Macro-micro compound five free degree light-emitting diode (LED) bonding machine actuating mechanism

A technology with actuators and degrees of freedom, applied in the field of wire bonding machines, can solve problems such as poor LED welding consistency, position deviation, and long time, and achieve the effects of meeting precision requirements, increasing yield, and short adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work shall fall within the protection scope of the present invention.

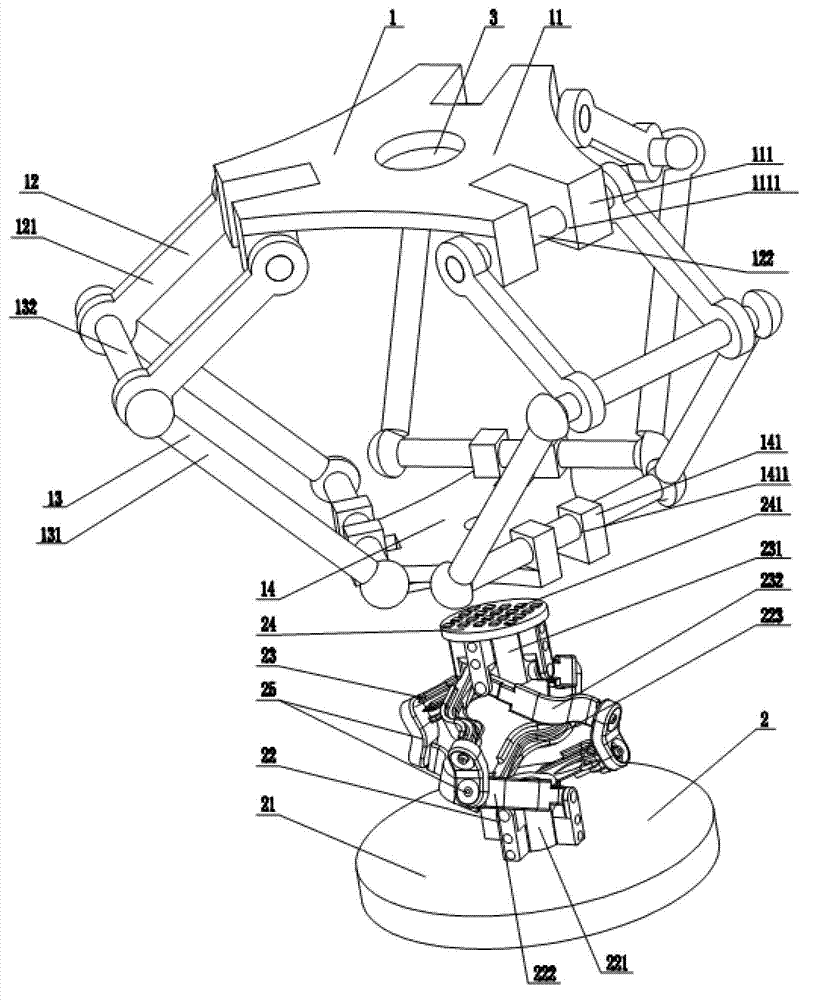

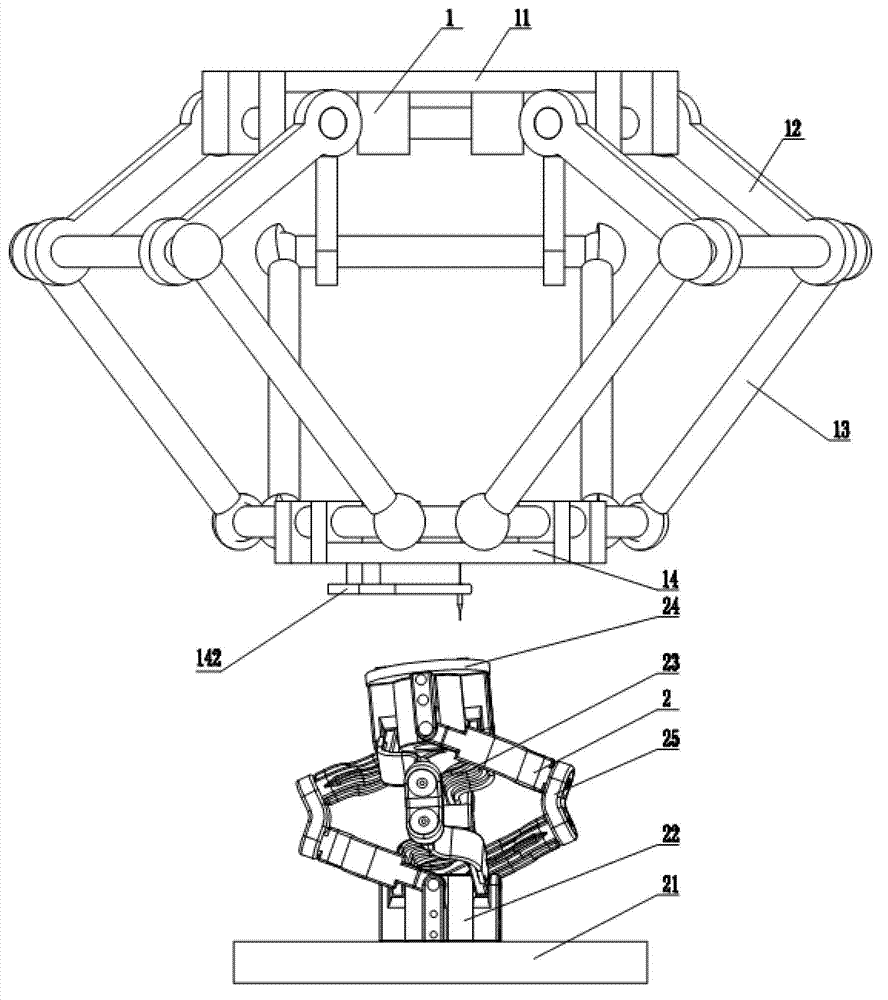

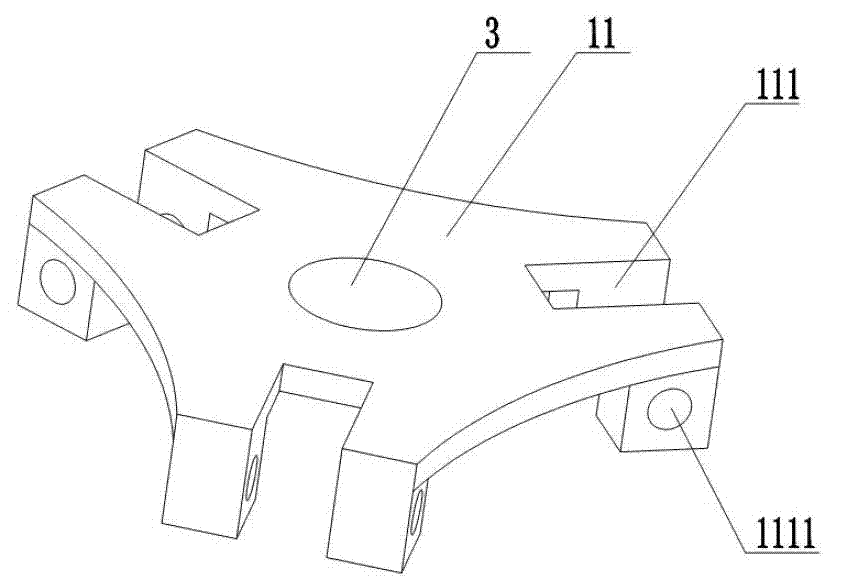

[0028] according to Figure 1-Figure 6 In the preferred embodiment shown, a macro-micro composite five-degree-of-freedom LED wire bonding machine actuator includes a welding head mechanism 1, a worktable mechanism 2 connected to the welding head mechanism 1, and the welding head mechanism 1 includes an upper substrate 11, and The driving component 12 connected to the upper substrate 11, the driven component 13 connected to the driving com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com