Thin-walled part producing method, bearing raceway ring, thrust needle roller bearing, rolling bearing raceway ring producing method, rolling bearing raceway ring, and rolling bearing

A technology for thrust needle roller bearings and thin-walled parts, applied in the field of thin-walled parts manufacturing, can solve problems such as uneven cooling, slow cooling, difficult processing, etc., and achieve the effect of clean working environment, uniform processing, and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

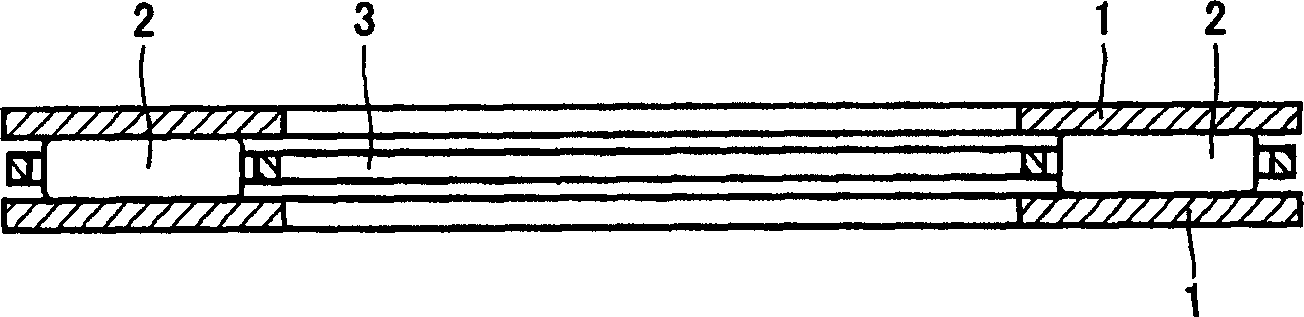

[0080] Using medium carbon steel S53C as a raw material, a thrust needle roller bearing ring (NTN trade name: AS1112) with an outer diameter of 60mm, an outer diameter of 85mm, and a wall thickness of 1mm was produced by punching the plate.

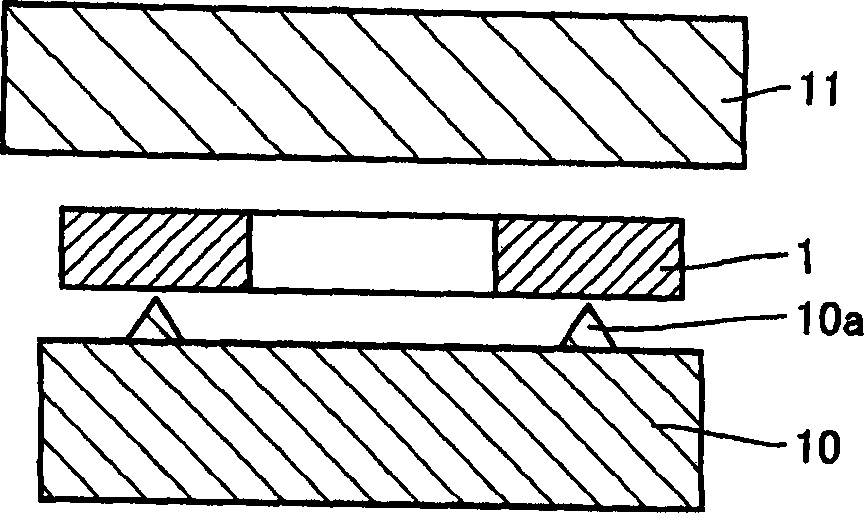

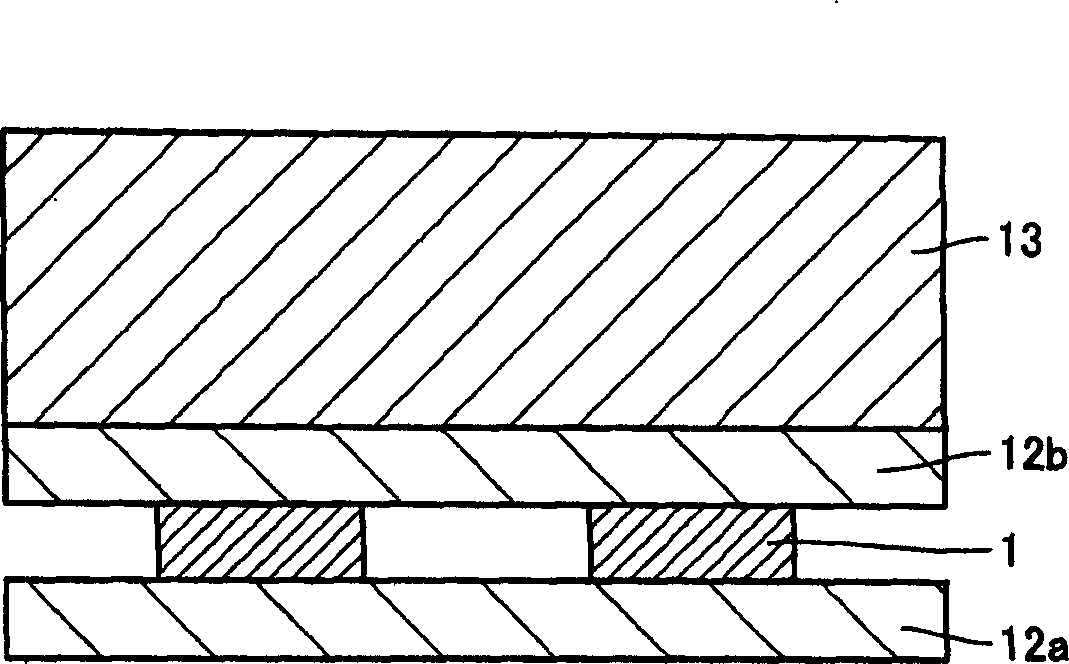

[0081] Using a high-frequency induction heating device (80kHz), while rotating the above-mentioned bearing ring, a predetermined current is applied to the induction coil close to one side for induction heating ( figure 1 ). At this time, heating is performed slowly so that the entire temperature becomes uniform (about 900°C). After that, the bearing ring was installed in an iron upper and lower pressurized mold with a heat capacity much larger than that of the bearing ring, and immediately pressed with a prescribed pressure by pressurizing, and at the same time, the pressurized mold was used to cool the bearing ring to transform and harden ( figure 2 ). The relationship between hardness and microstructure was investigated by changing the mo...

Embodiment 2

[0098] Used as a raw material: medium carbon steel S53C; and improved quenching characteristics, through slow cooling to obtain sufficient hardness of composite steel (0.7 mass% C-1.0 mass% Si-0.6 mass% Mn-1.5 mass% Cr-0.3 mass% Mo ).

[0099] A thrust needle roller bearing ring (NTN product name: AS1112) with an outer diameter of 60 mm, an outer diameter of 85 mm, and a wall thickness of 1 mm was produced by rotating cutting using these raw materials.

[0100] Using a high-frequency induction heating device (80kHz), while rotating the above-mentioned bearing ring, a predetermined current is applied to the induction coil close to one side for induction heating ( figure 1 ). At this time, heating is performed slowly so that the entire temperature becomes uniform (about 900°C). After that, the bearing ring was installed in an iron upper and lower pressurized mold with a heat capacity much larger than that of the bearing ring, and immediately pressed with a predetermined pressure by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com