Adjustable hot mineral smashing mechanism based on real-time analysis

A technology of real-time analysis and crushing mechanism, applied in grain processing and other directions, can solve the problems of size reduction, mineral crushing efficiency decline, mineral processing efficiency and cost impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

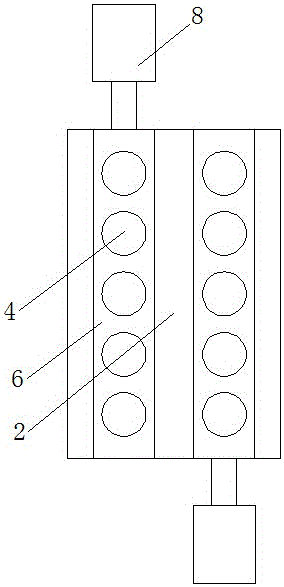

[0024] Such as figure 1 and figure 2 The shown adjustable hot ore crushing mechanism based on real-time analysis includes a crushing body 1, and a crushing roller shaft 2 is arranged inside the crushing body 1, which is driven by a driving motor 3 arranged outside the crushing body 1; A plurality of crushing end teeth 4 extending perpendicularly to the axis of the crushing roller shaft 2 are arranged on the crushing roller shaft 2, and a plurality of auxiliary crushing end teeth 5 are arranged on the inner wall of the crushing body 1, and the crushing end teeth 4 and The auxiliary crushing end teeth 5 are distributed alternately.

[0025] The radial section of the crushing roller shaft 2 adopts a rounded rectangular structure, and two groups of crushing end teeth 4 are arranged on each side end surface of the crushing roller shaft 2, and each group of crushing end teeth 4 includes a The placement end body 6 extending from the axis of the roller shaft is provided with a plur...

Embodiment 2

[0033] As an improvement of the present invention, such as Figure 5 As shown, three detection port holes 11 are arranged on the side surface of each crushing end tooth 4, which can uniformly detect each position of the crushing end tooth axially, so that the detection range of the pressure detection device can be improved. significantly improved.

[0034] The remaining features and advantages of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0036] As an improvement of the present invention, such as Figure 5 As shown, the end of the detection end body 12 located inside the detection end hole 11 is provided with a limit plate 13 extending perpendicular to the axial direction of the detection end body, and the limit plate 13 is connected to the end of the detection end hole 11 An elastic spring 14 is arranged between them. With the above technical solution, the detection end body can automatically return to the original position after being impacted by minerals through the setting of the limit plate and the elastic spring, so as to prevent the detection end body from sinking into the detection end hole.

[0037] The remaining features and advantages of this embodiment are the same as those of Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com