Preparation method of completely peeled oxidation graphene/ rubber nanometer composite material

A technology of rubber nano-composite materials is applied in the field of preparation of graphene oxide/rubber nano-composite materials to achieve the effects of no environmental pollution, high tensile strength, and easy large-scale industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

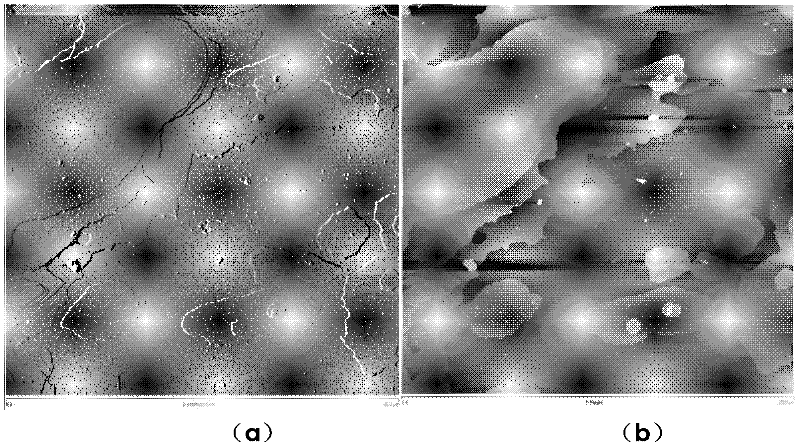

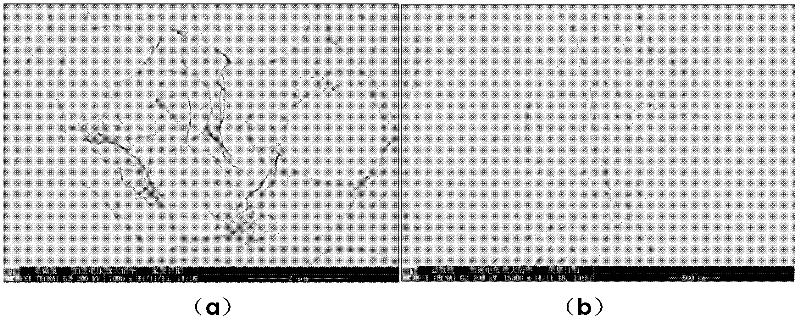

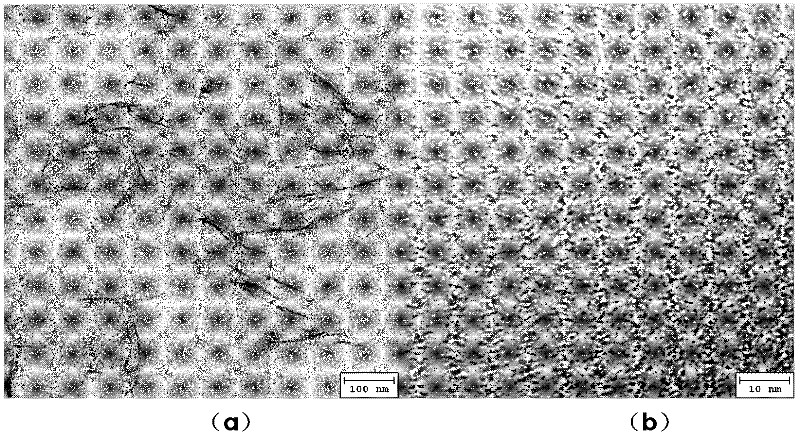

Image

Examples

Embodiment 1

[0033] Add 10 g of graphite oxide into 10 L of water, use a power of 800 W, a frequency of 1000 Hz, and a temperature of 25 ° C under ultrasonication for 2 hours to obtain a solid content of 0.1 wt % graphene oxide / water sol; take 100 g of graphene oxide / water sol, in Mix with 0.625g butylpyridine latex (40wt% solid content) for 10min at a rotating speed of 500r / min to obtain a pretreated graphene oxide / water predispersion. The 500g styrene-butadiene latex (solid content is 20wt%) that continues to add under the rotating speed of 500r / min continues to mix 20min; Adding concentration is that the calcium chloride solution of 1% carries out flocculation; After the micelles were washed with water, they were dried at 80° C. for 24 hours to obtain a graphene oxide / styrene-butadiene rubber nanocomposite material with an amount of graphene oxide of 0.1 phr and an interface agent of 0.25 phr.

[0034] The obtained graphene oxide / styrene-butadiene rubber nanocomposite material is on the...

Embodiment 2

[0036] Add 10 g of graphite oxide into 10 L of water, use a power of 800 W, a frequency of 1000 Hz, and a temperature of 25 ° C under ultrasonication for 2 hours to obtain a solid content of 0.1 wt % graphene oxide / water sol; take 1200 g of graphene oxide / water sol, in Mix with 7.5g butylpyridine latex (40wt% solid content) for 10min at a rotating speed of 500r / min to obtain a pretreated graphene oxide / water predispersion. The 500g styrene-butadiene latex (solid content is 20wt%) that continues to add under the rotating speed of 500r / min continues to mix 20min; Adding concentration is that the calcium chloride solution of 1% carries out flocculation; After the micelles were washed with water, they were dried at 80° C. for 24 hours to obtain a graphene oxide / styrene-butadiene rubber nanocomposite material with a graphene oxide dosage of 1.2 phr and an interface agent dosage of 3 phr.

[0037] The obtained graphene oxide / styrene-butadiene rubber nanocomposite material is on the ...

Embodiment 3

[0039] Add 10 g of graphite oxide into 10 L of water, use a power of 800 W, a frequency of 1000 Hz, and a temperature of 25 ° C under ultrasonication for 2 hours to obtain a solid content of 0.1 wt % graphene oxide / water sol; take 2000 g of graphene oxide / water sol, in Mix with 12.5g butylpyridine latex (40wt% solid content) for 10min at a rotating speed of 500r / min to obtain a pretreated graphene oxide / water predispersion. The 500g styrene-butadiene latex (solid content is 20wt%) that continues to add under the rotating speed of 500r / min continues to mix 20min; Adding concentration is that the calcium chloride solution of 1% carries out flocculation; After the micelles were washed with water, they were dried at 80° C. for 24 hours to obtain a graphene oxide / styrene-butadiene rubber nanocomposite material with a graphene oxide dosage of 2 phr and an interface agent dosage of 5 phr.

[0040] The obtained graphene oxide / styrene-butadiene rubber nanocomposite material is on the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| solid containing ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com