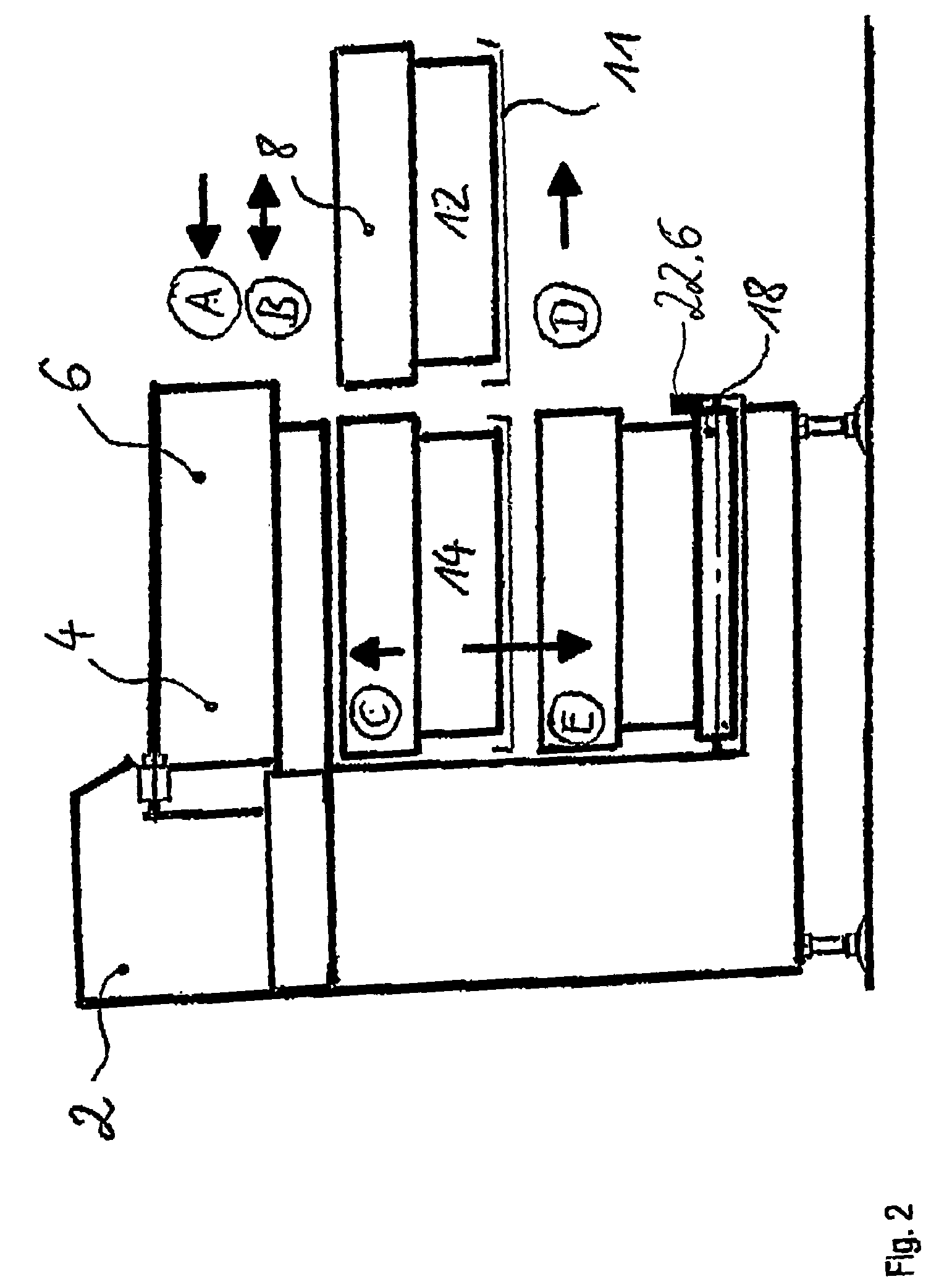

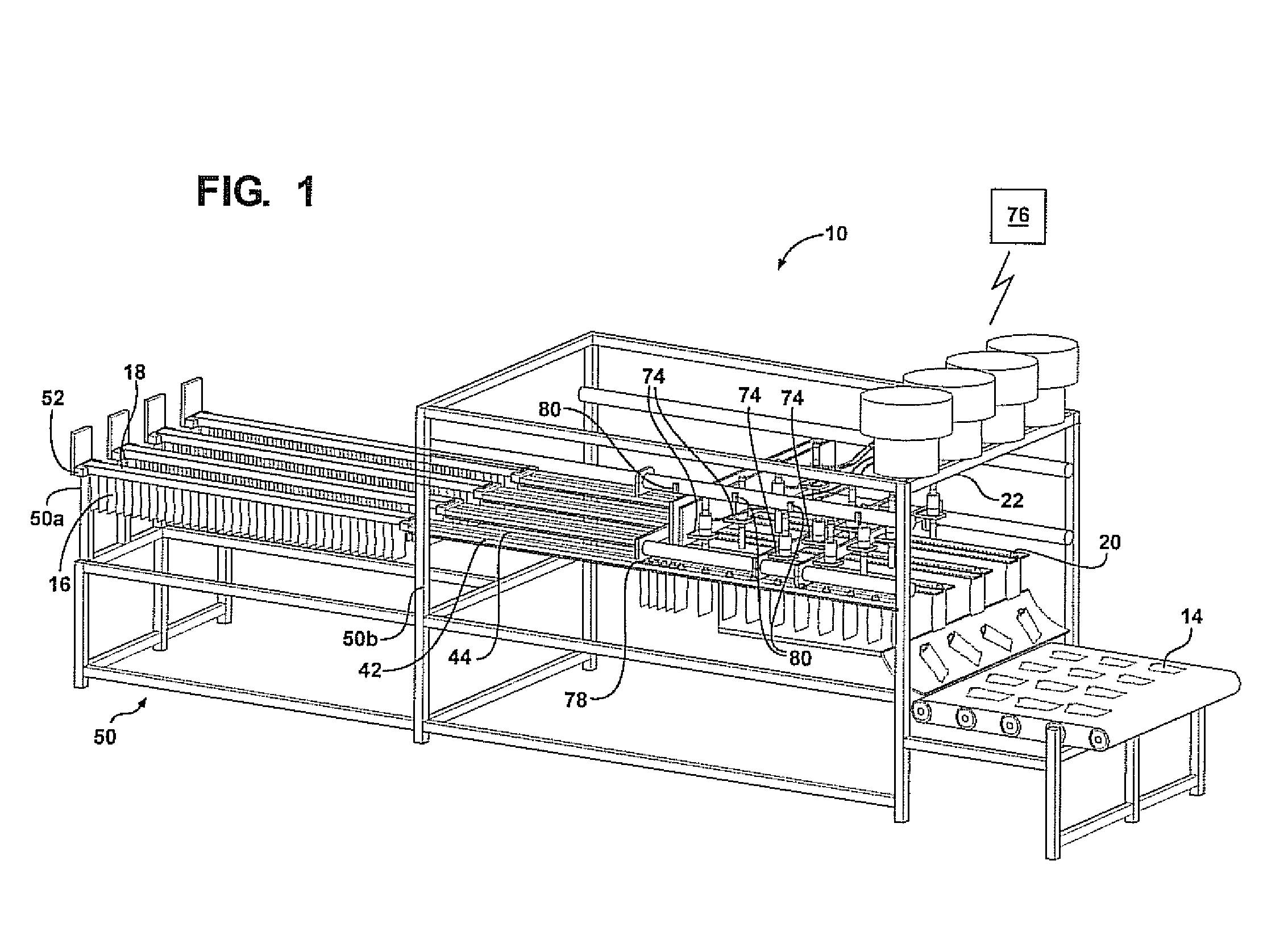

Machine and method for manufacturing a packaged product

ActiveUS20100170591A1Implemented cost-effectivelyImprove processing speedConveyorsBarrels/casks fillingSupport surfaceFlange

A machine and method for filling a container is provided. The container has a fitment. The fitment includes a spout having a collar. The collar includes a support surface for supporting the container in suspension. The machine includes a filling apparatus configured to fill the container with a product, a rail system, a loader, and a carrier. The carrier is configured to hold multiple containers. The carrier is generally elongated and has a pair of spaced apart flanges. The spaced apart flanges define a slot extending the length of the carrier. The slot is configured to slidingly receive the spout of the container and the support surface of the collar engages each of the pair of flanges so as to suspend the container within the carrier. The carrier may be placed into communication with the rail system so as to feed the containers to the filling apparatus.

Owner:POUCH PAC INNOVATIONS

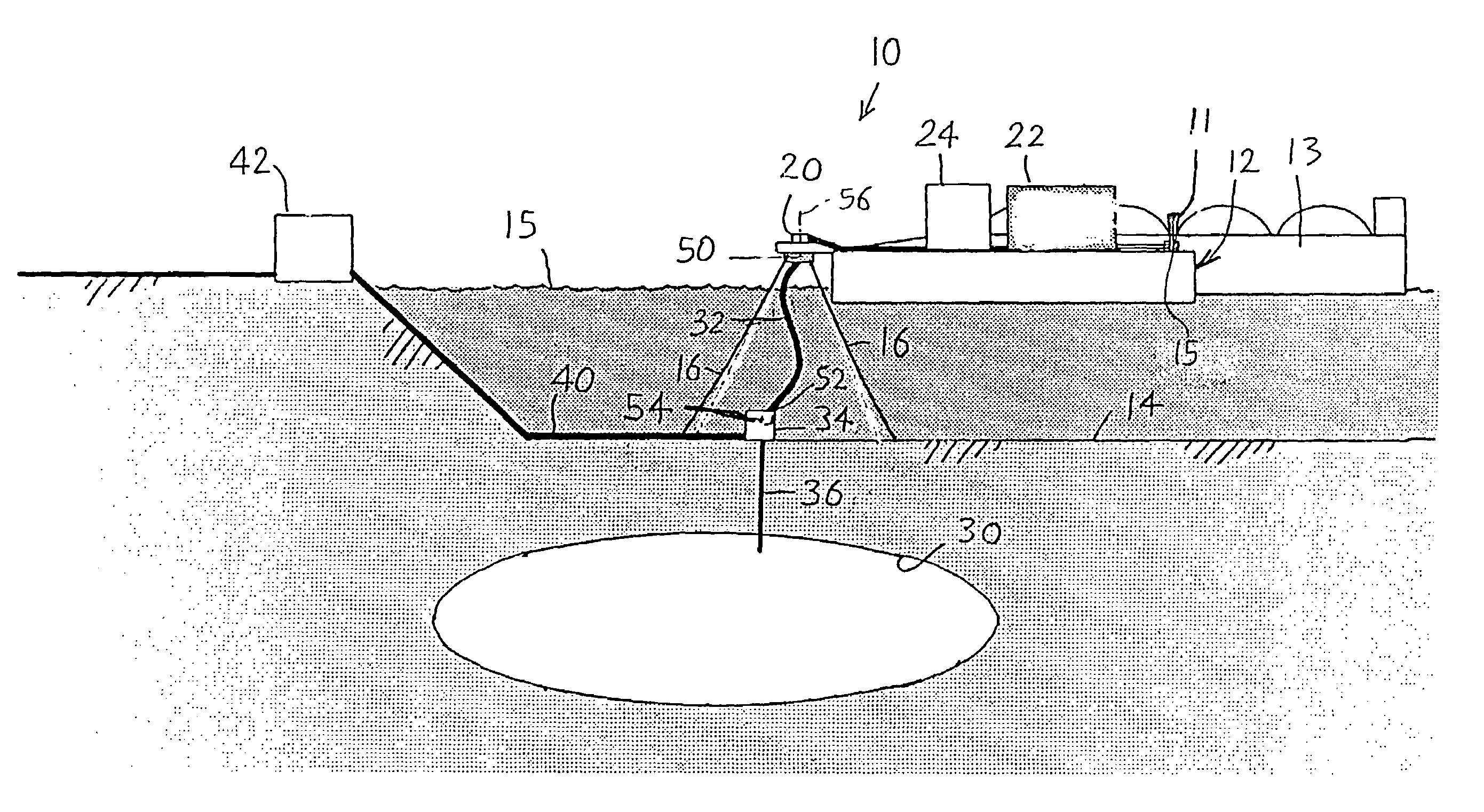

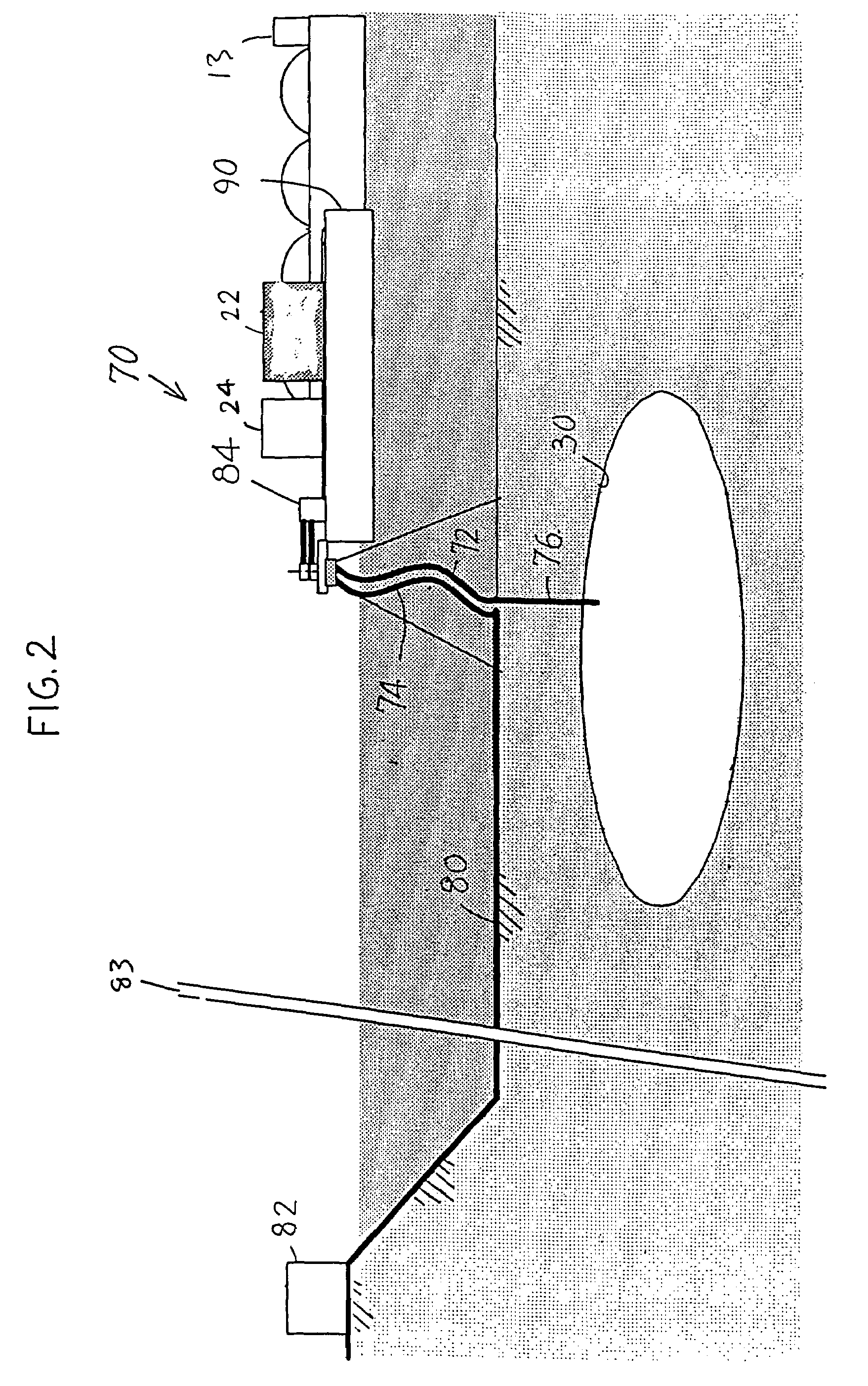

Gas offloading system

ActiveUS6973948B2Easy to passGas handling applicationsGas handling/storage effectsElectricityOcean bottom

A system is described for offloading LNG (liquified natural gas) from a tanker for eventual delivery to an onshore gas distribution station. The system includes a floating structure that floats at the sea surface and that is connected to the tanker so they weathervane together. The floating structure carries a regas unit that heats the LNG to produce gas, and delivers the gas through a riser to an underground cavern that stores the gas. Gas from the cavern is delivered through a seafloor pipeline to an onshore gas distribution station. The regas unit includes water pumps and other equipment that is powered by electricity. The electricity can be obtained from an electric generator on the floating structure, with surplus electricity delivered through a sea floor electric power line that extends along the sea floor to an onshore electricity distribution facility. The electricity can instead be obtained by delivery from an onshore facility though a sea floor electric power line that extends up to the floating structure and to the regas unit.

Owner:SINGLE BUOY MOORINGS INC

Anti-siphon fuel filler assembly and method of manufacturing the same

Owner:MFB INVESTMENTS +1

Keg filling plant for filling kegs with a liquid beverage material, such as beer, wine, soft drinks, or juice, and a method of operating same, and a handling and treatment station for kegs

Keg filling plant for filling kegs with a liquid beverage material, such as beer, wine, soft drinks, or juice, and a method of operating same, and a handling and treatment station for kegs. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b ). As stated in 37 C.F.R. §1.72(b ): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

Fingerboard with pneumatically actuated finger latches

Owner:VARCO I P INC

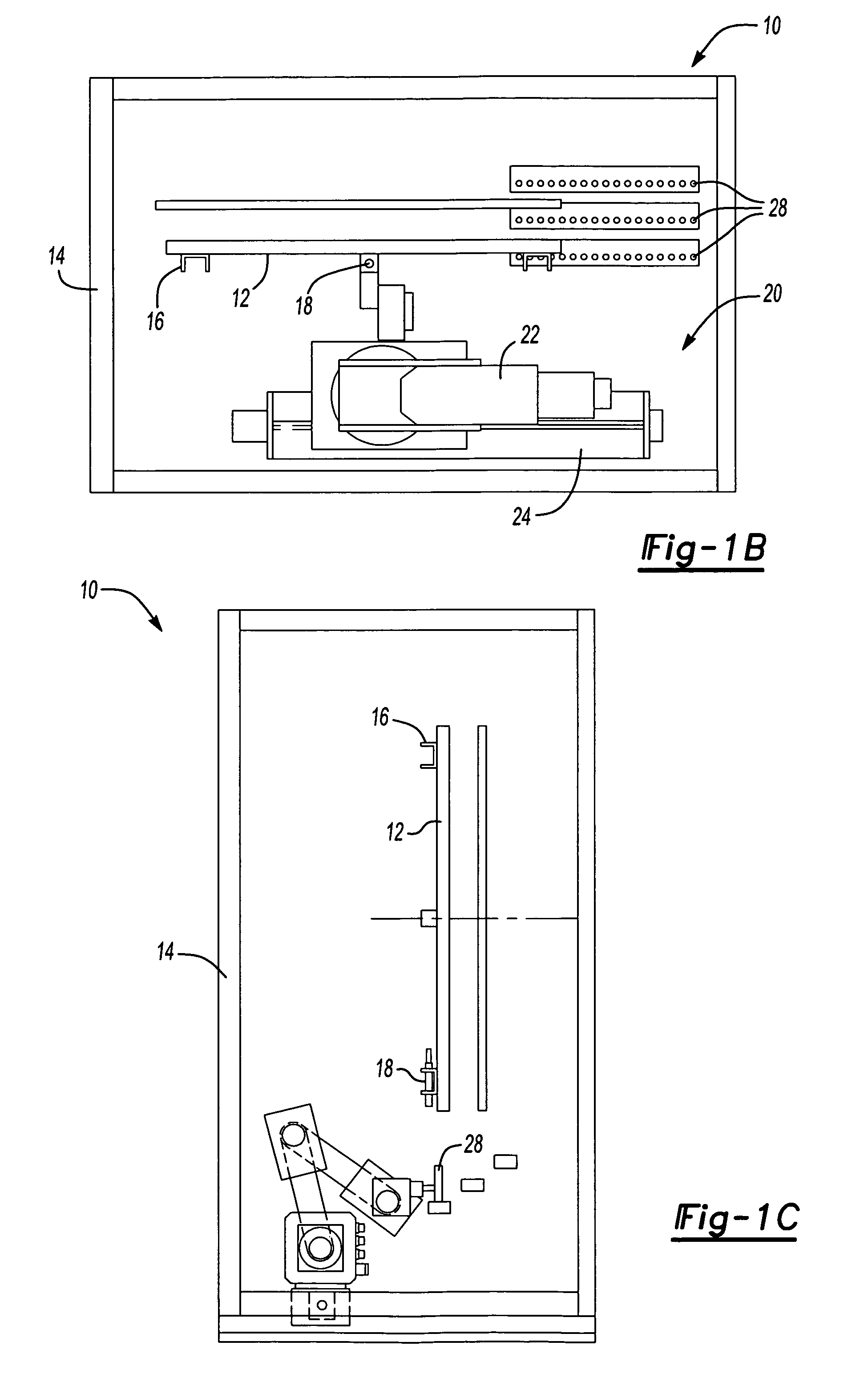

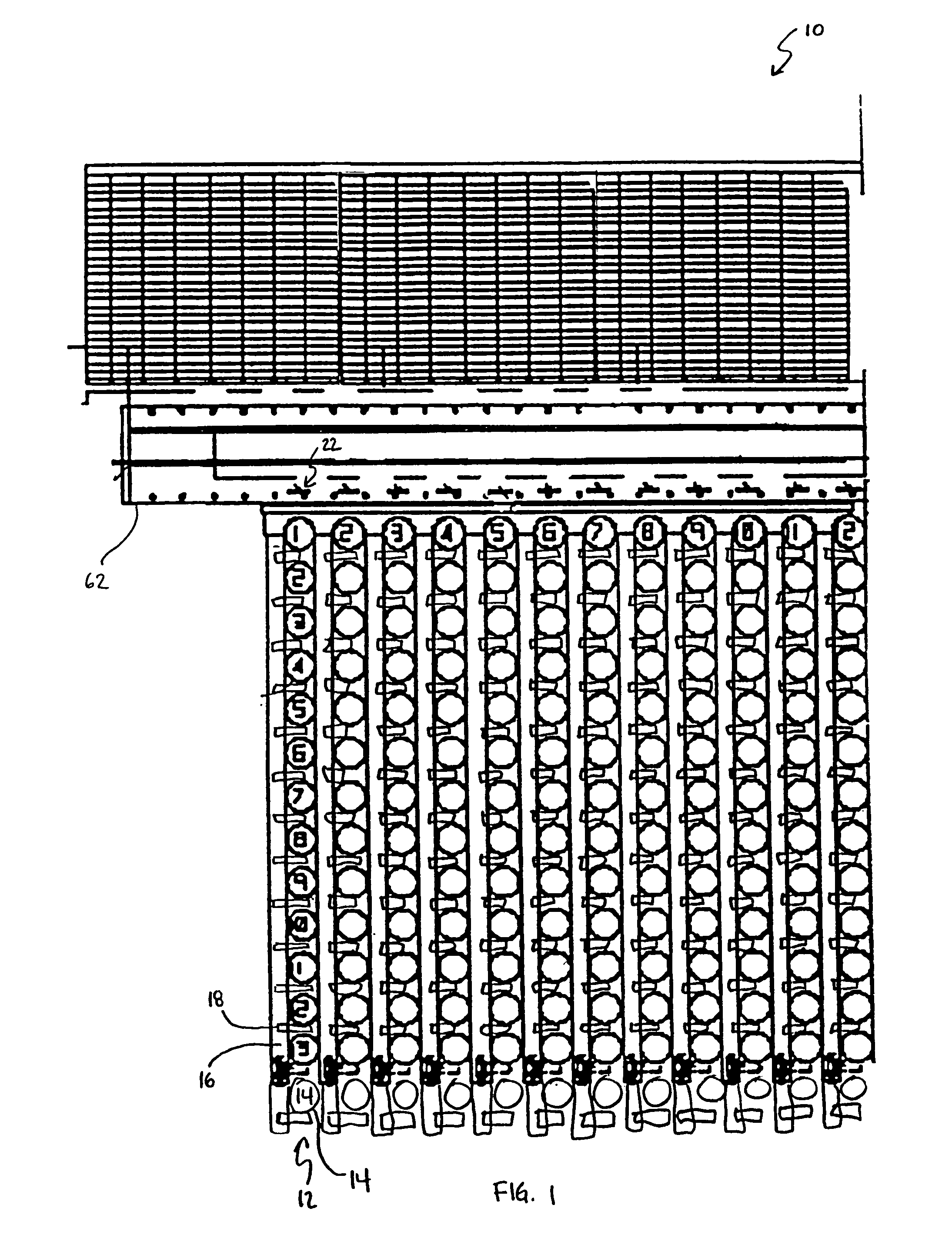

Shelving systems and holders for flexible bags for containing fluid for use in fluid dispensing systems

InactiveUS7320416B2Limiting pivotal movementIncrease percentageClosuresBarrels/casks fillingMechanical engineeringEngineering

An improved holder for pivotally supporting a flexible bag containing a liquid component is disclosed for use in a multiple fluid dispensing system. The holder supports the bag in an upright position for space efficiency as well as for dispensing efficiency. An improved shelving system for pivotally supporting a plurality of holders in a compact row and in an upright dispensing position is also disclosed. An improved dispensing system incorporating the disclosed shelving system and flexible bag holder is also disclosed.

Owner:FLUID MANAGEMENT LLC

Apparatus and method for filling containers with liquid

InactiveUS6053219AEliminate lossImprove accuracyBarrels/casks fillingSolid materialEngineeringControl valves

Apparatus and method for filling containers with liquid utilizing apparatus of the type having a tubular filling lance operatively connected to a source of liquid and being vertically movable between raised and lowered positions, raising and lowering of the lance being controlled so that the lower emission end of the lance is disposed just below the surface of liquid in the container as the container is being filled through the lance. The apparatus comprises: first and second control valves, each having actuators, providing fluid communication between the source of liquid and the tubular filling lance; a weight measuring device for real time measurement of the weight of liquids placed in a container through the tubular filling lance; and controls operatively connected to the weight measuring device and each actuator of the first and second control valves for controlling the movement of the first and second control valves and the flow of liquids through the tubular filling lance into the container in response to predetermined weight of liquids in the container.

Owner:SEIVER MICHAEL J

No-spill, vapor-recovery, container spout

InactiveUS6889732B2Prevent escapeBarrels/casks fillingLiquid transferring devicesFuel tankEngineering

A vapor recovery spout for a portable fuel container. The spout includes an inner sleeve attached to the container to provide a fuel flow passage through the spout. The passage has an outlet port for fuel to flow through into a tank. A sliding sleeve is mounted on the inner sleeve for sliding axial movement from an outwardly extended position to a retracted position. A radially extending annular seal is mounted on the sliding sleeve for sealing the fuel tank opening when the spout is inserted. Vapor recovery passages are provided between the inner sleeve and the sliding sleeve for displaced vapor to flow from the tank to the container. The sliding sleeve closes the fuel passage and the vapor recovery passageways when in its extended position and opens the fuel passage and the vapor recovery passageways when in its retracted position. A spring urges the sliding sleeve to its extended position.

Owner:FLORENCE E ALLEN SUCCESSOR TRUSTEE OF THE CLIFFORD H ALLEN TRUST DATED JULY 22 1998

Apparatus and method for dispensing substances into containers

InactiveUS20060137760A1Avoid accumulationMinimize timeBottle/container closurePower operated devicesMechanical engineeringEngineering

An apparatus for dispensing substances, specifically powders and liquids, into a container, is designed as a compact module containing a weighing device with a load receiver, a holder device which is attached to the load receiver and serves to receive and loosely hold the container while the substances are dispensed into the container, and a liquid-dispensing device for dispensing a liquid into the container while the latter is seated in the holder device. The apparatus includes a clamping device for firmly gripping and immobilizing the container, so that a capping device that is not part of the apparatus can put a cap on the container or remove the cap from the container while the latter is seated in the holder device.

Owner:METTLER TOLEDO AG

Bottle filler

An improved bottle filler assembly for filling bottles from kegged carbonated or non carbonated beverages without carbonation loss or oxidation that is intuitive to use, sanitize, and keep free of bacteria. In the preferred embodiment, a long hose gradually reduces the pressure of the beverage on the way to the filler. Two tubes are placed inside each other forming an annulus where CO2 can be forced to the bottom of the bottle via a CO2 valve thereby purging the bottle of air (O2). A valve seat placed on the bottom of the tubes allows the beverage to flow into the bottle from the bottom by depressing a trigger.

Owner:BLICHMANN JOHN RICHARD

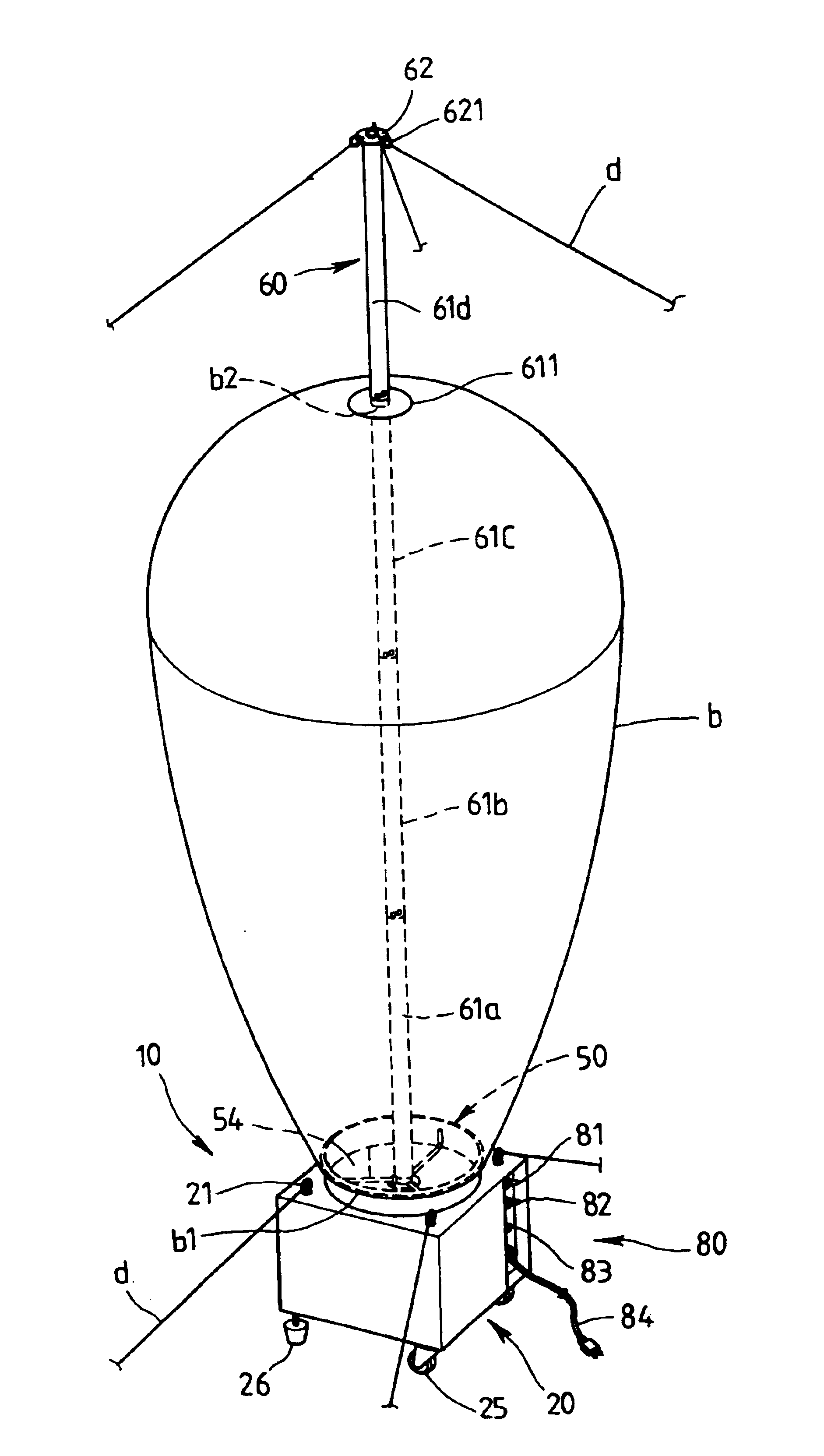

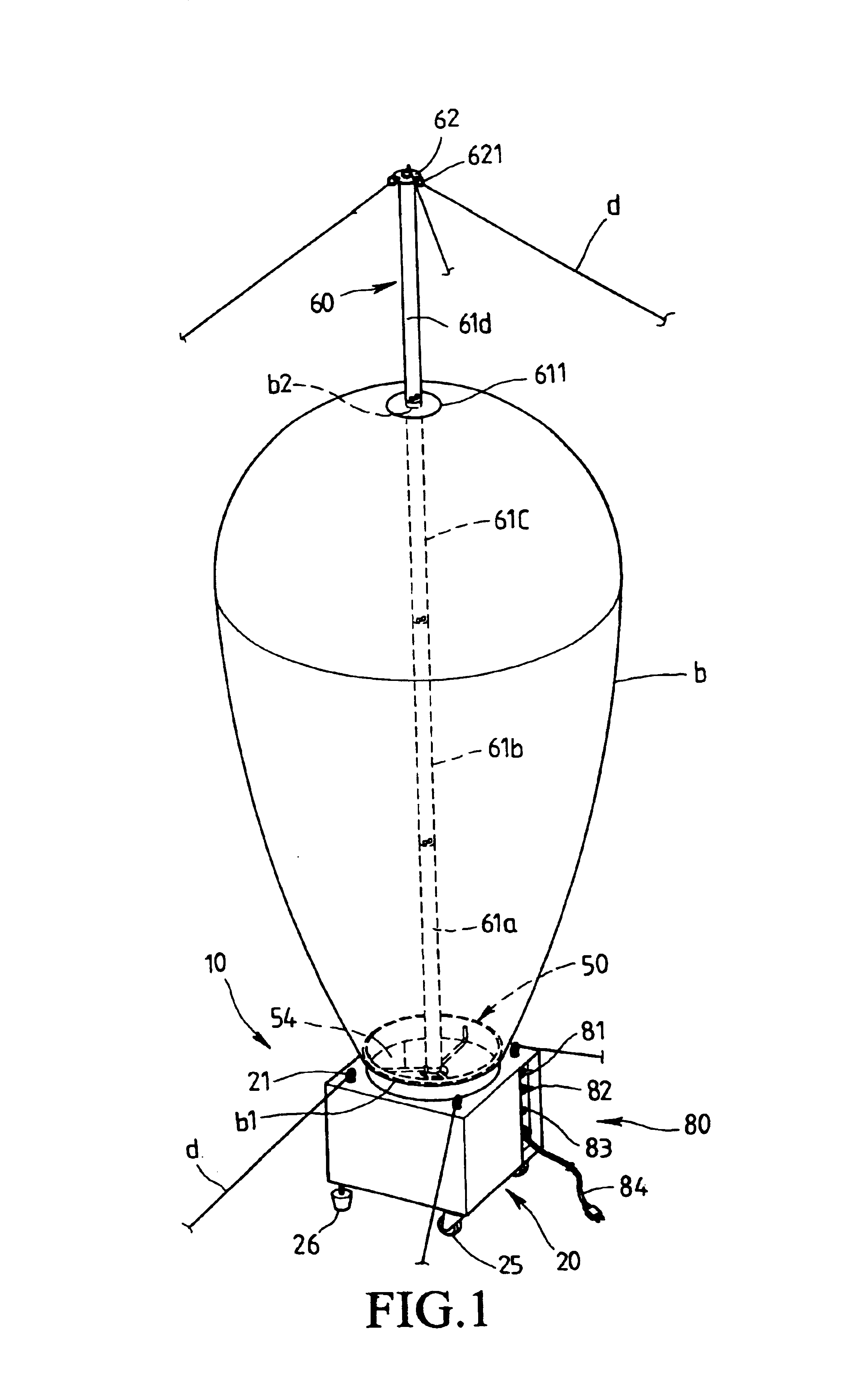

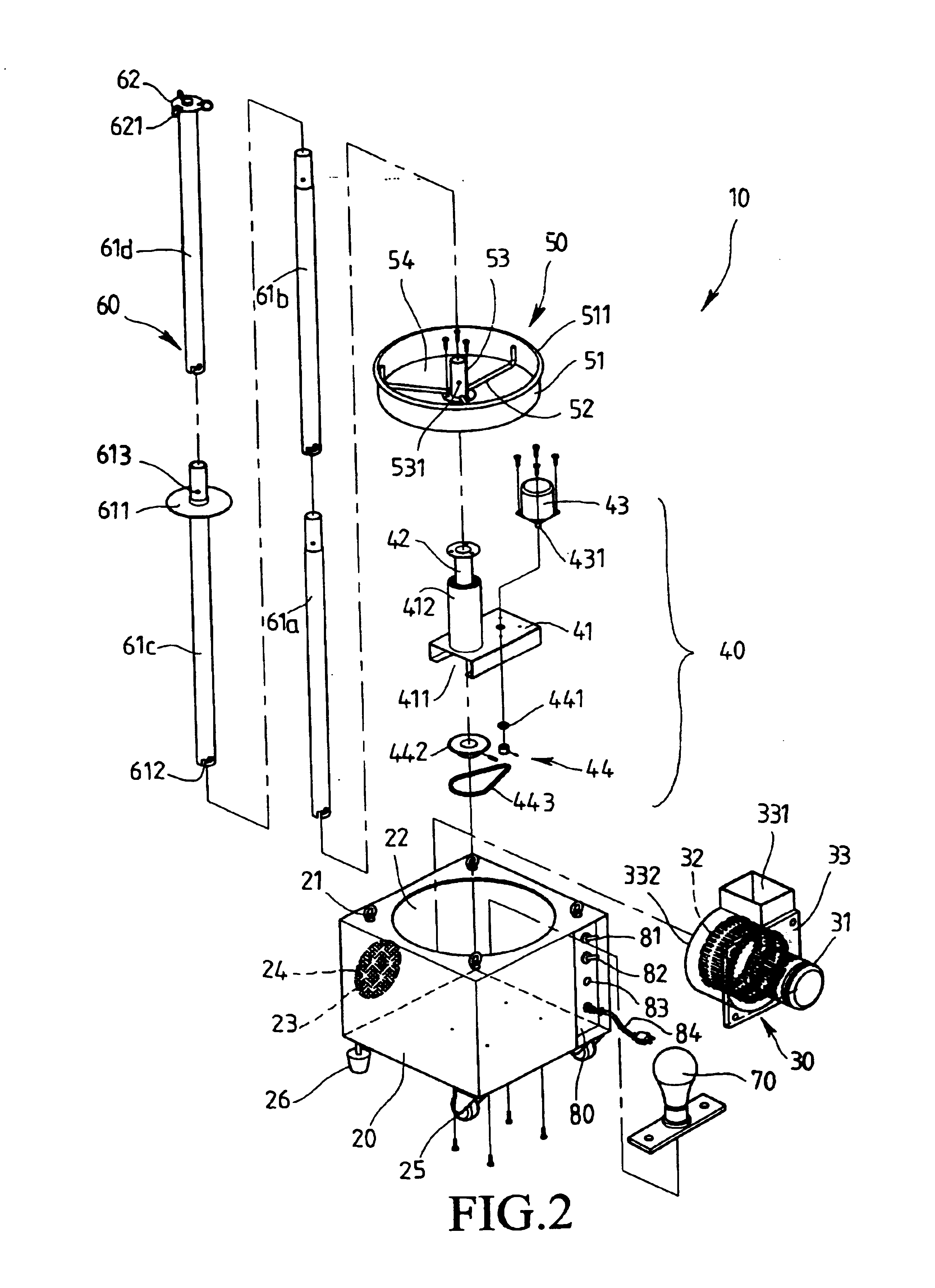

Rotating inflatable device with built-in blower and sensor light

A rotating inflatable device includes a base having an outlet a top thereof and an inlet in a side of the base. A blower is received in the base and driven by a motor. A drive part is received in the base and includes a rotating rod which is driven by another motor via a speed reduction unit. A drum to which a lower opening is mounted includes an annular ring and a central part which is located at a center of the drum by a plurality of ribs connected between the annular ring and the central part. A top end of the rotating rod is co-axially connected to the central part. A central shaft composed of a plurality of sections has its a lower end connected to the central part. A top end of the central shaft extends through a top opening of the balloon and is connected to a plate which seals on the top opening of the balloon.

Owner:WANG HUA CHIANG +1

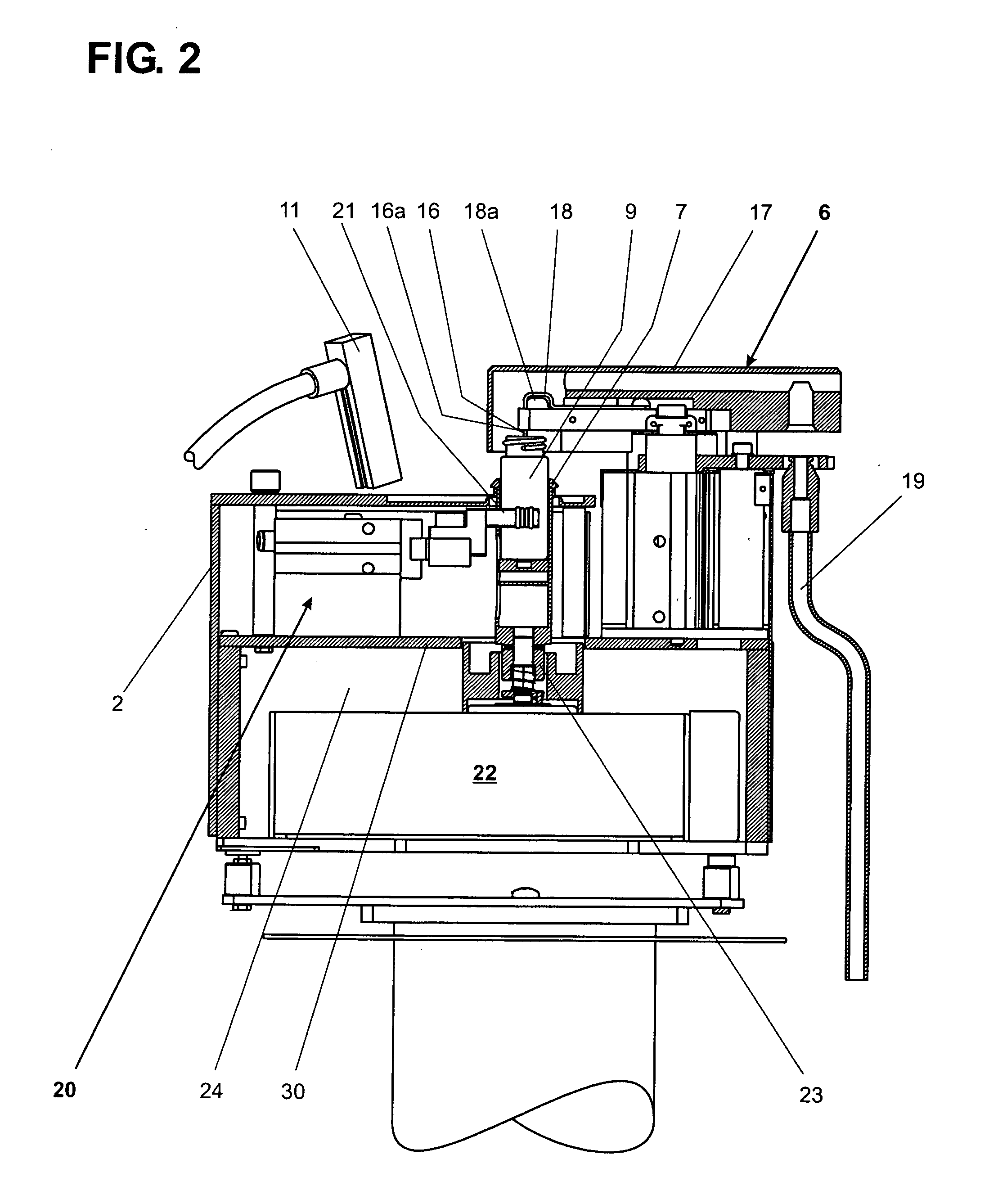

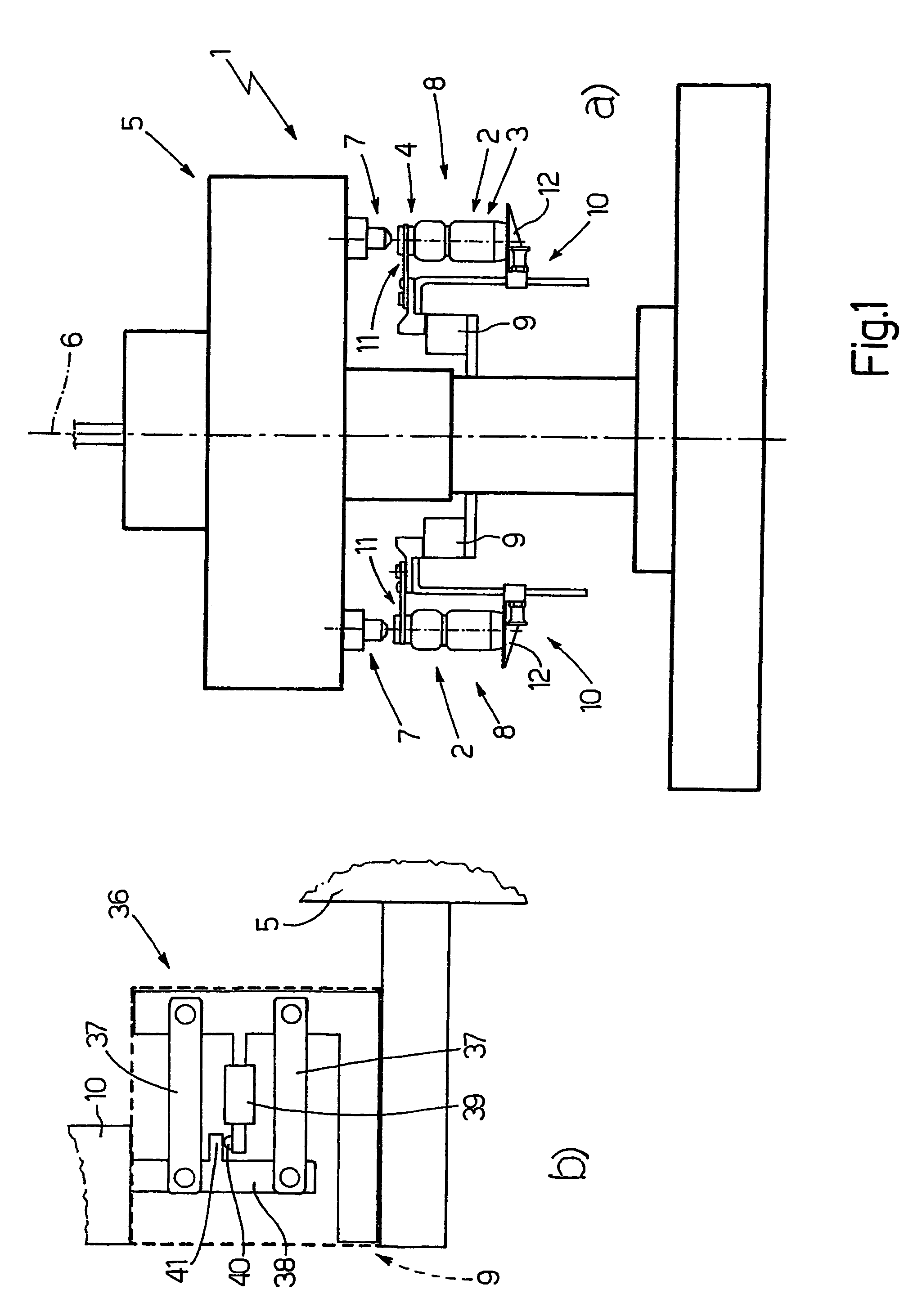

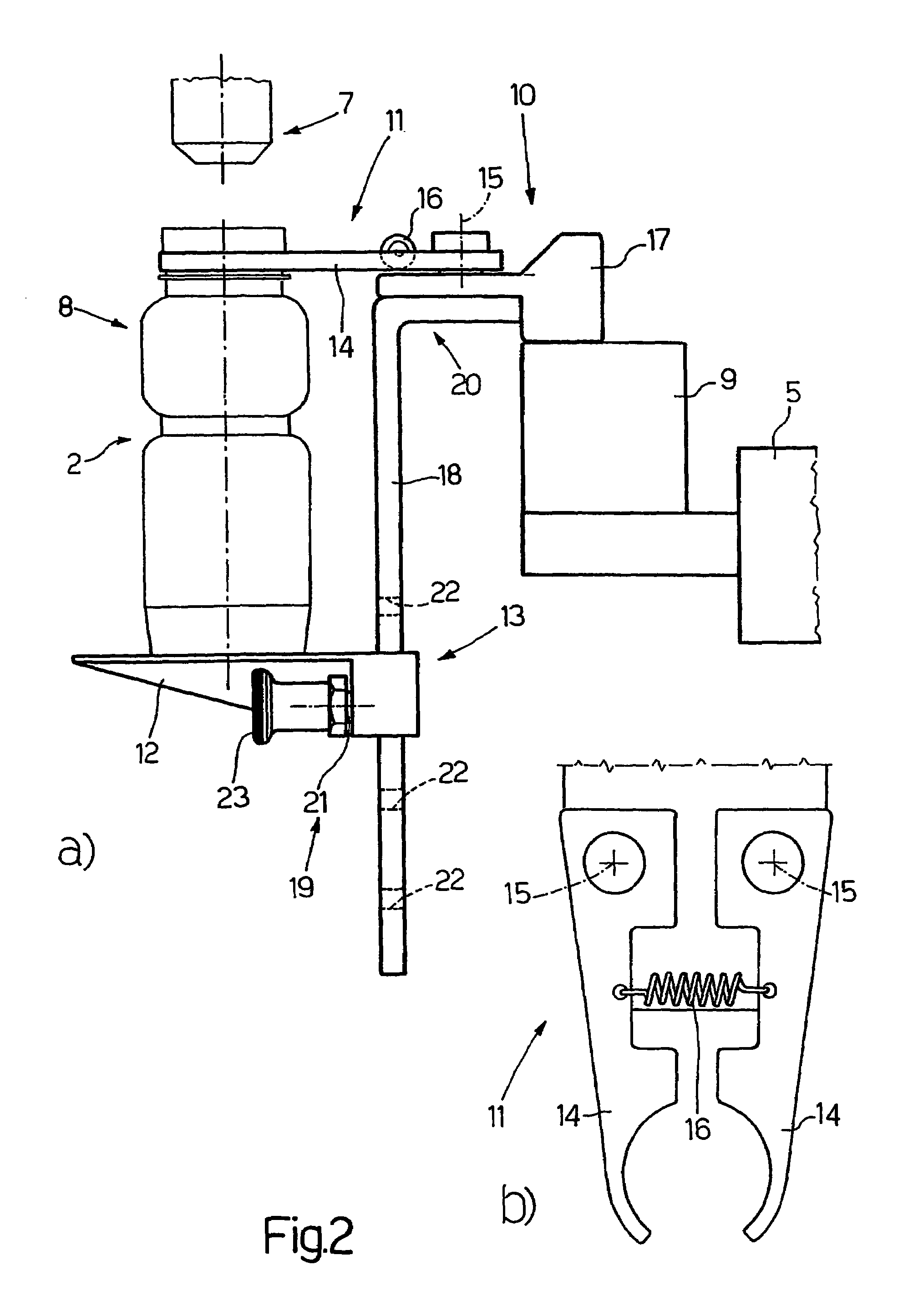

Machine for filling containers

InactiveUS7278451B2Easy and cheap to produceBarrels/casks fillingSolid materialEngineeringFixed position

A machine (1) for filling containers (2) has a carousel conveyor (5) having a vertical axis (6) and in turn having a number of filling heads (7), and an equal number of seats (8), each of which houses a respective container (2), is associated with a respective filling head (7), and is connected to the carousel conveyor (5) via the interposition of a weighing device (9) supported in a fixed position by the carousel conveyor (5). Each seat (8) has a frame (10), which supports a gripper (11) for engaging a top portion (4) of a respective container (2), and a plate (12) defining a horizontal supporting surface for the bottom of the respective container (2), and an adjusting device (13) for adjusting the vertical position of the plate (12), while maintaining the gripper (11) in a given vertical position close to the respective filling head (7).

Owner:AZIONARIA CONSTR MASCH AUTOMATICHE A C M A SPA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com