Preparation method of CoCrFeMnNi high-entropy alloy cladding layer

A high-entropy alloy, cladding layer technology, applied in the direction of metal material coating process, coating, etc., to achieve the effect of high efficiency, low dilution rate, and avoiding metallurgical defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

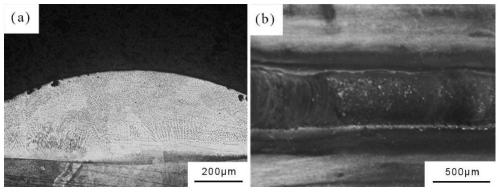

Image

Examples

example 1

[0051] In this embodiment, a CoCrFeMnNi high-entropy alloy cladding layer is prepared by prefabricated cladding using a cladding current of 10A;

[0052] 1): Weigh 30g of the prepared CoCrFeMnNi alloy powder and put it into an oven, set the drying temperature to 100°C and the drying time to 4h to obtain the original powder without moisture;

[0053] 2): Evenly mix the dried high-entropy alloy powder and PVA binder in a mortar at a ratio of 30g:0.90ml to form a colloidal powder, and then put it into a mold groove of 50×4×1.5mm, Press to obtain powder bars;

[0054] 3): Put the prefabricated powder strips in an oven at 100°C for 4 hours, and take them out after drying;

[0055] 4): Clean the surface of the 200×100×2mm workpiece or substrate with an angle grinder, and then polish it with 80#, 120#, 240#, 400#, 800#, 1200# SiC sandpaper in sequence, after ultrasonic 40HZ After cleaning for 10 minutes, use plasma water and alcohol to clean, and dry in an oven at 60°C for 2 hours;...

example 2

[0059] In this embodiment, a CoCrFeMnNi high-entropy alloy cladding layer is prepared by prefabricated cladding using a cladding current of 30A;

[0060] 1): Weigh 30g of the prepared CoCrFeMnNi alloy powder and put it into an oven, set the drying temperature to 150°C and the drying time for 2 hours to obtain the original powder without moisture;

[0061] 2): Evenly mix the dried high-entropy alloy powder and PVA binder in a mortar at a ratio of 30g:1.10ml to form a colloidal powder, and then put it into a mold groove of 60×5×1.5mm, Press to obtain powder bars;

[0062] 3): Put the prefabricated powder strips in an oven at 150°C for 2 hours, and take them out after drying;

[0063] 4): Clean the surface of the 200×100×2mm workpiece or substrate with an angle grinder, and then polish it with 80#, 120#, 240#, 400#, 800#, 1200# SiC sandpaper in sequence, after ultrasonic 60HZ After cleaning for 5 minutes, use plasma water and alcohol to clean, and dry in an oven at 80°C for 1 h...

example 3

[0066] In this embodiment, a CoCrFeMnNi high-entropy alloy cladding layer is prepared by prefabricated cladding using a cladding current of 50A;

[0067] 1): Weigh 30g of the prepared CoCrFeMnNi alloy powder and put it into an oven, set the drying temperature at 100-150°C and the drying time for 2-4 hours to obtain the original powder without moisture;

[0068] 2): Evenly mix the dried high-entropy alloy powder and PVA binder in a mortar at a ratio of 30g:1.0ml to form a colloidal powder, and then put it into a mold groove of 50×4×2.0mm, Press to obtain powder bars;

[0069] 3): Put the prefabricated powder strips in an oven at 120°C for 3 hours, and take them out after drying;

[0070] 4): Clean the surface of the 200×100×2mm workpiece or substrate with an angle grinder, and then polish it with 80#, 120#, 240#, 400#, 800#, 1200# SiC sandpaper in sequence, after ultrasonic 50HZ After cleaning for 8 minutes, use plasma water and alcohol to clean, and place in an oven to dry a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com