Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

178 results about "Microbeam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

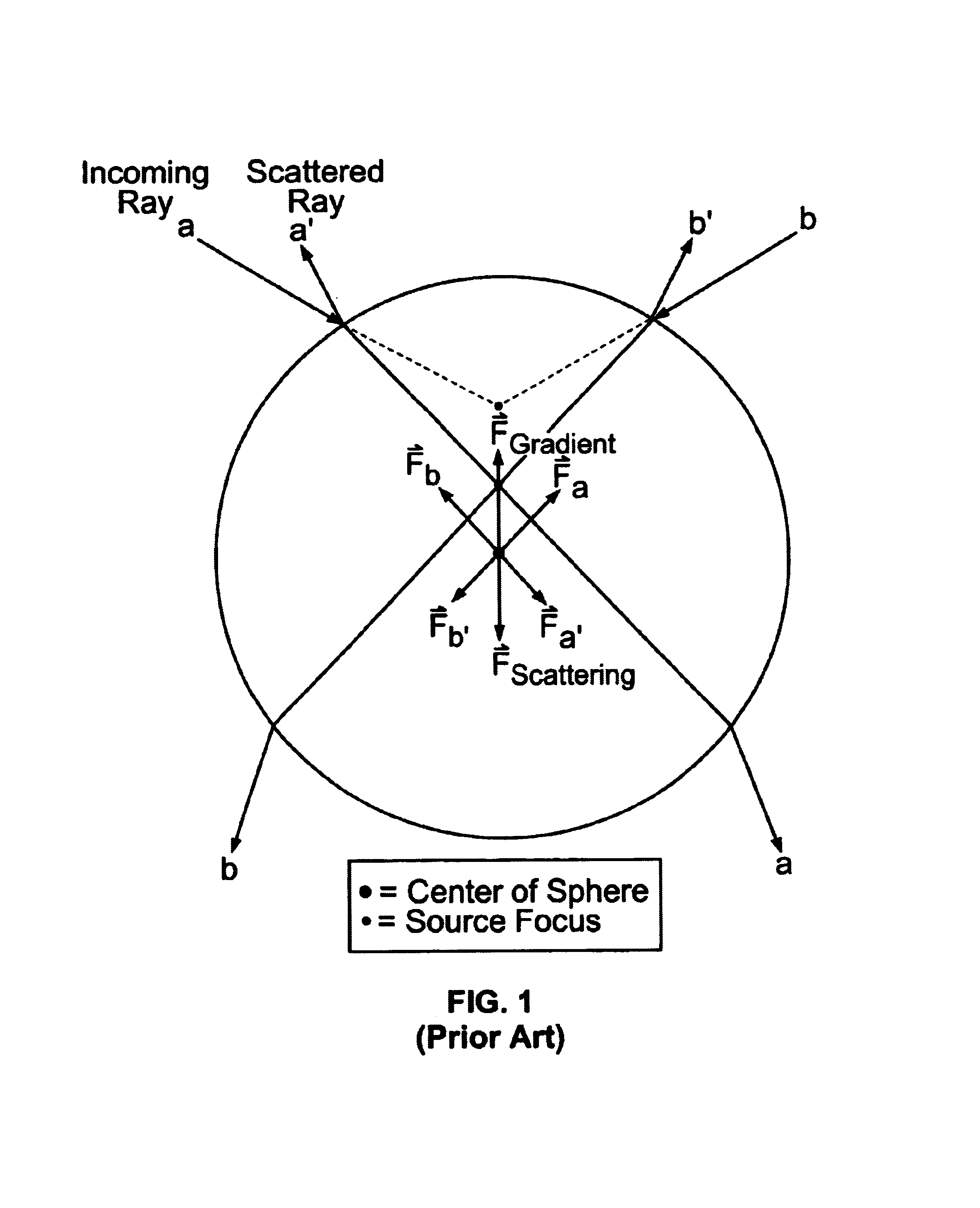

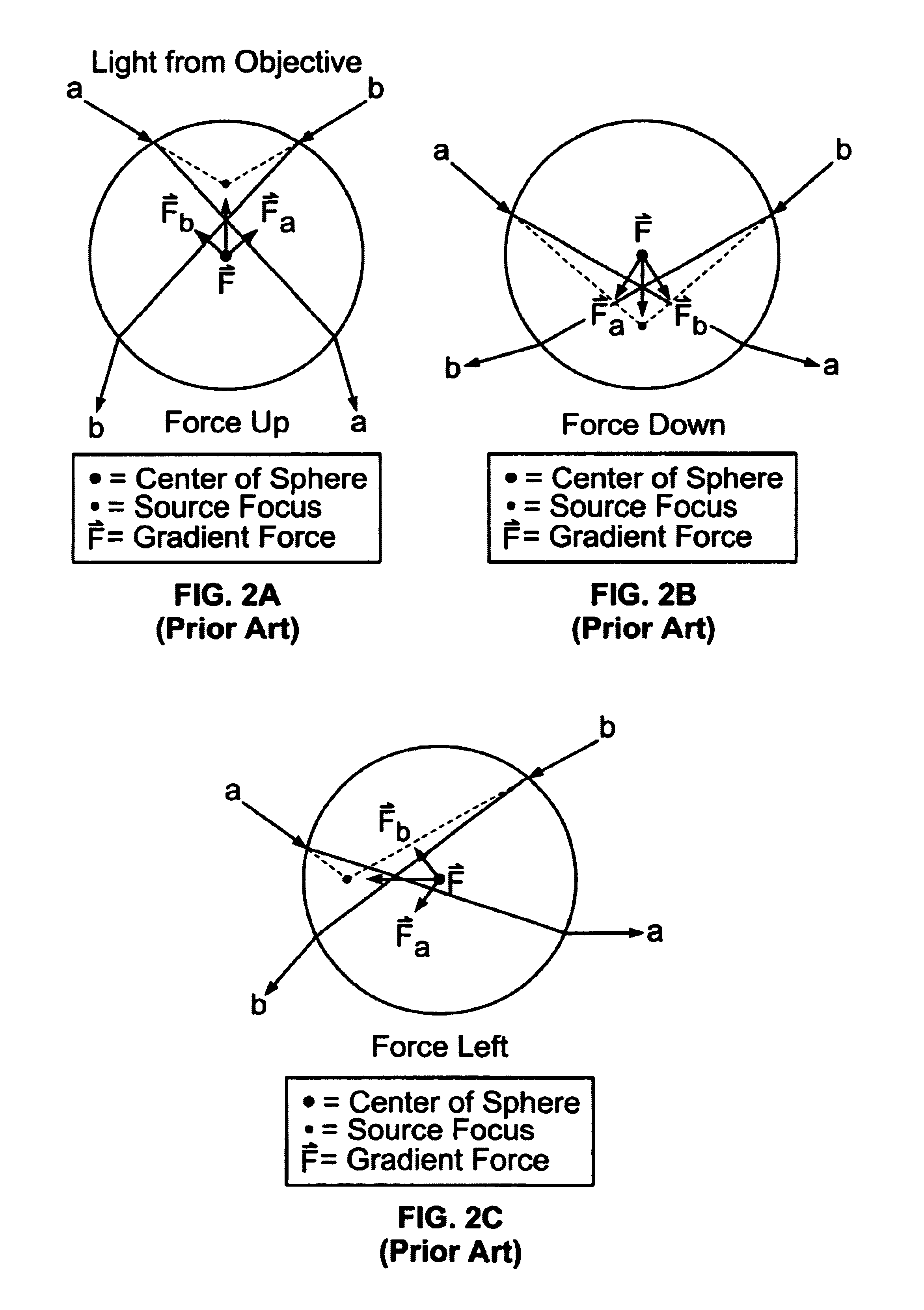

A microbeam is a narrow beam of radiation, of micrometer or sub-micrometer dimensions. Together with integrated imaging techniques, microbeams allow precisely defined quantities of damage to be introduced at precisely defined locations. Thus, the microbeam is a tool for investigators to study intra- and inter-cellular mechanisms of damage signal transduction.

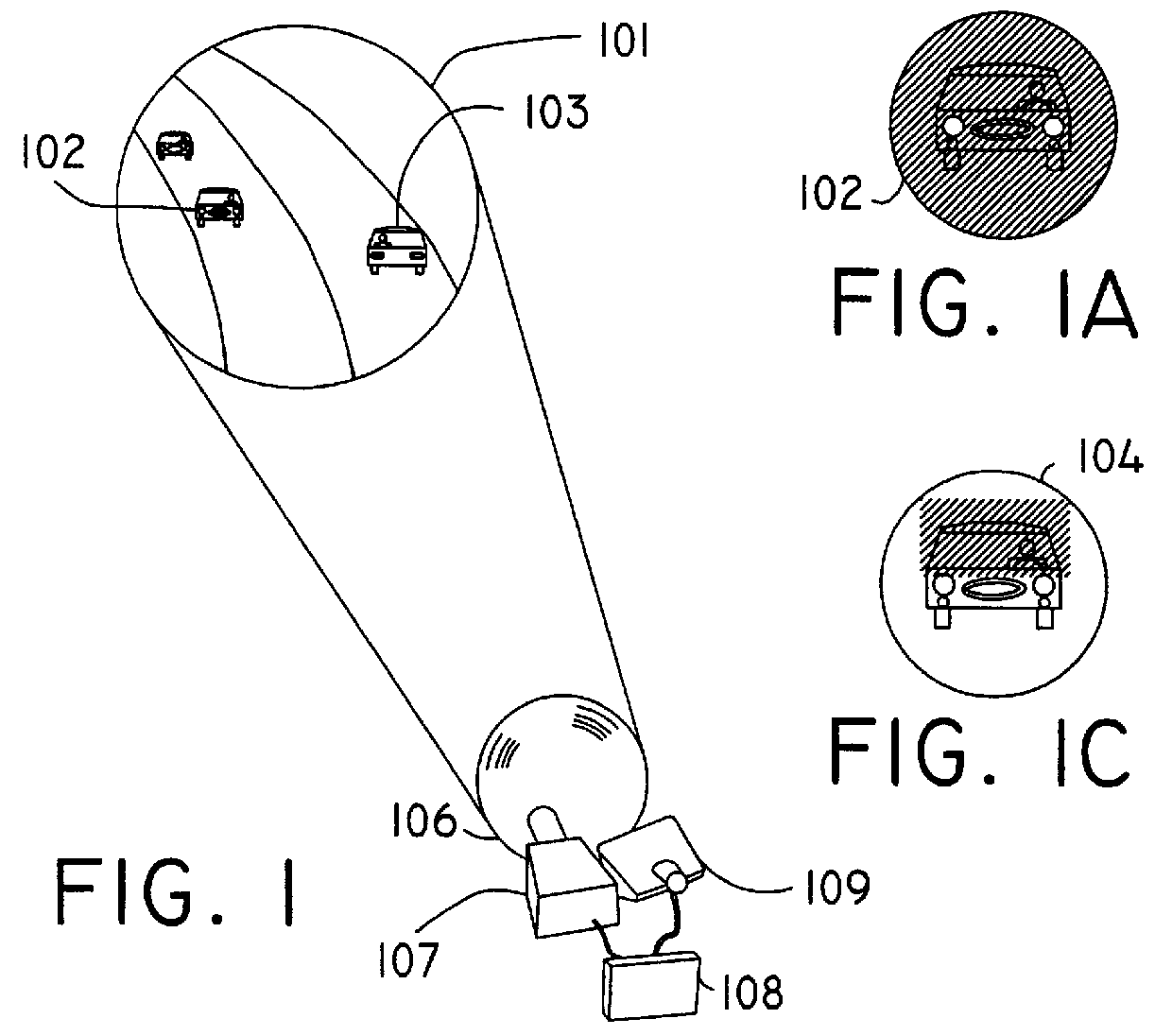

Adaptive/anti-blinding headlights

InactiveUS6144158AReduce glareImprove eyesightVehicle headlampsSolid-state devicesLight beamClassical mechanics

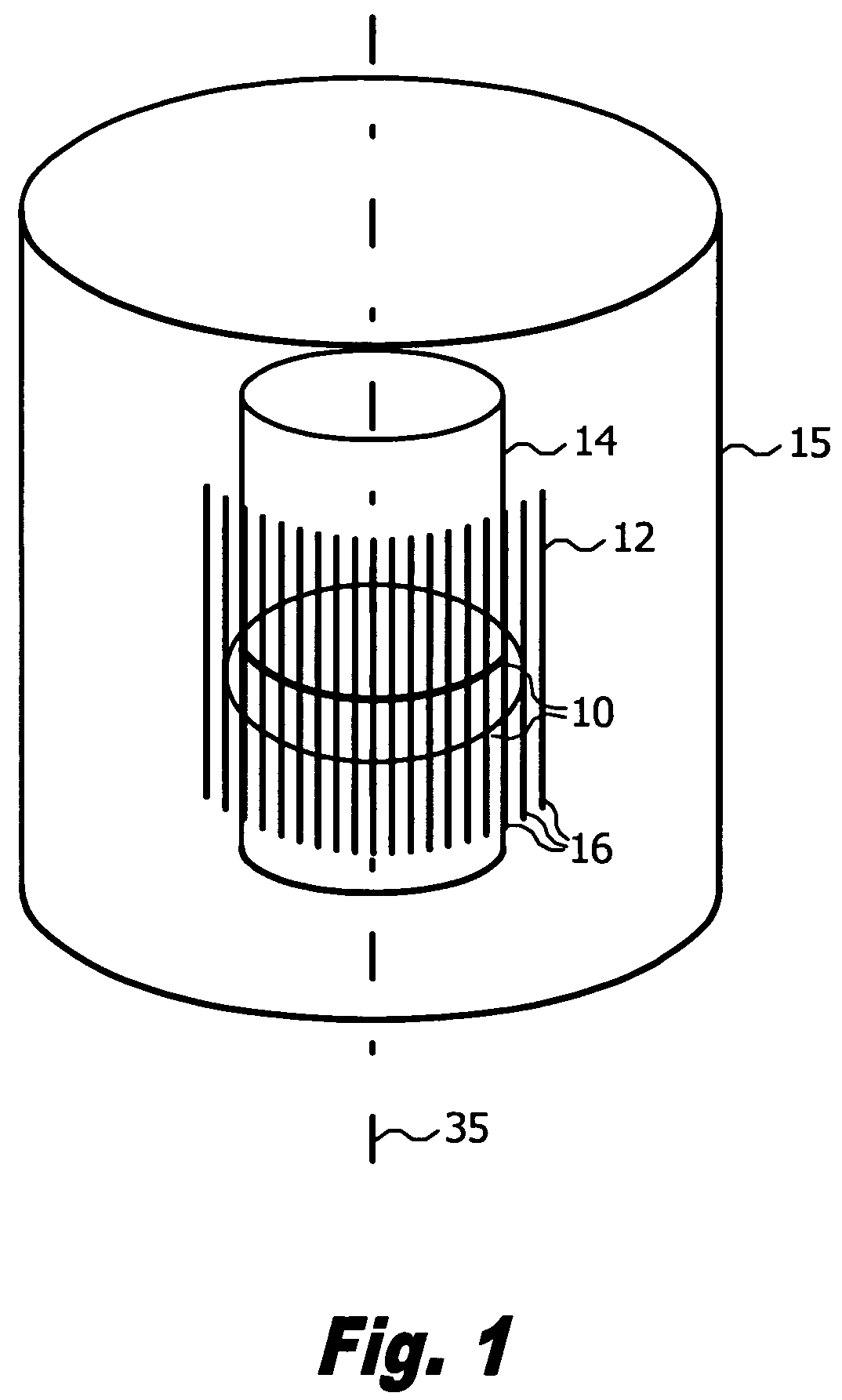

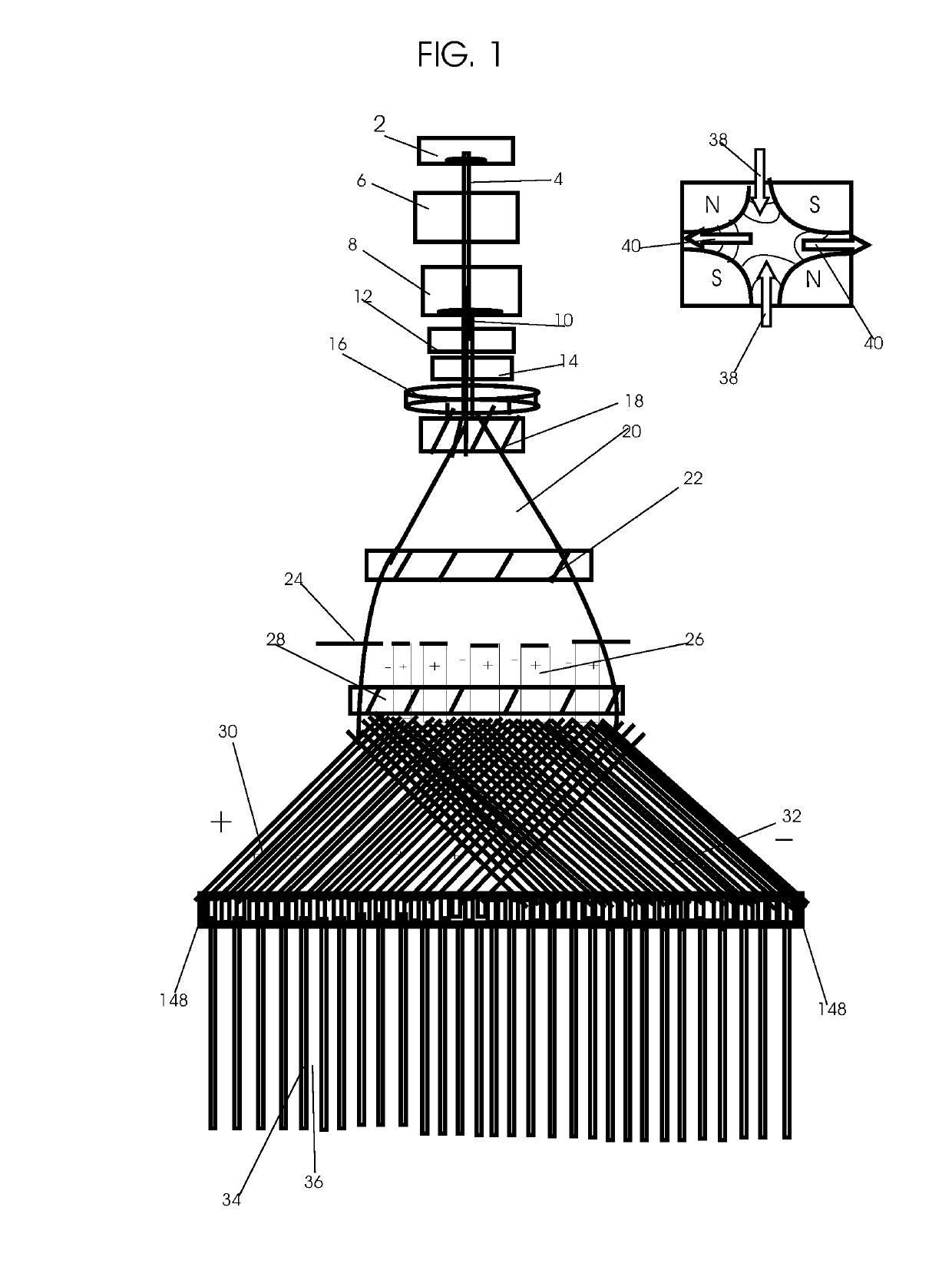

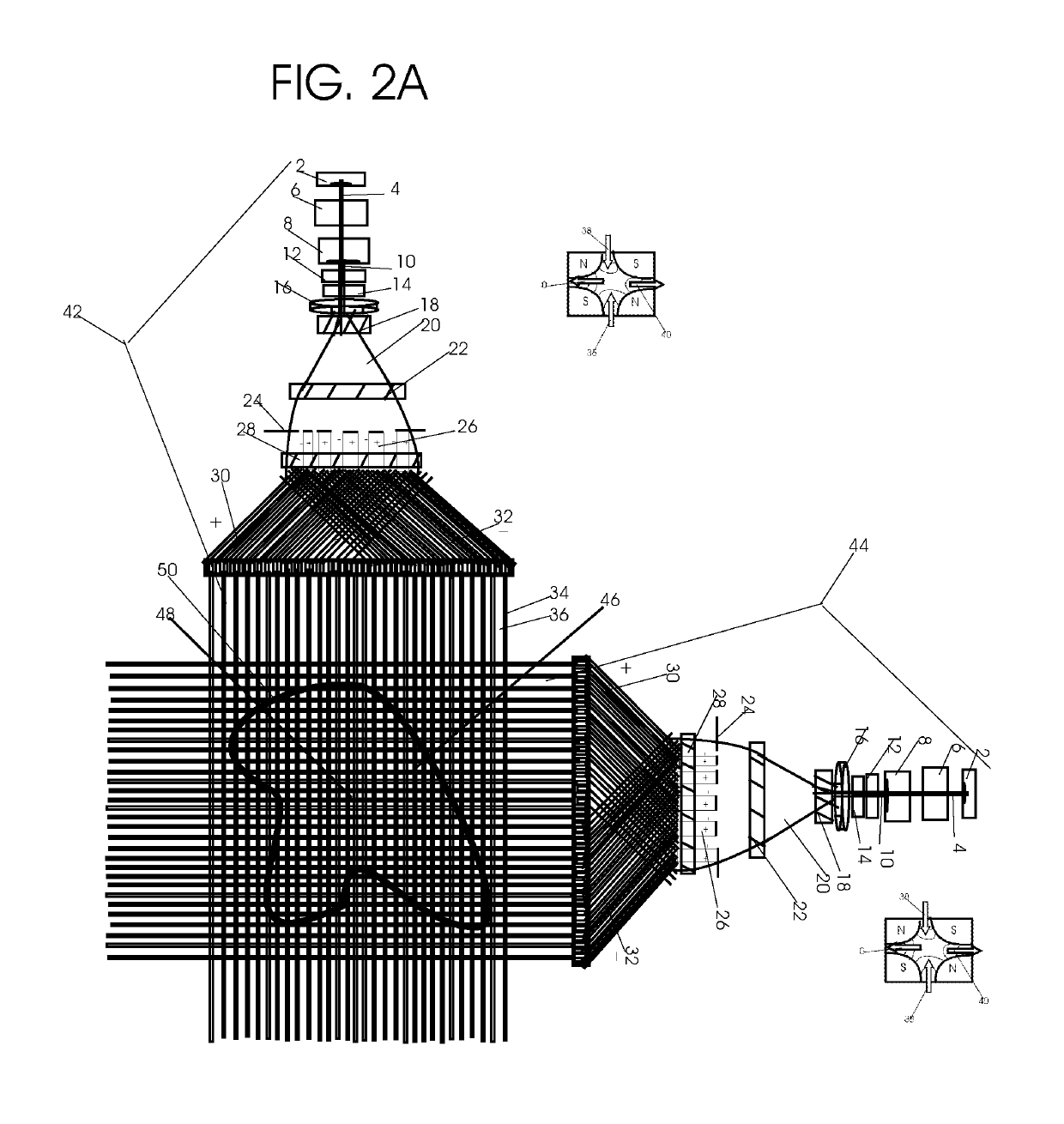

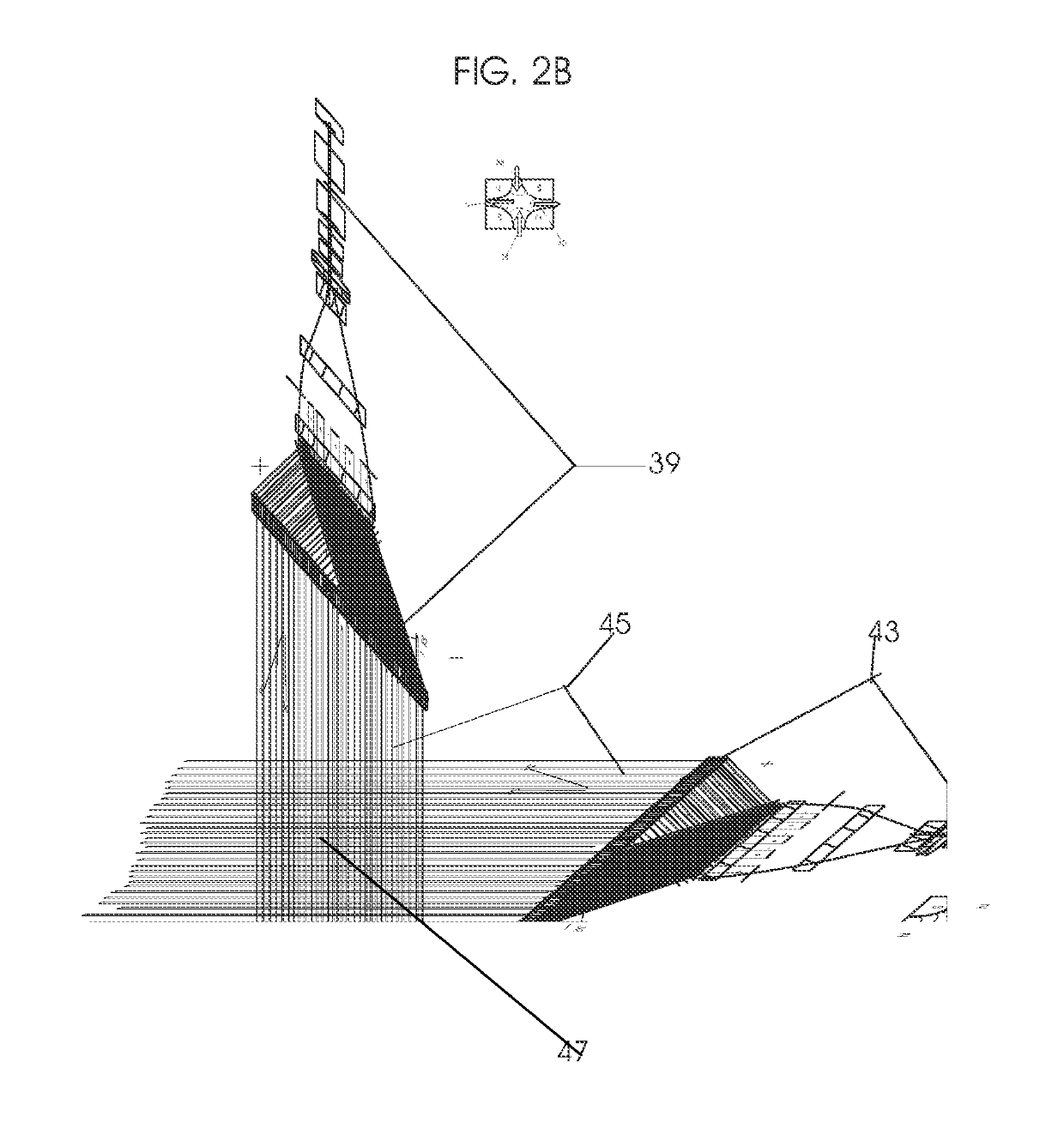

This invention relates to the production of a beam of light comprised of many microbeams, controlled by incoming radiation, employing a sensor to determine the location of light sources forward of the apparatus and using that information to control the intensity, and / or the angular position, of one or more narrow-angle microbeams, which are part of a large number of beams comprising the overall output beam.

Owner:SENSCI CORP

Methods for assisting recovery of damaged brain and spinal cord using arrays of X-ray microplanar beams

ActiveUS7158607B2Promote regenerationMaximum functionX-ray/gamma-ray/particle-irradiation therapyIrradiation devicesX-rayInjury Site

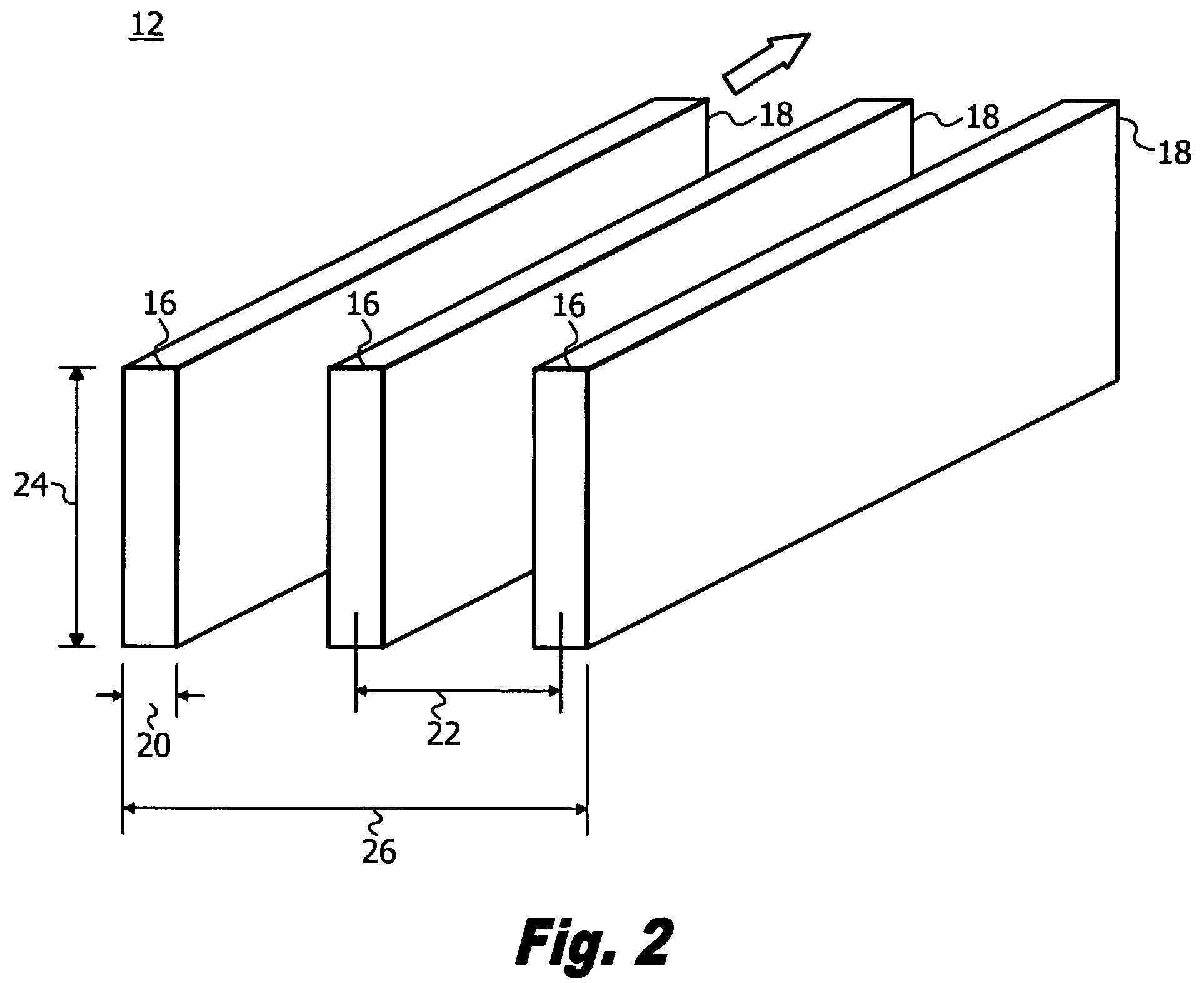

A method of assisting recovery of an injury site of brain or spinal cord injury includes providing a therapeutic dose of X-ray radiation to the injury site through an array of parallel microplanar beams. The dose at least temporarily removes regeneration inhibitors from the irradiated regions. Substantially unirradiated cells surviving between the microplanar beams migrate to the in-beam irradiated portion and assist in recovery. The dose may be administered in dose fractions over several sessions, separated in time, using angle-variable intersecting microbeam arrays (AVIMA). Additional doses may be administered by varying the orientation of the microplanar beams. The method may be enhanced by injecting stem cells into the injury site.

Owner:WASHINGTON UNIV IN SAINT LOUIS +1

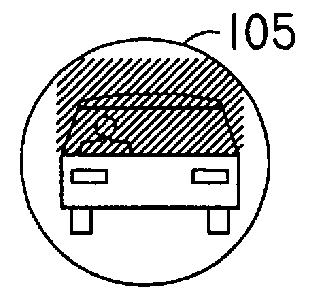

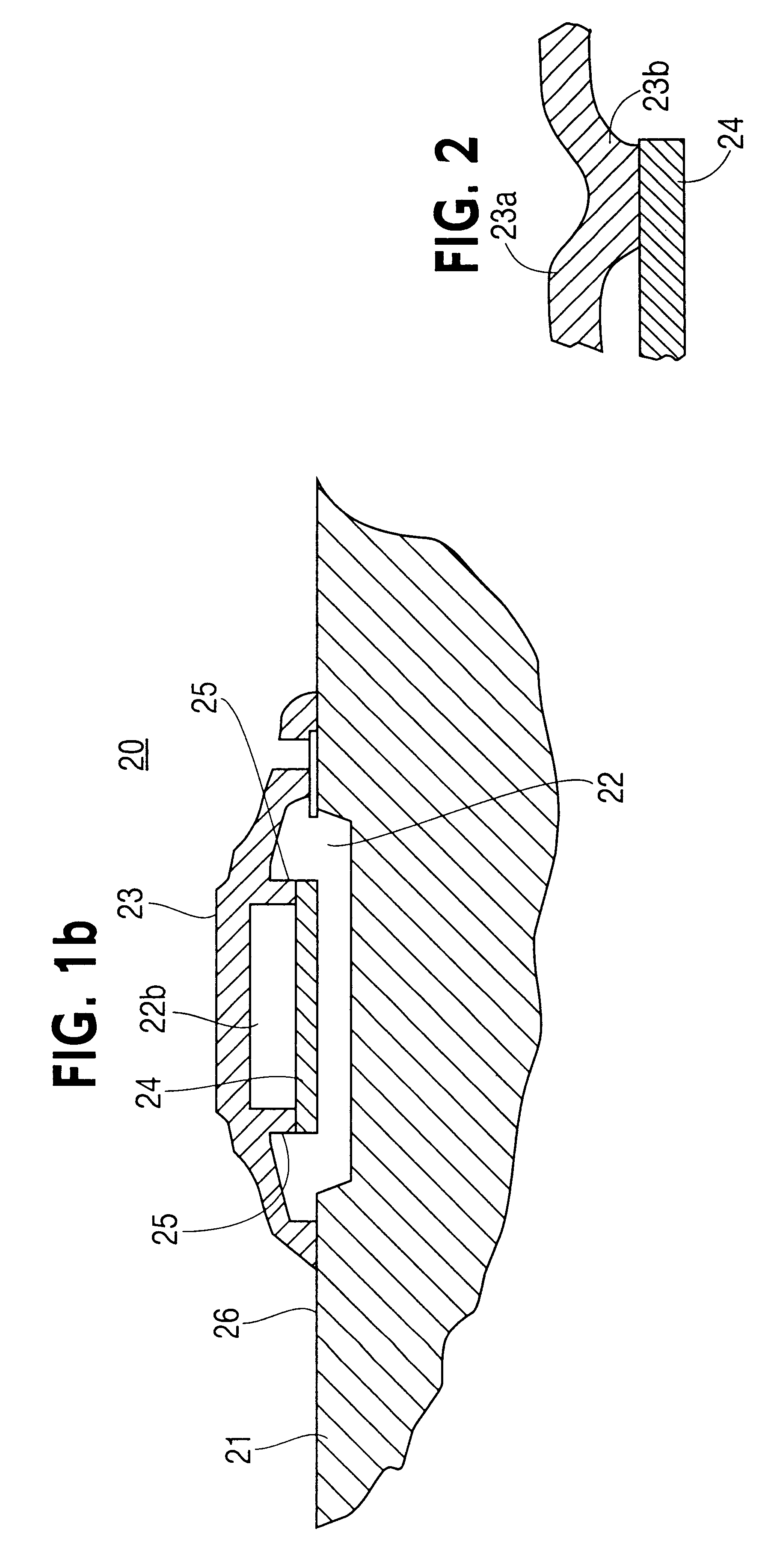

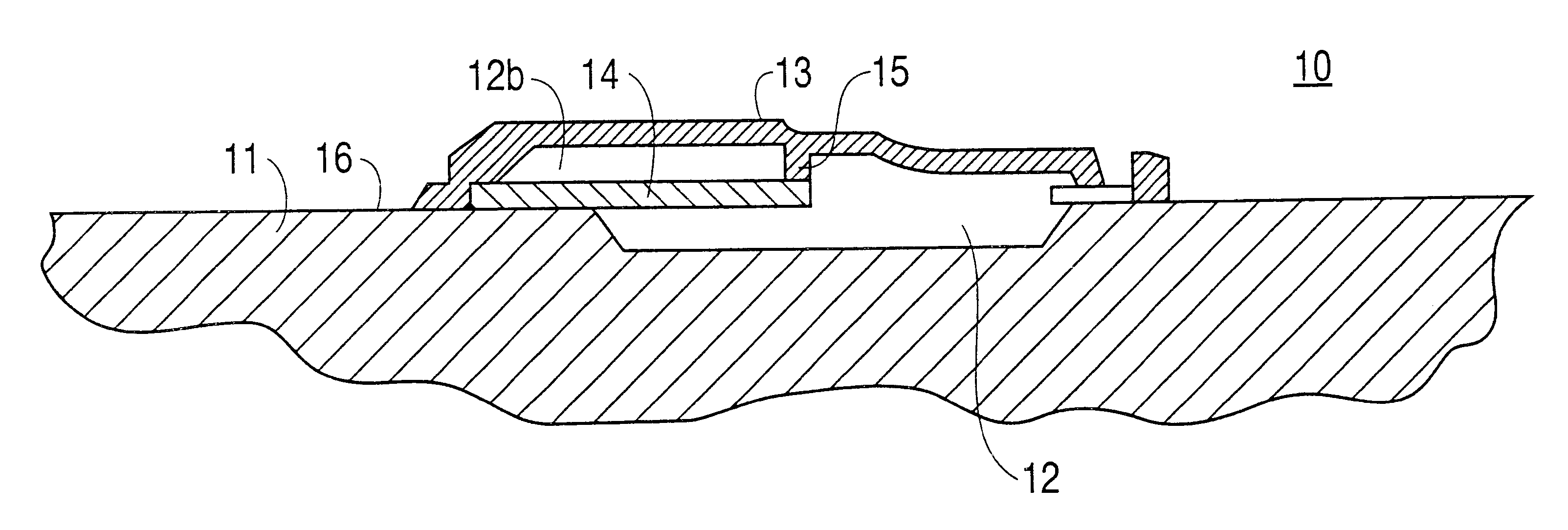

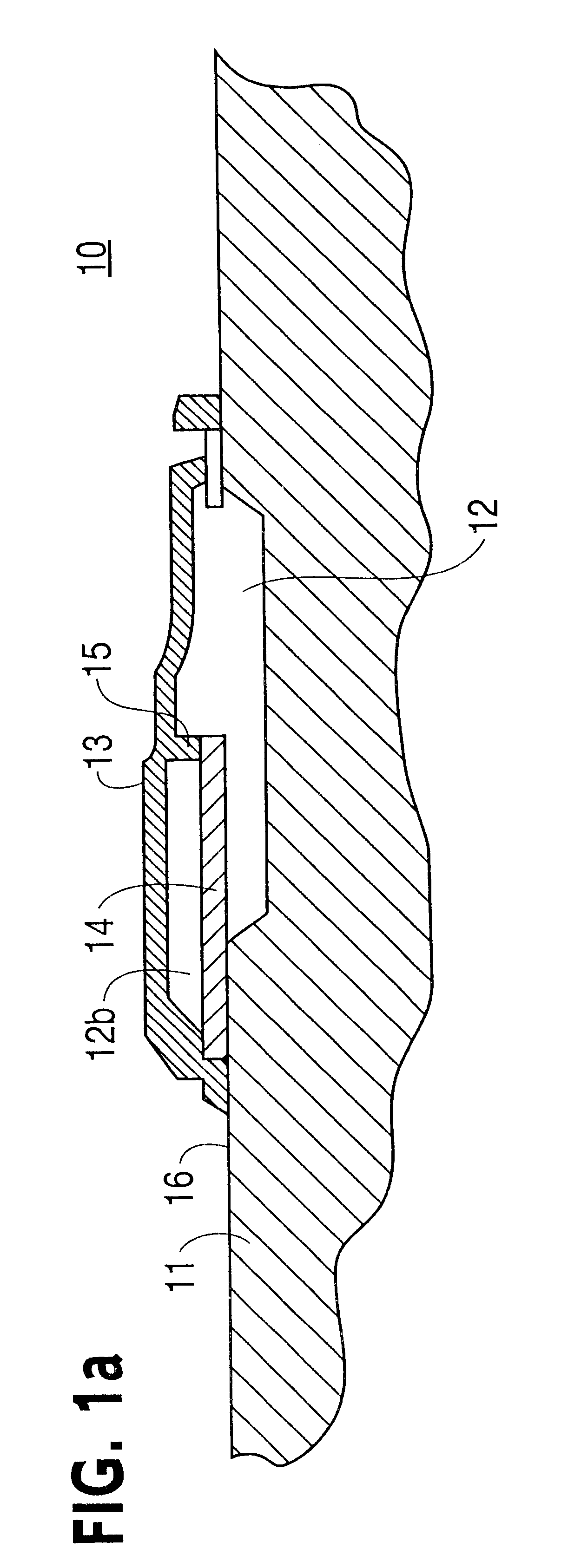

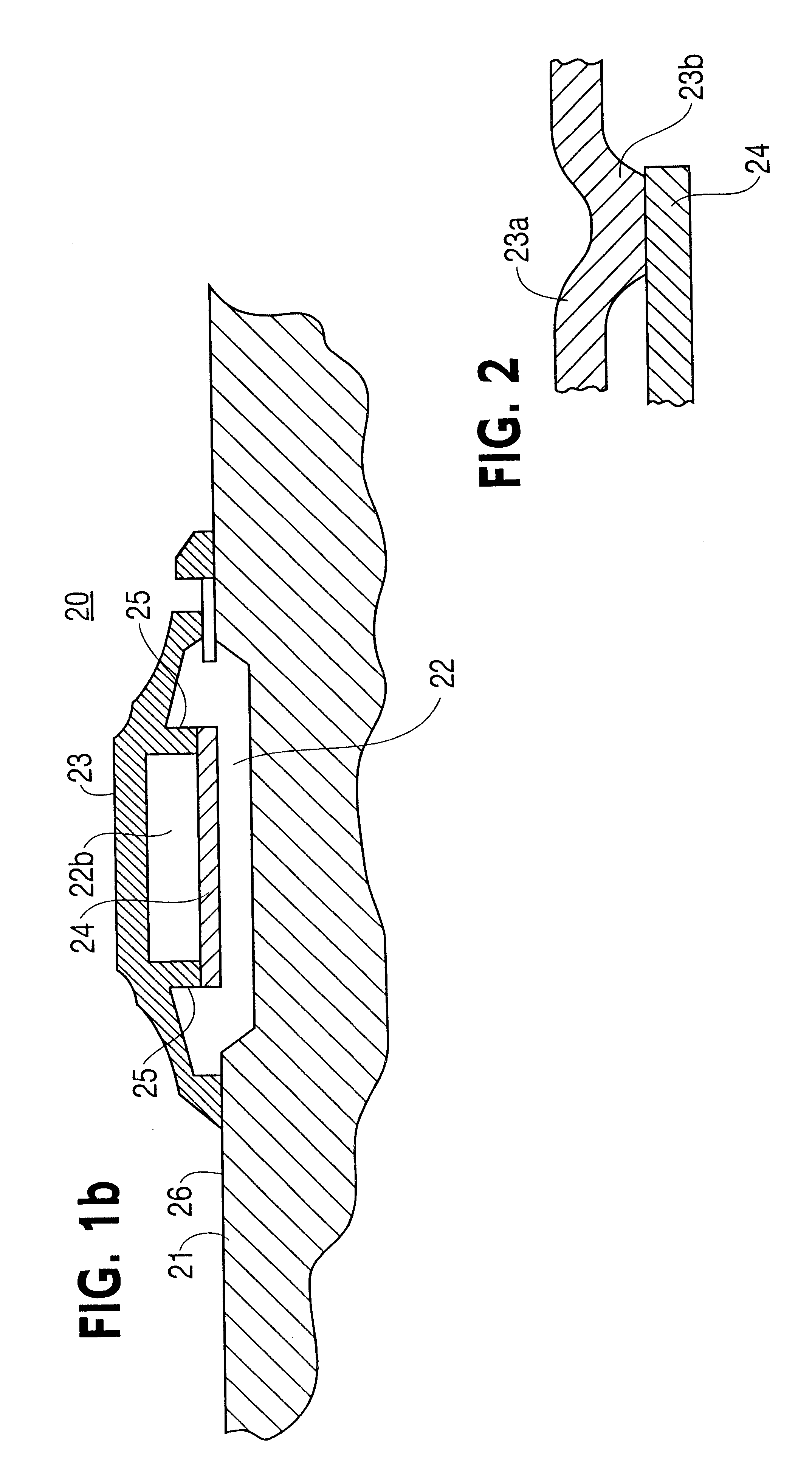

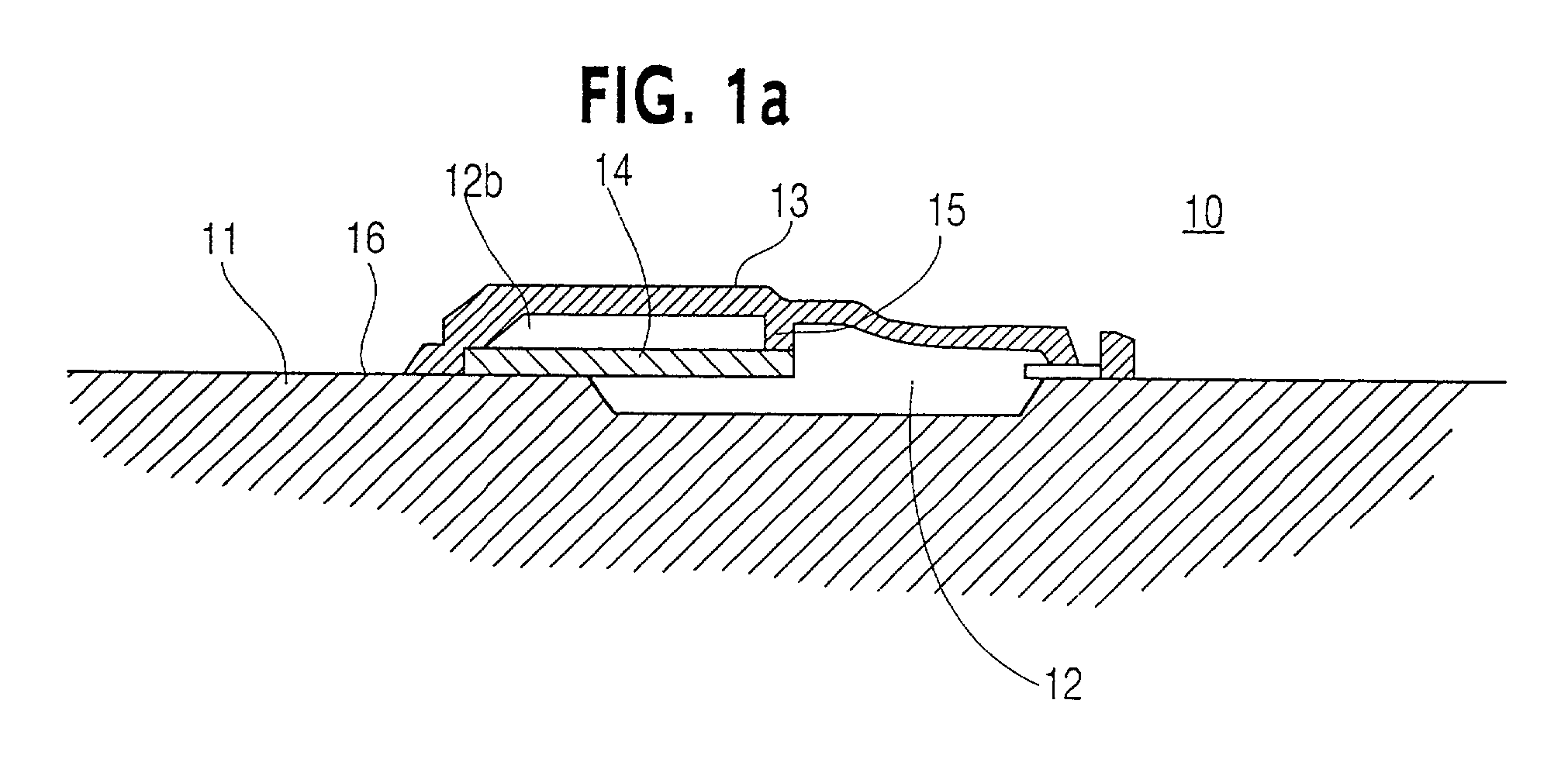

Resonant sensor and method of making a pressure sensor comprising a resonant beam structure

InactiveUS6182513B1Fluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by electric/magnetic elementsLight beamResonant sensor

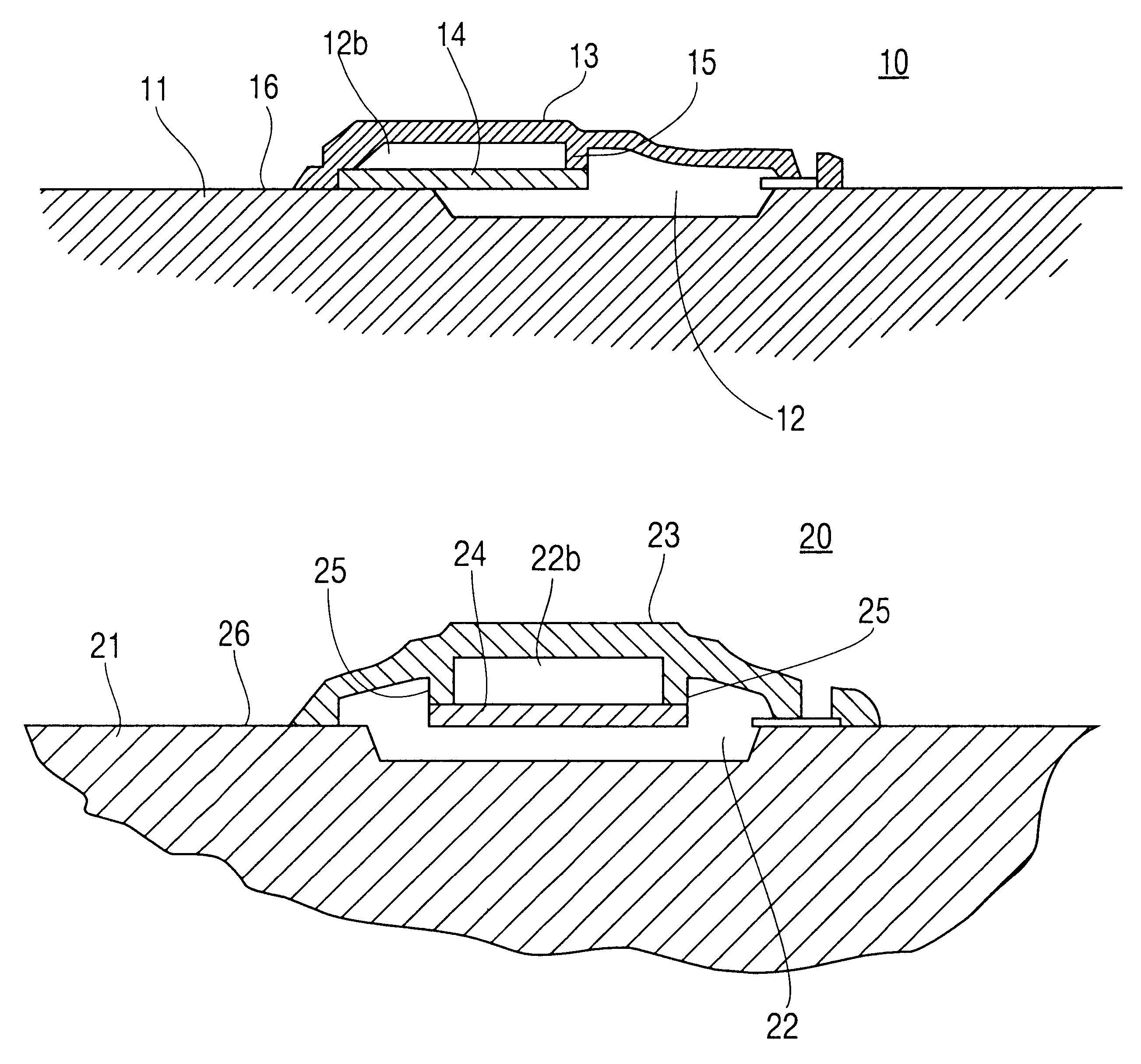

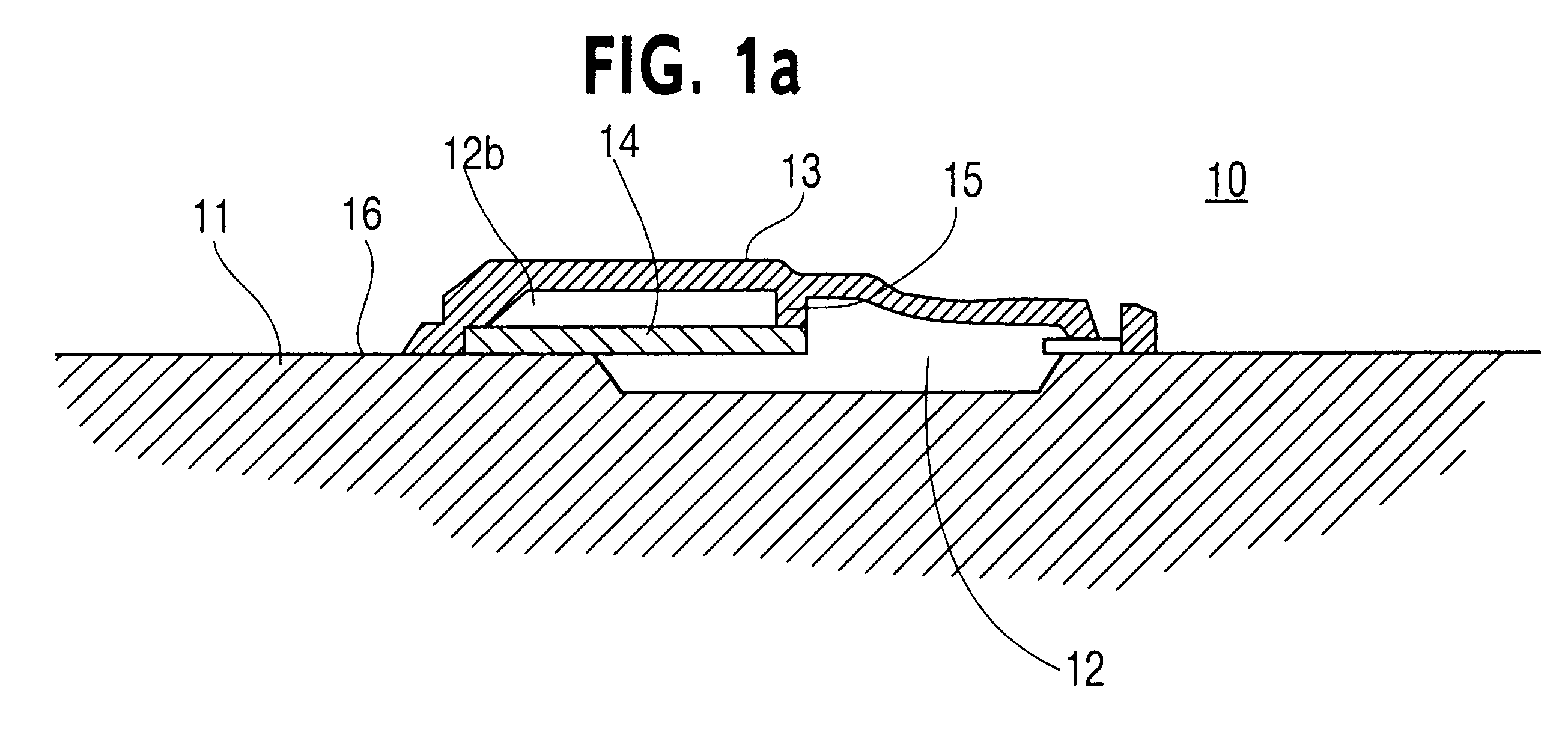

A resonant microbeam pressure sensor is disclosed, comprising a microbeam suspended in a diaphragm in at least one point by suspension elements. Pressure applied to the diaphragm will cause the resonance frequency of the beam to shift. This shift is detectable and proportional to the pressure. The device is manufactured by surface micromachining.

Owner:ST JUDE MEDICAL COORDINATION CENT

Method and apparatus for hard tissue treatment and modification

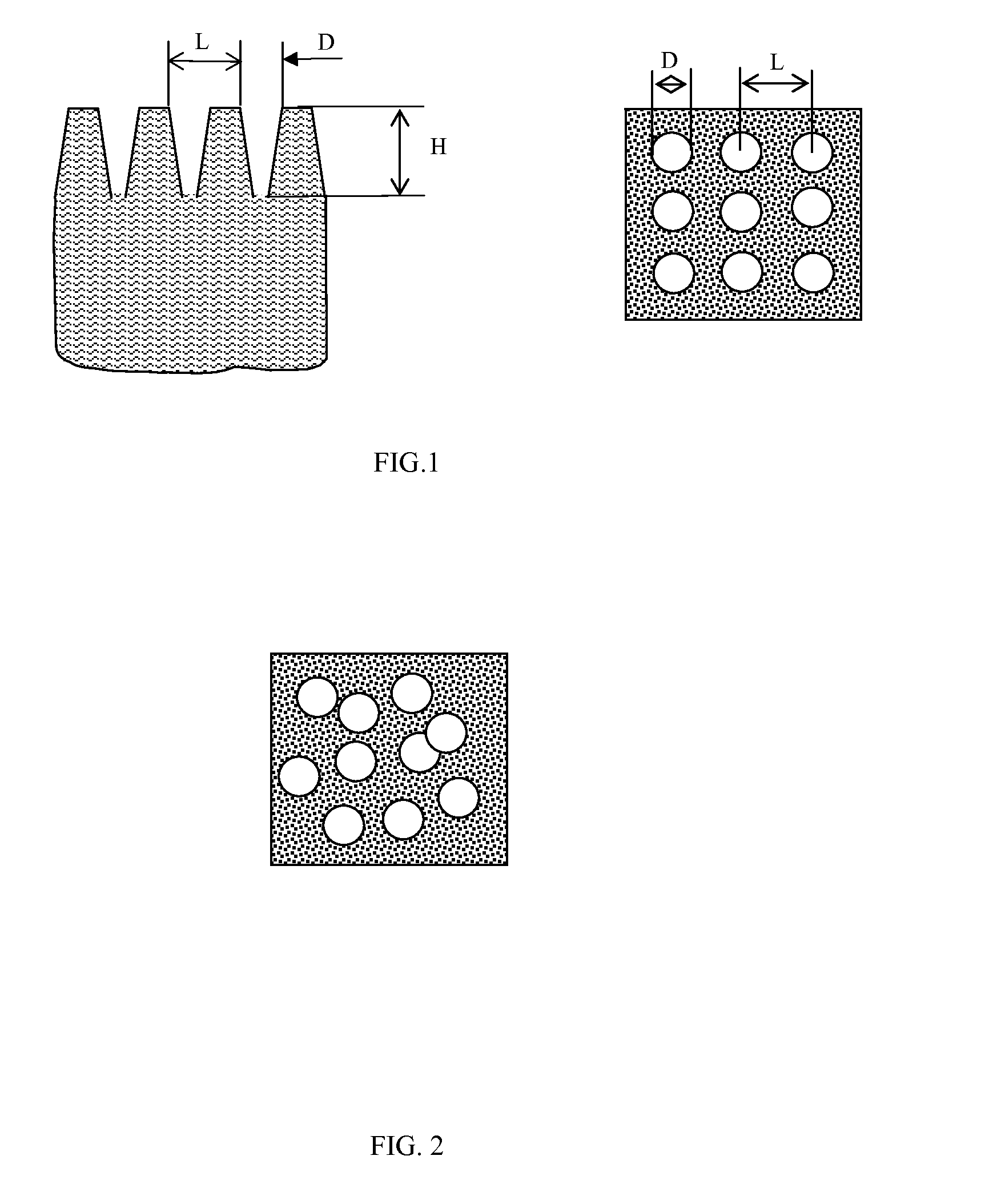

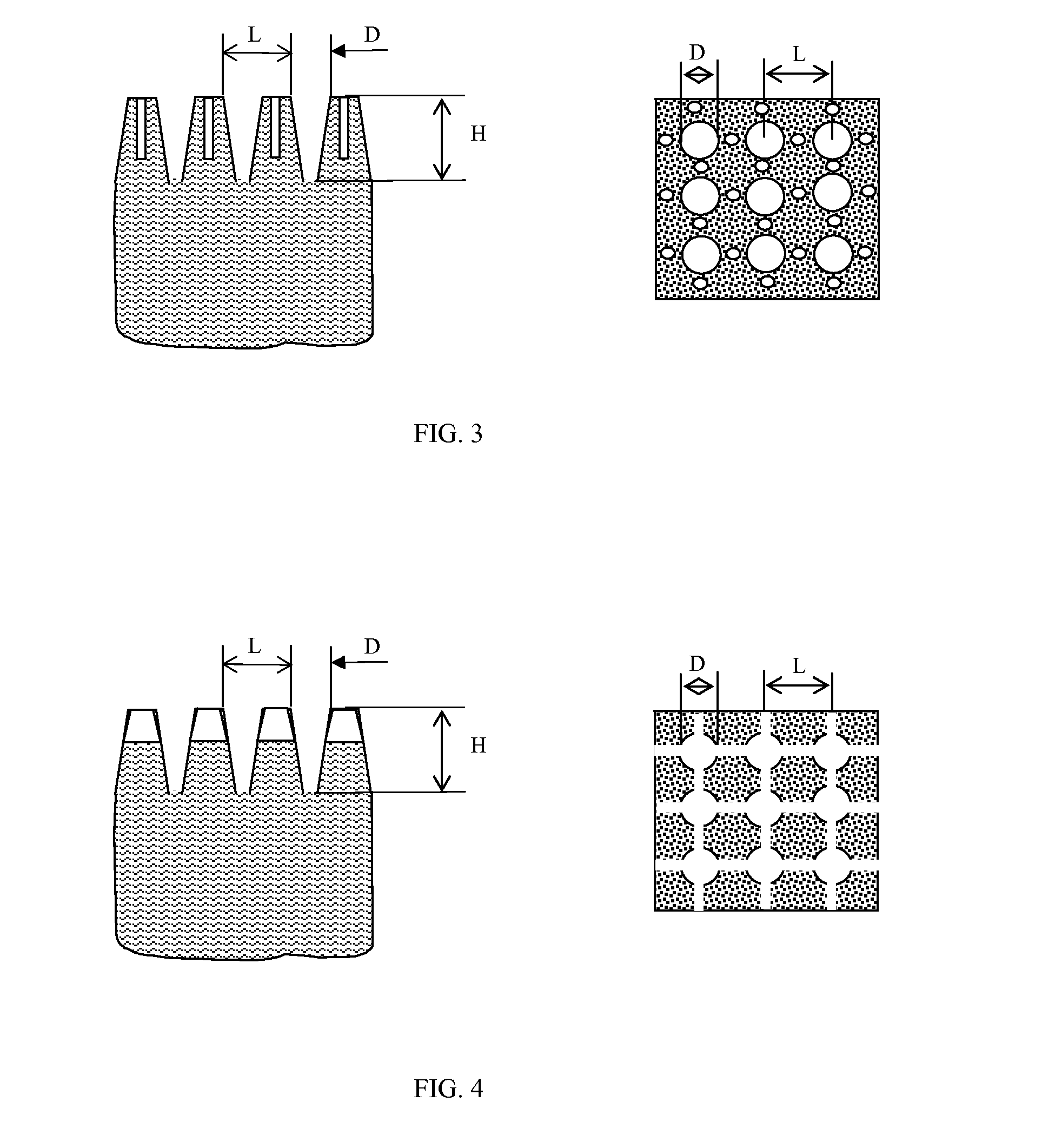

A device and method for forming a texture on a surface of a hard material. Spatial patterns, such as an array of microbeams, are delivered to the tissue through the handpiece. The plurality of microbeams illuminate and ablate the hard material simultaneously. Each of the microbeams has of a sufficient fluence and pulse width to ablate the surface of the hard material and form the texture. Alternatively, one microbeam of a sufficient fluence and pulse width to ablate the surface of the hard material and form the texture is scanned over the surface either manually or in an automatic fashion.

Owner:REJUVEDENT

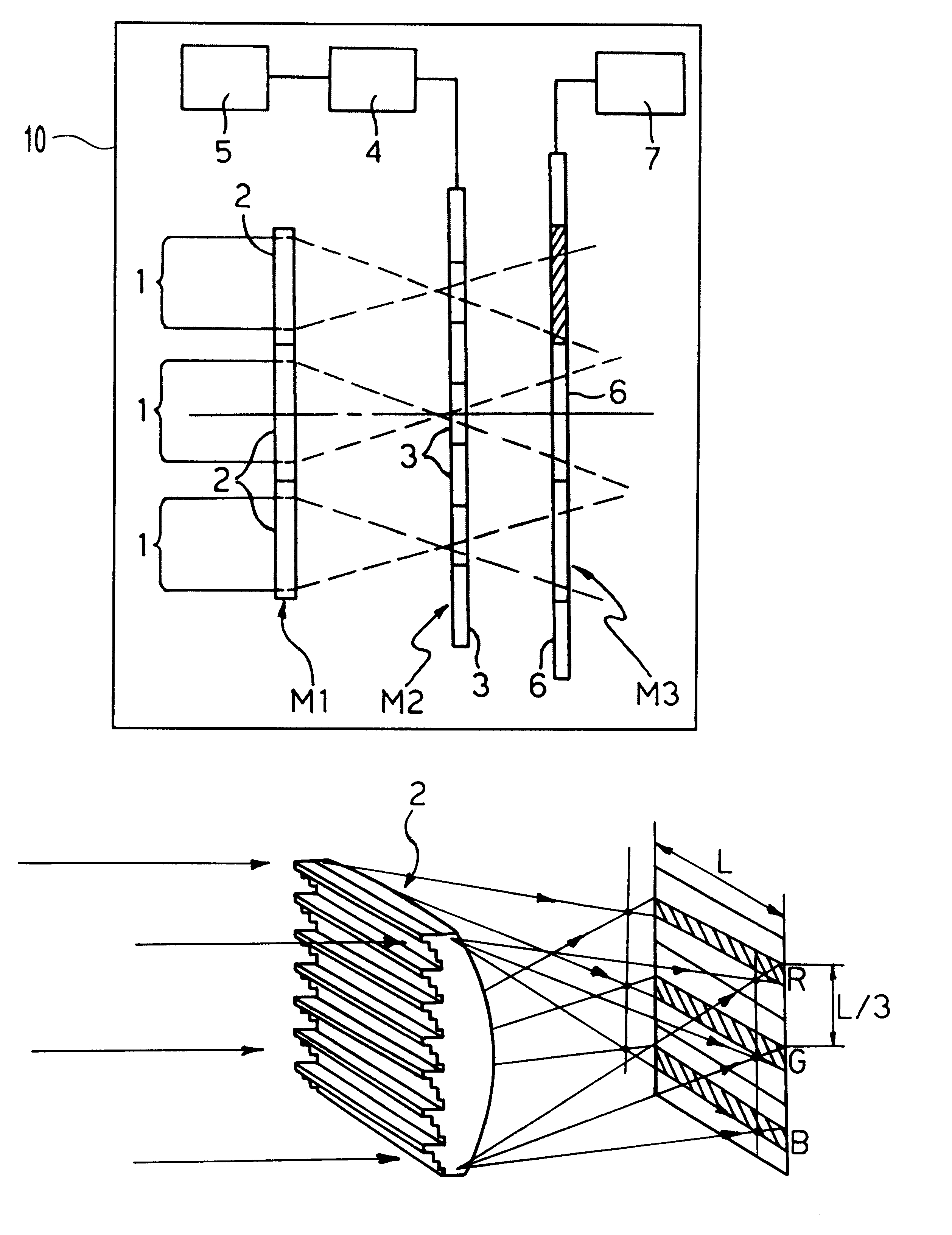

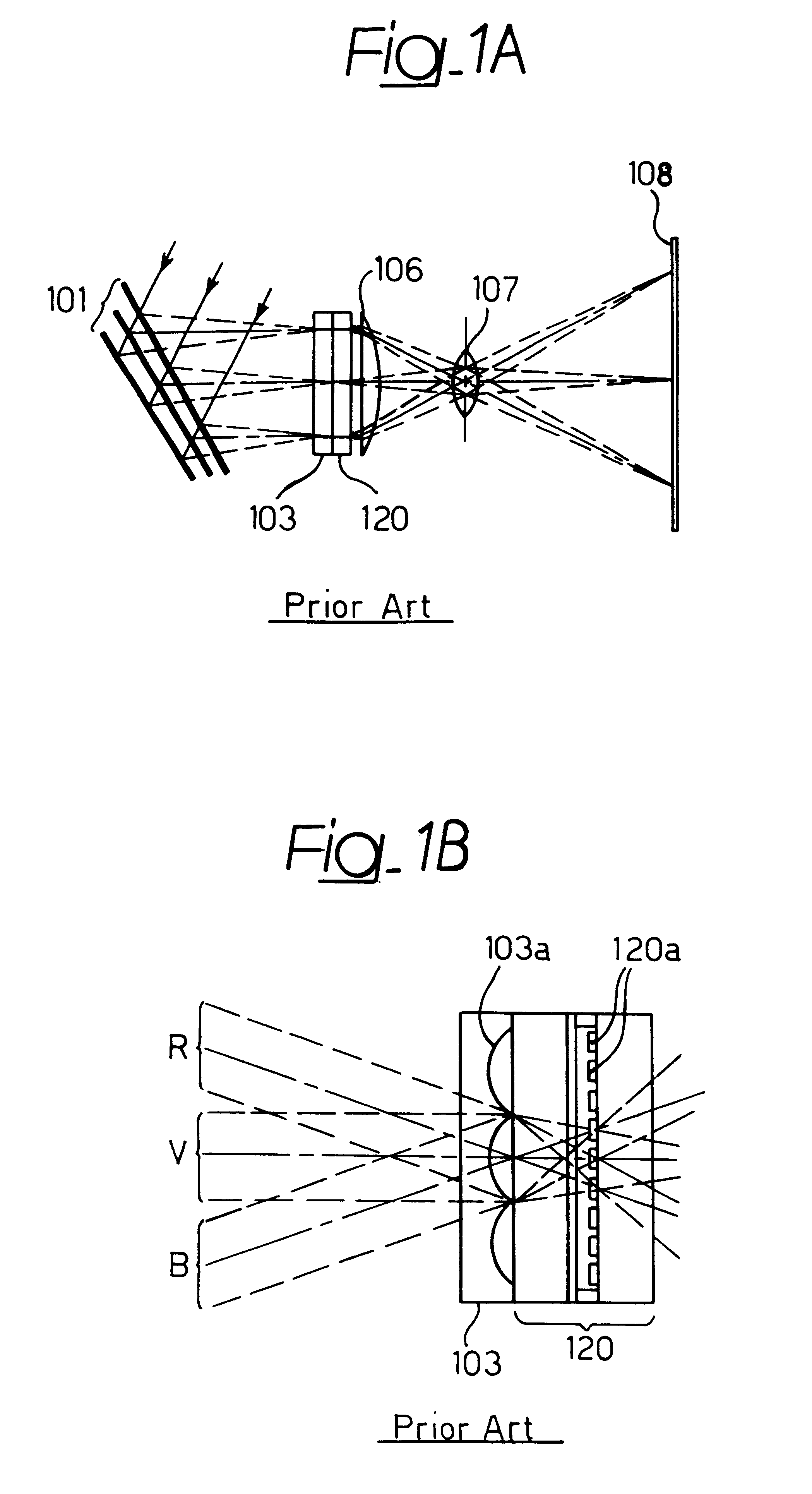

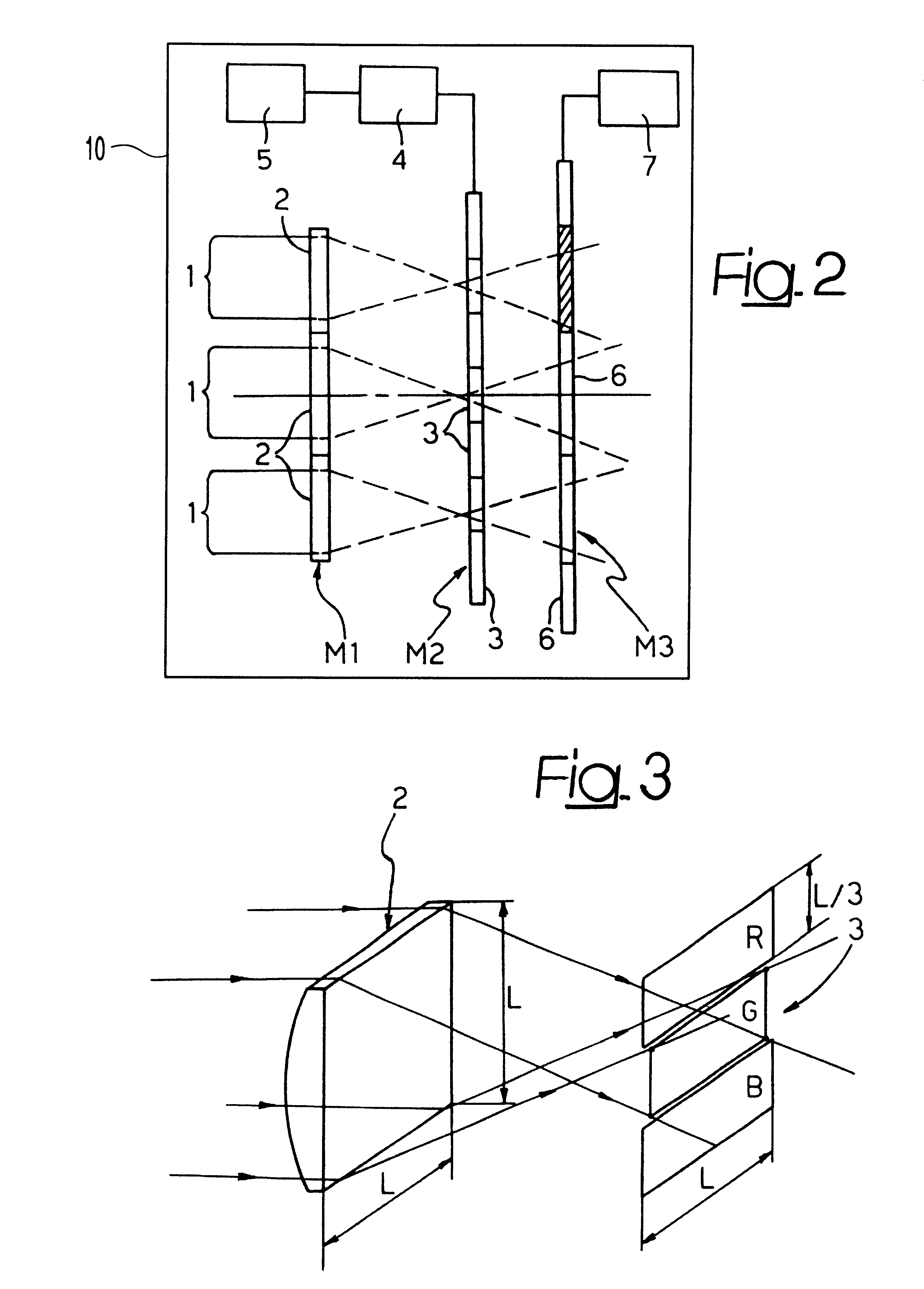

Devices with micro-filters and micro-choppers for dynamic selection of colours and images

InactiveUS6262786B1Low costStatic indicating devicesColor television detailsLight beamMicro lens array

The radiation beam emitted by a polychromatic source of finite dimension is incident onto an array of microlenses which have the function of converging and dividing the beam into a plurality of microbeams directed towards a matrix containing colored microfilters. Once the microfilters have been passed, the radiation reaches a matrix of microchoppers which can be selected independently from each other by a controller, for generating images.

Owner:CENT RICERCHE FIAT SCPA

Multifunctional optical micro-control device

InactiveCN101216414AOvercome singleOvercome deficienciesSurface/boundary effectMaterial analysis by optical meansFemto second laserCcd camera

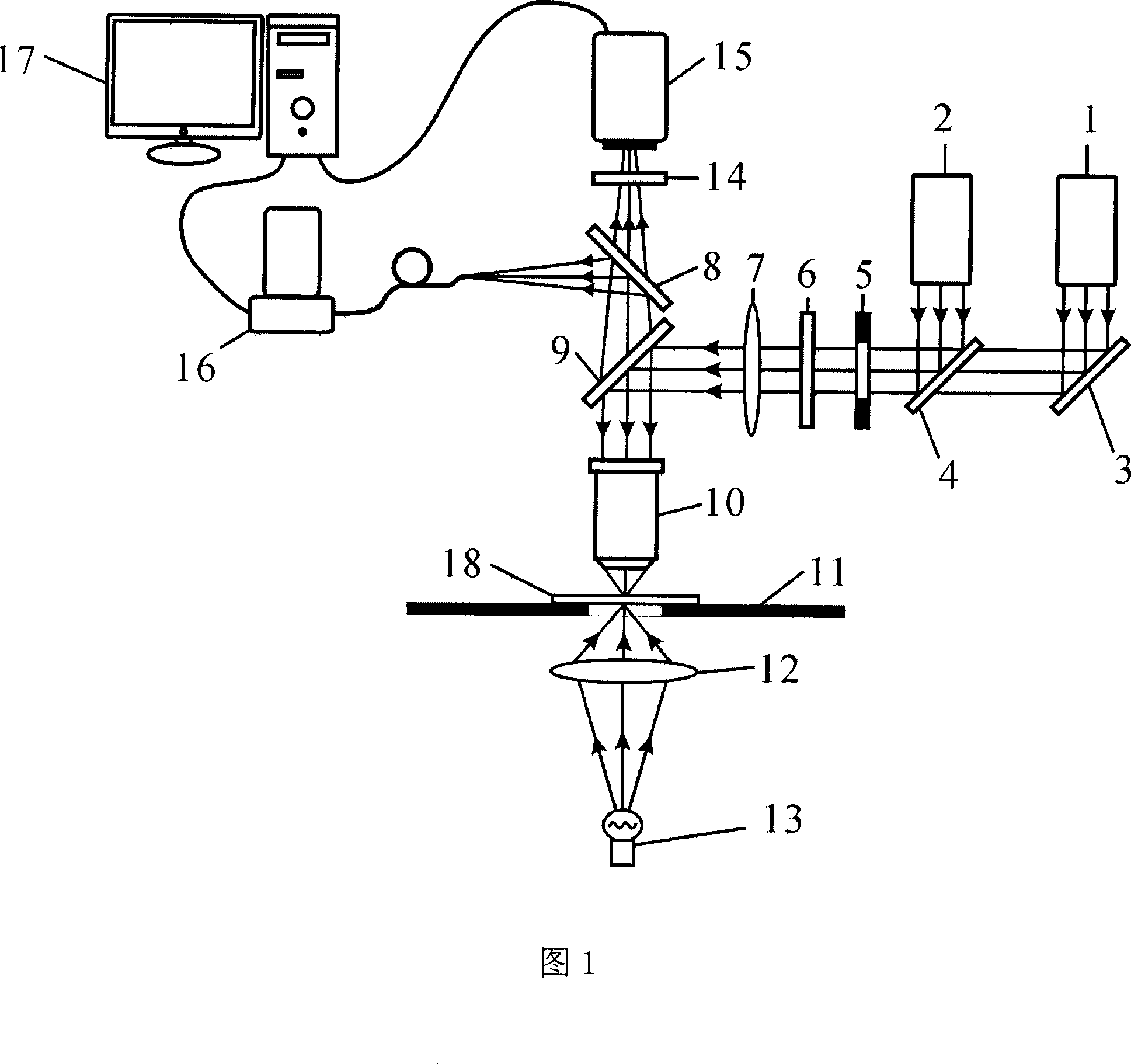

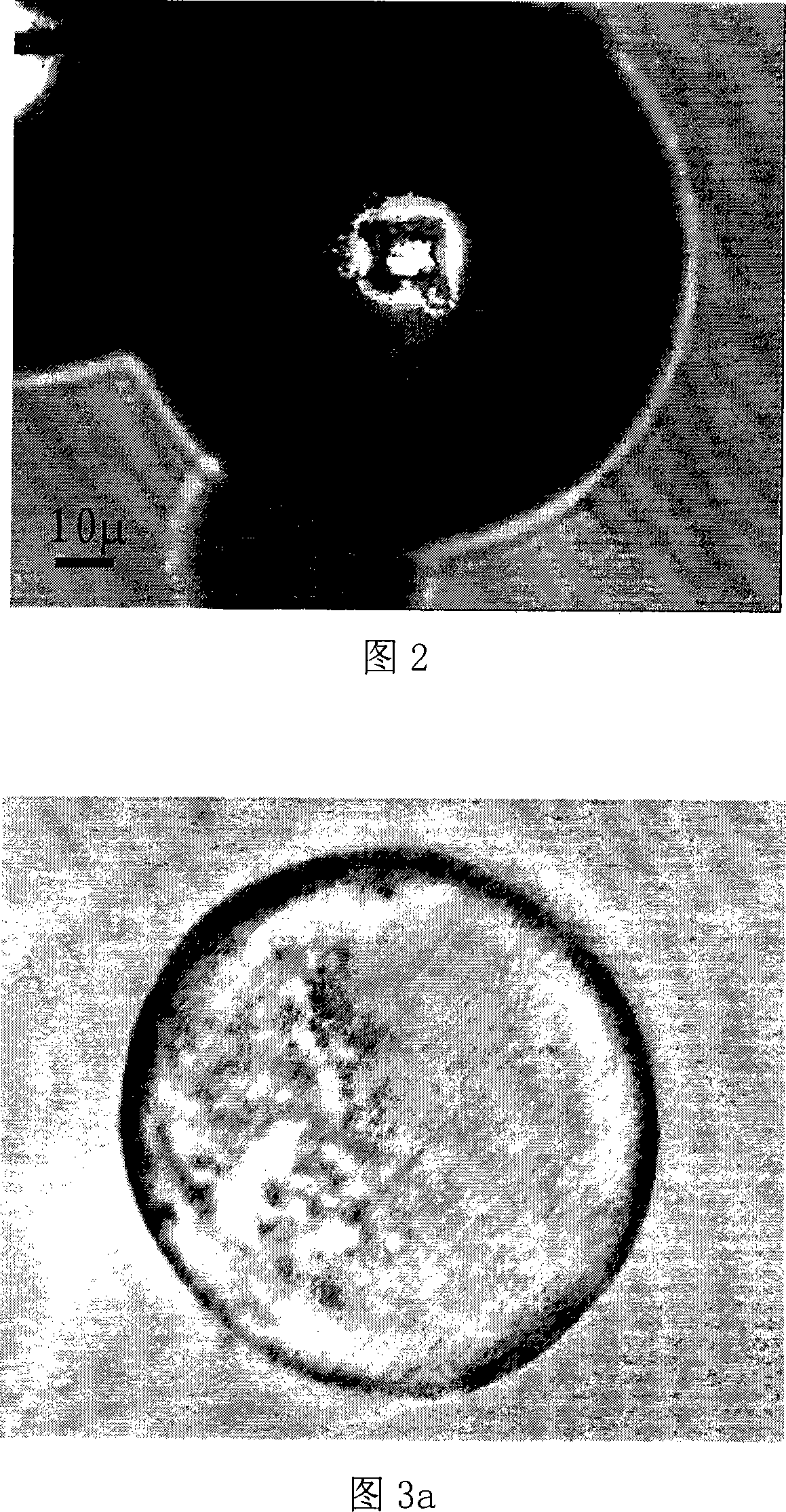

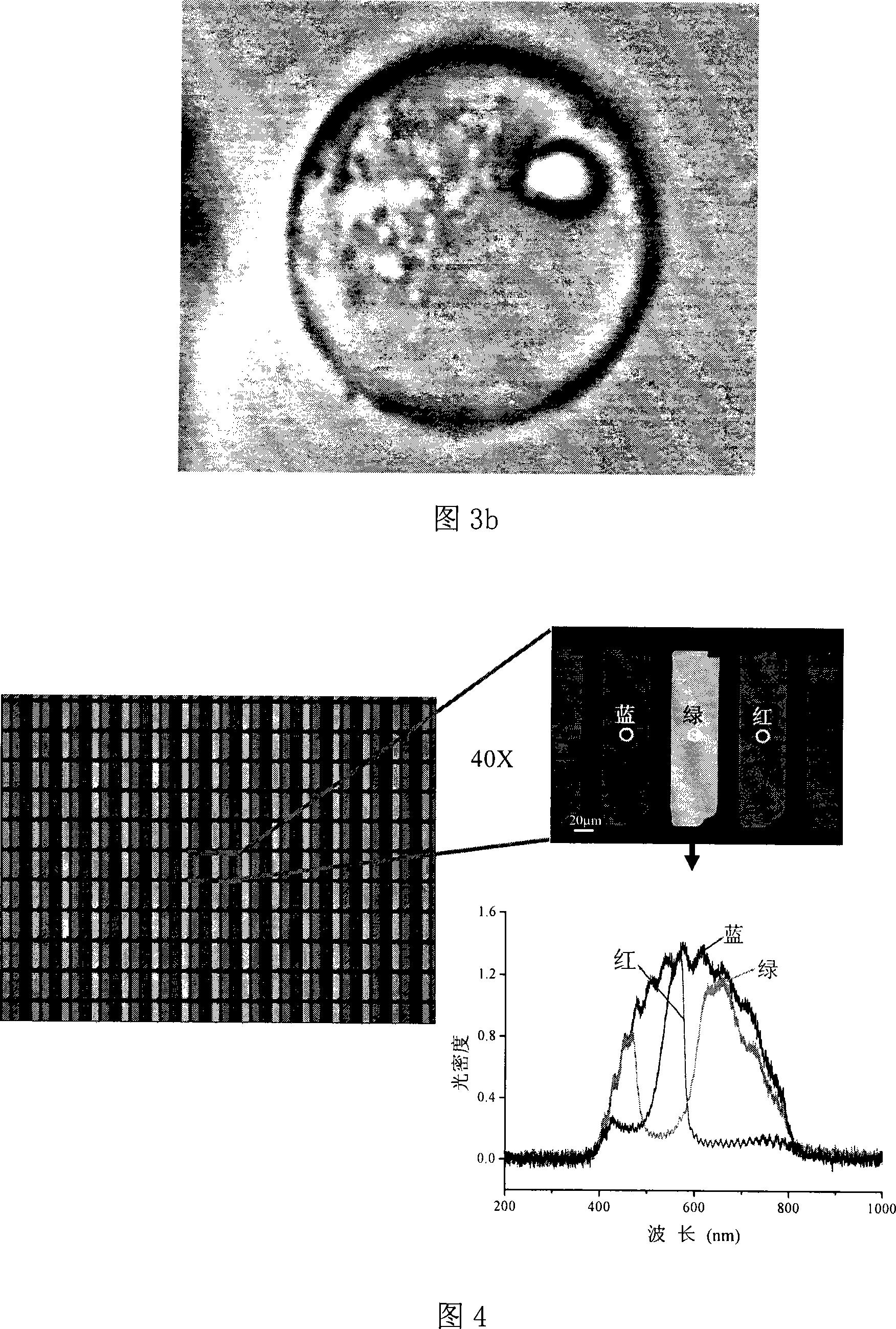

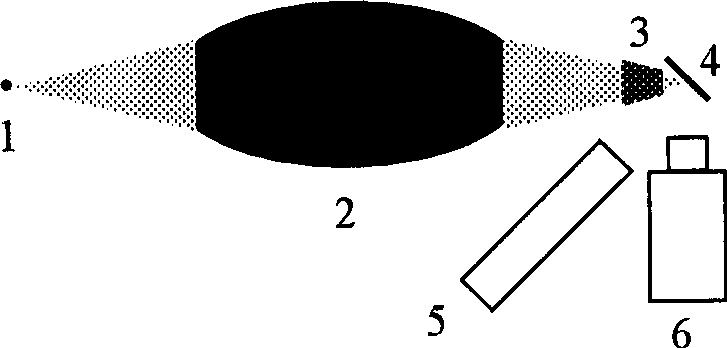

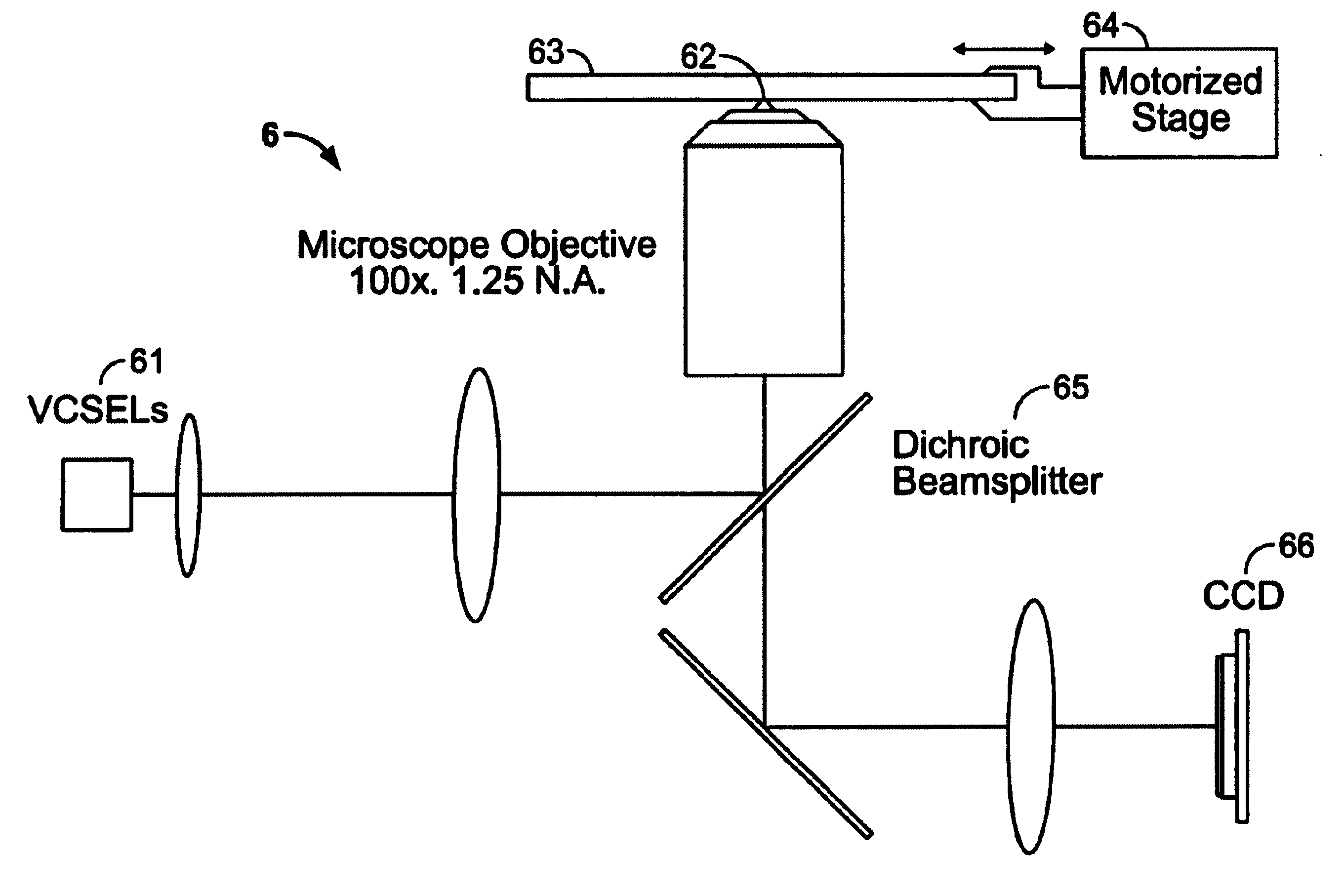

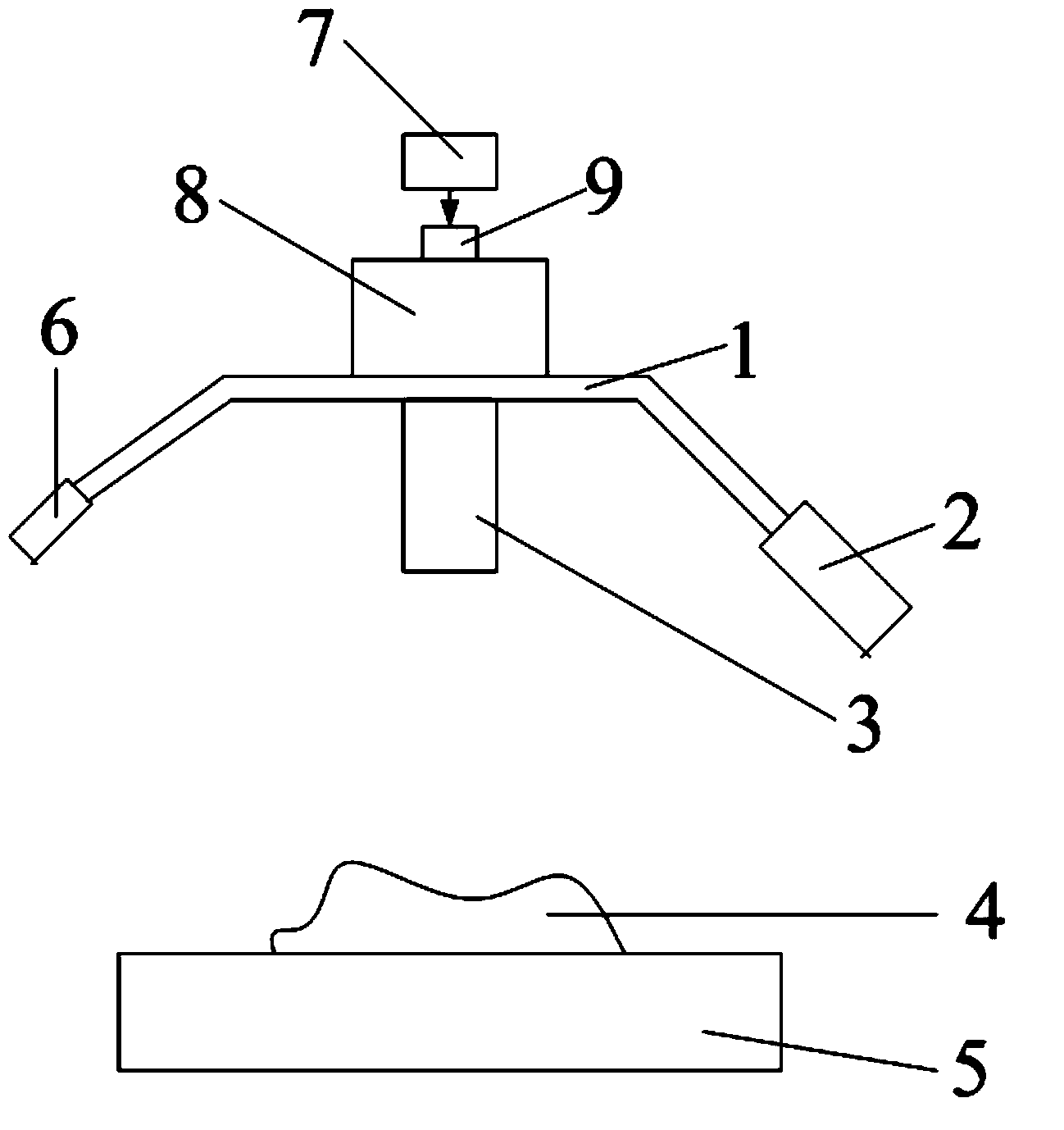

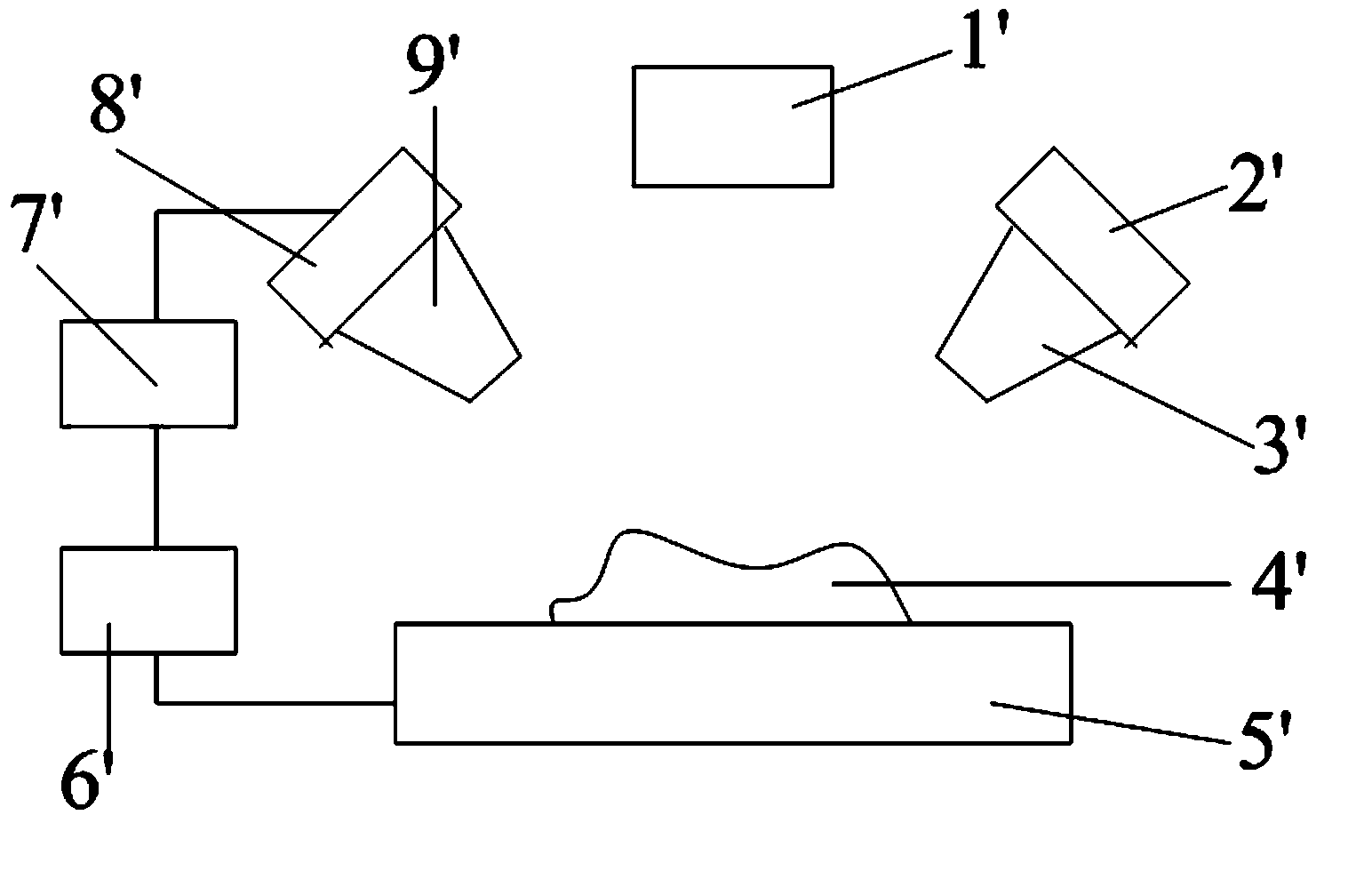

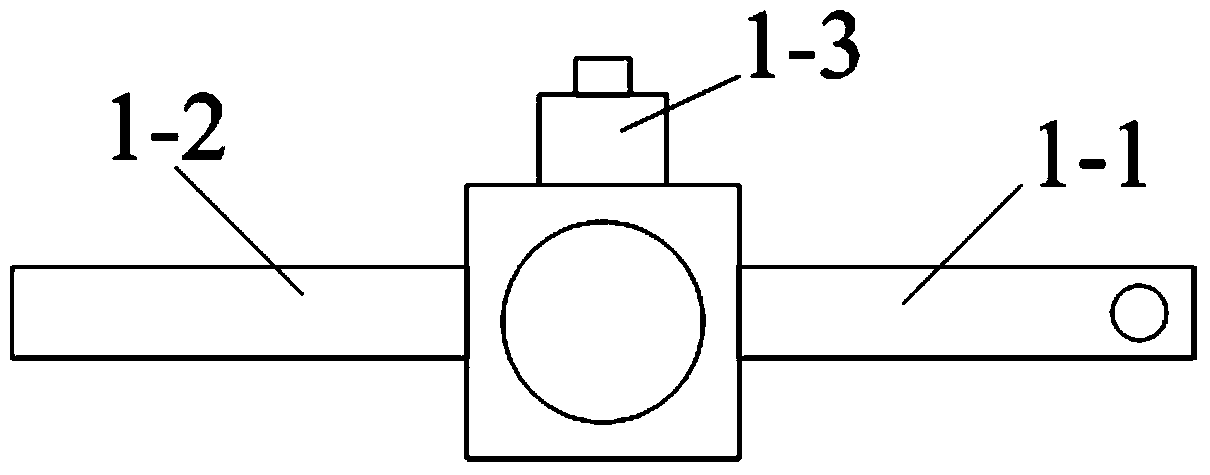

A multifunctional optical micro-manipulation device comprises a femtosecond laser, an optical tweezers laser, an optical system, a stage, a light source system, an imaging system, a spectral measurement system and a computer, wherein the optical system comprises a shutter, an attenuator, a focusing lens, a near IR reflector and a microscopic objective lens; the light source system comprises an illumination light source and a condenser lens; the microscopic objective lens is arranged on the stage for condensing a laser beam emitted by a laser generator onto a sample; the condenser lens is arranged below the stage for condensing a visible light emitted by the illumination light source onto the sample; and the imaging system includes an IR filter and CCD camera sequentially disposed on the projection light path of the near IR reflector. By integrating three functions of laser tweezers, femtosecond laser scissors and microspectrometer in one system, the invention can overcome the singleness and the disadvantages of the prior laser micro-beam technology and can be widely used for studying in biological, medical, biophysical, material chemistry and nano-technology fields.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

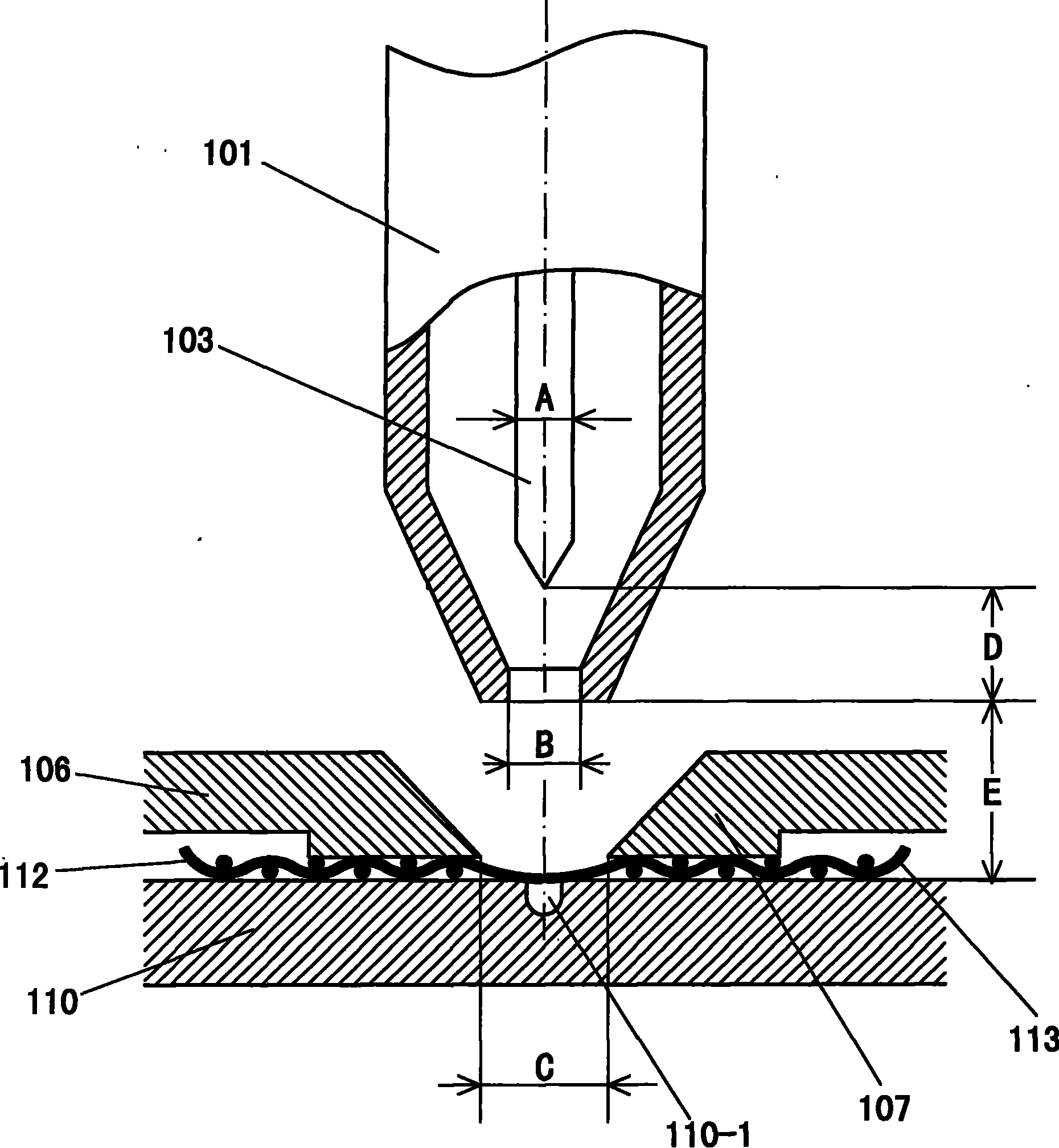

Microbeam tungsten argon arc welding method for magnesium alloy thin-walled tube

InactiveCN102554418AIncrease the difficultyLow yieldArc welding apparatusWelding/cutting media/materialsArc stabilityManganese

The invention relates to a microbeam tungsten argon arc welding method for a magnesium alloy thin-walled tube. A low-magnesium aluminum alloy welding wire is used as a filling material, and the thin-walled tube is welded by a microbeam tungsten argon arc welding process under inert gas shielding. The low-magnesium aluminum alloy welding wire comprise 9.5%-11.6% of Al (aluminum), 0.6%-1.75% of Zn (zinc), 0.15%-0.35% of Mn (manganese), 0.01%-0.05% of Cu (copper), 0.02%-0.05% of Si (silicon) and the balance Mg (magnesium) in mass percent. The microbeam tungsten argon arc welding method for the magnesium alloy thin-walled tube is high in welding efficiency and convenient and flexible in application, and can be used for obtaining a crack-free welding joint without magnesium-aluminum brittle compounds. Compared with a conventional tungsten argon arc welding method, the microbeam tungsten argon arc welding method has the advantages that arc stability of microbeam argon arc welding for the magnesium alloy thin-walled tube is obviously improved, the tensile strength of the welding joint is 30% higher than that of a conventional tungsten argon arc welding joint, the elongation of the welding joint is increased by 10%, and the use requirements of industrial production on magnesium alloy thin-walled tube welding component can be met.

Owner:SHANDONG UNIV

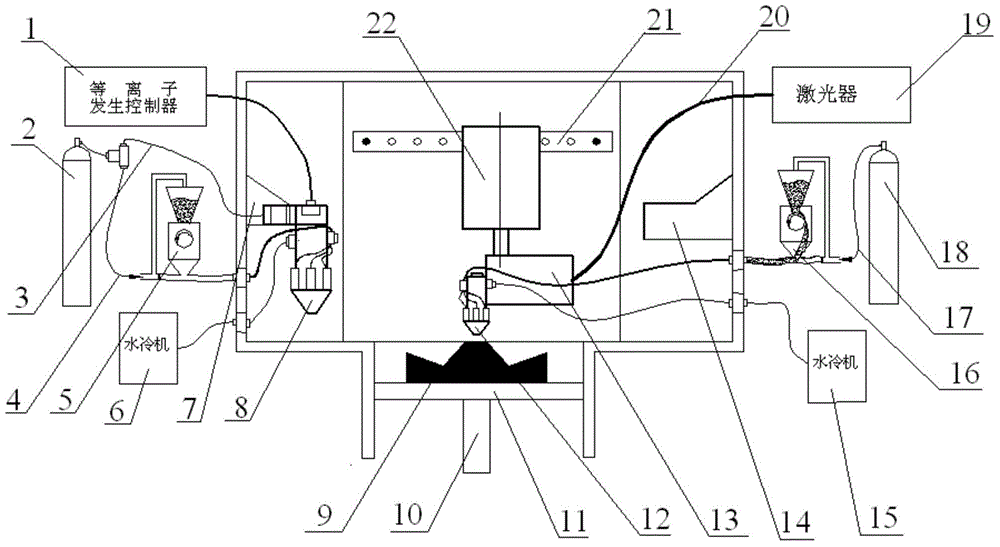

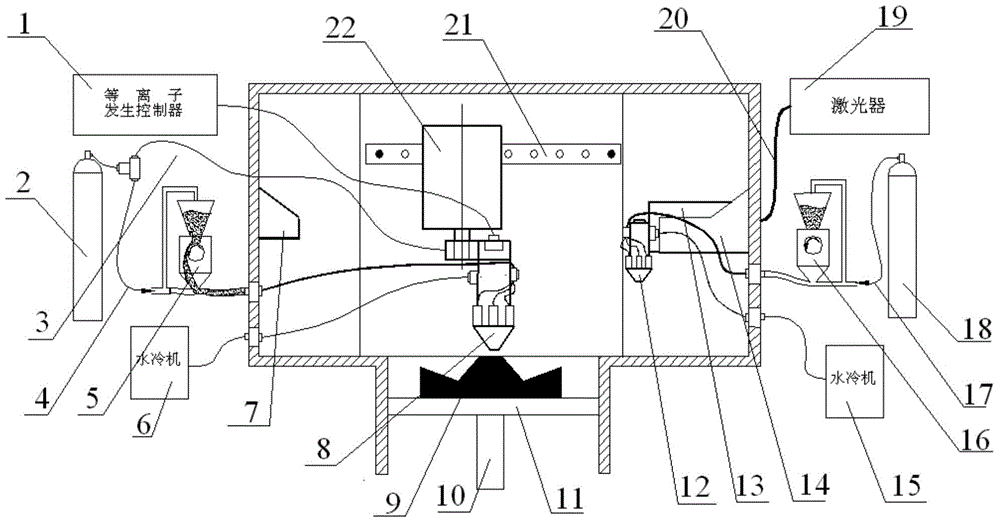

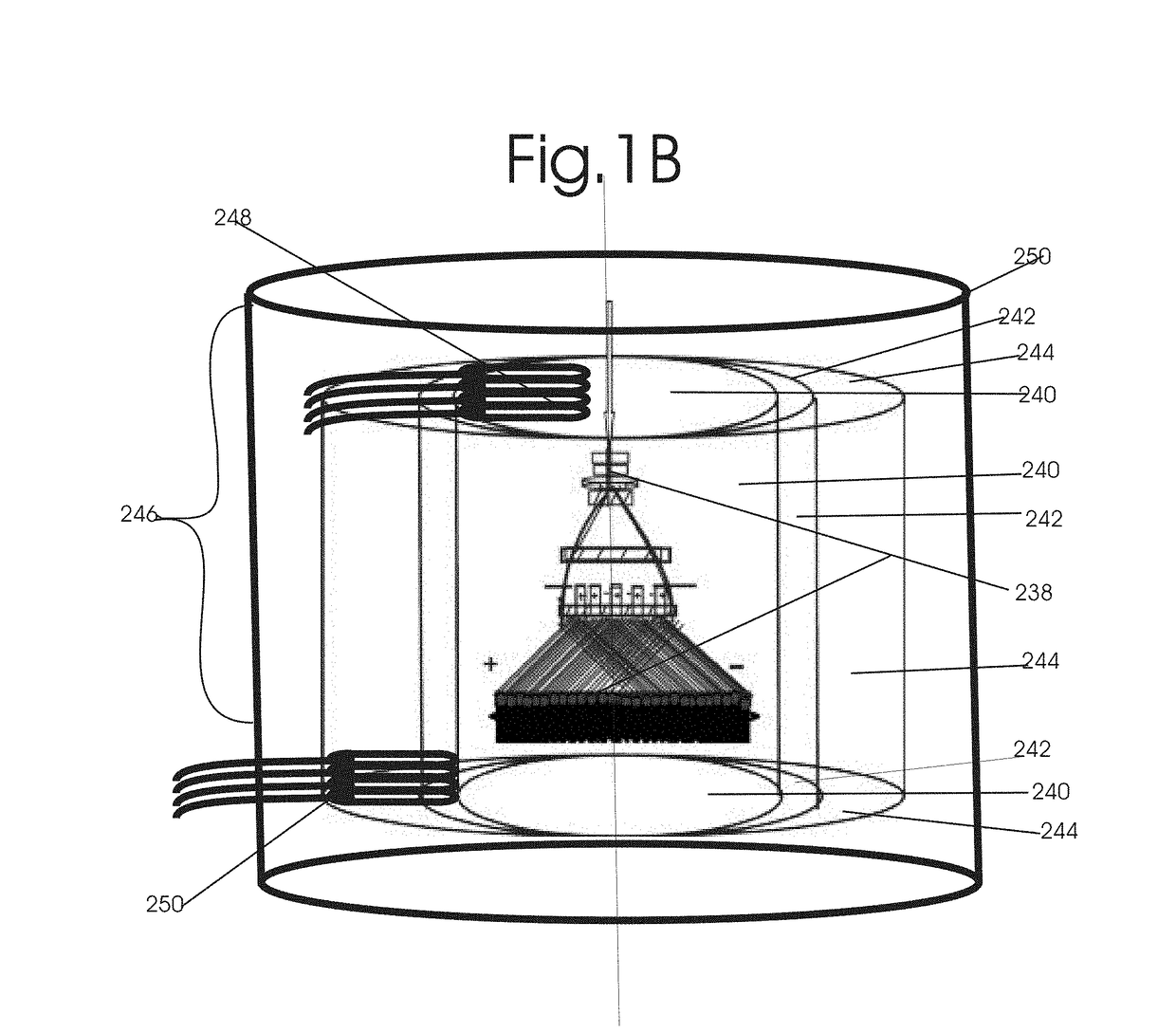

Laser and microbeam plasma composite 3D (3-dimensional) printing equipment and method

ActiveCN104801712ASolve efficiency problemsSolve the accuracy problemAdditive manufacturing apparatusNumerical controlControl system

The invention discloses a laser and microbeam plasma composite 3D (3-dimensional) printing equipment and method. The equipment comprises a central control system, a sealing forming chamber, a laser forming device and a plasma processing device, wherein a laser forming spray head and a plasma gun are correspondingly put on a support frame arranged at the left and right side inner walls of the sealing forming chamber, and the laser forming spray head or the plasma gun is clamped through a co-work numerical control main shaft, so that the laser forming spray head or the plasma gun moves in the Z, X and Y directions in the sealing forming chamber. The central control system controls the co-work numerical control main shaft for conveying back the laser forming spray head back to the support frame, then, the co-work numerical control main shaft clamps the plasma gun for filling the inside of the profile of a formed metal part, and the work is alternately carried out in such a way until the part manufacturing is completed, so that the scanning time is reduced to a great degree. The laser fast forming is combined with the plasma, the problem of conflict between the efficiency and the precision of a metal 3D printing technology is solved, and in addition, the plasma is adopted for replacing the laser to be used as a heat source, so that the high-efficiency and low-cost industrial level metal 3D printing equipment is obtained.

Owner:SOUTH CHINA UNIV OF TECH

Method of making a pressure sensor comprising a resonant beam structure

A resonant microbeam pressure sensor is disclosed, comprising a microbeam suspended by a diaphragm at one or more points by suspension elements. Pressure applied to the diaphragm will cause the resonance frequency of the beam to shift. This shift is detectable and proportional to the pressure. The device is manufactured by surface micromachining.

Owner:ST JUDE MEDICAL COORDINATION CENT

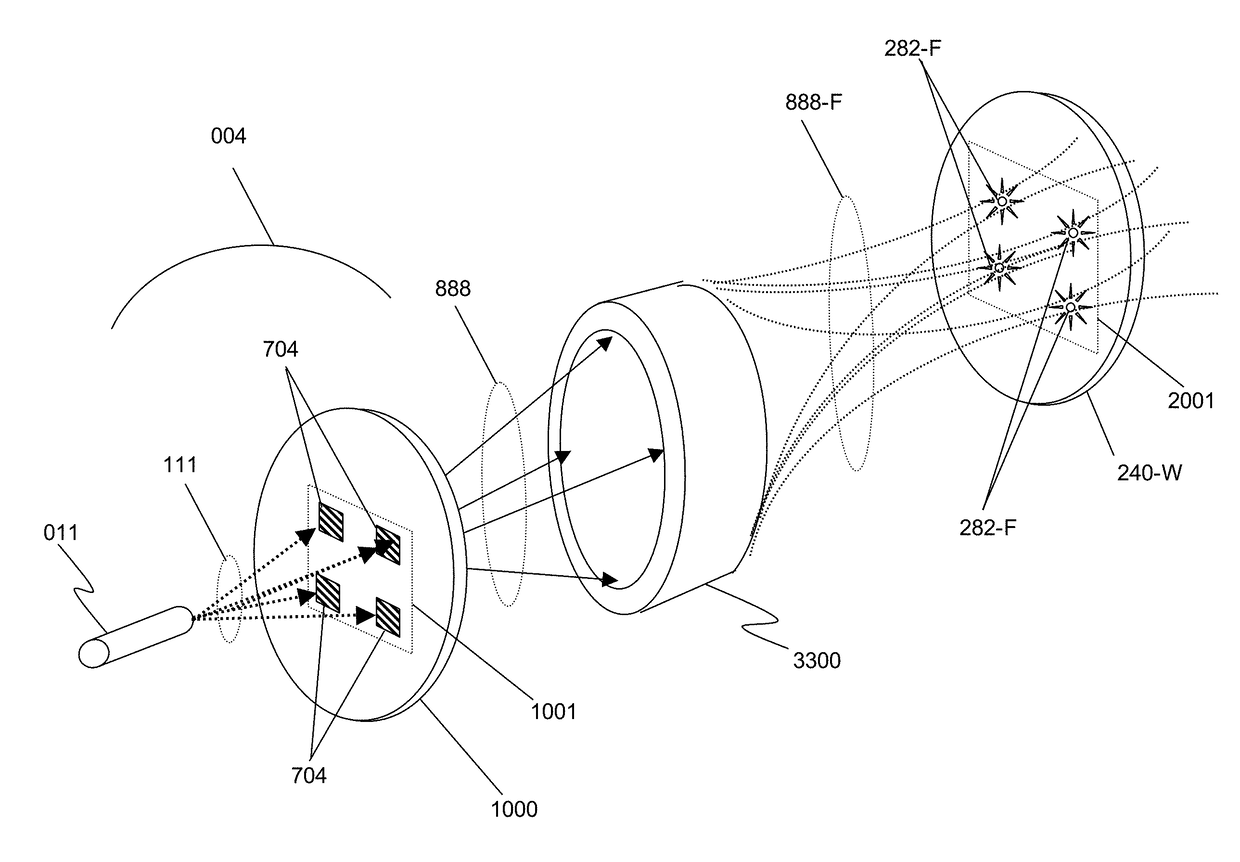

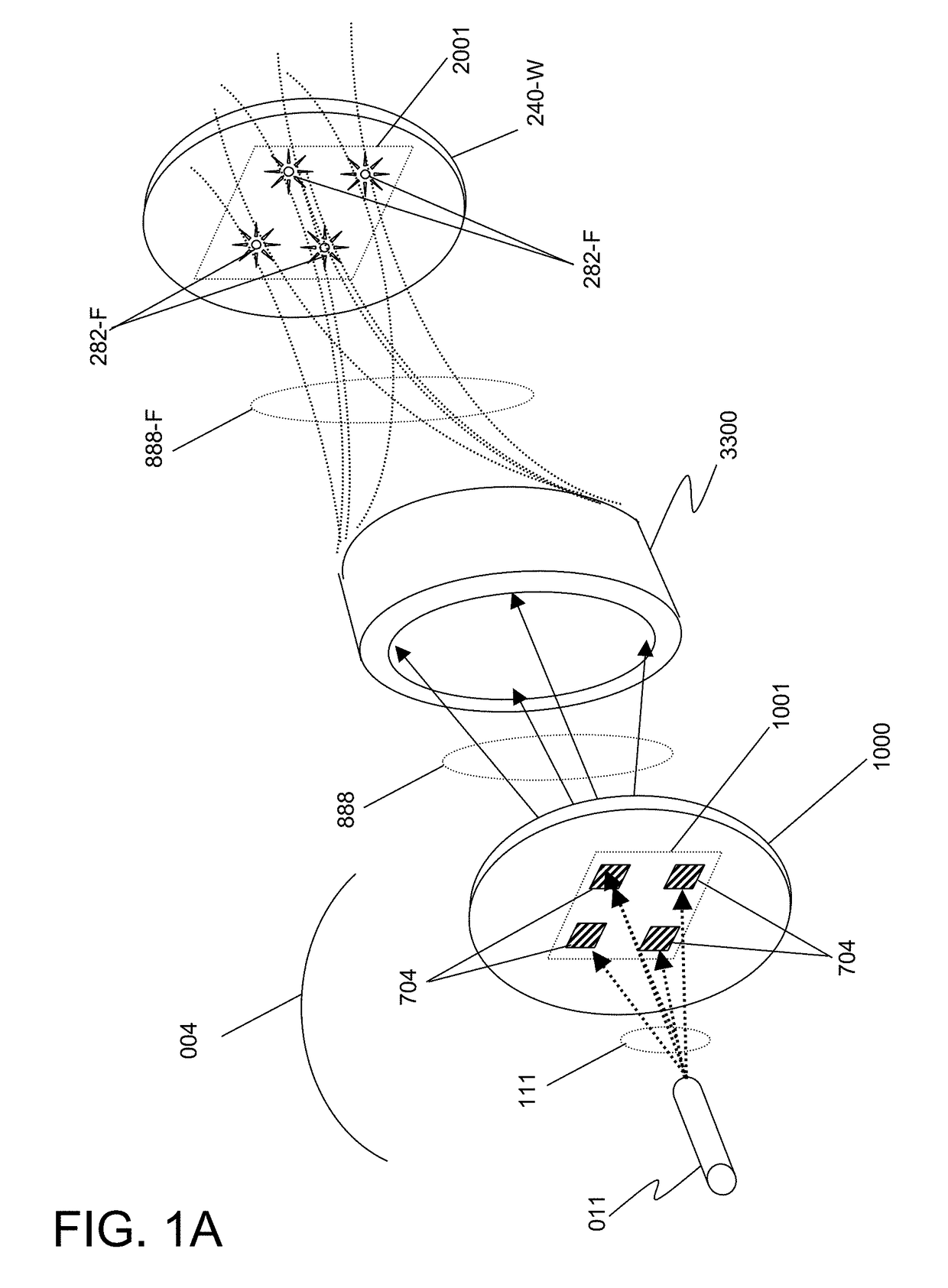

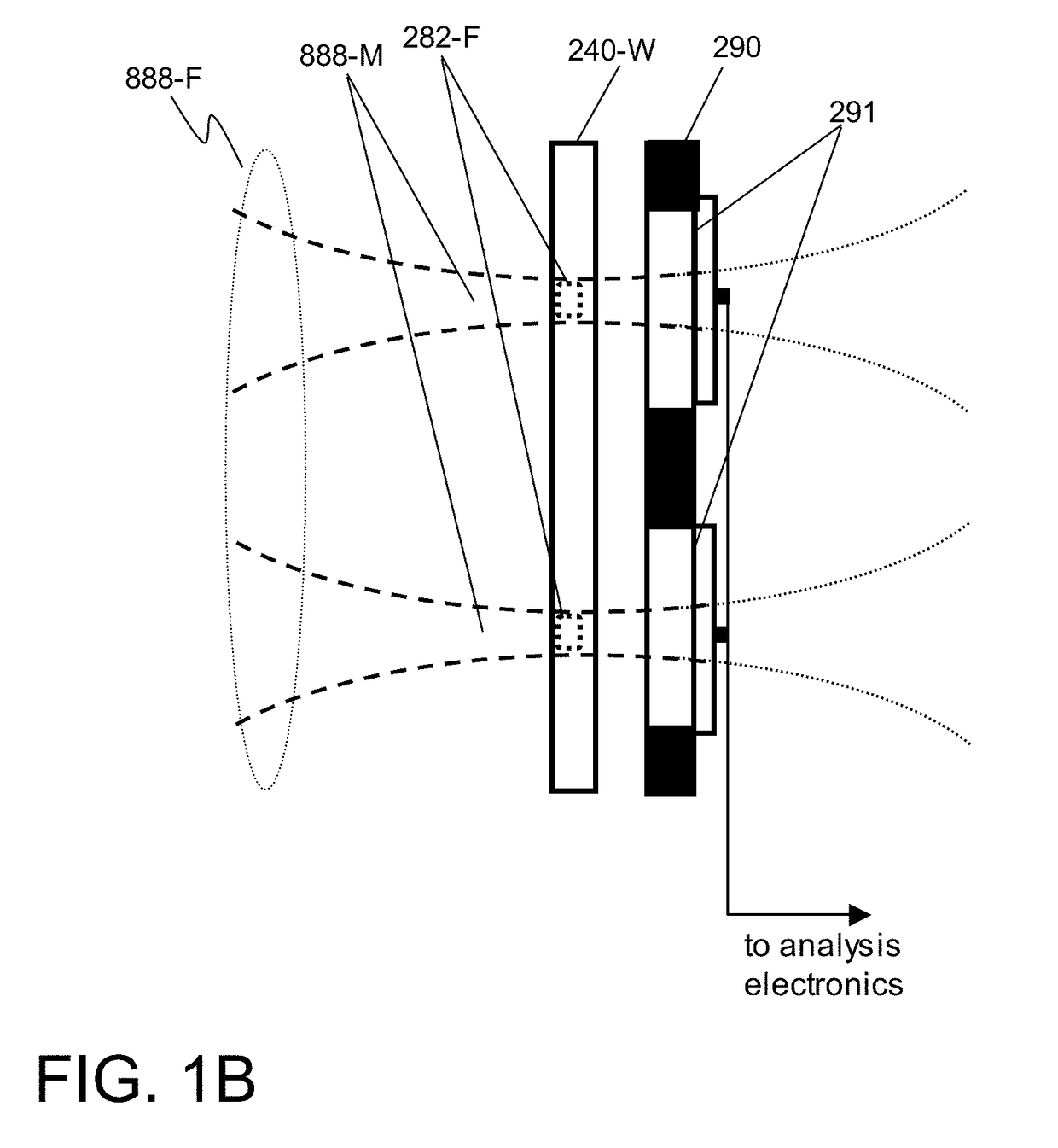

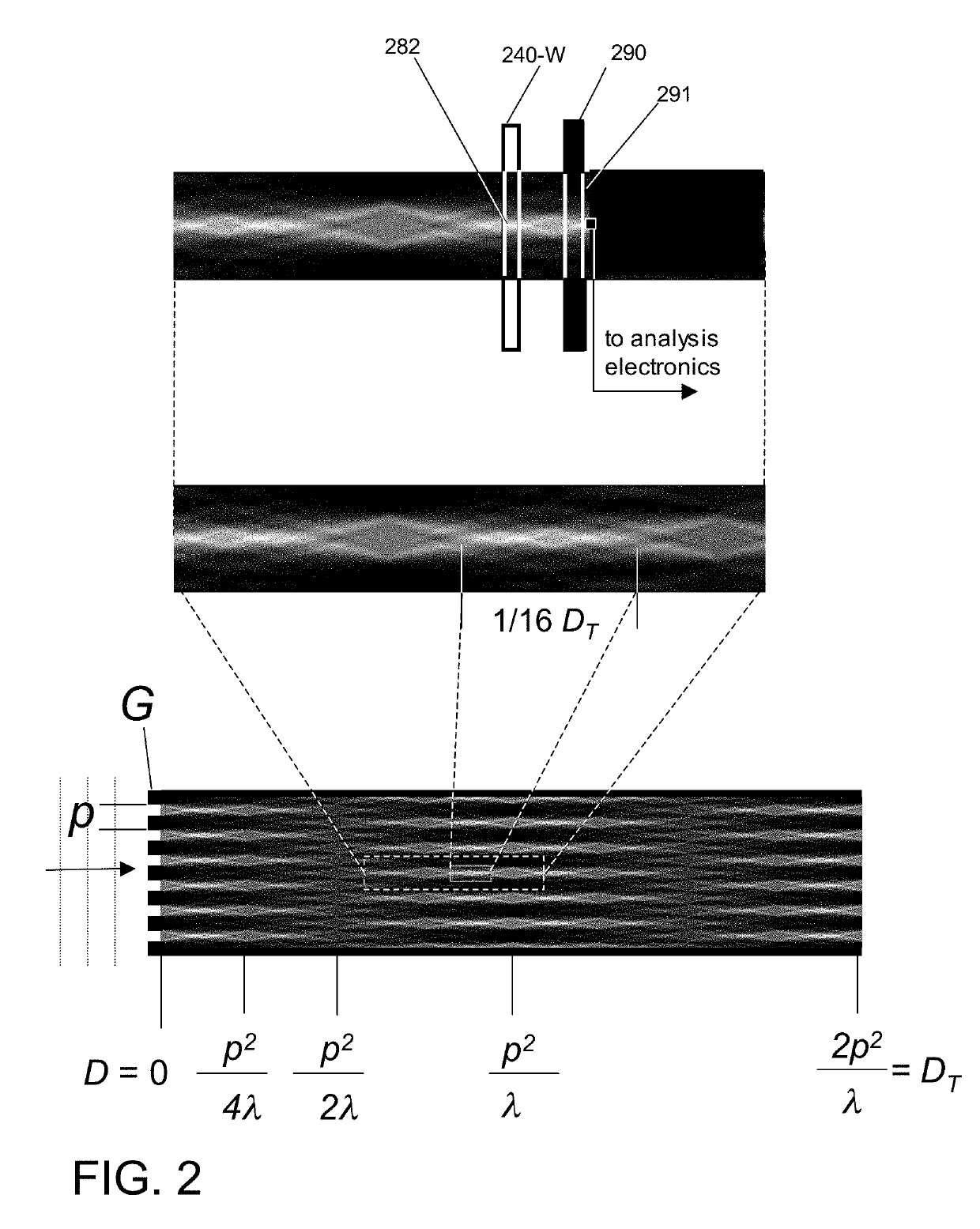

Method and apparatus for x-ray microscopy

ActiveUS20170261442A1Large pixel sizeImprove detection efficiencyImaging devicesHandling using diffraction/refraction/reflectionX-rayNanoscopic scale

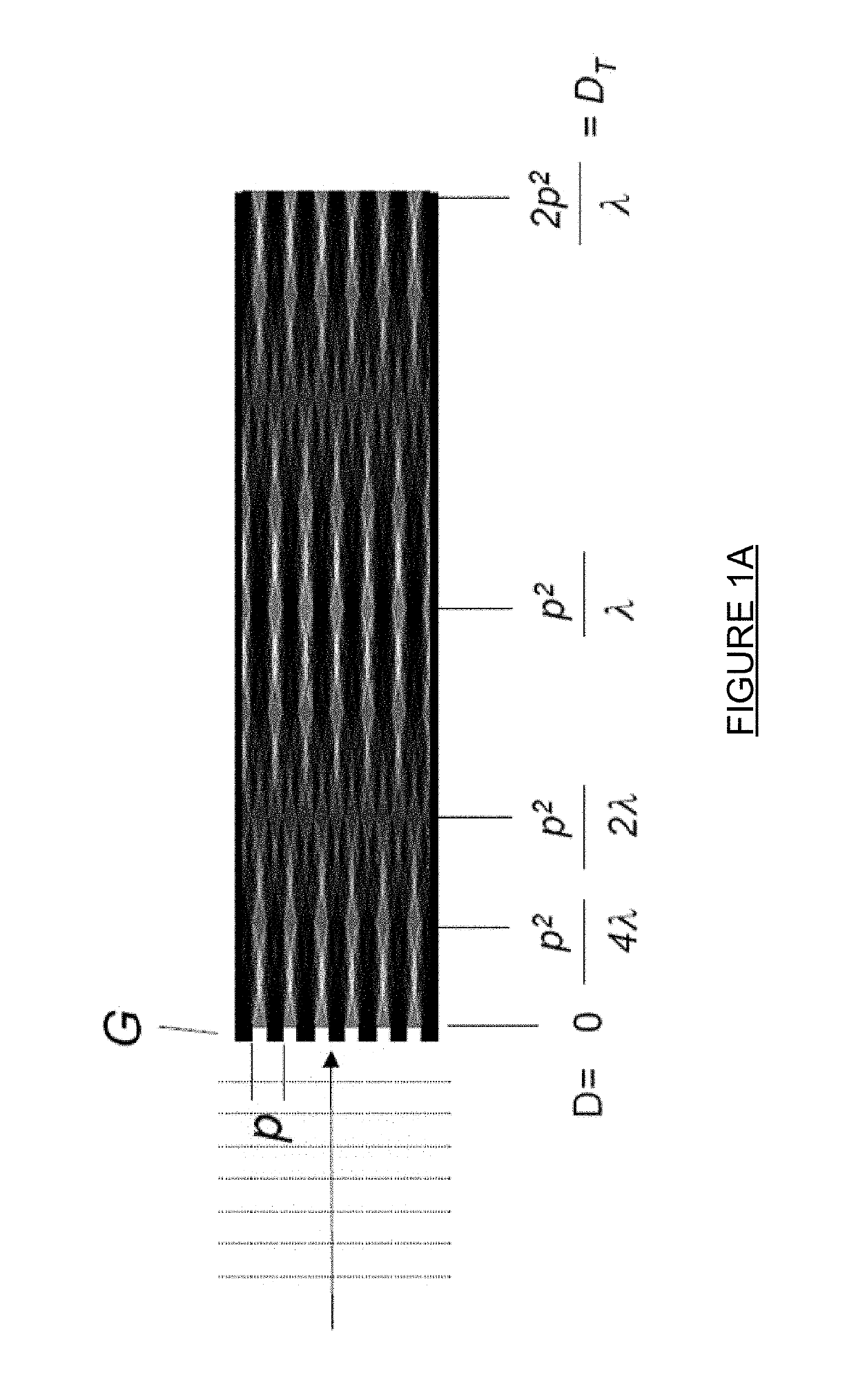

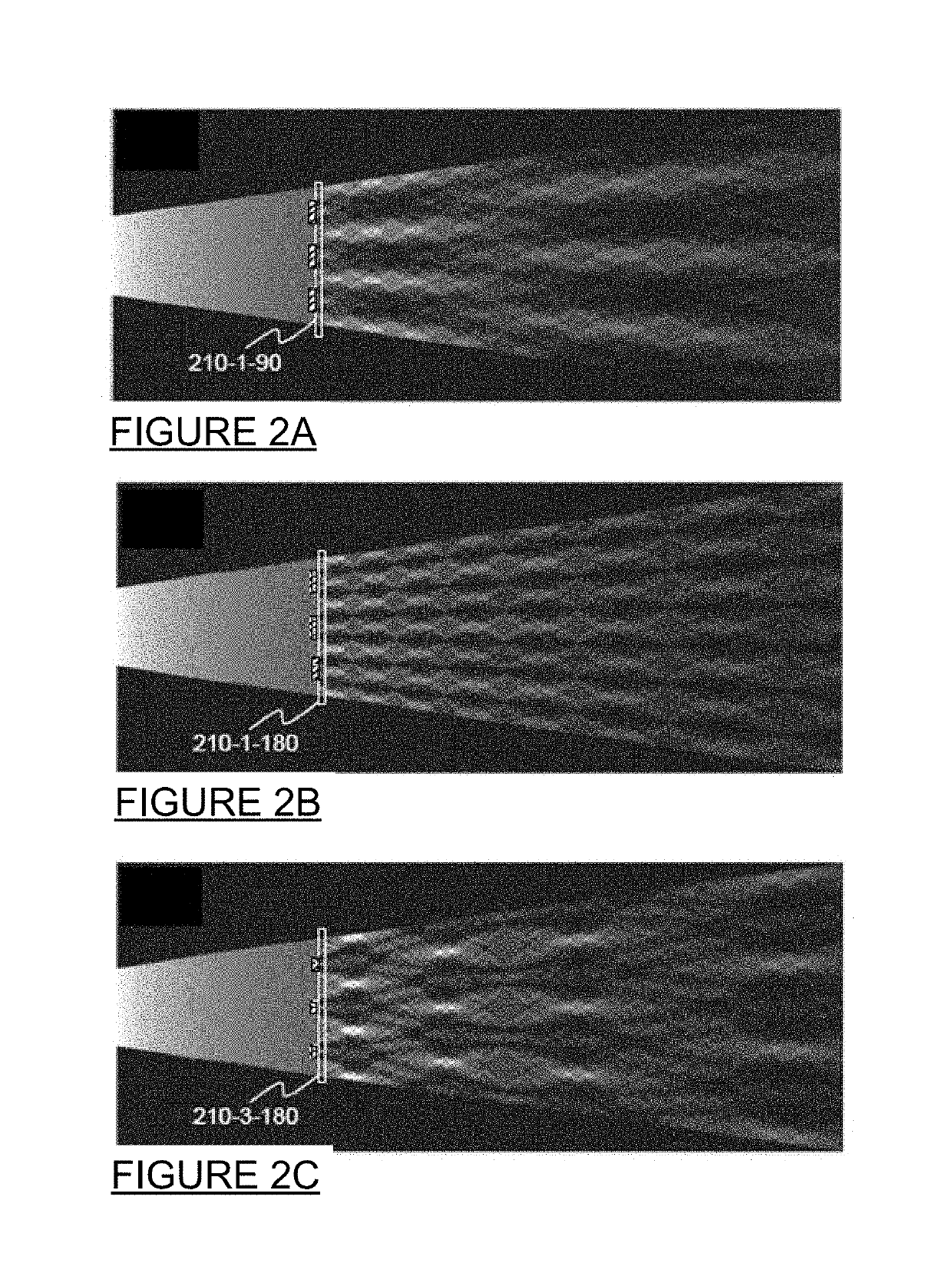

This disclosure presents systems for x-ray microscopy using an array of micro-beams having a micro- or nano-scale beam intensity profile to provide selective illumination of micro- or nano-scale regions of an object. An array detector is positioned such that each pixel of the detector only detects x-rays corresponding to a single micro- or nano-beam. This allows the signal arising from each x-ray detector pixel to be identified with the specific, limited micro- or nano-scale region illuminated, allowing sampled transmission image of the object at a micro- or nano-scale to be generated while using a detector with pixels having a larger size and scale. Detectors with higher quantum efficiency may therefore be used, since the lateral resolution is provided solely by the dimensions of the micro- or nano-beams. The micro- or nano-scale beams may be generated using an arrayed x-ray source or a set of Talbot interference fringes.

Owner:SIGRAY INC

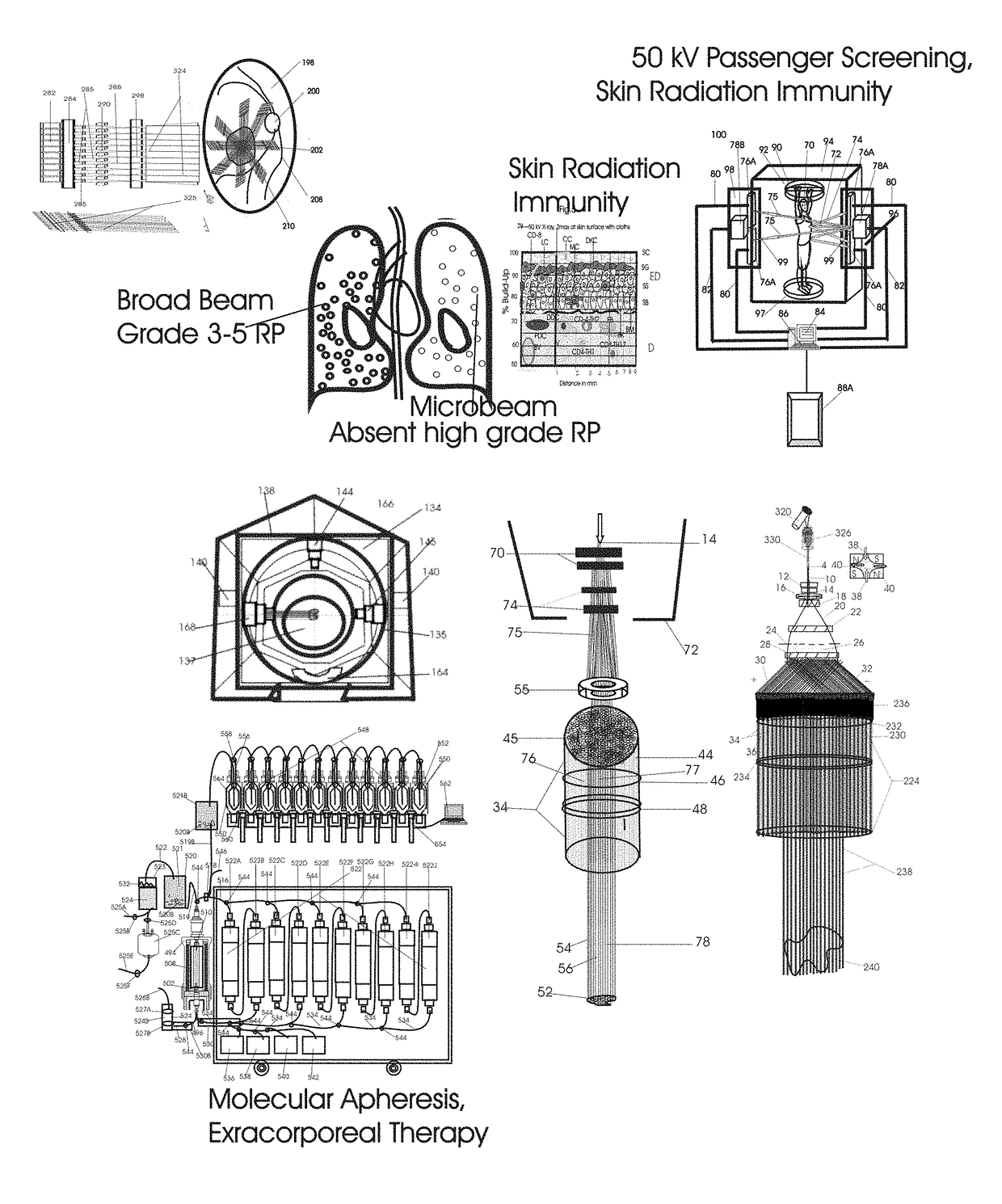

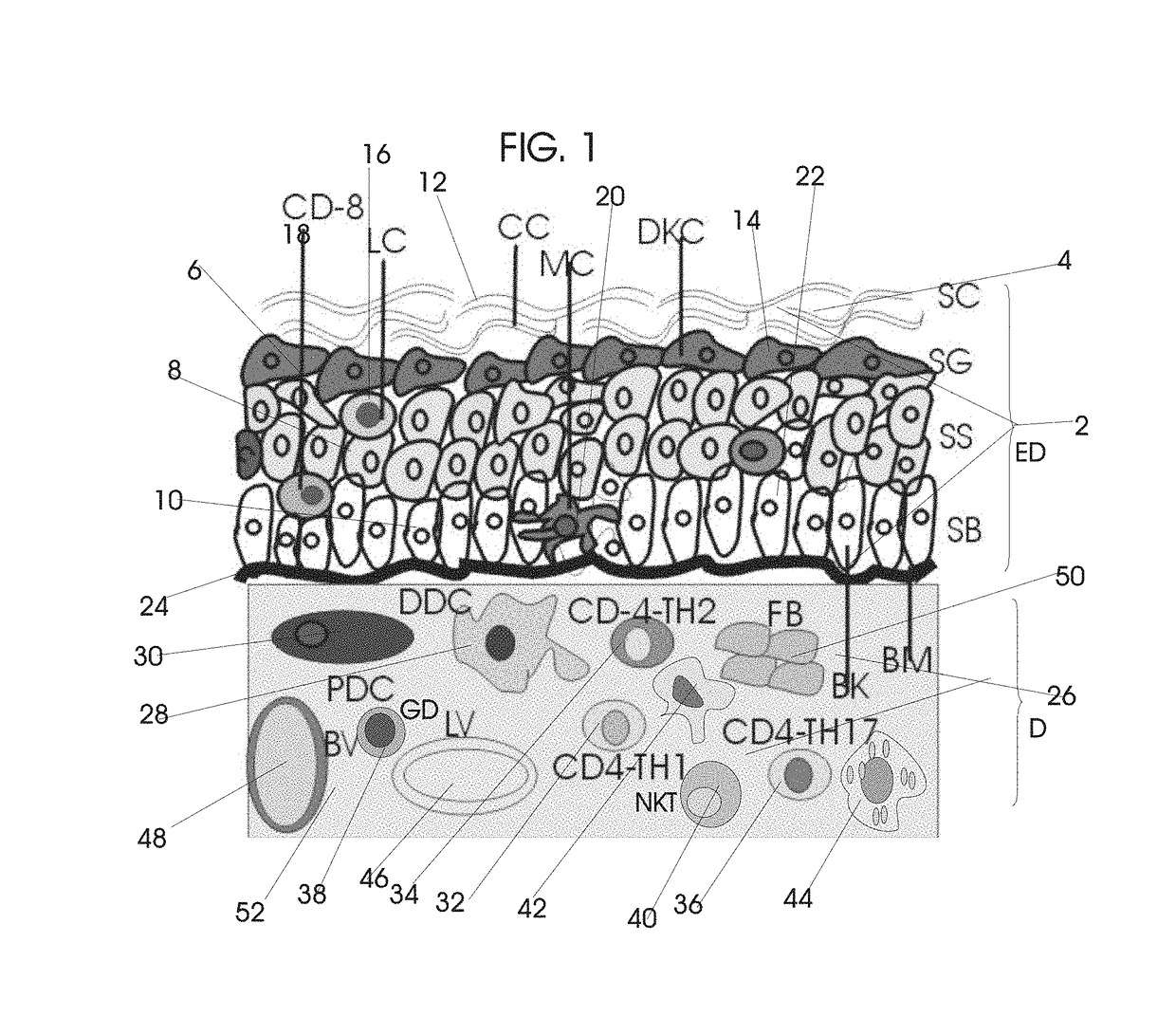

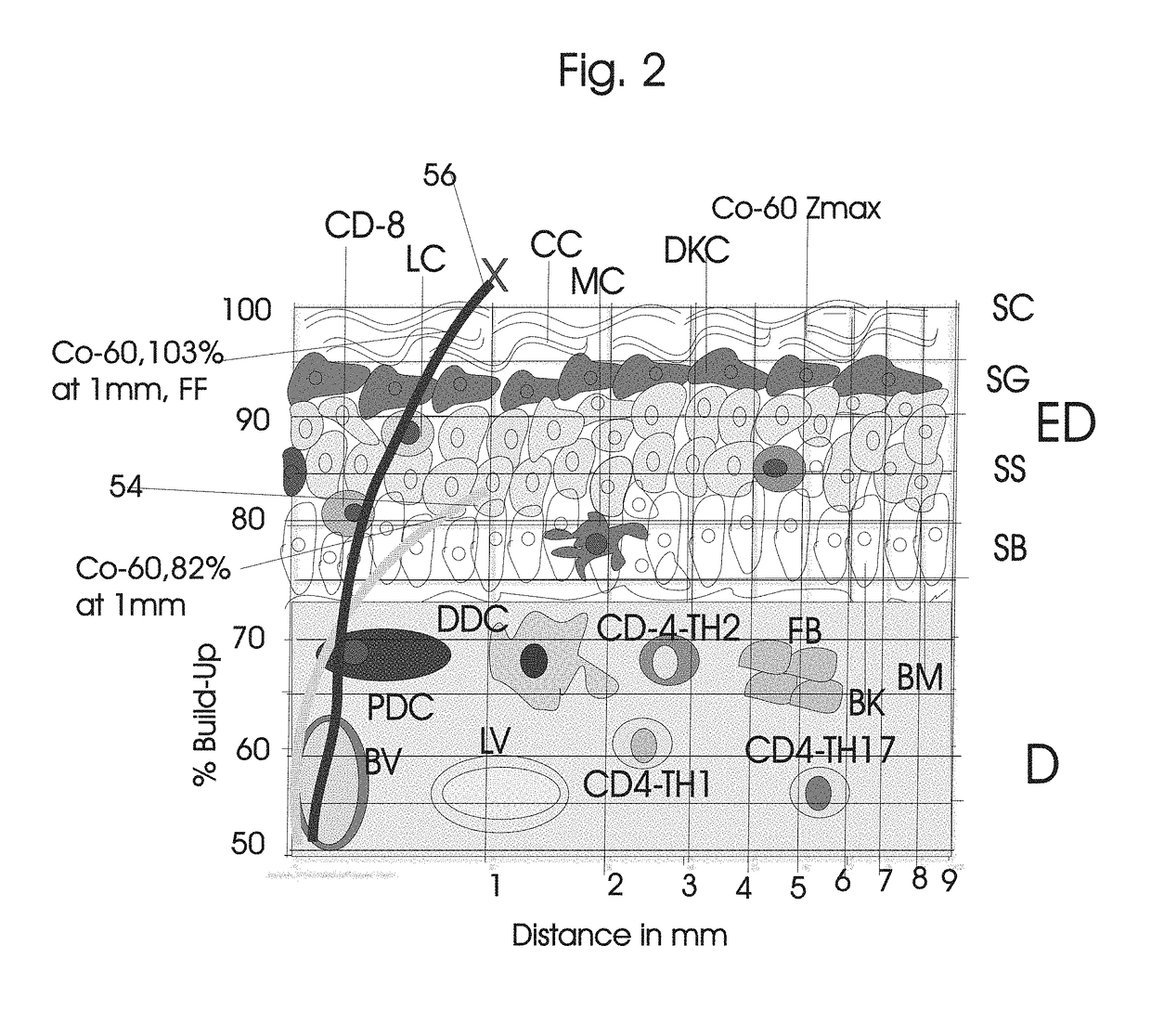

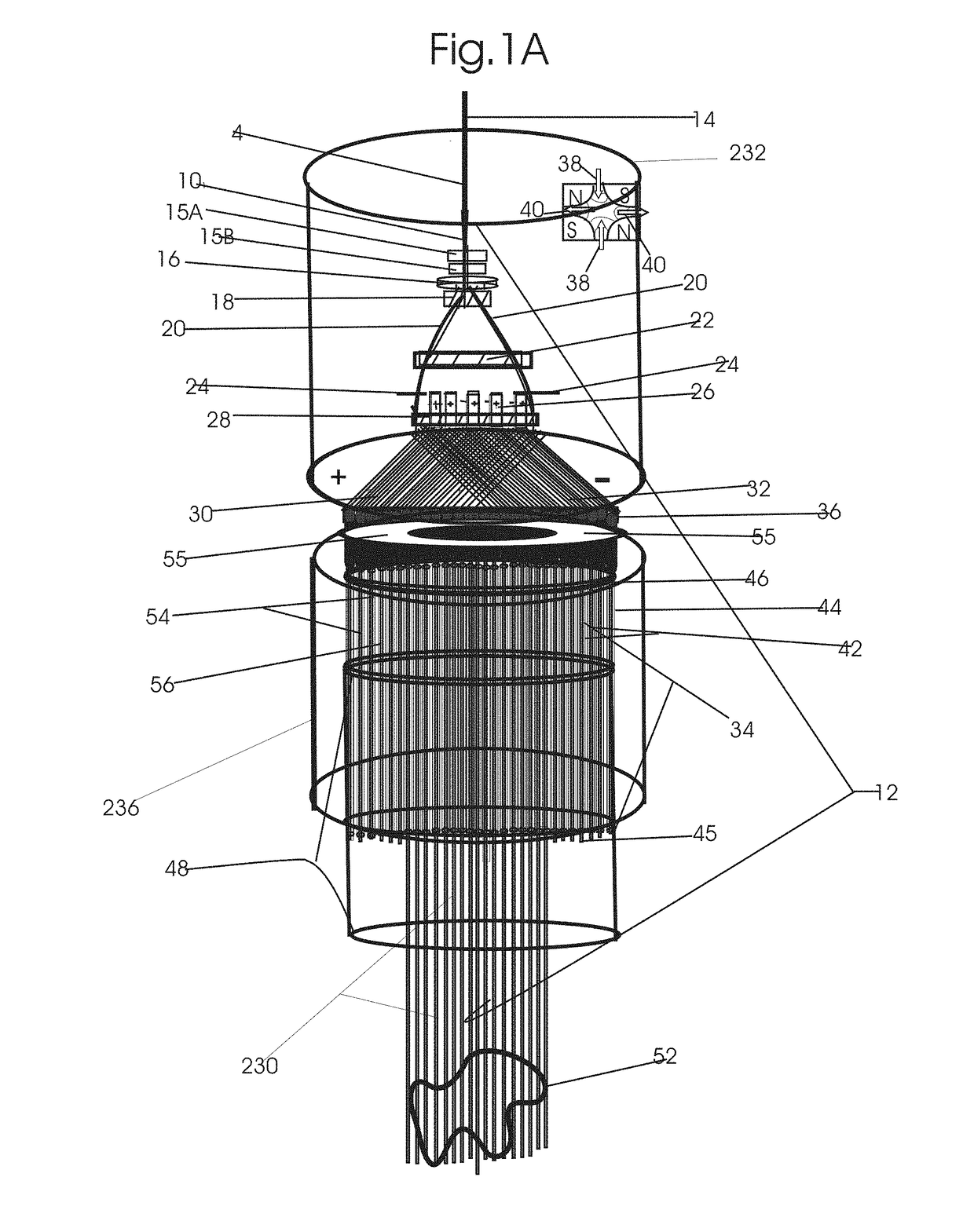

Normal Tissue Toxicity Reducing Microbeam-Broadbeam Radiotherapy, Skin's Radio-Response Immunotherapy and Mutated Molecular Apheresis Combined Cancer Treatments

InactiveUS20180154183A1Improve treatment outcomesIncreased toxicityOther blood circulation devicesHaemofiltrationAbnormal tissue growthGamma ray

Normal tissue complications limit curative broadbeam radiotherapy to tumors including lung cancer. Radiation retinitis causing blindness limits quality of life and long term survival for patients with ocular melanoma. This invention pertains to alternative, normal tissue sparing 100 to 1,000 Gy microbeam radiations with least normal tissue complications and concomitant radio-immunotherapy by innate immune response of epidermis and dermis to low dose radiation with 50 kV X-rays. Total body skin radiation with former airport passenger screening machines with 50 kV X-ray is disclosed. Microbeams are generated without contaminating scatter and neutron radiations from collinear gamma ray and electron beam produced by inverse Compton interaction with high energy laser and electron beam and from proton and carbon ion beams in tissue equivalent cylindrical collimators. Extracorporeal immunotherapy and chemotherapy and apheresis of mutated subcellular particles released into circulation in response to cancer-therapies are by clinical continuous flow ultracentrifugation combined chromatography.

Owner:SAHADEVAN VELAYUDHAN

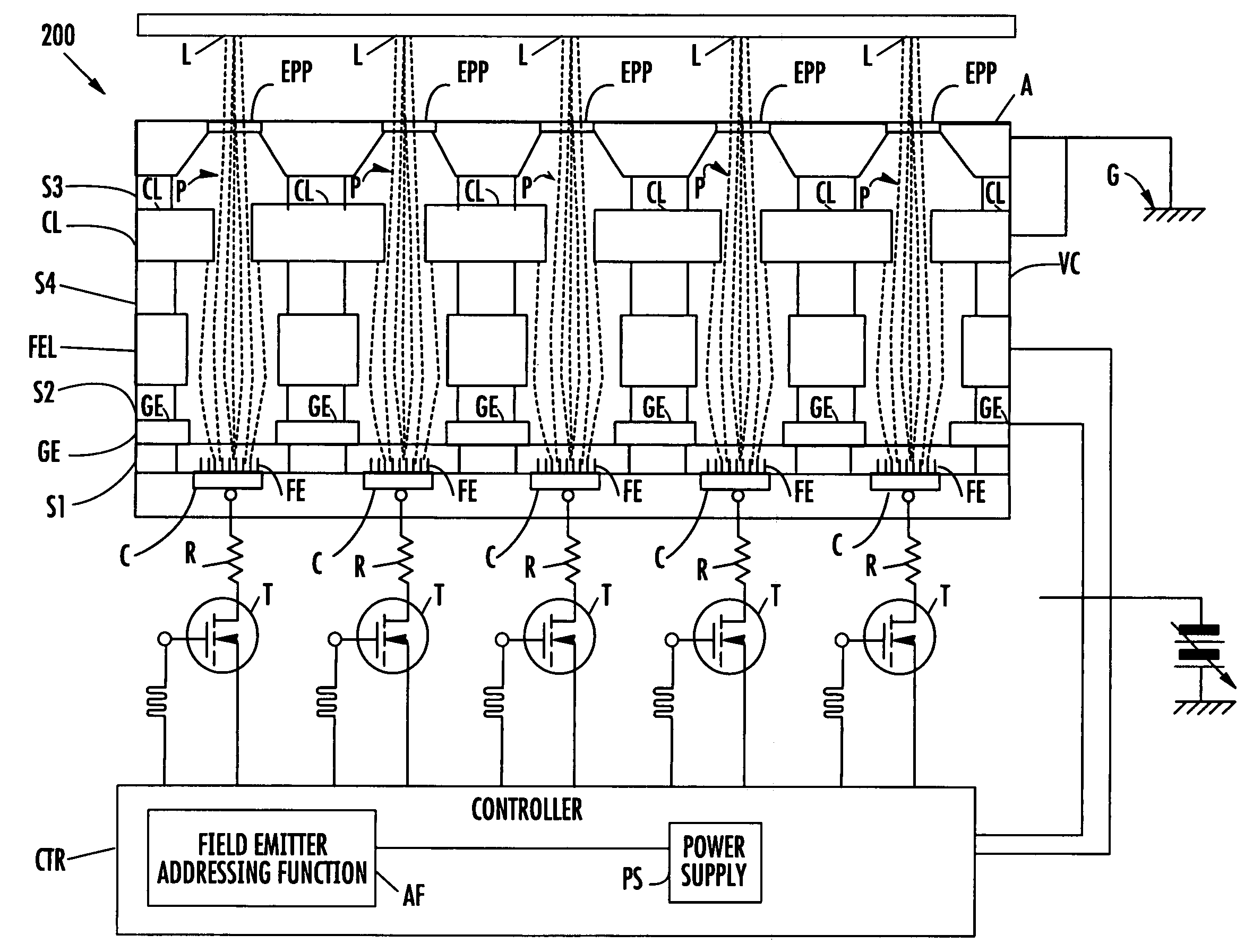

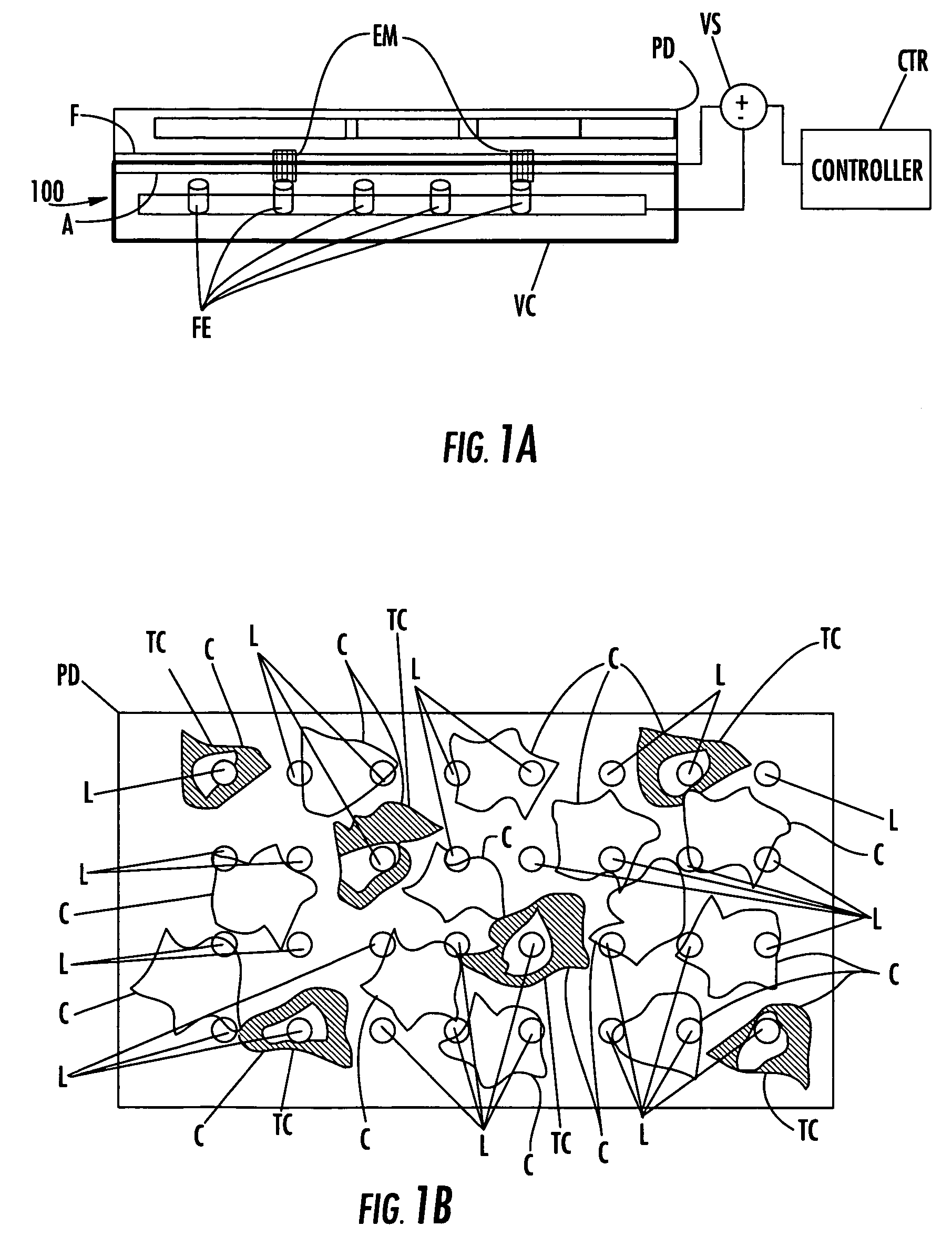

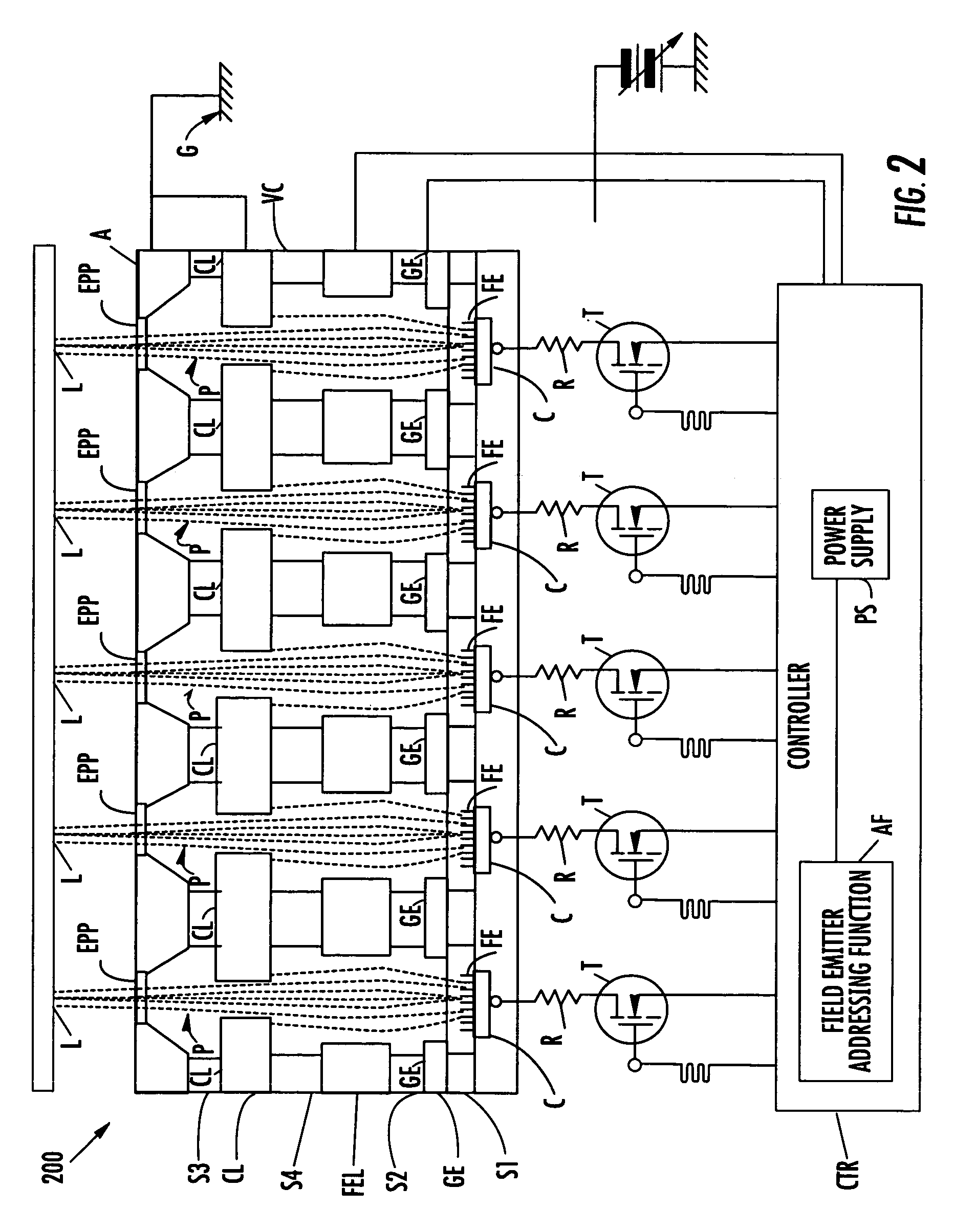

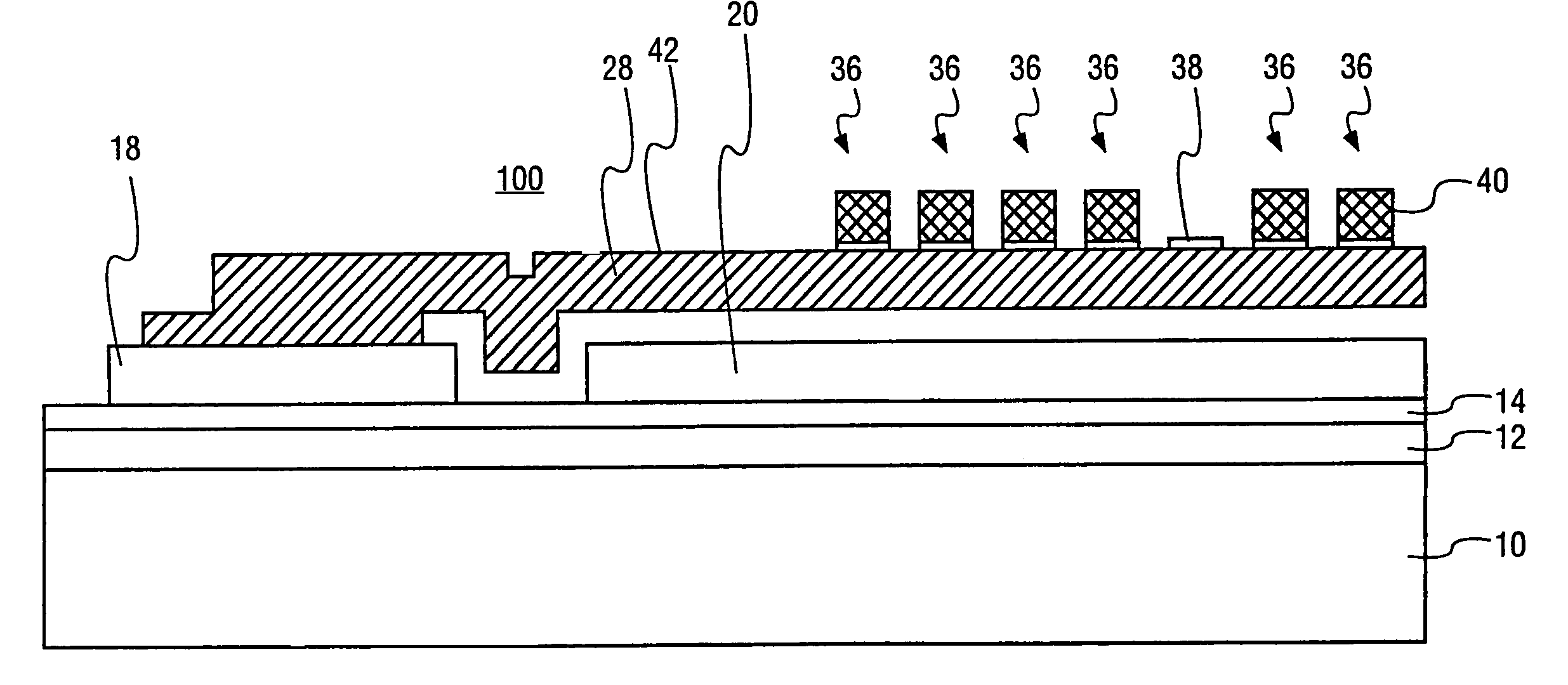

Multi-pixel electron microbeam irradiator systems and methods for selectively irradiating predetermined locations

ActiveUS7220971B1Thermometer detailsBeam/ray focussing/reflecting arrangementsElectronMolecular physics

Multi-pixel electron microbeam irradiator systems and methods are provided with particular applicability for selectively irradiating predetermined cells or cell locations. A multi-pixel electron microbeam irradiator system can include a plurality of individually addressable electron field emitters sealed in a vacuum. The multi-pixel electron microbeam irradiator system can include an anode comprising one or more electron permeable portions corresponding to the plurality of electron field emitters. Further, the multi-pixel electron microbeam irradiator system can include a controller operable to individually control electron extraction from each of the electron field emitters for selectively irradiating predetermined locations such as cells or cell locations.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

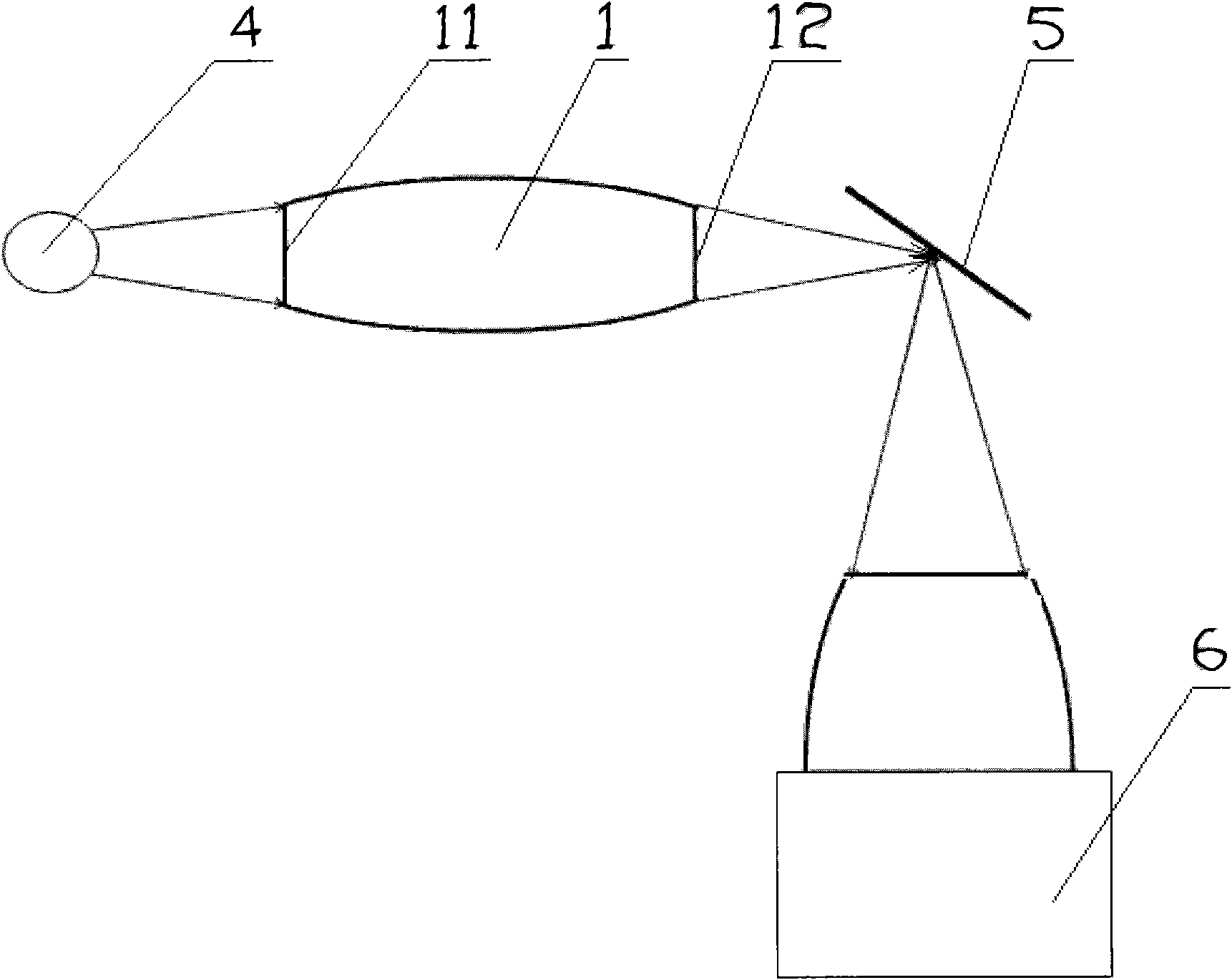

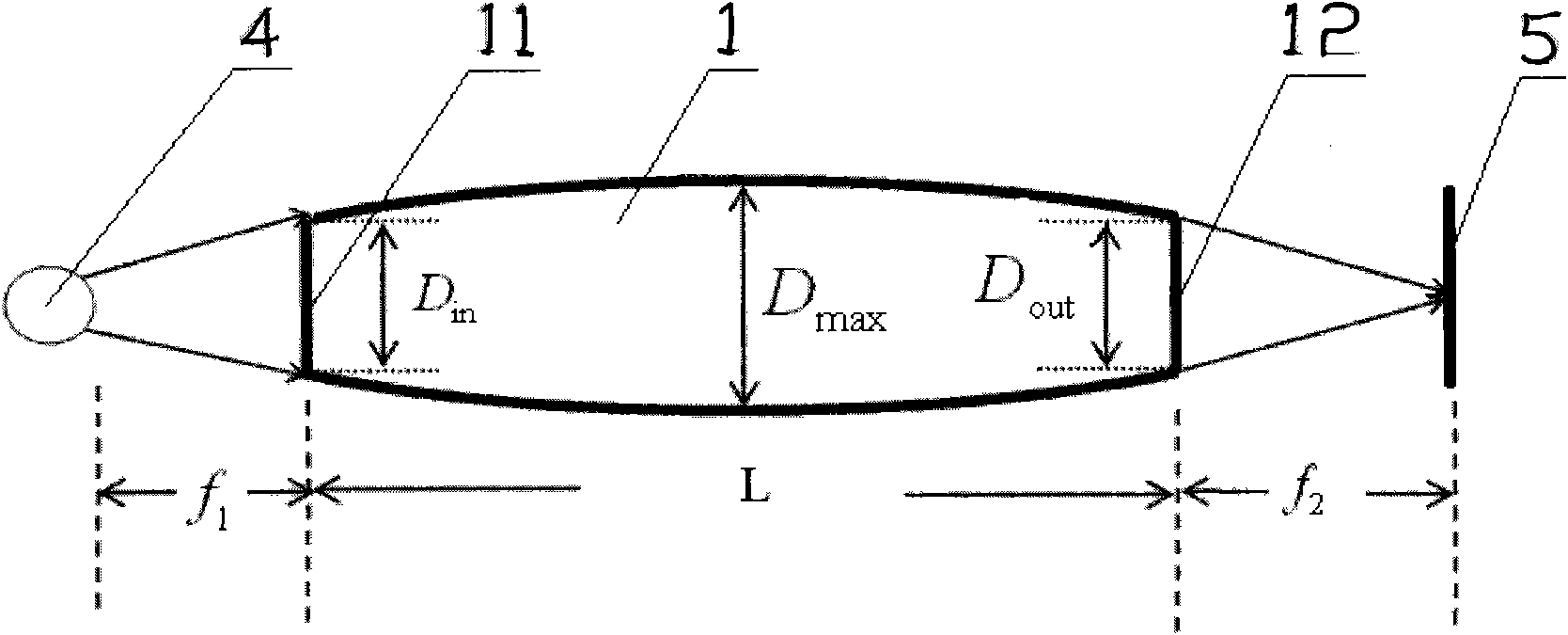

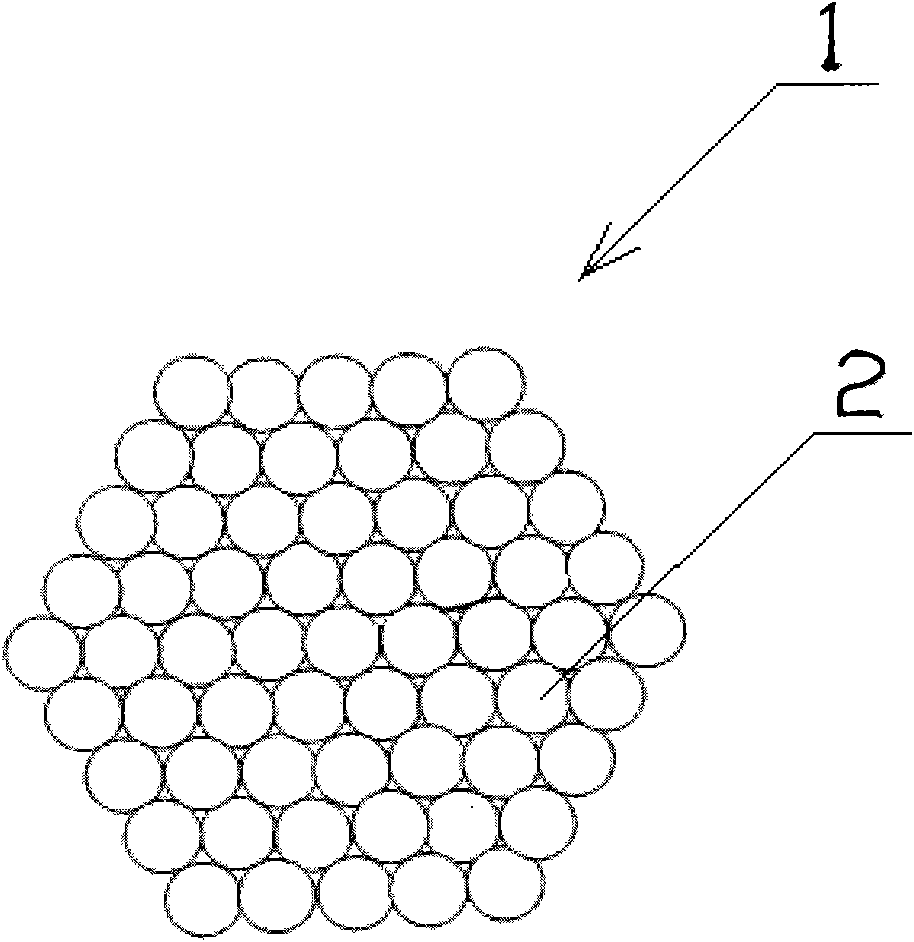

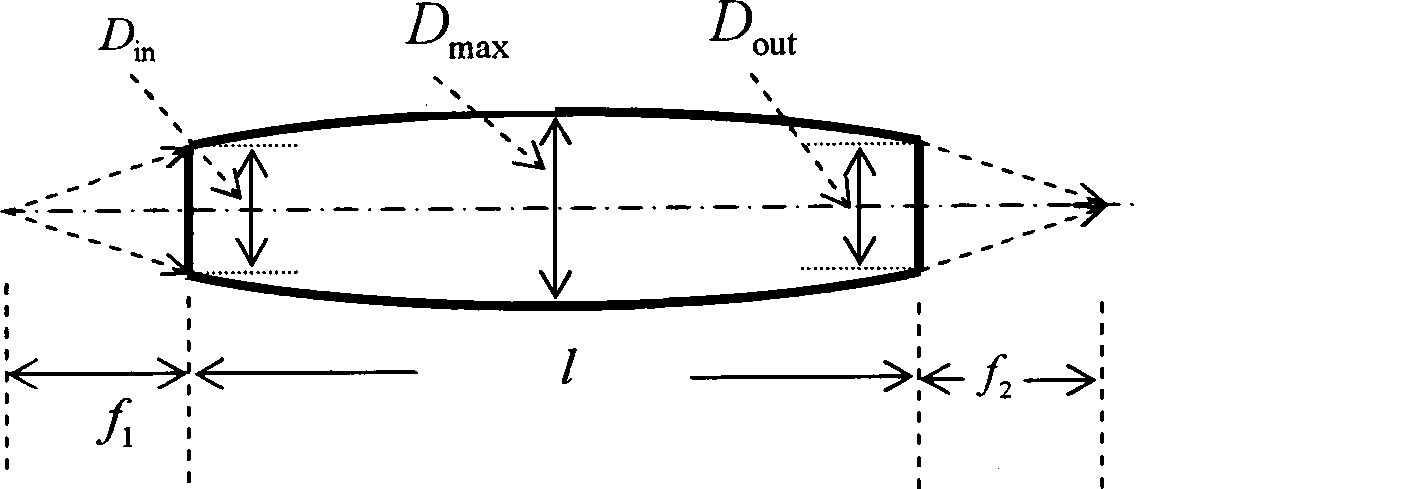

Microbeam proton fluorescence spectrometer

ActiveCN101858874ASimple structureLow costMaterial analysis using wave/particle radiationProtonFluorescence spectrometer

The invention discloses a microbeam proton fluorescence spectrometer, which comprises a proton accelerator (4), a proton convergence component and a detector (6), wherein the proton accelerator (4) is used for emitting protons, the proton convergence component is used for converging protons emitted by the proton accelerator (4), and the detector (6) is used for receiving the fluorescence excited from the protons; the proton convergence component is a capillary optical converger (1); and the capillary optical converger (1) at least comprises a single capillary (2). The fluorescence spectrometer converges protons by using the capillary optical converger (1); and the capillary optical converger (1) is made of glass capillaries, and does not need to be supported by a bracket. Thus, the invention has the advantages of simple structure and low cost, thereby realizing proton convergence in a simple, economical and practical way. In addition, the invention simplifies the structure of the fluorescence spectrometer and lowers the production and use cost of the fluorescence spectrometer.

Owner:BEIJING NORMAL UNIVERSITY

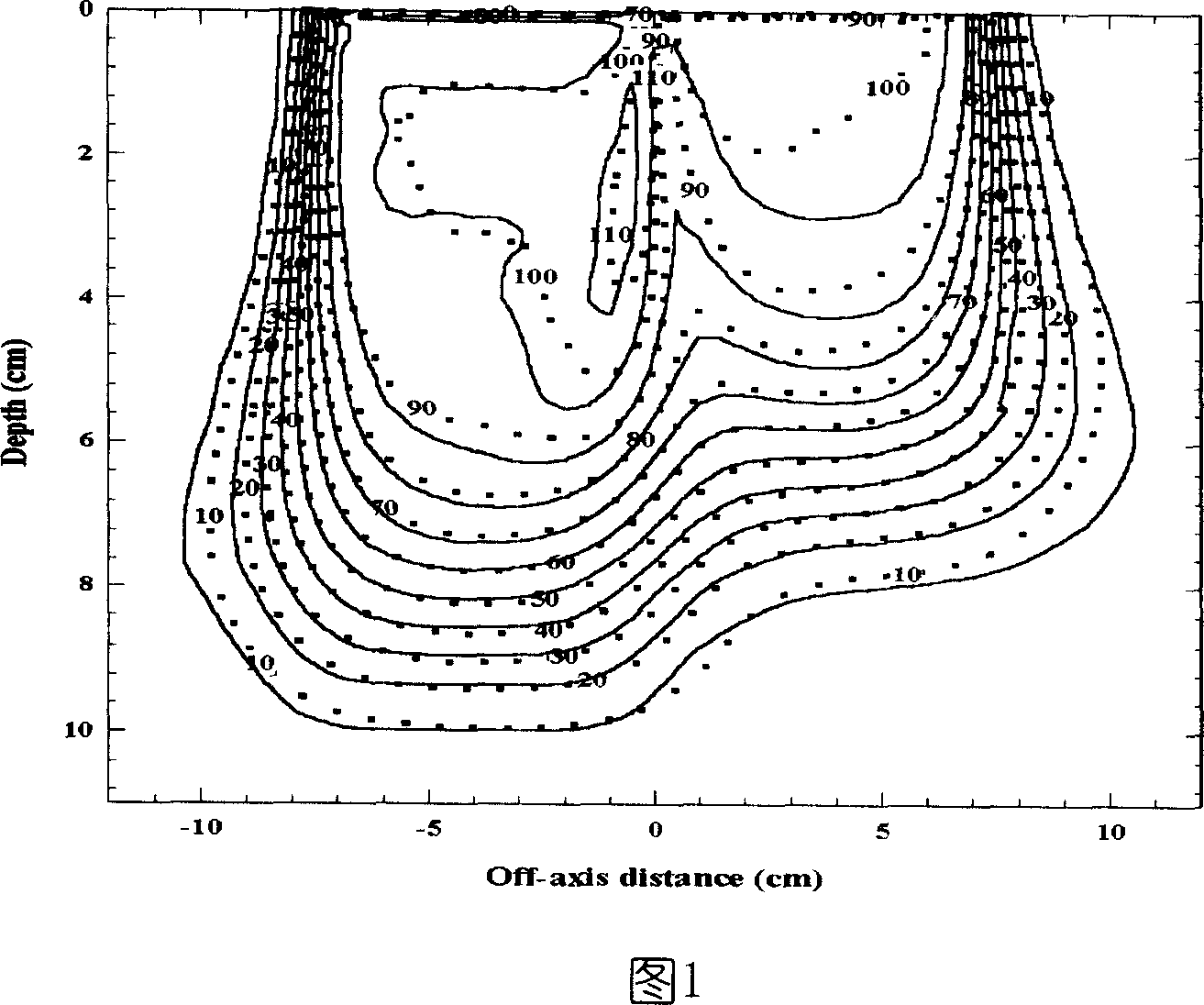

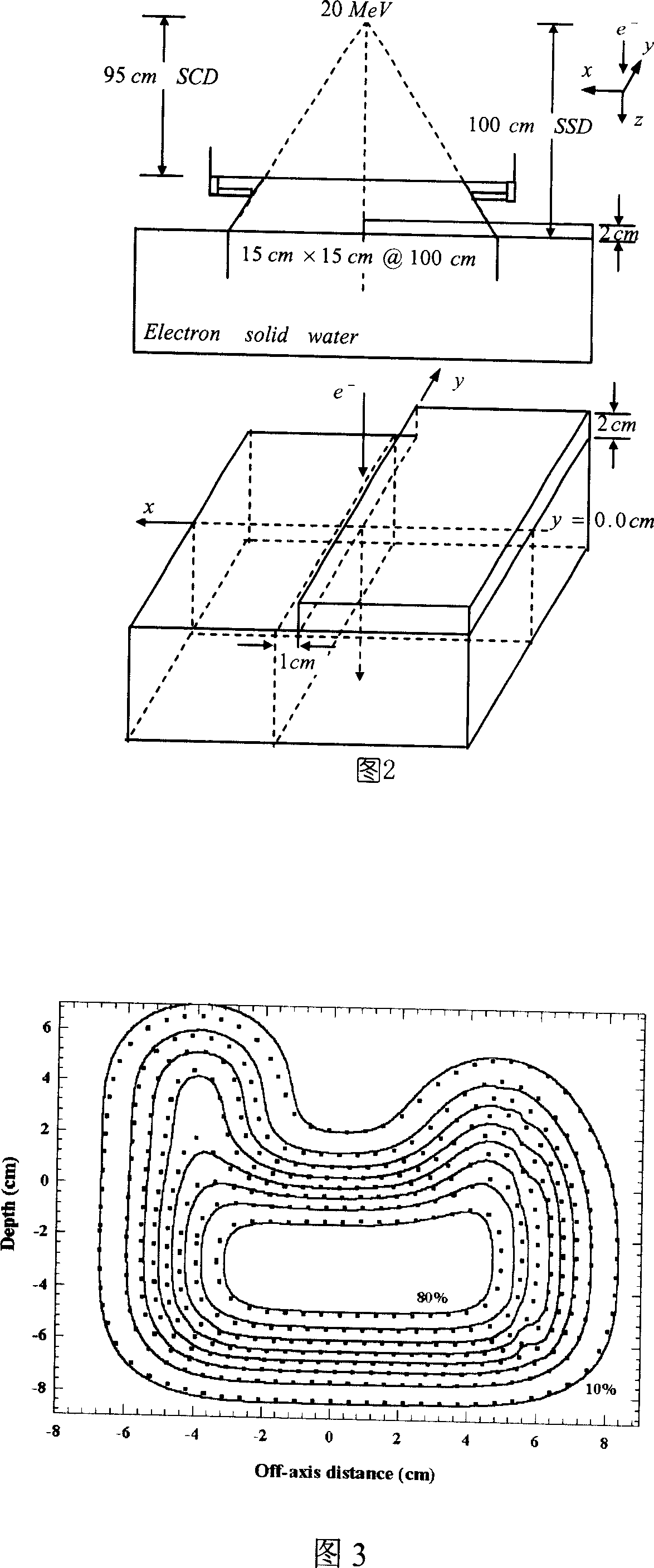

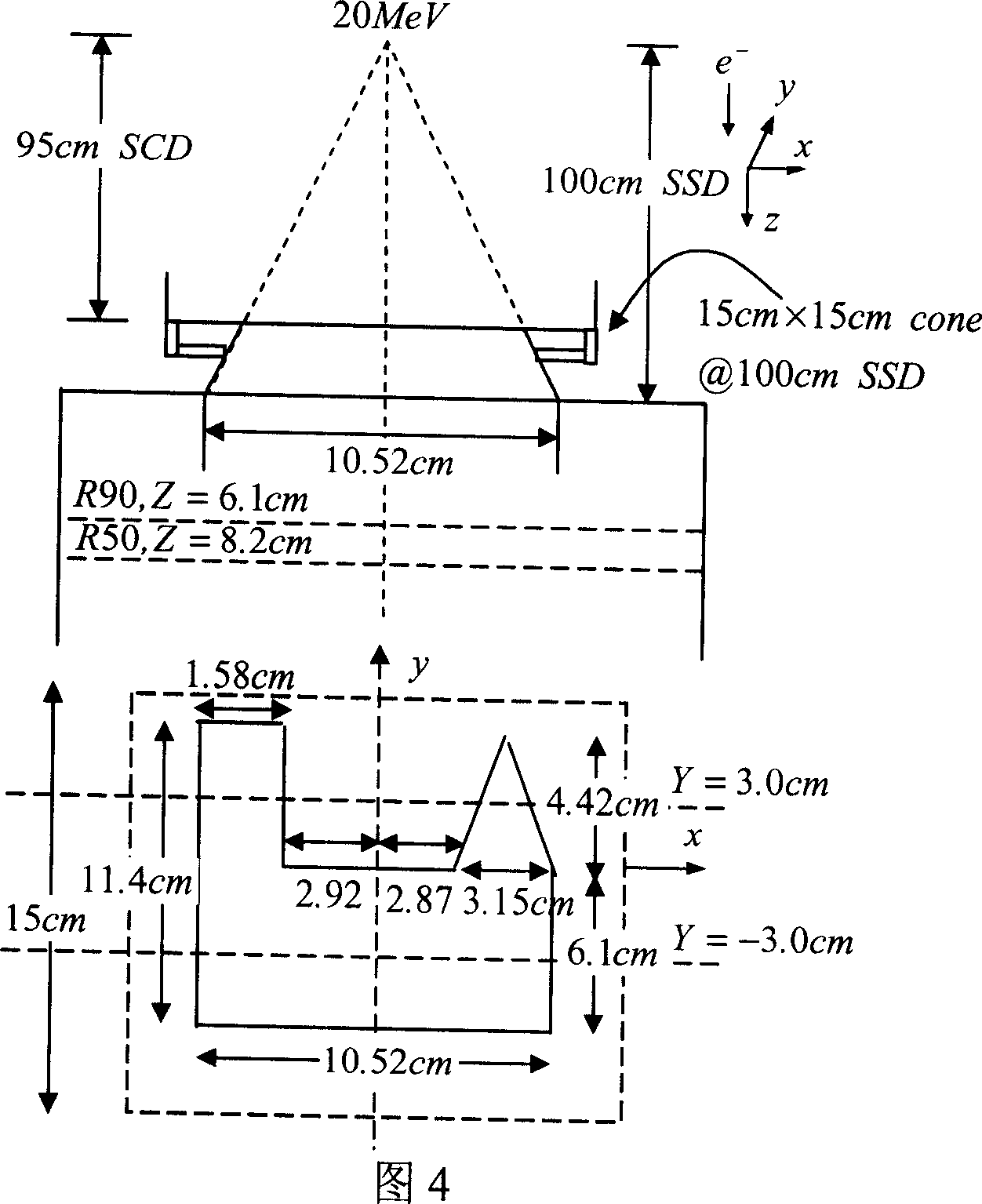

Method for determining distribution of electron beam dosage

InactiveCN100998497ALess measurement dataCalculation speedElectrotherapyDiagnostic recording/measuringElectronic densityElectron

A method for determining the dose distribution of electronic beam includes such steps as using CT to measure the electronic density array of the irradiated object, measuring and recording the initial lateral parameters of electronic beam, its energy spectrum and the source-skin distance, debunching the irradiating electronic beam into an electronic microbeam array, calculating the 3D dose distribution of each microbeam in irradiated object, and adding all the electronic microbean arrays to obtain a 3D dose distribution array of an electronic beam in irradiated object.

Owner:SICHUAN UNIV

Method and apparatus for hard tissue treatment and modification

A device and method for forming a texture on a surface of a hard material. Spatial patterns, such as an array of microbeams, are delivered to the tissue through the handpiece. The plurality of microbeams illuminate and ablate the hard material simultaneously. Each of the microbeams has of a sufficient fluence and pulse width to ablate the surface of the hard material and form the texture. Alternatively, one microbeam of a sufficient fluence and pulse width to ablate the surface of the hard material and form the texture is scanned over the surface either manually or in an automatic fashion.

Owner:REJUVEDENT

Procession welding method for superfine stainless steel mesh

InactiveCN101774069AImprove filtering effectFast solderingPlasma welding apparatusCarbon Dioxide / HeliumShielding gas

The invention relates to the technical field of welding, and discloses a procession welding method for a superfine stainless steel mesh. In order to solve the problem of incapability of rapid welding in the prior art, the invention provides the following technical scheme: the method is characterized by comprising the steps: a, preparation work; b, mesh alignment and compression; c, one-time successive welding from one end of a joint to the other end thereof by utilizing a microbeam plasma arc welding machine, wherein, the diameter of a tungsten rod is 0.8-1.2 mm, the aperture of a nozzle is 0.8-1.2 mm, the neck-in amount of the tungsten rod is 1.8-2.2 mm, the height of a welding torch is 2.8-3.2 mm, the current of DC welding is 1.9-2.1 A, the welding speed is 10.0-13 mm / s, the shielding gas flow is 3.0-4.0 L / min, and the ionic gas flow is 0.25-0.35 L / min. The invention has the beneficial effects of realizing automatic rapid welding and high welding line strength; in addition, normal screenability is maintained.

Owner:SHANGHAI UNIV OF ENG SCI

Device and methods for adaptive resistance inhibiting proton and carbon ion microbeams and nanobeams radiosurgery

ActiveUS10413755B1Eliminate inefficienciesGood prospectsX-ray/gamma-ray/particle-irradiation therapyDiamond-like carbonCarbon ion

This invention relates to adaptive resistance inhibiting 100 to 10,000 Gy, single fraction proton and carbon ion microbeam and nanobeam radiosurgery, proton spray chemotherapy and proton spray gadolinium and boron neutron capture therapy with least normal tissue toxicity. Secondary neutrons, protons, ions and radiation from the accelerator and the patient specific collimator are removed with tissue equivalent collimator that also generates proton and carbon ion microbeam and nanobeam. Laser interaction with micrometer and nanometer thick metallic and diamond like carbon targets are also used for proton and carbon ion beam generation. Polyenergetic proton beam is spatially separated. Ion beam and Laser ion beam is accelerated in a hybrid RF accelerator. It is split into microbeam and nanobeam. Secondary neutrons, protons and gamma radiation are removed with tissue equivalent collimators that also generate microbeams and nanobeams. Adaptive resistance to cancer treatment is inhibited by dual target radiation, DNA strands break and enzymes inactivation.

Owner:SAHADEVAN VELAYUDHAN

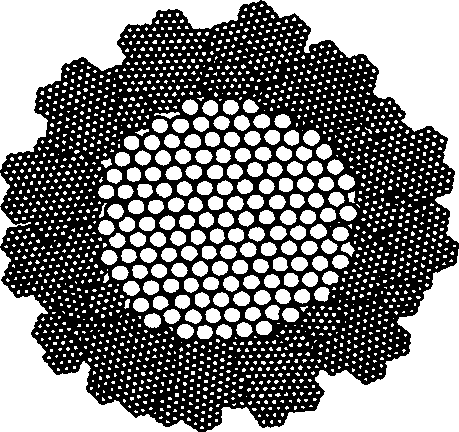

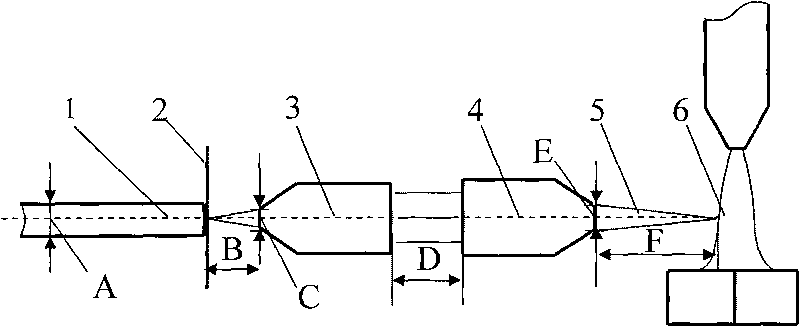

Micro-beam X-ray fluorescence equipment used for atmosphere particle single-particle analysis

ActiveCN101498647AMaterial analysis using wave/particle radiationIndividual particle analysisCore componentX-ray

A microbeam X-ray analytical device based on a capillary X-ray convergent lens with a micro focal spot flat area comprises an X-ray light source, a pinhole diaphragm, the capillary X-ray convergent lens with a micro focal spot flat area, a sample, a microscope and a probe, wherein the capillary X-ray convergent lens with a micro focal spot flat area is a core component. The intensity distribution of X-rays at the micro focal spot flat area of the capillary X-ray convergent lens is quite uniform, and the X-rays have higher power density gain, so the microbeam X-ray analytical device is especially suitable for analyzing single atmospheric particle and other micro particle so as to rapidly obtain the element characteristic peak relative intensity and the single particle power spectrum which is single particle fingerprint spectrum unrelated to the position of the single particle in the micro focal spot flat area of the capillary X-ray convergent lens.

Owner:BEIJING NORMAL UNIVERSITY

Resonant sensor and method of making a pressure sensor comprising a resonant beam structure

InactiveUS20020157473A1Fluid pressure measurement by electric/magnetic elementsLight beamResonant sensor

A resonant microbeam pressure sensor is disclosed, comprising a microbeam suspended in a diaphragm in at least one point by suspension elements. Pressure applied to the diaphragm will cause the resonance frequency of the beam to shift. This shift is detectable and proportional to the pressure, The device is manufactured by surface micromachining.

Owner:ST JUDE MEDICAL COORDINATION CENT

Method and apparatus for x-ray microscopy

ActiveUS10352880B2Increase in sizeImprove detection efficiencyImaging devicesX-ray tube electrodesQuantum efficiencyImage resolution

This disclosure presents systems for x-ray microscopy using an array of micro-beams having a micro- or nano-scale beam intensity profile to provide selective illumination of micro- or nano-scale regions of an object. An array detector is positioned such that each pixel of the detector only detects x-rays corresponding to a single micro- or nano-beam. This allows the signal arising from each x-ray detector pixel to be identified with the specific, limited micro- or nano-scale region illuminated, allowing sampled transmission image of the object at a micro- or nano-scale to be generated while using a detector with pixels having a larger size and scale. Detectors with higher quantum efficiency may therefore be used, since the lateral resolution is provided solely by the dimensions of the micro- or nano-beams. The micro- or nano-scale beams may be generated using an arrayed x-ray source or a set of Talbot interference fringes.

Owner:SIGRAY INC

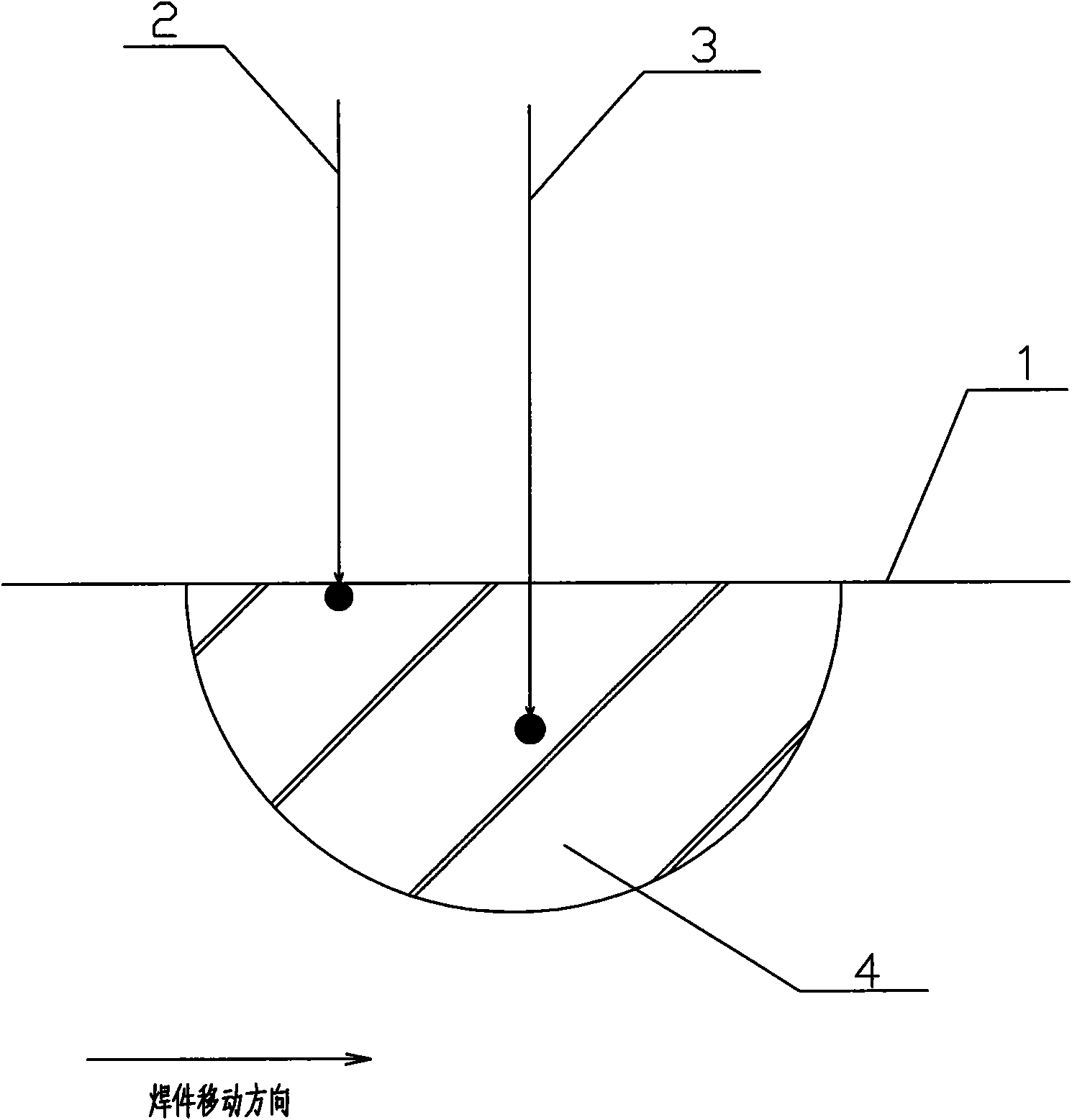

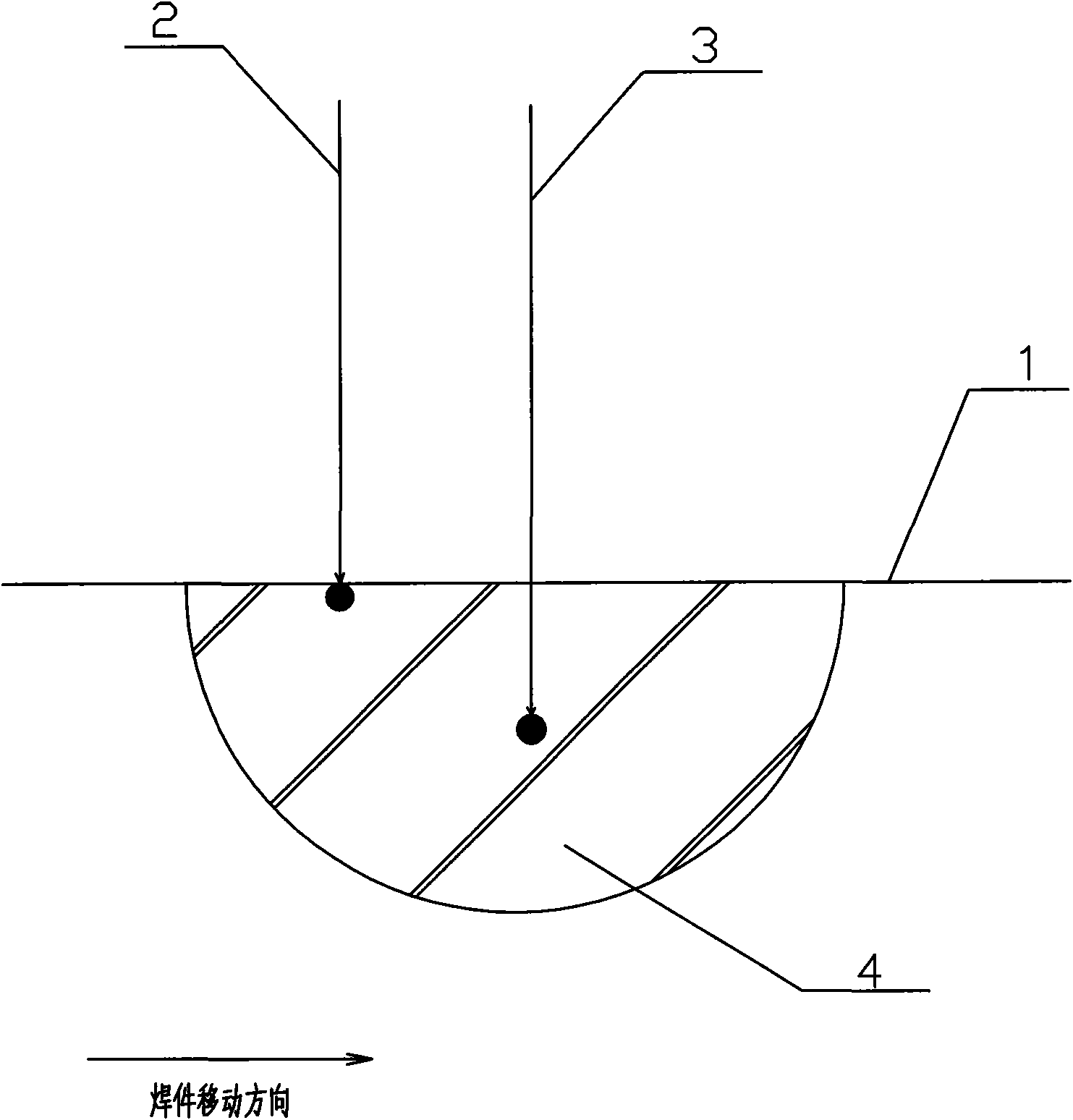

Micro-beam plasma arc/laser hybrid welding method

InactiveCN101992354AReduce reflectivityIncrease the effective heating depthPlasma welding apparatusLaser beam welding apparatusLaser-hybrid weldingAbsorption rate

The invention relates to a micro-beam plasma arc / laser hybrid welding method, which comprises the following steps: fixing a micro-beam plasma arc transmitter and a laser beam transmitter, providing a workpiece which moves at a constant speed, and forming a mode of micro-beam plasma arc preposition; carrying out initial fusion on the surface of a welded part of the workpiece by micro-beam plasma arcs, then irradiating laser beams to the welded part, thereby deepening the depth of fusion of micro-beam plasma arc welding, and then completing the welding. The welding method of the invention can reduce the reflectance of aluminium alloys to lasers, and improve the absorption rate of aluminium alloys to laser energies, thereby improving the effective heating depth of laser, increasing the depths of fusion of weld joints and effectively reducing the widths of weld joints and heat affected zones; and finally, obtaining weldments which have the advantages of large depth of fusion, extremely small heat affected zone and beautiful appearance.

Owner:CRRC QINGDAO SIFANG CO LTD

Micro-electromechanical structure resonator frequency adjustment using radiant energy trimming and laser/focused ion beam assisted deposition

InactiveUS7245057B2Impedence networksPiezoelectric/electrostriction/magnetostriction machinesIon beamResonator

Owner:INTEL CORP

Manipulation of live cells and inorganic objects with optical micro beam arrays

InactiveUS7049579B2Permit manipulationIncrease optical powerLaser detailsBeam/ray focussing/reflecting arrangementsLiving cellLaser

Owner:RGT UNIV OF CALIFORNIA

Portable microbeam X-ray fluorescence spectrophotometer

InactiveCN103454299ASmall sizeSimple preparation processMaterial analysis using wave/particle radiationCollection systemMicro cell

The invention discloses a portable microbeam X-ray fluorescence spectrophotometer, comprising a main frame, wherein an X-ray light tube and an X-ray detector are arranged on the main frame; a detected sample is arranged within a detection beam range of the X-ray light tube; the X-ray detector is arranged right above the detected sample; the fluorescence spectrophotometer also comprises an X-ray combined refractor which is used for selectively collecting an X-ray fluorescent light generated by a detected sample micro-cell; the X-ray combined refractor is connected with the lower end of the X-ray detector; the X-ray detector is arranged inside an image space of the X-ray combined refractor; the detected sample is arranged inside an object space of the X-ray combined refractor; the upper end of the X-ray detector is connected with a port for connecting an information collection system; a laser device is also arranged on the main frame; the detected sample is arranged within an irradiation range of the laser device. By adopting the portable microbeam X-ray fluorescence spectrophotometer, the structure is simplified and the size is reduced while the microcell resolution ratio is smaller than 10 microns; the portable microbeam X-ray fluorescence spectrophotometer is convenient to carry.

Owner:ZHEJIANG UNIV OF TECH

Talbot X-ray microscope

ActiveUS10304580B2Improve detection efficiencyIncrease in sizeImaging devicesMaterial analysis using wave/particle radiationQuantum efficiencyImage resolution

Owner:SIGRAY INC

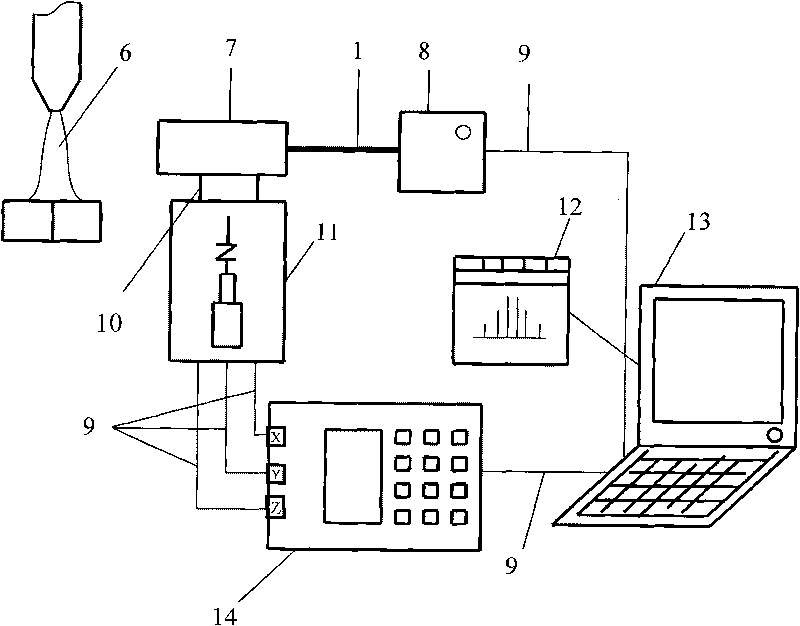

Electron beam fast-forming equipment with on-line monitoring function and operation method thereof

InactiveCN106180718AOvercoming the disadvantage of susceptibility to contaminationAdditive manufacturing apparatusIncreasing energy efficiencySecondary electronsTransmitter

The invention discloses electron beam fast-forming equipment with an on-line monitoring function and an operation method thereof. The electron beam fast-forming equipment comprises a central control unit, an electronic gun power source, a deflector / scanner power source, a workbench power source, an electronic gun, a work room, a powder-filling box, a workbench, a secondary electron collector and a secondary electron transmitter. The secondary electron collector receives secondary electron information generated in the microbeam scanning process of electron beams. The secondary electron transmitter is used for shaping and amplifying of the secondary electron information and then feeding the information into the central control unit. The central control unit can analyze and process synchronously-recorded secondary electronic signals and judge whether flaws exist in a manufacturing layer. According to the electron beam fast-forming equipment with the on-line monitoring function and the operation method thereof, secondary reflection electronic signals are used for performing on-line quality monitoring on the element manufacturing process of the electron beam fast-forming equipment, and hence the defect that pollution is likely to occur by the adoption of optical monitoring means is overcome.

Owner:GUILIN THD TECH CO LTD

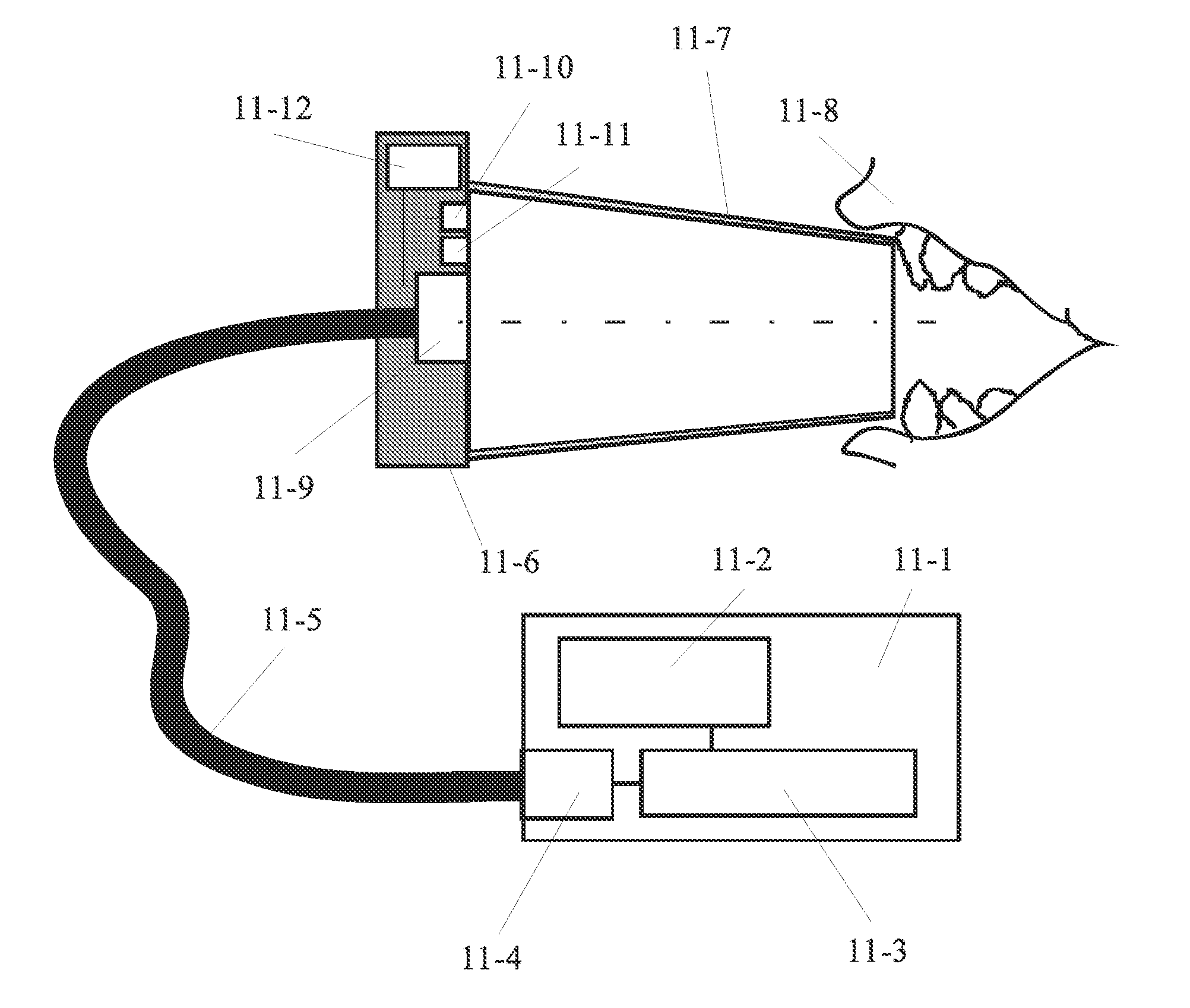

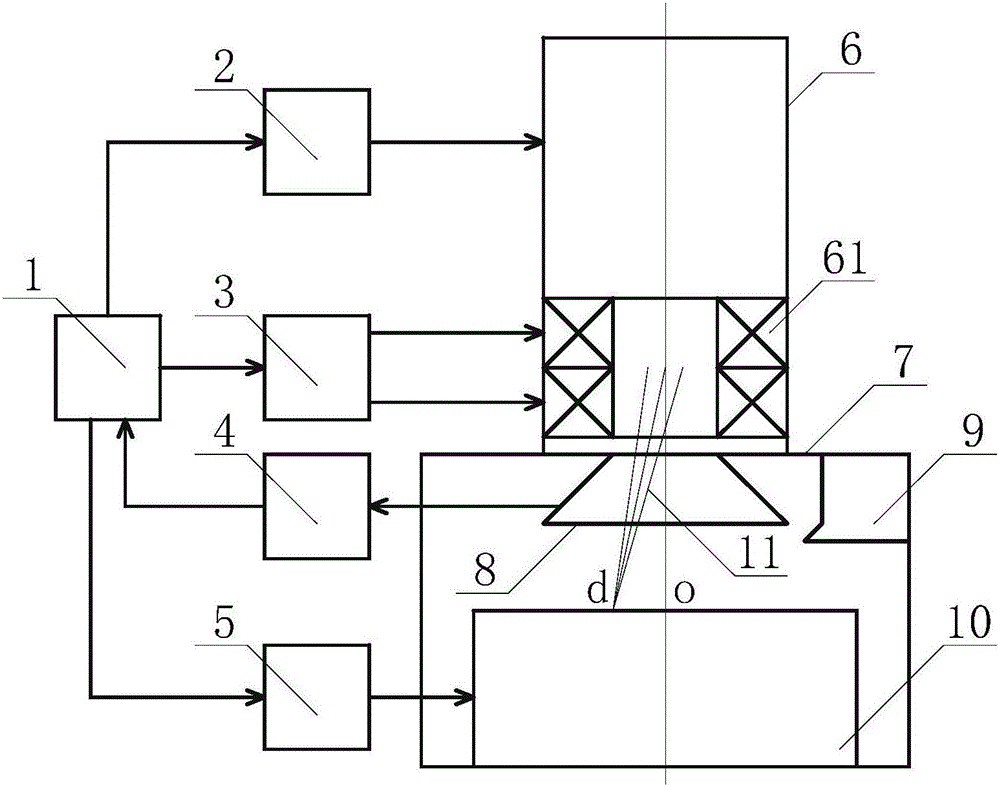

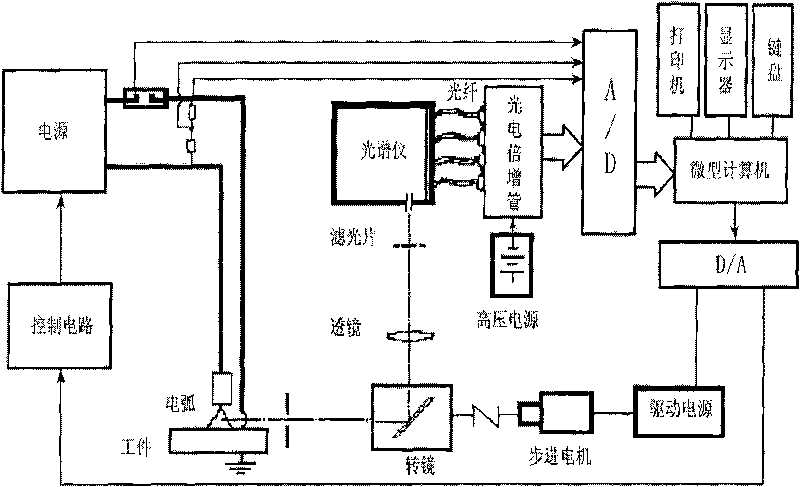

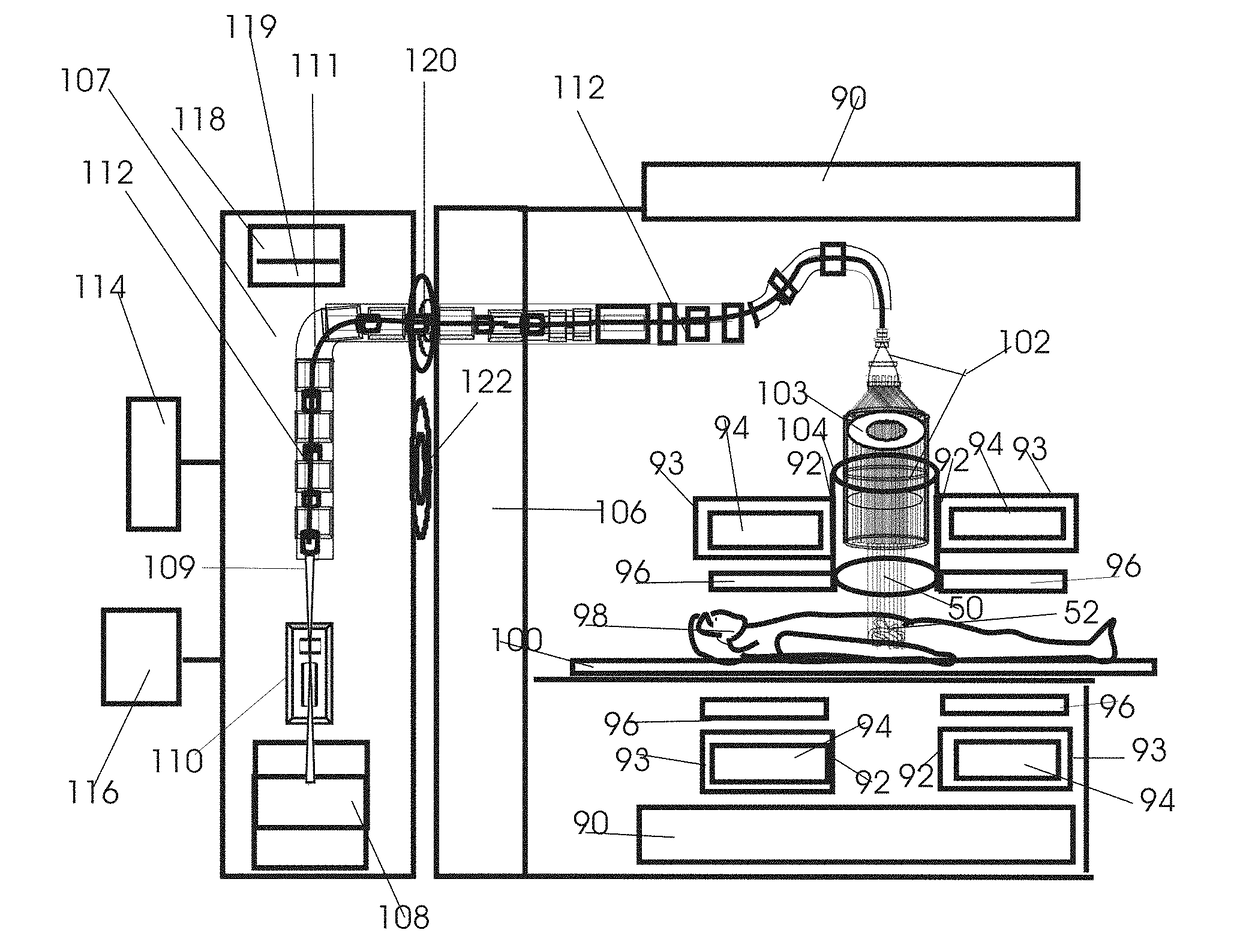

System for detecting micro-beam plasma arc three-dimensional dynamic spectrum

The invention discloses a system for detecting a micro-beam plasma arc three-dimensional dynamic spectrum and relates to the technical field of spectrum detection. The system comprises a three-dimensional precision inching platform (11), a light path system, a light path system fixing device (10), a spectrum collecting control system and a data line (9). The three-dimensional precision inching platform (11) comprises a stepping motor which can realize the stepping motion on X,Y and Z three-dimensional directions, a screw rod mechanism and a base. The light path system comprises a detecting lens (7), an optical fiber (1) and a spectrometer (8), wherein two ends of the optical fiber (1) are respectively connected with the detecting lens (7) and the spectrometer (8). The spectrum collecting control system comprises a spectrum collecting software (12), a stepping motor controller (14) and a computer (13). The stepping motor controller (14) and the spectrometer (8) are connected with the computer (13) by the data line (9). The system of the invention can identify and collect the spectrum information on the periphery and the interior point of the arc and the precision is 10 microns.

Owner:SHANGHAI UNIV OF ENG SCI

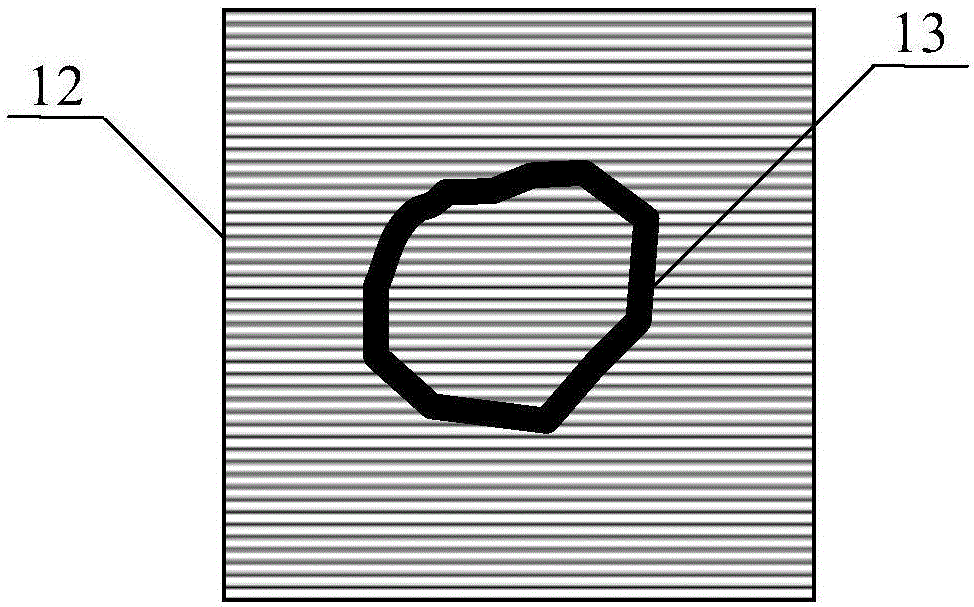

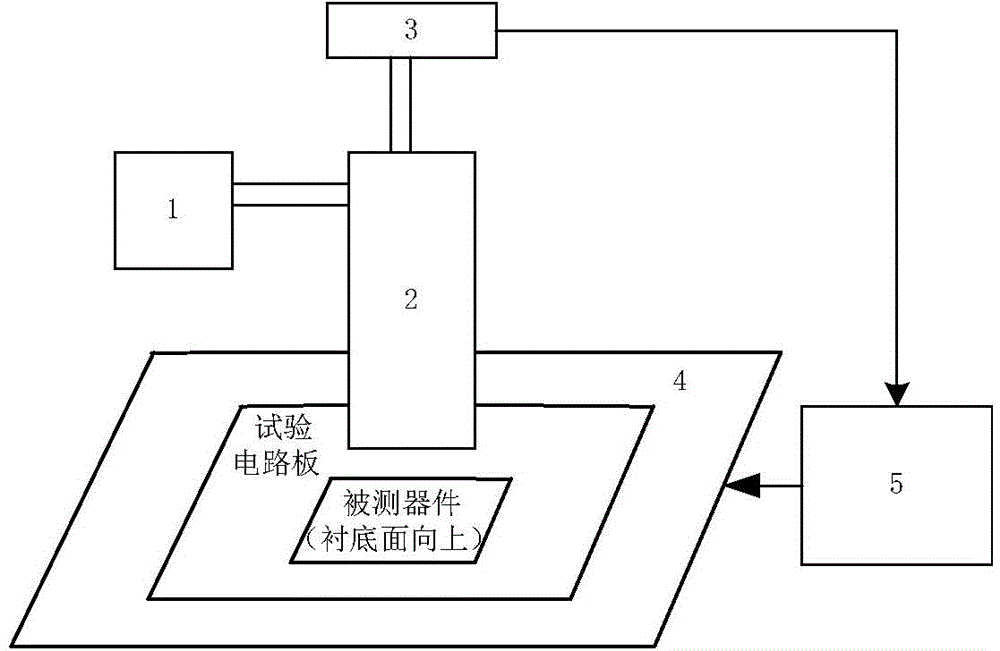

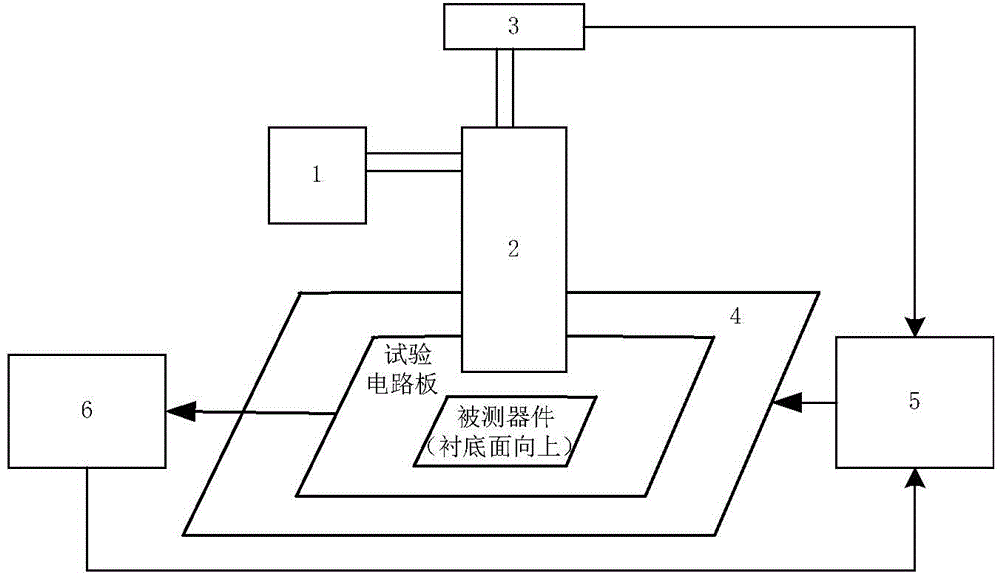

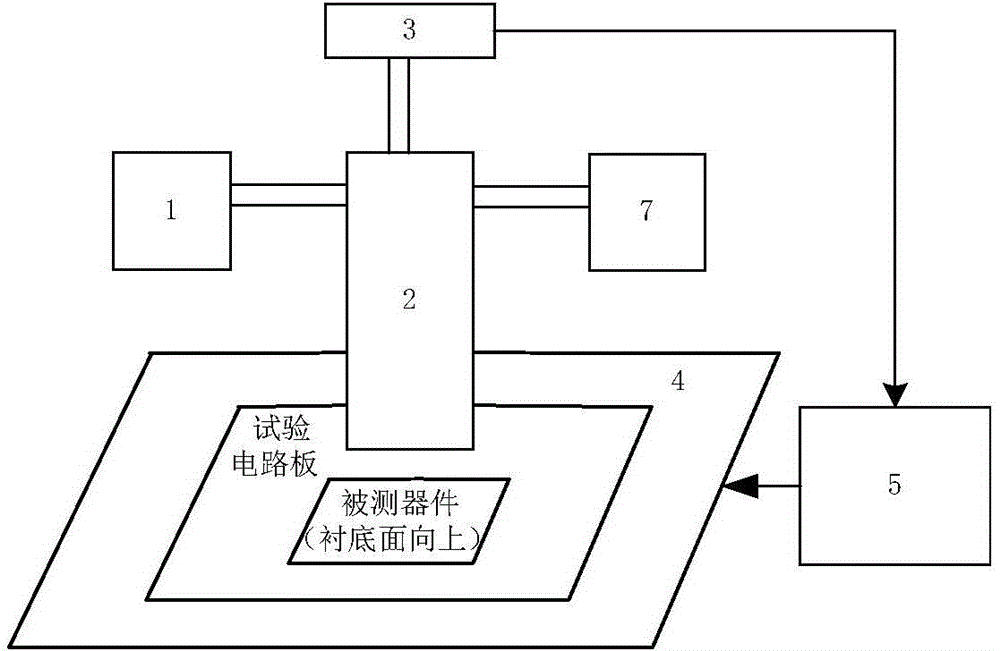

Focusing plane positioning device and method of laser micro-beam back irradiation chip test

ActiveCN104931509ARealize flatness adjustmentRealize in-situ measurementOptically investigating flaws/contaminationIndividual semiconductor device testingImage contrastIrradiation

The invention provides a focusing plane positioning device of a laser micro-beam back irradiation chip test. The focusing plane positioning device used for performing focusing plane positioning on a to-be-tested device comprises a laser source (1) for the test, a focusing light path adjusting module (2), an imaging CCD module (3), a three-dimensional movable platform (4) and a three-dimensional movable platform control module (5), wherein the laser source (1) is used for transmitting fixed-parameter pulse laser; the focusing light path adjusting module (2) is used for adjusting the pulse laser transmitted by the laser source (1); the imaging CCD module (3) is used for imaging the laser reflecting light spot of the to-be-tested device; the three-dimensional movable platform (4) is used for placing the test circuit board of the to-be-tested device; the three-dimensional movable platform control module (5) is used for receiving the reflecting light spot signals output by the imaging CCD module (3) and forming a feedback signal instruction after imaging contrast detecting to automatically adjust the positions of the three-dimensional movable platform (4).

Owner:NAT SPACE SCI CENT CAS

Device and Methods for Broadbeam and Microbeam Chemo-Radiosurgery Combined with Its Tumor Exosome Apheresis

InactiveUS20170368373A1Breathing protectionOther blood circulation devicesImmune complex depositionAtm kinase

Conventional single fraction 20-Gy broadbeam photonbeam or protonbeam chemo-radiosurgery does not sterilize EMT-MET cancer stem cell radiodurans but single fraction 100 to 10,000 Gy microbeam radiosurgery sterilizes them. Device and methods for microbeam chemo-radiosurgery including 250 MeV wakefield electronbeam is disclosed.Surgery, chemotherapy and broadbeam and microbeam radiosurgery releases billions of abscopal metastasis causing, tumor specific plasma soluble proteins, cell membranes, apoptotic bodies, DNA and RNAs, exosomes like telomere-telomerase, ATM-ATM kinase and others. They and adaptive resistance to chemo-radiosurgery, paraneoplastic and non-paraneoplastic diseases causing immune complexes are removed by pulse flow combined continuous flow ultracentrifugation apheresis and immune affinity chromatography. Chemotherapy and high dose radiation exposed tumor cells and their exosomes are made sensitive to telomerase inhibiting and apoptosis inducing and least toxic epigallocatechin and to heparin bound receptors. They convert triple negative breast tumors into receptor positive tumors which open new avenues for treating most aggressive breast cancers.

Owner:SAHADEVAN VELAYUDHAN

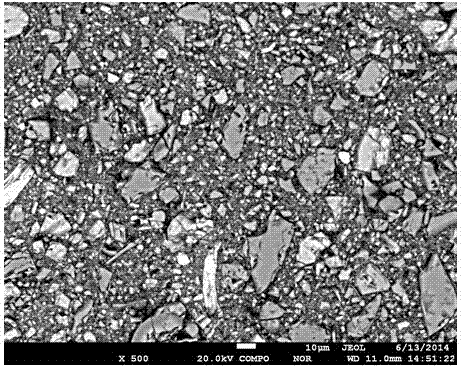

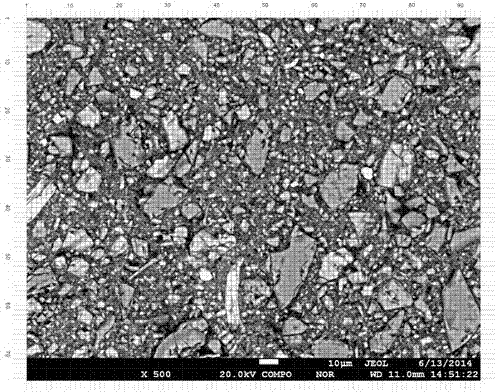

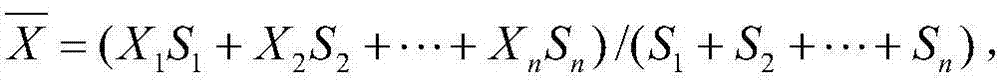

Total-rock component testing method based on in-situ electronic probe analysis

InactiveCN104122283AEasy to makeQuick analysisMaterial analysis using wave/particle radiationElectron probe microanalysisX-ray

The invention discloses a total-rock component testing method based on in-situ electronic probe analysis. The total-rock component testing method comprises the steps of jet-plating a manufactured rock X-ray plate or a thin X-ray plate with a carbon conductive film, putting a jet-plated sample into an electronic probe sample chamber for analysis, shooting a back scattering electronic image under the condition of a magnification factor of 450-550, performing precision quantitative analysis on different minerals in the image through an electronic probe wavelength dispersive spectrometer, and counting the area percentages of the different minerals in the shot back scattering image by adopting a grid method; calculating a result which is the content of a total-rock element of the rock sample by performing a weighing average operation on an element content average value of different analysis points of the same mineral and the area percentages of the minerals. The method disclosed by the invention has the advantages of no destroy to the sample, in-situ microbeam analysis, high analysis precision, easiness in sample preparation, zero pollution and the like, and has an extremely good application prospect in the analysis of aerolite, gem-jade and precious rare rock samples.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com