Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1885 results about "Nanoscopic scale" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The nanoscopic scale (or nanoscale) usually refers to structures with a length scale applicable to nanotechnology, usually cited as 1–100 nanometers. A nanometer is a billionth of a meter. The nanoscopic scale is (roughly speaking) a lower bound to the mesoscopic scale for most solids.

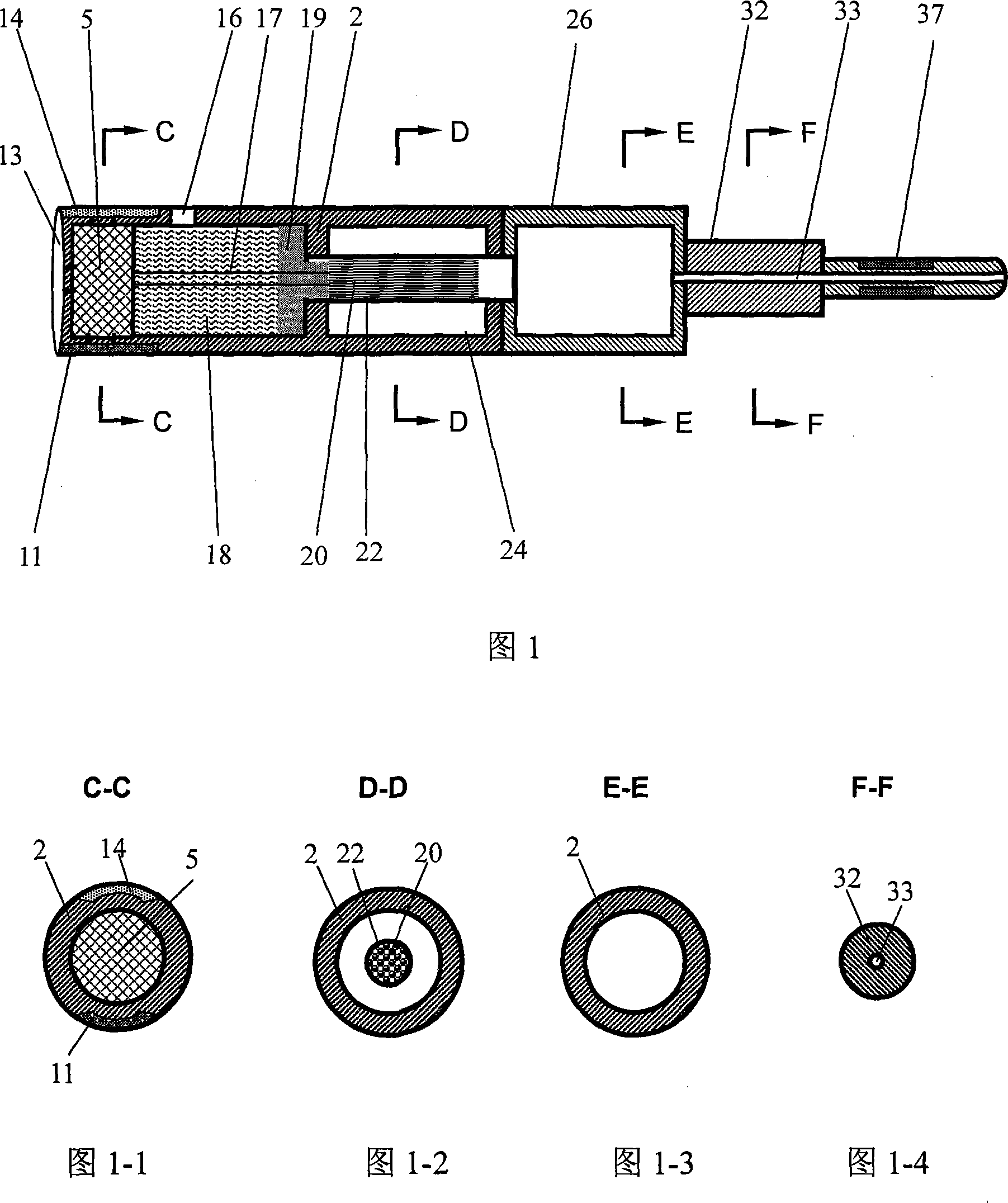

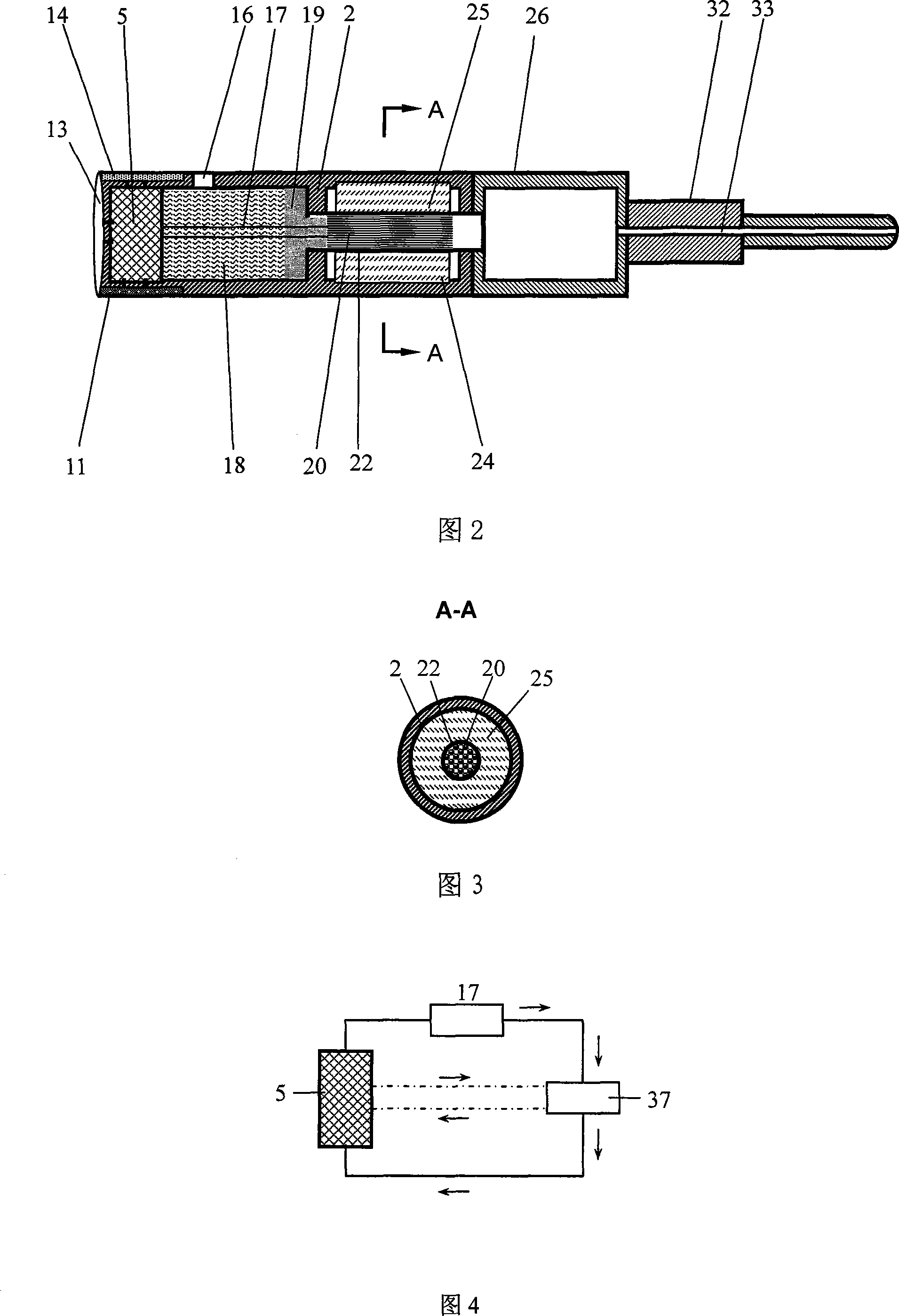

Electronic cigarette having nanometer sized hyperfine space warming atomizing functions

ActiveCN101116542ALarge amount of atomizationConcentrated use of energy and high efficiencyMedical devicesTobacco devicesMouth pieceElectricity

An electric-cigarette undertaking nanometer dimension fineness space heating pulverization to nicotine solution comprises a cigarette pole and a cigarette holder connected with the front end of the cigarette pole. The cigarette pole is a hollow rod shape cigarette pole welded with a plug at the back end. The intracavity of the cigarette pole is provided with a rechargeable battery, a liquid storage tank for storing nicotine solution, an imbibition liquid core arranged at the front end of the liquid storage tank and contacted with the nicotine solution, and a heater of space heating pulverization arranged inside the heating cavity positioned in the front part of the cigarette pole. The wall of the cigarette pole corresponding to the liquid storage tank is provided with a liquid inlet communicated with the liquid storage tank. Any place of the wall of the cigarette pole is provided with an electric heating switch. The center of the cigarette holder is provided with a hollow pipe which extends into the cigarette pole. The wall of front part of the cigarette holder is provided with a piezoelectric press sensor. The back end of the cigarette pole is provided with a recharging connection device which can charge the rechargeable battery through outer power. The piezoelectric press sensor is communicated with the rechargeable battery all the time. The electric heating switch, the piezoelectric press sensor and the rechargeable battery constitute a circuit loop. The invention has the advantages of convenient assembly and installation, easy carry, wide application and convenient use.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

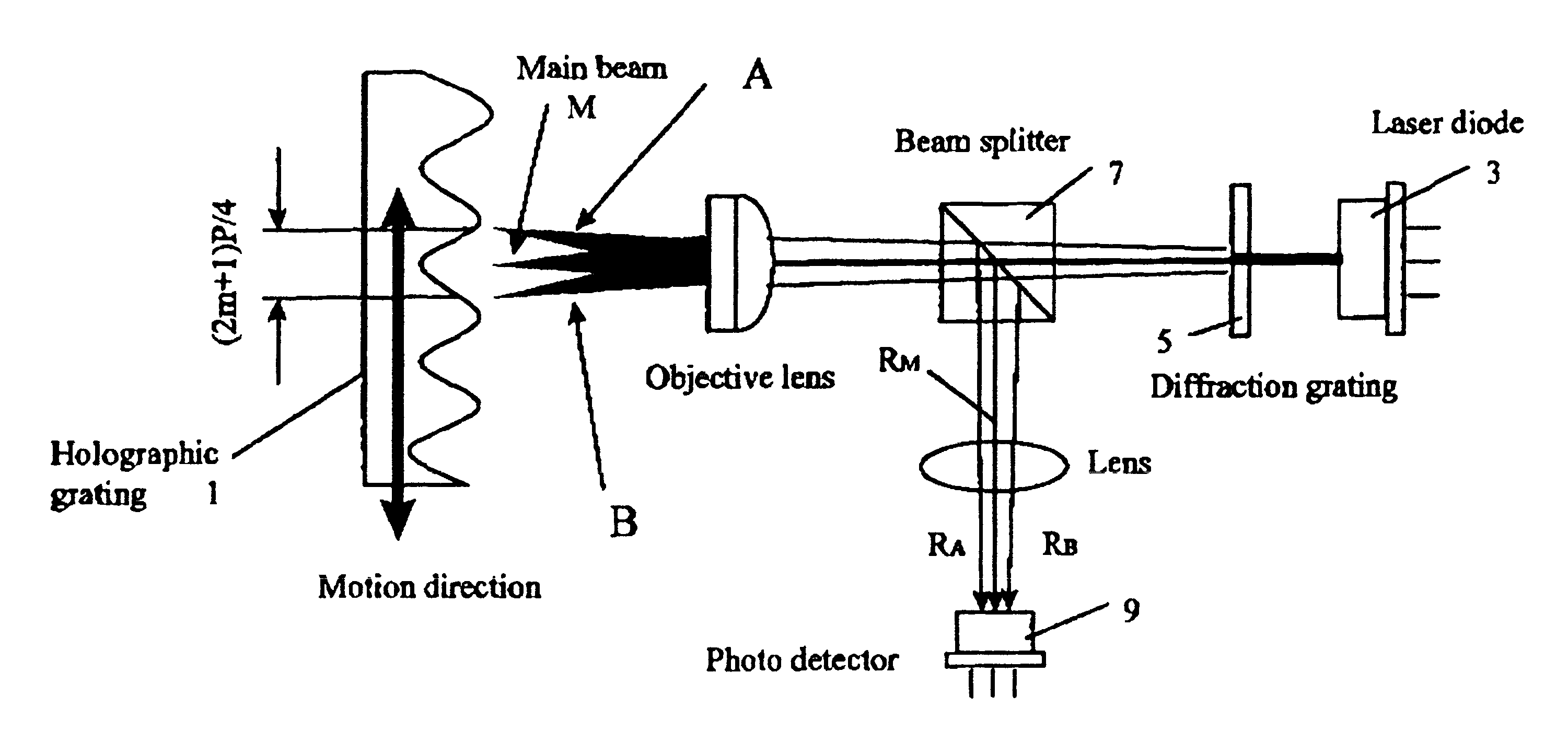

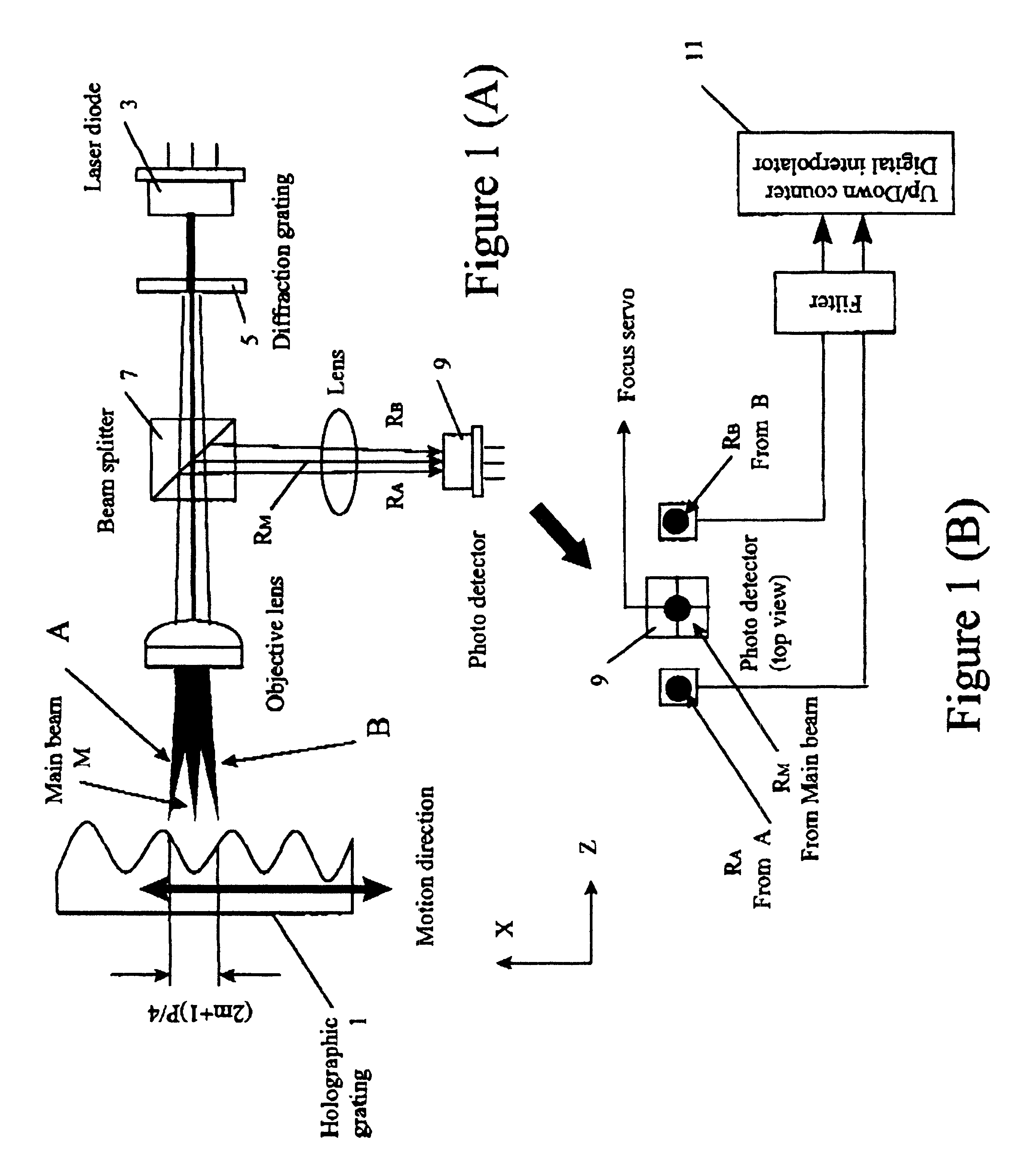

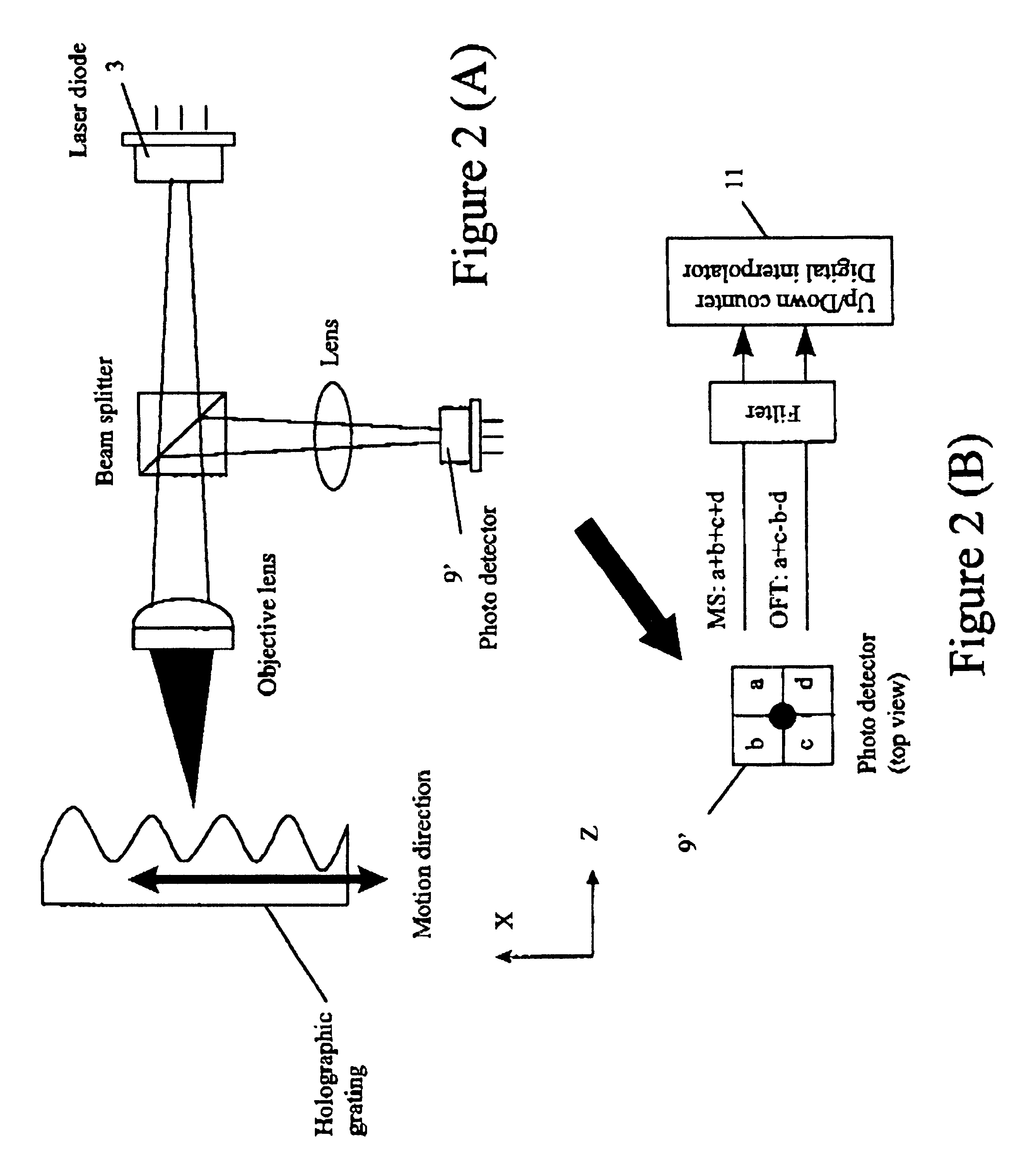

Method of and apparatus for real-time continual nanometer scale position measurement by beam probing as by laser beams and the like of atomic and other undulating surfaces such as gratings or the like relatively moving with respect to the probing beams

InactiveUS6639686B1Improved position sensing responseImprove operationNanoopticsInstrumental componentsGratingLight beam

An improved method of and apparatus for real-time continual nanometer scale position measurement by beam probing as by laser beams and the like, both fixed and oscillating or scanning, over an atomic and other undulating surface such as gratings or the like, relatively moving with respect to the probing beams; and providing, where desired, increased detection speeds, improved positioning sensing response, freedom from or relaxed requirements of strict control on probing oscillation amplitude, and multi-dimensional position measurement with focused beam probes and the like.

Owner:NANOWAVE

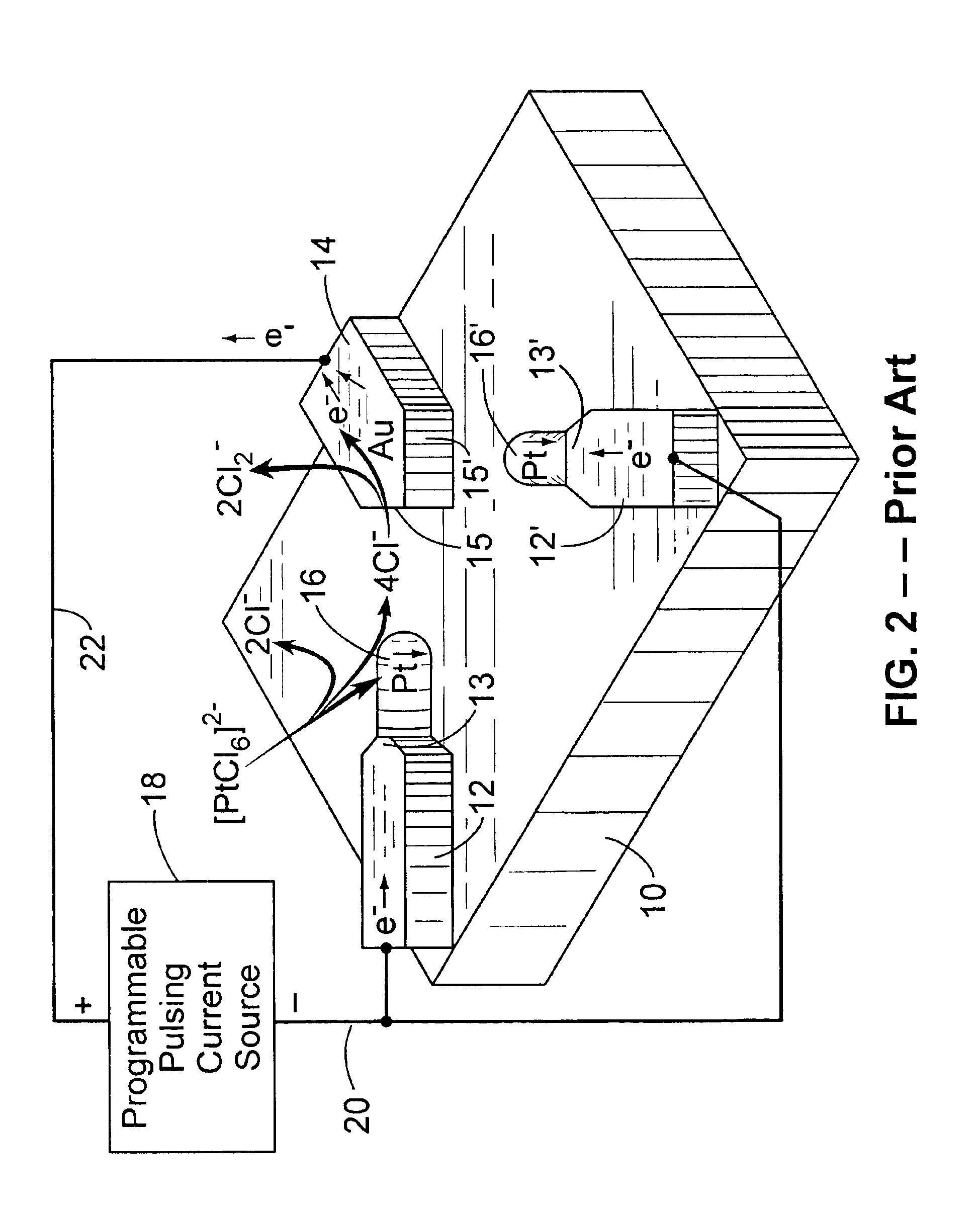

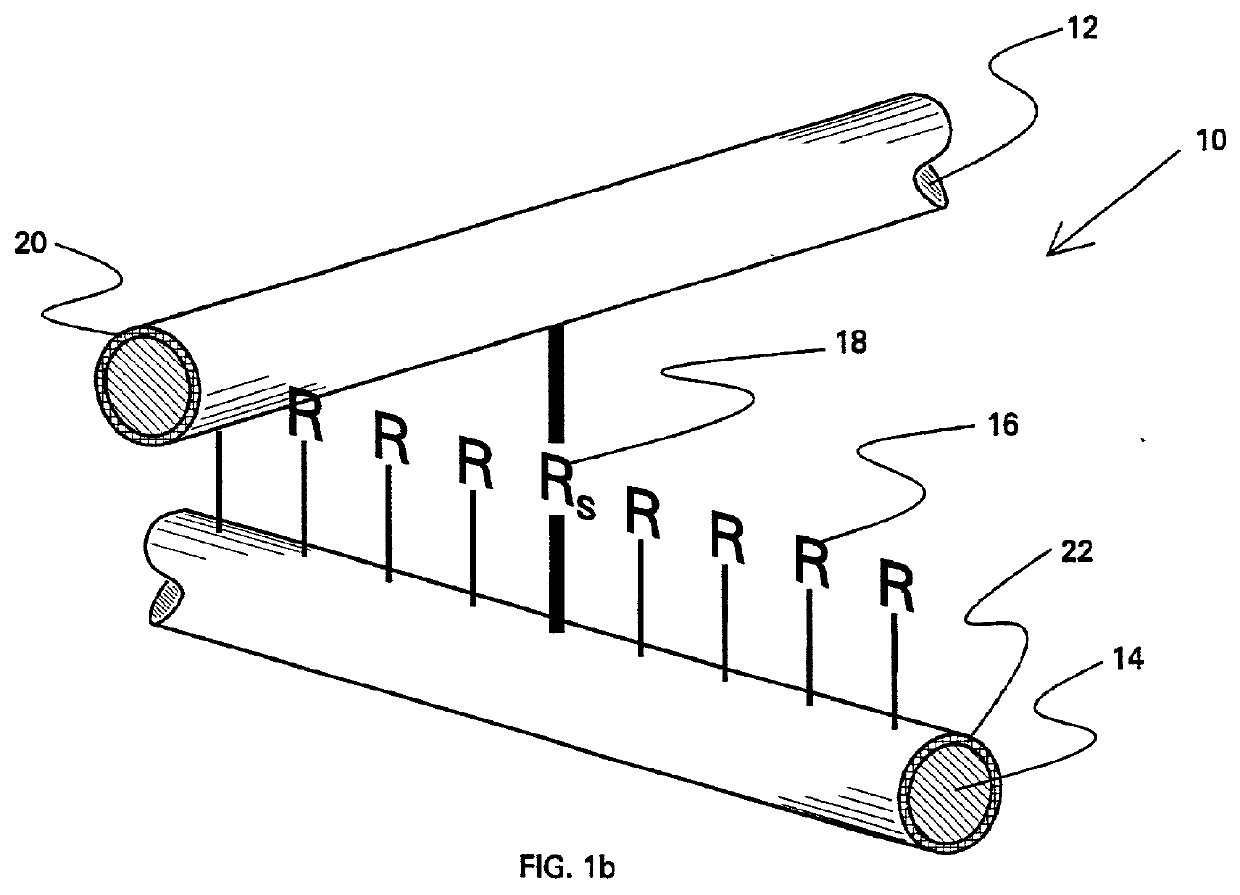

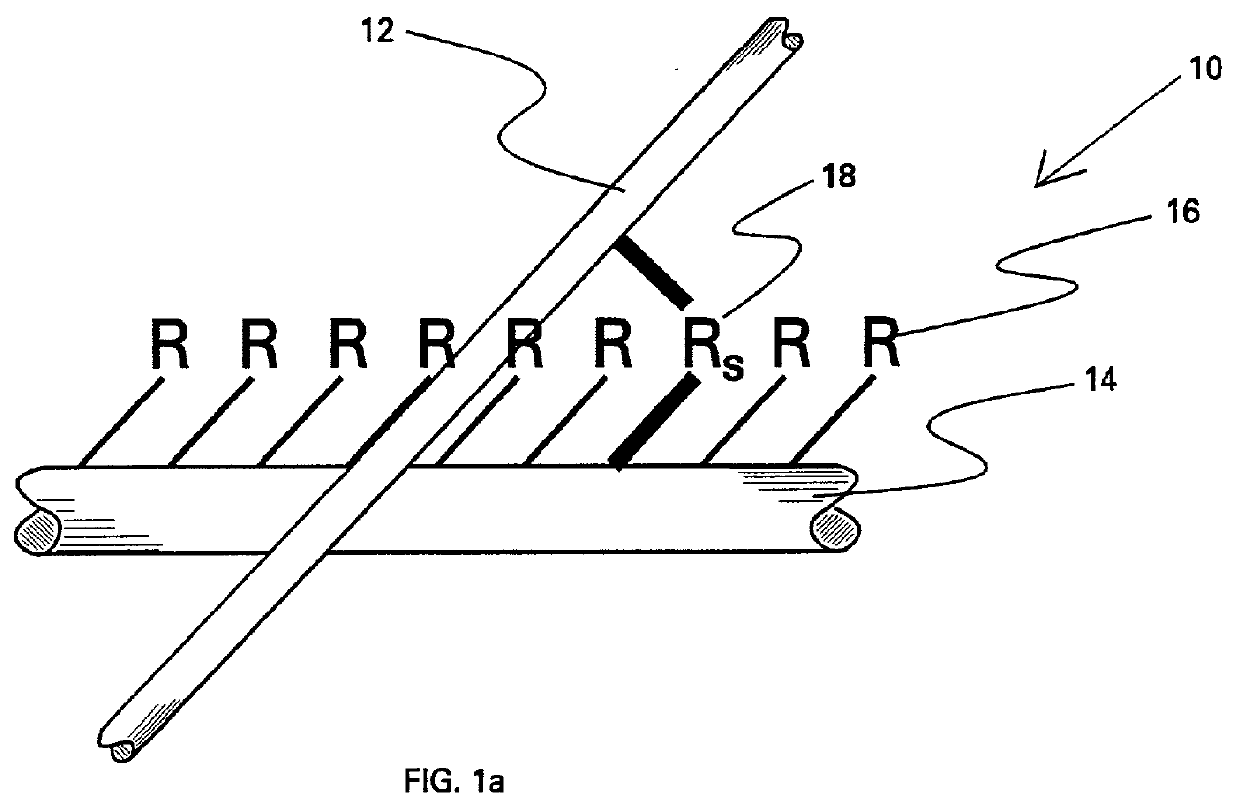

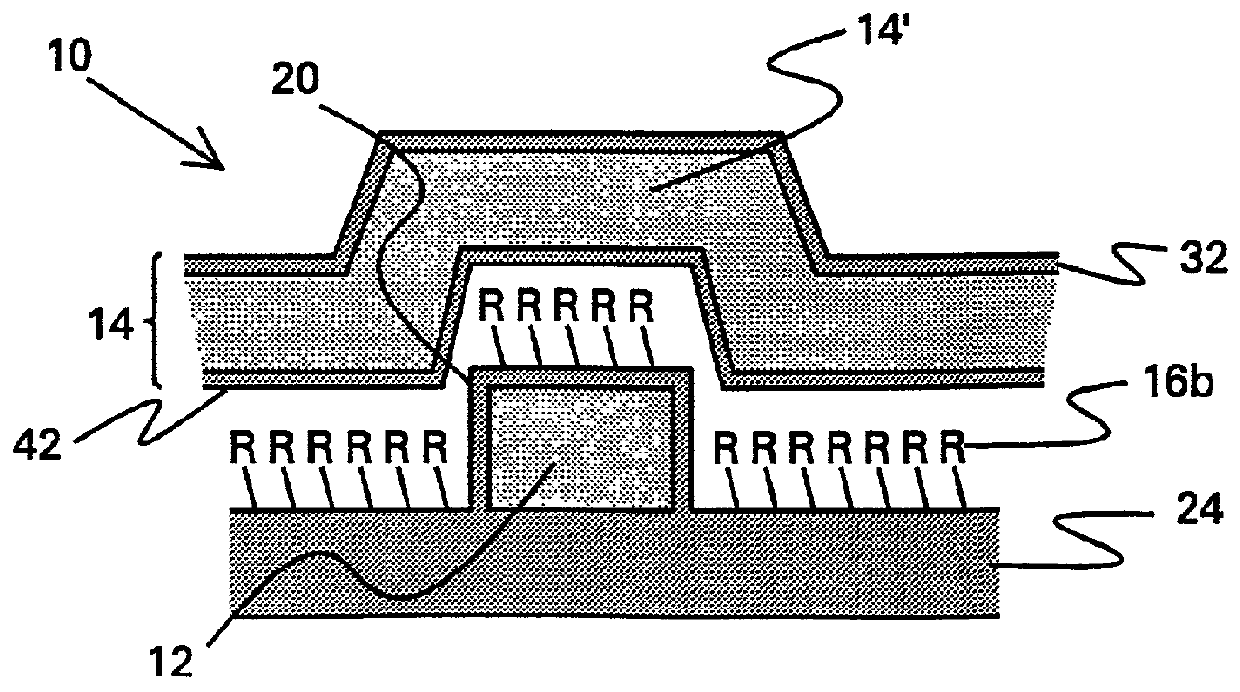

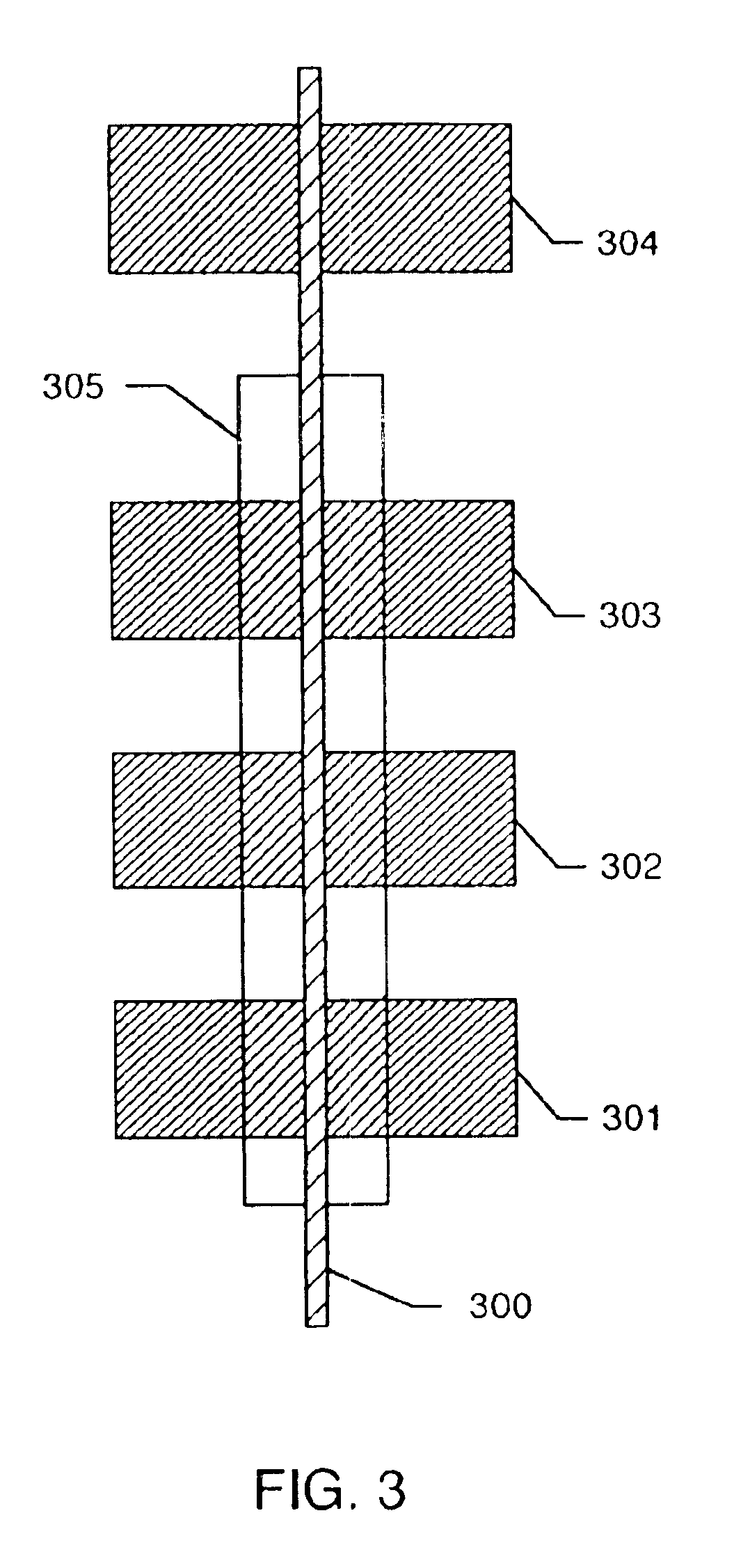

Chemically synthesized and assembled electronics devices

InactiveUS6459095B1Simple and inexpensive implementationMaterial nanotechnologyElectronic circuit testingCrossbar switchChemical synthesis

A route to the fabrication of electronic devices is provided, in which the devices consist of two crossed wires sandwiching an electrically addressable molecular species. The approach is extremely simple and inexpensive to implement, and scales from wire dimensions of several micrometers down to nanometer-scale dimensions. The device of the present invention can be used to produce crossbar switch arrays, logic devices, memory devices, and communication and signal routing devices. The present invention enables construction of molecular electronic devices on a length scale than can range from micrometers to nanometers via a straightforward and inexpensive chemical assembly procedure. The device is either partially or completely chemically assembled, and the key to the scaling is that the location of the devices on the substrate are defined once the devices have been assembled, not prior to assembly.

Owner:HEWLETT PACKARD CO +1

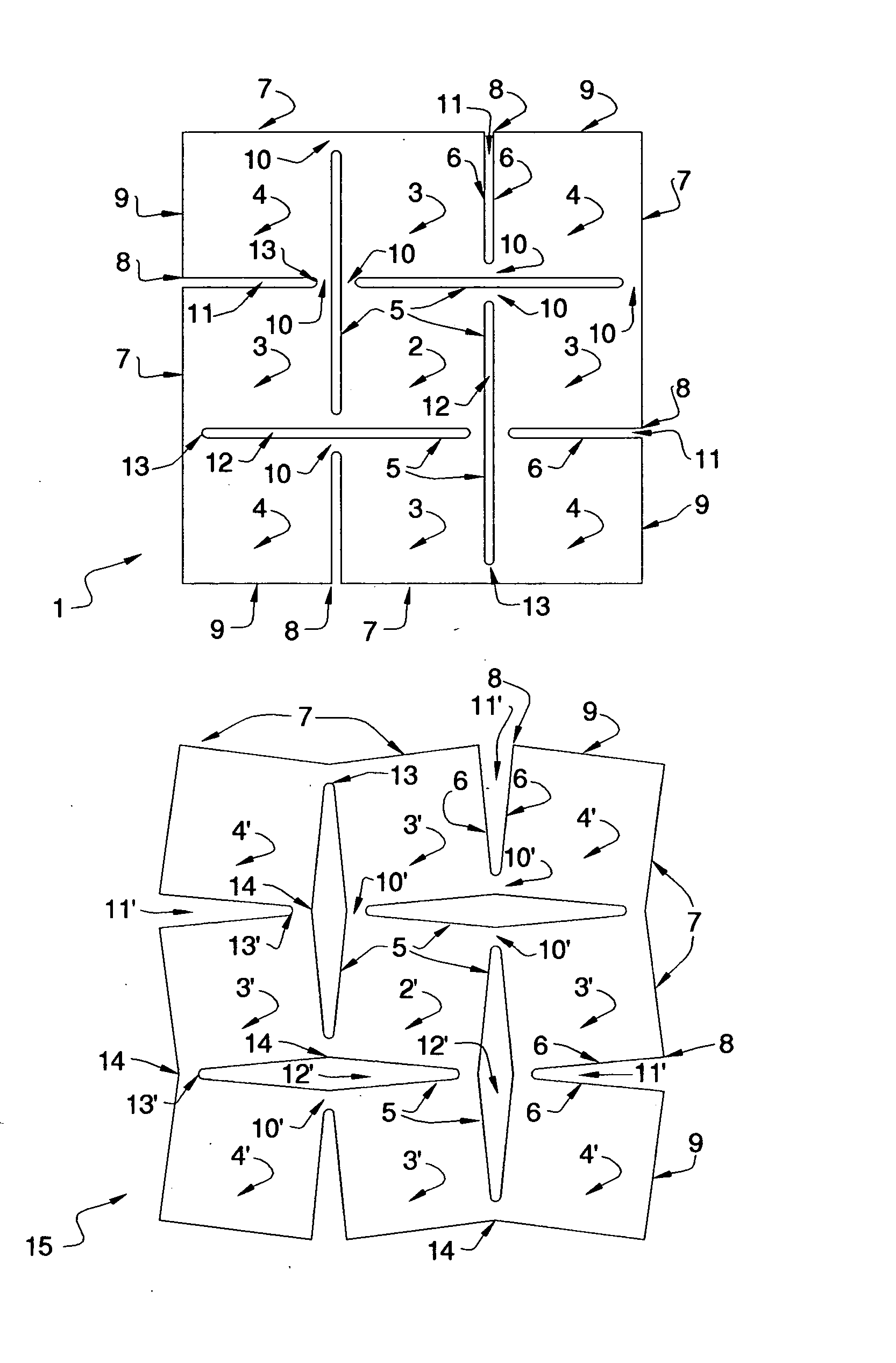

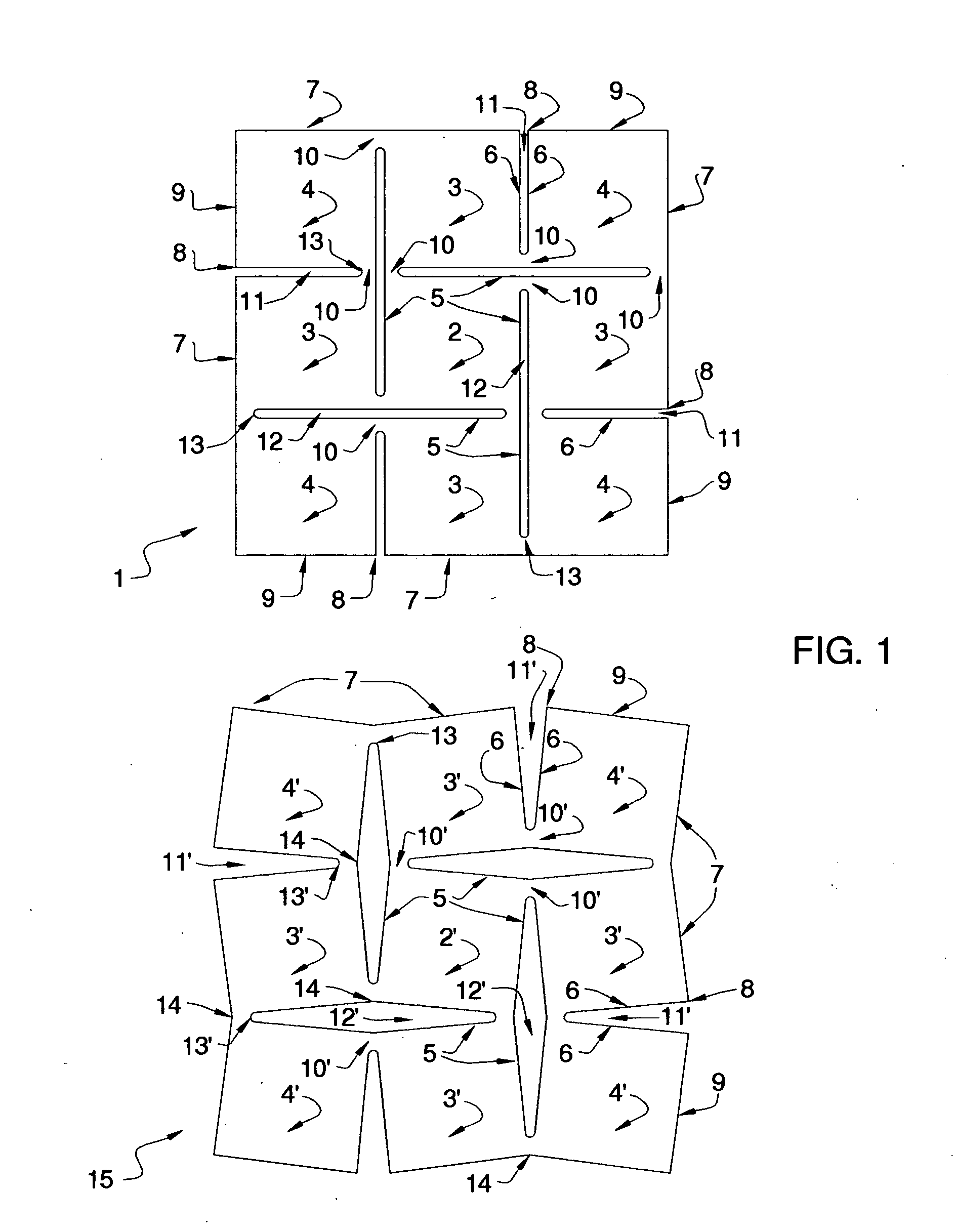

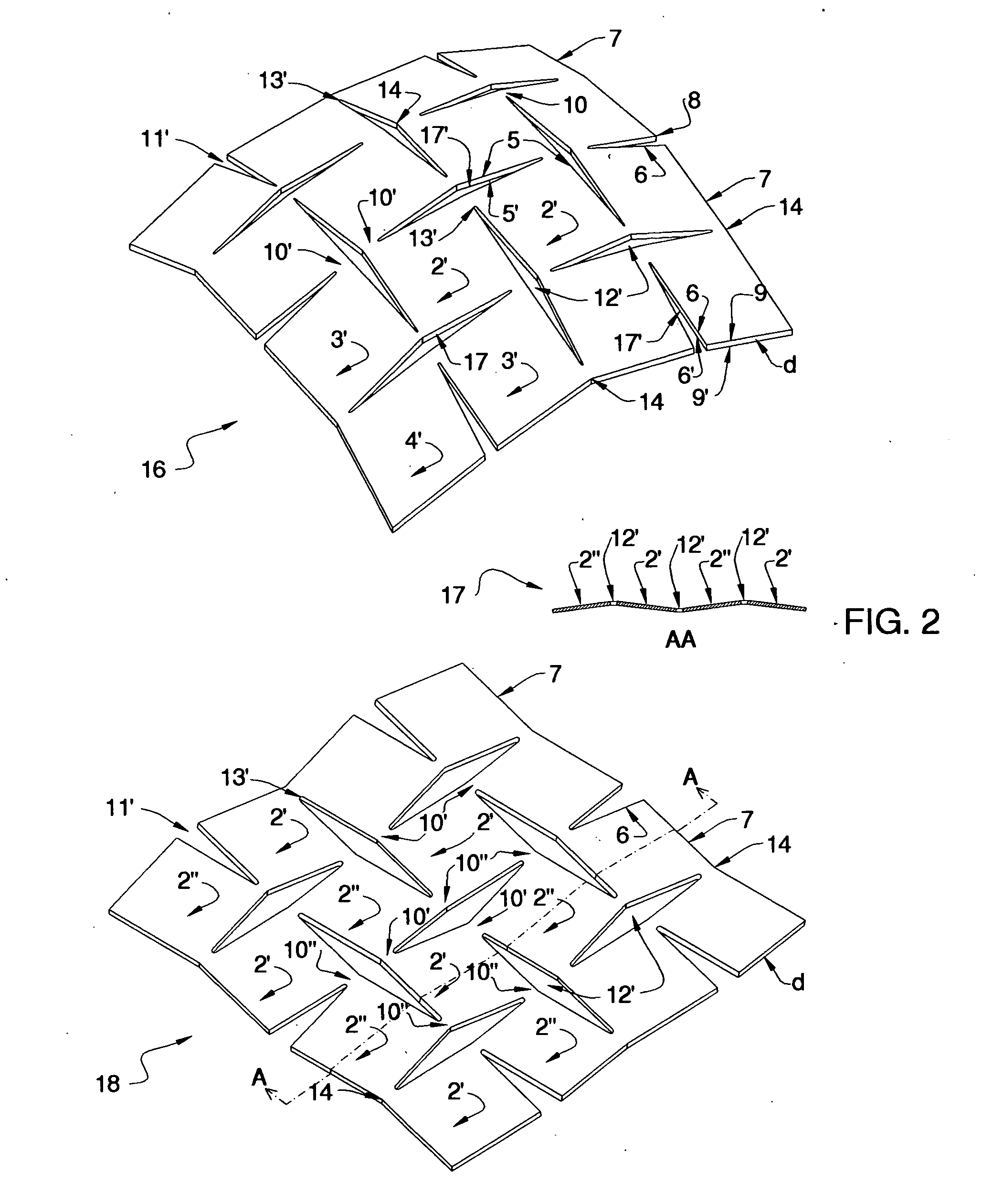

Multi-directional and variably expanded sheet material surfaces

ActiveUS20070122590A1Efficient use ofIncrease surface areaPaper/cardboard articlesFloorsLaser cuttingNanoscopic scale

Expandable surfaces made from sheet materials with slits distributed on the surface of sheet material where the surfaces expand by application of force along or / and across the surface of sheet material. The unexpanded surfaces are flat sheets, or closed surfaces like cylinders, spheres, tubes, or custom-designed organic shapes marked with pre-formed or post-formed slit designs. The expanded surfaces can be single units or modules which can be attached to one another through various means. The sheet materials range from hard surfaces like metals, to softer materials like papers and plastics, or pliable materials like fabrics, rubbers, synthetic surfaces or bio-surfaces. The slits are arranged in patterns ranging from periodic, non-periodic to irregular designs. The slits can be straight, bent, curved or irregularly shaped with even or uneven spacing. Slitting can be achieved by digital cutting or punching devices like laser-cutting, water-jet cutting, digital punching, automated dies, etc. or pre-formed when casting the sheet material. Force can be applied manually with tools or through the use of machines and special set-ups. Applications range from architectural surfaces, walls, ceilings, panel systems, structures and sculpture. On a smaller scale, applications include containers, packaging material, fabrics and human wear. On micro- to nano-scale, applications range from expandable surfaces for gauzes, band-aids, stent designs, skin grafts, semi-permeable membranes and micro-filters for various industries including purification of fluids and chemical substances.

Owner:LALVANI HARESH

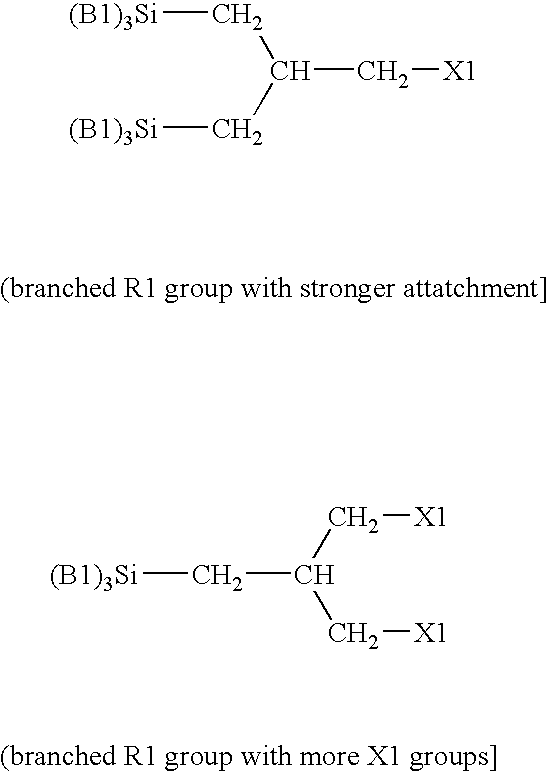

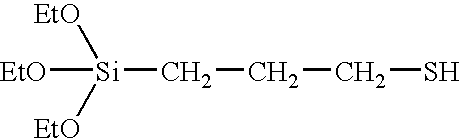

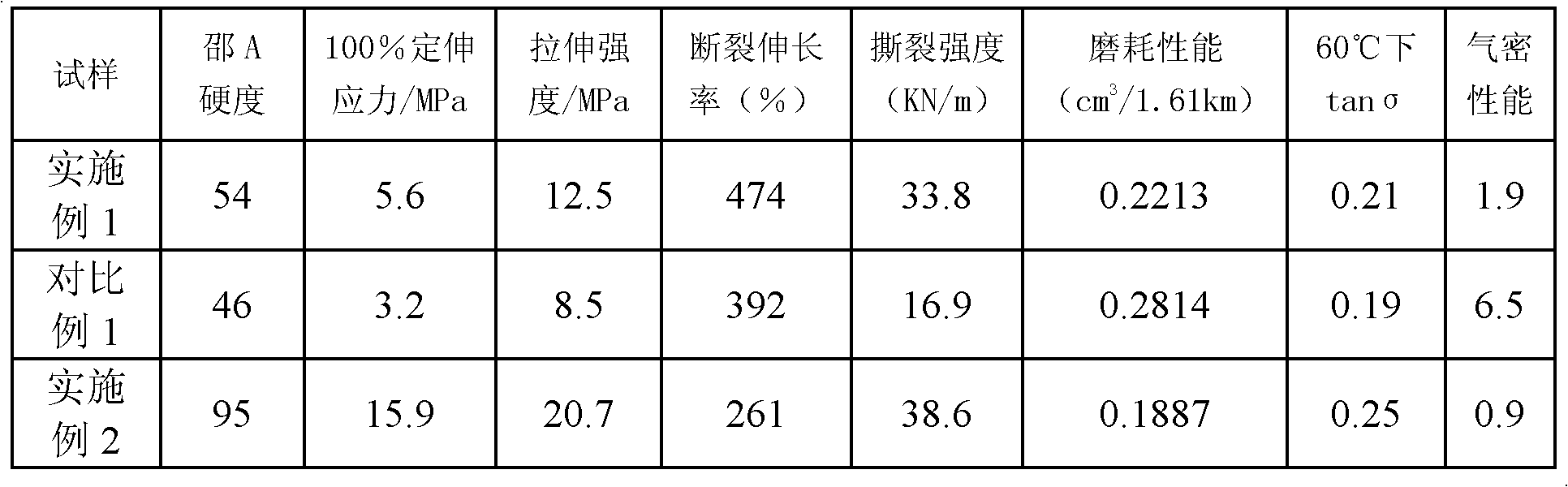

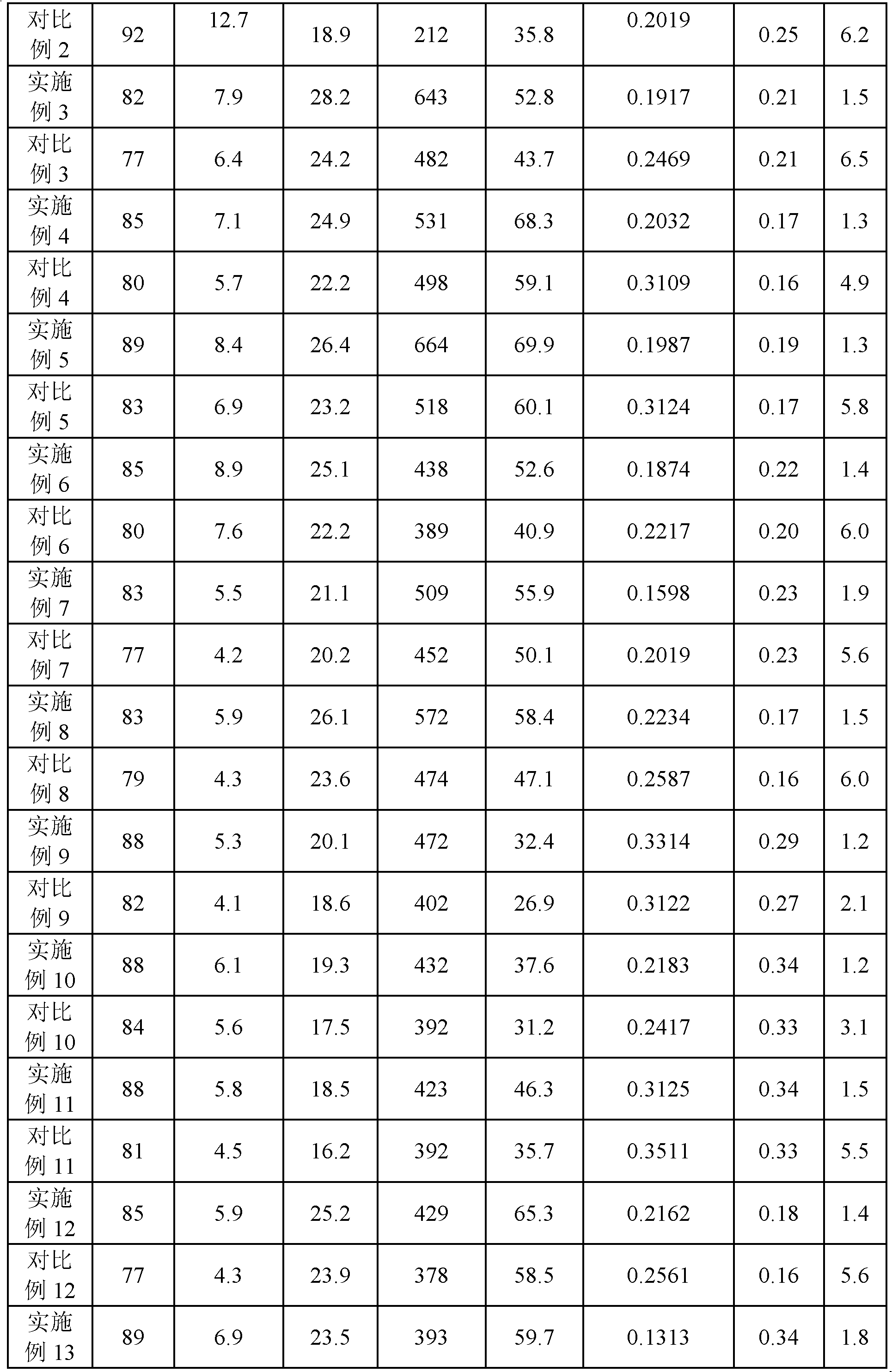

Preparation method of completely peeled oxidation graphene/ rubber nanometer composite material

A preparation method of completely peeled oxidation graphene / rubber nanometer composite material adopts combination of emulsion compounding and flocculation processes or combination of emulsion compounding and spraying drying processes. The preparation method retains the phase state structure of the oxidation grapheme / rubber composite emulation in the liquid state and obtains the phase-state structure which is highly dispersed, highly peeled and dispersed in nanometer scale dispersion. Simultaneously, substances capable of acting with generating ionic bond effect or chemical bond effect with an oxidation graphene surface functional group are added into the oxidation graphene / hydrosol to serve as an interface agent, thereby improving interface combination effect of oxidation graphene and rubber. Vulcanized rubber prepared by the composite material of the preparation method through follow-up mixing and vulcanizing has mechanical property such as high tensile strength, stretching stress and tearing strength and is capable of greatly improving abrasion resistance and gas separation performance of the vulcanized rubber. The preparation method is simple, easy, low in cost, apt to industrialization and wide in suitable aspect, saves energy and has better economical and social benefits.

Owner:JIANGSU LVYUAN RUBBER RESOURCE RECYCLING INNOVATION CENT CO LTD

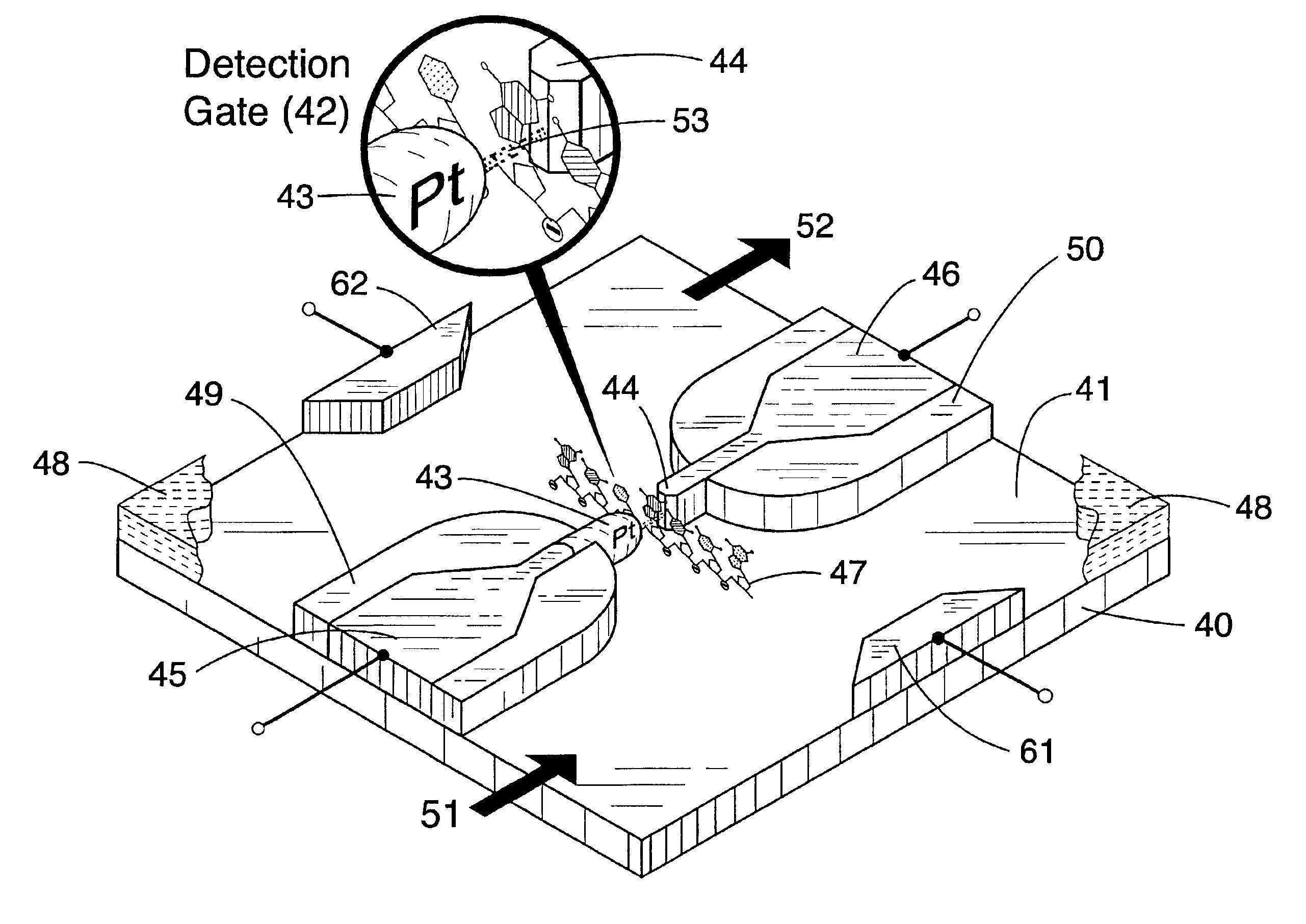

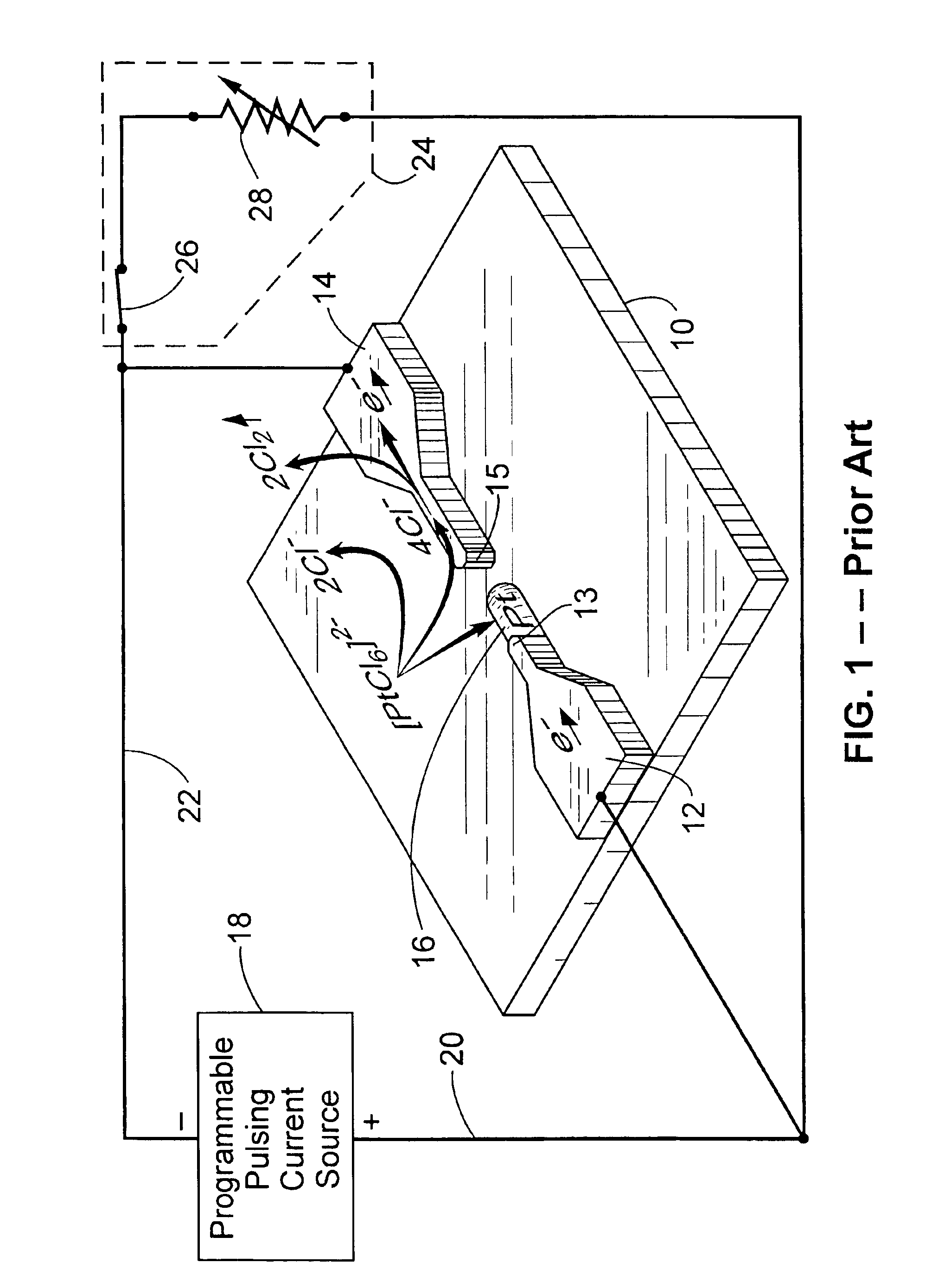

DNA and RNA sequencing by nanoscale reading through programmable electrophoresis and nanoelectrode-gated tunneling and dielectric detection

An apparatus and method for performing nucleic acid (DNA and / or RNA) sequencing on a single molecule. The genetic sequence information is obtained by probing through a DNA or RNA molecule base by base at nanometer scale as though looking through a strip of movie film. This DNA sequencing nanotechnology has the theoretical capability of performing DNA sequencing at a maximal rate of about 1,000,000 bases per second. This enhanced performance is made possible by a series of innovations including: novel applications of a fine-tuned nanometer gap for passage of a single DNA or RNA molecule; thin layer microfluidics for sample loading and delivery; and programmable electric fields for precise control of DNA or RNA movement. Detection methods include nanoelectrode-gated tunneling current measurements, dielectric molecular characterization, and atomic force microscopy / electrostatic force microscopy (AFM / EFM) probing for nanoscale reading of the nucleic acid sequences.

Owner:UT BATTELLE LLC

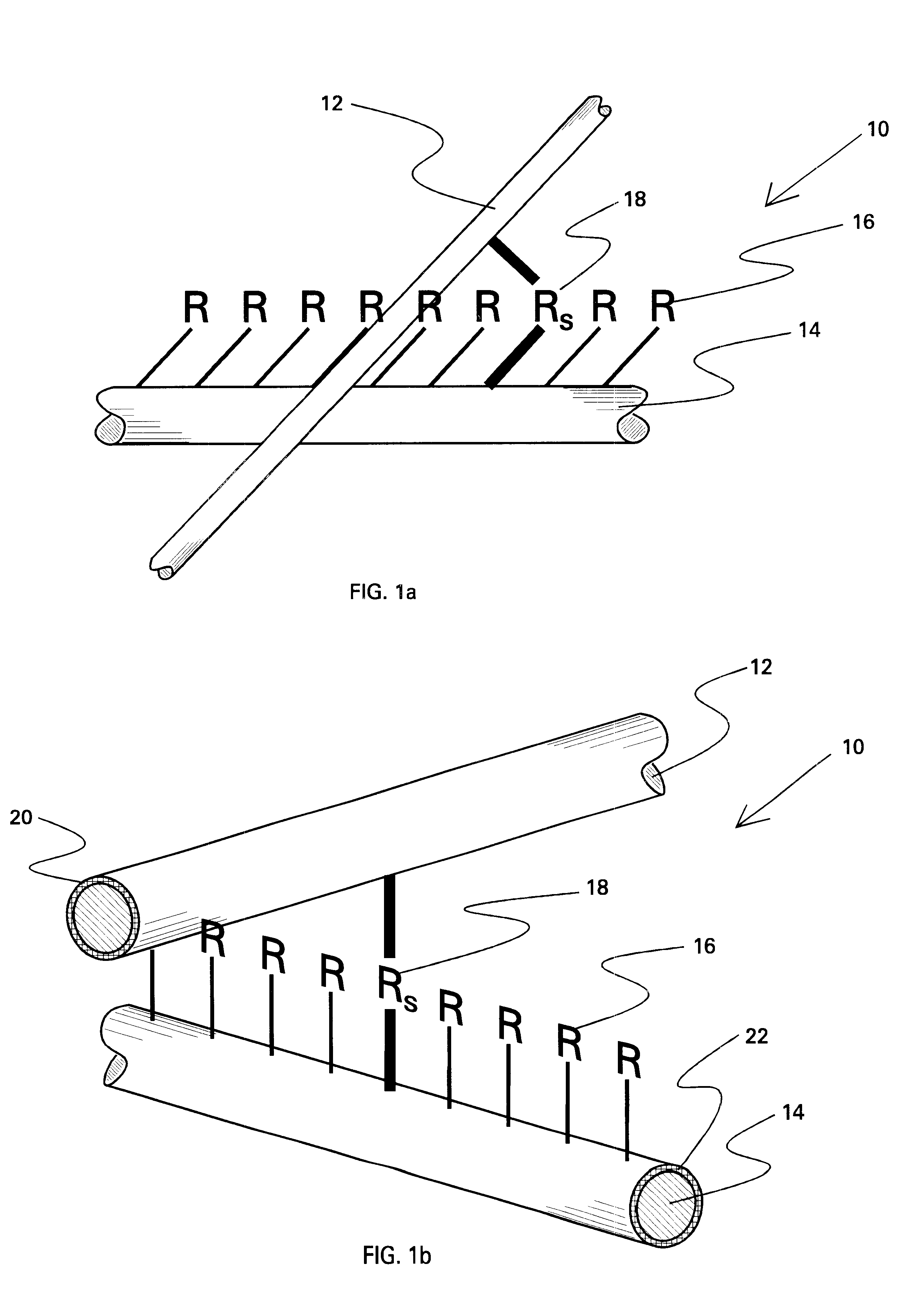

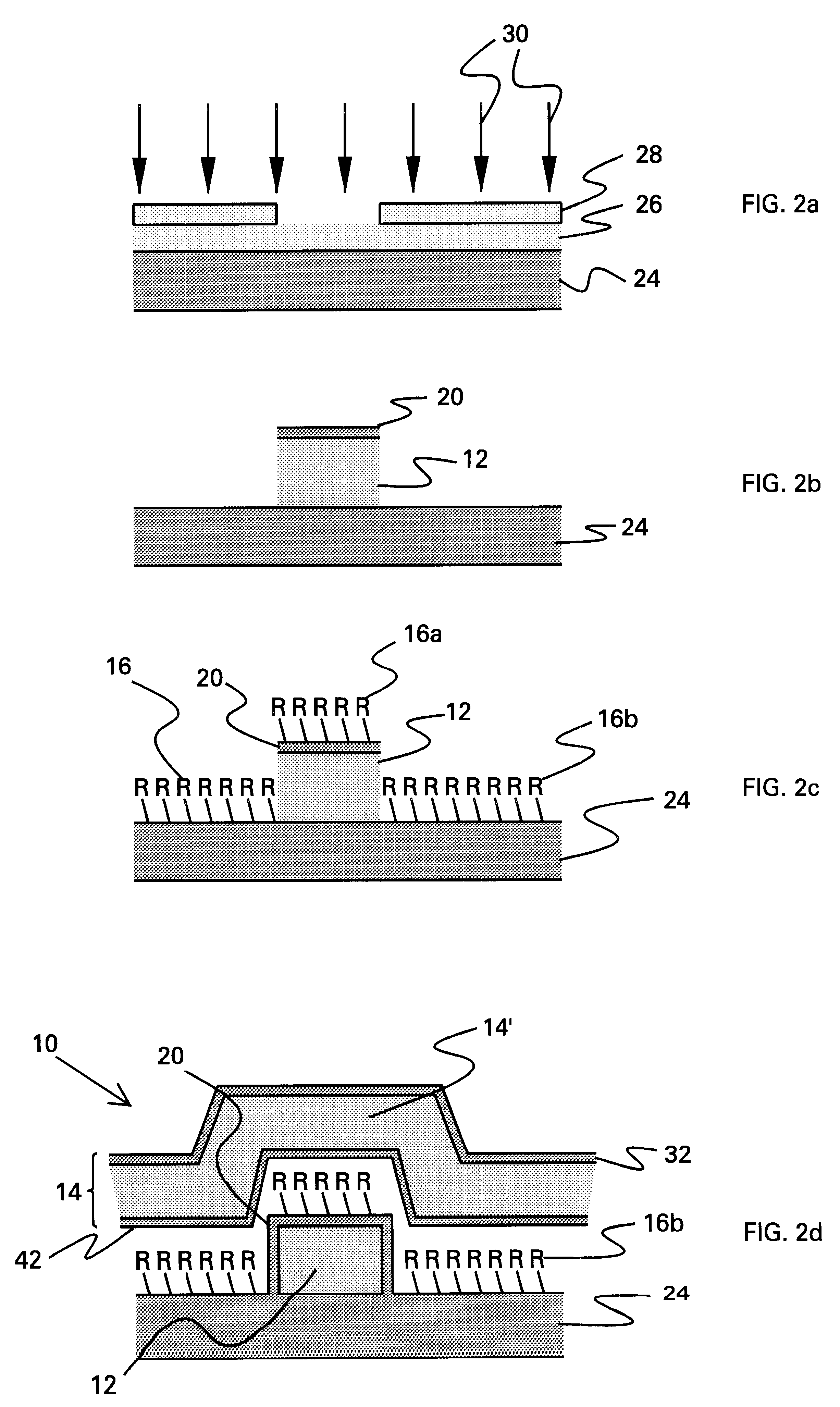

Chemically synthesized and assembled electronic devices

InactiveUS20010054709A1Simple and inexpensive implementationMaterial nanotechnologyElectronic circuit testingSignal routingChemical synthesis

A route to the fabrication of electronic devices is provided, in which the devices consist of two crossed wires sandwiching an electrically addressable molecular species. The approach is extremely simple and inexpensive to implement, and scales from wire dimensions of several micrometers down to nanometer-scale dimensions. The device of the present invention can be used to produce crossbar switch arrays, logic devices, memory devices, and communication and signal routing devices. The present invention enables construction of molecular electronic devices on a length scale than can range from micrometers to nanometers via a straightforward and inexpensive chemical assembly procedure. The device is either partially or completely chemically assembled, and the key to the scaling is that the location of the devices on the substrate are defined once the devices have been assembled, not prior to assembly.

Owner:HEWLETT PACKARD CO +1

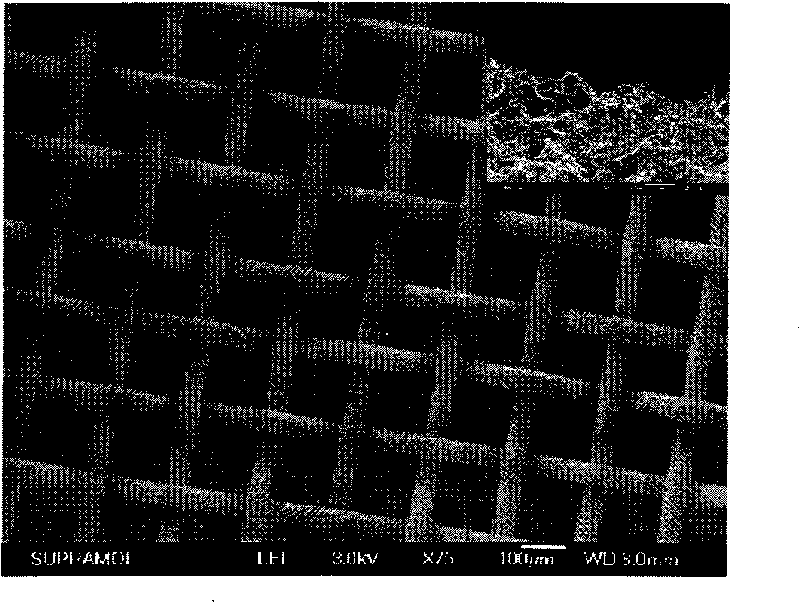

Method for preparing metal mesh for oil-water separation

InactiveCN101708384AAchieve the purpose of separationAcid resistantFiltration separationLiquid separationChemical industryNanoscopic scale

The invention belongs to the technical field of chemistry and chemical industry and functional materials, and relates to a method for preparing a metal mesh which has special wetting properties and is used for oil-water separation. The method adopts simple wet-method chemical etching technology, nano-scale microscopic bulges are prepared on the surface of a metal mesh with micron-grade pore diameters, and then a compound which does not contain fluorine and has low surface energy is modified on the surfaces of the microscopic bulges. For the surface of the prepared material, a contact angle of a water drop is more than 150 degrees, and a contact angle of oil is close to 0 degree. Due to the specific wetting properties, the material can allow the oil to pass through the metal mesh smoothly, but the water cannot permeate through the metal mesh completely, so that the property of effectively separating oil-water mixtures is realized. Particularly, the specific wetting properties of the surface of the material can keep stable in acid solution, alkali solution and salt solution, and thus the functional metal mesh can be excellently applied in aspects of metal corrosion prevention and the like. A mesh membrane does not contain the fluorine, and has the advantages of simple preparation method, high permeability of pore space and good oil-water separation effect, and corrosion resistance.

Owner:JILIN UNIV

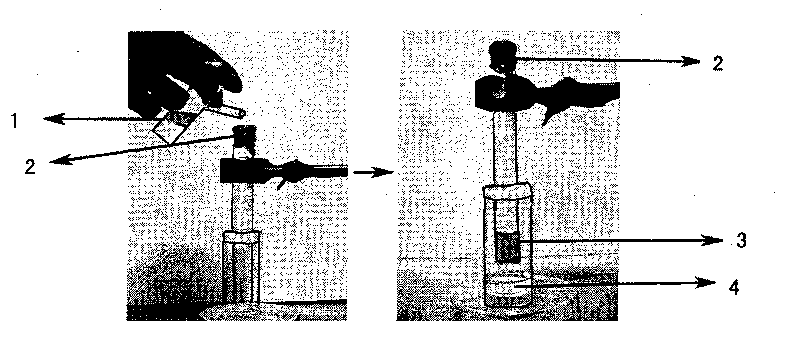

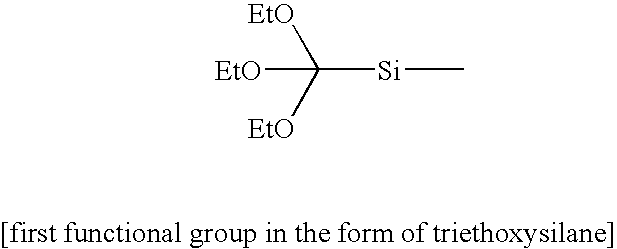

Stamp having an antisticking layer and a method of forming of repairing such a stamp

InactiveUS20050039618A1Good effectStable antisticking layerNanoinformaticsPhotomechanical apparatusCouplingNanoscopic scale

A stamp for use in transferring a pattern in nano-scale has a monomolecular antisticking layer. The anti-sticking layer comprises molecular chains, which are covalently bound to the surface of the stamp and which each comprise at least one fluorine-containing group. Each molecular chain contains a group Q, which comprises a bond which is weaker than the other bonds in the molecular chain as well as the covalent bond that binds the molecular chain to the surface of the stamp. Splitting of said bond in the group Q creates a group Q1, which is attached to the part of the molecular chain being left on the surface of the stamp and which is capable of reacting with a fluorine-containing compound to restore the antisticking layer. In a method of manufacturing a stamp for use in transferring a pattern in nanoscale, the stamp is provided with the above-mentioned molecular chain. In a method of repairing a damaged antisticking layer of the above-mentioned stamp, the stamp is treated with a repairing reagent, which has a coupling end, which is capable of reacting with the group Q1, and a fluorine-containing group located at the other end of the repairing reagent.

Owner:OBDUCAT AB SE

Method for preparing graphene oxide/white carbon black/rubber nanocomposite

The invention relates to a method for preparing a graphene oxide / white carbon black / rubber nanocomposite, which adopts a solution blending method or a mechanical blending method. In the graphene oxide / white carbon black / rubber nanocomposite prepared by the method provided by the invention, graphene and white carbon black are inserted with each other to effectively effective the aggregation of the two fillers, so as to obtain a highly-dispersed highly-stripped nano-sized composite. Not only the composite has high modulus and low rolling resistance, but also the wear resistance of a rubber material is greatly improved, and the modulus and tear resistance of the composite are further improved; in addition, due to the lamellar structure and good self-recovery capability of graphene oxide, the rubber material is also endued with good gas barrier performance and self-recovery capability, and the nanocomposite has the advantages that cannot be matched by any traditional filler. The method provided by the invention is simple and feasible, and suitable for industrial production, and has low cost, wide application range and good economic and social benefits.

Owner:BEIJING UNIV OF CHEM TECH

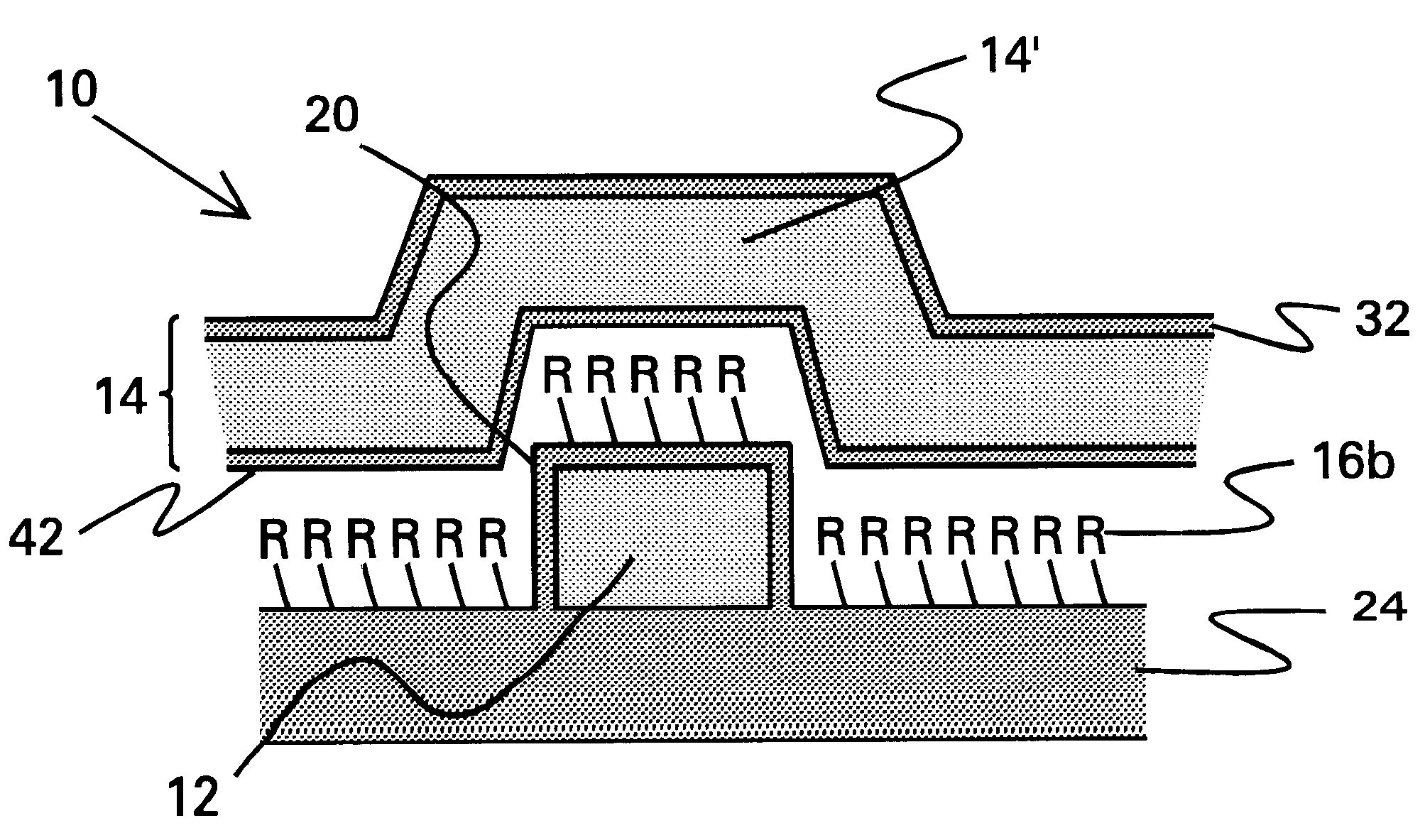

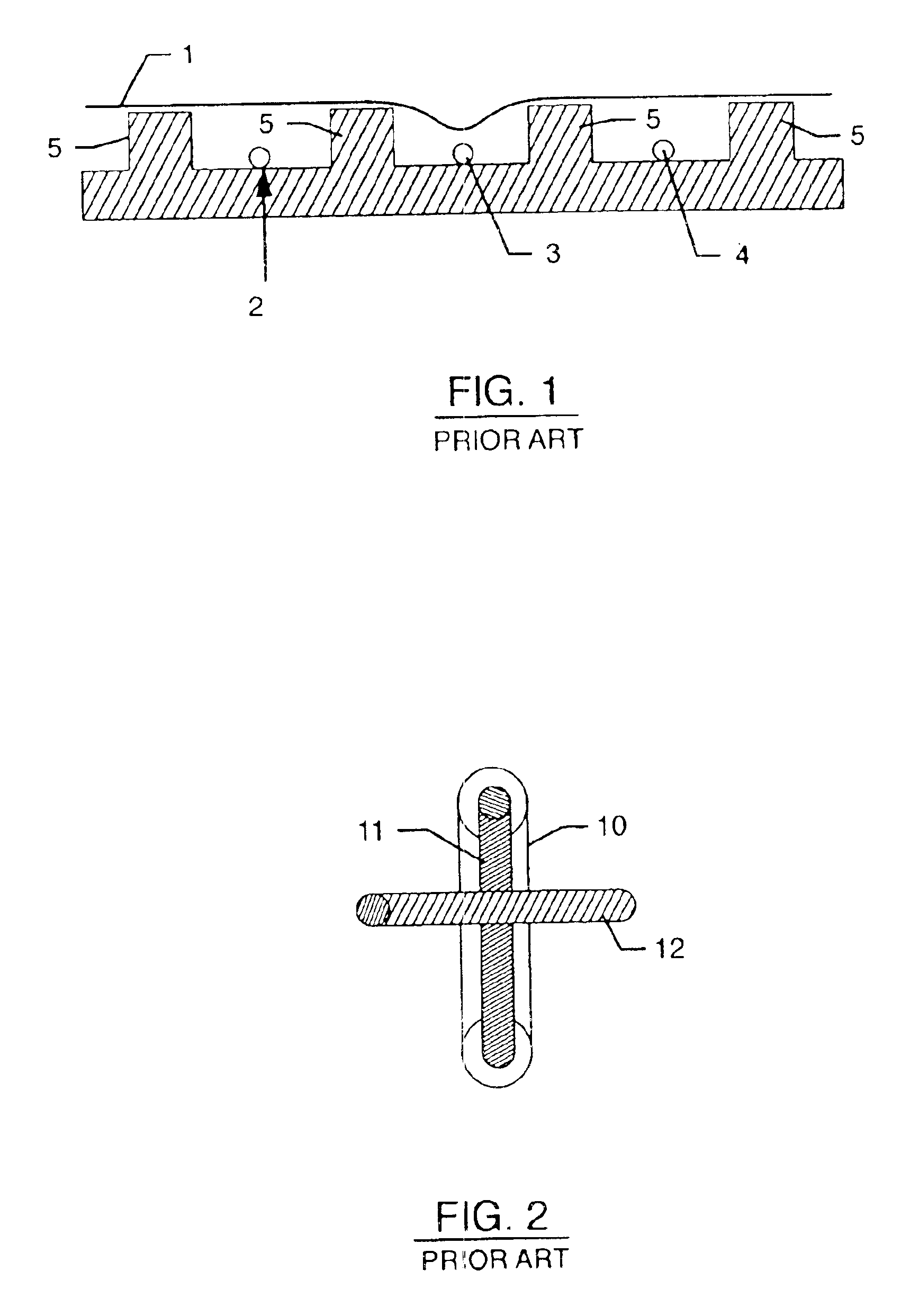

Stochastic assembly of sublithographic nanoscale interfaces

InactiveUS6900479B2Tighter address encodingReasonable efficiencySemiconductor/solid-state device detailsNanoinformaticsWire rodEngineering

A method for controlling electric conduction on nanoscale wires is disclosed. The nanoscale wires are provided with controllable regions axially and / or radially distributed. Controlling those regions by means of microscale wires or additional nanoscale wires allows or prevents electric conduction on the controlled nanoscale wires. The controllable regions are of two different types. For example, a first type of controllable region can exhibit a different doping from a second type of controllable region. The method allows one or more of a set of nanoscale wires, packed at sublithographic pitch, to be independently selected.

Owner:CALIFORNIA INST OF TECH +3

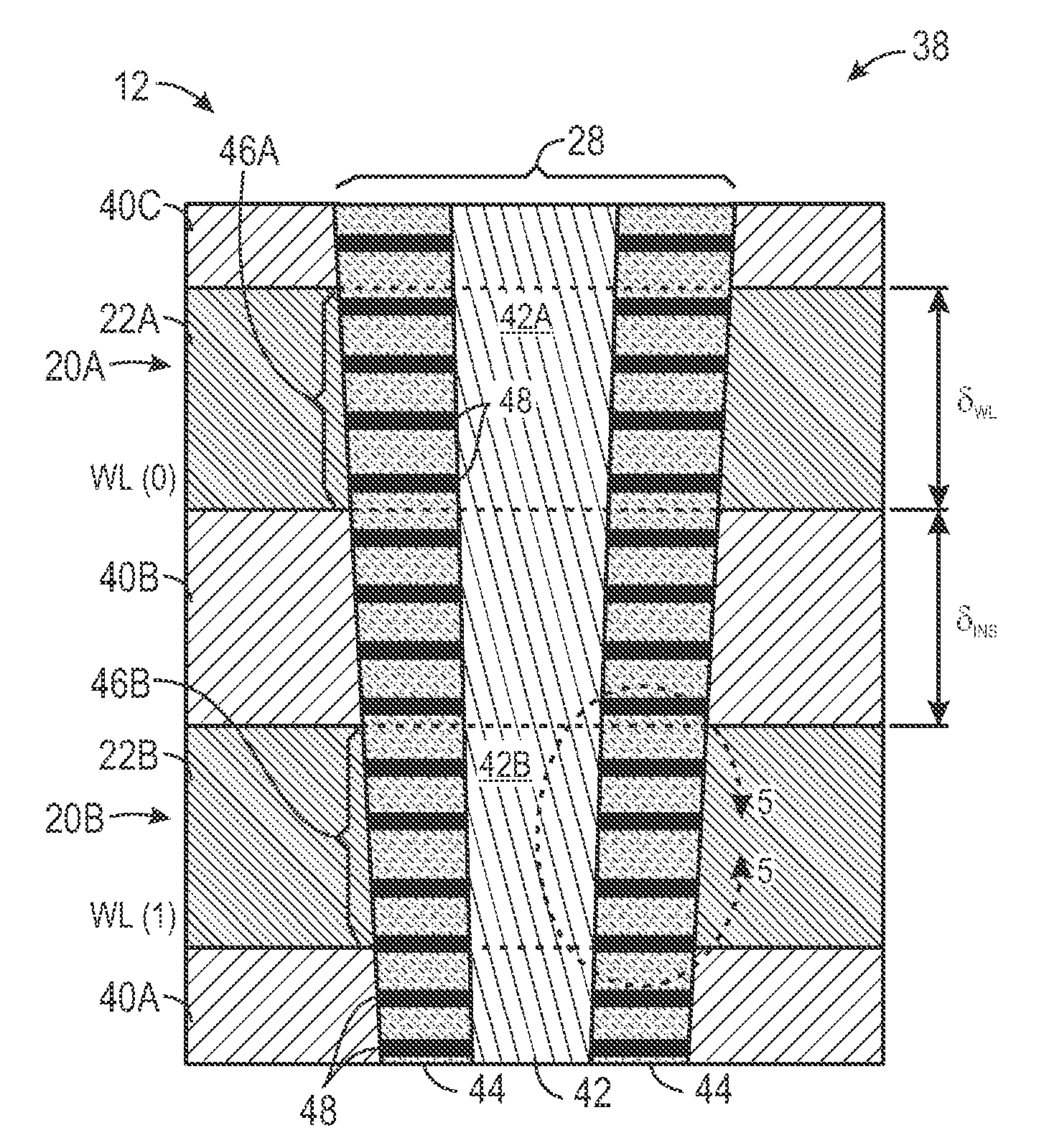

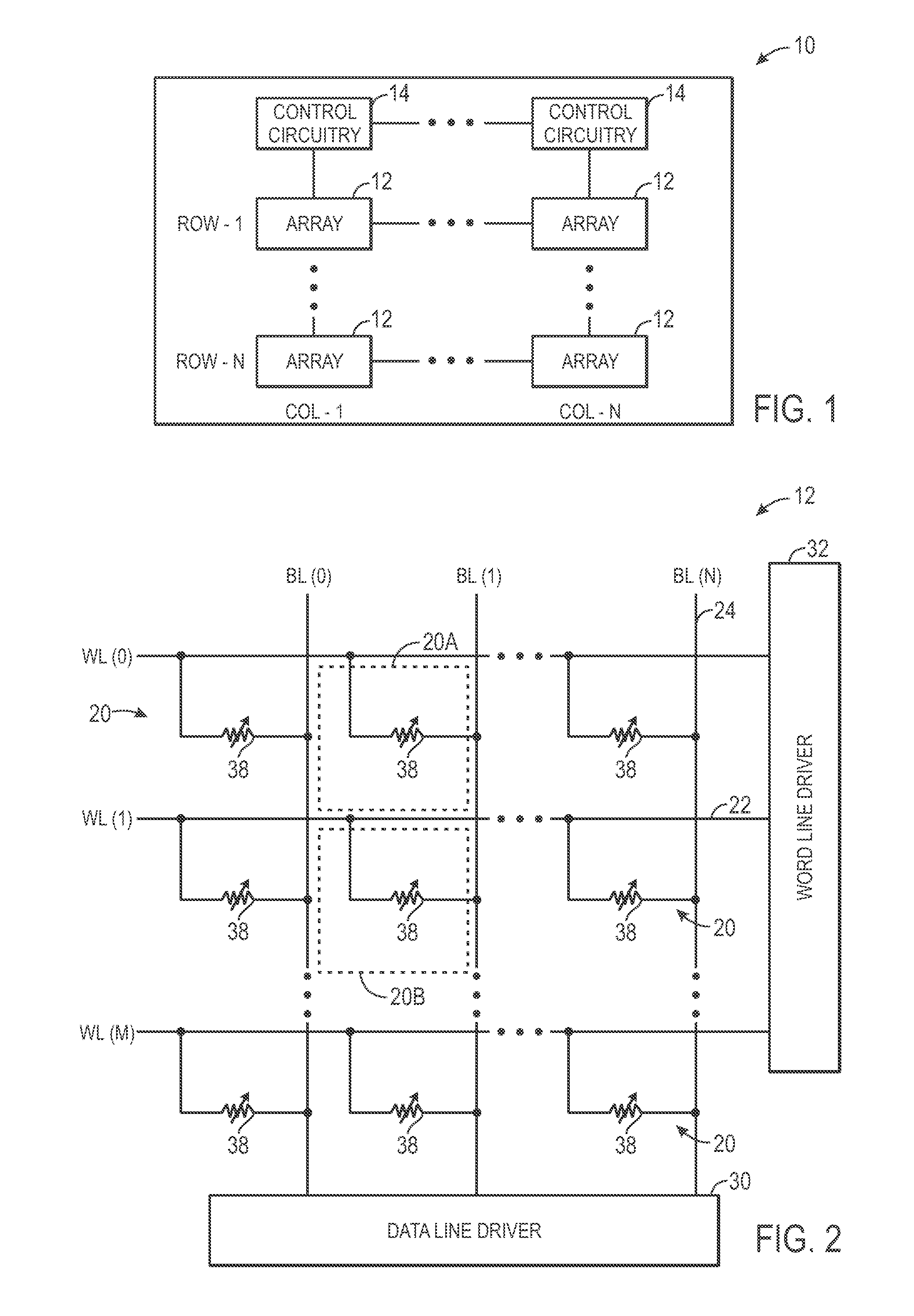

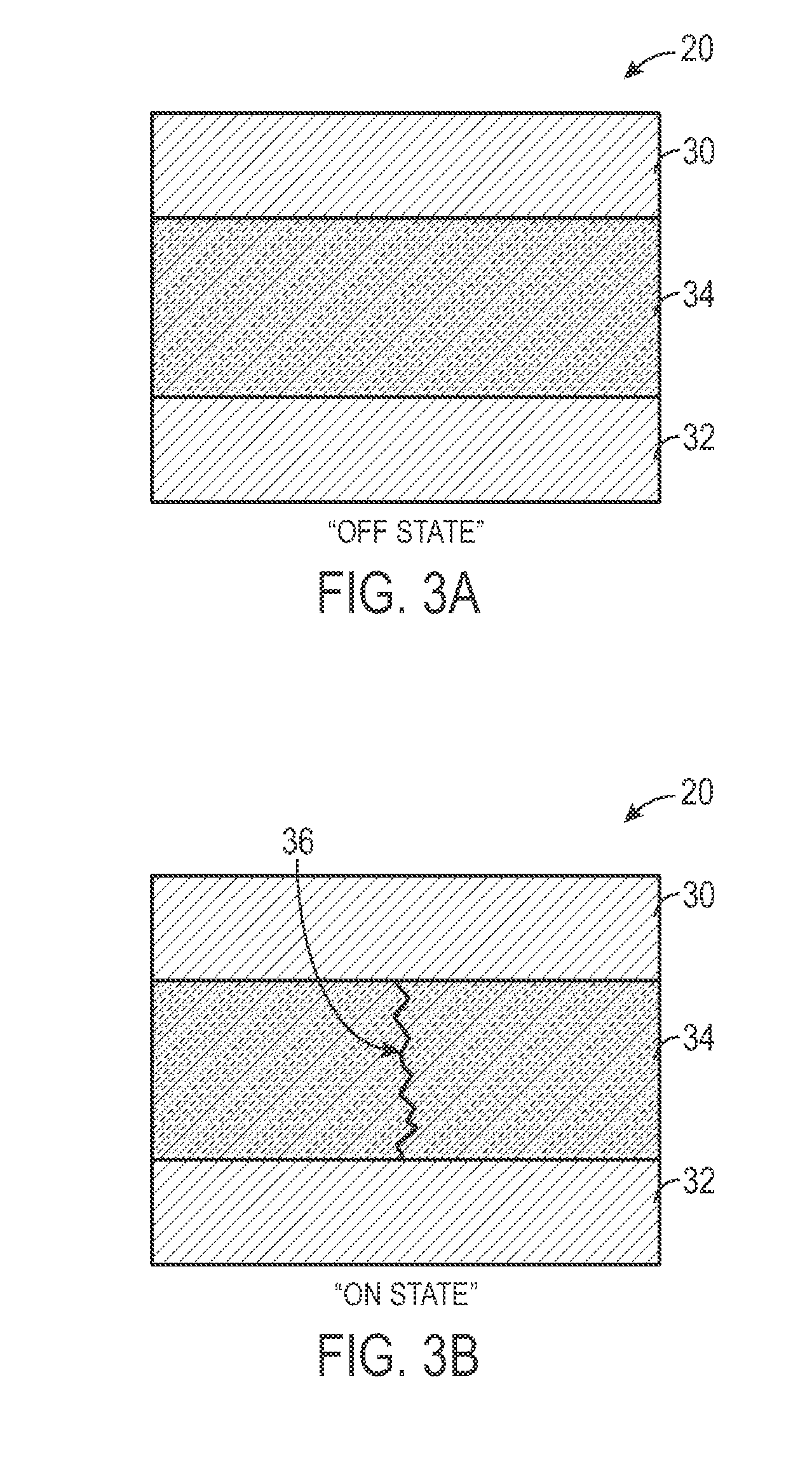

Vertical memory cell for high-density memory

ActiveUS20120261638A1Solid-state devicesBulk negative resistance effect devicesHigh densityUnit structure

This disclosure provides embodiments for the formation of vertical memory cell structures that may be implemented in RRAM devices. In one embodiment, memory cell area may be increased by varying word line height and / or word line interface surface characteristics to ensure the creation of a grain boundary that is suitable for formation of conductive pathways through an active layer of an RRAM memory cell. This may maintain continuum behavior while reducing random cell-to-cell variability that is often encountered at nanoscopic scales. In another embodiment, such vertical memory cell structures may be formed in multiple-tiers to define a three-dimensional RRAM memory array. Further embodiments also provide a spacer pitch-doubled RRAM memory array that integrates vertical memory cell structures.

Owner:MICRON TECH INC

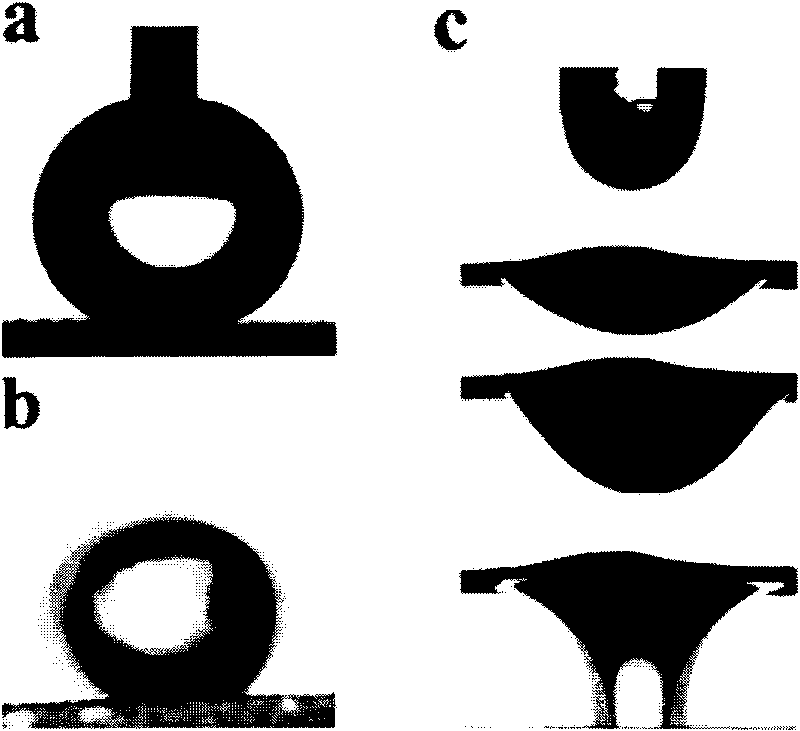

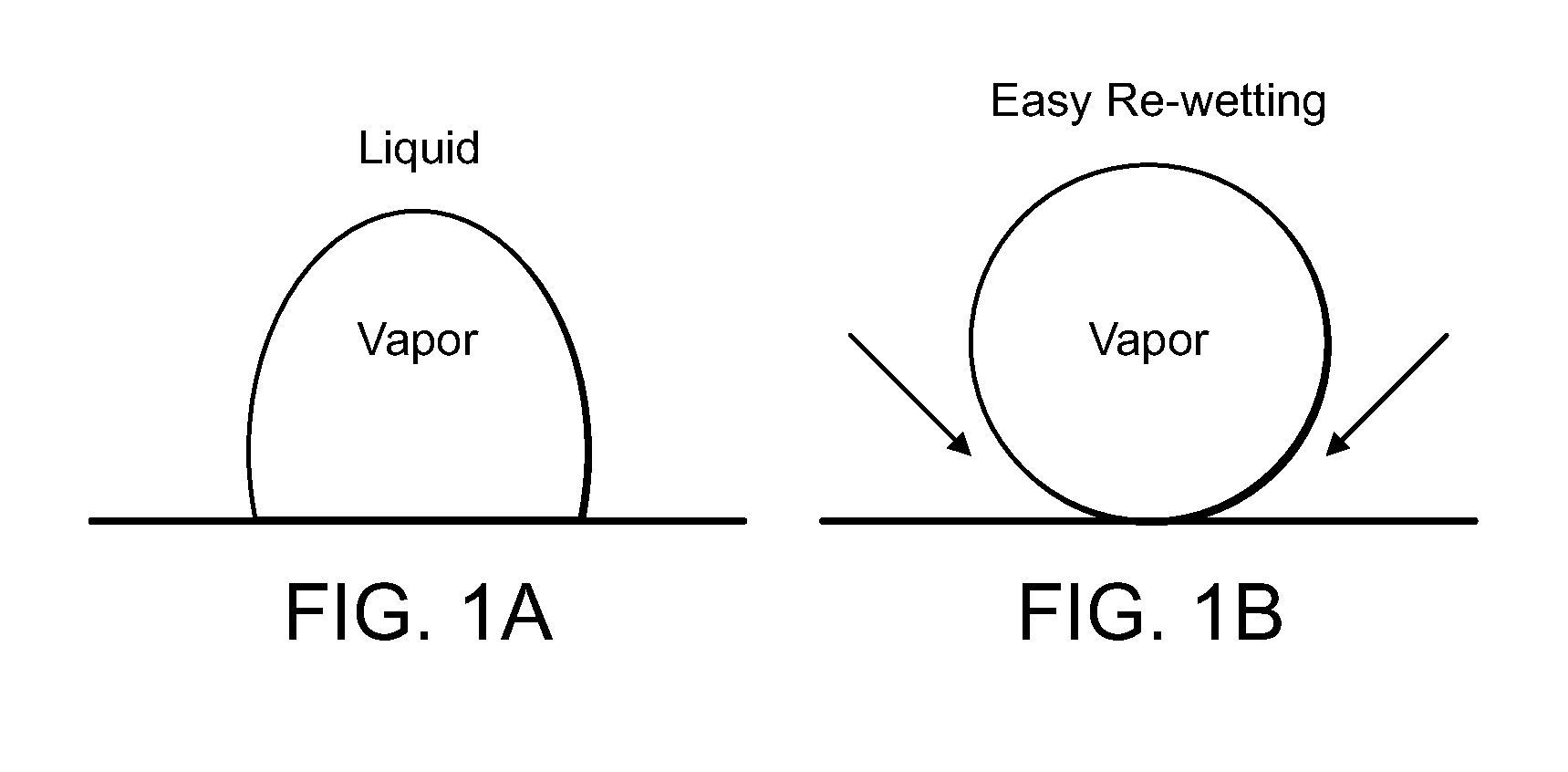

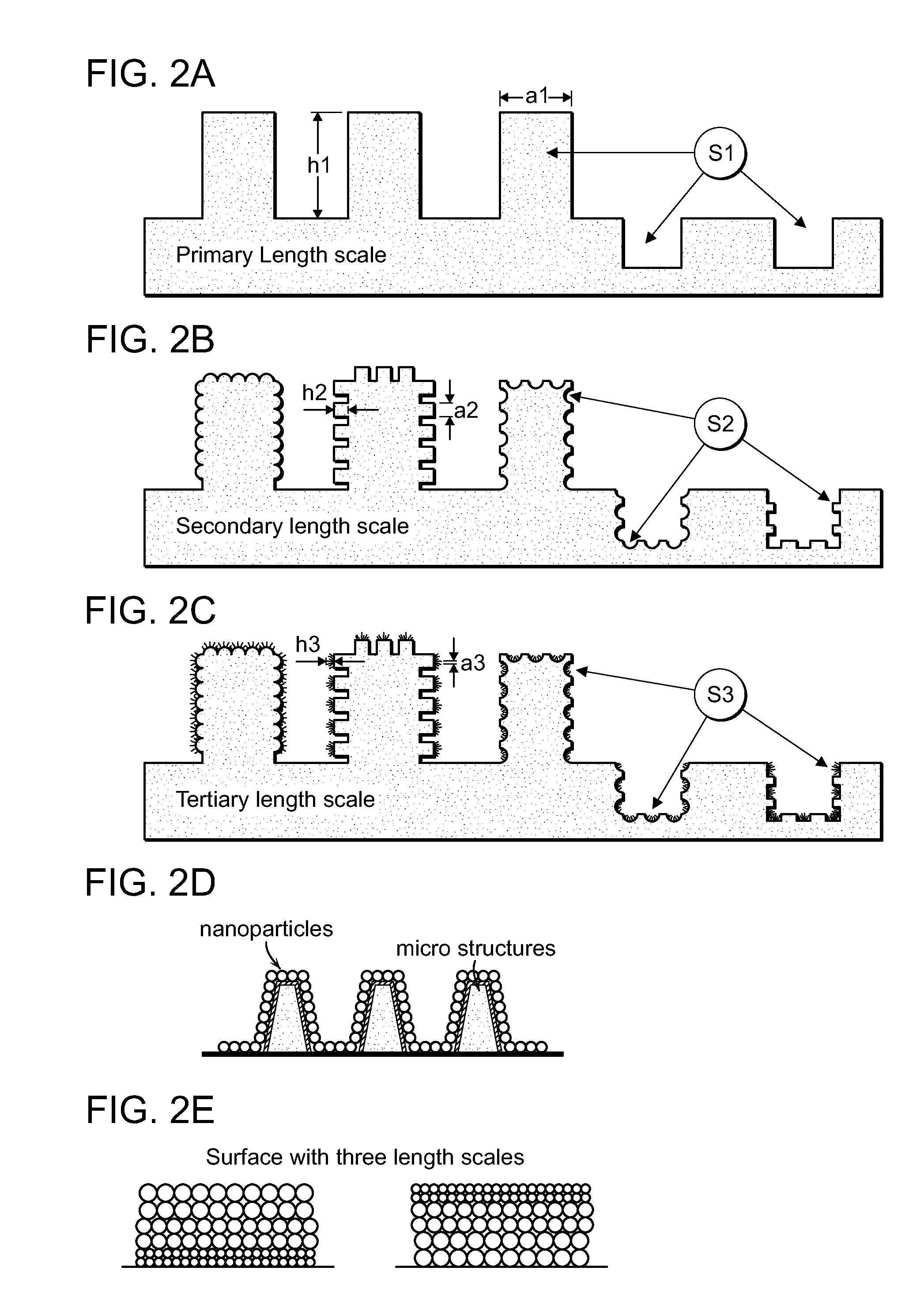

Superwetting surfaces for diminishing leidenfrost effect, methods of making and devices incorporating the same

ActiveUS20120051489A1Increasing Leidenfrost temperatureMaximize Leidenfrost temperatureFuel elementsNuclear energy generationEngineeringNanoscopic scale

Textured surface for increasing Leidenfrost temperature. The texture comprises of surface features over multiple length scales—from micro to nanoscale—wherein the features at each length scale have a size, aspect ratio, and spacing selected to increase the Leidenfrost temperature. The structure includes an array of microscale structures disposed on the surface, the structure having size, aspect ratio and spacing selected to increase Leidenfrost temperature. The microscale structures may also include nanoscale structures on their surface to create a hierarchical structure. The structures result in an increased Leidenfrost temperature.

Owner:MASSACHUSETTS INST OF TECH

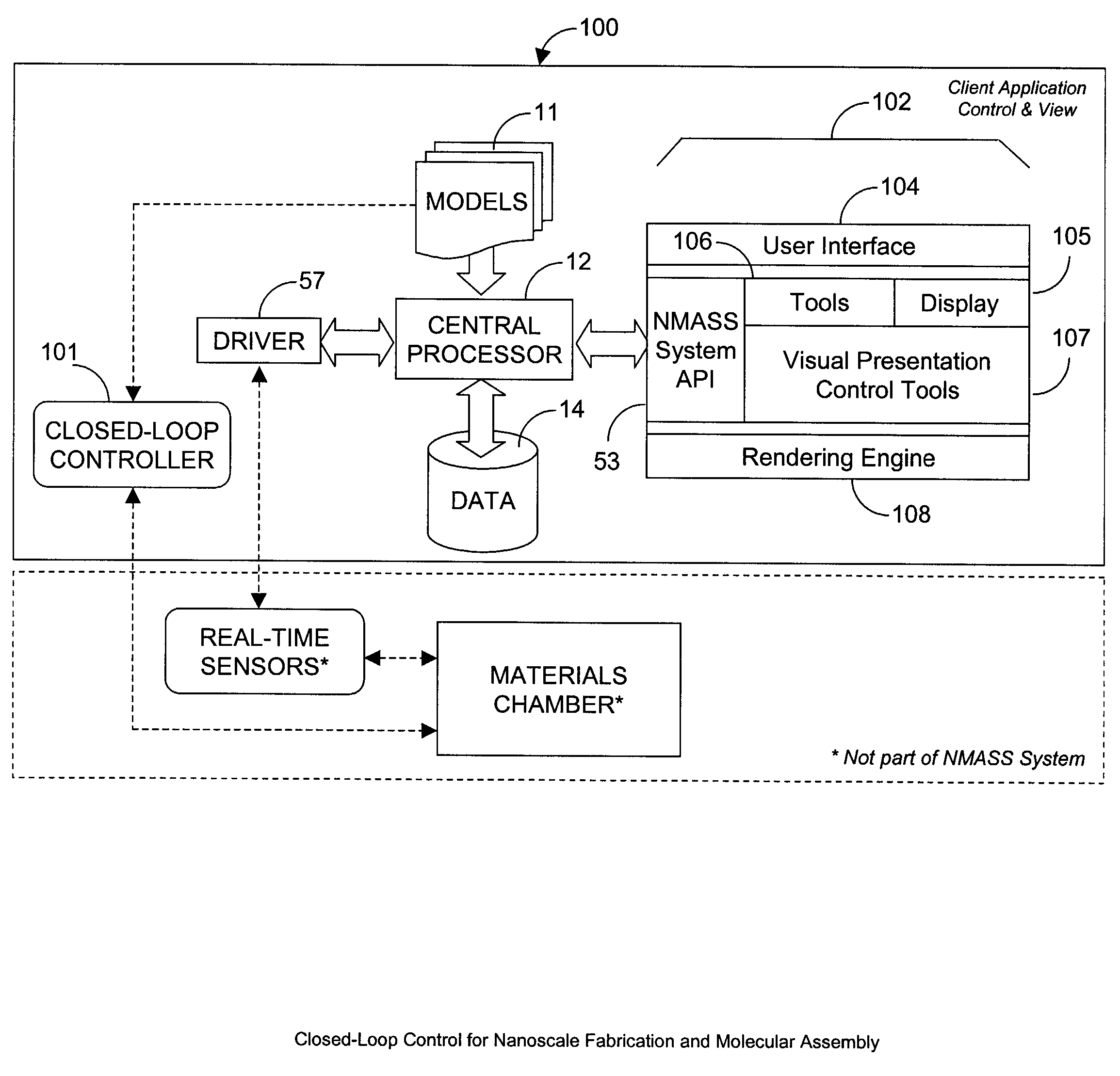

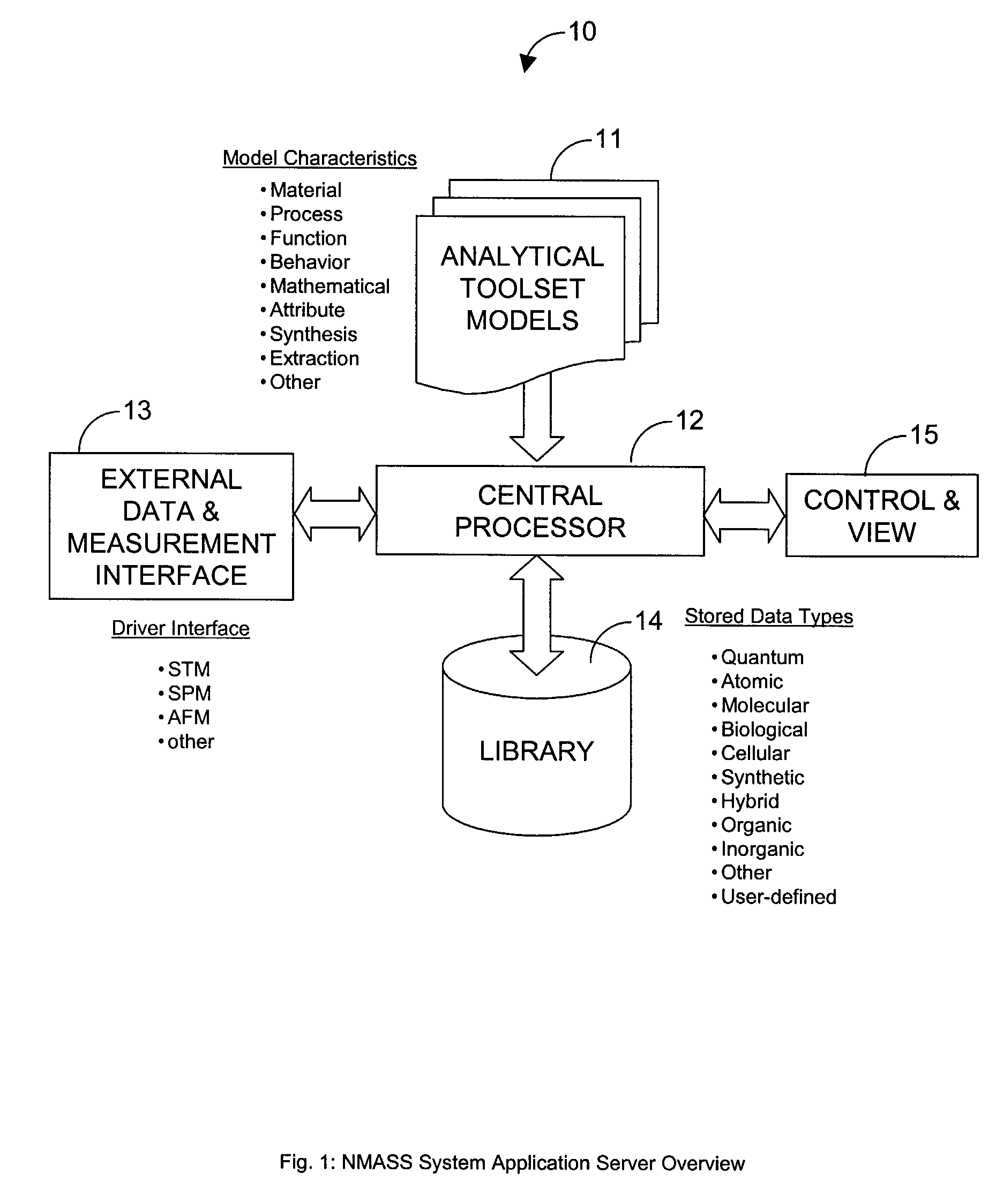

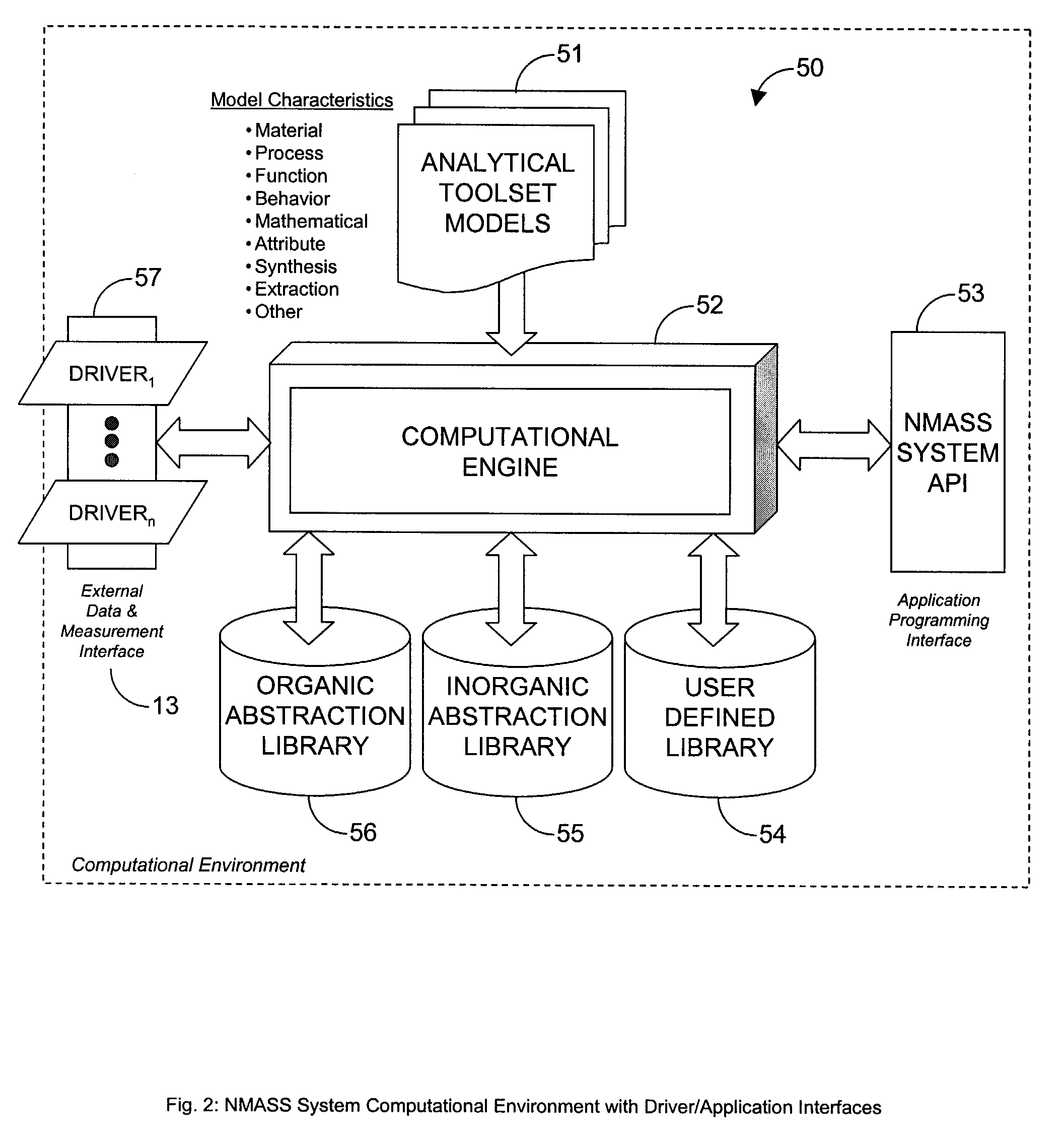

System, Method, and Product for Nanoscale Modeling, Analysis, Simulation, and Synthesis (NMASS)

InactiveUS20030139907A1Chemical property predictionSimulator controlPerformance functionLinear control

Abstract of Disclosure A computer-based system is described that provides users with the ability to develop high-fidelity digital quantitative representations of physical and chemical phenomena, and to employ an optimization-based approach to control associated physiochemical processes. The system includes a computational environment, intuitive user interface(s), integrated software libraries, analytical tools, and visualization / rendering engine that together provide an integrated framework for nanoscale modeling, analysis, simulation, and synthesis. Additionally, the system includes an optimal linear control synthesis methodology that incorporates a first order dynamic mathematical representation (of the conceptual molecular system) suitable for applying various pragmatic control system techniques including optimization of structured singular values, linear quadratic performance functions, Lyapunov criteria, or similar, for the purposes of nanoscale fabrication and molecular assembly.

Owner:MCCARTHY ROBERT J

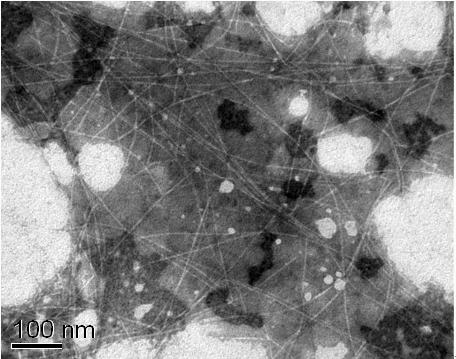

Preparation method of homogenized fine nano-cellulose fiber

InactiveCN101851295ALow degree of mutual aggregationEvenly dispersedArtificial filaments from cellulose solutionsStrong acidsCatalytic oxidation

The invention relates to a preparation method of a homogenized fine nano-cellulose fiber. The preparation method can solve the problems of uniform diameter distributor of biomass nano-cellulose prepared by the existing strong acid hydrolysis method and the high-strength mechanical shearing method, easy gathering among the nano-fiber and a narrow range of applications of the TEMPO catalytic oxidation method. The preparation method comprises the following steps: 1) extracting biomass fiber with benzyl alcohol solution; 2) carrying out treatment by using acidified sodium chlorite; 3) carrying out gradient treatment with alkaline liquor; 4) using TEMPO, sodium bromide and sodium hypochlorite for catalytic oxidation treatment; 5) using sodium chlorite for treatment; and 6) carrying out nano-scale processing by using the long-term stirring method, the ultrasonic method or the high-pressure homogenization method, drying, and then obtaining the homogenized fine nano-cellulose fiber. The fiber has the uniform diameter distribution, the diameter is 3-5nm, the length-diameter ratio is not less than 500, the fiber is mutually interwoven into a mesh snarling structure, and the method is applicable to preparing the nano-cellulose fiber by using wood pulp, paper-making pulp, wood, bamboo and crop straw.

Owner:NORTHEAST FORESTRY UNIVERSITY

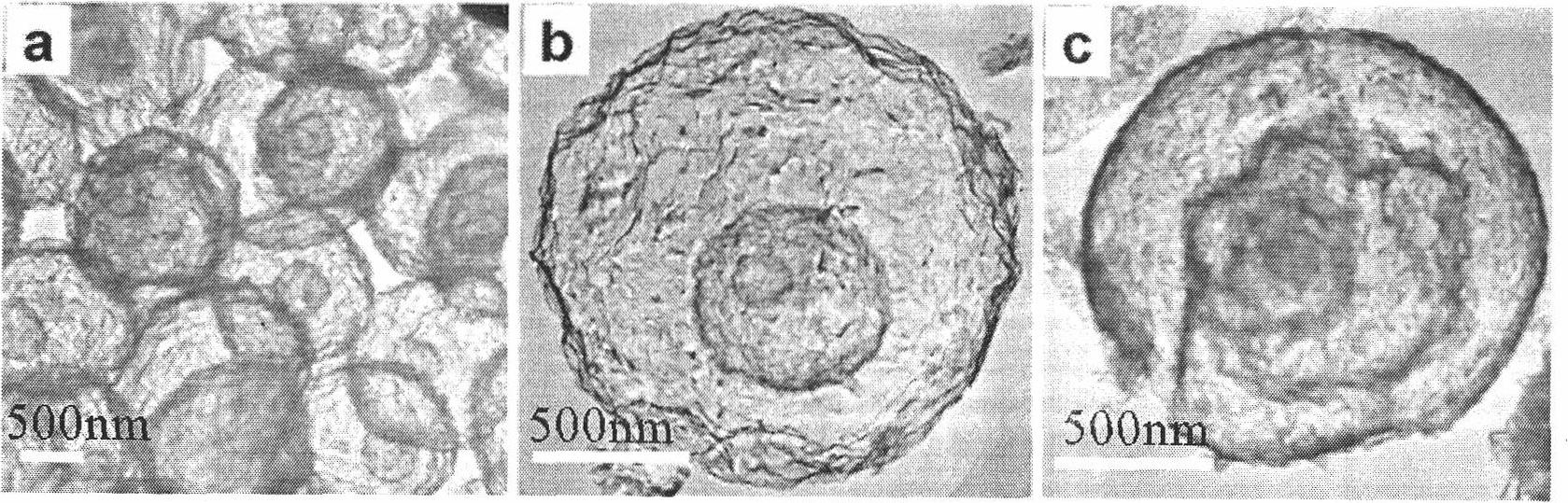

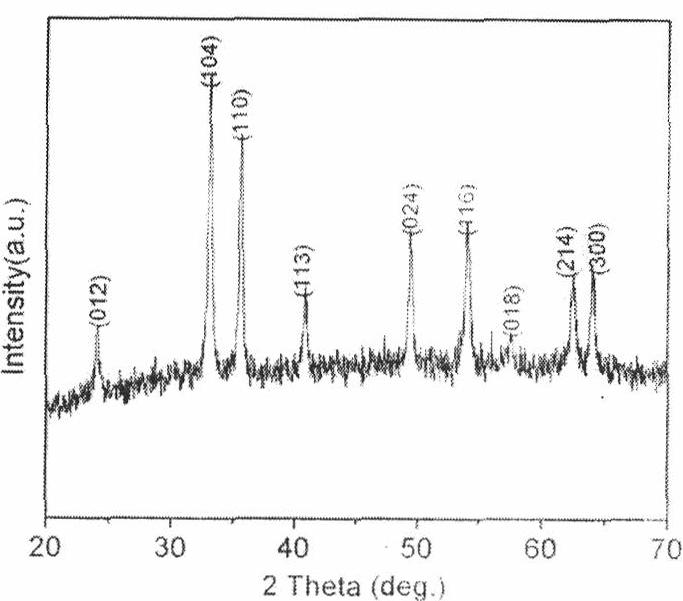

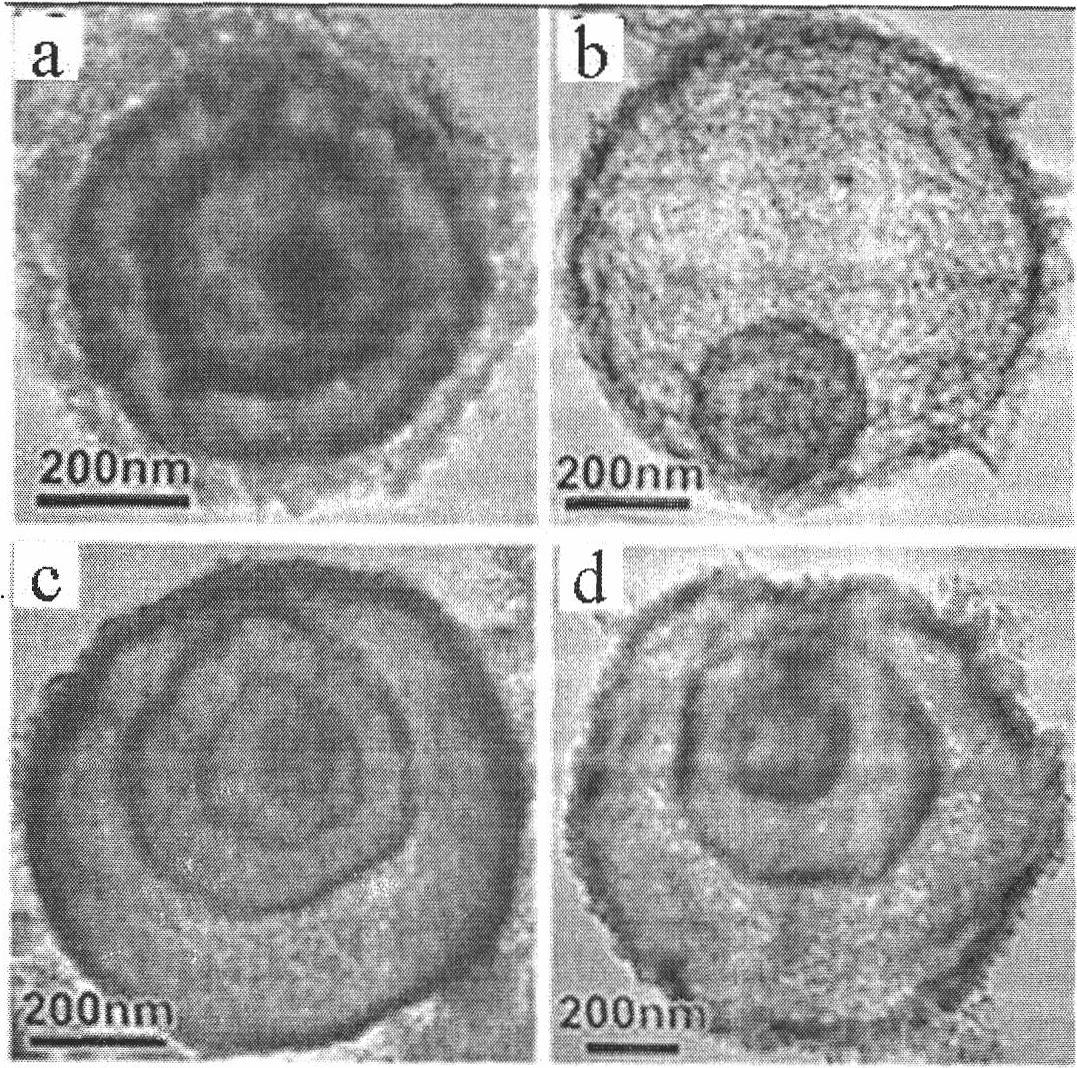

Multi-shell-layer metal oxide hollow ball and preparation method thereof

ActiveCN102464304AHigh specific surface areaSimple processOxide/hydroxide preparationZinc oxides/hydroxidesControllabilityNanoscopic scale

The invention provides a multi-shell-layer metal oxide hollow ball and a preparation method thereof. A hydrothermal method is used for preparing a carbon ball template; metal salts are dissolved in carbon ball suspension liquid, and the gradient distribution, the depth and the number of metal salts entering carbon balls are controlled through regulating adsorption conditions such as metal salt concentration, solution pH value, soaking temperature and time and the like; and the heat treatment is carried out on the carbon balls adsorbing metal ions, and the multi-shell-layer metal oxide hollow ball can be obtained. The shell-layer of the hollow ball prepared by the method is formed by accumulating nanometer crystal particles of metal oxides, the shell layer number can be regulated and changed from two to four, and both the size of the hollow ball and the thickness of the shell layers are controllable. The method provided by the invention is simple and is easy to implement, the controllability is high, the pollution is little, the cost is low, and in addition, the general applicability is realized. The prepared product has a hollow structure and the shell layers with the thickness inthe nanometer level, simultaneously, the internal space can be effectively utilized through the multilayer structure, and the multi-shell-layer metal oxide hollow ball is applied to gas sensitivity and photocatalysis and has the more excellent performance through being compared with the traditional nanometer material and a single-layer hollow ball.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

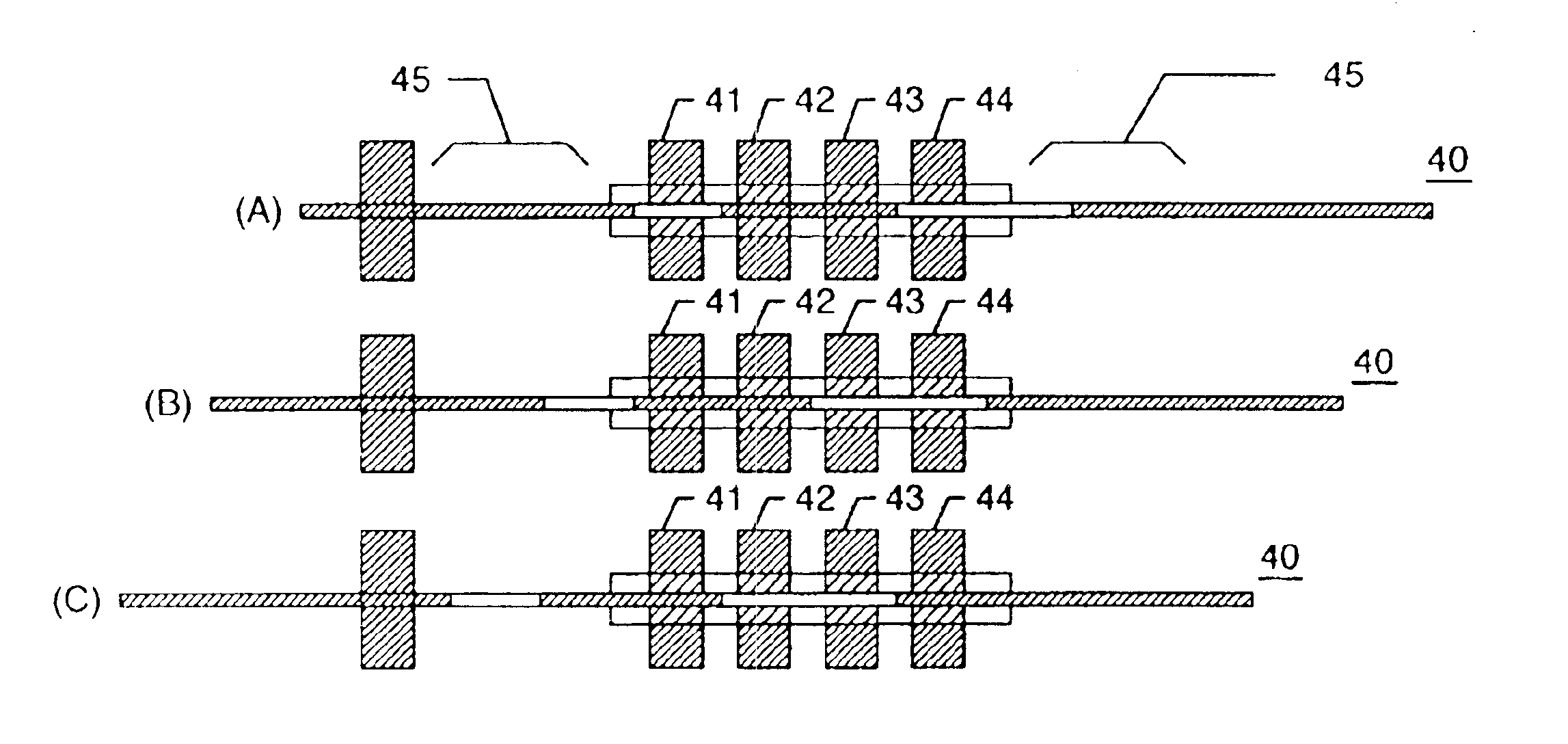

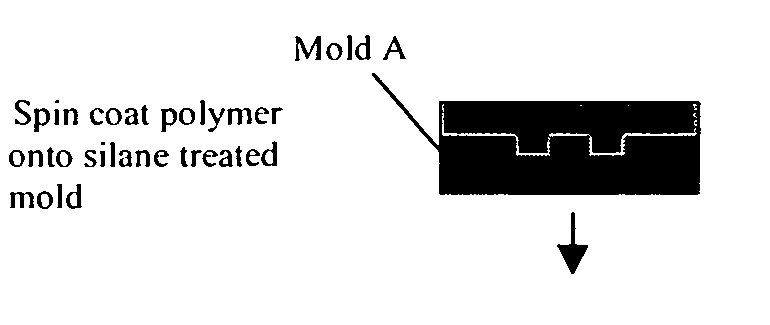

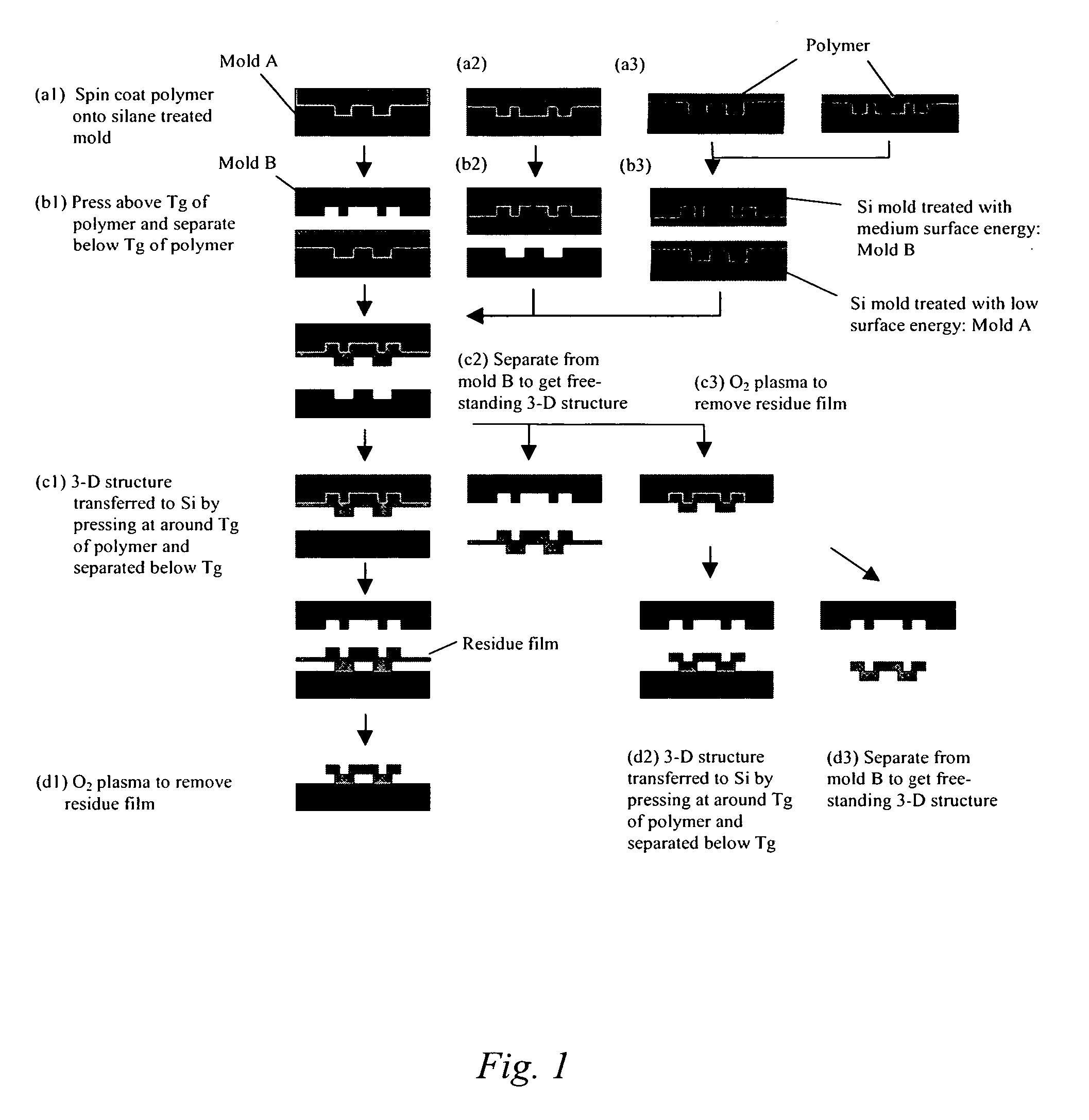

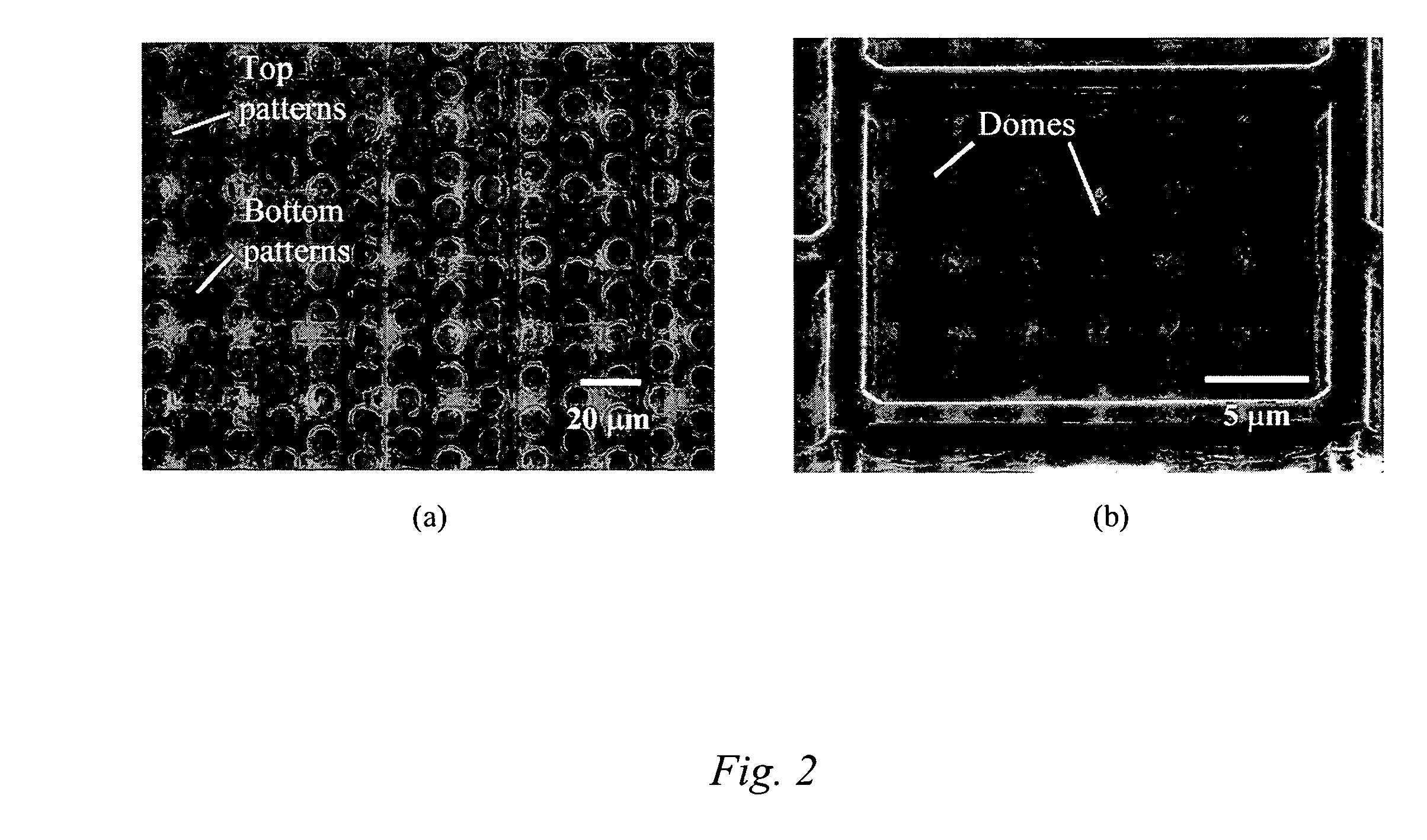

Imprinting of supported and free-standing 3-D micro- or nano-structures

InactiveUS20050258570A1Easy to separateRemove heatNanostructure manufactureLayered productsVitrificationMetallic materials

The present invention is directed to micro- and nano-scale imprinting methods and the use of such methods to fabricate supported and / or free-standing 3-D micro- and / or nano-structures of polymeric, ceramic, and / or metallic materials. In some embodiments, a duo-mold approach is employed in the fabrication of these structures. In such methods, surface treatments are employed to impart differential surface energies to different molds and / or different parts of the mold(s). Such surface treatments permit the formation of three-dimensional (3-D) structures through imprinting and the transfer of such structures to a substrate. In some or other embodiments, such surface treatments and variation in glass transition temperature of the polymers used can facilitate separation of the 3-D structures from the molds to form free-standing micro- and / or nano-structures individually and / or in a film. In some or other embodiments, a “latch-on” assembly technique is utilized to form supported and / or free-standing stacked micro- and / or nano-structures that enable the assembly of polymers without a glass transition temperature and eliminate the heating required to assemble thermoplastic polymers.

Owner:AGENCY FOR SCI TECH & RES +1

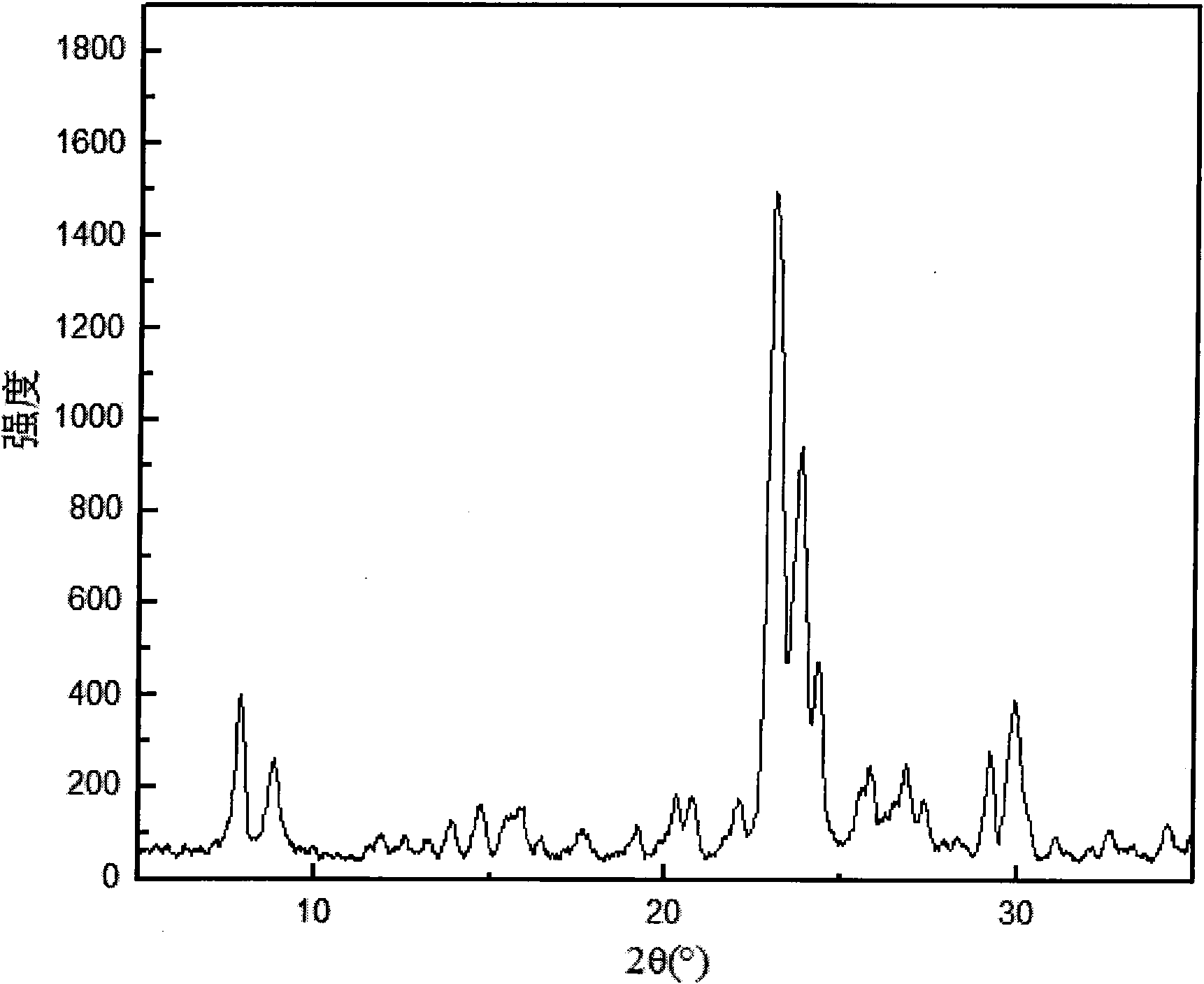

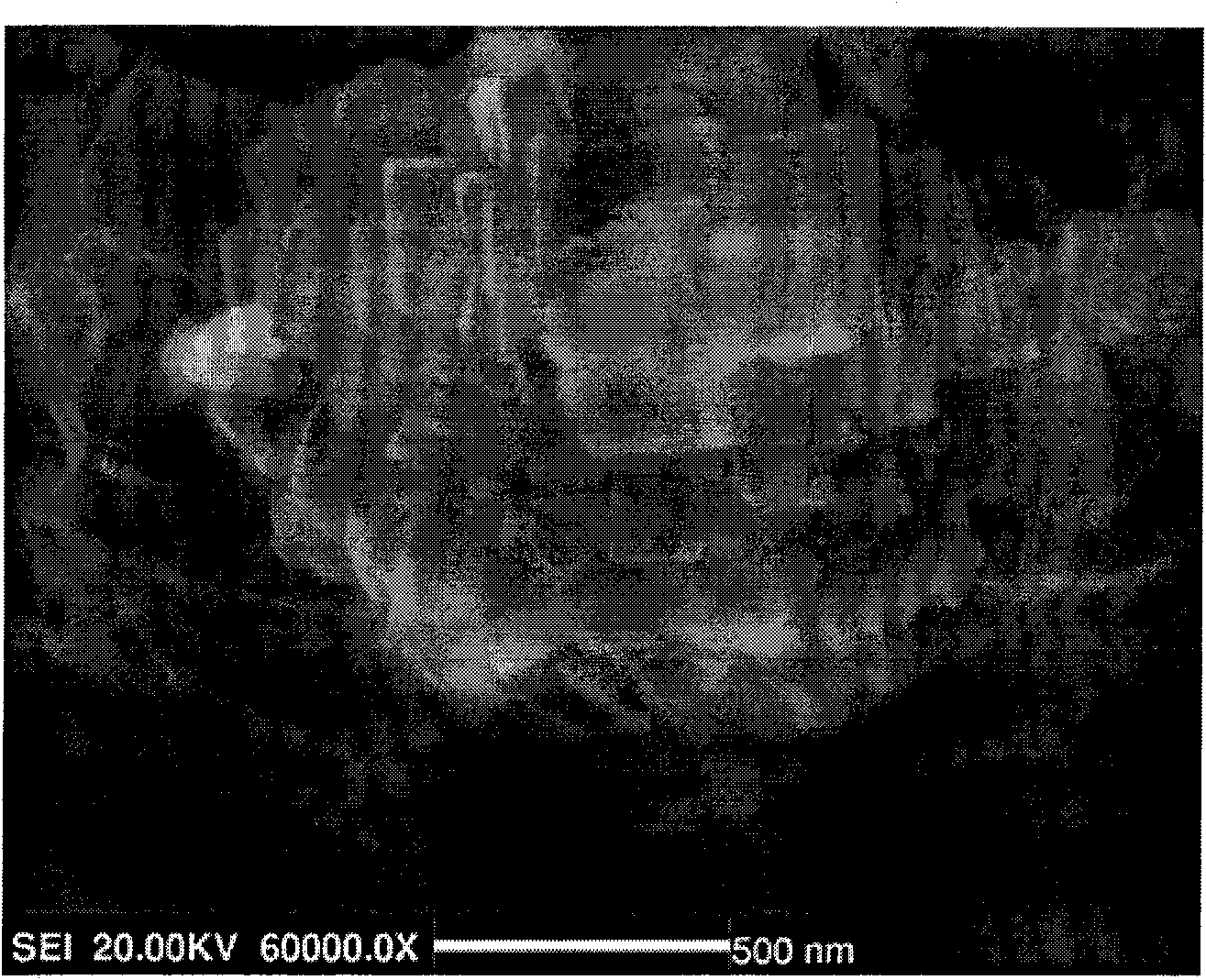

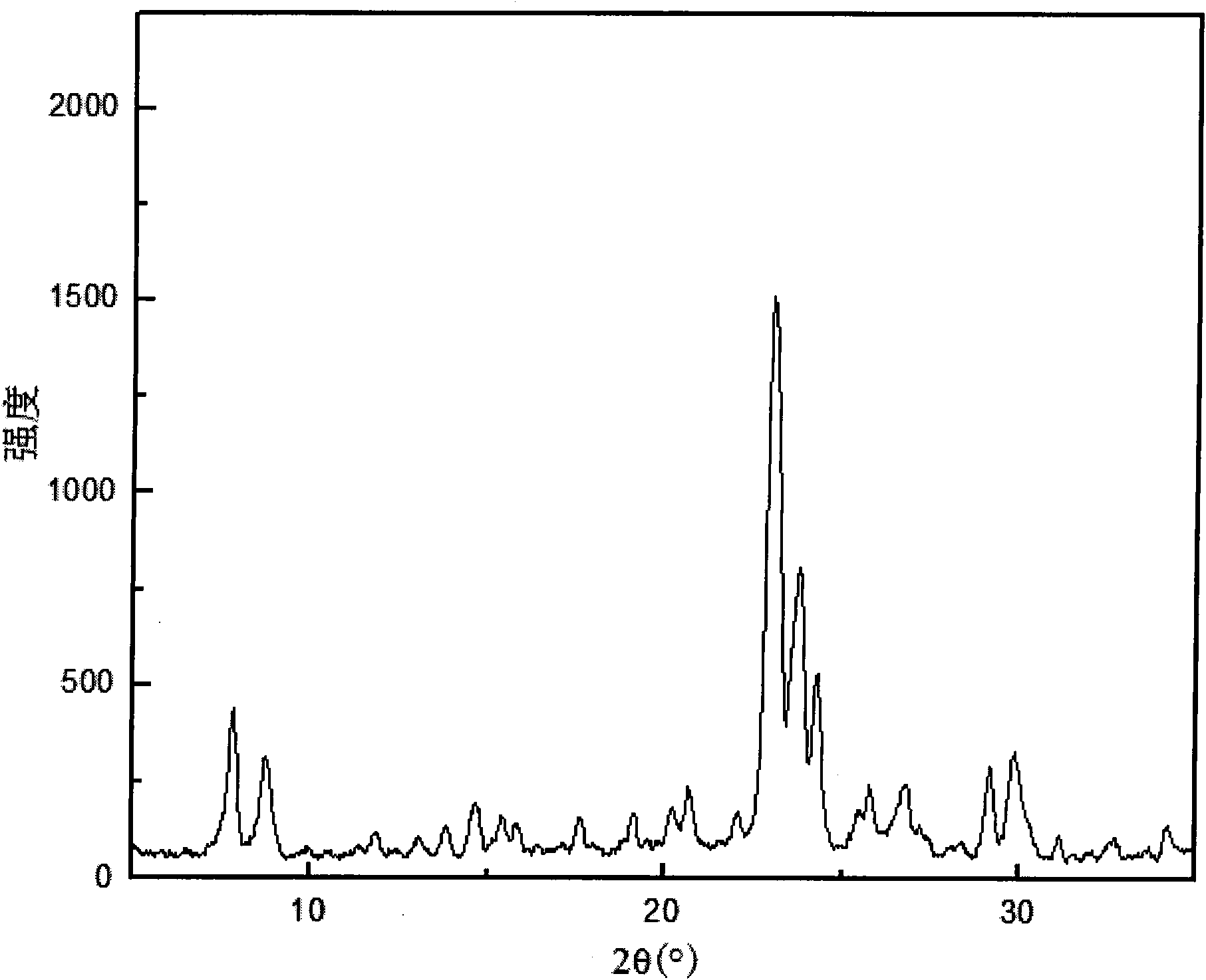

Preparation method of nano-ZSM-5 molecular sieve

InactiveCN101643219ASolve the costSolve pollutionPentasil aluminosilicate zeoliteRoom temperatureNanoscopic scale

The invention relates to a preparation method of a nano-ZSM-5 molecular sieve, which belongs to the field of preparation of zeolite molecular sieve catalysts. The preparation method can solve the problem that the existing synthesis technology has the defects of easy emergence of mixed crystal phase, high cost, environmental pollution and easy loss of features of nanomaterials. The method is as follows: adding pre-crystallized crystal seeds into a gel system of the template-free synthetic nano-ZSM-5 molecular sieve, carrying out crystallization for 24 hours at the temperature of 160-180 DEG C,cooling to room temperature, carrying out centrifugal filtration on products, washing, drying and baking. The prepared nano-ZSM-5 molecular sieve is highly concentrated nanoscale crystals without themixed crystal phase; and the method has the advantages of low cost and environmental protection.

Owner:HEILONGJIANG UNIV

Porous and non-porous nanostructures

ActiveUS20110266521A1Material nanotechnologyNanoinformaticsHigh resistivity siliconMicroscopic scale

Disclosed are a variety of porous and non-porous wire-like structures of microscopic and nanoscopic scale. For instance, disclosed are structures that comprise a porous object that comprises: (i) a first region; and (ii) a second region adjacent to the first region along an axis of the object, where the first region has at least one porous property different from that of the second region. Also disclosed are structures that include: (i) a high resistivity silicon; and (ii) a cross-section that is substantially perpendicular to an axis of the object. Also disclosed are methods of making and using such structures. For instance, the present invention provides methods of making a porous object by: (i) obtaining an etchable substrate; (ii) forming on a surface of the substrate a patterned porosification assisting metal layer that has at least one opening; and (iii) subsequently exposing the substrate to a first etching solution and a second etching solution to form respectively a first region and a second region of a porous object.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

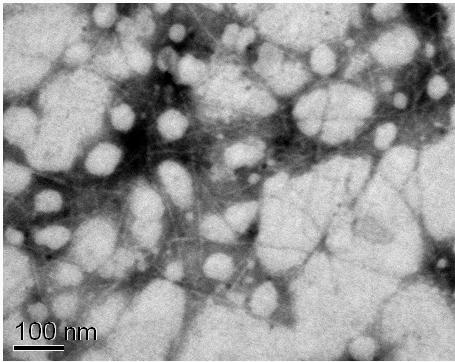

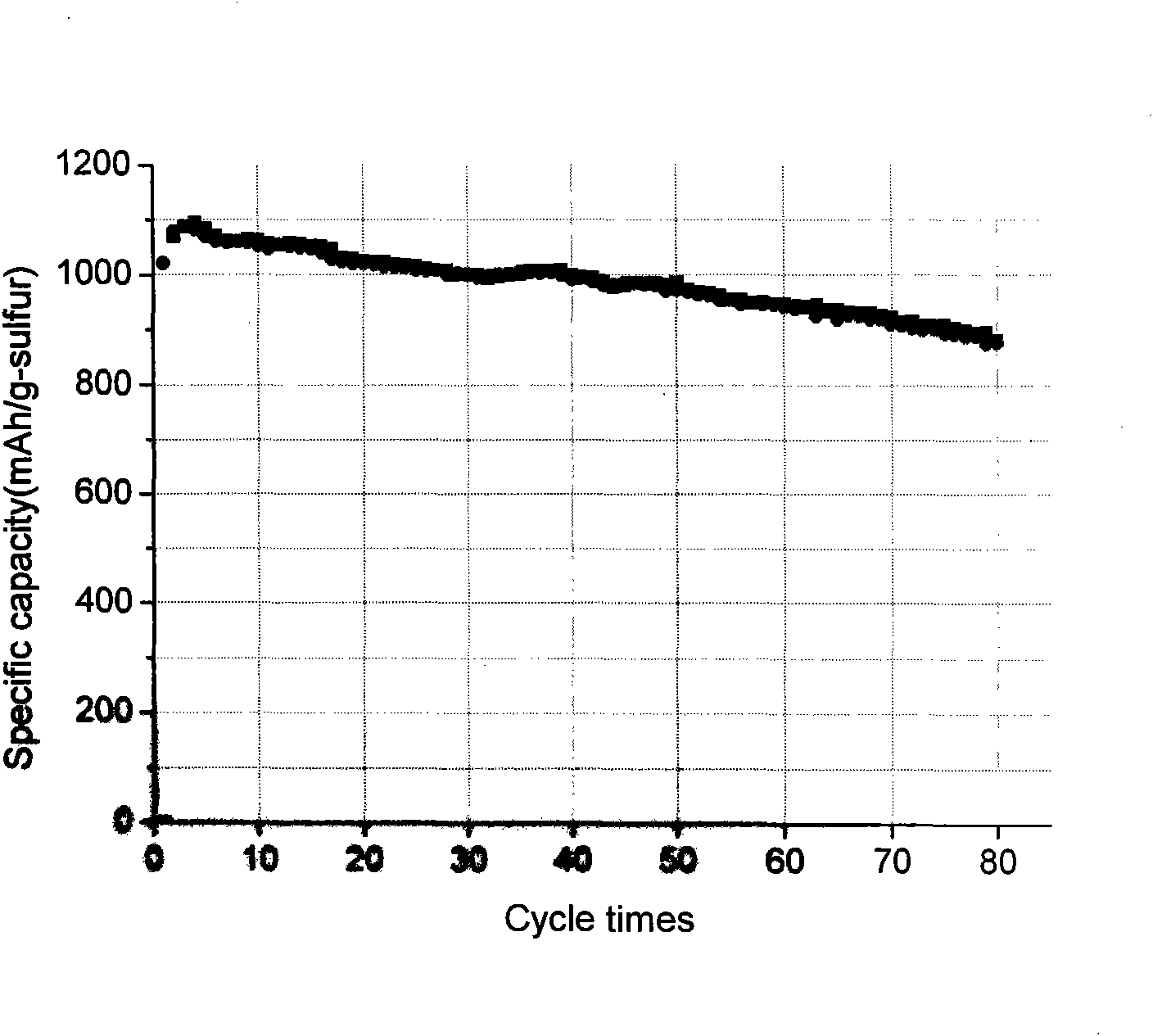

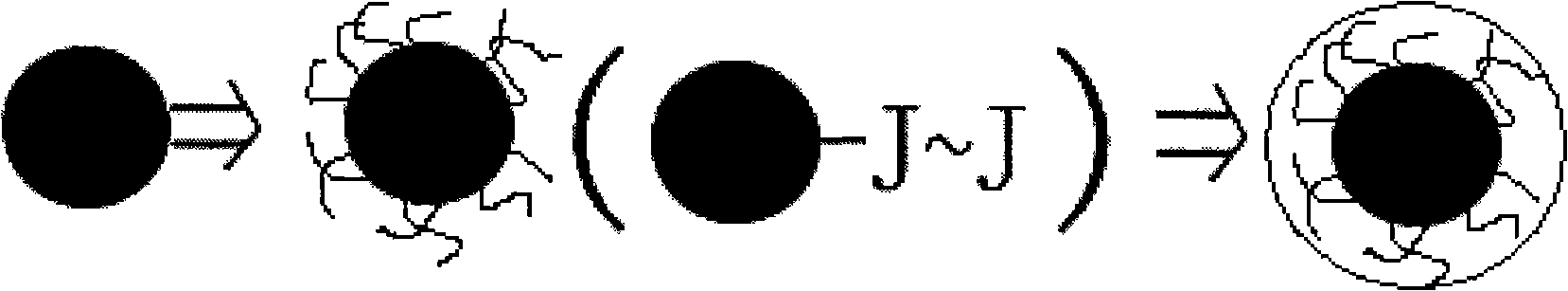

Nano carbon sulfur composite material with network structure and preparation method of nano carbon composite material

InactiveCN102142554AImprove conductivityImprove electrochemical performanceMaterial nanotechnologyCell electrodesCross-linkPorosity

The invention relates to a nano carbon material with a network structure consisting of polymer chains, in particular to a nano carbon sulfur composite material with a network structure suitable to be used in a secondary lithium sulfur battery anode and a preparation method thereof. The carbon sulfur composite material is formed by adopting the following steps of: introducing functional groups onto carbon particles by adopting the electric conductivity and the porosity of a carbon material and the reaction capacity of similar condensed aromatics of the carbon material and by means of an irreversible chemical reaction; introducing the polymer chains, wherein the polymer chains are stretched, bent and cross-linked on the surfaces of the carbon particles to form a cross-linked network structure; and compounding a sulfur element or a polysulfide (m is more than 2) containing -Sm- structure into the network structure to form the nano carbon sulfur composite material with the network structure. The carbon sulfur composite material has a rich cross-linked network structure, nano-scale network pores constrain the sulfur element or the polysulfide (m is more than 2) containing the -Sm- structure in the network, and the active substances are limited in a certain region to react, so that the composite material has predominant electrochemical performance.

Owner:NO 63971 TROOPS PLA

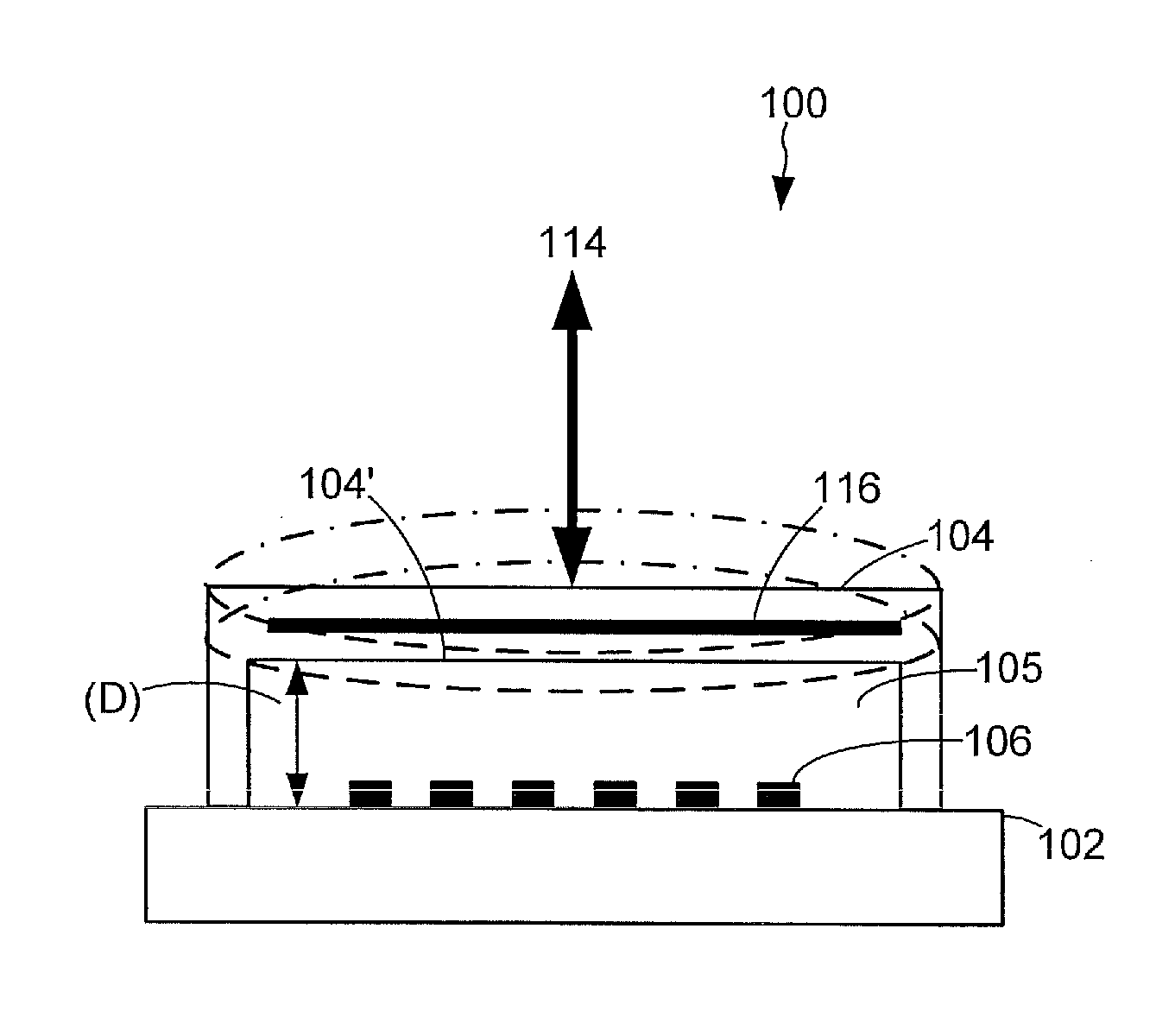

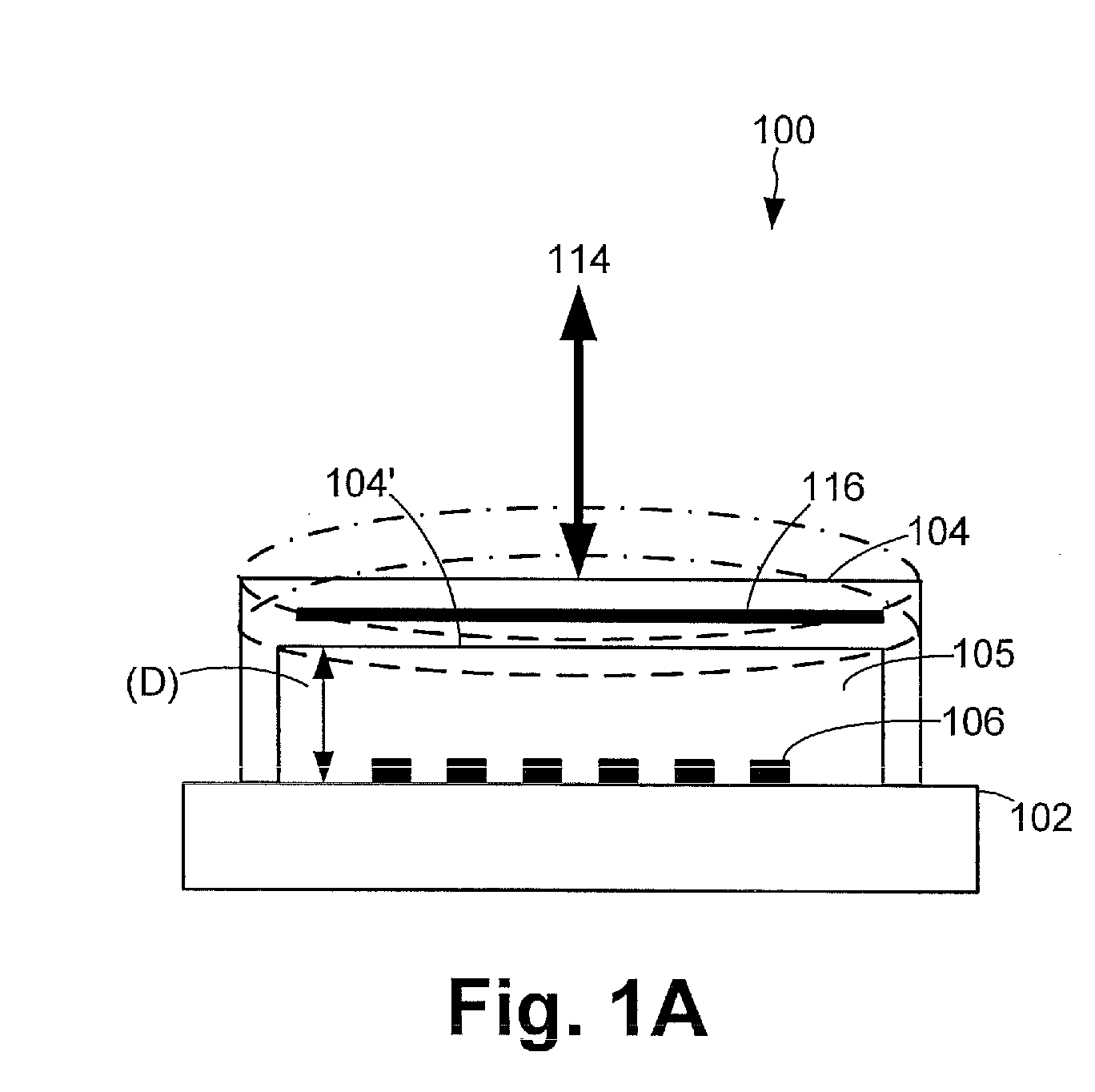

Three-dimensional nanoscale metrology using firat probe

In accordance with an embodiment of the invention, there is a force sensor for a probe based instrument. The force sensor can comprise a detection surface and a flexible mechanical structure disposed a first distance above the detection surface so as to form a gap between the flexible mechanical structure and the detection surface wherein the flexible mechanical structure is configured to deflect upon exposure to an external force, thereby changing the first distance over a selected portion of the gap, the change in distance at the selected portion orienting a probe tip of the force sensor for multi-directional measurement.

Owner:GEORGIA TECH RES CORP

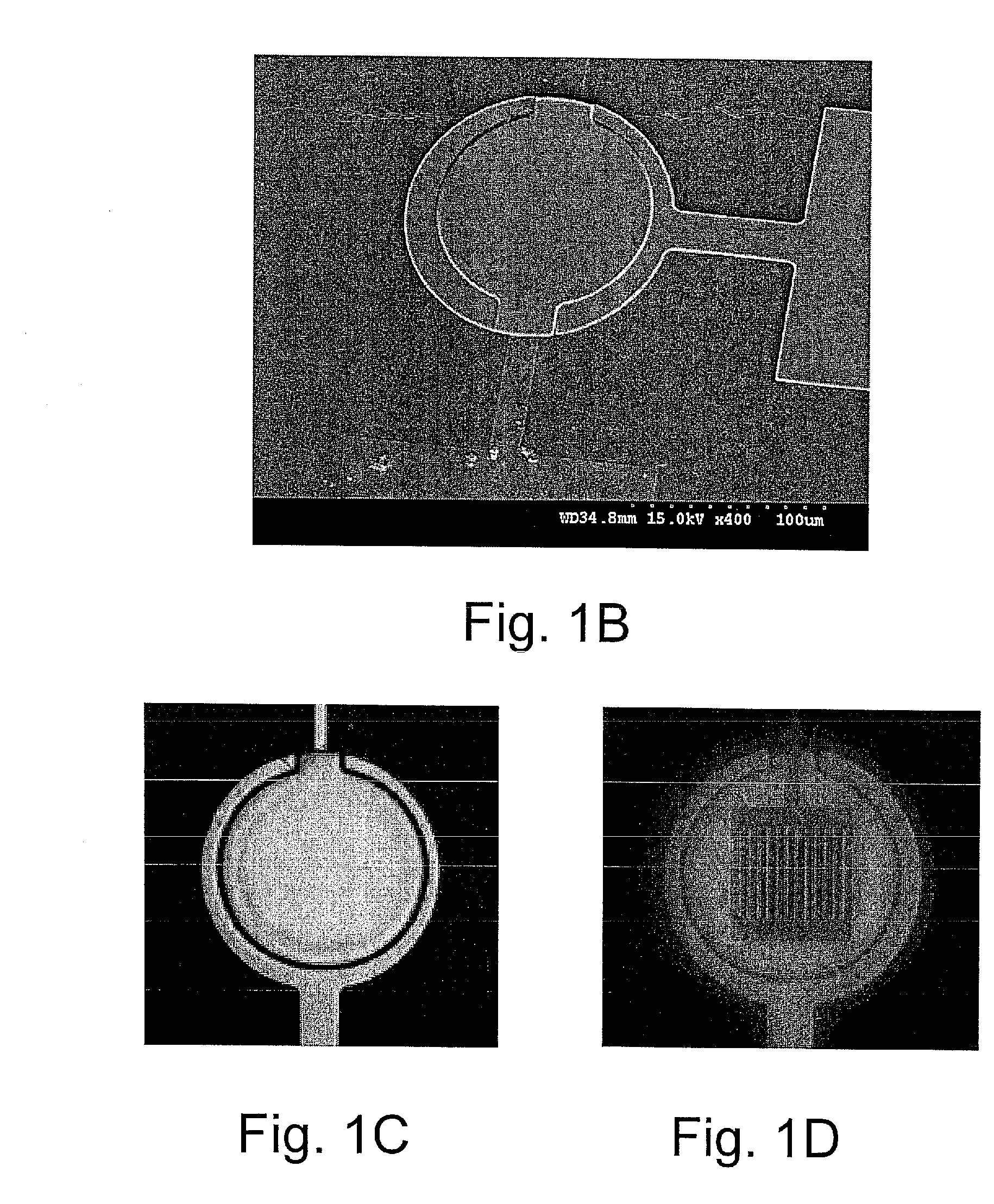

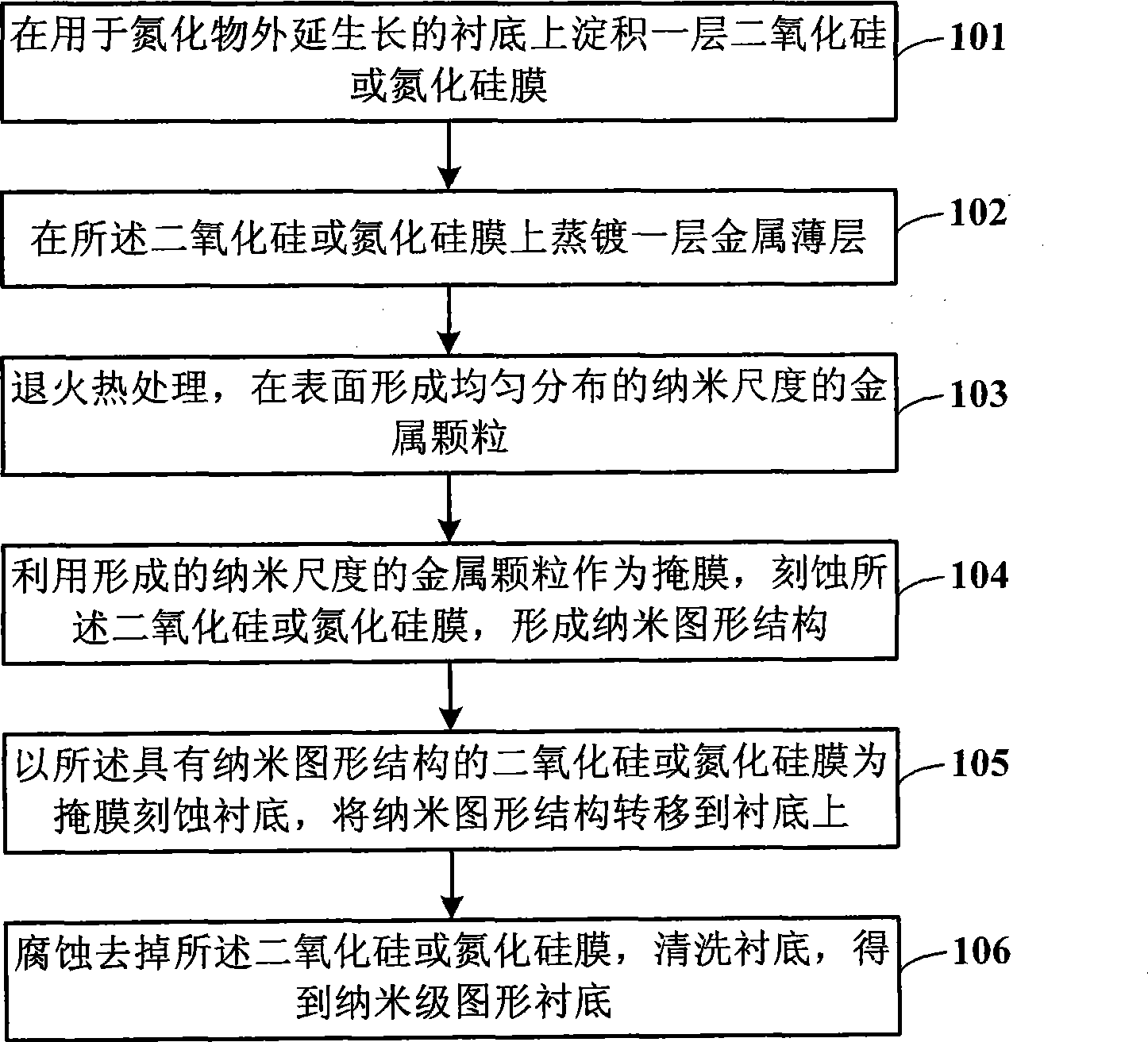

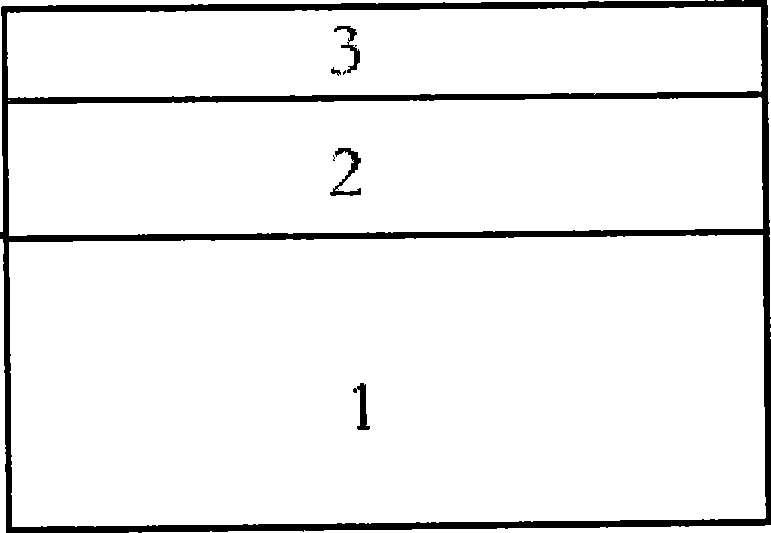

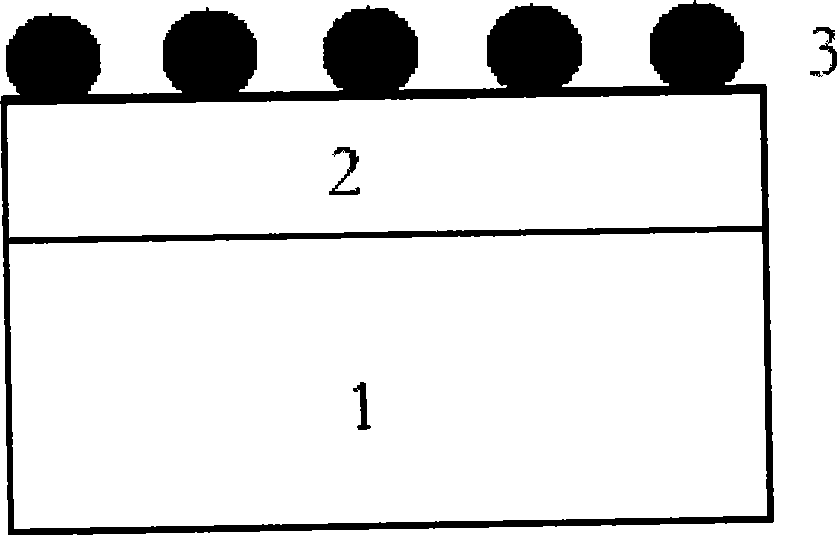

Method for preparing nano-scale pattern substrate for nitride epitaxial growth

InactiveCN101373714AReduce dislocation densityImprove crystal qualitySemiconductor/solid-state device manufacturingThin metalEpitaxial material

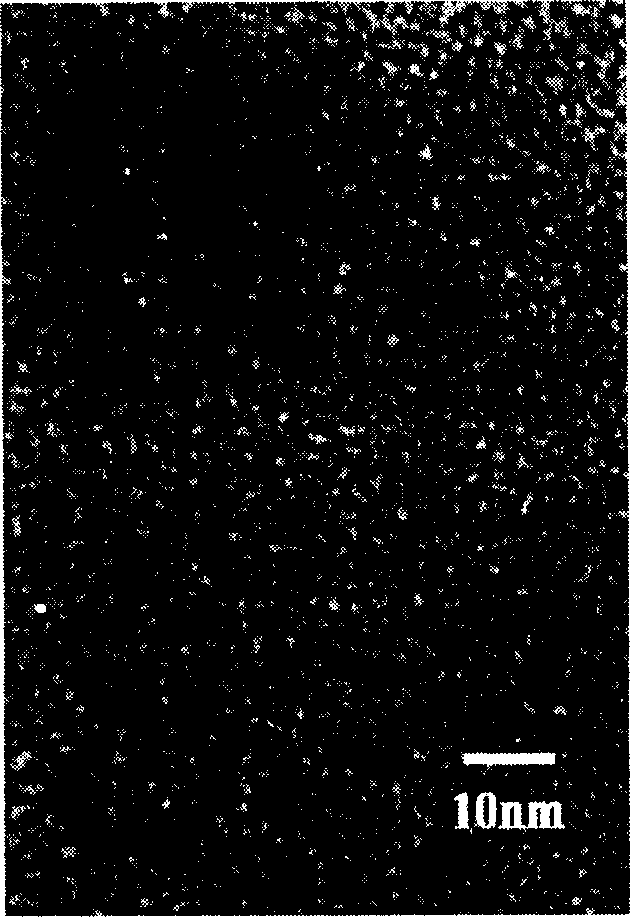

The invention relates to the semiconductor technical field and discloses a method for manufacturing a nanometer pattern substrate used for the epitaxial growth of a nitride. The method comprises the followings steps: settling a layer of silicon dioxide or silicon nitride film on a substrate used for the epitaxial growth of the nitride; the silicon dioxide or silicon nitride film is coated with a layer of thin metal layer through vapor deposition; conducting the annealing heat treatment, and forming uniformly distributed nano-scaled metal particles; utilizing the formed nano-scaled metal particles as masks to etch the silicon dioxide or silicon nitride film so as to form a nanometer pattern structure; using the silicon dioxide or silicon nitride film with the nanometer pattern structure as a mask etching substrate to transfer the nanometer pattern structure of the substrate; and etching to remove the silicon dioxide or silicon nitride film, cleaning the substrate, and obtaining the nanometer pattern substrate. The invention can reduce the dislocation density in the epitaxial layer of the nitride, improve the crystal quality of epitaxial materials, improve the performance of devices and help to realize the scaled and large area manufacture.

Owner:UNILUMIN GRP

Method for enhancing nylon selectivity laser sintering forming element by inorganic nano particles

The present invention discloses process of preparing selectively laser sintered inorganic nanometer particle reinforced nylon part. The process includes the following steps: surface organizing treatment of inorganic nanometer particle and ultrasonic treatment to disperse the inorganic nanometer particle homogeneously in mixed solvent to form inorganic nanometer particle suspension; heating the mixture of inorganic nanometer particle suspension, nylon resin and antioxidant inside a sealed container to dissolve the nylon resin in the solvent; cooling, decompression distilling to recover solvent, vacuum drying, ball milling and sieving to obtain composite nylon / inorganic nanometer particle composite material; and final selectively laser sintering to form. The selectively laser sintered inorganic nanometer particle reinforced nylon part has raised strength and high toughness.

Owner:HUAZHONG UNIV OF SCI & TECH

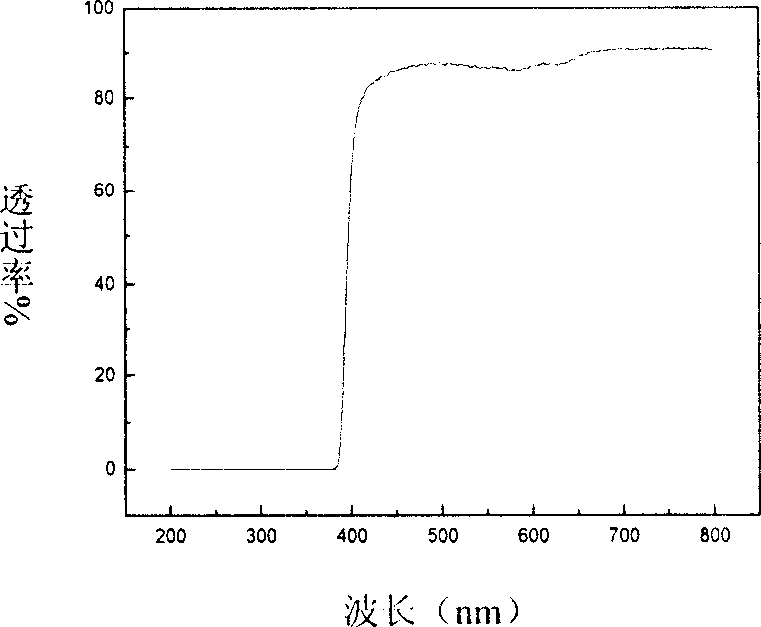

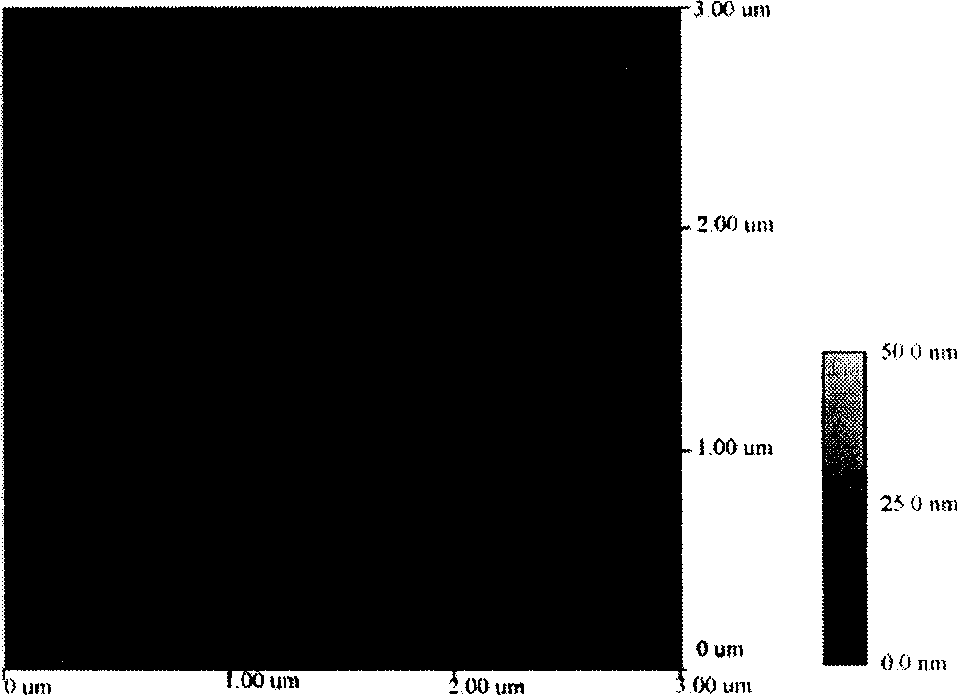

High strength organic / inorganic nano composite transparent film layer materials and method for preparing same

InactiveCN1699488AHigh refractive indexHigh transparencyCoatingsOptical elementsComposite filmRefractive index

Owner:JILIN UNIV

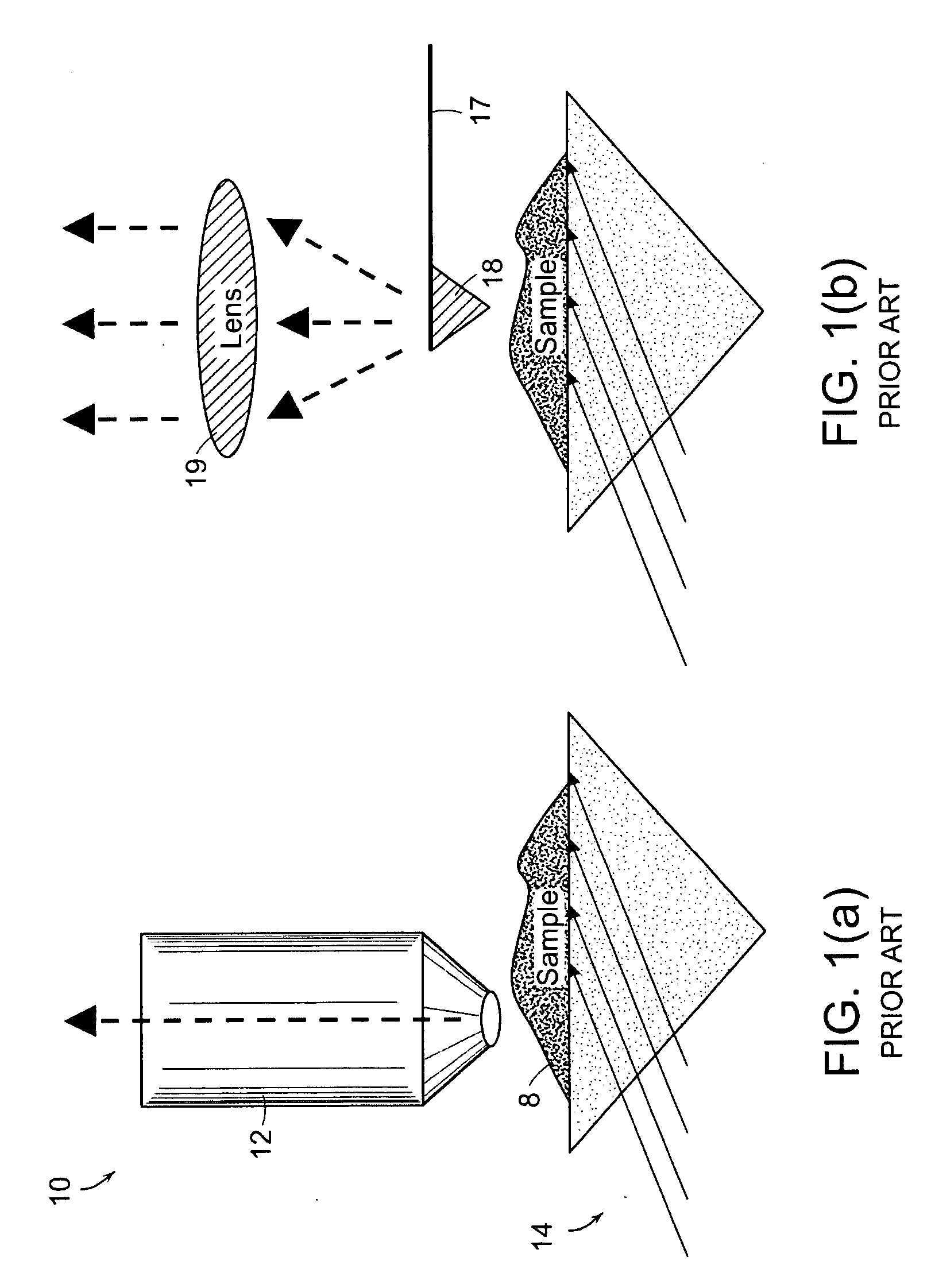

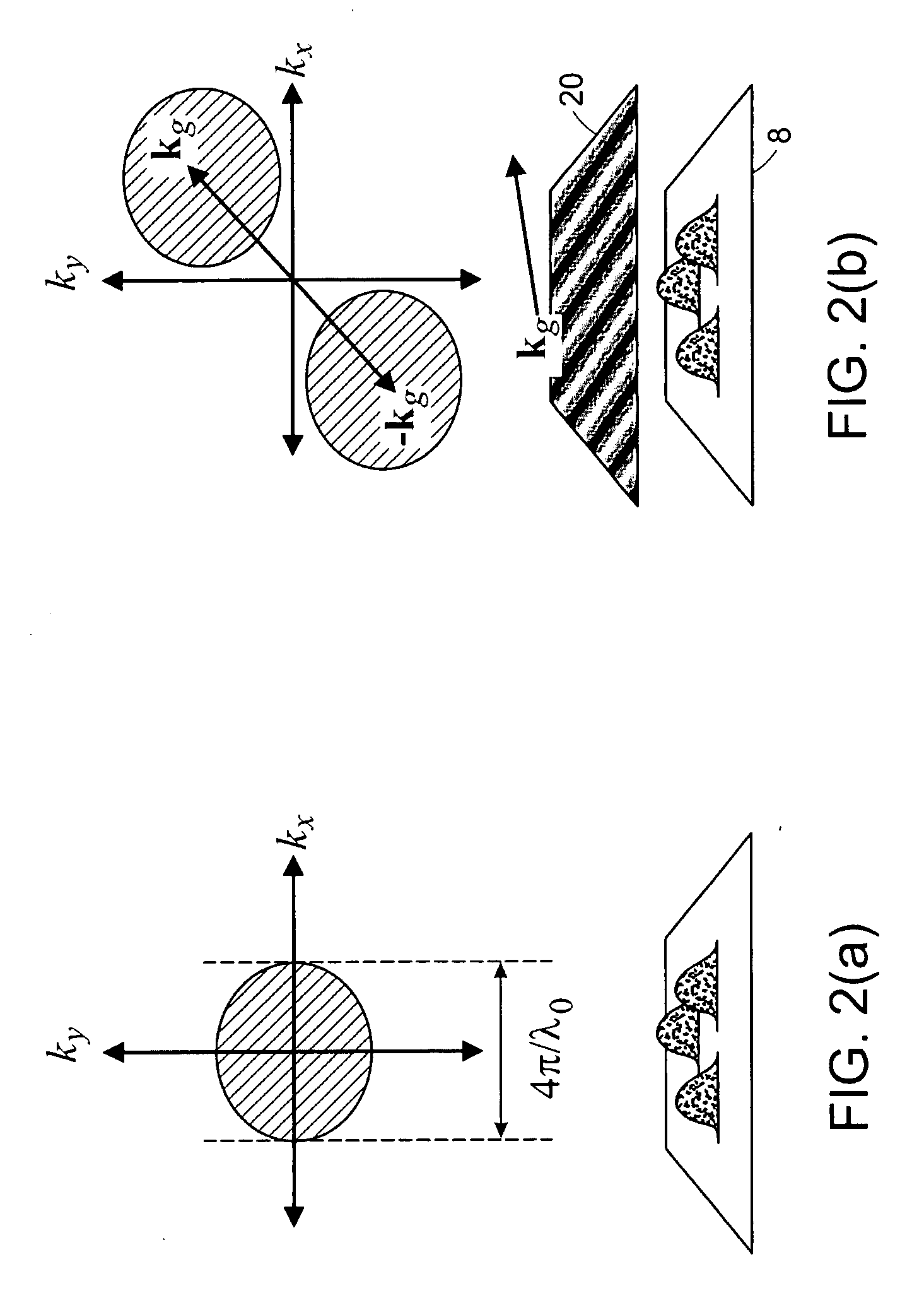

Multiplex near-field microscopy with diffractive elements

A near-field microscope using one or more diffractive elements placed in the near-field of an object to be imaged. A diffractive covers the entire object, thus signal may thereby be gathered from the entire object, and advantageously increase the signal-to-noise ratio of the resulting image, as well as greatly improve the acquisition speed. Near-field microscopy overcomes the limitation of conventional microscopy in that subwavelength and nanometer-scale features can be imaged and measured without contact.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Preparation method of colored zirconia ceramics

The invention discloses a preparation method of colored zirconia ceramics, which belongs to the field of doped ceramic material preparation. The method comprises the following steps that: stabilizer and colorant are added into the suspension of zirconia powder by the mixture ratio of 850 to 980 parts of zirconia powder, 10 to 50 parts of stabilizer and 10 to 120 parts of colorant; by controlling the pH value of the solution or using various precipitant, the stabilizer and the colorant are precipitated on the surface of the zirconia powder; the solution is filtered and dried; the obtained powder is ground, screened, formed, degreased and sintered to obtain the colored zirconia ceramics. In nano-scale, the preparation method realizes the homogeneous compounding of the stabilizer, the colorant and the nano zirconia powder, can greatly reduce the volatilization of the colorant in the high-temperature sintering phase of the zirconia ceramics, has uniform sample color and good repeatability, and the colored zirconia ceramics prepared by the method can be widely applied to arts and crafts decoration, clocks and watches, mobile phone cases, jewelry and other fields.

Owner:TSINGHUA UNIV

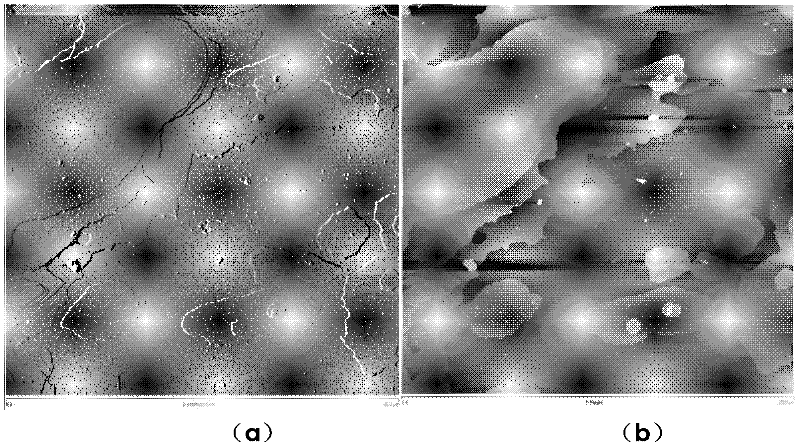

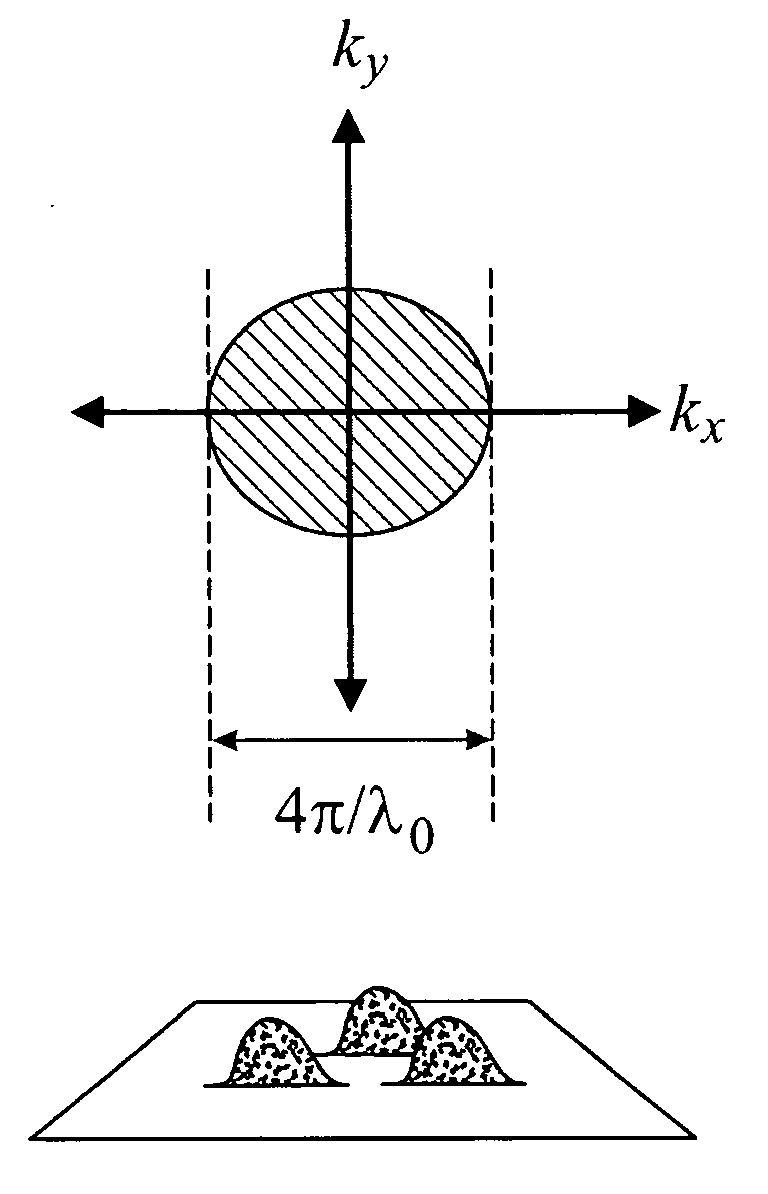

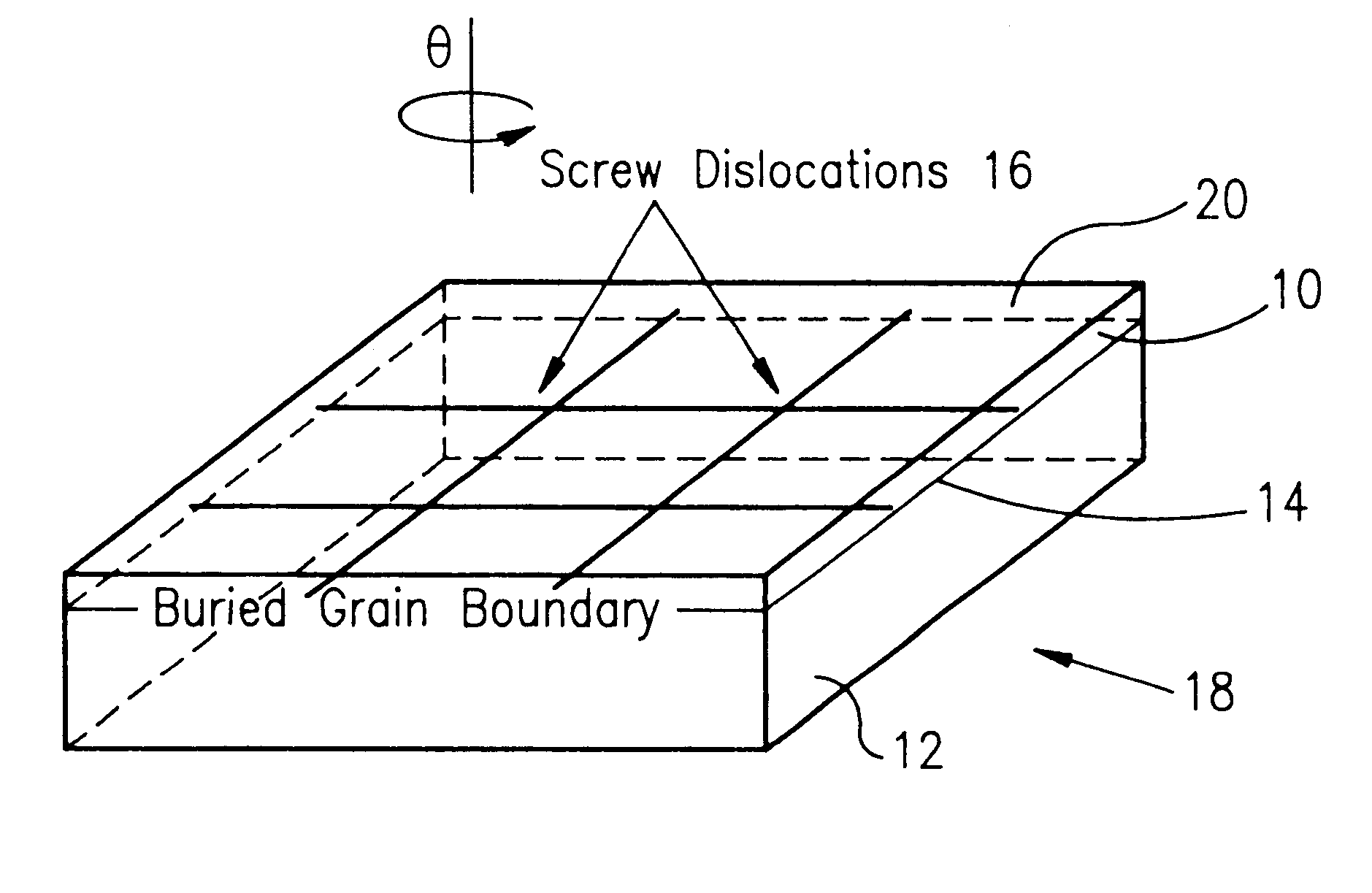

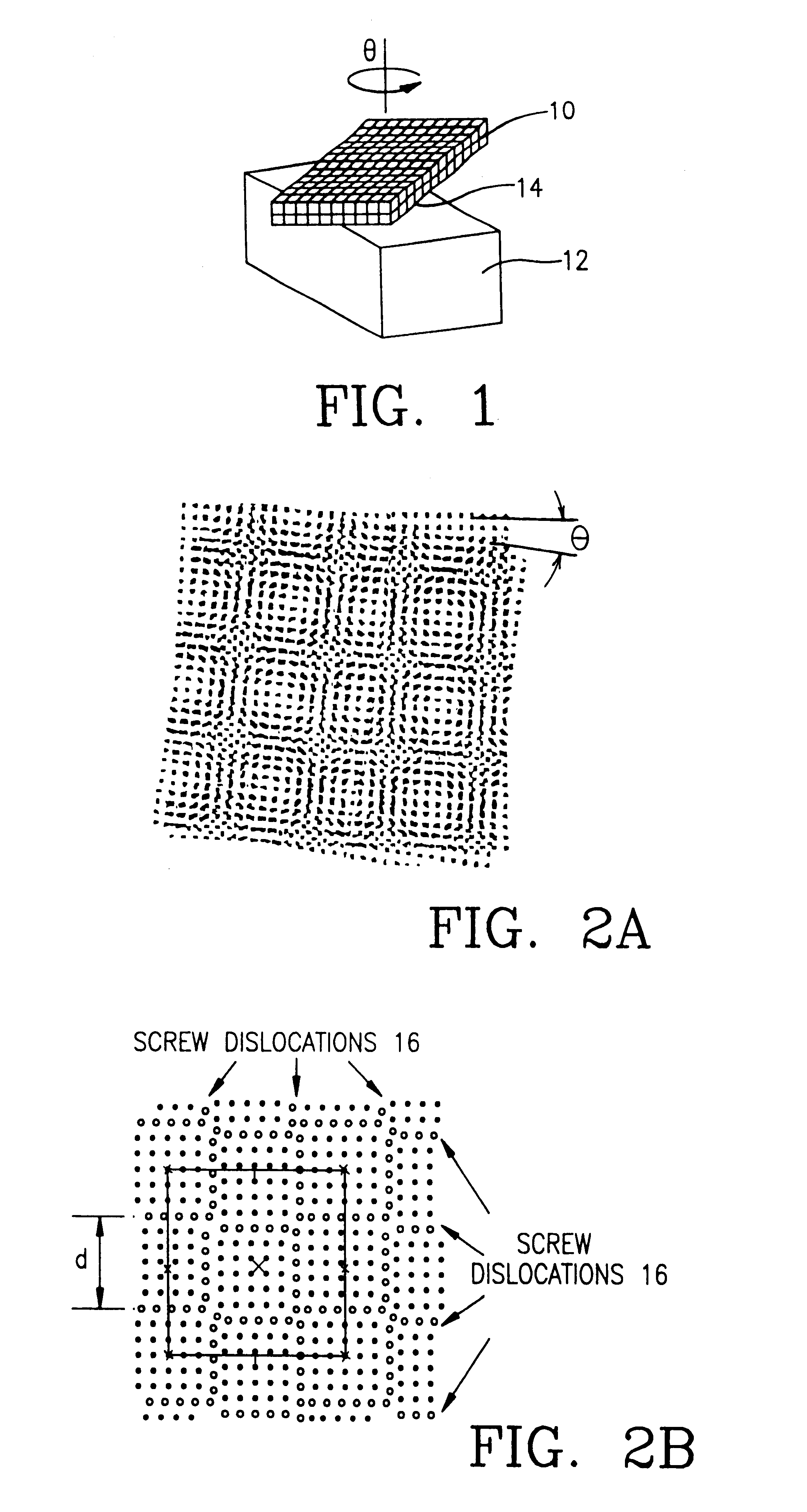

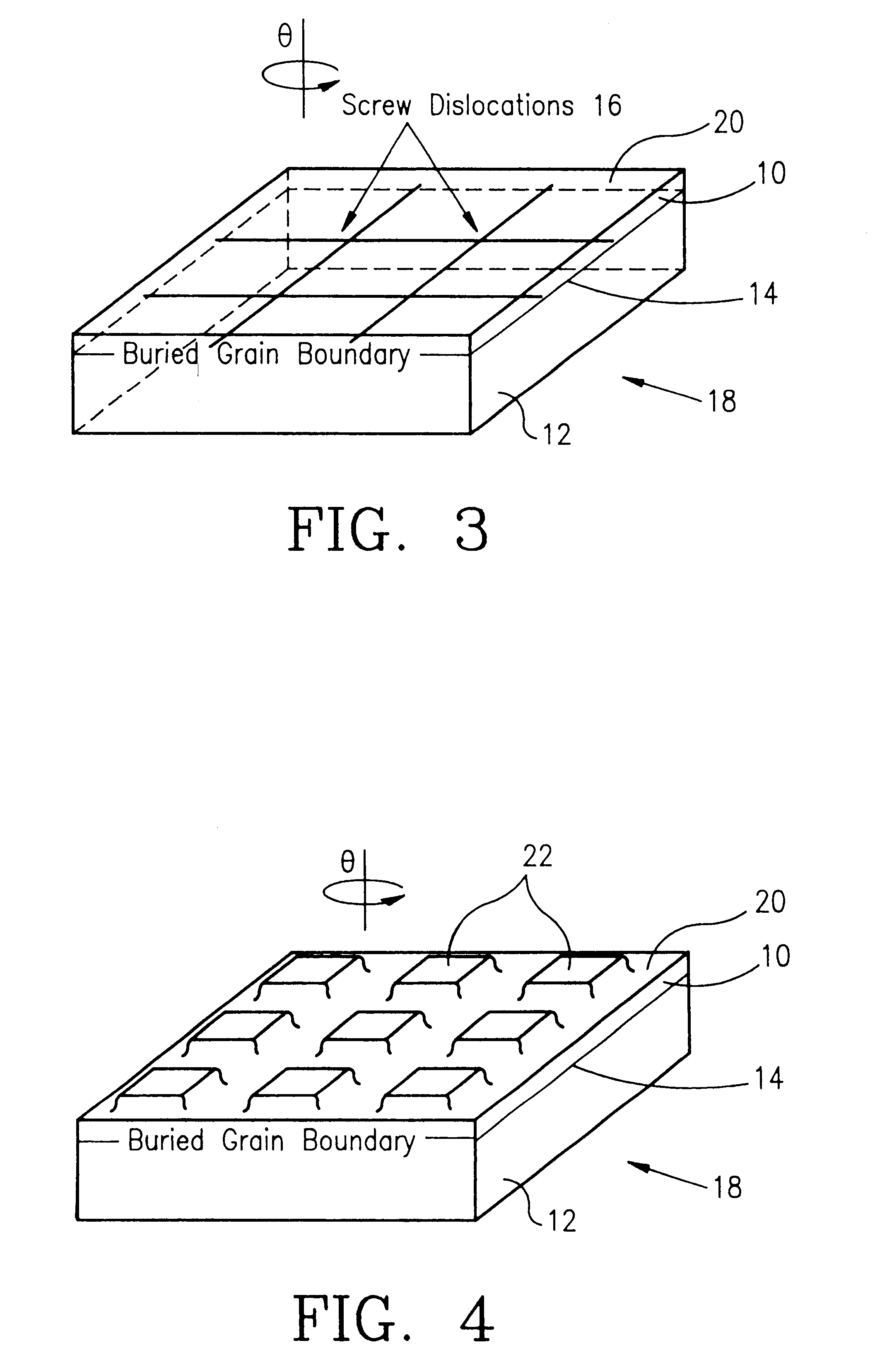

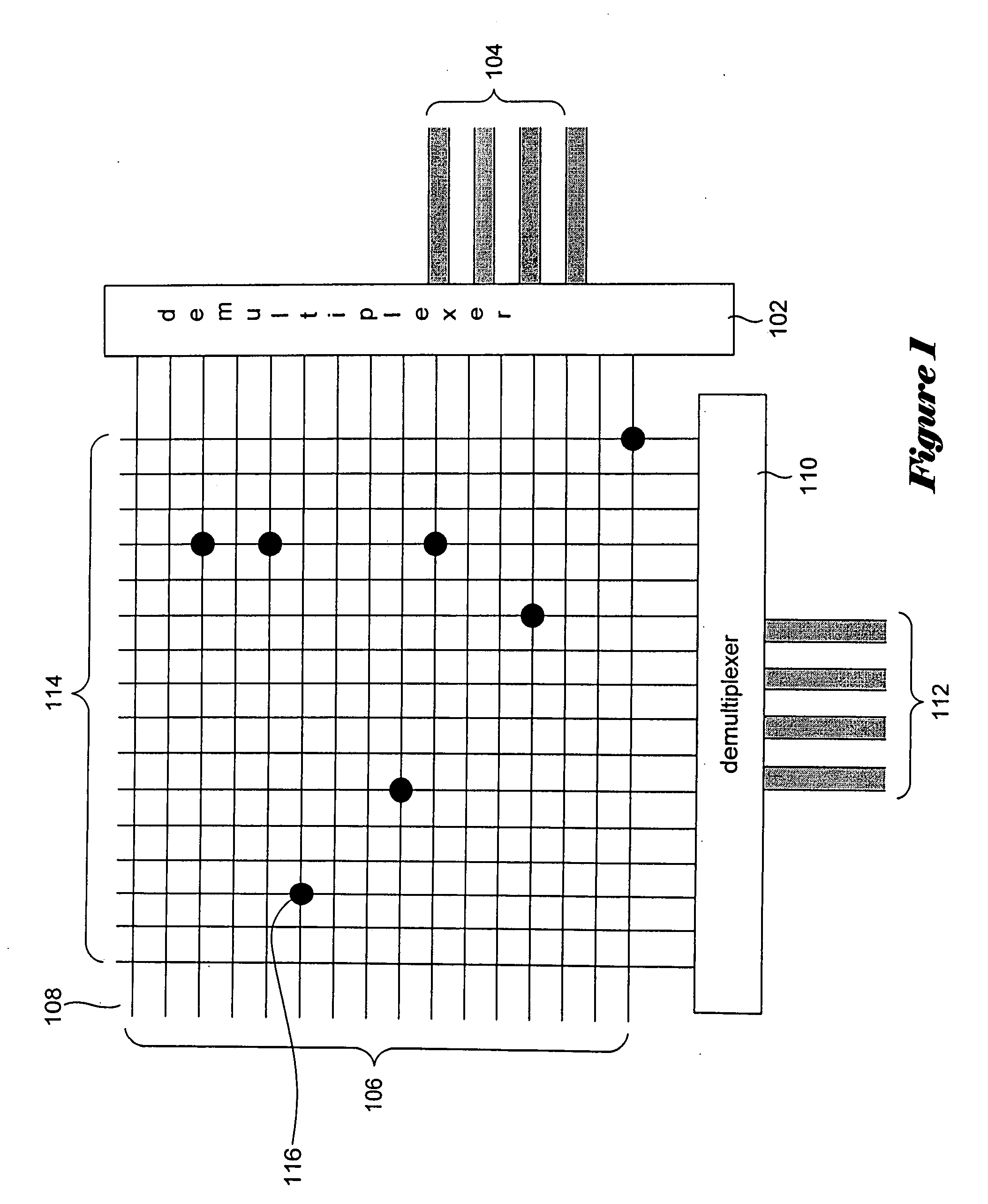

Fabrication of periodic surface structures with nanometer-scale spacings

The periodic stress and strain fields produced by a pure twist grain boundary between two single crystals bonded together in the form of a bicrystal are used to fabricate a two-dimensional surface topography with controllable, nanometer-scale feature spacings (e.g., from 50 nanometers down to 1.5 nanometers). The spacing of the features is controlled by the misorientation angle used during crystal bonding. One of the crystals is selected to be thin, on the order of 5-100 nanometers. A buried periodic array of screw dislocations is formed at the twist grain boundary. To bring the buried periodicity to the surface, the thin single crystal is etched to reveal an array of raised elements, such as pyramids, that have nanometer-scale dimensions. The process can be employed with numerous materials, such as gold, silicon and sapphire. In addition, the process can be used with different materials for each crystal such that a periodic array of misfit dislocations is formed at the interface between the two crystals.

Owner:CORNELL RES FOUNDATION INC

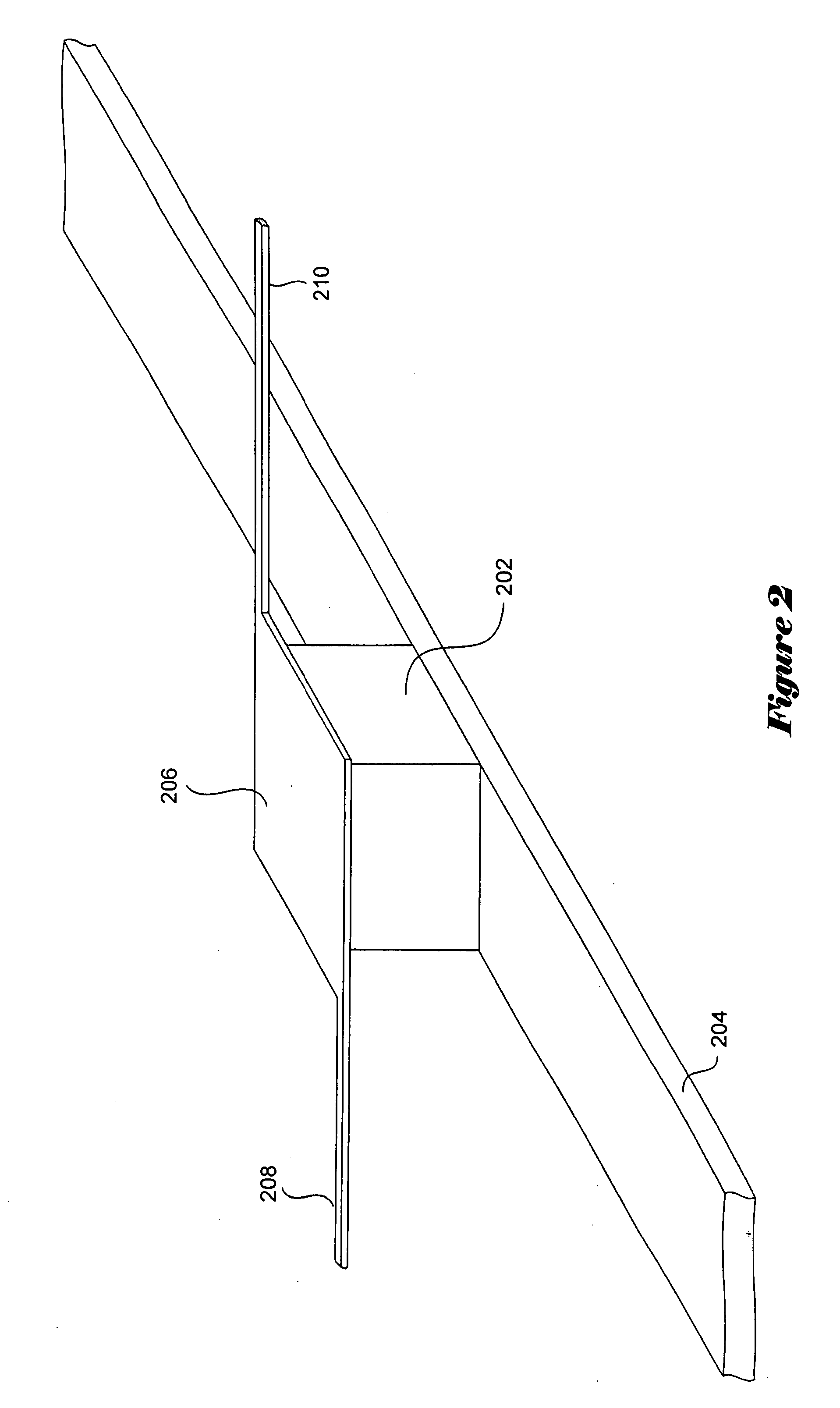

Mixed-scale electronic interface

Embodiments of the present invention are directed to mixed-scale electronic interfaces, included in integrated circuits and other electronic devices, that provide for dense electrical interconnection between microscale features of a predominantly microscale or submicroscale layer and nanoscale features of a predominantly nanoscale layer. The predominantly nanoscale layer, in one embodiment of the present invention, comprises a tessellated pattern of submicroscale or microscale pads densely interconnected by nanowire junctions between sets of parallel, closely spaced nanowire bundles. The predominantly submicroscale or microscale layer includes pins positioned complementarily to the submicroscale or microscale pads in the predominantly nanoscale layer. Pins can be configured according to any periodic tiling of the microscale layer.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

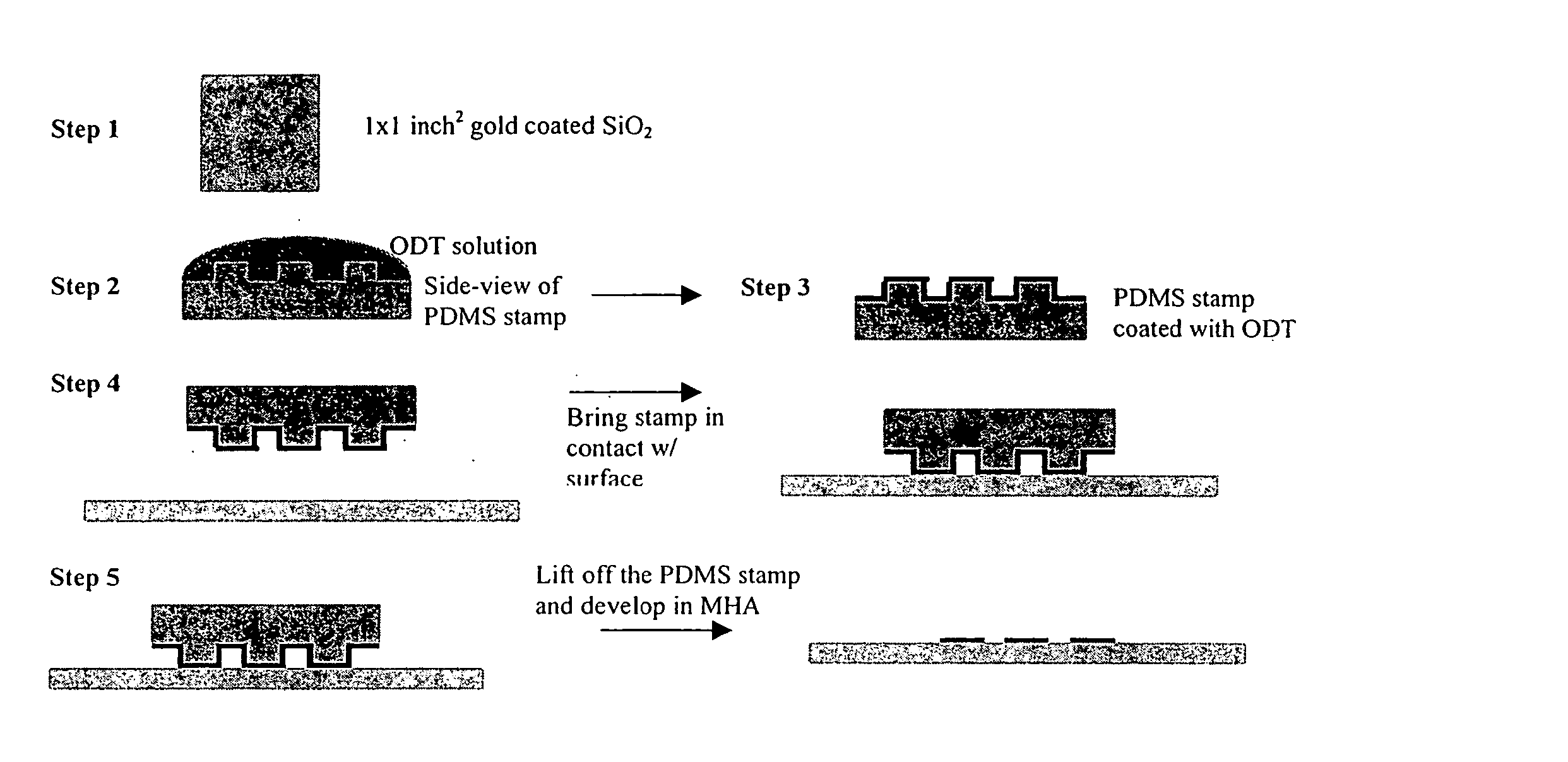

Control of the spatial distribution and sorting of micro-or nano-meter or molecular scale objects on patterned surfaces

InactiveUS20050118338A1Wide applicabilityEasy to classifyMaterial nanotechnologyNanoinformaticsSurface patternCrystallography

A method of depositing and sorting micro-scale, nano-scale and molecular-scale objects onto a surface. In particular, the methods can be used to produce arrays of micro- and nanoscale objects on a surface by use of fluidic alignment with surface patterning techniques. In a preferred embodiment of the invention, the objects are sorted and / or spatially distributed and arrayed into micro- or nanometer scale geometries with periodicity on a larger area by evaporation (or other means of selective removal of solvent) of liquid containing molecular scale solutes, nanowires, metallic particles, polymeric particles, inorganic particles or composite particles formed from such materials or preferably, such particles may be sorted and deposited from suspensions by continuously creating and evaporating films of the suspension on patterned substrates.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

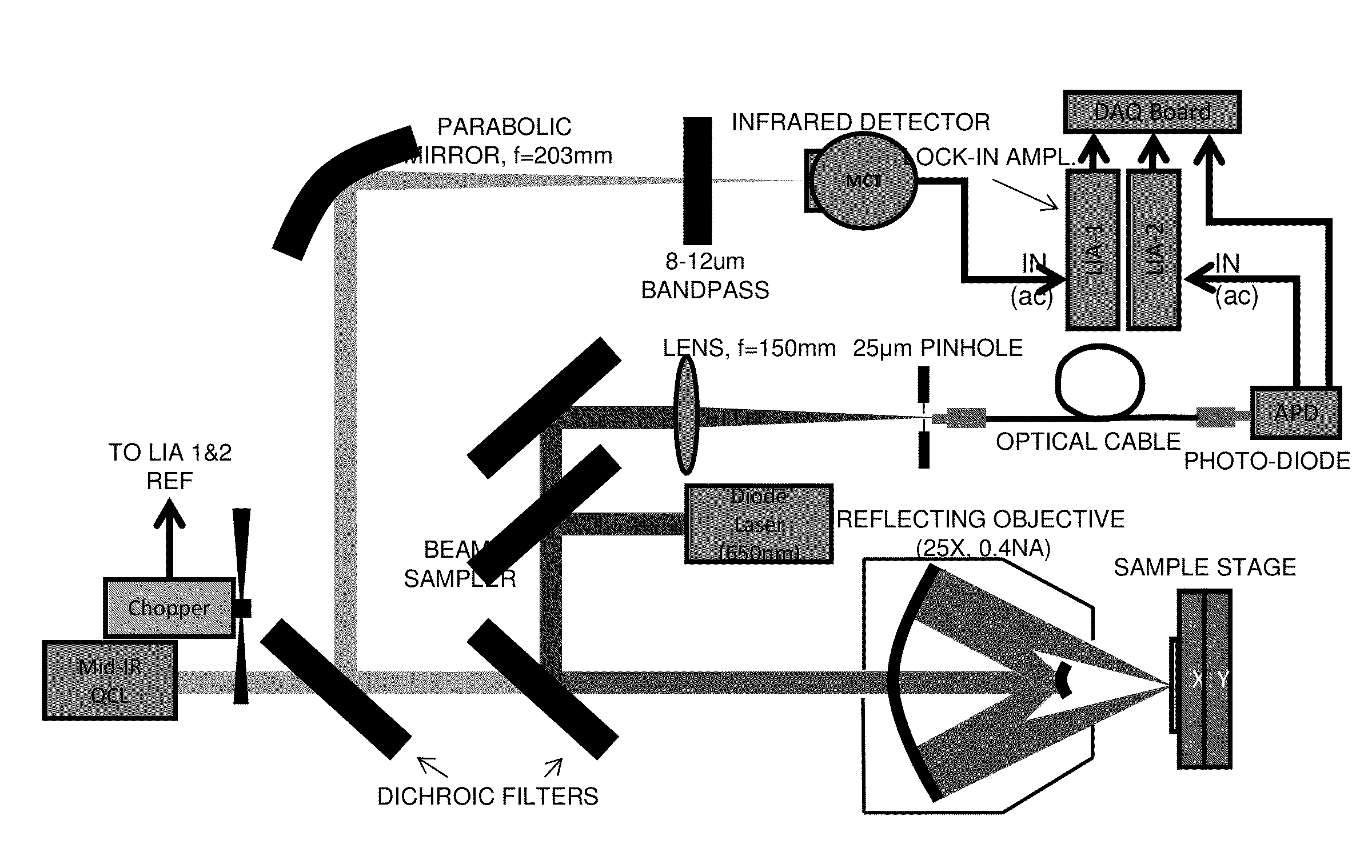

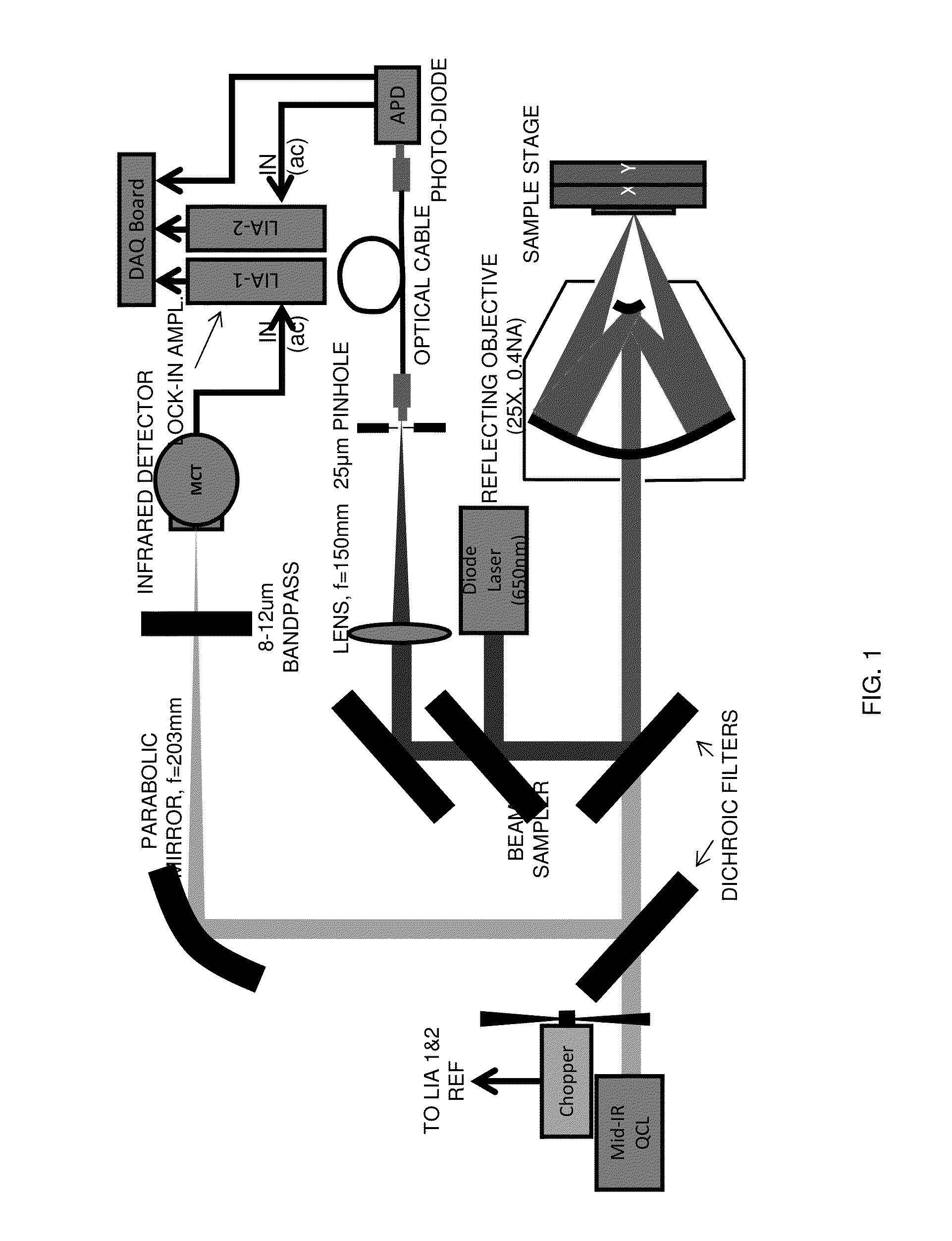

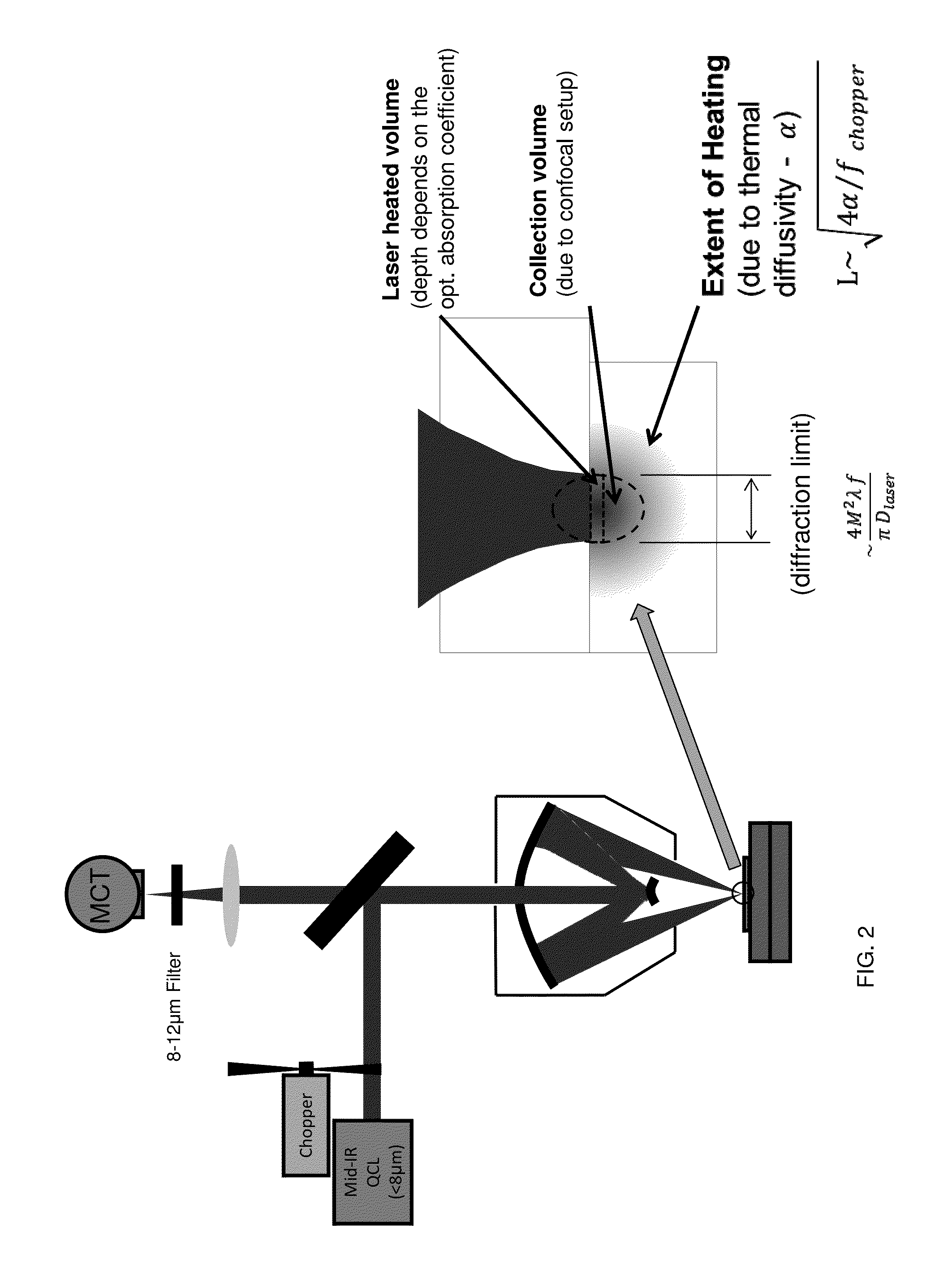

Chemical mapping using thermal microscopy at the micro and NANO scales

ActiveUS20130134310A1Small sizeReduce impactEmission spectroscopyRadiation pyrometryThermionic emissionLaser probe

A non-destructive method for chemical imaging with ˜1 nm to 10 μm spatial resolution (depending on the type of heat source) without sample preparation and in a non-contact manner. In one embodiment, a sample undergoes photo-thermal heating using an IR laser and the resulting increase in thermal emissions is measured with either an IR detector or a laser probe having a visible laser reflected from the sample. In another embodiment, the infrared laser is replaced with a focused electron or ion source while the thermal emission is collected in the same manner as with the infrared heating. The achievable spatial resolution of this embodiment is in the 1-50 nm range.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com