Novel polycarbosilane and preparation method thereof

A polycarbosilane, a new type of technology, applied in the field of new ceramic materials, can solve the problems of reducing the high temperature stability of pyrolysis products, unfavorable material processing, large heat release, etc., achieve excellent heat resistance, increase ceramic yield, reduce freedom The effect of carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

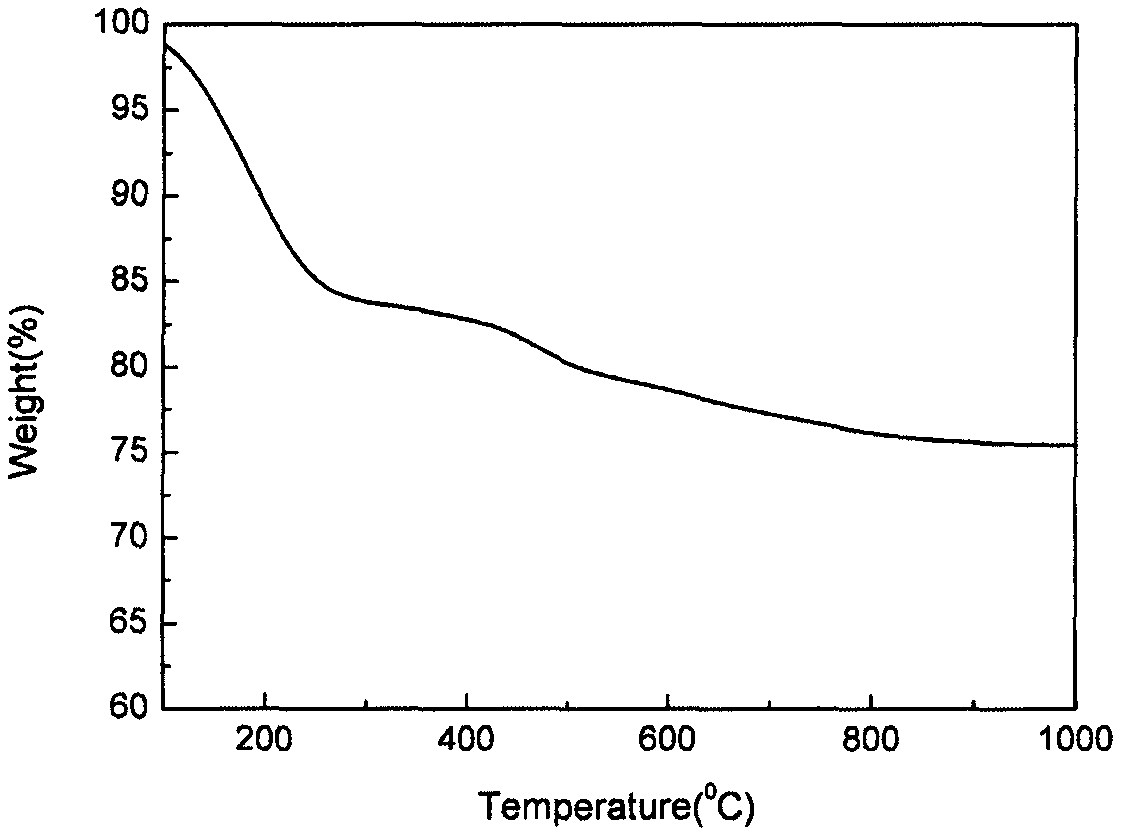

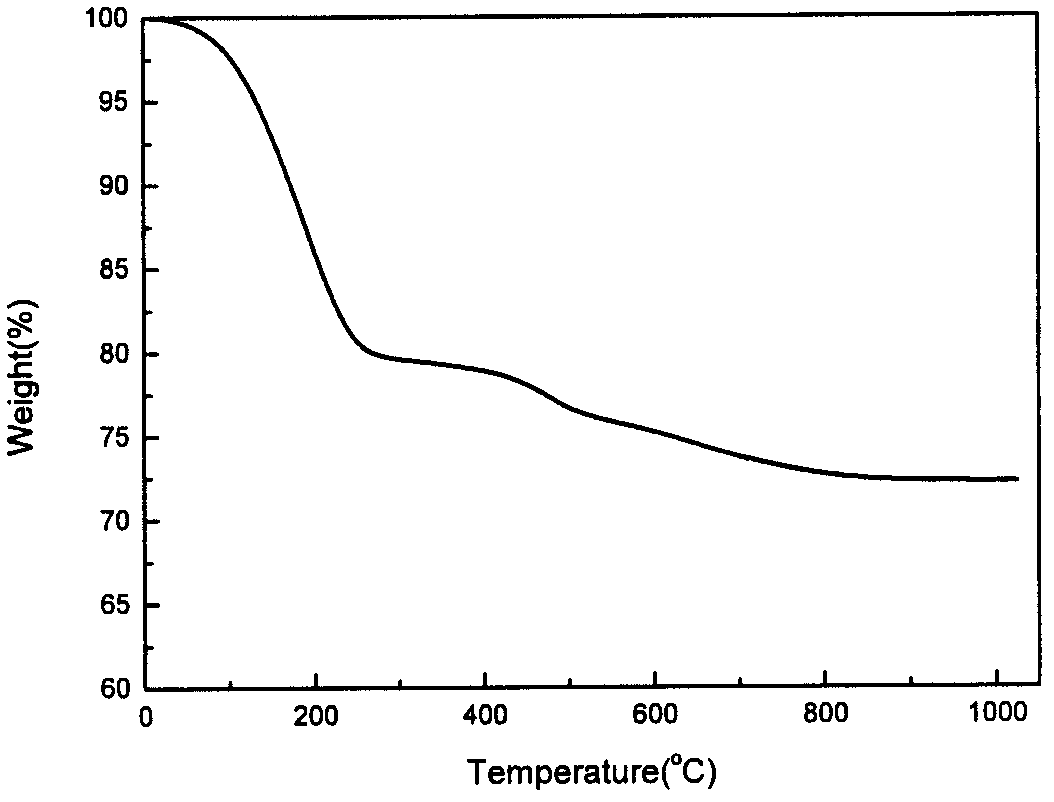

Image

Examples

Embodiment 1

[0044] 500ml dry three-neck bottle, equipped with N 2 Import piston, condensation tube, nitrogen outlet piston, constant pressure dropping funnel and electromagnetic force stirring, vacuumize, and replace the air in the system with nitrogen gas, and bake with alcohol lamp to remove adsorbed water. Add 8.0g magnesium chips to the reaction flask, add 50ml tetrahydrofuran to the reaction flask with a syringe; add 100ml tetrahydrofuran, 2.0g allyl chloride and 42.3g chloromethyl alkoxy dichlorosilane to the constant pressure dropping funnel, A mixed solution was formed. At 60°C, slowly add the mixed solution dropwise into the mixed system of magnesium chips and tetrahydrofuran under stirring, and continue stirring for 10 h after the dropwise addition is completed. Add 5.0 g of granular lithium aluminum hydride and stir at room temperature for 5-20 hours.

[0045] Add 100 ml of petroleum ether, 350 ml of deionized water and 10 ml of concentrated hydrochloric acid (commercial standa...

Embodiment 2

[0049] 1000ml dry three-neck bottle, equipped with N 2 Import piston, condensation tube, nitrogen outlet piston, constant pressure dropping funnel and electromagnetic force stirring, vacuumize, and replace the air in the system with nitrogen gas, and bake with alcohol lamp to remove adsorbed water. Add 8.0g of magnesium chips into the reaction flask, add 30ml of tetrahydrofuran into the reaction flask with a syringe; add 200ml of tetrahydrofuran, 1.7g of vinyl chloride and 42.3g of chloromethylalkoxydichlorosilane into the constant pressure dropping funnel to form mixture. At 60°C, slowly add the mixed solution dropwise into the mixed system of magnesium chips and tetrahydrofuran under stirring, and continue stirring for 10 h after the dropwise addition is completed. Add 5.0 g of granular lithium aluminum hydride and stir at room temperature for 5-20 hours.

[0050] Add 100 ml of petroleum ether, 200 ml of deionized water and 10 ml of concentrated hydrochloric acid (commerci...

Embodiment 3

[0054] 1000ml dry three-neck bottle, equipped with N 2 Import piston, condensation tube, nitrogen outlet piston, constant pressure dropping funnel and electromagnetic force stirring, vacuumize, and replace the air in the system with nitrogen gas, and bake with alcohol lamp to remove adsorbed water. Add 8.0g magnesium chips in the reaction flask, add 80ml tetrahydrofuran into the reaction flask with a syringe; add 300ml tetrahydrofuran, 1.6g propargyl chloride and 42.3g chloromethylalkoxydichlorosilane into the constant pressure dropping funnel, A mixed solution was formed. At 60°C, slowly add the mixed solution dropwise into the mixed system of magnesium chips and tetrahydrofuran under stirring, and continue stirring for 10 h after the dropwise addition is completed. Add 5.0 g of granular lithium aluminum hydride and stir at room temperature for 5-20 hours.

[0055] Add 100 ml of petroleum ether, 500 ml of deionized water and 10 ml of concentrated hydrochloric acid (commerci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com