Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1231results about "Resistance electrode holders" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

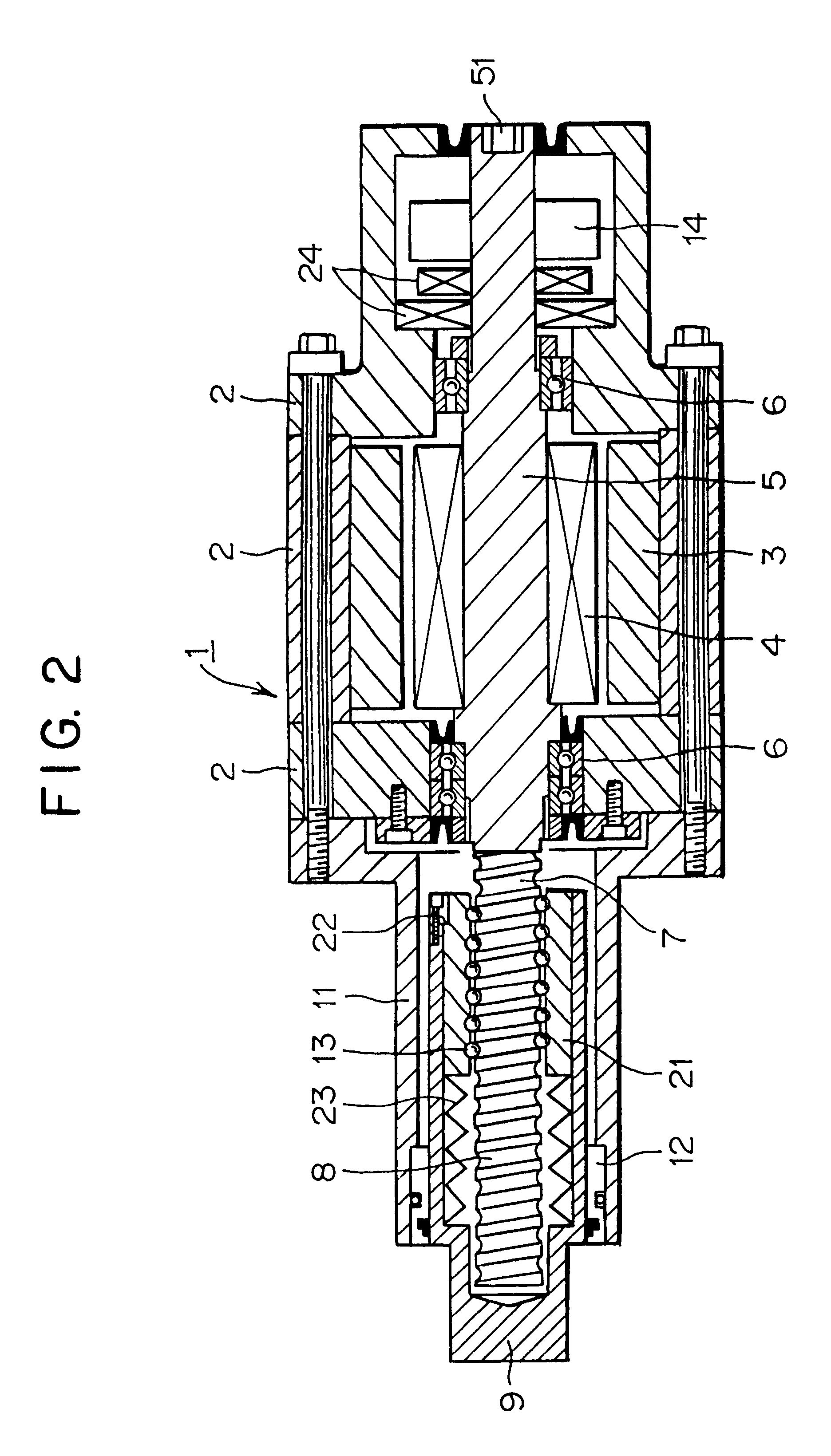

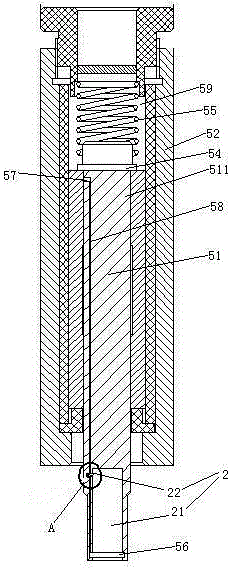

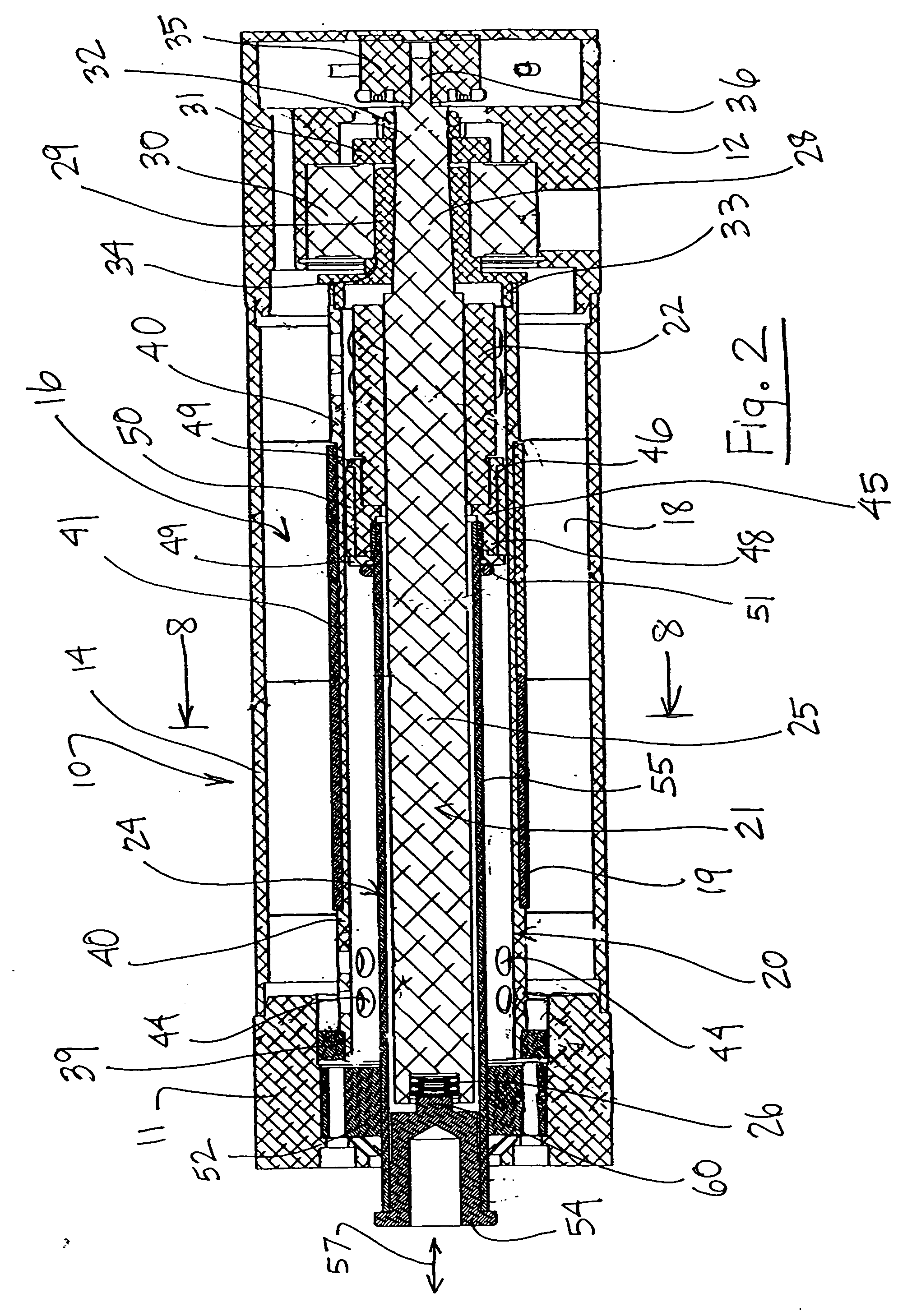

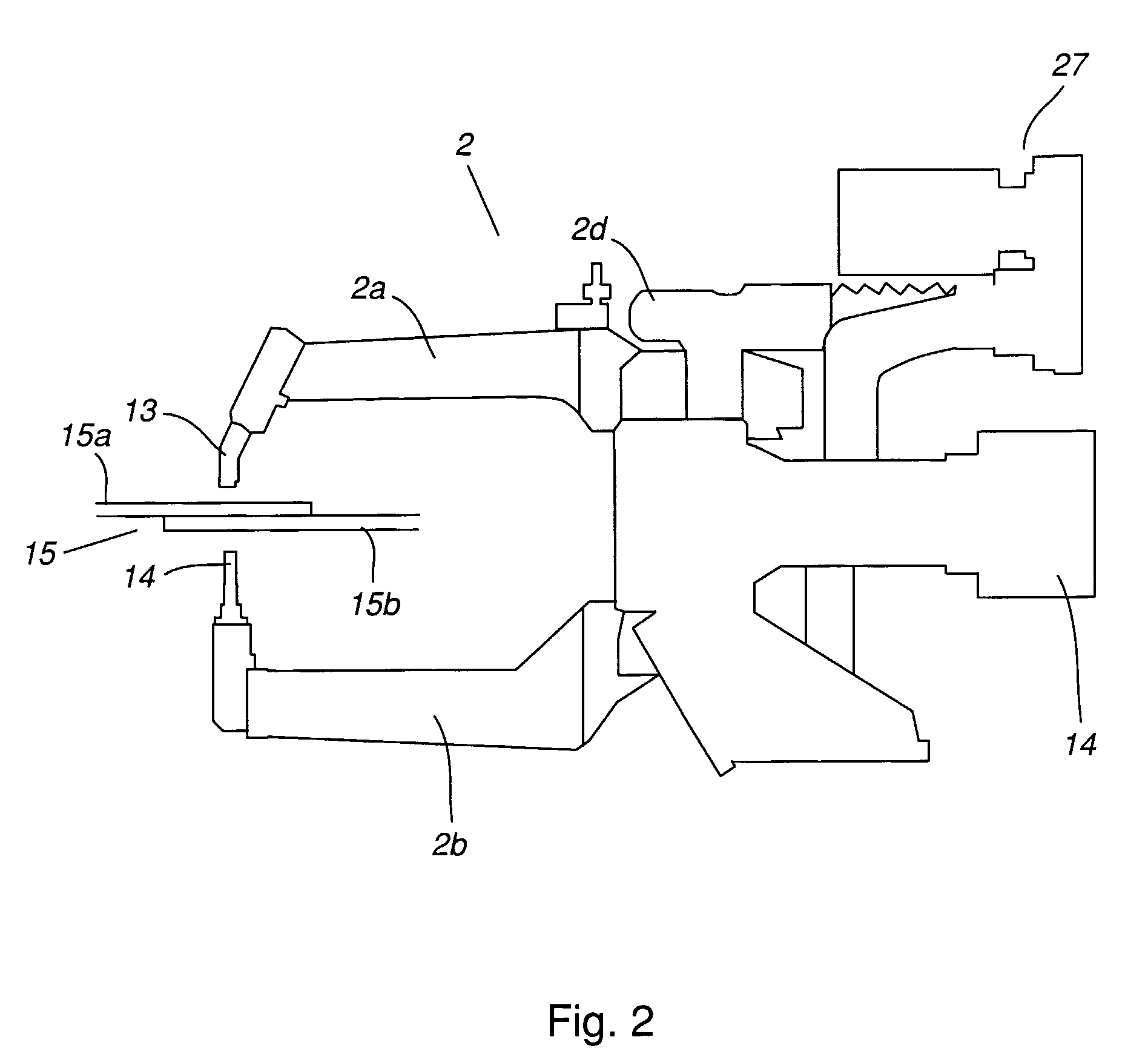

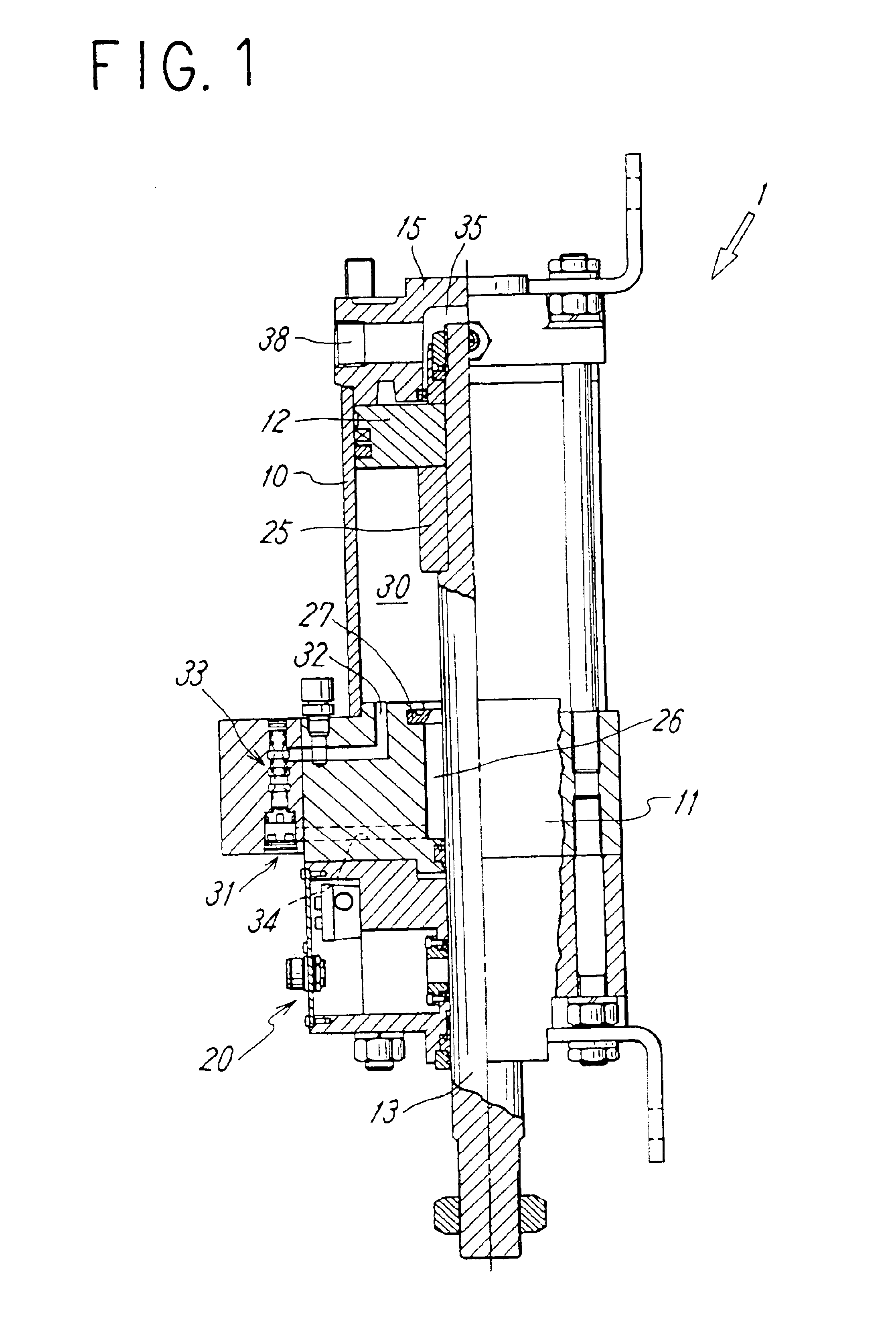

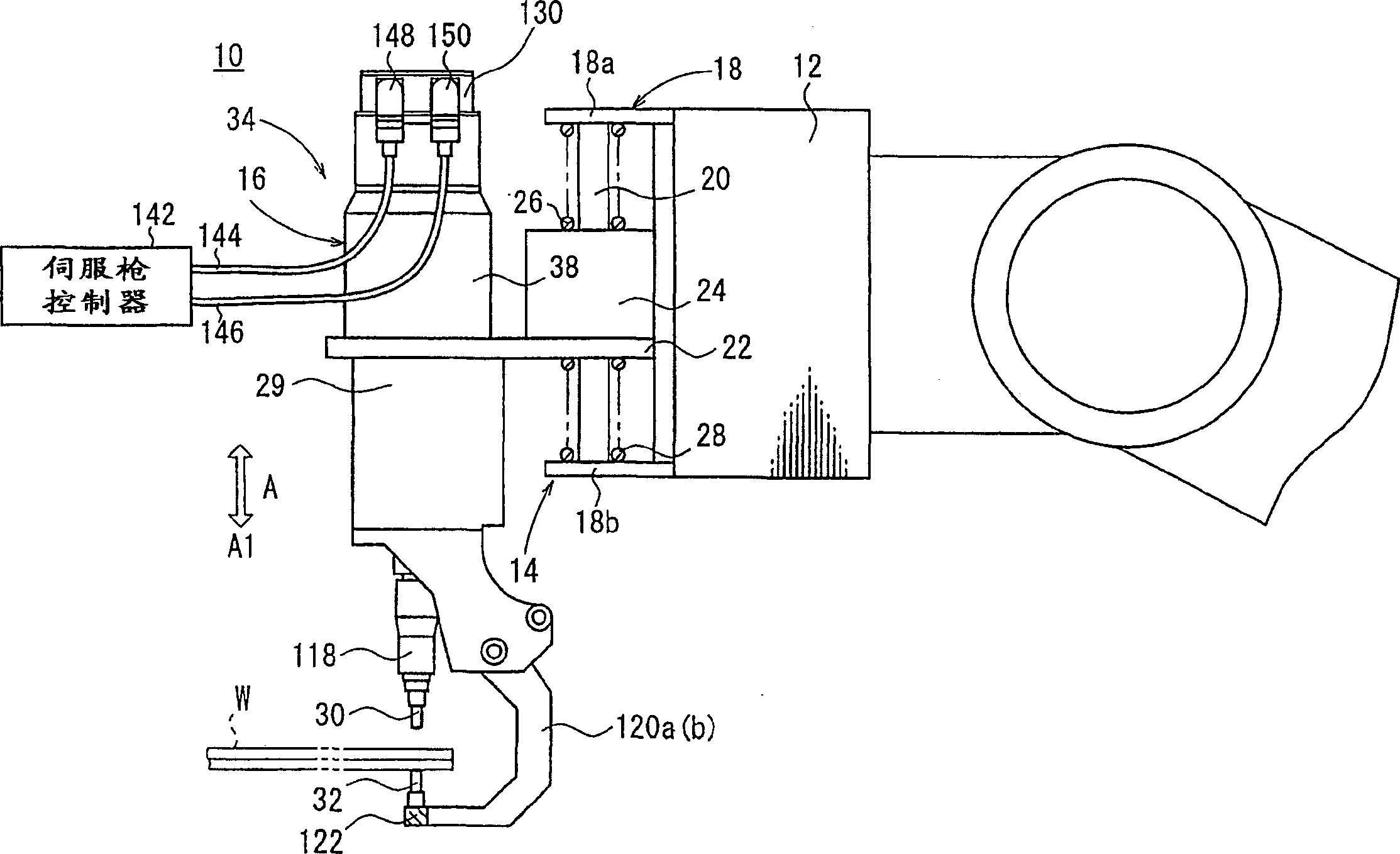

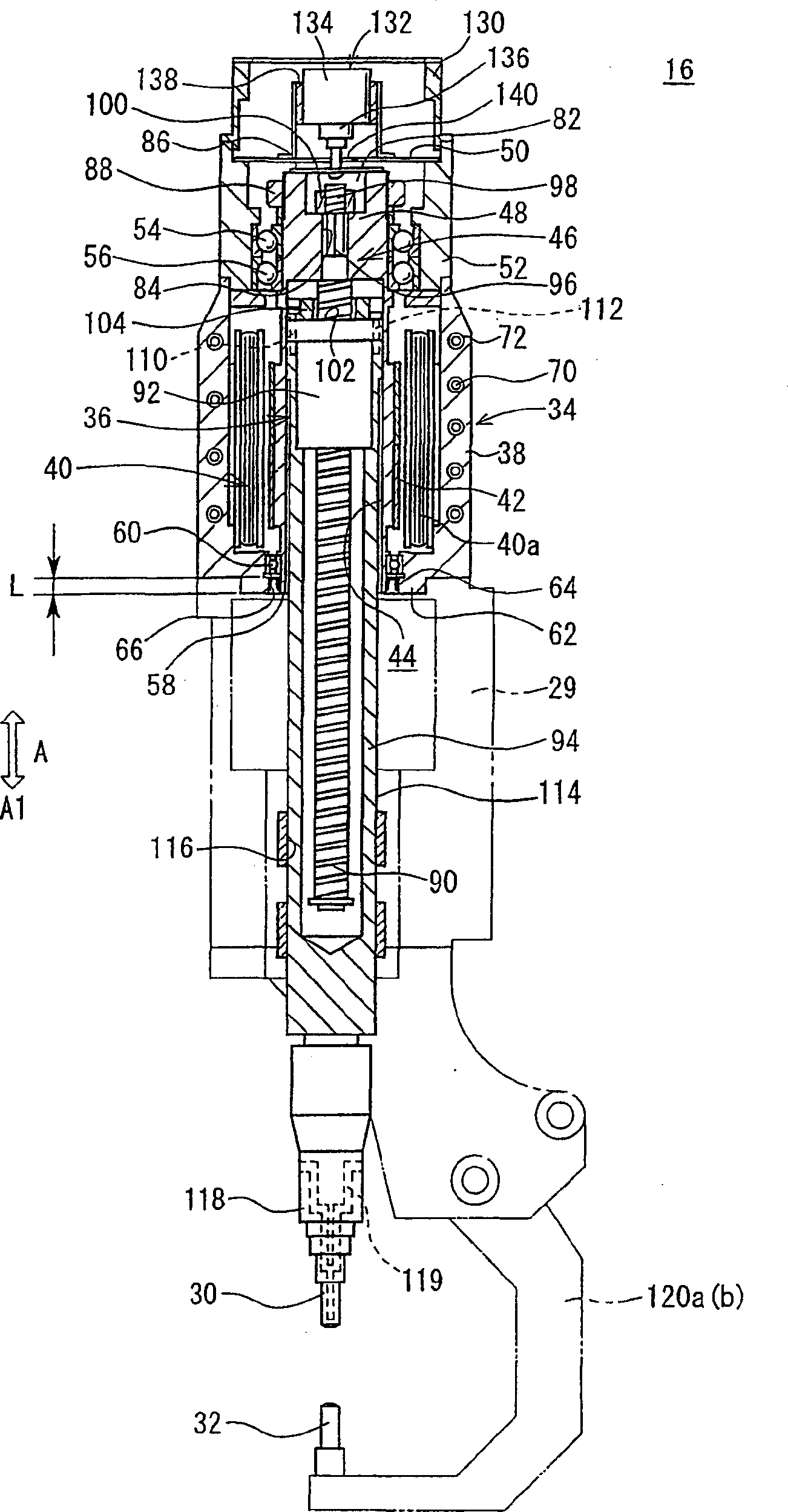

Driving unit of a welding equipment

InactiveUS6223971B1Resistance electrode holdersAutomatic control devicesRotational axisReciprocating motion

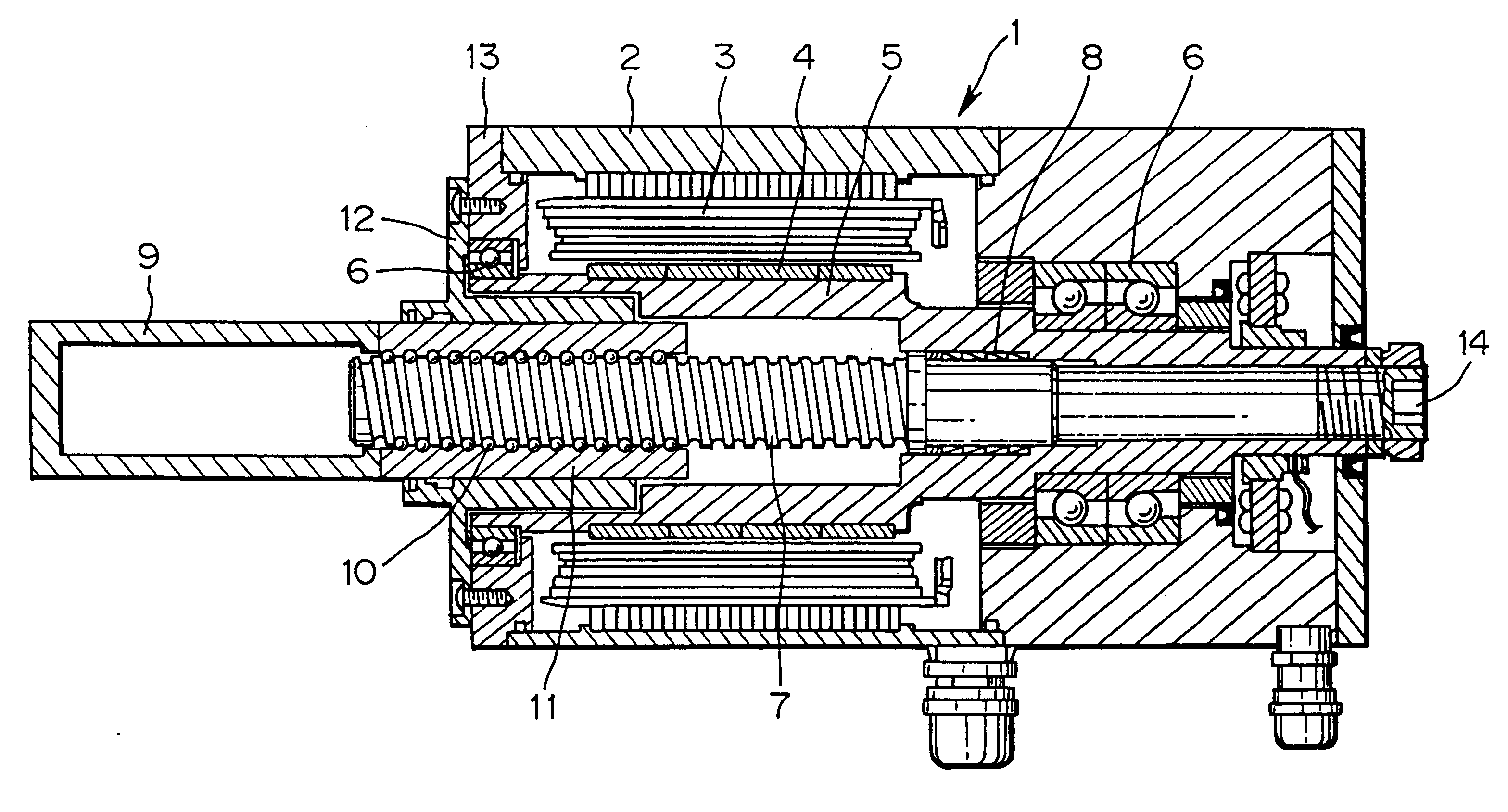

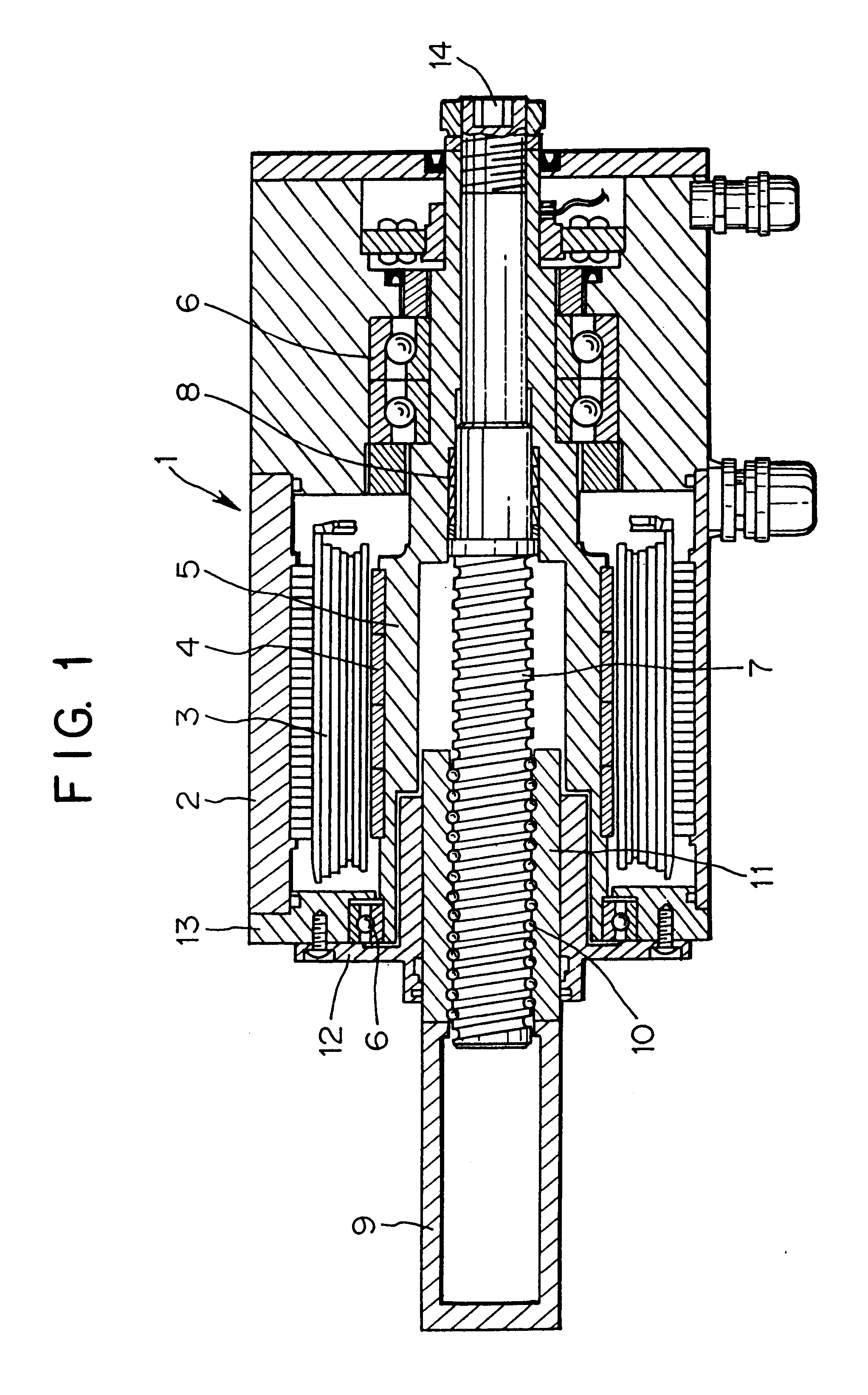

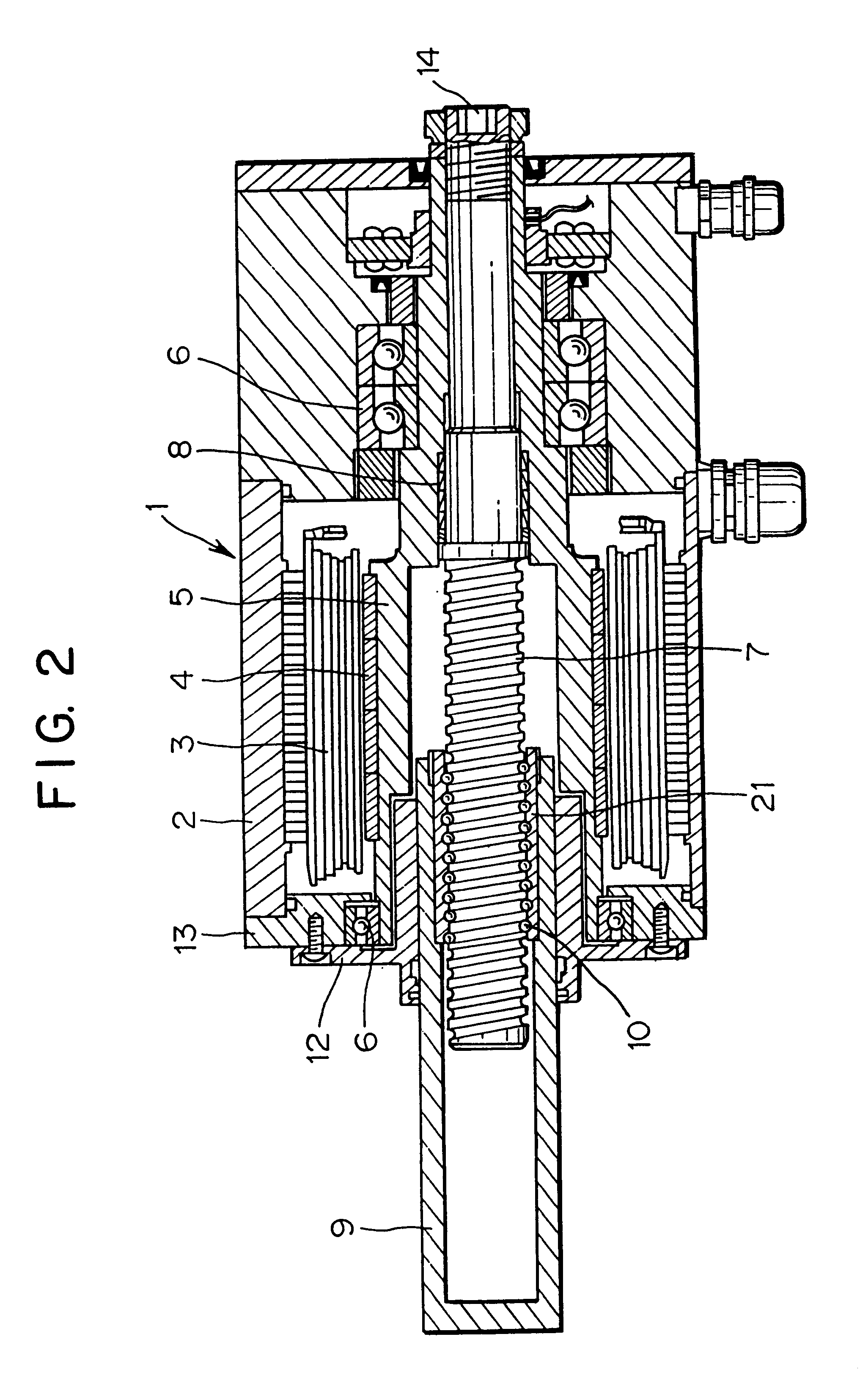

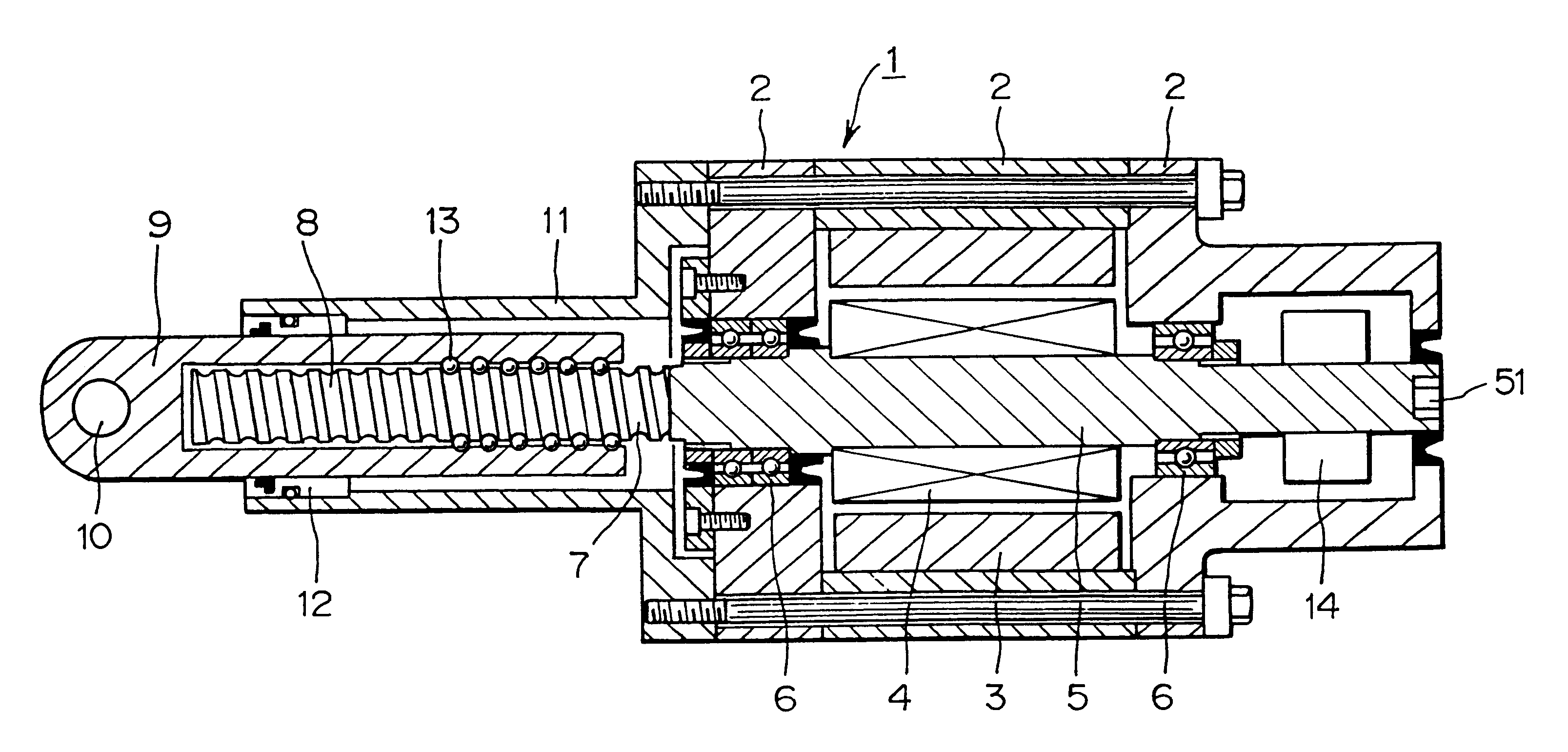

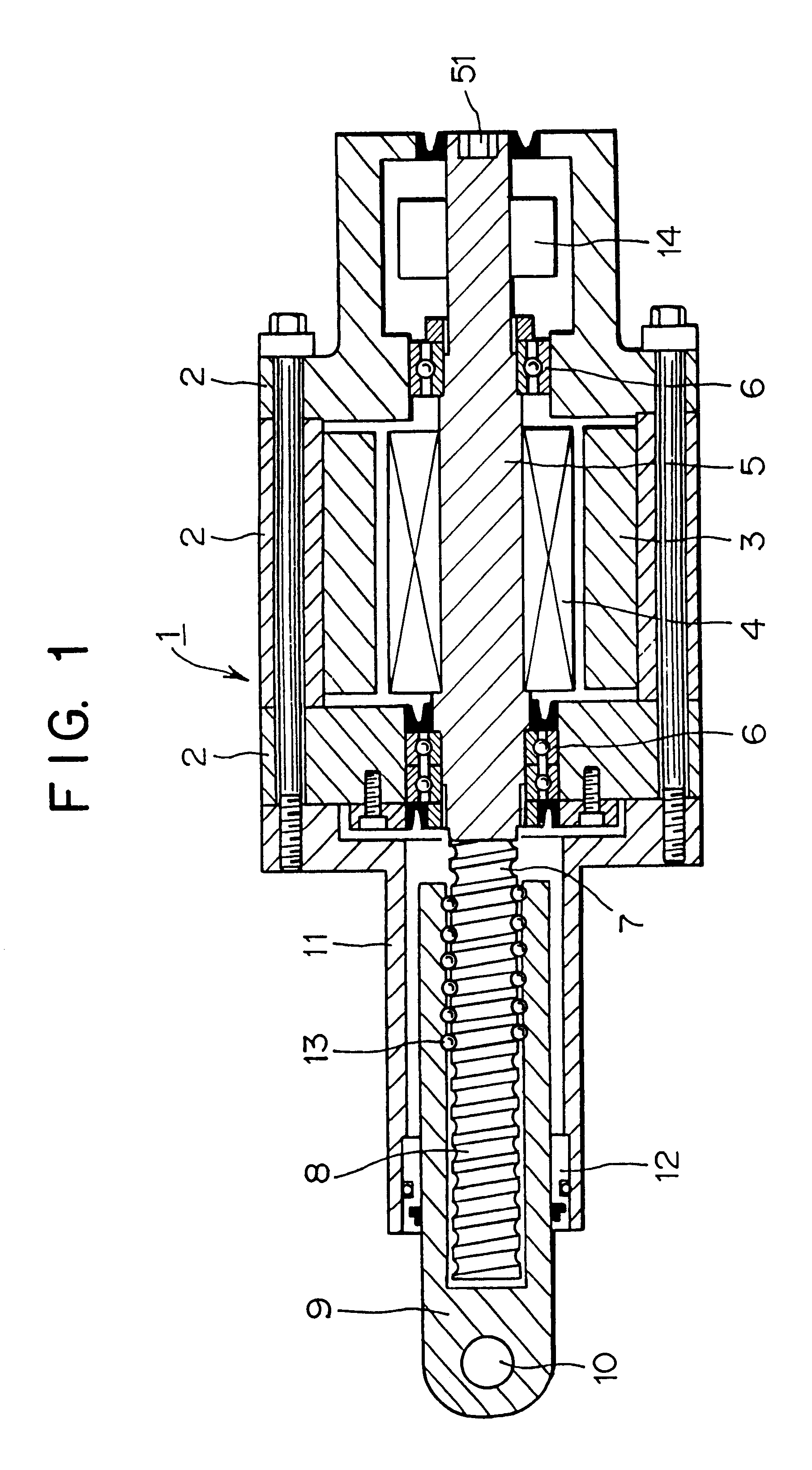

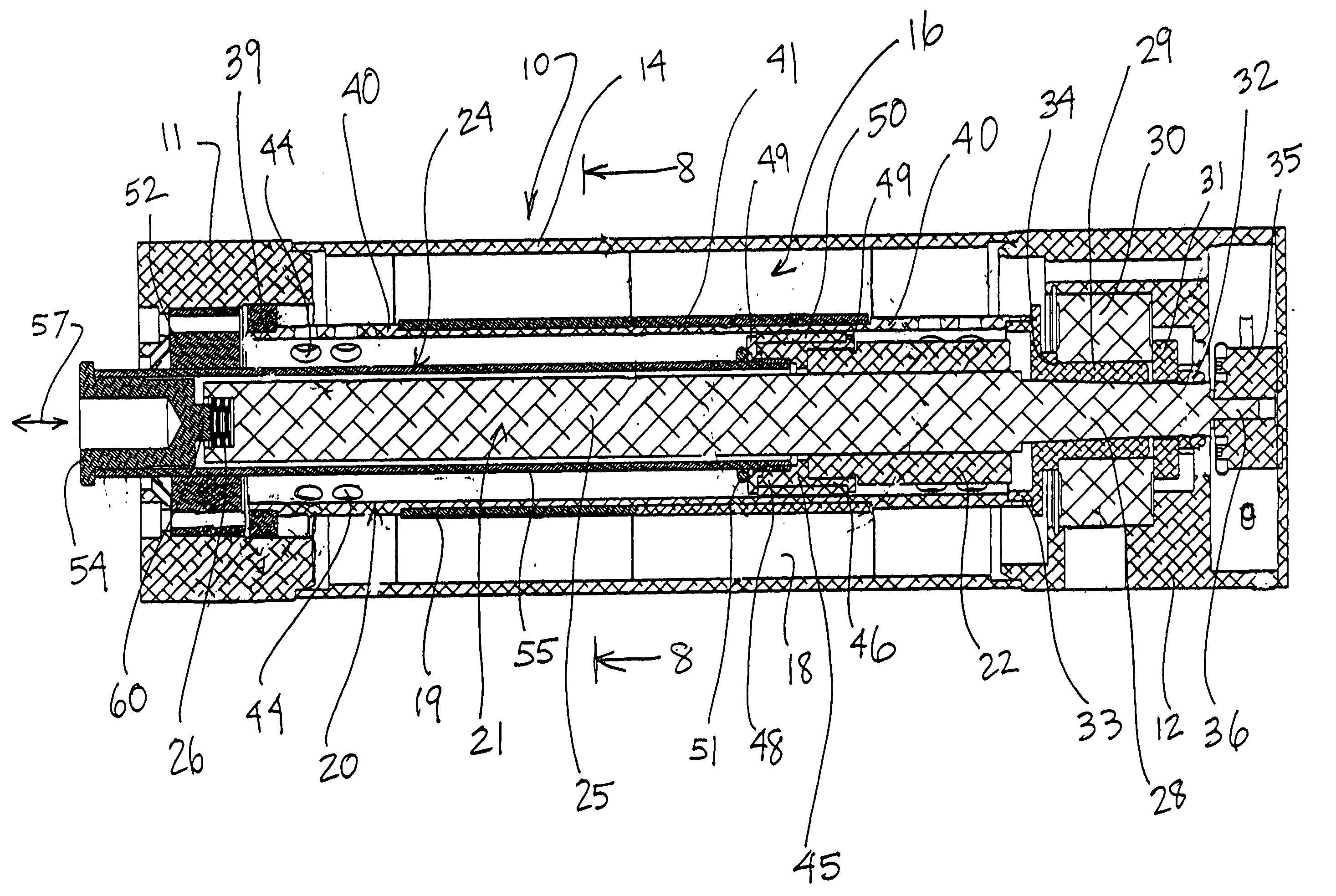

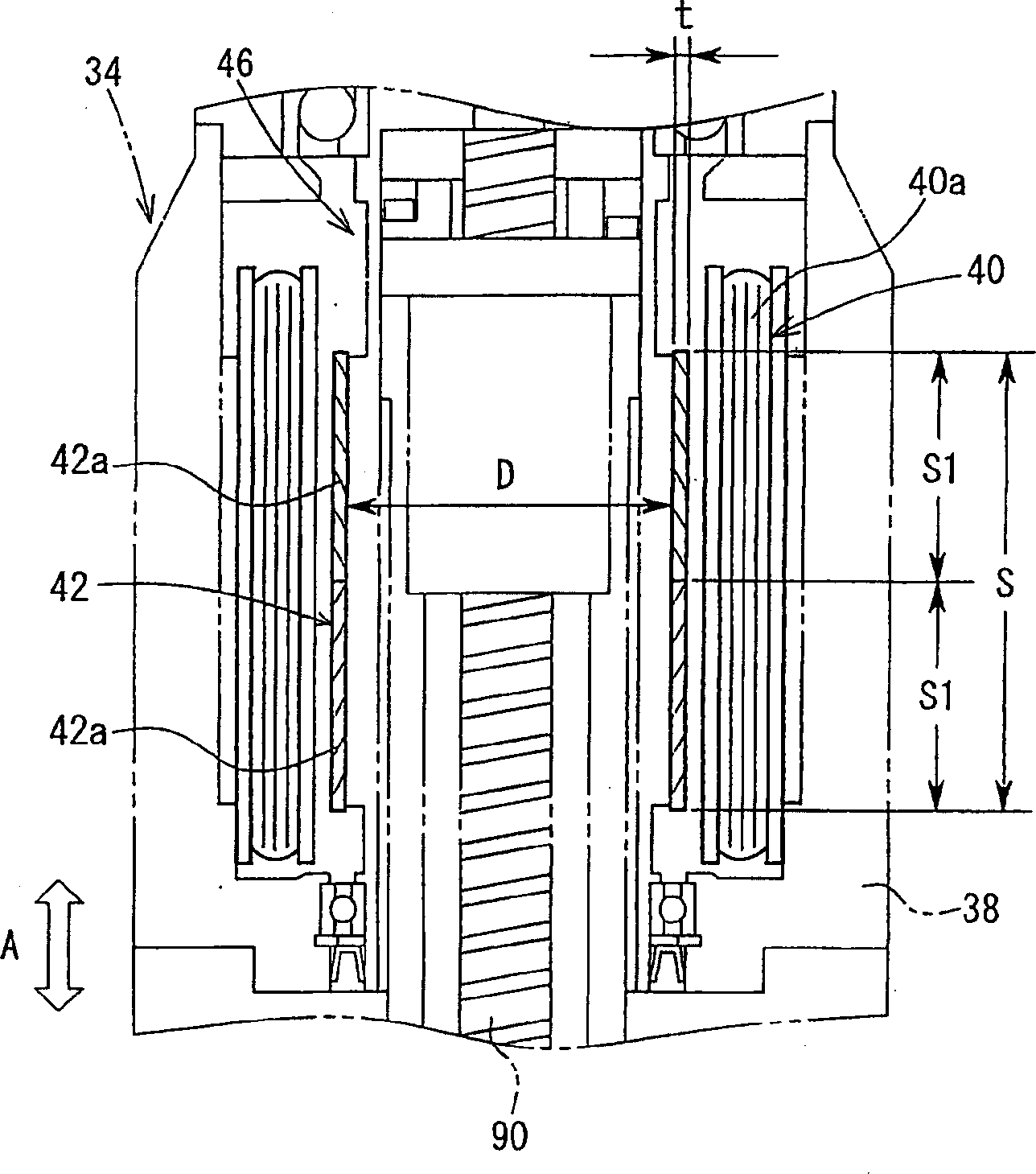

A small-sized motor is employed by a driving unit of a welding equipment wherein the inner diameter of a rotary shaft of the motor can be reduced as much as possible, and the entire length of the driving unit is reduced. The driving unit of a welding equipment is provided with a pressure application shaft. The pressure application shaft is driven by a motor including a hollow rotary shaft, a screw shaft fixed inside the rotary shaft, and a nut provided integrally with or substantially integrally with the pressure application shaft, the nut being screwed with a screw provided on the screw shaft. The rotary shaft of the motor is substantially coaxially positioned with the screw shaft. Outer diameters of the nut and pressure application shaft are respectively smaller than an inner diameter of the rotary shaft to form a direct moving guide part. The direct moving guide part is movable on an inner periphery surface of the rotary shaft and a rotary force of the rotary shaft of the motor is converted into a reciprocating motion.

Owner:OBARA GRP

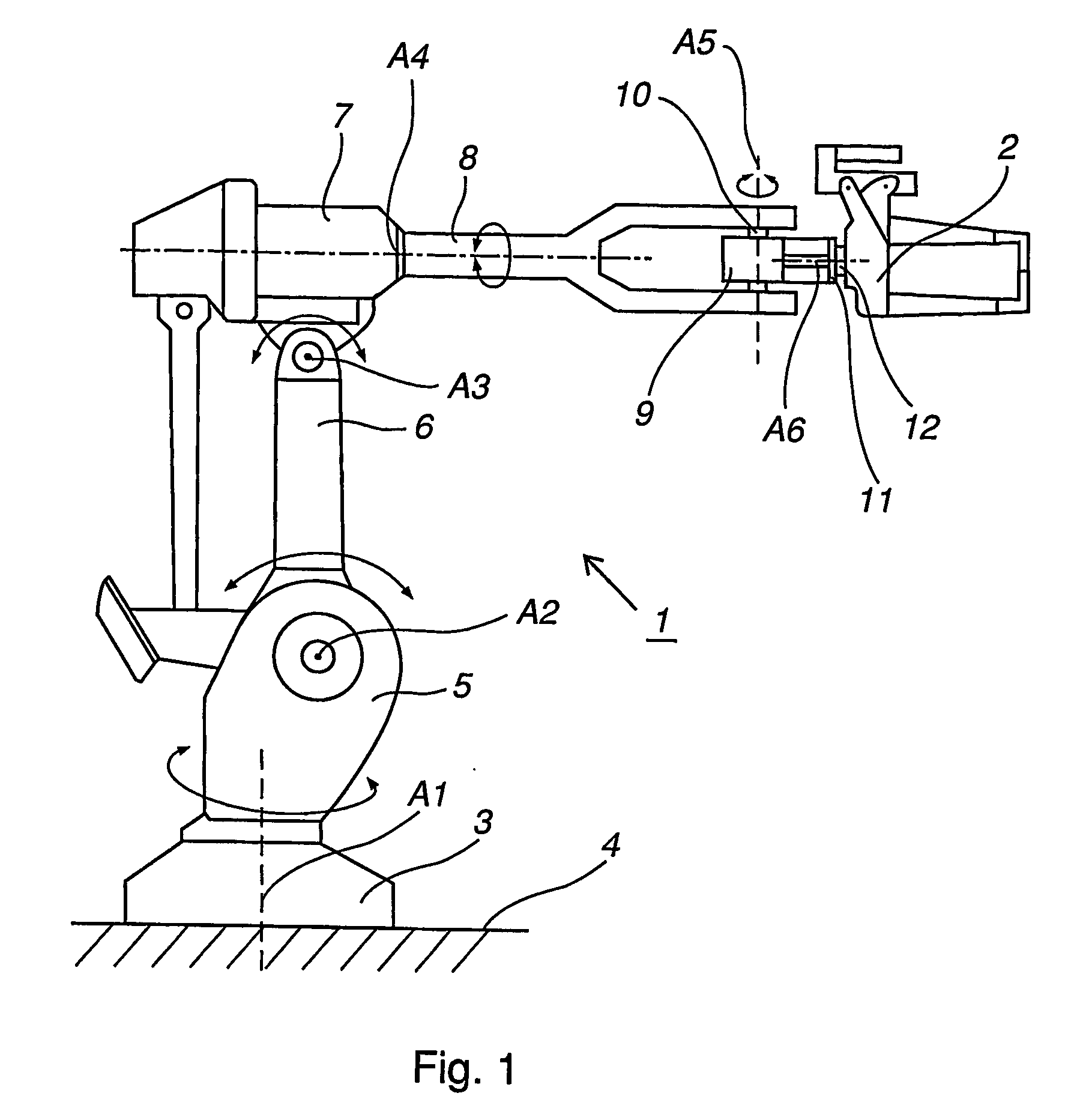

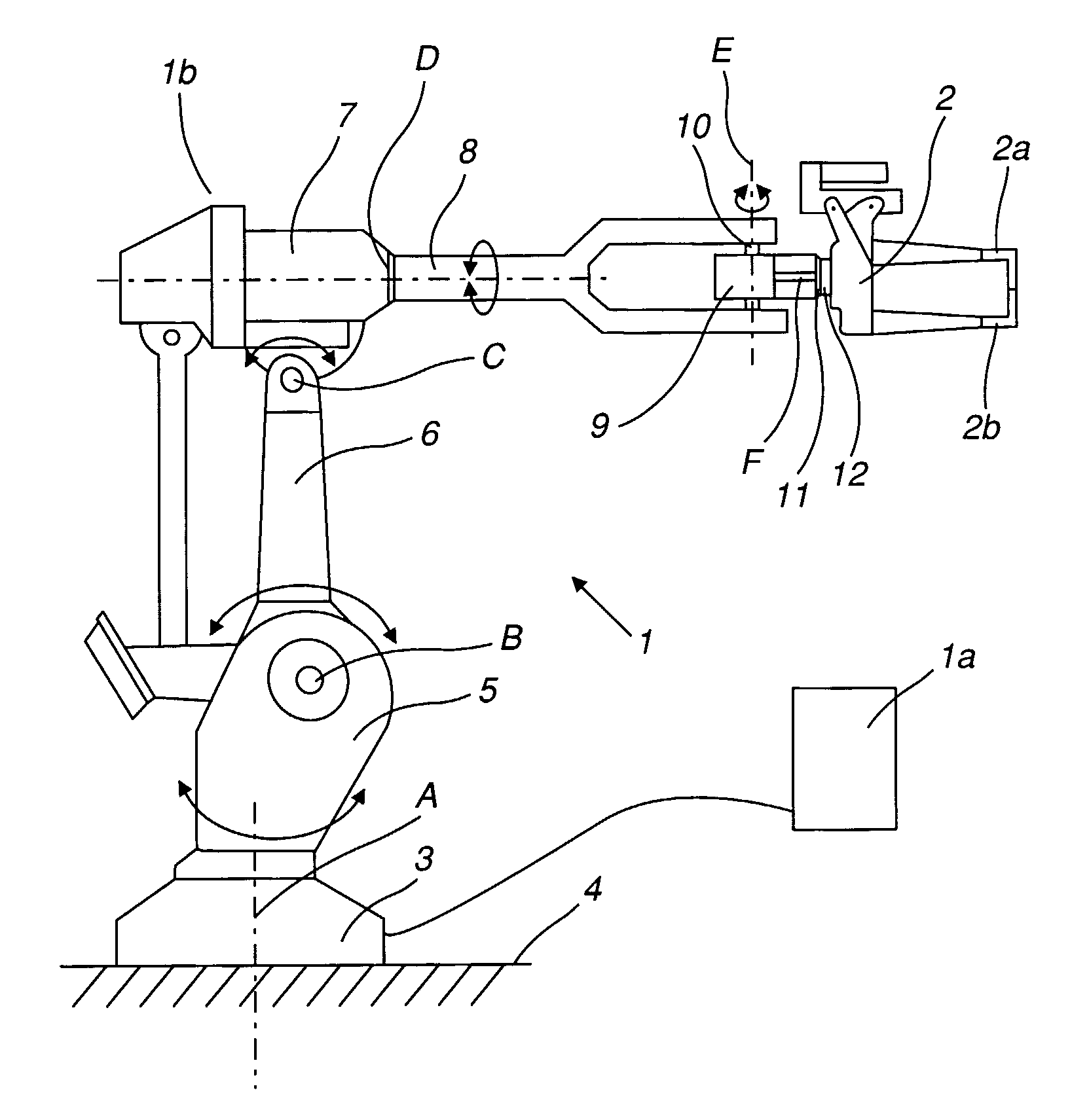

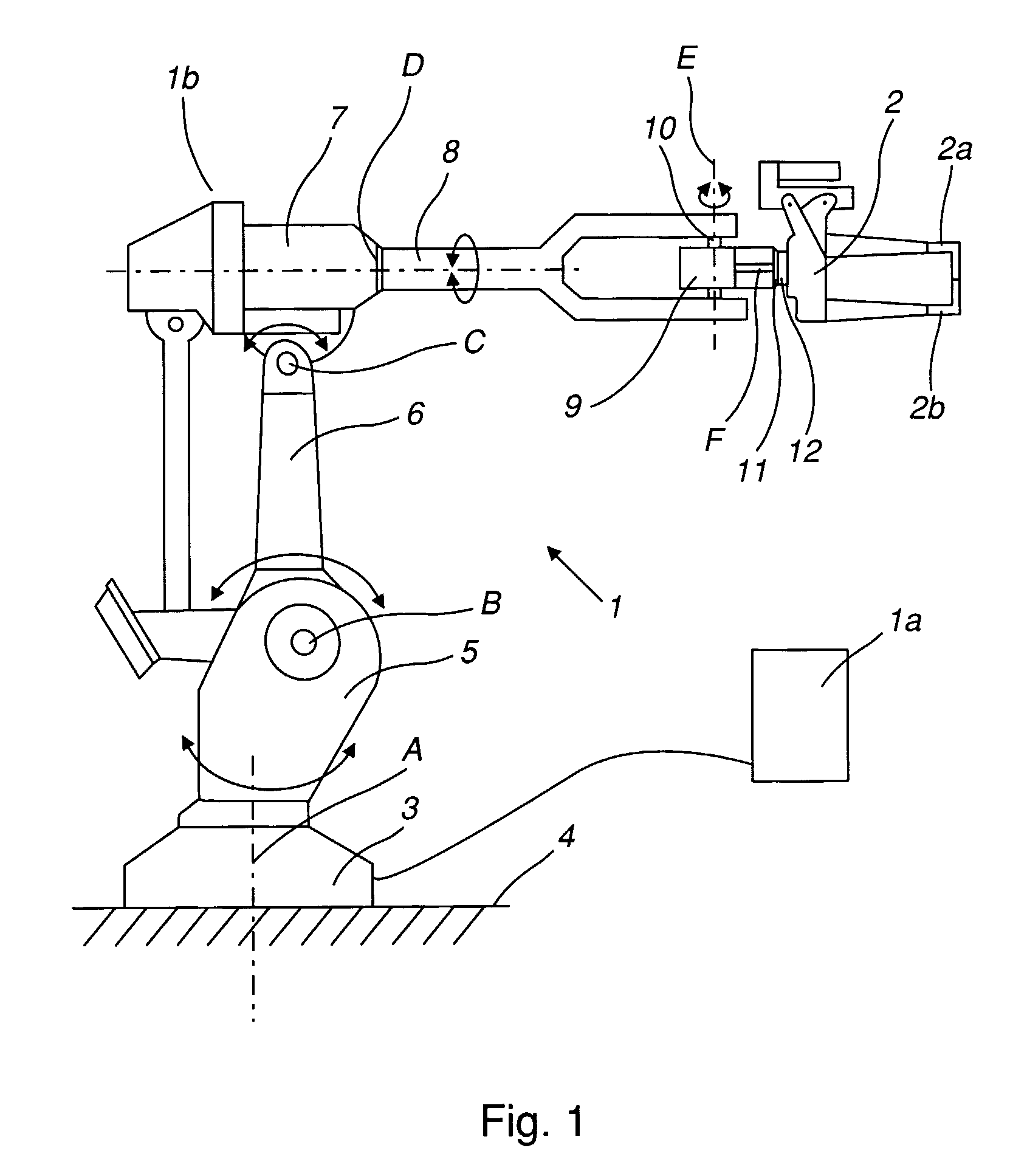

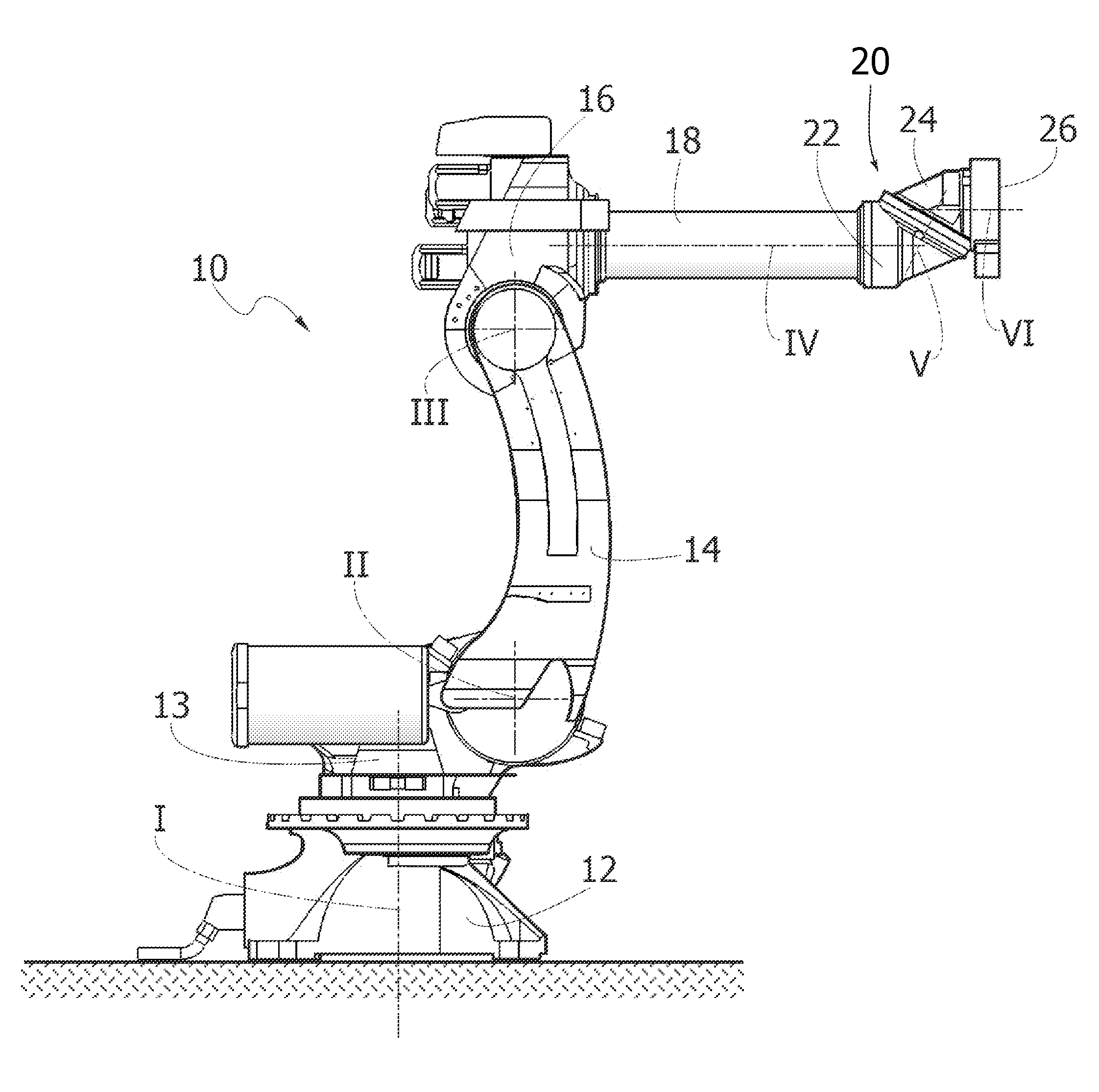

Method for positioning a welding robot tool

ActiveUS20060212169A1Reduce investmentReduce operating costsProgramme-controlled manipulatorResistance electrode holdersControl theoryIndustrial robot

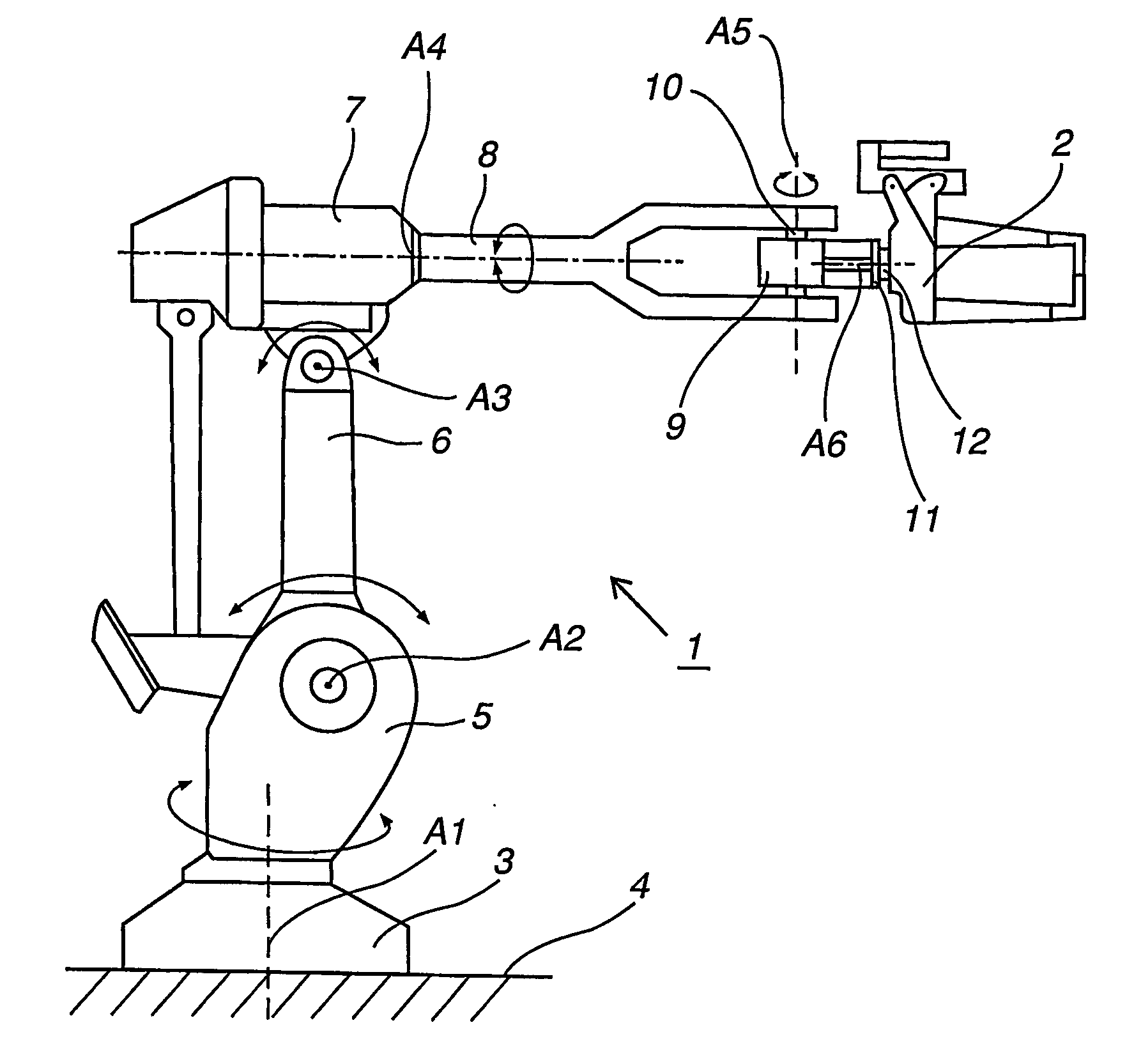

A method for joining together at least two sheets with a tool controlled by an industrial robot and including a first arm and a second arm that are mutually movable in relation to each other. An actual position of the sheets is detected by bringing one of the arms to sense the actual position of the sheets. The distance between an ideal position and the actual position is calculated and the actual position of the tool is moved the calculated distance, whereafter the sheets are joined together.

Owner:ABB (SCHWEIZ) AG

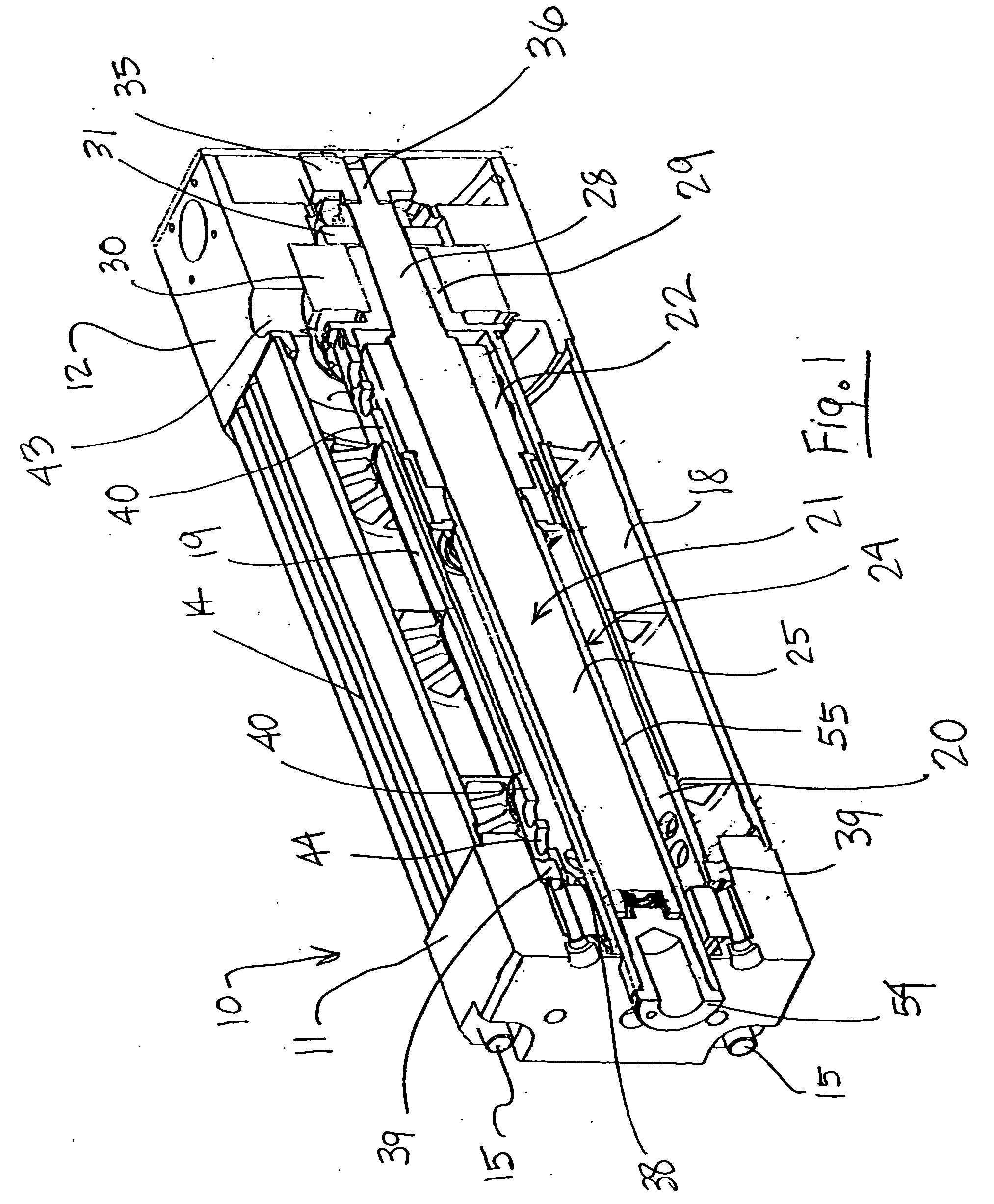

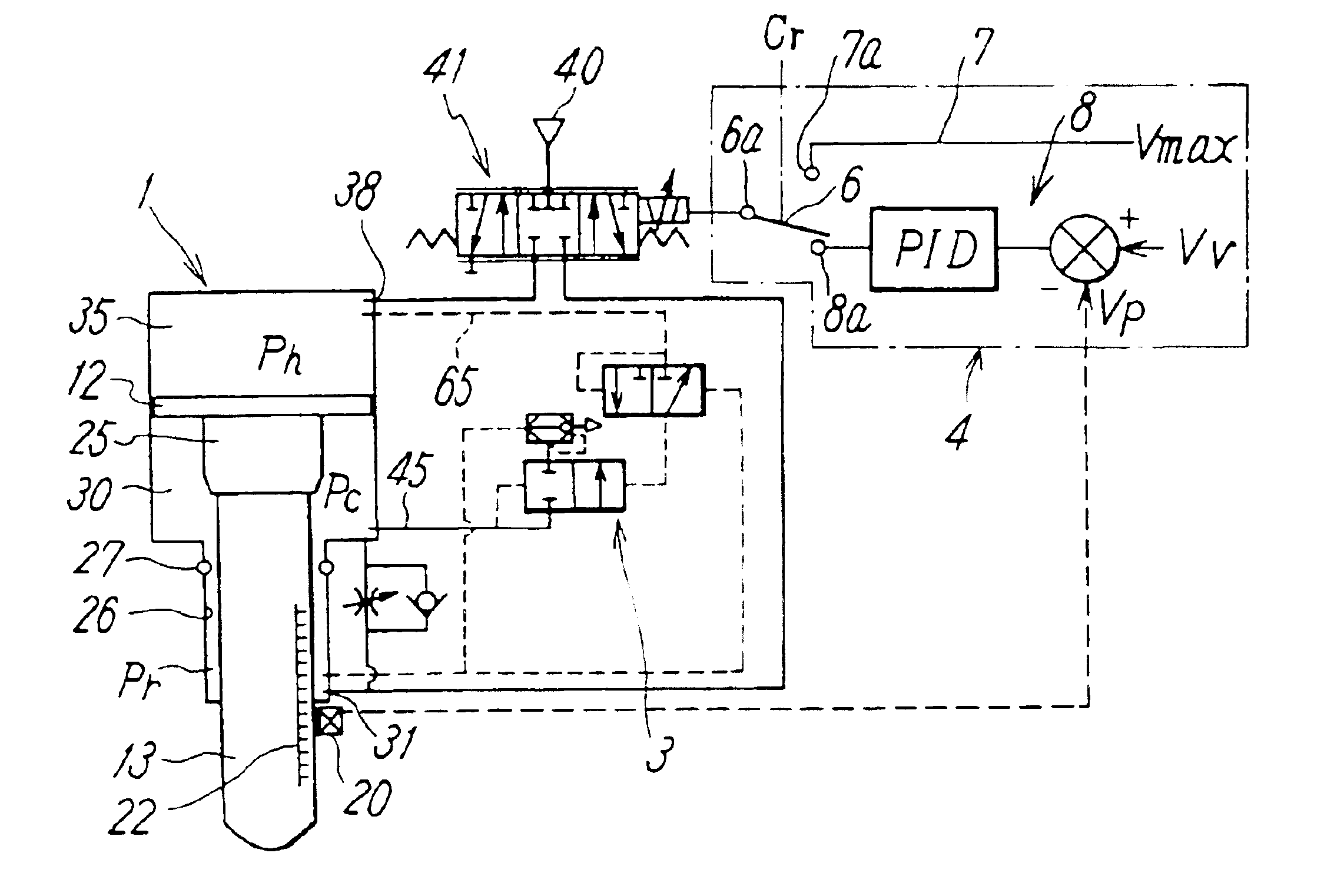

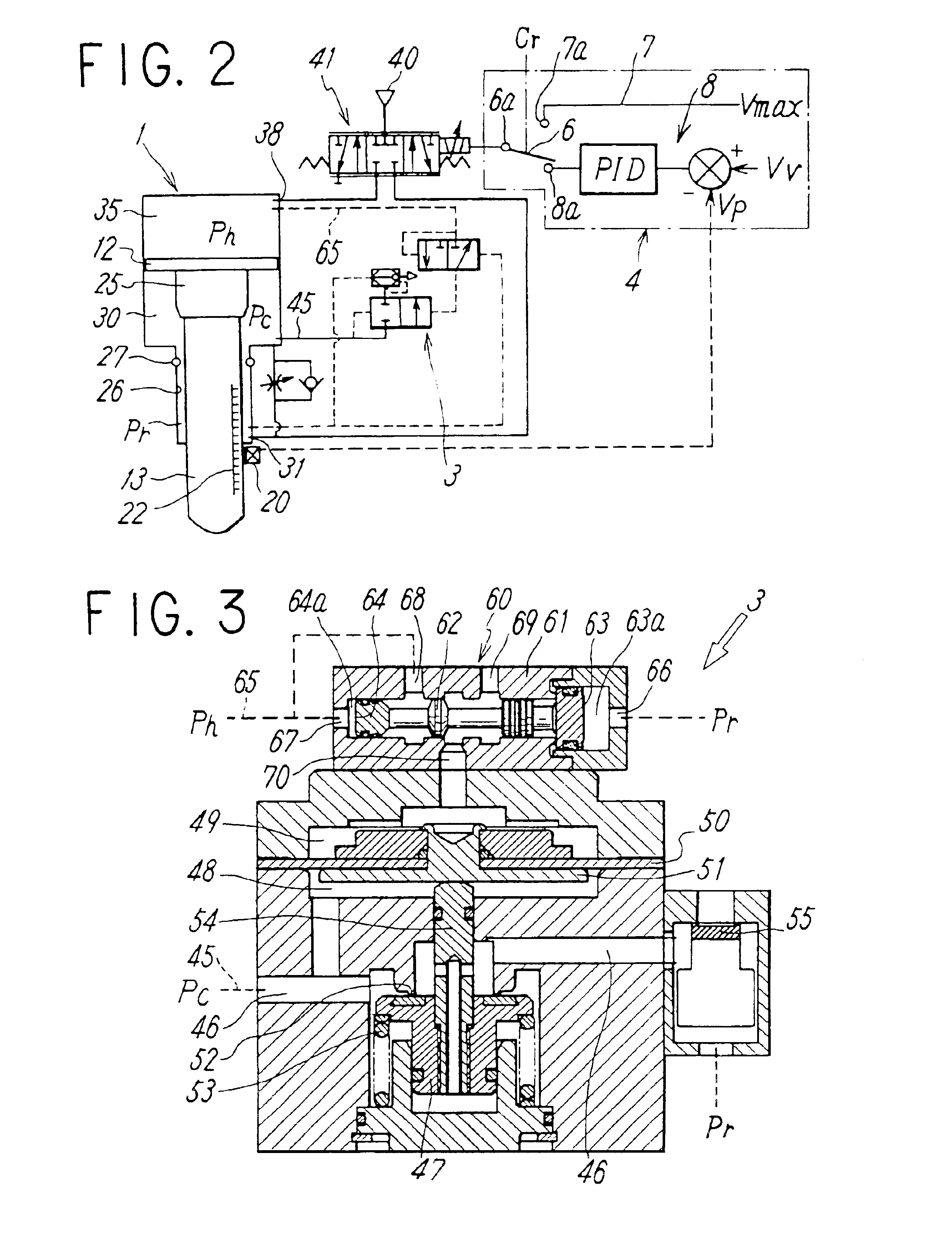

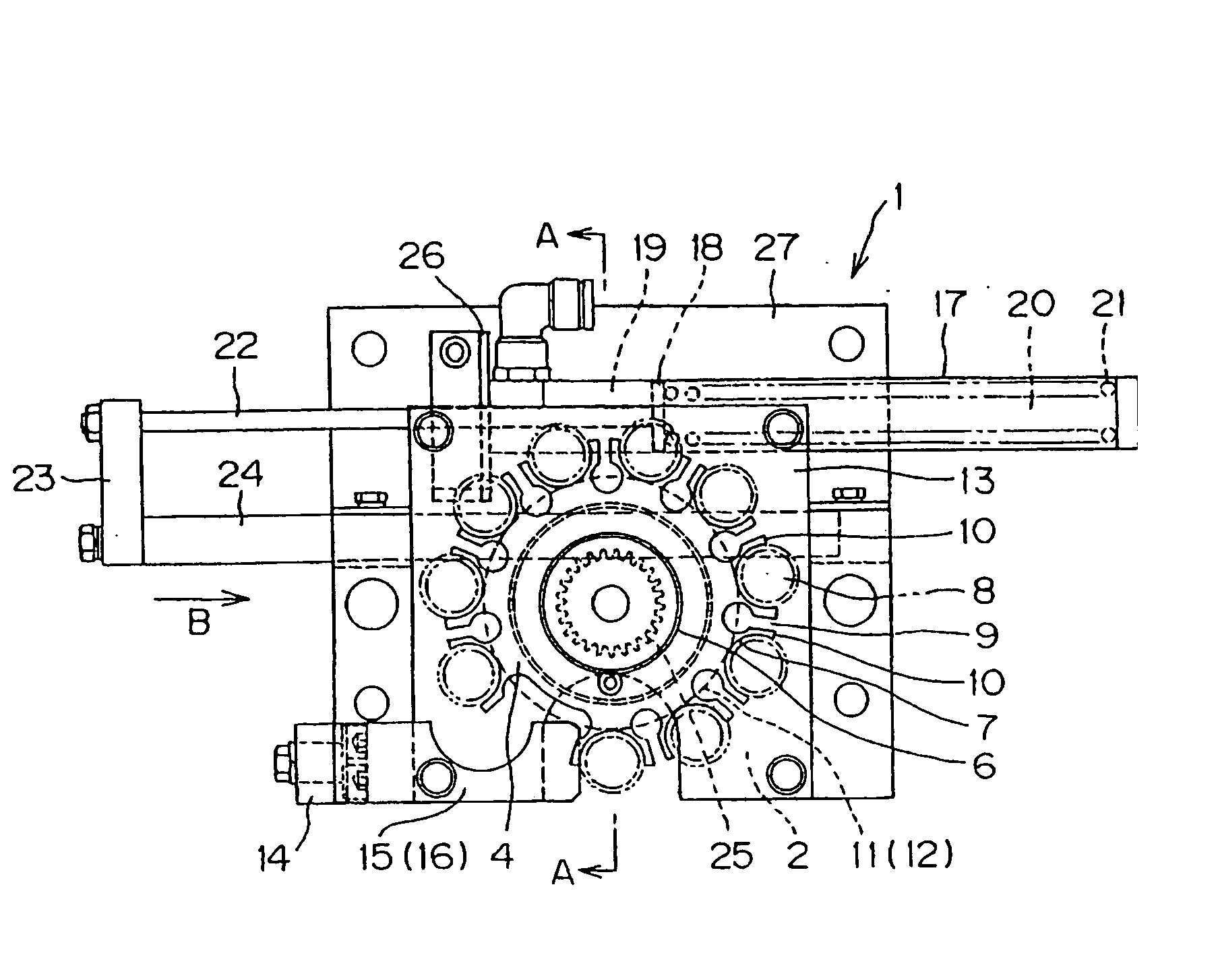

Driving unit of a welding equipment

There is provided a driving unit of a welding equipment capable of reducing the size of the driving unit, of reducing the moment of inertia, and of being compact and having an excellent operability. The driving unit of a welding equipment provided with a pressure application shaft that is driven by a motor comprises a screw shaft provided integrally with or substantially integrally with a rotary shaft of the motor, a nut provided integrally with or substantially integrally with the pressure application shaft and is screwed with a screw of the screw shaft, and a baffling mechanism provided on the pressure application shaft, and wherein the rotary shaft of the motor is positioned substantially coaxially with the screw shaft and a rotary force outputted from the rotary shaft of the motor is converted into a reciprocating motion of the pressure application shaft.

Owner:OBARA GRP

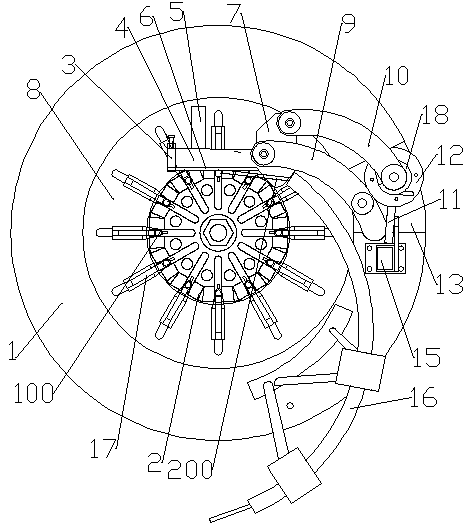

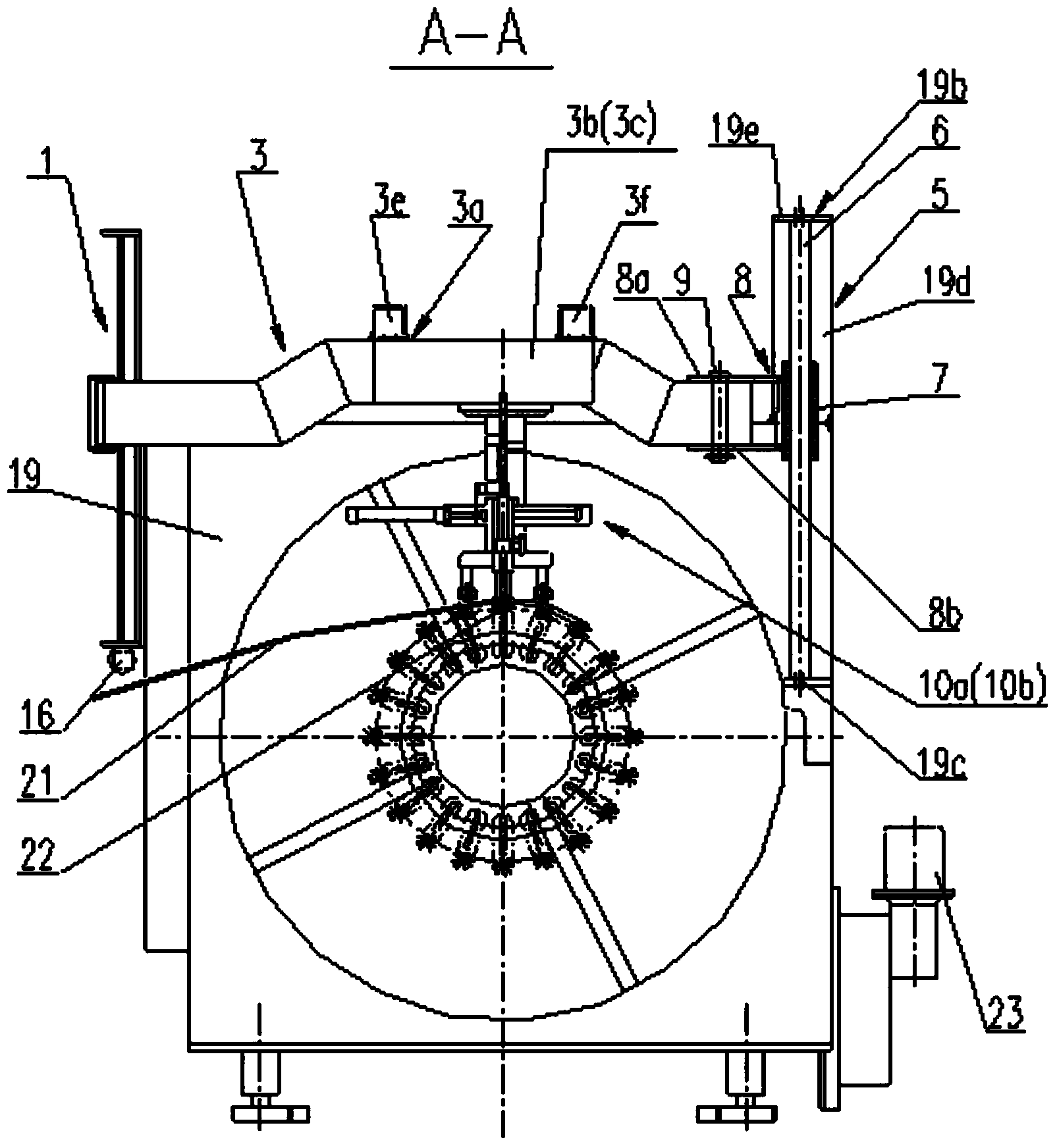

Spiral welding device of conic electric pole reinforcement cage seam welder

ActiveCN104128701AThe pressure is guaranteed to be constantGuarantee welding qualityResistance electrode holdersMeshed-ring wire networkEngineeringRebar

The invention relates to welding devices, in particular to a spiral welding device of a conic electric pole reinforcement cage seam welder. The spiral welding device comprises a longitudinal reinforcement fixing device, a welding device body and a circumferential reinforcement fixing device. The circumferential reinforcement fixing device and the welding device body rotate around the longitudinal reinforcement fixing device. Circumferential reinforcements are welded to longitudinal reinforcements in a wound mode through the welding device body. The welding device body comprises a welding electrode and a pressure mechanism. The pressure mechanism exerts constant pressure to the welding electrode, so that constant pressure of a welding point is kept by the welding electrode. According to the spiral welding device of the conic electric pole reinforcement cage seam welder, the longitudinal reinforcements do not rotate, the circumferential reinforcements are welded in the wound mode, it is guaranteed that the longitudinal reinforcements are not twisted, high noise generated by rotation of the longitudinal reinforcements is avoided as well, the welding speed can be increased by over two times, it can be guaranteed that pressure of the welding electrode is constant all the time along with change of the diameter of a reinforcement cage in the welding process, and therefore welding quality is guaranteed.

Owner:TANGSHAN TIANZE SPECIAL WELDING EQUIP

Welding device for side sealing plate barb of switch cabinet

InactiveCN105057865AImprove connection strengthImprove quality consistencyResistance electrode holdersWelding/cutting auxillary devicesRubber ringElectricity

The invention relates to the technical field of manufacturing of low-voltage drawer-type switch cabinets and discloses a welding device for a side sealing plate barb of a switch cabinet. The welding device comprises an electric welding machine, a spot welding gun, supporting pillars, a lower base, an electric conduction block, a suspending plate and an upper seat. The electric welding machine is provided with two electrodes, and the spot welding gun is connected with one of the electrodes. Clamps are arranged on the lower seat, and the suspending plate is connected with the upper seat through an air cylinder. The electric conduction block is connected to the suspending plate. The electric conduction block is electrically connected with the other electrode. The spot welding gun is connected to the suspending plate and is provided with a barb fixing structure. The supporting pillars comprise damper springs, upper sections and lower sections, wherein the upper sections and the lower sections are sleeved together. The upper ends of the upper sections are provided with connecting rings, inner rings are arranged in the connecting rings in a penetrating mode, the inner rings and the connecting rings are connected together through rubber rings, and connecting pins connected to the lower seat are arranged in the inner rings in a penetrating mode. The welding device has the advantages that a welded part does not need to be fixed manually, and the vibration isolation effect is good; the problems that much effort is cost in welding and the welding quality is poor due to welding by manually fixing the welded part are solved.

Owner:张进

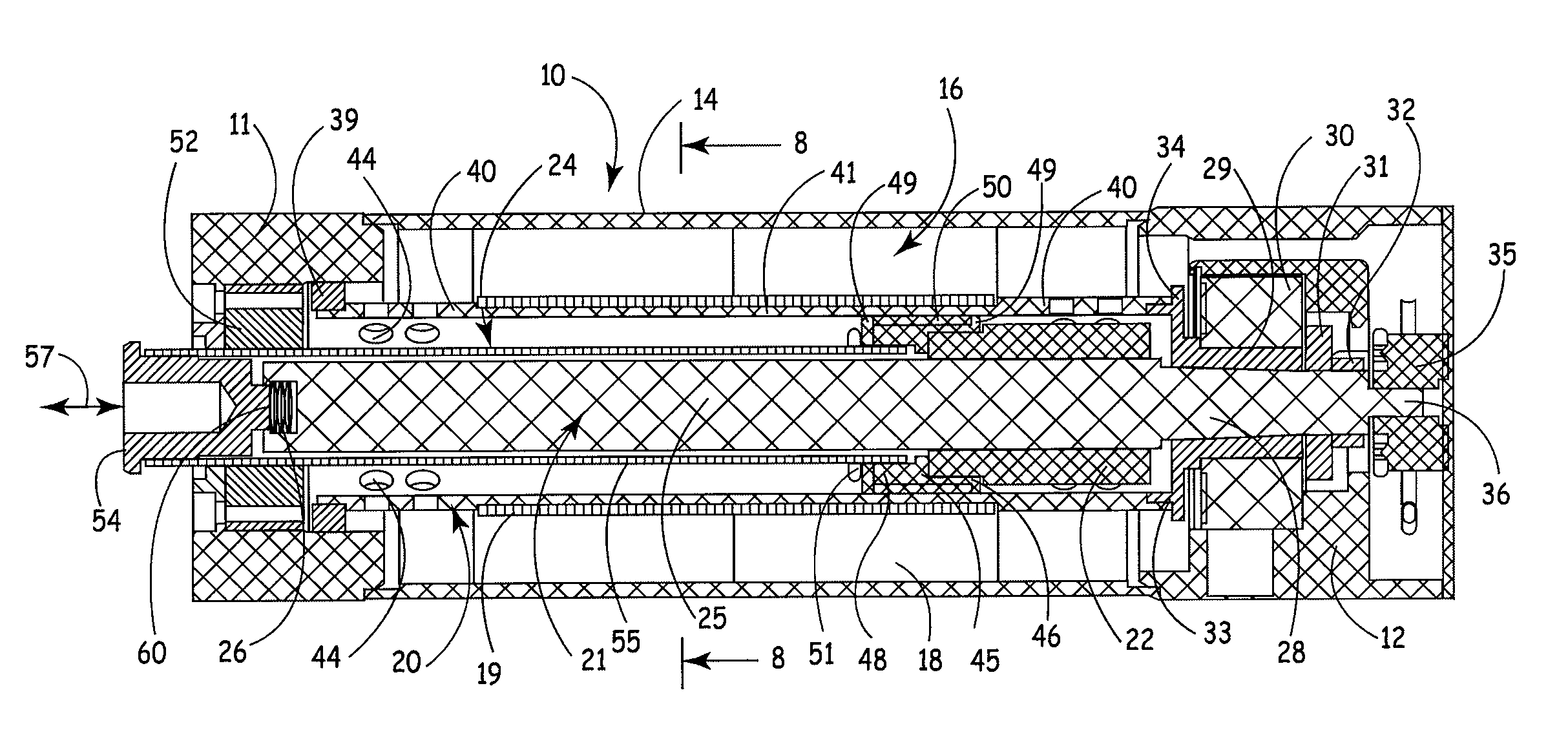

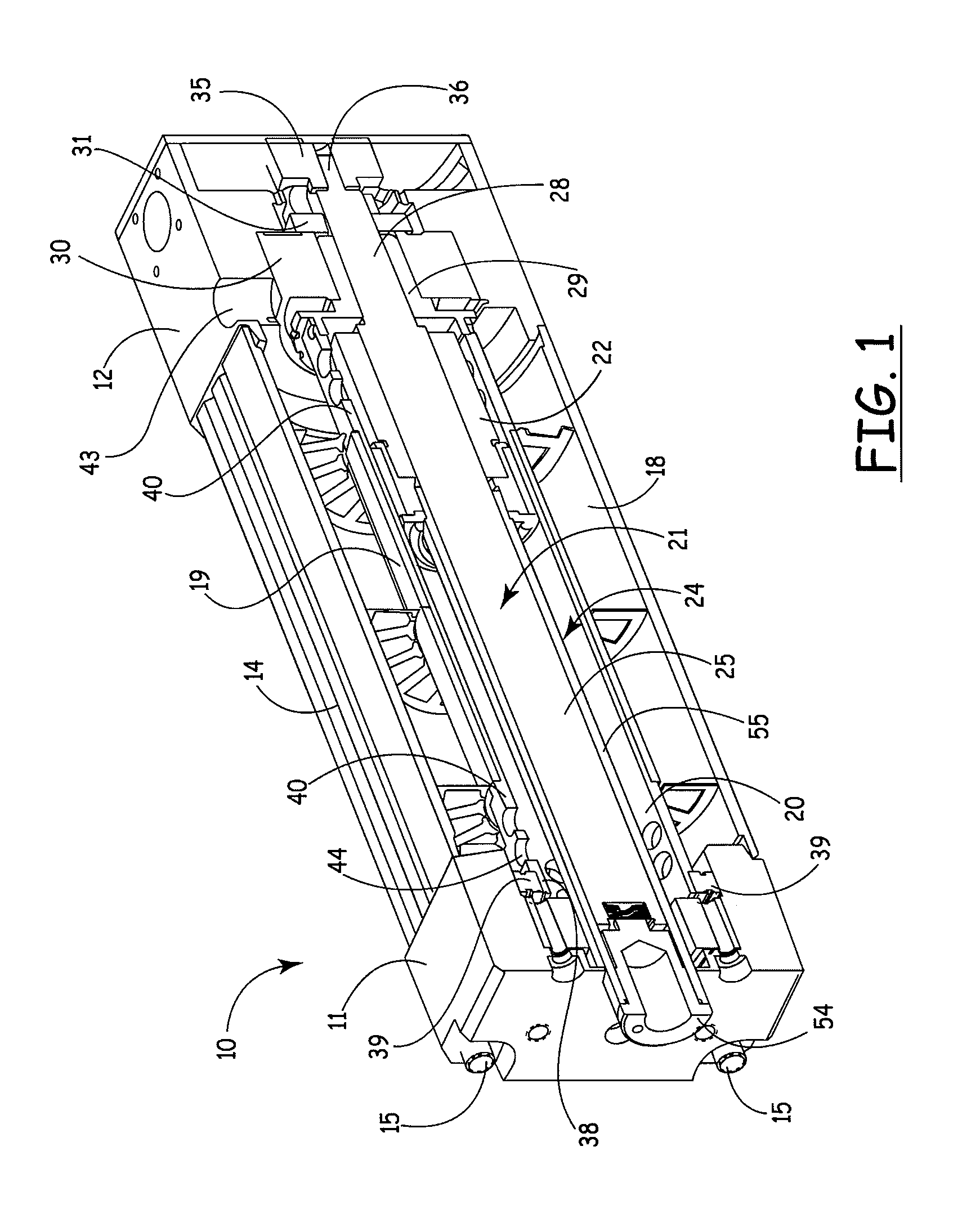

Electric actuator

ActiveUS7541707B2Facilitates a high torqueHigh thrust actuatorResistance electrode holdersGear lubrication/coolingLinear actuatorRotary encoder

Owner:TOL O MATIC

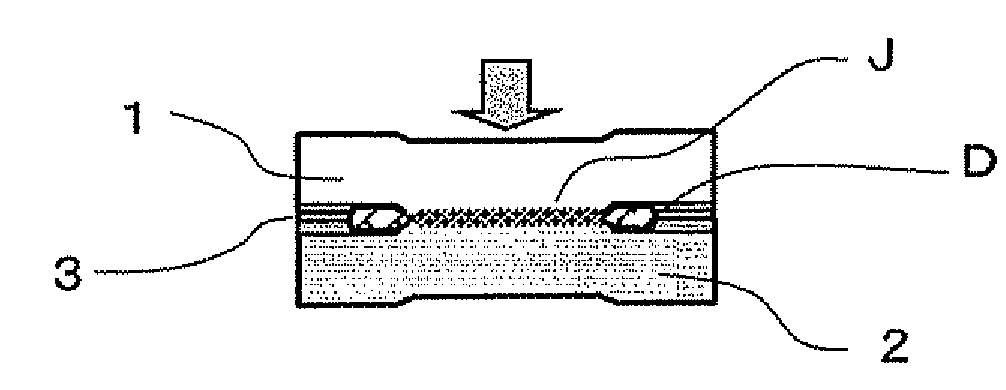

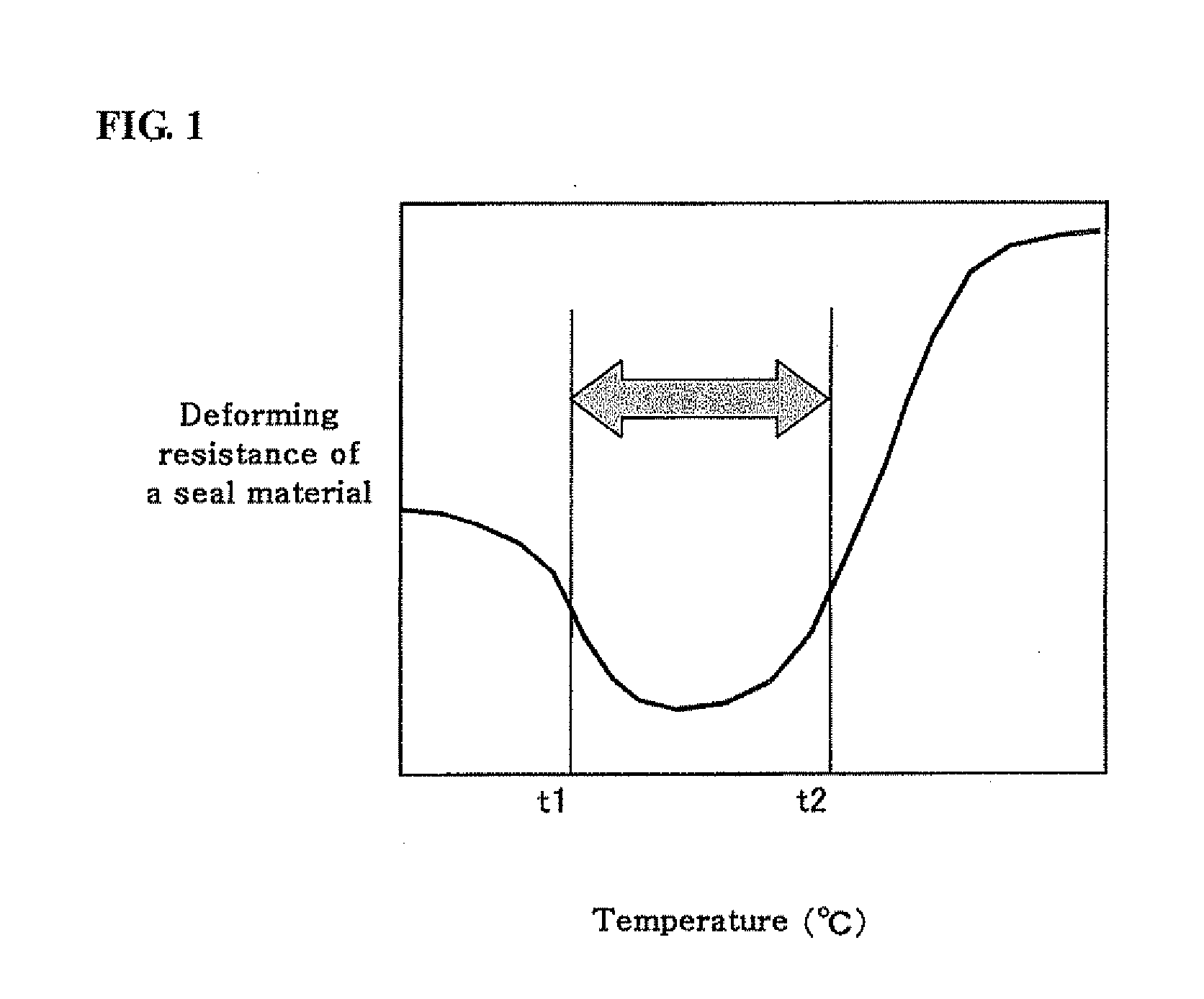

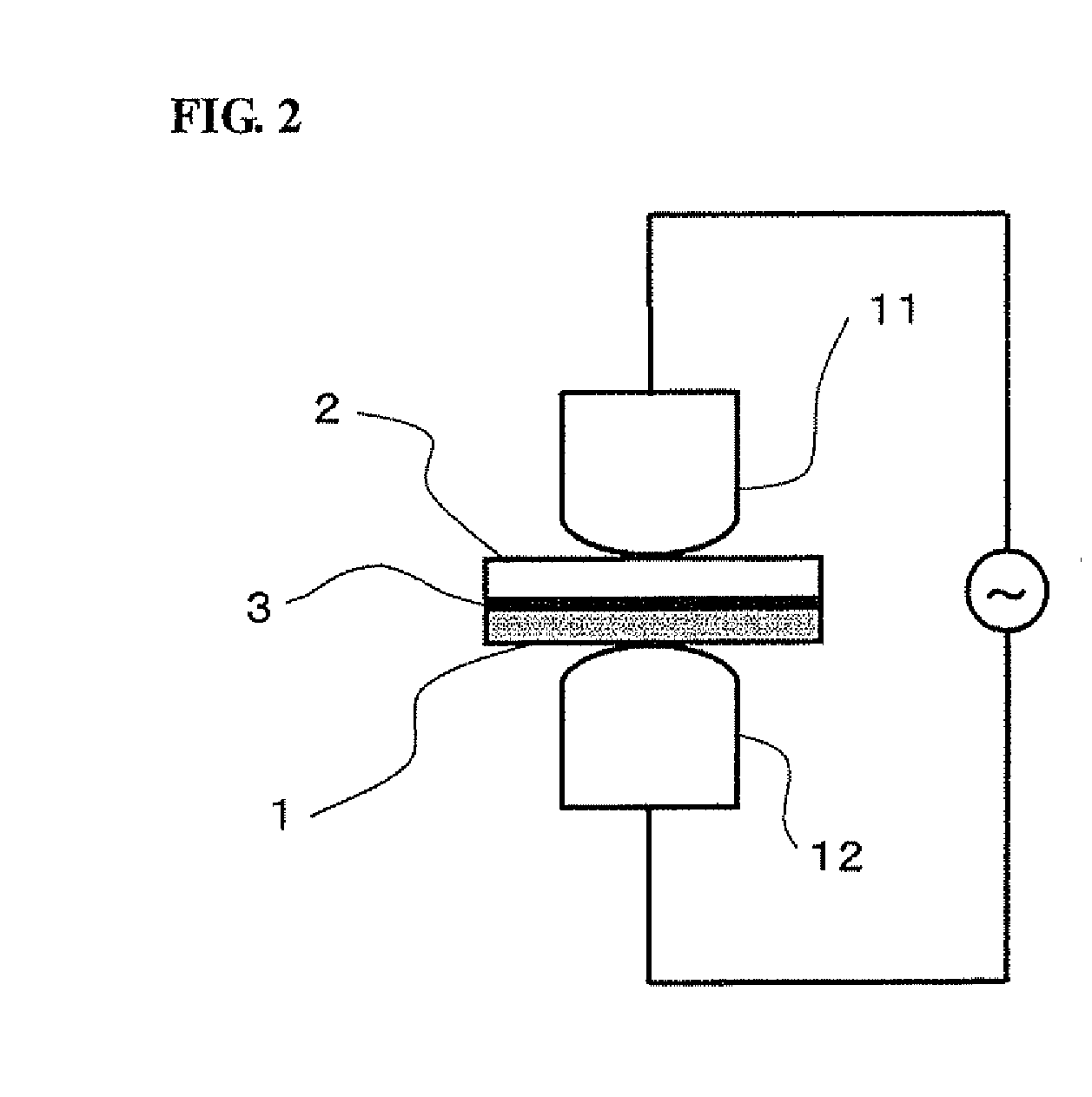

Method and apparatus for bonding dissimilar materials made from metals

ActiveUS20080026247A1Resistance electrode holdersWelding/cutting auxillary devicesBond interfaceUltimate tensile strength

A method of bonding dissimilar metals, a bonding structure formed by such a method and a bonding apparatus for performing such a method. The resulting bond is capable of preventing corrosion (e.g., electric corrosion) resulting from contact of the dissimilar metals and obtains a dissimilar material joint exhibiting anti-corrosive property and bonding strength at low costs. The method includes overlapping two materials made from dissimilar metals having a seal material interposed therebetween and discharging the seal material from a bonding interface and bonding the two materials in direct contact with each other.

Owner:NISSAN MOTOR CO LTD

Electric actuator

ActiveUS20050253469A1Facilitates a high torqueHigh thrust actuatorResistance electrode holdersGear lubrication/coolingLinear actuatorRotary encoder

An electrically powered linear actuator having a thrust assembly, a motor with a rotor surrounding at least a portion of the thrust assembly and a rotary encoder with a rotation sensing member rotatable with the rotor.

Owner:TOL O MATIC

Control method for robots

InactiveUS20090069936A1Accurate and fast and robustEasy to implementResistance electrode holdersProgramme-controlled manipulatorManipulatorIndustrial engineering

A method of an industrial robot including a control unit and a manipulator including a tool including a defined tool center point and a device for determining a distance error between an inaccurately programmed position for a spot on a surface of a work piece and a corresponding actual position.

Owner:ABB (SCHWEIZ) AG

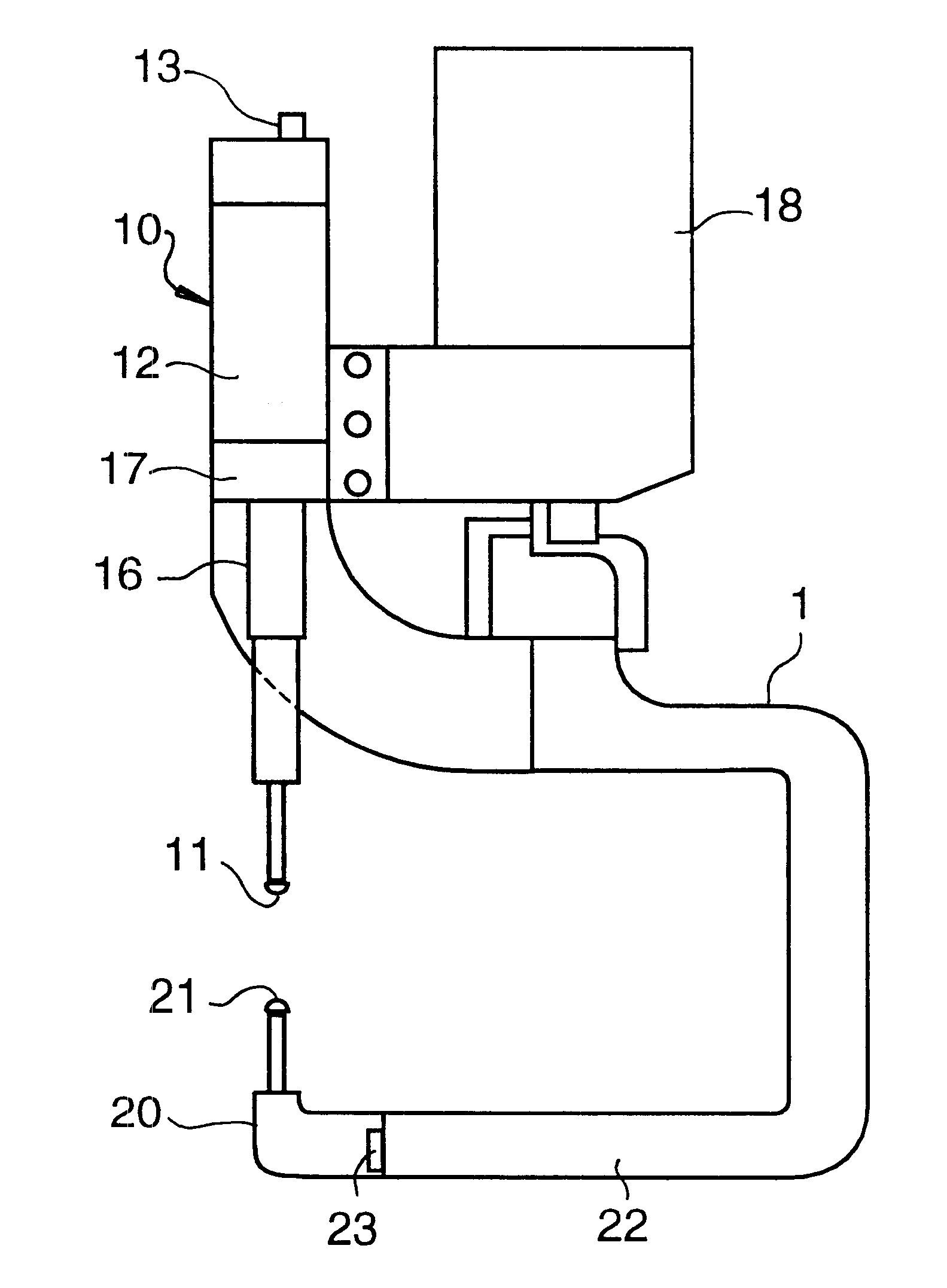

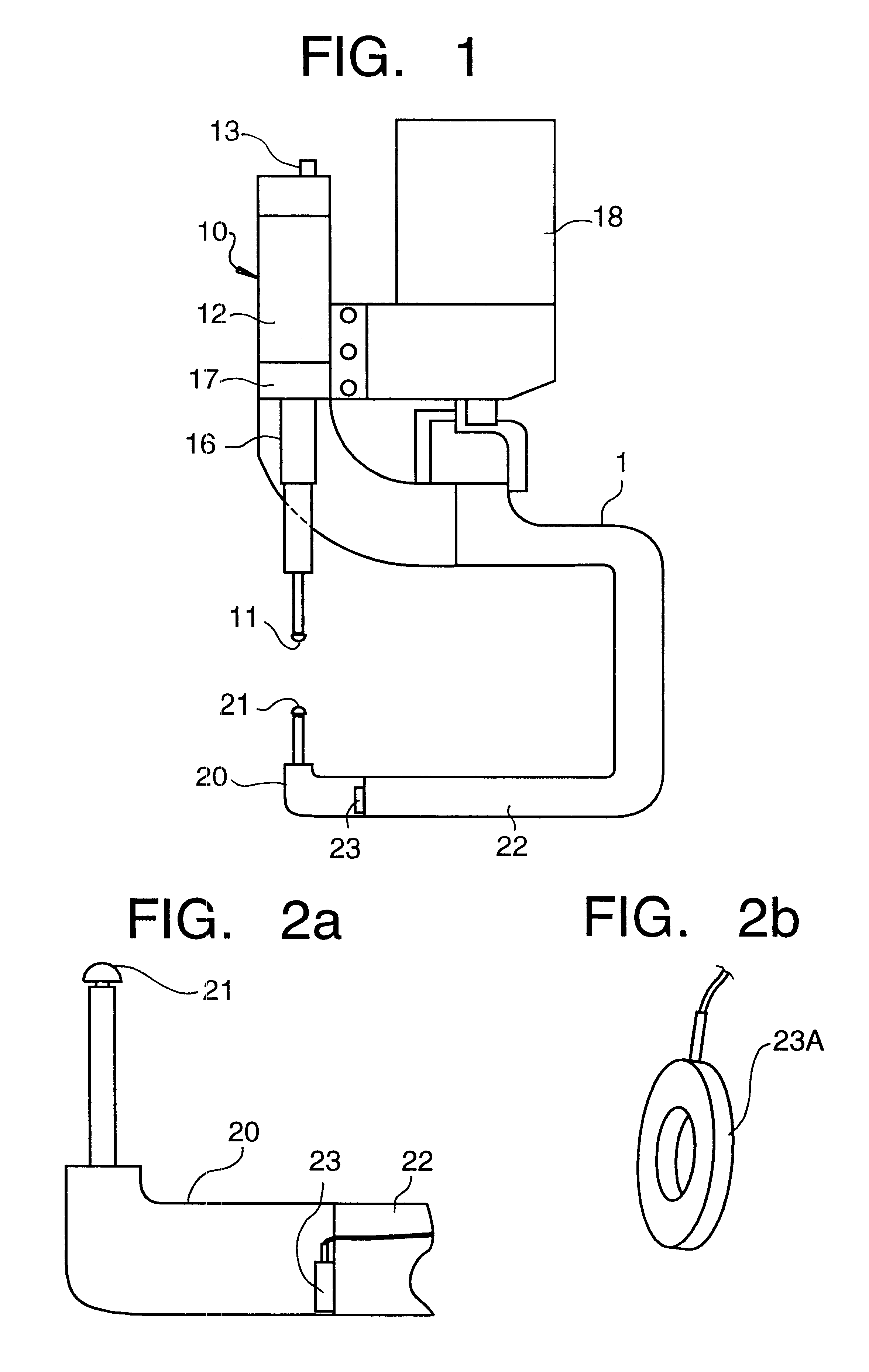

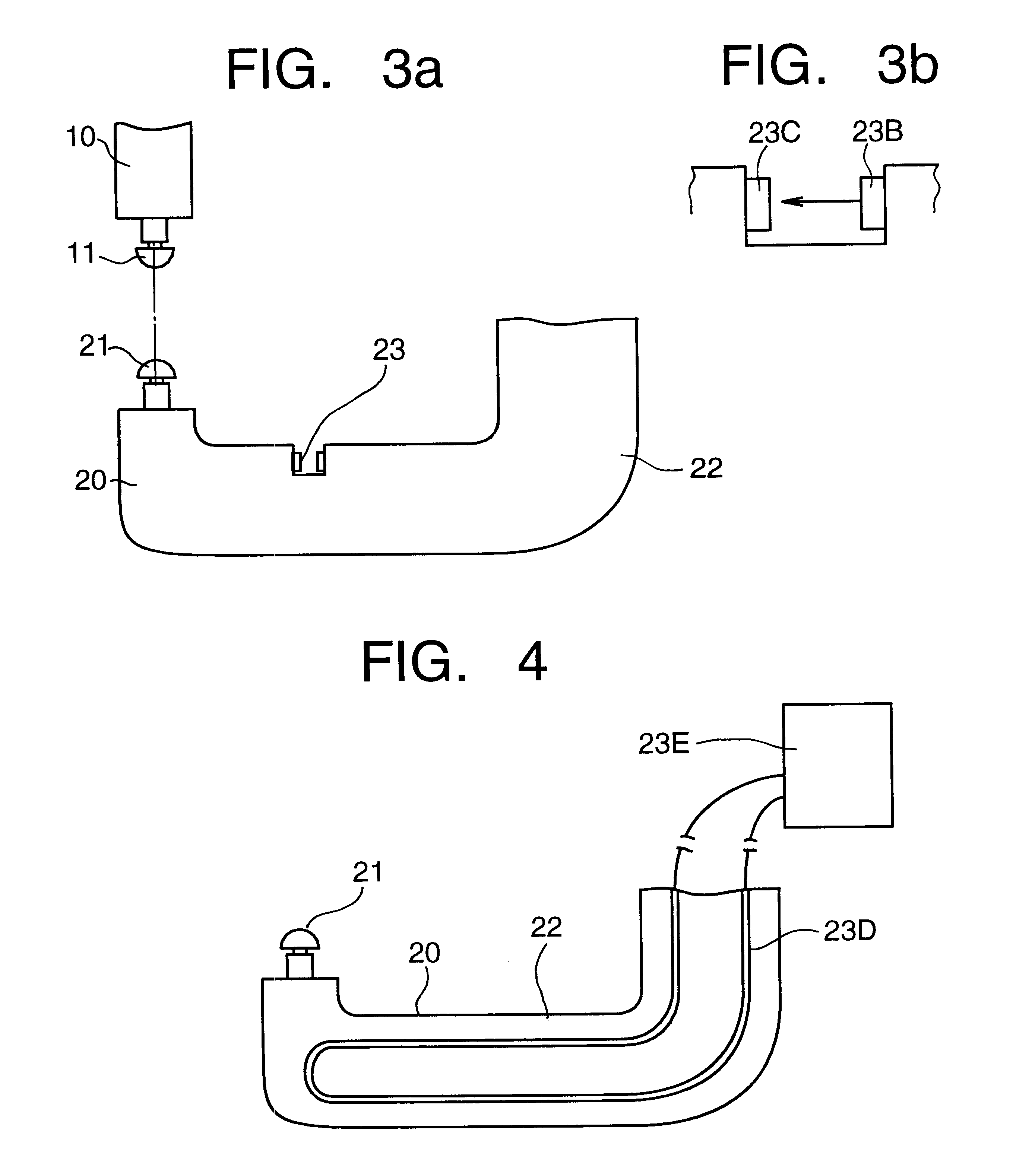

Welding gun and methods conducted using the same

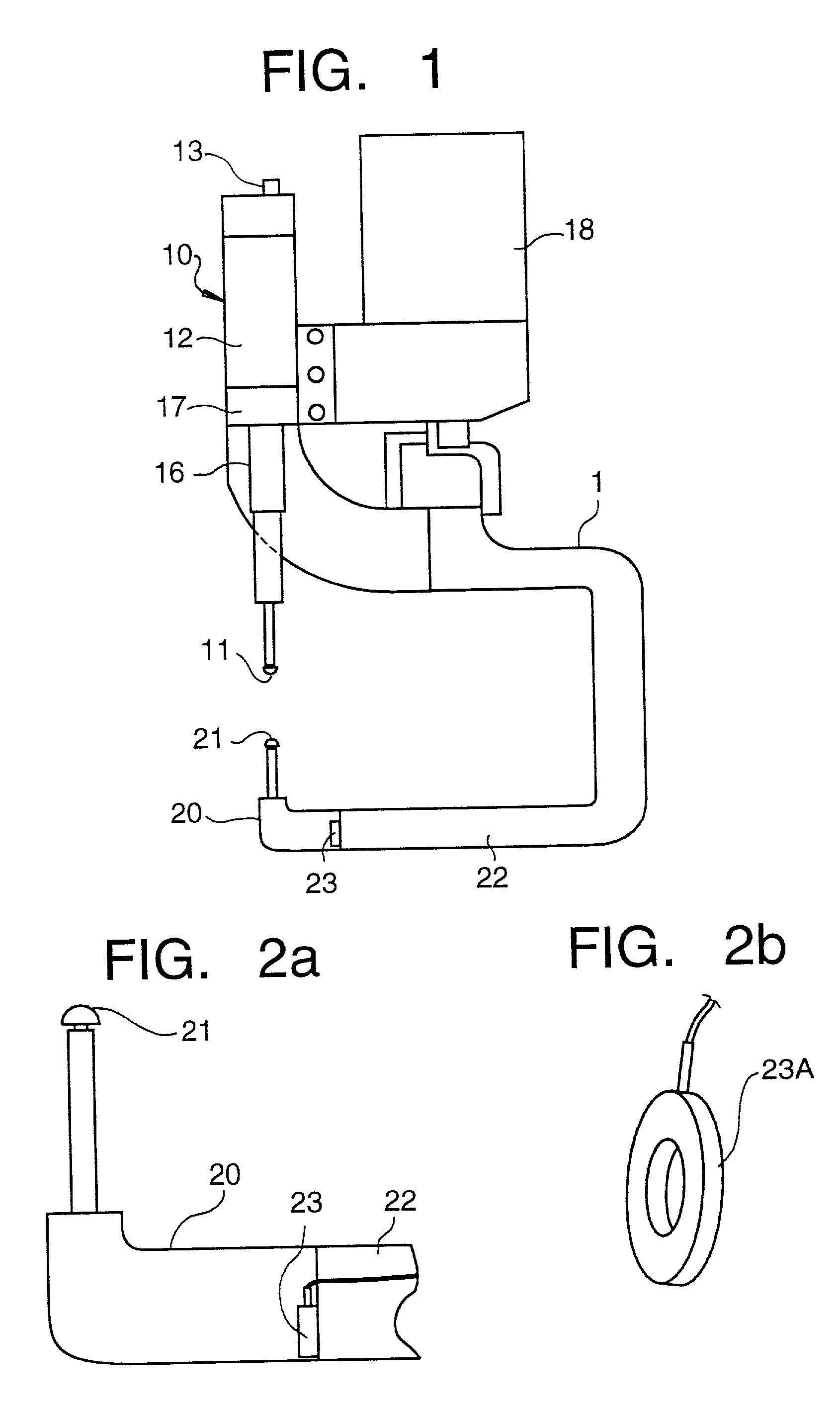

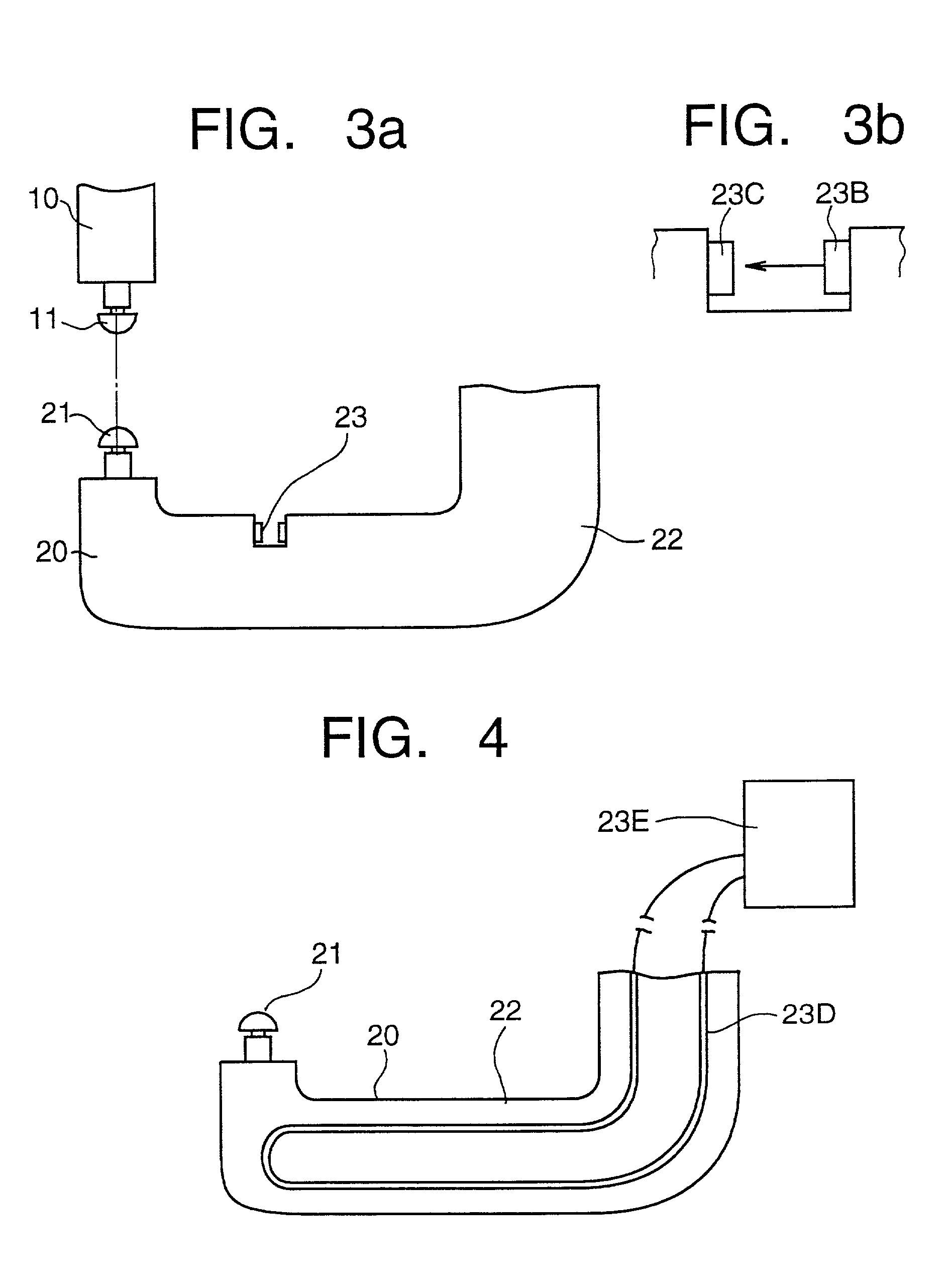

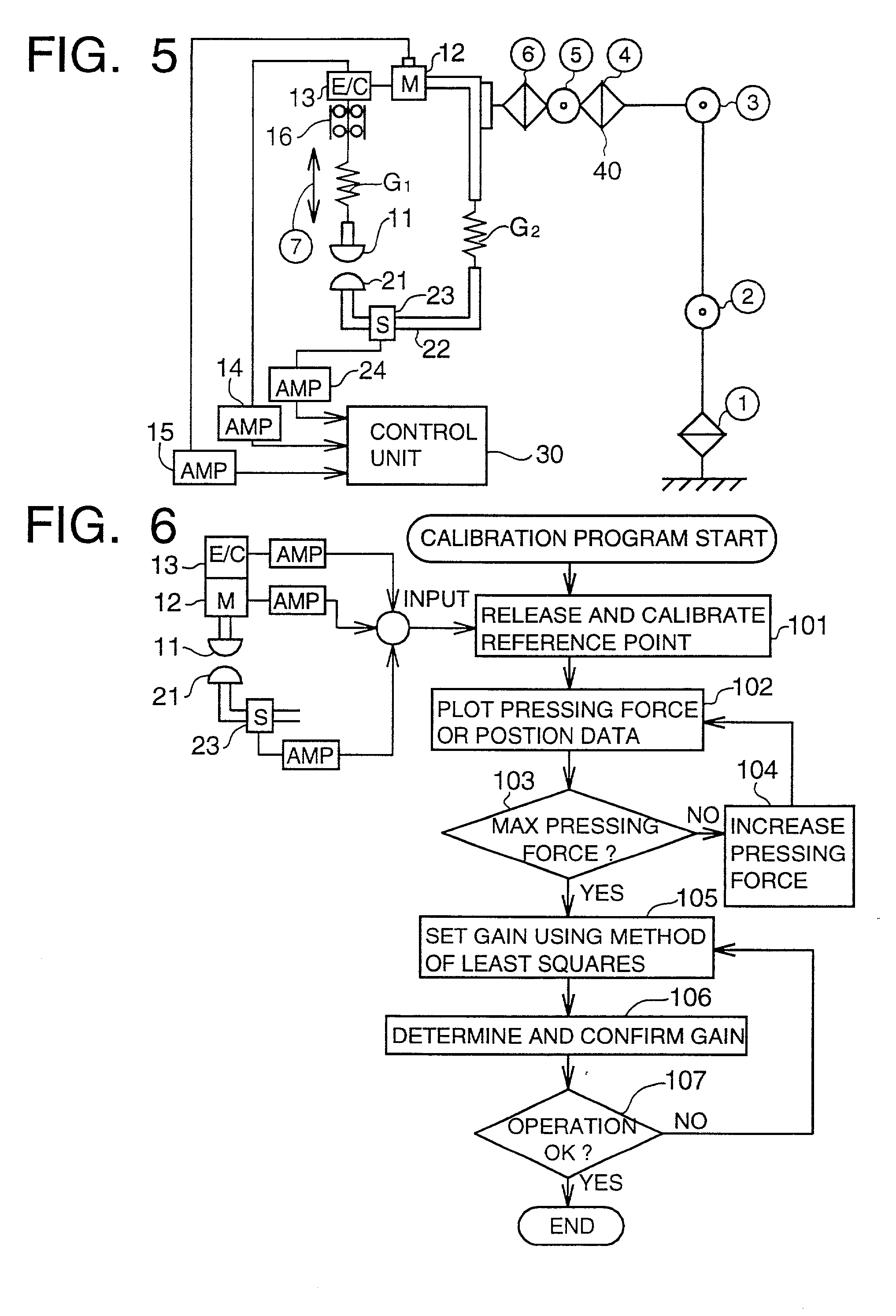

InactiveUS6313427B1Decreased in size and rigidityEliminate gapsResistance electrode holdersArc welding apparatusEngineeringWeld strength

An intelligent welding gun is provided with a fixed side sensor in a fixed side portion. The mechanical impedance of the fixed side portion is kept small, which permits the mechanical impedance to be set in a range where the fixed side sensor can effectively detect at least one of a position of a fixed side welding tip and a pressing force imposed on the fixed side welding tip. The fixed side sensor and a moving side sensor constitute a redundant sensor measurement system. Various kinds of methods conducted using the above welding gun include a method of calibrating a sensor (including calibration of a reference point and a gain), a control method of suppressing a welding expulsion, a re-welding feedback control method, a control method of a welding strength, a control method of reducing a clearance between workpieces, a method of correcting a welding robot track, and a method of managing a positional accuracy change at a welding point.

Owner:TOYOTA JIDOSHA KK

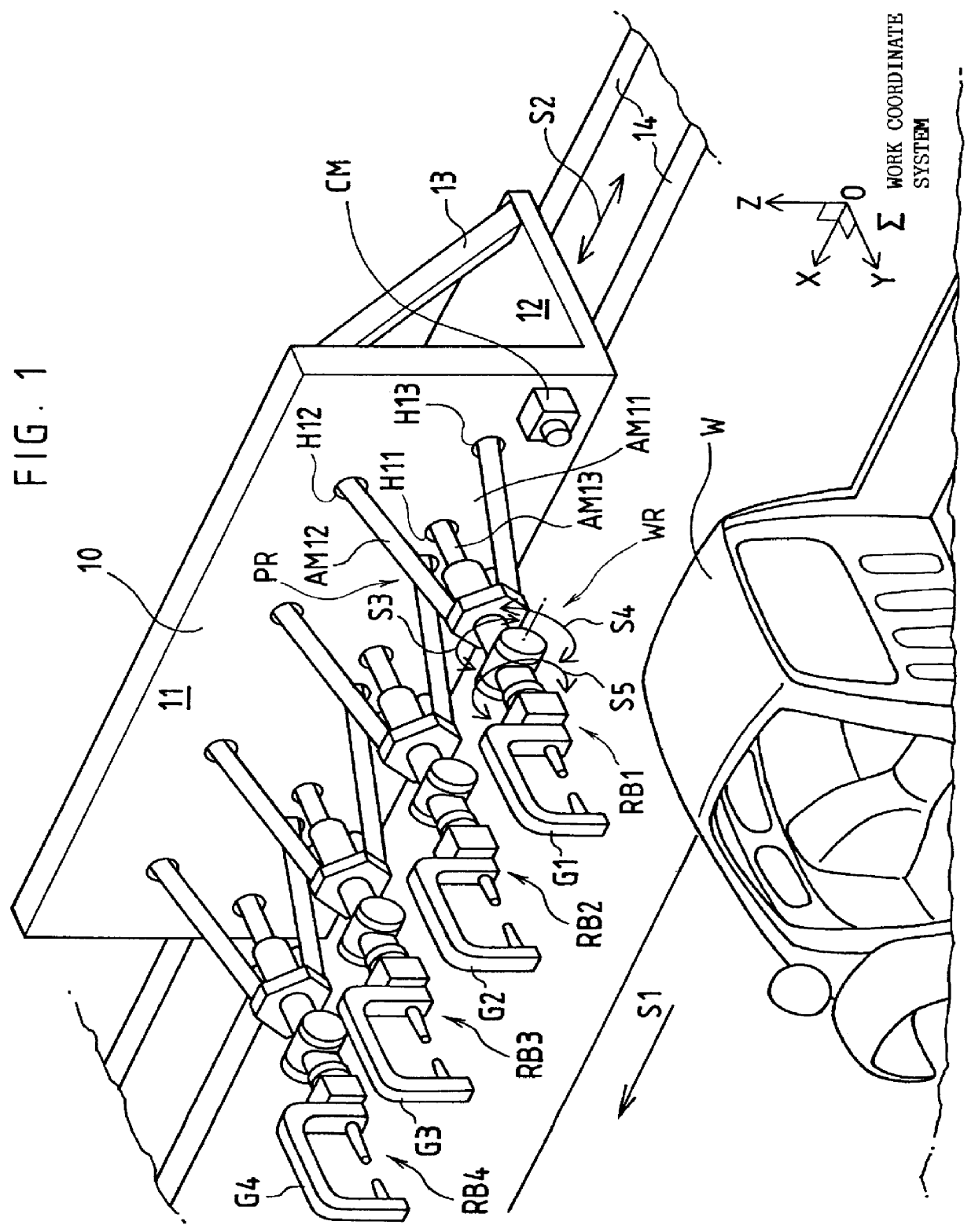

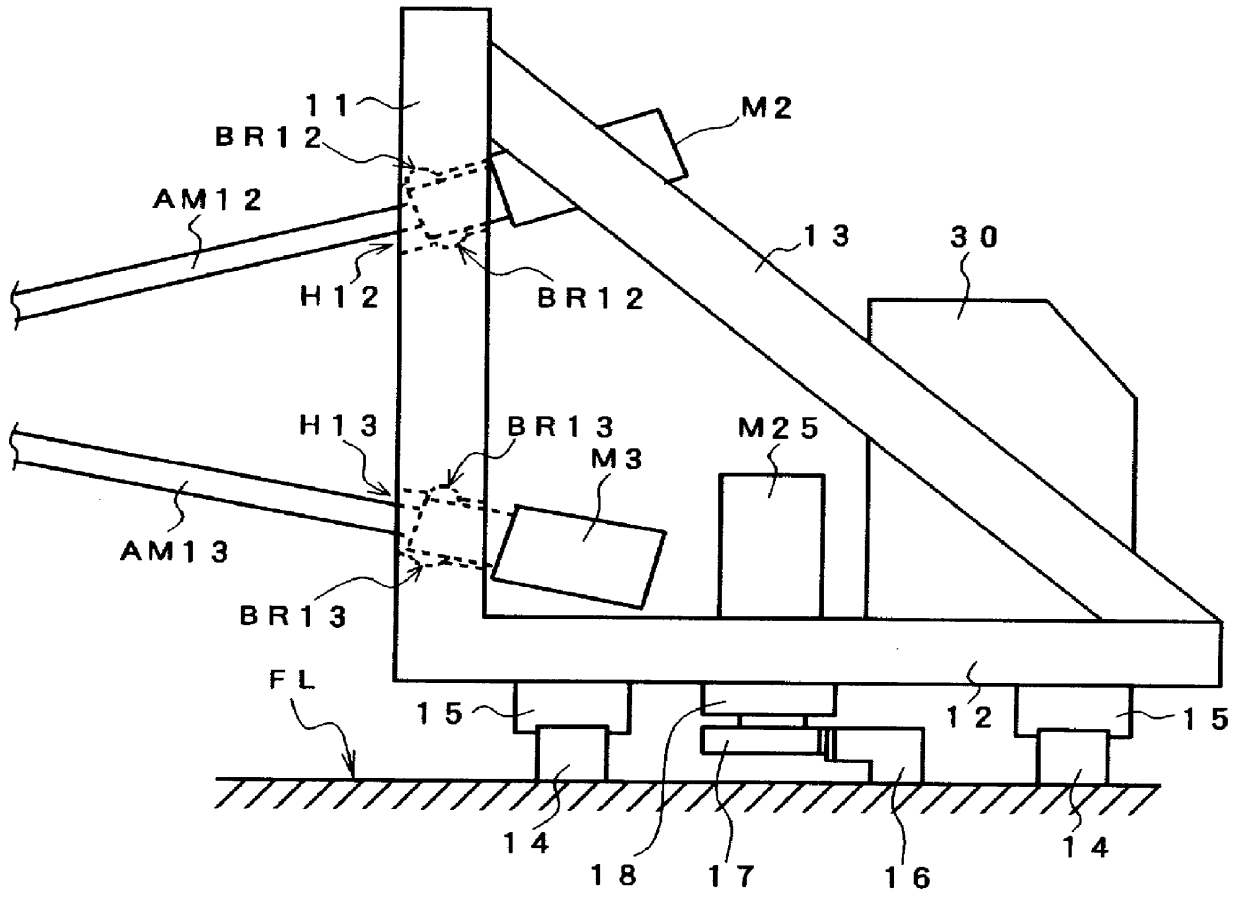

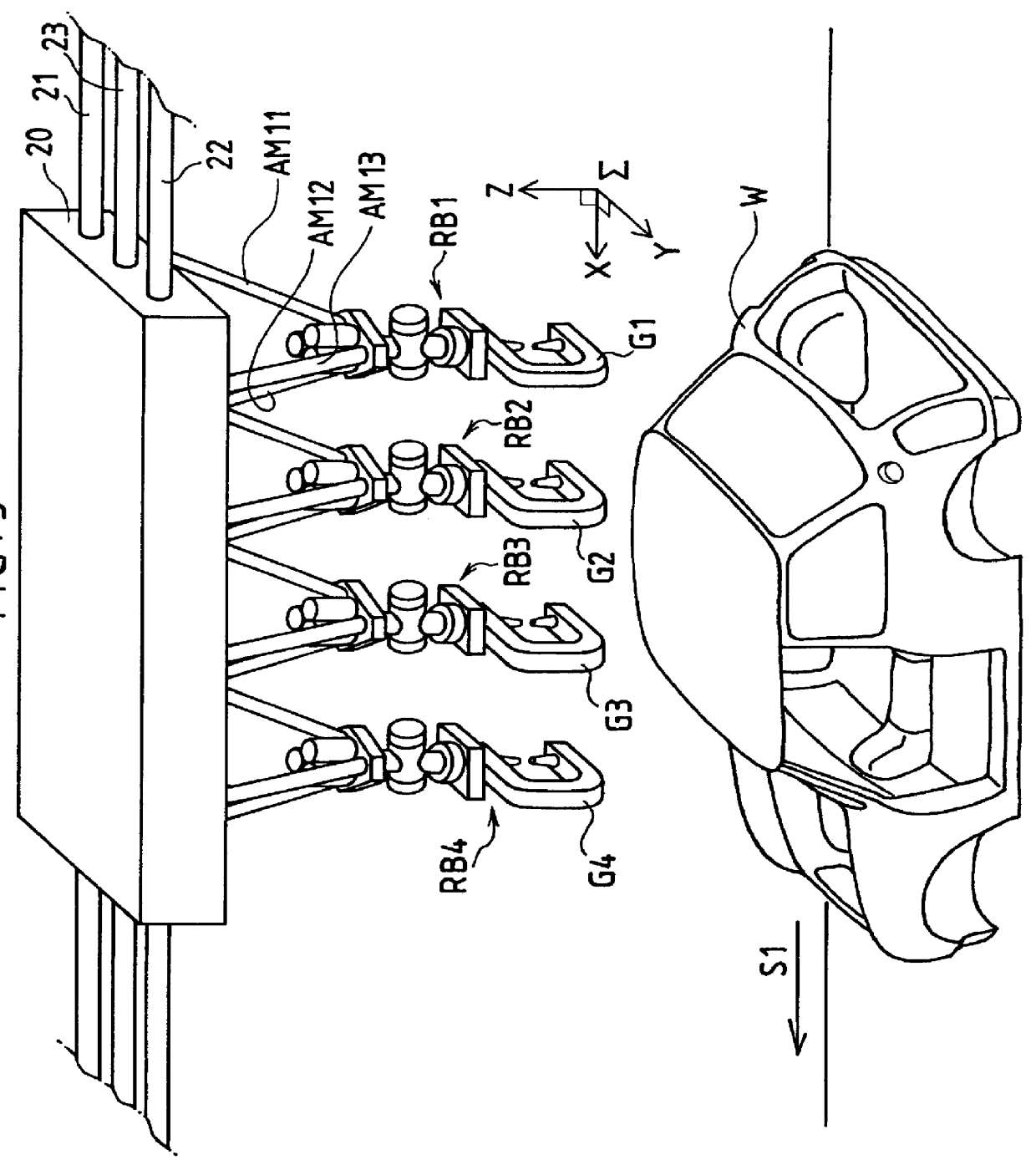

Spot welding system

InactiveUS6059169AImprove Spot Welding EfficiencySave spaceResistance electrode holdersWelding/cutting auxillary devicesEngineeringSpot welding

PCT No. PCT / JP97 / 01462 Sec. 371 Date Dec. 22, 1997 Sec. 102(e) Date Dec. 22, 1997 PCT Filed Apr. 25, 1997 PCT Pub. No. WO97 / 39853 PCT Pub. Date Oct. 30, 1997A spot welding system employing parallel link robots arranged densely with one another. When an arrival of a workpiece W being conveyed is detected by a camera CM, a frame moves along guides to start tracking of the workpiece, and a plurality of robots RB1-RB4, each having a parallel link with a plurality of expandable / retractable arms and a wrist mounted on a distal end of the parallel link, start operation. A plurality of points on the workpiece are welded by spot welding guns G1-G4 attached to the wrists of the respective robots. Proximal end portions of the expandable / retractable arms are swingably supported by an upright wall of the frame, and the respective robots are disposed so as to project from the frame. The parallel link robots may be suspended from the frame to be arranged densely.

Owner:FANUC LTD

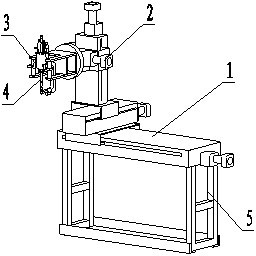

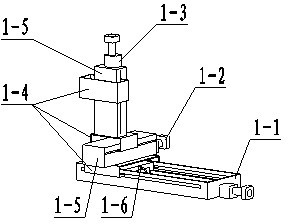

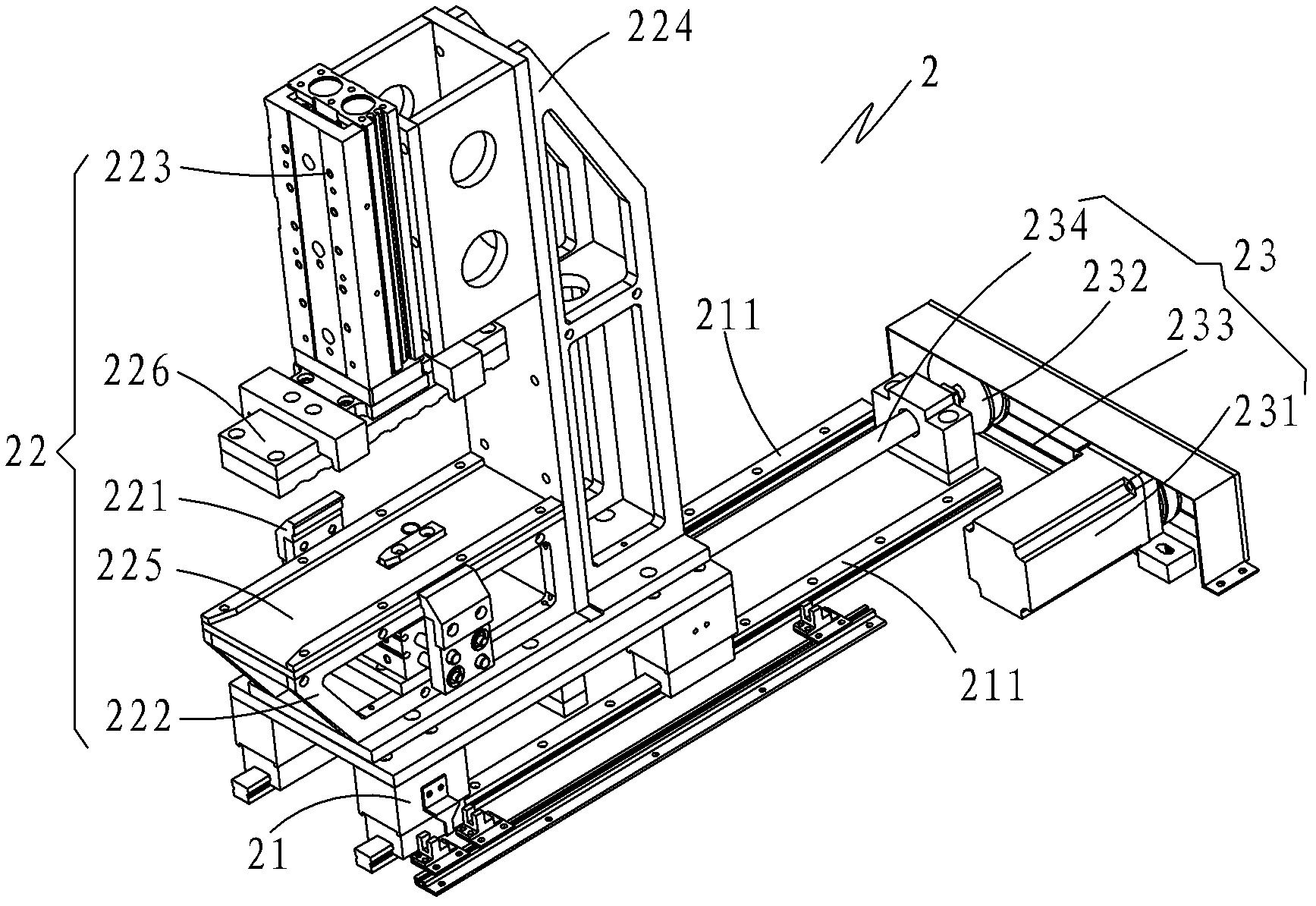

Four-axis linkage automatic spot welding machine

InactiveCN102513677AGuarantee welding qualityReduce labor intensityResistance electrode holdersSpot weldingManufacturing line

A four-axis linkage automatic spot welding machine is used for welding of welding spots at various spatial positions in automobile body welding production, and solves the problems of high equipment cost and high labor intensity of manual operation. The four-axis linkage automatic spot welding machine comprises a parallel moving mechanism, a rotating mechanism, a welding clamp suspension mechanism, a welding clamp and a base, wherein the base is of a frame structure, the parallel moving mechanism is mounted on the base, the rotating mechanism is connected with the parallel moving mechanism through a connecting support, the welding clamp suspension mechanism is fixedly connected with the rotating mechanism, and the welding clamp is mounted on the welding clamp suspension mechanism. The four-axis linkage automatic spot welding machine has the advantages of simplicity in operation, safety and reliability, is applied to an automobile body part welding production line, and on the premise of ensuring the welding quality of a workpiece, the labor intensity of operators can be remarkably reduced, and equipment cost input is reduced.

Owner:GREAT WALL MOTOR CO LTD

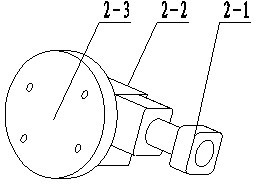

Spot welding system for electrode plates of power battery pack

ActiveCN102554438AGet rid of the phenomenon of sticky needlesImprove welding qualityResistance electrode holdersPower batteryProgrammable logic controller

The invention provides a spot welding system for electrode plates of a power battery pack, which comprises a spot welding device and a spot welding jig clamping device which are oppositely arranged side by side and connected with a PLC (programmable logic controller). The spot welding device comprises a bottom plate, a lateral plate, a lifting table, a spot welding mechanism, an X-axis movement mechanism and a Z-axis movement mechanism, wherein the X-axis movement mechanism drives the lifting table to longitudinally move, and the Z-axis movement mechanism drives the spot welding mechanism to transversely move. The spot welding jig clamping device comprises a spot welding jig sliding table, a clamping mechanism and a Y-axis movement mechanism, wherein the clamping mechanism is used for clamping a spot welding jig, the Y-axis movement mechanism drives the spot welding jig sliding table to transversely move, the clamping mechanism is arranged on the spot welding jig sliding table and is perpendicular to the spot welding mechanism, and the Y-axis movement mechanism is connected with the spot welding jig sliding table. Besides, two sliding rails beneficial to sliding of the spot welding jig sliding table are arranged below the spot welding jig sliding table. The spot welding system is an intelligent full-automatic spot welding system, which is high in efficiency, low in consumption and high in welding quality.

Owner:FUJIAN NEBULA ELECTRONICS CO LTD

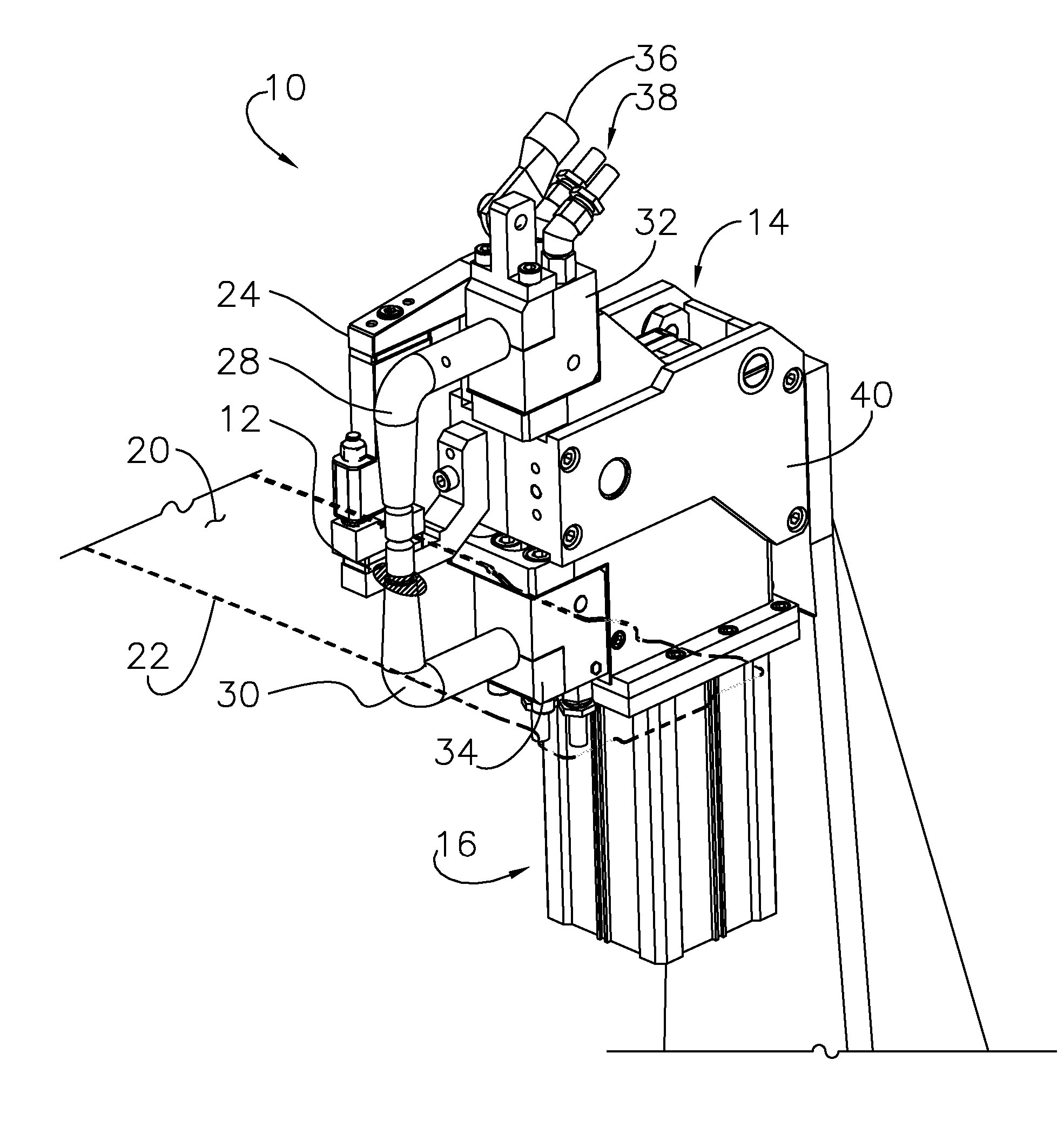

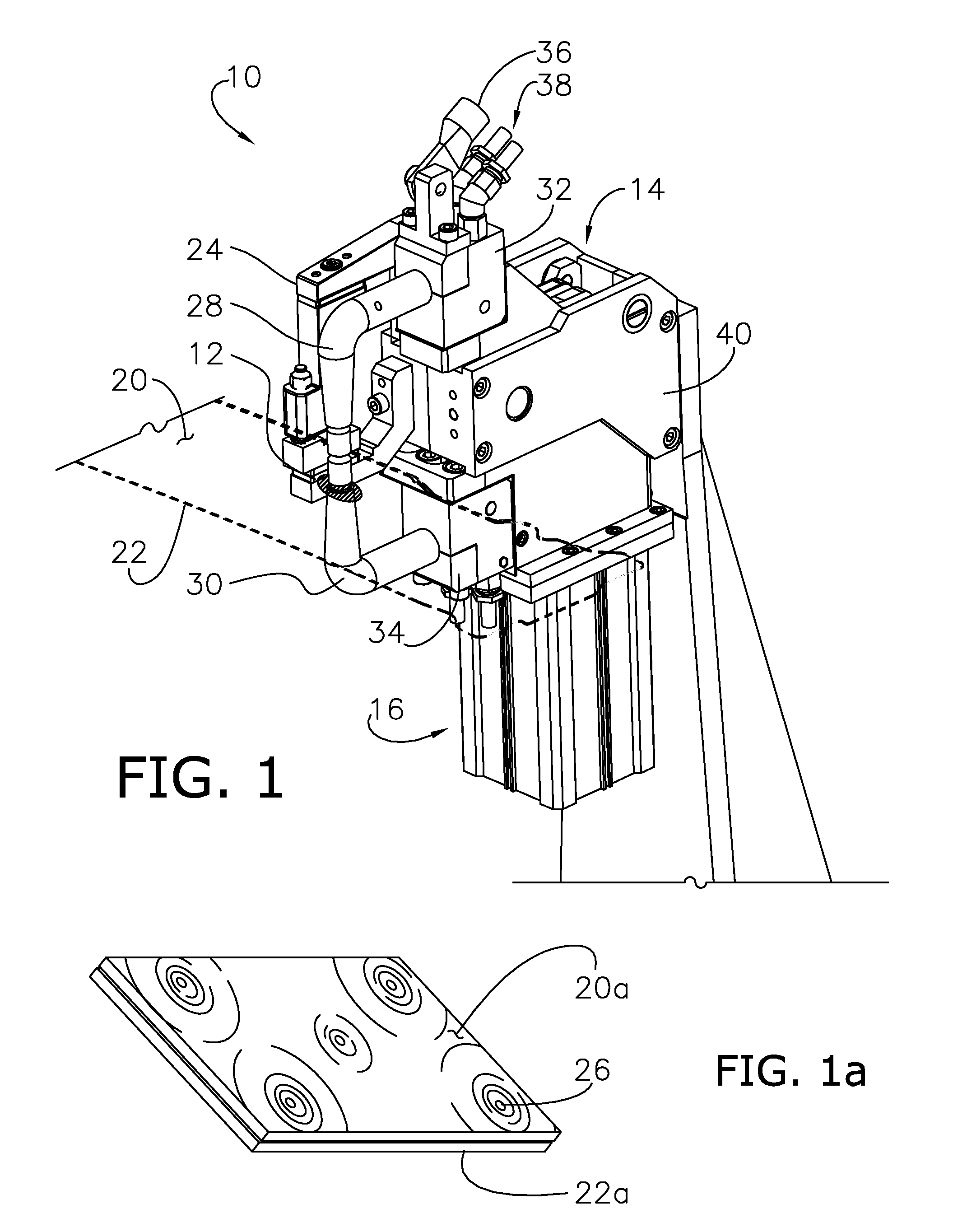

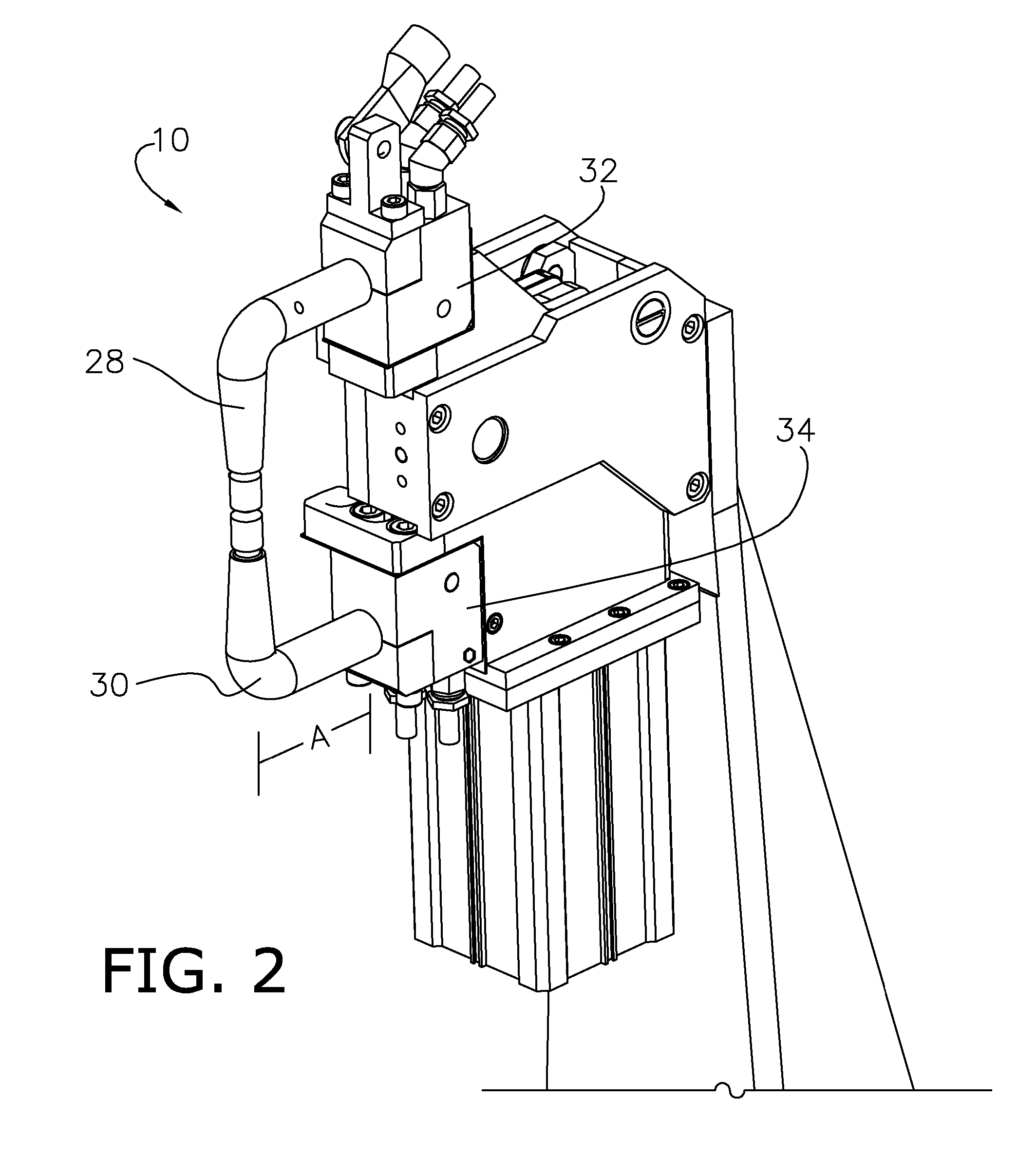

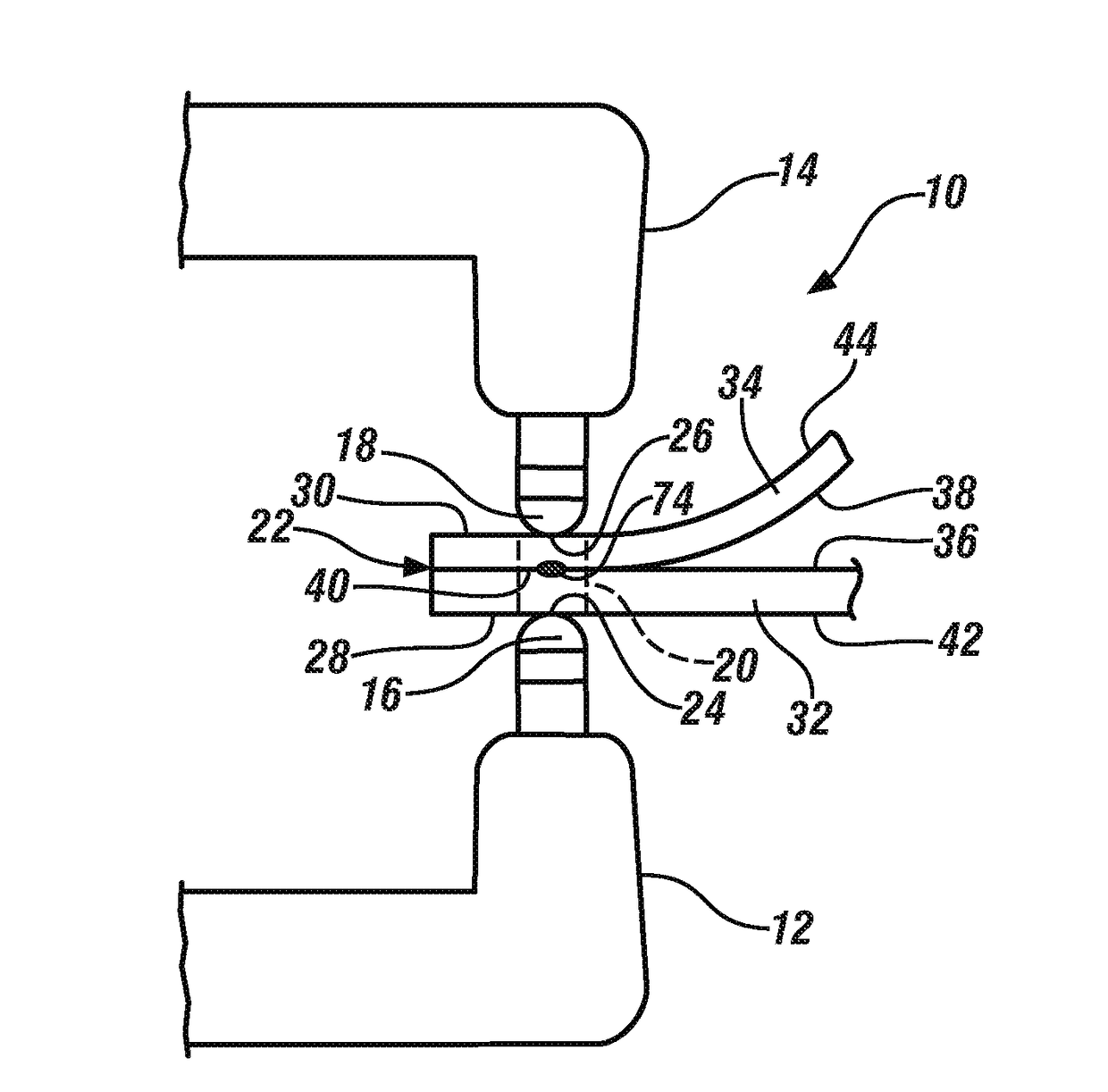

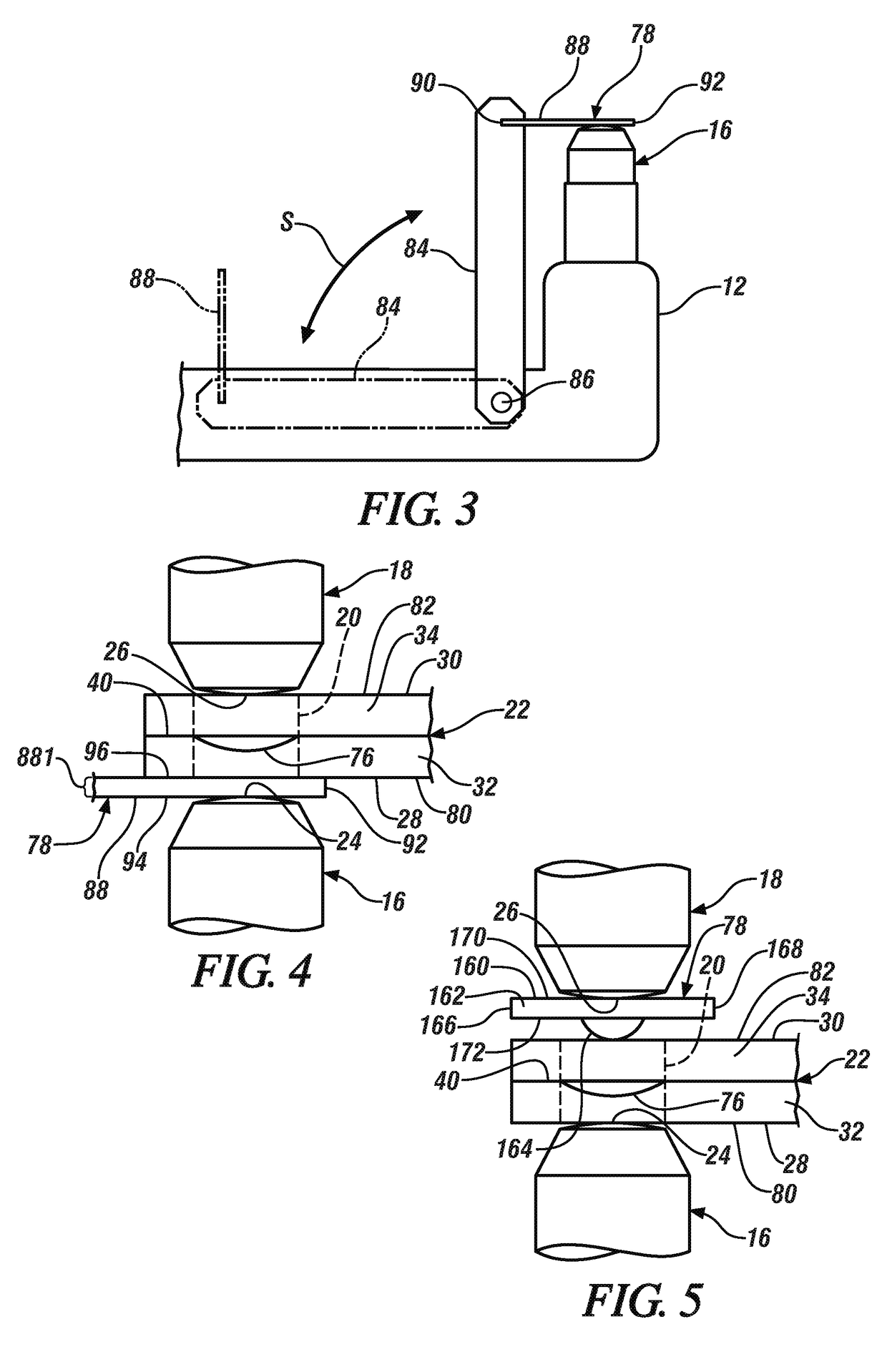

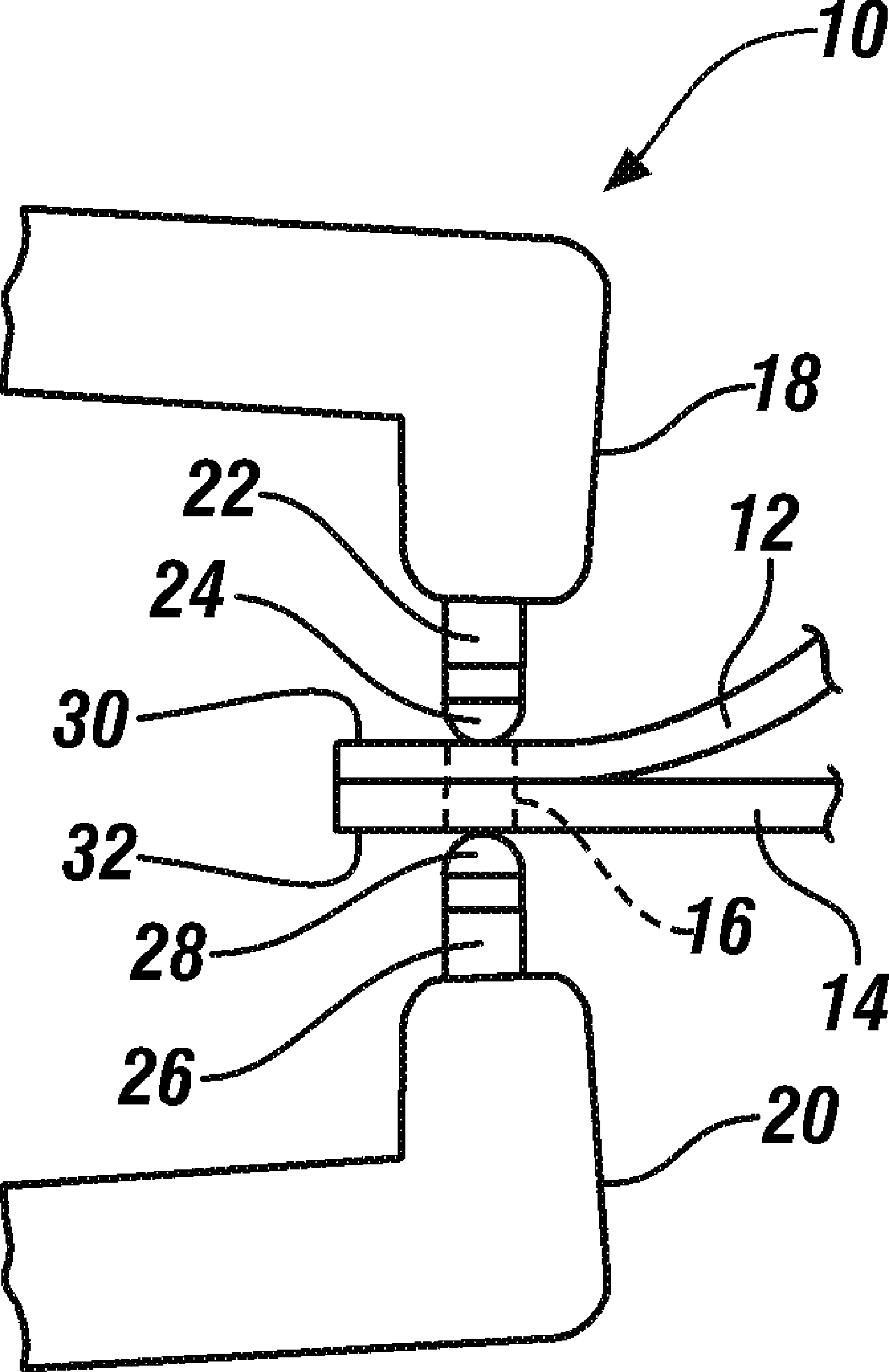

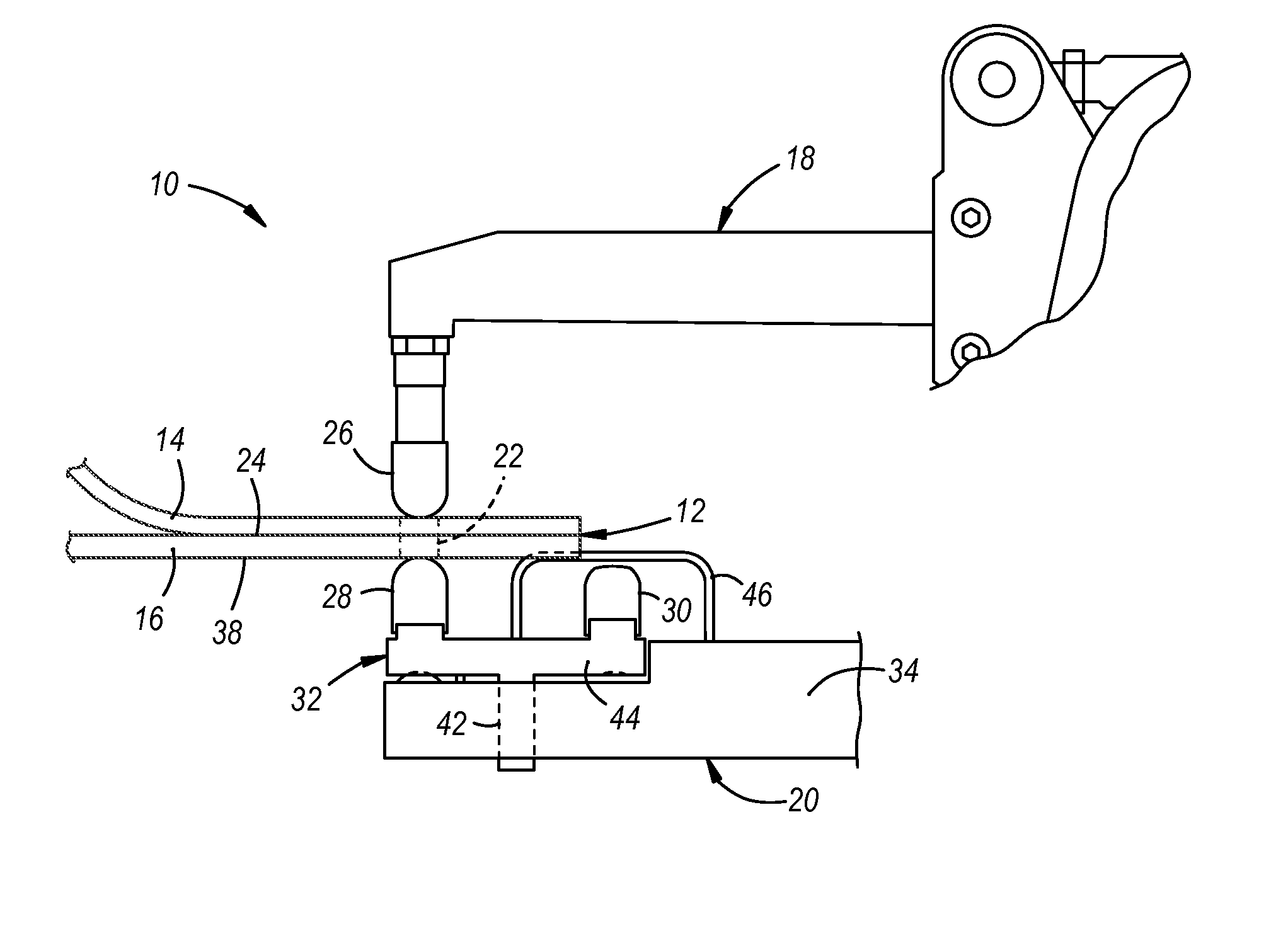

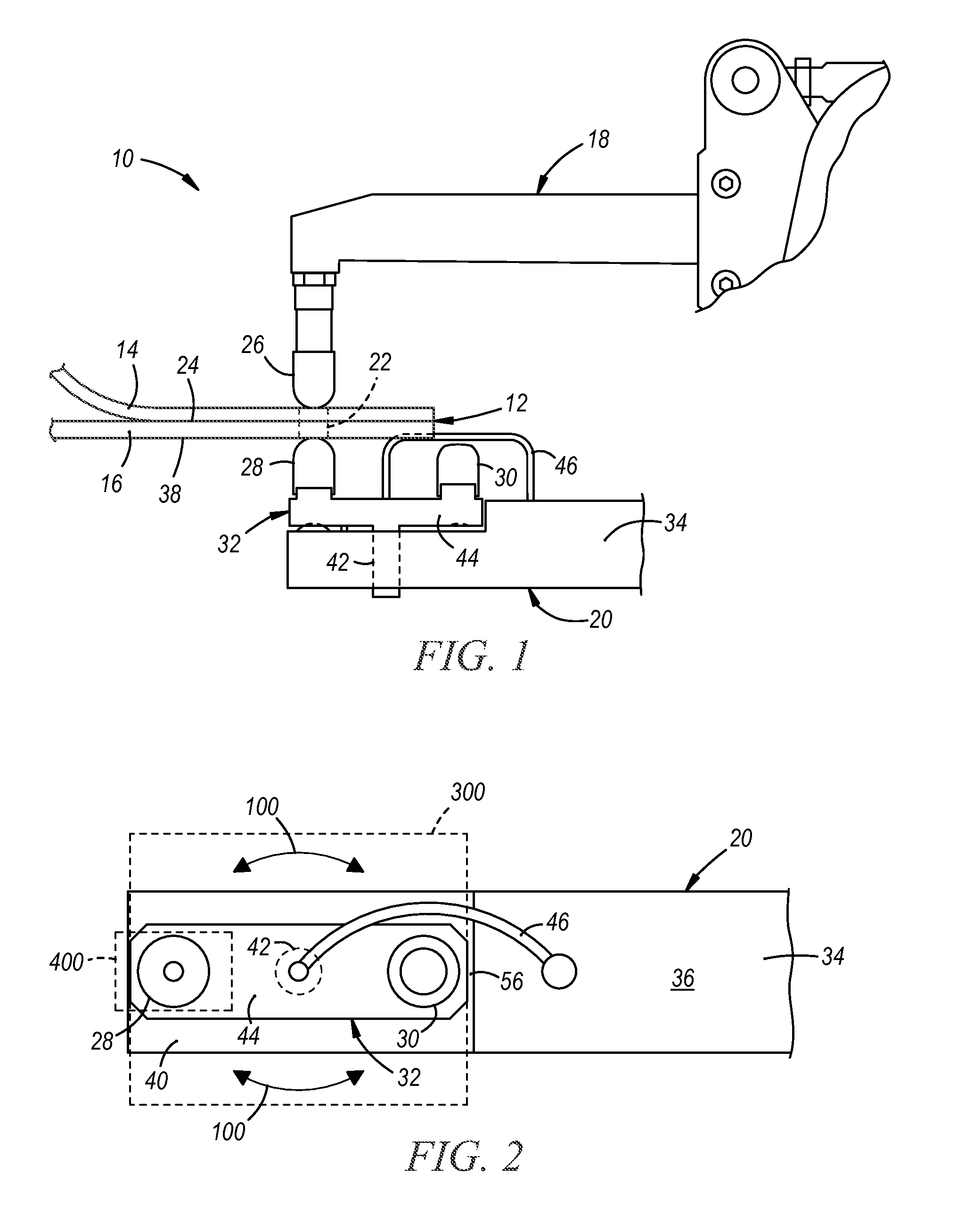

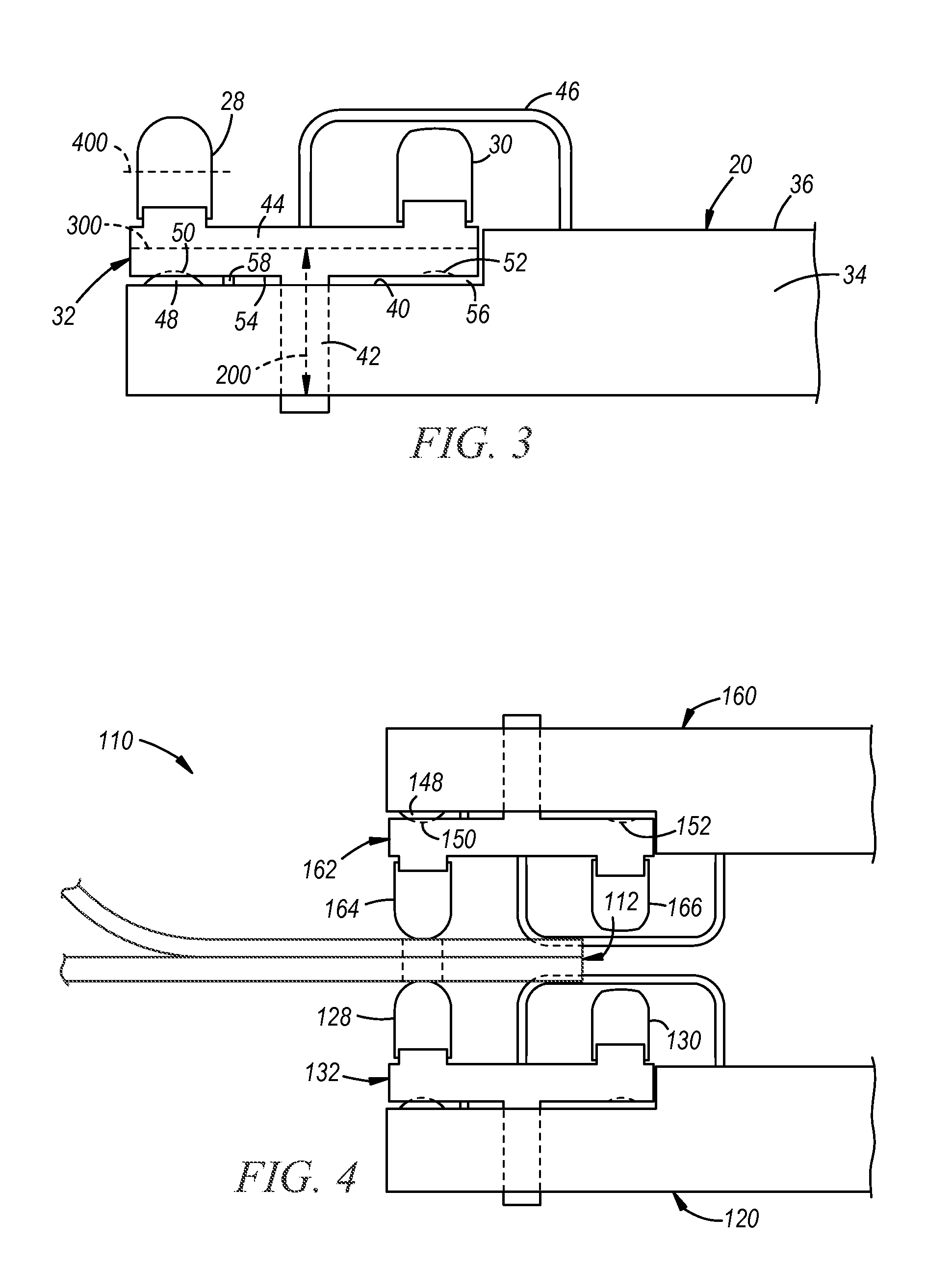

Single drive and source for adjacently clamping and resistance welding

InactiveUS20070175868A1Deformation MinimizationReduce assemblyResistance electrode holdersWelding accessoriesCamEngineering

A resistance spot welding system (10) for sequentially clamping a plurality of workpieces (20,22) at predetermined locations and welding the workpieces (20,22) substantially adjacent the locations, including a clamping element (24) able to be locked in a workpiece engaged position, at least one set of equalizing welding electrodes (28,30) for oppositely engaging the workpieces (20,22) so as to produce the weld (12) without deformation, a singular drive mechanism (14) including a cam coupled to the clamping element (24) and electrodes (28,30), and a singular source (16) for actuating the mechanism (14) and generating the welding and clamping forces.

Owner:GM GLOBAL TECH OPERATIONS LLC

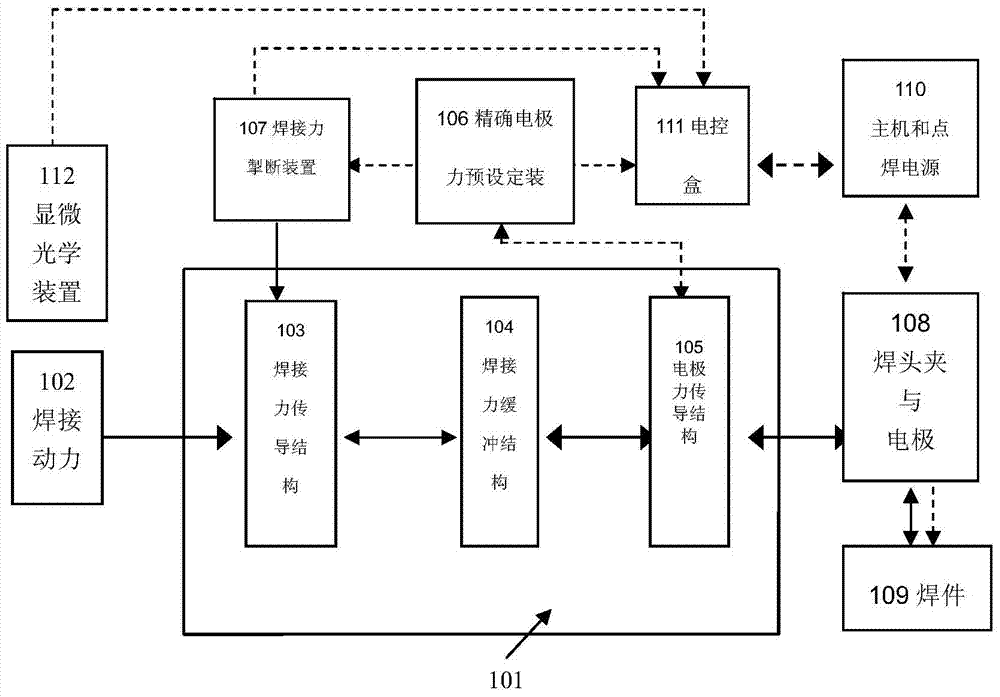

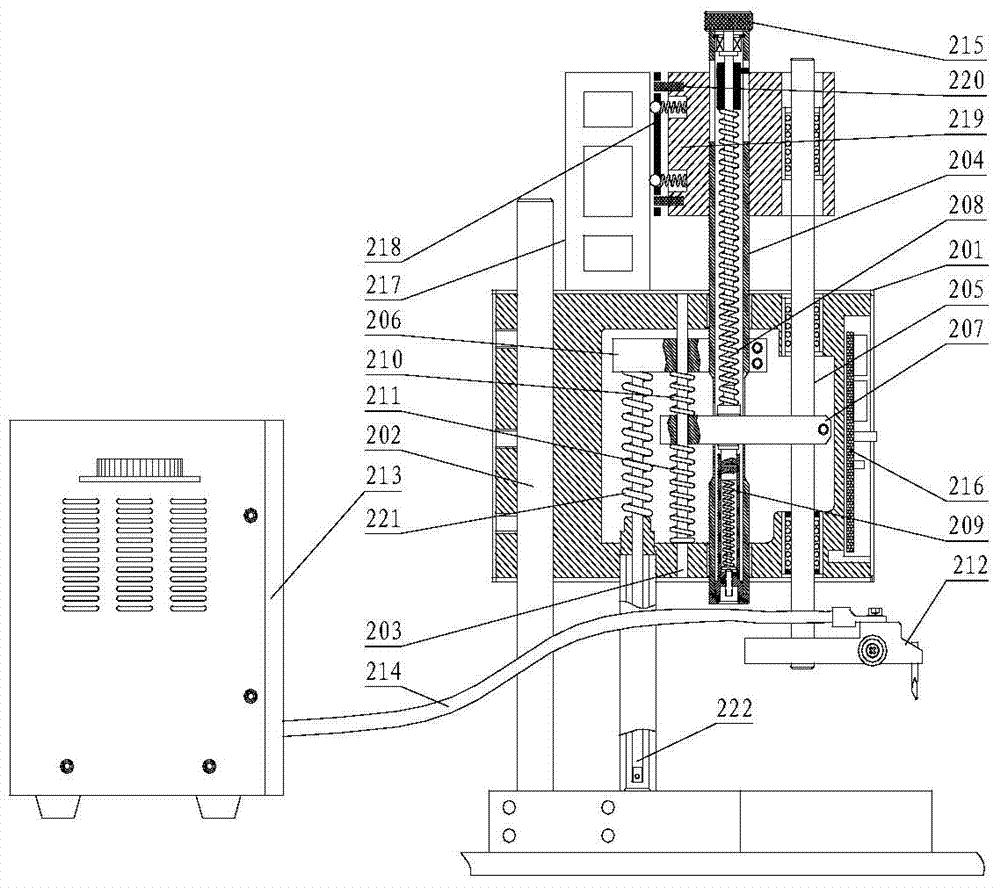

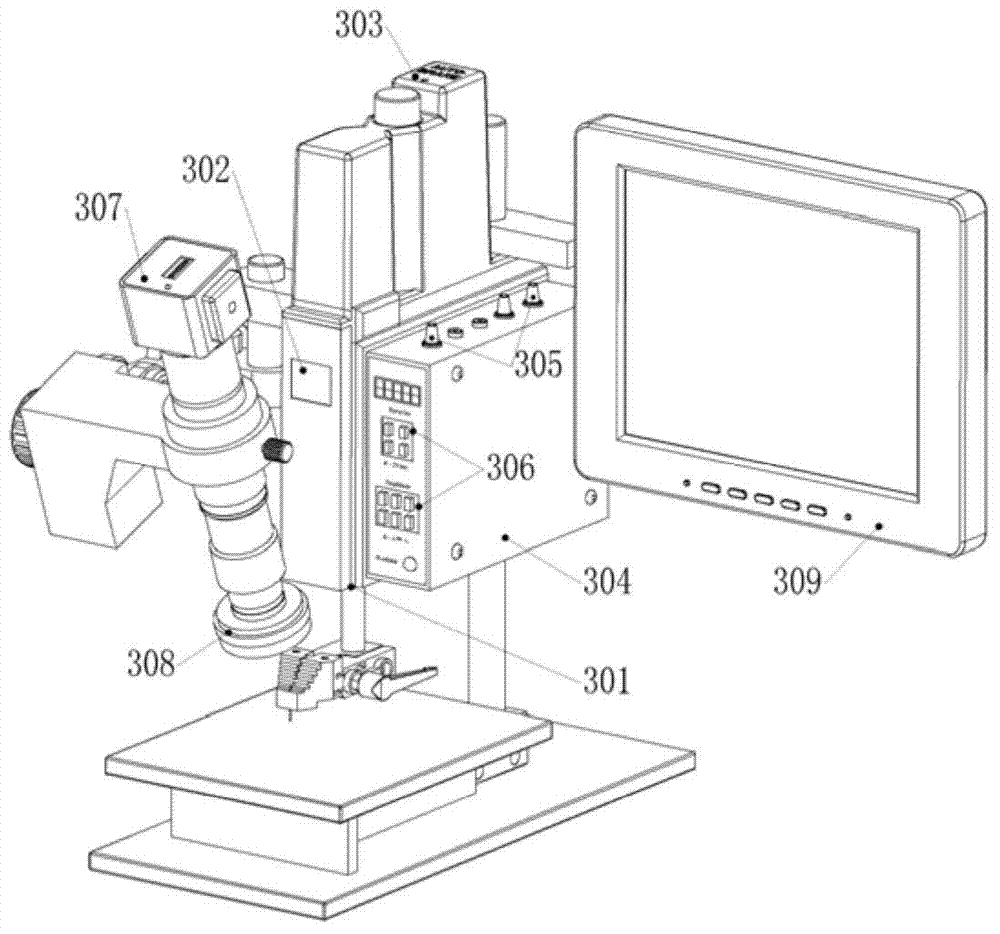

Electric resistance welding micro-welding spot welding machine

ActiveCN103920981ASimplify and reduce electrical connectionsImprove verticalityResistance electrode holdersWelding monitoring devicesElectricityElectrical resistance and conductance

The invention discloses an electric resistance welding micro-welding spot welding machine and mainly relates to noses. A mechatronics accurate electrode force pressurizing system is mounted on a nose frame, and electrode force is kept in a preset range and relatively constant during whole spot welding by the synergy and interaction of a welding acting force transmission device, an accurate electrode force presetting device and a welding force switching off device. A spot welding machine nose structure with an electric control box is provided, and nose feed and spot welding power supply output presetting are performed through the electric control box. A plastic nose frame and a stepped welding head clamp structure are provided to guarantee accurate torque transmission. A nose and a microscopy optical device are integrated, and the brand new electric resistance welding micro-welding spot welding machine is provided with the unique optical mechatronics spot welding machine nose.

Owner:GUANGZHOU MICRO WELDING EQUIP

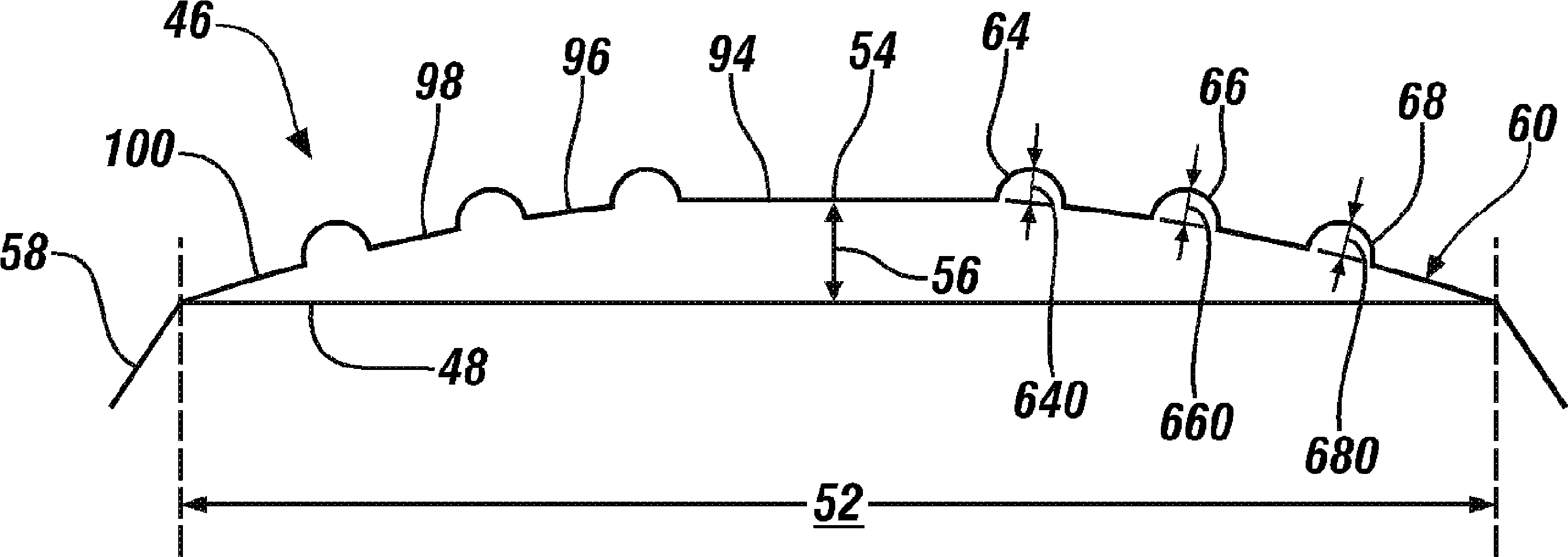

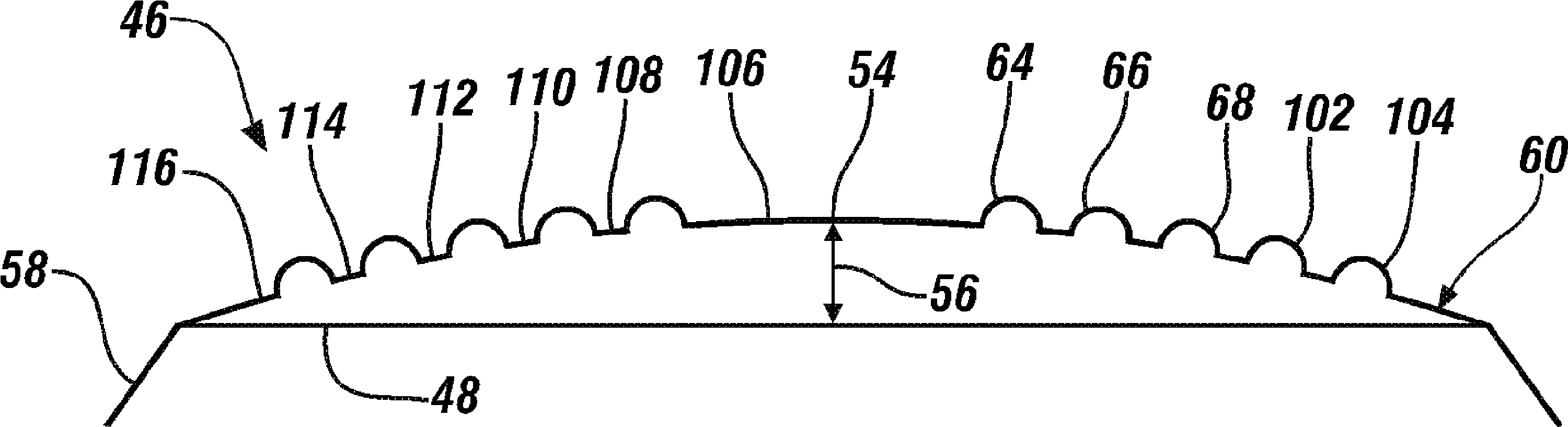

Resistance spot welding of aluminum-to-aluminum, aluminum-to-steel, and steel-to- steel in a specified sequence and using a cover

A series of many electrical resistance spot welds is to be formed in members of an assembled, but un-joined, body that presents workpiece stack-ups of various combinations of metal workpieces including all aluminum workpieces, all steel workpieces, and a combination of aluminum and steel workpieces. A pair of spot welding electrodes, each with a specified weld face that includes oxide-disrupting features, is used to form the required numbers of aluminum-to-aluminum spot welds, aluminum-to-steel spot welds, and steel-to-steel spot welds. A predetermined sequence of forming the various spot welds may be specified for extending the number of spot welds that can be made before the weld faces must be restored. And, during at least one of the aluminum-to-steel spot welds, a cover is inserted between the weld face of one of the welding electrodes and a side of a workpiece stack-up that includes the adjacent aluminum and steel workpieces.

Owner:GM GLOBAL TECH OPERATIONS LLC

Welding surface design of spot welding

The invention relates to the welding surface design of spot welding. Specifically, a welding electrode for being engaged with an aluminum alloy workpiece during a spot welding process includes a welding surface, the welding surface comprises a base surface and a plurality of circular ridges projecting from the base surface to the outside, the circular ridges are dull and their presence on the welding surface provides some useful abilities for a first welding electrode, including the ability to make a better mechanical and electrical contact with the aluminum alloy workpiece.

Owner:GM GLOBAL TECH OPERATIONS LLC

Resistance spot welding workpiece stack-ups of different combinations of steel workpieces and aluminum workpieces

InactiveUS20160346865A1Easy accessOvercome bias forceResistance electrode holdersWelding/soldering/cutting articlesPower flowEngineering

A method of resistance spot welding workpiece stack-ups of different combinations of steel workpieces and aluminum workpieces includes several steps. In one step, a workpiece stack-up is brought between a first weld gun arm and a second weld gun arm. The first weld gun arm includes a first welding electrode, and the second weld gun arm includes a carrier that supports a second welding electrode and a third welding electrode. Another step involves rotating the carrier and passing electrical current through the workpiece stack-up using the first welding electrode in conjunction with either the second welding electrode or the third welding electrode depending on which electrode has been rotated into facing alignment with the first welding electrode.

Owner:GM GLOBAL TECH OPERATIONS LLC

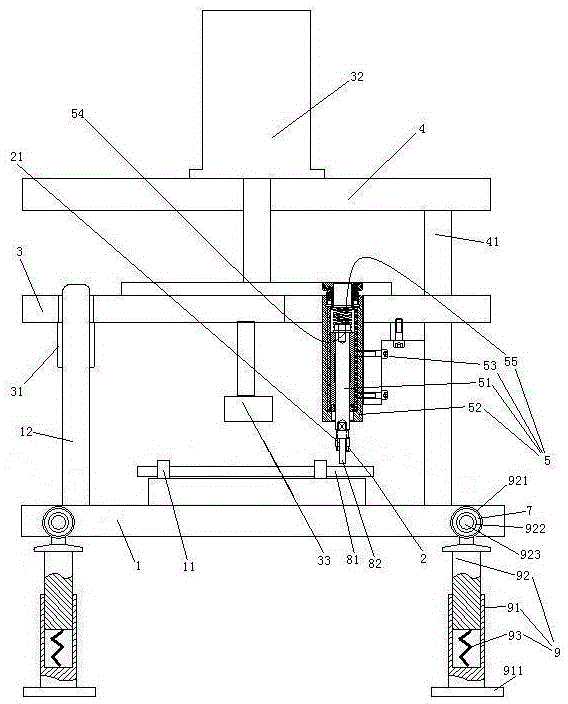

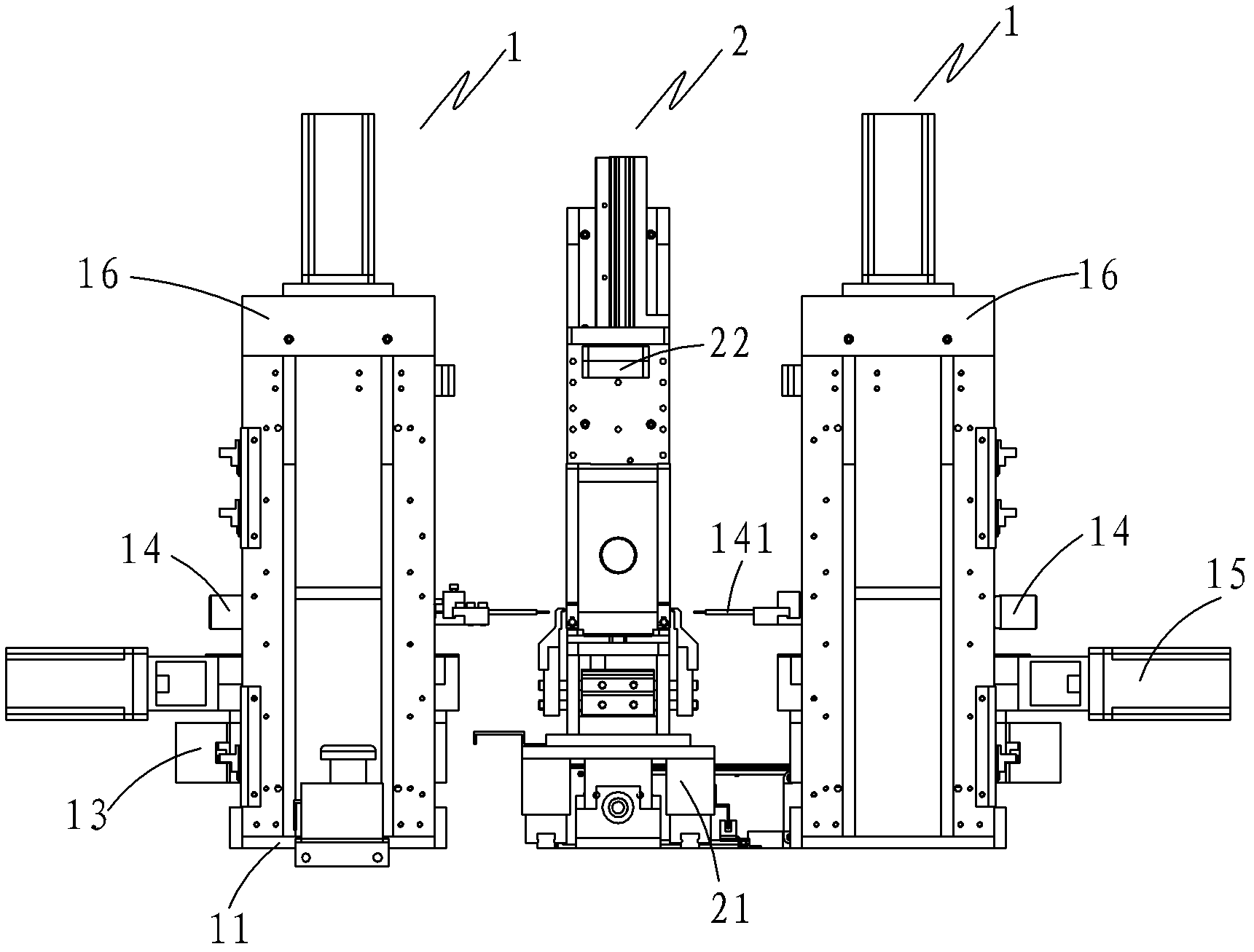

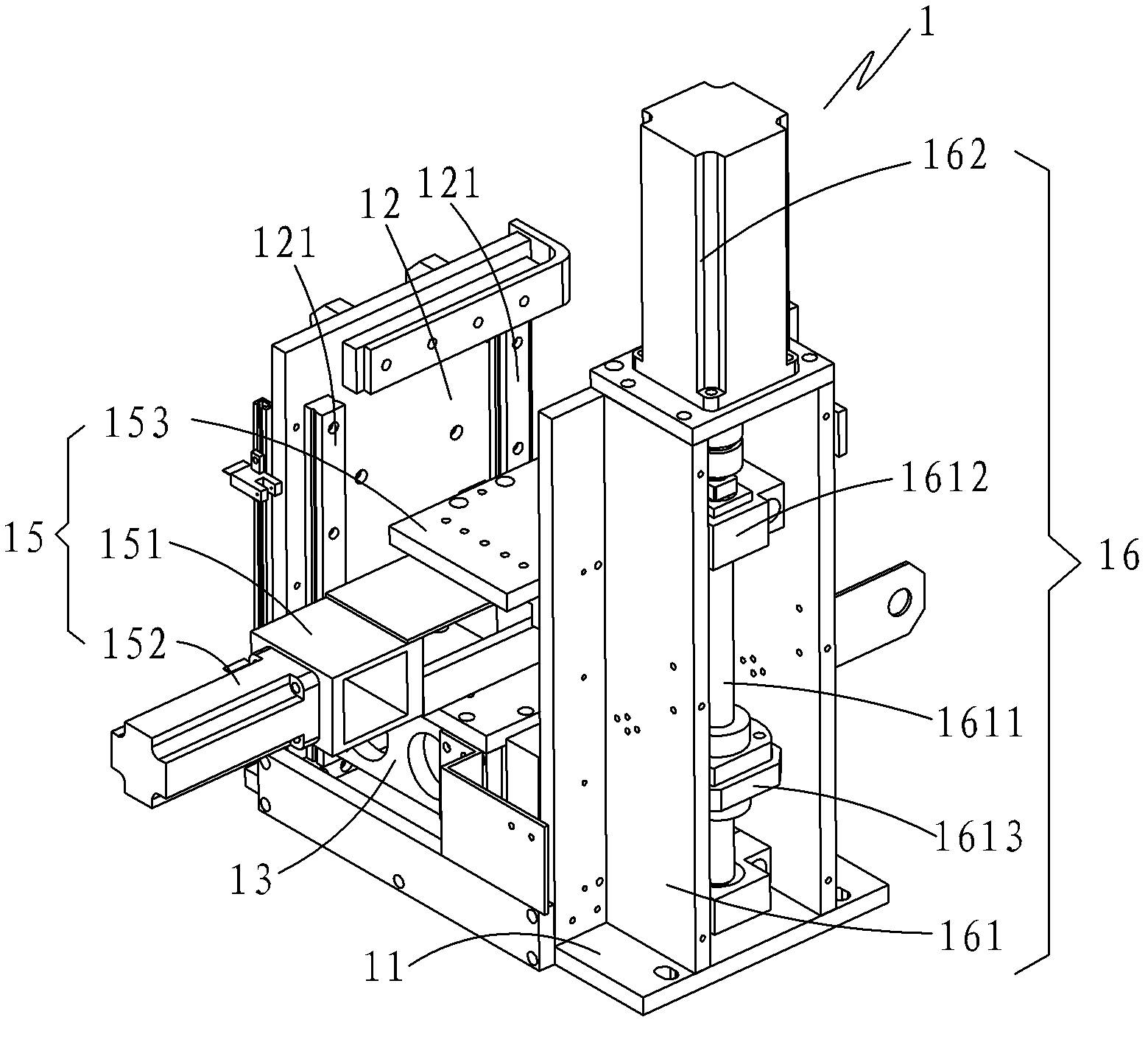

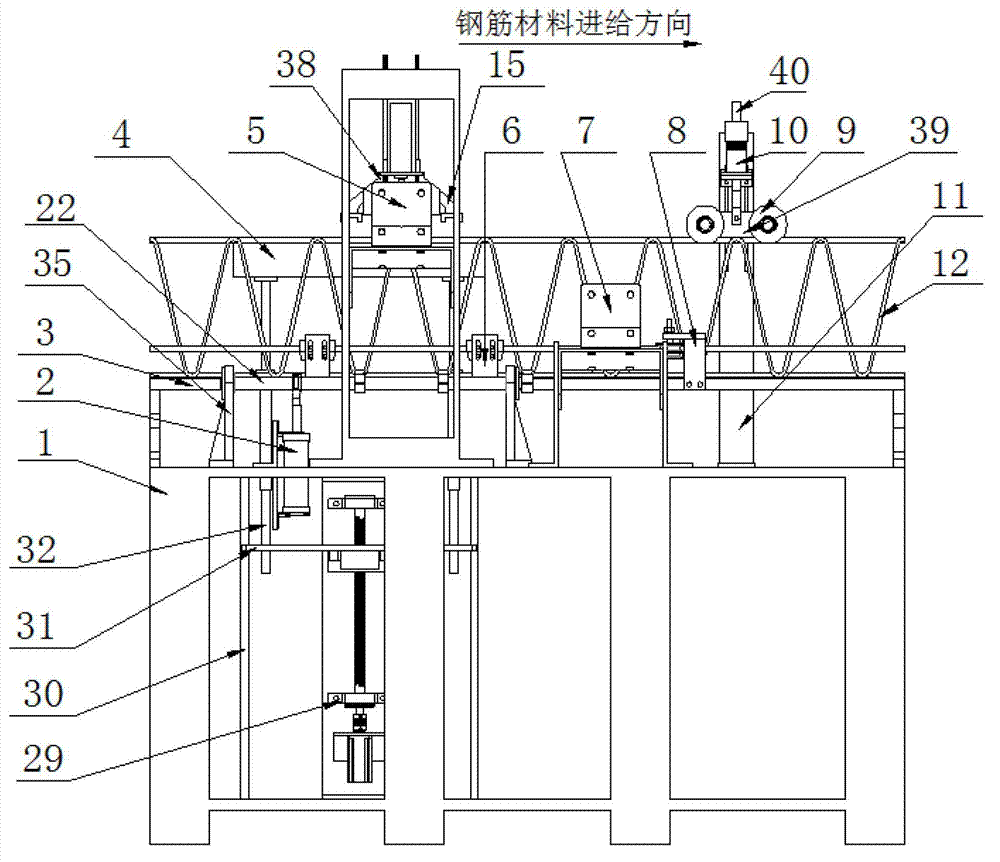

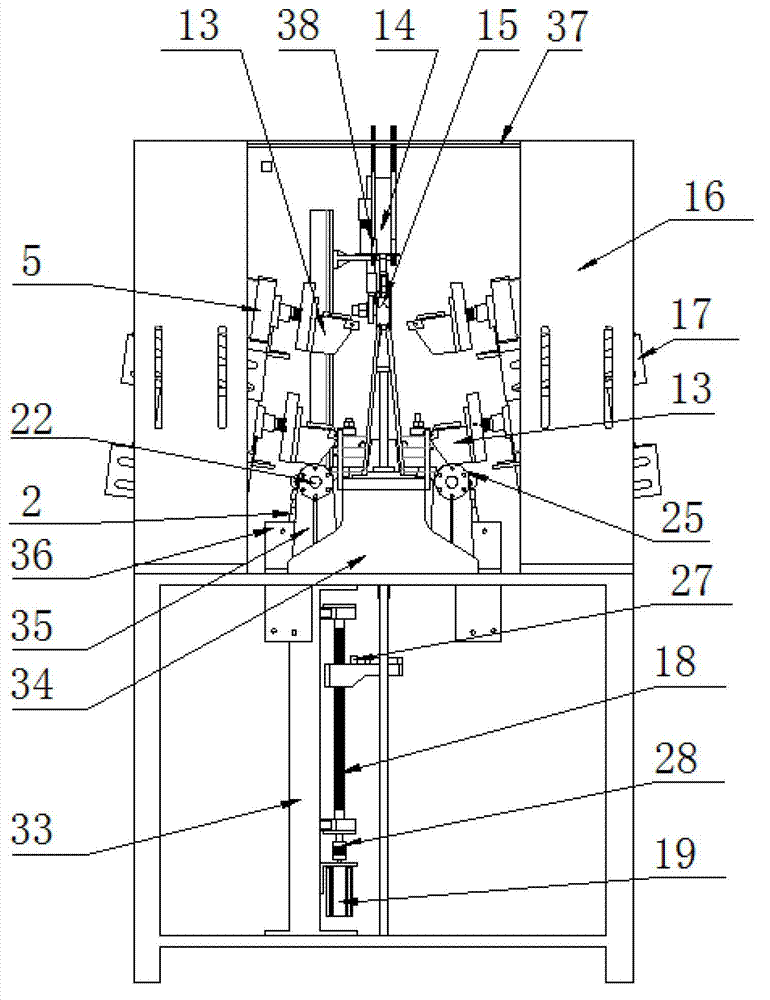

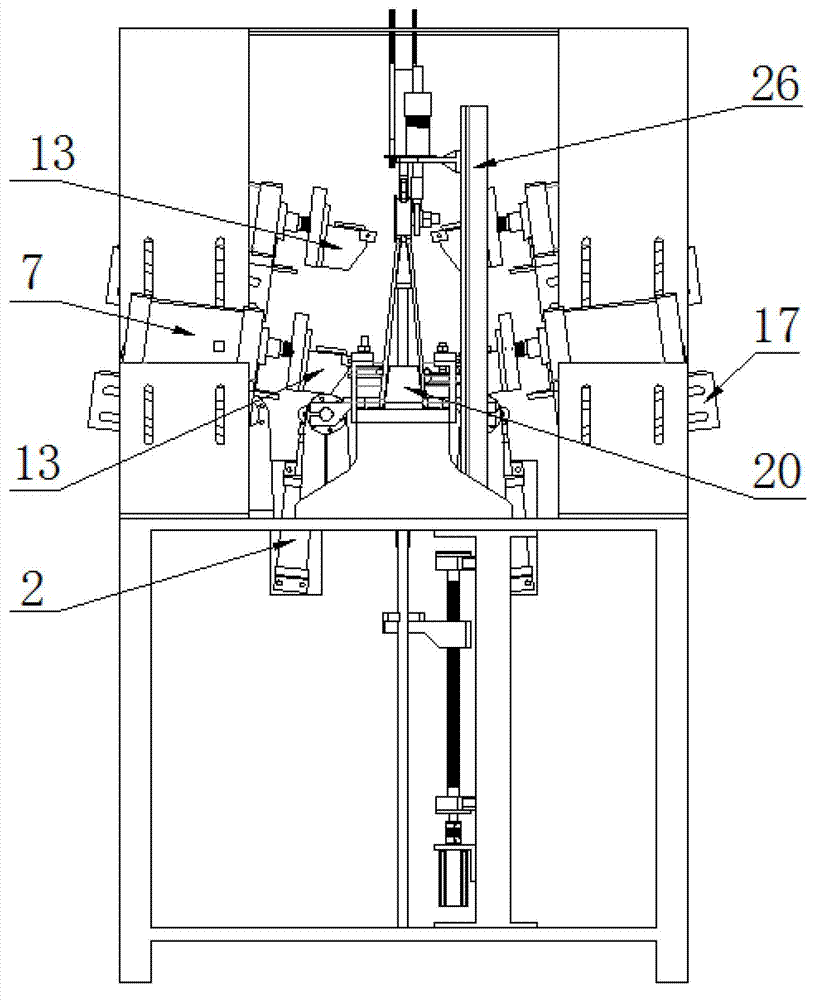

Special single-beat welding machine for steel bar trusses

InactiveCN103240518ARealize automatic weldingAchieve regulationResistance electrode holdersWelding/cutting auxillary devicesProduction lineEngineering

The invention discloses a special single-beat welding machine for steel bar trusses on an automatic production line of steel bar trusses. The special single-beat welding machine structurally comprises a machine base, a worktable, an upper welding device and a lower welding device, wherein the worktable is mounted on the machine base, a web member steel bar positioning and tensioning device, an upper string rib support and the upper welding device are arranged at the front end of the machine base, and the lower welding device and the steel bar truss positioning and guiding device are arranged at the rear end of the machine base. Lower string rib positioning and guiding devices are symmetrically arranged on two sides of the worktable. The web member steel bar positioning and tensioning device can fixe relative positions of web member steel bars and upper string ribs before the steel bar trusses are welded. The upper string rib support can be applicable to production of the steel bar trusses different in height, and the upper string ribs and the lower string ribs are respectively welded with the web member steel bars by the upper welding device and the lower welding device. After welding and forming, the steel bar trusses are fed to subsequent production units by an automatic step system. The special single-beat welding machine is simple in structure, high in automation degree and low in production cost.

Owner:NANJING UNIV OF SCI & TECH

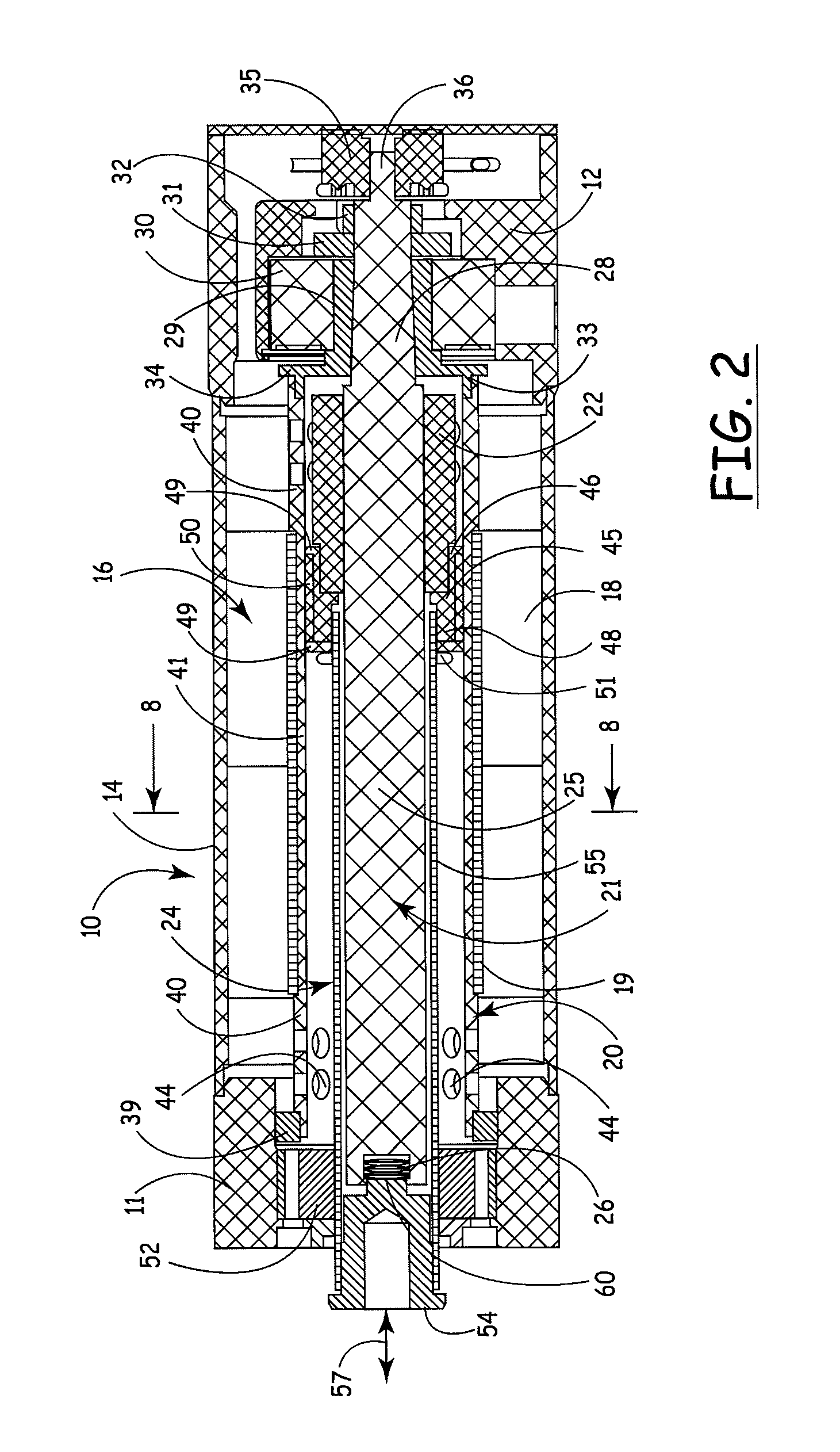

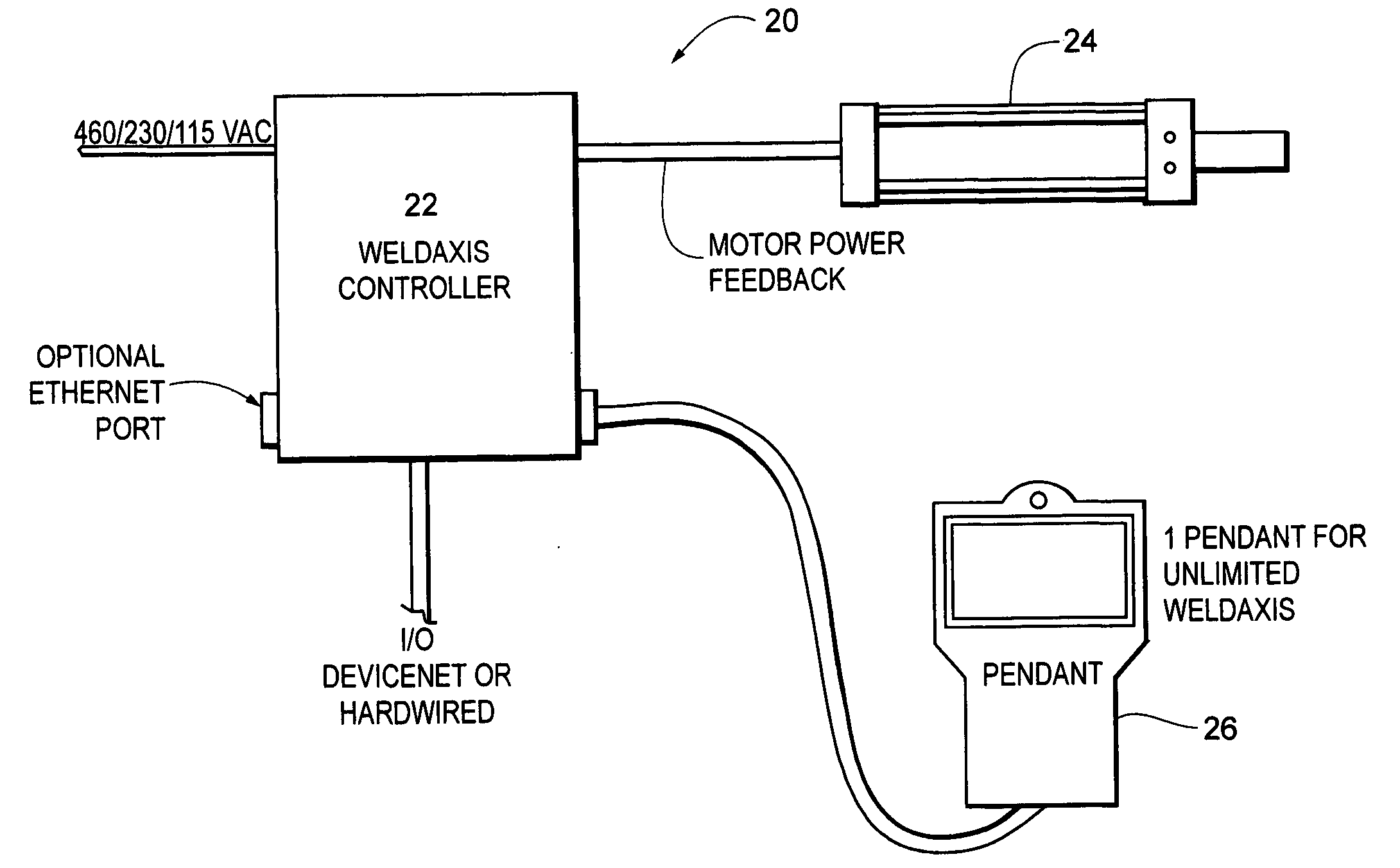

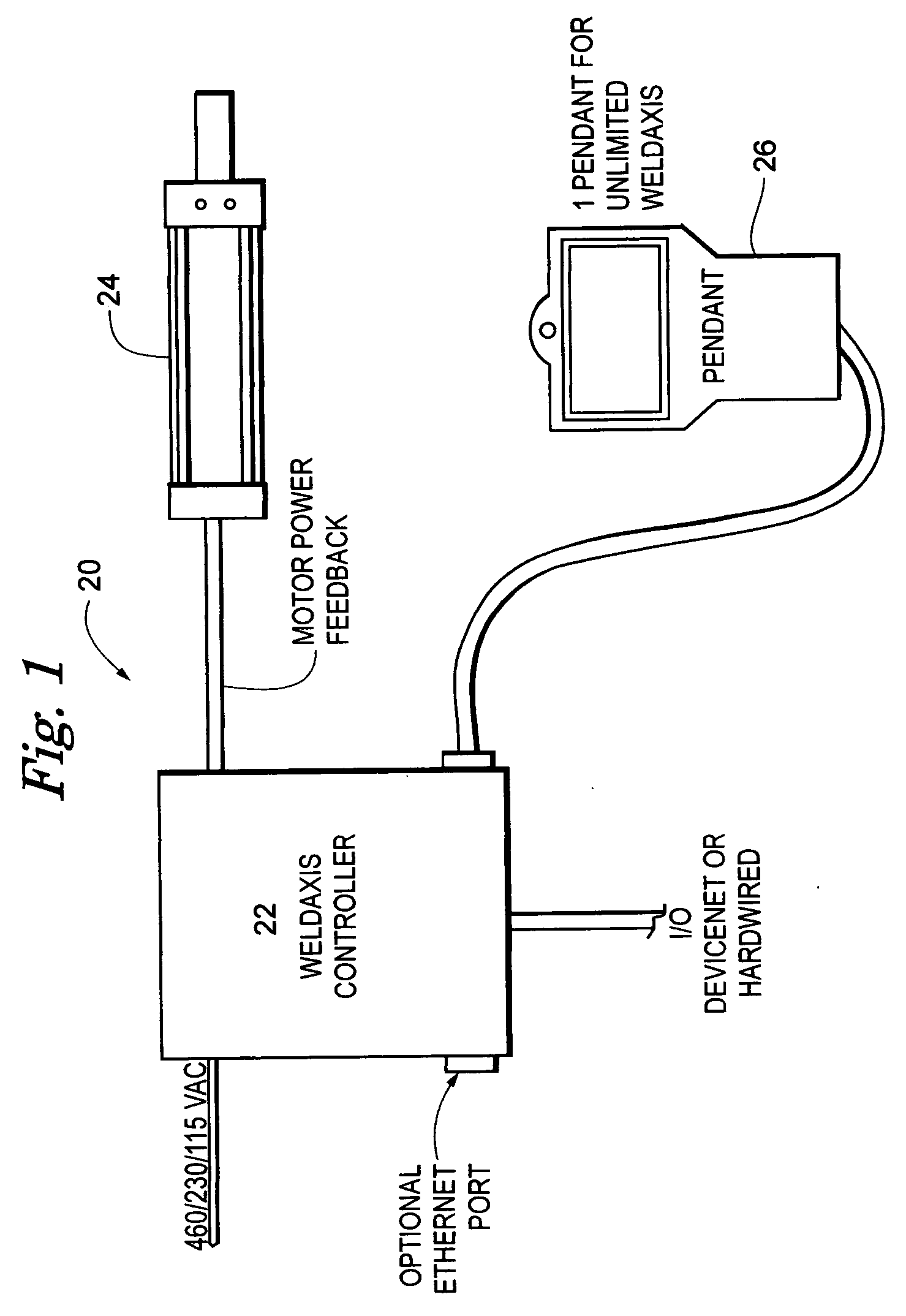

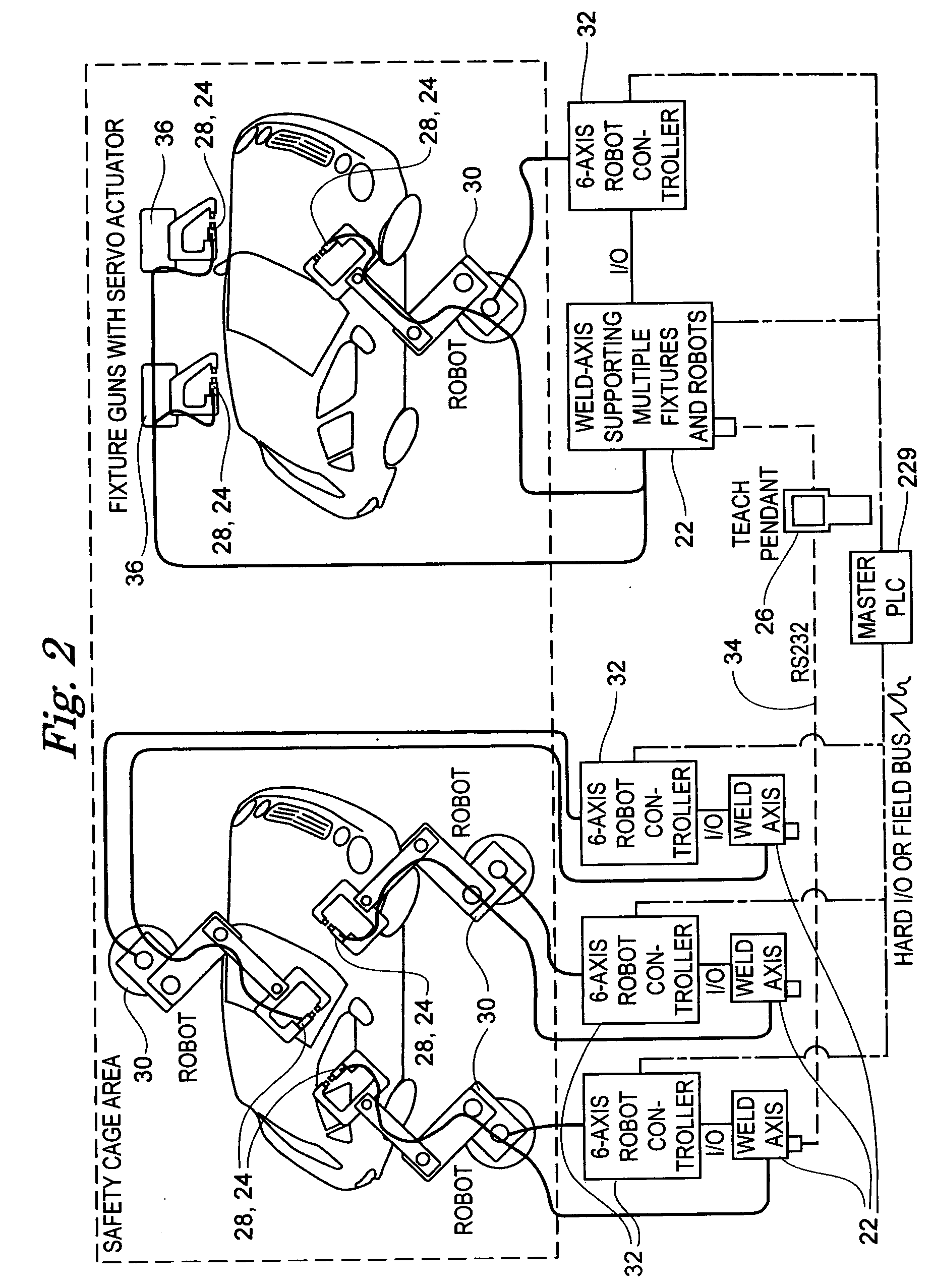

Adaptable servo-control system for force/position actuation

InactiveUS20050077855A1Resistance electrode holdersComputer controlElectrical resistance and conductanceProgrammable logic controller

An adaptable, servo-control system for force / position actuation generally includes an electric linear actuator and a controller. The controller interfaces with the electric linear actuator and with a number of I / O signals that are independent from the electric linear actuator. The controller interface to the independent I / O signals is transparent to the manner in which the I / O signals are produced. Rather the controller simply looks for the status of the I / O that is preferably received into the controller by hard-wiring or field bus I / O messaging such as from a industrial robot or programmable logic controller. The adaptable servo-control system is particularly suited to resistance weld systems wherein the electric linear actuator can replace the pneumatic actuator providing position and force actuation of the weld tip of the welding gun.

Owner:TOL O MATIC

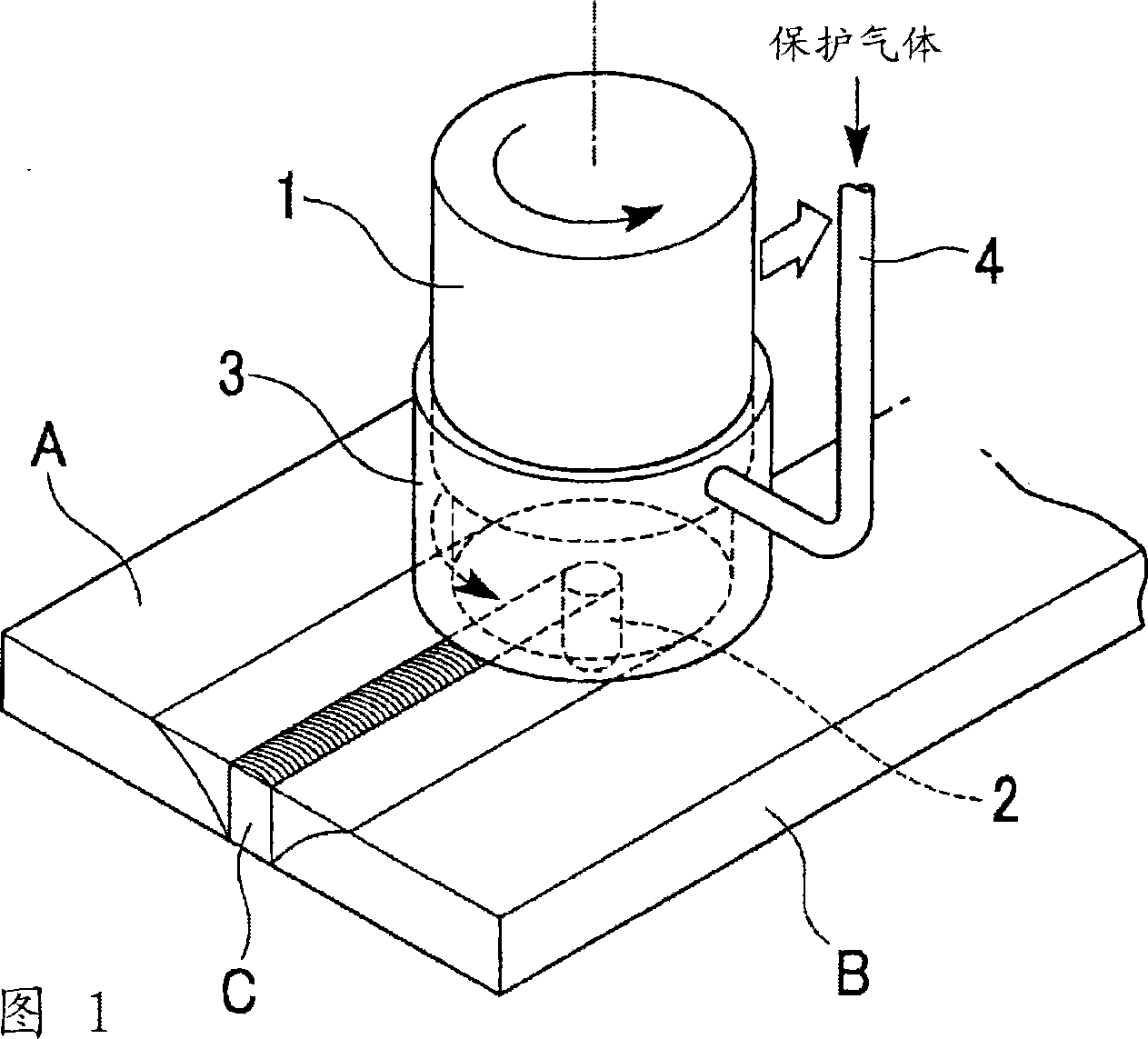

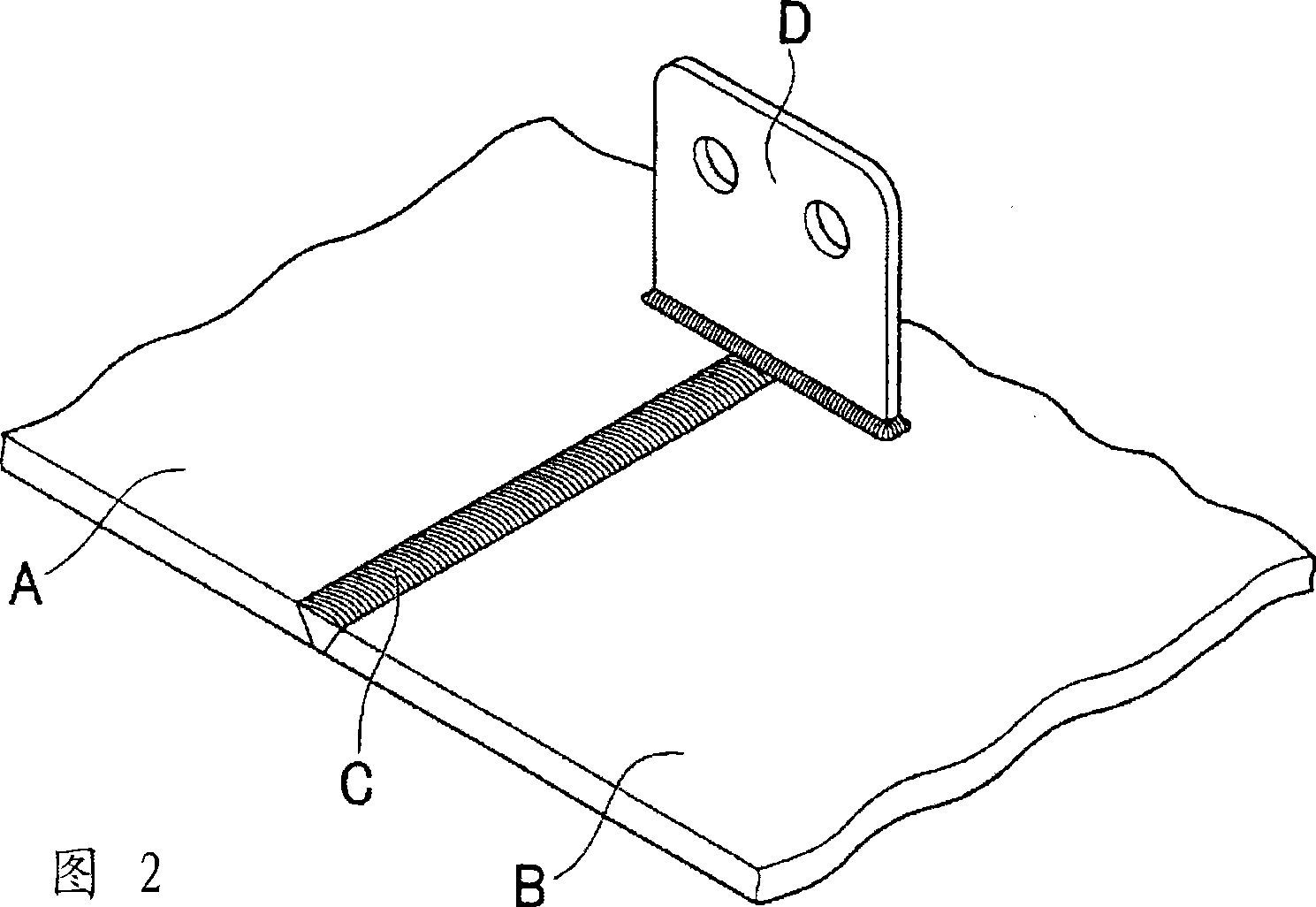

Joining method

InactiveCN101437642AReduce intensityGet strengthResistance electrode holdersArc welding apparatusShielding gasEngineering

A joining method of the present invention includes conducting friction-stir-welding of members to be joined, to form a joint; and then conducting melt-welding or resistance-welding of the joint, wherein the friction-stir-welding of members to be joined is conducted while flowing an inert shielding gas, or the melt-welding or resistance-welding of the joint is conducted while applying an ultrasonic wave.

Owner:OSAKA UNIV +1

High speed driving method and apparatus of pressure cylinder

InactiveUS6799501B2Soft touchReduce back pressureResistance electrode holdersServomotor componentsControl theoryPiston rod

A pressure cylinder is connected to an air pressure source through a servo valve, the servo valve is controlled as an on / off switching valve by a control section in an advancing working step of a piston rod, and at the time of backward stroke of the piston rod, an operation position of the piston rod is detected by a position detector to feedback a detection signal to the control section, the servo valve is controlled by the control section such that a deviation between the operation position and a preset stopping position is eliminated, the piston rod is stopped at an intermediate stopping position, and a state in which substantially the same pressures are supplied to pressure chambers formed on opposite sides of the piston is maintained.

Owner:SMC CORP

Welding gun and methods conducted using the same

InactiveUS20010045413A1Decreased in size and rigidityResistance electrode holdersWelding/cutting auxillary devicesEngineeringWeld strength

An intelligent welding gun is provided with a fixed side sensor in a fixed side portion. The mechanical impedance of the fixed side portion is kept small, which permits the mechanical impedance to be set in a range where the fixed side sensor can effectively detect at least one of a position of a fixed side welding tip and a pressing force imposed on the fixed side welding tip. The fixed side sensor and a moving side sensor constitute a redundant sensor measurement system. Various kinds of methods conducted using the above welding gun include a method of calibrating a sensor (including calibration of a reference point and a gain), a control method of suppressing a welding expulsion, a re-welding feedback control method, a control method of a welding strength, a control method of reducing a clearance between workpieces, a method of correcting a welding robot track, and a method of managing a positional accuracy change at a welding point.

Owner:TOYOTA JIDOSHA KK

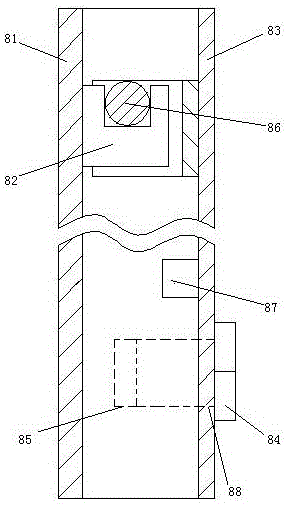

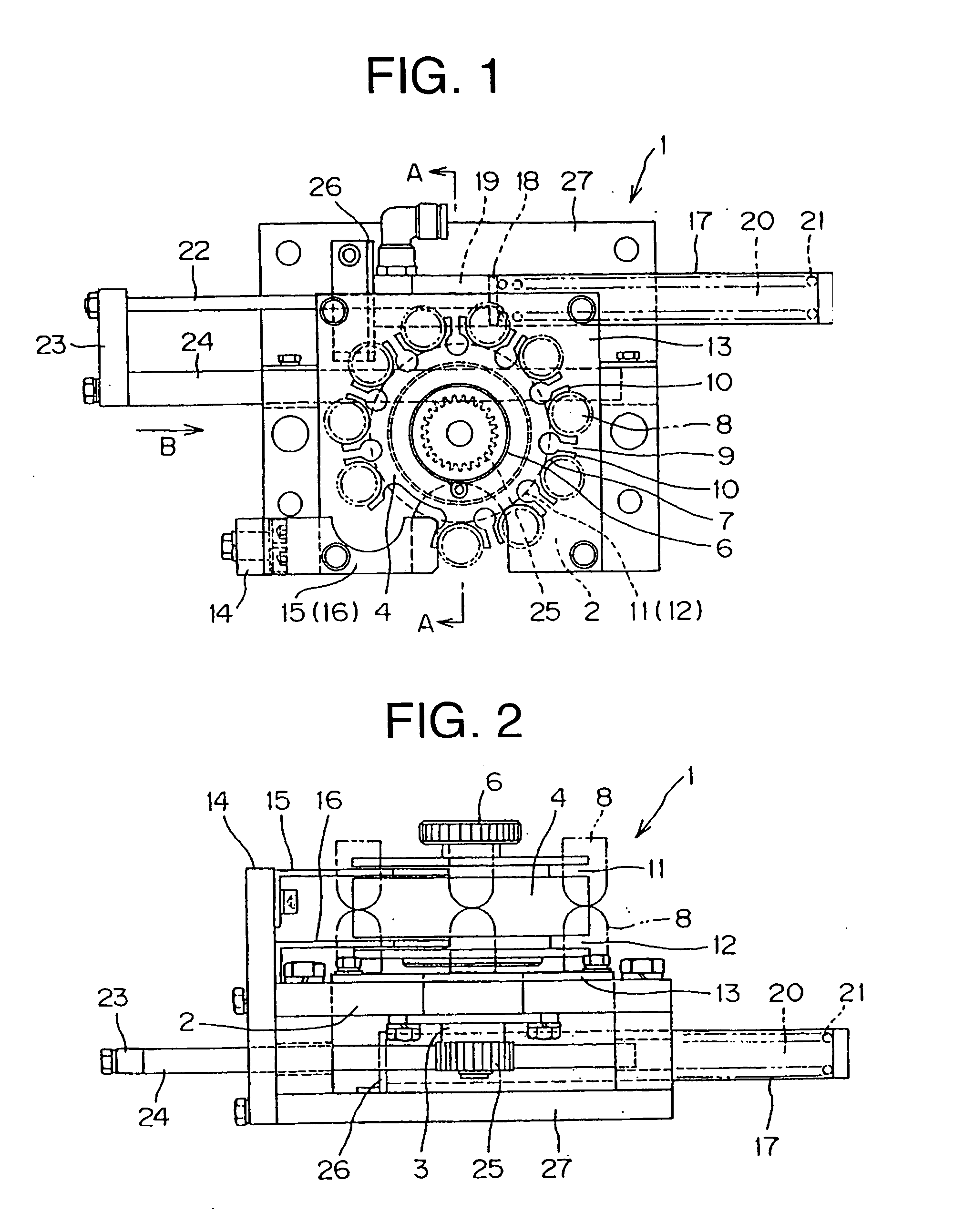

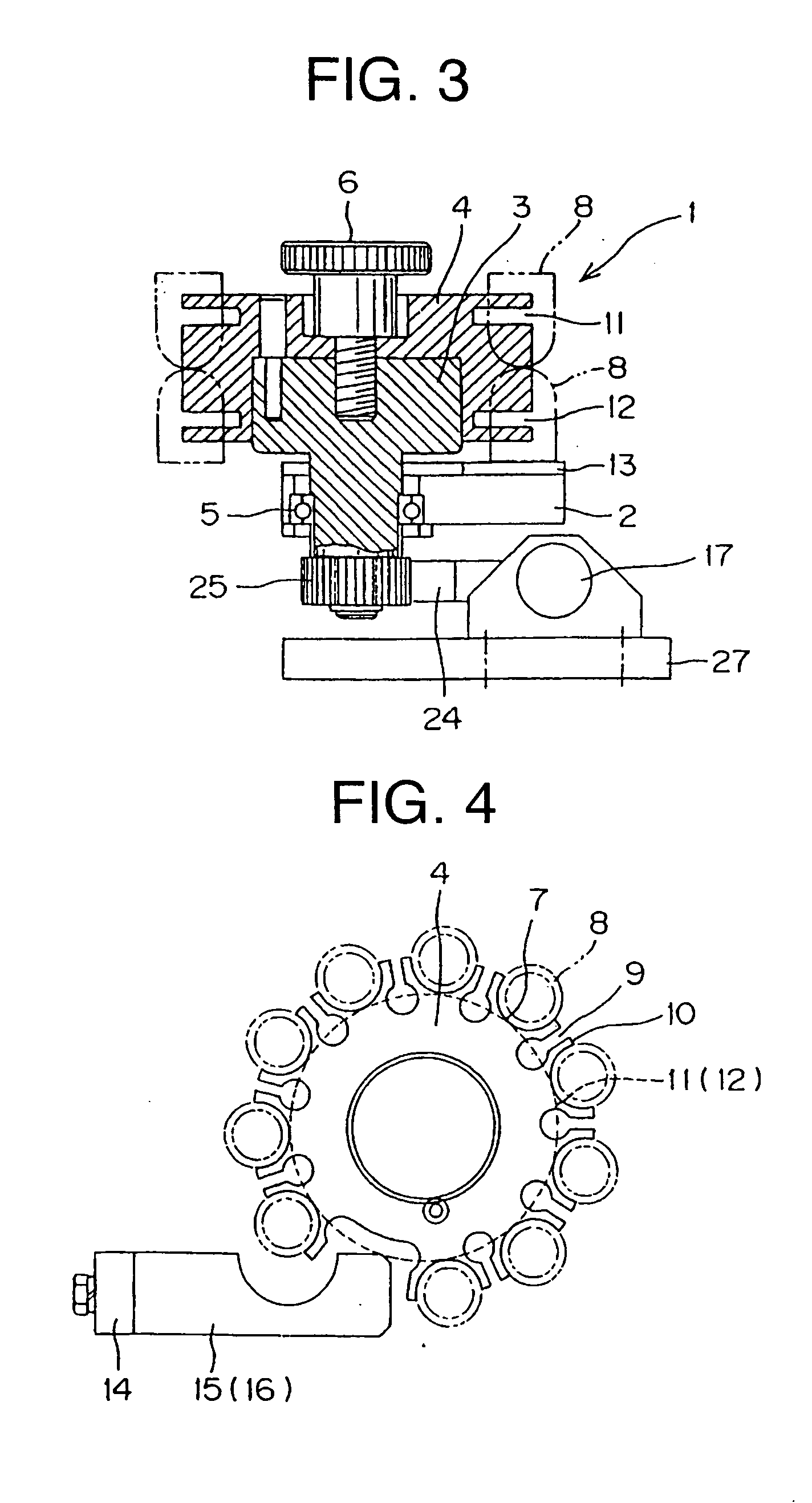

Fixed type electrode tip take-out device

ActiveUS20050023250A1Resistance electrode holdersWelding/cutting auxillary devicesEngineeringSlide plate

There is provided a fixed type electrode tip take-out device capable of solving the problem of irregularities of positions of the upper and lower electrode tips by urging a tip magazine to be movable, and fixing the locations of the electrode tips of each group at the portions to be fixed to a welder, thereby taking out the electrode tips from the tip magazine with accuracy. The tip magazine is urged to be movable relative to a base plate by a driving unit, boundary portions of respective through holes are partitioned by elastic boundary walls in which wedges are inserted in the same direction as an axis of each through hole, and lowest end portions of electrode tips of each group housed in the tip magazine are brought into contact with a slide plate fixed to the base plate, and the upper and lower electrode tips of each group located at portions to be fixed to a welder and positioned by stoppers fixed to the base plate, thereby forming passages of the stoppers on the elastic boundary walls.

Owner:OBARA GRP

Motor driven resistance spot welding gun

InactiveCN1509218AHigh torqueLow costResistance electrode holdersGearingElectrical resistance and conductanceMotor drive

Owner:HONDA MOTOR CO LTD

Soldering pliers

ActiveCN102941407AEasy to controlThe control can be precisely controlled and accurateResistance electrode holdersWelding/cutting auxillary devicesSolderingMechanical engineering

A pair of soldering pliers comprises a power element, a driving mechanism, an electrode installing seat, an electrode, a clamping head installing seat and a clamping head, wherein the driving mechanism is connected with the power element; the electrode installing seat is driven by the driving mechanism to perform motion; the electrode is installed on the electrode installing seat and driven by the electrode installing seat to perform closing work or achieve an open state; the clamping head installing seat is connected with the driving mechanism, driven by the driving mechanism to perform motion and arranged corresponding to the electrode installing seat; and the clamping head is installed on the clamping head installing seat and driven by the clamping head installing seat to perform closing or opening motion. By enabling the electrode installing seat and the clamping head installing seat which are corresponding to each other to be simultaneously arranged on the driving mechanism, the electrode and the clamping head are correspondingly arranged on the same pair of soldering pliers, an integrated structure is formed, integral driving and control can be performed through the power element, the problems that the distance between a traditional pair of soldering pliers and a clamp for clamping a workpiece is far and installing positioning and the like caused by separated arrangement of the soldering pliers and the clamp are inconvenient to control and operate are solved, and uniform driving is performed through the driving mechanism so as to perform uniform control and facilitate control and automatic operation.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

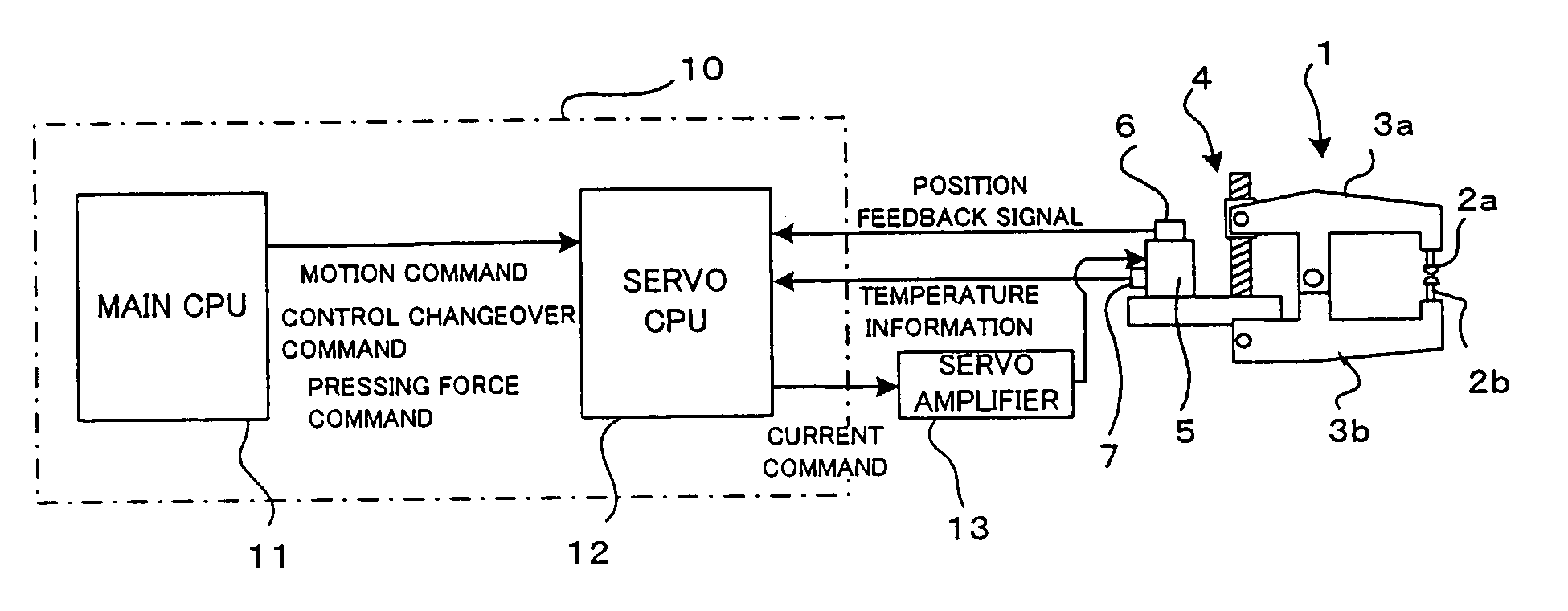

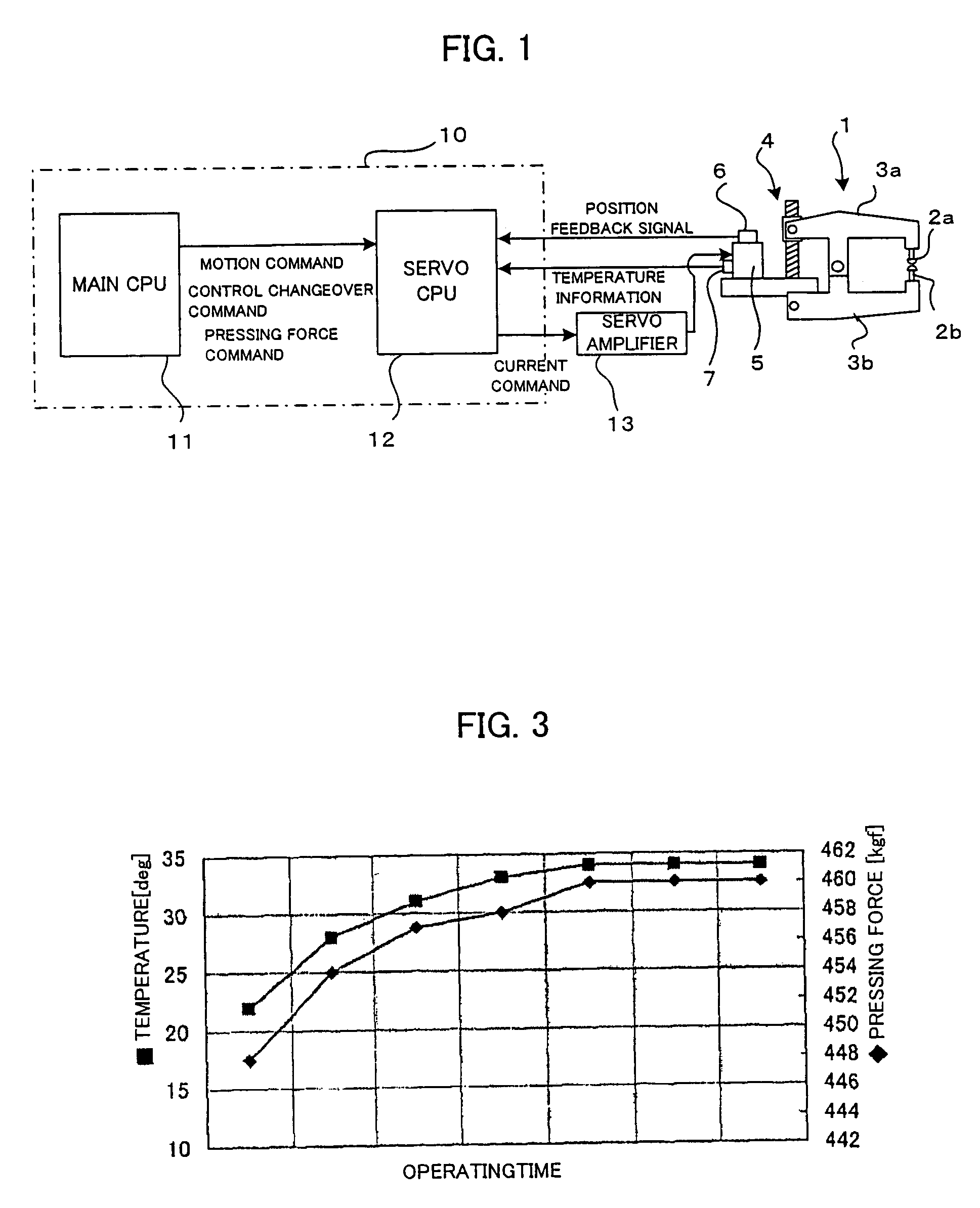

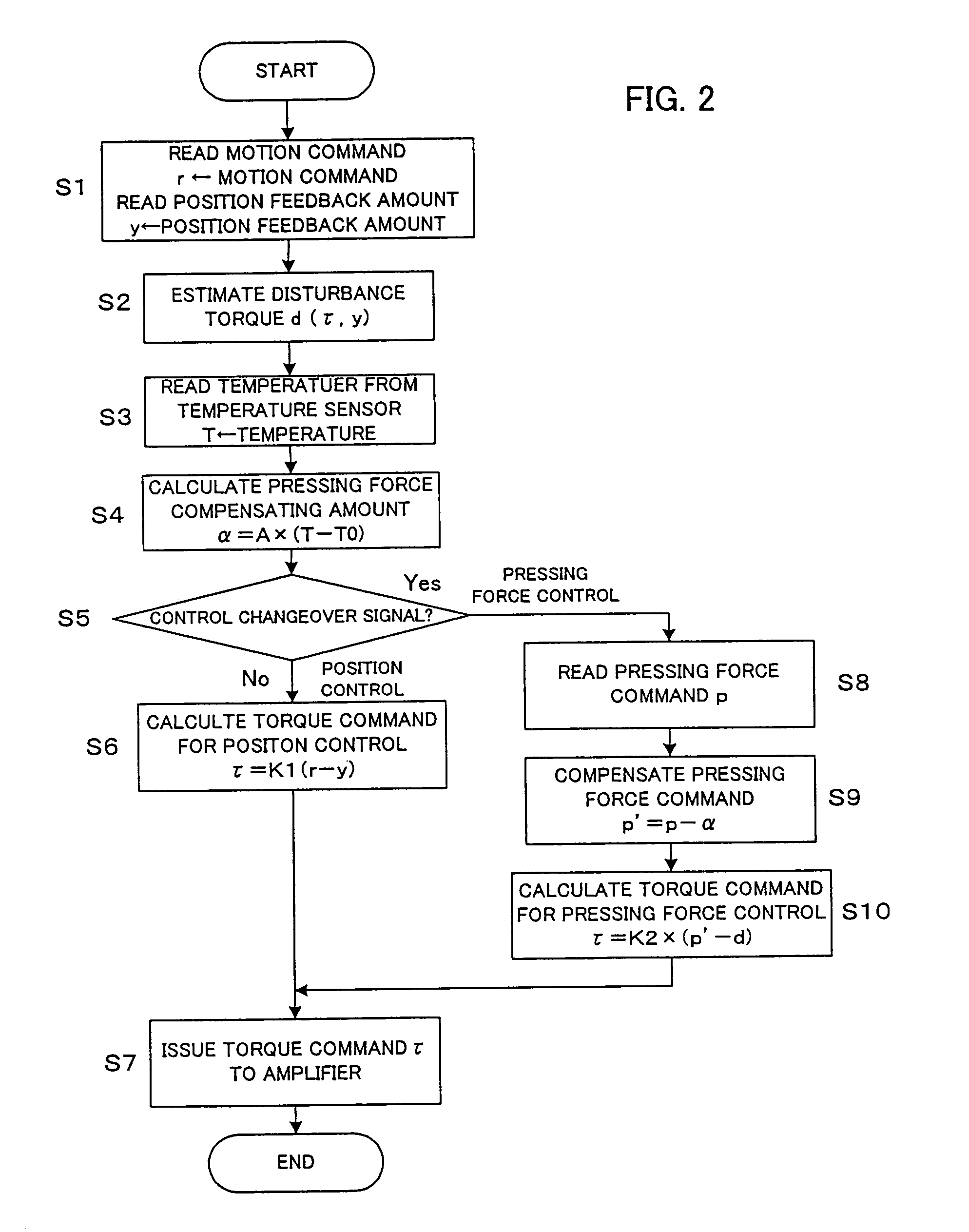

Spot welding system and method of controlling pressing force of spot welding gun

ActiveUS7002095B2Suppress mutationUniform pressureResistance electrode holdersElectrode supporting devicesEngineeringSpot welding

A spot welding system using a spot welding gun having a servomotor for driving welding tips capable of suppressing variation of pressing force due to influence of heat generated by welding current to obtain an uniform pressing force. A difference between the temperature T detected by a temperature sensor and an initial temperature T0 is multiplied by a coefficient A to obtain a pressing force compensation amount α. A pressing force d estimated by an observer is subtracted from the compensated command pressing force p′ and an obtained difference is multiplied by a constant K2 to obtain a torque command (current command) τ for driving the servomotor to press the objects by the welding tips. Since the commanded pressing force is compensated in accordance with the temperature, a constant and stable pressing force is produced without influence of the temperature variation.

Owner:FANUC LTD

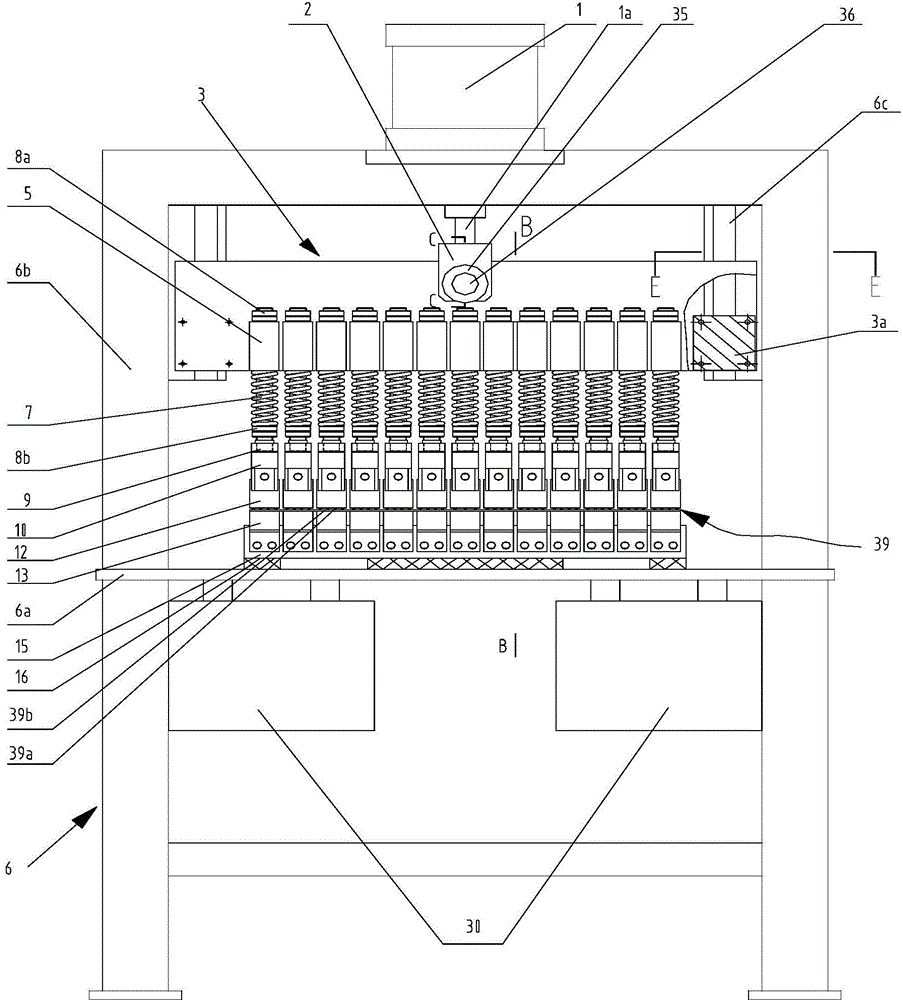

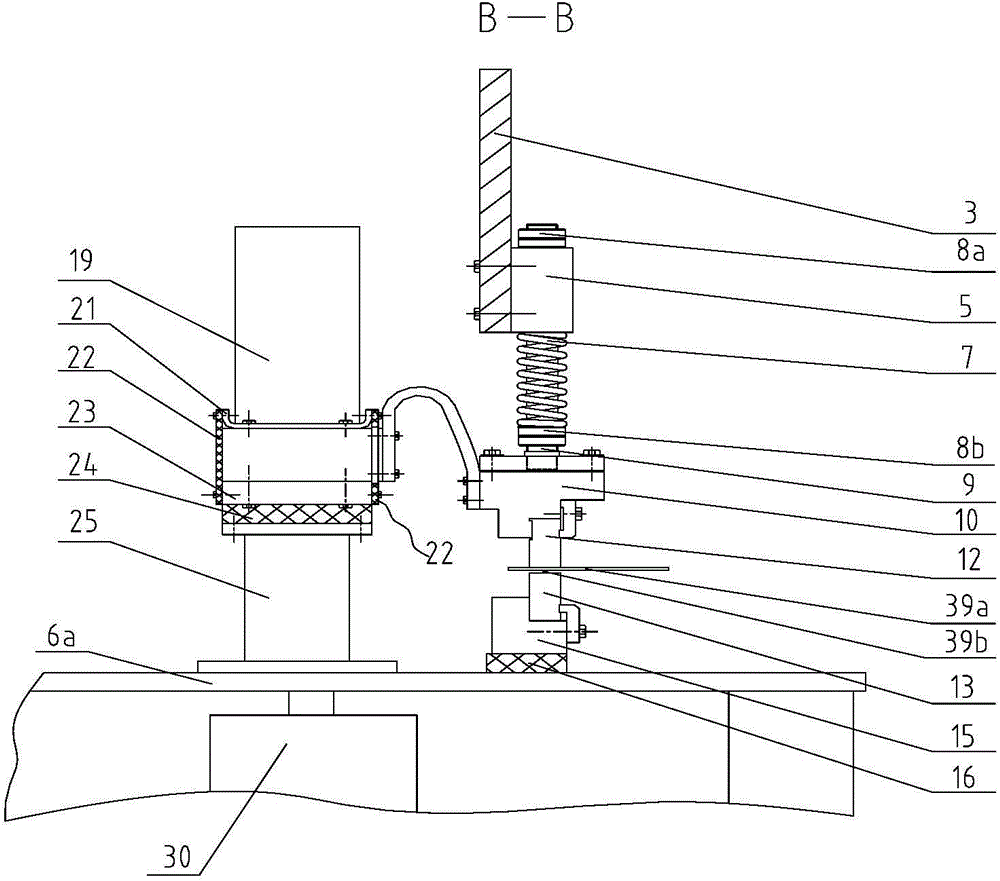

Double-welding mechanism of reinforcement cage seam welder

ActiveCN104002034AGuaranteed uptimeRealize weldingResistance electrode holdersMeshed-ring wire networkControl systemEngineering

The invention discloses a double-welding mechanism of a reinforcement cage seam welder. The double-welding mechanism structurally comprises a movable rotary table and an installing arm. A first set of welding gun device and a second set of welding gun device which are arranged in a spaced mode in parallel are installed on the installing arm in the direction of a longitudinal rib. The two ends of the installing arm are arranged on the two sides of the movable rotary table in a sliding fit mode respectively, one side of the movable rotary table is provided with a welding gun position adjusting mechanism driving the installing arm to move vertically and move horizontally, and the other side of the movable rotary table is provided with an auxiliary position adjusting mechanism moving along with the installing arm. The double-welding mechanism has the advantages that the two sets of welding gun devices are used for welding a reinforcement cage in a dot interlace mode under the control of a control system, the two ends of the installing arm are arranged on the two sides of the movable rotary table in the sliding fit mode respectively, the two sets of welding gun devices can operate stably through the welding gun position adjusting mechanism at one end of the installing arm and the auxiliary position adjusting mechanism at the other end of the installing arm, and welding is achieved at the accurate welding position. The double-welding mechanism has the advantages of being suitable for welding reinforcement cages with different specifications, wide in welding type and standard range, high in welding efficiency, good in quality and stable in working.

Owner:TJK MACHINERY TIANJIN

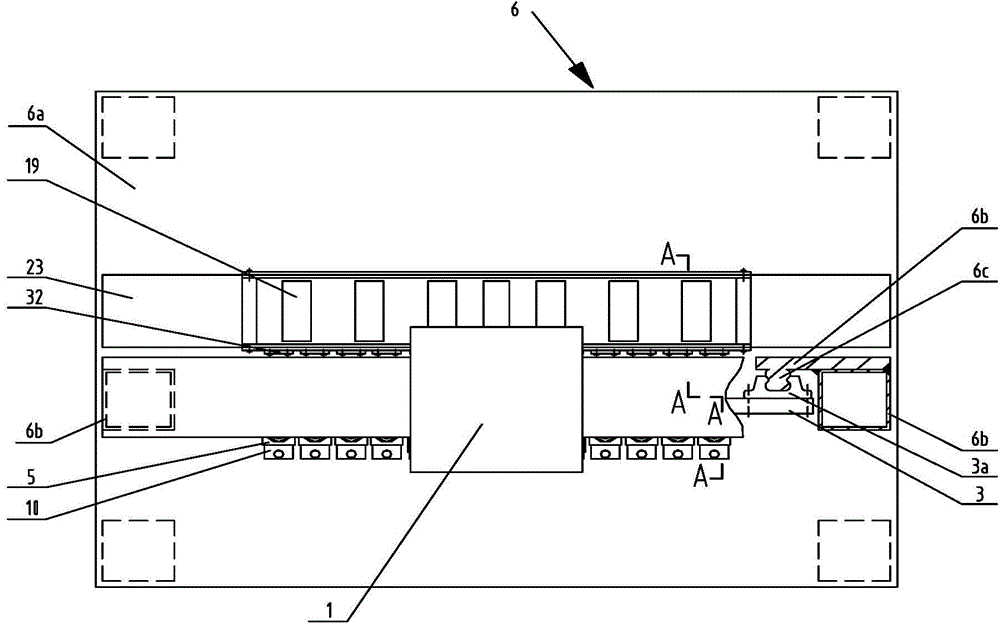

Mesh welding machine with functions of simultaneously pressing multiple electrodes down and respectively welding single electrode

ActiveCN104475957AGuaranteed flatnessGuarantee welding qualityResistance electrode holdersWelding/cutting auxillary devicesElectricityTransformer

The invention discloses a mesh welding machine with the functions of simultaneously pressing multiple electrodes down and respectively welding a single electrode. The mesh welding machine structurally comprises a transformer, a plurality of upper electrodes and a plurality of lower electrodes, wherein the plurality of lower electrodes are arranged on a lower electrode seat, and the lower electrode seat is connected with one output end of the transformer; each upper electrode is provided with an upper electrode seat, and the multiple upper electrode seats are arranged on a drive mechanism; a second conductive copper bar is arranged between each upper electrode seat and a welding cylinder, wherein one end of each second conductive copper bar is connected with the corresponding upper electrode seat, and the other end of each second conductive copper bar is connected with a piston rod of the welding cylinder in an insulated manner; the bottom surfaces of the second conductive copper bars are adjacent to an upper electrode plate, and the upper electrode plate is connected with another output end of the transformer. The mesh welding machine disclosed by the invention has the beneficial effects that multiple welding points of a metal mesh are simultaneously pressed by the upper electrodes and the lower electrodes, the welding cylinder respectively drives the upper electrodes to contact the welding points and the lower electrodes to weld the welding points respectively, so that the flatness of the metal mesh and the welding quality are ensured. The mesh welding machine disclosed by the invention has the advantages of low electricity consumption and energy conservation.

Owner:TJK MACHINERY TIANJIN

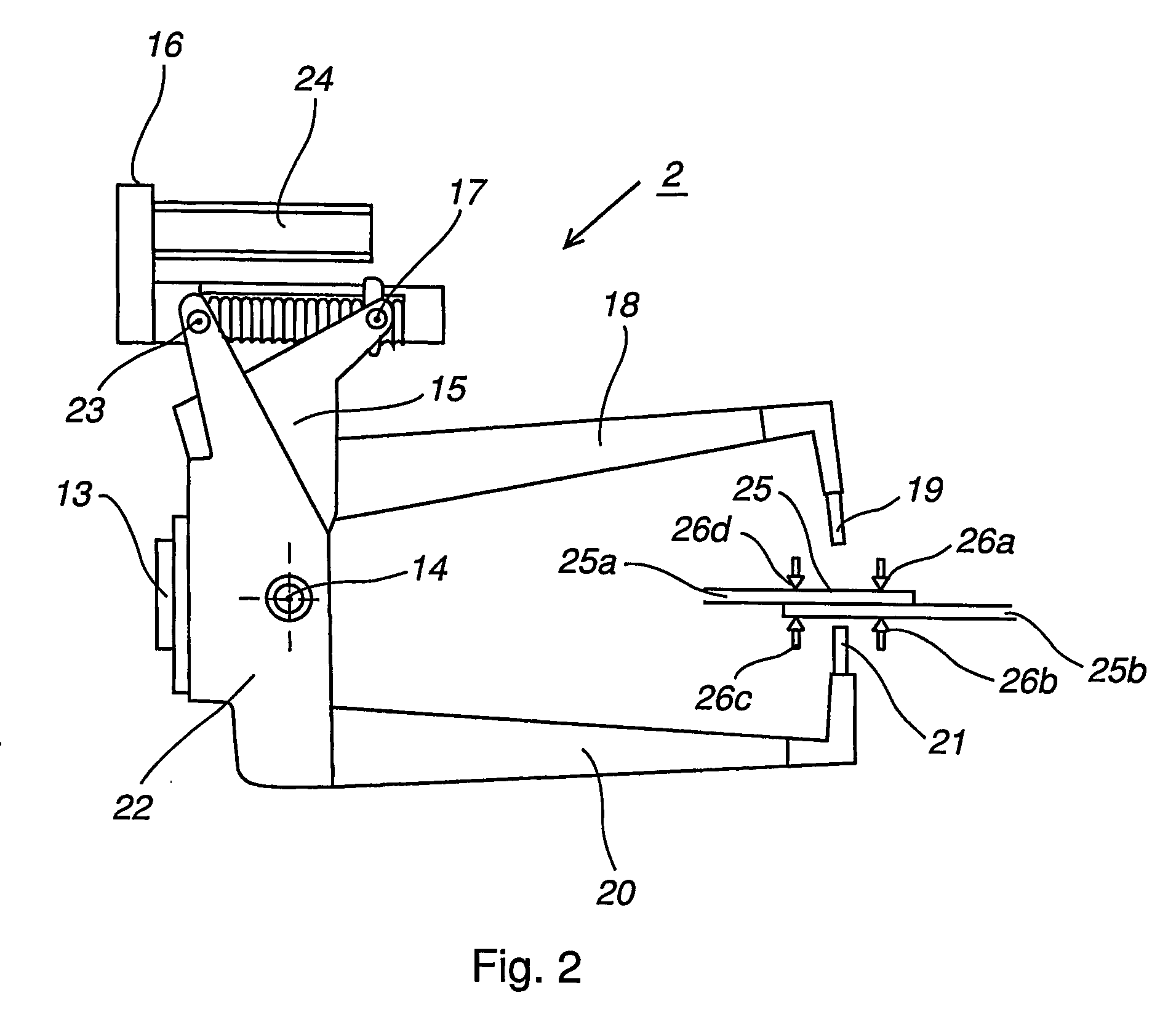

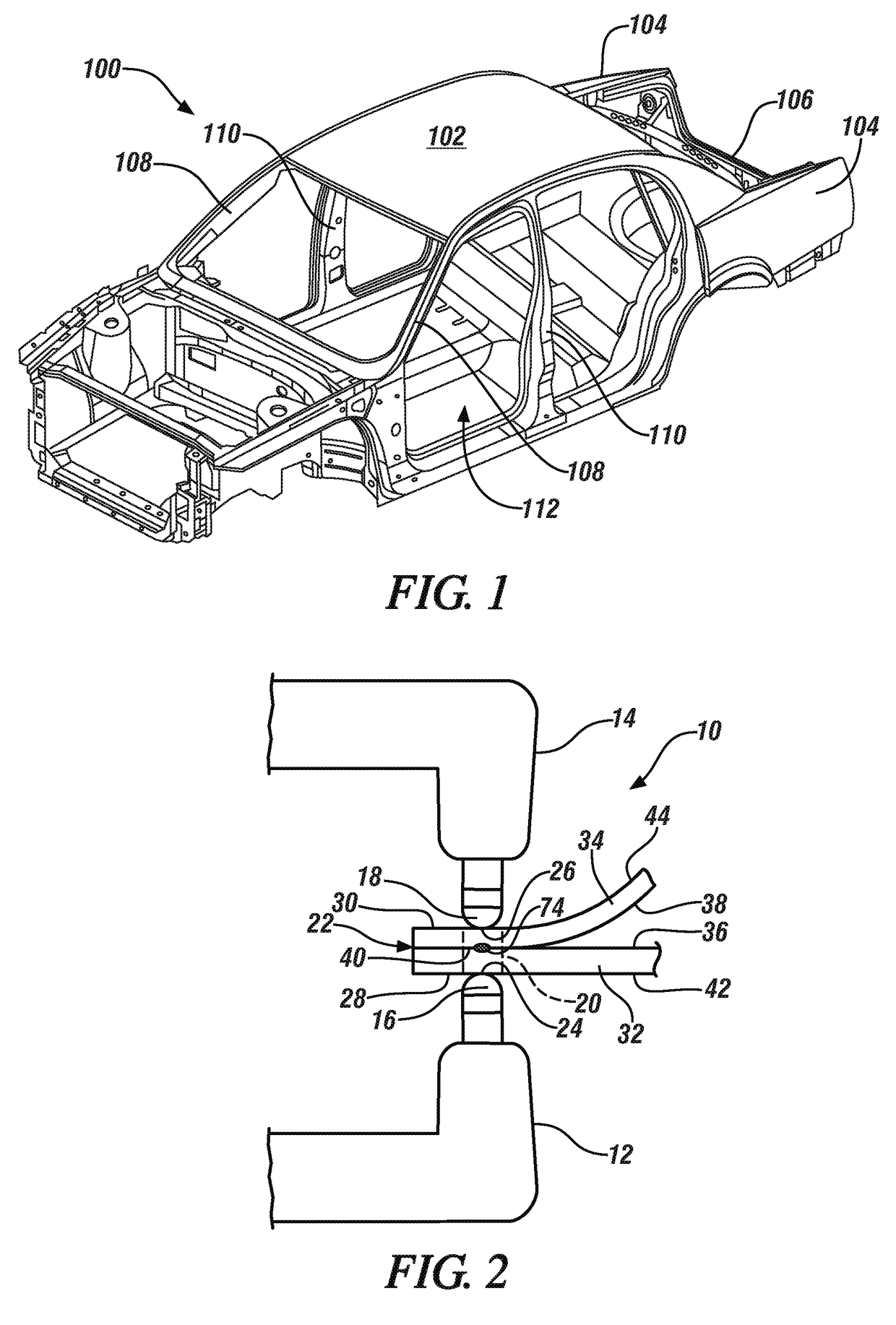

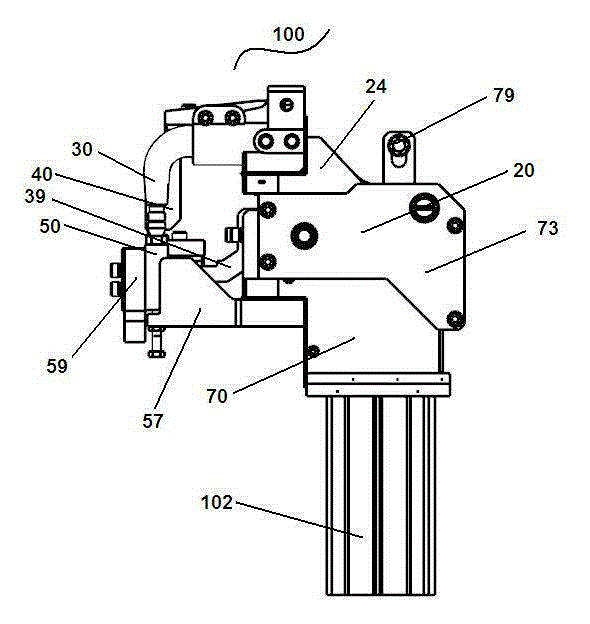

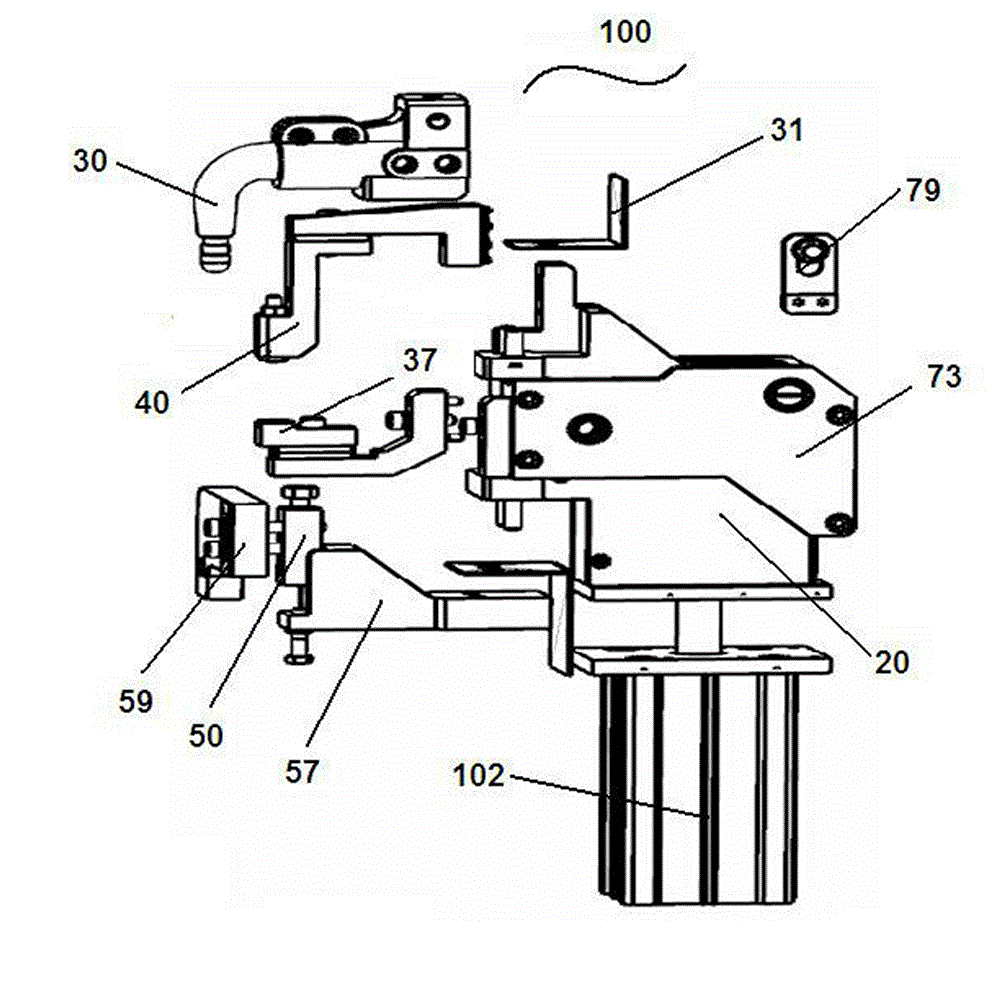

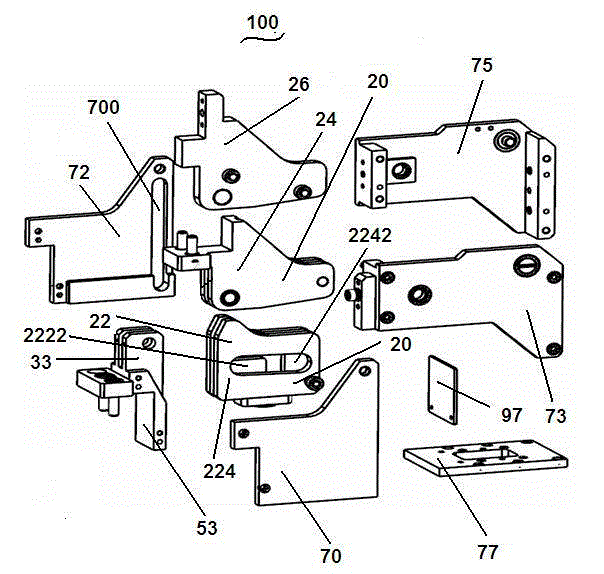

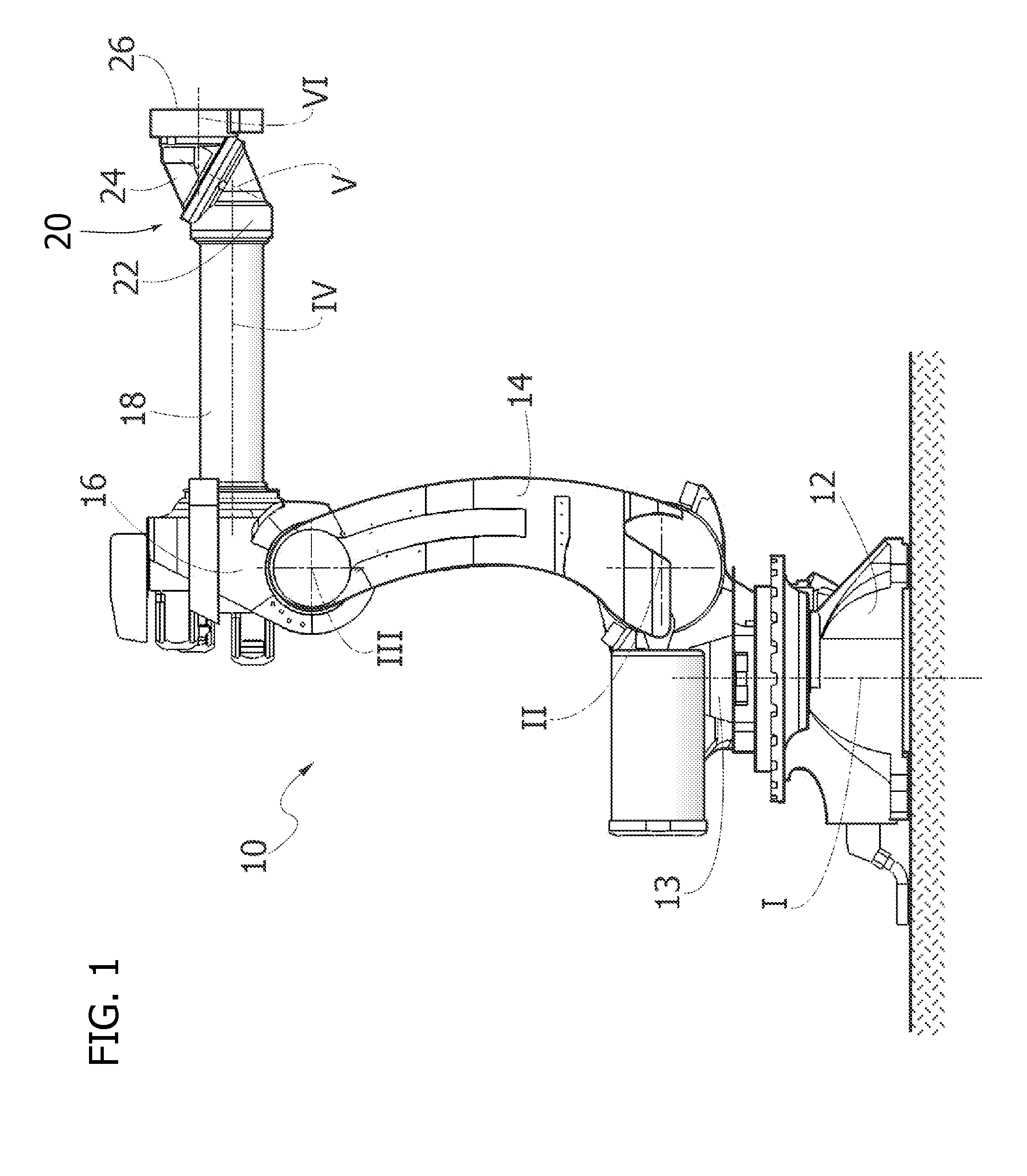

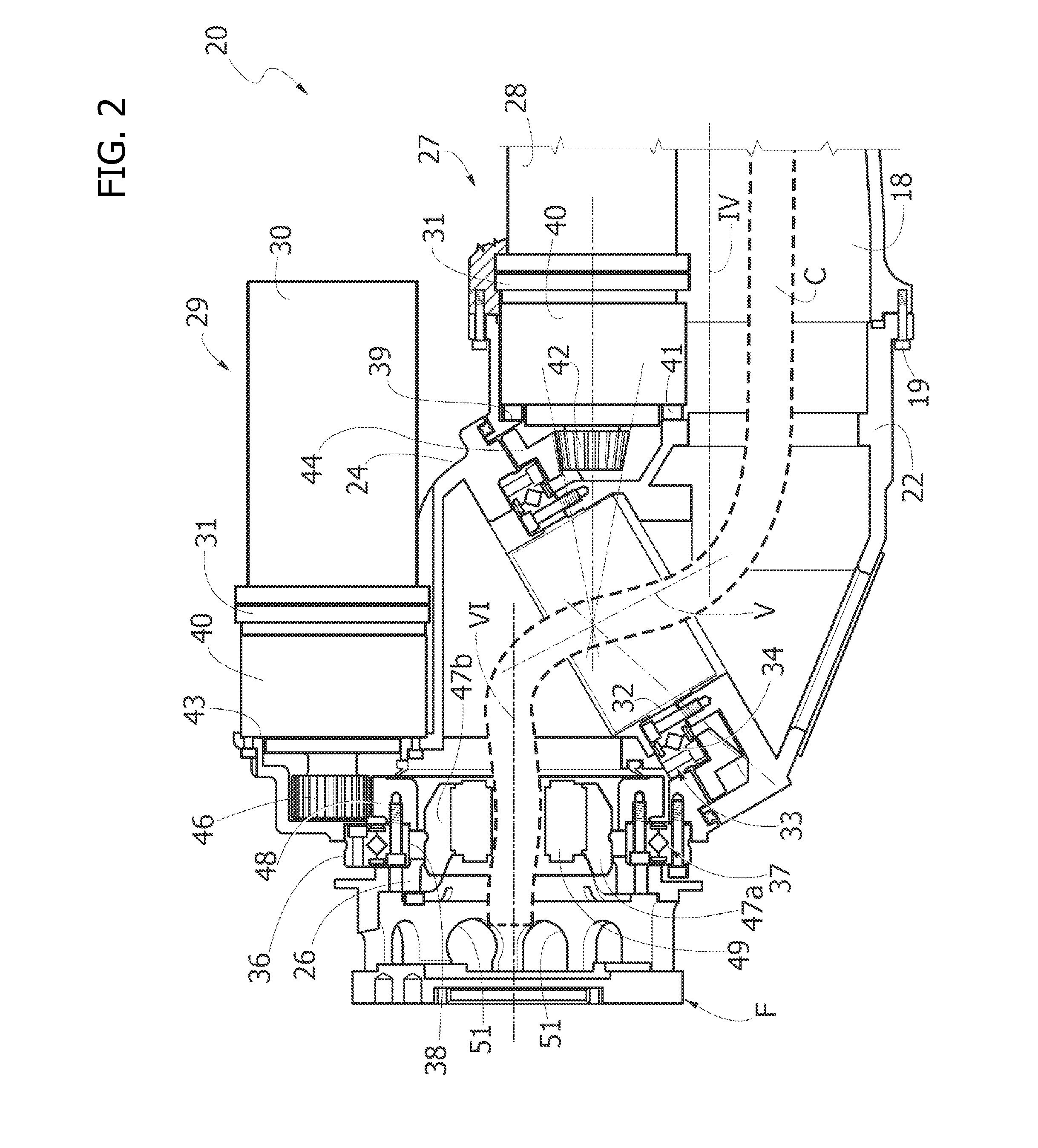

Multi-Axis Industrial Robot With Integrated Tool

InactiveUS20150108099A1Easy to useMinimal numberResistance electrode holdersMechanical apparatusMulti axisControl theory

An industrial robot including a robot chain of elements, a robot wrist bearing a tool (100) and a continuous internal passage through which one or more cables and / or pipes for the power supply and / or the fluid supply to the tool. The cables and pipes continue without interruption through the passage and through a flange of the robot up to respective connections of said tool, whereby the cables and pipes are arranged completely inside the robot and inside the tool, without the need to provide separate cables and pipes of the tool connected to the cables and the pipes of the robot at the flange of the robot.

Owner:COMAU SPA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com