Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85results about How to "Reduced contact area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

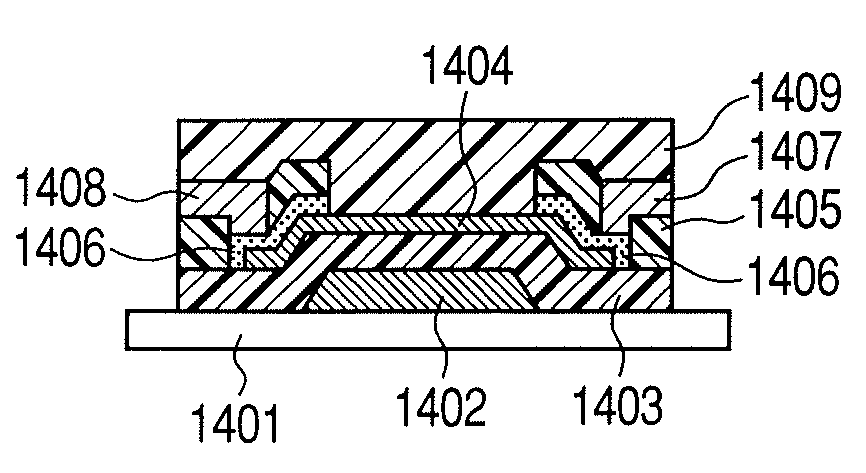

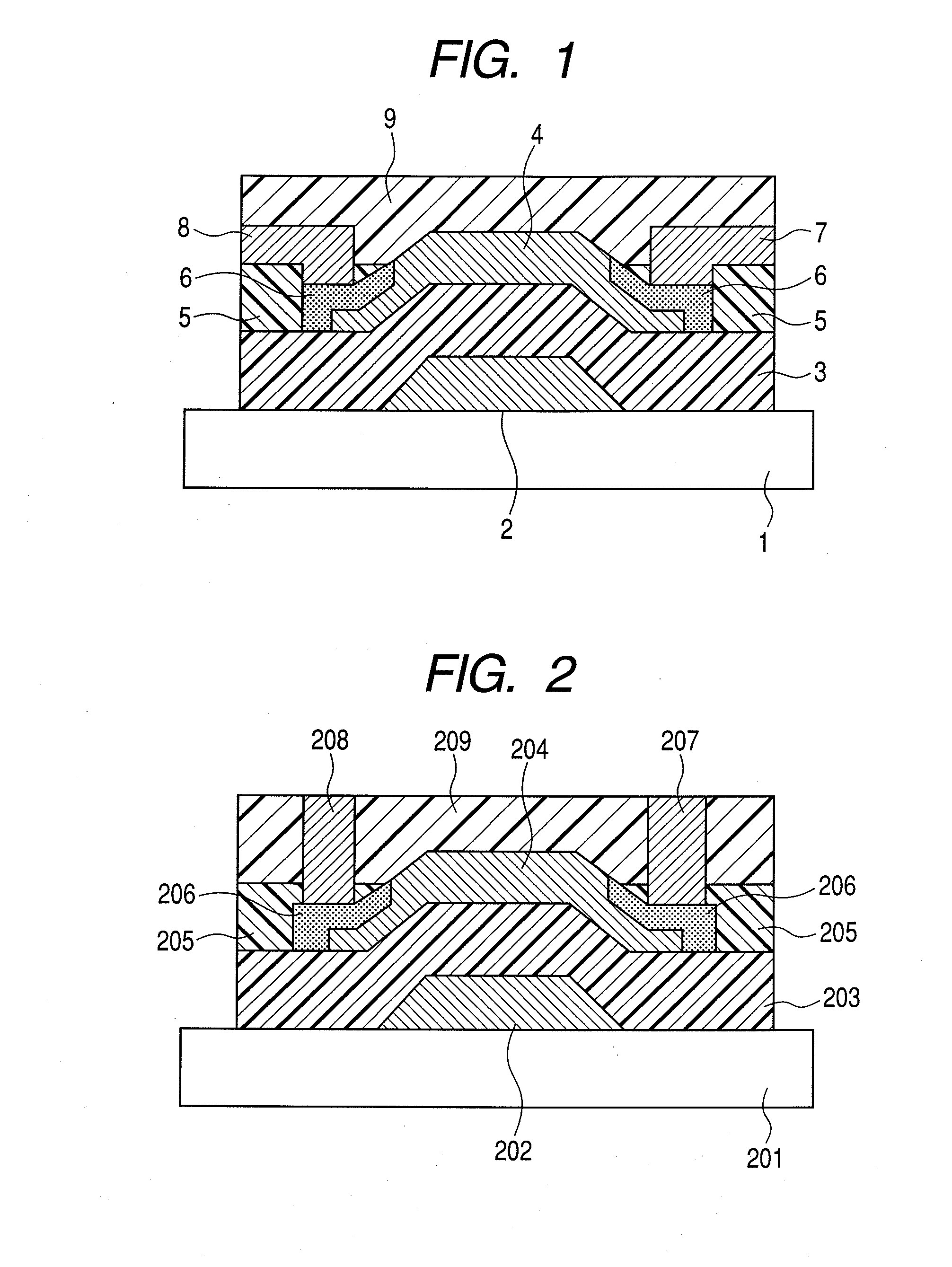

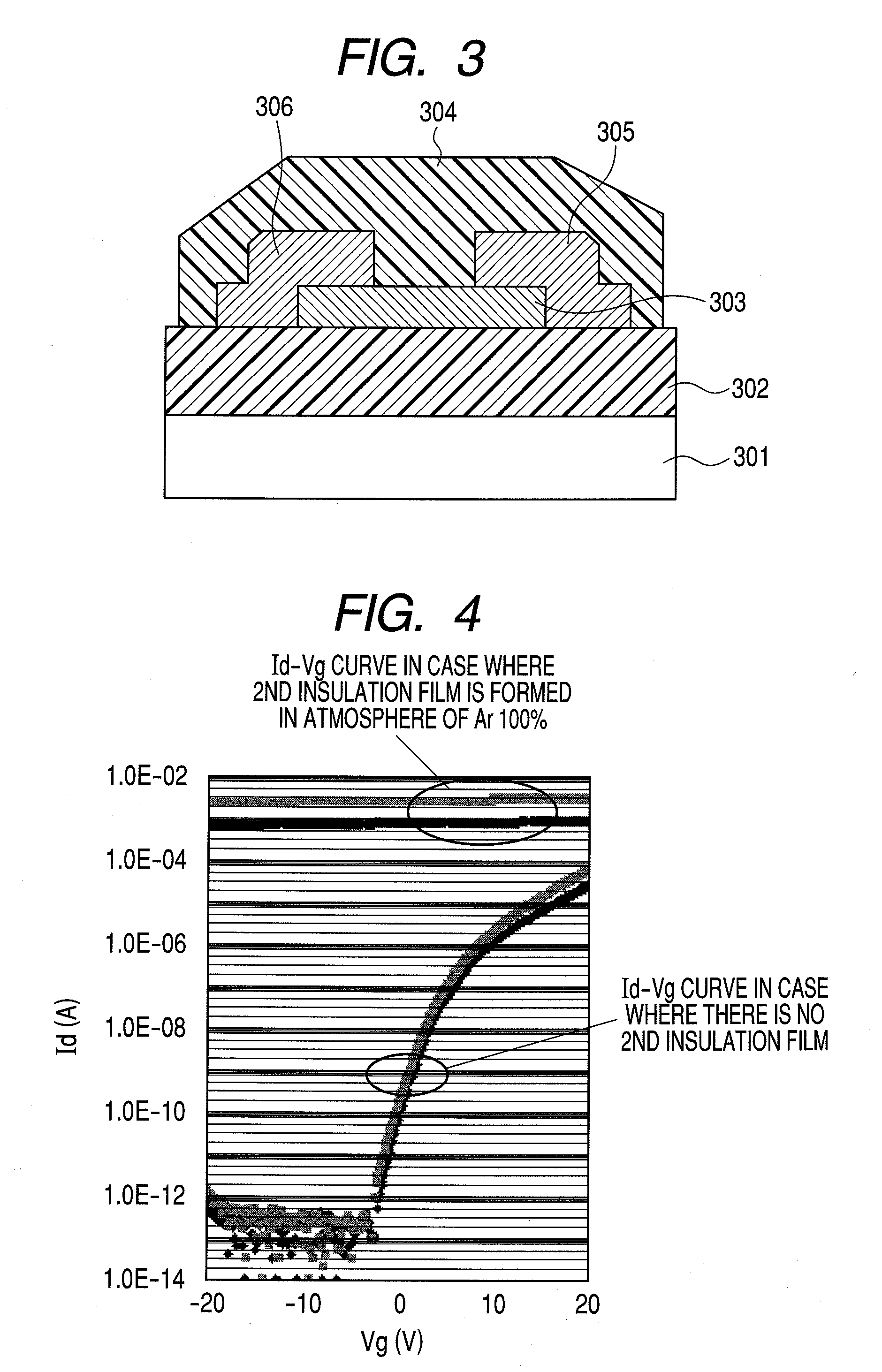

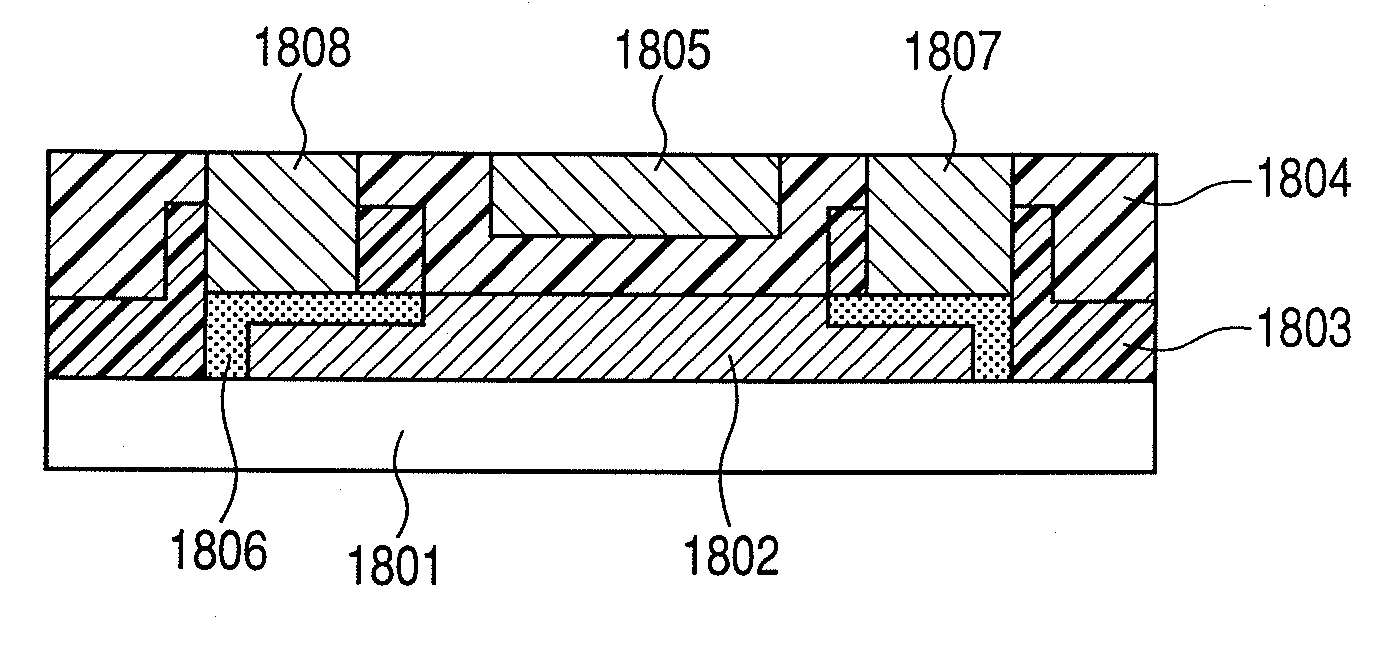

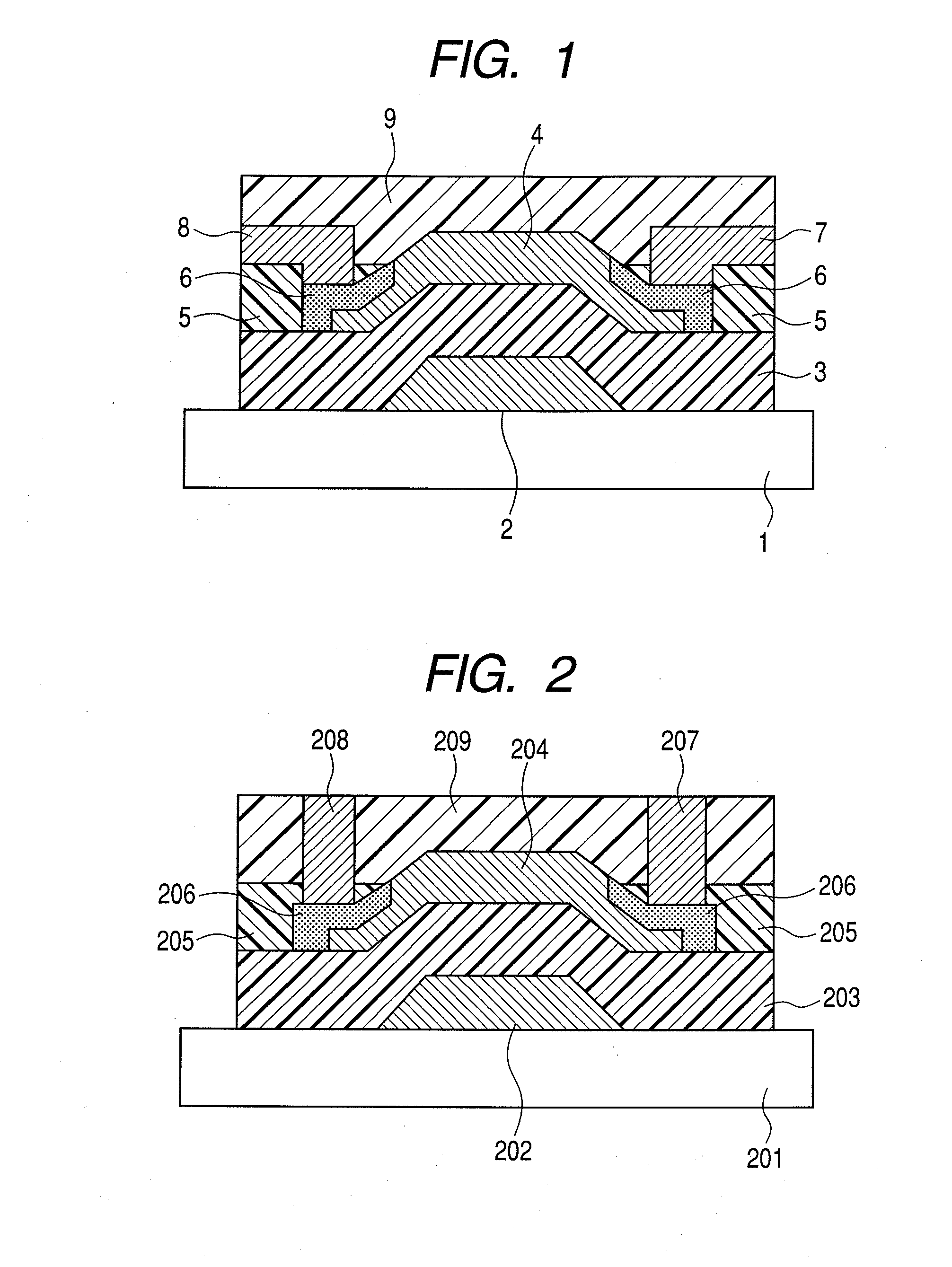

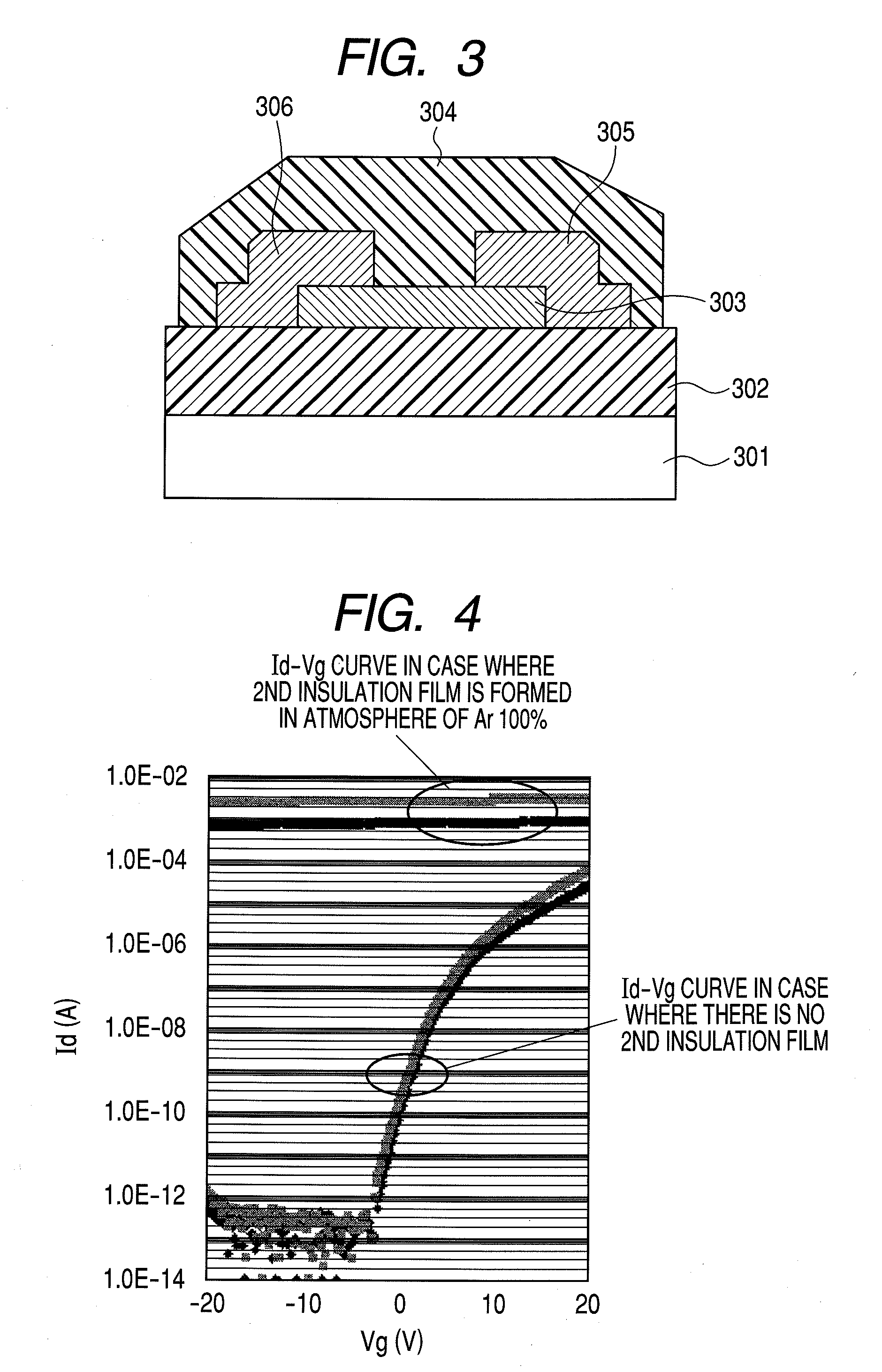

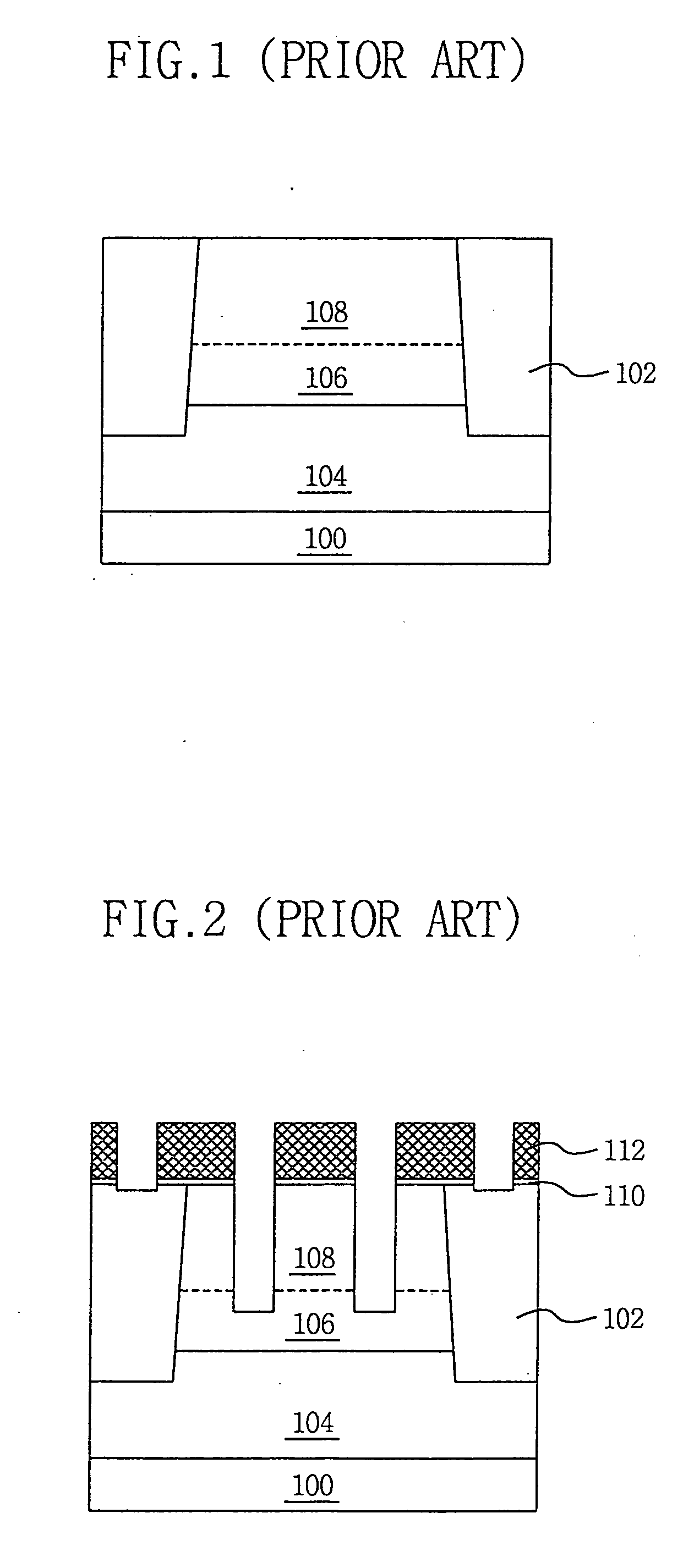

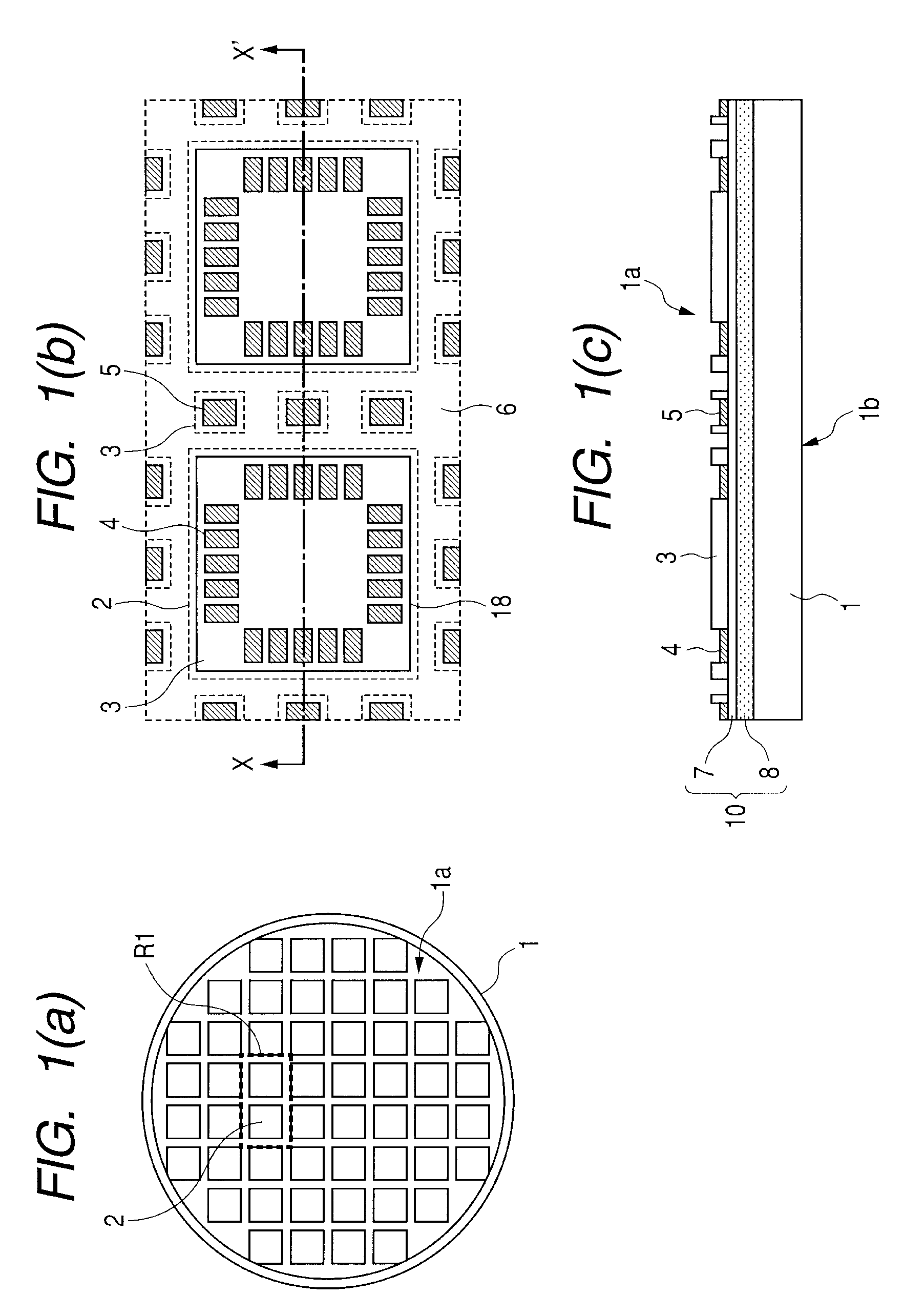

Manufacturing method of thin film transistor using oxide semiconductor

InactiveUS8193045B2Improve transistor characteristicsReduced contact areaSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A manufacturing method of a thin film transistor having at least a gate electrode, a gate insulation film, an oxide semiconductor layer, a first insulation film, a source electrode, a drain electrode, and a second insulation film on a substrate, including: forming the gate electrode on the substrate; forming the gate insulation film on the gate electrode; forming a semiconductor layer including amorphous oxide on the gate insulation film; patterning the gate insulation film; patterning the oxide semiconductor layer; reducing the oxide semiconductor layer in resistance by forming the first insulation film on the oxide semiconductor layer in the atmosphere not including an oxidized gas; patterning the first insulation film and forming a contact hole between the source electrode and the drain electrode and the oxide semiconductor layer; forming a source electrode layer and a drain electrode layer in the oxide semiconductor layer through the contact hole; forming the source electrode and the drain electrode through the contact hole and allowing the first insulation film to be exposed; patterning the exposed first insulation film and allowing a channel region of the oxide semiconductor layer to be exposed; and increasing the channel region in resistance by forming the second insulation film on the surface including the channel region of the oxide semiconductor layer in the atmosphere including an oxidized gas.

Owner:CANON KK

Manufacturing method of thin film transistor using oxide semiconductor

InactiveUS20100140612A1Excellent transistor characteristicReduce resistanceTransistorSolid-state devicesAmorphous oxideOxide semiconductor

A manufacturing method of a thin film transistor having at least a gate electrode, a gate insulation film, an oxide semiconductor layer, a first insulation film, a source electrode, a drain electrode, and a second insulation film on a substrate, including: forming the gate electrode on the substrate; forming the gate insulation film on the gate electrode; forming a semiconductor layer including amorphous oxide on the gate insulation film; patterning the gate insulation film; patterning the oxide semiconductor layer; reducing the oxide semiconductor layer in resistance by forming the first insulation film on the oxide semiconductor layer in the atmosphere not including an oxidized gas; patterning the first insulation film and forming a contact hole between the source electrode and the drain electrode and the oxide semiconductor layer; forming a source electrode layer and a drain electrode layer in the oxide semiconductor layer through the contact hole; forming the source electrode and the drain electrode through the contact hole and allowing the first insulation film to be exposed; patterning the exposed first insulation film and allowing a channel region of the oxide semiconductor layer to be exposed; and increasing the channel region in resistance by forming the second insulation film on the surface including the channel region of the oxide semiconductor layer in the atmosphere including an oxidized gas.

Owner:CANON KK

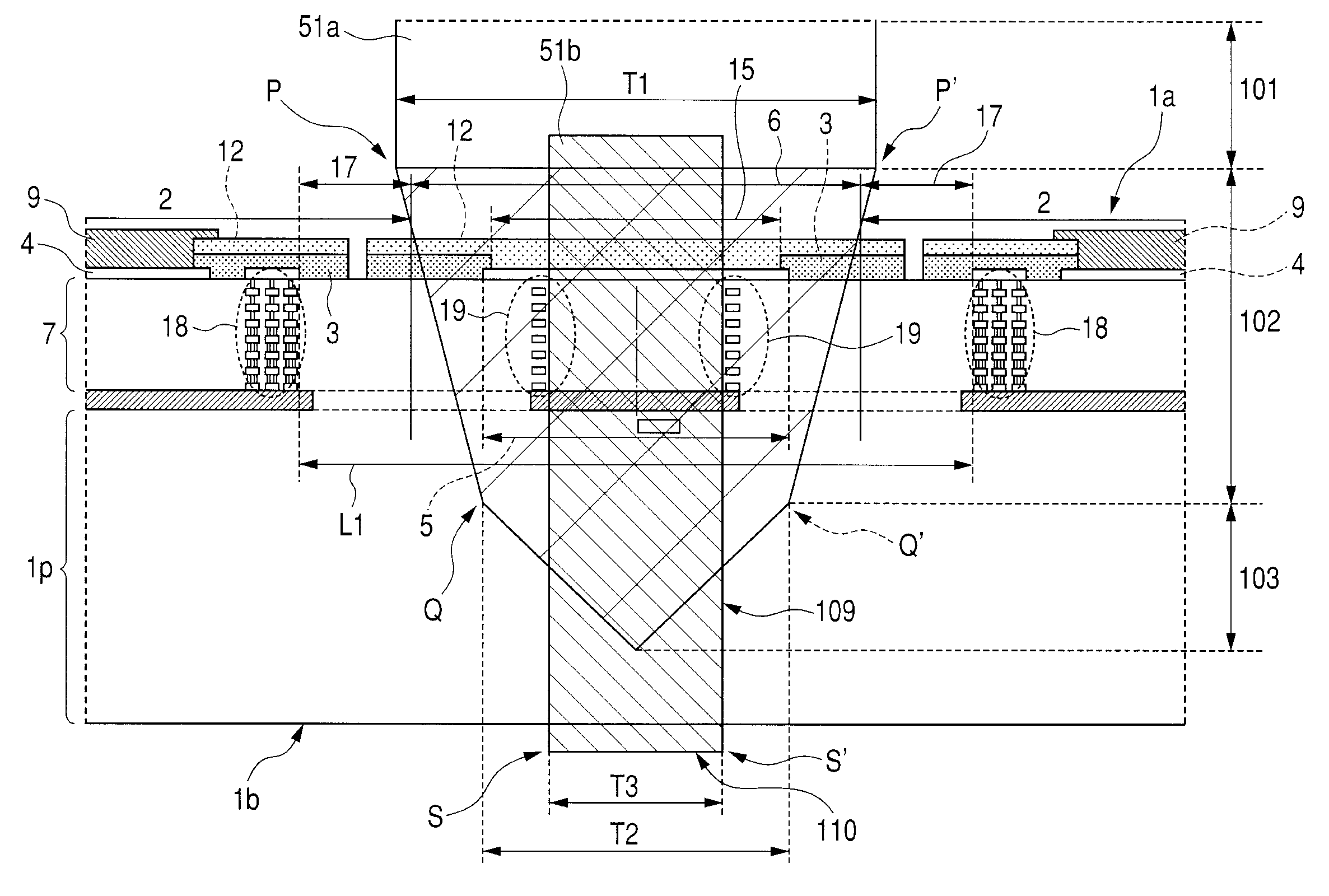

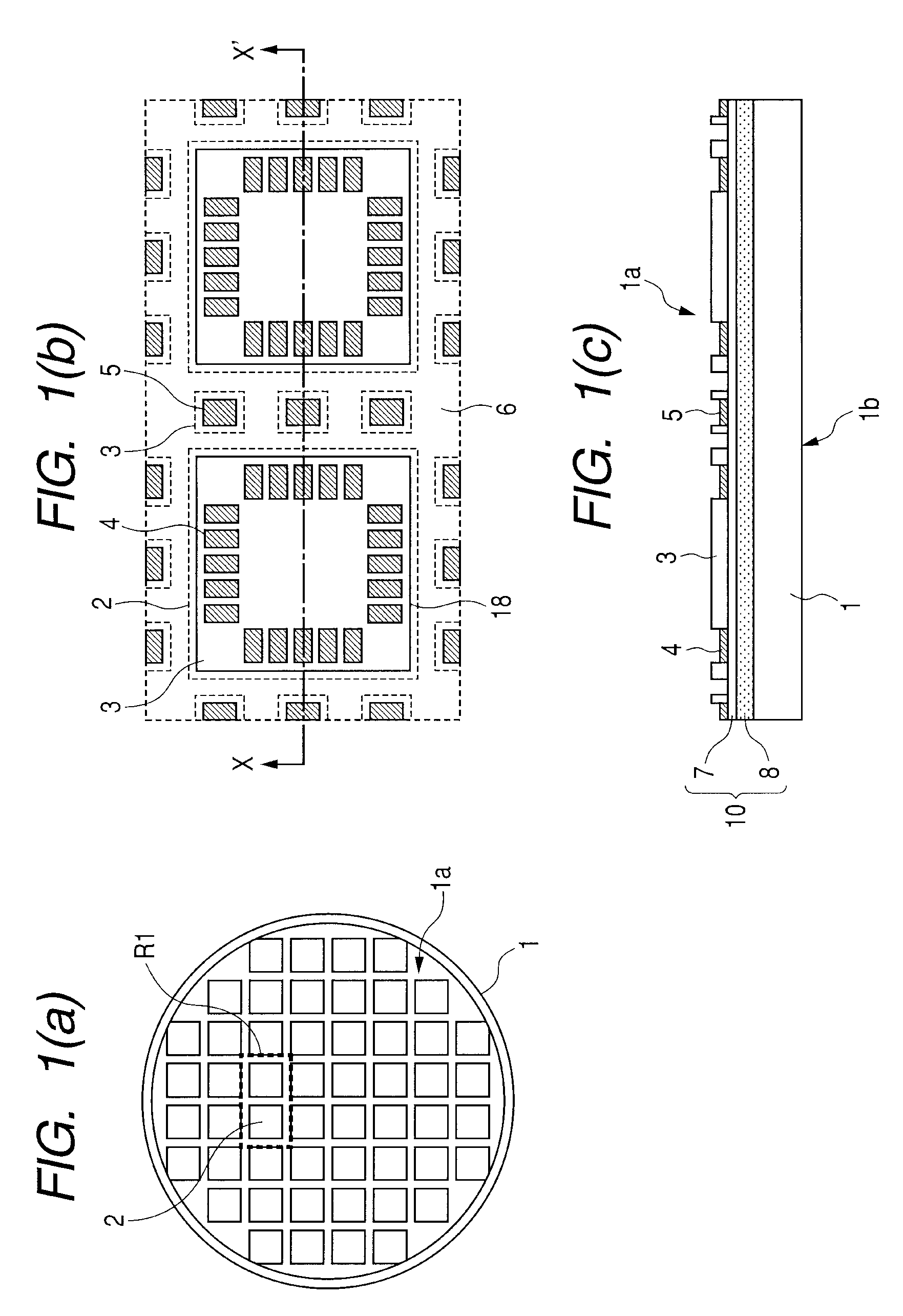

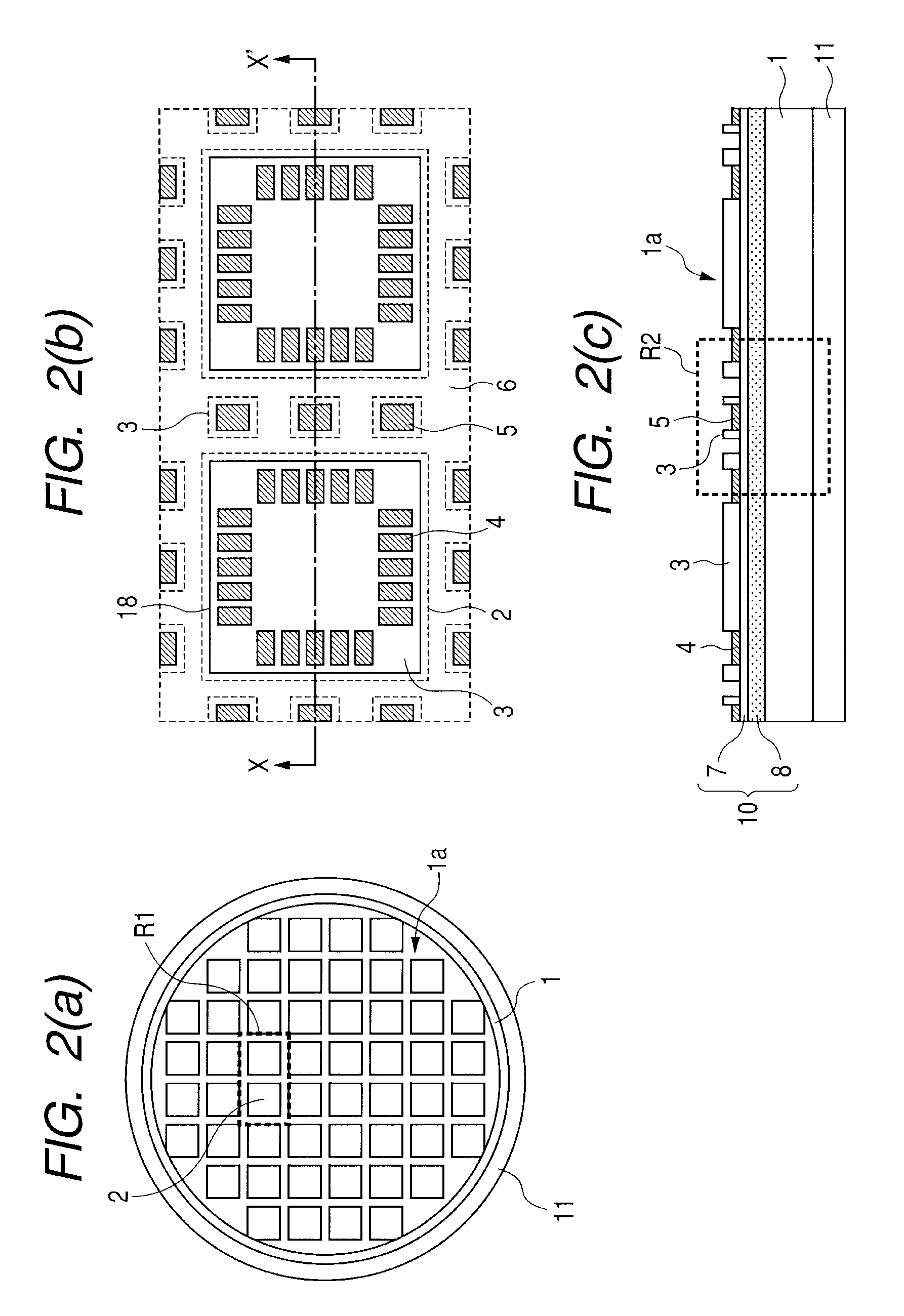

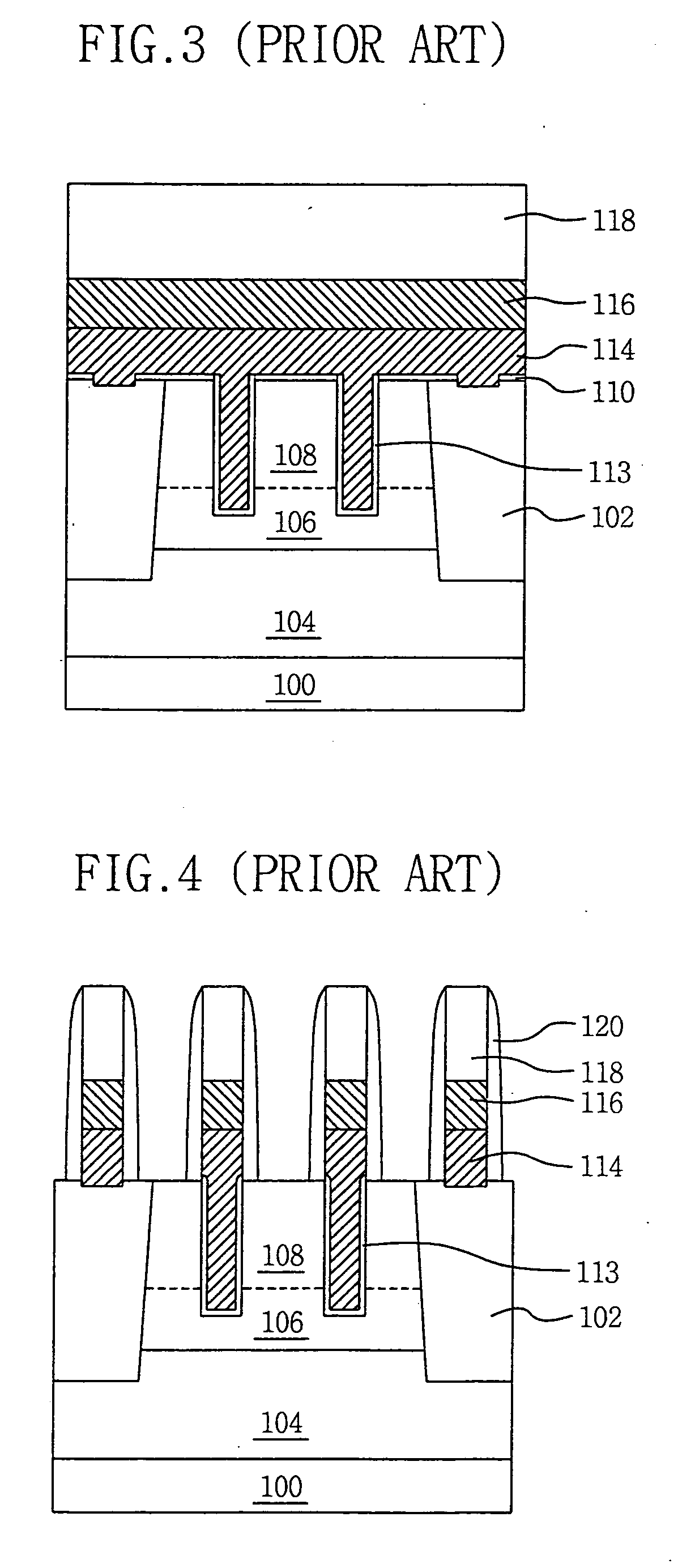

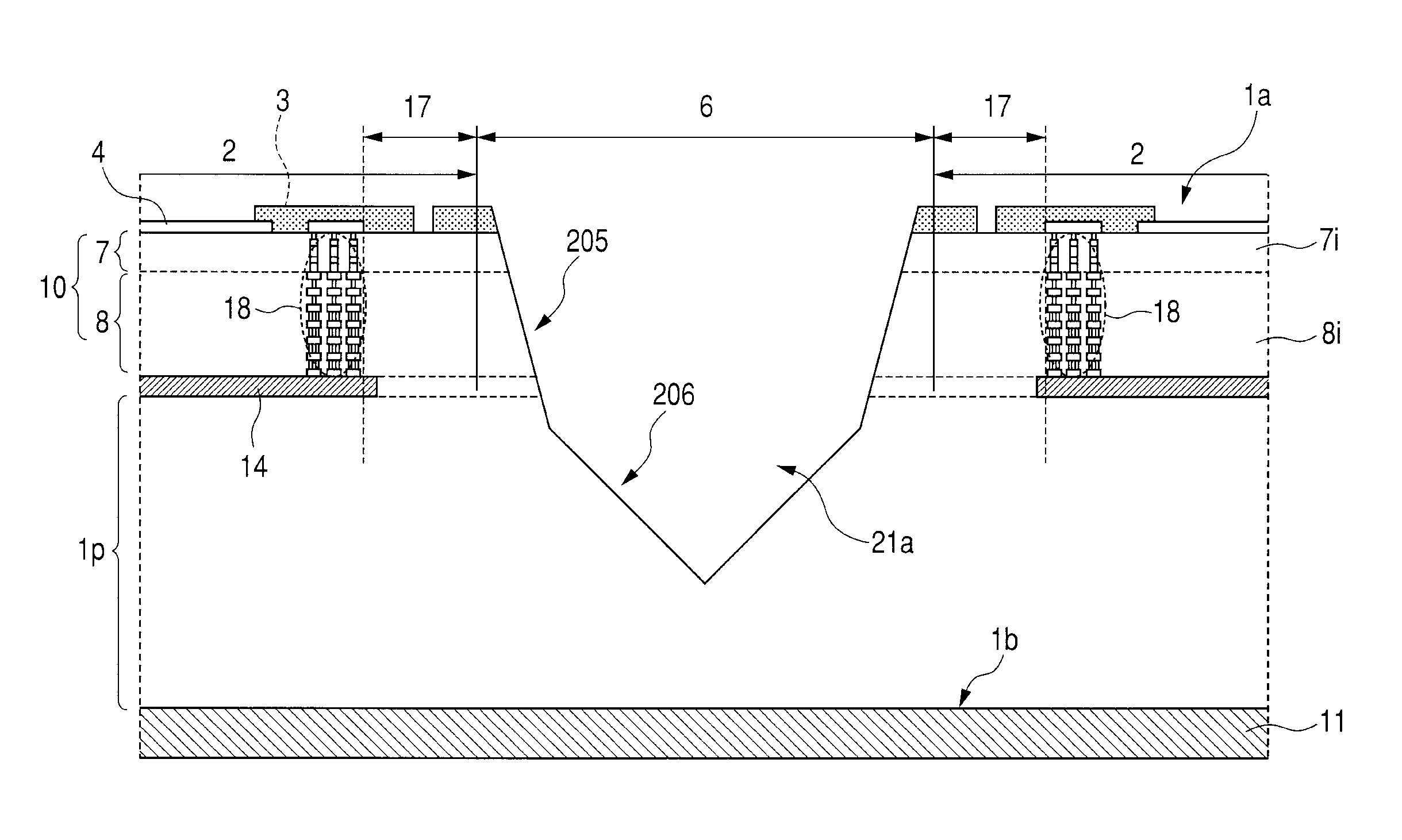

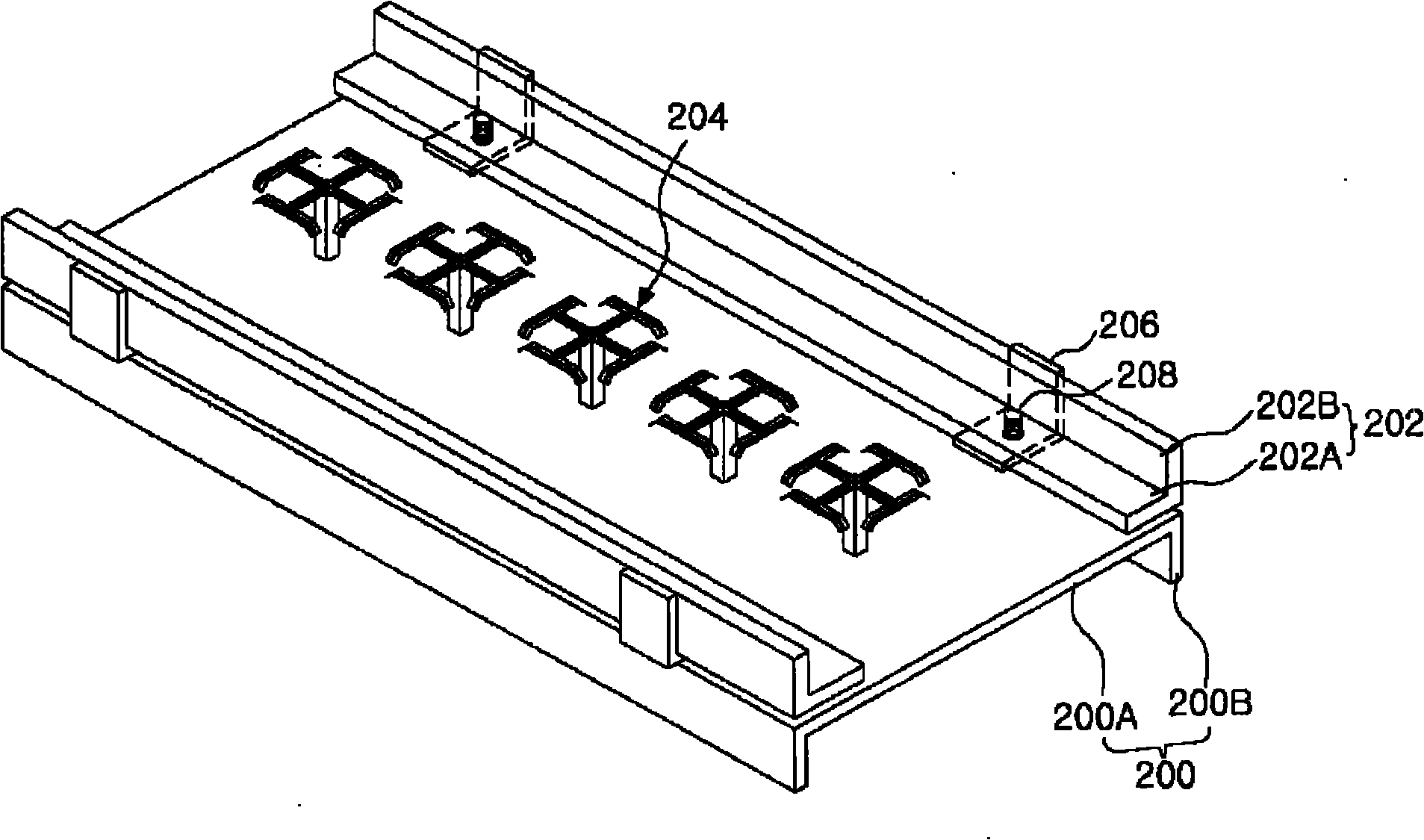

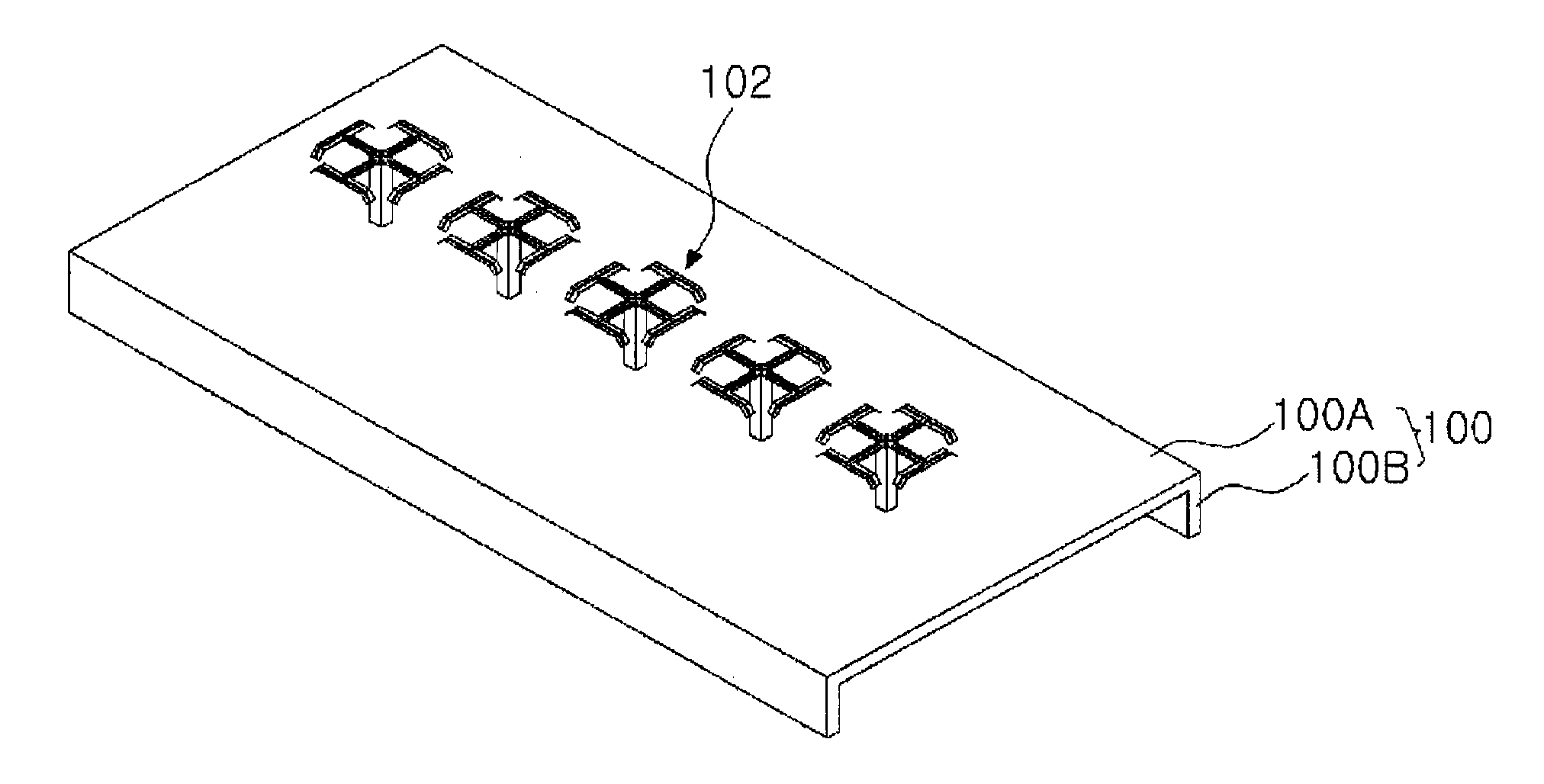

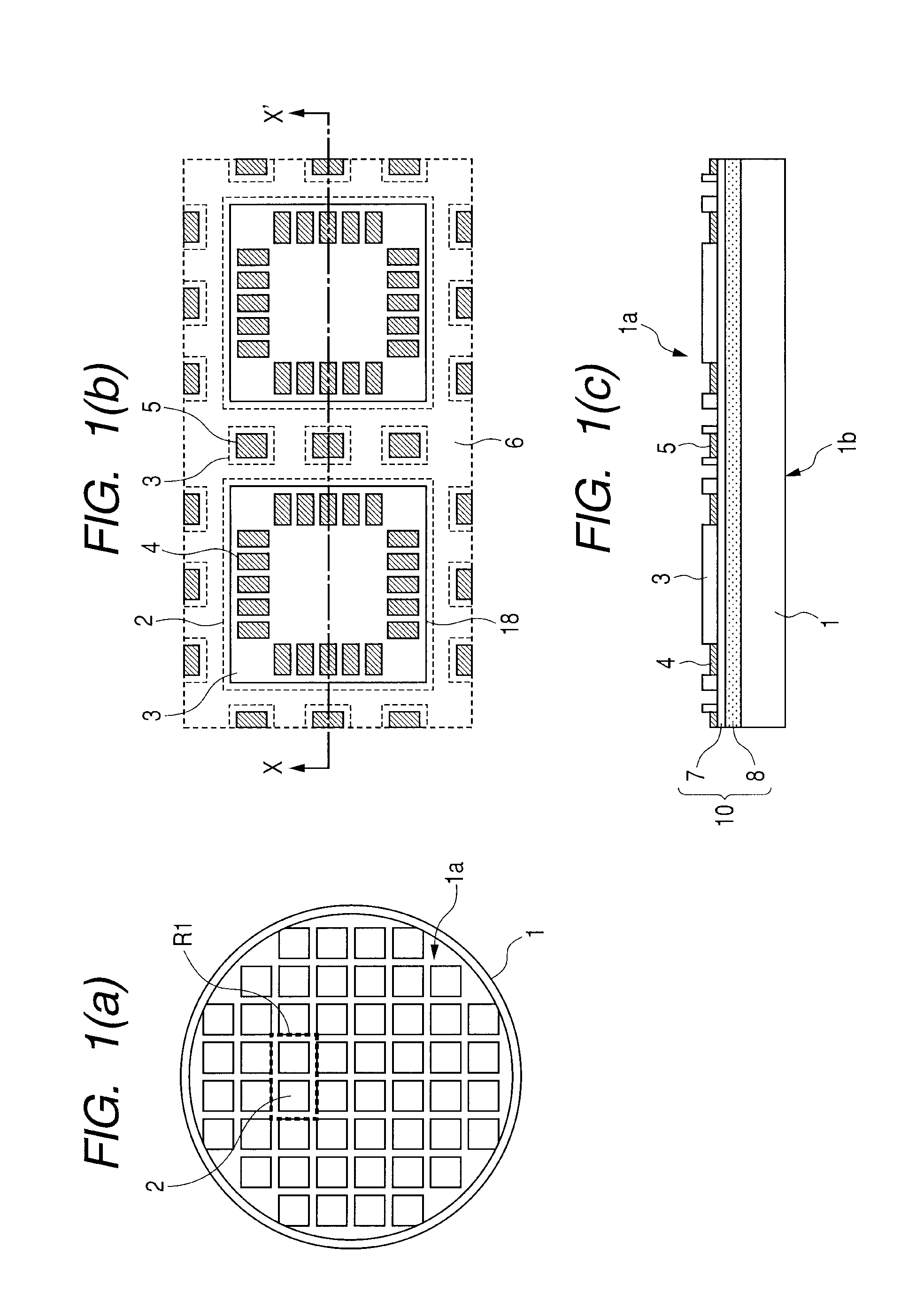

Semiconductor device and manufacturing method of the same

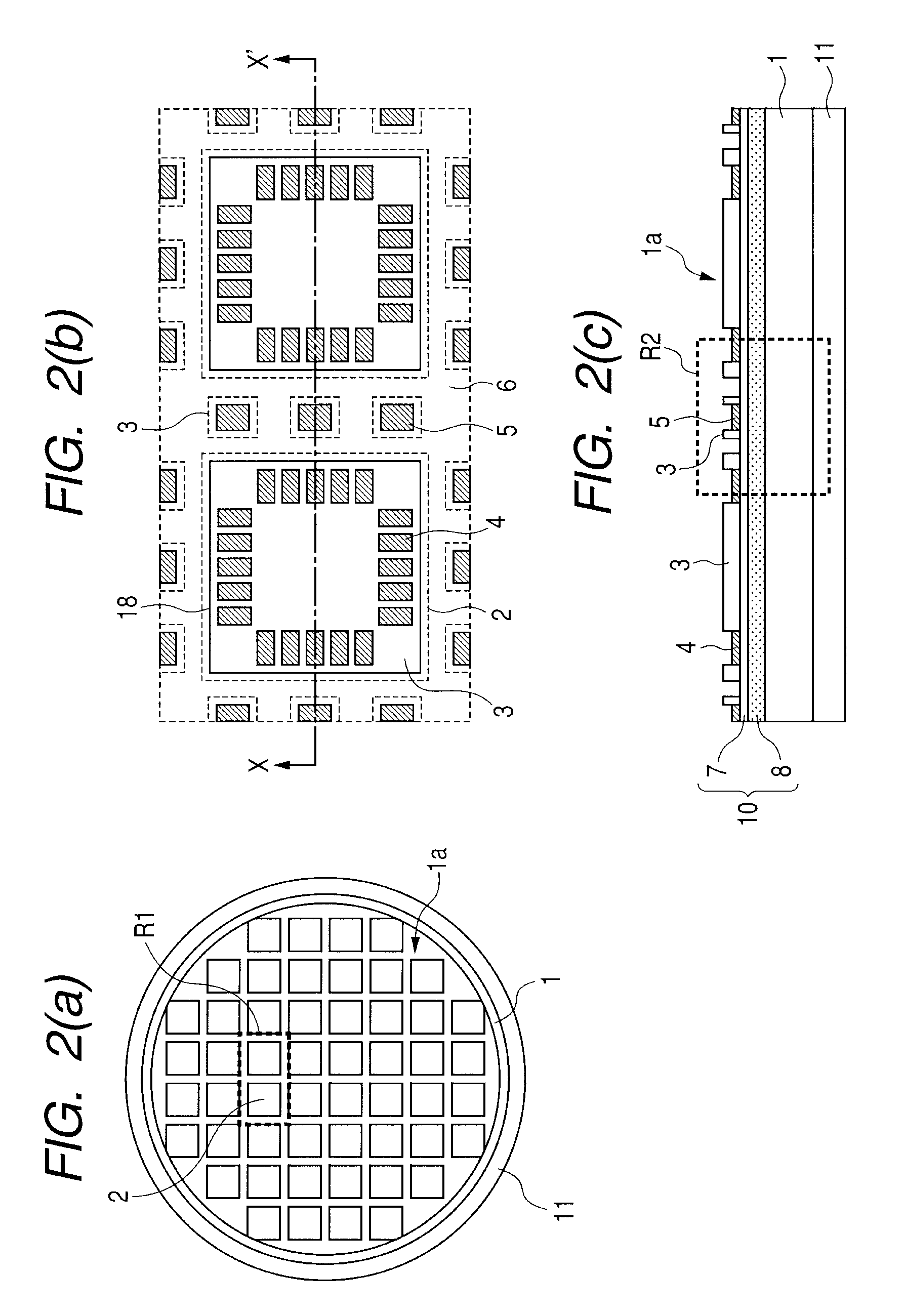

InactiveUS20100181681A1Easy to crackReliability is deterioratedSemiconductor/solid-state device detailsSolid-state devicesParasitic capacitorWafering

With a recent shrinking semiconductor process, insulating layers formed between interconnect layers are becoming thin. To avoid parasitic capacitance between them, materials of a low dielectric constant have been used for an insulating layer in a multilevel interconnect. Low-k materials, however, have low strength compared with the conventional insulating layers. Porous low-k materials are structurally fragile. The invention therefore provides a manufacturing method of a semiconductor device having a multilevel interconnect layer including a low-k layer. According to the method, in a two-step cutting system dicing in which after formation of a groove in a semiconductor water with a tapered blade, the groove is divided with a straight blade thinner than the groove width, the multilevel interconnect layer portion is cut while being covered with a tapered face and then the wafer is separated with a thin blade which is not brought into contact with the multilevel interconnect layer portion. The wafer can be diced without damaging a relatively fragile low-k layer.

Owner:RENESAS ELECTRONICS CORP

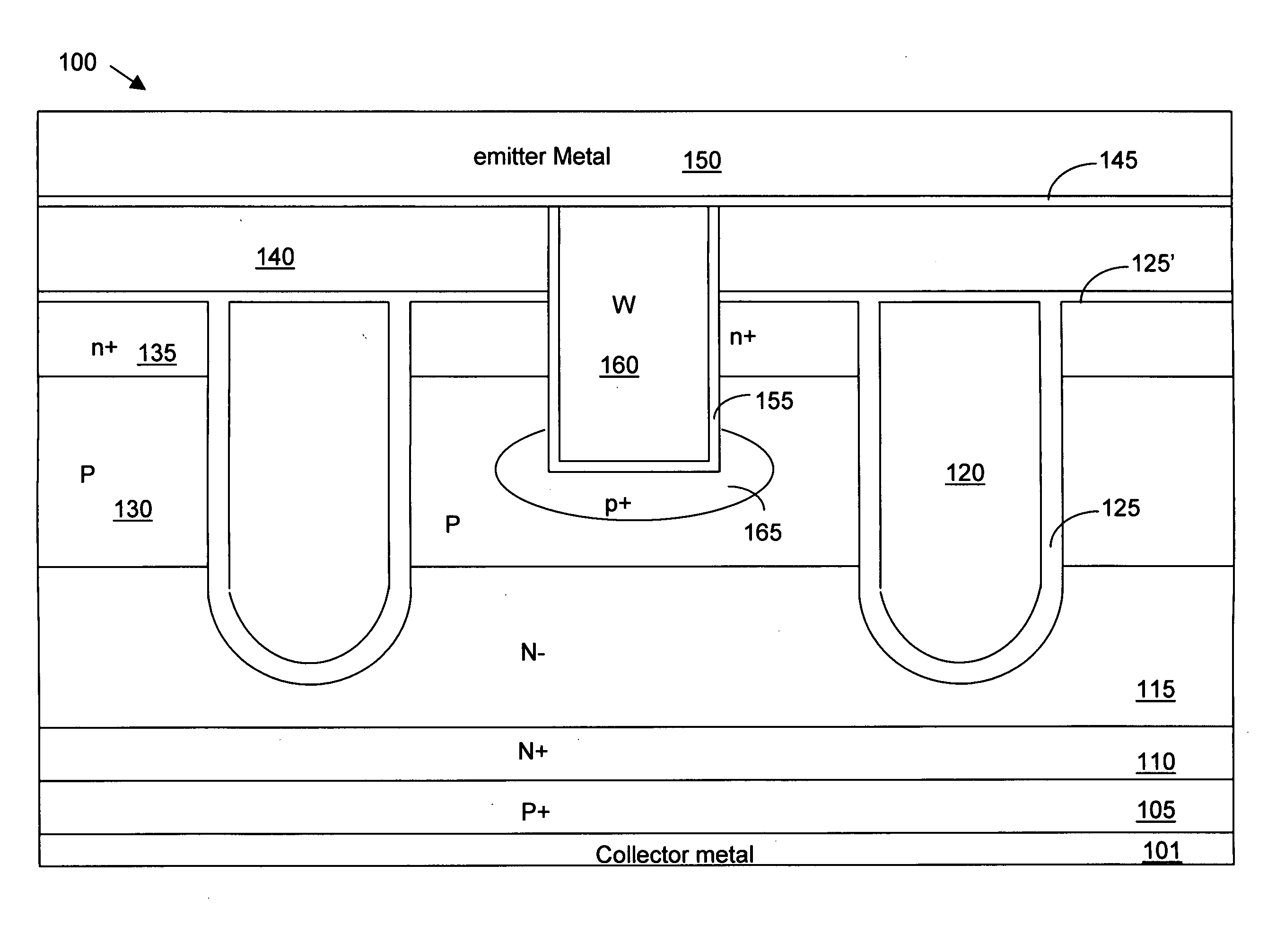

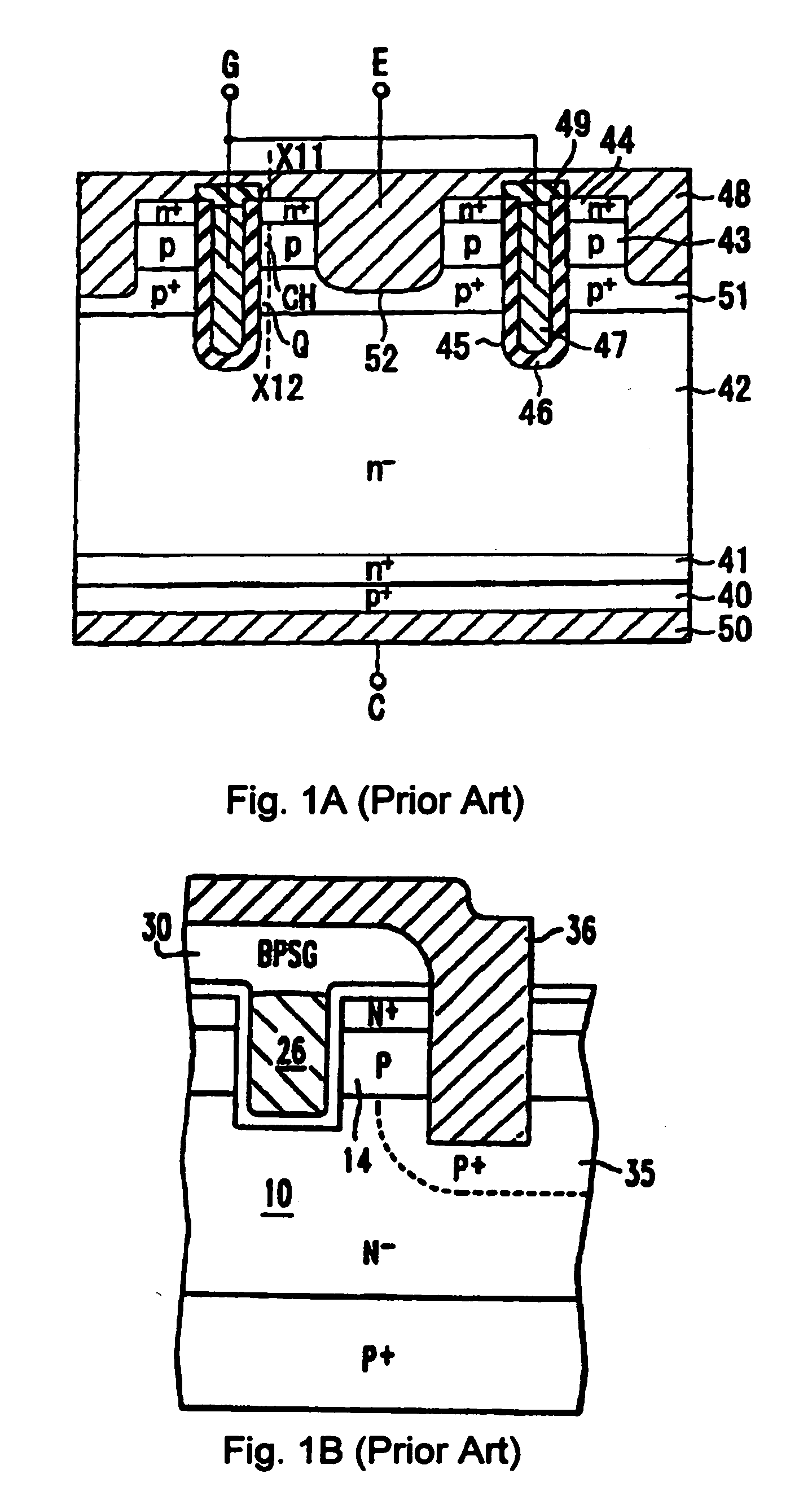

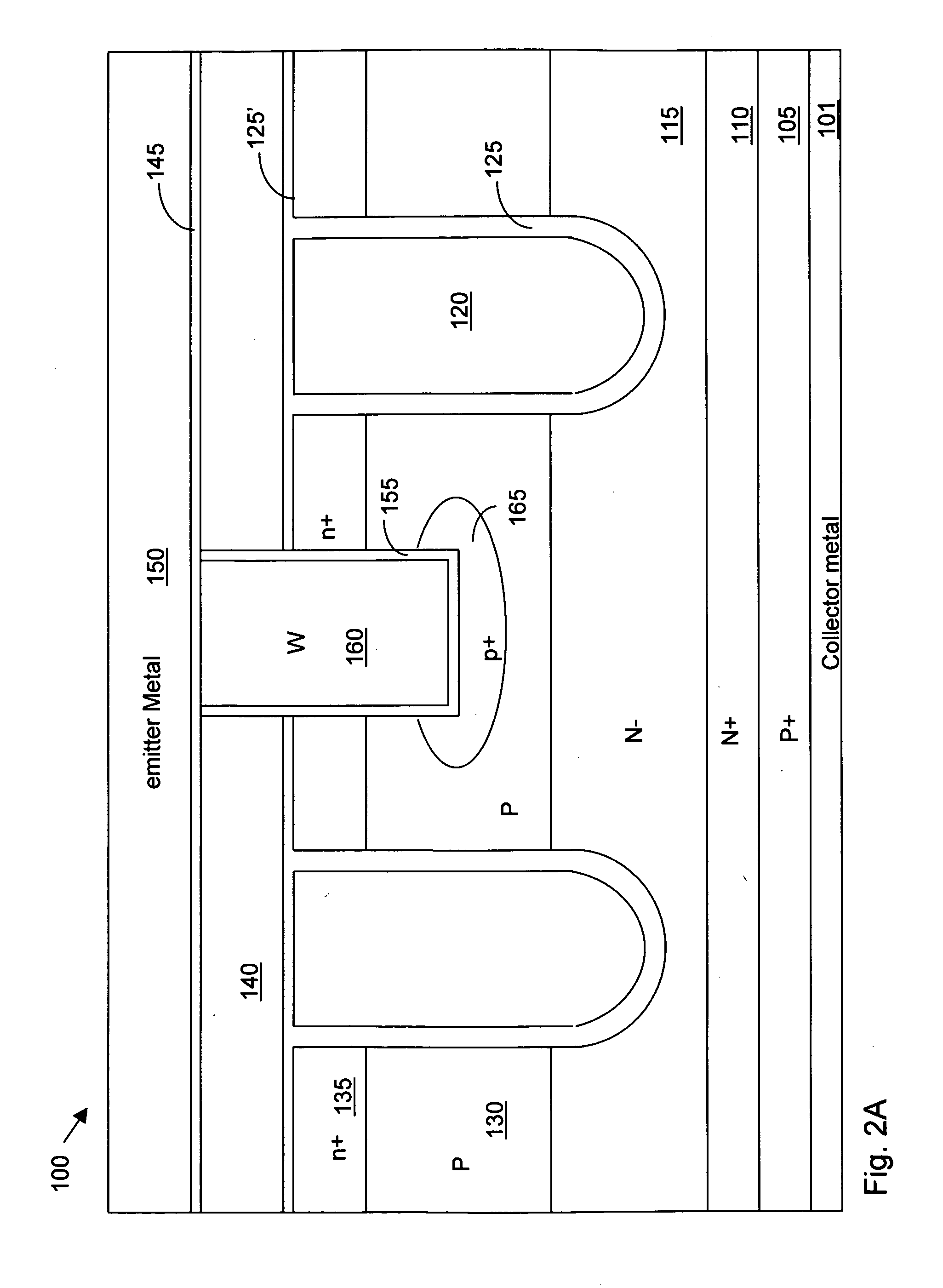

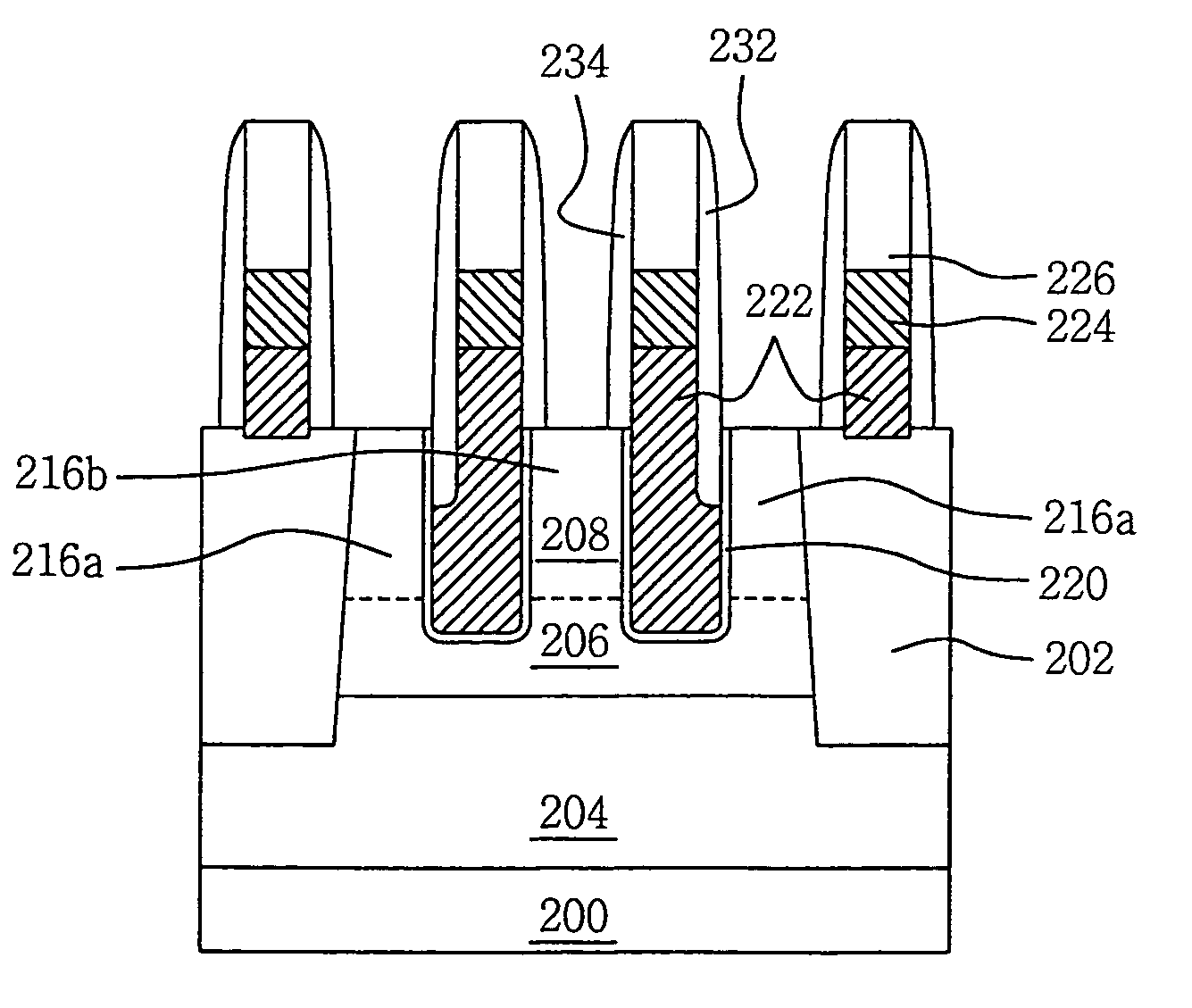

Trench insulated gate bipolar transistor (GBT) with improved emitter-base contacts and metal schemes

InactiveUS20100193835A1Reduce base contact resistanceEnhance latch-up immunity capabilitySemiconductor/solid-state device manufacturingSemiconductor devicesTrench igbtDopant

A trench insulation gate bipolar transistor (IGBT) power device includes a plurality of trench gates surrounded by emitter regions of a first conductivity type near a top surface of a semiconductor substrate encompassed in base regions of a second conductivity type and a collector layer disposed at a bottom surface of the semiconductor substrate. The trench IGBT power device further includes an insulation layer covering over the top surface over the trench gate and the emitter regions having emitter-base contact trenches opened therethrough between the trench gates and extending to the base regions and an emitter-base contact dopant region disposed in the base region of the second conductivity type surrounding a lower region of the contact trenches. The emitter-base contact dopant region is disposed at a distance away from a channel near the trench gates for reducing an emitter-base resistance without increasing a gate-emitter threshold voltage.

Owner:FORCE MOS TECH CO LTD

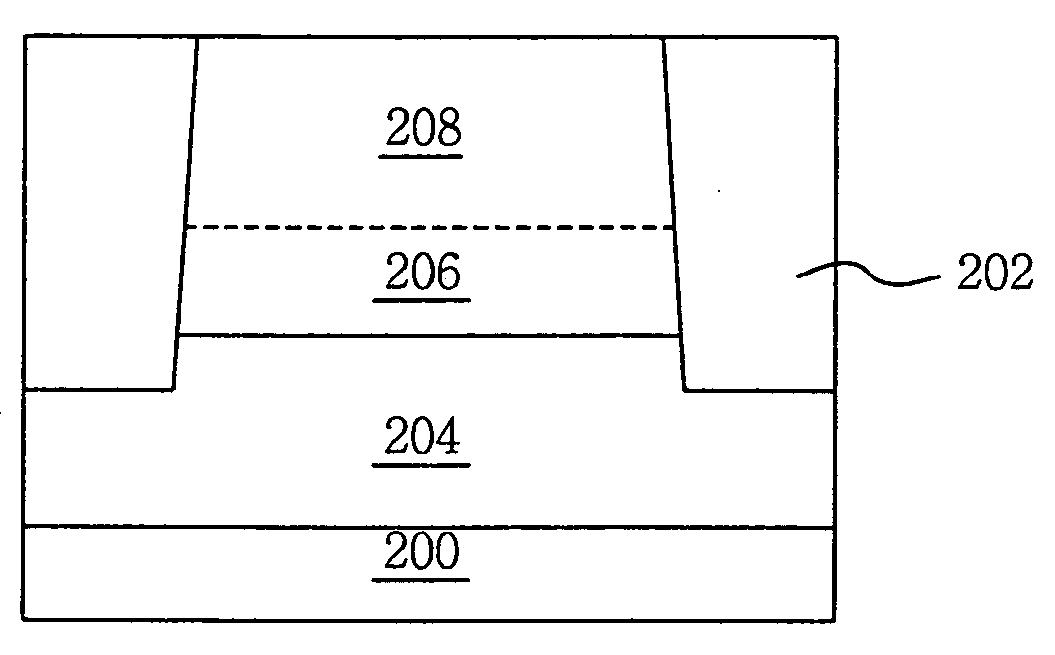

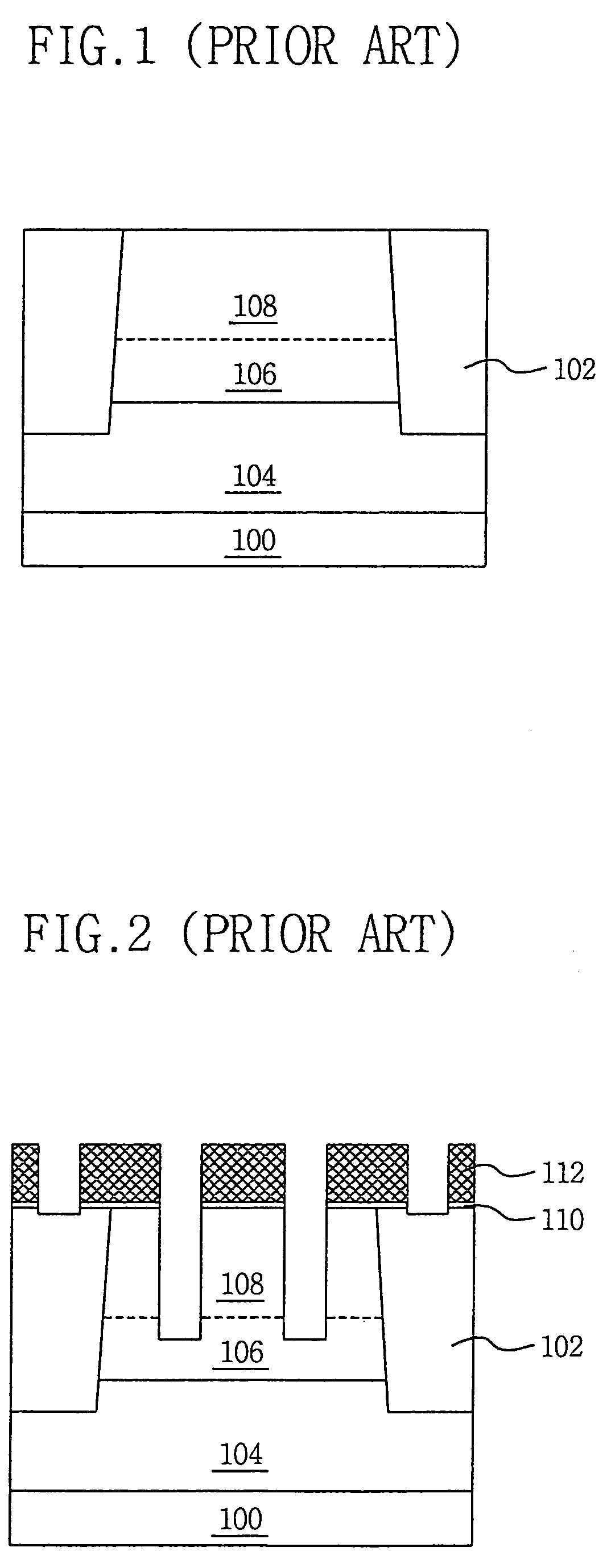

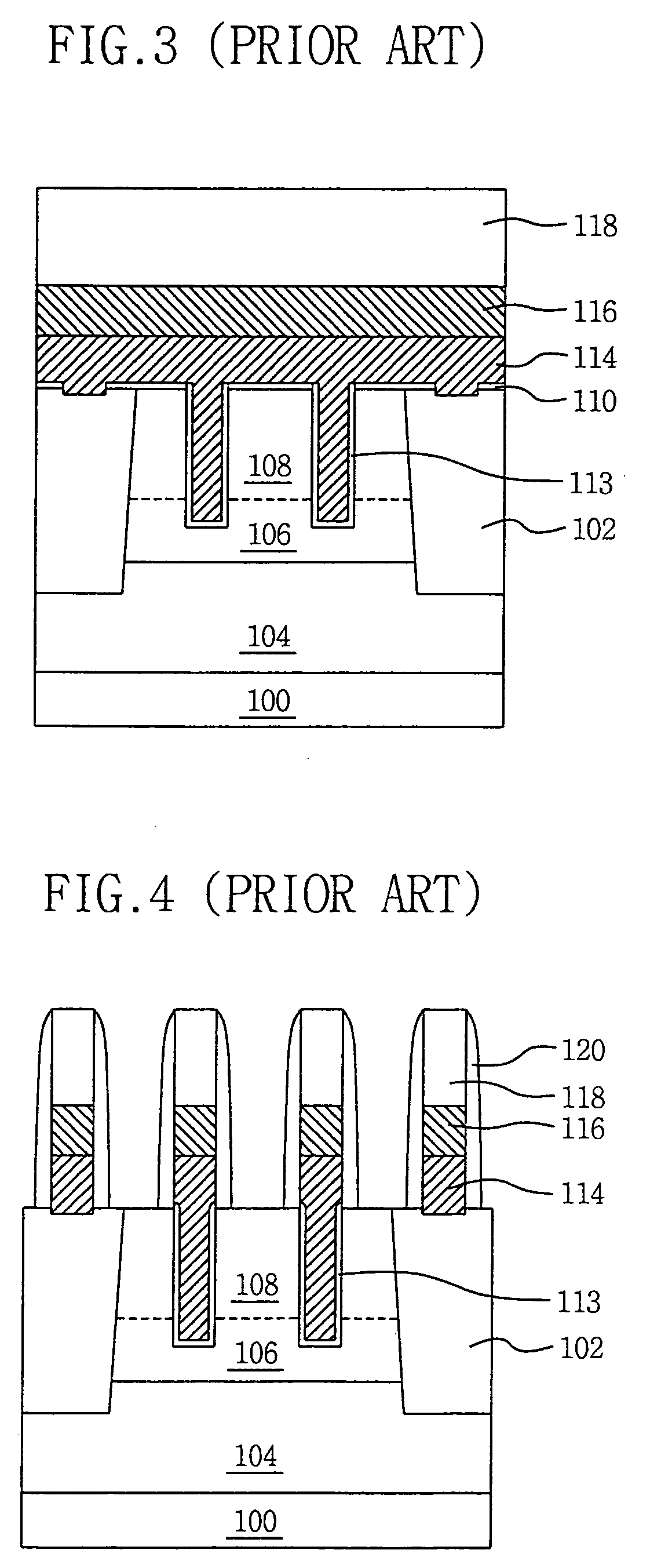

Recess gate transistor structure for use in semiconductor device and method thereof

InactiveUS20050087776A1Reduce load capacityReduction of gate lengthTransistorSemiconductor/solid-state device manufacturingInsulation layerDevice material

An inner spacer is formed in a sidewall of a gate in contact with a first active region that is electrically connected to an upper capacitor, thereby reducing a gate induced drain leakage (GIDL). A structure of a recess gate transistor includes a gate insulation layer, a gate electrode, a first gate spacer, a second gate spacer and source / drain regions. The gate insulation layer is formed within a recess. The gate electrode is surrounded by the gate insulation layer and is extended from within the recess. The first gate spacer is spaced with a predetermined distance horizontally with a portion of the gate insulation layer, being formed in a sidewall of the gate electrode. The second gate spacer is formed in another part of the sidewall of the gate electrode. The source / drain regions are formed mutually oppositely on first and second active regions with the gate electrode therebetween.

Owner:SAMSUNG ELECTRONICS CO LTD

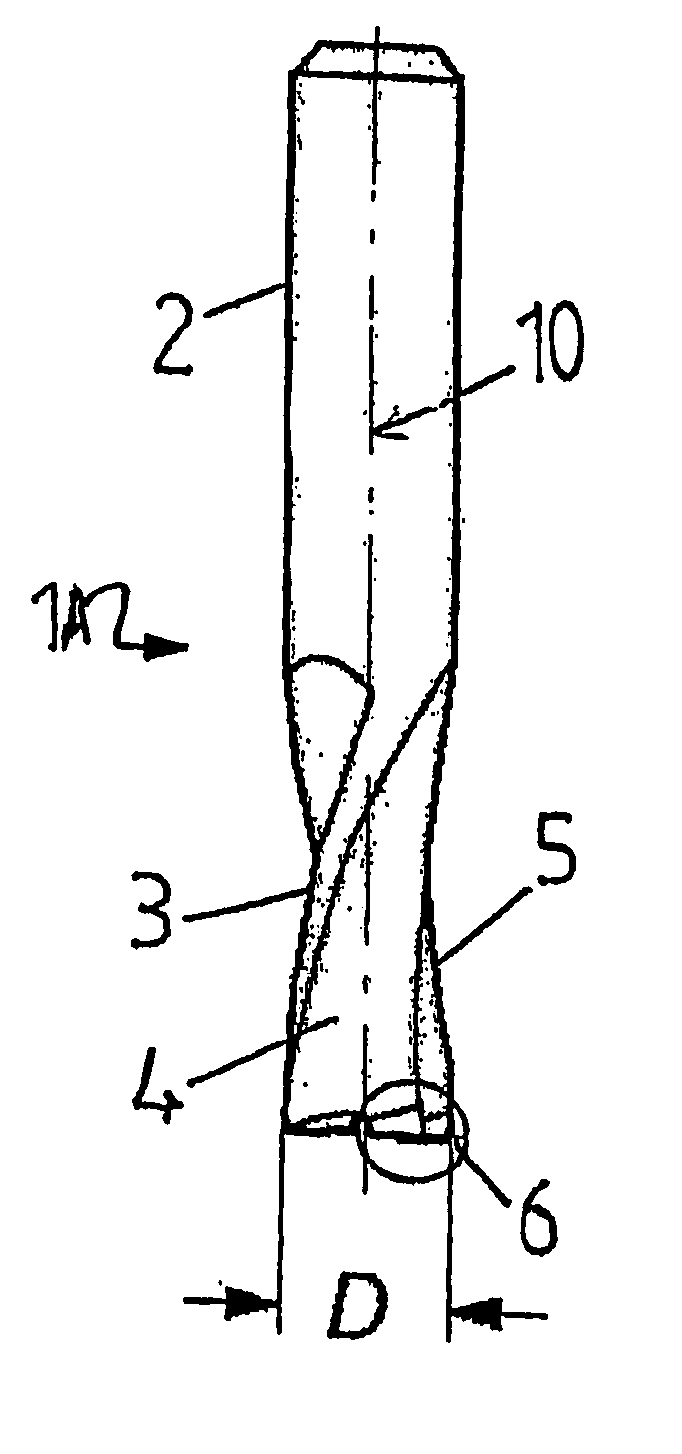

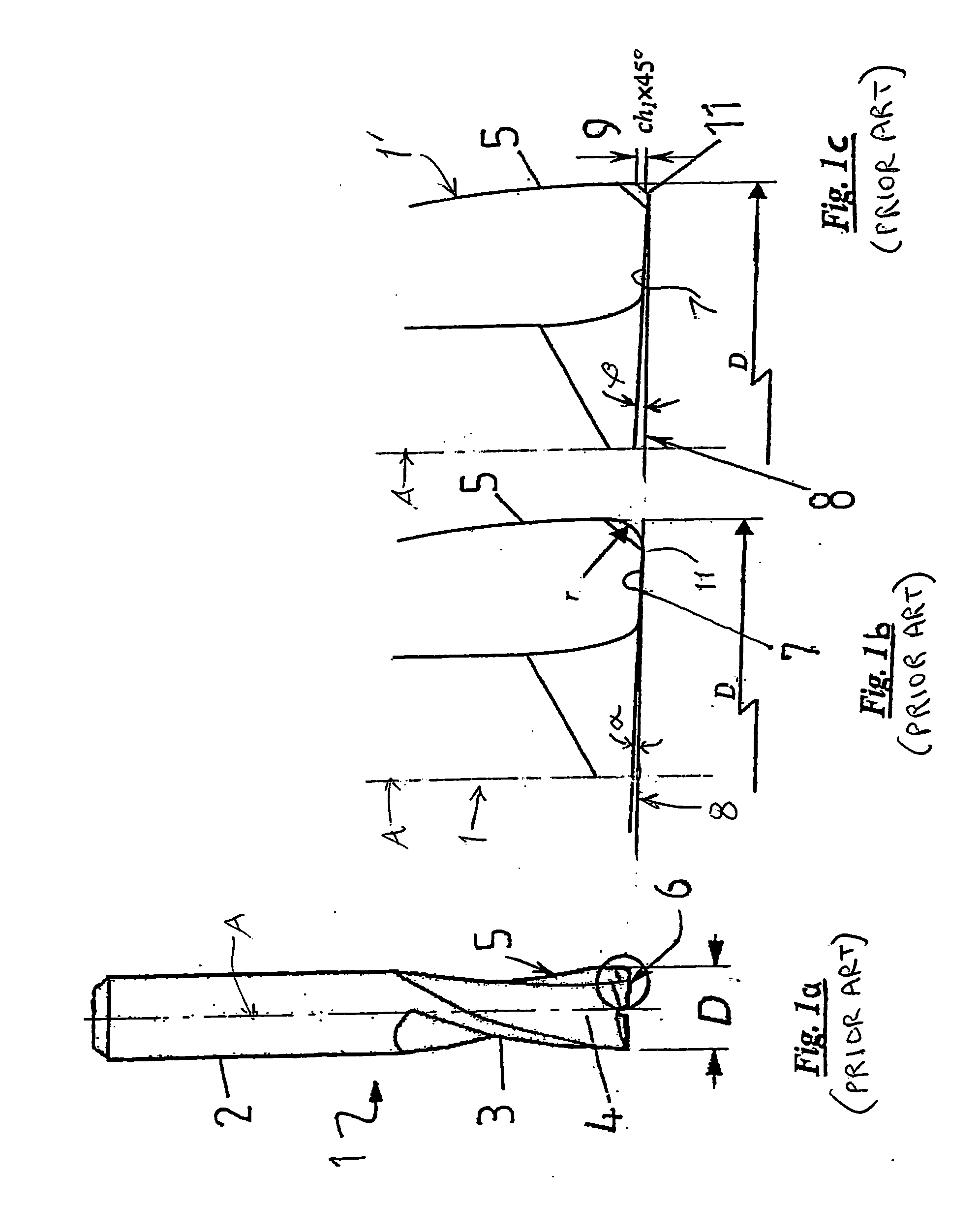

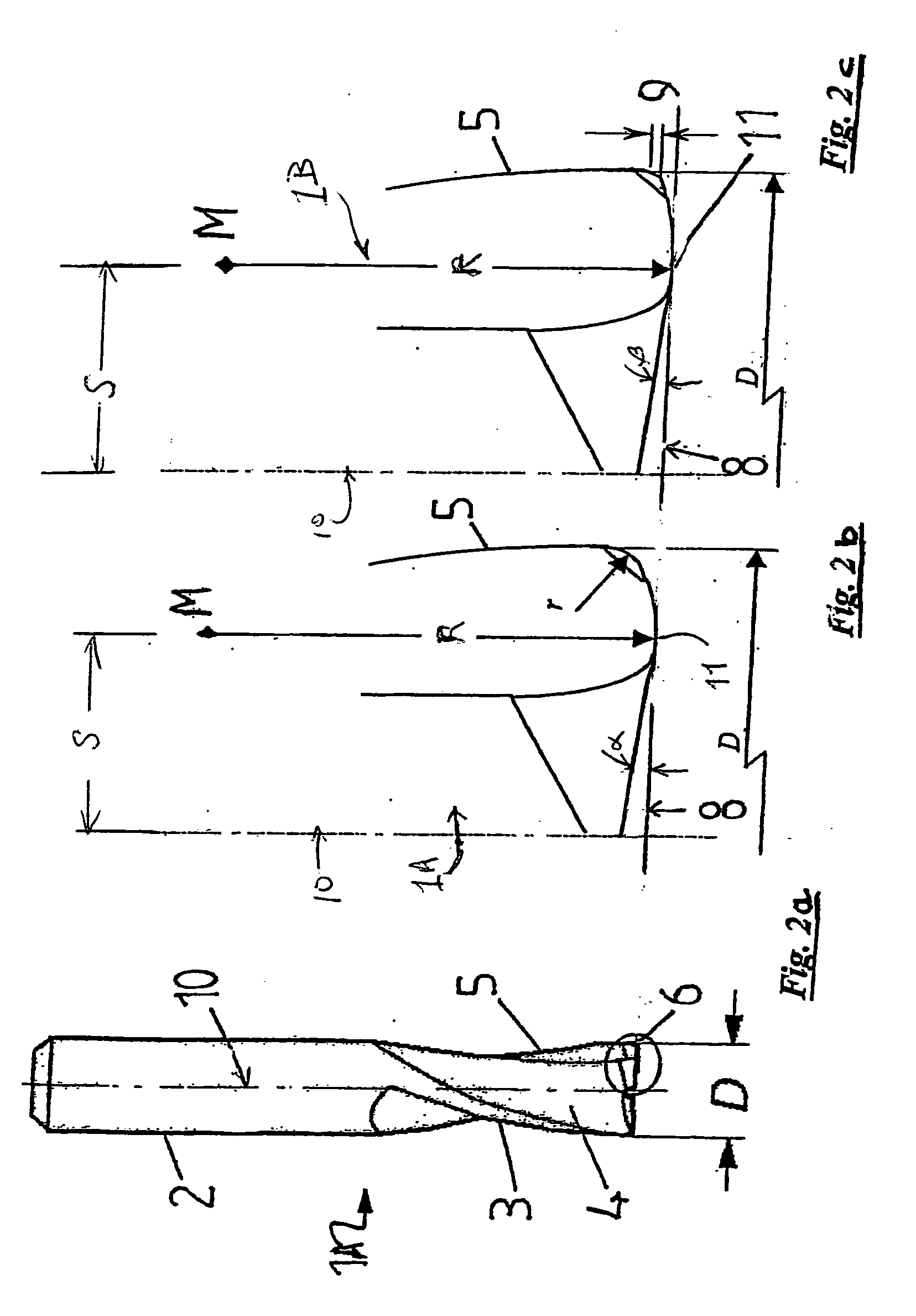

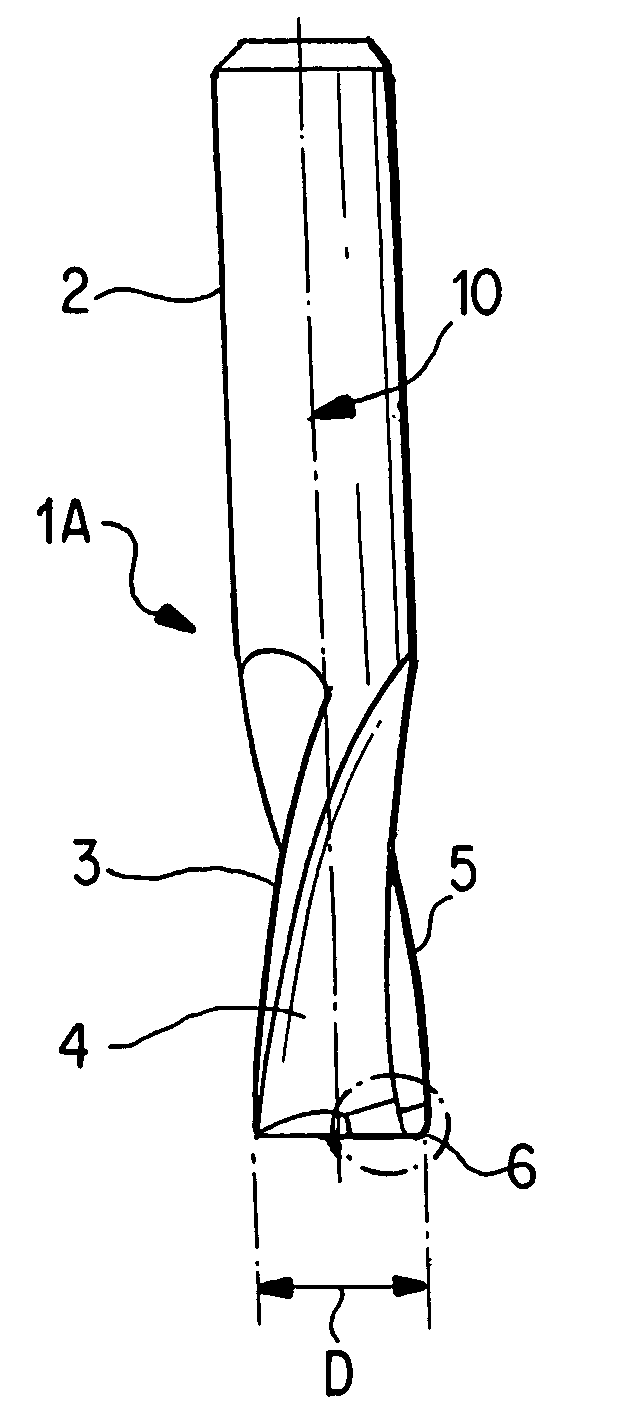

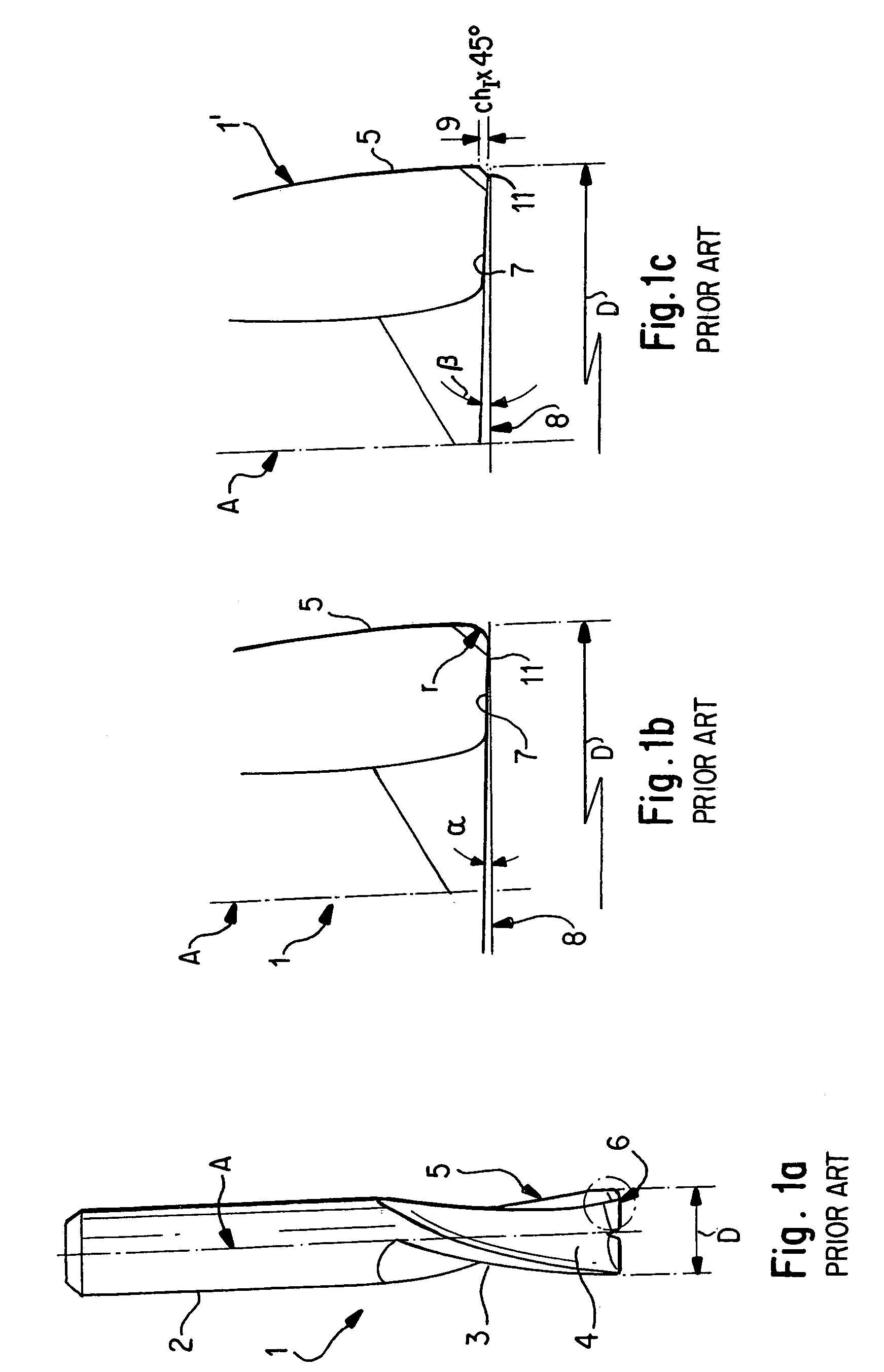

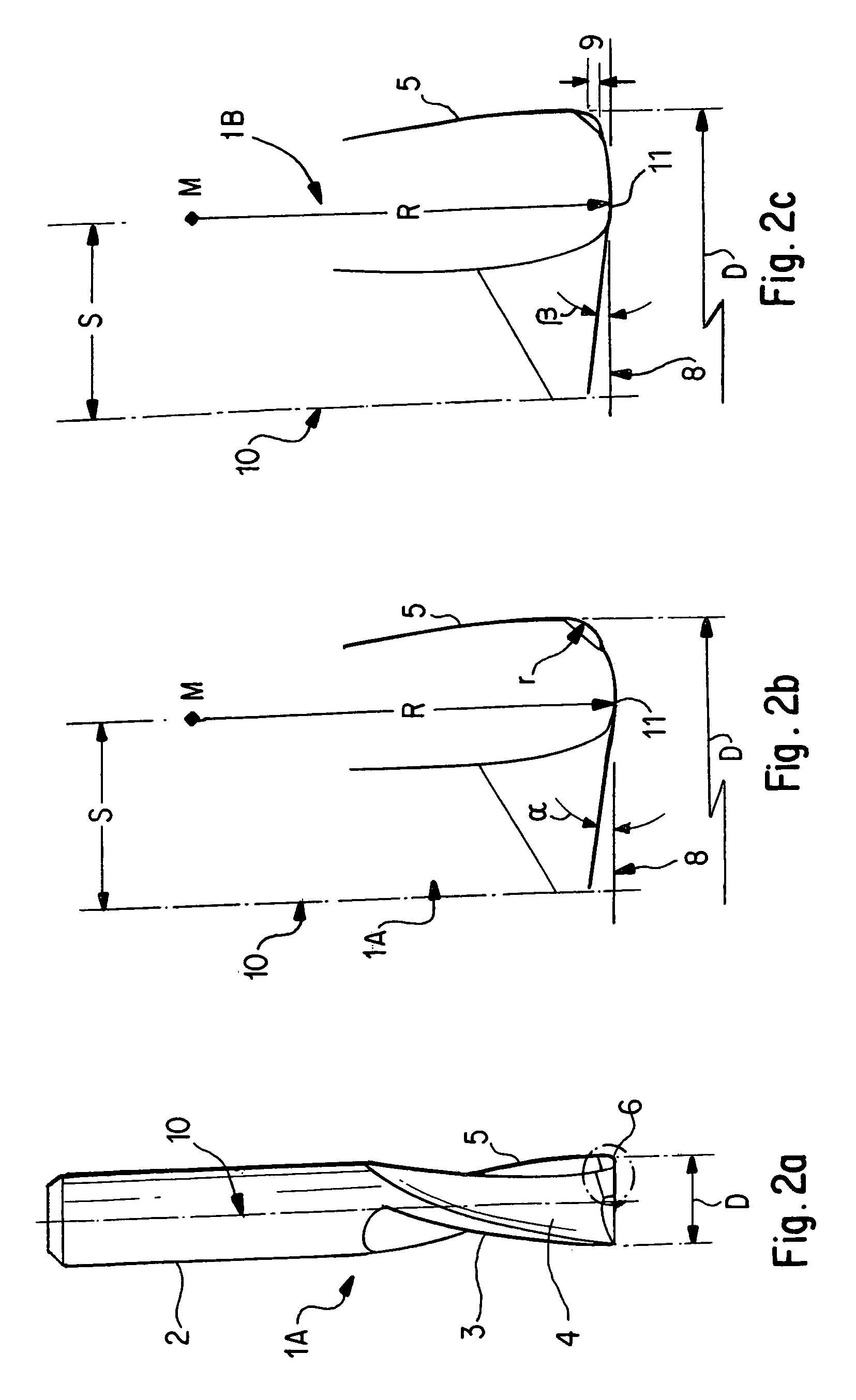

Shank milling cutter having a wiper radius

InactiveUS20050186037A1Easy surface processingExtend your lifeMilling cuttersShaping cuttersMilling cutterEngineering

A shank milling cutter includes a cutting portion which is intended to come into engagement with the workpiece, wherein the envelope surface of the cutting portion is substantially cylindrical. At least one major cutting edge is arranged at the peripheral surface of the cutting portion and at least one minor cutting edge (face cutting edge) is arranged at the end face of the cutting portion and with an end diameter D. The minor cutting edge, in projection onto a plane containing the milling cutter axis, has a convexly curved portion with a radius of curvature R>D / 2 and a center of curvature M located such that a distance from the center of curvature M to the axis is in a range from zero to a value smaller than D / 2.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Semiconductor device and manufacturing method of the same

InactiveUS8298963B2Easy to crackReliability is deterioratedSemiconductor/solid-state device detailsSolid-state devicesGroove widthParasitic capacitance

With a recent shrinking semiconductor process, insulating layers formed between interconnect layers are becoming thin. To avoid parasitic capacitance between them, materials of a low dielectric constant have been used for an insulating layer in a multilevel interconnect. Low-k materials, however, have low strength compared with the conventional insulating layers. Porous low-k materials are structurally fragile. The invention therefore provides a manufacturing method of a semiconductor device having a multilevel interconnect layer including a low-k layer. According to the method, in a two-step cutting system dicing in which after formation of a groove in a semiconductor water with a tapered blade, the groove is divided with a straight blade thinner than the groove width, the multilevel interconnect layer portion is cut while being covered with a tapered face and then the wafer is separated with a thin blade which is not brought into contact with the multilevel interconnect layer portion. The wafer can be diced without damaging a relatively fragile low-k layer.

Owner:RENESAS ELECTRONICS CORP

Recess gate transistor structure for use in semiconductor device and method thereof

InactiveUS7164170B2Reduce leakageShorten the lengthSemiconductor/solid-state device manufacturingSemiconductor devicesInsulation layerDevice material

An inner spacer is formed in a sidewall of a gate in contact with a first active region that is electrically connected to an upper capacitor, thereby reducing a gate induced drain leakage (GIDL). A structure of a recess gate transistor includes a gate insulation layer, a gate electrode, a first gate spacer, a second gate spacer and source / drain regions. The gate insulation layer is formed within a recess. The gate electrode is surrounded by the gate insulation layer and is extended from within the recess. The first gate spacer is spaced with a predetermined distance horizontally with a portion of the gate insulation layer, being formed in a sidewall of the gate electrode. The second gate spacer is formed in another part of the sidewall of the gate electrode. The source / drain regions are formed mutually oppositely on first and second active regions with the gate electrode therebetween.

Owner:SAMSUNG ELECTRONICS CO LTD

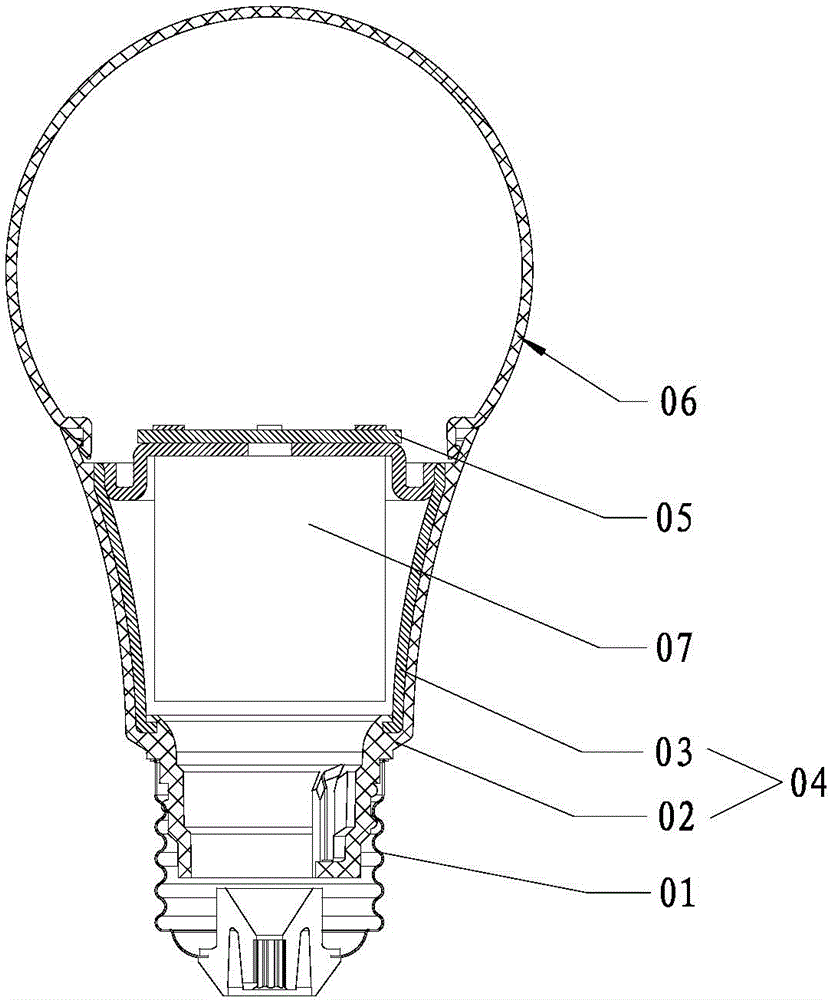

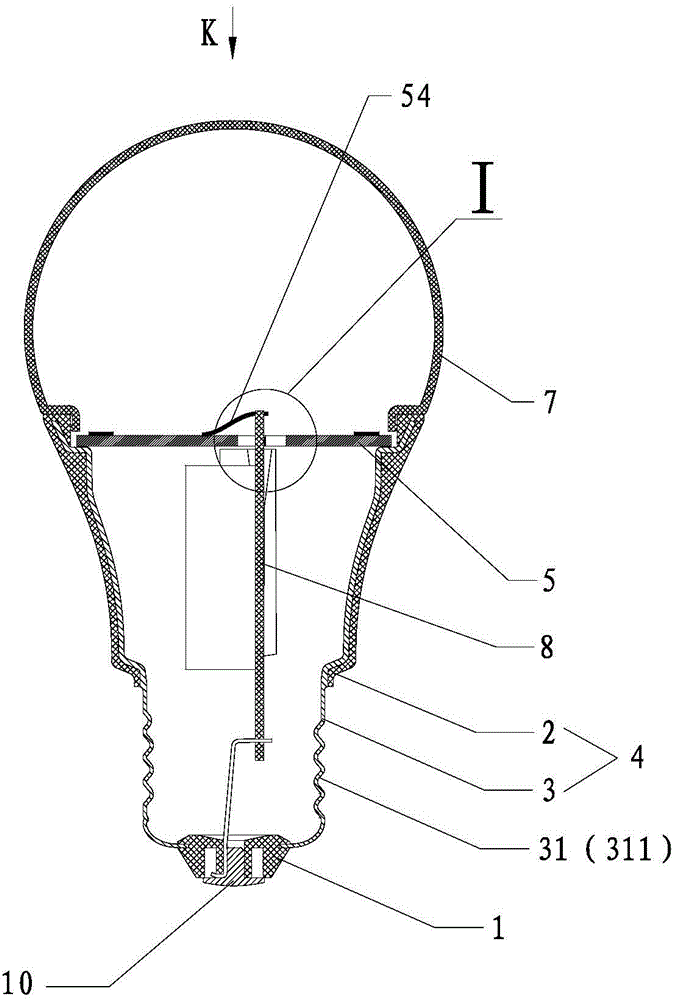

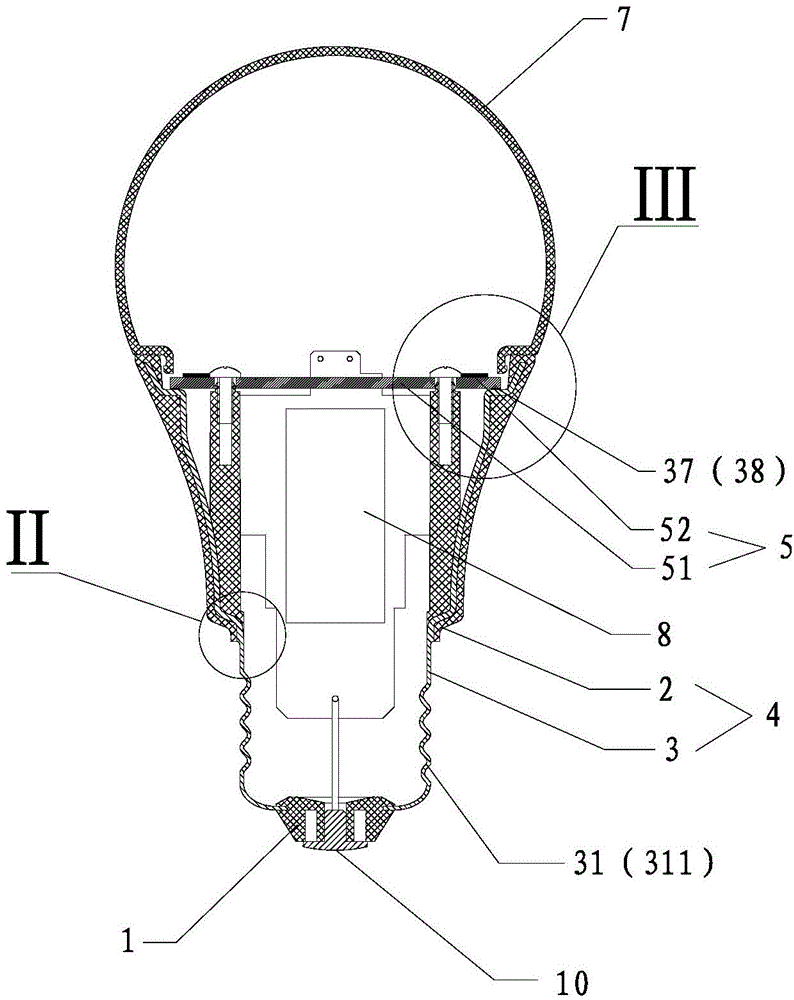

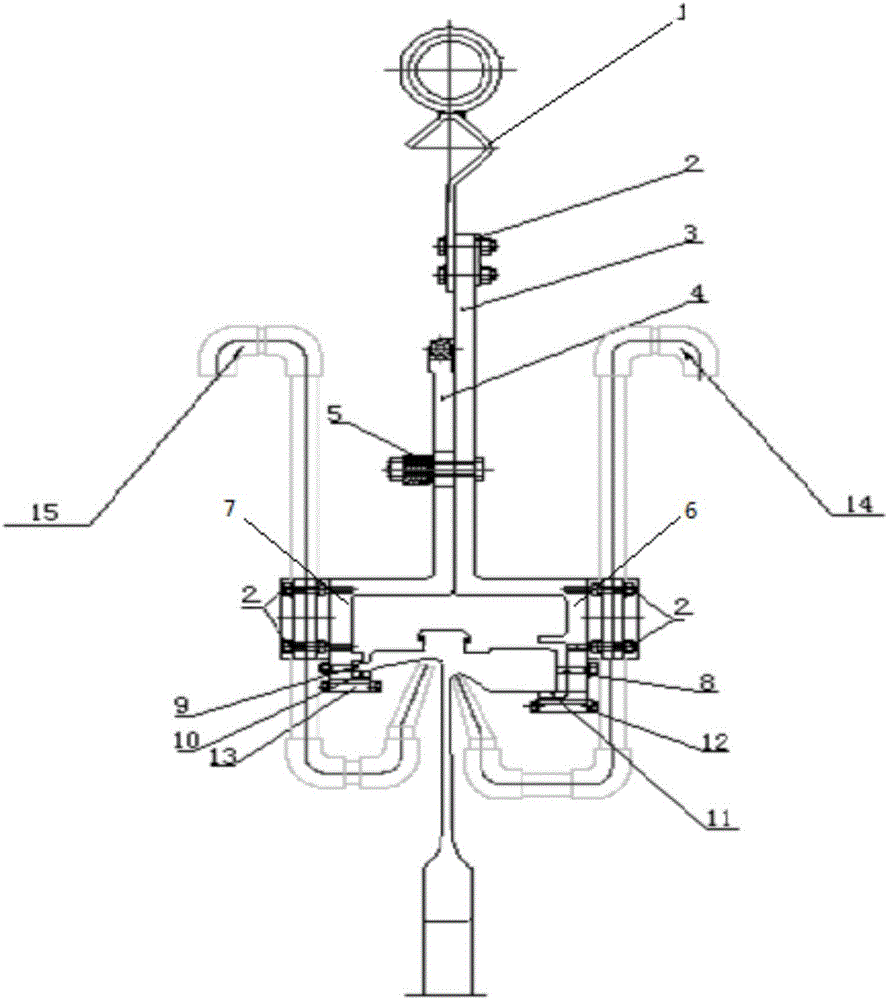

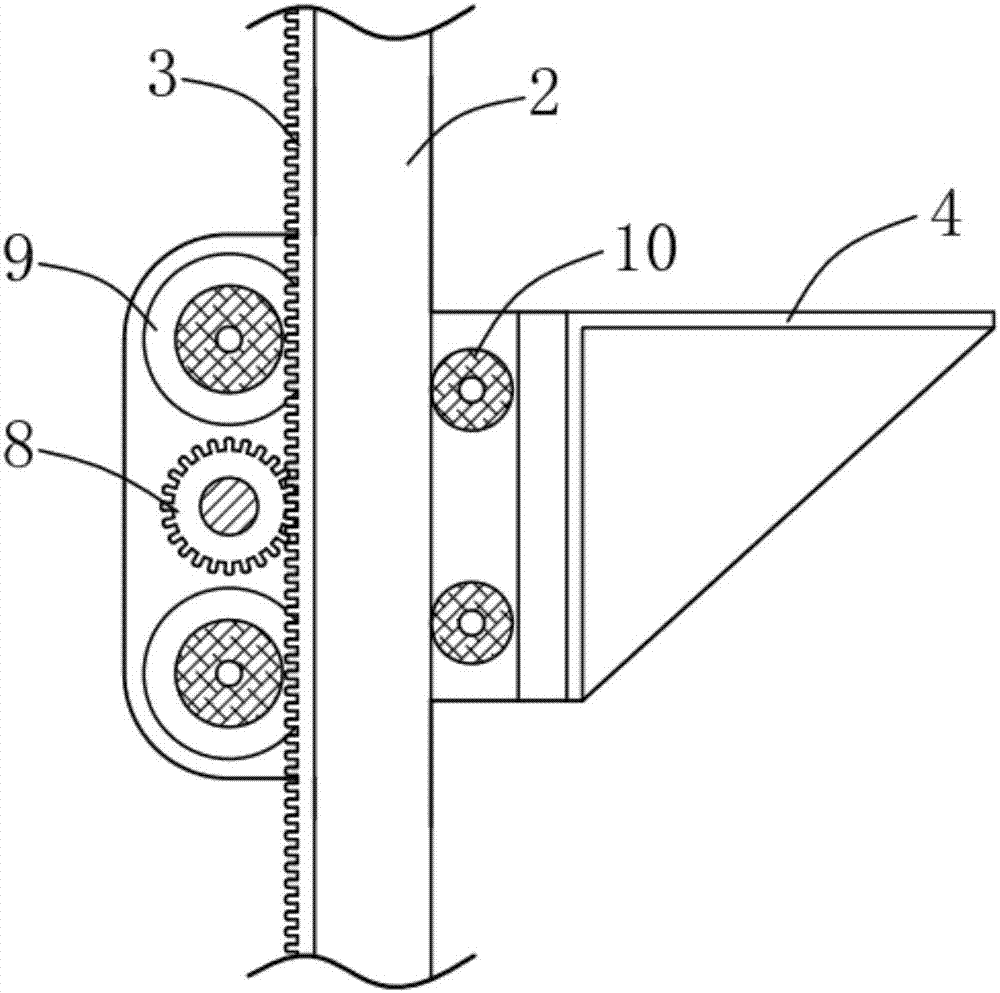

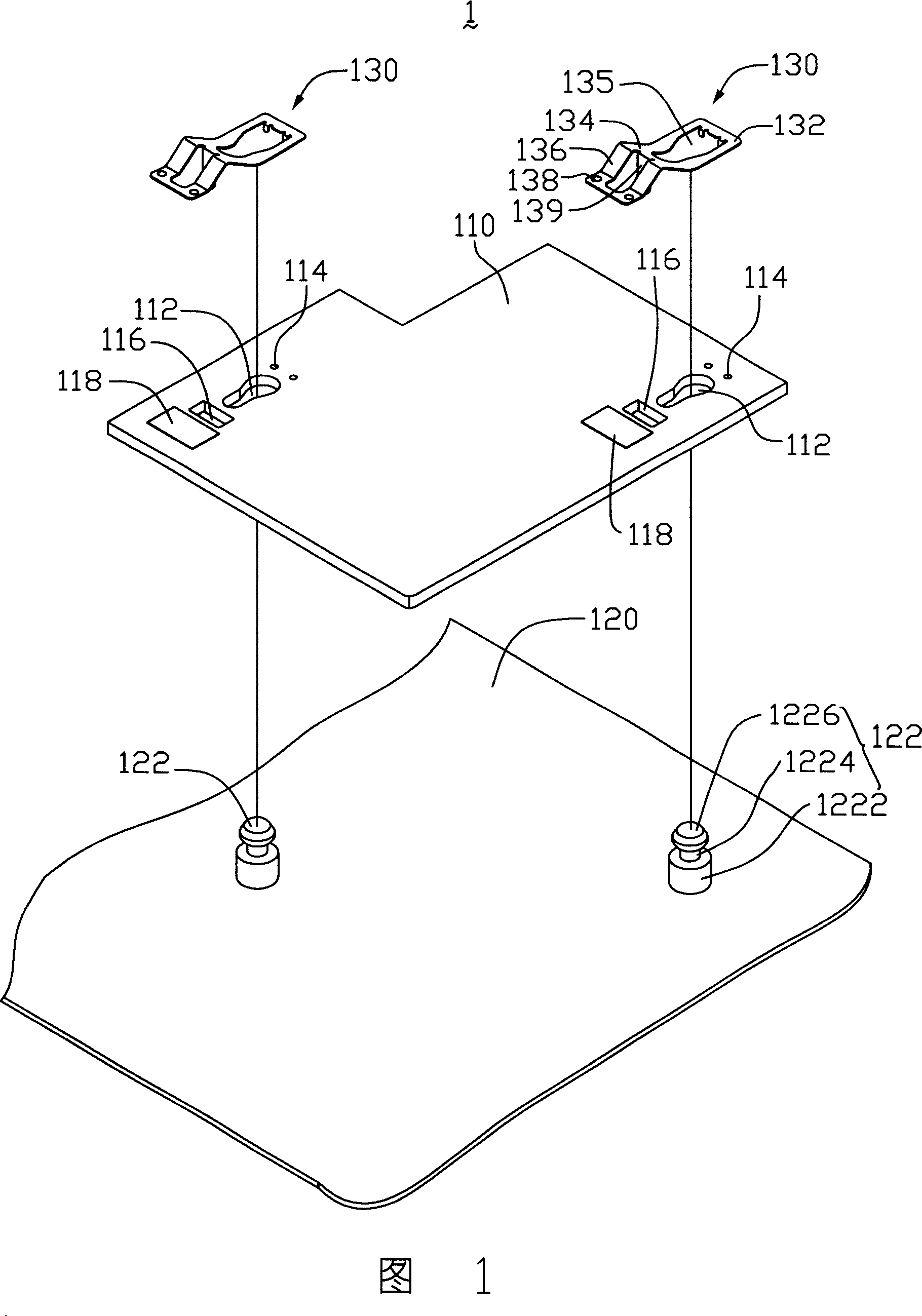

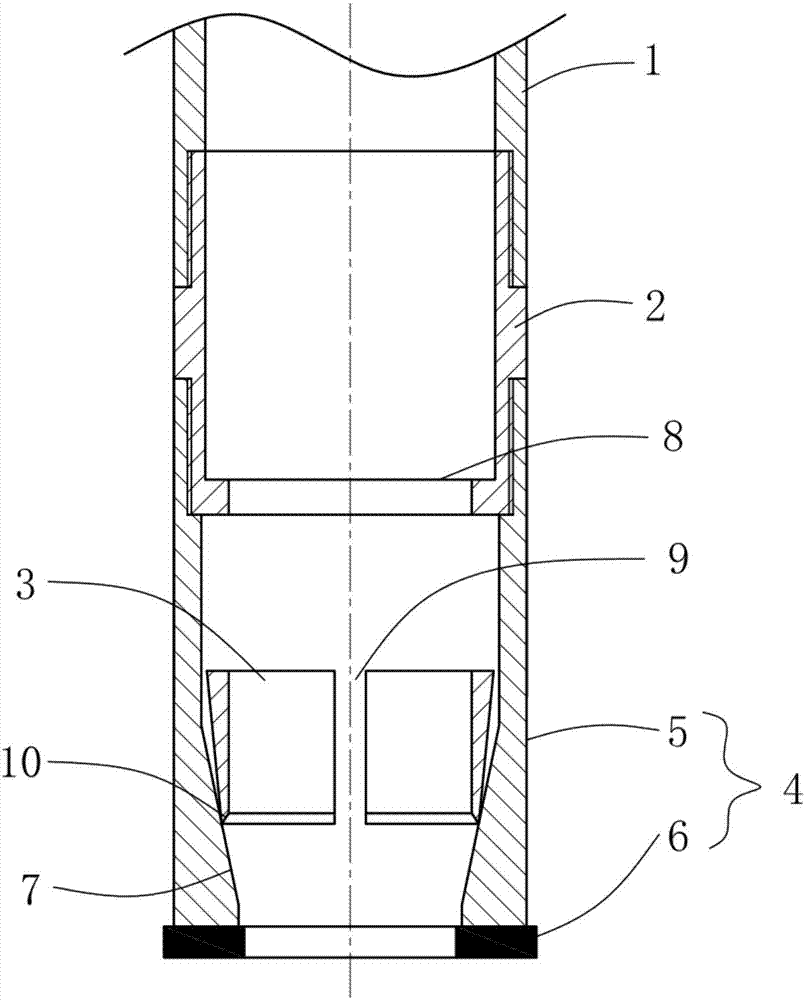

LED lamp with radiator and lamp holder integrated structure

InactiveCN104976538ASimple structureReduce production processPoint-like light sourceElectric circuit arrangementsEngineeringLED lamp

The invention belongs to the technical field of LEDs and particularly relates to an LED lamp with a radiator and lamp holder integrated structure. The radiator and lamp holder integrated structure comprises an electrode insulator (1), a second electrode (10) and a radiator (4). The radiator (4) comprises a metal heat conductor (3) and an insulating shell (2). A standard lamp holder shell (31) is formed at the lower end of the metal heat conductor (3) and serves as an electrode. The electrode insulator (1) is arranged at an opening in the middle of the top of the standard lamp holder shell (31). The electrode (10) is arranged in the middle of the electrode insulator (1). The insulating shell (2) is wrapped outside the portion, except the standard lamp holder shell (31), of the metal heat conductor (3). The LED lamp is simple in structure, safe and reliable, the heat dissipation performance is improved, the number of the production procedures can be reduced, and mechanical assembly production can be achieved.

Owner:FUJIAN YDJ LIGHT

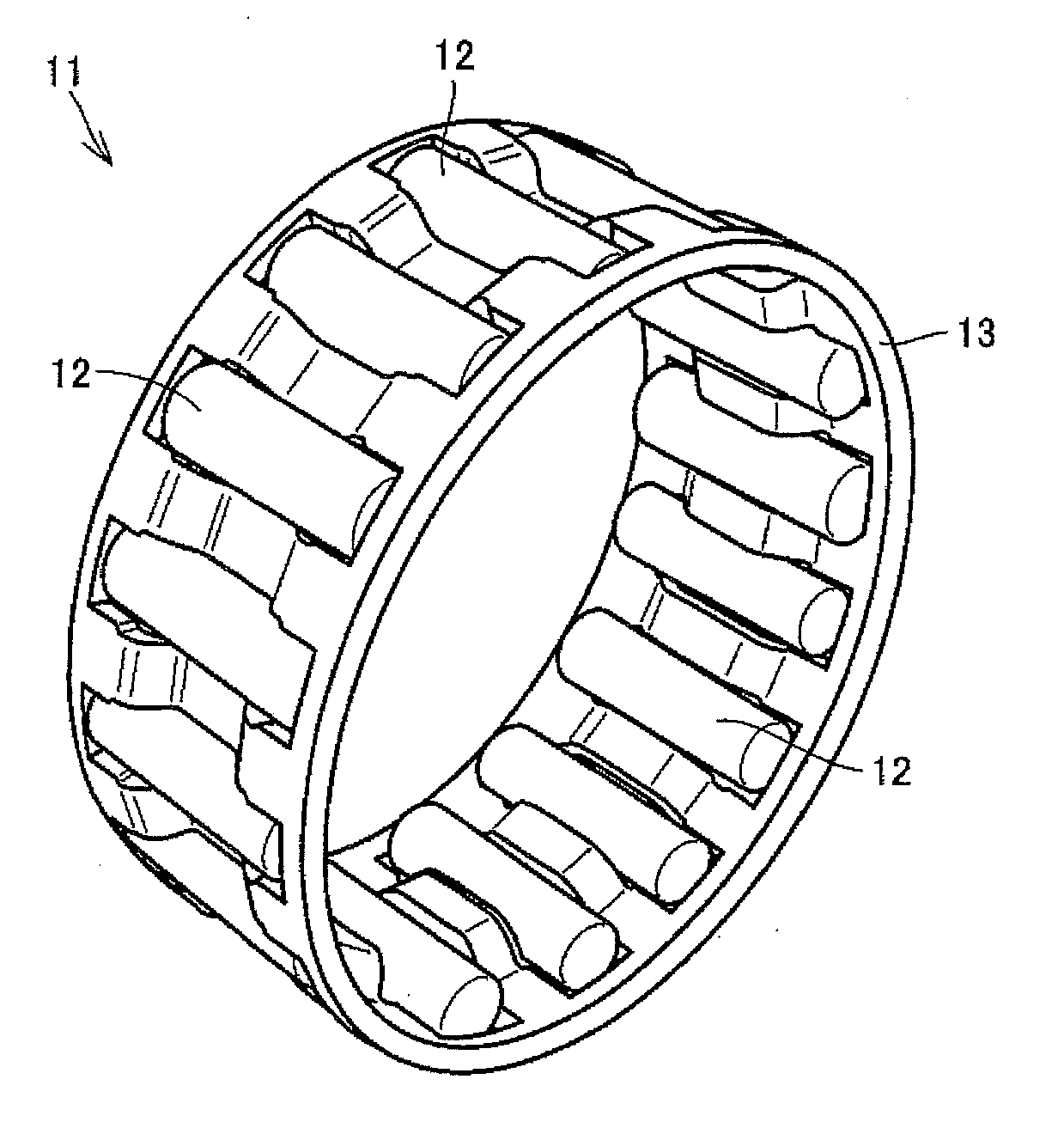

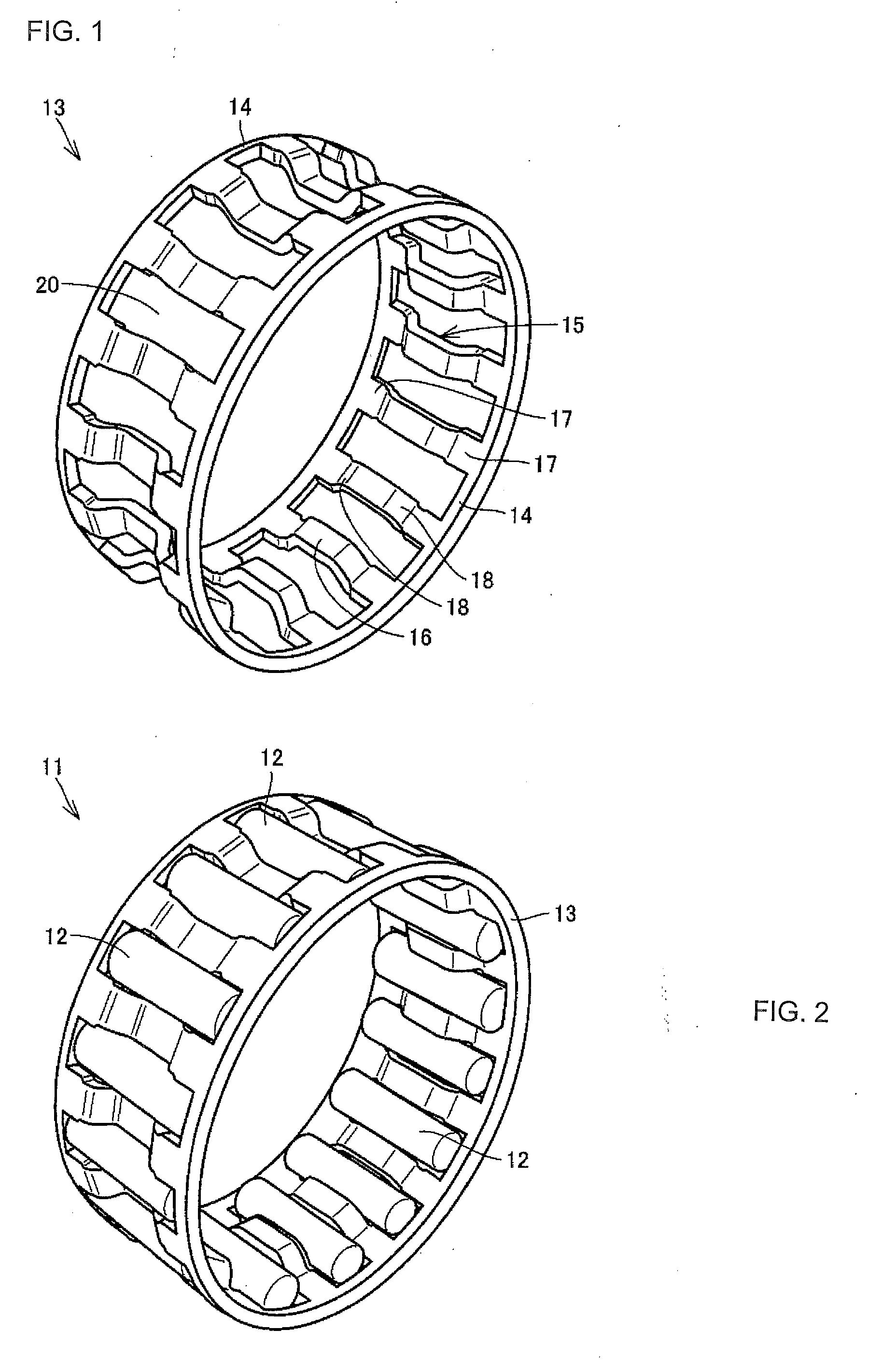

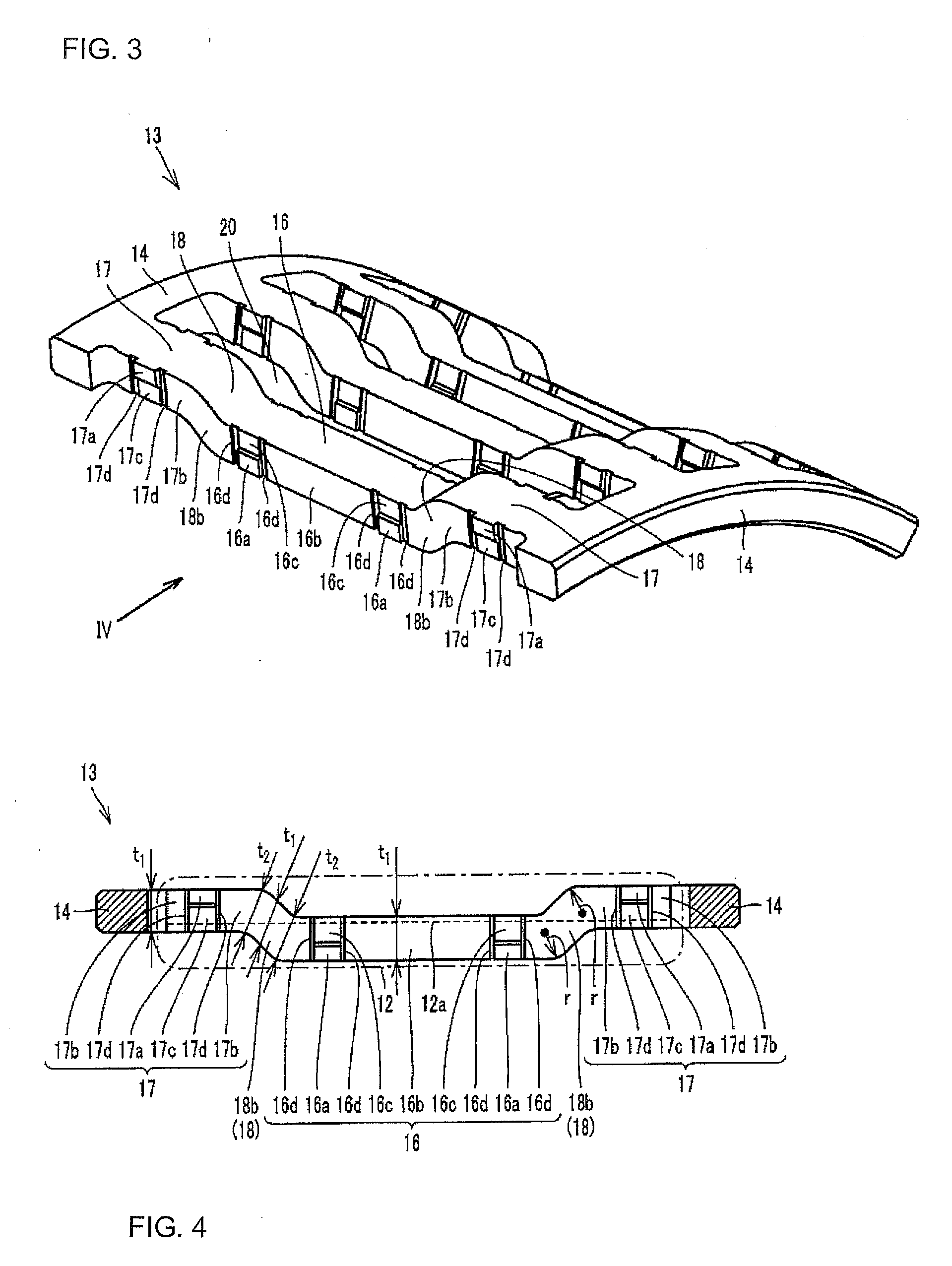

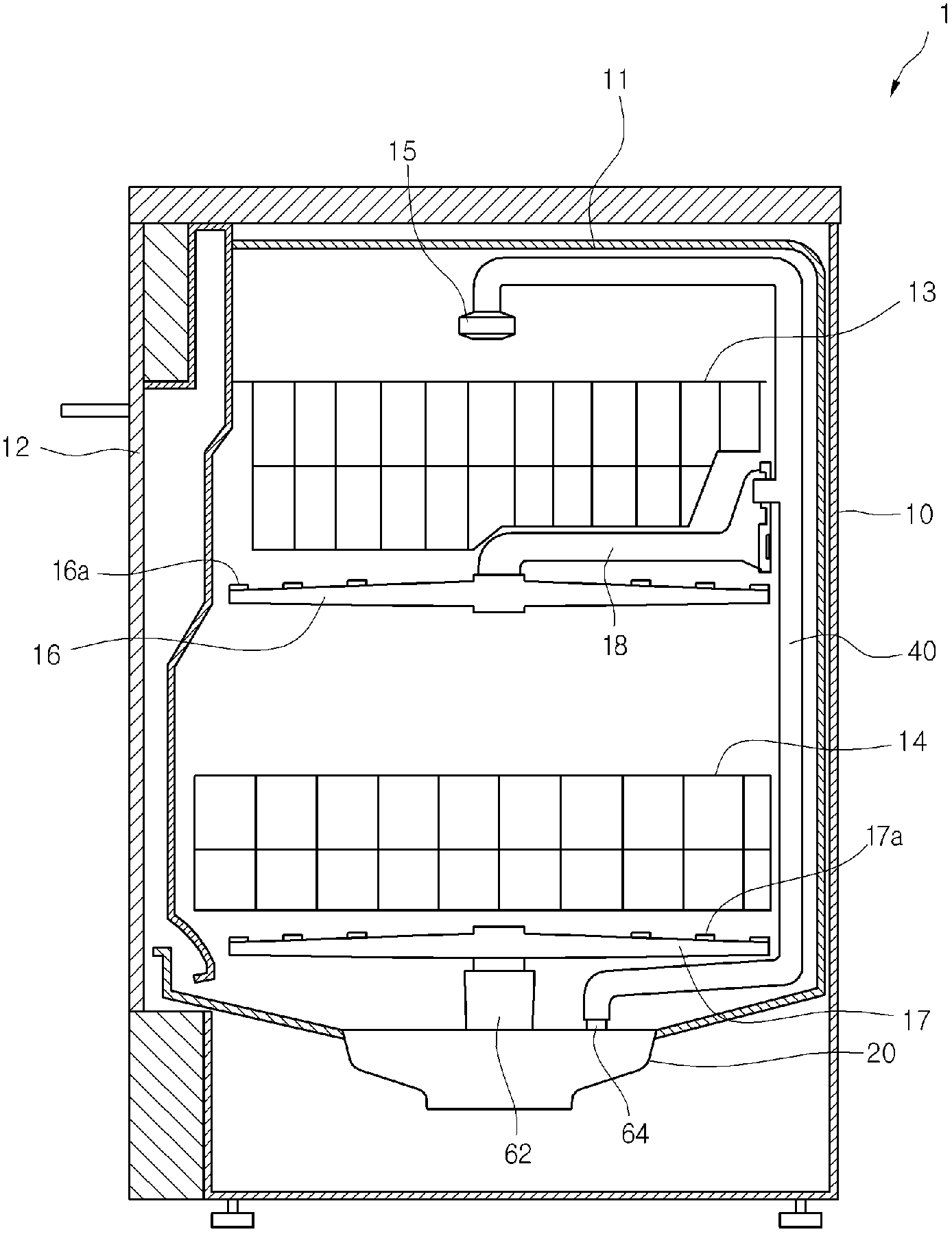

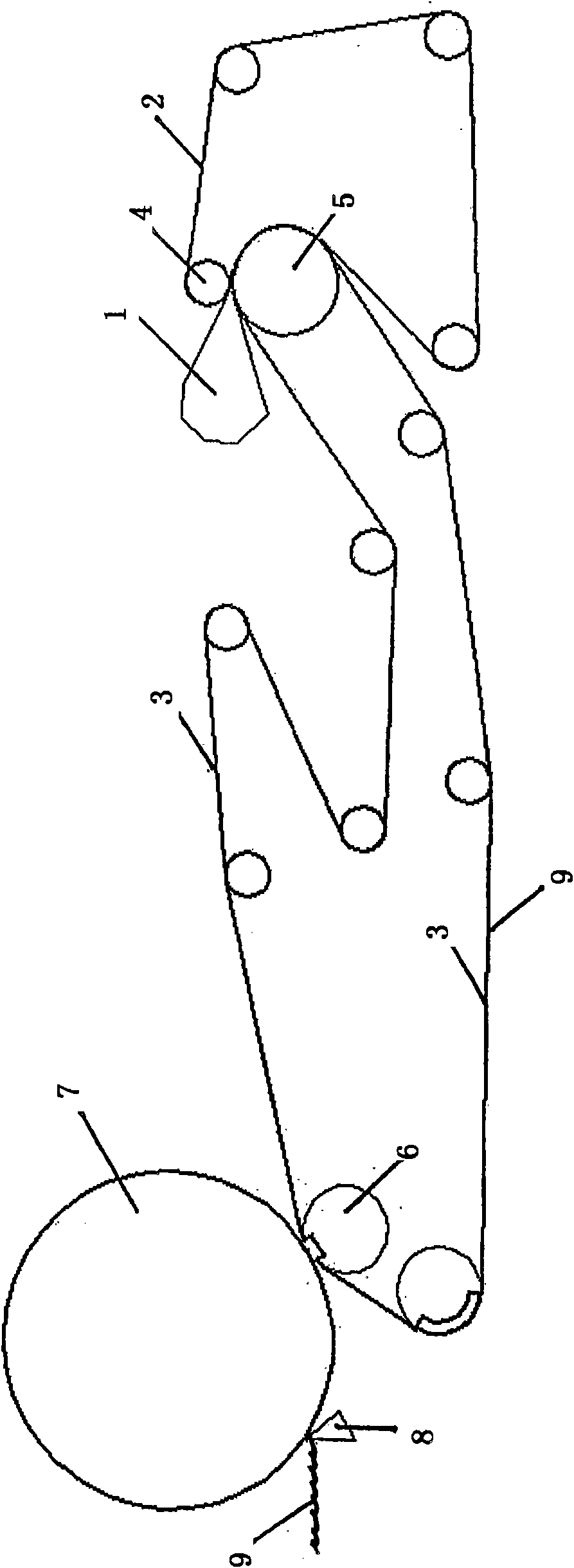

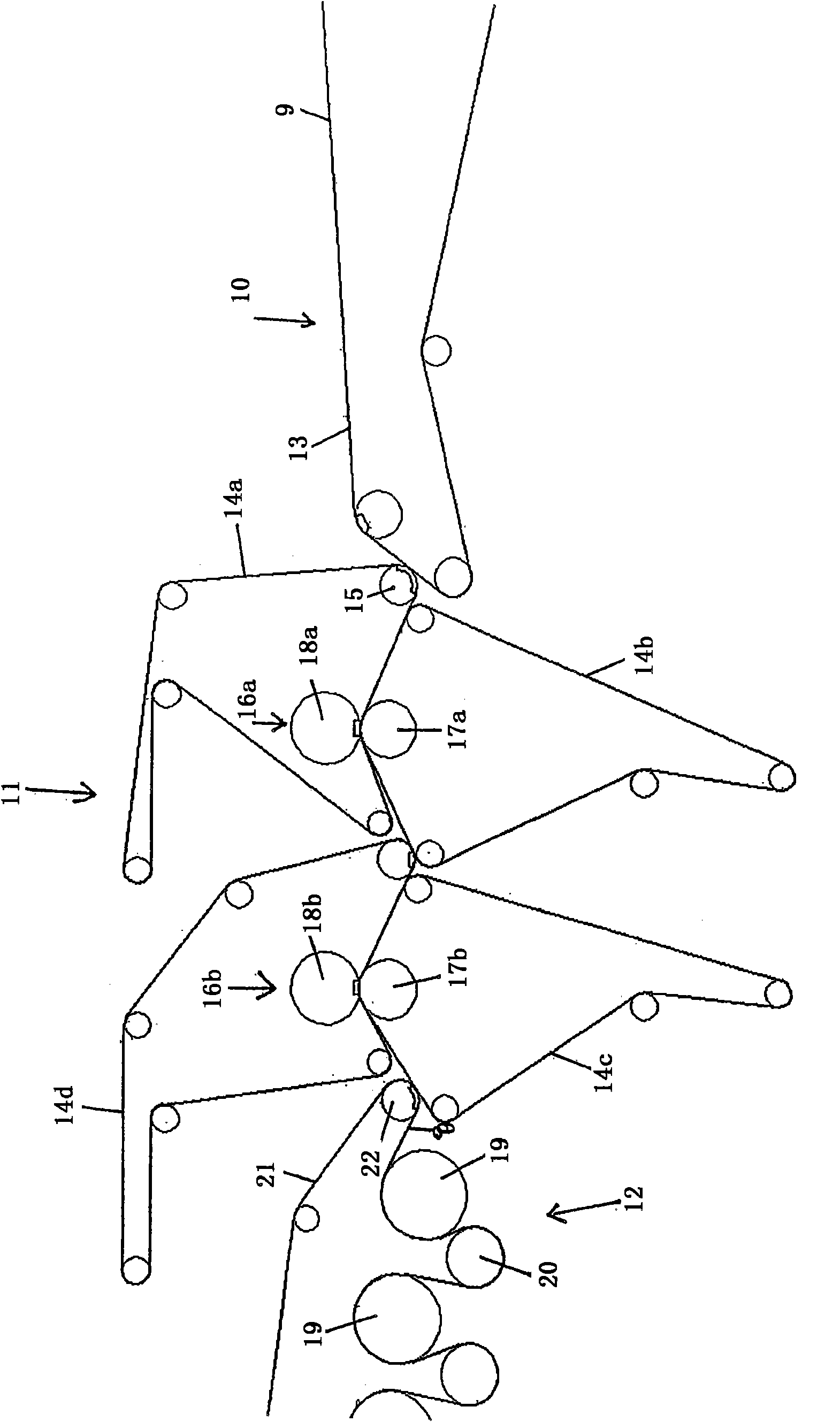

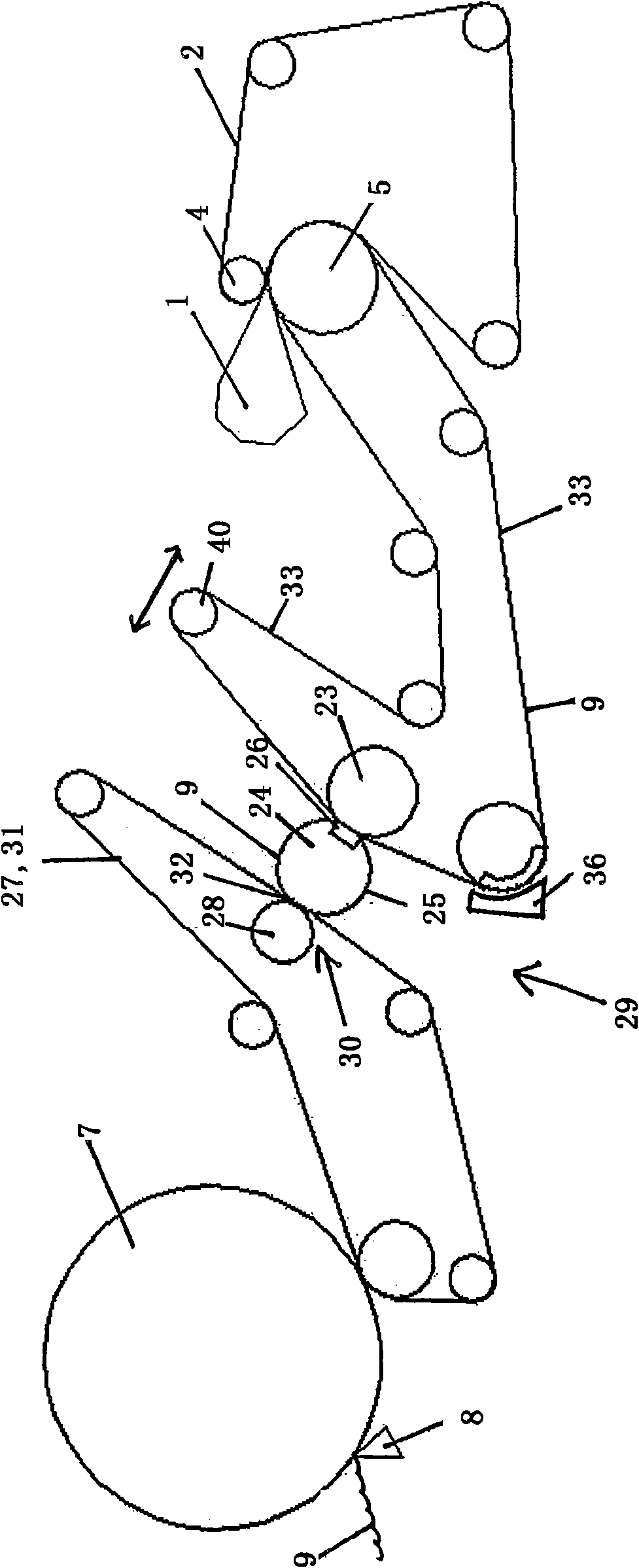

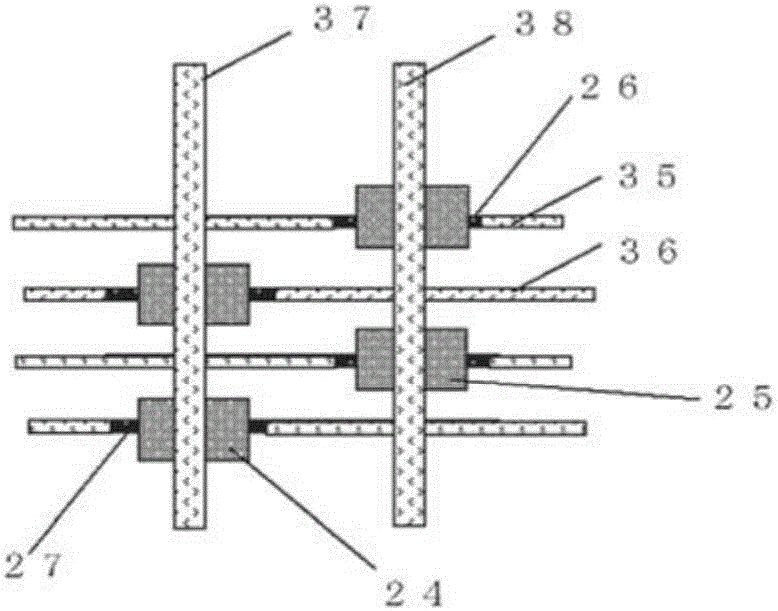

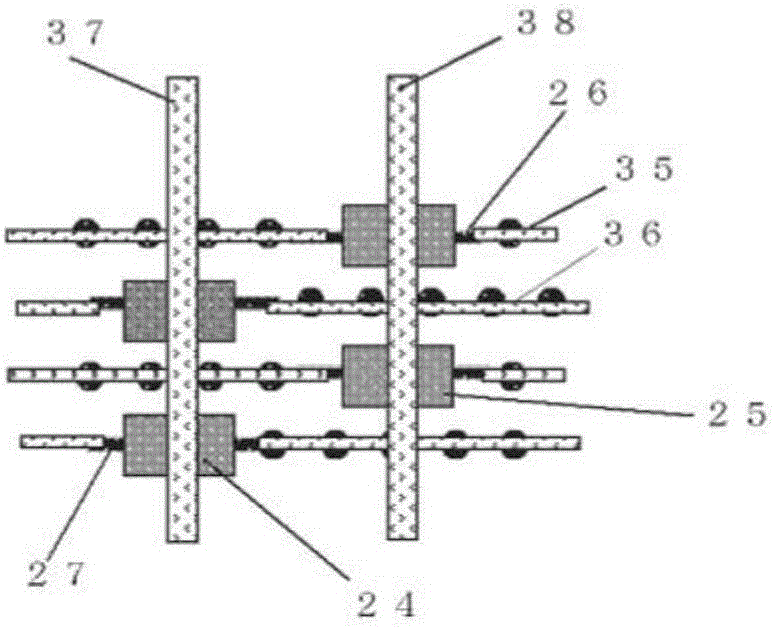

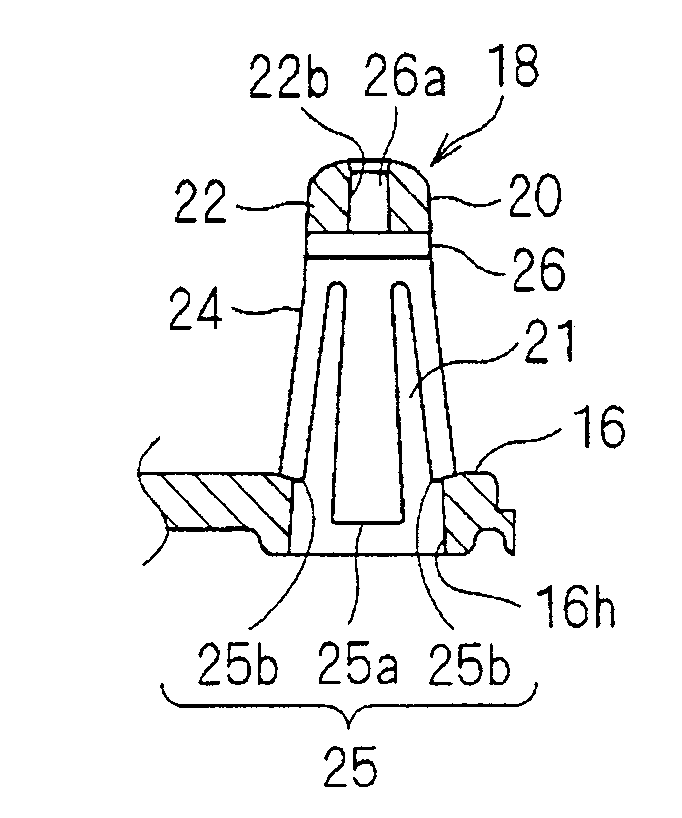

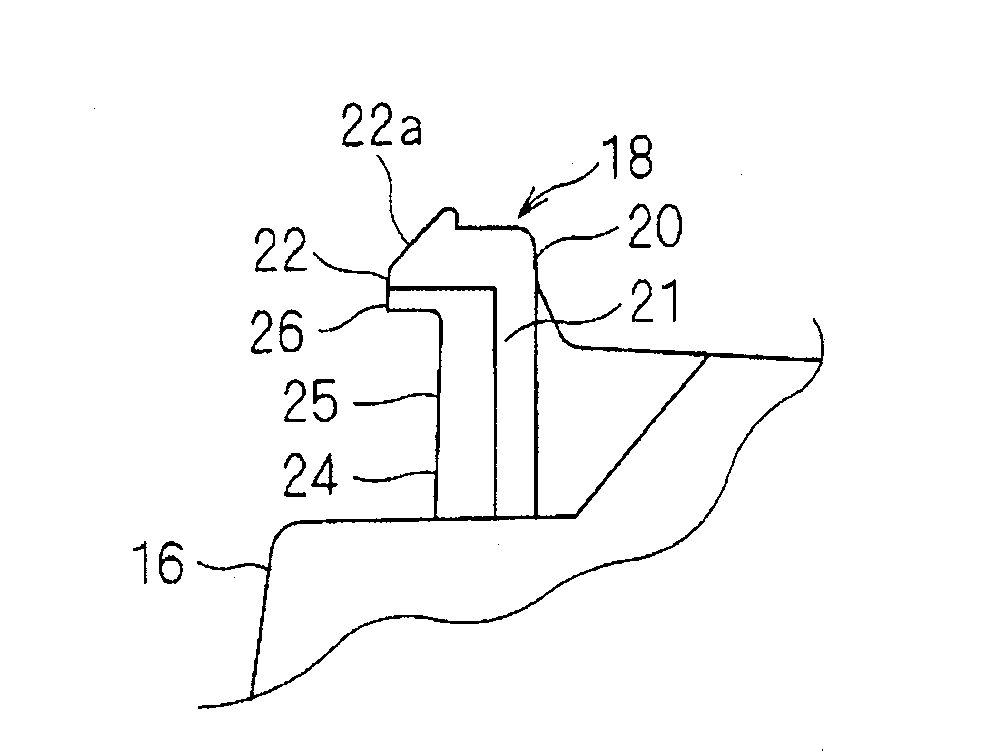

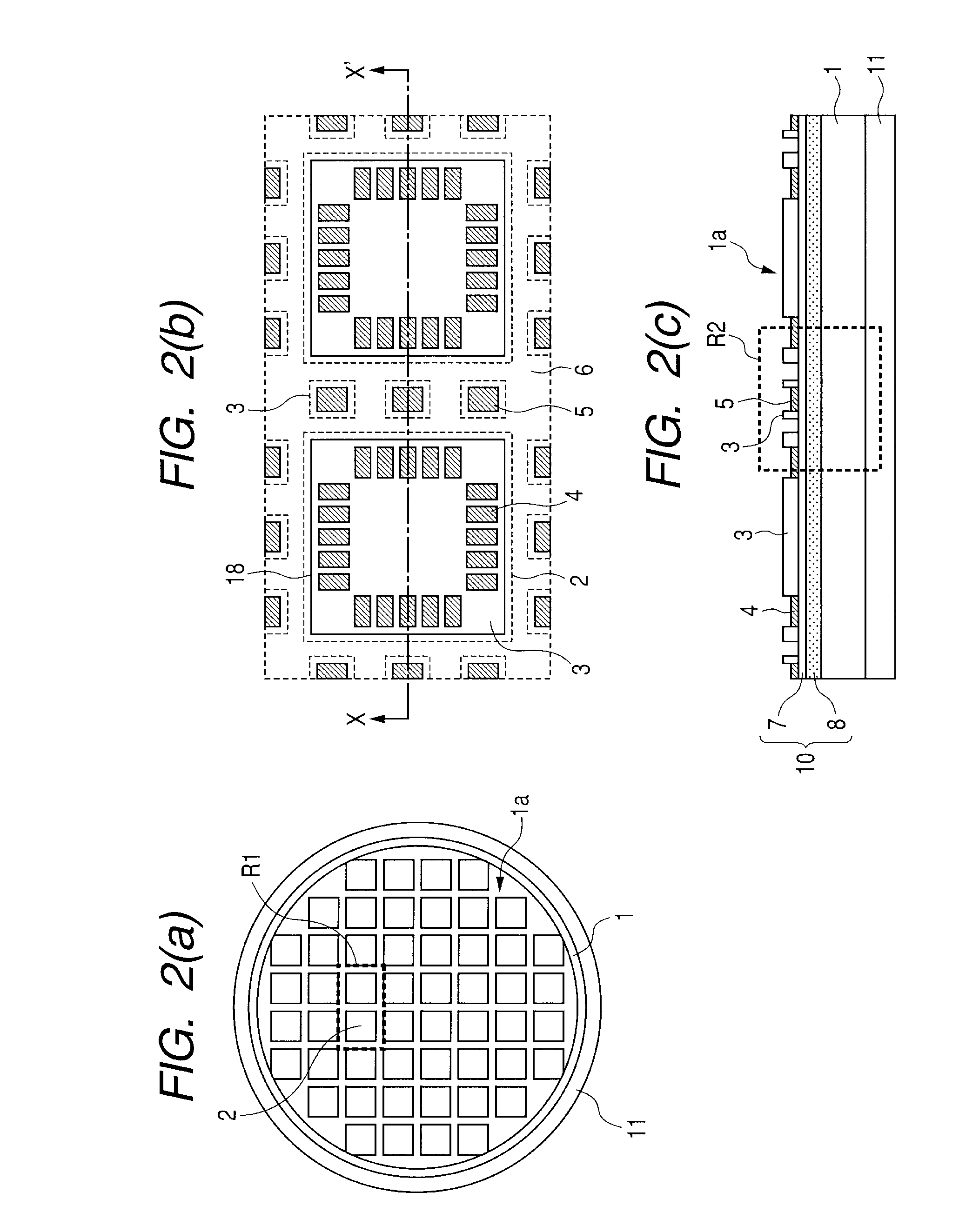

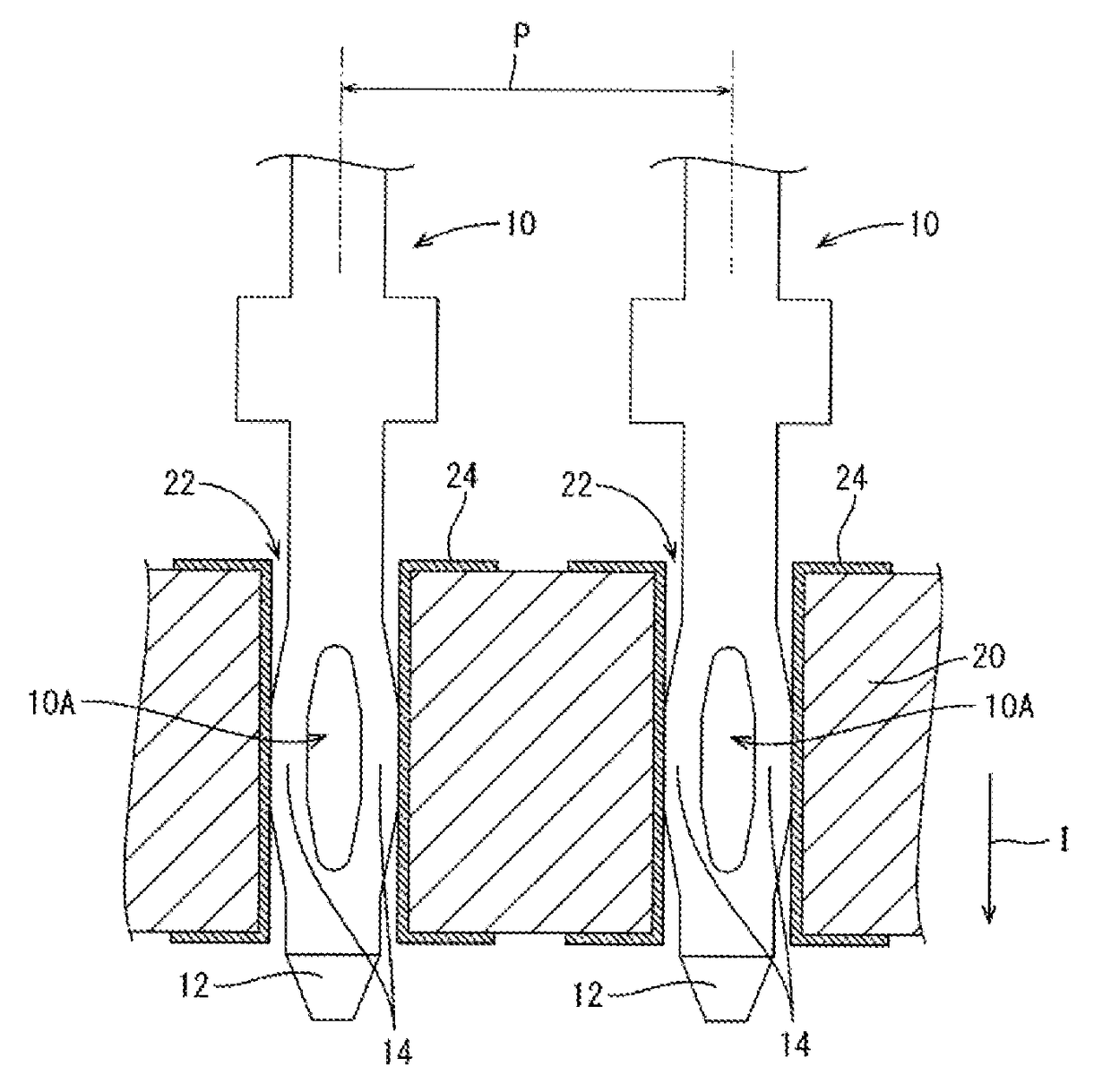

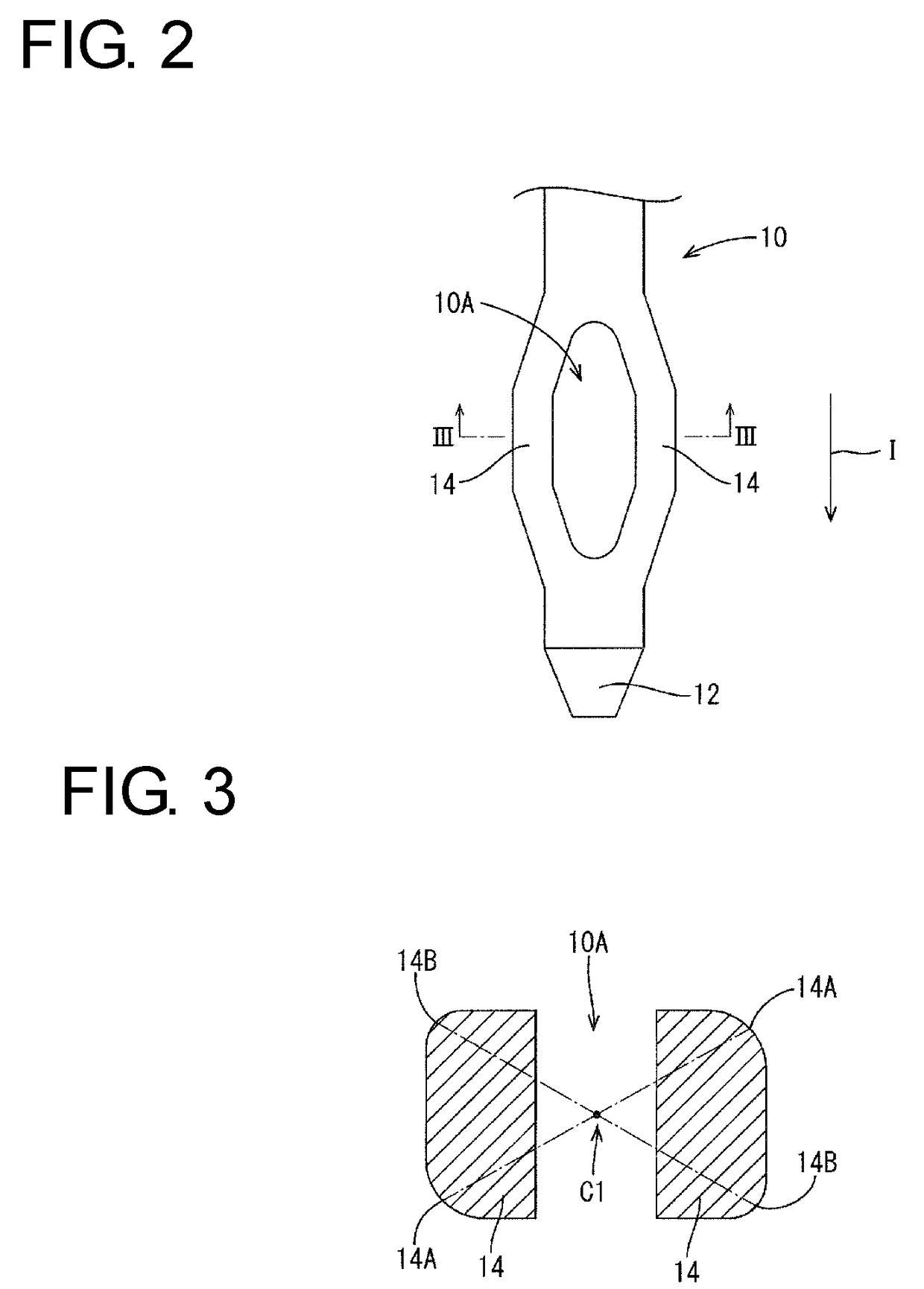

Roller bearing retainer and needle roller bearing

ActiveUS20100278471A1Reduced contact areaAvoid abrasionsShaftsBearing componentsNeedle roller bearingEngineering

A roller bearing retainer (13) includes a pair of annular ring parts (14) and a plurality of column parts (15) each including a column center part (16) provided in an axial center region so as to be positioned relatively on the radial inner side, a pair of column end parts (17) provided in axial end regions so as to be positioned relatively on the radial outer side, and a pair of column sloped parts (18) positioned between the column center part (16) and the pair of column end parts (17), and connecting the pair of ring parts to each other. A thickness of each part of the column center part, the pair of column end parts, and the pair of column sloped parts is smaller than a thickness of a boundary part between the adjacent parts.

Owner:NTN CORP

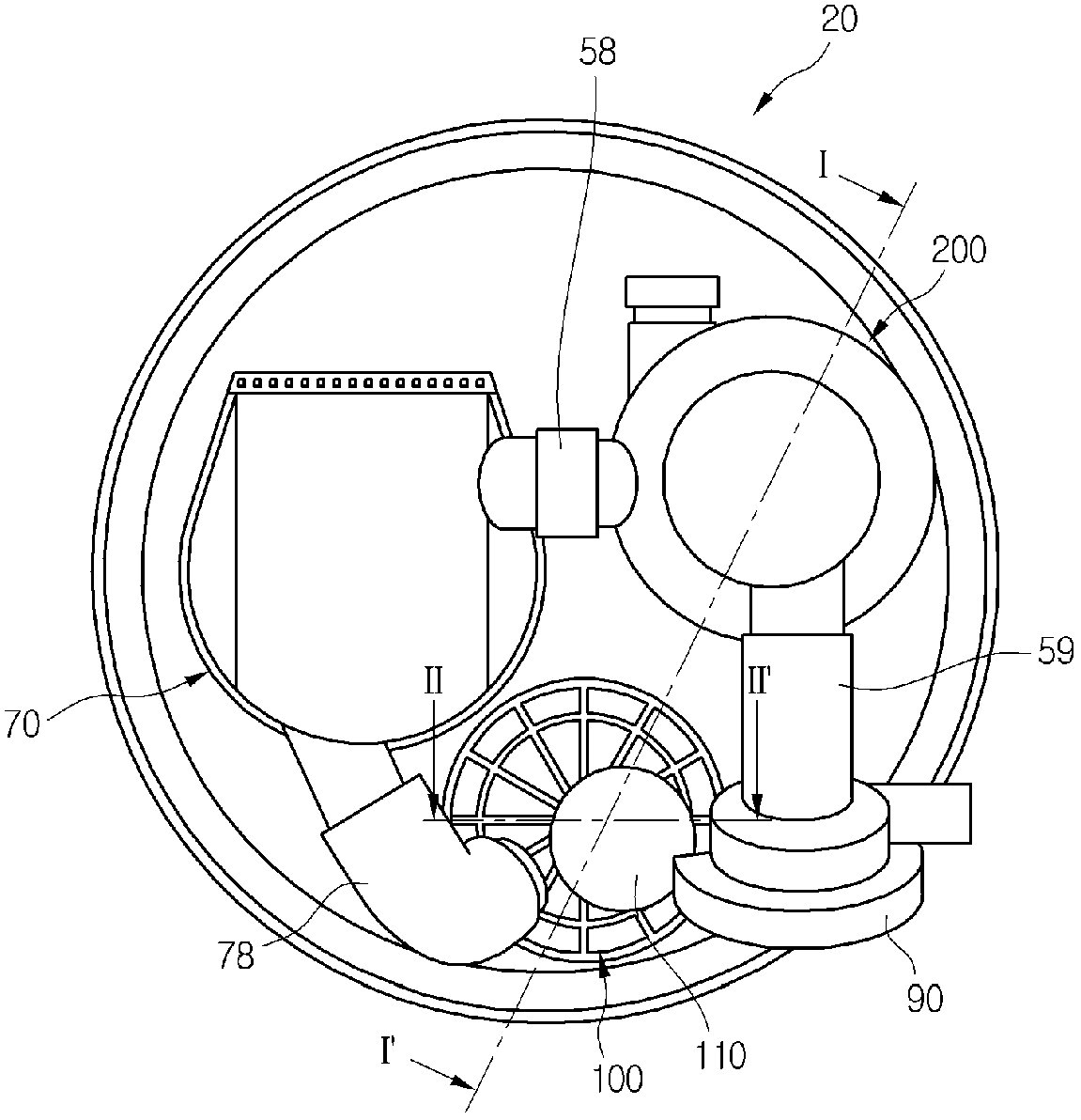

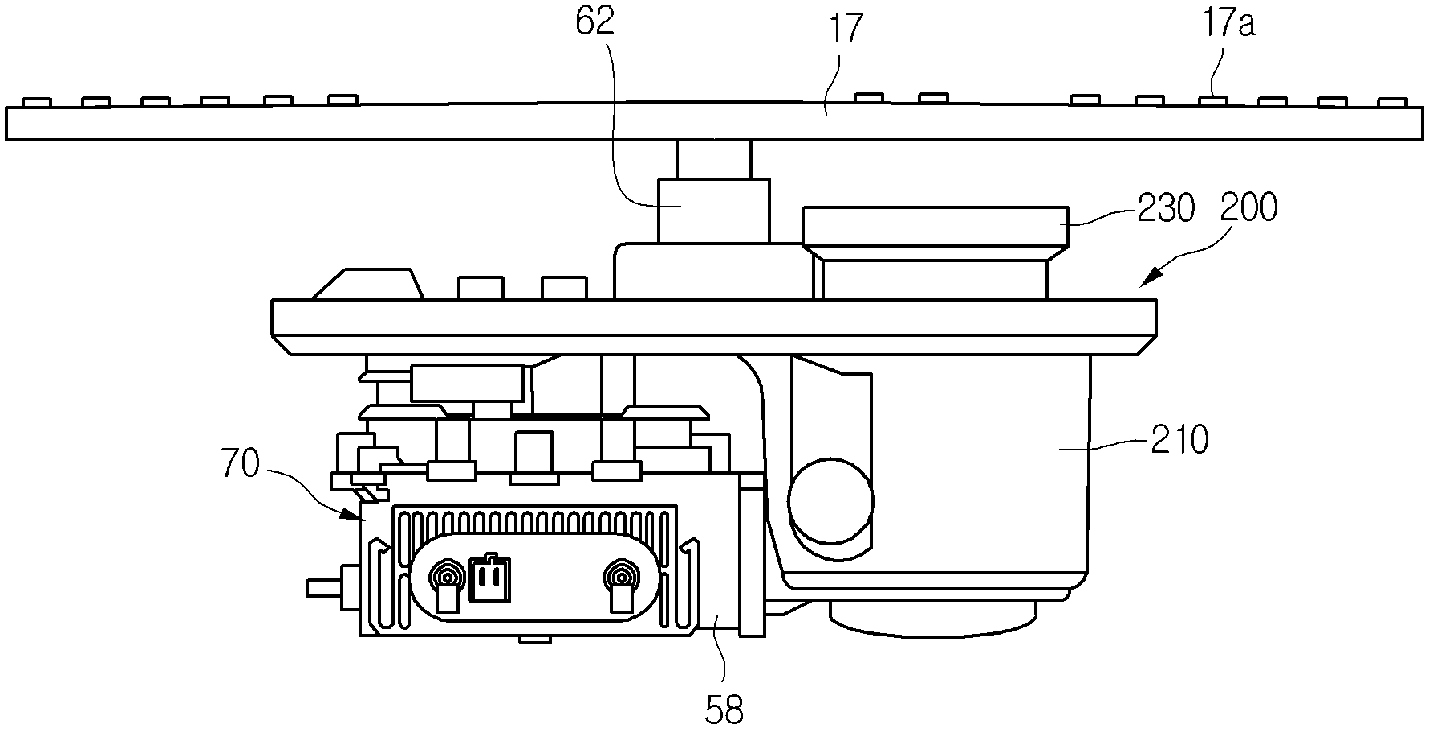

A dishwasher

InactiveCN103188985AReduce channel lengthReduce the amount of washing waterTableware washing/rinsing machine detailsImpellerSuction force

Provided is a dishwasher, which includes a washing chamber, a sump, and a washing water pump. The washing chamber accommodates a dish. The sump stores washing water supplied to the washing chamber. The washing water pump is provided to the sump and generates suction force for circulating washing water. The washing water pump includes a washing water motor for generating driving force, an impeller part disposed under the washing water motor and rotated by the driving force, and a heating space under the impeller part. Washing water is heated by a heater in the heating space.

Owner:LG ELECTRONICS INC

Shank milling cutter having a wiper radius

InactiveUS7094005B2Quality improvementGo fastMilling cuttersShaping cuttersMilling cutterEngineering

A shank milling cutter includes a cutting portion which is intended to come into engagement with the workpiece, wherein the envelope surface of the cutting portion is substantially cylindrical. At least one major cutting edge is arranged at the peripheral surface of the cutting portion and at least one minor cutting edge (face cutting edge) is arranged at the end face of the cutting portion and with an end diameter D. The minor cutting edge, in projection onto a plane containing the milling cutter axis, has a convexly curved portion with a radius of curvature R>D / 2 and a center of curvature M located such that a distance from the center of curvature M to the axis is in a range from zero to a value smaller than D / 2.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Auxiliary device for blue anodic corrosion of low-pressure turbine disc

The invention discloses an auxiliary device for blue anodic corrosion of a low-pressure turbine disc. The auxiliary device comprises a fixture, the tail end of the fixture serves as a clamping end for fixedly clamping the turbine disc, the clamping end comprises a first clamping arm and a second clamping arm, the first clamping arm and the second clamping arm are provided with a first positioning bolt and a second positioning bolt which are used for transversely fixing the turbine disc respectively, and the tail end of the first clamping arm and the tail end of the second clamping arm are provided with a first fixing base and a second fixing base which are used for longitudinally fixing the turbine disc respectively; the auxiliary device further comprises bubble discharging pipes for discharging bubbles in a groove formed in the lower surface of the turbine disc, and the bubble suction ends of the bubble discharging pipes stretch into the bottom of the groove formed in the lower surface of the turbine disc. According to the auxiliary device, the turbine disc is effectively fixed through the positioning bolts arranged on the fixture and the fixing bases arranged at the bottom ends of the positioning bolts, and therefore the condition that when the low-pressure turbine disc is subjected to blue anodic corrosion, unexpected accidents occur due to the fact that the turbine disc swings back and forth due to stirring is avoided.

Owner:AECC AVIATION POWER CO LTD

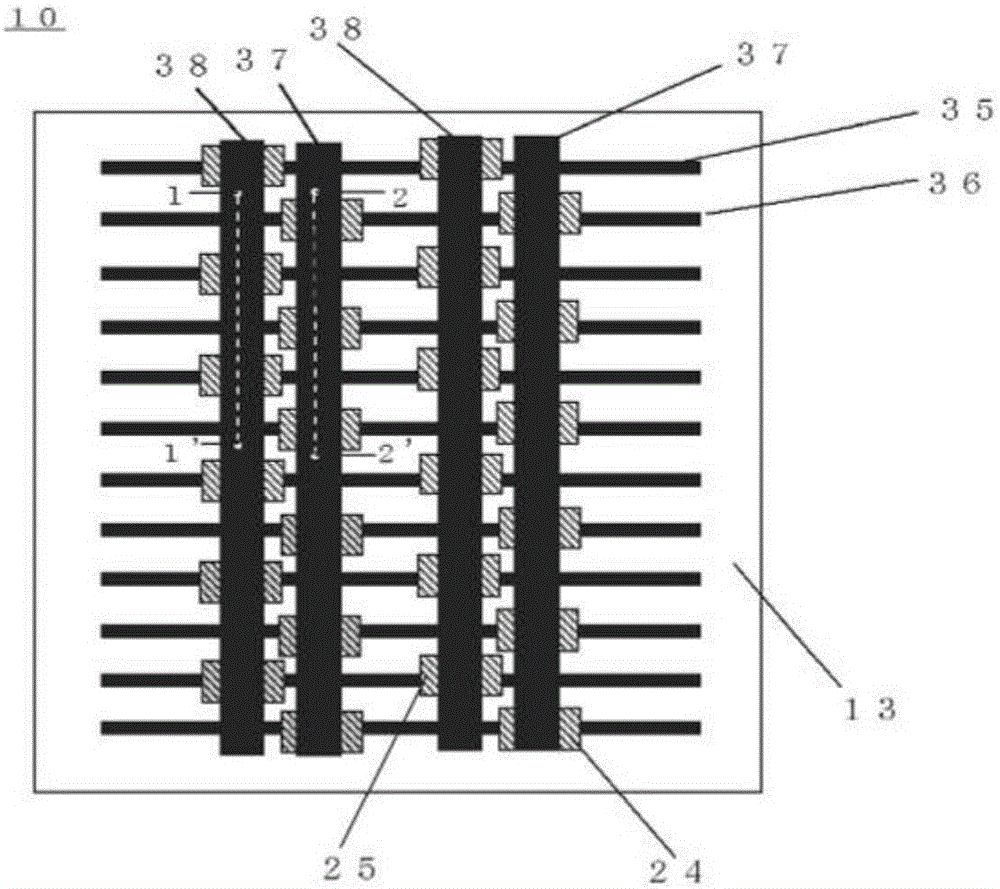

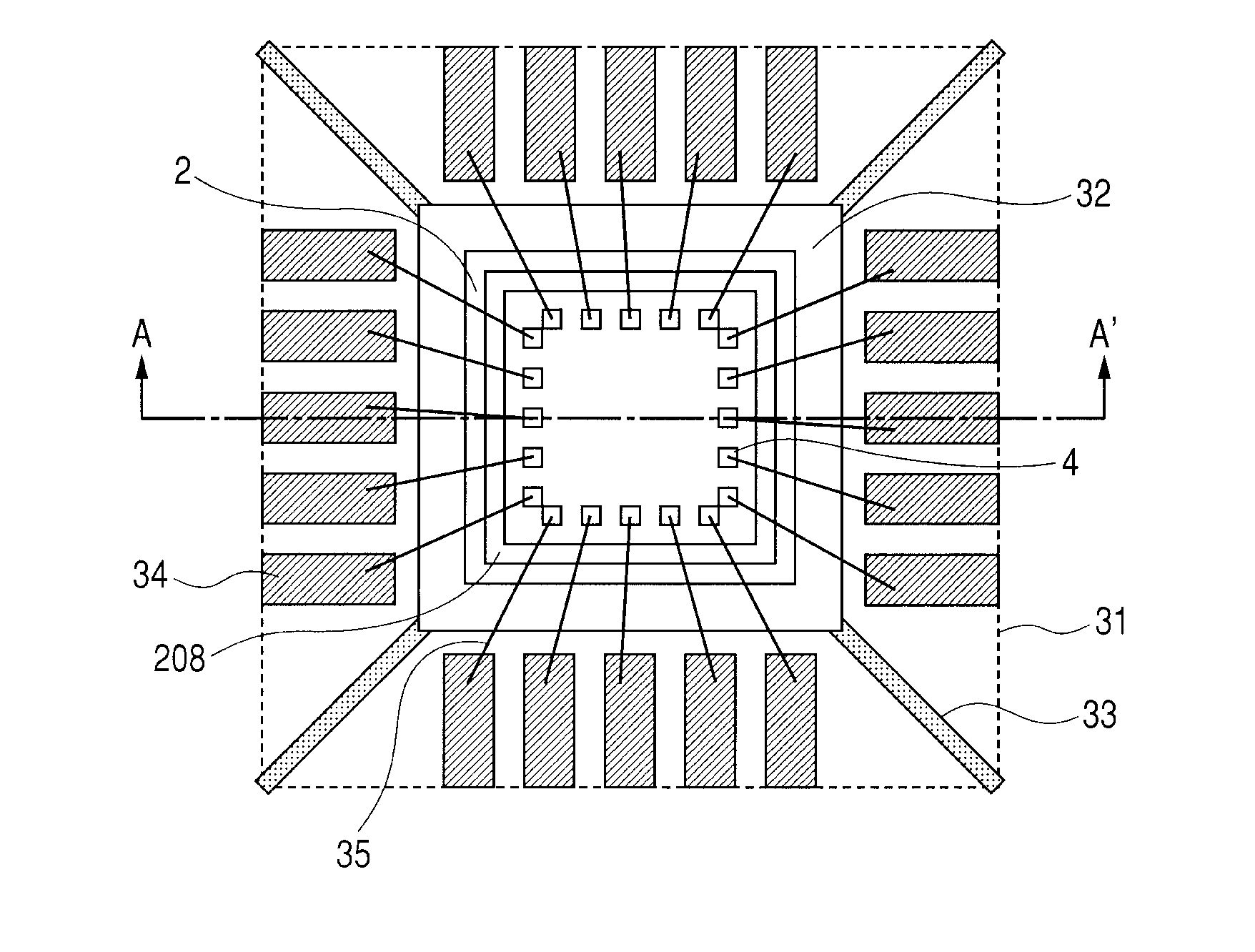

Solar cell and method for manufacturing solar cell

ActiveCN106463549AIncrease the number of rootsShorten the lengthSemiconductor/solid-state device manufacturingPhotovoltaic energy generationSolar cellDiffusion layer

The present invention is a solar cell wherein: a diffusion layer of a first conductivity type and a diffusion layer of a second conductivity type are formed on a surface of a substrate, said surface being on the reverse side of a light-receiving surface of the substrate; a first electrode part, a second electrode part, a first electrode line part, a second electrode line part, a first electrode bus bar part and a second electrode bus bar part are arranged; a first insulating film is formed so as to cover the lateral surface part and the upper part of the second electrode part in a region where the second electrode part and the first electrode bus bar part intersect with each other; a second insulating film is formed so as to cover the lateral surface part and the upper part of the first electrode part in a region where the first electrode part and the second electrode bus bar part intersect with each other; the second electrode part is continuously formed in the form of a line immediately below the first insulating film; and the first electrode part is continuously formed in the form of a line immediately below the second insulating film. Consequently, the present invention provides: a back contact solar cell which has low wiring resistance and high conversion efficiency; and a method for manufacturing a solar cell, which is capable of manufacturing such a back contact solar cell at low cost.

Owner:SHIN ETSU CHEM CO LTD

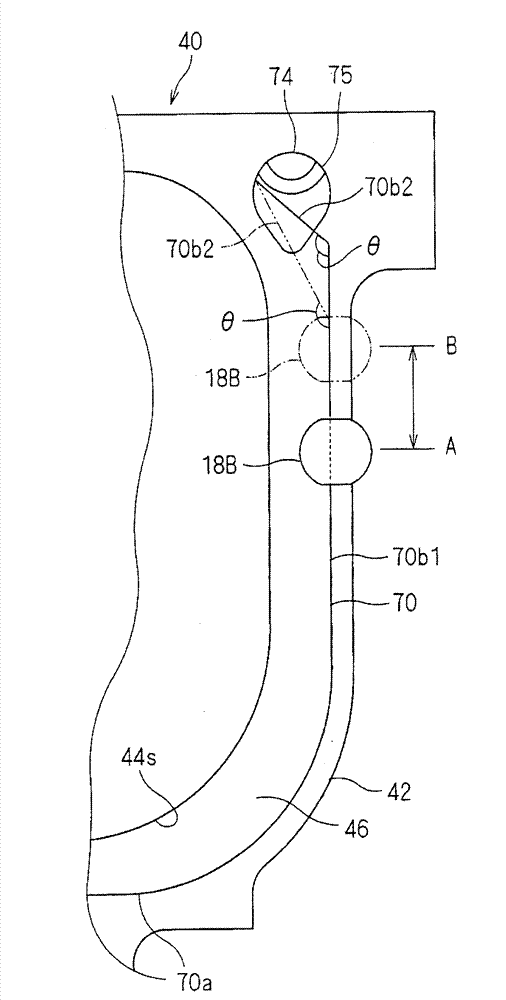

Airbag device

InactiveCN102811890AIncreased Design FreedomLow costPedestrian/occupant safety arrangementSteering columnsAirbagEngineering

An airbag device is provided with: a mounting plate (40) to which an airbag, an inflator, and a cover are affixed; an engagement body (70) consisting of an elastically deformable linear material and formed in a shape having a pair of side wire portions (70b) and an intermediate wire portion (70a) which are interconnected in a U-shape; and a holding member (60) for holding the engagement body (70) relative to the mounting plate (40). The respective ends of the pair of side wire portions are formed as tilted portions (70b2) for pressing. A pair of pressing auxiliary members (74) which can respectively make contact with the pair of tilted portions for pressing is provided to the mounting plate (40). The engagement body (70) is held relative to the mounting plate (40) while the pair of tilted portions (70b) for pressing are respectively made to contact with the pair of pressing auxiliary members (74) to press the intermediate wire portion (70a) in the direction in which the intermediate wire portion (70a) is engaged with a first mounting member (18A).

Owner:ASHIMORI INDS

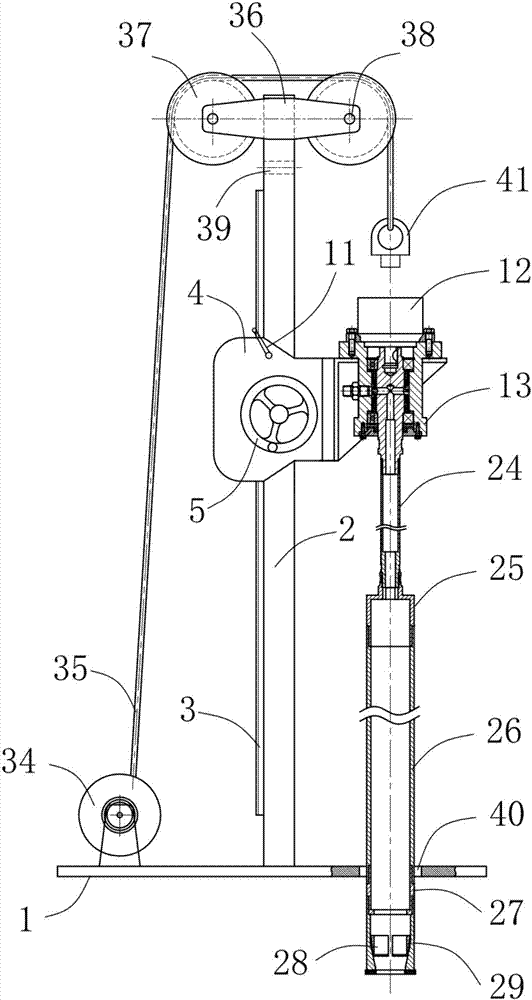

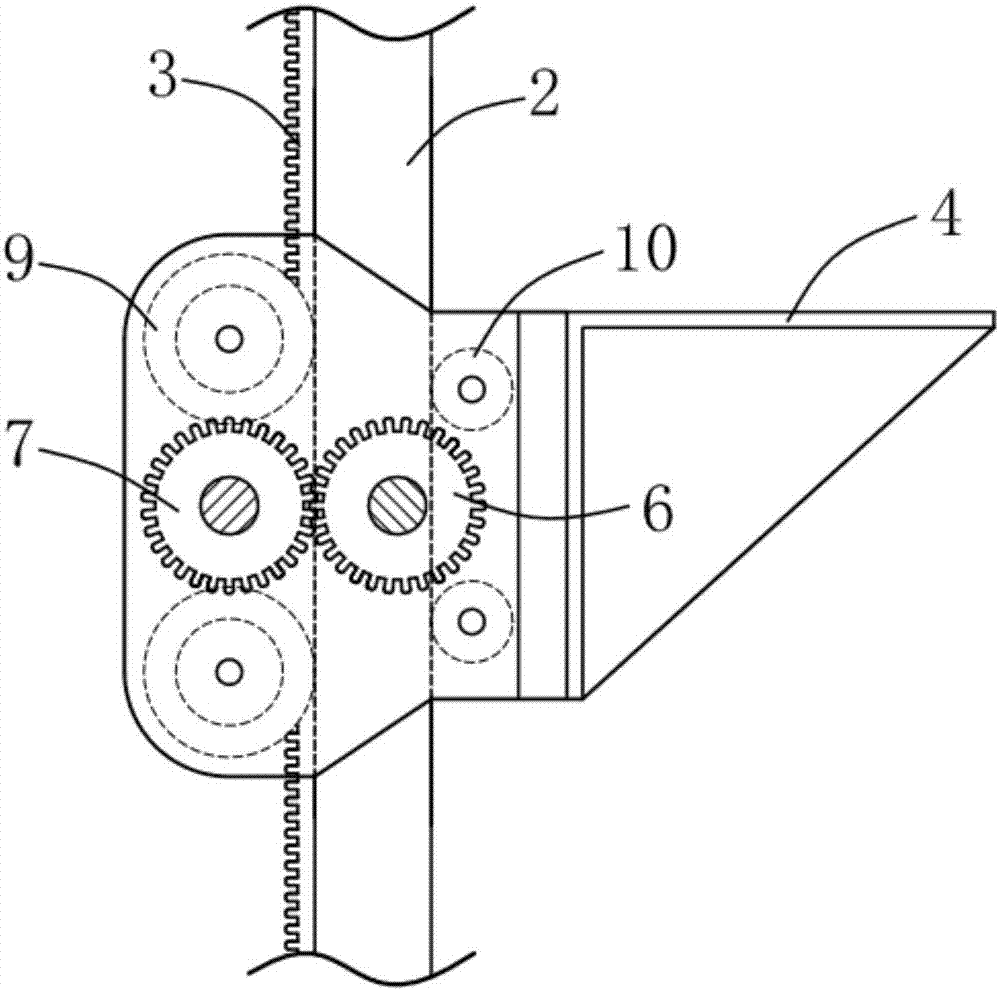

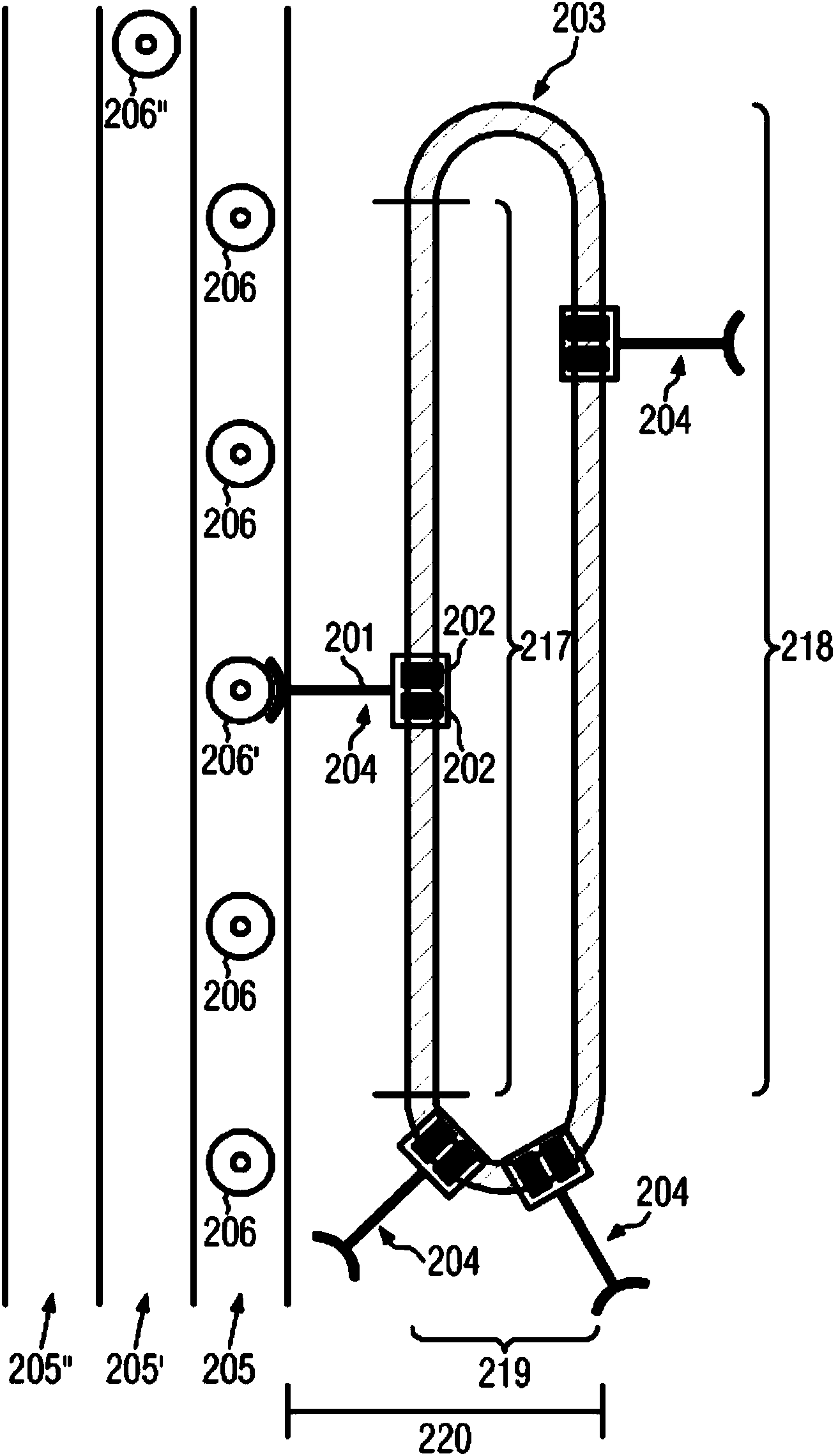

Portable hydraulic drive underwater drilling machine

PendingCN107386976AReduce operationImprove drill efficiencyDrilling rodsConstructionsEngineeringDrill pipe

The invention discloses a portable hydraulic drive underwater drilling machine which comprises a base, a mast, a main lifting mechanism, an auxiliary drill pipe lifting mechanism and a drilling machine body, wherein the mast is vertically mounted on the base, the main lifting mechanism and the auxiliary drill pipe lifting mechanism are mounted on the mast, and the drilling machine body is mounted on the main lifting mechanism and comprises a hydraulic motor, a power head and a drilling tool. The power head is mounted on a bearing support, drives the drilling tool to rotate by the hydraulic motor and drives the drilling tool to vertically move by the main lifting mechanism. According to the portable hydraulic drive underwater drilling machine, underwater staff and machinery are stabilized by the aid of an underwater operation platform comprising the base, the main lifting mechanism and the auxiliary drill pipe lifting mechanism, cores can be easily sampled in the presence of flashy flow, the drilling machine can automatically advance downwards along the lifting mechanism under the action of dead weight, operation of the underwater staff is decreased, advance speed can be freely adjusted by the main lifting mechanism, and drilling efficiency is improved.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI +1

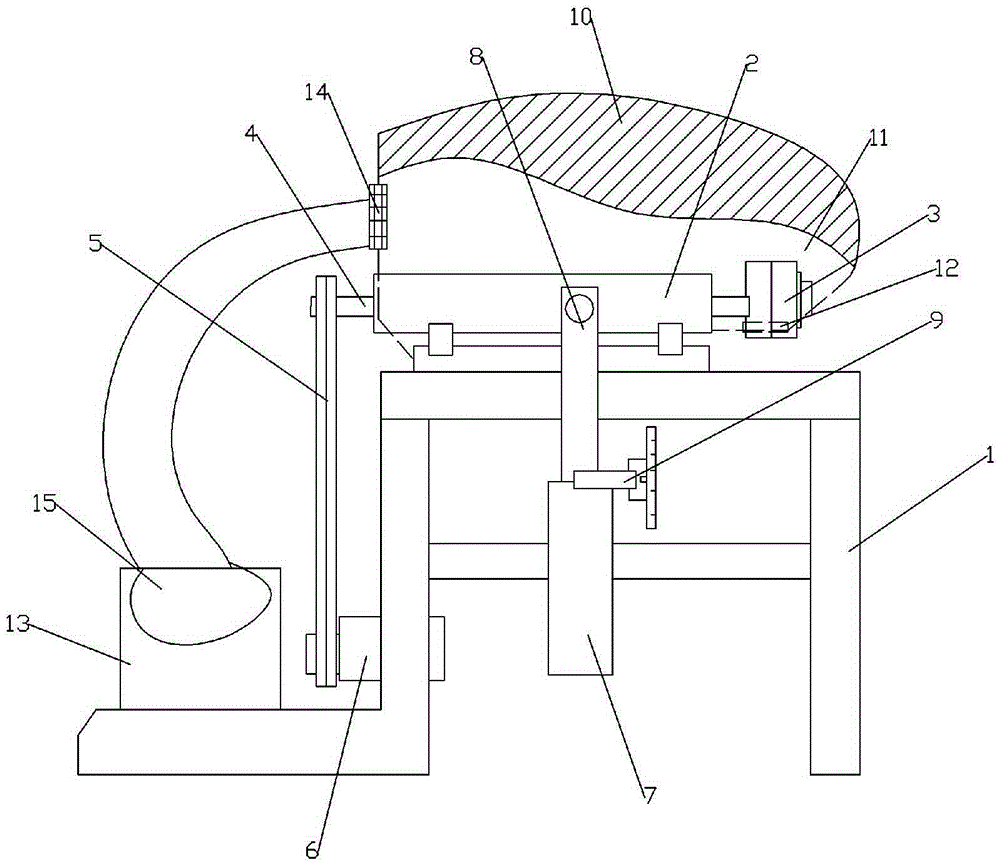

Polishing device for casting parts

InactiveCN105415129AEffective protectionEffective personal safetyEdge grinding machinesGrinding/polishing safety devicesDrive motorEngineering

The invention discloses a polishing device for casting parts. The polishing device for casting parts comprises a rack and a grinding wheel frame arranged on the rack. A grinding wheel for polishing workpieces is arranged on the grinding wheel frame and is hinged to the grinding wheel frame through a rotating shaft. The rotating shaft is connected with a driving motor through a belt. The driving motor is installed on the rack. The rack is provided with supporting columns located below the two sides of the grinding wheel frame. Adjusting rods are arranged on the two sides of the grinding wheel frame and sleeved with the supporting columns. Adjusting bolts are arranged on the joints of the adjusting rods and the supporting columns. An arc-shaped hollow protective box is installed on the adjusting rods. A shielding part is arranged on one side of the protective box and is provided with a polishing hole which is inclined downwards, and the grinding wheel penetrates the polishing hole. By means of the polishing device for casting parts, personal safety of operators can be effectively protected, operating difficulty of the polishing device is reduced, and finished product quality is improved.

Owner:CHONGQING YU DA LIU XING POWER PLANT

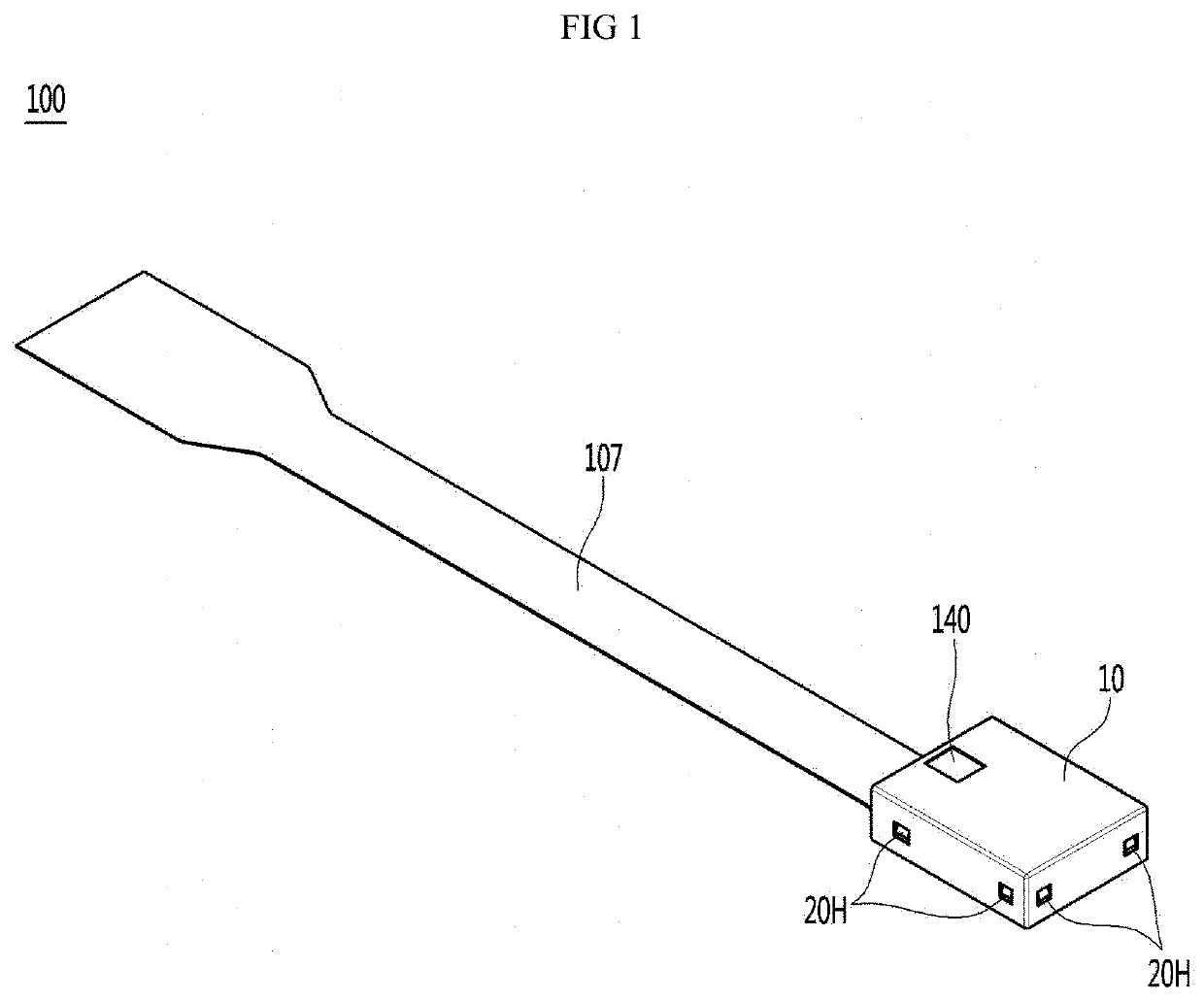

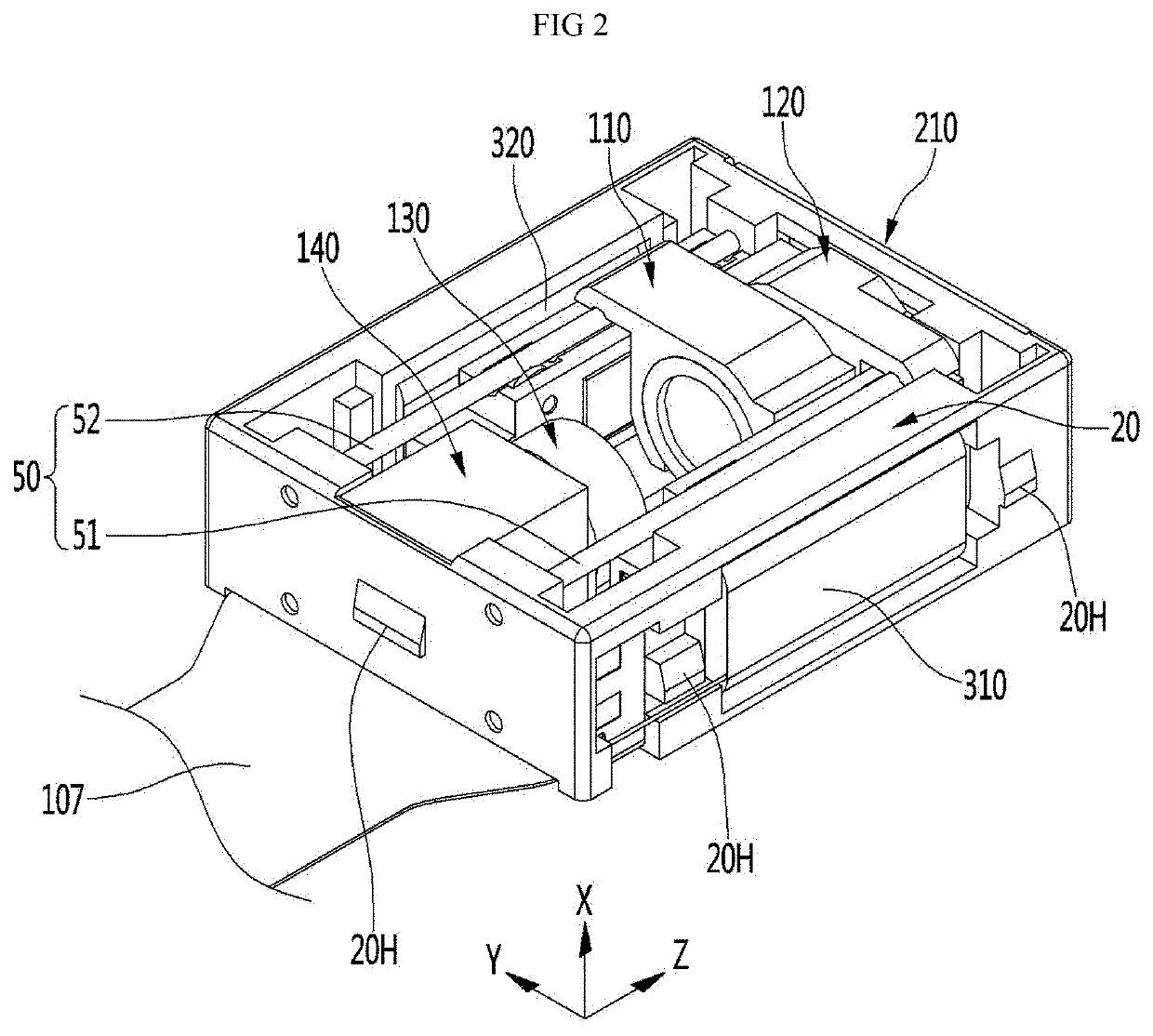

Antenna having a choke member

InactiveCN101816098AReduced contact areaAntenna supports/mountingsIndividually energised antenna arraysElectrical conductorEngineering

An antenna for enhancing characteristic of a beam with reducing PIMD is disclosed. The antenna includes a reflection plate, at least one first choke member disposed on one side of the reflection plate, an insulated member disposed between the reflection plate and the first choke member, thereby separating the first choke member from the reflection plate, wherein the insulated member is an insulator, and a connection member configured to connect electrically the first choke member to the reflection plate through the insulated member, wherein the connection member is a conductor.

Owner:ACE TECH

Semiconductor device and manufacturing method of the same

ActiveUS20130062747A1Easy to crackReduce contact regionSemiconductor/solid-state device detailsSolid-state devicesWaferingDevice material

In a manufacturing method of a semiconductor device having a multilevel interconnect layer including a low-k layer, a two-step cutting technique is used for dicing. After formation of a groove in a semiconductor wafer with a tapered blade, the groove is divided with a straight blade thinner than the groove width. The multilevel interconnect layer portion is cut while being covered with a tapered face and then the wafer is separated with a thin blade which is not brought into contact with the multilevel interconnect layer portion. The wafer can thus be diced without damaging a relatively fragile low-k layer.

Owner:RENESAS ELECTRONICS CORP

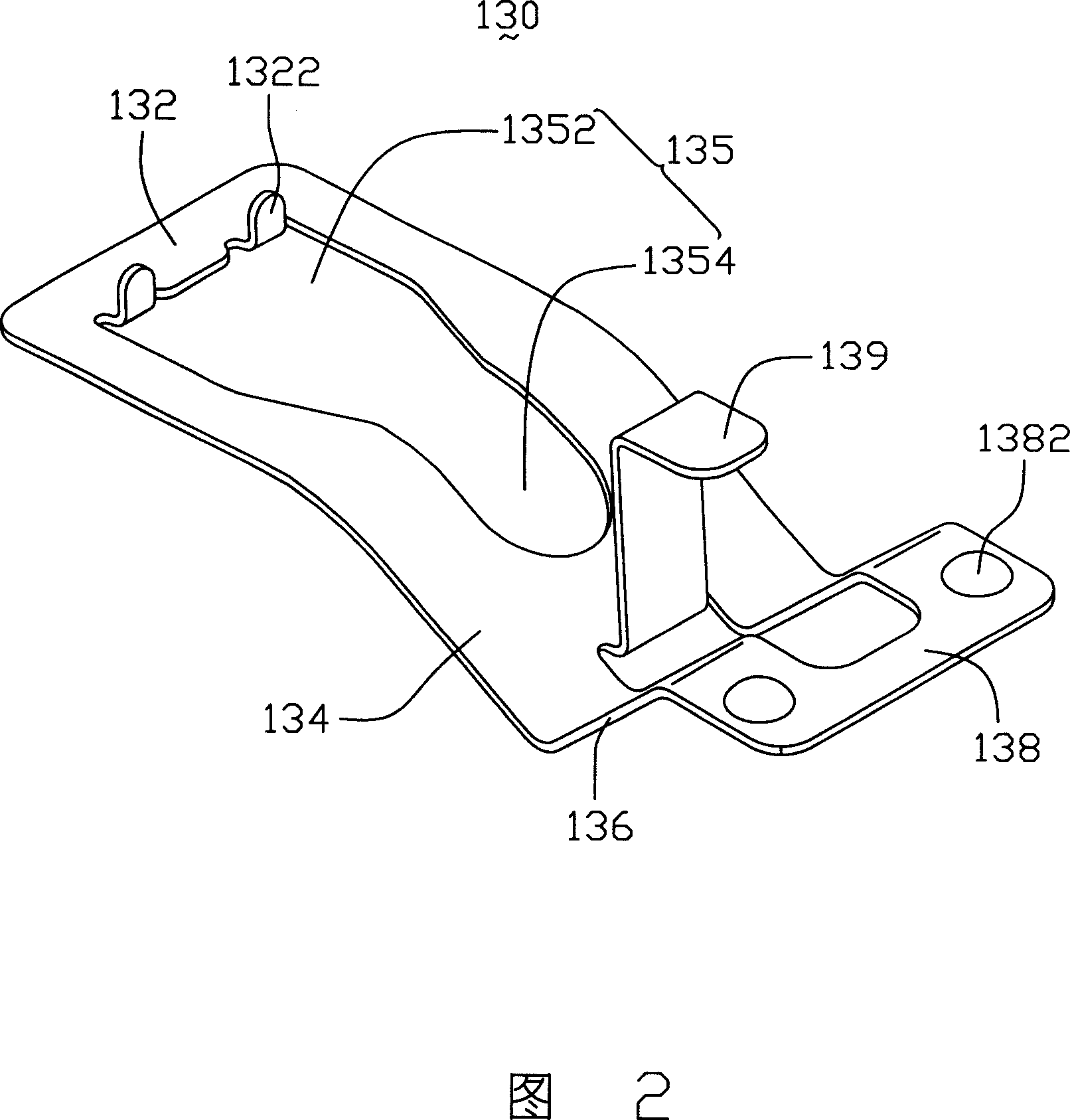

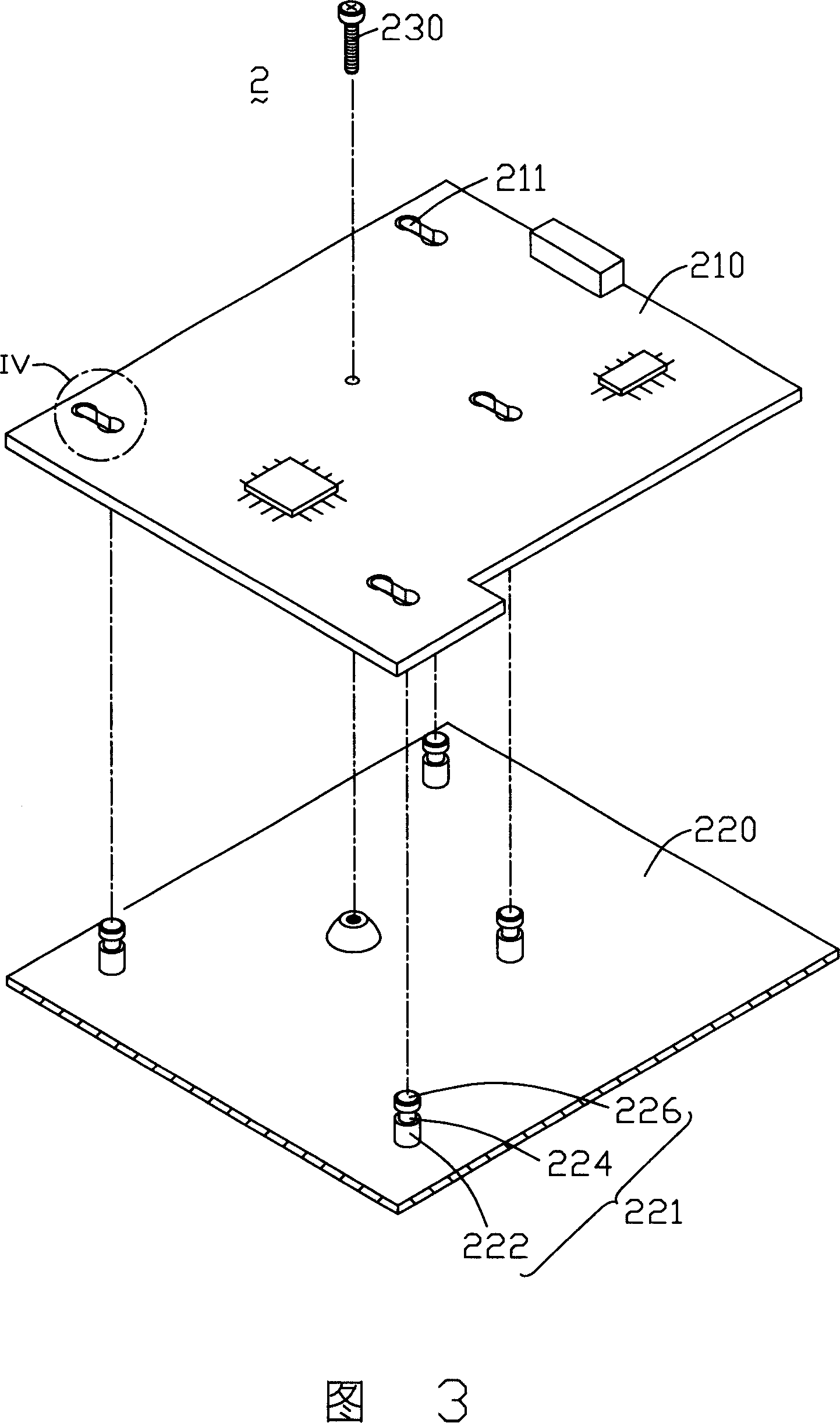

Electronic device with grounding structure

InactiveCN1983110ASimple structureReduce usageDigital processing power distributionElectricityGround plane

Owner:INNOCOM TECH SHENZHEN +1

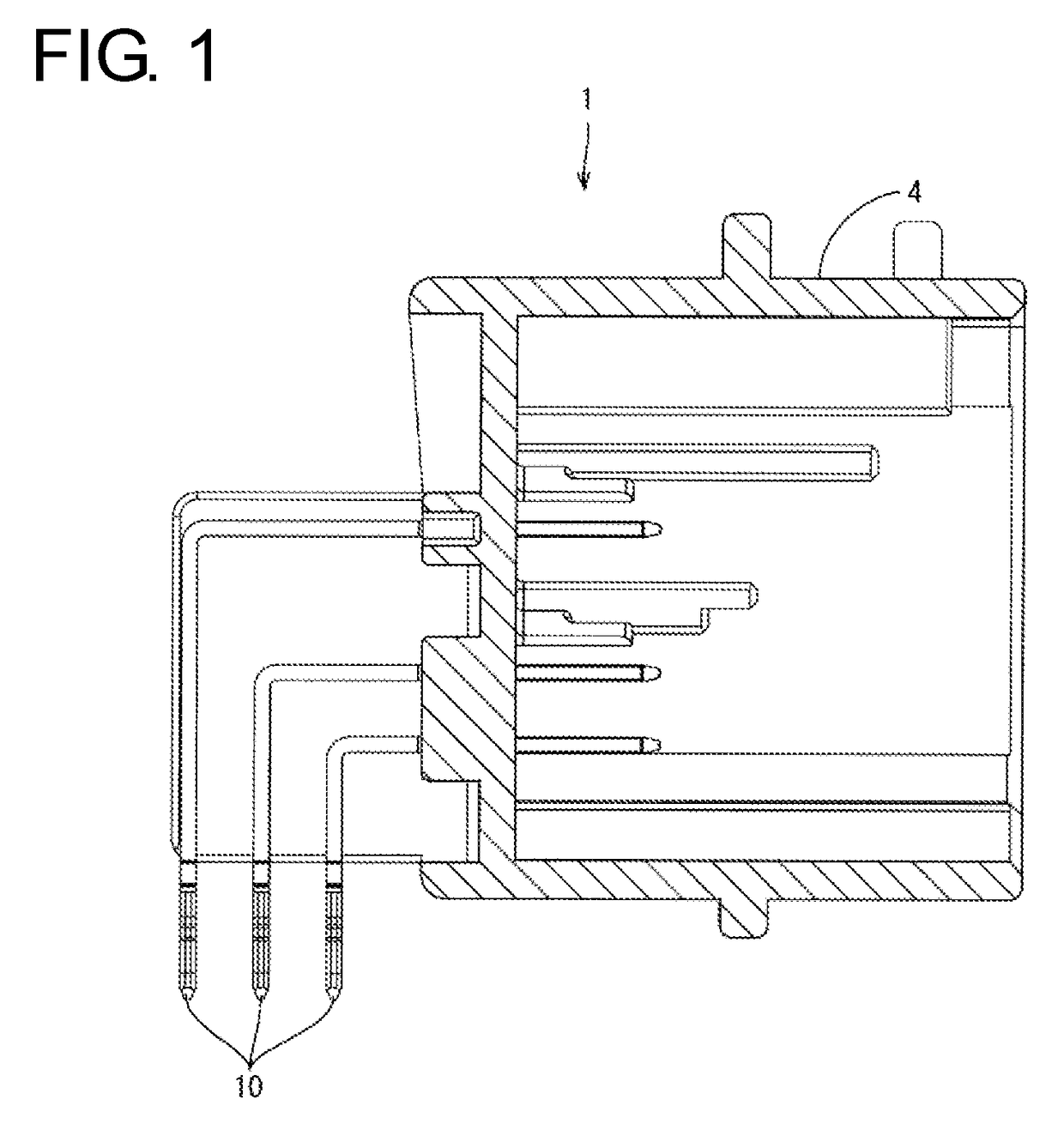

Lens assembly

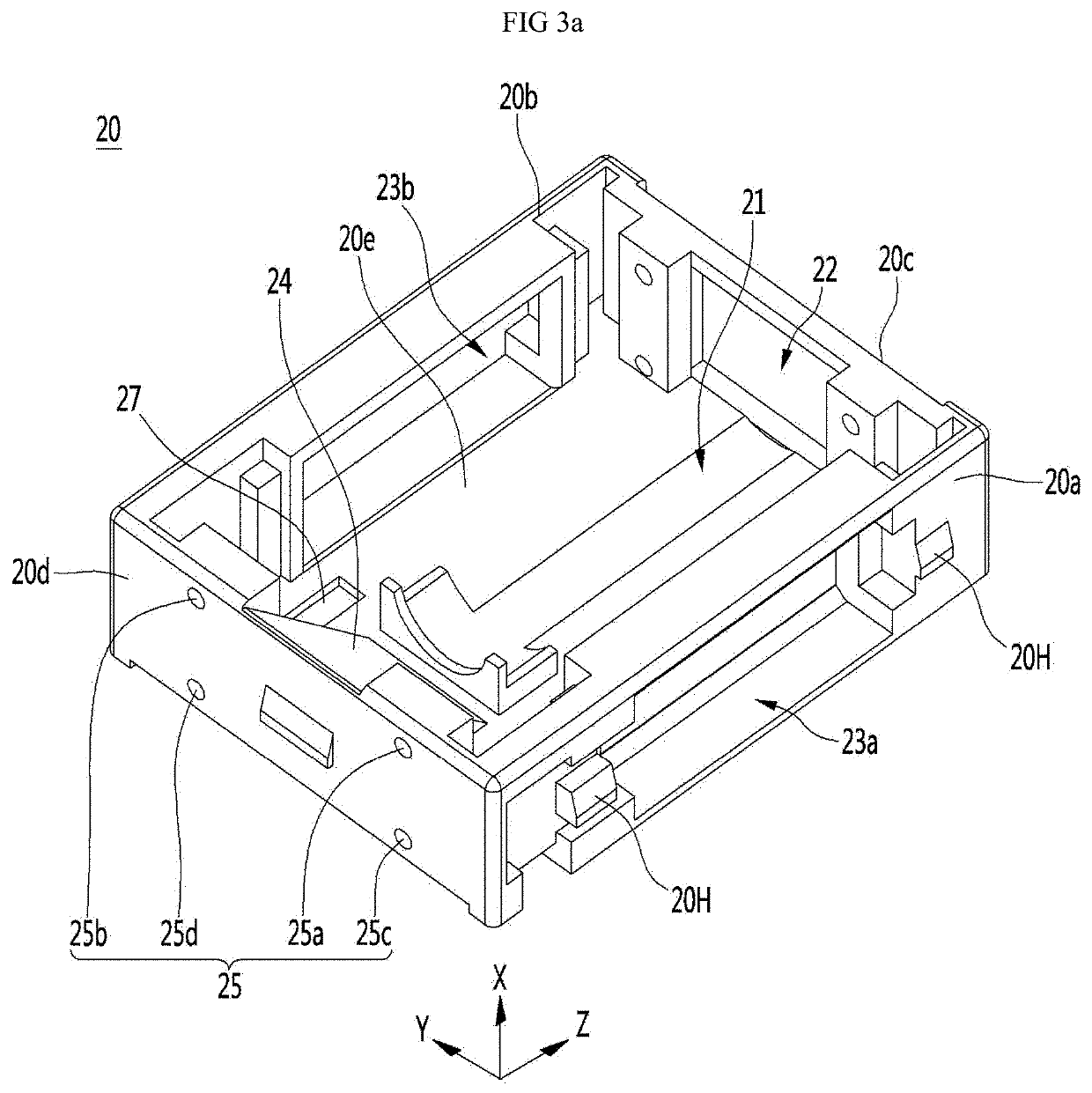

PendingUS20210018719A1Solve the real problemEasy to driveProjector focusing arrangementCamera focusing arrangementRotational axisEngineering

Embodiments relate to a lens assembly, a lens driving apparatus, and a camera module comprising same. A lens assembly according to an embodiment may comprise: a first pin; a first housing which moves along the first pin; a first lens group arranged in the first housing; and a first wheel which is arranged in the first housing and moves along the first pin. The first wheel may include a first rotation shaft coupled to the first housing, and a first rotation part which rotates about the first rotation shaft. The first rotation part may include a groove corresponding to the first pin, wherein the maximum depth of the groove may be less than one-half the maximum thickness of the first pin in a direction perpendicular to the first rotation shaft.

Owner:LG INNOTEK CO LTD

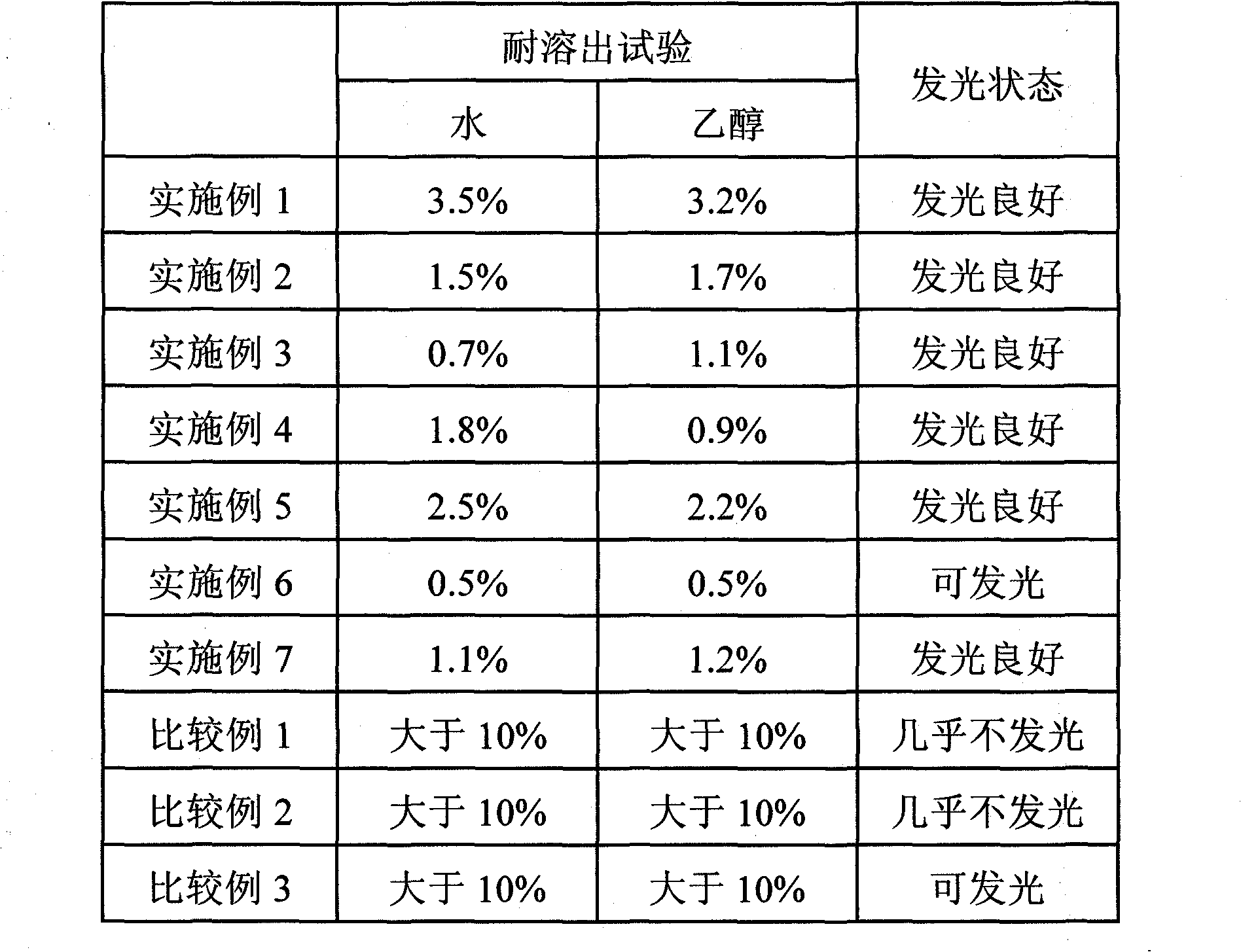

Fluorescent dye-containing particles and manufacturing method thereof

InactiveCN102257098AEvenly dispersedReduce the numberCosmetic preparationsMake-upFluorescenceWater soluble

The fluorescent dye-containing particles contain a porous matrix configured primarily with a metal oxide, an organic fluorescent dye contained in the porous matrix, and a water-soluble polymer contained in the porous matrix. Such dye-containing particles can be manufactured by executing a step in which a dye-containing sol solution that includes a sol solution obtained by hydrolysis of a metal compound, an organic fluorescent dye and a water-soluble polymer is prepared, and a step in which particles are formed from the dye-containing sol solution by means of a spray-dry method.

Owner:NIPPON SHEET GLASS CO LTD

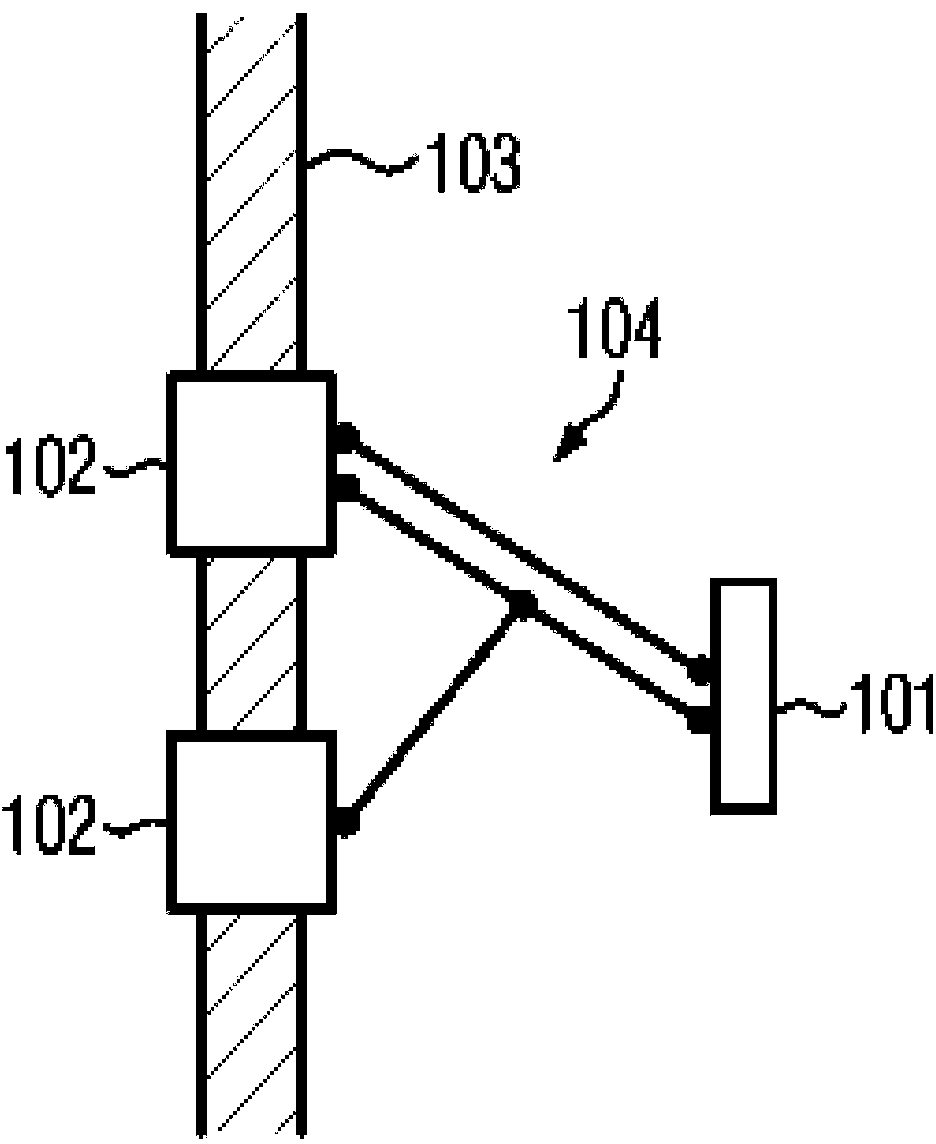

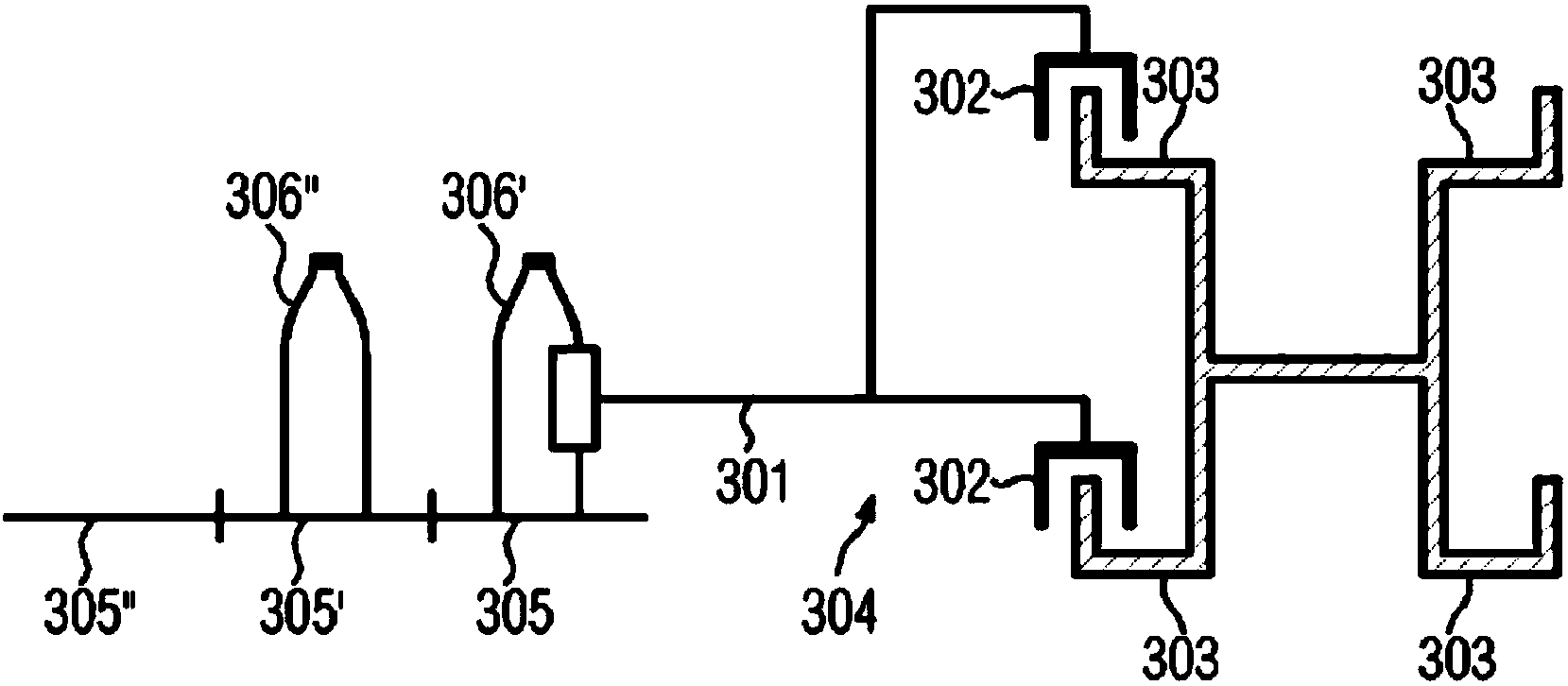

Device and method for discharging products, particularly product containers such as bottles

ActiveCN104066663AIncrease flexibilityFlexible and accurate controlNon-mechanical conveyorsConveyor partsBottleCarriage

The invention relates to a device and a corresponding method for discharging products, particularly product containers such as bottles from a transport path by means of one or more discharge segments (104), wherein the or each discharge segment (104) comprises a carriage (102) and a discharger (101), and said discharger (101) can effect the discharge of the product by a deflection, wherein the or each discharge segment (104) comprises a second carriage, wherein each of the two carriages is mounted on a guide and the discharger (101) and the carriages (102) are mechanically connected to one another such that the relative distance of the carriages from one another determines the deflection of the discharger (101).

Owner:KRONES AG

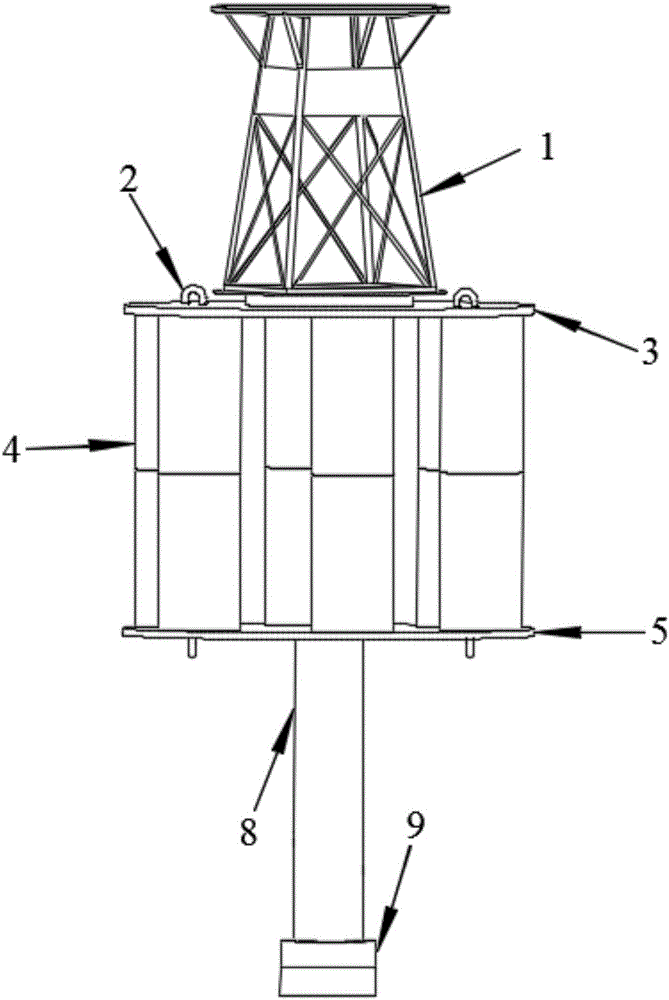

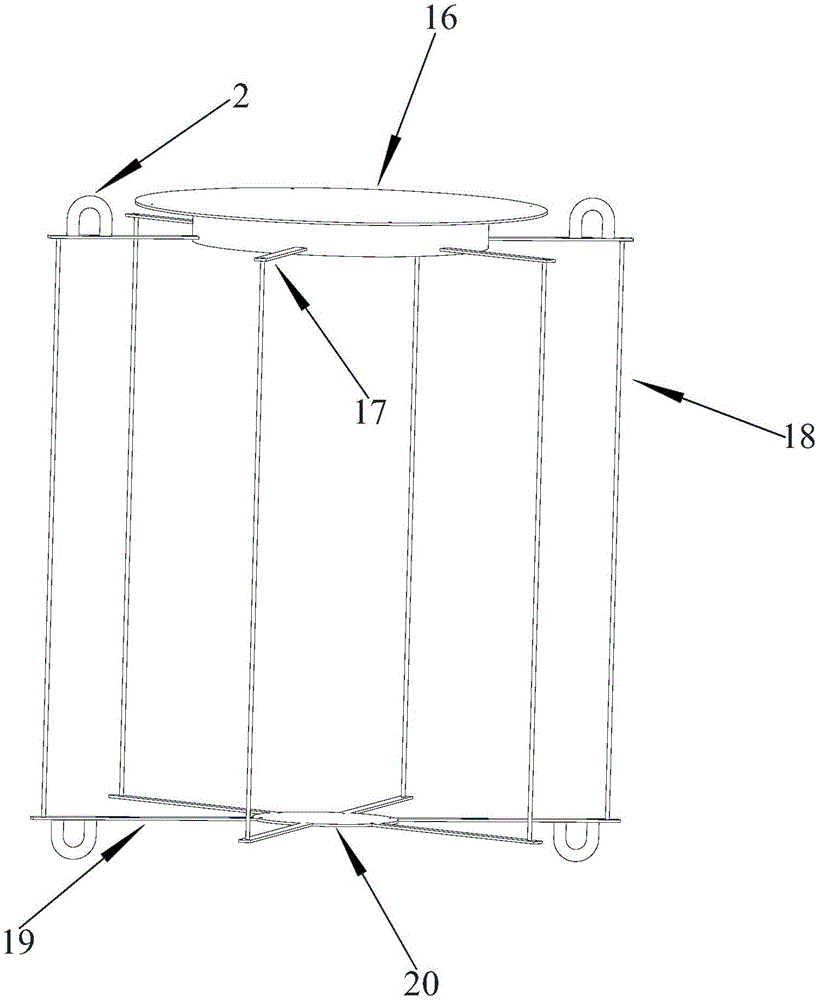

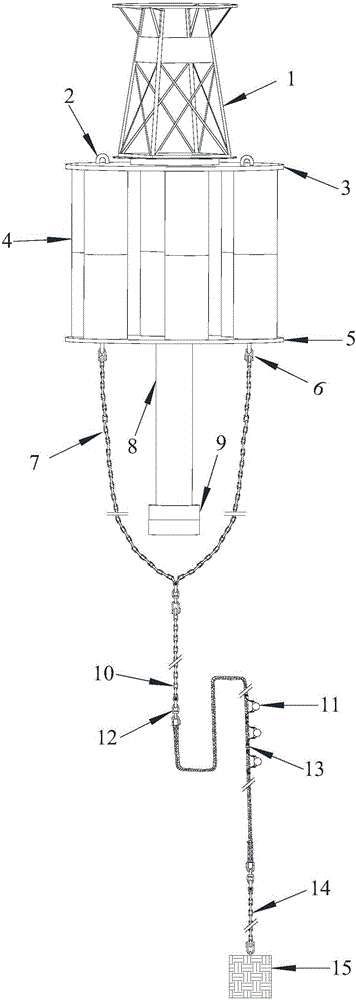

Wave piercing type buoy structure and buoy system

The invention discloses a wave piercing type buoy structure and a buoy system. The wave piercing type buoy structure comprises an upper end cover plate, middle pontoons, a lower end cover plate, a tail cylinder and a balance weight, wherein the multiple middle pontoons are arranged between the upper end cover plate and the lower end cover plate, gaps are formed between adjacent middle pontoons, and the tail cylinder and the balance weight are arranged at the bottom of the lower end cover plate sequentially; multiple lifting lugs are arranged at the top of the upper end cover plate and the bottom of the lower end cover plate respectively. The wave piercing type buoy structure and the buoy system can allow wind, waves and flow to pass through, the action areas of the wind, the waves and the flow contacted with a buoy are effectively reduced, the acting force of the wind, the waves and the flow to the buoy is reduced, the stability of the buoy is effectively improved, and the working reliability of the buoy is improved by means of the multiple middle pontoons.

Owner:DALIAN MARITIME UNIVERSITY

Hydraulic driving underwater drilling machine drill bit structure

The invention discloses a hydraulic driving underwater drilling machine drill bit structure. The hydraulic driving underwater drilling machine drill bit structure comprises a core barrel, a straight joint, a clamp spring and a drill bit which are coaxially arranged. The drill bit is of an integrated structure which is formed by a drill bit steel body and a diamond carcass through hot pressing, the clamp spring is of an inverted circular cone elastic tubular structure which is consistent with the conicity of the inverted circular cone face, an axial opening is formed in the side wall and installed in the drill bit steel body, and an inward annular boss is arranged at the front end of the straight joint. According to the hydraulic driving underwater drilling machine drill bit structure, the structural design of the drill bit and the clamp spring is ingenious, using of the tools of the clamp spring, a clamp spring seat, a short circuit, a reamer and the like in a traditional core-taking process is simplified, in the drilling process, abrasion of the clamp spring and the clamp spring seat can be effectively slowed down, the service life is prolonged, the surface of the rock core is prevented from being damaged, in the core-taking process, the clamp spring seat extrudes the whole clamp spring inwards simultaneously, so that the clamp spring tightly clamps the rock core, the clamp sprig is effectively prevented from moving upwards along with the clamp spring seat, and therefore rock core drilling and taking can be completed with once operation.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI +2

Blades

ActiveUS20180272447A1Reduce frictional resistanceReduce contact regionMetal sawing accessoriesMetal sawing toolsKnife bladesEngineering

A cutting or grinding tool includes a blade. The blade includes a disc-shaped base metal, cutting or grinding tips (edges) provided on a peak (outer circumferential edge) of the base metal, and a protruding coating on a side face of the base metal along the entire outer circumference of the base metal.

Owner:KANEFUSA HAMONO KOUGIYOU KK

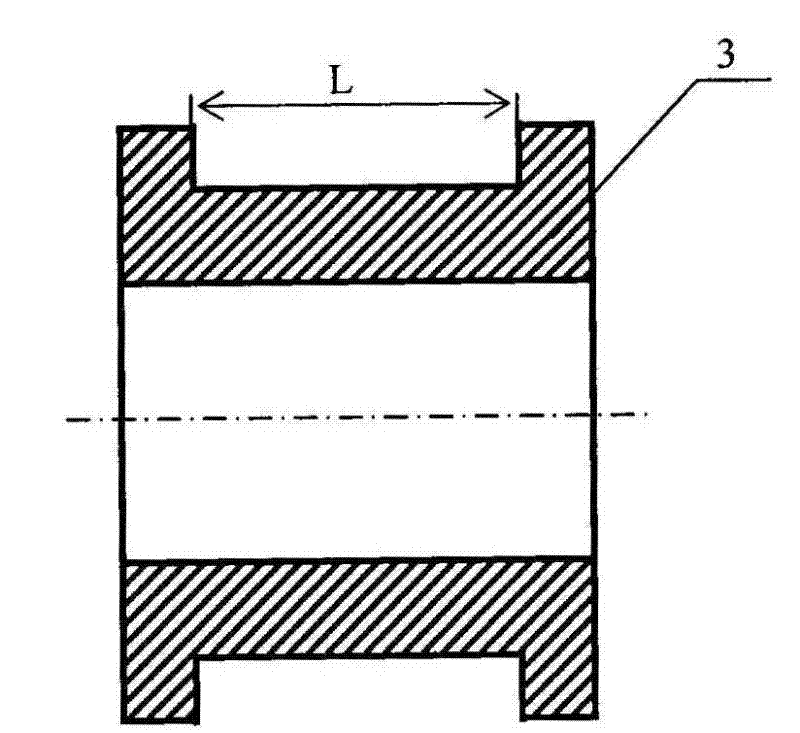

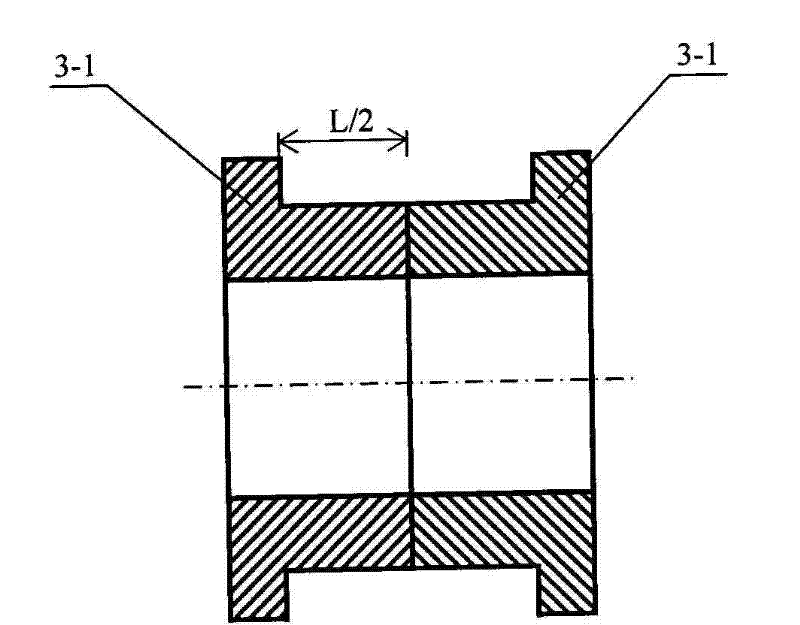

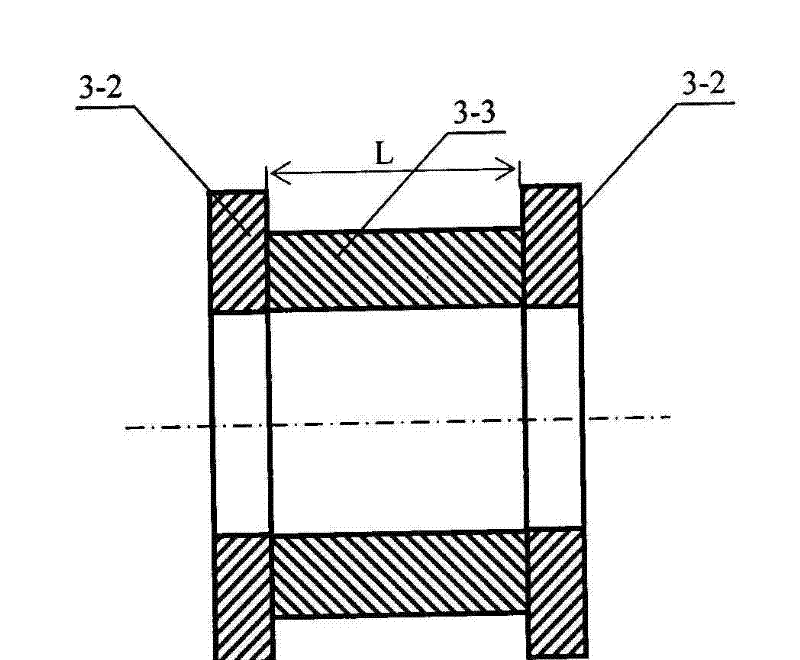

Axial laminated contact/noncontact combined sealing tape type conveyer plastic carrier roller

ActiveCN102363466AAvoid secondary processingGuaranteed concentricityRollersInterference fitClassical mechanics

The invention discloses an axial laminated contact / noncontact combined sealing tape type conveyer plastic carrier roller. The conveyer plastic carrier roller comprises a carrier roller shaft (8), a polyvinyl chloride (PVC) roller body (1) supported and sleeved on a bearing seat (2) through the bearing seat (2) and a bearing (7) arranged at two ends of the shaft, and an axial laminated contact / noncontact combined seal sealed in an annular cavity between the bearing seat (2) and the carrier roller shaft (8) through an end cover (4). The conveyer plastic carrier roller is characterized in that: the axial laminated contact / noncontact combined seal consists of a lamination seat (3) with a hollow columnar structure and an axial combined lamination assembly (6) arranged in a sealed groove machined in the inner wall or the outer wall of the lamination seat; the lamination seat (3) is combined with the carrier roller shaft (8) or the bearing seat (2) in an interference fit mode, and the radialclearance between the lamination seat (3) and the bearing seat (2) or the carrier roller shaft (8) is 0.1 to 1 millimeter; and the clearance between the width of the sealed groove of the lamination seat (3) and the total length of the axial combined lamination assembly (6) is 0.1 to 1 millimeter.

Owner:焦作精创科技有限责任公司

Press-fit terminal and board connector

ActiveUS20180083377A1Improve performanceEnsure connection reliabilityCoupling device connectionsContact pressure

A press-fit terminal held in a through hole provided in a board by being inserted into the through hole along an inserting direction includes a first contacting portion and a second contacting portion configured to resiliently contact an inner peripheral surface of the through hole. A value obtained by dividing a radius of curvature of the second contacting portion by a radius of curvature of the first contacting portion is 0.75 or smaller in a cross-sectional view perpendicular to the inserting direction. By providing the first and second contacting portions adjacent between adjacent press-fit terminals, a contact part where a contact pressure applied to the inner peripheral surface is small and a contact part where a contact pressure applied to the inner peripheral surface is large are adjacent between adjacent through holes. Thus, it can be suppressed that damaged parts of the board approach between the adjacent through holes.

Owner:AUTONETWORKS TECH LTD +2

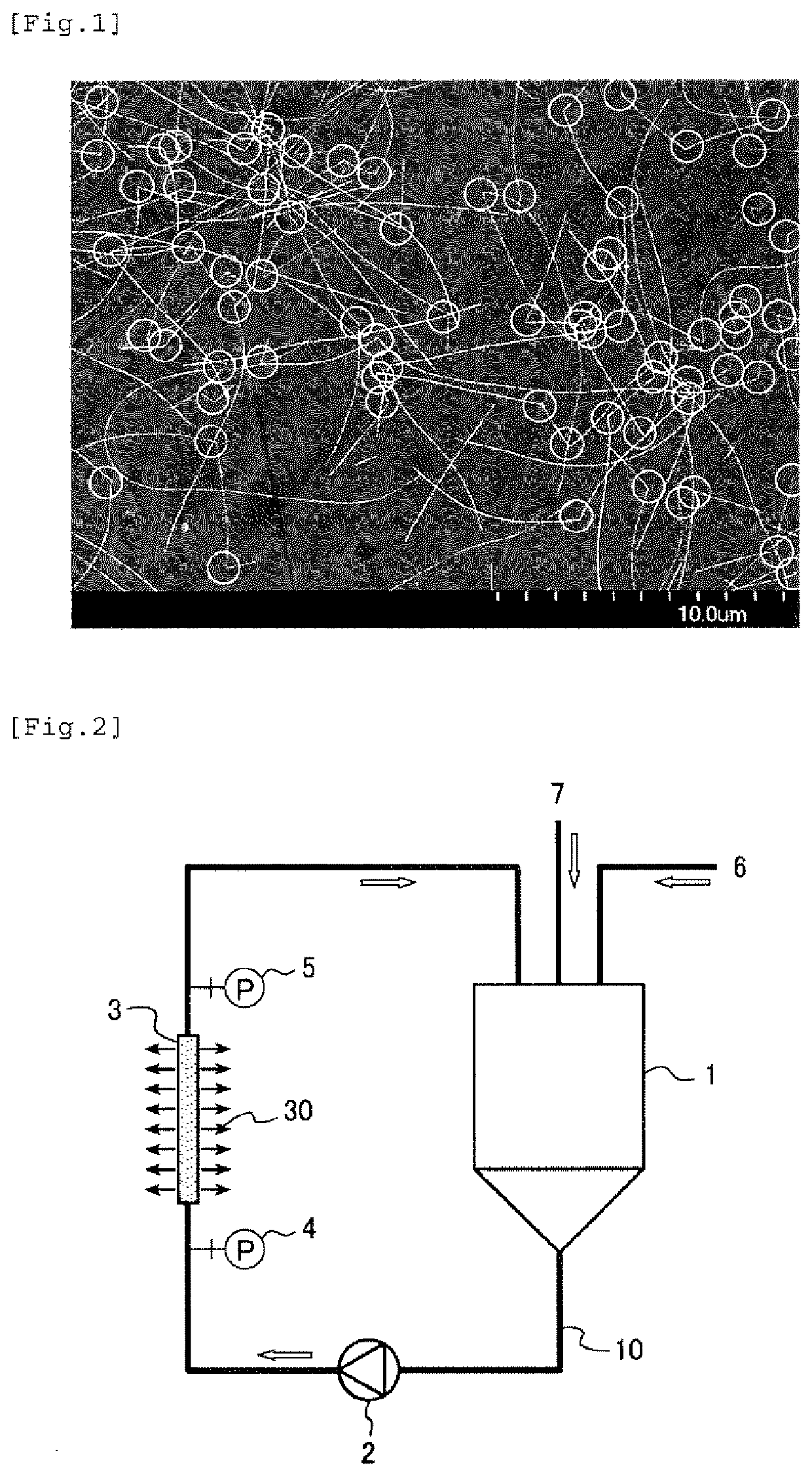

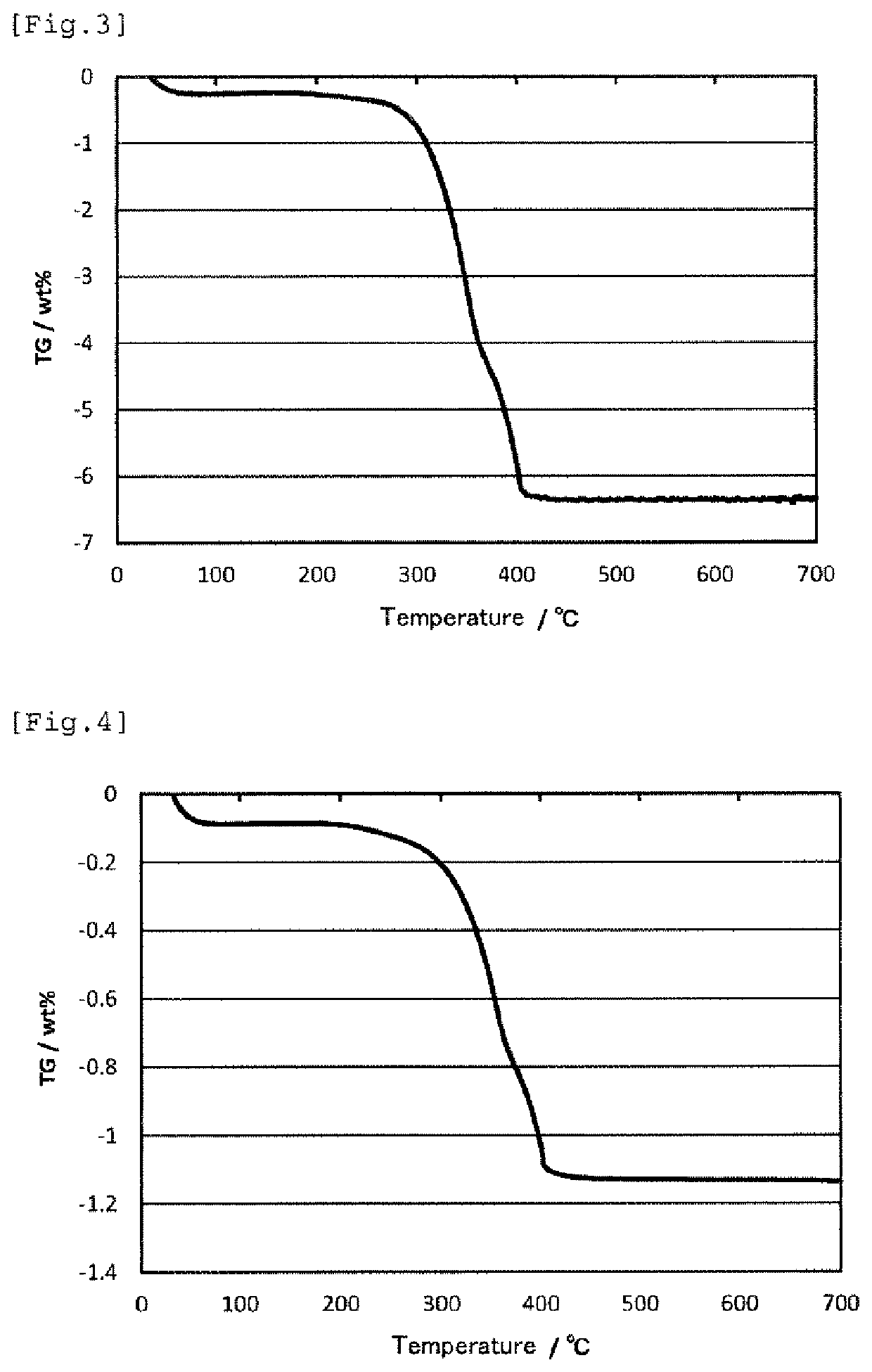

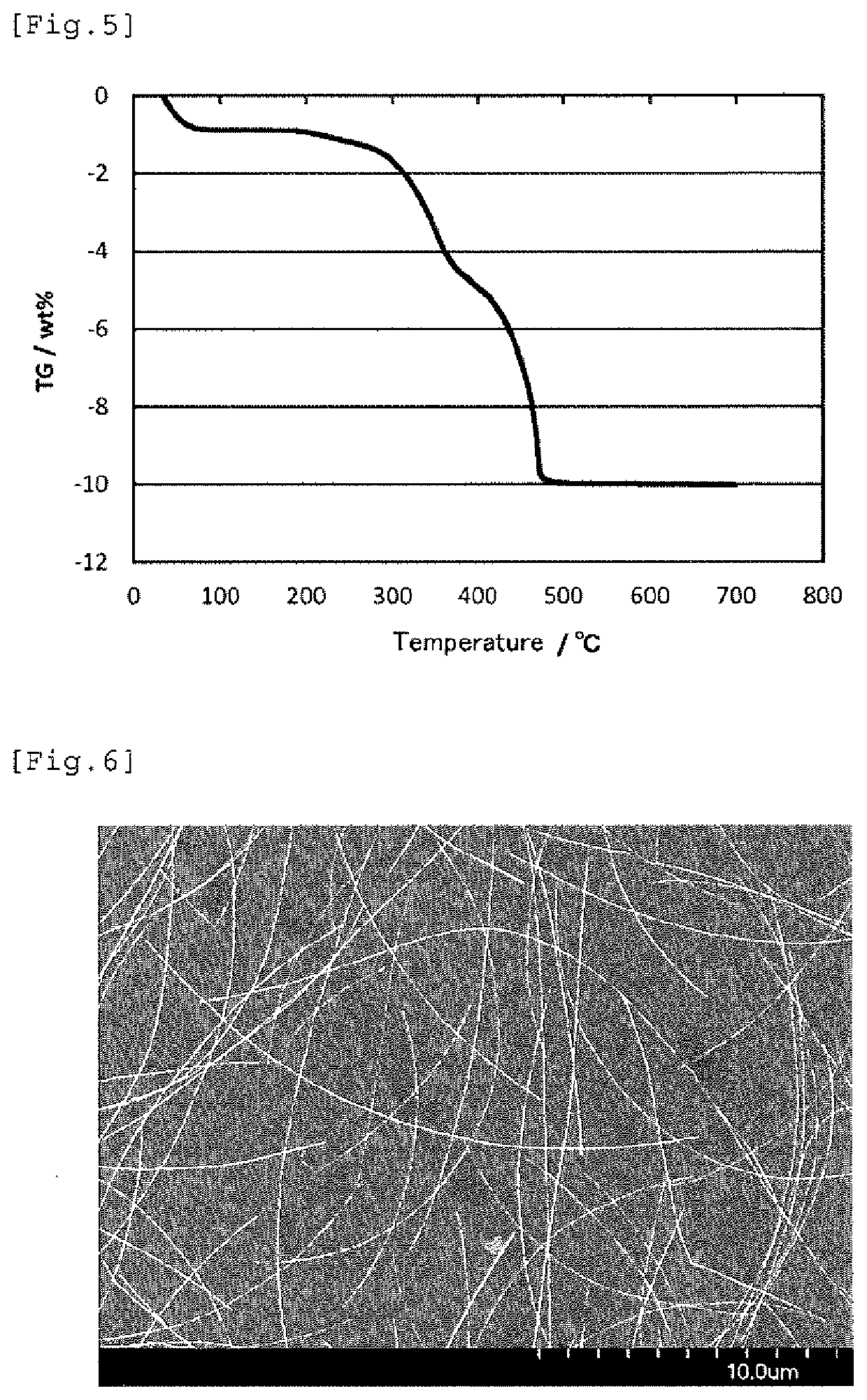

Silver nanowire ink and method for producing same

InactiveUS20200362187A1Good lookingSound thinMaterial nanotechnologyConductive layers on insulating-supportsTransparent conducting filmMaterials science

A silver nanowire ink intermediate product having dispersed therein silver nanowires has an organic protective agent attached to a surface thereof, the protective agent being 1.5 to 8.0% by mass based on the total amount of the organic protective agent and silver. The intermediate product is subjected to a dispersion treatment by a thin film revolution method to control the silver nanowires in the ink to have a number of folds per unit length of the wires of 20.0 per mm or less, obtained by measuring over a total wire length of 1.0 mm or more. The ink has an existing amount of particles having a particle diameter exceeding 7 μm of 50 per mL or less per unit volume of the ink, measured with a liquid borne light extinction particle counter. The ink has a suppressed amount of coarse foreign particles to enhance conductivity of a transparent conductive film.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com