Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

79results about How to "Improve Spot Welding Efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

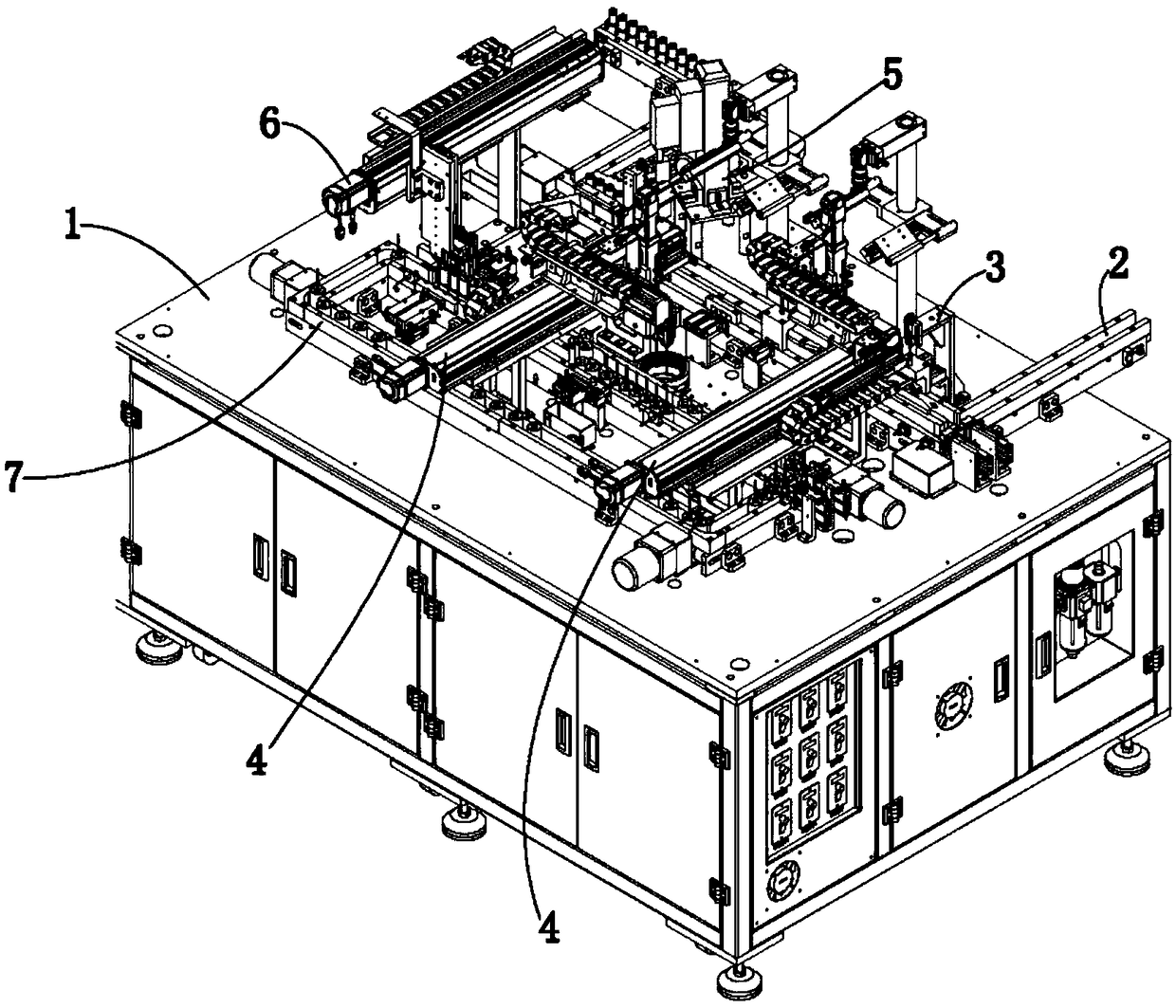

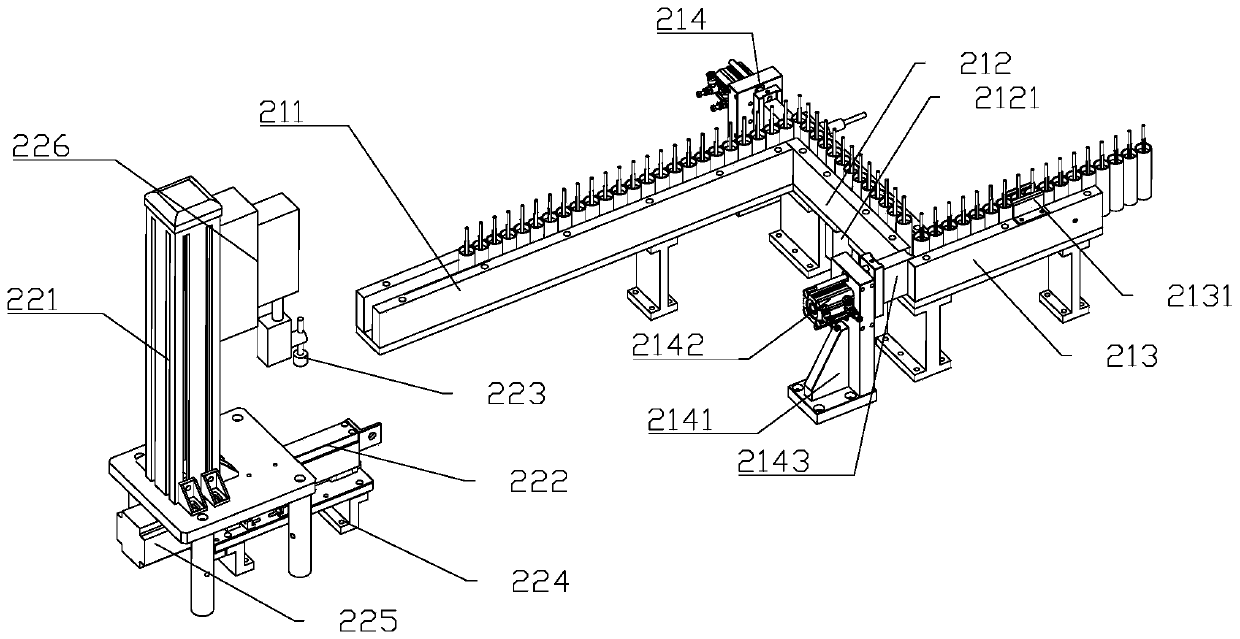

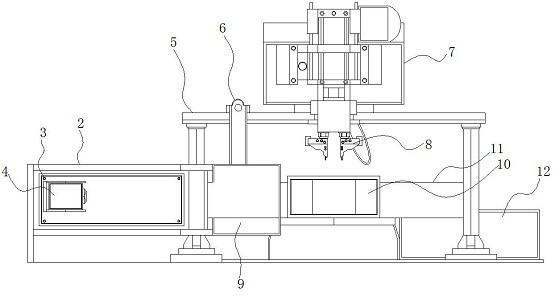

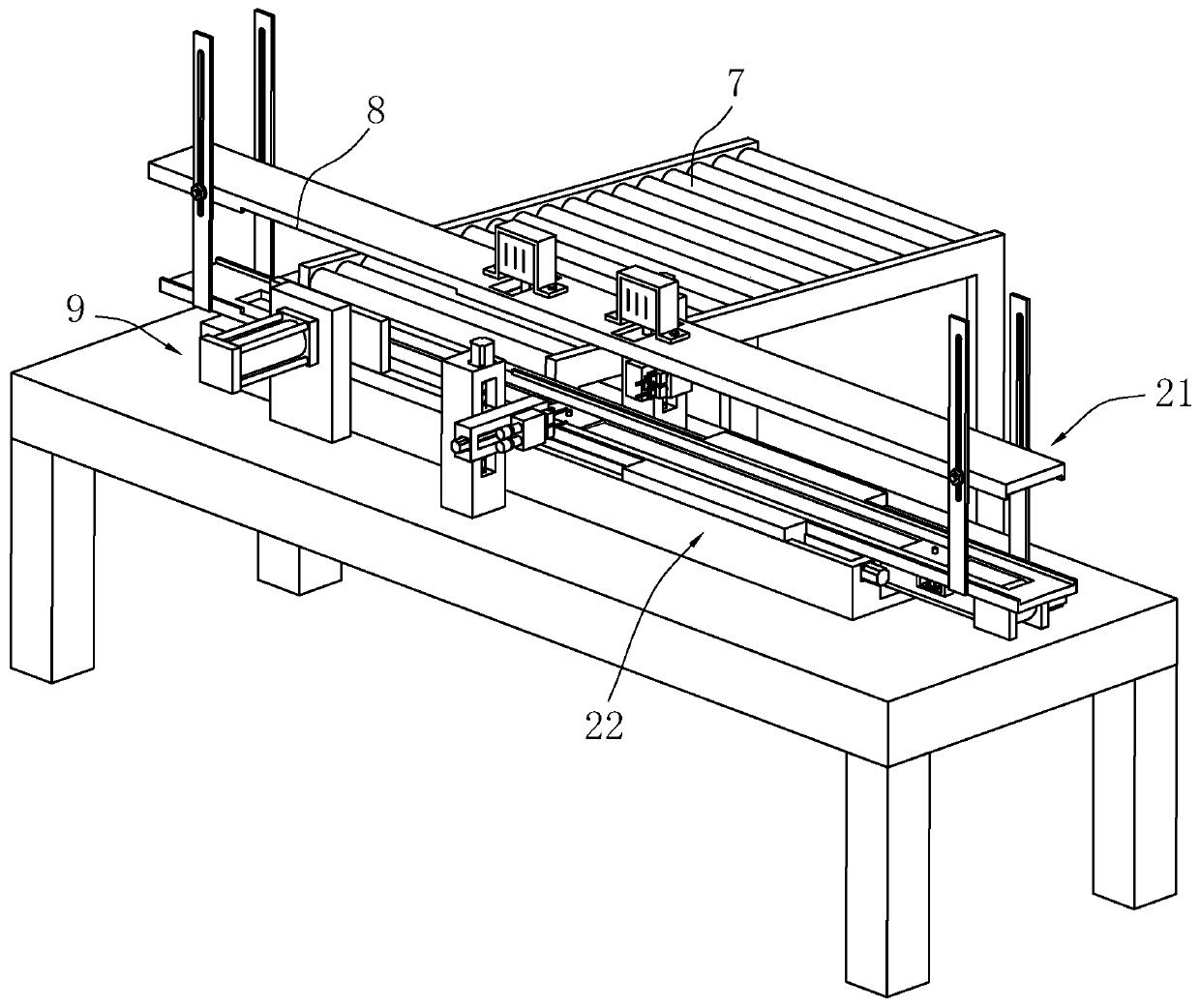

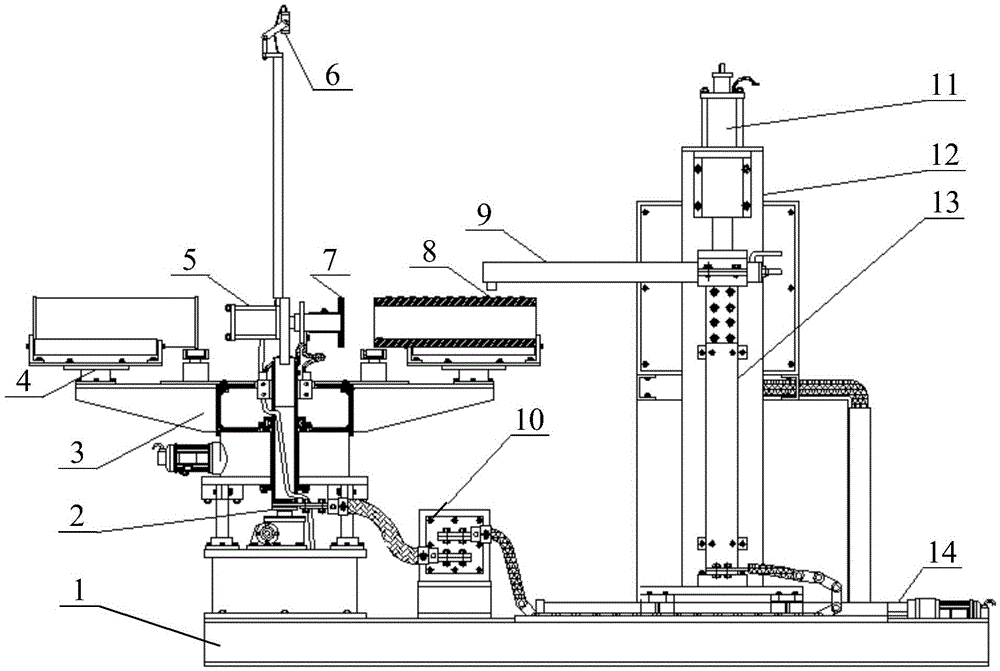

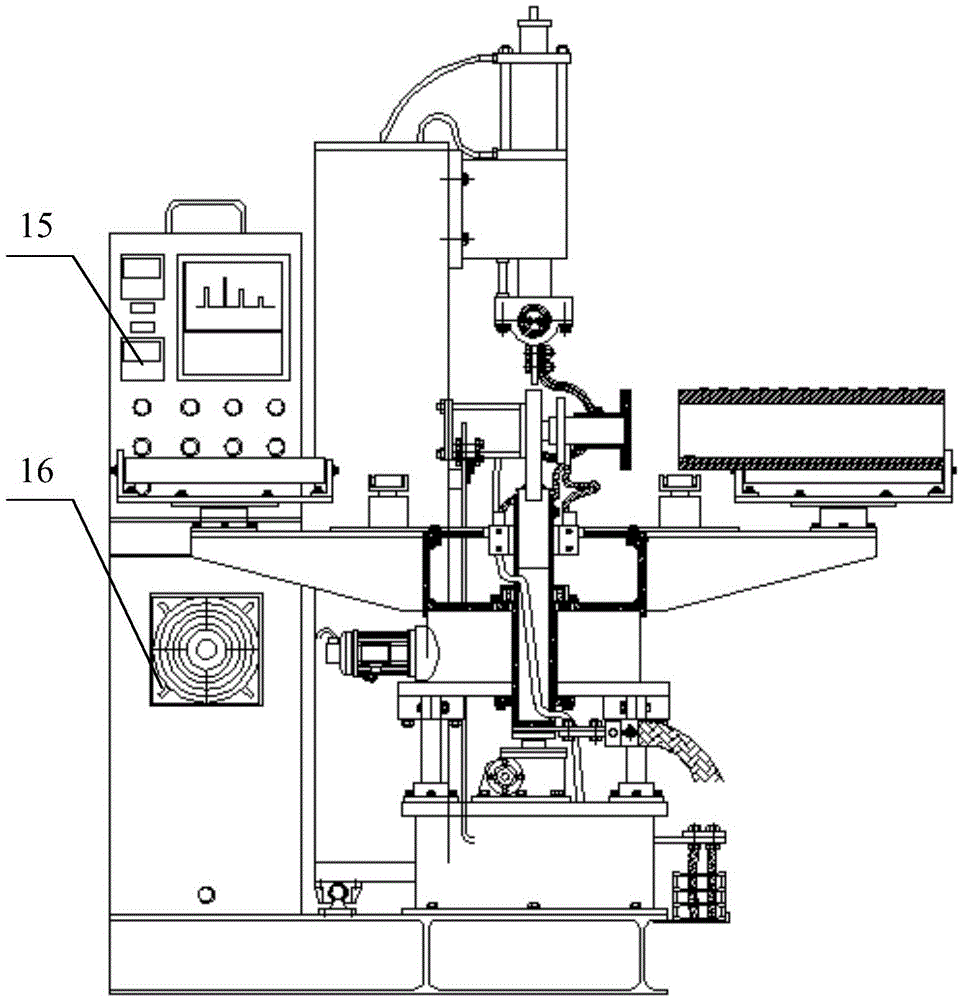

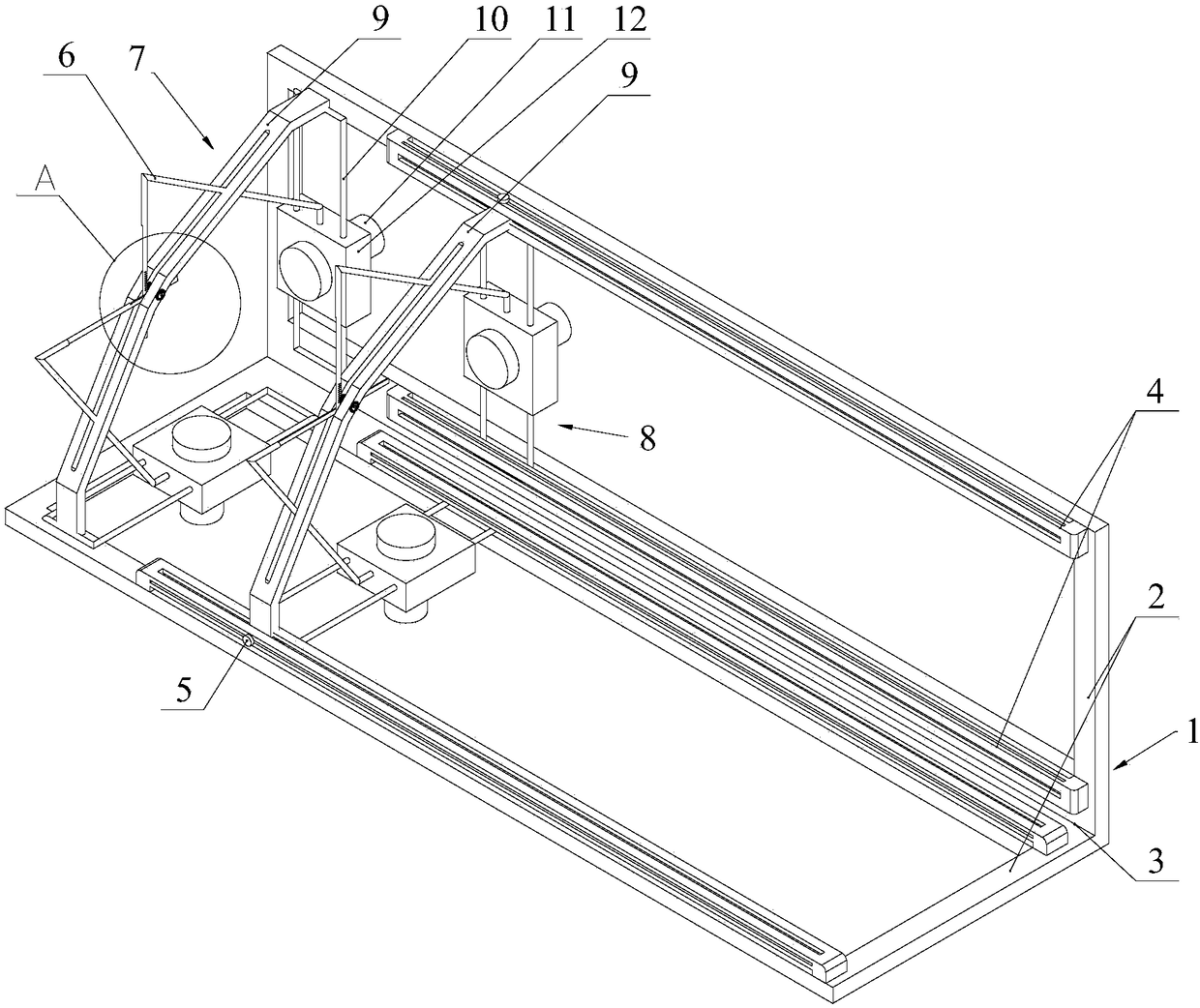

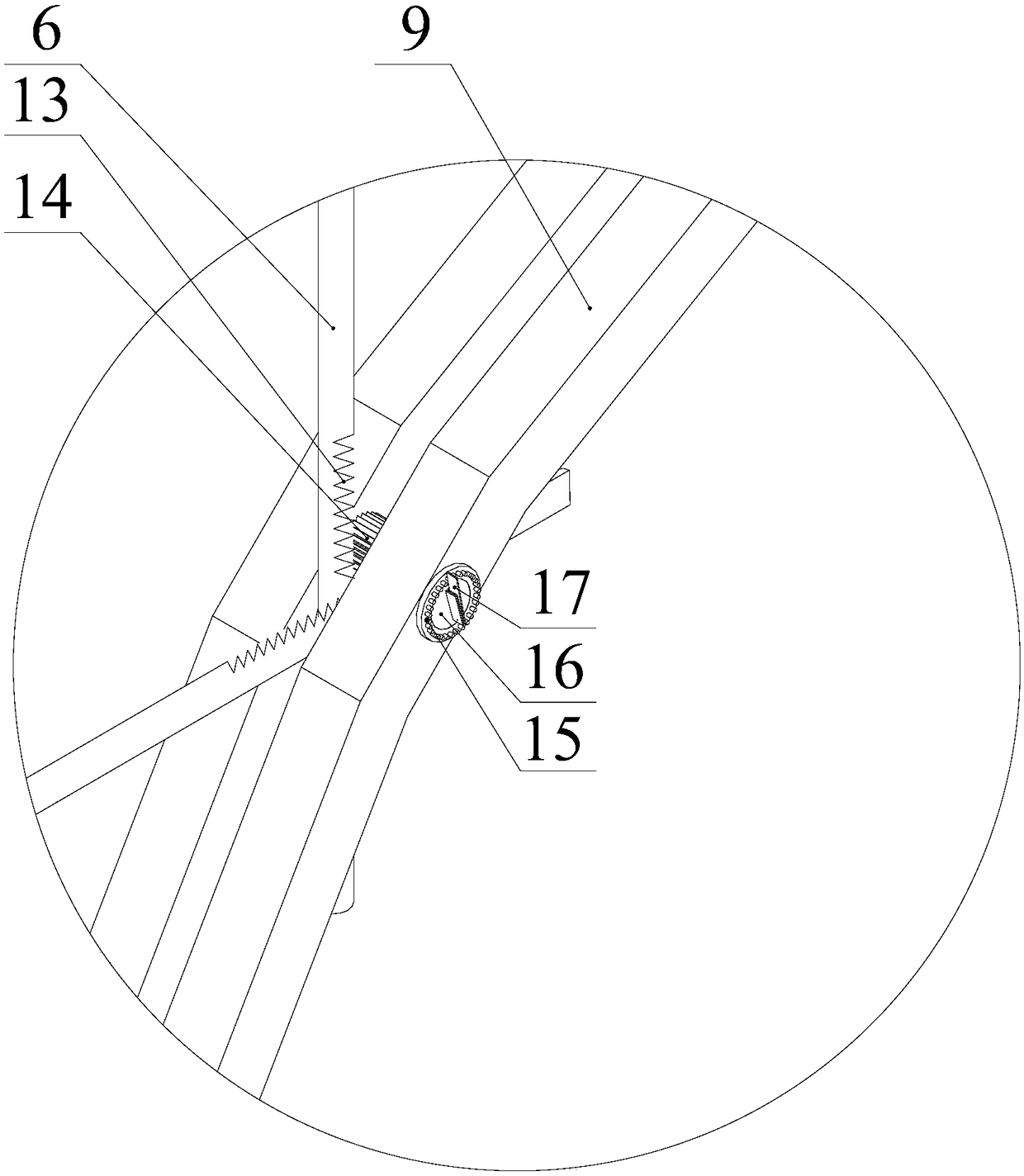

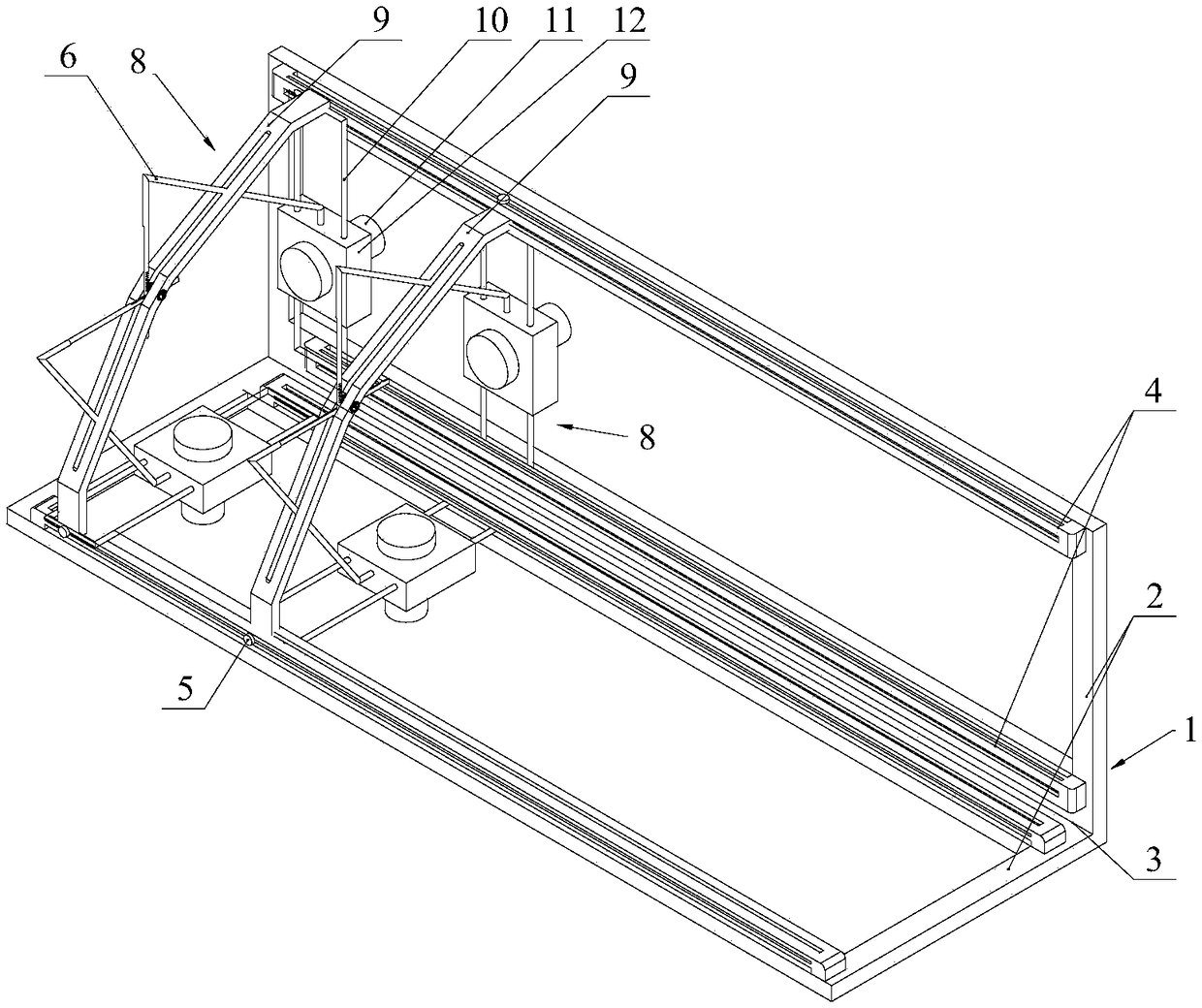

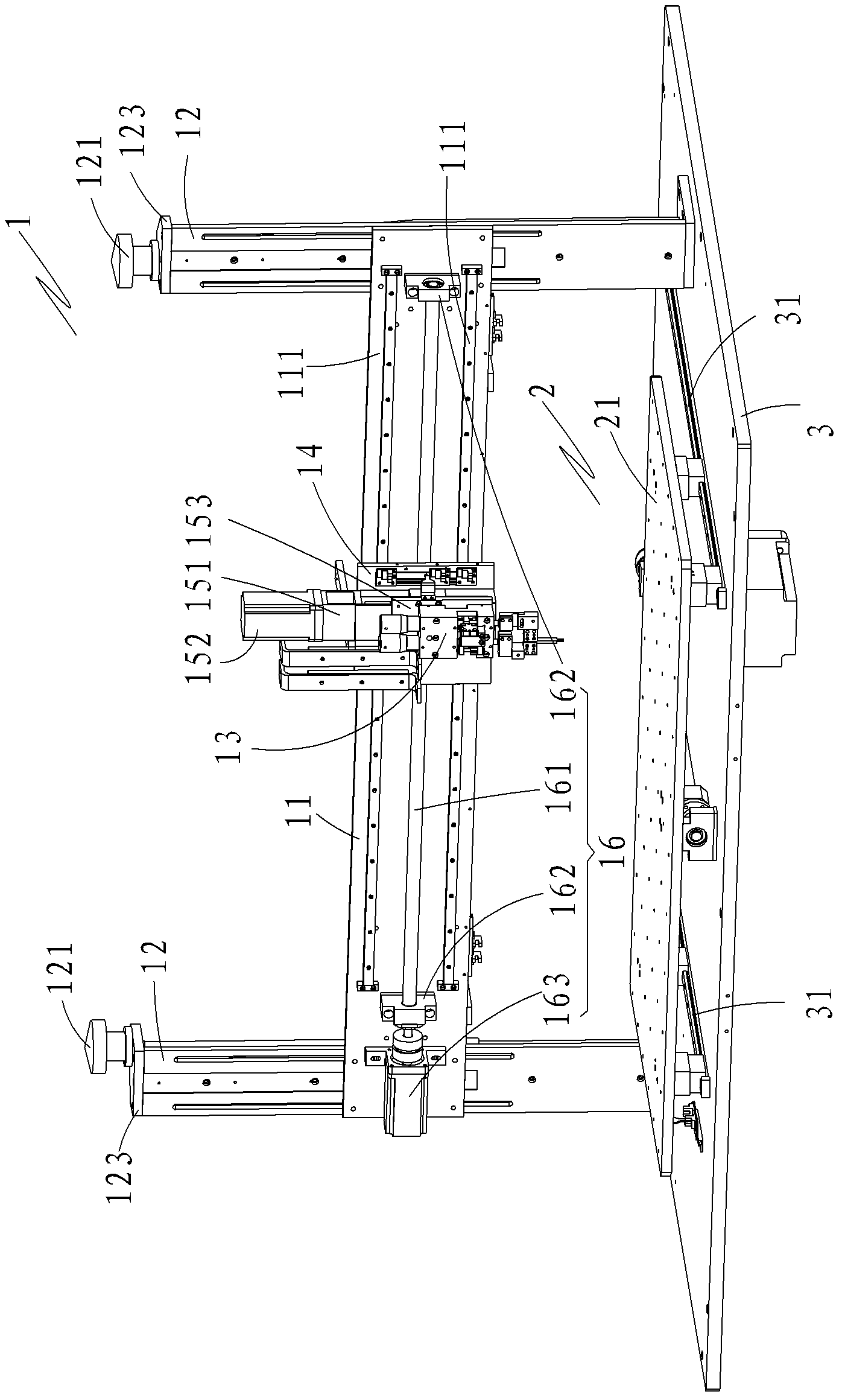

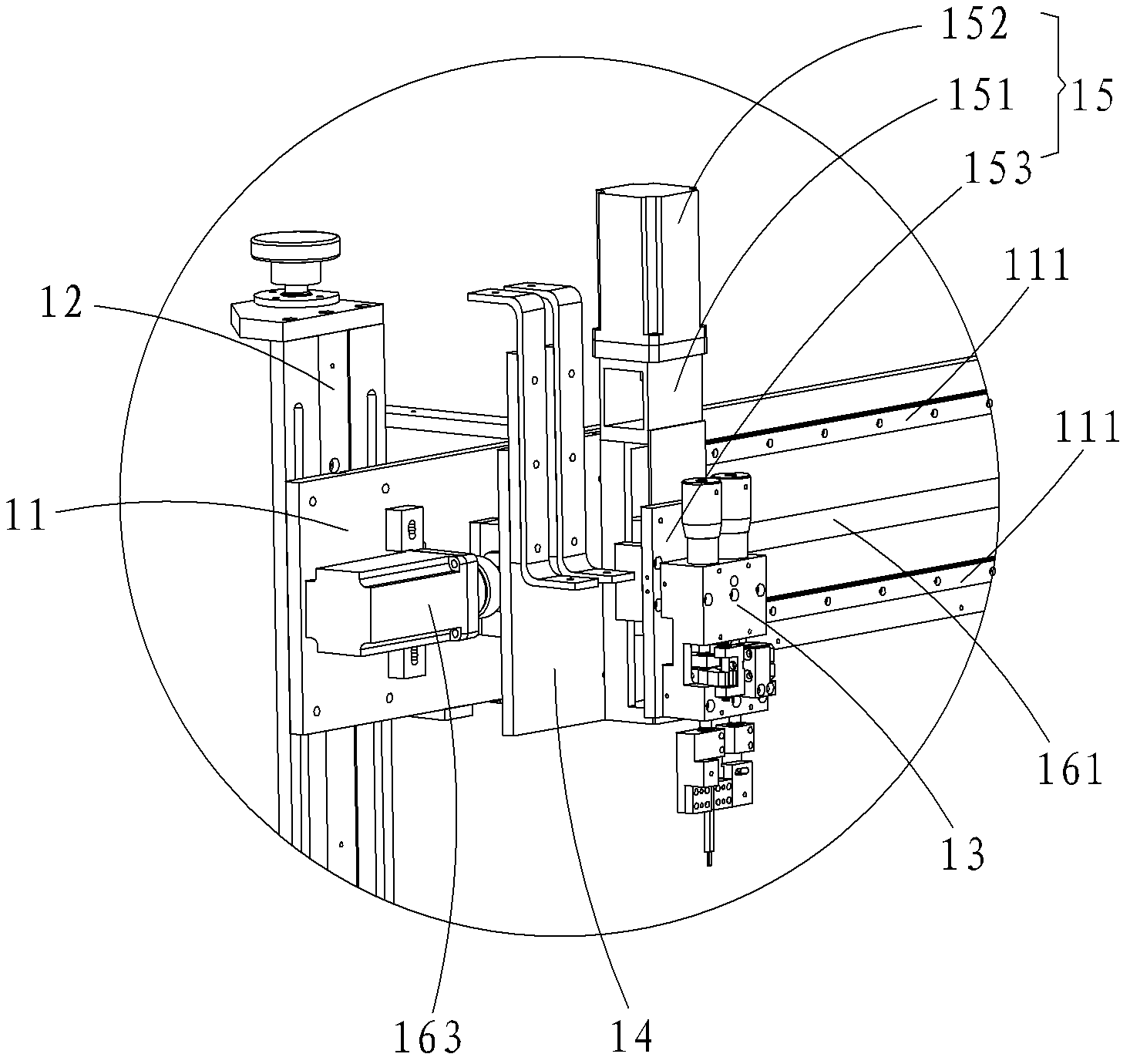

Gantry-type automatic spot welding system for battery pack

ActiveCN102554437AIncrease the number of installations andReduce manual labor intensityResistance welding apparatusProgrammable logic controllerMechanical engineering

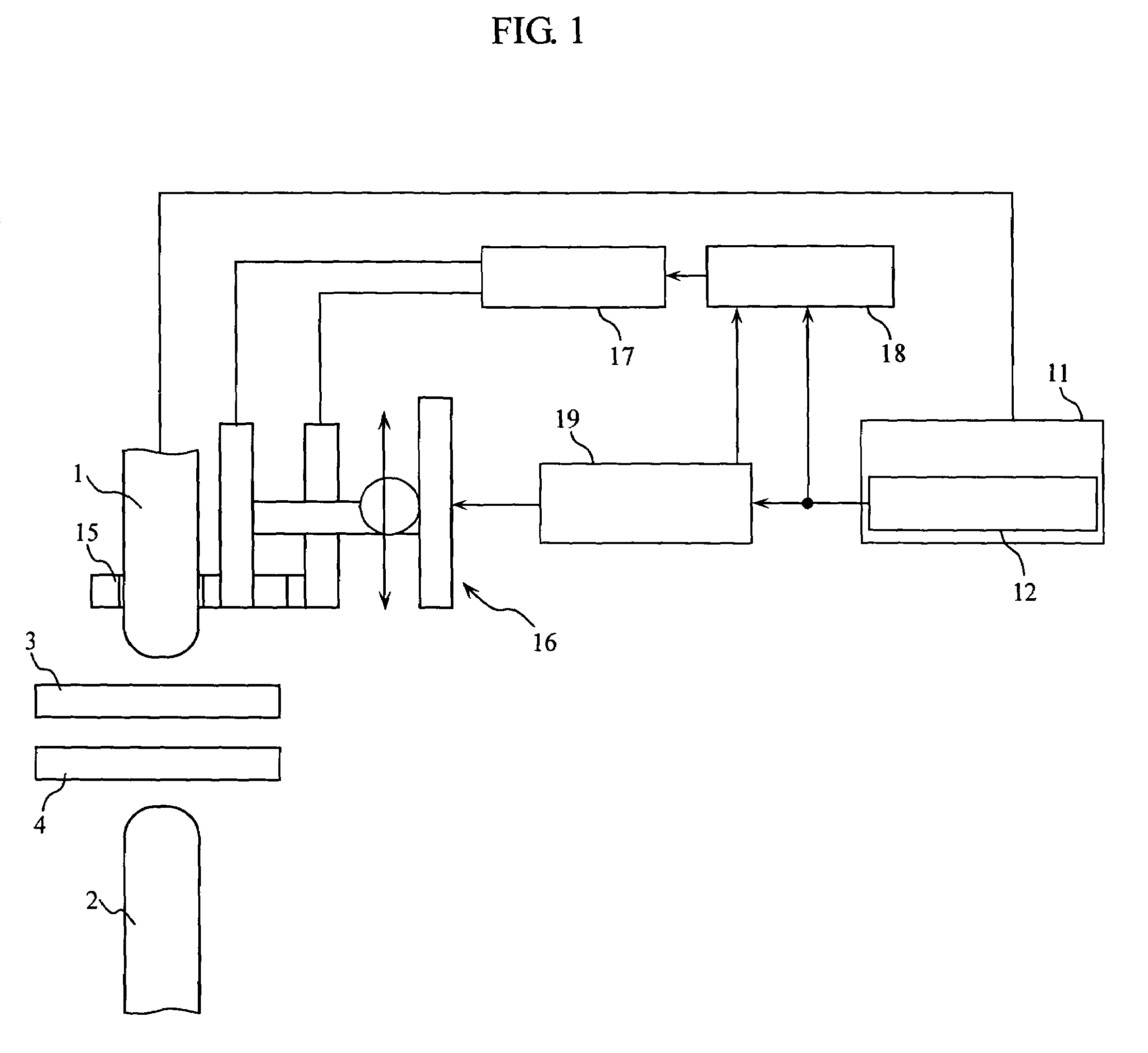

The invention provides a gantry-type automatic spot welding system for a battery pack, which comprises a spot welding device and a spot welding jig fixing device which are vertically arranged and are connected with a PLC (programmable logic controller) of the system. The spot welding device comprises a beam, a group of opposite vertical columns in parallel, a spot welding mechanism, an X-axis sliding table, a Y-axis movement mechanism and an X-axis movement mechanism, wherein the vertical columns are used for adjusting the height of the beam, the X-axis sliding table is used for fixing the spot welding mechanism, the Y-axis movement mechanism enables the spot welding mechanism to transversely move, and the X-axis movement mechanism enables the X-axis sliding table to transversely move. The spot welding jig fixing device comprises a spot welding jig platen and a clamping mechanism for clamping a spot welding jig, wherein the clamping mechanism is arranged on the spot welding jig platen and is perpendicular to the spot welding mechanism. By the aid of a gantry-type structure, clamping is performed once, cells are numerous, spot welding parameters are controllable, and the system is fast in running speed, high in spot welding efficiency, highly adaptable to the cells, accurate in positioning and fine in spot welding quality.

Owner:FUJIAN NEBULA ELECTRONICS CO LTD

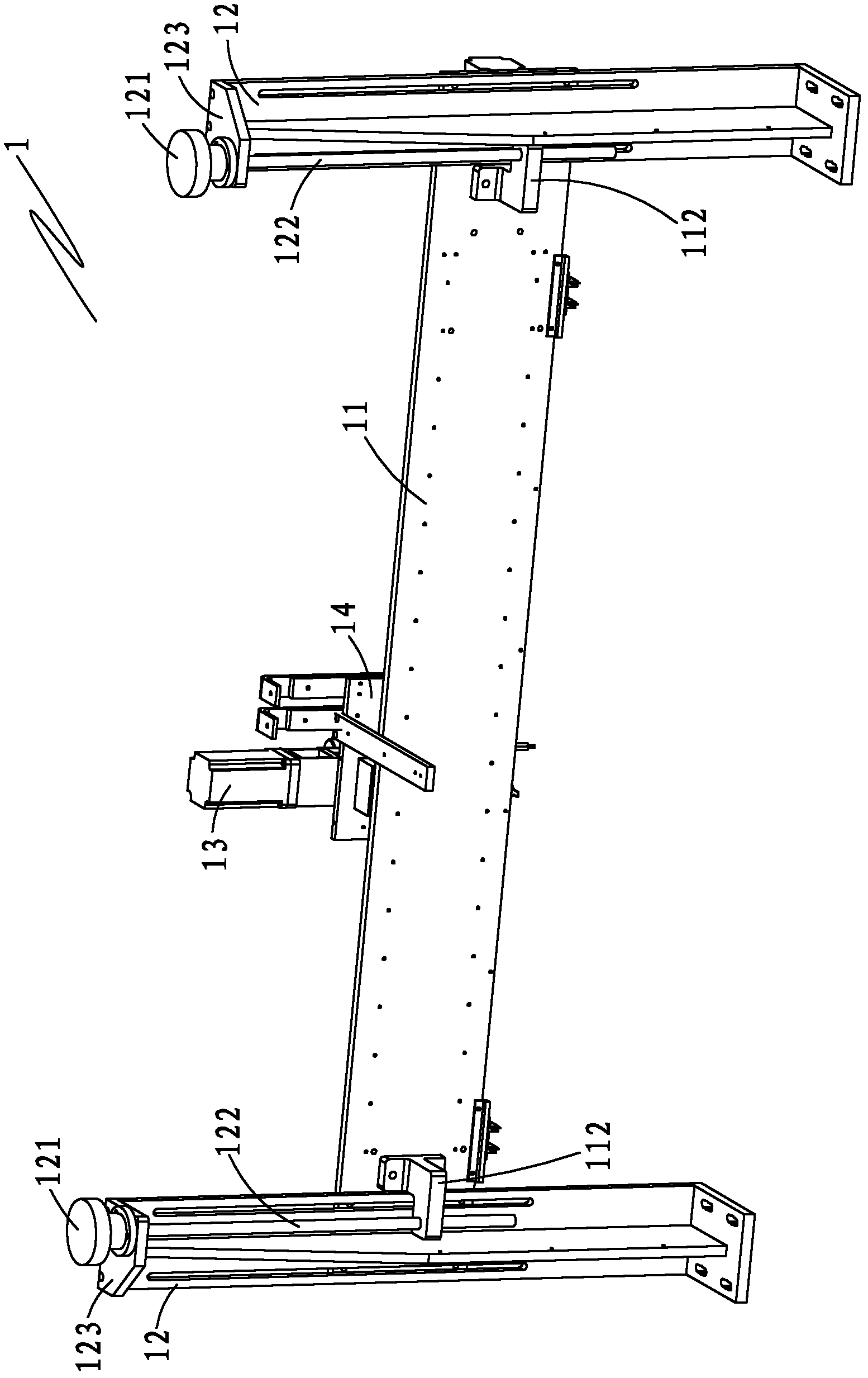

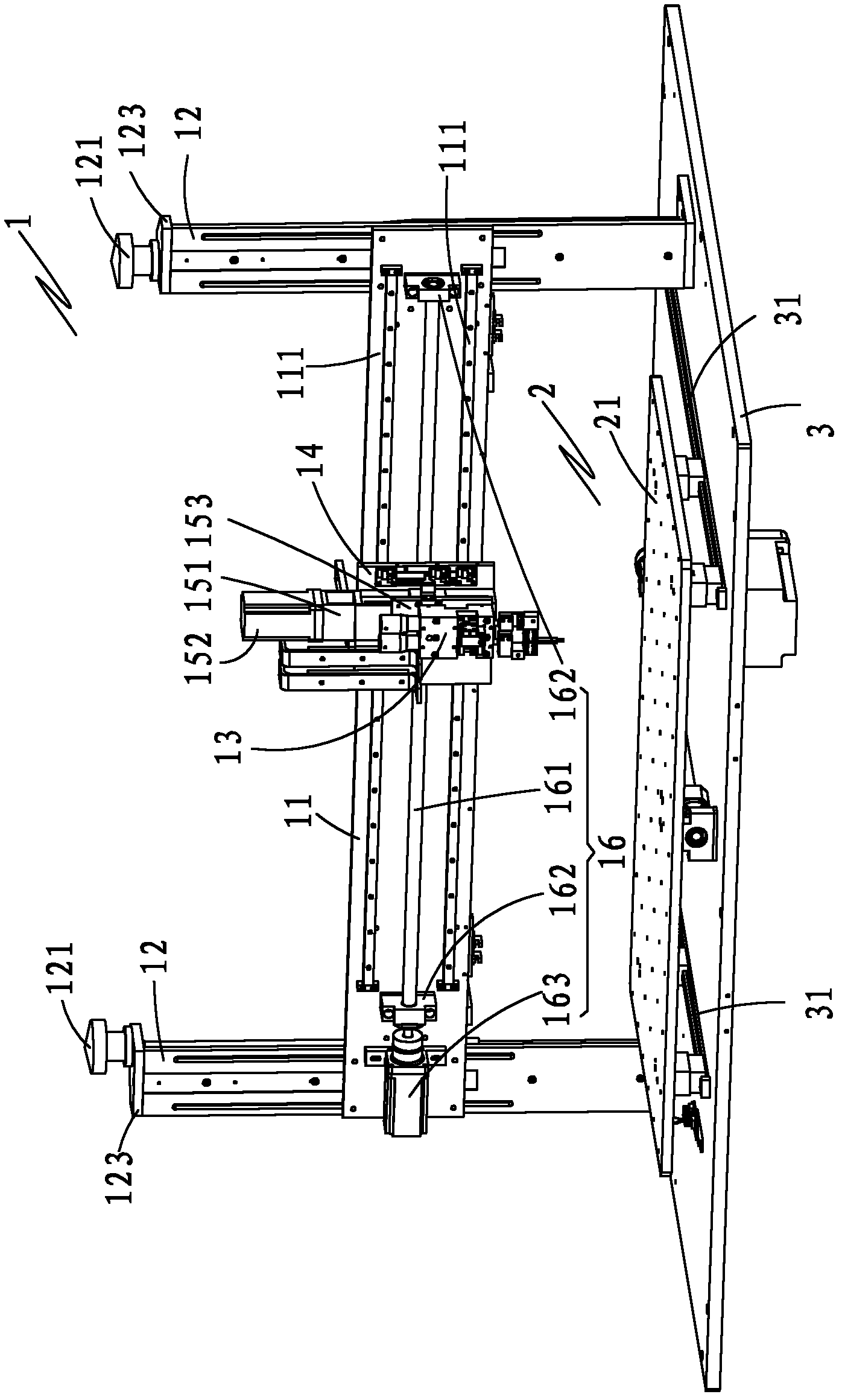

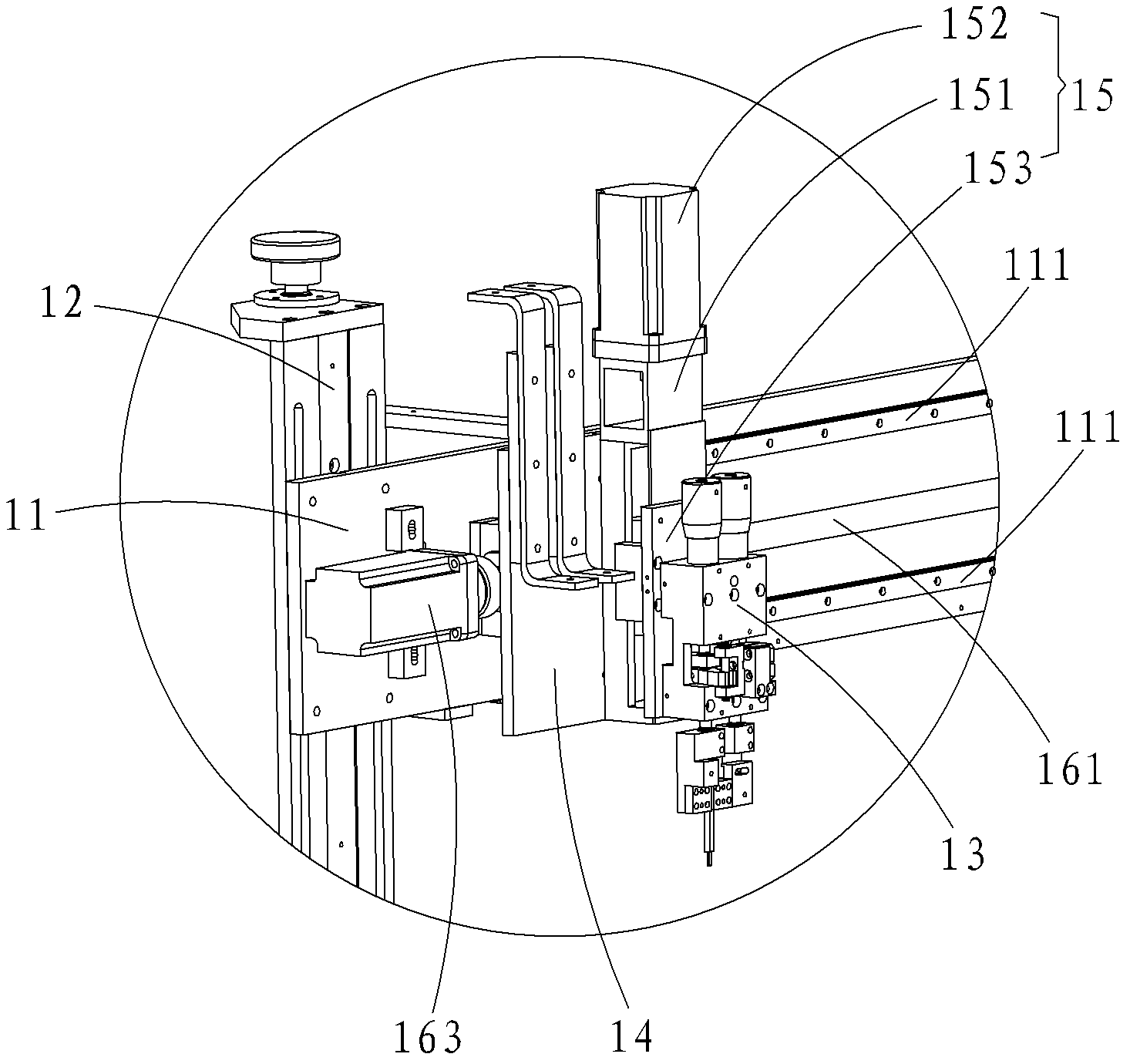

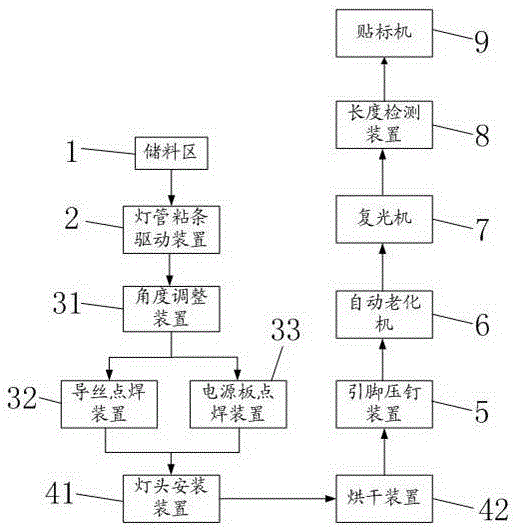

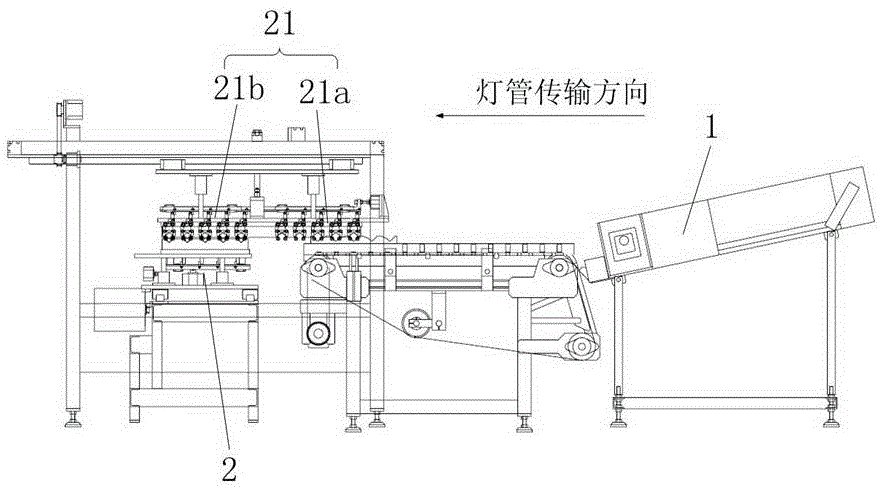

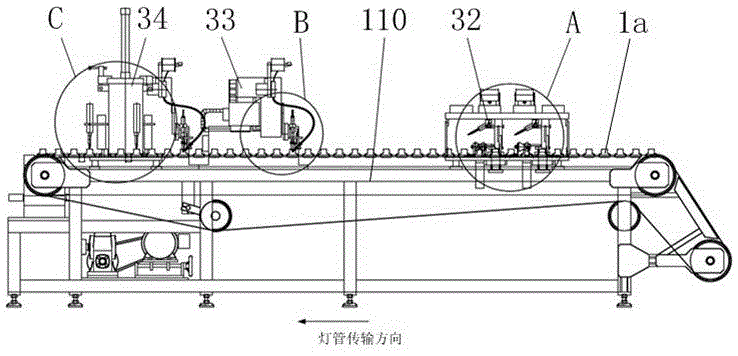

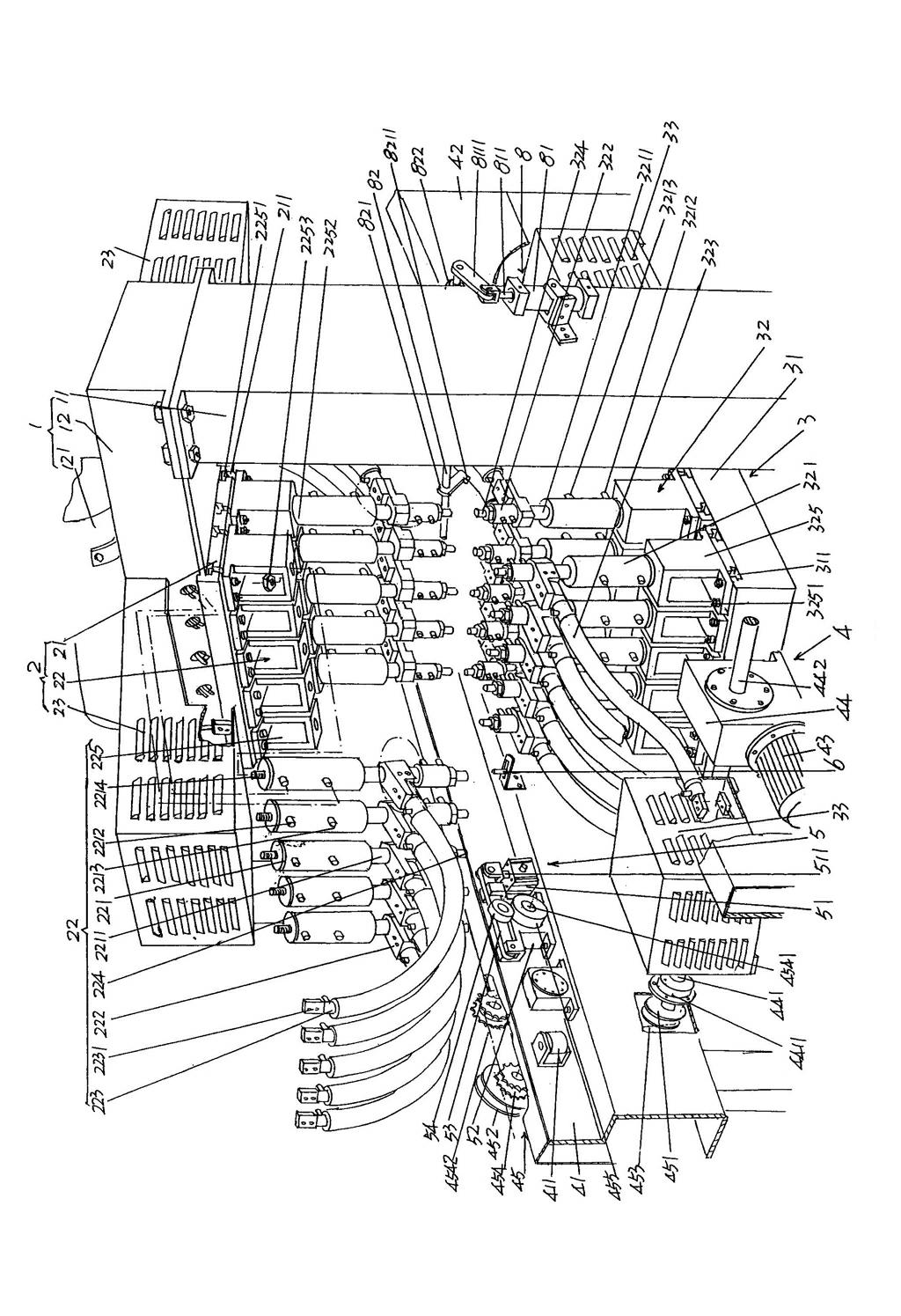

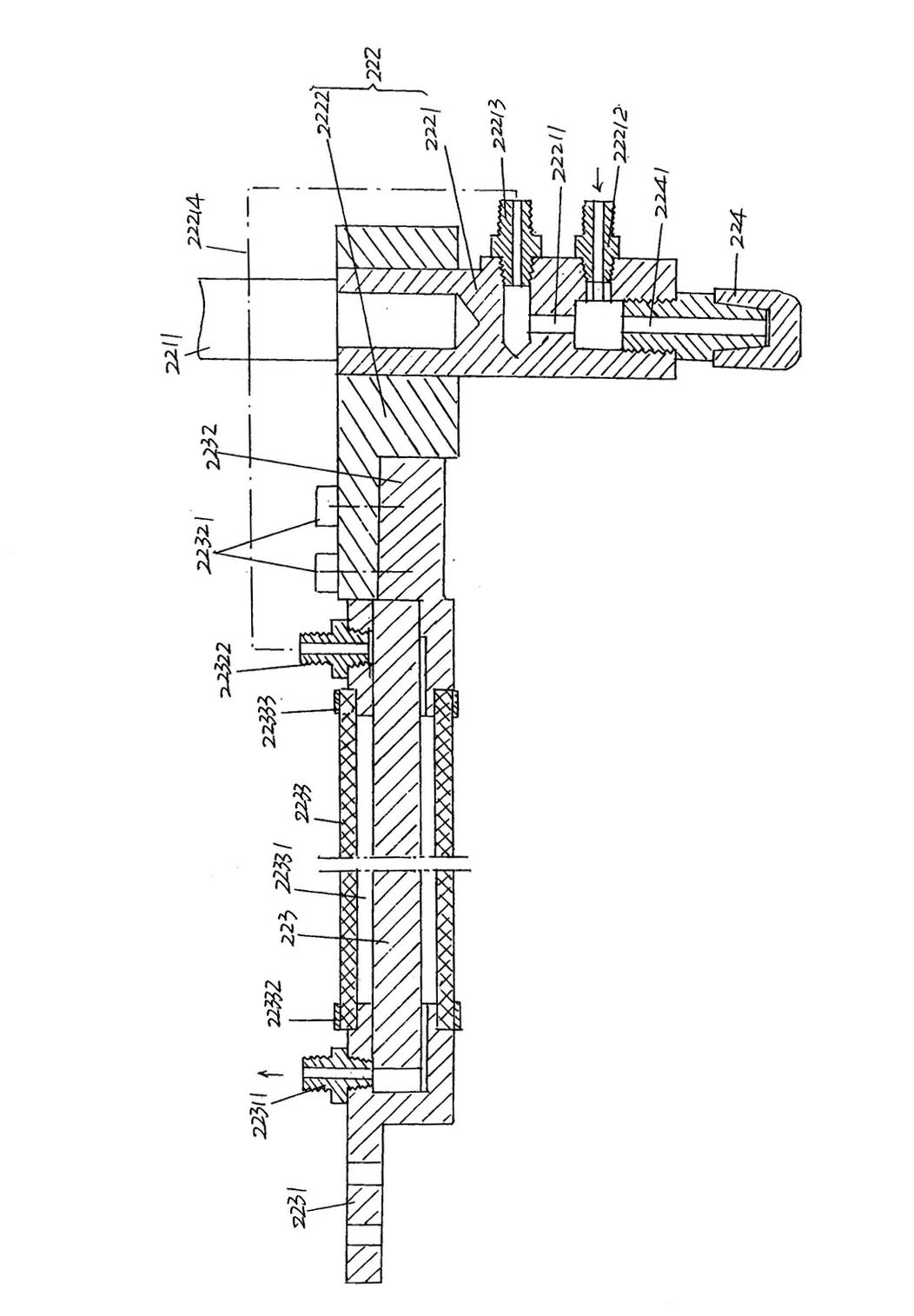

Full-automatic production line for LED lamp tube

ActiveCN106112317ARealize automatic transferImprove Spot Welding EfficiencyLiquid surface applicatorsWelding/cutting auxillary devicesProduction lineAdhesive

The invention discloses a full-automatic production line for an LED lamp tube. The full-automatic production line comprises a conveying chain, a material storage area, a lamp strip dispensing tube sticking area, a spot welding area and a lamp head installation area, wherein the conveying chain is used for conveying the lamp tube, and the material storage area, the lamp strip dispensing tube sticking area, the spot welding area and the lamp head installation area are sequentially arranged along the conveying chain. The lamp strip dispensing tube sticking area comprises a lamp strip dispensing device used for conducting glue feeding on the upper surface of a lamp strip, a lamp tube adhesive tape driving device used for driving the lamp tube to move back and forth in the length direction of the lamp strip and a lamp tube feeding and discharging device. The lamp tube spot welding area comprises a first angle adjusting device, a guide wire spot welding device and a power board spot welding device. The first angle adjusting device drives the lamp tube entering the lamp tube spot welding area to rotate till the lamp strip is located at the bottom of the lamp tube. The lamp head installation area comprises a lamp head installation device and a drying device. The lamp head installation device comprises a transfer mechanical arm and a leading wire alignment mechanism. The drying device comprises a lamp tube feeding and discharging mechanism, a lamp tube rotating mechanism used for conveying the lamp tube and a lamp tube heating mechanism which is arranged on the lamp tube rotating mechanism and used for heating and curing a lamp head. The full-automatic production line for the LED lamp tube is high in efficiency.

Owner:FOSHAN ELECTRICAL & LIGHTING

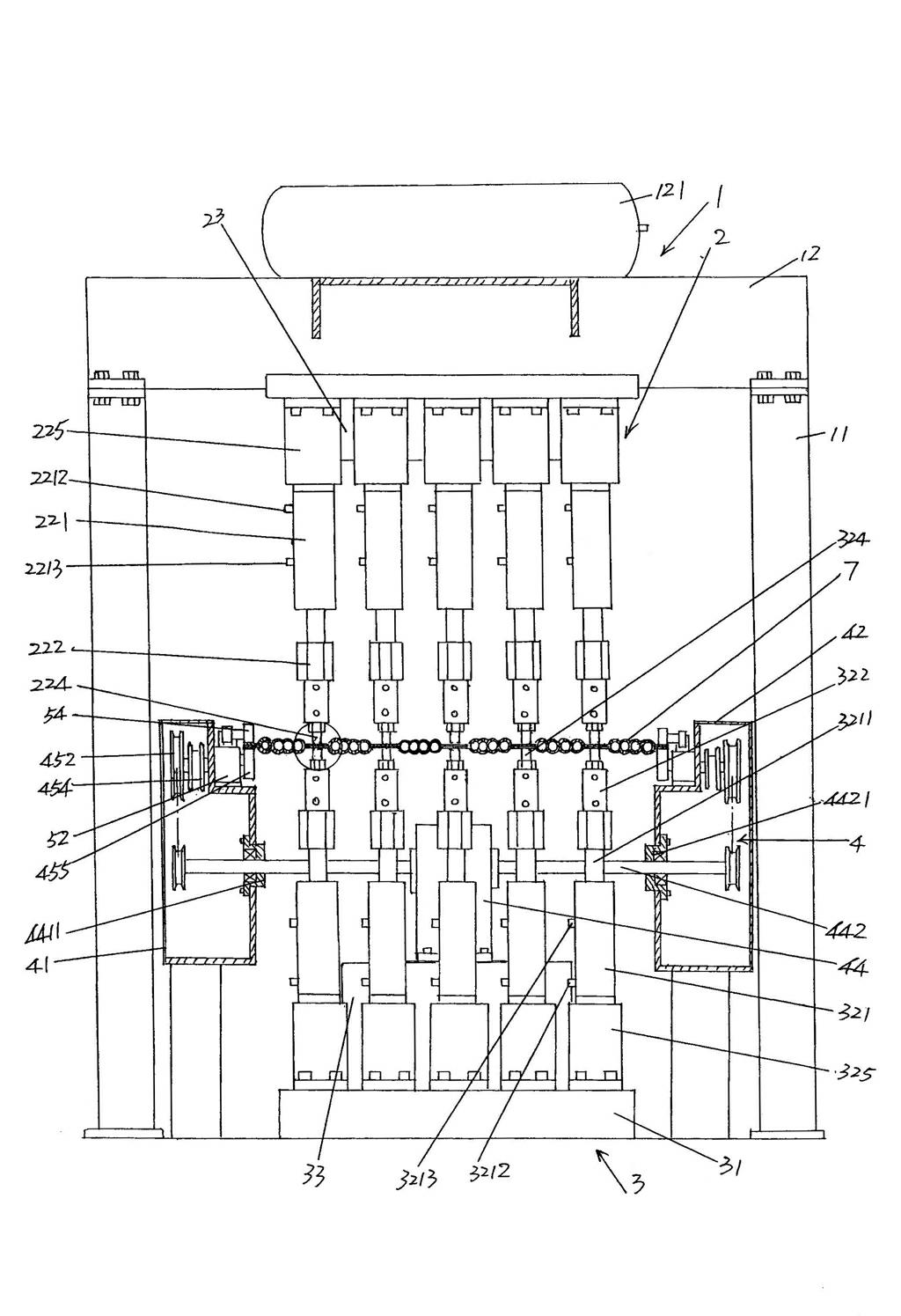

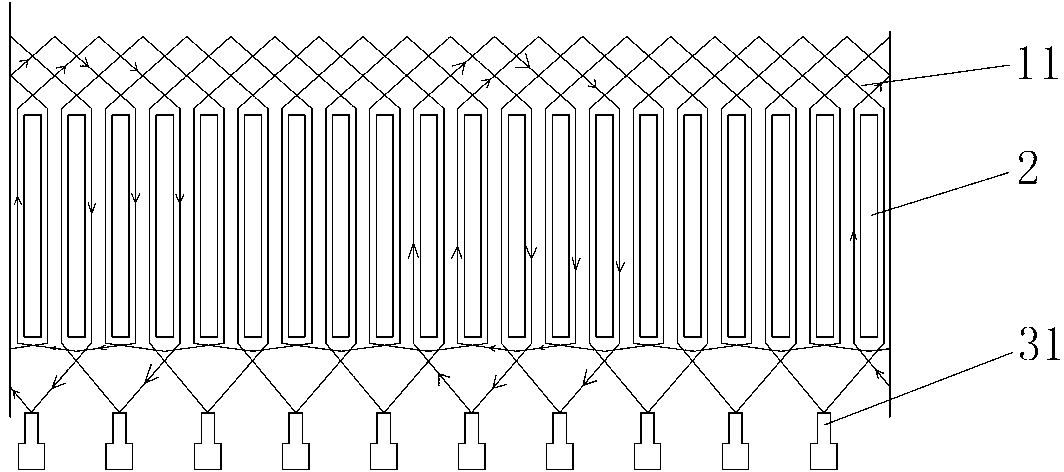

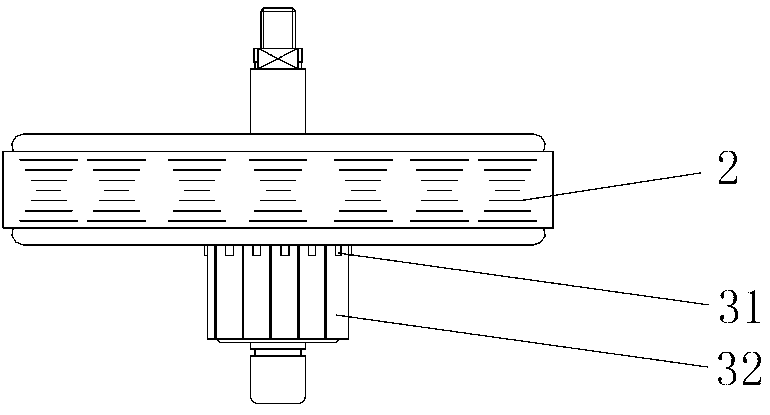

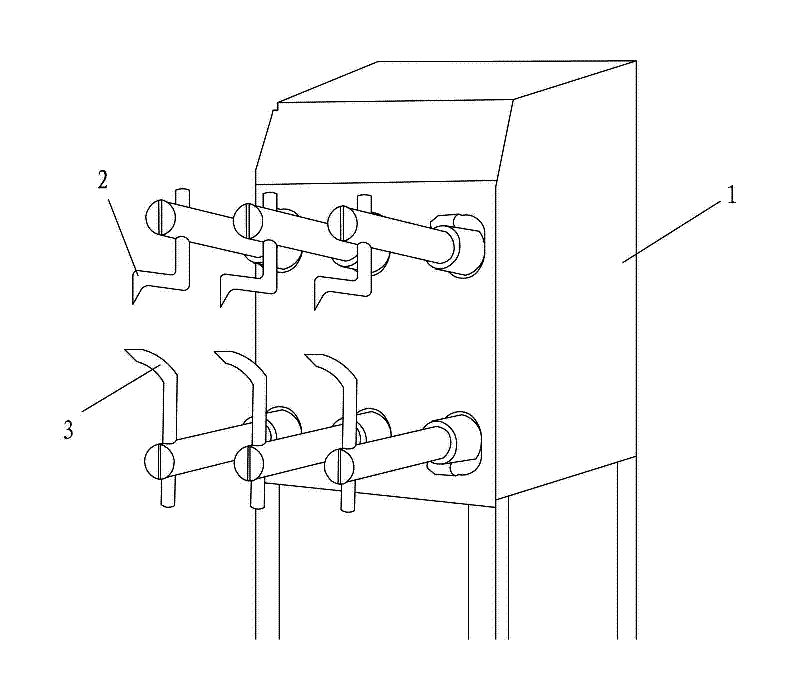

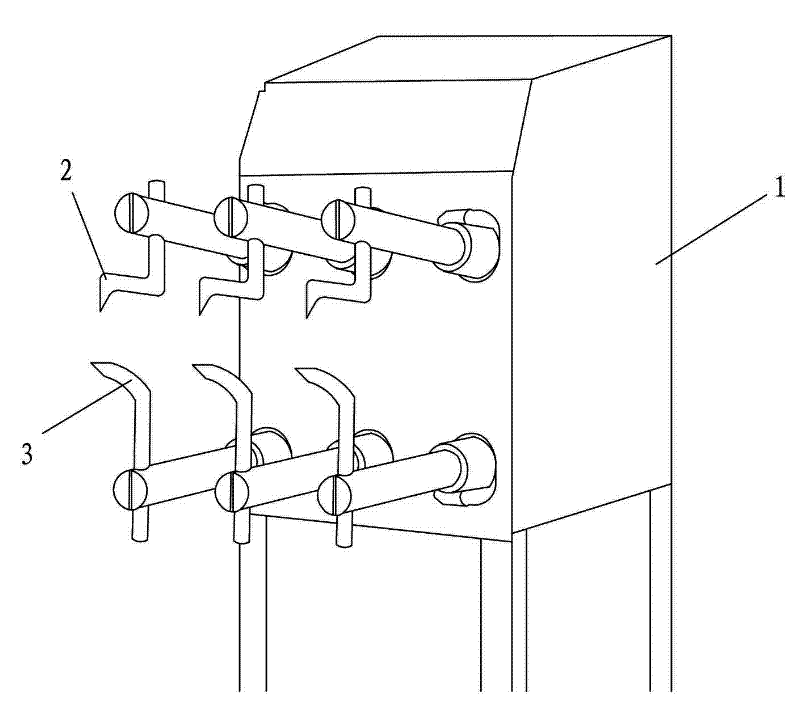

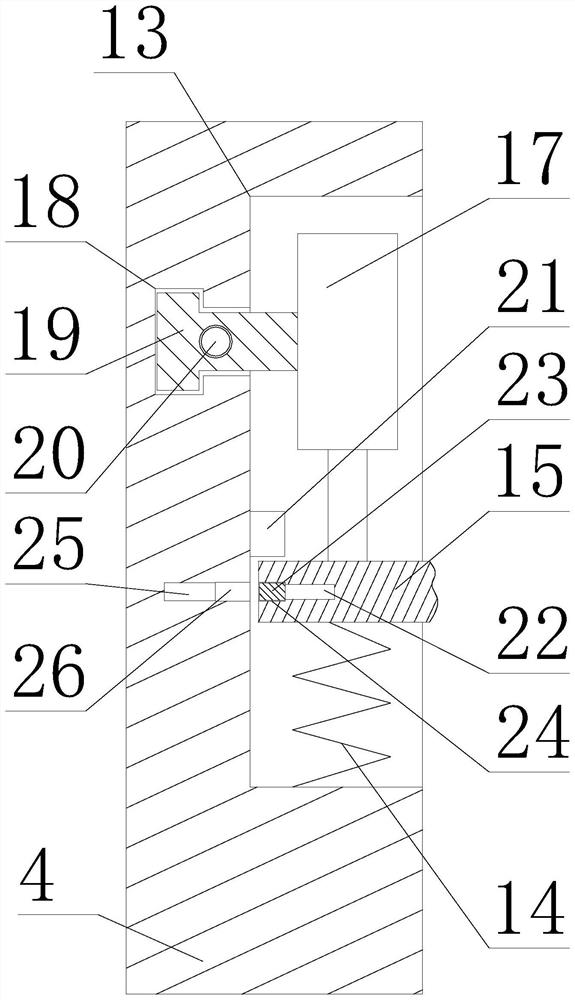

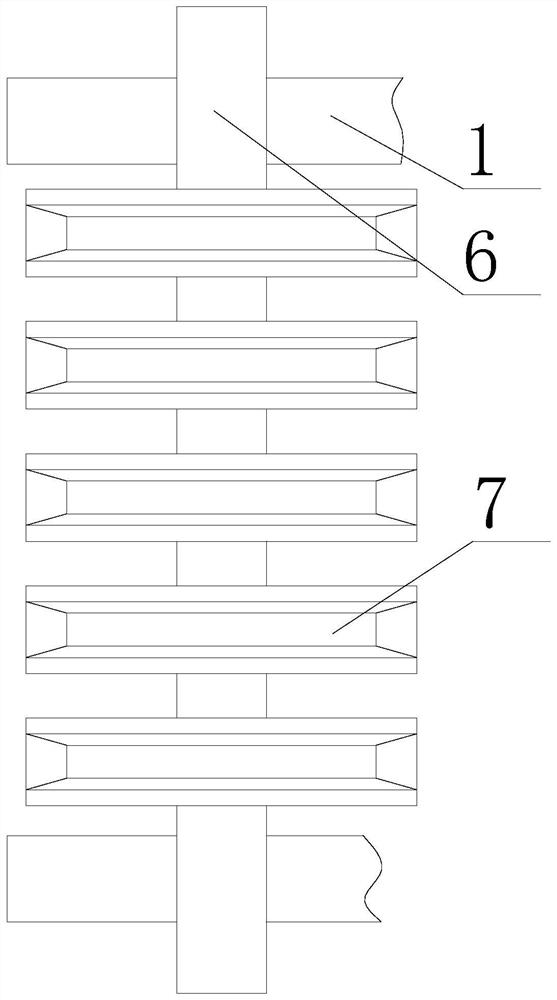

Cooling fin point welding machine of transformer finned radiator

InactiveCN102528261AImprove Spot Welding EfficiencyGuaranteed RegularityResistance welding apparatusEngineeringHeat spreader

The invention relates to a cooling fin point welding machine of a transformer finned radiator, and belongs to the technical field of welding machines. The cooling fin point welding machine comprises a rack, upper and lower point welding mechanisms, and a cooling fin convey mechanism, wherein the rack is composed of a pair of upright posts and a beam, and an air tank is arranged on the beam; the upper point welding mechanism comprises a first base and at least two groups of upper point welding devices and upper electric welders, and the lower point welding mechanism comprises a second base, lower point welding devices and lower electric welders the quantity of which are equal to that of the upper point welding devices; the lower point welding devices are electrically connected with the lower electric welders, and also are connected with a gas path of the air tank; and the second base is arranged on the bottom corresponding to the space between the pair of upright posts, and is corresponding to the first base. The cooling fin point welding machine provided by the invention has the advantages of being capable of remarkably improving point welding efficiency on cooling fins on the premise of not increasing the quantity of single point welding machines, being capable of saving equipment investment, reducing occupancy space of a production field and saving labor resources, and particularly being capable of insuring finishing effects of bonding points and guaranteeing the welding quality of the cooling fins.

Owner:CHANGSHU YOUBANG RADIATOR

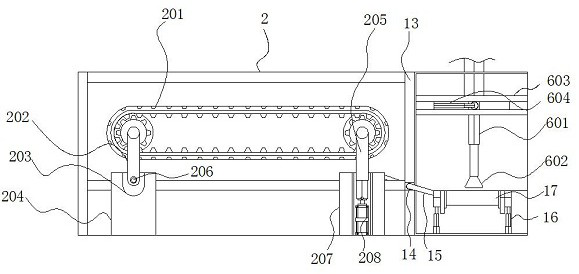

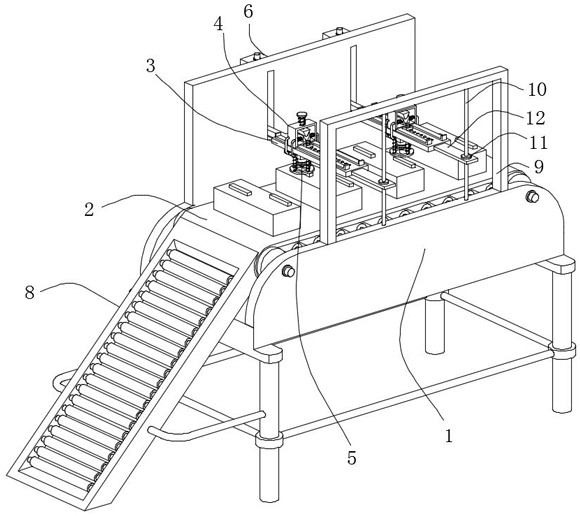

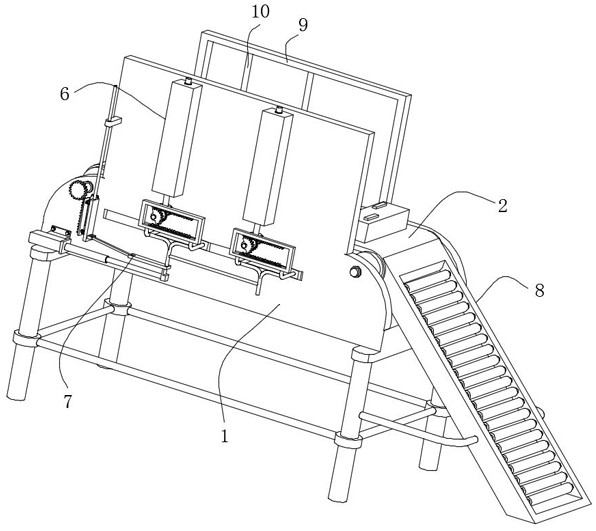

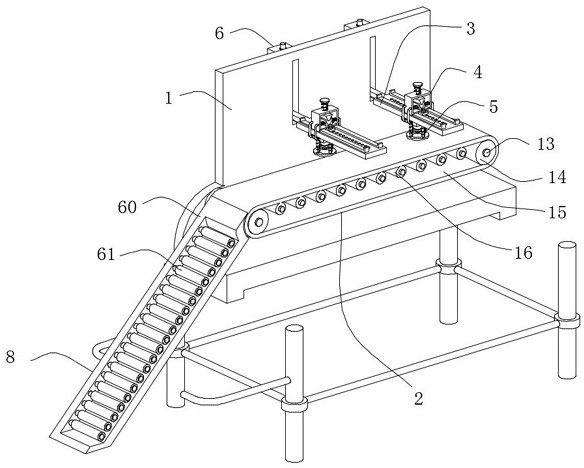

Spot welding machine for batteries

ActiveCN103418947AReasonable structureImprove spot welding qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention discloses a spot welding machine for batteries. The spot welding machine for the batteries comprises a rack, a spot welding device and a jig returning belt, wherein the spot welding device and the jig returning belt are arranged on the rack. The spot welding device comprises a conveying belt, a spot welding frame and a spot welding machine. The conveying belt is located in the middle of a worktable, passes through the spot welding frame and is used for conveying the batteries from front to back; welding heads of the spot welding machine are respectively located at both sides of the spot welding frame; a lead screw is driven by a motor to control the welding heads to horizontally move; when the batteries are conveyed to a spot welding station by the conveying belt, a spot welding operation can be performed. After all the batteries are welded, a tray assembly falls, and a jig falls to the conveying belt, and the conveying belt continues to move forward to convey the batteries; after the welded batteries are taken out by personnel in the rear of the rack, the jig is put to the jig returning belt to return to the worktable of the rack for cycle use. The spot welding machine for the batteries has the advantages that the structure is reasonable, the spot welding quality is high, the spot welding efficiency is high, and the like.

Owner:XIAMEN LIJU AUTOMATION TECH

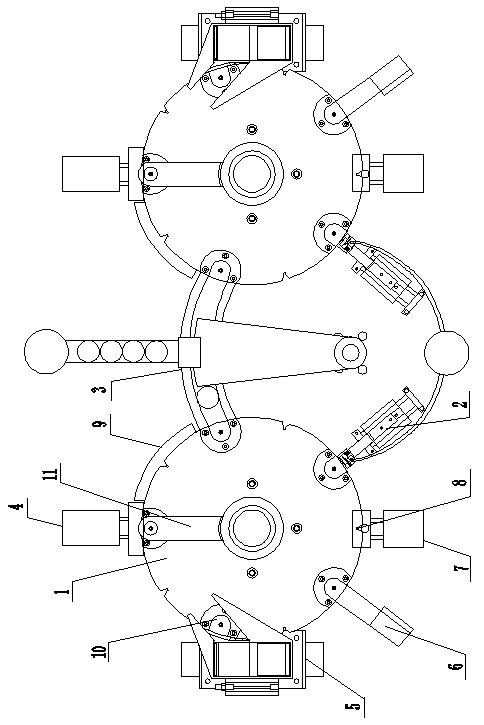

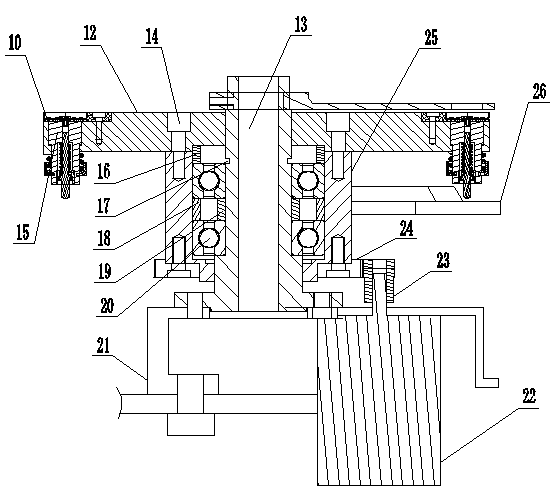

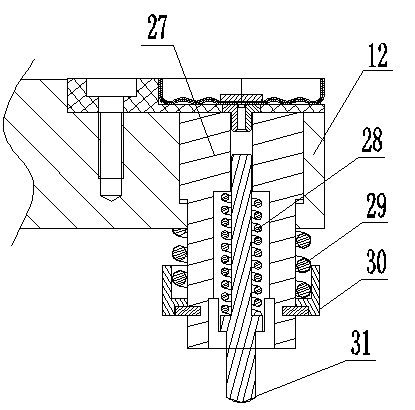

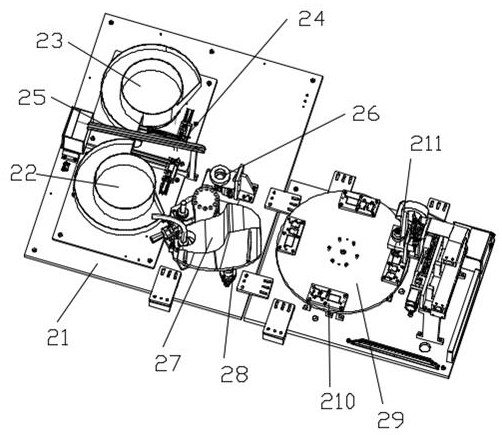

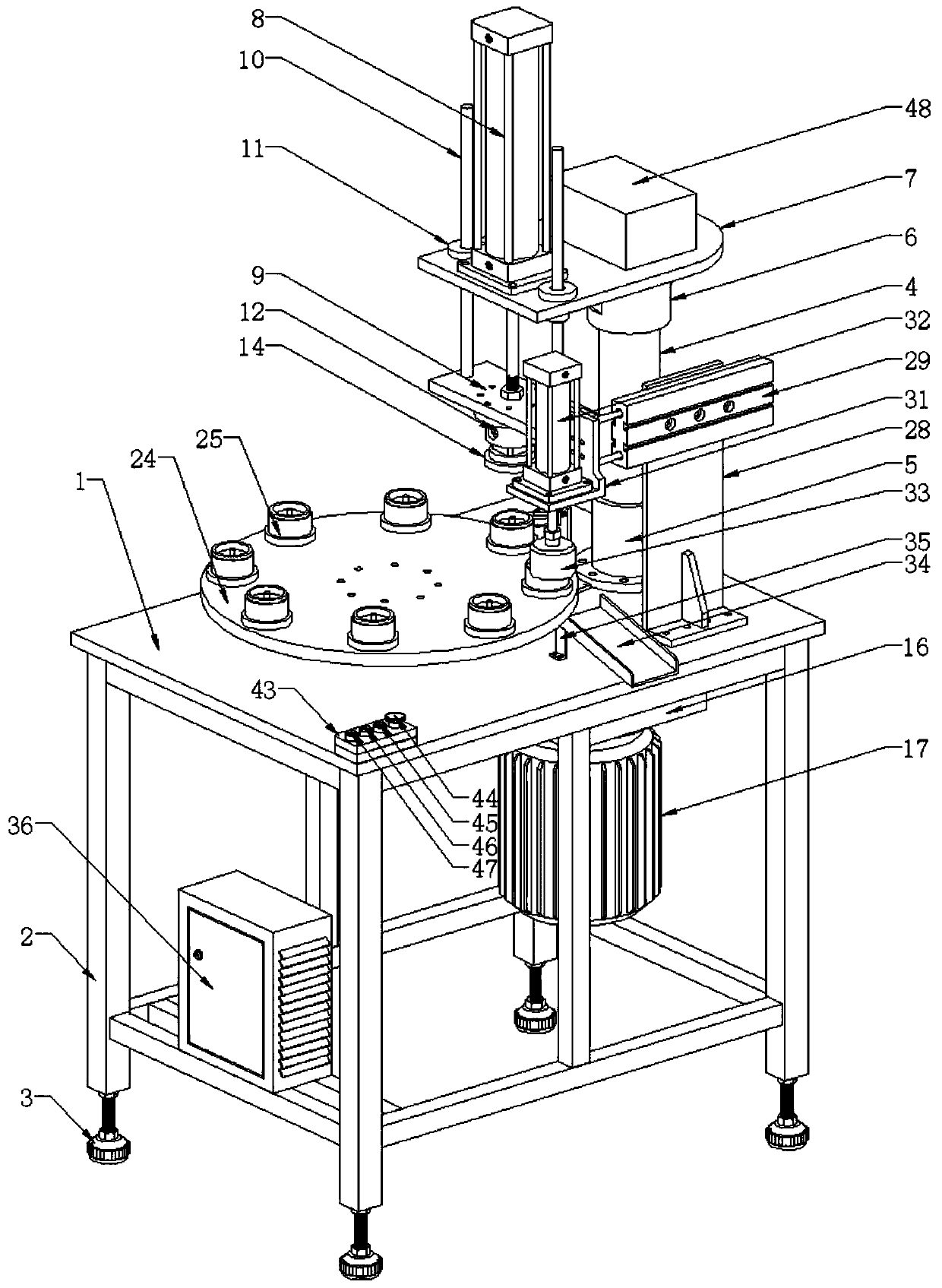

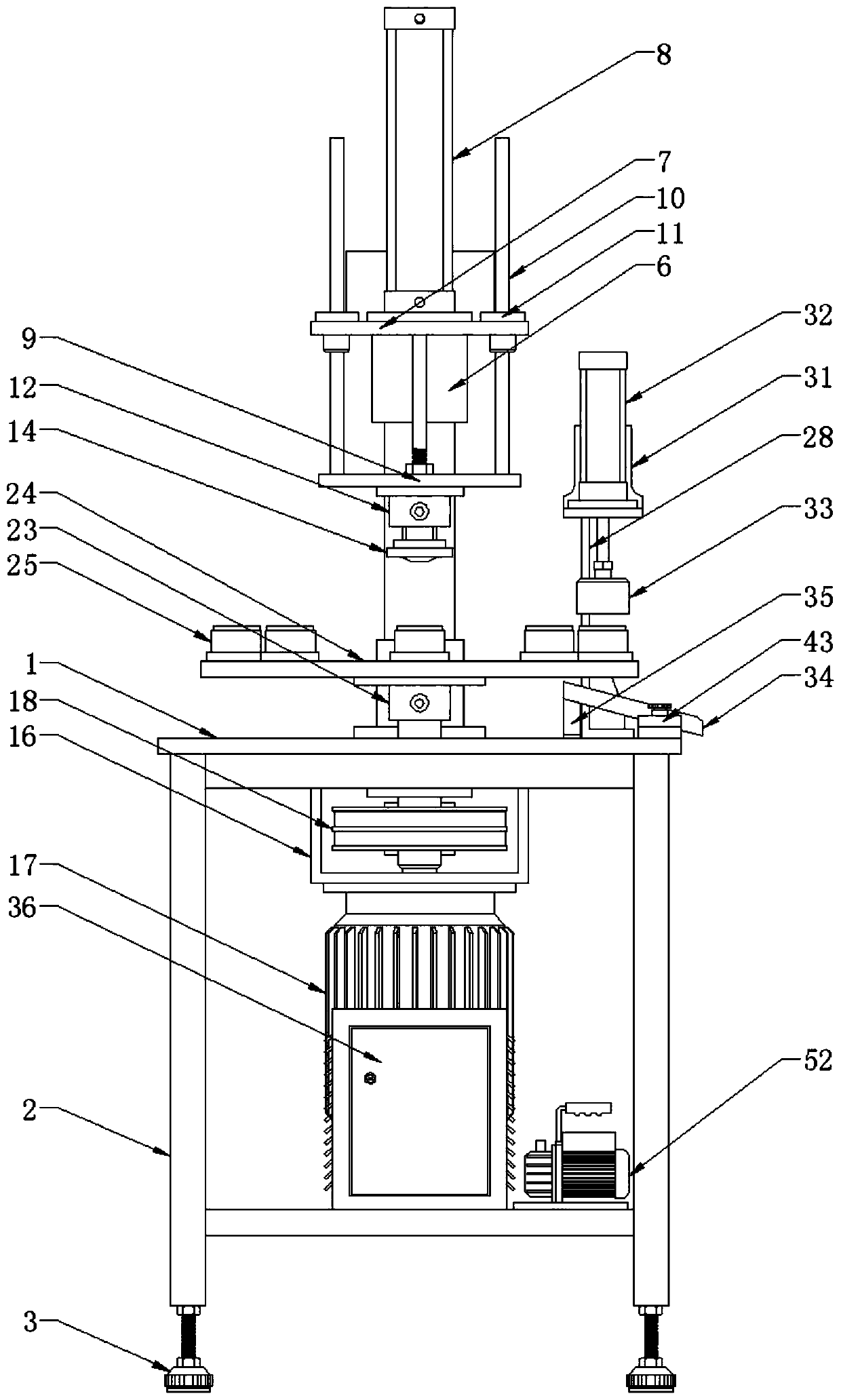

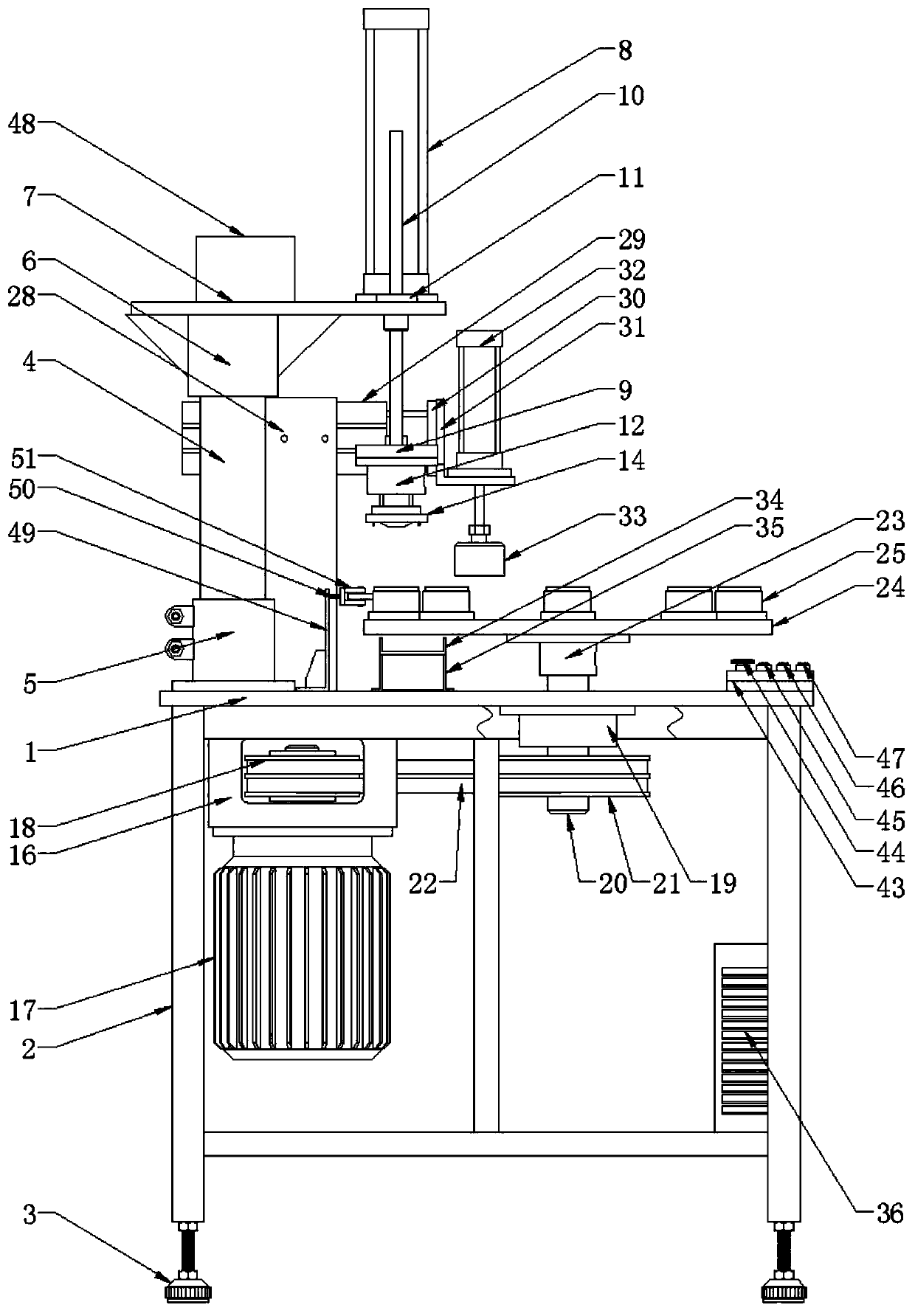

Automatic spot welding machine for welding capsule

InactiveCN103252592AQuality improvementLiberate human laborWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention provides an automatic spot welding machine for welding a capsule and relates to the field of spot welding equipment. The automatic spot welding machine comprises two turntable devices, handle feeding devices, a sheet feeding device, welding devices, unloading devices, mold cleaning devices and turntable positioning devices, wherein the two turntable devices are distributed on the two sides of the sheet feeding device; a sheet feeding guide groove capable of conveying capsule sheets to the turntable devices on the two sides respectively is formed in the sheet feeding device; each handle feeding device, each welding device, each unloading device, each mold cleaning device and each turntable positioning device are distributed around each turntable device; each turntable device comprises a turntable; clamp grooves matched with each turntable positioning device is distributed at the circumferential edge of each turntable at intervals; capsule positioning grooves with center through holes are distributed on the upper surface of the turntable around the periphery of the turntable at intervals; and a welding ejection mechanism is arranged below each capsule positioning groove. With the adoption of the automatic spot welding machine, spot welding is conducted automatically, the labor is liberated, the potential safety hazards of manual operation are avoided, and the spot welding efficiency and the quality of a spot welding product are improved.

Owner:平顶山市联立机电有限公司

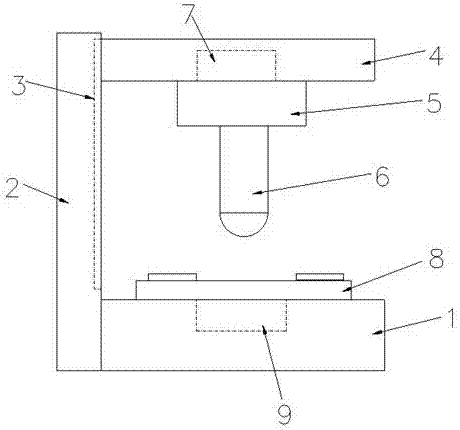

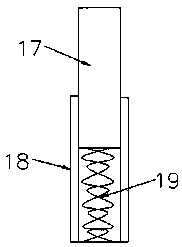

Spot welding apparatus

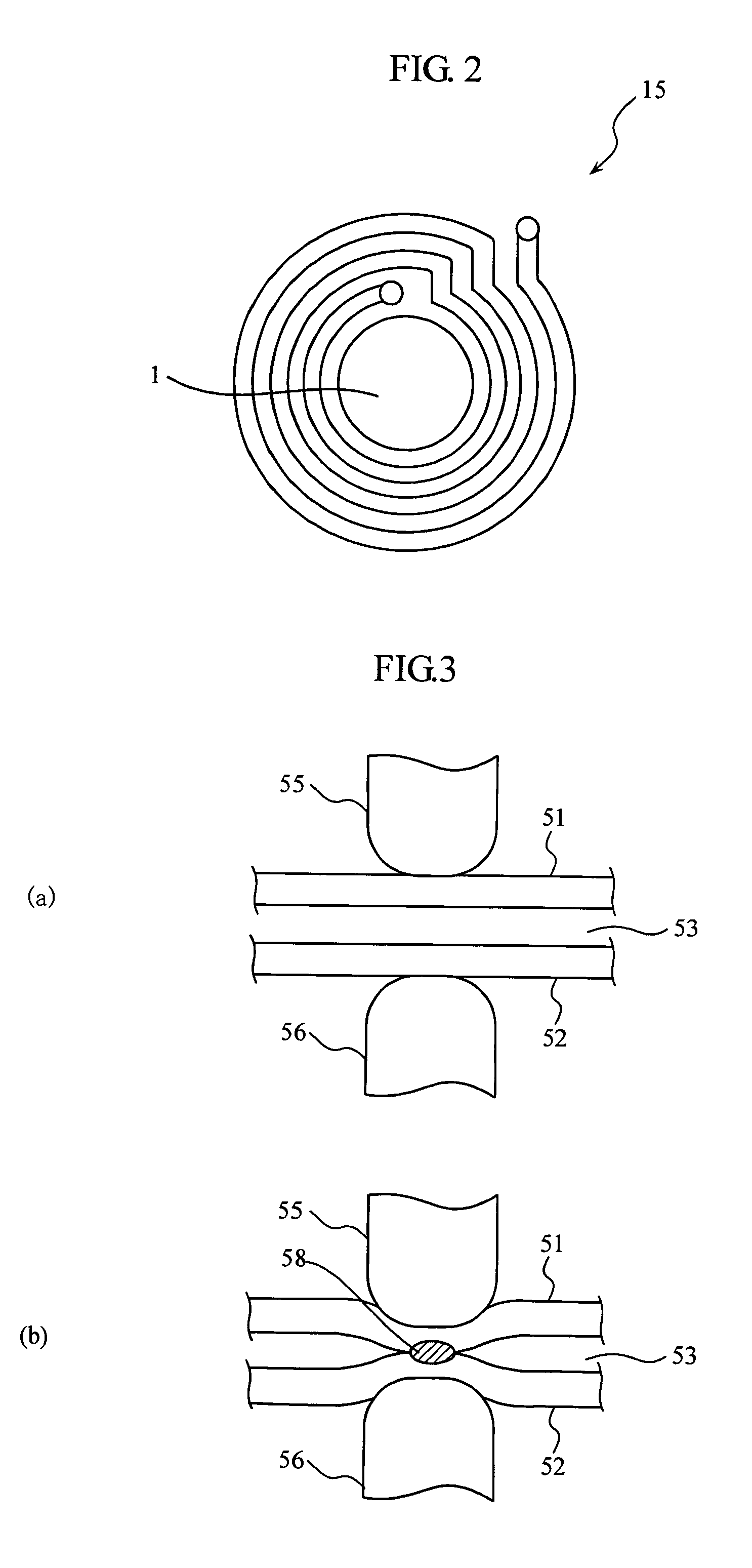

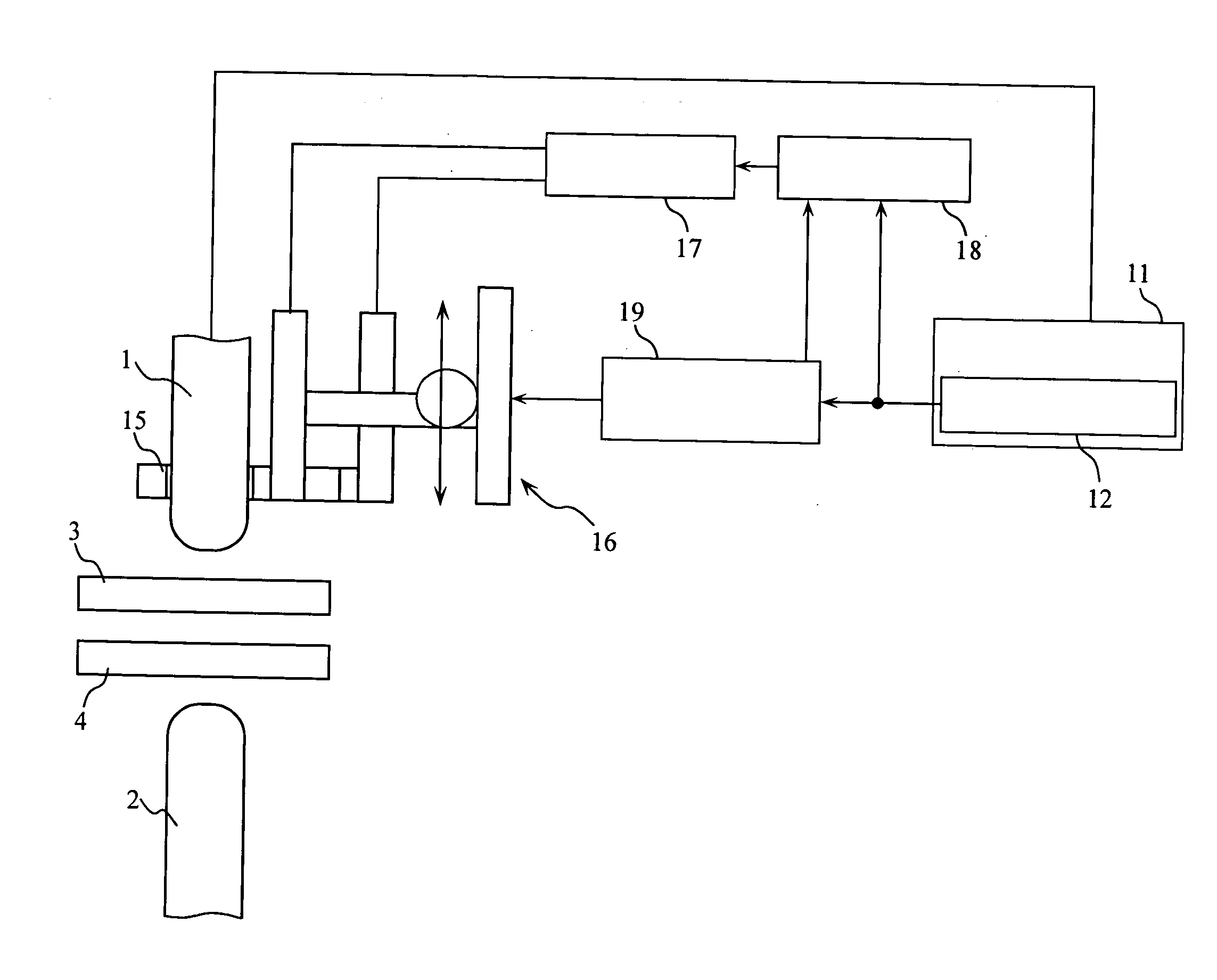

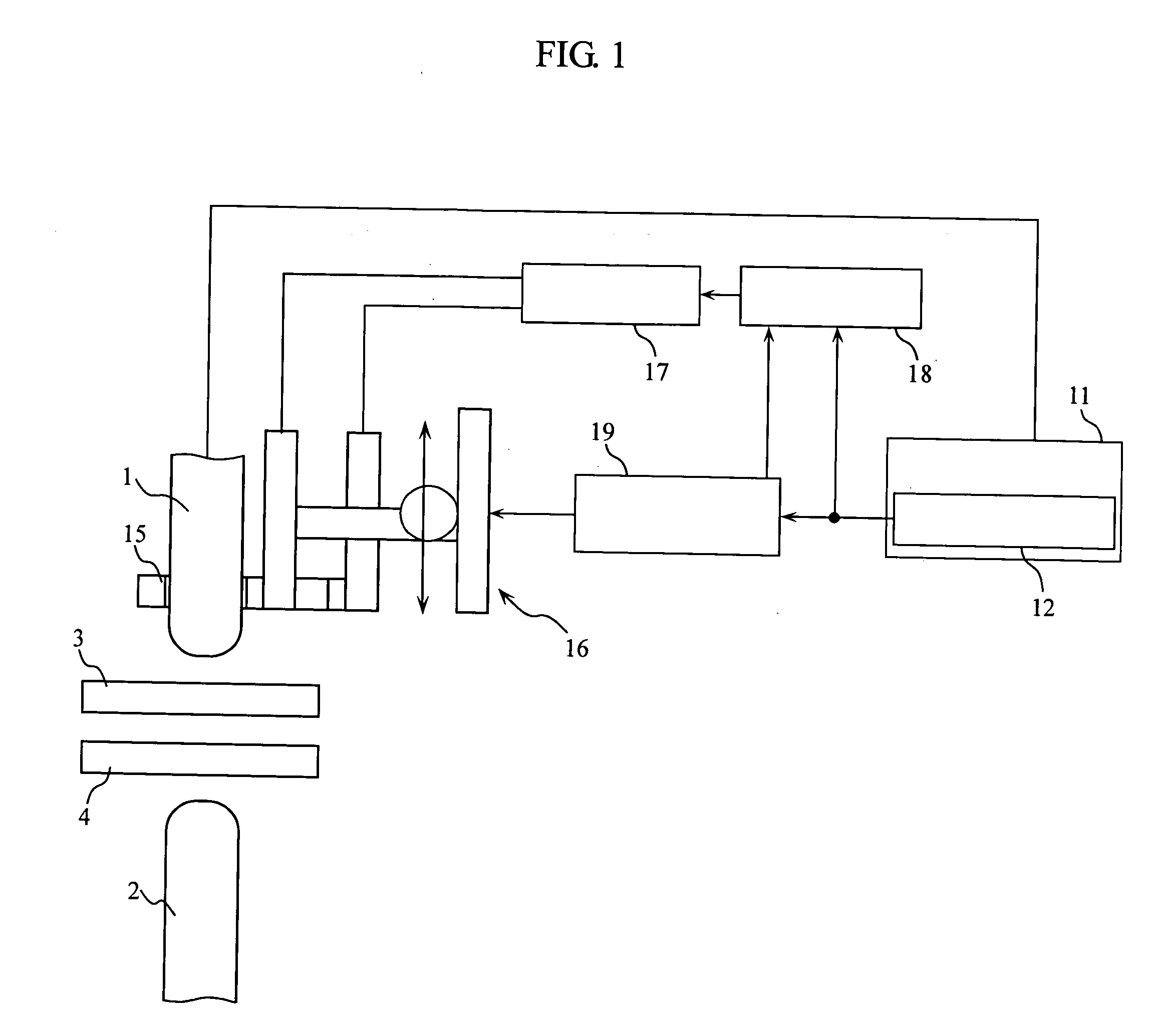

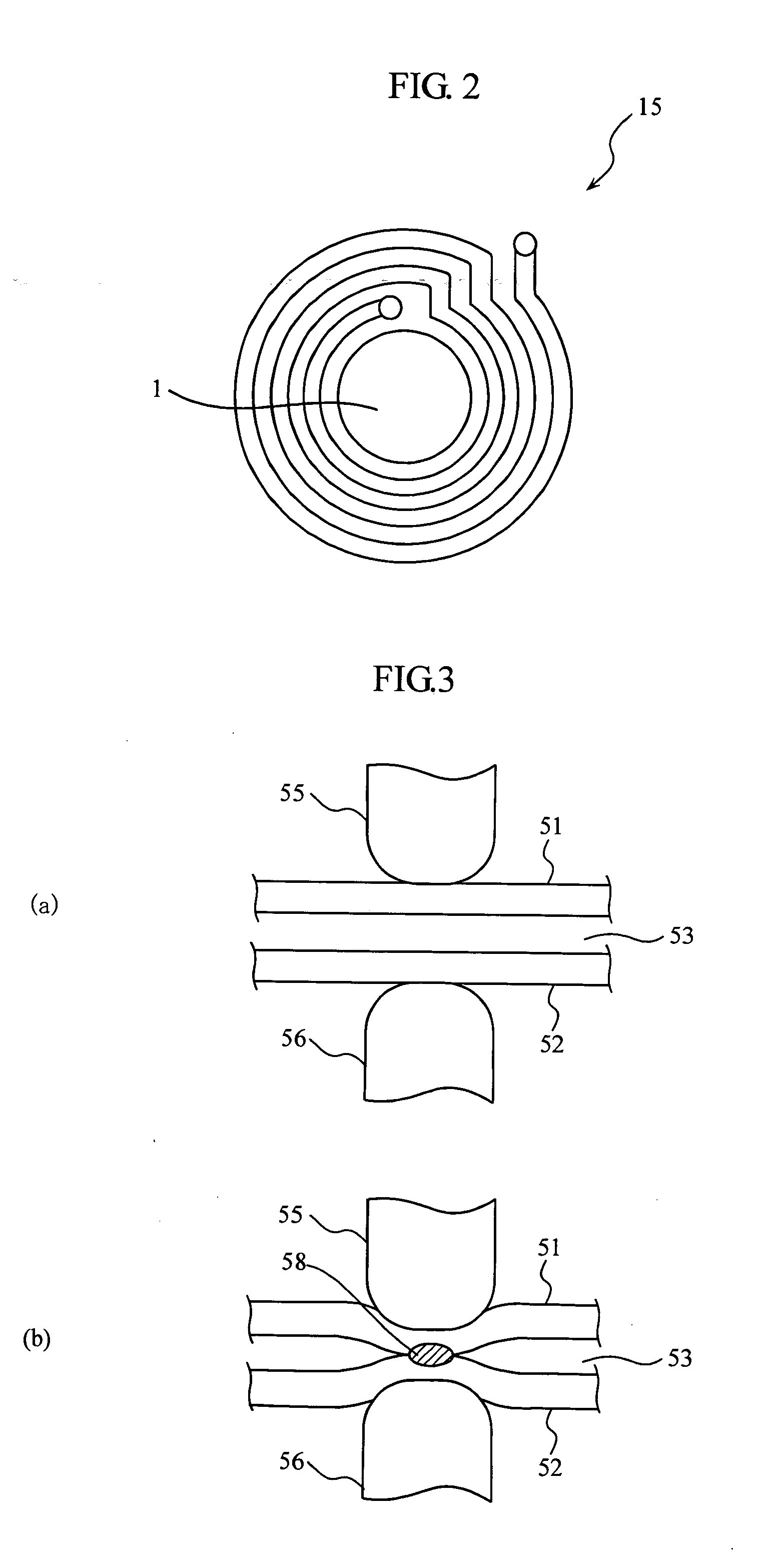

ActiveUS7087854B2Improve reliabilityFully deformedCoil arrangementsOhmic-resistance electrodesEngineeringHigh intensity

A spot welding apparatus for spot welding superposed workpieces by putting the superposed workpieces 3, 4 between a pair of electrodes 1, 2 and applying a welding current between the electrodes under application of pressure, the apparatus having heating coils 15 wound on each of the electrodes 1, 2, and being provided with high frequency heating means 17 for induction-heating welding portions of the workpieces contacted by the electrodes. The spot welding apparatus is capable of firmly spot welding workpieces made of high tension steel even if there is opening between the workpieces.

Owner:SUBARU CORP

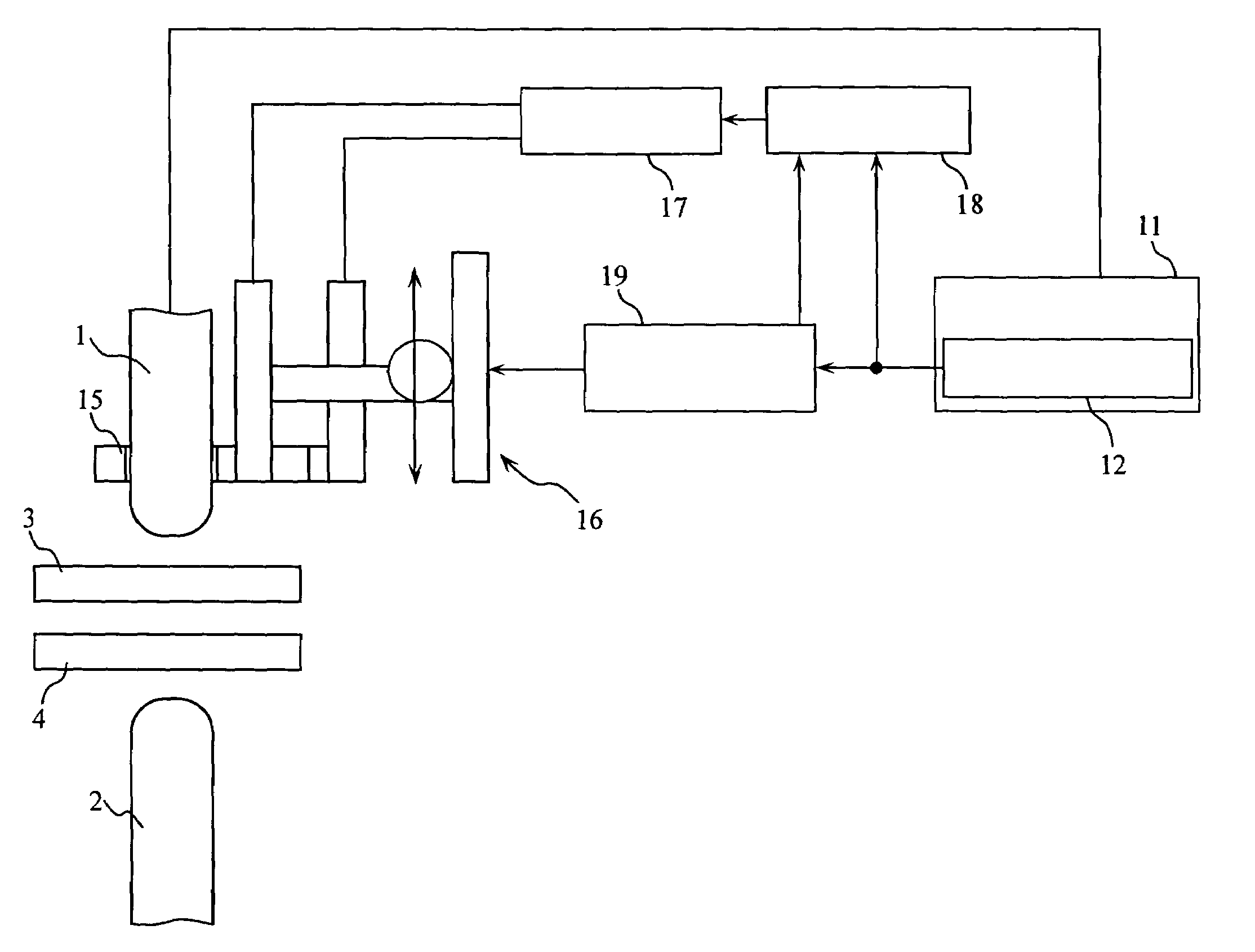

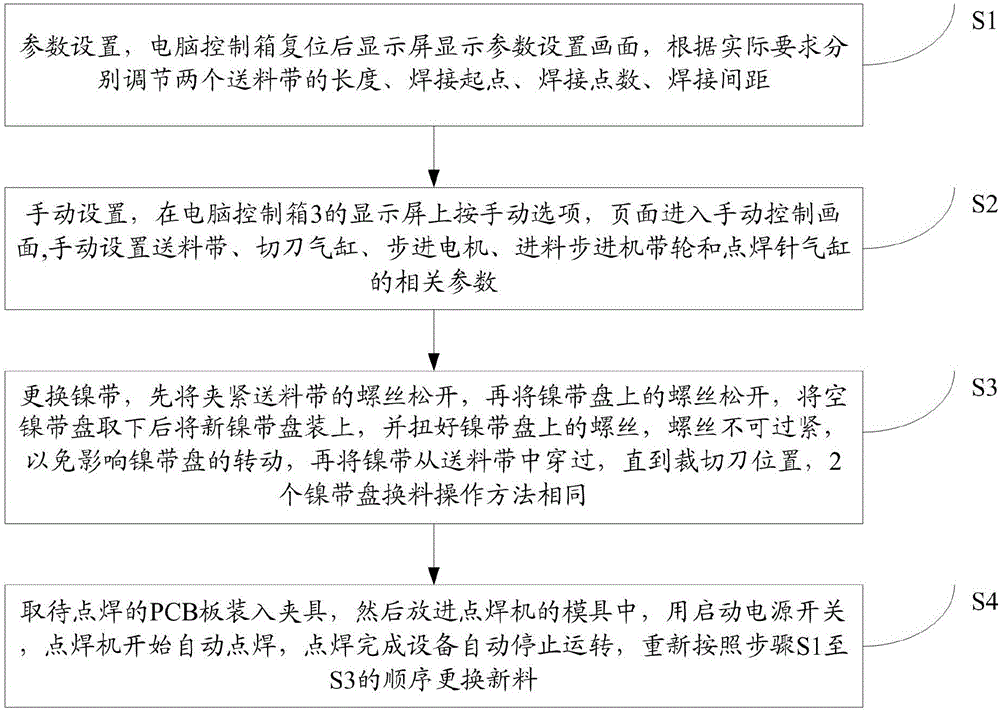

Automatic welding equipment for nickel sheet of lithium-ion battery and welding technology

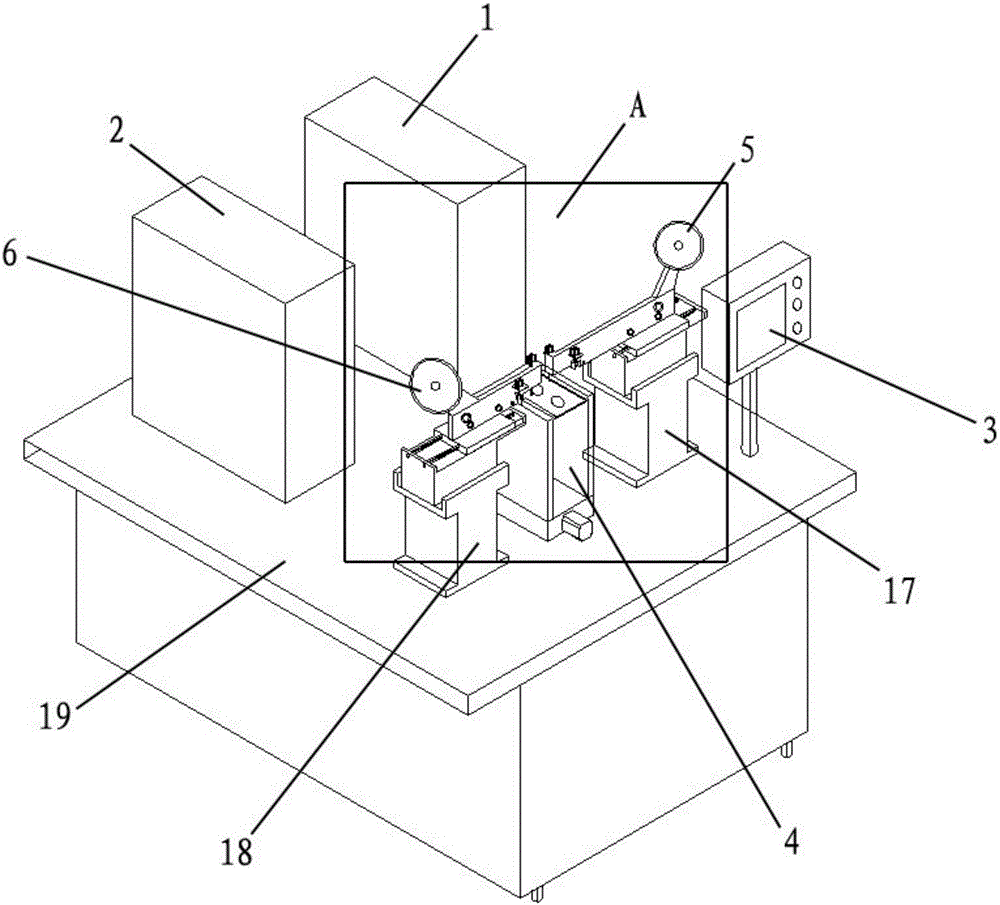

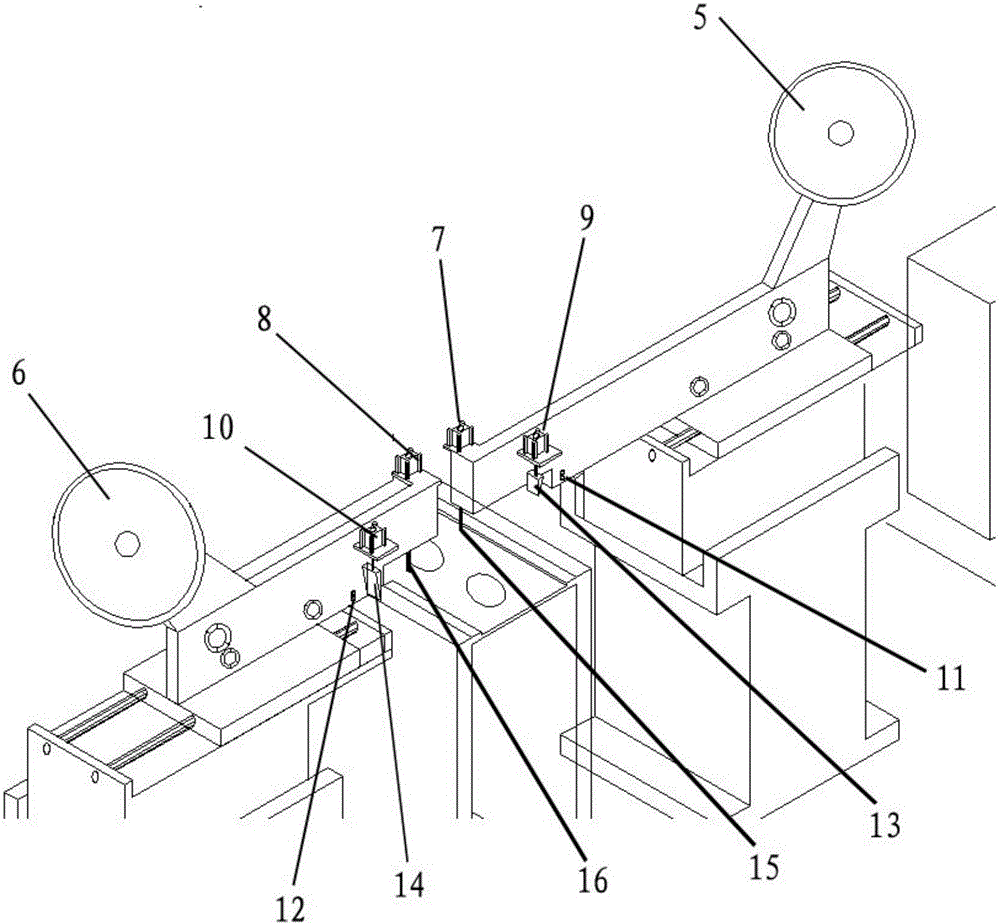

ActiveCN105772918AReduce welding costsHigh precisionFinal product manufactureWelding/cutting auxillary devicesElectrical batteryEngineering

The invention discloses automatic welding equipment for a nickel sheet of a lithium-ion battery and a welding technology and relates to the technical field of battery production equipment. The automatic welding equipment for the nickel sheet of the lithium-ion battery comprises a first spot welding machine, a second spot welding machine, a computer control box, a stepper motor, a first feeding belt, a second feeding belt, a first spot welding needle cylinder, a second spot welding needle cylinder, a first cutter cylinder, a second cutter cylinder, a first feeding stepper belt pulley, a second feeding stepper belt pulley, a first cutter, a second cutter, a first spot welding needle, a second spot welding needle, a first support frame, a second support frame and an operation platform. The automatic welding equipment is simple in structure and convenient to use, additional equipment cost is reduced by changing a cutting mode, requirements for skills of an employee at a welding operation post are reduced greatly through technology improvement, operation is finished only by starting the equipment simply, and the operation intensity of the employee is reduced.

Owner:DONGGUAN GREENWAY NEW ENERGY CO LTD

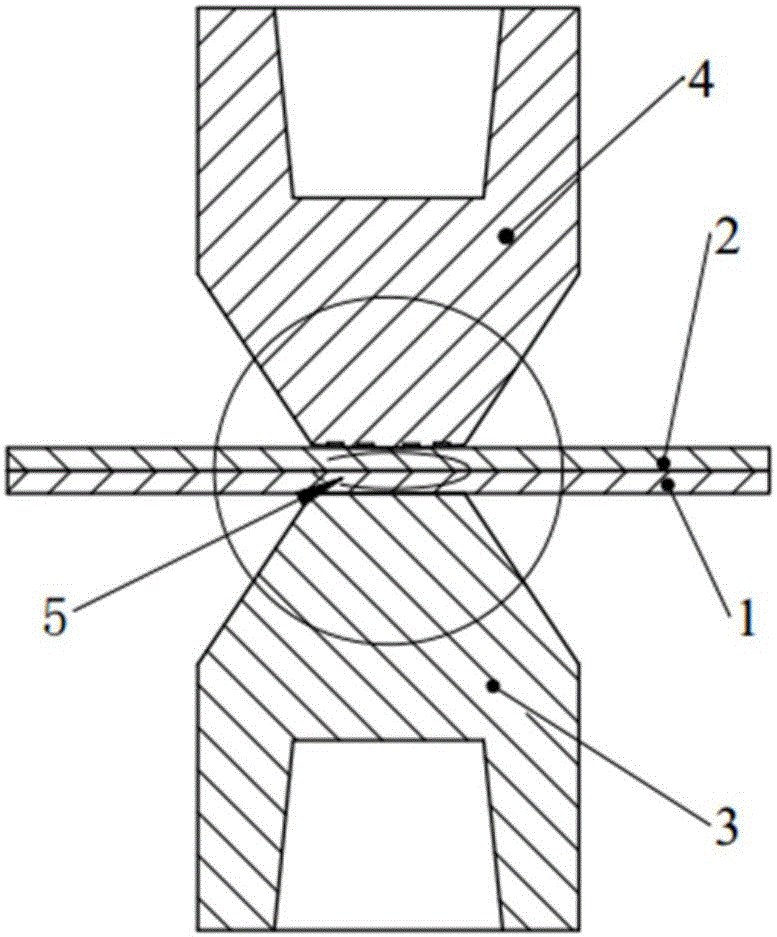

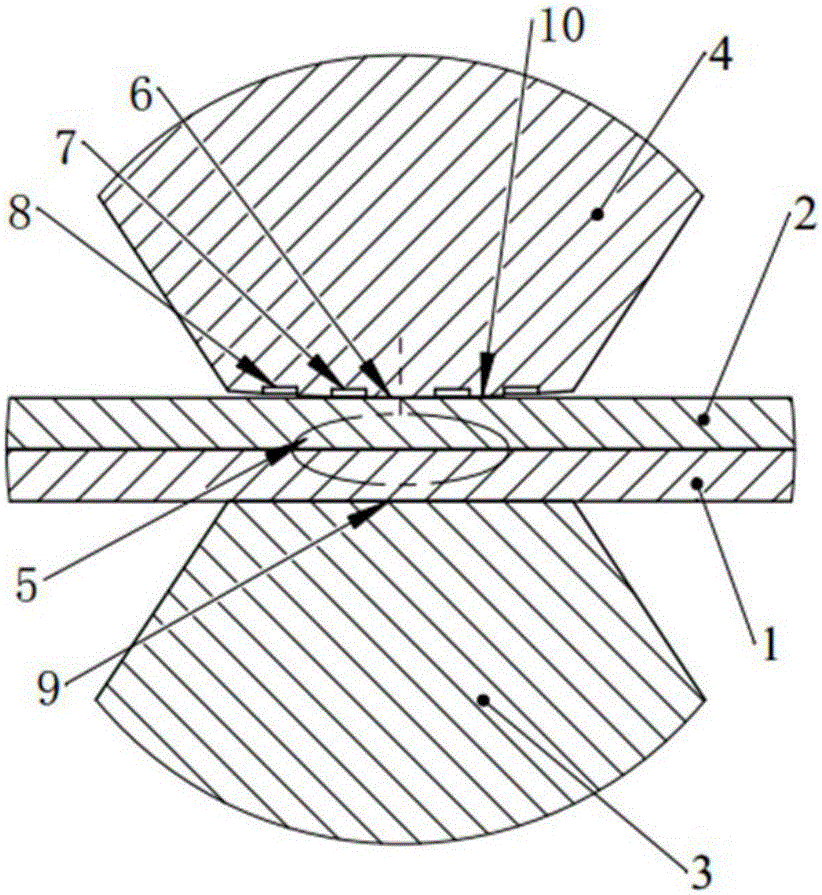

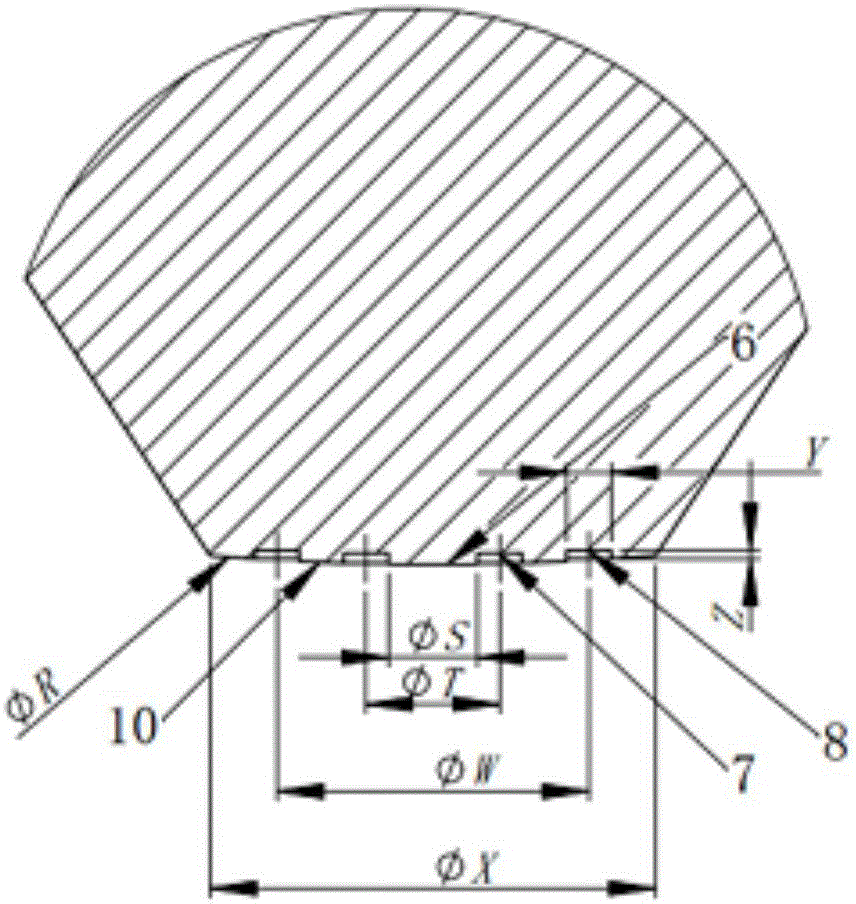

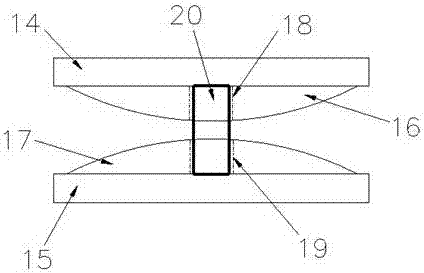

Electrode system for improving performances of steel-aluminum dissimilar metal resistance spot welding head

InactiveCN106736000AReduce high temperature residence time or reaction timeReduce atomic diffusionWelding/cutting media/materialsWelding/soldering/cutting articlesHeat distributionSteel quality

The invention relates to an electrode system for improving performances of a steel-aluminum dissimilar metal resistance spot welding head. The system comprises a pair of positive electrode and negative electrode, which are arranged oppositely and have different end face structures; the end face of the positive electrode is a ball end face and is in contact with the surface of an aluminum part to be machined; two annular grooves, which are concentrically arranged and have different radiuses, are formed in the ball end face; and the end face of the negative electrode is a fat end face and is in contact with the surface of a steel part to be machined. Compared with the prior art, heat distribution of a steel-aluminum interface can be effectively improved, the growth of an IMC (Intermetallic Compound) on a connector interface is weakened, a stable button breaking mode is obtained, and the reliability of a connector in connection is improved.

Owner:SHANGHAI JIAO TONG UNIV

Spot welding apparatus

ActiveUS20050167402A1Improve reliabilityFully deformedCoil arrangementsOhmic-resistance electrodesSpot weldingHigh tension

A spot welding apparatus for spot welding superposed workpieces by putting the superposed workpieces 3, 4 between a pair of electrodes 1, 2 and applying a welding current between the electrodes under application of pressure, the apparatus having heating coils 15 wound on each of the electrodes 1, 2, and being provided with high frequency heating means 17 for induction-heating welding portions of the workpieces contacted by the electrodes. The spot welding apparatus is capable of firmly spot welding workpieces made of high tension steel even if there is opening between the workpieces.

Owner:SUBARU CORP

Bottom spot welding machine for cylindrical lithium battery and spot welding method of bottom spot welding machine

PendingCN108747126AImprove product qualityCompact structureFinal product manufactureWelding/cutting auxillary devicesSpot weldingBiomedical engineering

The invention discloses a bottom spot welding machine for a cylindrical lithium battery. The bottom spot welding machine comprises a machine table and a conveying material channel arranged on the machine table. The bottom spot welding machine further comprises a battery core center hole positioning device, a first thrusting needle taking device, a second thrusting needle taking device, a spot welding device and a needle pulling device, wherein the first thrusting needle taking device and the second thrusting needle taking device are of the same structure, and the battery core center hole positioning device, the first thrusting needle taking device, the second thrusting needle taking device, the spot welding device and the needle pulling device are arranged on the machine table in the lithium battery conveying direction in sequence. One side of the conveying material channel is provided with a welding needle backflow device, and the first thrusting needle taking device, the second thrusting needle taking device and the needle pulling device are arranged between the conveying material channel and the welding needle backflow device. The invention further discloses a spot welding method, the spot welding process is completed automatically, spot welding efficiency can be improved, product quality of the lithium battery is improved, and the labor cost is saved.

Owner:广东彩扬能源装备有限公司

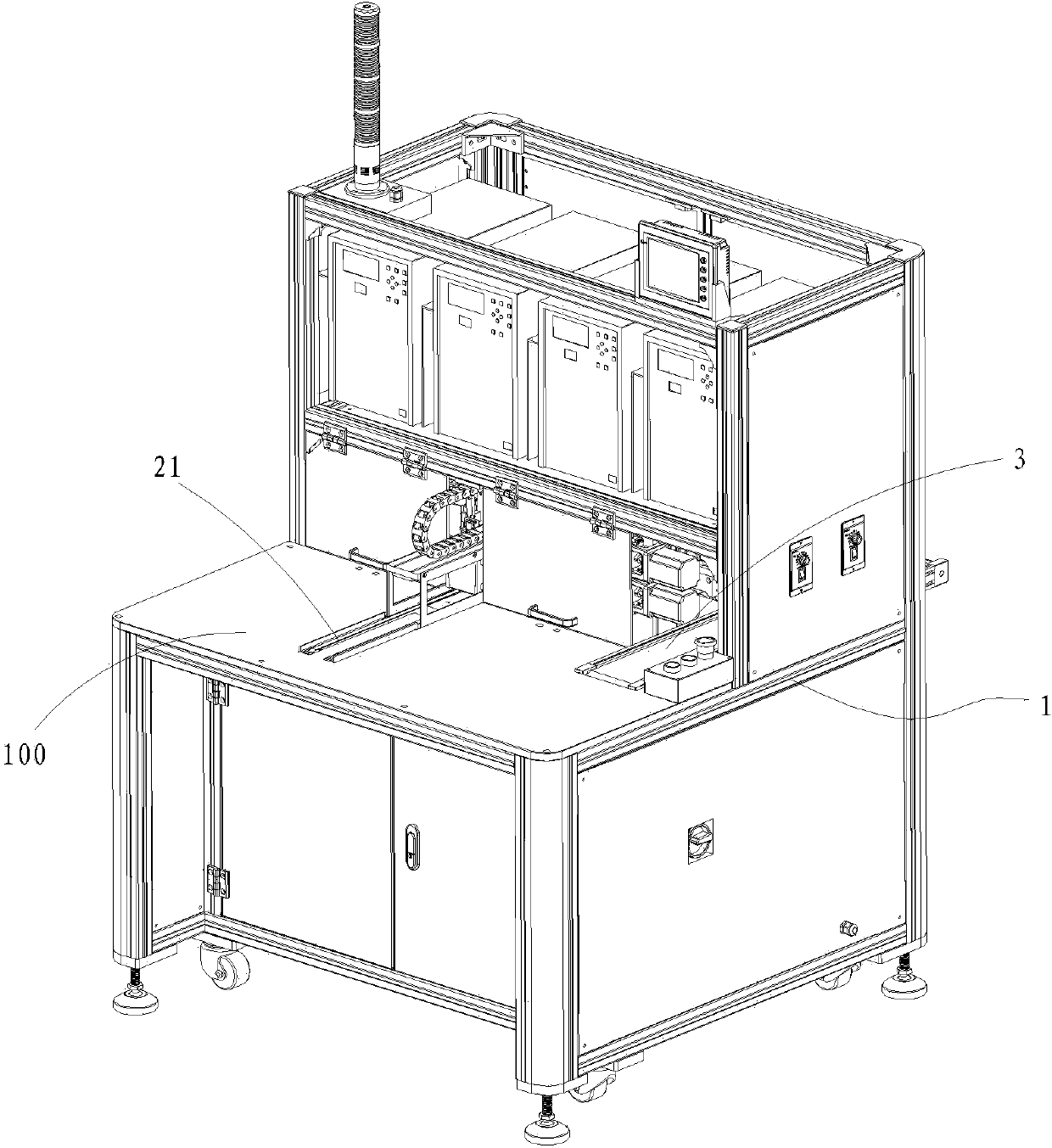

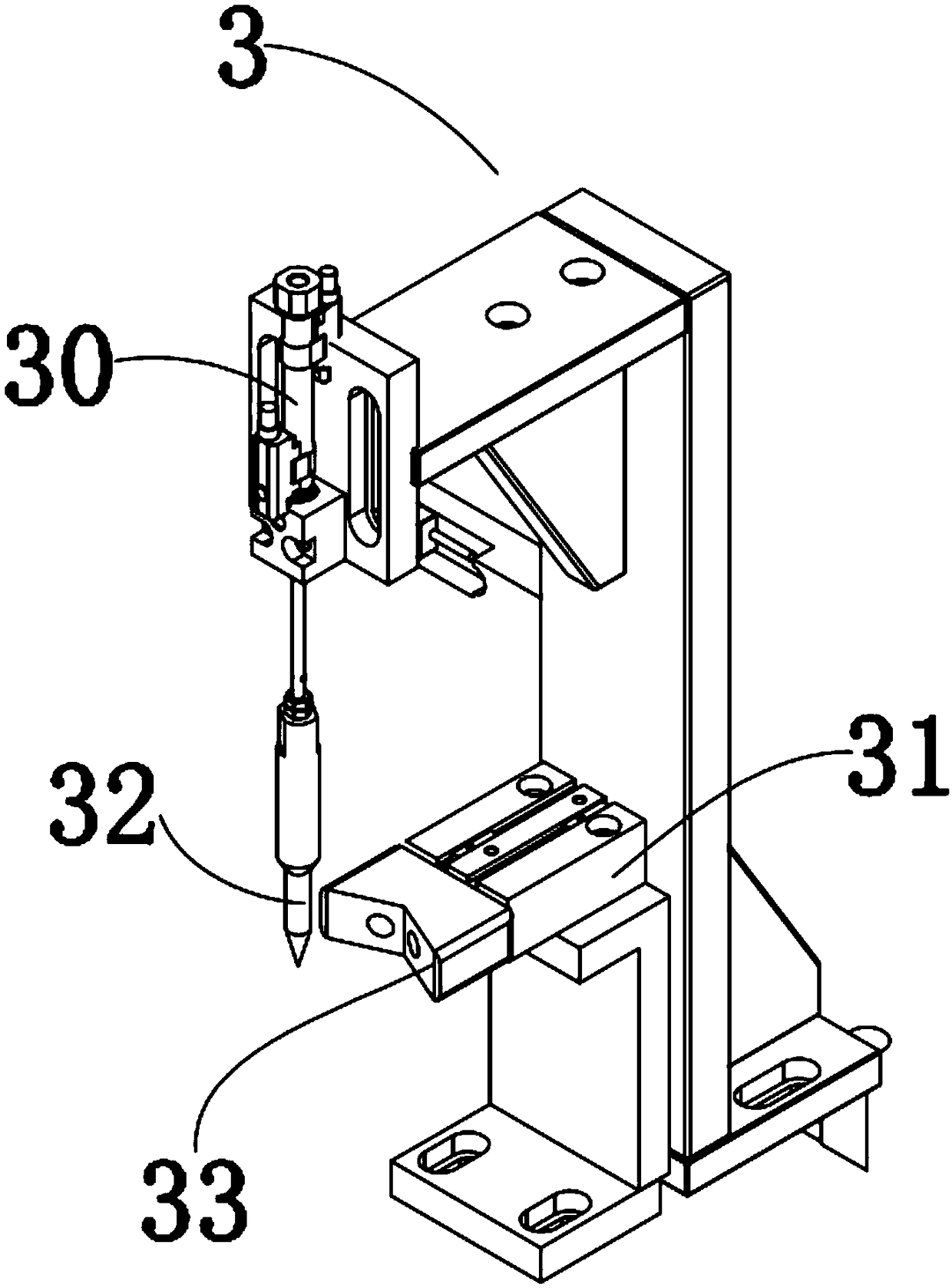

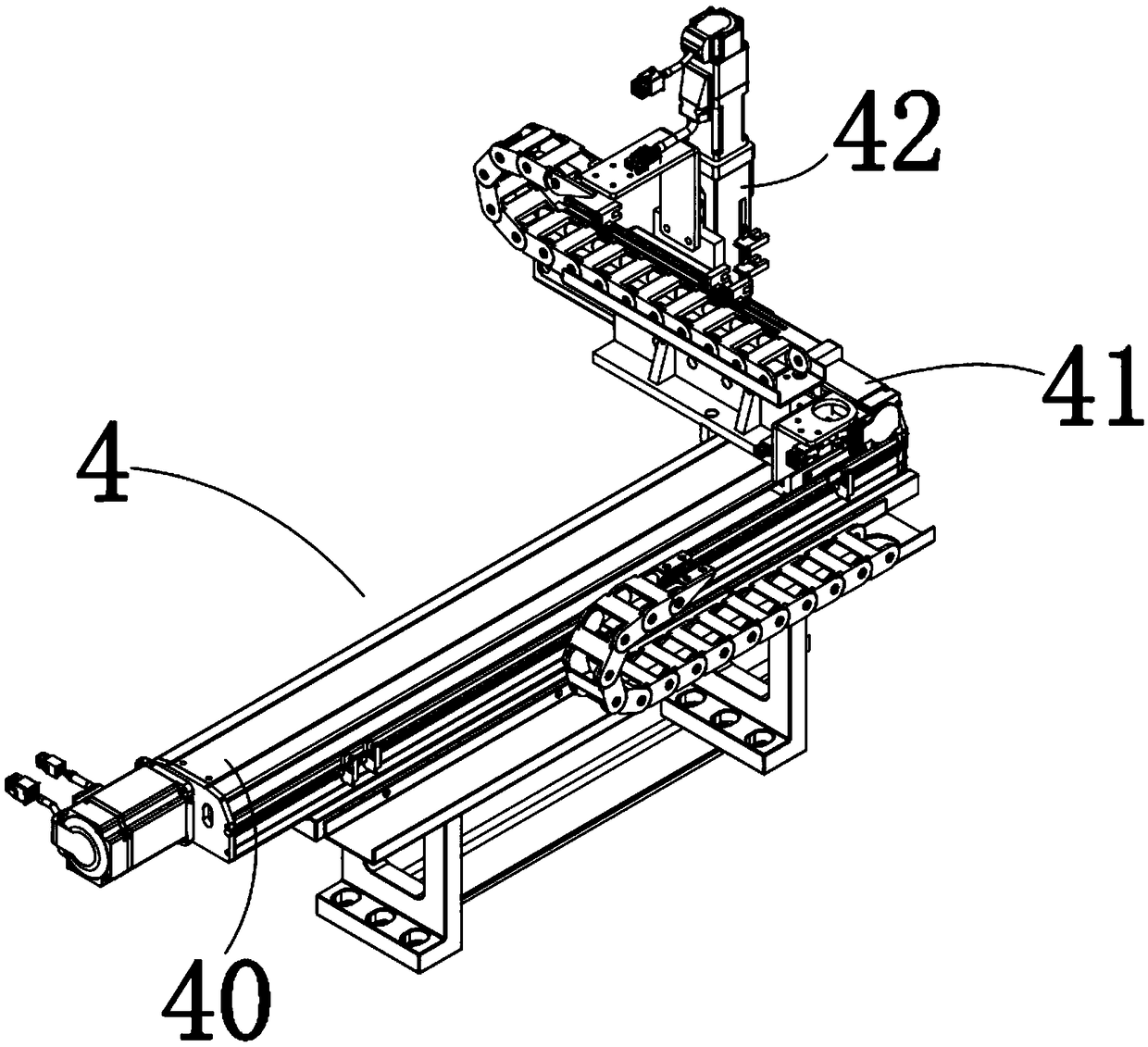

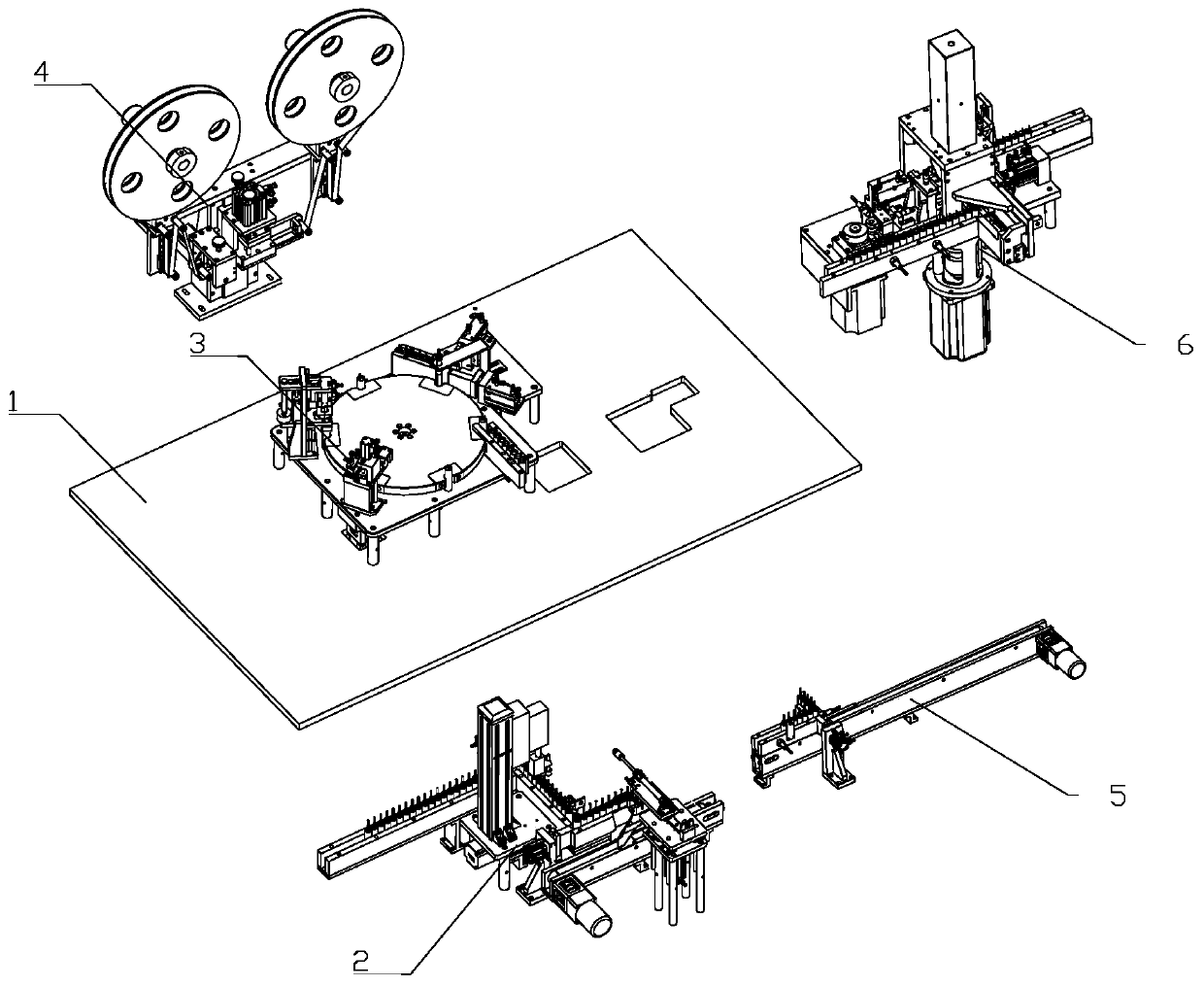

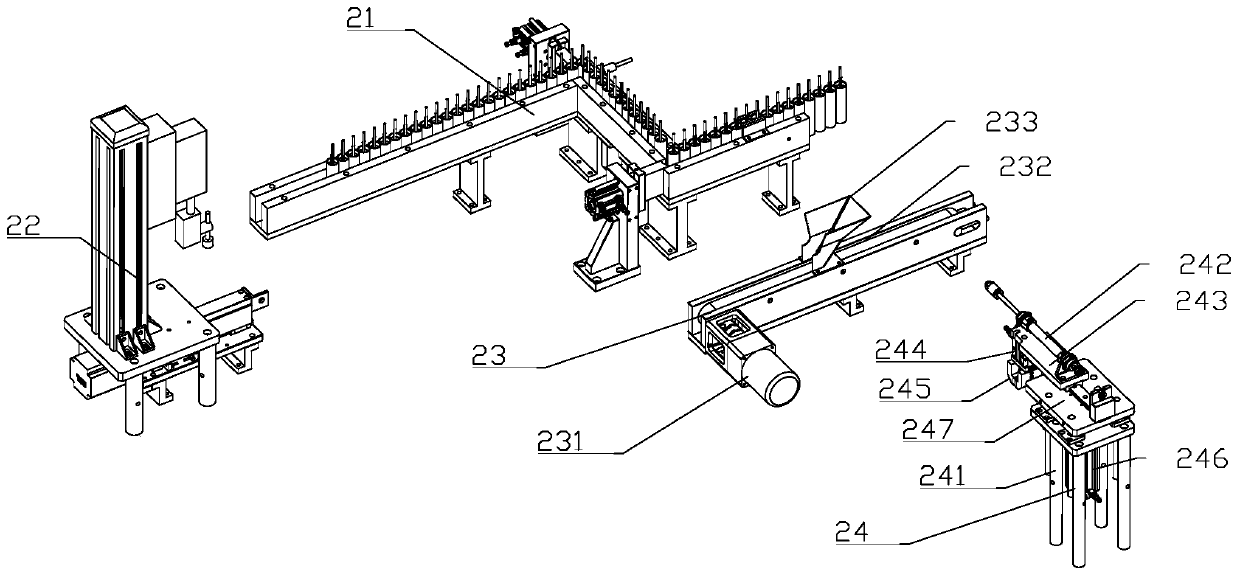

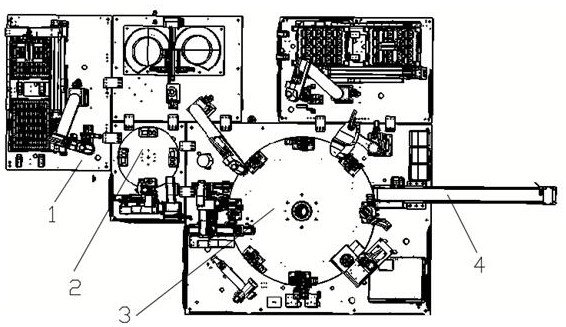

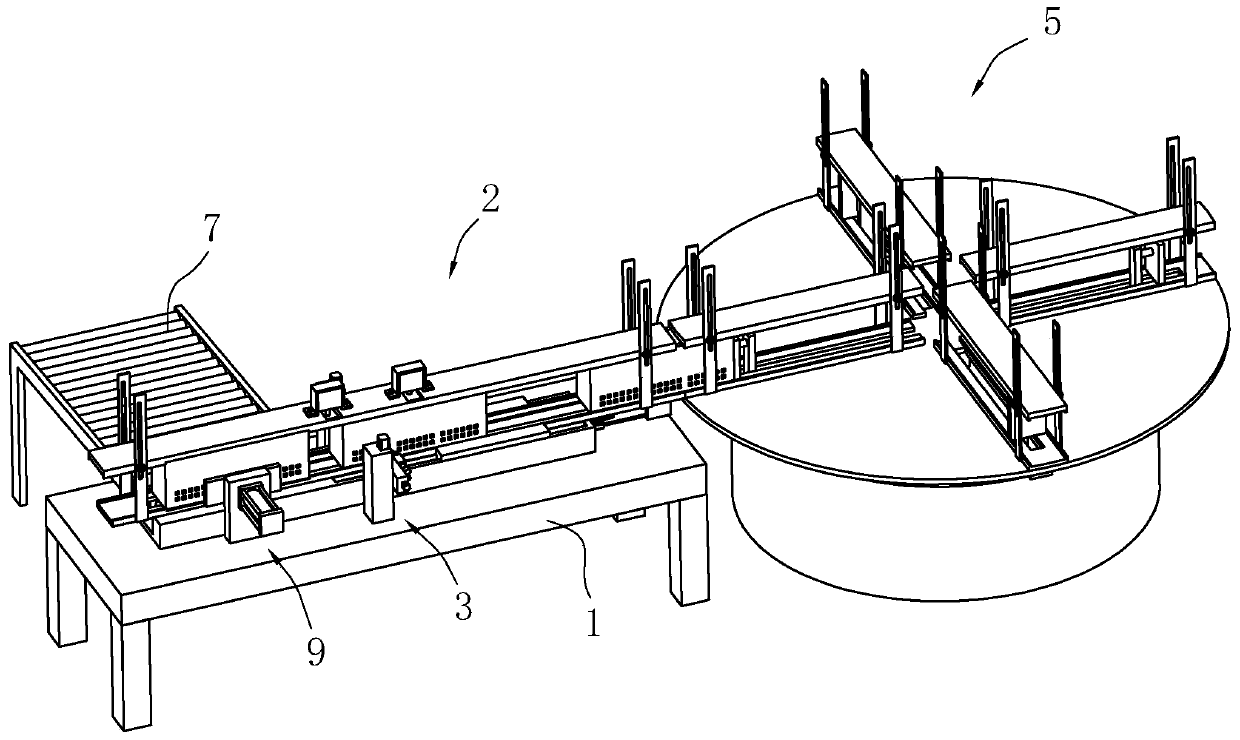

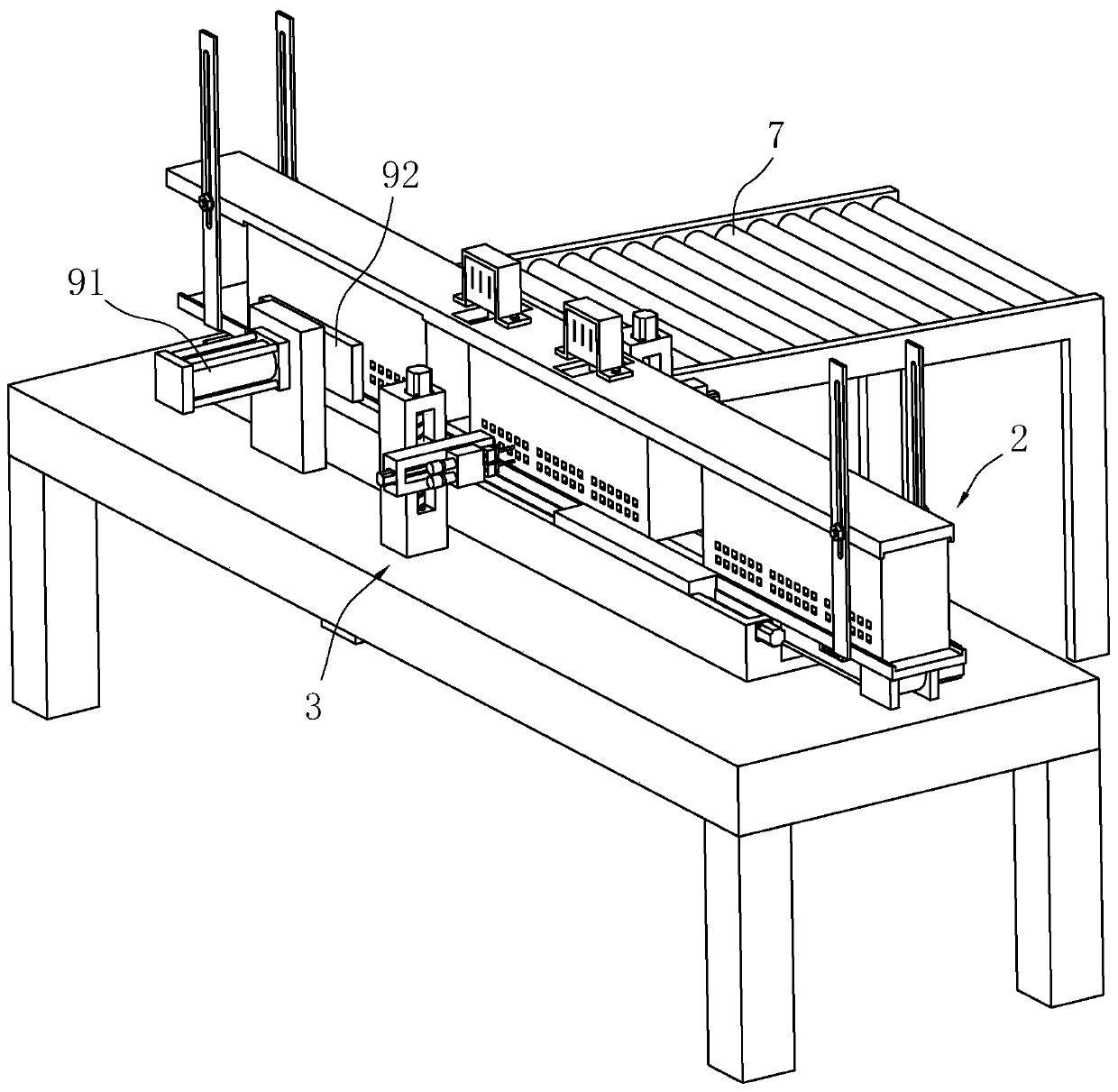

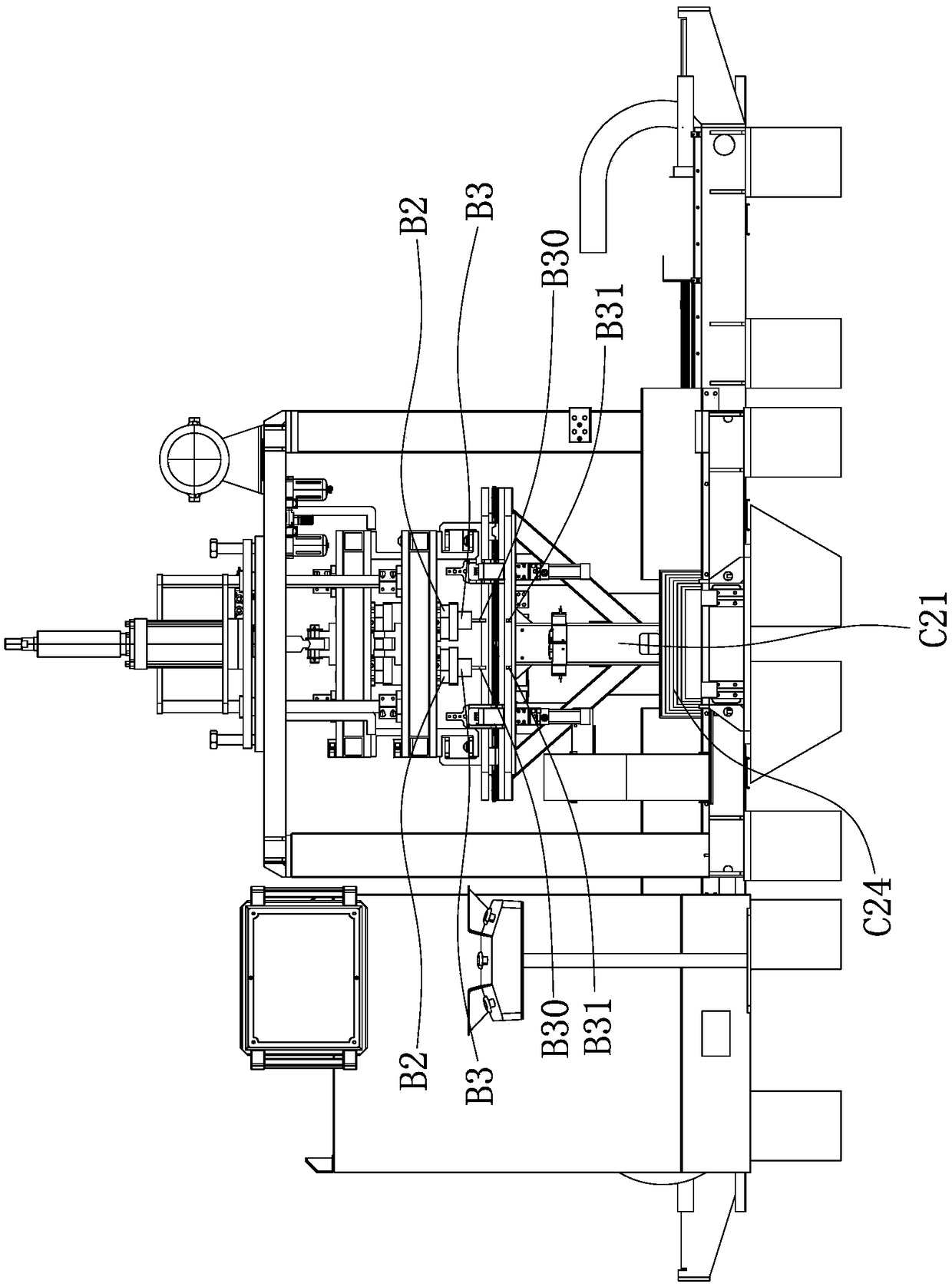

Cylindrical lithium battery production equipment and cylindrical lithium battery production method

InactiveCN111463491APrevent take outImprove Spot Welding EfficiencyAssembling battery machinesFinal product manufactureEngineeringBattery cell

The invention relates to the technical field of lithium battery production, and discloses cylindrical lithium battery production equipment. The equipment comprises a rack, and a bottom welding device,a turntable jig device, a diaphragm mounting device, a conveying device and a dispensing device which are mounted on the rack, wherein the bottom welding device is connected with the conveying device, the conveying device is arranged on the side of the turntable jig device, the diaphragm mounting device corresponds to the turntable jig device, and the dispensing device corresponds to the middle part of the conveying device. The equipment has the advantages that a separable copper bar is adopted as the welding electrode, the spot bottom welding position of a negative tab is accurate, the rigidity of the conveying mechanism is high, and the welding efficiency is high; the roundness of a battery shell is detected, a positive tab is straightened, the shape precision is high, and subsequent processing is facilitated; a diaphragm is processed by a double-station conforming die, so that the forming and assembling efficiency is improved; the forming effect is good, the battery is prevented from rolling over, the dispensing efficiency is high, and the conveying is convenient.

Owner:潘丽君

Micro-arc spot welding process for secondary coil terminal lug

InactiveCN101552133AIncreased durabilityImprove Spot Welding EfficiencyArc welding apparatusCoils manufactureIgnition coilEmery paper

The invention relates to a micro-arc spot welding process for the secondary coil terminal lug of an ignition coil, comprising the two steps of removing oxidation layer and micro-arc spot welding. Firstly, the winding position of the secondary coil terminal lug is polished by a fine emery paper; subsequently, the micro-arc spot welding is carried out at the winding position according to the setup parameters and the operation standard so as to lead the melted metal to form a solder joint ball, thus covering the secondary winding end at the winding position of the secondary coil terminal lug; and after arc-extinguishing, the argon is postponed to be closed for 0.5 seconds so as to protect the cooling and solidification of the solder joint ball. Compared with the general electric soldering iron welding process, the micro-arc welding process has the advantages of containing no lead, environment protection, having no harm to human, high spot welding efficiency, smooth solder joint ball, covering the secondary winding end at the winding position of the secondary coil terminal lug, thus preventing point discharge and improving the durability of the ignition coil.

Owner:北京慨尔康科技发展有限公司

License plate small lamp assembling machine

PendingCN112643337ACompact structureSmall footprintWelding/cutting auxillary devicesAssembly machinesComputer hardwareEngineering

The invention discloses a license plate small lamp assembling machine. The machine comprises a small lamp feeding device, a small lamp welding device, a small lamp shell assembling detection device and a small lamp automatic output line, wherein the right side of the small lamp feeding device is connected with the small lamp welding device, the right side of the small lamp welding device is connected with the small lamp shell assembling detection device, and the right side of the small lamp shell assembling detection device is connected with the small lamp automatic output line. The license plate small lamp assembling machine has the beneficial effects that the small lamp device automatically feeds small lamp circuit boards, the small lamp welding device performs spot welding on small lamps and the small lamp circuit boards, the spot welding efficiency is high, and a lamp body feeding mechanical arm on the small lamp shell assembling detection device feeds two kinds of small lamp shells on a small lamp shell feeding device; and a small lamp shell assembling mechanism is used for assembling the small lamps, the small lamps are recycled through a discharging mechanical arm, qualified products are automatically discharged through the small lamp automatic output line, small lamp assembling is accurate, and the assembling efficiency is high.

Owner:昆山卓勇工业设备有限公司

Multi-station full-automatic spot welding machine for tablet personal computer earphone machining

ActiveCN112171037AEasy to useFlexible adjustmentResistance electrode holdersMachine partsEngineering

The invention discloses a multi-station full-automatic spot welding machine for tablet personal computer earphone machining, and relates to the technical field of tablet personal computer earphone machining. The multi-station full-automatic spot welding machine comprises a machined part and a hydraulic air cylinder, a conveying device is arranged outside the machined part, and side plates are installed at the two ends of the outer portion of the conveying device. By arranging the conveying device, the machined part needing spot welding can be placed on a first conveying belt to be subjected tothe unified conveying treatment in a using process, meanwhile, the interaction of a right bottom block and an electric push rod and the mutual cooperation of a left supporting rod, a connecting block, a left bottom block, a right supporting rod and a connecting shaft can be utilized according to the actual using requirement to properly adjust the placing angle of the first conveying belt, so thatmore flexibility is achieved in an article conveying process, conveying guiding can be conducted through the gravity effect of the machined part when the first conveying belt cannot be used, manual operation of a user is not needed, and the user can use conveniently.

Owner:DONGGUAN UNIV OF TECH

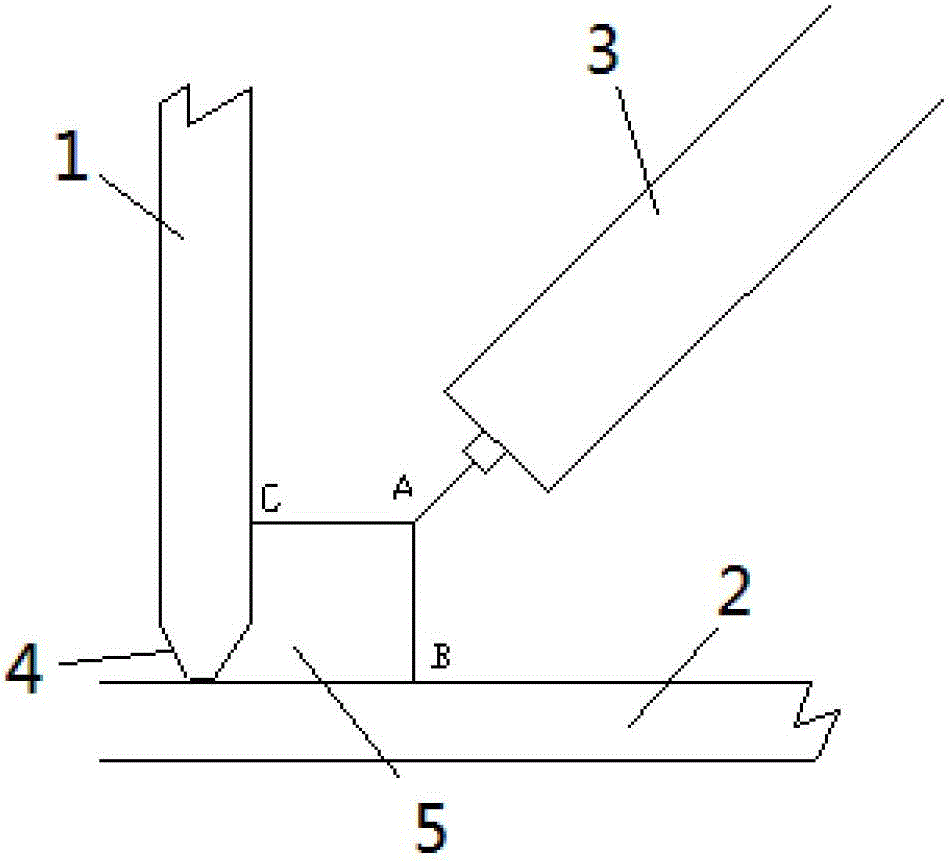

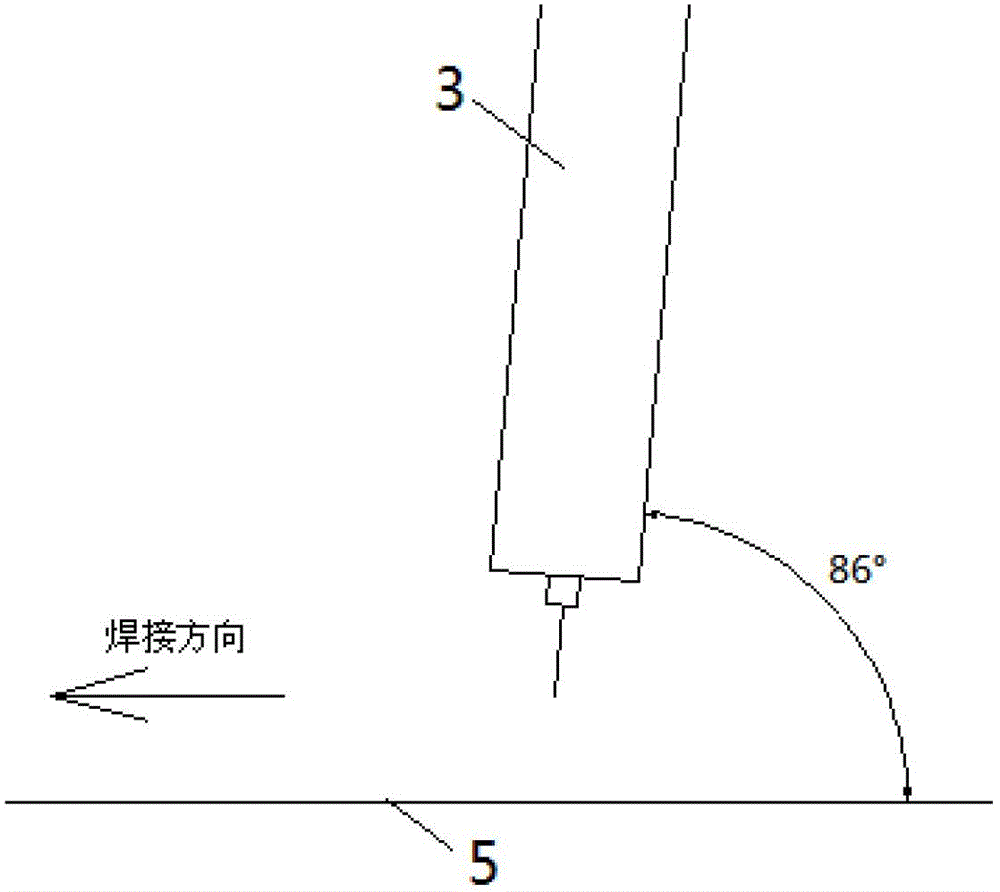

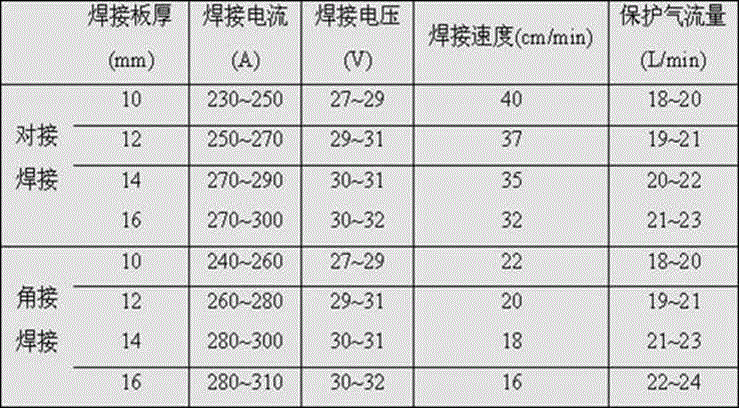

Welding method

ActiveCN102717172ALow costEnsure spot weld strengthArc welding apparatusStress concentrationImpurity

The invention belongs to the technical field of welding and relates to a welding method. In order to solve the problems that an excess weld metal on a weld joint surface is difficult to reduce after the welding is performed, the weld joint with higher excess weld metal is easy for causing stress concentration, impurities, such as water, are easy to accumulate on a dent part on the surface, and the weld joint is easily corroded by the outside, the invention provides the welding method which comprises the steps of assembling a welding plate and symmetrically welding the welding plate and further comprises a step of causing a welding gun to deviate for 93-95 degrees from a welding direction after the assembling step and before the welding step. According to the technical scheme, the technical problems are effectively solved.

Owner:浙江元利江东铁塔有限公司

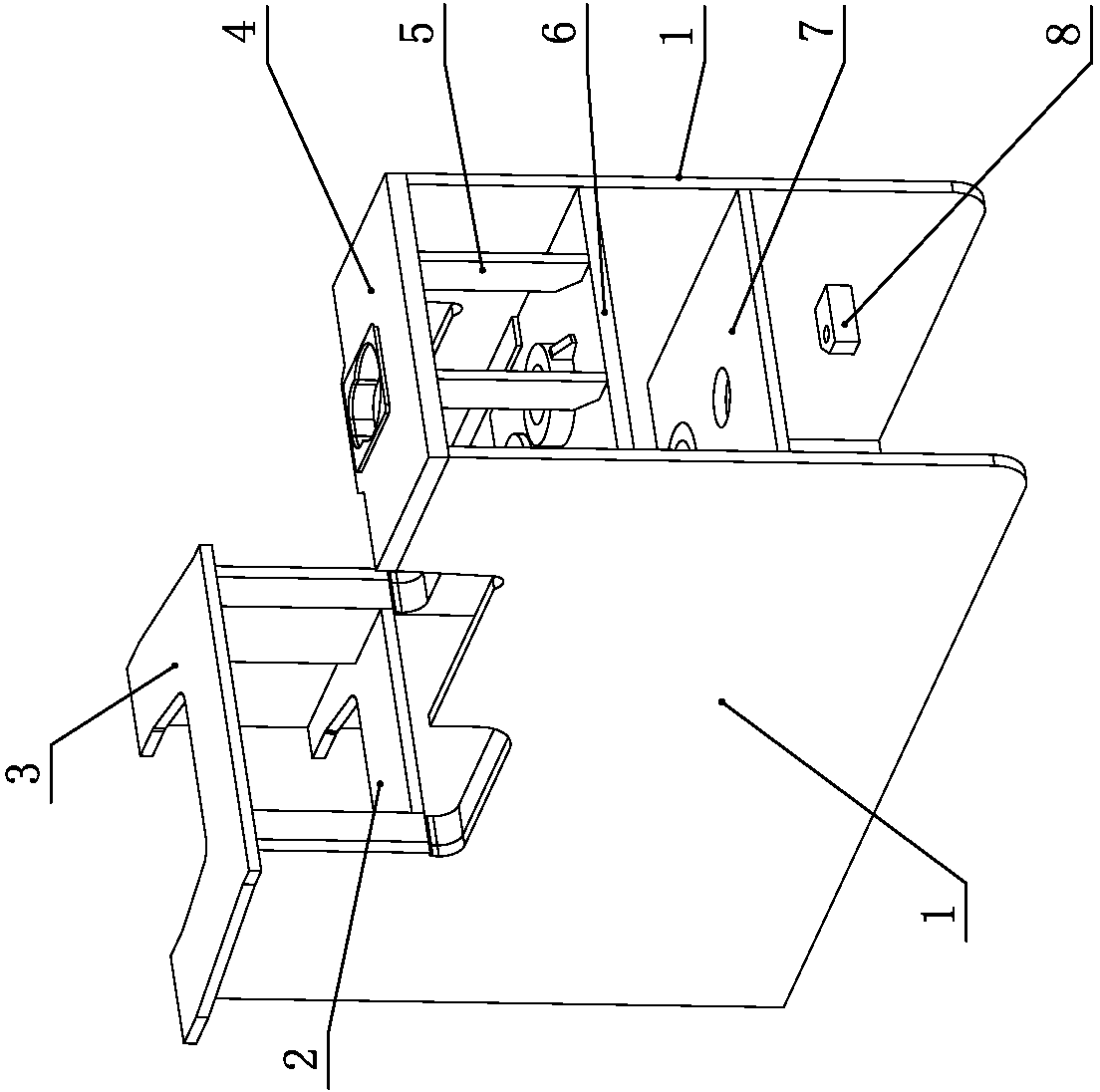

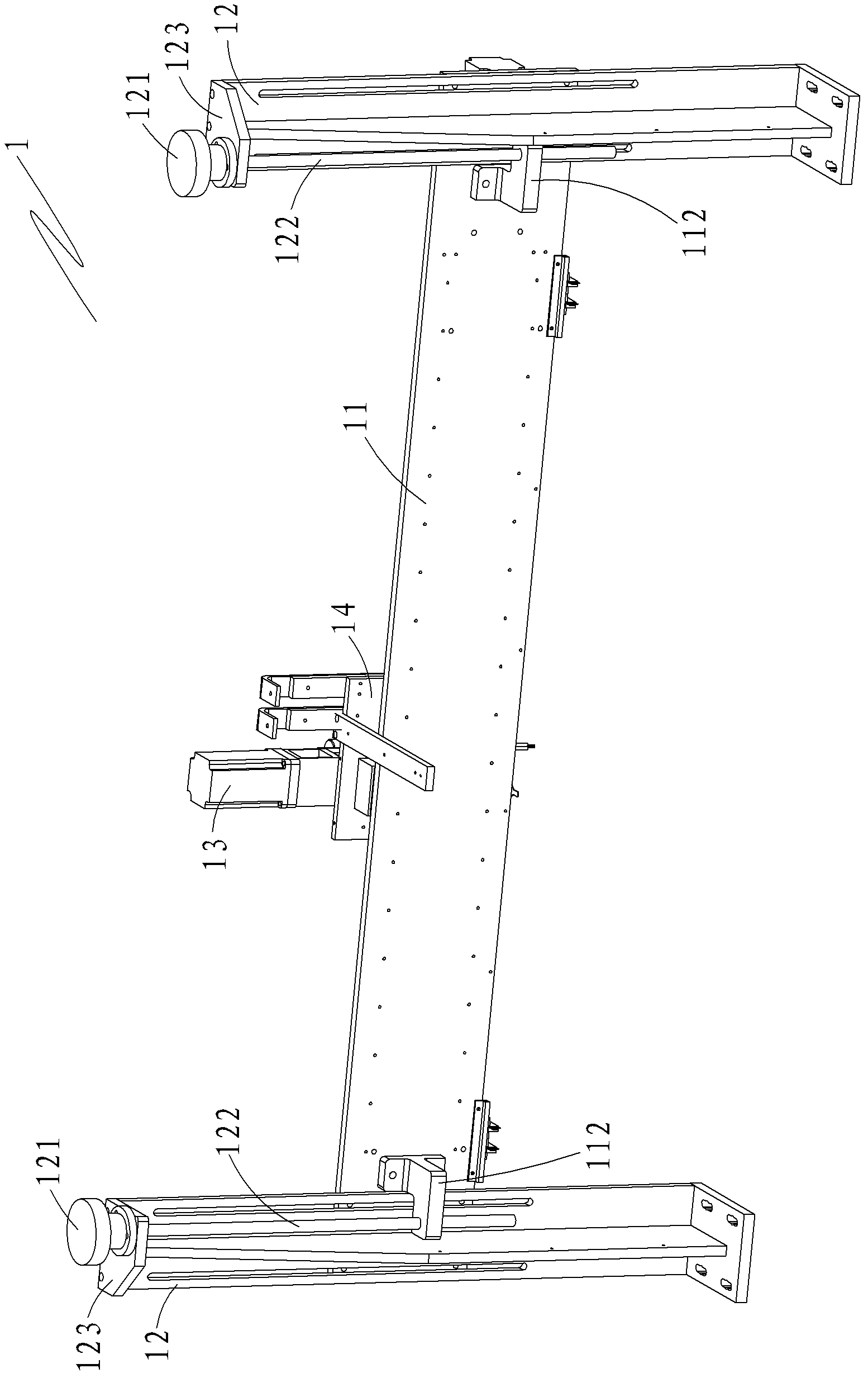

Spot welding tooling of machine body of press machine and spot welding method employing spot welding tooling

ActiveCN103722338AImprove Spot Welding EfficiencyHigh precisionWelding/cutting auxillary devicesAuxillary welding devicesSlide plateSpot welding

The invention relates to the field of welding process devices, and in particular relates to spot welding tooling with a simple structure and high spot welding efficiency for the machine body of a press machine and a spot welding method employing the spot welding tooling. The spot welding tooling comprises spot welding workbenches, wherein main baffle plates used for positioning two main plates of the machine body from the outer side are oppositely arranged on the left side and the right side of the spot welding workbenches; a bracket 1 and a bracket 3 which are used for positioning the two main plates of the machine body from the inner side are respectively arranged on the inner sides of the two main baffle plates; limiting stoppers are respectively arranged on the spot welding workbenches of the front end of the main baffle plate at the front end and the rear end of the main baffle plate at the rear end; adjusting bolts used for tightening the main plates of the machine body are respectively and correspondingly arranged on the main baffle plates, the bracket 1, the bracket 3 and the limiting stoppers; a bracket 2 as high as the bracket 1 is arranged on the front side of the bracket 1 side by side; the bracket 1 and the bracket 2 are used for supporting and positioning a rear drive plate; an adjusting bracket with an adjustable height is arranged on the rear drive plate; a bracket 4 as high as the bracket 3 is arranged on the front side of the bracket 3 side by side; the bracket 3 and the bracket 4 are used for supporting a workbench sliding plate; a clutch overlapping bracket is also arranged on each spot welding workbench.

Owner:YANGLI GRP CORP LTD

Automatic spot welding device for sealing plate of filter

PendingCN110064868AEasy to operateReasonable structureWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention discloses an automatic spot welding device for a sealing plate of a filter, and relates to the technical field of filters. The automatic spot welding device for the sealing plate of thefilter comprises a support plate, a support frame, support legs, a spot welding assembly, a placement assembly and a taking assembly, wherein the support plate is horizontally installed at the top ofthe support frame; the support legs are installed at the bottom of the support frame in a manner of uniform distribution; the spot welding assembly is arranged above the support plate centrally and inback and used for carrying out spot welding on the sealing plate of the filter; the placement assembly is arranged above the support plate centrally and in front and used for placing the sealing plate subjected to the spot welding, of the filter; and the taking assembly is arranged aside the spot welding assembly and used for taking away the welded sealing plate of the filter. The spot welding assembly comprises an installation column, a welding cylinder, a welding block and a welding column; the placement assembly comprises a position changing motor, a rotary shaft, a rotary block and a location block; and the taking assembly comprises a telescopic cylinder, a lifting cylinder, a taking block and a vacuum pump. The automatic spot welding device for the sealing plate of the filter has theadvantages of being reasonable in structure, convenient to operate, automatic in welding, high in spot welding efficiency, and the like.

Owner:安徽法西欧汽车部件有限公司

Novel spot welder

InactiveCN107414272ASimple structureImprove Spot Welding EfficiencyResistance electrode holdersWelding/cutting auxillary devicesSpot weldingIndustrial engineering

The invention discloses a novel spot welding machine, which comprises a base cavity and a column, the column is fixed on one side of the base cavity, a slide rail is arranged inside the column, the spot welding head fixing seat is slidably connected on the slide rail, and the lower end of the spot welding head fixing seat passes through a worm wheel The worm screw pair is connected to the spot welding head, and the worm gear and worm screw pair is electrically connected to the motor set on the spot welding head fixing seat. The motor is equipped with a workpiece clamping mechanism on the rotating platform. The invention has a simple structure, can realize multi-angle and spot welding of different parts of the workpiece, and has high spot welding efficiency.

Owner:马鞍山市中马金属材料有限公司

Spot welding device for power battery pack electrode slice

InactiveCN110091047AEfficient SupplementSupplementary fill worksElectrode featuresWelding/soldering/cutting articlesPower batteryEngineering

The invention discloses a spot welding device for a power battery pack electrode slice. The spot welding device comprises a conveying assembly, two spot welding assemblies and a moving assembly, wherein the conveying assembly comprises a conveying rail and a first driving part used for driving the conveying rail to slide along the X axis of a rack; a conveying space for allowing a spot welding jigto be embedded in a sliding manner is formed in the conveying rail; a preparation station, a spot welding station and a finish station are sequentially arranged in the conveying space in the conveying direction of the spot welding jig; the two spot welding assemblies are arranged on the rack and are positioned on the two sides of the spot welding station of the conveying rail; the spot welding assemblies comprise spot welding heads, second driving parts used for driving the spot welding heads to slide along the Y axis of the rack, and third driving parts used for driving the spot welding heads to slide along the Z axis of the rack; and the moving assembly is arranged on the conveying assembly, and is used for conveying the spot welding jig between the preparation station and the spot welding station and between the spot welding station and the finish station along the conveying space. The main point of the technical scheme is that spot welding efficiency is high.

Owner:东莞市腾威动力新能源有限公司

Spot welding machine

InactiveCN105562914AWill not damage the internal structureReduce mistakesWelding/cutting auxillary devicesAuxillary welding devicesSpot weldingMechanical engineering

The invention discloses a spot welding machine. The spot welding machine comprises a platform, a welding main unit and a driving device, wherein the platform is provided with stations (4), an electrode (9) is installed on the welding main unit, and the driving device is used for driving the welding main unit to operate. The welding main unit is installed on a traveling mechanism (14) which can move in the axis direction of a workpiece (8). The working efficiency of the spot welding machine is effectively improved.

Owner:SEED TECH CORP LTD

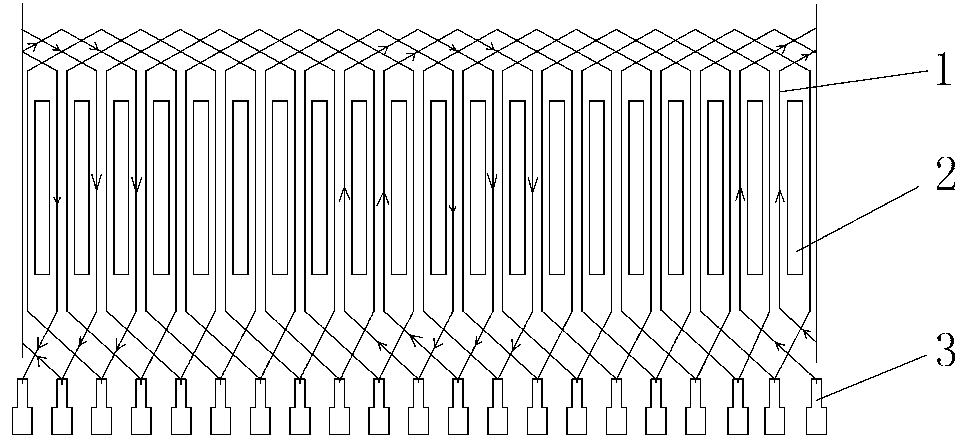

Commutator segment halved rotor and motor thereof

InactiveCN103219855AGood for spot weldingReduce the number of spot weldingDC commutatorFailure rateElectricity

The invention discloses a commutator segment halved rotor comprising a rotating shaft, an iron core, a commutator and coil windings wound by enamel wires, wherein each commutator segment in the commutator is provided with a hook; the coil windings are wound on the iron core; the quantity of the commutator segments is half of that of the coil windings; and after being wound into two coil windings, the enamel wires are electrically connected at one hook. The invention further provides a motor comprising a stator, a motor shell with a built-in end cover, a carbon brush component and the commutator segment halved rotor. The invention has the following beneficial effects: the quality problem and hidden troubles of inter-turn short circuit are eliminated, commitator spot welding can be performed conveniently; during a wiring process, the hooking frequency is less than traditional rotor wiring, and the rotor wiring efficiency is improved; the commutator spot welding frequency is reduced; the spot welding frequency is improved; the spot welding failure rate is reduced; the output power and efficiency of the motor are improved by 2-4%; or under the condition of achieving the original output power, the wire diameters of the enamel wires can properly reduced, so that the copper weight is reduced.

Owner:ZHEJIANG KAITUO AUTOMOBILE ELECTRICAL APPLIANCE

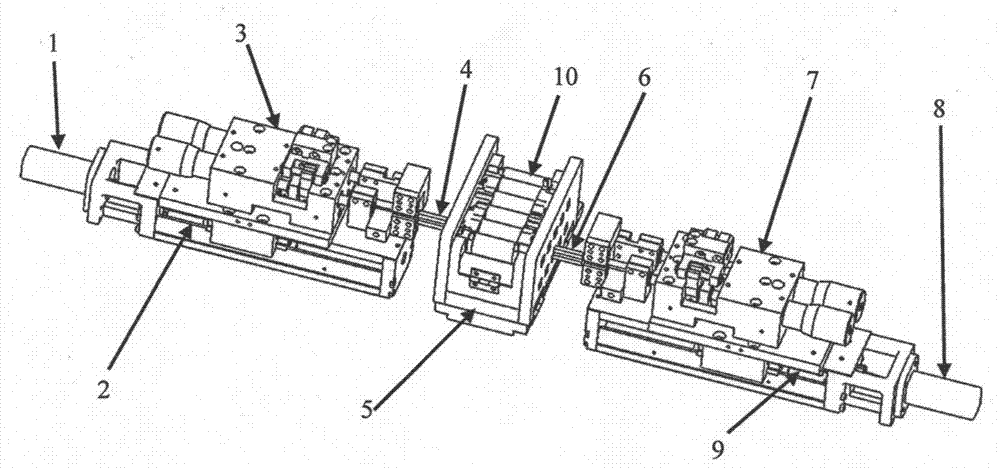

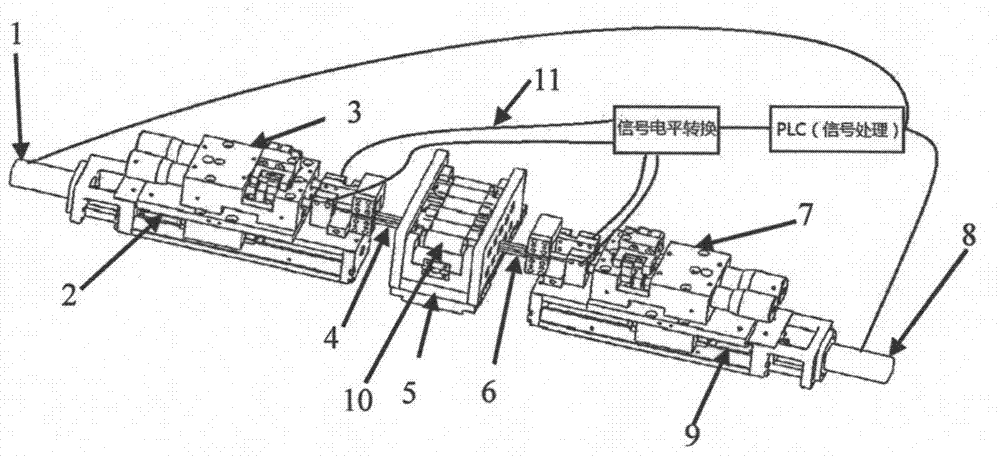

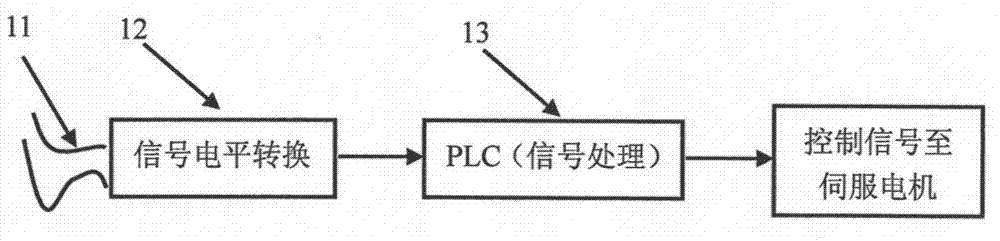

Double-sided automatic spot welding machine control device and method

ActiveCN104493352ANo movementNot misplacedWelding electric supplyMetal working apparatusMachine controlProgrammable logic controller

The invention provides a double-sided automatic spot welding machine control device. A double-sided automatic spot welding machine comprises a left screw rod, a right screw rod and a jig used for assembling a cell. A left servo motor and a right servo motor are connected with the left and right screw rods respectively, a left spot welding head and a right spot welding head are connected on the left and right screw rods respectively, a left electrode bar and a right electrode bar are arranged on the left and right spot welding heads respectively, a level conversion device is connected with a PLC (programmable logic controller), the left and right spot welding heads are both connected with the level conversion device, and the PLC is further connected with the left and right servo motors; a contact position is arranged on the surface of the cell. The invention further provides a double-sided automatic spot welding machine control method. After the spot welding heads on both sides reach the contact position, the electrode bars on two sides contact with the cell, and then the spot welding heads reach the spot welding position, so that the cell cannot move and a nickel plate cannot be misplaced. By the device, spot welding quality is improved, the servo motors can be set to be in full speed operation during movement before contact with the cell due to the contact position, and thus spot welding efficiency is improved as well.

Owner:上海电动工具研究所(集团)有限公司

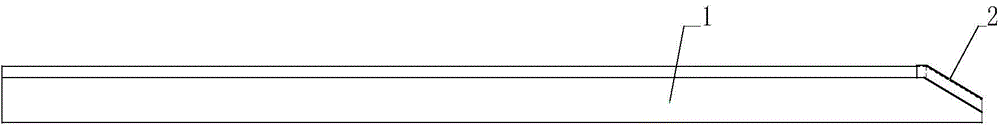

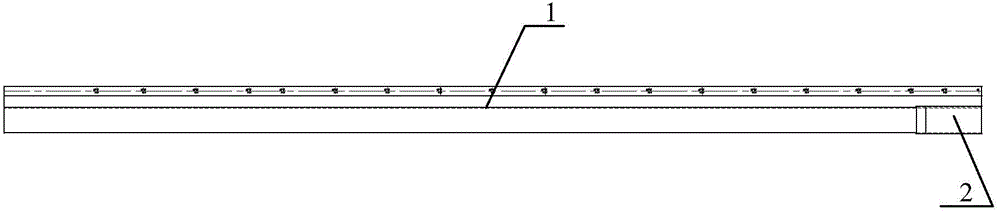

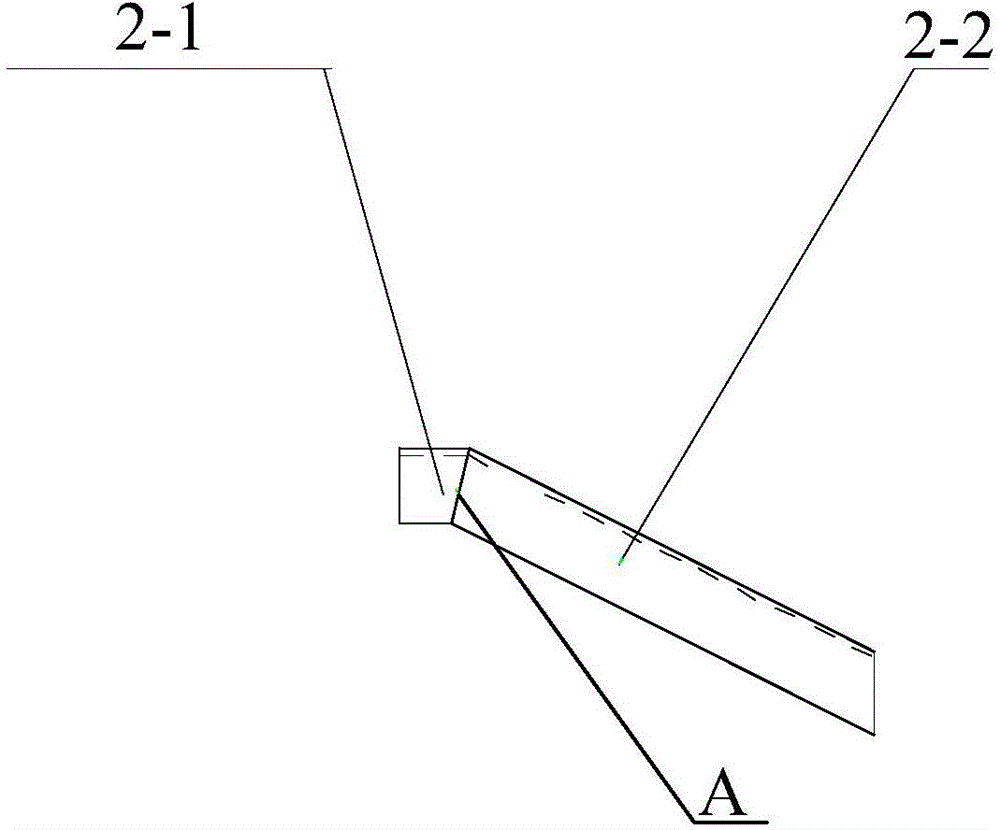

Process for machining boundary beam of vehicle carrying plate

The invention relates to a process for machining a boundary beam of a vehicle carrying plate. The process comprises the following machining steps of (1) shearing a galvanized steel sheet through a plate shearing machine, punching the sheared galvanized steel sheet through a turret punch press to obtain a workpiece, forming the end of the workpiece in a stamping mode to obtained the workpiece with the end subjected to stamping formation, and performing bending formation on the end of the workpiece with the end subjected to stamping formation through a bending machine to obtain a beam body; (2) shearing a cold-roll steel sheet through the plate shearing machine to obtain a welding connector and an inclined plate which are integrally formed, performing press formation on the welding connector and the inclined plate through a die by means of a pressing machine, performing welding, and spraying caution paint on the surfaces of the welding connector and the inclined plate to obtain an end head; (3) welding the end head to the beam body through a spot welding machine to obtain the boundary beam of the vehicle carrying plate. According to the process, the principle of electric resistance welding is adopted in the spot welding machine, electric resistance welding is completed instantly due to the small contact area of the workpiece and the spot welding machine, and the galvanized sheet can be welded while the galvanized surface is not damaged.

Owner:TANGSHAN TOP PARKING EQUIP CO LTD

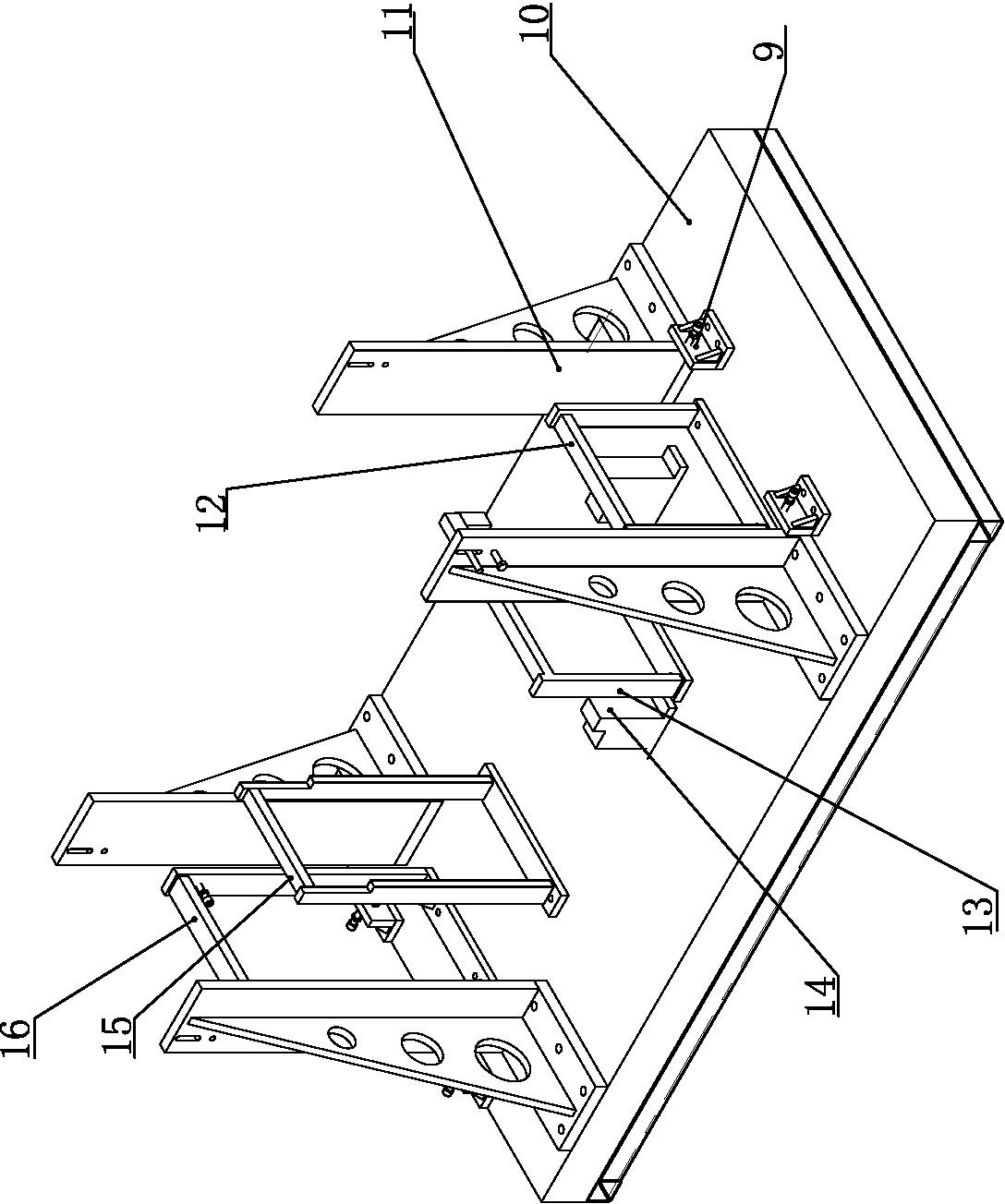

Spot welding general mold

ActiveCN106826064BSave materialImprove Spot Welding EfficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention discloses a universal mold for spot welding. The universal mold comprises two subframes which are vertical to each other, one fixed end hole site control assembly and at least one movable end hole site control assembly, wherein a hole spacing sliding track is arranged on each subframe, and each hole site control assembly comprises two datum line sliding tracks, datum line control blocks which are mounted on the datum line sliding tracks in a sliding manner, and a first limiting mechanism; the two datum line sliding tracks of each movable end hole site control assembly are arranged on the corresponding hole spacing sliding track in a sliding manner, and each movable end hole site control assembly further comprises a connecting rack for connecting the corresponding two datum line sliding tracks, and a second limiting mechanism. According to the universal mold for spot welding, disclosed by the invention, corresponding hole spacing and datum line distance can be adjusted as required; compared with the prior art, the universal mold for spot welding has the advantages that materials can be saved, and the efficiency of spot welding is increased.

Owner:ZHEJIANG SHENGDA STEEL TOWER

Gantry-type automatic spot welding system for battery pack

ActiveCN102554437BImprove adaptabilityReduce labor intensityResistance welding apparatusProgrammable logic controllerEngineering

The invention provides a gantry-type automatic spot welding system for a battery pack, which comprises a spot welding device and a spot welding jig fixing device which are vertically arranged and are connected with a PLC (programmable logic controller) of the system. The spot welding device comprises a beam, a group of opposite vertical columns in parallel, a spot welding mechanism, an X-axis sliding table, a Y-axis movement mechanism and an X-axis movement mechanism, wherein the vertical columns are used for adjusting the height of the beam, the X-axis sliding table is used for fixing the spot welding mechanism, the Y-axis movement mechanism enables the spot welding mechanism to transversely move, and the X-axis movement mechanism enables the X-axis sliding table to transversely move. The spot welding jig fixing device comprises a spot welding jig platen and a clamping mechanism for clamping a spot welding jig, wherein the clamping mechanism is arranged on the spot welding jig platen and is perpendicular to the spot welding mechanism. By the aid of a gantry-type structure, clamping is performed once, cells are numerous, spot welding parameters are controllable, and the system is fast in running speed, high in spot welding efficiency, highly adaptable to the cells, accurate in positioning and fine in spot welding quality.

Owner:FUJIAN NEBULA ELECTRONICS CO LTD

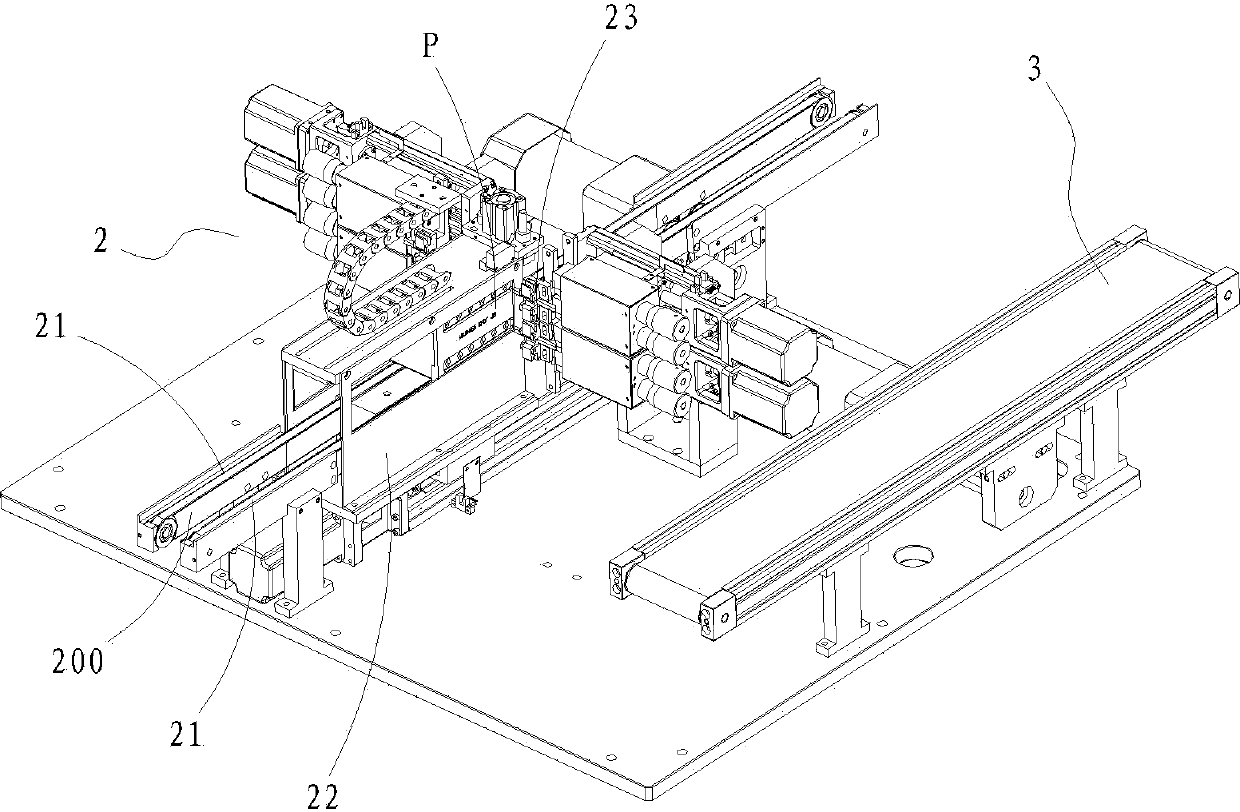

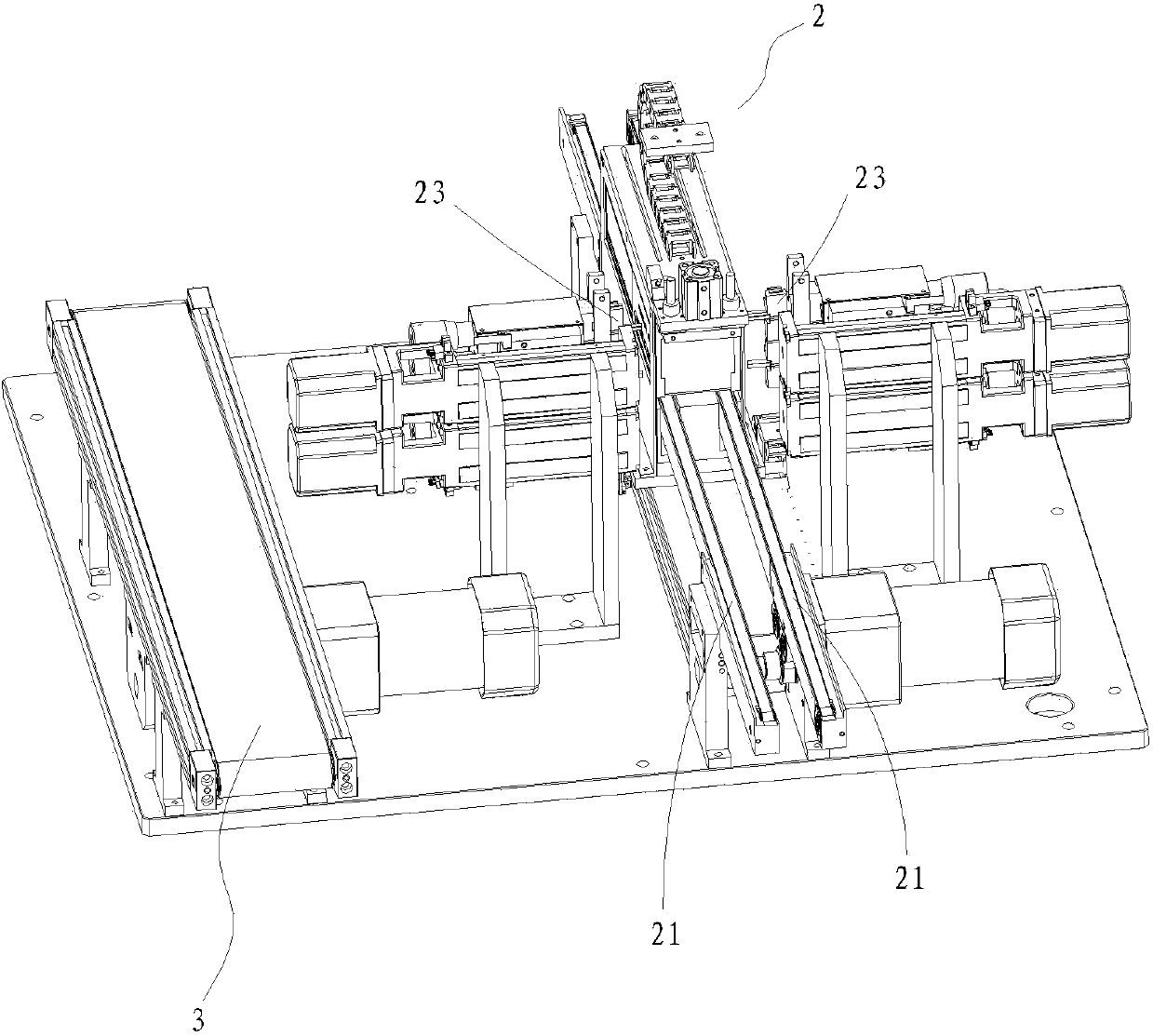

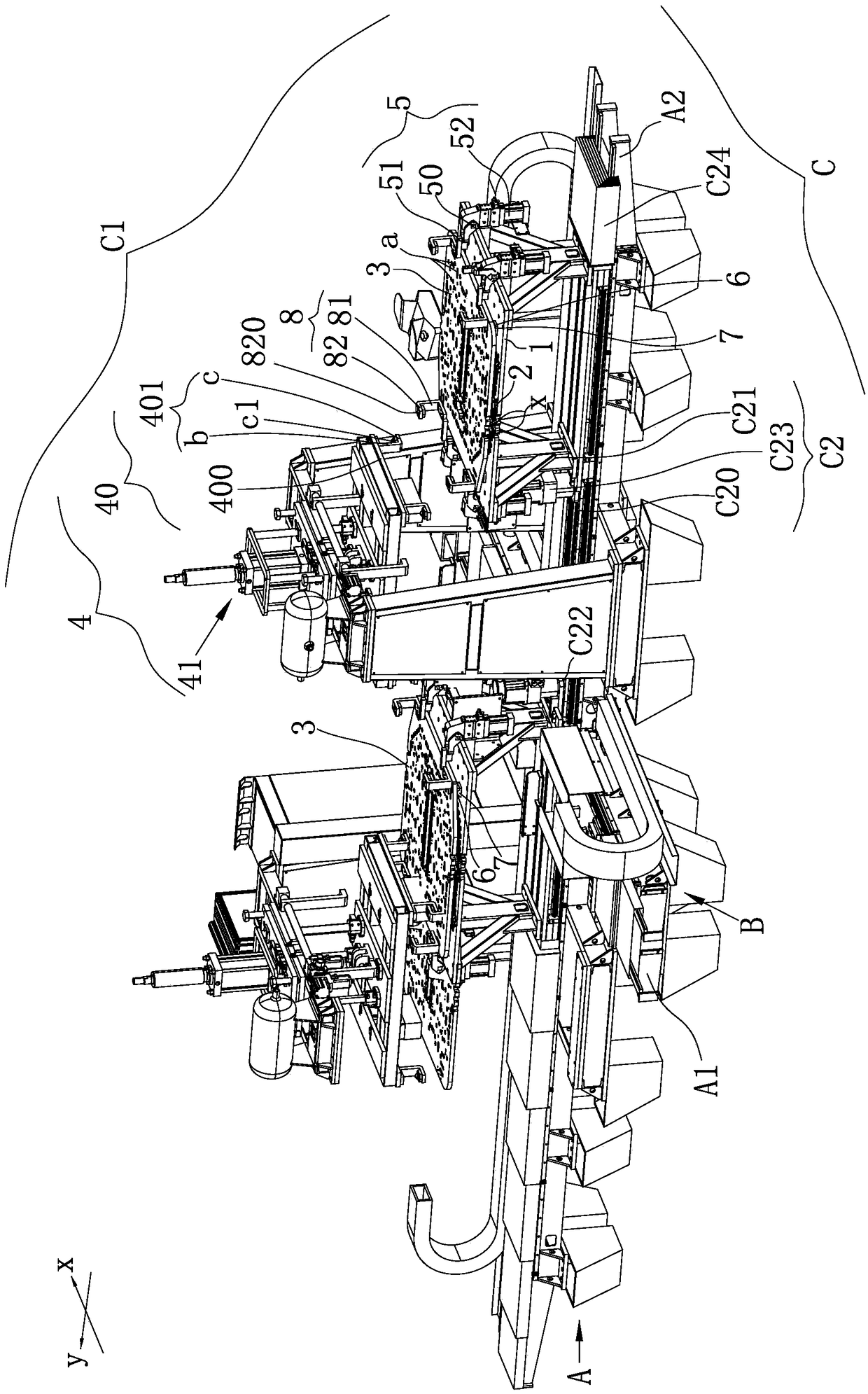

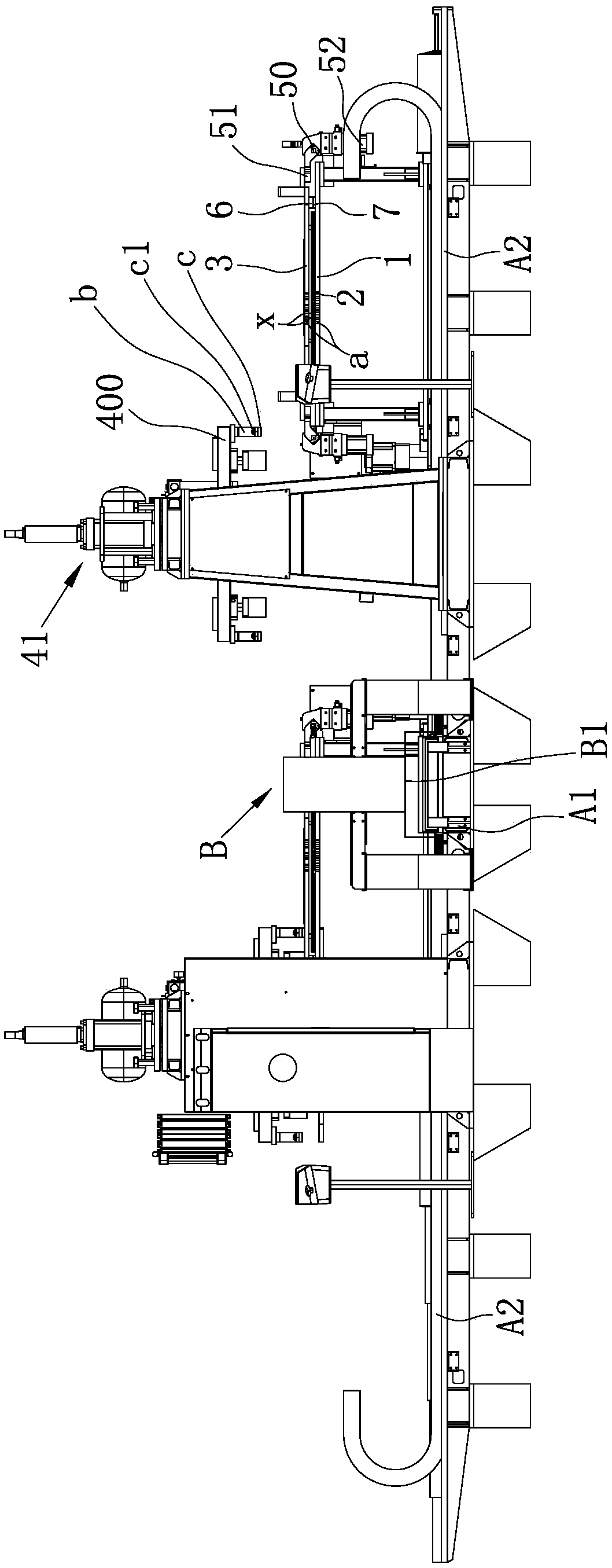

Full-automatic dual-spot welding machine for welding of automobile pallets

ActiveCN108971829AImprove Spot Welding EfficiencySimple structureWelding/cutting auxillary devicesAuxillary welding devicesDual accessEngineering

The invention discloses a full-automatic dual-spot welding machine for welding of automobile pallets. The full-automatic dual-spot welding machine includes: a frame including two rail racks extended along x axis and y axis and in a same horizontal plane; two welding torch units arranged on the rail rack where the x axis locates in a manner of symmetry about an intersection of the x axis and the yaxis, wherein the two welding torch units can move synchronously to provide synchronous welding for an automobile pallet on the two sides in a manner of symmetry about the y axis; two feeding sets each including an automobile pallet positioning unit and a shifting unit, wherein the two feeding sets are arranged on the rail rack where the y axis locates in a manner of symmetry about the intersection of the x axis and the y axis, and wherein when one feeding set finishes spot welding of one automobile pallet and removes the automobile pallet from a welding area, the other feeding set shifts a positioned automobile pallet to the welding area so that continuous welding is achieved. The full-automatic dual-spot welding machine allows dual-torch nonstop continuous welding in the dual-access mode, so that spot welding efficiency is greatly improved; the full-automatic dual-spot welding machine is simple in structure, convenient to implement and low in cost.

Owner:JIANGSU BOJUN IND TECH

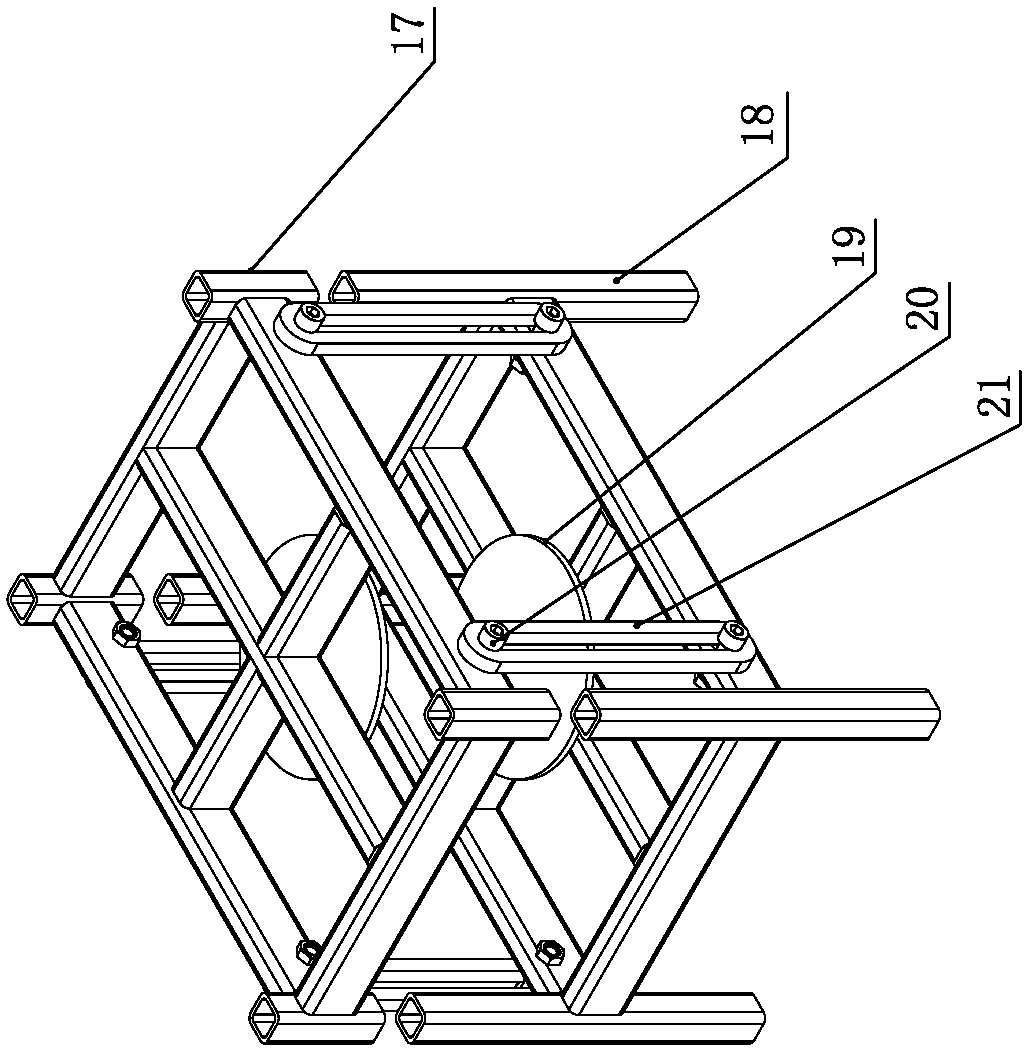

Continuous spot welding device for welding lithium battery pack and using method

ActiveCN113351975AGuaranteed continuous intermittentImprove Spot Welding EfficiencyResistance welding apparatusHydraulic cylinderEngineering

The invention discloses a continuous spot welding device for welding a lithium battery pack, and belongs to the technical field of lithium battery production. The continuous spot welding device comprises a machine frame, a spot welding machine body, a conveyor and two mounting plates, the conveyor is arranged on the machine frame and is used for conveying pole pieces and battery shells to be conveyed and conveying welded pole pieces and battery shells, the two mounting plates are horizontally arranged above the conveyor, and the spot welding machine body is arranged below the two mounting plates through a positioning assembly. A power assembly, the conveyor and a driver are arranged to be used in cooperation, a piston rod of a hydraulic cylinder extends to drive the spot welding machine body to move downwards and drive the conveyor to convey workpieces at the same time, when the piston rod of the hydraulic cylinder contracts, the piston rod of the hydraulic cylinder drives the spot welding machine body to move upwards and the conveyor does not work at the same time, therefore, continuous and intermittent welding operation of the pole pieces and the battery shells can be guaranteed, the spot welding efficiency and the spot welding precision are effectively improved, the structure is simple, and the overall mechanical linkage performance is high.

Owner:南通劲胜新能源科技有限公司

Electric welder provided with multiple welding heads

InactiveCN102363243AImprove efficiencyIncrease productivityResistance welding apparatusElectric heatingEngineering

The invention discloses an electric welder provided with multiple welding heads, which comprises a case; and the case is provided with at least two electric heating point welding heads which extend forwards. When the electric welder provided with the multiple welding heads in the design is adopted, point welding can be carried out on a plurality of positions for once, so that the point welding efficiency is improved, and the production efficiency of a lamp box is effectively improved.

Owner:江门市三泰照明制品有限公司

Lithium battery spot welding device

ActiveCN113210821AImprove Spot Welding EfficiencyEasy to operateResistance welding apparatusElectric machineryEngineering

The invention provides a lithium battery spot welding device, and relates to the field of lithium batteries. The lithium battery spot welding device comprises opposite side plates, a rotating shaft located between the two side plates, a first motor, two vertical plates, connecting plates, spot welding machines, rotating wheels, pushing parts and driving parts; the first motor is fixed on the outer side surface of one side plate, and an output shaft of the first motor is fixedly connected with one end of the rotating shaft; the two vertical plates are located between the side plates and symmetrically arranged, and the two ends of each vertical plate are in sliding connection with vertical grooves formed in the inner side faces of the side plates correspondingly; the several connecting plates are located between the vertical plates, the several spot welding machines are fixed to the connecting plates, and the two ends of each connecting plate are located in inner side grooves formed in the inner side faces of the vertical plates; the rotating wheels are uniformly distributed on the rotating shaft, are used for winding nickel sheets and are in one-to-one correspondence with the connecting plates; and the pushing parts are used for driving the vertical plates to move up and down, and the driving parts are used for driving the connecting plates to move up and down. According to the device, each row of lithium batteries in a jig can be welded through one-time spot welding, operation is easy, and the spot welding efficiency of the lithium batteries is greatly improved.

Owner:安徽瑞露科技有限公司

Efficiency workpiece point welding machine

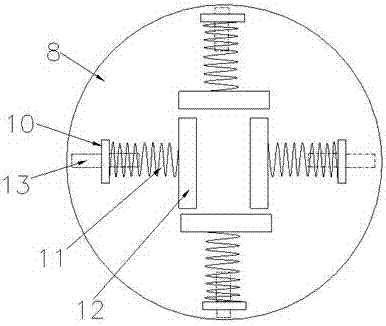

InactiveCN109551093APlay a buffer rolePlay a guiding roleResistance welding apparatusEngineeringMechanical engineering

The invention discloses an efficiency workpiece point welding machine. The efficiency workpiece point welding machine comprises a u-shaped bracket. A transverse sliding rail is fixedly mounted on theinner side of the upper end of the u-shaped bracket. A first sliding block is mounted in the transverse sliding rail. The first sliding block is mounted at the upper end of a longitudinal sliding rail. A second sliding block is mounted in the longitudinal sliding rail. A welding head mounting seat is mounted on the second sliding block. A welding head is mounted below the welding head mounting seat. Two sets of buffer springs are arranged between the upper end of the welding head and the lower end of the welding head mounting seat. A guide assembly is mounted between the two sets of buffer springs. A workpiece placing mechanism is mounted on the inner side of the u-shaped bracket. The physical design is novel. A workpiece can be welded transversely and longitudinally. The workpiece placingmechanism is arranged to clamp workpieces of different sizes. It is unnecessary to replace the whole placing mechanism, and therefore the point welding efficiency can be improved.

Owner:马鞍山迪斯福工业设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com