Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

438results about "Needle bearings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

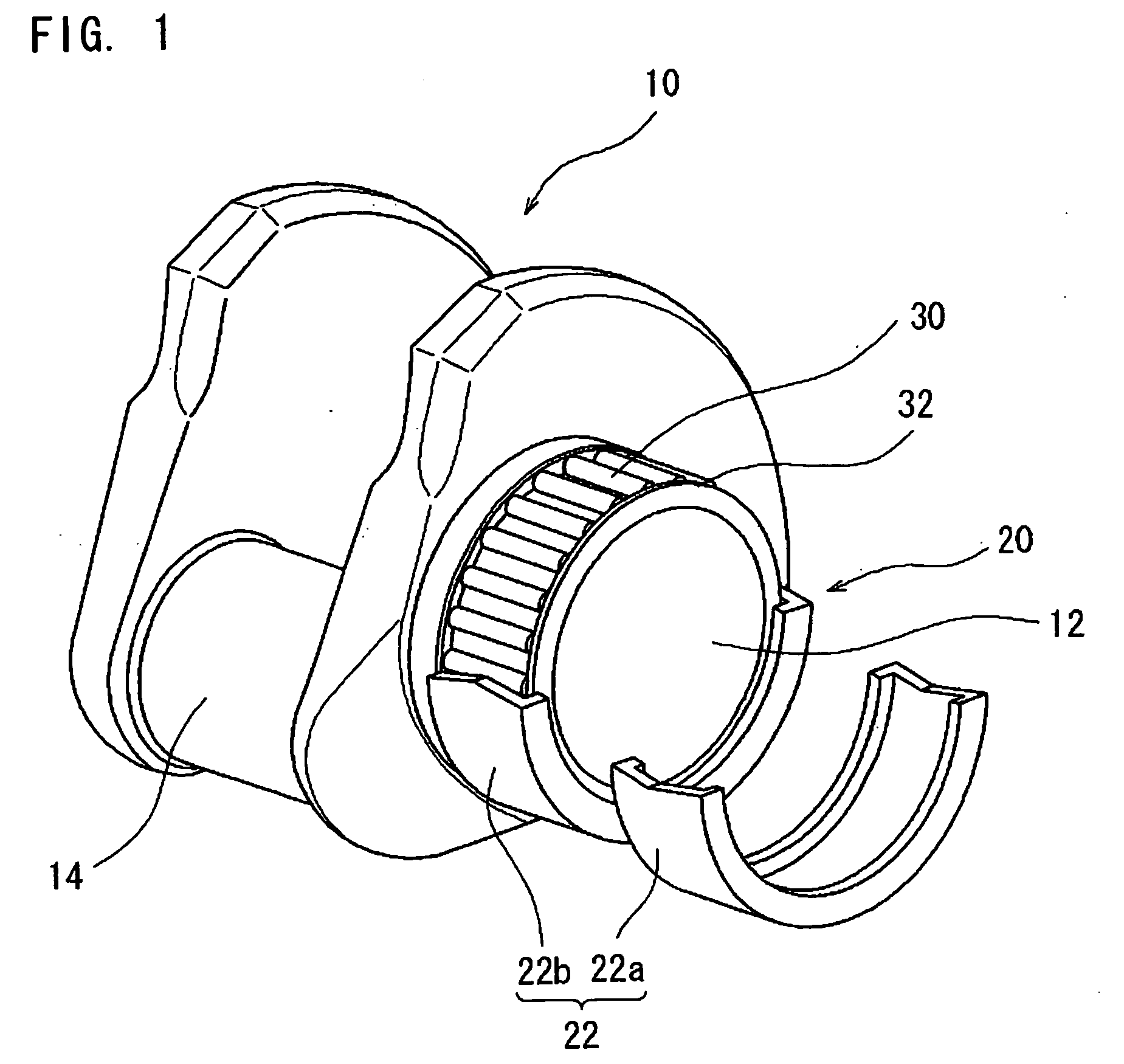

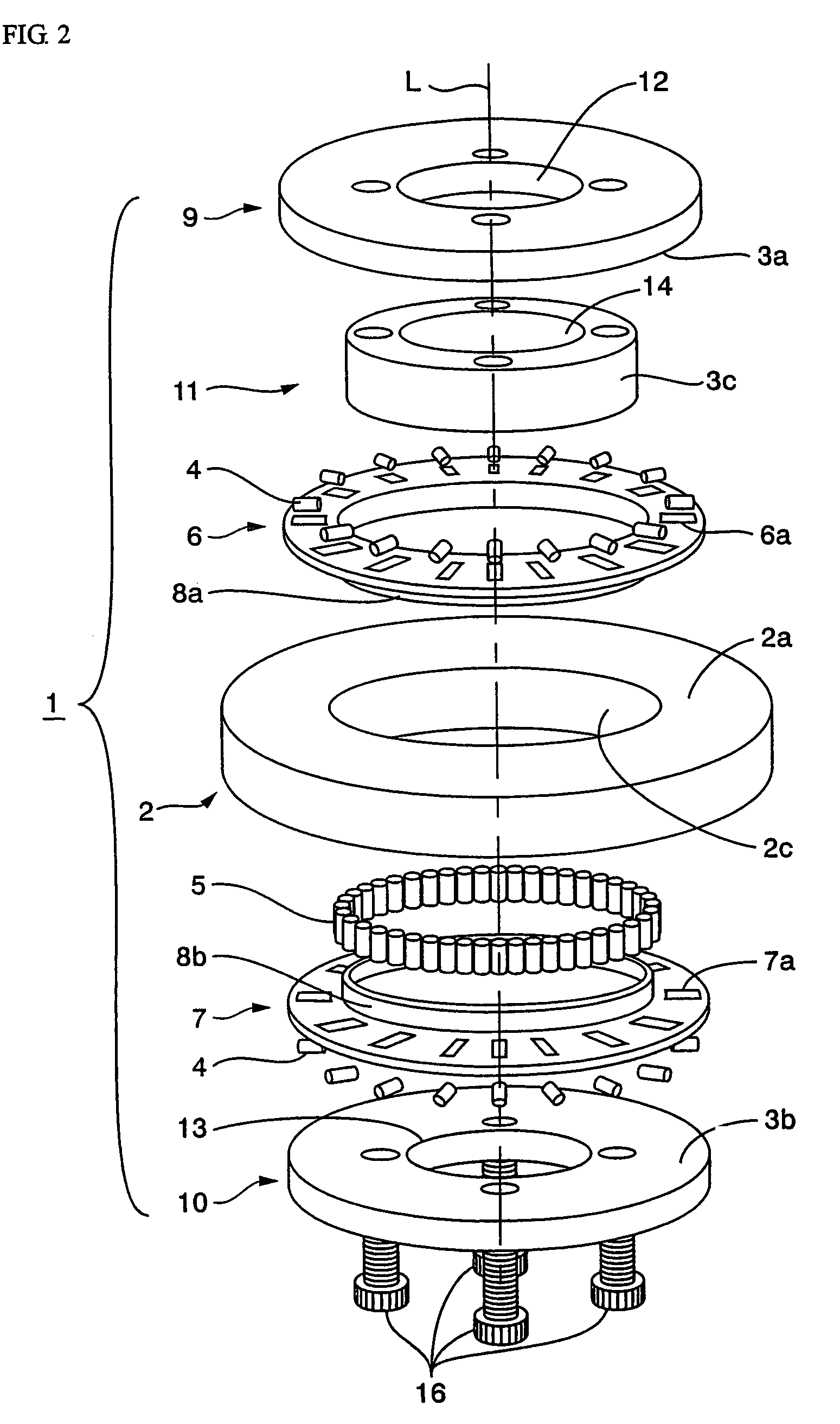

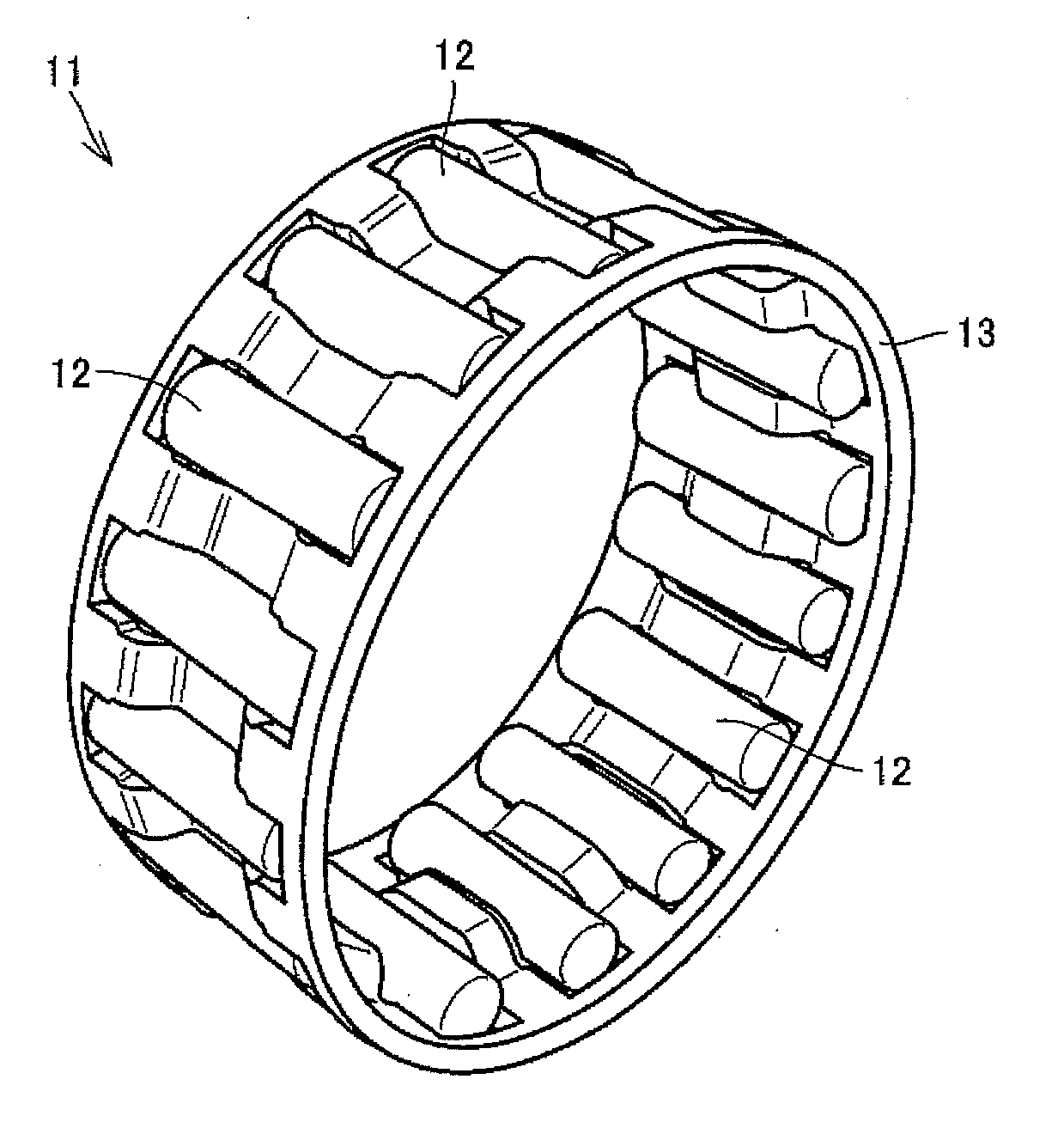

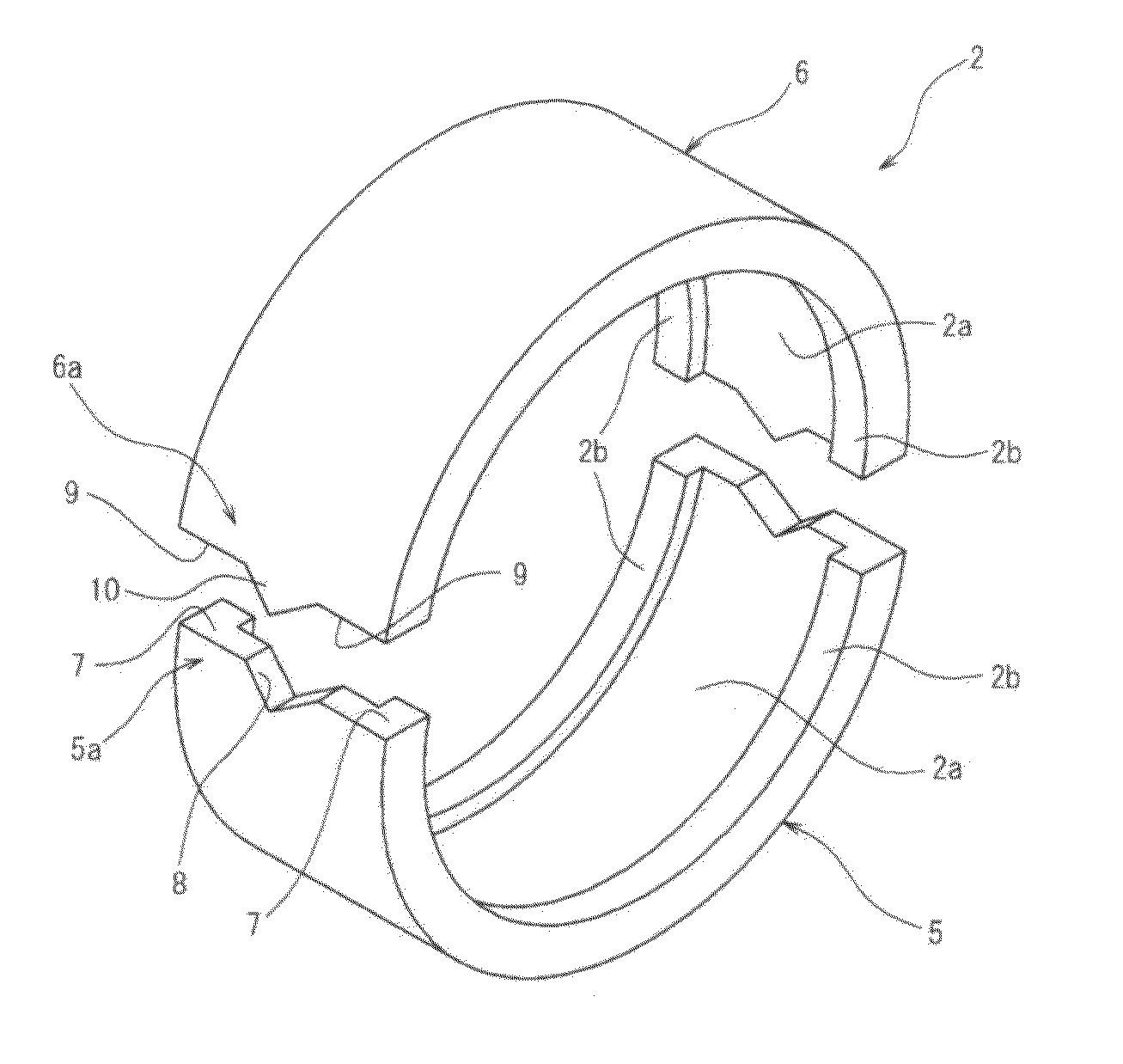

Rolling-contact bearing containing solid lubricant therein

ActiveUS7234873B2Improve air tightnessSmooth movementBearing componentsNeedle bearingsRolling-element bearingEngineering

A cage, rollers and solid lubricant are all formed integrally into a complete unitary molding with using difference in thermal expansion in a mold. Assembling the complete unitary molding into the race in the rolling-contact bearing is made easier. The complete unitary molding is made such that the rollers remain exposed partially at their rolling surfaces above the inside circular surface of the complete unitary molding while the solid lubricant on the outside circular surface of the complete unitary molding is squeezed out from between the rolling surfaces of the rollers and the inside circular surface of the outside mold upon molding operation, thereby getting the rolling surfaces of the rollers exposed partially. The mold is composed of an outside mold, an inside mold and an intermediate mold, which is made of a substance larger in thermal expansion than other substance for the outside and inside molds.

Owner:NIPPON THOMPSON

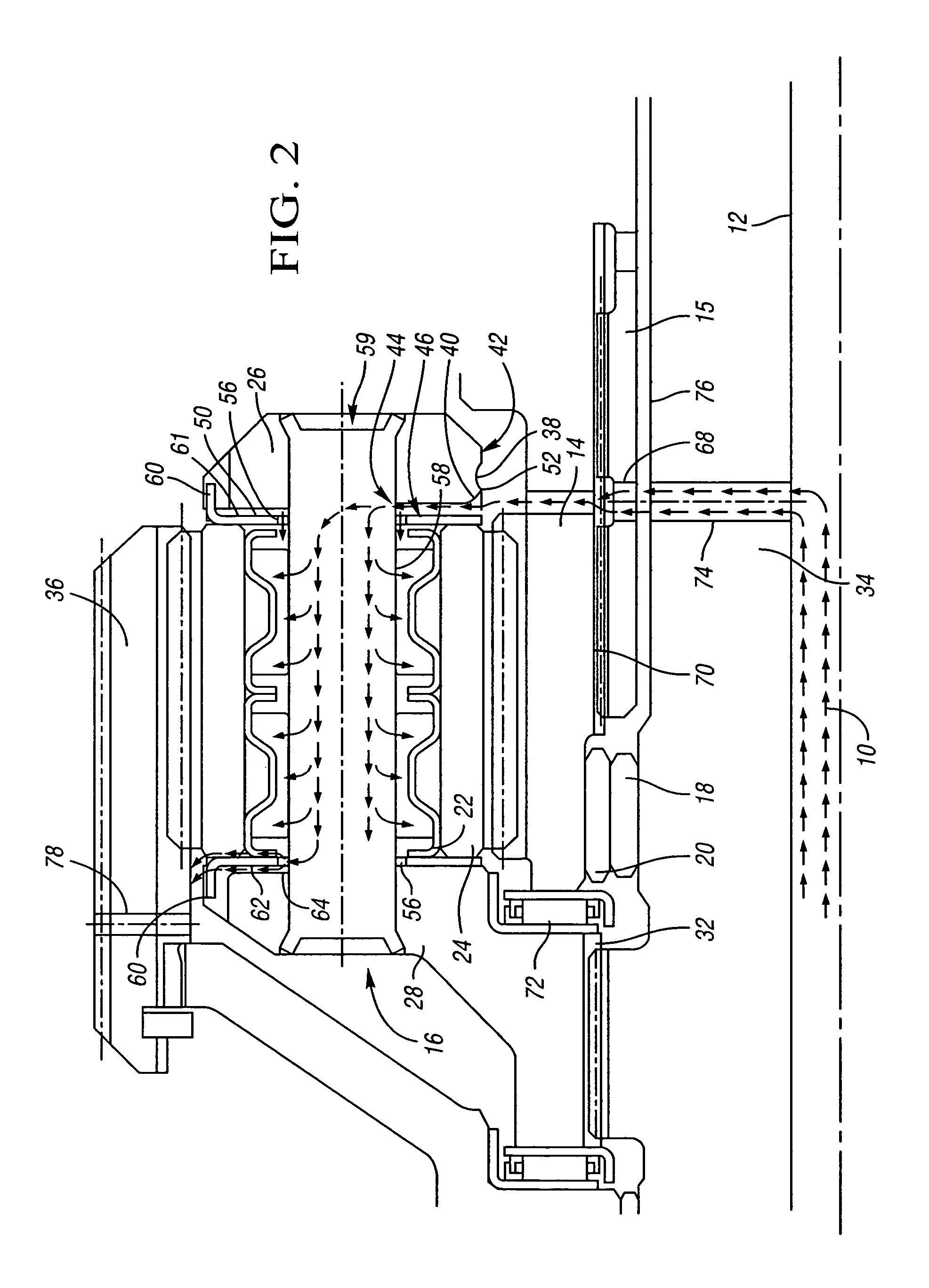

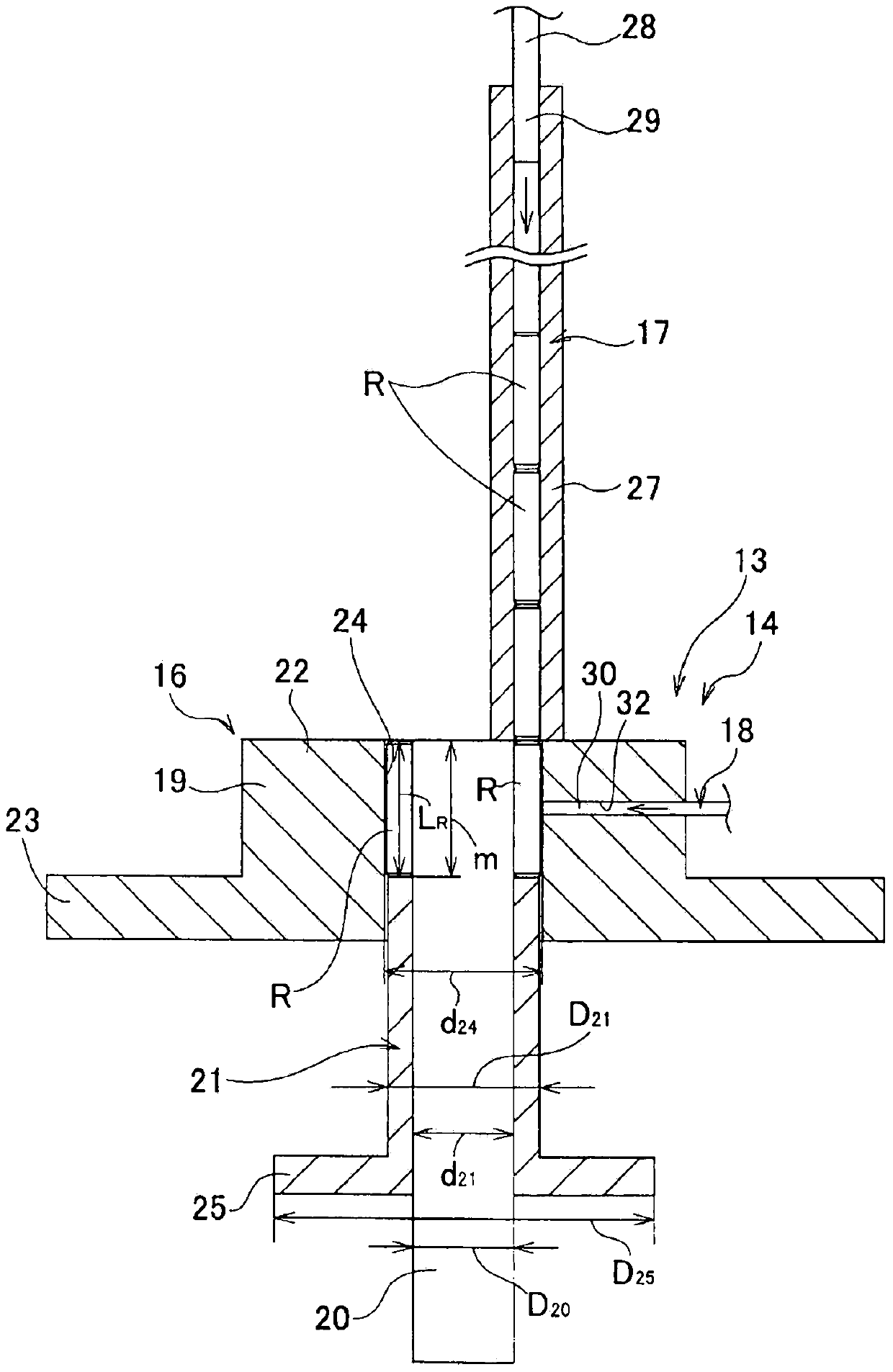

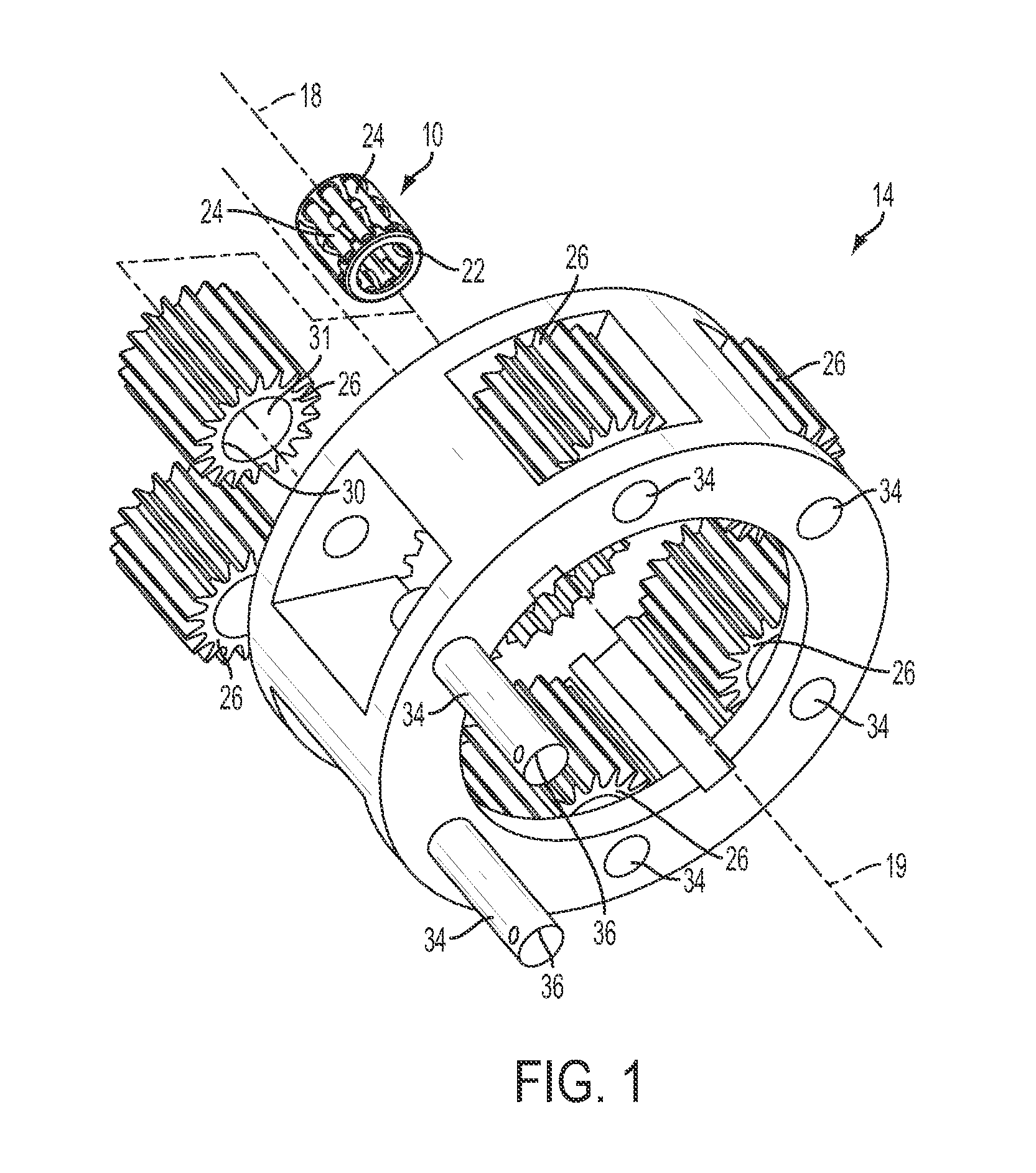

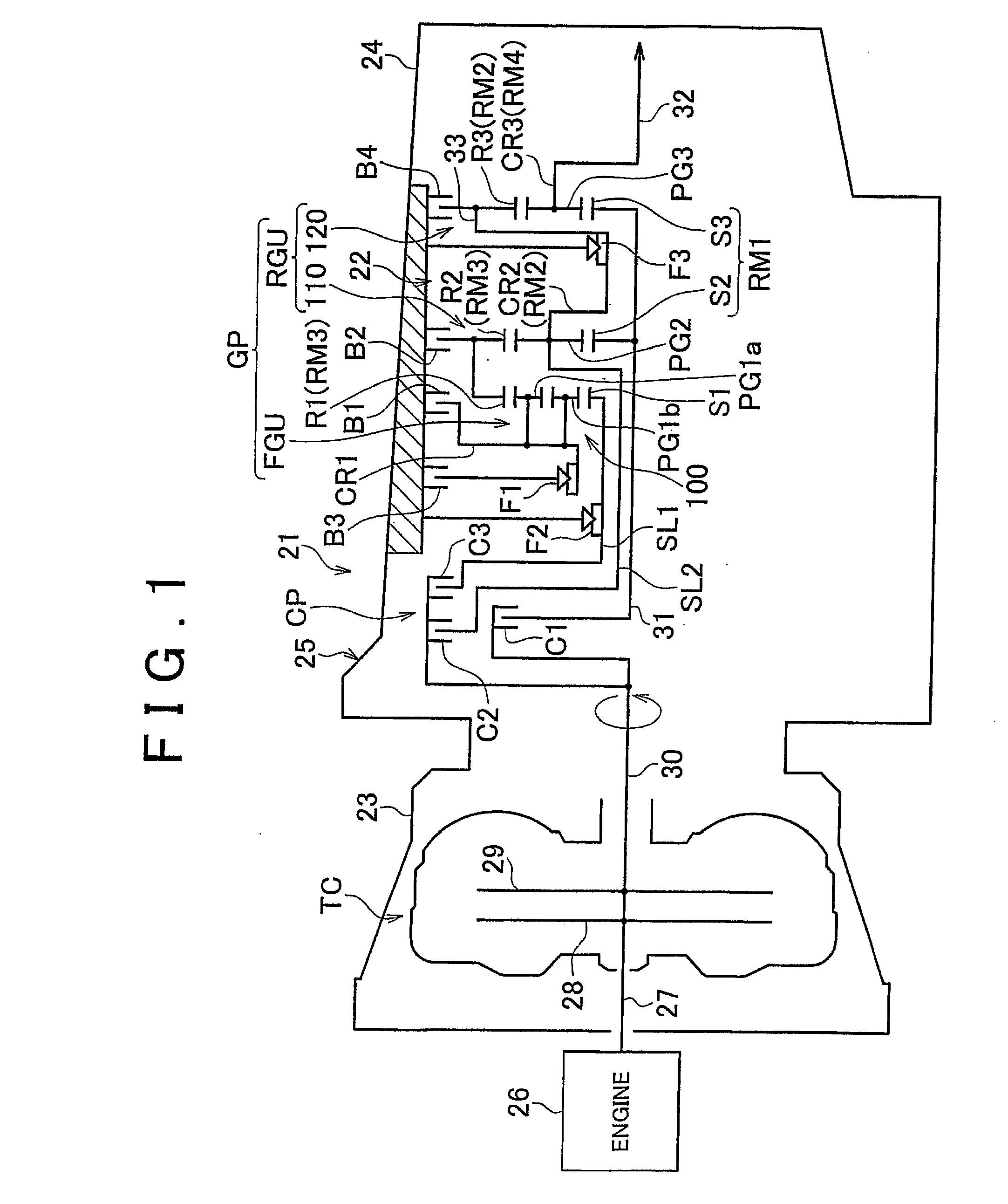

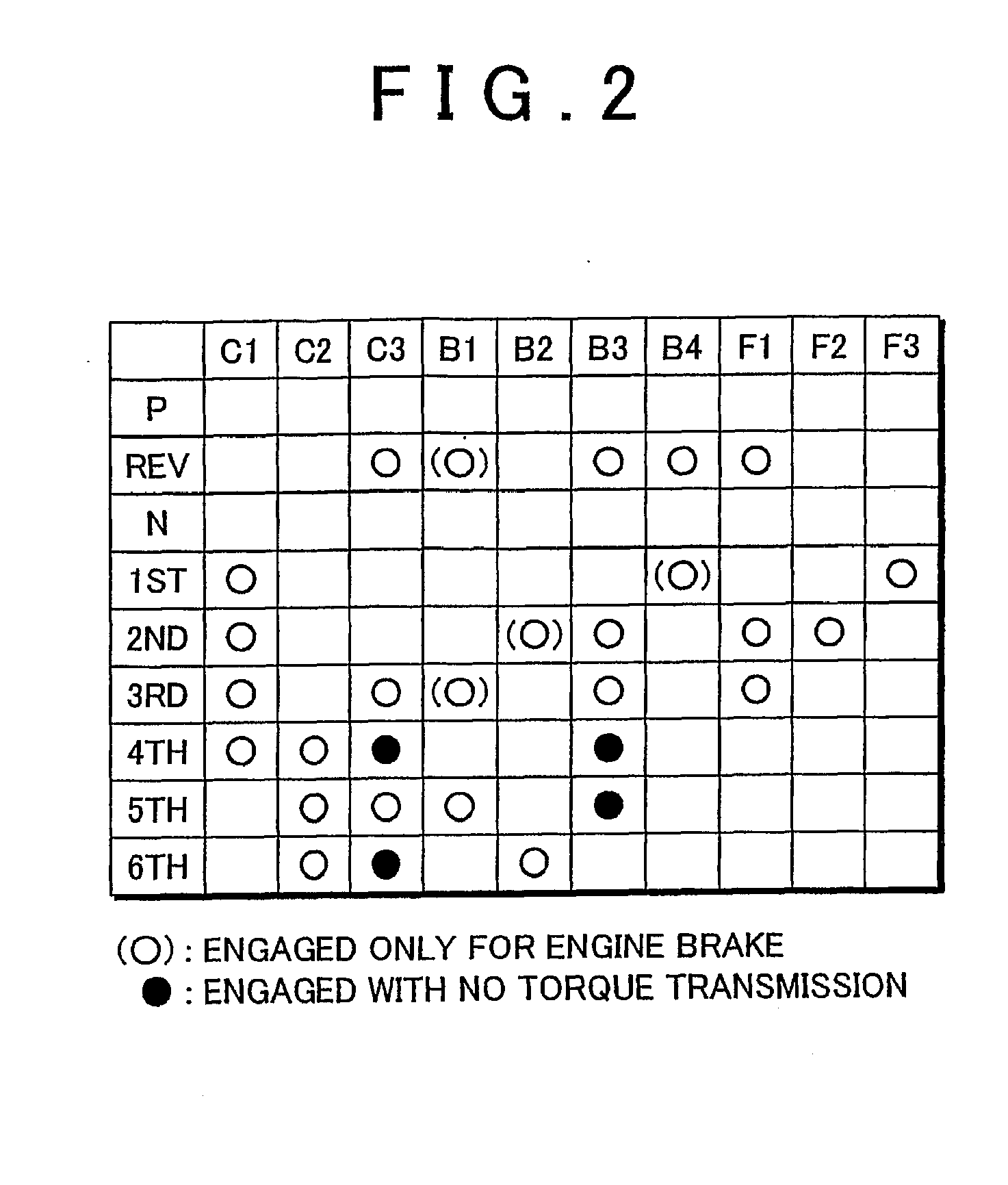

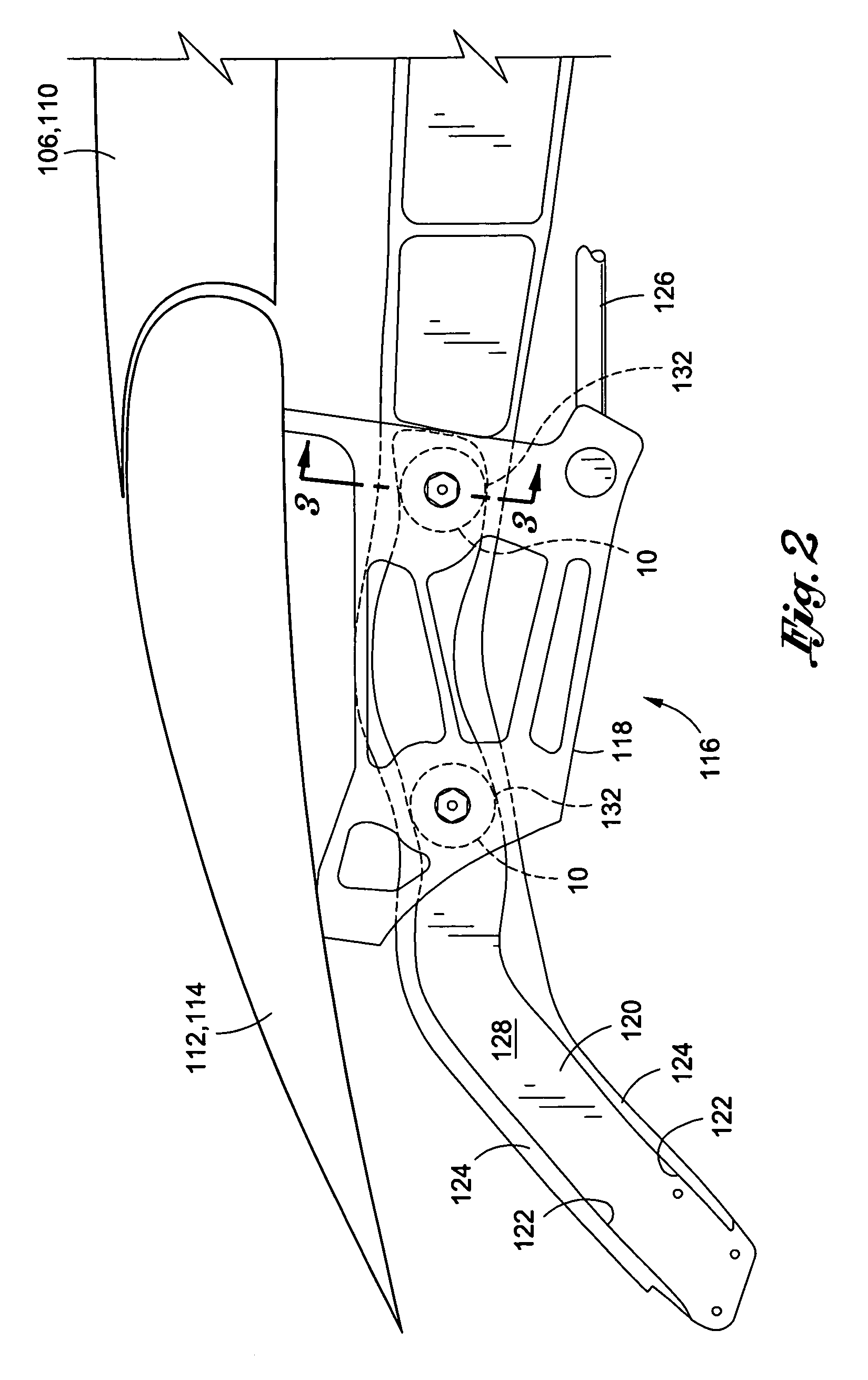

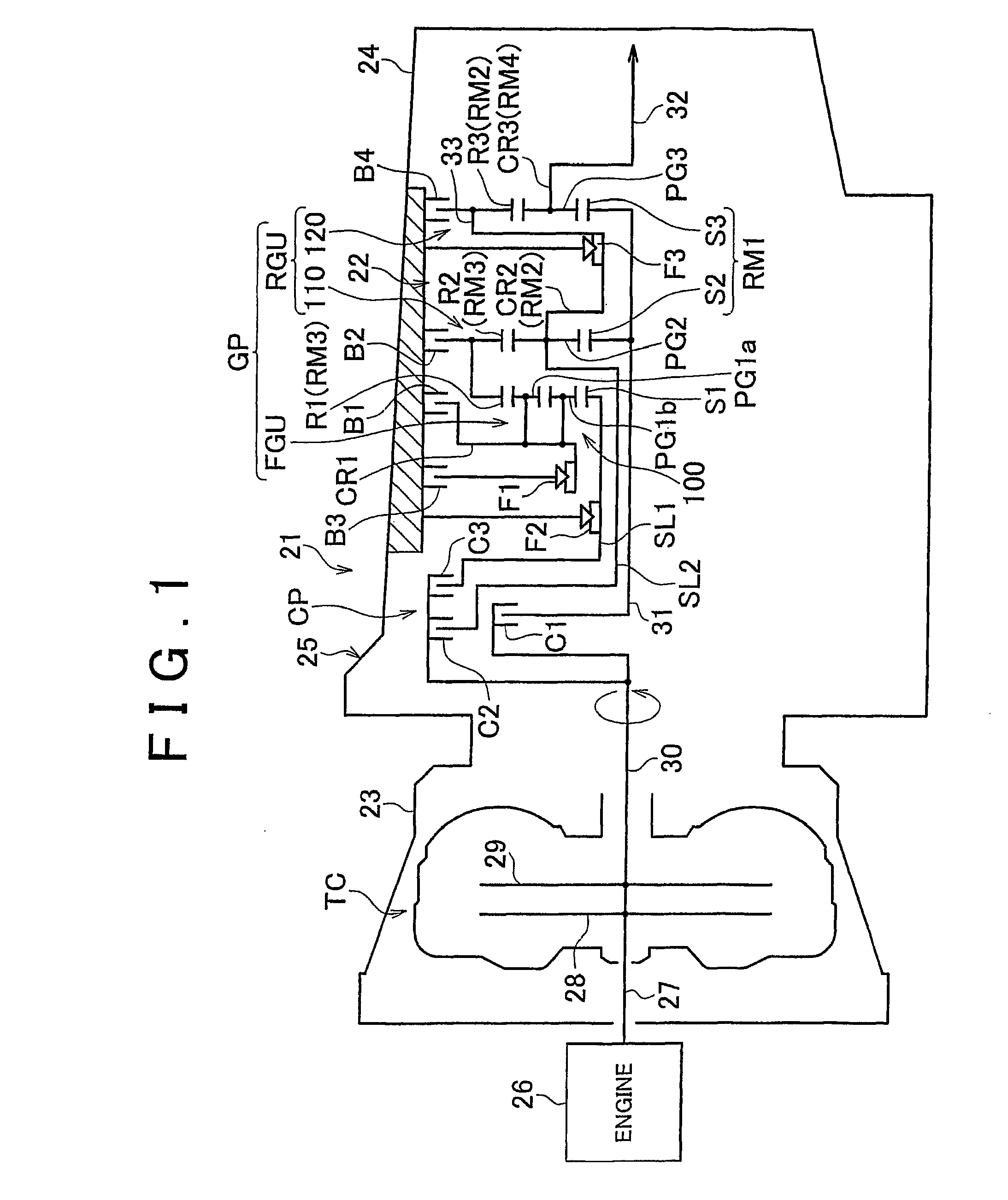

Lubrication system and method for hybrid electro-mechanical planetary transmission components

ActiveUS7252615B2Prevent flow awayRotary combination bearingsGear lubrication/coolingAutomatic transmissionEngineering

This invention details a lubrication system for an automatic transmission, specifically the bearings of the planetary pinion gears. The planetary carriers have grooves formed in spider and flange sections thereof to carry the lubricating material from the inner diameter of the planetary carrier to the inner diameter of each pinion gear bearing mounted in the planetary carrier. The invention further includes two thrust washers that are assembled on opposing sides of each pinion gear that have axially and radially extending slots that further carry the oil between the inner diameter of the planetary carrier and the outer diameter of the planetary carrier. Lastly, the invention discloses a method for lubricating the pinion gears of the planetary carrier.

Owner:GM GLOBAL TECH OPERATIONS LLC

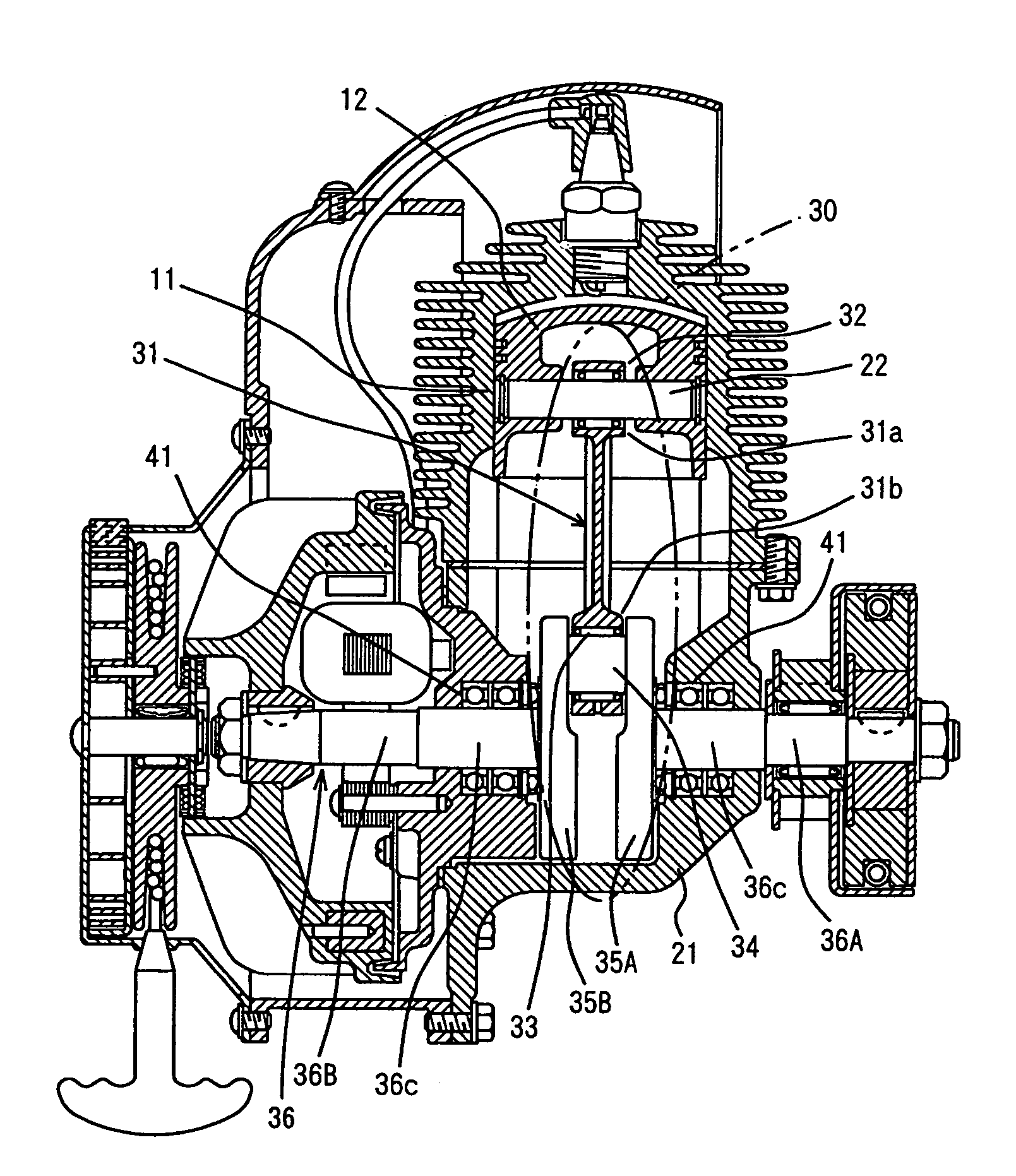

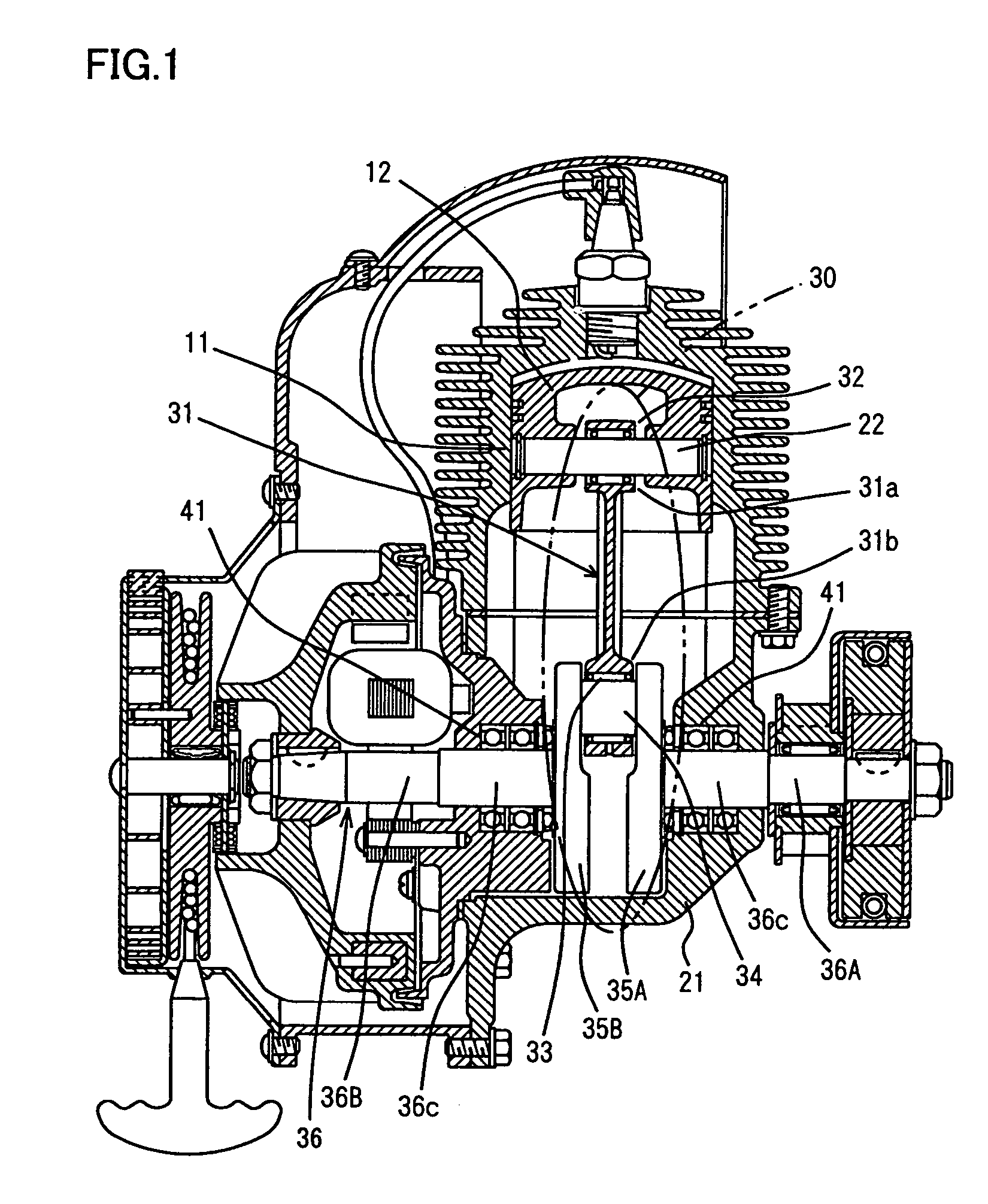

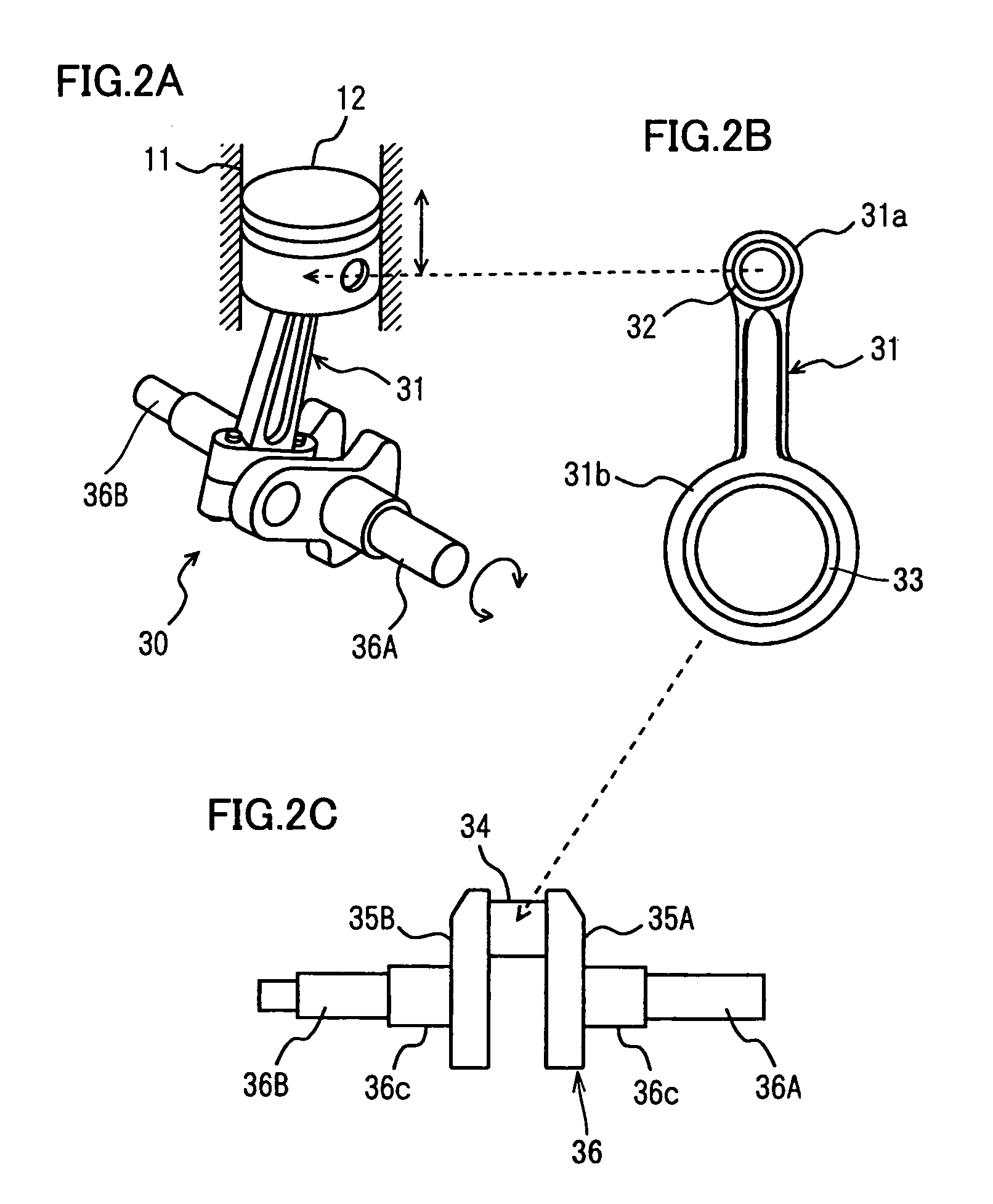

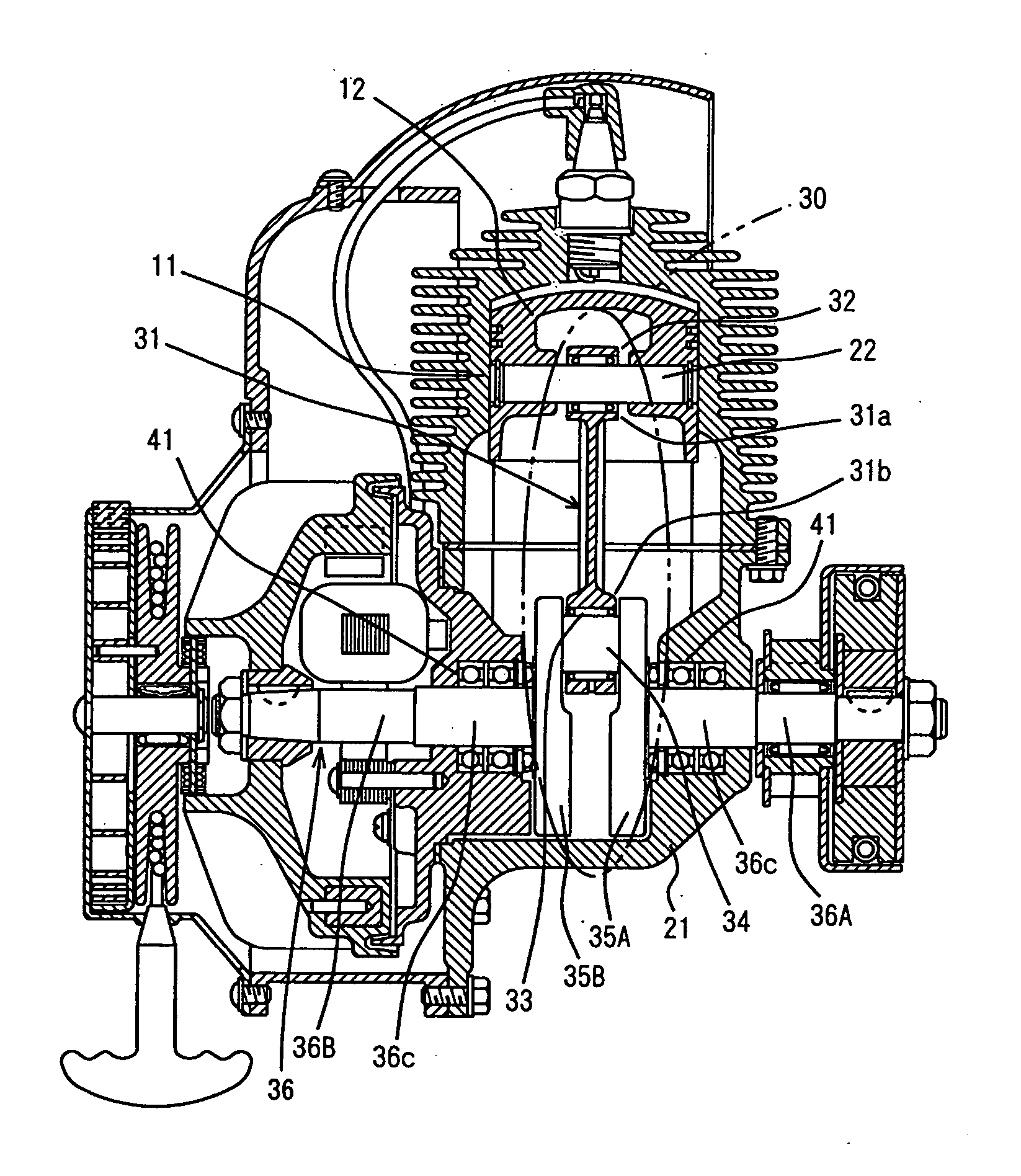

Support structure in crank mechanism and component constituting crank mechanism

InactiveUS7147382B2High strengthSuppressing an increase in rate of secular dimensional changeCrankshaftsConnecting rodsAustenite grainReciprocating motion

A component of a crank mechanism is incorporated in the crank mechanism that converts reciprocating motion of a piston to rotary motion by means of a crank pin, a crank arm and a crank shaft via a connecting bar, and has a hydrogen content of no more than 0.5 ppm, austenite crystal grains of a grain size number exceeding 10, or a fracture stress value of no less than 2650 MPa. Thus, a support structure in and a component of a crank mechanism ensuring a long fatigue life, high anti-crack strength, and a reduced rate of secular dimensional change to improve dimensional stability, can be obtained.

Owner:NTN CORP

Thrust needle roller bearing

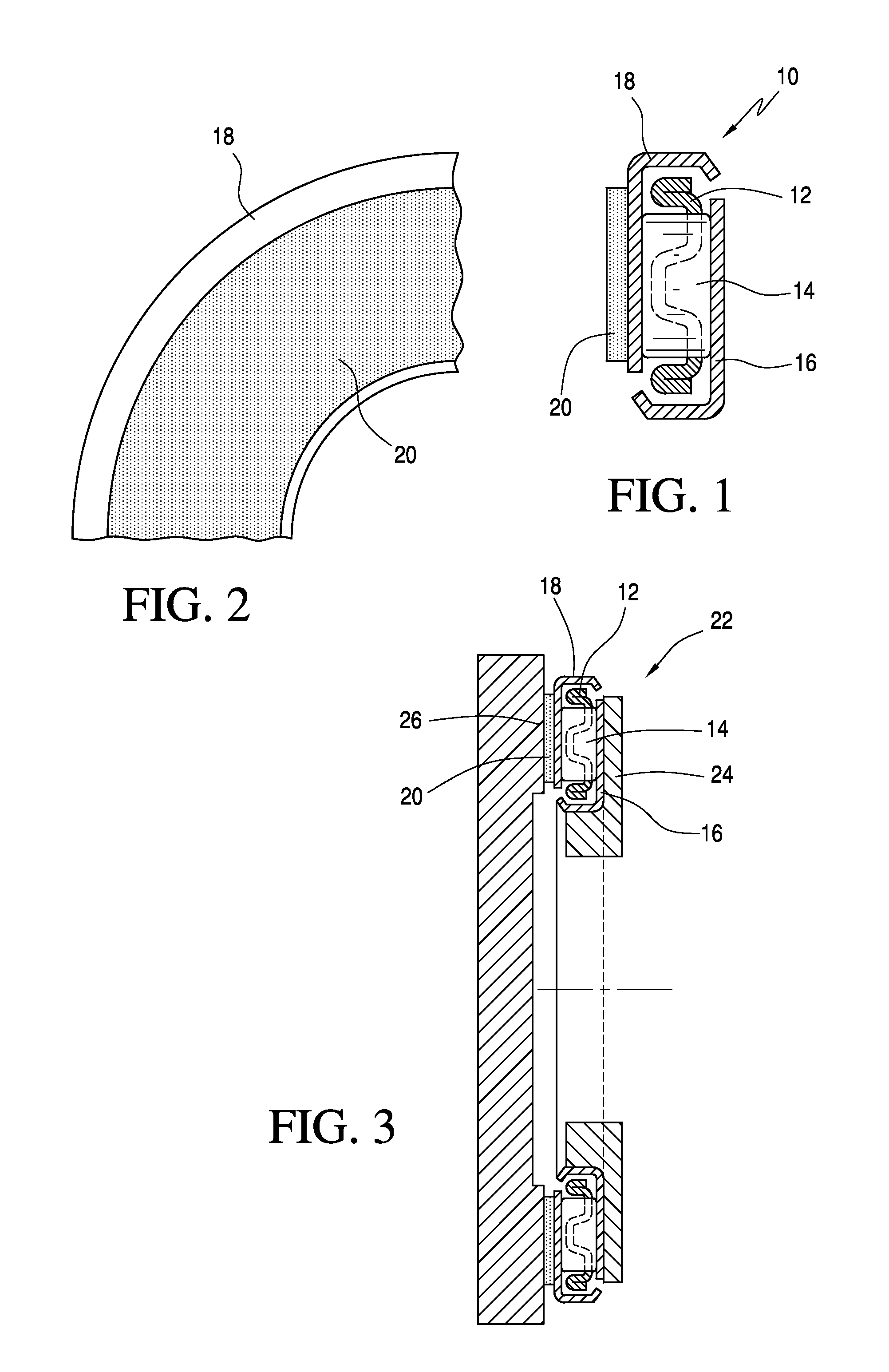

InactiveUS20050018940A1Reduce frictionIncreased durabilityShaftsBearing componentsNeedle roller bearingEngineering

A thrust needle roller bearing includes a plurality of needle rollers, and an annular retainer having a plurality of pockets for retaining the needle rollers. The plurality of pockets accommodate the needle rollers arranged in multiple rows shifted from each other in a radial direction of the retainer, and the retainer is made of synthetic resin. The thrust needle roller bearing is light, can reduce friction between the retainer and the needle rollers, and has high durability.

Owner:NTN CORP

Split roller bearing device

InactiveUS20070223854A1Improve accuracyAdd supportValve arrangementsShaftsPulp and paper industryRoller bearing

A split roller bearing device of the invention includes a roller bearing of which at least the outer ring is separated into a plurality of split parts and a cap member that fixes the outer ring of the roller bearing between the body shaft and a housing and the outer ring split part is fixed inside the arc-shaped recess of the cap member.

Owner:JTEKT CORP

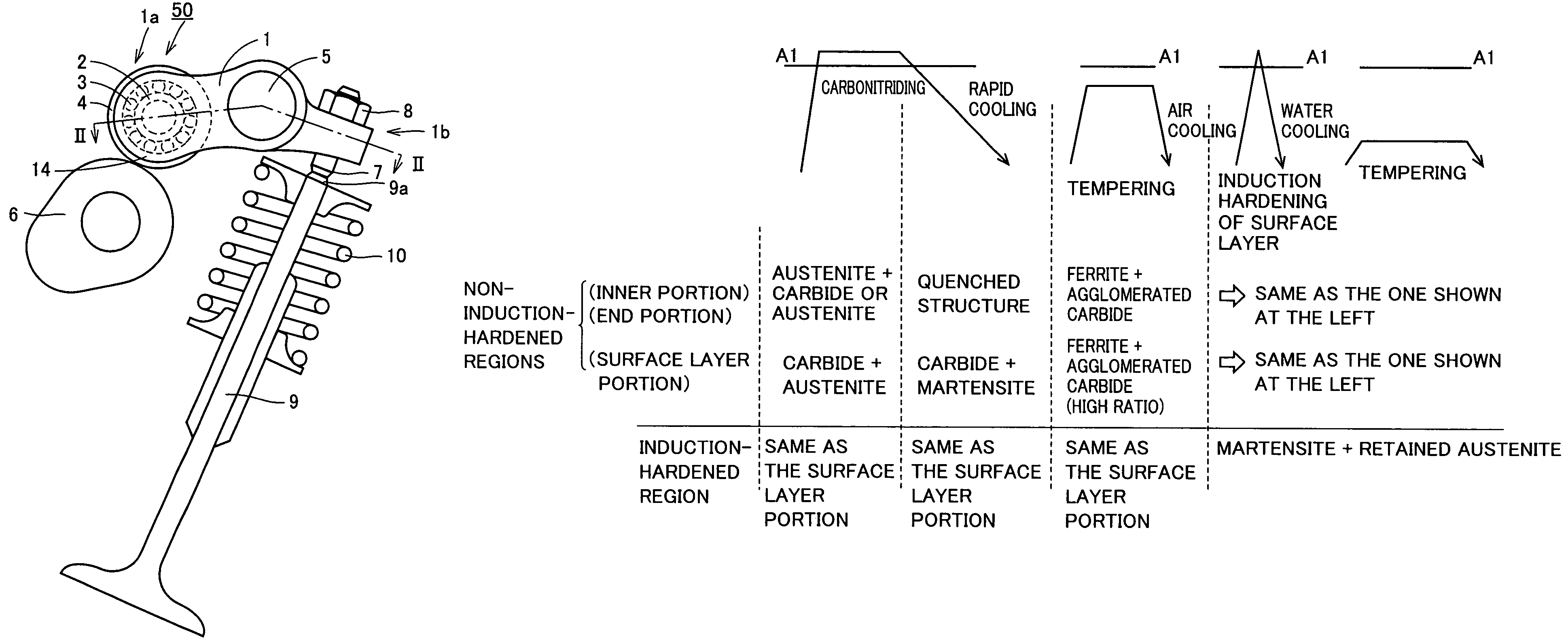

Support structure in crank mechanism and component constituting crank mechanism

InactiveUS20050109308A1High strengthImprove fatigue lifeConnecting rod bearingsCrankshaftsAustenite grainReciprocating motion

A component of a crank mechanism is incorporated in the crank mechanism that converts reciprocating motion of a piston to rotary motion by means of a crank pin, a crank arm and a crank shaft via a connecting bar, and has a hydrogen content of no more than 0.5 ppm, austenite crystal grains of a grain size number exceeding 10, or a fracture stress value of no less than 2650 MPa. Thus, a support structure in and a component of a crank mechanism ensuring a long fatigue life, high anti-crack strength, and a reduced rate of secular dimensional change to improve dimensional stability, can be obtained.

Owner:NTN CORP

Rolling bearing, rolling bearing for fuel cell, compressor for fuel cell system and fuel cell system

InactiveUS20060252655A1Little scatteringMaintain good propertiesMaterial nanotechnologyOrganic chemistryLithiumFuel cells

Owner:NSK LTD

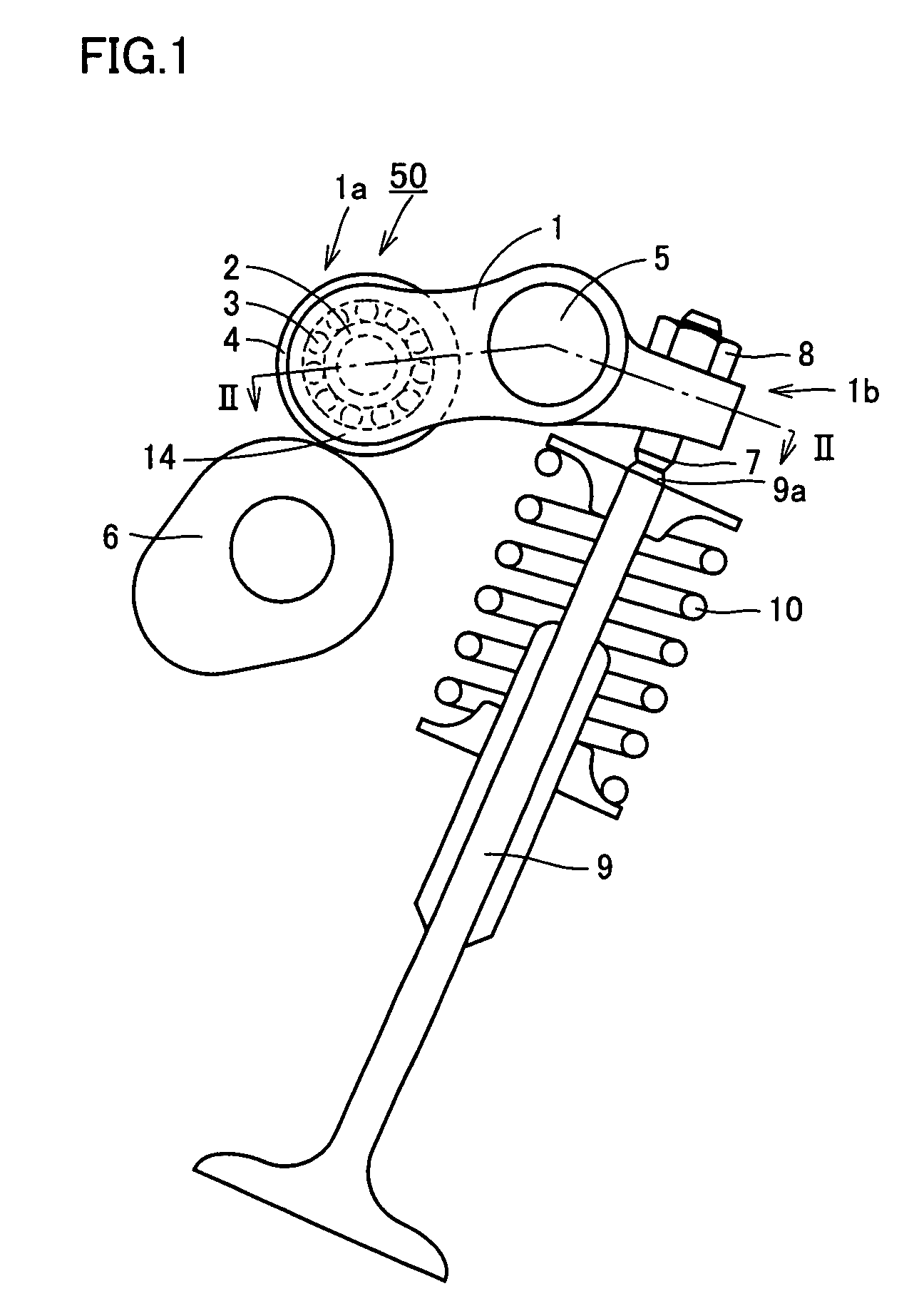

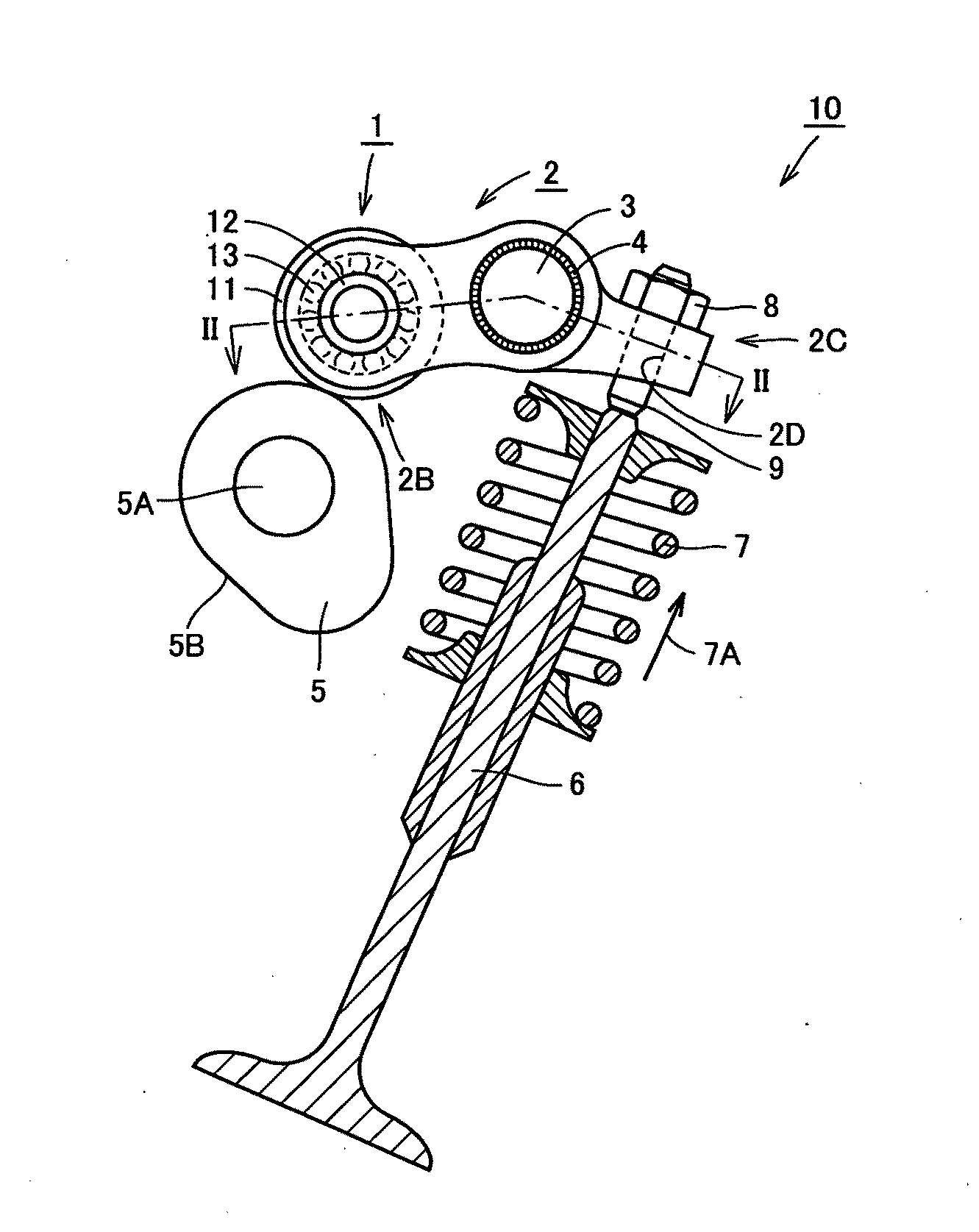

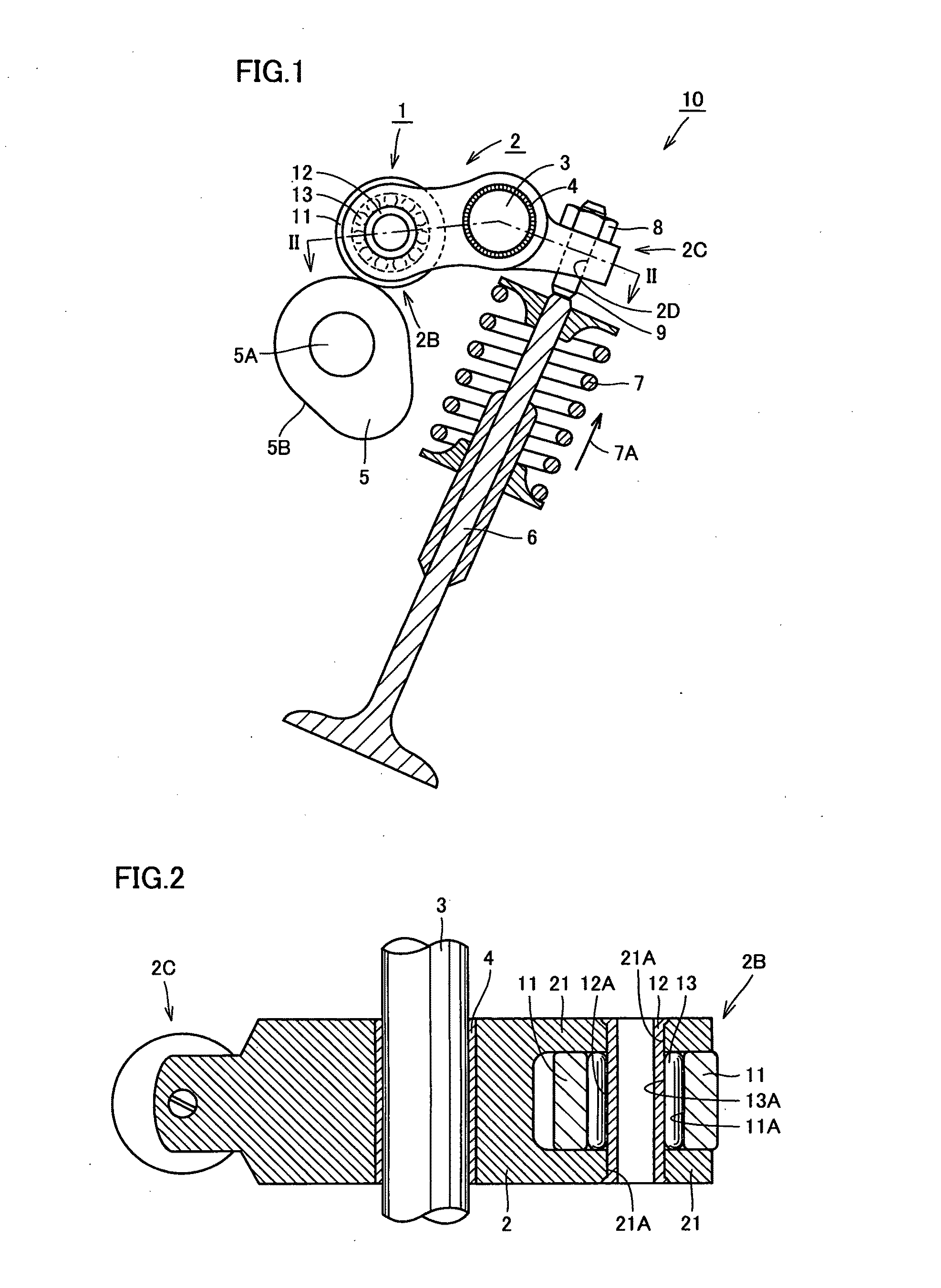

Rolling bearing for rocker arm

ActiveUS7614374B2Improve fatigue lifeImprove cracking strengthControlling membersValve arrangementsAustenite grainRolling-element bearing

A rolling bearing for a rocker arm includes an outer ring in rolling contact with a cam of an engine, an outer-ring shaft placed inside the outer ring and fixed to the rocker arm, and a plurality of rollers provided between the outer ring and the outer-ring shaft. At least one of the outer ring, the outer-ring shaft and the rolling elements has a nitrogen-rich layer, an austenite crystal grain size number in a range exceeding 10, and a surface hardness Hv of at least 653. Thus, the life can be extended.

Owner:NTN CORP

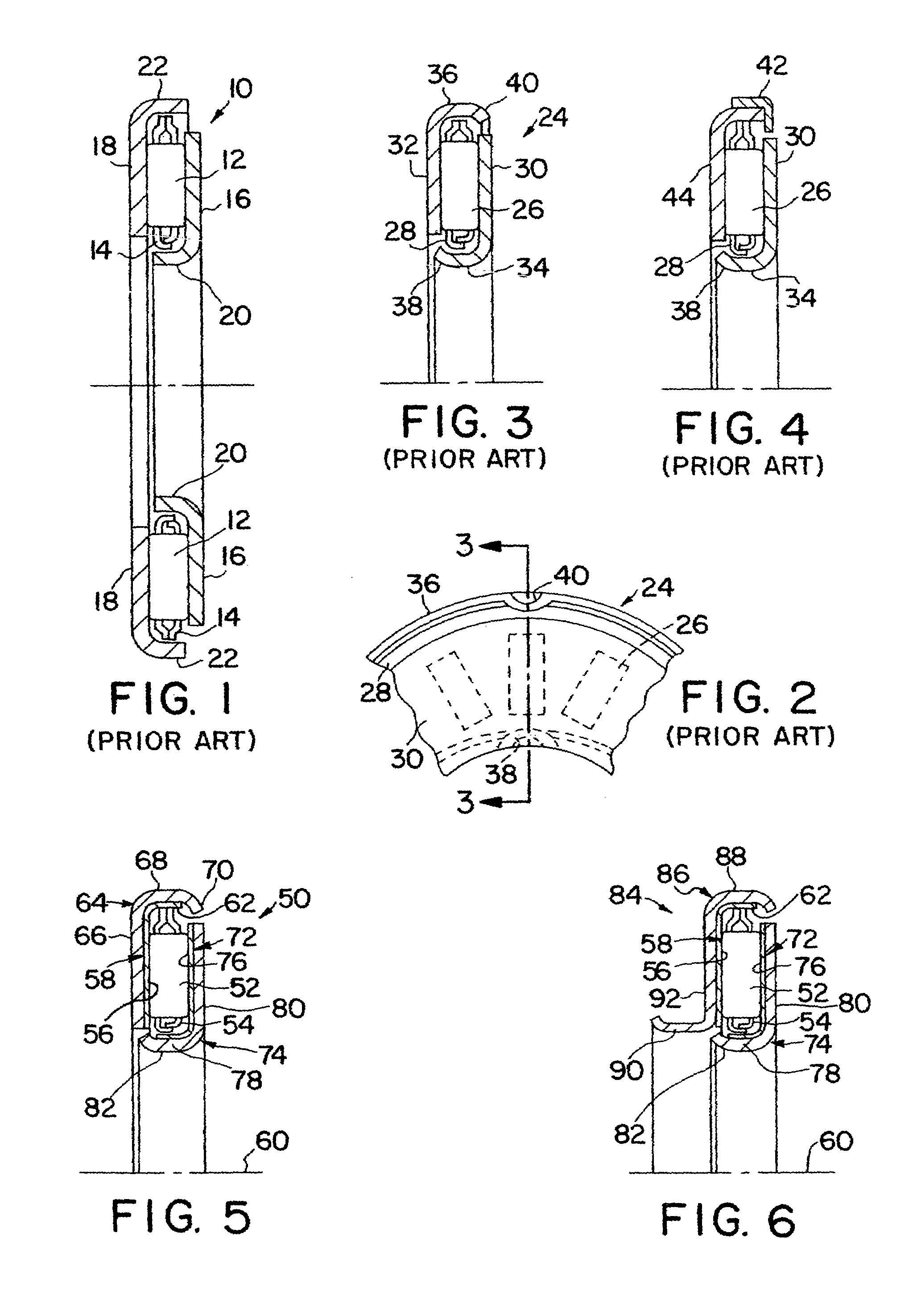

Thrust bearing and method of making same

A first race component includes a flat, circular raceway portion, defined about an axis, and an axially extending lip portion. A plurality of needle rollers is arranged radially with respect to the axis for rolling contact with the flat raceway. A bearing cage retains the needle rollers and is engageable with the lip portion of the first component for piloting of the bearing cage. A second race component, made of different material, includes a flat portion in contact with the raceway portion of the first race component and a lip portion extending axially and radially from the flat portion and beyond the lip portion of the first race component such that the second race component is engageable by the bearing cage to hold the first race component, the second race component and the bearing cage together as an assembly.

Owner:KOYO BEARINGS NORTH AMERICA LLC

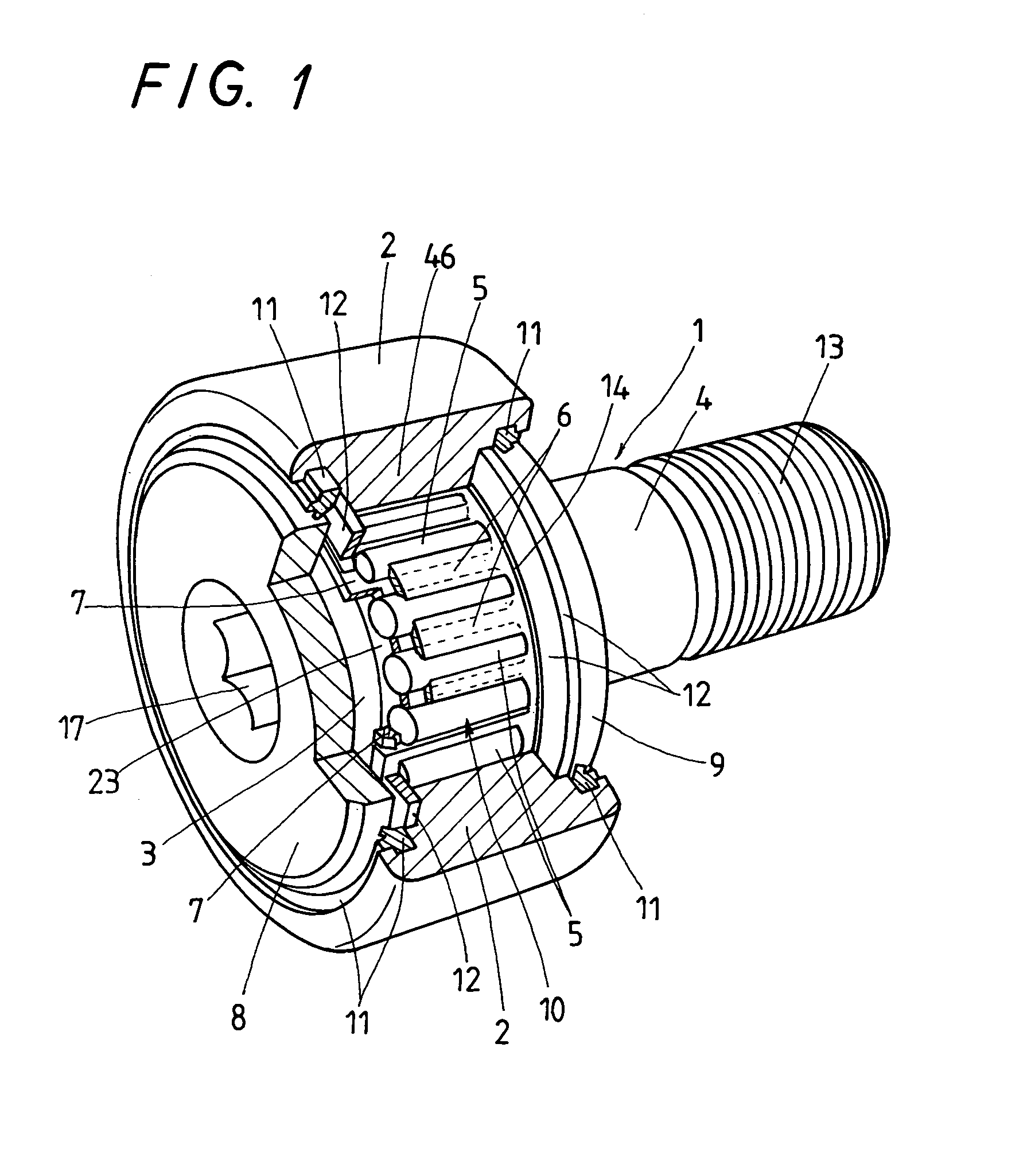

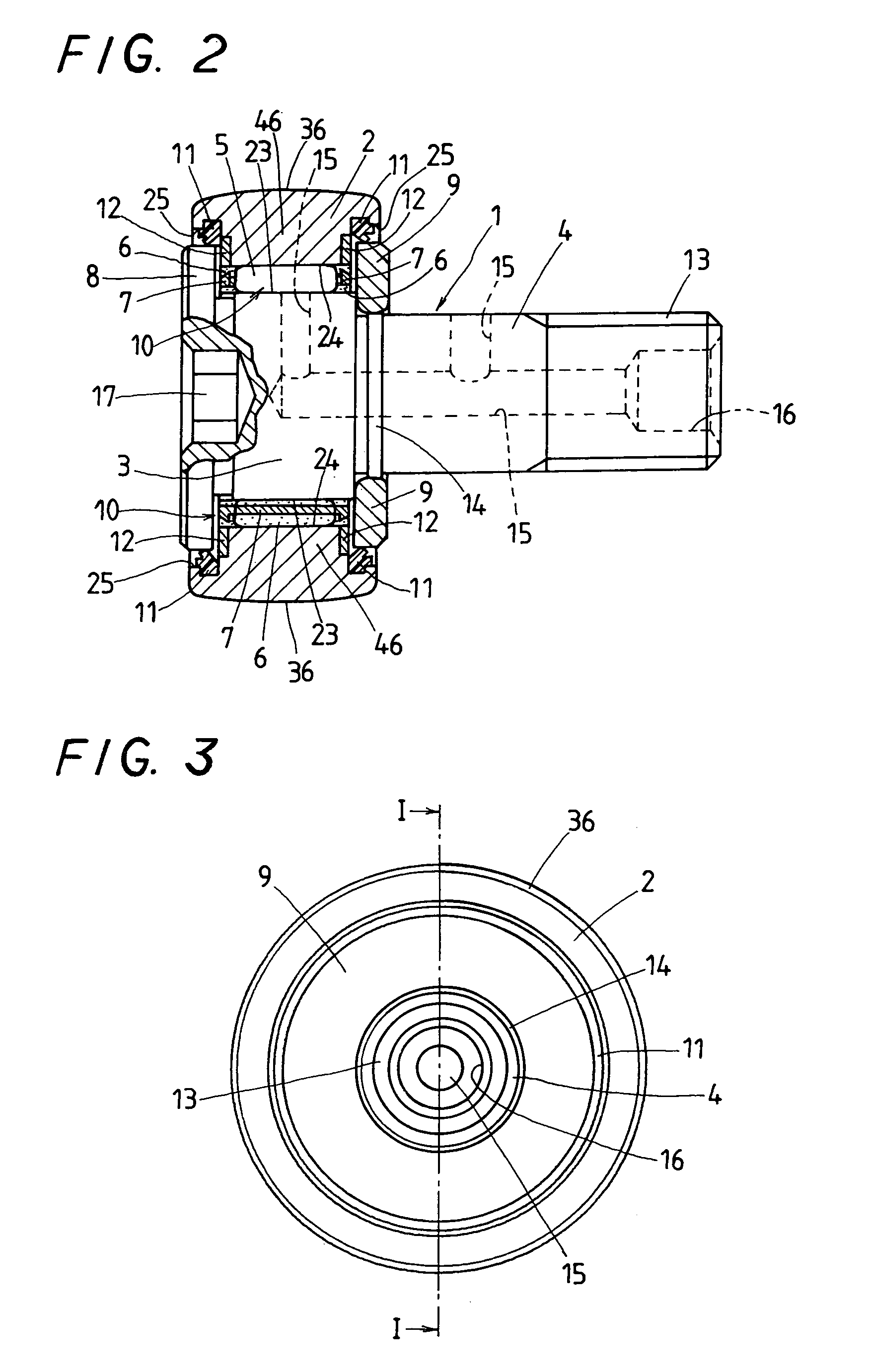

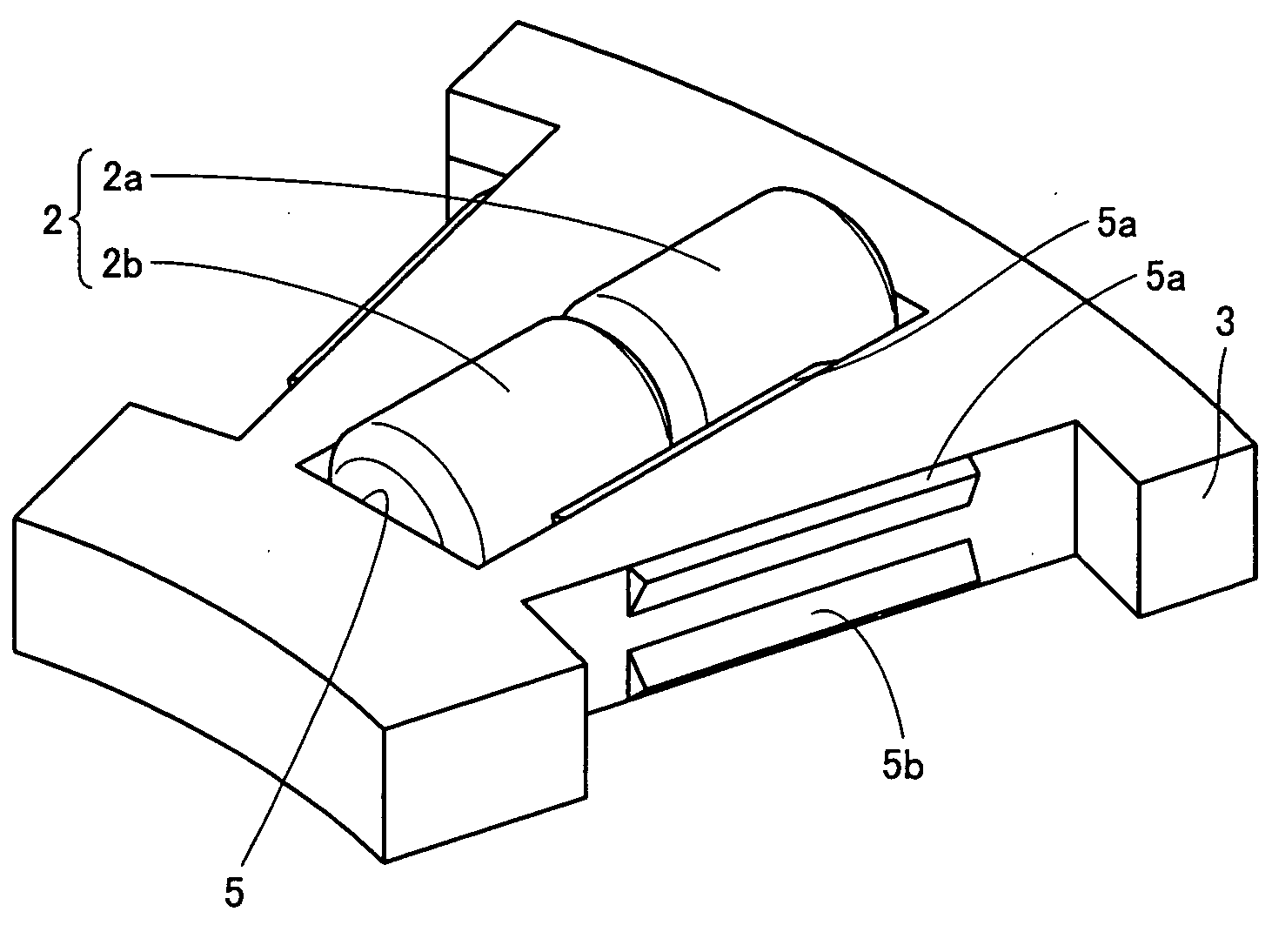

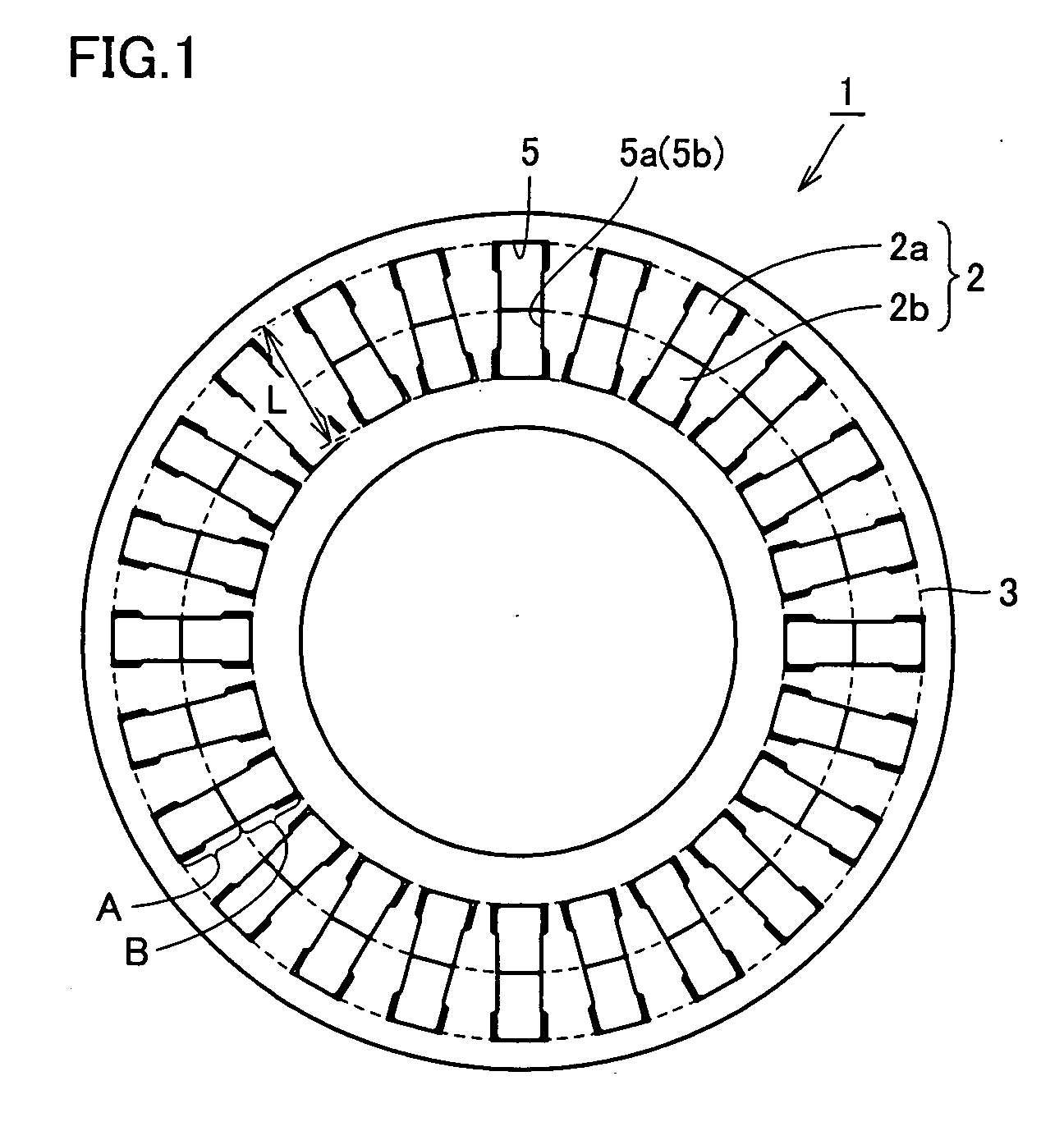

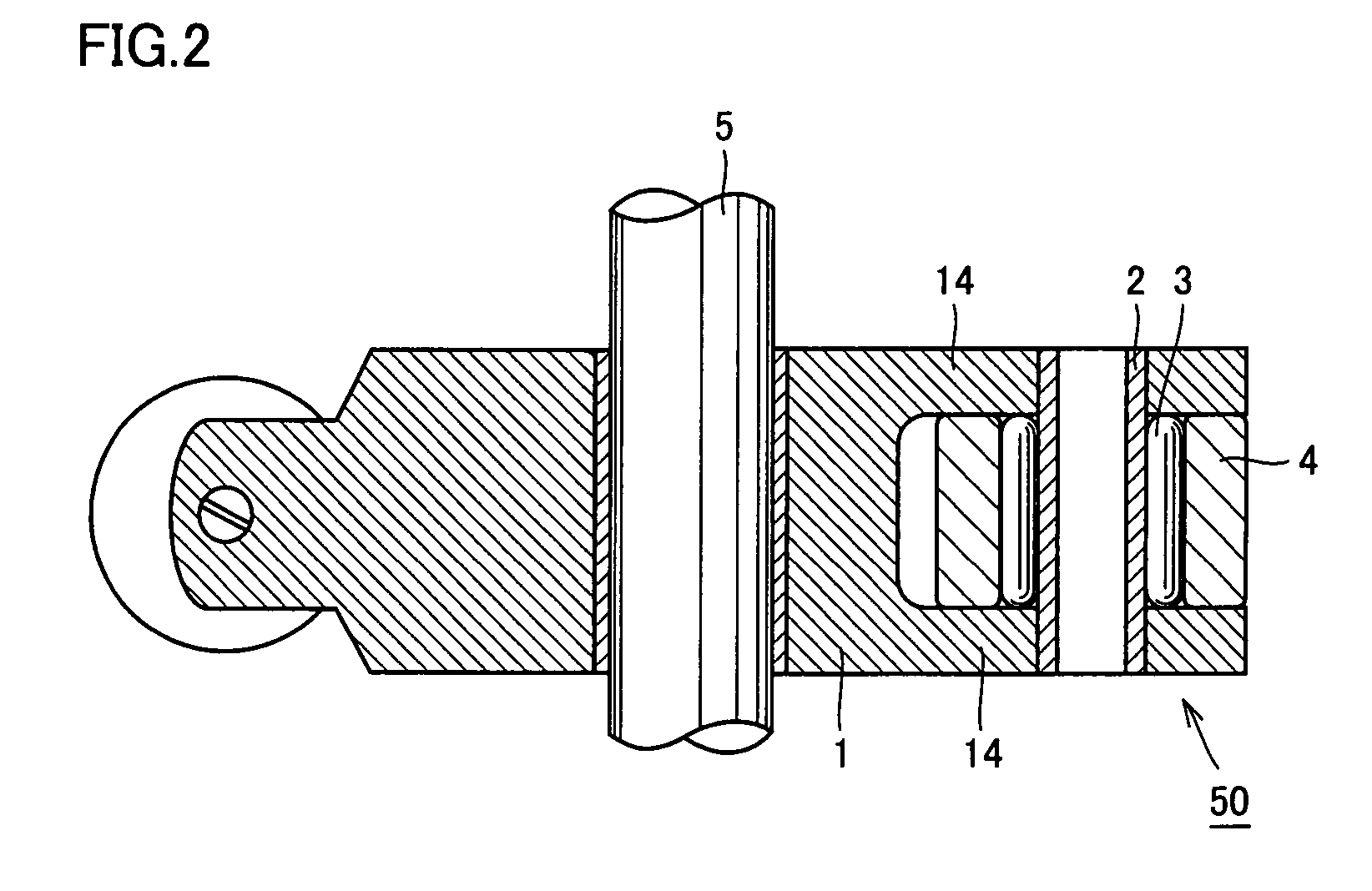

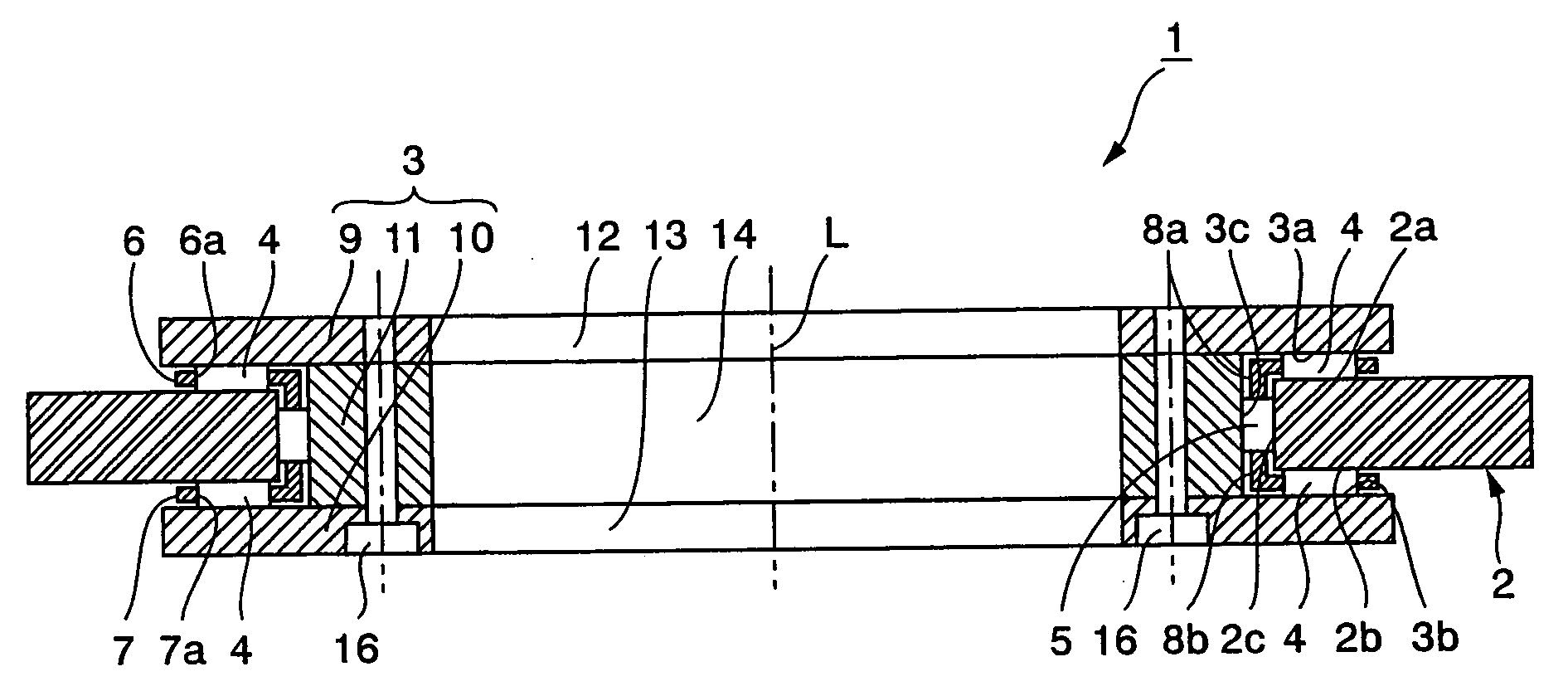

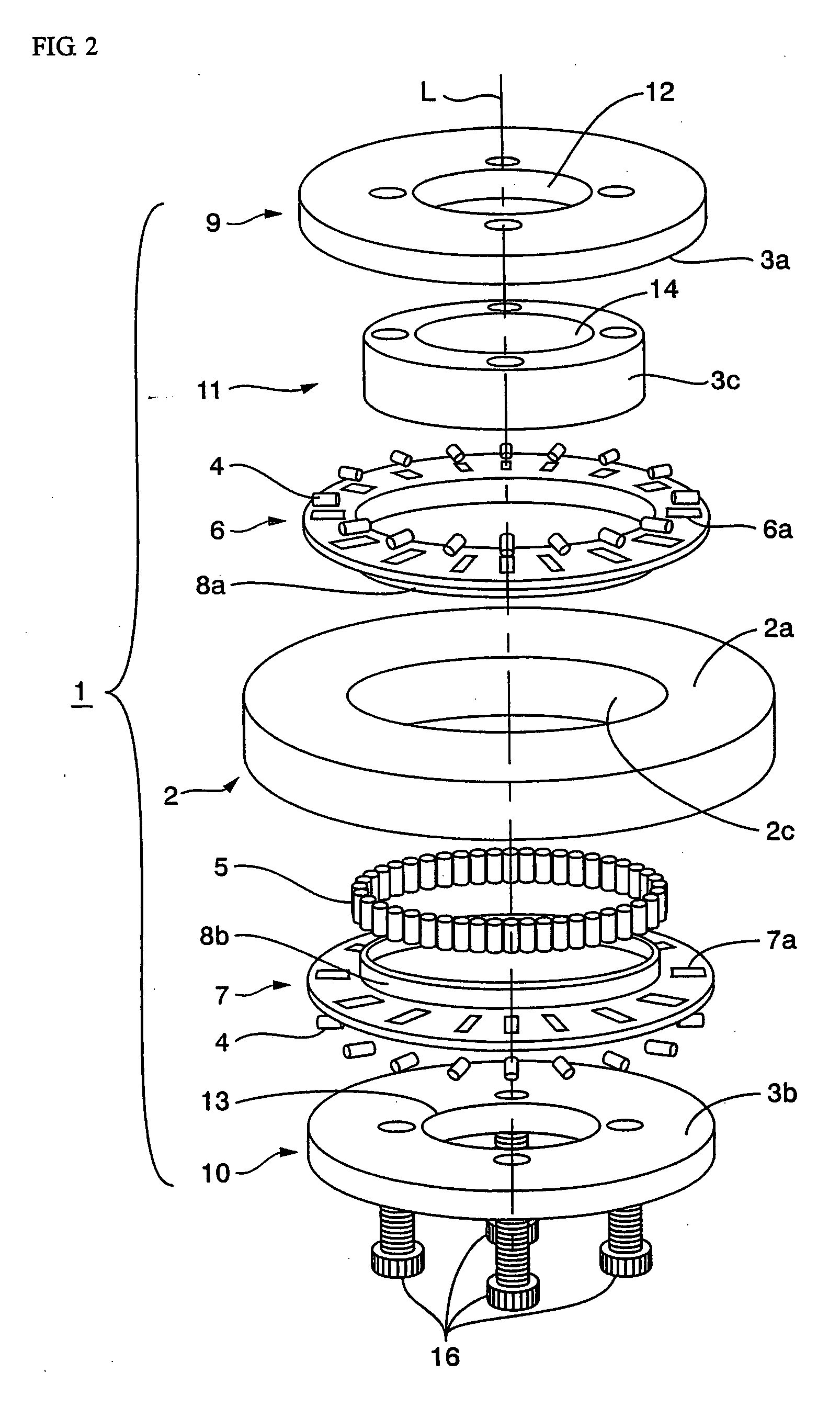

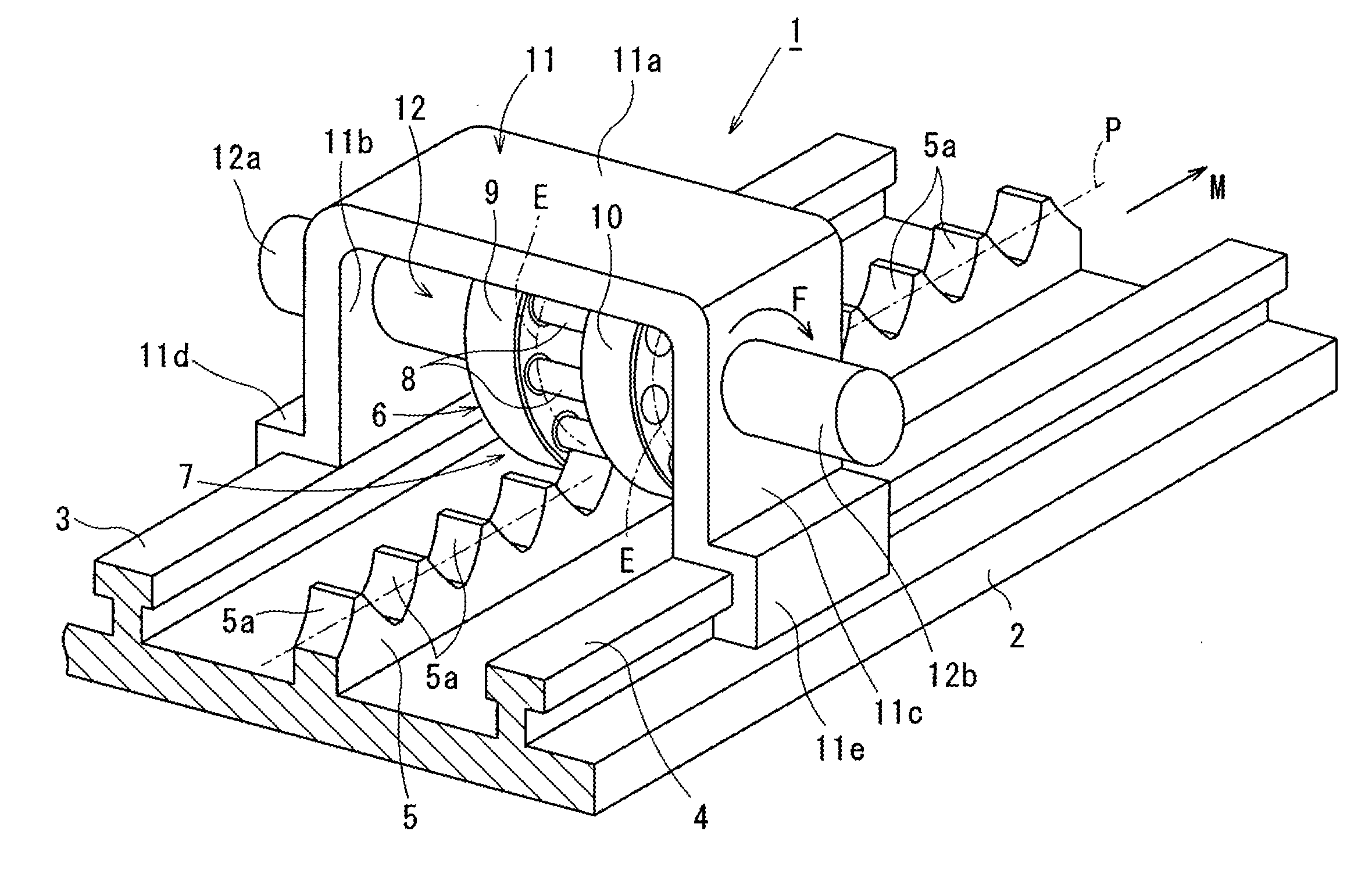

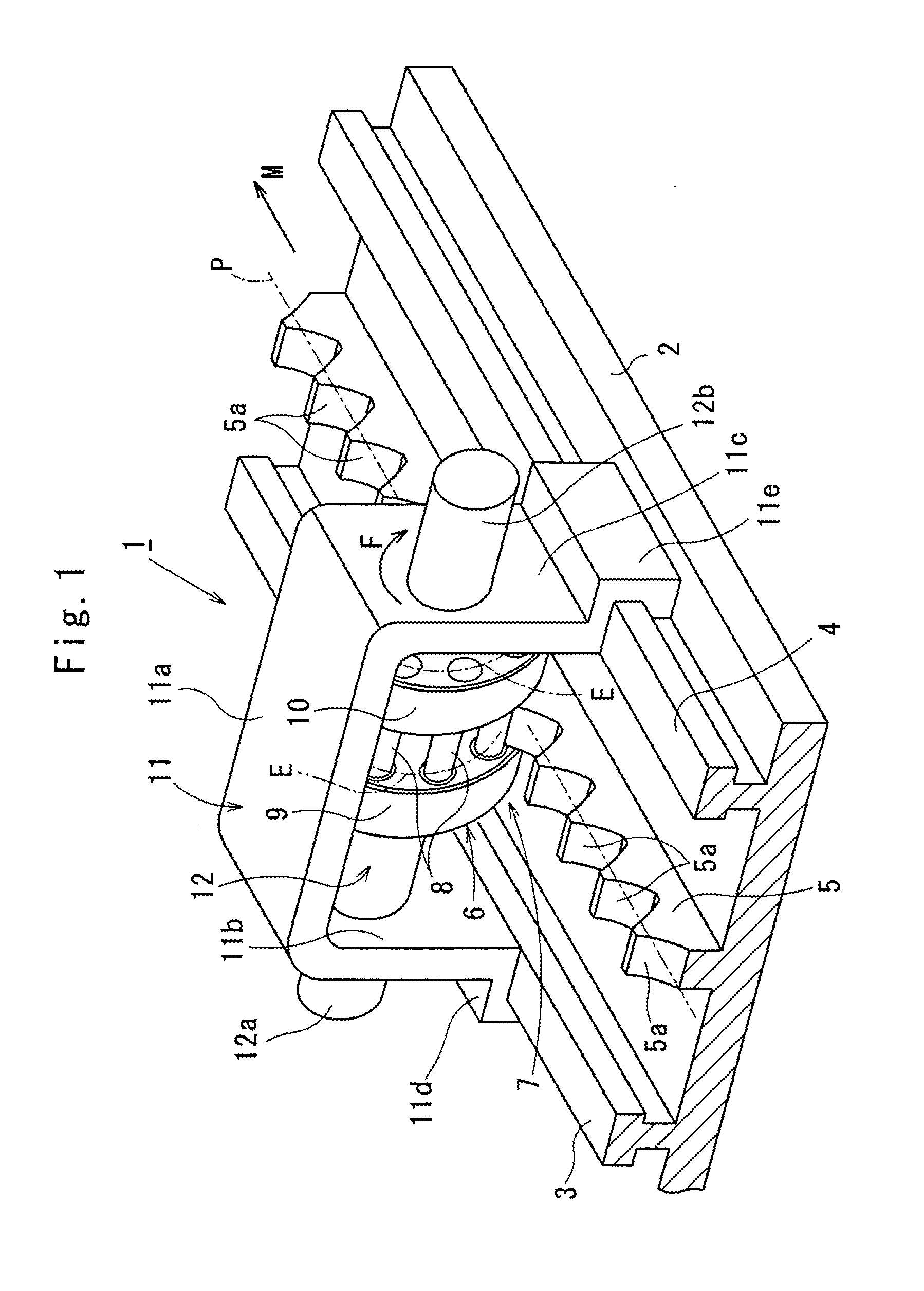

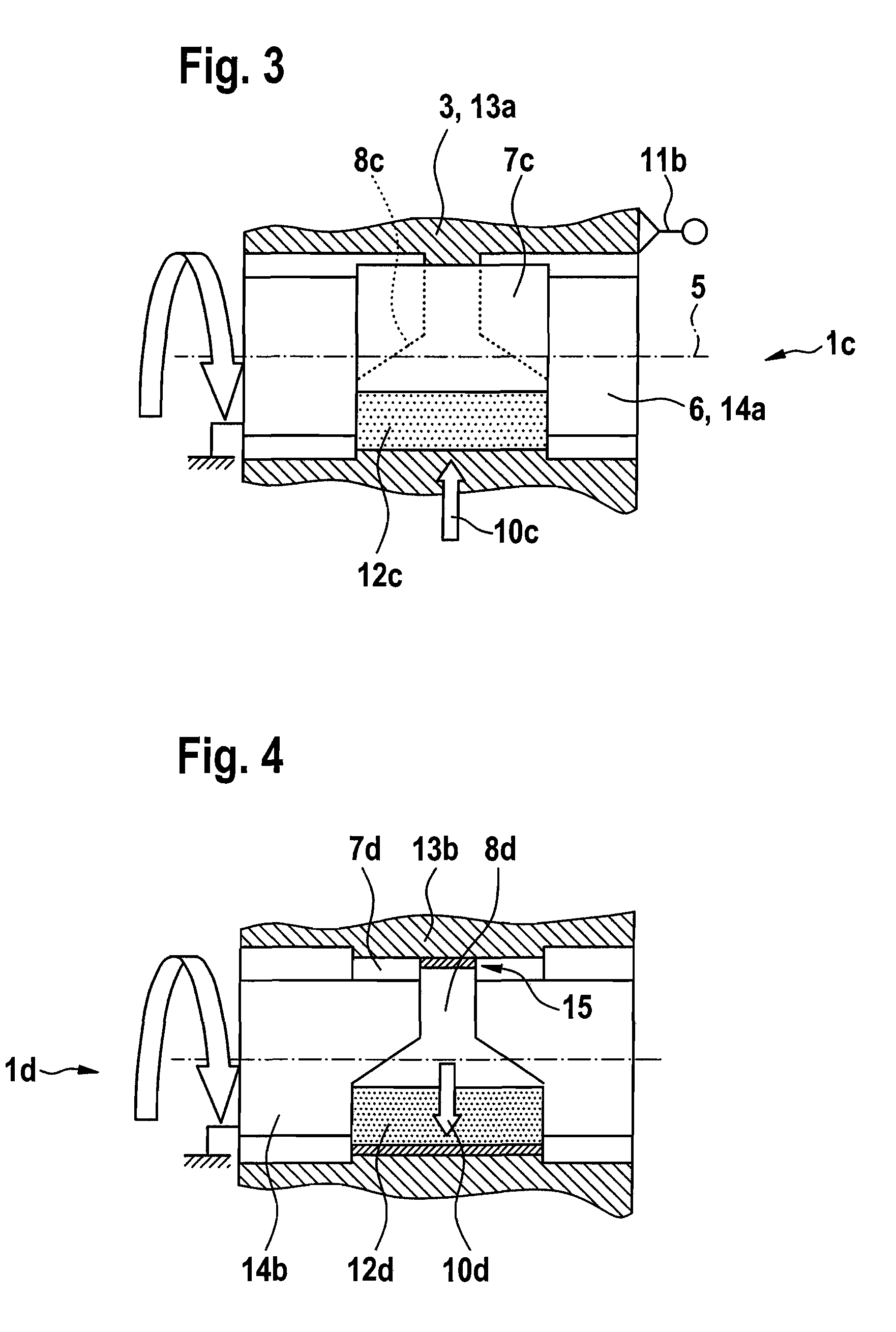

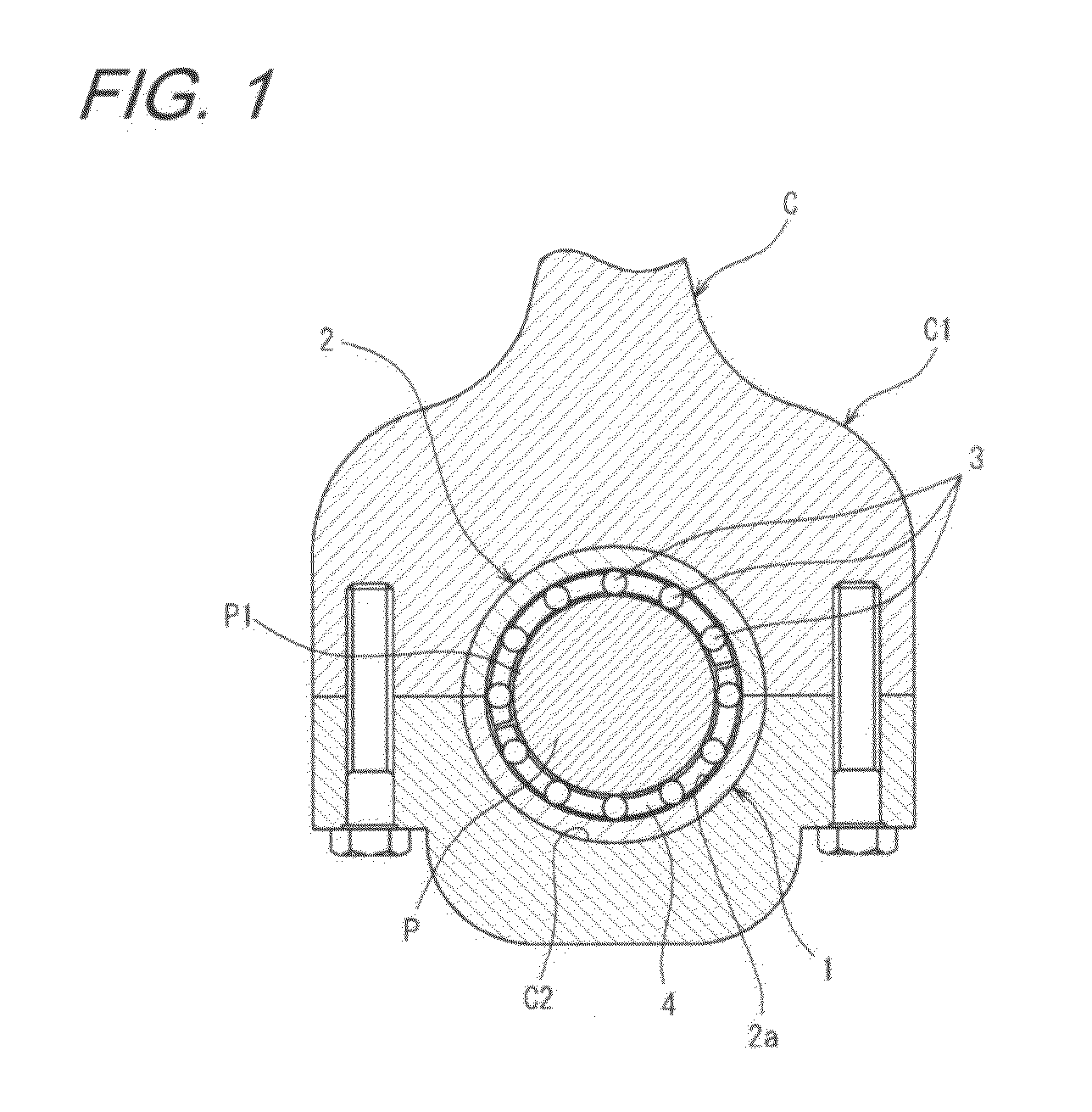

Composite Roll Bearing

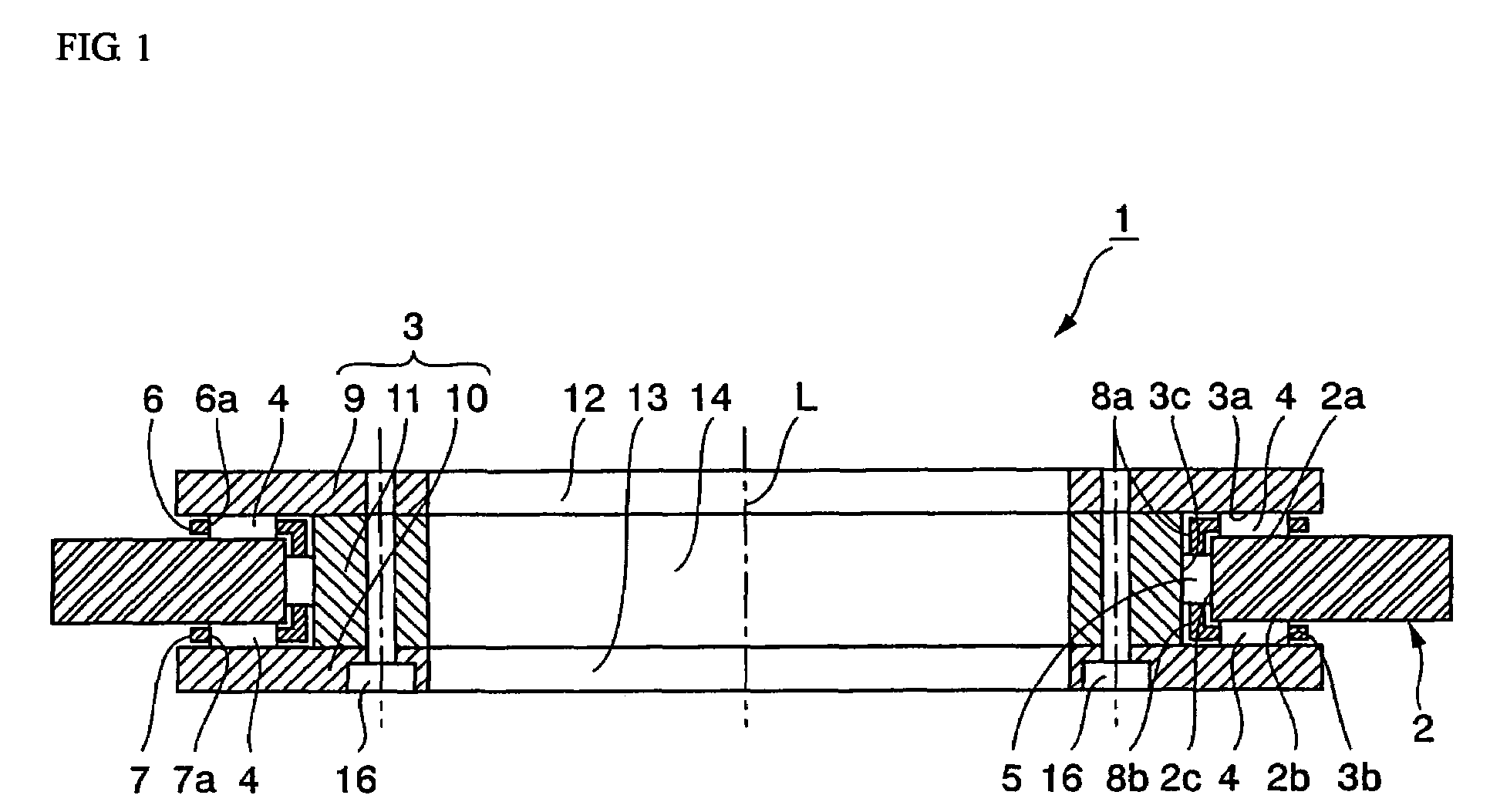

ActiveUS20080285905A1Reduce rolling resistanceReduce frictional resistanceShaftsBearing componentsThrust bearingMechanical engineering

A composite roll bearing (1), comprising an outer ring (2) and an annular inner ring (3) of groove shape in cross section having first, second, and third receiving surfaces (3a, 3b, 3c) facing the both end face inner peripheral portions (2a, 2b) and the circular inner peripheral surface (2c) of the outer ring (2) at specified intervals. A plurality of rollers (4) for thrust bearing are installed between one end face portion (2a) of the outer ring (2) and the first receiving surface (3a) of the inner ring (3) and between the other end face (2b) of the outer ring (2) and the second receiving surface (3b) of the inner ring (3). A plurality of rollers (5) for radial bearing are installed between the circular inner peripheral surface (2c) of the outer ring (2) and the third receiving surface (3c) of the inner ring (3). The rollers (5) are restricted to move in a thrust direction by retainer portions (8a, 8a) formed at the inner ends of retainers (6, 7) for the rollers (4) for thrust bearing.

Owner:HARMONIC DRIVE SYST IND CO LTD

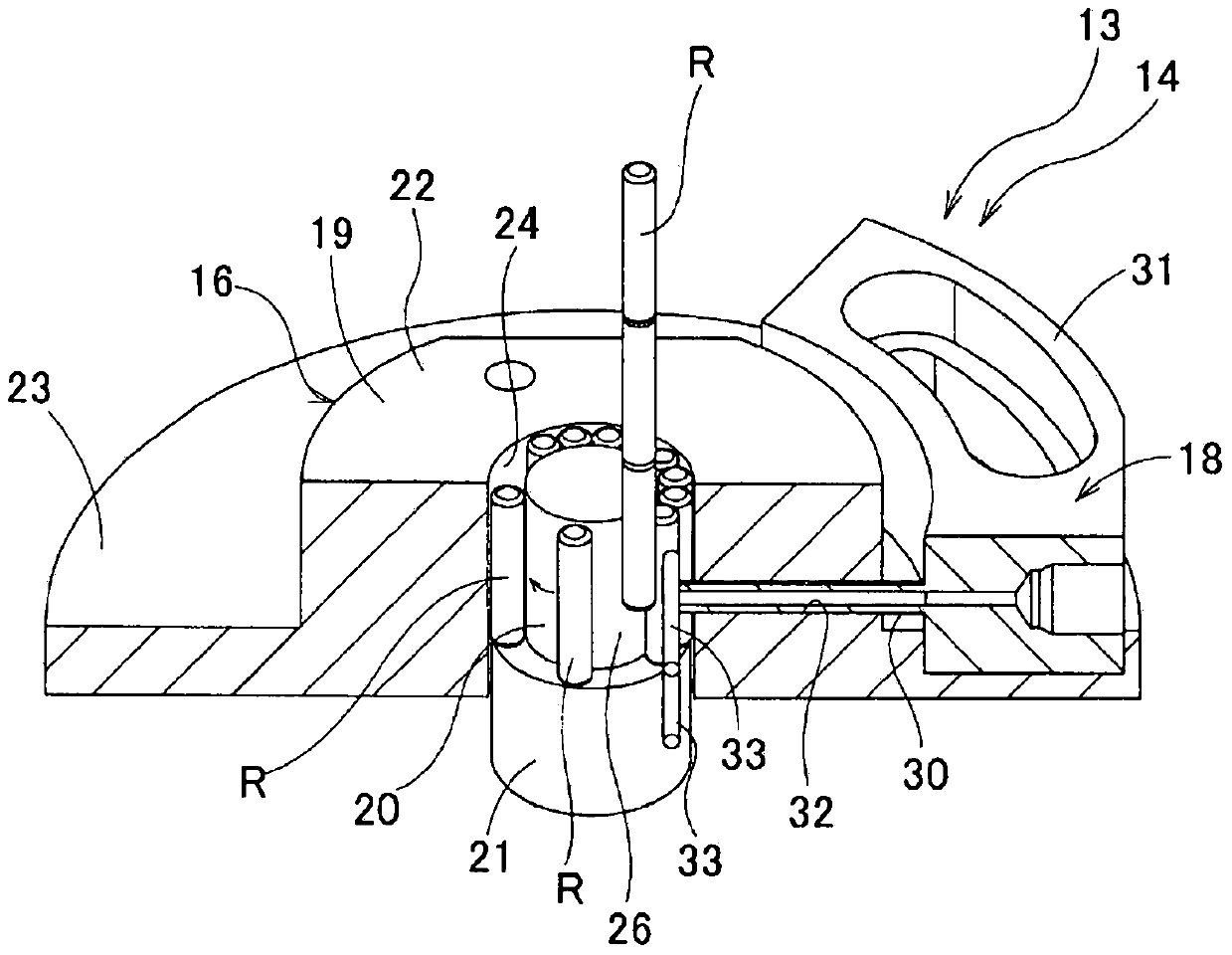

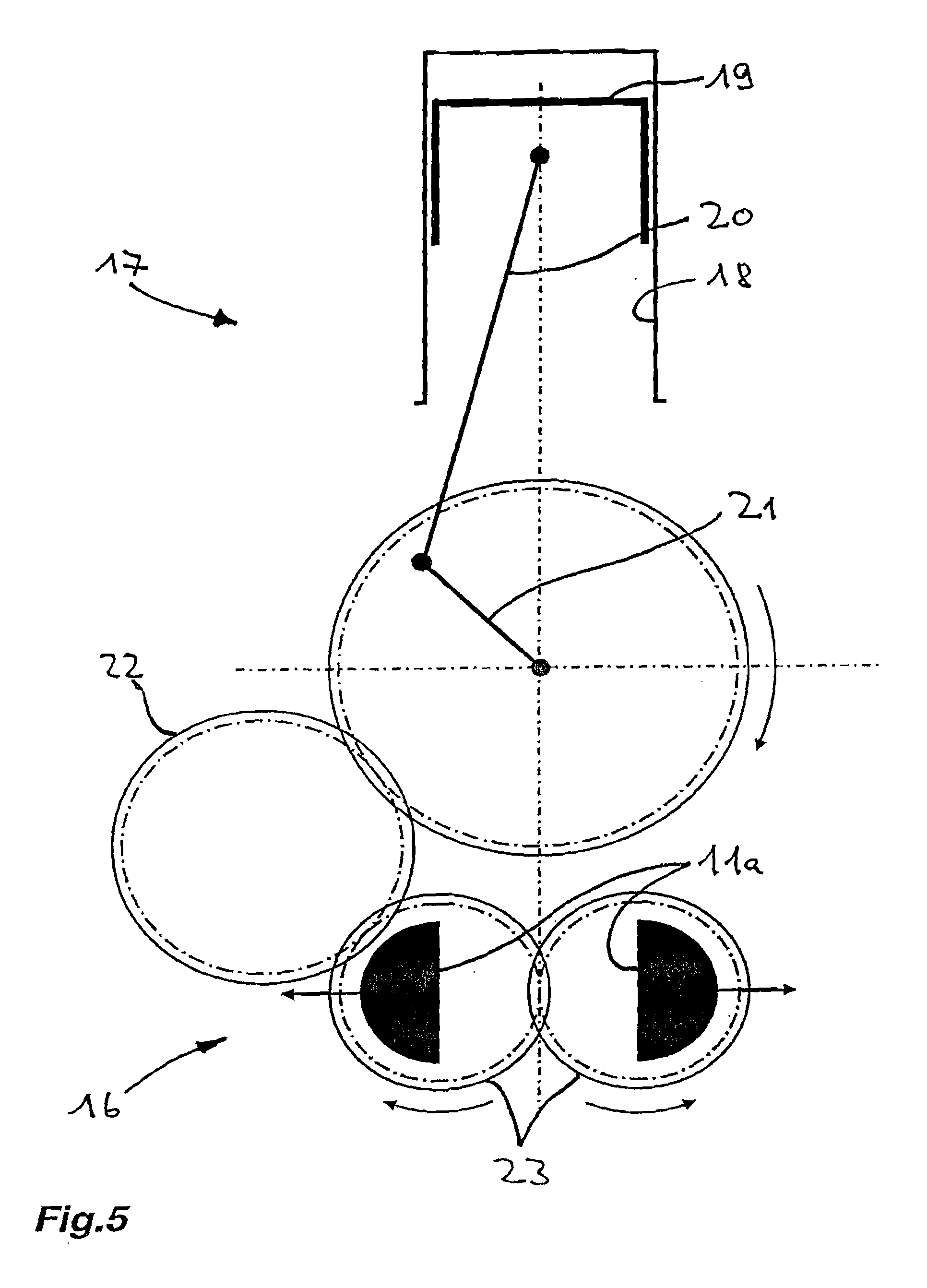

Method for assembling and device for assembling roller bearing

InactiveCN103619532AAvoid leaningPrevent the situationAssembly machinesBearing componentsEngineeringMechanical engineering

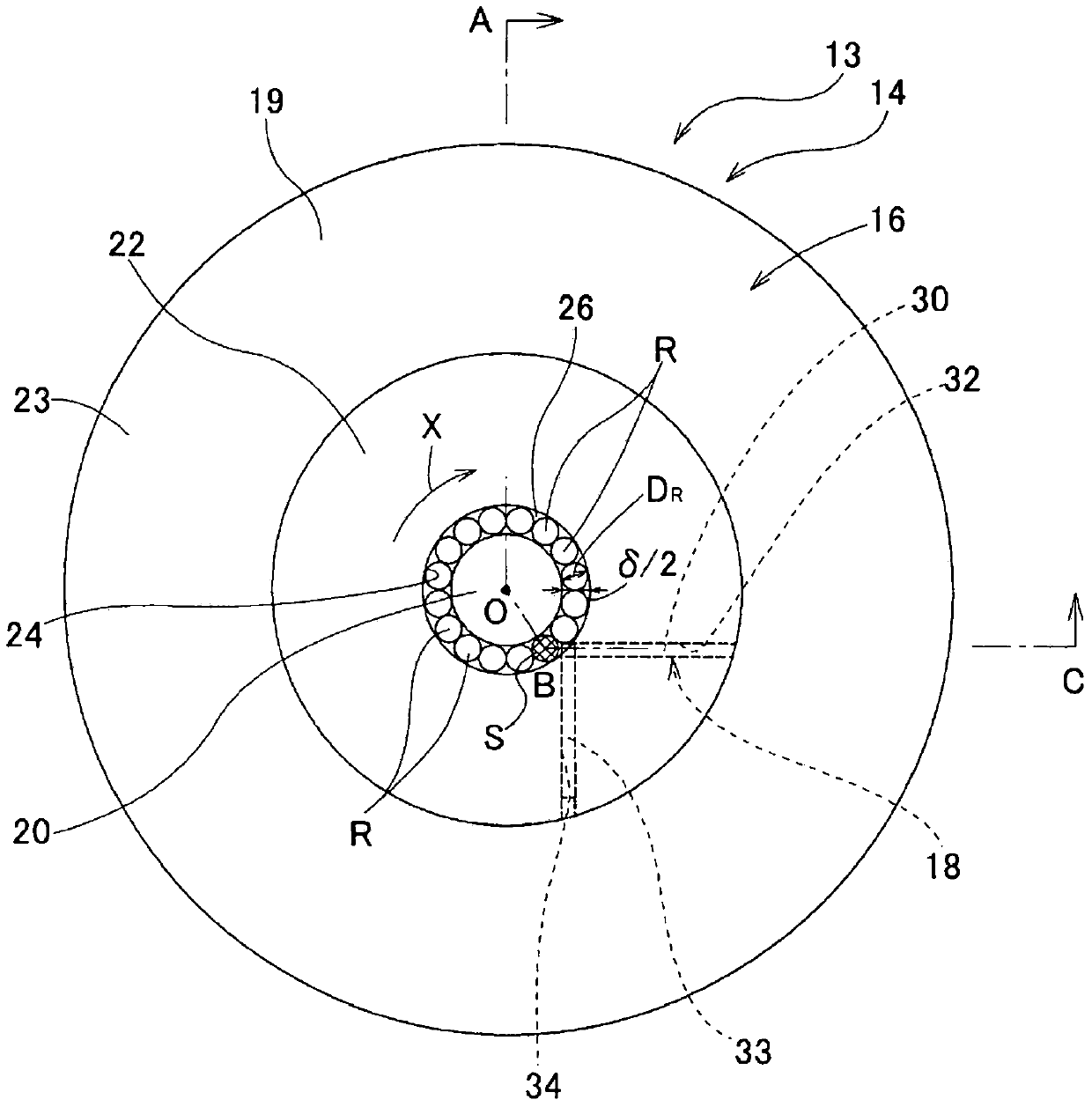

When assembling a roller bearing, the present invention effectively prevents rollers (R) assembled to the inside of an outer race (W) from tilting or dropping out from the state immediately after assembly. After arranging the rollers (R) in an annular shape by means of an arrangement jig (14), the roller group (G) arranged in an annular shape is ejected from the arrangement space (26) of the arrangement jig (14), and is pressed into a guide hole (39) of an insertion jig (15). As a result, in the state of inhibiting the diameter of the roller group (G) from widening by means of the inner peripheral surface of the guide hole (39), a holding member (36) made from an elastic material is inserted within the roller group (G) in the state of the holding member (36) being elastically compressed in diameter. Thereafter, an ejection tube (38) configuring the insertion jig (15) is displaced in the axial direction, simultaneously ejecting the roller group (G) and the holding member (36) from the guide hole (39), simultaneously assembling same within the outer race (W).

Owner:NSK LTD

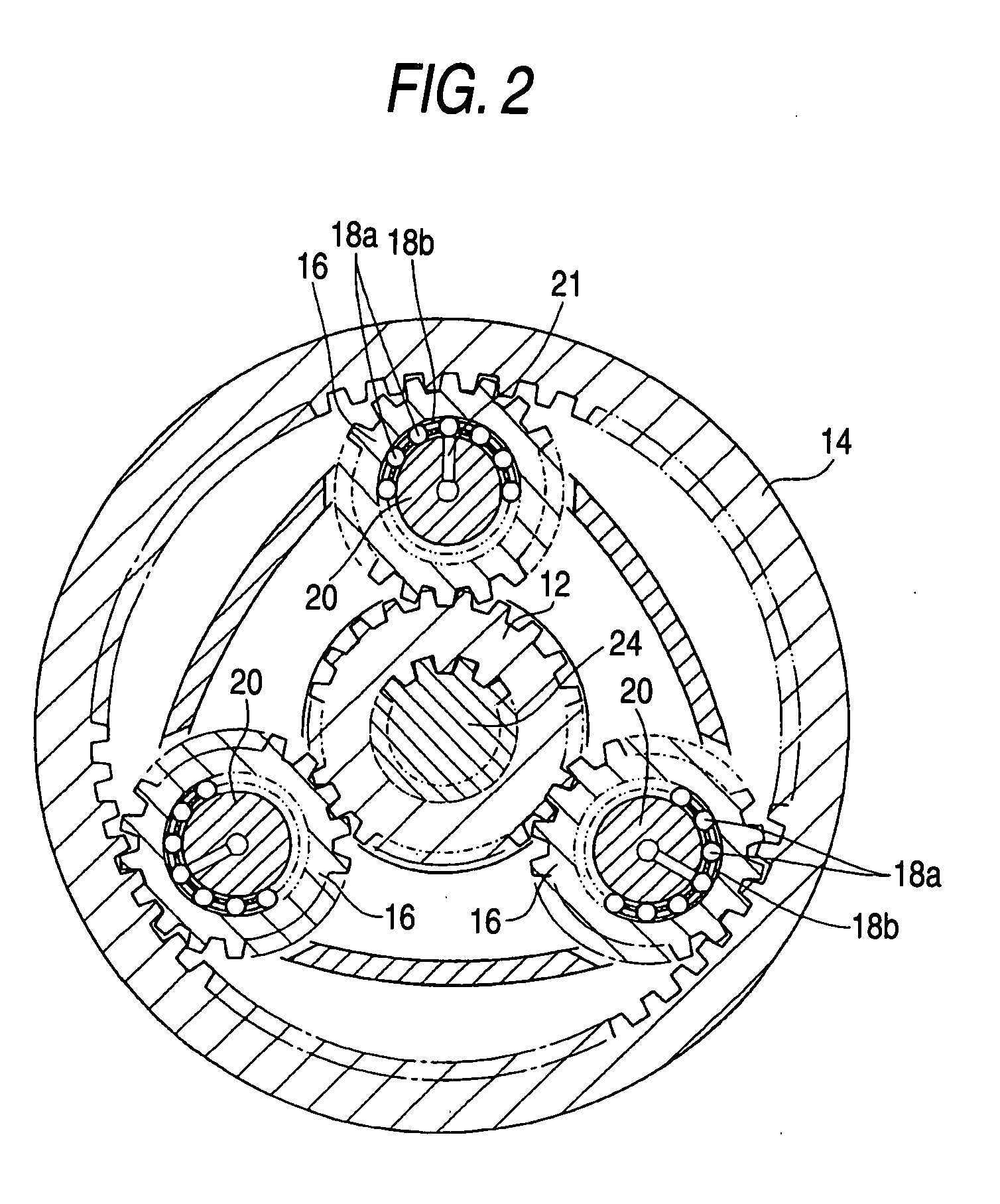

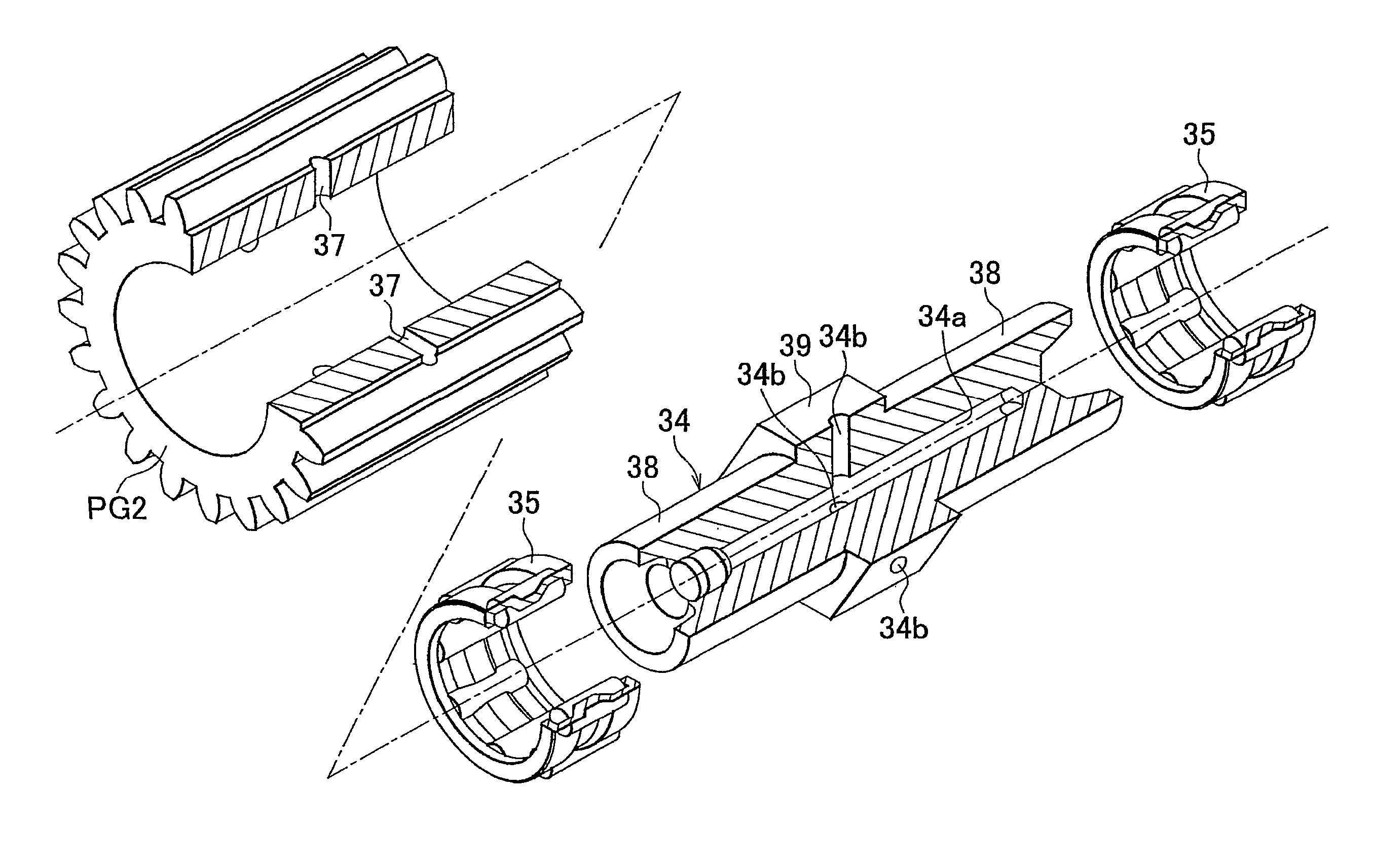

Roller bearing for planetary gear mechanism

InactiveUS20070202986A1Sliding resistanceAvoid deformationShaftsBearing componentsNeedle roller bearingGear wheel

A roller bearing (needle roller bearing) of the cage-and-roller type for a planetary gear mechanism includes a plurality of rollers (needle rollers), and a cage positioning and holding these rollers, and an outside diameter surface of the cage is guided by a bore diameter surface of a planetary gear. An outside diameter dimension of the cage is set to a value which is not smaller than 95% and not larger than 97% of an inner diameter dimension of the planetary gear.

Owner:JTEKT CORP

Pin Roller Type Pinion Device

InactiveUS20130031996A1Increase their wear-resistant propertyEnhance their rupture strengthShaftsPortable liftingPins needlesPinion

In a pin roller type pinion device, a first bearing has first pin needles rollably arranged around pin rollers between an inner surface of first circular holes and one end portion of the pin rollers. A second bearing has second pin needles rollably arranged around the pin rollers between an inner surface of second circular holes and the other end portion of the pin rollers. This prevents an external pressure from developing on the inner surface of the circular holes when inserting the pin needles between the inner surface of the circular holes and the end portions of the pin rollers.

Owner:KAMOSEIKO

Retainer for radial roller bearing

Owner:NSK LTD

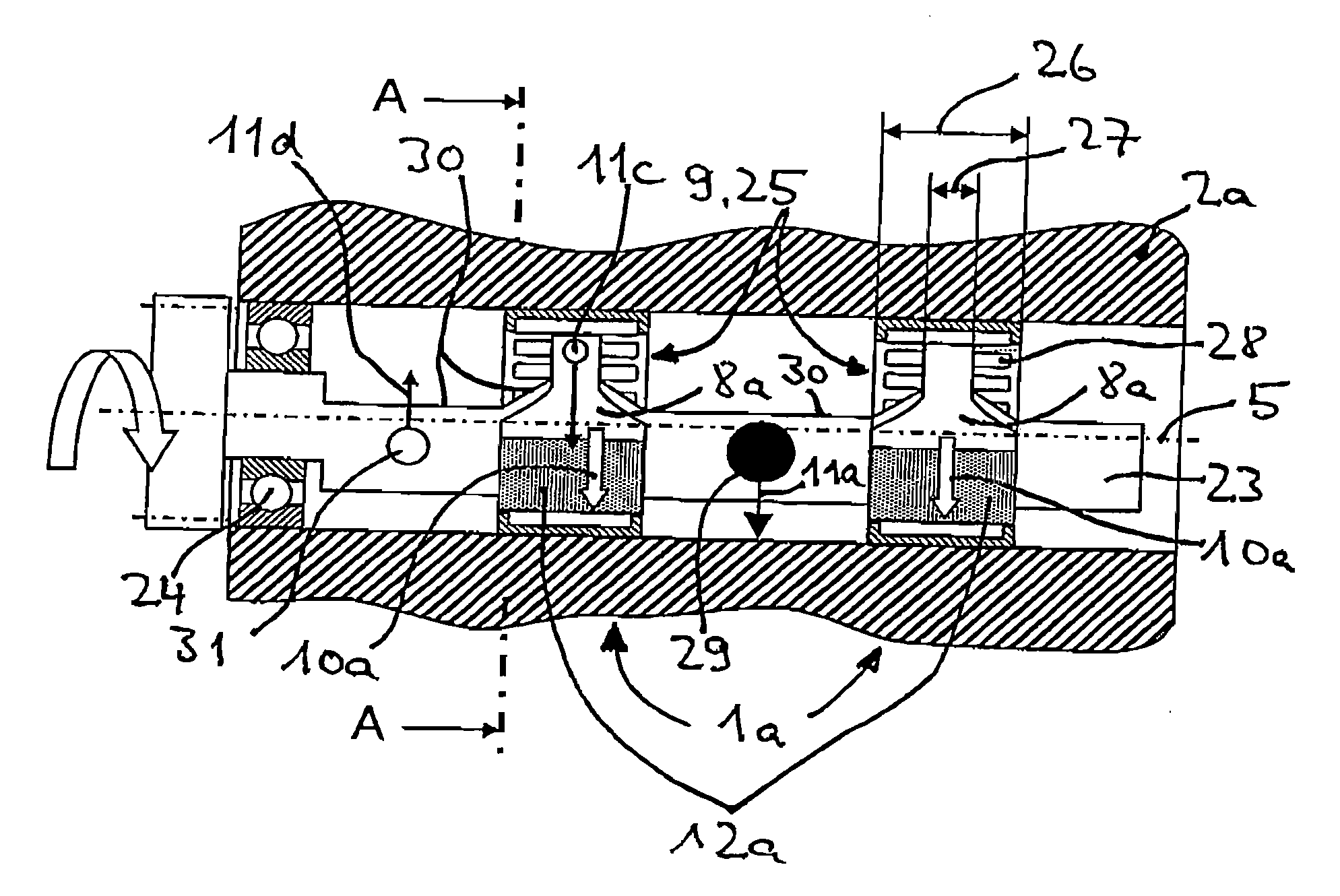

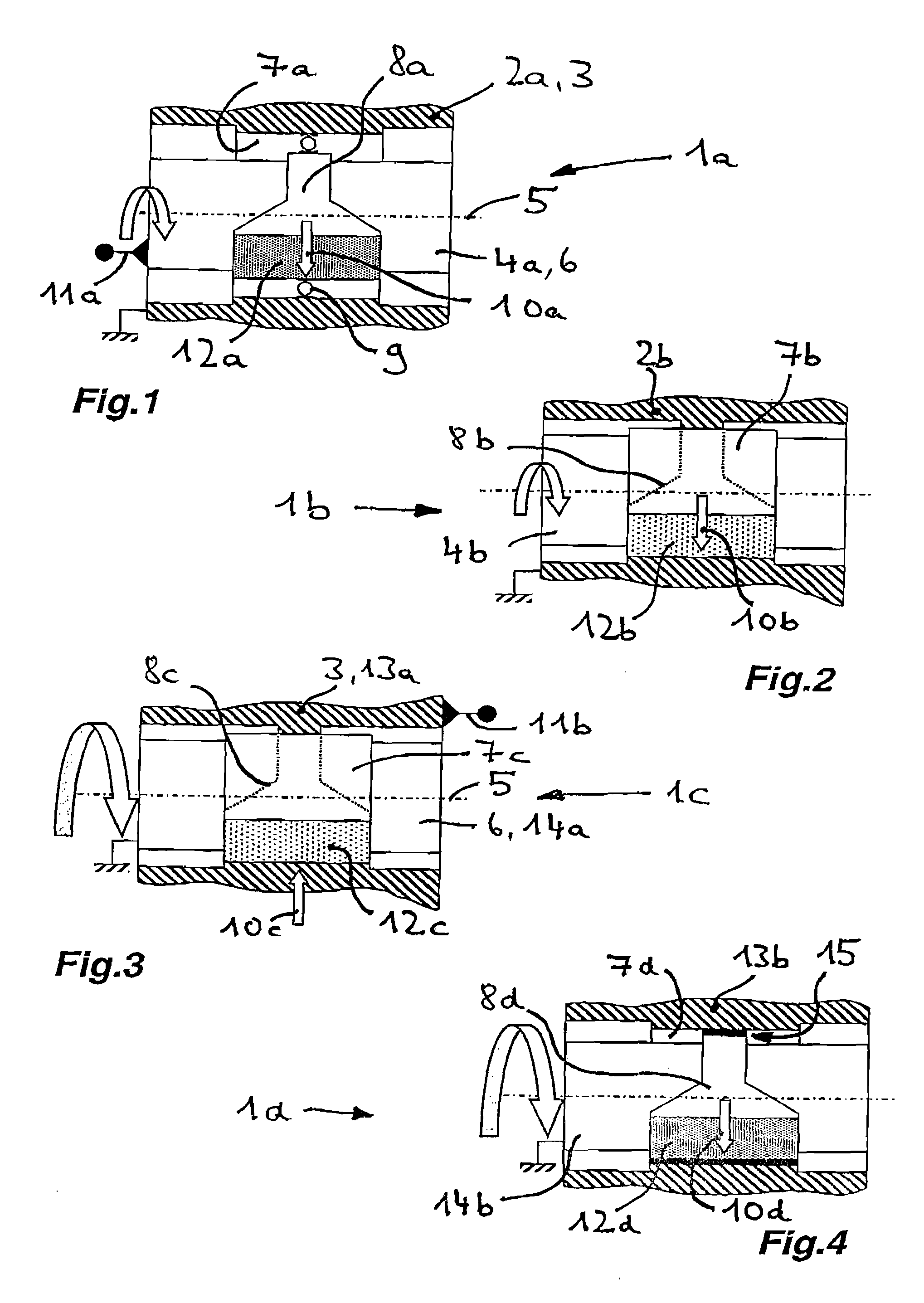

Radial bearing

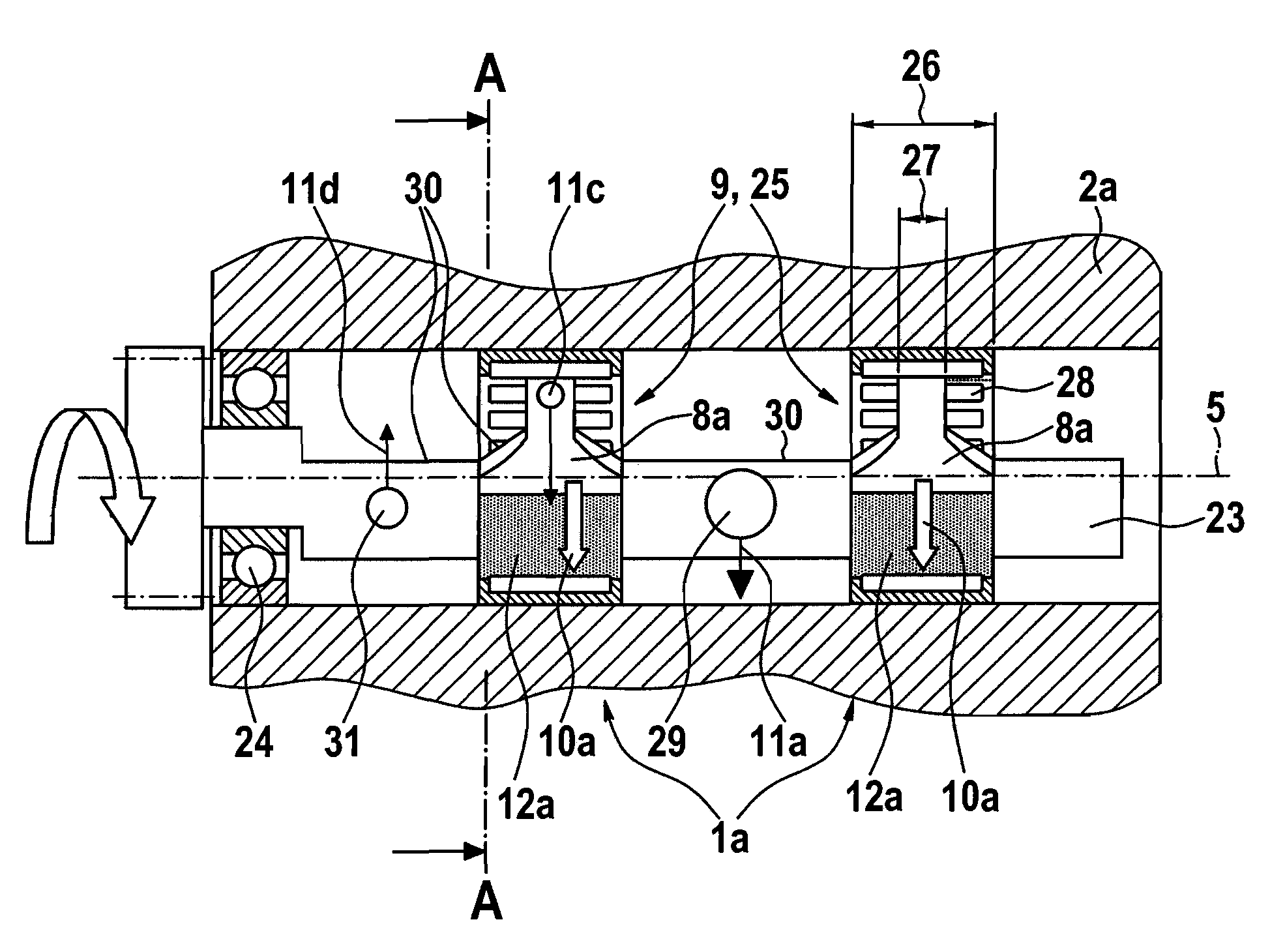

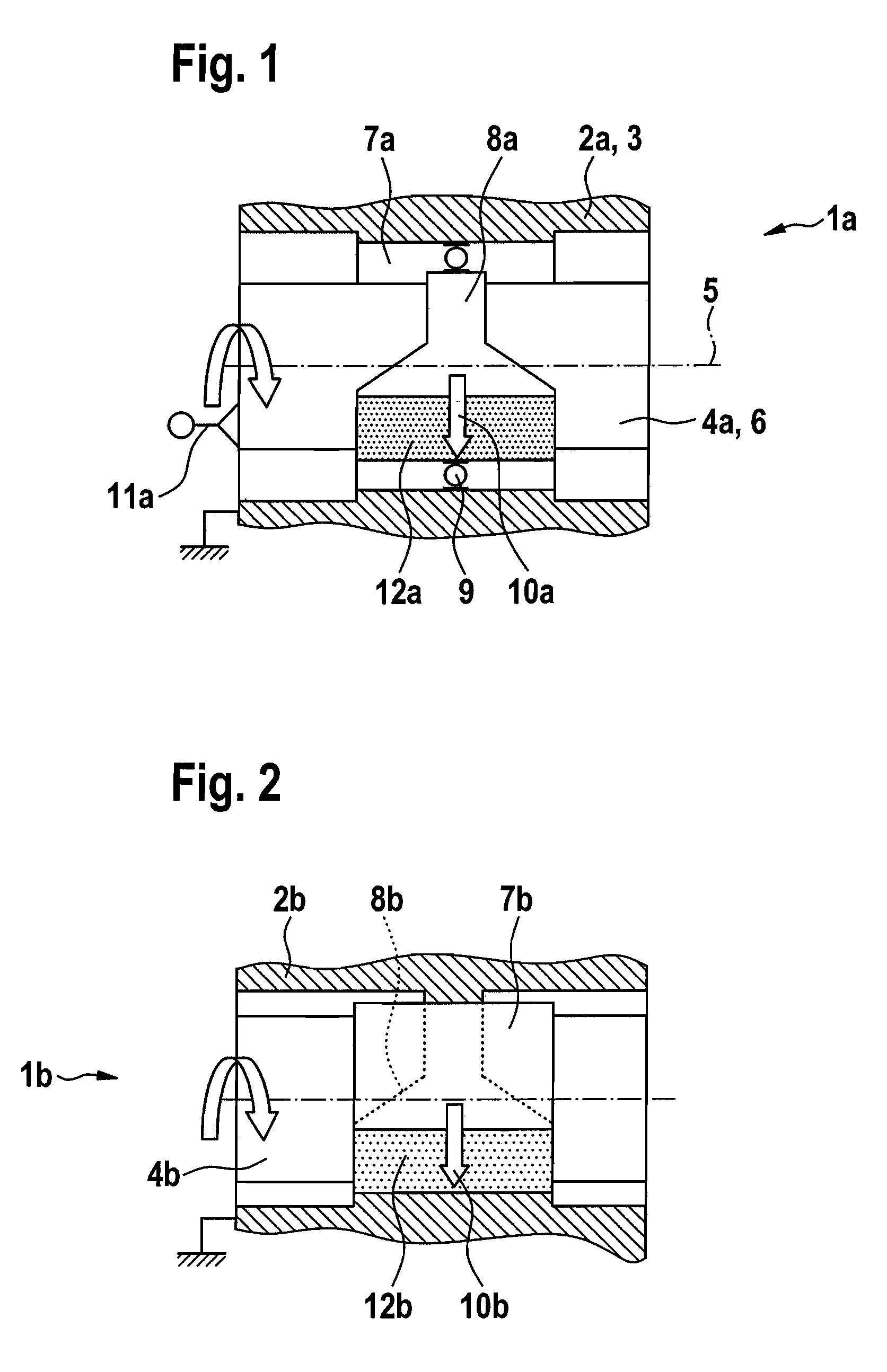

ActiveUS20070177837A1Improve friction performanceConsiderable friction power lossBall bearingsBearing componentsMechanical engineeringRoller bearing

A radial bearing (1a, 1b, 1c, 1d), especially a roller bearing (9) comprising an outer part (3) opposite an inner part (6), which rotate relative to each other about a common longitudinal axis (5) is provided, wherein the radial bearing (1a, 1b, 1c, 1d) includes a bearing seat (8a, 8b, 8c, 8d), which is formed in the outer part (3) or on the inner part (6) and which is generally stationary relative to a radial load (10a, 10b, 10c, 10d) acting on the bearing seat (8a, 8b, 8c, 8d) in a load zone (12a, 12b, 12c, 12d). The bearing seat (8a, 8b, 8c, 8d) features a variable width over its extent in a direction of the longitudinal axis (5), such that, starting from the load zone (12a, 12b, 12c, 12d), the bearing seat (8a, 8b, 8c, 8d) is significantly narrowed outside of the load zone (12a, 12b, 12c, 12d).

Owner:SCHAEFFLER TECH AG & CO KG

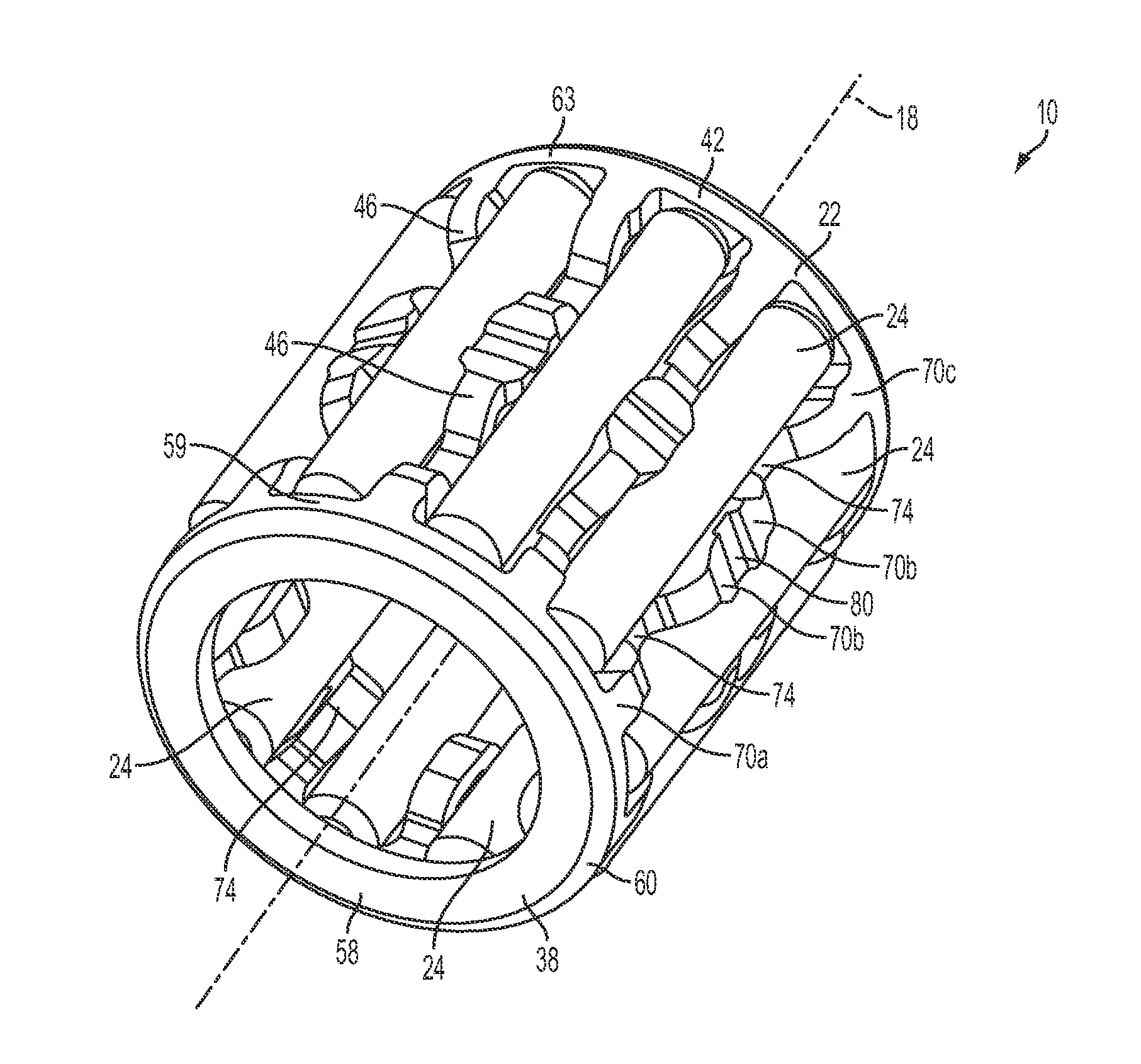

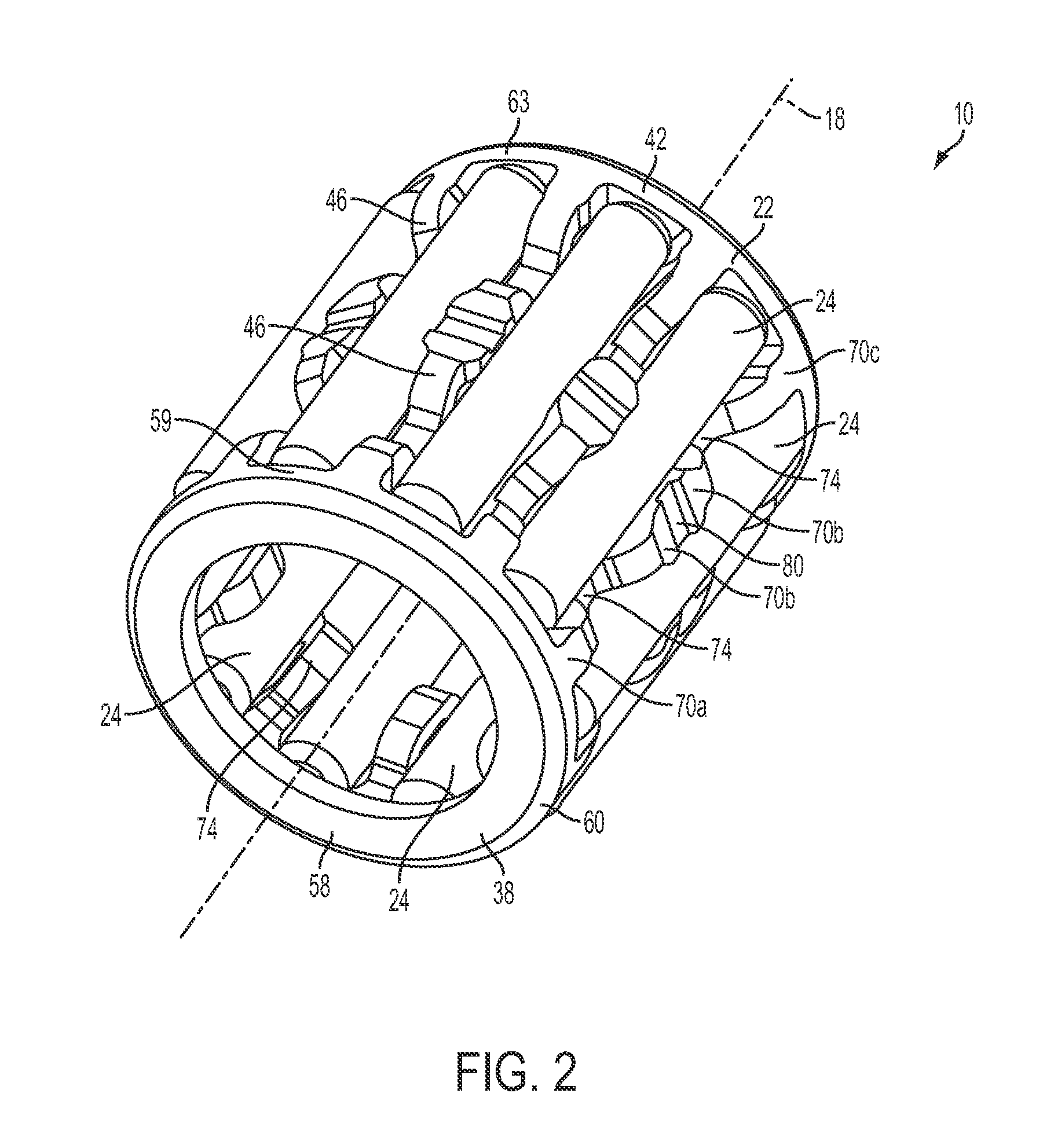

Cage for bearing assembly

A bearing cage defines an overall axial length and includes a first end portion defining a first contact surface extending at a radially-outermost diameter of the bearing cage a first axial contact length, and a second end portion spaced a distance from the first end portion and defining a second contact surface extending at the radially-outermost diameter of the bearing cage a second axial contact length. The bearing cage further includes a plurality of spanning members extending between the first and second end portions to define a spanning member axial contact length defined at the radially-outermost diameter of the bearing cage by at least one contact pad. The bearing cage produces a total contact ratio, defined as the ratio of the sum total of the first axial contact length, the second axial contact length, and the spanning member axial contact length to the overall axial length, of at least 0.380.

Owner:KOYO BEARINGS NORTH AMERICA LLC

Split bearing

InactiveUS20090028482A1Easy to optimizeEasily and reliably incorporatedNeedle bearingsBearing unit rigid supportRolling-element bearingEngineering

Owner:JTEKT CORP

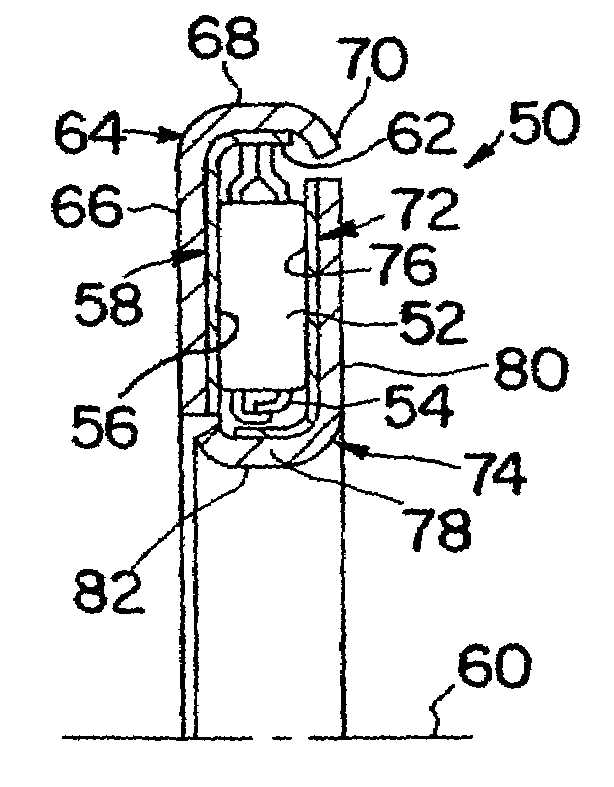

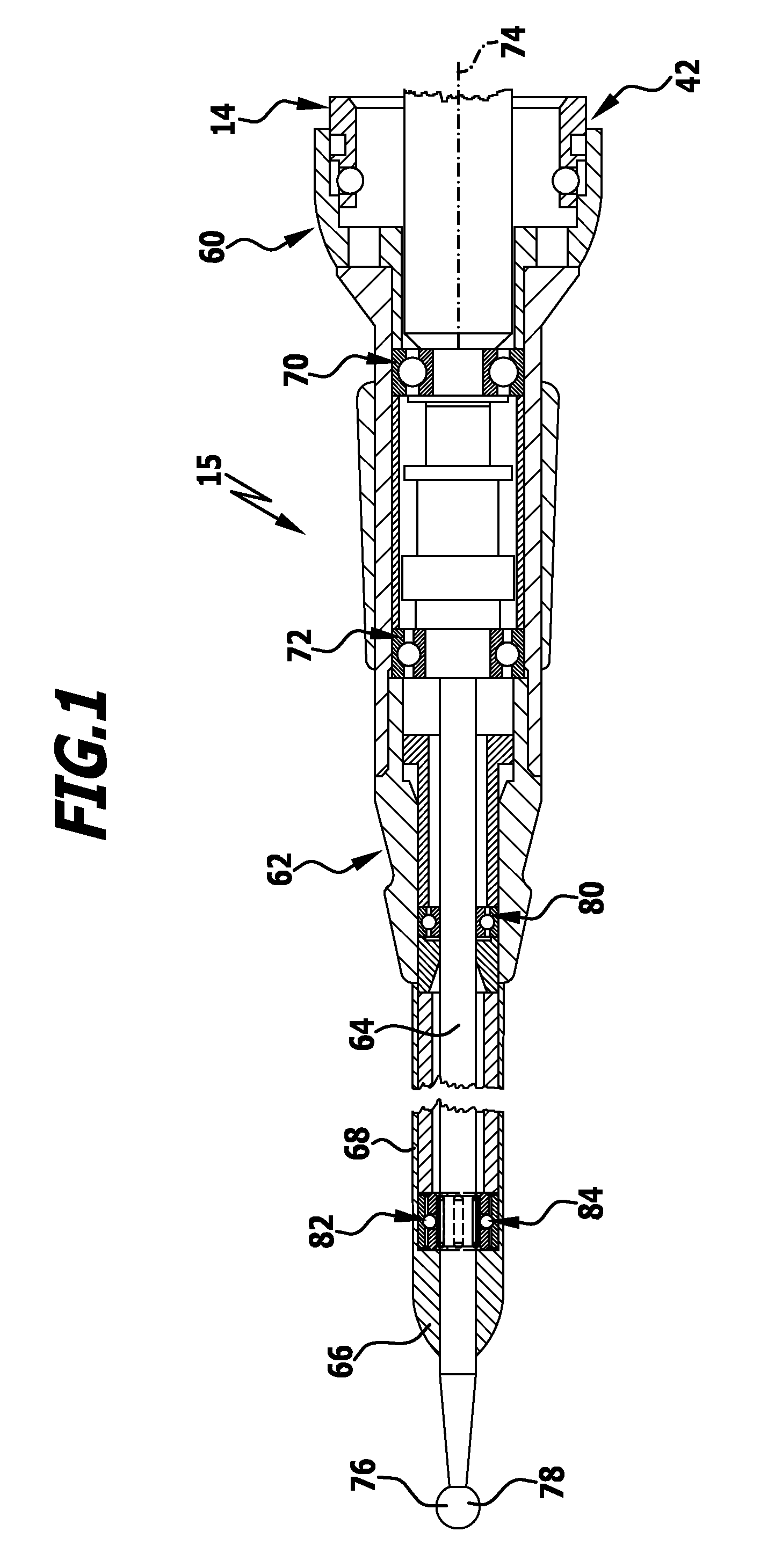

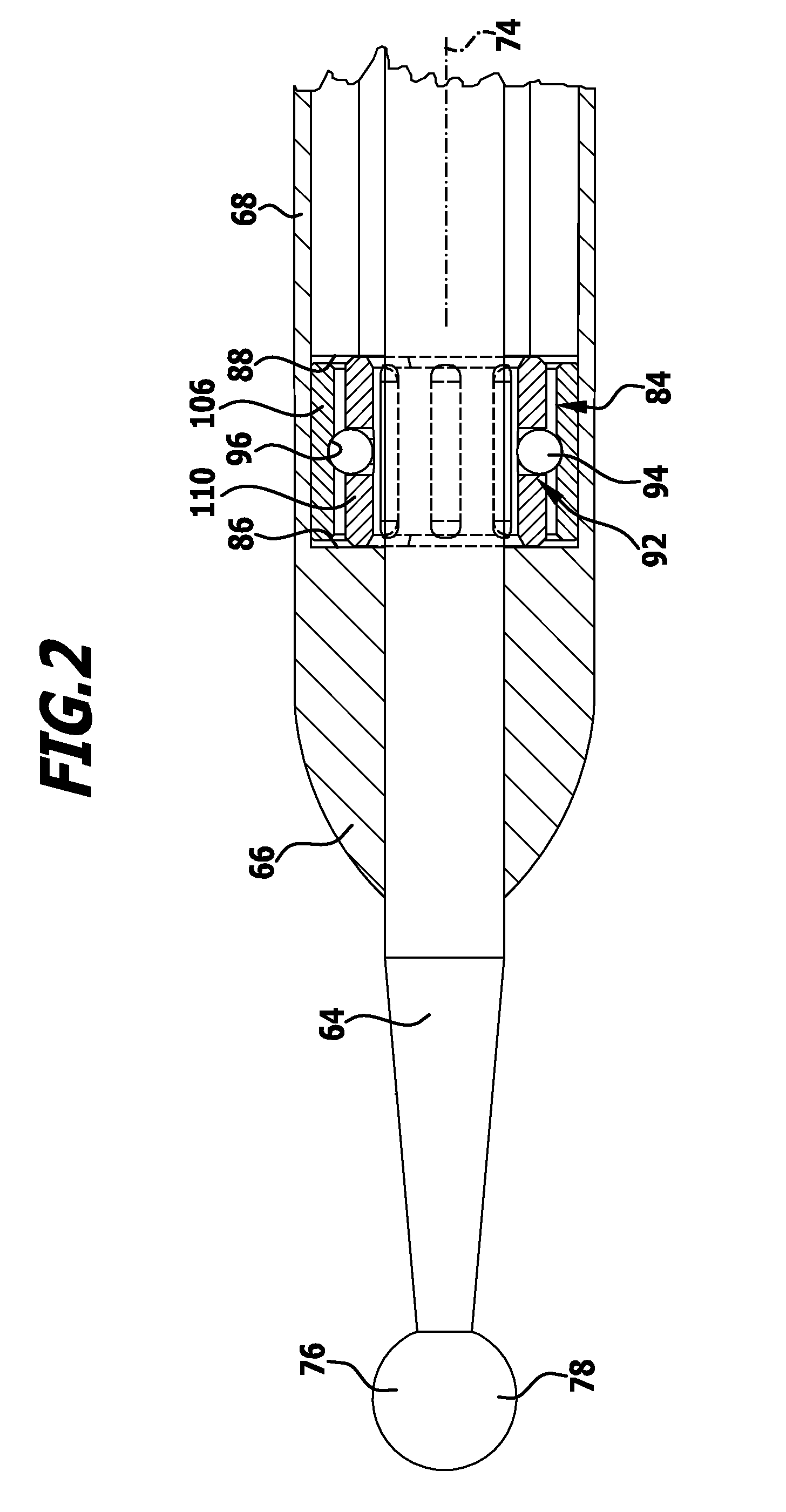

Surgical instrument, surgical handpiece and surgical drive system

In order to improve a surgical instrument comprising a shank and a drive shaft, which is rotatably mounted in the shank and bears or comprises a tool element at its distal end, wherein in the distal end region of the shank a radial bearing is arranged or configured for the rotatable mounting of the drive shaft on the shank, such that a reliable operation is possible even with increasing miniaturisation of the shanks, it is proposed that the radial bearing is configured in the form of a needle bearing.An improved surgical handpiece as well as an improved surgical drive system are additionally proposed.

Owner:AESCULAP AG

Lubrication of a planetary gearset

InactiveUS20100144479A1Improve the lubrication effectWear minimizationToothed gearingsGear lubrication/coolingAutomatic transmissionEngineering

In a planetary gearset and an automatic transmission according to the invention, a pinion shaft on which a pinion gear is rotatably supported includes a bearing portion on which a bearing is attached and a polygonal portion having a polygonal outer periphery. An axial oil passage and radial oil passages that communicate with the axial oil passage are formed in the polygonal portion, and the inlet of each radial oil passage formed in the pinion gear faces the polygonal portion.

Owner:TOYOTA JIDOSHA KK

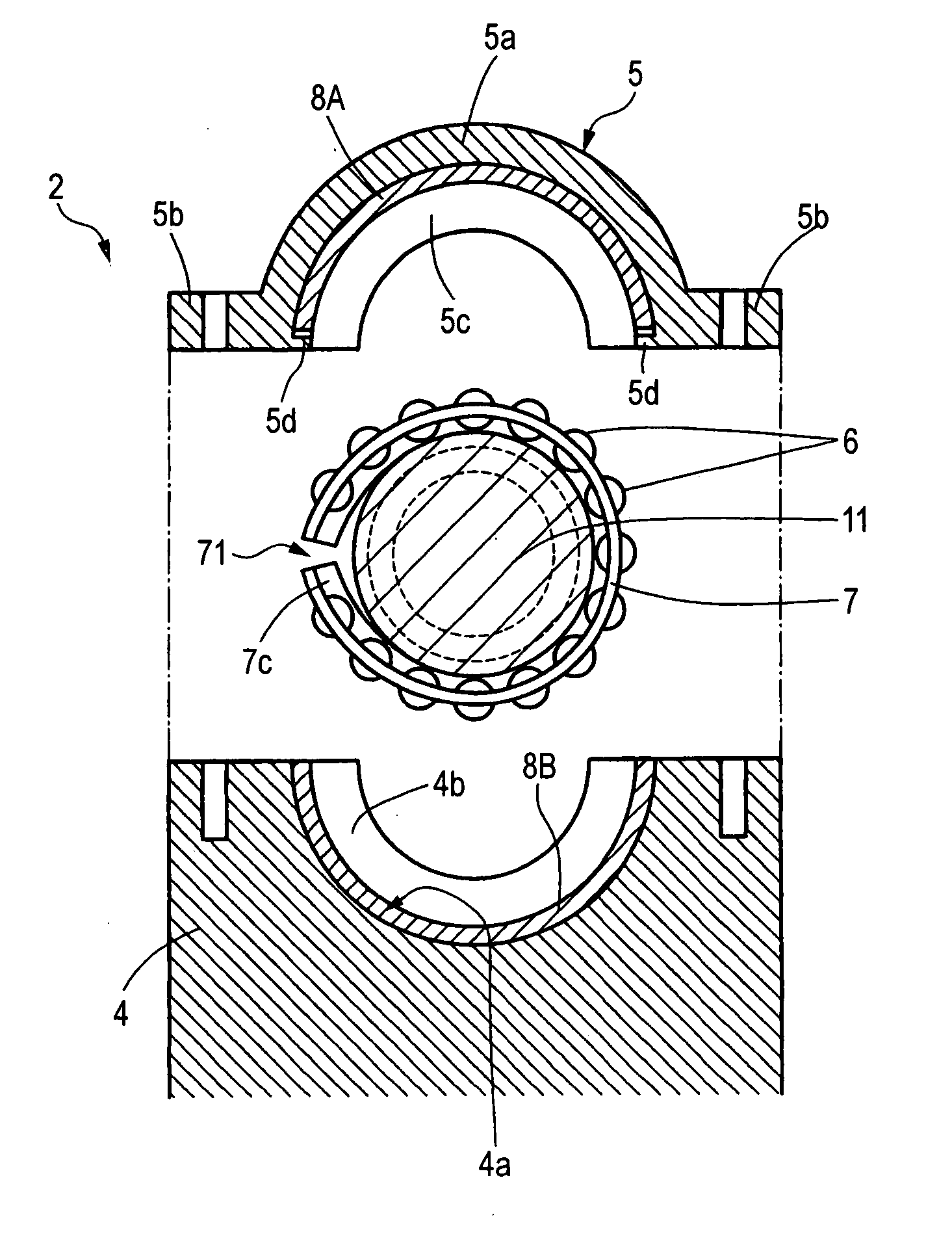

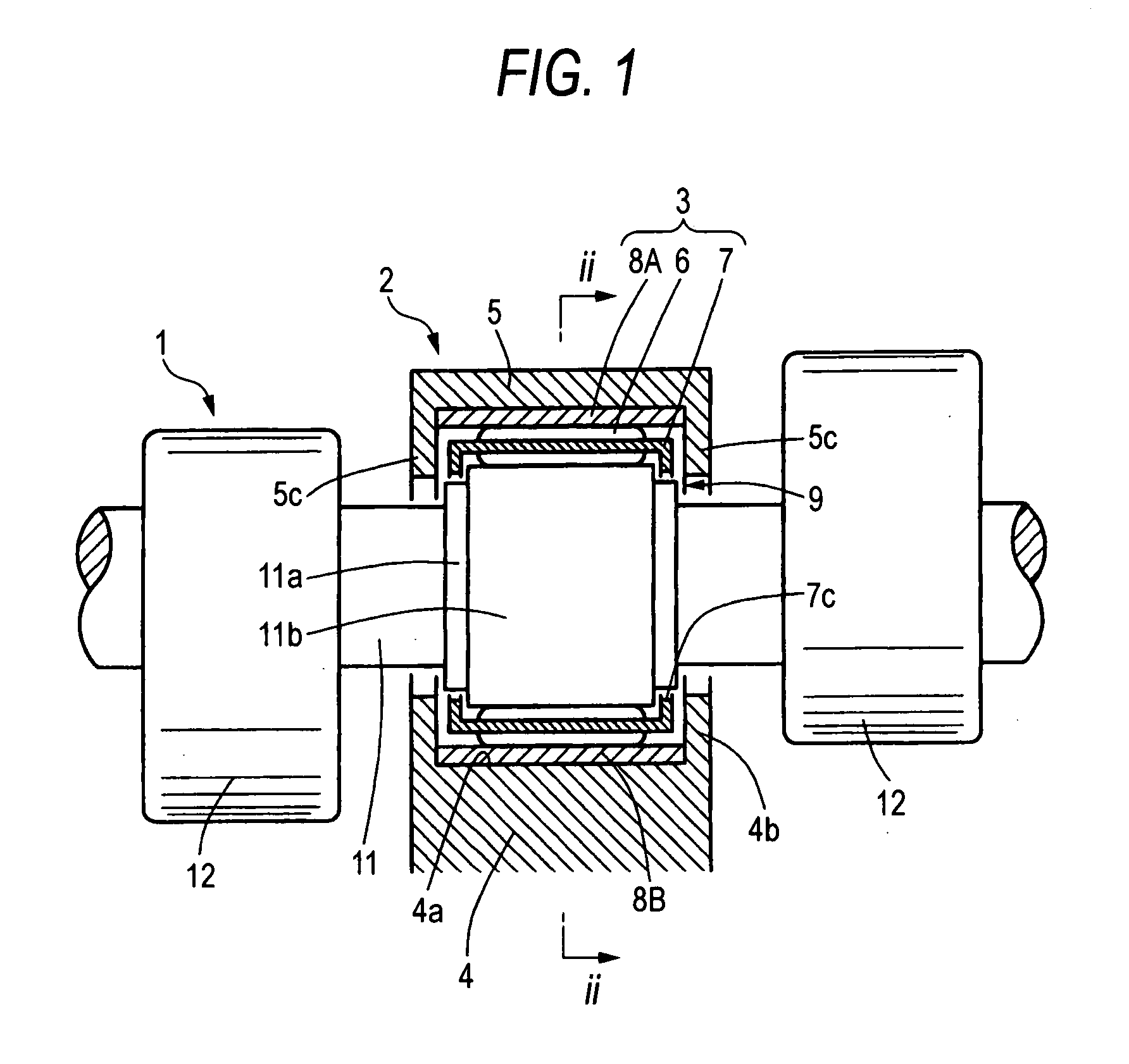

Composite roll bearing

ActiveUS7637664B2Reduce rolling resistanceReduce frictional resistanceShaftsBearing componentsThrust bearingEngineering

A composite roll bearing (1), comprising an outer ring (2) and an annular inner ring (3) of groove shape in cross section having first, second, and third receiving surfaces (3a, 3b, 3c) facing the both end face inner peripheral portions (2a, 2b) and the circular inner peripheral surface (2c) of the outer ring (2) at specified intervals. A plurality of rollers (4) for thrust bearing are installed between one end face portion (2a) of the outer ring (2) and the first receiving surface (3a) of the inner ring (3) and between the other end face (2b) of the outer ring (2) and the second receiving surface (3b) of the inner ring (3). A plurality of rollers (5) for radial bearing are installed between the circular inner peripheral surface (2c) of the outer ring (2) and the third receiving surface (3c) of the inner ring (3). The rollers (5) are restricted to move in a thrust direction by retainer portions (8a, 8a) formed at the inner ends of retainers (6, 7) for the rollers (4) for thrust bearing.

Owner:HARMONIC DRIVE SYST IND CO LTD

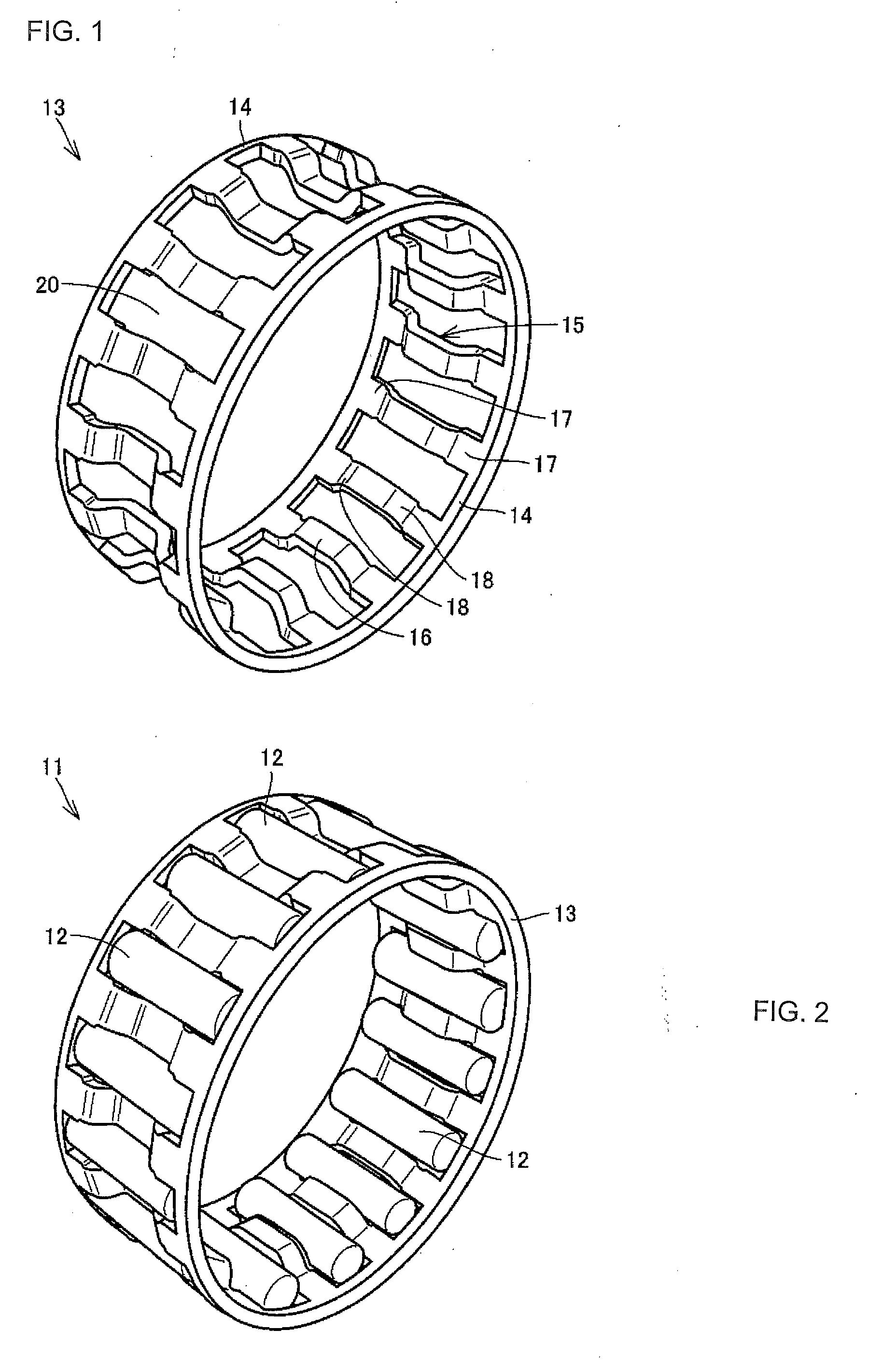

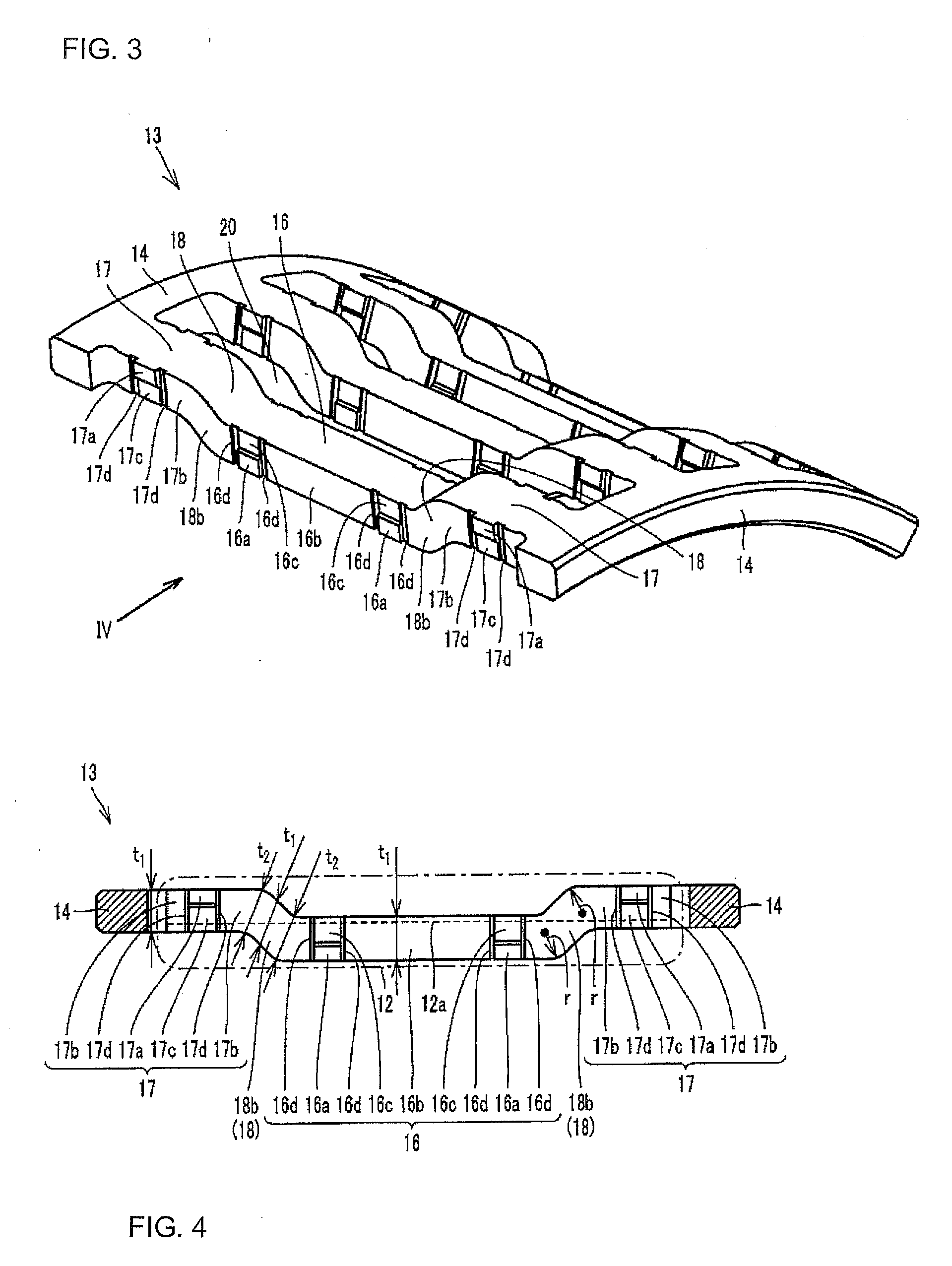

Roller bearing retainer and needle roller bearing

ActiveUS20100278471A1Reduced contact areaAvoid abrasionsShaftsBearing componentsNeedle roller bearingEngineering

A roller bearing retainer (13) includes a pair of annular ring parts (14) and a plurality of column parts (15) each including a column center part (16) provided in an axial center region so as to be positioned relatively on the radial inner side, a pair of column end parts (17) provided in axial end regions so as to be positioned relatively on the radial outer side, and a pair of column sloped parts (18) positioned between the column center part (16) and the pair of column end parts (17), and connecting the pair of ring parts to each other. A thickness of each part of the column center part, the pair of column end parts, and the pair of column sloped parts is smaller than a thickness of a boundary part between the adjacent parts.

Owner:NTN CORP

Track roller bearings with rolling elements or liners

A track roller assembly includes a split inner ring, a split outer ring, a one piece inner ring and / or a one piece outer ring and a liner or plurality of rolling elements engaging therewith, the track roller assembly being disposed in a structure of an Airbus A-350 aircraft, an Airbus A-320 aircraft, an Airbus A320Neo aircraft, an Airbus A330 aircraft, an Airbus A330Neo aircraft, an Airbus A321 aircraft, an Airbus A340 aircraft, and an Airbus A380 aircraft.

Owner:ROLLER BEARING OF AMERICA

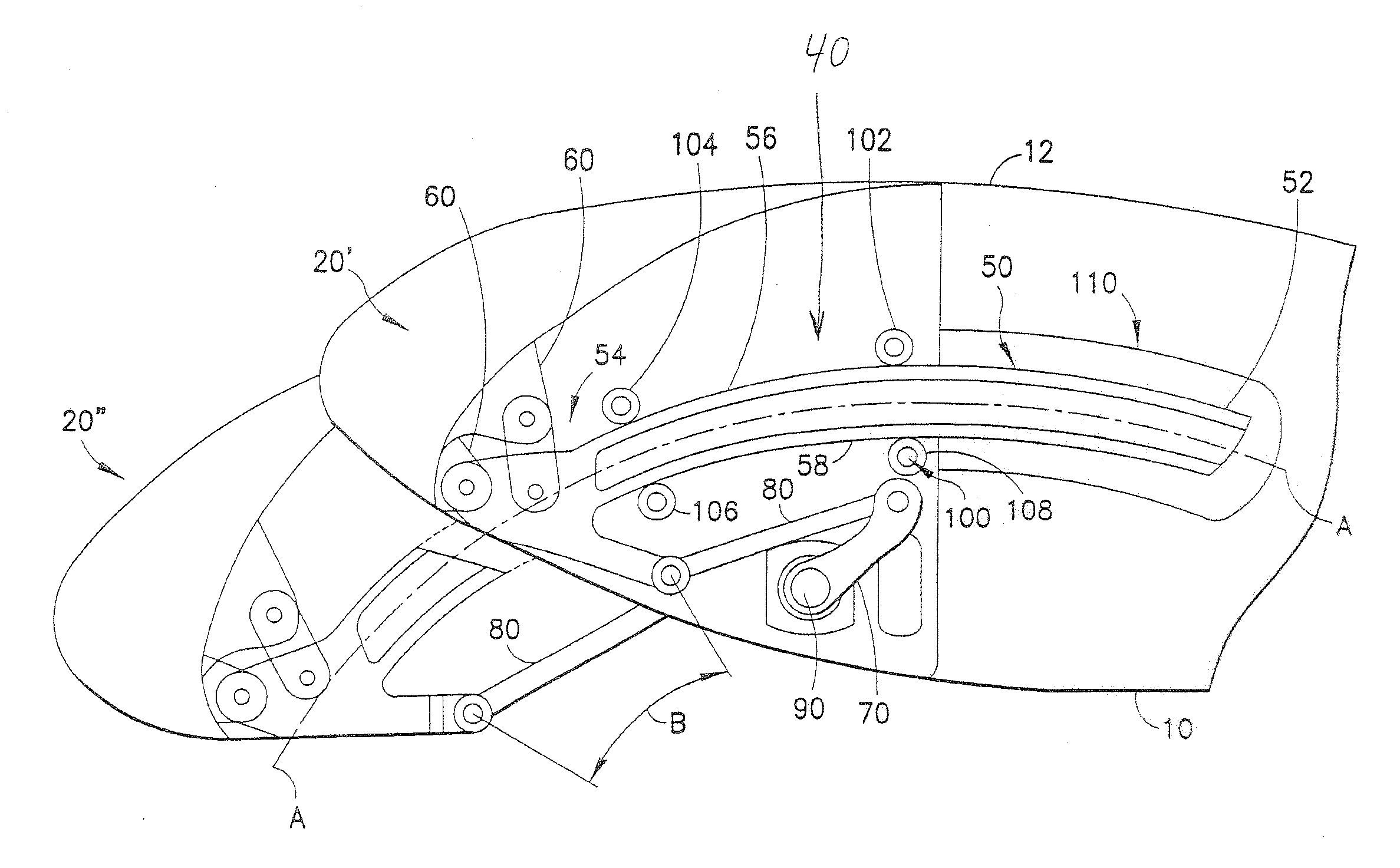

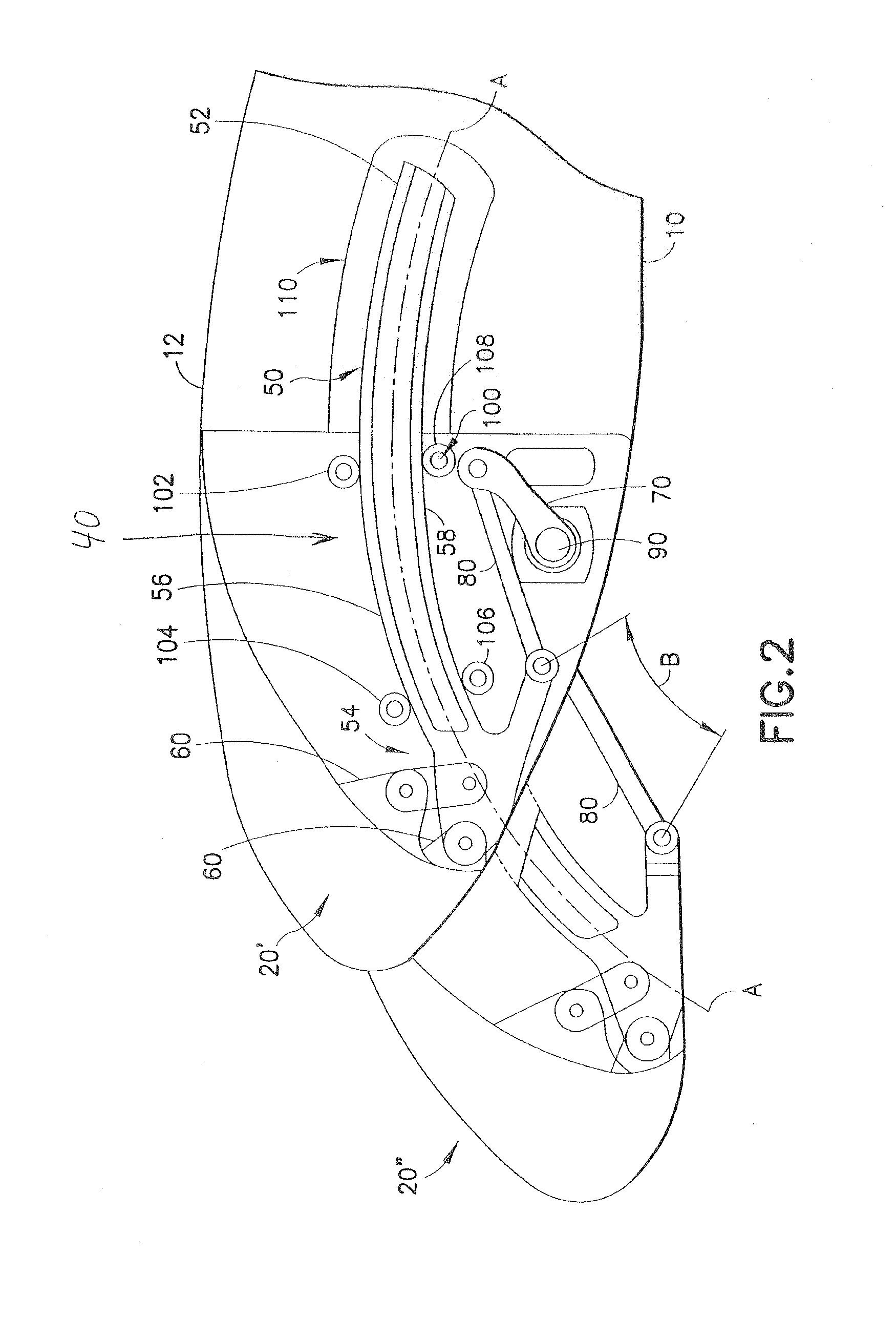

Spring track roller assembly

ActiveUS8393799B2Extended service lifeFacilitates controlled axial displacementAircraft controlBearing componentsEngineeringMechanical engineering

A roller assembly comprises a first race and a second race. The second race is coaxial with the first race and is axially movable relative to the first race. The first and second races are movable between a static axial position and a dynamic axial position relative to one another. The roller assembly includes at least one biasing member that is operative to bias the first and second races from the dynamic axial position toward the static axial position.

Owner:THE BOEING CO

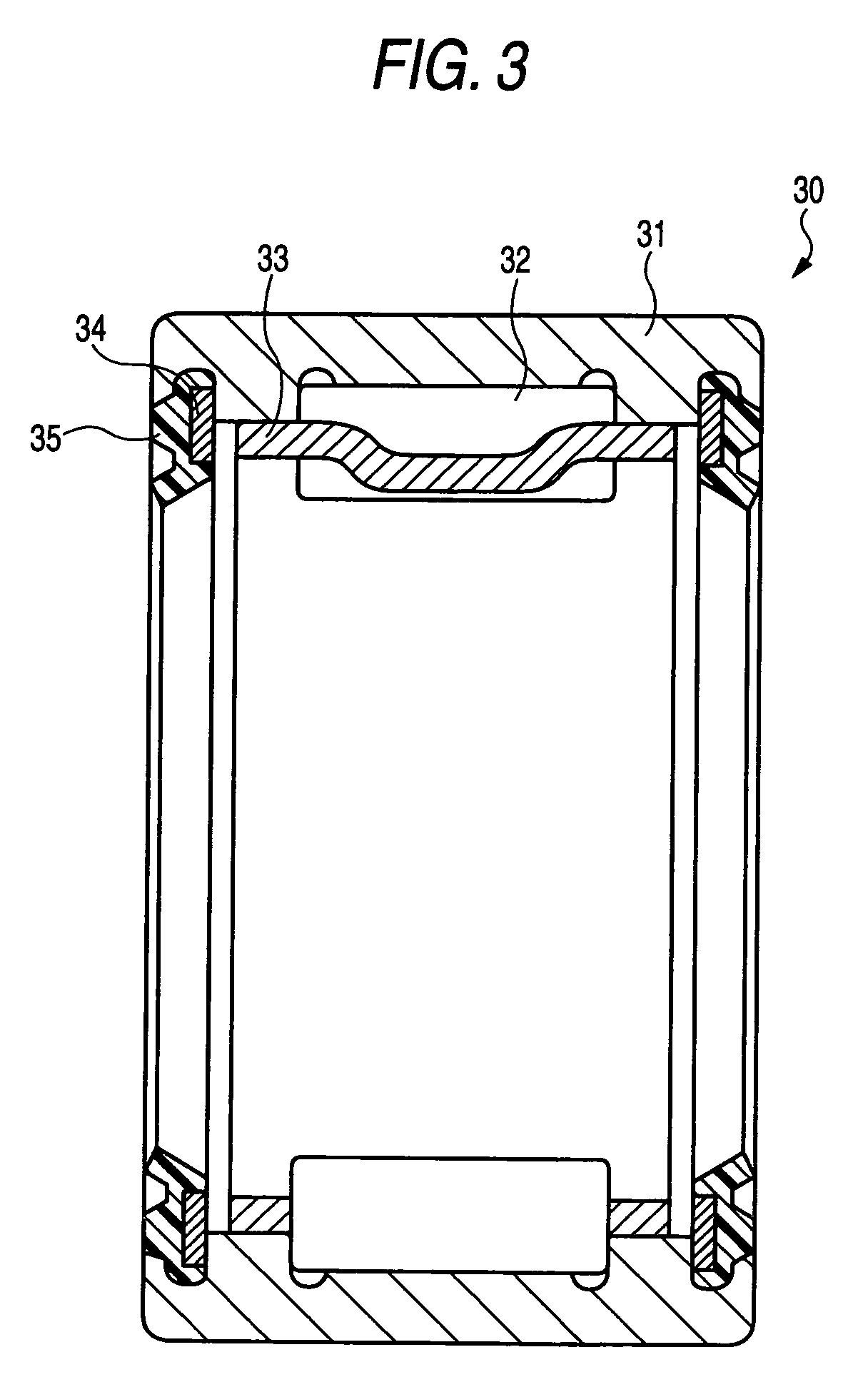

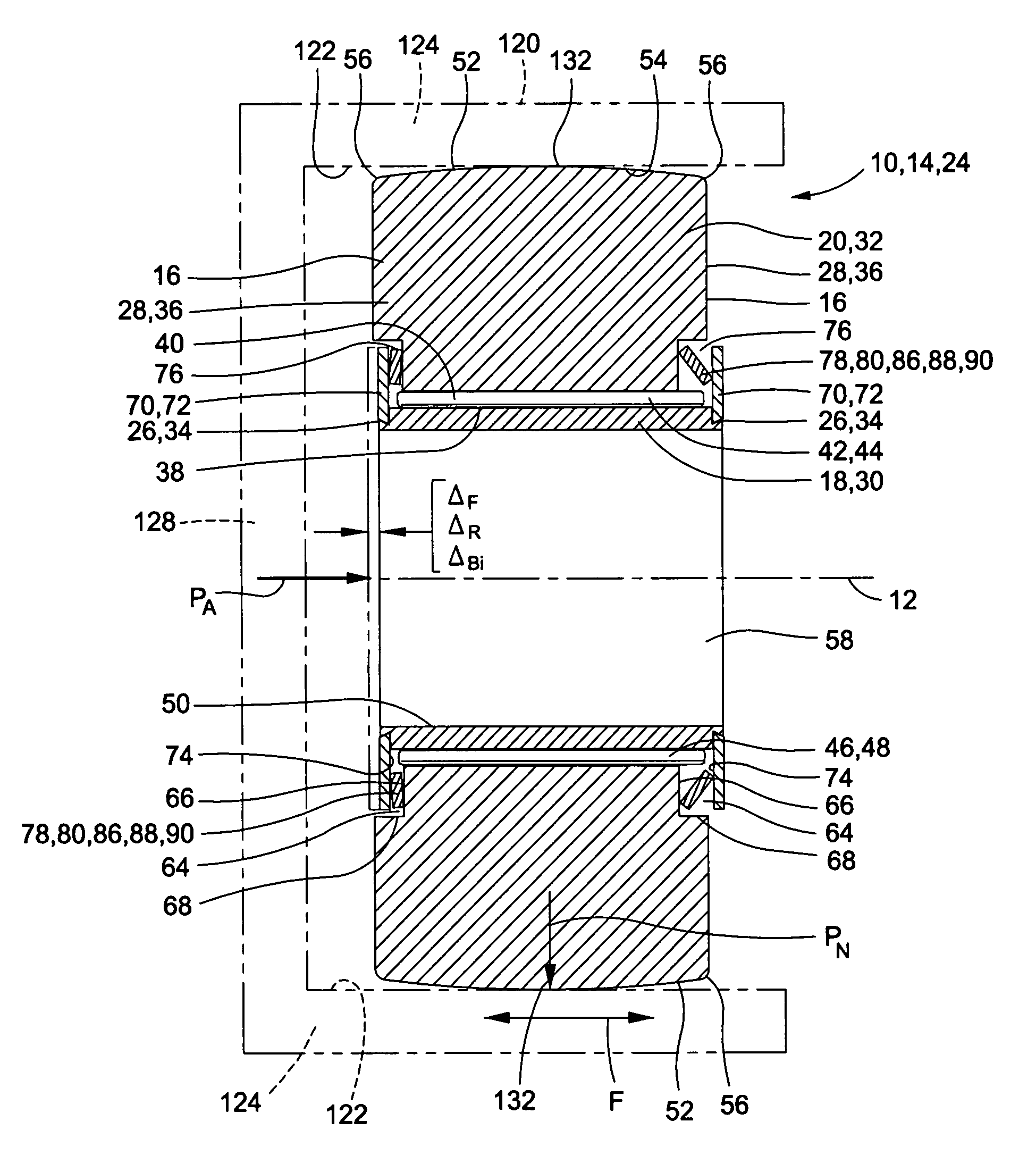

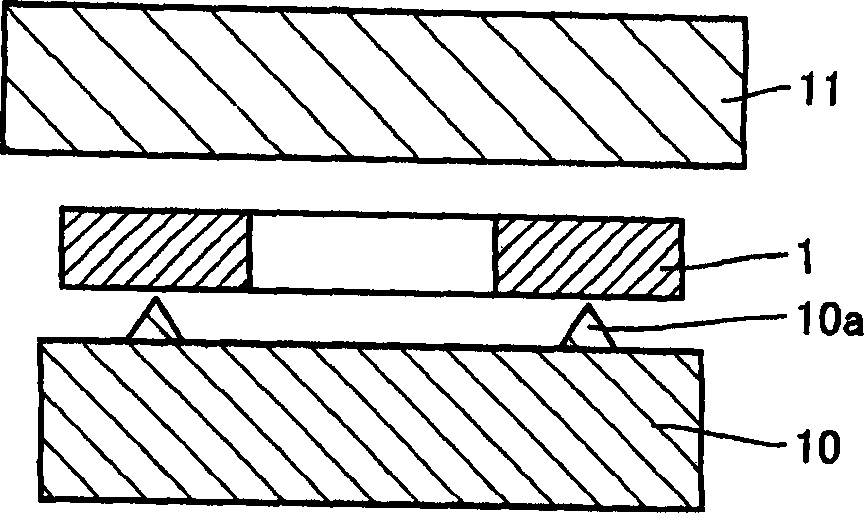

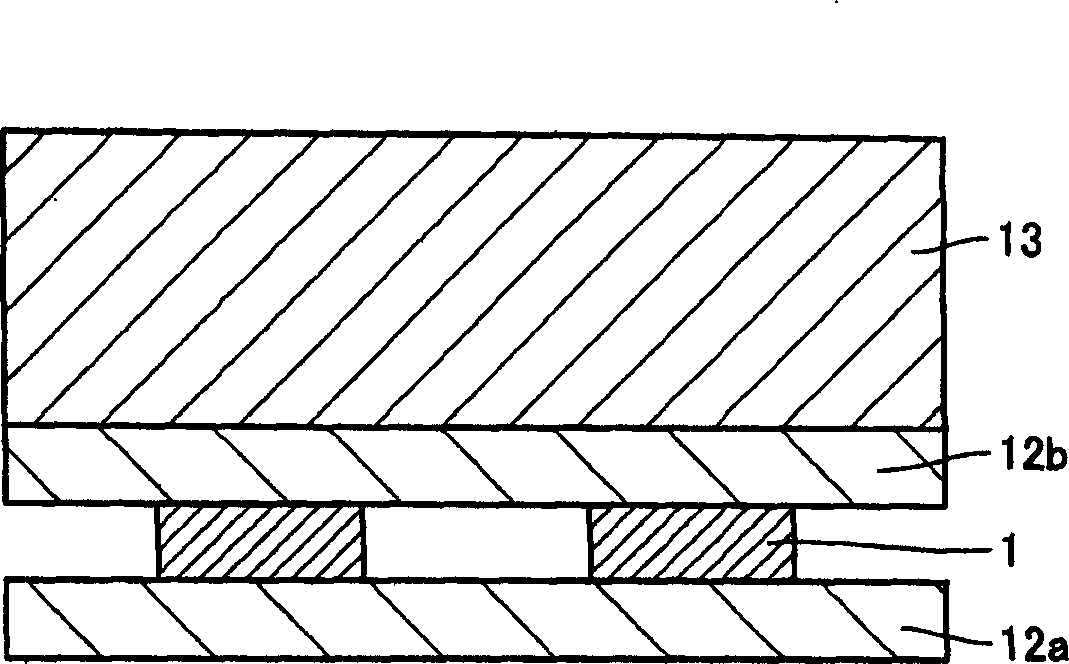

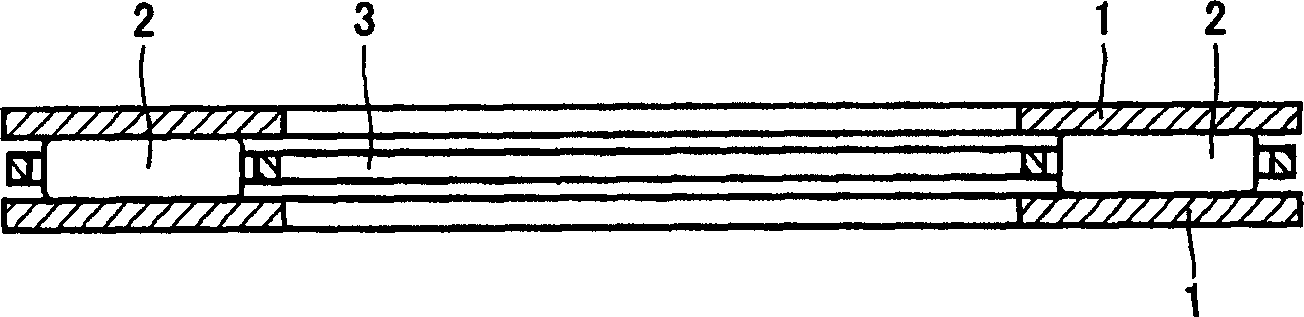

Thin-walled part producing method, bearing raceway ring, thrust needle roller bearing, rolling bearing raceway ring producing method, rolling bearing raceway ring, and rolling bearing

InactiveCN1863931AWarpage suppressionStable temperatureBearing componentsFurnace typesNeedle roller bearingRolling-element bearing

A method of producing thin-walled parts is characterized in that after being heated, a thin-walled part (1) is subjected to either hardening or isothermal transformation while being pressed in a mold (12a, 12b) with the latter being used as a cooling medium. This makes it possible to provide a method of producing thin-walled parts which can be prevented from warping or deforming during heat treatment and which have a uniform and high hardness; a bearing raceway ring; a thrust needle roller bearing; a method of producing rolling bearing raceway rings; a rolling bearing raceway ring; and a rolling bearing.

Owner:NTN CORP

Radial bearing

ActiveUS7628133B2Low costReduce expensesBall bearingsBearing componentsEngineeringMechanical engineering

A radial bearing (1a, 1b, 1c, 1d), especially a roller bearing (9) comprising an outer part (3) opposite an inner part (6), which rotate relative to each other about a common longitudinal axis (5) is provided, wherein the radial bearing (1a, 1b, 1c, 1d) includes a bearing seat (8a, 8b, 8c, 8d), which is formed in the outer part (3) or on the inner part (6) and which is generally stationary relative to a radial load (10a, 10b, 10c, 10d) acting on the bearing seat (8a, 8b, 8c, 8d) in a load zone (12a, 12b, 12c, 12d). The bearing seat (8a, 8b, 8c, 8d) features a variable width over its extent in a direction of the longitudinal axis (5), such that, starting from the load zone (12a, 12b, 12c, 12d), the bearing seat (8a, 8b, 8c, 8d) is significantly narrowed outside of the load zone (12a, 12b, 12c, 12d).

Owner:SCHAEFFLER TECH AG & CO KG

Thrust needle roller bearing with isolating layer

InactiveUS20110182542A1Prevent creepAvoid sliding wearBearing componentsNeedle bearingsNeedle roller bearingAdhesive

A thrust needle bearing with an isolating layer has a cage with rollers, washers on which the rollers run, at least one of the washers is attached to the cage, backup surfaces fixed external to each of the washers and an isolating layer attached to at least one of the washers, which is interposed between the at least one of the washers and at least one of the backup surfaces of the bearing. The isolating layer is a layer of vibration-attenuating material. Alternatively, the isolating layer is a layer of material which has properties that prevent creep or sliding wear for at least one of the backup surfaces. The isolating layer is attached to the washers by bonding, use of adhesives or mechanical means.

Owner:SCHAEFFLER TECH AG & CO KG

Lubrication of a planetary gearset

InactiveUS7967712B2Improve the lubrication effectWear minimizationGear lubrication/coolingToothed gearingsAutomatic transmissionEngineering

Owner:TOYOTA JIDOSHA KK

Roller follower, valve train, induction hardening apparatus, method of heat treatment of shaft member, method of manufacturing shaft, and shaft

InactiveUS20100319642A1Increased durabilitySufficient workabilityValve arrangementsShaftsCarbideInduction hardening

A roller follower includes a roller ring, a shaft and a plurality of rollers. At least one of the roller ring, the shaft and the rollers is a steel member made of steel containing 0.7 to 2.4% carbon and 10.0 to 20.0% chromium, with remainder iron and impurities. In addition, carbide containing at least any one of iron and chromium as well as carbon and having an area of 12.6 μm2 or greater is generated at an area ratio of 5.0% or higher, at a rolling contact surface of the steel member (a roller ring rolling contact surface, a shaft rolling contact surface and a roller rolling contact surface).

Owner:NTN CORP

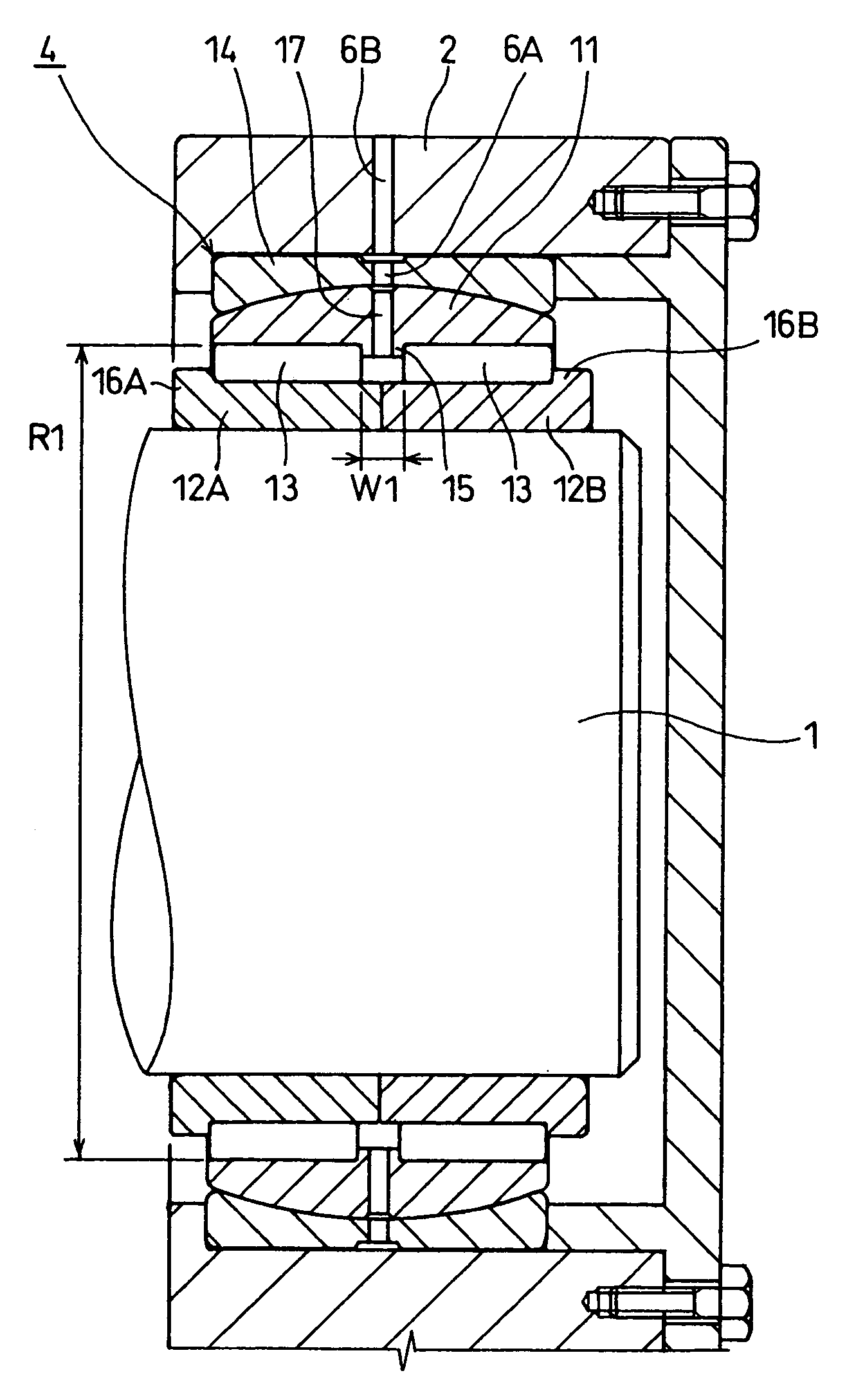

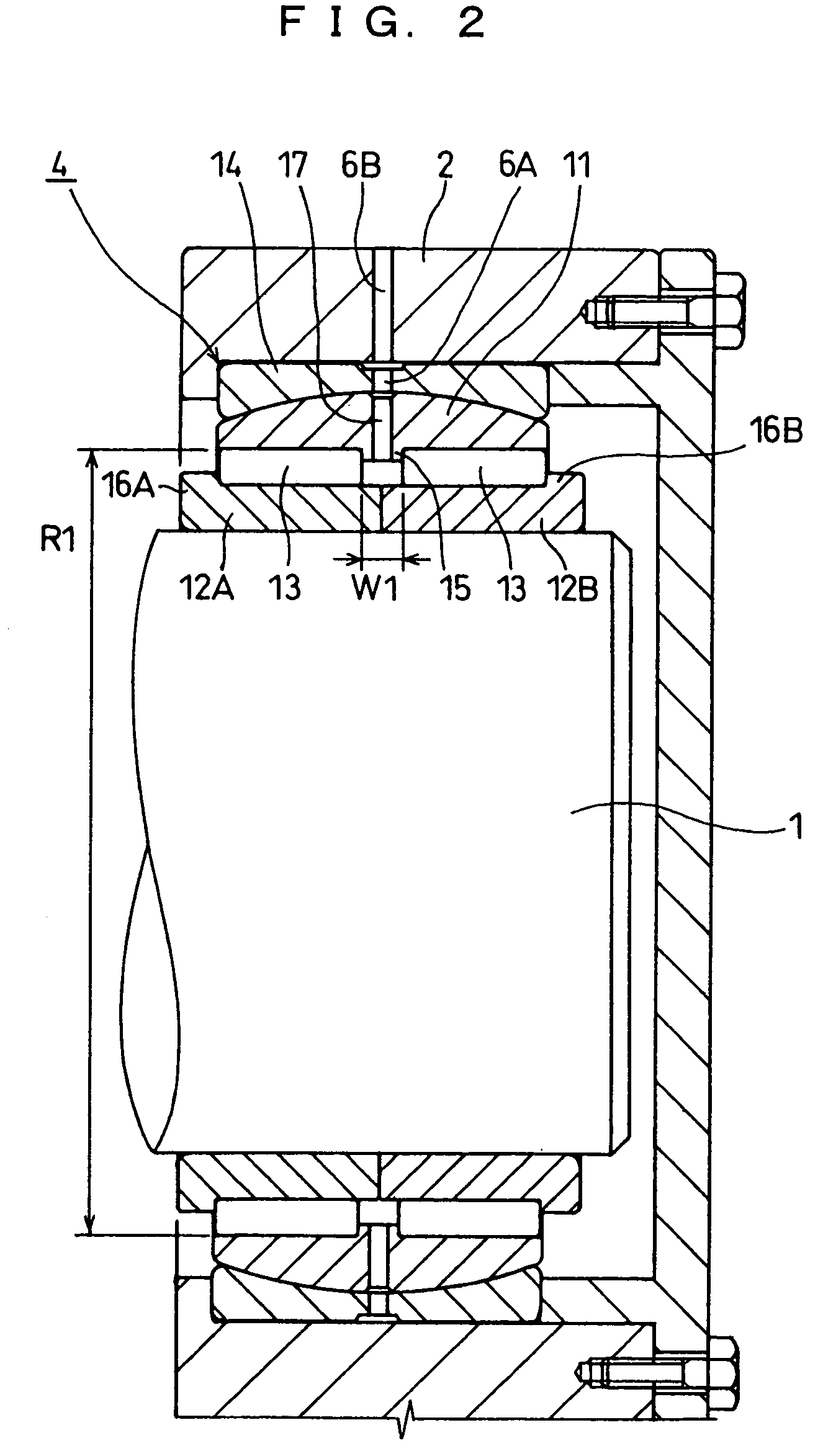

Self-aligning bearing

In a self-aligning bearing positioning and supporting one end of a rotation shaft in an axial direction and allowing the rotation shaft to bend, the bearing is structured as a double row cylindrical roller bearing with aligning ring, a first row of cylindrical roller group is positioned by being held in an axial direction between a radially inward flange provided in an intermediate portion in an axial direction of an outer ring having an outer peripheral surface formed in a spherical surface shape, and a flange provided in one outer end of two inner rings, and a second row of cylindrical roller group is positioned by being held in the axial direction between the flange of the outer ring and a flange provided in another outer ends of the two inner rings.

Owner:KOYO SEIKO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com