Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

341results about How to "Avoid secondary processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

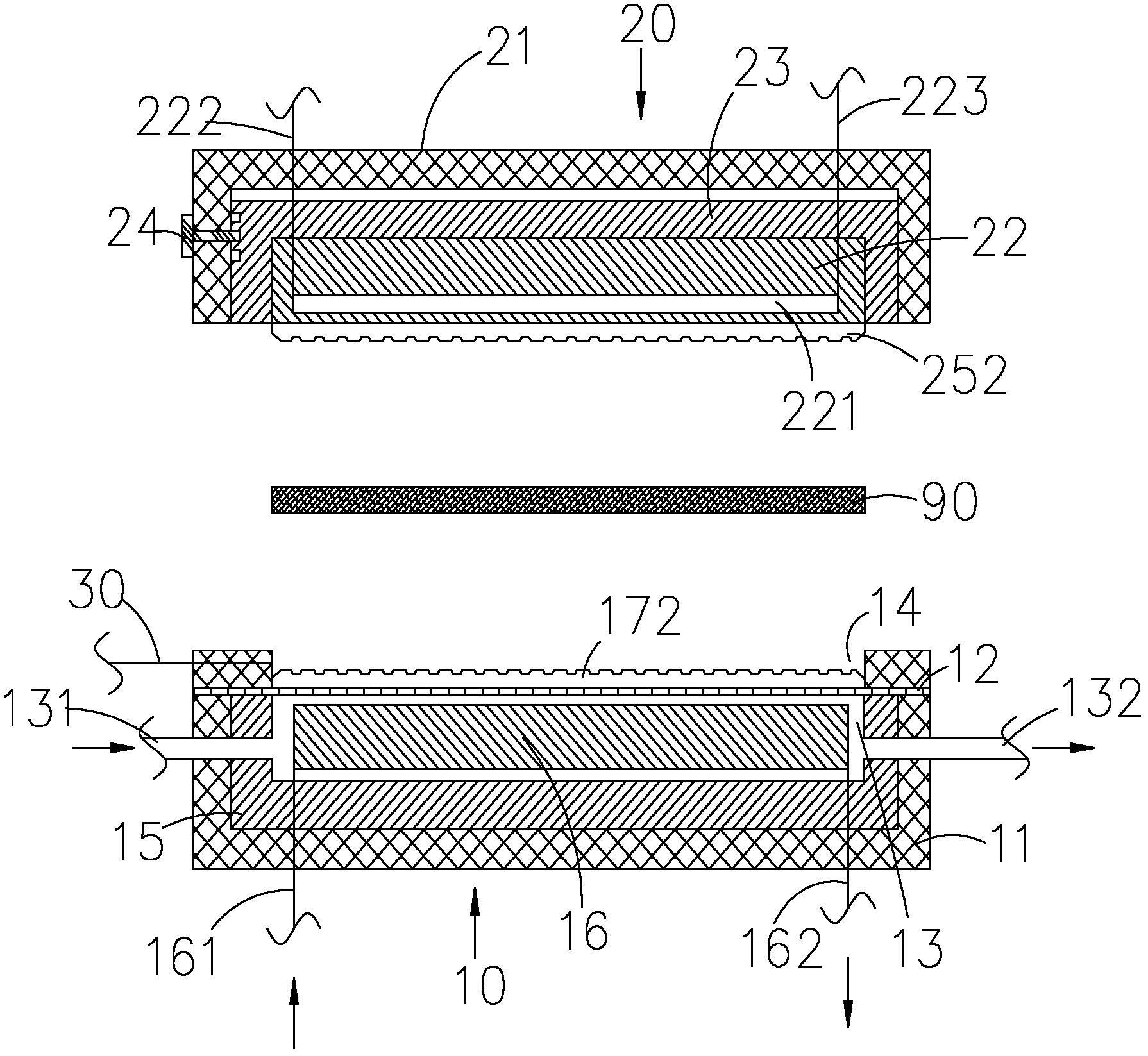

Silicon substrate top emission organic light emitting microdisplay and method for producing same

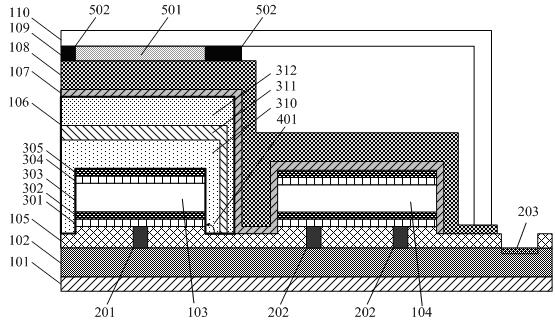

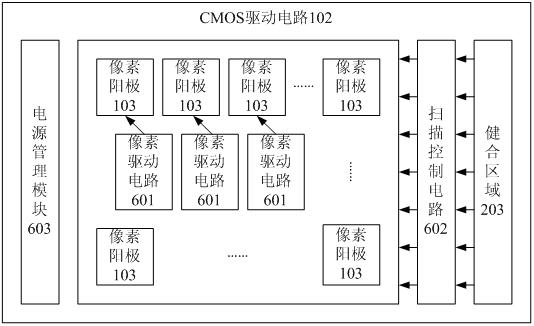

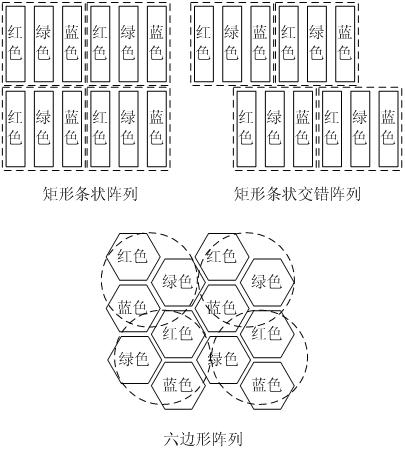

ActiveCN102629667AAvoid secondary processingSimple processStatic indicating devicesSolid-state devicesTitanium nitrideDisplay device

The invention relates to a silicon substrate top emission organic light emitting microdisplay and method for producing the same. An organic light emitting device is arranged on the surface of a silicon-based chip, and a driving circuit and a controlling circuit of the organic light emitting device are integrated in the silicon-based chip. The structure (from bottom to top) of the microdisplay is a monocrystalline silicon substrate, the driving circuit, a top through-hole layer and a top through-hole, a pixel anode and a common-cathode, an organic layer, a transparent cathode layer, a multi-layer film packaging layer, a color filtering layer and a glass sealing cap, wherein the pixel anode adopts a vertical five-layer structure and the five layers are titanium, titanium nitride, aluminum, titanium and titanium nitride; the organic layer comprises at least a hole transporting layer, a multi-layer organic light emitting layer and an electron transporting layer. The organic light emitting pixel unit area of the microdisplay is less than 100 square microns and the pixel resolution is more than 640*480. Besides, a processing procedure of chip cutting is performed before production of the organic light emitting layer and the film packaging layer, and various masks are used for producing organic displaying devices, so that laser etchers with high cost cannot be introduced.

Owner:LUMICORE MICROELECTRONICS SHANGHAI CO LTD

Method for recovering metallic copper and zinc from copper smelting ash

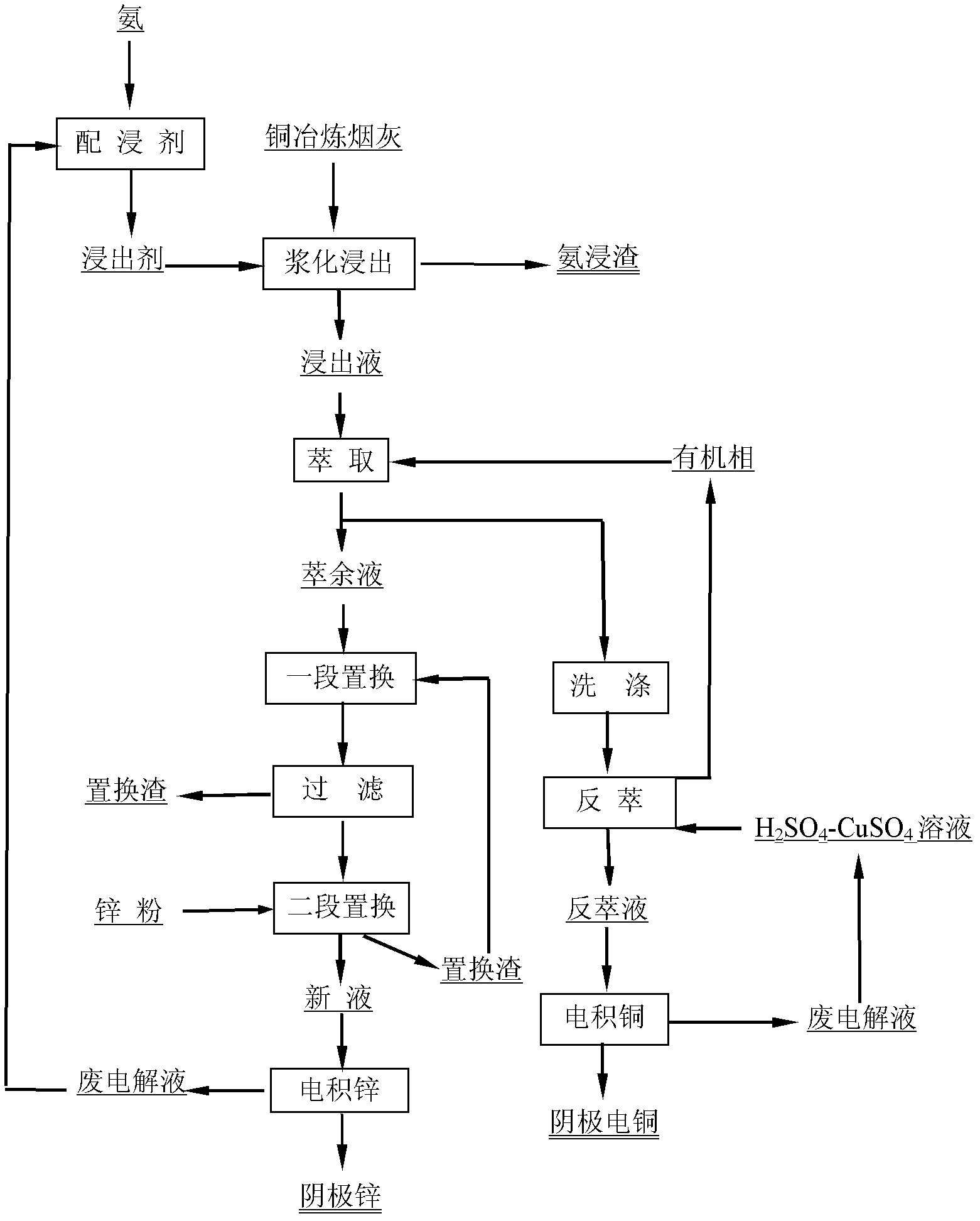

InactiveCN102212701AIncrease valueEasy to sellPhotography auxillary processesProcess efficiency improvementCopperZinc

The invention discloses a method for recovering metallic copper and zinc from copper smelting ash, comprising the following steps of: by using a NH4Cl-NH3 solution as a leaching agent, leaching copper and zinc from copper smelting ash at normal temperature; after filtering and separating, selectively extracting copper by using an extraction agent LIX-84-IT; after washing load organic phase, back extracting copper by using a solution containing 120-250 g / L of sulfuric acid, wherein the back extraction solution is used for electro-deposition production of copper; performing two-section counter-current replacement of the copper extraction residual solution at normal temperature by using zinc powder; producing metallic zinc from the obtained Zn(II)-NH3-NH4Cl solution through an electro-deposition method; and after preparing the zinc electro-deposition waste solution, returning the leached ash. The method is simple in process and easy to operate. Products are high-value metals, can be sold easily and have other advantages. The method can be used for widely treating various types of copper smelting ashes containing copper and zinc.

Owner:江西南城鑫业环保处置有限公司 +1

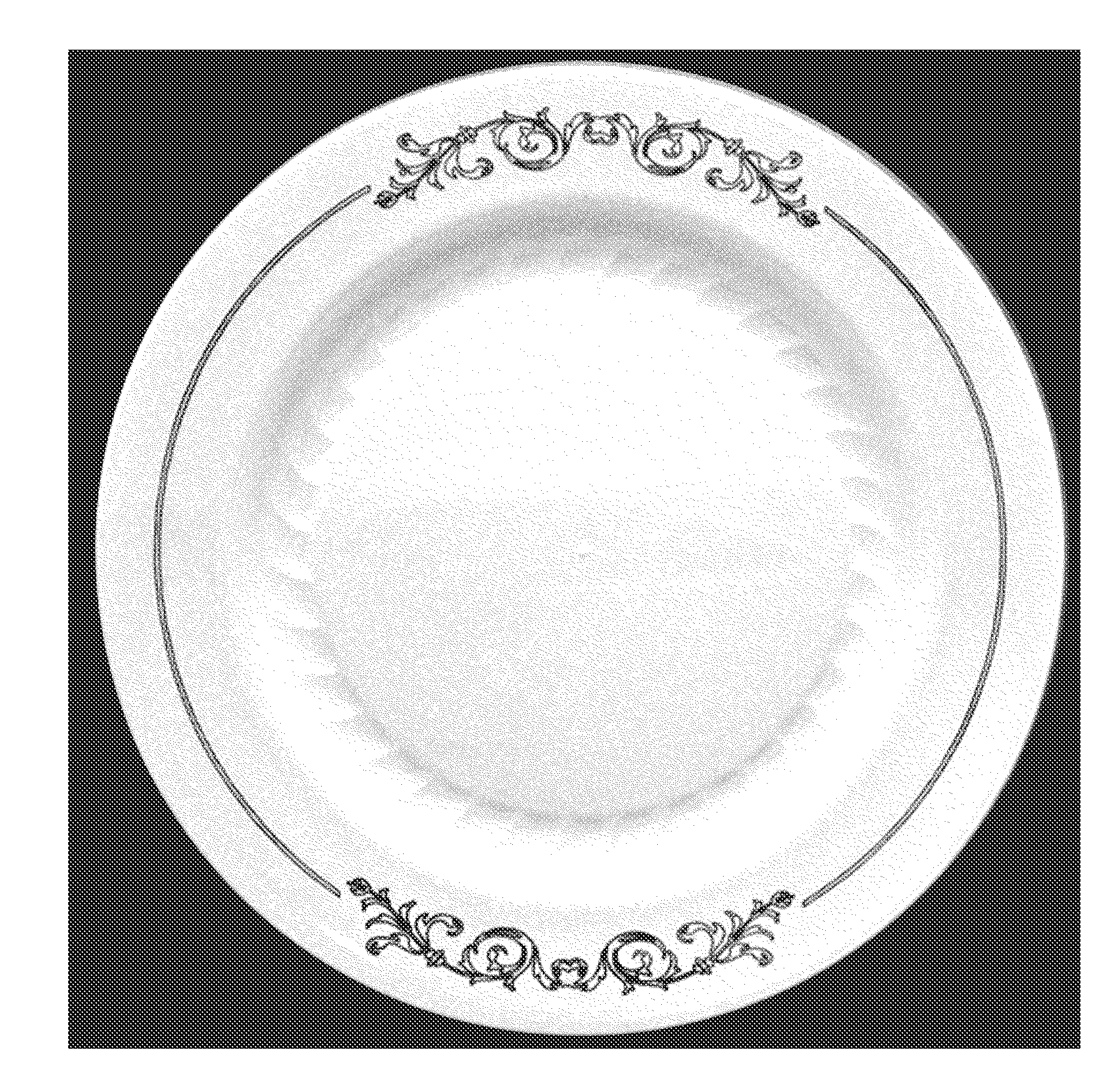

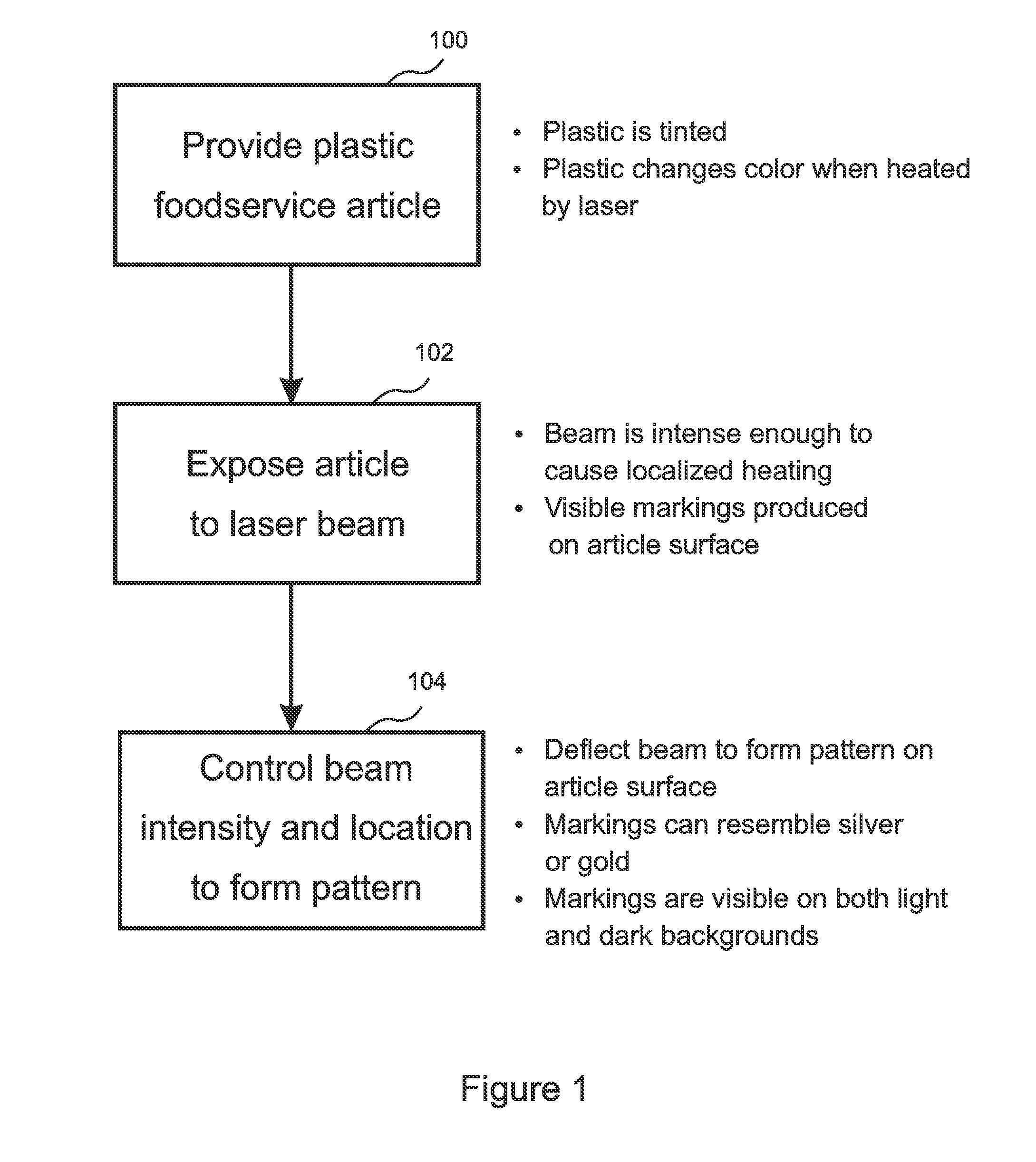

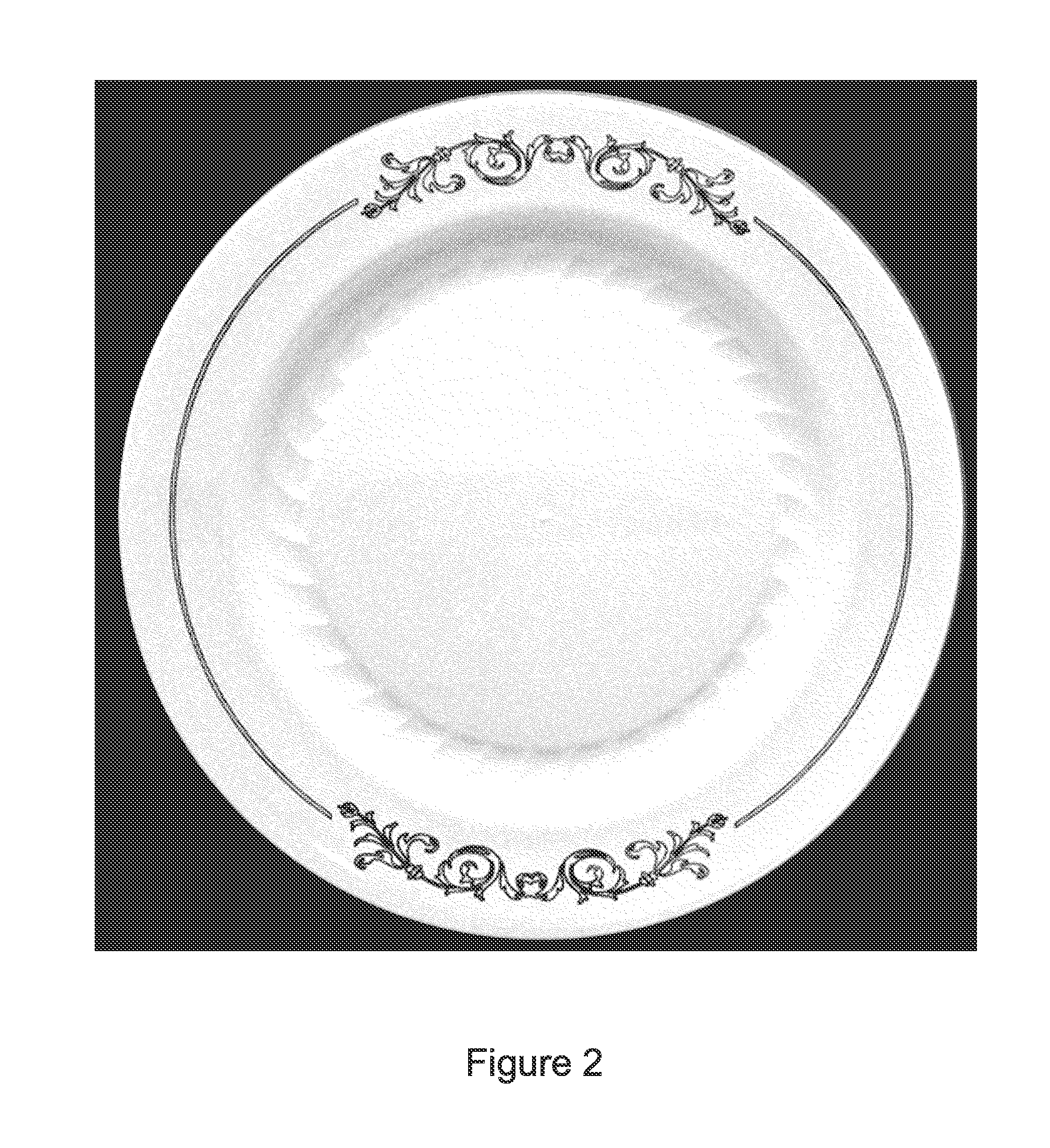

Food service articles bearing decorative markings, images, and/or custom content and method therefor

InactiveUS20130140746A1Increase contrastRemoving key impedimentDecorative surface effectsDuplicating/marking methodsPersonalizationPolystyrene

A plastic food service article bearing a decorative mark or image and method therefor is disclosed. The method includes providing an article made from a colored plastic such as polystyrene, polypropylene, polyethylene, PET, PLA, ABS, etc., that discolors when irradiated with a laser beam; applying a laser beam to cause localized surface discoloration; and controlling the deflection and amplitude of the beam to form a surface decoration and / or image. In embodiments, the laser is a YAG or Fiber laser, the markings emulate silver or gold or pewter without applying metals, inks, or coatings to the plastic articles. The markings are clearly visible against both light and dark backgrounds, and can be placed in food-contact areas of the articles. The technique can be used for marking customized and personalized designs, images, and photographs on food service articles. Embodiments can be used to decorate plates and / or cutlery.

Owner:WADDINGTON NORTH AMERICA

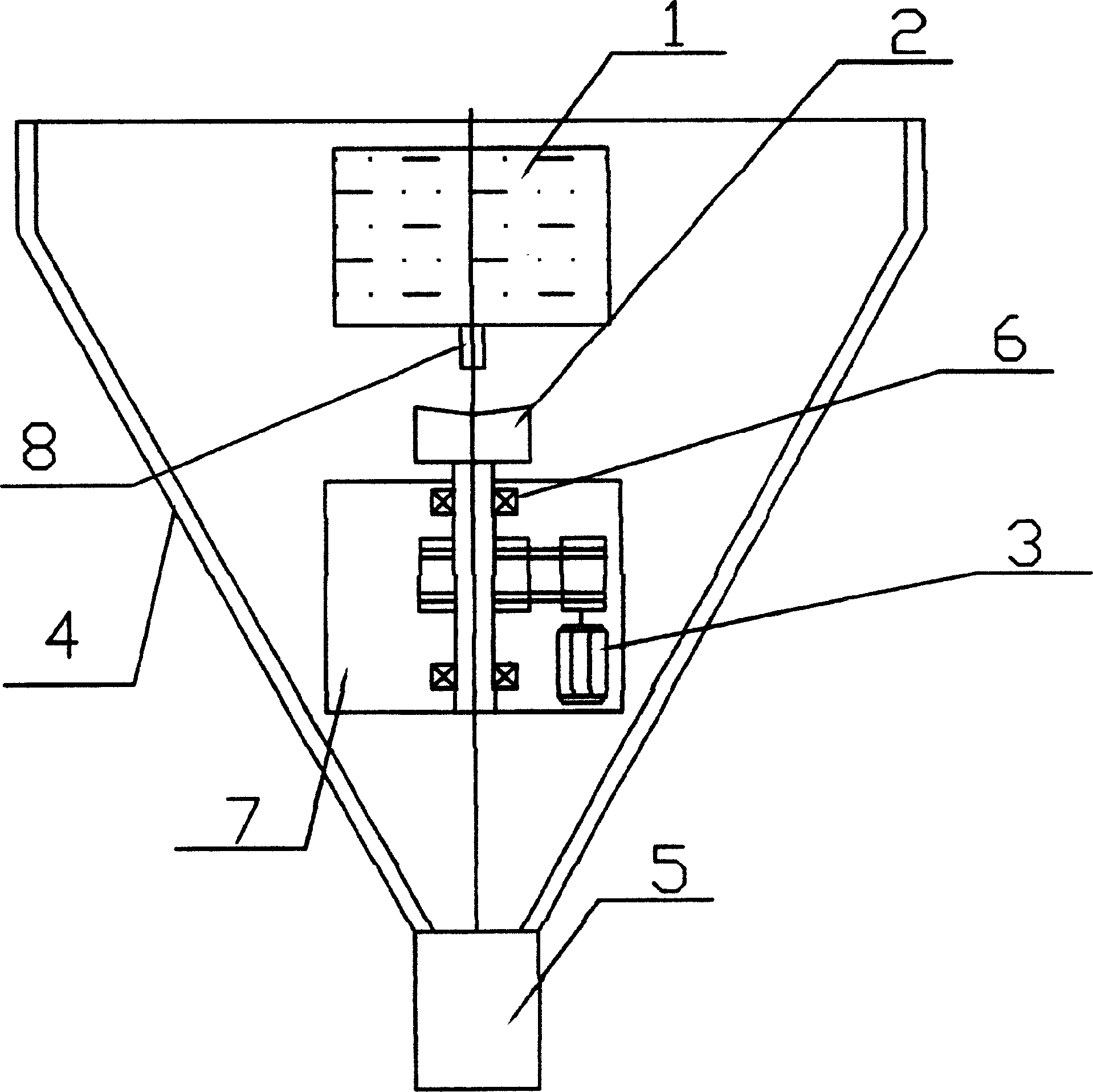

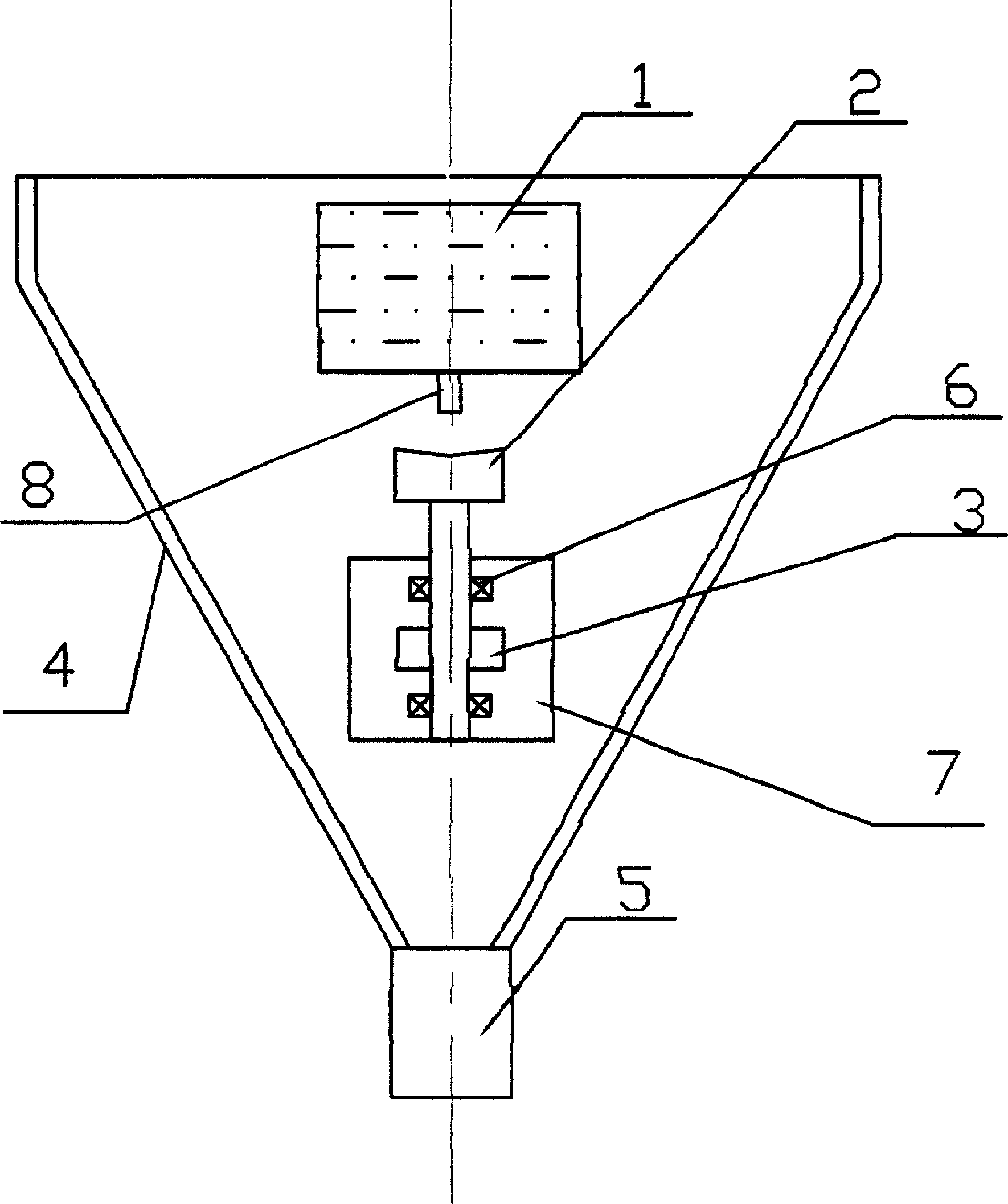

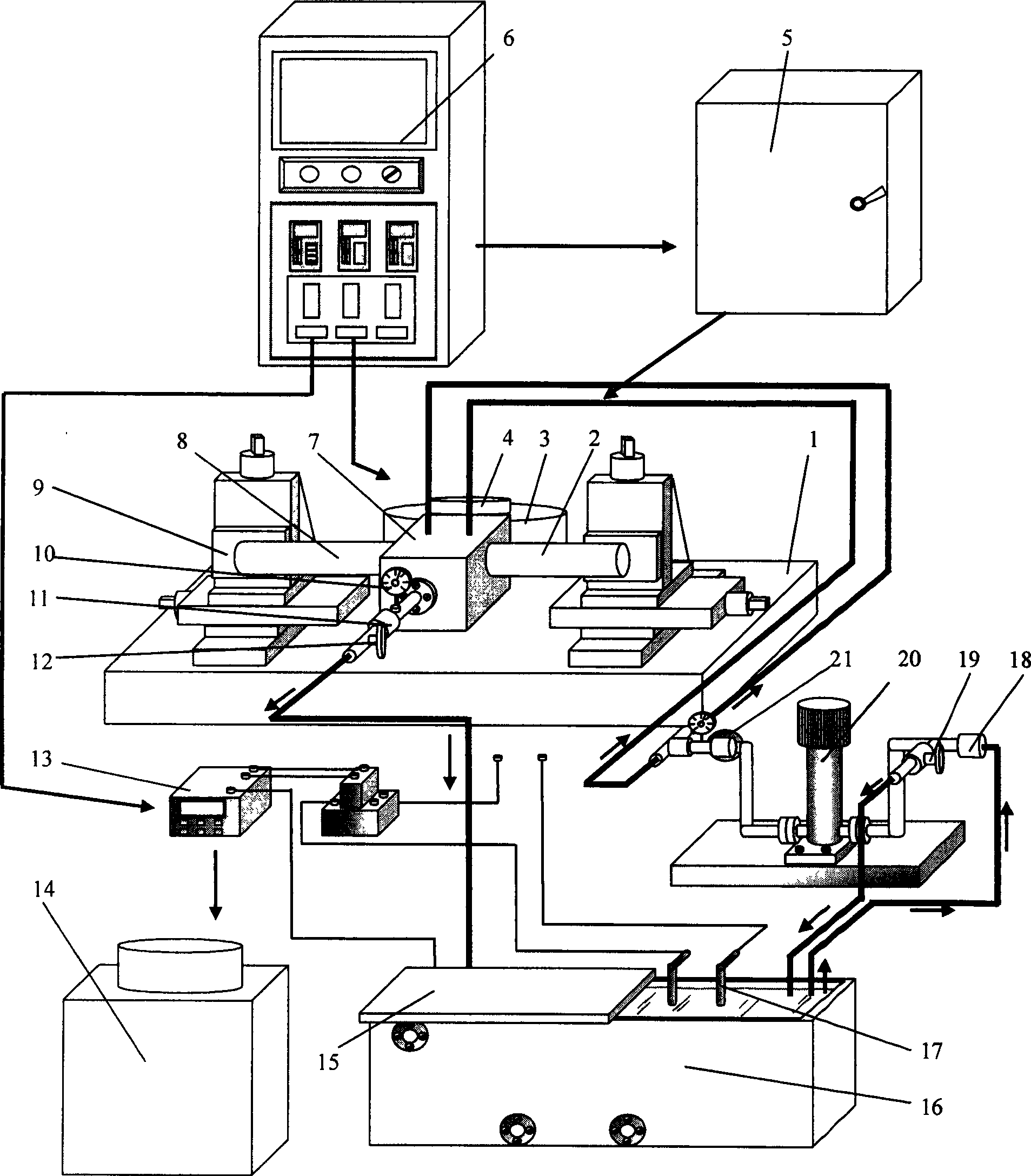

Method and apparatus for preparing sheet-type metal pwoder by atomized drop deformation

The present invention relates to a method for preparing flake metal powder by means of atomizing liquid drop deformation. Said method includes the following steps: heating and melting metal raw material, then making the molten metal be passed through the discharge spout of crucible bottom portion according to stable flow rate of 3-30g / sec. And be poured onto the center of disk rotated at high speed, the rotating speed of the disk is 1000-5000 rpm, under the action of centrifugal force atomizing and forming so as to obtain the invented product. Said equipment comprises, smelting crucible, rotating disk atomizer, drive motor, atomizing chamber, bearing and water-cooling chamber.

Owner:UNIV OF SCI & TECH BEIJING

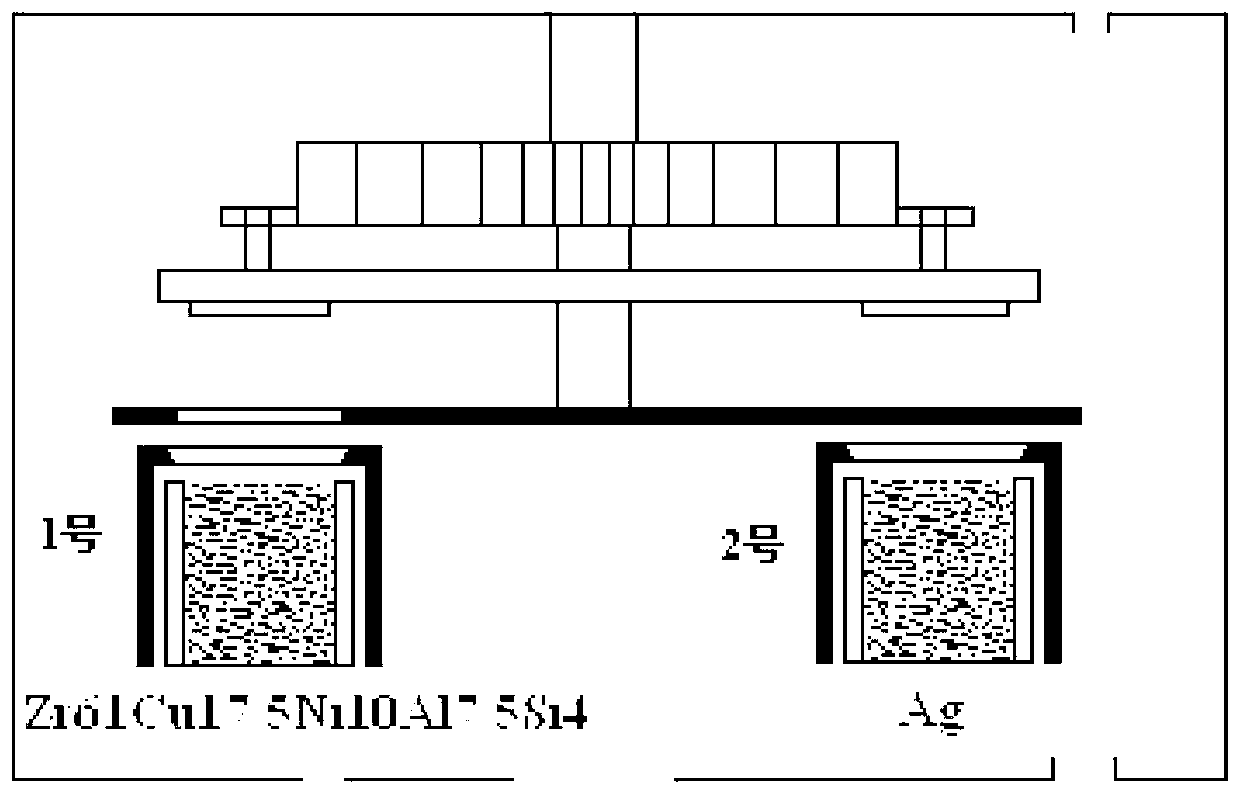

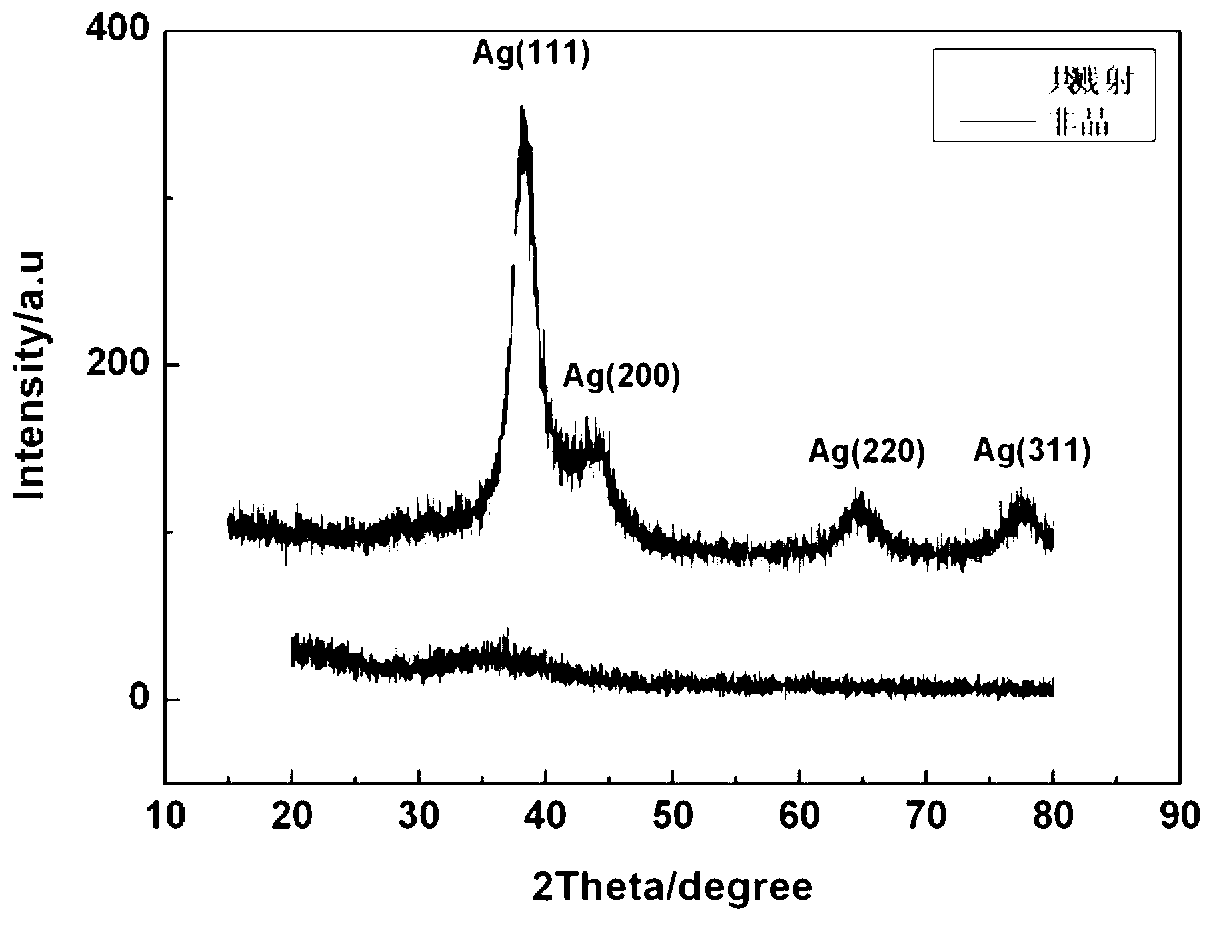

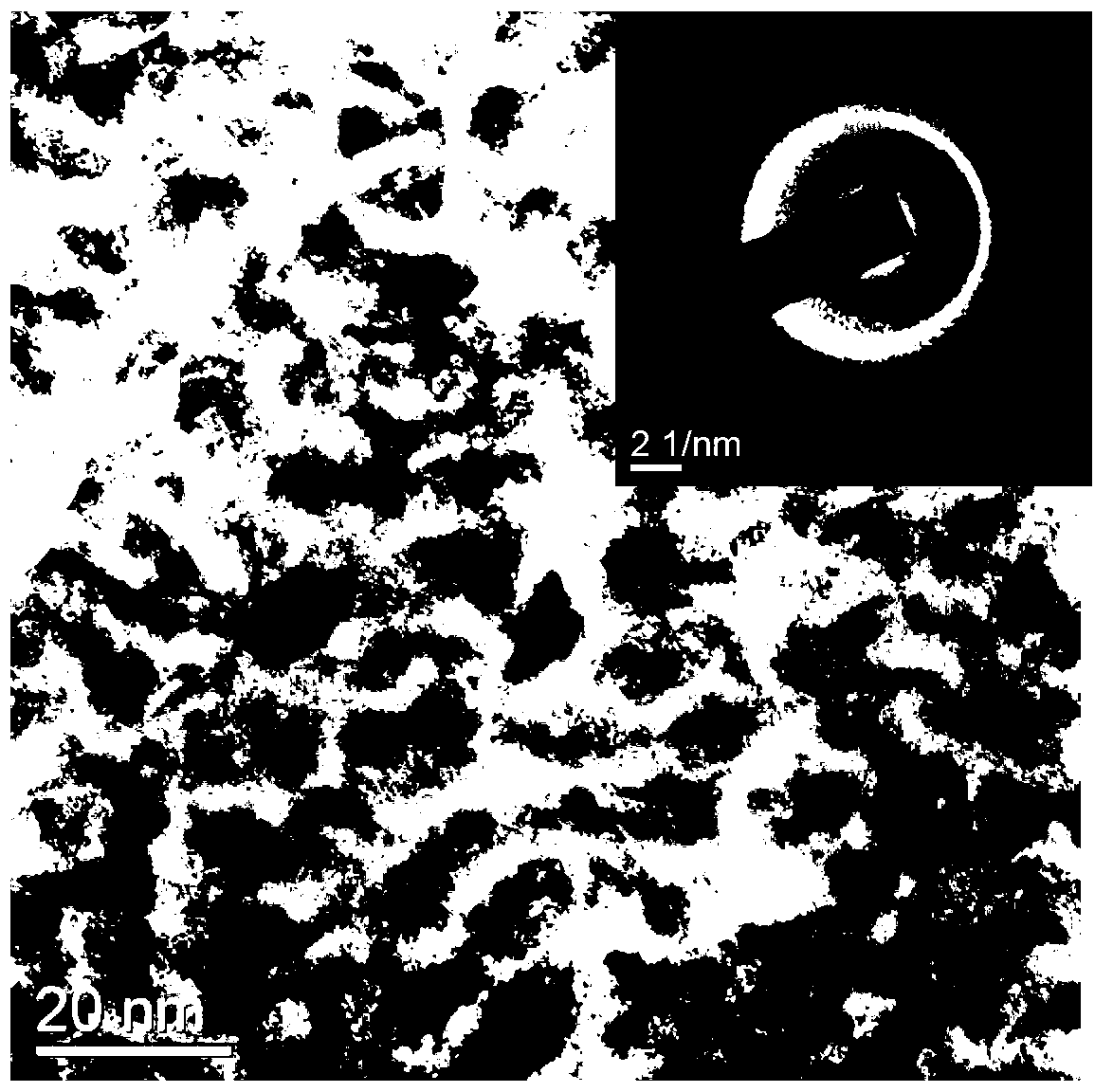

Method for preparing noncrystalline-nanocrystalline composite membrane by adopting co-sputtering method

InactiveCN103215555AAvoid secondary processingEasy to controlVacuum evaporation coatingSputtering coatingSputteringCreep strain

The invention discloses a method for preparing a noncrystalline-nanocrystalline composite membrane by adopting a co-sputtering method, wherein a mixture thin membrane with a noncrystalline phase and a crystalline phase coexisting is prepared by means of implementing double-target magnetron sputtering on a matrix and simultaneously depositing the noncrystalline phase and a nanocrystalline phase. The noncrystalline co-sputtered membrane prepared by the method has a high creep strain rate sensitive value, an excellent mechanical property and uniform plastic deformation. By virtue of the method which is simple and feasible, the noncrystalline mixture thin membrane with the noncrystalline phase and the crystalline phase coexisting is prepared. The thin membrane can be widely applied to the fields of protective coating, functional coating and the like of various precise instruments such as micro electro mechanical systems (MEMS) and nanometer electro mechanical systems (NEMS).

Owner:昆山昊盛泰纳米科技有限公司

Pre-mixed fluidized stabilized soil

The invention relates to pre-mixed fluidized stabilized soil which is composed of water, soil, a composite strengthening material and cement according to a certain ratio, wherein the soil is natural soil or building waste recycled powder and a complex of the two; the composite strengthening material is composed of activated silica alumina and dispersing agent, a crystallization inducer, an excitant and a micro-expanding agent. The pre-mixed fluidized stabilized soil is prepared by the following steps: compounding the water, the soil, the composite strengthening material and the cement according to a certain ratio, uniformly stirring through stirring equipment, forming a mixture with fluidity, pouring through self-flowing or pumping, hardening, thereby forming the integral block with strength. The stabilized soil has a stabilizing effect, can regulate the strength, permeability and volume stability according to the ratio, and has the characteristics of being stable in quality, short inconstruction period, low in cost, simple in process and the like.

Owner:王继忠 +1

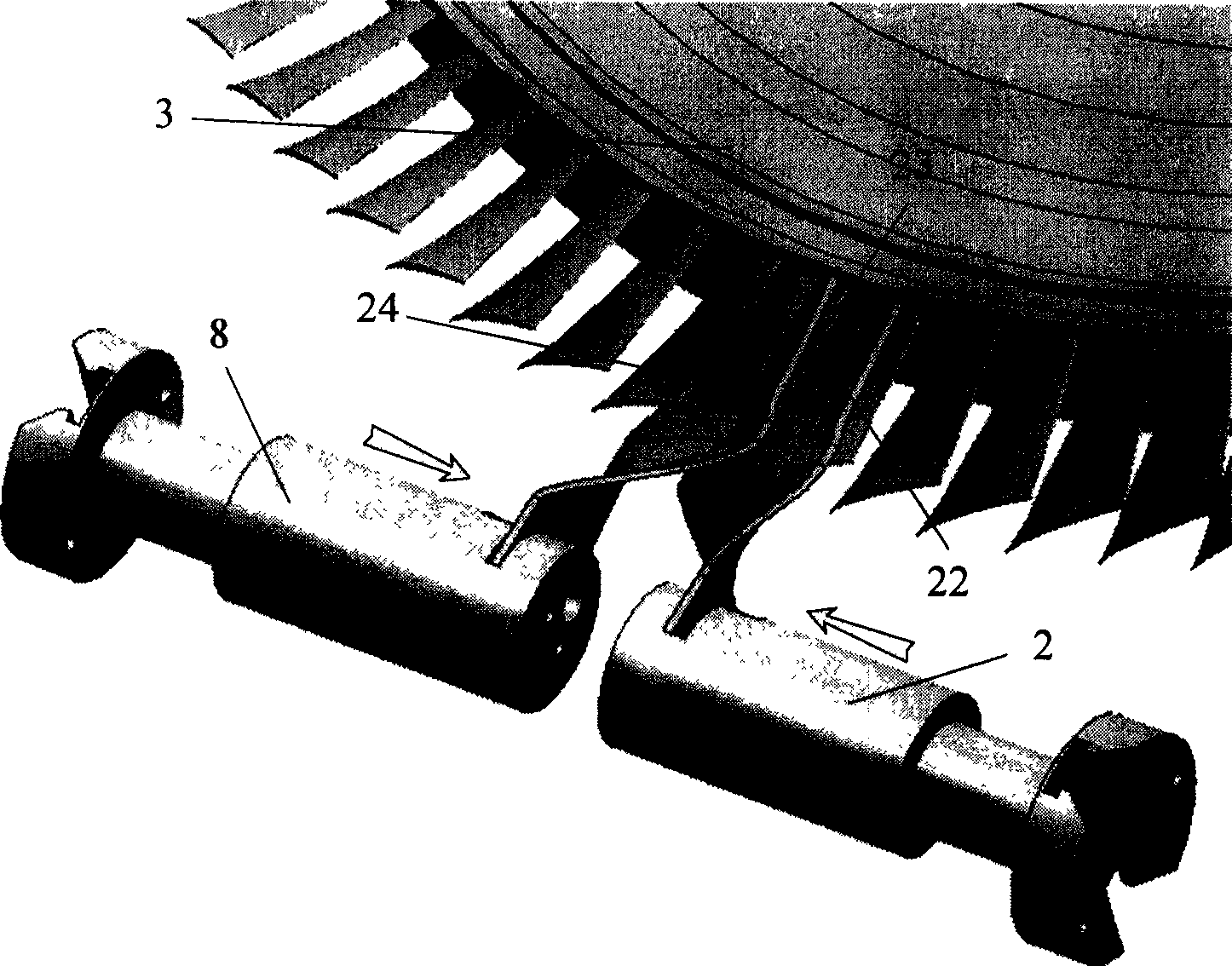

Thin electrode for electrolytic machining of integral wheel

InactiveCN101502901AImproving the precision of electrolytic machiningNo significant increase in thicknessMachining electrodesElectrical-based machining electrodesImpellerEngineering

The invention relates to an electrolytically-processed slice electrode of an integral impeller and pertains to the field of electrolytic processing. The invention is characterized in that the slice electrode is a twisted profile and the twist extent is similar to a blade profile; one side of the slice electrode is a processing surface and the other side is a non-processing surface; the non-processing surface is coated with an insulation layer; wherein the thickness of the insulation layer varies along the axial direction of a cathode slice, the insulation layer close to the mounting end of the cathode slice is thicker and the coating layer close to the processing end is thinner; the slice electrode is vertically arranged on an electrode fixture. With twisted profile, the invention can process deformed and narrow impeller slots; the insulation layer with optimized thickness coated on the non-processing surface of the cathode prevents the secondary erosion on the non-processing surface and increases the intensity of the cathode slice, thus achieving the stable feeding of the cathode slice in the processing and ensuring smoothness and stability of a flow field in the processing area.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

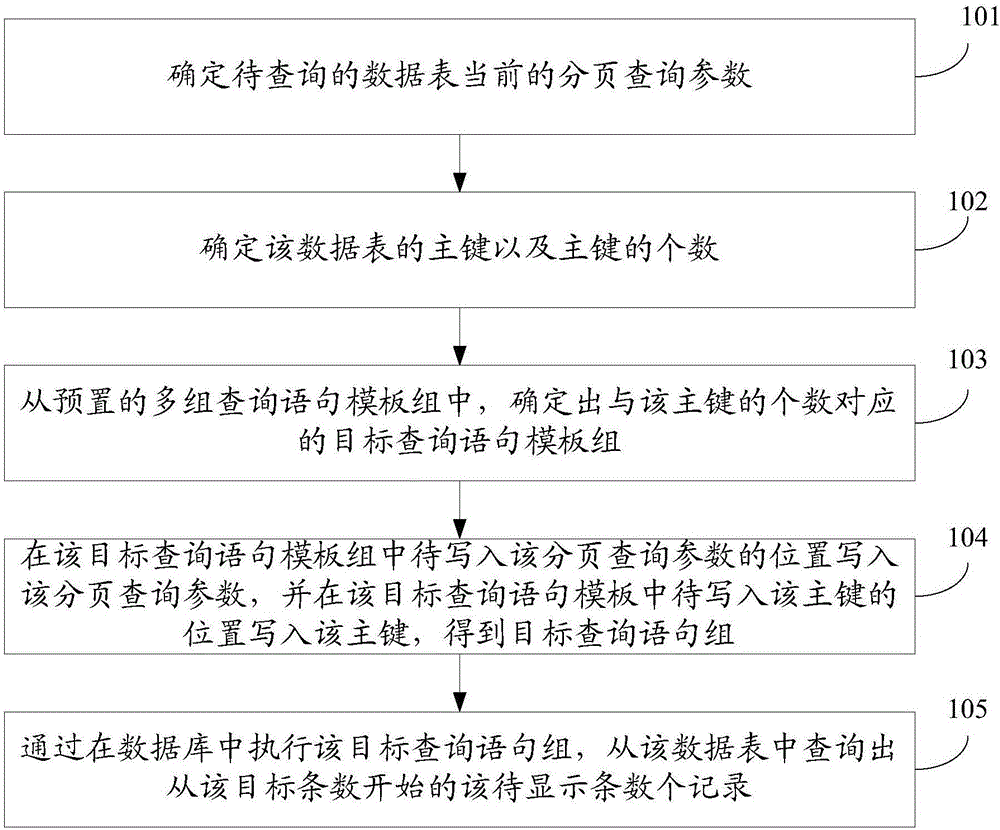

Data paging query method and device

ActiveCN106227894AReduce data volumeAvoid secondary processingRelational databasesSpecial data processing applicationsPagingQuery statement

The invention provides a data paging query method and device. The method includes the steps: determining current paging query parameters of a data table to be queried; determining main keys and the number of the main keys of the data table; determining target query statement template groups corresponding to the number of the main keys from preset multi-group query statement template groups; writing the paging query parameters at the positions with the paging query parameters to be written in the target query statement template groups, writing the main keys at the positions with the main keys to be written in target query statement templates to obtain target query statement groups; executing the target query statement groups in a database and querying a plurality of entry records to be displayed from target entry records in the data table. The paging query parameters comprise current paging number of branches to be displayed, query conditions and of target number of branches of initial query. By the method and the device, network resources and data processing resources consumed by data paging can be reduced.

Owner:AGRICULTURAL BANK OF CHINA

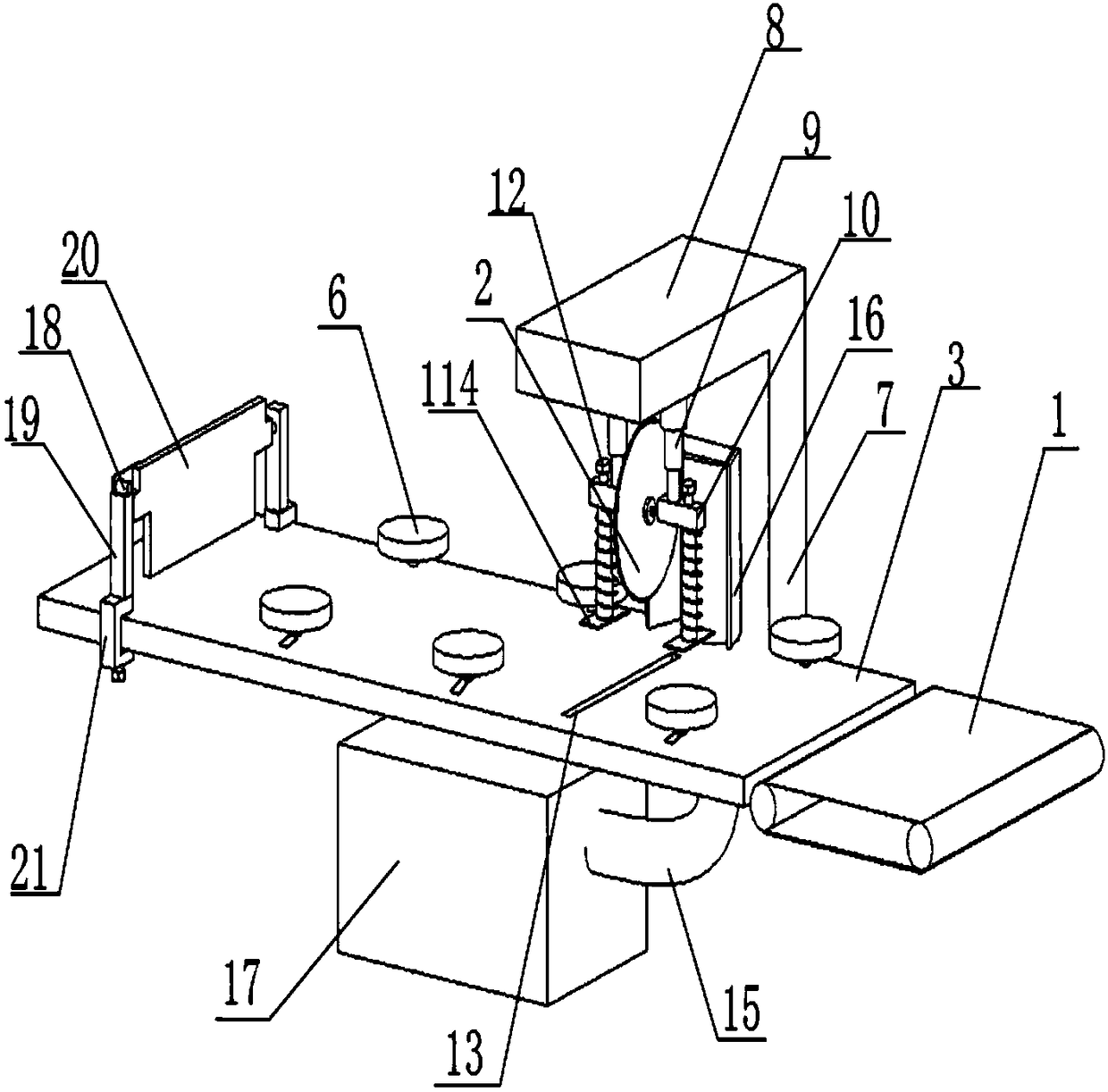

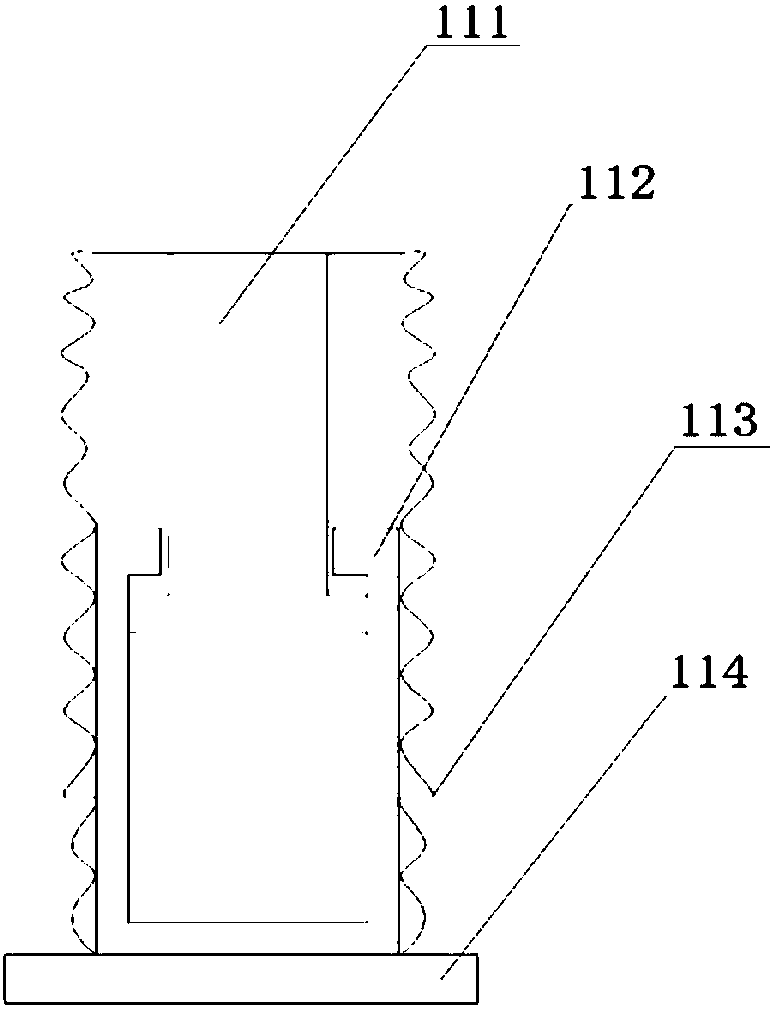

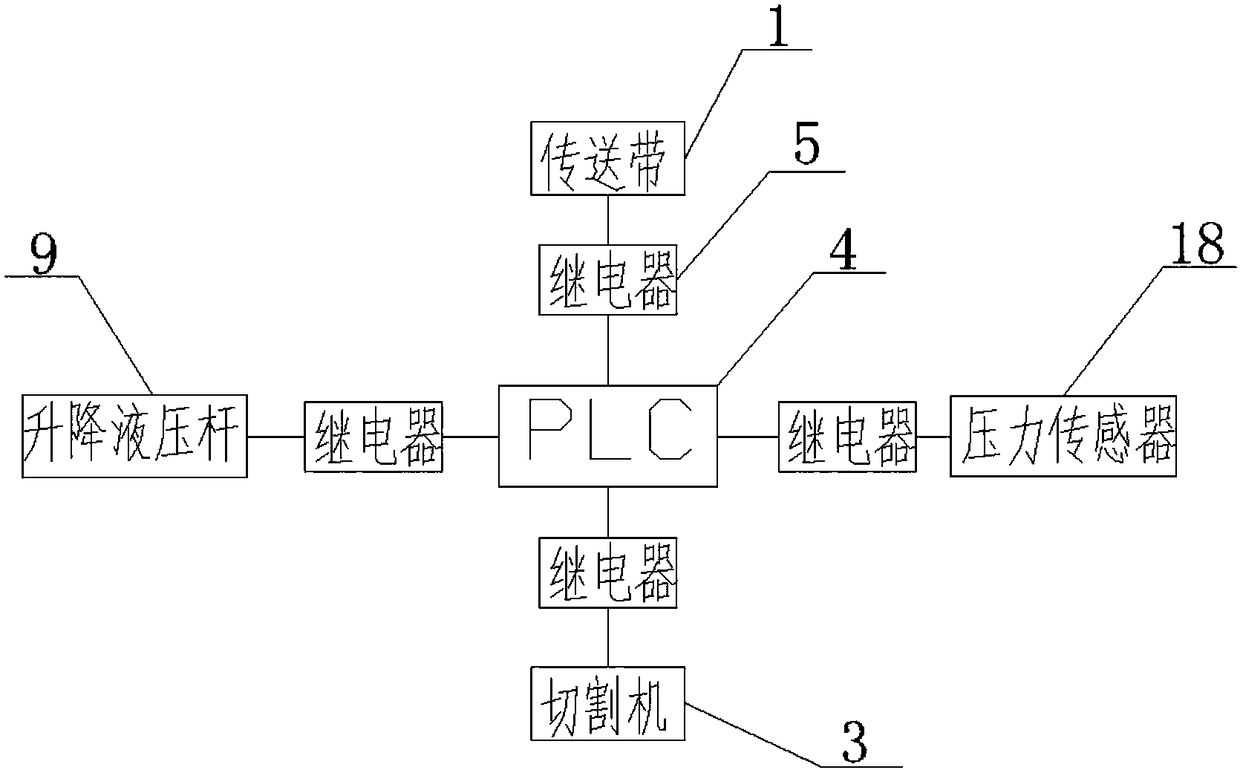

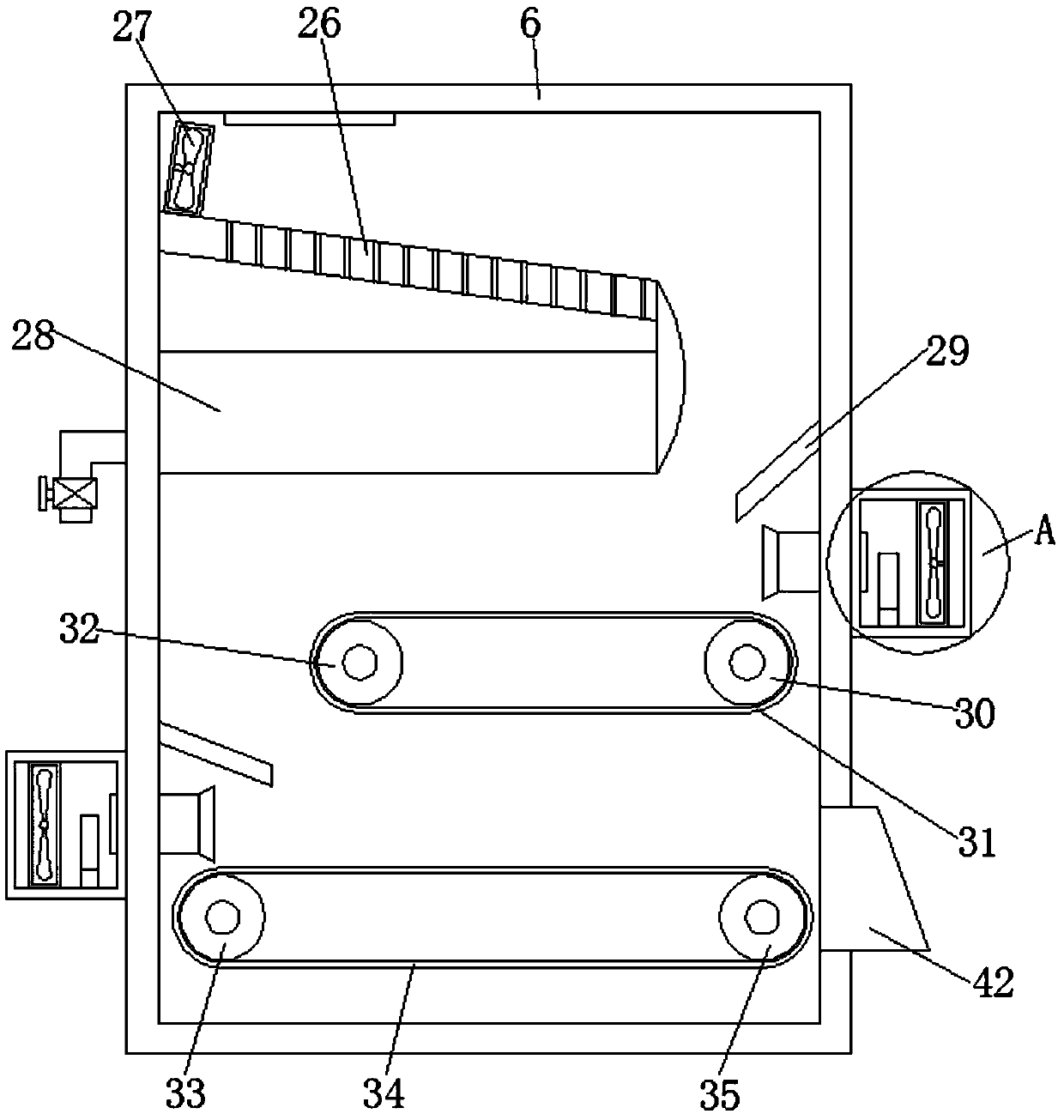

Wood-plastic plate cutting mechanism

InactiveCN108274512AAvoid the problem of tilting and uneven cuttingReduce the impactMetal working apparatusAutomatic controlWorking environment

The invention discloses a wood-plastic plate cutting mechanism. The wood-plastic plate cutting mechanism comprises a conveying belt, a cutting machine and a cutting table; limiting pulleys are arranged on two sides of the cutting table, a supporting beam and a cross beam are arranged on the side, close to the conveying belt, of the cutting table, lifting hydraulic rods are arranged on the two sides of the lower end of the cross beam, connecting beams are correspondingly arranged at the lower parts of the lifting hydraulic rods, one ends of the lifting hydraulic rods are fixedly connected withthe cross beam, and the other ends of the lifting hydraulic rods are fixedly connected with the connecting beams; screw holes are formed in the connecting beams, pressing devices are correspondingly arranged at the lower ends of the screw holes, and the pressing devices are fixed on the connecting beams through bolts; the cutting machine is installed on one of the connecting beams, and a cutting groove corresponding to the cutting machine is formed in the cutting table below the cutting machine; and the cutting mechanism further comprises a PLC, and the conveying belt, the cutting machine andthe lifting hydraulic rods are all connected with the PLC through a relay. The wood-plastic plate cutting mechanism has the beneficial technical effects that the cut surface of a wood-plastic plate can be flat, so that secondary processing is avoided; dust generated in the cutting process is cleared timely, so that a safe and sanitary working environment is provided; and the automatic control is realized, so that the workload is reduced.

Owner:重庆蓝兔塑胶制品有限公司

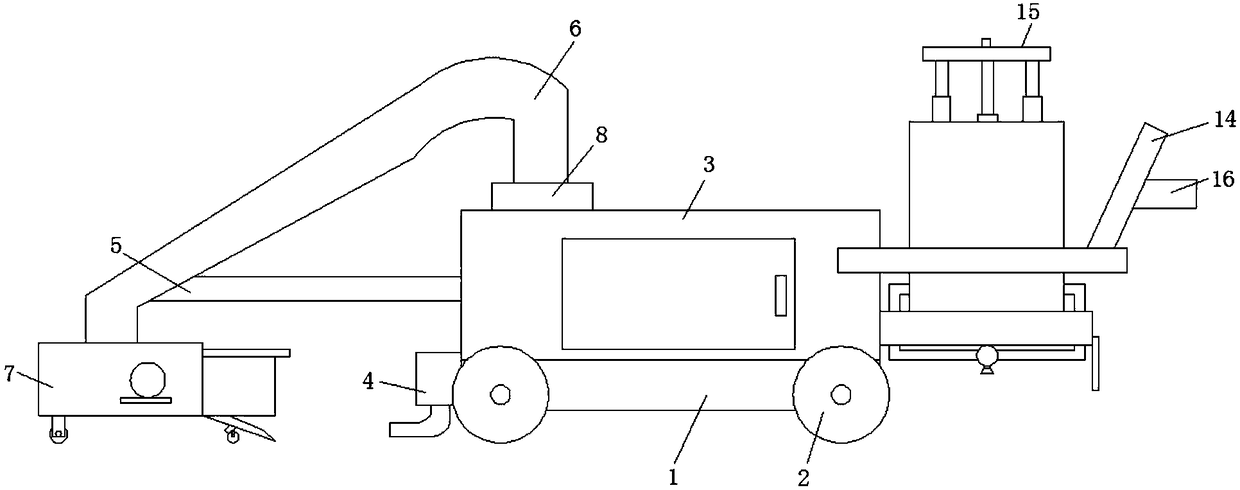

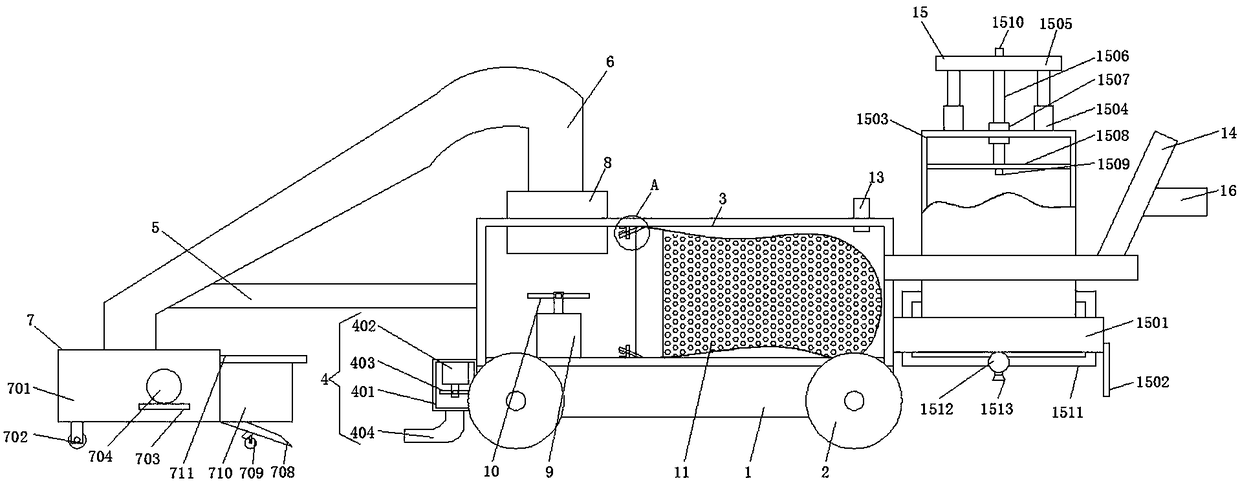

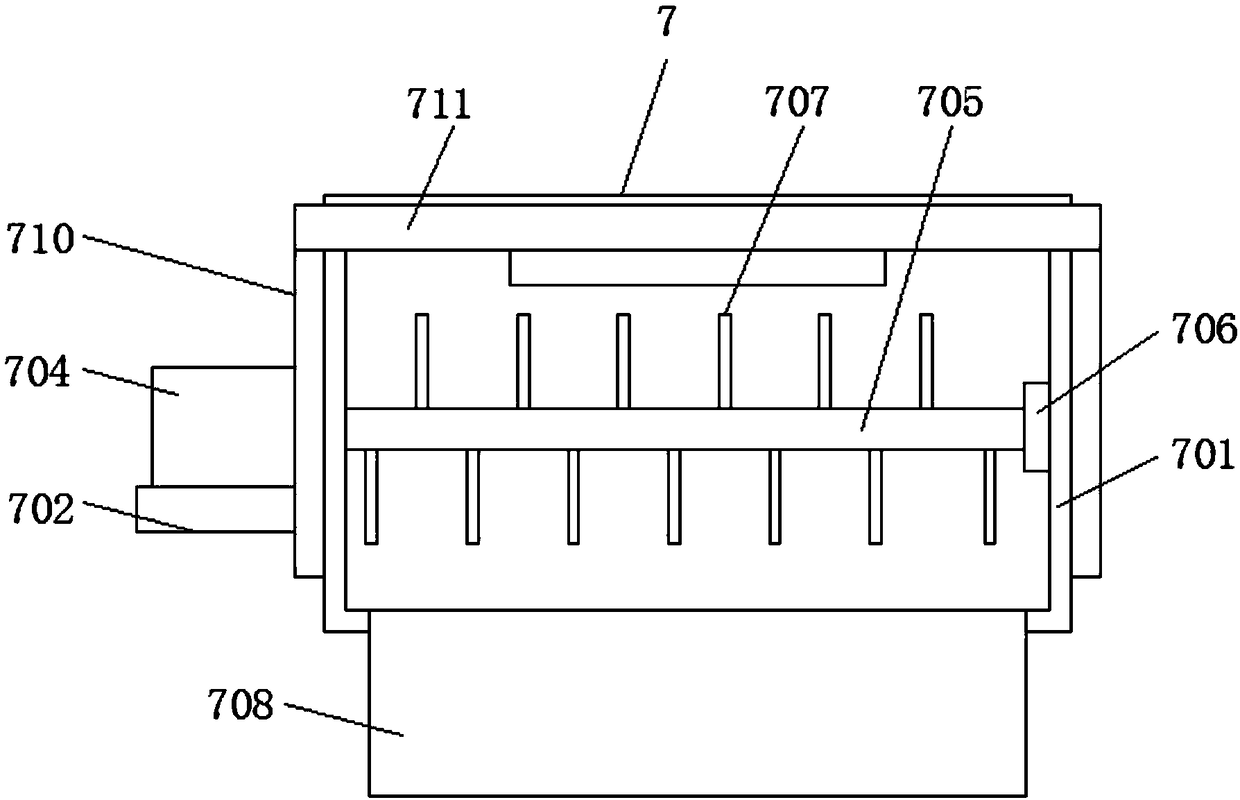

Leaf cleaning device for garden road based on opposite blowing type and negative pressure type

The invention relates to the technical field of garden leaves cleaning, and discloses a leaf cleaning device for a garden road based on an opposite blowing type and a negative pressure type. The leafcleaning device comprises a supporting bottom plate, and the supporting bottom plate is provided with four moving rollers driven by a power source. A collection box is installed on the supporting bottom plate, a blowing deice is installed on the left side of the collection box, a reinforced supporting rod is installed on the middle portion of the left side of the collection box, one end of the reinforced supporting rod is fixedly connected with a guiding pipe, one end of the guide pipe is inserted into a leaf collection device and fixedly connected with the leaf collection device. According tothe leaf cleaning device, when leaves on the garden road are cleaned, the opposite blowing type can be formed to collect the leaves, then the leaves are packed in the negative pressure type, the problem of artificial leaf cleaning is solved, and meanwhile, the problem of tree branch damage to a machine by cutting off and collecting branches due to the presence of the tree branches on the garden road is solved.

Owner:袁松贵

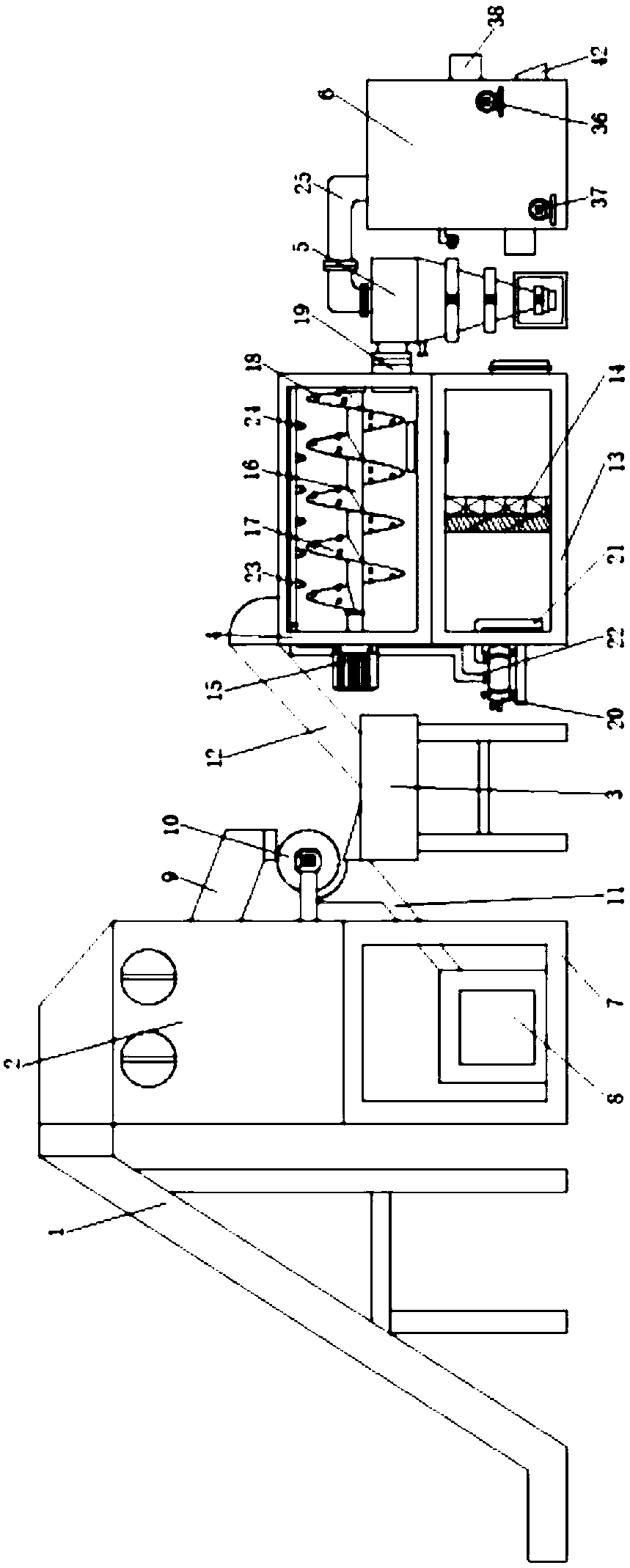

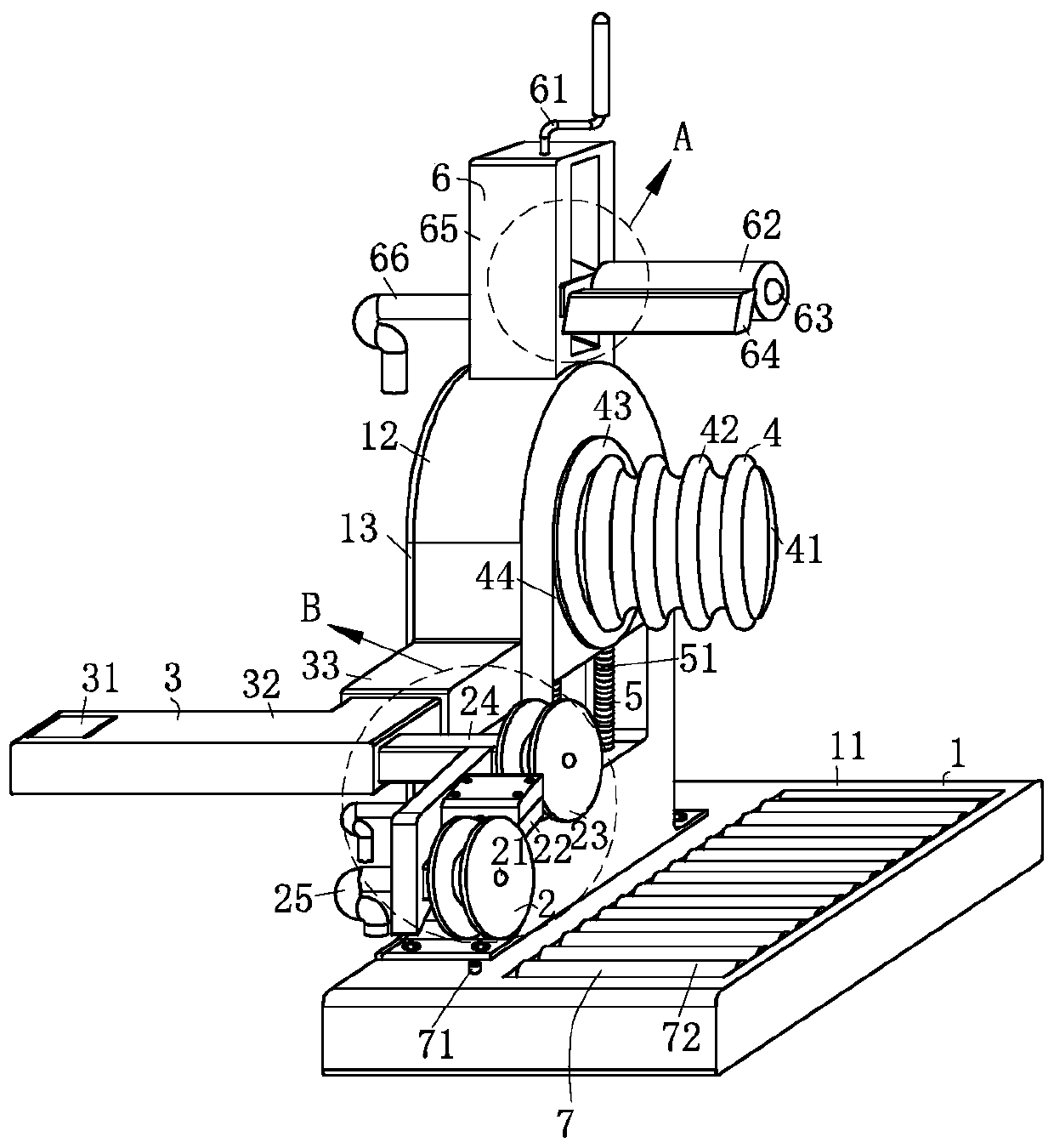

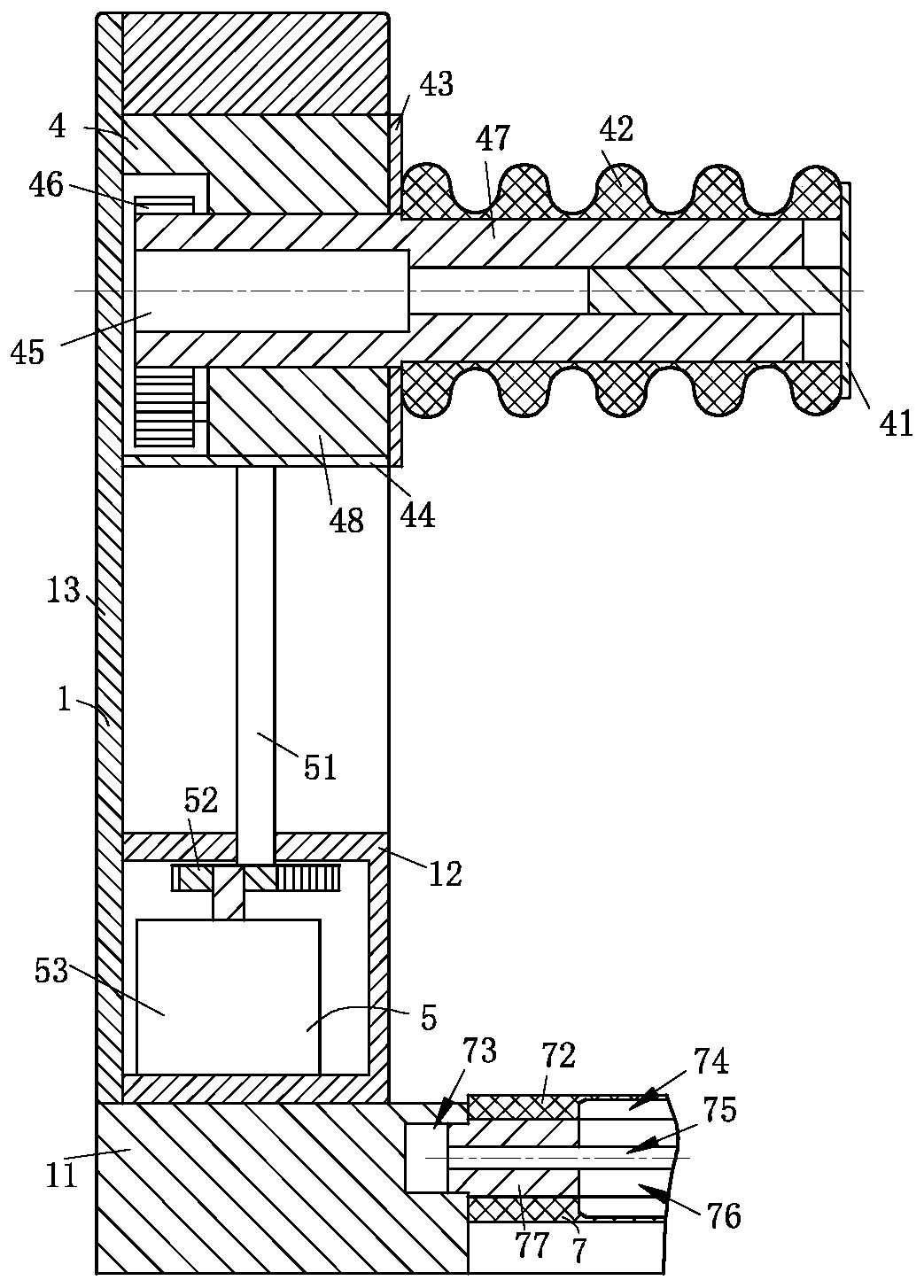

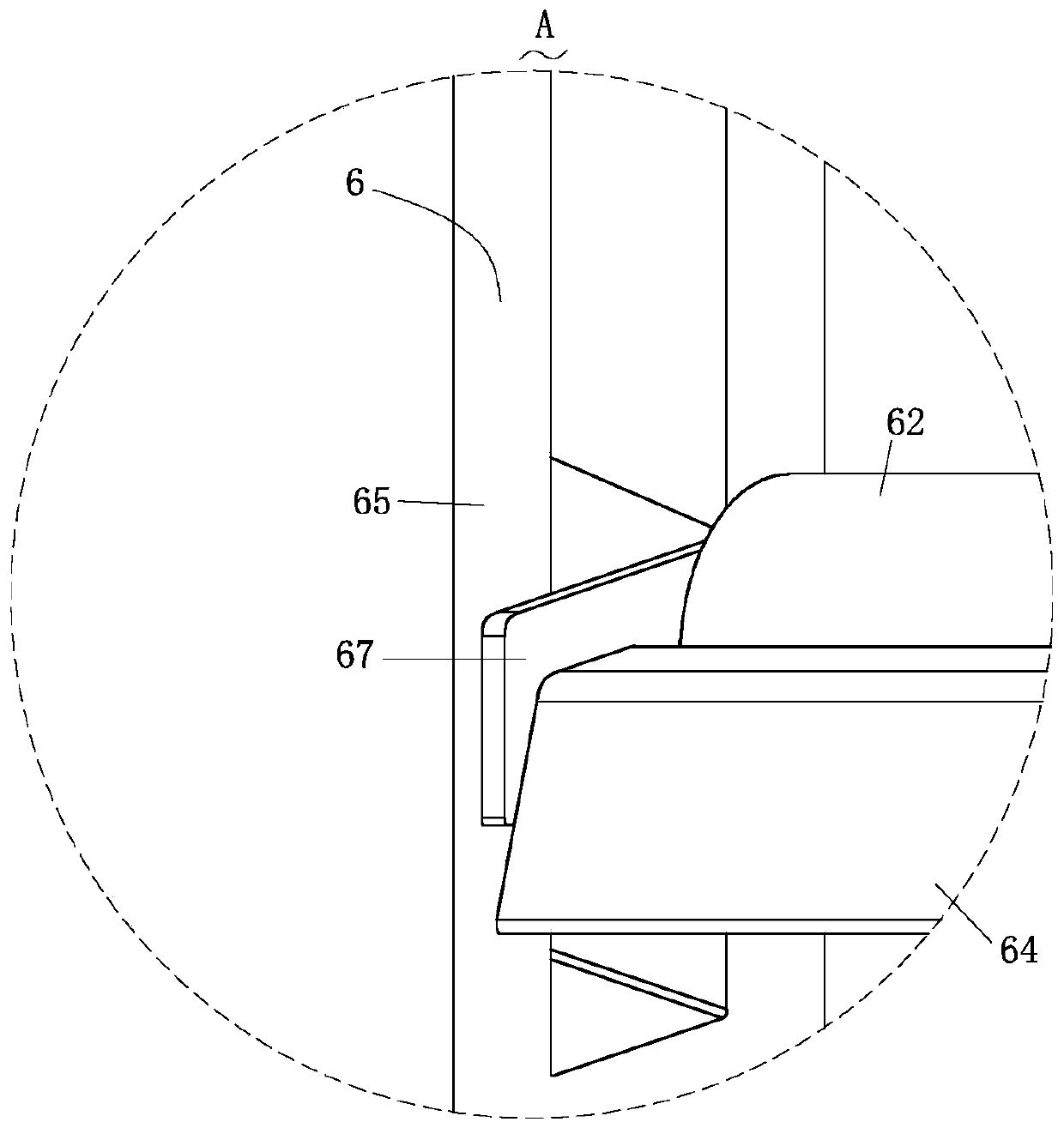

Steel bar connecting end polishing and threading equipment and application method thereof

InactiveCN104985398AThe butt joint is firm and reliableAvoid cutsEdge grinding machinesThread cutting machinesButt jointArchitectural engineering

The invention relates to the field of manufacturing equipment, in particular to steel bar connecting end polishing and threading equipment and the application method thereof. The equipment is characterized in that a rolling and threading device and a polishing device are arranged on a machine frame, the rolling and threading device is fixed to the machine frame, and the rolling and threading device is provided with a steel bar clamping position; the polishing device is located on one side of the clamping position, and the polishing device can move in the direction of the axis of the clamping position. The equipment has the advantages that steel bar burrs can be polished conveniently and quickly, secondary transfer and secondary machining are avoided, and then working efficiency is improved; meanwhile, burrs at the ends of butt joint steel bars are polished off, so that workers are prevented from being cut by the burrs at the ends of butt joint steel bars in the steel bar transfer process, and safety is guaranteed; furthermore, the number of threads in a connecting sleeve meets the butt joint requirement in the steel bar butt joint process, so that steel bar butt joint firmness is ensured and a project meets the quality requirement.

Owner:MUNICIPAL ENVIRONMENTAL PROTECTION ENG CO LTD OF CREC SHANGHAI GRP +1

Preparation method of laminated composite material of titanium-aluminum/nickel-aluminum intermetallic compound

InactiveCN107053814ASimple production processLow equipment requirementsLamination ancillary operationsLaminationMaterials scienceMetallic Nickel

The invention belongs to the technical field of composite material preparation and particularly relates to a preparation method of a laminated composite material of a titanium-aluminum / nickel-aluminum intermetallic compound. The method comprises the following steps of (1) cutting a titanium foil, a nickel foil and an aluminum foil subjected to surface treatment into metal sheets with set shapes and sizes to form a sandwich laminated structure, wrapping the outermost side by using a pure titanium foil, putting a graphite mold into a vacuum hot press sintering device, applying pre-tightening pressure of 1-3MPa at a room temperature, keeping the pressure for 10-30min and controlling various foils in the sandwich laminated structure for mutual fit contact; (2) releasing the pressure applied to the sandwich laminated structure in the step (1); (3) heating the foils in the sandwich laminated structure to 900-1300 DEG C, simultaneously applying pressure of 10-30MPa and carrying out heat preservation for 0.1-2h; and (4) carrying out furnace cooling and demolding to obtain the laminated composite material of the titanium-aluminum / nickel-aluminum intermetallic compound.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

Adjustable hot mineral smashing mechanism based on real-time analysis

ActiveCN105709877AImprove impact performanceSmall sizeGrain treatmentsRounded RectangleReal time analysis

The invention discloses an adjustable hot mineral smashing mechanism based on real-time analysis. The adjustable hot mineral smashing mechanism comprises a smashing machine body. A smashing roll shaft is arranged in the smashing machine body. A rounded rectangle structure is adopted for the radical section of the smashing roll shaft. Each side end face is provided with two sets of smashing end teeth. Each set of smashing end teeth comprise an arrangement end body, wherein a plurality of smashing end teeth are arranged on the arrangement end body. In the mashing roll shaft, an adjustment groove body is arranged at the corresponding position of each set of smashing end teeth, and the side end of each arrangement end body is correspondingly connected with a drive pneumatic cylinder. A pressure detection device is arranged on each smashing end tooth. By means of the adjustable hot mineral smashing mechanism based on real-time analysis, real-time detection can be conducted on the machining size of mineral in the smashing machine body, the distance between every two adjacent smashing end teeth in the smashing roll shaft is adjusted in real time according to the detection result within the unit time, and therefore the machining precision of the mineral can be remarkably improved.

Owner:TANGSHAN ZHENGFENG IRON & STEEL CO LTD

Swirling flow type waste plastic crushing sorting cleaning system

InactiveCN109551664AQuality improvementReduce metal magnetic impuritiesPlastic recyclingMechanical material recoveryWater resourcesPlastic recycling

The invention provides a swirling flow type waste plastic crushing sorting cleaning system. The swirling flow type waste plastic crushing sorting cleaning system includes a first transfer machine, a crushing machine, a transfer box, a cleaning device, a swirler, a box body and a fixing frame, and the top of the fixing frame is fixed to the bottom of the crushing machine. According to the swirlingflow type waste plastic crushing sorting cleaning system, metal magnetic impurities in waste plastic are reduced, the quality of waste plastic recycling is improved, meanwhile, the waste metal magnetic impurities are collected, post-processing and production of processing are convenient, multi-angle cleaning is realized, cleaning is more even, the efficiency and quality of cleaning are ensured, thus the recycling efficiency of the waste plastic is improved, reuse of water resources is improved, the cleanliness degree of the cleaning process is increased, thus the recycling quality of the wasteplastic is ensured, the water content of waste plastic recycling is decreased, and the quality of production is ensured, so that secondary processing is avoided.

Owner:开平市源成达塑胶制品有限公司

Hot pressing molding device and method thereof

InactiveCN103042681ASolve the problem of burr-prone flashSolve the overflow problemEngineeringHot pressing

The invention discloses a hot pressing molding device and a method thereof, comprising a first die and a second die, wherein the first die includes a first formwork and a first main housing and the second die includes a second formwork and a second main housing. The first formwork is provided with a first circular structure which is arranged on the edge of the first formwork; an upper surface of the first formwork is provided with first optical lines. The second formwork is provided with a second circular structure relative to the first formwork; the second circular structure is arranged on the edge of the second formwork; a lower surface of the second formwork is provided with second optical lines. The first die and the second die are connected to imprint panels to be imprinted to make the imprint panels possess a first circular structure or a second circular structure. According to the invention, the problem can be solved that a hot pressing molding device and a method thereof of prior arts can generate rough selvedge and flash, which may lead to multiple processing and breakdown of instruments.

Owner:CHENMING MOLD IND CORP

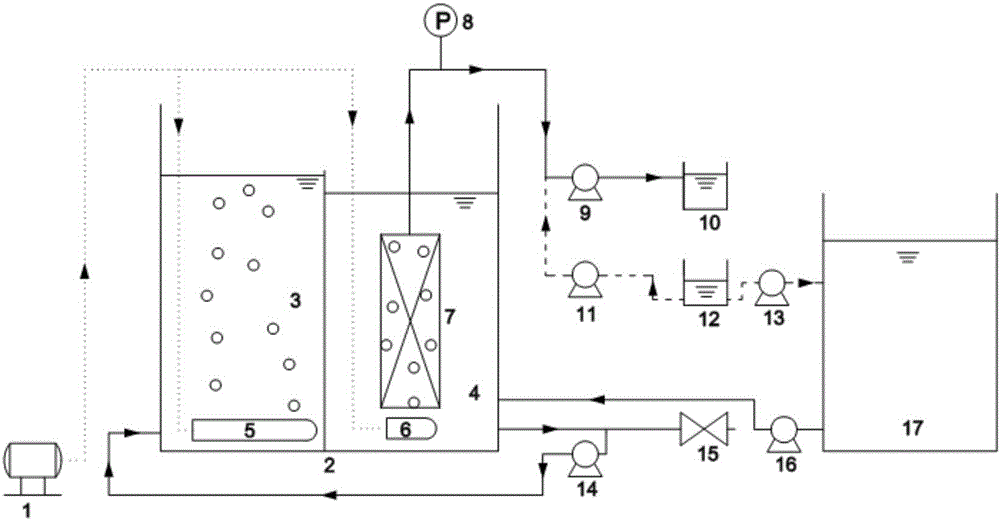

Ceramic membrane chemical cleaning system and method

InactiveCN106542631AEasy to cleanImprove oxidation efficiencySemi-permeable membranesSpecific water treatment objectivesWater treatment systemCeramic membrane

The invention relates to a ceramic membrane chemical cleaning system and method which are used for cleaning a ceramic membrane in a water treatment system. The chemical cleaning system comprises an online cleaning part, wherein the online cleaning part comprises a dosing pump and a sucking pump; the dosing pump is coupled onto the ceramic membrane arranged in a membrane pool by virtue of a pipeline, so as to inject a cleaning liquid into the ceramic membrane; the sucking pump is coupled onto the ceramic membrane by virtue of a pipeline, so as to discharge water from a back absorption membrane of the ceramic membrane; and the cleaning liquid on the ceramic membrane is discharged into the membrane pool in a sucking process. The system and method which are provided by the invention can be used for solving the problems of pollution of the ceramic membrane in a water treatment process, production of secondary pollutants by the cleaning liquid in a membrane cleaning process, secondary treatment of the membrane cleaning liquid, and the like.

Owner:深圳市康源环境纳米科技有限公司 +1

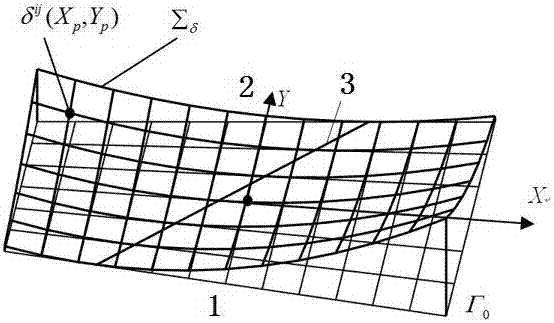

Machining method for assisting line heating forming of ship hull plate by utilizing electromagnetic force

ActiveCN105013920AImprove forming efficiencyHigh forming precisionPower flowElectromagnetic interference

The invention provides a machining method for assisting line heating forming of a ship hull plate by utilizing electromagnetic force, and belongs to the technical field of ship hull plate forming machining. In the process of line heating forming, forming of a steel plate is assisted by utilizing the electromagnetic force, an electromagnetic coil is placed on the steel plate, and the position of the electromagnetic coil is adjusted. Due to the fact that a magnetic field generated by the electromagnetic coil acts on a vortex in the steel plate, mutually-interacted electromagnetic force is generated between the electromagnetic coil and the steel plate, the steel plate is extruded by the radial electromagnetic force, and the steel plate is promoted to carry out partial transverse shrinkage; and angle changing is generated on the steel plate by the axial electromagnetic force. Meanwhile, due to the fact that current parameters are adjusted to change the magnitude of the electromagnetic force, changing of stress and strain of the steel plate is controlled in the line heating forming process. Compared with traditional line heating forming, the method is higher in working efficiency and low in cost, and it is avoided that due to the over-temperature, the material performance is deteriorated and cracks are generated. The entire technology operation is simple, the stability is higher, the repeatability is better, the method can be adopted by an aluminum alloy plate and the like, and the universality is high.

Owner:DALIAN UNIV OF TECH

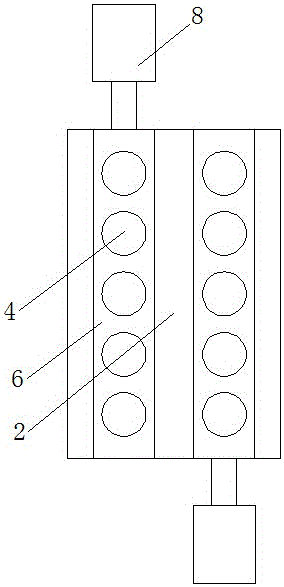

Online automatic pipe cutting device

InactiveCN105436598AHigh degree of automationGood precisionTube shearing machinesShearing machine accessoriesProduction linePinion

The invention provides an online automatic pipe cutting device. The online automatic pipe cutting device comprises a box; a guide disc is arranged in the box; a turntable is arranged on one side of the guide disc; a through hole penetrates through the box, the guide disc and the turntable in sequence, and the through hole is concentric with the turntable; multiple cutters are arranged on the outer side of the through hole, and are uniformly distributed about the axis of the through hole; the cutters include cutter bits and rotating shafts mutually connected; a Lelo polygonal slide way is formed in a guide piece; the rotating shafts are arranged in the slide way after penetrating through the box and the turntable; the cutter bits are positioned on the outer side of the box; deflection pinions are arranged on the rotating shafts; an inner gear ring is arranged on the box, and is concentrically arranged with the through hole; and the pinions and the inner gear ring are matched in an engaged manner. The online automatic pipe cutting device is simple in structure and strong in practicability, adopts an annular cutting method to cut steel pipes to obtain tidy incisions, can be applied to a steel pipe production line, is high in automation degree and excellent in precision, prevents the material waste, needs no secondary processing, reduces the cost, and is high in efficiency.

Owner:TIANJIN SHANGJI HYDRAULIC PRESSURE EQUIP

Spiral bevel gear female die tooth surface design method and spiral bevel gear machining method

ActiveCN107273612AAvoid secondary processingSimplify processingGeometric CADMetal-working apparatusMachining processEngineering

The invention relates to a spiral bevel gear female die tooth surface design method and a spiral bevel gear machining method. The spiral bevel gear female die tooth surface design method includes the steps: taking tooth surface parameters of an actually-machined small gear as reference parameters; calculating parameters of a large gear tooth surface according to transmission relationships and tooth surface contact properties of a large gear and the small gear and deformation amount after forging of the large gear tooth surface; acquiring parameters of a female die tooth surface for forging the large gear tooth surface according to the parameters of the large gear tooth surface; machining a female die according to the parameters, forging the large gear by the aid of the female die, and enabling the forged large gear tooth surface and a small gear tooth surface to meet preset meshing performance. Secondary repairing and matching of the small gear tooth surface is avoided, the machining process of a spiral bevel gear is simplified, and machining efficiency is improved.

Owner:HENAN UNIV OF SCI & TECH

Method and device for real-time thickness measurement and feedback of laser cladding

ActiveCN110093601AImprove pass rateReal-time control of laser processing parametersMeasurement devicesMetallic material coating processesObservational errorLaser processing

The invention relates to the technical field of laser cladding, and specifically discloses a method and a device for real-time thickness measurement and feedback of laser cladding. The method for real-time thickness measurement and feedback of laser cladding is characterized in that: a laser displacement sensor is installed near a laser processing head and driven along the laser processing head; the measurement laser of the laser displacement sensor is perpendicular to the laser cladding layer of a workpiece, and a measurement point of the measurement laser is arranged on the same arc as a molten pool and close to the joint of the two laser cladding layers; the laser displacement sensor is used for measuring the height of the cladding layer and feeding the measured value back to a controller; the controller finishes the value calculation, display and feedback, and then the controller controls the cladding parameters of the laser processing head, so that the final size meets the requirement. The method and device provided by the invention can adjust the laser processing parameters through the closed-loop control, control the thickness of the cladding layer precisely, reduce the manual measurement error, reduce the powder waste, and effectively improve the cladding efficiency and the qualified rate of the processed finished product.

Owner:山东镭研激光科技有限公司

Sliding mode construction method for subway vehicle depot beam plate concrete structure

ActiveCN106088608AReduce construction costsShorten the construction periodBuilding material handlingRebarBuilding construction

The invention provides a sliding mode construction method for a subway vehicle depot beam plate concrete structure. The sliding mode construction method comprises the following specific construction steps of concrete frame column constructing, steel bracket installing, main beam track installing, guide wheel and main beam installing, steel truss installing, steel plate laying, beam side formwork support installing, first construction section formwork support erecting, first construction section formwork installing, first construction section beam plate steel bar binding, first construction section beam plate concrete pouring, sliding mode platform moving, second construction section beam plate steel bar lifting and second construction section beam plate concrete pouring. According to the sliding mode construction method for the subway vehicle depot beam plate concrete structure, the construction cost can be reduced to a large extent, and the construction period can be shortened to a large extent; and due to the fact that the bottom of a frame body is isolated through thick steel plates, the common safety risks of insufficient stability of the frame body, falling from high places, object strike and the like in the high and large formwork construction process are effectively reduced.

Owner:THE 4TH CONSTR ENG CO LTD OF CHINA RAILWAY NO 4 ENG GRP

Cable manufacturing equipment

ActiveCN110422702AEasy to placeEasy to rollFilament handlingCable/conductor manufactureConductor CoilMechanical engineering

Owner:重庆燕牌电线电缆有限公司

Building solid waste mixed cement soil

InactiveCN112624670AReduce occupancyAchieve recyclingSolid waste managementEnvironmental engineeringCurtain wall

The invention discloses building solid waste mixed cement soil, which comprises building solid waste, soil and a soil body curing agent; according to the building solid waste mixed cement soil, inorganic nonmetal building solid waste and soil which are obtained nearby are used as main materials, the soil body curing agent is used as a secondary material, a certain proportion of water is added, and then through ground mechanical transmission and uniform stirring, a building material with fluidity and certain strength after hardening is formed, and the material can be widely applied to foundation reinforcement, groove backfill, roadbeds, foundation pit supporting curtain walls and mine goaf backfill; the composition and dosage are determined and adjusted according to different requirements of the component properties of soil and the strength of finished products.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +2

Producing method of snap spring

The invention relates to a producing method of a snap spring. The technical problems of that existing snap springs are complex in producing craft, more in personnel input and equipment input, high in production cost, low in automation degree, not suitable for mass production and the like are mainly resolved. The producing method of the snap spring has the advantages that an auto feeder is used for feeding to a punch, and then the punch can carry out continuous stamping work through a progressive mould, once automation form of the snap spring is achieved. Compared with the prior art, the process is high in automation degree, capable of avoiding manual operation with many people and many orders. Quality is easy to control. Accuracy requirements of the snap spring can be ensured effectively. Secondly, a chamfer of the snap spring is finished directly through process optimization when the snap spring is formed, and then secondary operation after the snap spring is formed can be avoided, the equipment input and the personnel input are reduced correspondingly, production cost is reduced remarkably, and consistency of products is ensured during the mass production, and the yield of the snap spring is improved.

Owner:WENZHOU HTM MOLD DEV

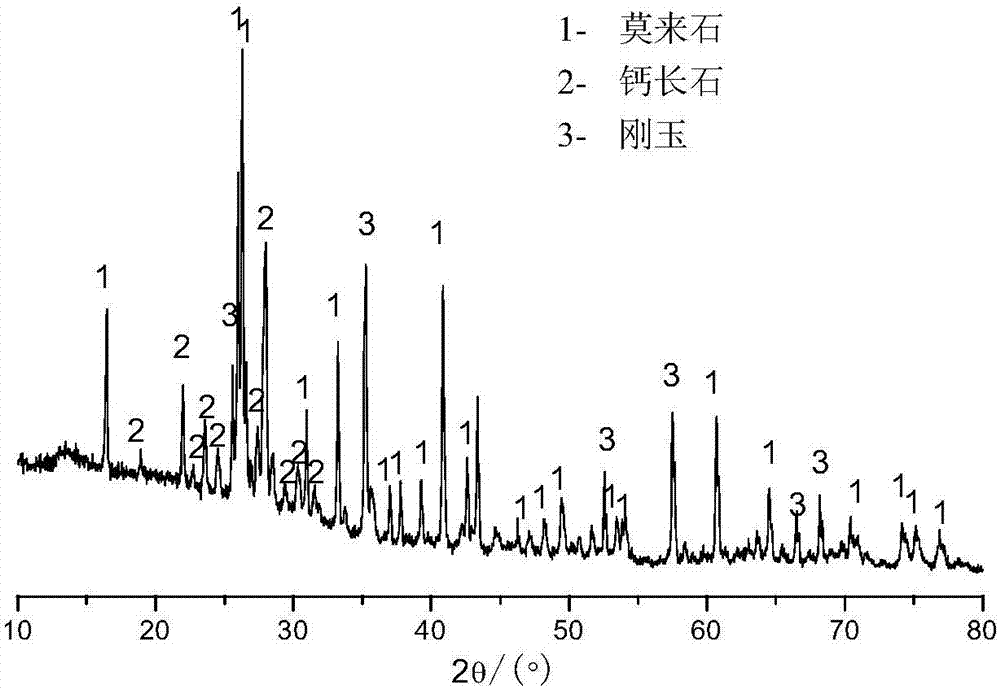

Mullite-anorthite-corundum multiphase microporous thermal insulation material and preparation method thereof

InactiveCN107973619AAvoid secondary processingAvoid introducingCeramic materials productionCeramicwareThermal insulationMullite

The invention relates to a mullite-anorthite-corundum multiphase microporous thermal insulation material and a preparation method thereof, and belongs to the technical field of inorganic thermal insulation materials. The mullite-anorthite-corundum multiphase microporous thermal insulation material is prepared from the following raw materials in percentages by weight: 40-70% of aluminum siliceous natural raw material, 1-20% of aluminum oxide raw material, 10-25% of expansion agent, 5-20% calcium carbonate raw material, and 5-10% inorganic pore-increasing agent. The mullite-anorthite-corundum multiphase microporous thermal insulation material has a wide source of raw materials, is low in cost, has a high use temperature, and has a good thermal insulation effect. The invention also provides asimple, easy, energy-saving and environment-friendly preparation method.

Owner:ZIBO CITY LUZHONG REFRACTORIES CO LTD +2

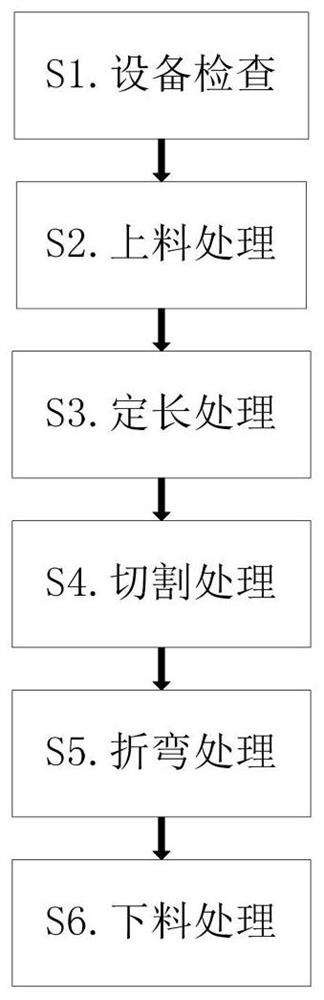

Novel building decorative plate material cutting forming machining method

InactiveCN112405000AImprove bending efficiencyAvoid secondary processingFeeding apparatusOther manufacturing equipments/toolsStructural engineeringMachining

The invention relates to a novel building decoration plate material cutting forming machining method. The bending work of an aluminum-plastic plate is completed through the cooperation of a base plate, a workbench, a fixing device, a length control device, a cutting device and a bending device. According to the novel building decorative plate material cutting forming machining method, the problemsthat a conventional device directly bends the aluminum-plastic plate without fixing, the aluminum-plastic plate is prone to dislocation and wrinkles in the bending process, secondary machining needsto be conducted on the aluminum-plastic plate, and the bending efficiency of the aluminum-plastic plate is reduced are solved, and the problems that according to the conventional device, V-shaped grooves are cut at the inner side of the aluminum-plastic plate and then bent, while the conventional device can only cut the V-shaped grooves of one specification, and different cutters need to be replaced when the V-shaped grooves of different specifications are cut so that the cutting process of the V-shaped grooves is complex, and the bending efficiency of the aluminum-plastic plate is reduced aresolved.

Owner:金巧蒙

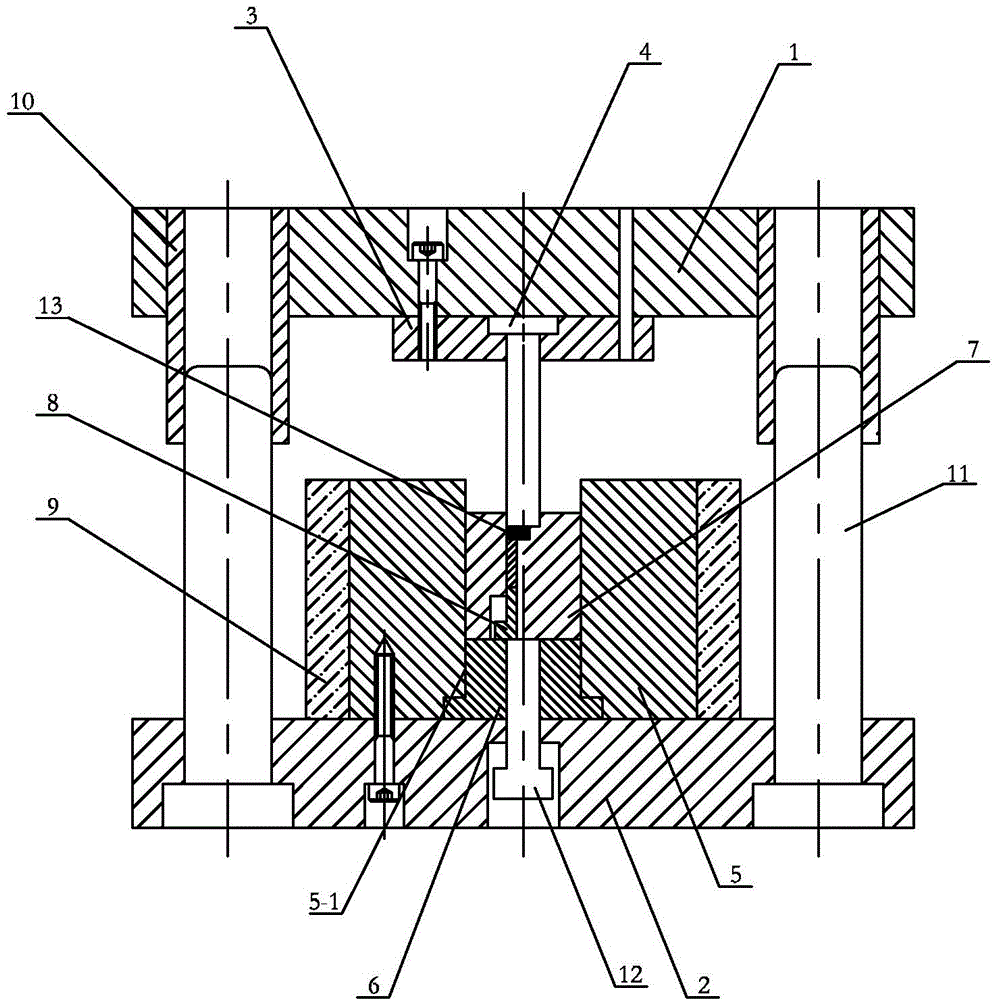

Device and method for manufacturing mould of mini-sized impeller with high height-thickness ratio

ActiveCN103600015AAvoid secondary processingLow costForging/hammering/pressing machinesImpellerPunching

The invention relates to a device and a method for manufacturing a mould of a mini-sized impeller with high height-thickness ratio, and relates to a device and a method for the mould of the mini-sized impeller with high height-thickness ratio. The device and method solve the problems of high manufacturing cost, low processing efficiency, less processing material and unsuitability for batch manufacturing realization in the prior art. The device is characterized in that an upper mould base and a lower mould base are parallelly arranged top and bottom; a punching head is arranged on a punching head fixed plate; a concave mould fixed plate is fixed on the lower mould base; a concave mould shim plate is arranged in a concave mould installation plate; an embedded lump type concave mould is arranged in the concave mould installation hole; an ejector rod is arranged in the embedded lump type concave mould; an ejecting screw sequentially penetrates through the lower mould base and the concave mould shim plate from bottom to top to support against the lower end surface of the ejector rod. The method comprises the following steps of: 1, placing a blank into a cavity, and heating to the mould forging temperature of the blank; 2, filling the blank into the cavity of the embedded lump type concave mould; 3, reaching the set load of a pressing machine, maintaining pressure, and then unloading to completely form the mini-sized impeller with high height-thickness ratio. The device and method which are disclosed by the invention are used for manufacturing the mini-sized impeller with high height-thickness ratio.

Owner:HARBIN INST OF TECH

Splashing-proof liquid for welding metal

InactiveCN102061110APrevent splashAvoid secondary processingWelding/cutting auxillary devicesAuxillary welding devicesCelluloseChemical industry

The invention relates to a chemical agent, in particular relates to a splashing-proof liquid for welding metal, belonging to the technical field of metallurgy and chemical industry. The splashing-proof liquid for welding metal is prepared from the following raw materials in parts by weight: 4-7 parts of calcium nitrate, 5-10 parts of zinc oxide, 5-8 parts of butyl cellulose, 10-15 parts of benzyl alcohol, 10-20 parts of graphite powder and 100-150 parts of water. The method comprises: successively adding the calcium nitrate, the zinc oxide, the butyl cellulose, the benzyl alcohol, the graphite powder and the water into a mixer in a material taking sequence, and mixing the raw materials; after the raw materials are mixed, injecting the mixture into a grinding and crushing machine to be ground; and grinding the mixture until the granularity is less than 150 meshes, thus obtaining the splashing-proof liquid for welding metal. During welding, the splashing-proof liquid for welding metal is coated on the surface of base metal. By utilizing the splashing-proof liquid for welding metal provided by the invention, 'weld spatter' can be effectively prevented from splashing, the secondary treatment is not required for a weld spatter ball on the surface of the base metal after welding, the labor intensity of workers is greatly decreased, and the welding efficiency is improved.

Owner:安丽艳

Reciprocating jaw type crusher for sintered bricks

The invention relates to a crusher of sintered bricks in building waste. A reciprocating jaw type crusher for sintered bricks comprises a crushing bin body I, a crushing bin body II, crushing devices and reciprocating power mechanisms, wherein the crushing bin body I and the crushing bin body II are longitudinally laminated and arranged; the crushing devices are arranged in each crushing bin body in a matched mode; the reciprocating power mechanisms drive the crushing devices; the crushing devices comprise static jaw plates, movable jaws and movable jaw plates, wherein the static jaw plates are fixedly arranged on one side surfaces in the crushing bin bodies; the movable jaws correspond to the static jaw plates and are matched with and in sliding fit with the crushing bin bodies; the movable jaw plates are fixed on the movable jaws; the driving ends of the reciprocating power mechanisms are in connection driving with the movable jaws. The crusher is reasonable in structure design, is high in sintered brick utilization ratio, can control the crushing and discharge particle diameter easily, can obviously reduce the content of needle-shaped or flaky aggregate after discharging, so that the regenerated aggregate can be well adaptive to regenerated concrete preparation and other fields of engineering construction.

Owner:ZHENGZHOU UNIV

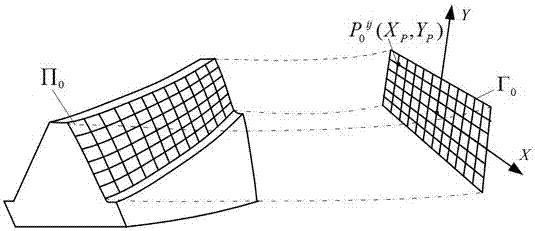

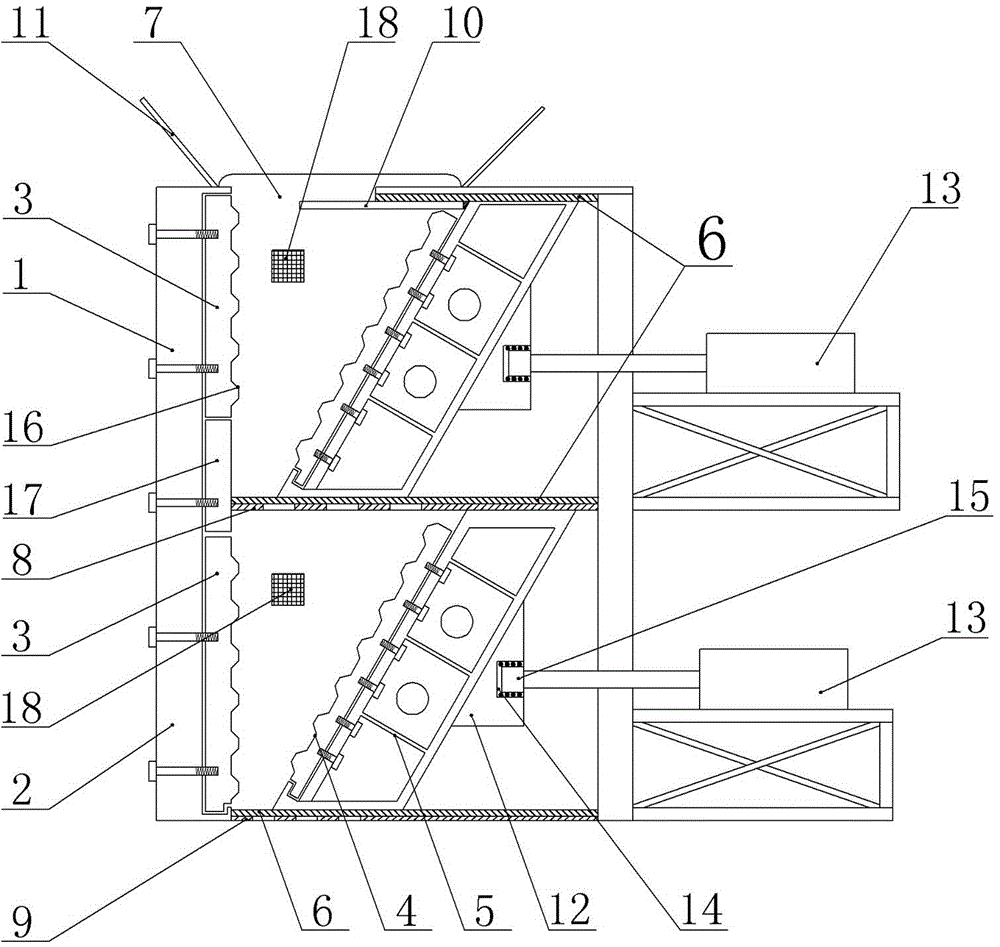

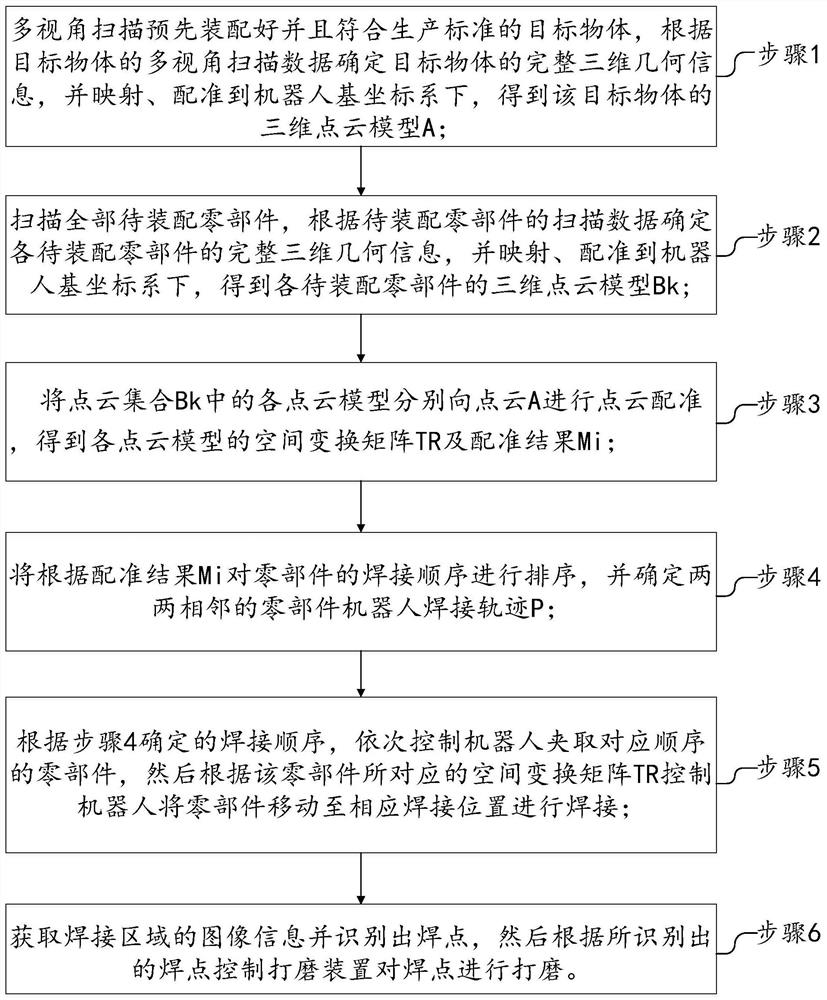

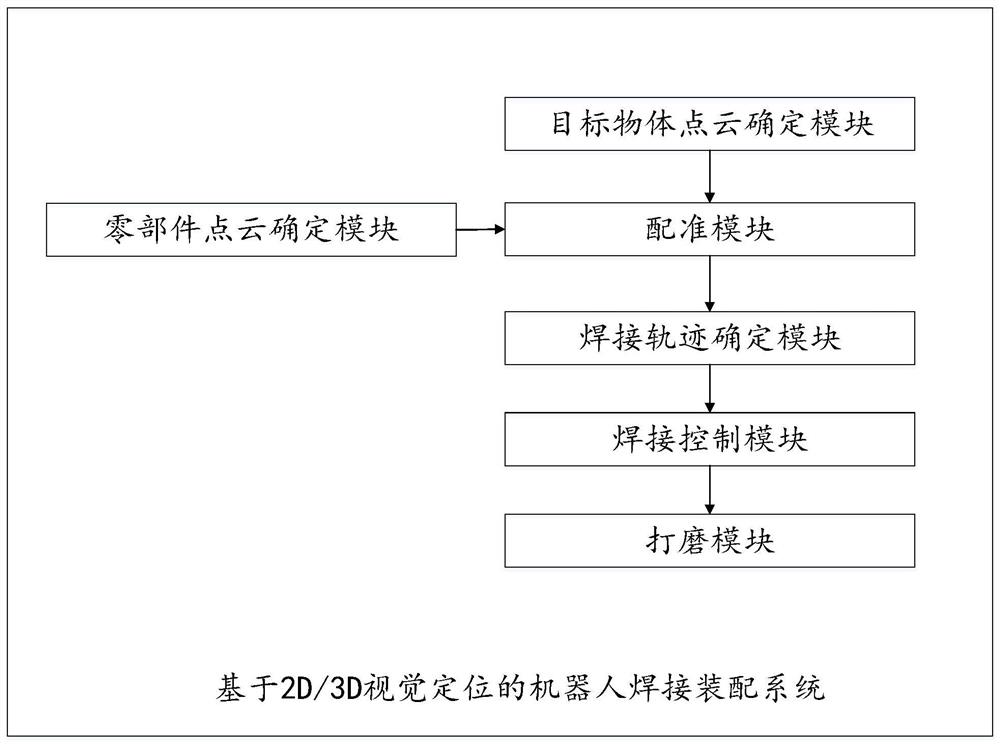

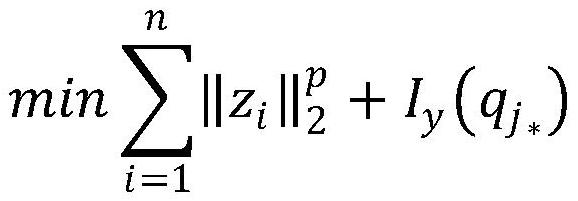

Robot welding assembly method and system based on 2D/3D visual positioning

ActiveCN112743270AAddress workforce redundancyAvoid secondary processingProgramme-controlled manipulatorWelding/cutting auxillary devicesPoint cloudEngineering

The invention provides a robot welding assembly method and system based on 2D / 3D visual positioning. The method comprises the following steps: 1, carrying out multi-view scanning of a pre-assembled target object meeting a production standard, so as to obtain a three-dimensional point cloud model A of the target object; 2, scanning all the to-be-assembled parts to obtain a three-dimensional point cloud model Bk of each to-be-assembled part; 3, performing point cloud registration on the point cloud A by each point cloud model in the point cloud set Bk to obtain a spatial transformation matrix TR and a registration result Mi of each point cloud model; 4, ranking the welding sequence of the parts according to the registration result Mi, and determining robot welding tracks P of every two adjacent parts; and 5, controlling the robot sequentially to clamp the parts in the corresponding sequence to move to the corresponding welding positions for welding according to the welding sequence. The method and system can be applied to a welding task of large batch of parts, and the robot can replace manual work to conduct intelligent welding and polishing.

Owner:GUANGZHOU ZSROBOT INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com