Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6412 results about "Rolling-element bearing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

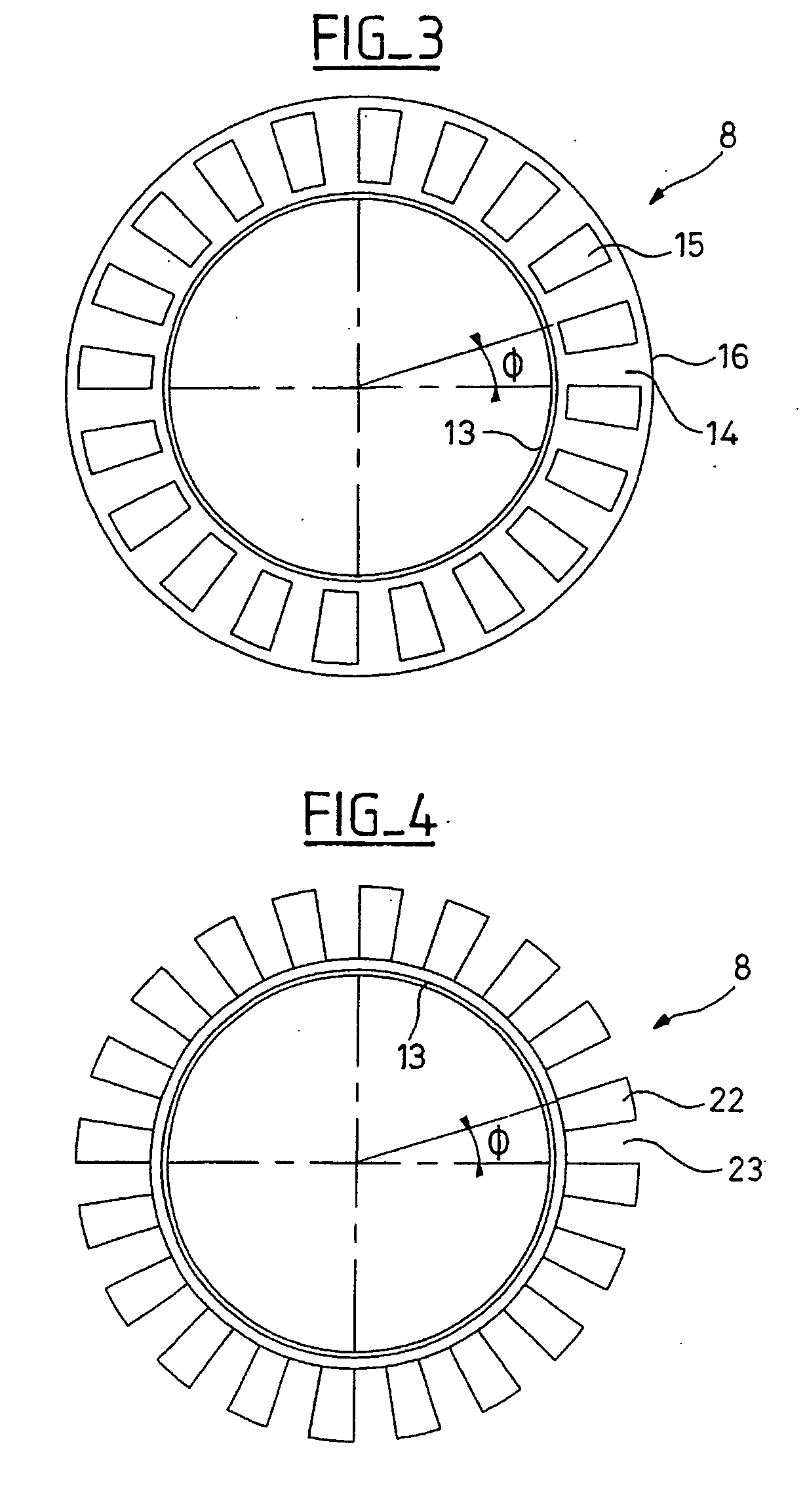

A rolling-element bearing, also known as a rolling bearing, is a bearing which carries a load by placing rolling elements (such as balls or rollers) between two bearing rings called races. The relative motion of the races causes the rolling elements to roll with very little rolling resistance and with little sliding.

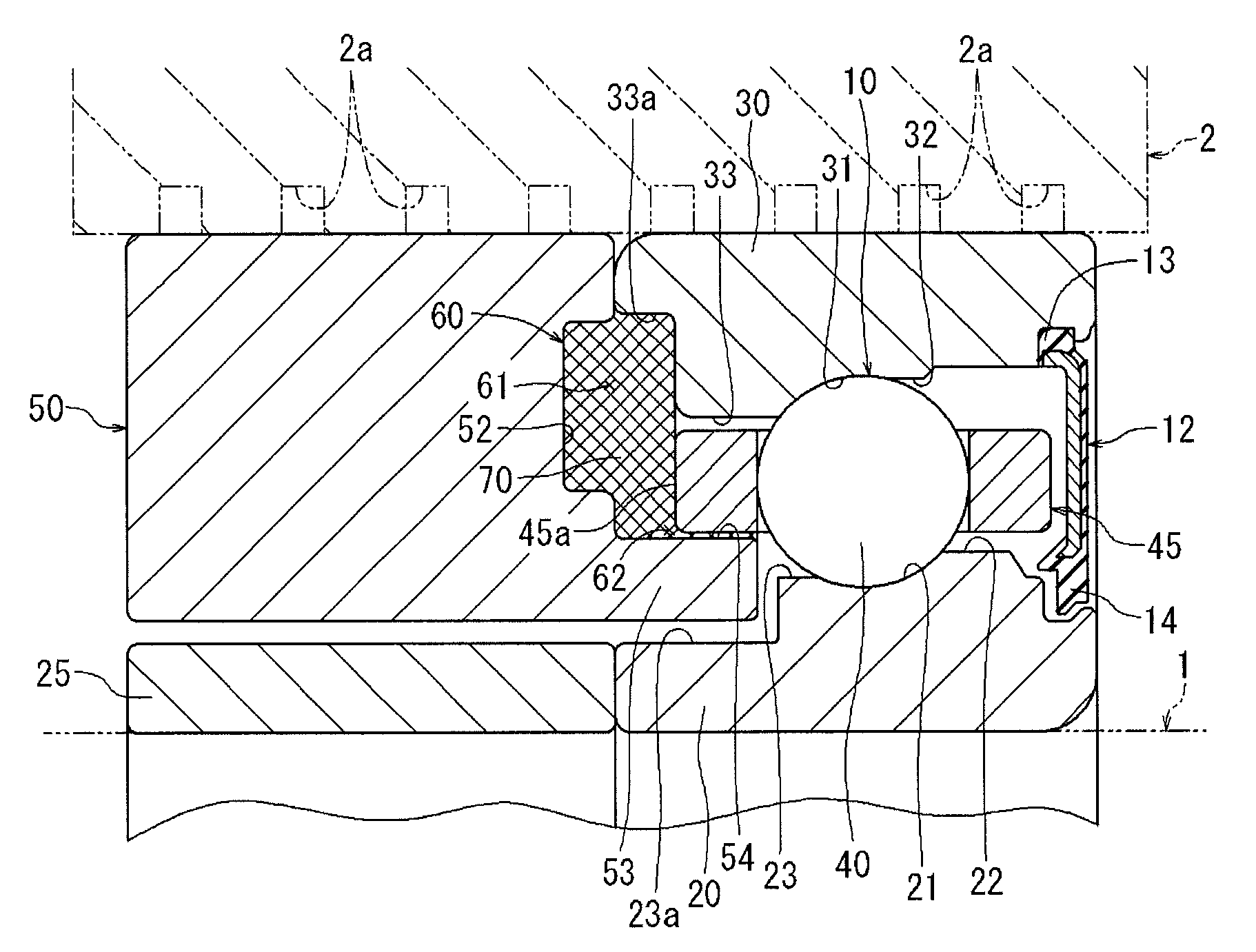

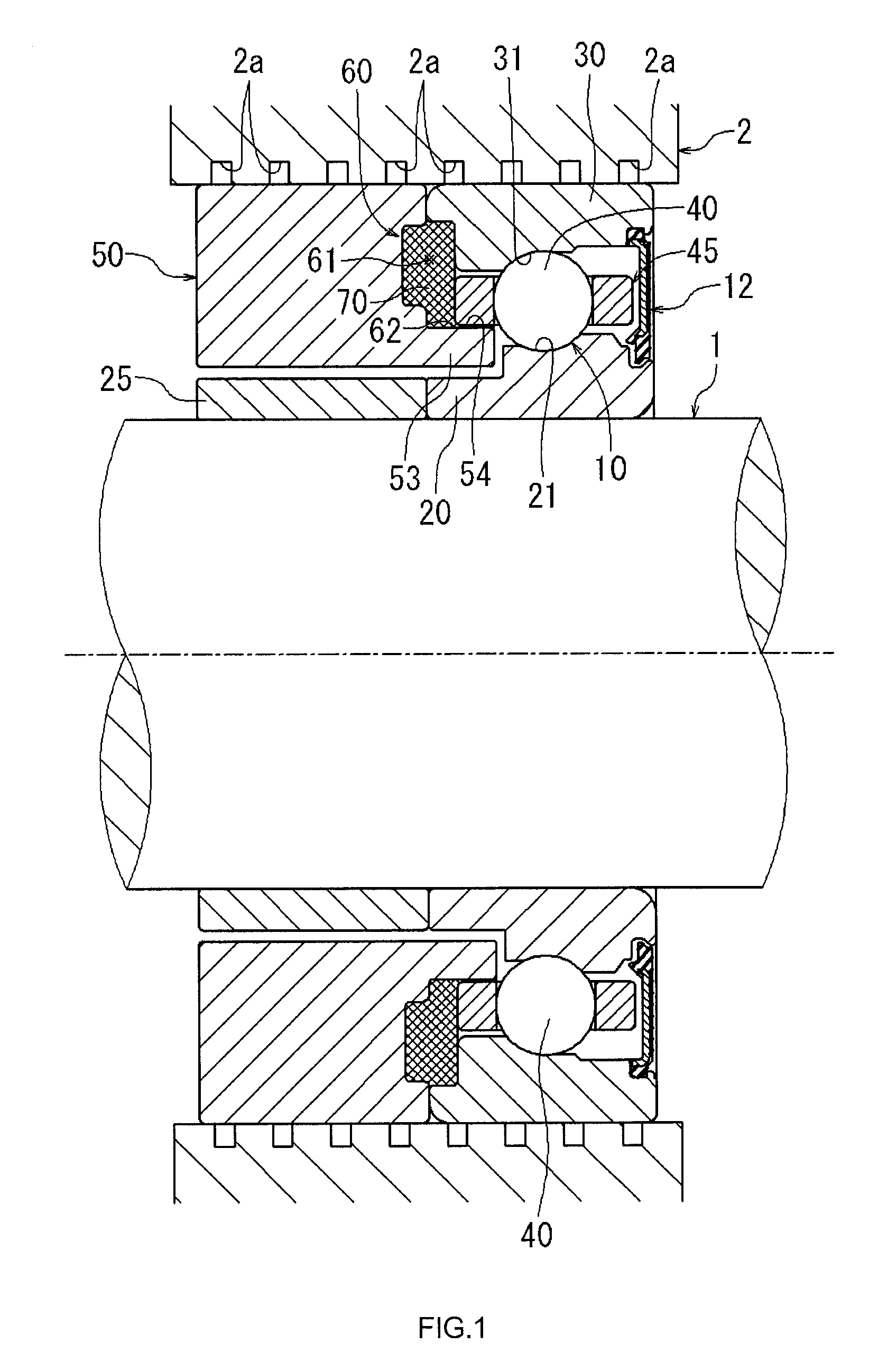

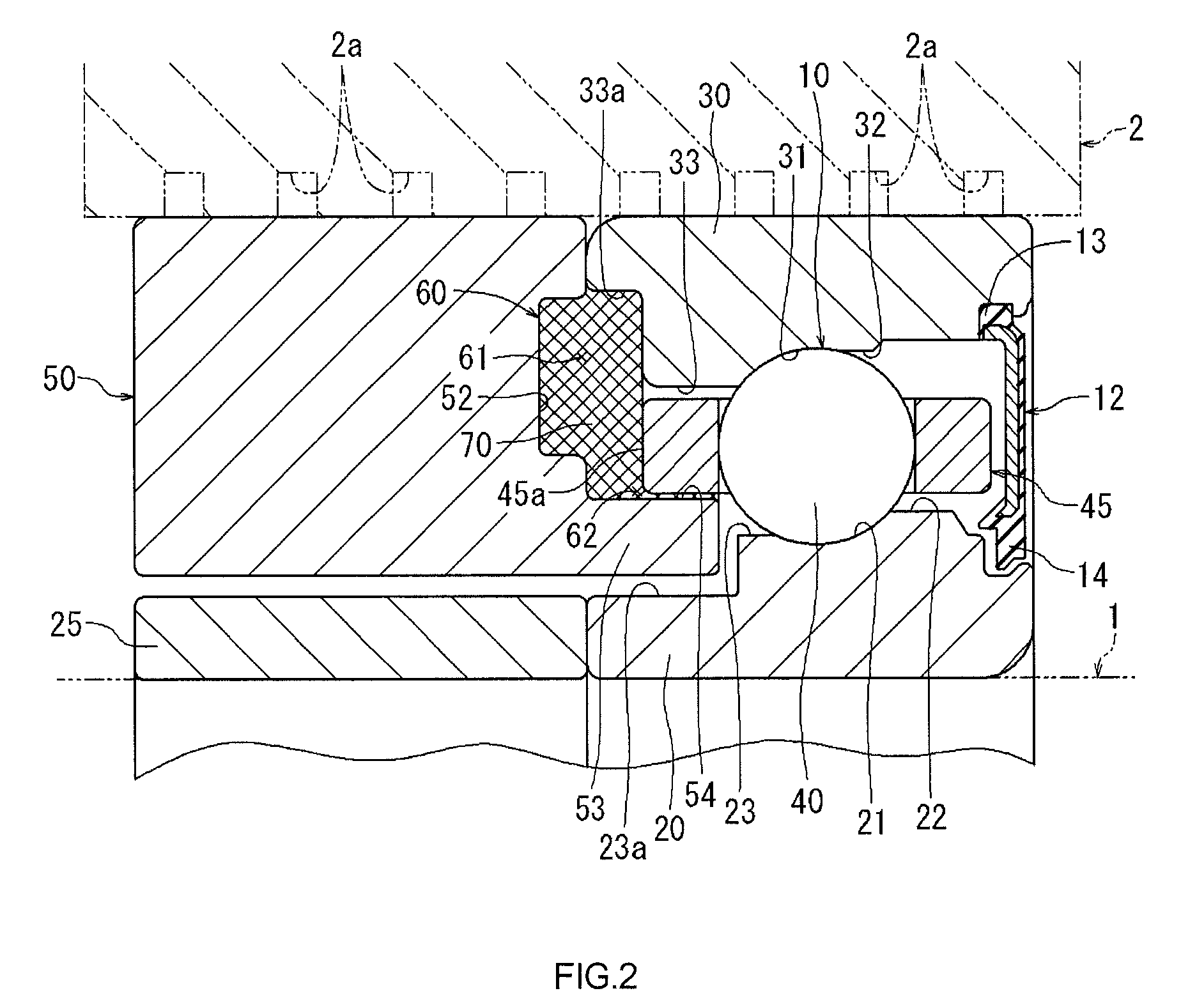

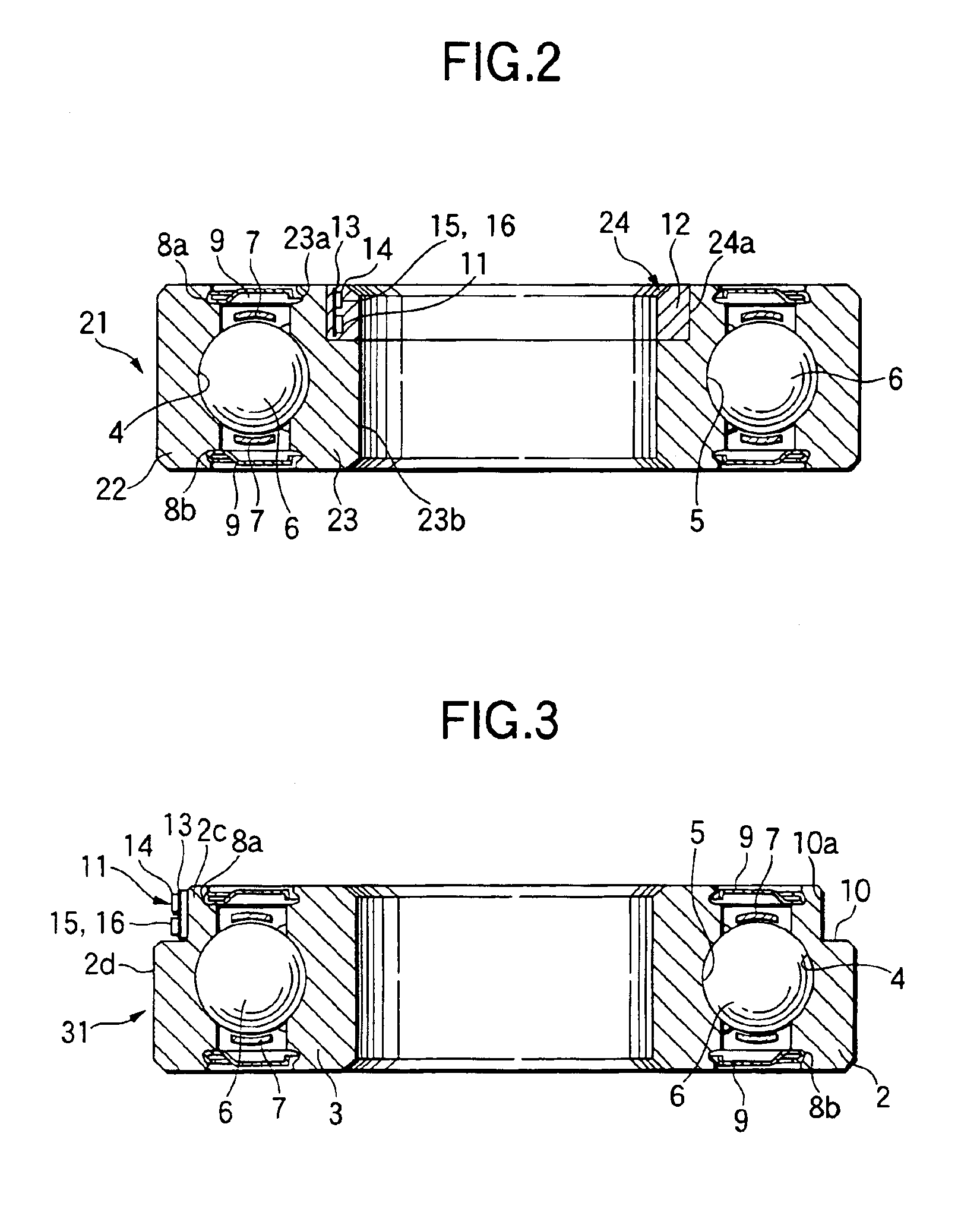

Rolling bearing unit

InactiveUS9109630B2Rolling contact bearingsBearing coolingRolling-element bearingMechanical engineering

Owner:JTEKT CORP

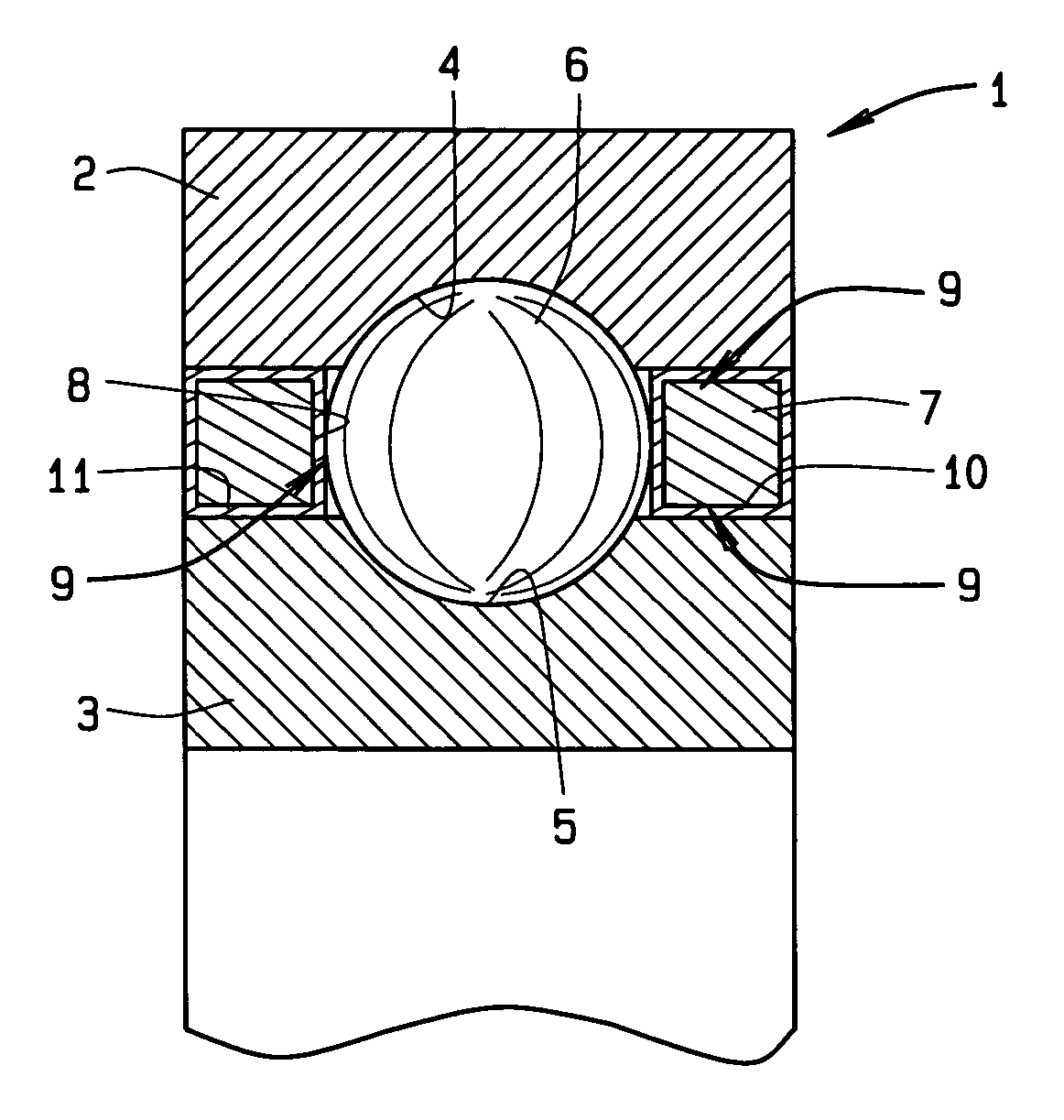

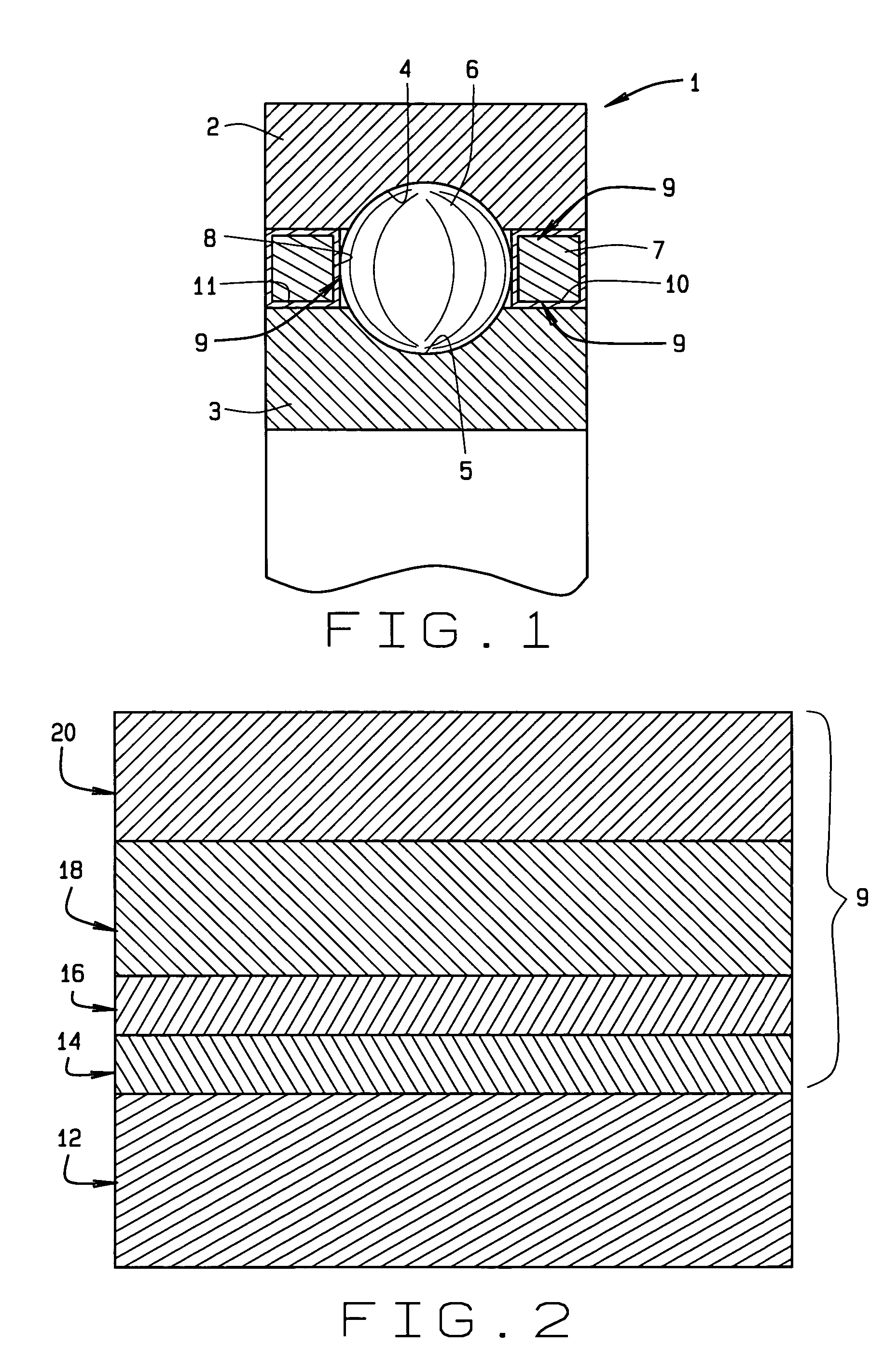

Rolling-contact bearing containing solid lubricant therein

ActiveUS7234873B2Improve air tightnessSmooth movementBearing componentsNeedle bearingsRolling-element bearingEngineering

A cage, rollers and solid lubricant are all formed integrally into a complete unitary molding with using difference in thermal expansion in a mold. Assembling the complete unitary molding into the race in the rolling-contact bearing is made easier. The complete unitary molding is made such that the rollers remain exposed partially at their rolling surfaces above the inside circular surface of the complete unitary molding while the solid lubricant on the outside circular surface of the complete unitary molding is squeezed out from between the rolling surfaces of the rollers and the inside circular surface of the outside mold upon molding operation, thereby getting the rolling surfaces of the rollers exposed partially. The mold is composed of an outside mold, an inside mold and an intermediate mold, which is made of a substance larger in thermal expansion than other substance for the outside and inside molds.

Owner:NIPPON THOMPSON

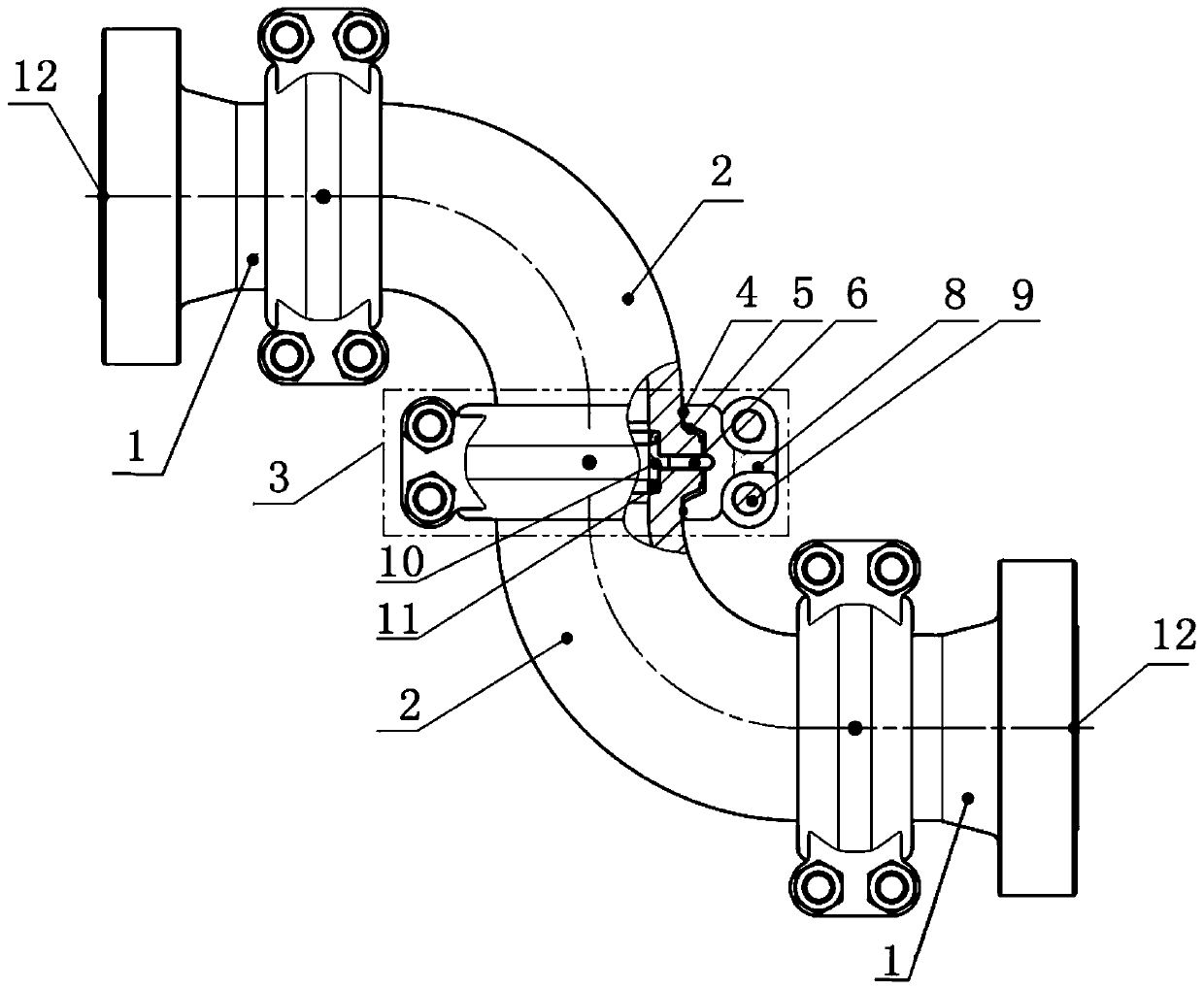

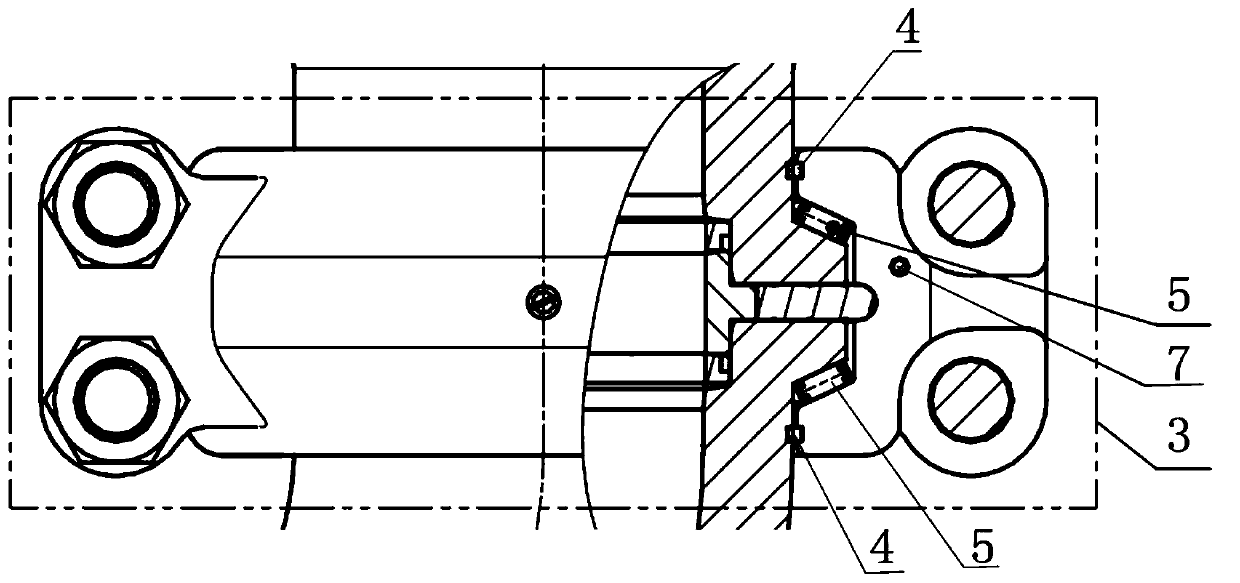

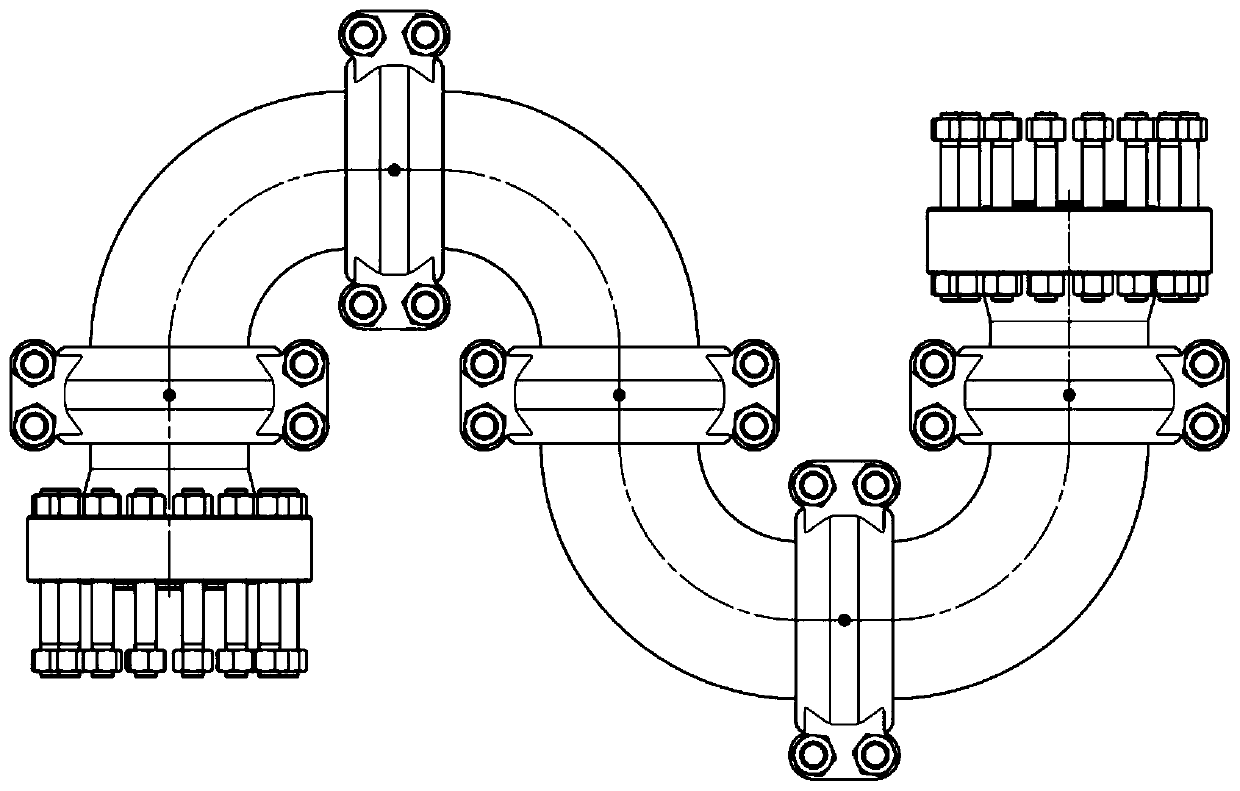

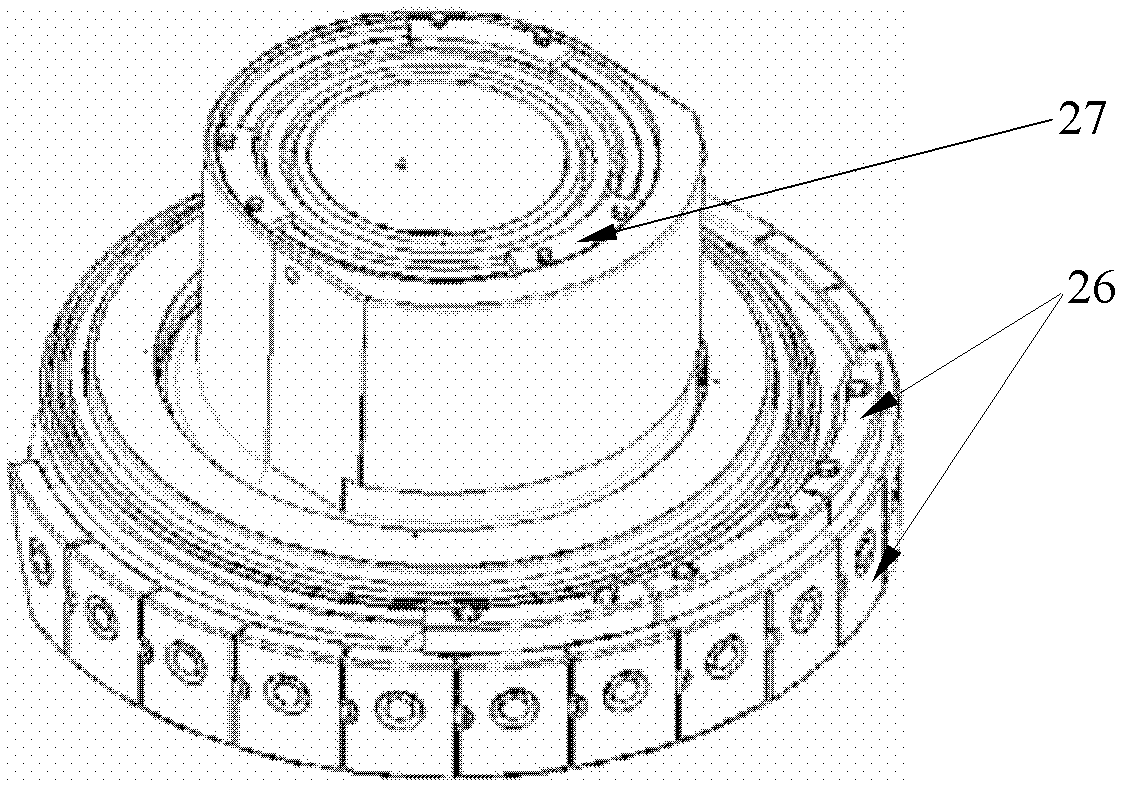

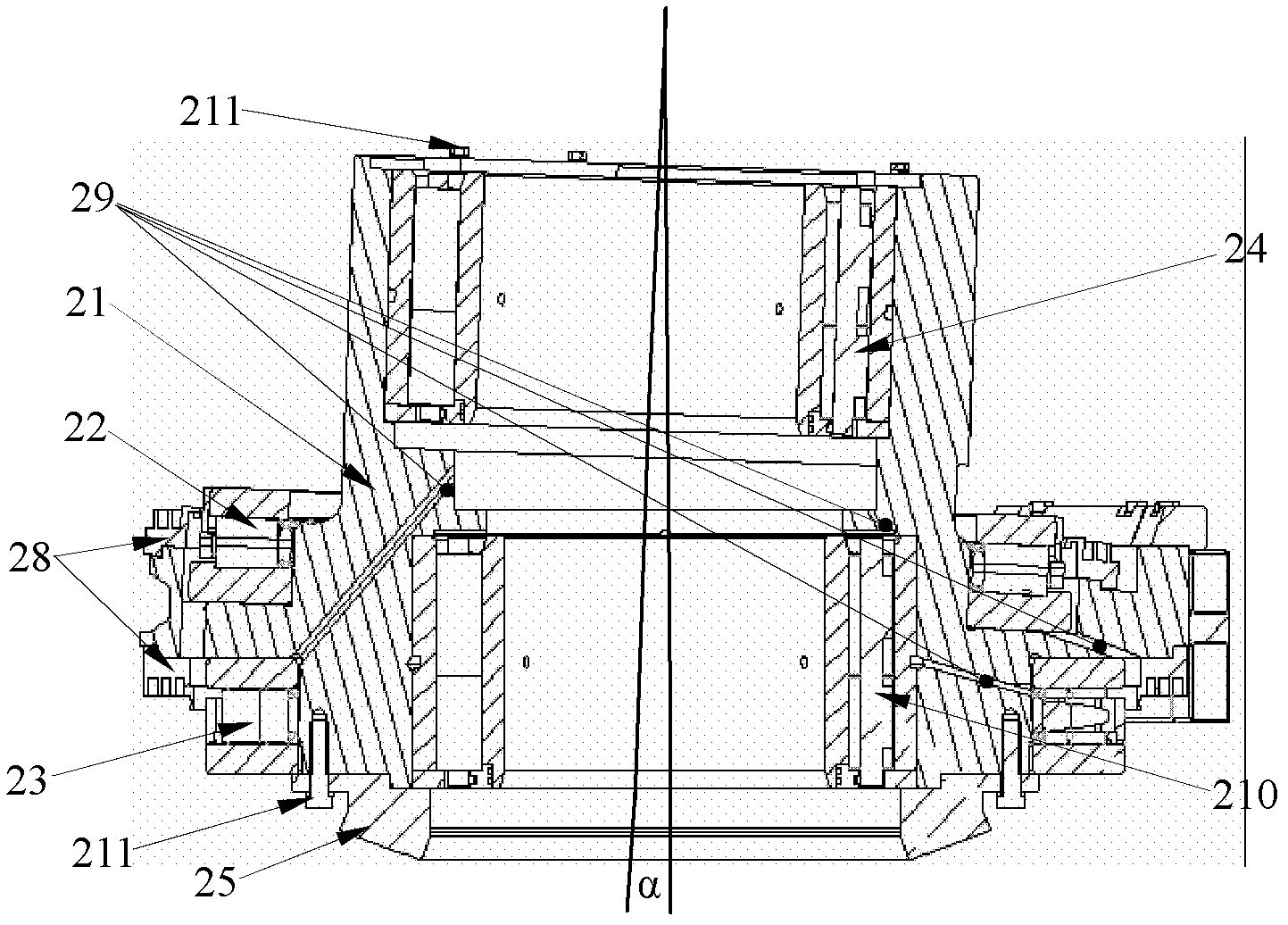

Large-sized high-pressure movable bend structure

PendingCN111594062ASmall structureVarious molding methodsDrilling rodsDrilling casingsSlider bearingRolling-element bearing

The invention discloses a large-sized high-pressure movable bend structure which comprises a connector, bends and hinging assemblies. The connector and the bend, and the bends are connected by the hinging assemblies. The connector is connected to upstream and downstream equipment. Each hinging assembly comprises a sealing mechanism, a rotating part and a hoop. The sealing mechanism is used for hermetically connecting the connector and the bend, and the bends. The hoop is used for connecting and fixing the connector and the bend, and the bends. The hoop and the connector or the hoop and the bend are connected by the rotating part. The rotating part is a rolling bearing or a sliding bearing. The large-sized high pressure movable bend structure has the beneficial effects that the structure islarger in diameter, flexible to connect, small in size, light in weight and diversified in forming mode, meets the operation demand of high pressure and large displacement of shale gas, lowers the input cost of operation equipment greatly, optimizes the site layout and is connected to the upstream and downstream equipment flexibly.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

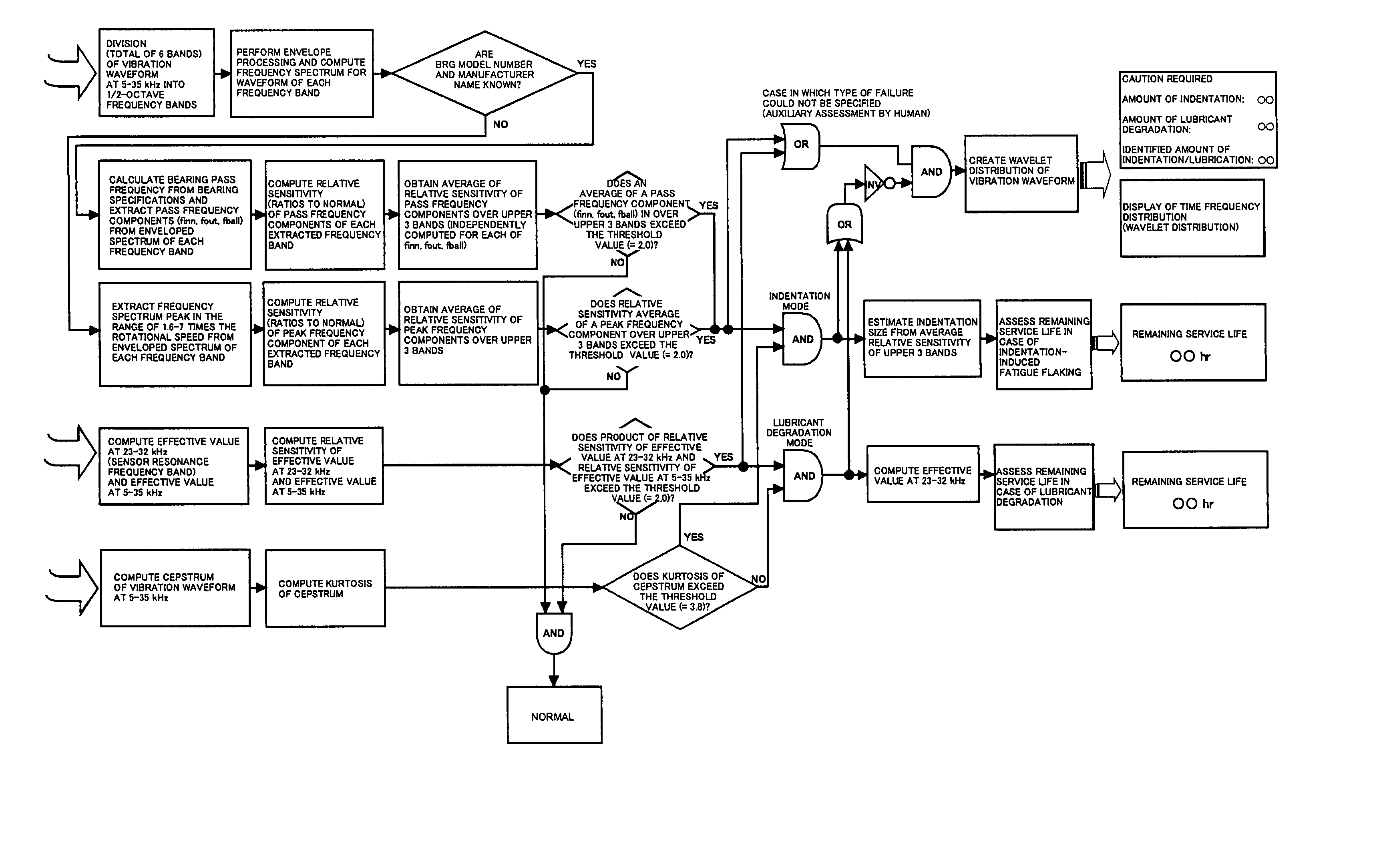

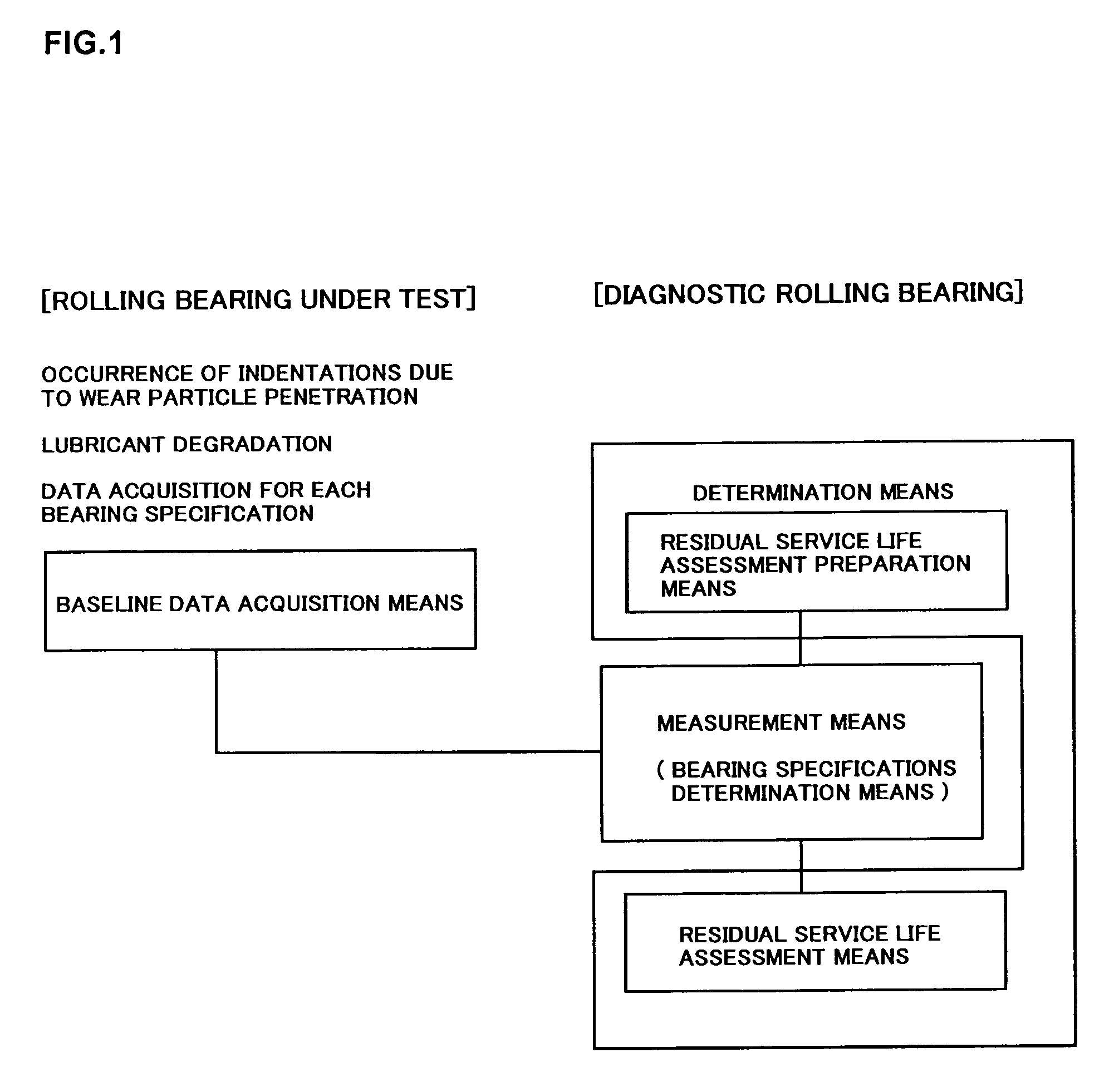

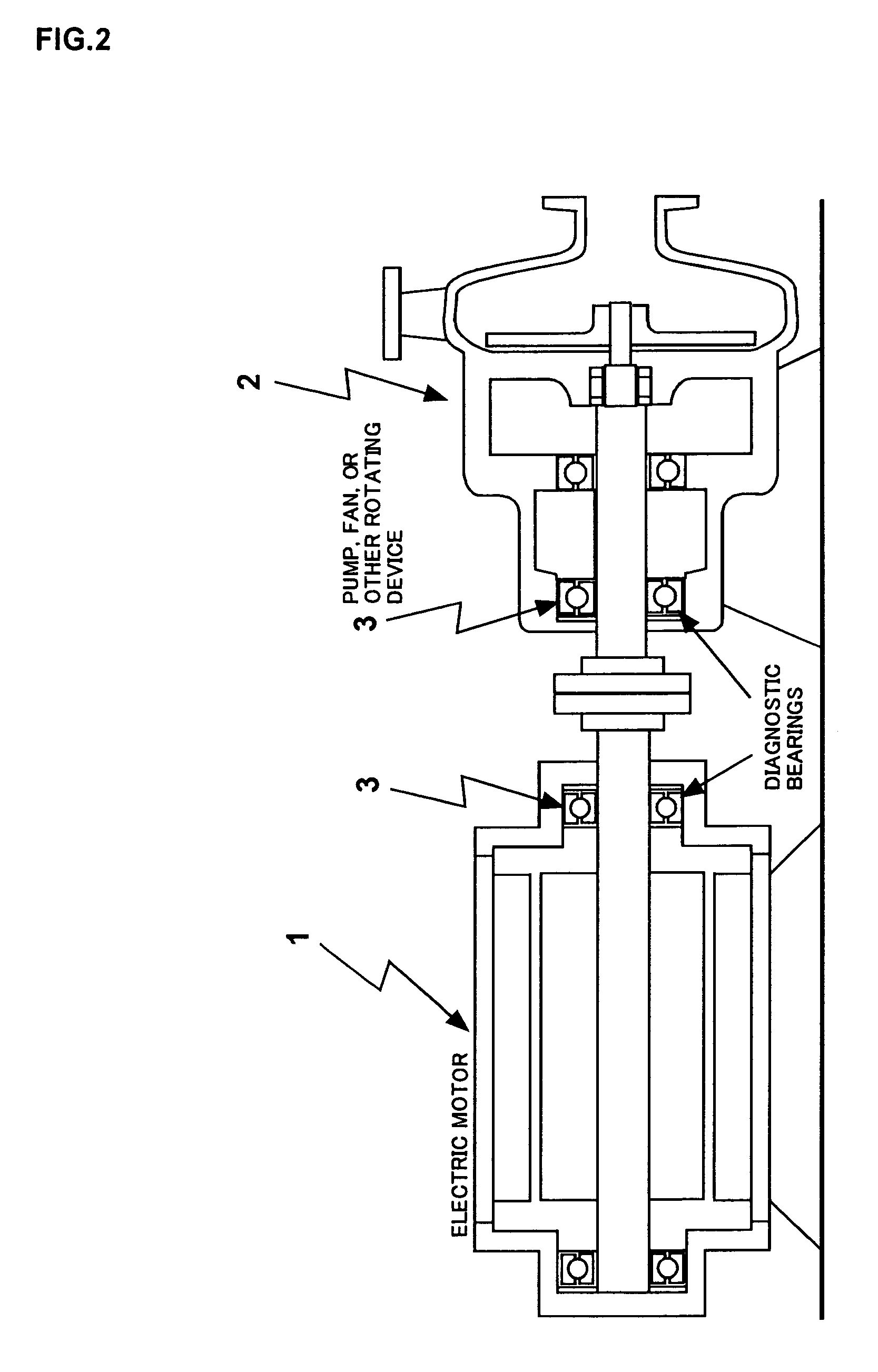

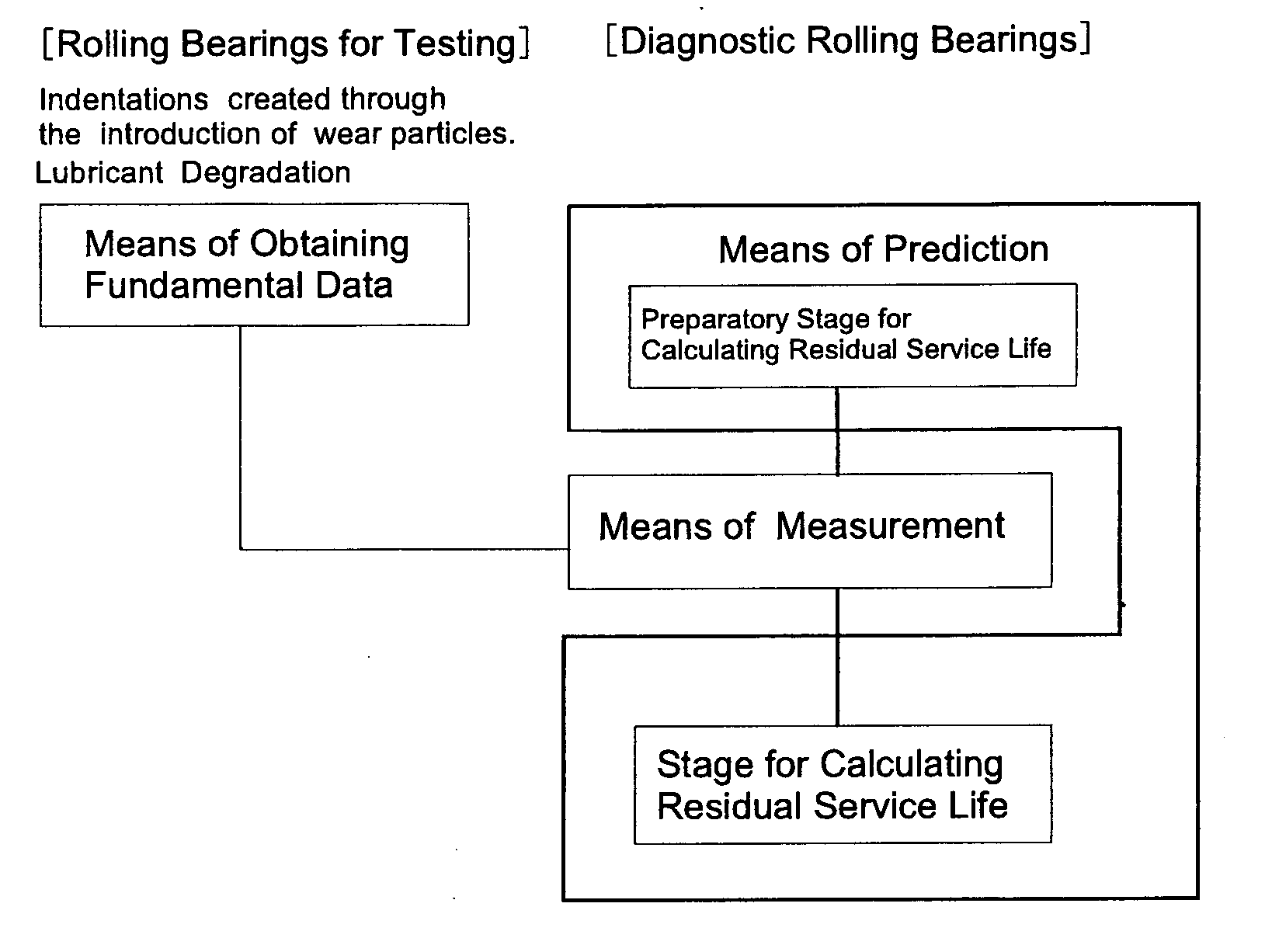

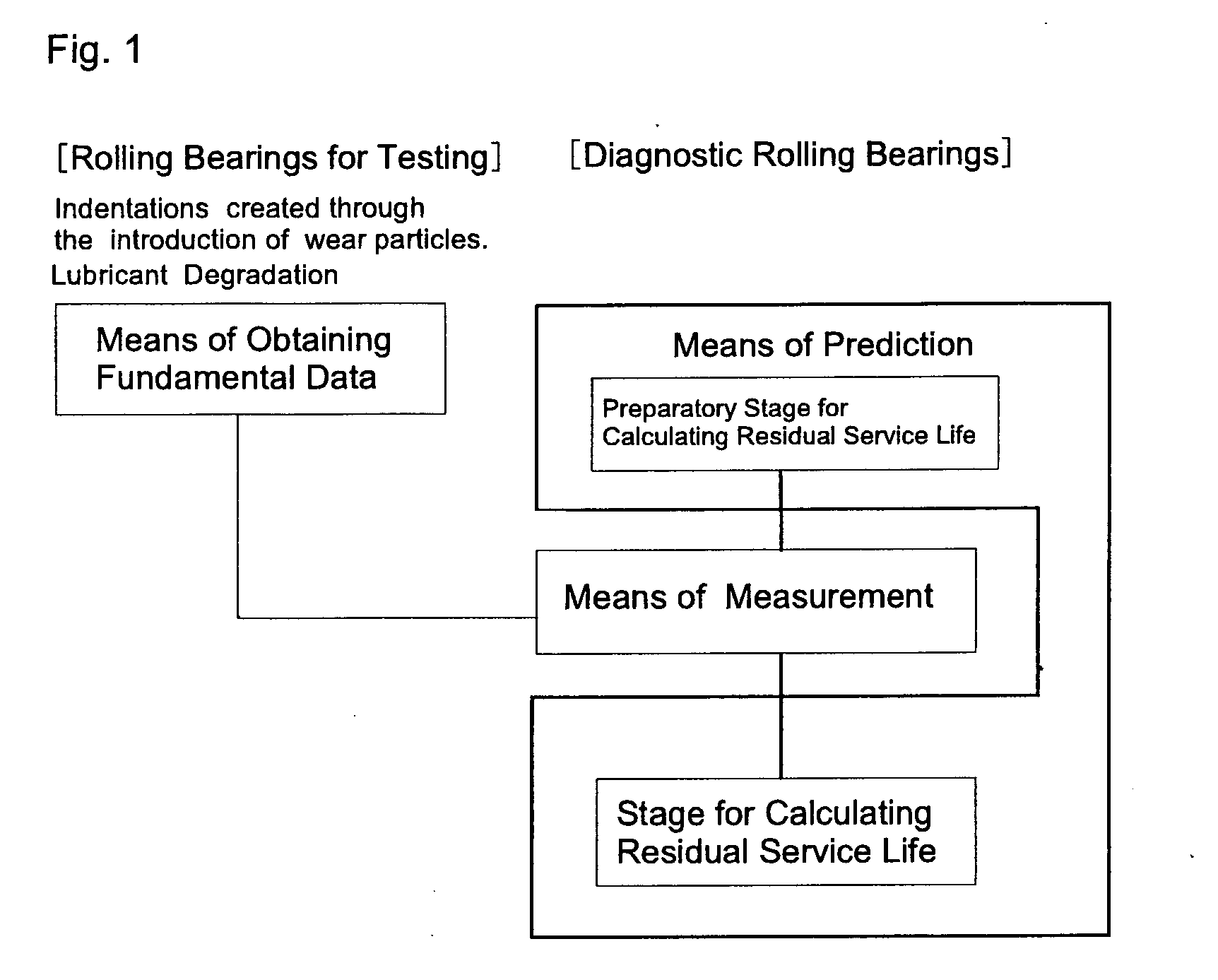

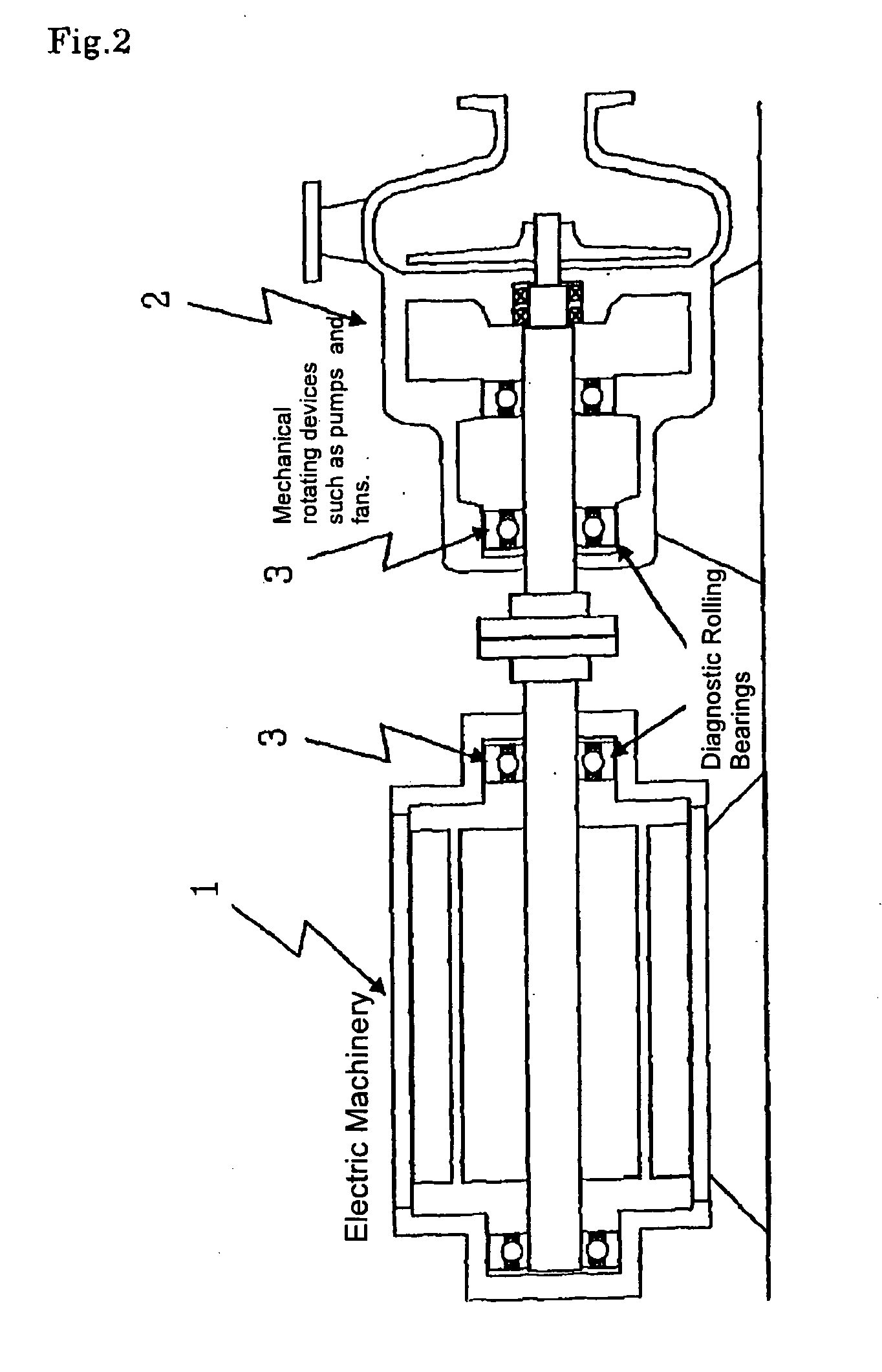

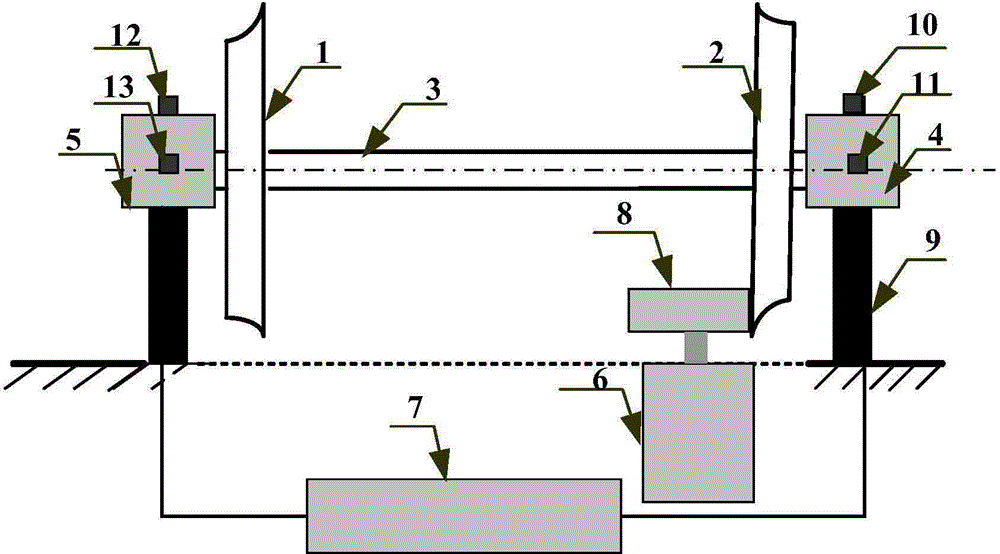

Method And Device For Assessing Residual Service Life Of Rolling Bearing

InactiveUS20070277613A1Improve accuracyVibration measurement in solidsMachine part testingBaseline dataAccelerometer

Degradation of the lubricant due to contamination of the lubricant with wear particles or moisture, which greatly affects the service life of rolling bearings, can be detected in a cost-effective manner through the use of a resonance frequency band signal or high-frequency signal of an accelerometer, and the service life of a rolling bearing can be estimated with high precision at an early stage on the basis of the detected state of the wear particles and lubricant. Provided is a method comprising baseline data acquisition means for obtaining vibration signals by using an accelerometer 4 and using a testing device to acquire resonance frequency band signals detectable at the highest sensitivity, for each specification such as model number, manufacturer name, and other specifications for a rolling bearing 3 as pertains to the relationship between the state of wear particle penetration in a rolling bearing 3 and the vibration / bearing service life, and to lubricant degradation and vibration / bearing service life; measurement means whereby an accelerometer 4 is used to obtain vibration signals for the rolling bearing 3 whose remaining service life is being assessed and which resides on a fan, a pump, or another rotating device 1, 2, for the purpose of measuring resonance frequency band signals detectable at the highest sensitivity; and determination means for estimating the state of wear particle penetration and the state of lubricant degradation of the diagnostic rolling bearing 3, and computing the remaining service life of the diagnostic rolling bearing 3 by using measurement values obtained by the measurement means, determination results of the bearing specification determination means, and data obtained by the baseline data acquisition means.

Owner:THE CHUGOKU ELECTRIC POWER CO INC +1

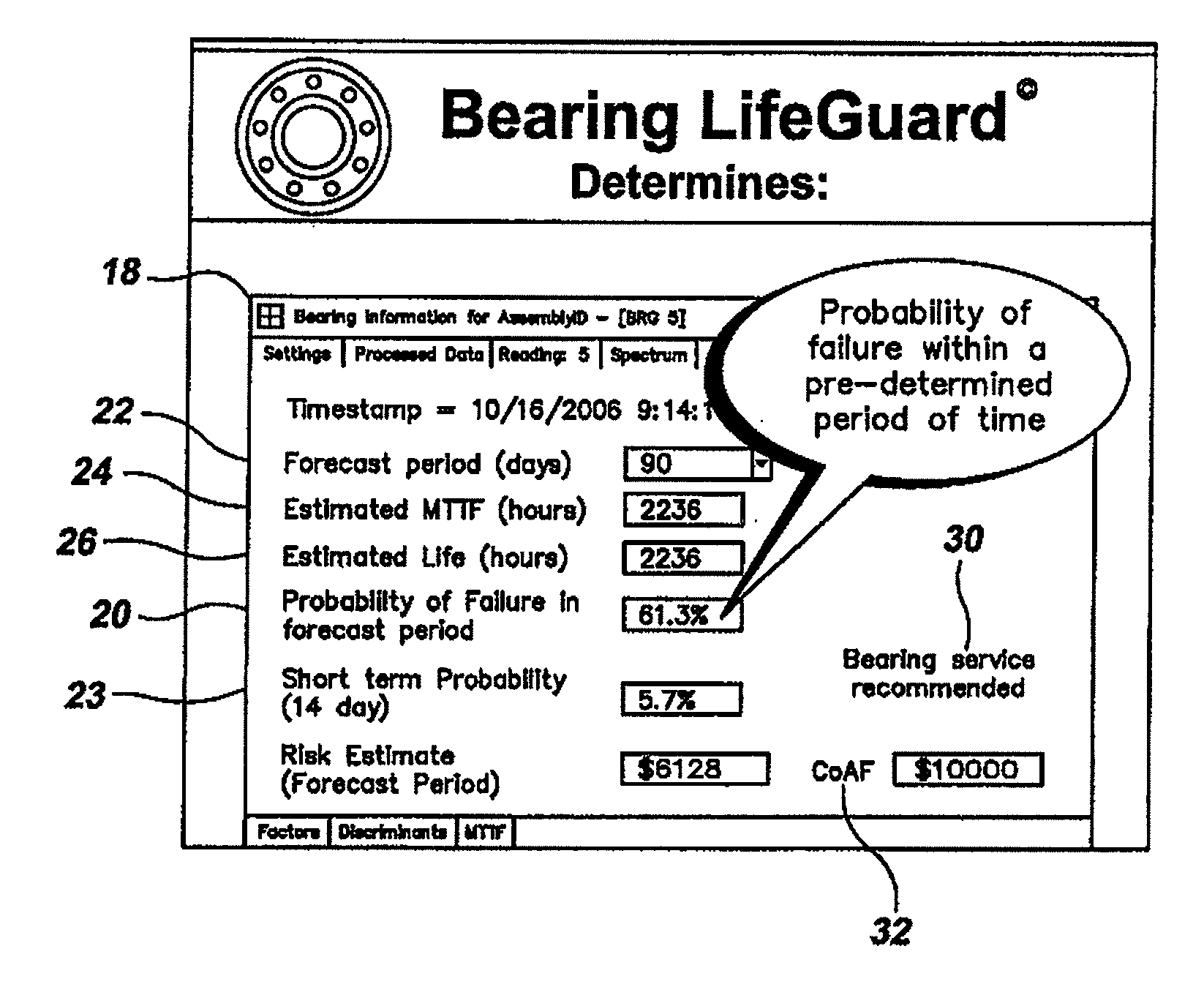

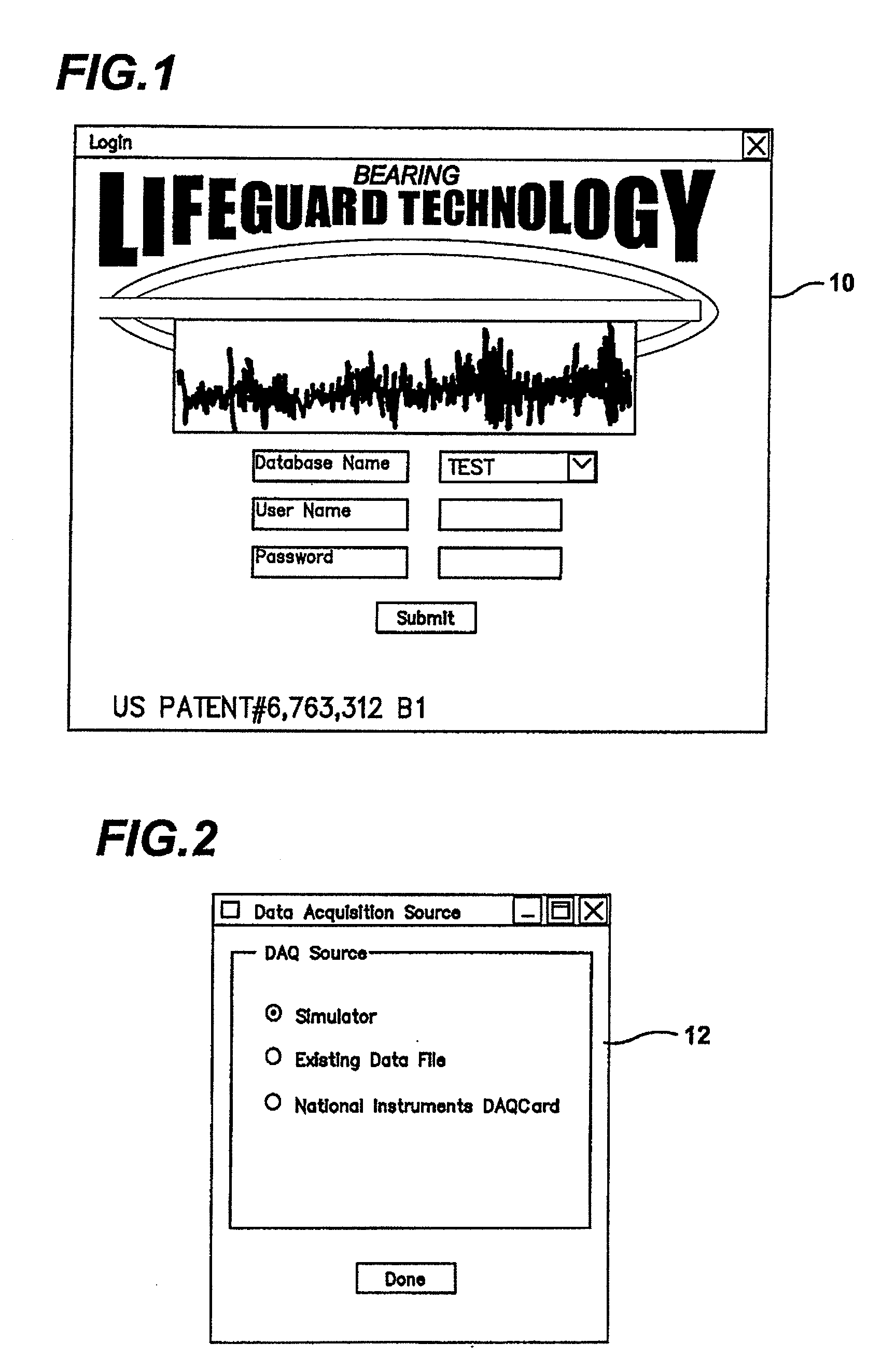

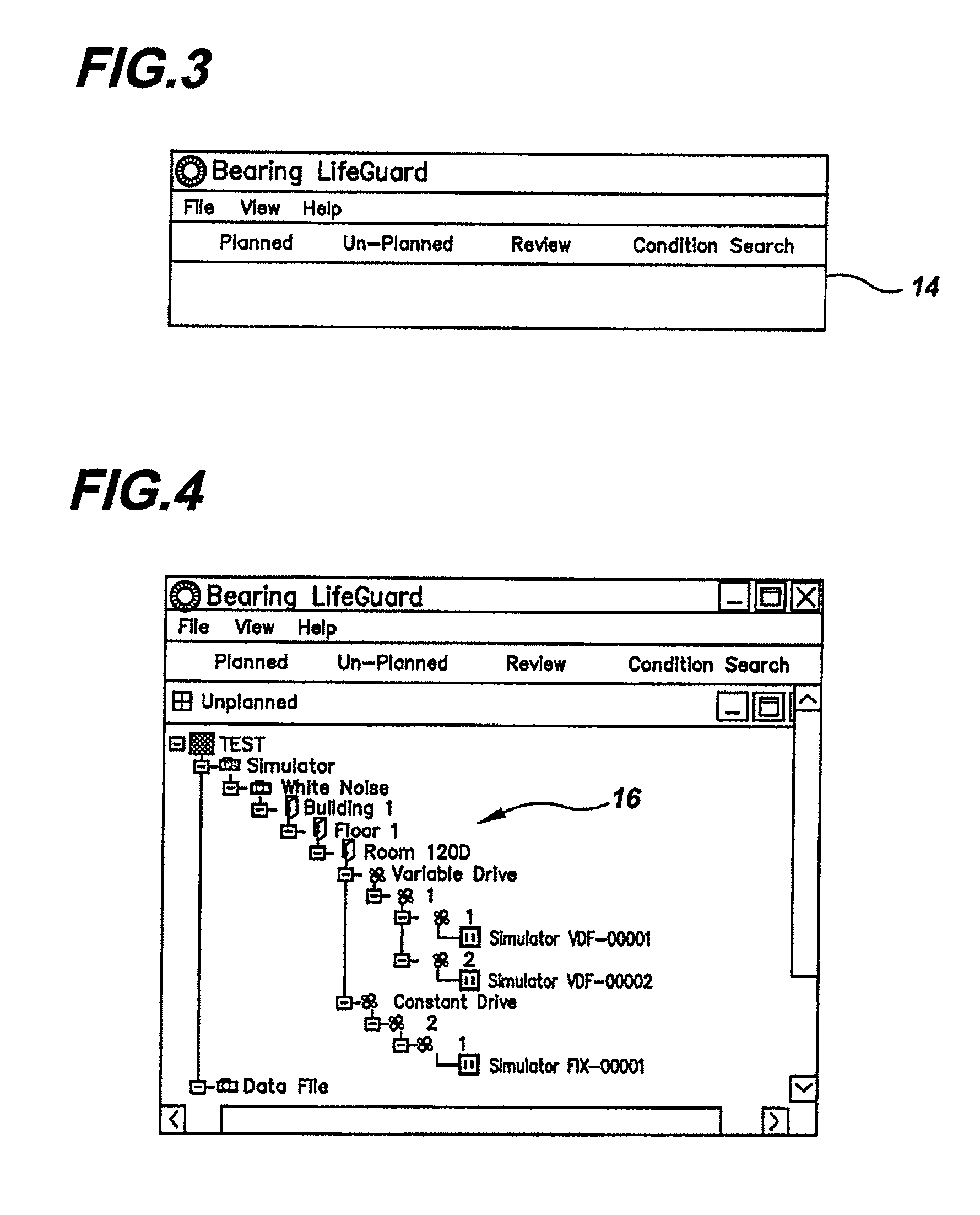

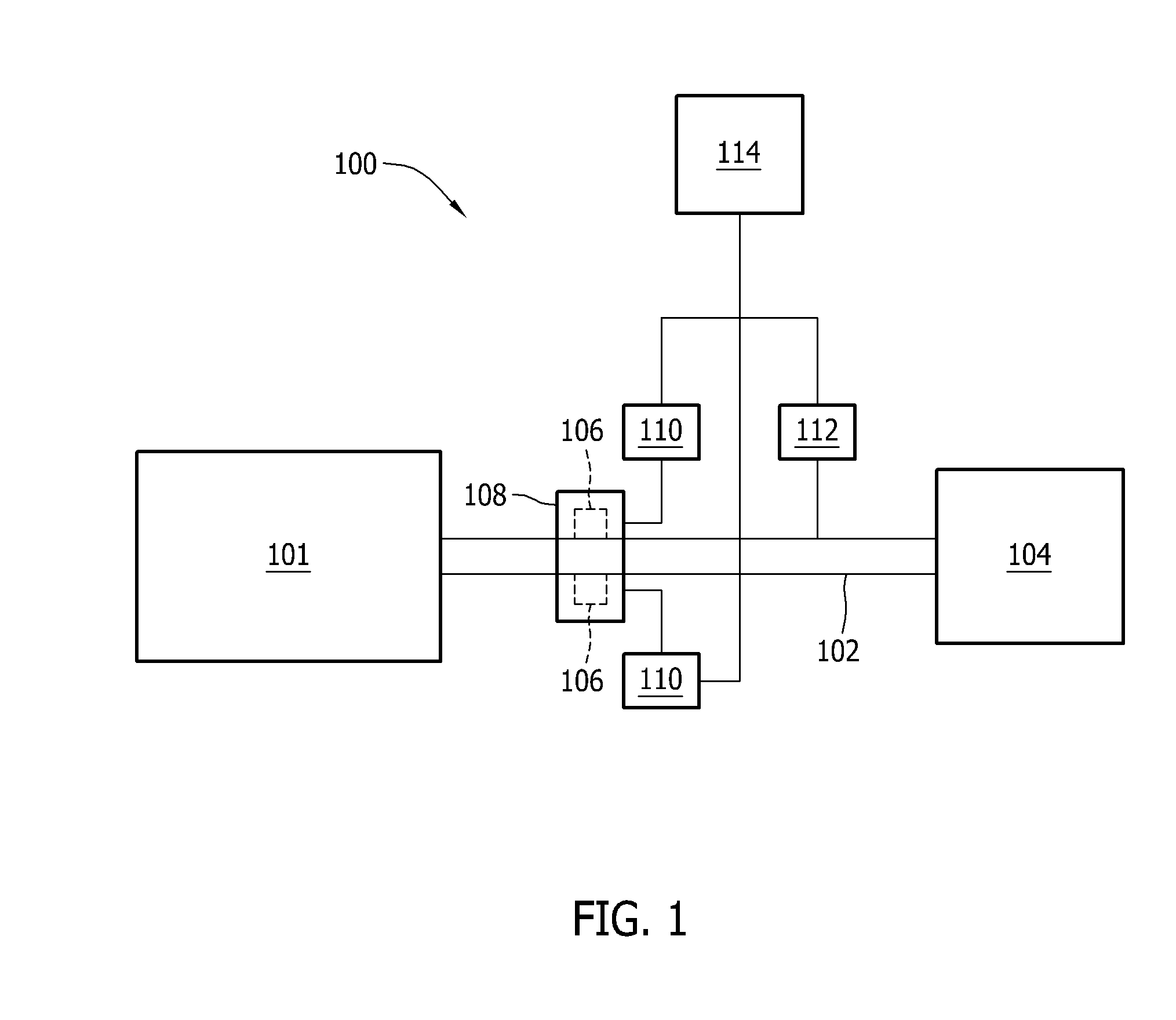

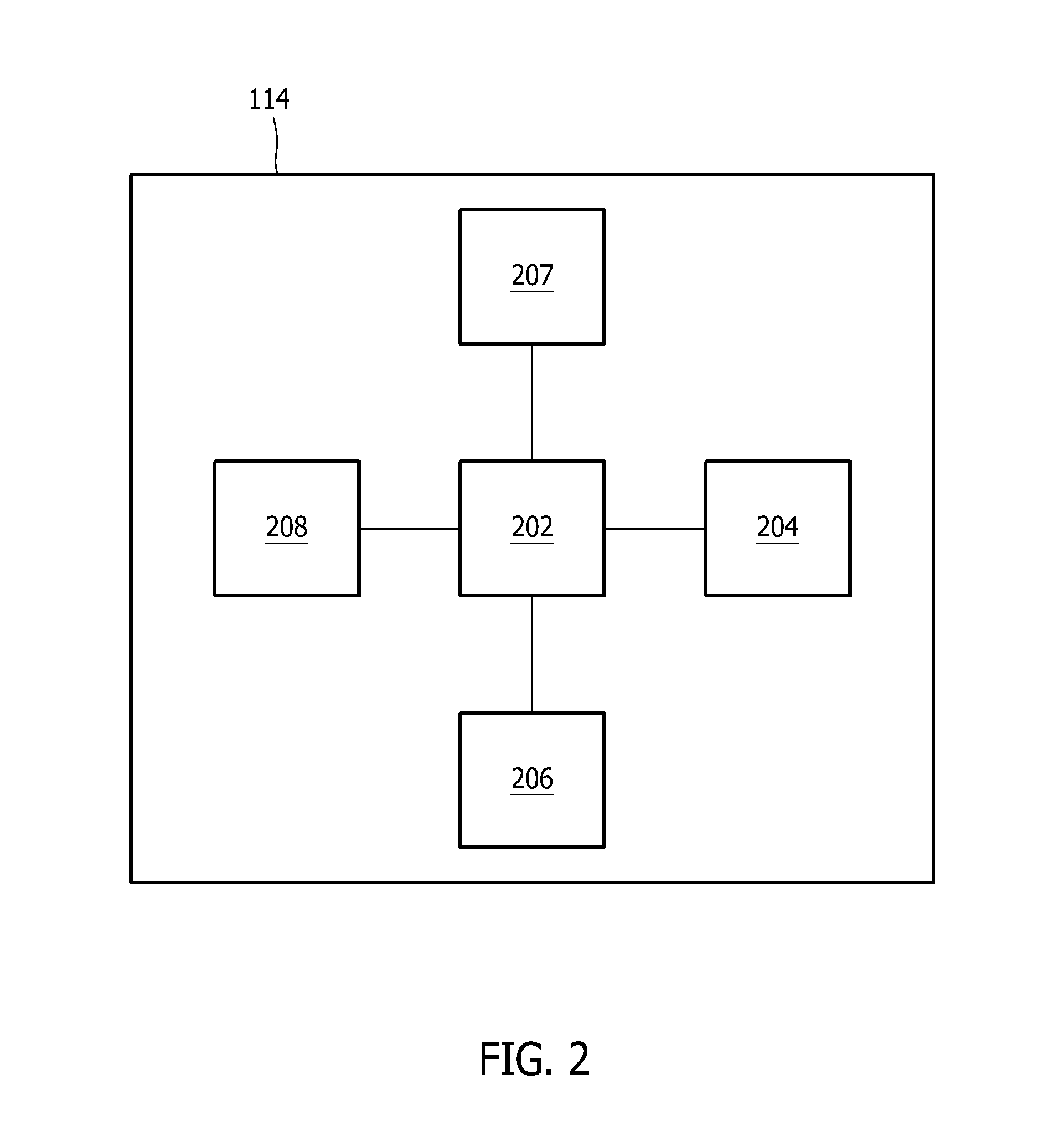

Rotating bearing analysis and monitoring system

A method of analyzing vibrations of a rolling element bearing installed in a rotating machine includes accessing vibration data corresponding to the bearing to be analyzed, determining a degraded condition factor BD for the bearing, selecting an expected designer-determined mean-time-to-failure MTTF of the bearing operating under a design load in the operating environment of the rotating machine, selecting a forecast time period, calculating a reduced mean-time-to-failure RMTTF of the bearing using the expected designer-determined mean-time-to-failure MTTF and the degraded condition factor BD, calculating a probability of failure of the bearing in the forecast time period using the reduced mean time to failure RMTTF, accessing cost data corresponding to a cost of failure of the bearing in the rotating machine, calculating a financial risk from the calculated probability of failure in the forecast time period and the cost data, and displaying the financial risk for the selected time period.

Owner:DYNAMIC MEASUREMENT CONSULTANTS

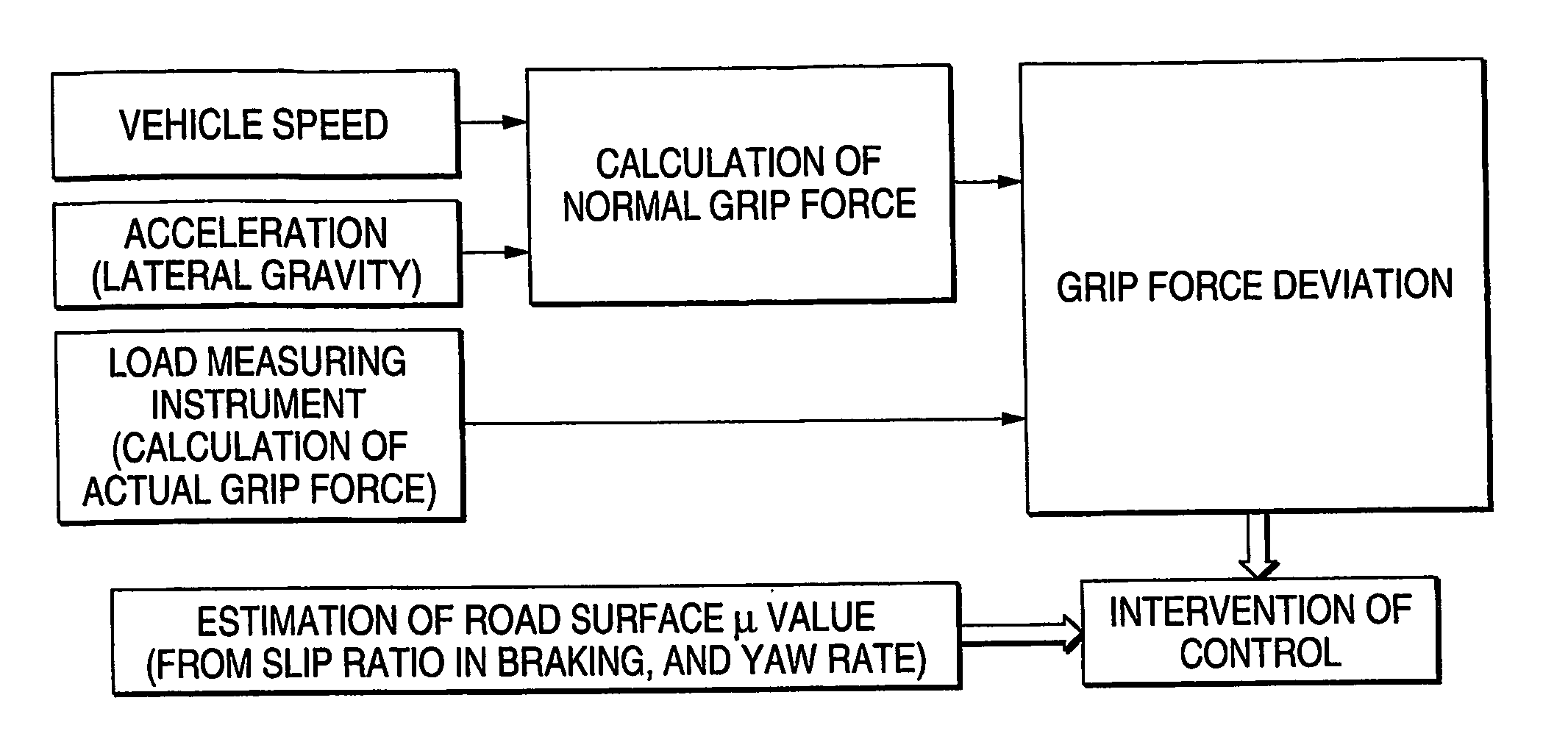

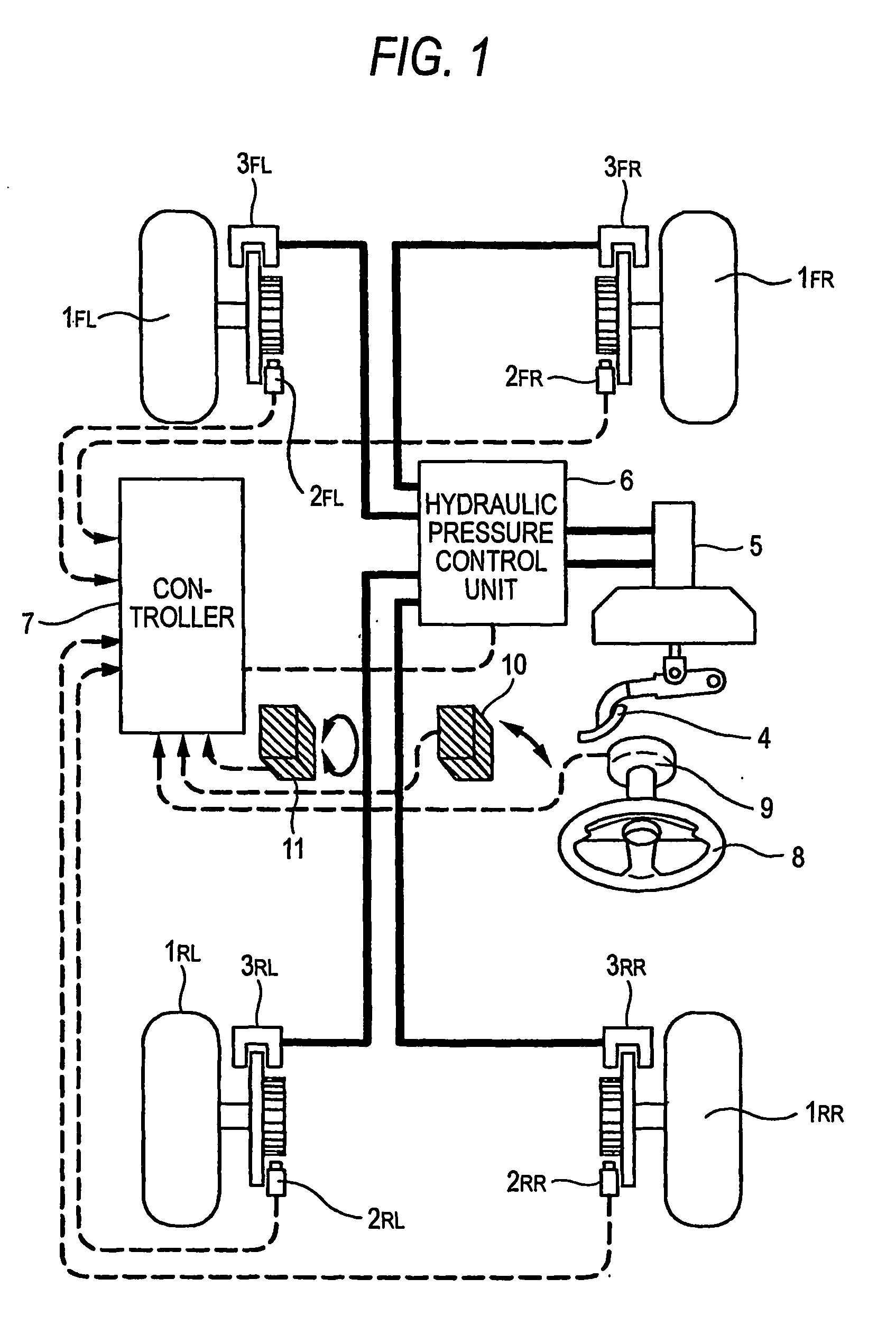

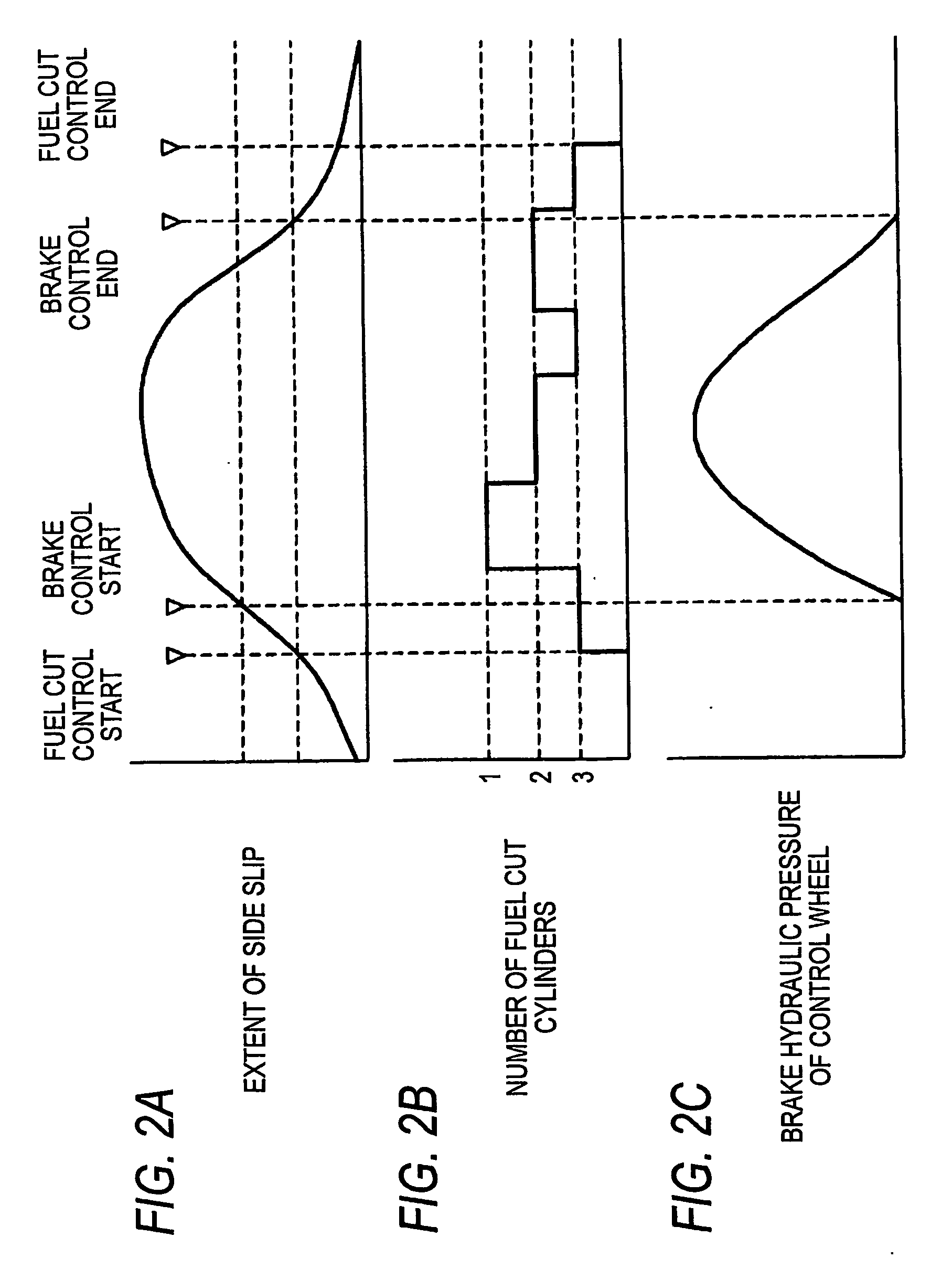

Stability control apparatus and load measuring instrument for wheel supporting rolling bearing unit

ActiveUS20060259225A1Enhancing responsibility of controlImprove running stabilityRotary bearingsBearing assemblyGrip forceMeasuring instrument

A stability control apparatus, includes: a grip detector that changes an output based on a grip force applied in a direction hindering a slippage of a wheel, acting on a contact face between the wheel supported by a wheel supporting rolling bearing unit and the road surface, the wheel supporting rolling bearing unit for supporting freely rotatably the wheel to a vehicle body; and a controller that performs a control for keeping a running stability of the vehicle in response to an input of a detection signal of the grip detector.

Owner:NSK LTD

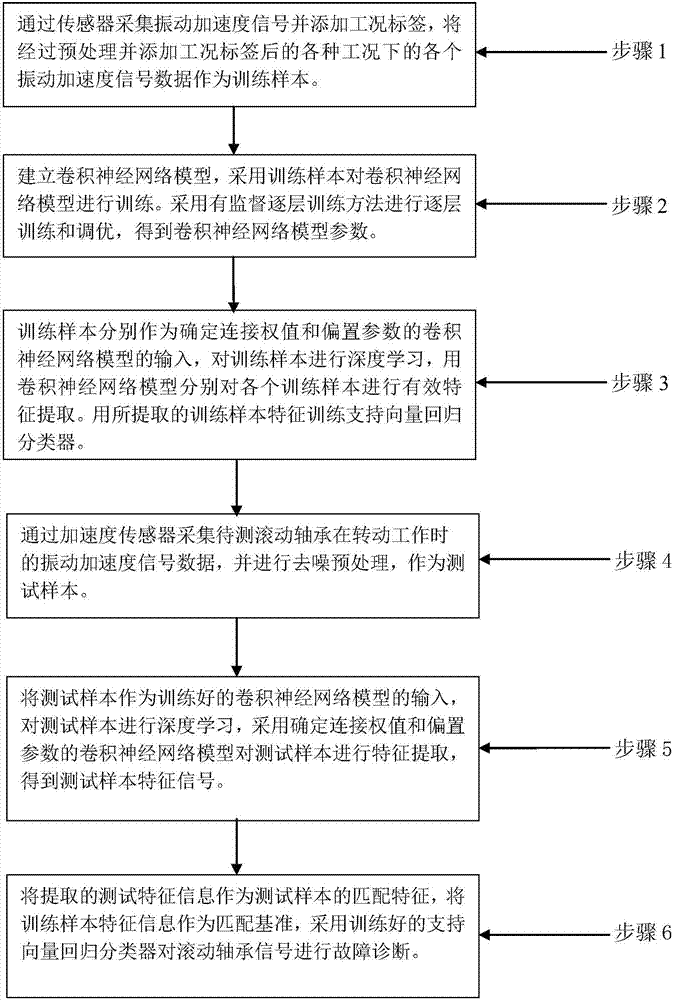

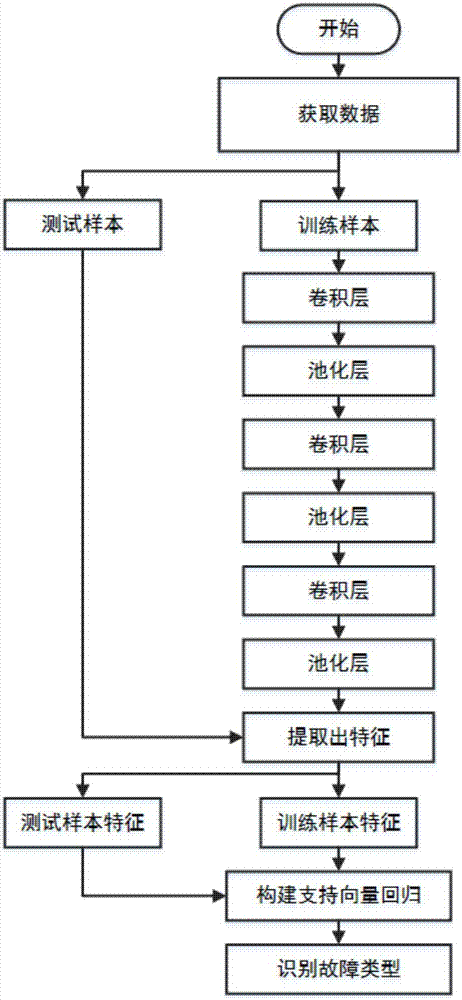

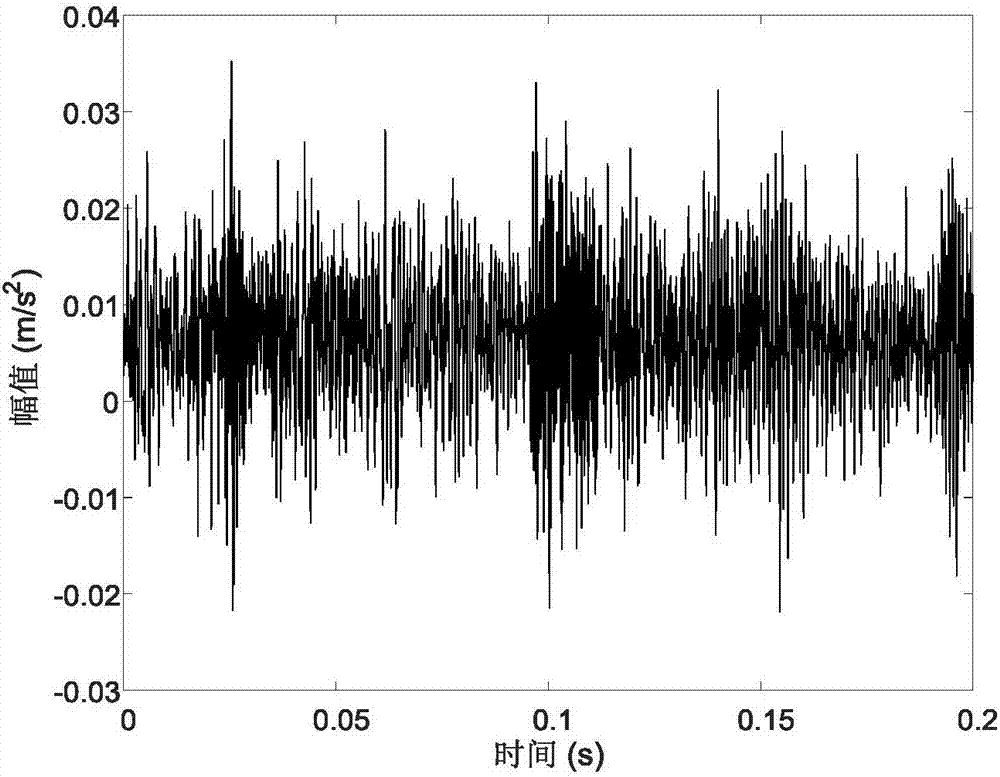

Rolling bearing fault diagnosis method

InactiveCN106874957AGet rid of dependenceSave labor timeMachine bearings testingCharacter and pattern recognitionAviationChemical industry

The invention relates to a rolling bearing fault diagnosis method. The method uses a learning algorithm of a CNN (Convolutional Neural Network) theory to complete a feature extraction task needed by fault diagnosis, and does not rely one manual selection, intrinsic features of input data are extracted automatically from simple to complex and from low-level to high-level, and abundant information hidden in known data can be dug out automatically; and a support vector regression method is used to identity a test sample in a classifying manner, support vector regression with a high generalization capability can be used to identity an unknown new sample in higher precision, and the disadvantage that a default classifier of deep learning tends to be low in the generalization capability can be overcome when support vector regression serves as a classifier to identify samples in the classified manner. The rolling bearing fault diagnosis accuracy and validity can be improved, a new effective approach is provided for solving problems in rolling bearing fault diagnosis, and the method of the invention can be widely applied to fault analysis of complex mechanical systems in the fields of chemical industry, metallurgy, electric power, aviation and the like.

Owner:SUZHOU UNIV

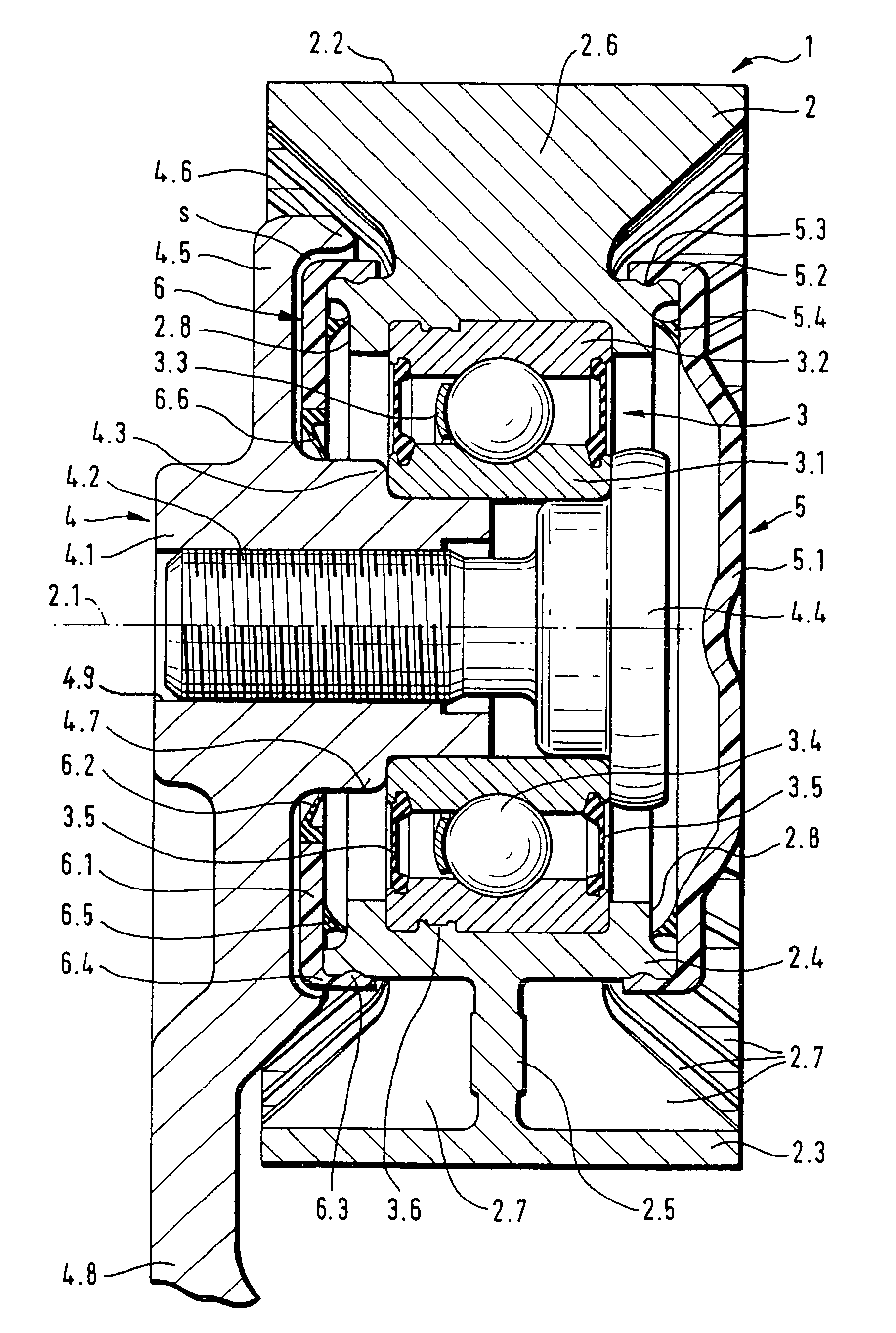

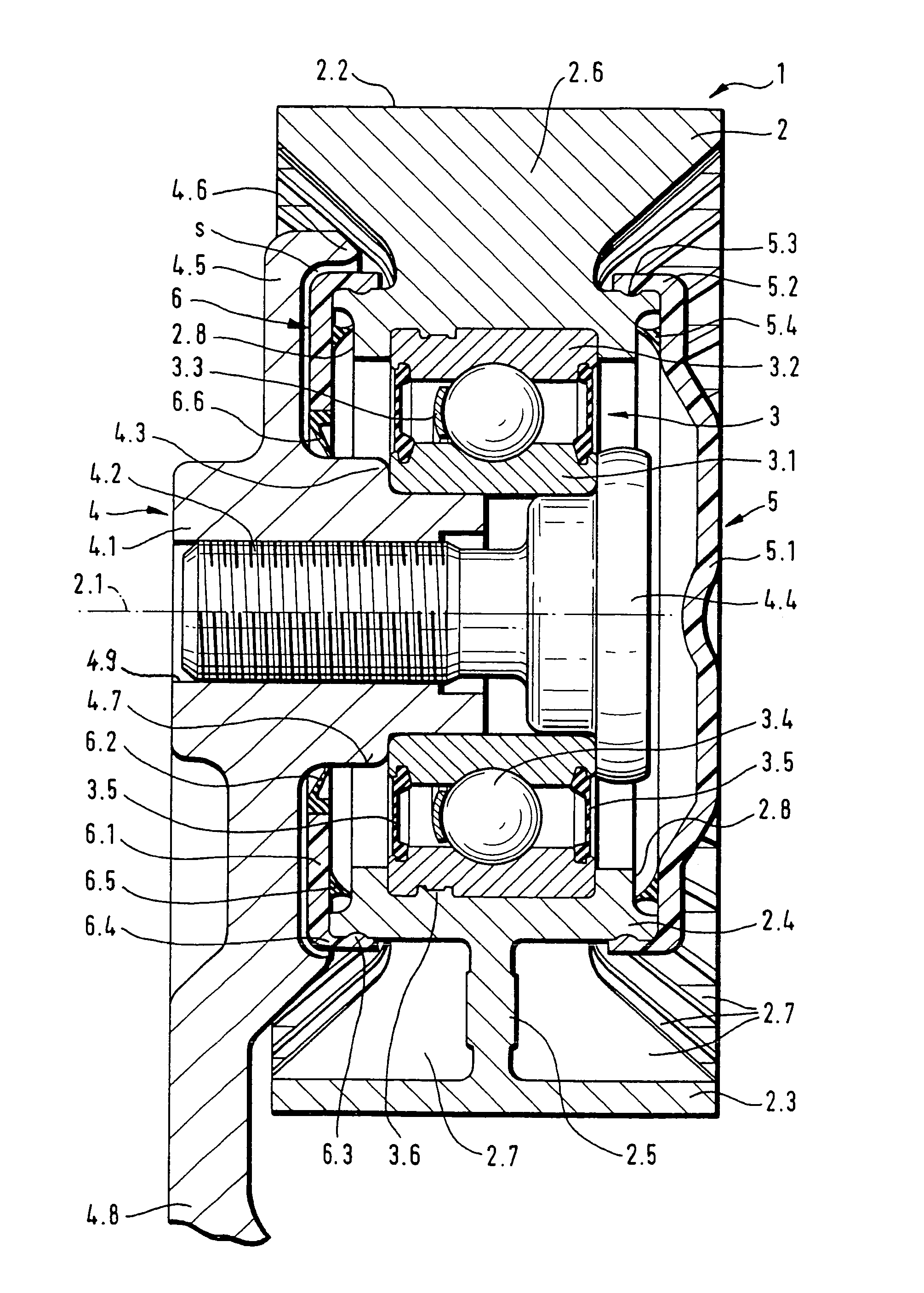

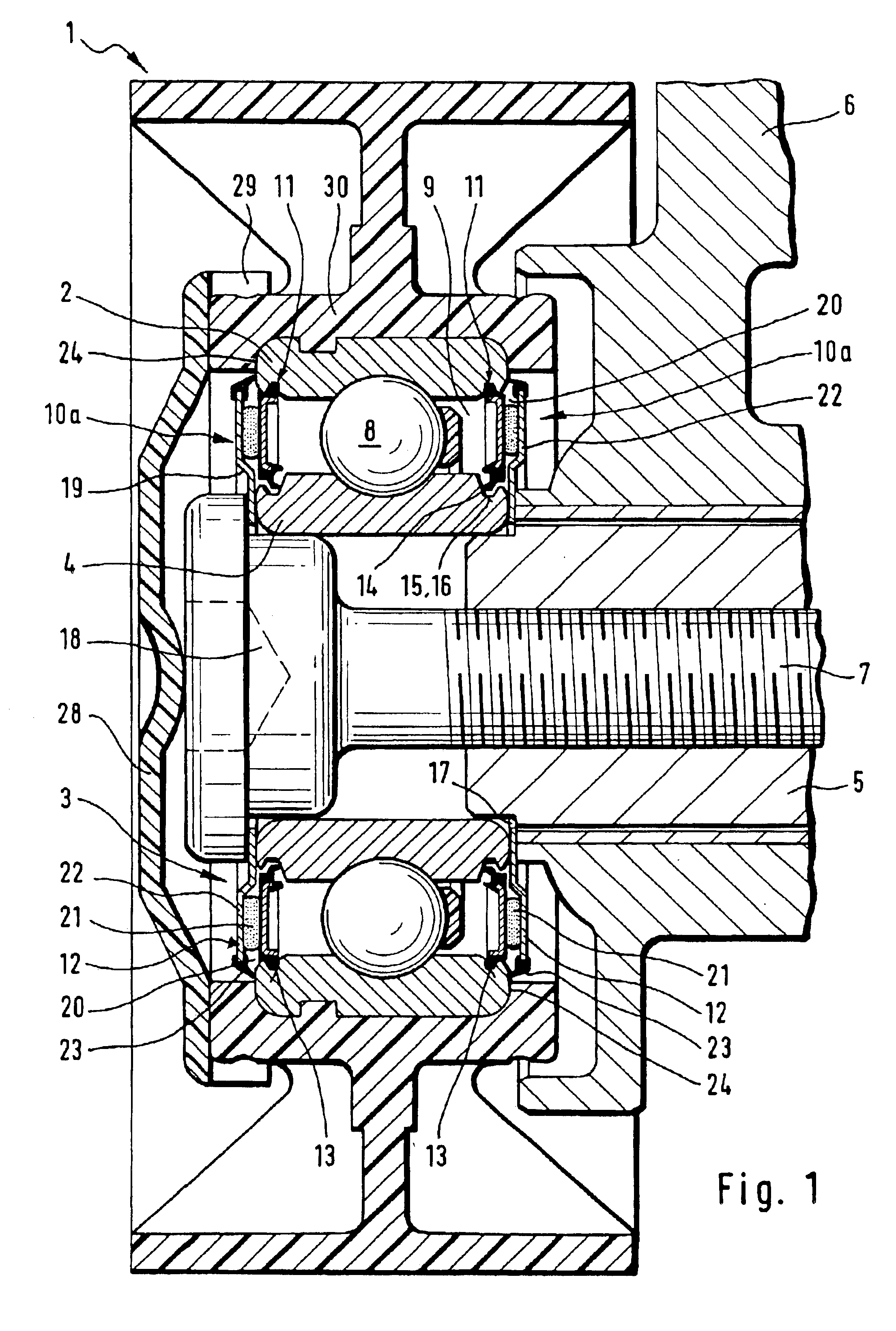

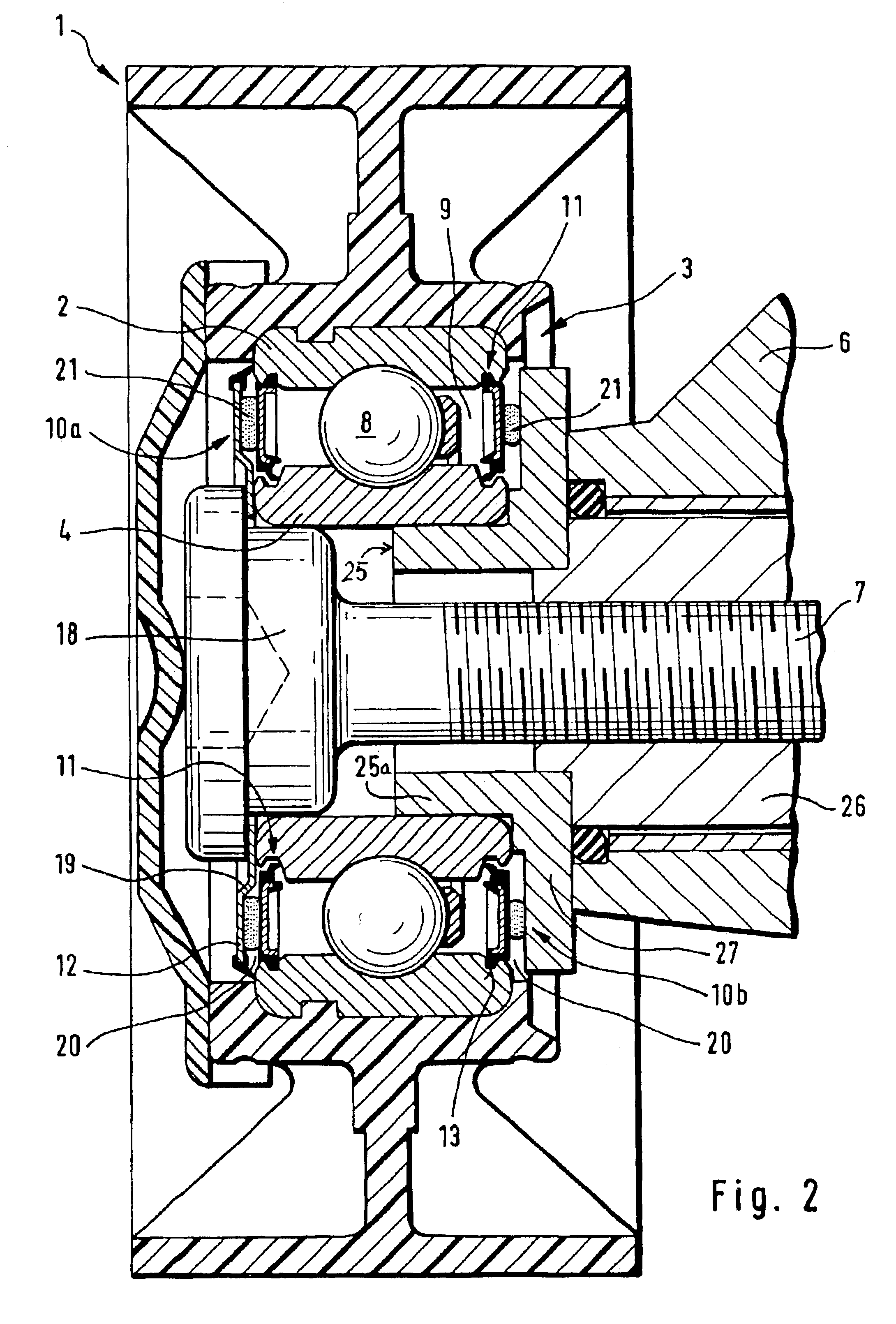

Tensioning or deflection pulley for a belt drive

InactiveUS7011593B2Easy to installFirmly connectedGearingBall bearingsRolling-element bearingEngineering

A tensioning or deflection pulley for a belt drive includes a carrier and a track roller comprised of an inner ring, an outer ring, and a connecting assembly, including a wheel disk extending between the inner and outer rings, and a rib assembly disposed in both sides of the disk in circumferential spaced-apart relationship, for interconnecting the inner and outer rings. The track roller is supported on the carrier by a sealed rolling-contact bearing via a fastening screw. A first sealing element is connected to the track roller on a carrier-distal side, and a second cap-shaped sealing element is disposed between the carrier and the track roller and detachably secured to the inner ring of the track roller to thereby seal the track roller on both sides.

Owner:INA SCHAEFFLER KG

Rolling bearing device and ring with sensor for the rolling bearing device

InactiveUS6948856B2Minimize formationGood adhesionBearing assemblyBall bearingsRolling-element bearingElectrical and Electronics engineering

Owner:NSK LTD

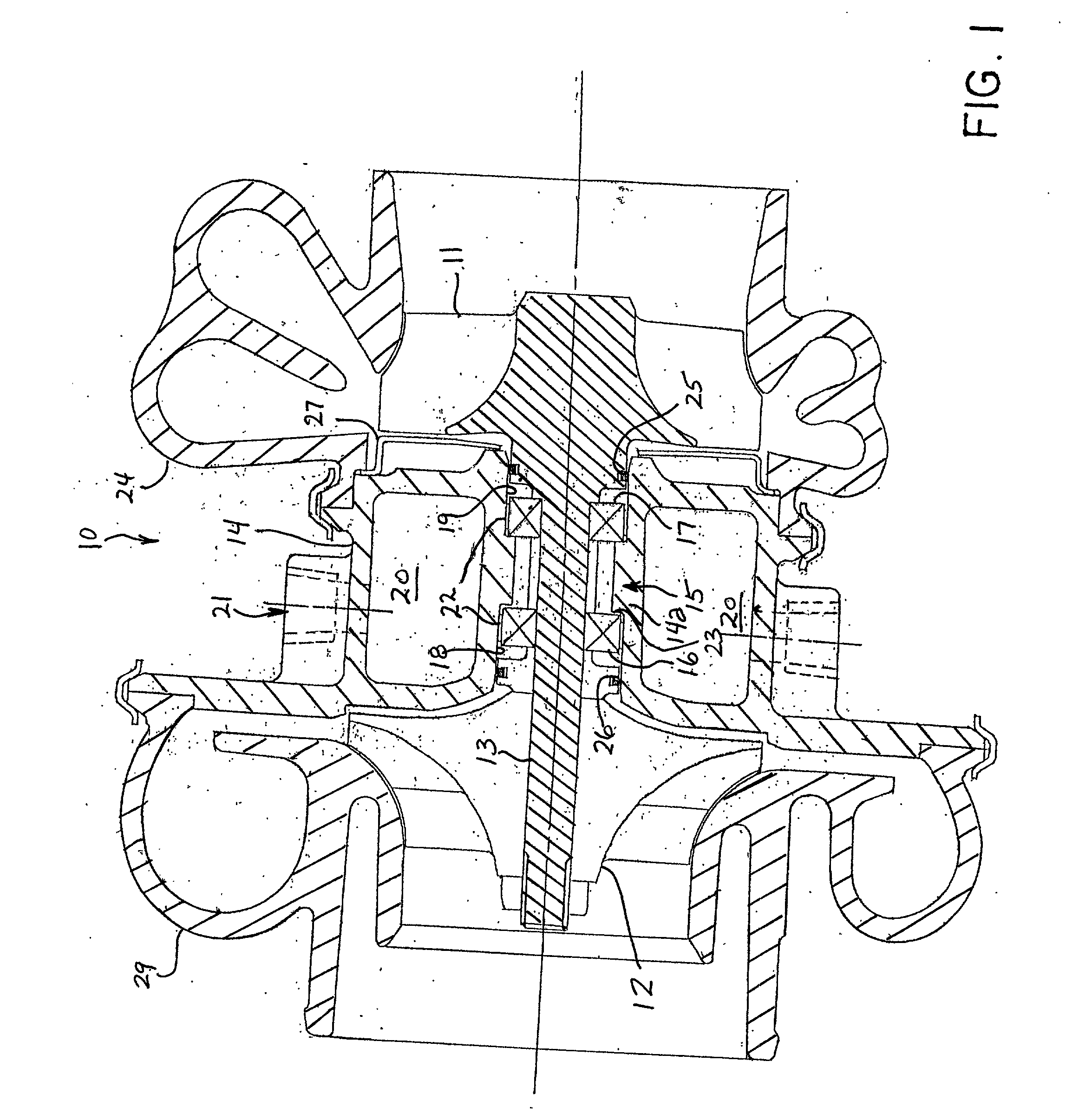

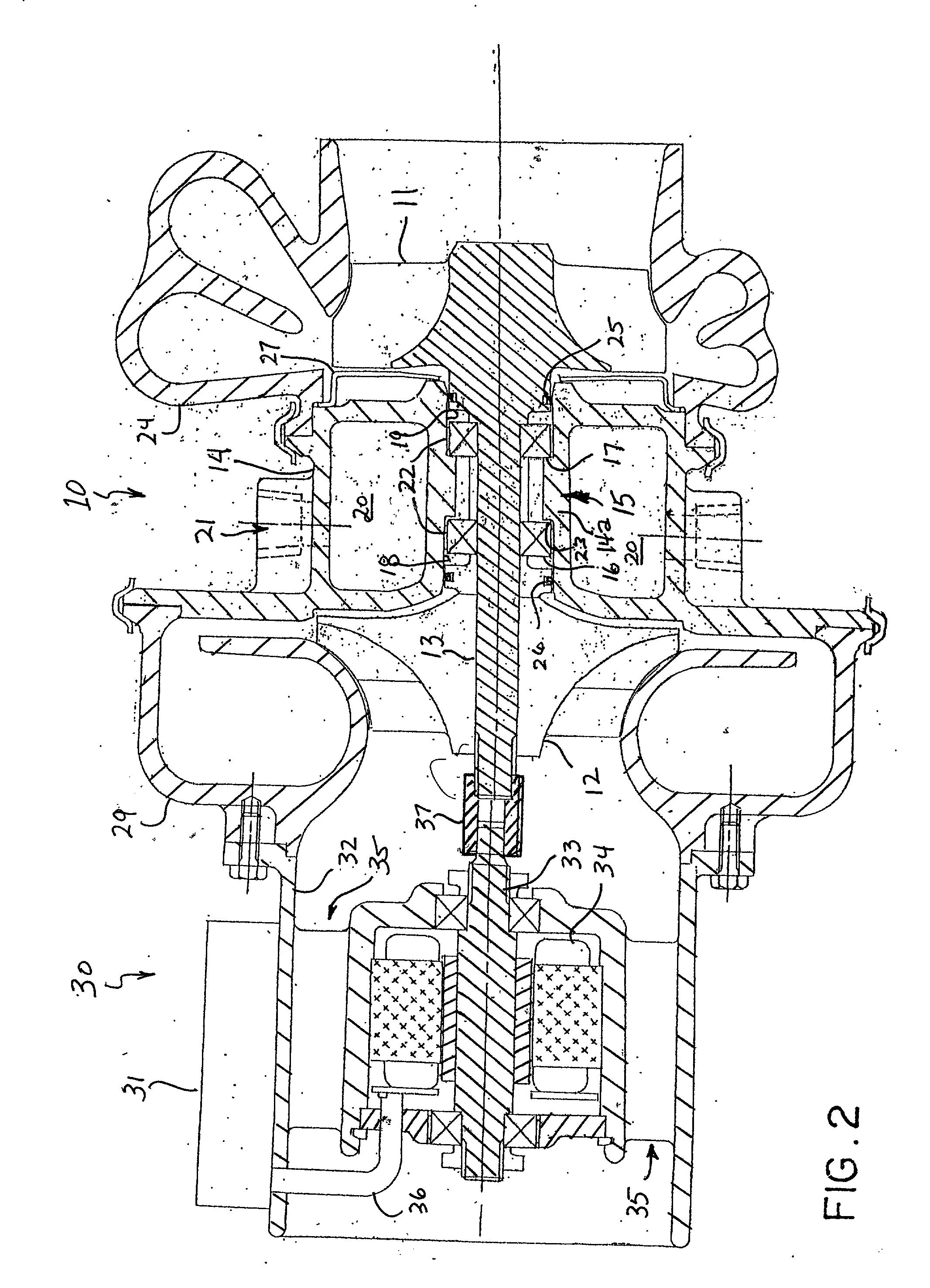

Compact turbocharger

InactiveUS20030223892A1Minimal lengthLow thermal expansionInternal combustion piston enginesPump componentsClose couplingBall bearing

The use of anti-friction ball bearings in a unique arrangement does not require the use of lubricating oil from the internal combustion engine lubricating system and permits close coupling of the bearings and a compact turbocharger. A turbocharger bearing housing forms a coolant jacket with an inner bearing engaging portion that has two bearing engagement surfaces engaged with the outer races of two anti-friction bearings whose inner races carry rotating shaft, turbine and compressor of the turbocharger. The anti-friction bearings are, preferably, angular contact ball bearings, and the two bearing engagement surfaces of the bearing housing are closely spaced, providing a turbocharger shaft of minimal length and substantially reducing the thermal expansion of the shaft. The coolant jacket protects the anti-friction bearings from exposure to the extreme heat of the exhaust gas driven turbine, notwithstanding their increased proximity due to the shortened turbocharger shaft. In addition, an external motor-generator may be carried by the compact turbocharger, and its motor may be connected to the turbocharger rotor assembly by a permanent, solid connector and stay connected throughout the entire operating range of the turbocharger. In such assembly, the electronic motor-generator control is mounted on the motor housing and energizes the motor from battery power during the engine acceleration period up to approximately the torque peak speed; thereafter, the control changes to a generator mode when excess energy is available in the engine exhaust gas.

Owner:WOOLLENWEBER WILLIAM E

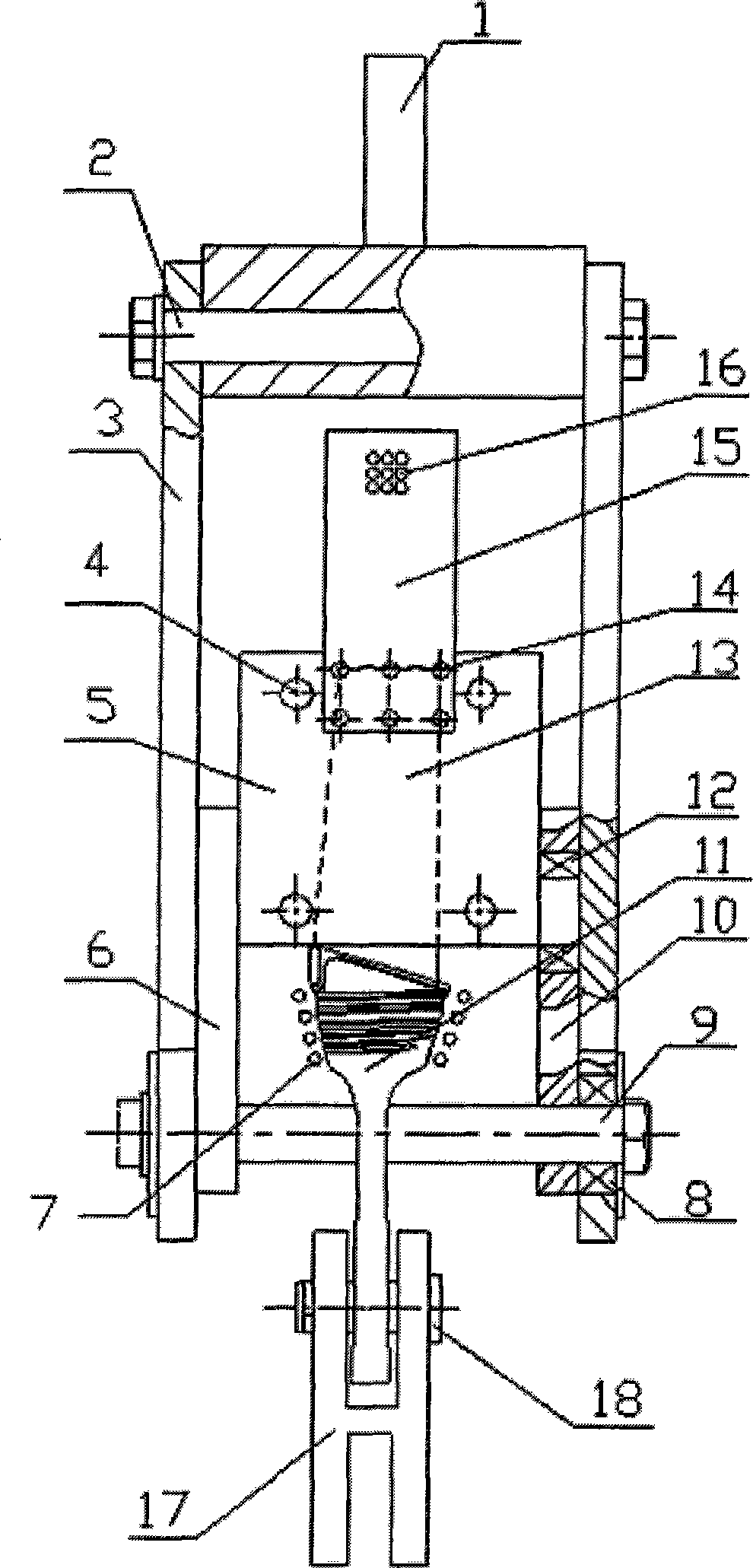

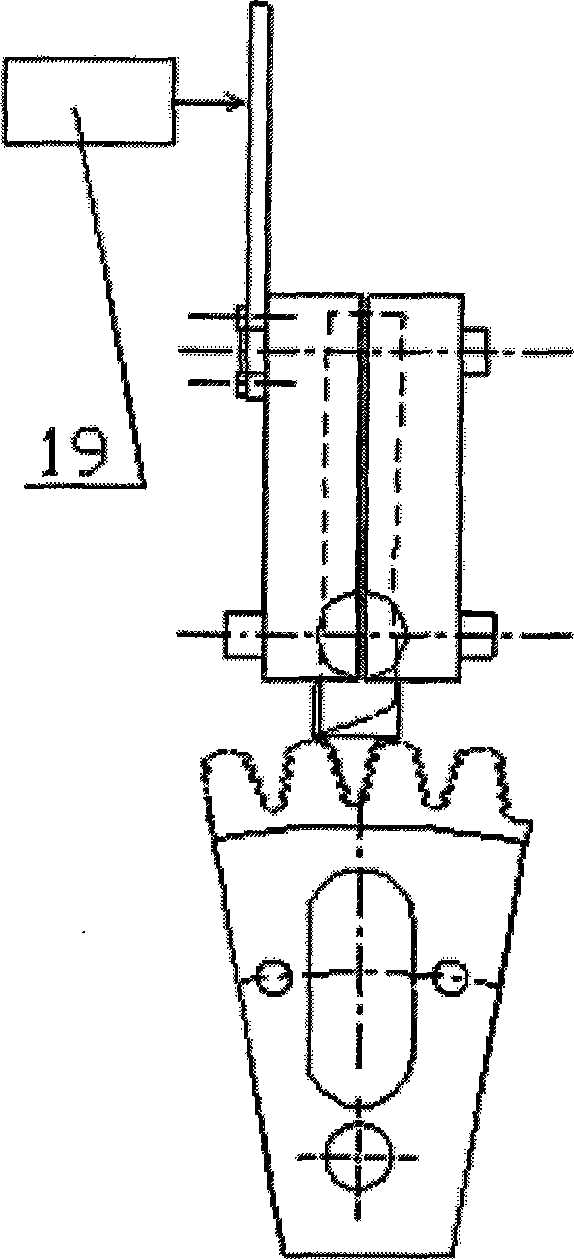

High temperature composite fatigue loading method and apparatus for turbine disc/blade joggled joint

InactiveCN101464240AResolve mutual interferenceReduce resistanceMaterial strength using repeated/pulsating forcesStress distributionFatigue loading

A turbine disc / blade tenon connection high-temperature combined fatigue loading device comprises a low cycle load stress application mechanism, a force transmission pin, a force transmission main tension plate, a force transmission crown plate, a force transmission round bar, a blade clamp, a rolling bearing, a hold-down bolt, a high cycle transmission plate, a high-frequency heating cycle, and a vibration generator, wherein, the low cycle load stress application mechanism is connected with the force transmission main tension plate through the force transmission pin; the force transmission main tension plate is connected with the force transmission round bar through the rolling bearing; the lower end of the force transmission crown plate is sleeved on the force transmission round bar, and the upper end is connected with the load bearing dummy club of the blade clamp through the rolling bearing; the blade clamp is connected with the blade of a turbine through the hold-down bolt; the turbine disc is connected with the low cycle load stress application mechanism through the force transmission pin; the high cycle transmission plate is connected with the blade clamp through the hold-down bolt; and the vibration generator is positioned on one side above a high cycle load transmission plate. The loading method is characterized in that the force application point of low cycle loads is moved backwards, thereby enabling small high cycle loads to be smoothly transferred to the tenon connection position, ensuring the stress distribution along the tenon tooth is reasonable, and preventing combined loads from interfering with each other.

Owner:BEIHANG UNIV

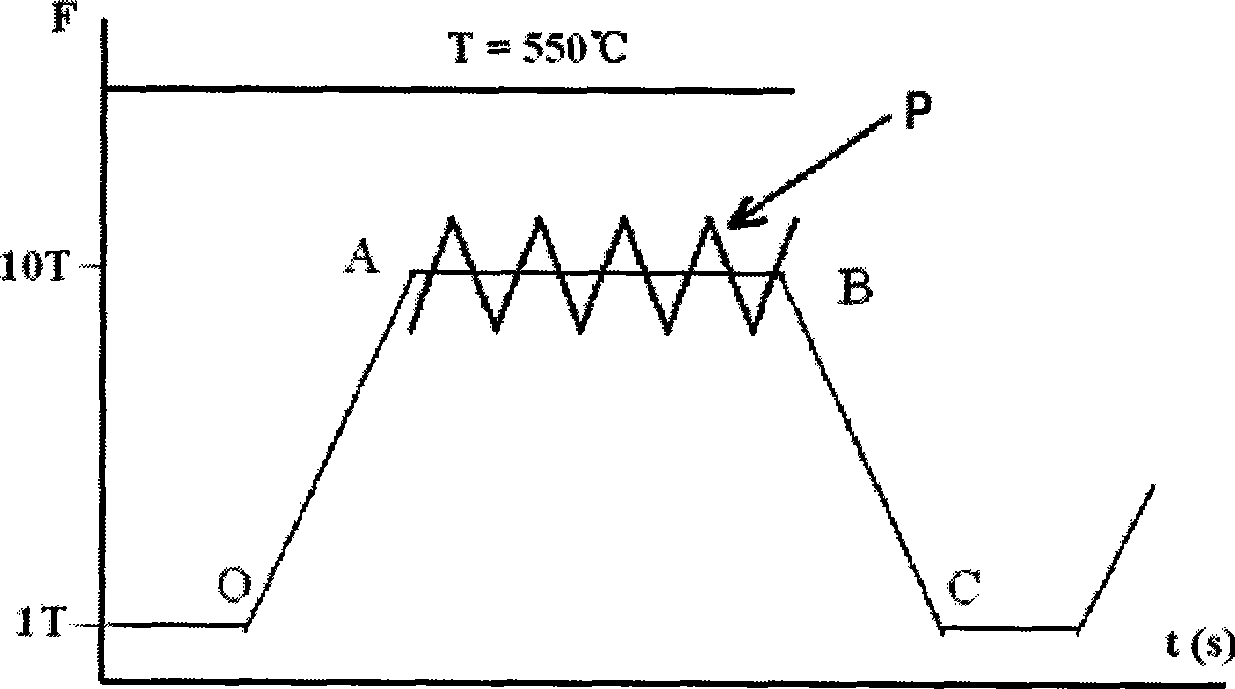

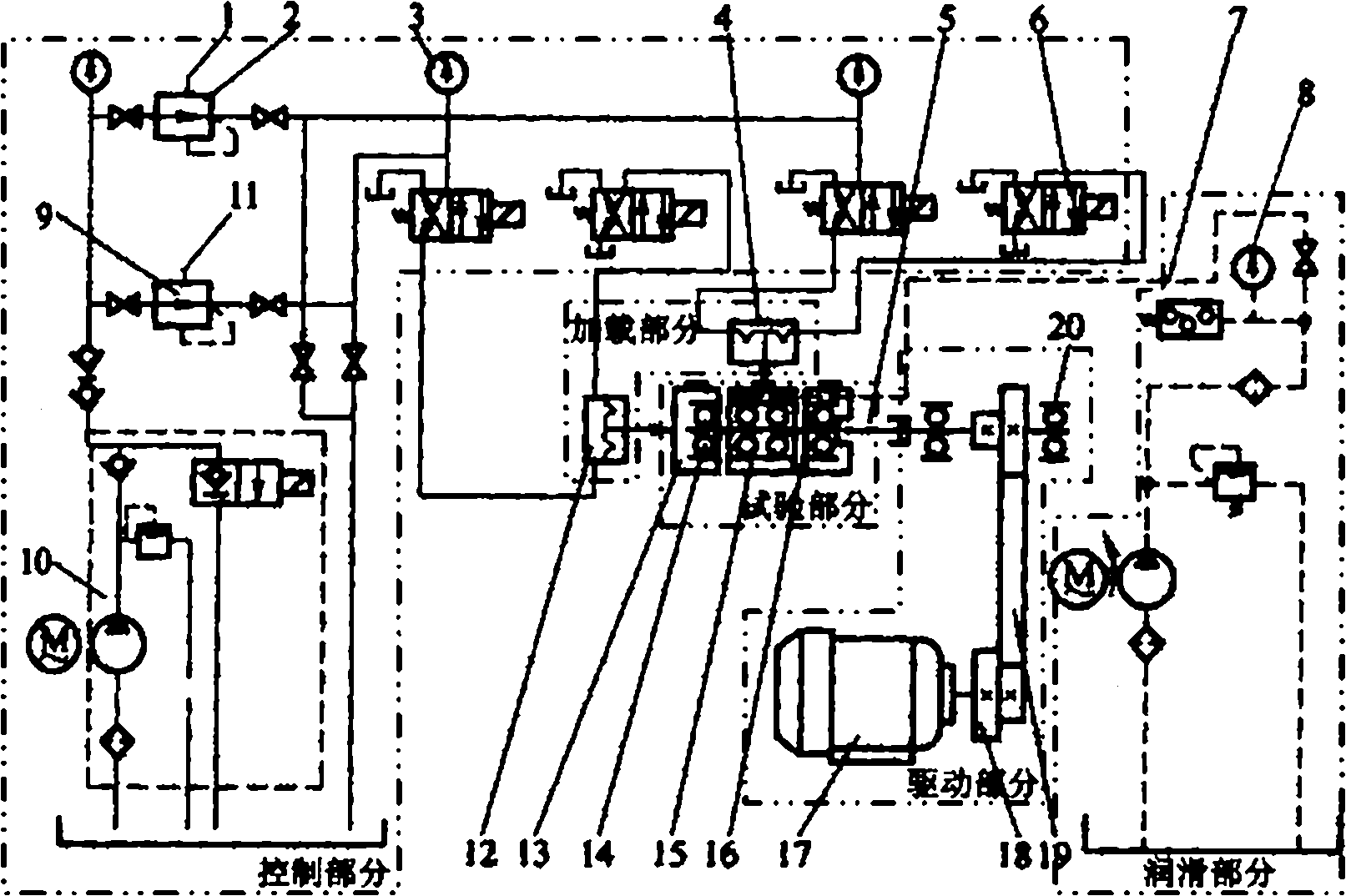

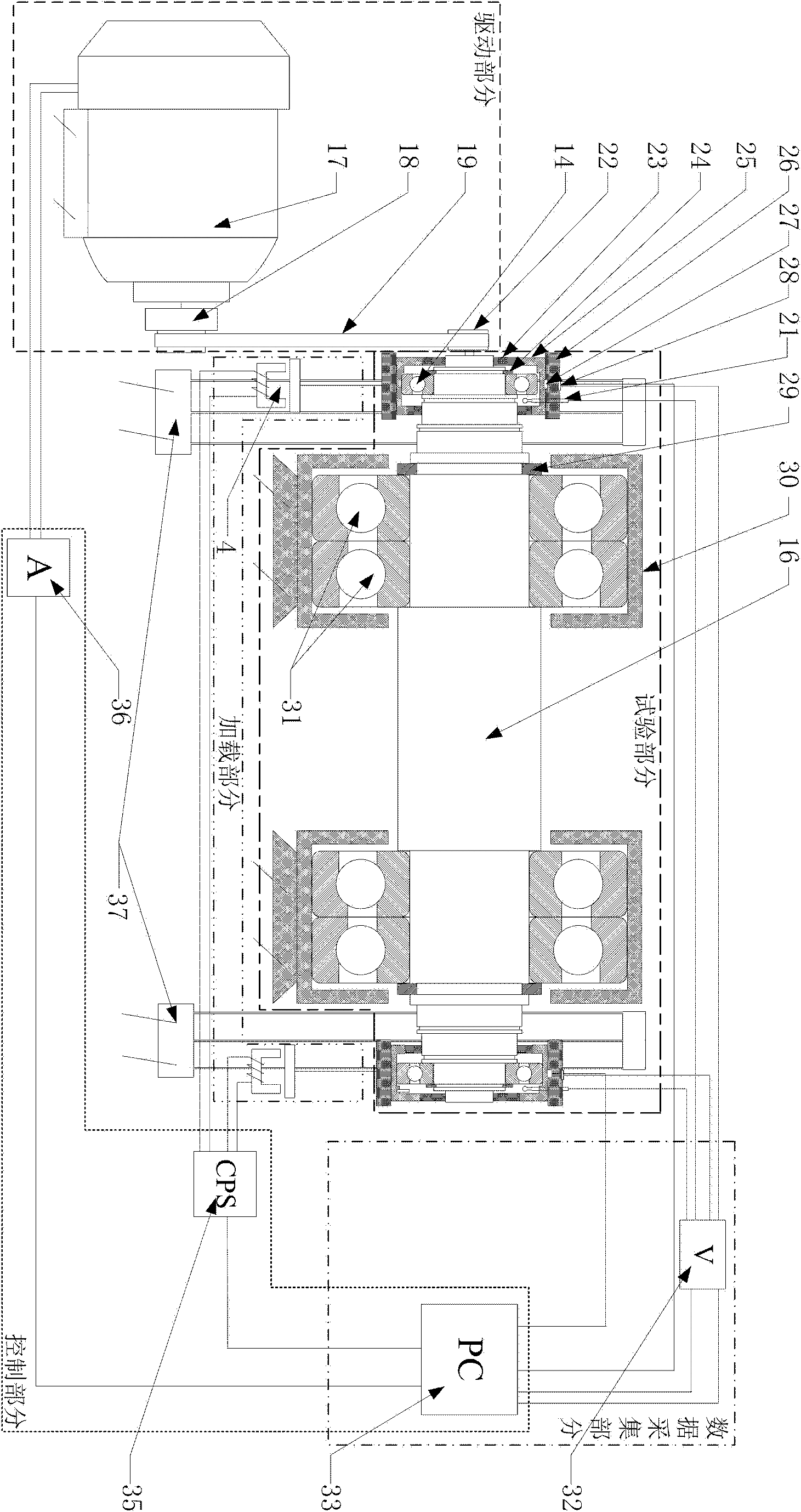

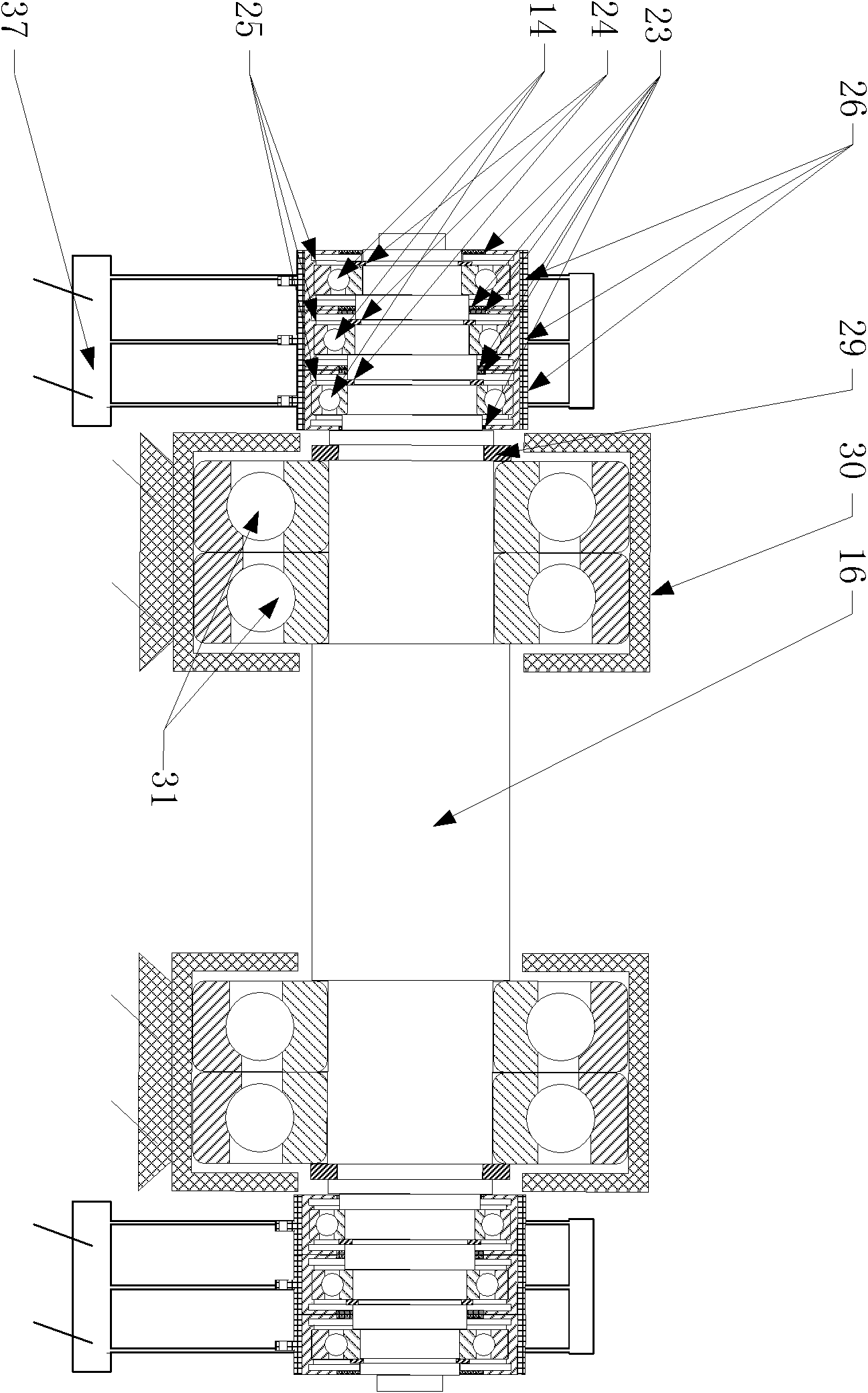

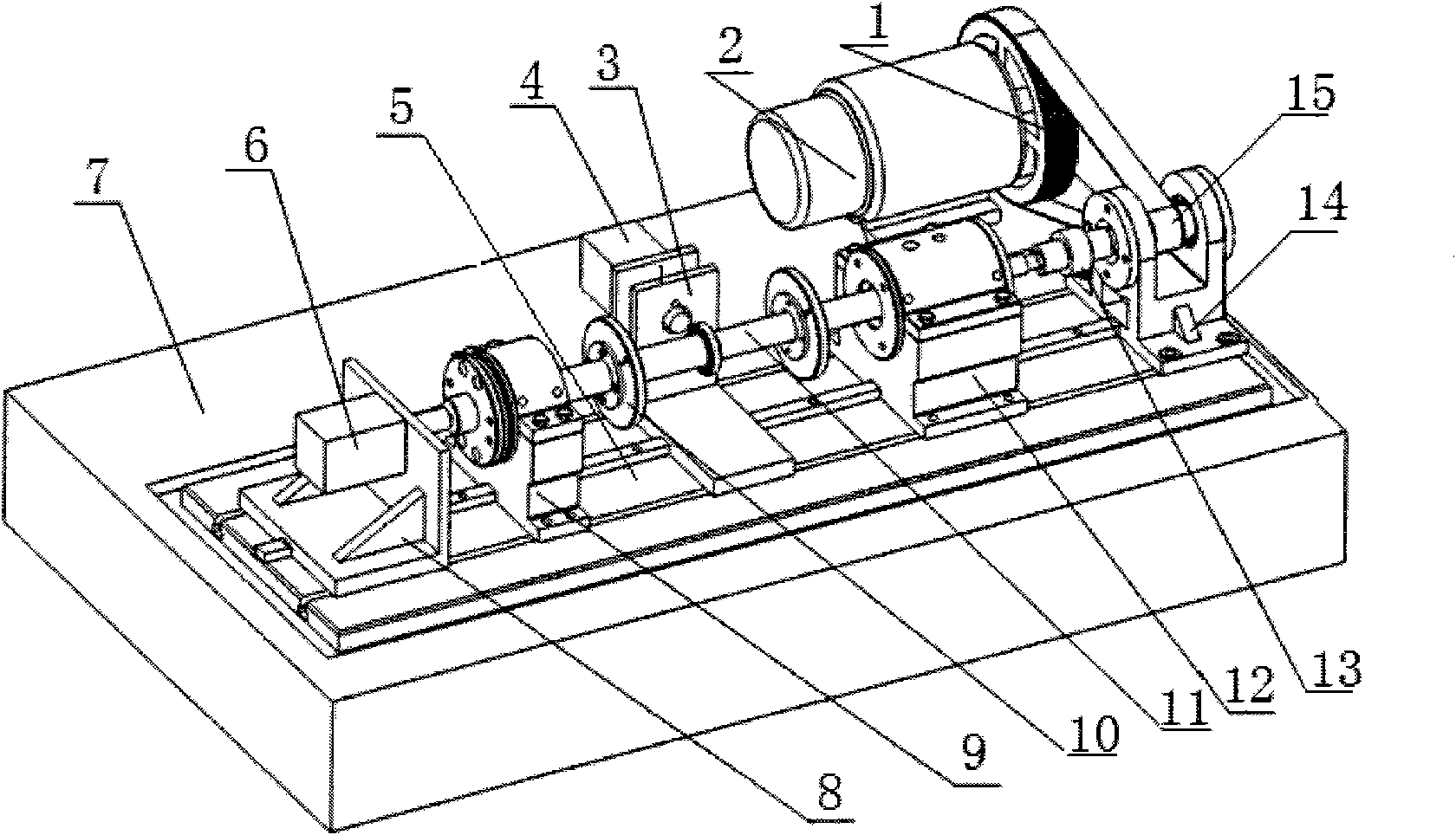

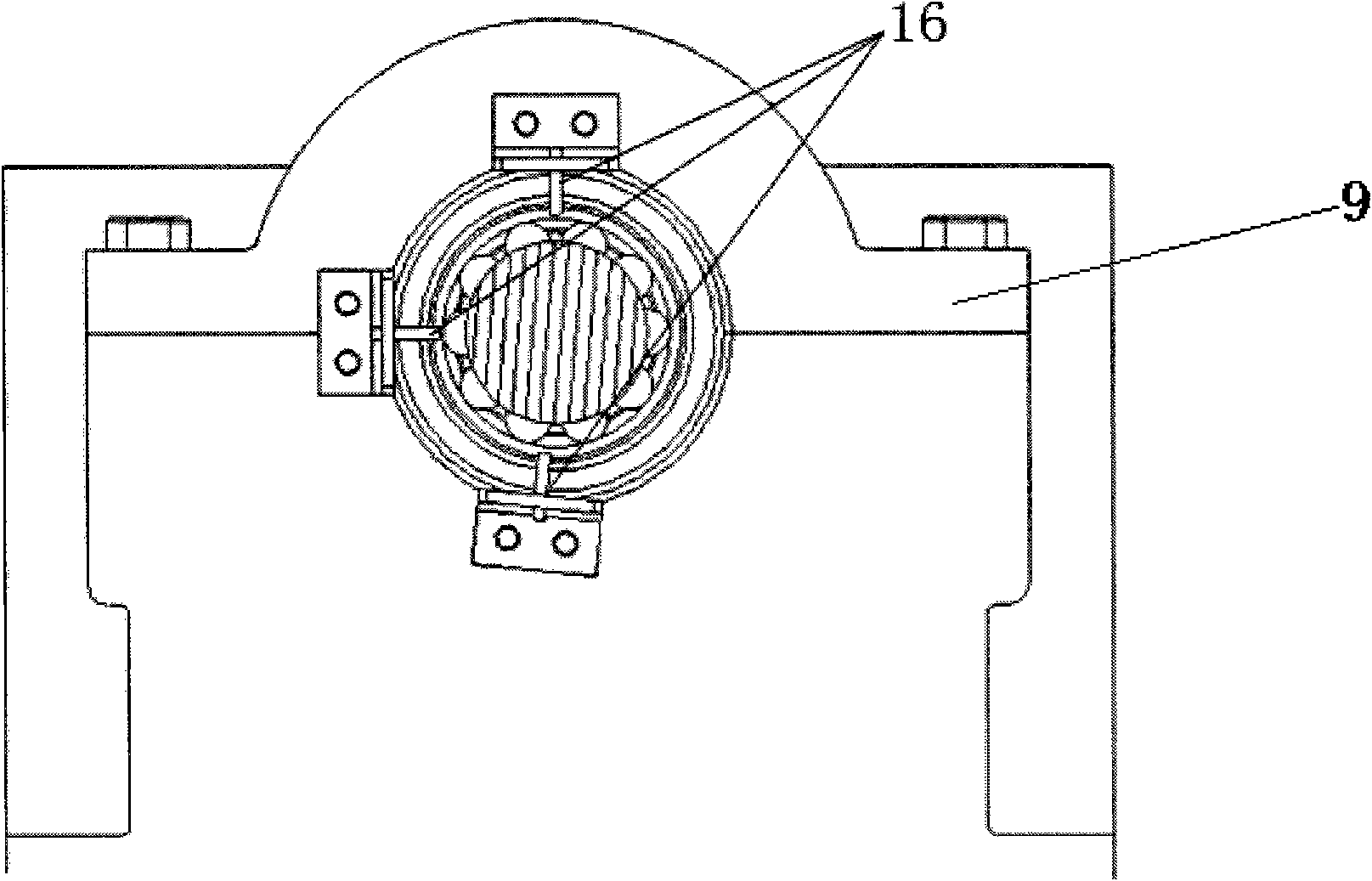

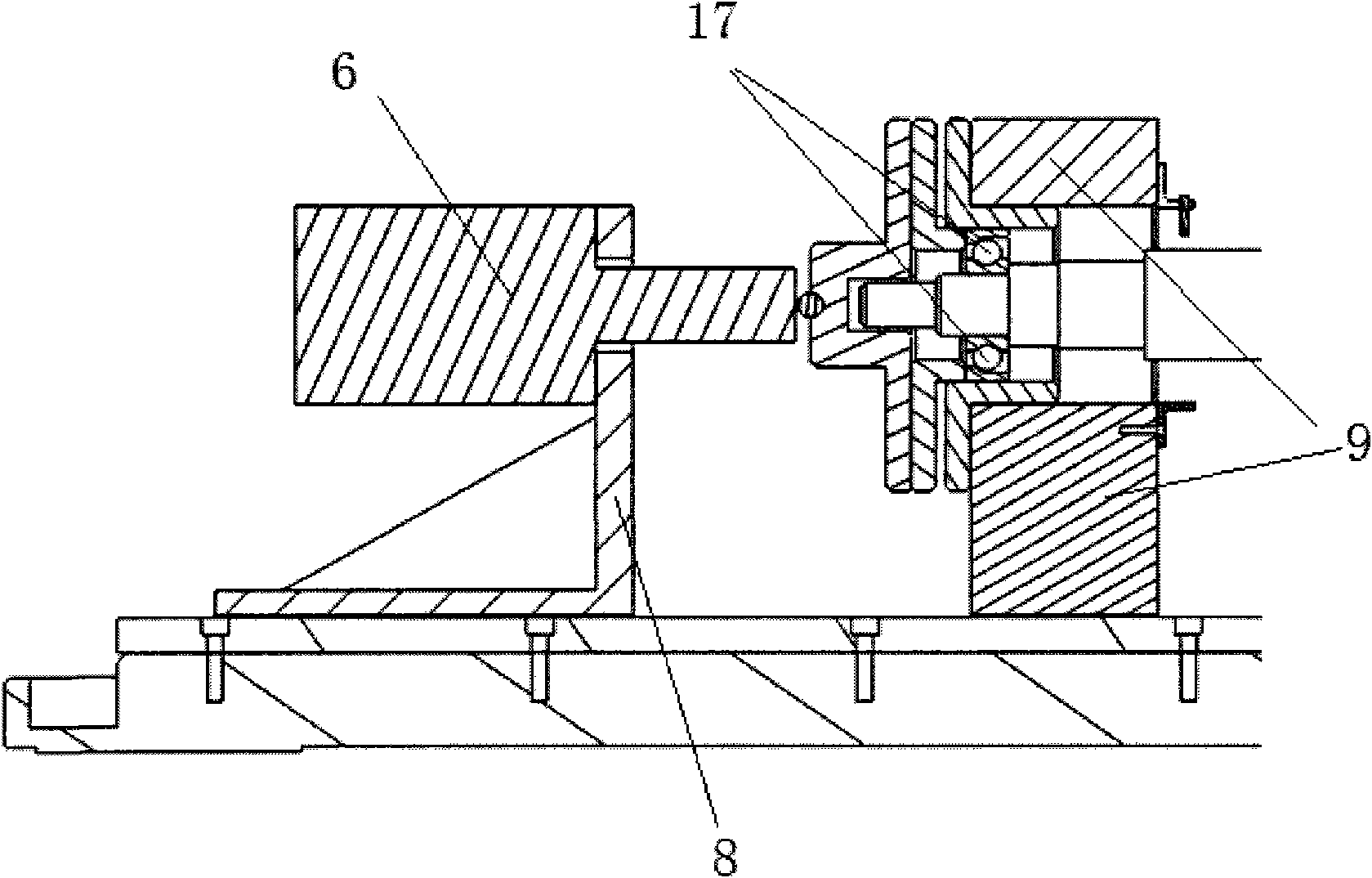

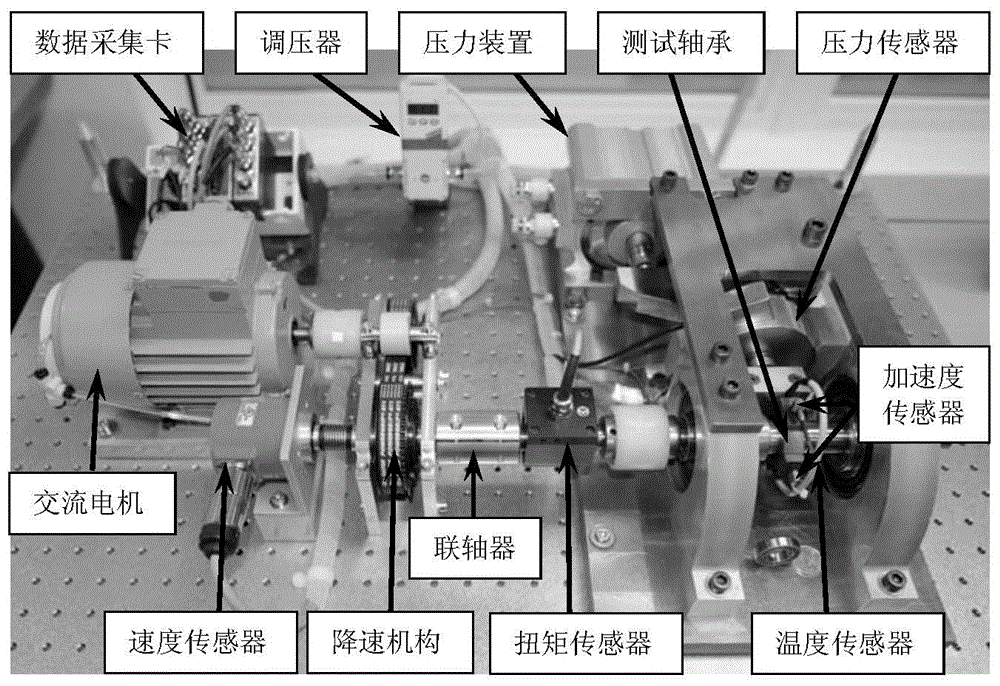

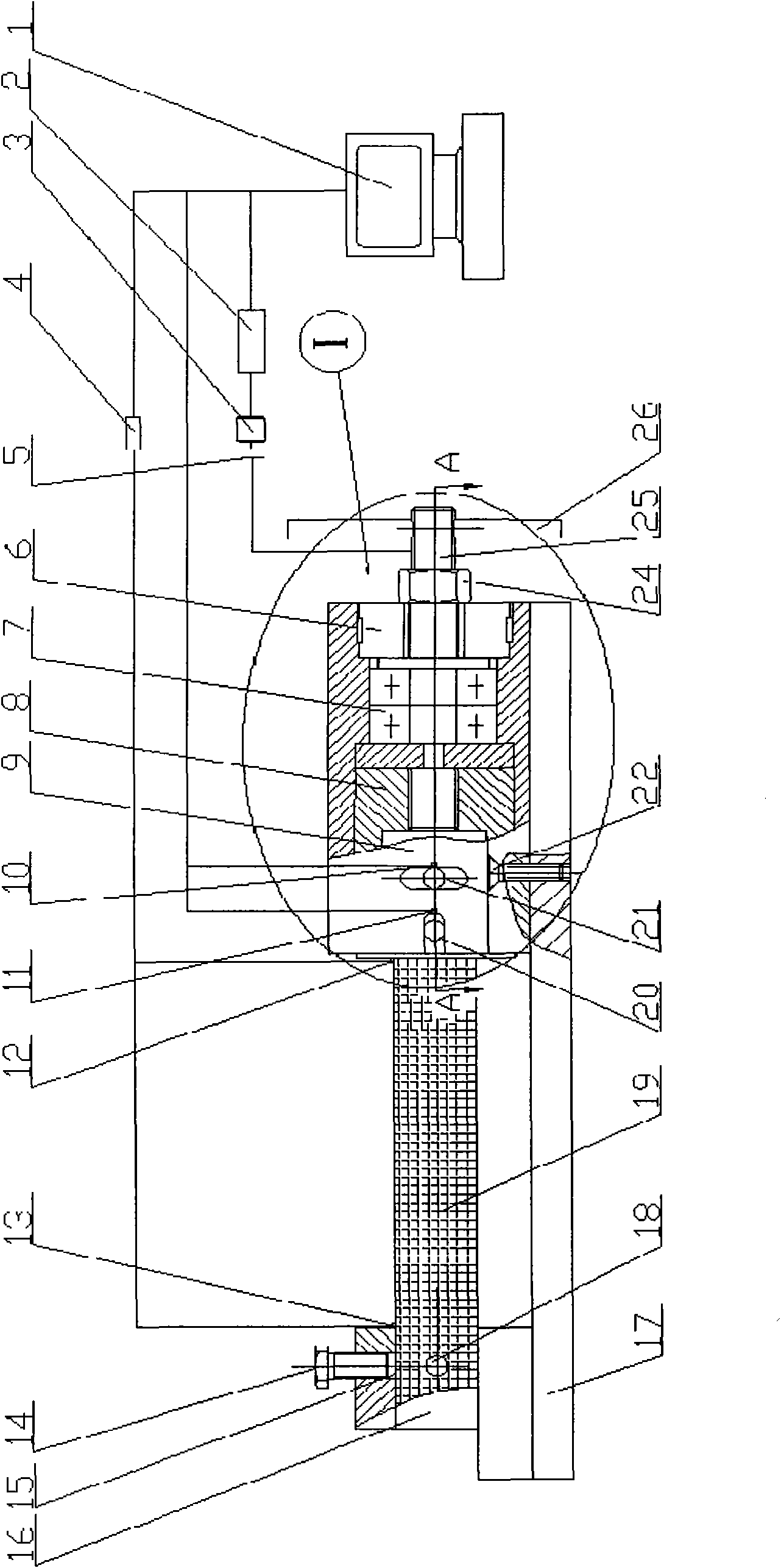

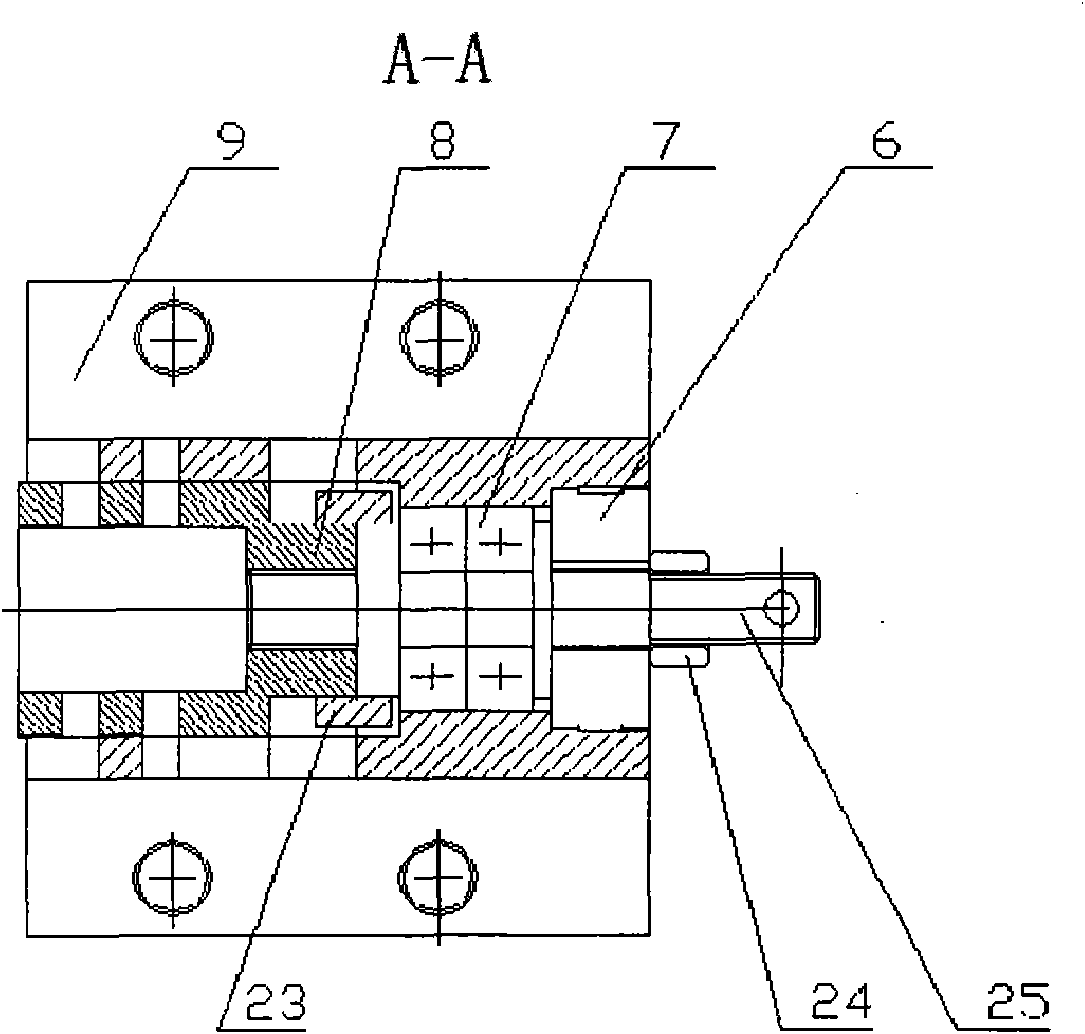

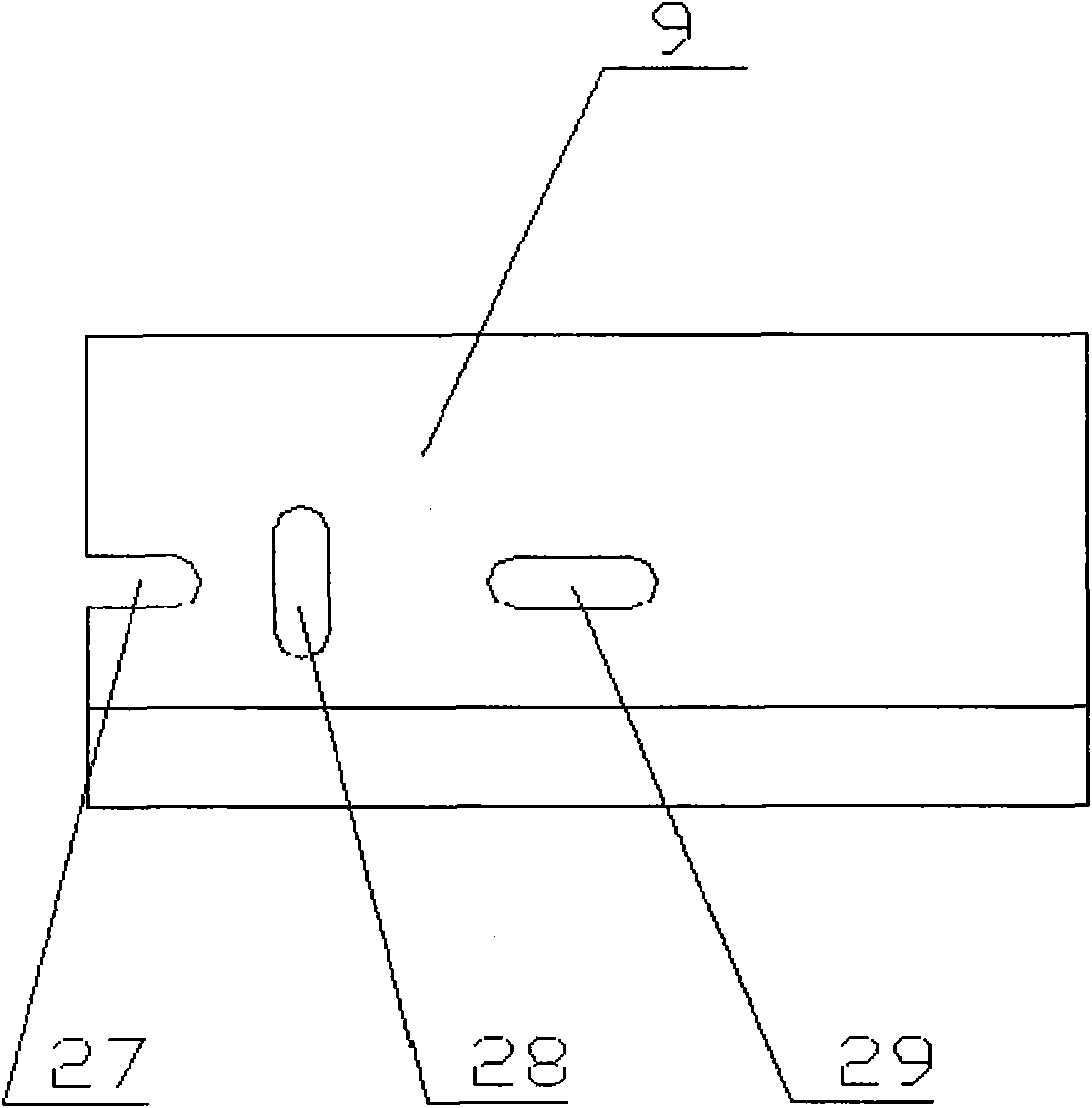

Antifriction bearing multi-functional fatigue life test bed

InactiveCN101957261AReduce current intensityReduce energy consumptionMachine bearings testingRolling-element bearingData acquisition

The invention discloses an antifriction bearing multi-functional fatigue life test bed which comprises a drive part, a test part, a loading part, a control part and a data acquisition part, wherein the drive part comprises an electromotor, a polywedge belt wheel, a polywedge belt and a special polywedge belt wheel; the test part comprises a test main shaft, a supporting bearing, a supporting bearing pedestal, a test bearing, a test bearing box, a test bearing box bracket, a test bearing box bracket fixing truss, a bearing thrust ring and an oil seal ring; the loading part comprises a pull rod, an armature, an electromagnet array, an electromagnet array base, a nut and a plurality of weights; the control part comprises a computer, a current controller and a programmable power supply; and the data acquisition part comprises a vibration sensor, a temperature sensor, a pressure sensor and a vibration, temperature and pressure data acquisition system. The antifriction bearing multi-functional fatigue life test bed can be used for carrying out a fatigue life test on single or multiple antifriction bearings and can apply different loading methods to each antifriction bearing respectively.

Owner:NAT UNIV OF DEFENSE TECH

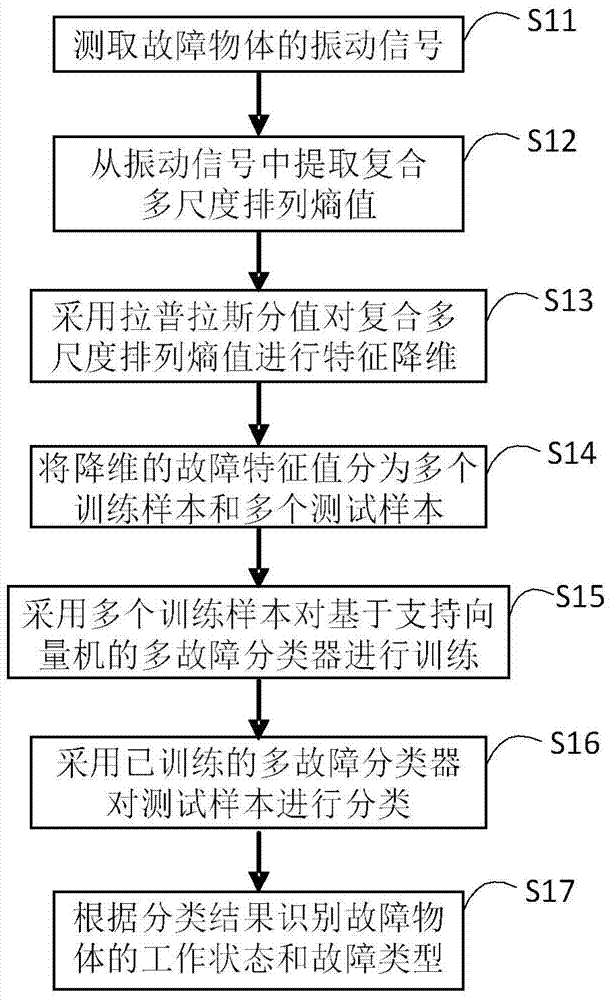

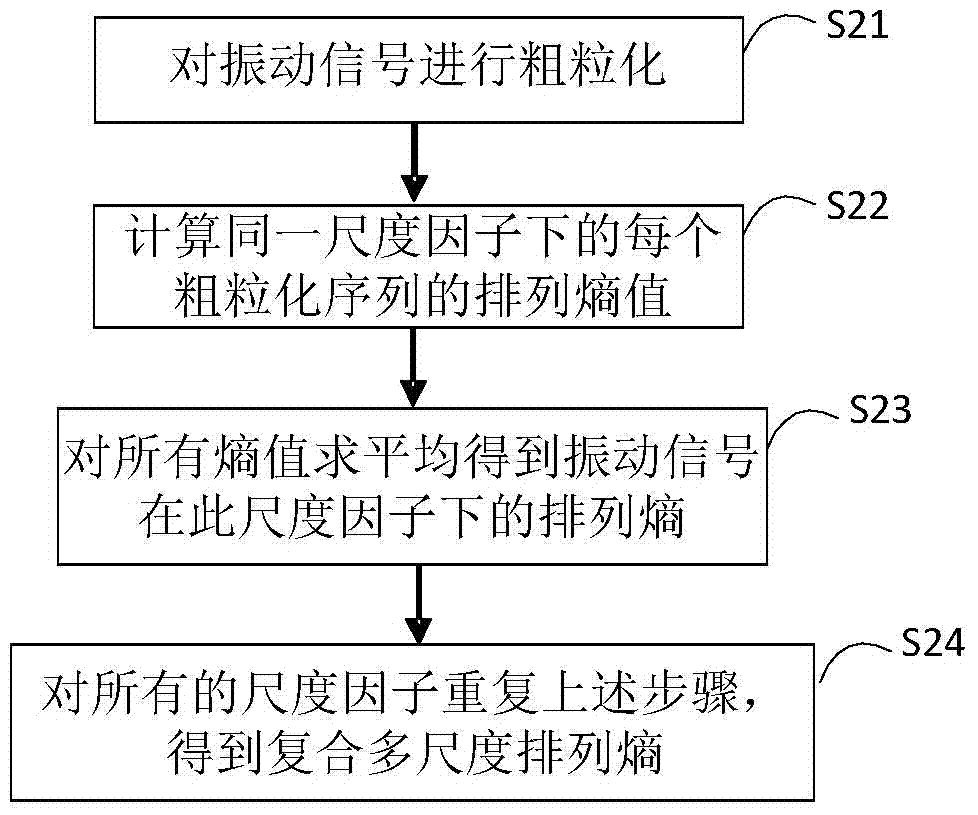

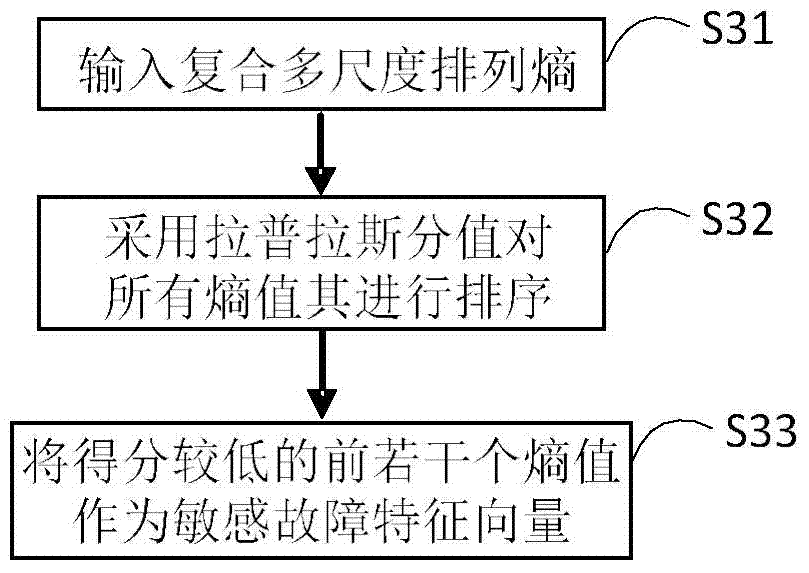

Rolling bearing fault diagnosis method based on composite multi-scale permutation entropies

ActiveCN104849050AEfficient extractionHighly innovativeSubsonic/sonic/ultrasonic wave measurementMachine bearings testingSupport vector machineFeature vector

The invention discloses a rolling bearing fault diagnosis method based on composite multi-scale permutation entropies, and belongs to the technical field of fault diagnosis. The method comprises the following steps: measuring a vibration signal of a faulty object; extracting composite multi-scale permutation entropies from the vibration signal; reducing the dimension of the composite multi-scale permutation entropies with use of a Laplacian score; taking the first multiple composite multi-scale permutation entropies with low scores after dimension reduction as fault feature vectors and dividing the fault feature vectors into multiple training samples and multiple test samples; inputting the multiple training samples into a multi-fault classifier established based on a support vector machine to perform learning so as to classify the test samples; and identifying the working mode and the fault type of the faulty object according to the classifying result. According to the fault diagnosis method disclosed by the invention, feature extraction is highly innovative, and the degree of identification is high in the process of fault mode identification.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method and apparatus for diagnosing residual life of rolling element bearing

InactiveUS20050246150A1Effective maintenanceEasy to implementVibration measurement in solidsPump componentsAccelerometerPredictive methods

An invention that utilizes signals from an accelerometer in resonant frequency bands or high frequency bands to, in a cost-effective manner, measure wear particle penetration of lubricant and lubricant degradation, both of which greatly affect prediction of residual service life; and, using as a basis these measurements of wear particle penetration and lubricant degradation, enables accurate estimation of residual service life for rolling bearings in the early stages. The invention is comprised of a means of obtaining fundamental data that uses a testing device to obtain data regarding the relationship, for rolling bearings (3), of wear particle penetration levels to vibration levels and service life, or to obtain data regarding the relationship, for rolling bearings (3), of lubricant degradation levels to vibration levels and service life; a means of measurement, where an accelerometer (4) is used to obtain vibration signals of diagnostic rolling bearings (3) residing on mechanical rotating devices (1, 2) for the purpose of measuring signals in resonant frequency bands only detectable at extremely high levels of sensitivity or signals in high frequency bands; and a means of prediction that uses readings obtained via said means of measurement and data obtained via said means of obtaining fundamental data to predict, for diagnostic rolling bearings (3), wear particle penetration levels and lubricant degradation levels, and to calculate residual service life for diagnostic rolling bearings (3).

Owner:THE CHUGOKU ELECTRIC POWER CO INC +1

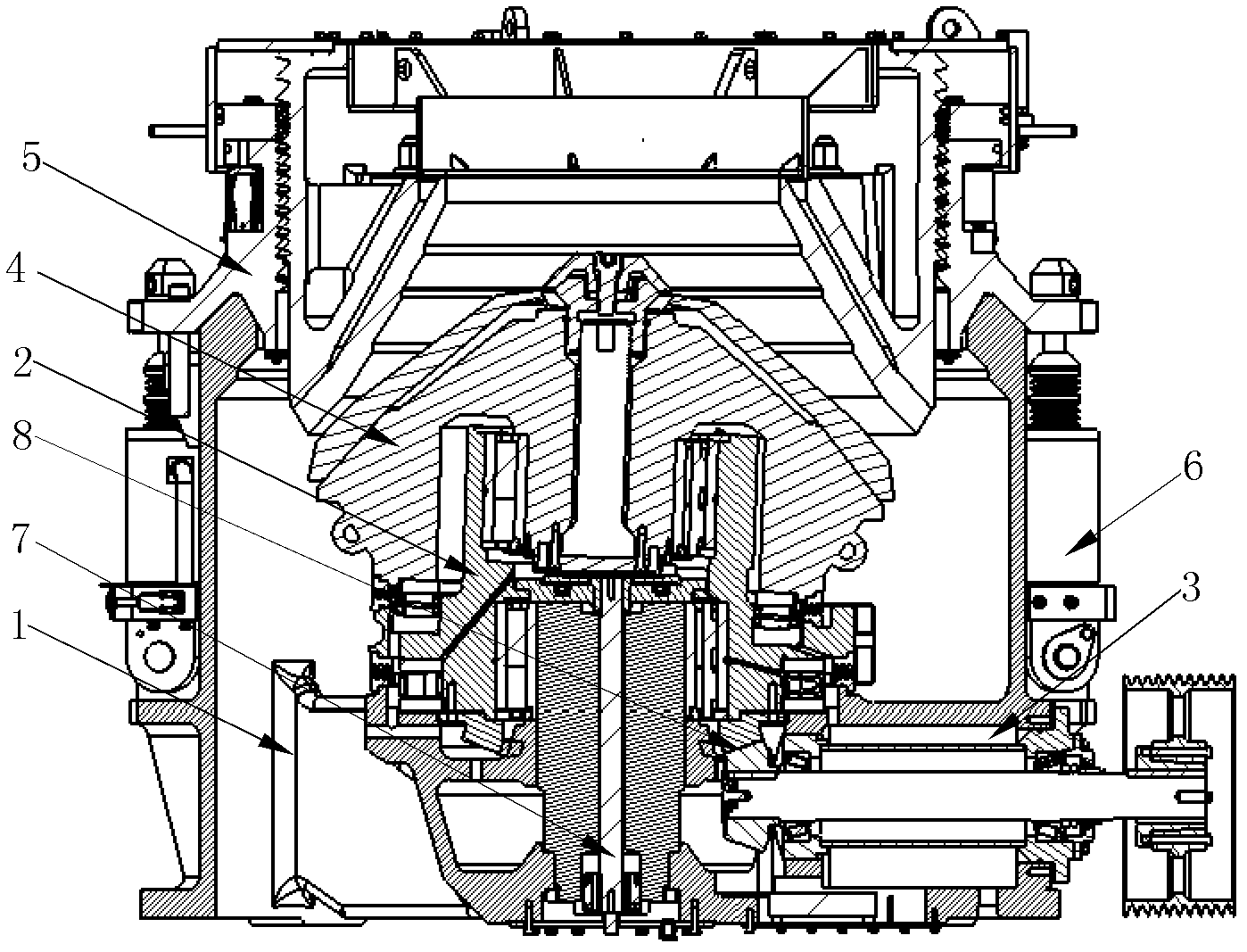

Comprehensive test experiment device for dynamic and static properties of rolling bearing-main shaft system

InactiveCN101936810AImprove utilization efficiencyThe test data is close toMachine bearings testingEngineeringSingle type

A comprehensive test experiment device for dynamic and static properties of a rolling bearing-main shaft system comprises a main shaft in which the front end is installed on a front end bearing support saddle; the end surface of the front end bearing support saddle is provided with three laser displacement sensor test probes; the front end bearing support saddle is internally provided with an experiment bearing; load is carried out through a radial load hydraulic tank and an axial load hydraulic tank; the back end of the main shaft is assembled on a back end bearing support saddle, and the back end bearing support saddle is configured to be paired angle contact bearings, and both an integrated monitoring ring and a pre-tightening push block are installed between the angle contact bearings to realize self-adapting pre-tightening of the bearing; the main shaft is provided with an eccentric quality shock excitation disk for applying bearing shock excitation; and the main shaft is driven by a variable-frequency electric motor. The comprehensive test experiment device for dynamic and static properties of a rolling bearing-main shaft system is used for detecting the influence on the dynamic and static properties of multiple types of bearings and the main shaft system, thereby overcoming the defect that the existing rolling bearing-main shaft experiment platform has the characteristics of single-type tested bearing, too low integration degree and rough single processing, being capable of carrying multiple experimental researches, and improving the flexibility of the rolling bearing-main shaft experiment platform.

Owner:SHENJI GRP KUNMING MACHINE TOOL +1

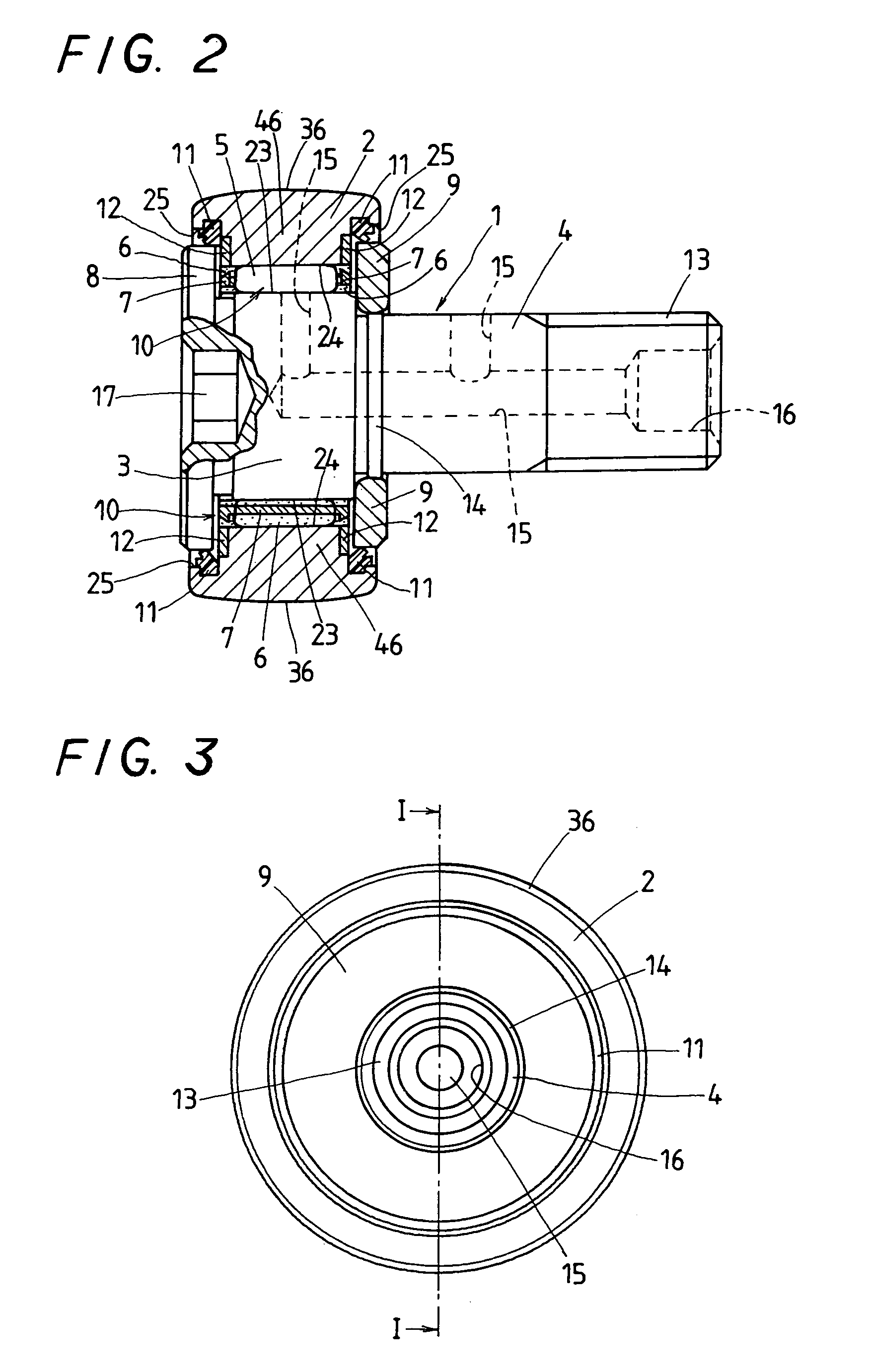

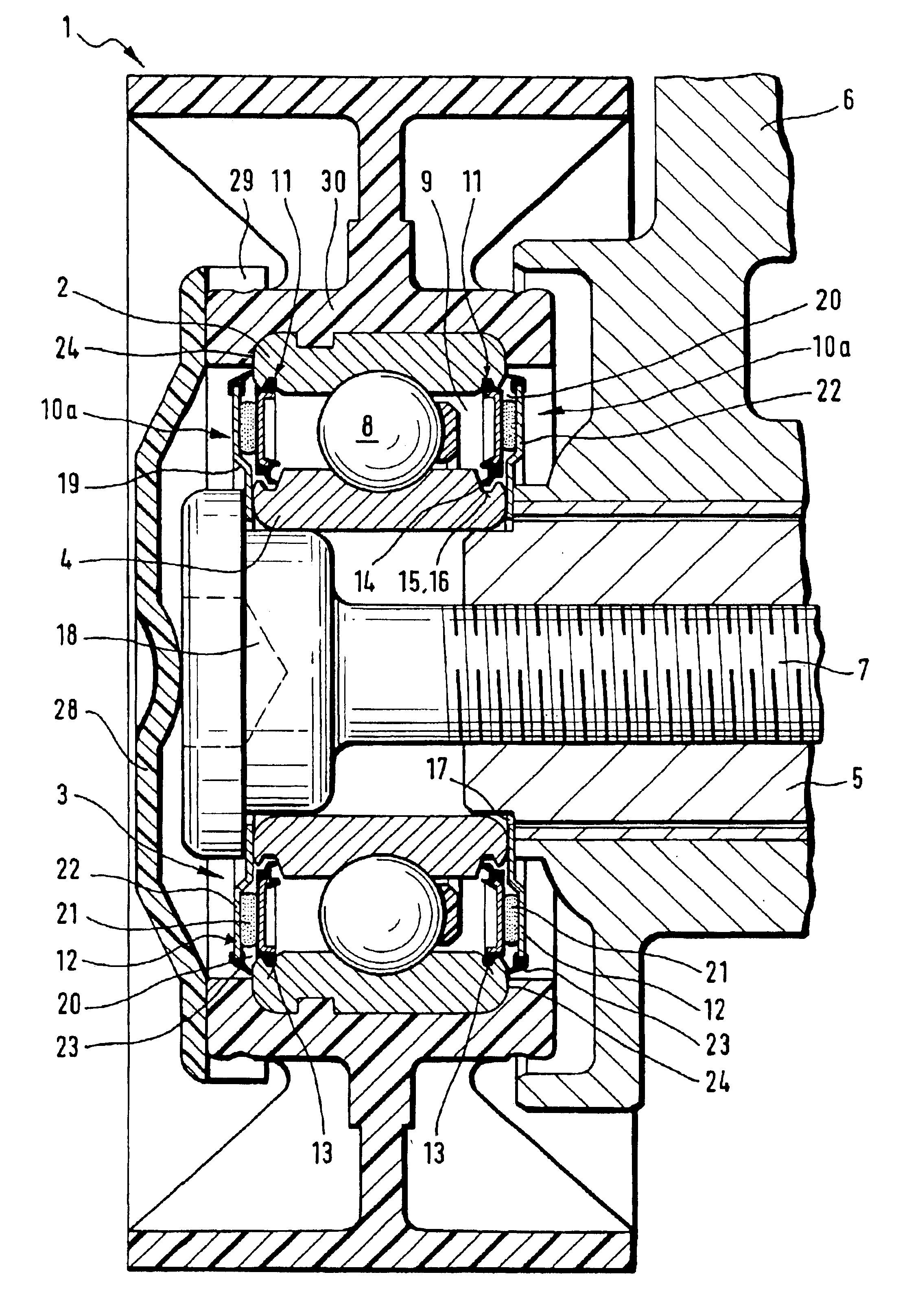

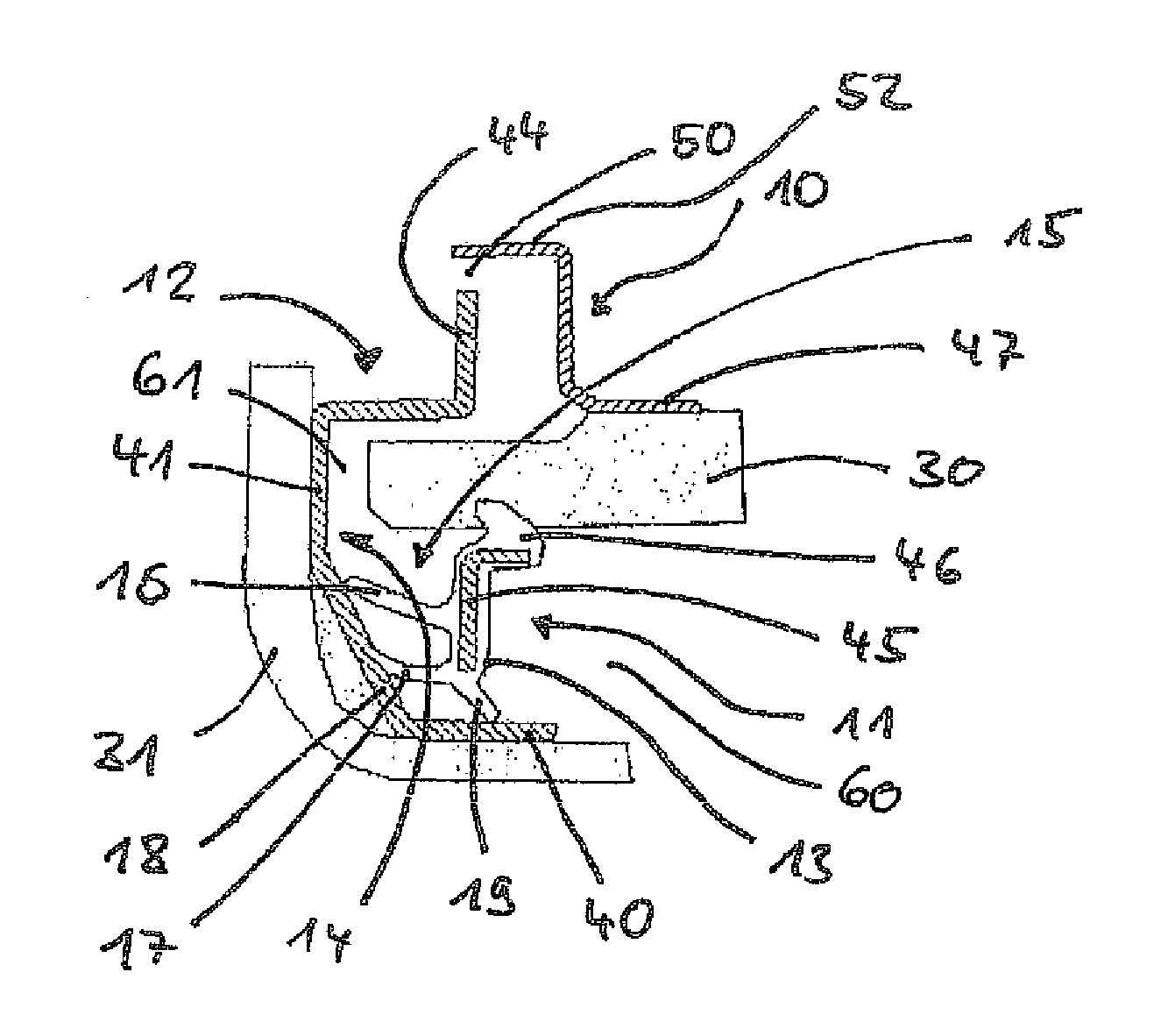

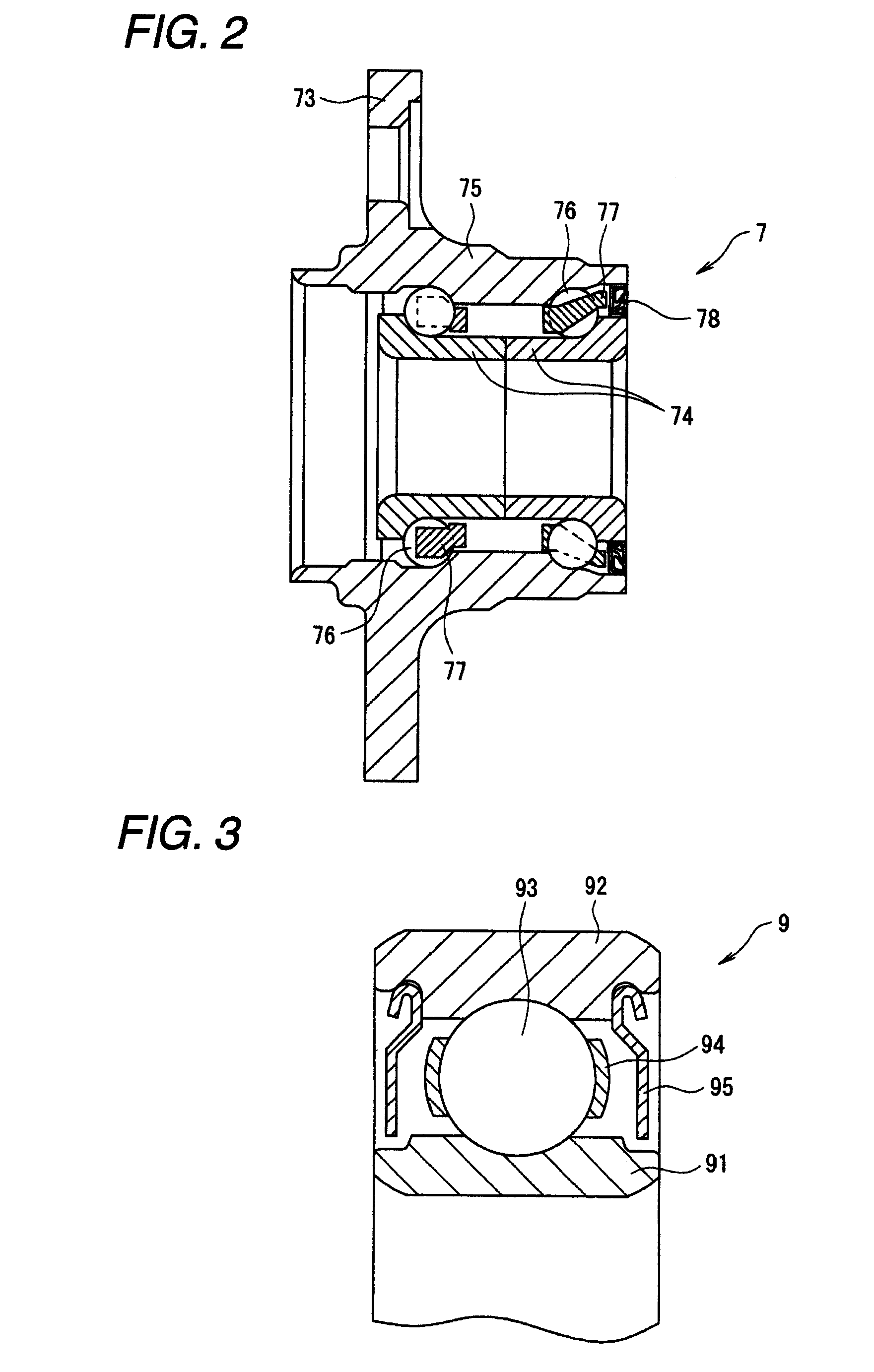

Sealing arrangement for a rolling-contact bearing

InactiveUS6854893B2Improve efficiencyAdded costEngine sealsGearingRolling-element bearingEngineering

A two-stage sealing arrangement for sealing an annular gap between an outer bearing ring and an inner bearing ring of a rolling-contact bearing, includes a first sealing element securely fixed to the outer bearing ring and having at least one sealing lip supported against the inner bearing ring. A second sealing element is disposed at an axial distance to the first sealing element, thereby defining a circular ring shaped sealing gap in a radial direction for accommodating, at least partially, a sealing material.

Owner:SCHAEFFLER TECH AG & CO KG

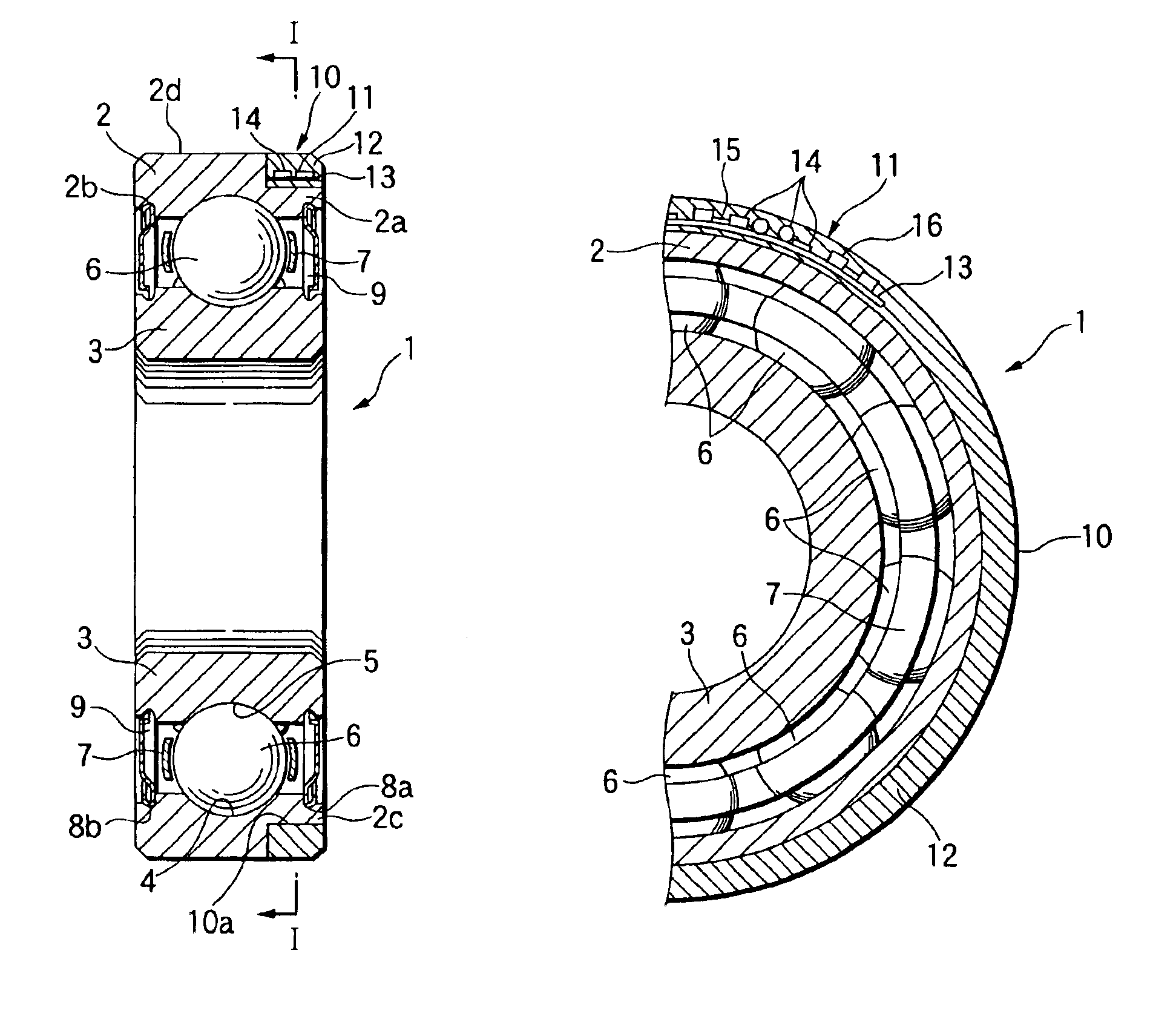

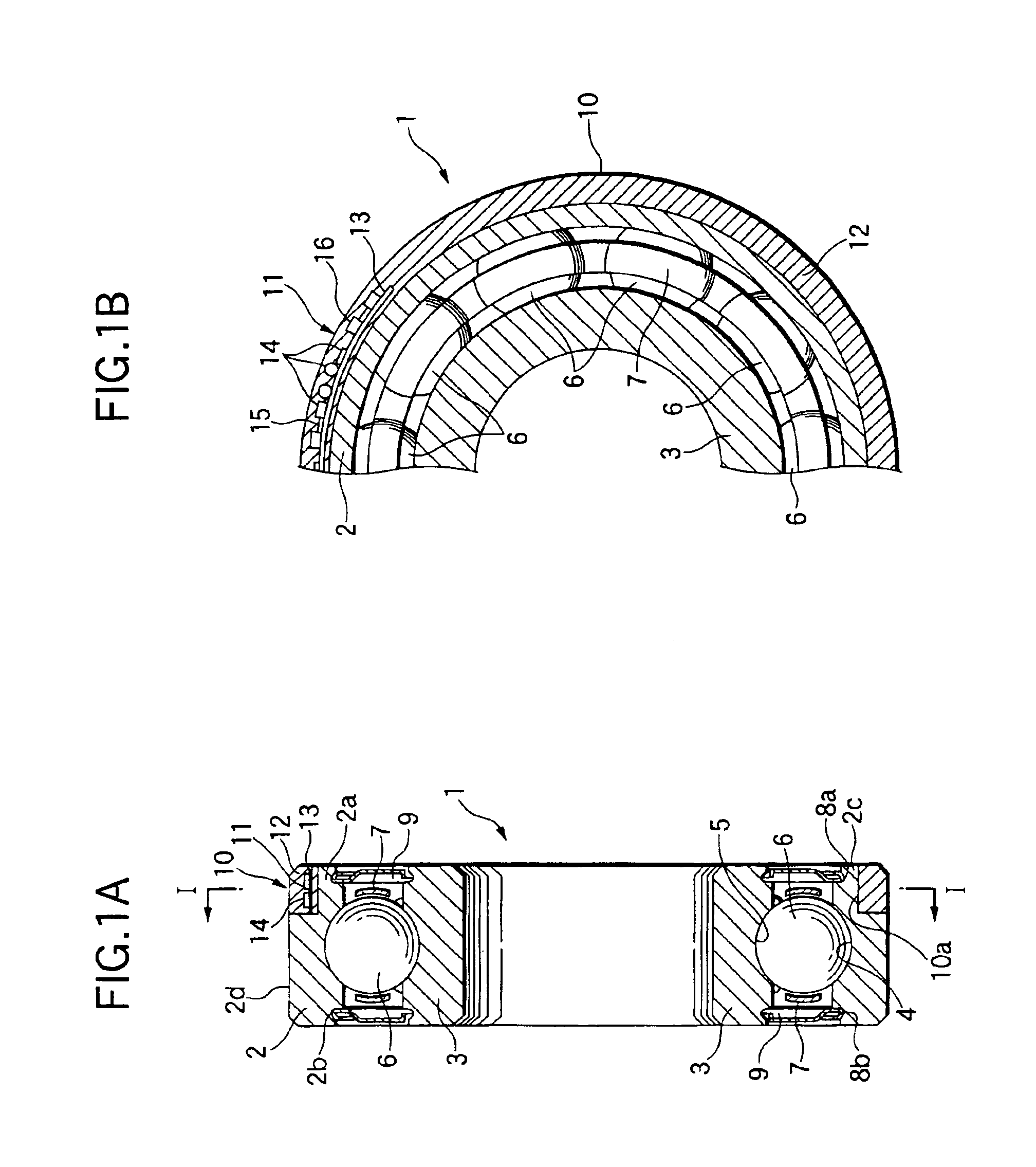

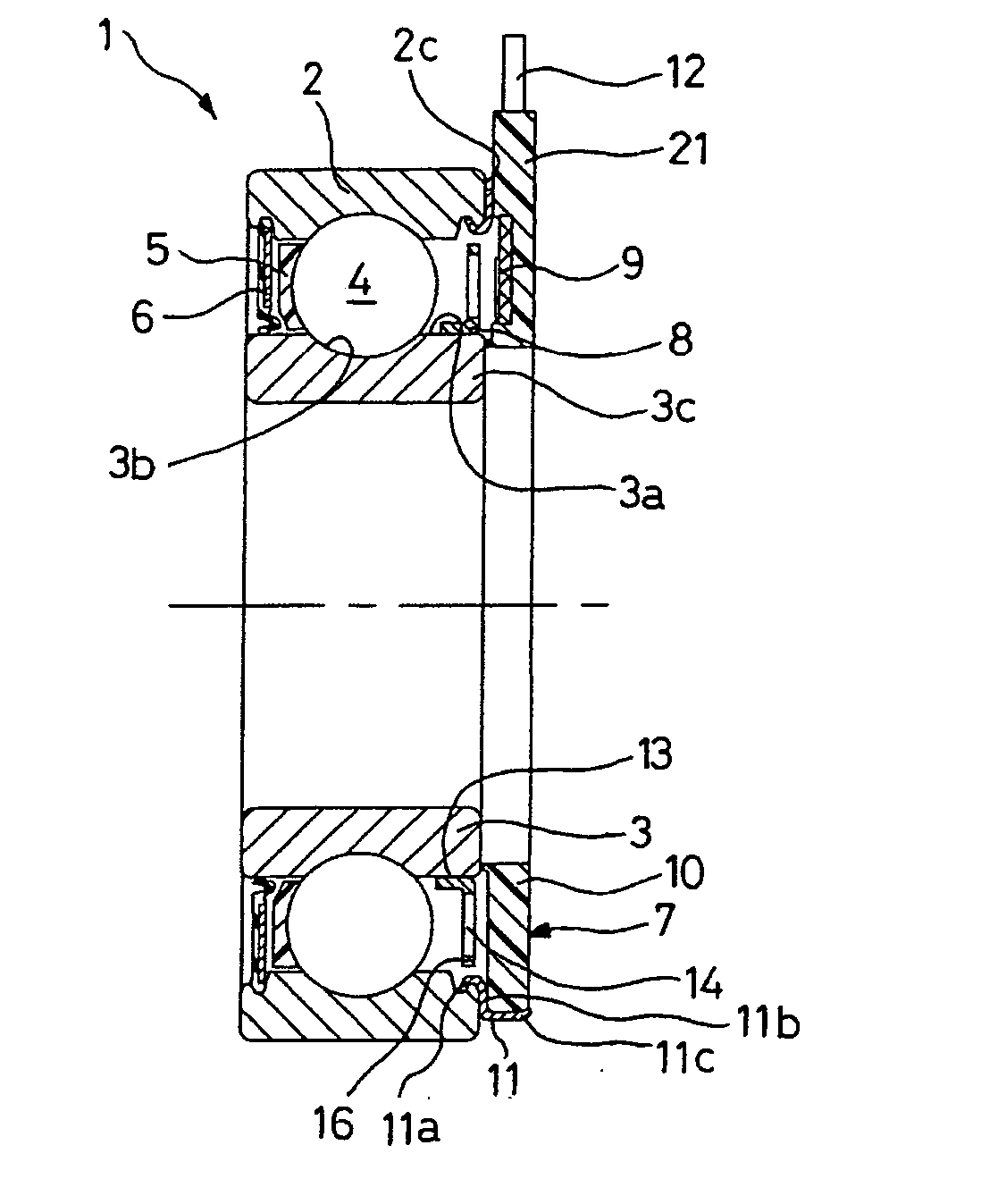

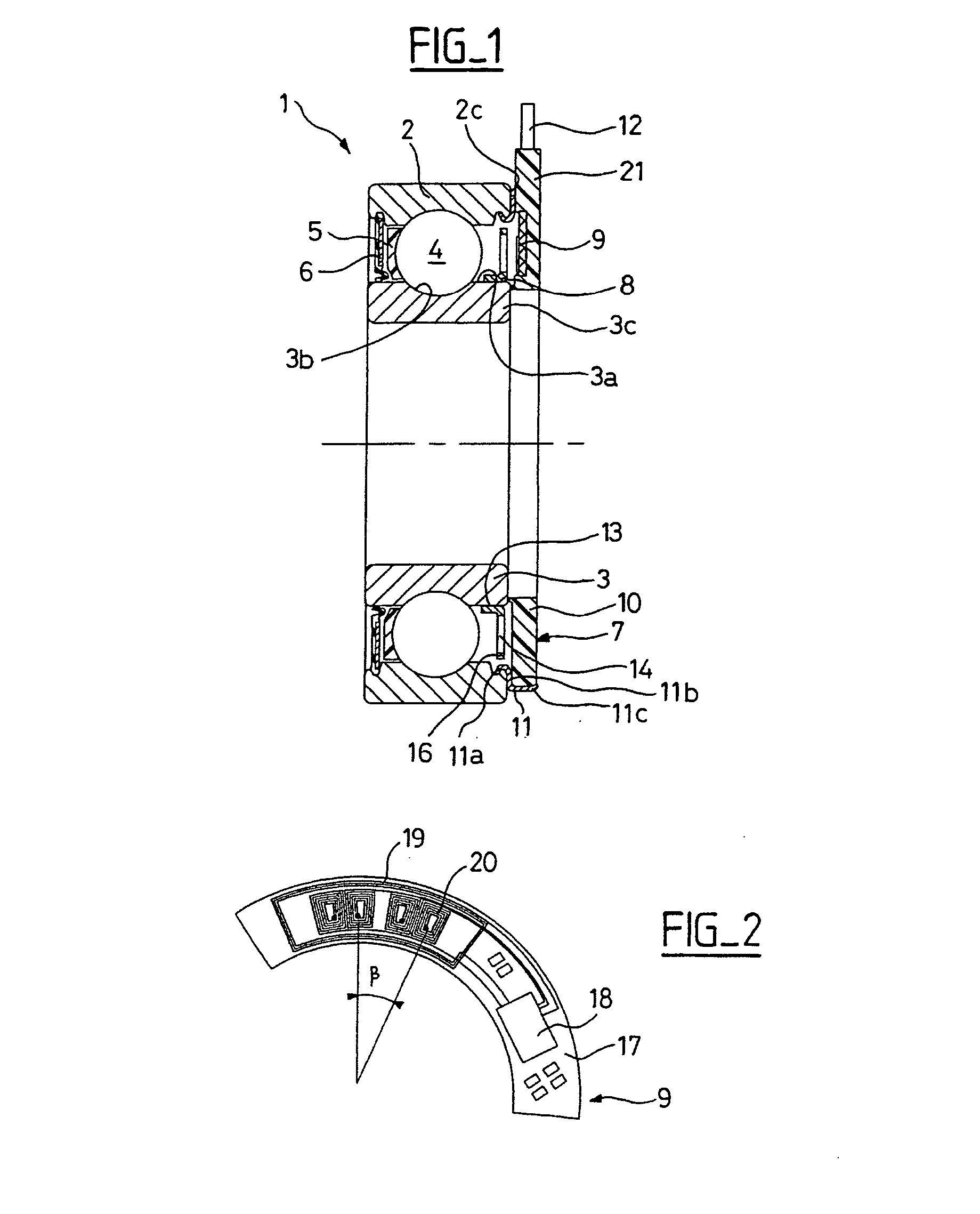

Instrumented antifriction bearing and electrical motor equipped therewith

InactiveUS20060104558A1Satisfactory axial compactnessAccurate detectionBearing assemblyShaftsBall bearingRolling-element bearing

An instrumented ball-bearing may include a rotating part, a non-rotating part, and an assembly for detecting rotation parameters. The assembly for detecting rotation parameters may include an encoder and a sensor. The sensor may be integrated with the non-rotating part. The sensor may include a sensor unit and at least a microcoil. The microcoil may have a substantially planar winding. The microcoil may be positioned in the sensor unit of the non-rotating part such that the microcoil may be positioned axially opposite the encoder.

Owner:AB SKF

Methods and systems for automatic rolling-element bearing fault detection

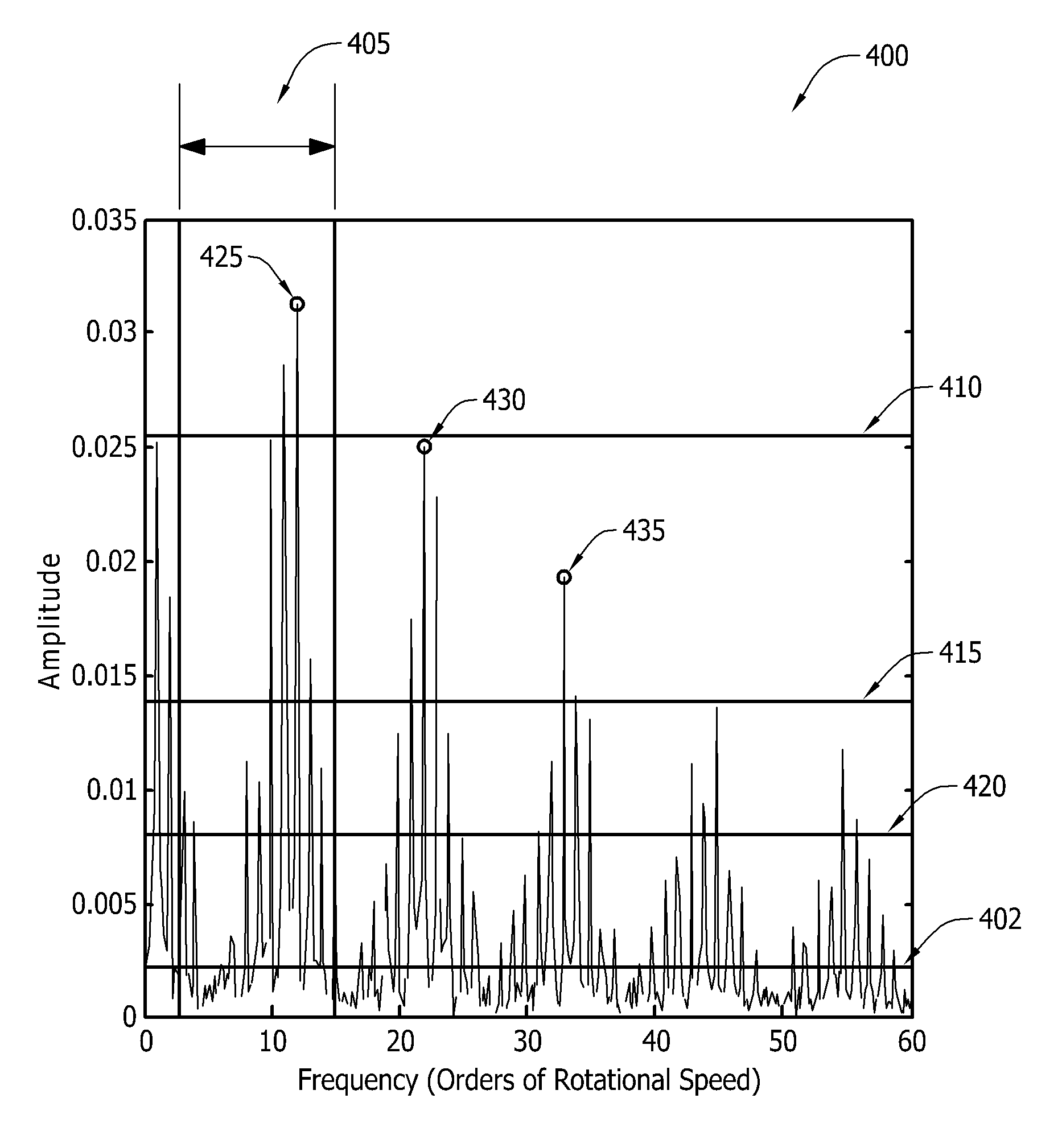

InactiveUS20130096848A1Machine part testingSpecial data processing applicationsRolling-element bearingHarmonic

A method of automatically detecting a rolling-element bearing fault in a rotating machine is provided. The method includes receiving, from at least one sensor, a sensor signal that includes at least one frequency, converting the sensor signal to a digital vibration signal, modifying the vibration signal to generate an envelope signal, and applying a transform to the enveloped signal to generate an envelope spectrum. The method uses certain relationships among envelope spectral line amplitudes and their harmonics to detect bearing faults. As such, the method detects a bearing fault without reference to predefined fault frequencies. Systems for implementing the method are also provided.

Owner:GENERAL ELECTRIC CO

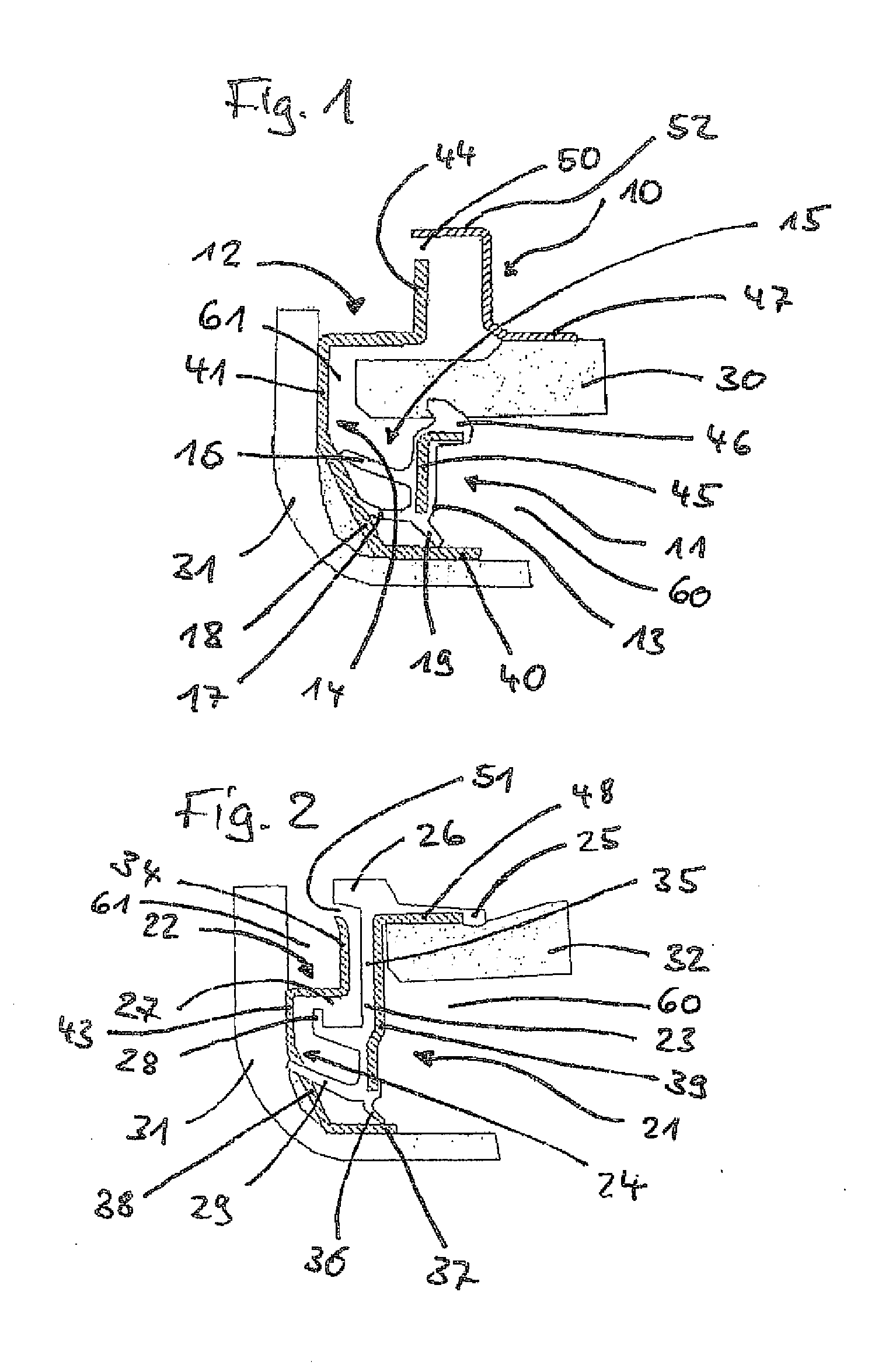

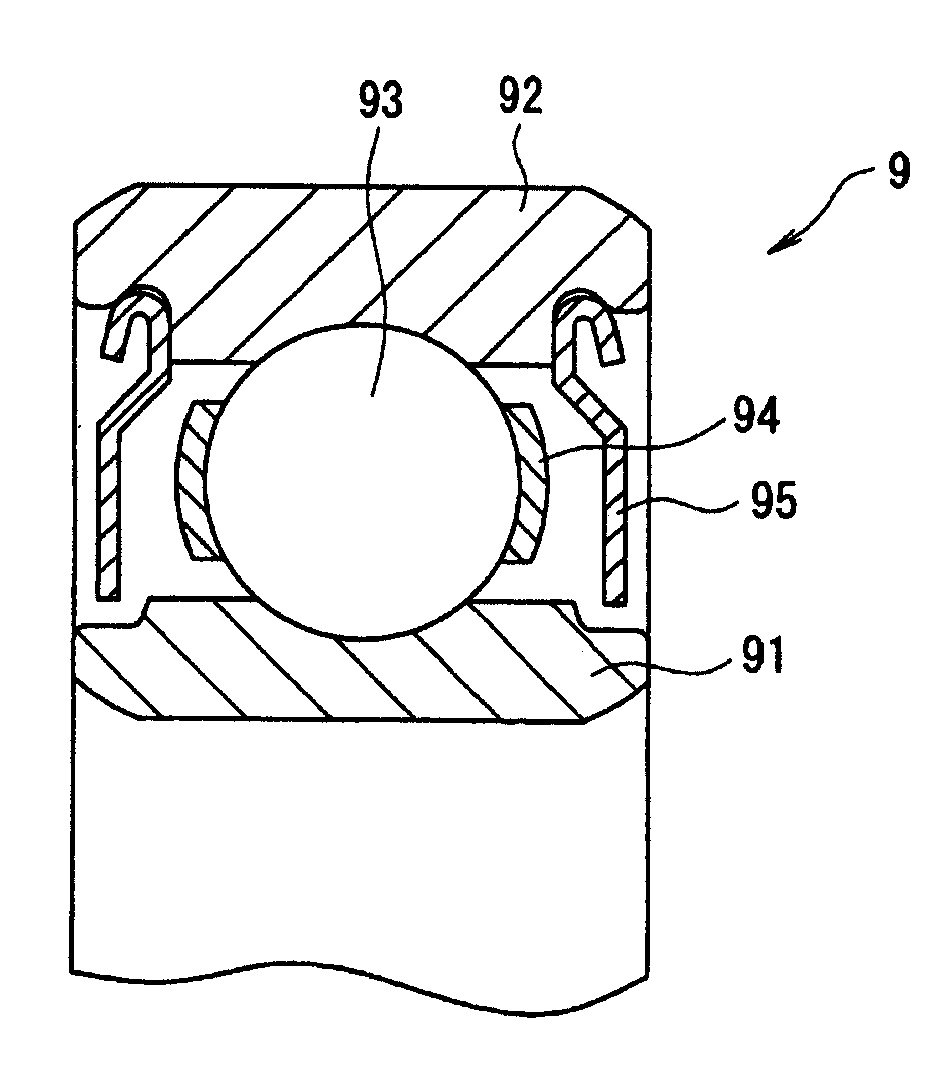

Sealing assembly for rolling bearings

InactiveUS20130127119A1Improve life performanceIncreasing sealing performanceEngine sealsRolling contact bearingsRolling-element bearingEngineering

A sealing assembly for sealing a rolling bearing, between a first and a second bearing part, where the two bearing parts are rotatable relative to each other and form therebetween both an axial space and a radial space. The sealing assembly includes: A contact member having a mounting section for attachment and a ring-shaped contact section for positioning the contact member on the second bearing part, and a carrier mountable to the first bearing part and has an elastic member forming a first axial sealing lip and / or a radial sealing lip. The contact member and a radially extending portion of the second bearing part together form a first collecting channel, and that an opening leading into the first collecting channel should be at least partially defined by an end section of the contact member.

Owner:SCHAEFFLER TECH AG & CO KG

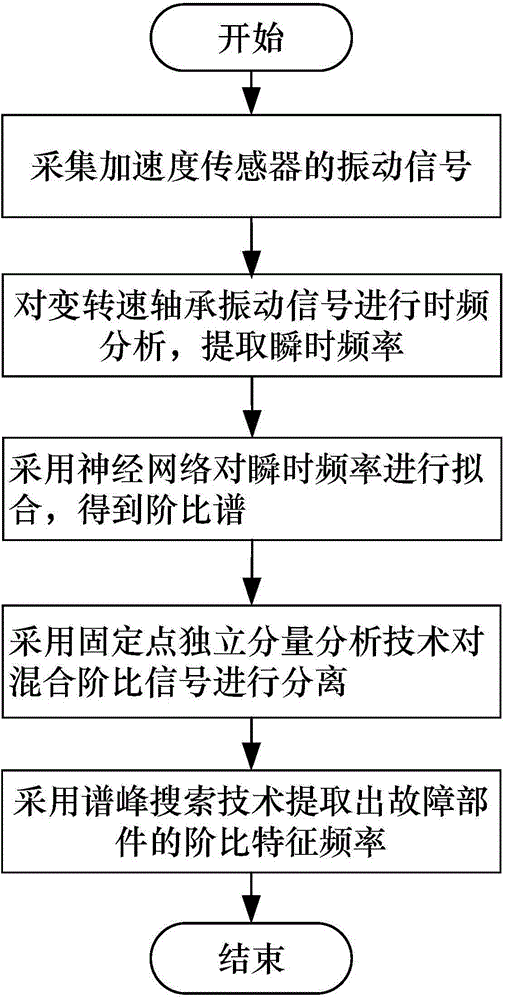

Method for extracting fault characteristic frequencies of train rolling bearings with variable rotational speeds

ActiveCN104568444AIncrease flexibilityCancel noiseMachine bearings testingRolling-element bearingSignal on

The invention discloses a method for extracting fault characteristic frequencies of train rolling bearings with variable rotational speeds, and belongs to the field of technologies for diagnosing faults and processing signals. The method includes steps of analyzing vibration signals of the bearings with the variable rotational speeds in time and frequency domains, searching local peak values of the vibration signals and extracting instantaneous frequency values corresponding to the rotational speeds at different moments; fitting instantaneous frequencies by the aid of neural networks, acquiring rotational speed curves of reference spindles, re-sampling original signals at uniform angles on the basis of the rotational speed curves and analyzing order ratios of the original signals on the basis of the rotational speed curves; separating signals with mixed order ratio signals by the aid of fixed-point independent component analysis and spectrum peak search technologies to acquire order ratio component characteristics of fault components of the bearings. The method has the advantages that the method is used for estimating the rotational speeds of the train bearings without tachometers in real time, the instable fault bearing signals can be converted into the stable signals in uniform-angle domains, independent order ratio components can be effectively separated from the signals, and the method is favorable for extracting the fault characteristic frequencies of the train bearings and detecting the fault characteristic frequencies of the train bearings in an online manner.

Owner:BEIJING UNIV OF POSTS & TELECOMM

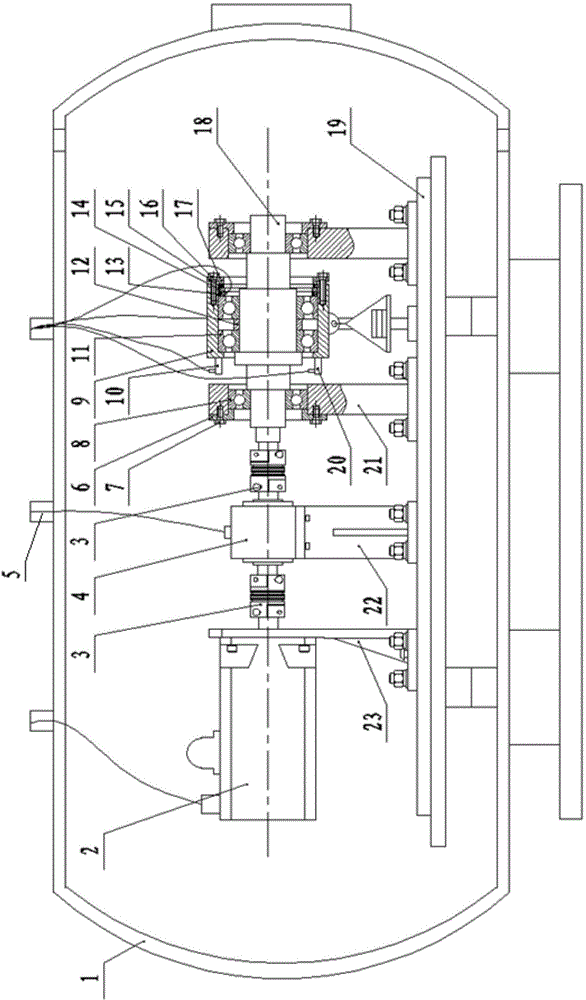

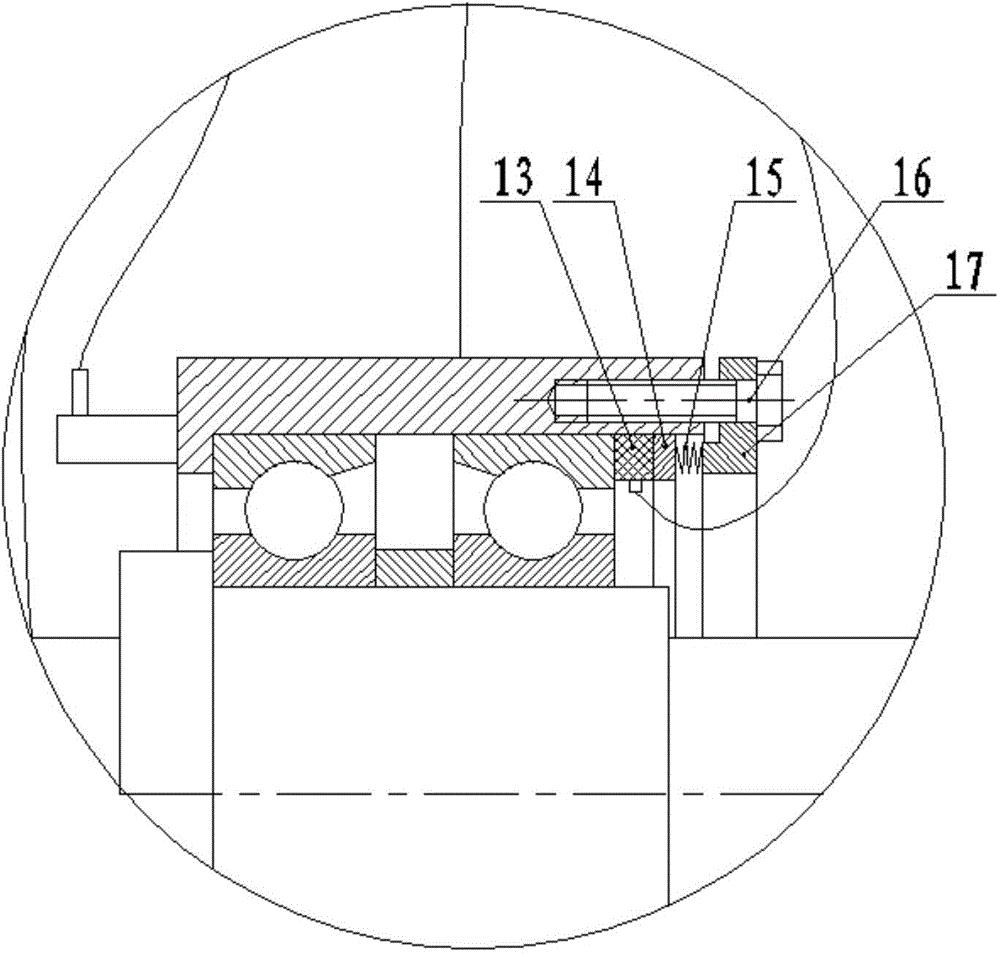

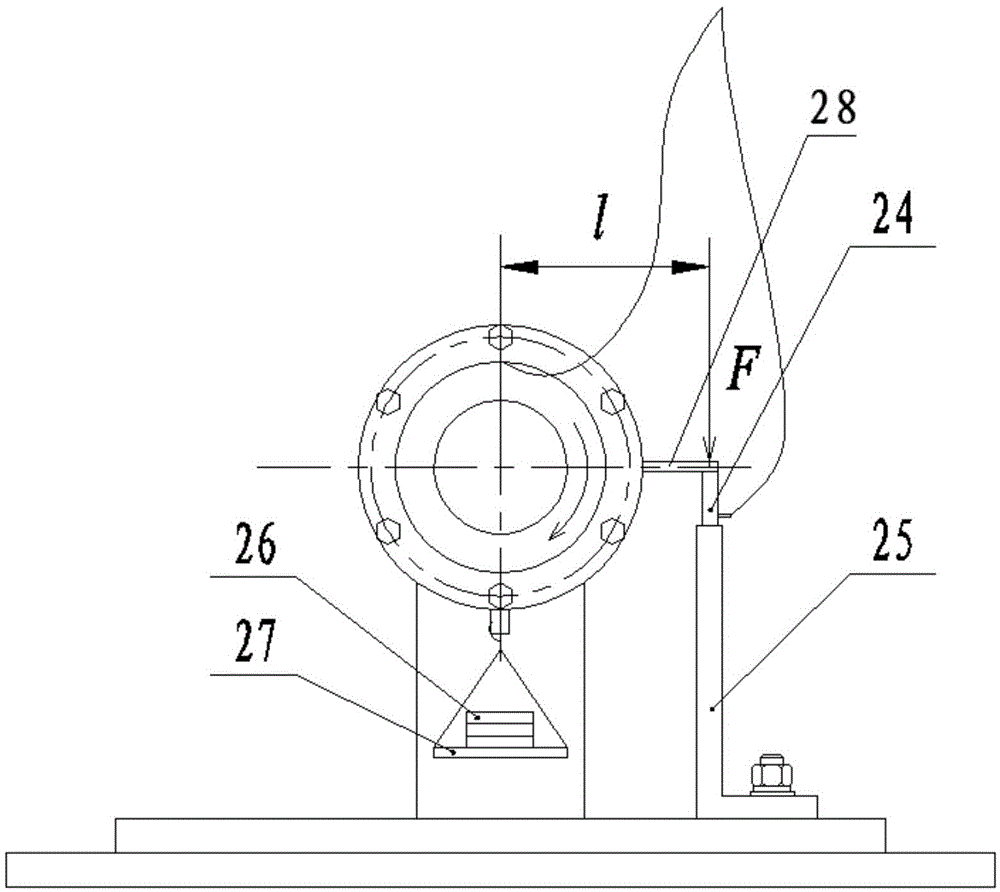

Space rolling bearing comprehensive performance experiment device

ActiveCN104568443ALoad accuratelyAccurate and stable loadingMachine bearings testingAviationFriction torque

The invention discloses a space rolling bearing comprehensive performance experiment device, relates to an experiment device and provides an experiment device capable of accurately measuring axial and redial united loads of a space rolling bearing and basic data including friction moment, bearing temperature rise, vibration and the like under different rotation speed working conditions. The space rolling bearing comprehensive performance experiment device can simultaneously conduct axial force and radial force accurate load on a measured bearing through an axial loading device and a radial loading device. A three-axis acceleration sensor is used for measuring radial, axial and peripheral vibration situations of the measured bearing. A temperature sensor is used for measuring the temperature rise situation of the measured bearing. A pressure sensor is used for measuring the friction moment of the measured bearing. An annular pressure sensor is used for measuring axial force borne by the measured bearing. Weights are used for marking radial force borne by the measured bearing. The space rolling bearing comprehensive performance experiment device can evaluate the comprehensive performance of the space rolling bearing and provide key scientific technical basis and test platform support for development of high-end bearings in the aerospace field of our country.

Owner:SICHUAN UNIV

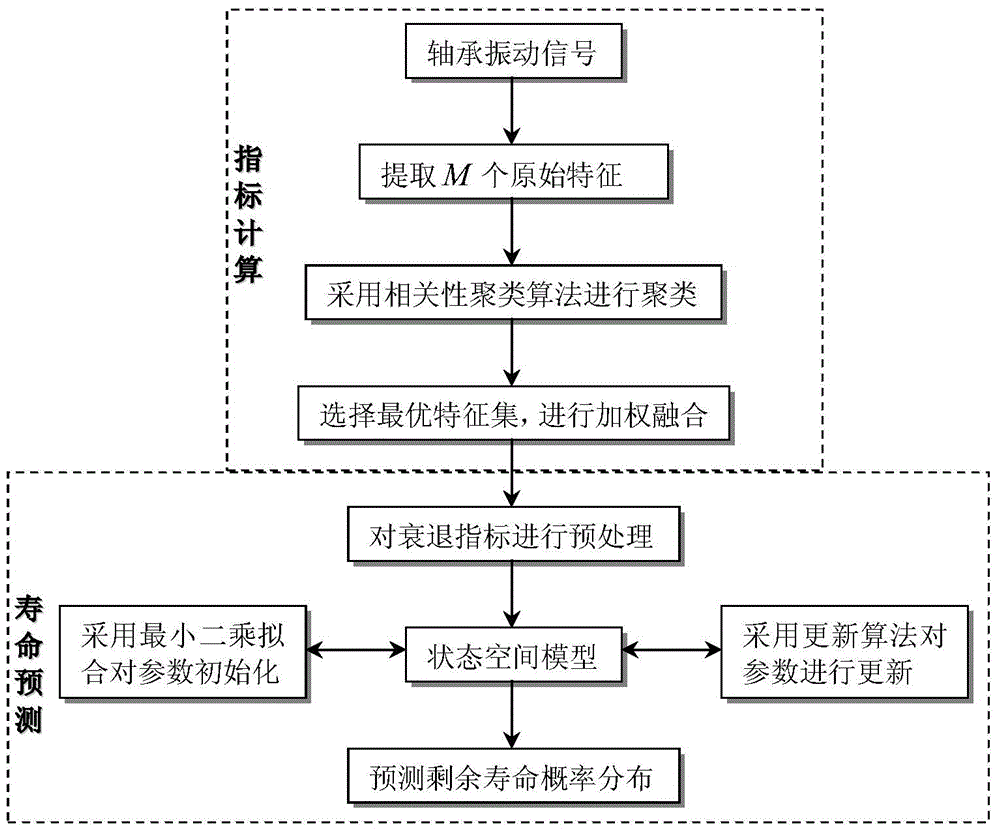

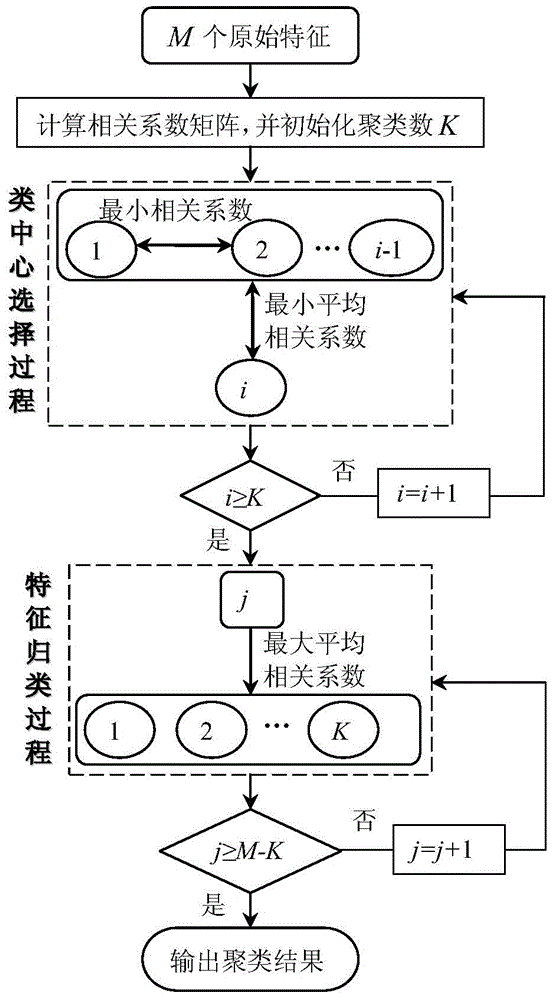

Rolling bearing remaining life prediction method based on feature fusion and particle filtering

Disclosed is a rolling bearing remaining life prediction method based on feature fusion and particle filtering. According to an index calculation process, firstly, original features are extracted from bearing vibration signals, the extracted original features are clustered by the adoption of a relevance clustering method, then, one typical feature is selected from each cluster to form optimal feature sets, and finally the feature sets are fused by the adoption of a weight fusion method into a final recession index. According to a life prediction process, firstly, smoothing and resampling are carried out on the recession index, the time interval is adjusted to be an expected value, state-space model initial parameters are calculated by the adoption of least square fitting, then, model parameters are updated in real time according to new observation data, and finally the remaining life of a bearing can be predicted. According to the rolling bearing remaining life prediction method based on feature fusion and particle filtering, the difference between the life prediction result and a true value is small, and the application effect is good.

Owner:CHANGXING SHENGYANG TECH CO LTD

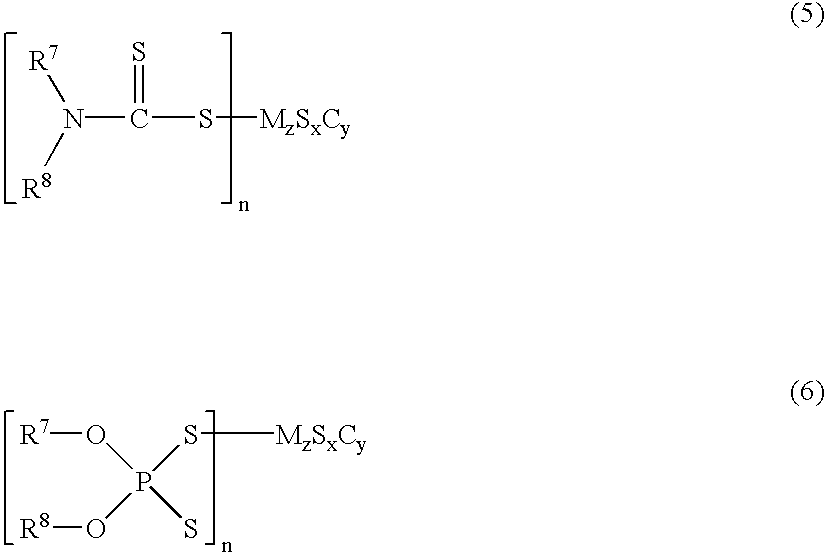

Rolling bearing

InactiveUS20030040442A1Reaction can be suppressedImprove fatigue strengthLiquid carbonaceous fuelsThickenersAlternatorRolling-element bearing

The invention aims to provide a rolling bearing that secures a sufficient bearing life economically even when used under such conditions that water from the outside or water formed by moisture condensation may seep into the lubricant or the bearing is affected by the vibrations, and particularly a rolling bearing suited to the electric parts and accessaries of au automobile engine, such as an alternator. To accomplish the object, the hydrogen ion exponent pH of the grease sealed into the inside of the bearing is adjusted in a range of from 7 to 13. For the same purpose, the hydrogen ion exponent pH of the grease is adjusted in a range of from 5 to 13 where a prescribed amount of an organic metal salt or ADTC is added to the grease, where a prescribed amount of an inorganic compound having an average particle size of 2 squarem or smaller is added to the grease, or where a diurea compound containing an aromatic amine or a mixture of the diurea compound is added to the grease as a thickener.

Owner:NSK LTD

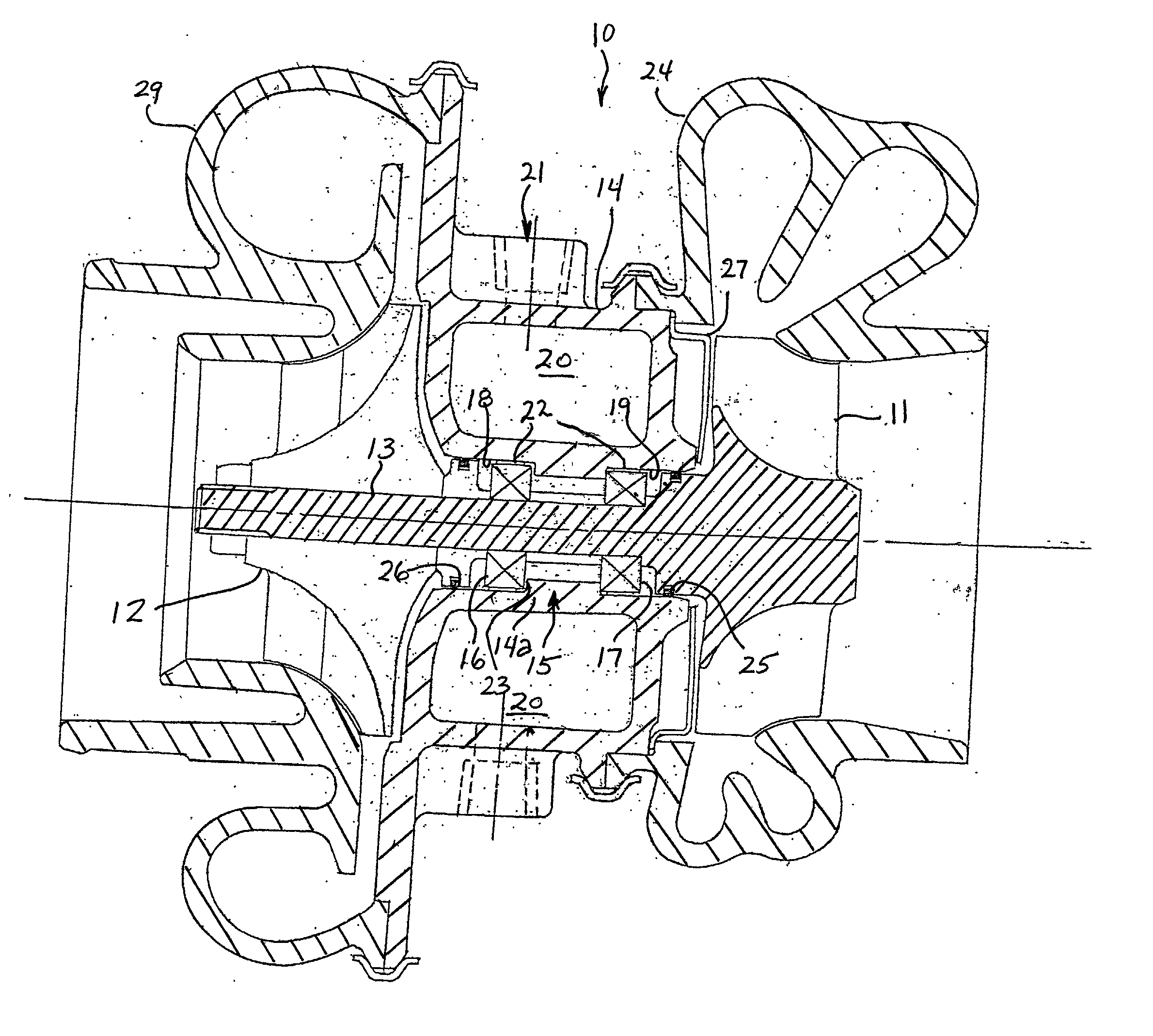

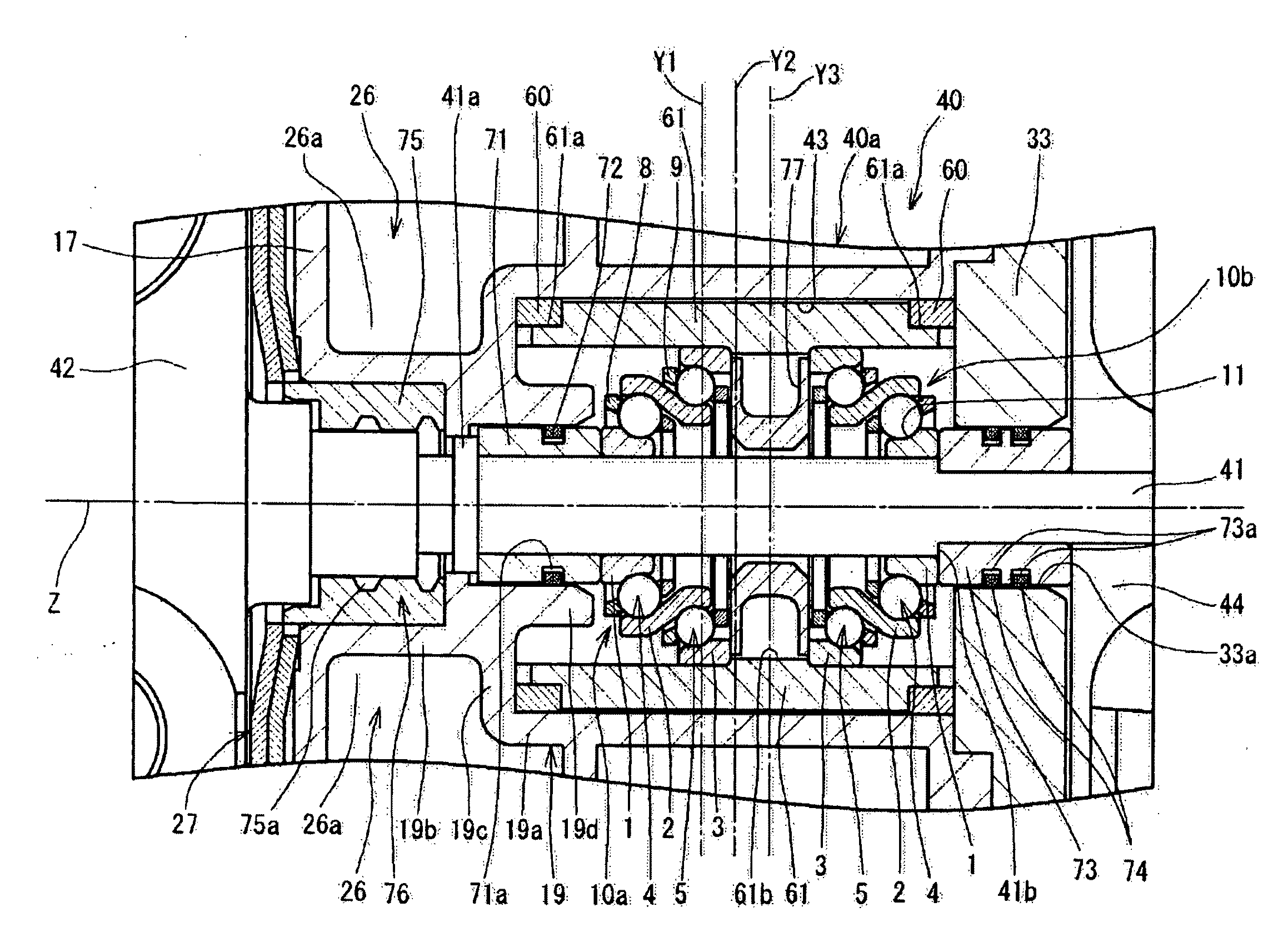

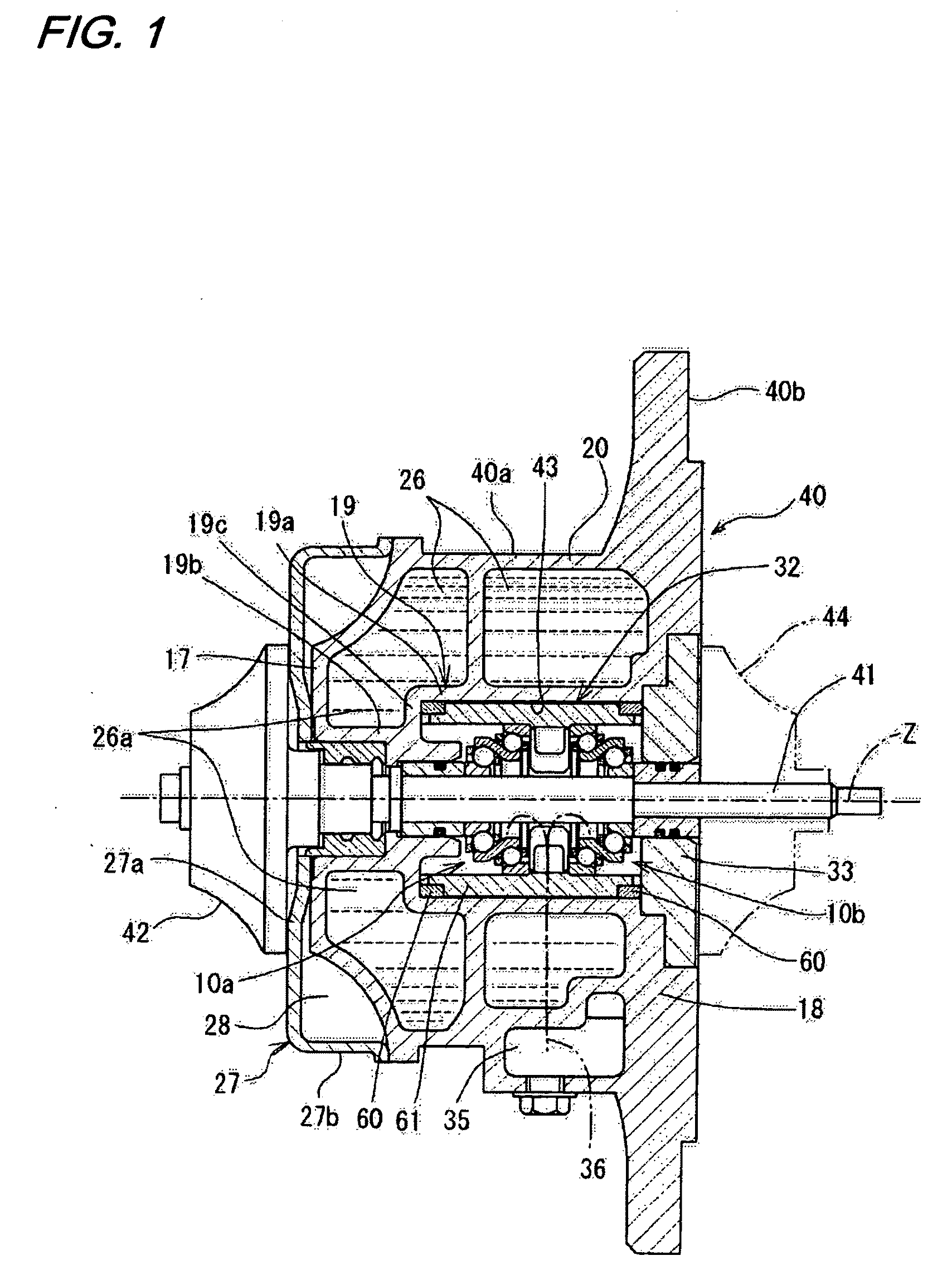

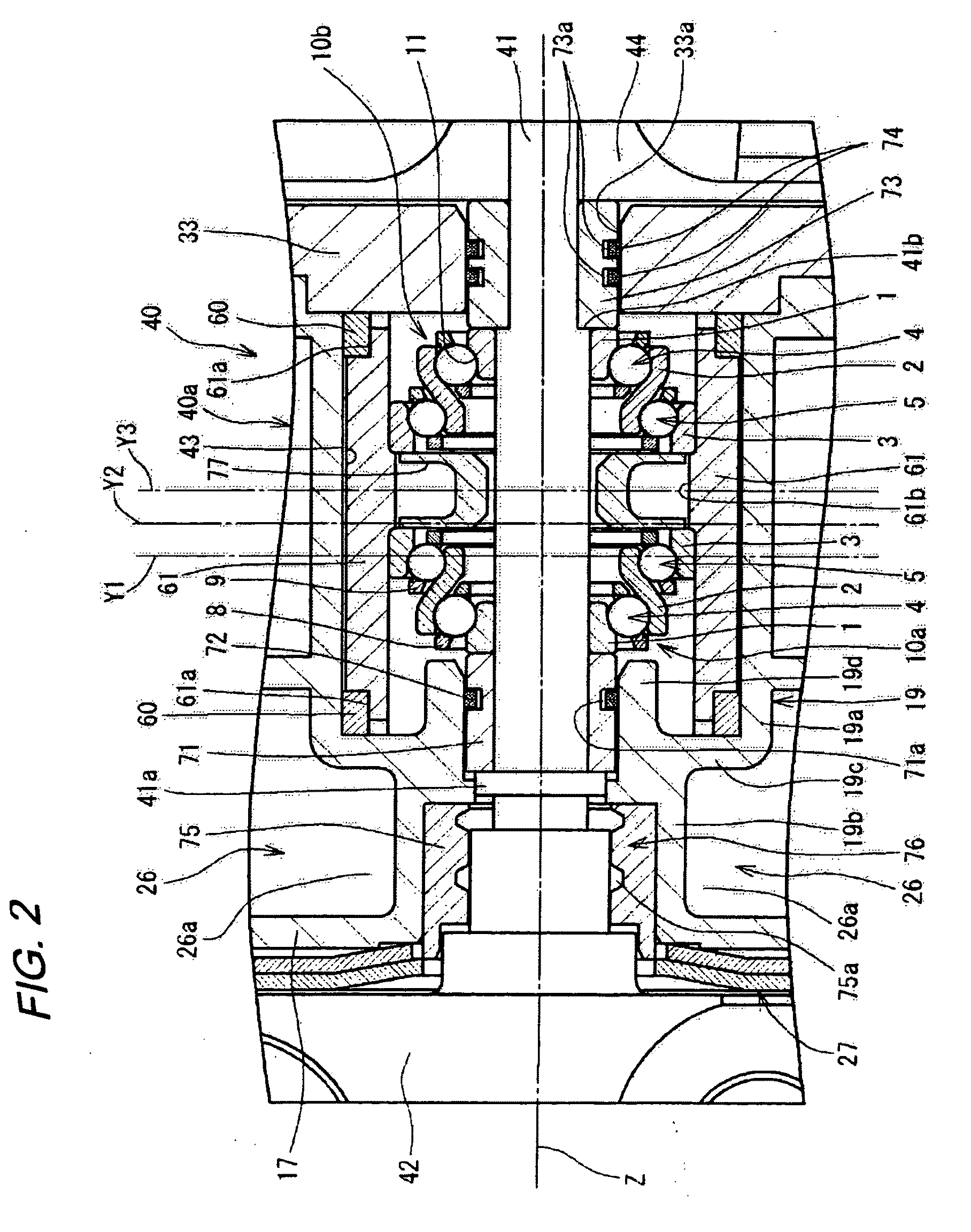

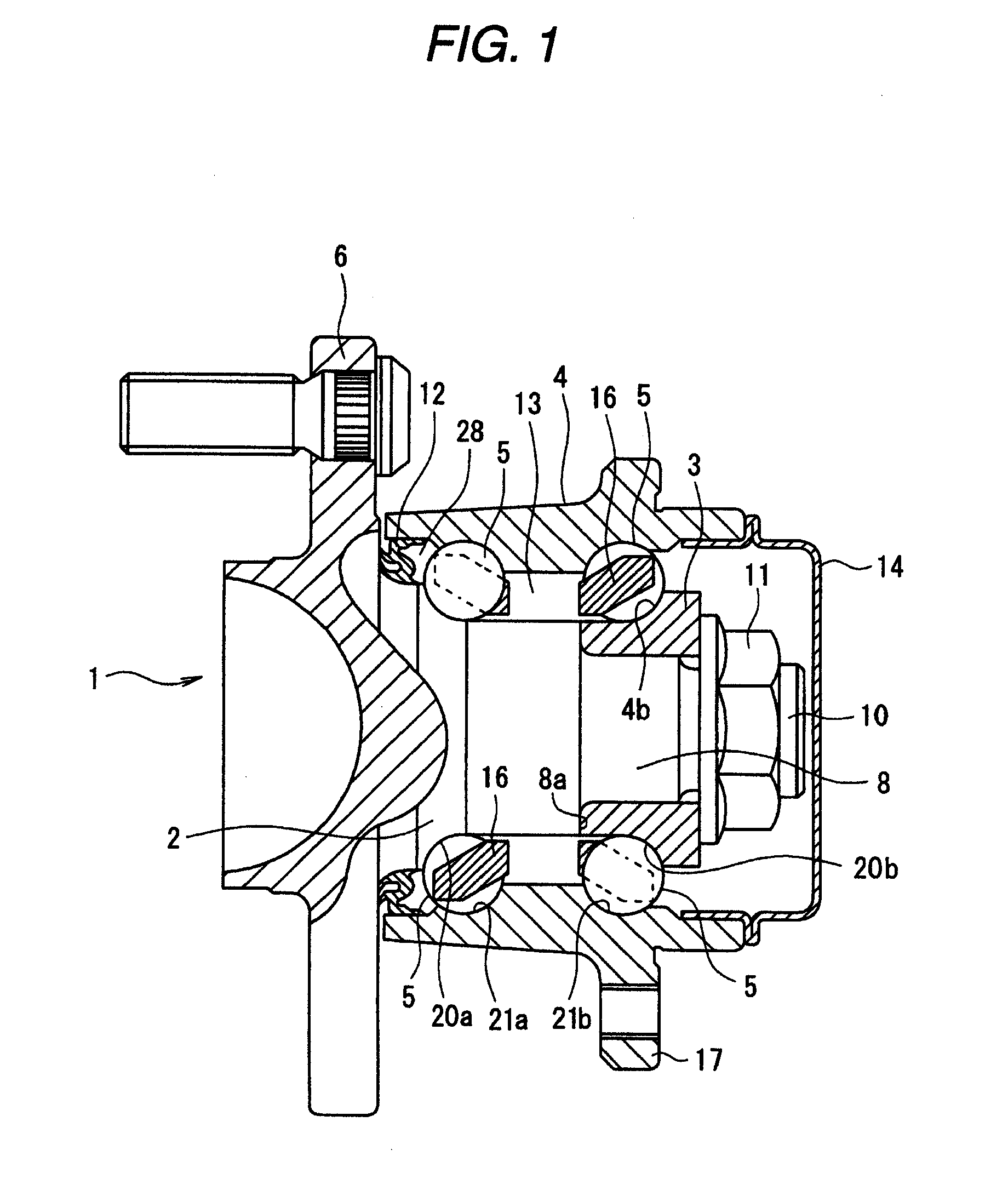

Rolling bearing device and turbocharger incorporating same

InactiveUS20090081040A1Heating effectReduce vibrationPump componentsShaftsRolling-element bearingTurbocharger

A rolling bearing device includes a bearing housing supported on a casing of a turbocharger, and a pair of rolling bearings mounted within the bearing housing and rotatably supporting a turbine shaft. A middle position between the pair of rolling bearings in an axial direction and a central portion of the bearing housing in the axial direction are offset from each other in the axial direction. Each of the rolling bearings includes an inner ring, an outer ring, an intermediate ring interposed between the inner and outer rings, a row of rolling elements rollably interposed between the inner ring and the intermediate ring, and a row of rolling elements rollably interposed between the intermediate ring and the outer ring. The intermediate ring has a damper function to be very slightly displaced or very slightly deformed elastically so as to damp vibration produced during rotation of the turbine shaft.

Owner:JTEKT CORP

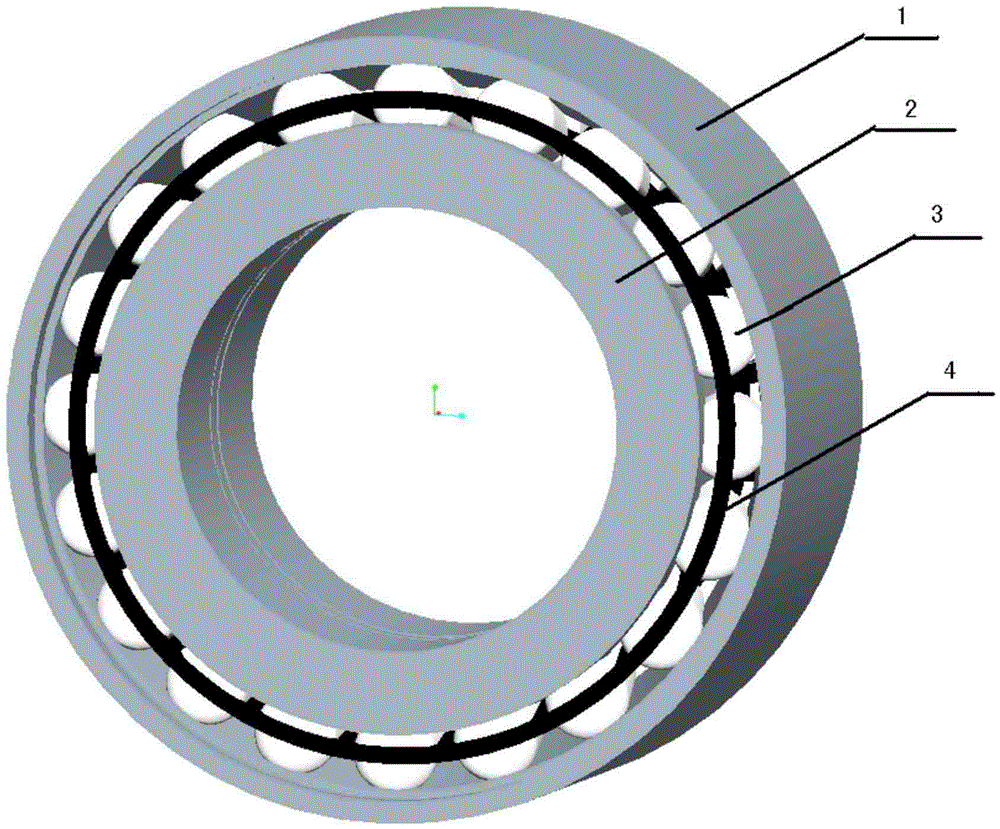

Coated rolling element bearing cages

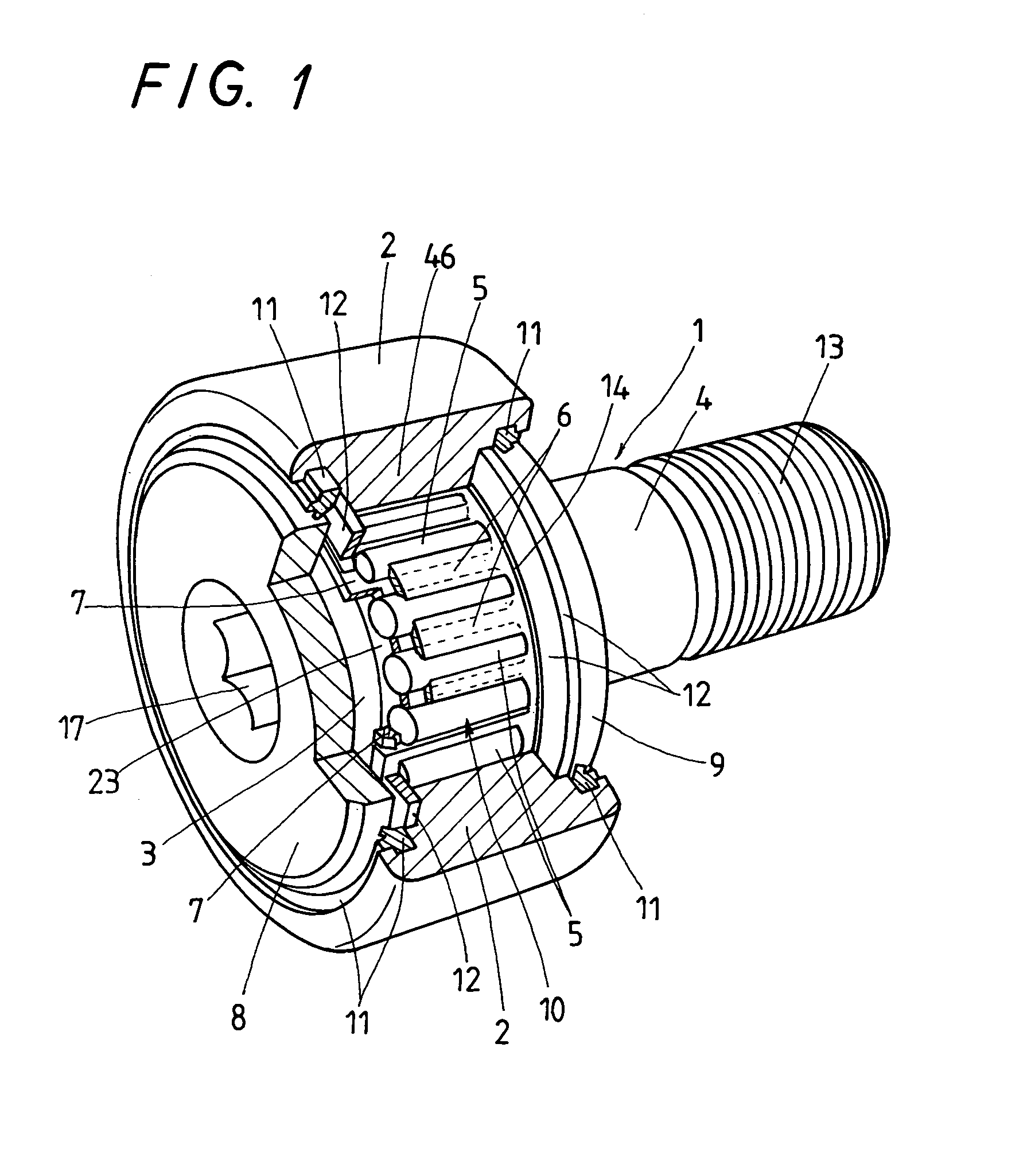

ActiveUS6994475B2Eliminate wear and tearShaftsBall bearingsRolling-element bearingMechanical engineering

A rolling element bearing comprises an inner ring (3) and an outer ring (2) each provided with a raceway (4, 5), said rings having land regions (10, 11) on opposite sides of their raceways, and a series of rolling elements (6) which are in rolling contact with the raceways and which are mutually spaced by a cage (7), said cage (7) engaging the land regions (10, 11) of said ring, said cage (7) being coated with a wear and friction reducing coating over its full surface.

Owner:THE TIMKEN CO

Grease Composition For Hub Unit Bearing, And Hub Unit Bearing For Vehicle

InactiveUS20090003742A1Improve peeling resistanceImprove the lubrication effectOrganic chemistryHubsRolling-element bearingAdditive ingredient

An object of the invention is to provide a grease composition capable of keeping a good lubrication condition for a long period of time even when water has mixed therein, thereby inhibiting white structure flaking and corrosion. Another object is to provide a vehicular hub unit bearing which hardly suffers from white structure flaking and corrosion even when used in an environment where water may penetrate into it and which therefore has a long life.The invention provides a rolling bearing with, sealed up therein, a grease composition containing a waterproof film-forming additive added thereto; a grease composition for hub unit bearings, containing a base oil that comprises at least one of mineral oil and synthetic oil as the main ingredient thereof, and a thickener and a flaking inhibitor; and a vehicular hub unit bearing with the grease composition sealed up therein.

Owner:NSK LTD +1

Motor with a stationary shaft with formed knurled grooves on shaft and/or housing

InactiveUS6630758B2Prevent occurrence of abnormalityAvoid it happening againBearing assemblyBall bearingsRolling-element bearingEngineering

A motor comprises a rotor, a stator, and a shaft wherein one of the stator and the rotor is provided with a housing, a rolling bearing is provided between the housing and the shaft and having an inner race and outer race, the inner race is fixed to the shaft through adhesion between the outer peripheral surface of the shaft and the inner peripheral surface of the inner race, the outer race is fixed to the housing through press-fitting, and the outer peripheral surface of the shaft is formed with knurled grooves, where the number (P) of the knurled grooves in the circumferential direction and the number (Z) of the rolling members in the rolling bearing are in the relations of P≢n Z and P≢nZ±1 where n is a positive integer.

Owner:NSK LTD

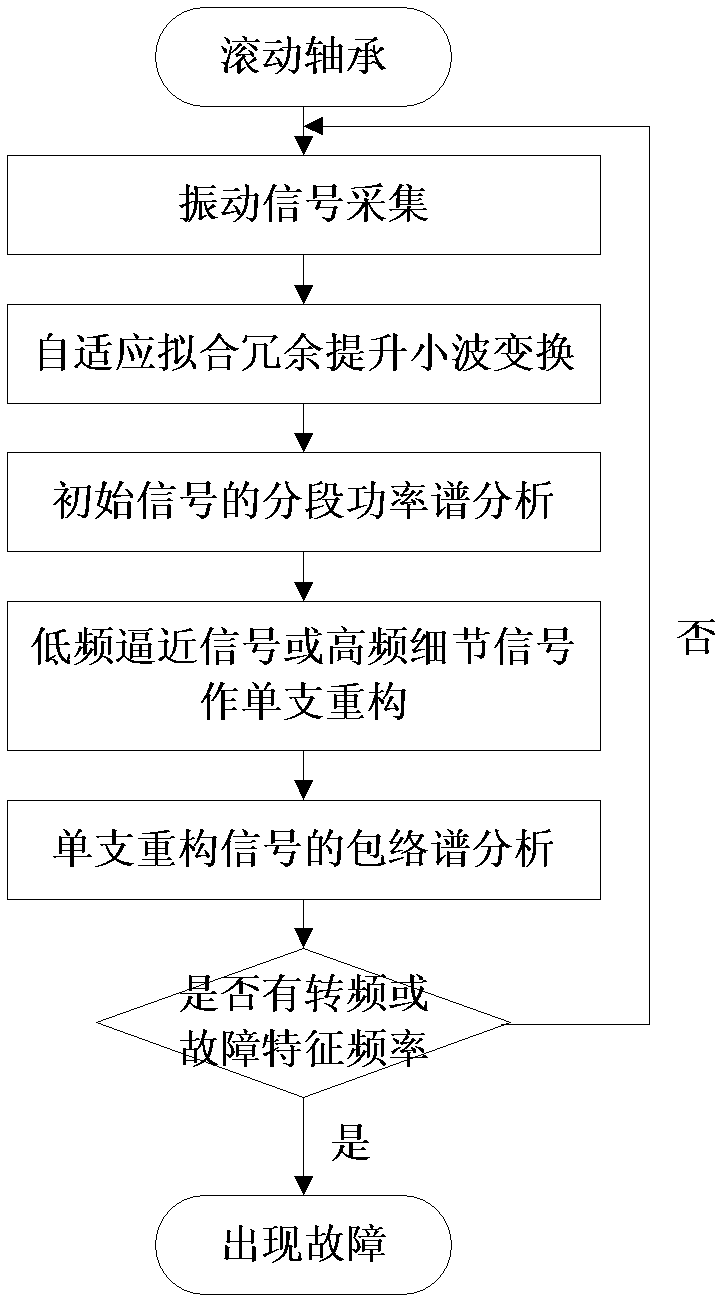

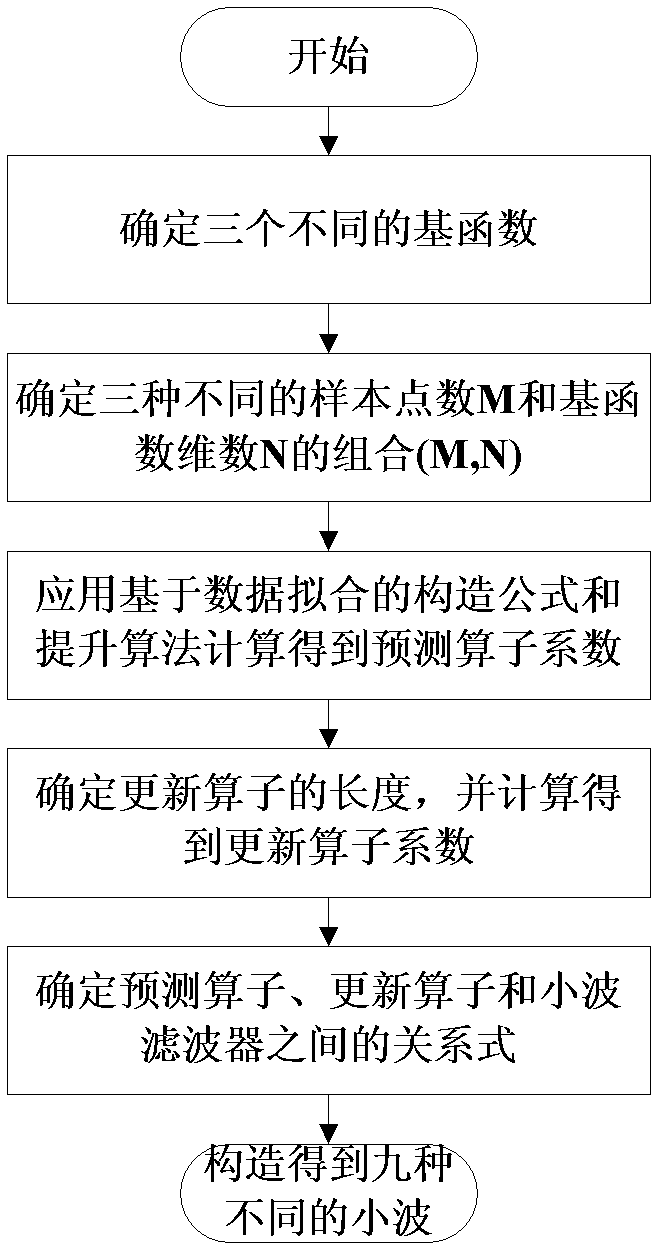

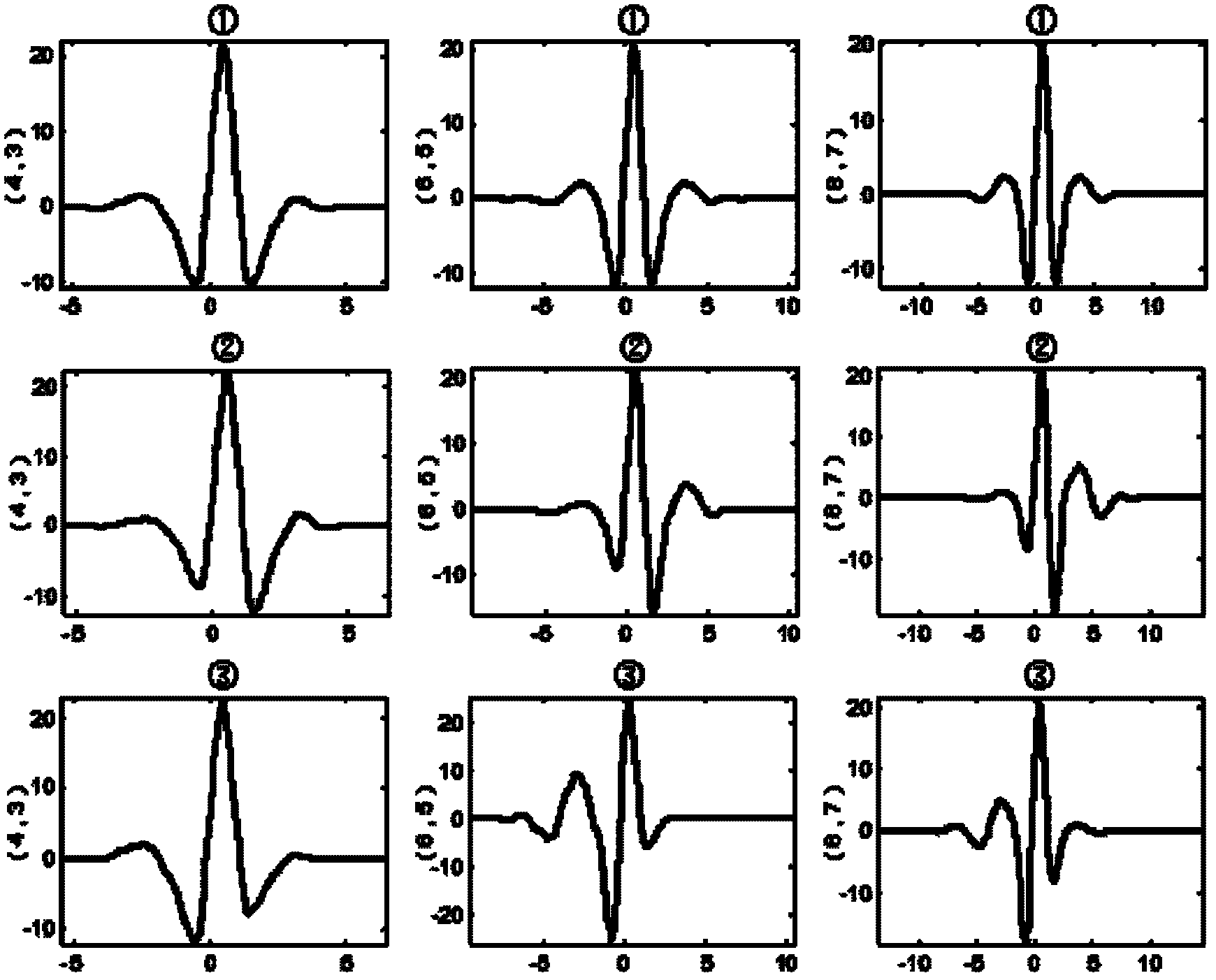

Bearing fault characteristic extracting method for redundantly lifting wavelet transform based on self-adaptive fitting

InactiveCN102607845AImprove matchEfficient extractionMachine bearings testingVibration accelerationFeature extraction

The invention provides a bearing fault characteristic extracting method for lifting wavelet transform based on self-adaptive fitting. The bearing fault characteristic extracting method is used for diagnosing faults of a rolling bearing through a vibration acceleration signal, and comprises the following steps of: creating nine wavelets with different characteristics through calculation formulas and lifting algorithms based on data fitting; carrying out redundant lifting wavelet transform on a vibration signal by using the nine created wavelets in sequence; determining the optimum and abandoning the other eight in nine groups of decomposition results according to a normalized 1P norm value; analyzing segmented power spectrums of the initial vibration acceleration signal; selecting the optimum low-frequency approximation signal or a high-frequency detail signal for single reconstruction; subjecting the signal obtained by the single reconstruction to Hilbert demodulation; and judging running state of the rolling bearing according to frequency components in an enveloping spectrum. According to invention, early weak fault characteristic information of the rolling bearing can be extracted more effectively, and evidences are provided for state monitoring and fault diagnosis of the rolling bearing, so that accidents can be avoided as possible.

Owner:北京工大智源科技发展有限公司

Location loading material testing machine

InactiveCN101881710ASimple structureCompact structureMaterial strength using tensile/compressive forcesTension compressionTorsion test

The invention relates to a location loading material testing machine which belongs to the technical field of material test. The location loading material testing machine is characterized in a location loading system; a support stand and a loading support part of the location loading system are respectively positioned at both ends of a fixing base; the loading support part comprises a location loading stand, a flange shaft, an overrunning clutch, a rolling bearing, a groove-shaped nut and two sliding blocks; three guide grooves are arranged on the location loading stand; the sliding blocks are respectively positioned in two keyways of the right external diameter of the groove-shaped nut; the overrunning clutch and the rolling bearing are fixed in the location loading stand in parallel; one end of the flange shaft is fixed by a hexagon nut through threads, and the other end is connected with the groove-shaped nut by threads; the left side of the groove-shaped nut is provided with a groove-shaped cavity; two through holes which are distributed left and right are radially arranged in the groove-shaped cavity; and the positions of the two through holes correspond to the first guide groove and the second guide groove on a loading support stand. The invention can realize a series of tension and compression tests and torsion tests by applying the guide grooves in the horizontal direction and the vertical direction of a location tension-compression-torsion loading stand.

Owner:JIANGSU UNIV

Multi-cylinder hydraulic antifriction bearing taper crusher

ActiveCN102357371AIncrease speedImprove crushing efficiencyGrain treatmentsRolling-element bearingWorking pressure

The invention discloses a multi-cylinder hydraulic antifriction bearing taper crusher, which comprises a lower machine frame, an eccentric sleeve mechanism, a transmission set, a movable tapper, an upper machine frame set and an iron passing and cavity clearing device. The upper machine frame set is arranged above the lower machine frame, the transmission set and the eccentric sleeve mechanism are both installed on the lower machine frame, the transmission set is connected with the eccentric sleeve mechanism where the movable tapper is arranged, the iron passing and cavity clearing device is directly installed on the lower machine frame and the upper machine frame set, the eccentric sleeve mechanism adopts an antifriction bearing type eccentric sleeve mechanism, the iron passing and cavity clearing device adopts a relief valve type iron passing and cavity clearing device, and a movable tapper body rotating-proof device is connected to the bottom of the movable tapper. The multi-cylinder hydraulic antifriction bearing taper crusher improves crushing efficiency and output of the taper crusher, and prolongs service life of a machine, reduces using cost of equipment. The iron passing and cavity clearing device can not only bear higher working pressure of a system, but also be safe and reliable, convenient to assemble and capable of controlling a tapper body to rotate according to certain direction, thereby improving production efficiency and saving energy.

Owner:ZHEJIANG ZHEKUANG HEAVY IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com