Welding method

A welding method and welding plate technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of arc crater slag inclusion, low overall welding quality, and difficulty in controlling the flatness and straightness of the weld surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

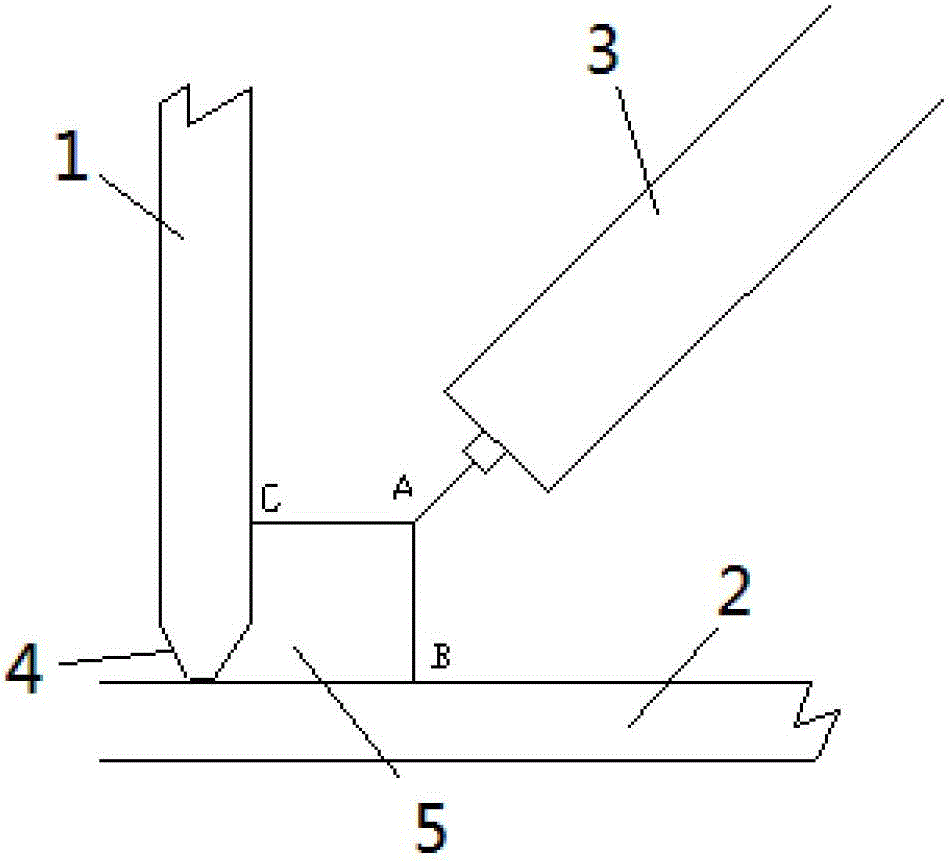

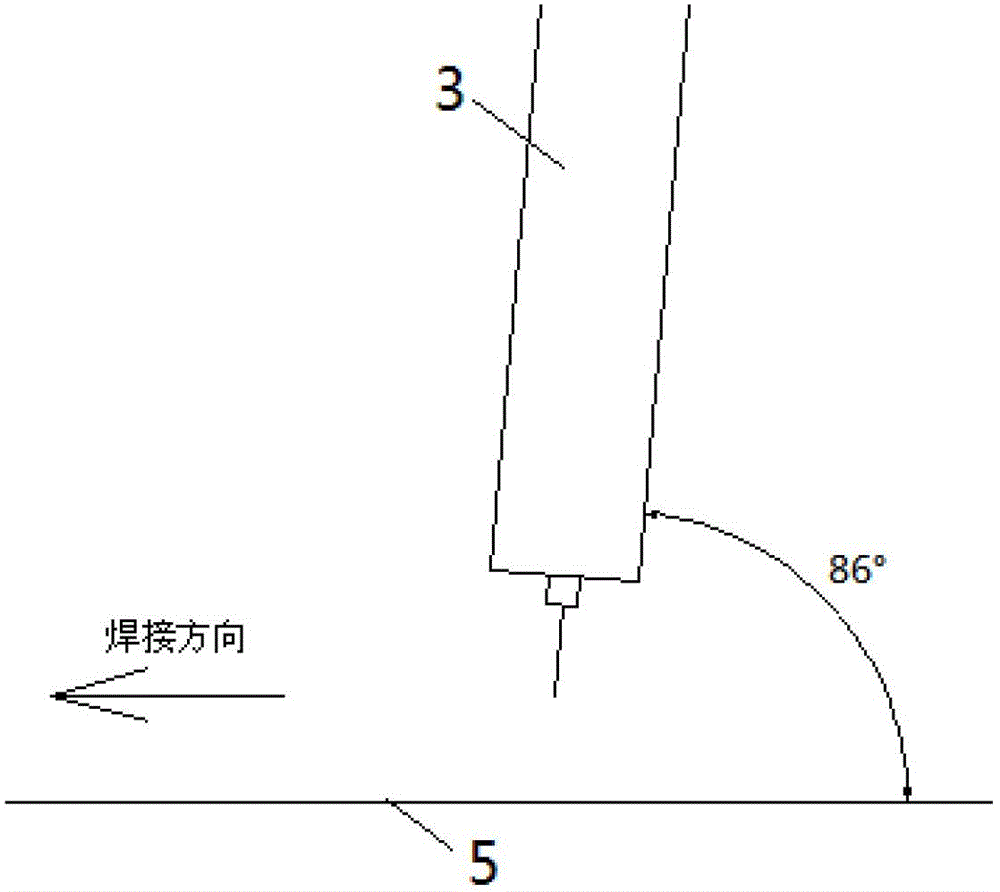

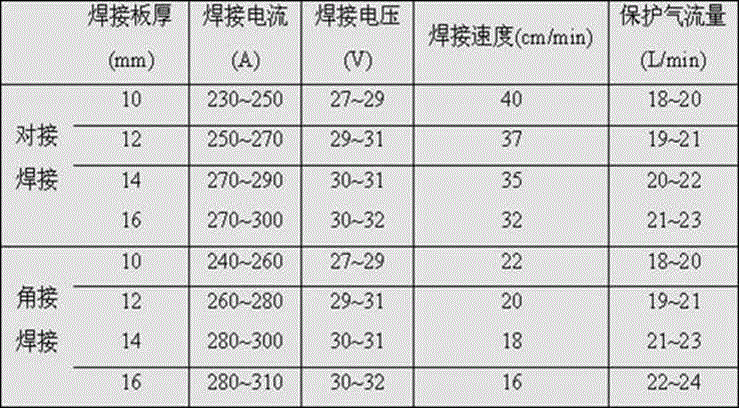

[0024] A welding method, which uses a welding robot to perform shielded welding on the foot of a transmission line tower at a temperature above 0°C with argon and carbon dioxide as shielding gases (the volume ratio of argon and carbon dioxide is 85:15), including the following Steps:

[0025] 1. Steps of the tower foot cutting

[0026] CNC cutting the steel plate to obtain the welded plate that constitutes the tower foot to ensure that the welded plate meets the accuracy requirements. Of course, the operator can also use flame cutting or shearing machine to cut and blank the material, but after the operation, it must be corrected with a straightening machine to ensure that the welded plate meets the requirements. precision requirements.

[0027] 2, point installation steps

[0028] The welding plate is further processed by means of numerical control cutting to form the welding groove 4, and then the groove and both sides of the inner and outer walls are cleaned with a poli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com