Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

744results about How to "Fully infiltrated" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

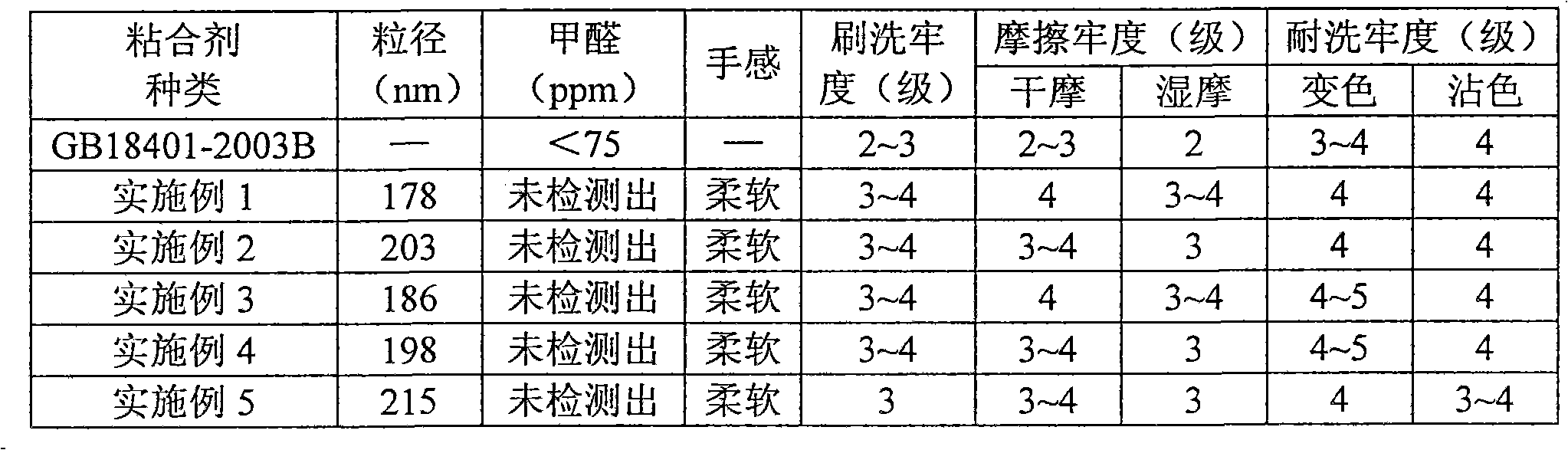

Environmentally-friendly acrylic ester coating printing adhesive emulsion and preparation method

InactiveCN101928367AThe polymerization process is stableEvenly distributedEster polymer adhesivesDyeing processEpoxyFunctional monomer

The invention discloses environmentally-friendly acrylic ester coating printing adhesive emulsion and a preparation method. An emulsion polymerization process is adopted. The emulsion comprises the following raw materials in part by weight: 50 to 90 parts of soft monomer, 10 to 20 parts of hard monomer, 2 to 10 parts of functional monomer, 2 to 5 parts of emulsifying agent, 0.2 to 0.5 part of initiator, 0.2 to 0.5 part of pH buffer, 80 to 120 parts of deionized water and a proper amount of pH adjustor, wherein the total amount of the soft monomer, the hard monomer and the functional monomer is 100 parts by weight. The three monomers are cooperatively used as functional monomers for generating carboxyl crosslinking, hydroxy crosslinking, epoxy crosslinking and the like so that the obtained printing adhesive emulsion has excellent water tolerance and mechanical property. The crosslinking monomers and the emulsifying agent do not contain the components such as N-methylol acrylamide, APEO and the like, so the emulsion does not release formaldehyde during baking and using and is suitable for high-grade environmentally-friendly printing adhesive.

Owner:SOUTH CHINA UNIV OF TECH

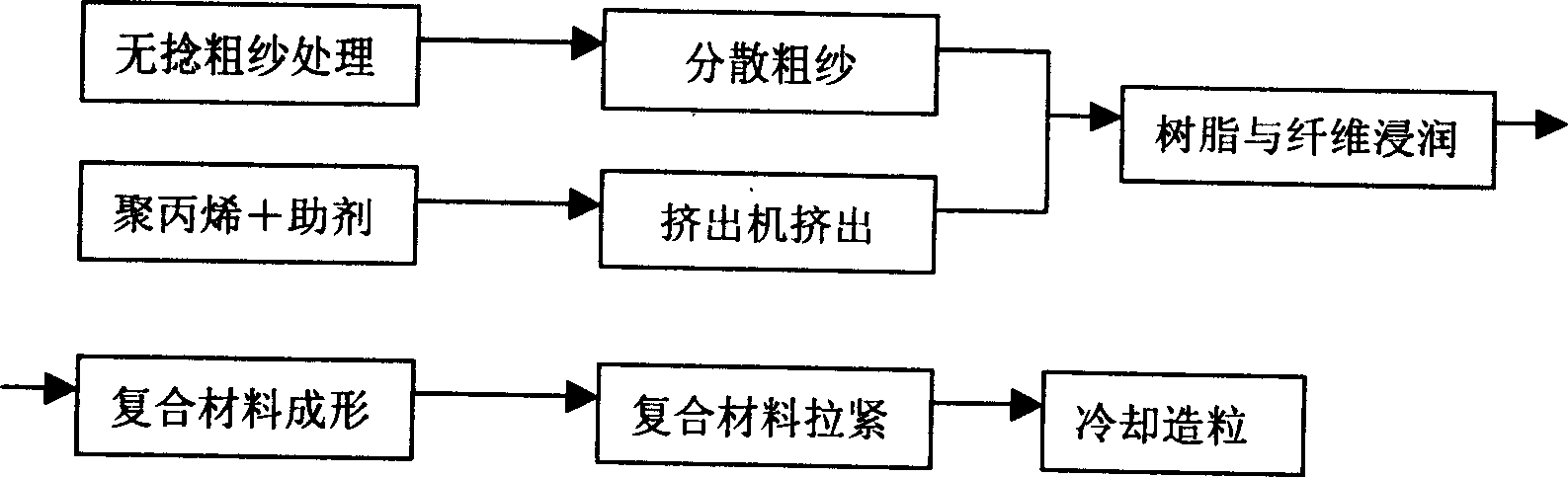

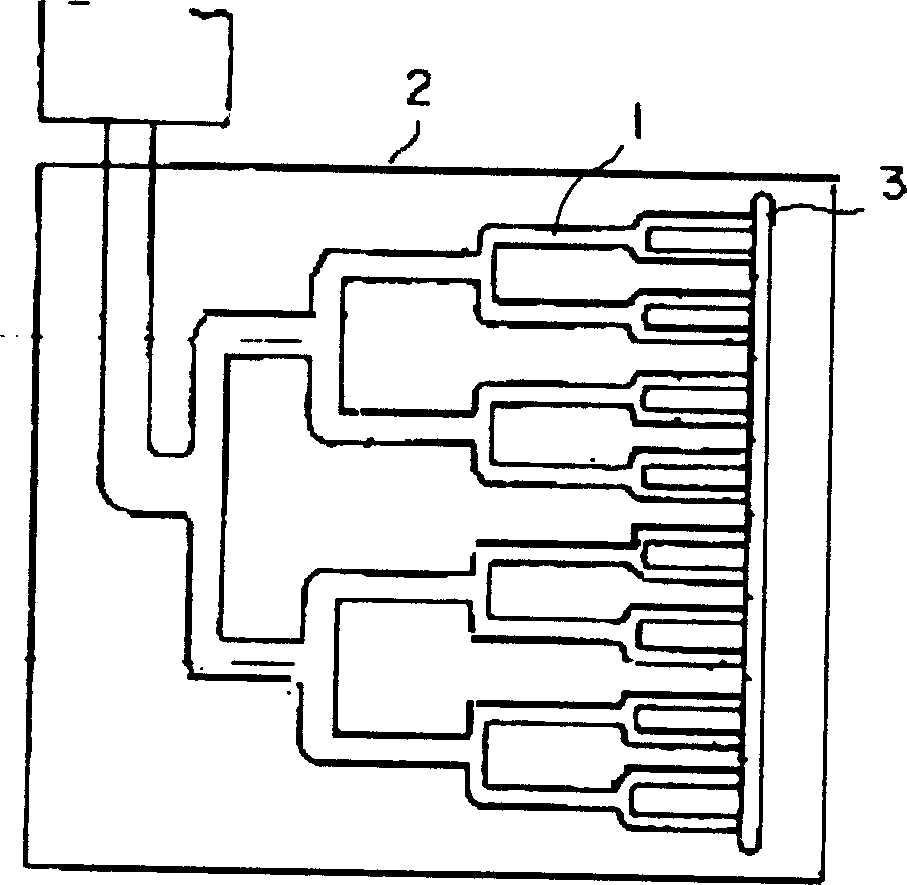

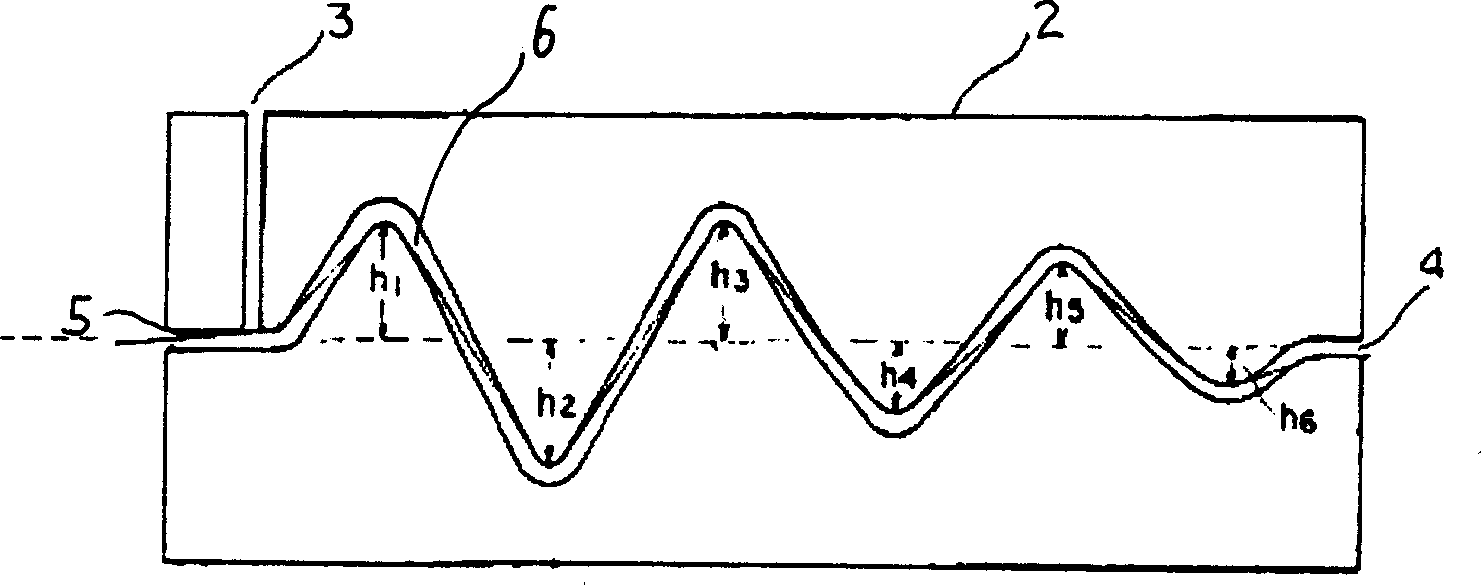

Continuous fiber reinforced composite materials, its production method and special equipment therefor

The invention relates to a glass fiberreinforced thermoplastic composite and a continuous fiber-reinforced composite, which are prepared with the following raw materials percentagewise by weight: 35-60 % of resin, 35-60 % of dip treated glass fiber and 0.5-5 % of auxiliary agent. The invention adopts resin and dip treated glass fiber as main raw materials, mixtures of antioxidant, ultraviolet absorbent and light-stability agent as main auxiliary agents, with logical formulations, eliminates the damage to glass fibrous surface caused by twin-screw with continuous fiber-reinforced composite producted by this manufacturing technique, improves product lustrous surface, binding properties between fiberglass and resins by a treatment for glass fibrous surface and mechanical properties of products, protects the materials for long periods from destruction because of addition of various stabilizing agents, and solves the limitation that general materials can not be used for a long time in extreme conditions such as high temperature, high humidity, radiation and so on.

Owner:JIANGSU QIYI TECH

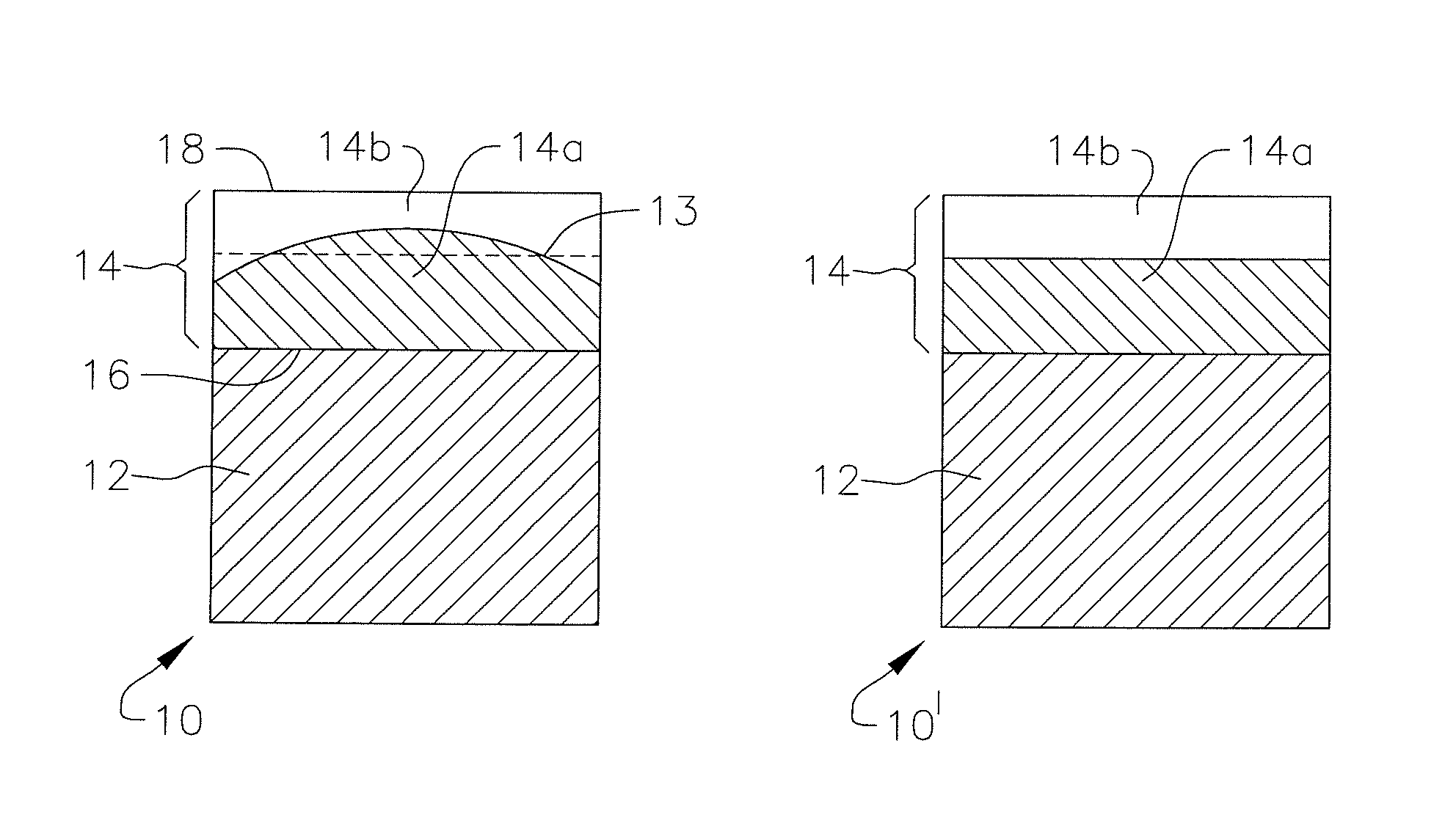

Lithium ion battery and lithium-rich anode sheet

ActiveCN103490041AImprove the first Coulombic efficiencyIncrease energy densityElectrode carriers/collectorsSecondary cellsPhysicsCurrent collector

The invention provides a lithium ion battery and a lithium-rich anode sheet. The lithium-rich anode sheet comprises: a current collector; and a diaphragm, which contains an active substance and is formed on the current collector, wherein the diaphragm and the current collector form an initial anode sheet. The current collector in the initial anode sheet is a porous current collector. The initial anode sheet is rich in lithium on one side, and the lithium rich amount matches the lithium supplement capacity needed by the initial anode sheet. The lithium ion battery includes: a cathode sheet; an anode sheet; an isolation membrane disposed between the cathode sheet and the anode sheet; and an electrolyte solution. The anode sheet is a lithium-rich anode sheet. The lithium-rich anode sheet of the lithium ion battery provided by the invention not only overcomes the excess lithium supplement problem in traditional lithium-rich anode sheets, and also can effectively control the lithium supplement amount of the anode so as to realize uniform lithium supplement and enhance the first coulombic efficiency of the lithium ion battery adopting the lithium-rich anode sheet. Thus, the energy density of the lithium ion battery is greatly improved, and the lithium ion battery can be ensured with better electrochemical properties.

Owner:DONGGUAN AMPEREX TECH

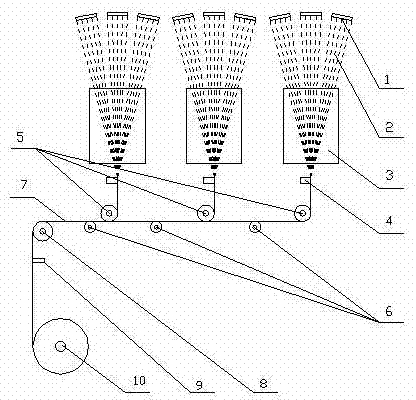

Preparation method of continuous filament of asphalt-based carbon fiber

InactiveCN103046165ASmall diameterIncrease the number of filamentsNew-spun product collectionArtificial thread manufacturing machinesFiber bundleCarbonization

The invention discloses a preparation method of a continuous filament of an asphalt-based carbon fiber, and belongs to the field of carbon fiber production. The preparation method solves the problems that the existing spinning speed is lower, the fiber bundle damage is large, the infusibility efficiency is low, and doubling and embrittlement are easy. The preparation method comprises the specific process steps that a, spinning asphalt is extruded into fines by spinning position fusion, humidified, oiled and bundled to form a protogenic asphalt fiber bundle; b, double roller stranding and tensioning are conducted; c, the asphalt fiber bundle is wound on a spinning roller sleeve; d, an asphalt fiber reel is immersed in an oxidability liquid phase, and a liquid-phase oxidized fiber bundle reel is obtained; e, the reel is immersed in a high-temperature-resistant oil solution; the filament is unreeled and rollers are removed at a low speed; the oxidized fiber bundle continuously enters a continuous infusible furnace and a continuous low-temperature pre-carbonization furnace to form a pre-carbonization fiber bundle reel; and f, drawing heat treatment is conducted through a continuous carbon-fiber high-temperature carbonization furnace and a graphitization furnace, and then the continuous filament of the asphalt-based carbon fiber is obtained.

Owner:SICHUAN CHUANGYUE CARBON MATERIAL

Transmission electron microscope processing method for insect antenna samples

ActiveCN103115809AEffective immobilizationEffective preservationPreparing sample for investigationElectron microscopeBiology

The invention belongs to the field of experimental sample processing technologies, relates to insect antenna sample processing methods and particularly relates to a transmission electron microscope processing method for insect antenna samples. The method sequentially comprises the following steps of: (A) preparing fixing liquid; (B) preparing various embedding agents; (C) dissecting, fixing and rinsing; (D) dewatering and soaking; and (E) gathering, so as to obtain the samples. The method has the advantages that the problems of difficulty in fixing liquid soaking and insufficiency in embedding agent soaking during the process of insect antenna transmission processing are solved, finally-obtained sample slices can be relatively flat, the phenomena of sample wrinkling, damaging and losing are greatly reduced, internal structures of the sample slices are all effectively fixed, and subcellular structures are clearly visible.

Owner:ZHEJIANG UNIV

Production technique for chicken powder with great freshness flavor

ActiveCN103689522AIncrease umamiImprove sensory qualityFood ingredientsFood preparationMonosodium glutamateAdditive ingredient

The invention discloses a production technique for chicken powder with a great freshness flavor, and belongs to the technical field of processing food seasoning. The chicken powder comprises the following materials according to mass: 30kg of fresh chicken skeletons, 30kg of fresh chicken, 7kg of maltodextrin, 2.5kg of disodium nucleotide, 0.1kg of sodium citrate, 7kg of trehalose, 10kg of edible salt, 10kg of monosodium glutamate, 2kg of lentinula edodes, 1kg of radix puerariae, and 0.4kg of pepper; the production technique comprises the steps: pretreating active ingredients, and carrying out high-temperature high-pressure sealed cooking, fine treatment, enzymolysis for flavor, mixing, spray drying, filling and capping. According to the production technique, the processes are simple, the energy consumption can be reduced, the loss of flavor components can be effectively reduced and sufficient release of flavor substances is promoted, the chicken powder is rich in chicken flavor, harmonious in saline taste, delicate flavor and perfume, luminous in color, good in rehydration property, smooth in mouthfeeling, free from sand grains, and milkily white in soup feeling.

Owner:GUANGDONG JIALONG FOOD

Modified pearl cherry vitamin C sleeping mask and preparation method thereof

ActiveCN101982164AAvoid churnGood conditionCosmetic preparationsToilet preparationsBiotechnologyVitamin C

The invention relates to a modified pearl cherry vitamin C sleeping mask. The preparation method of the sleeping mask comprises the following steps: heating nanometer pearl powder to activate, reacting with surfactant to prepare modified nanometer pearl powder, dispersing the modified pearl powder in aqueous phase through turbine stirring, dissolving sodium hyaluronate, glyceryl polyether and butanediol in water, fully stirring, heating, then adding the components of the formula such as Tween-20, isononyl isononanoate and cetearyl alcohol in a pan, stirring to homogenize, cooling to about 45 DEG C, and adding additives, essence, preservative and the like in turn to prepare the modified pearl cherry vitamin C sleeping mask. In the sleeping mask of the invention, the surfactant reacts with the surface hydroxyl groups of the nanometer pearl powder so that the affinity of pearl powder to organic medium is increased and the detects of the nanometer pearl powder that the specific area is large and the nanometer pearl powder is easy to agglomerate and is hydrophilic and oleophobic can be overcome; and cherry vitamin C and nutrient components with permeability and moisture retention capacity are also used, thus the moisture and nutrient components in the mask of the invention can completely permeate the skin during sleep and the state of the skin can be improved intensively.

Owner:浙江长生鸟健康科技股份有限公司

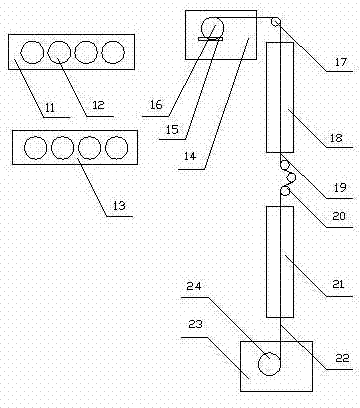

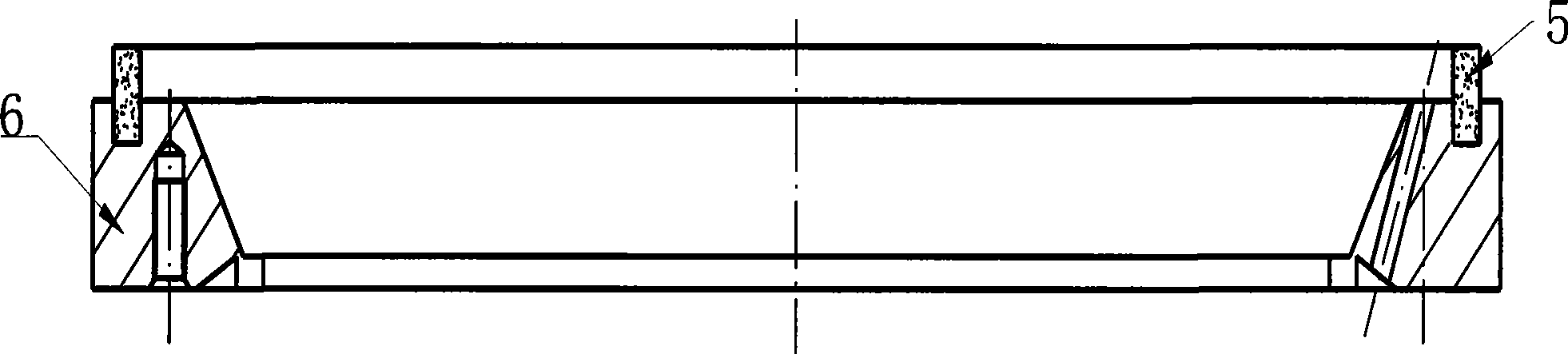

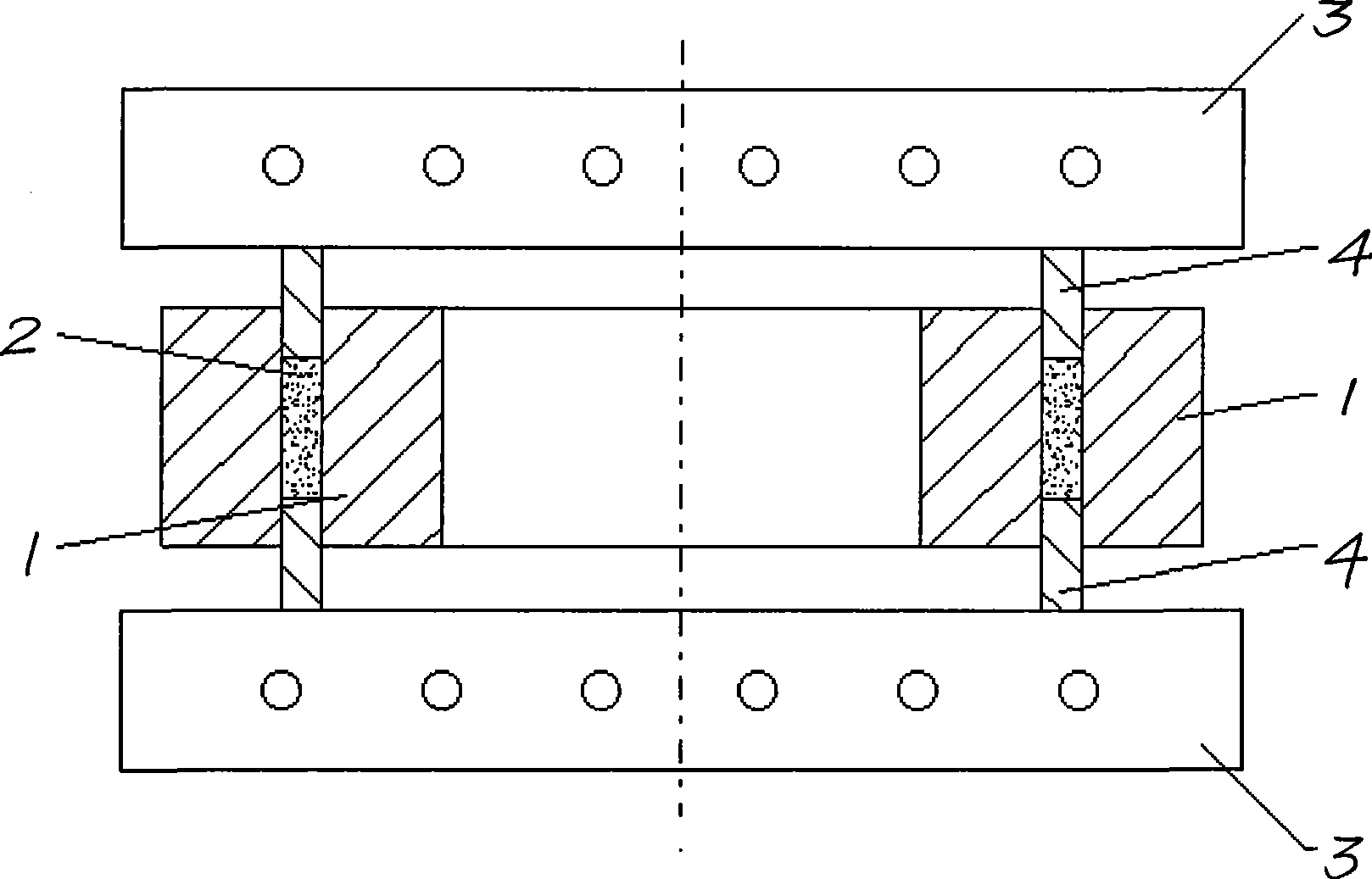

Three-dimensional printing forming method of long fiber thermoplastic composite material component

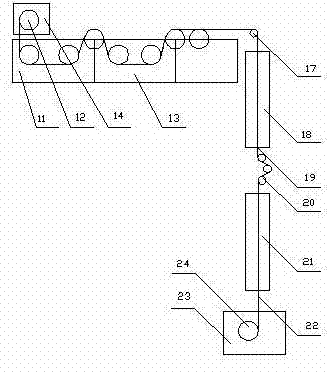

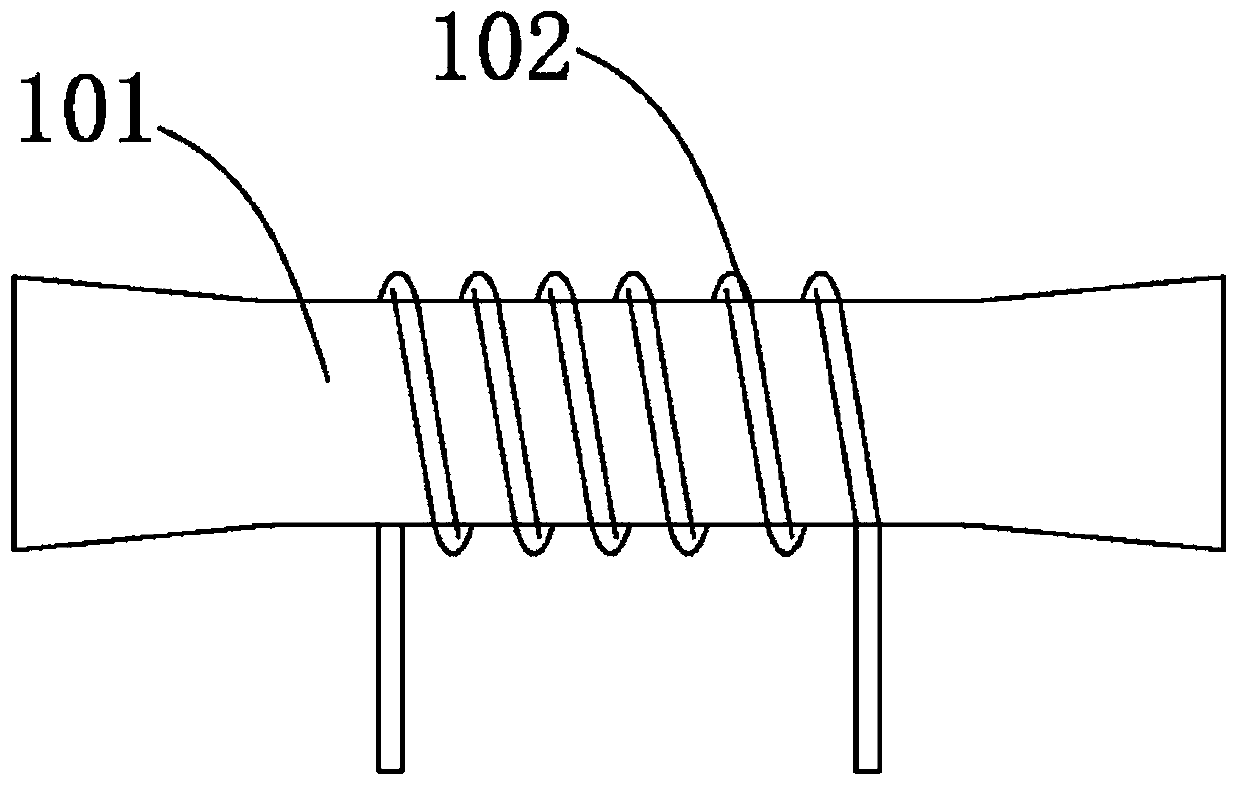

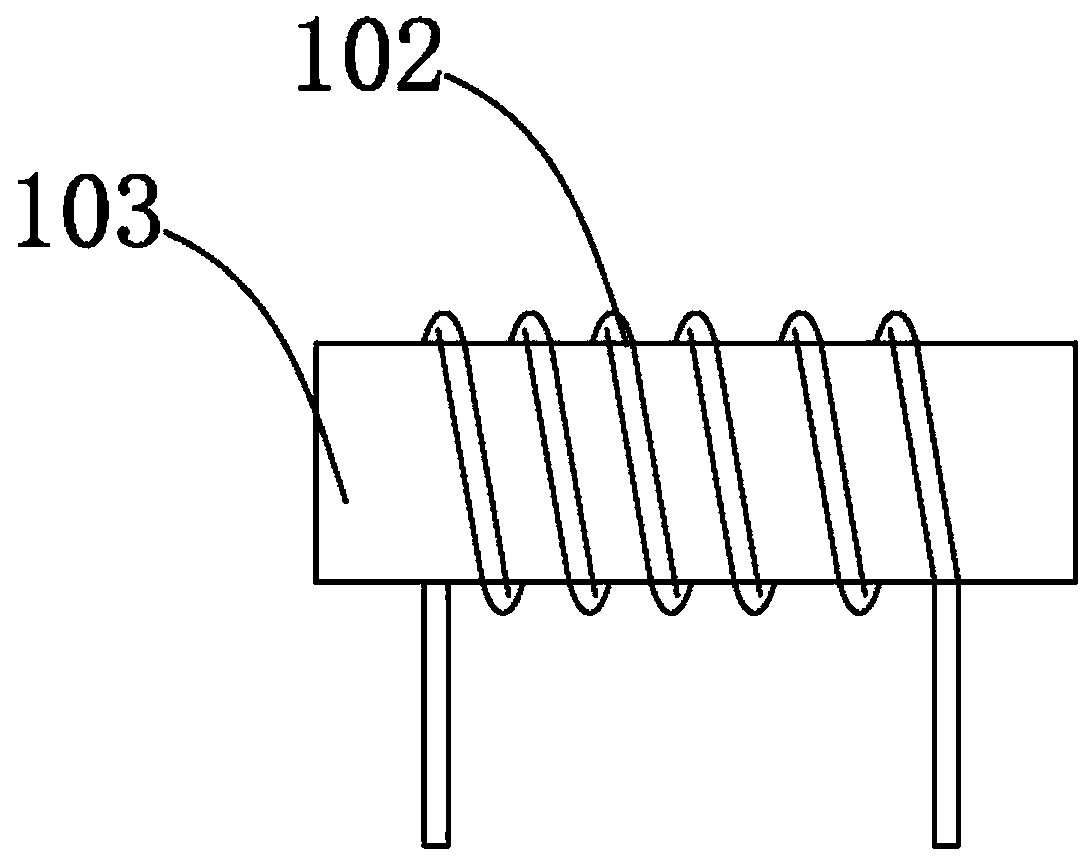

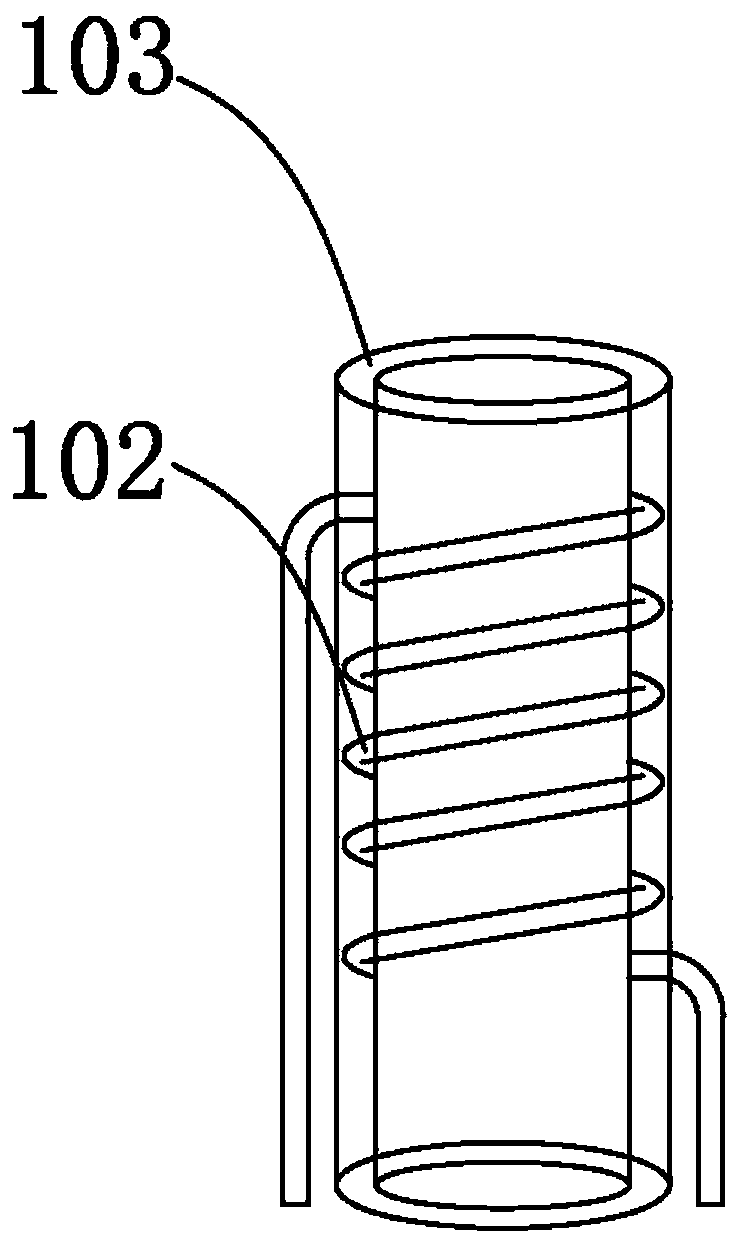

InactiveCN106515041AFully infiltratedEnhanced interface bindingAdditive manufacturing apparatusManufacturing material handlingYarnThermoplastic composites

The invention discloses a three-dimensional printing forming method of a long fiber thermoplastic composite material component, and belongs to the field of composite material forming technologies. A reinforced yarn is expanded as a thinner yarn strip, and is fully infiltrated with a drawn resin strip to form a single-layer prepreg yarn; the single-layer prepreg yarn is extruded by a shaping device to form a prepreg tow with appointed shape and size; and the prepreg tow is guided by a guide device to bond with a previous layer of composite material to form a composite material laminating structure after heating fusion by a compaction device. Through unfolding of continuous fibers and drawing of a basal body material, the method effectively improves the infiltration effect of the yarn and the resin so as to improve the interface bonding strength of the fiber and the basal body; the prepreg tow can be printed by any angle; and meanwhile, after the prepreg tow is compacted by the compaction device, the fiber volume fraction is prominently increased, so that the added material manufacturing of a high-performance composite material component with complex structure can be realized.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

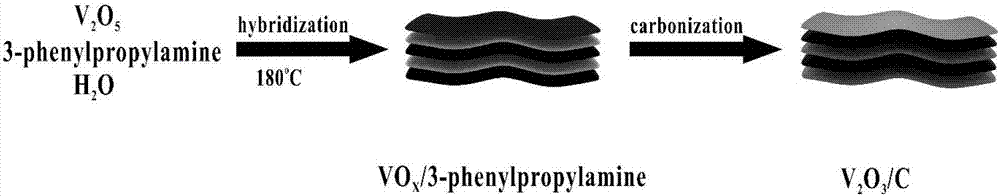

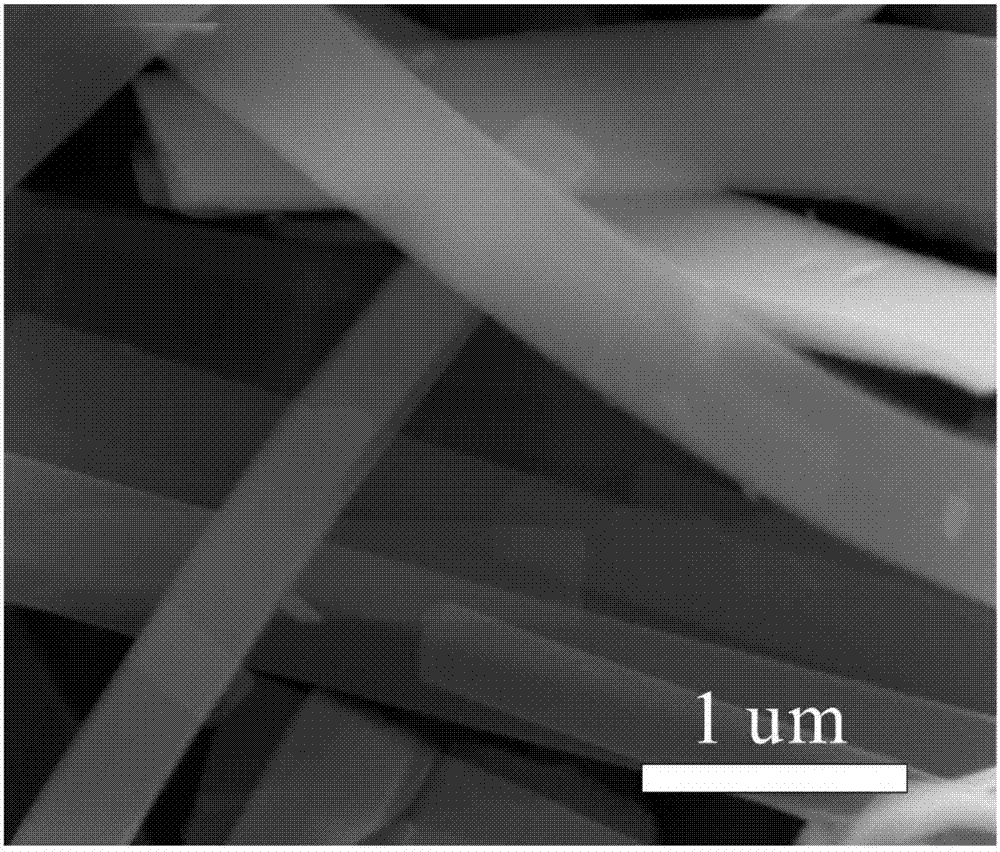

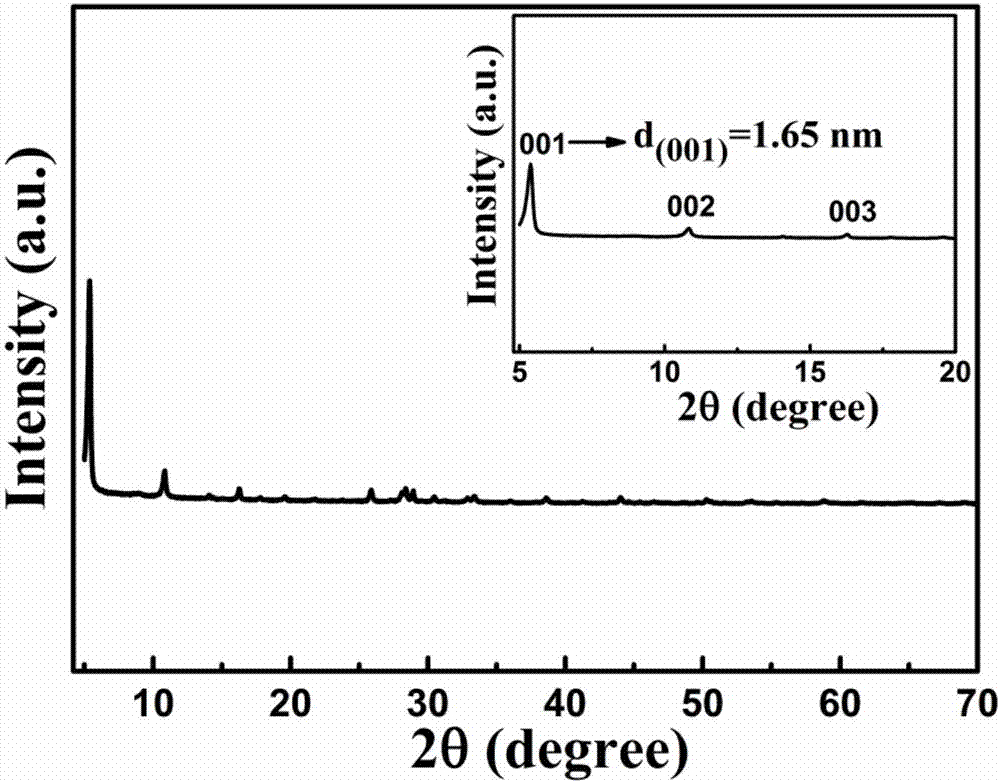

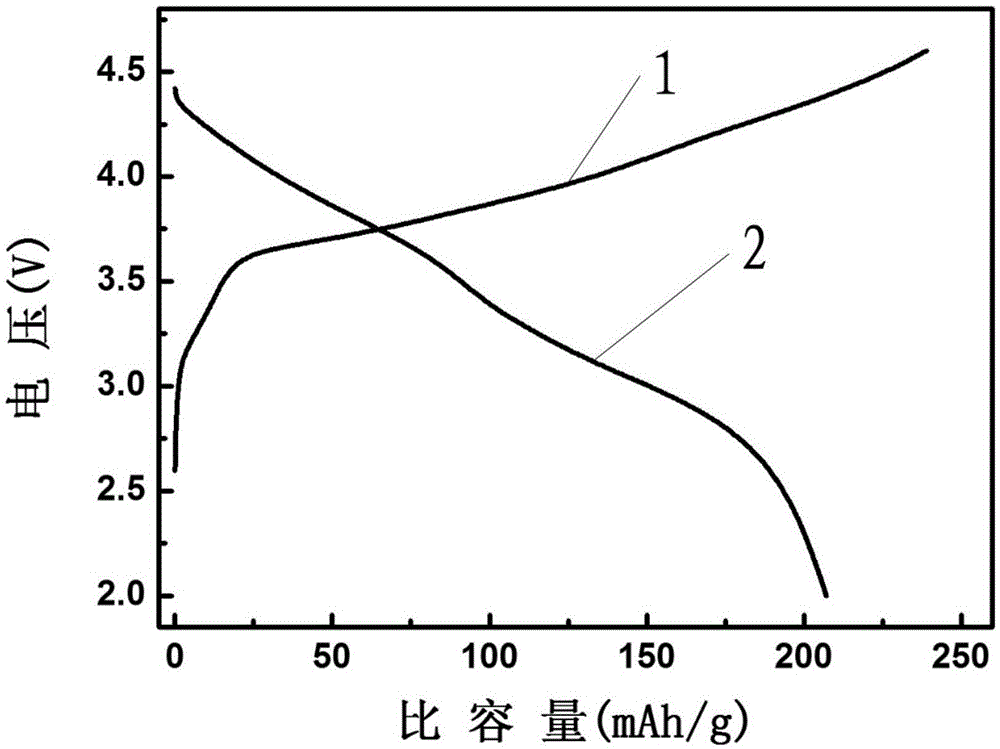

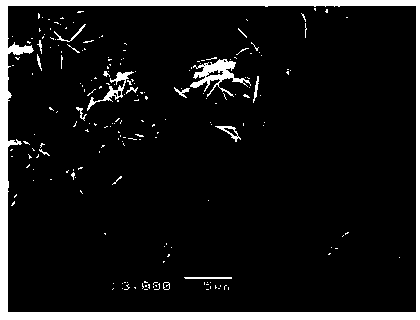

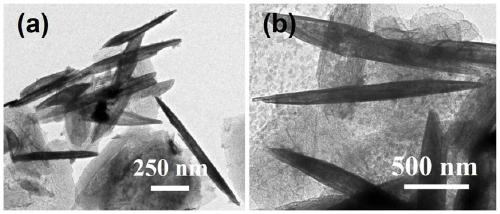

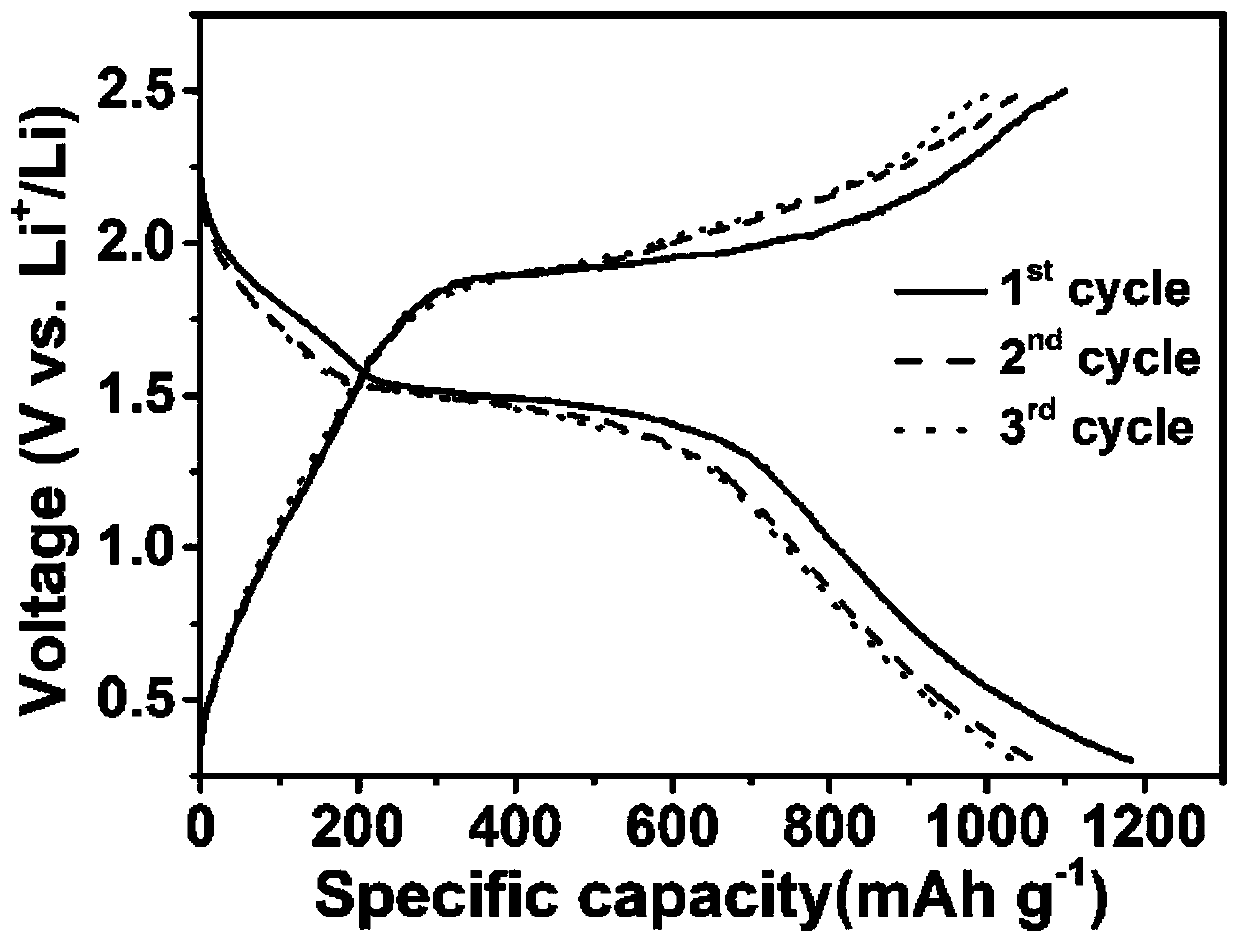

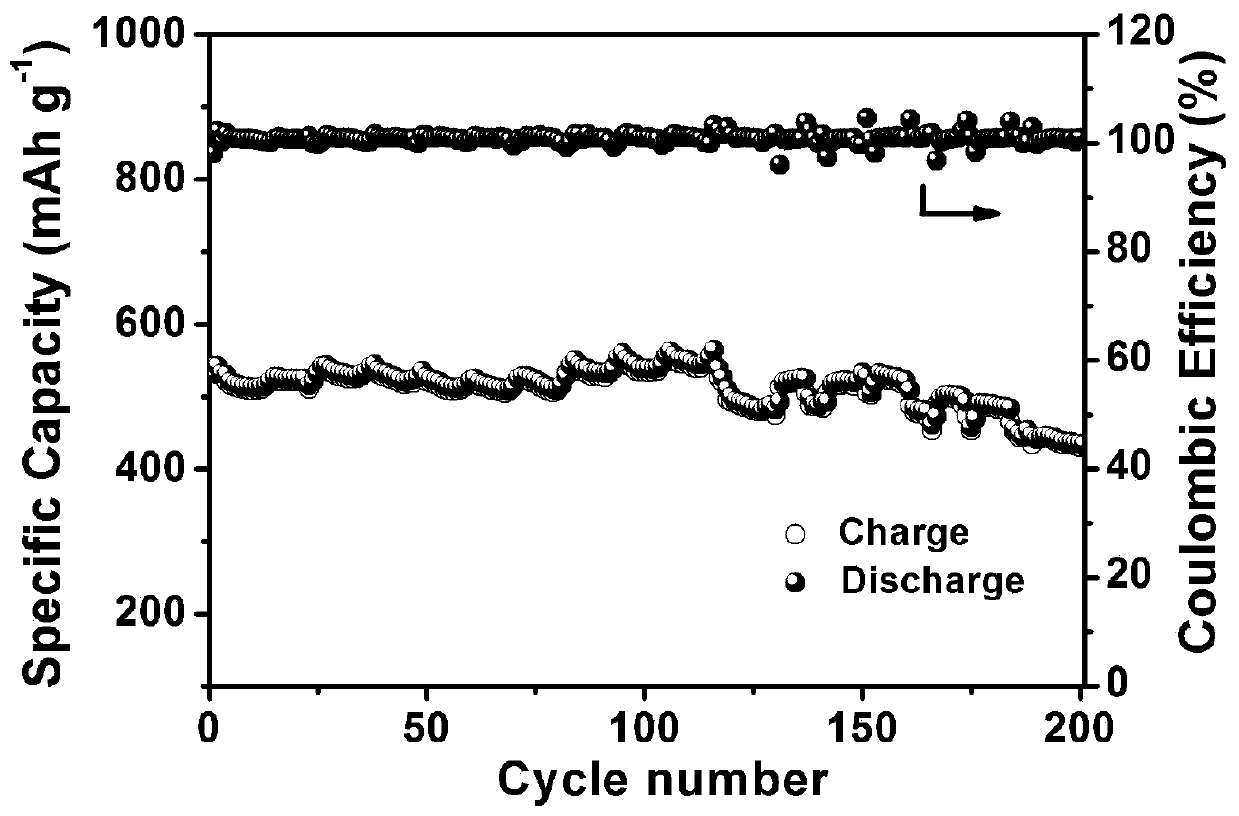

Carbon intercalation layer V2O3 nanometer material and preparation method and application thereof

ActiveCN106935860AAlleviate volume changesImprove cycle stabilityCell electrodesCarbon layerCarbonization

The invention discloses a preparation method and application of a carbon intercalation layer V2O3 nanometer material. The preparation method comprises the following steps of (1) adding vanadium pentoxide powder into an organic amine liquid, and uniformly stirring and mixing the powder; (2) transferring a mixed liquid to a reaction kettle for hydrothermal reaction; and (3) placing the obtained hybrid precursor in a furnace after drying, introducing an inert gas for carbonization to obtain a V2O3 / C hybrid nanometer material. The V2O3 / C hybrid nanometer material prepared by the method is uniform in morphology, and a carbon layer can be effectively dispersed in a nanometer substrate in the material. When the material is applied to a lithium ion battery or sodium ion battery negative electrode, the rate performance of a metal oxide used as an electrode material can be greatly improved, the volume energy density of the battery is improved, and the material has relatively large application prospect.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method for jute-based active carbon

InactiveCN102633259AIncrease profitIncrease added valueCarbon compoundsActivated carbonO-Phosphoric Acid

The invention discloses a preparation method for jute-based active carbon, and the method comprises the following steps of: weighing jute fibres or crushed jute stem materials, cleaning and drying, soaking in a beaker filled with a 3-5mol / L phosphoric acid solution, boiling for 3-10 hours in a water bath, adequately penetrating an activating agent into the fibres, then taking out and drying; placing in a vacuum tubular high-temperature sintering furnace, activating to 400-500 DEG C in a nitrogen atmosphere, insulating for 1-3 hours, or placing in a columnar quartz tube, placing in a microwave device, and performing a microwave irradiation reaction with a microwave irradiation power of 100-700 W and an irradiation time of 5-30 minutes in the presence of nitrogen used as protective gas; and cooling to a room temperature, then taking out, acid-washing and repeatedly water-washing until the pH is 6-7, and then drying to obtain the jute-based active carbon. The jute-based active carbon prepared by the method has the advantage of being high in methylene blue adsorption value and activation yield.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

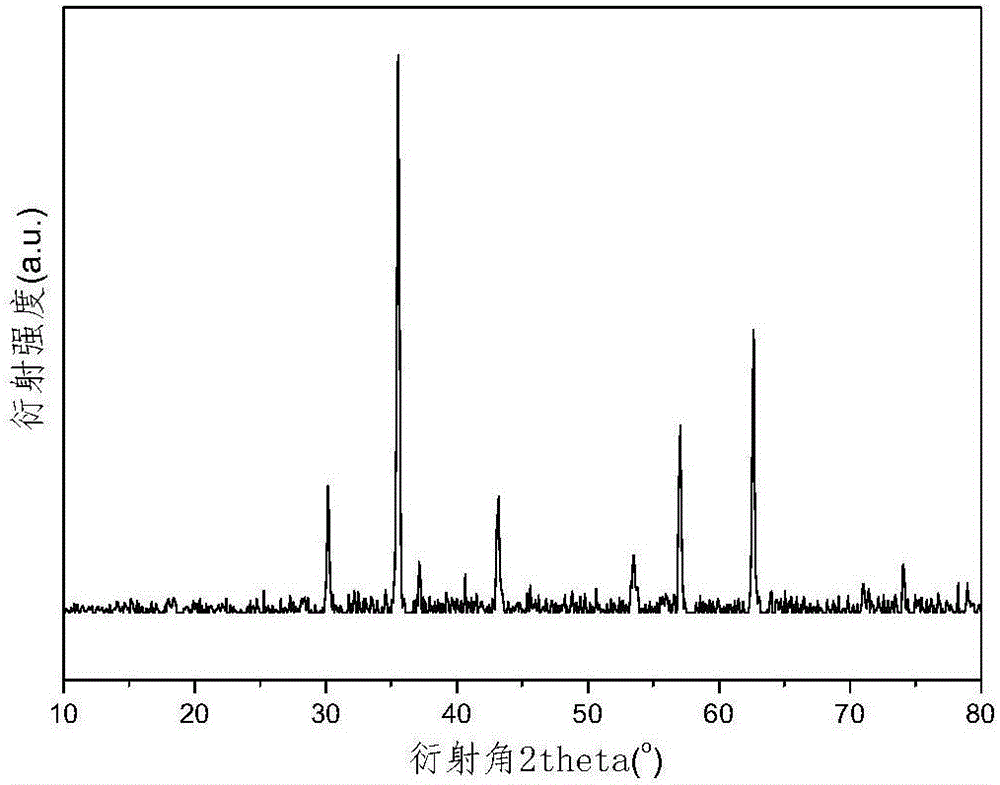

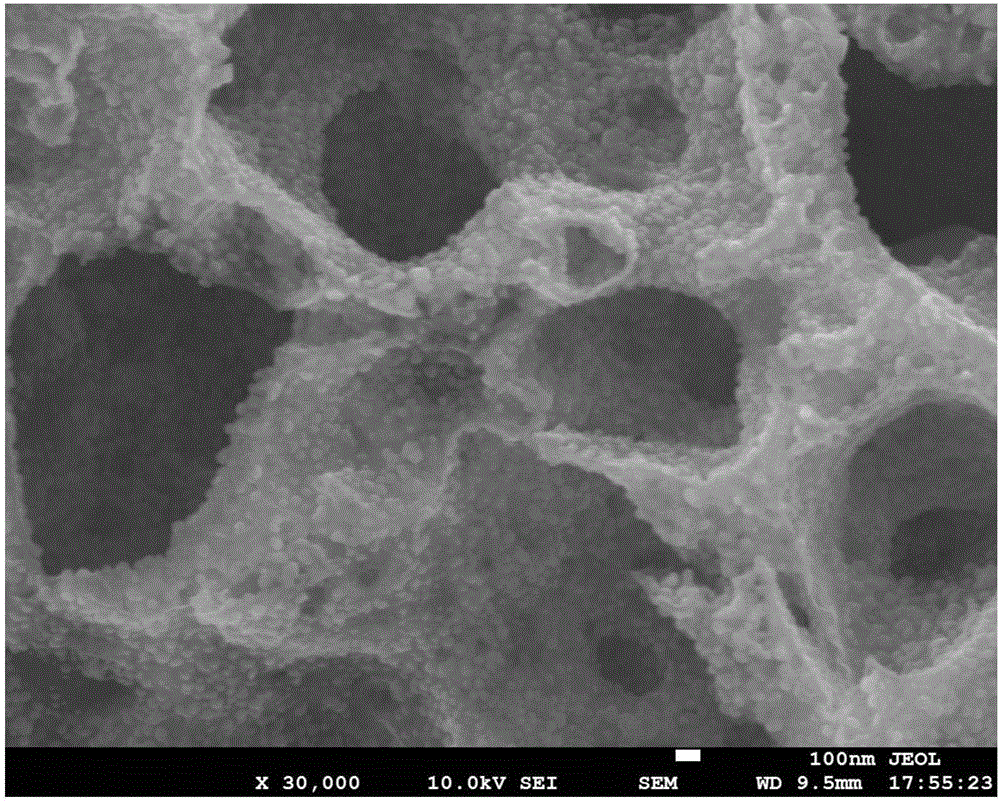

Porous graphene supported carbon coated iron oxide nanoparticle composite material and preparation method thereof

ActiveCN106207121AAlleviate volume changesHigh lithium storage capacityCell electrodesWater bathsPorous graphene

The invention belongs to the technical field of lithium ion battery materials, and specifically relates to a porous graphene supported carbon coated iron oxide nanoparticle composite material and a preparation method thereof. The porous graphene supported carbon coated iron oxide nanoparticle composite material is prepared from the following steps: (1) directly preparing graphene oxide with graphite ore as a raw material by using a closed oxidation method; (2) preparing a ferric salt aqueous solution, wherein the specific steps are as follows: weighing and dissolving cetyl trimethyl ammonium bromide in water to obtain a clear cetyl trimethyl ammonium bromide solution, adding a ferric salt, stirring until the ferric salt is completely dissolved, and adding an ammonia solution to prepare the ferric salt aqueous solution; and (3) stirring and ultrasonic mixing the graphene oxide solution with the ferric salt aqueous solution, placing the mixture in a water bath kettle, reacting at 80-100 DEG C for 0.5-5h, stewing at a room temperature, removing clear liquid, freeze drying a head product, and carrying out heat treatment on the head product in an inert atmosphere to obtain the porous graphene supported carbon coated iron oxide nanoparticle composite material.

Owner:SHANXI UNIV

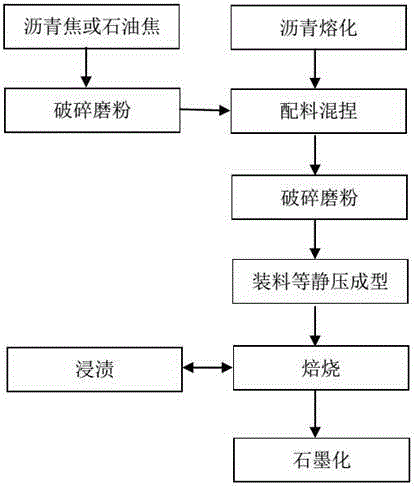

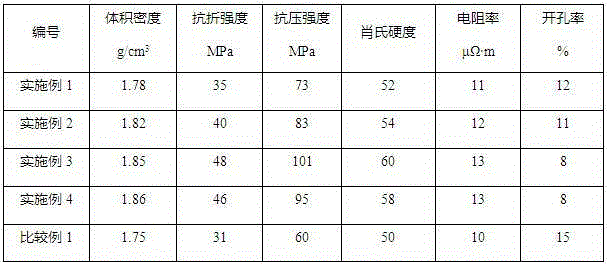

Preparation method of isostatic pressing formed graphite of ultra-thin structure

The invention discloses a preparation method of isostatic pressing formed graphite of an ultra-thin structure. The preparation method includes the steps that calcined petroleum coke or pitch coke is crushed to be smaller or equal to 1 mm, smashed to be within the range of 5 micrometers-10 micrometers and preheated to 100-150 DEG C, then brute-force mixing kneading, cooling, crushing and secondary powder grinding are performed on the calcined petroleum coke or pitch coke and liquid-state molten pitch, and heat treatment is performed on a green body obtained through isostatic pressing forming to obtain a carbon green body; immersion treatment is performed on the carbon green body through low-quinoline intermediate-temperature coat tar pitch, then the carbon green body is heated to 1000-1200 DEG C at 5-10 DEG C / h, and finally the isostatic pressing formed graphite of the ultra-thin structure is obtained through graphitization treatment. The prepared isostatic pressing formed graphite of the ultra-thin structure has the advantages of being compact in structure, good in evenness, high in mechanical strength and isotropy, low in production cost, short in production period and the like.

Owner:CHENGDU CARBON

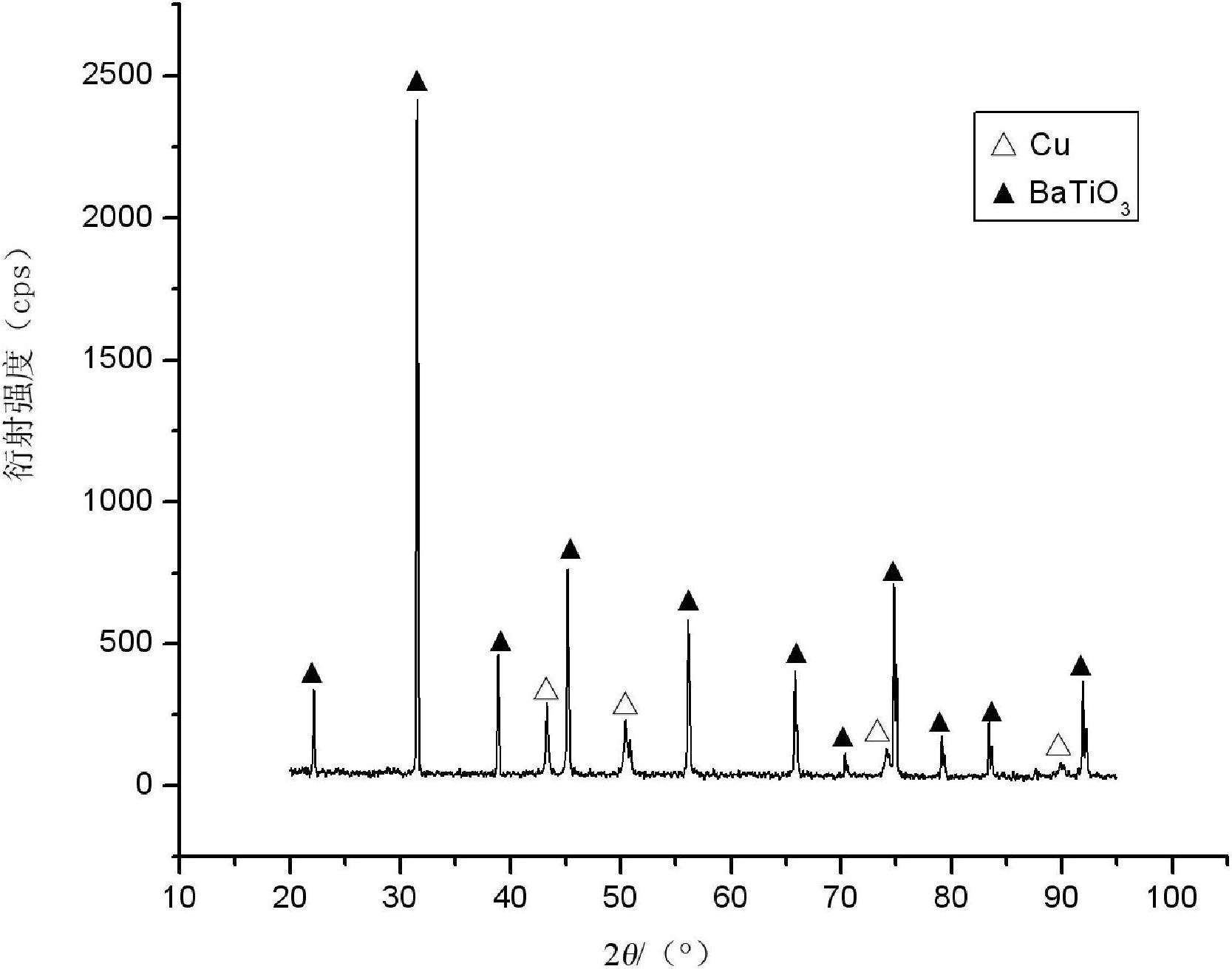

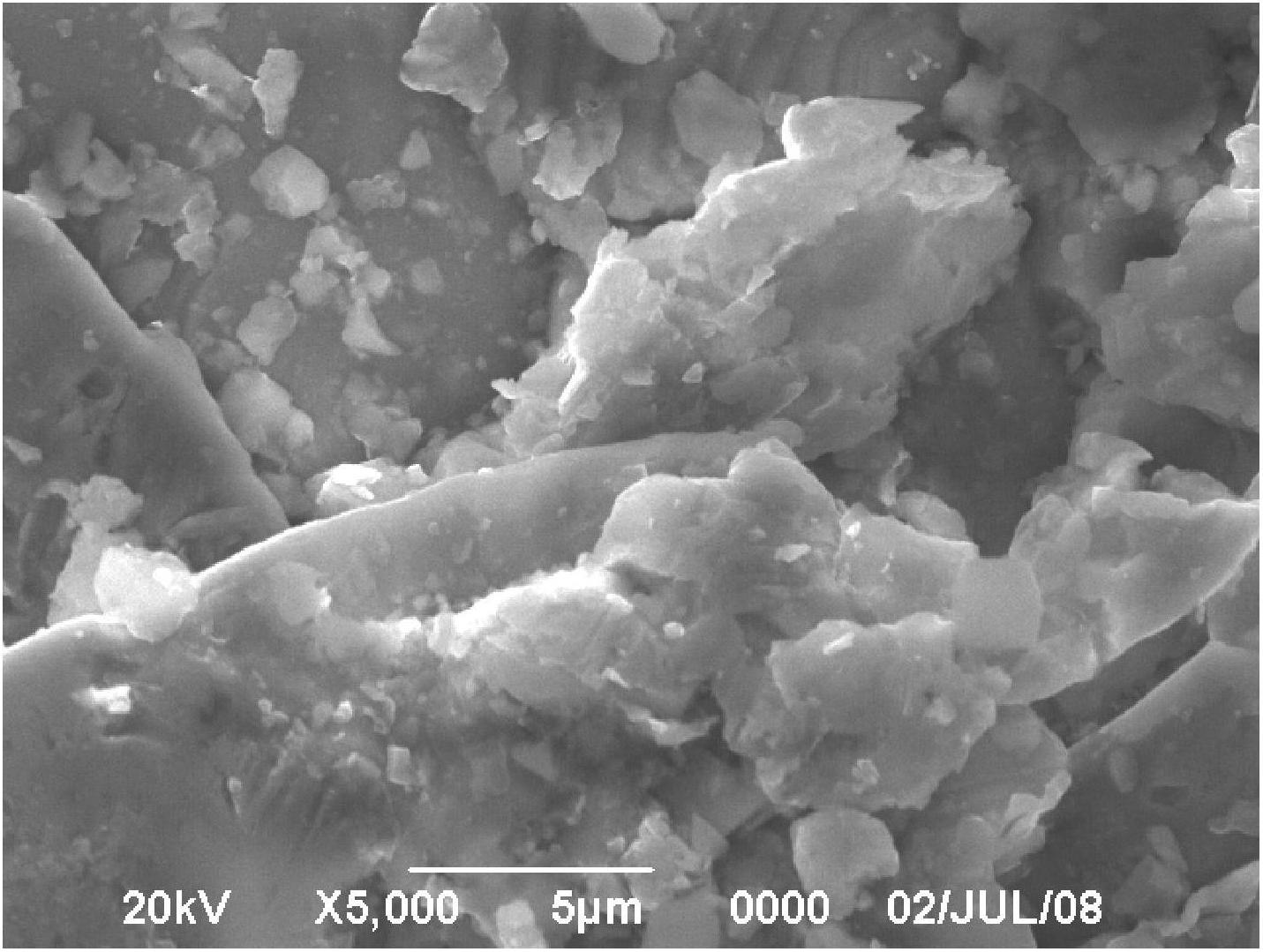

Conductive copper paste for surface electrodes of chip ceramic capacitor and preparation method thereof

InactiveCN102664057AMeet technical requirementsImprove liquidityFixed capacitor electrodesNon-conductive material with dispersed conductive materialScreen printingSilver paste

The invention discloses conductive copper paste for surface electrodes of a chip ceramic capacitor. The conductive copper paste comprises the following raw materials in percentage by mass: 65 to 72 percent of metal powder, 4 to 7 percent of glass powder and 24 to 30 percent of organic binder, wherein the metal powder consists of Cu and W or Cu and Mo; the glass powder consists of CaO, ZnO, Bi2O3, BaO, SiO2, B2O3 and Al2O3; and the organic binder consists of solvent, ethyl cellulose, silane coupling agent and surfactant. The conductive copper paste is printed through silk screens and sintered under the protection of N2 gas, the performance of the obtained finished product of the chip ceramic capacitor can completely meet the technical requirements of the ceramic capacitor, and the conductive copper paste can be used for replacing conductive silver paste on the surface of the corresponding chip ceramic capacitor.

Owner:HEFEI UNIV OF TECH

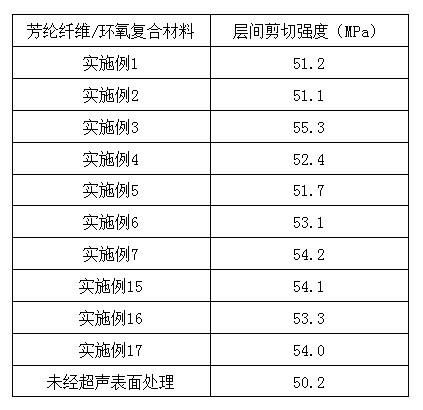

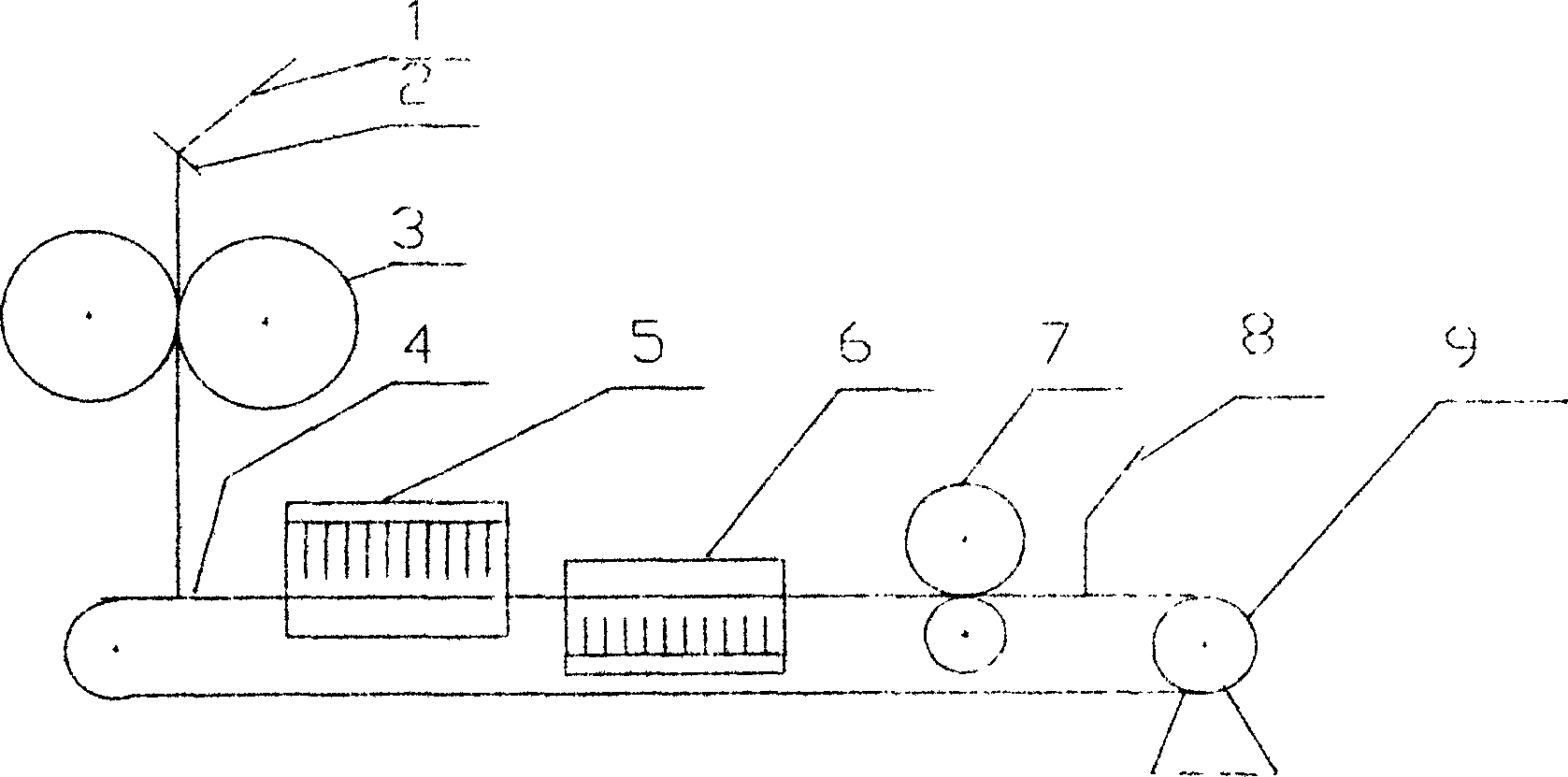

Ultrasonic surface modification treatment method for aramid fibers

InactiveCN102605606AImprove surface conditionQuality improvementFibre typesUltrasonic/sonic fibre treatmentPolymer scienceOrganic solvent

The invention provides an ultrasonic surface modification treatment method for aramid fibers. One or more amidic organic solvents in any proportion are selected as an ultrasonic treatment medium; under an ultrasonic action, fiber surfaces can be etched effectively by the amidic solvents; simultaneously, the sticking points among aramid fiber filaments can be reduced, and the state of the surfaces can be improved, so that the bonding strength between a resin and a fiber is increased; and meanwhile, the online treatment of the fibers is easy to realize by the ultrasonic treatment, and the time for modifying the fiber surfaces is shortened.

Owner:中蓝晨光化工有限公司

Diamond grinding wheel and method for manufacturing tool bit thereof

ActiveCN101412207AImprove self-sharpening abilityIncrease chip spaceAbrasion apparatusGrinding devicesSilicon chipDiamond grinding

The invention provides a diamond grinding wheel for precise polishing for the surface of a silicon material and a manufacturing method for a tool bit thereof. Surface roughness Ra of a silicon chip polished by the grinding wheel is lower than 0.03, Ry is lower than 0.27, and Rz is lower than 0.29. The diamond grinding wheel comprises a steel basal body and the tool bit embedded in the steel basal body; the tool bit is manufactured by the following steps: putting a mixed material into a die cavity of a die; and heating and pressurizing the mixed material, so as to press the mixed material to the required size; and a preparation method for the mixed material comprises the following steps: preparing powder from the following components in volume percentage: 20 to 40 percent of phenolic resin, 12. 5 to 25 percent of diamond, 10 to 15 percent of Fe2O3, 10 to 15 percent of CeO2, 5 to 10 percent of Al2O3, and 5 to 10 percent of Cu powder; and then 20 to 50 percent powder mass of pore forming agent is added into the powder.

Owner:NANJING SANCHAO ADVANCED MATERIALS

Process for making composite fabric needle felt

The invention discloses a process for preparing composite fiber punched felt consisting of fiber glass and polypropylene fiber, which comprises introducing the composite fiber into the two filament throwing rollers, falling down to the conveyer belt, securing the structure through twice punching actions, distributing homogeneously, compacting with pressure roller, cutting needed width with a cutting knife, winding up into composite fiber punched felt.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Method for preparing leather sample observed by metallurgical microscope

InactiveCN102305736AFast penetrationFully infiltratedPreparing sample for investigationFiberMicroscopic observation

The invention relates to a method for preparing a leather sample observed by a metallurgical microscope, and belongs to the technical field of leather inspection. The method comprises the following steps of: (1) adding a promoter into an unsaturated polyester resin, stirring, adding a curing agent, stirring, standing, and discharging the mixed air to obtain an immobilized resin; (2) immersing a sample into the immobilized resin, and curing to obtain a cured sample; (3) grinding both ends of the cured sample until the ends are flat, fixing in a mould, injecting the immobilized resin into the mould, curing, demoulding, and post-curing to obtain a post-cured sample block; and (4) grinding and polishing the post-cured sample block by using abrasive paper to obtain the leather sample observed by the metallurgical microscope. In the method, the unsaturated polyester resin is used as a main ingredient of the immobilized resin, and operation steps are designed according to a capillary action principle to ensure that the immobilized resin can be quickly and fully permeated into the leather sample, so the adhesion and deformation of section fiber of leather are furthest avoided.

Owner:QILU UNIV OF TECH

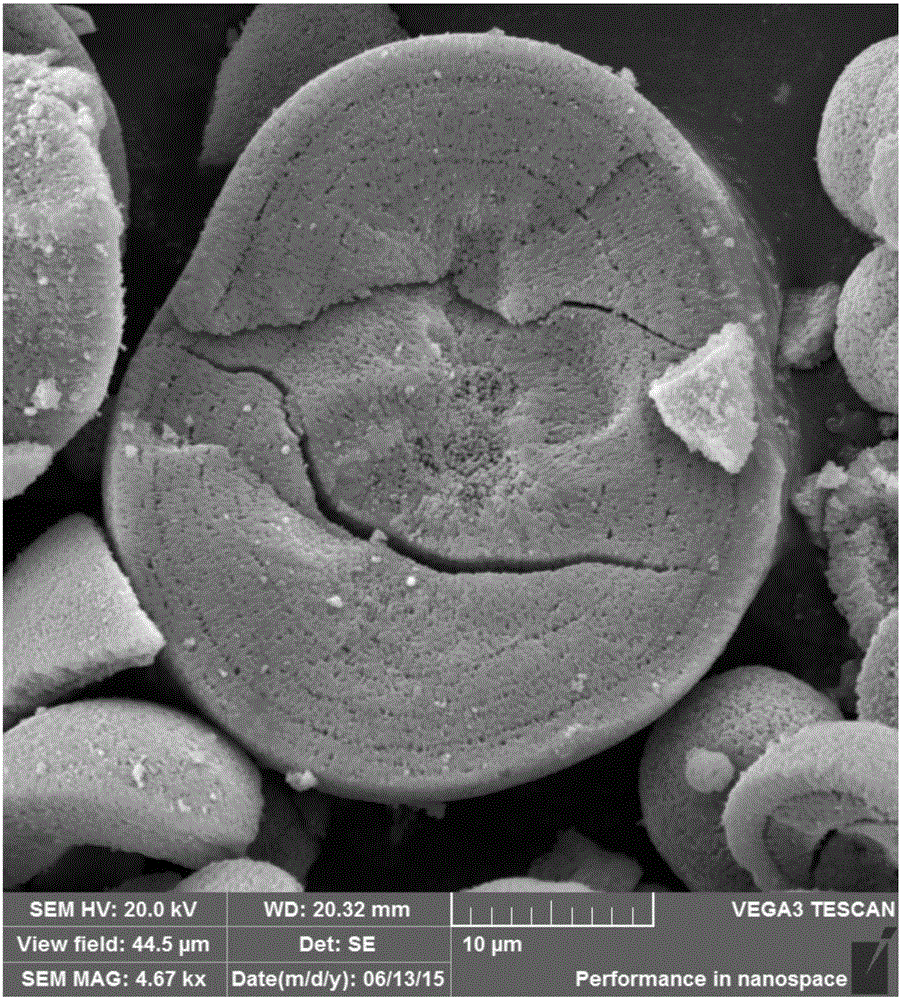

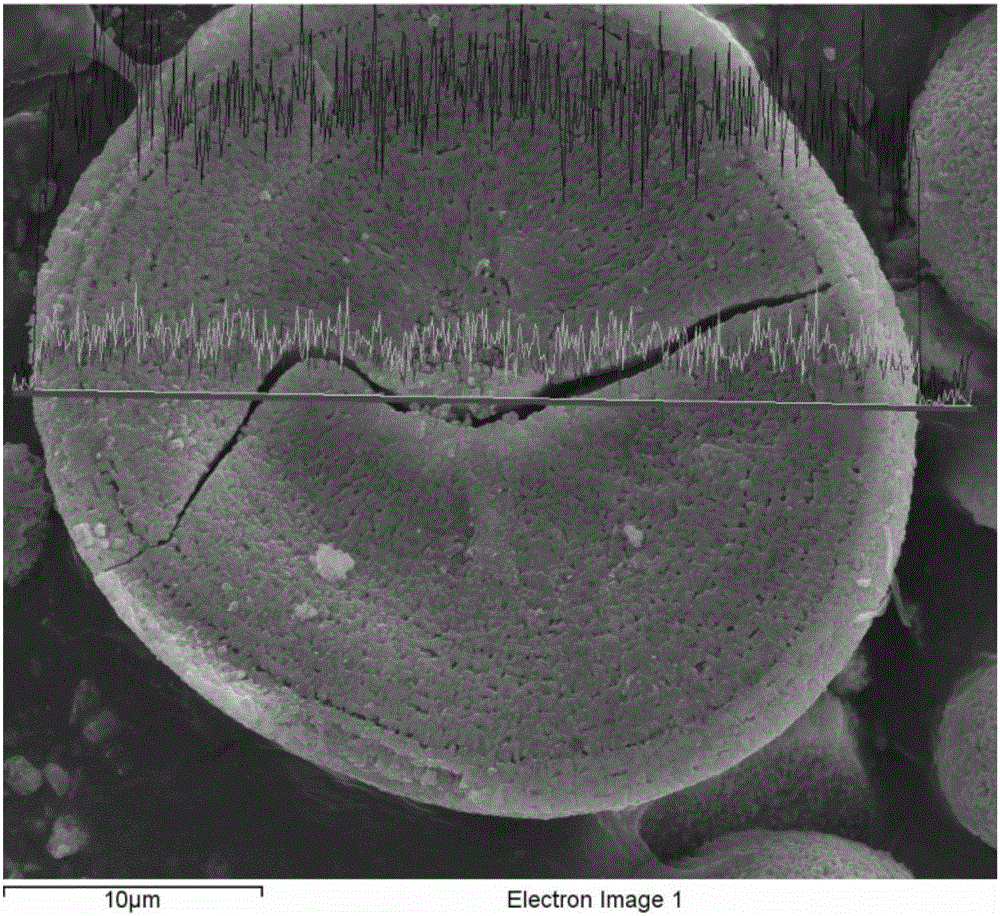

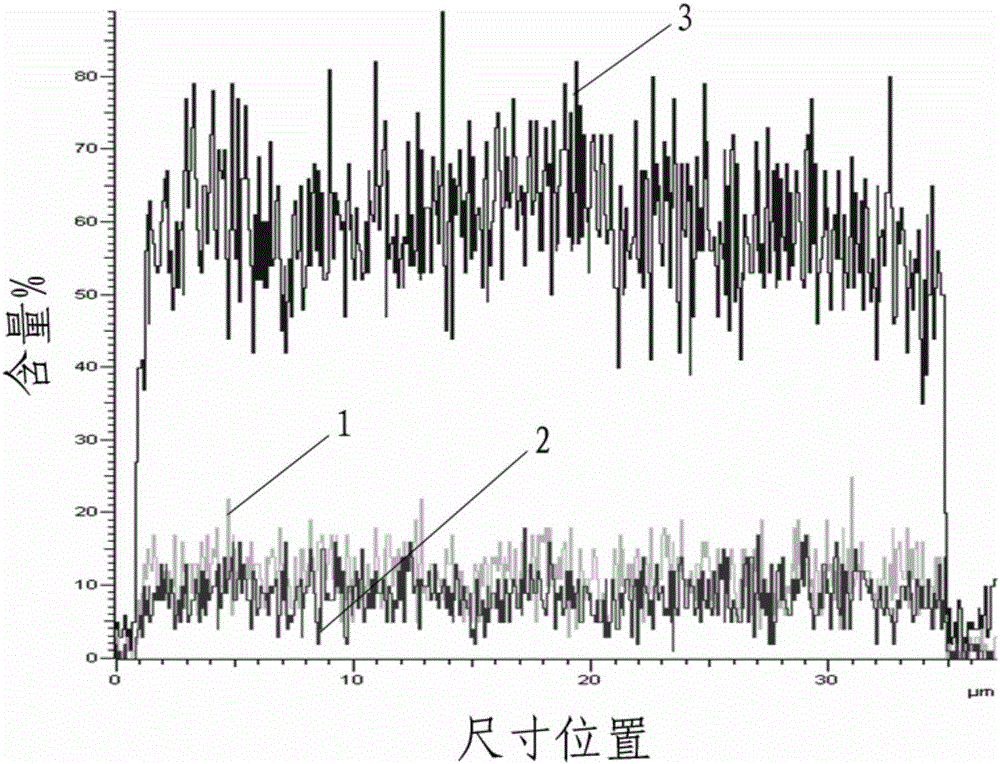

Lithium metal oxide composite positive electrode material with multilayer structure, precursor material for constituting same, and preparation method and application for precursor material

ActiveCN105552327AImproved magnification performanceFully infiltratedCell electrodesSecondary cellsLithium metalOxide composite

The invention provides a lithium metal oxide composite positive electrode material with a multilayer structure, a precursor material for constituting the same, and a preparation method and an application for the precursor material. The invention relates to the lithium metal oxide composite positive electrode material used for a lithium ion battery, and a preparation method and an application for the lithium metal oxide composite positive electrode material. The invention aims to solve the ubiquitous problems of low specific capacity, bad cycling performance, high improvement cost and low tap density existing in the lithium metal oxide composite positive electrode material. According to the preparation method, primary granules are controlled in real time to be arranged based on layers in a coprecipitation method reaction process by enabling metal salt solution components to be subjected to stage changes and cease type overflowing; the metal salt components of the primary granules in each layer are different; a precursor of the high-performance lithium metal oxide composite positive electrode material with the multilayer structure is obtained; and the lithium metal oxide composite positive electrode material with the multilayer structure is finally synthesized by the combination of a gradient temperature rise way. The lithium metal oxide composite positive electrode material is used for the lithium ion battery.

Owner:HARBIN INST OF TECH

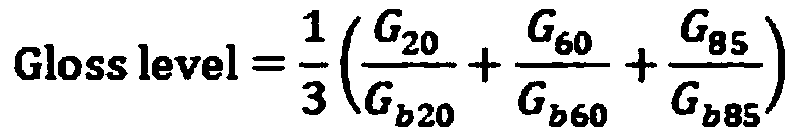

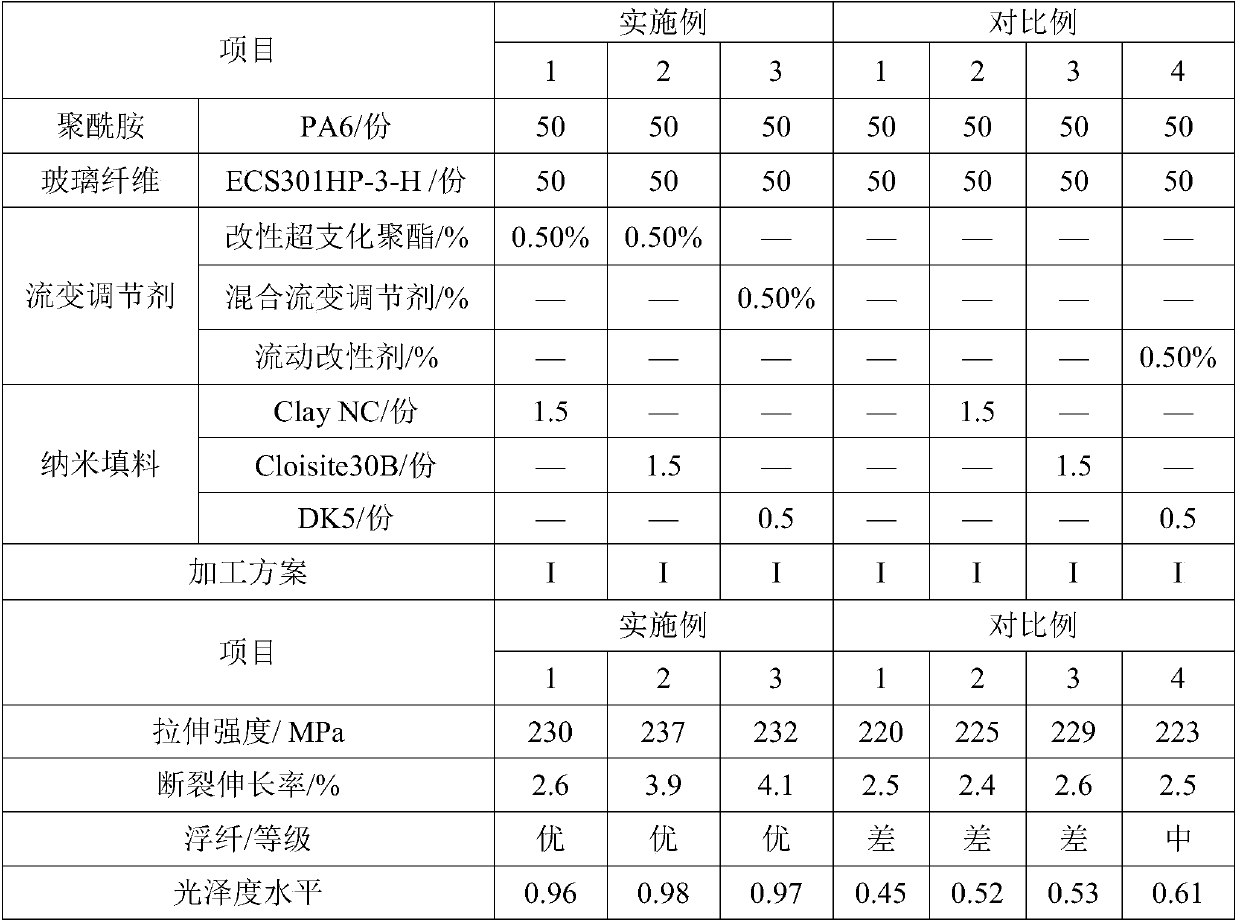

Low-floating-fiber high-glossiness glass fiber reinforced polyamide composition

The invention discloses a low-floating-fiber high- glossiness glass fiber reinforced polyamide composition and a preparation method thereof. The composition comprises 30 to 85 parts by weight of polyamide resin, 15 to 60 parts by weight of glass fiber, 0.1 to 10 parts by weight of nanometer filler and a rheological regulator in an amount which is 0.08 to 5.0 percent of the weight of the glass fiber, wherein the nanometer filler and the rheological regulator are limited, particularly the structure of modified hyperbranched polymer in the rheological regulator is specifically limited. Due to adoption of the rheological regulator, the retention distribution range of melt in processing equipment can be reduced to a great degree and the product appearance defect caused by the part which exceedsthe ideal retention time limit value is reduce; in particular, the nanometer filler which integrates the special structure and the effect has remarkable beneficial effect of improving the appearanceof the glass fiber reinforced polyamide composition; the obtained polyamide composition has high glossiness and little floating fiber, and still can maintain excellent physical and mechanical properties while embodying good product appearance.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +1

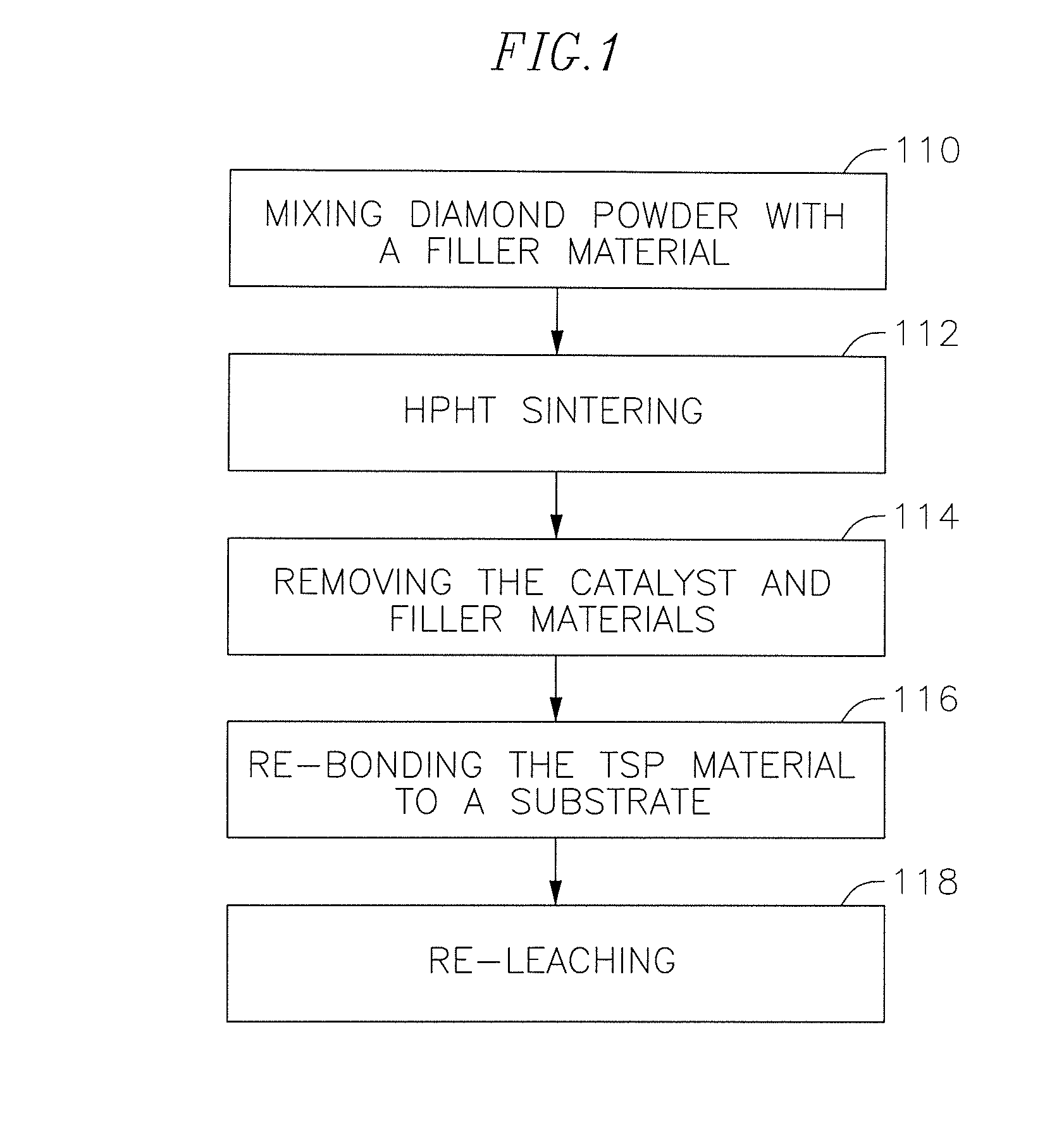

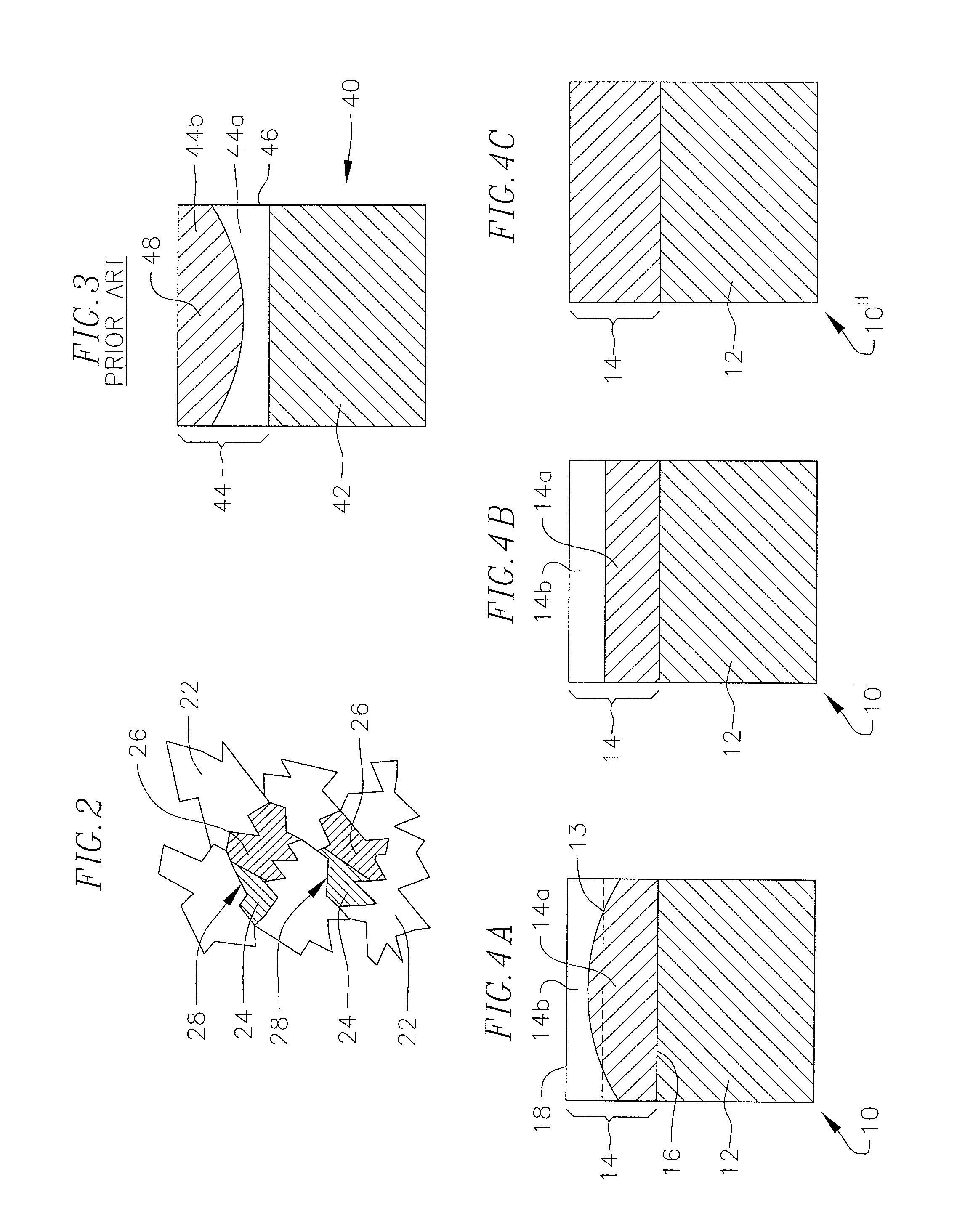

Polycrystalline diamond cutting elements with engineered porosity and method for manufacturing such cutting elements

A method for facilitating infiltration of an infiltrant material into a TSP material during re-bonding of the TSP material to a substrate, by enhancing the porosity of the TSP material near the interface with the substrate is provided. Cutting elements formed by such method and downhole tools including such cutting elements are also provided.

Owner:SMITH INT INC

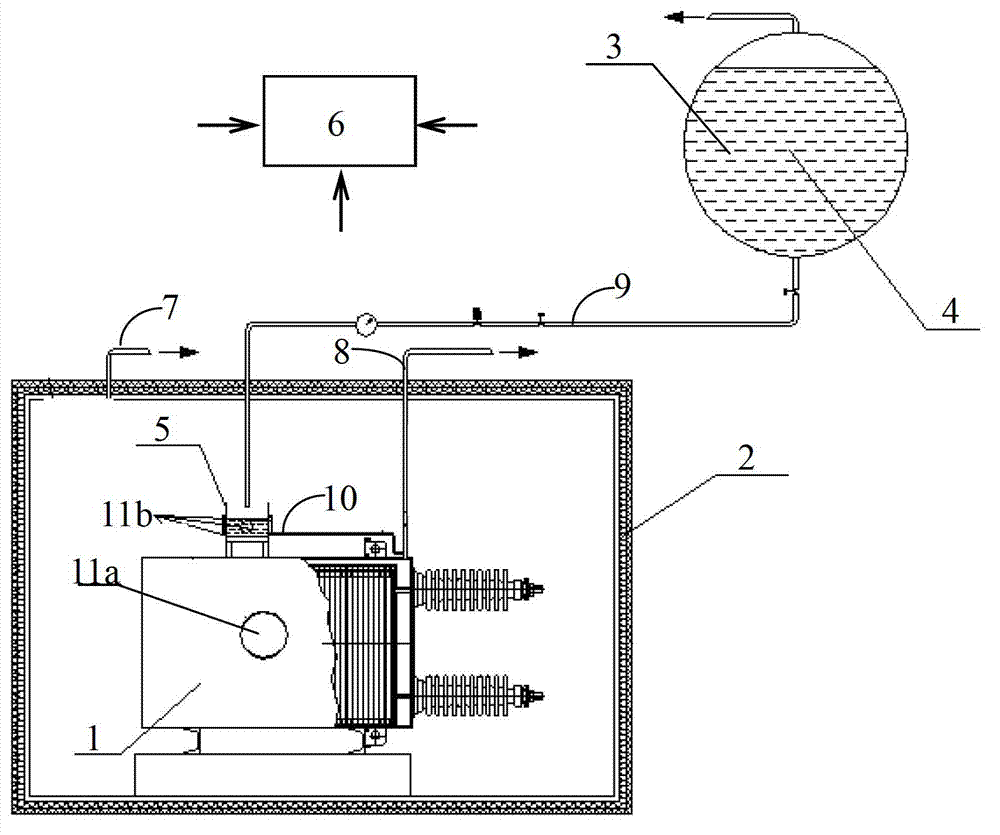

Processing method for vacuum drying impregnation of capacitor

InactiveCN102856084AEasy to integrateRemove completelyDrying/impregnating machinesLow vacuumAluminum foil

The invention discloses a processing method for vacuum drying impregnation of a capacitor. The method comprises the following steps of heating a power capacitor to 80-90 DEG C; cooling the internal temperature of the power capacitor to 70-80 DEG C, and improving the vacuum degree of the gas partial pressure in a vacuum tank to 0.5-1 Pa step by step; opening an ultrasonic generating component which is arranged on the external wall of the power capacitor, and cooling the internal temperature of the power capacitor to 40-60 DEG C, and reducing the gas partial pressure of the vacuum tank at 0.2-0.5 Pa, and meanwhile slowly pouring insulating medium oil in the power capacitor shell for 8-22 h; after the internal part of the power capacitor is filled with the insulating medium oil, maintaining the opening state of the ultrasonic, reducing the internal temperature of the power capacitor, maintaining the internal temperature at 30-40 DEG C, and controlling the vacuum degree of the gas partial pressure in the vacuum tank about 0.2-0.5 Pa. According to the processing method provided by the invention, the gas integrated into the insulation medium oil and the local few low vacuum gas which is sealed between solid medium layers and between medium and aluminum foil layers by the insulation medium oil can be exhausted more easily.

Owner:ENERTECH SUZHOU ENERGY TECH CO LTD

Metal TiN ceramic coating preparation process method

According to the invention, a high energy micro-arc alloying technology and a glow plasma nitriding technology are combined to prepare a TiN coating on the surface of a metal. The process method comprises: adopting a high energy micro-arc alloying technology to deposit a layer of a pure Ti coating on the surface of a metal, wherein pure Ti with a certain specification is selected as a deposition electrode during the preparation process, and a variable thickness of the pure titanium layer can be achieved through controlling key technology parameters in the preparation process; and carrying out a nitriding treatment on the deposited pure titanium layer through a glow plasma nitriding technology to form a TiN layer, wherein during the treatment process, a furnace is adopted as an anode, the titanium layer is adopted as a cathode, ammonia gas or mixed gas of hydrogen gas and nitrogen gas is introduced, and nitrogen ions and nitrogen atoms generated from glow discharge are easily absorbed and permeated by the micro-crystallized Ti layer so as to form the TiN coating on the surface of the micro-crystallized Ti layer.

Owner:南通泓盛手套有限公司

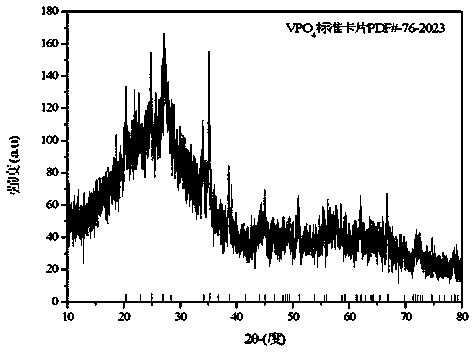

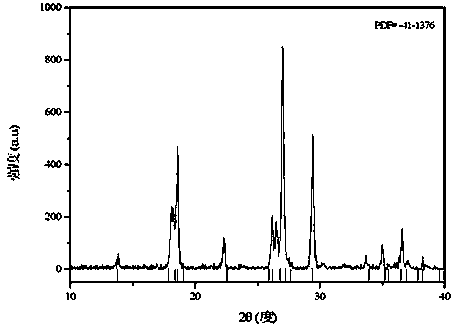

Preparation method for nano sheet-shaped lithium ion battery positive electrode material fluorine lithium vanadium phosphate

ActiveCN103840157AEasy to passEasy to embedMaterial nanotechnologyCell electrodesWater bathsLithium-ion battery

The invention provides a preparation method for a nano sheet-shaped lithium ion battery positive electrode material fluorine lithium vanadium phosphate. The preparation method comprises the following step: (1) dissolving a vanadium source, a phosphorus source and a reducing agent into water; (2) agitating in a water bath; (3) adjusting the pH to 2-12; (4) transferring the solution to a polytetrafluoroethylene tank; putting the polytetrafluoroethylene tank into a pyrolysis tank, and heating and reacting at 220-280 DEG C for 15-25 hours; cooling to a room temperature; (5) filtering and drying in vacuum; (6) arranging into an agate mortar to be grinded; then sintering under a non-oxidization atmosphere; cooling to the room temperature to obtain a crystallized-state vanadium phosphate precursor; (7) mixing the crystallized-state vanadium phosphate precursor with a lithium source and a fluorine source; uniformly grinding; and (8) arranging a mixture into a pipe type sintering furnace and sintering under the non-oxidization atmosphere; and cooling to the room temperature to obtain the nano sheet-shaped lithium ion battery positive electrode material fluorine lithium vanadium phosphate. According to the preparation method, the microcosmic appearance of the positive electrode material is in a sheet-shaped structure with the thickness being in a nano grade; the surface of a nano sheet is uniformly coated with carbon and the appearance of the material is special; the excellent electrochemical performance is represented.

Owner:CENT SOUTH UNIV

Manufacturing method of high-temperature resistant fiber wound composite material shell

The invention discloses a manufacturing method of a high-temperature resistant fiber wound composite material shell in the field of monitoring. The manufacturing method comprises the following steps:(1) a tool and a mold are prepared; (2) preparation of a gypsum layer: gypsum powder, polyvinyl alcohol and water are mixed as gypsum according to a weight ratio of 2: (1-2): 1; after uniform mixing,the mixed gypsum is coated on a metal core mold; and an outer molding surface of the core mold is treated to a theoretical inner molding surface of a thermal insulation layer by using a molding surface scraper; (3) a skirt mold is prepared; and (4) a skirt is prepared. The composite material shell produced by the method has the characteristics of low mass, high reliability, low cost, high-temperature resistance and high blasting pressure, and can meet the requirement of normal flying of a novel aerospace aircraft under harsh high-temperature environment; and the manufacturing method can be used for manufacturing the high-temperature resistant fiber wound composite material shell.

Owner:JIANGSU XINYANG NEW MATERIALS CO LTD

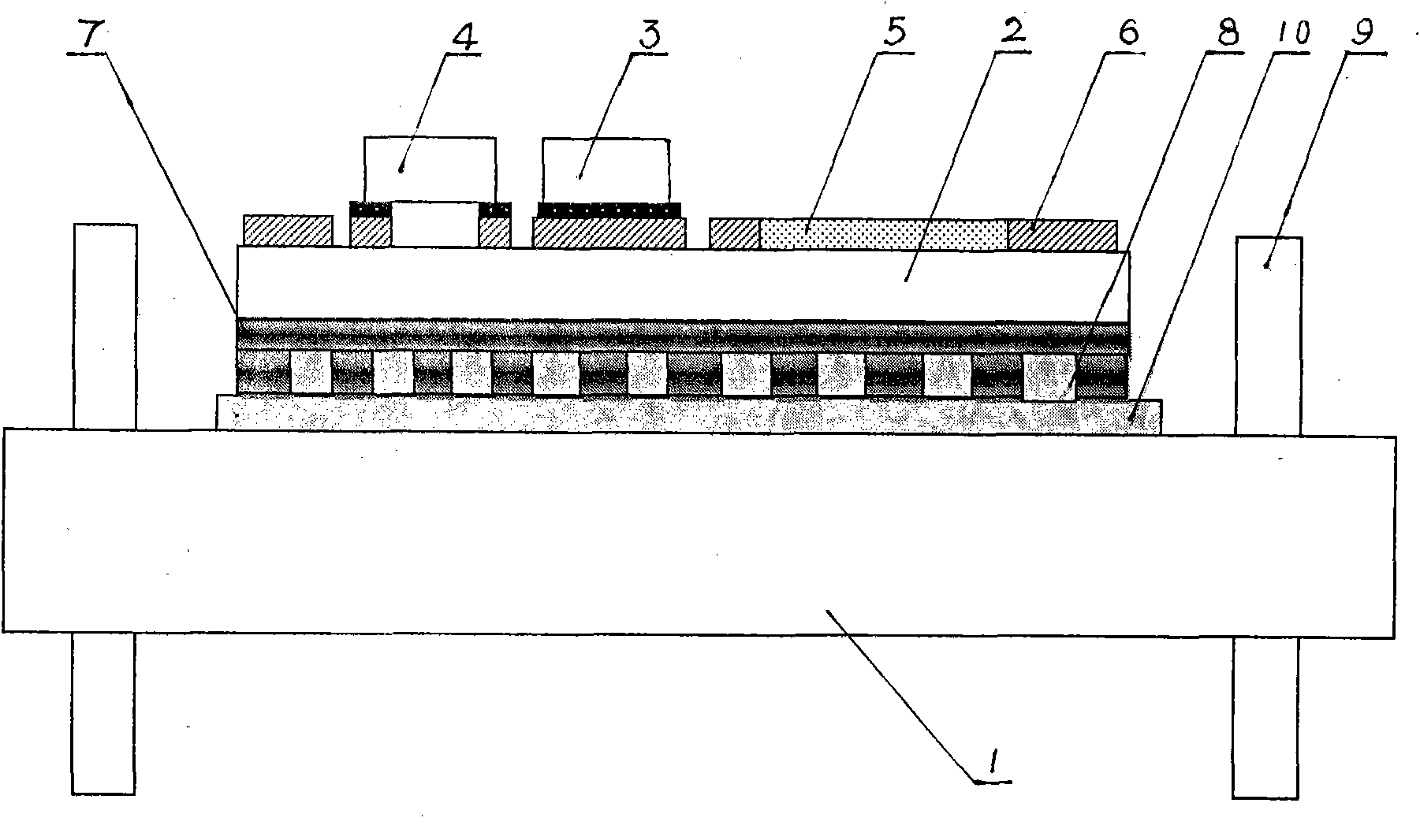

Integration method of high-reliability power hybrid integrated circuit

InactiveCN101866861AExcellent performanceGuaranteed compactnessSolid-state devicesSemiconductor/solid-state device manufacturingHybrid integrated circuitIntegrated circuit

The invention discloses an integration method of a high-reliability power hybrid integrated circuit. The method comprises the following steps of: (1) firstly, washing an original thick film substrate with ultra sound and drying; (2) forming a multilayer Cu-Ni-Cr-Au composite film at the back of a ceramic substrate in a high-vacuum magnetically-controlled sputtering platform in one step by using a high-vacuum sputtering method; (3) selectively sputtering another Cu-Ni-Cr-Au composite film again on the basis so that a multilayer metal film grooved mesh is formed in a selected region; (4) then, annealing at a high temperature to obtain a thick film substrate; and (5) assembling the thick film substrate on a shell base, assembling a semiconductor chip and other separate devices, bonding with silicon-aluminum wires to connect the circuit and seal a lid to obtain a made high-reliability power hybrid integrated circuit. The integrated circuit made by the method has favorable welding system compactness, adhesion, heat conductivity, rapid radiation and circuit reliability and is widely applied to the fields of aerospace, aviation, ships, precise instruments, geological exploration, oil exploration, communication, and the like.

Owner:GUIZHOU ZHENHUA FENGGUANG SEMICON

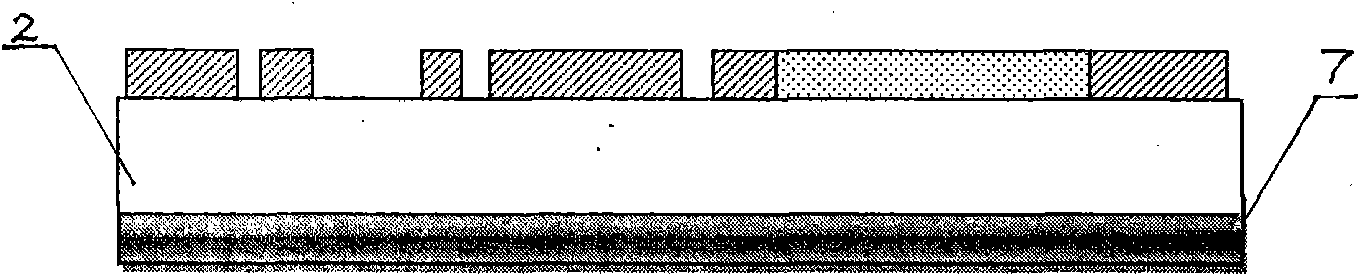

Microporous ceramic thick film heating element for electronic cigarette tar atomization core and manufacturing method of element

PendingCN110074463AImprove liquidityHigh bonding strengthTobacco devicesHeating element shapesElectrical resistance and conductanceTar

The invention relates to the technical field of electronic cigarettes, and particularly discloses a microporous ceramic thick film heating element for an electronic cigarette tar atomization core anda manufacturing method of the element. The microporous ceramic thick film heating element comprises a microporous ceramic base plate, a heating resistance film layer and an electrode layer, wherein the heating resistance film layer comprises a middle part and two connecting parts; the electrode layer comprises two electrode films arranged at intervals; the two connecting parts are respectively connected with the upper ends of the two electrode films; the middle part is connected with the upper surface of the microporous ceramic base plate; the heating resistance film layer is used for heatingthe microporous ceramic base plate so that the cigarette tar of an electronic cigarette is atomized and escapes through micropores of the microporous ceramic base plate. The microporous ceramic thickfilm heating element disclosed by the invention has the advantages that the use is safe and reliable; the service life is long; the cigarette tar reducing degree is high; the user experience and the mouthfeel are good, and the like; the manufacturing method of the element is simple and efficient; the operation and control are convenient; the product quality is stable; industrialized production isfacilitated.

Owner:东莞市东思电子技术有限公司

Preparation method for three-dimensional cover glaze

The invention provides a preparation method for three-dimensional cover glaze. The preparation method comprises the following steps: I, selecting at least one monochrome from an image to prepare a silk screen plate; II, applying cover glaze on a semi-finished blank in a silk screen printing pattern, wherein the cover glaze is powder; III, baking in a kiln to obtain ceramic with the three-dimensional cover glaze. In the preparation method for the three-dimensional cover glaze, an image pre-treating scheme is adopted, and the advantage of bright color of silk screen printing is utilized, so that a ceramic product with a bright image is obtained.

Owner:XINLAILI CERAMIC DEV CO LTD

Lithium ion battery assembly method and lithium ion battery

InactiveCN110690506AImprove securityImprove cycle performanceFinal product manufactureElectrolyte accumulators manufacturePhysical chemistryBattery cell

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a lithium ion battery assembly method which comprises the following steps: baking a positive plate, anegative plate and a diaphragm to obtain a baked positive plate, a baked negative plate and a baked diaphragm; laminating and / or winding the baked positive plate, the baked negative plate and the baked diaphragm; welding a tab to obtain a bare battery cell; soaking the bare battery cell in an electrolyte to obtain a battery cell soaked in the electrolyte; putting the battery cell soaked in the electrolyte into a shell, and performing packaging; and forming and re-packaging the packaged battery cell to obtain the lithium ion battery. According to the method, the bare battery cell is directly soaked in the electrolyte, so that the battery pole piece and the diaphragm are fully soaked by the electrolyte; then the liquid supplementing procedure is added according to the designed weight, so that the electrical consistency among battery batches can be ensured; and the standing time of a battery after liquid injection can be shortened, and the production efficiency is improved. The lithium ion battery prepared by the method disclosed by the invention is high in safety performance and good in cycle performance.

Owner:汇洋世纪新能源科技有限公司

Lithium metallic oxide precursor material with annual ring type structure, anode material prepared by lithium metallic oxide precursor material, and preparation method and application

ActiveCN105355907AHigh tap densityImprove cycle stabilitySecondary cellsPositive electrodesLiquid ratioLithium metal

The invention relates to lithium metallic oxide precursor material with an annual ring type structure, an anode material prepared by the lithium metallic oxide precursor material, and a preparation method and application, and in particular to the lithium metallic oxide precursor material for a lithium ion battery and a preparation method of the lithium metallic oxide precursor material, and the anode material prepared by the lithium metallic oxide precursor material, the preparation method and the application. The invention aims to solve the problems of small discharge capacity, poor circulating performance and low tap density of a common lithium metallic oxide anode material. According to the lithium metallic oxide precursor material with the annual ring type structure, the anode material prepared by the lithium metallic oxide precursor material, and the preparation method and the application, disclosed by the invention, the solid-to-liquid ratio of a solution in a coprecipitation reaction process is controlled to be in periodic linear variation in rear time by using an intermittent equivalent overflowing way; the prepared lithium metallic oxide precursor material and the anode material prepared by the lithium metallic oxide precursor material are used in the field of batteries.

Owner:HARBIN INST OF TECH

Preparation method of metal organic framework derived iron sulfide and carbon nano composite material

PendingCN111584871AHigh charge and discharge capacityLarge specific surface areaMaterial nanotechnologyNegative electrodesMetal-organic frameworkCarbon nanocomposite

The invention discloses a preparation method of a metal organic framework derived iron sulfide@carbon nano composite material, and belongs to the technical field of lithium ion battery negative electrode materials. Fumaric acid and nitric acid molten iron are subjected to a hydrothermal reaction to obtain spindle-shaped MIL-88 nanoparticles, and then sulfur doping and calcining are performed to obtain a carbon-coated sulfur-doped core-shell structure iron sulfide@carbon nano composite material. The MIL-88(MOFs)-derived metal sulfide prepared by the preparation method disclosed by the inventionkeeps the frame structure of a precursor, and in the calcining process, an organic ligand in the metal organic framework material MIL-88 is cracked to form the core-shell structure of the carbon-coated iron sulfide core; the structure can inhibit the volume expansion of the electrode material in the charging and discharging process to adjust the integrity of the structure, and the formed activated carbon can improve the conductivity of the electrode material and improve the performance of the battery; and the preparation process has the advantages of low cost, simplicity and convenience in operation, environmental friendliness and the like, and has good realizability.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com