Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1436 results about "Static friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

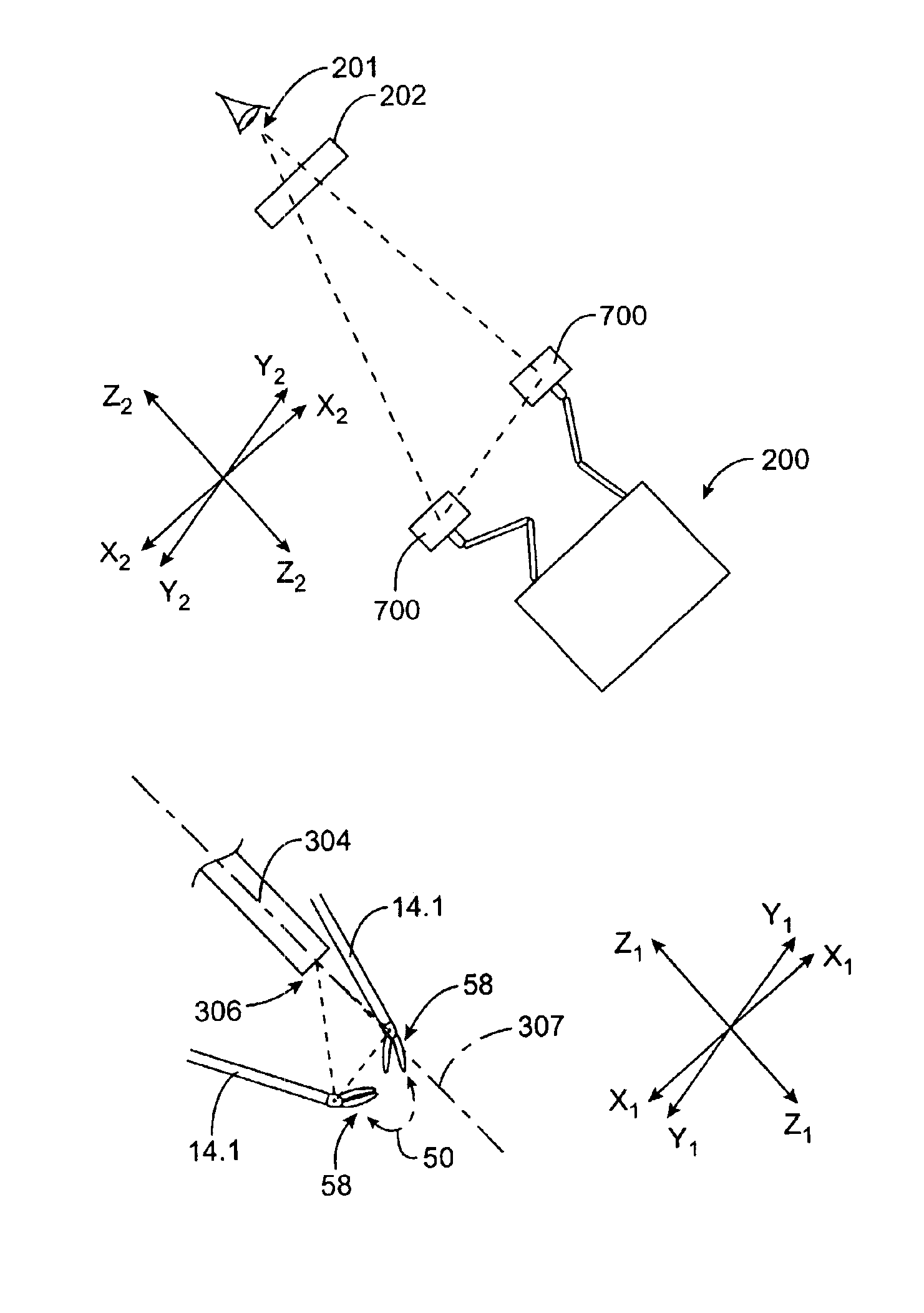

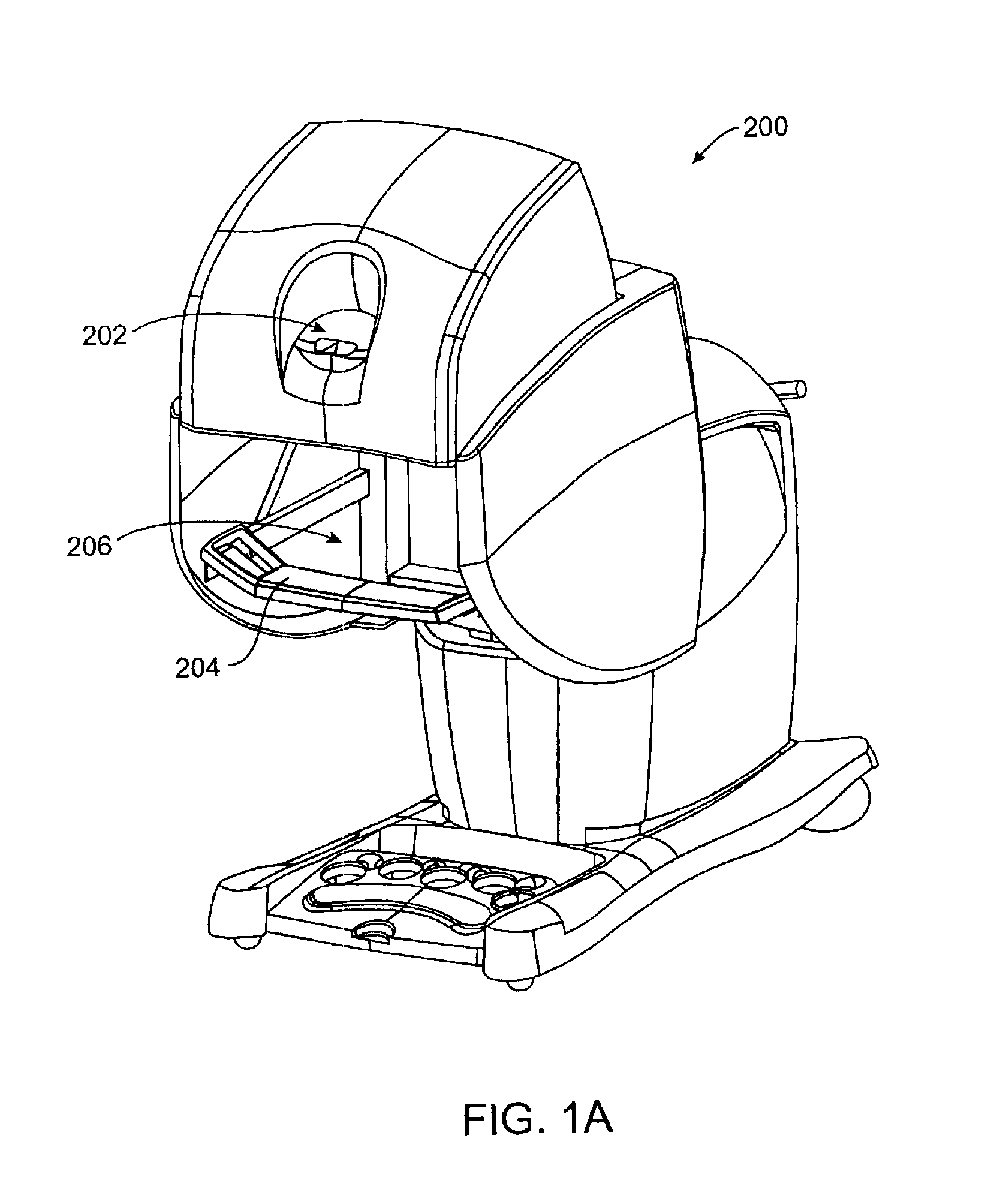

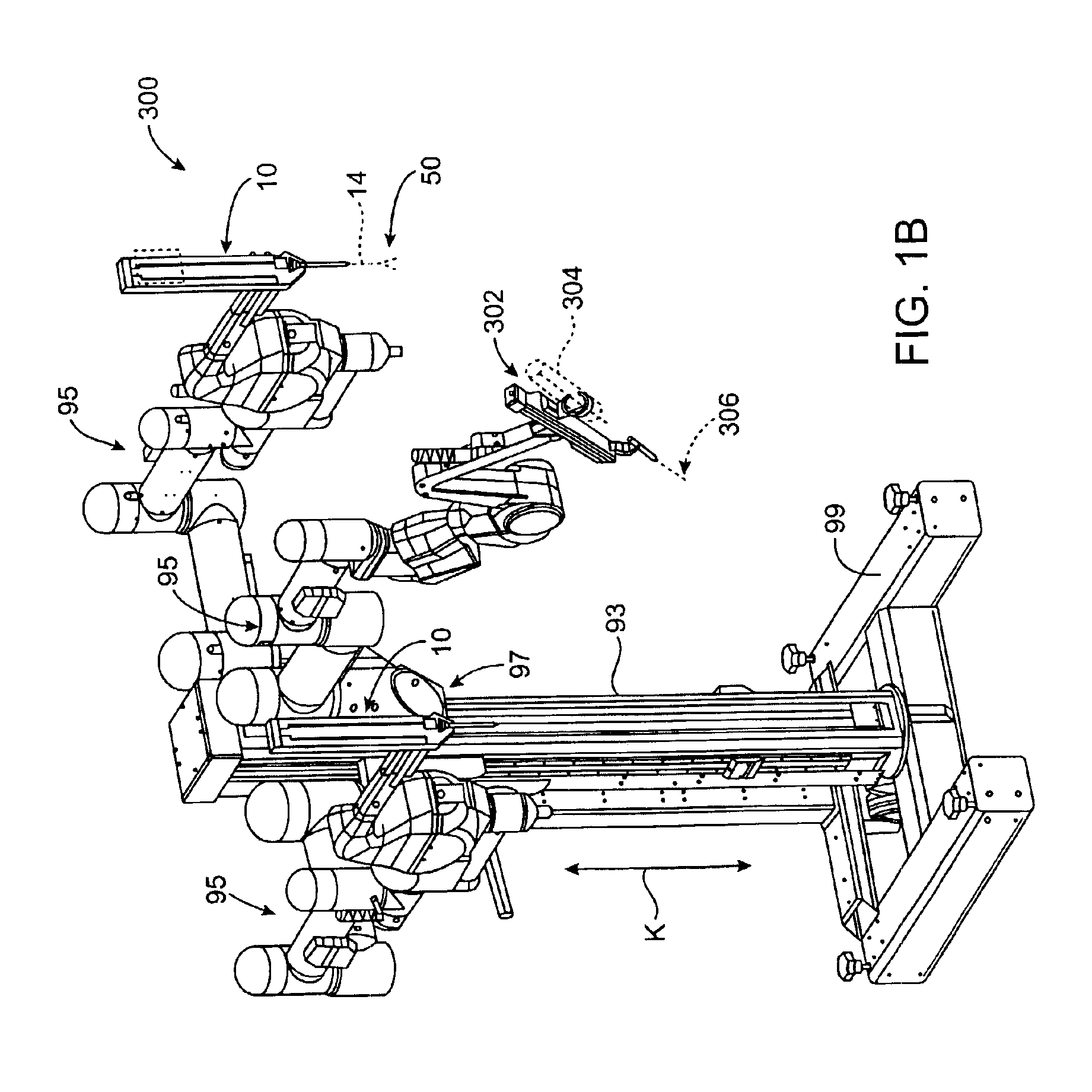

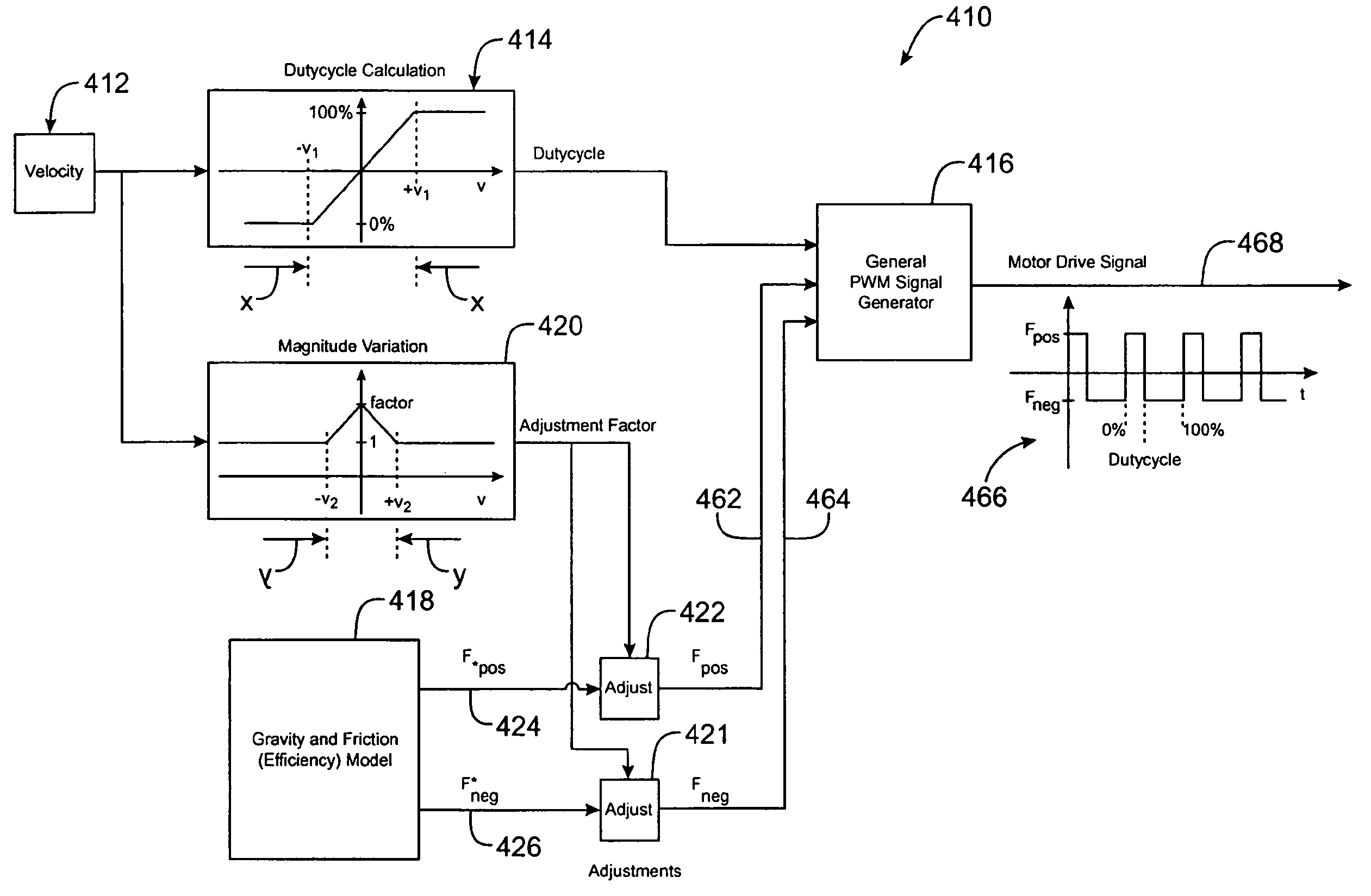

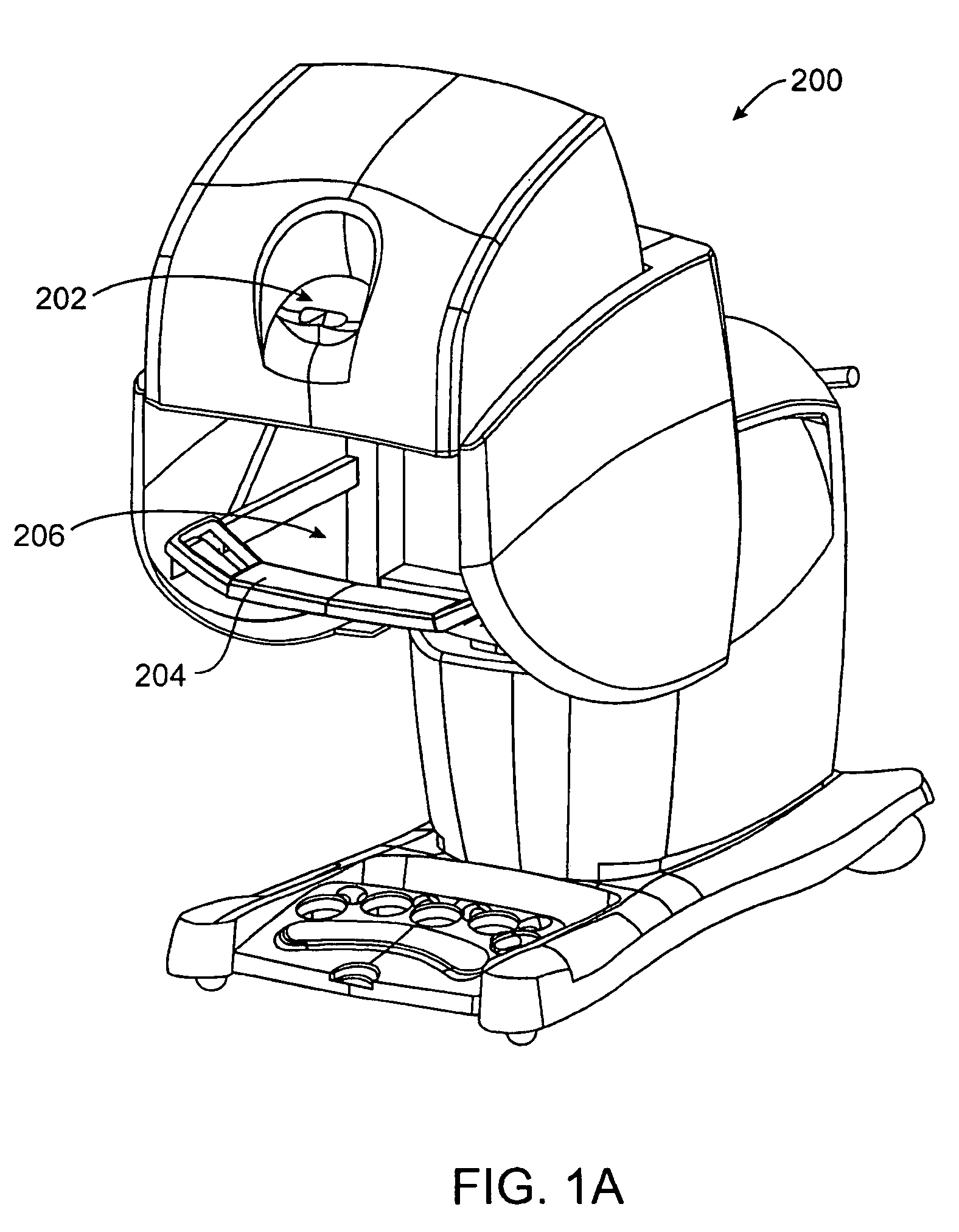

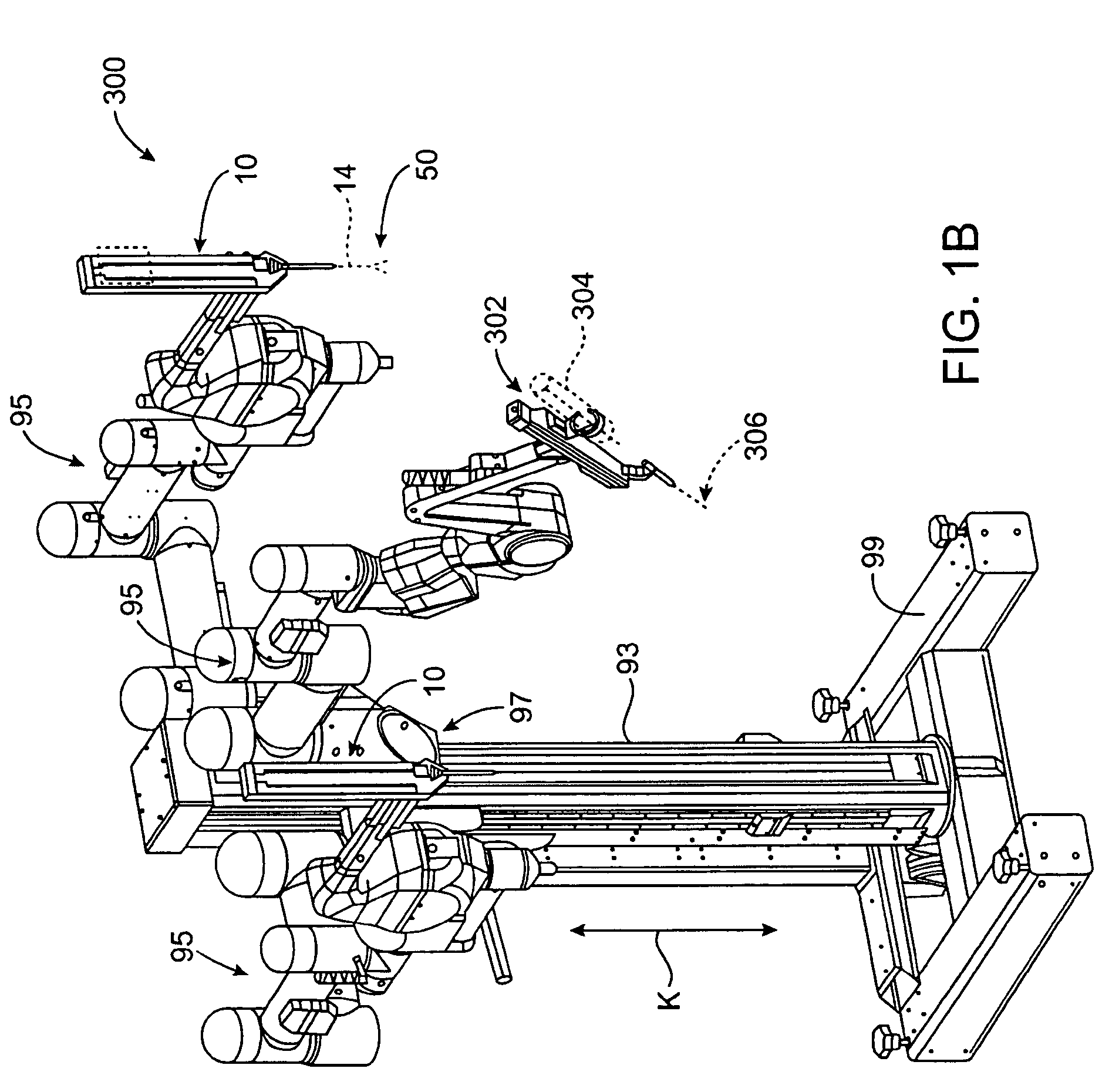

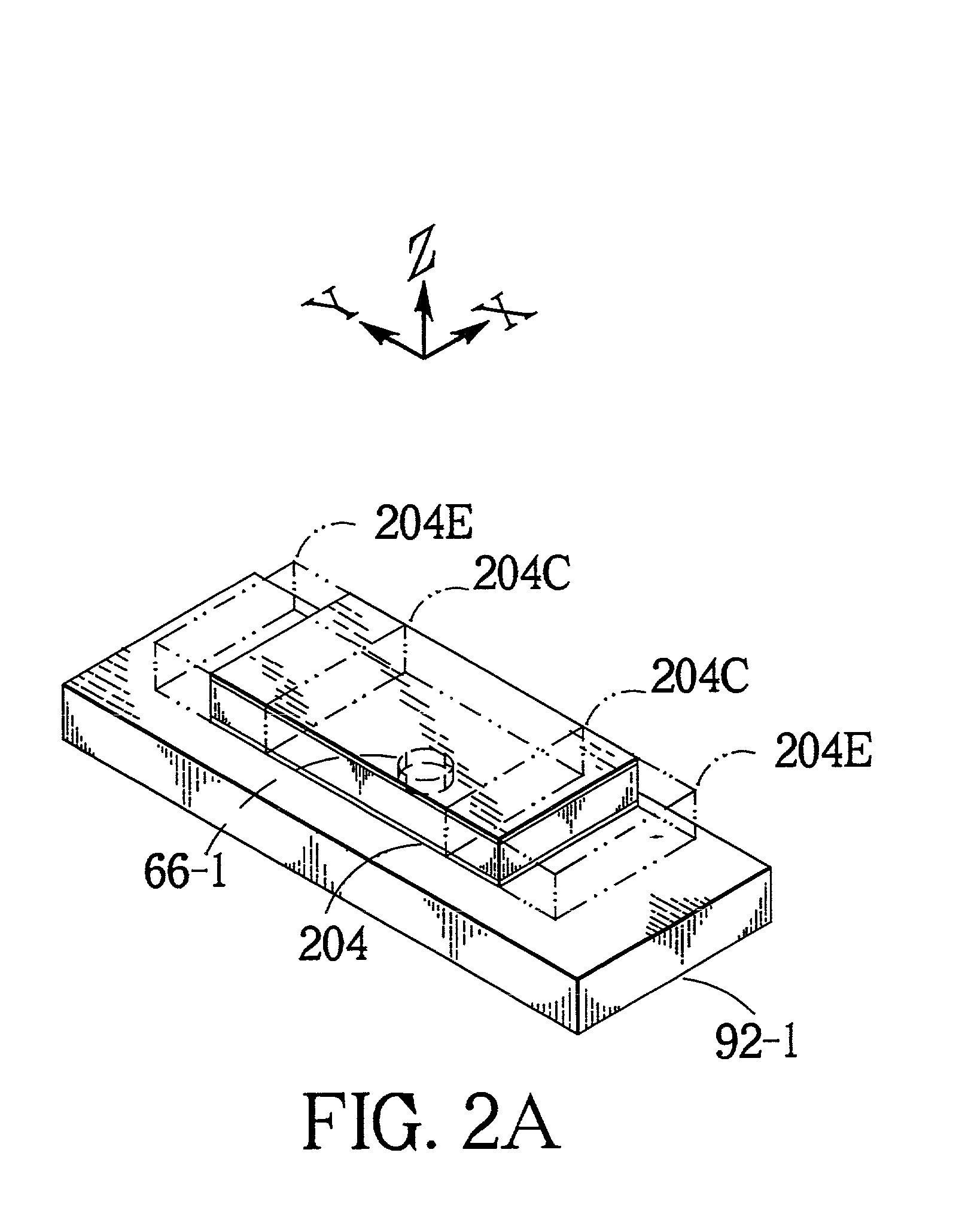

Friction compensation in a minimally invasive surgical apparatus

InactiveUS6899705B2High dexterityImprove precisionDiagnosticsSurgical manipulatorsLess invasive surgeryLow speed

Devices, systems, and methods for compensate for friction within powered automatic systems, particularly for telesurgery and other telepresence applications. Dynamic friction compensation may comprise applying a continuous load in the direction of movement of a joint, and static friction compensation may comprise applying alternating loads in positive and negative joint actuation directions whenever the joint velocity reading falls within a low velocity range.

Owner:INTUITIVE SURGICAL OPERATIONS INC

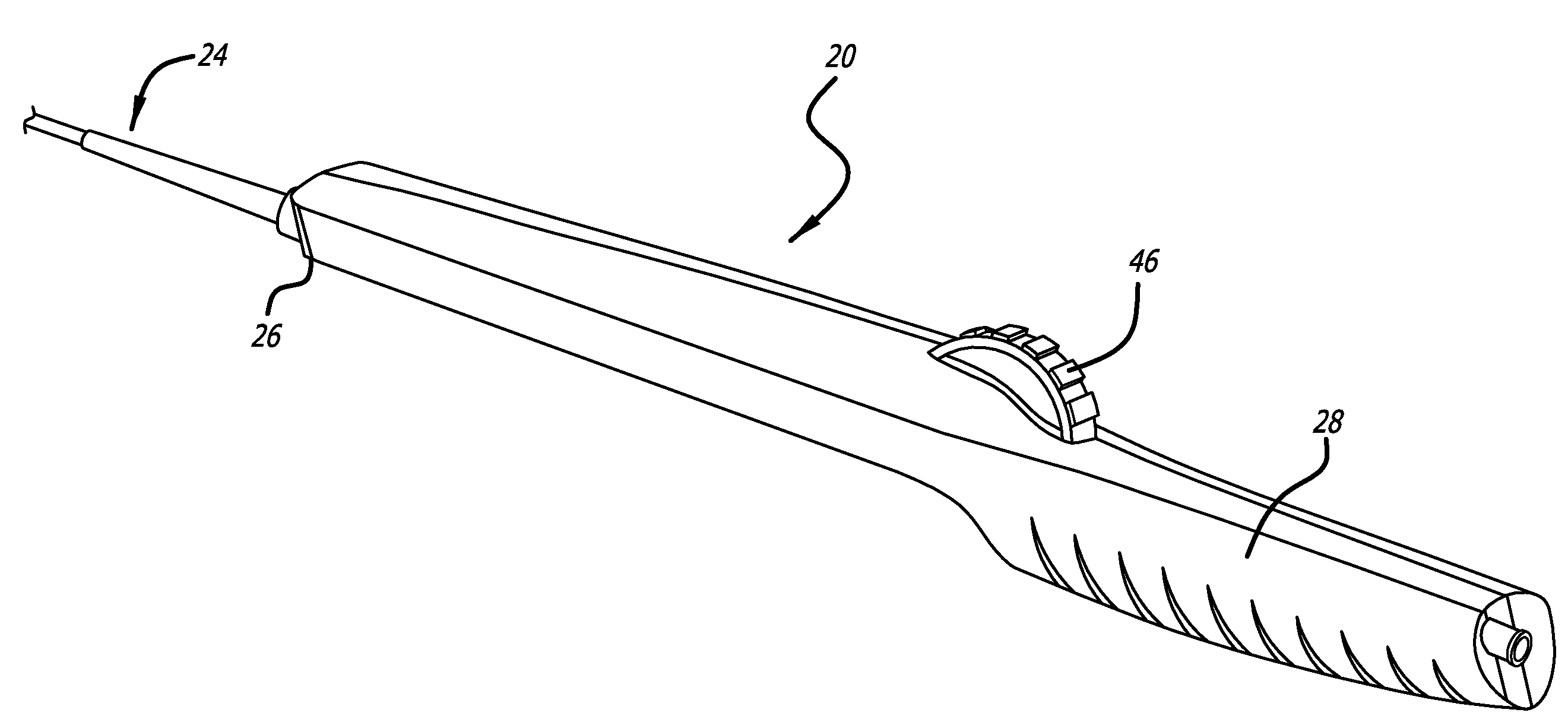

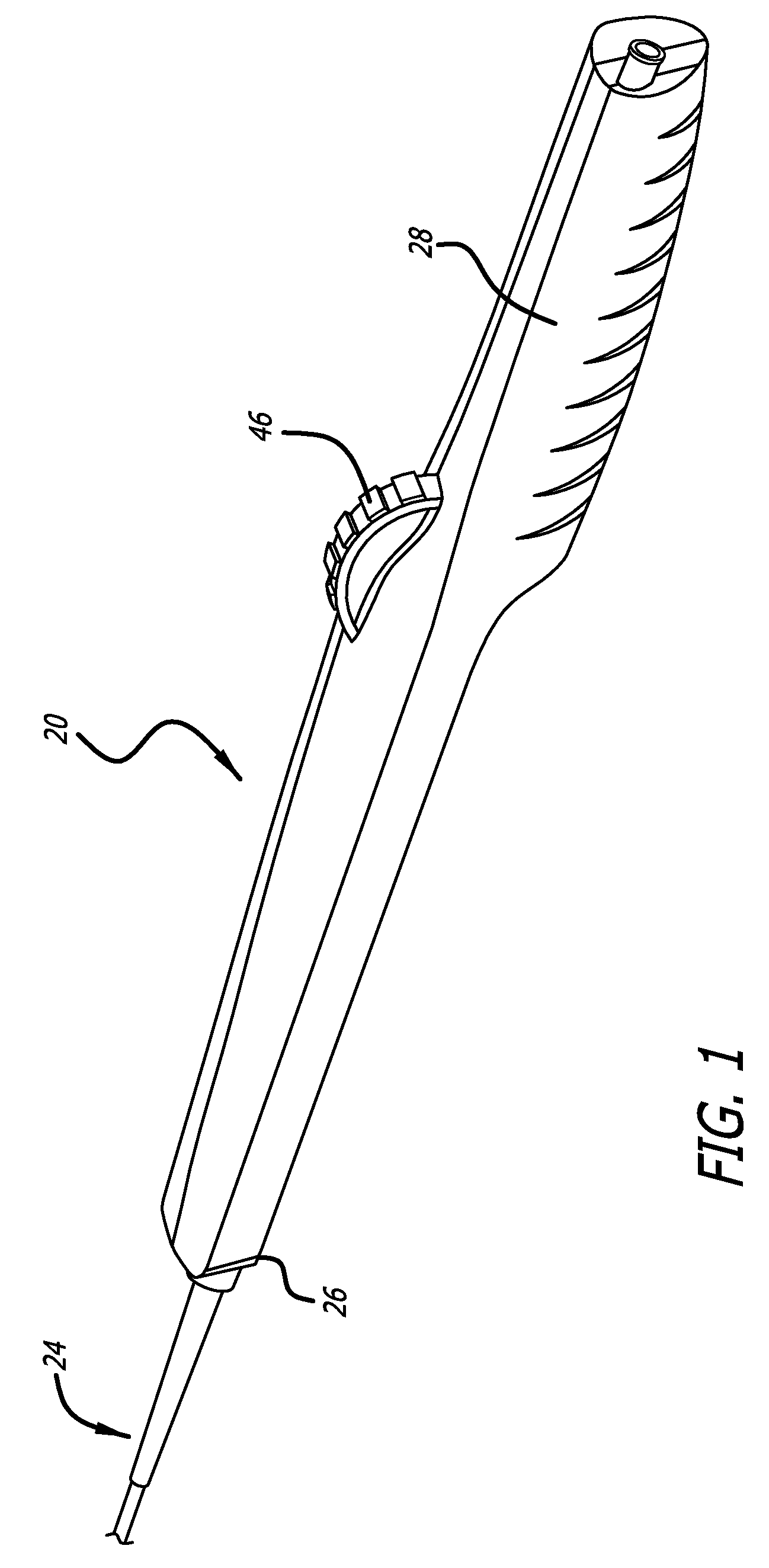

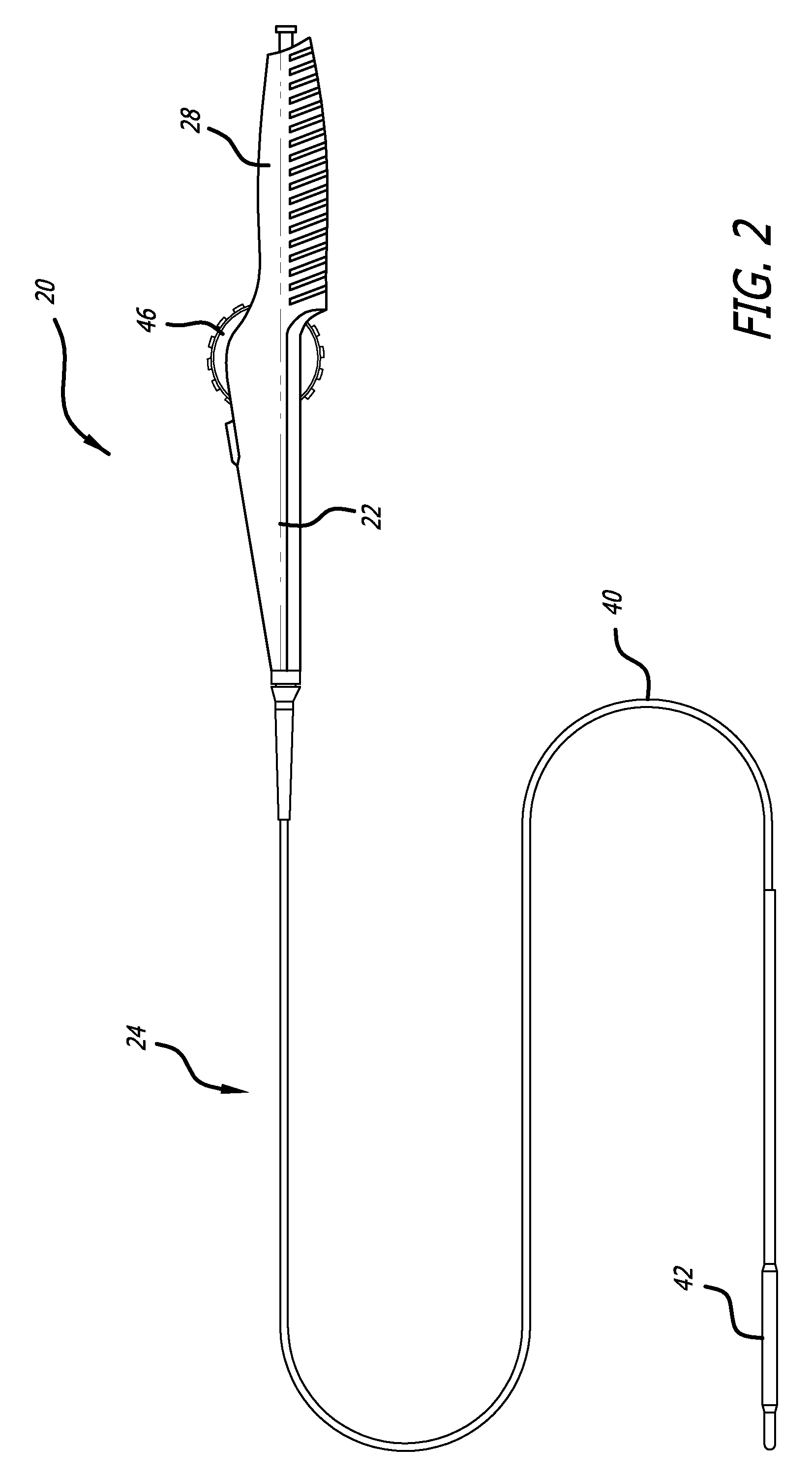

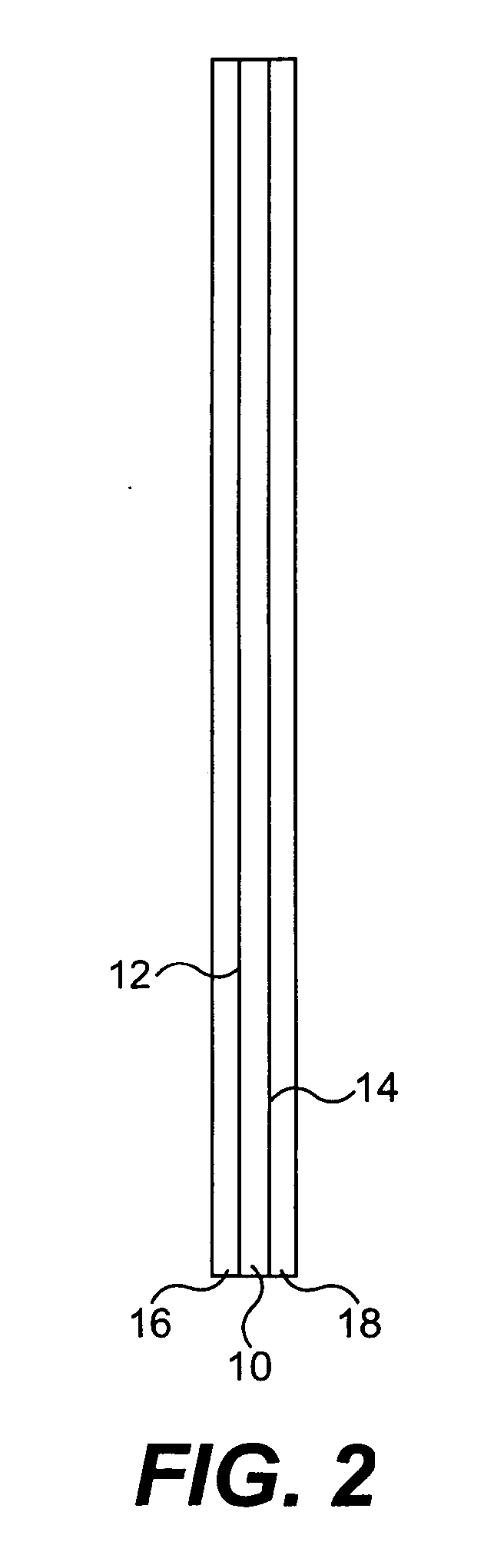

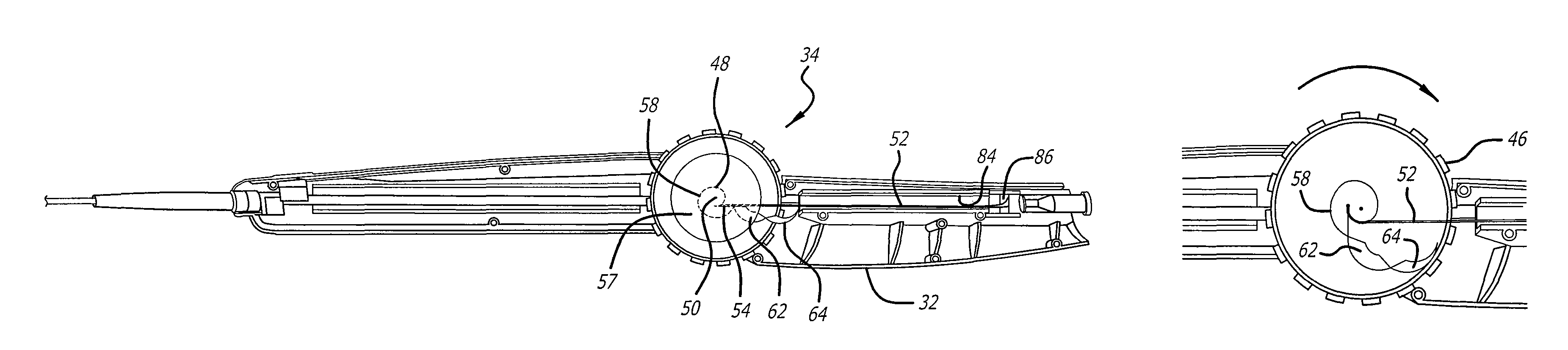

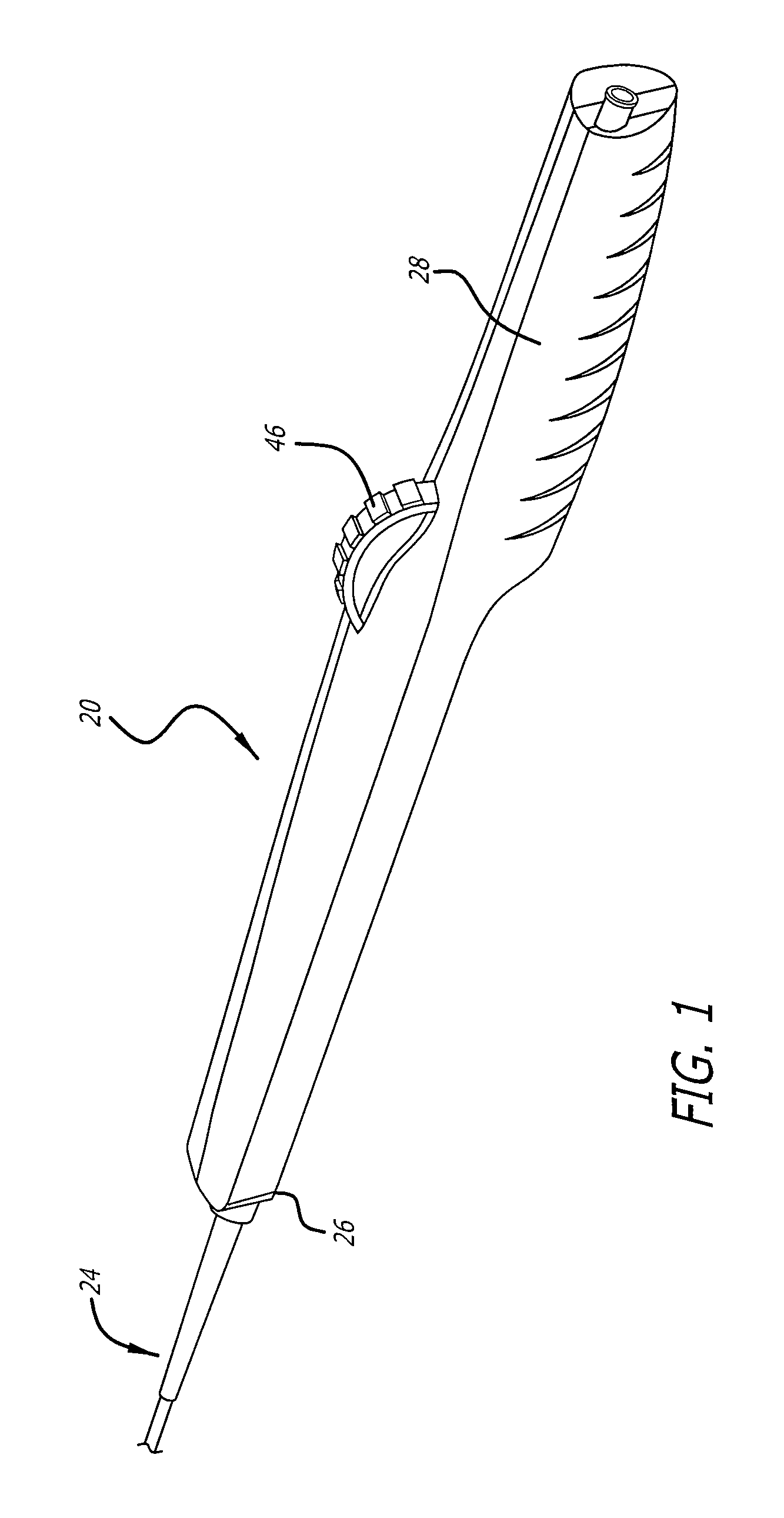

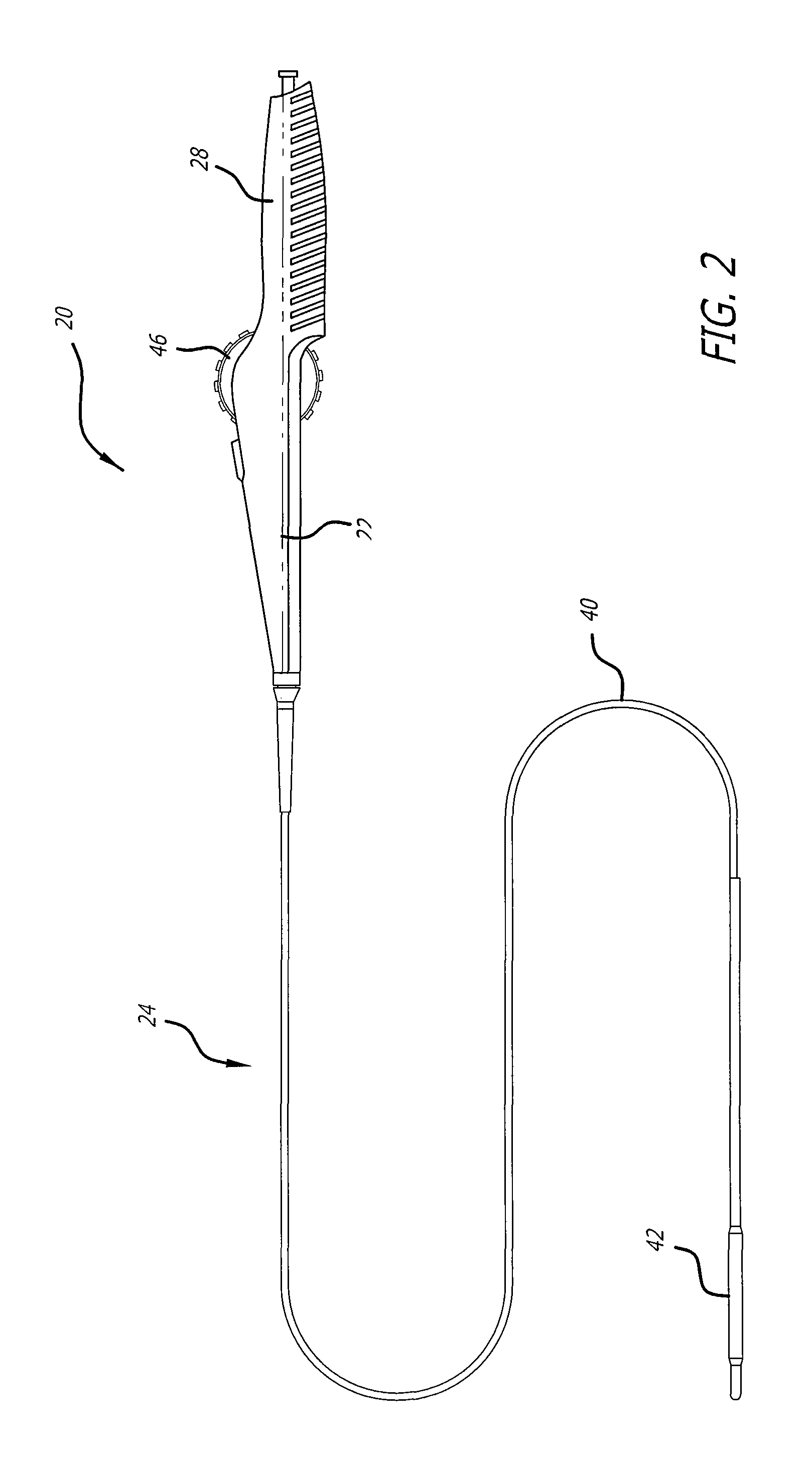

Delivery system with variable delivery rate for deploying a medical device

InactiveUS20100036472A1Less torqueReduce the amount requiredStentsBlood vesselsStatic frictionEngineering

A delivery system utilizes a handle assembly including an actuating mechanism capable of initially providing sufficient mechanical advantage to overcome static friction when initiating deployment of the medical device. The actuating mechanism includes components which help to increase the speed of deployment as the physician continues to manipulate the actuating mechanism.

Owner:ABBOTT CARDIOVASCULAR

Friction compensation in a minimally invasive surgical apparatus

InactiveUS6974449B2High dexterityImprove precisionDiagnosticsSurgical manipulatorsLess invasive surgeryLow speed

Devices, systems, and methods for compensate for friction within powered automatic systems, particularly for telesurgery and other telepresence applications. Dynamic friction compensation may comprise applying a continuous load in the direction of movement of a joint, and static friction compensation may comprise applying alternating loads in positive and negative joint actuation directions whenever the joint velocity reading falls within a low velocity range.

Owner:INTUITIVE SURGICAL OPERATIONS INC

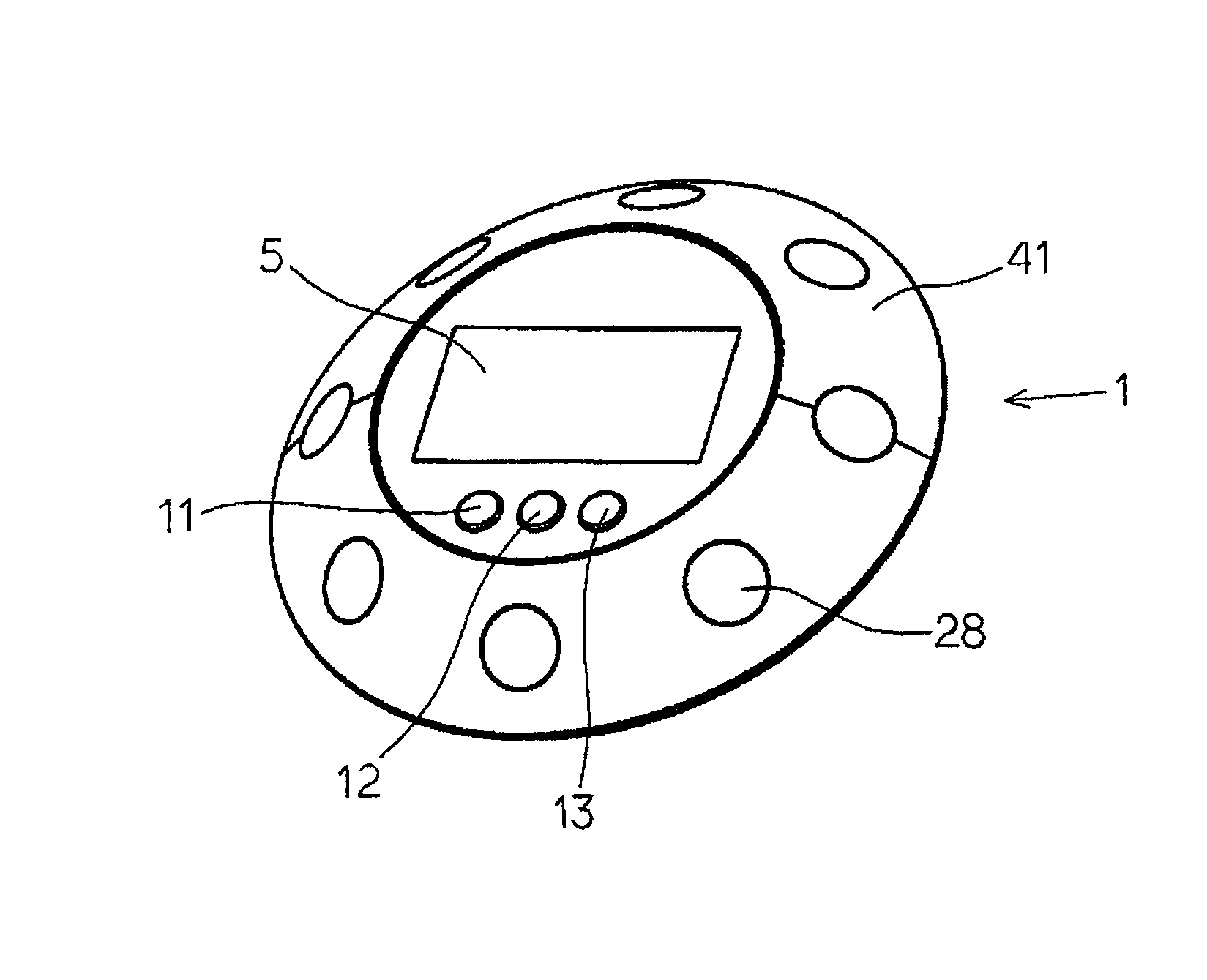

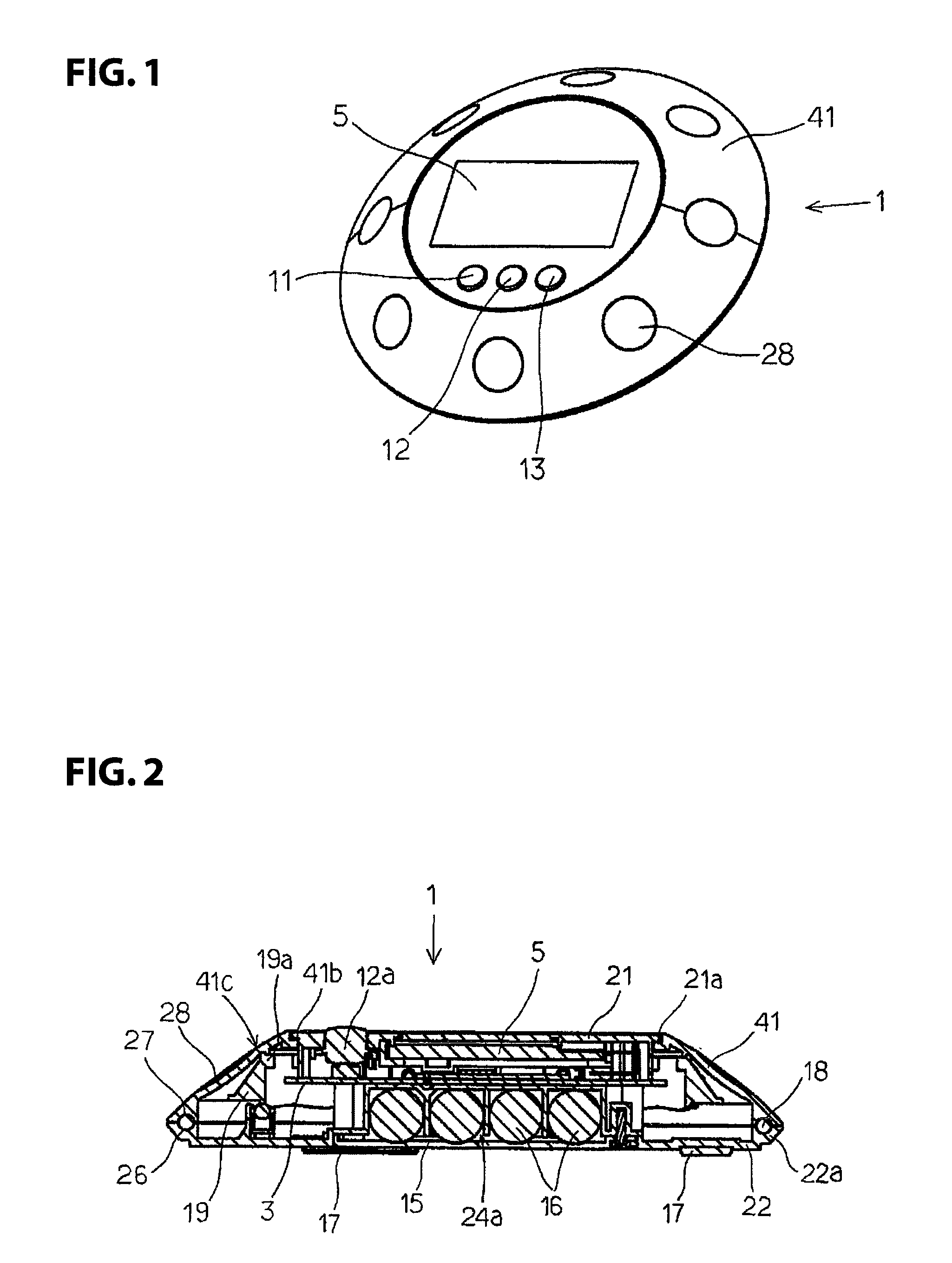

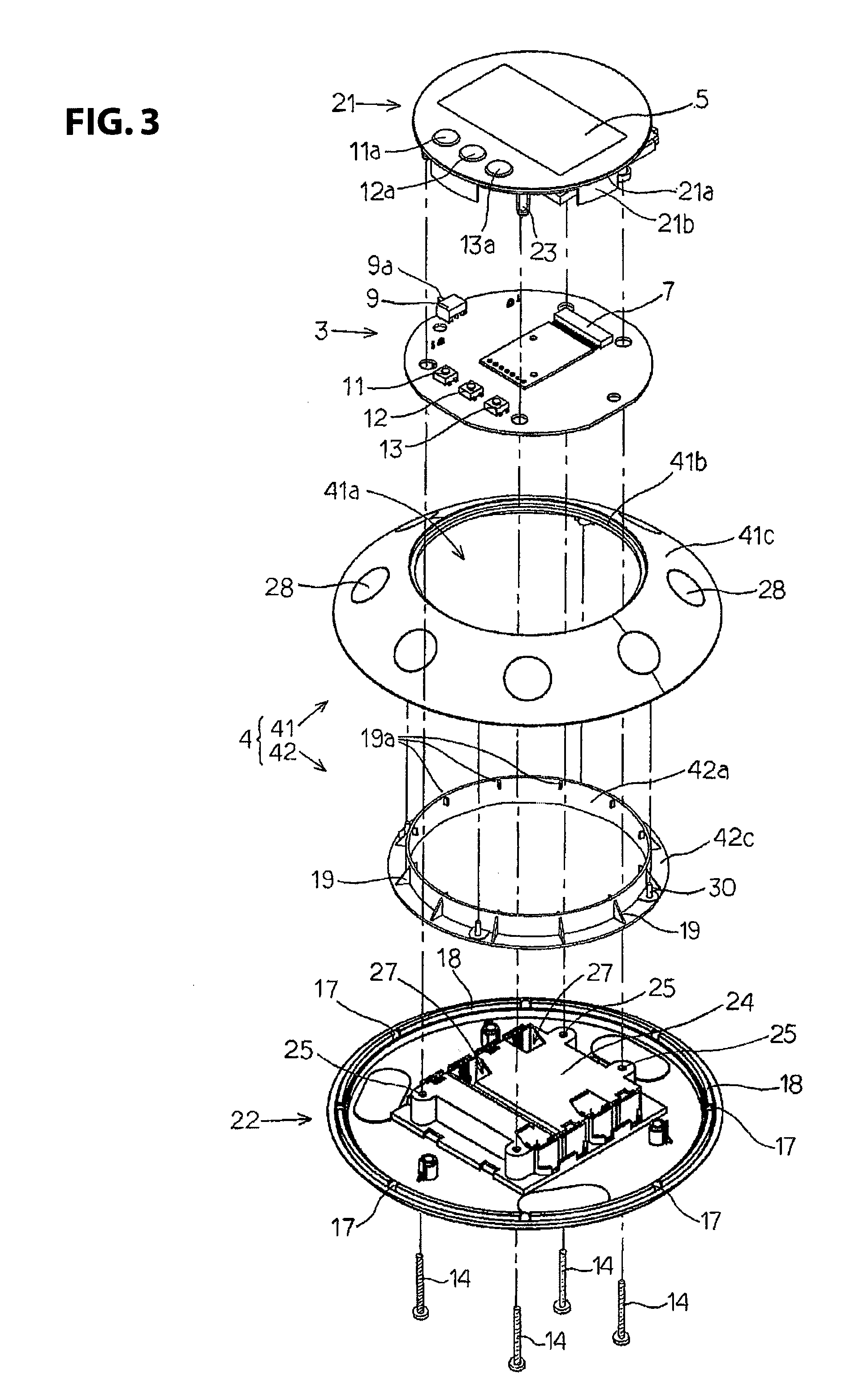

Stationary remote control transmitter

InactiveUS8188842B2Easy to implementInput/output for user-computer interactionTelevision system detailsRemote controlStatic friction

The rotation operation plane of the ring-shaped operation members that operate the rotation is inclined with respect to the horizontal plane so that the rotation operation of the ring-shaped operation member can be performed without holding a finger in the vertical direction. Furthermore, since the rotation operation plane is inclined with respect to the placement plane of the case, static friction on the placement plane is generated by a force component of the operation force acting on the rotation operation plane and is perpendicular to the placement plane, thus the case does not move toward the rotation operation direction during the rotation operation.

Owner:SMK CORP

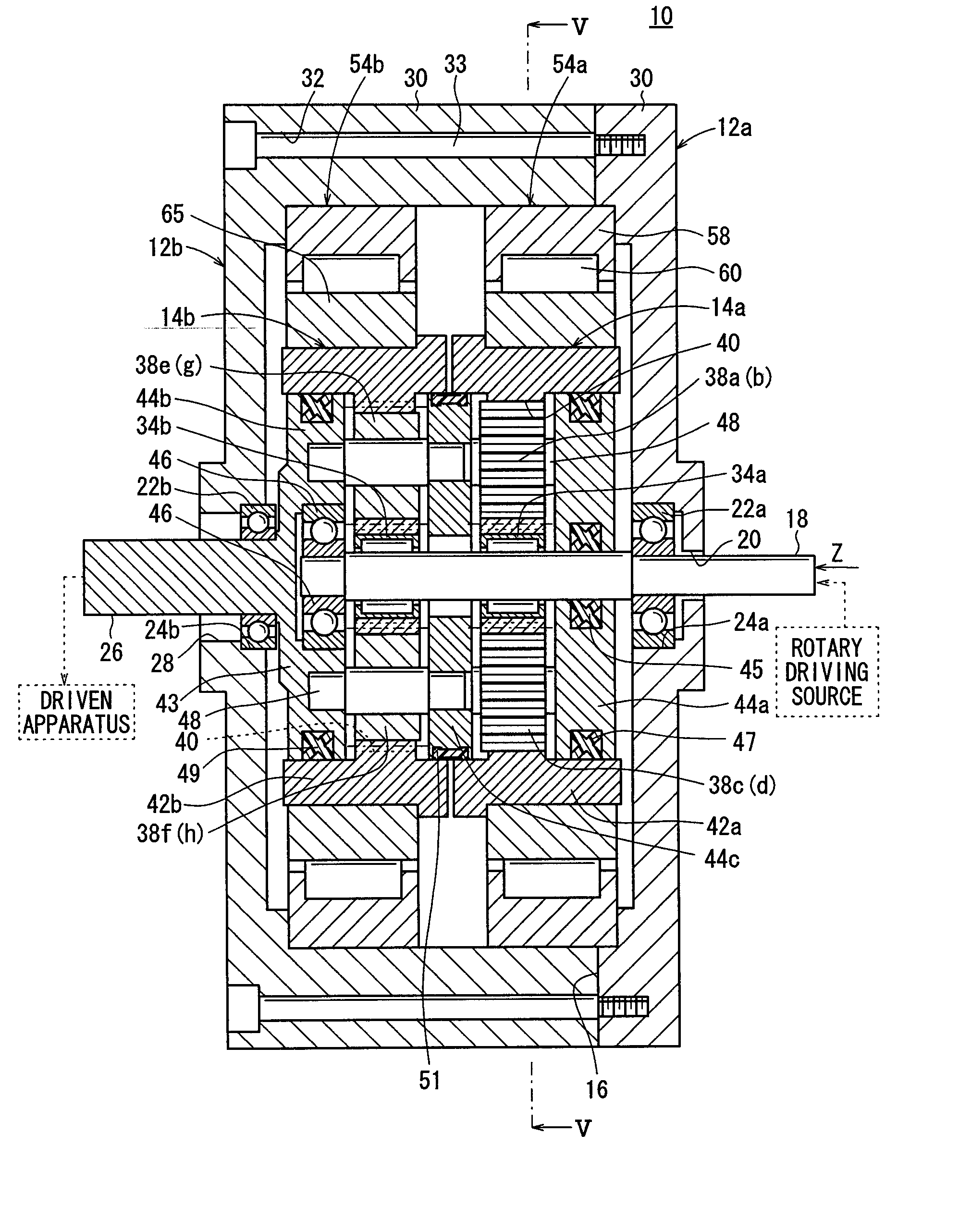

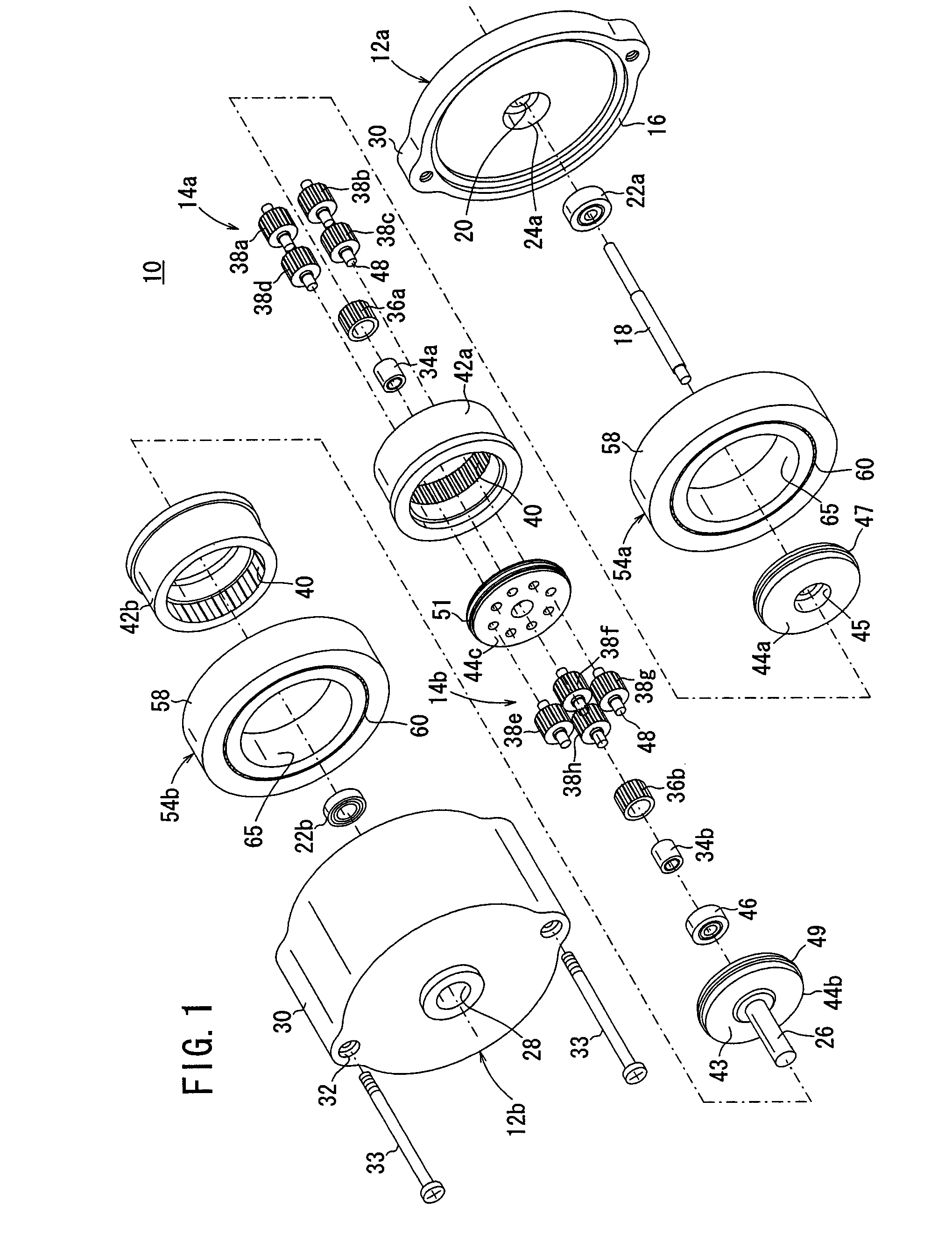

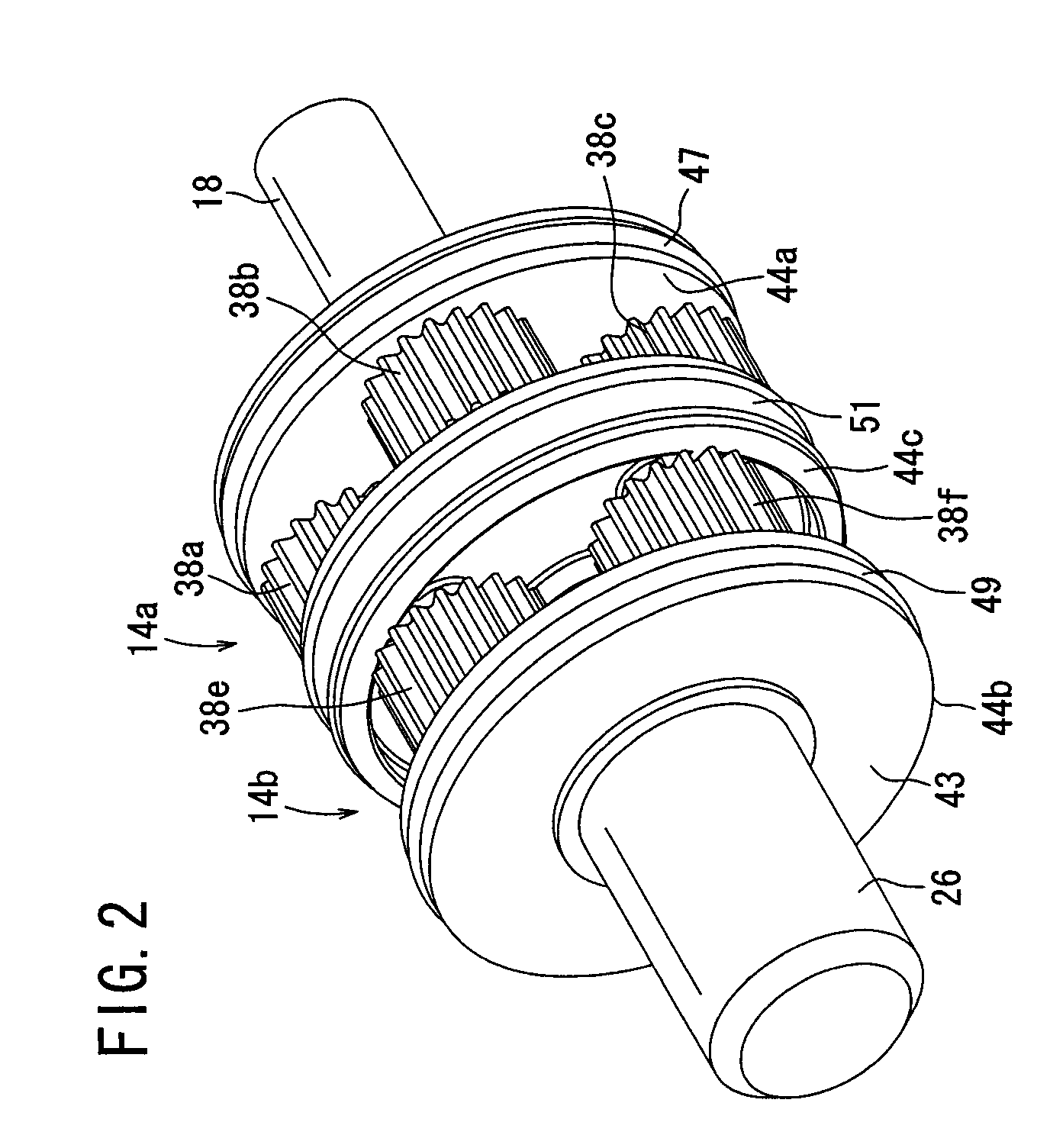

Automatic Speed Reducing Ratio-Switching Apparatus

ActiveUS20070191177A1Smooth transmissionToothed gearingsDifferential gearingsGear wheelStatic friction

An automatic speed reducing ratio-switching apparatus comprising an input side carrier, an output side carrier, and an intermediate carrier includes first and second planetary gear mechanisms juxtaposed in the axial direction of an input shaft, first and second inner clutch members which are rotatable in one direction while locking rotation in the other direction of the input shaft, and have mutually different locking directions, first and second outer clutch members which are rotatable in one direction while locking rotation in the other direction of the input side or output side ring gear, and have mutually different locking directions, and a viscous resistance member functioning under a static frictional force to integrally rotate the input side or output side sun gear, the input side or output side planet gears, and the input side or output side ring gears respectively in an identical direction.

Owner:SMC CORP

Glassy carbon thermoplastic compositions

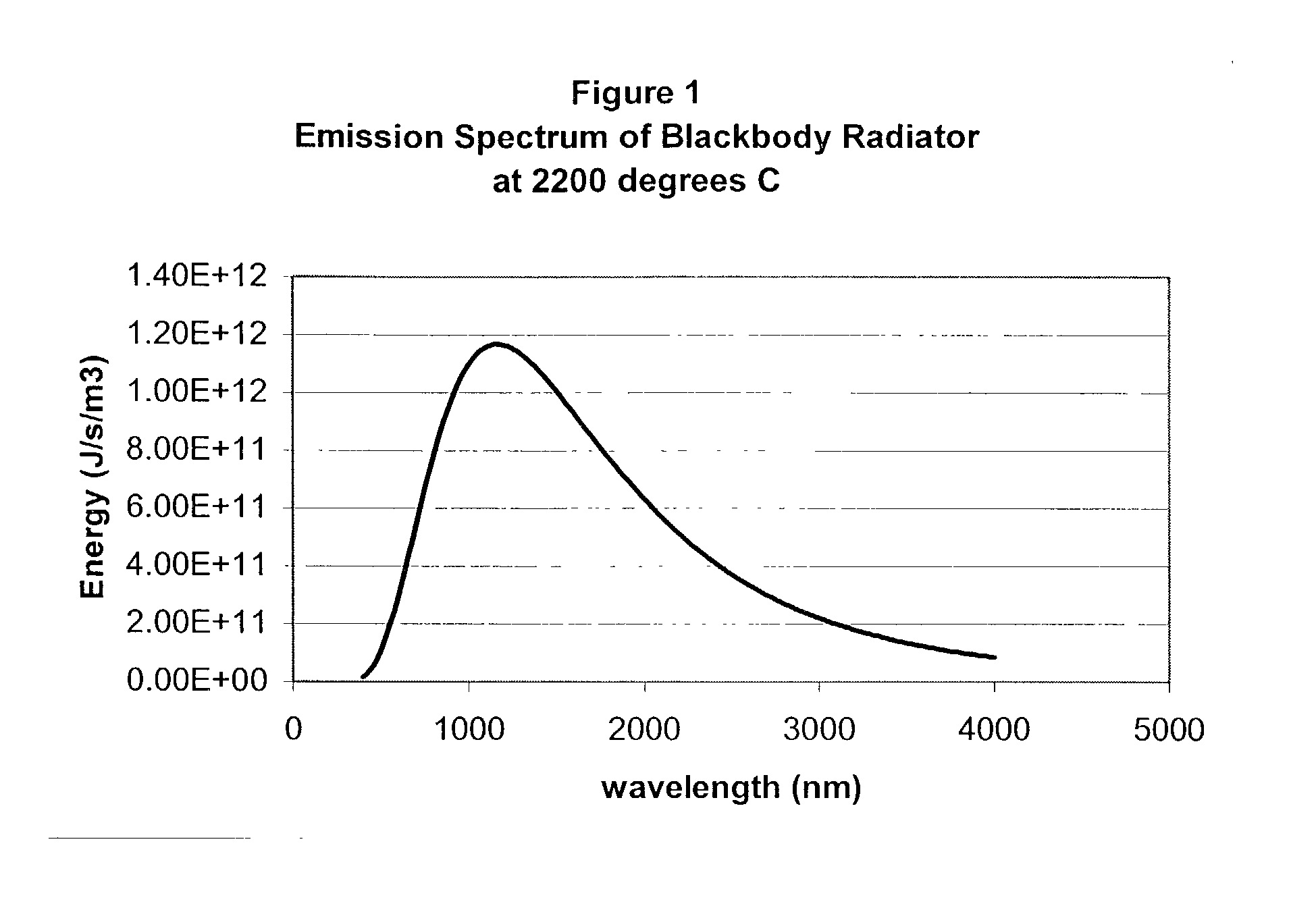

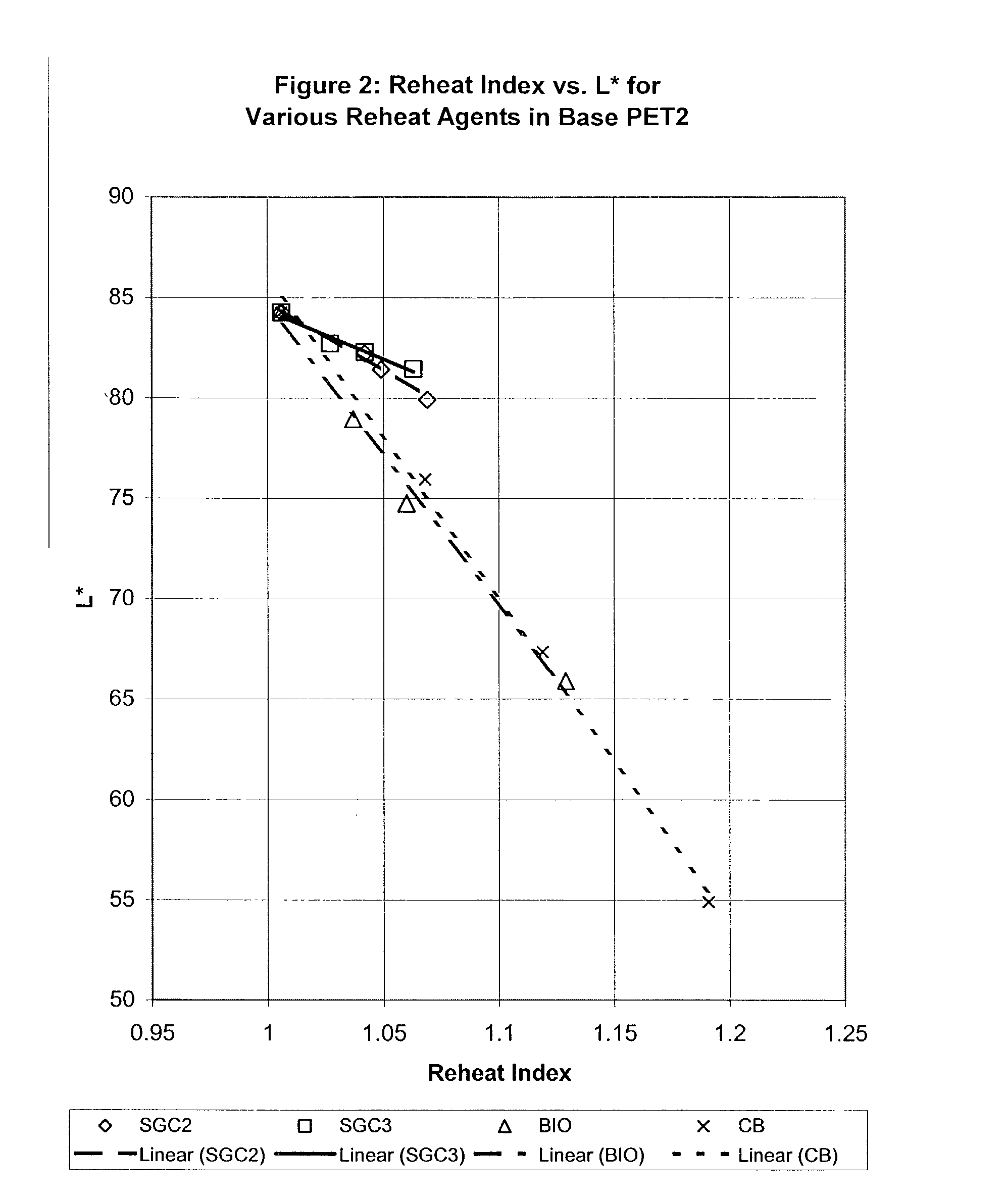

InactiveUS20040101642A1Good reheat rateImproved * b * ratingSynthetic resin layered productsThin material handlingPolyesterStatic friction coefficient

A thermoplastic composition such as a polyester composition including polyethylene terephthalate polymers containing glassy carbon, and the preforms, bottles, sheets, rods, tubes, films and other articles made from these compositions. Also, polyester compositions are provided which have a certain individual or combination of properties, including low coefficient of static friction, low coefficient of static friction and low haze or high L* or low positive b* or a combination thereof, and those having low L* and low positive b* at given reheat rates.

Owner:EASTMAN KODAK CO

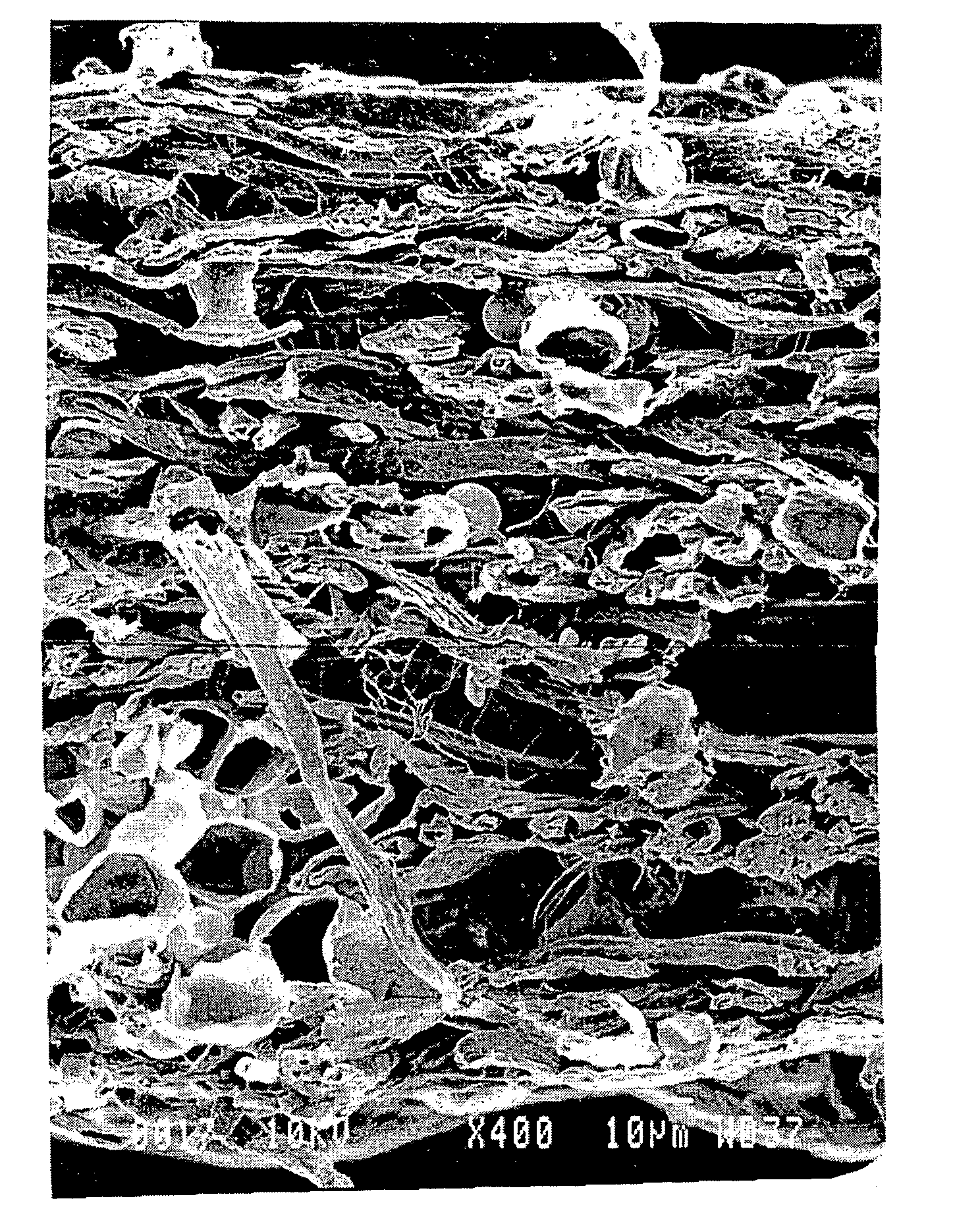

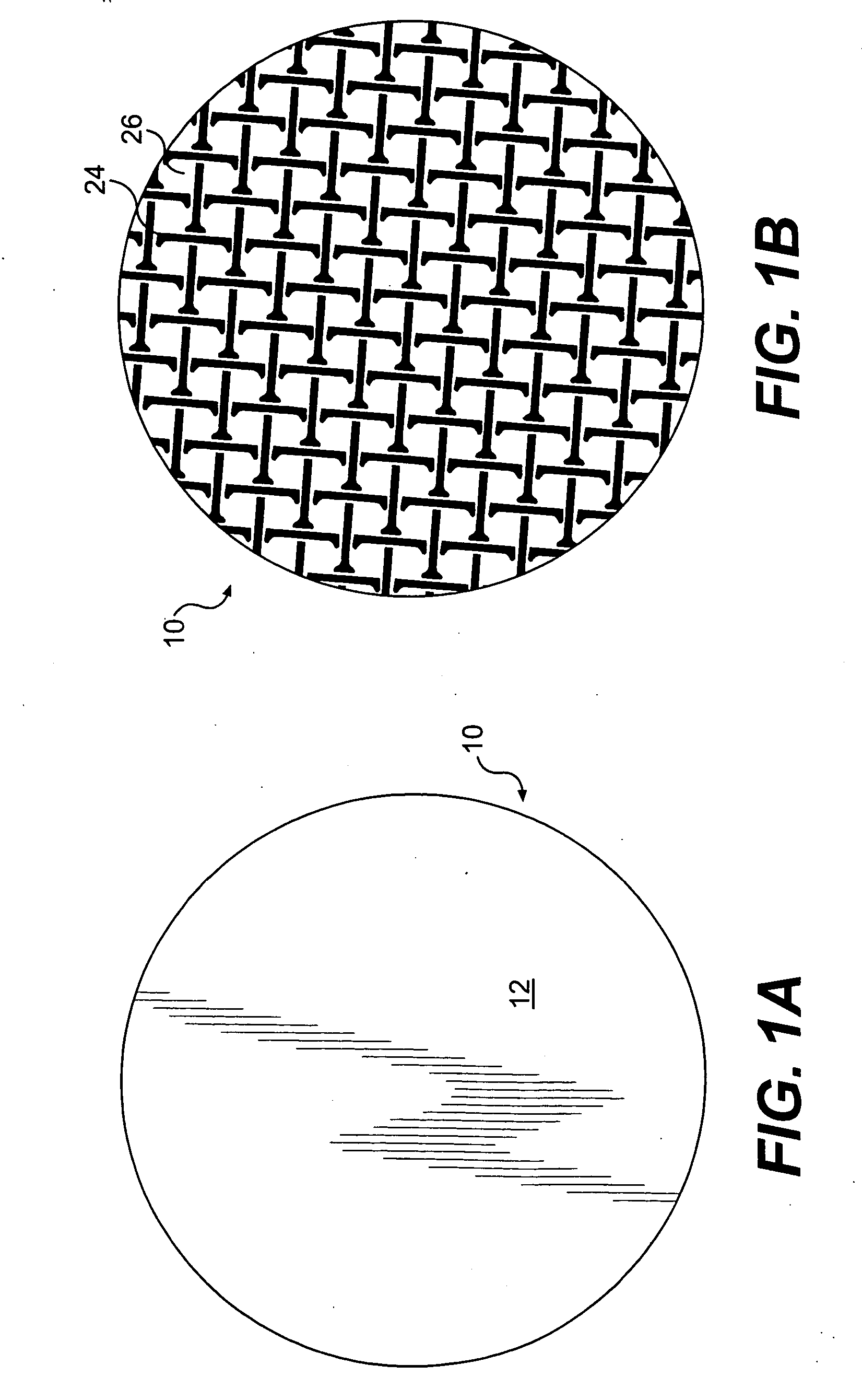

Coated paperboards and paperboard containers having improved tactile and bulk insulation properties

InactiveUS20050112305A1Improve insulation performanceIncrease stiffnessNon-fibrous pulp additionWrappersStatic friction coefficientPaperboard

A method of making a texture-coated and / or insulation coated container from a flat paperboard blank in which a heat-hardenable liquid polymeric binder texturizing and / or insulating agent coating mixture is applied to one surface of the blank in a pattern of covered and open areas. This coating mixture is subjected to heat to cure the polymeric binder and expand the texturizing and / or insulating agent, optionally treated with moisture, and optionally heated to form the blank into the shape of a container, and the container produced by this method. The containers such as cups, plates, etc., are useful in food service. These containers have a coefficient of static friction which is about 0.2 to 2.0 and over and a kinetic coefficient of friction which is about 0.22 to 1.5.

Owner:DIXIE CONSUMER PROD

Delivery system with variable delivery rate for deploying a medical device

InactiveUS7976574B2Reduce the amount requiredShorten the timeStentsBlood vesselsStatic frictionEngineering

A delivery system utilizes a handle assembly including an actuating mechanism capable of initially providing sufficient mechanical advantage to overcome static friction when initiating deployment of the medical device. The actuating mechanism includes components which help to increase the speed of deployment as the physician continues to manipulate the actuating mechanism.

Owner:ABBOTT CARDIOVASCULAR

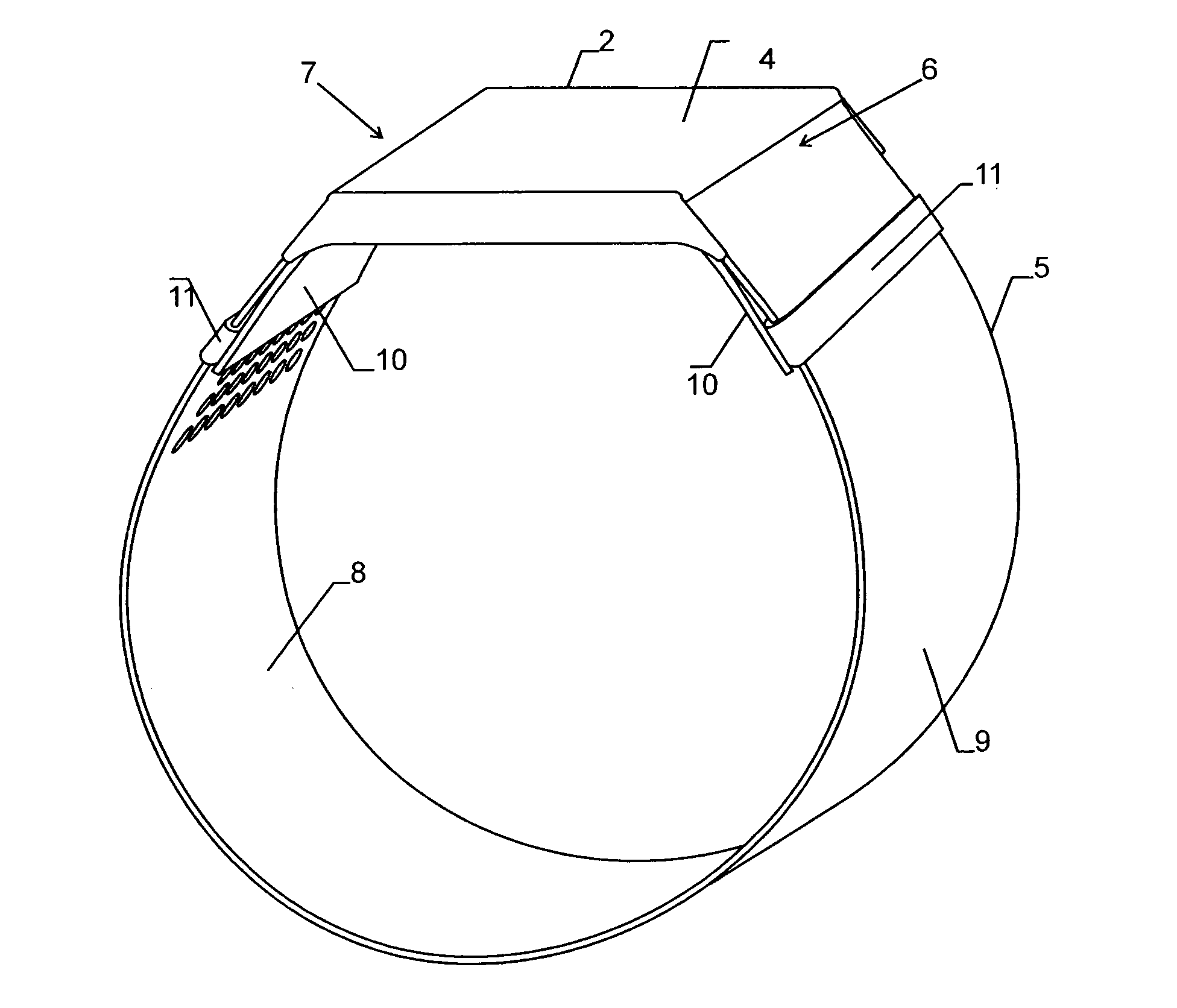

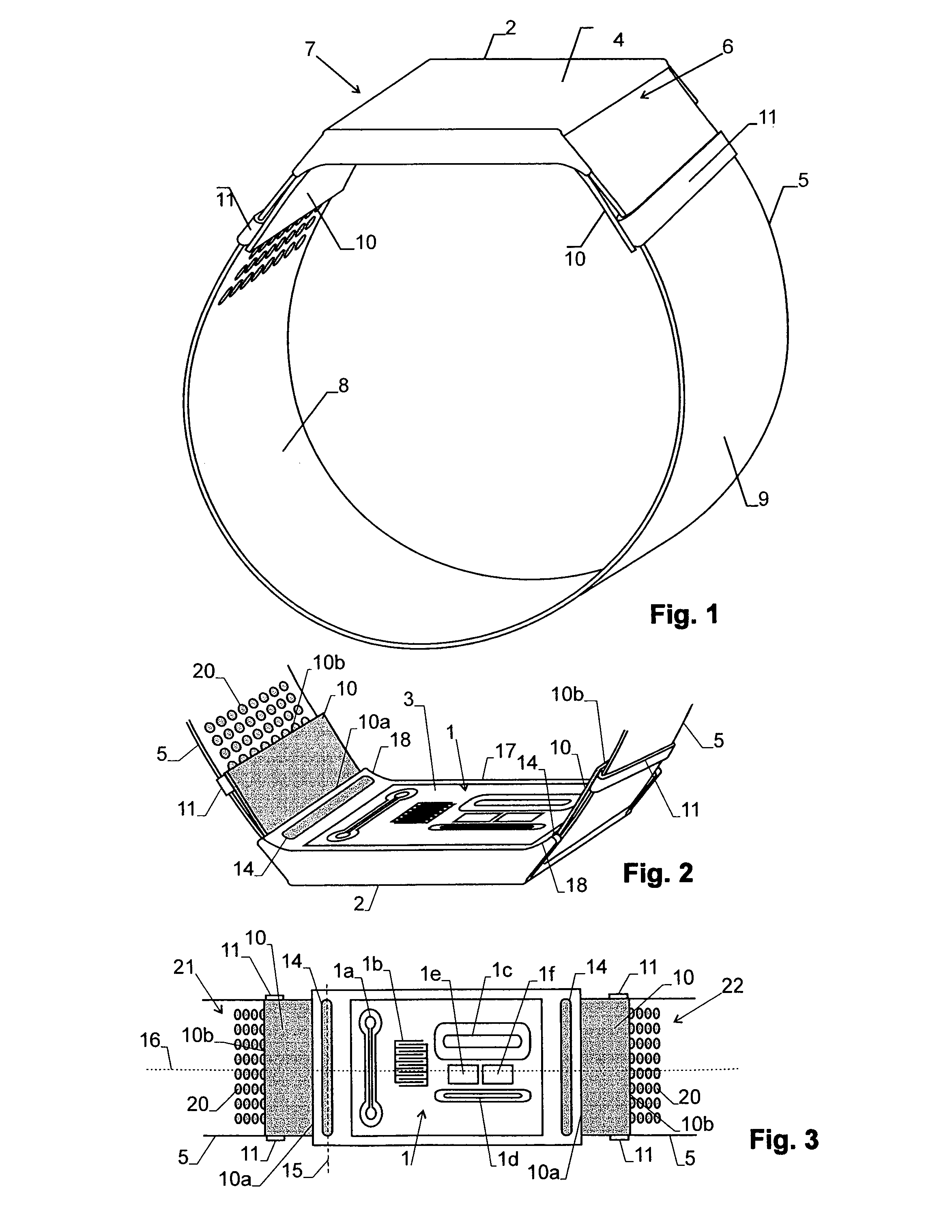

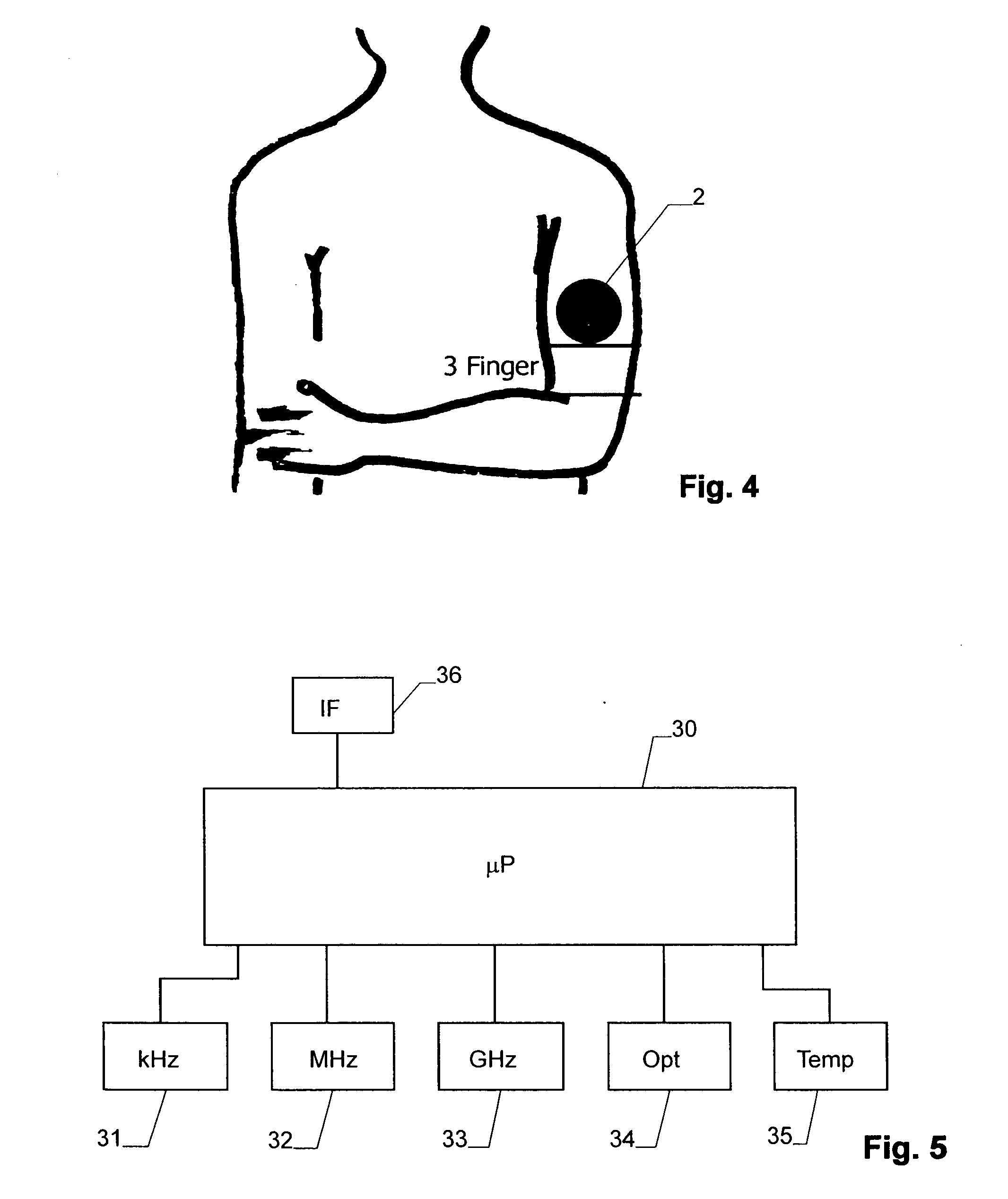

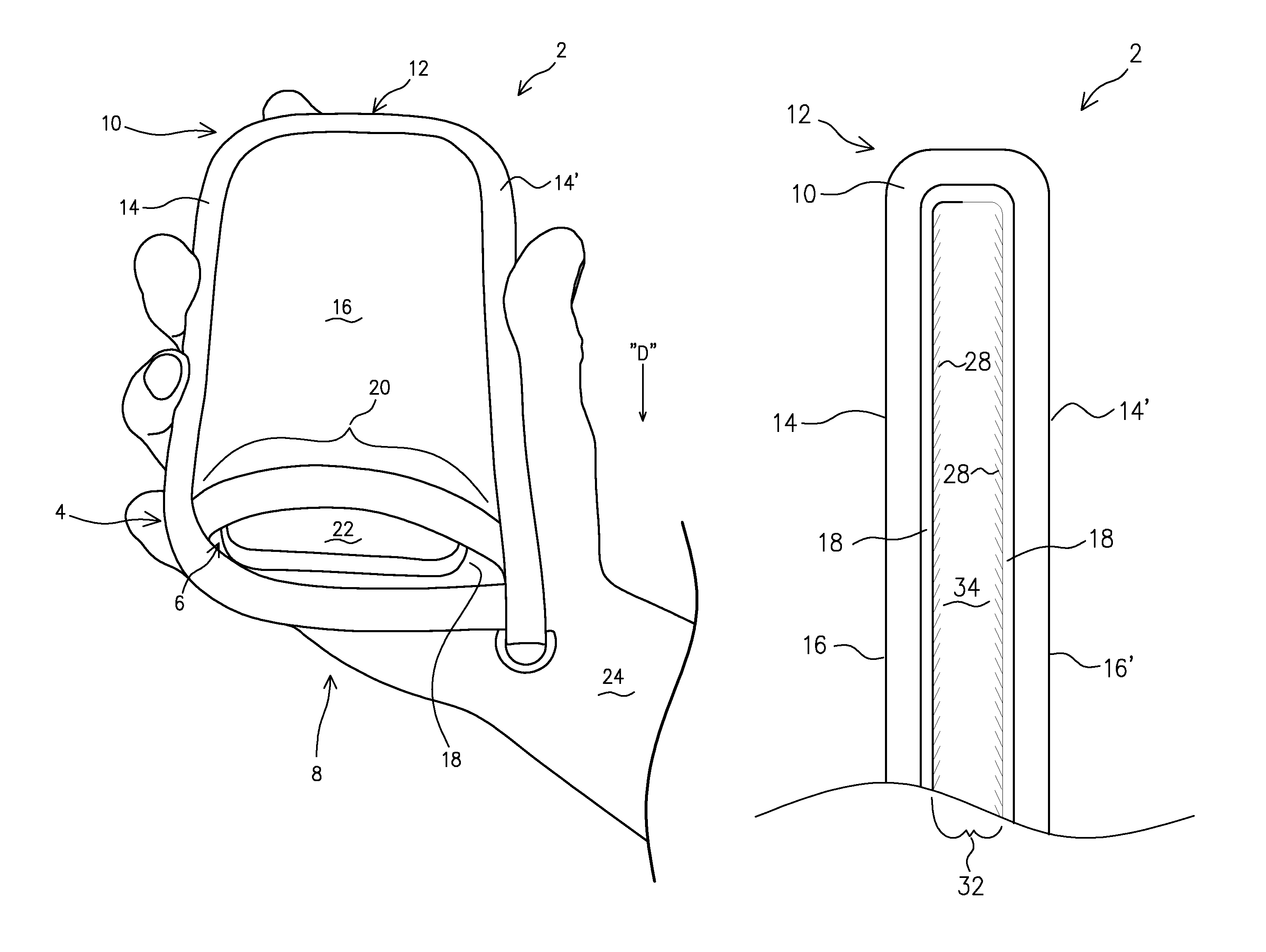

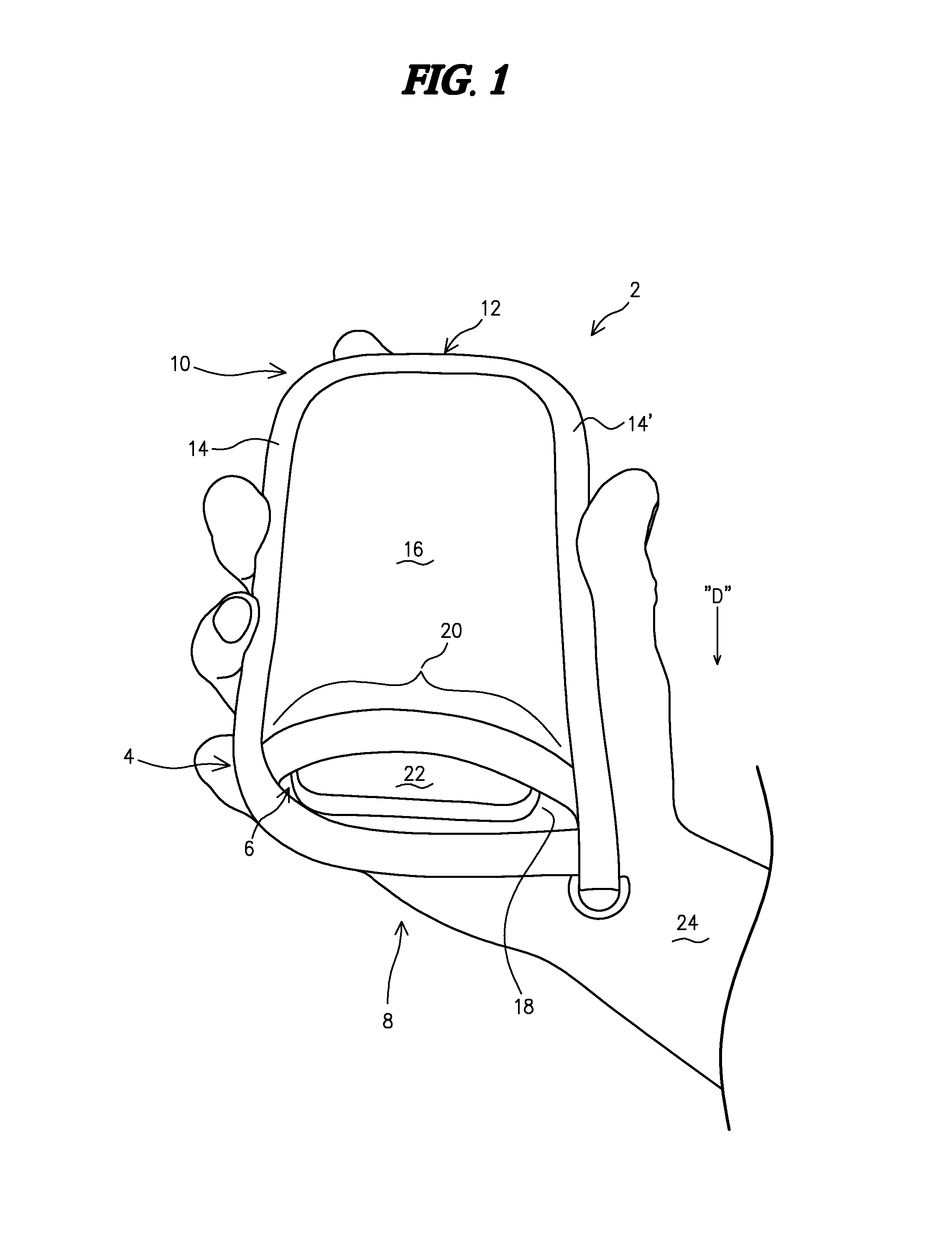

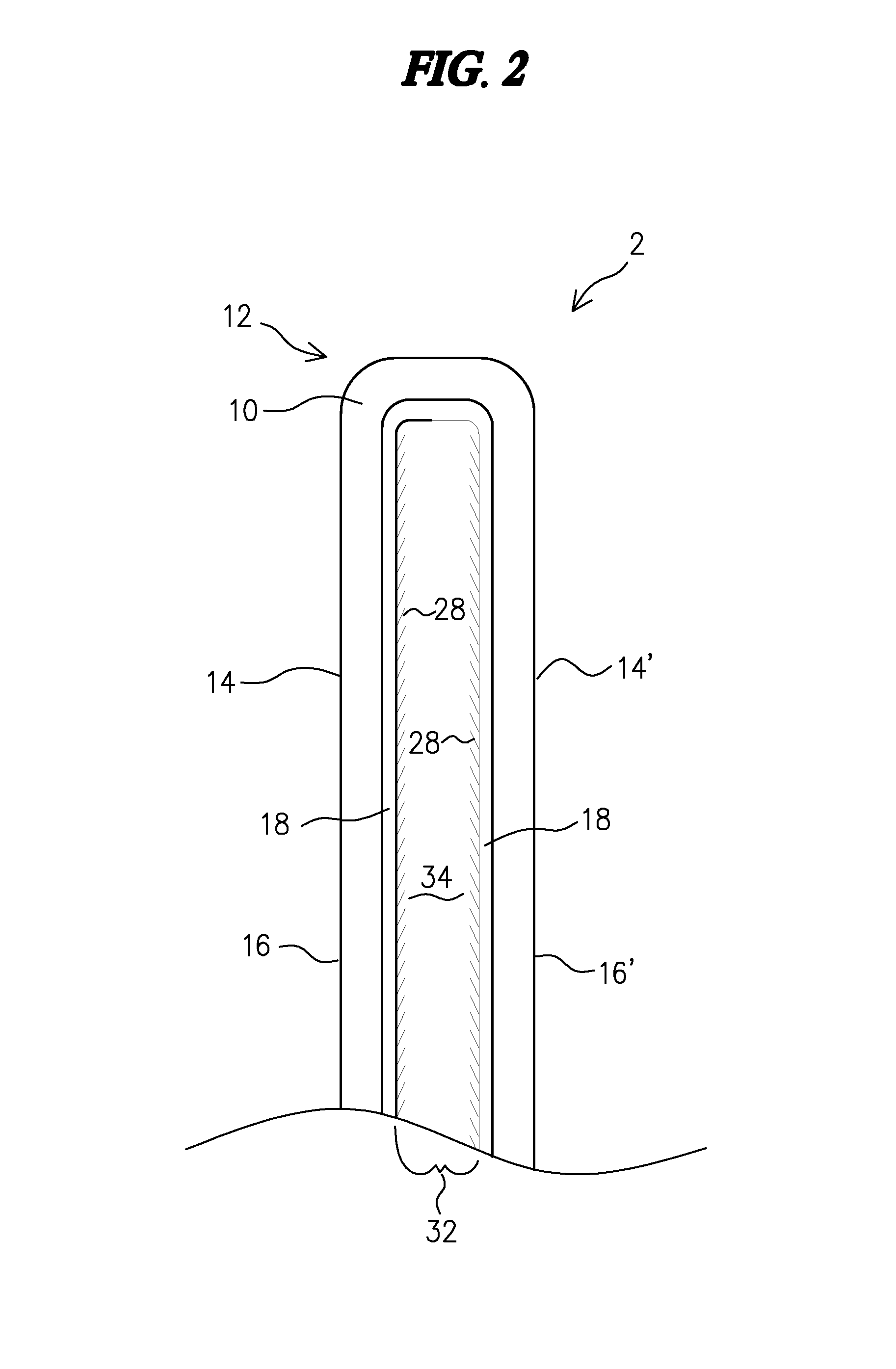

Wearable sensor device

ActiveUS20130211204A1Improve mechanical isolationIncrease static frictionTravelling sacksTravelling carriersStatic frictionBiomedical engineering

A sensor device comprises a sensor (1) to be held against the wearer's skin. The sensor (1) is arranged on one side of a housing (2), and the housing is connected to a band (5) for mounting it to a body part, such as an arm or leg. Various stopper devices (10, 14, 20) are arranged on the side of the housing (2) and the band (5) that face the skin. The stopper devices improve static friction, thereby holding the housing (2) in place.

Owner:BIOSIGNS PTE LTD

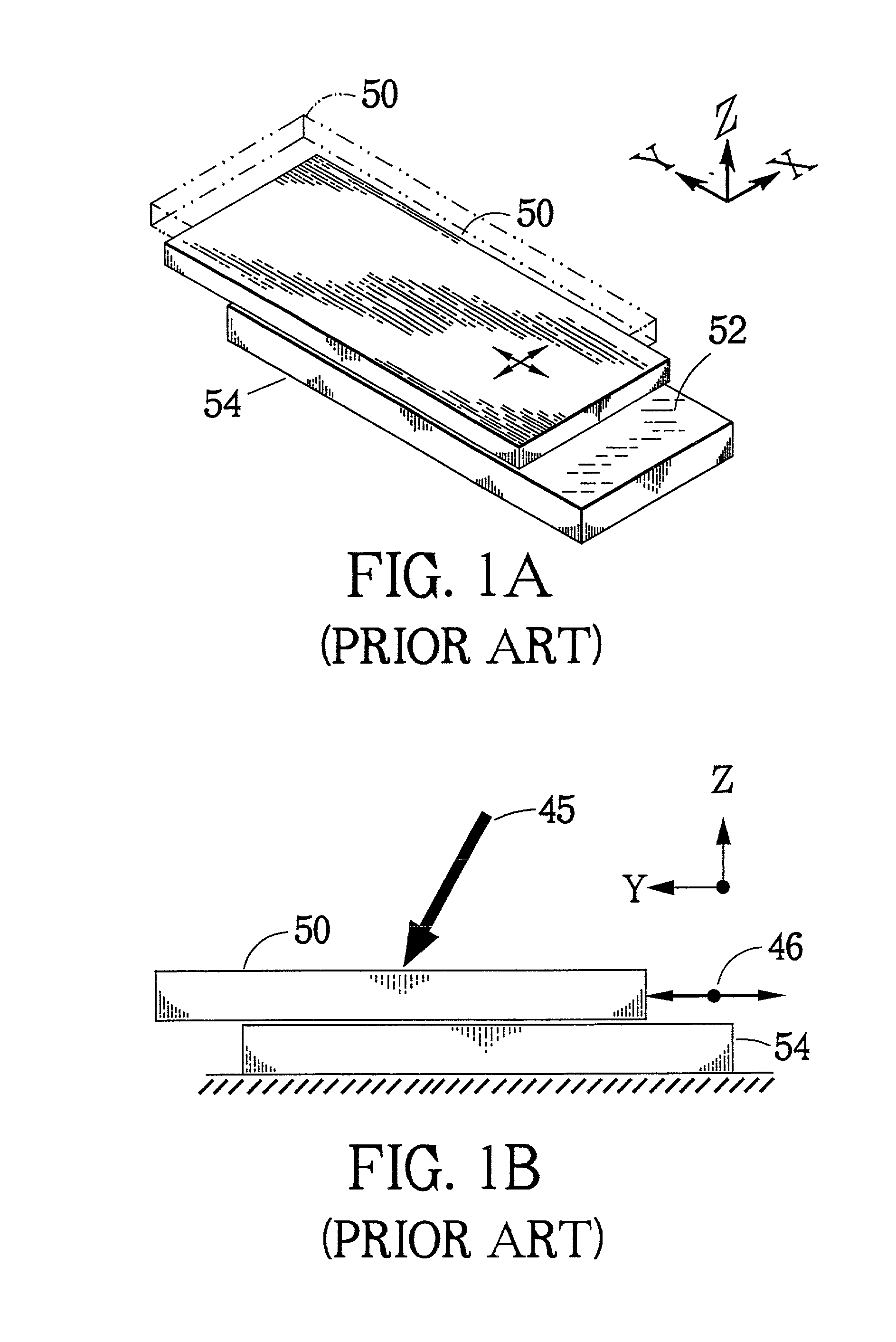

Smart Sonic bearings for frictional force reduction and switching

InactiveUS20020126922A1High compression stiffnessReduce sensitivityPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesFriction reductionStatic friction

An ultrastiff precision sonic bearing assembly and method thereof for controlling an effective coefficient of friction between two elements in slidable contact configured along an interface under a force sufficient to maintain contact and having static friction therebetween, by inducing a repetitive motion in one of the elements parallel to the interface thereby altering the effective coefficient of friction therebetween. The bearing assembly also provides for additional and independent electronic control over the average thickness thereof and senses the force thereon to allow the bearing assembly stiffness to be altered.

Owner:GRQ INSTR

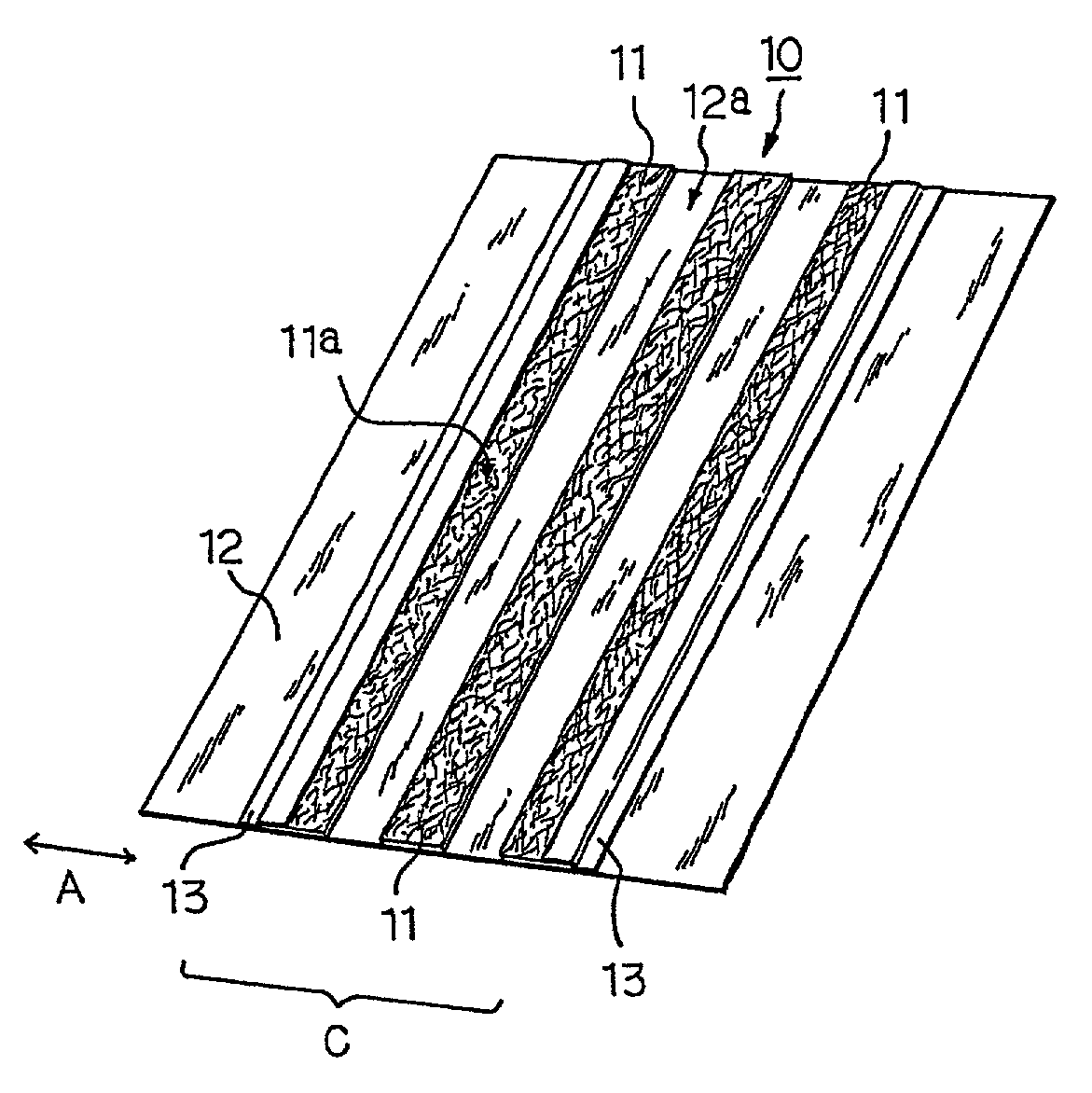

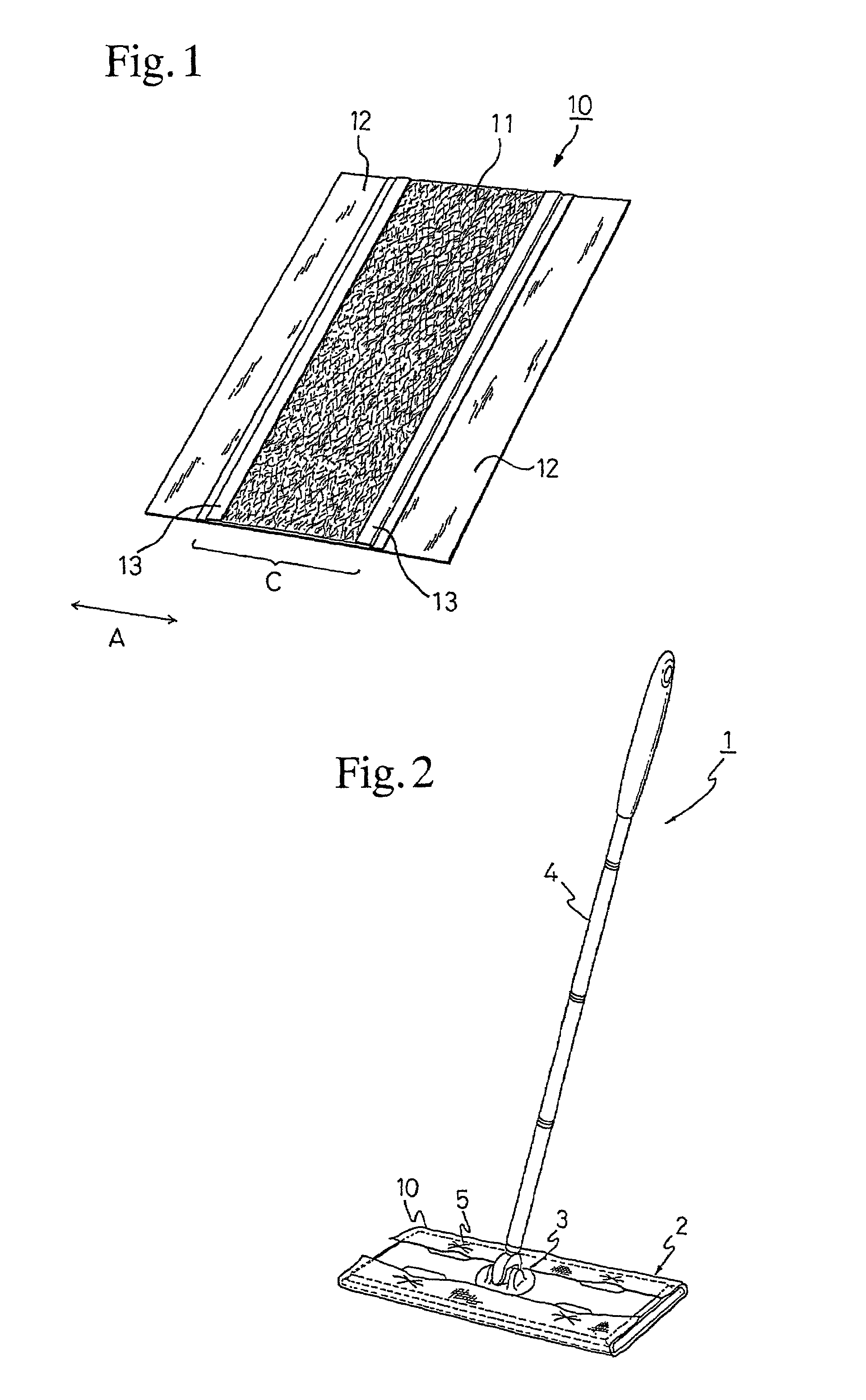

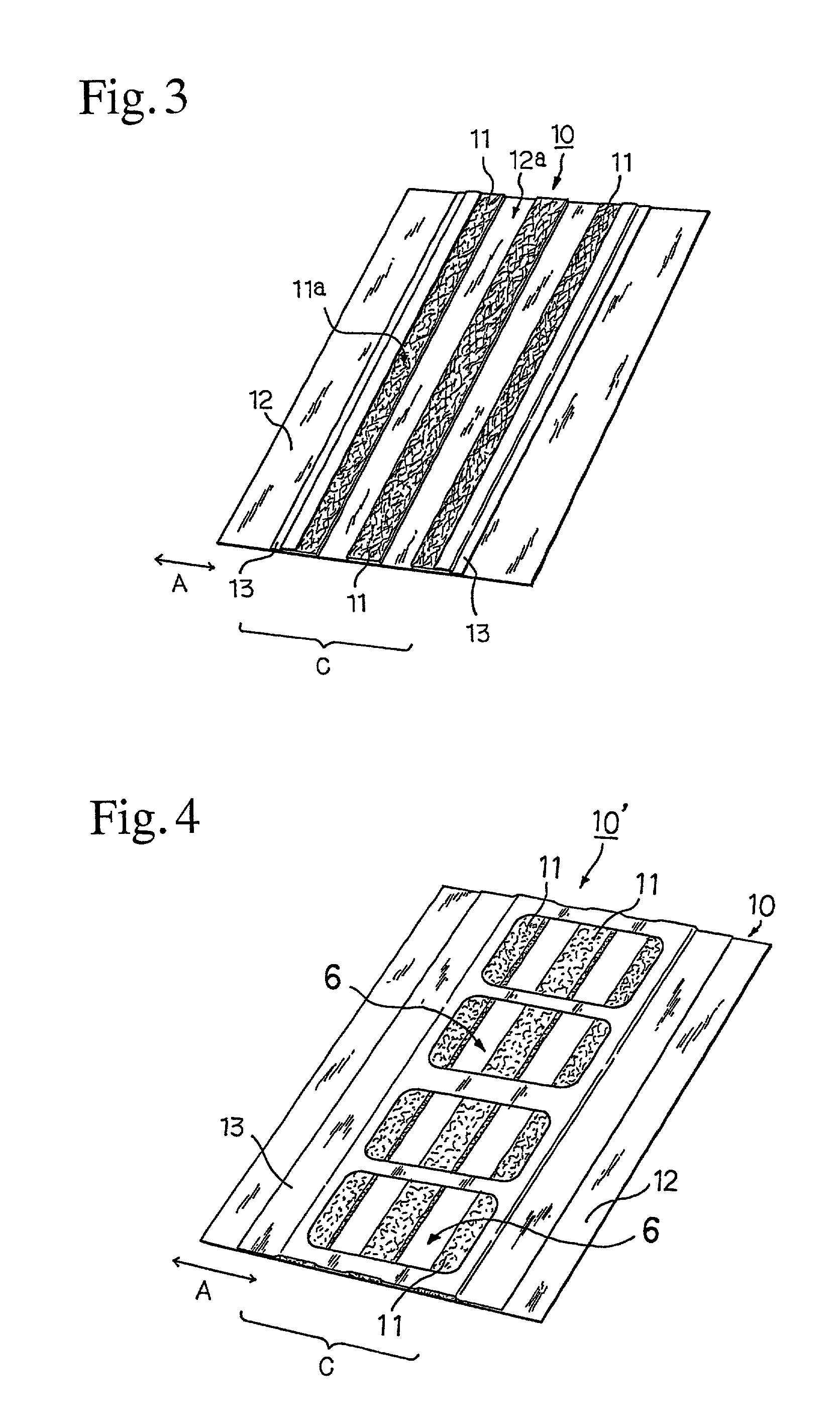

Cleaning Sheet

InactiveUS7033965B2Easy to cleanKitchenware cleanersBathroom accessoriesStatic friction coefficientStatic friction

A cleaning sheet having a cleaning surface comprising a cleaning area for cleaning a piled surface and a low-friction area which adjoins the cleaning area. The cleaning area has a coefficient of static friction of 0.1 to 4.0 against wool press felt (JIS L3201 R33W). The low-friction area comprises a film or nonwoven fabric and has a coefficient of static friction of 0.01 to 1.0 against wool press felt (JIS L3201 R33W).

Owner:KAO CORP

Anti-slip electronic device sleeve

A fabric-based electronic device sleeve with a stiff directional nap lining the interior of a pocket. The directional nap (or plush) of the fabric is oriented to permit easy slidable insertion of an electronic device into the sleeve's pocket, with static friction forces between the directional nap and the device preventing the device from slipping out on its own or falling from the sleeve when held in a downward direction. As a user removes the electronic device from the sleeve, a gentle pull upon pinching the device between thumb and index finger overcomes the static friction forces between the device and the directional nap lining to permit easy removal and access.

Owner:TOM BIHN

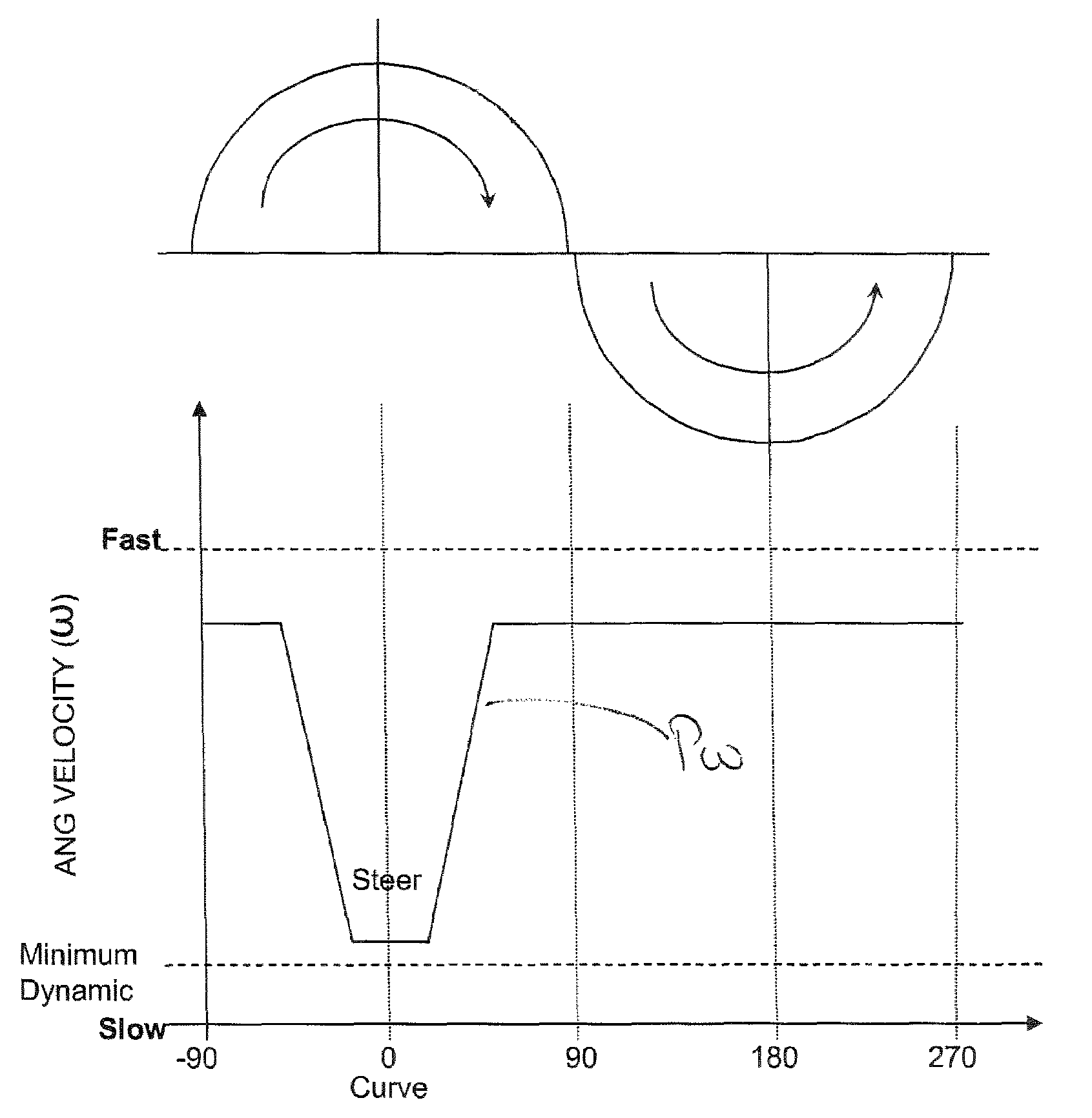

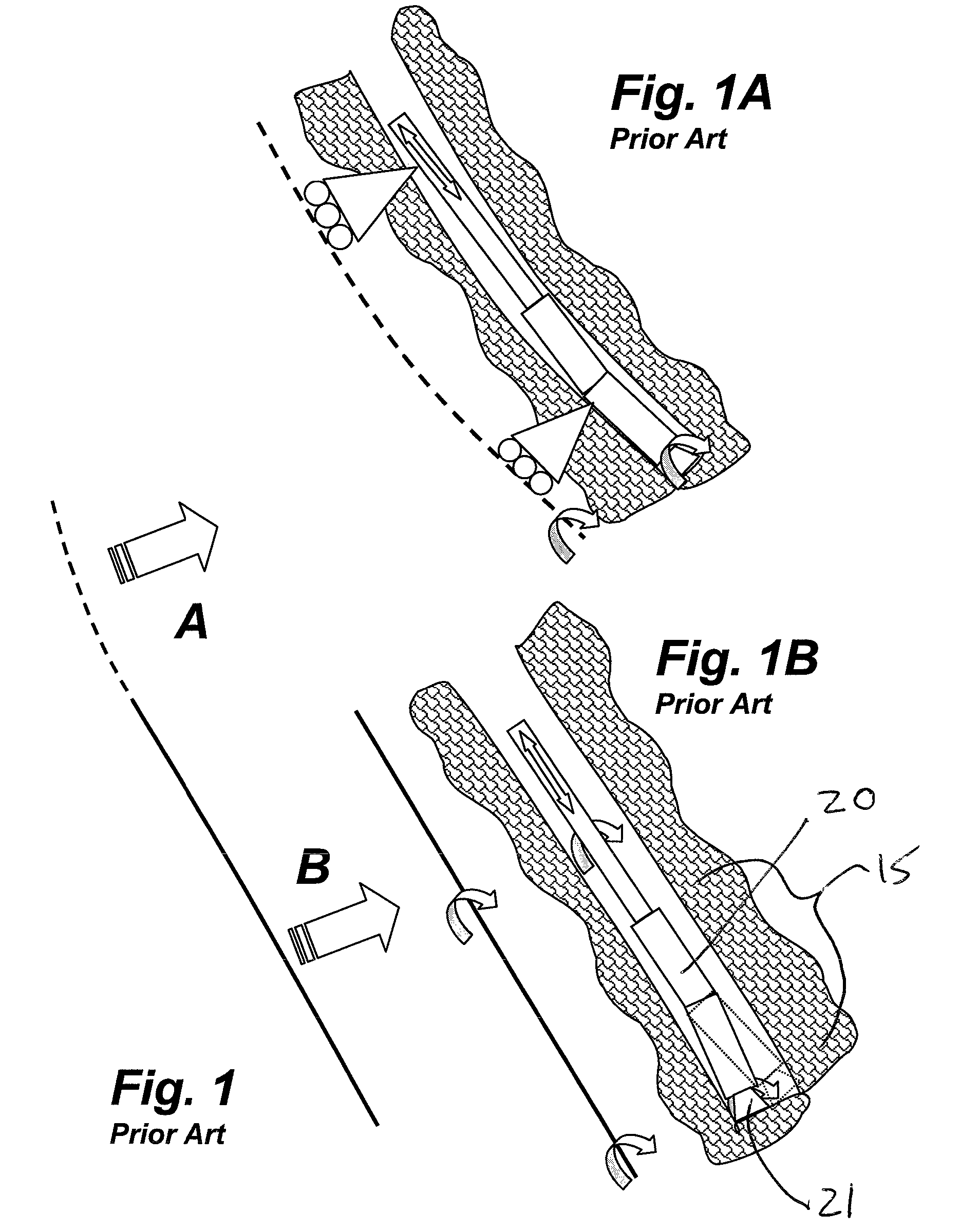

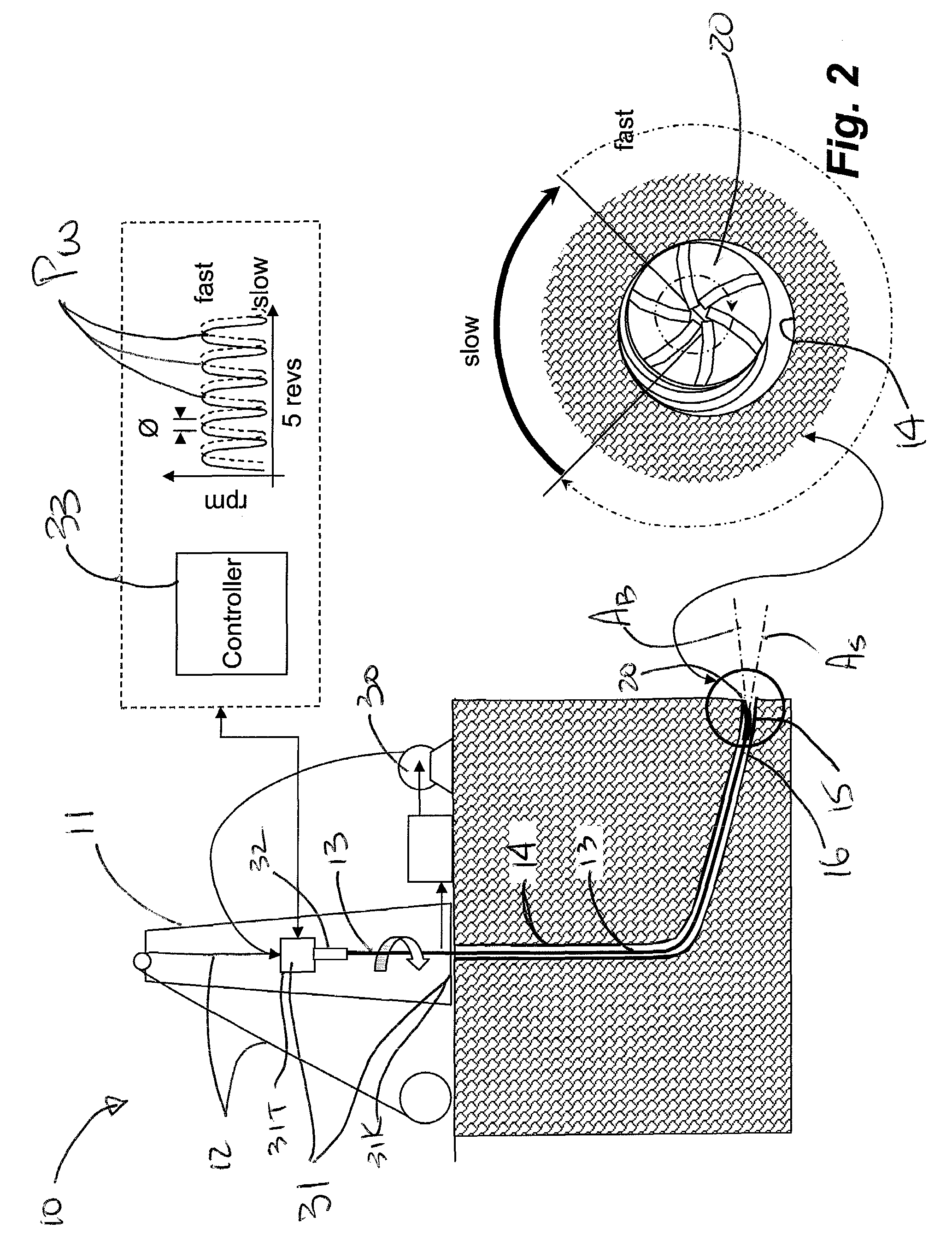

Method and apparatus for directional drilling with variable drill string rotation

Apparatus and methodology is provided for directional drilling which avoid the effects of static friction between the drill string and the borehole. The drill string is rotated continuously in one direction during rotating drilling and during steering. During steering, the rotary speed of the drill string is varied within a revolution and substantially similarly for each of a plurality of subsequent revolutions. The drill string is rotated very slowly when oriented at or near the desired orientation to achieve the desired change in direction and then rotated much faster during the balance of each revolution. This angular velocity profile results in drilling at or near a desired orientation for a high percentage of the time it takes for each revolution. Changes in an effective tool-face orientation can be effected by shifting the phase of the velocity profile.

Owner:PRECISION DRILLING CORP

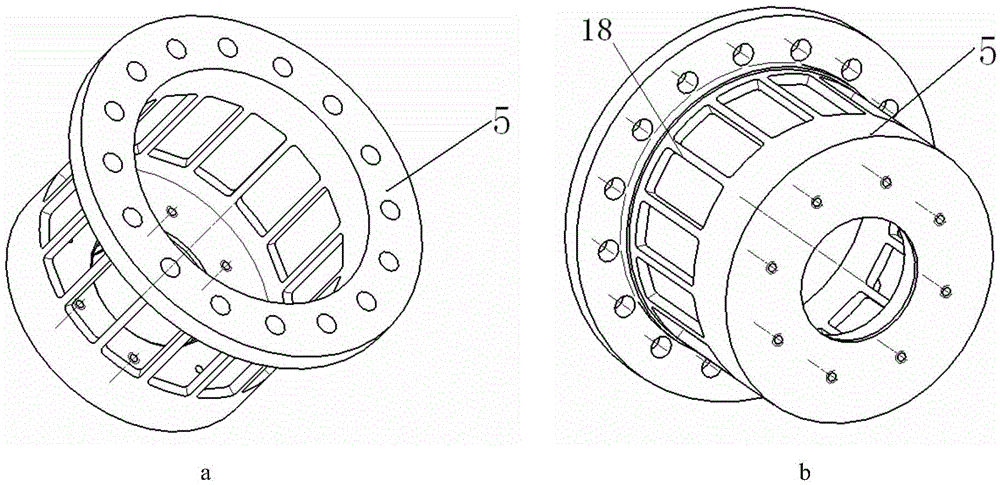

Raw paper of high-performance environment-friendly paper based friction material and manufacturing method of friction plate

ActiveCN101805589AGood physical and mechanical propertiesIncrease coefficient of frictionOther chemical processesNon-macromolecular organic additionAdhesiveStatic friction

The invention discloses raw paper of a high-performance environment-friendly paper based friction material and a manufacturing method of a friction plate. The high-performance environment-friendly paper based friction material is characterized by comprising the following components in percentage by weight: a substrate comprises 7-15% of carbon fiber, 5-10% of chopped aramid fiber, 5-10% of aramidpulp and 9-30% of bamboo fiber pulp; a friction agent comprises 10-20% of kieselguhr and 8-12% of cashew nut shell powder; a frictional property regulator adopts 2-4% of rubber particles, 5-10% of calcium carbonate and 10-15% of flake graphite; and a forming adhesive comprises 1-2% of fluororubber, 3-15% of silicone resin and 3-15% of phenolic resin. The invention fully forms the materials of thefriction material into a whole by changing the traditional impregnation process, effectively improves the physical and mechanical properties of the friction plate, improves the friction factors, regulates the dynamic and static friction ratio factors, and reduces the abrasion ratio of the friction plate.

Owner:陕西帕若德新材料科技有限公司

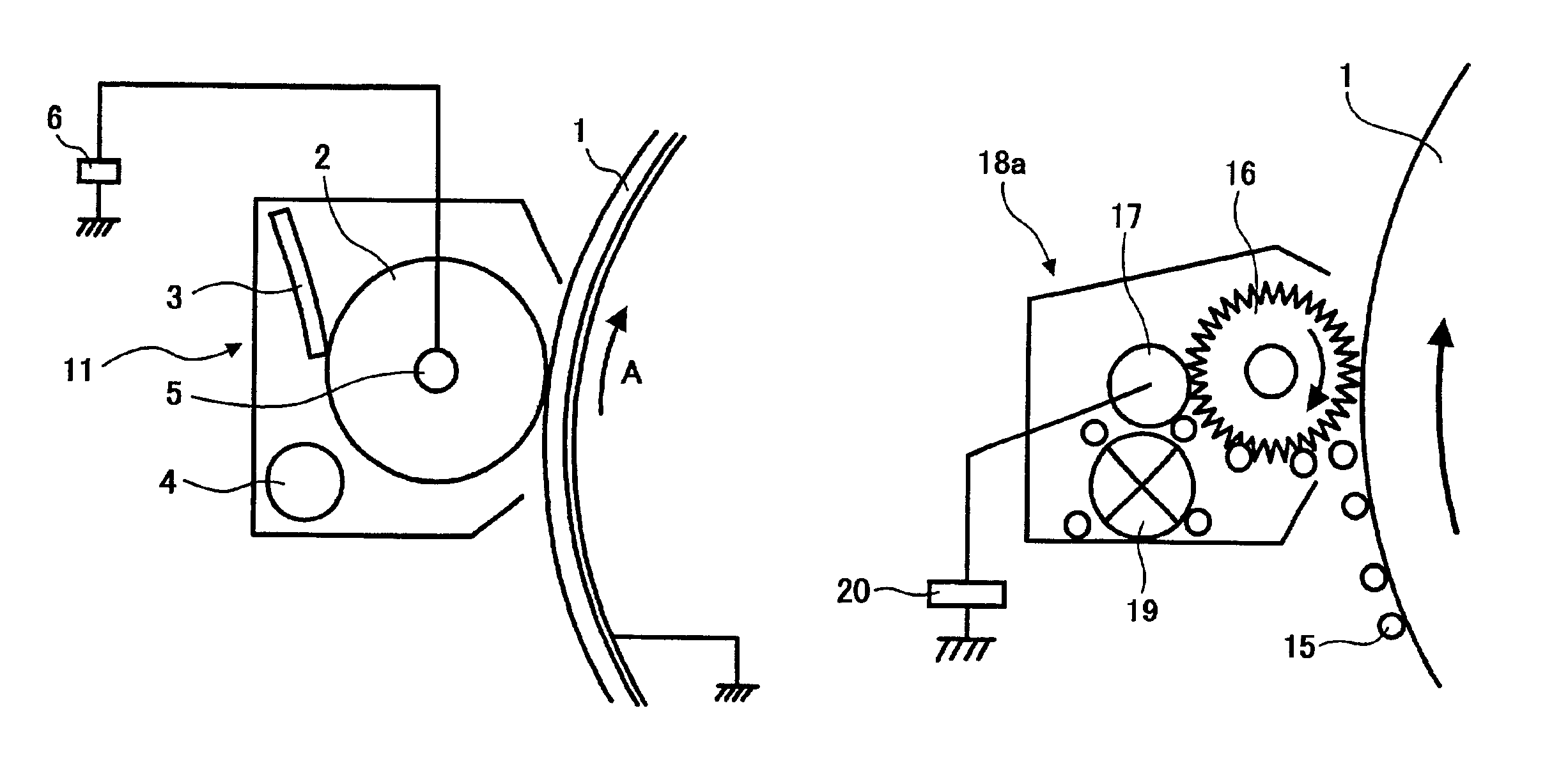

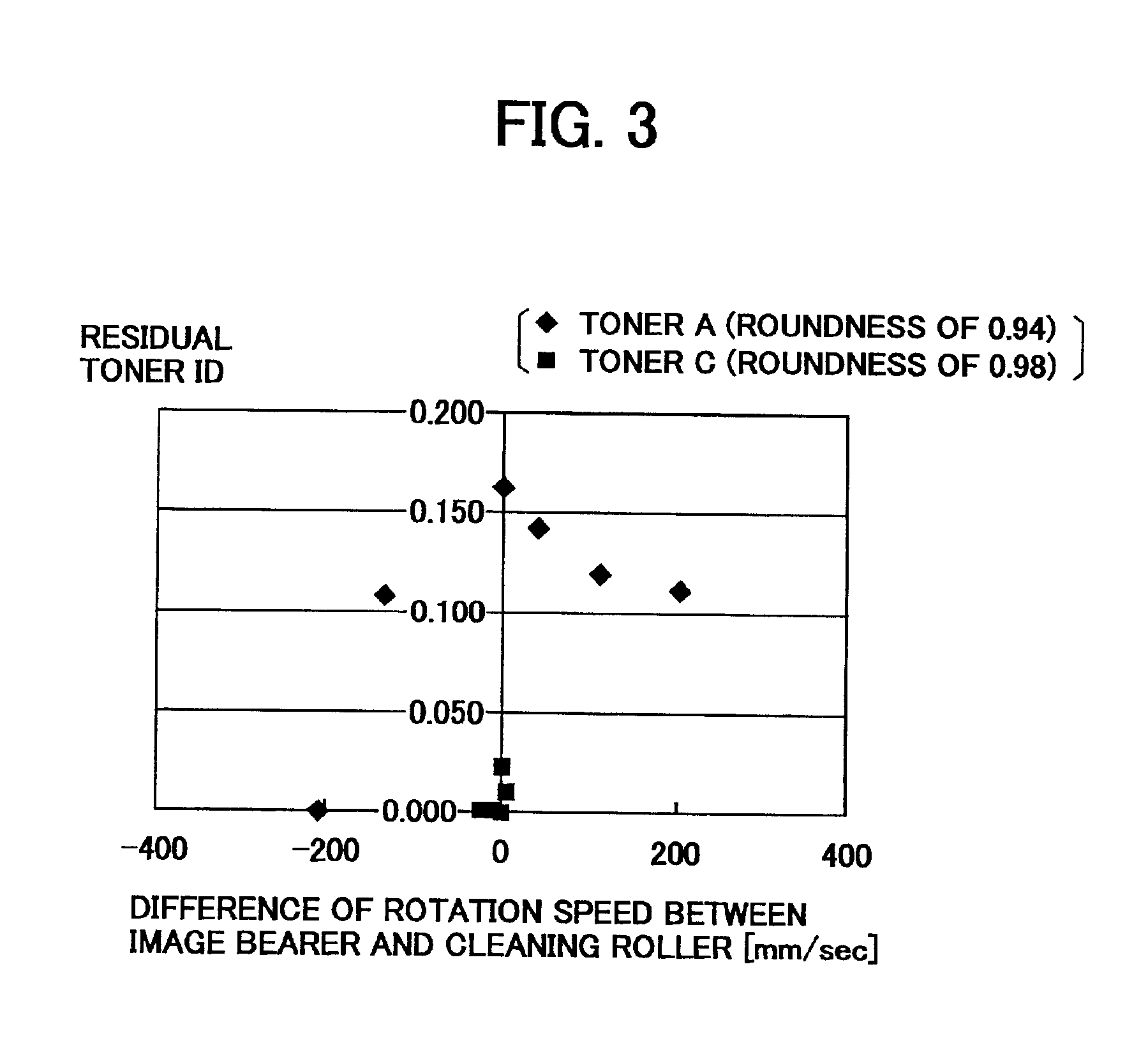

Cleaning device and image forming apparatus using the cleaning device

InactiveUS6987944B2Electrographic process apparatusCorona dischargeStatic friction coefficientBristle

An image forming apparatus includes an image bearer, a charging device that charges a surface of the image bearer, a latent image forming device that forms a latent image on the image bearer, a developing device that develops the latent image on the image bearer with a spherical toner into a toner image, a transfer device that transfers the toner image to a transfer material, and a cleaning device that removes the spherical toner remaining on the image bearer after the toner image is transferred to the transfer material. The cleaning device including a cleaning roller that removes the spherical toner on the image bearer while rotating and contacting the image bearer and which has a greater coefficient of static friction than the surface of the image bearer. An electric field is formed between the cleaning member and the image bearer by applying a voltage to the cleaning member so that the spherical toner adhered onto the image bearer is electrostatically attracted to the cleaning member. The cleaning member may also include a brush roller having bristles planted in a specific configuration.

Owner:RICOH KK

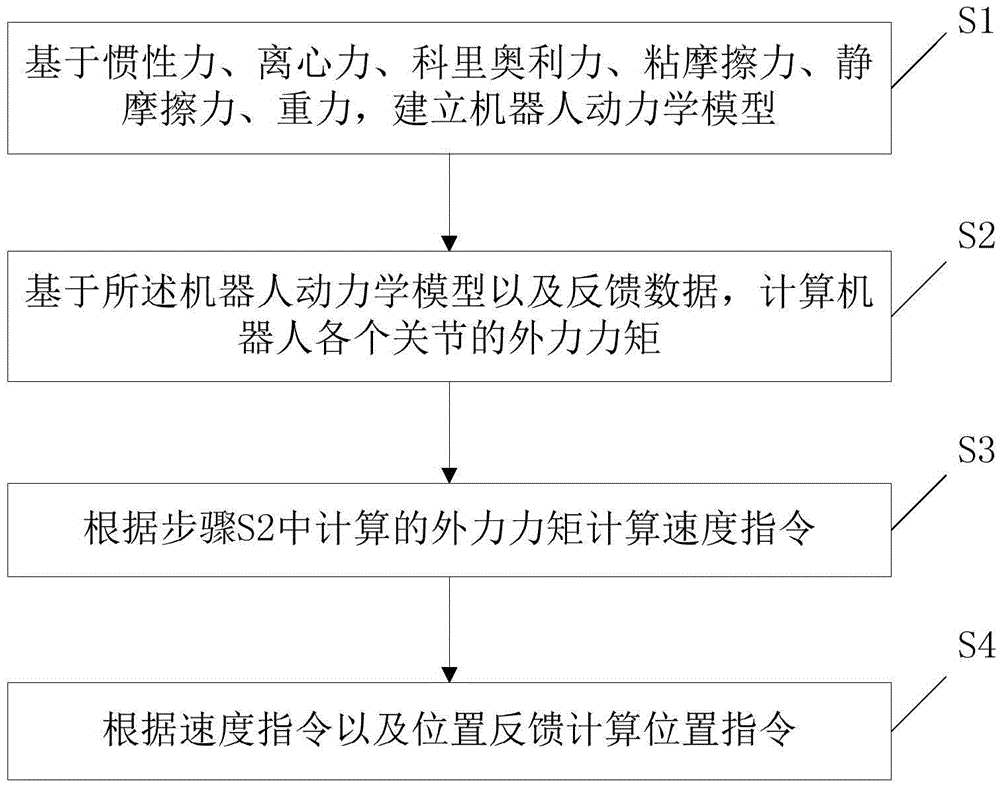

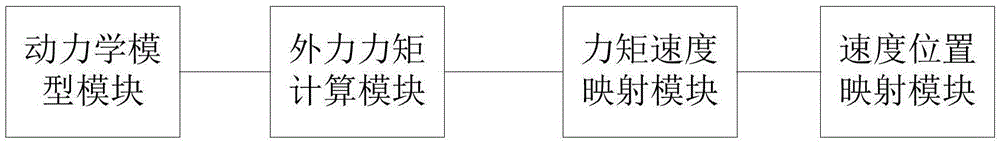

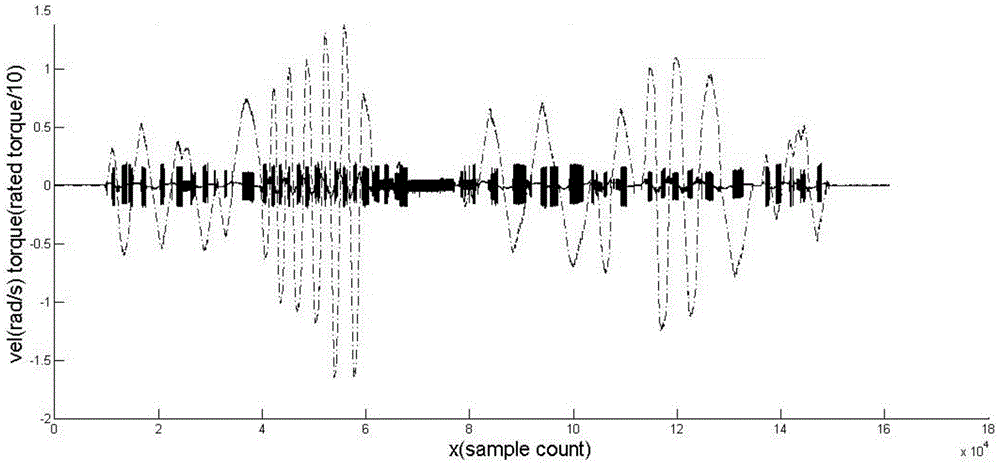

Zero-force control method and system for robot

ActiveCN105479459AReduce system costReduce system complexityProgramme-controlled manipulatorControl mannerStatic friction

The invention relates to a zero-force control method and system for a robot. The zero-force control method comprises the following steps: S1, a robot kinetic model is built on the basis of inertia force, centrifugal force, coriolis force, viscous friction force, static friction force and gravity; S2, external force moments of all the joints of the robot are calculated on the basis of the robot kinetic model and feedback data; S3, a speed command is calculated according to the external force moments calculated in the step 2; and S4, a position command is calculated according to the speed command and position feedback. Through the building of the kinetic model, the external force moments of all the joints can be directly calculated, without the assistance of a power-assisted sensor or a torque sensor, so that the cost and the complexity of the system are reduced; by the adoption of a position command control manner instead of a direct torque control manner, the design difficulty in the safety and the stability of the system is reduced; and in addition, since inertia force is considered when the external force moments are calculated, the zero-force control method and system can be suitable for robots with greater dead weight.

Owner:SHENZHEN INOVANCE TECH +1

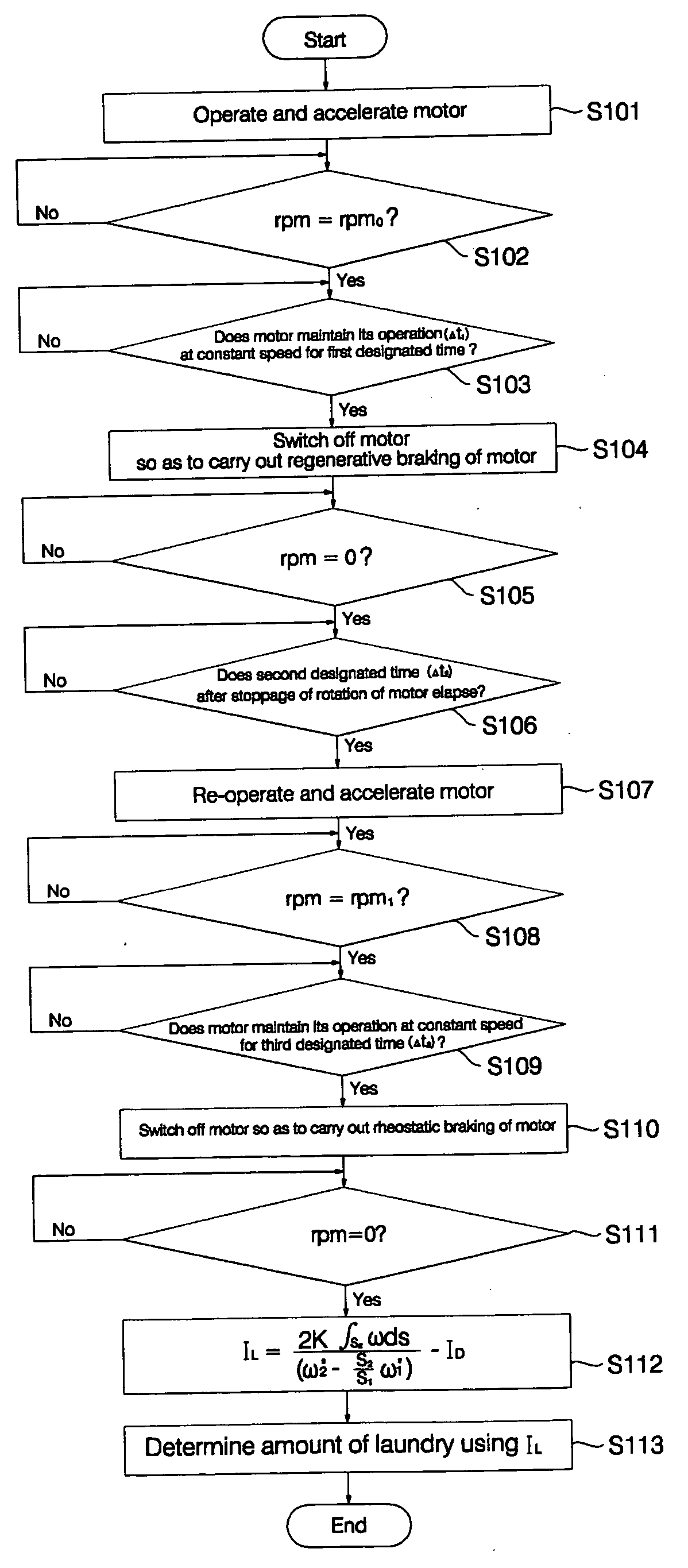

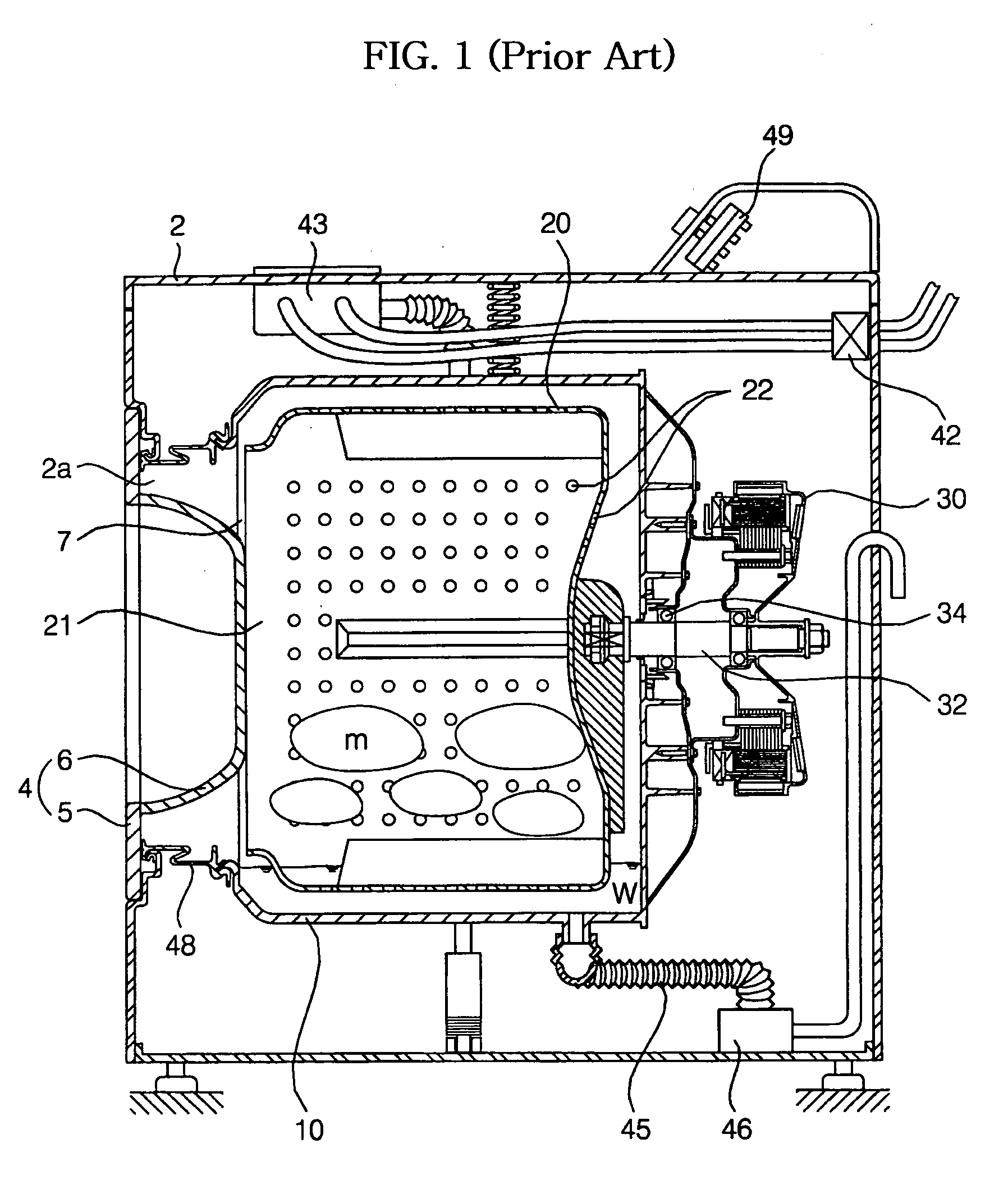

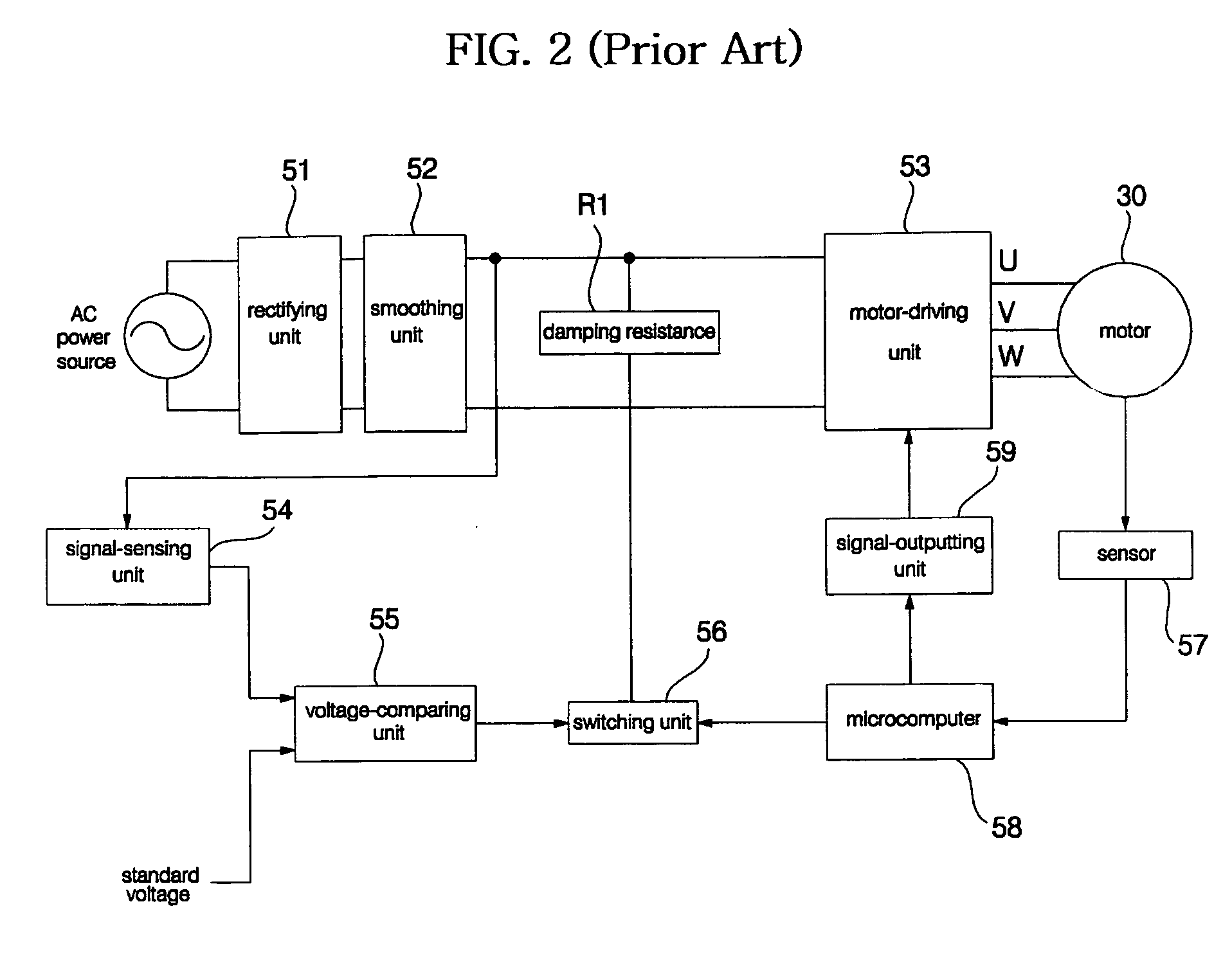

Method for sensing amount of laundry of washing machine

InactiveUS20050050646A1Accurate inductionOther washing machinesControl devices for washing apparatusRegenerative brakeStatic friction

Disclosed is a method for precisely sensing an amount of laundry of a washing machine without influence of static friction. The method includes the steps of (a) operating a motor, and then carrying out regenerative braking of the motor, (b) re-operating the motor after the step (a), and then carrying out rheostatic braking of the motor, and (c) determining the amount of laundry by means of the principle of the conservation of energy in the regenerative braking of the motor in the step (a) and the principle of the conservation of energy in the rheostatic braking of the motor in the step (b).

Owner:LG ELECTRONICS INC

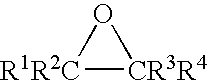

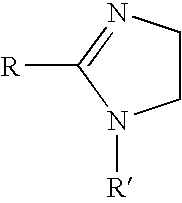

Friction modifiers for improved anti-shudder performance and high static friction in transmission fluids

A fluid composition of (a) a friction modifier derived from the reaction of a carboxylic acid or a reactive equivalent thereof with an aminoalcohol, the friction modifier containing at least two hydrocarbyl groups; and (b) a dispersant other than a species of (a), provides good friction properties to an automatic transmission.

Owner:THE LUBRIZOL CORP

Robot for overhauling primary side of steam generator of nuclear power plant

InactiveCN101667465AReduce volumeReduce weightNuclear energy generationNuclear monitoringNuclear powerGas cylinder

The invention provides a robot for overhauling the primary side of a steam generator of a nuclear power plant, comprising a substrate unit, a rotating unit and a sliding unit. Each modularizing unit is internally provided with two gas cylinders capable of generating two lifting motions with different functions, wherein one pair of modularizing units can simultaneously provide loading spaces for adetecting device. When in use, a pneumatic self-locking expansion mechanism of a pair of modularizing units extends into a heat transfer pipe and is expanded, and a static friction force generated with the inner wall is used for supporting the total weight of the robot; the rotating unit is driven by one servomotor and two gas cylinders for respectively generating two motions of rotation and lifting; and the sliding unit converts the rotation motion of the servomotor into a rectilinear motion by a ball screw shaft and drives the modularizing unit to move on a tube plate hole. The invention isconvenient to be installed through a manhole of the steam generator so as to largely improve the overhauling efficiency, and can realize the fast replacement of operating apparatus for the eddy current inspection, the ultrasonic testing, the tube blockage detection, the water chamber surface condition detection and the like of the heat transfer tube.

Owner:HARBIN ENG UNIV

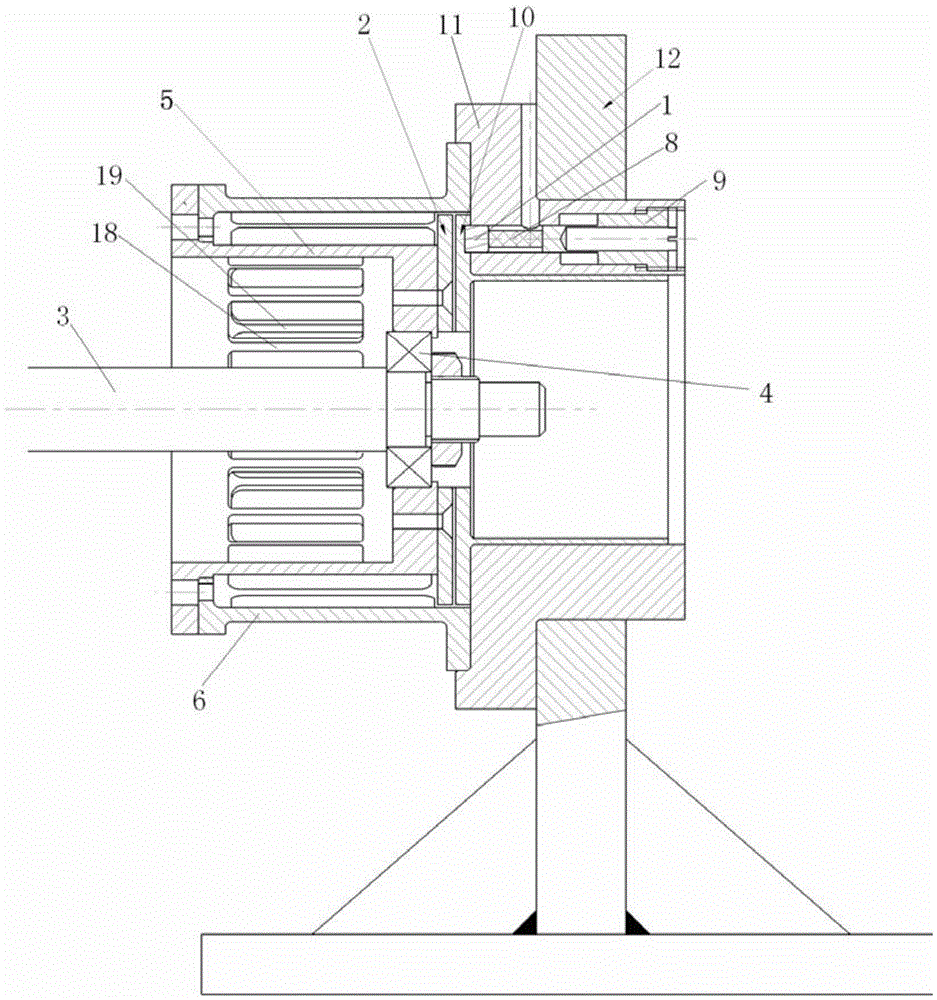

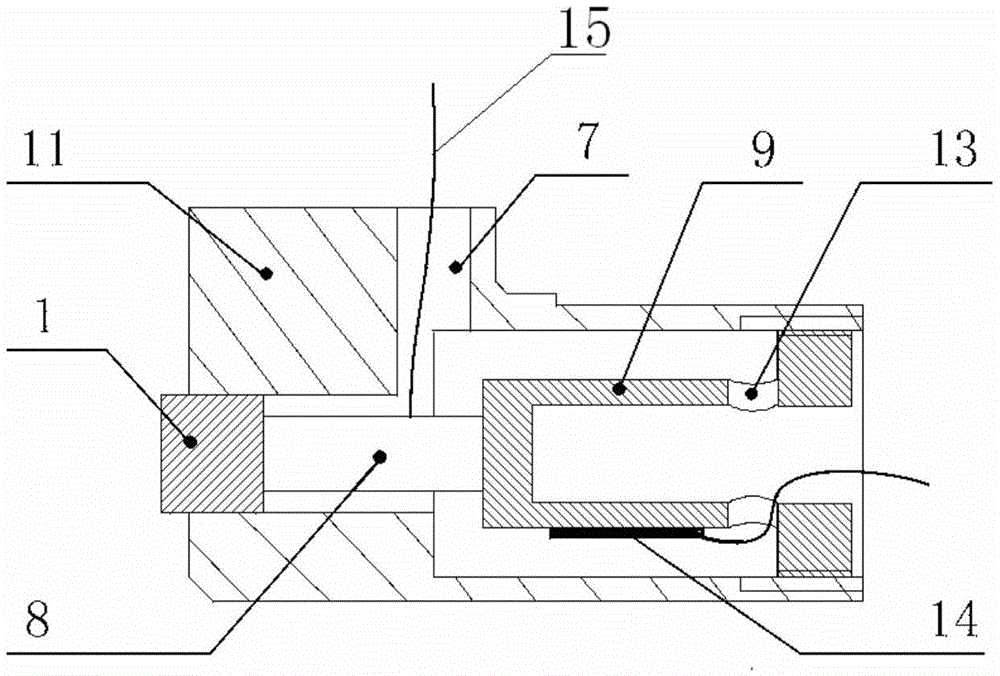

Elastic support dry-friction damper with intelligent structure

ActiveCN105526304AControl vibrationSuppression of destabilizing vibrationNon-rotating vibration suppressionAviationRolling-element bearing

The invention discloses an elastic support dry-friction damper with an intelligent structure. The elastic support dry-friction damper comprises a fold-back type elastic support, a supporting base, piezoelectric ceramic, a movable friction plate, a static friction plate, a plurality of strain gauges and three regulating bolts. The two ends of an inner mouse cage elastic support are respectively connected to the outer mouse cage elastic support and a rotary shaft. The end surface of one end, matched with a rolling bearing, of the inner mouse cage elastic support and the movable friction plate are connected through bolts. The end surface of one end, matched with the rolling bearing, of the inner mouse cage elastic support is connected to the movable friction plate. The static friction plate is arranged at one end of the rotary shaft in a sleeving mode. The movable friction plate is arranged on the rotary shaft in the sleeving mode. The outer mouse cage elastic support is arranged at the outer circumference of the inner mouse cage elastic support. After the elastic support dry-friction damper with the intelligent structure is introduced, a rotor is effectively controlled through vibration at a critical rotation speed, and unstable vibration of the rotor and sudden vibration increase caused by other unknown reasons further can be restrained, and therefore, the elastic support dry-friction damper has a wide application prospect in the fields of aviation and spaceflight.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

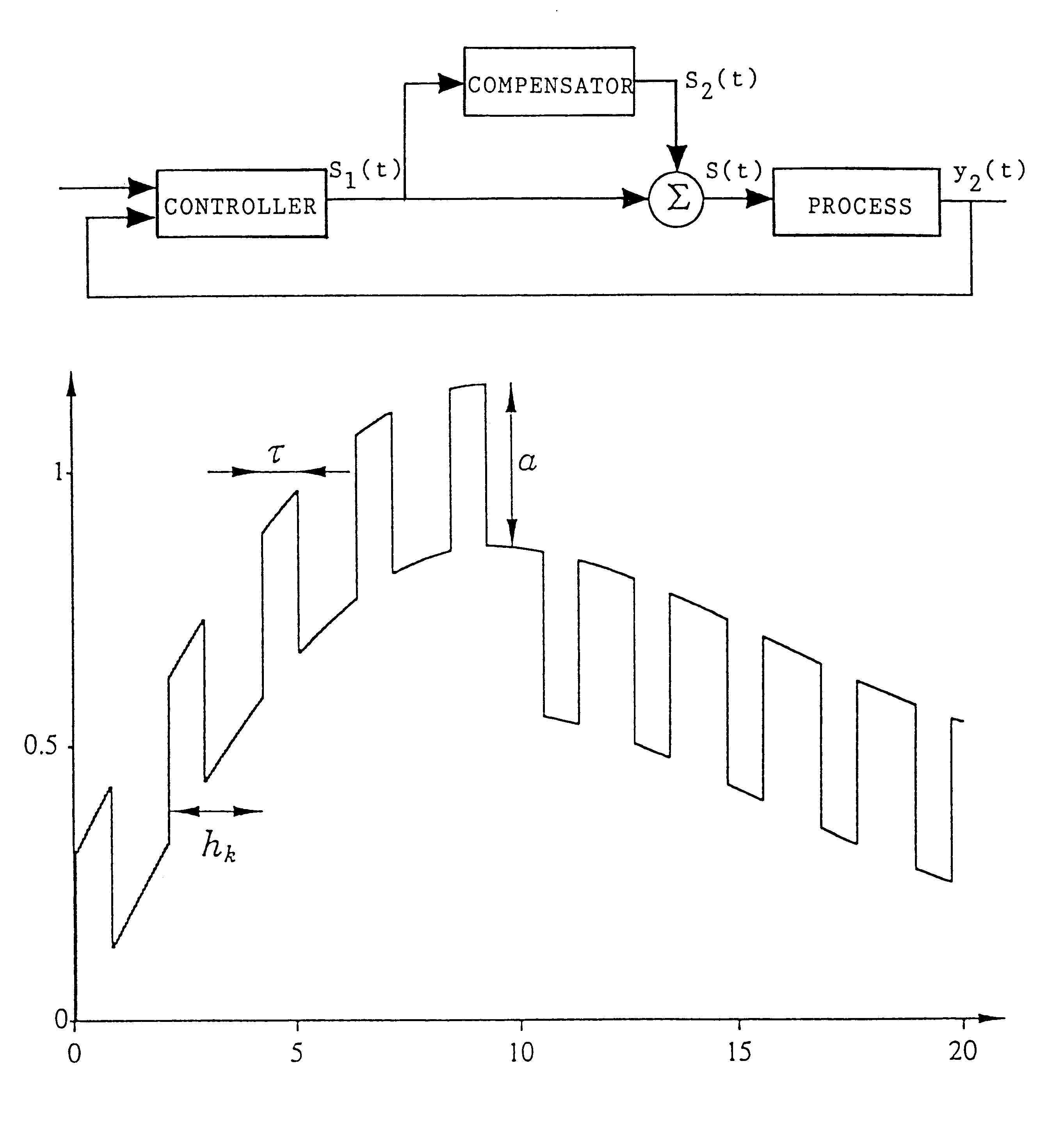

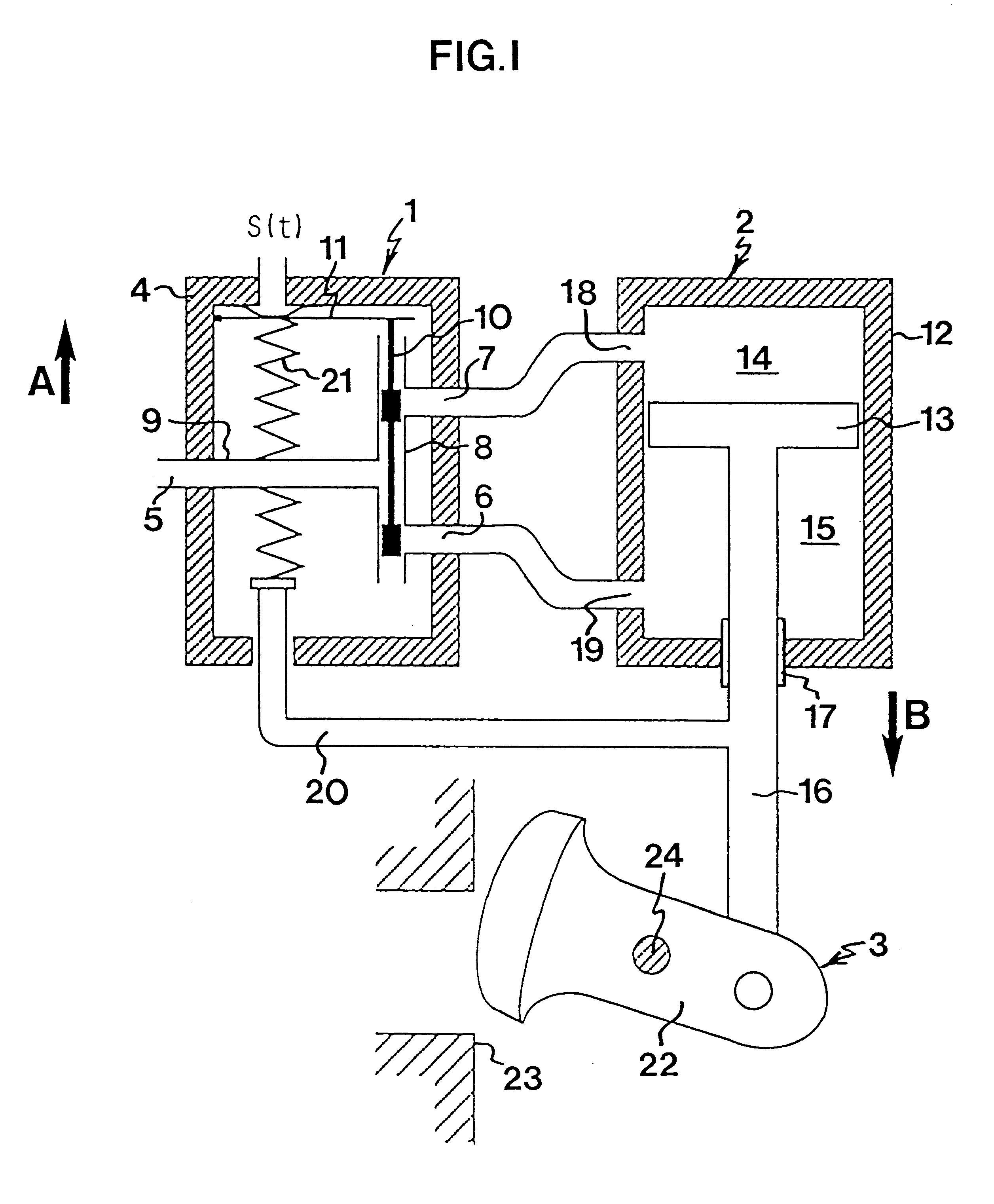

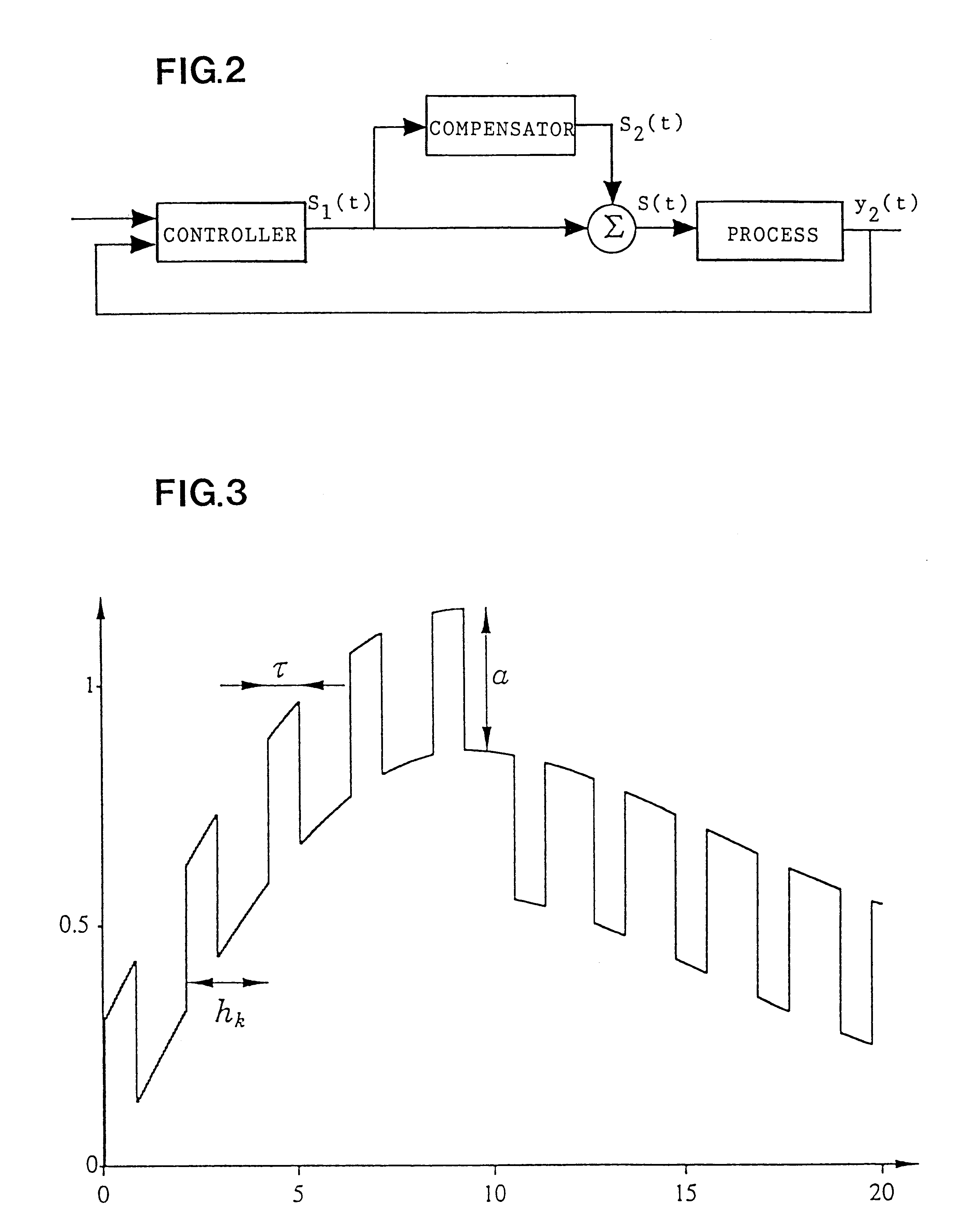

Method and control system for compensating for friction

InactiveUS6285913B1Reduce impactMinimal wearProgramme controlOperating means/releasing devices for valvesControl systemControl signal

A method for compensating for static friction in an actuating device includes the steps of generating an actual signal y2(t) corresponding to a quantity which is controllable by the actuating device, generating a set value signal y1(t) generating a control signal s1(t) based on the set value signal y1(t) and the actual value signal y2(t), and supplying the control signal to the actuating device for controlling the same. The method also includes the steps of generating an intermittent signal s2(t) compensating for friction, sensing the sign of the derivative with respect to time of the control signal s1(t), giving the signal s2(t) compensating for friction the same sign as the derivative, and adding the signal s2(t) compensating for friction to the control signal s1(t) before supplying the same to the actuating device.

Owner:ALFA LAVAL AUTOMATION

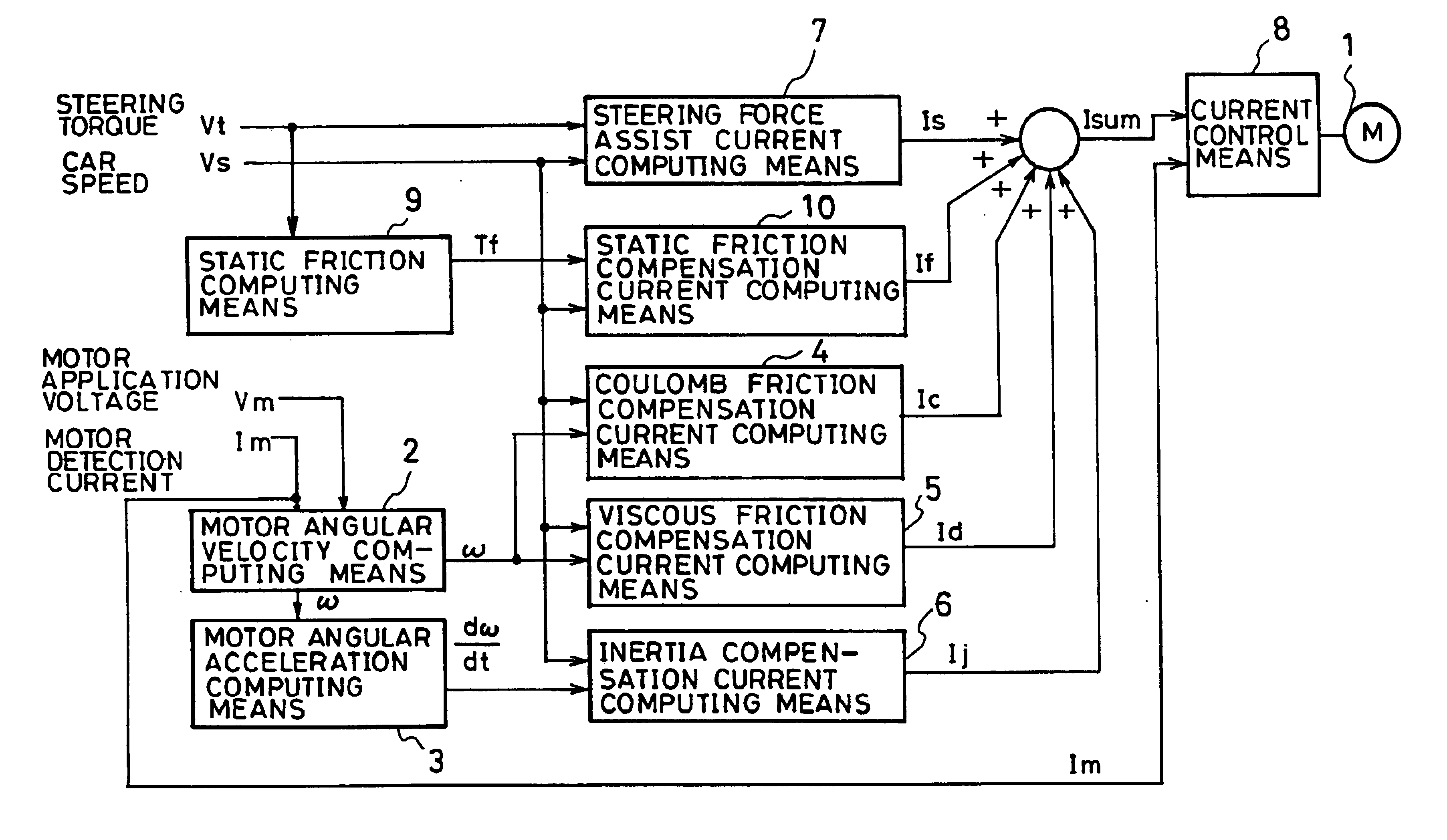

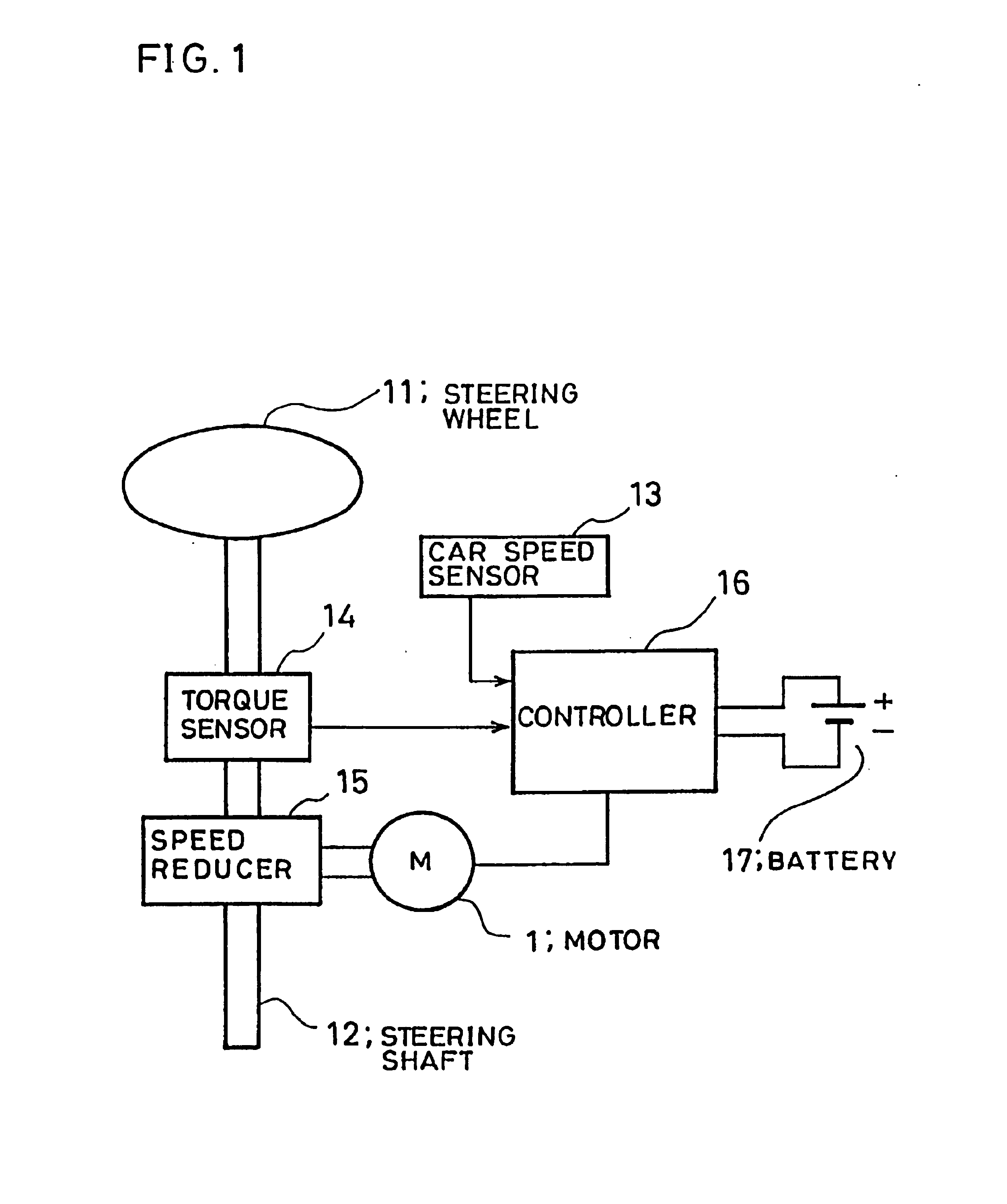

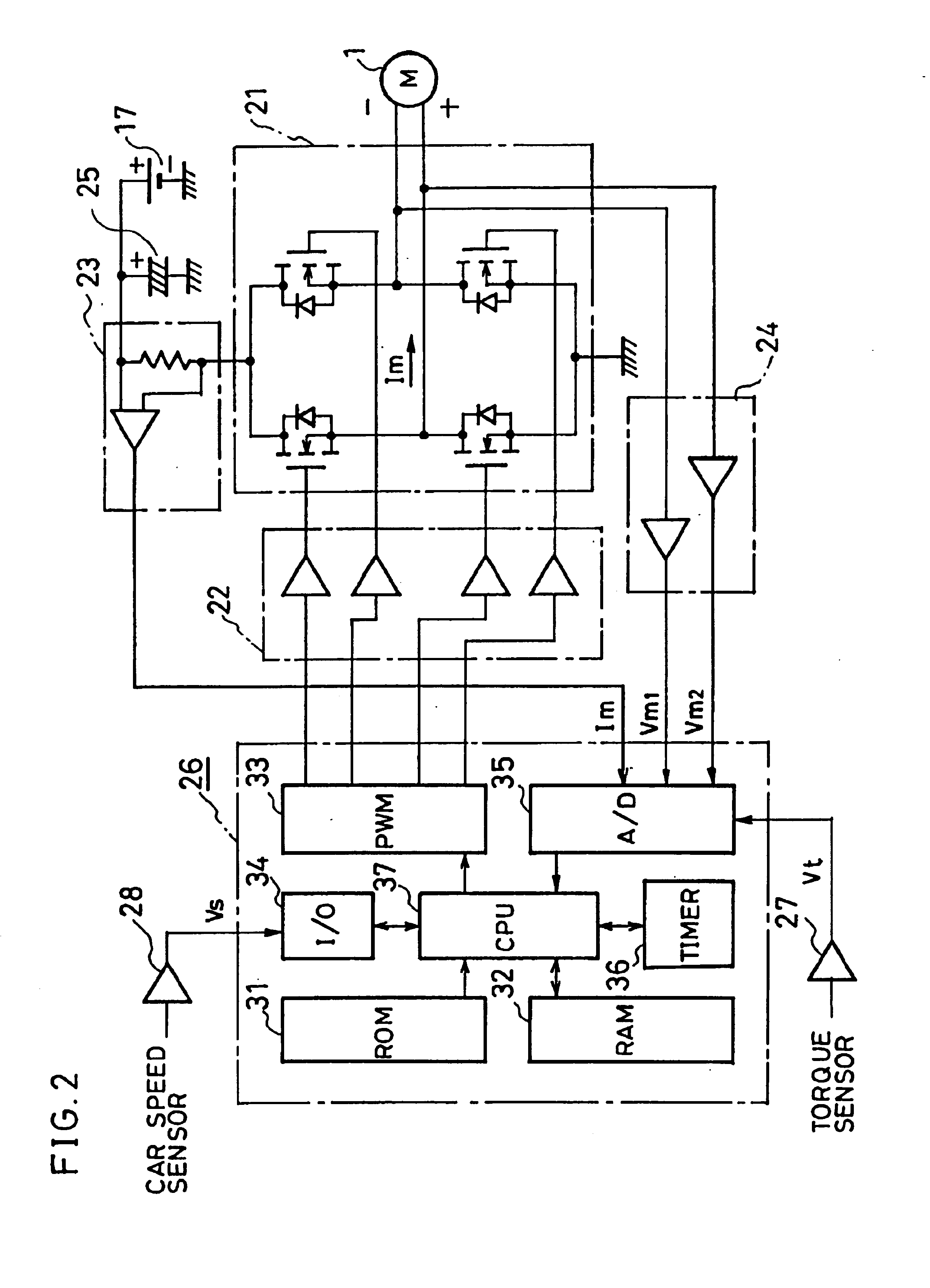

Electric power steering system

InactiveUS6876910B2Digital data processing detailsSteering initiationsElectric power steeringSteering wheel

To improve a steering feeling, an estimated value of static friction of a steering system is obtained by static friction computing means and a static friction compensation current is computed based on this estimated value of static friction by static friction compensation current computing means to compensate for the static friction of the steering system.

Owner:MITSUBISHI ELECTRIC CORP

Piezoelectric and triboelectric coupling-based flexible micro energy harvester and preparation method

ActiveCN103532430AEase of mass productionMiniaturizationPiezoelectric/electrostriction/magnetostriction machinesLayered productsMicron scaleEnergy harvester

The invention discloses a piezoelectric and triboelectric coupling-based flexible micro energy harvester. The energy harvester comprises a piezoelectric layer, first electrode layers, second electrode layers, friction layers and substrate layers, wherein the first electrode layers, the friction layers, the second electrode layers and the substrate layers are arranged on the upper and lower sides of the piezoelectric layer from inside to outside in sequence; the friction layers comprise bumps with micron-scale structures. The invention also provides a corresponding preparation method. Each metal electrode layer and each metal compound layer are obtained from flexible piezoelectric materials such as PVDF (Polyvinylidene Fluoride) obtained through a spin coating, deposition or electrostatic spinning process by using processes such as sputtering, spin coating and evaporation, the flexible polymer bump static friction layer is prepared by using a molding method, meanwhile, a flexible substrate polymer is adopted and a piezoelectric and triboelectric principle is combined to manufacture the micro energy harvester of a hamburger structure stacked by central piezoelectric layers. The device has the characteristics of simple structure, easiness in implementation of micro machining, variable size, wide frequency band, high conversion efficiency and the like.

Owner:SHANGHAI JIAO TONG UNIV

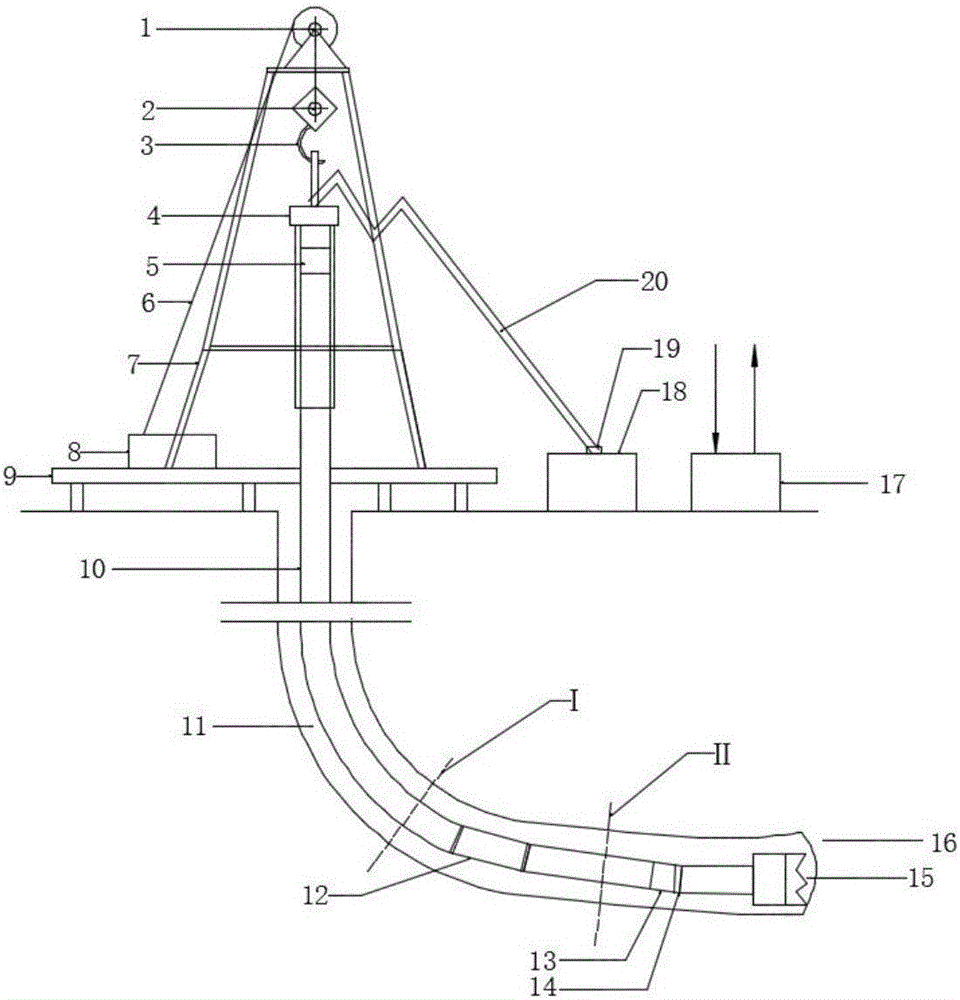

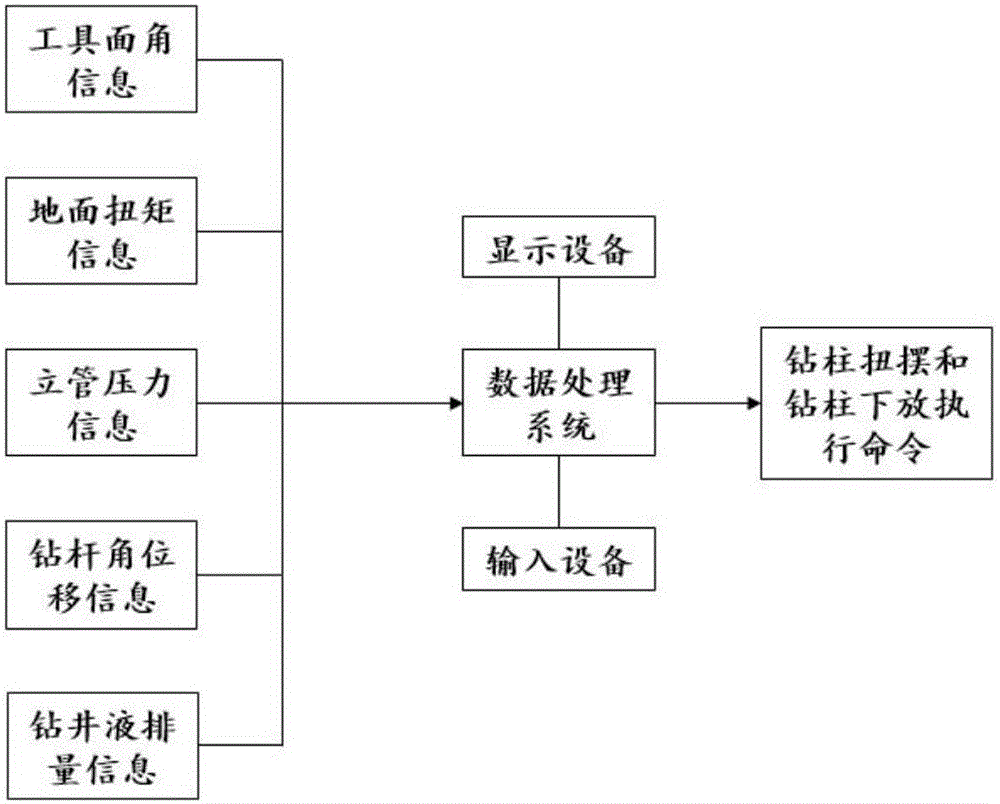

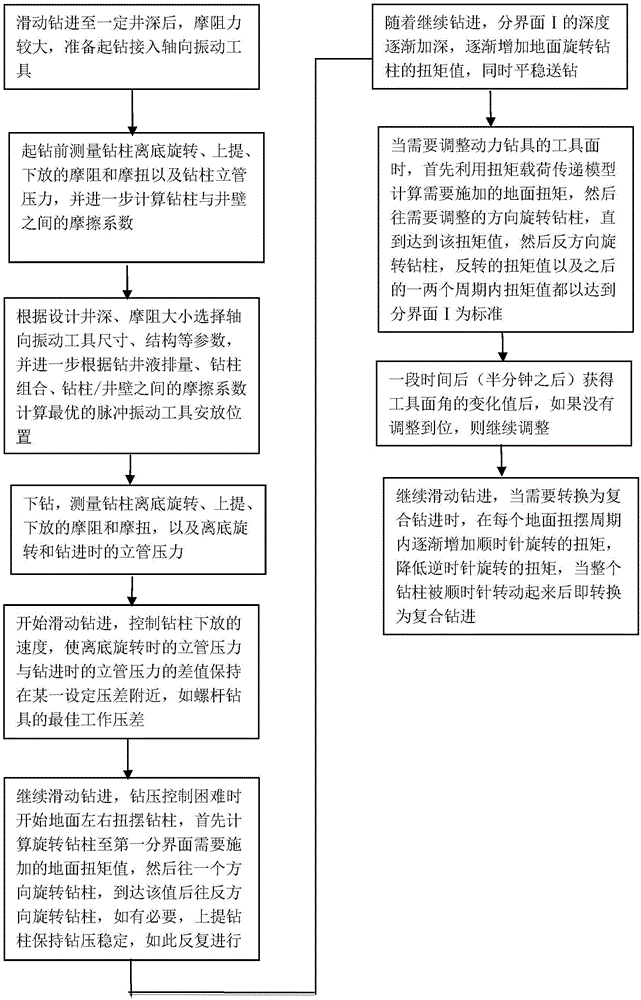

Complex structural well friction resistance reduction and power drill tool face adjusting method

InactiveCN106437513AReduce frictional resistanceReduce resistanceDrilling rodsDirectional drillingTop driveWell drilling

The invention belongs to the technical field of well drilling, and relates to a complex structural well friction resistance reduction and power drill tool face adjusting method. A whole originally pure sliding drilling string is divided into three portions, the upper portion of the drilling string rotates in a reciprocating manner under the action of torque applied by a surface well drilling top drive, the middle of the drilling string axially vibrates / creeps under the action of an axial vibration resistance reduction tool, and static friction between the drilling string and a well wall is transformed into dynamic friction, so that axial feeding resistance of the drilling string is reduced. A drill bit on the lower portion of the drilling string can axially vibrates, so that bit pressure fluctuates, rock breaking torque and reaction torque fluctuate, the fluctuating reaction torque acts on the lower portion of the drilling string close to the drill bit, the lower portion of the drilling string rotates in a reciprocating manner, and friction resistance can be reduced. The method is convenient in operation and scientific in principle, power drill tool face adjusting time can be saved, drilling is continued while a tool face is adjusted, the drilling efficiency of a complex structural well, particularly the complex structural well with long horizontal displacement is improved, and well drilling cost is reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

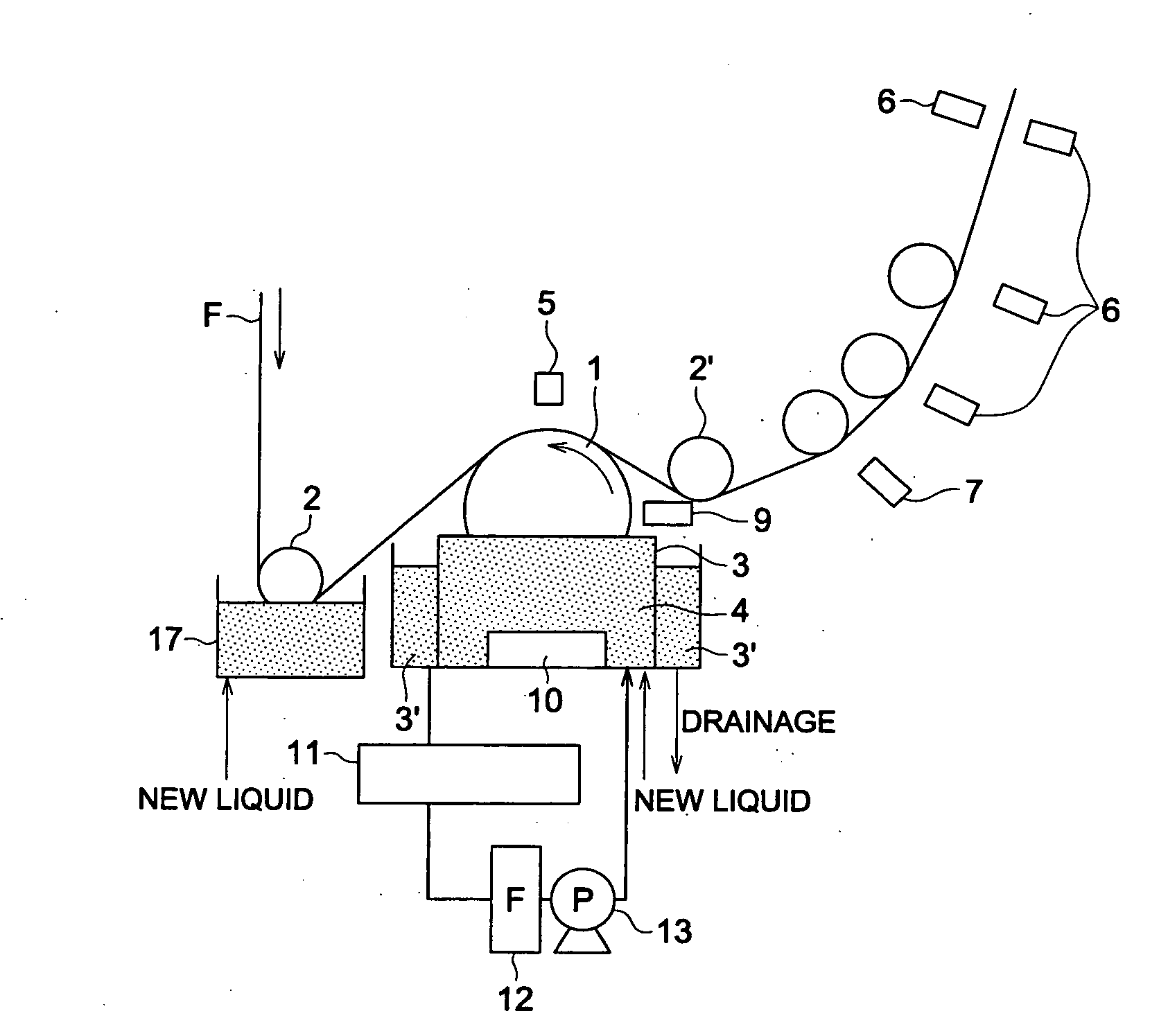

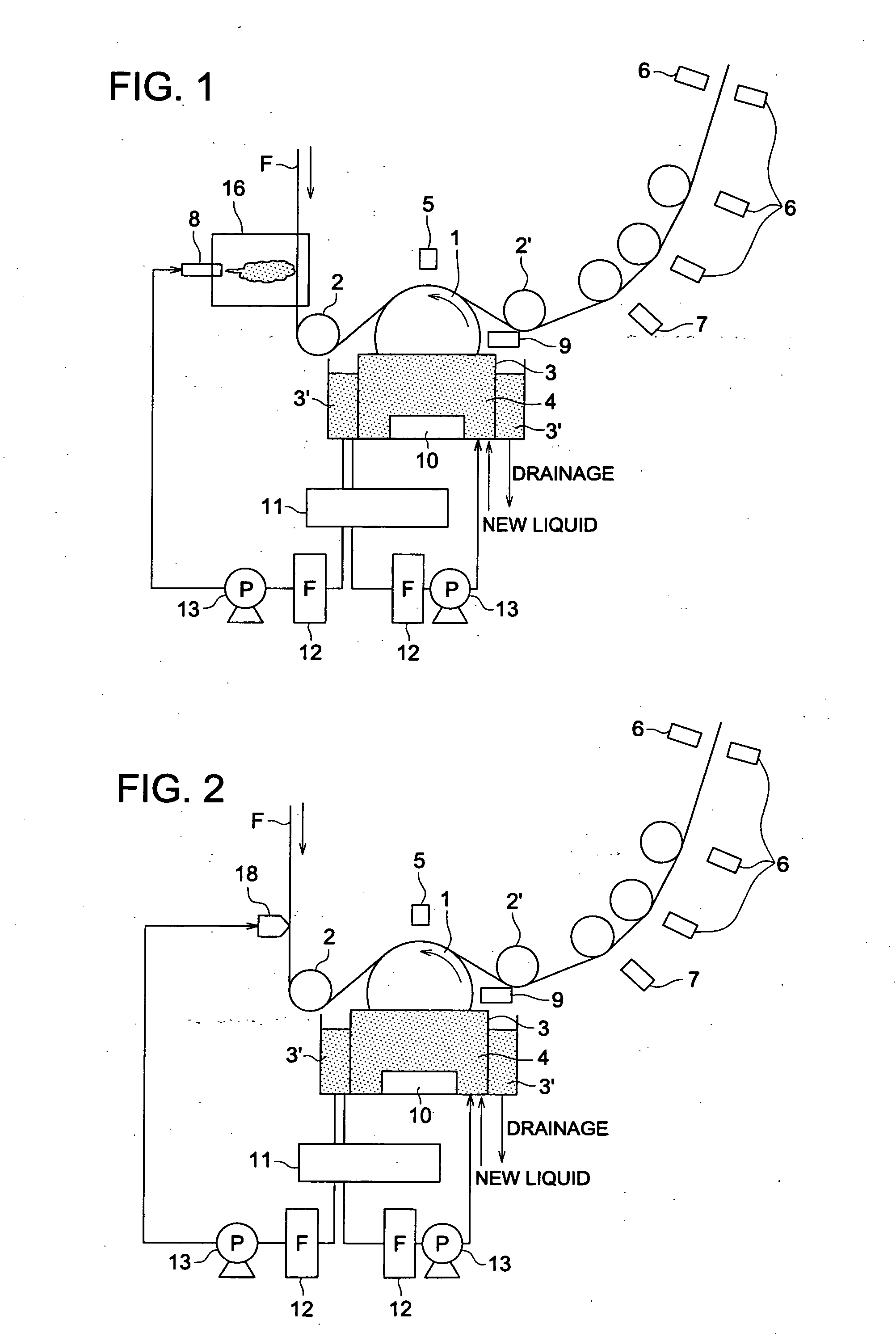

Optical Film Treating Method, Optical Film Treating Apparatus, and Optical Film Producing Method

InactiveUS20090232977A1Improve unevennessTransversely streaked unevennessMechanical cleaningPressure cleaningStatic friction coefficientElastomer

A method of optical-film treatment in which coating troubles apt to occur in the formation of a functional layer, e.g., an antireflection layer, on a continuous film by coating fluid application, such as transverse thickness-difference lines, coating streaks, and tailing, are diminished. The method of optical-film treatment comprises wetting with a liquid a continuous film which is being continuously conveyed, continuously rubbing the continuous film with an elastomer, and then removing the liquid from the continuous-film surface, and is characterized in that the surface of the elastomer has a coefficient of static friction of 0.2-0.9.

Owner:KONICA MINOLTA OPTO

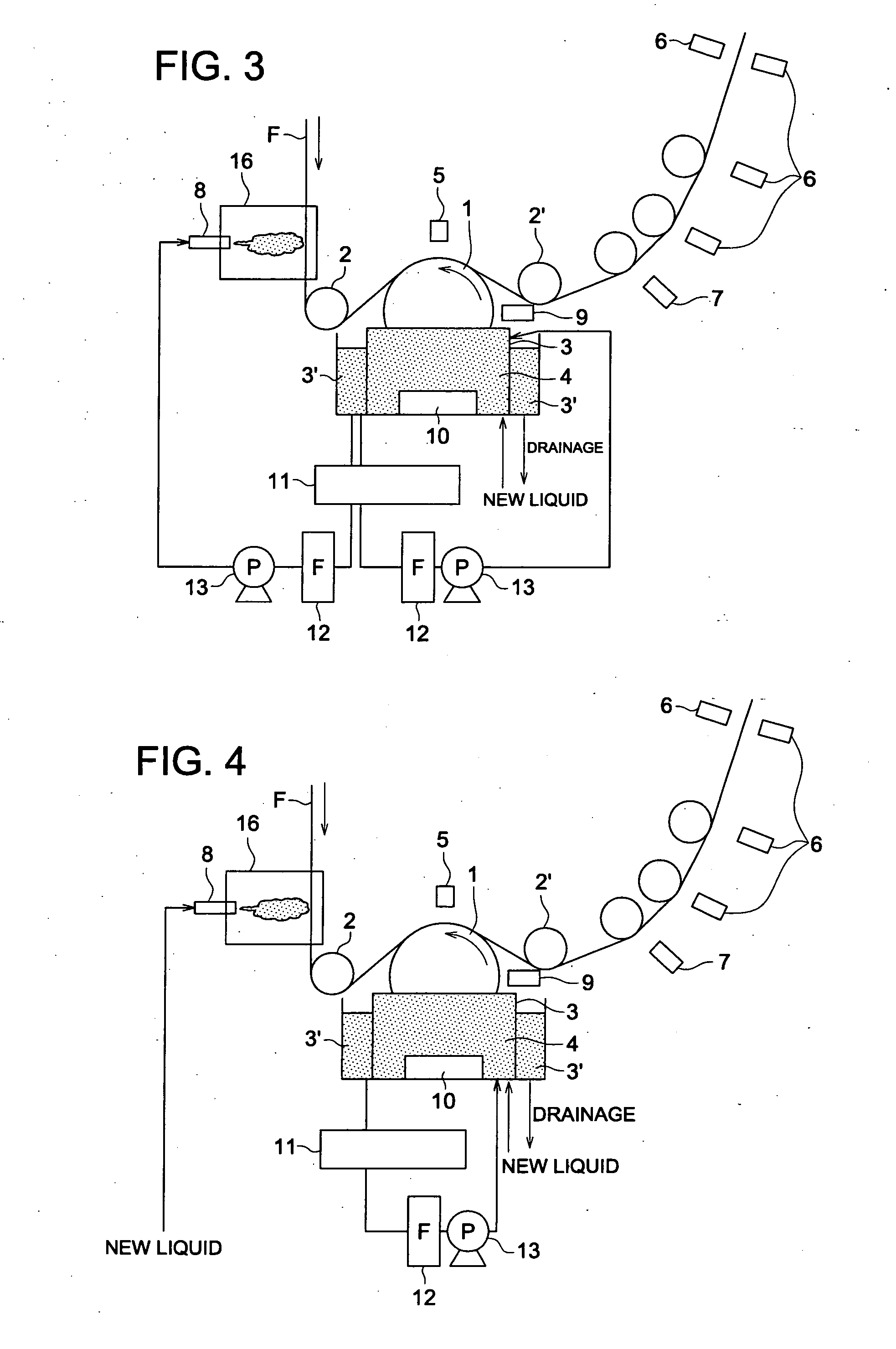

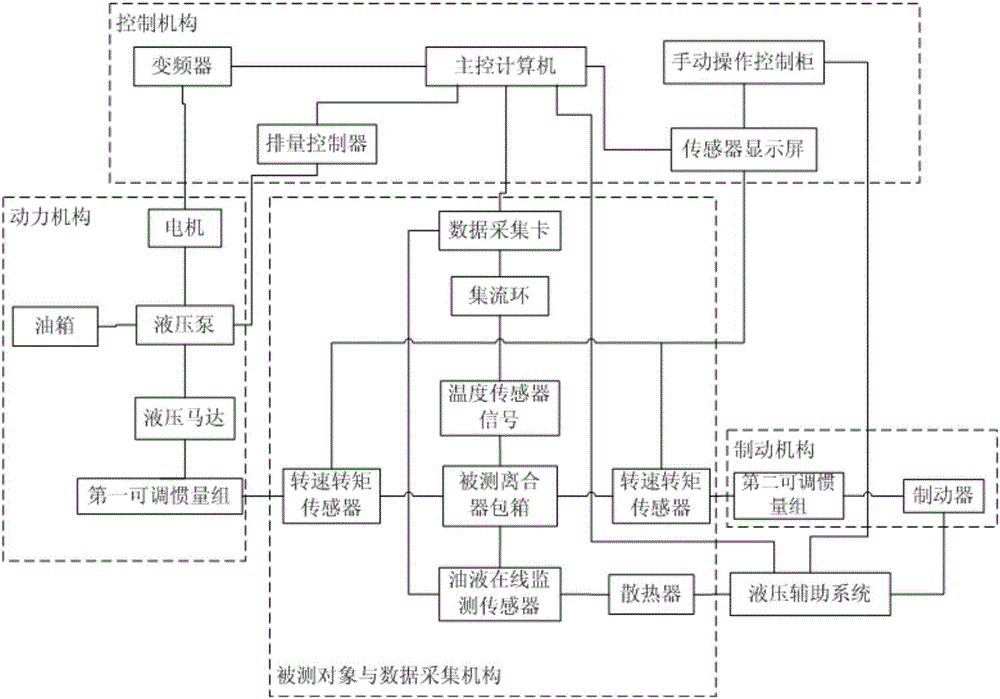

Wet-clutch friction plate's wear extent testing method and testing stand

ActiveCN105021483ASafe and reliable operationAvoid damageUsing mechanical meansInvestigating abrasion/wear resistanceStatic friction coefficientFriction torque

Owner:BEIJING INFORMATION SCI & TECH UNIV

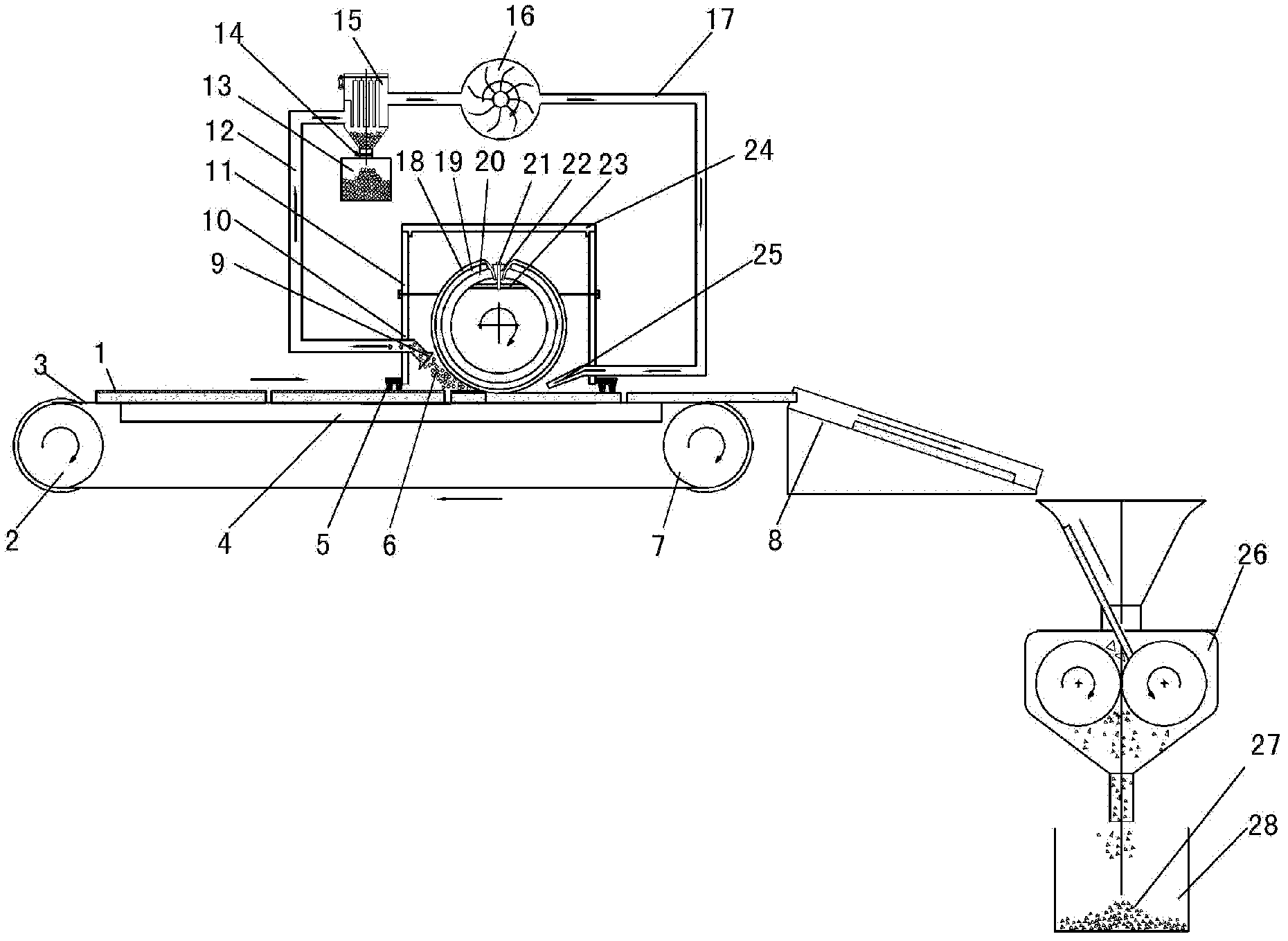

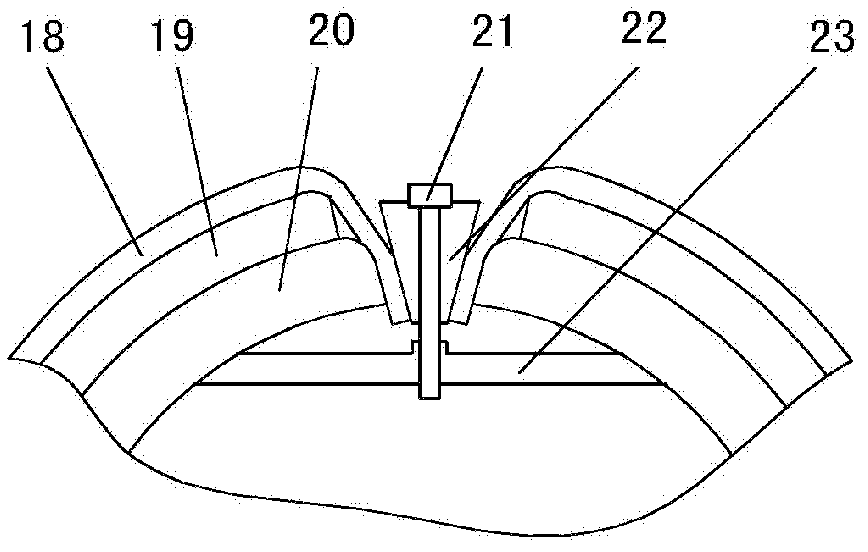

Industrialized recovery method and recovery device for glass panel of waste liquid crystal display

InactiveCN102632072AImprove recycling efficiencyImprove environmental benefitsSolid waste disposalRecovery methodOrganic solvent

The invention discloses an industrialized recovery method and a recovery device for a glass panel of a waste liquid crystal display. The industrialized recovery method is characterized by comprising the steps of placing glass substrate on a conveying belt, with the surface a coating located on being upward; realizing self-locking and positioning of the glass substrate by virtue of static friction force between the glass substrate and the conveying belt; separating the glass substrate of the LCD (Liquid Crystal Display) from the coating by grinding; collecting grindings, thereby obtaining indium metallurgical materials; and finally conducting smashing, soaking in organic solvent, and centrifugal separation on the ground glass substrate, thereby sorting and recycling glass and polaroids. The recovery method and the recovery device are simple, practical and available for sorting and recovering the glass panel of the waste liquid crystal display, in an industrialized, high-efficient and high-quality way.

Owner:HEFEI UNIV OF TECH

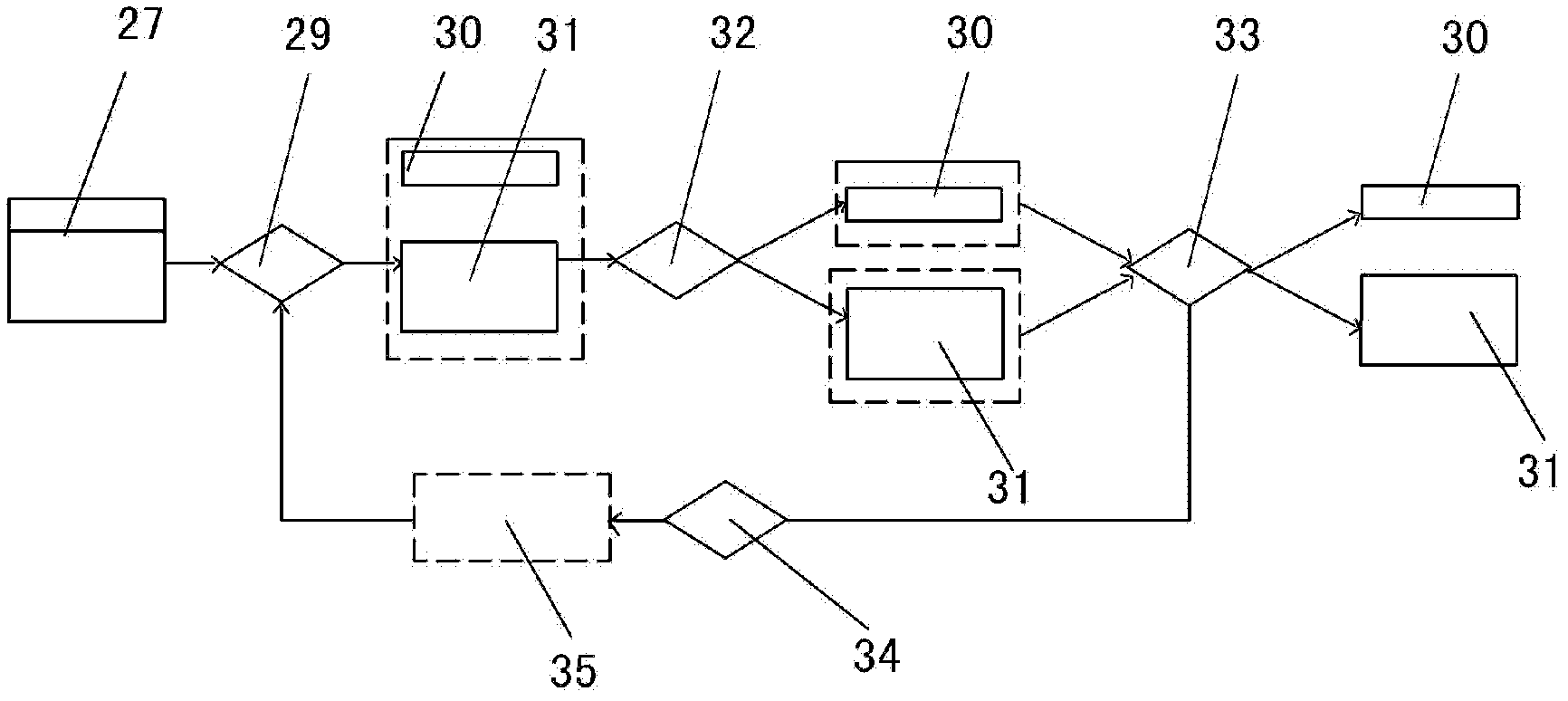

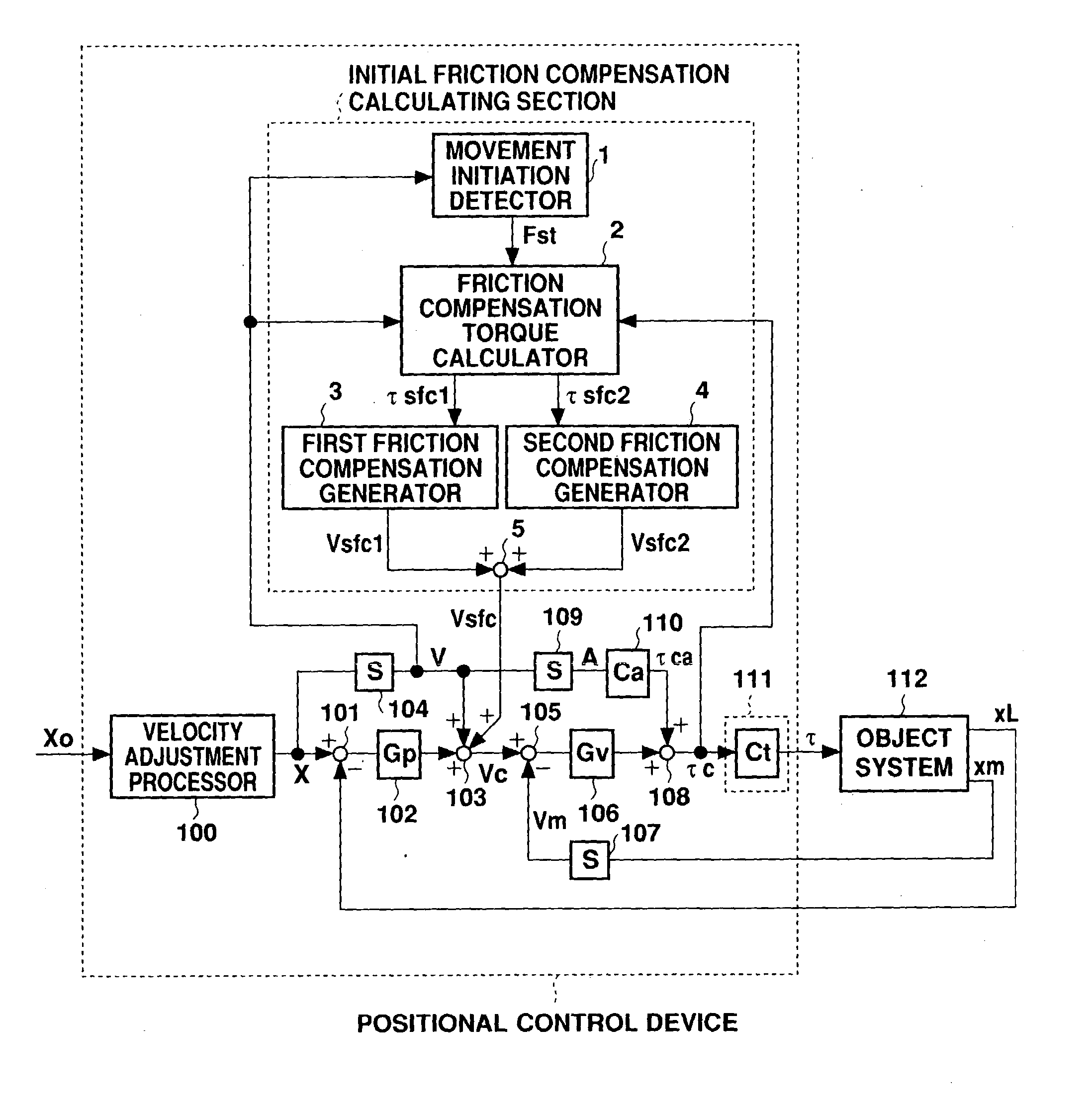

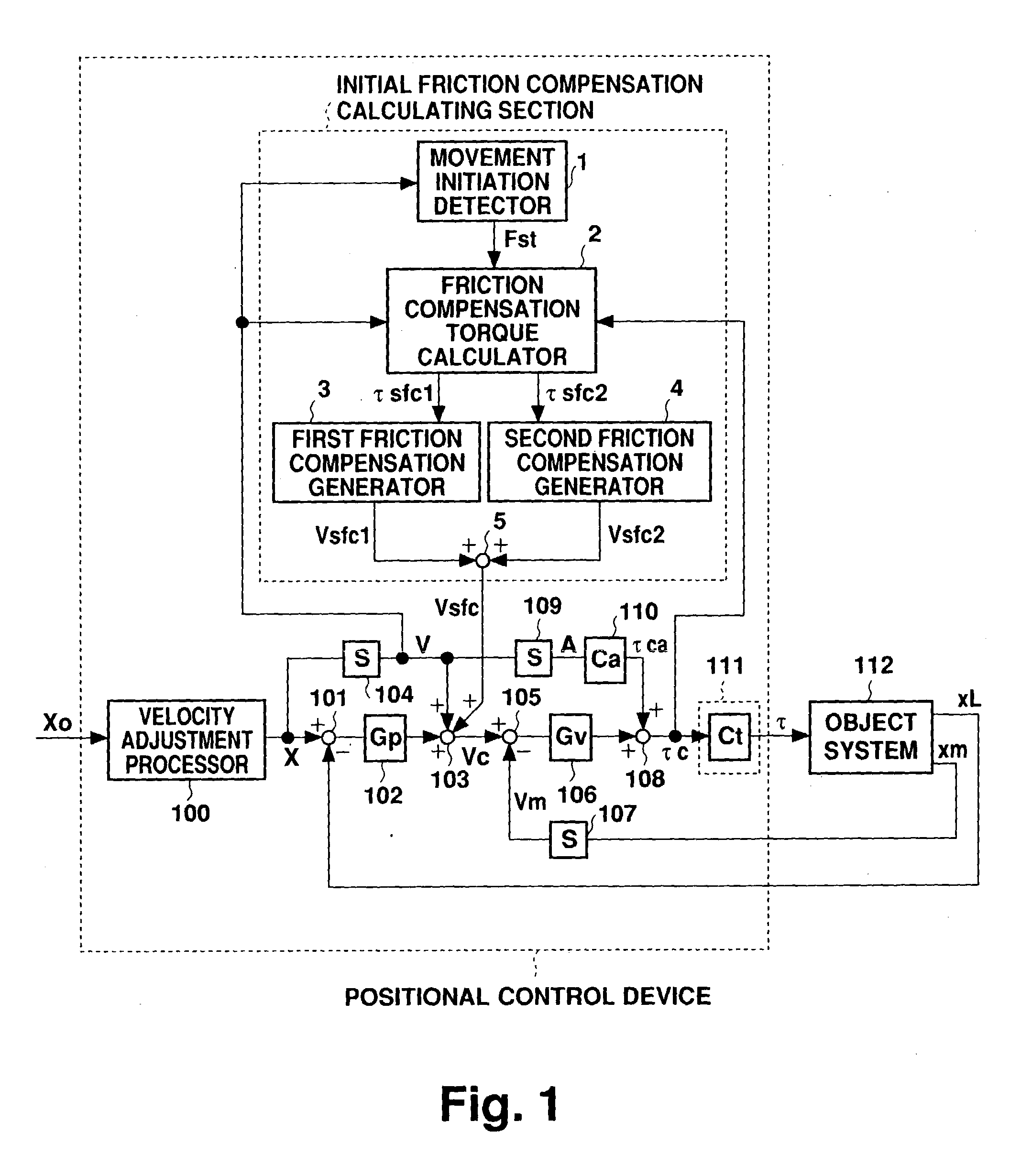

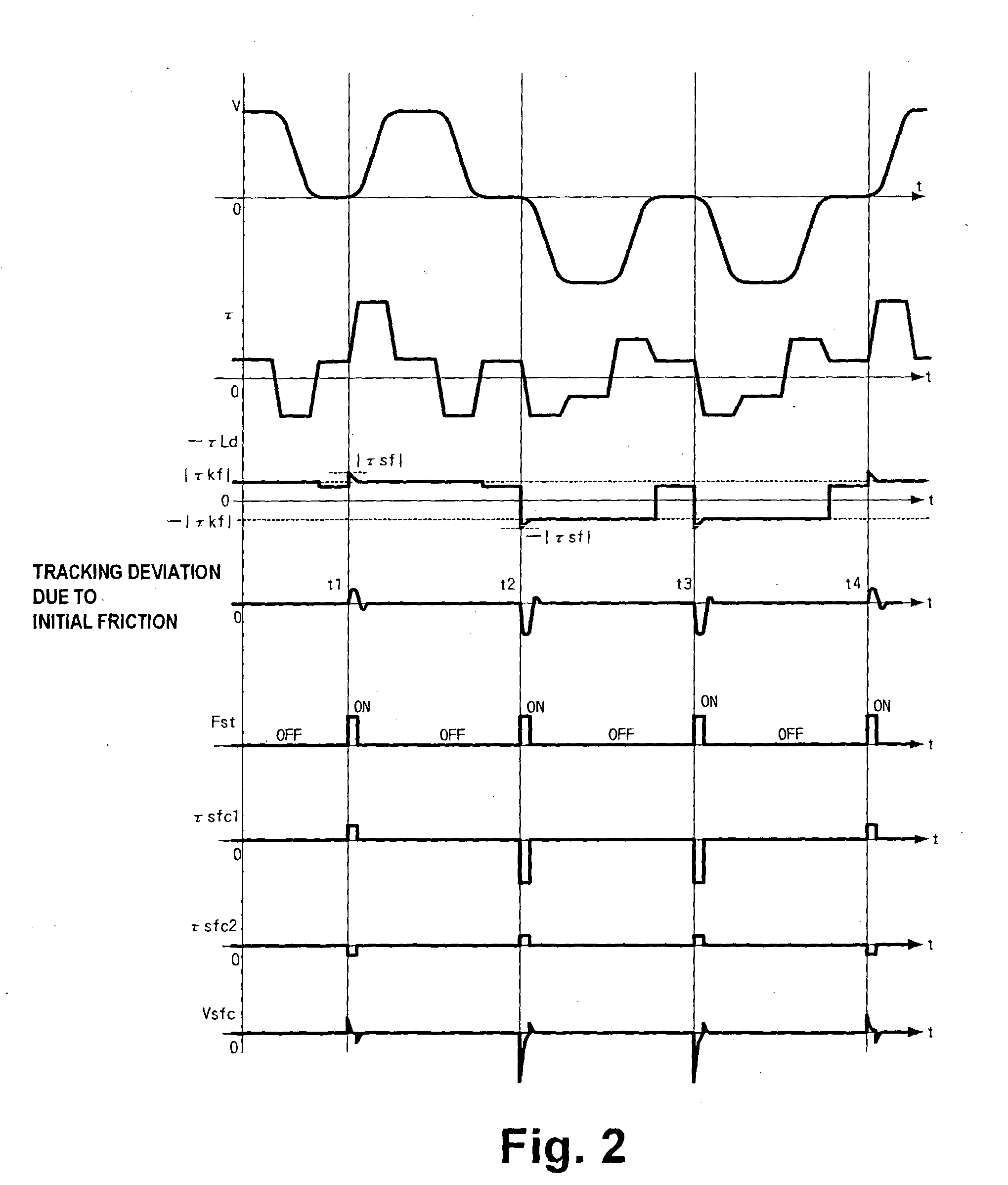

Positional control of a controlled object during movement initiation

In a positional control device for controlling a position of a controlled object using a motor, when generating a torque command value tauc which serves as the command value for the servo motor of the controlled object system (112), a friction compensation value for use when the controlled object initiates a movement is calculated based on a velocity command value V and a torque command value tauc determined according to a positional command value Xo supplied from a superordinate device. More specifically, an initial friction compensation calculating section calculates a torque compensation amount Vsfc1 corresponding to a difference between torque being generated during the standstill state and torque required by the controlled object to initiate the movement, and a torque compensation amount Vsfc2 corresponding to an amount of change in friction that occurs during a transition from static friction to kinetic friction in a period immediately before and after initiation of the movement. Vsfc1 and Vsfc2 are then used to calculate compensated values of the torque command value tauc. Positional tracking deviation generated due to friction during a movement initiation can thereby be reduced, regardless of operational conditions during the standstill state or of the movement direction and velocity effected thereafter.

Owner:OKUMA CORP

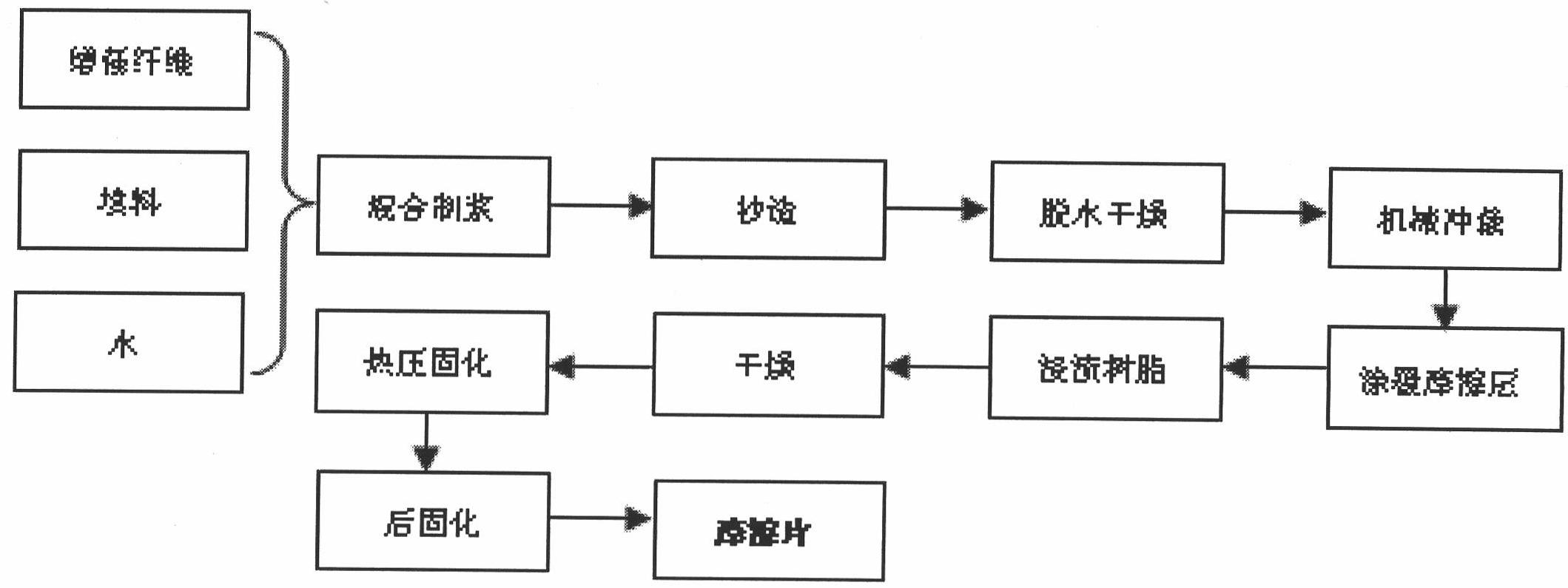

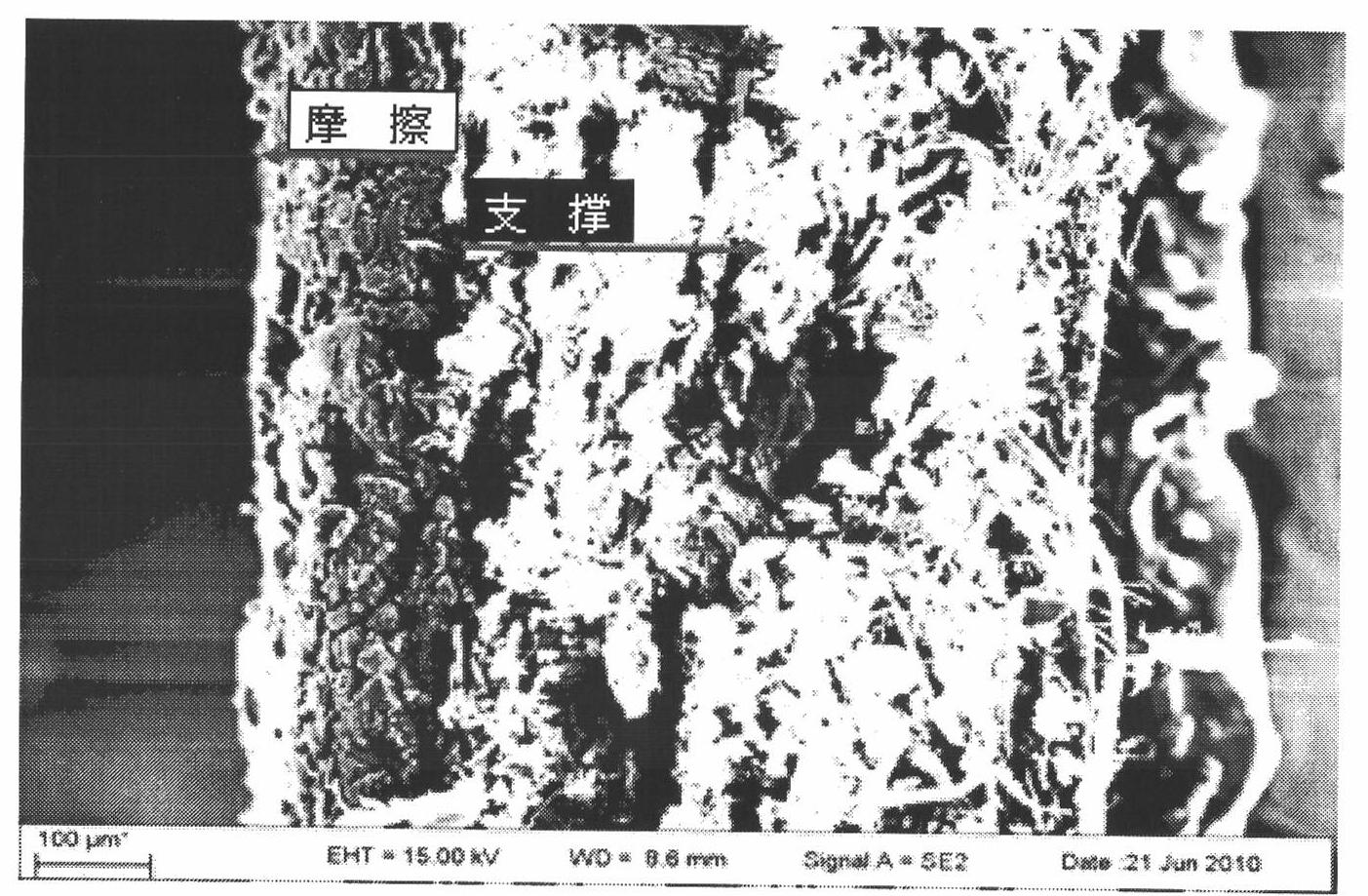

Carbonaceous double-layer paper-based friction material and preparation method thereof

InactiveCN102093842AIncrease coefficient of frictionCopy molding process is simpleOther chemical processesFiberStatic friction coefficient

The invention discloses a carbonaceous double-layer paper-based friction material and a preparation method thereof, aiming at solving the technical problem of low friction coefficient of the traditional double-layer paper-based friction material. According to the technical scheme, the carbonaceous double-layer paper-based friction material is prepared from 15-30% of reinforced fibre, 20-35% of filler, 5-15% of carbonaceous material, 5-10% of alumina and graphite and 25-35% of cashew nut shell oil modified phenolic resin. The preparation method comprises the following steps of: manufacturing and shaping a support layer in one time; and coating a friction layer on the surface of the support layer to obtain the carbonaceous double-layer paper-based friction material. Compared with the two-time manufacturing and shaping process in the background art, the preparation method is simpler. The coefficient of dynamic friction of the carbonaceous double-layer paper-based friction material is improved to 0.145-0.168 from 0.112-0.140 in the background art, and the coefficient of static friction is improved to 0.194-0.232 from 0.155-0.191 in the background art.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

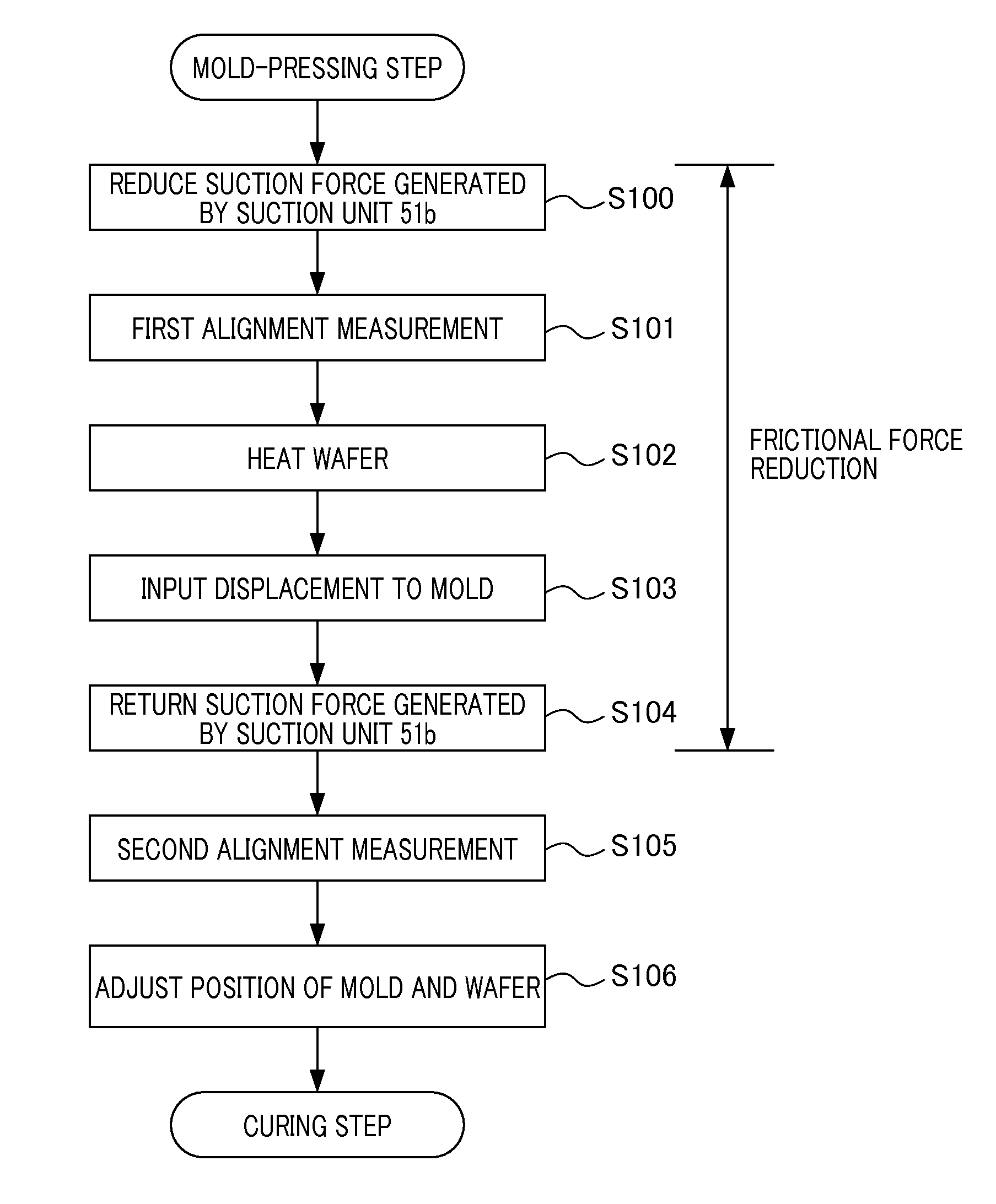

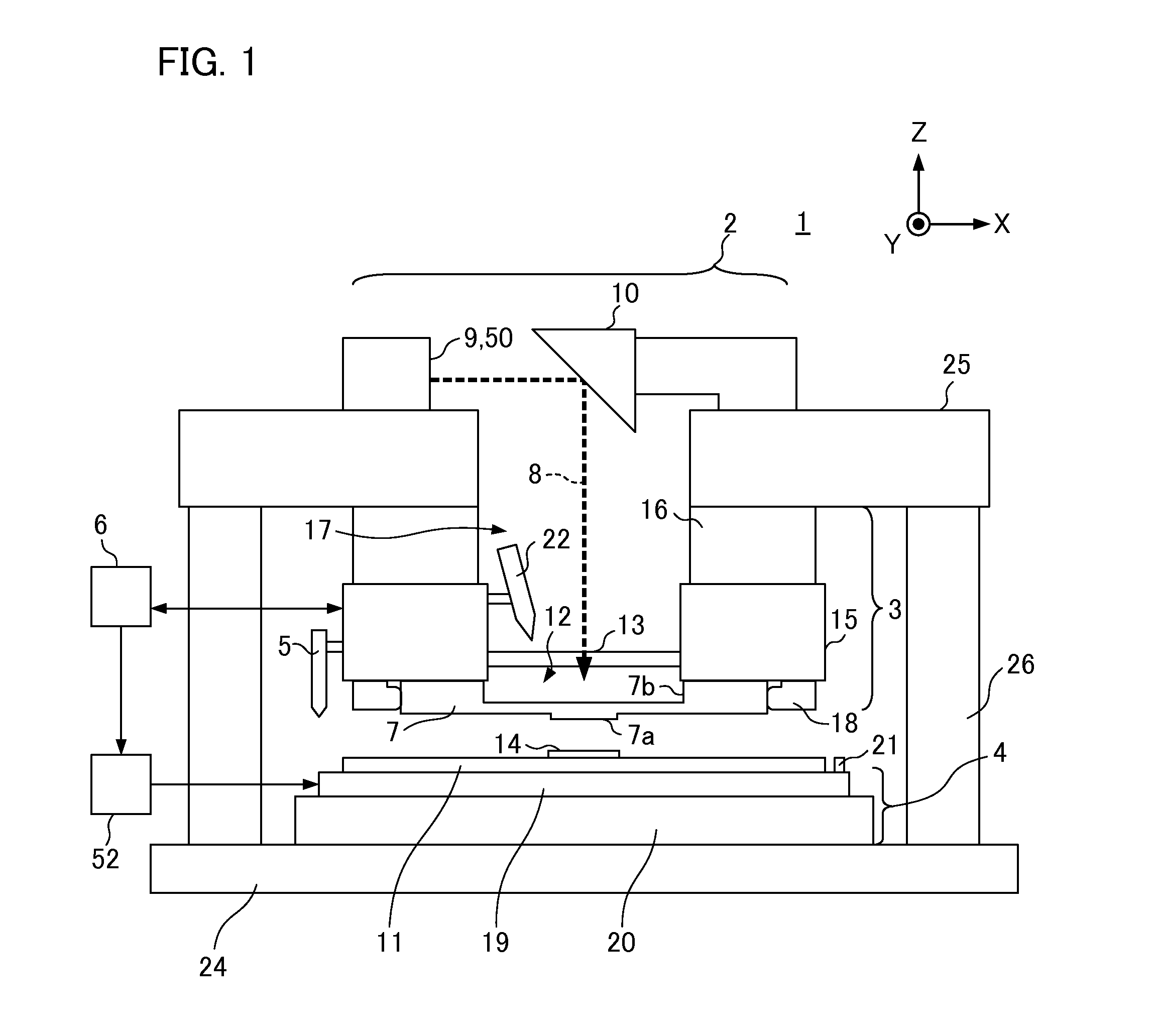

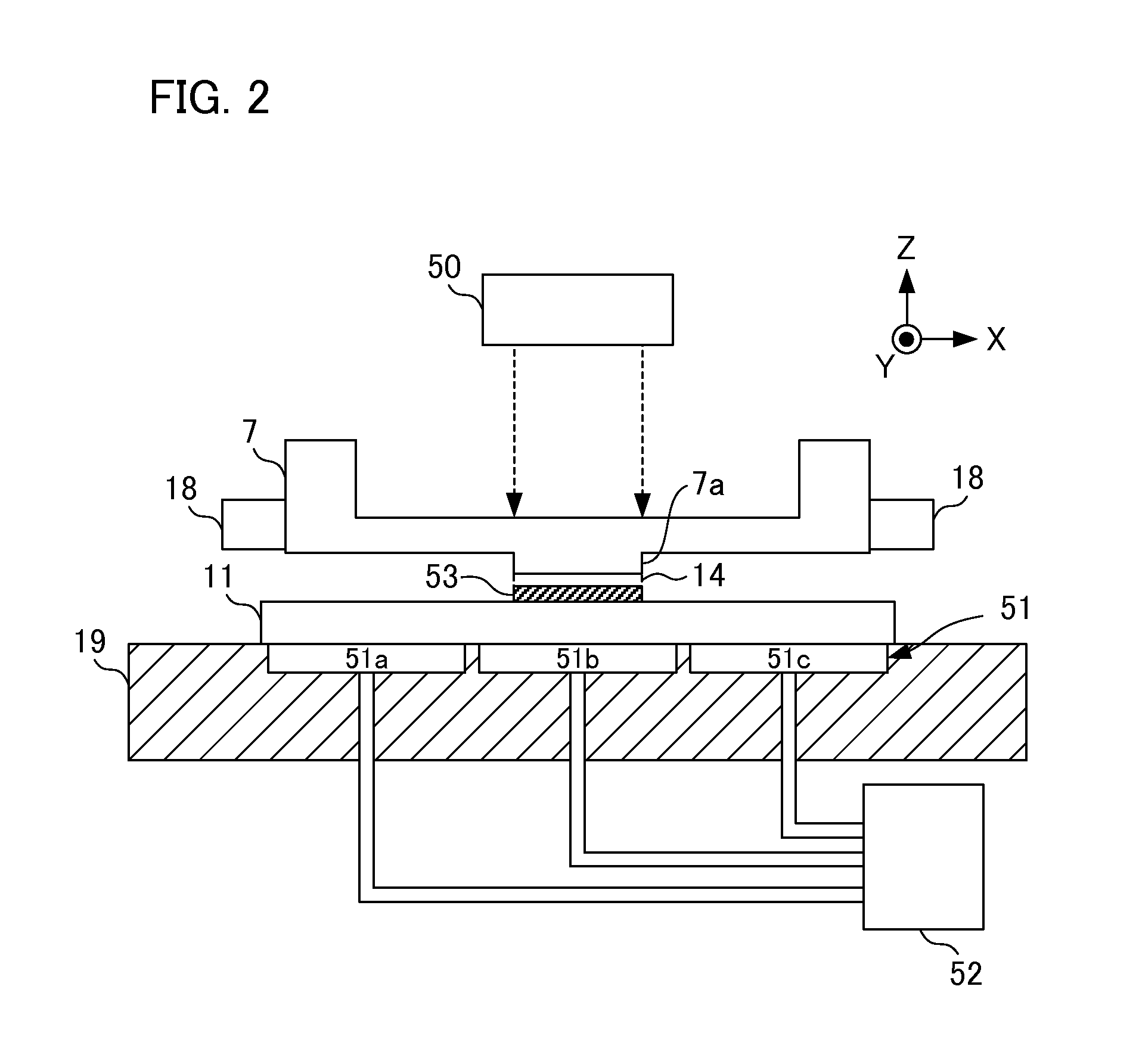

Imprint method imprint apparatus, and article manufacturing method

ActiveUS20130112097A1Improving superposition accuracySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsStatic frictionMechanical engineering

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com