Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

398results about How to "Fast soldering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing technique and device for composite board

ActiveCN103231216AQuality assuranceAchieve mass productionOther manufacturing equipments/toolsVacuum pumpingComposite slab

The invention discloses a manufacturing technique for a composite board and belongs to the technical field of composite metal strip rolling. The manufacturing technique comprises the following steps implemented successively: joint surface machining, end surface machining, press fit, blank assembly, vacuum pumping and inert gases filling, heating, hot rolling and verifying. By means of the manufacturing technique, the machining accuracy is improved, and volume production of carbon steel-stainless steel composite boards is achieved; simultaneously, air in a combination blank is replaced through vacuum pumping and inert gases filling, oxidization of interfaces of the combination blank is prevented in a subsequent heating process, a little of residual air between the composite interface and two layers of stainless steel interfaces can be squeezed into an air storage bag gradually along with the moving of a roller and the composite blank simultaneously, and the residual air is prevented from expelling a separating agent or oxidizing the composite interfaces, accordingly, the joint of the finished composite slab is improved effectively, and the quality of the composite slab is further improved.

Owner:山东易川新材料科技股份有限公司

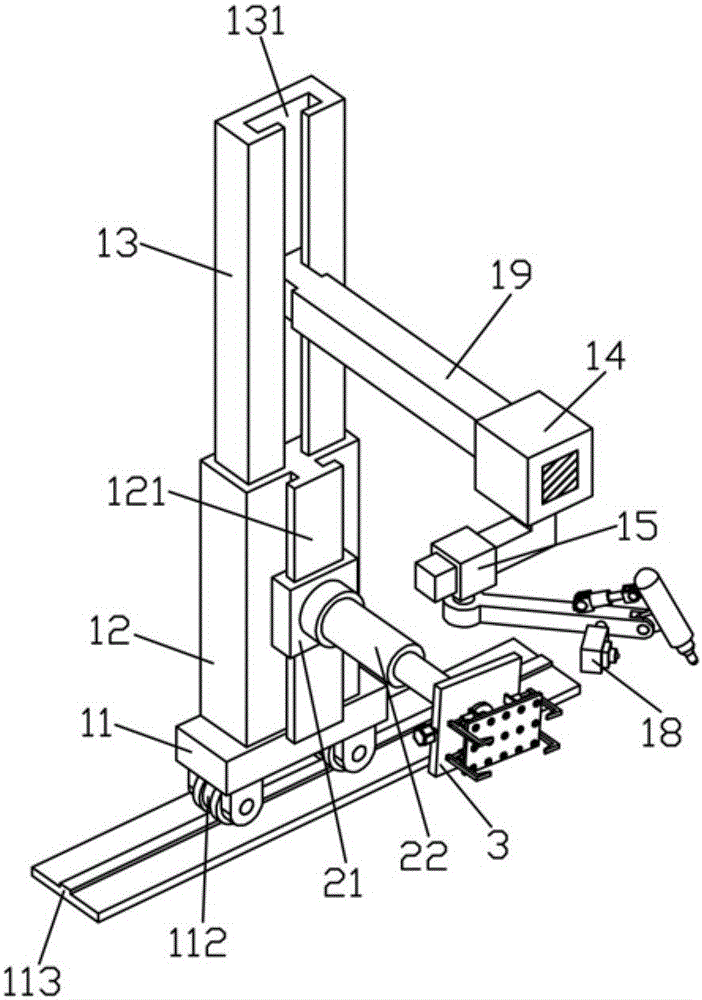

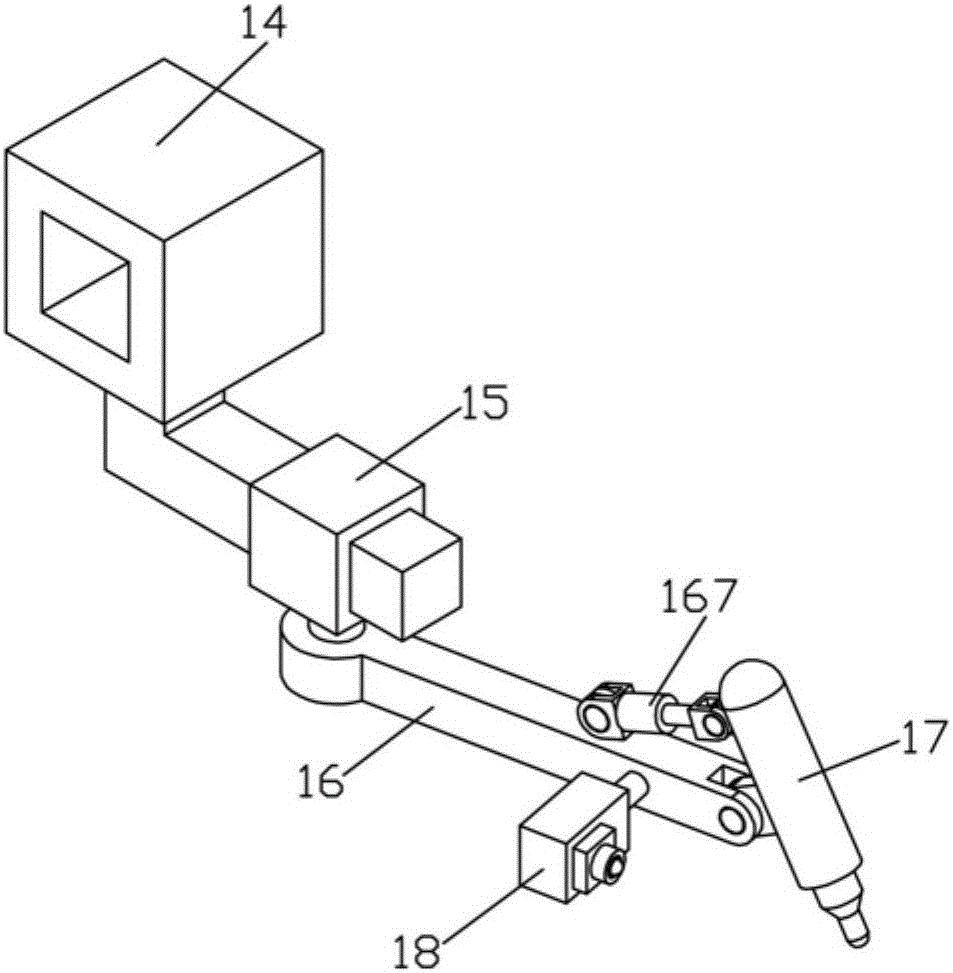

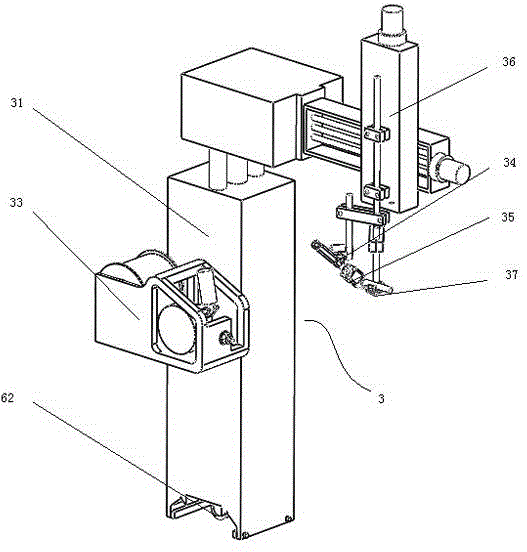

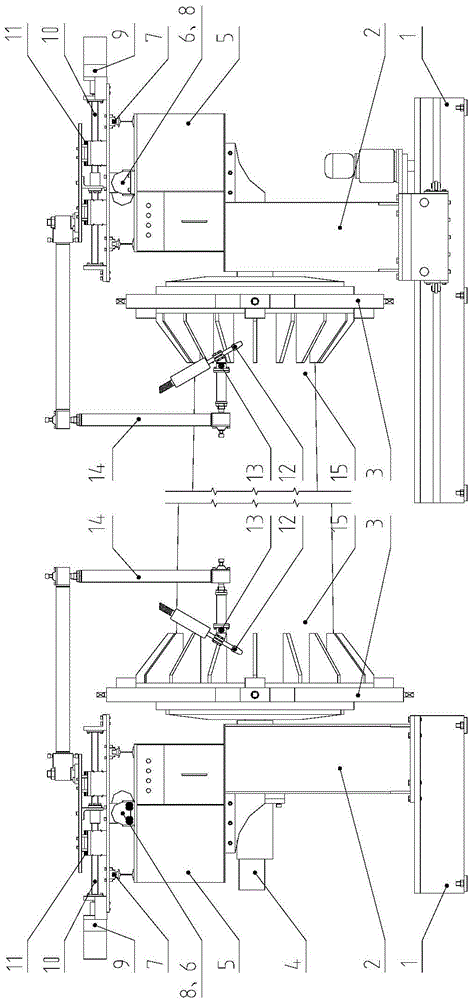

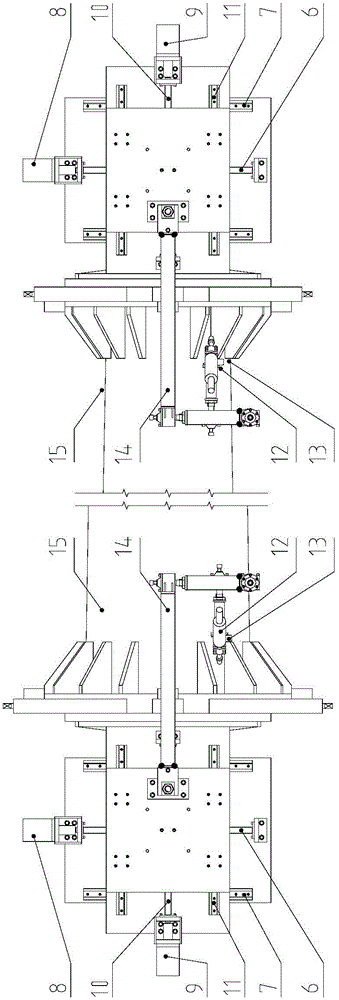

Complete equipment of welding robot and welding jig

InactiveCN105880894AGive full play to the role of flexibilityEasy to moveWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMulti degree of freedom

The invention discloses complete equipment of a welding robot and a welding jig. The complete equipment comprises a multi-degree-of-freedom welding manipulator assembly, a CCD camera, the welding jig and a control box, wherein the multi-degree-of-freedom welding manipulator assembly, the CCD camera and the welding jig are electrically connected with the control box; the control box is positioned beside the welding jig; the multi-degree-of-freedom welding manipulator assembly is positioned above the middle of the welding jig; the CCD camera is positioned on the multi-degree-of-freedom welding manipulator assembly; the control box comprises a host computer and a PLC; the PLC controls the actions of the multi-degree-of-freedom welding manipulator assembly and the welding jig at any time; in the welding process, a workpiece is fixed by the welding jig and is subjected to welding operation of the multi-degree-of-freedom welding manipulator assembly. The equipment simultaneously comprises the welding robot and the welding jig, the welding robot and the welding jig are excellent in mobility performance, the equipment is high in repeated positioning accuracy and convenient and rapid to load and unload, rapid welding of different products can be realized, and the flexibility effect of the welding robot is brought into well play.

Owner:唐山松众科技有限公司

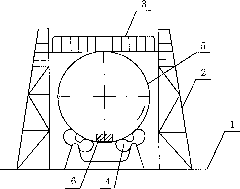

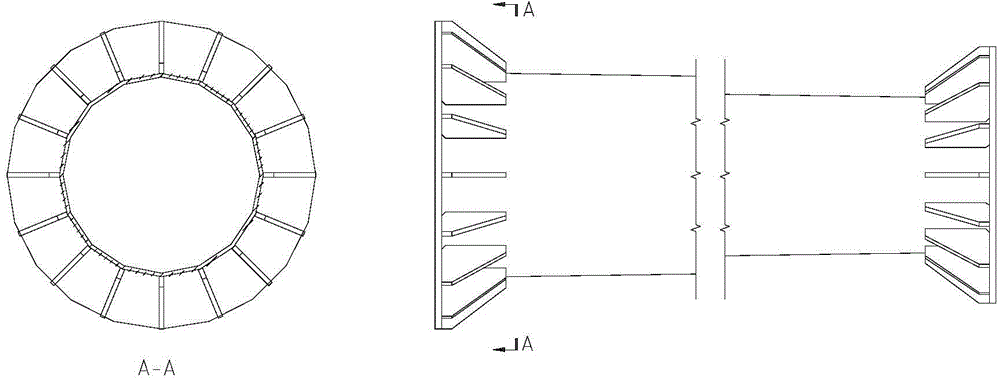

Submerged-arc welding process of large-size cylinder body

InactiveCN101823177AReduce labor intensityImprove welding efficiencyWelding/cutting auxillary devicesArc welding apparatusSubmerged arc weldingMotion direction

The invention relates to a submerged-arc welding process of a large-size cylinder body, comprising the following steps of: firstly laying a standard operation platform at a construction field, erecting a submerged-arc welding bracket and installing an electric rotator on the standard operation platform, and arranging an automatic welding operation platform on the submerged-arc welding bracket; then horizontally placing the cylinder body to be welded on the electric rotator, wherein the electric rotator drives the cylinder body to rotate during rotation; installing a travelable submerged-arc welding trolley at the lower part of an inner ring welding line when the inner ring welding line is welded, wherein the traveling speed of the submerged-arc welding trolley is equal to the rotating speed of the electric rotator, and the submerged-arc welding trolley and the electric rotator are inversed in motion directions so that the submerged-arc welding trolley is positioned on the welding line position of a starting point of the lower part of the cylinder body all the time; and placing the submerged-arc welding trolley on the automatic welding operation platform when an outer ring welding line is welded, wherein the electric rotator drives the cylinder body to rotate, and the submerged-arc welding trolley is in a static state. The invention realizes the purpose of automatic welding through the rotation of the cylinder body and the coordination of the submerged-arc welding trolley, greatly reduces the labor intensity of welders, also enhances the welding efficiency and the welding quality and has very high practical value.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

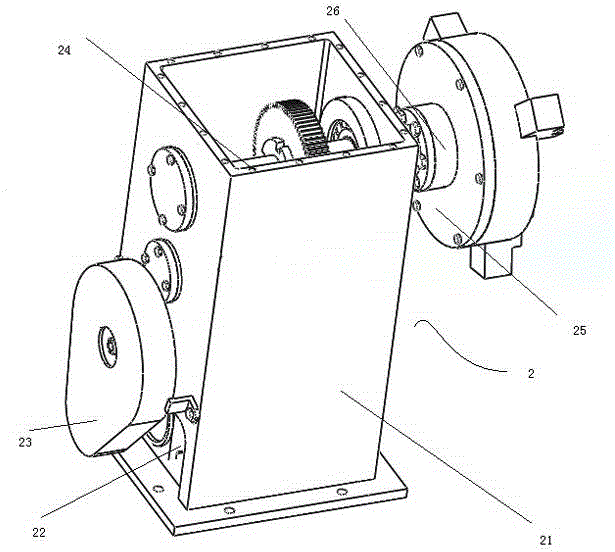

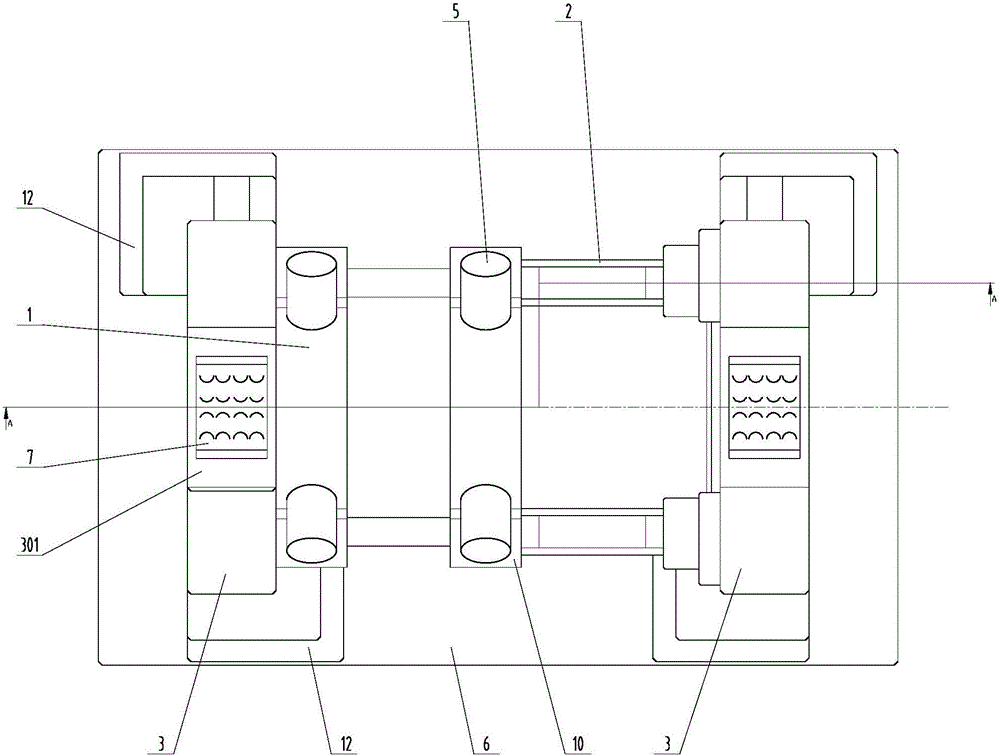

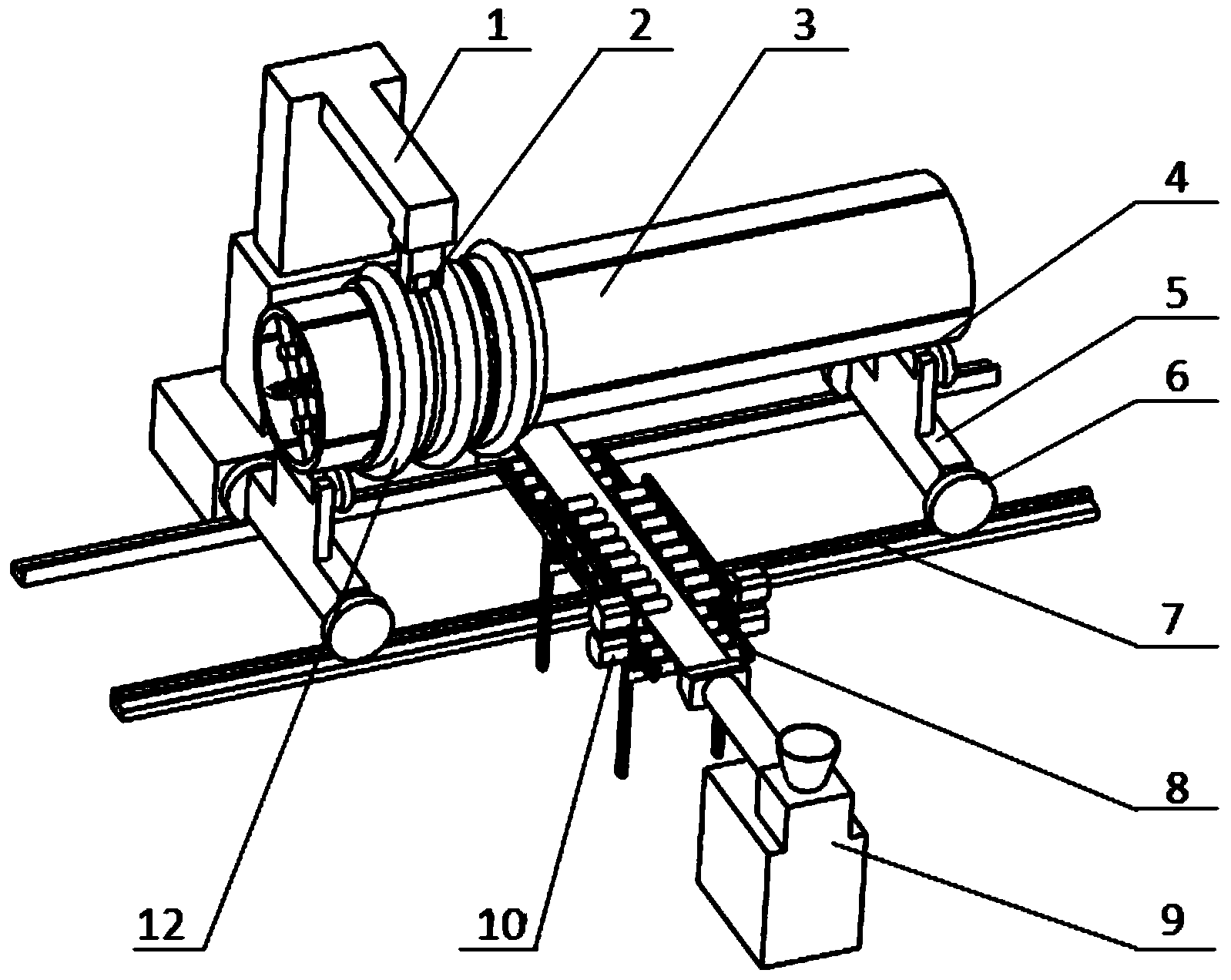

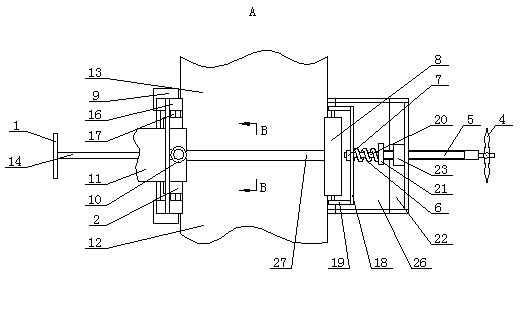

Welding machine tool

ActiveCN104690458AUniform supportGuaranteed stabilityWelding/cutting auxillary devicesArc welding apparatusControl systemEconomic benefits

The invention discloses a welding machine tool. The welding machine tool comprises a machine tool body and a control system; a main spindle box, a tail base mechanism and a welding mechanism for performing the welding operation are arranged on the machine tool body; the control system is connected with the main spindle box, the welding mechanism and the tail base mechanism, the welding mechanism is arranged between the main spindle box and the tail base mechanism; the main spindle box is fixed on the machine tool body, and the welding mechanism and the tail base mechanism are glided along the length direction of the machine tool body. The welding machine tool has variable functions, and not only can satisfy spot welding, simple linear welding and simple arc welding but also the welding of spiral vanes with different length requirements; the welding machine tool is simple in mechanism, convenient to operate, and high in efficiency; the welding machine tool has very big economic benefit and is worth to be popularized.

Owner:HOHAI UNIV CHANGZHOU

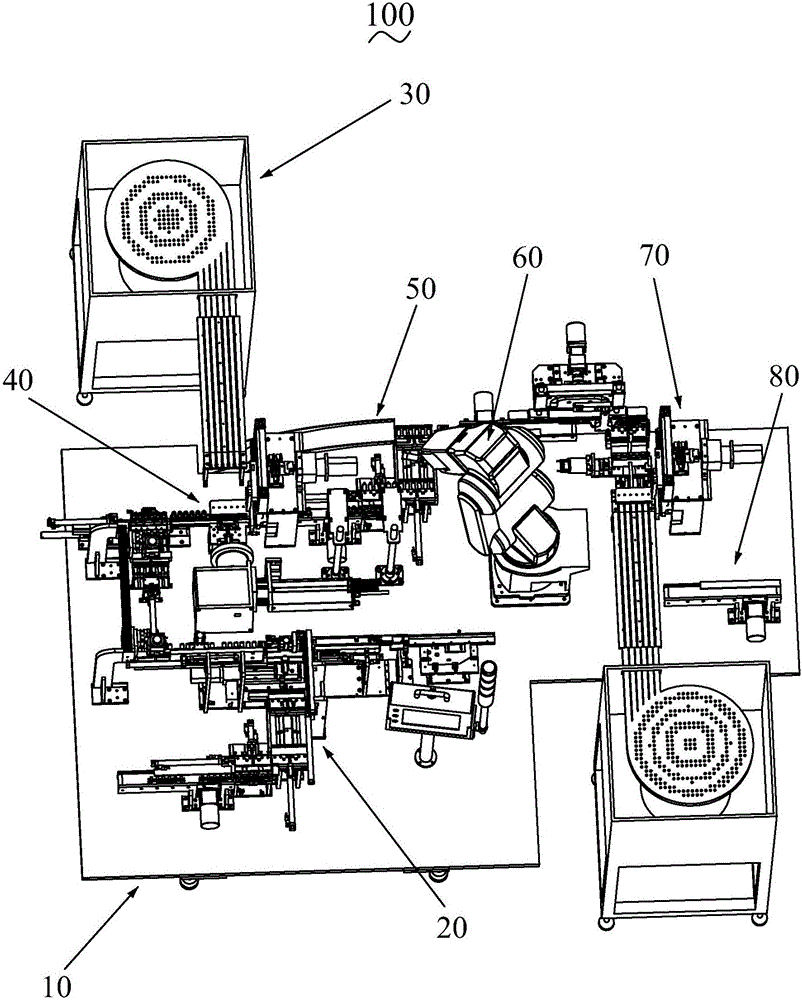

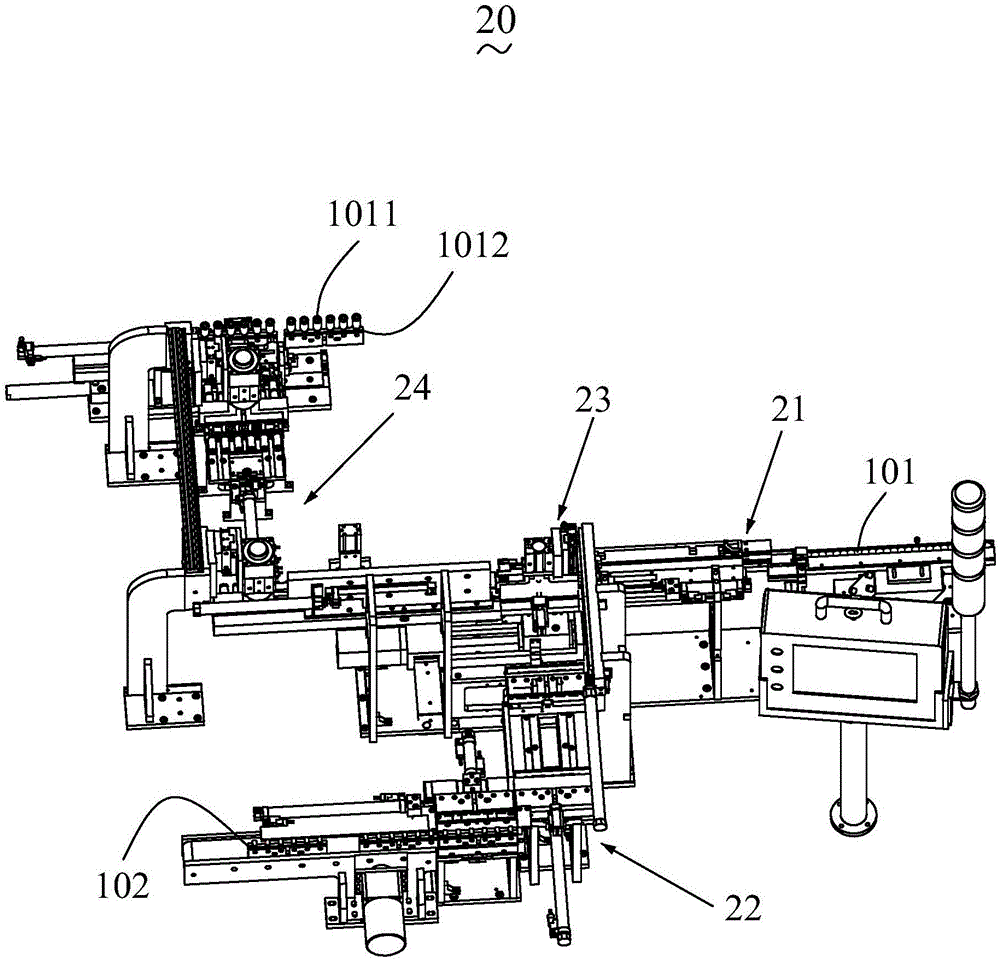

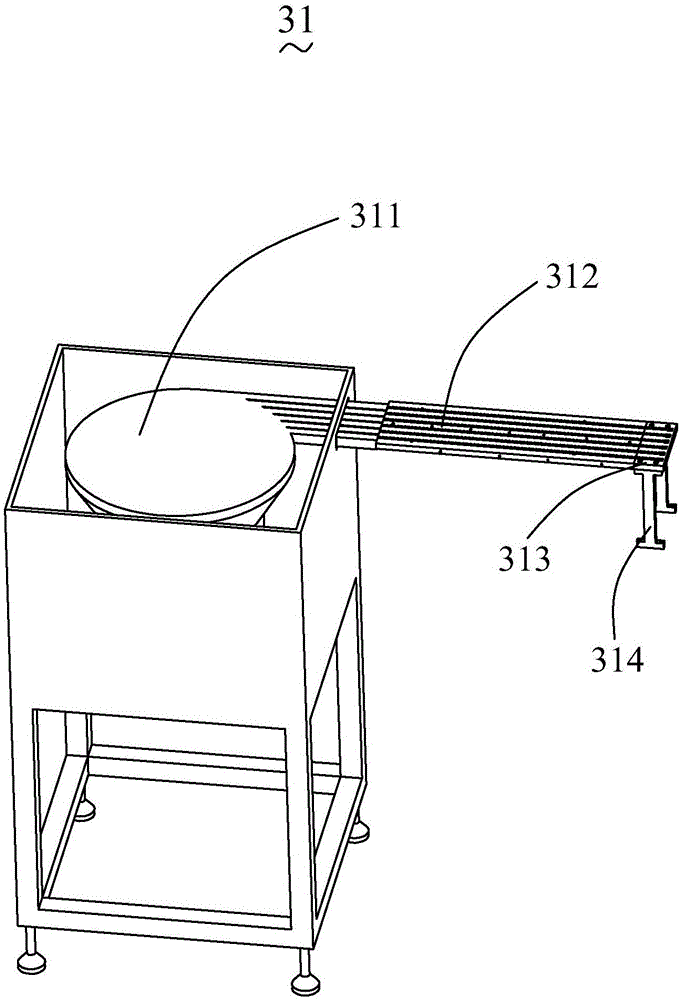

Full-automatic battery spot welding equipment

PendingCN106624309AContinuous weldingFast solderingResistance welding apparatusButt weldingEngineering

The invention provides full-automatic battery spot welding equipment. The equipment comprises a rack and a battery carrying mechanism, two material charging mechanisms, a spot welding mechanism, a detection mechanism, a transfer mechanism, a butt welding mechanism and a discharging mechanism which are arranged on the rack. According to the full-automatic battery spot welding equipment, full-automatic operation can be achieved, battery charging and transportation, screw / double-screw bolt charging and transportation, screw and battery spot welding, CCD detection, unqualified product screening, double-screw bolt and battery butt welding, product outputting and other operation are integrated, screws and double-screw bolts can be welded to the two ends of a battery continuously and rapidly, batched production is met, and the precision of product machining can be improved.

Owner:OPTIMUM BATTERY CO LTD

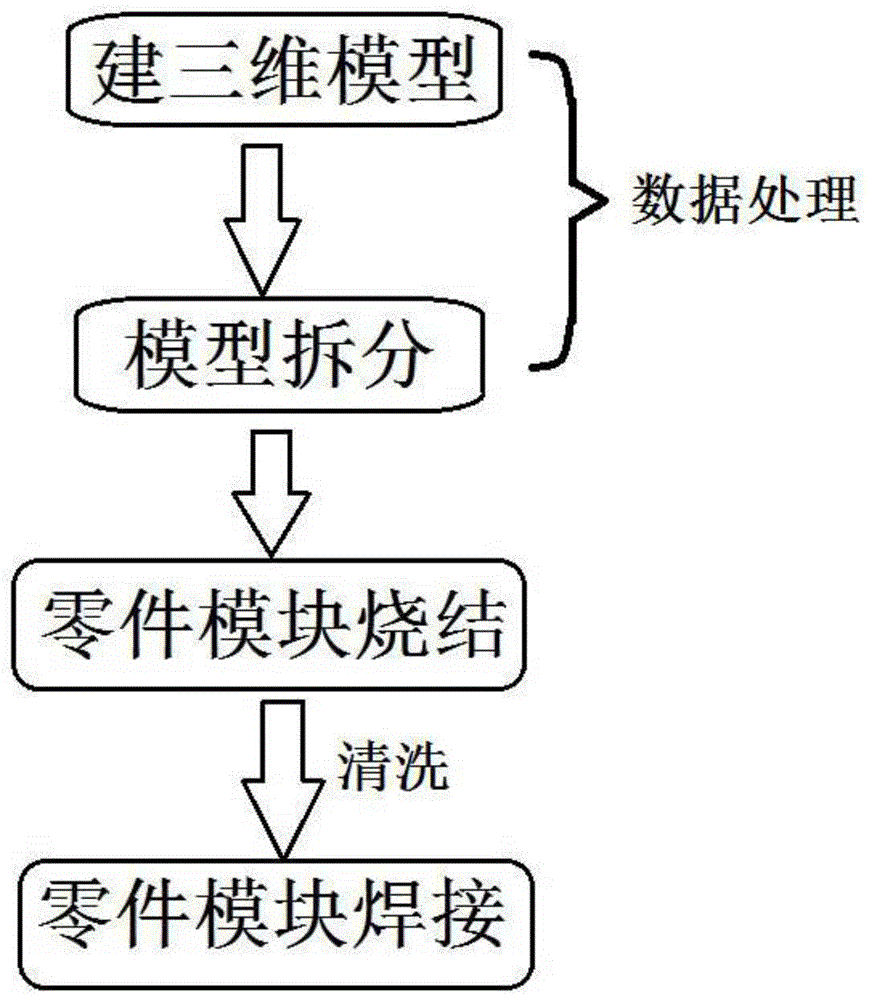

Quick precision mold preparation method

InactiveCN104802339AWide range of mold materialsNo waste of mold materialThree dimensional modelThermoplastic

The invention discloses a quick precision mold preparation method which comprises the following steps: 1, constructing a three-dimensional model, and partitioning into part modules; 2, performing laser sintering to prepare part modules; 3, performing ultrasonic welding on the part modules. By adoption of laser sintering for manufacturing a mold, the mold materials are readily available, waste is avoided, and the cost is low; after 3D modeling, a prototype with complicated structure can be quickly manufactured; by adoption of partitioning design, the whole mold is split and then subjected to ultrasonic welding after laser sintering, so that the preparation requirement of a large-size mold can be met. The ultrasonic plastic welding has the advantages that the welding speed is high, the welding intensity is high, and the sealing property is high; polystyrene is colorless transparent thermoplastic plastic, has glass conversion temperature higher than 100 DEG C, is stable and quick in sintering and small in shrinking percentage fluctuation which is generally 0.2-0.6 percent; ultrasonic welding is pollution-free, and a workpiece cannot be damaged; the welding process is stable.

Owner:SHENZHEN XINLIYANG PRECISION TECH

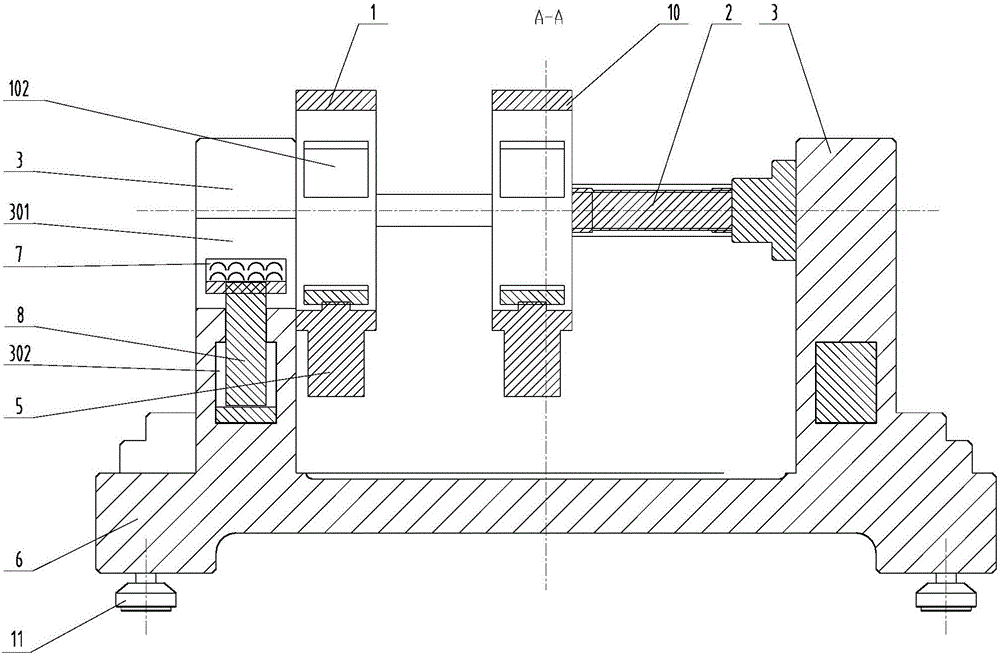

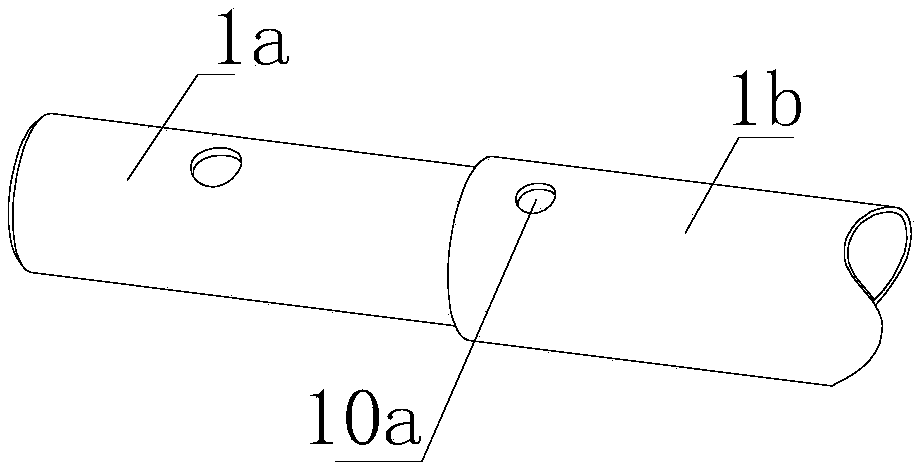

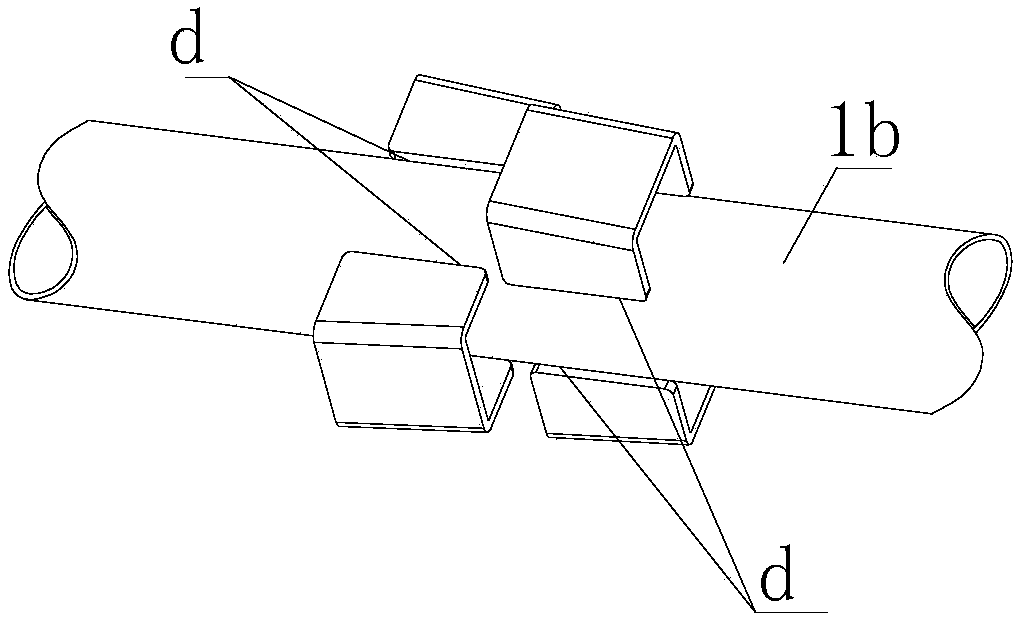

Tubular part welding rapid butt-joint positioning device

InactiveCN105817829ACompact structurePrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesButt jointDepth direction

The invention discloses a tubular part welding rapid butt-joint positioning device. A fixed clamping assembly and a movable clamping assembly are coaxially arranged in a spaced mode on the inner sides of a pair of supporting frames arranged in a spaced mode. The movable clamping assembly can be driven by a first pushing assembly to translate in the axial direction so as to change the distance between the fixed clamping assembly and the movable clamping assembly. Through grooves are formed in the tops of the two supporting frames in the axial directions of the clamping assemblies correspondingly. Movable supporting blocks are arranged at the bottoms of the through grooves. A plurality of universal balls are movably installed on the movable supporting blocks at intervals and can rotate on the movable supporting blocks. The tops of the universal balls are exposed out of the upper portions of the movable supporting blocks to form supporting faces. The movable supporting blocks can be pushed by a third pushing assembly to move in the depth direction of groove cavities of the through grooves. The device further comprises a plurality of independently separated buffer gaskets with different thicknesses. The device is simple and compact in structure, positioning is accurate, operation is simple and the safety performance is high.

Owner:SHANGHAI UNIV OF ENG SCI

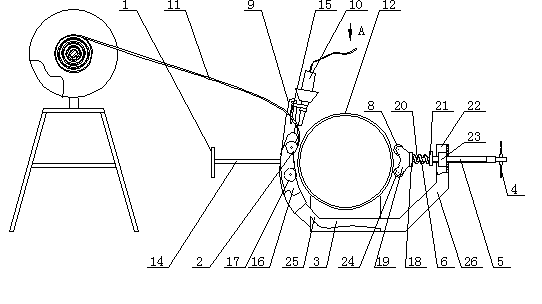

Mould-less large-caliber PVC pipe dynamic molding method and device

ActiveCN103991221AReduce demoulding timeImprove molding efficiencyTubular articlesUltrasonic weldingSheet film

The invention discloses a mould-less large-caliber PVC pipe dynamic molding device and method. The device is mainly composed of an extruder, a film bracket, bracket rolls, a bracket motor, a heating box, a three-point circle setting instrument, rollers, pressure rollers, supporting rollers, a pipe support frame, a support frame motor, guide rollers, a guide roller motor, guide rails and an ultrasonic welding instrument, etc. The three-point circle setting instrument can be used for continuous molding, and the PVC pipe length is not restricted by a roller mould. Compared with existing PE large-caliber pipes, the PVC raw material is much cheaper than PE, thus greatly lowering the production cost. The device provided by the invention omits the large-caliber roller mould, thus being able to save demoulding time and improving the molding efficiency. Also, the ultrasonic welding temperature is precisely controlled, thus effectively avoiding the PVC degradation problem caused by a high melting welding temperature. And the welding is fast. The mould-less large-caliber PVC pipe dynamic molding method and device provided by the invention can be used for molding large-caliber PVC smooth wall round pipes and outer corrugated pipes simultaneously.

Owner:BEIJING UNIV OF CHEM TECH

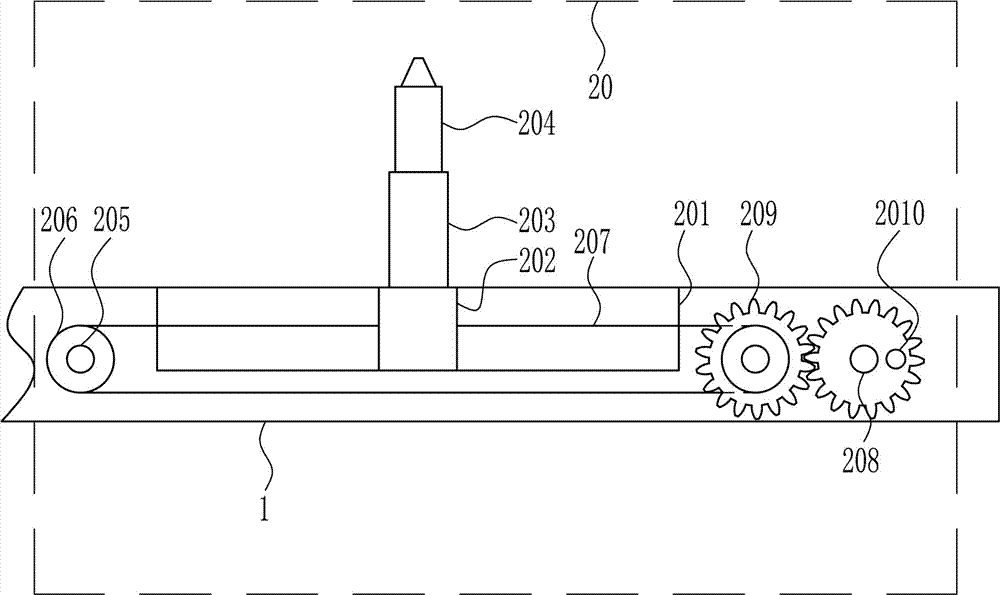

Vacuum welding furnace and welding technology

ActiveCN107931768AReduce the temperaturePrevent oxidationHeating appliancesMetal working apparatusEngineeringOxygen

The invention provides a vacuum welding furnace and a welding technology, and belongs to the technical field of vacuum welding. The vacuum welding furnace is characterized in that one end, close to the feeding end, of a welding platform (20) is used as a heating area; one side, close to the discharging end, of the welding platform (20) is used as a cooling area; a negative pressure pumping module(9) is arranged at the upper side of one end, close to the cooling area, of the heating area, and the negative pressure pumping module (9) is mounted on a furnace cover (4) by lifting; the bottom partof the negative pressure pumping module (9) and the heating area encircles a closed negative pressure chamber; a protecting gas inlet pipe is arranged on a welding chamber (18) or the furnace cover (4). According to the vacuum welding furnace, material sheets can be heated through the heating area, so that the material sheets can be quickly welded in the negative pressure chamber; protecting gasis charged, so that the material sheets are prevented from reacting with oxygen during being heated; the material sheets can be cooled and prevented from being oxidized through the cooling area. According to the welding technology, the welding time is decreased; the welding is accelerated; with the adoption of the cooling area, the material sheet can be completely cooled and is prevented from deformation caused by excessively quick cooling.

Owner:SHANDONG CAIJU ELECTRONICS TECH CO LTD

Plate bending forming process

ActiveCN111922138AWill not be affected by shrinkageImprove molding efficiencyMetal-working feeding devicesPositioning devicesEngineeringForming processes

The invention relates to the technical field of plate bending forming, in particular to a plate bending forming process. The plate bending forming process includes the following steps that S1, cuttingand blanking are carried out, and a plate is cut for blanking according to the process required dimensions; S2, plate bending is carried out, a plate bending machine with a quick positioning mechanism is used for bending the plate cut in the first step, and the quick positioning mechanism of the plate bending machine makes the connecting gap positions of the two ends of the bent plate be arrangedvertically upwards; S3, gap shrinkage is carried out, and the two ends of the bent plate are in precise contact by means of a gap shrinkage mechanism arranged on the plate bending machine; S4, welding is carried out, a laser welding mechanism is installed over the plate bending machine, and the laser welding mechanism is utilized to carry out laser welding at the joints of the two ends of the bent plate; and S5, discharging is carried out after the formed barrel is obtained. The plate bending forming process is ingenious in concept and high in practicability, through the cooperation effect ofthe gap shrinkage mechanism, the quick positioning mechanism and the welding mechanism, the formed barrel can be subjected to quick positioning, gap shrinkage and then rapid welding, and the plate bending forming process is wide in application range and suitable for use and popularization.

Owner:佛山市金常旺不锈钢有限公司

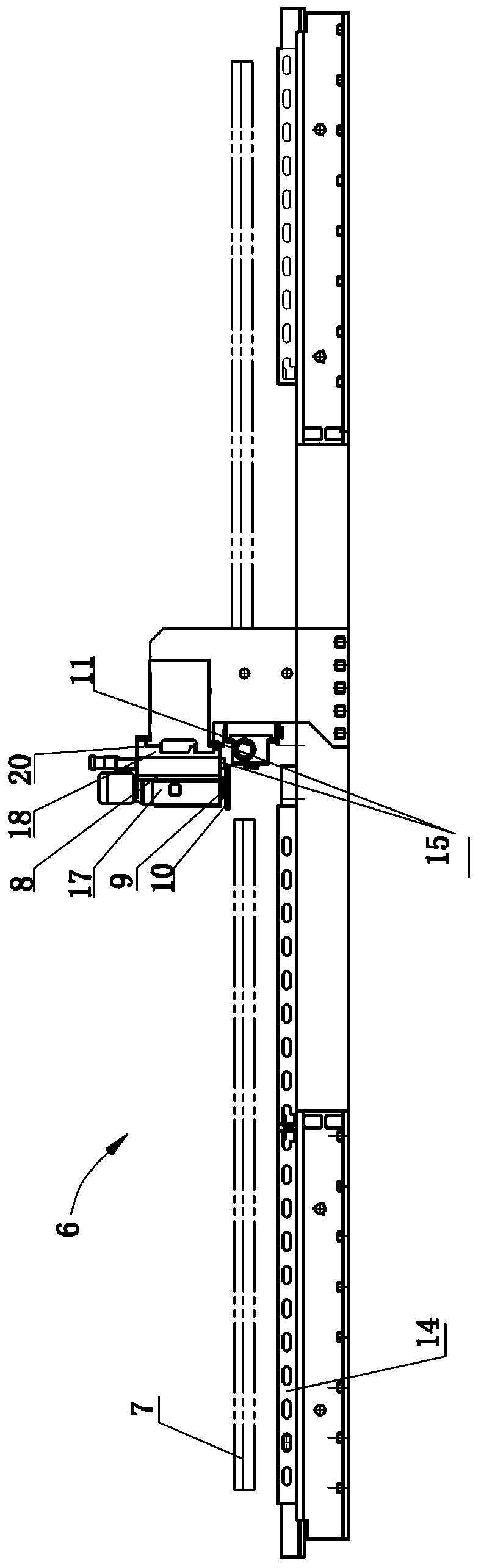

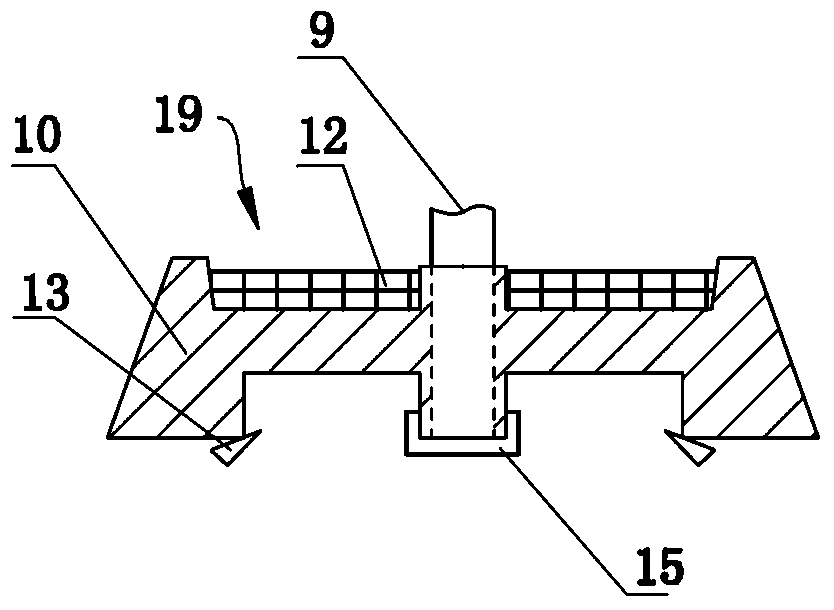

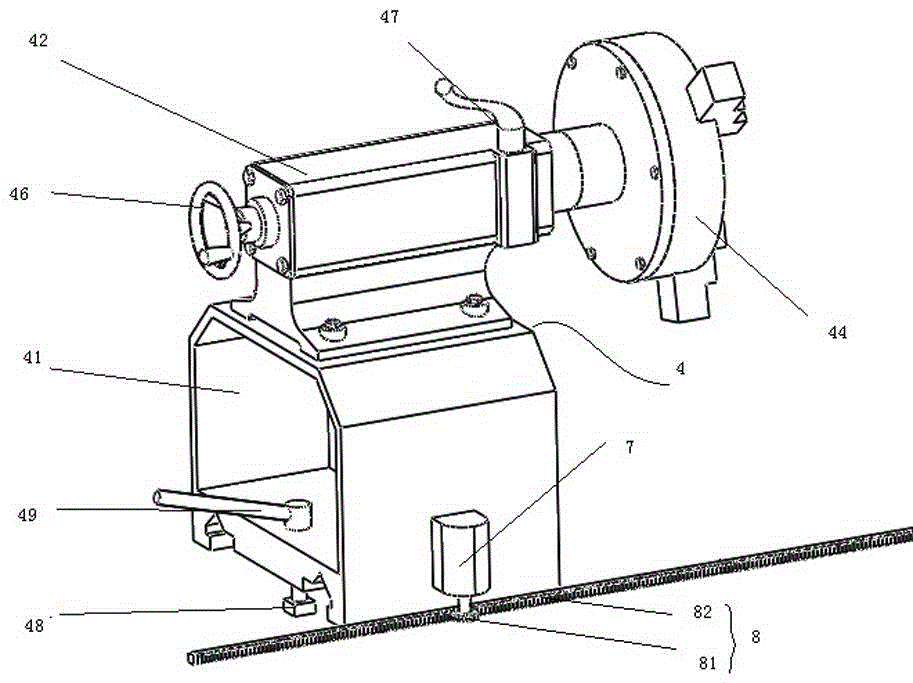

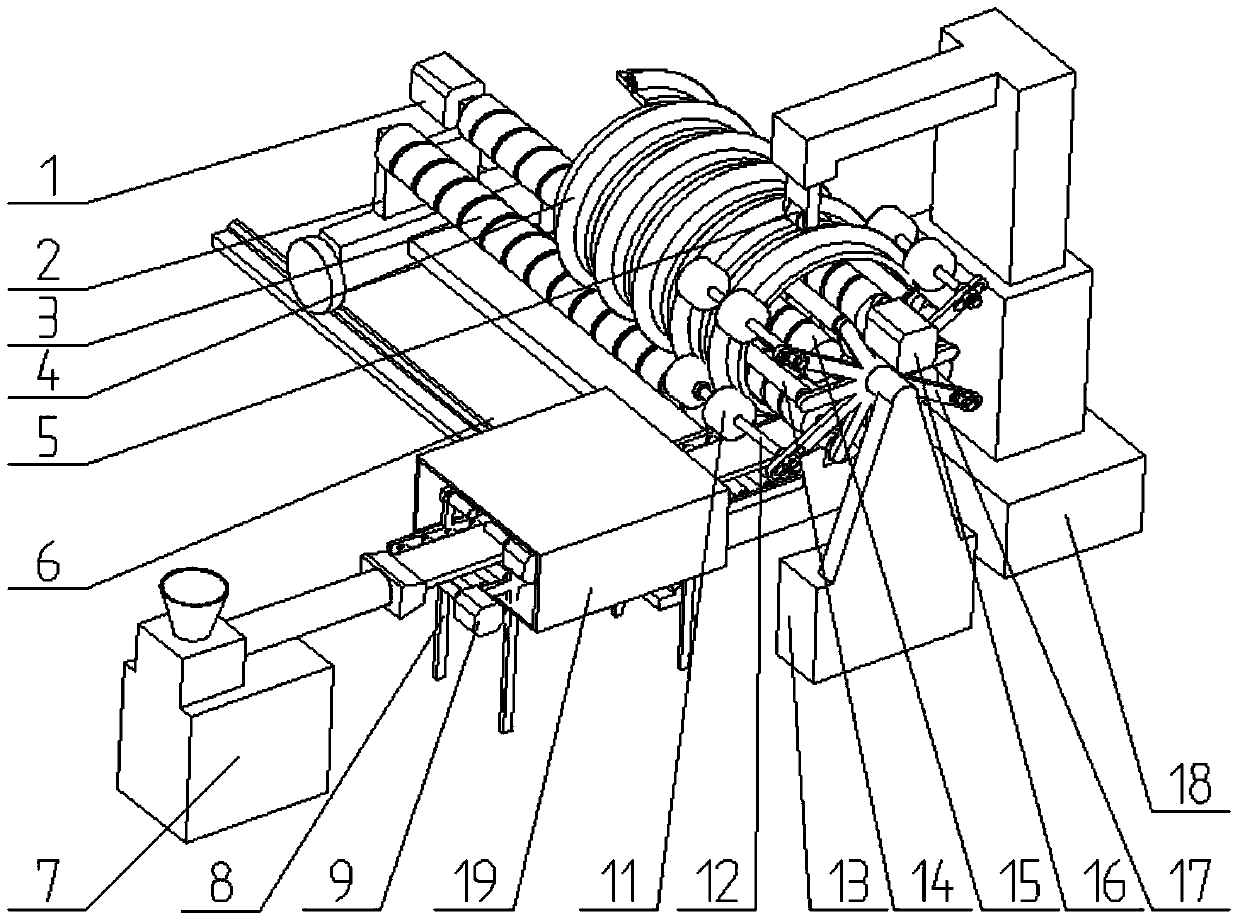

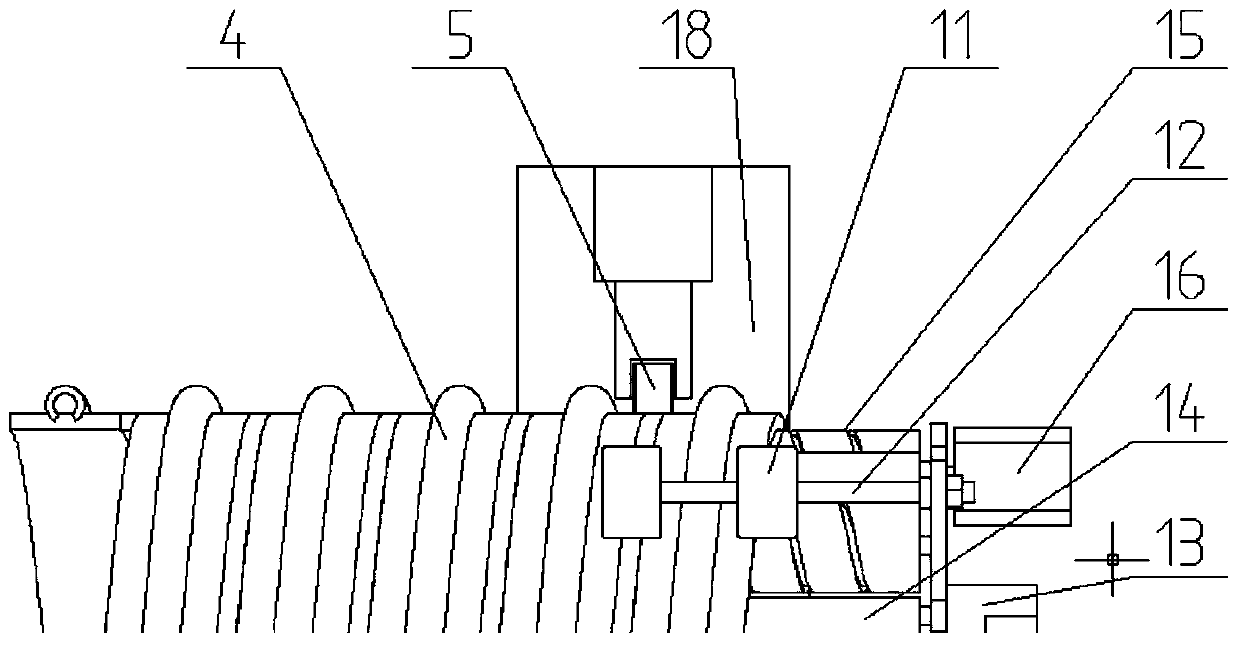

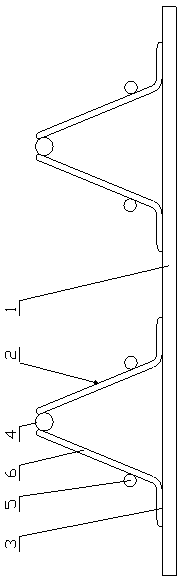

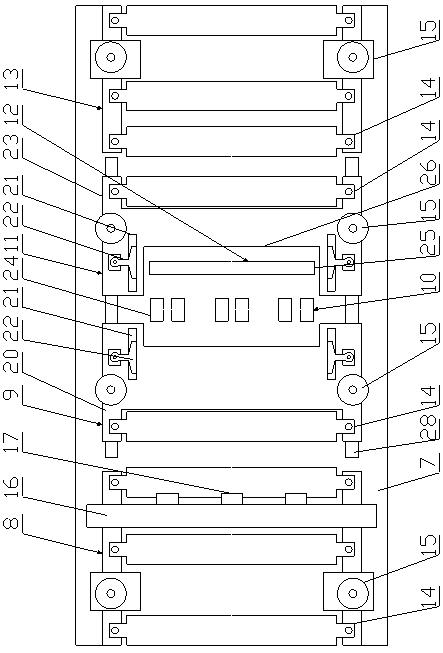

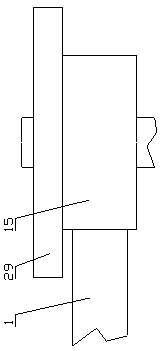

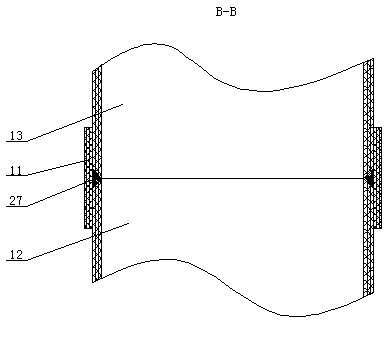

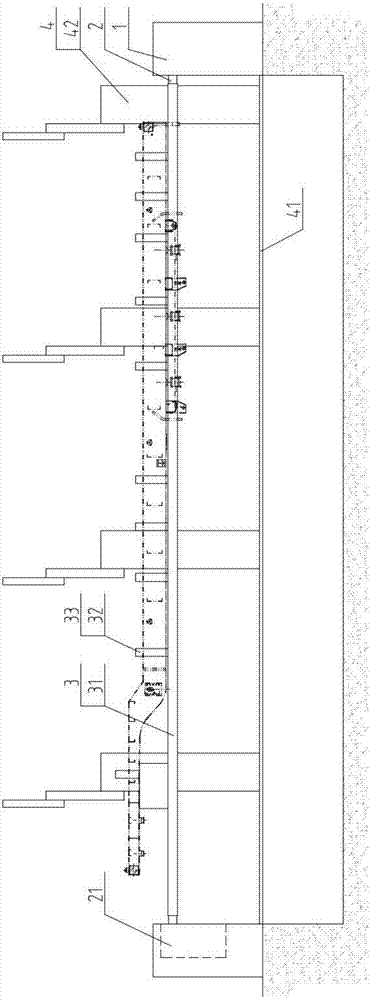

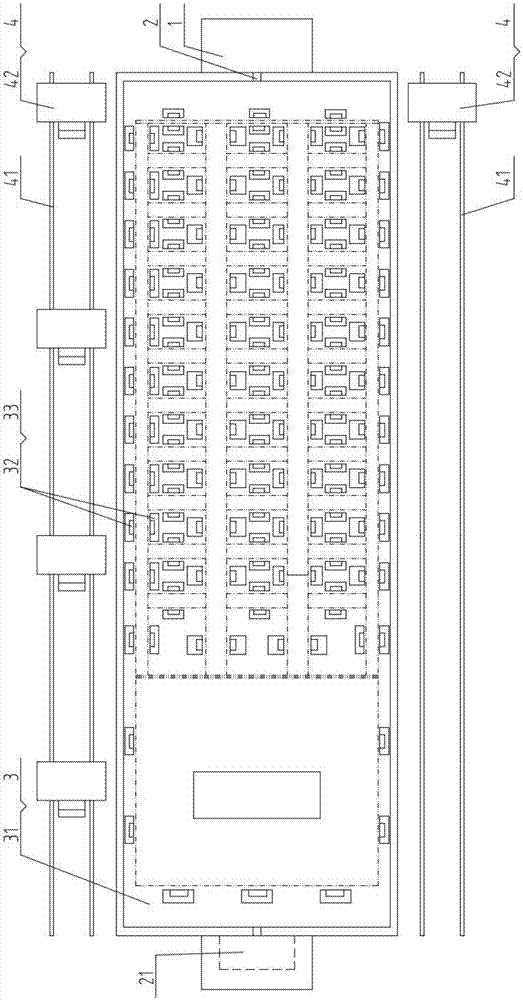

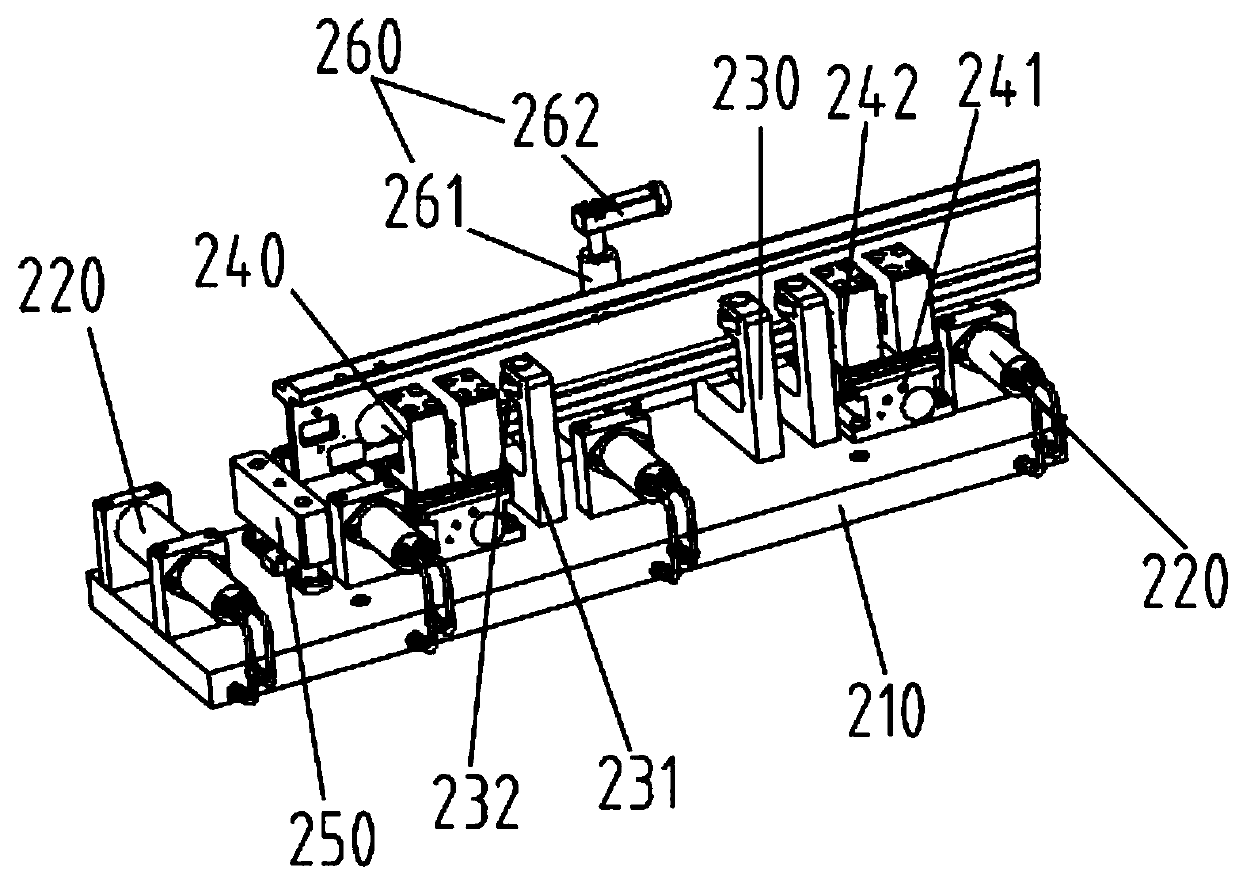

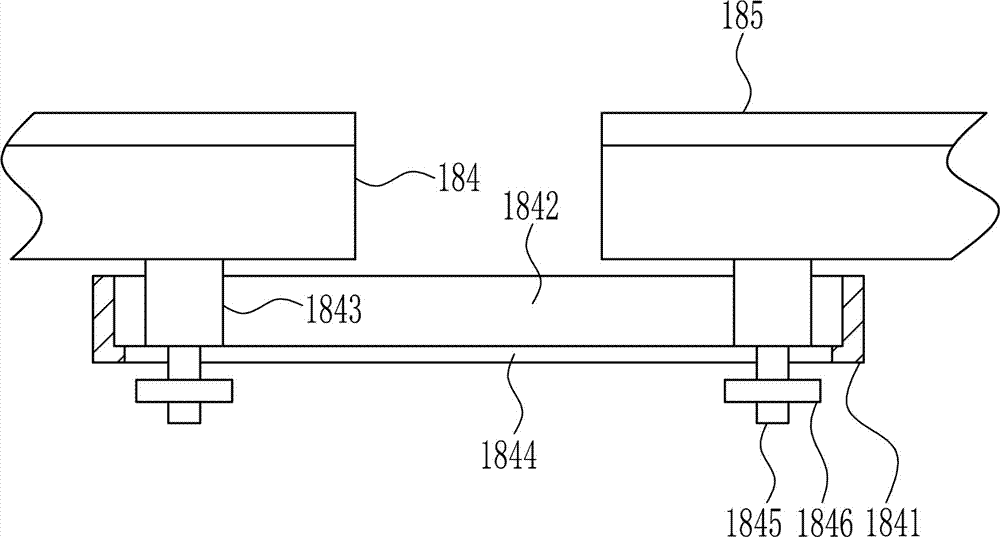

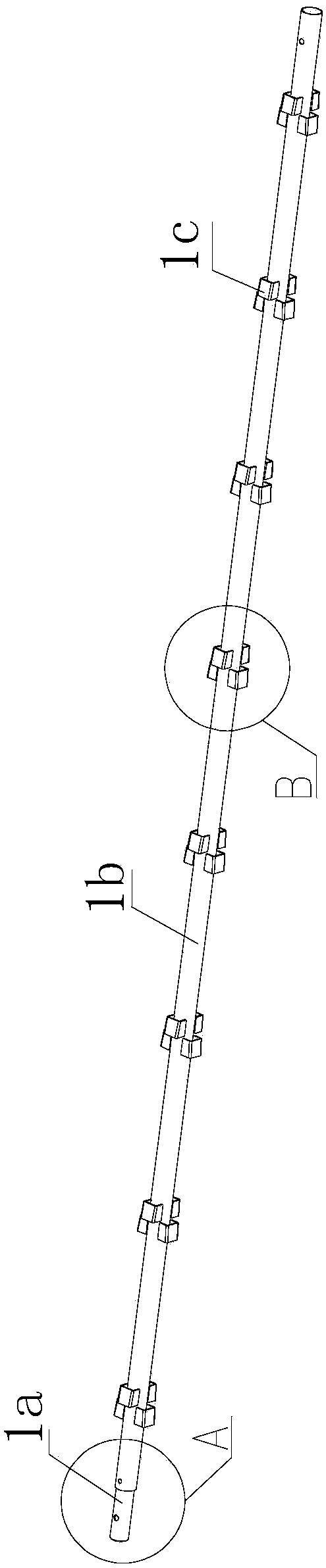

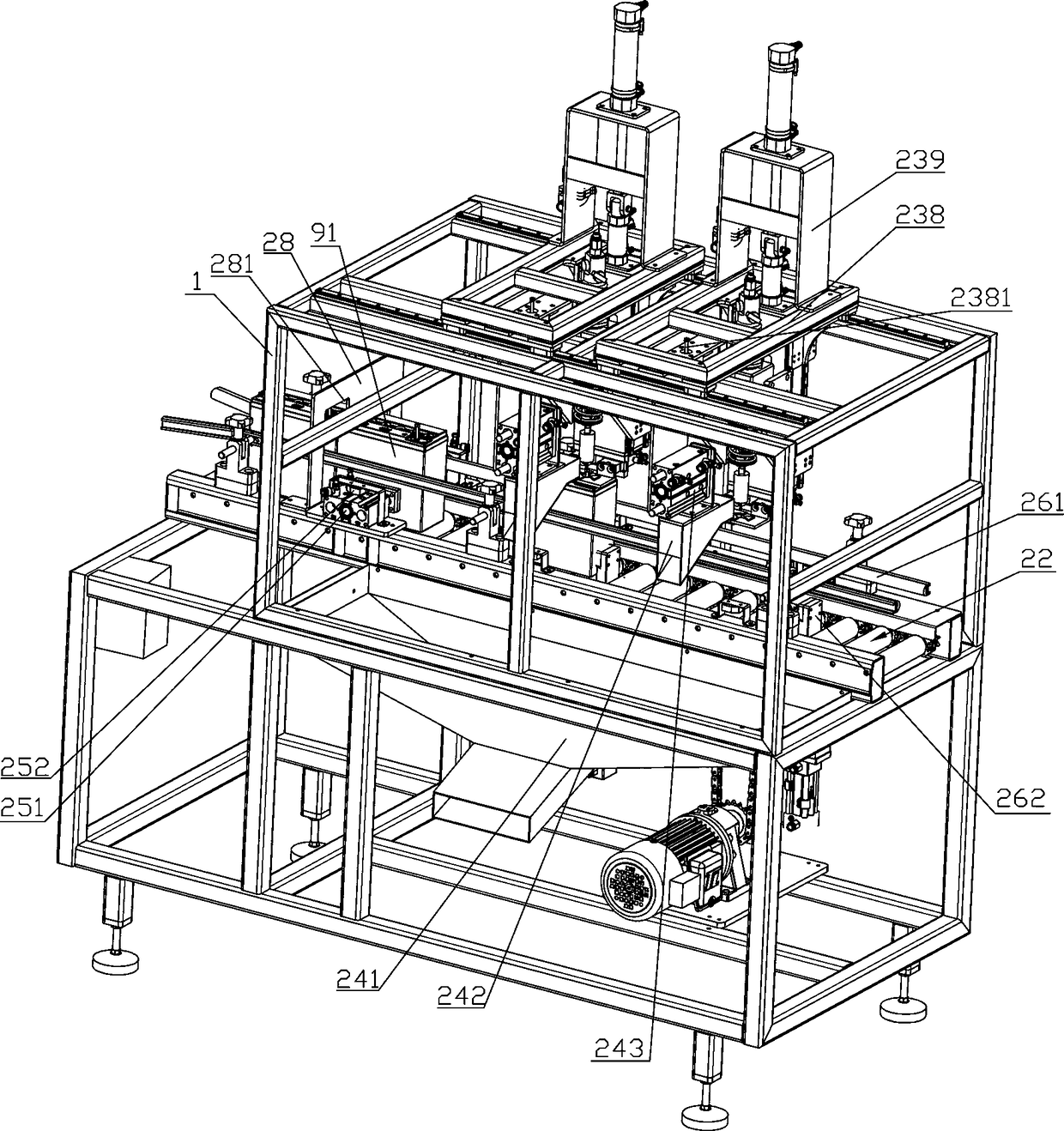

Automatic assembling device and automatic assembling method for welded steel bar truss deck

ActiveCN109014536AFast solderingRealize automatic controlWelding/cutting auxillary devicesAuxillary welding devicesProgrammable logic controllerDrive motor

Th invention discloses an automatic assembling device and an automatic assembling method for a welded steel bar truss deck, and belongs to the technical field of building material production equipment. The device comprises a rack, a feeding platform, a front feeding slide plate, a spot-welding structure, a back feeding slide plate, a positioning structure and a discharging platform, wherein the feeding platform, the front feeding slide plate, the spot-welding structure, the back feeding slide plate, the positioning structure and the discharging platform are sequentially arranged on the rack from front to back. According to the method, only a steel bar truss needs to be placed by manpower (1 to 2 persons) in the step (2), and other processes can be automatically controlled through the cooperation of an electric control cabinet (programmable logic controller (PLC) and other accessory circuits can be arranged inside, and the electric control cabinet is provided with the structure which isthe same as a common control structure), various touch switches, a control switch of an air cylinder, a control switch of a drive motor for a guide wheel and a guide roller, and the like, so that theoperation can be carried out simply and safely (no interference with an electrode), the efficiency is high, multiple steel bar trusses can be quickly assembled at the same time, the welding between the steel bar trusses and a soffit formwork is equidistantly realized, and the assembling efficiency can achieve more than 50m<2> / h. Automatic positioning and centering can be basically realized automatically, the operation is simplified, and the assembled product meets the requirement.

Owner:湖北绿建杭萧钢结构有限公司

Dynamic forming method and device for large-diameter PVC pipe

The invention aims to overcome the defect that the large-aperture PVC pipe is difficult to produce in the prior art and provides a dynamic forming method and device for a large-diameter PVC pipe. The forming device comprises an extruder, a baking oven, an ultrasonic welding device and a large-diameter roller mould. Plasticizing extrusion is performed on PVC special materials by an extruder, the PVC special materials are transferred through a conveying belt, and are heated again through the baking oven on the conveying belt, meanwhile, a motor pulls the materials at a high speed, so as to enable the materials to be oriented in the extrusion direction, finally, the materials are wound on the surface of the large-diameter roller mould, the mould rotates while performs rectilinear motion forwards, the component force for mould performing rectilinear motion enables the materials to be oriented in the axial direction of the mould, the gapes among materials are welded and sewed through the ultrasonic welding device, a cylindrical welding head is pressed on the PVC material and rotates together with the mould, so that synchronous extrusion winding and welding are achieved, and the cycle is shortened greatly due to continuous production. The mould is shrinkable, the demoulding is convenient, and when the PVC-O pipe with the diameter of 2,000 or even larger is produced, all that is needed is to replace the roller mould with larger diameter.

Owner:BEIJING UNIV OF CHEM TECH

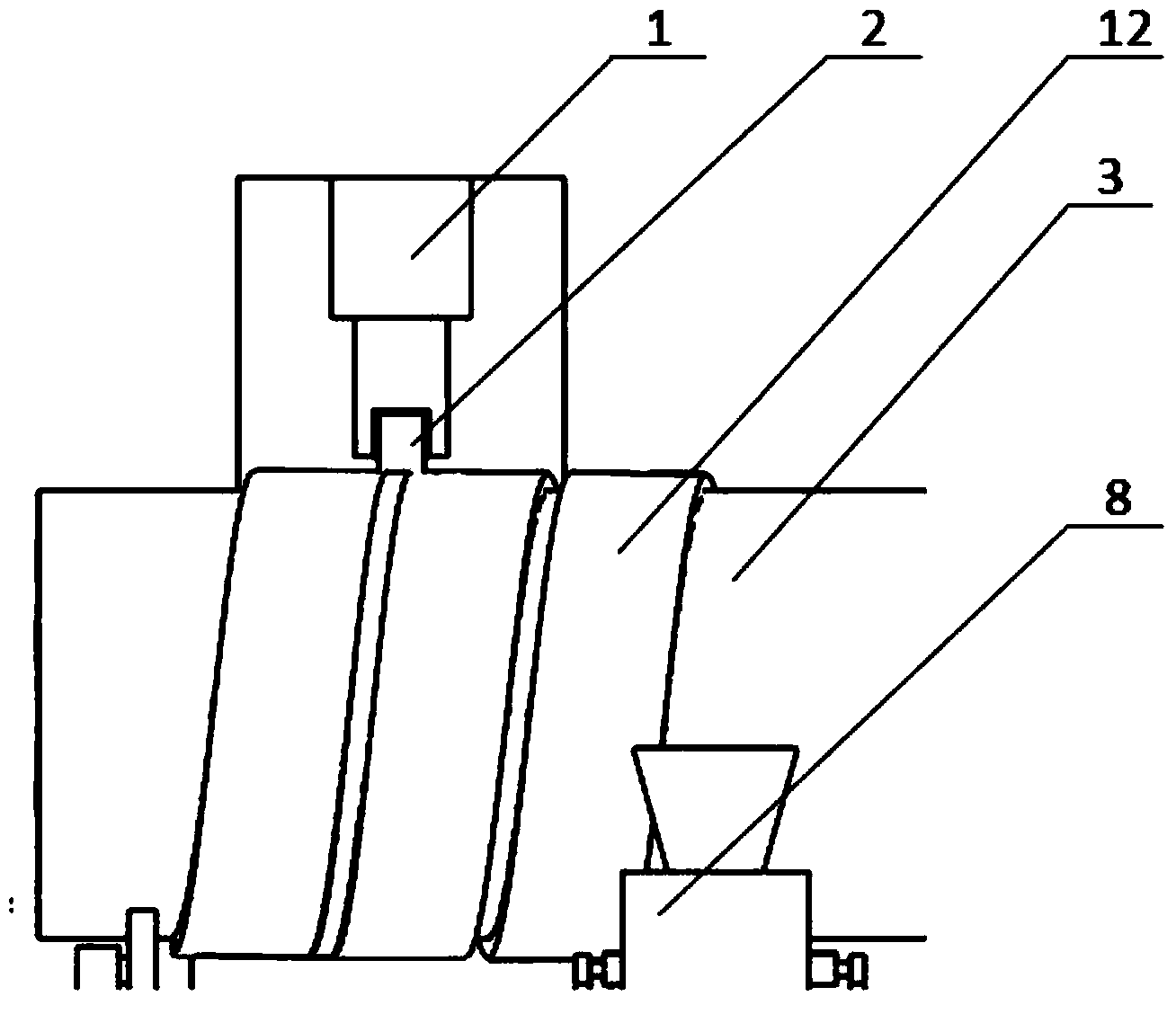

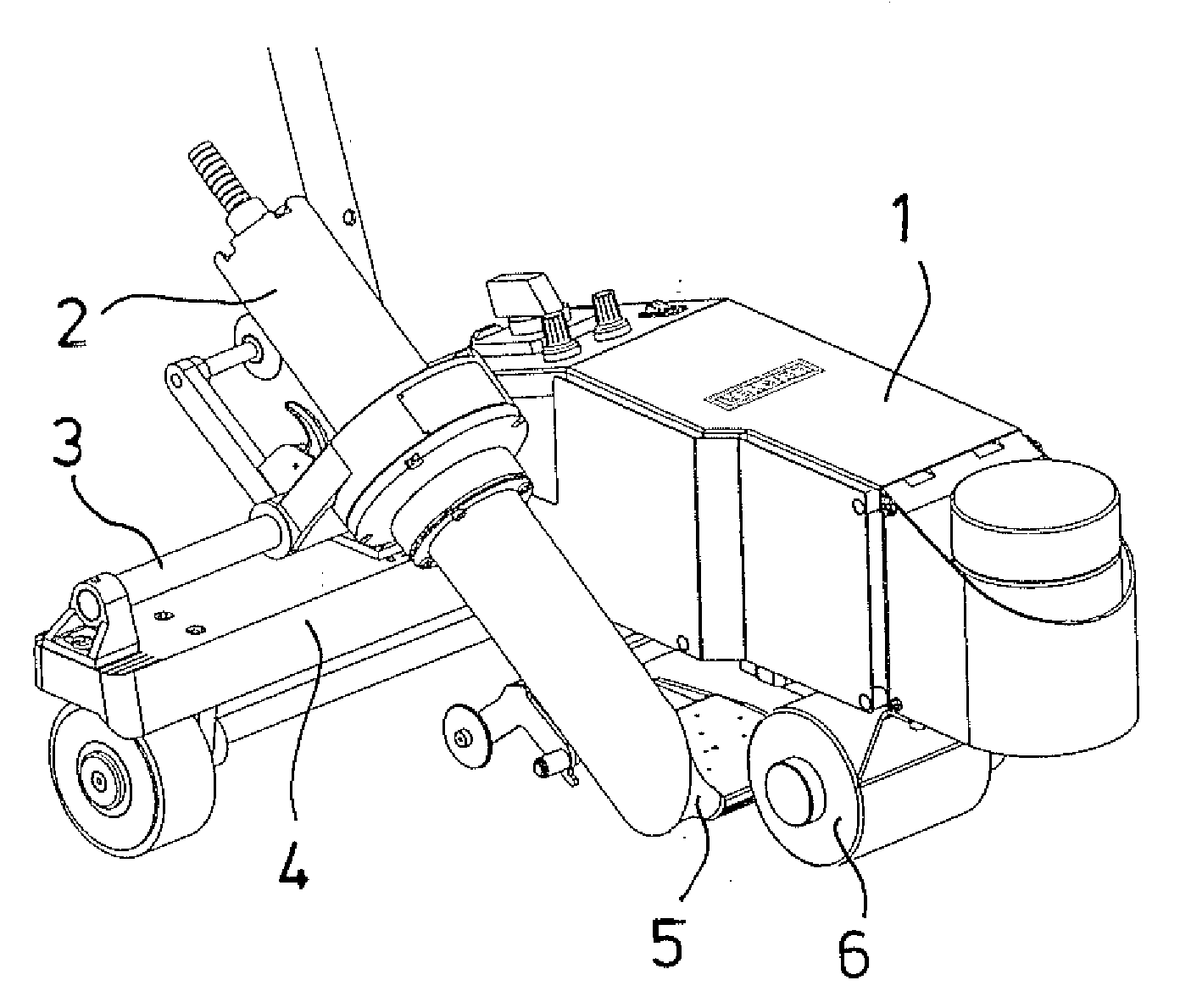

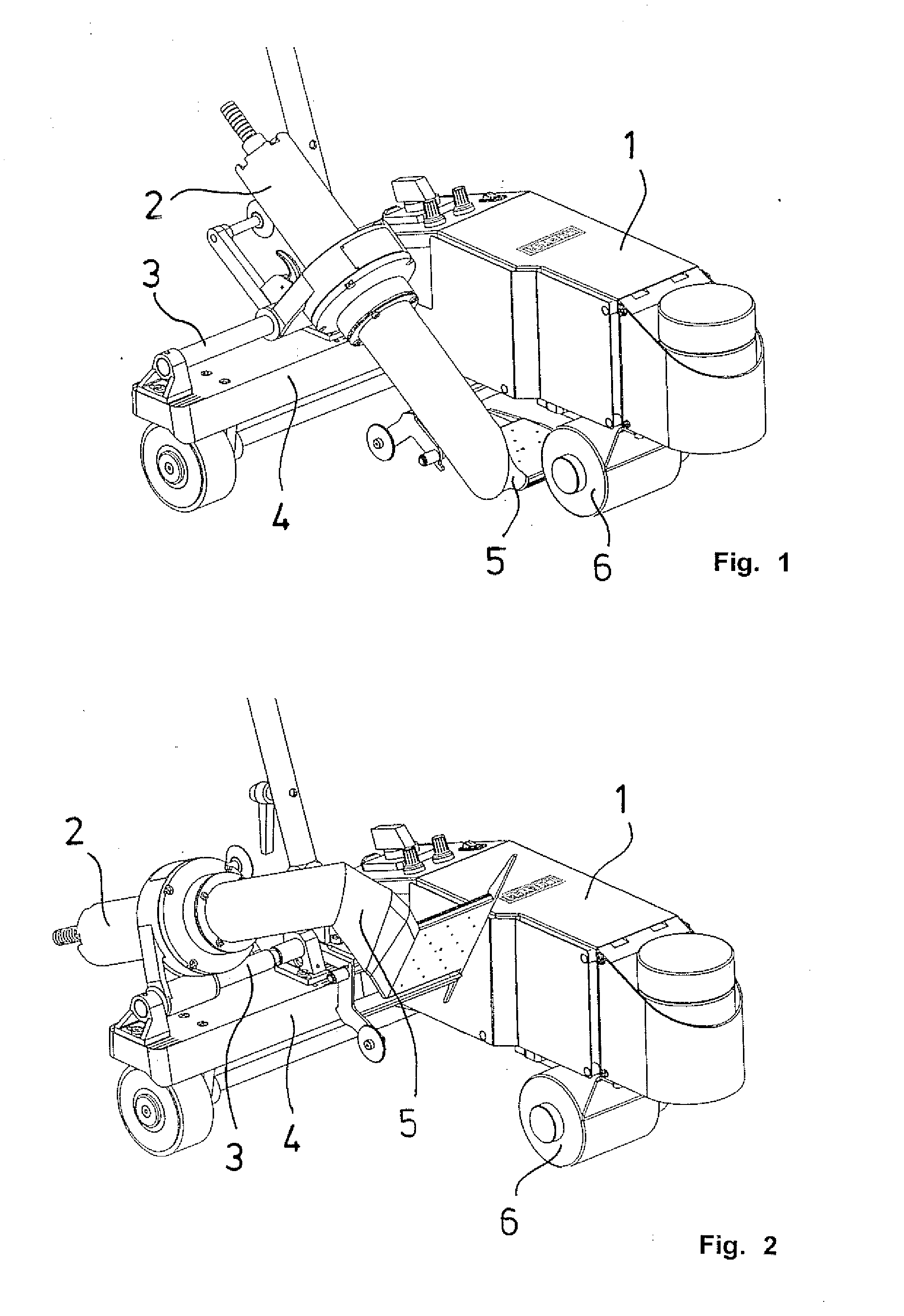

Method and welding machine for welding pipe by using ultra-high molecular weight polyethylene membrane belt through hot melting

The invention provides a method and a welding machine for welding a pipe by using an ultra-high molecular weight polyethylene membrane belt through hot melting. The method comprises the following steps of: (1) grinding the joint of a pipe to be connected or a common pipe to form an inclined surface; (2) aligning the joints of two pipes to each other and then flatly filling a V-shaped groove with a solder wire; (3) enabling the surface of the weld joint and the outer surfaces of the pipes to be in the same plane through an angle grinder; (4) covering the periphery of the pipe by using a welding machine; (5) towing one end of a single-sided membrane welding belt to the pipe weld joint so that the end of the membrane welding belt is held down by a roller; (6) starting a heat gun on the welding machine; and (7) rotating the welding machine so that the welding machine rotates along the peripheral joint of the pipe. The welding machine comprises a support, wherein the membrane welding belt made of ultra-high molecular weight polyethylene is arranged on the support; one end of the membrane welding belt is attached to the weld joint through a special-shaped holder; and the heat gun is fixed at one end of the special-shaped holder. The method provided by the invention is capable of quickly and firmly welding the joint of the ultra-high molecular weight polyethylene membrane pipe with the joint of the common polyethylene pipe.

Owner:SHUNFANG PIPES

Efficient shape welding machine and using method thereof

InactiveCN103008942AQuick welding jobConvenient welding workWelding/cutting auxillary devicesAuxillary welding devicesDrive motorEngineering

The invention relates to an efficient shape welding machine and a using method thereof. The efficient shape welding machine comprises a working platform, wherein a rotary barrel is arranged on the working platform; a magnet of which the section is circular-arc-shaped is arranged in the rotary barrel, so that the outer circumferential wall of a welded part is fixed on the inner side arc face of the magnet; and a support frame for fixing a welding gun is arranged beside the rotary barrel. The method comprises the following steps of: I, adsorbing a welded part onto the inner circumferential wall of the magnet to realize fixing of the welded part; II, covering a separation blade for matching the separation blade with the magnet to sleeve the outer circumferential wall of the welded part; III, adjusting relative positions of a vertical rod, a first slide block and a swing stem to make a circular tube reach a corresponding position and position the welding gun erected on the circular tube at a welding position; and IV, starting the welding gun and a driving motor, wherein the driving motor is used for driving the rotary barrel to rotate for driving the welded part to rotate, and the welding gun is used for welding the welded part at the welding position through the driving motor, so that welding work of bent parts can be finished conveniently and rapidly.

Owner:江苏冠赛达工贸有限公司

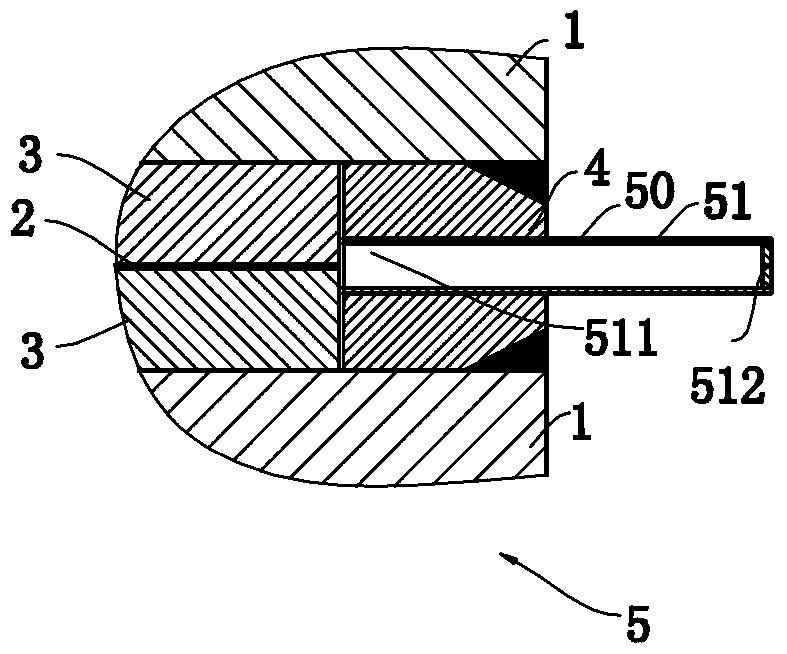

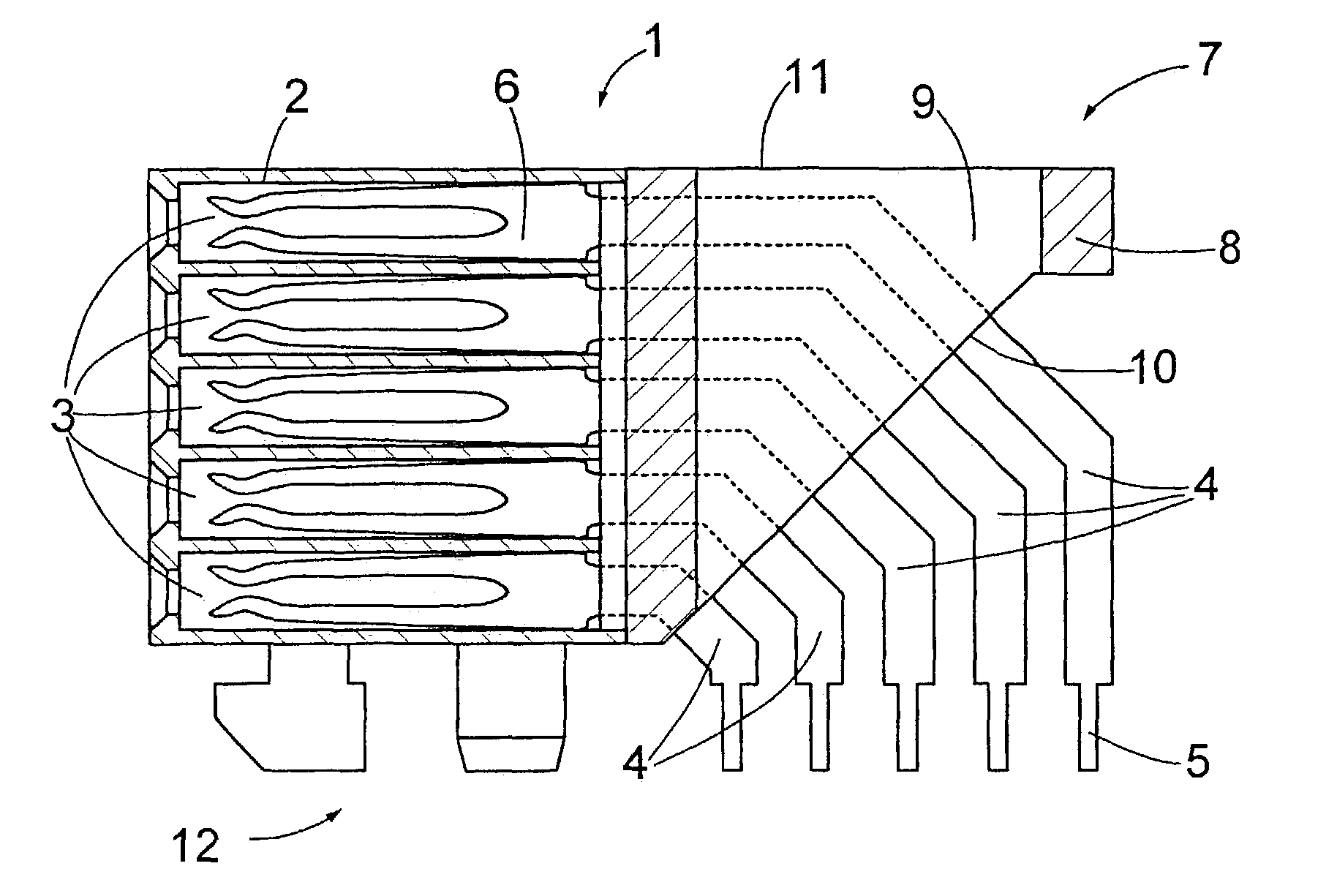

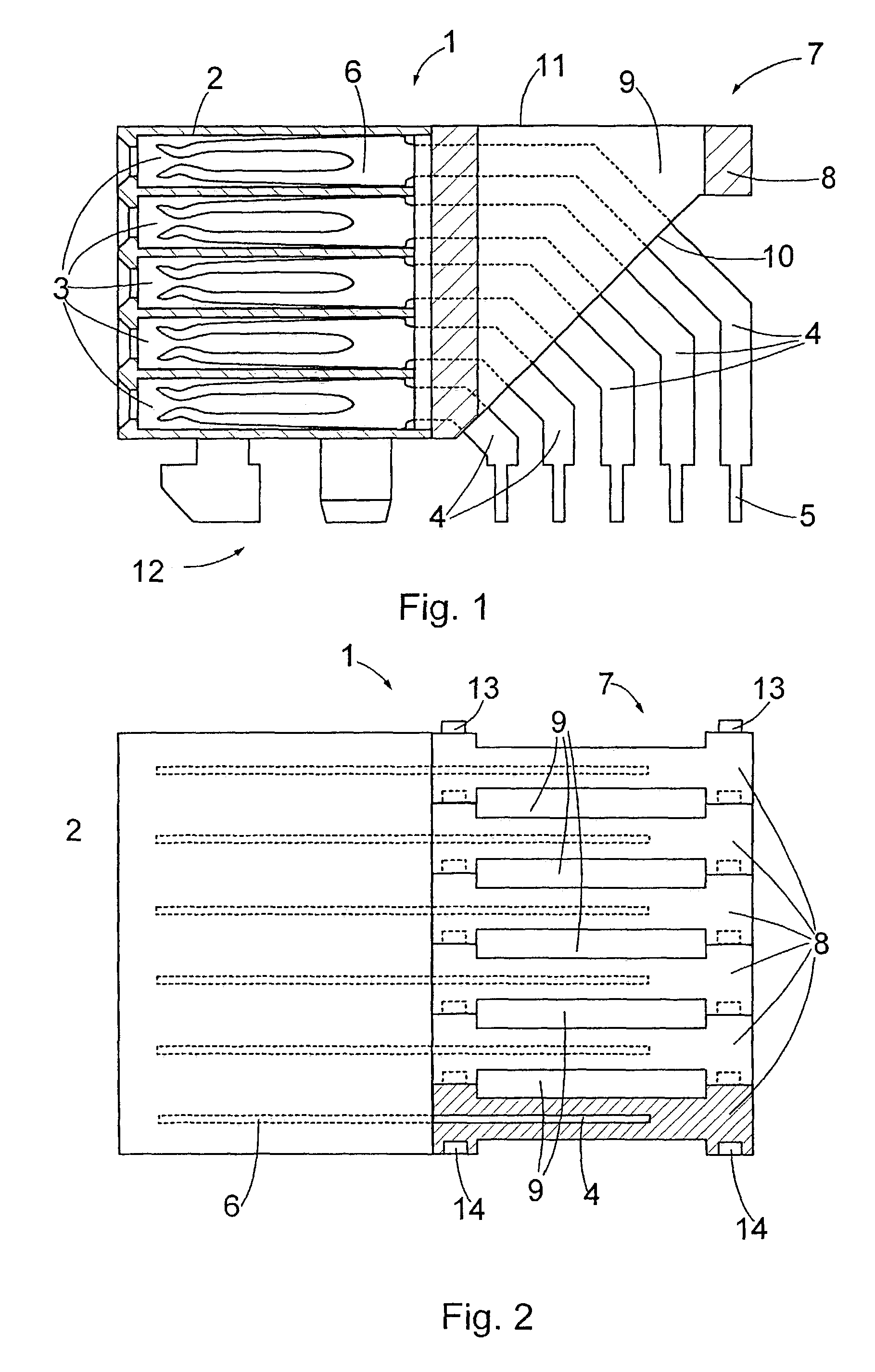

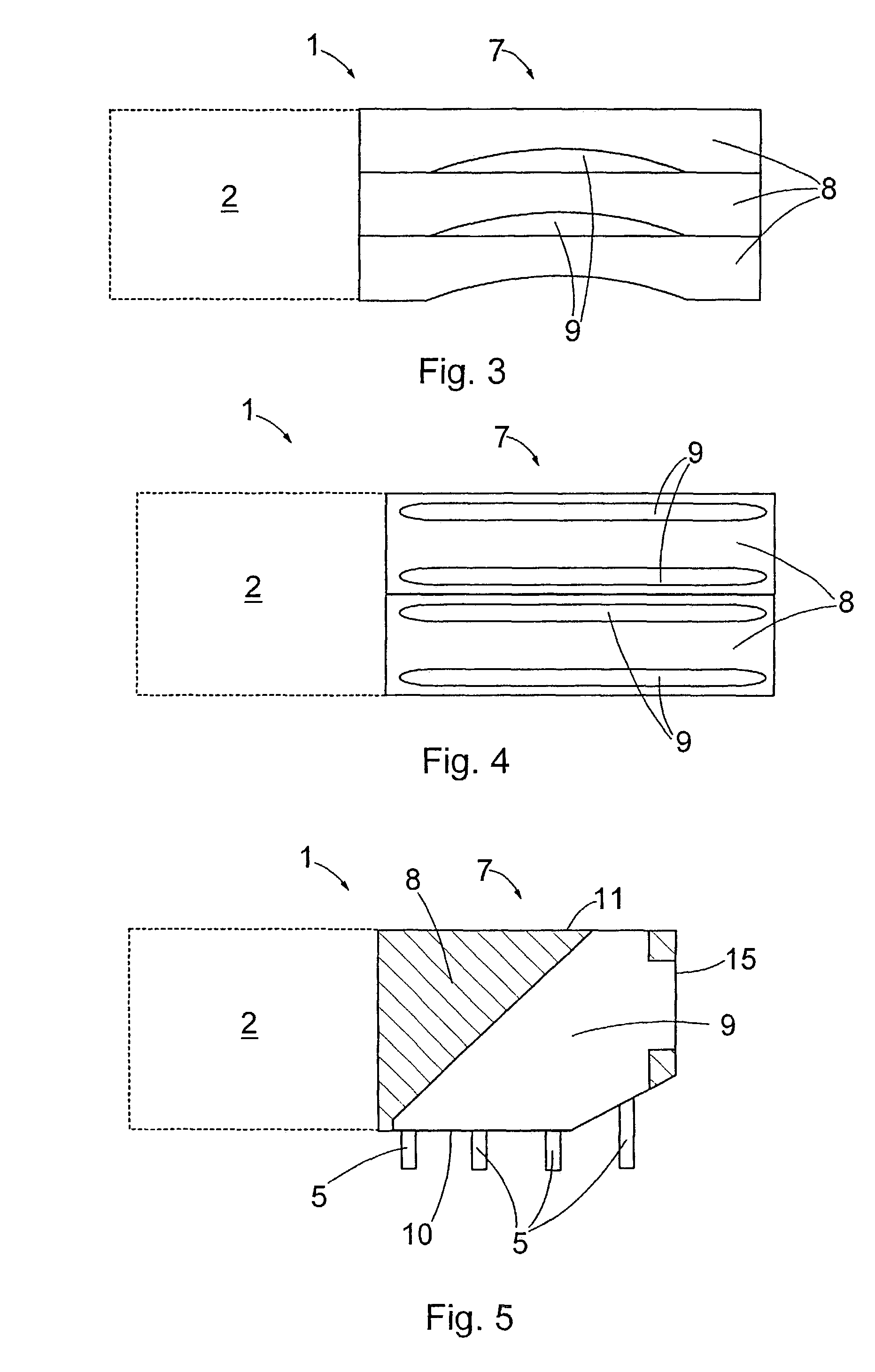

Connector and contact wafer

InactiveUS6997755B2Improve solderabilityReduce componentsPrinted circuit assemblingTwo-part coupling devicesElectrical and Electronics engineeringEngineering

Owner:PERLOS OY

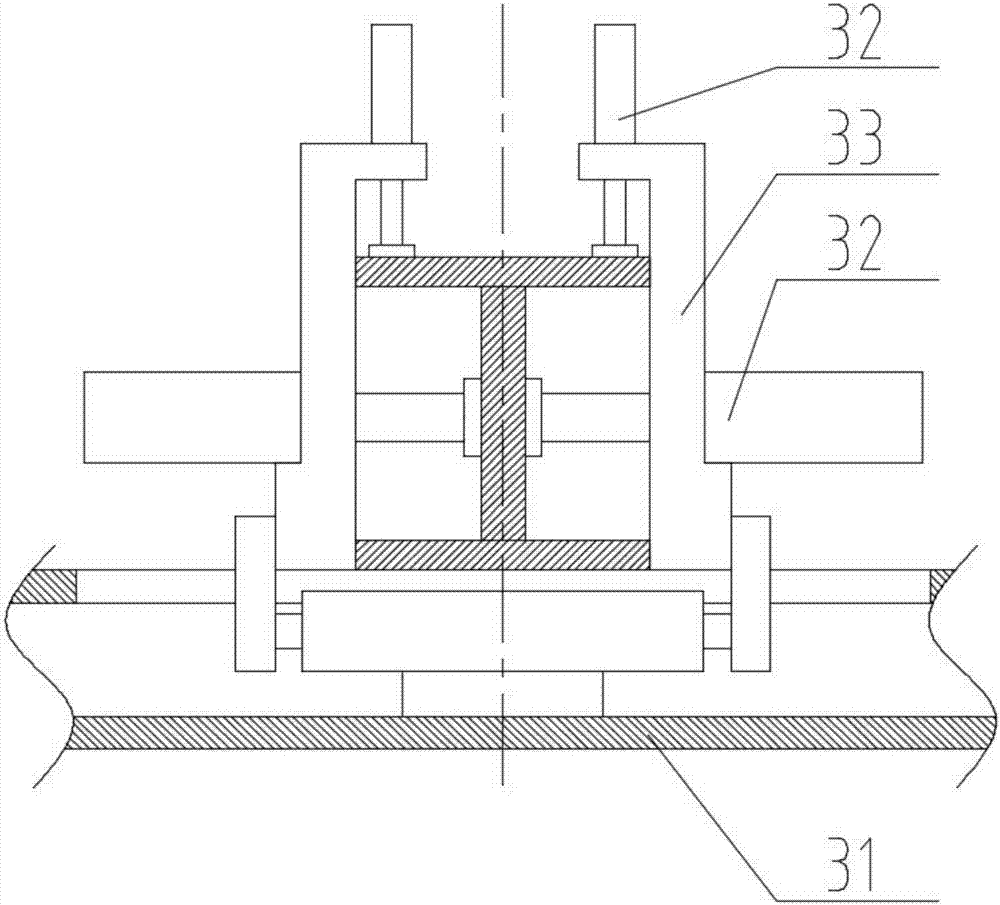

Panel positioning components of trailer frame assembly splicing welding system

ActiveCN107160079AReduce institutional settingsEasy to set upWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngineering

The invention discloses panel positioning components of a trailer frame assembly splicing welding system. The number of the panel positioning components is multiple, and the multiple panel positioning components are arranged on the upper surface of a workpiece supporting plate (31), and the panel positioning components comprise compression devices (32) and positioning devices (33); each compression device comprises a supporting base fixedly installed on the workpiece supporting plate, a stretchable control mechanism installed on the supporting base and a pressing head installed on the stretchable control mechanism, the compression directions of each compression device at least comprise the horizontal direction and the vertical direction, the compression devices are symmetrically arranged with respect to a positioned panel, and the pressing heads are oppositely arranged; and each positioning device comprises a large beam positioning mechanism, a transverse beam positioning mechanism and an edge beam positioning mechanism. By means of the panel positioning components of the trailer frame assembly splicing welding system, overall and quick splicing and welding of a trailer can be achieved, and the splicing and welding efficiency is high.

Owner:江苏富华交通运输设备股份有限公司

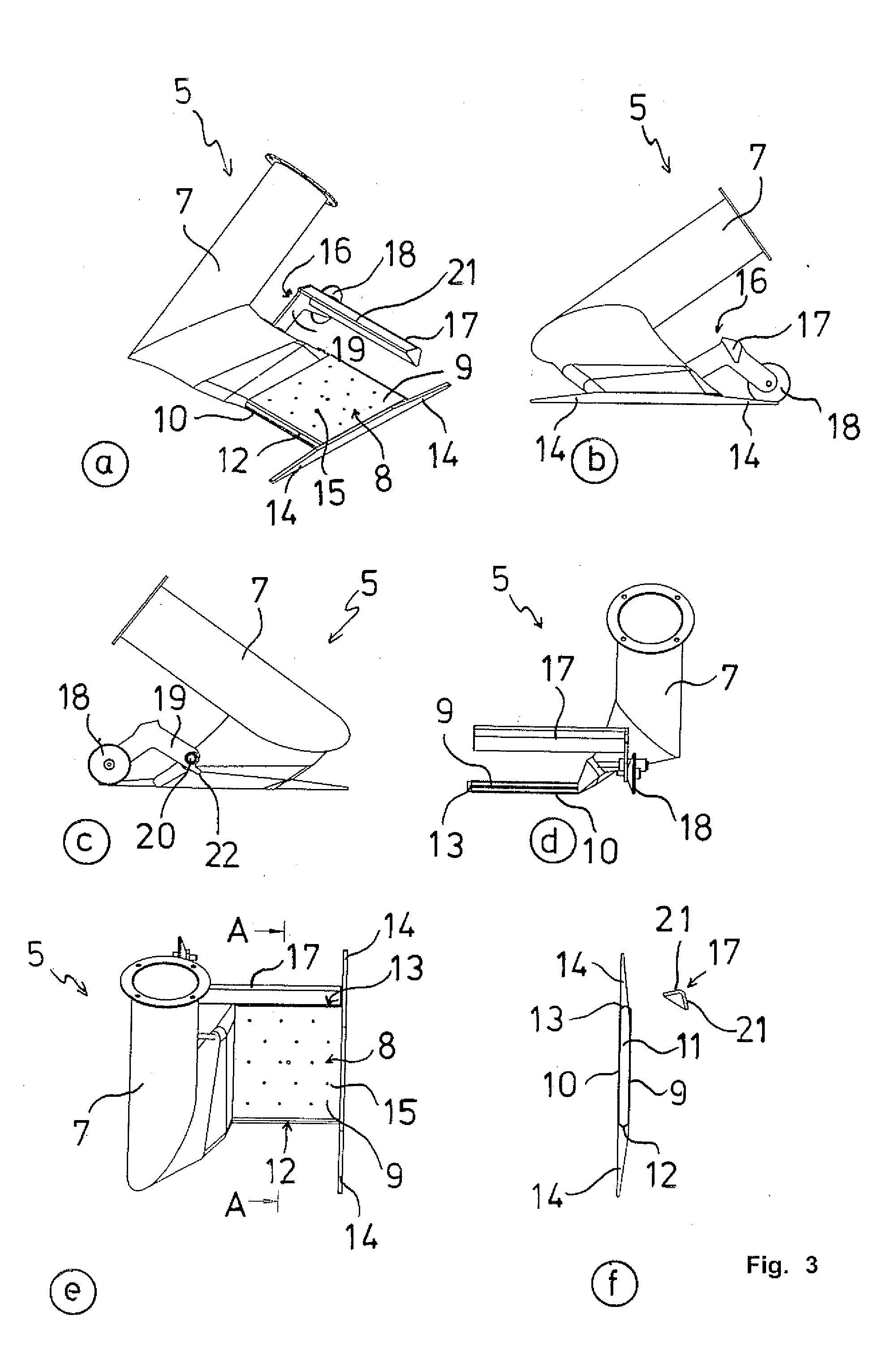

Hot air nozzle

A hot air welding nozzle for a hot air welding device for welding overlapping webs of sealing material, in particular webs of bitumen. The hot air welding nozzle includes a connection for a hot air supply, a top and a bottom heat plate forming an air space, and at least one rear outlet between the top and bottom heat plate on a facing side that is oriented in a direction opposite to the moving direction of the hot air welding device, with at least one front outlet relative to the moving direction of the hot air welding device, and with air guides that extend beyond the facing sides of the heat plates, at least on the inner side, i.e. the side facing away from the connection for a hot air supply. With the hot air welding nozzle designed as proposed by the invention, and / or a hot air welding device of appropriate design, it is now possible to weld webs of sealing material, in particular webs of sealing material made of bitumen, considerably faster due to the long pre-heating zone.

Owner:LEISTER TECHNOLOGIES

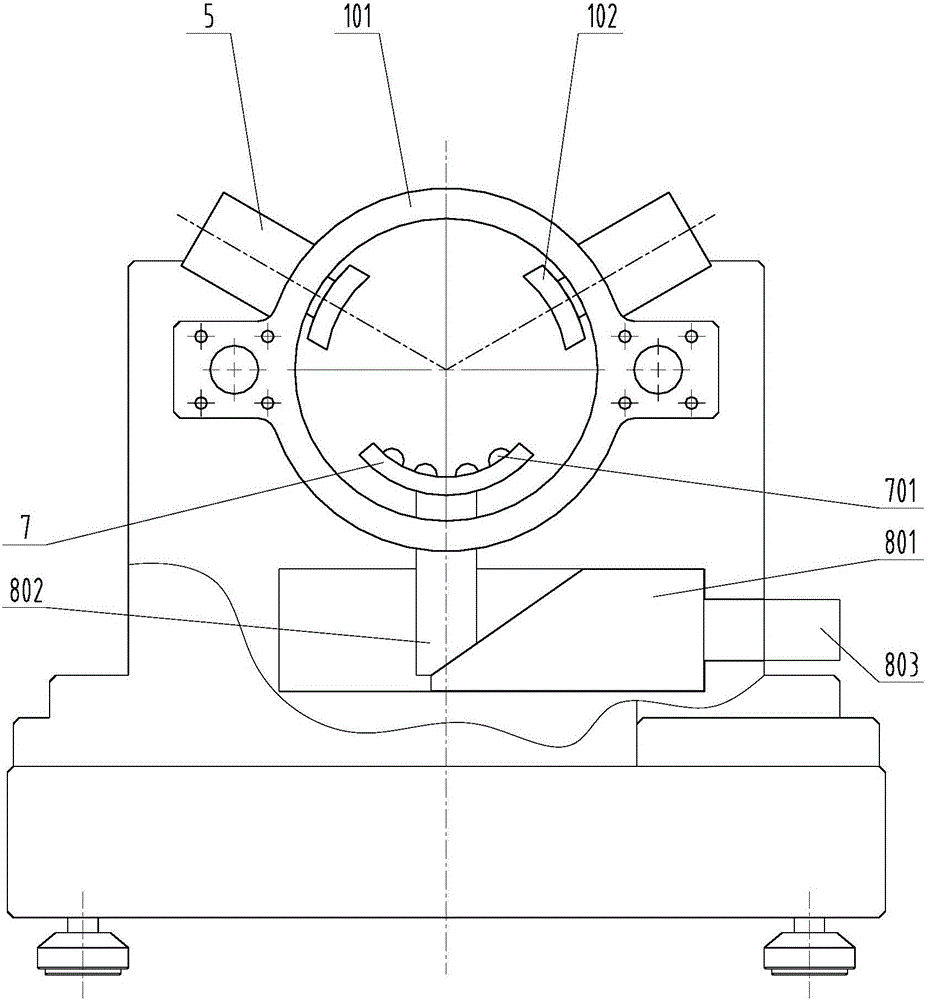

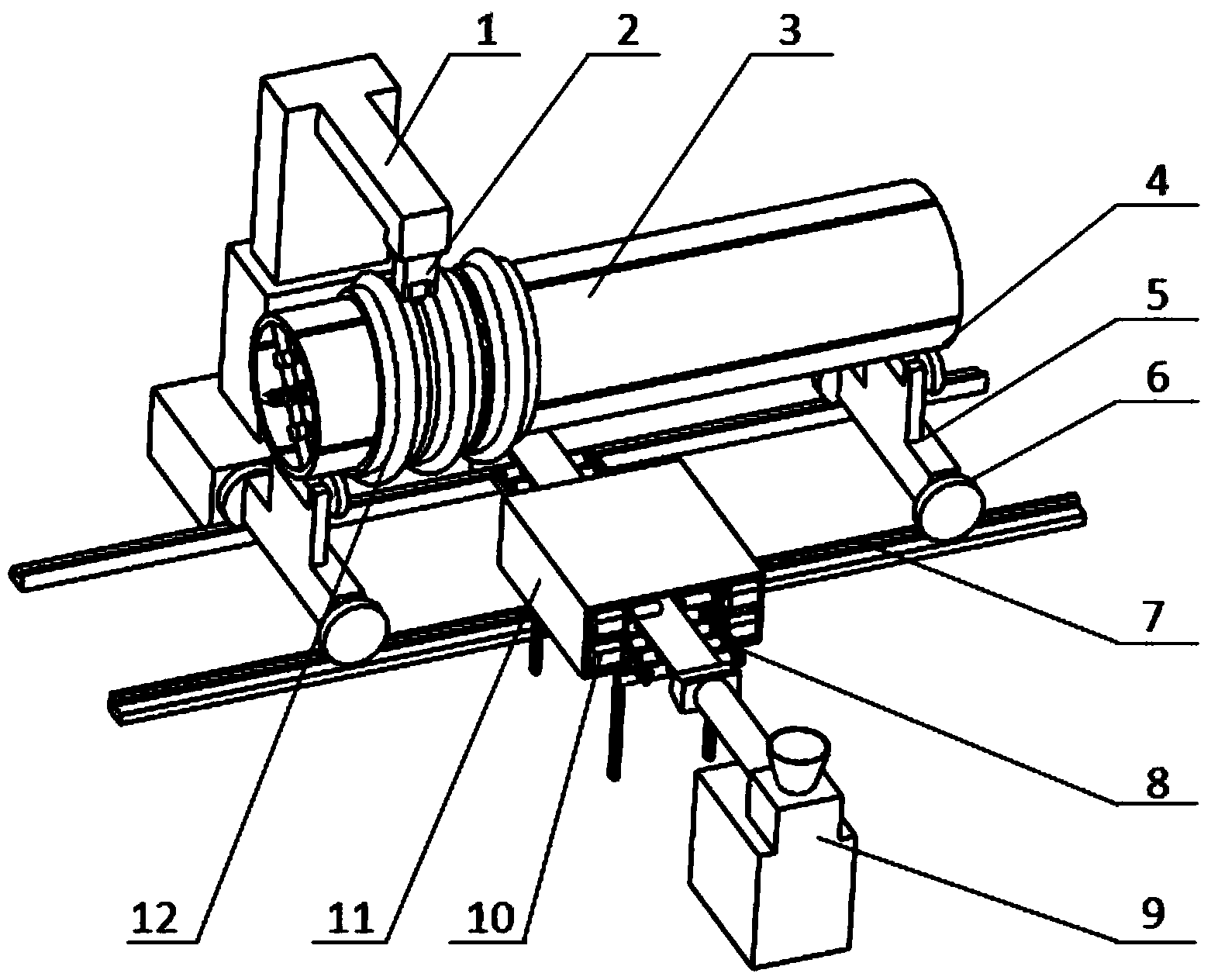

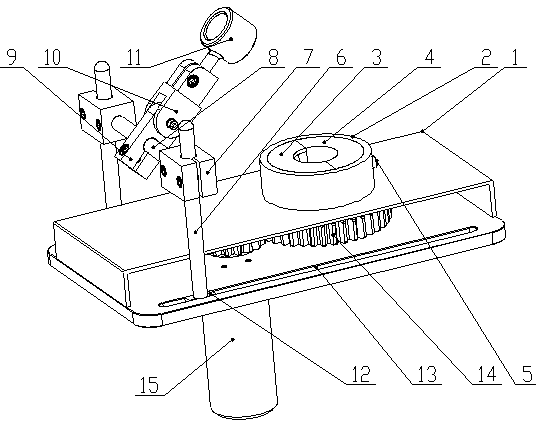

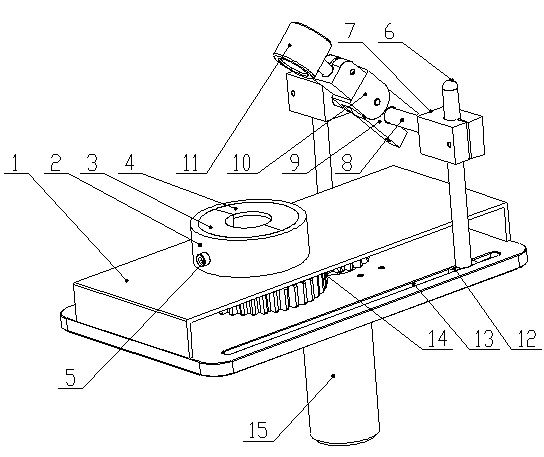

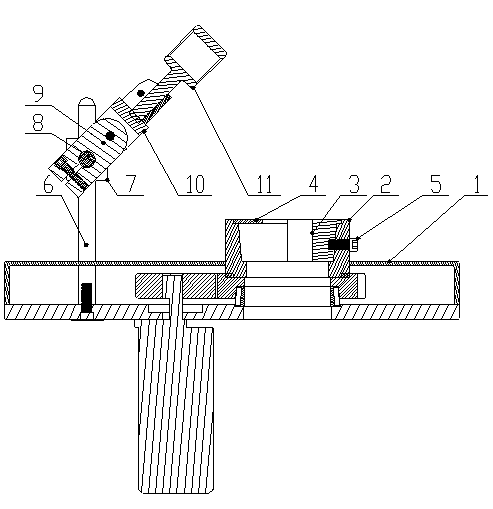

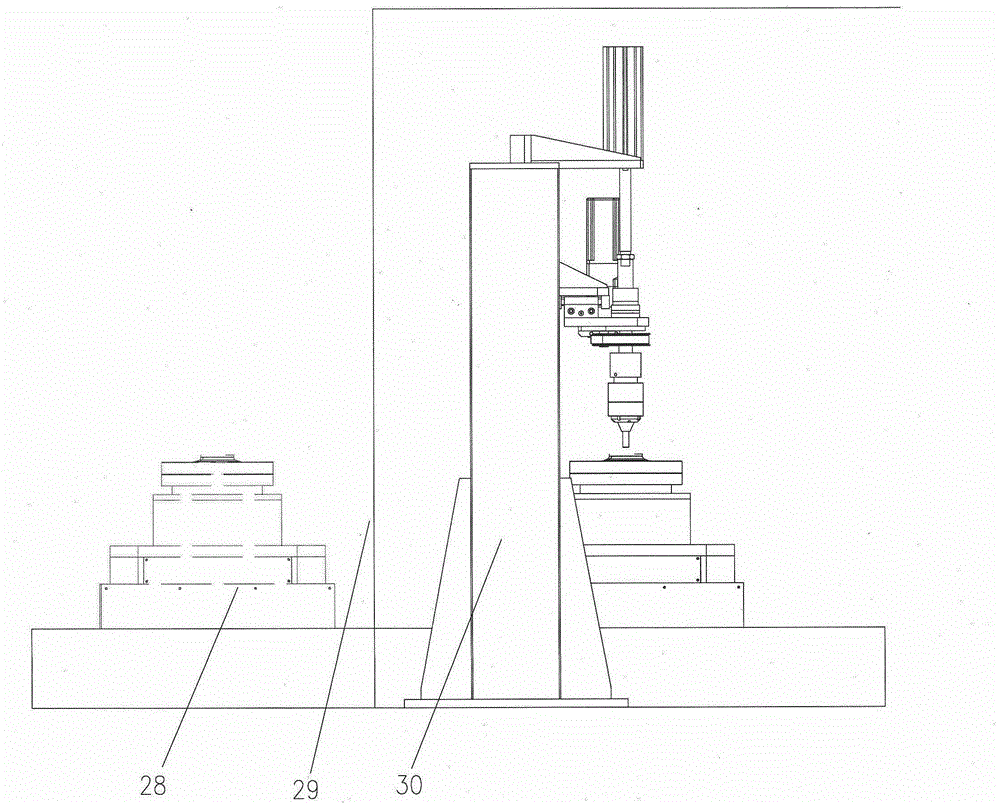

Welding clamp of water pump impeller

ActiveCN106312338AEasy and fast clampingPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesNumerical controlImpeller

The invention relates to a welding clamp of a water pump impeller. The welding clamp comprises a rotating base, a mold seat, a pressing and rotating device, a friction transmission pair, a portal frame, a discharging device and a one-dimensional numerical control workbench. The mold seat is mounted on the rotating base and is coaxial with the rotating base, and the rotating base is mounted on the one-dimensional numerical control workbench. The pressing and rotating device is mounted on the portal frame. One end of the friction transmission pair is mounted on the pressing and rotating device, and the other end of the friction transmission pair is mounted on the mold seat. The discharging device is mounted on the lower portion of the rotating base. The portal frame is mounted above the rotating base in a stretching-over manner. It can be guaranteed that a rotating shaft of the pressing and rotating device and the rotating base are coaxial by adjusting the portal frame and the pressing and rotating device. Compared with a traditional welding device, the welding clamp is simple and fast in clamping and accurate in locating; through combination with the modern laser welding process, fast welding can be achieved; the welding quality is reliable; the zero rejection rate is achieved; the production efficiency is high; and the labor intensity is low.

Owner:WUHAN CHUTIAN IND LASER EQUIP

Numerical control flange assembly special welding machine

ActiveCN104476061ABest soldering positionGuaranteed straightnessWelding/cutting auxillary devicesElectrode holder supportersNumerical controlBall screw

The invention discloses a numerical control flange assembly special welding machine. The numerical control flange assembly special welding machine comprises a base, a machine case, a self-aligning chuck, a Z-axis servo motor, a Z-axis reducer, a numerical control operating machine, an X-axis ball screw, an X-axis linear guide rail, an X-axis servo motor, a Y-axis servo motor, a Y-axis ball screw, a Y-axis linear guide rail, a welding gun, a welding unit, a welding wire, a protective gas cylinder, an oscillator and a universal bracket. Compared with the prior art, the numerical control flange assembly special welding machine has the advantages that the numerical control operating machine simultaneously controls the X-axis servo motor, the Y-axis servo motor and the Z-axis servo motor to achieve three-axis linkage, and the three-axis linkage and the universal bracket can bidirectionally adjust the optimal butt jointing positions of the welding gun, the flange of a steel pipe pole and the welding joints of rib plates.

Owner:ANHUI JIXI JIADE STEEL STRUCTURE

Low-temperature quick welding method for zirconia or zirconia-based composite materials

InactiveCN105364284AFast solderingWelding/soldering/cutting articlesResistance welding apparatusElectric fieldMaterials science

The invention relates to a low-temperature quick welding method for zirconia or zirconia-based composite materials. According to the facts that zirconia or zirconia-based composite materials can perform mass transfer through spreading, and then diffusion bonding between the materials is formed, quick mass transfer can be achieved in the zirconia or zirconia-based composite materials when the density of current passing the materials is larger than a critical value. The critical electric field assisting method is adopted, and quick welding between zirconia materials or between zirconia and zirconia-based composite materials or between the zirconia-based composite materials is achieved by applying preset pressure at the temperature of 500-1200 DEG C and with the density larger than the critical current density.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

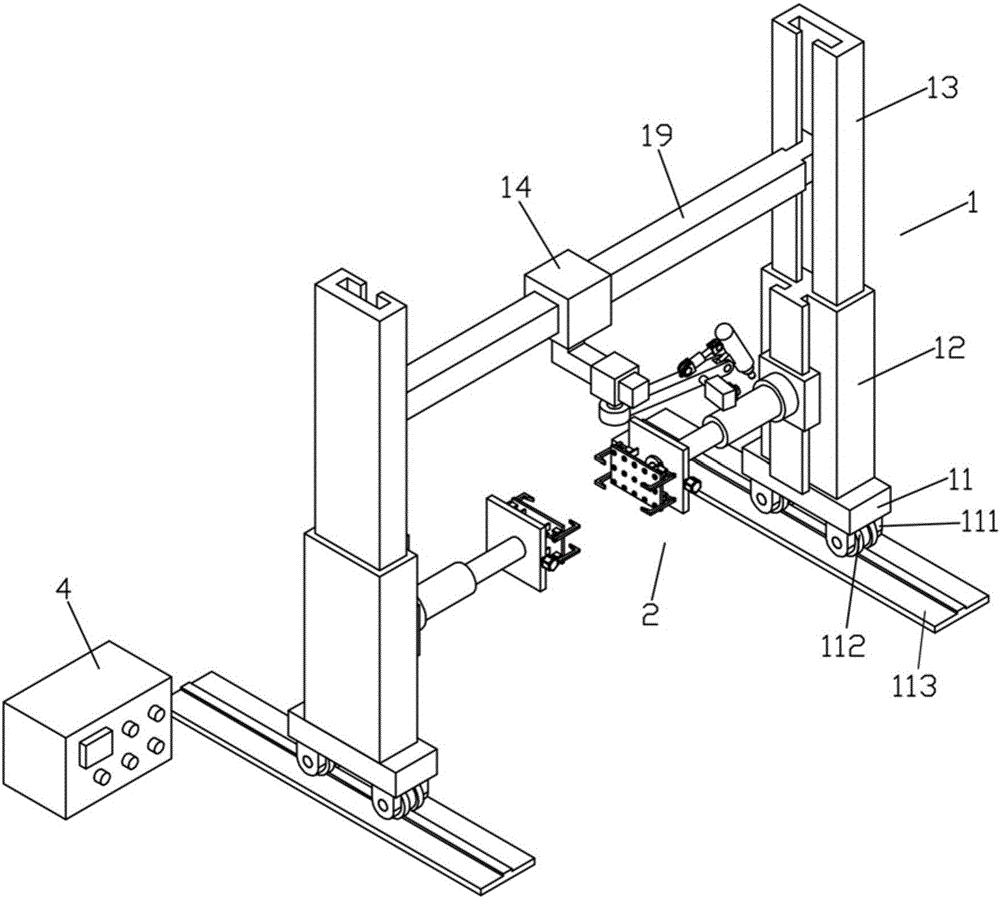

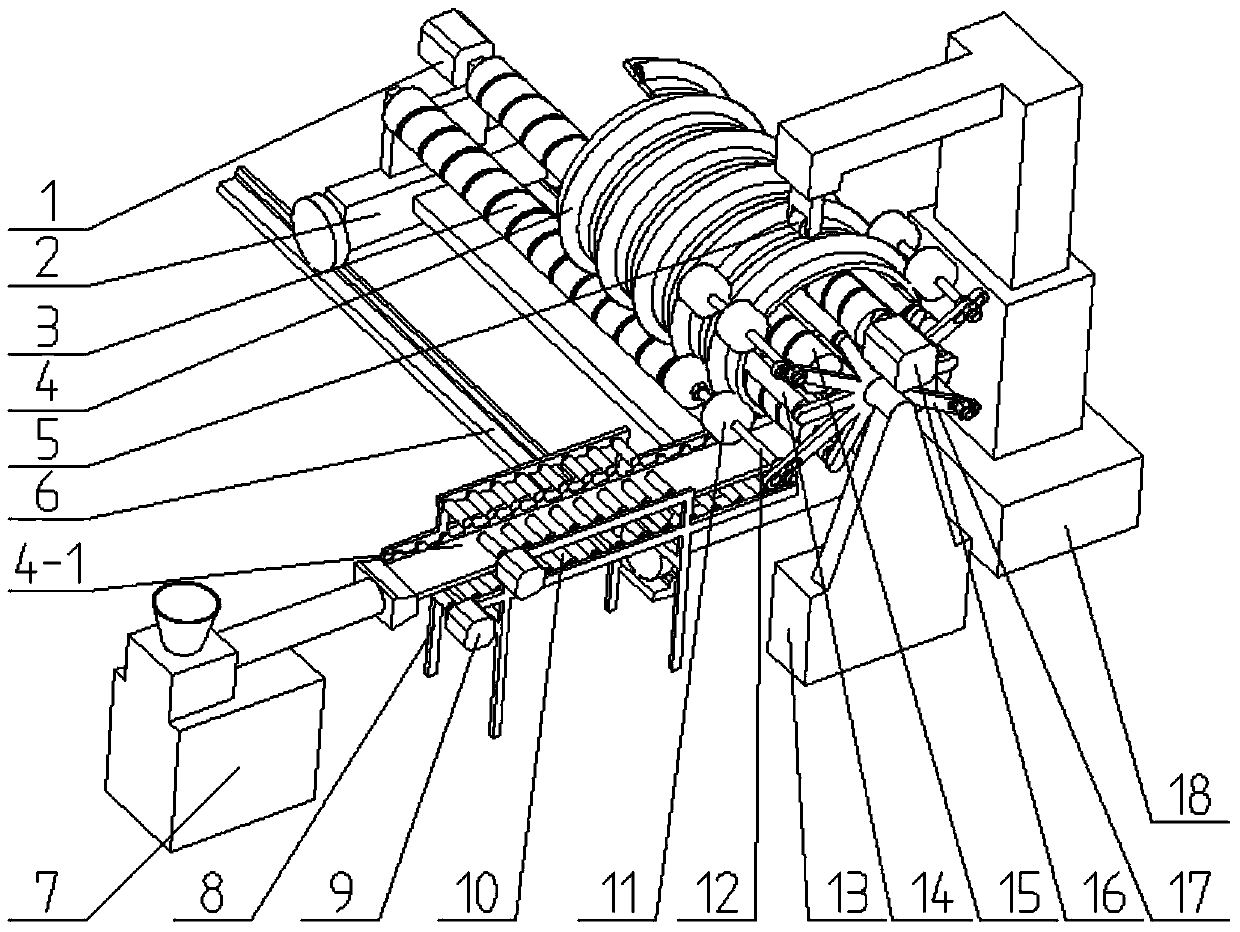

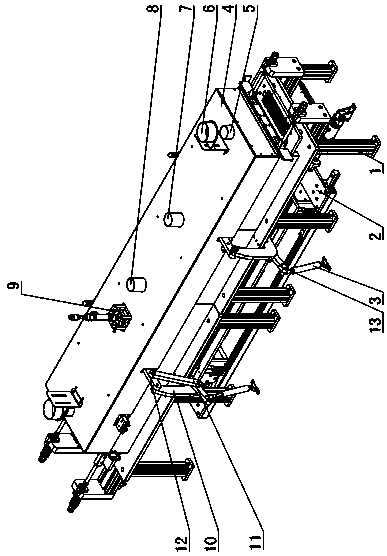

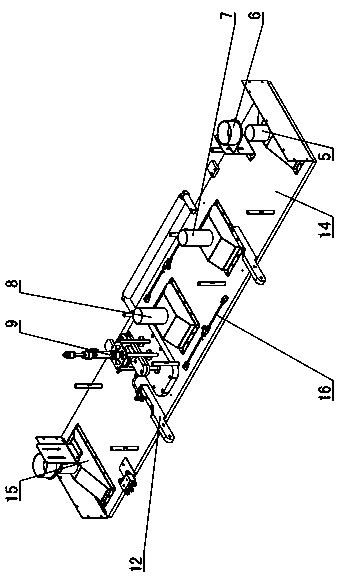

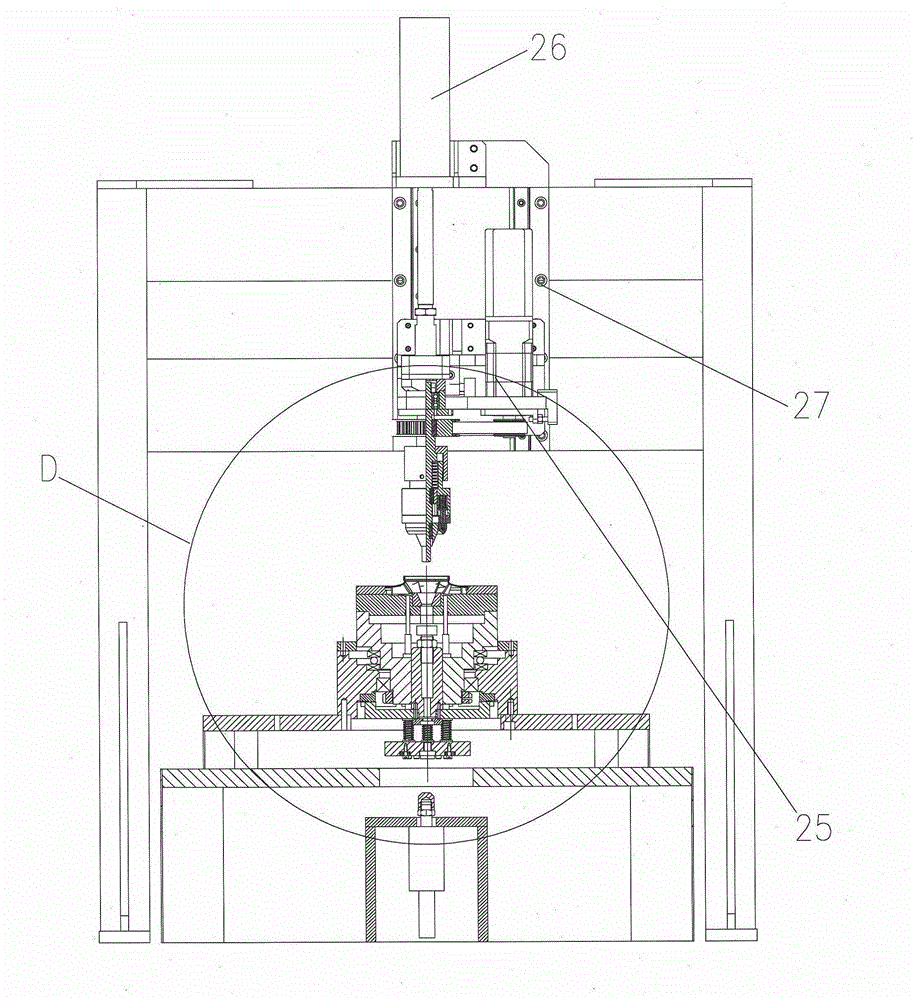

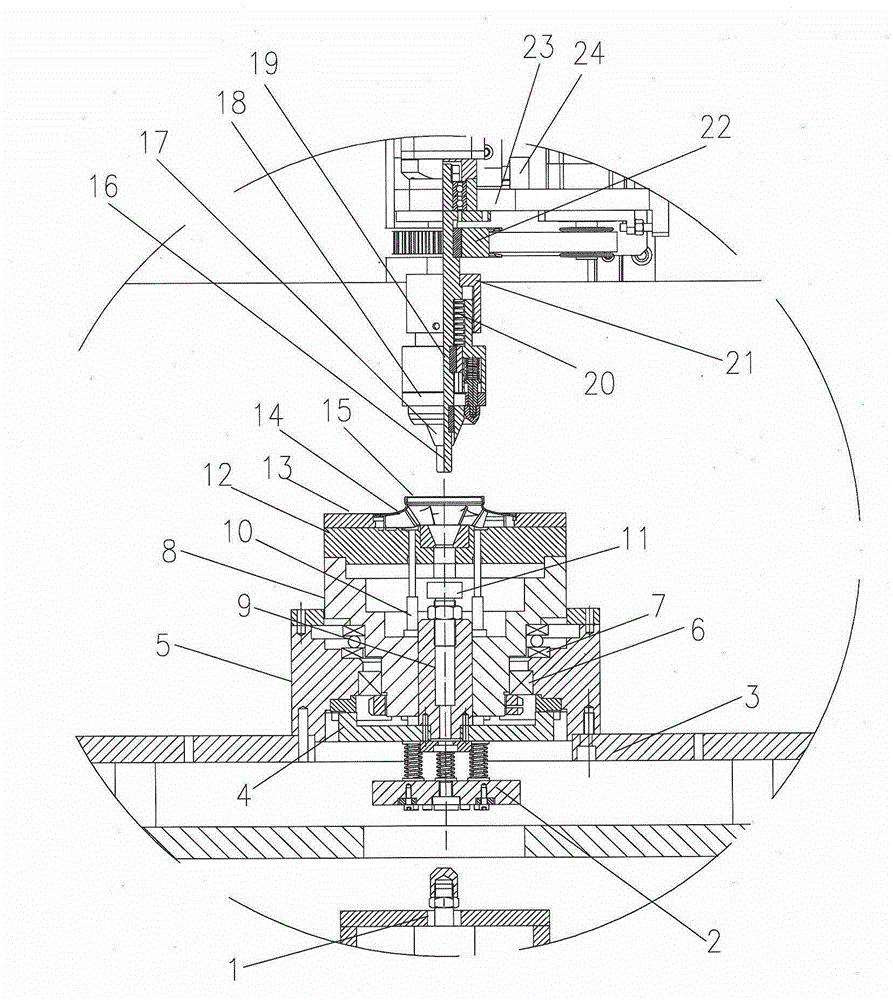

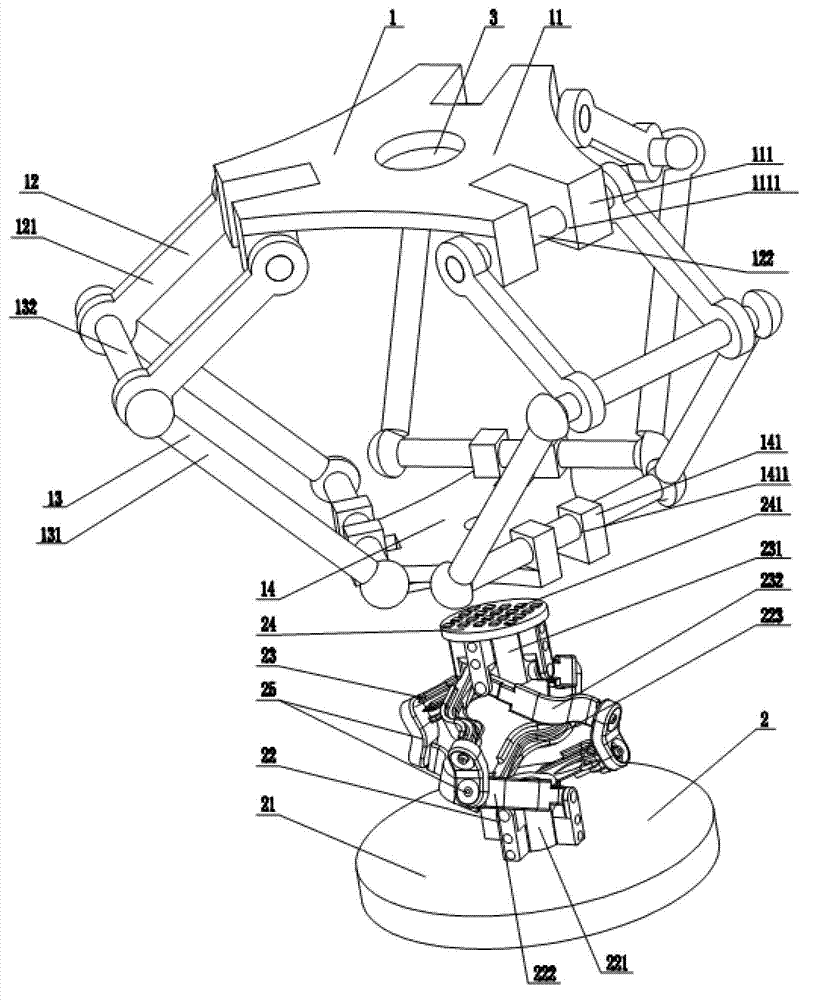

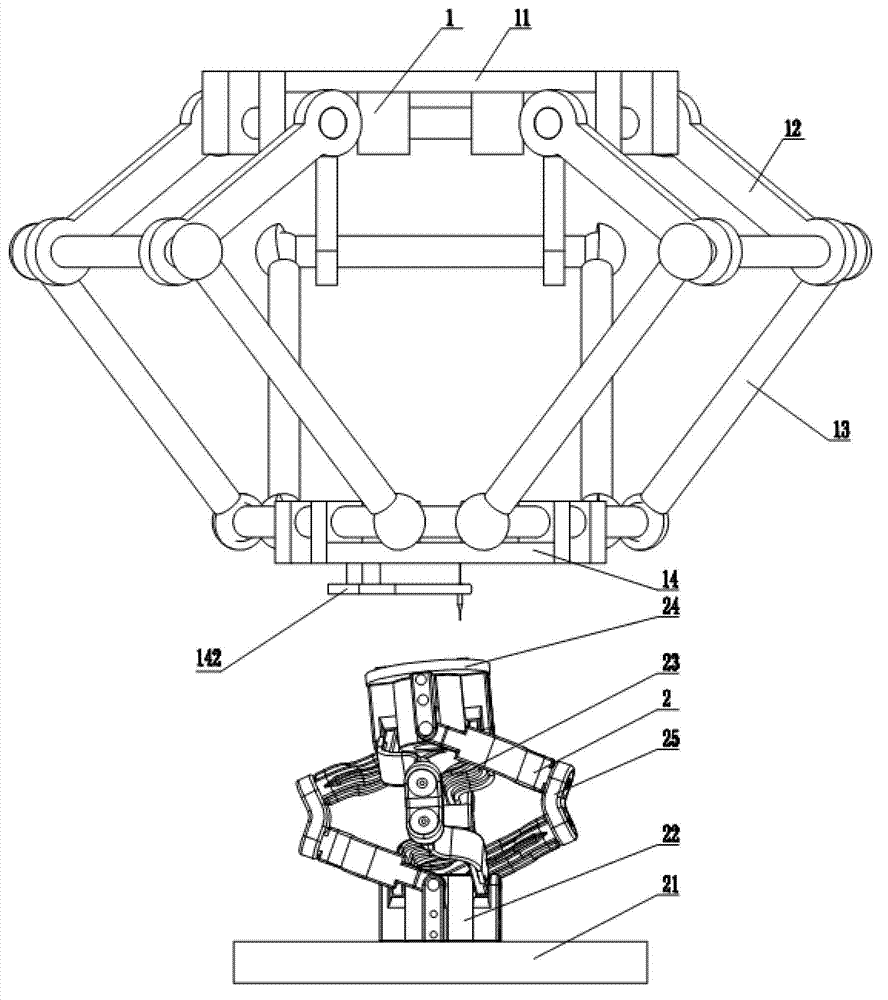

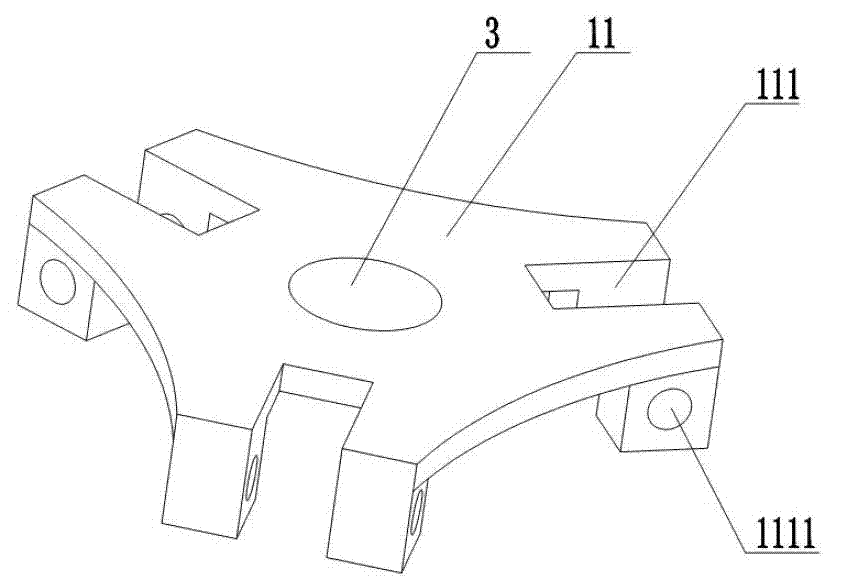

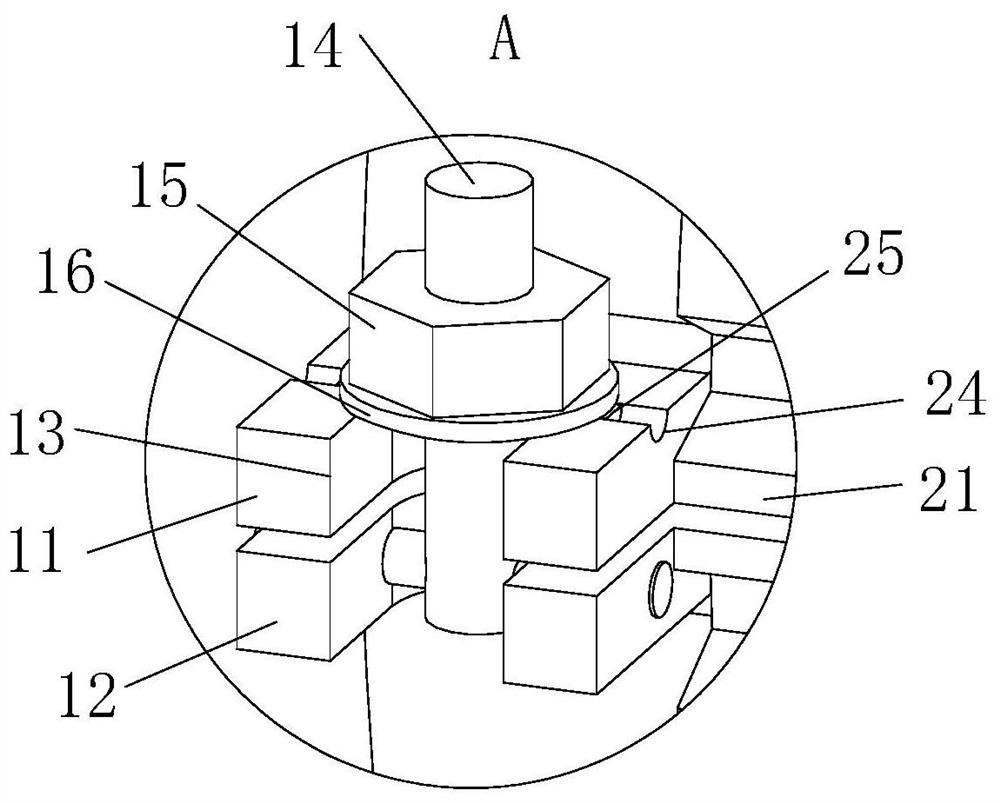

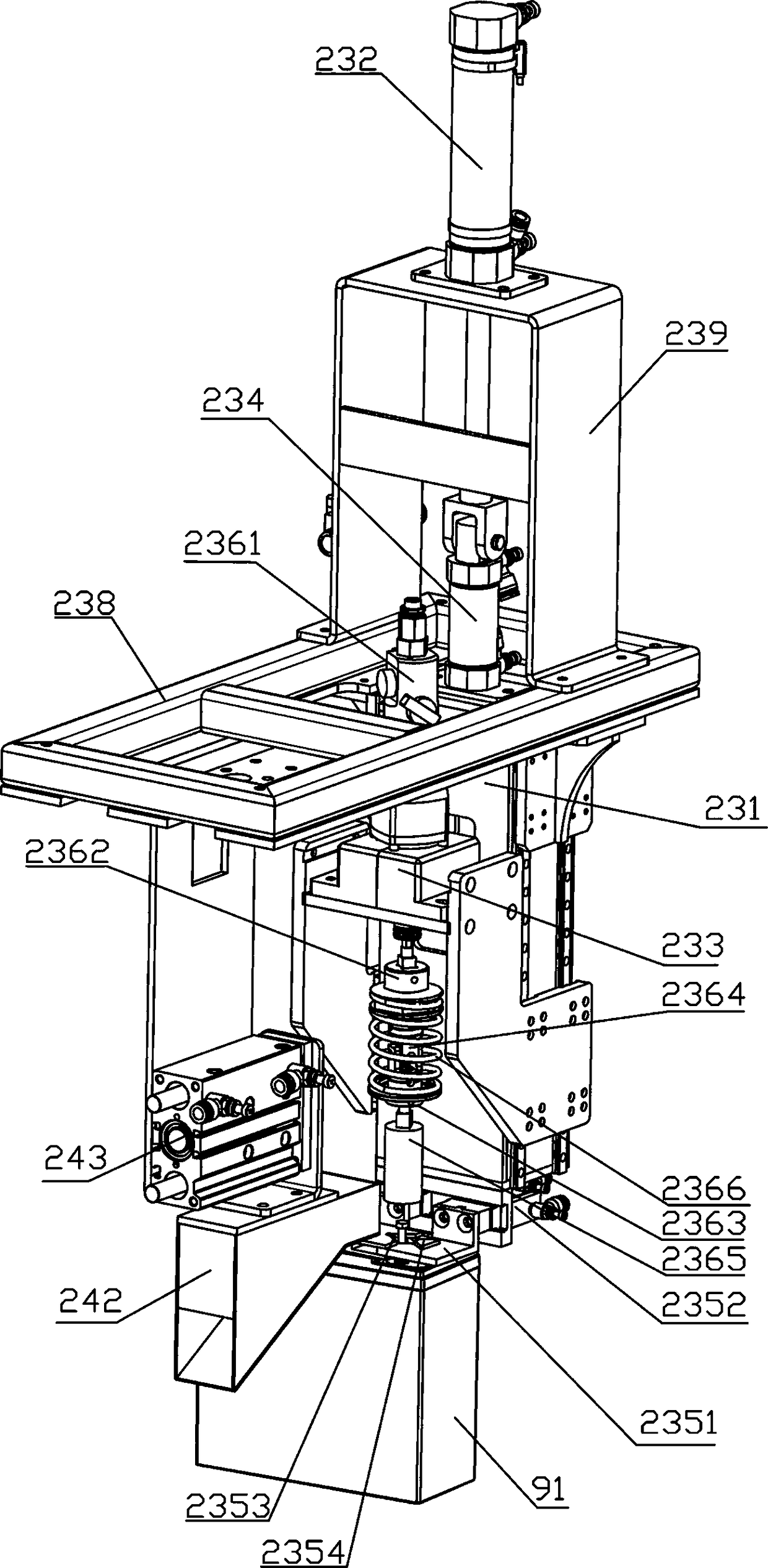

Macro-micro compound five free degree light-emitting diode (LED) bonding machine actuating mechanism

InactiveCN103085061AFast solderingGuaranteed verticalityProgramme-controlled manipulatorNon-electric welding apparatusHigh accelerationEngineering

The invention provides a macro-micro compound five free degree light-emitting diode (LED) bonding machine actuating mechanism which comprises a welding head mechanism and an operating platform mechanism which is connected with the welding head mechanism. The operating platform comprises a lower baseplate, a first component which is connected with the lower baseplate, a second component which is connected with the first component and a material platform which is connected with the second component. The first component and the second component are connected through a double revolute pair. The first component comprises a lower base, first driving arms and first driven arms. The first driving arms and the first driven arms are arranged on the outer side of the lower base. The second component comprises an upper base and a connecting rod which is arranged on the outer side of the upper base. The first driving arms and the first driven arms are connected respectively through the double revolute pair and the connecting rod. On one hand, the welding head mechanism can achieve moving with high speed and high acceleration and meets accuracy requirements, and on the other hand, a micro transmission mechanism can ensure perpendicularity between a chopper and a welding plane, and therefore motion control and force control of a welding mechanism of the whole bonding machine is enabled to be more stable, and the welding quality is better.

Owner:GUANGDONG UNIV OF TECH

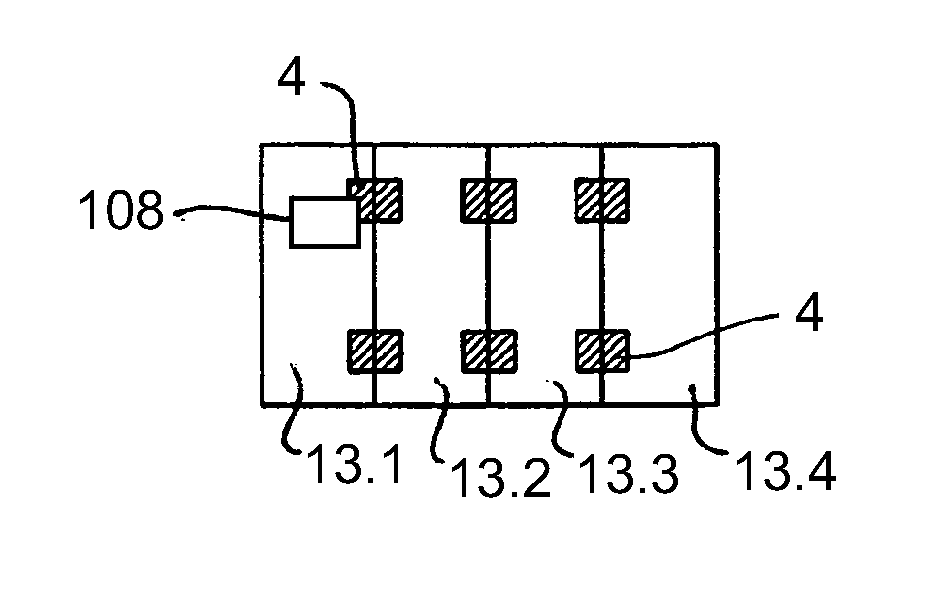

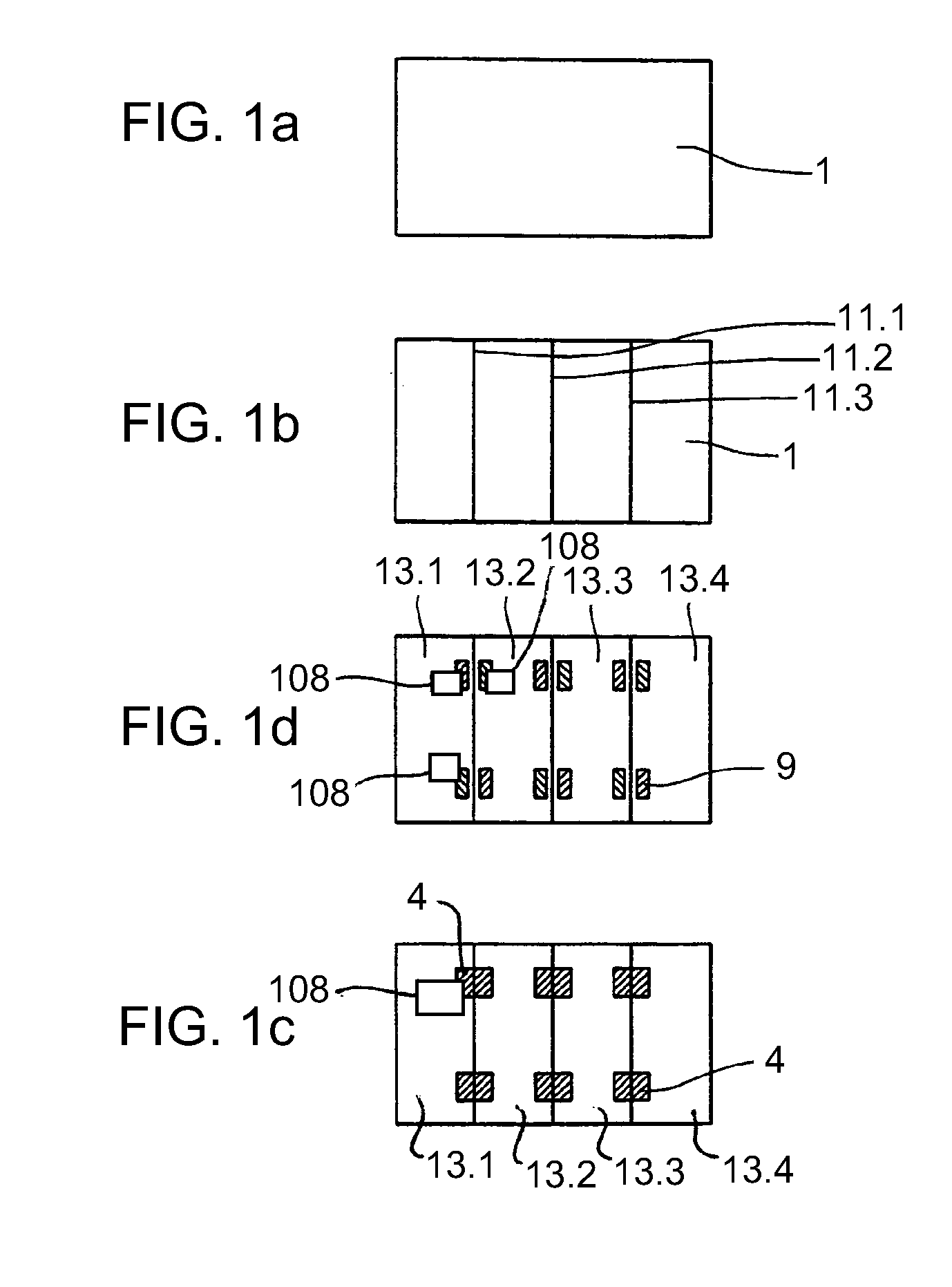

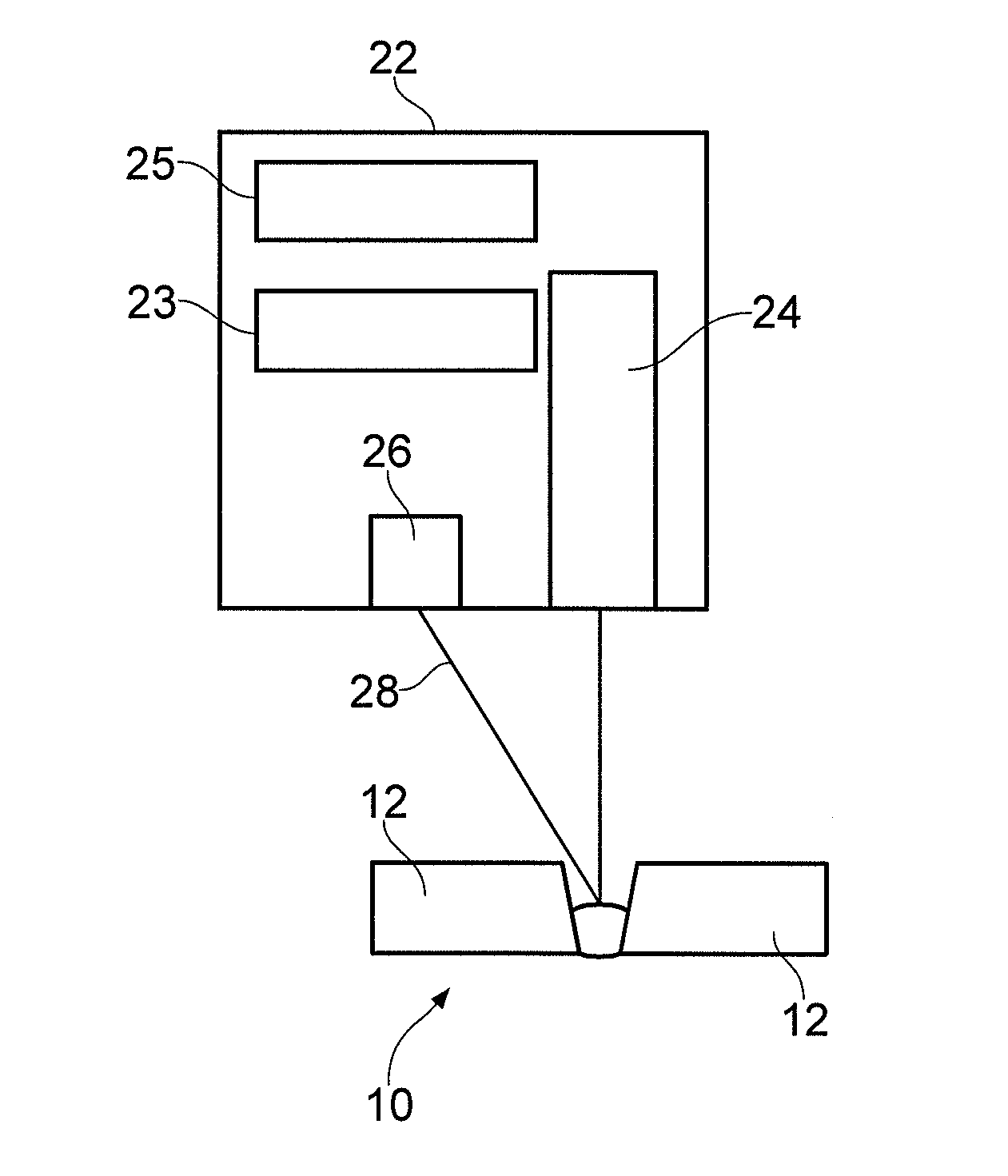

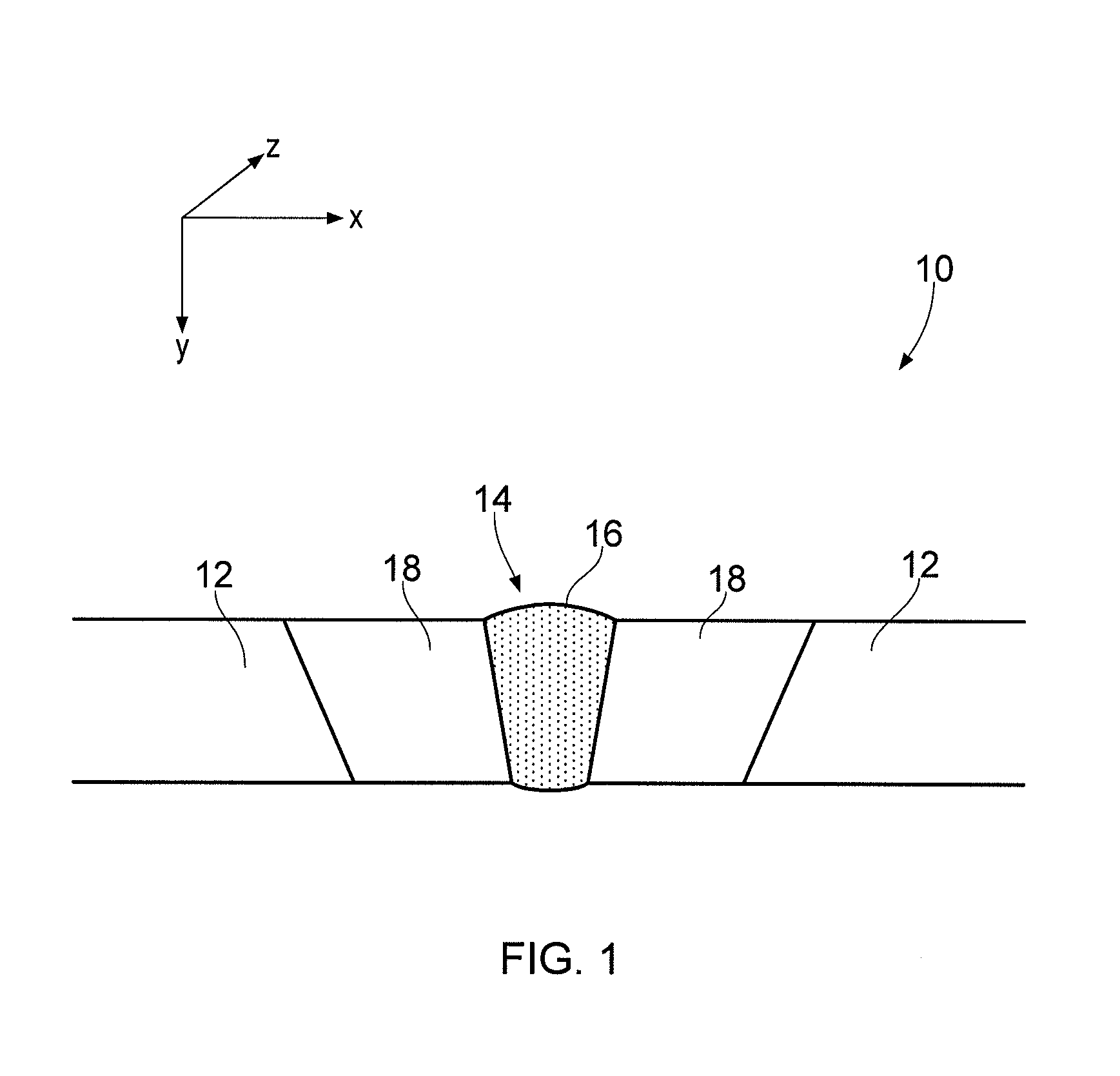

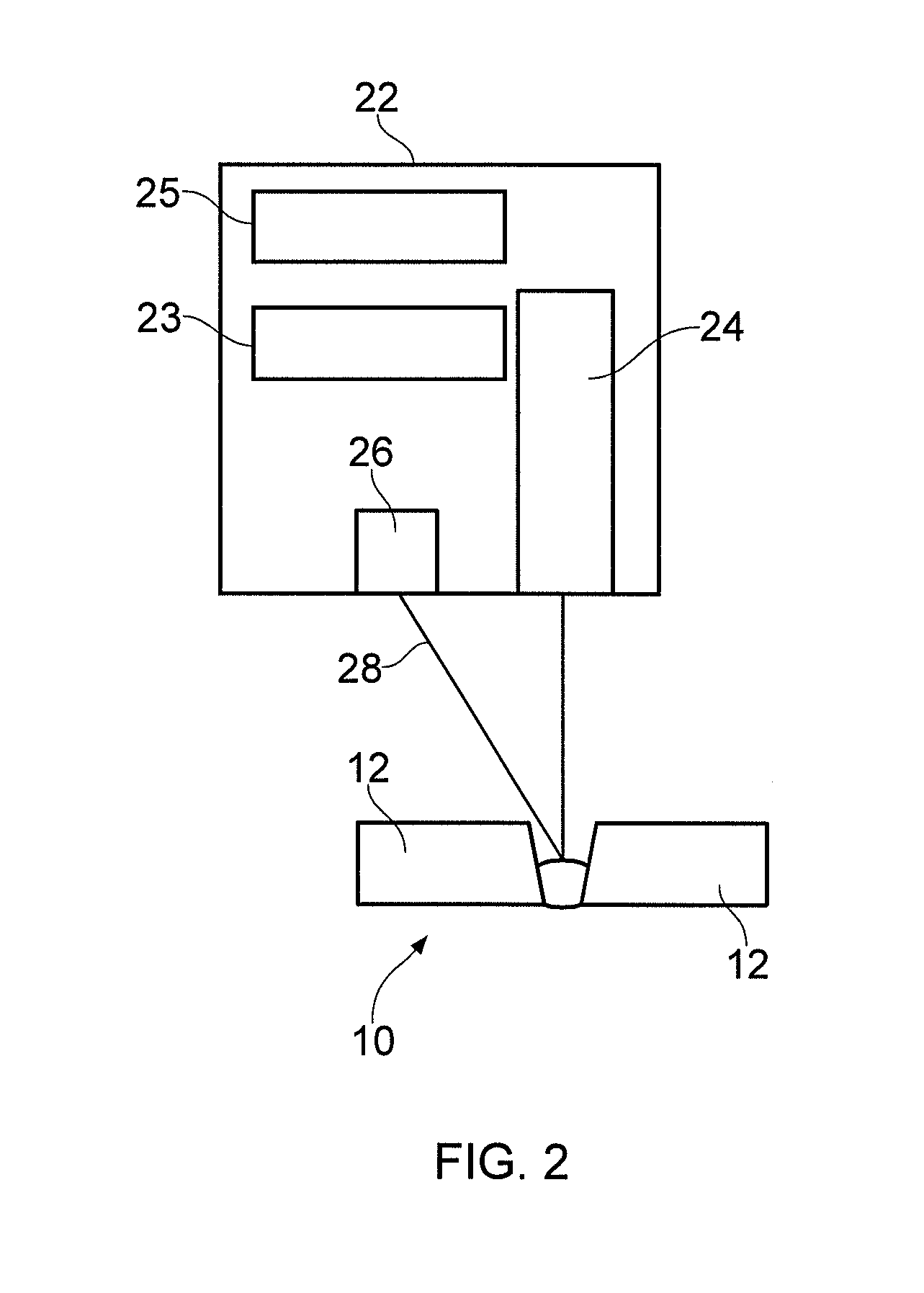

Method for conductively connecting a component on a transparent substrate

InactiveUS20120266461A1Great mechanical strengthShorter solder timePrinted circuit assemblingLight absorption dielectricsSupply energySoldering

The invention relates to a method to conductively connect an electrical component with at least one conductive layer, whereby the conductive layer is applied to a substrate which is essentially transparent in the visible wavelength zone of light, comprising the following steps: the electrical component or the conductive layer is provided with a soldering material in the area where the component is to be connected to the conductive layer; the soldering material is provided with energy supplied by an energy source, such that the soldering material melts and a non-detachable, material-bonded conductive connection between the electrical component and the conductive layer is established.

Owner:SCHOTT AG

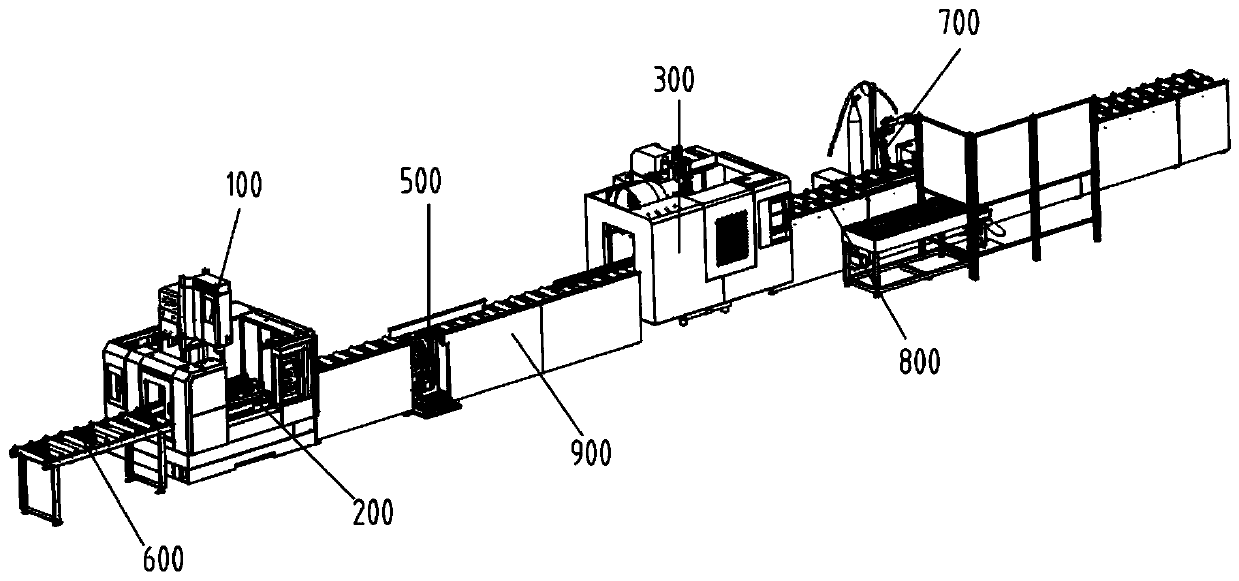

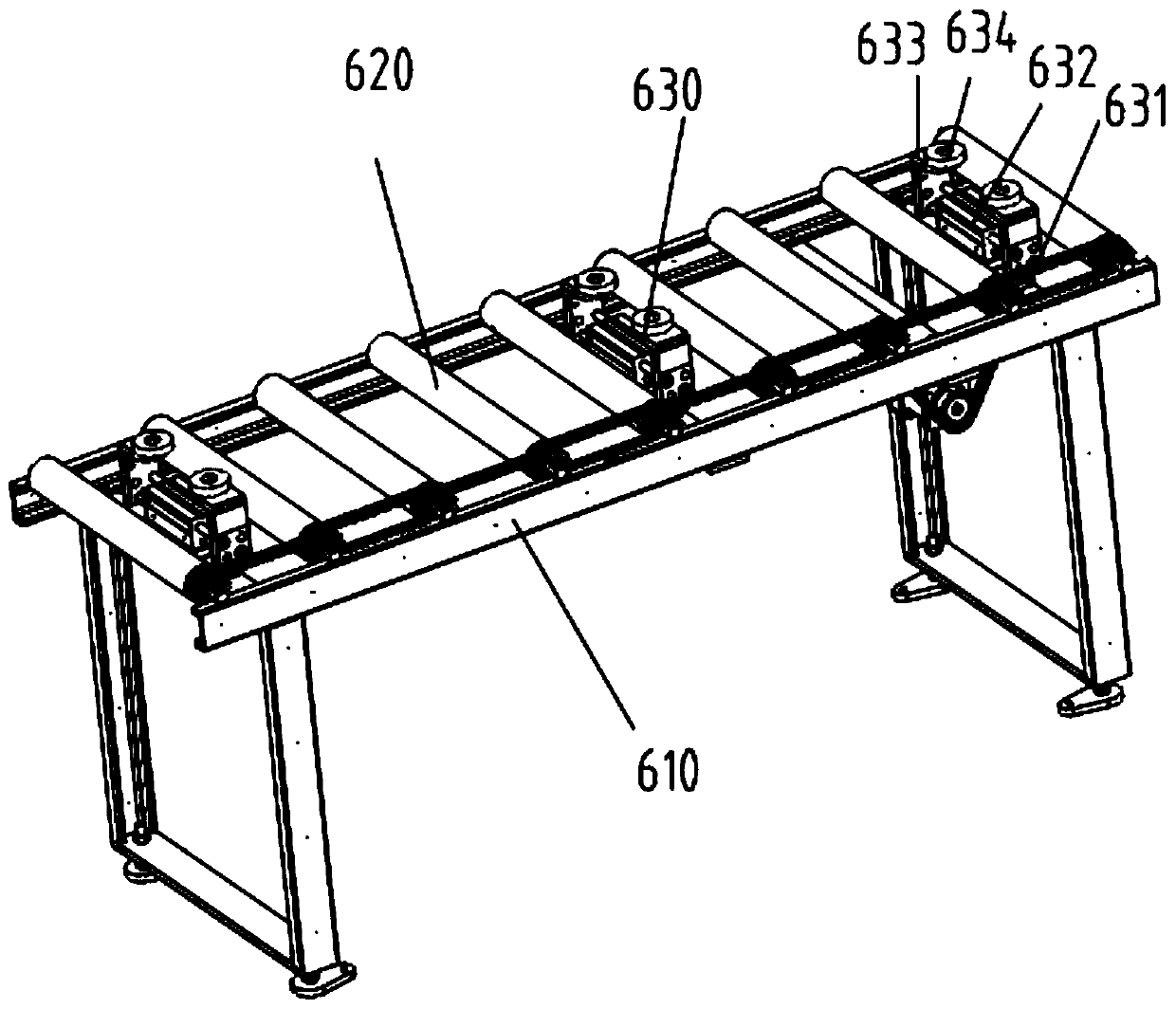

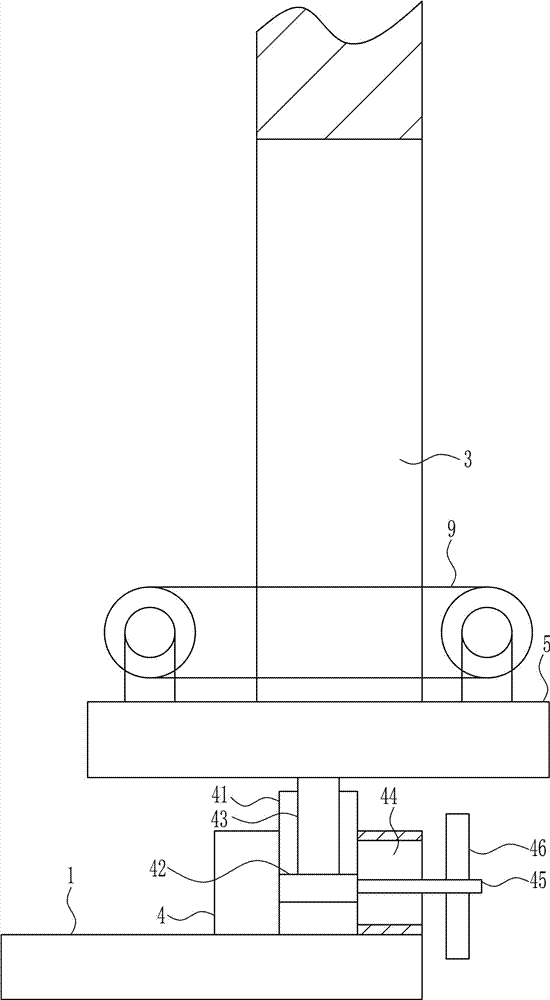

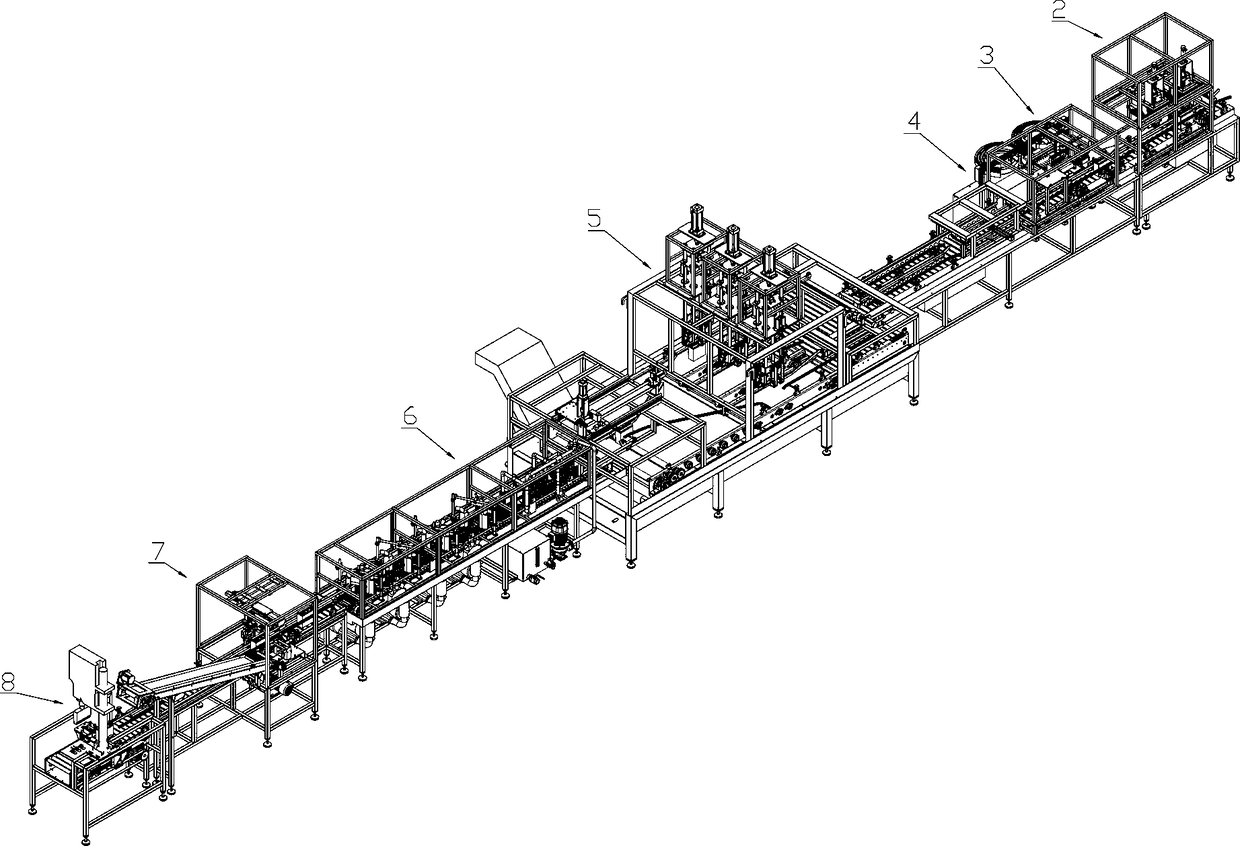

Automatic production line applied to machining of steel channel of forklift gantry

PendingCN110587319AEasy to limitEasy clampingOther manufacturing equipments/toolsProduction lineEngineering

The invention provides an automatic production line applied to machining of a steel channel of a forklift gantry. The automatic production line comprises a first machining center, a first positioningmold, a second machining center, a second positioning mold, a steel channel turnover center, a guide roller way, a rolling wheel shaft welding station and a clamping roller way, wherein the first machining center is used for forming screw holes in the steel channel which is in a vertical state; the first positioning mold is used for fixing the steel channel which is in the vertical state; the second machining center is used for forming screw holes in the steel channel which is in a horizontal state; the second positioning mold is used for fixing the steel channel in the horizontal state; the steel channel turnover center is used for switching the steel channel between the vertical state and the horizontal state; the guide roller way is used for conveying the steel channel to the first positioning mold; the rolling wheel shaft welding station is used for welding a rolling wheel shaft on the steel channel; and the clamping roller way is used for conveying the steel channel which is machined by the second machining center to the rolling wheel shaft welding station. By reasonably arranging the first machining center, the steel channel turnover center, the second machining center and the rolling wheel shaft welding station, the automatic production line provided by the invention implements four processes including formation of screw holes in the steel channel, turnover of the steelchannel, formation of screw holes in the steel channel and welding of the rolling wheel shaft, and improves the machining and welding efficiency of the steel channel.

Owner:ANHUI HAOYUN MACHINERY

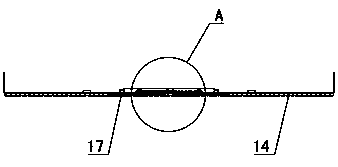

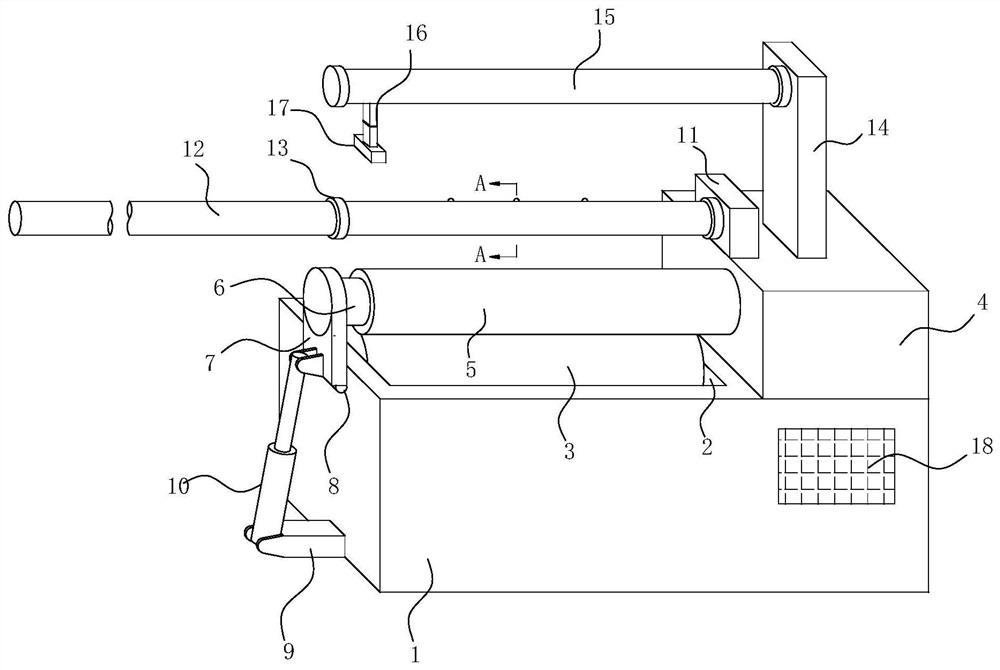

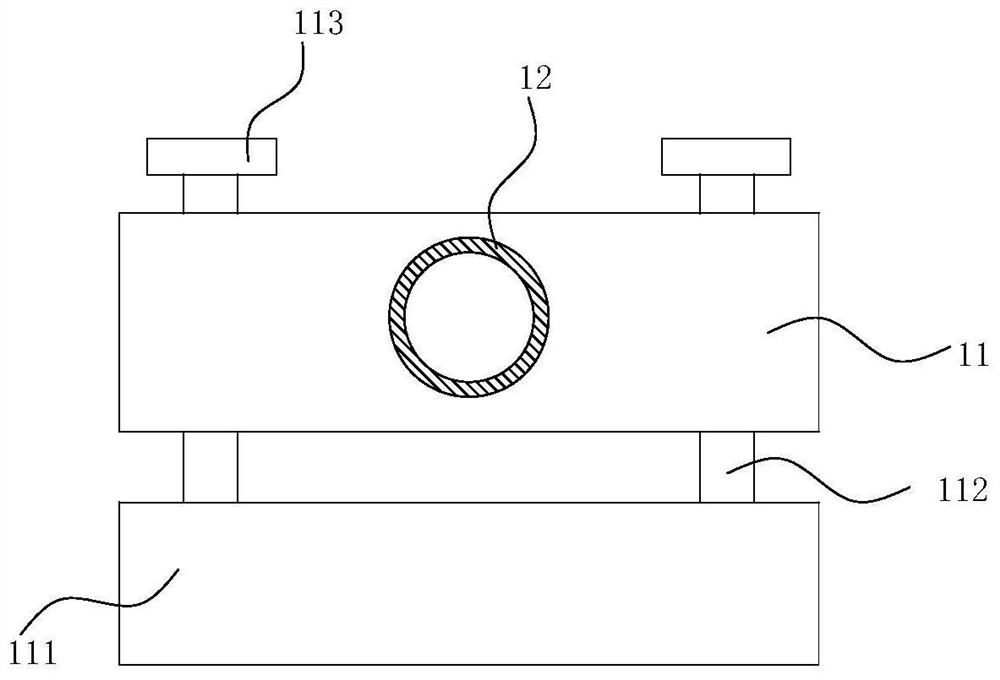

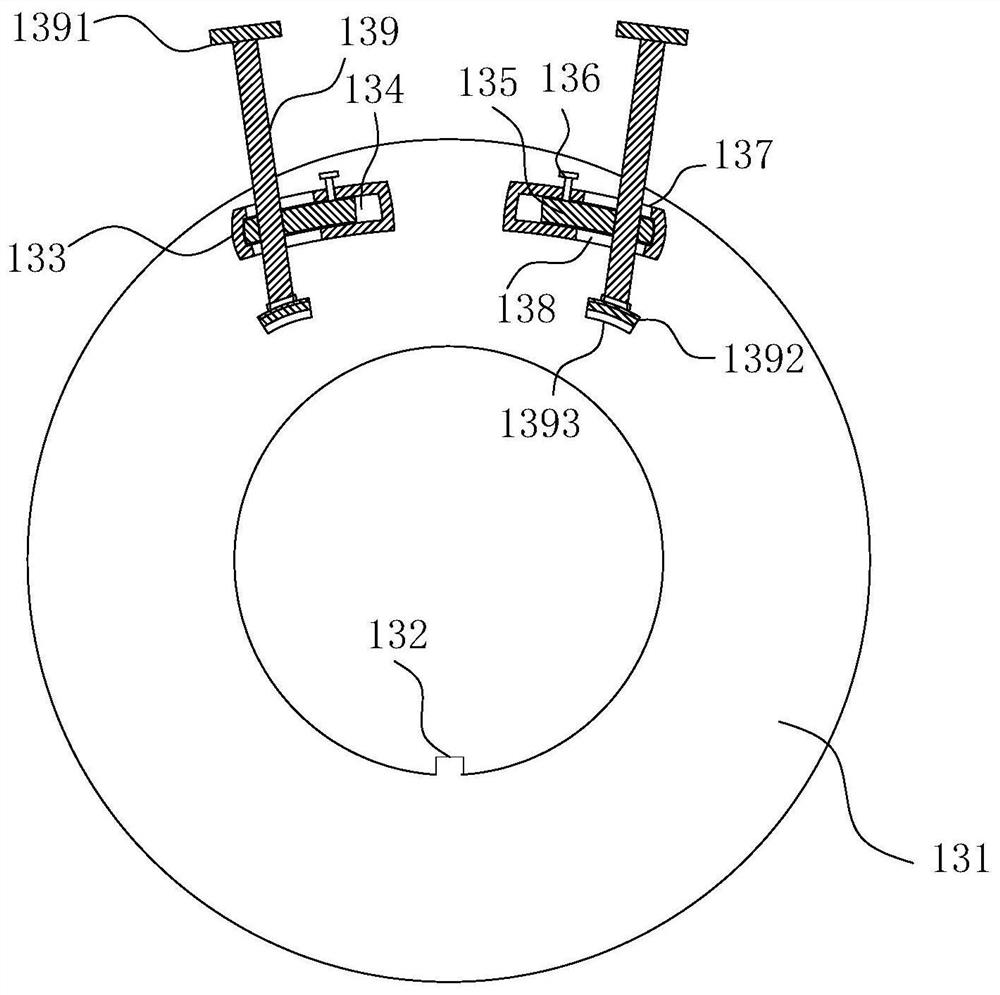

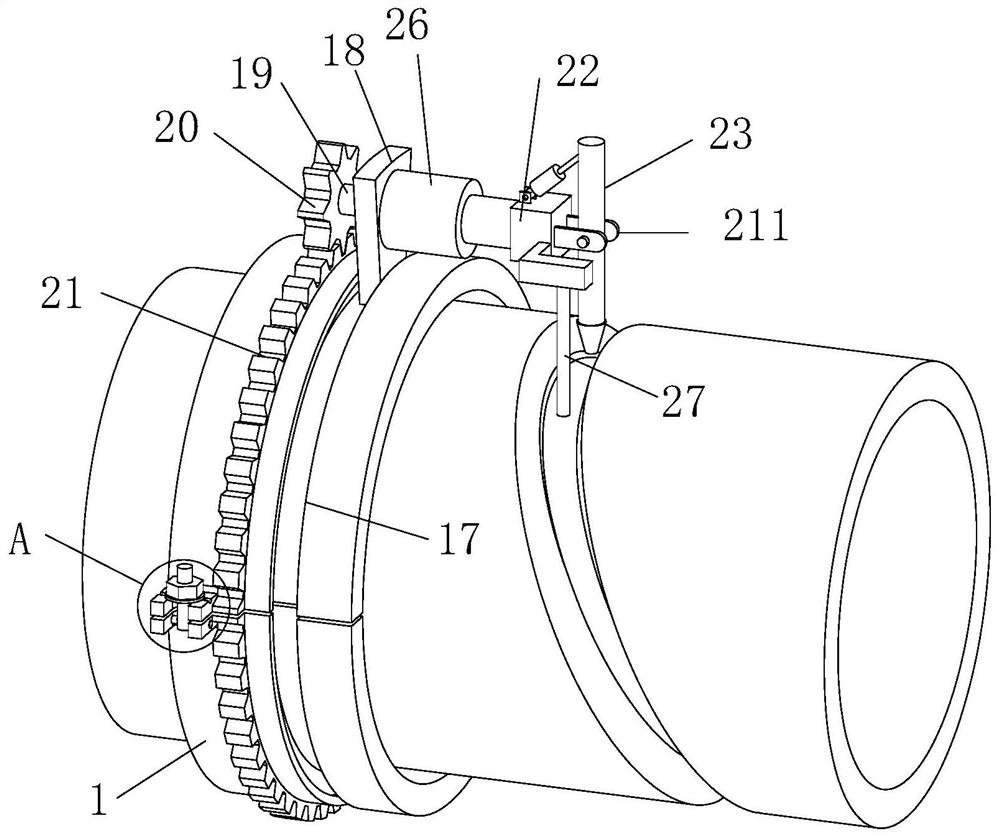

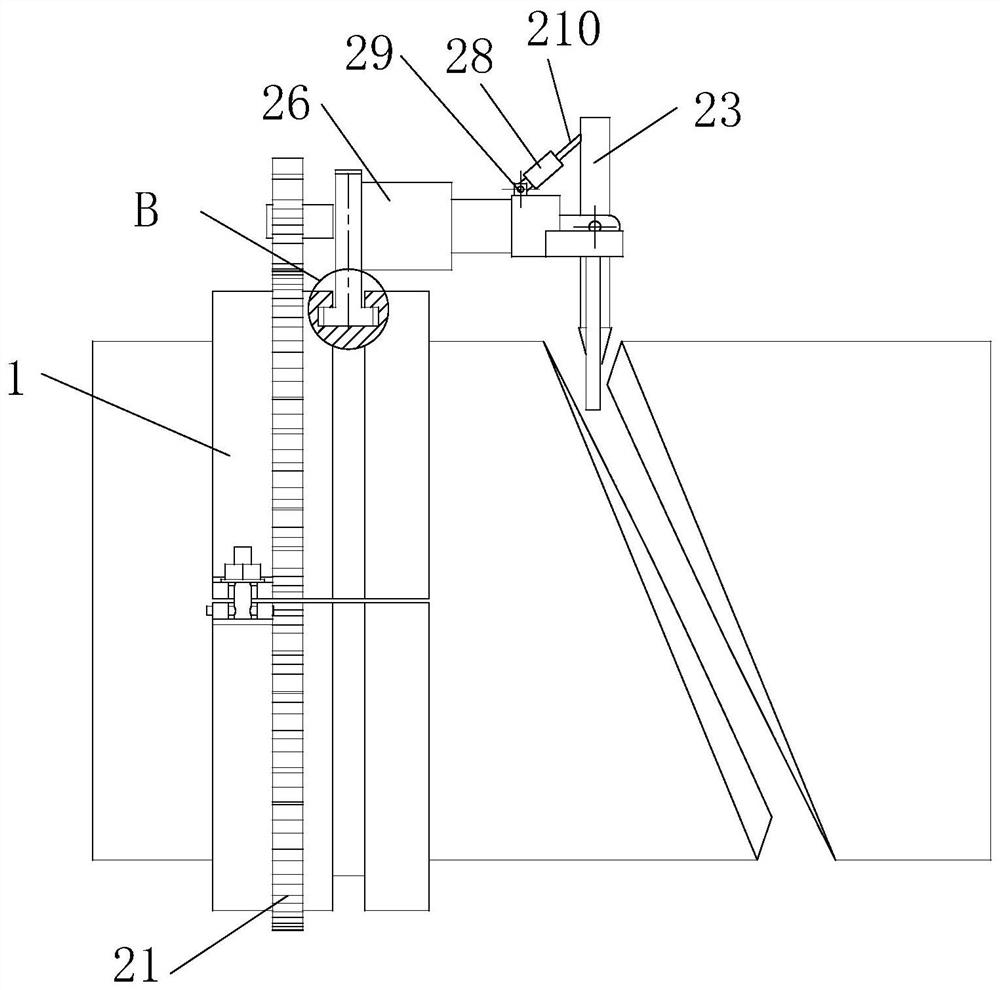

Rotary pipe welding machine

InactiveCN112059361AImprove welding efficiencyImprove welding precisionMetal working apparatusTubular articlesEngineeringPipe welding

The invention belongs to the technical field of welding machines, and particularly relates to a rotary pipe welding machine which comprises two semicircular clamping rings. The adjacent ends of one sides of the two clamping rings are hinged to each other, a first clamping plate and a second clamping plate are arranged at the ends of the other sides of the two clamping rings respectively, and U-shaped grooves are formed in the first clamping plate and the second clamping plate; a stud is hinged into the U-shaped groove of the first clamping plate through a rotating pin, the end, away from the rotating pin, of the stud is in threaded connection with a nut, and the part, between the nut and the rotating pin, of the stud is sleeved with a gasket; and an annular sliding groove is formed in theperipheries of the clamping rings, a T-shaped block is slidably connected into the sliding groove, a welding table is arranged at one side of the T-shaped block, and a welding gun is installed on thewelding table. According to the rotary pipe welding machine, the two semicircular clamping rings are opened and then clamped into the periphery of a round pipe, the stud is clamped into the U-shaped groove in the first clamping plate, and then the two clamping rings are quickly locked in cooperation with the nut and the gasket, so that the welding efficiency and the welding precision of the welding machine on the round pipe are improved.

Owner:东阳市菊苏科技有限公司

Rapid steel pipe electric welding equipment for iron and steel plant

ActiveCN106862717AFast solderingEfficient weldingWelding/cutting auxillary devicesArc welding apparatusMaterials scienceSteel plates

The invention relates to electric welding equipment and particularly relates to rapid steel pipe electric welding equipment for an iron and steel plant. The technical problem to be solved by the invention is to provide the rapid steel pipe electric welding equipment for the iron and steel plant, which is capable of saving time and labor in a working process and realizing welding by automatically rotating a steel pipe. In order to solve the technical problem, the invention provides the rapid steel pipe electric welding equipment for the iron and steel plant. The rapid steel pipe electric welding equipment comprises a bottom plate, supporting plates, first supporting seats, supporting platforms, second supporting seats, first rotating shafts, first turning wheels, first driving strips, connecting plates, first sliding rails and the like; the left and right sides of the bottom plate are provided with the supporting plates in a welding way; first through holes are formed in the lower sides of the supporting plates; and the lower side walls of the first through holes are provided with the first supporting seats in a welding way. By using the rapid steel pipe electric welding equipment, the effects of saving time and labor in the working process and realizing welding by automatically rotating the steel pipe are achieved, and a way of rotating a placing ring after carrying out alignment by placing the steel plate on the placing ring is adopted.

Owner:滦南县鑫发农具有限责任公司

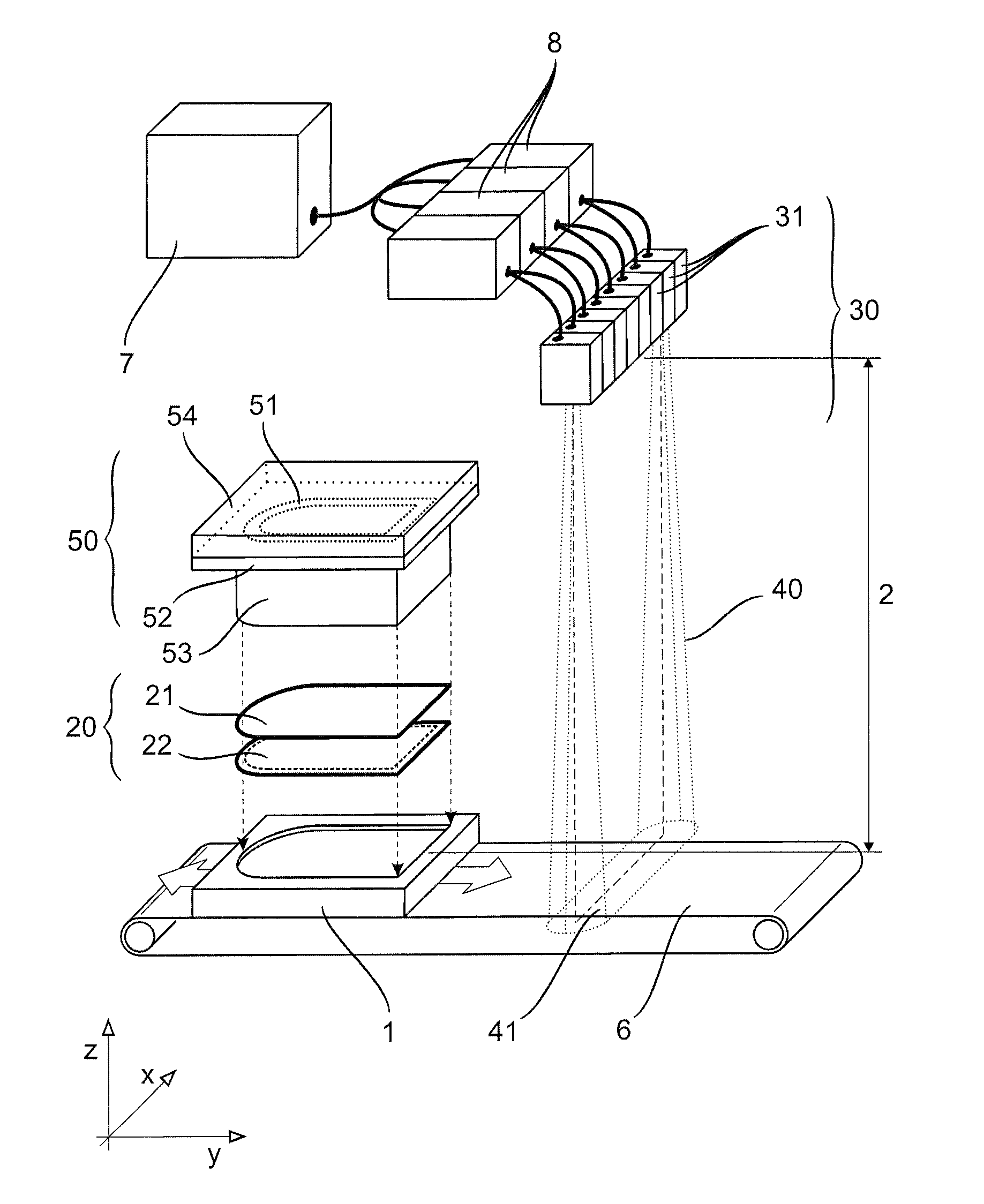

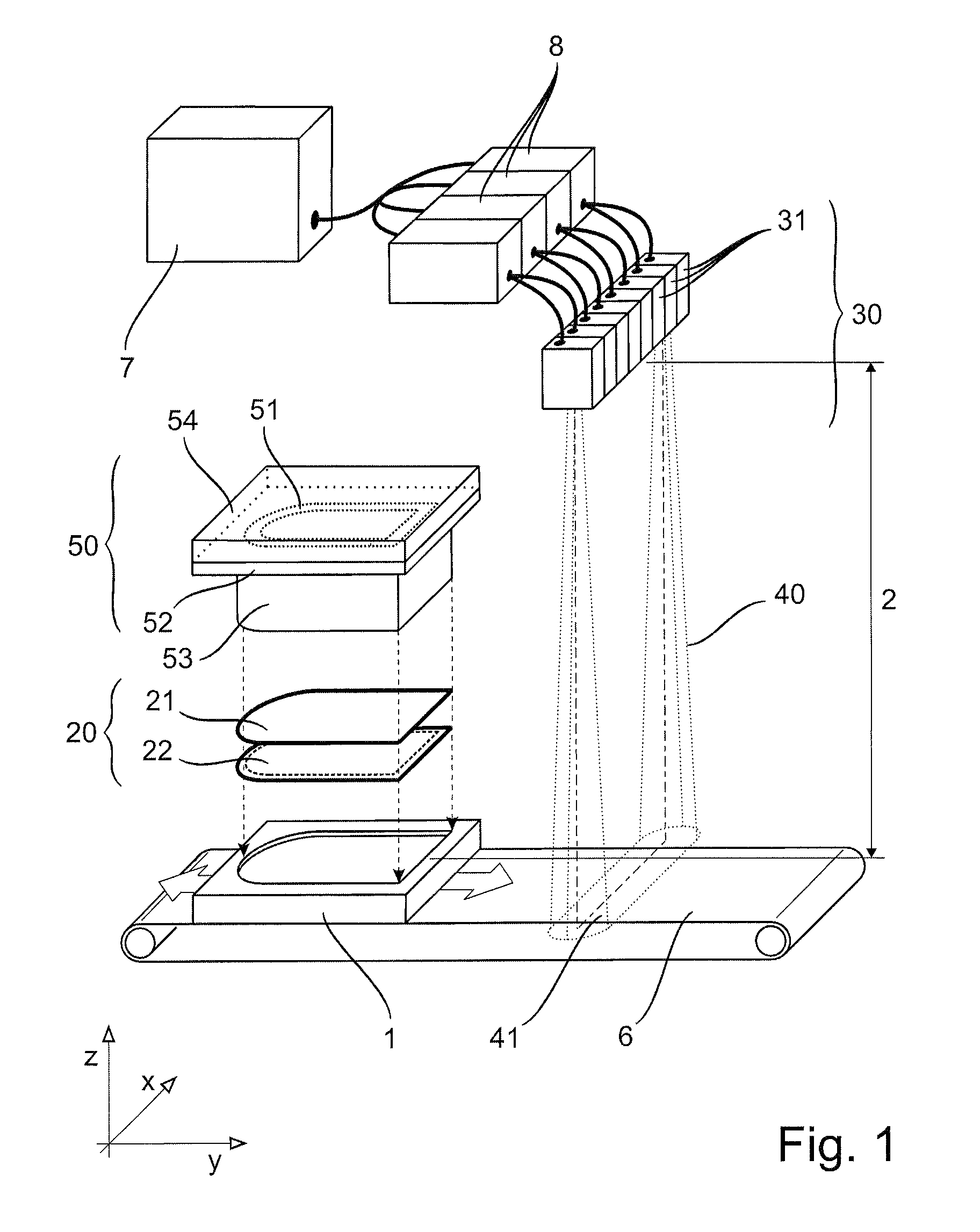

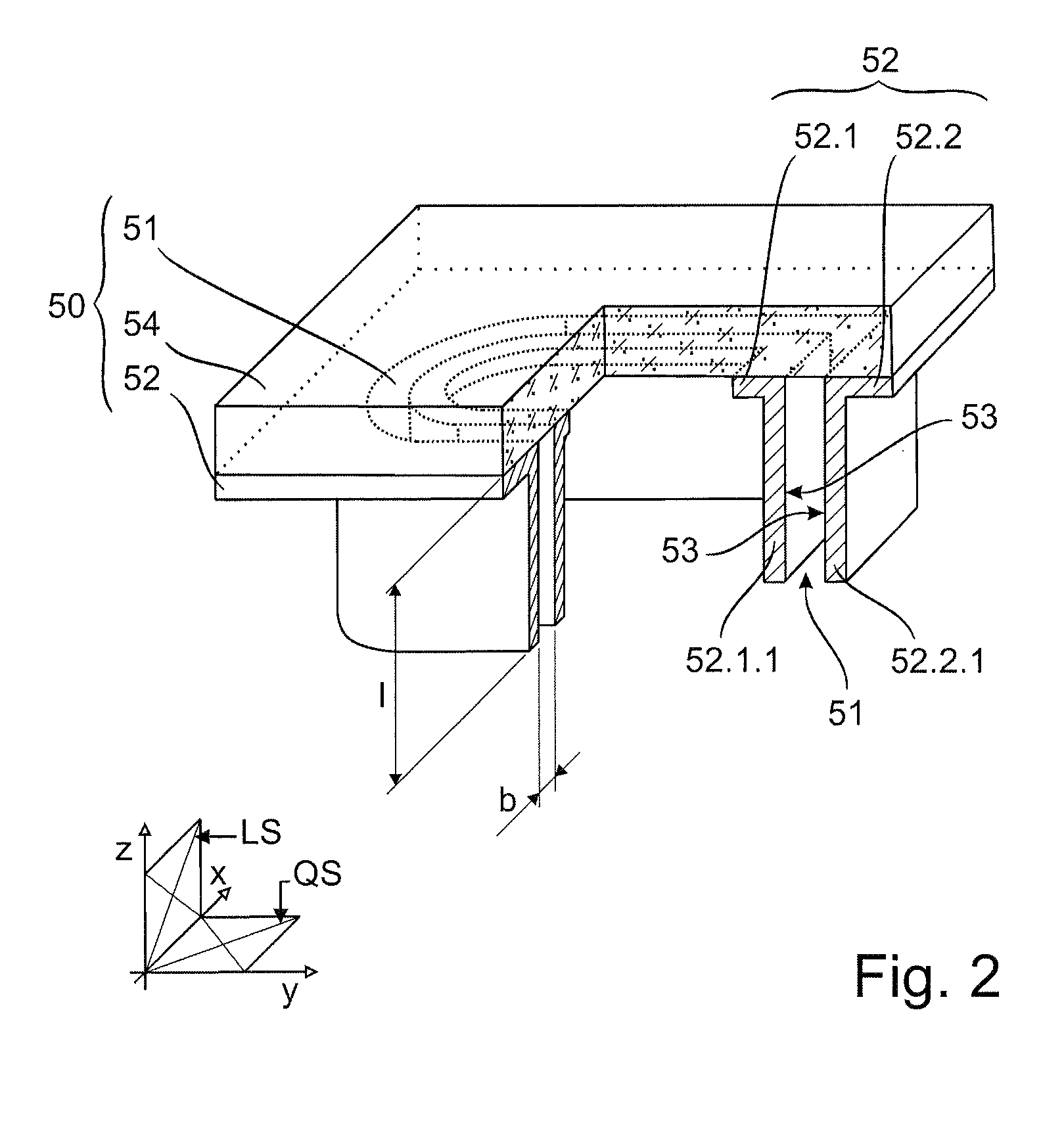

Apparatus for joining two workpiece parts along a weld by means of transmission welding

InactiveUS8981256B2Easy constructionFast solderingMechanical working/deformationWelding/cutting auxillary devicesEngineeringChannel width

Owner:JENOPTIK AUTOMATISIERUNGSTECHN

Automatic scaffold welding machine and welding method thereof

ActiveCN108098126AFast solderingEasy to replaceResistance electrode holdersWelding/soldering/cutting articlesEngineeringSpot welding

The invention provides an automatic scaffold welding machine. The welding machine is used for automatic welding of a main steel pipe serving as a vertical rod in a steel pipe scaffold with socket andspigot joints and a socket pipe and an U-shaped socket part. The welding machine comprises a base, the front side of the base is provided with a three-shaft position-changing device for switching a feeding station with a workpiece to be welded and a welding station and realizing rapid welding of the two surfaces of the workpiece to be welded through 180-degree-rotation of the welding station; twogantry type welding gun supports which are vertically arranged are installed on the two sides of the rear side of the base, a cross frame beam is arranged between the two welding gun supports, and thecross frame beam is provided with a spot welding mechanism which is used for carrying out spot welding on the socket pipe which is at the welding station of the three-shaft position-changing device and fixed on the main steel pipe and a multiple sets of double-gun welding mechanisms which are used for simultaneously welding weld joints of all U-shaped socket parts; and one end of the cross framebeam is provided with a welding gun walking mechanism which is used for pulling the multiple sets of double-gun welding mechanisms to move at the same time to carry out welding on the welding joints of all the U-shaped socket parts correspondingly. The invention further provides a welding method of the automatic scaffold welding machine.

Owner:ZHUHAI RUILING WELDING AUTOMATION CO LTD

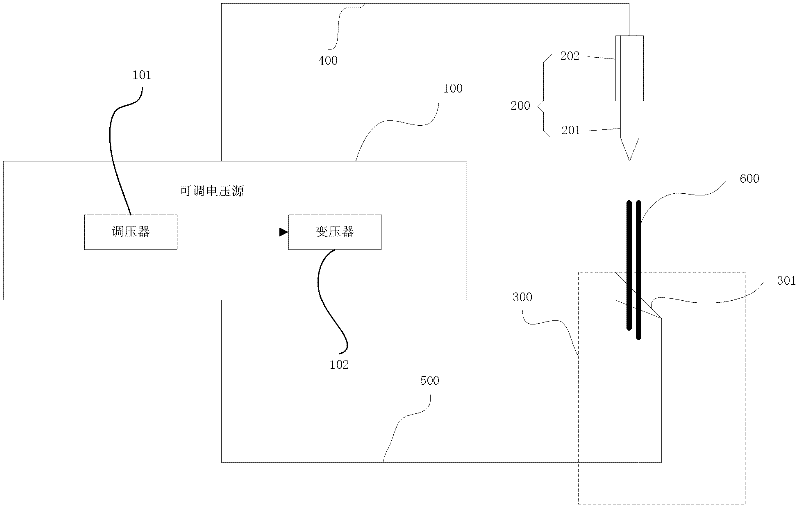

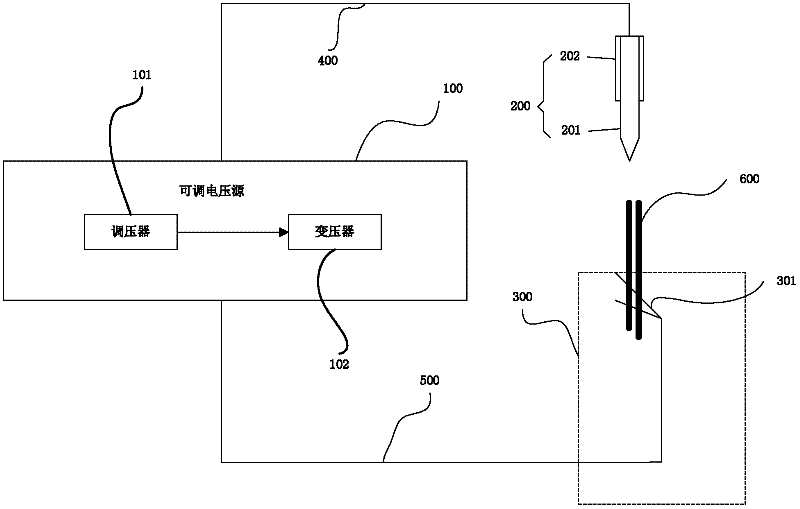

Thermocouple welding device and welding method

The invention relates to a thermocouple welding device which comprises an adjustable voltage source for outputting adjustable voltage outwards; a welding head connected with one output end of the adjustable voltage source through a lead I; a welding seat connected with the other output end of the adjustable voltage source through a lead II, wherein the welding seat is used for fixing thermo wires of the thermocouple to be welded. The thermocouple welding device of the invention is characterized by regulating the adjustable voltage source to produce electric sparks to melt two thermo wires together when the welding head is contacted with the thermo wires needing welding, thereby achieving the fast welding purpose. The invention is simple in structure, convenient in use and low in cost.

Owner:深圳深爱半导体股份有限公司

Welding method

InactiveUS20160346860A1Reduce processing timeImprove welding qualityArc welding apparatusThermodynamicsHeat flux

A method of welding two adjacent components together includes determining geometrical dimensions of the components to be welded and determining material properties of the components to be welded. The method includes selecting an optimised weld torch velocity and voltage by selecting an iteration parameter of weld torch velocity and voltage, and calculating an expected heat flux distribution that will be generated in components during a welding process as a function of the geometrical dimensions of the components and the material properties of the components. The heat flux distribution is constrained to be ellipsoidal in an initial weld region and conical in the remainder of the weld. The method includes iterating using the iteration parameter until an optimised weld torch velocity and voltage is obtained. The welding torch is then set to weld the components at the determined optimum velocity and voltage.

Owner:ROLLS ROYCE PLC

Storage battery pre-packaging treatment production line

PendingCN108736075AQuick washEasy to dryFinal product manufactureLead-acid accumulators constructionProduction lineCap device

The invention discloses a storage battery pre-packaging treatment production line which comprises a rack. A charging screw disassembling device, a cap device, a film tearing device, a cover plate covering device and a cover welding device are sequentially arranged on the rack from back to front. According to the storage battery pre-packaging treatment production line, two charging screws on a storage battery can be efficiently disassembled, each acid adding hole on the storage battery can be effectively covered with a sealing cap, whether the charging screws on the storage battery are disassembled and whether the sealing cap on each acid adding hole is covered well can be detected, after detection, an unqualified storage battery can also be sorted out to avoid influence of the unqualifiedstorage battery on the back-end processing, a protection film on the storage battery can be efficiently torn, the storage battery can also be rapidly cleaned and air-dried, a cover plate groove on thestorage battery can be efficiently covered with a cover plate, and the covered cover plate can also be welded in the cover plate groove, so that labor cost of storage battery pre-packaging treatmentis greatly reduced, and working efficiency is also greatly improved.

Owner:江苏云天高胜机器人科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com