Method for preparing metal mesh for oil-water separation

A technology of oil-water separation and metal mesh, which is applied in separation methods, filtration separation, liquid separation, etc., can solve the problems of cumbersome preparation process, poor stability of separation mesh, environmental pollution, etc., achieve simple equipment and preparation process, and good oil-water separation effect , The effect of cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

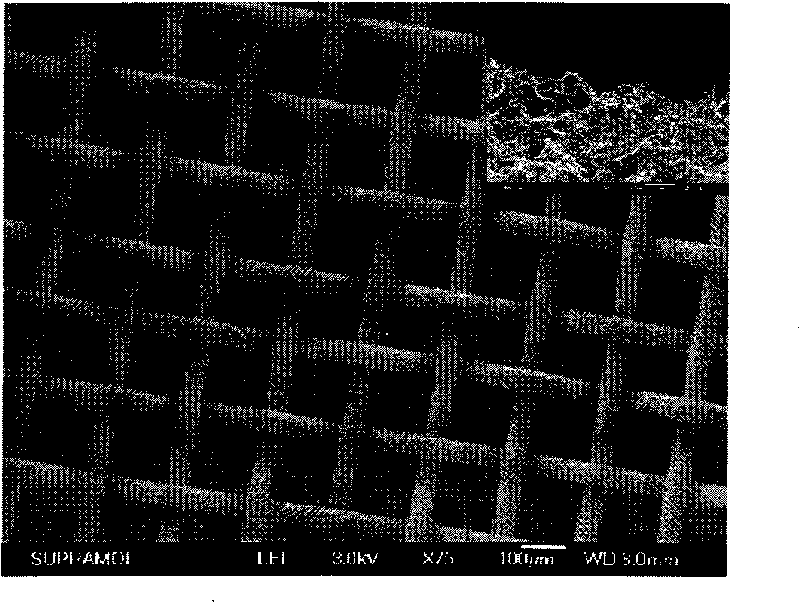

[0027] (1) Add 50mL of hydrochloric acid solution with a concentration of 3mol / L into a 100mL beaker, soak the metal iron mesh with a pore size of 160 mesh in this solution for 50 seconds, take it out, wash it with water and dry it. Nanoscale protrusions appear on the surface of the metal mesh, such as figure 1 shown.

[0028] (2) Add 30mL of ethanol and 0.003mol of cetyl mercaptan into a 100mL beaker, mix well, and prepare an ethanol solution with a concentration of 0.1mol / L. Soak the above-mentioned acid-treated metal iron net in this solution for 50 minutes, take it out, wash it with ethanol, and blow dry. That is, the oil-water separation metal mesh is obtained, such as figure 1 shown.

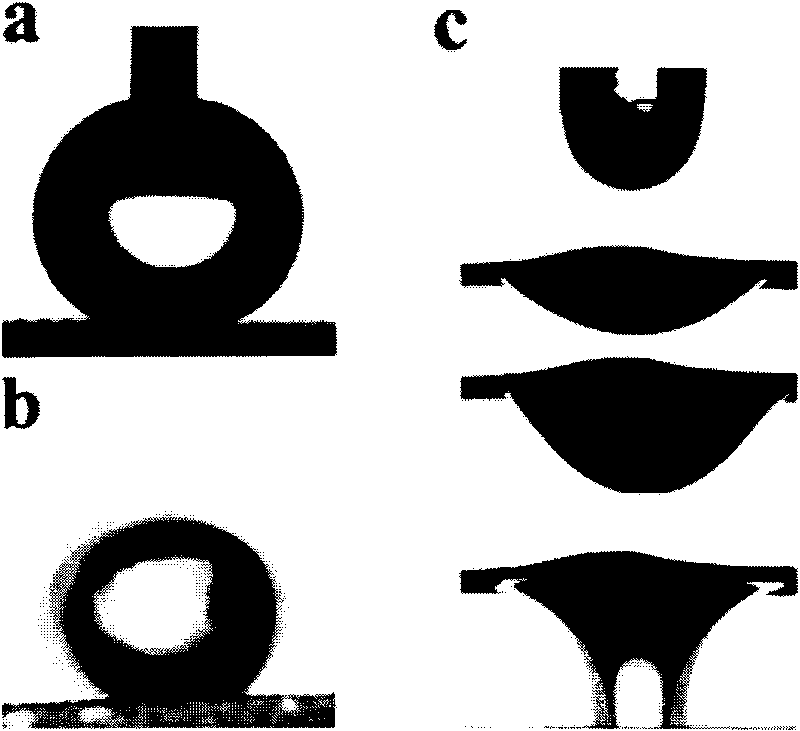

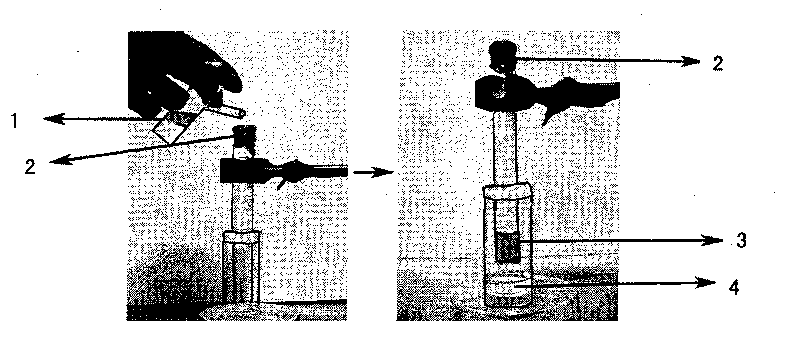

[0029] (3) On the surface of the metal mesh, the contact angle of water is 155° and the rolling angle is less than 5°, while the contact angle of oil on its surface is close to 0°, as figure 2 a. figure 2 b and figure 2 as shown in c. Cover the metal mesh on the mouth of the test...

Embodiment 2

[0032] (1) Add 50mL of nitric acid solution with a concentration of 4mol / L into a 100mL beaker, soak the metal copper mesh with a pore size of 100 mesh in this solution for 4 minutes, take it out, wash it with water and dry it.

[0033] (2) Add 50mL of ethanol and 0.01mol of sodium dodecylsulfonate into a 100mL beaker, mix well, and prepare an ethanol solution with a concentration of 0.2mol / L. Soak the acid-treated metal copper mesh in this solution for 100 minutes, take it out, wash it with ethanol, and blow dry.

[0034] (3) On the surface of the metal mesh, the contact angle of water is 152° and the rolling angle is less than 5°, while the contact angle of oil on the surface is close to 0°. The metal mesh can separate the oil-water mixture.

Embodiment 3

[0036](1) Add 50mL of hydrochloric acid solution with a concentration of 2.5mol / L into a 100mL beaker, soak the metal zinc mesh with a pore size of 120 mesh in this solution for 3 minutes, take it out, wash it with water and dry it.

[0037] (2) Add 50mL ethanol and 0.01mol sodium hexadecyl carboxylate into a 100mL beaker, mix well, and prepare an ethanol solution with a concentration of 0.5mol / L. Soak the acid-treated metal zinc mesh in this solution for 120 minutes, take it out, wash it with ethanol, and blow dry.

[0038] (3) On the surface of the metal mesh, the contact angle of water is 150° and the rolling angle is less than 5°, while the contact angle of oil on the surface is close to 0°. The metal mesh can separate the oil-water mixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com