Recovery method of copper-nickel heavy metals in electroplated mixed-flow waste water

A recovery method and technology of heavy metals, which are applied in the fields of metallurgical wastewater treatment, chemical instruments and methods, and multi-stage water/sewage treatment, etc., can solve the problems of non-reuse, large mixed sludge output, and difficulty in realizing wastewater diversion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

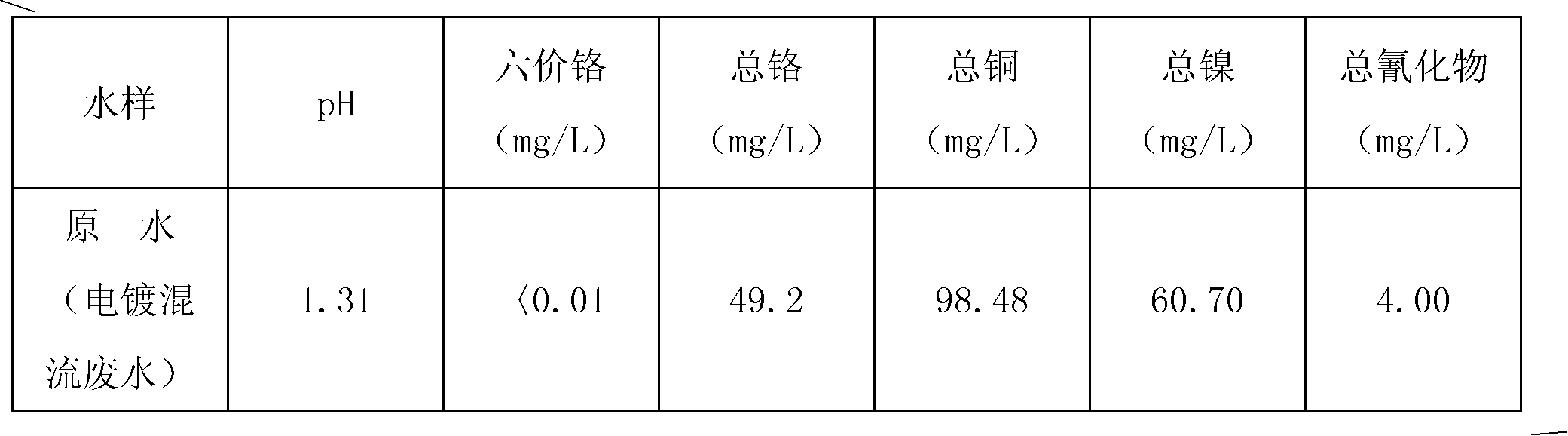

[0018] The influent water quality index of electroplating mixed flow wastewater from an electroplating sludge water plant is shown in Table 1 below:

[0019] Table 1 Influent water quality of electroplating mixed flow wastewater

[0020]

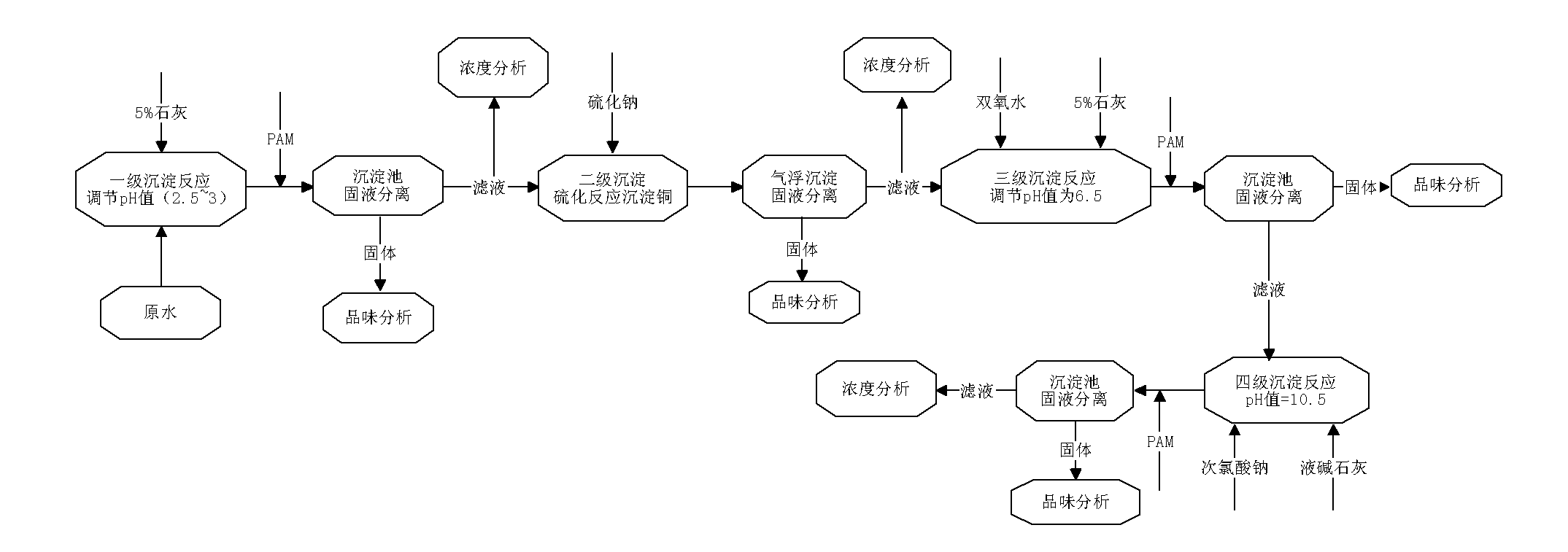

[0021] see figure 1 A method for recovering heavy metals from electroplating wastewater containing copper and nickel, taking the primary precipitation pH value of 2.5 as an example, includes the following steps:

[0022] a, primary precipitation: take 20L of the above-mentioned raw water, add 5% (mass percentage) of lime to adjust the pH value to 2.5, and add flocculant PAM to strengthen the precipitation effect, and the generated precipitation is carried out solid-liquid separation through the sedimentation tank; Contain copper 93.3mg / L in the filtrate after step a treatment, contain nickel 55.15mg / L;

[0023] B, secondary precipitation: add sodium sulfide in the waste water after step a treatment, the mol ratio of the add-on of sodium...

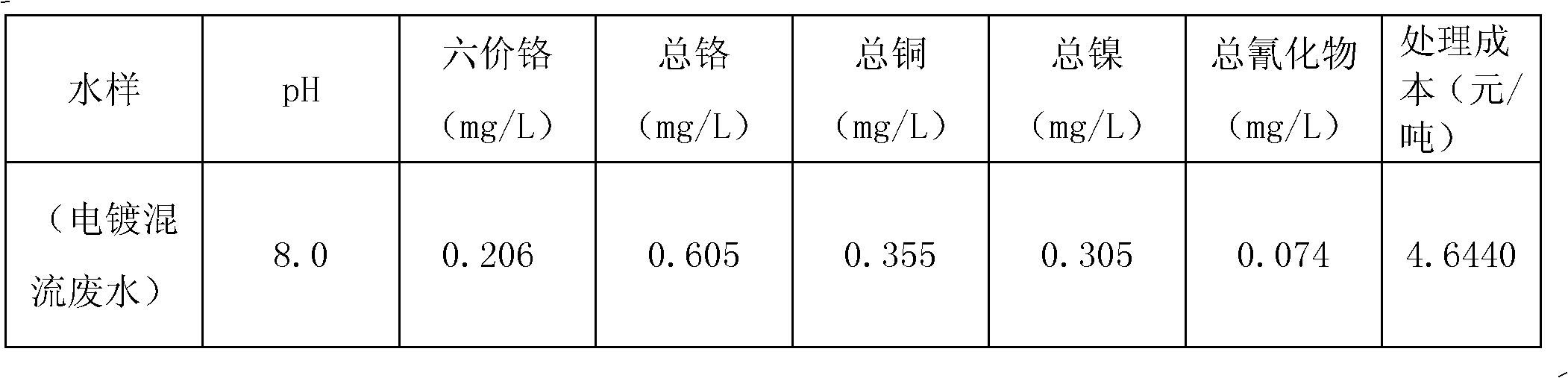

Embodiment 2

[0032] The influent water quality index of electroplating mixed flow wastewater from an electroplating sludge water plant is shown in Table 1 below: (same as above)

[0033] Table 1 Influent water quality of electroplating mixed flow wastewater

[0034]

[0035] see figure 1 , an experiment of heavy metal recovery method of electroplating wastewater containing copper and nickel, taking the primary precipitation pH value of 3.0 as an example, including the following steps:

[0036] a, primary precipitation: take 20L of the above-mentioned raw water, add 5% (mass percentage) of lime to adjust the pH value to 3.0, and add flocculant PAM to strengthen the precipitation effect, and the generated precipitation is carried out solid-liquid separation through the sedimentation tank; Copper-containing 80.0mg / L, nickel-containing 52.95mg / L in the filtrate after step a treatment;

[0037] B, secondary precipitation: add sodium sulfide in the waste water after step a treatment, the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com