Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Good phase stability at high temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multielement rare earth oxide doped zirconia thermal barrier coating with craze crack structure and preparing method thereof

InactiveCN101723667AGood phase stability at high temperatureLow temperature for long-term useMolten spray coatingEfficient propulsion technologiesThermal insulationRare earth

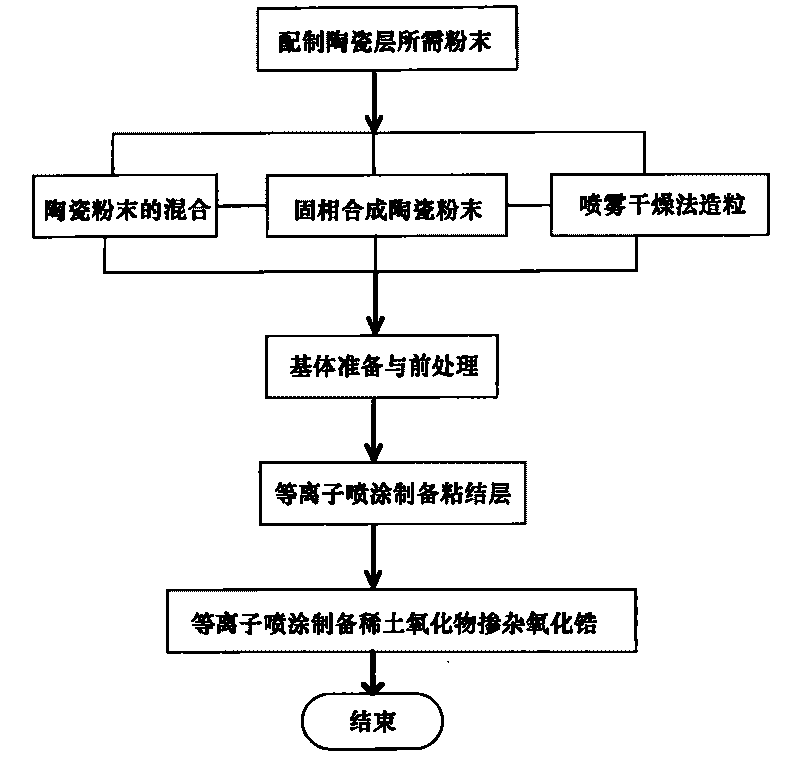

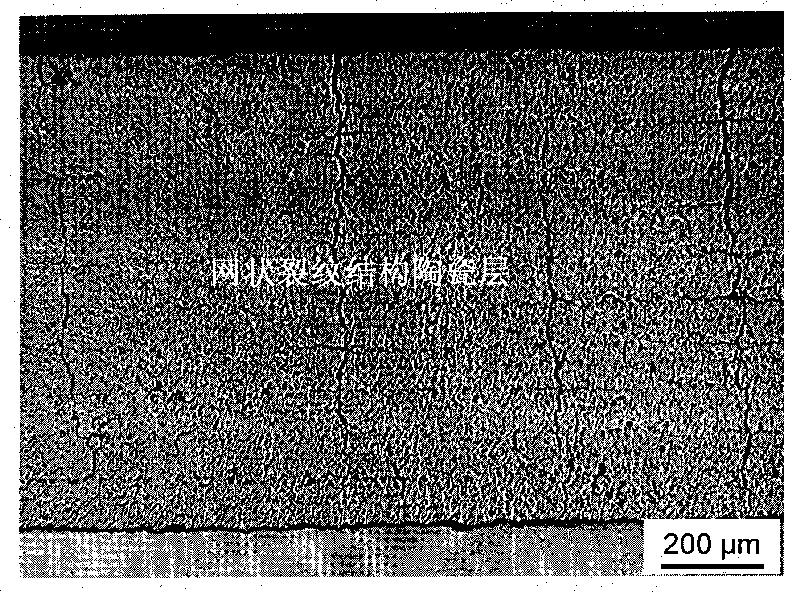

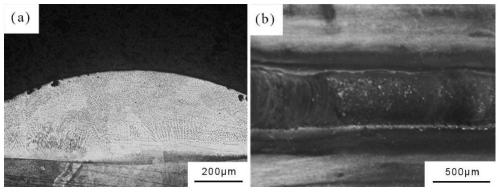

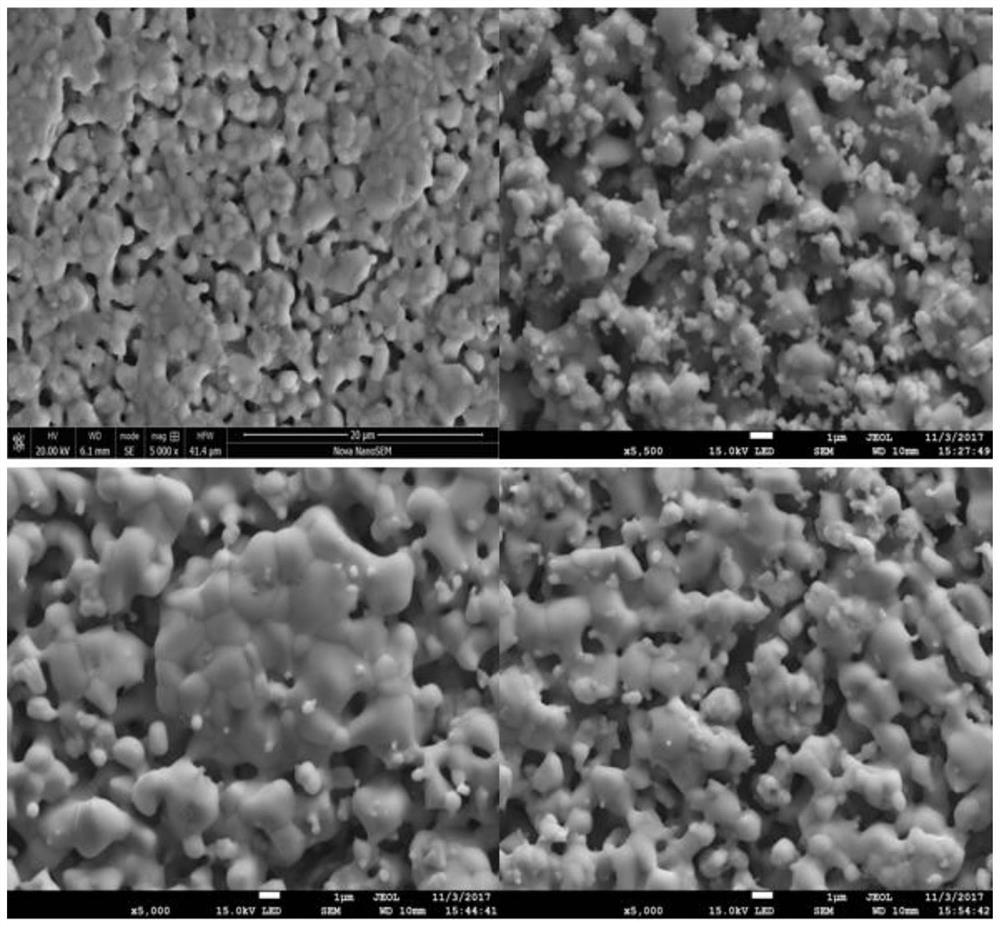

The invention discloses a method for preparing a rare earth oxide doped zirconia thermal barrier coating with a craze crack structure, which solves the problems of low thermal shock resistance property, difficult further thermal conductivity reduction and the like of the thermal coating prepared by conventional plasma spraying. Under the condition of the plasma spraying technology, the preheating temperature of a base body, the moving speed of a plasma spraying gun and a powder delivery rate are adjusted, then a rare earth oxide doped zirconia thermal barrier coating (BH-TBCO1) with a craze crack structure and stable thermodynamics is prepared. The rare earth oxide doped zirconia thermal barrier coating with a craze crack structure has good high-temperature phase stability at the temperature below 1300 DEG C; the thermal insulation property of the thermal barrier coating is further enhanced, and the thermal insulation temperature achieves more than 150 DEG C and is enhanced by more than 50% when compared with the coating prepared by the conventional plasma spraying; the thermal shock life of the coating exceeds 4000 cycles and is enhanced by more than 1 time when compared with the coating prepared by the conventional plasma spraying.

Owner:BEIHANG UNIV

Pyrochlore structural rare-earth zirconate material and preparation method and application thereof

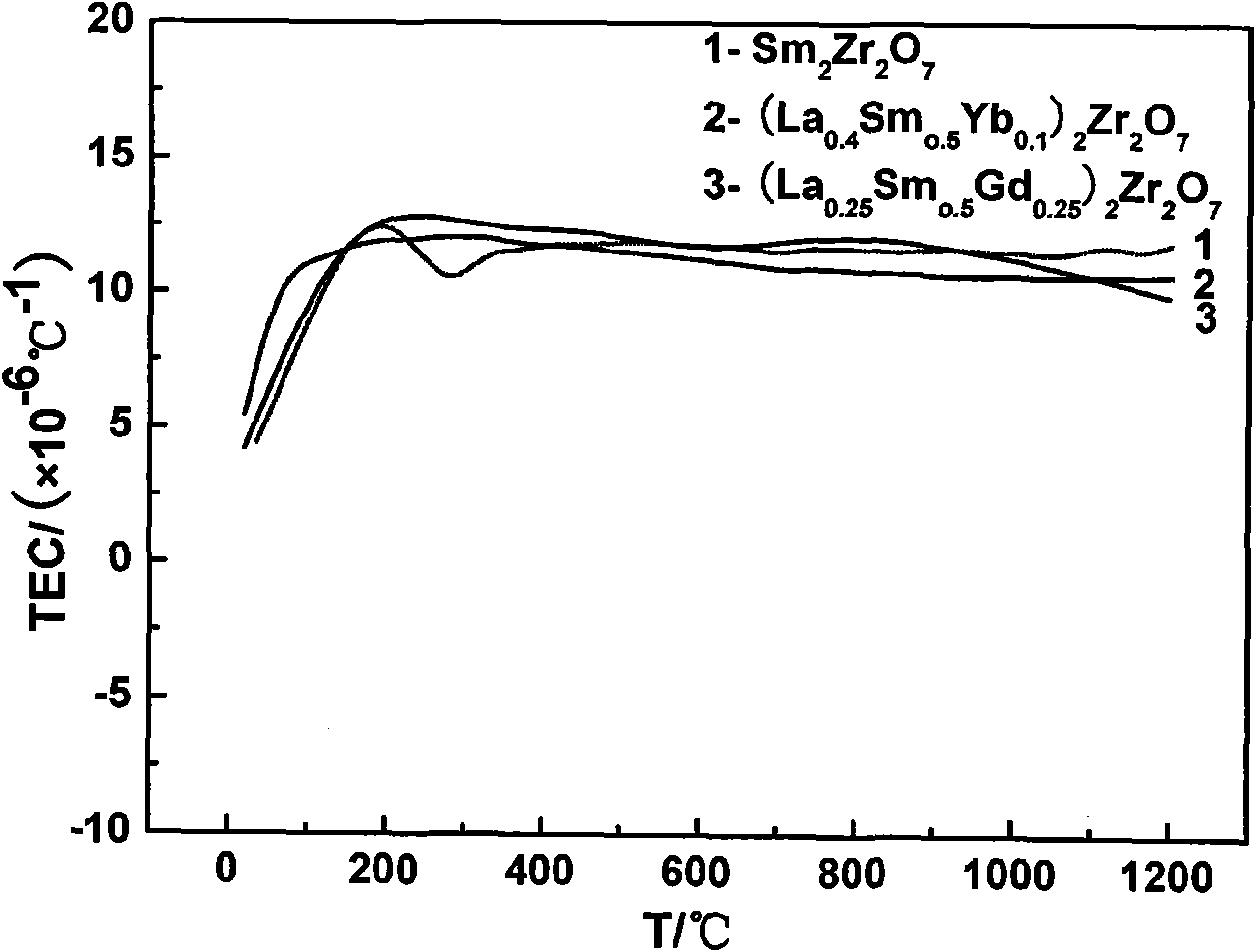

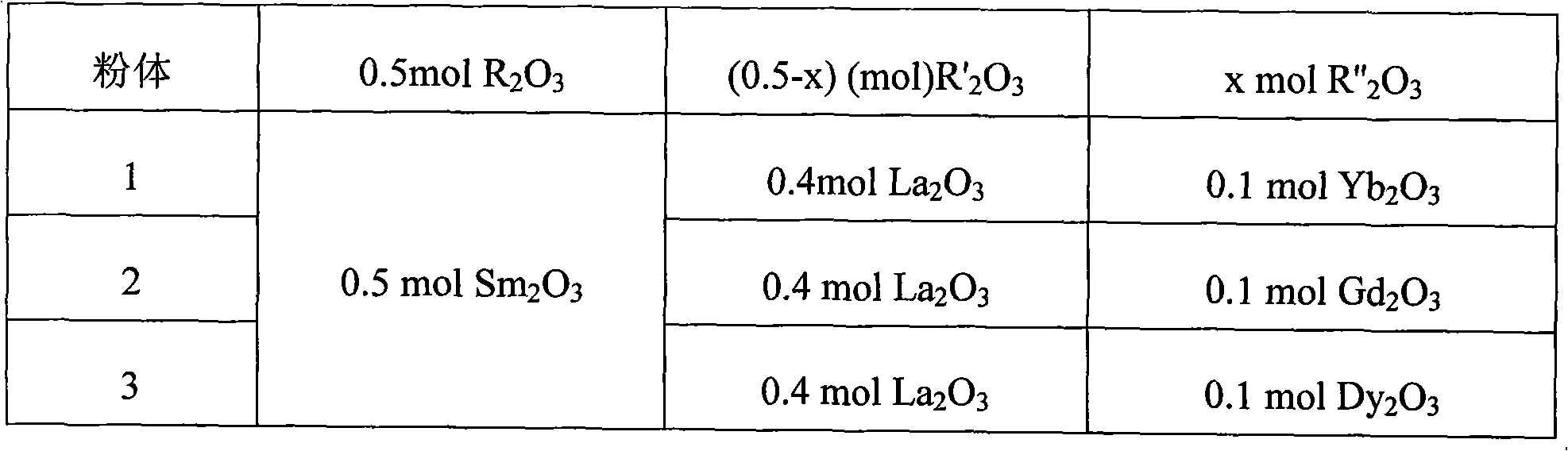

ActiveCN102070335AImprove wild swingsLow thermal conductivityMolten spray coatingRare-earth elementZirconate

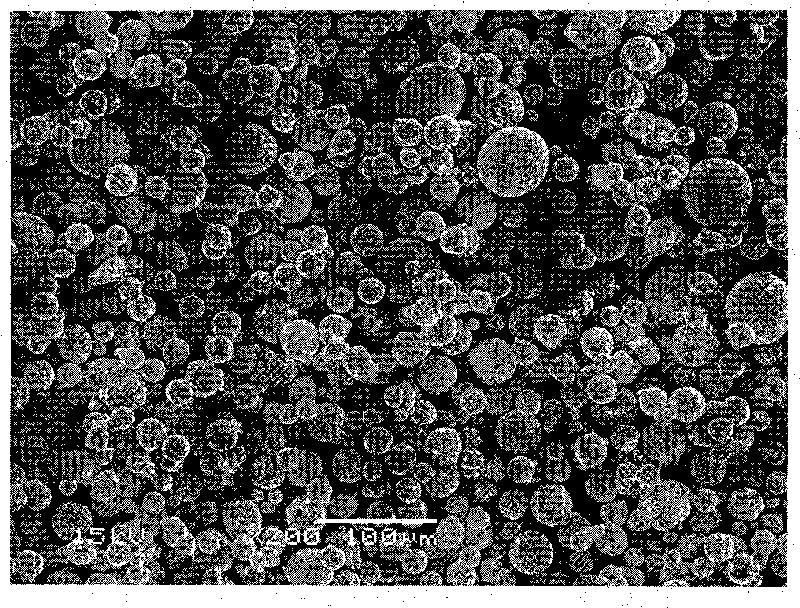

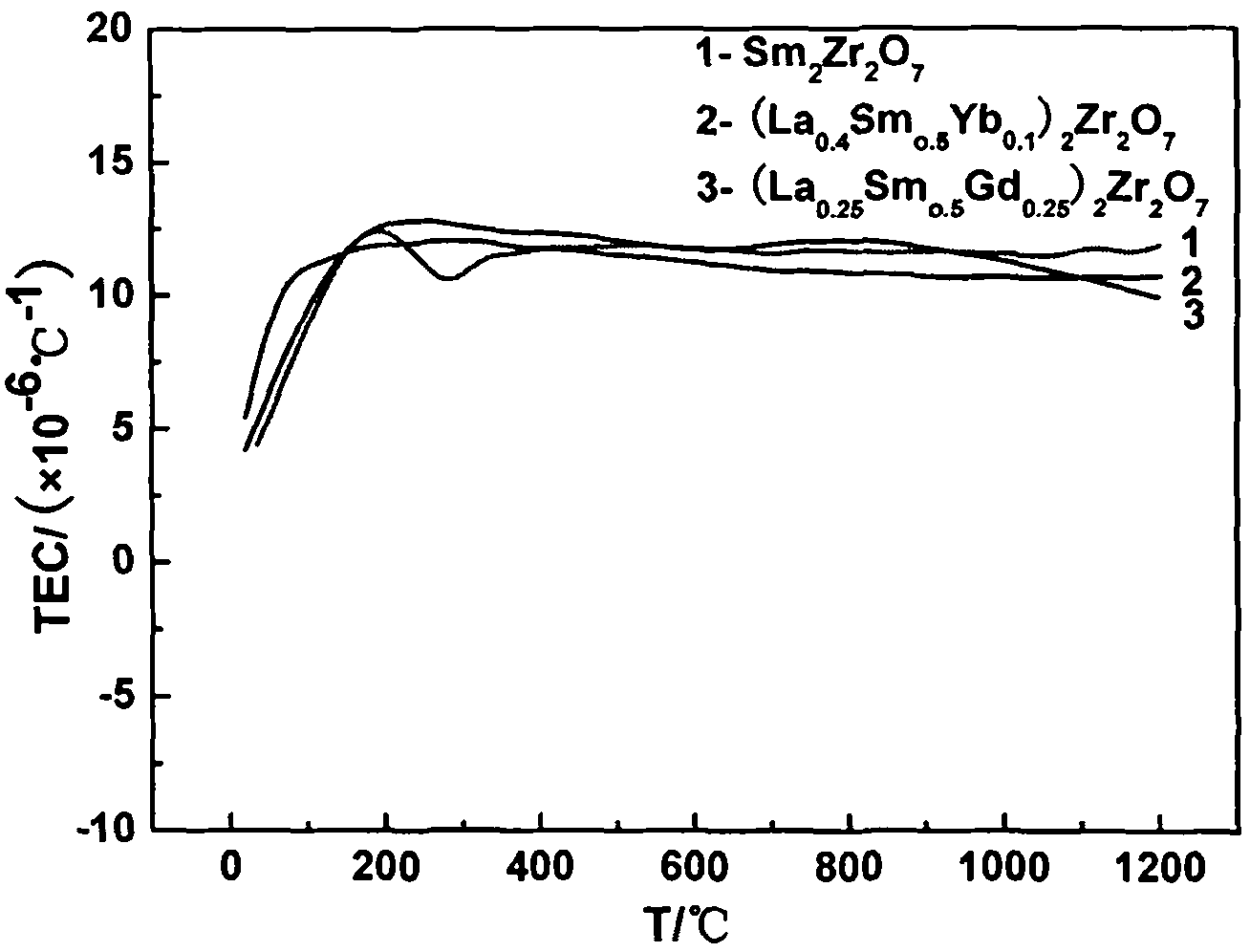

The invention discloses a pyrochlore structural rare-earth zirconate material system capable of being used for a heat barrier coating. The chemical composition of the material is (0.5-x)R'2O3-0.5Sm2O3-xR''2O3-2ZrO2, wherein x is more than 0 and less than or equal to 0.25; the R' is rare-earth elements or composition thereof, the ion radius of which is greater than that of Sm; and R'' is rare-earth elements or composition thereof, the ion radius of which is smaller than that of Sm. The material provided by the invention has low thermal conductivity, high thermal stability and high-temperature sintering resistance; the thermal expansion performance of the material is stable compared with a single pyrochlore structural material; and the material is favorable for reducing thermal stress generated by mismatching of thermal expansion coefficients in the thermal cycle process, and can prolong the thermal cycle life of the coating. Because of good high-temperature phase stability, the pyrochlore structural rare-earth zirconate material can be used for designing and preparing a novel high-temperature heat barrier coating material, the use temperature of which is below 1,550 DEG C.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Novel perovskite structure high-entropy ceramic and preparation method thereof

ActiveCN112919908AGood phase stability at high temperatureLow thermal conductivityAlcoholPolyvinyl alcohol

The invention discloses a novel perovskite structure high-entropy ceramic and a preparation method thereof. The structure of the ceramic is an ABO3 type perovskite structure, the A-site element is Sr, and the B-site element is Zr, Hf, Ce, Yb and Me which are in an equal molar ratio. The preparation method comprises the following steps: putting the components into a mortar, adding absolute ethyl alcohol, and performing grinding; performing drying in a drying oven after the grinding, then transferring dried material into a muffle furnace for pre-calcining, and naturally cooling obtained material to room temperature to obtain a ceramic powder; putting the ceramic powder into the mortar, adding a polyvinyl alcohol aqueous solution and absolute ethyl alcohol, performing grinding again, and performing drying and sieving after the grinding is sufficient, adding the sieved ceramic powder into a steel mold of a table type powder tablet press, pre-pressing into a disc-shaped or strip-shaped block material, and then putting the block material into a cold isostatic press for cold isostatic pressing treatment to obtain a ceramic green body; and finally, calcining the ceramic green body in a muffle furnace, and performing cooling in the furnace to obtain the novel perovskite structure high-entropy ceramic. The high-entropy ceramic has the advantages of high stability, low thermal conductivity and relatively high hardness and density.

Owner:INNER MONGOLIA UNIV OF TECH

Preparation method of CoCrFeMnNi high-entropy alloy cladding layer

InactiveCN110117788AImprove wear resistanceAccelerated corrosionMetallic material coating processesHigh entropy alloysCorrosion resistant

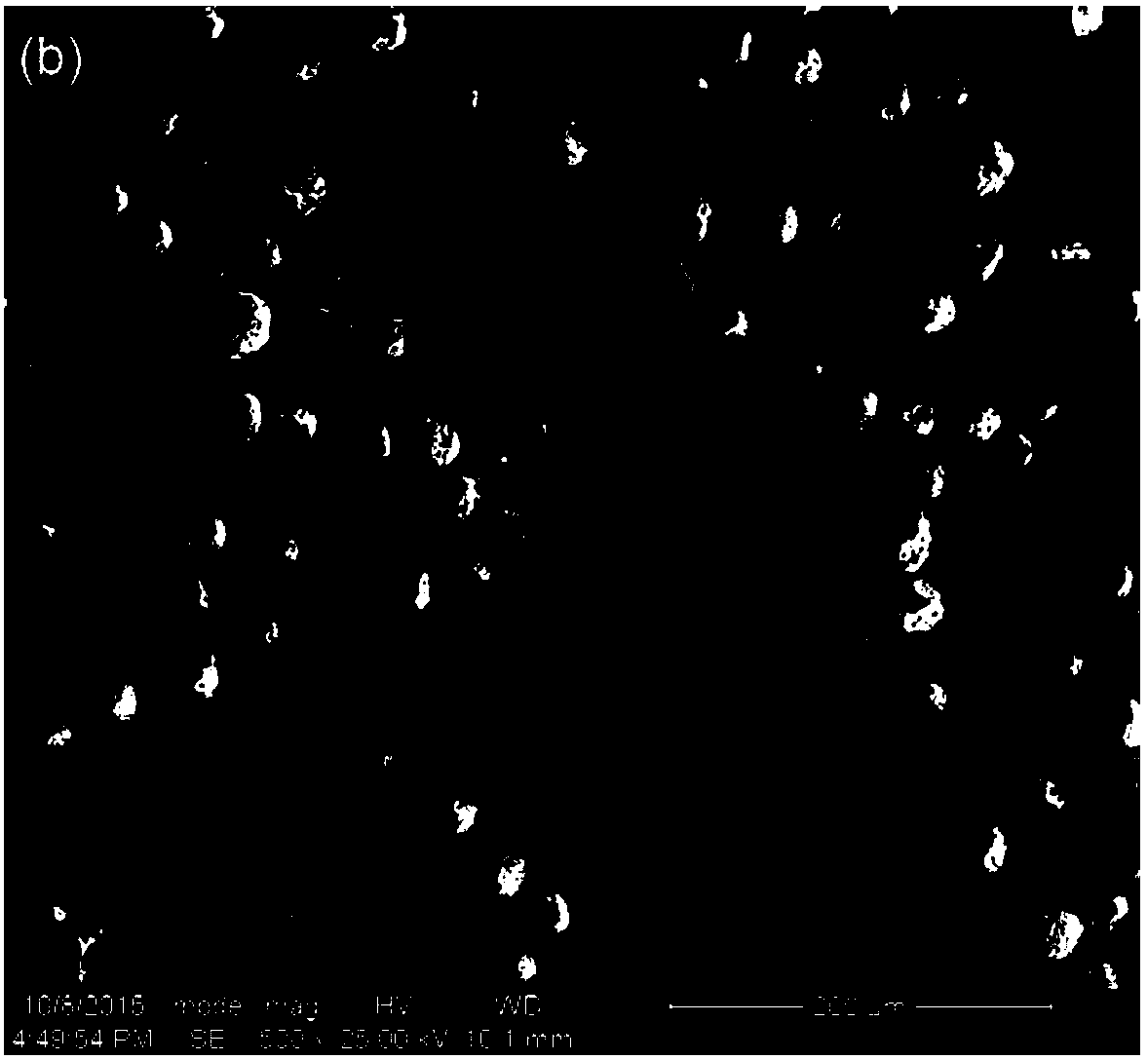

The invention relates to a preparation method of a CoCrFeMnNi high-entropy alloy cladding layer. With the adoption of a microbeam plasma welding machine, the surface of a part is covered with CoCrFeMnNi high-entropy alloy powder through powder feeding cladding or spray welding cladding, and the cladding layer is formed on the surface of a mechanical part through the changing process of a metallurgical reaction, cooling solidification and solid-state phase transformation. The dilution rate of the high-entropy alloy cladding layer is within 10%, and is remarkably less than that of laser cladding; the cladding layer is dense and has no defects of cracks, air holes and the like; the corrosion resistance is higher than that of a 304 corrosion-resistant plate; the comprehensive performance is good; and the life of a workpiece under the bad working condition is prolonged. The cladding layer is prepared with the adoption of a microbeam plasma arc cladding technology, so that the defects in thesolidification process are reduced; and the production efficiency is improved substantially, the cost is reduced substantially, the adaptability is high, and the technologized production is easy to achieve.

Owner:TIANJIN UNIV

Low-thermal-conductivity high-entropy ceramic thermal barrier coating material

A preparation method of the low-thermal-conductivity high-entropy ceramic thermal barrier coating material comprises the steps that A, nitrate of trivalent rare earth elements and acetate of tetravalent metal elements serve as raw materials, and high-entropy ceramic powder of a hollow spherical structure is prepared through a plasma spraying technology; step B, sequentially adding a polyvinyl alcohol aqueous solution and an ethanol solution into the high-entropy ceramic powder for grinding, and then putting the high-entropy ceramic powder into a drying oven for drying to obtain precursor powder; step C, pre-pressing the precursor powder into a disc-shaped or strip-shaped block material, putting the block material into a disposable rubber fingerstall, vacuumizing, and carrying out cold isostatic pressing treatment to obtain a ceramic green body; and D, firing the ceramic body, namely calcining the ceramic body in a muffle furnace, and cooling the ceramic body along with the furnace after calcining is finished. The high-entropy ceramic thermal barrier coating material disclosed by the invention is a pyrochlore phase, and compared with a YSZ material, the high-entropy ceramic thermal barrier coating material has lower thermal conductivity, good high-temperature phase stability and a thermal expansion coefficient closer to that of a base material.

Owner:INNER MONGOLIA UNIV OF TECH

Shining thermal barrier coating system of rare earth niobate based on defective fluorite structure and preparation method of shining thermal barrier coating system

InactiveCN106967953ALow thermal conductivityImprove oxygen barrier performanceMolten spray coatingVacuum evaporation coatingElectron beam physical vapor depositionGas phase

Owner:乐延伟

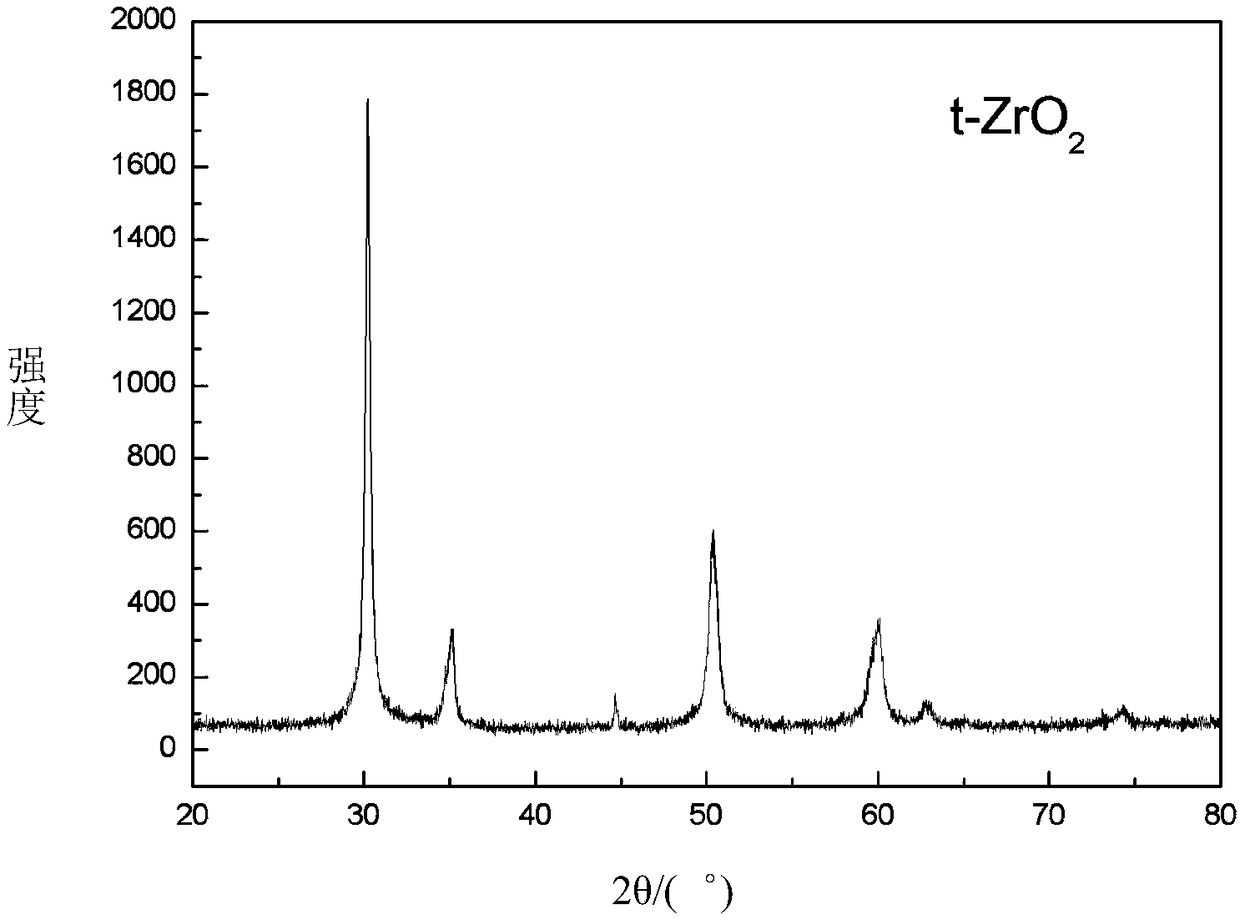

High-performance thermal barrier coating and ceramic layer thereof

ActiveCN107815633AImprove efficiencyIncrease working temperatureMolten spray coatingNano structuringThermal diffusion coefficient

The invention discloses a preparation method for a high-performance thermal barrier coating and specifically discloses a 4YSZ (4mol% Y2O3 stabilized ZrO2) thermal barrier coating and the preparation method of the 4YSZ thermal barrier coating. The 4YSZ powder which is of a fine nano-structure, uniform ingredients and a pure tetragonal phase structure is prepared utilizing a sol-spray pyrolysis synthetic process, and the 4YSZ powder is subjected to spray drying granulation, screening and atmospheric plasma spraying (APS) in sequence to prepare the coating. The high-performance thermal barrier coating prepared by the invention is of a pure tetragonal phase nano-structure with uniform ingredients, compared with a traditional YSZ casting, the high-performance thermal barrier coating has the advantages of being low in thermal diffusion coefficient, good in high temperature phase stability and thermal shock resistance, simple in preparation process and low in cost and the like; and the high-performance thermal barrier coating is more conducive to improving the efficiency and working temperature of a turbine engine, and the service life of the engine is prolonged.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

High-temperature-resistant anti-oxidation anti-abrasion low-heat-expansion-coefficient aluminum tantalite ceramic material as well as preparation method and application thereof

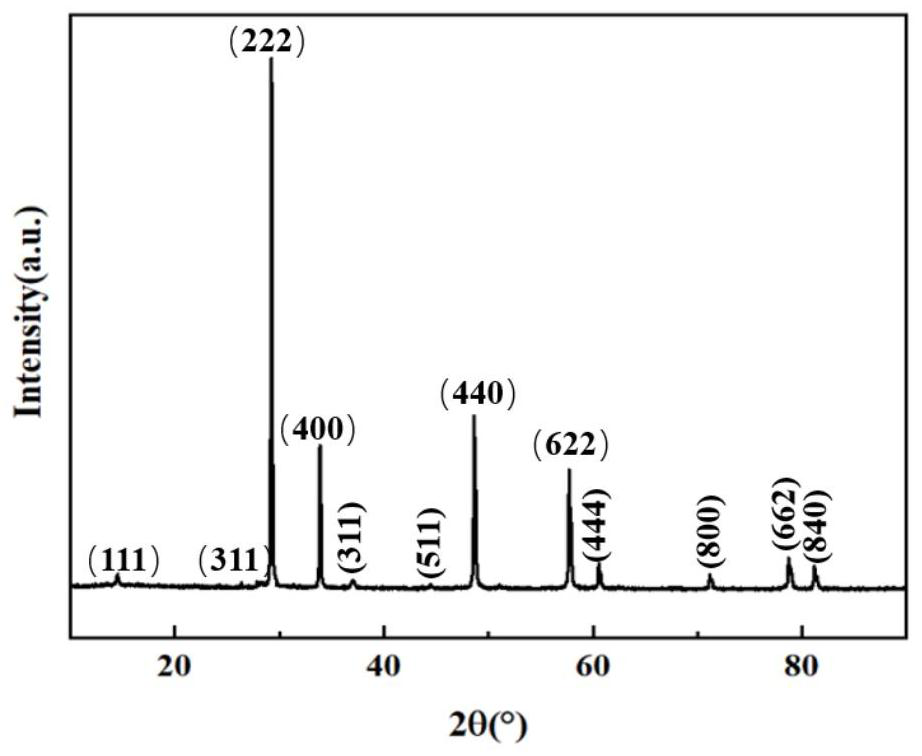

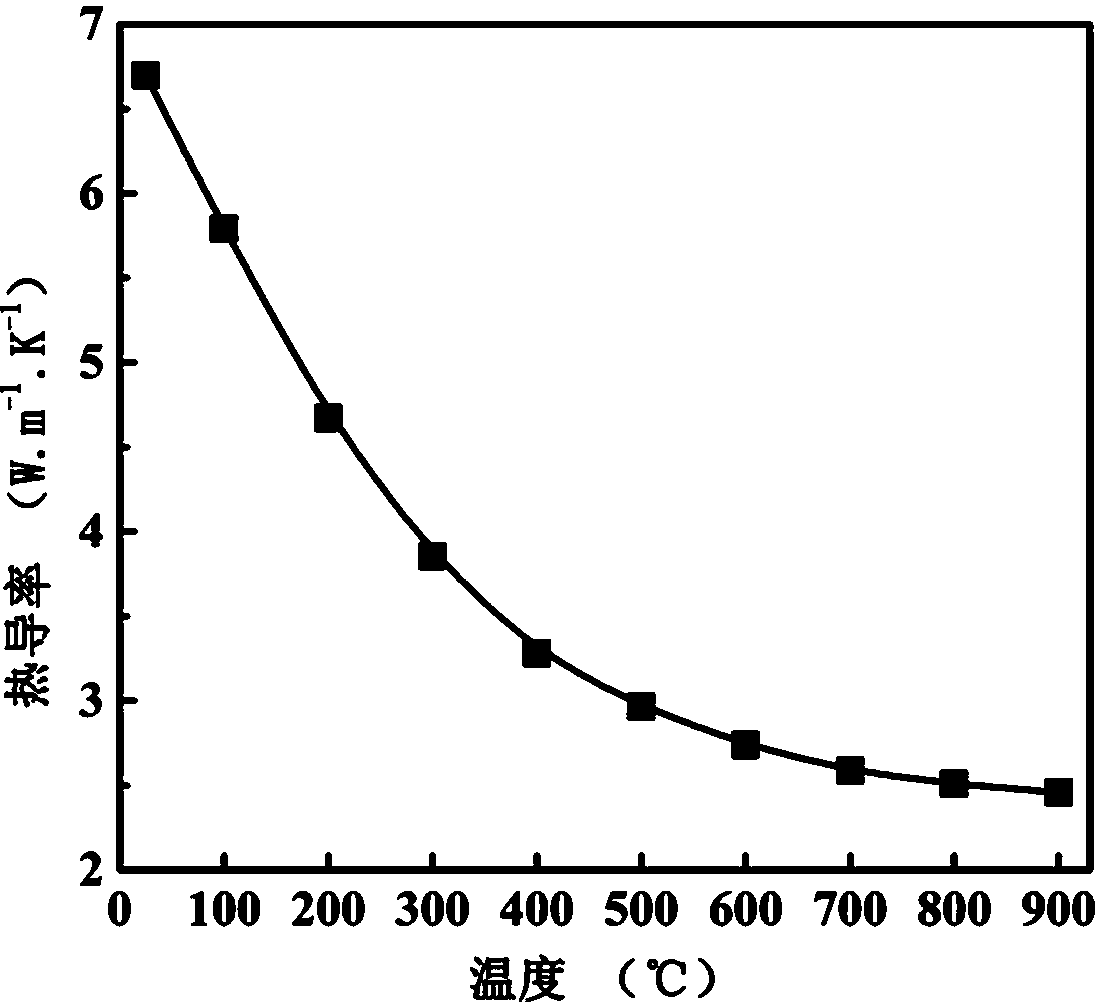

The invention discloses a high-temperature-resistant anti-oxidation anti-abrasion low-heat-expansion-coefficient aluminum tantalite ceramic material as well as a preparation method and application thereof. The high-temperature-resistant anti-oxidation anti-abrasion low-heat-expansion-coefficient aluminum tantalite ceramic material is prepared from aluminum oxide and tantalum pentoxide as raw materials; the compactness of the high-temperature-resistant anti-oxidation anti-abrasion low-heat-expansion-coefficient aluminum tantalite material is 98 percent; the heat diffusion coefficient is 0.6 to2.4mm<2> / s (25 to 900 DEG C); the heat conduction rate is 2.2 to 6.2W.K<-1>(25 to 900 DEG C); the hardness is 9.0 GPa; the phase change cannot occur at the temperature of 25 to 1200 DEG C. The preparation method comprises the steps of pretreatment and sintering. The application is the application of the high-temperature-resistant anti-oxidation anti-abrasion low-heat-expansion-coefficient aluminumtantalite ceramic material to the preparation of a coating with thermal and mechanical property.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of novel interface phase material

ActiveCN113248266AGood high temperature resistance and oxidation resistanceExtended service lifeO-Phosphoric AcidPhosphate

The invention provides a preparation method of a novel interface phase material. The method comprises the following steps: preparing silica sol, preparing a citrate stock solution from RE<3+> soluble nitrate and citric acid, and mixing the citrate stock solution with a phosphoric acid solution to obtain a mixed solution; pretreating SiC fibers; dipping the pretreated SiC fiber in the prepared silica sol, dipping, coating and drying, and then keeping in a vacuum furnace at a constant temperature for 1 hour to obtain the SiC fiber with a SiO2 coating on the surface; putting the SiC fiber with the SiO2 coating into the prepared mixed solution, keeping in a constant-temperature water bath for a period of time, washing, drying, and carrying out first heat treatment under the protection of inert gas to form a rare earth phosphate coating on the surface of the SiO2 coating; and performing secondary heat treatment on the prepared sample under the protection of inert gas to form an interface phase with a rare earth pyrosilicate coating on the surface of the SiC fiber.

Owner:NAT UNIV OF DEFENSE TECH

High-temperature and low-thermal conductivity bismuth oxide-based thermal barrier coating material and preparation method thereof

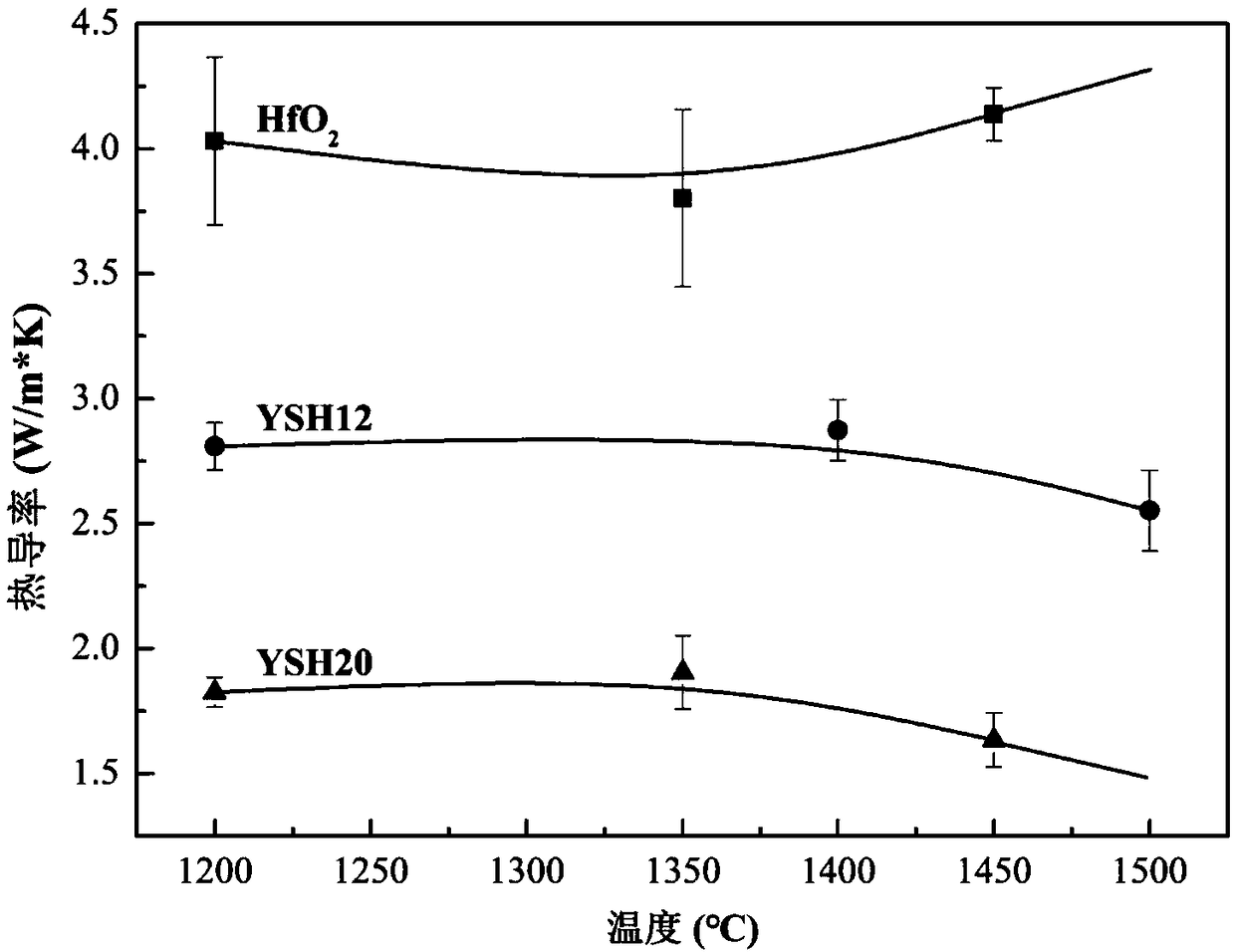

ActiveCN108439977AGood phase stability at high temperatureBlocking heat radiation and good heat transfer performanceHafnium oxideCombustion chamber

The invention discloses a high-temperature and low-thermal conductivity bismuth oxide-based thermal barrier coating material and a preparation method thereof and belongs to the technical field of thermal barrier coating materials. The thermal barrier coating material is an yttrium oxide-stabilized hafnium oxide material system, and the chemical composition of the material is Hf1-xYxO2-0.5x, wherein x is more than 0 but less than or equal to 0.2. The material disclosed by the invention has the characteristics of high-temperature phase stability and low radiation heat transfer at a high temperature and can ensure that in a combustion chamber high temperature service environment, the thermal conductivity is not greatly increased by thermal radiation. Due to high high-temperature phase stability, the yttrium oxide-stabilized hafnium oxide ceramic material can be used for designing and preparing a novel high-temperature thermal barrier coating material of which the usage temperature is notlower than 1500 DEG C.

Owner:BEIHANG UNIV

Titanium alloy surface TiO2-FHA biological gradient active coating and preparation method thereof

InactiveCN101455860AImprove performanceGood matching mechanicsElectrophoretic coatingsProsthesisMass ratioBiocompatibility Testing

The invention discloses a bioactive gradient coating on the surface of titanium alloy and a preparation method thereof. The composition of the coating is TiO2-FHA. The preparation method comprises: preparing FHA powder by a precipitation method; and preparing the TiO2-FHA biological gradient coating on a titanium alloy substrate by an electrophoretic codeposition-sintering method and adjusting the composition mixture ratio of TiO2 and the FHA in a deposition solution, wherein the mass ratio of the TiO2 to the FHA is between 5:1 and 1:5. The thickness of the gradient coating is controlled by changing the deposition voltage and the deposition time, wherein the deposition voltage is between 10 and 80 volts, and the deposition time is between 15 and 90 seconds; and the coating after sintering has superior binding ability with the substrate, and has superior biocompatibility.

Owner:CENT SOUTH UNIV

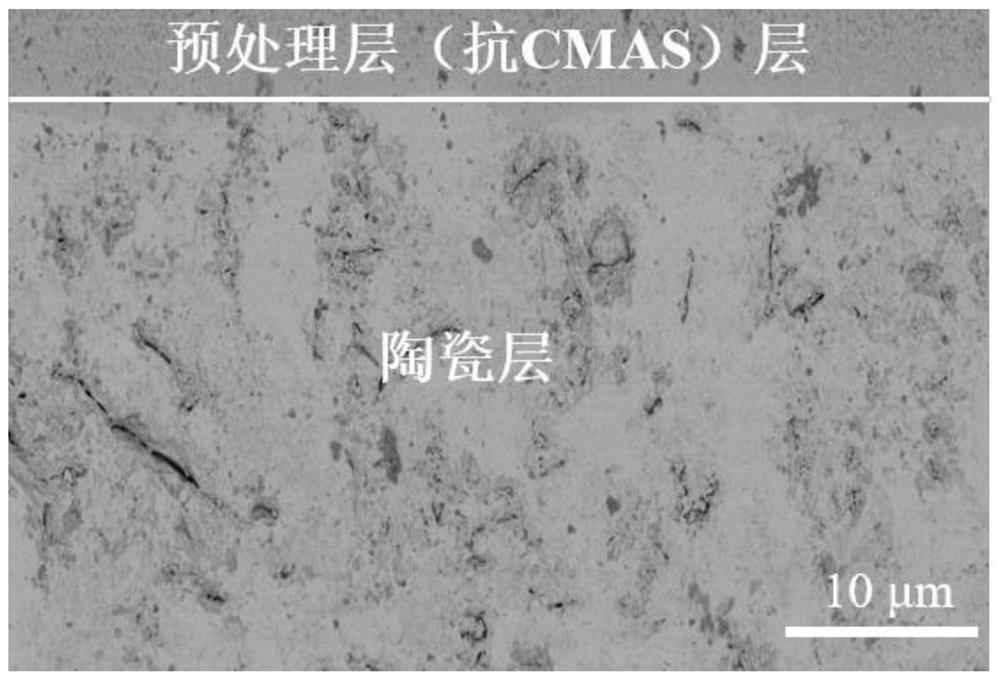

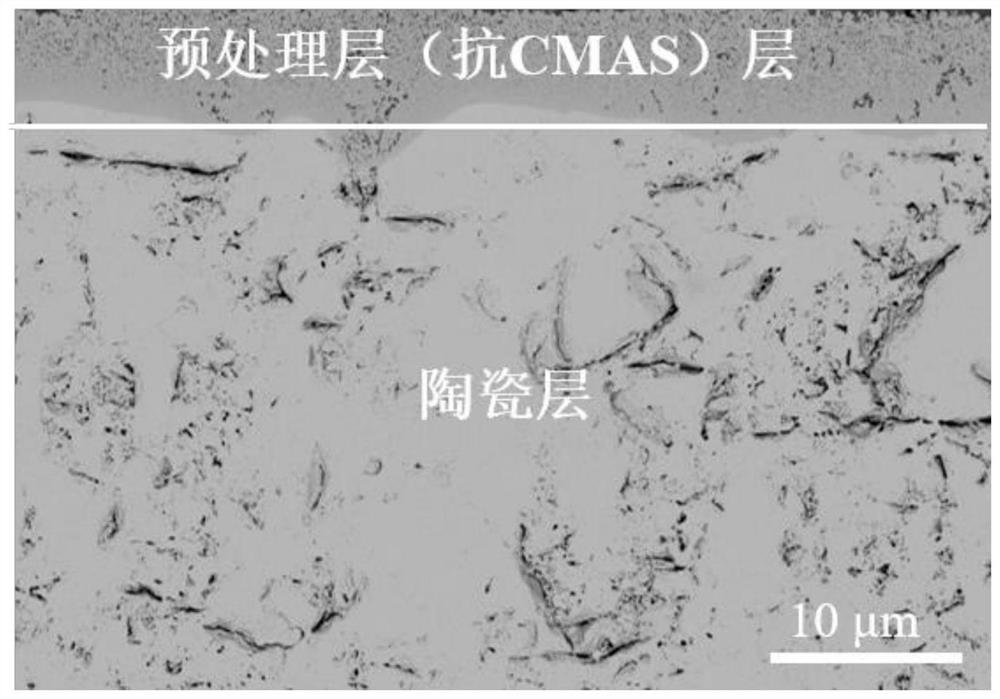

Thermal barrier coating layer resisting CMAS erosion and preparation method

ActiveCN111850454AImprove the ability to resist CMAS erosionHigh melting pointMolten spray coatingEfficient propulsion technologiesCrazingThermal barrier coating

The invention relates to the technical field of surface corrosion and protection of thermal barrier coating layers, specifically to a thermal barrier coating layer resisting CMAS erosion and a preparation method. In the technical solution of the invention, prefabricated CMAS suspension is uniformly coated on the surface of a thermal barrier coating layer; and then, the coating layer is sintered for a period of time in a high-temperature furnace to form a compact apatite phase barrier layer on the surface. The layer has the features of high melting point, high compactness, excellent phase stability and high bonding force, not only can fill inevitable holes and cracks in the surface spraying process of ceramic layers, but also can block CMAS diffusion channels in the ceramic layers, effectively improves the CMAS erosion resistance of the thermal barrier coating layer.

Owner:JIANGSU UNIV

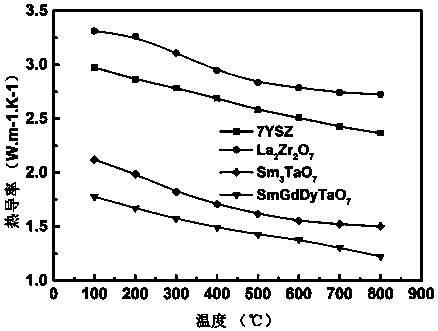

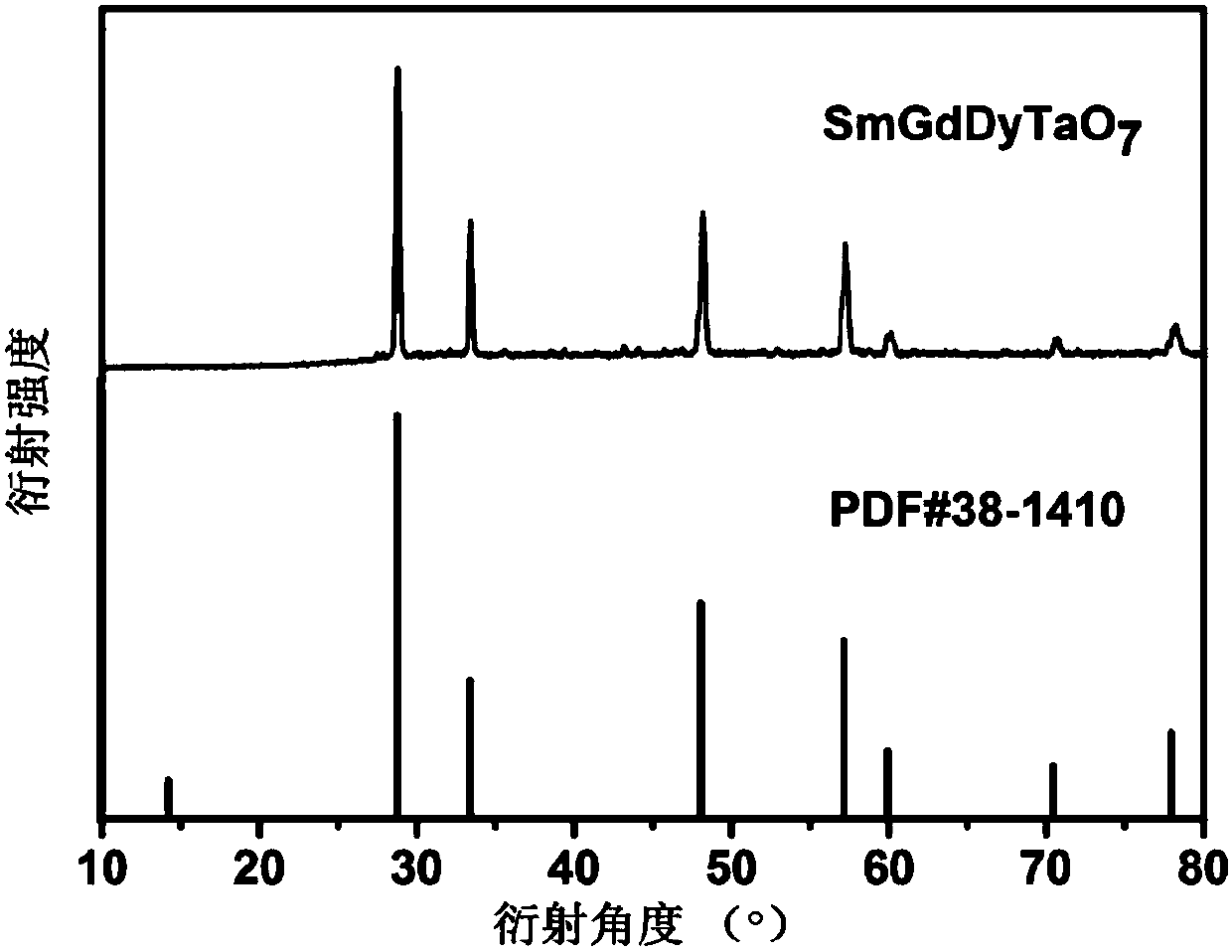

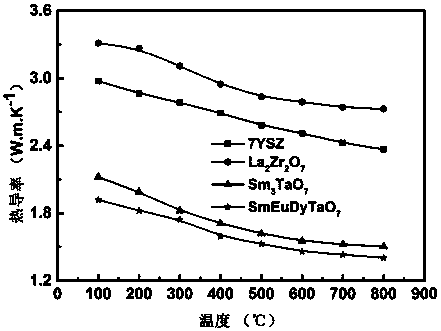

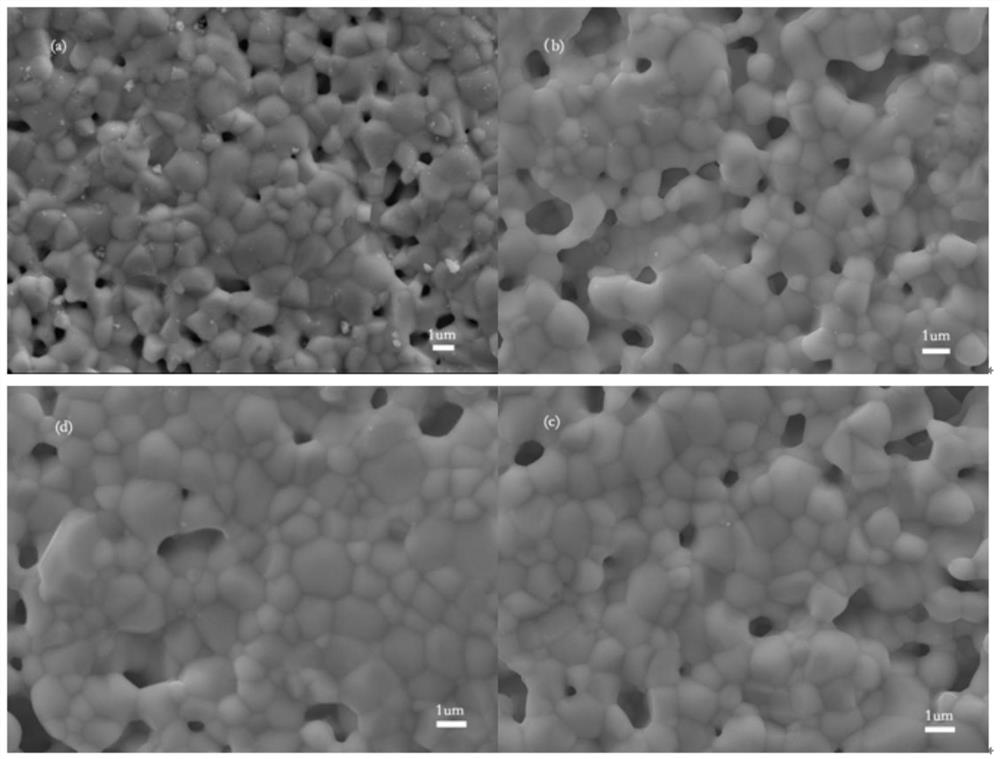

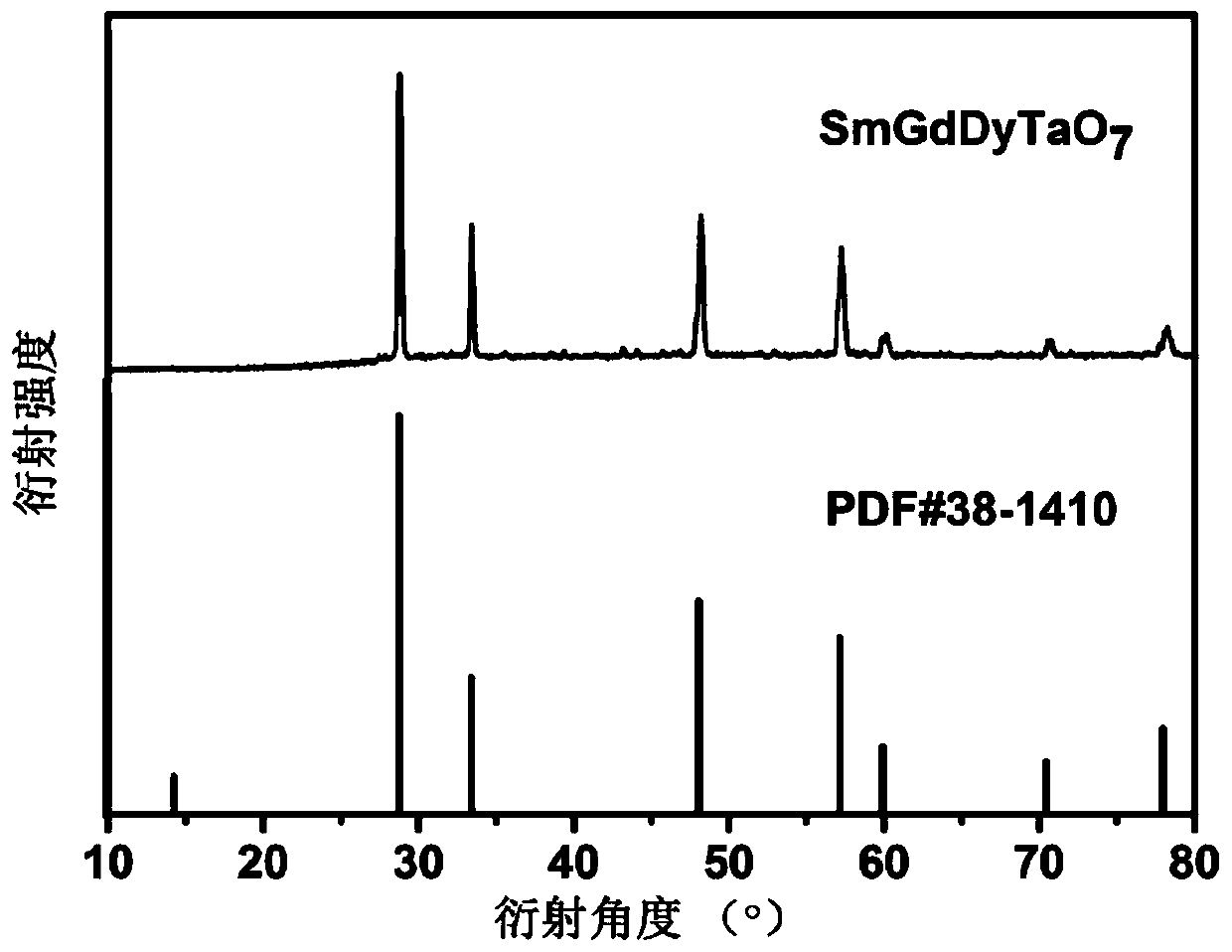

Sm-Gd-Dy tri-rare-earth ion tantalate and preparation method and application thereof

The invention discloses a Sm-Gd-Dy tri-rare-earth ion tantalate and a preparation method and application thereof. The general chemical formula of the Sm-Gd-Dy tri-rare-earth ion tantalate is SmGdDy<c>TaO<7>, wherein the a, b and c meet the relationship of a+b+c=3 and are separately in a range of 0.8-1.2. The preparation method comprises the following steps: (1) weighing samarium nitrate, gadolinium nitrate, dysprosium nitrate and tantalum oxalate according to a stoichiometric ratio, performing mechanical mixing with citric acid with a preset amount under a heat preservation condition, adding a concentrated ammonia water neutralization solution during the mixing process, and carrying out mechanical mixing to promote a complexation reaction under a heat preservation condition; and (2)drying the obtained solution, and then carrying out calcination at a high temperature to remove carbon impurities to obtain the Sm-Gd-Dy tri-rare-earth ion tantalate powder. The Sm-Gd-Dy tri-rare-earth ion tantalate has good high-temperature thermal stability and low thermal conductivity, and can be used as a thermal barrier coating material.

Owner:陕西天璇涂层科技有限公司

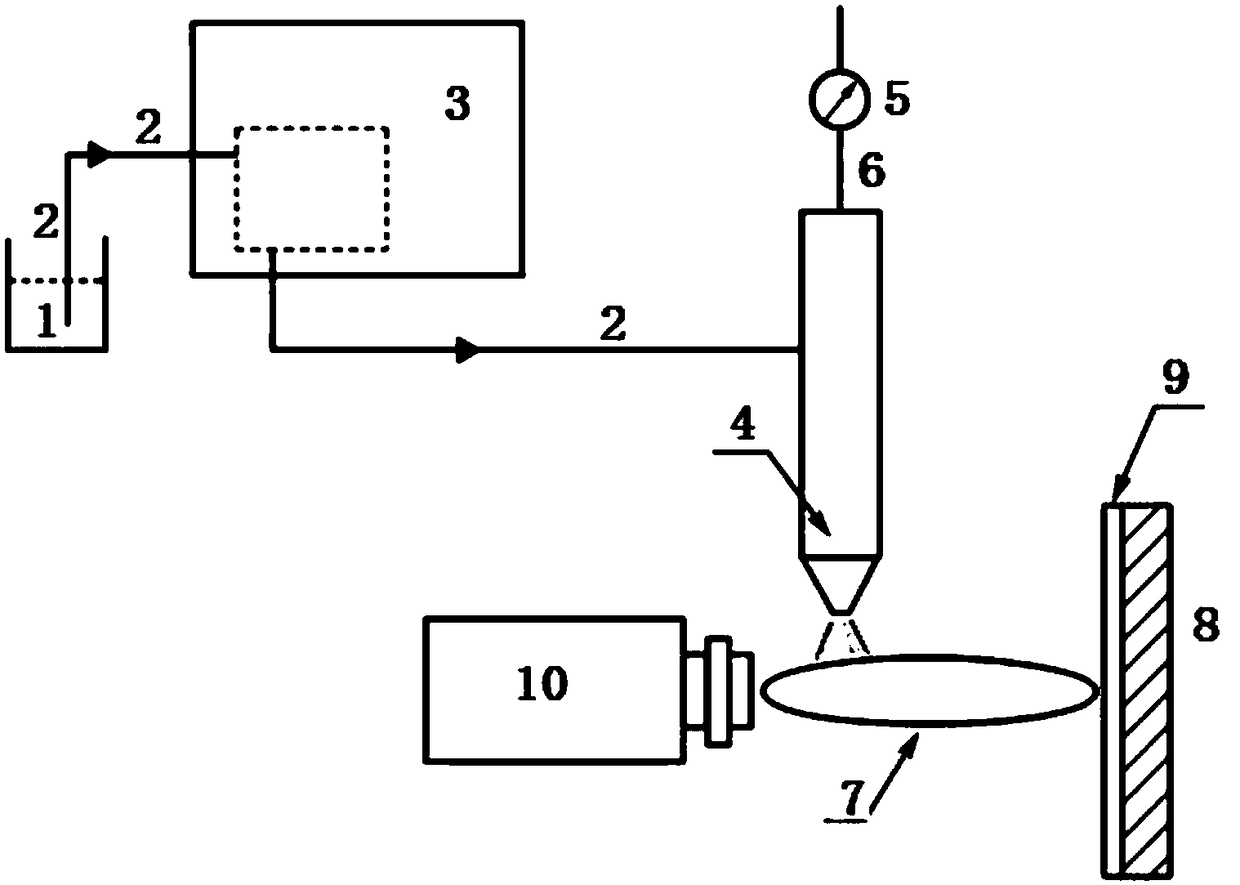

Preparation method of thermal barrier coating and thermal barrier coating prepared through preparation method

InactiveCN108441806AOptimal Control StructureSimplify the tedious process of granulationMolten spray coatingPlasma jetNano structuring

The invention provides a preparation method of a thermal carrier coating and the thermal barrier coating prepared through the preparation method. According to the preparation method, a precursor solution prepared from zircon salt and ytterbium salt is used as a spraying raw material, and in a liquid-phase plasma spraying device, the precursor solution is delivered into plasma jet flow through a two-flow atomization nozzle and then deposits on a matrix to form the thermal barrier coating provided with evenly-distributed pores and vertical crack structures. The thermal barrier coating prepared through the method is a nano-structure thermal barrier coating provided with vertically-cracked columnar crystals and the evenly-distributed pores. According to the preparation method of the thermal carrier coating and the thermal barrier coating prepared through the preparation method, the precursor solution replaces agglomeration powder to serve as the raw material, so that a complex traditionalraw material pelletizing process based atmosphere plasma spraying is greatly simplified, the production efficiency is improved, and the cost is reduced. The structure of the coating is controllable, and the thermal barrier coating prepared through the preparation method is of a nano-structure and is provided with vertical crack structures. A ceramic material YbSZ has high phase stability and low thermal conductivity.

Owner:TIANJIN UNIV

Preparation method of tetravalent ion-doped toughened hafnium oxide-based high-temperature thermal protection material

InactiveCN110835264AImprove fracture toughnessGood phase stability at high temperatureHigh fractureTitanium oxide

The invention discloses a preparation method of a tetravalent ion-doped toughened hafnium oxide-based high-temperature thermal protection material, and the product obtained therethrough. The preparedthermal protection material is a yttrium oxide and tetravalent oxide co-doped hafnium oxide material system, the chemical composition of the material is (Hf1-xLnx)0.92Y0.08O1.96, and Ln is selected from Ti, Sn or Th. The material has the characteristics of high phase stability, high toughness and low thermal conductivity high fracture toughness can be guaranteed when the material is used as a thermal protection material, and when x is 0.25, the highest fracture toughness can reach 3.62 MPa.m<1 / 2>, meanwhile, the low thermal conductivity of about 1.8 W / (m*K) is kept at 1200 DEG C, and phase change does not occur within 1400 DEG C. The yttrium oxide and titanium oxide co-doped stable hafnium oxide material has good high-temperature phase stability, and can be used for designing and preparinghigh-temperature thermal protection material with the use temperature of 1400 DEG C or above.

Owner:BEIHANG UNIV

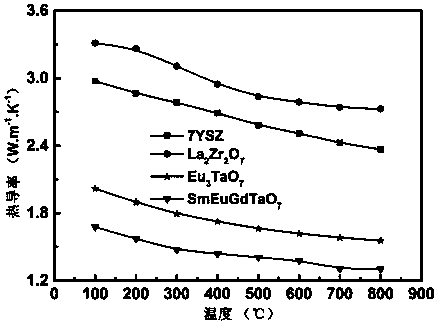

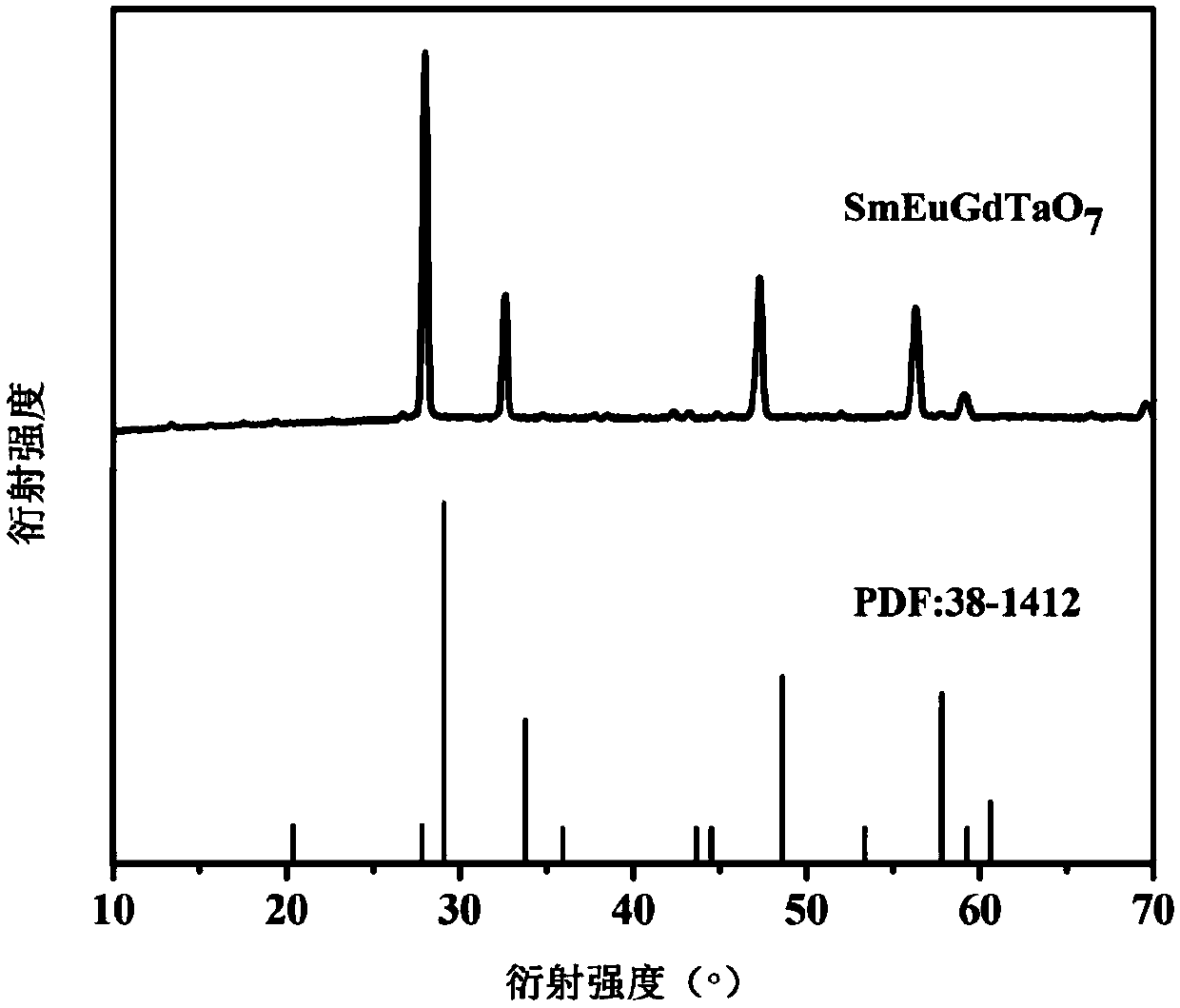

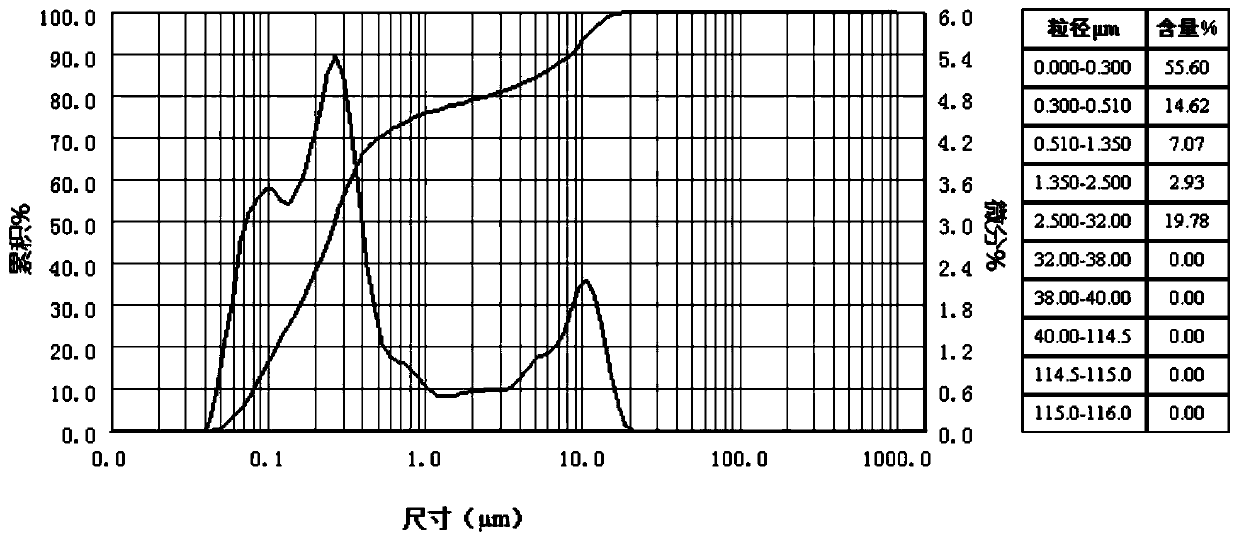

Sm-Eu-Gd trirare earth ion tantalate as well as preparation method and application thereof

ActiveCN107662947AGood thermal propertiesGood thermal stability at high temperatureMolten spray coatingTantalum compoundsChemistryAmmonium hydroxide

The invention discloses Sm-Eu-Gd trirare earth ion tantalate as well as a preparation method and application thereof. The chemical general formula of the Sm-Eu-Gd trirare earth ion tantalate is SmaEubGdcTaO7, wherein a+b+c is equal to 3, and a,b,c is equal to 0.8 to 1.2. The preparation method of the Sm-Eu-Gd trirare earth ion tantalate comprises the following steps: (1) weighing europium chloride, gadolinium nitrate, samarium nitrate and tantalum oxalate according to a stoichiometric ratio, mechanically mixing with a set amount of citric acid under heat preservation conditions, adding a concentrated ammonium hydroxide neutralizing solution in a mixing process, and then mechanically mixing under the heat preservation conditions to promote the process of reaction; (2) drying the obtained solution, and then calcining at high temperature to remove carbon impurities to obtain Sm-Eu-Gd trirare earth ion tantalate powder. The Sm-Eu-Gd trirare earth ion tantalate is high in high-temperature thermal stability and low in thermal conductivity coefficient, and can be applied as a thermal barrier coating material.

Owner:陕西天璇涂层科技有限公司

High-fracture-toughness thermal barrier coating material of high-entropy rare earth aluminate toughened high-entropy rare earth zirconate as well as preparation method and application of high-fracture-toughness thermal barrier coating material

PendingCN114516761AGood phase stability at high temperatureImprove fracture toughnessEfficient propulsion technologiesAluminateHigh fracture

The invention discloses a high-fracture-toughness thermal barrier coating material of high-entropy rare earth aluminate toughened high-entropy rare earth zirconate and a preparation method of the high-fracture-toughness thermal barrier coating material. The thermal barrier coating material is x [nRE1 / nAlO3]-(1-x) [n (RE1 / n) 2Zr2O7] (x is more than 0 and less than or equal to 0.5, and n is more than or equal to 5 and less than or equal to 13). The preparation method comprises the following steps: S1, preparing a rare earth source, a zirconium source and an aluminum source according with a stoichiometric ratio into a mixed solution; s2, the mixed solution is added into an ammonia water solution in a stirring state, and the pH value of the system is always kept to be larger than or equal to 10.0; s3, washing and drying a precipitation product obtained in S2; and S4, heat treatment is conducted, and heat treatment is conducted for 2-20 h at the temperature of 950-1600 DEG C. The double-phase high-entropy thermal barrier coating material has good high-temperature phase stability and high fracture toughness, and the fracture toughness of the double-phase high-entropy thermal barrier coating material reaches 1.92 MPa.m < 1 / 2 > to 2.77 MPa.m < 1 / 2 >.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Preparation method of thermal barrier coating with interlayer pore structure

ActiveCN110106463AGood phase stability at high temperatureLow thermal conductivityMolten spray coatingBall millPhase stability

The invention relates to a preparation method of a thermal barrier coating with an interlayer pore structure. The preparation method comprises the following steps of performing heat treatment on the La2o3, Ceo2, Zro2 powders; mixing the heat-treated powders with a dispersing agent according to a ratio, adding deionized water and carrying out ball milling to obtain slurry; the molar ratio of La2o3,Ceo2, Zro2 powders are 0.5:(1-X): X, wherein X is greater than or equal to 0 and less than or equal to 0.8; drying the ball-milled slurry and carrying out heat treatment to form a phase, so as to obtain the phase-forming powders; mixing the phase-forming powders with deionized water and the dispersing agent for ball milling to obtain a suspension liquid; taking the suspension liquid as a raw material, and spraying the suspension liquid on a matrix material by adopting a suspension liquid plasma spraying method. The La2 (Ce1-xZrx) 2O7 coating prepared by adopting the suspension liquid plasma spraying method has excellent high-temperature phase stability, the prepared coating has a uniform interlayer pore structure, the structure is beneficial to reducing the heat conductivity of the coating and prolonging the heat cycle life of the coating.

Owner:INNER MONGOLIA UNIV OF TECH

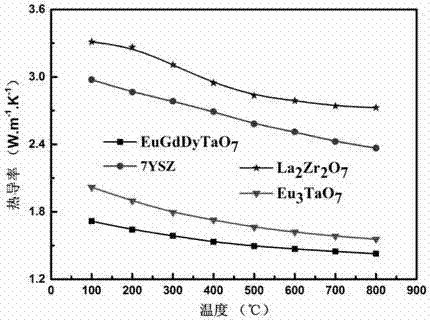

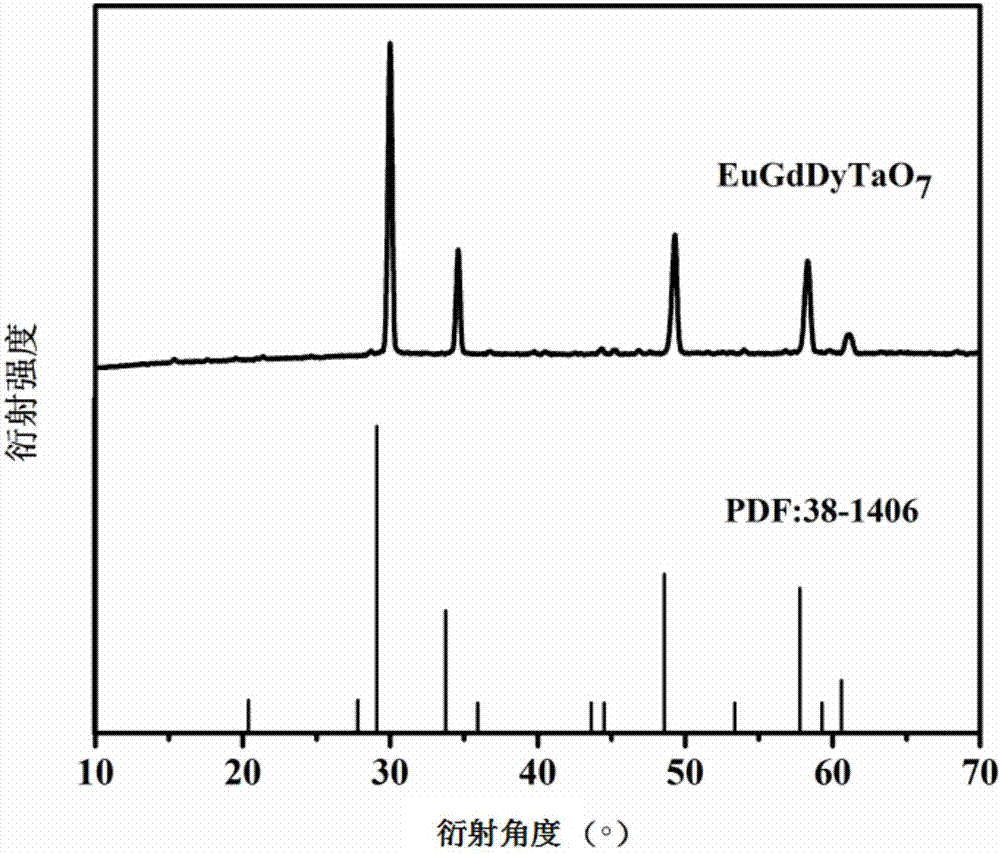

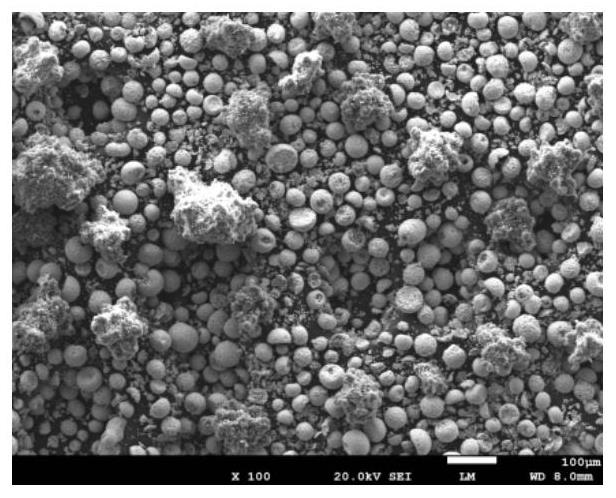

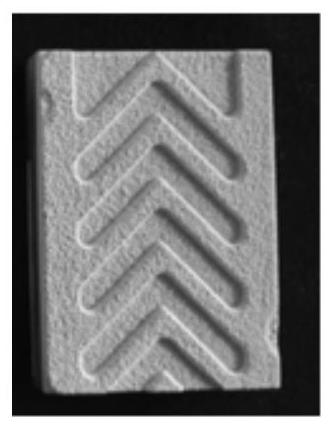

Eu-Gd-Dy trirare earth ion tantalate and preparation method and application thereof

The invention discloses Eu-Gd-Dy trirare earth ion tantalate and a preparation method and an application thereof, the Eu-Gd-Dy trirare earth ion tantalate has the chemical general formula of EuaGdbDycTaO7, wherein a+b+c=3, and a, b and c is 0.8-1.2. The preparation method comprises the following steps: 1) according to the stoichiometric ratio, weighing europium chloride, gadolinium nitrate, dysprosium nitrate and tantalum oxalate, mechanically mixing with citric acid with a set amount under a heat-retaining condition, adding strong aqua ammonia in the mixing process to neutralize the solution,and then mechanically mixing to promote the process of the reaction under a heat-retaining condition; and 2) drying the obtained solution, then calcining at high temperature to remove carbon impurities, and thus obtaining an Eu-Gd-Dy trirare earth ion tantalate powder. The Eu-Gd-Dy trirare earth ion tantalate has the advantages of good high temperature thermal stability and low thermal conductivity coefficient, and can be used as a thermal barrier coating material.

Owner:陕西天璇涂层科技有限公司

Conductive abradable seal coating material and preparation method thereof

PendingCN114479531AStrong resistance to water and oxygenImprove conductivityElectrically-conductive paintsPolyesterCoated surface

The invention belongs to the field of inorganic non-metallic materials, and particularly relates to a conductive abradable seal coating material and a preparation method thereof. The conductive abradable seal coating material comprises the following components in percentage by weight: 60 to 70 percent of rare earth silicate, 20 to 30 percent of conductive filler, 2.0 percent of lubricating phase and 8.0 percent of polyester. A powder material is prepared by adopting a solid-phase sintering and mechanical mixing method, a conductive abradable sealing coating is prepared by utilizing a plasma spraying process, and the surface configuration is processed by electric spark. The abradable seal coating material has the advantages of being good in interface matching performance with a ceramic matrix composite matrix, high in water and oxygen resistance, good in conductivity and the like, the surface of the coating is subjected to structural modeling through an electric spark technology, and the scraping matching performance of the abradable seal coating and a rotor material can be effectively improved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Pyrochlore structural rare-earth zirconate material and preparation method and application thereof

ActiveCN102070335BLow thermal conductivityImprove thermal stabilityMolten spray coatingRare-earth elementZirconate

The invention discloses a pyrochlore structural rare-earth zirconate material system capable of being used for a heat barrier coating. The chemical composition of the material is (0.5-x)R'2O3-0.5Sm2O3-xR''2O3-2ZrO2, wherein x is more than 0 and less than or equal to 0.25; the R' is rare-earth elements or composition thereof, the ion radius of which is greater than that of Sm; and R'' is rare-earth elements or composition thereof, the ion radius of which is smaller than that of Sm. The material provided by the invention has low thermal conductivity, high thermal stability and high-temperature sintering resistance; the thermal expansion performance of the material is stable compared with a single pyrochlore structural material; and the material is favorable for reducing thermal stress generated by mismatching of thermal expansion coefficients in the thermal cycle process, and can prolong the thermal cycle life of the coating. Because of good high-temperature phase stability, the pyrochlore structural rare-earth zirconate material can be used for designing and preparing a novel high-temperature heat barrier coating material, the use temperature of which is below 1,550 DEG C.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

In-situ generated SiC -doped Gd2Zr2O7 thermal barrier coating ceramic material and preparation method thereof

ActiveCN113105238AGood phase stability at high temperatureImprove anti-sintering performanceEfficient propulsion technologiesThermal dilatationThermal barrier coating

The invention discloses a SiC-doped Gd2Zr2O7 thermal barrier coating ceramic layer material and a preparation method thereof. The SiC-doped Gd2Zr2O7 thermal barrier coating ceramic layer material has the chemical formula of Gd2Zr2O7-XTiSi2-YC (X = 0-5 wt%, Y = 0-1.7 wt%), and the Gd2Zr2O7-XTiSi2-YC (X = 0-5 wt%, Y = 0-1.7 wt%) series thermal barrier coating ceramic layer material has the following remarkable advantages: after being doped in-situ generated second-phase substance SiC with different contents, the material has high temperature phase stability and sintering resistance at 1500 DEG C; compared with a traditional Gd2Zr2O7 thermal barrier coating ceramic material, the SiC-doped Gd2Zr2O7 thermal barrier coating ceramic layer material has the advantages that the thermal expansion coefficient at the high temperature of 1000 DEG C can reach 11 W / m.K, the thermal conductivity at the temperature of 1000 DEG C can reach 0.6-0.7 W.m-1. k-1, the fracture toughness is improved to 1.5-1.6 MPa.m1 / 2, and the SiC-doped Gd2Zr2O7 thermal barrier coating ceramic layer material has the potential to serve as a high-temperature-resistant thermal barrier coating ceramic layer material.

Owner:江苏航运职业技术学院

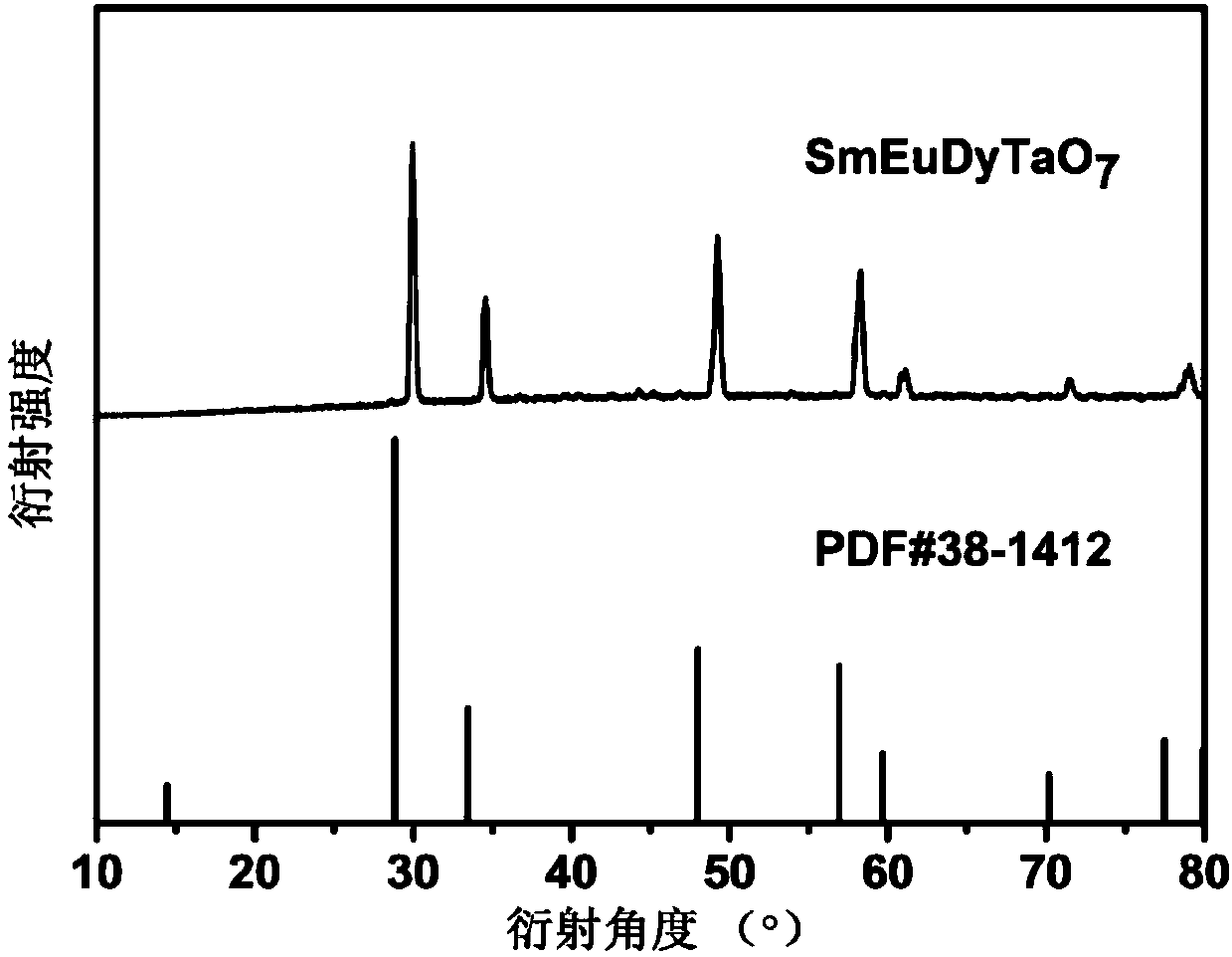

Sm-Eu-Dy tri-rare-earth ion tantalate and preparation method and application thereof

The invention discloses a Sm-Eu-Dy tri-rare-earth ion tantalate and a preparation method and application thereof. The general chemical formula of the Sm-Eu-Dy tri-rare-earth ion tantalate is SmEuDy<c>TaO<7>, wherein the a, b and c meet the relationship of a+b+c=3 and are separately in a range of 0.8-1.2. The preparation method comprises the following steps: (1) weighing europium chloride, samarium nitrate, dysprosium nitrate and tantalum oxalate according to a stoichiometric ratio, performing mechanical mixing with citric acid with a preset amount under a heat preservation condition, adding a concentrated ammonia water neutralization solution during the mixing process, and carrying out mechanical mixing to promote a chemical reaction under a heat preservation condition; and (2) drying the obtained solution, and then carrying out calcination at a high temperature to remove carbon impurities to obtain the Sm-Eu-Dy tri-rare-earth ion tantalate powder. The Sm-Eu-Dy tri-rare-earth iontantalate has good high-temperature thermal stability and low thermal conductivity, and can be used as a thermal barrier coating material.

Owner:陕西天璇涂层科技有限公司

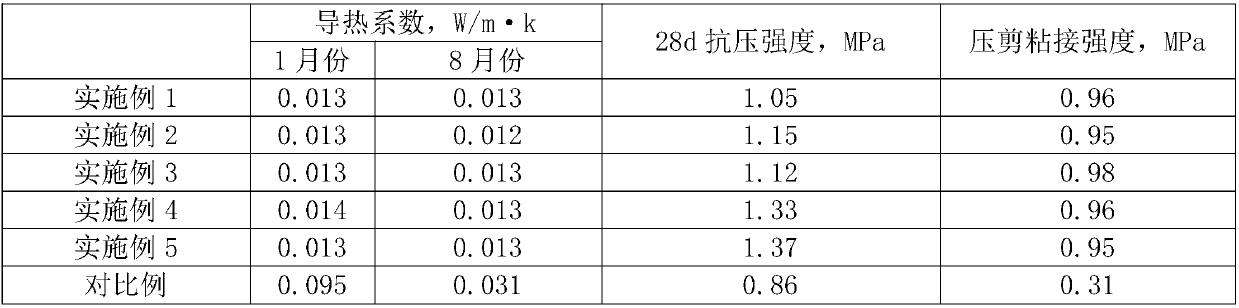

Preparation method of engineering thermal-insulation material based on thermochemical energy storage

The invention discloses a preparation method of an engineering thermal-insulation material based on thermochemical energy storage. The method includes: preparing a thermochemical-energy-storage material, and preparing modified monazite powder; mixing and stirring slag, fly ash, hollow carbon fibers, the thermochemical-energy-storage material, the modified monazite powder, gypsum and Portland cement, placing into a three-roller grinder, adding distilled water, grinding for 1 hour, performing vacuum drying, and grinding and sieving the dried material to obtain the engineering thermal-insulationmaterial. The engineering thermal-insulation material prepared by the method is excellent in thermal-insulation performance, good in impact resistance, good in aging resistance and cracking resistanceand low in preparation cost.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

TiSi2 doped Gd2Zr2O7 ceramic material, preparation method and thermal barrier coating

InactiveCN114368969AGood phase stability at high temperatureImprove anti-sintering performanceMetallic material coating processesThermal dilatationThermal barrier coating

The invention discloses a TiSi2-doped Gd2Zr2O7 ceramic material, a preparation method and a thermal barrier coating, and the design idea is that the Gd2Zr2O7 thermal barrier coating ceramic material is doped by using the TiSi2 material with excellent fracture toughness, and the order degree of the original internal crystal structure is changed, so that the toughening effect is achieved; and meanwhile, related thermal physical properties such as thermal expansion coefficient and thermal conductivity can be improved, so that related problems existing in the original Gd2Zr2O7 material are solved. Compared with the prior art, the Gd2Zr2O7 thermal barrier coating ceramic material and the preparation method thereof have the following remarkable advantages that the Gd2Zr2O7 thermal barrier coating ceramic material doped with different contents of TiSi2 can still keep good high-temperature phase stability and relatively good sintering resistance at 1500 DEG C; the high-temperature-resistant thermal barrier coating ceramic layer material has higher thermal expansion coefficient, lower thermal conductivity and better fracture toughness at high temperature, and is suitable for being used as a high-temperature-resistant thermal barrier coating ceramic layer material.

Owner:江苏航运职业技术学院

Composite coating, preparation method thereof and thermal barrier coating

ActiveCN114231908AHigh melting pointHigh phase stabilityVacuum evaporation coatingSputtering coatingThermal barrier coatingCoated surface

The invention relates to the technical field of thermal barrier coatings, in particular to a composite coating, a preparation method thereof and a thermal barrier coating. A micro-nano composite structure is arranged on the surface of the composite coating, the composite coating comprises Al2O3-doped GYbZ, the GYbZ is Yb modified gadolinium zirconate, and the doping amount of Al2O3 is 5 mol%-20 mol%. Al2O3 can effectively inhibit growth of GYbZ crystal grains and nanoparticles in a micro-nano structure of the coating, so that the high-temperature sintering resistance and high-temperature stability of the composite coating are improved, and the high-temperature melting CMAS dredging capacity of a thermal barrier coating system for a long time at high temperature is guaranteed.

Owner:BEIHANG UNIV

Method for improving CMAS corrosion resistance of thermal barrier coating

PendingCN113699479ASurface texture improvementEffective blockingMolten spray coatingPorosityReaction layer

The invention relates to the technical field of thermal barrier coating surface corrosion and protection, in particular to a method for improving the CMAS corrosion resistance of a thermal barrier coating. The thermal barrier coating is of a multi-layer structure and comprises a bonding layer, a ceramic layer, a remelting layer formed by laser remelting part of the ceramic layer and a pre-corrosion layer formed through high-temperature pretreatment. Surface cracks of the ceramic layer are remelted through laser, and the surface of the ceramic layer is coated with a layer of pre-designed mixed oxide. According to the remelting layer, nanosecond pulse laser is used for carrying out surface modification treatment on the ceramic layer, the surface structure of the ceramic layer can be optimized, the density can be improved, the porosity can be reduced, and a diffusion channel of CMAS can be blocked. According to the pre-corrosion layer, the pre-designed mixed oxide and a gadolinium zirconate ceramic layer react in advance under the high-temperature condition, an apatite phase reaction layer is formed, and therefore the CMAS corrosion resistance of the thermal barrier coating is greatly improved.

Owner:苏州金航纳米技术研究有限公司

High-temperature thermal barrier coating material and preparation method thereof

InactiveCN101898889BGood phase stability at high temperatureNo phase changeRare-earth elementRoom temperature

The invention belongs to material technology, a high-temperature thermal barrier coating material and a preparation method thereof. When used at a high temperature, the conventional thermal barrier coating material is easy to undergo phase change and cause the failure of a coating. The general formula of a multi-component rare-earth high-temperature thermal barrier coating material is that: LnyLn<'>zLn<''>1-y-zMexAl12-xO19+delta, wherein Ln, Ln<'> and Ln<''> are rare earth elements such as La, Ce, Nd, Sm, Gd, Dy, Er and Yb; Me is metal elements such as Mn, Mg, Ni, Co, Sr, Ca and Ba; x is between 0 and 12; y is between 0 and 1; z is between 0 and 1; and y+z is less than or equal to 1. The preparation method comprises the following steps of: preparing mixed metal salt solution; preparing complexing agent solution; preparing mixed metal ion sol; and drying the mixture at the temperature of between 70 and 180 DEG C, and grinding and calcining the dried product to obtain the high-temperature thermal barrier coating material. The high-temperature thermal barrier coating material has the advantages of high temperature resistance, melting point of over 2,000 DEG C, high stability of high-temperature phase, no phase change from room temperature to 2,000 DEG C or higher temperature and low thermal conductivity.

Owner:SHANGHAI UNIV OF ENG SCI

sm-gd-dy triple rare earth ion tantalate and its preparation method and application

ActiveCN107585786BExtended service lifeGood thermal propertiesTantalum compoundsDysprosium nitrateCalcination

Owner:陕西天璇涂层科技有限公司

An in-situ generation of sic-doped gd 2 zr 2 o 7 Thermal barrier coating ceramic material and preparation method thereof

ActiveCN113105238BGood phase stability at high temperatureImprove anti-sintering performanceEfficient propulsion technologiesThermal dilatationThermal barrier coating

The invention discloses a SiC-doped Gd2Zr2O7 thermal barrier coating ceramic layer material and a preparation method thereof. The chemical formula of the SiC-doped Gd2Zr2O7 thermal barrier coating ceramic layer material is Gd2Zr2O7-XTiSi2-YC (X=0-5wt%, Y =0-1.7wt%), Gd2Zr2O7-XTiSi2-YC (X=0-5wt%, Y=0-1.7wt%) series thermal barrier coating ceramic layer materials, have the following significant advantages: doping different contents of in-situ After the second phase substance SiC is formed, it can still maintain good high temperature phase stability and good sintering resistance at 1500°C. The thermal expansion coefficient can reach 11W / m.K, the thermal conductivity at 1000°C can reach 0.6‑0.7W m‑1 k‑1, and the fracture toughness can be increased to 1.5‑1.6MPa m1 / 2. Barrier coating ceramic layer material.

Owner:江苏航运职业技术学院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com