Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1415 results about "Emery paper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Emery paper is a type of abrasive paper or sandpaper, that can be used to abrade (remove material from) surfaces or mechanically finish a surface. Operations include deburring, polishing, paint removal, corrosion removal, sizing, etc. This is accomplished by moving the abrasive-coated paper, with some pressure, against the object being processed. Abrasion may be performed by hand, electrically powered, or air powered equipment.

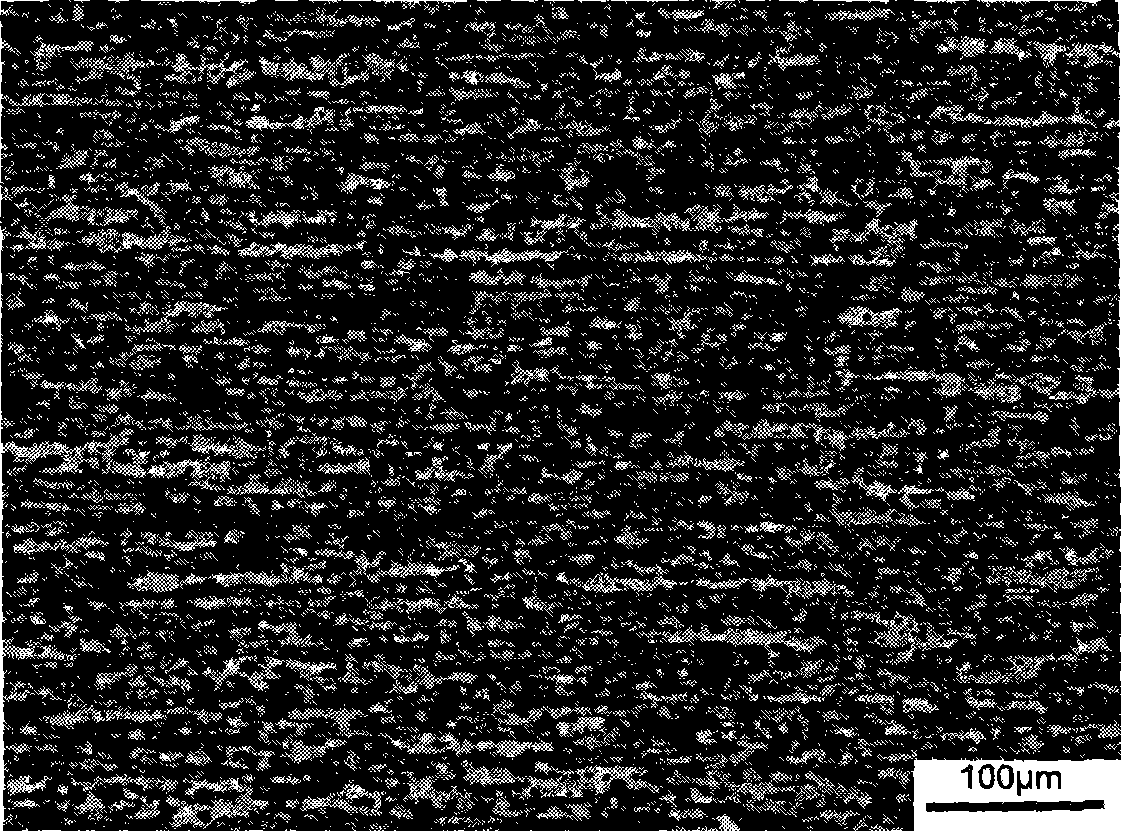

Method for preparing thermal barrier coating by laser compound plasma spraying

InactiveCN101768714AImprove thermal shock resistanceImprove mechanical propertiesMolten spray coatingEfficient propulsion technologiesAdhesivePlasma sprayed

The invention discloses a method for preparing a thermal barrier coating by laser compound plasma spraying, which relates to the field of surface coatings. The method comprises the following steps: 1) cutting a material to be treated into required size by adopting line cutting; 2) polishing the surface of the cut material by using abrasive paper; 3) cleaning the surface of the polished material by adopting pulse laser; 4) performing laser texturing treatment on the surface of the cleaned material to roughen the surface of the material; and 5) filling spraying material powder into a powder feeder, fixing the roughened material on a turntable, and preparing the thermal barrier coating by plasma spraying; or first preparing a middle adhesive layer, then repeating the cleaning and texturing processes in the steps 3) and 4), and preparing the thermal barrier coating by the plasma spraying process. The interface of the thermal barrier coating prepared by the method is firmly combined, and the thermal shock resistance and mechanical property of the thermal barrier coating are remarkably improved. The method has simple processes, is suitable for large-scale mass production, and can prepare the high-performance thermal barrier coating with firm interface combination.

Owner:JIANGSU UNIV

Granulation type pouncing paper, preparation method and application thereof

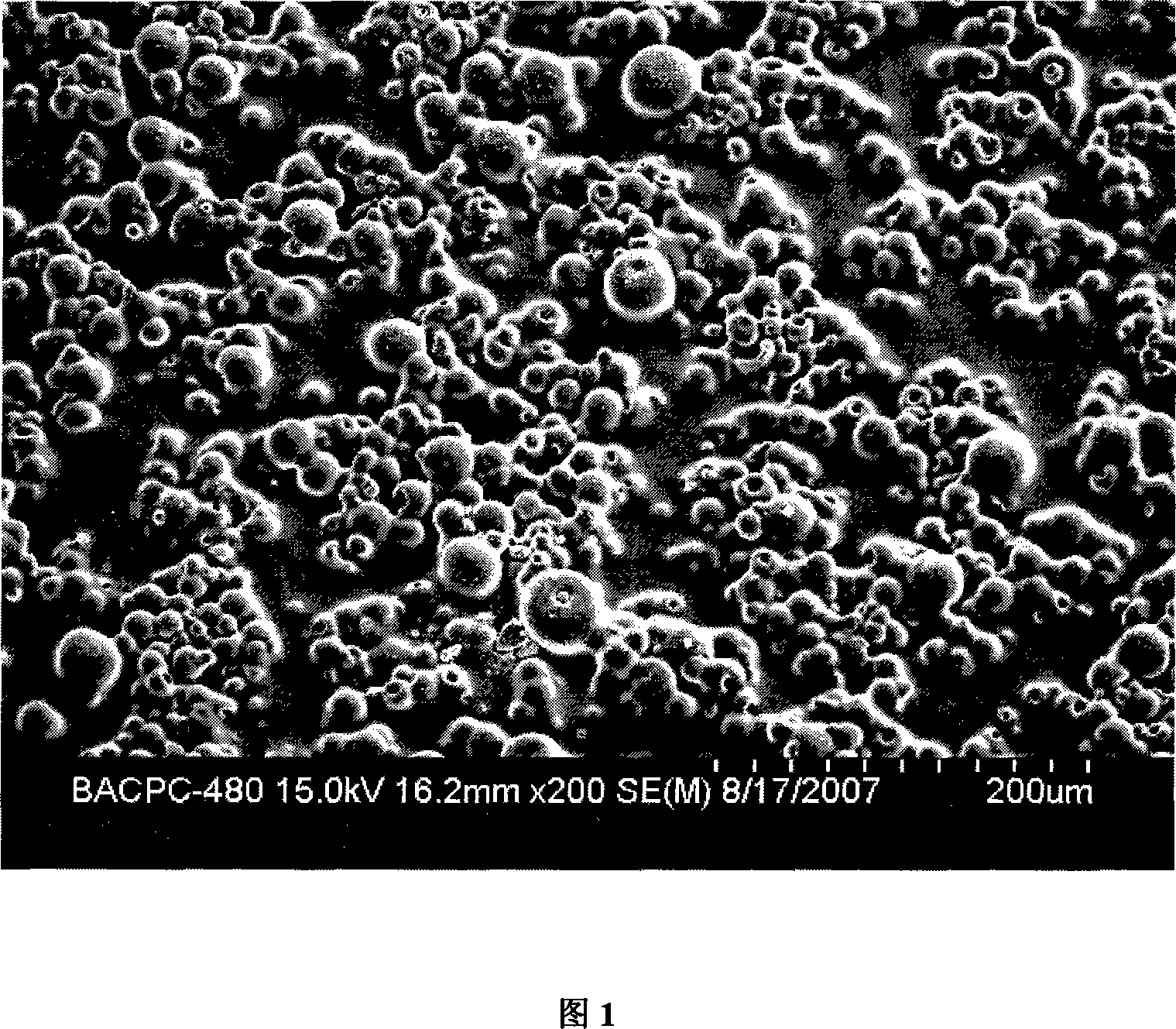

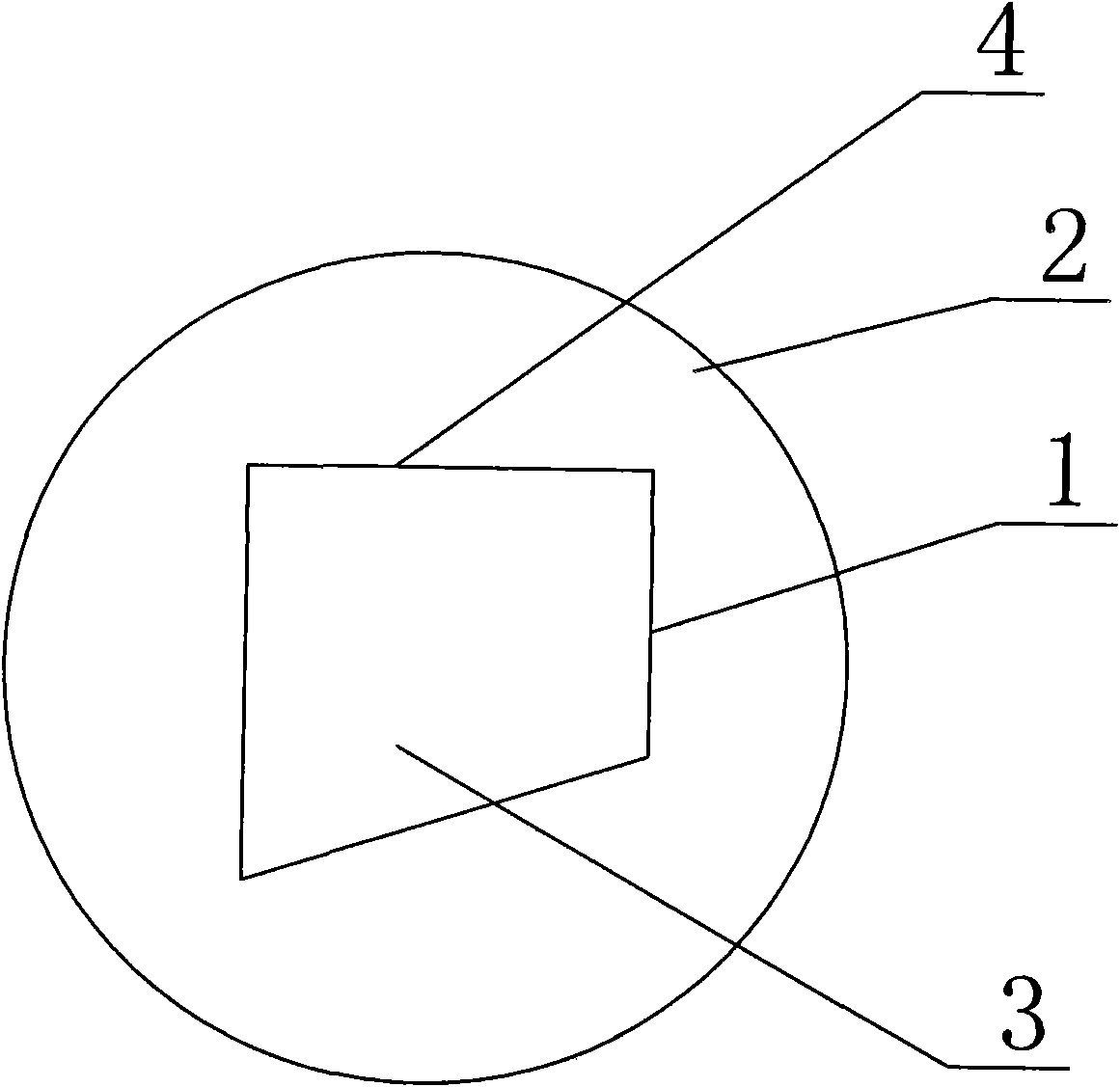

ActiveCN101219530AEvenly dispersedGrinding force does not decreaseAbrasion apparatusFiberMetal alloy

The invention provides a pelleting emery paper which can sharpen self and has durable grinding property and a preparation method and applications thereof. The invention comprises compound grinding grains which are coated to the surface of a substrate through adhesive and show aggregate ball shape. The grinding powders in the compound grinding grains are dispersed in one or more metal oxide sol which is mixed with organic adhesives or inorganic adhesives. The grain diameter of the grinding powder is not more than 10 micron meters and the diameter of the compound grinding grain is 5-50 micron meters. The emery paper is applicable in the grinding and polishing of most work pieces including metal, metal alloy, ceramic, optical element, fiber connecter, hard disc and semiconductor, etc.

Owner:BEIJING GRISH HITECH

A method to rinse blots on surfaces of ceramics

InactiveCN101217101AEfficient removalEffective surface stainSemiconductor/solid-state device manufacturingCleaning using toolsProcess equipmentCeramic

The invention provides a method for removing the ceramic surface stains, the method firstly uses dust-free cloth to dip isopropanol to polish the ceramic surface till being colorless; the solution of NH4OH: H2O2: H2O which is equal to 1: 0.6 to 1.5 to 2 to 5 is used for soaking the ceramics after the flushing by deionized water; then the ceramics is arranged in the deionized water to carry out the ultrasonic cleaning, if the stains are not removed still, emery paper with 1500 to 2000 mesh is dipped with the solution of HCl: H2O2: H2O which is equal to 1: 2 to 4: 8 to 10 to carry out the grinding removal of the stains; finally, the deionized water is used for flushing, the N2 is used for drying, and the baking is carried out for 1.5 to 3 hours in an oven at 90 to 120 DEG C. The application of the method of the invention can effectively remove the ceramic surface pollutants, in particular to the surface stains on a ceramic part of semiconductor process equipment.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Multi-principal element alloy powder and method for preparing coating on die steel through laser cladding by applying multi-principal element alloy powder

InactiveCN105401038AHigh hardnessImprove wear resistanceMetallic material coating processesPolyvinyl alcoholHigh entropy alloys

The invention discloses multi-principal element alloy powder and a method for preparing a coating on die steel through laser cladding by applying the multi-principal element powder. The multi-principal element alloy powder comprises the following components according to molar ratios: Co, Cr, Al, Ni and Mn with equal molar ratios. The method for manufacturing the coating comprises the steps that firstly, an oxidation film on the surface of the die steel is polished off by using metallographic abrasive paper, and absolute ethyl alcohol or acetone is used for cleaning the polished die steel; then a polyvinyl alcohol solution is utilized for being mixed with the multi-principal element alloy powder to form a pasty mixture; the pasty mixture is pre-arranged on the surface of the polished and cleaned die steel to form a pre-arranged cladding layer; after 5-6 h of vacuuming drying at 80 DEG C, the pre-arranged cladding layer is subjected to irradiation treatment, so that a cladding layer is obtained. By utilizing the cooperative compatibility effect of a multi-principal element high-entropy alloy, the manufactured cladding layer has the excellent properties of high rigidity, high abrasion-resistance, high corrosion-resistance and the like.

Owner:CHONGQING UNIV OF TECH

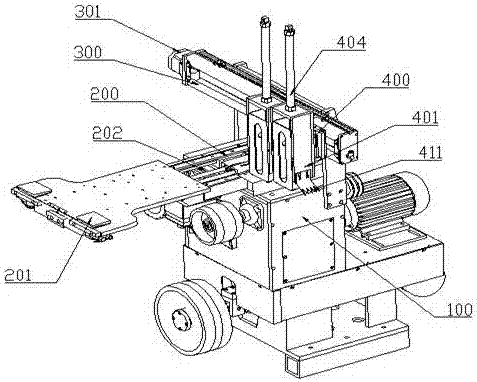

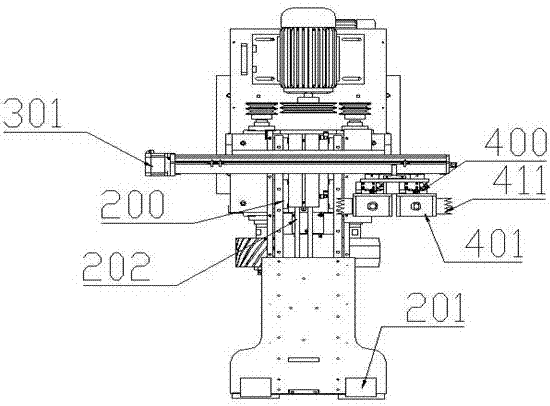

Abrasive paper (cloth) width slitting machine

InactiveCN103935815ANo pollution in the processRealize full automationArticle deliveryWebs handlingLoop controlHuman–machine interface

The invention discloses an abrasive paper (cloth) width slitting machine and relates to equipment for slitting grinding, polishing and cleaning materials. According to the abrasive paper (cloth) width slitting machine, an unreeling device is arranged on an adjustable machine frame, guiding rollers are arranged on the right side of the adjustable machine frame, a machine frame is arranged on the right side of the guiding rollers, one guiding roller and a guiding roller adjusting hand wheel are arranged on the left lateral side of the machine frame, the other guiding roller, a light-operated automatic deviation rectifying device and a splitting device are arranged on the top of the machine frame from left to right in sequence, an upper reeling device and a lower reeling device are arranged on the right side of the machine frame, a motor is arranged on the bottom of the machine frame and is connected with the splitting device and the lower reeling device through chains respectively, and the lower reeling device is further connected with the upper reeling device through a chain. According to the abrasive paper (cloth) width slitting machine, by omitting the secondary slitting procedure and adopting computer close-loop control and the human-computer interface, automation is realized in the whole process, the machine is made to be low in noise, accurate in splitting, high in speed and free of pollution in the whole splitting process, production efficiency is improved, product quality is guaranteed, production cost is reduced, and production cycle is shortened.

Owner:YANCHENG XIEHE MACHINERY

Preparation method of metallographic sample of cast iron oxidizing layer

ActiveCN101551307AAvoid interferenceAvoid heat meltingPreparing sample for investigationEmery paperMetal

The invention discloses a preparation method of a metallographic sample of a cast iron oxidizing layer, comprising the steps: (1) manually cutting a sample; (2) grinding the abrasive surface of the sample; (3) embedding the sample; (4) grinding the abrasive surface of the embedded sample; (5) manually polishing the abrasive surface of the embedded sample: (6) manually polishing the abrasive surface of the embedded sample by sequentially utilizing a plurality of pieces of waterproof abrasive paper from thick to thin, and rotating the embedded sample by 90 DEG in the same direction as changing the abrasive paper once; and (7) polishing the abrasive surface of the embedded sample. In the steps, the embedded sample needs to be always ground in a single direction from the oxidizing layer to be tested to the cast iron layer on the abrasive surface. The preparation method prevents the metal tissue of the cast iron layer from disturbing the oxidizing layer to be tested and is easy to align to a grinding direction and convenient for operation.

Owner:FEILONG AUTO COMPONENTS CO LTD

Method for producing ultra-coating dry abrasive paper

The present invention relates to the field of grinding tools, in particular to a production method of a super-coating dry abrasive paper widely used to sand and polish the painted surfaces of furniture, musical instruments, etc. The production method of the super-coating dry abrasive paper of the present invention includes the following steps: substrate; primer; sand planting; composite glue; rolling; solidifying; flexing and humidifying; super coating; drying; rolling; cutting; packaging. The abrasive paper produced according to the production method has the advantages of sharpness, wear resistance, non-blocking and high strength, and the super coating of the soft basal body ensures that the abrasive paper can be slowly shed along with wood dust and abraded paint while sanding, thus greatly prolonging the service life of the abrasive paper.

Owner:CHANGZHOU KINGCATTLE ABRASIVES

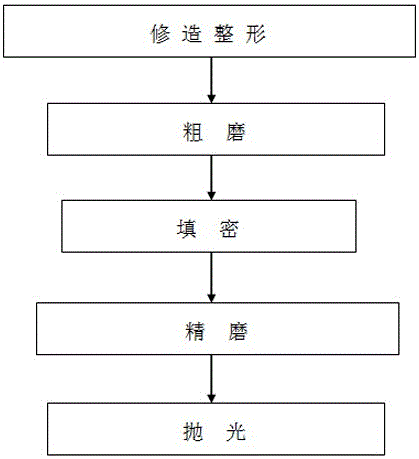

Grinding and polishing process for repair of aluminum alloy hub

The invention discloses a grinding and polishing process for repair of an aluminum alloy hub. The process includes the steps of S1, trimming and reshaping; S2, rough grinding; S3, packing; S4, accurate grinding; and S5, polishing. In the step S1, a scratched part of the hub or a protrusion at a welding repair part is trimmed to form a required model by an aluminum file or a grinding head; in the step S2, dry abrasive paper from number 80 to number 400 is successively selected to grind and trim the surface preliminarily; in the step S3, whether pores and pits exist in the ground surface is examined, and unsaturated resin putty or aluminum putty is used for filling the pores and the pits; in the step S4, for the trimmed surface with a curved surface examined to be qualified, waterproof abrasive paper from number 400 to number 800 is selected for modifying grinding in a skipping mode; and in the step S5, on the basis of accurate grinding, waterproof abrasive paper from number 1200 to number 2000 is further selected for grinding layer by layer in the order from thick to thin until scratches and grinding traces of the abrasive paper of the upper layer cannot be seen, and finally a polishing agent and a polishing wheel are used for polishing operation until the mirror surface effect is formed. According to the process, polishing treatment is carried out for repairing the aluminum alloy hub after rough grinding and accurate grinding, and therefore the surface of the aluminum alloy hub can have the mirror surface effect, and the repair effect is good.

Owner:上海车功坊智能科技股份有限公司

Method for preparing leather sample observed by metallurgical microscope

InactiveCN102305736AFast penetrationFully infiltratedPreparing sample for investigationFiberMicroscopic observation

The invention relates to a method for preparing a leather sample observed by a metallurgical microscope, and belongs to the technical field of leather inspection. The method comprises the following steps of: (1) adding a promoter into an unsaturated polyester resin, stirring, adding a curing agent, stirring, standing, and discharging the mixed air to obtain an immobilized resin; (2) immersing a sample into the immobilized resin, and curing to obtain a cured sample; (3) grinding both ends of the cured sample until the ends are flat, fixing in a mould, injecting the immobilized resin into the mould, curing, demoulding, and post-curing to obtain a post-cured sample block; and (4) grinding and polishing the post-cured sample block by using abrasive paper to obtain the leather sample observed by the metallurgical microscope. In the method, the unsaturated polyester resin is used as a main ingredient of the immobilized resin, and operation steps are designed according to a capillary action principle to ensure that the immobilized resin can be quickly and fully permeated into the leather sample, so the adhesion and deformation of section fiber of leather are furthest avoided.

Owner:QILU UNIV OF TECH

Automatic abrasive paper replacing device and method

ActiveCN107199510AReduce vibrationReduce loadGrinding wheel securing apparatusGrinding drivesEmery paperIndustrial engineering

The invention discloses an automatic abrasive paper replacing device and method. The automatic abrasive paper replacing device comprises a base and an X-axis guide rail arranged on the base; a Y-axis guide rail is arranged above the X-axis guide rail, and the Y-axis guide rail is provided with Z-axis guide rails; the X-axis guide rail is connected with polishing heads, and the polishing heads are connected with first air cylinders for driving the polishing heads to move forwards and backwards along the X-axis guide rail; the Y-axis guide rail is connected with a motor for driving the Z-axis guide rails to move leftwards and rightwards along the Y-axis guide rail; the Z-axis guide rails are connected with material storage boxes, and the material storage boxes are connected with second air cylinders for driving the material storage boxes to move up and down along the Z-axis guide rails; the material storage boxes contain abrasive paper, and third air cylinders for driving the abrasive paper to move downwards are connected over the material storage boxes; and the bottoms of the side plates of the material storage boxes are connected with abrasive disc shovels for shoveling the abrasive paper. According to the automatic abrasive paper replacing device, the abrasive paper is pasted and torn off automatically, polishing time is saved, and polishing efficiency is improved.

Owner:东莞市尚弘博实业有限公司

Nickel plating/organic coating double-layer surface protection method for NdFeB (neodymium-iron-boron) magnet material

ActiveCN102534697AImprove neutral salt spray resistanceBinding is not affectedLiquid surface applicatorsPolyurea/polyurethane coatingsAdhesion forceChemical plating

The invention relates to a surface protection technology for a NdFeB (neodymium-iron-boron) magnet material, in particular to a nickel plating / organic coating double-layer surface protection method for the NdFeB magnet material. The nickel plating / organic coating double-layer surface protection method comprises the following steps of: firstly removing oil and rust from NdFeB, and polishing by using sand paper; then carrying out nickel plating process on the NdFeB; and coating a layer of organic paint so as to form an organic coating. According to the nickel plating / organic coating double-layer surface protection method, disclosed by the invention, aiming at the problem of poor corrosion resistance of some single-layer surface protections, such as electric plating, chemical plating and organic coating, a surface protection technology of nickel plating / organic coating double-layer protection is adopted, so that the application restriction of the NdFeB is eliminated, and the neutral salt spray corrosion resistance of a coating is improved greatly on the premise of ensuring the adhesion force and magnetic property of the coating and a substrate to be unaffected.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

NbC particle reinforced iron-based abrasion-resistant laser cladding coating containing rare earth elements and preparation method

InactiveCN103526198ADense tissueUnlimited sizeMetallic material coating processesRare-earth elementChemical composition

The invention relates to an NbC particle reinforced iron-based abrasion-resistant laser cladding coating containing rare earth elements and a preparation method thereof, and belongs to the technical field of laser cladding. The preparation method comprises the following steps: polishing the surface of a steel base body with abrasive paper and then derusting and degreasing the surface of the steel base body so as to obtain a smooth and clean surface; mechanically mixing alloy powder for cladding and CeO2 in proportion according to chemical components; drying the powder after being evenly mixed; feeding the powder into a powder feeder; preparing an abrasion-resistant coating on the surface of the steel base body in a coaxial powder-feeding laser cladding manner, wherein the alloy powder comprises the following components by weight percent: 10% to 15% of Nb, 10% to 15% of Cr, 1% to 3% of B, 1% to 3% of Si, 1.5% to 5.5% of C and the balance of Fe and inevitable trace impurities; the adding amount of the CeO2 accounts for 3% to 8% of the alloy powder according to the weight percent. A hard ceramic phase is generated by performing an in-situ reaction on the NbC particle reinforced iron-based abrasion-resistant laser cladding coating; the good metallurgical bonding between the NbC particle reinforced iron-based abrasion-resistant laser cladding coating and the base body is realized. The NbC particle reinforced iron-based abrasion-resistant laser cladding coating is compact in tissue and free of pores and cracks.

Owner:BEIJING UNIV OF TECH

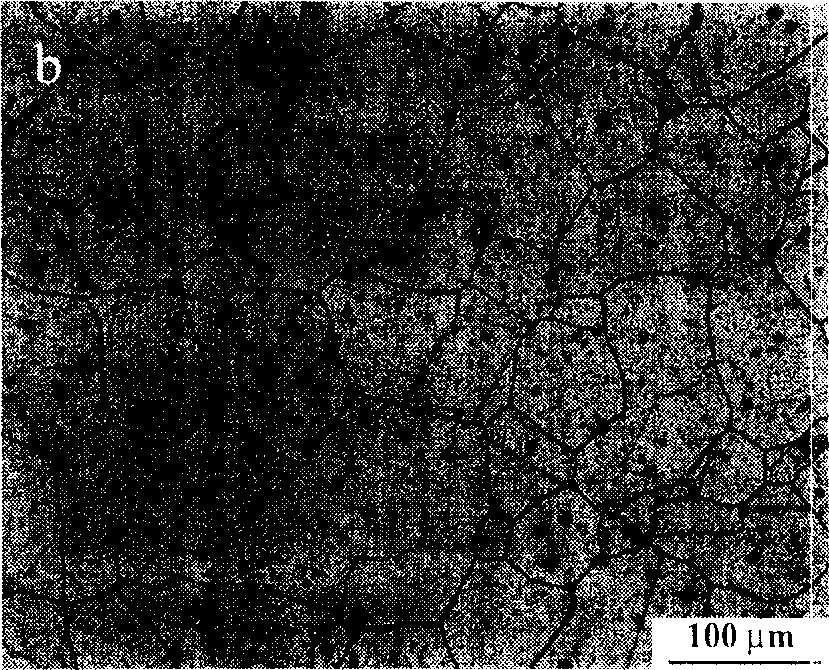

Method for showing 6082 aluminum alloy structure

InactiveCN101382498AFix hard-to-display issuesEasy to implementSurface/boundary effectPreparing sample for investigationHydrofluoric acidBoronic acid

The invention provides a method for displaying 6082 aluminium alloy structure, pertaining to the technical field of metallographic specimen preparation. The specific steps of the method are: a 6082 aluminium alloy test specimen is put on a waterproof abrasive paper for coarse grinding and polishing, then anode oxidation is carried out, the formulation of anode oxidation solution is 45 to 70mL of hydrofluoric acid and 12 to 16g of boronic acid, then distilled water is added for dilution to be 1L; the voltage of anode oxidation is 20 to 40V, the time of anode oxidation is 70 to 120s, then the test specimen is washed and blow-dried; and the clear 6082 aluminium alloy structure can be observed under a polarizing microscope. The invention has the advantage that the problem that 6082 aluminium alloy structure is difficult to display is solved, the structure of aluminium alloy structure after recrystallization and extrusion is clearly displayed. The method is simple and convenient to be implemented.

Owner:SHANGHAI UNIV

Abrasion resistance testing device

InactiveCN102645387AWear resistance testInvestigating abrasion/wear resistanceEngineeringMechanical engineering

The invention provides an abrasion resistance testing device which comprises a sliding mechanism, a rotating mechanism, a press part and an abrasive disc, wherein the press part is arranged on the sliding mechanism, and carries out reciprocating sliding under the driving of the sliding mechanism; and the abrasive disc is used for placing to-be-tested abrasive paper, and arranged on the rotating mechanism, meanwhile, the abrasive disc drives the to-be-tested abrasive paper to carry out a rotating motion under the driving of the rotating mechanism, and is rubbed with the press part which carries out reciprocating sliding.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Metal part surface polishing technology

ActiveCN105441952APolished evenlyGuaranteed smoothnessEdge grinding machinesPolishing machinesSteel ballEmery paper

The invention discloses a metal part surface polishing technology. Multi-time acid pickling and washing are additionally carried out to thoroughly clear away rust, impurities and oxidation layers on the surface of a metal part, and meanwhile, the double polishing technology including physical polishing and chemical polishing is adopted for polishing, and smoothness of the surface of the metal part is ensured; before oil on the metal part is removed, 40-mesh abrasive paper is used for polishing the surface of the metal part, and therefore the rust, impurities and the like on the surface can be put away in advance; after secondary washing is carried out, the metal part is aired in a drying manner, and after the metal part is washed, acid liquid still residues, and therefore the airing manner is adopted to facilitate volatilization of the acid liquid; the diameter of steel balls for polishing is 3 mm, the steel balls with the diameter can polish all positions of the surface of the metal part, and meanwhile, the polishing efficiency cannot be affected; and the concentration of a polishing agent is 30 g / L, and under the effect of the thick polishing agent, the metal part can be polished more smoothly.

Owner:深圳誉格金属制品有限公司

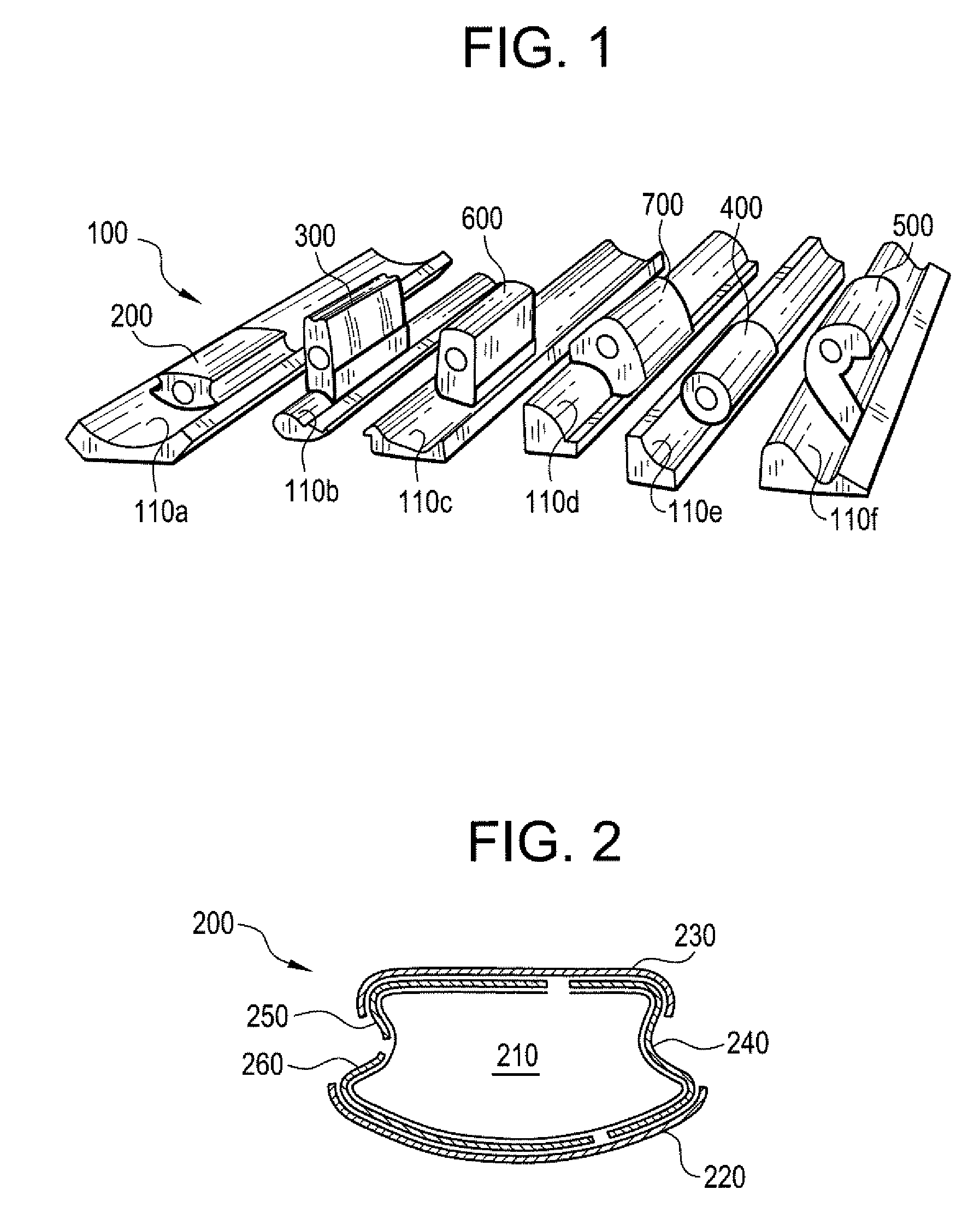

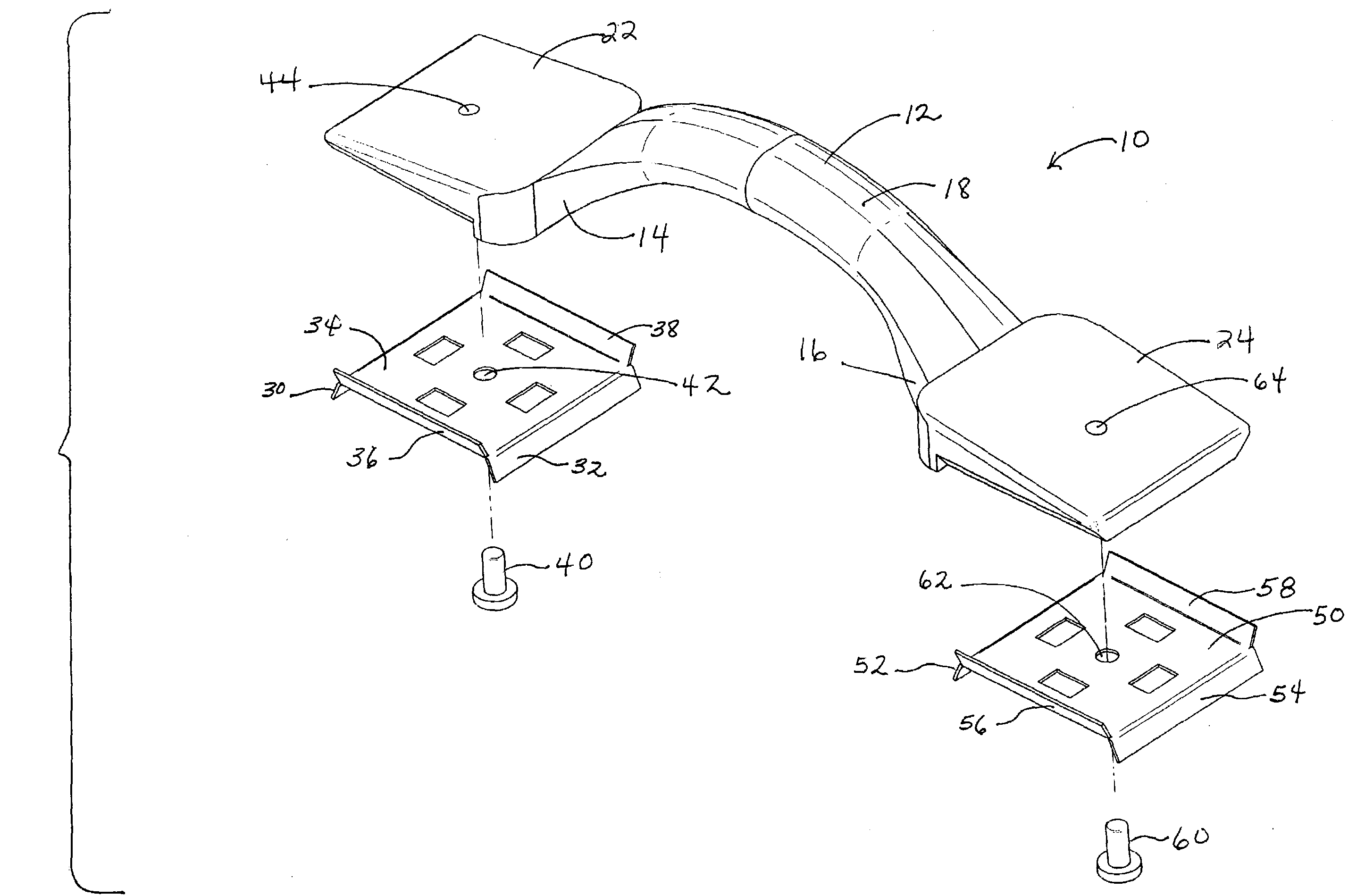

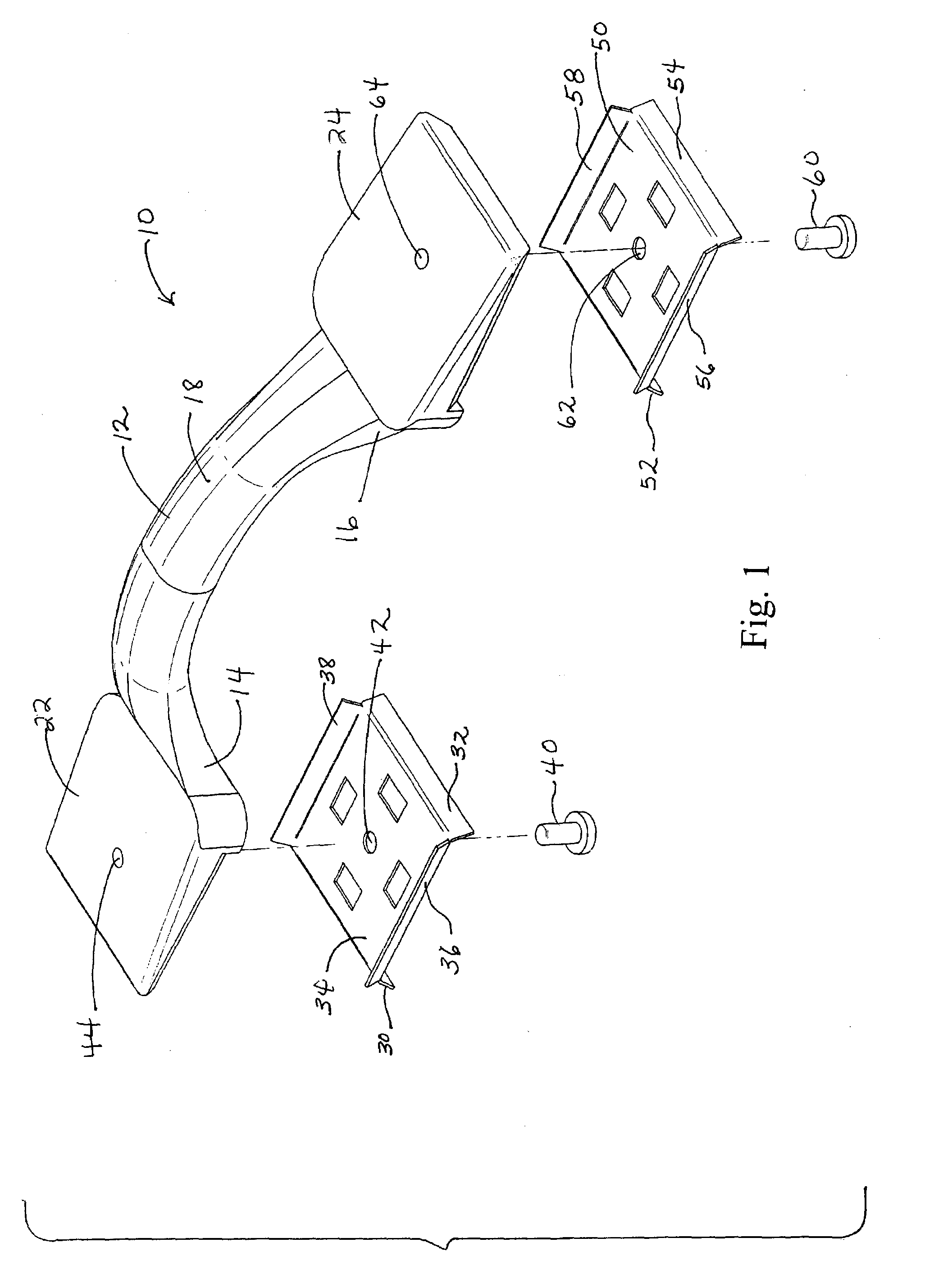

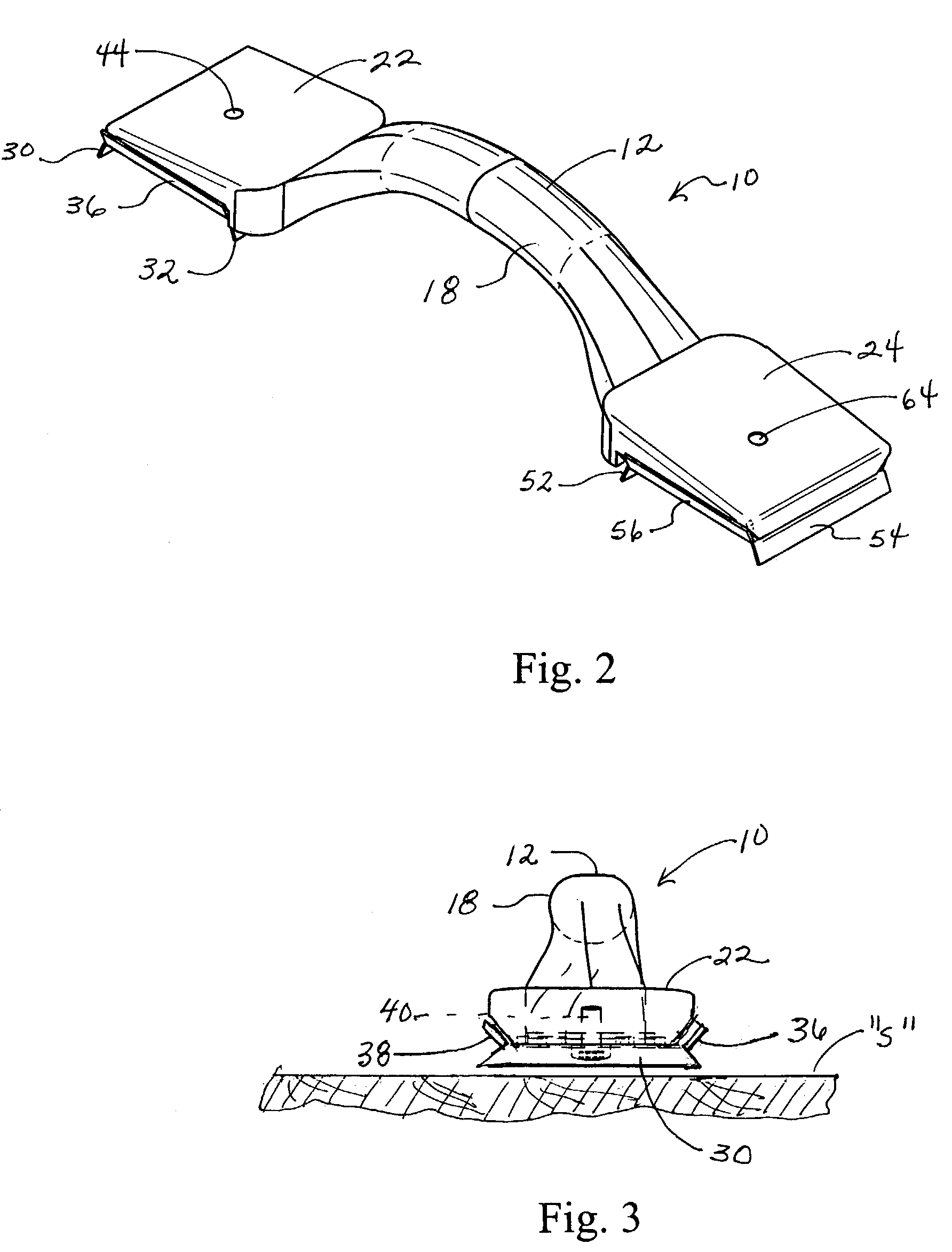

Sanding blocks for use with adhesive-backed sandpaper

A sanding block and a kit for sanding curved surfaces are provided. The sanding block includes an elongated body which has a first sanding surface; and a sandpaper removably affixed to the first sanding surfaces wherein the body is elastically deformable such that the block can conform against a curved surface to be sanded.

Owner:STYLE LINE CORP INT

Process for preparing metallographic lead sample and displaying structure

InactiveCN1800813AEasy to prepareImprove clarityPreparing sample for investigationEngineeringEmery paper

The invention provides a method to prepare lead metallic phase sample, which comprises: coarse grinding: using 320#-600# carbofrax emery paper and water as lubricant, then using carbofrax emery papers of 1000#, 1500# and 2000# to grinding; midst grinding: clearing the sample in supersonic device, polishing with polished cotton flannel; final grinding: clearing the sample in supersonic device, polishing the sample for 20-60s to drop 40ml H2O2+40ml CH3COOH etchant on new flannel; then, cleaning the sample, drying, and obtaining the final sample. This invention is simple but high definition.

Owner:UNIV OF SCI & TECH BEIJING

Scraper

A wood scraper having two oppositely angled blades on a single head, and preferably two heads with two oppositely angled blades on each head. Thus, on both the forward and reverse stroke, there are two spaced apart blades scraping the work piece. This covers twice the surface area with the same effort as a single-bladed or single-headed scraper. All the blades are rigid and have a straight edge. All the blade edges are aligned with the planar surface of the work piece. This produces a level cut and makes the tool more stable, making gouging unlikely and enhancing the efficiency of the scraping action. The tool can be operated easily with one hand. In addition, the use of straight blades allows all the blades to be sharpened easily and quickly and at the same time using a belt sander or on a sheet of emery paper on a flat surface.

Owner:BRANDON L D

Method for improving weld structure and performance of magnesium alloy

The invention provides a method for improving a weld structure and performance of a magnesium alloy, which comprises the following steps: firstly, placing an magnesium alloy welding plate in a heat treatment furnace to carry out stress relief annealing for a certain time at a temperature of 250 DEG C to 350 DEG C; then, polishing and flattening a weld joint by adopting abrasive paper for metallograph to enable the magnesium alloy welding plate to be at the same height with a base material; and heating the magnesium alloy to a certain temperature higher than a recrystallization temperature and carrying out hot rolling after carrying out heat preservation for a certain time. The method is generally suitable for weld penetration magnesium alloy plates such as an AZ31 magnesium alloy plate, an AZ61 magnesium alloy plate, an AZ80 magnesium alloy plate and the like. Intensity of the weld joint and a heat affected zone of the welded magnesium alloy plate is obviously lower than that of the base material. By a means of carrying out hot rolling after carrying out heat preservation at a certain temperature, the method can effectively improve intensity of a magnesium alloy welding part and enables tissues and performance of the weld joint, the heat affected zone and a base metal to be consistent.

Owner:CHONGQING UNIV

Metal plate polishing device

InactiveCN102029557AReduce wear rateImprove stabilityGrinding drivesPlane surface grinding machinesEngineeringUltimate tensile strength

The invention discloses a metal plate polishing device. The device is characterized by comprising a base frame, a motor, a bearing mechanism and a transmission mechanism, wherein a polishing table face for arranging a metal plate is arranged on the upper end face of the base frame; the motor is arranged on the base frame and can rotate clockwise and anticlockwise; the bearing mechanism can be arranged on the polishing table face in a way of moving back and forth; sanding paper is detachably arranged on the bottom face; and the transmission mechanism is provided with a power input end connected with the motor and a power output end connected with the bearing mechanism. Compared with the prior art, the metal plate polishing device has the advantages that: the clockwise and anticlockwise rotation of the motor is converted into the back and forth movement of the bearing mechanism, so that the sanding paper on the bearing mechanism polishes the metal plate; the structure is simple; the automation degree is high; the polishing efficiency is improved; the whole polishing operation does not need manual operation substantially, so that the labor intensity is greatly reduced and human factors are reduced; and the uniformity and quality stability of the polished product are obviously better than those of the product polished by manual operation.

Owner:NINGBO SOKEN CHEM

Non-metallic material and metal material brazing method capable of forming interpenetrating network structure brazing seams

ActiveCN103990880AReduce residual stressHigh strengthSoldering apparatusNetwork structureMetallic materials

The invention relates to a brazing method for a non-metallic material and a metal material, in particular to a non-metallic material and metal material brazing method capable of forming interpenetrating network structure brazing seams. The problem that large residual stress exists on a joint welded through the brazing method for the non-metallic material and the metal material is solved. The method comprises the steps that grinding is carried out through abrasive paper; acetone is used for cleaning; the materials are overlapped according to a certain sequence; welding is carried out, and the materials are placed in a vacuum brazing furnace to be welded. The brazing method is used for brazing of the non-metallic material and the metal material.

Owner:HARBIN INST OF TECH

Post-processing technology for SLS workpiece surface

ActiveCN103521773ASpray evenlyImprove the optimization rateIncreasing energy efficiencySurface finishPolyester

The invention discloses a post-processing technology for an SLS workpiece surface. The post-processing technology comprises S1, surface abrasive blasting, wherein spraying materials of the size of 75-115 microns are adopted to carry out abrasive blasting processing on the surface of a workpiece; S2, polishing, wherein abrasive paper is used for polishing the surface of the workpiece; S3, resin blending agent spraying, wherein epoxy resin, EP curing agents and anhydrous alcohol are blended according to a ratio of 1:1:1-2, spraying is carried out on the surface of the workpiece, and the thickness of a sprayed resin layer is 50-70 microns; S4, polishing, wherein after the workpiece is dried, the surface of the workpiece is polished through the abrasive paper, and the resin layer is polished to be 35-50 microns thick; S5, polyester paint mixed liquor spraying, wherein after polyester main color paint, curing agents and diluents are blended according to a ratio of 1:0.5-1:1-1.5, spraying is carried out on the workpiece to form a finishing coat layer with a thickness of 40-60 microns. The post-processing technology is adopted to process the nylon SLS workpiece, the surface roughness, surface finish degree and coloring condition of the workpiece can be greatly improved, the strength of the surface of the workpiece is strengthened, and the workpiece is made to meet actual using needs.

Owner:SHENZHEN SUNSHINE LASER & ELECTRONICS TECH CO LTD

High temperature brazing method between multiple hard alloy slices and strip stainless steel tool body

InactiveCN104801805AStress reliefRelieve deformationSoldering apparatusWelding/soldering/cutting articlesAlloyThermal expansion

The invention relates to a high temperature brazing method between multiple hard alloy slices and a strip stainless steel tool body. 304 stainless steel, hard alloy and sheet-shaped brazing filler metal are prepared, wherein transition layer metal is clamped in the middle of the sheet-shaped brazing filler metal; oxide layers on the surfaces of a stainless steel tool rest, the hard ally and the brazing filler metal are removed by abrasive paper; a brazed surface, the brazing filler metal and the transition layer alloy are cleaned by acetone; then brazing flux is coated on faces to be connected of the tool rest and the hard alloy slices; the brazing filler metal is placed between the steel tool rest and the hard alloy; each slice of hard alloy is respectively fixed on the tool rest by a fixture and then is placed into a closed box-type furnace filled with industrial argon to be heated and subjected to heat preservation; then the hard alloy is cooled to the room temperature with the furnace; workpieces are taken out; the fixtures are disassembled. A great number of alloy slices exist, the strip tool body is bent and deformed due to different coefficients of thermal expansion after welding and cold-pressed rectification on deformation can crush the hard alloy slices, and thus, a welded tool is heated to 450 DEG C, is subjected to heat preservation for 5 minutes, is directly taken out and is hot-pressed to eliminate welding deformation so as to obtain the product with a regular shape and high connection intensity.

Owner:HENAN POLYTECHNIC UNIV

Container lid having multiple utilities

The prevention from hardening upon storage of paste-like material by use of a lid having an inlet port, an outlet port, and a plastic bag attached to the inlet port. By expelling the air in contact with the paste-like material, the material can be prevented from hardening during storage. A similar lid is used in a pre-cleaning device situated between a dust-producing tool and a wet / dry vacuum. Dust-laden air enters the device through an inlet port and is discharged over a water filter. The pre-cleaned air is vacuumed to a wet / dry vacuum. The pre-cleaning process lengthens the useful life of the wet / dry vacuum. A hand-held sander is disclosed which provides for rapid change of sandpaper. The sander has a hollow upper handle component and a lower surface component which are held together with a latch. Depressing of a quick-release button allows separation of the two parts.

Owner:YARBROUGH GLEN A

Aircraft repairing composite flexible automatic grinding device and grinding method

PendingCN111037415ASemi-automaticFully automatedGrinding feed controlGrinding machinesStructural engineeringPlastic film

The invention discloses an aircraft repairing composite flexible automatic grinding device and a grinding method, and relates to the technical field of composite grinding. The aircraft repairing composite flexible automatic grinding device comprises a movable platform, a collaborative robot, a floating force sensitive grinding head mechanism, a dust suction device and a control assembly. The collaborative robot comprises a six-axis light mechanical arm, a six-dimensional force sensor, a robot controller and a demonstrator. The floating force sensitive grinding head mechanism comprises a floating constant-force device, an air control main shaft, an automatic changing tool installing interface, and a tool handle with a grinding wheel and abrasive paper. The dust suction device comprises a dust suction host and a dust suction cover installed at the tail end of the six-axis light mechanical arm. The dust suction cover is of an umbrella-shaped transparent plastic thin film elastic structure. One-way air guide holes from outside to inside are evenly distributed in the outer surface of the dust suction cover. A rubber suction strip is arranged on the edge of the cover mouth of the dust suction cover. By means of the aircraft repairing composite flexible automatic grinding device, the semi-automatic or automatic grinding, excavating, polishing and other operation processes related to the composite repairing are realized, the manual operation intensity is reduced, the occupational health hazards are relieved, and the repairing quality is improved.

Owner:SHANGHAI HANGYI HI TECH DEV RES INST CO LTD

Alumina-based abrasive grains and method for preparing same

InactiveUS6015442AImprove the immunityImprove mechanical propertiesPigmenting treatmentOther chemical processesAluminum hydrateSodium silicate

PCT No. PCT / FR96 / 01609 Sec. 371 Date Sep. 22, 1998 Sec. 102(e) Date Sep. 22, 1998 PCT Filed Oct. 15, 1996 PCT Pub. No. WO97 / 14759 PCT Pub. Date Apr. 24, 1997Alumina-based abrasive grains having a skin constituted by a mixture of finely dispersed aluminum hydrate and sodium silicate, and a process for the production of such grains consisting of (a) preparing a gel by mixing a solution of sodium silicate and a colloidal solution of aluminum hydrate in acid medium, (b) coating the abrasive grains with the gel in an amount of 0.1 to 5 percent weight, and (c) subjecting the coated grains to a drying treatment at a temperature of between 100 and 500 DEG C. The grains according to the invention are used for the manufacture of cloths and abrasive paper and also grinding wheels.

Owner:PEM ABRASIFS REFRACTAIRES

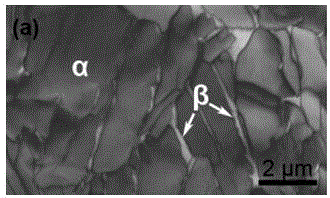

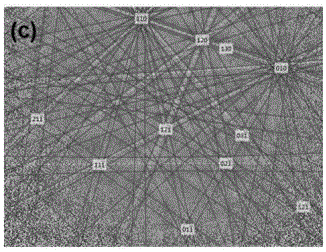

Method for preparation of double-phase zirconium alloy EBSD sample by electrolytic polishing

InactiveCN106556532AHigh surface finishExtensive sources of raw materialsPreparing sample for investigationMaterial analysis using radiation diffractionElectrolysisDouble phase

Owner:CHONGQING UNIV OF TECH

High-solid-content quick-drying water-based white primer and preparation method thereof

The invention relates to a high-solid-content quick-drying water-based white primer and a preparation method thereof. The high-solid-content quick-drying water-based white primer is basically prepared from 25-35% of acrylic emulsion, 15-25% of white slurry, 10-18% of calcium carbonate, 5-10% of kaolin, 5-10% of talcum powder, 2-5% of assistant, 2-6% of film-forming agent, 3-5% of thickening rheologic agent and 15-25% of water. The white primer has the characteristics of excellent sanding property, excellent filling property and high drying rate, does not adhere to abrasive paper after drying 1 hour in summer, and is economical and practical; the white primer can effectively seal the wood seams in a medium-titer plate base, and stabilize the internal structure of the base material; after construction, the deformation rate of the base is low, and the fibers do not expand basically; and thus, the white primer can be used for solid color painting of a medium-titer plate base wood door, and can also be used for painting a sealed splint base, thereby having high market application value.

Owner:UNION FOSHAN CHEM

Preparation method for transmission electron microscope (TEM) specimen of cadmium zinc tellurium (CdZnTe) and metal interface

InactiveCN102539213AAvoid damageAccurate to thicknessPreparing sample for investigationEvaporationSingle crystal

The invention discloses a preparation method for a transmission electron microscope (TEM) specimen of a cadmium zinc tellurium (CdZnTe) and metal interface. The preparation method is used for solving the technical problem that the reject rate is high because the specimen is broken very easily when the TEM specimen of the CdZnTe and metal interface is prepared in the prior art. The technical scheme is that the preparation method comprises the following steps of: after a CdZnTe single crystal is linearly cut, washed and polished, conducting chemical corrosion; preparing a metal electrode in a resistive evaporation coating machine; folding and sticking the specimen and drying the specimen on a heating table; and grinding, polishing and thinning the specimen along the normal line direction ofa sticking gap, polishing the two surfaces of the specimen, sticking a copper grid on one surface, using a manual grinder to thin the specimen, and finally using a Gatan 691 ion mill to thin the specimen till the specimen is punctured. Since a multi-piece sticking method and a manual grinder for grinding and polishing through high-grade abrasive paper are adopted, after thinning and polishing arecompleted, the damage caused to an interface area in the thinning process is minimized and the success rate of specimen preparation is improved. The success rate of specimen preparation is improved from 30-40 percent in the background technology to 60-70 percent.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Surface super-hydrophobization method for aluminum material

InactiveCN101935834AGood antifoulingEffective protectionMetallic material coating processesMetal layered productsChemical bondPolymer solution

The invention provides a novel surface super-hydrophobization method for an aluminum material (aluminum or an aluminum alloy). The method comprises the following steps of: polishing the aluminum material with metallographic abrasive paper, cleaning the polished aluminum material with acetone and ethanol and treating the washed aluminum material in boiling water; and putting the aluminum material into coupling agent-containing solution of toluene for reaction at the temperature of 80 DEG C for 4 to 8 hours, reacting the reaction product with solution of an end functional group polymer at the temperature of between 80 and 120 DEG C for 4 hours and cleaning and drying the reaction product to obtain a super-hydrophobization metal aluminum material of which the surface is grafted with a hydrophobic polymer layer, wherein the surface contact angle of the super-hydrophobization metal aluminum material is up to 150 to 157 degrees. An aluminum-based material used in the method is not limited by any crystal lattice and a prepared super-hydrophobic functional membrane is bonded with the surface of an aluminum substrate through a chemical bond, so that an obtained material with super-hydrophobic property has easily controlled quality and stable performance. A surface pre-treatment method and a surface coating method adopted by the aluminum substrate have the advantages of simple process, convenient operation, no need of complex and expensive equipment or long processing time, easy realization of industrialization and suitability for surface super-hydrophobic modification on large-area or specially-shaped or complex aluminum material parts.

Owner:LANZHOU JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com