Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2922 results about "Ceramic matrix composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ceramic matrix composites (CMCs) are a subgroup of composite materials as well as a subgroup of ceramics. They consist of ceramic fibres embedded in a ceramic matrix. The matrix and fibres can consist of any ceramic material, whereby carbon and carbon fibres can also be considered a ceramic material.

Two-dimensional fiber cloth reinforced composite material and preparation method thereof

InactiveCN101224989AImprove fracture toughnessImprove use reliabilityMetal powderStructural stability

The invention discloses a two-dimensional fiber cloth reinforced ceramics based composite material and the preparation technique, which adopts the two-dimensional fiber cloth as the reinforcing phase and the ceramic powder or the refractory metal powder as the stuffing, and the carbon and the carborundum as the base. The process steps are following: first the sizing agent with different ceramic powder and metal powder is coated on the two-dimensional fiber cloth, and then overlapping, puncturing and repeated densification are carried out. The preparation method has the advantages of lowering preparation cost and shortening preparation cycle, and the two-dimensional fiber cloth reinforced ceramics based composite material has the advantages of high shear strength between layers, structural stability and high reliability. The types of fiber cloth and the base can be adjusted and optimized in a wider range according to the applications, so as to be applicable for different fields.

Owner:NAT UNIV OF DEFENSE TECH

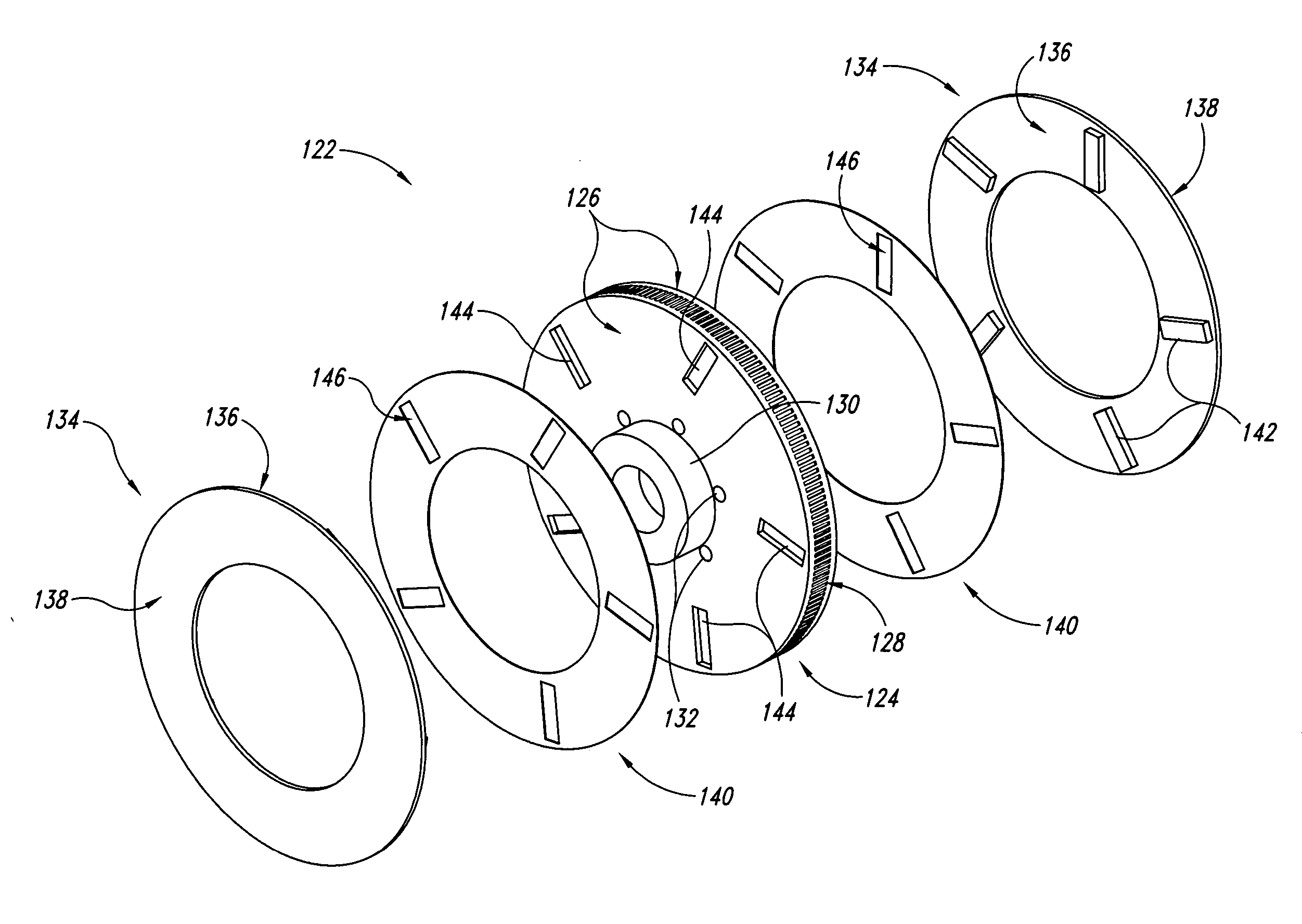

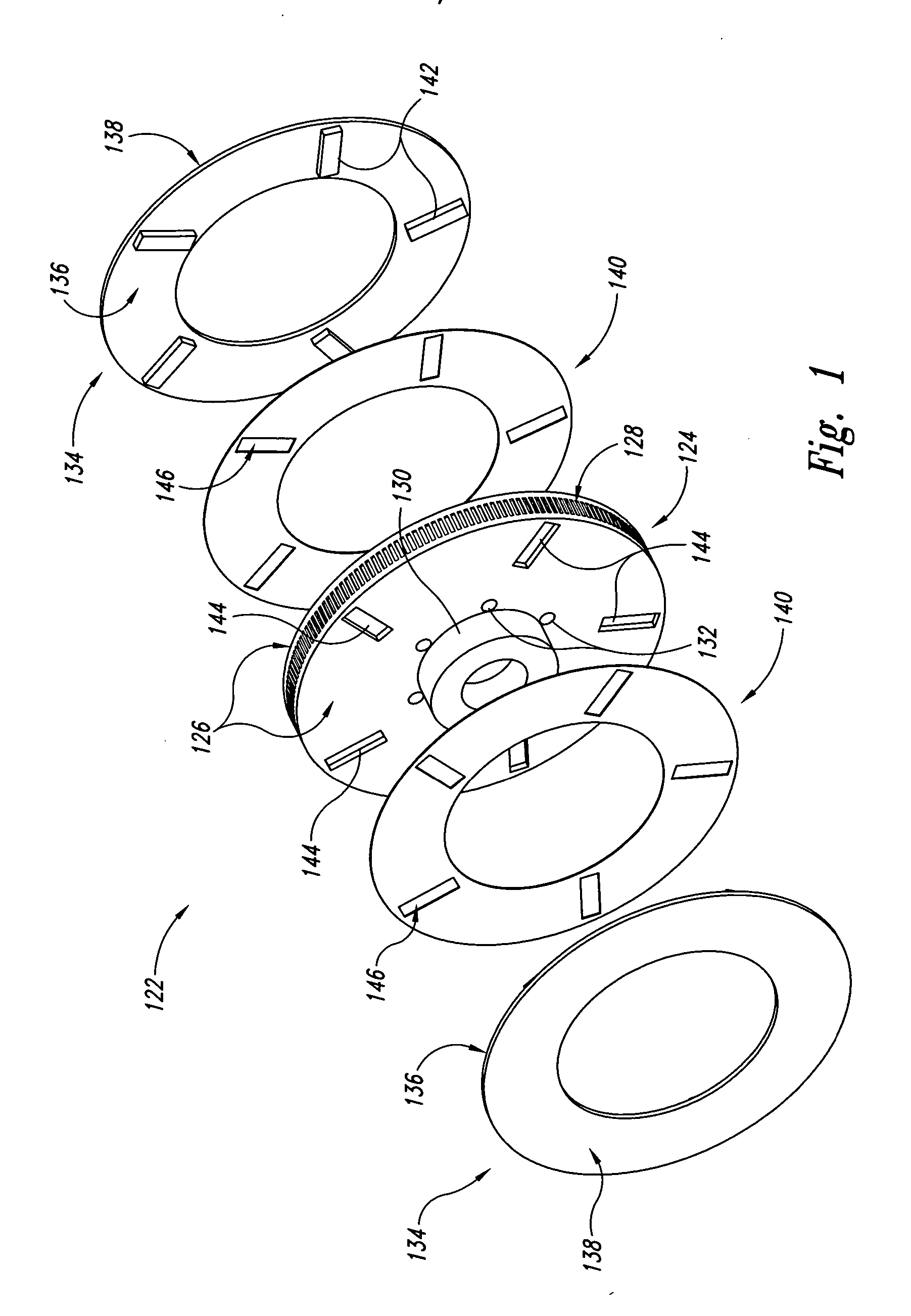

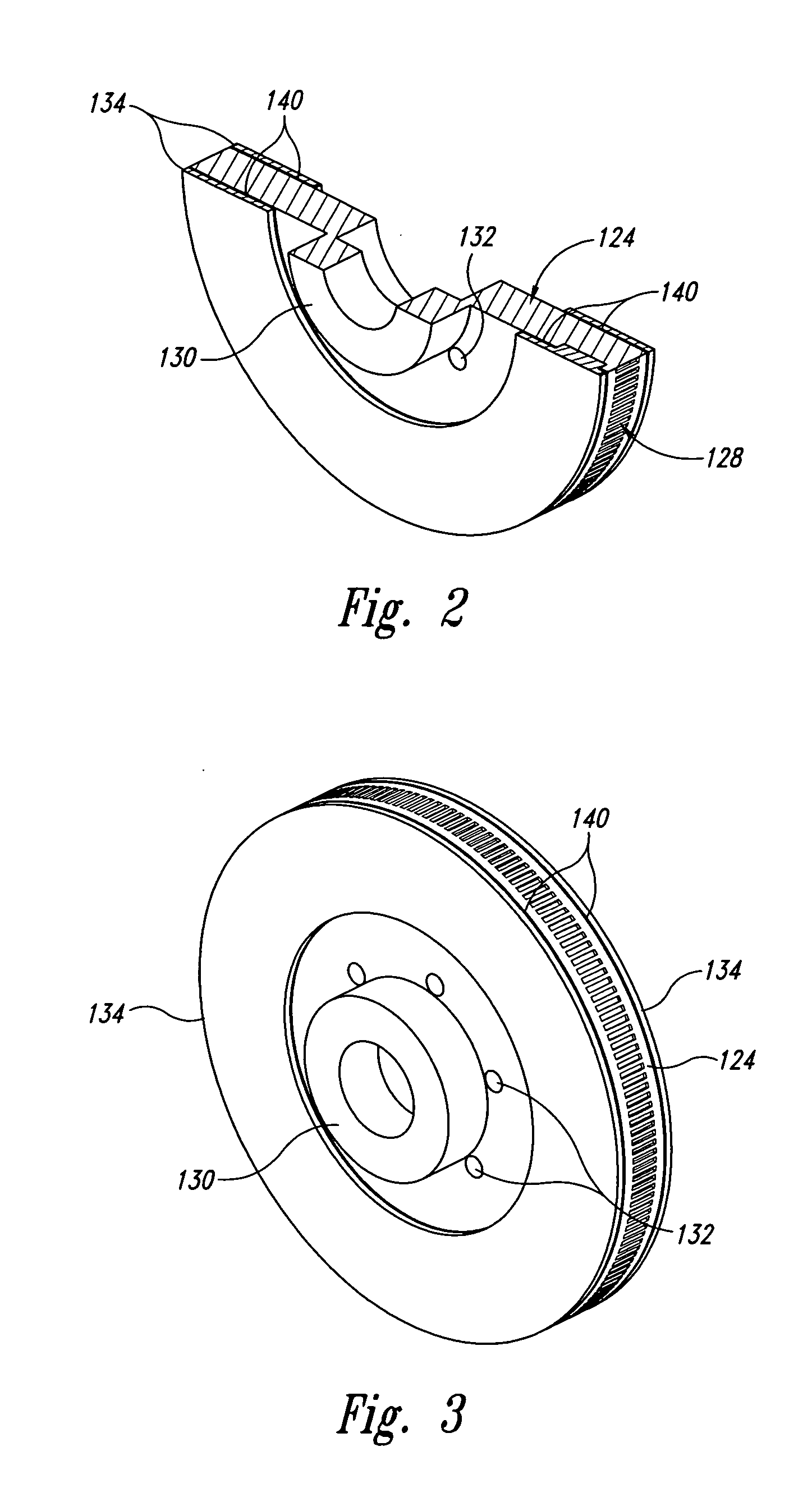

Disc brake rotor assembly and method for producing same

InactiveUS20050183909A1Improve thermal conductivityOptimize acoustic frequency transferBraking element arrangementsNoise/vibration controlAdhesiveMetal alloy

Novel composite disc brake rotor assemblies are provided, along with novel and efficient methods for manufacturing them. Preferably, the rotor assemblies comprise annular wear plates formed of particle reinforced aluminum-based metal matrix composite (MMC), ceramic matrix composite (CMC), or of ‘carbon graphite foam.’ The wear plates, made of a first material, are attached to annular surfaces of a central rotor, made of a second material, by fusing bonding layers between the wear plates and the rotor surfaces. The bonding layers are comprised of at least one of a metal alloy having a melting temperature lower than that of either the first or second materials, and a high-temperature adhesive. Preferably, the wear plates comprise projections that are positioned within adjacent receiving recesses in the center rotor. The bonding layers and projections enhance thermal and acoustical transference between the wear plates and the center rotor section. Carbon graphite foam provides for substantially enhanced heat transference. Use of the fusable binding layer, or adhesive provides for an efficient, low cost method of manufacturing for composite disc brake rotor assemblies.

Owner:BENMAXX

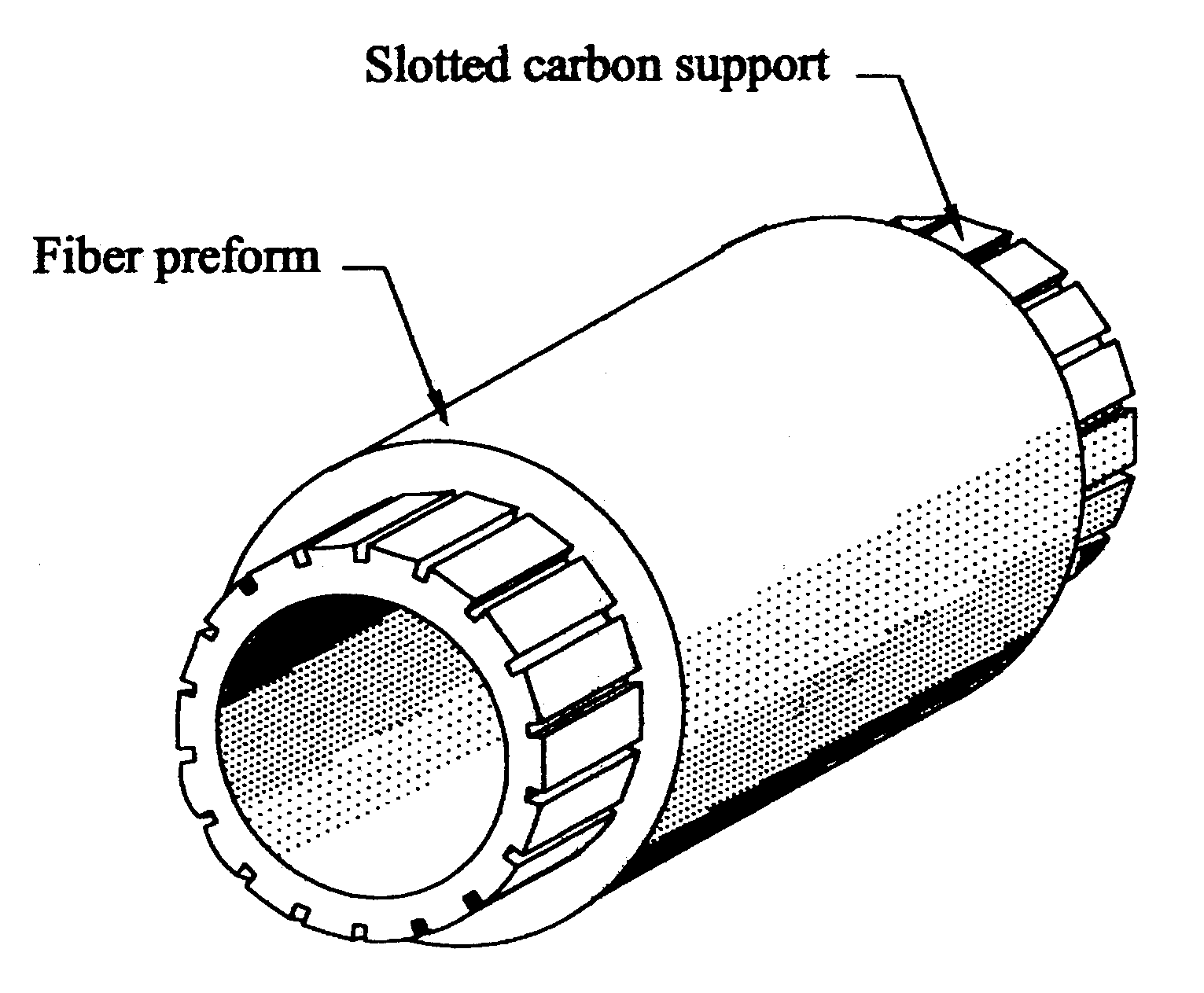

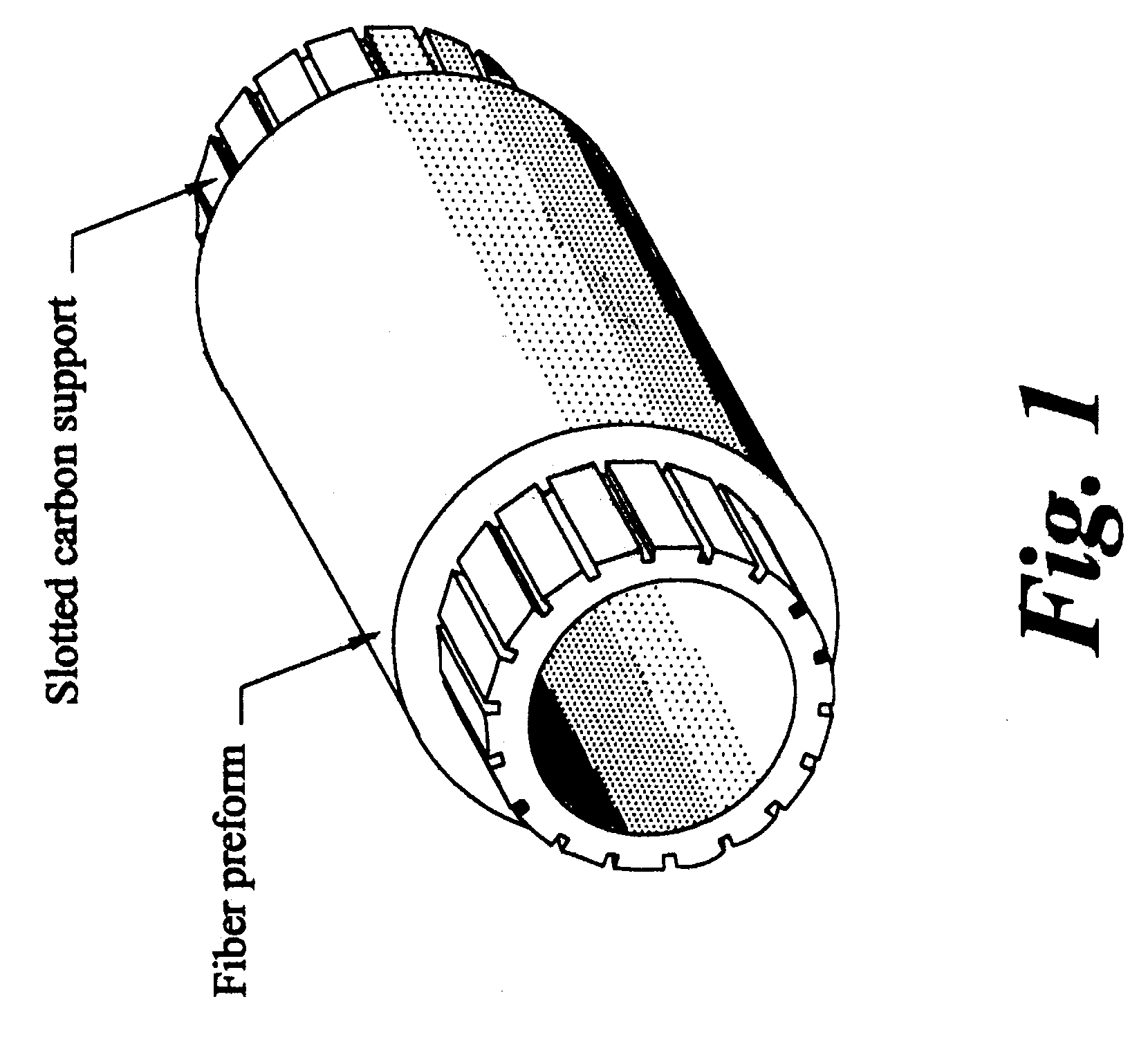

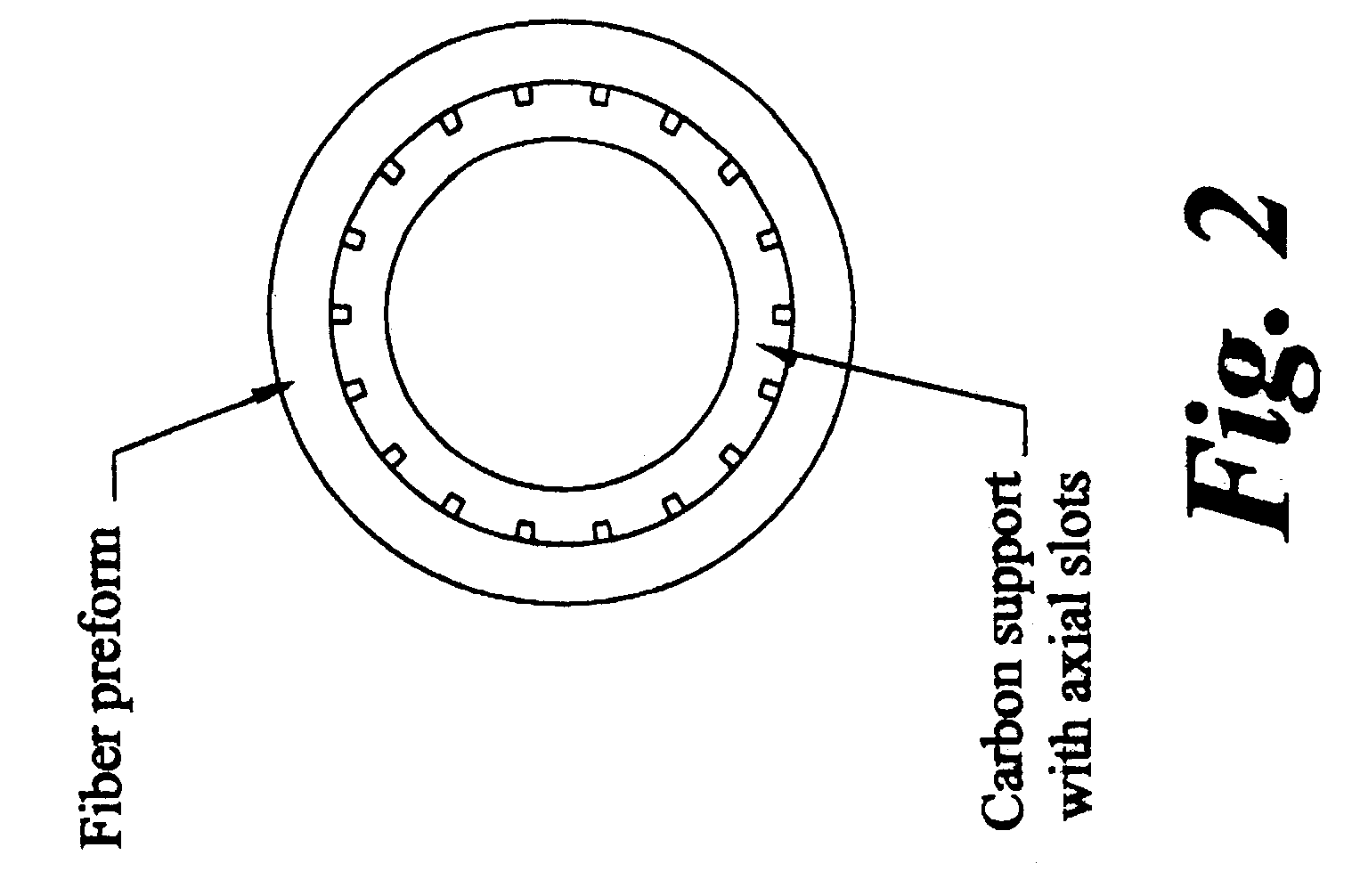

Method for producing melt-infiltrated ceramic composites using formed supports

InactiveUS6503441B2Avoid distortionEvenly distributedPretreated surfacesCeramic shaping apparatusCeramic compositeMetallurgy

A method for producing shaped articles of ceramic composites provides a high degree of dimensional tolerance to these articles. A fiber preform is disposed on a surface of a stable formed support, a surface of which is formed with a plurality of indentations, such as grooves, slots, or channels. Precursors of ceramic matrix materials are provided to the fiber preform to infiltrate from both sides of the fiber preform. The infiltration is conducted under vacuum at a temperature not much greater than a melting point of the precursors. The melt-infiltrated composite article substantially retains its dimension and shape throughout the fabrication process.

Owner:GENERAL ELECTRIC CO

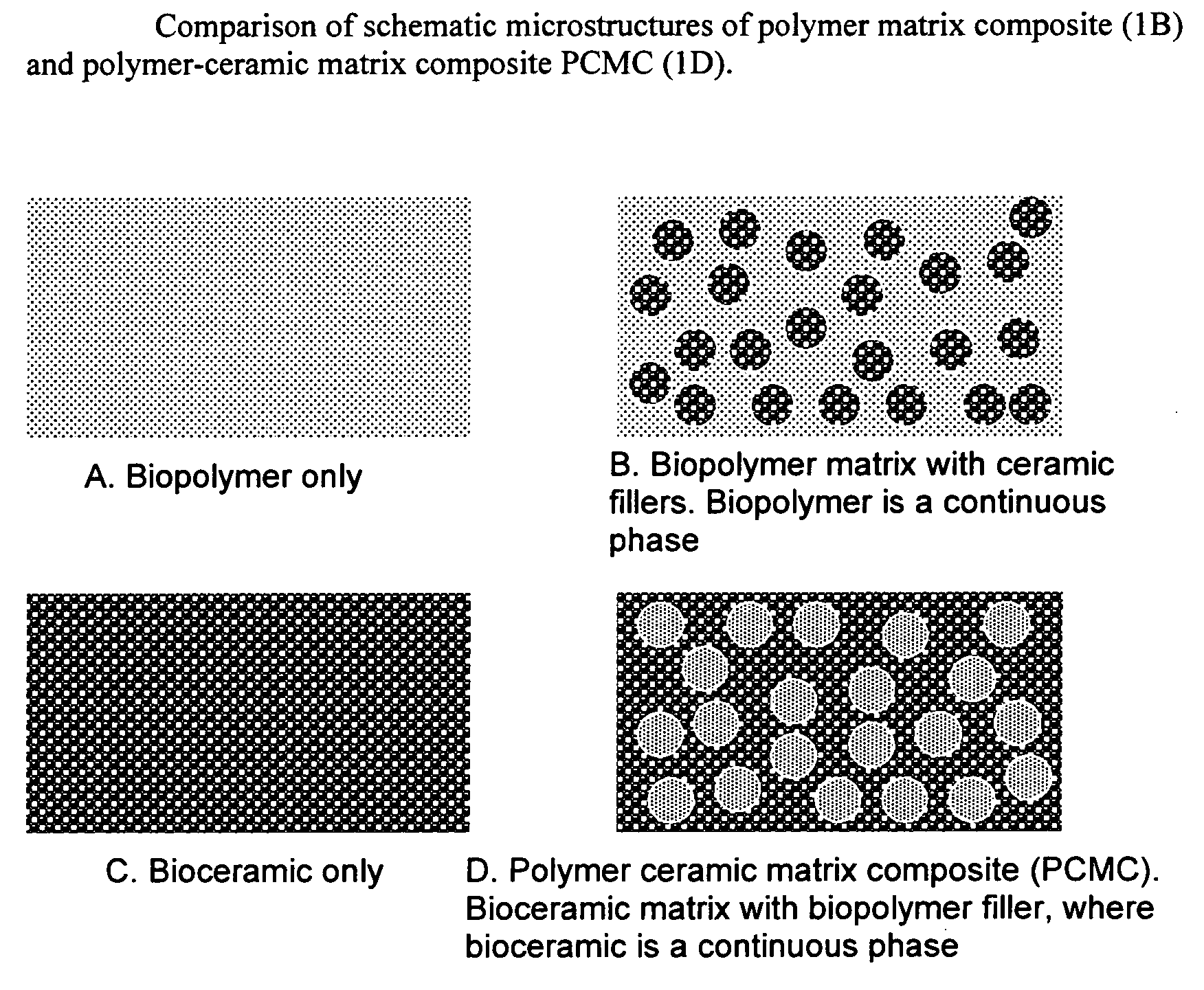

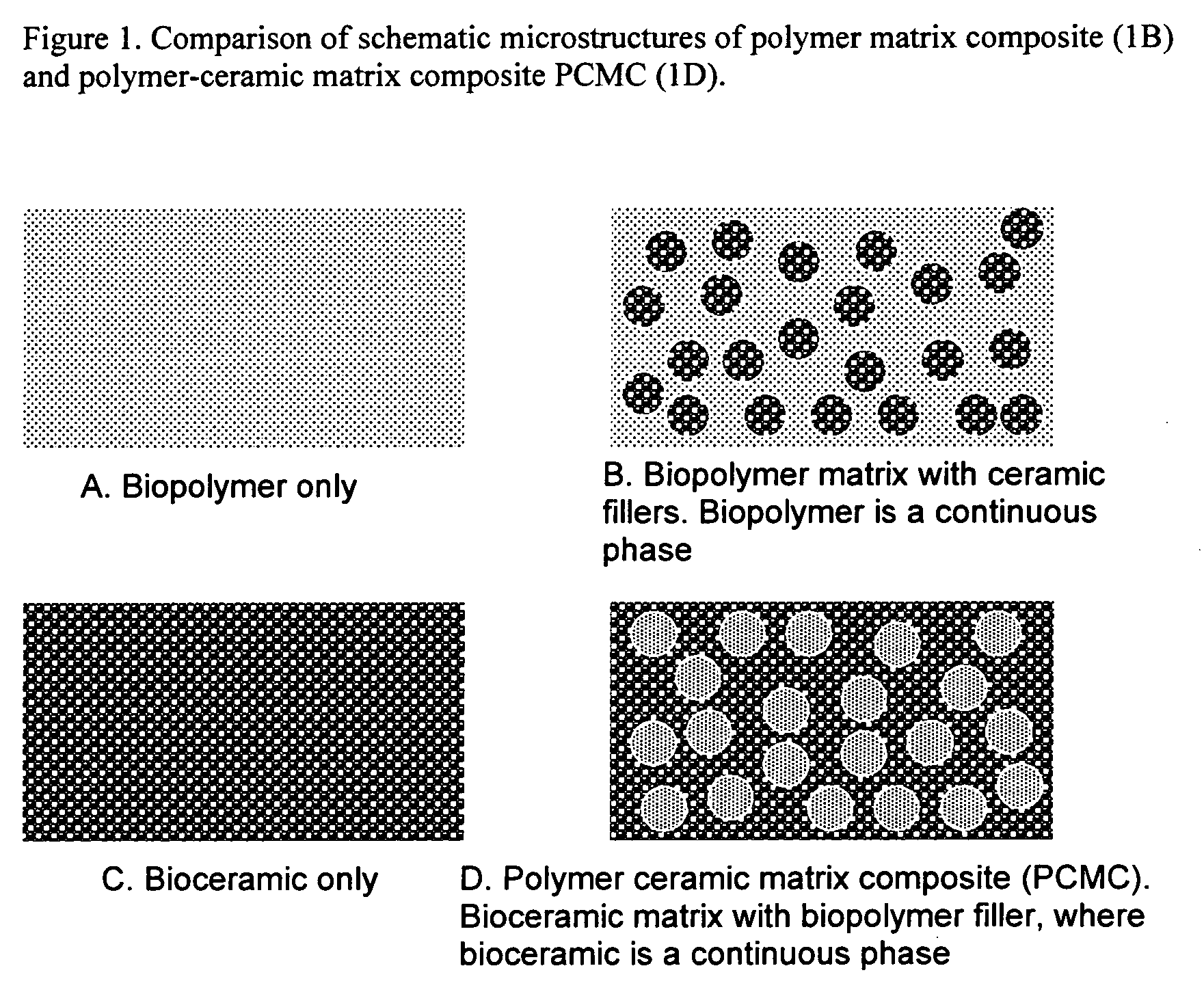

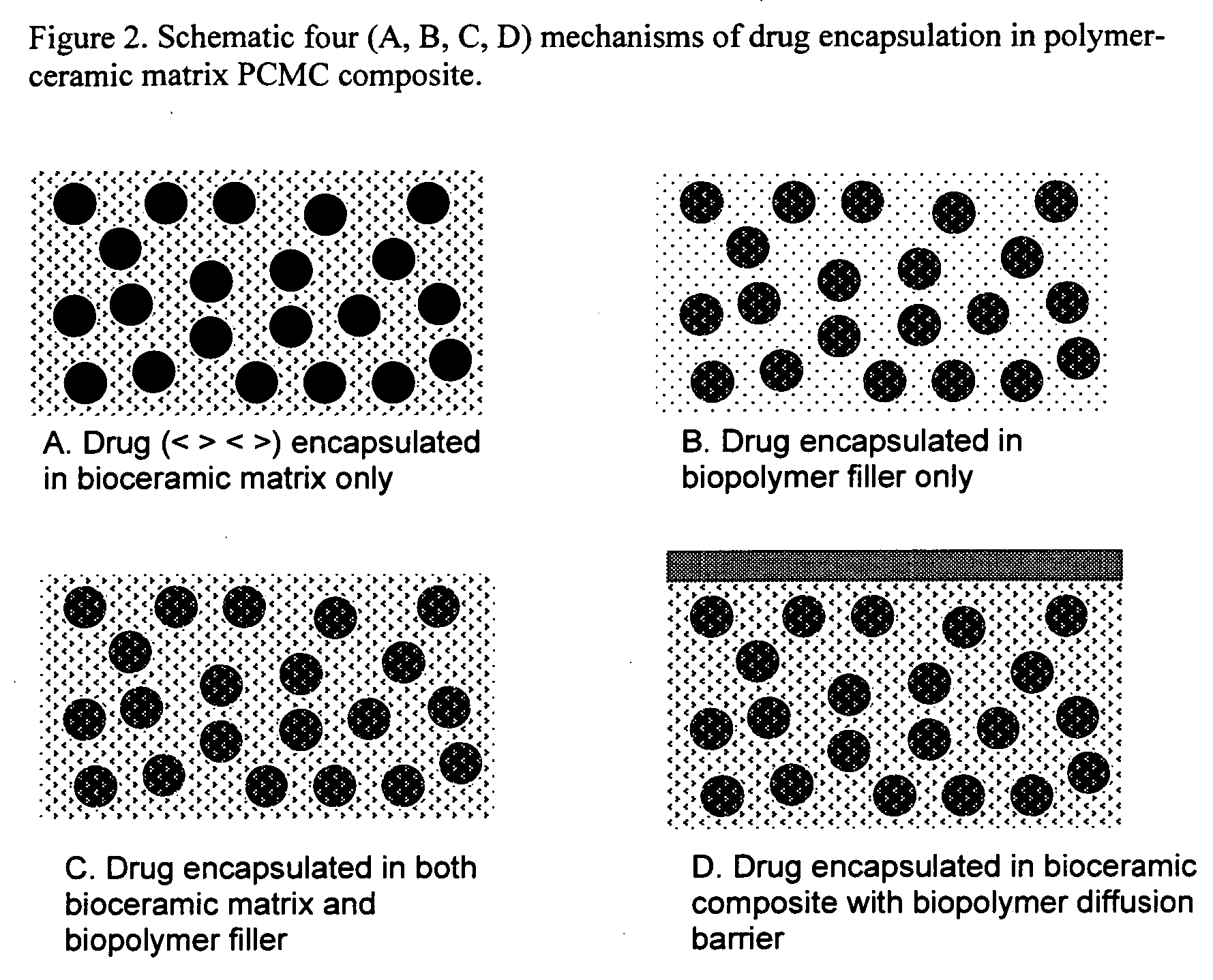

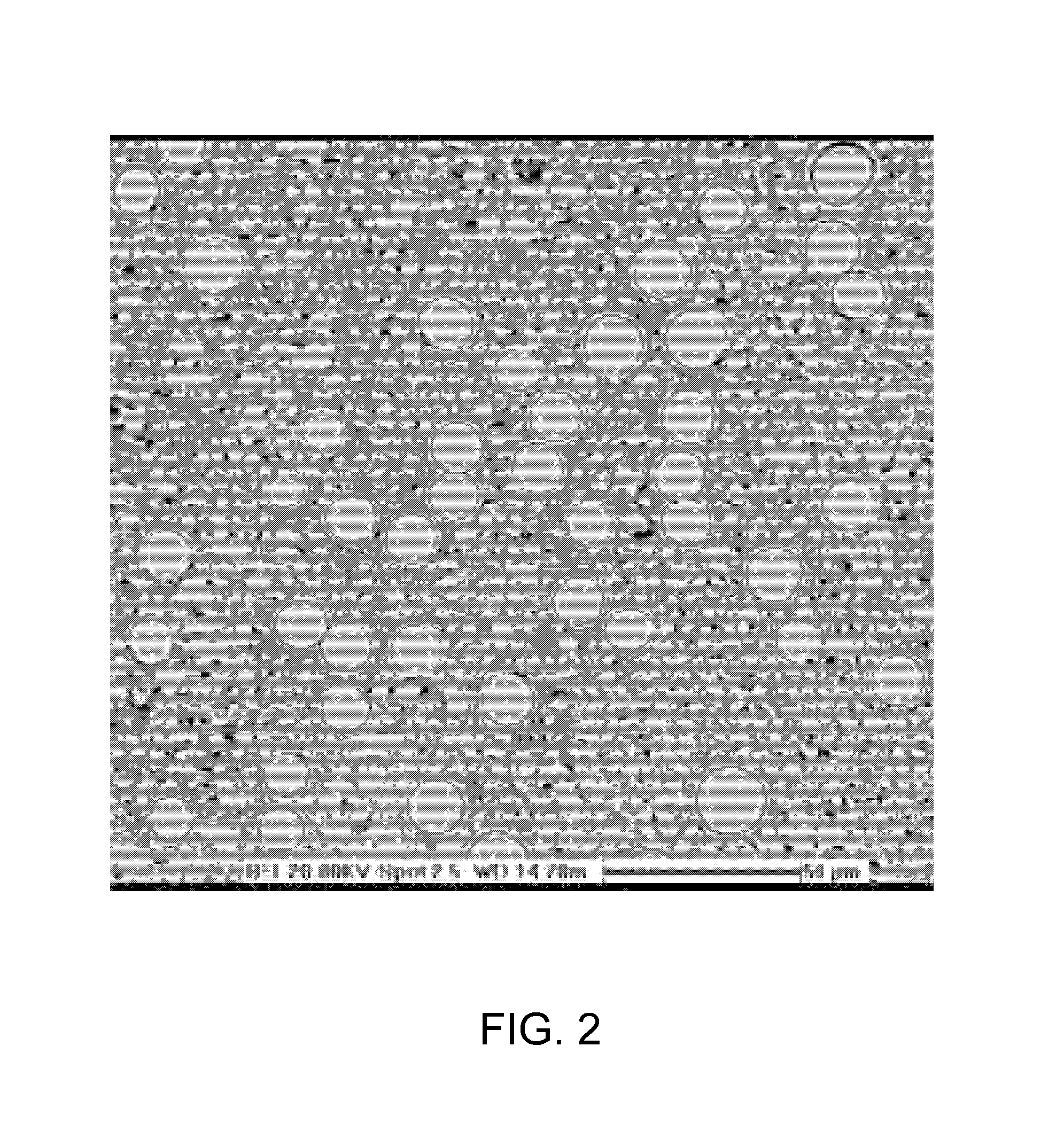

Bioceramic composite coatings and process for making same

The present invention discloses novel polymer-ceramic matrix composites and processes for making same. The composites can be used in biomedical applications, in particular, coatings of implants and other medical devices, where both the ceramic phase and the polymer phase are bio-compatible. The composites combine a reinforcing polymer phase with a continuous ceramic matrix to create materials with properties that are new and superior to polymer or ceramic phases alone. The composites can incorporate a bioactive agent.

Owner:THE UNIV OF BRITISH COLUMBIA

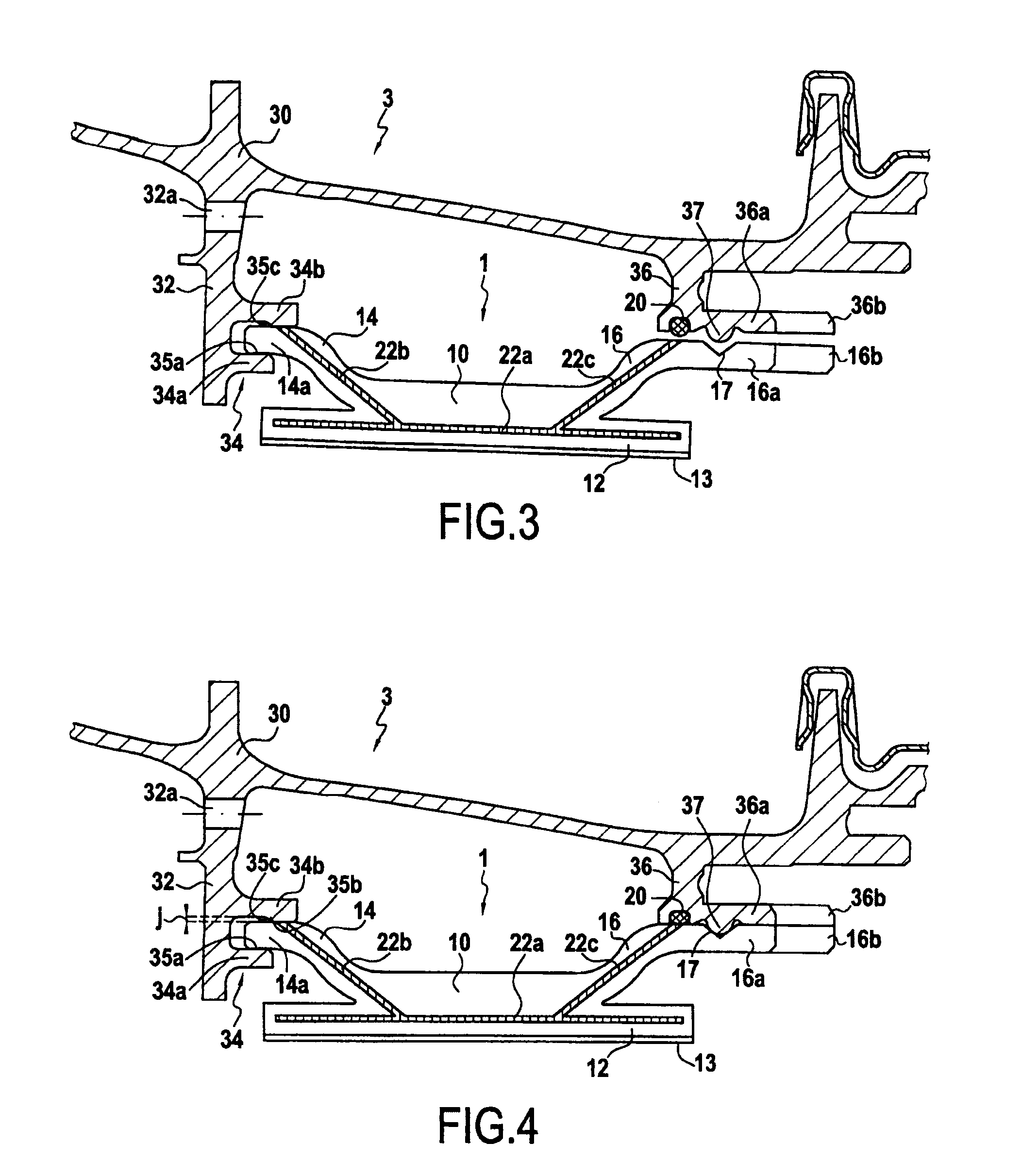

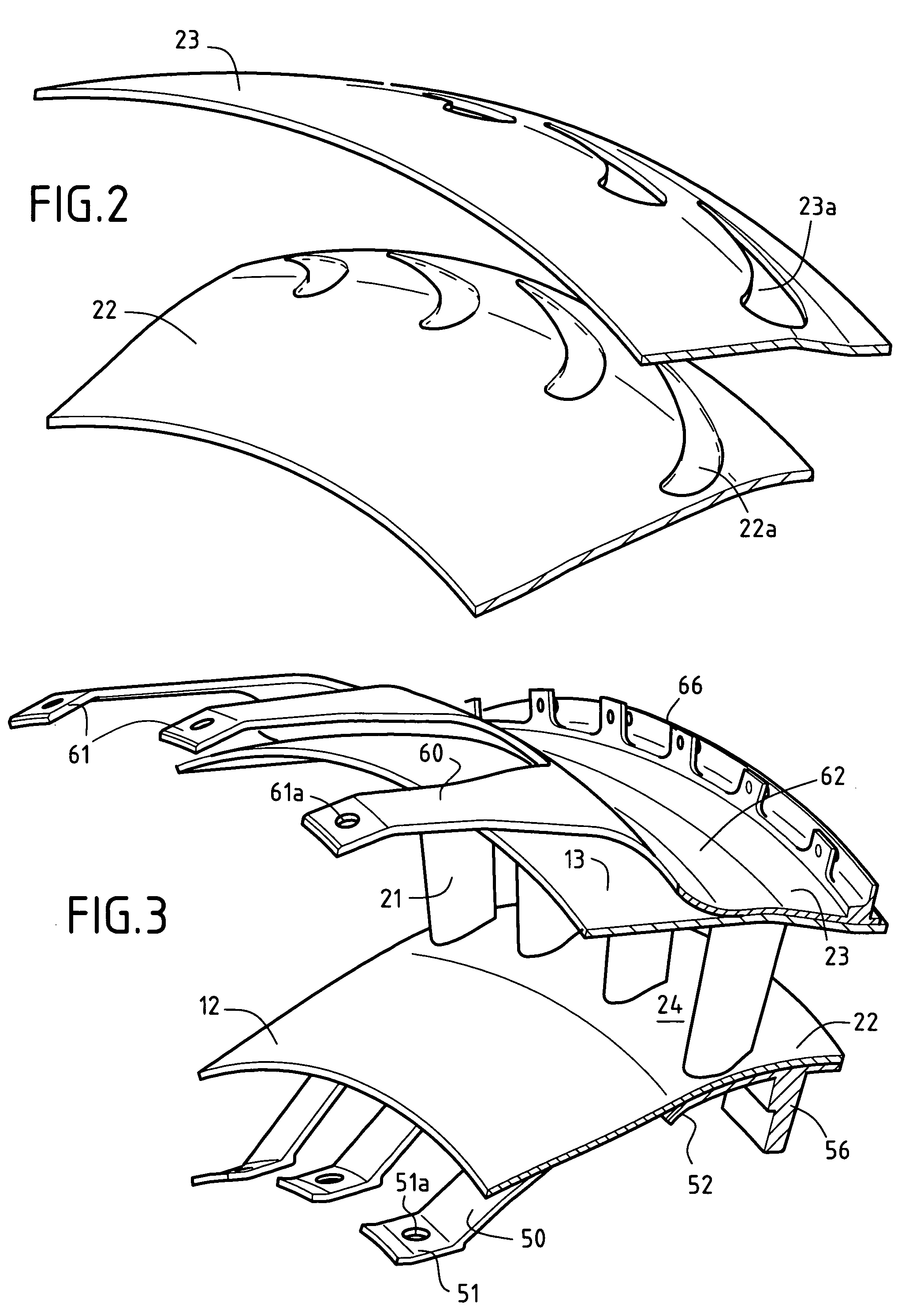

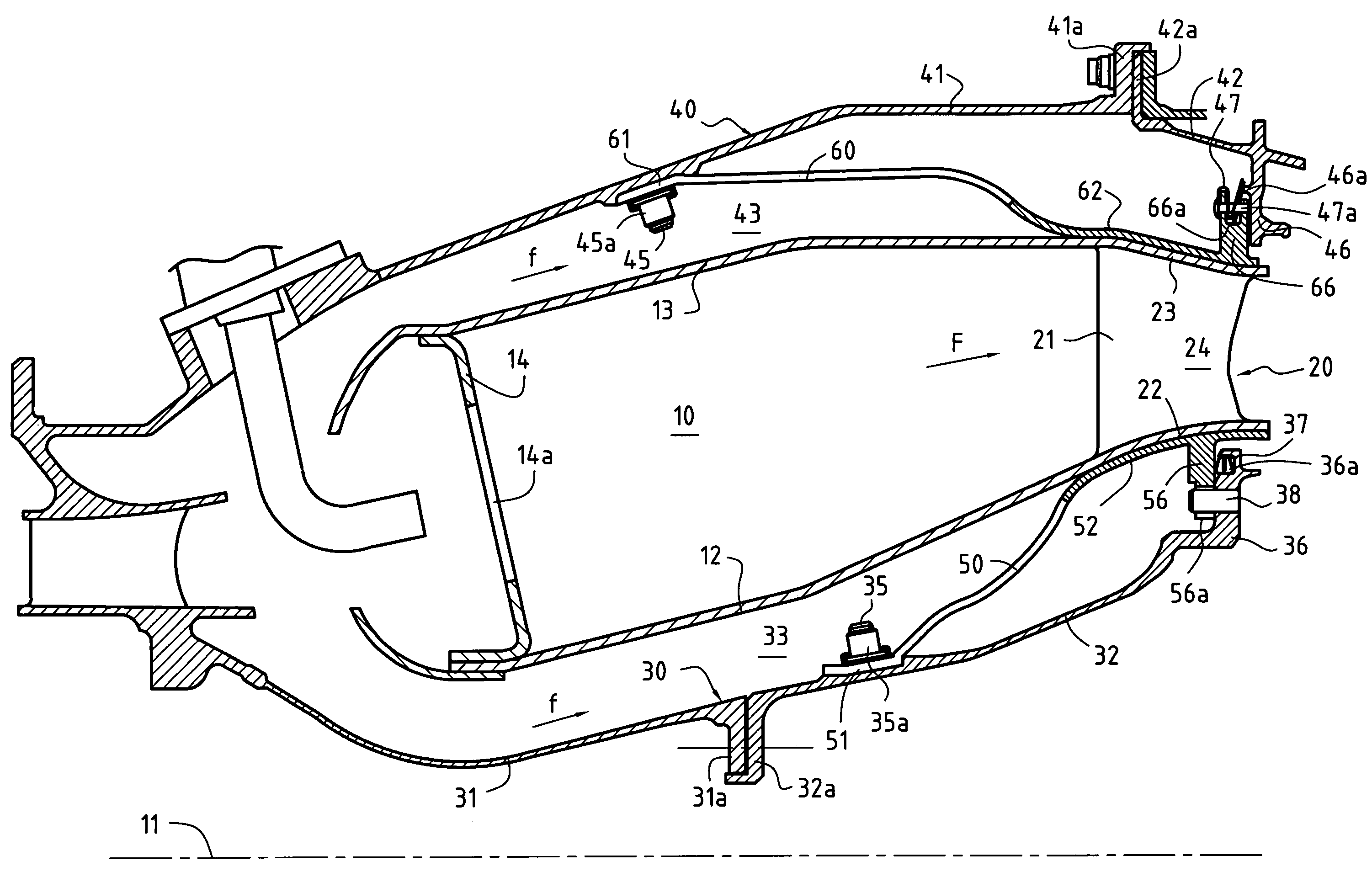

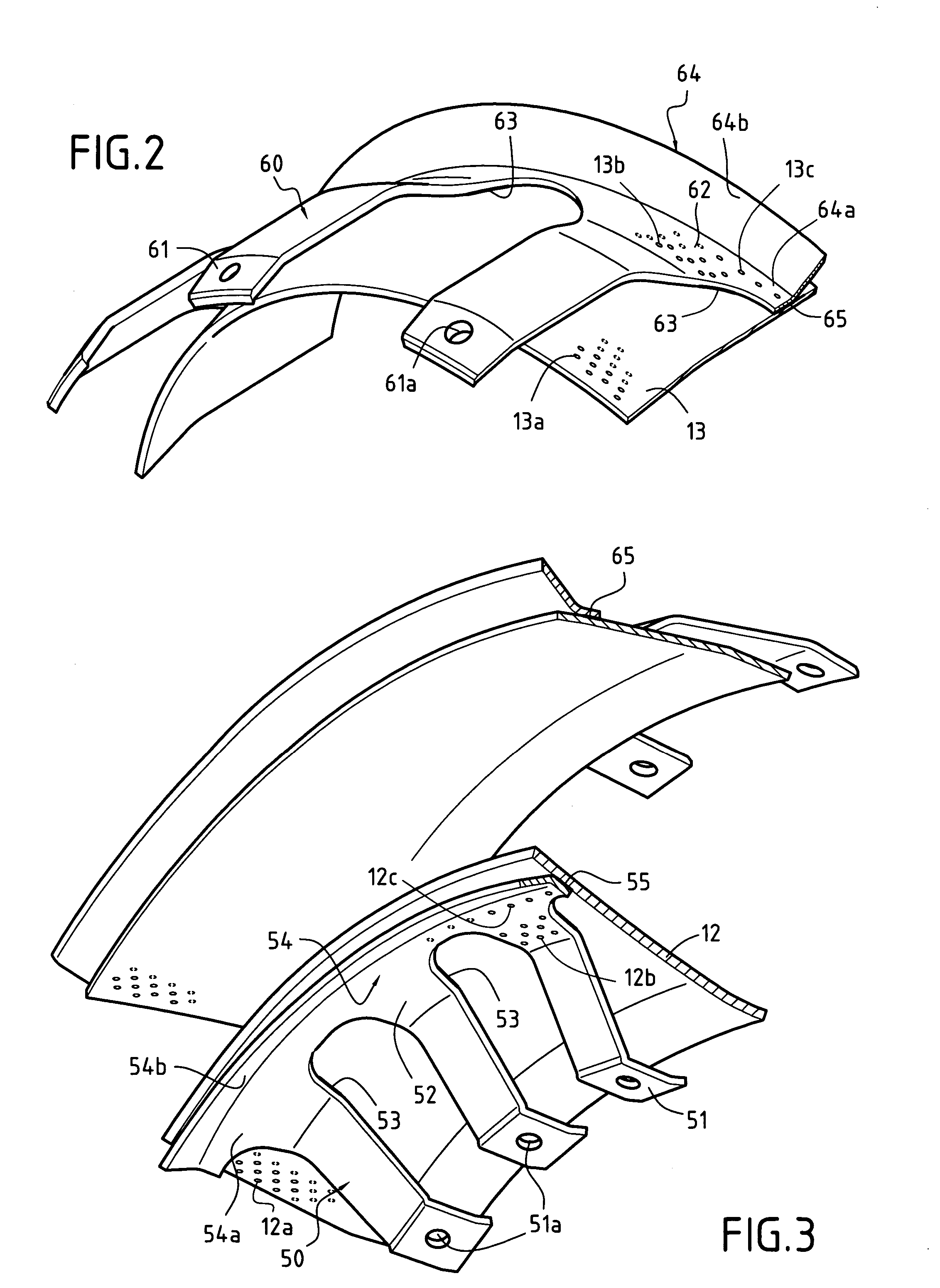

Turbine ring assembly

A turbine ring assembly includes a ring support structure and a plurality of ring sectors, each including a single piece of ceramic matrix composite material. Each ring sector includes a first portion forming an annular base with an inside face defining an inside face of the turbine ring and an outside face from which there extends two tab-forming portions including ends that are engaged in housings in the ring support structure. The ring sectors present a section that is substantially π-shaped and the ends of the tabs are held without radial clearance by the ring support structure. The tabs can have a free length in meridian section that is not less than three times their mean width.

Owner:GERAKL

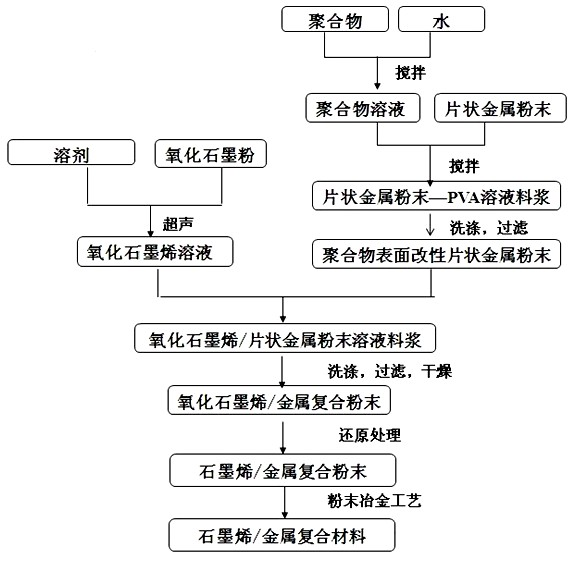

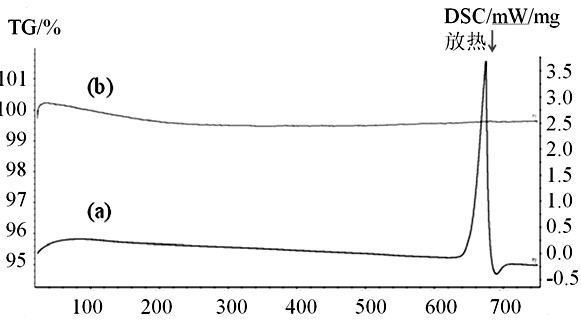

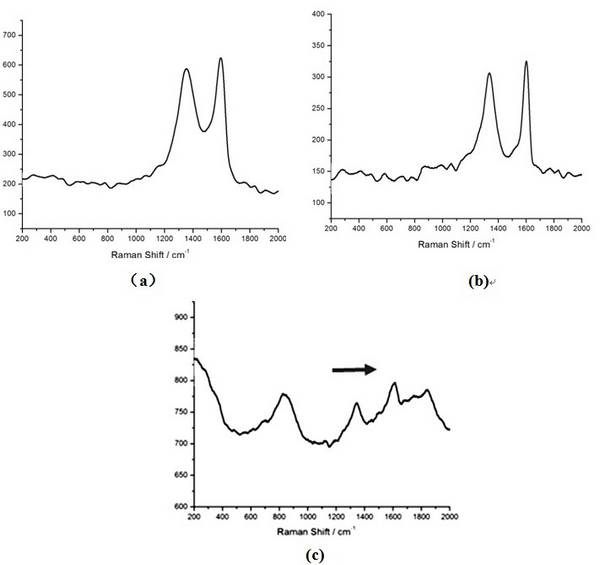

Preparation method of graphene reinforced metal-matrix composite

ActiveCN102329976AFacilitate induced orientation distributionPotential for large-scale applicationMetal matrix compositeCvd graphene

The invention discloses a preparation method of a graphene reinforced metal-matrix composite, which comprises the following steps of: firstly, dispersing the graphene oxide on the surface of the flaky metal powder; and then obtaining the graphene / metal composite powder through the reducing treatment; and at last, carrying out densification treatment by adopting a powder metallurgic technology to obtain the compact graphene reinforced metal-matrix composite. The flaky metal powder has the plane two-dimensional form, is inclined to the directional piling to form a laminated structure, and is helpful for inducing the graphene orientation distribution and giving play to the reinforcing effect. The preparation method disclosed by the invention is simple and feasible, is capable of regulating the graphene content and is suitable for preparing the massive composite.

Owner:SHANGHAI JIAO TONG UNIV

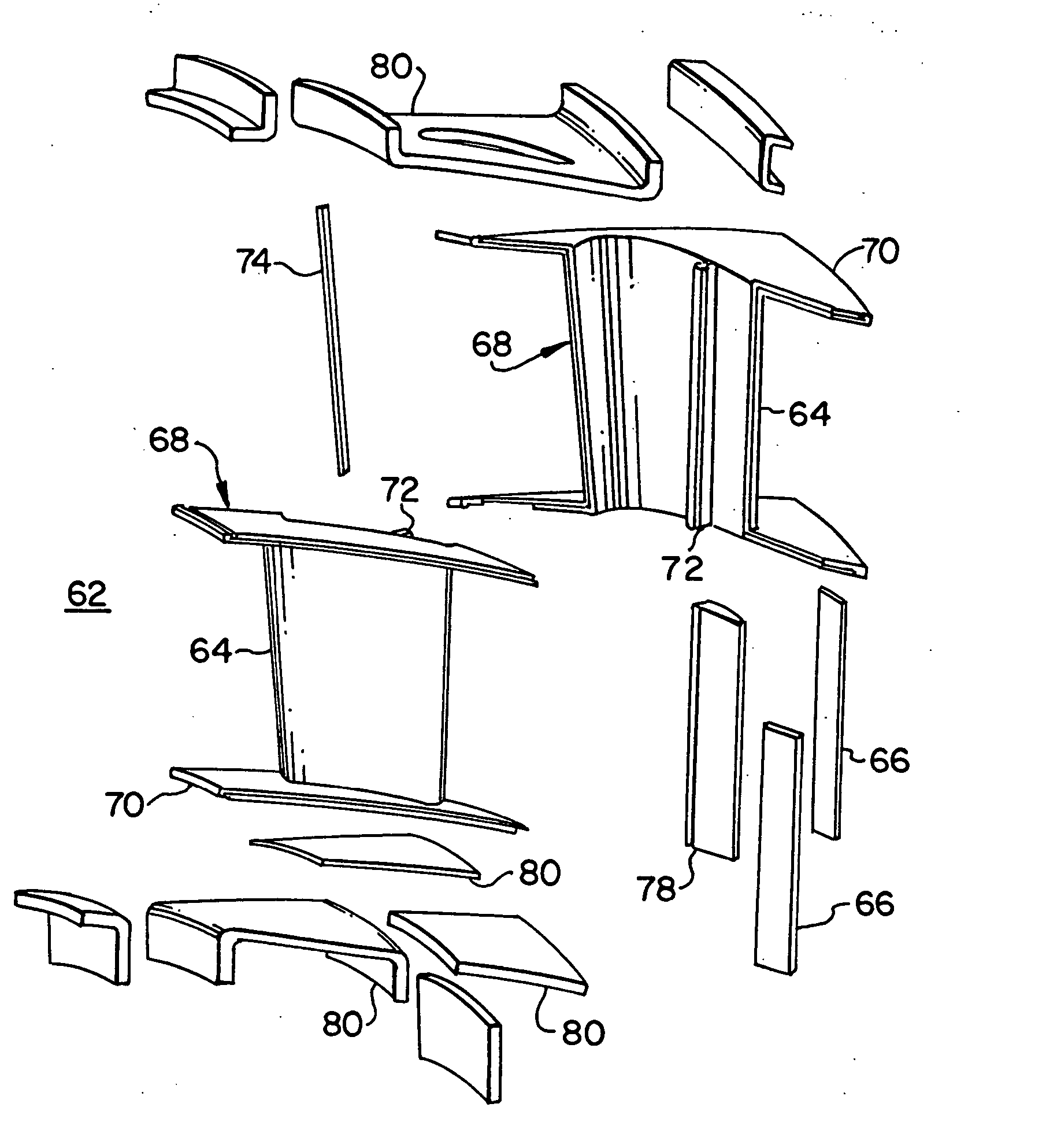

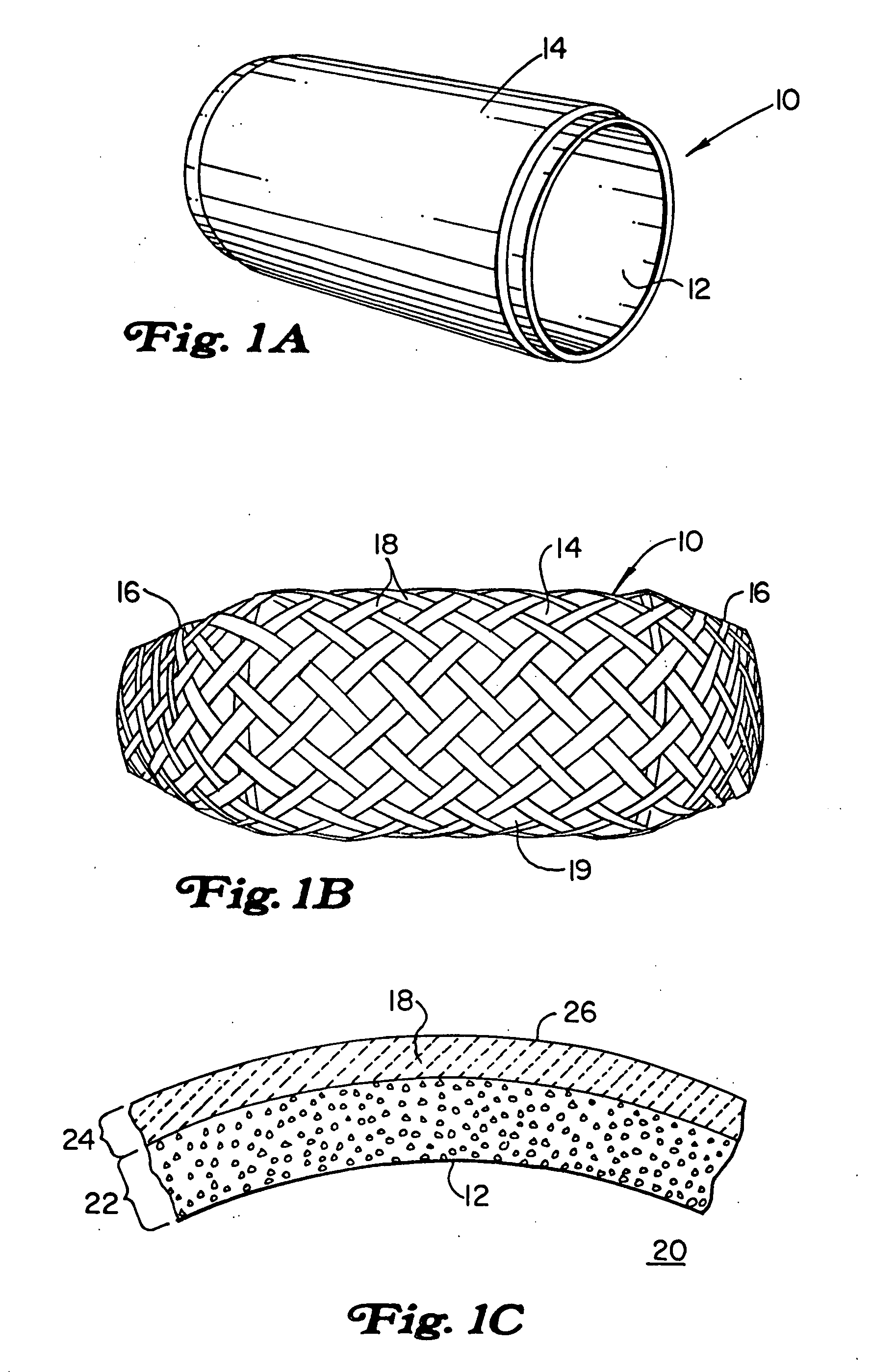

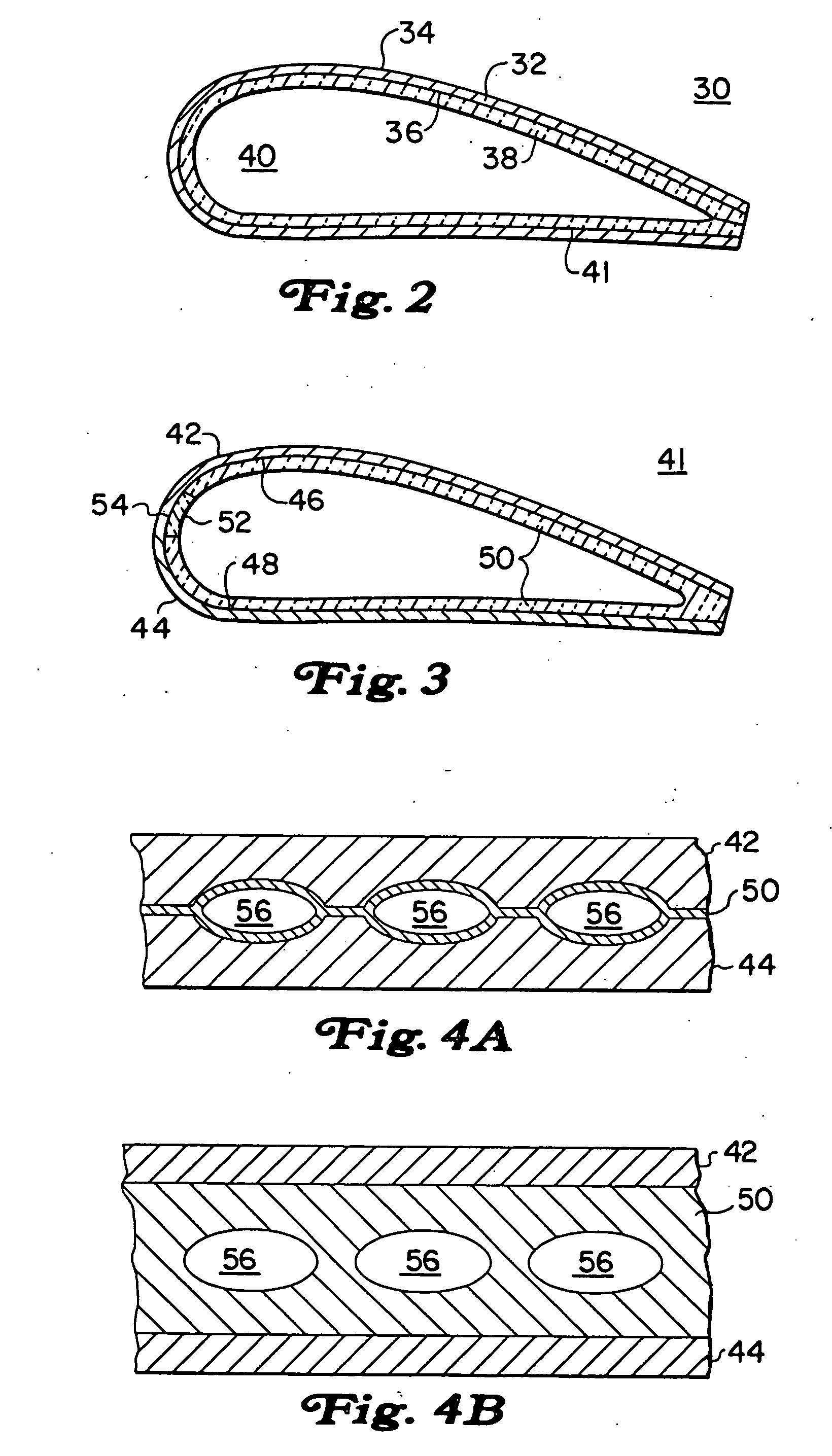

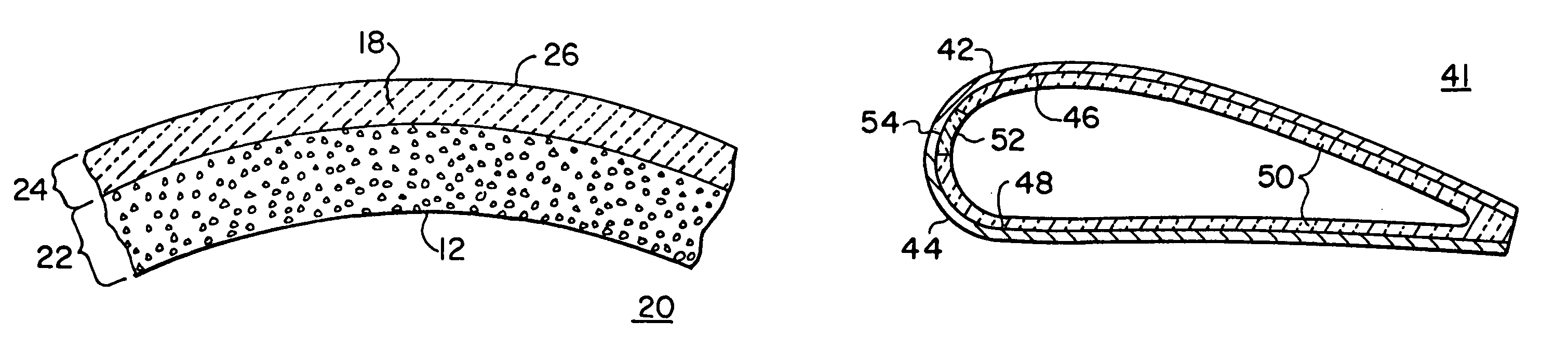

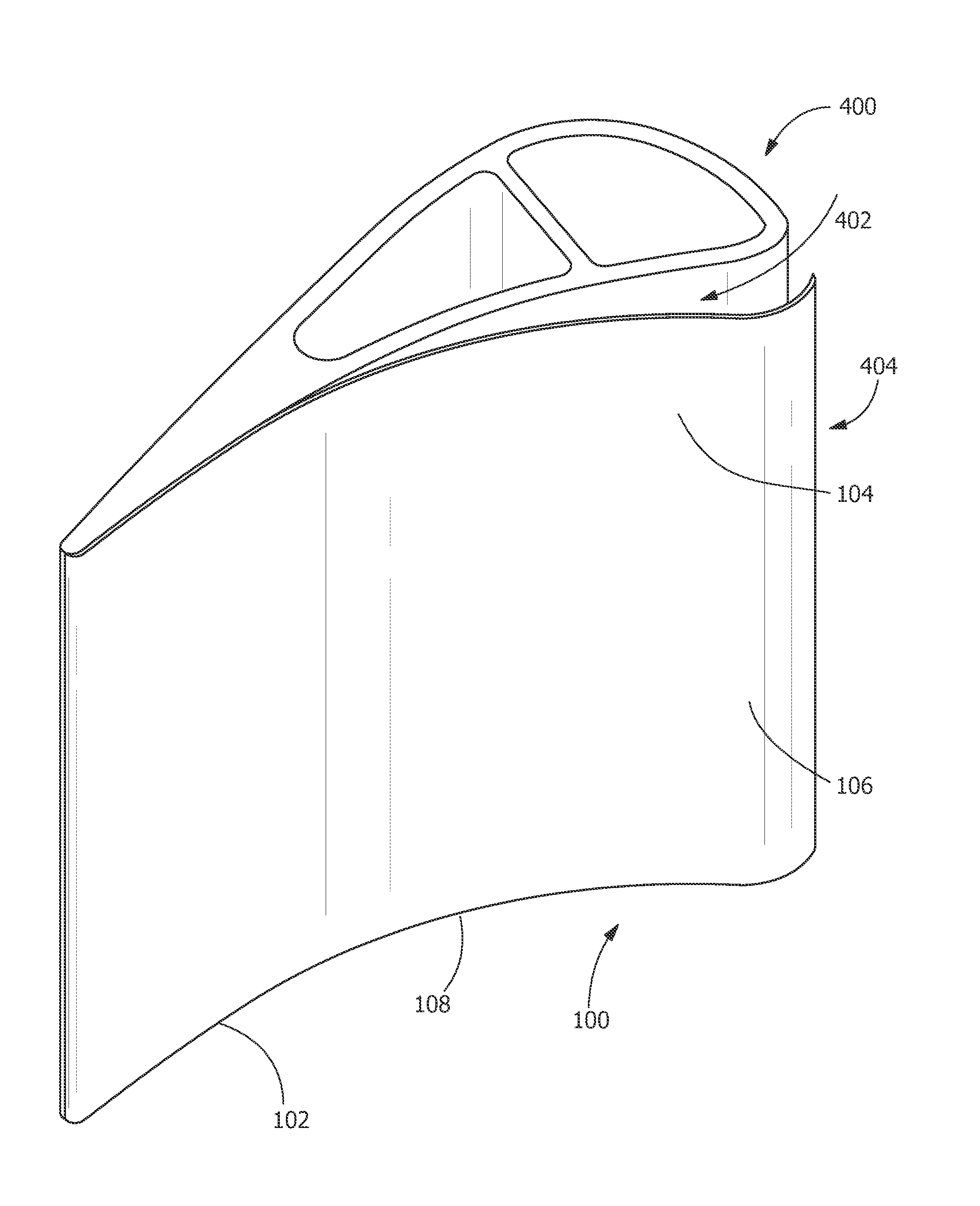

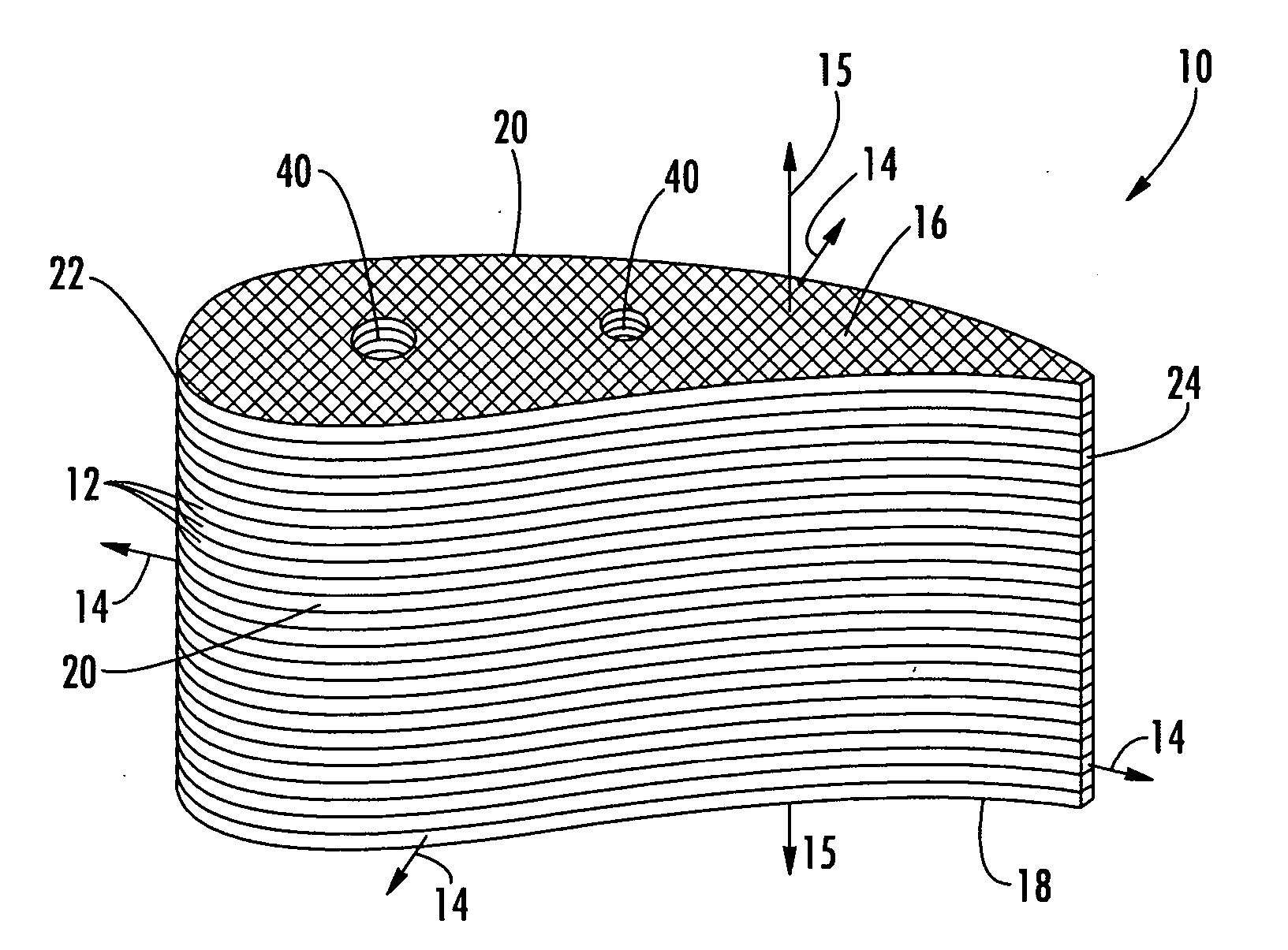

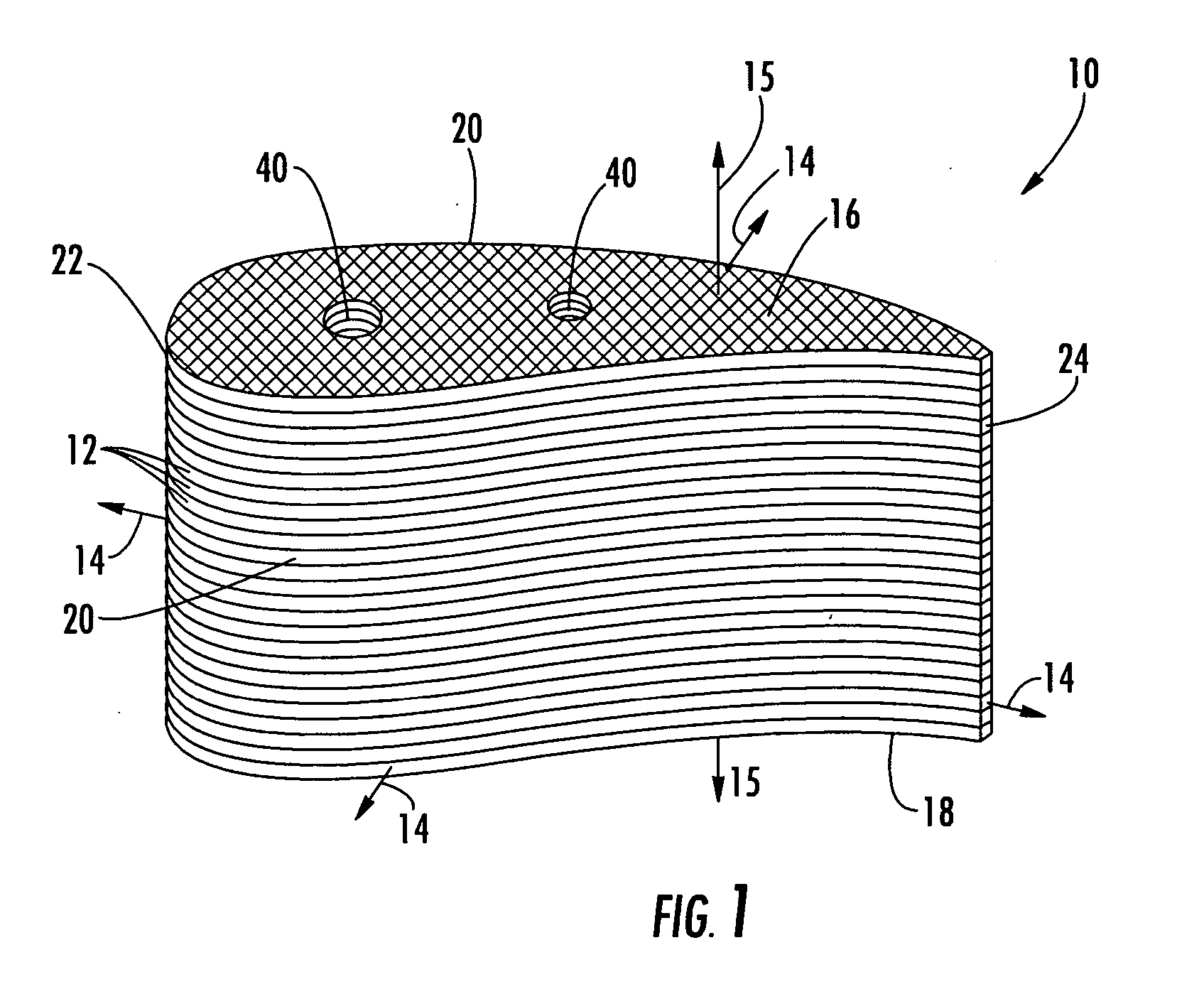

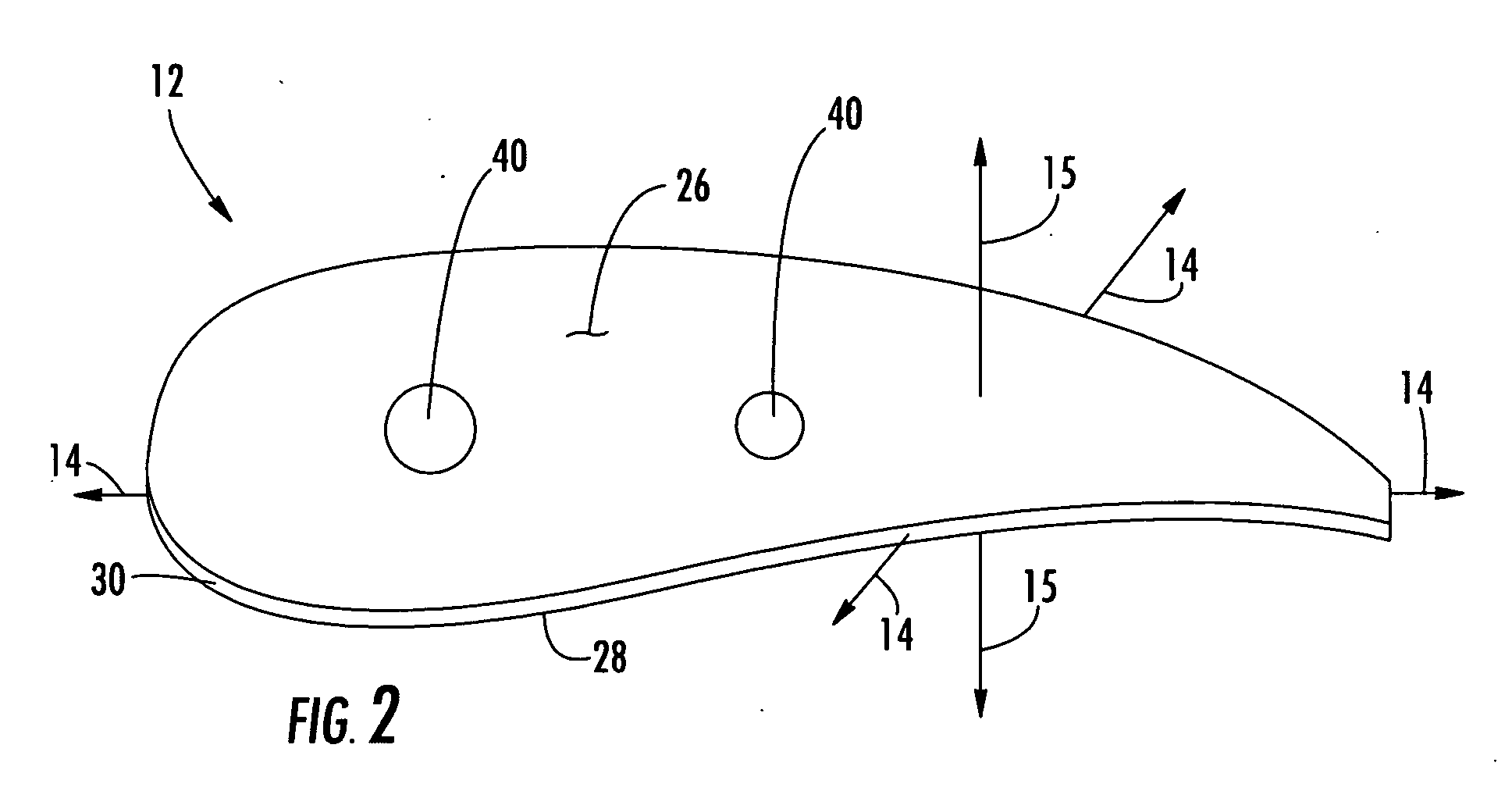

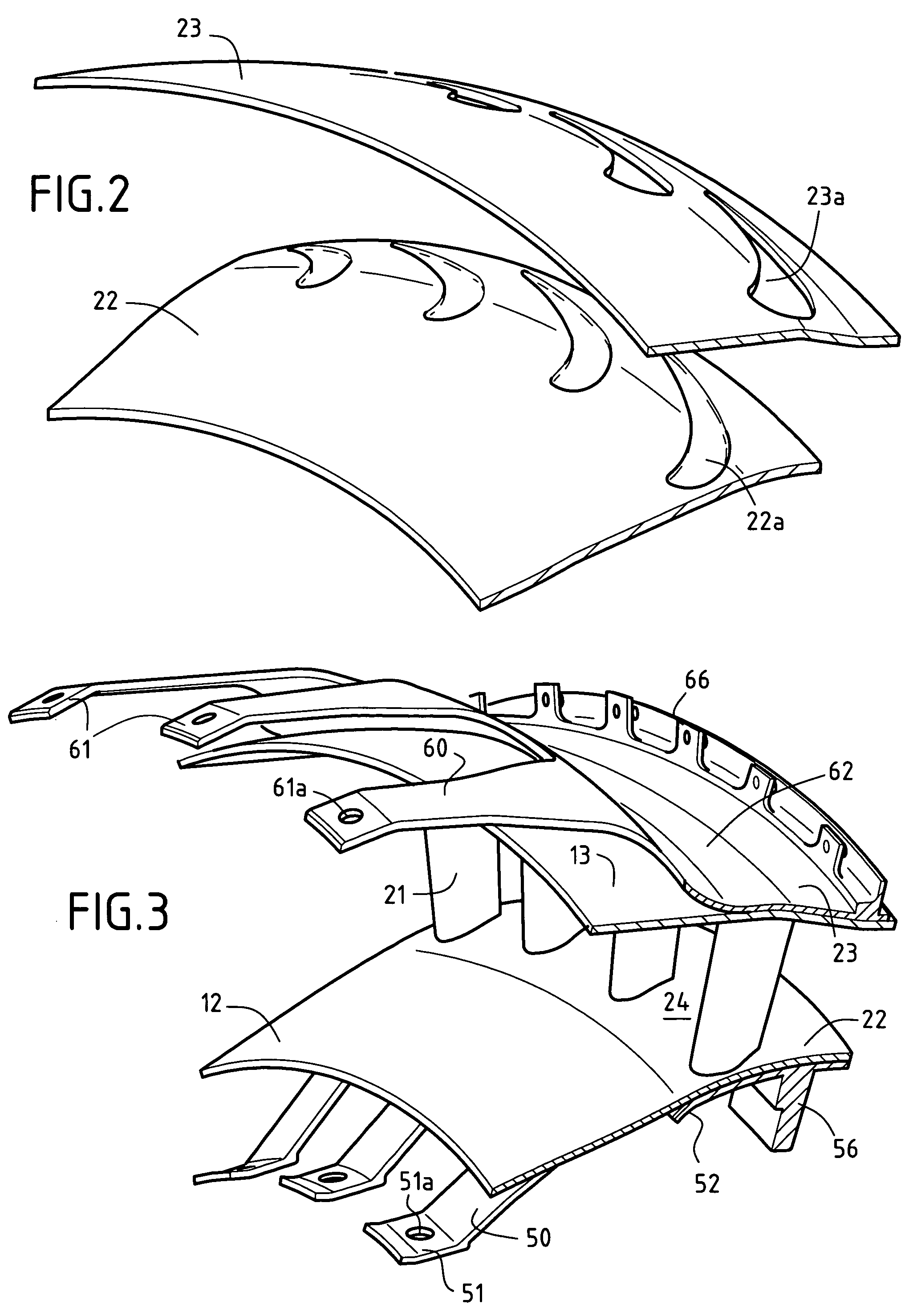

Composite structure formed by CMC-on-insulation process

ActiveUS20050076504A1Improved ceramic composite structureWood working apparatusCeramic layered productsCombustorEngineering

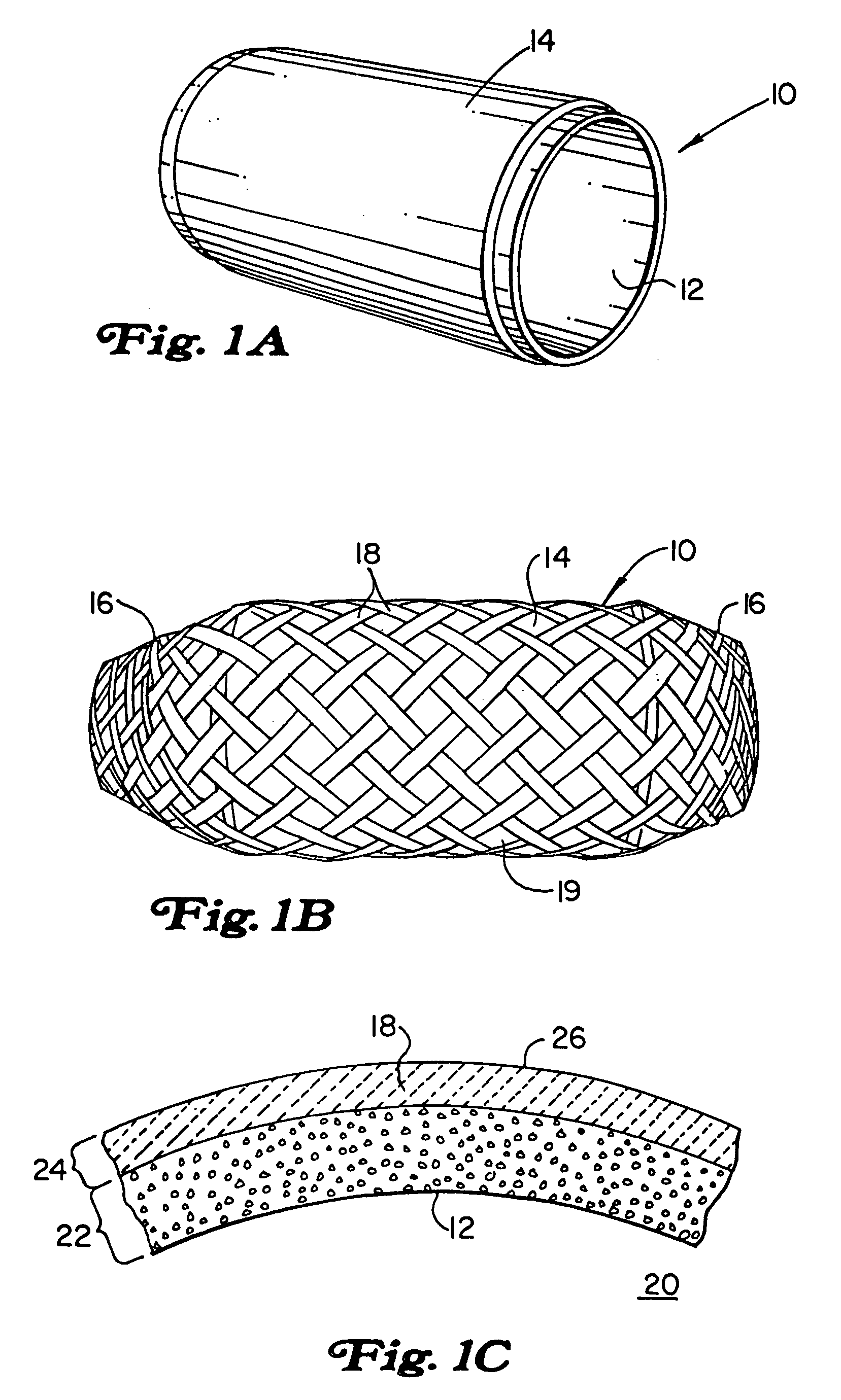

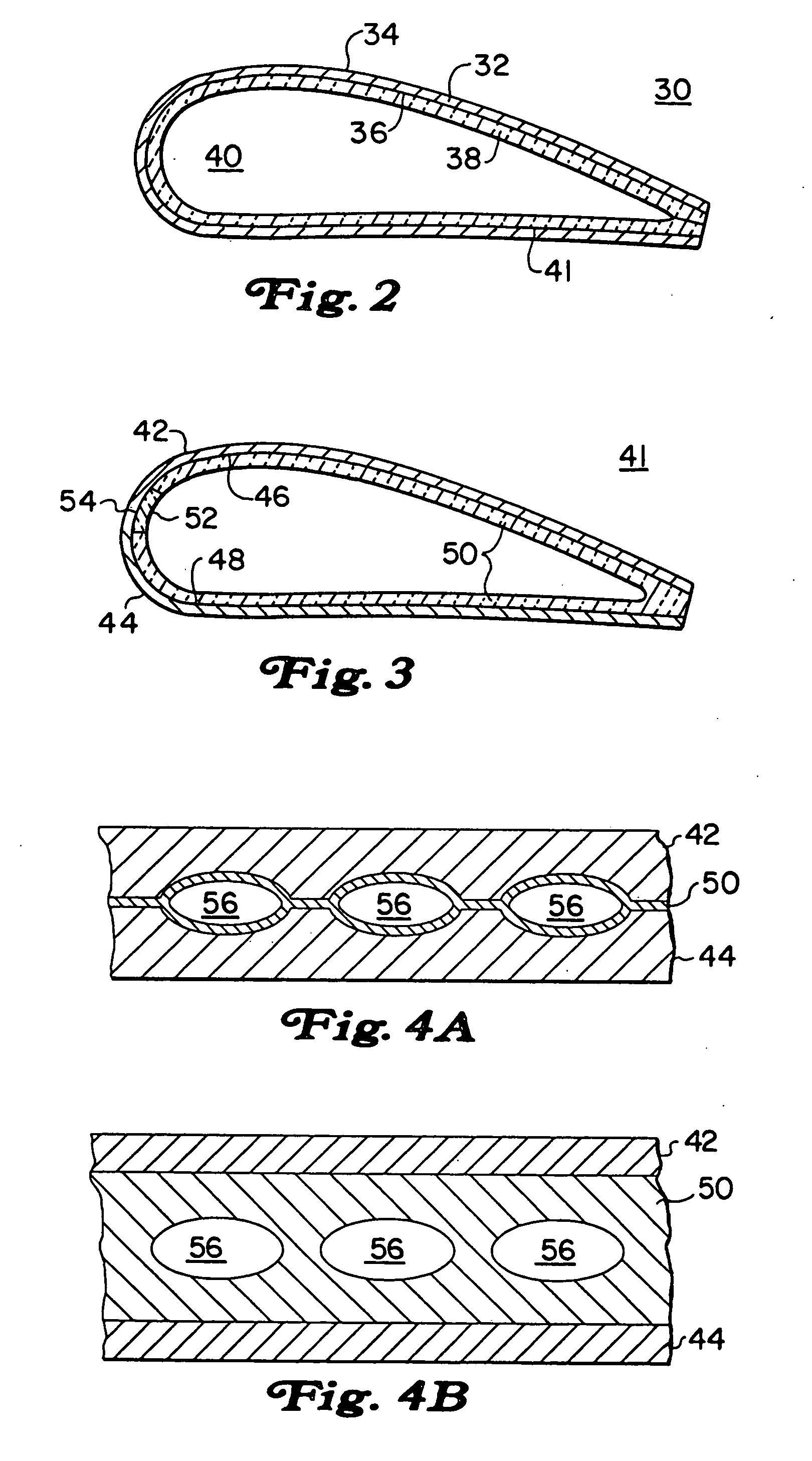

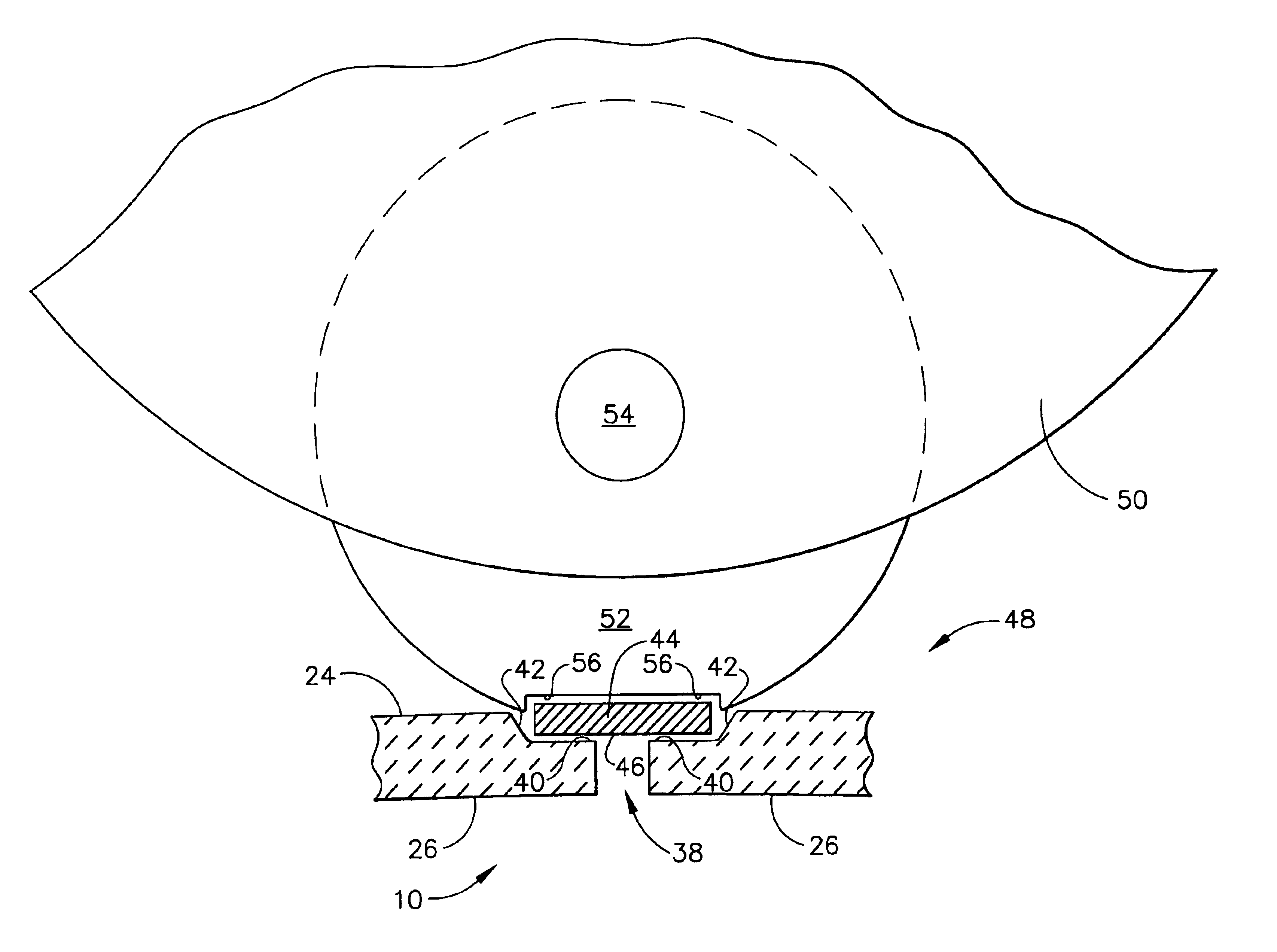

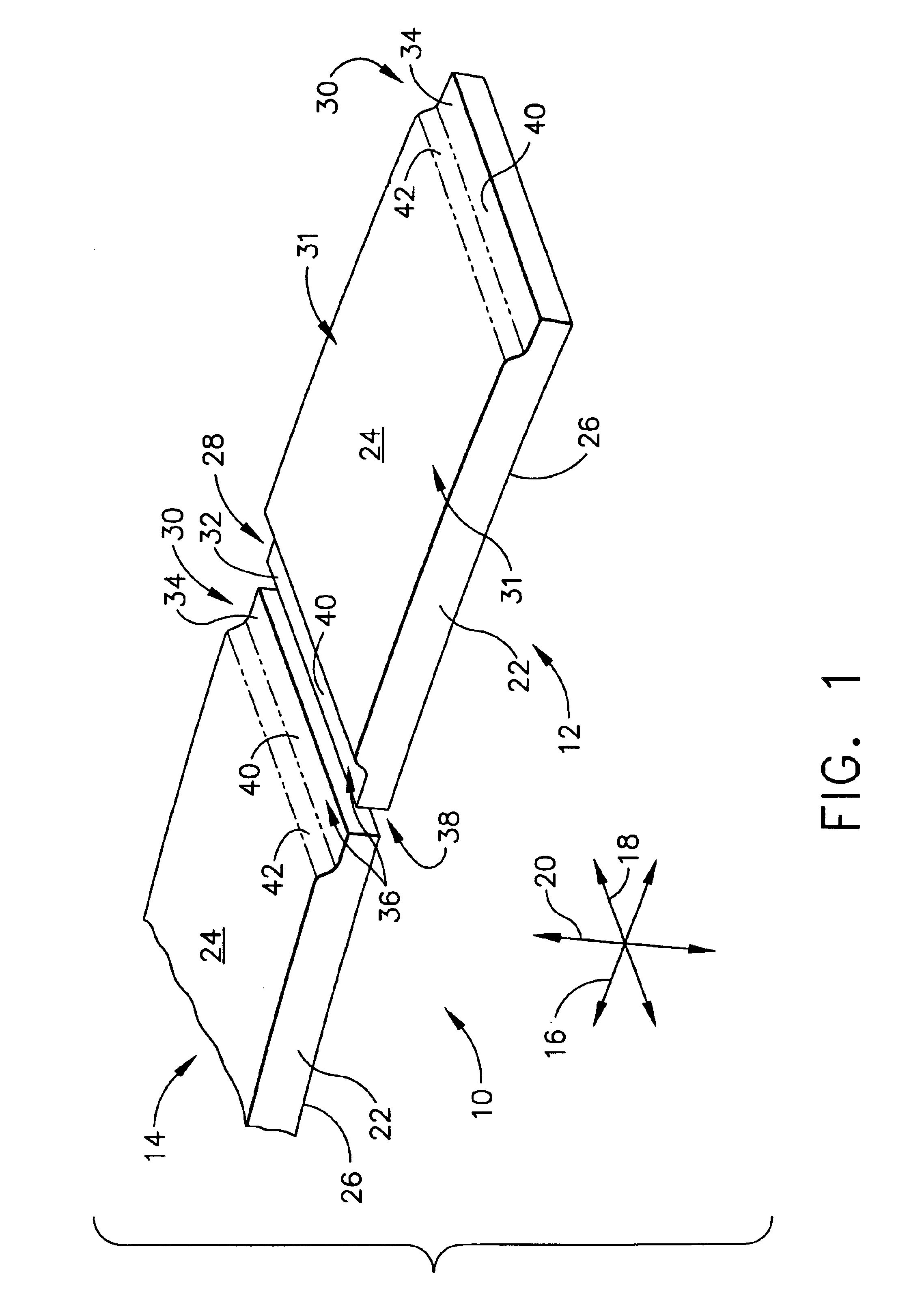

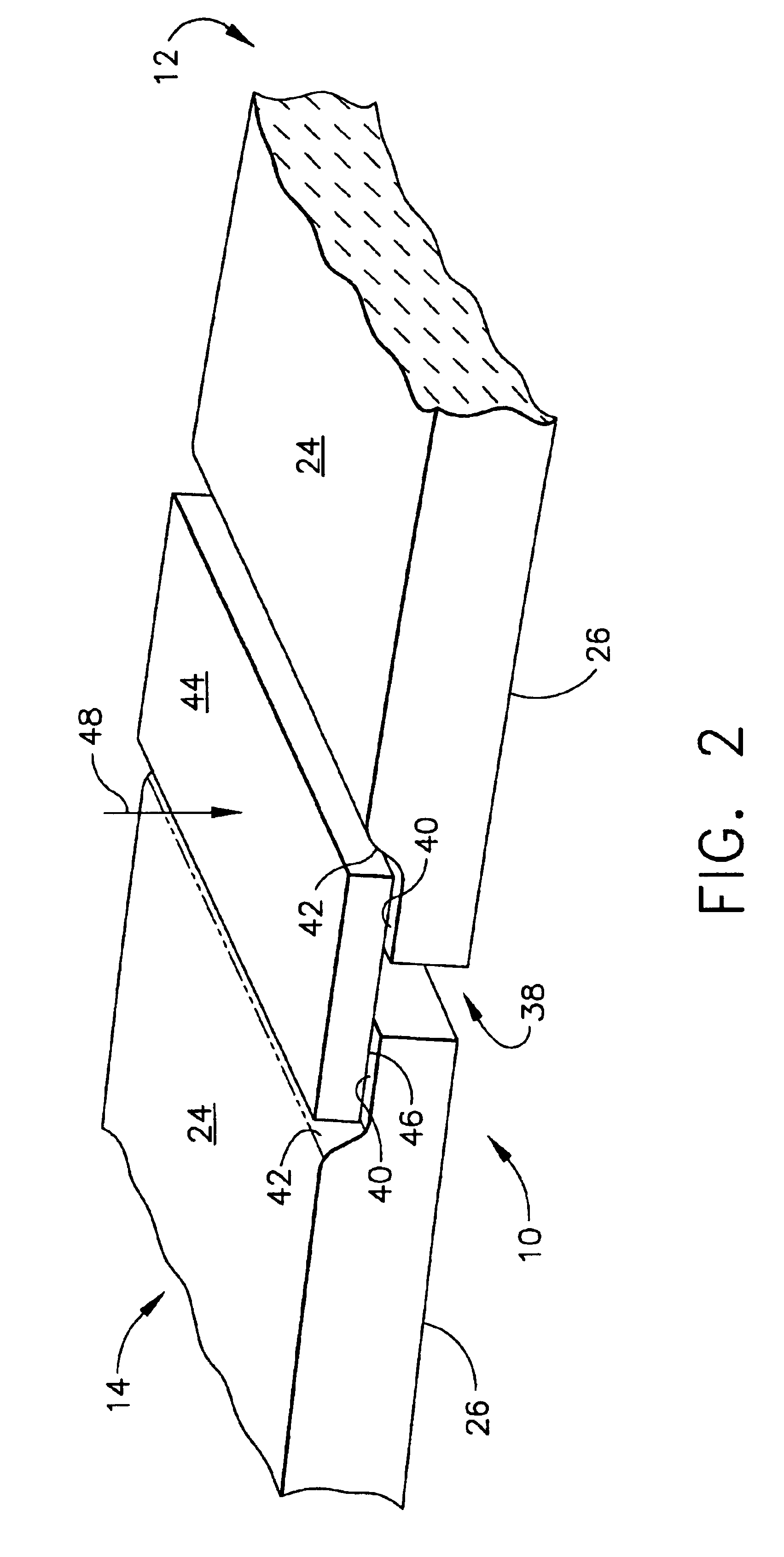

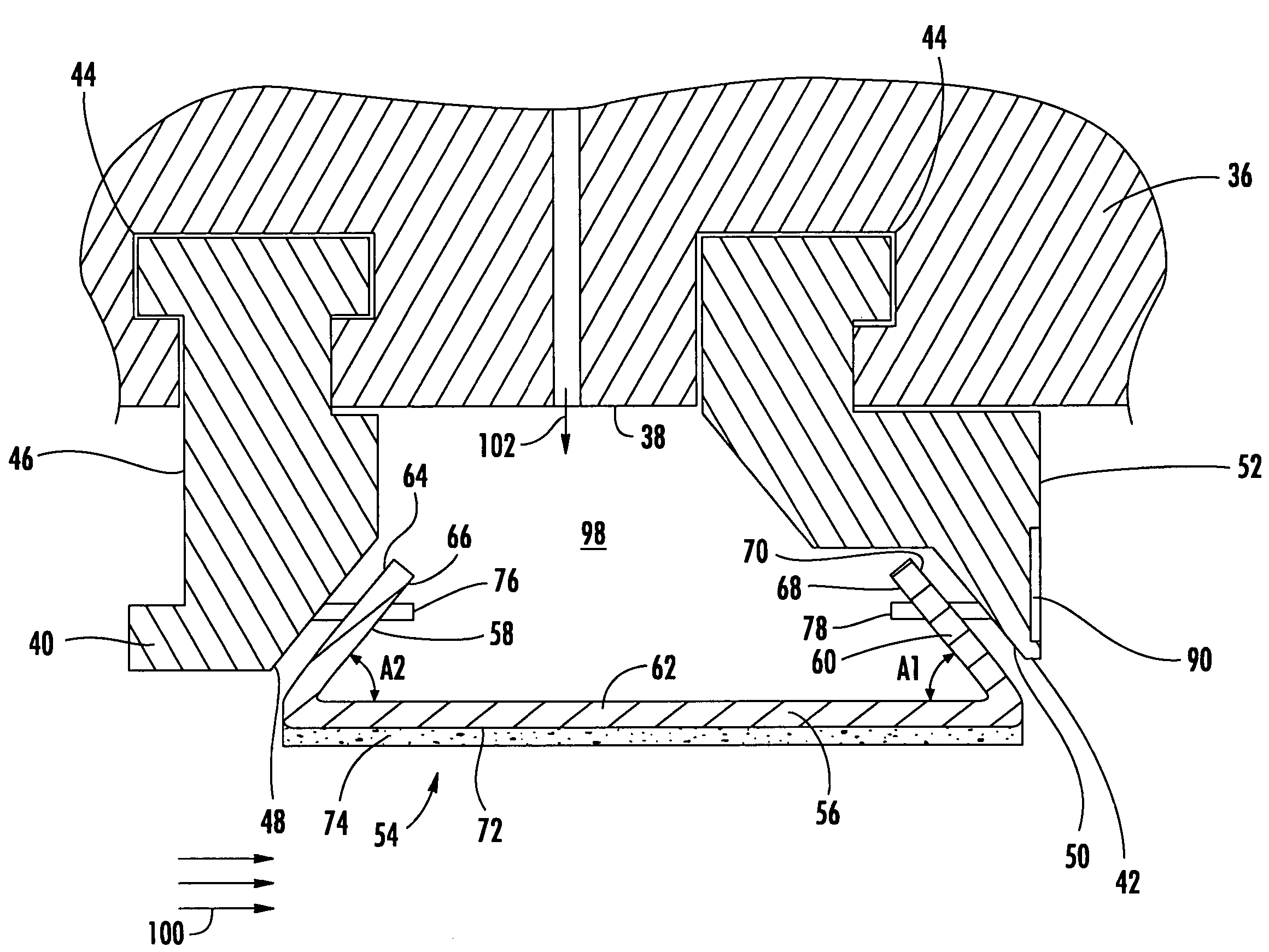

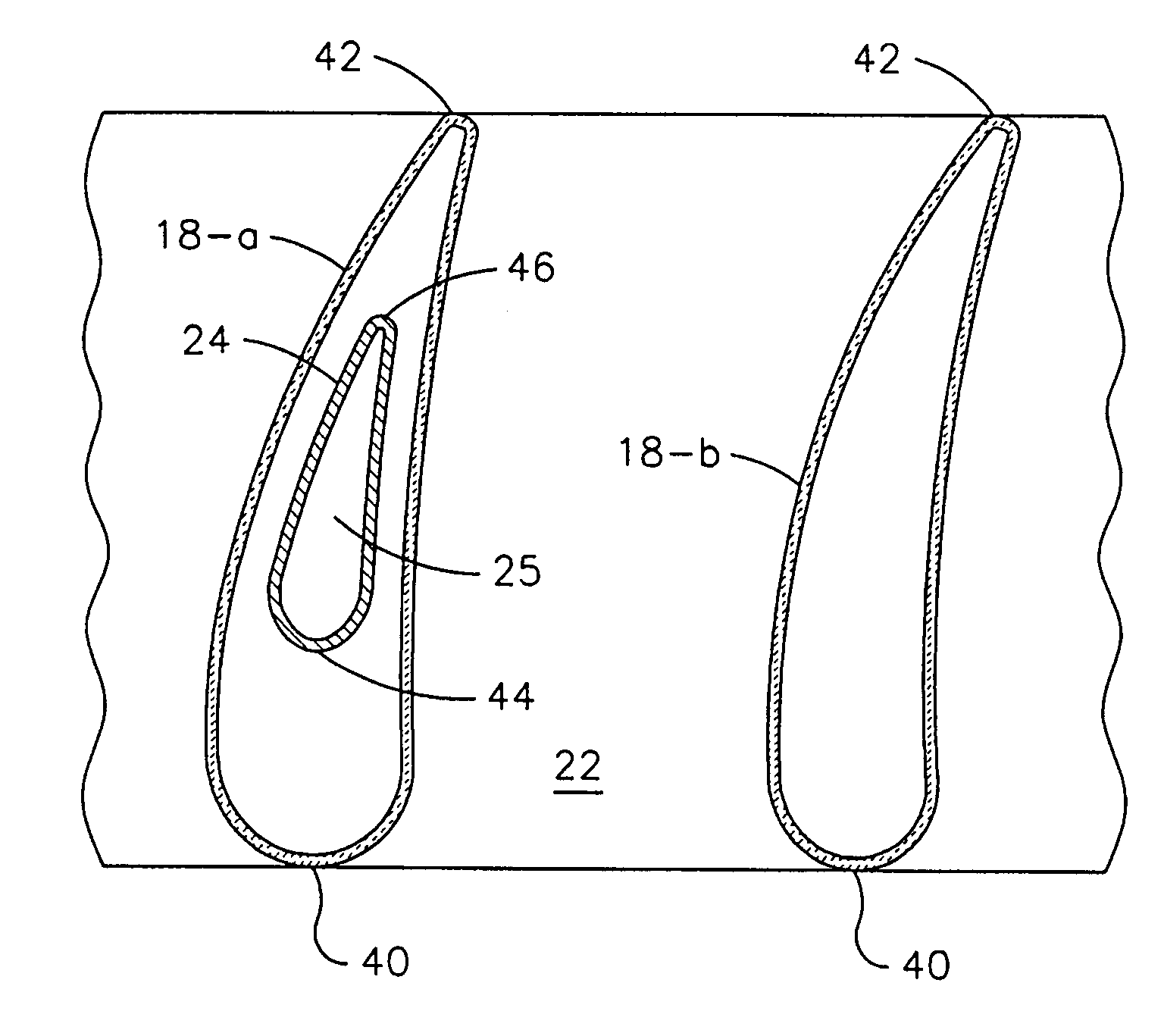

A method of manufacturing a composite structure uses a layer of an insulating material (22) as a mold for forming a substrate of a ceramic matrix composite (CMC) material (24). The insulating material may be formed in the shape of a cylinder (10) with the CMC material wound on an outer surface (14) of the cylinder to form a gas turbine combustor liner (20). Alternatively, the insulating material may be formed in the shape of an airfoil section (32) with the CMC material formed on an inside surface (36) of the insulating material. The airfoil section may be formed of a plurality of halves (42, 44) to facilitate the lay-up of the CMC material onto an easily accessible surface, with the halves then joined together to form the complete composite airfoil. In another embodiment, a box structure (102) defining a hot gas flow passage (98) is manufactured by forming insulating material in the shape of opposed airfoil halves (104) joined at respective opposed ends by platform members (109). A layer of CMC material (107) is then formed on an outside surface of the insulating material. A number of such composite material box structures are then joined together to form a vane ring (100) for a gas turbine engine.

Owner:SIEMENS ENERGY INC

Composite structure formed by CMC-on-insulation process

A method of manufacturing a composite structure uses a layer of an insulating material (22) as a mold for forming a substrate of a ceramic matrix composite (CMC) material (24). The insulating material may be formed in the shape of a cylinder (10) with the CMC material wound on an outer surface (14) of the cylinder to form a gas turbine combustor liner (20). Alternatively, the insulating material may be formed in the shape of an airfoil section (32) with the CMC material formed on an inside surface (36) of the insulating material. The airfoil section may be formed of a plurality of halves (42, 44) to facilitate the lay-up of the CMC material onto an easily accessible surface, with the halves then joined together to form the complete composite airfoil. In another embodiment, a box structure (102) defining a hot gas flow passage (98) is manufactured by forming insulating material in the shape of opposed airfoil halves (104) joined at respective opposed ends by platform members (109). A layer of CMC material (107) is then formed on an outside surface of the insulating material. A number of such composite material box structures are then joined together to form a vane ring (100) for a gas turbine engine.

Owner:SIEMENS ENERGY INC

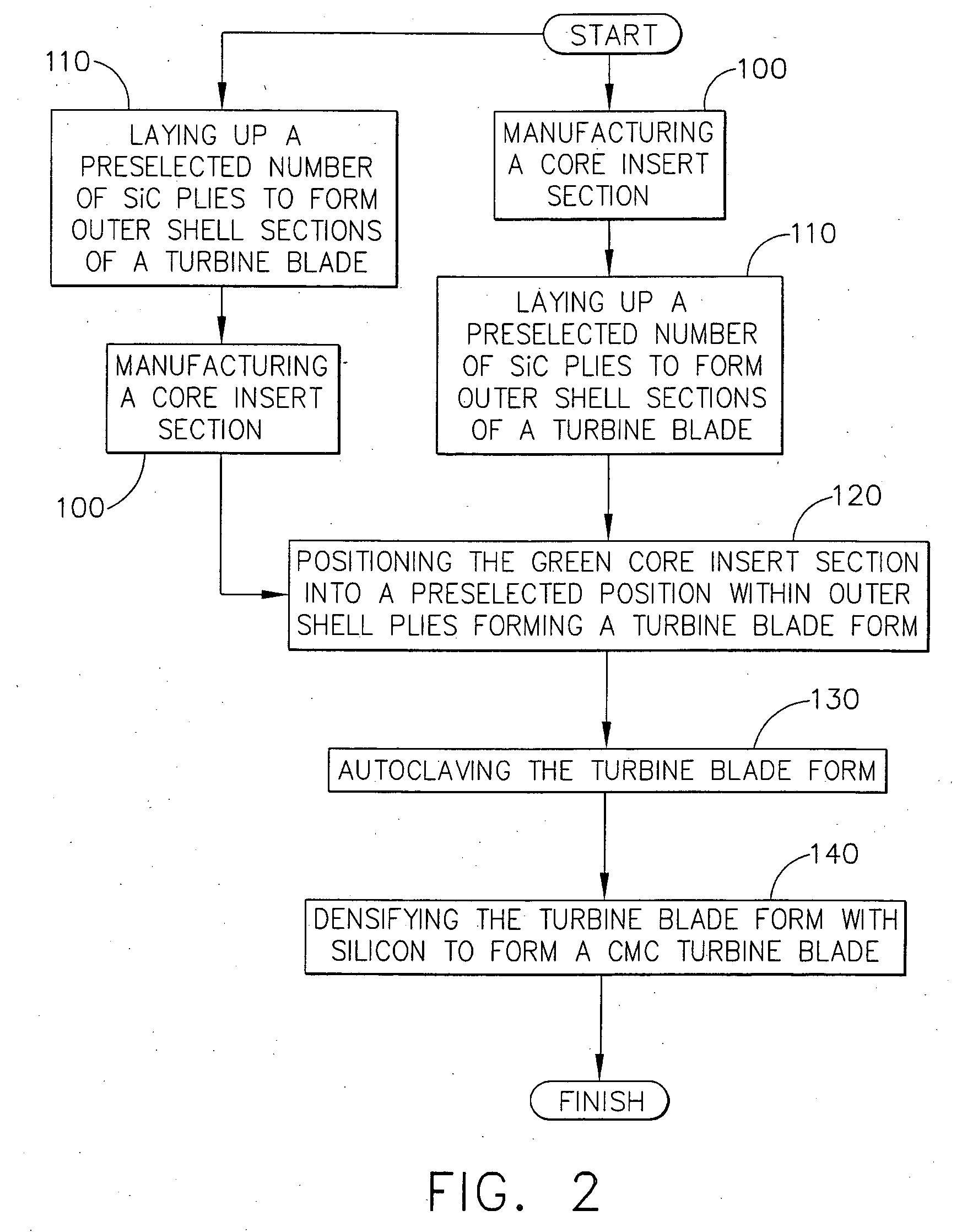

Hybrid ceramic matrix composite turbine blades for improved processibility and performance

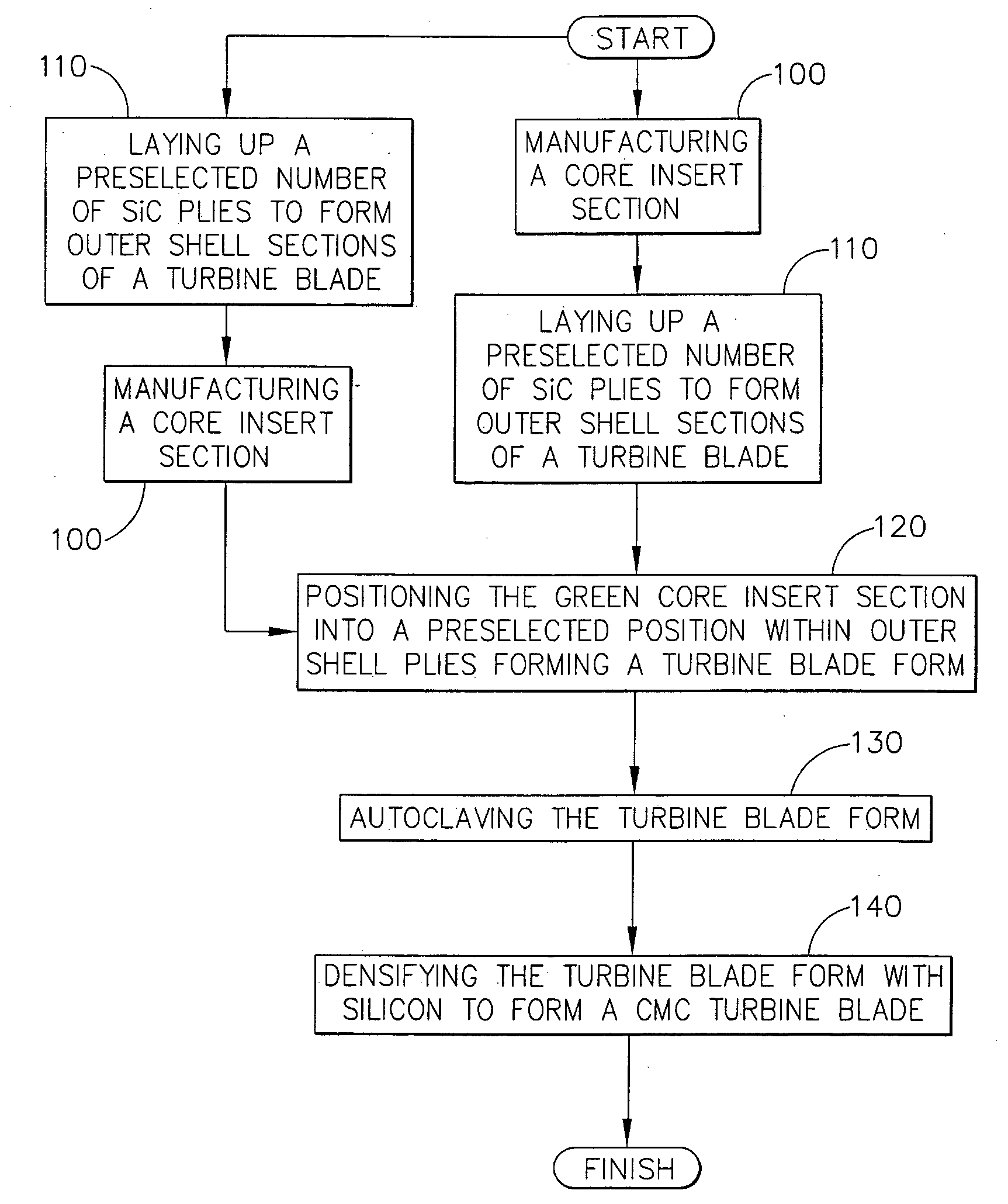

InactiveUS20050158171A1Easy to buildImproving back fracture toughnessPump componentsGas turbine plantsMetallurgyTurbine blade

The present invention is a hybrid ceramic matrix composite turbine engine component comprising an outer shell section(s) and an inner core section(s), wherein the outer shell section(s) and the inner core section(s) were bonded together using an MI process. The outer shell section(s) comprises a SiC / SiC material that has been manufactured using a process selected from the group consisting of a slurry cast MI process and a prepreg MI process. The inner core section(s) comprises a material selected from the group consisting an Si / SiC composite material and a monolithic ceramic material. The Si / SiC composite material may be manufactured using the Silcomp process. The present invention may be a high pressure turbine blade, a high pressure turbine vane, a low pressure turbine blade, or a low pressure turbine vane. The present invention is also a method of manufacturing a hybrid ceramic matrix composite turbine engine component.

Owner:GENERAL ELECTRIC CO

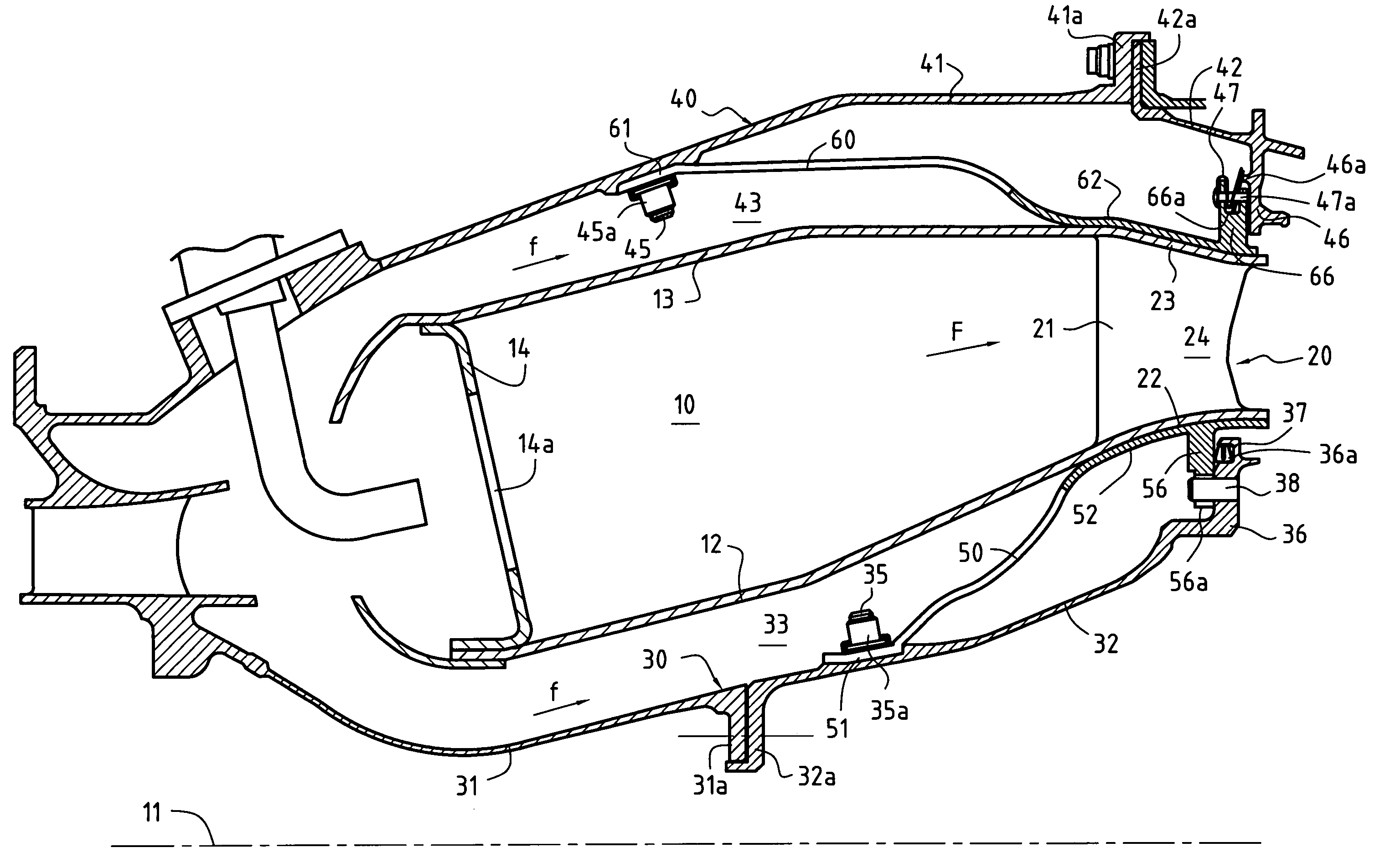

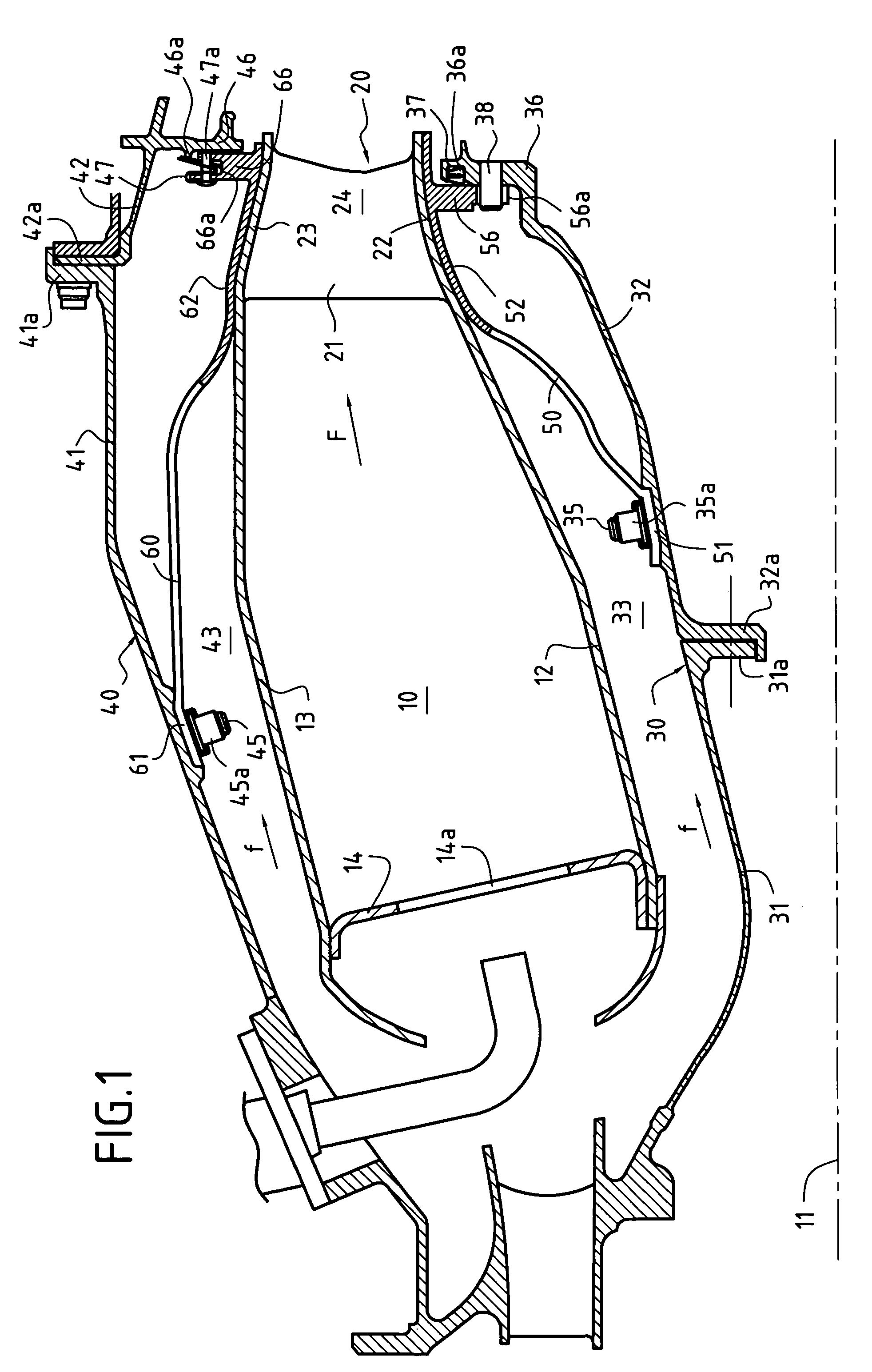

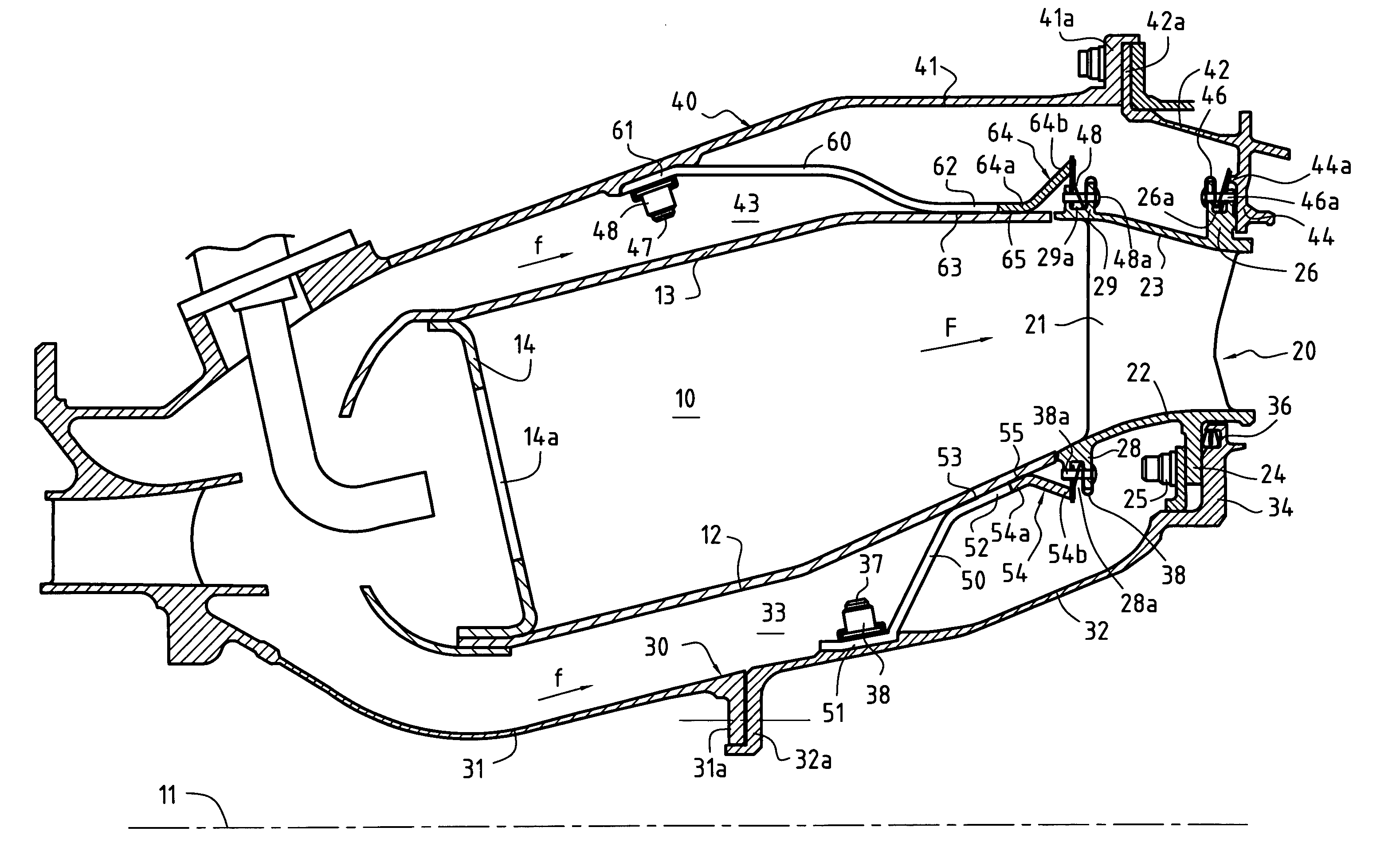

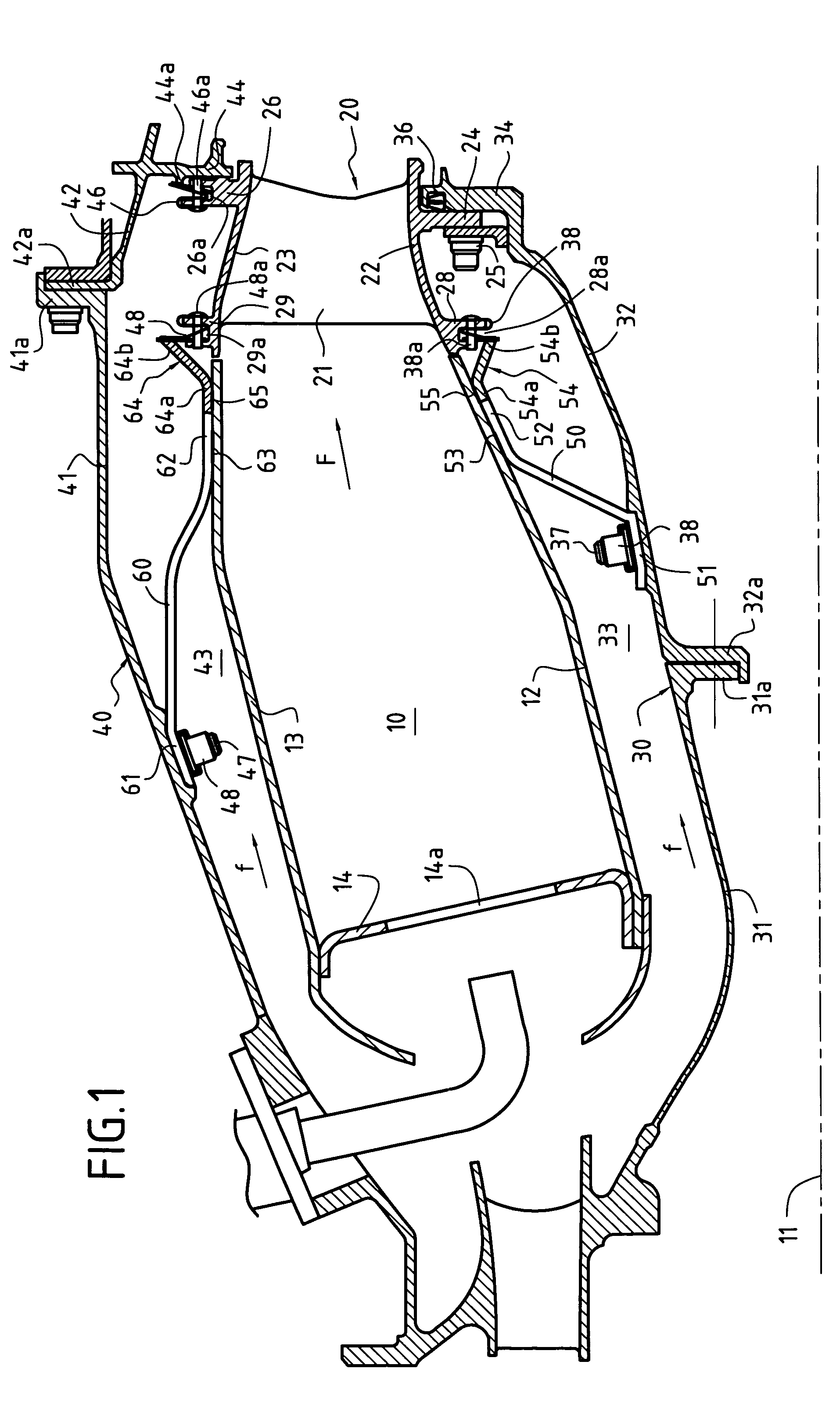

Mounting a turbine nozzle on a combustion chamber having CMC walls in a gas turbine

ActiveUS20060010879A1Reduce in quantityReduce weightPump componentsGas turbine plantsCombustion chamberHigh pressure

The gas turbine comprises an annular combustion chamber having inner and outer walls made of ceramic matrix composite material, and a high pressure turbine nozzle secured to a downstream end of the combustion chamber and comprising a plurality of stationary airfoils extending between the inner and outer walls of an annular flow path through the nozzle for the gas stream coming from the combustion chamber. The turbine nozzle is made of ceramic matrix composite material and it is connected to the downstream end of the combustion chamber by brazing.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

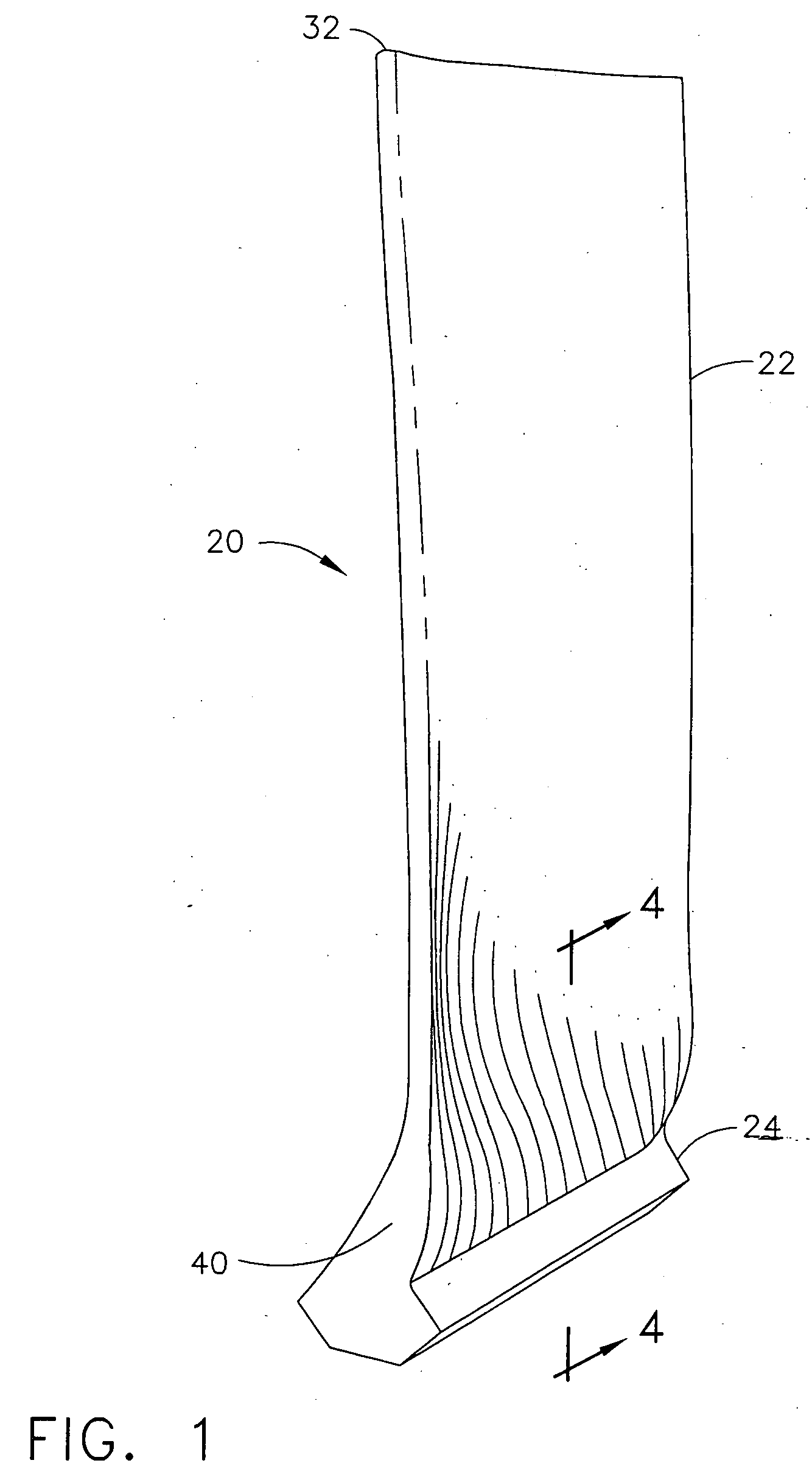

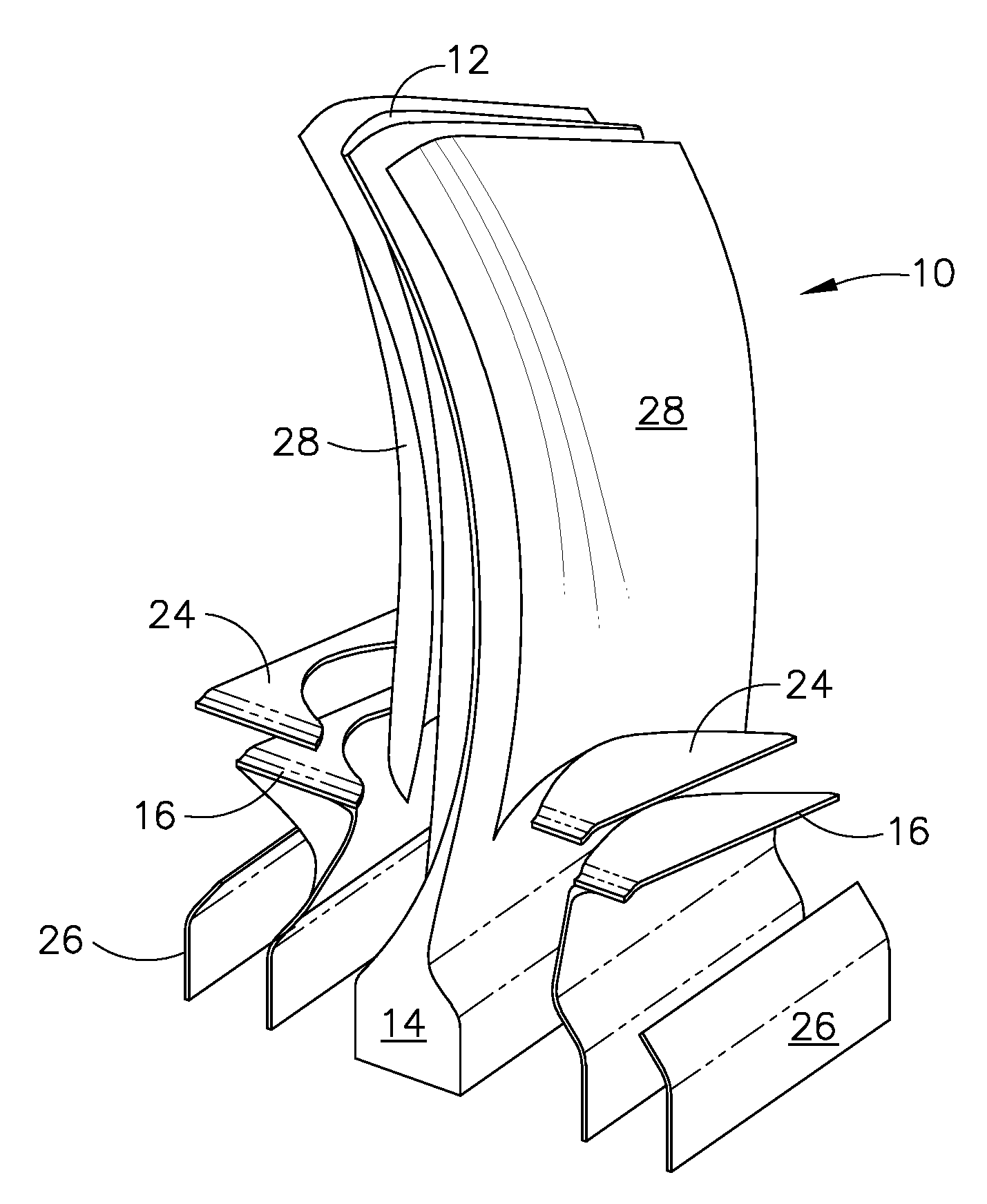

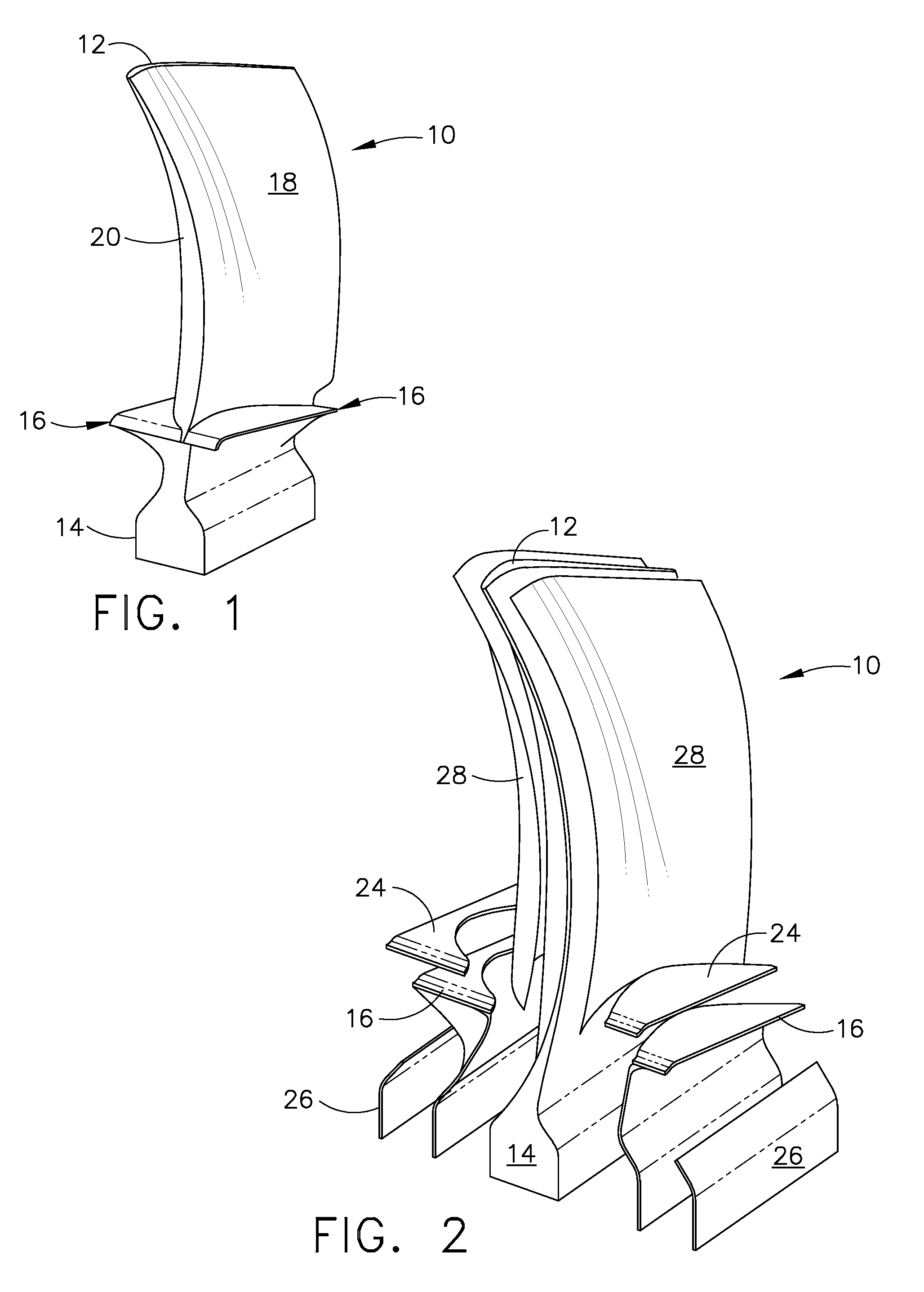

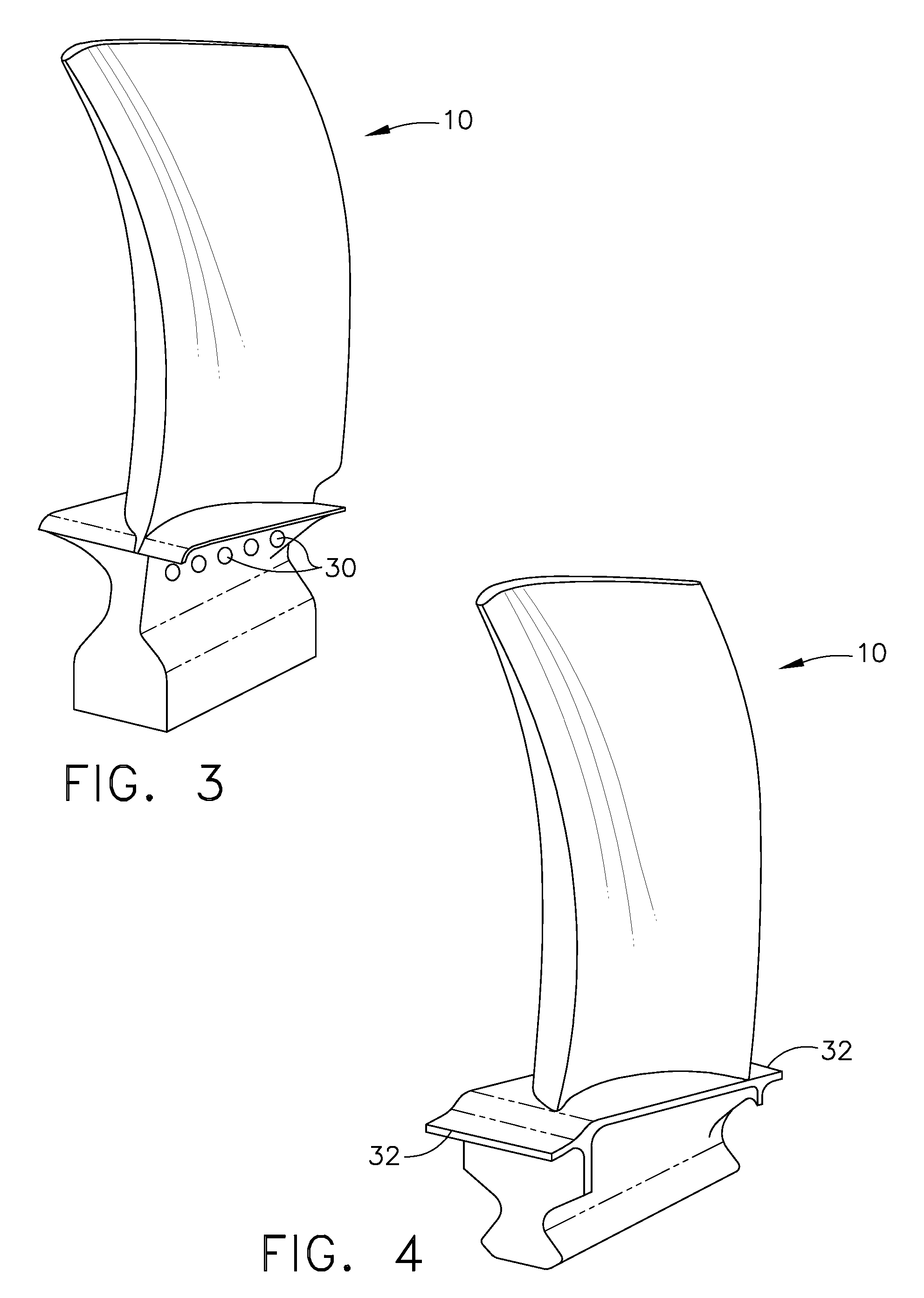

Ceramic matrix composite blade having integral platform structures and methods of fabrication

ActiveUS20110027098A1Improve the immunityHigh strengthMechanical working/deformationPropellersMetallurgyCeramic matrix composite

A method of making a ceramic matrix composite blade includes laying up at least one ply of the plurality of fibrous ceramic plies in a preselected arrangement to form an airfoil and dovetail preform, laying up at least one additional ply of the plurality of fibrous ceramic plies on the airfoil and dovetail preform in a second preselected arrangement to form an integral platform as part of the non-rigidized blade preform, rigidizing the blade preform to form a rigidized blade preform, and densifying the rigidized blade preform to form a ceramic matrix composite blade having an integral platform structure. A tool for making the ceramic matrix composite blade and a ceramic matrix composite blade are also disclosed.

Owner:GENERAL ELECTRIC CO

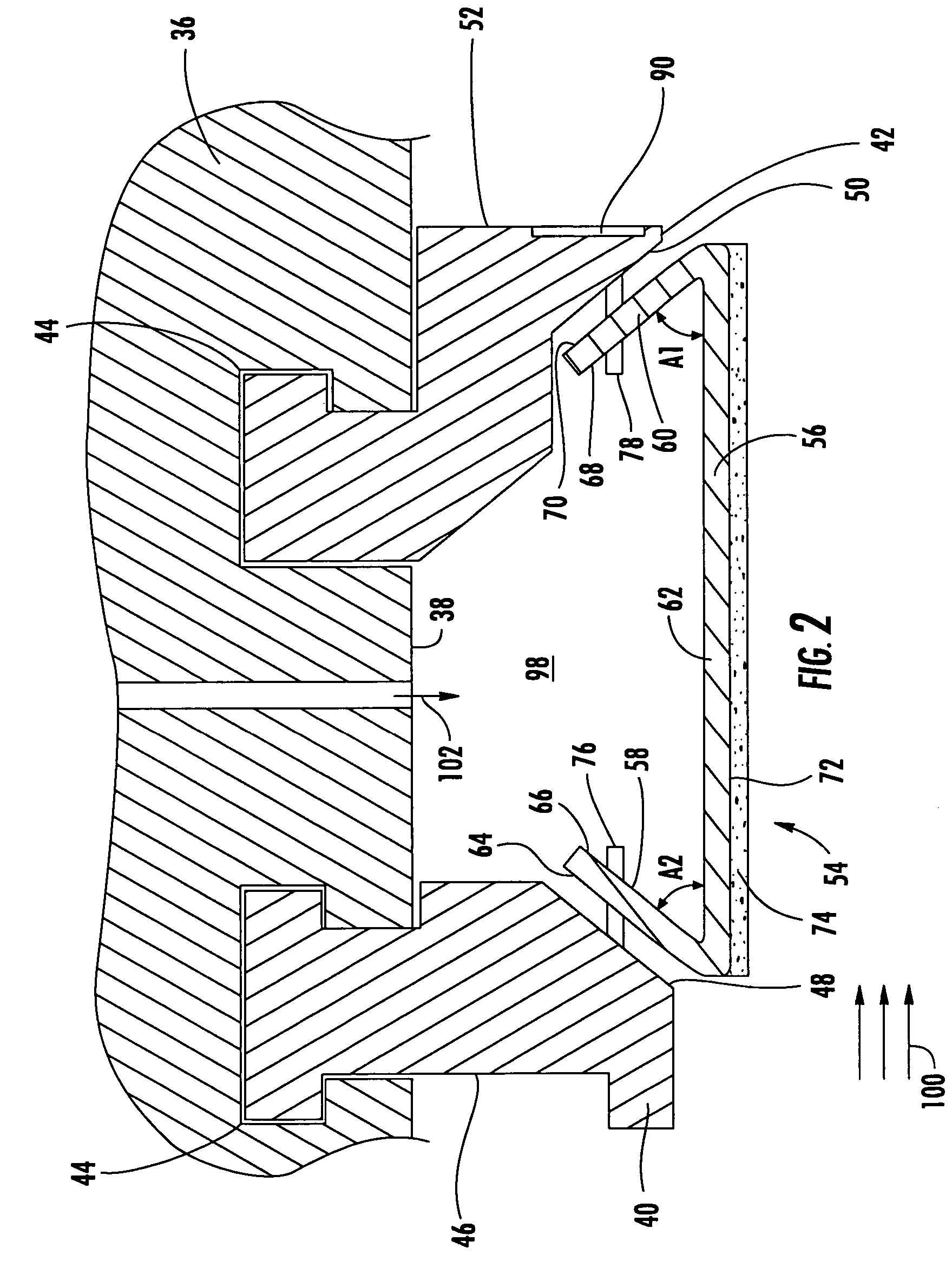

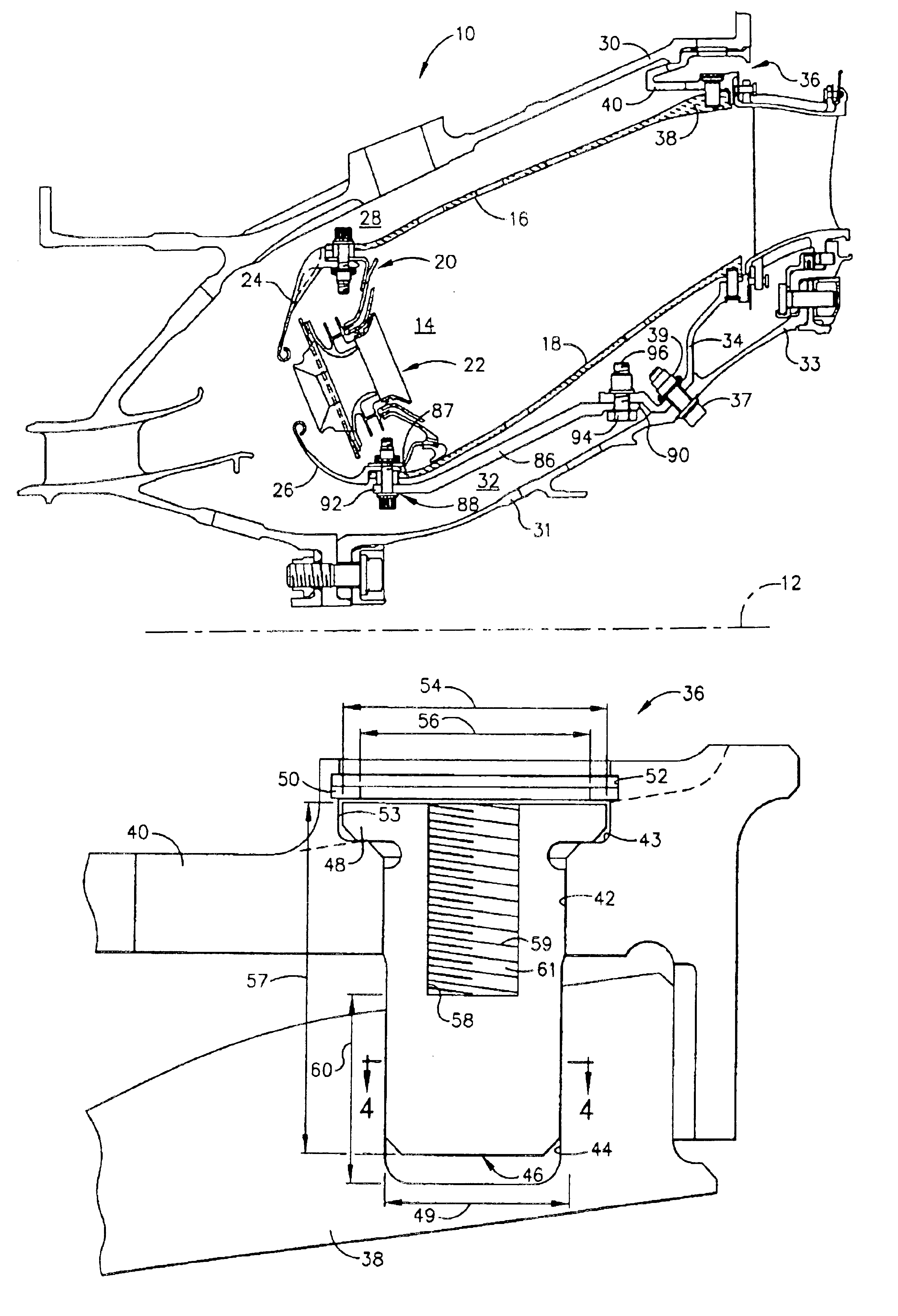

Sealing assembly for the aft end of a ceramic matrix composite liner in a gas turbine engine combustor

ActiveUS6895757B2Low thermal expansionContinuous combustion chamberGas turbine plantsCombustorEngineering

An assembly for providing a seal at an aft end of a combustor liner for a gas turbine engine including a longitudinal centerline axis extending therethrough. The sealing assembly includes a substantially annular first sealing member positioned between an aft portion of a support member and the liner aft end so as to seat on a designated surface portion of the liner aft end and a substantially annular second sealing member positioned between the support member aft portion and a turbine nozzle located downstream of the liner aft end so as to seat on a designated surface portion of the support member aft portion. Accordingly, the first sealing member is maintained in its seated position as the support member aft portion moves radially with respect to the liner aft end and the second sealing member is maintained in its seated position as the support member aft portion moves axially with respect to the turbine nozzle. The first and second sealing members are also maintained in their respective seating positions as the support member aft portion moves axially with respect to the liner aft end and radially with respect to the turbine nozzle.

Owner:GENERAL ELECTRIC CO

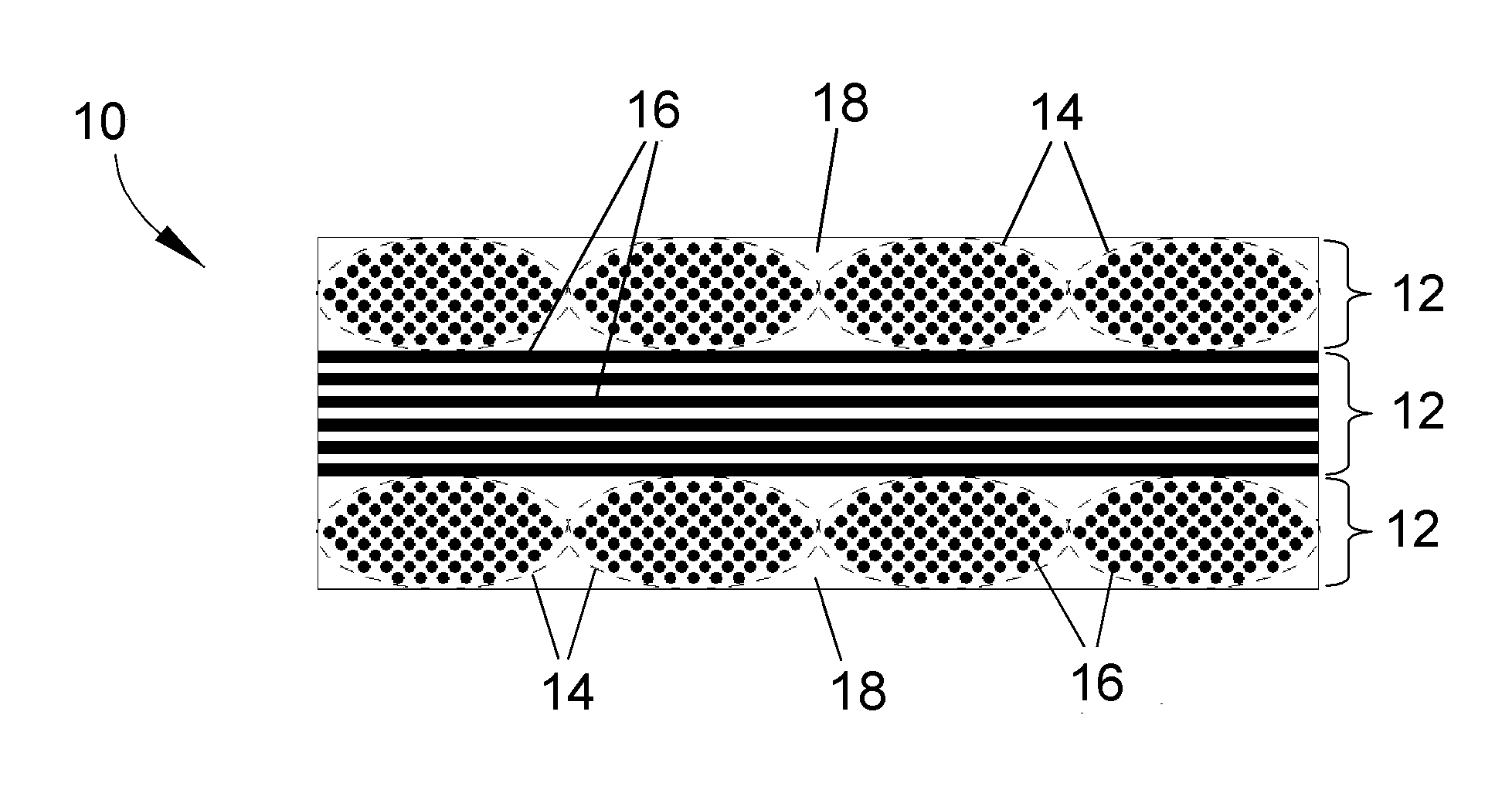

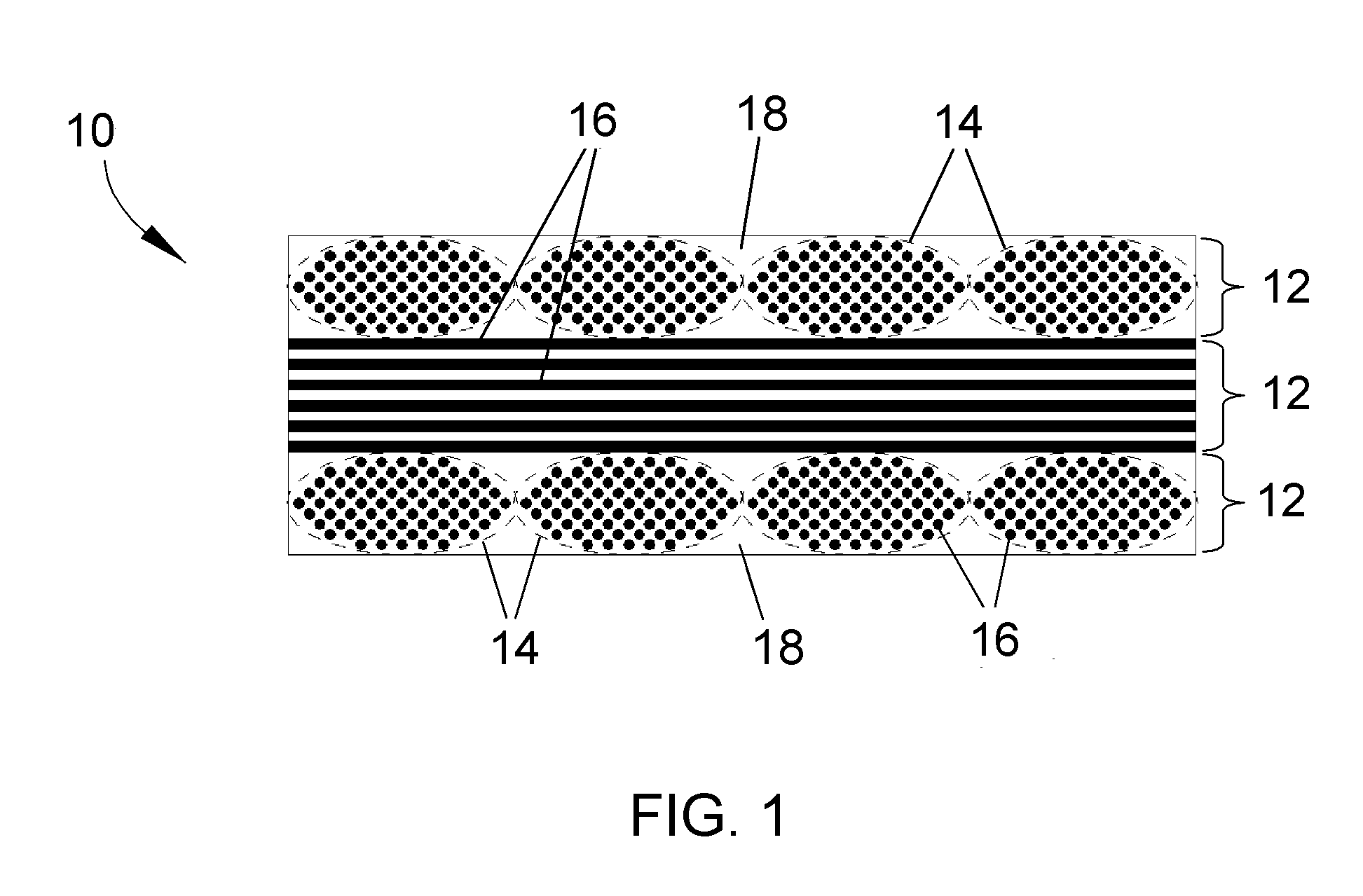

Ply, method for manufacturing ply, and method for manufacturing article with ply

ActiveUS20170030207A1Additive manufacturing apparatusContinuous combustion chamberNear net shapeMaterials science

A method for manufacturing a ply is disclosed. The method includes printing the ply, the ply including a near net shape and a ceramic matrix composite nonwoven material. A ply is disclosed wherein the near net shape is a predetermined layer of an article. A method for manufacturing an article is also disclosed. The method includes printing a first ply and a second ply. The first ply includes a first near net shape and a first ceramic matrix composite nonwoven material, and the second ply includes a second near net shape and a second ceramic matrix composite nonwoven material. The method further includes applying the second ply to the first ply, and consolidating the first ply and the second ply.

Owner:GENERAL ELECTRIC CO

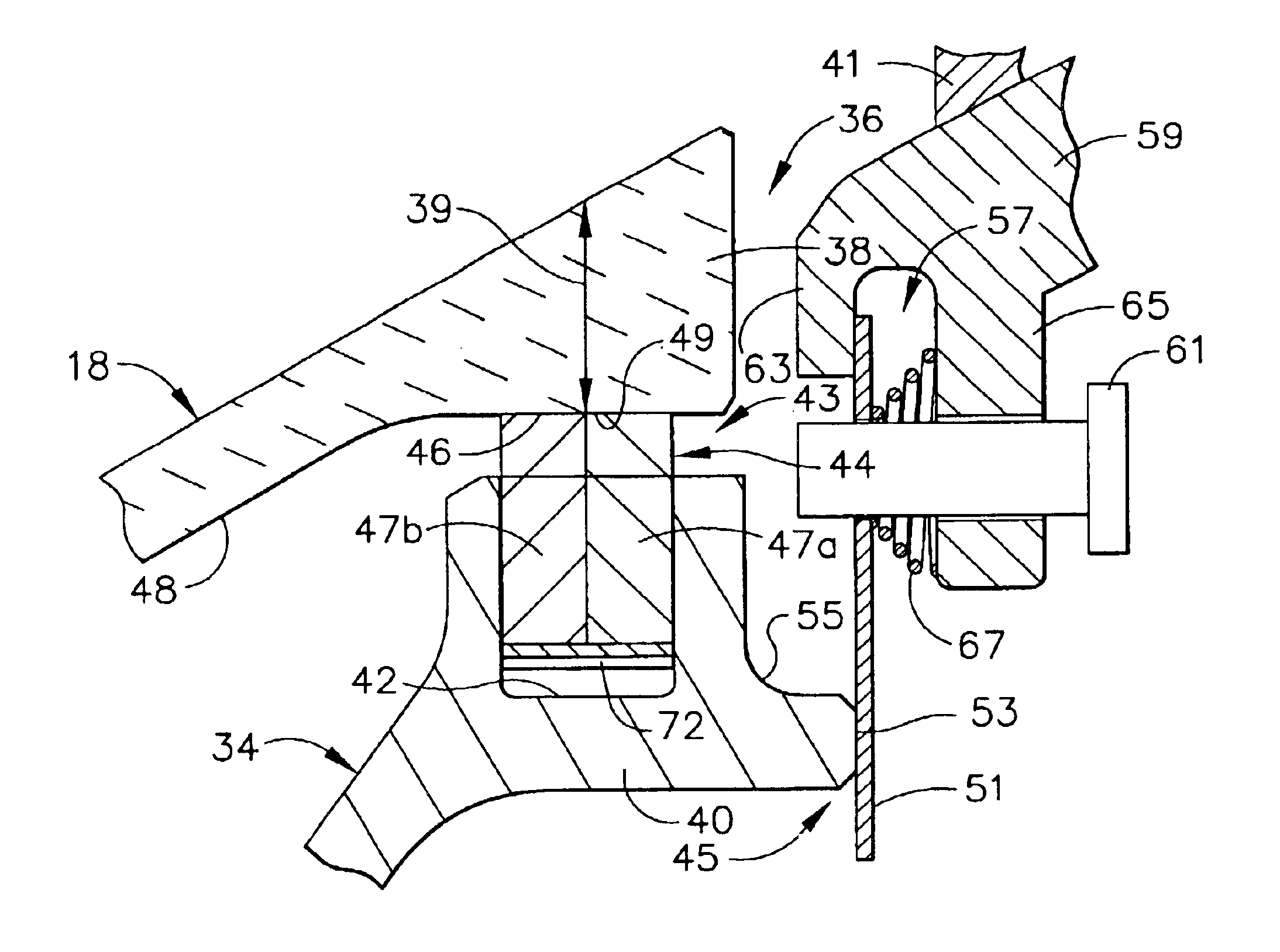

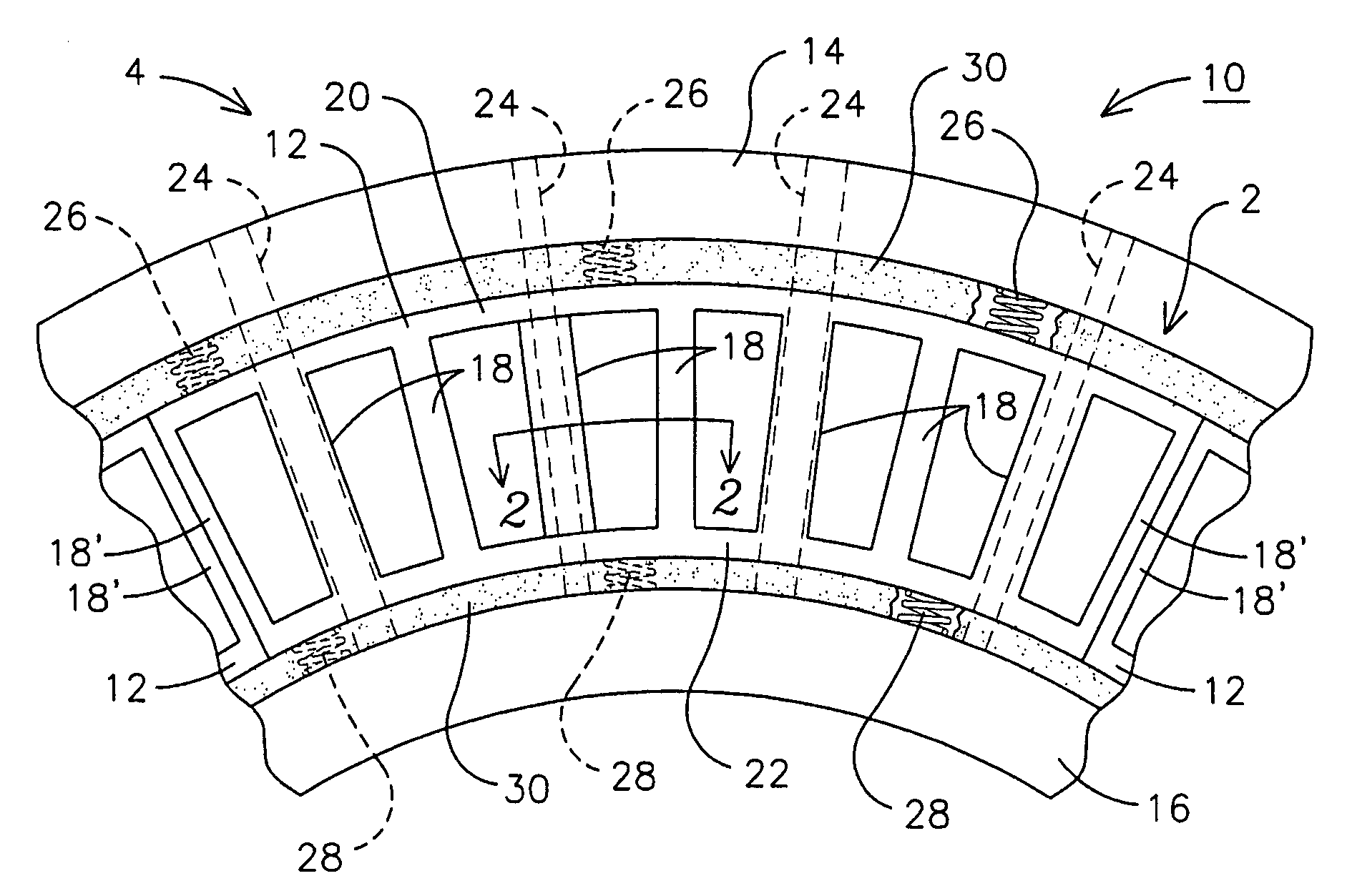

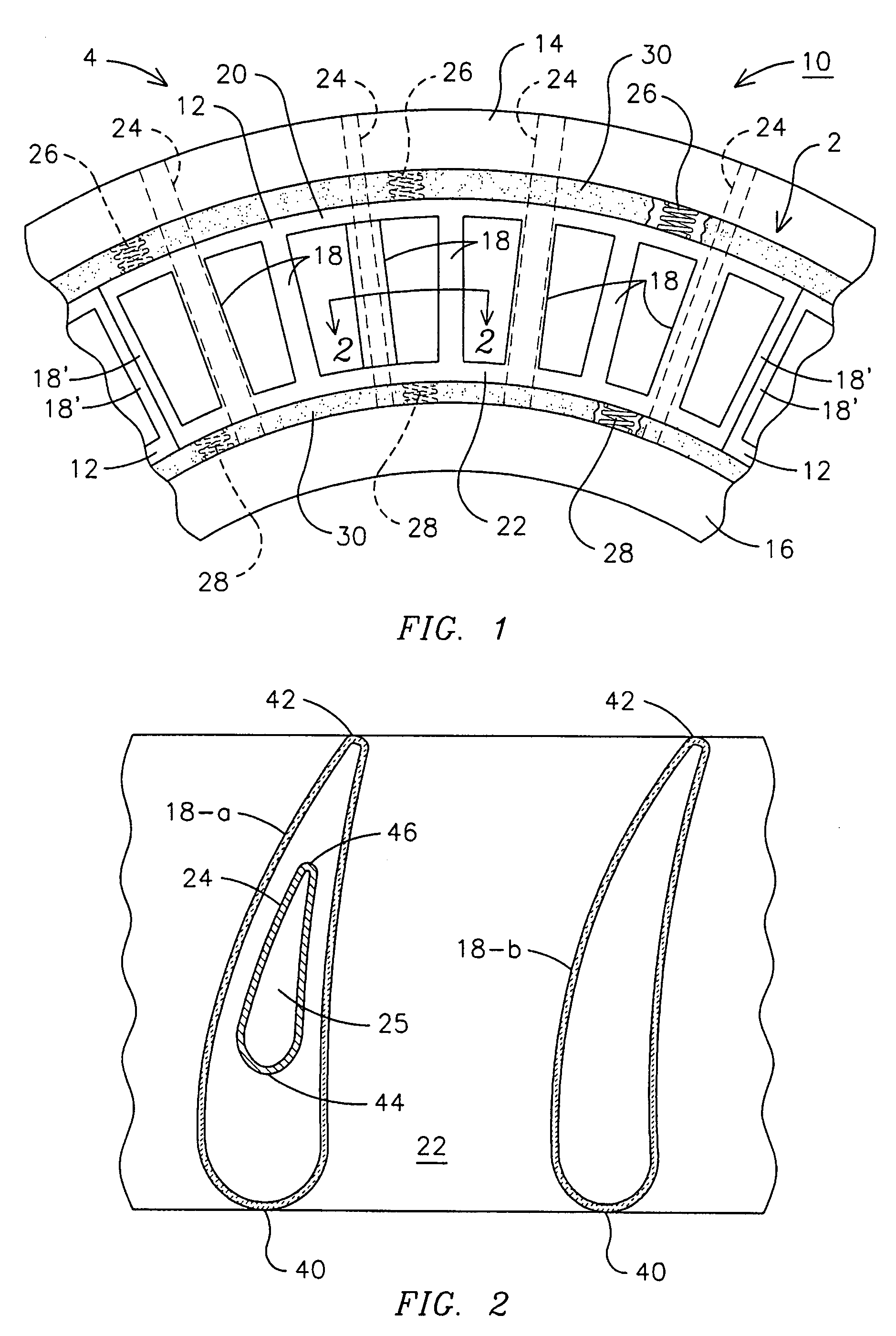

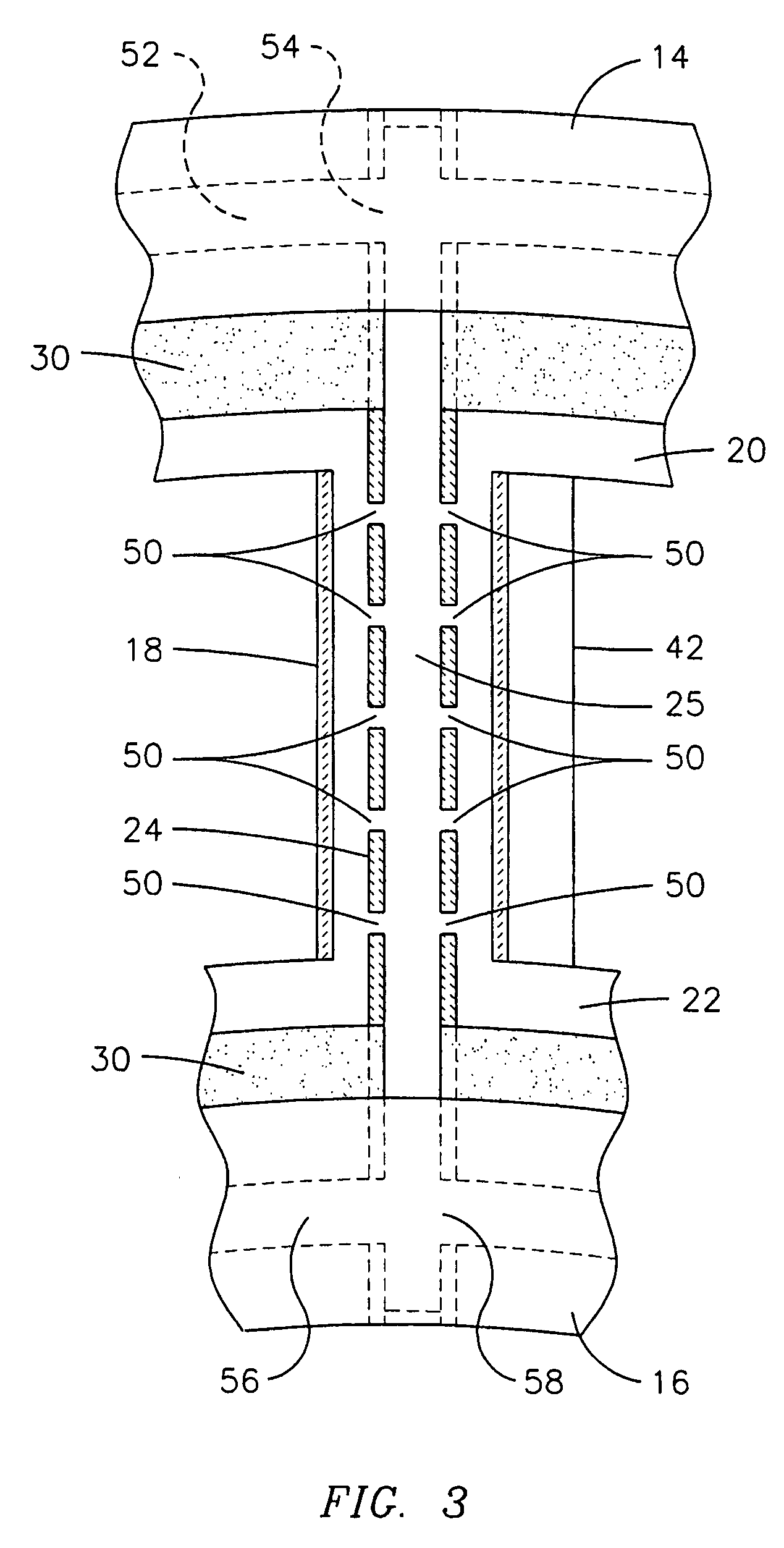

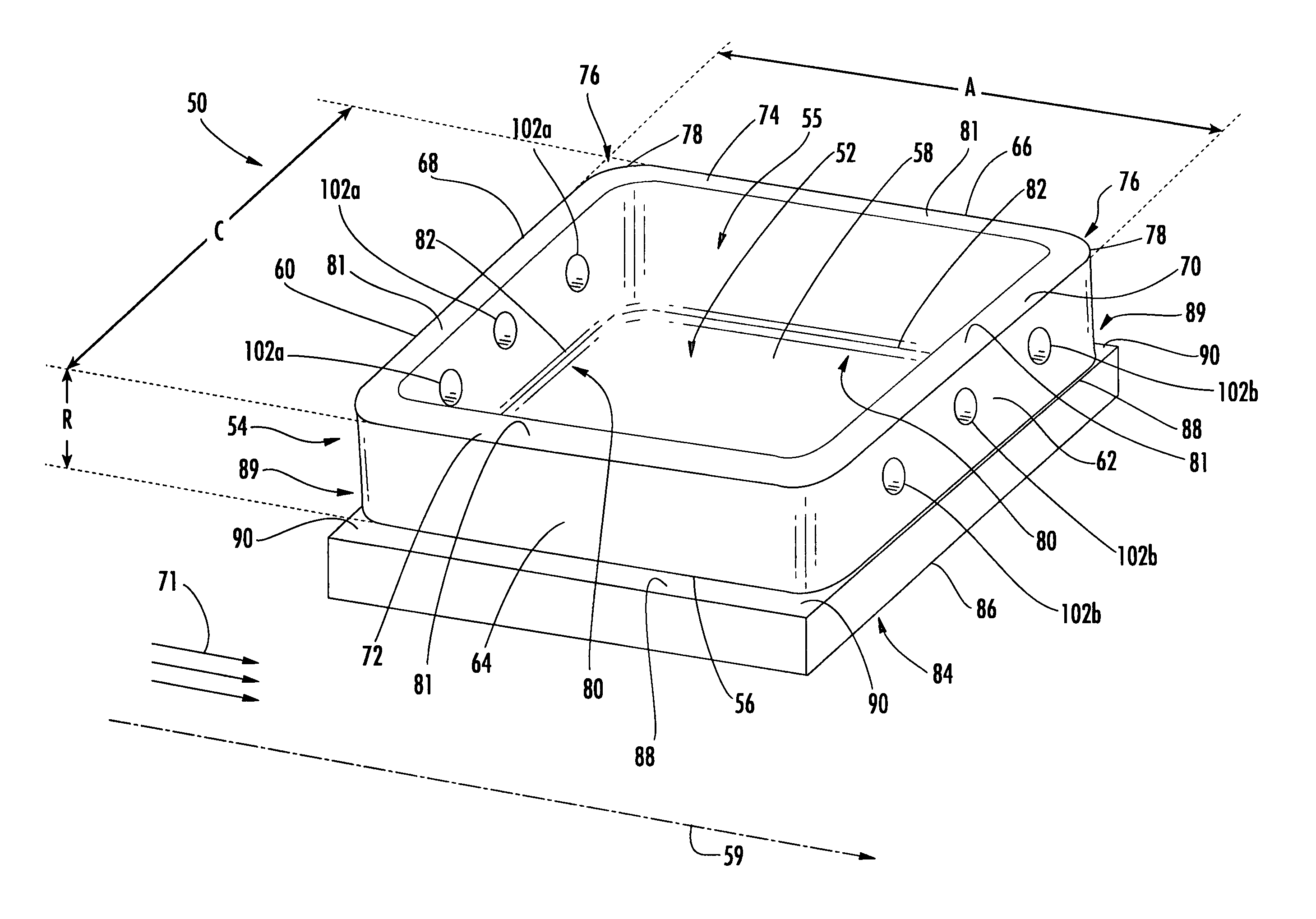

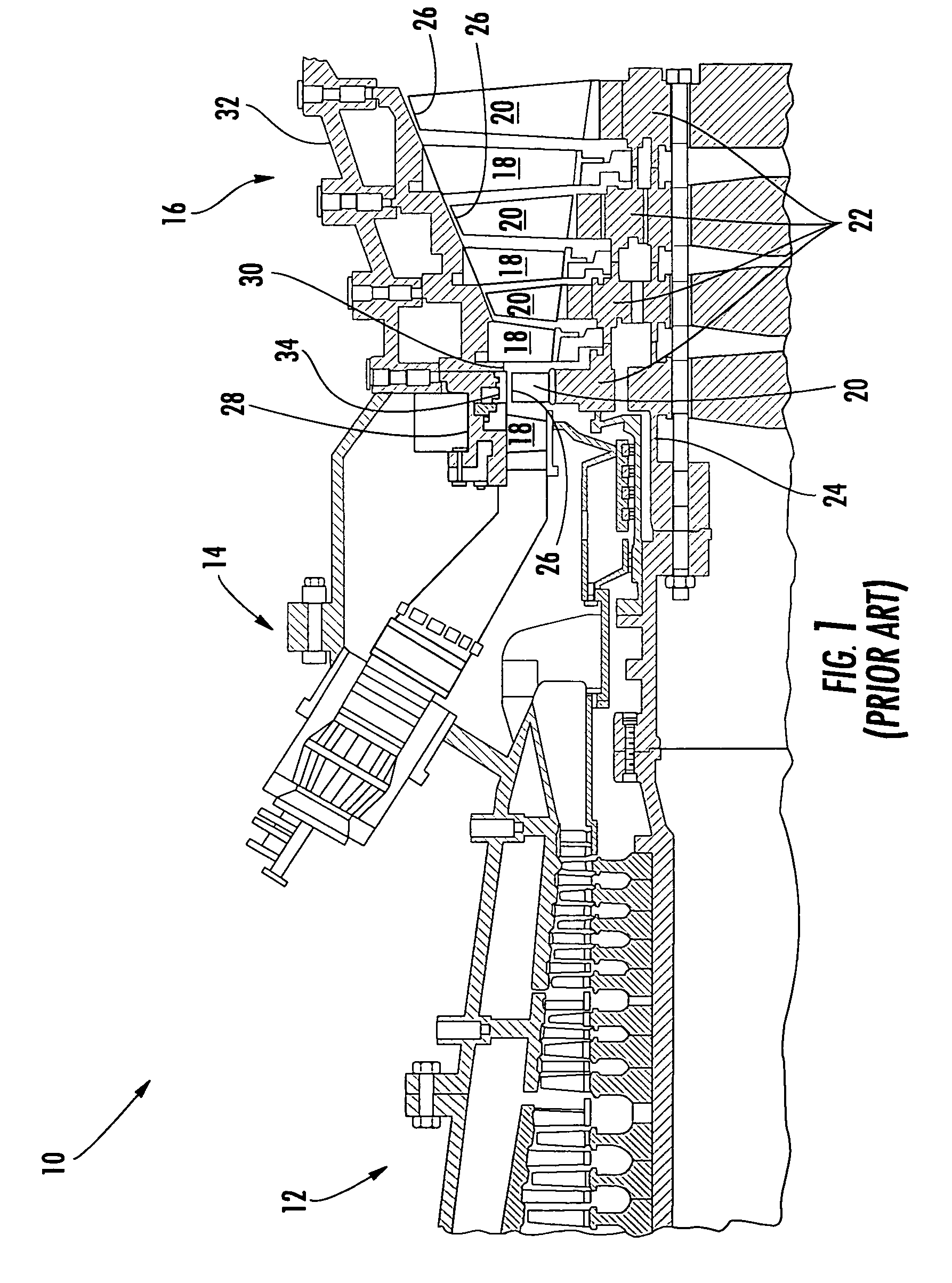

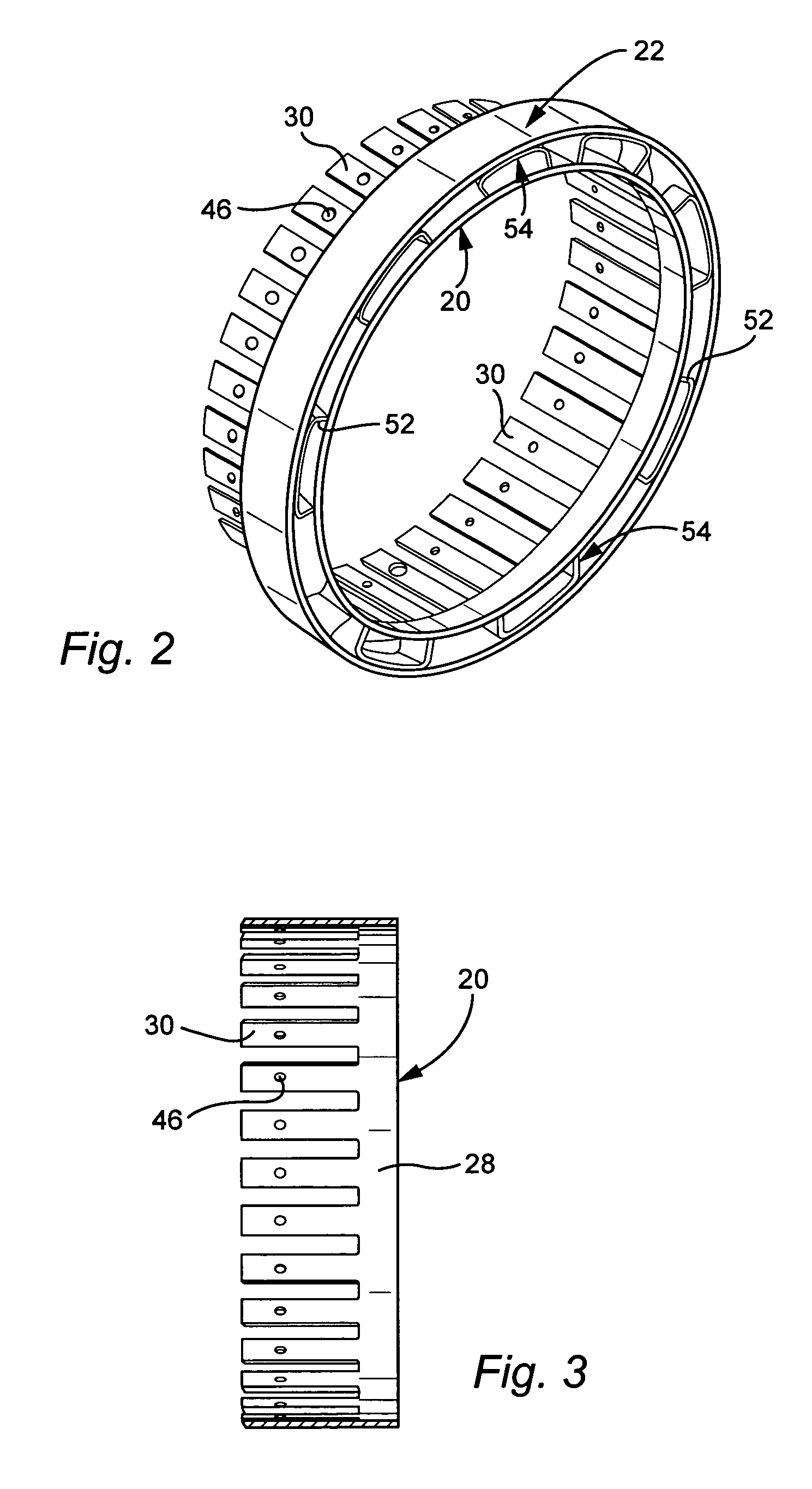

Multivane segment mounting arrangement for a gas turbine

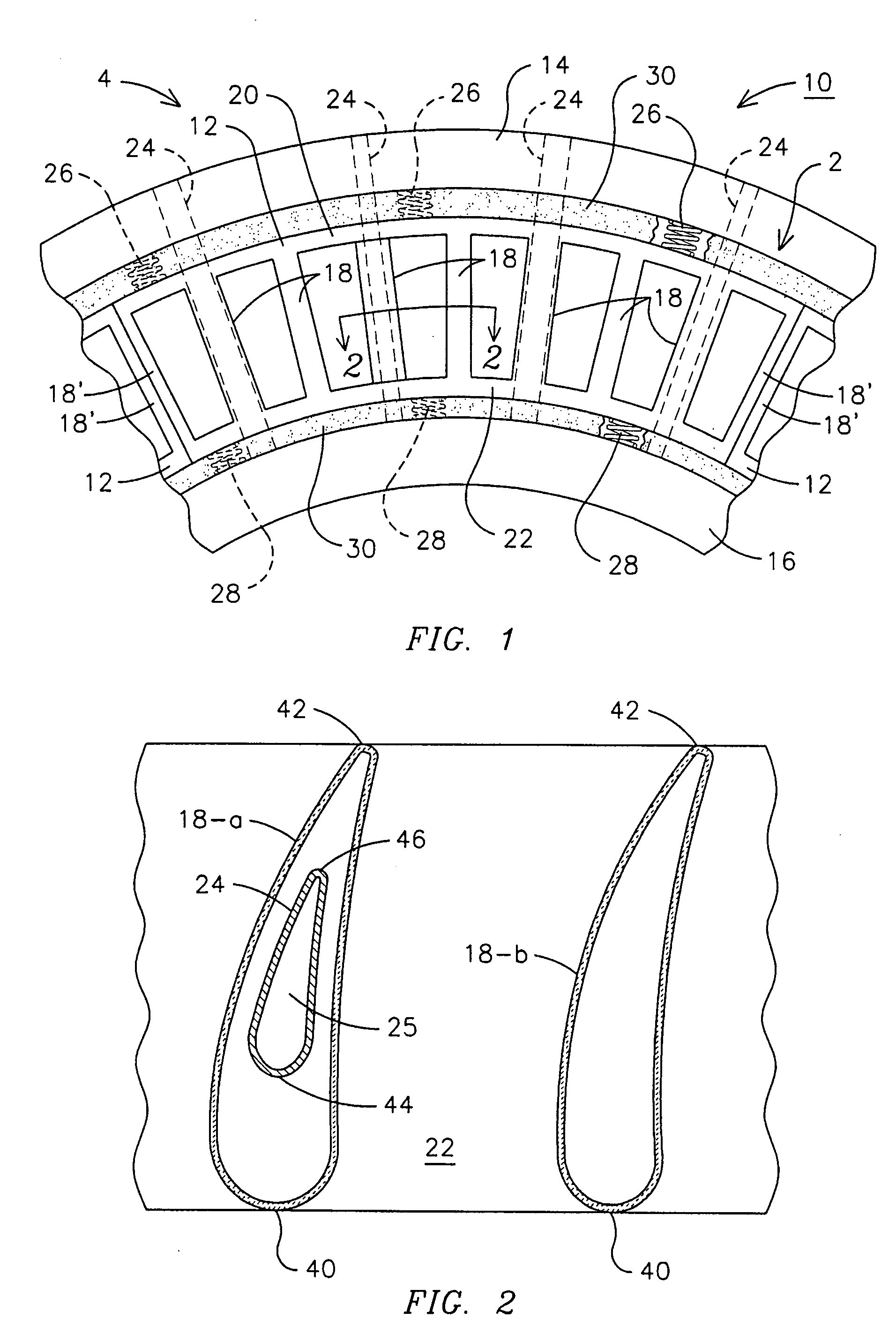

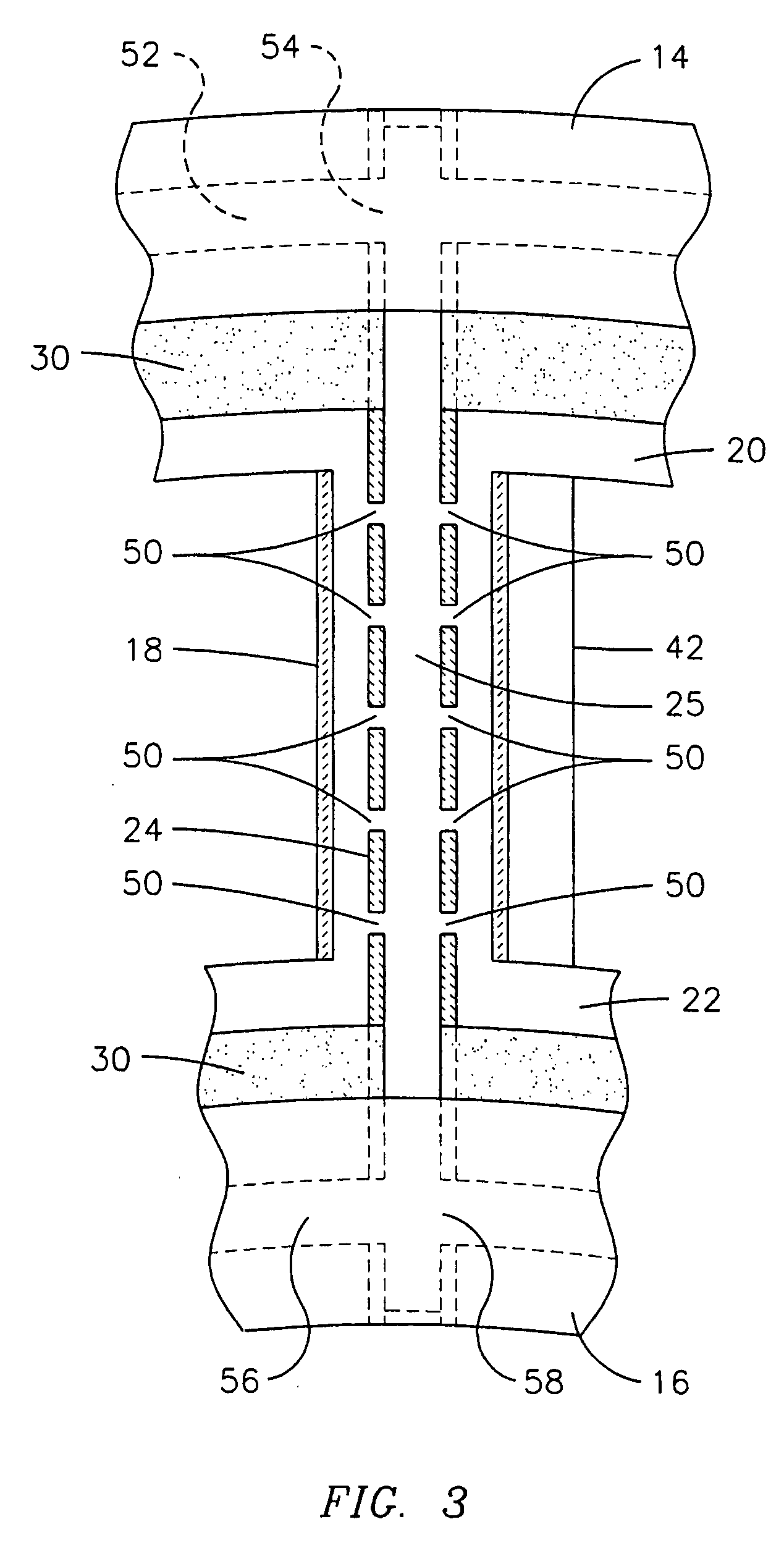

A mounting arrangement (10) for a multivane segment (12) of ceramic matrix composite (CMC) composition positioned between outer and inner metallic rings (14, 16). Selected ones of the vanes (18a) of the multivane segment surround internal struts (24) joining the outer and inner rings. Spring members (26, 28) accommodate differential thermal growth between the multivane segment and the outer and inner rings, and a compliant material (30) seals against gas leakage around the segments.

Owner:SIEMENS ENERGY INC

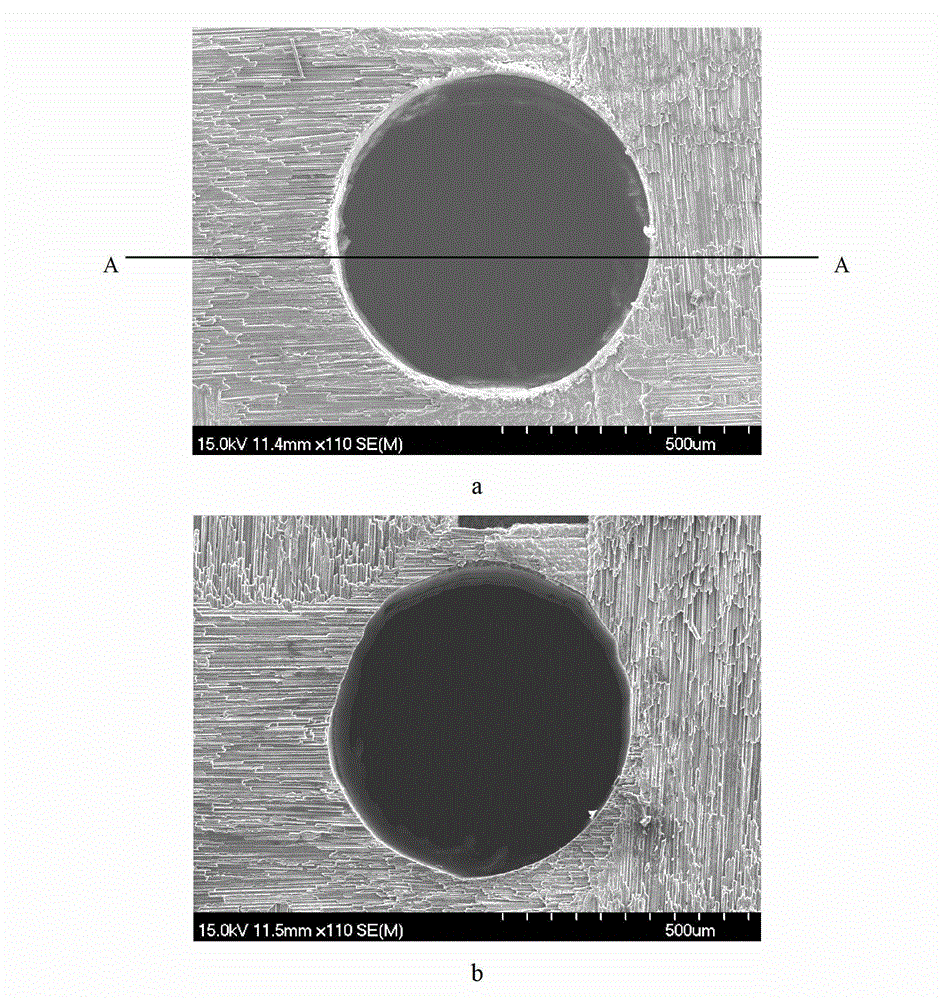

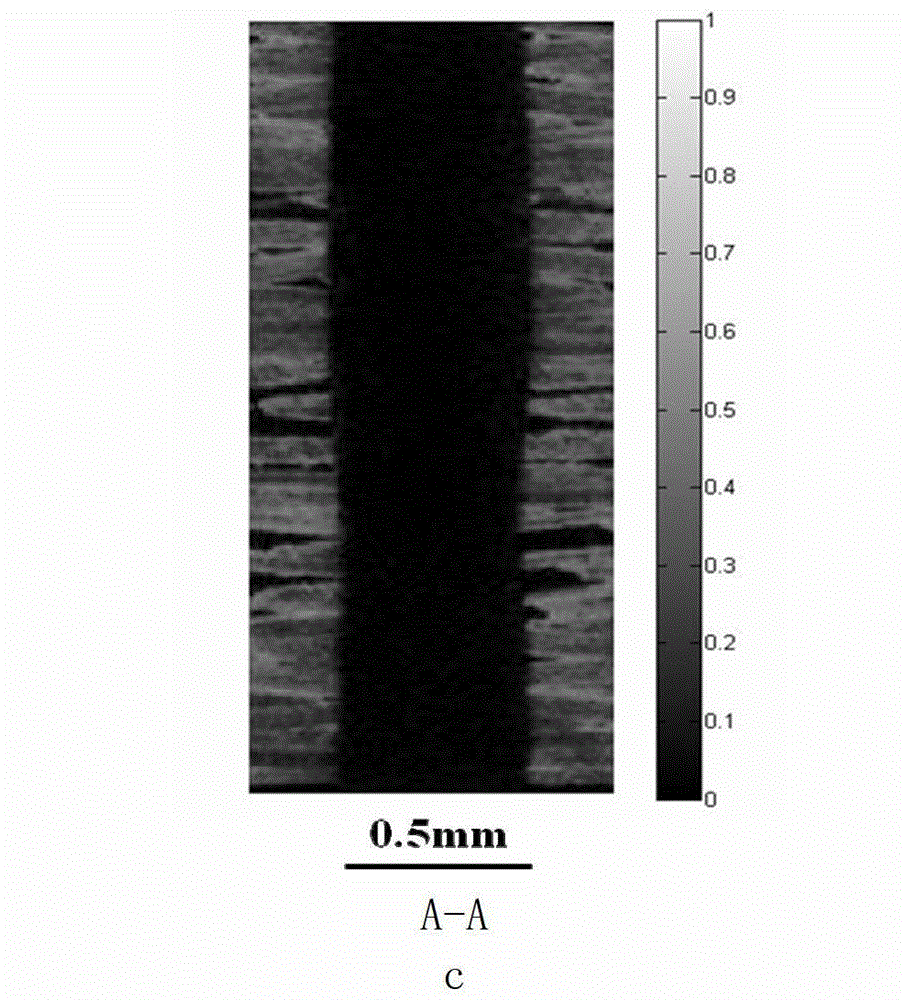

Method for hole machining with picosecond laser

ActiveCN103143841AImprove forming qualityGood processing designabilityLaser beam welding apparatusPicosecond laserOptoelectronics

A method for hole machining with picosecond laser realizes hole machining on CMC-SiC (Ceramic Matrix Composite-Silicon Carbide) material according to the characteristics of fiber composite materials and the machining feature that picosecond laser is suitable for various materials due to superhigh peak power of picosecond laser. According to the method, round holes or square holes are machined in the CMC-SiC material layer by layer in a distributed machining mode; the influence of tiny cracks can be ignored during machining; the stability is good; and the method is particularly suitable for mass repeated micro-hole machining. Layer-by-layer machining in a heliciform way is adopted when round holes are machined; and layer-by-layer machining in a linear scanning way is adopted when square holes are machined. The method has the advantages of good stability of the machining technology, strong designability, high precision and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

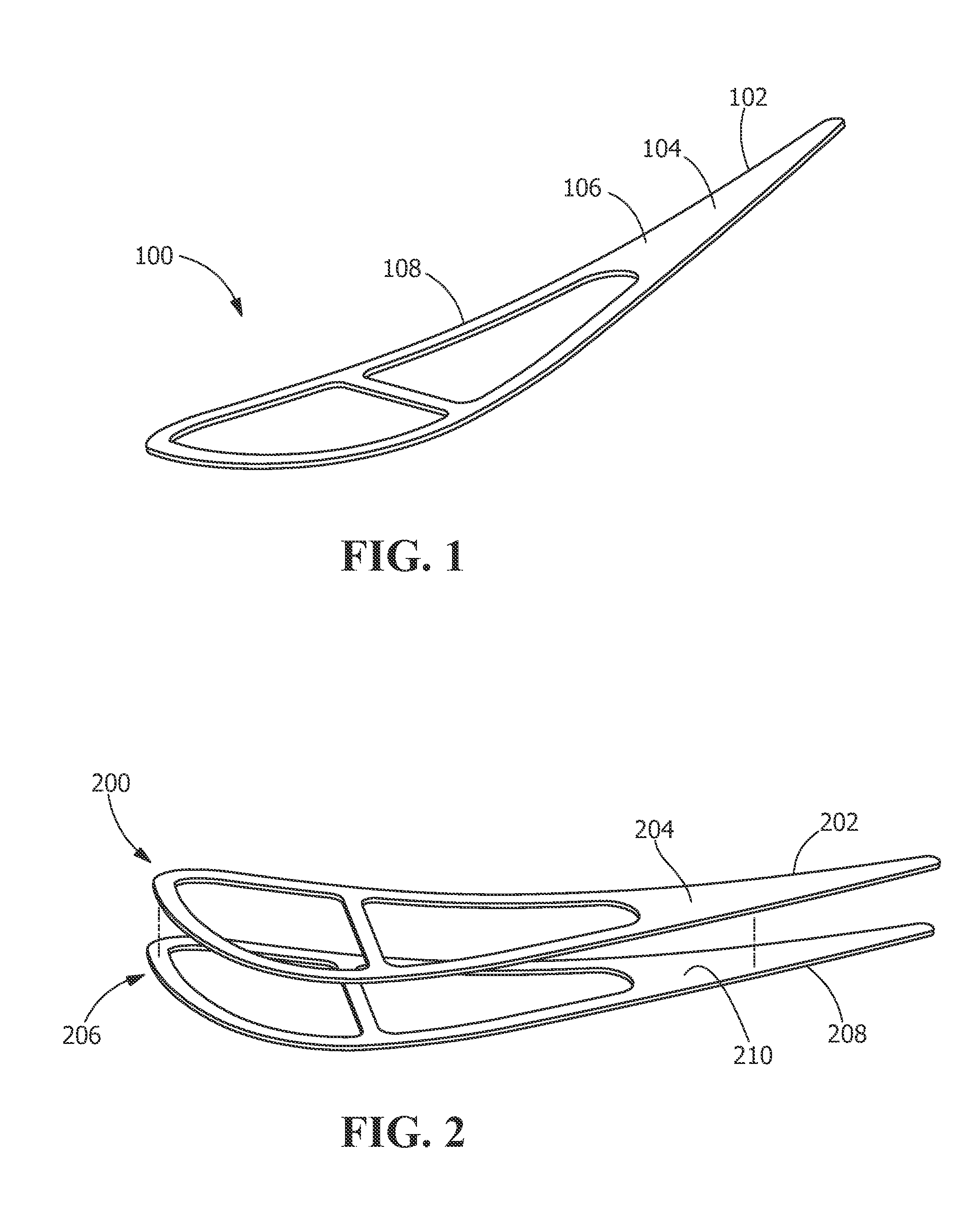

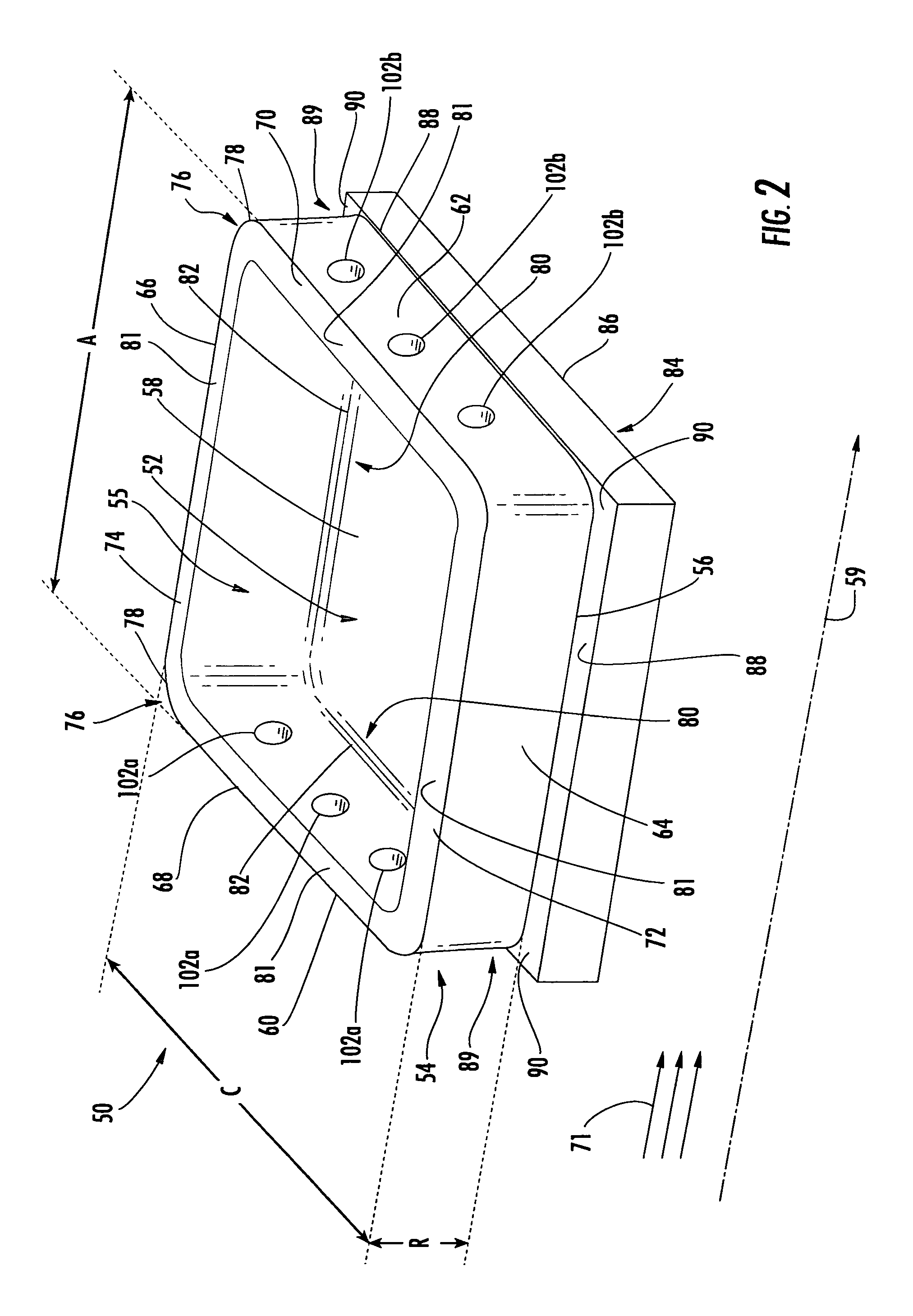

Cooling systems for stacked laminate CMC vane

Embodiments of the invention relate to various cooling systems for a turbine vane made of stacked ceramic matrix composite (CMC) laminates. Each airfoil-shaped laminate has an in-plane direction and a through thickness direction substantially normal to the in-plane direction. The laminates have anisotropic strength characteristics in which the in-plane tensile strength is substantially greater than the through thickness tensile strength. Such a vane construction lends itself to the inclusion of various cooling features in individual laminates using conventional manufacturing and forming techniques. When assembled in a radial stack, the cooling features in the individual laminates can cooperate to form intricate three dimensional cooling systems in the vane.

Owner:SIEMENS ENERGY INC

Process of producing ceramic matrix composites and ceramic matrix composites formed thereby

InactiveUS20130167374A1Exceeding melting pointMetal-working apparatusGas turbine plantsGas phaseSlurry

A process for producing a silicon-containing CMC article. The process entails depositing one or more coating layers on silicon carbide (SiC) fibers, drawing the coated SiC fibers through a slurry to produce slurry-coated fiber material, and then processing the slurry-coated SiC fiber material to form unidirectional prepreg tapes. The tapes are stacked and then fired to yield a porous preform. The porous preform is then further densified by infiltrating the porosity therein to yield a CMC article. Infiltration can be achieved by a series of polymer infiltration and pyrolysis (PIP) steps, by melt infiltration (MI) after filling the porosity in the preform with carbon or one or more refractory metal, by chemical vapor infiltration (CVI), or by a combination of these infiltration techniques.

Owner:GENERAL ELECTRIC CO

Shroud segment and assembly with surface recessed seal bridging adjacent members

A turbine engine shroud segment is provided with a radially outer surface including a pair of spaced apart, opposed first and second edge portion surface depressions, for example spaced circumferentially, having a seal surface shaped to receive, in a surface depression formed between assembled adjacent segments in a shroud assembly, or axially assembled adjacent segments and engine members, a radially outer fluid seal member. The depression portions of a shroud segment are joined with the radially outer surface of the shroud segment through an arcuate transition surface. Stresses generated during engine operation in the shroud material are reduced, enabling practical use of a low ductility material, for example a ceramic matrix composite. The edge portion surface depressions are provided with a first shape and the fluid seal member, disposed at the depression, is provided with a surface of a second shape matched in shape with the first shape.

Owner:GENERAL ELECTRIC CO

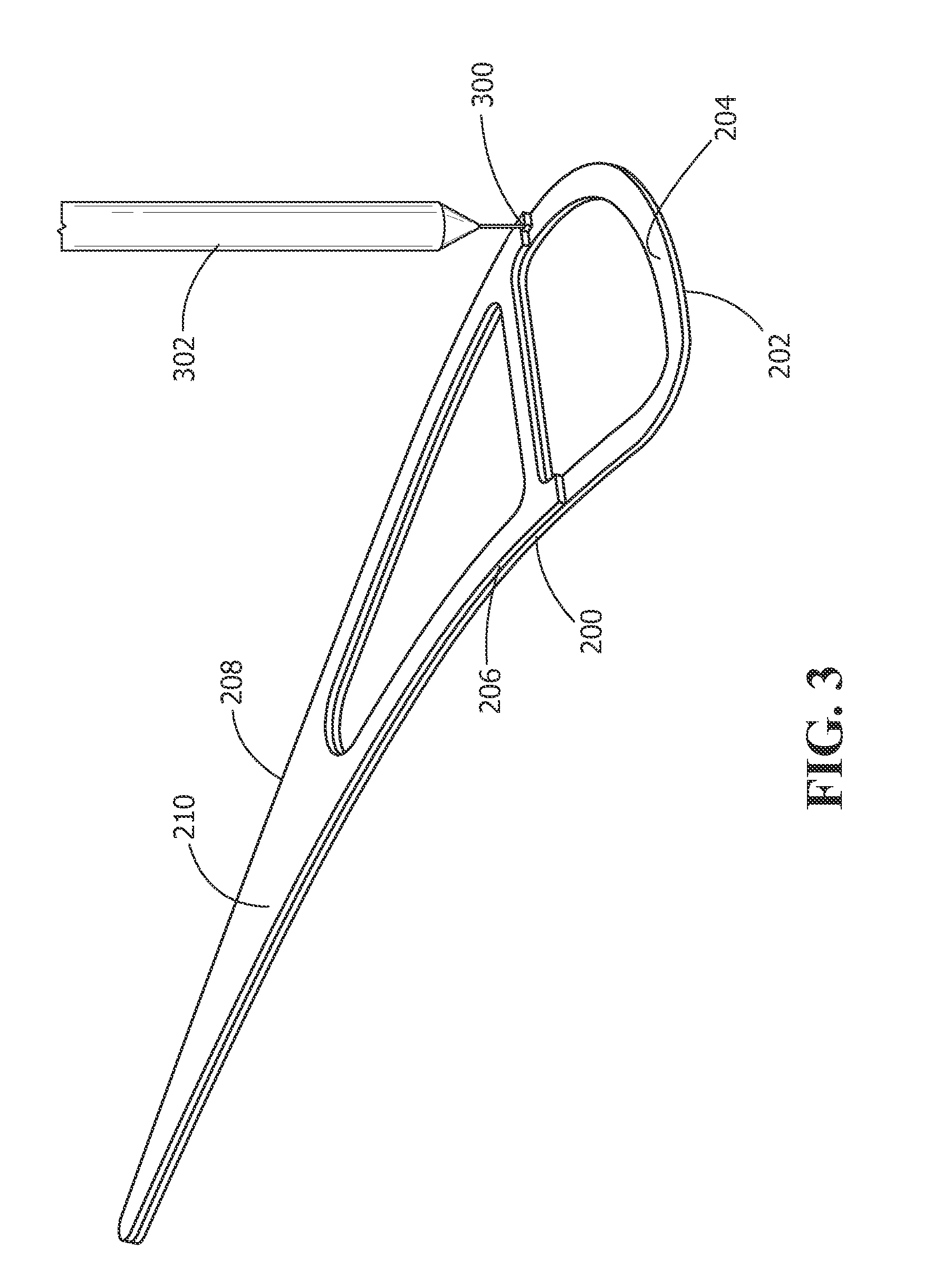

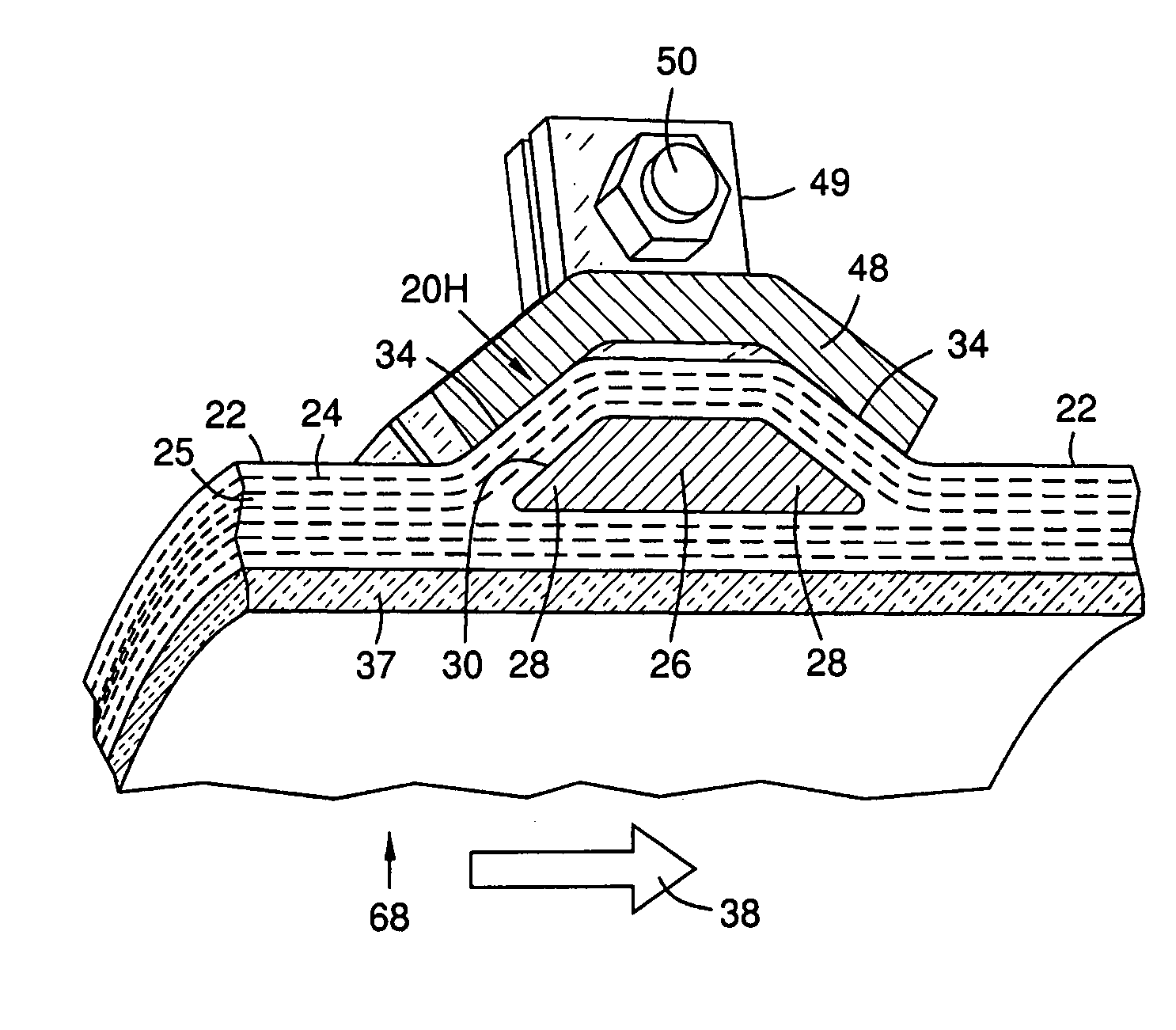

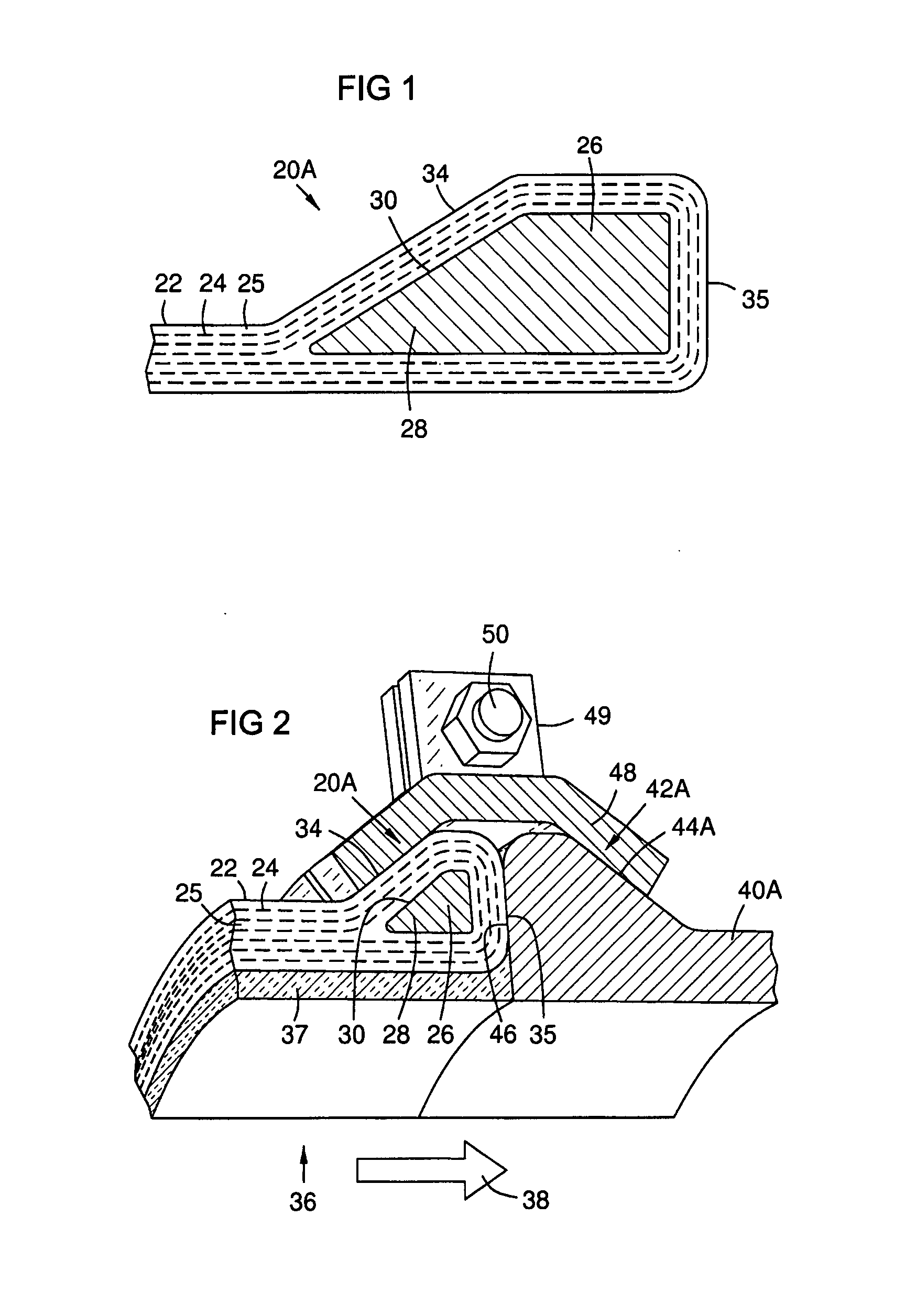

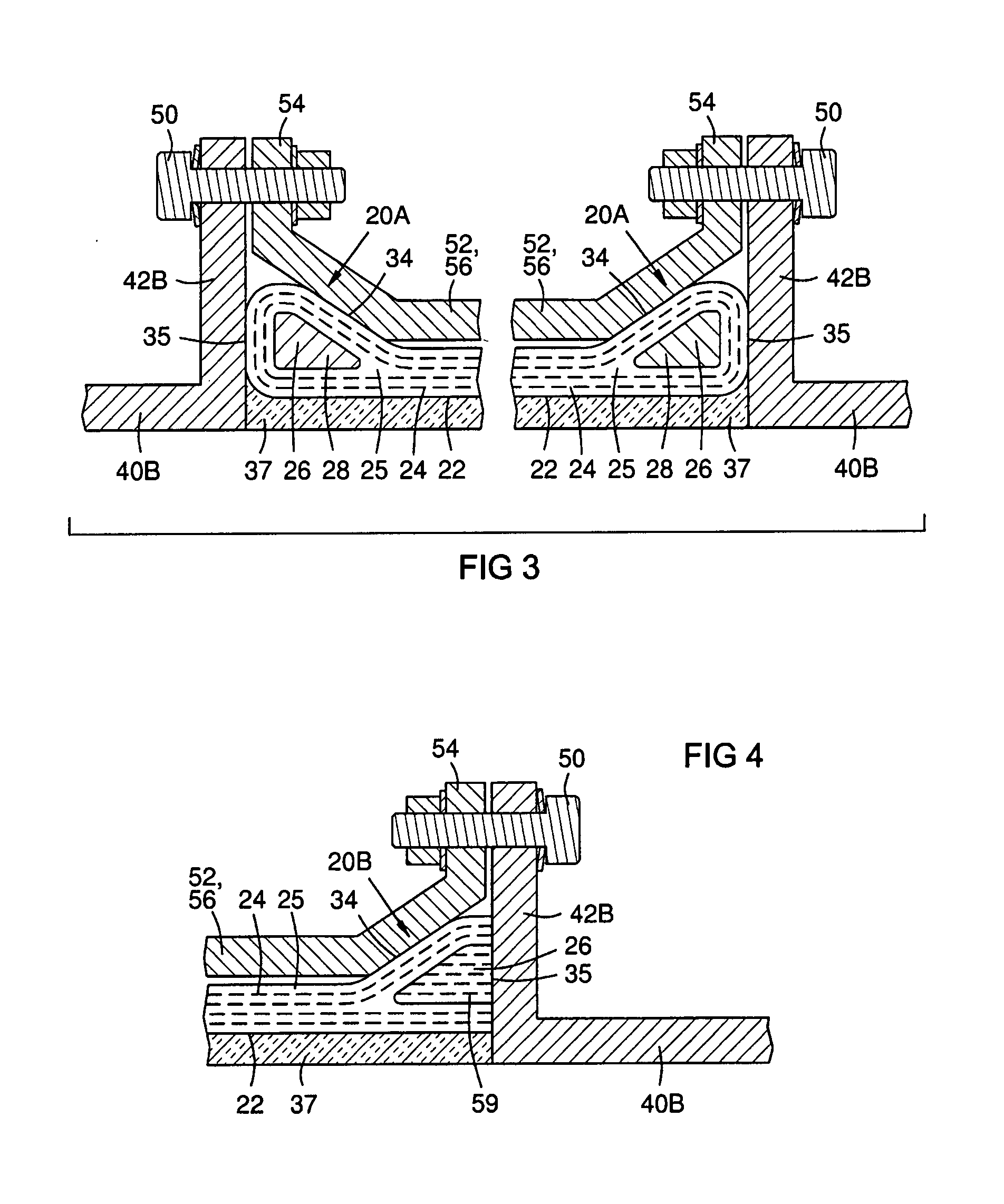

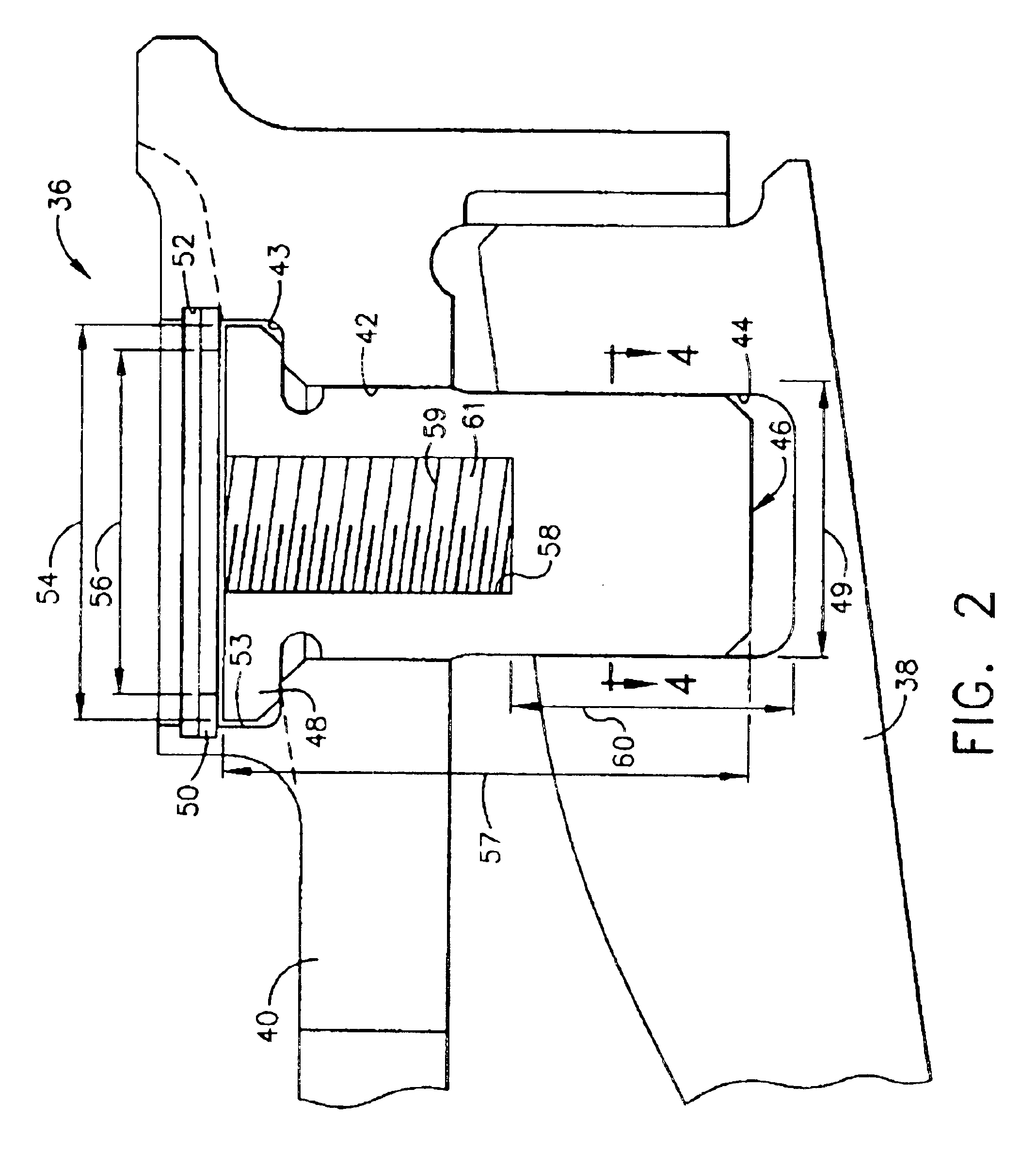

Ceramic matrix composite attachment apparatus and method

An attachment method and flange for connecting a ceramic matrix composite (CMC) component, such as a gas turbine shroud ring (36, 68), to a metal support structure. A CMC flange (20A) may be formed by attaching a wedge-shaped block (26) of a ceramic material to a CMC wall structure (22), and wrapping CMC layers (24) of the wall structure (22) at least partly around the block (26), forming the flange (20A) with an inner oblique face (34) and an outer face (35) normal to the wall structure. An adjacent support structure, such as a metal support ring (40A), may abut the outer face (35) of the CMC flange (20A) and be clamped or bolted to the CMC flange (20A).

Owner:SIEMENS ENERGY INC

Ring seal system with reduced cooling requirements

Aspects of the invention are directed to systems for reducing the cooling requirements of a ring seal in a turbine engine. In one embodiment, the ring seal can be made of a ceramic material, such as a ceramic matrix composite. The ceramic ring seal can be connected to metal isolation rings by a plurality of pins. The hot gas face of the ring seal can be coated with a thermal insulating material. In another embodiment, the ring seal can be made of metal, but it can be operatively associated with a ceramic heat shield. The metal ring seal can carry the mechanical loads imposed during engine operation, and the heat shield can carry the thermal loads. By minimizing the amount of ring seal cooling, the ring seal systems according to aspects of the invention can result in improved engine performance and emissions.

Owner:SIEMENS ENERGY INC

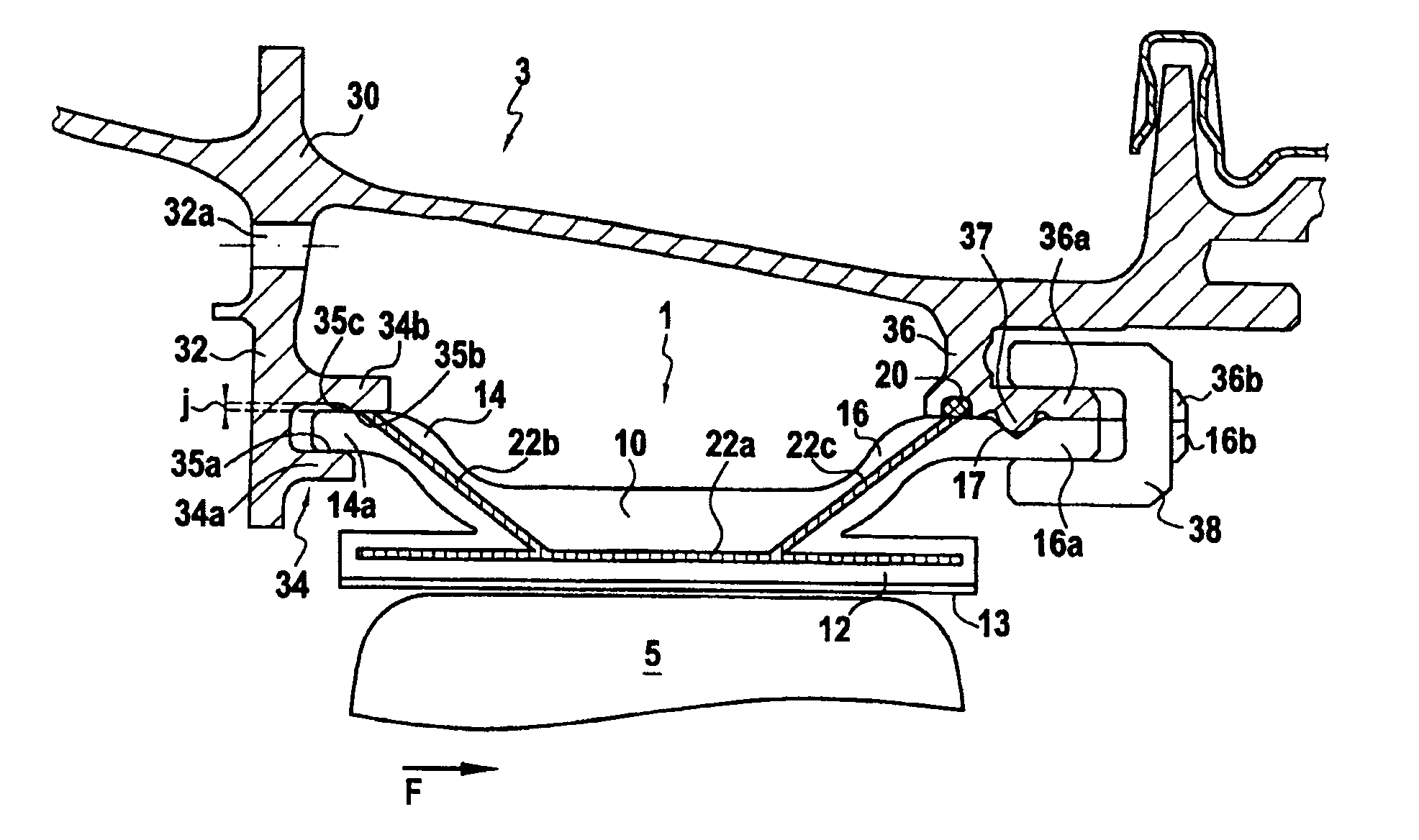

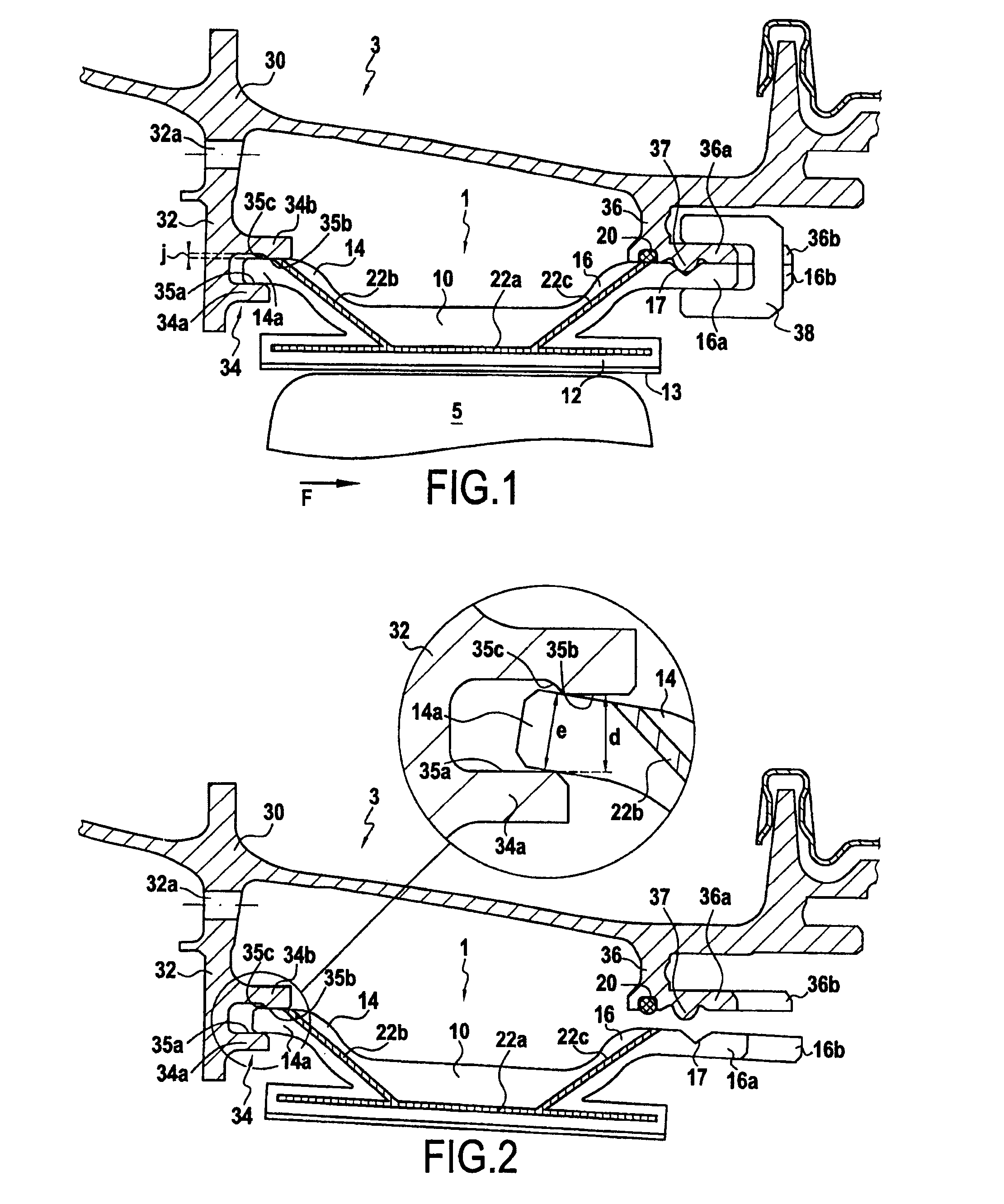

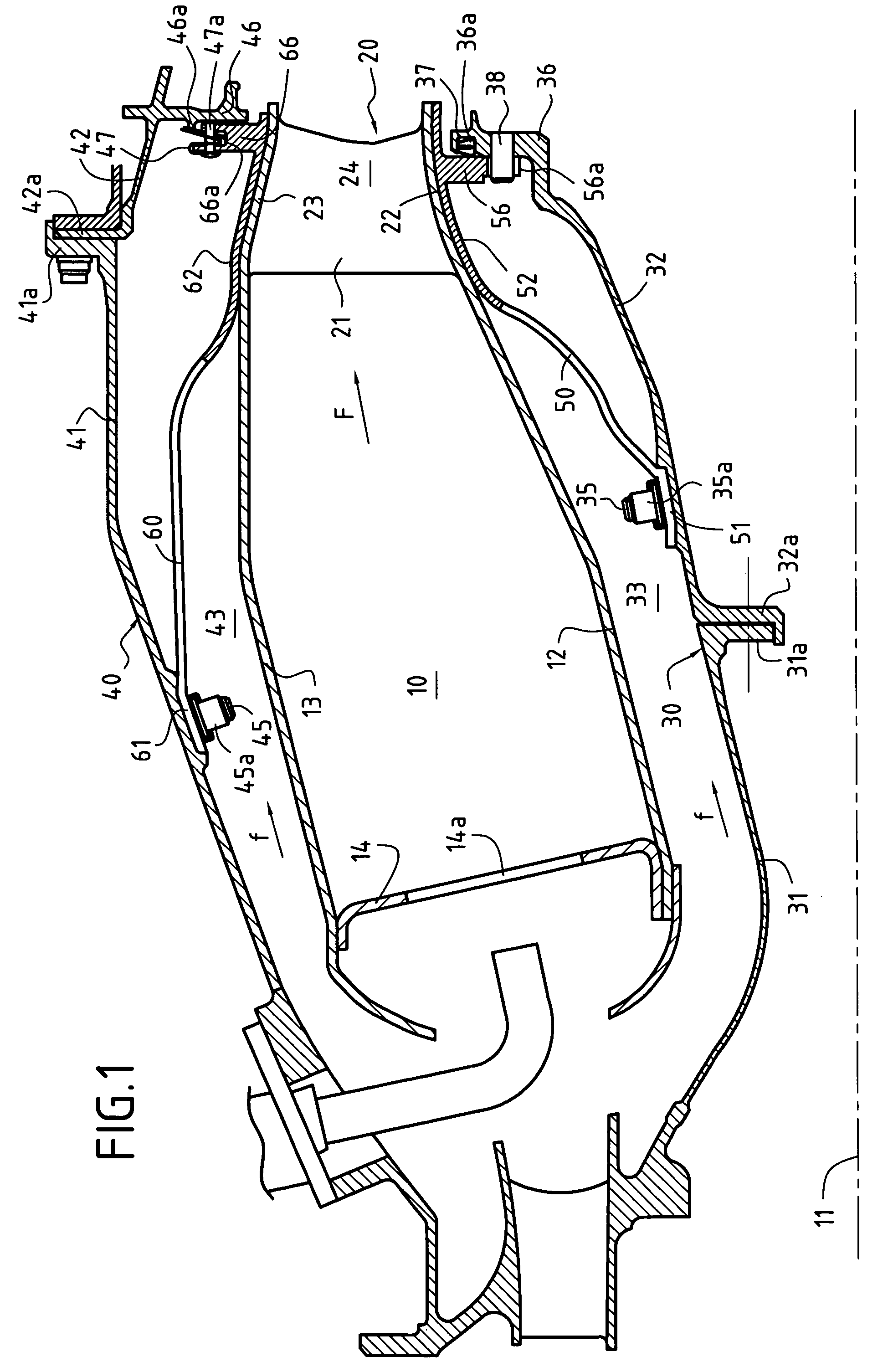

Mounting a turbine nozzle on a combustion chamber having CMC walls in a gas turbine

ActiveUS7249462B2Reduce in quantityReduce weightPump componentsGas turbine plantsCombustion chamberEngineering

The gas turbine comprises an annular combustion chamber having inner and outer walls made of ceramic matrix composite material, and a high pressure turbine nozzle secured to a downstream end of the combustion chamber and comprising a plurality of stationary airfoils extending between the inner and outer walls of an annular flow path through the nozzle for the gas stream coming from the combustion chamber. The turbine nozzle is made of ceramic matrix composite material and it is connected to the downstream end of the combustion chamber by brazing.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Ceramic matrix composite turbine engine vane

Owner:TECH UNITED

Ceramic matrix composite turbine engine components with unitary stiffening frame

Owner:SIEMENS ENERGY INC

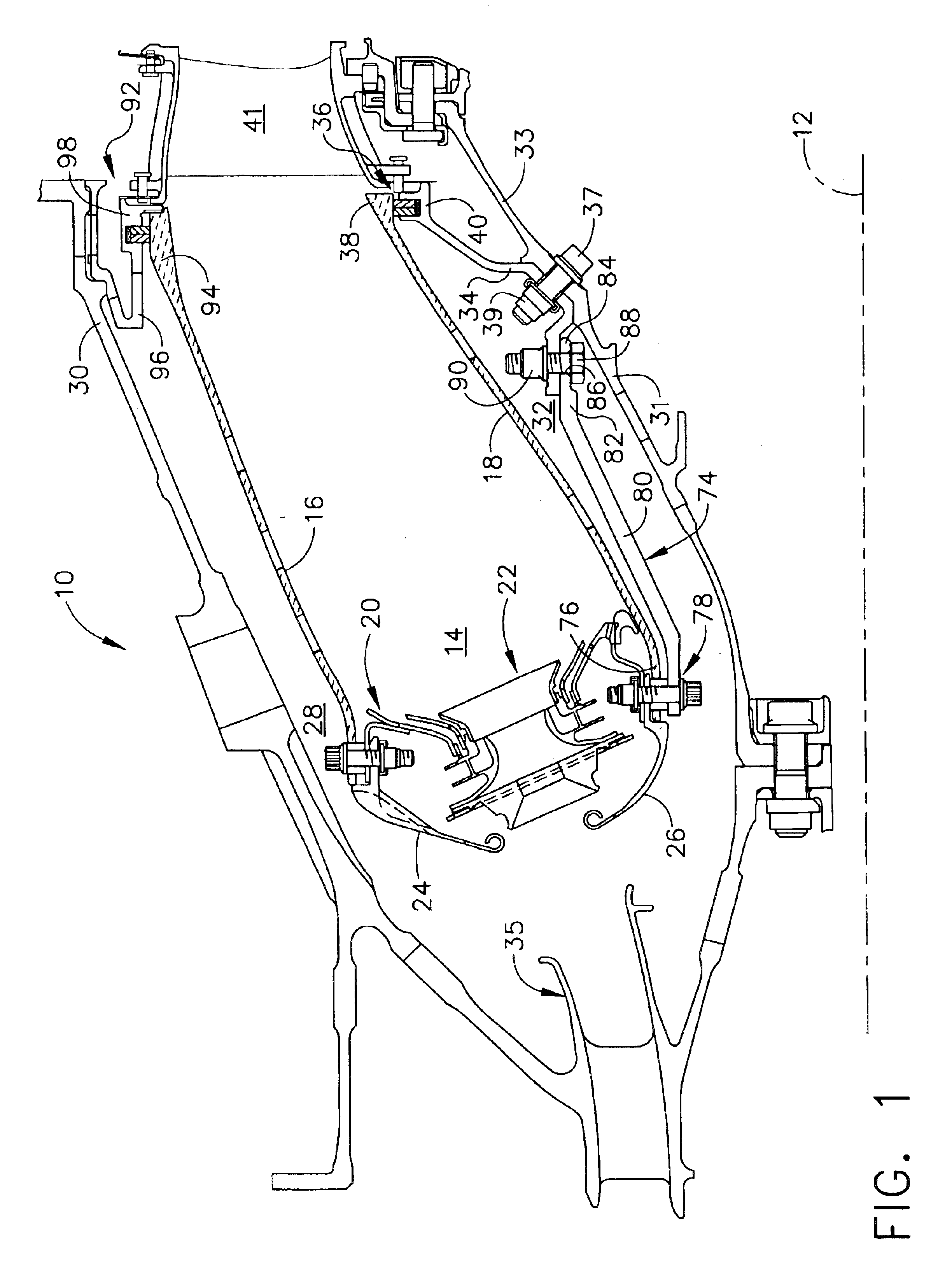

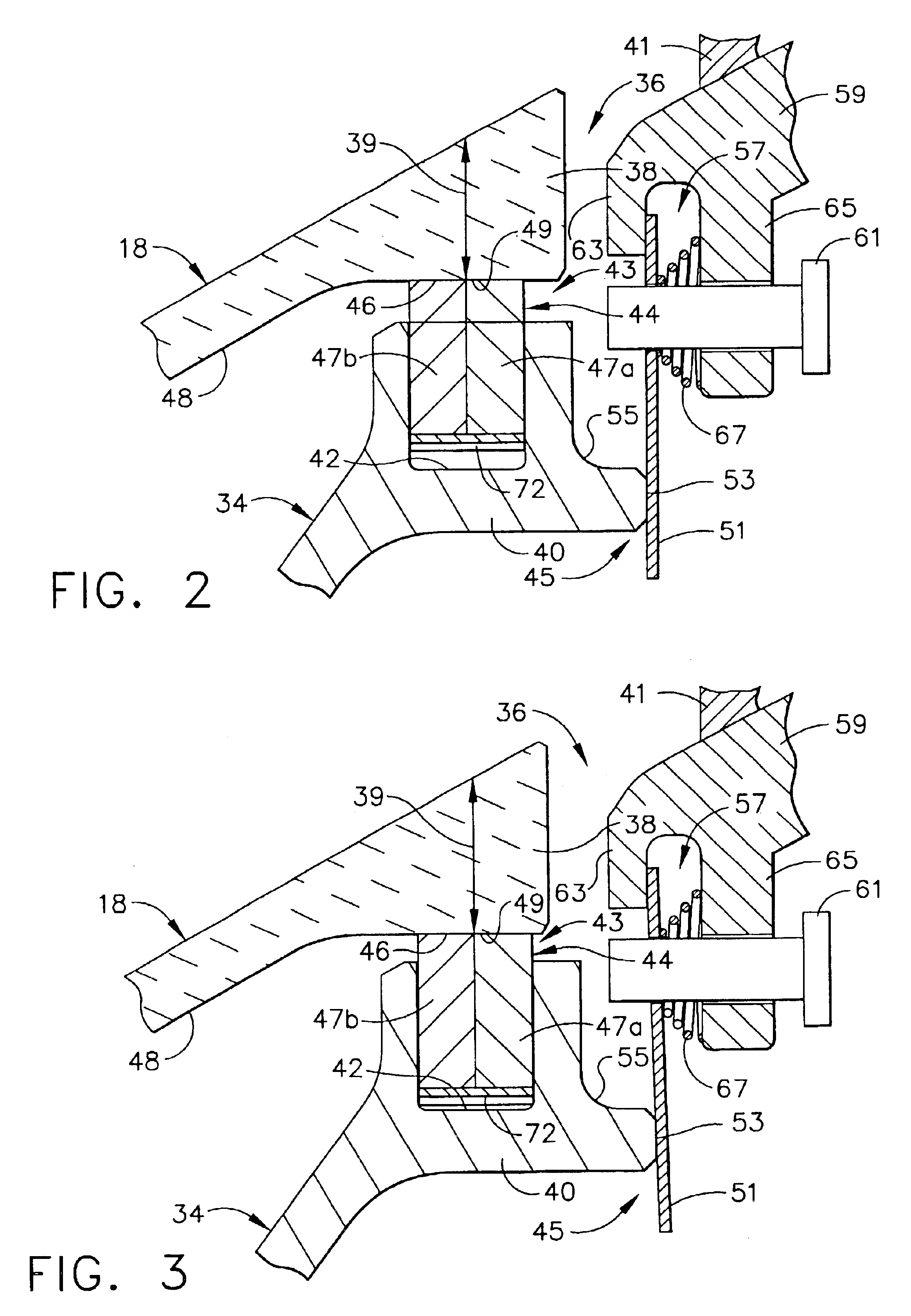

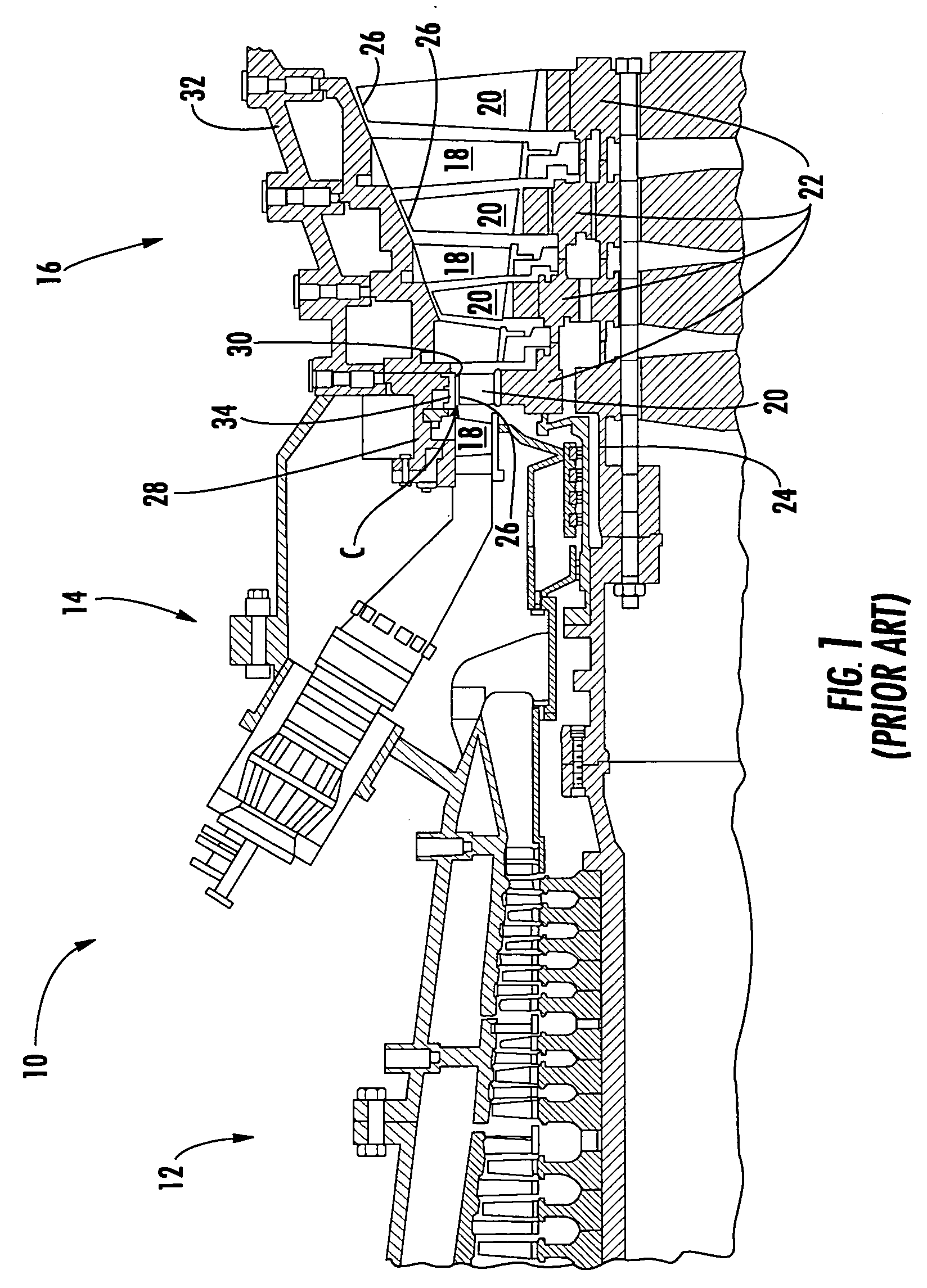

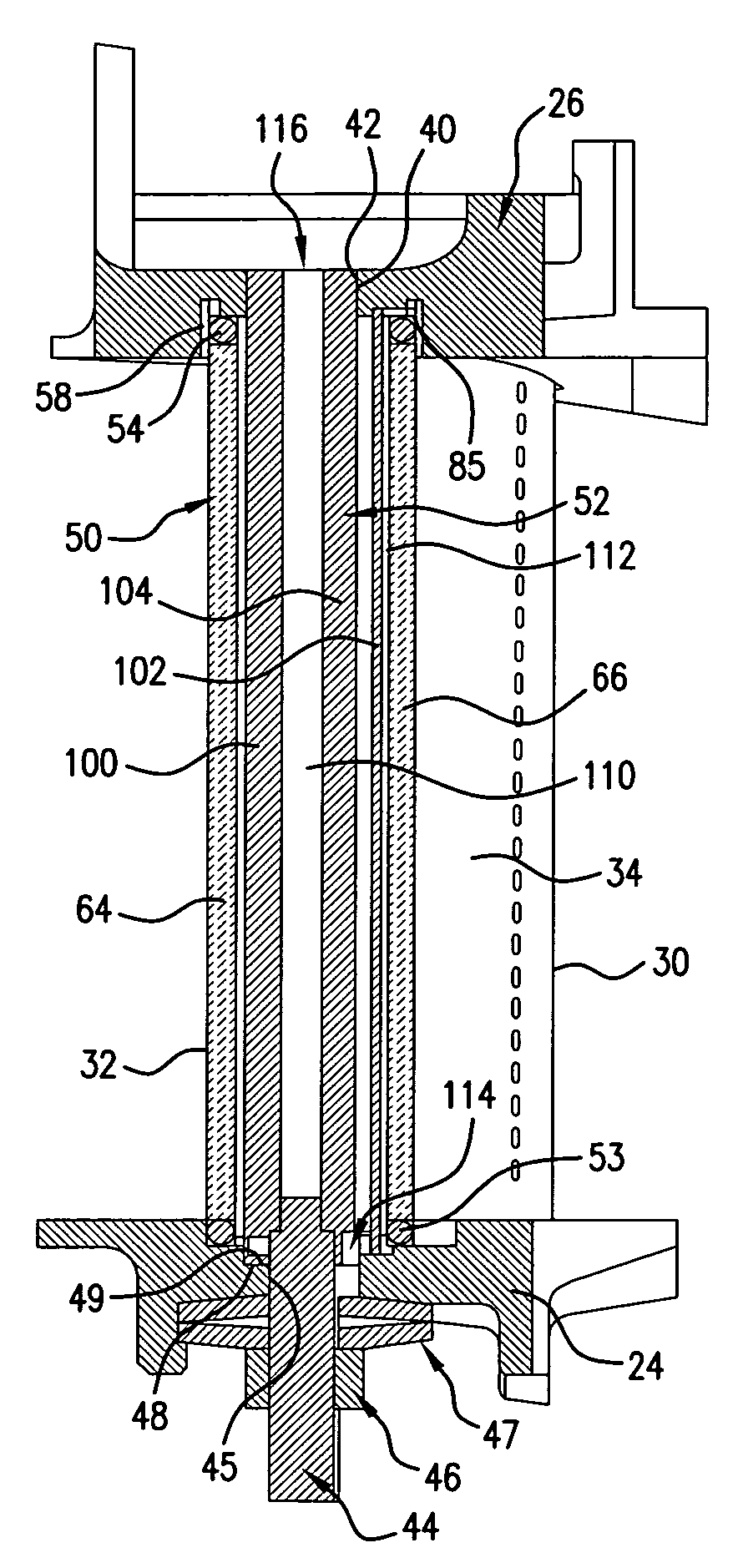

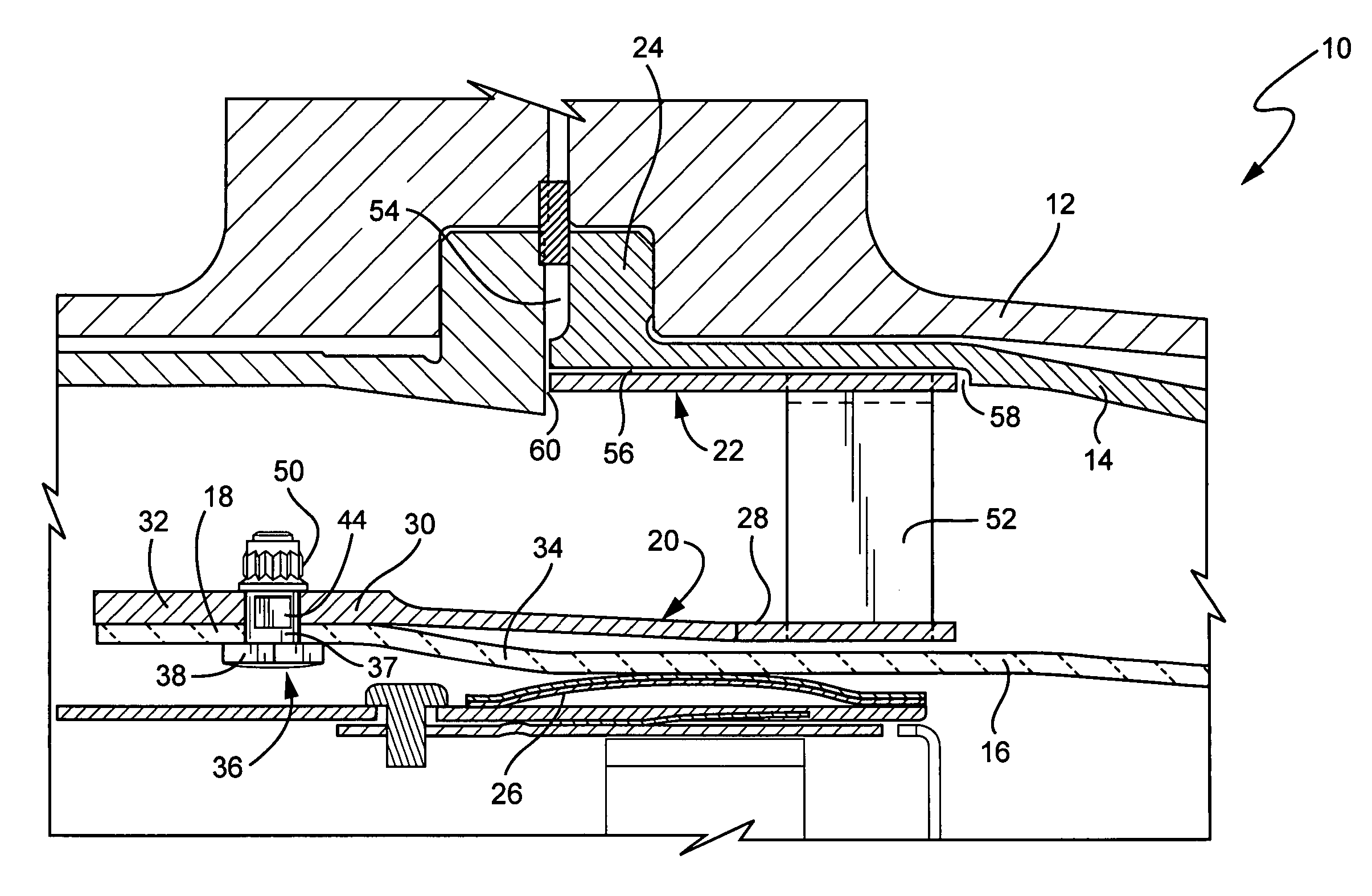

Mounting assembly for the aft end of a ceramic matrix composite liner in a gas turbine engine combustor

InactiveUS6895761B2Reduction factorPrevent circular motionContinuous combustion chamberEngine manufactureCombustorEngineering

A mounting assembly for an aft end of a liner of a gas turbine engine combustor including a support member, wherein a longitudinal centerline axis extends through the gas turbine engine. The mounting assembly includes a pin member extending through each one of a plurality of circumferentially spaced openings in a portion of the support member for the combustor and into a plurality of partial openings formed in the aft end of the liner, with each pin member including a head portion at one end thereof, and a device positioned within each opening in the support member so as to retain the pin members therein. The pin members and the support member are able to slide radially and / or axially with respect to the liner aft end as the support member experiences thermal growth greater than the liner.

Owner:GENERAL ELECTRIC CO

Method for forming interphase layers in ceramic matrix composites

InactiveUS7666475B2Avoid bondingSacrificing crack deflection and toughnessPretreated surfacesChemical vapor deposition coatingMatrix densitySlurry

A method for forming interphase layers in ceramic matrix composites. The method forms interphase layers in ceramic matrix composites thereby enabling higher matrix densities to be achieved without sacrificing crack deflection and / or toughness. The methods of the present invention involve the use fugitive material-coated fibers. These fibers are then infiltrated with a ceramic matrix slurry. Then, the fugitive material is removed and the resulting material is reinfiltrated with an interphase layer material. The ceramic matrix composite is then fired. Additional steps may be included to densify the ceramic matrix or to increase the strength of the interphase layer. The method is useful for the formation of three dimensional fiber-reinforced ceramic matrix composites envisioned for use in gas turbine components.

Owner:SIEMENS ENERGY INC

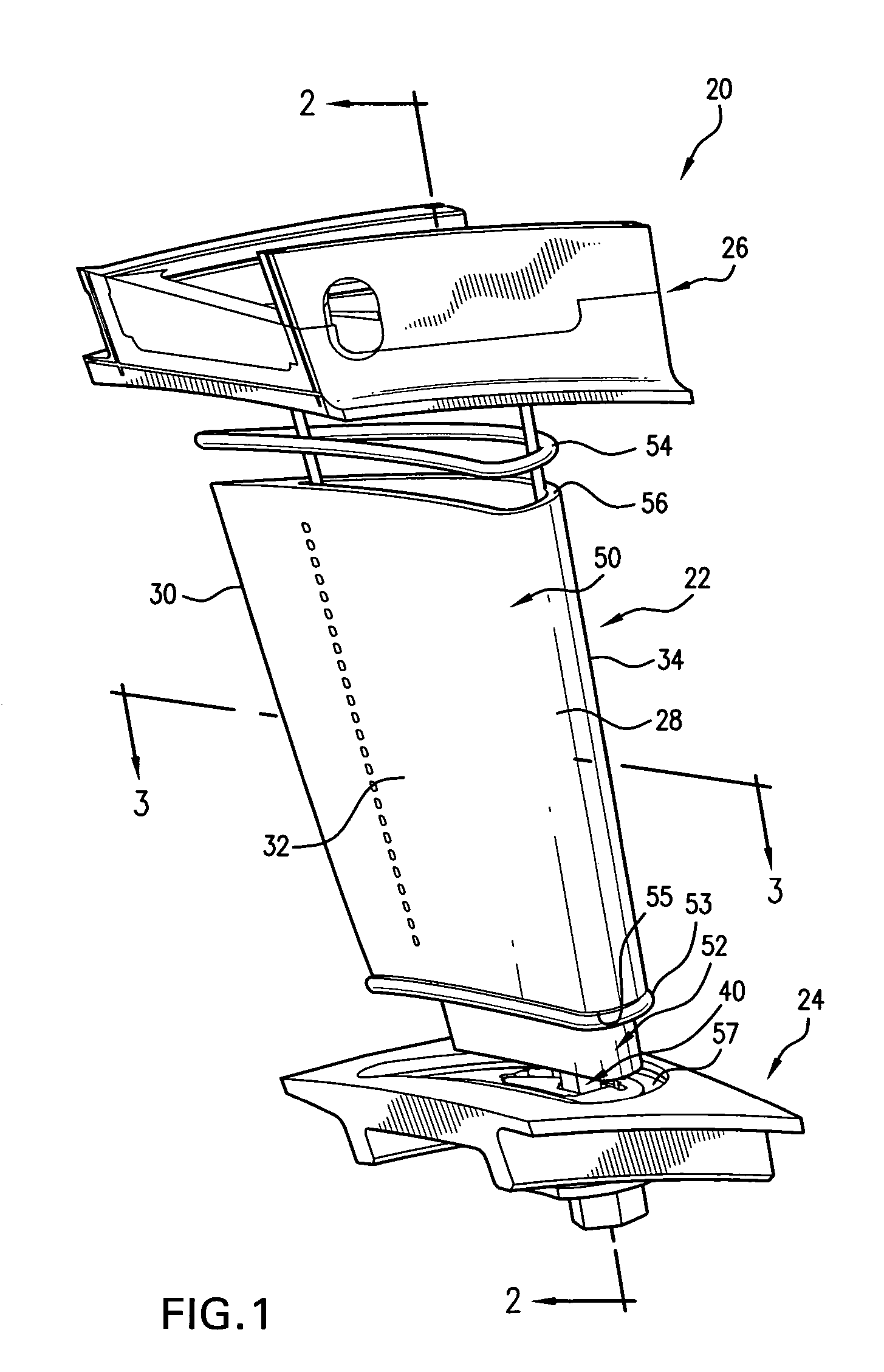

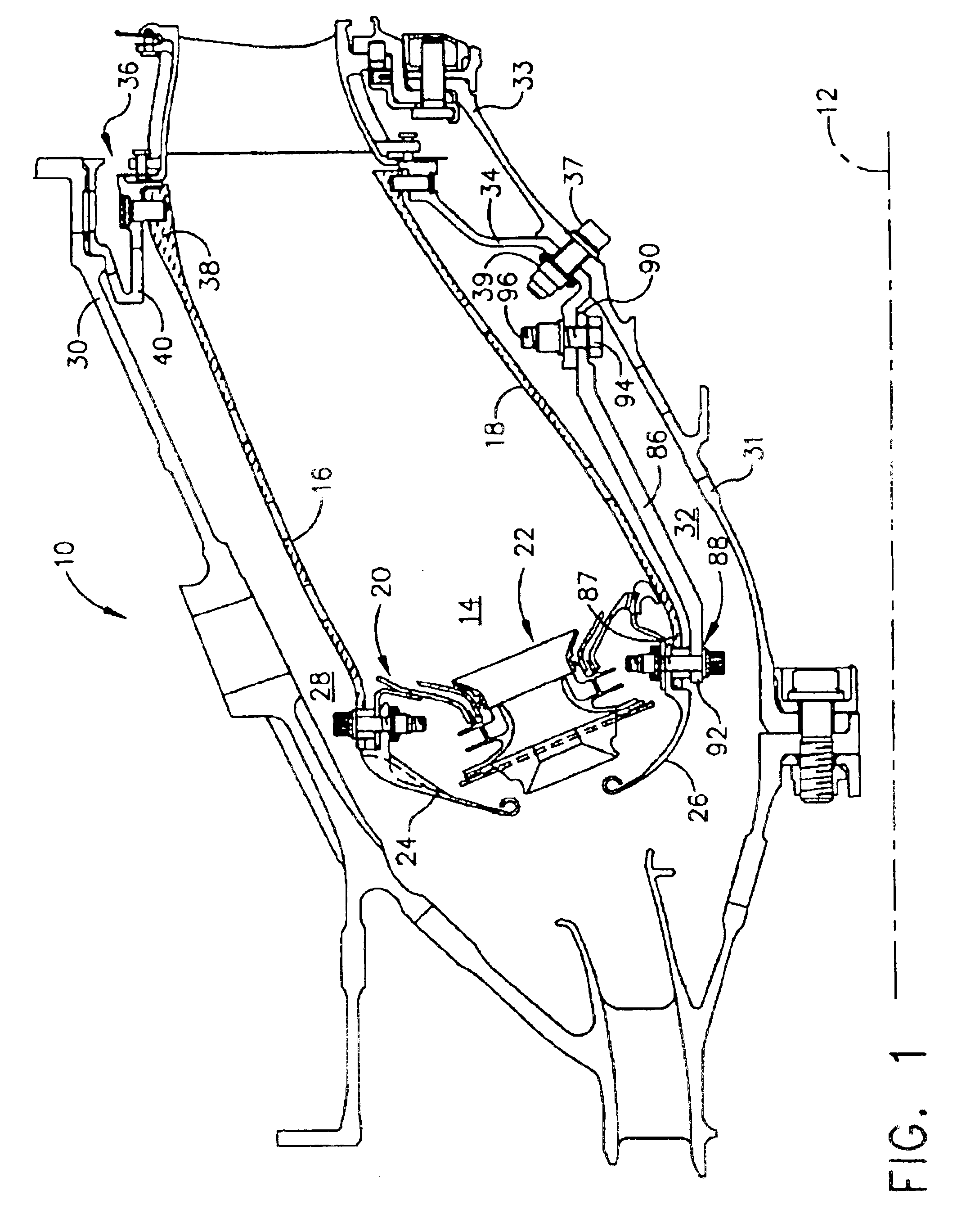

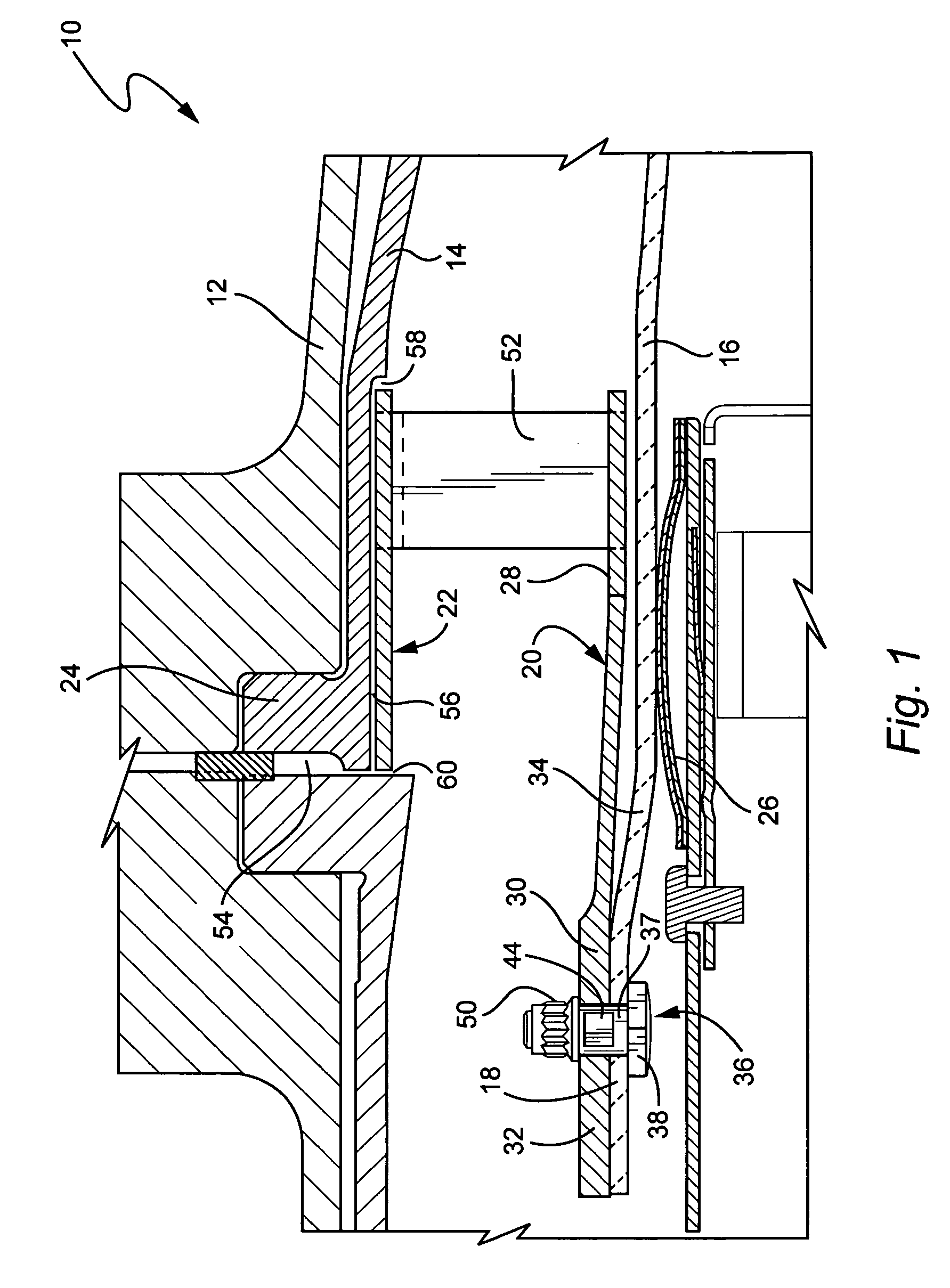

Bolting configuration for joining ceramic combustor liner to metal mounting attachments

ActiveUS7546743B2Easy to manufactureSolve the lack of lifeContinuous combustion chamberGas turbine plantsCombustorEngineering

A gas turbine combustor includes a substantially cylindrical combustor liner located substantially concentrically within a flow sleeve, the combustor liner composed through a ceramic matrix composite material, a forward end of the combustor liner provided with a plurality of circumferentially arranged bolt holes. An inner metal ring is located about an outside surface of the forward end of the combustor liner, the inner metal ring provided with a second plurality of circumferentially spaced bolt holes, with a plurality of bolts extending through the first and second pluralities of bolt holes and secured by self-locking nuts. An outer metal ring is spaced radially outwardly of the inner metal ring, with a plurality of circumferentially spaced struts extending between the inner and outer rings.

Owner:GENERAL ELECTRIC CO

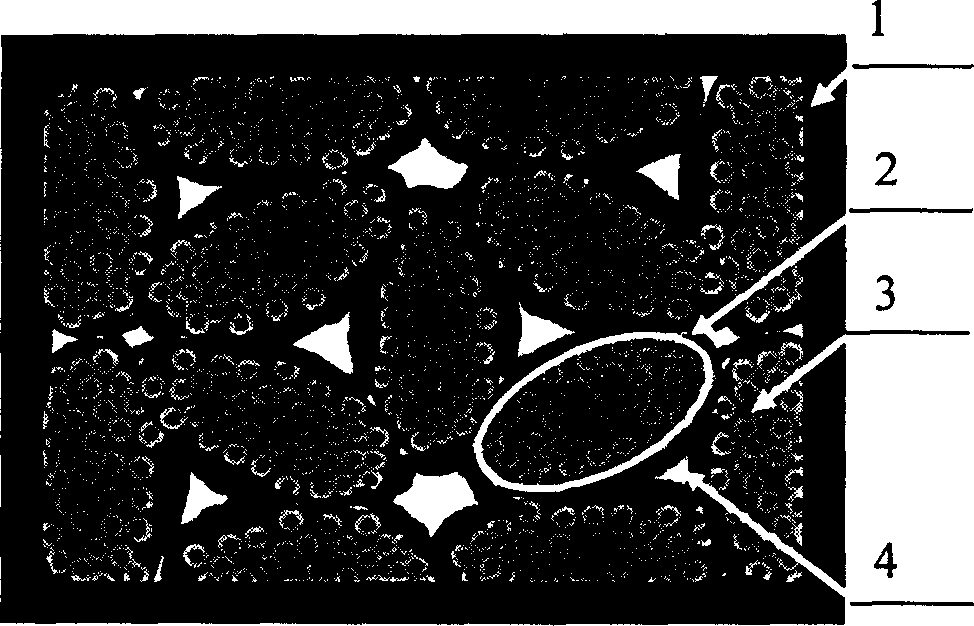

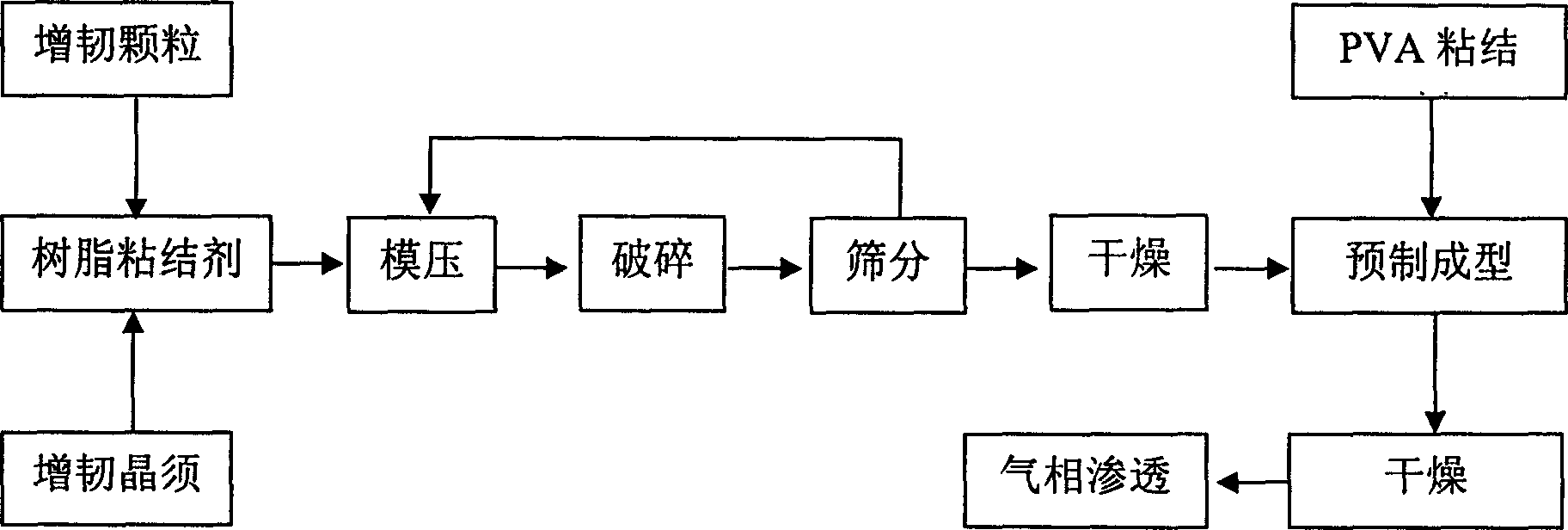

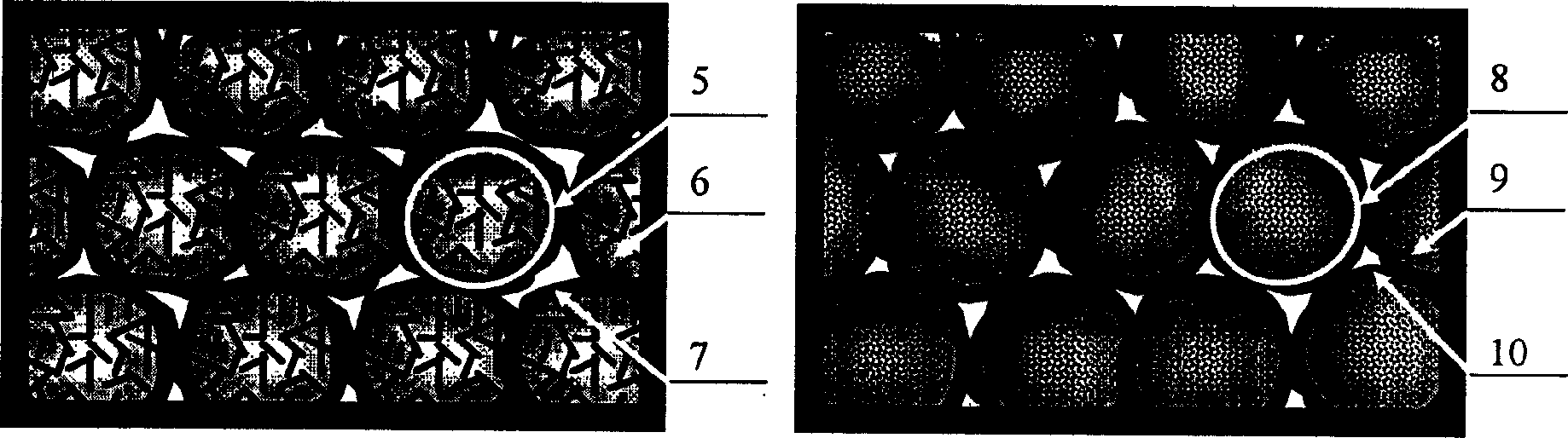

Preparation method of whisker and pacticle toughening ceramic base composite

A crystal whisker and particle toughened ceramic-based composition used to make large thin-wall member is prepared through granulating to prepare the coagulated substance of crystal whiskers and particles, preparing the prefabricated body of crystal whisker-particle reinforcing body, and depositing the ceramic base in said prefabricated body by chemical vapour osmosis process.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

Multivane segment mounting arrangement for a gas turbine

A mounting arrangement (10) for a multivane segment (12) of ceramic matrix composite (CMC) composition positioned between outer and inner metallic rings (14, 16). Selected ones of the vanes (18a) of the multivane segment surround internal struts (24) joining the outer and inner rings. Spring members (26, 28) accommodate differential thermal growth between the multivane segment and the outer and inner rings, and a compliant material (30) seals against gas leakage around the segments.

Owner:SIEMENS ENERGY INC

Gas turbine combustion chamber made of CMC and supported in a metal casing by CMC linking members

ActiveUS7234306B2Easy to controlAvoid violationsContinuous combustion chamberGas turbine plantsCombustion chamberCopper

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

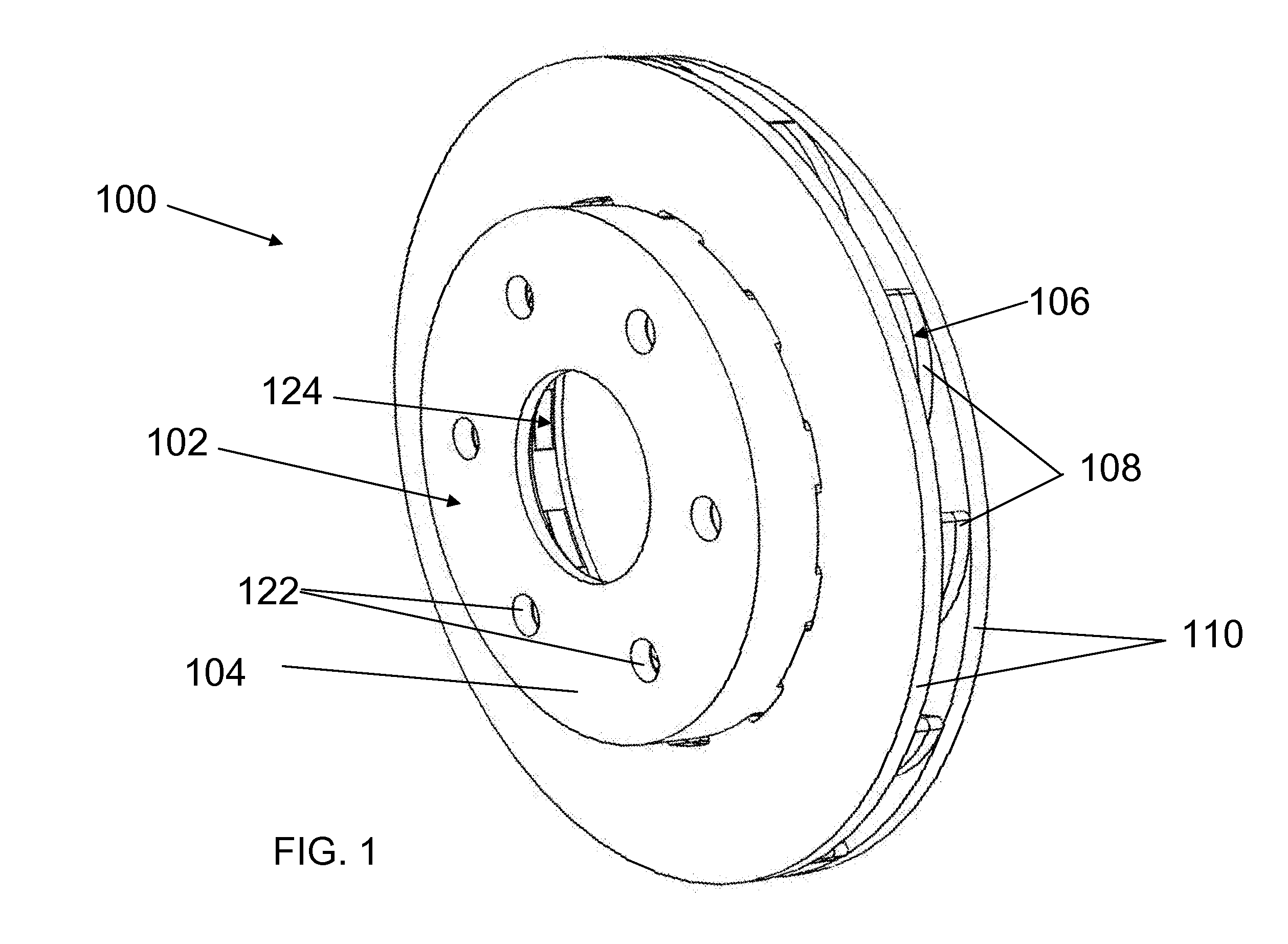

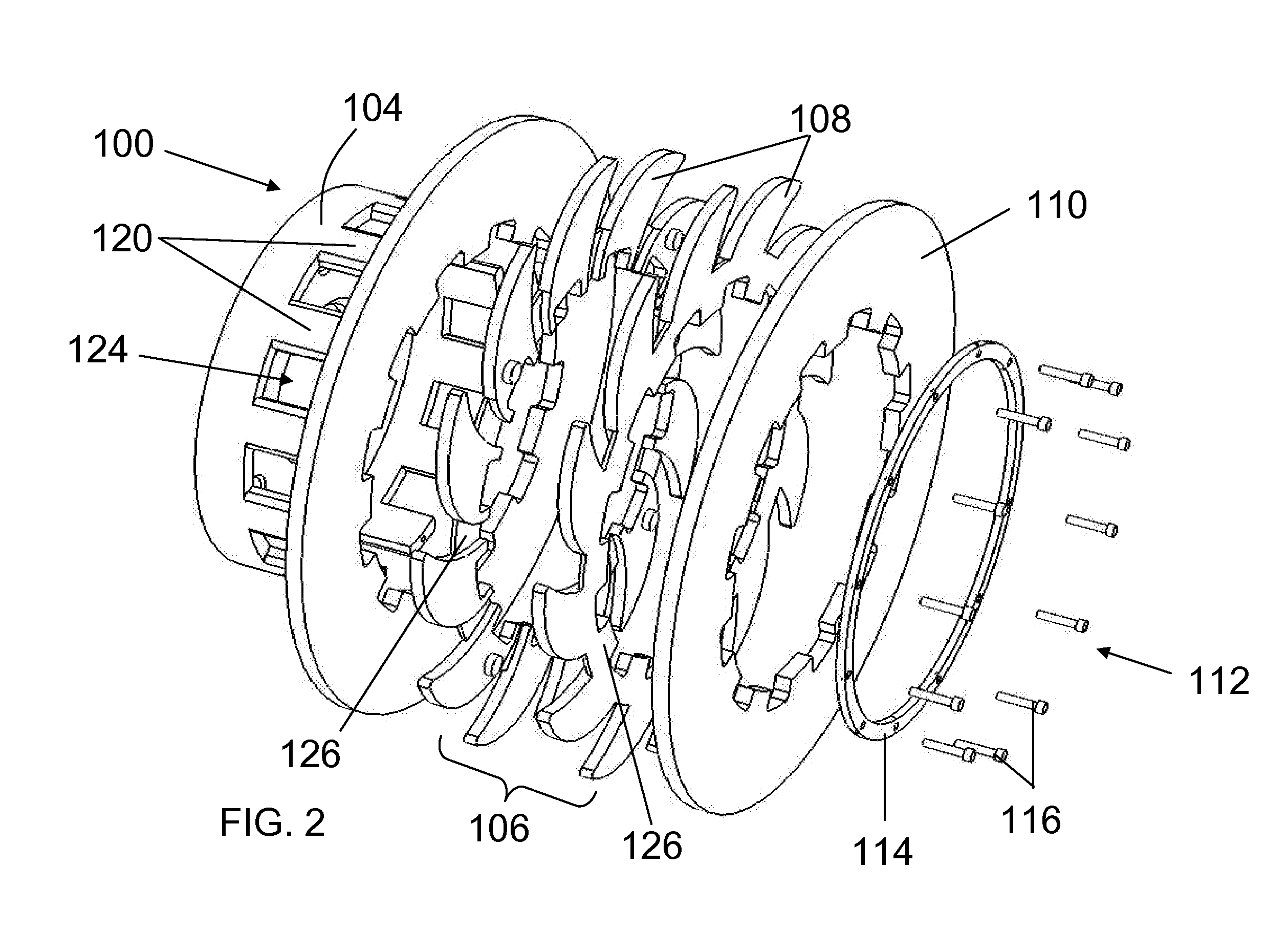

Brake rotor with ceramic matrix composite friction surface plates

The disclosure relates to structures and a method for providing an air cooled rotor with ceramic-metal composite friction surface plates, and in particular to a brake rotor including a rotor hat; a ventilation disc having a plurality of cooling vanes extending therefrom; a ceramic matrix composite (CMC) friction surface plate on each side of the ventilation disc; and a fastener for holding the CMC friction surface plates and the ventilation disc to the rotor hat.

Owner:STARFIRE SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com