Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

963results about How to "Address limitations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

LED light bulbs

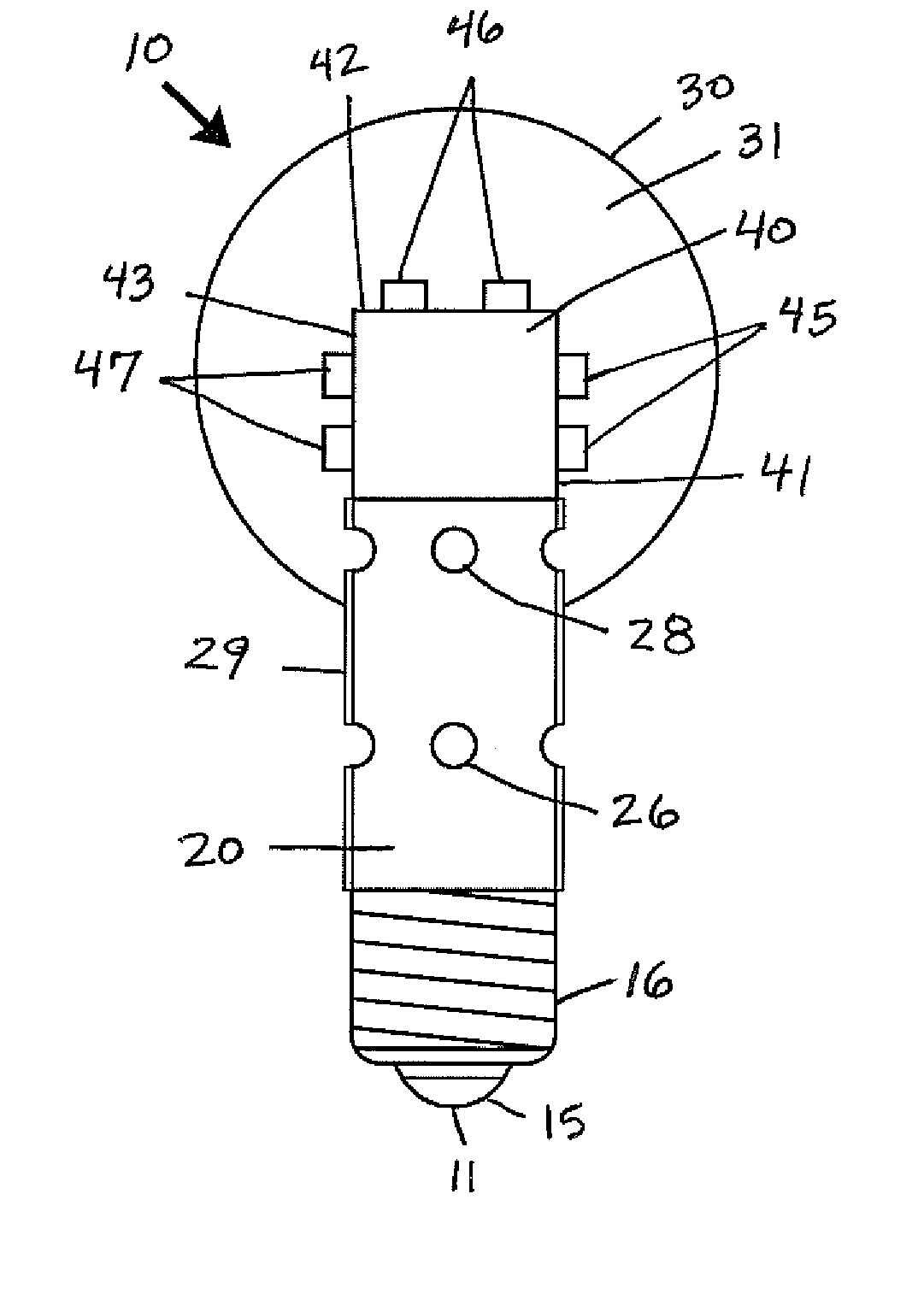

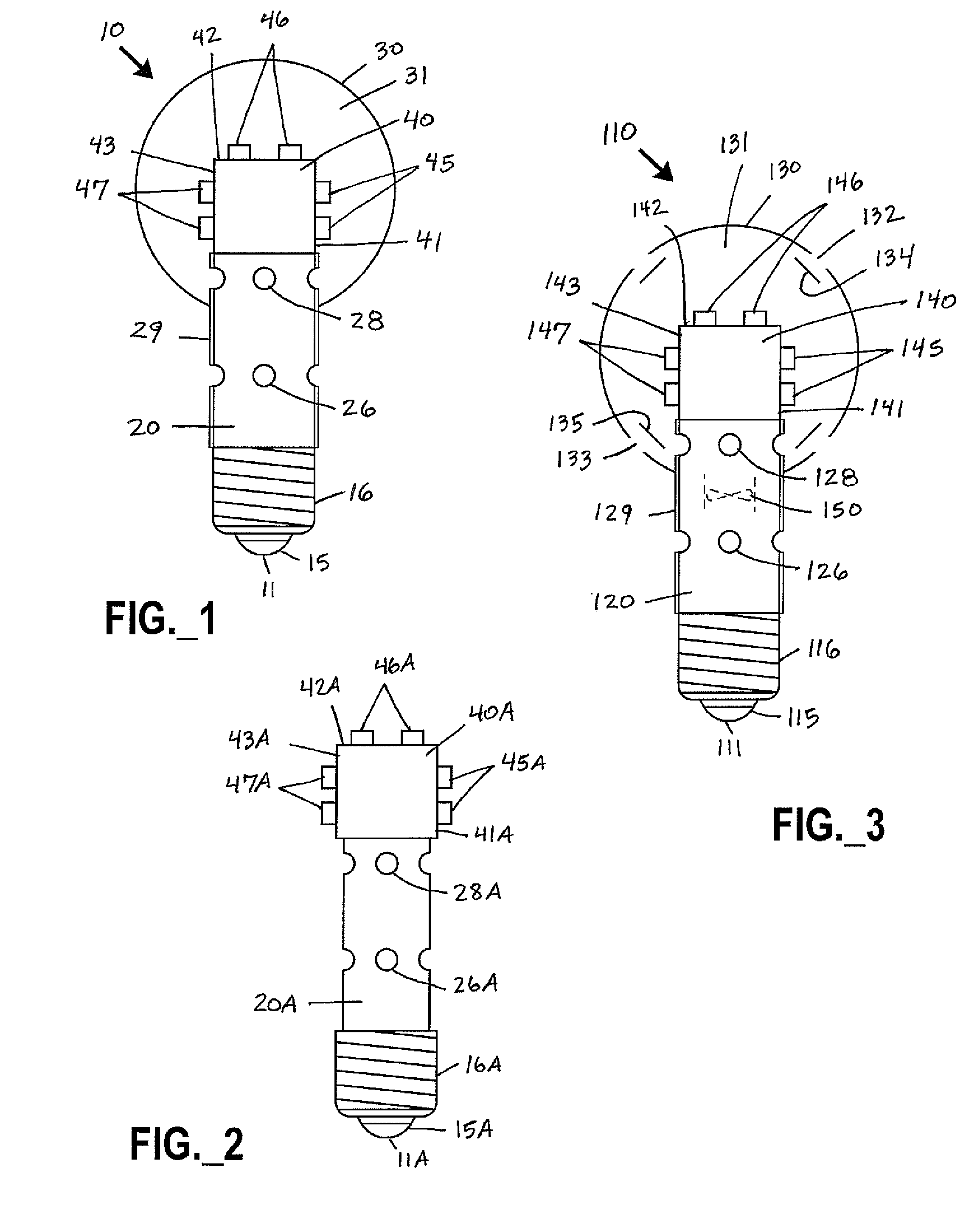

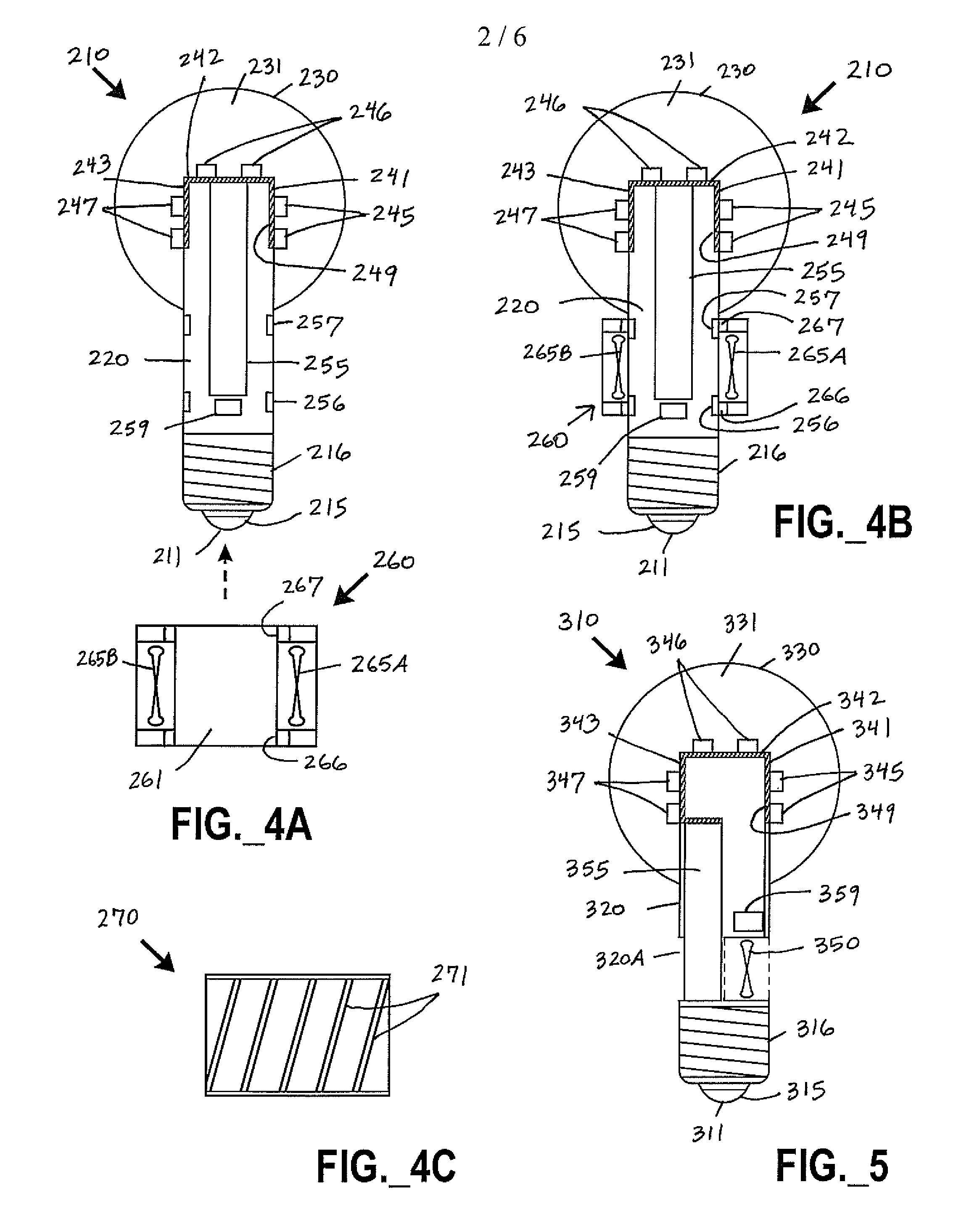

ActiveUS20110298371A1Address limitationsPlanar light sourcesPoint-like light sourceEngineeringLED lamp

LED light bulbs include openings in base or cover portions, and optional forced flow elements, for convective cooling. Thermally conductive optically transmissive material may be used for cooling, optionally including fins. A LED light engine may be fabricated from a substrate via planar fabrication techiques and shaped to form a substantially rigid upright support structure. Mechanical, electrical, and thermal connections may be made between a LED light engine and a LED light bulb.

Owner:IDEAL IND LIGHTING LLC

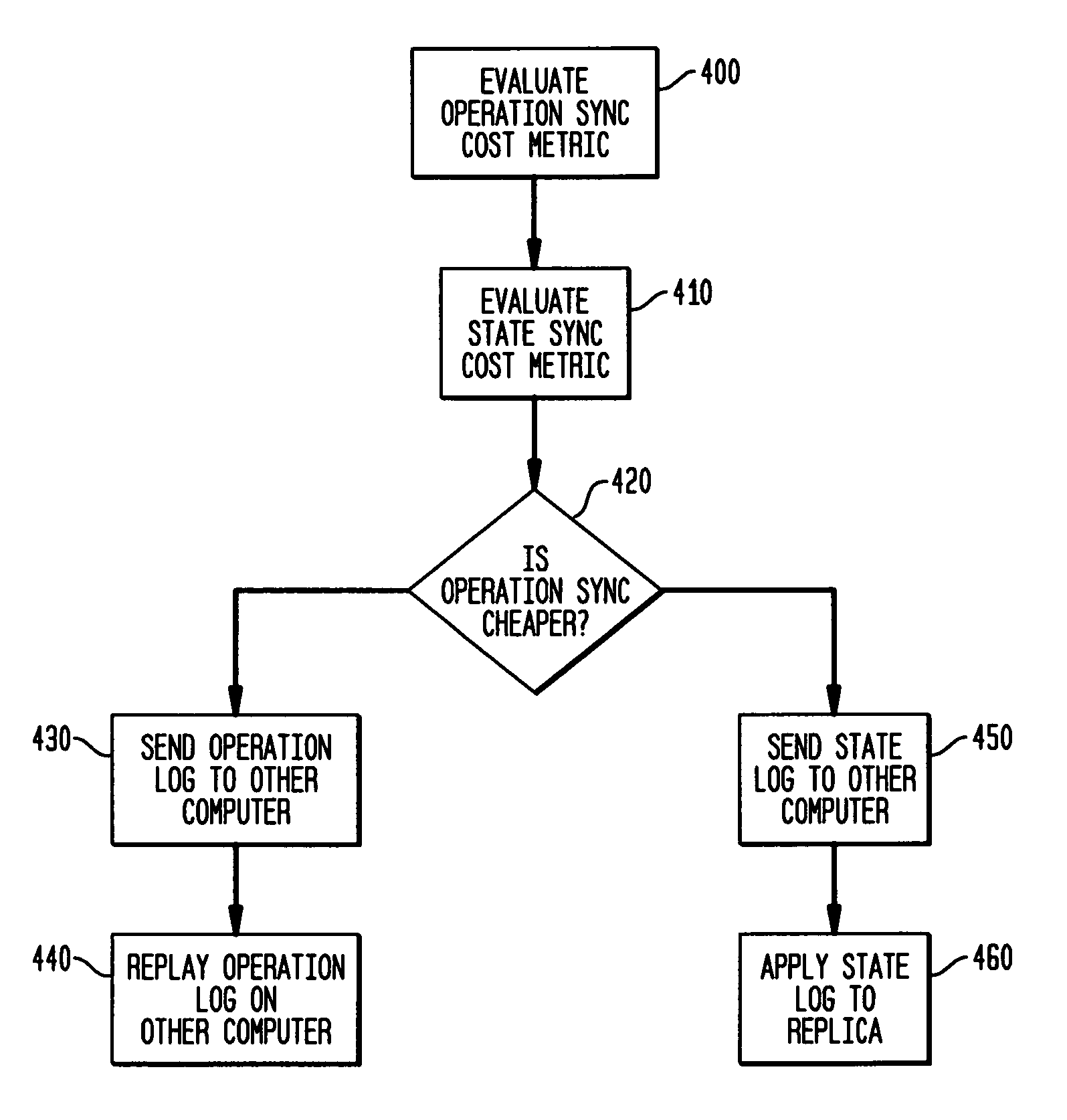

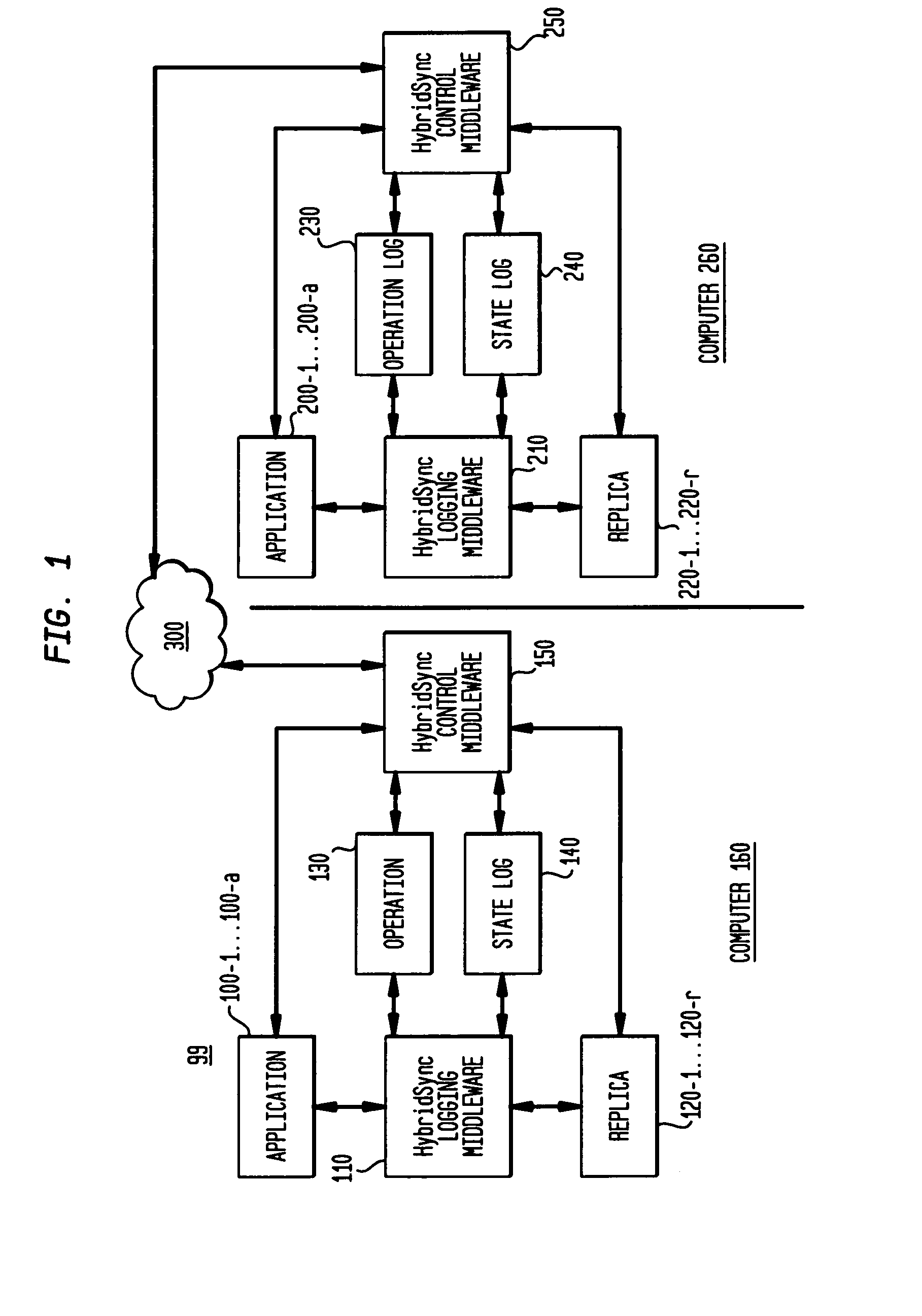

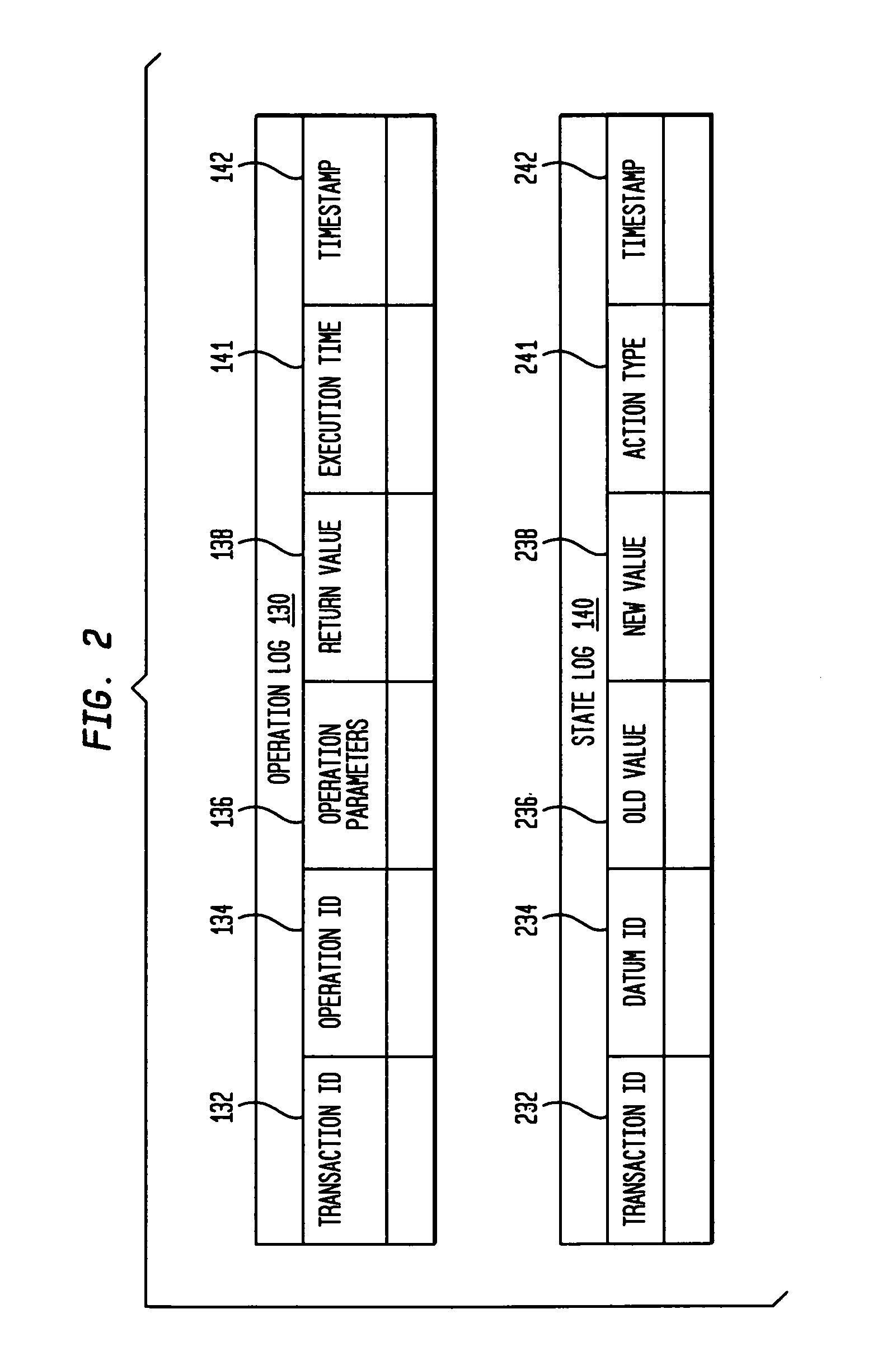

Method and system combining state replication and operational-replay synchronization

ActiveUS7543000B2Minimize powerConvenient timeData processing applicationsDigital data information retrievalData synchronizationComputerized system

A system, method and computer program product for synchronizing replicas of shared data structures associated with one or more computer systems. The method comprises: evaluating a metric for performing a replica synchronization operation on a first computer system according to a first synchronization method; evaluating the metric for performing a replica synchronization operation on the first computer system according to a second synchronization method; and, selecting, at synchronization time, based on the evaluated metric, whether to use the first or second synchronization methods, and communicating a command to a second computer system to replicate a shared data structure based on the selected synchronization method.

Owner:SAP AG

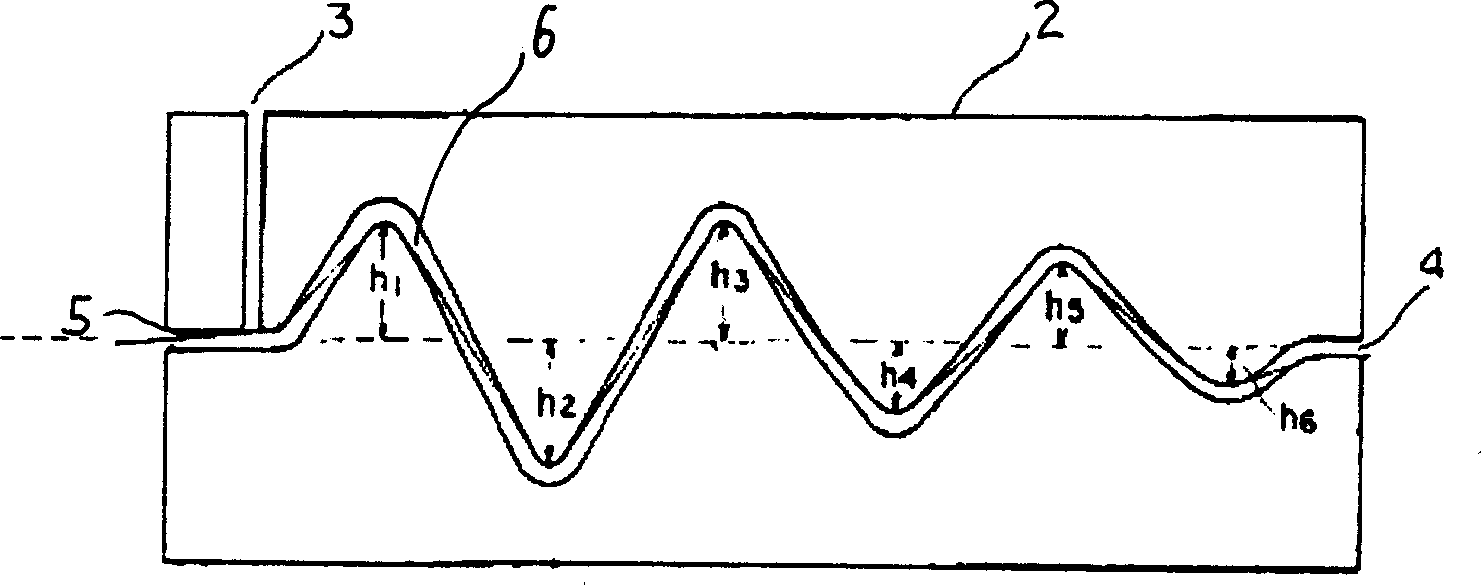

Technological process for producing super-thick plate

InactiveCN101439348AQuality improvementLow costTemperature control deviceElectron beam welding apparatusElectro-slag remeltingVacuum chamber

The invention relates to a process for producing an ultra-thick plate and belongs to the field of rolling and producing an ultra-thick steel plate in the metallurgical industry. The invention mainly overcome the defect of producing the ultra-thick steel plate by a traditional model casting manufacturing blank and an electro-slag remelting manufacturing blank. The method comprises the following steps: cutting and fixing lengths of the blanks, mechanically conditioning the blanks (eliminating, leveling and cleaning a single-surface oxide layer of a casting blank with a milling machine, a planer or a shot blast); clamping an assembly (relatively superposing the cleaning surfaces of the two blanks after processing, placing the two blanks oppositely and clamping the blanks); mounting the blanks in a vacuum chamber of an electronic beam welding machine for purpose of vacuuming; sewing the assembly on the electronic beam welding seal edge, heating the assembly in a furnace and rolling the assembly through temperature control; and then producing the ultra-thick steel plate. Compared with the traditional electro-slag remelting production process, the process has the advantages of high production efficiency, reduced electric power consumption, less investment of production devices and low production cost. Compared with the traditional die casting production process, the process solves the problem of segregation and looseness of a large-scale die casting ingot center part; the finished product ratio is high; and the finished product ratio of blank assembly is over 90 %.

Owner:SHANDONG IRON & STEEL CO LTD

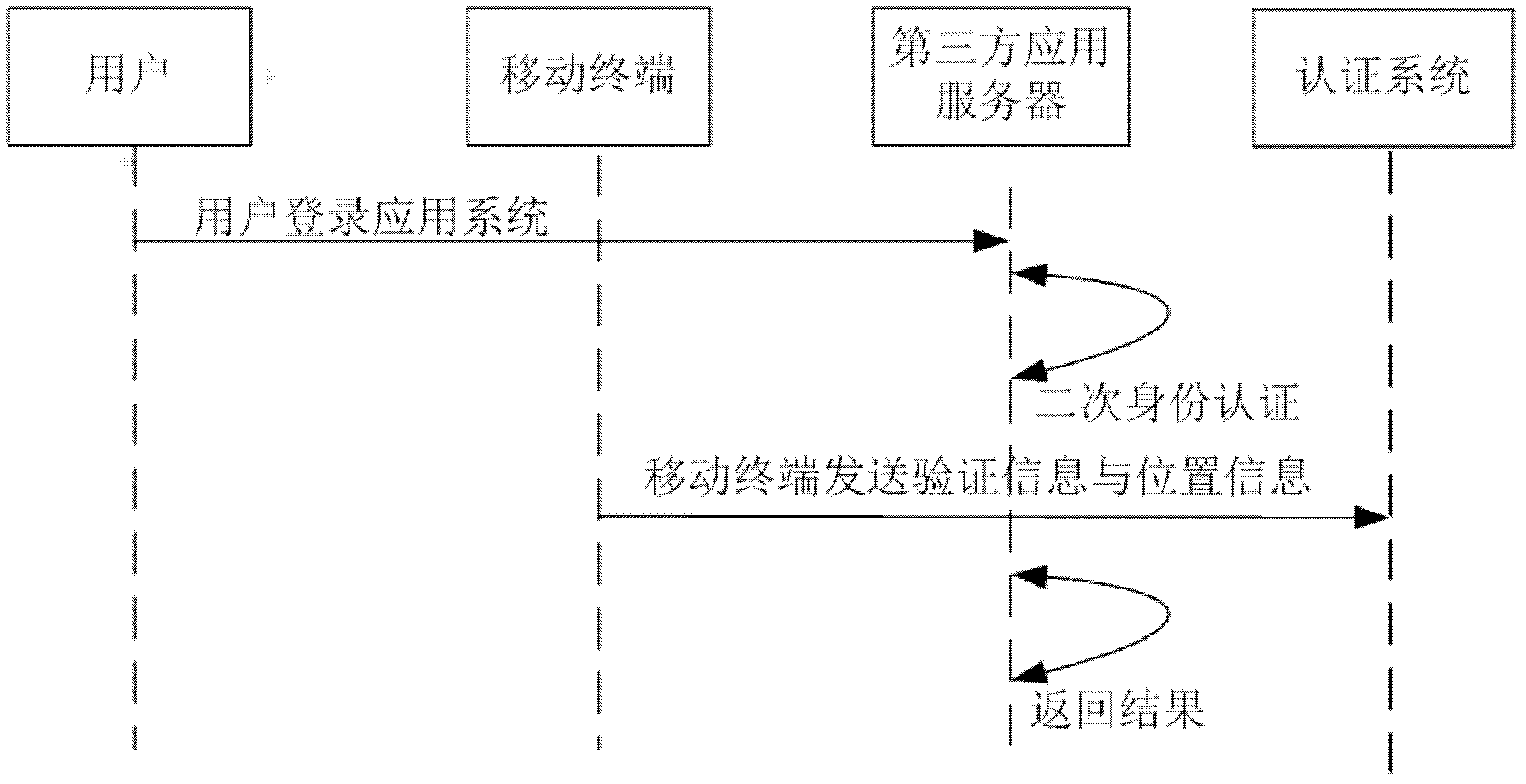

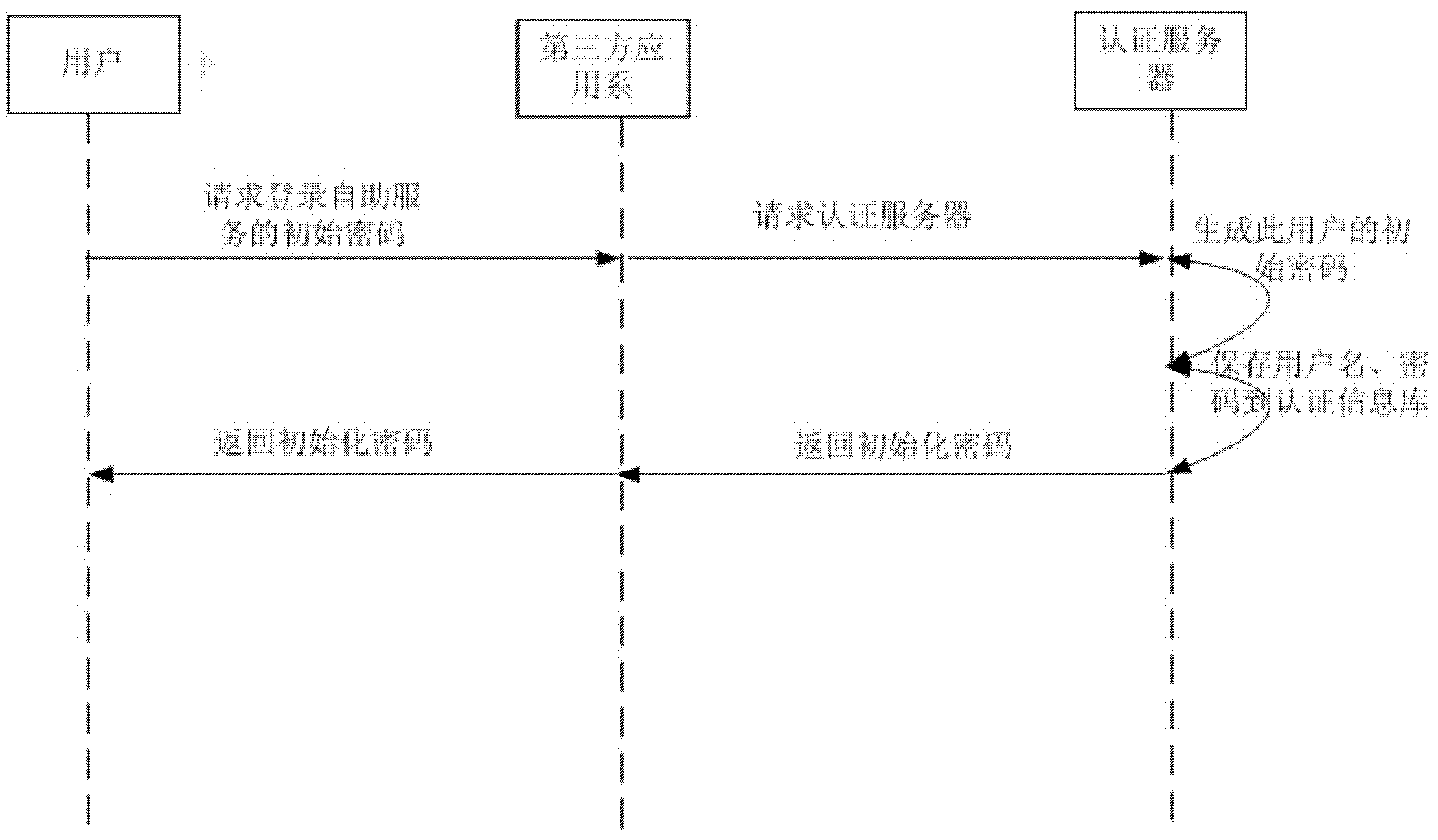

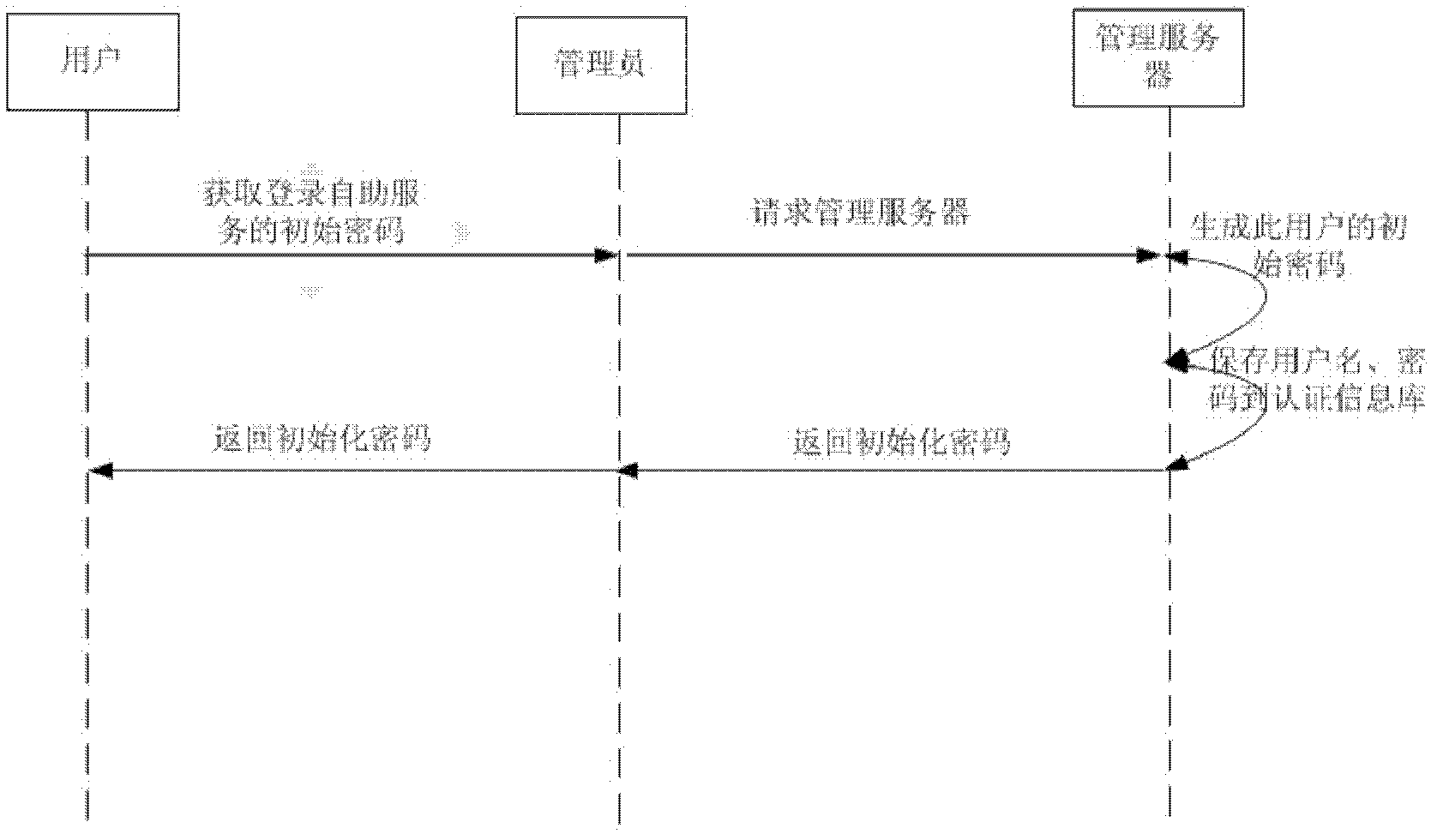

Mobile-terminal-based identity authentication system and method

ActiveCN102685093ALow costRich operating experienceUser identity/authority verificationThird partyApplication server

The invention provides a mobile-terminal-based identity authentication method and a mobile-terminal-based identity authentication system. The method comprises the following steps of: (1) acquiring an initial password for the login of a self-service server; (2) logging in the self-service server to acquire an initializing sequence number of a mobile client by a user; (3) initializing the mobile client; and (4) performing identity authentication, namely a user makes a login application to a third party application server, a mobile terminal makes an authentication request to an authentication server, and the third party application server returns an authentication result to the user after obtaining a mobile terminal authentication result from the authentication server, wherein the authentication request made by the mobile terminal to the authentication server comprises dynamic password authentication and position information authentication. Hardware equipment is replaced by a software client, so that the production cost of hardware is saved; and by a dynamic factor (a time factor or an event factor) between the software client and the authentication server, synchronization can be conveniently realized, and integration with a third party application system is facilitated, so that limitation and shortcomings caused by the use of the hardware equipment to the whole authentication system are completely overcome.

Owner:TIMESAFER BEIJING TECH

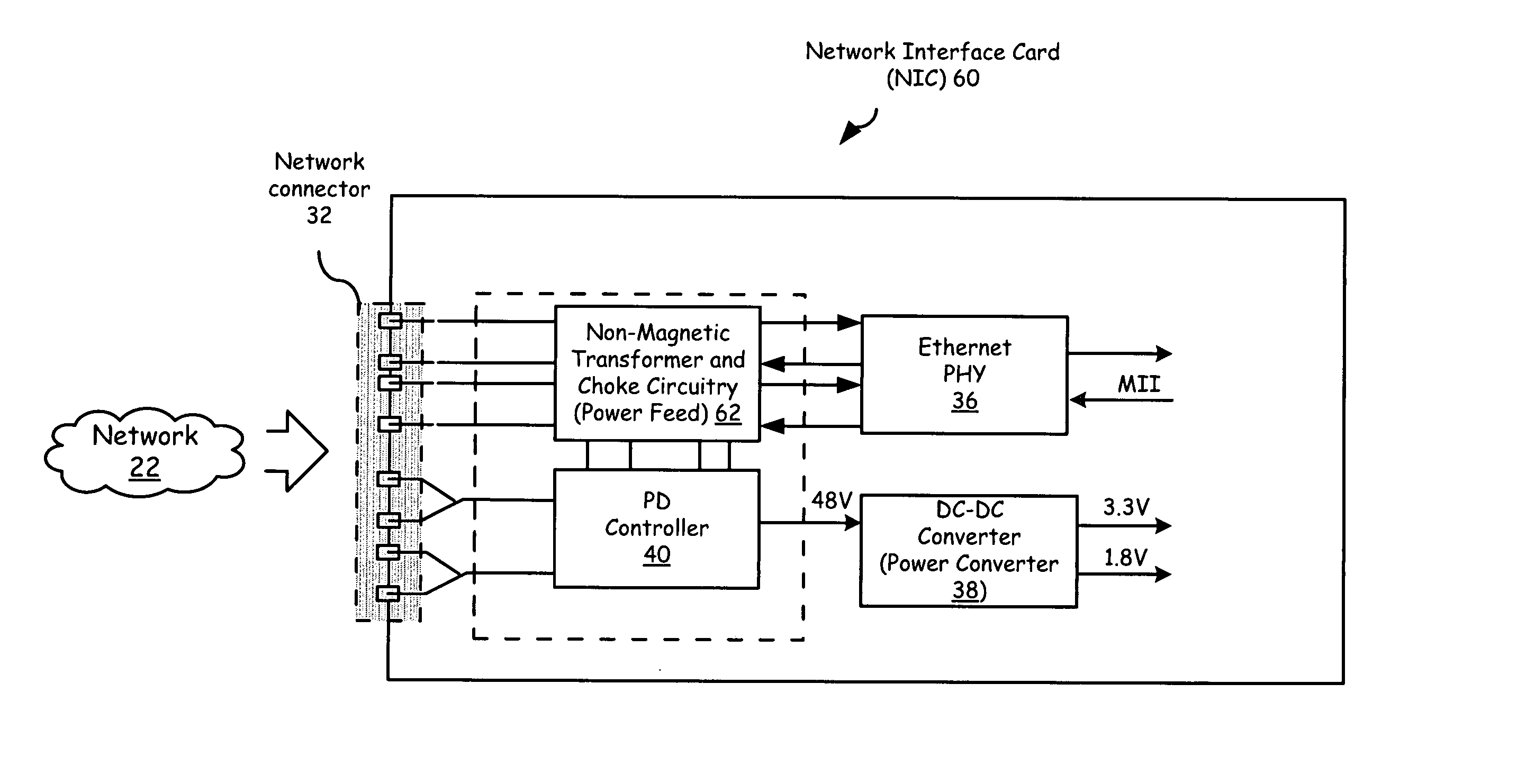

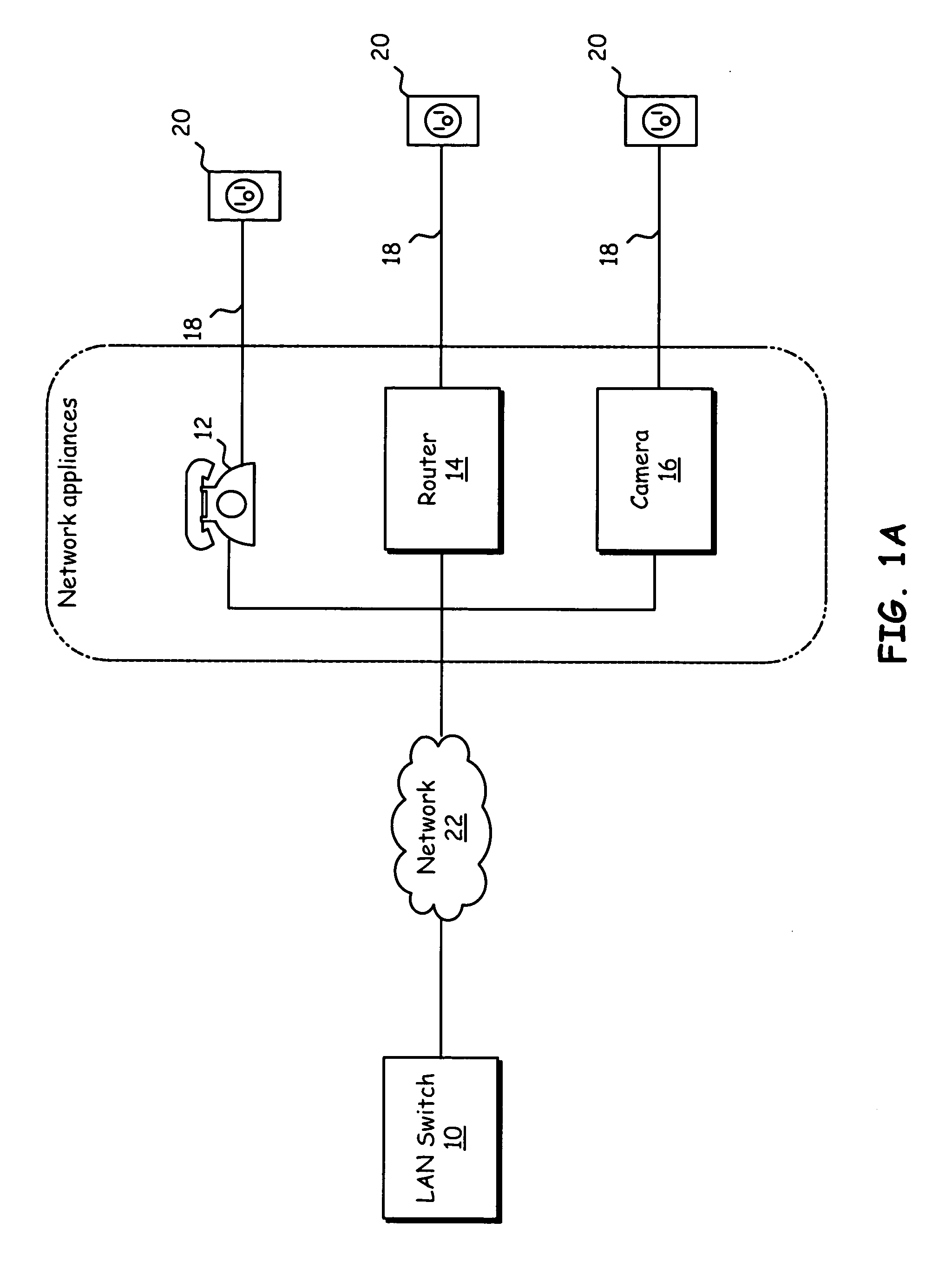

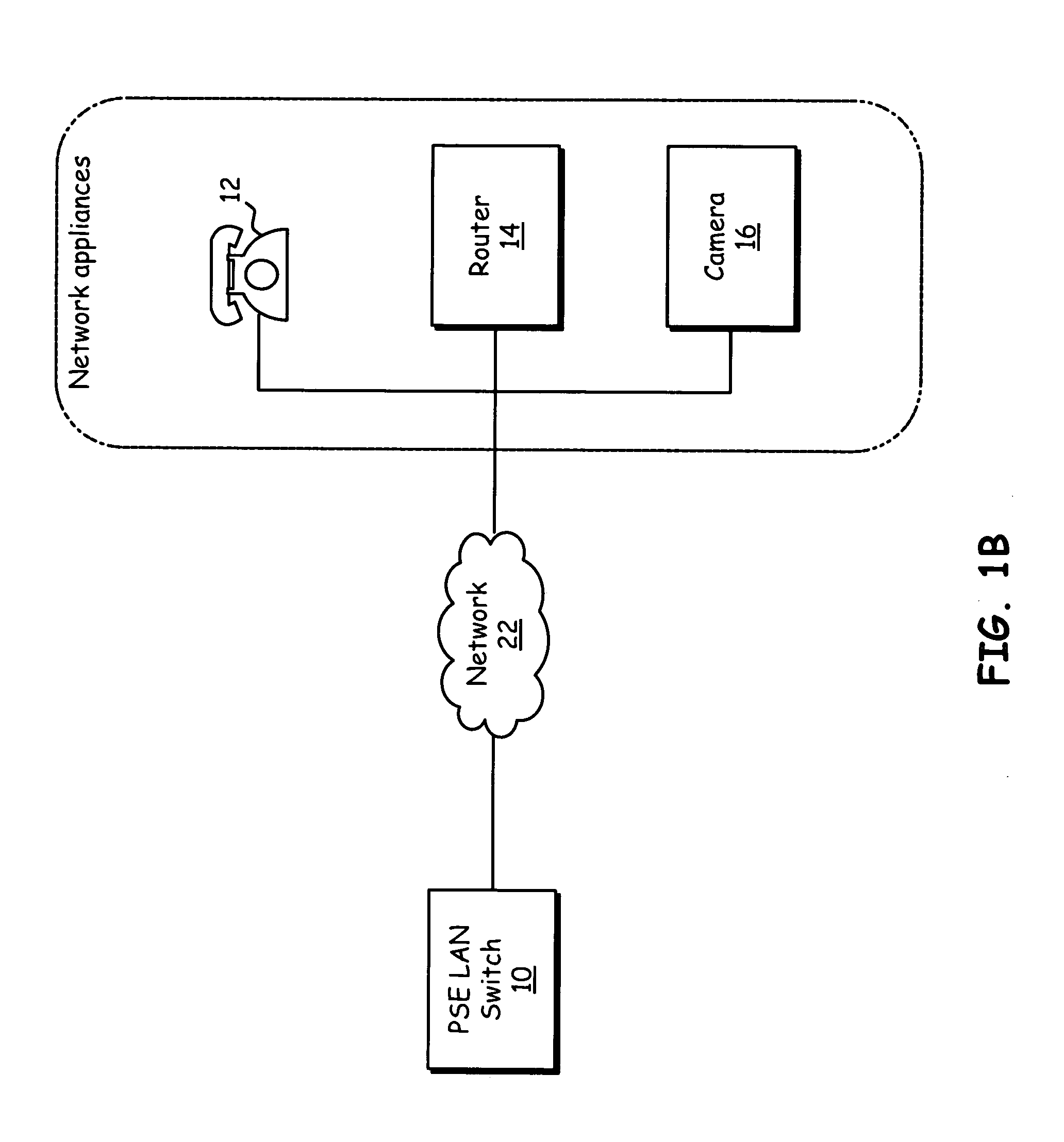

System and method to detect power distribution fault conditions and distribute power to a network attached power device

InactiveUS20070260904A1Improve approachAddress limitationsDigital data processing detailsData switching current supplyNetwork connectionDistributed power

Power feed circuitry within a power over Ethernet (PoE) device detects fault conditions within power and data distribution lines coupled to the power feed circuitry. This circuitry includes network interface circuitry coupled to the network in order to exchange both data and power signals. The power interface circuitry also communicatively couples to at least one isolated power supply in order to draw power. The power may then be distributed via the attached network interface circuitry. A fault detection module couples to the power interface circuitry and the network interface circuitry. This fault detection module senses fault conditions associated with the power interface circuitry, network interface circuitry, and associated distribution lines in order to better draw and distribute power signals using the power feed circuitry.

Owner:KINETIC TECH INC

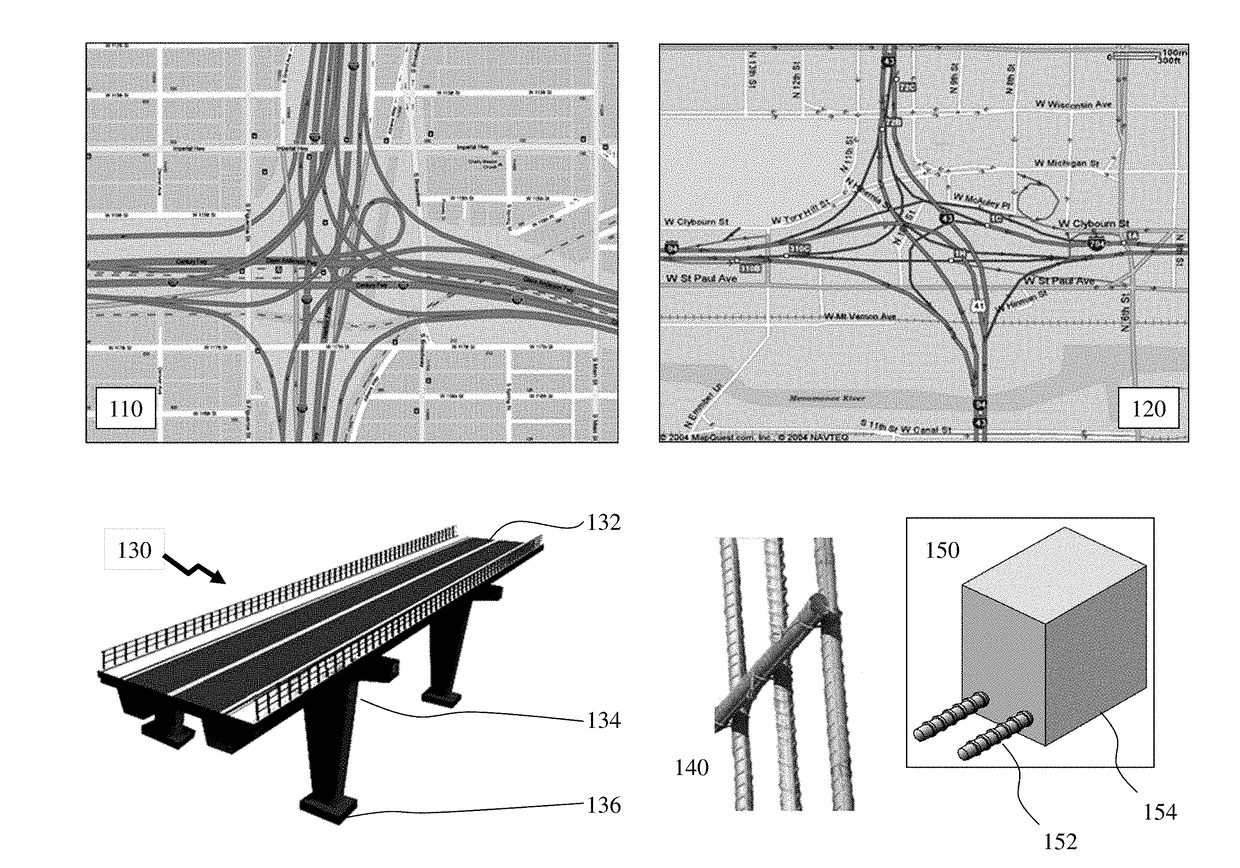

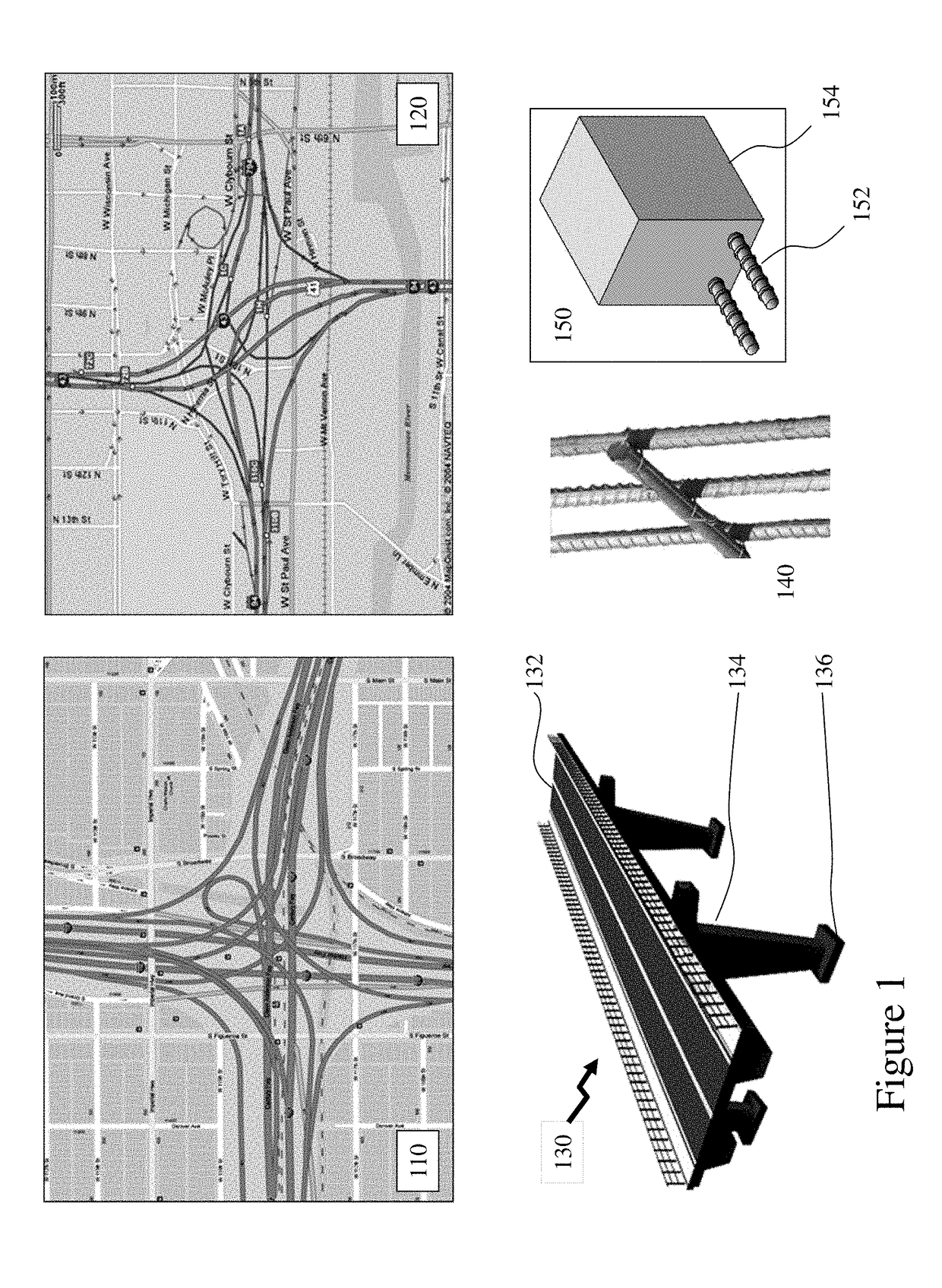

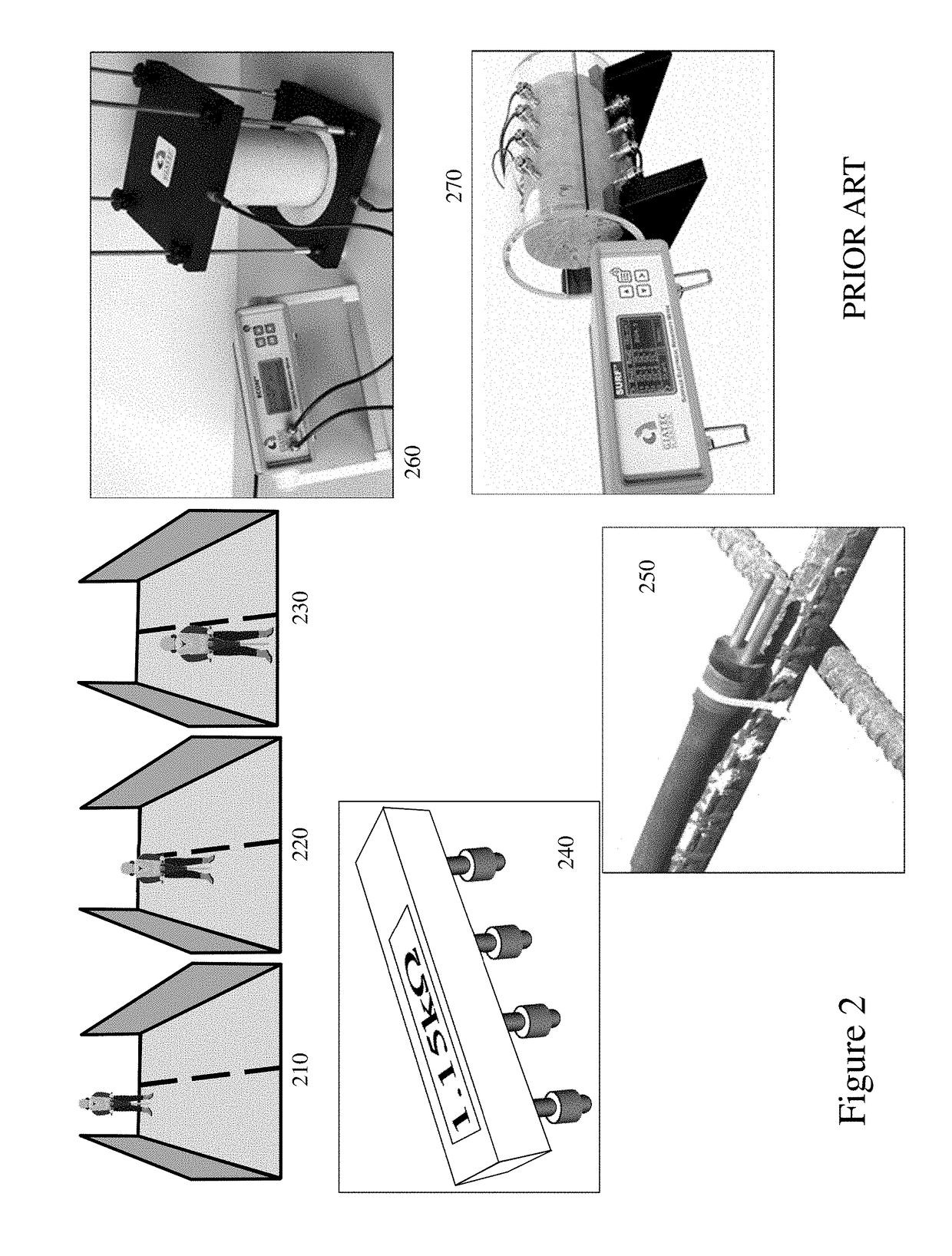

Method and systems relating to construction material assessment

ActiveUS20180238820A1Address limitationsForce measurement by measuring frquency variationsWeather/light/corrosion resistanceField testsWater content

Hundreds of thousands of concrete bridges, buildings etc. and hundreds of billions of tons of concrete require characterization throughout the process from manufacture to pouring and curing and on throughout service life. The characterization may relate to initial concrete properties, projected concrete properties, framework removal, corrosion, failure etc. Accordingly, a variety of measurements such as water content, electrical resistivity, and half-cell corrosion potential for example would be beneficially implemented as easy to use field test equipment or embedded sensors allowing lifetime monitoring to be performed rather than discrete assessments when issues become evident.

Owner:GIATEC SCI

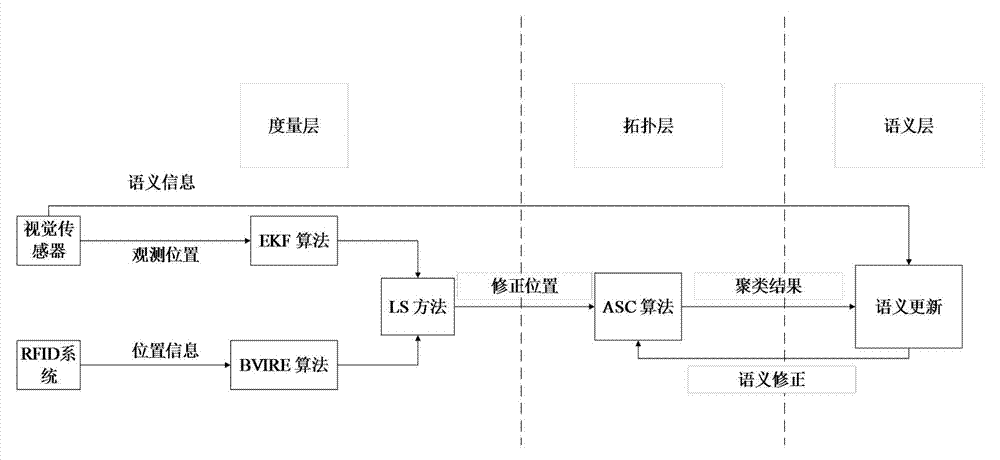

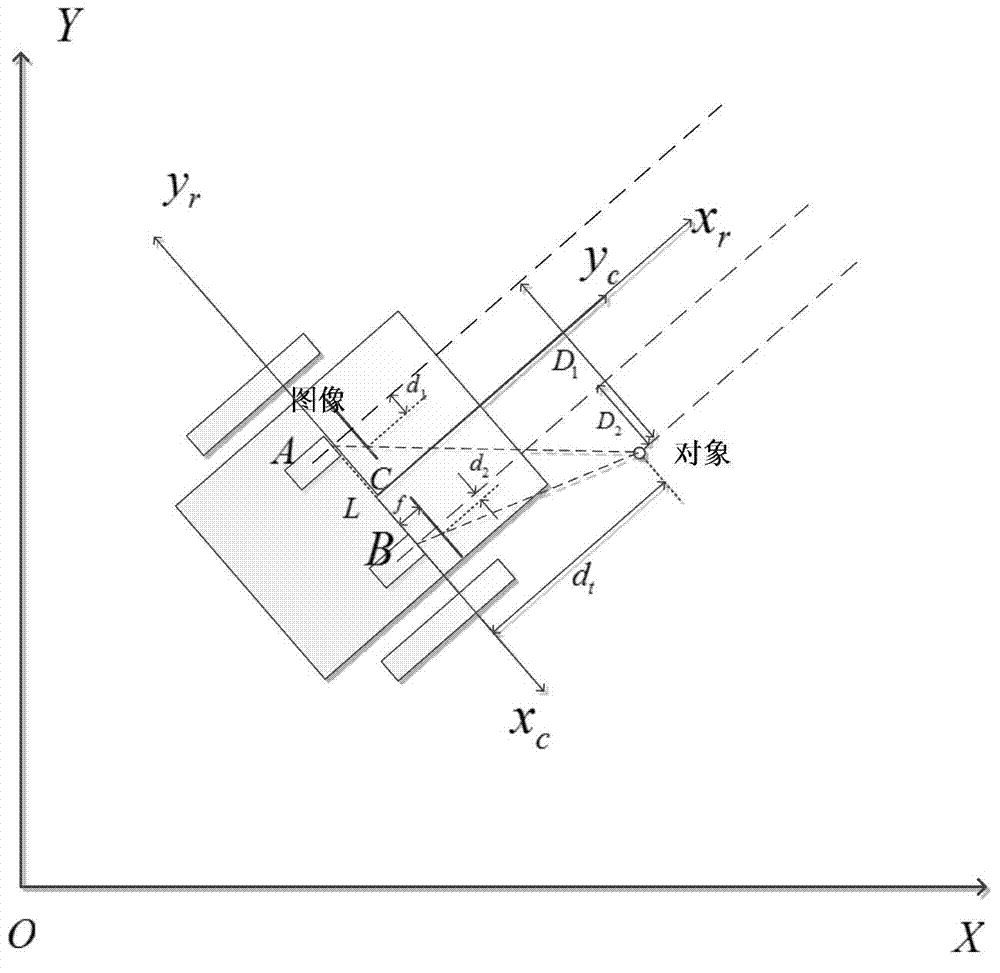

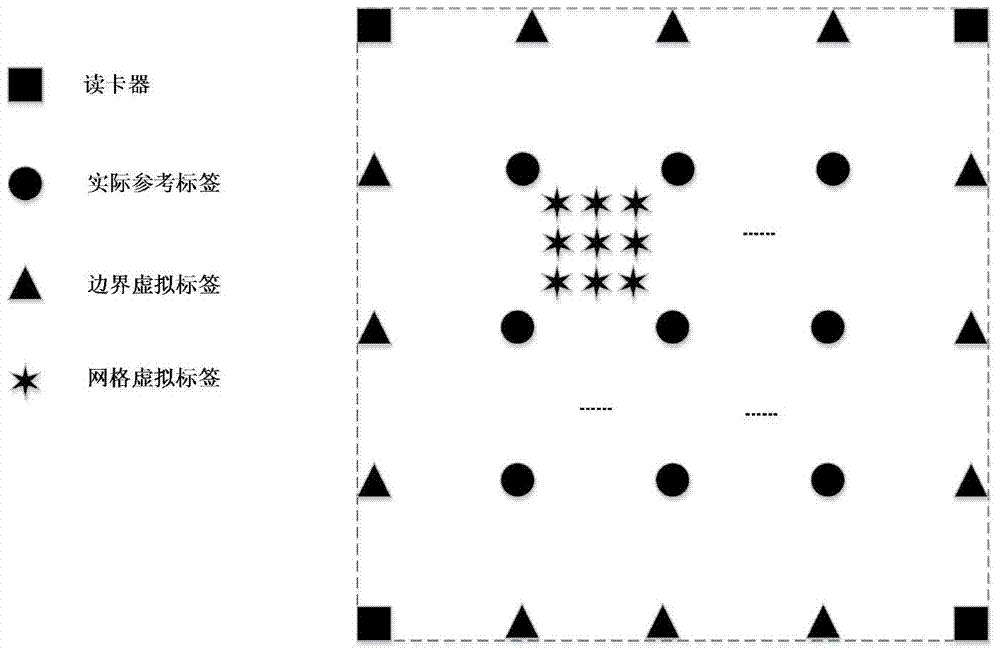

Robot distributed type representation intelligent semantic map establishment method

InactiveCN104330090AAddress limitationsHigh precisionInstruments for road network navigationVehicle position/course/altitude controlVisual positioningVisual perception

The invention discloses a robot distributed type representation intelligent semantic map establishment method which comprises the steps of firstly, traversing an indoor environment by a robot, and respectively positioning the robot and an artificial landmark with a quick identification code by a visual positioning method based on an extended kalman filtering algorithm and a radio frequency identification system based on a boundary virtual label algorithm, and constructing a measuring layer; then optimizing coordinates of a sampling point by a least square method, classifying positioning results by an adaptive spectral clustering method, and constructing a topological layer; and finally, updating the semantic property of a map according to QR code semantic information quickly identified by a camera, and constructing a semantic layer. When a state of an object in the indoor environment is detected, due to the adoption of the artificial landmark with a QR code, the efficiency of semantic map establishing is greatly improved, and the establishing difficulty is reduced; meanwhile, with the adoption of a method combining the QR code and an RFID technology, the precision of robot positioning and the map establishing reliability are improved.

Owner:BEIJING UNIV OF CHEM TECH

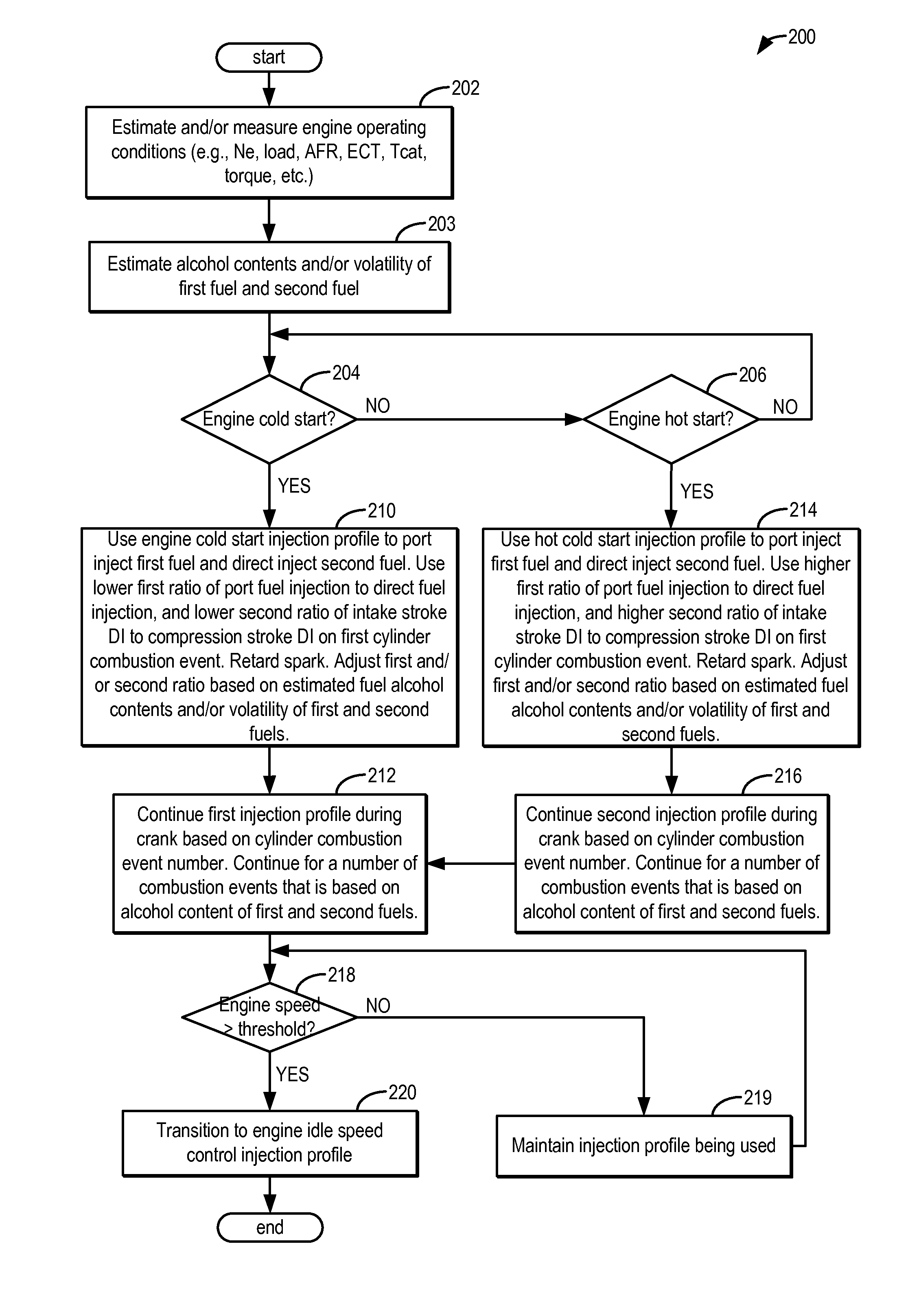

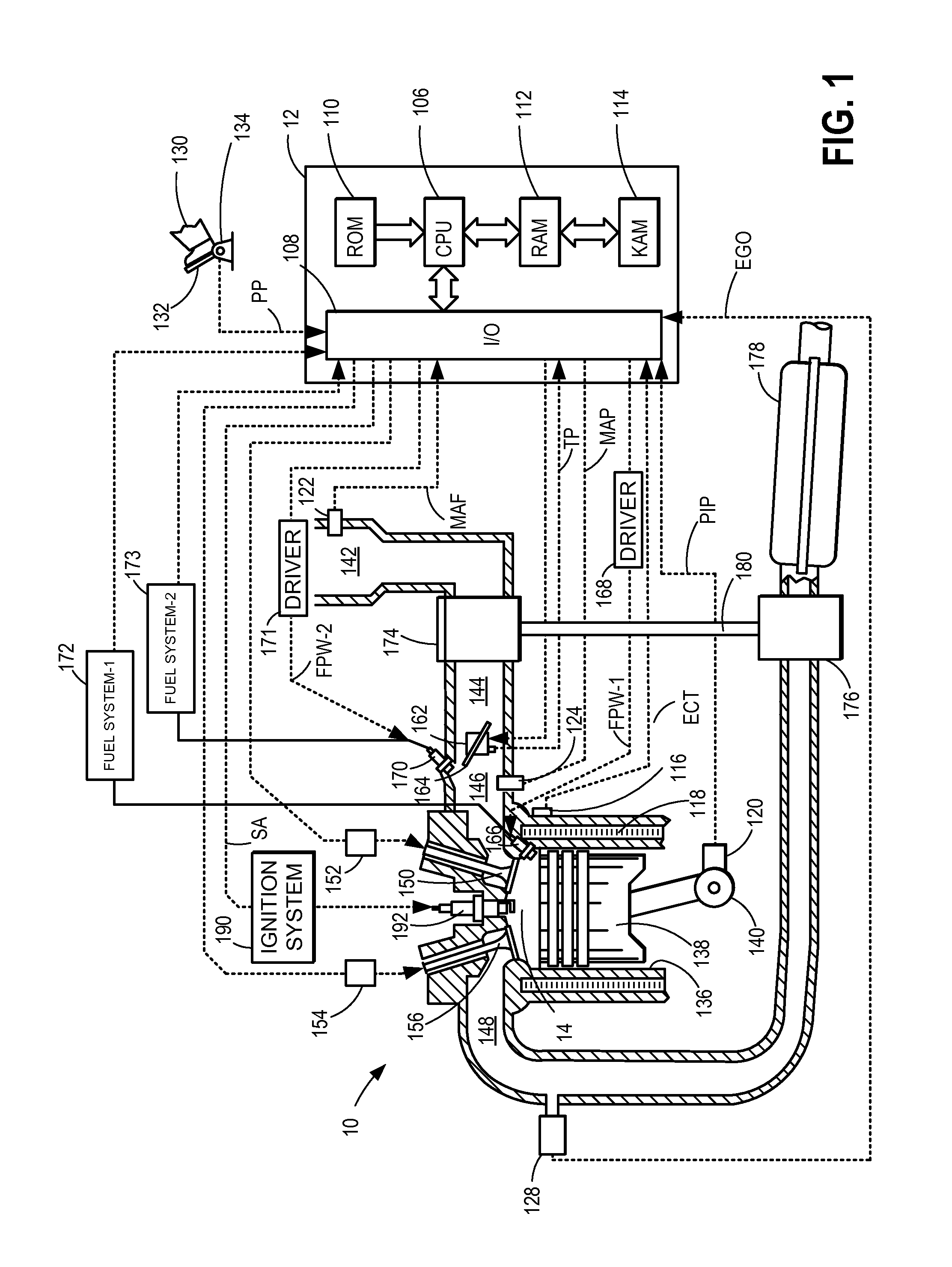

Method and system for engine control

ActiveUS20140297159A1Improve cooling effectIncrease heatValve arrangementsElectrical controlAlcohol contentMultiple injection

Methods and systems are provided for controlling exhaust emissions by adjusting an injection profile for different fuels injected into an engine cylinder from different fuel injectors during engine start and crank. By splitting fuel injection during start and cranking so that fuel of lower alcohol content is port injected and fuel of higher alcohol content is direct injected as one or multiple injections, the soot load of the engine can be reduced and fuel economy can be improved.

Owner:FORD GLOBAL TECH LLC

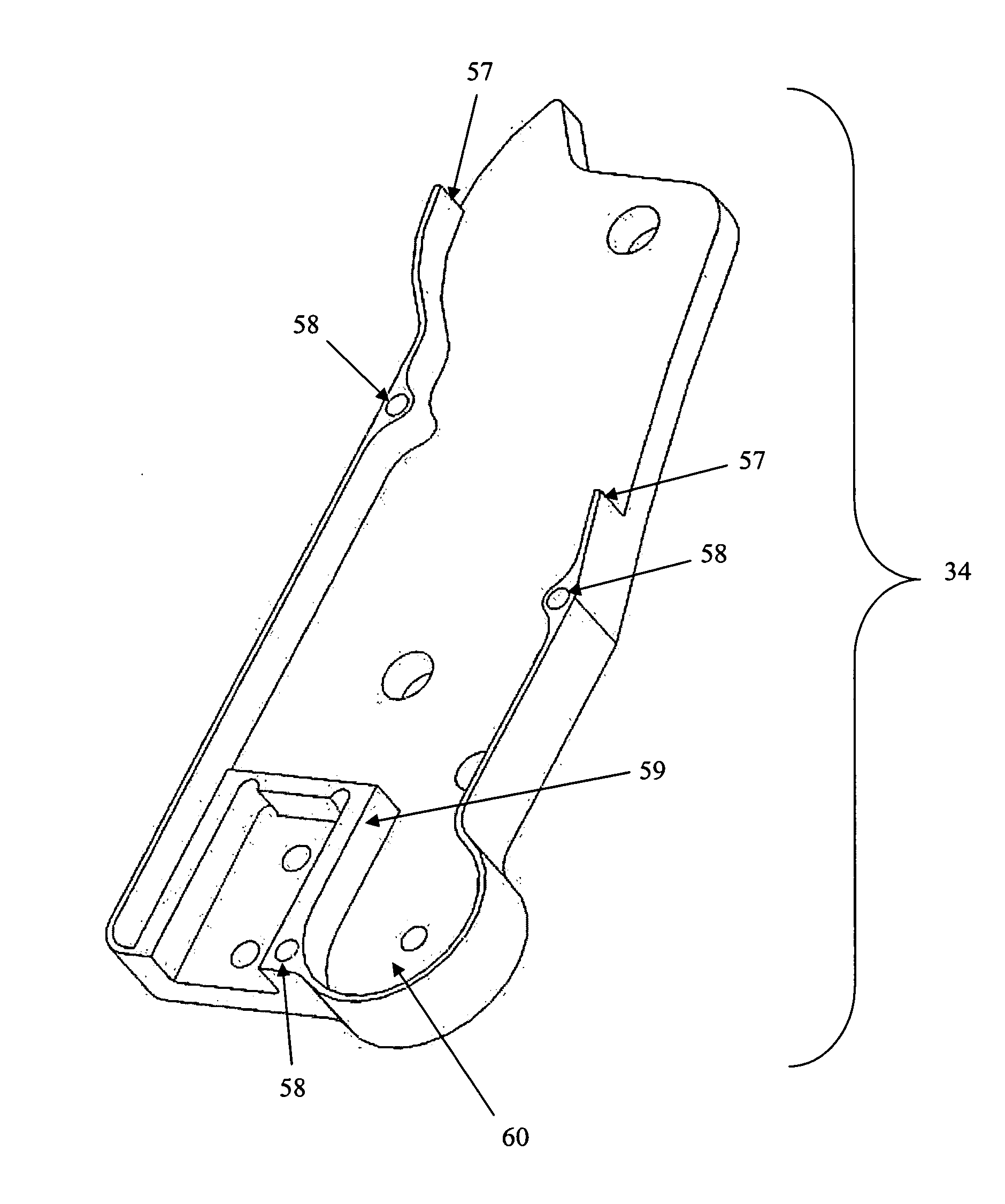

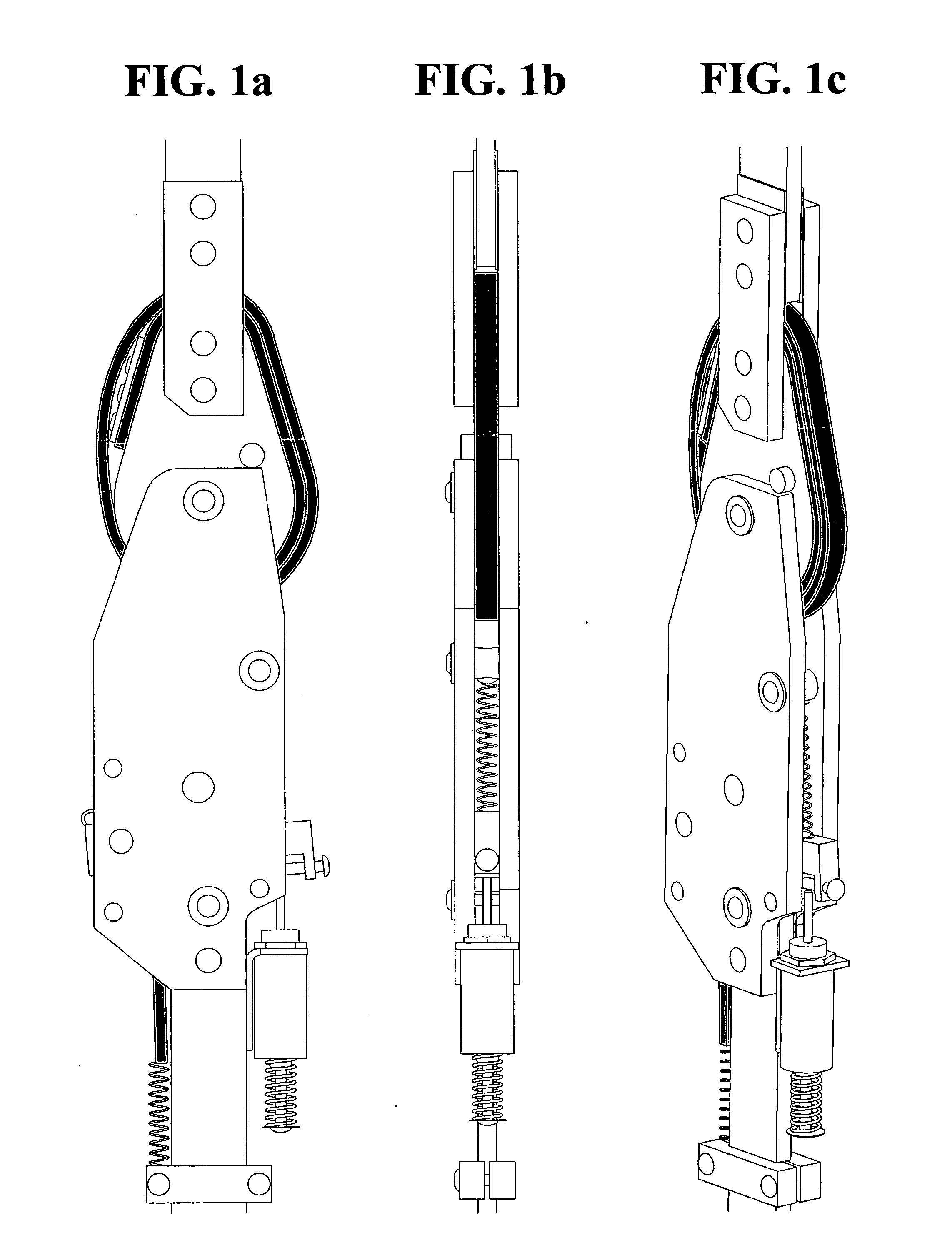

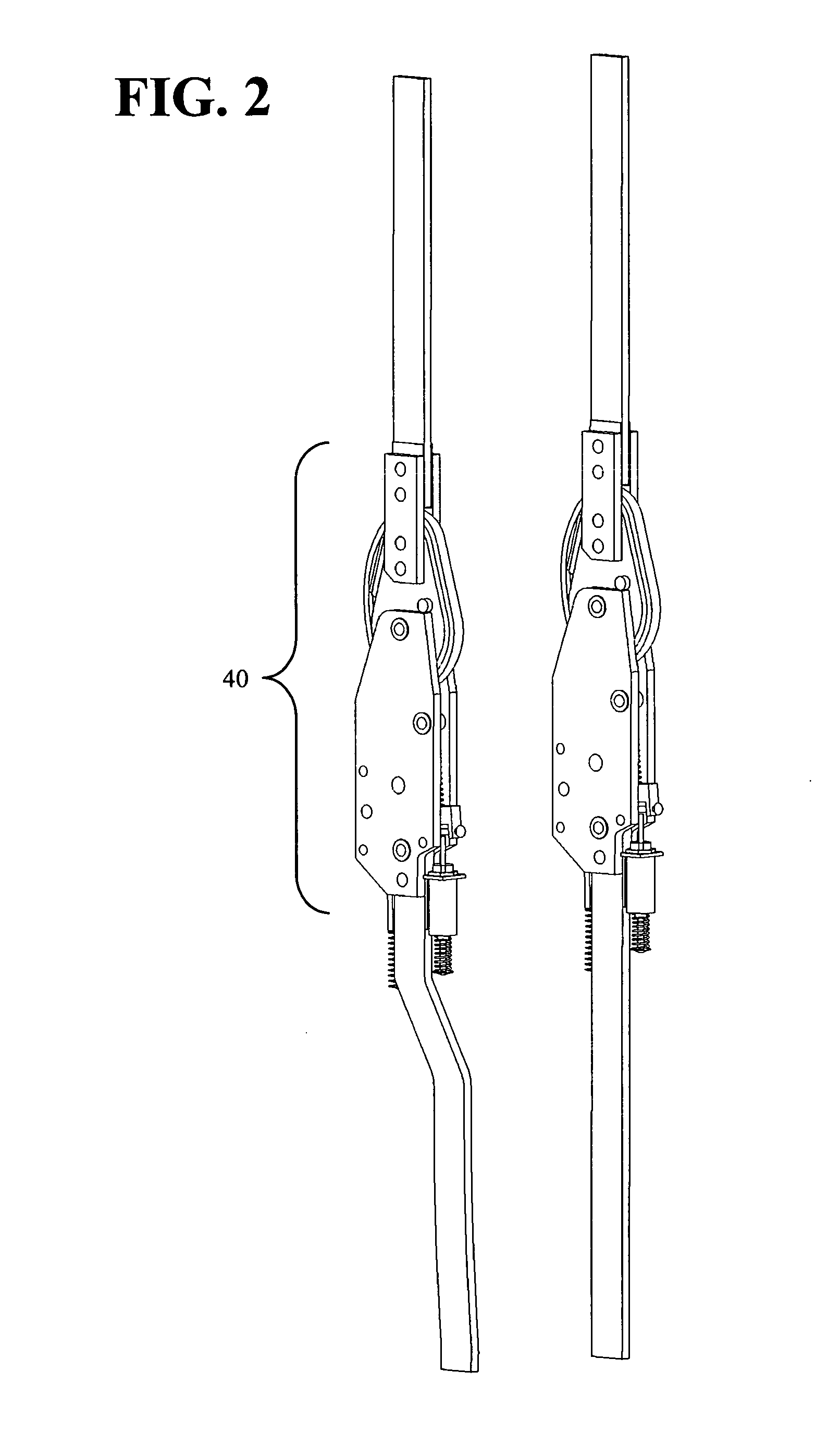

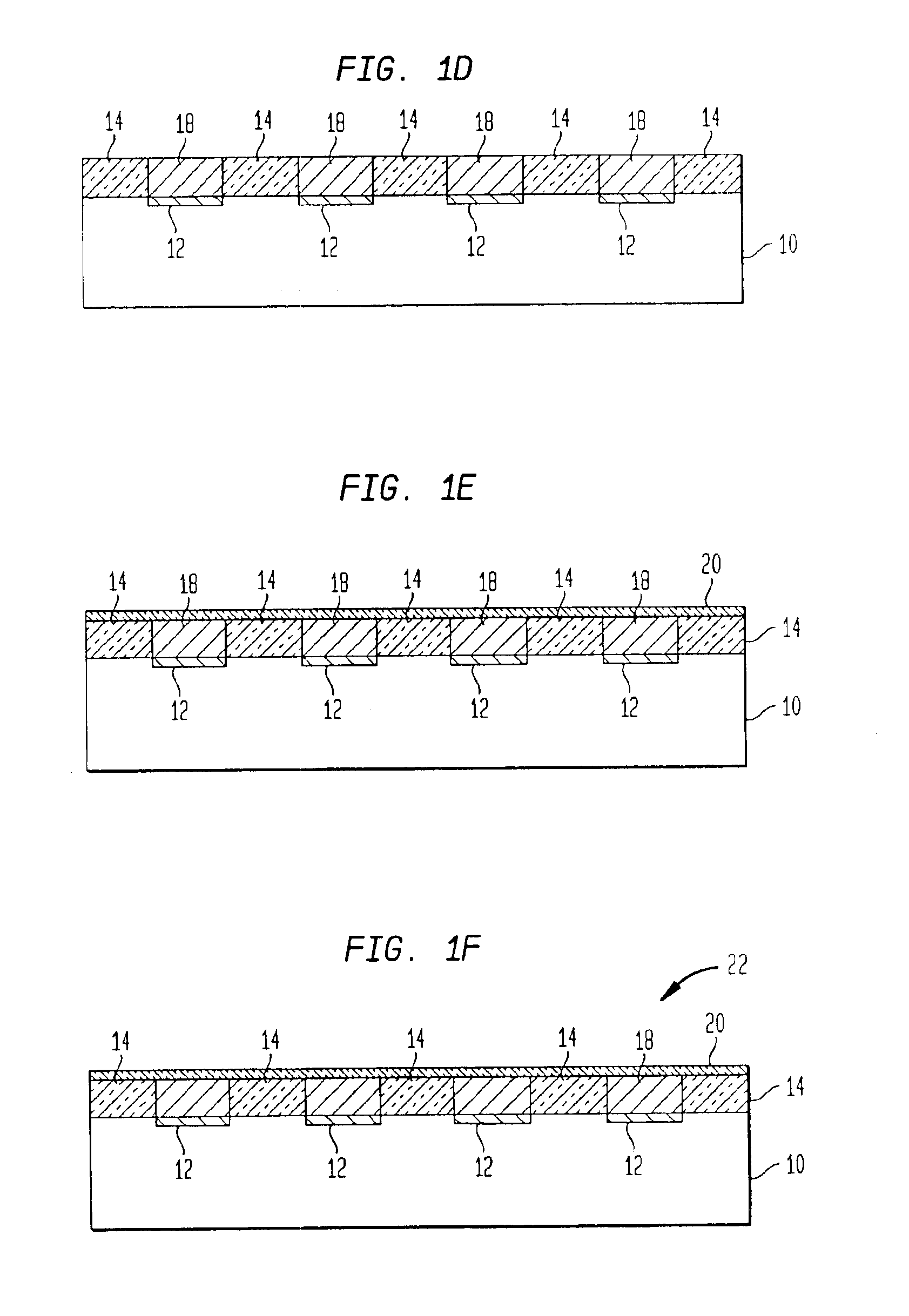

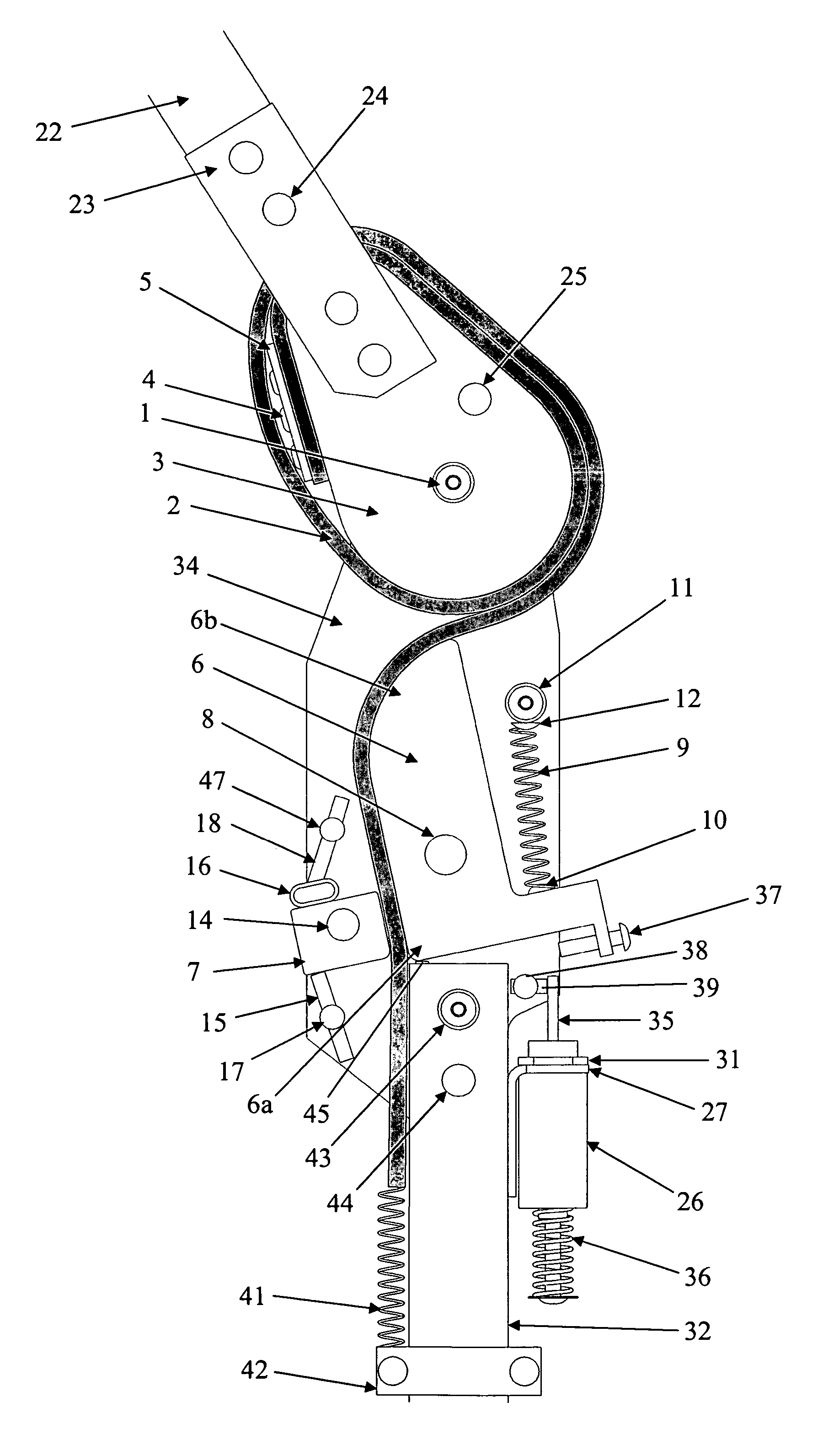

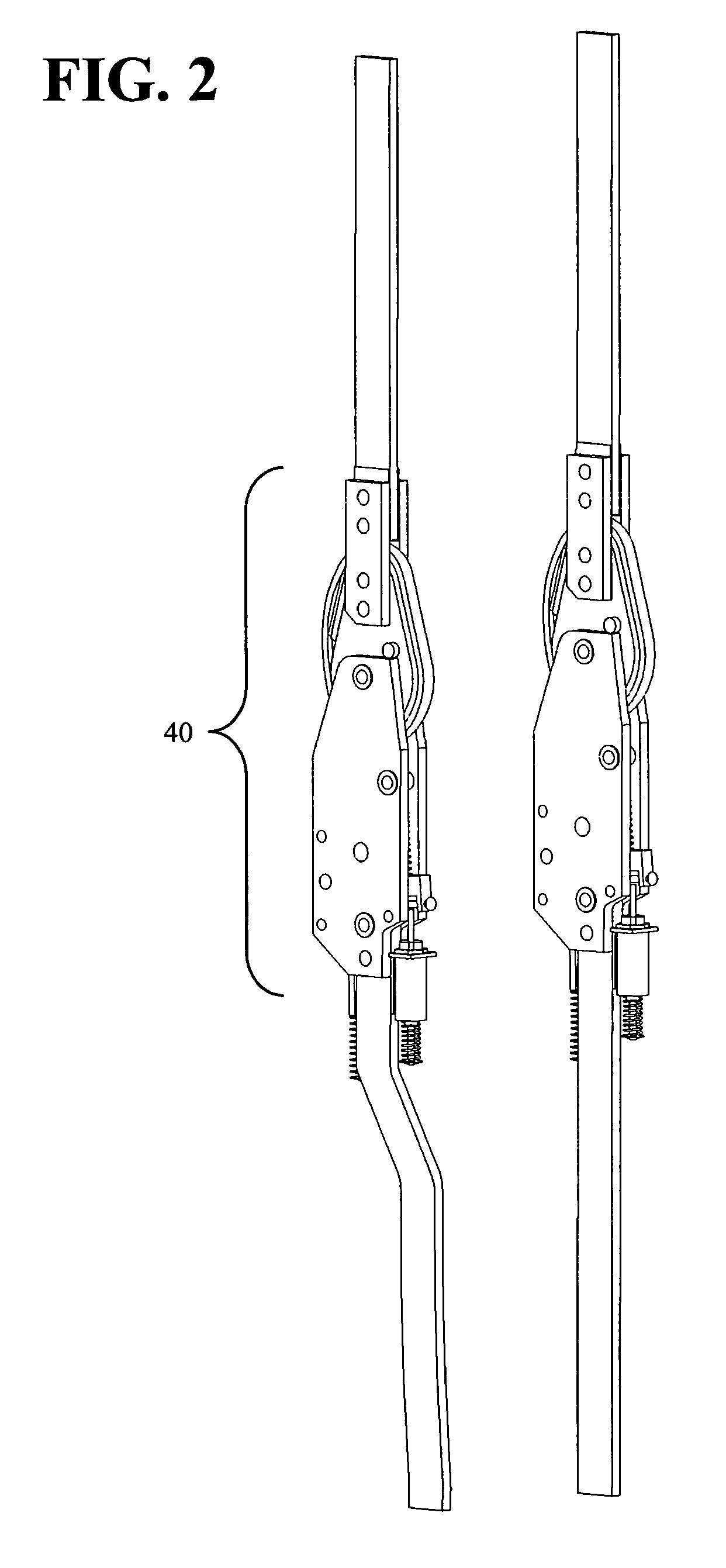

Articulating joint

InactiveUS20060206043A1Inhibits excessive knee flexionAddress limitationsFeet bandagesNon-surgical orthopedic devicesLocking mechanismEngineering

The present invention pertains to an articulating joint that is disengageable between two modes of operation: unidirectional movement of the joint or bi-directional movement of the joint, with features that allow the mode to be automatically switched as required. When fully locked, the joint inhibits joint flexion while allowing joint extension. When actuated, a locking mechanism is disengaged to allow both uninhibited flexion and extension of the joint.

Owner:OTTAVA HEALTH RES INST (CA) +1

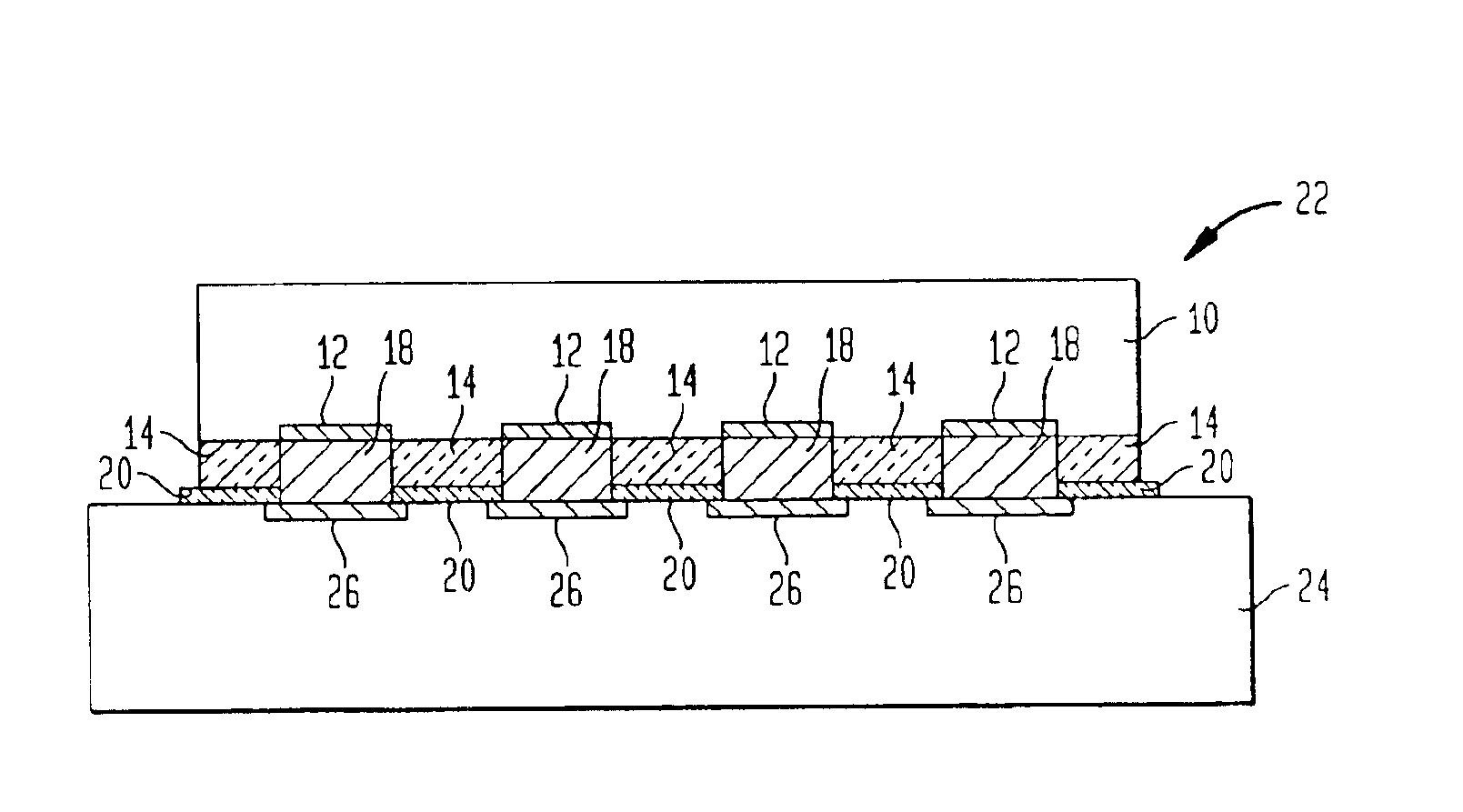

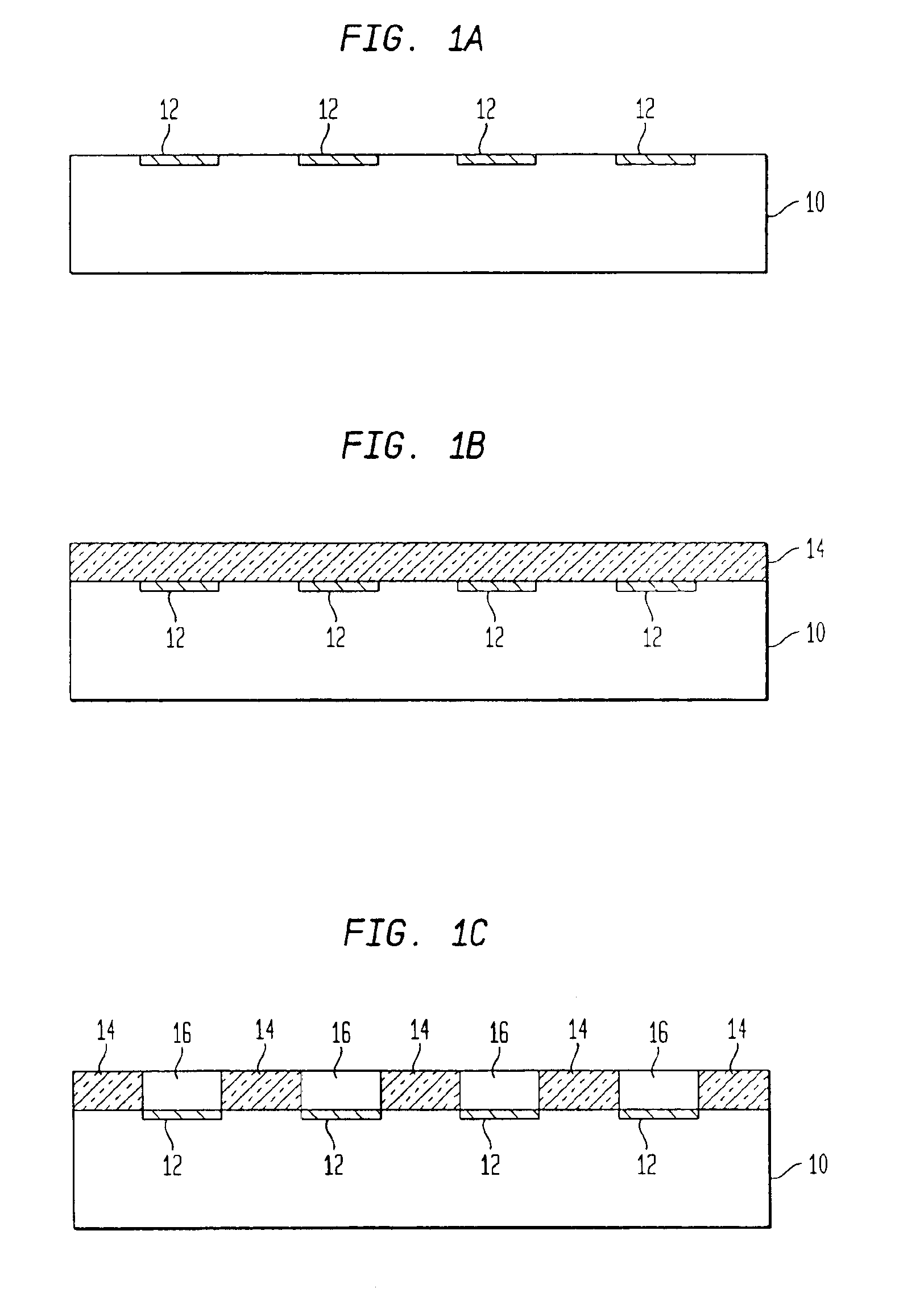

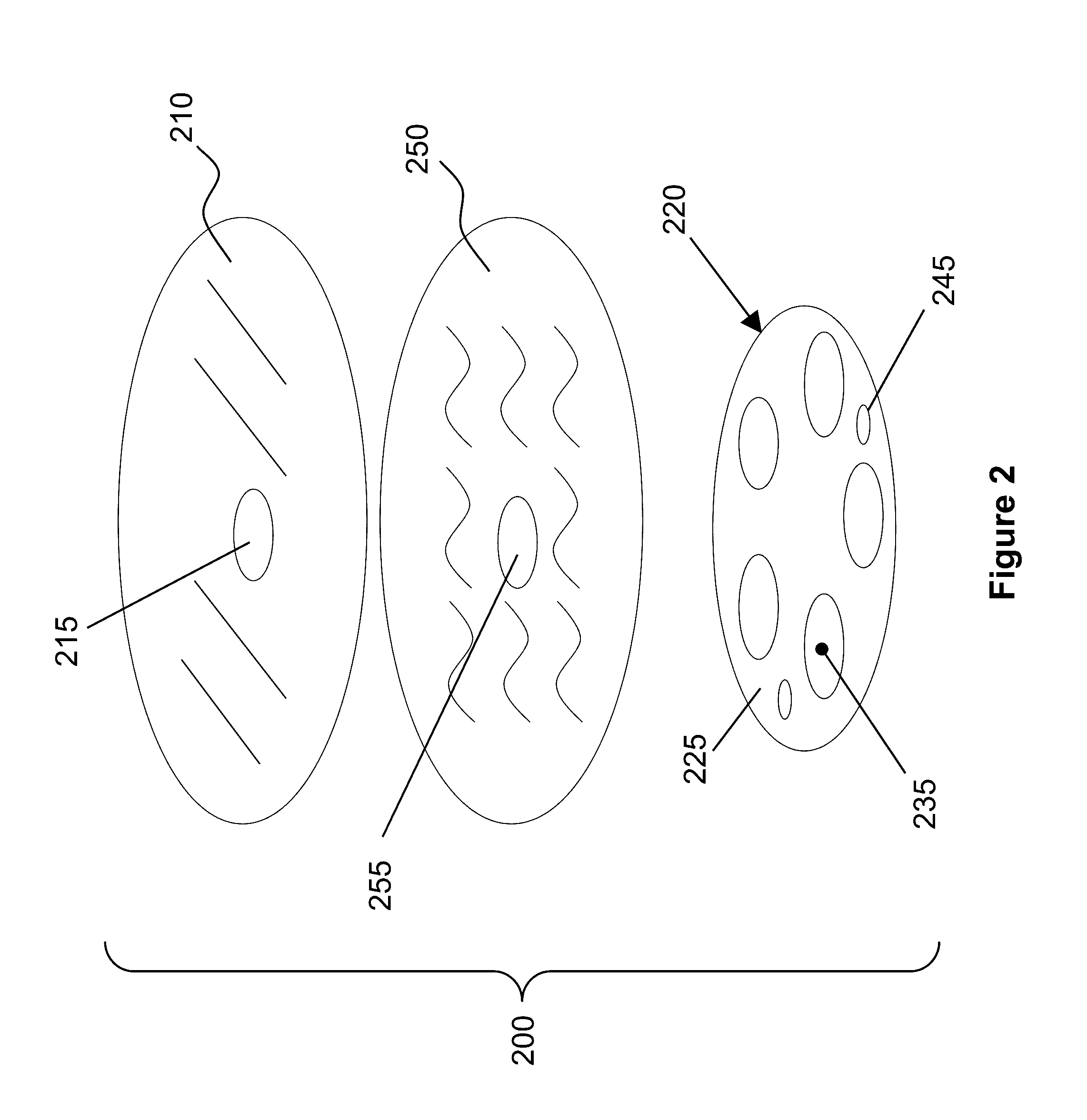

Bilayer wafer-level underfill

InactiveUS6924171B2Address limitationsEasy to implementSemiconductor/solid-state device detailsSolid-state devicesInterconnectionEngineering

Methods for fabricating microelectronic interconnection structures as well as the structures formed by the methods are disclosed which improve the manufacturing throughput for assembling flip chip semiconductor devices. The use of a bilayer of polymeric materials applied on the wafer prior to dicing eliminates the need for dispensing and curing underfill for each semiconductor at the package level, thereby improving manufacturing throughput and reducing cost.

Owner:IBM CORP

Articulating joint

InactiveUS7410472B2Inhibits excessive knee flexionAddress limitationsFeet bandagesNon-surgical orthopedic devicesLocking mechanismJoint flexion

Owner:OTTAVA HEALTH RES INST (CA) +1

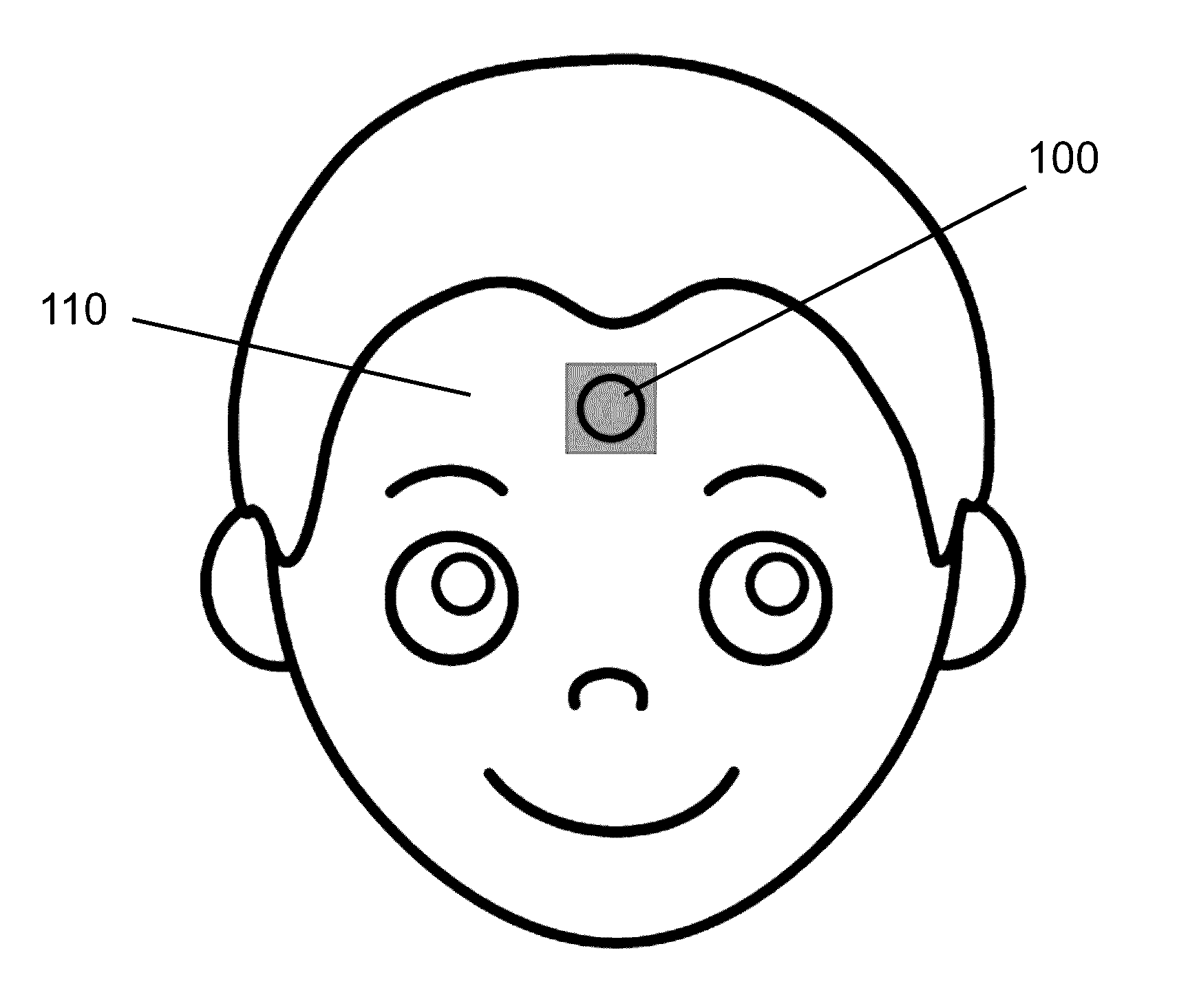

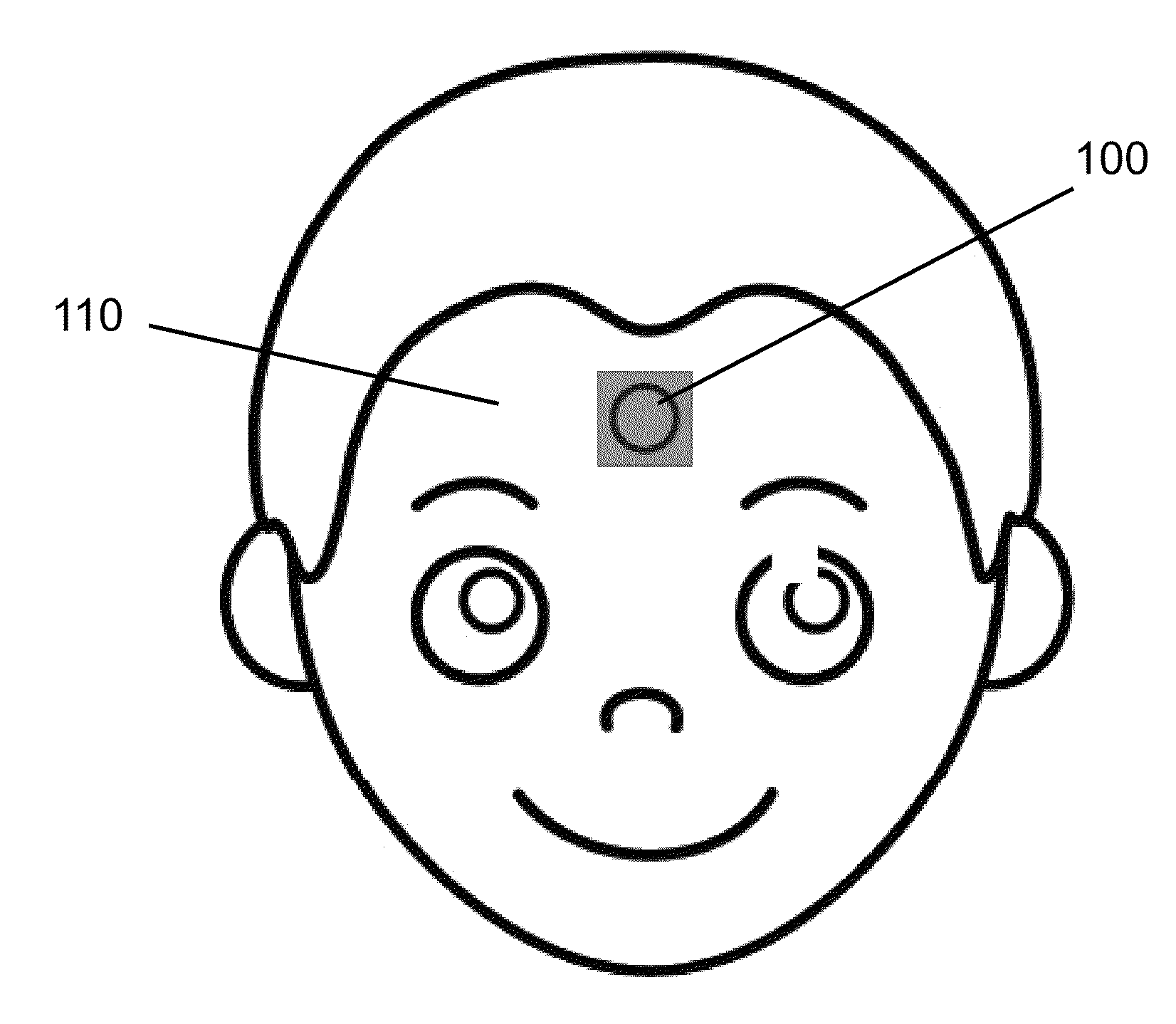

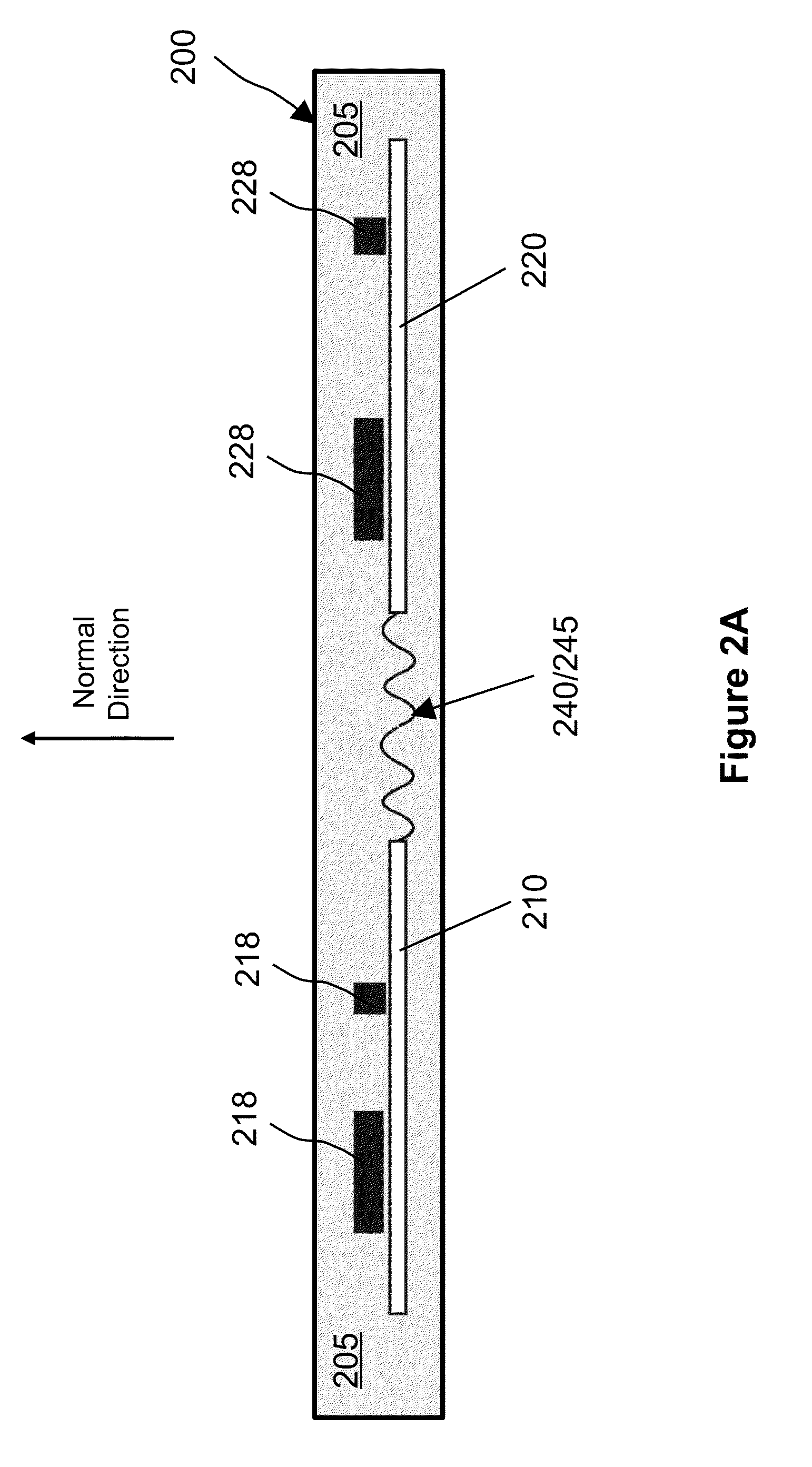

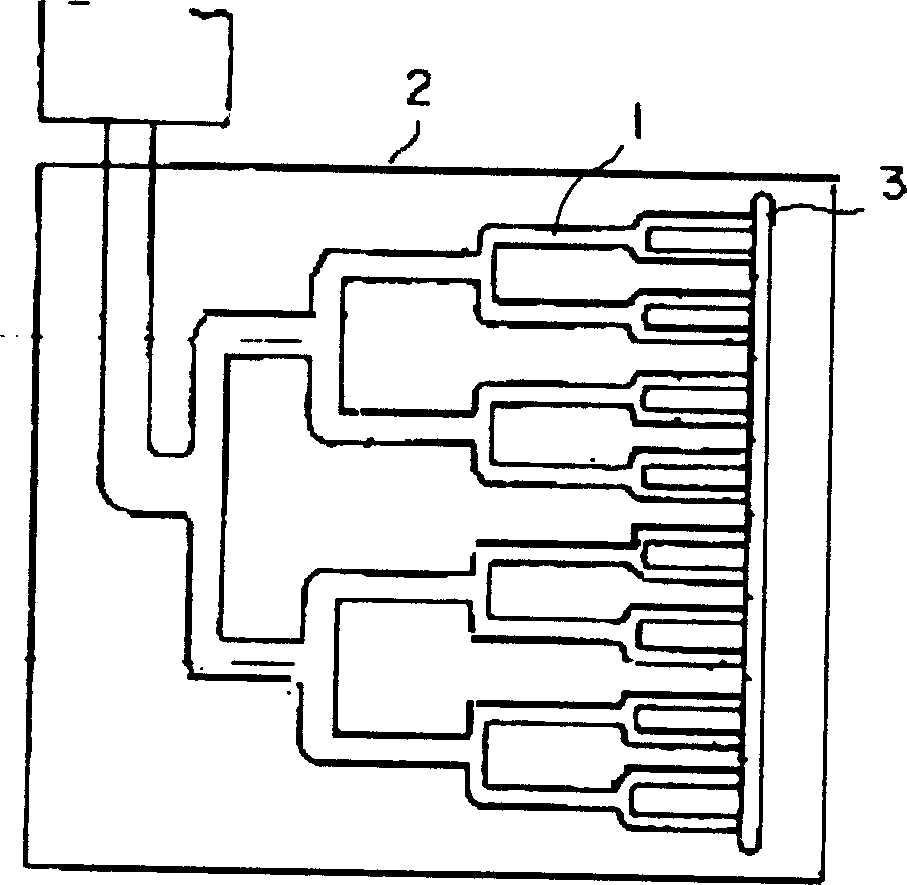

Compliant wearable patch capable of measuring electrical signals

InactiveUS20160317057A1Highly compliantHighly flexibleElectroencephalographyElectrocardiographyEngineeringElectric signal

A wearable patch capable of wireless communications includes an elastic layer, an adhesive layer under the elastic layer, and a shearable electrode layer that includes: a support substrate comprising one or more openings so positioned to allow the shearable electrode layer to be sheared and elongated, and breathable, an upper electrode layer on the support substrate, and a lower electrode layer under the support substrate. The support substrate can include a via that is conductively connected to the upper electrode layer and the lower electrode layer. The lower electrode can be in contact with a user's body and to pick up electric signals from the user's body.

Owner:VIVALNK

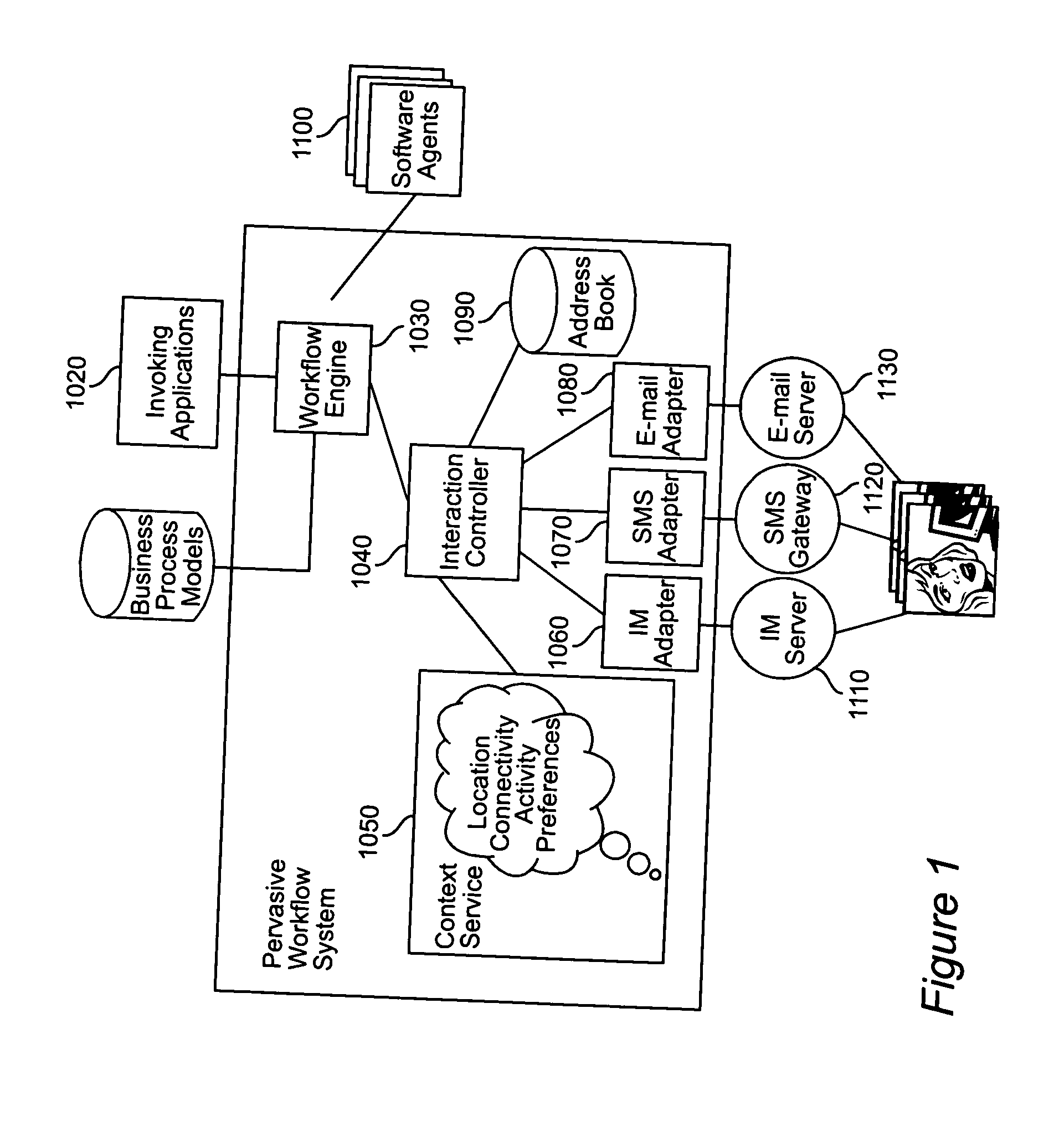

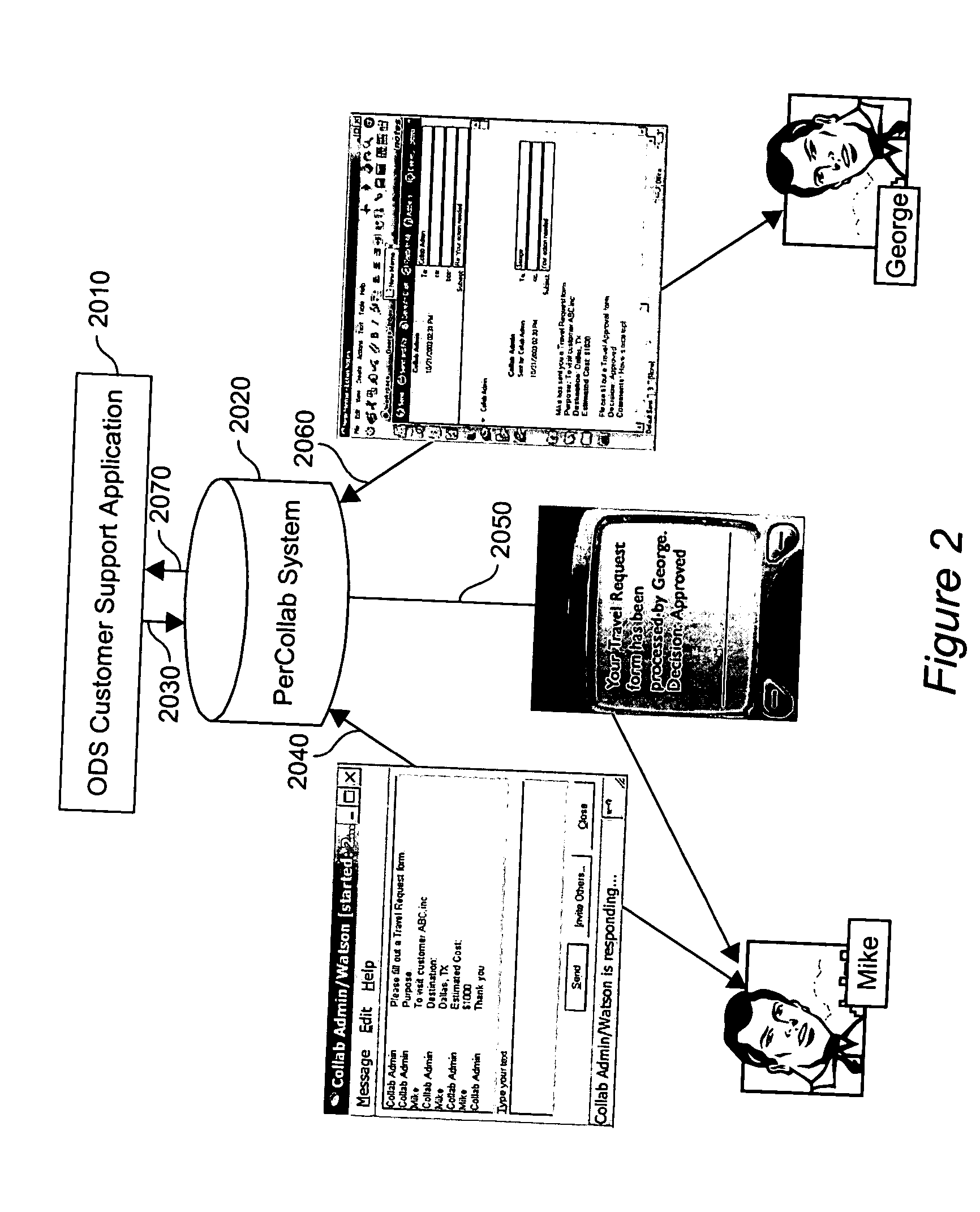

System and method for pervasive enablement of business processes

A system and method for pervasive enablement of business processes that effectively integrates workflow technology and ad-hoc collaboration tools. Collaboration tools comprise a plurality of native communication devices capable of interacting with the user either using text or voice mechanism. A modality adapter associated with each collaboration tool (or modality) performs the function of translating staff activities to device-specific messages and receiving replies from the users and sending them back to the engine. A Workflow Engine executes the business process and sends out staff activities meant for human users to the Interaction Controller and other activities meant for software agents to Web Services. An Interaction Controller entity utilizes the Context Service and the Address Book to determine the appropriate modality or collaboration tool for a user and sends the staff activity to the appropriate modality adapter. A Context Service that provides context information, user preferences to the Interaction Controller. The Address Book contains a repository of device addresses specific to each modality a user might use. The system enables users to collaborate with each other anytime and anywhere using an appropriate collaboration modality and participate in backend business processes by performing staff activities using their preferred collaboration device.

Owner:IBM CORP

Stretchable electronic patch having a foldable circuit layer

ActiveUS20160165719A1Highly compliantMore stretchablePrinted circuit assemblingCircuit bendability/stretchabilityStretchable electronicsComputer module

An electronic patch includes a foldable circuit layer that includes a foldable network that includes comprising: a plurality of electronic modules comprising a plurality of electronic components, and flexible straps that connect the plurality of electronic modules, wherein the flexible straps comprise conductive circuit that are conductively connected with the plurality of electronic components in the plurality of electronic modules. Neighboring electronic modules can undulate in opposite directions normal to the foldable circuit layer. The electronic patch also includes an elastic layer that encloses the foldable circuit layer.

Owner:VIVALNK

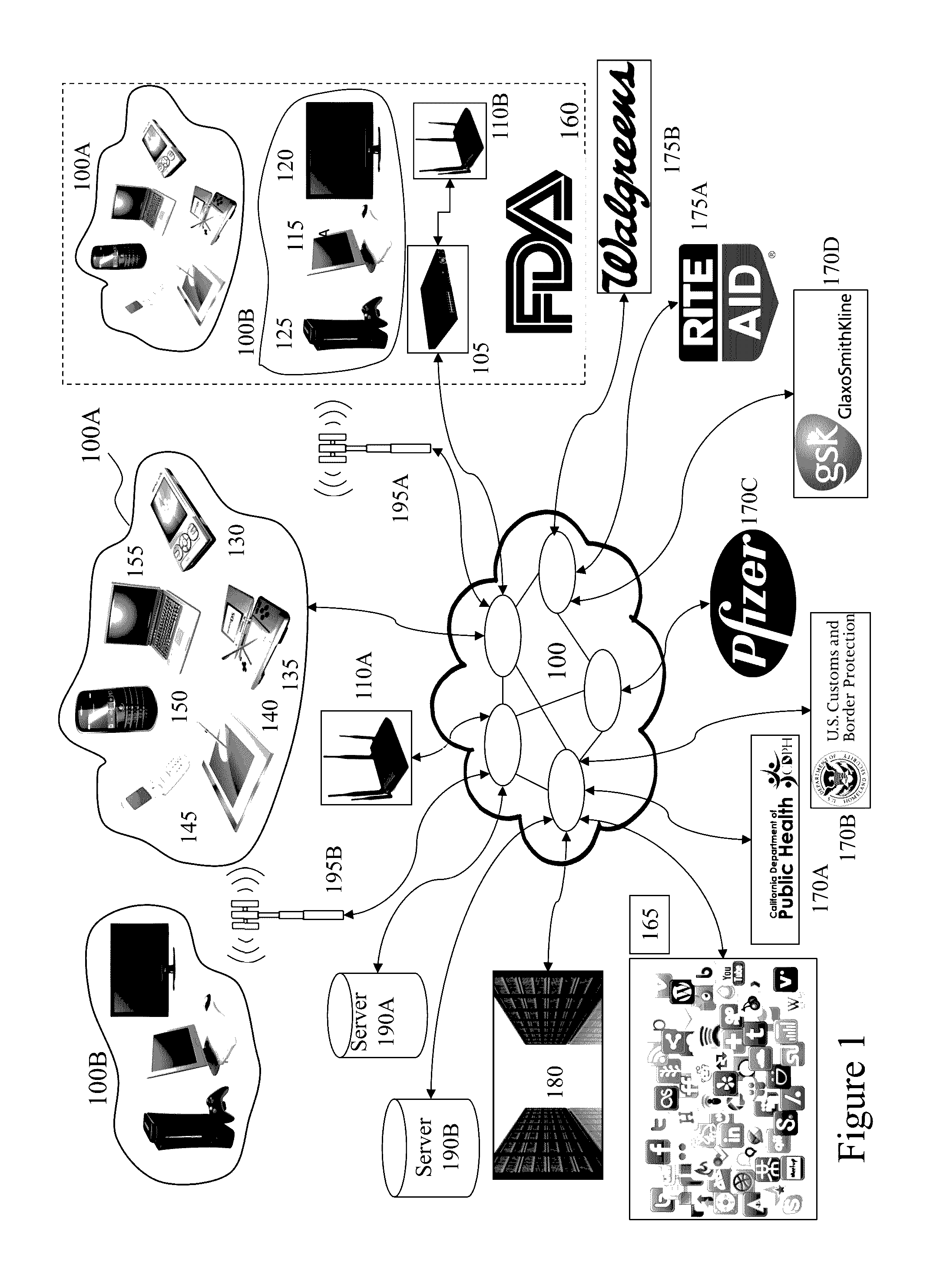

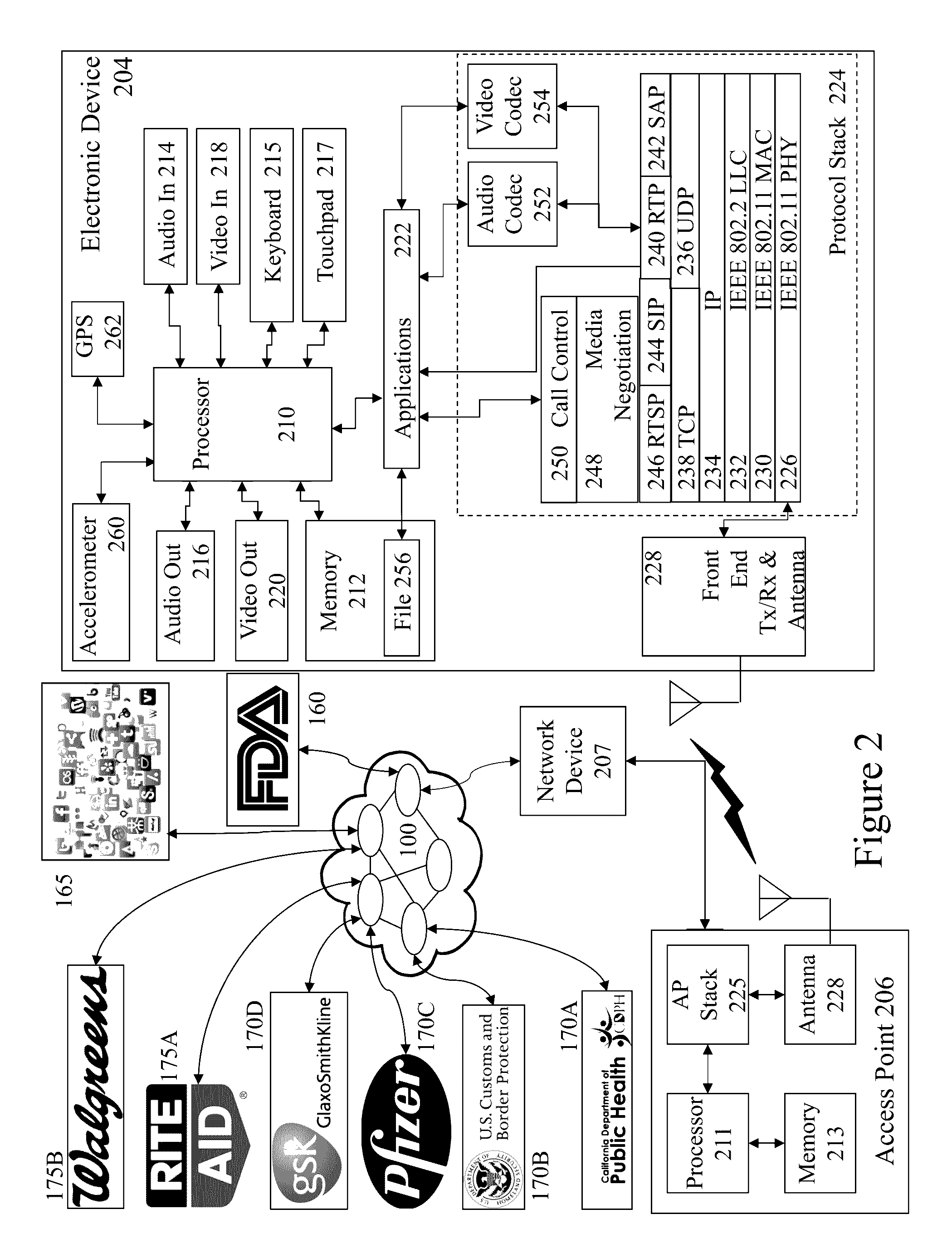

Methods and systems for product authenticity verification

InactiveUS20160321677A1Address limitationsCommerceSpecial data processing applicationsPurchasingComputer science

Consumer purchasing is increasingly being performed online and at the same time internationally so that consumers in one country can purchase directly other countries through online resources and have their purchases shipped directly. Accordingly, distributing counterfeit products becomes easier, especially if the consumer may never have seen, touched, tasted or experienced the original authentic product to recognise a counterfeit. In other instances, consumers know because they pay a fraction of the legitimate version's price. It would be beneficial to provide manufacturers with a means of labelling their products uniquely such that the consumer and / or retailer is able to verify the authenticity of the product quickly and automatically through a portable electronic device or point-of-sale terminal, for example. Further, it would be beneficial for the provisioning of such unique codes to support one-time use, traceability of authentic products and consumer registration to support subsequent sale of their authenticated product.

Owner:DOBAJ PATRICK

Building Information Tracking System and Method of Use

InactiveUS20120310906A1Quality improvementIncrease contentGeometric CADDigital data processing detailsWeb servicePhysical element

Systems and methods are disclosed for tracking the content of building information models. Embodiments include various computer-implemented methods for the tagging of BIM information, and for the monitoring of modification events involving BIM information. In addition, activities involving physical elements associated with BIM information are tracked. Providers of BIM content can tag content prior to distribution, enabling an internet-based service to track usage, enabling improved service to consumers of that BIM content. Designers can tag BIM content and BIM elements for tracking during the useful life of a building. Internet based messaging protocols can be used for communication between web services, client services and client applications. Monitoring and communication services function unattended. The system includes integration with BIM design applications, as well as stand-alone, end user system applications and browser interfaces. Analytic tools can be used to report on the tracking data.

Owner:IBD RESOURCE GROUP

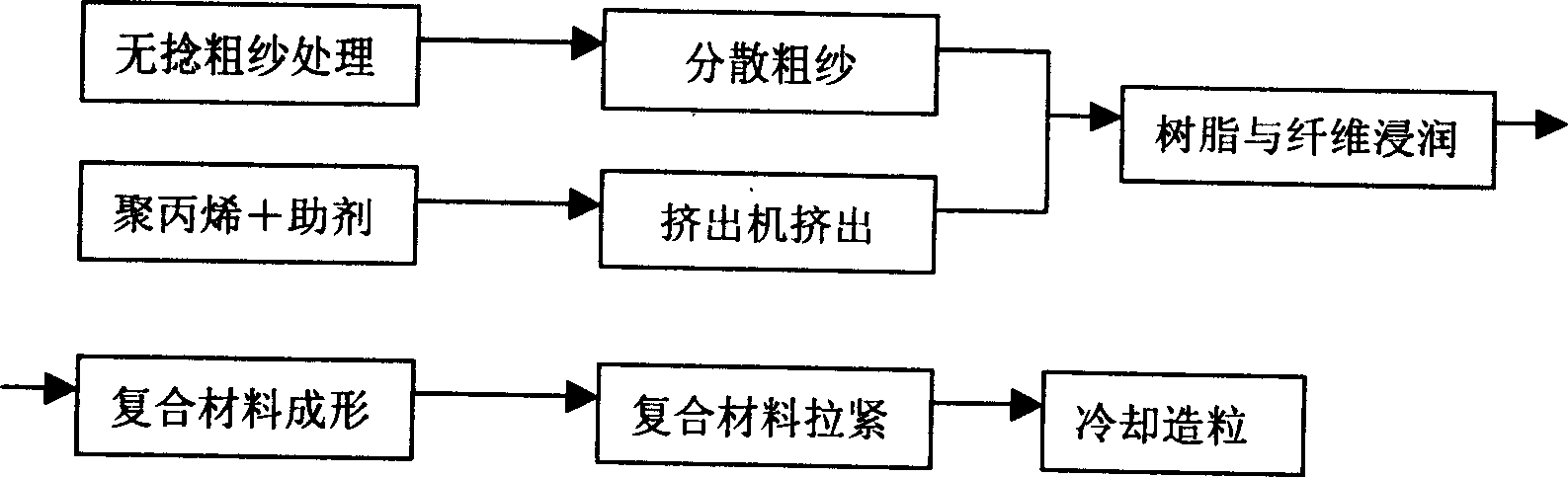

Continuous fiber reinforced composite materials, its production method and special equipment therefor

The invention relates to a glass fiberreinforced thermoplastic composite and a continuous fiber-reinforced composite, which are prepared with the following raw materials percentagewise by weight: 35-60 % of resin, 35-60 % of dip treated glass fiber and 0.5-5 % of auxiliary agent. The invention adopts resin and dip treated glass fiber as main raw materials, mixtures of antioxidant, ultraviolet absorbent and light-stability agent as main auxiliary agents, with logical formulations, eliminates the damage to glass fibrous surface caused by twin-screw with continuous fiber-reinforced composite producted by this manufacturing technique, improves product lustrous surface, binding properties between fiberglass and resins by a treatment for glass fibrous surface and mechanical properties of products, protects the materials for long periods from destruction because of addition of various stabilizing agents, and solves the limitation that general materials can not be used for a long time in extreme conditions such as high temperature, high humidity, radiation and so on.

Owner:JIANGSU QIYI TECH

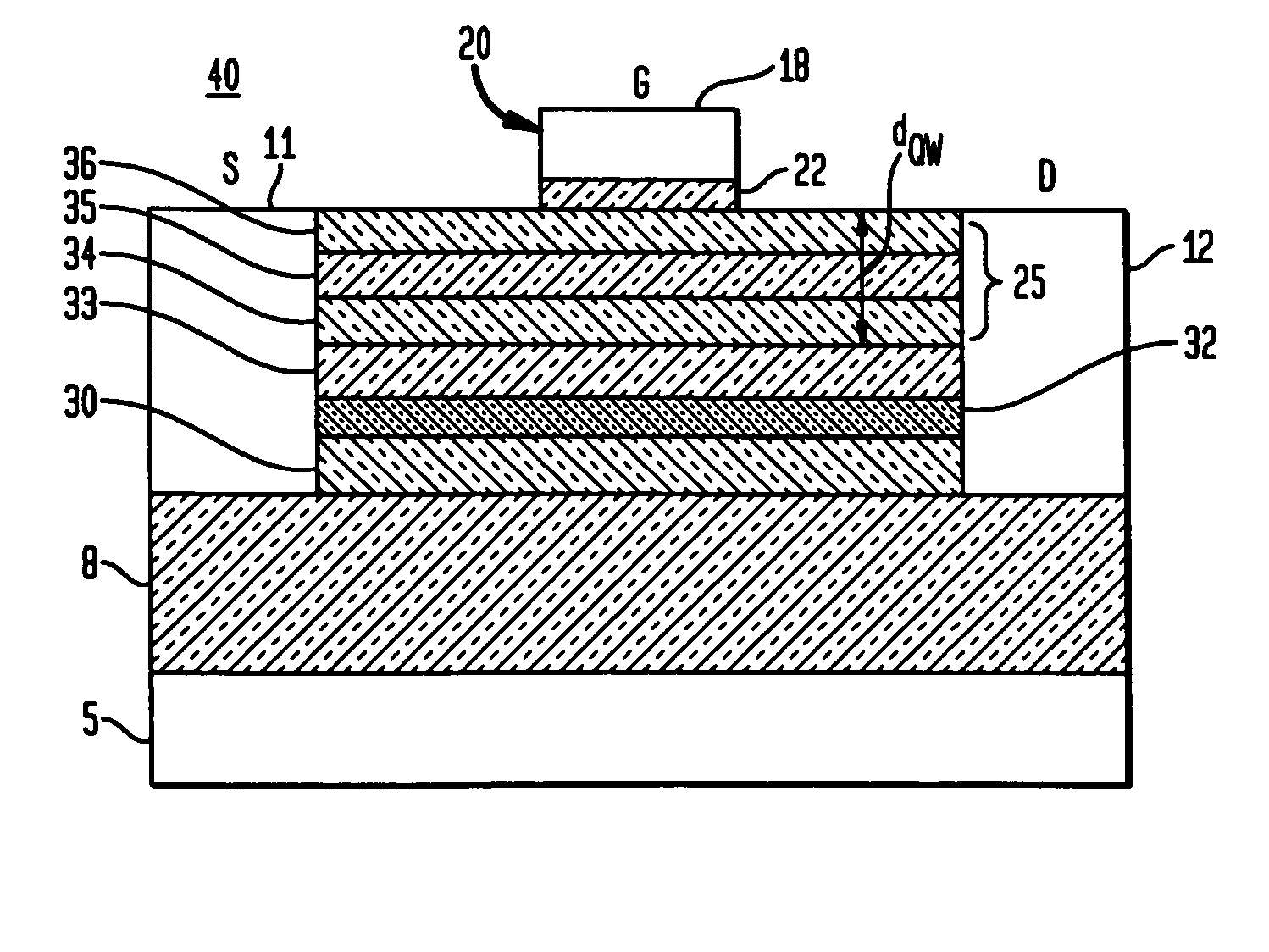

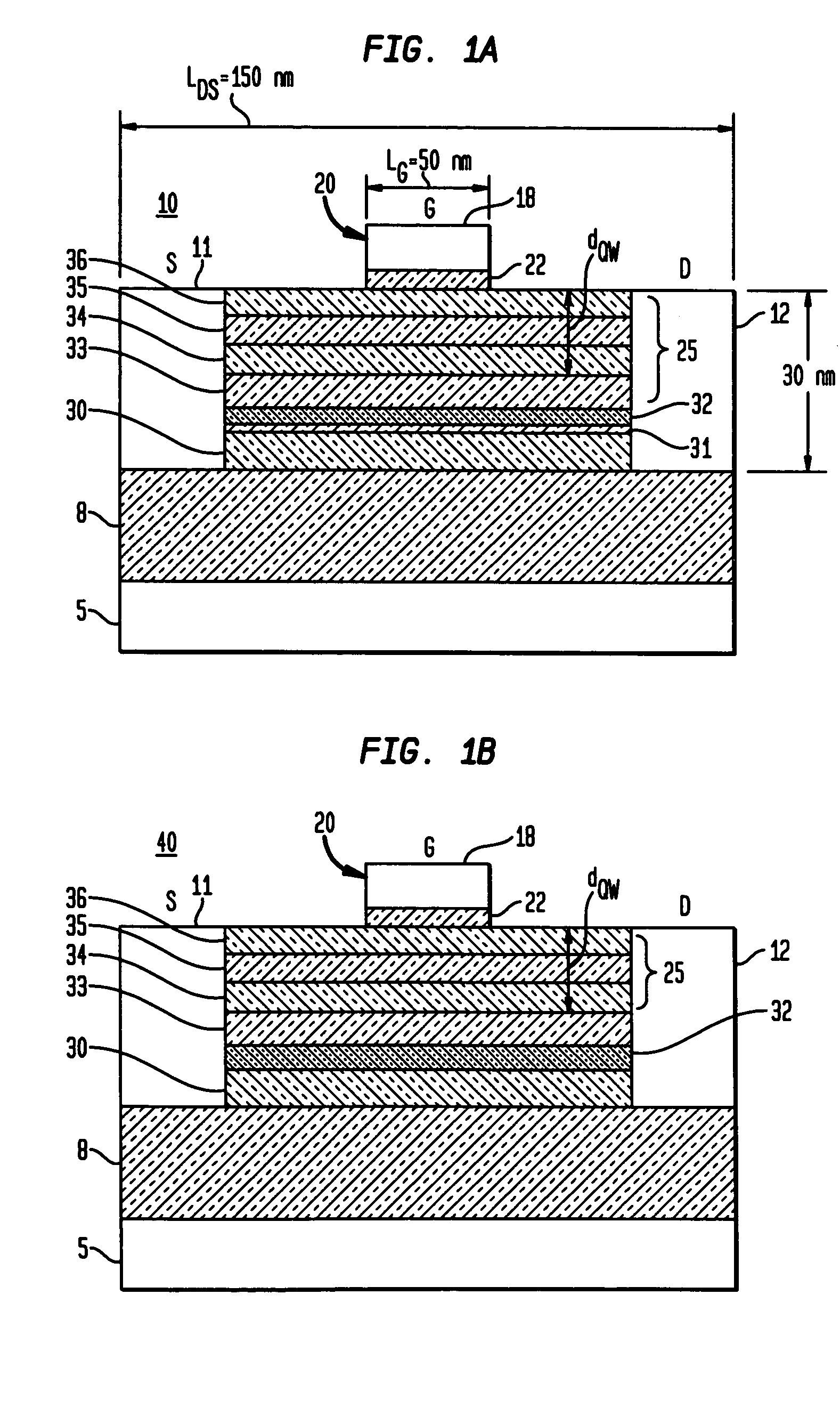

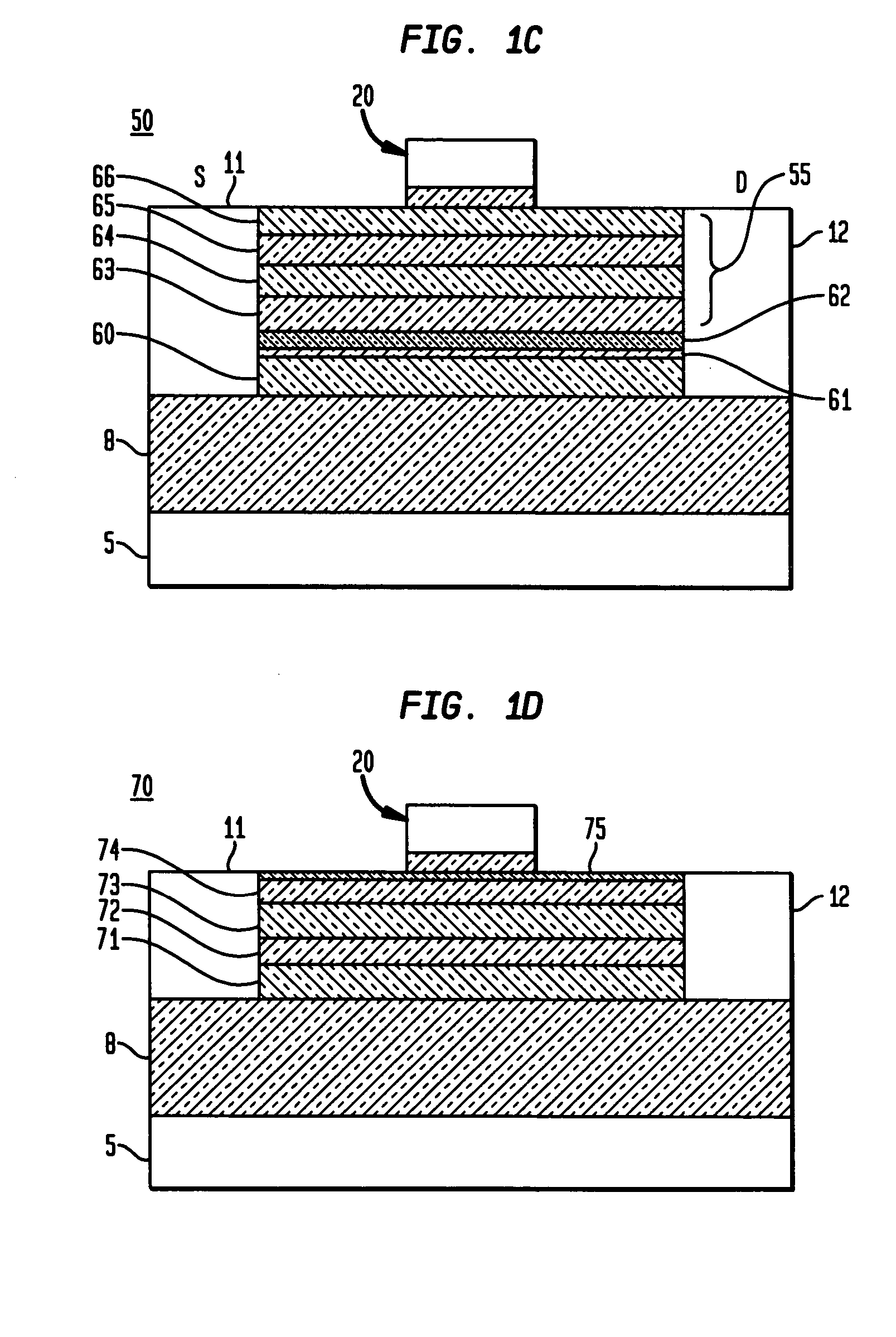

Ultra high-speed si/sige modulation-doped field effect transistors on ultra thin soi/sgoi substrate

InactiveUS20050045905A1Improve RF performanceUltra-high speed performanceTransistorSemiconductor/solid-state device detailsLow noiseUltra high speed

A silicon and silicon germanium based semiconductor MODFET device design and method of manufacture. The MODFET design includes a high-mobility layer structure capable of ultra high-speed, low-noise for a variety of communication applications including RF, microwave, sub-millimeter-wave and millimeter-wave. The epitaxial field effect transistor layer structure includes critical (vertical and lateral) device scaling and layer structure design for a high mobility strained n-channel and p-channel transistor incorporating silicon and silicon germanium layers to form the optimum modulation-doped heterostructure on an ultra thin SOI or SGOI substrate capable of achieving greatly improved RF performance.

Owner:GLOBALFOUNDRIES US INC

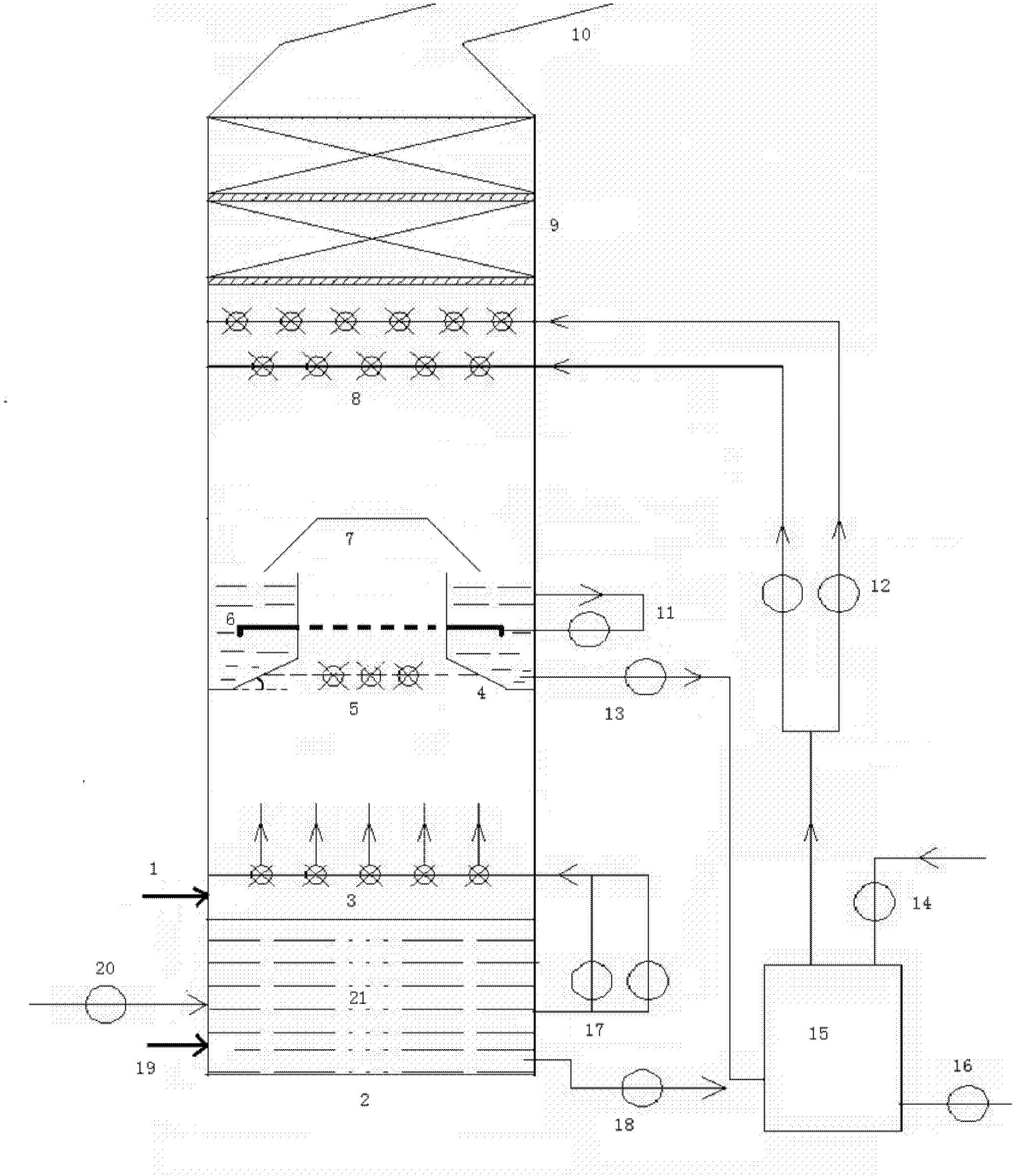

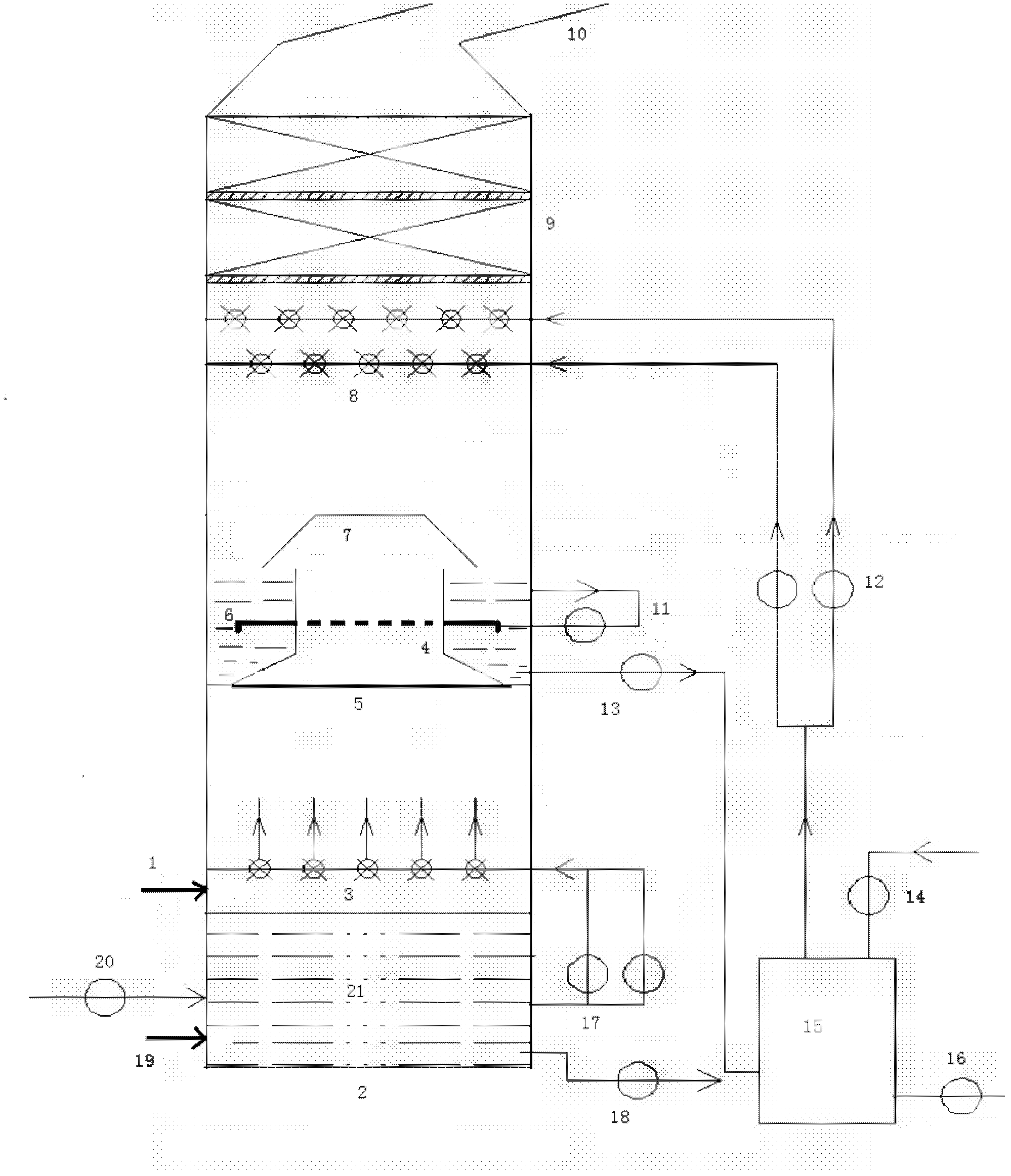

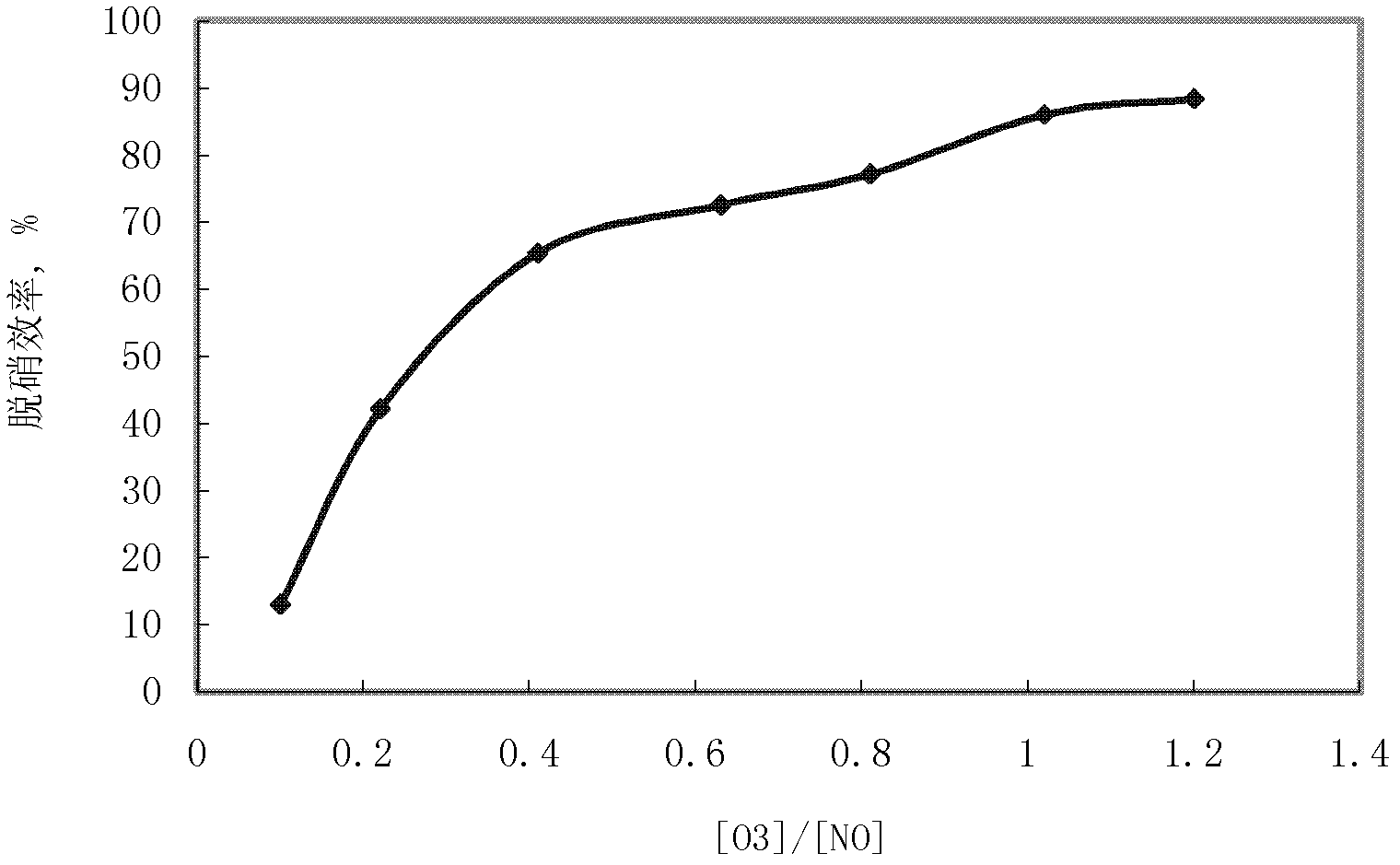

Absorption tower for desulfurization and denitrification combined with oxidant in forward-flow and back-flow spraying and method

InactiveCN102553428AAchieve removalUnique structureDispersed particle separationAir quality improvementOxidation zoneSlurry

The invention discloses an absorption tower for desulfurization and denitrification combined with an oxidant in forward-flow and back-flow spraying mode and a method. The absorption tower includes two washing sections: a first section is a desulfurization loop and arranged on the lower portion of the absorption tower, and sulfur dioxide and hydrogen chloride are removed through slurry forward-flow and back-flow and smoke contact cleaning; a second section cleans oxidized smoke pollutants in slurry back-flow and smoke contact mode mainly for removing oxynitride and heavy metal mercury. A slurry divider is arranged between the two cleaning sections, the bottom of the slurry divider is an oxidization area, and strong oxidant is sprayed in the area. For reducing consumption of the oxidant, a catalyst is added in second-loop slurry for achieving auxiliary oxidization. Sulfur dioxide, oxynitride, heavy metal mercury and the like can be removed simultaneously in a washing tower by the technology, and the absorption tower has the advantages of being high in efficient and simple and suitable for various combustion devices including fuel coal power stations, refuse incineration plants, organic and inorganic production enterprises and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

Method for detecting cloud height by utilizing cloud shadow information in satellite remote sensing data

InactiveCN101566692AStrong real-time monitoring abilityImprove observation effectElectromagnetic wave reradiationICT adaptationMeasurement deviceCloud height

The invention relates to a method for detecting cloud height by utilizing cloud shadow information in satellite remote sensing data, which pertains to the field of atmospheric exploration and comprises the following five steps: interpolation calculation, cloud and cloud shadow detection, the matching of the cloud with the cloud shadow by MODIS data, establishment of a cloud height model for obtaining the height of cloud layer, and cloud height calculation and analysis. The method for detecting the cloud height detects the information on the cloud and the cloud shadow in the remote sensing image data, matches the cloud with the cloud shadow by combining with digital image technology and obtains the distance between the cloud and the cloud shadow; and finally the cloud height model is established to obtain the height of the cloud layer. The method for detecting the cloud height can simultaneously calculate the heights of multiple points of a piece of cloud and the height values obtained in the way can greatly improve detection accuracy of cloud heights. The cloud height can be measured in any place where the measurement conditions are met and no measurement device is needed to be set locally.

Owner:JILIN UNIV

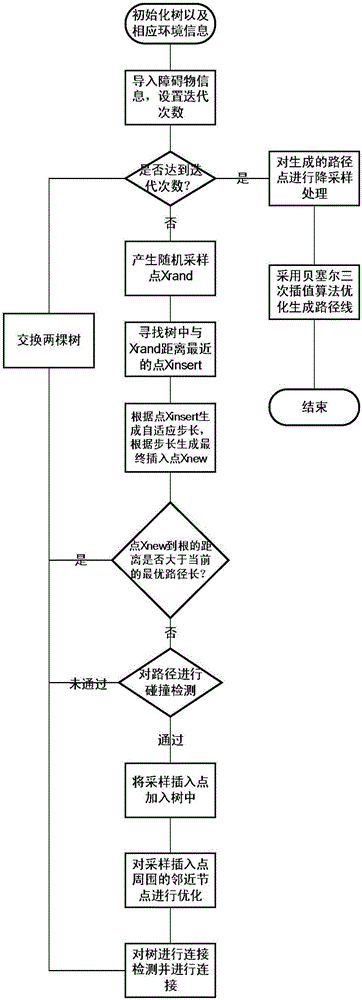

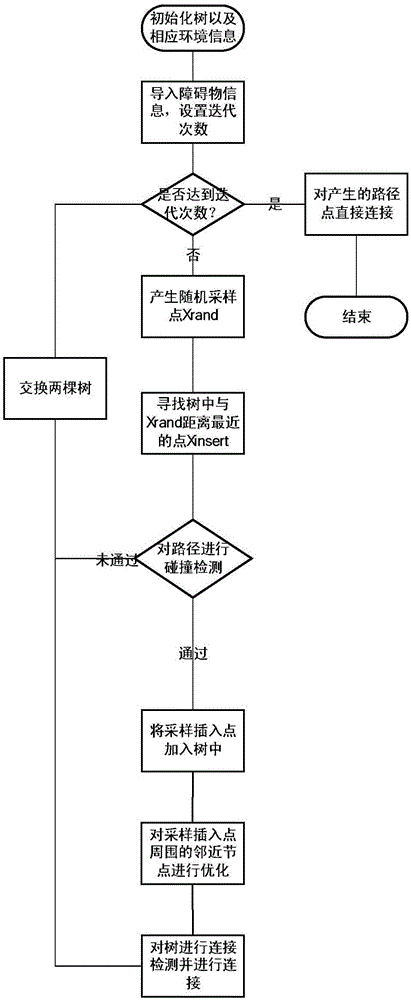

MB-RRT-based unmanned aerial vehicle two-dimensional track planning method

ActiveCN106444740AReduce memory usageAddress limitationsPosition/course control in two dimensionsPath lengthCollision detection

The invention discloses an MB-RRT-based unmanned aerial vehicle two-dimensional track planning method, comprising the steps of initializing a tree and environmental information; importing obstacle information, and setting a number of iterations; judging whether the number of iterations is arrived, if so, performing down-sampling on the generated path point and optimizing the generated path line by adopting an interpolation algorithm; otherwise, generating a random sampling point, looking for a point nearest to the random sampling point in the tree, generating an adaptive step length according to the point, generating a final interpolation point according to the step length, judging whether the distance between the interpolation point and the root is greater than the current optimal path length, if not, performing collision detection on the path, adding the interpolation point to the tree and optimizing adjacent nodes around the interpolation point; if not, performing connection detection and connection on the tree. The method is high in convergence rate and small in memory occupation space, solves the problem of limitation of growth nearby an obstacle, and can be directly applied to unmanned aerial vehicle control.

Owner:ZHEJIANG UNIV OF TECH

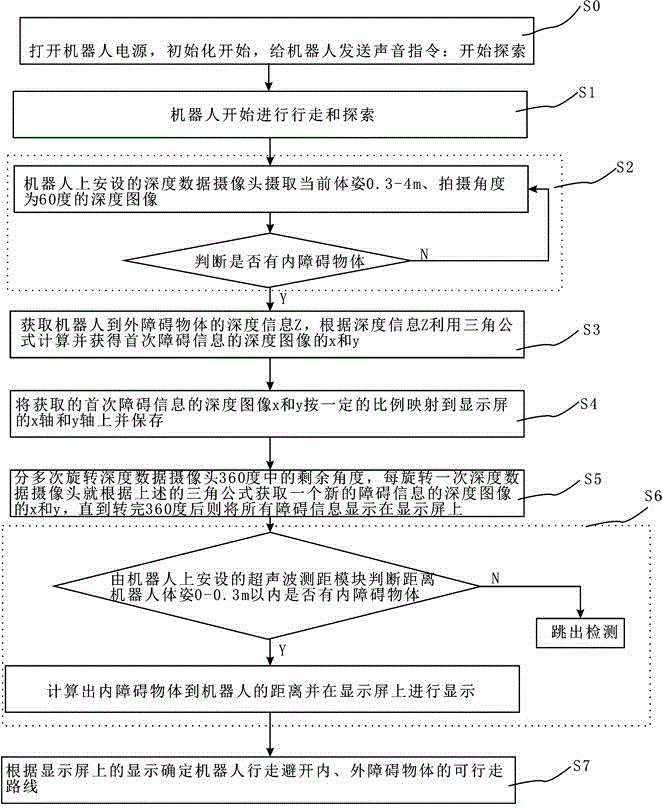

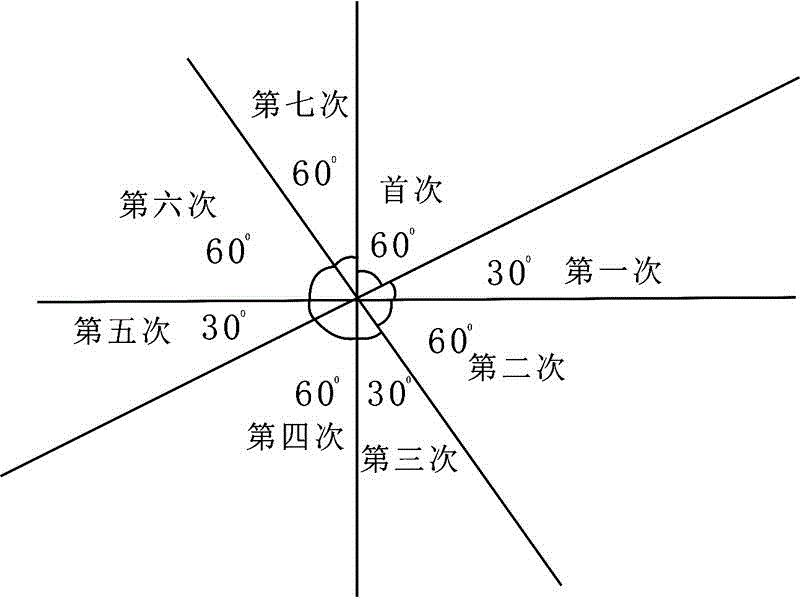

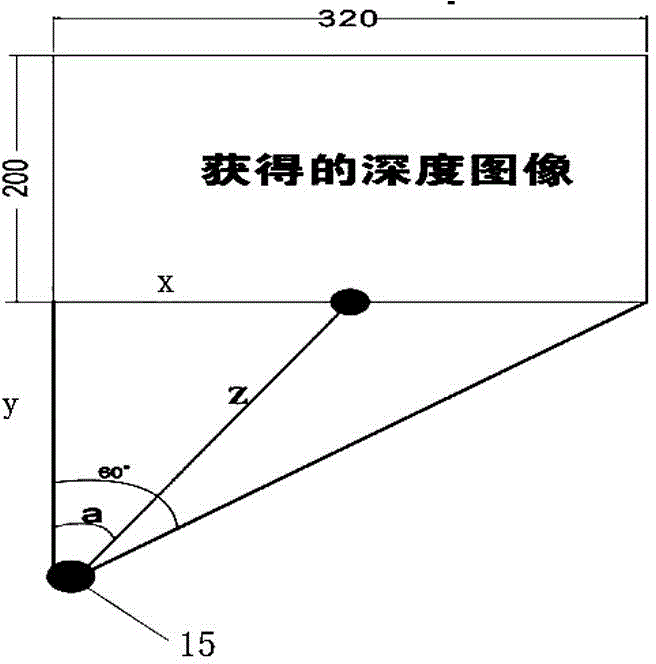

Barrier-avoidance control method combining depth camera and supersonic wave for robot and system thereof

ActiveCN104865965AImprove work efficiencyRealize no blind spot detectionPosition/course control in two dimensionsElectricitySupersonic waves

The invention discloses a barrier-avoidance control method combining a depth camera and supersonic wave for robot and a system thereof. The system comprises the depth camera and an ultrasonic ranging module installed on the robot, a control module which is installed in the robot for processing barrier information of inner and outer barriers, and a display screen for displaying obstacle information, wherein the depth data camera and the ultrasonic ranging module are electrically and respectively connected with the input end of the control module, and the output end of the control module is electrically connected with the display screen. The depth data camera shoots depth images with current posture of 0.3-4m and shooting angle of 60 degrees on a real-time basis and determines the existence of outer barriers. The ultrasonic ranging module determines the existence of inner barriers within 0-0.3m body posture of the robot. Non-blind area detection for environment by a robot is realized, so that the robot can effectively avoid barriers during walking.

Owner:SHENZHEN REEMAN INTELLIGENT EQUIP CO LTD

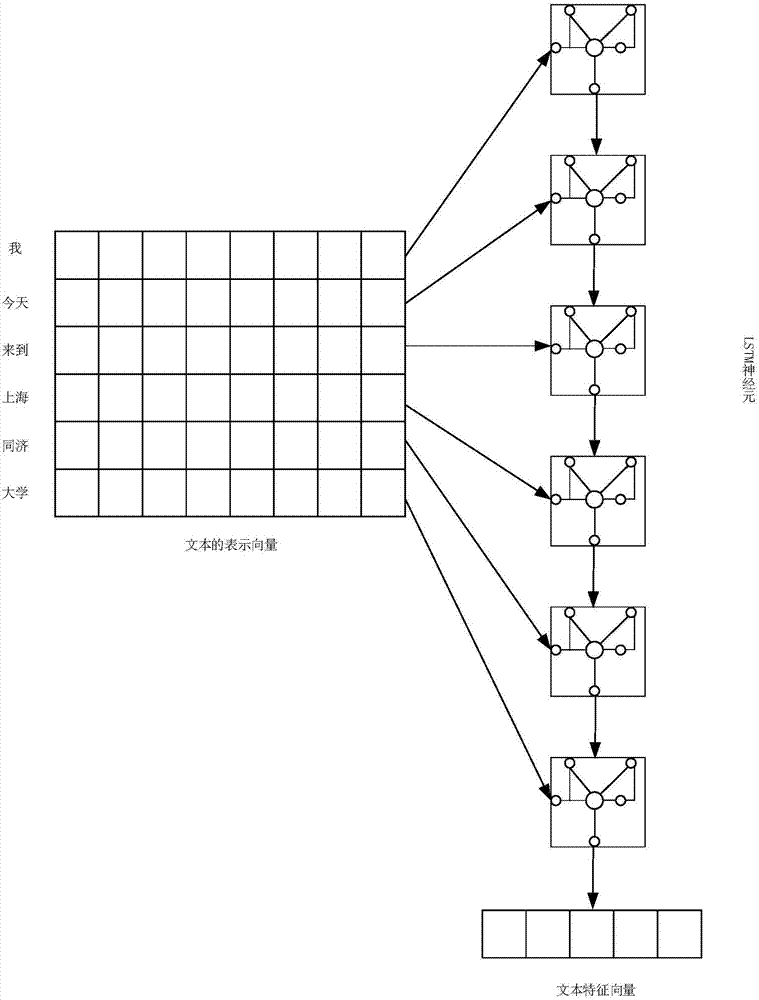

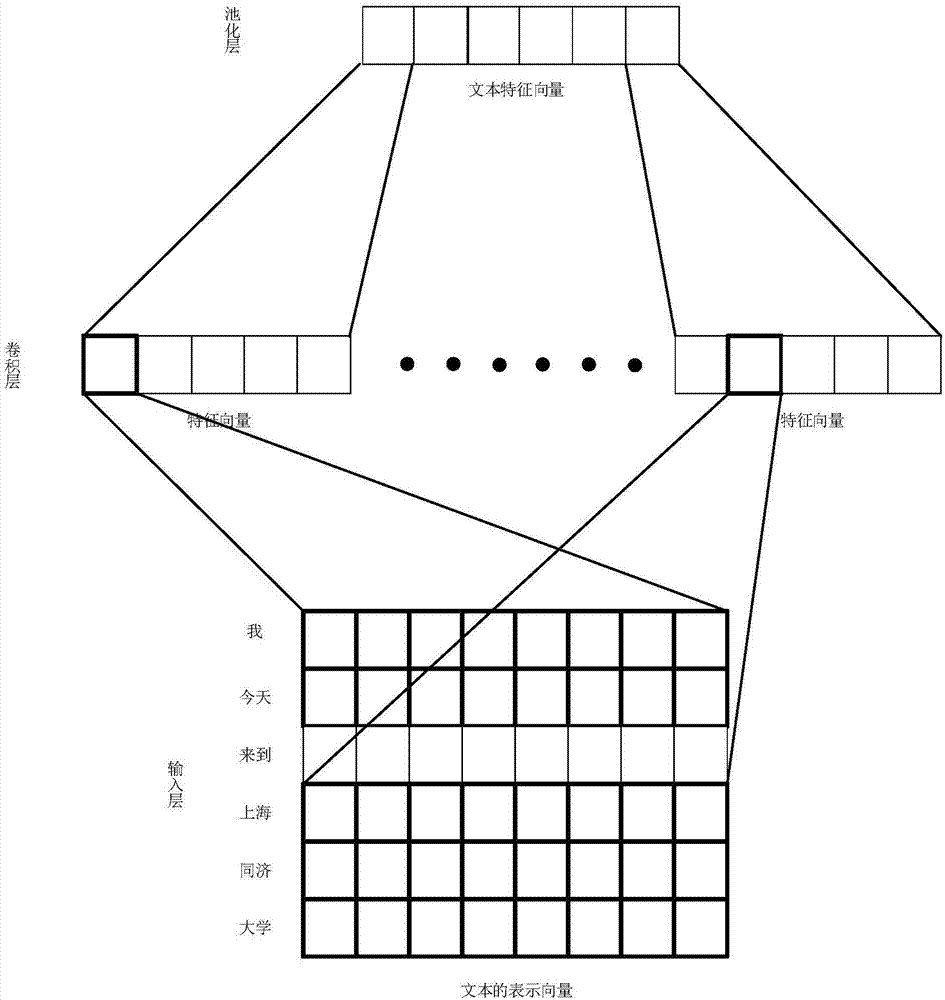

Combination-type text classification method based on deep learning

InactiveCN107885853AAdapt to needs wellFlexible combinationNeural architecturesSpecial data processing applicationsLearning modelsDeep learning

The invention relates to a combination-type text classification method based on deep learning. The method includes the following steps: preprocessing to-be-classified text; using the preprocessed textto obtain feature extraction results, which correspond to all deep learning models, through the different depth learning models; combining all the feature extraction results through a fully connectedlayer to obtain a combined feature vector; and using the combined feature vector as input to carry out classification recognition to obtain a class to which the text belongs. Compared with the priorart, the method has the advantages of lower requirements on training-corpus quality, high transplantability and expandability, a still better effect in a case of more classification classes and the like.

Owner:TONGJI UNIV

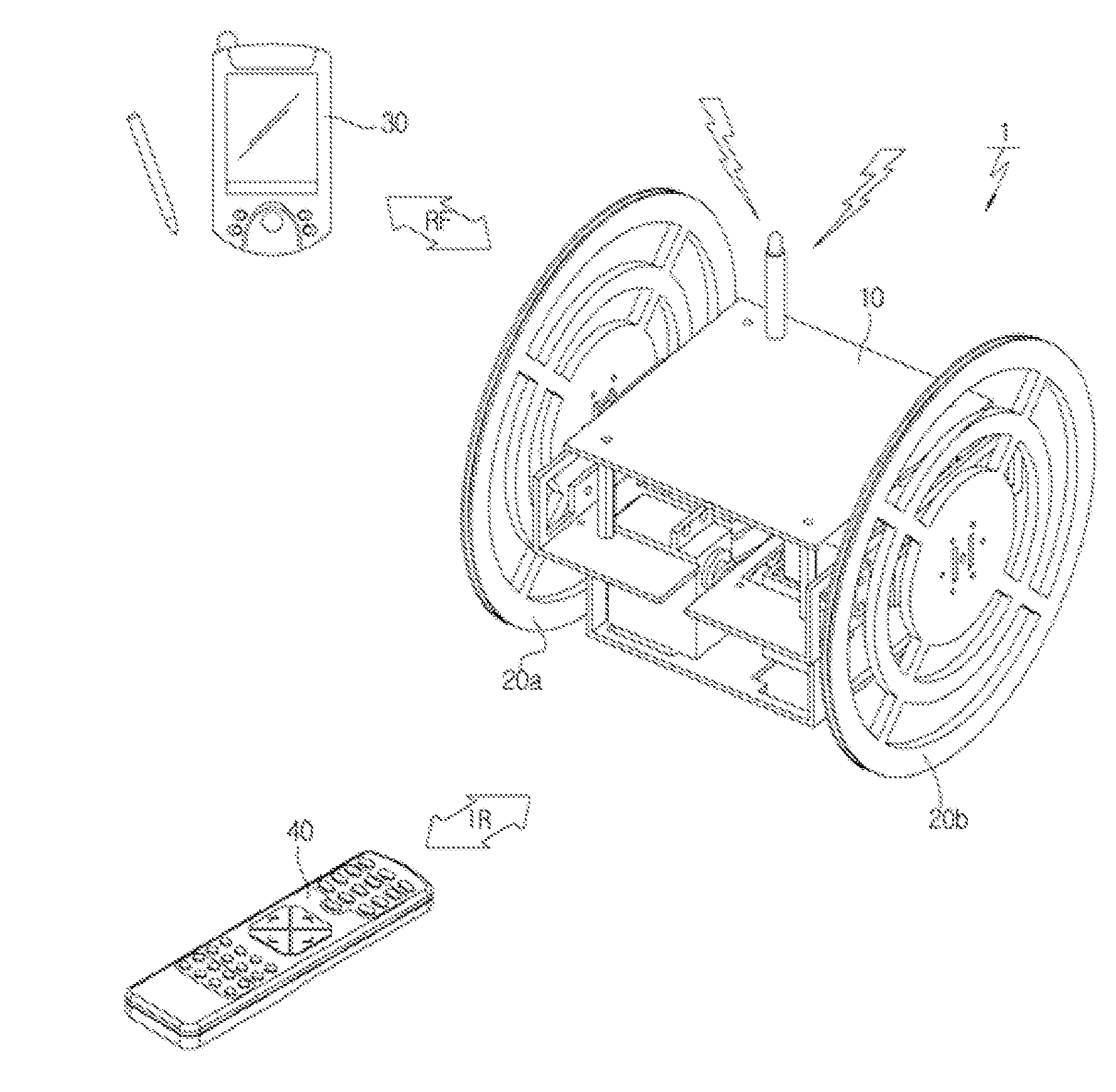

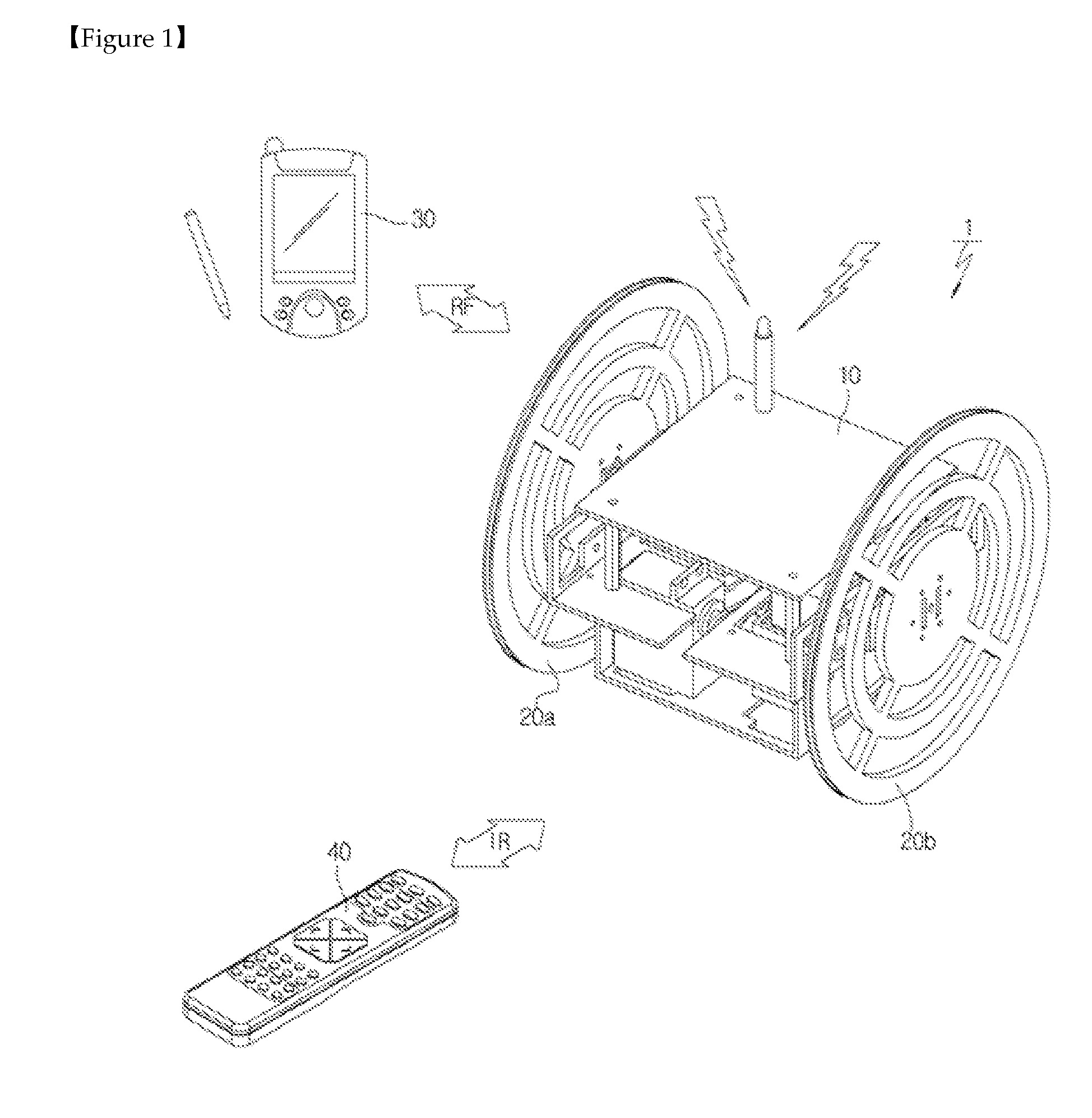

Small mobile robot with built-in auxiliary wheel for overcoming topography

InactiveUS20110132671A1Effective movementSimple structureProgramme-controlled manipulatorPedestrian/occupant safety arrangementWalking around obstaclesRemote control

Provided is a small mobile robot which moves back and forth and left and right while keeping its posture by two main wheels. The small mobile robot includes built-in auxiliary wheels to overcome topographical elevation differences. The auxiliary wheels of the small mobile robot are attached to a servomotor. The servomotor is driven by remote control, and the auxiliary wheel can be moved to the position required for operation. When the robot is in a normal state, the auxiliary wheels are retracted in the robot. When the robot meets a stepped topography, the auxiliary wheels are lowered out to contact a ground to support the main wheels going over the stepped topography. The small mobile robot includes a sensor for sensing obstacles and a control module to make a detour around obstacles while moving to a target point.

Owner:HOYA ROBOT

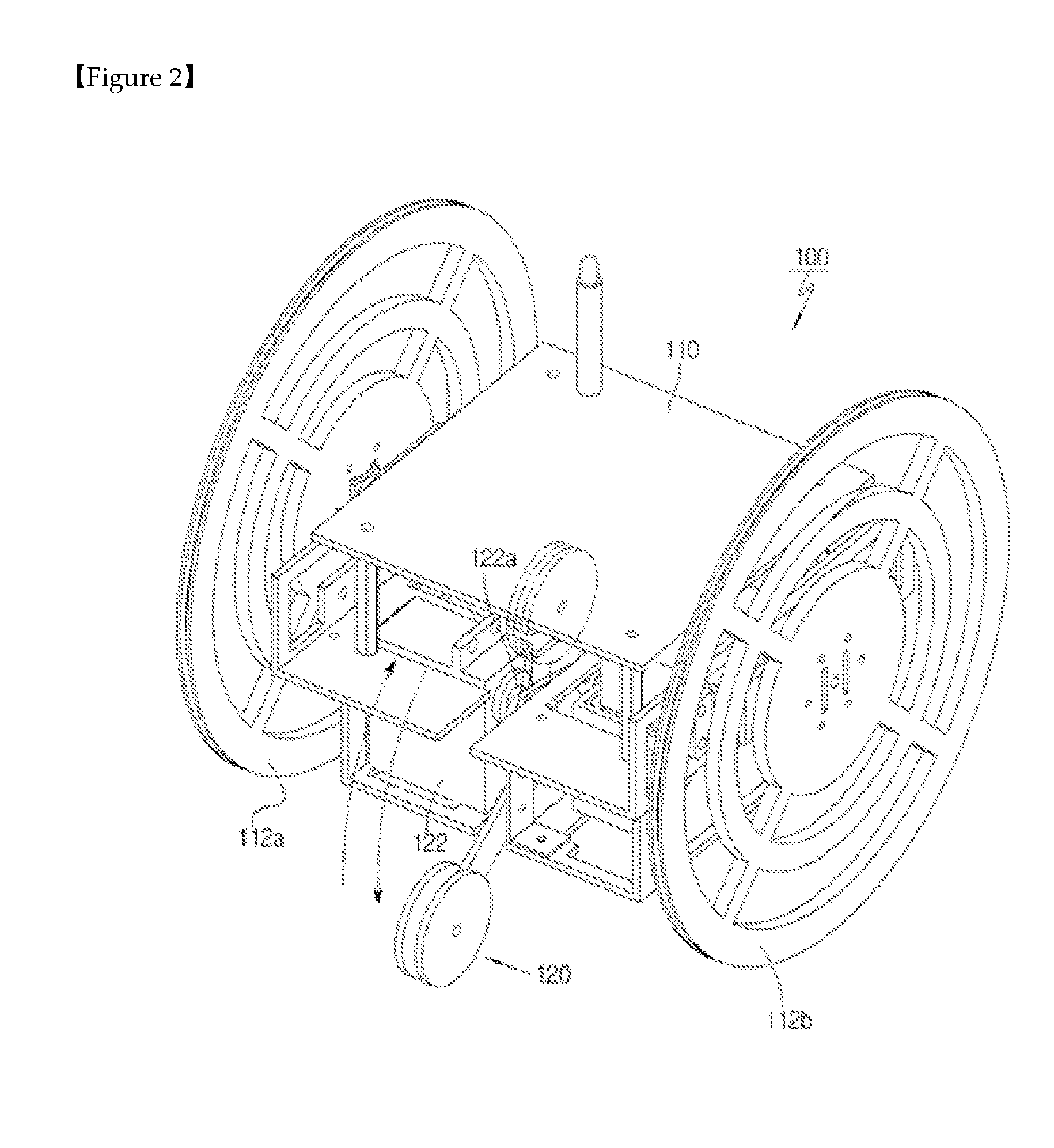

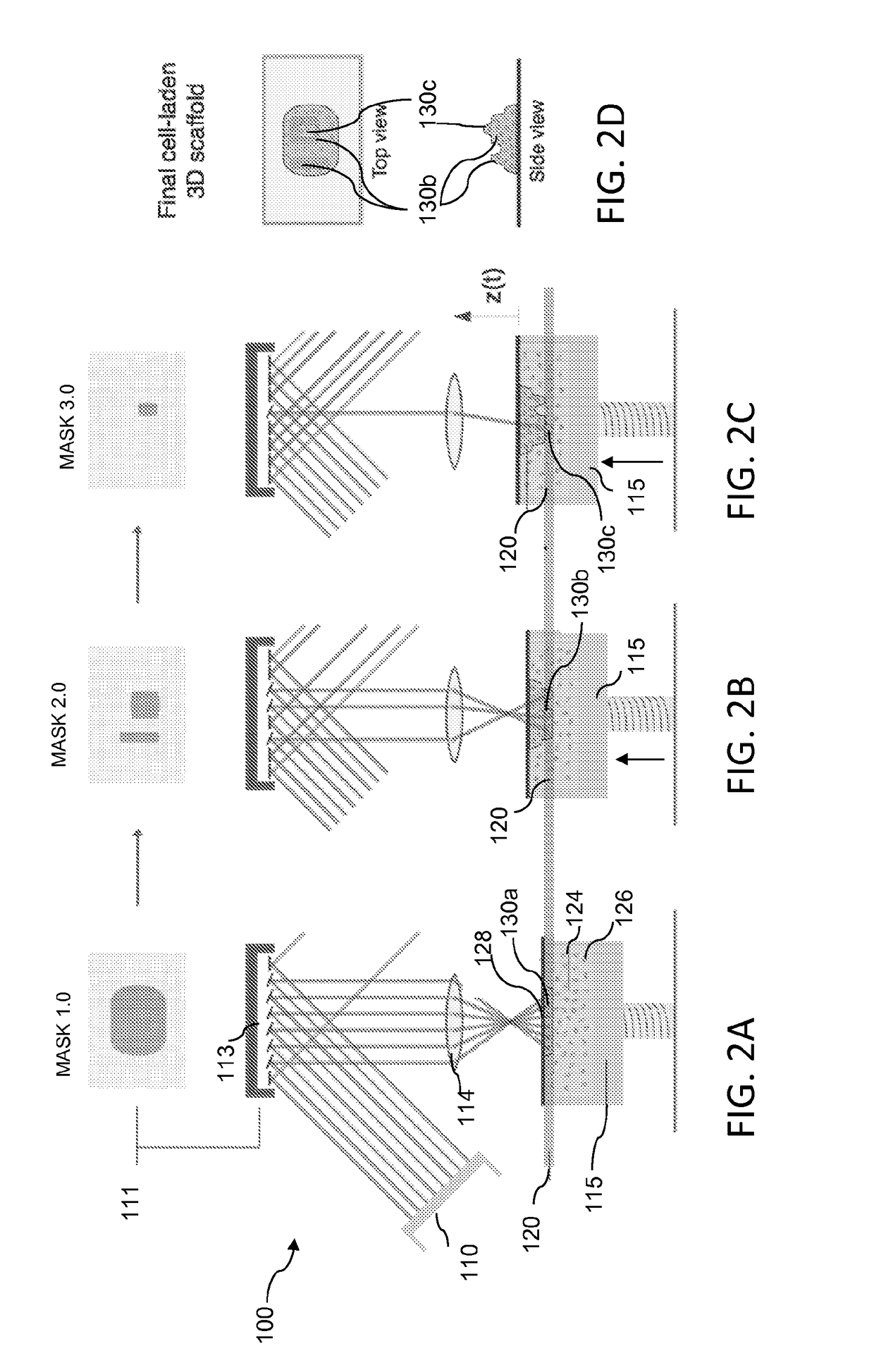

Layerless bioprinting via dynamic optical projection and uses thereof

ActiveUS20170087766A1Quick buildHigh resolutionAdditive manufacturing apparatusBiological testingProjection opticsSpatial light modulator

A system and method for 3D microfabrication projects light capable of initiating photopolymerization toward a spatial light modulator that modulates light responsive to digital masks corresponding to layers of the structure. Projection optics focus the modulated light onto an optical plane within a photopolymerizable material supported on a stage. A computer controller causes the spatial light modulator to project a sequence of images corresponding to the digital masks while coordinating movement of the stage to move a position of the optical plane within the photopolymerizable material to sequentially project each image of the sequence to generate the structure by progressively photopolymerizing the photopolymerizable material.

Owner:RGT UNIV OF CALIFORNIA

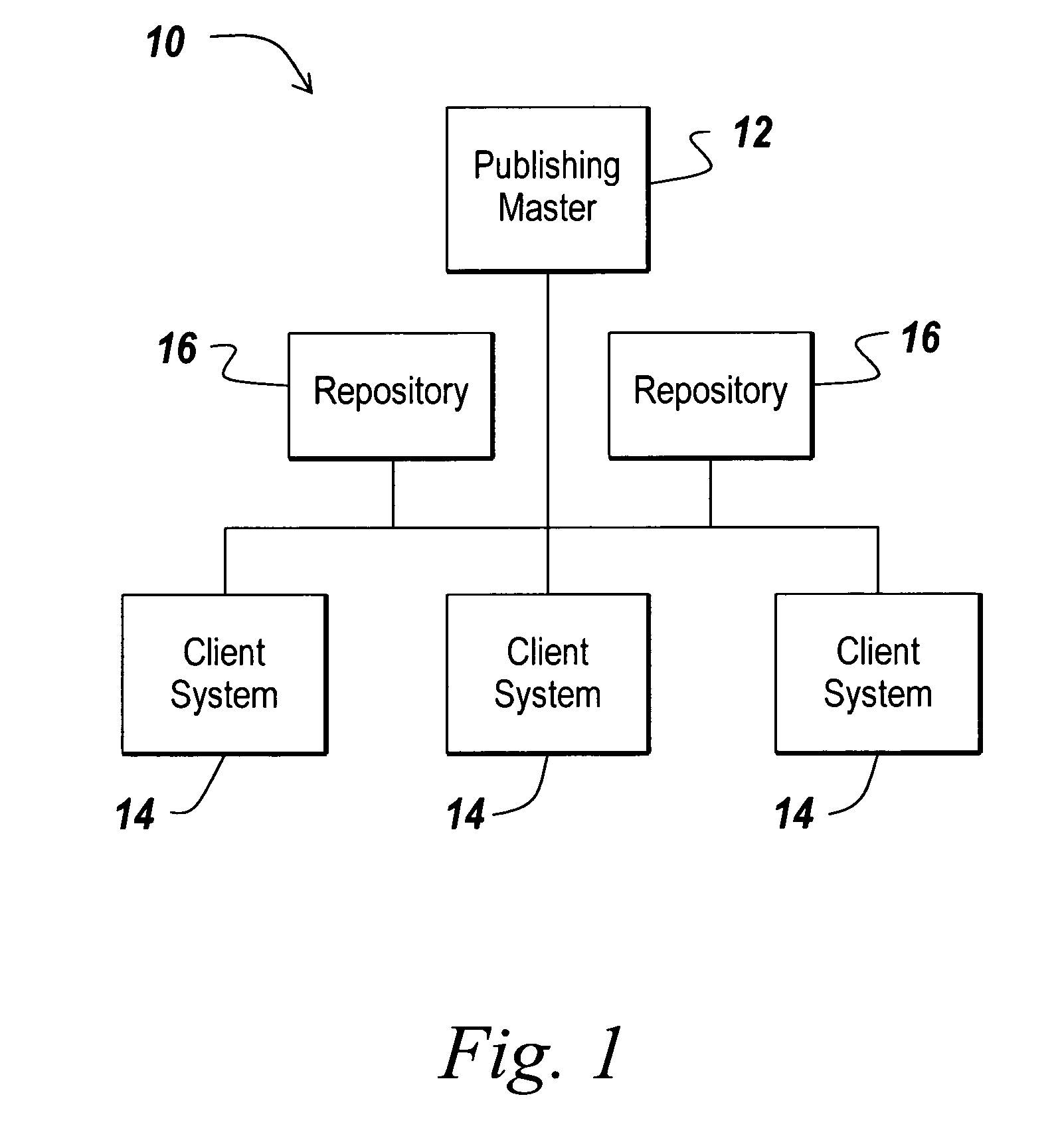

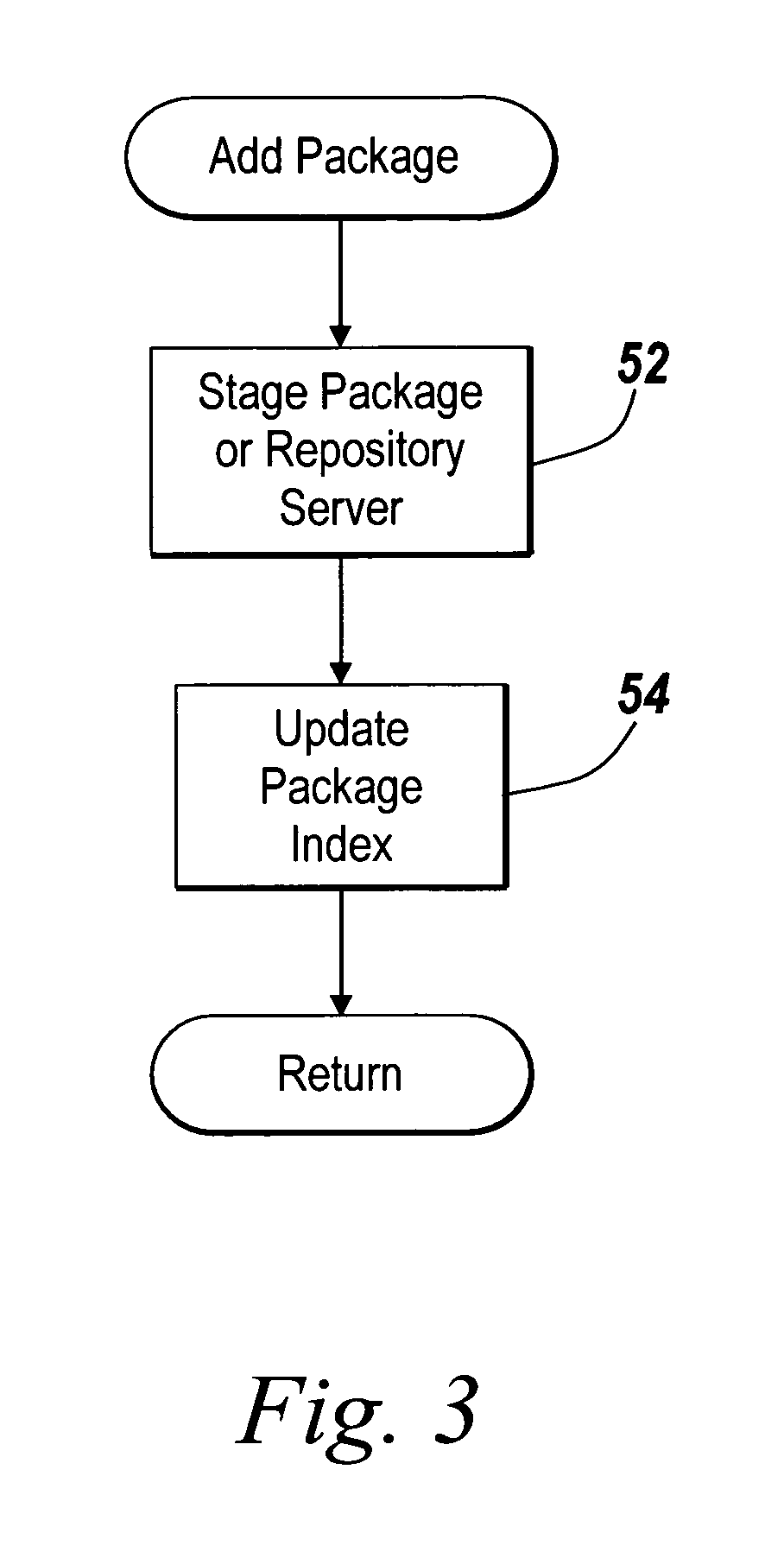

Lightweight global distribution mechanism

InactiveUS6986134B1Not incur overheadAddress limitationsProgram loading/initiatingTransmissionGlobal distributionData library

A lightweight global distribution mechanism distributes packages within a distributed system. The packages may hold any type of content and may hold contents such as patches, programs, documents or files. The distribution mechanism is lightweight in that it incurs minimal computational and memory overhead. With the distribution mechanism, a package index that identifies packages for installation is stored at a publishing master. Client systems may access and analyze the package index to determine which packages to install. The client systems may hold subscription lists that identify the packages to which the clients subscribe. The packages need not be stored at the publishing master but rather may be stored at separate repositories.

Owner:ORACLE INT CORP

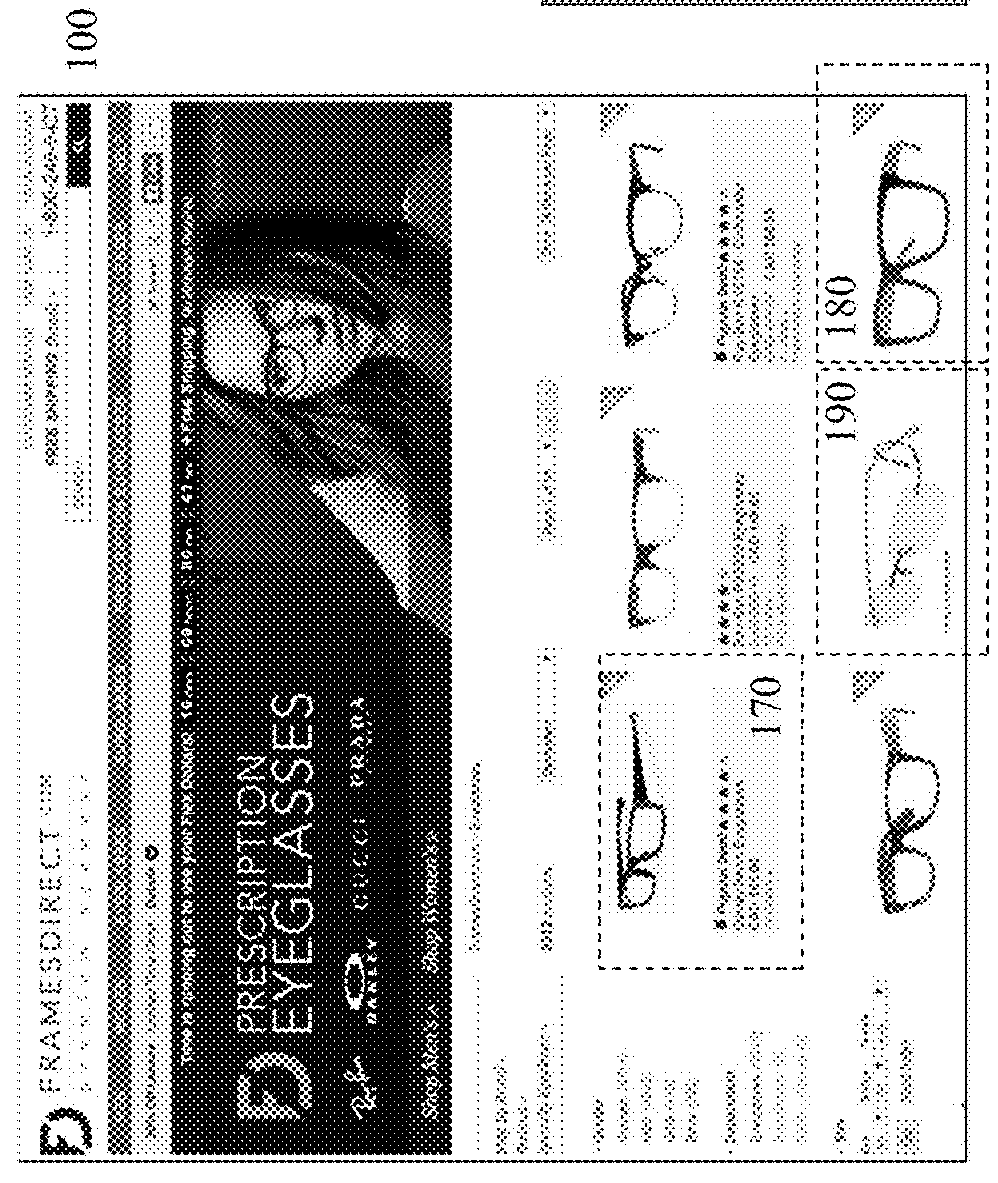

Automated recommendation and virtualization systems and methods for e-commerce

InactiveUS20180268458A1Address limitationsCharacter and pattern recognitionBuying/selling/leasing transactionsVirtualizationEyewear

Visual appearance is a significant aspect of how we perceive others and how we want to be perceived. With items such as eyewear, make-up and facial jewelry the style, colour, size not only impact how others perceive us based upon the selections themselves but also how these fit or suit the user's face, which is unique. With online retailing the purchaser does not get feedback as in bricks-and-mortar retailing from friends, retail assistants etc. At best the user is exposed to a basic recommendation system which is generally procedural based with a priori aesthetic rules and user classification. However, users are often incorrect in their classification of themselves whilst the aesthetic rules are hidden, can contradict, and do not take into account current fashion, age or culture. Embodiments of the invention provide automated recommendation engines for retail applications based upon simply acquiring an image of the user.

Owner:VALORBEC PARTNERSHIP

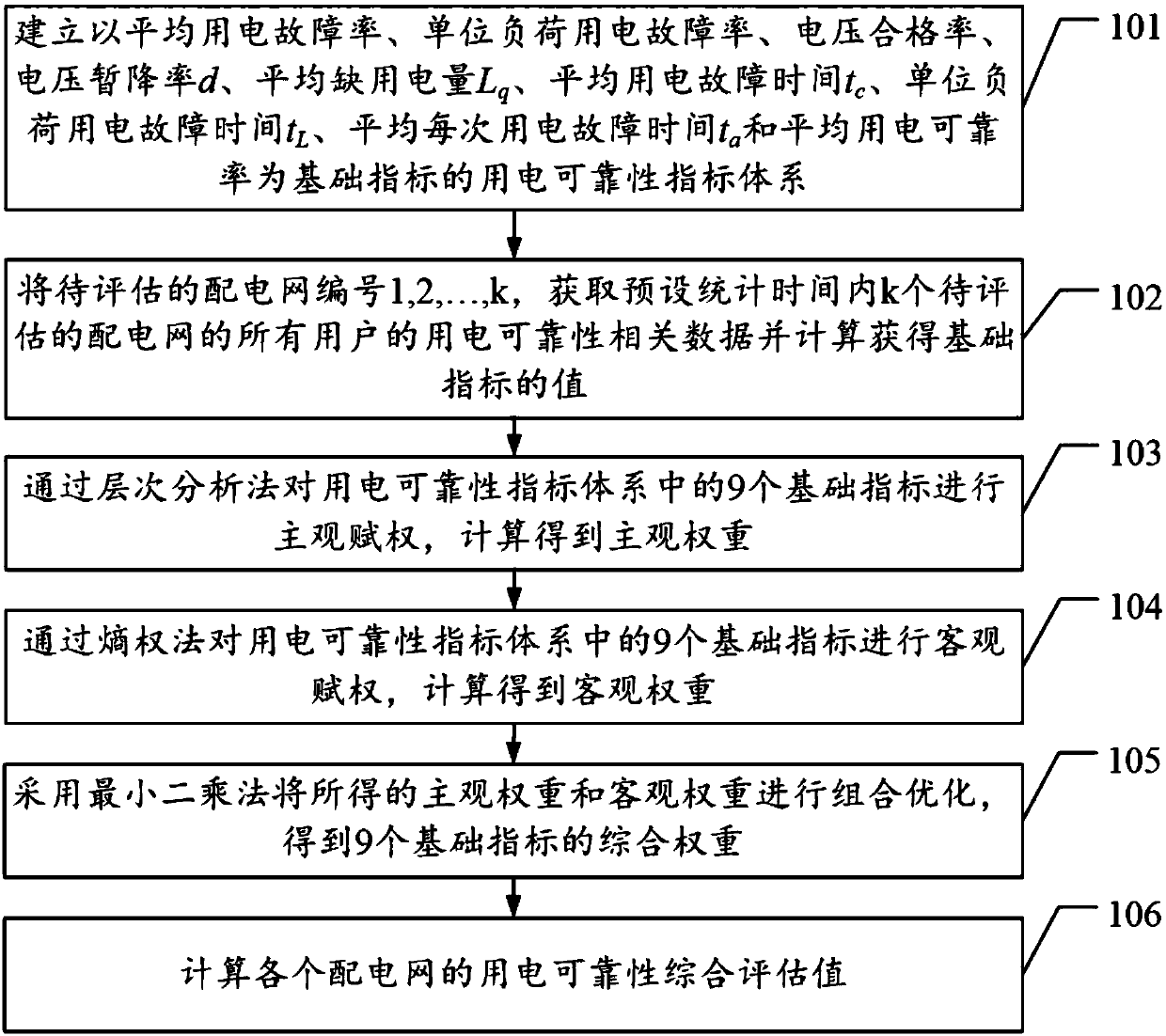

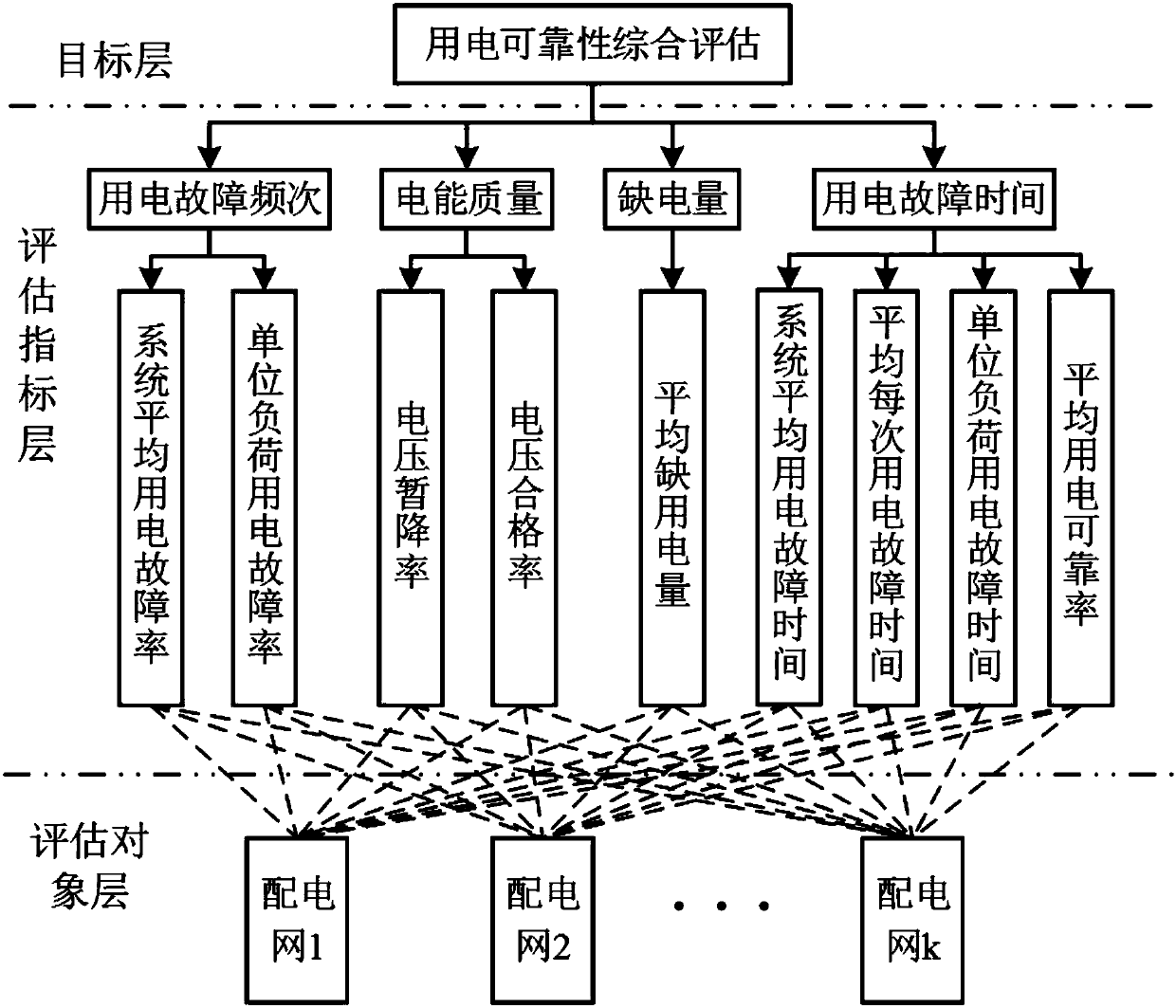

Power distribution network reliability evaluation method based on AHP and entropy weight method

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

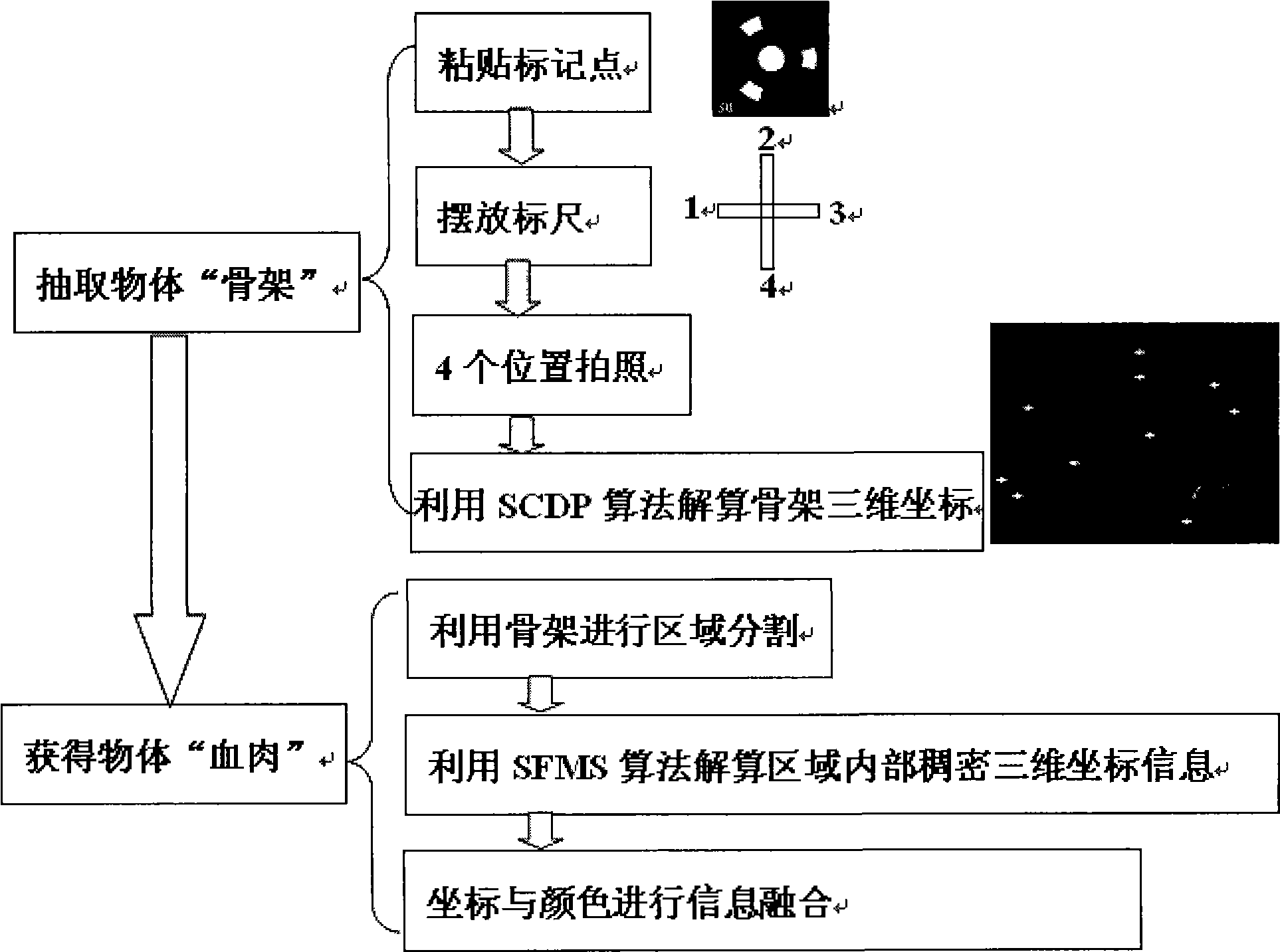

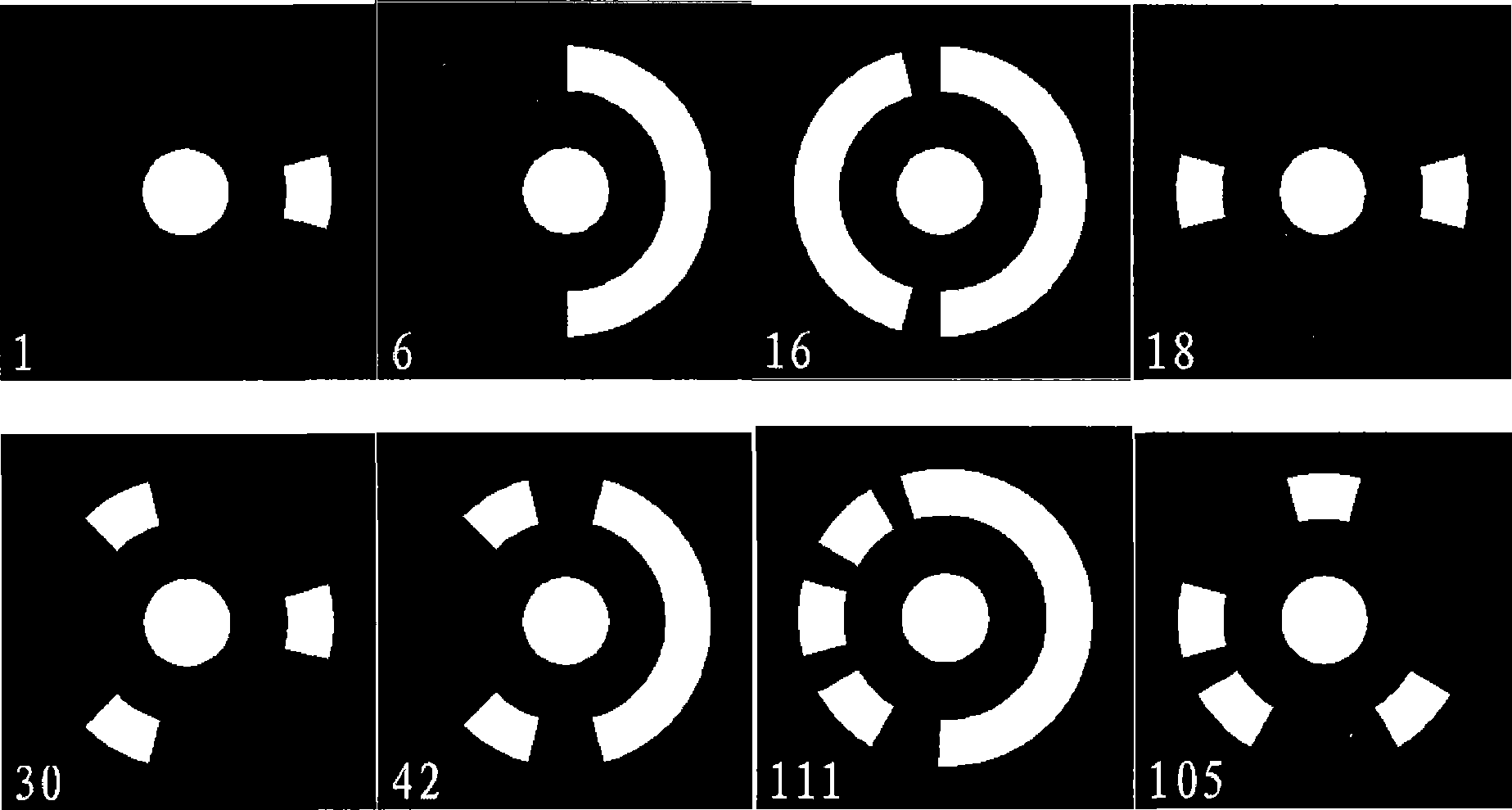

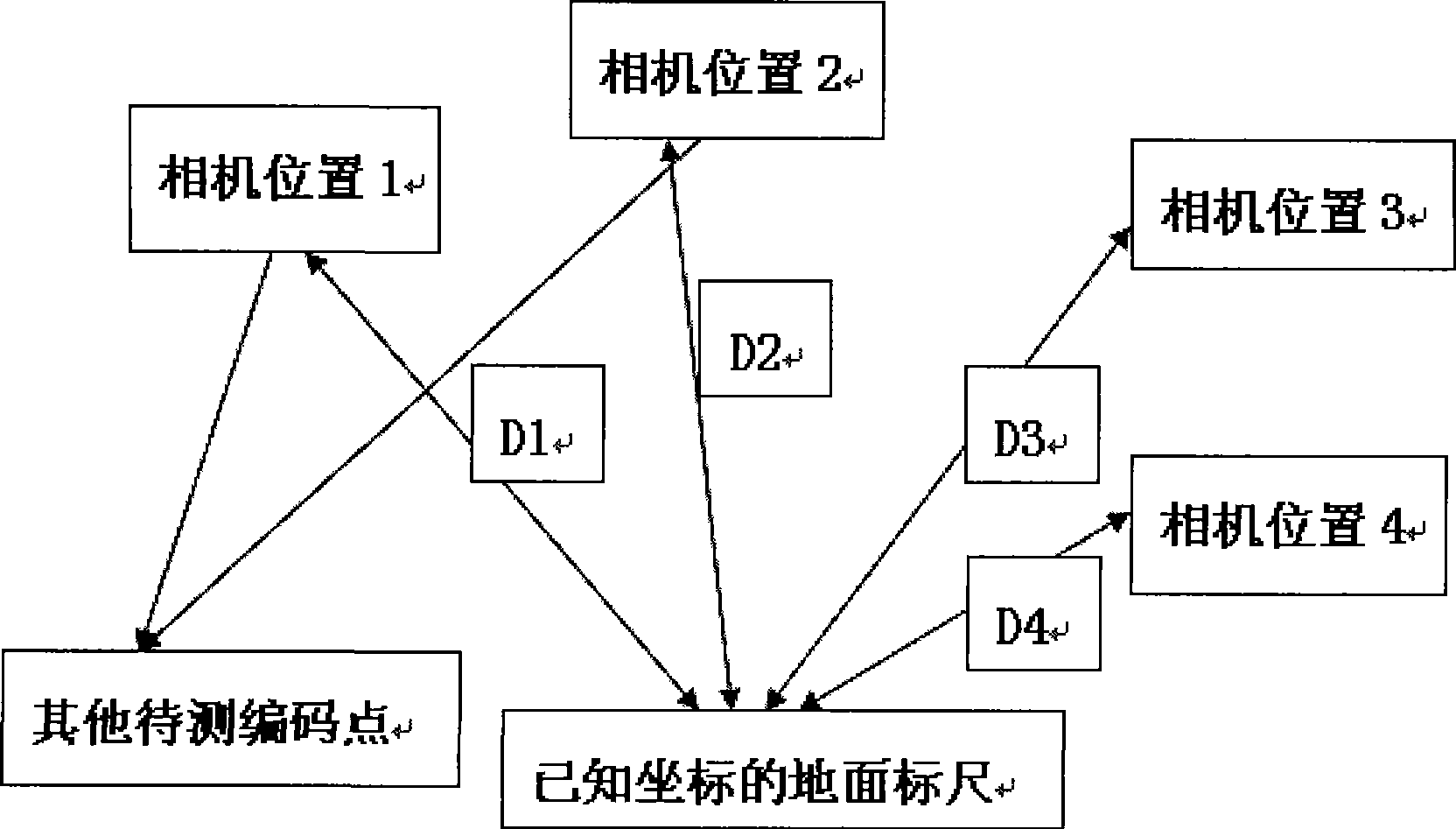

Single order high precision large-sized object three-dimensional digitized measurement system and measurement method thereof

InactiveCN101509763ASolve workpiece wearAddressing Probe Operational LimitationsUsing optical meansIntelligent designStimulus detection

The invention belongs to the field of image processing and pattern recognition and relates to a three-dimensional digital measurement method of a monocular high accuracy large-scale object. The method needs to attach a digital solid coding marking point at the key dimensional part of an object to be measured and put a cross target on which a coding marking point is attached beside the object, and the coding marking point can show the framework information of the object. A high accuracy digital camera is adopted first to collect images at four positions of the object to be measured; then an SCDP (Single Camera Different Position) method proposed by the invention is applied to obtain precision three-dimensional coordinate of the framework coding marking point, a space is divided into a plurality of sub-areas; inside the sub-areas, an SFMS (Shape From Multi Shading) method proposed in the invention is adopted to obtain the corresponding three-dimensional coordinate of each pixel point of images; and by combining with the color information of the coordinate, a color three-dimensional digital model of the object is consequently obtained to provide data foundation for the subsequent intelligent design. The SCDP and the SFMS method proposed in the invention enrich the basic theory of three-dimensional visualization measurement, lay a foundation for the monocular three-dimensional visualization detection theory and boost the level of Chinese manufacturing industry.

Owner:TIANJIN POLYTECHNIC UNIV

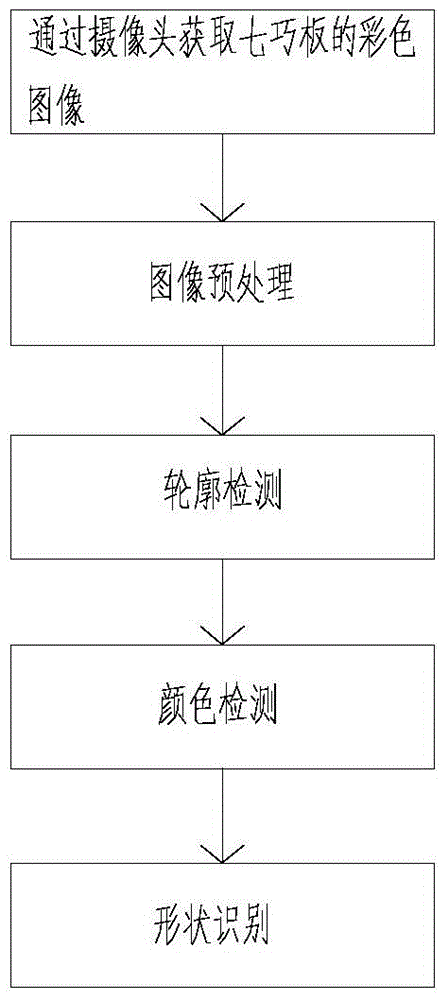

Seven-piece puzzle identification method based on contours and colors

The invention discloses a seven-piece puzzle identification method based on contours and colors. The seven-piece puzzle identification method comprises the following steps: S1, obtaining the color image of a seven-piece puzzle through a camera; S2, preprocessing the color image in the step S1; S3, carrying out contour detection on the color image in the step S1; S4, carrying out color detection on contour information in the step S3; S5, carrying out shape identification. The seven-piece puzzle identification method has the beneficial effects that the method is suitable for any electronic equipment and platforms, such as human-computer interaction, and a physical toy in traditional games and electronic equipment are skillfully combined together through an advanced computer algorithm, so that a game of combining the real world with a virtual technology together is realized, and the limitation problem for seven-piece puzzle game when an embedded platform is low in processing speed and limited in memory resources is effectively solved.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com