Absorption tower for desulfurization and denitrification combined with oxidant in forward-flow and back-flow spraying and method

A desulfurization, denitrification, and absorption tower technology, which is applied in chemical instruments and methods, separation methods, and dispersed particle separation to achieve the effects of unique structure, high mercury removal performance, and high desulfurization and denitrification rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

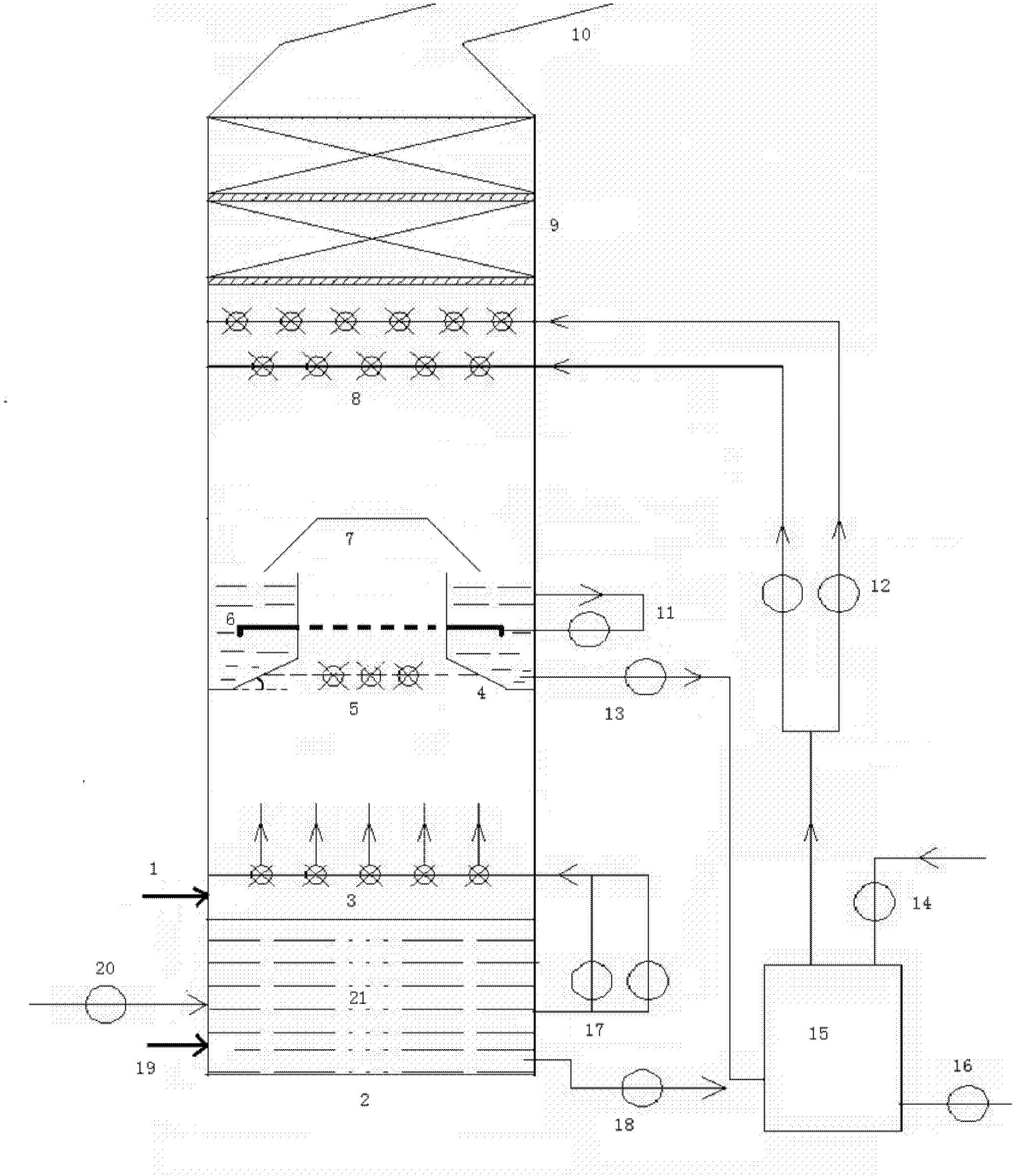

[0042] Such as figure 1 , an absorption tower combined with ozone oxidation desulfurization and denitrification by spraying along and countercurrent. The inner chamber of the absorption tower 2 is provided with a desulfurization slurry pool 21, a desulfurization slurry nozzle 3, a slurry separator 4, a denitrification slurry nozzle 8 and a demister in sequence from bottom to top. 9. There is a flue gas inlet 1 and a flue gas outlet 10 on the tower body. The flue gas inlet 1 is located between the desulfurization slurry nozzle 3 and the desulfurization slurry pool 21. The flue gas outlet 10 is located above the demister 9. The absorption tower is surrounded by a slurry separator 4 Divided into two loops: the lower loop is the desulfurization loop (also known as the primary loop), which mainly completes the dissolution of lime and SO 2 The removal; the upper loop is the denitrification loop (also known as the secondary loop). The absorption slurry of the first and second loops ...

Embodiment 2

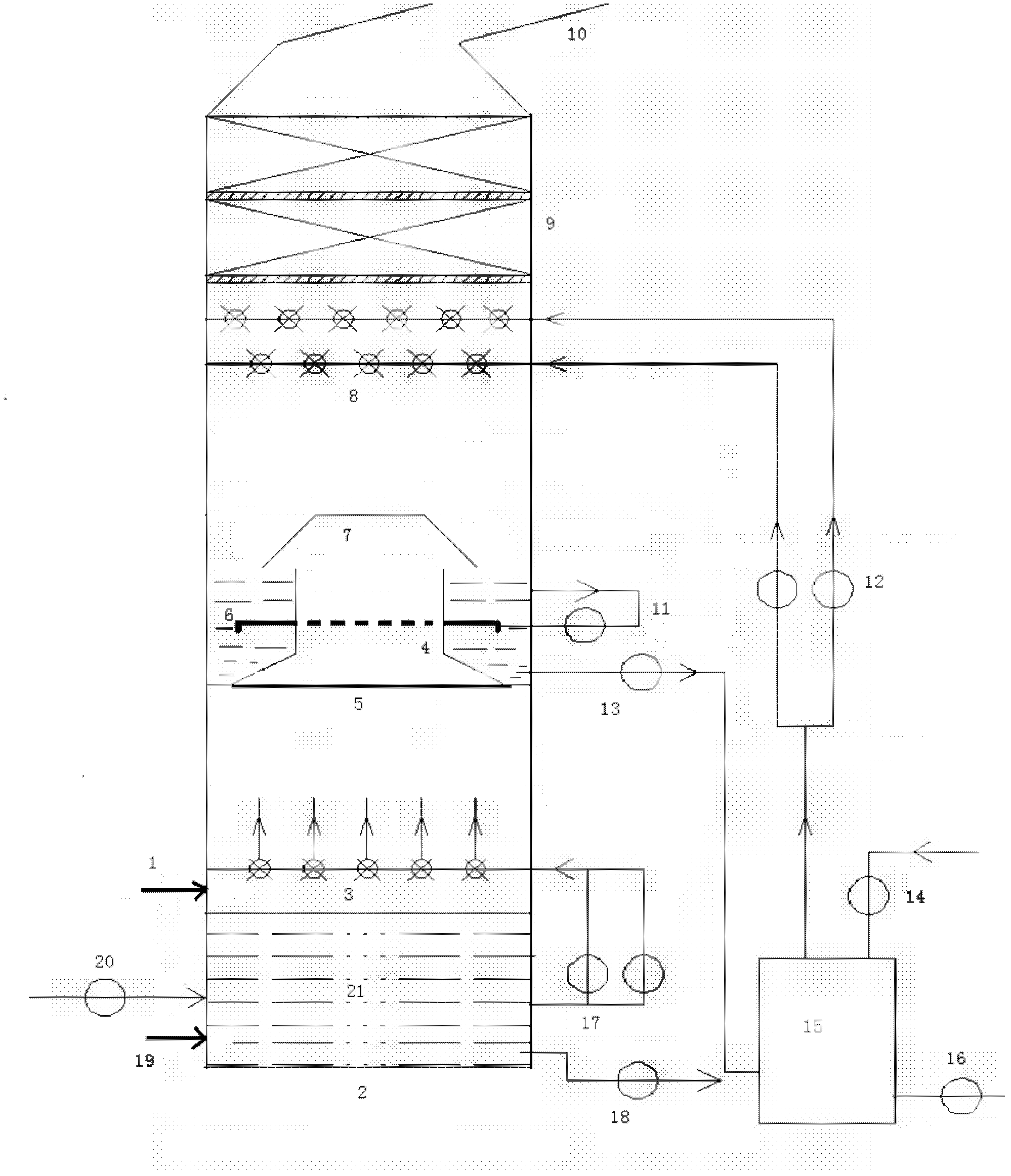

[0062] Such as figure 2 , this process is aimed at changing the oxidant, and other liquid-phase oxidants can be used, such as sodium hypochlorite. The liquid-phase oxidant is sprayed into the oxidant below the slurry separator 4 through the annular oxidant injection pipe 5, where the gas-liquid violently mixes, and the flue gas NO is oxidized to a high valence state, and the others are the same as in Example 1.

Embodiment 3

[0064] The present invention also has other changeable operation modes. For example, if only desulfurization is required, the addition of oxidant is stopped, and the secondary circuit is used as a desulfurization absorption section; if only denitrification is required, the primary circuit can be shut down, and only the secondary circuit can be guaranteed to operate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com