Process for Making Non-Uniform Patterns of Multiphase Compositions

a multi-phase composition and composition technology, applied in the direction of hair cosmetics, liquid handling, packaged goods, etc., can solve the problem of non-uniform appearance of the above-mentioned patterns visually

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

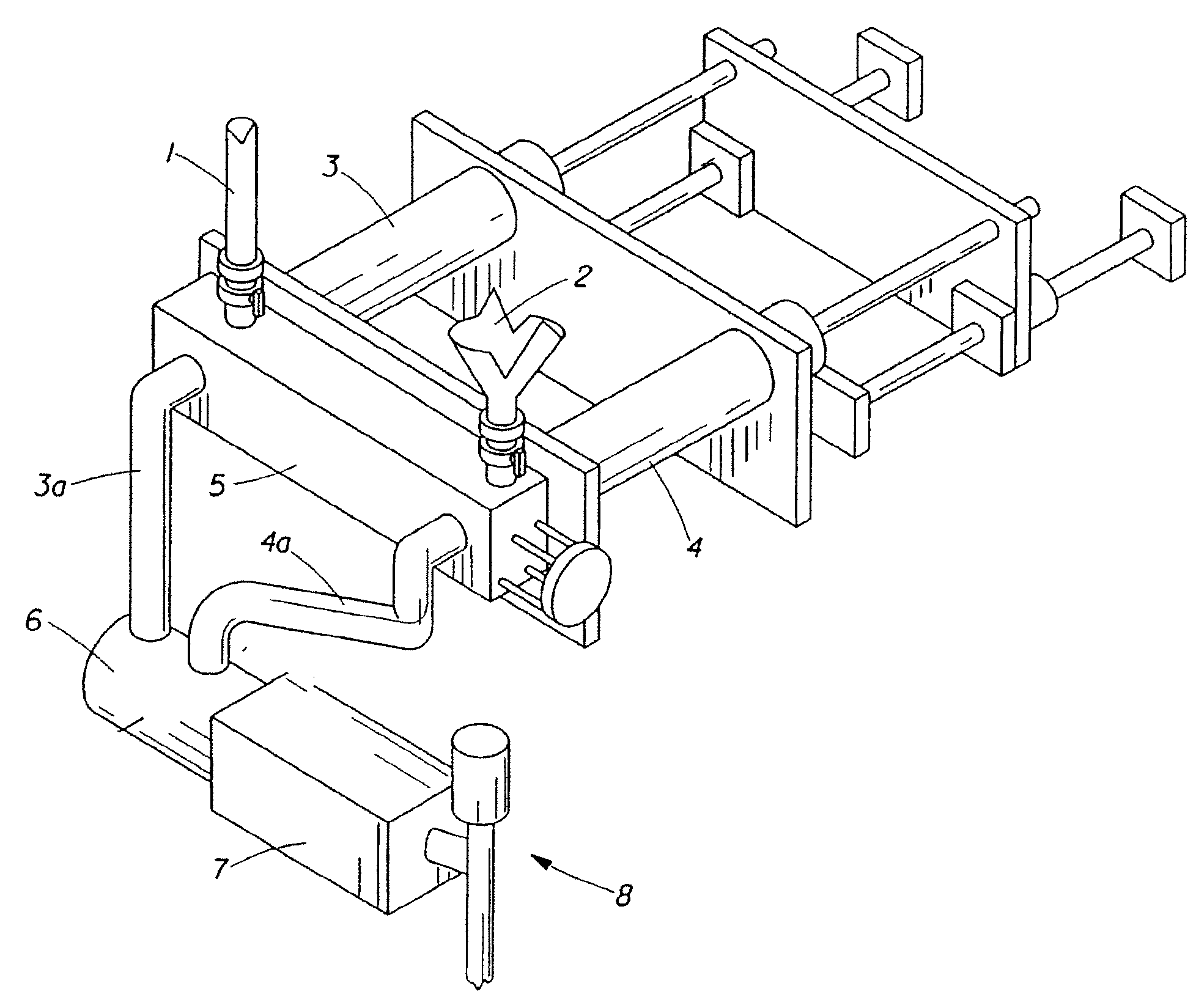

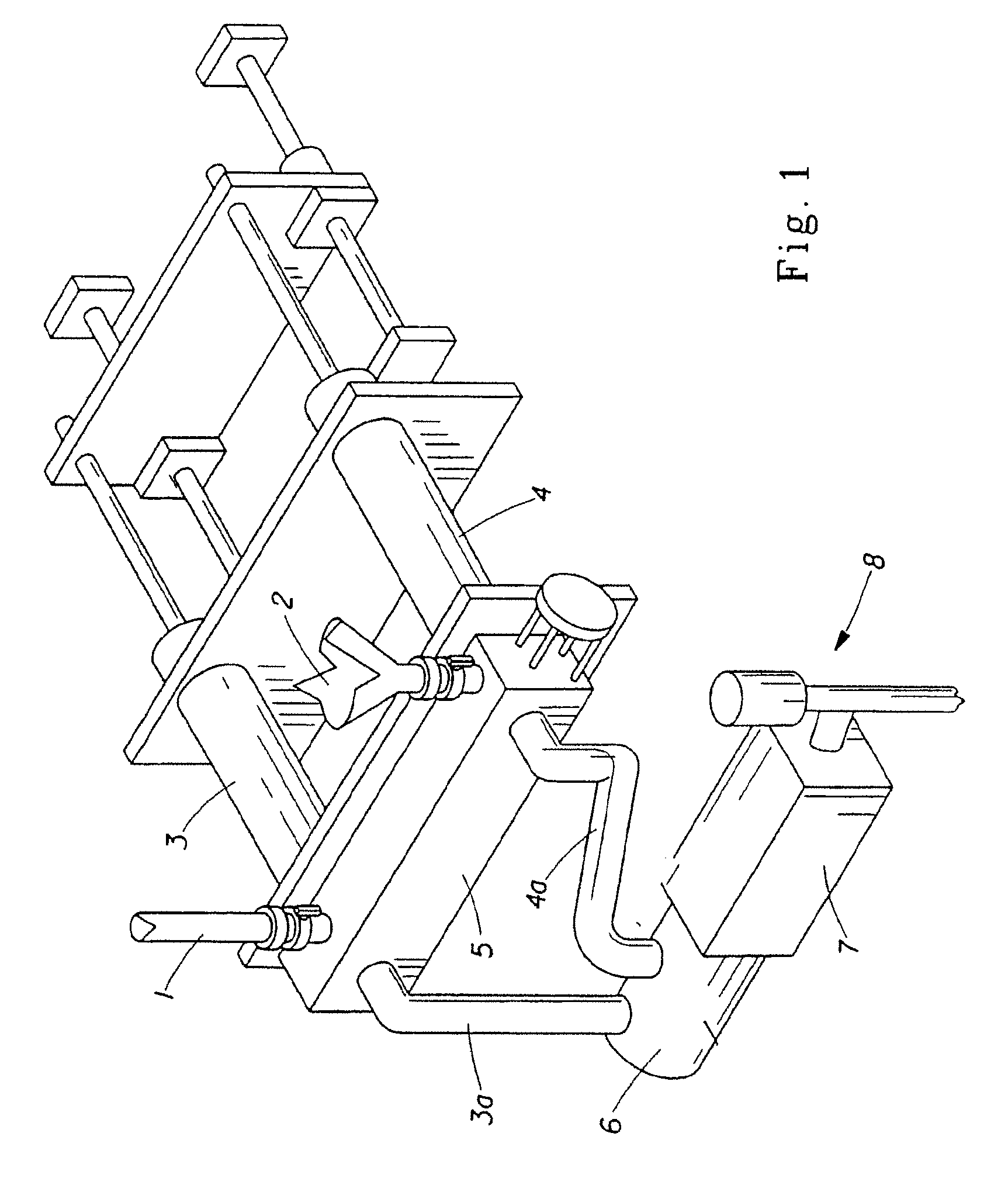

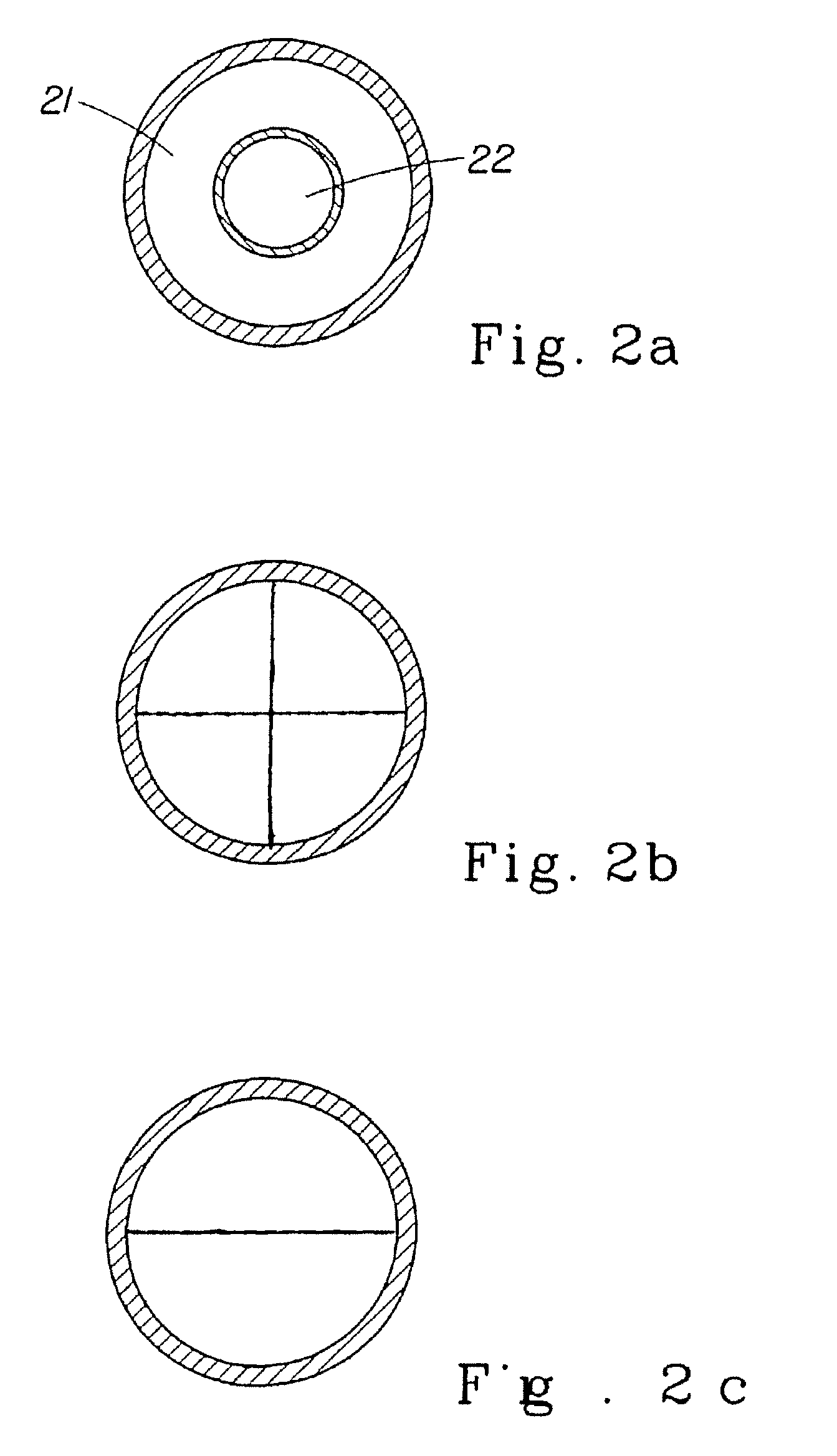

[0019]While many variations in the physical characteristics of the present components are possible, i.e., color, rheology, texture, density, etc., variations in color are widely sought. The specific design or pattern achieved (i.e., width, length of stripe or marbling, etc.) in the combination product can be varied by varying a number of additional factors including, but not limited to, rate of speed of rotation of the container or fill rate of the compositions into a rotating container.

[0020]As used herein, the term “accelerate” or “acceleration” refers to the increase in the rate of change of velocity with respect to time.

[0021]The term “anhydrous” as used herein, unless otherwise specified, refers to those compositions or materials containing less than about 10%, more preferably less than about 5%, even more preferably less than about 3%, even more preferably zero percent, by weight of water.

[0022]The term “ambient conditions” as used herein, unless otherwise specified, refers to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| Viscosity Method | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com