Continuous fiber reinforced composite materials, its production method and special equipment therefor

A reinforced composite material and continuous fiber technology, which is applied in the field of glass fiber reinforced thermoplastic composite materials, can solve the problems of easy warpage, complex product structure, high cost, etc., and achieve the goal of improving mechanical properties, surface gloss and adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

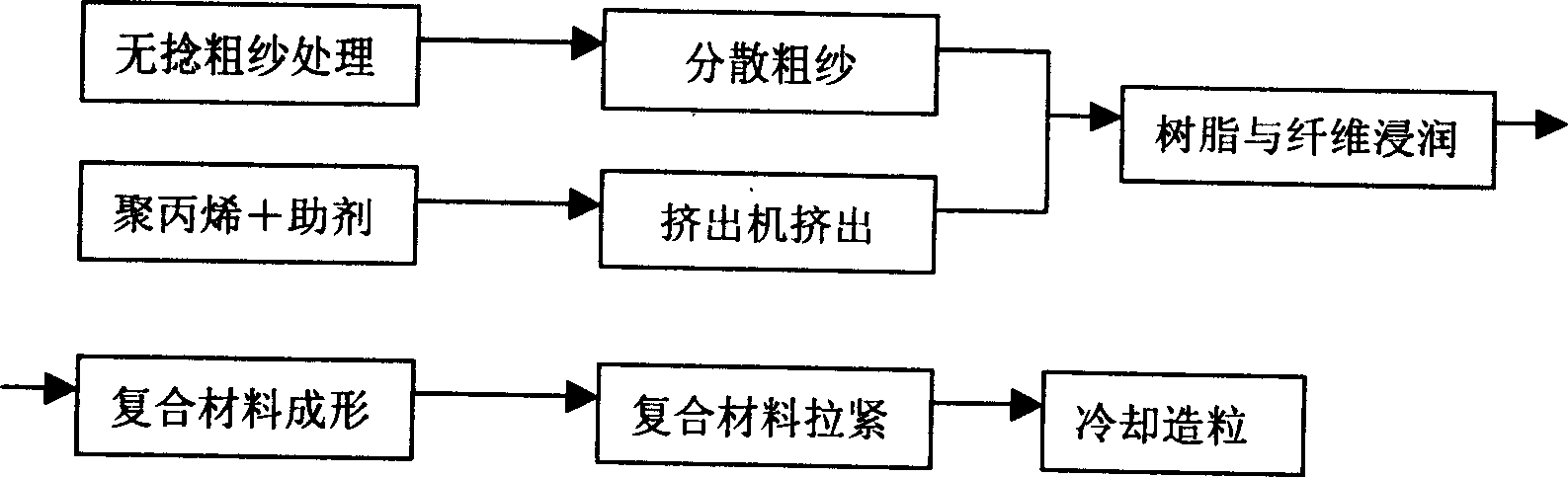

Method used

Image

Examples

Embodiment 1

[0032] The continuous fiber reinforced composite material prepared according to the following raw material weight (kg,

[0033] Polypropylene resin 50

[0034] impregnated fiberglass 47

[0035] 3,5-di-tert-butyl-4-hydroxyphenylpropionate octadecanyl 1

[0036] 2-Hydroxy-4-n-octyloxybenzophenone 0.5

[0037] Di(1,2,2,6,6-pentylmethyl-4-piperidinyl) sebacate 0.5

[0039]First, use electronic scales and platform scales to weigh the required raw materials according to the formula ratio, and add various raw materials except the soaked glass fiber to a low-speed mixer with a volume of 100L, and stir to make them evenly mixed and dispersed. The compounding time is determined according to the amount of compounding materials, about 3-5Min, and the compounding temperature is at room temperature. Finally, put the compounded materials into the hopper of the TE-65 twin-screw extruder. Start the extrusion unit to melt and knead the compounded materials. ...

Embodiment 2

[0048] raw material

[0049] project

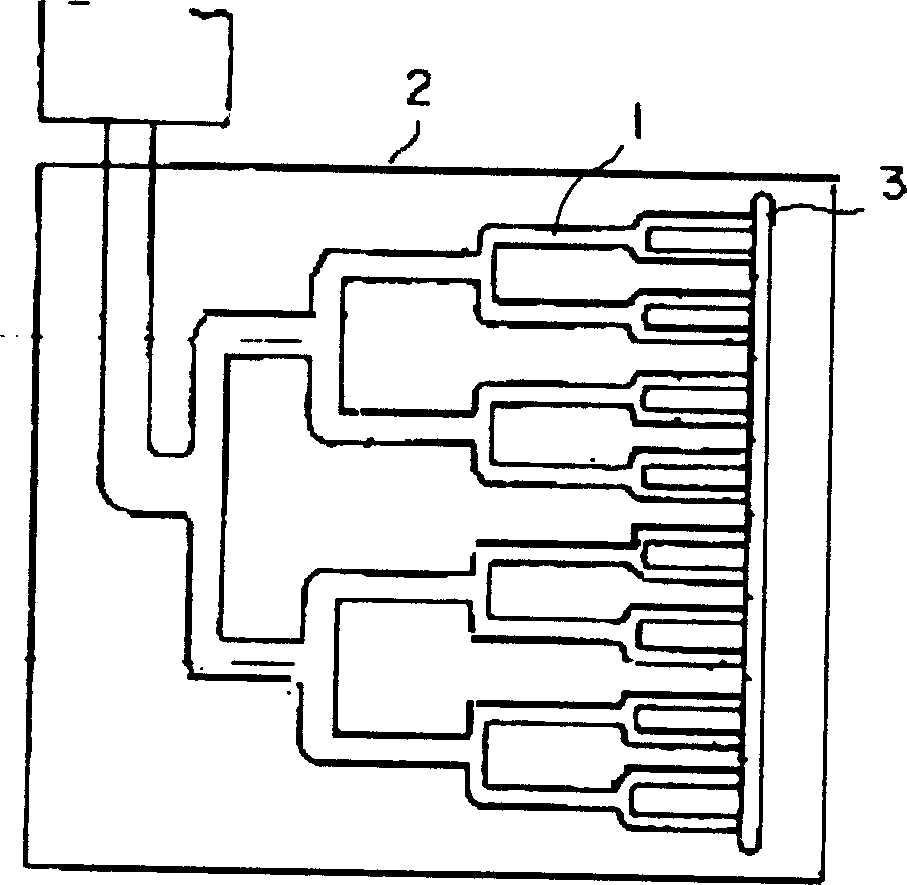

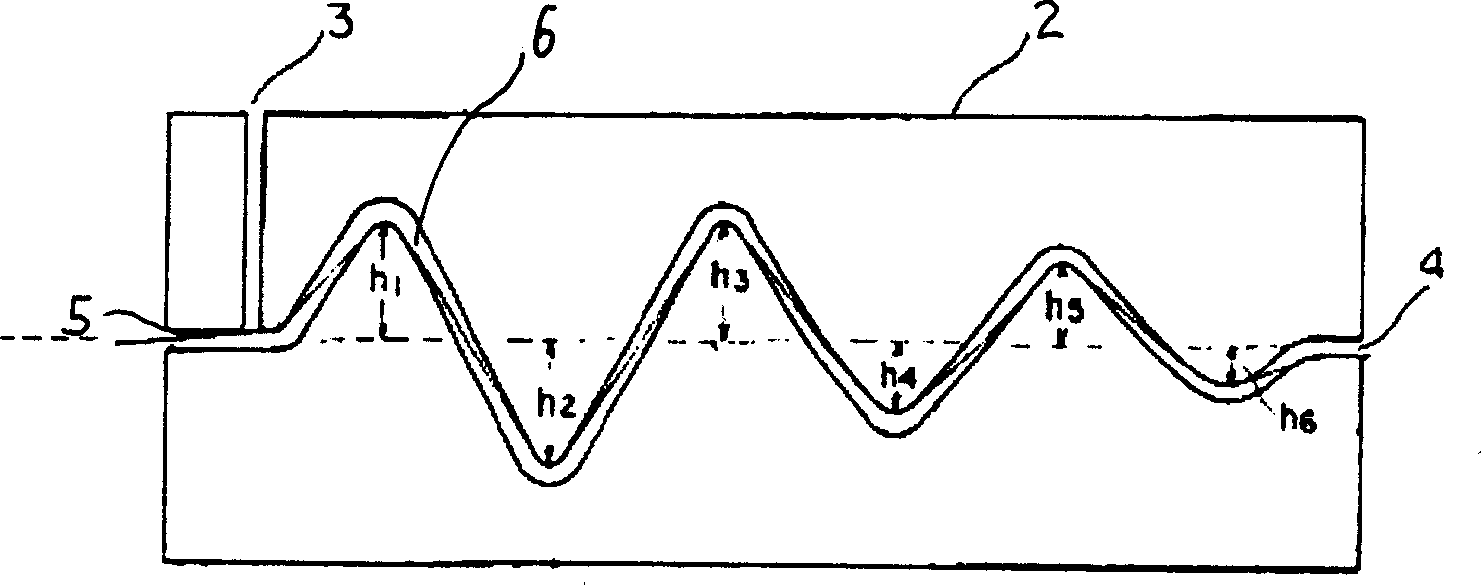

[0050] The special cross slit die head for the production of the above products such as figure 2 and 3 As shown, the die head 2 has two feed ports, namely the resin feed port 3 and the fiber feed port 5. The resin feed port is designed with a multi-branch melt flow channel 1, and the flow channel design is symmetrical about the center line of the die head. , the resin and fiber infiltration flow channel 6 adopts a serpentine design and bends along a certain slope. There are respectively the highest point and the lowest point from the feed port 5 to the discharge port 4, and the highest point that the fiber reaches first is lower than the fiber outlet. The height of the highest point, that is, the height of the highest point of the bend decreases in turn, where h 2 = h 3 , h 4 = h 5 , h 3 > h 4 , h 1 > h 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com