Method for hole machining with picosecond laser

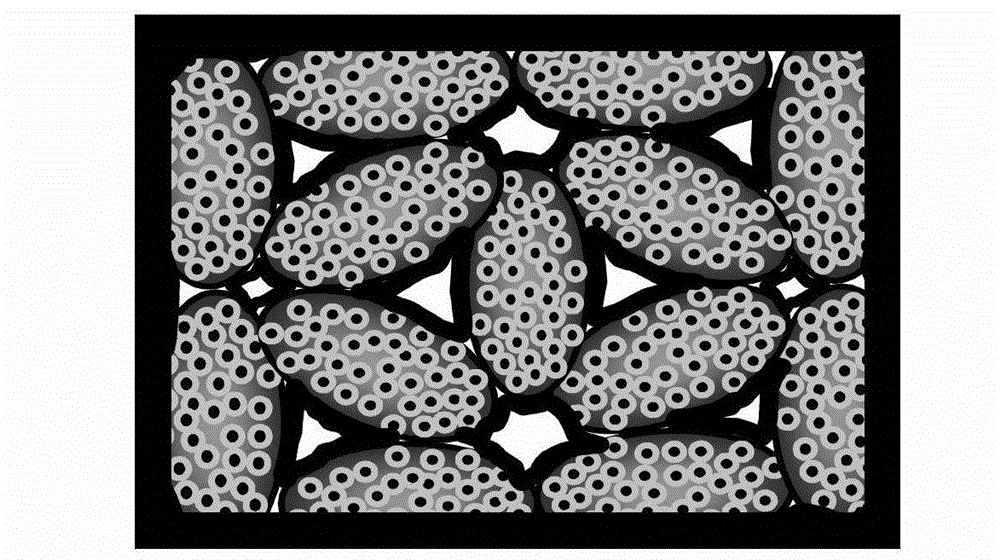

A picosecond laser and hole processing technology, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems affecting the application effect of CMC-SiC materials, CMC-SiC material processing, etc., to achieve strong designability, Good forming quality and good designability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

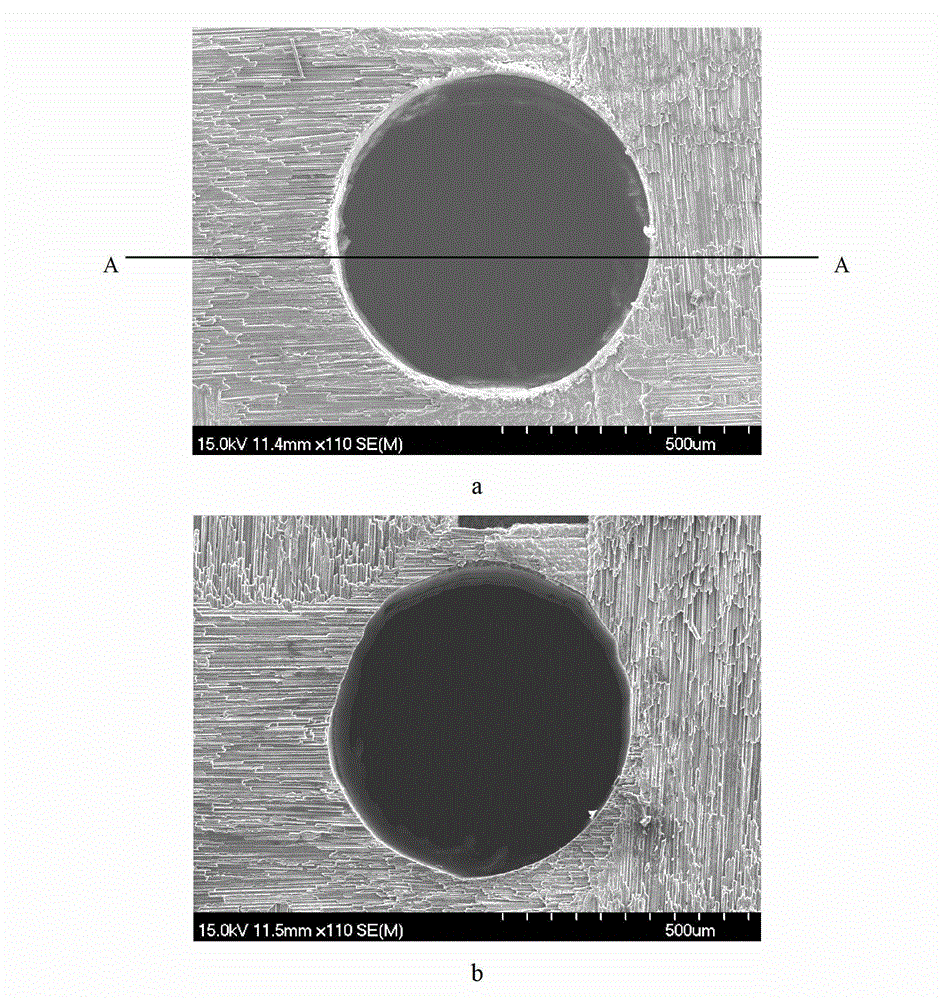

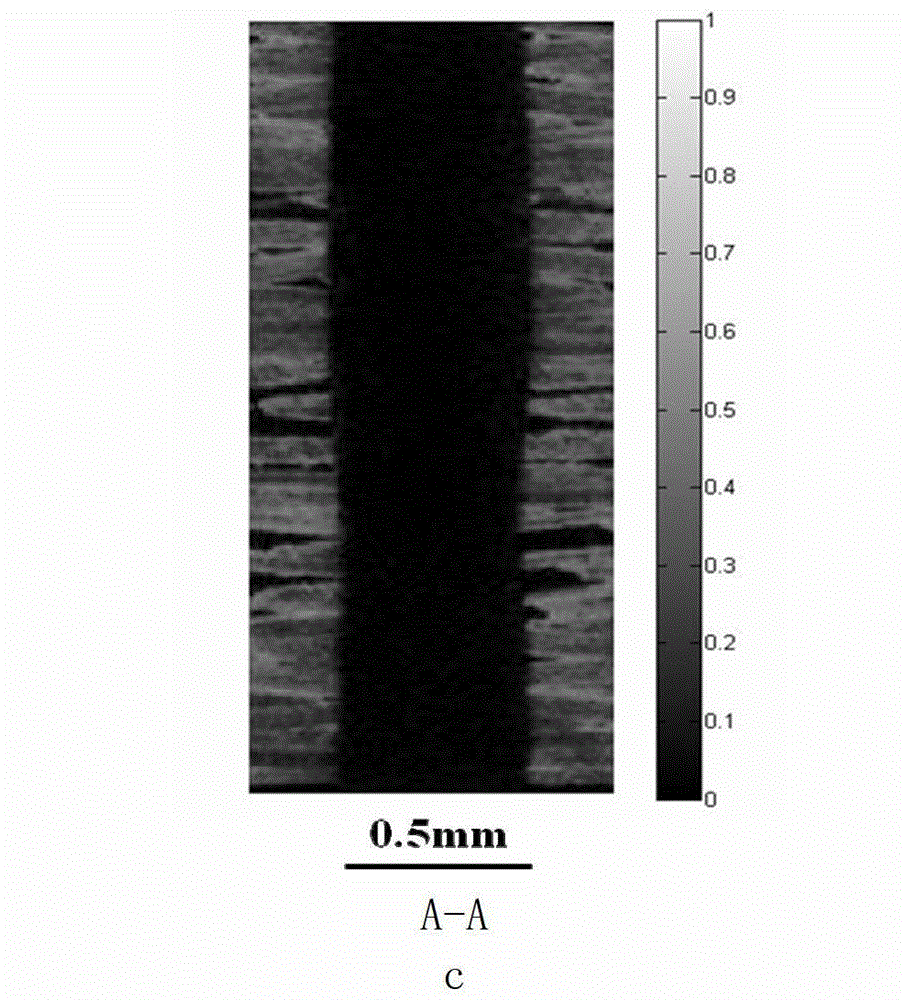

[0026] The method for forming round holes proposed in this embodiment is suitable for silicon carbide ceramic matrix composite materials, and in this embodiment only a C / SiC composite material sample is used as an example for illustration. The diameter of the formed pores was 650 μm.

[0027] In this embodiment, the picosecond laser used is a Nd:YAG picosecond laser from Light Conversion Company of Lithuania.

[0028] The concrete process of this embodiment is:

[0029] Step 1, the surface of the sample is cleaned. Cut the 2D CVI C / SiC composite material into a rectangular block sample of 20mm×10mm×3mm, then ultrasonically clean the sample for 15 minutes under alcohol immersion to remove surface dust, oil and other impurities, and finally dry it in a drying oven to obtain the cleaned of samples.

[0030] Step 2, machining holes. Micromachining of 2D CVI C / SiC composite samples by picosecond laser. During processing, the wavelength of the picosecond laser is 355-532nm, the...

Embodiment 2

[0041] The method for forming square holes proposed in this embodiment is suitable for silicon carbide ceramic matrix composite materials, and this embodiment only uses SiC / SiC composite material samples as an example for illustration. The plane size of the formed hole is: 650μm*650μm.

[0042] In this embodiment, the picosecond laser used is an Nd:YAG picosecond laser from Light Conversion Company of Lithuania.

[0043] The concrete process of this embodiment is:

[0044] Step 1, the surface of the sample is cleaned. Cut the 2D CVI C / SiC composite material into a rectangular block sample of 20mm×10mm×3mm, then ultrasonically clean the sample for 15 minutes under alcohol immersion to remove surface dust, oil and other impurities, and finally dry it in a drying oven to obtain the cleaned of samples.

[0045] Step 2, machining holes. Holes are machined on 2D CVI C / SiC composite samples by picosecond laser. During processing, the wavelength of the picosecond laser is 355-532...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com