Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

983 results about "Aluminum can" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An aluminum can (British English: aluminium can), sometimes erroneously referred to as a "tin can", is a container for packaging made primarily of aluminum. It is commonly used for foods and beverages such as milk and soup but also for products such as oil, chemicals, and other liquids. Global production is 180 billion annually and constitutes the largest single use of aluminum globally.

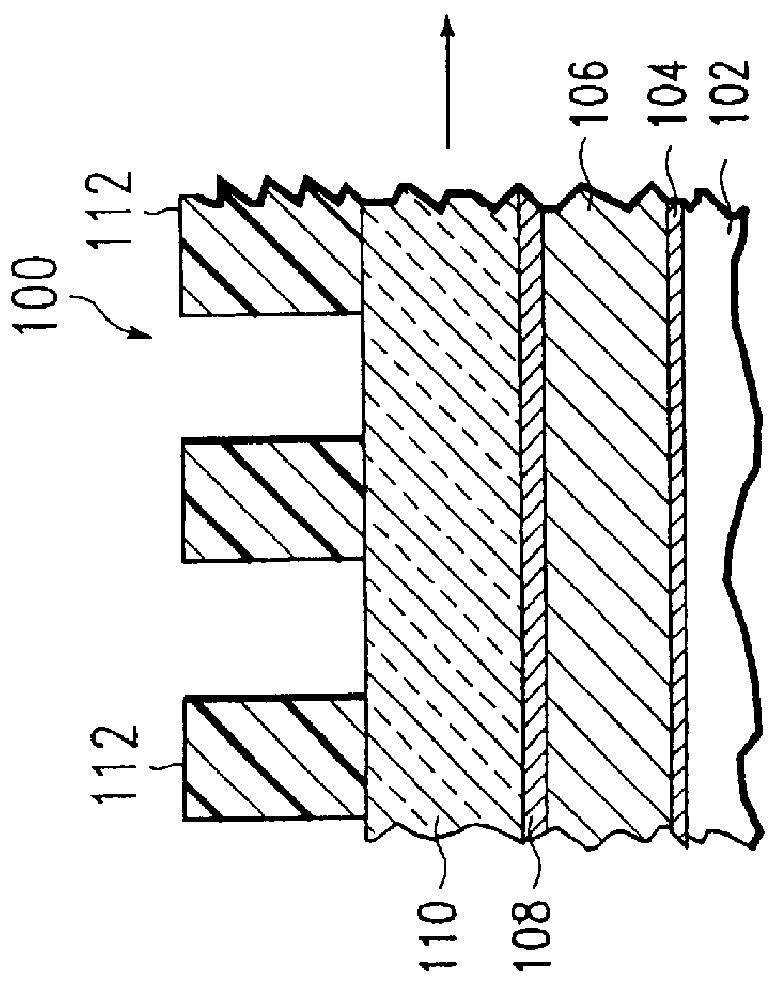

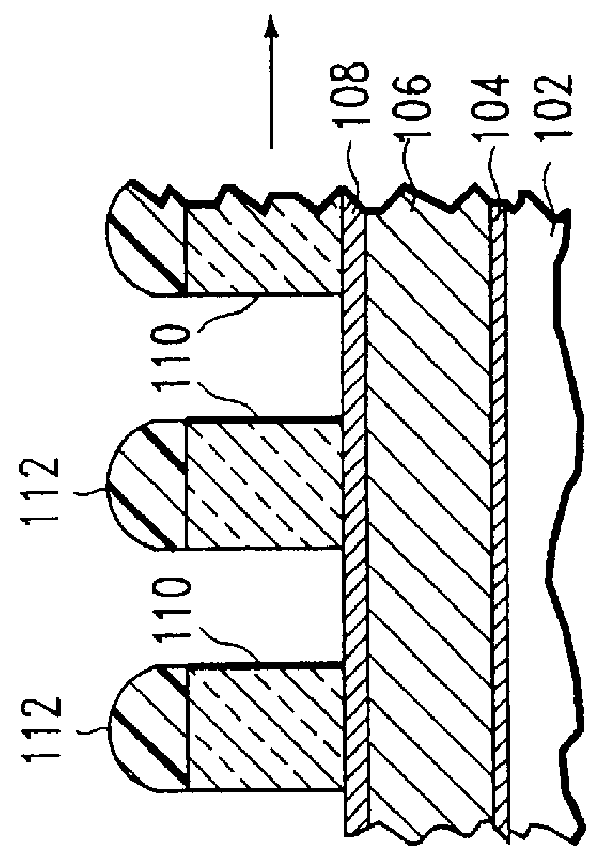

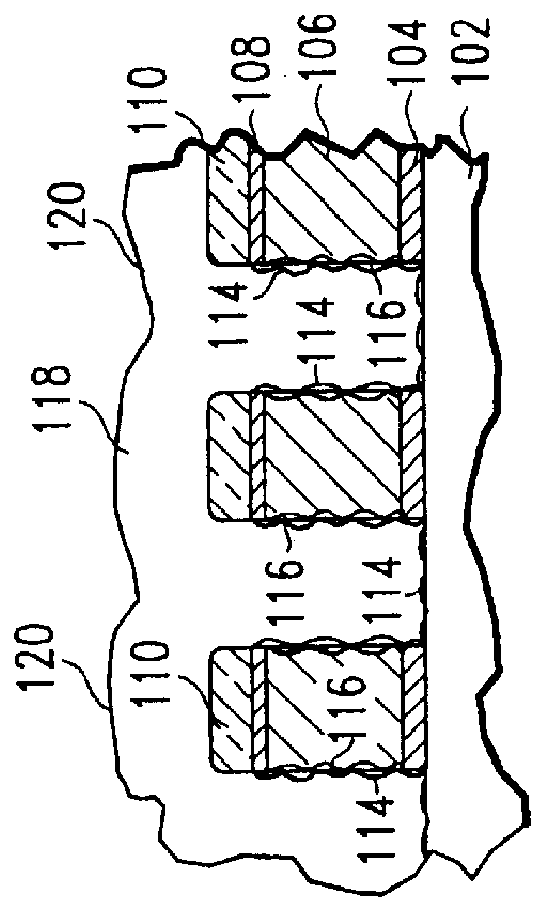

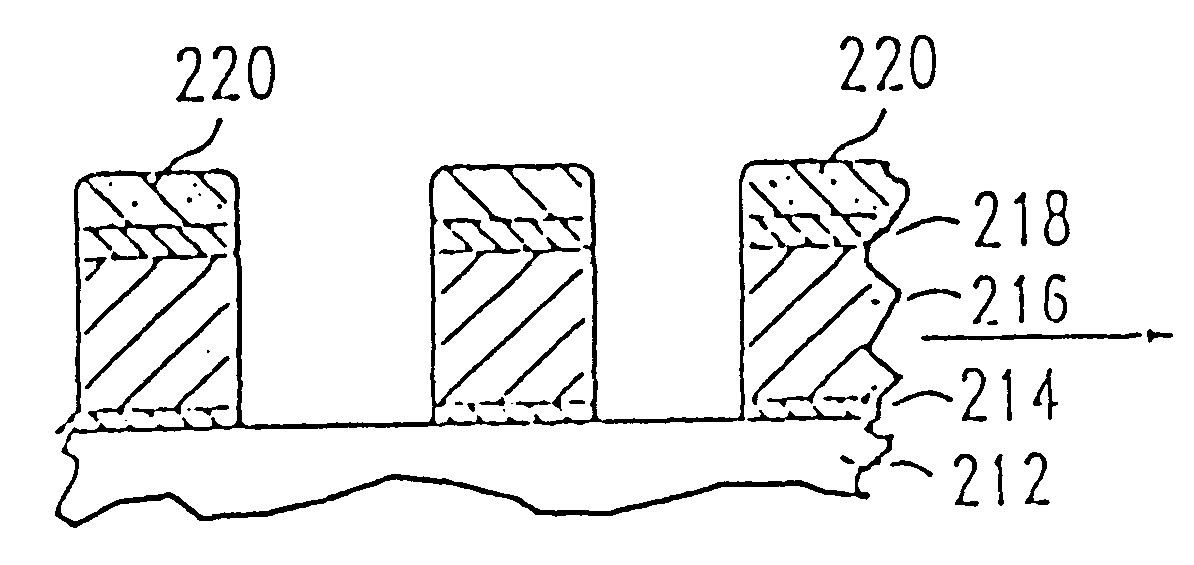

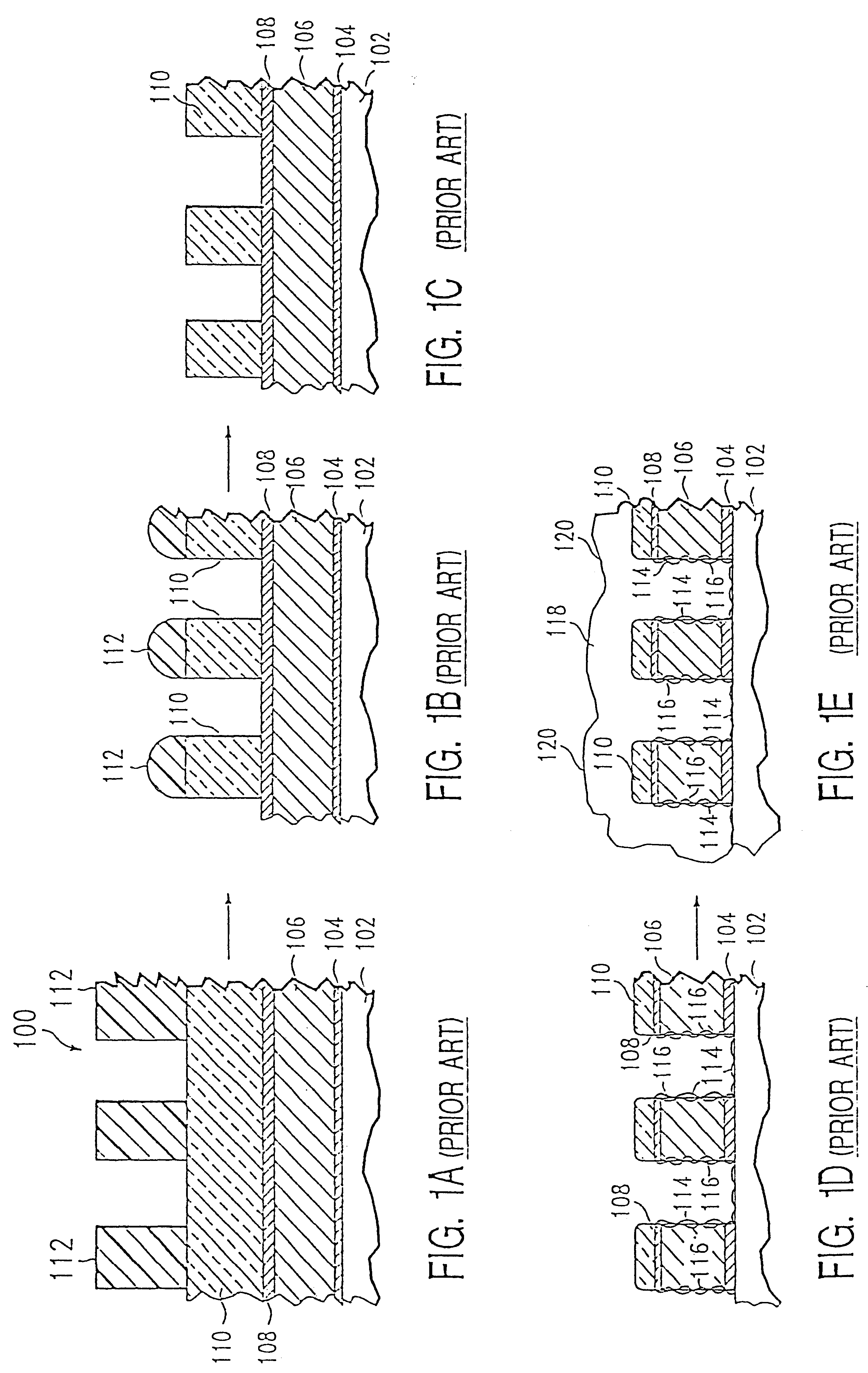

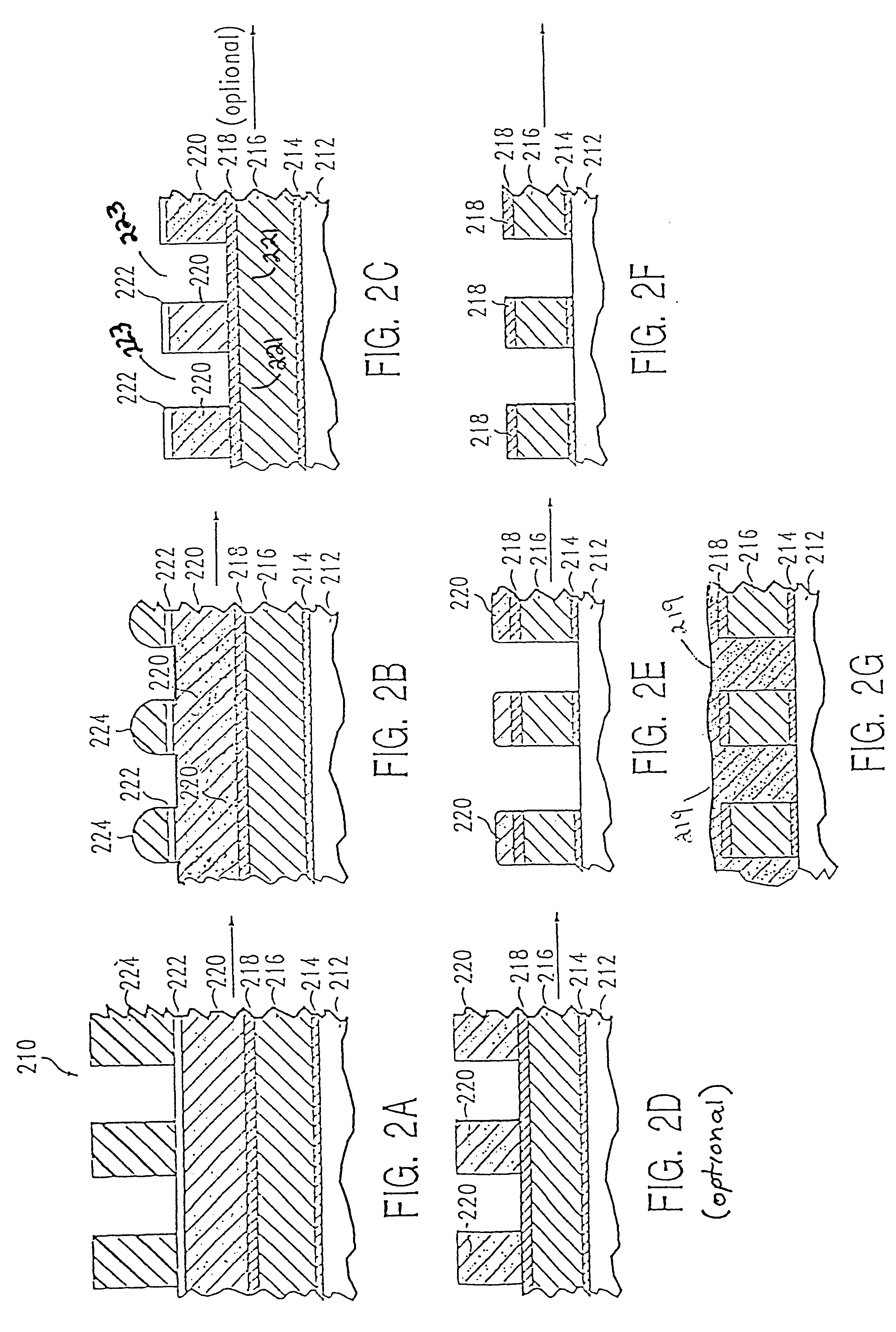

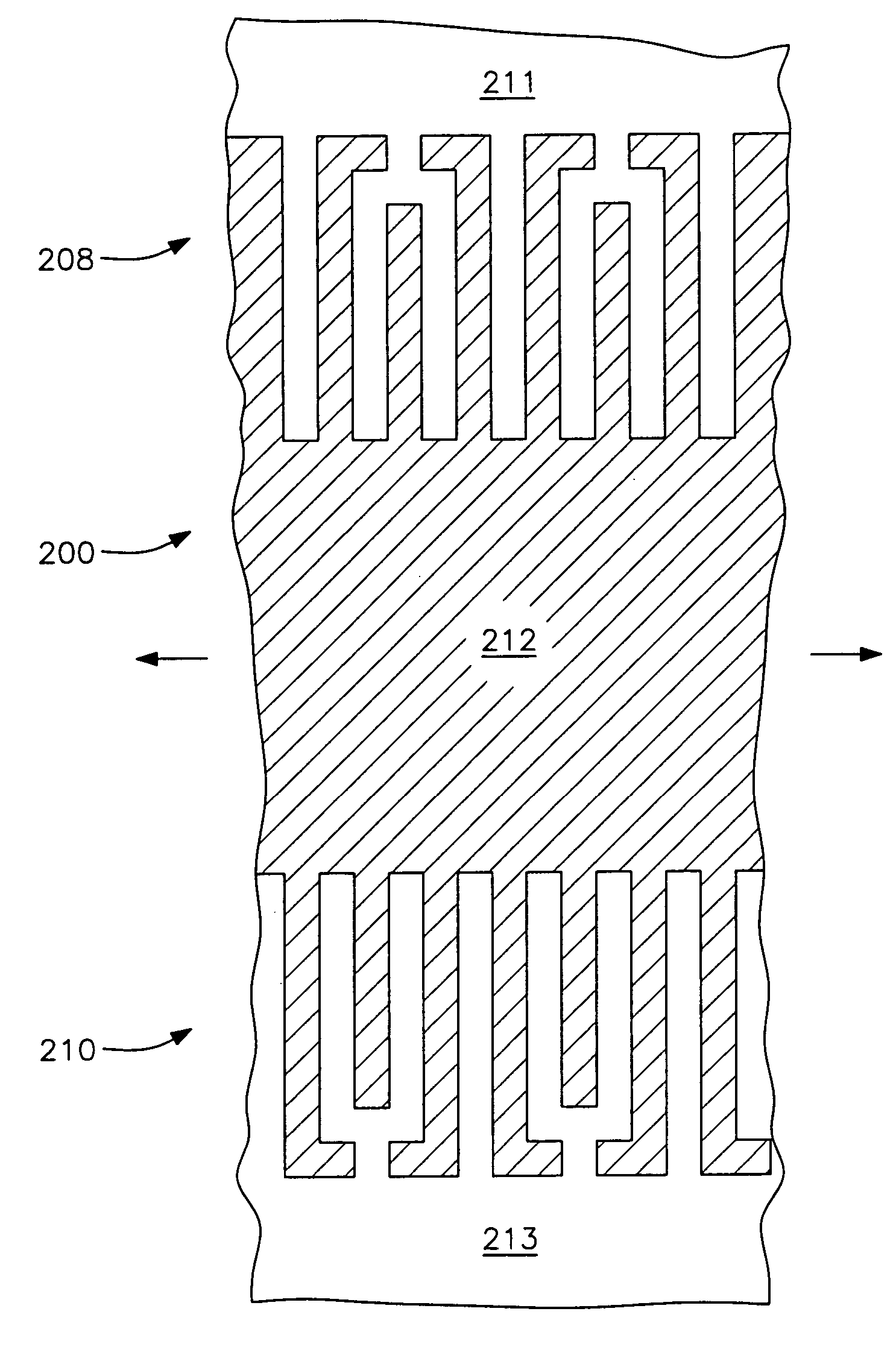

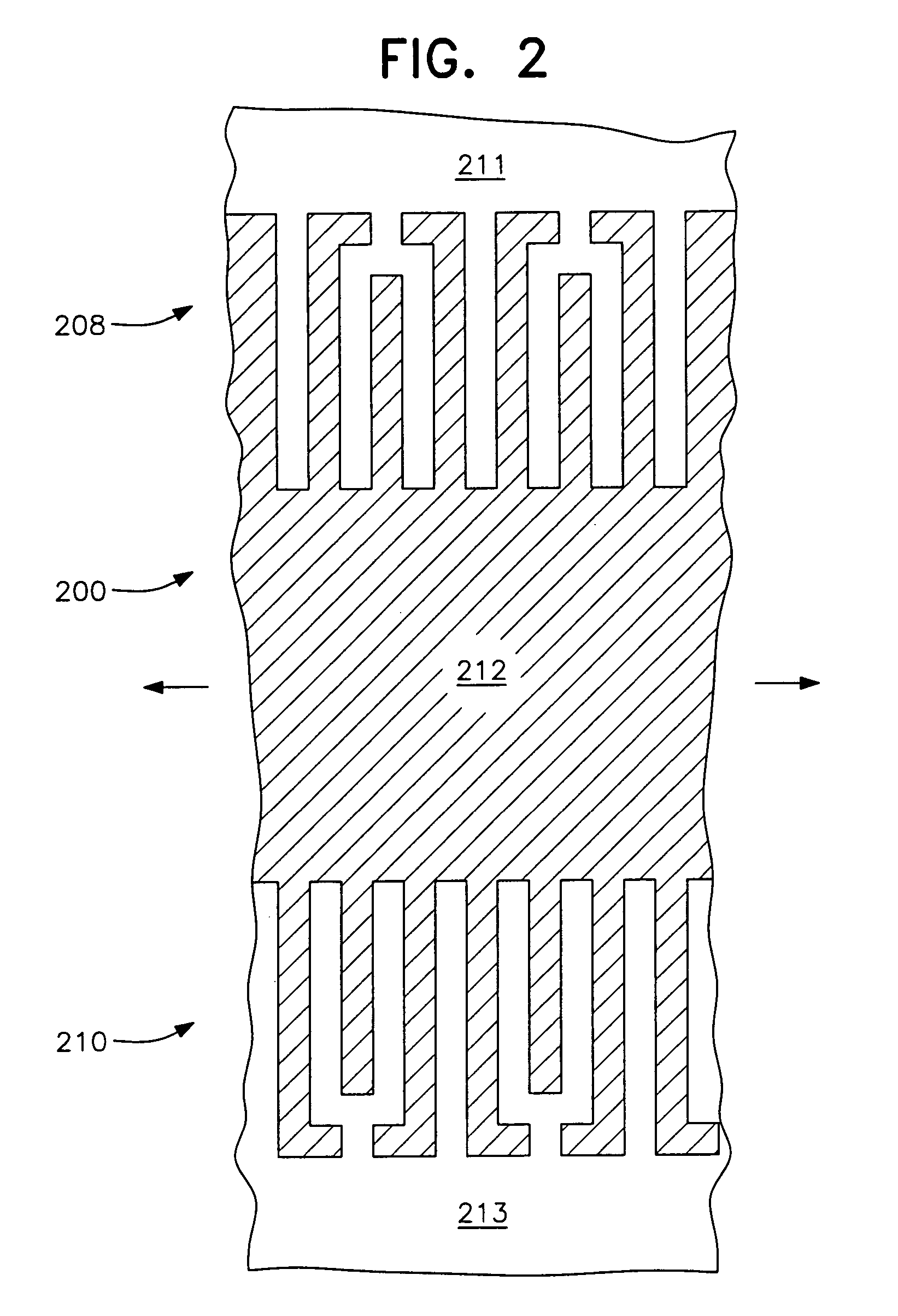

Method of etching patterned layers useful as masking during subsequent etching or for damascene structures

InactiveUS6080529APhotomechanical apparatusSemiconductor/solid-state device manufacturingConductive polymerOrganic base

A first embodiment of the present invention pertains to a method of patterning a semiconductor device conductive feature while permitting easy removal of any residual masking layer which remains after completion of the etching process. A multi-layered masking structure is used which includes a layer of high-temperature organic-based masking material overlaid by either a patterned layer of inorganic masking material or by a layer of patterned high-temperature imageable organic masking material. The inorganic masking material is used to transfer a pattern to the high-temperature organic-based masking material and is then removed. The high-temperature organic-based masking material is used to transfer the pattern and then may be removed if desired. This method is also useful in the pattern etching of aluminum, even though aluminum can be etched at lower temperatures. A second embodiment of the present invention pertains to a specialized etch chemistry useful in the patterning of organic polymeric layers such as low k dielectrics, or other organic polymeric interfacial layers. This etch chemistry is useful for mask opening during the etch of a conductive layer or is useful in etching damascene structures where a metal fill layer is applied over the surface of a patterned organic-based dielectric layer. The etch chemistry provides for the use of etchant plasma species which minimize oxygen, fluorine, chlorine, and bromine content.

Owner:APPLIED MATERIALS INC

Method of pattern etching a low K dielectric layer

InactiveUS6331380B1Photomechanical apparatusSemiconductor/solid-state device manufacturingOrganic baseOxygen

A first embodiment of the present invention pertains to a method of patterning a semiconductor device conductive feature while permitting easy removal of any residual masking layer which remains after completion of the etching process. A multi-layered masking structure is used which includes a layer of high-temperature organic-based masking material overlaid by either a patterned layer of inorganic masking material or by a layer of patterned high-temperature imageable organic masking material. The inorganic masking material is used to transfer a pattern to the high-temperature organic-based masking material and is then removed. The high-temperature organic-based masking material is used to transfer the pattern and then may be removed if desired. This method is also useful in the pattern etching of aluminum, even though aluminum can be etched at lower temperatures. A second embodiment of the present invention pertains to a specialized etch chemistry useful in the patterning of organic polymeric layers such as low k dielectrics, or other organic polymeric interfacial layers. This etch chemistry is useful for mask opening during the etch of a conductive layer or is useful in etching damascene structures where a metal fill layer is applied over the surface of a patterned organic-based dielectric layer. The etch chemistry provides for the use of etchant plasma species which minimize oxygen, fluorine, chlorine, and bromine content.

Owner:APPLIED MATERIALS INC

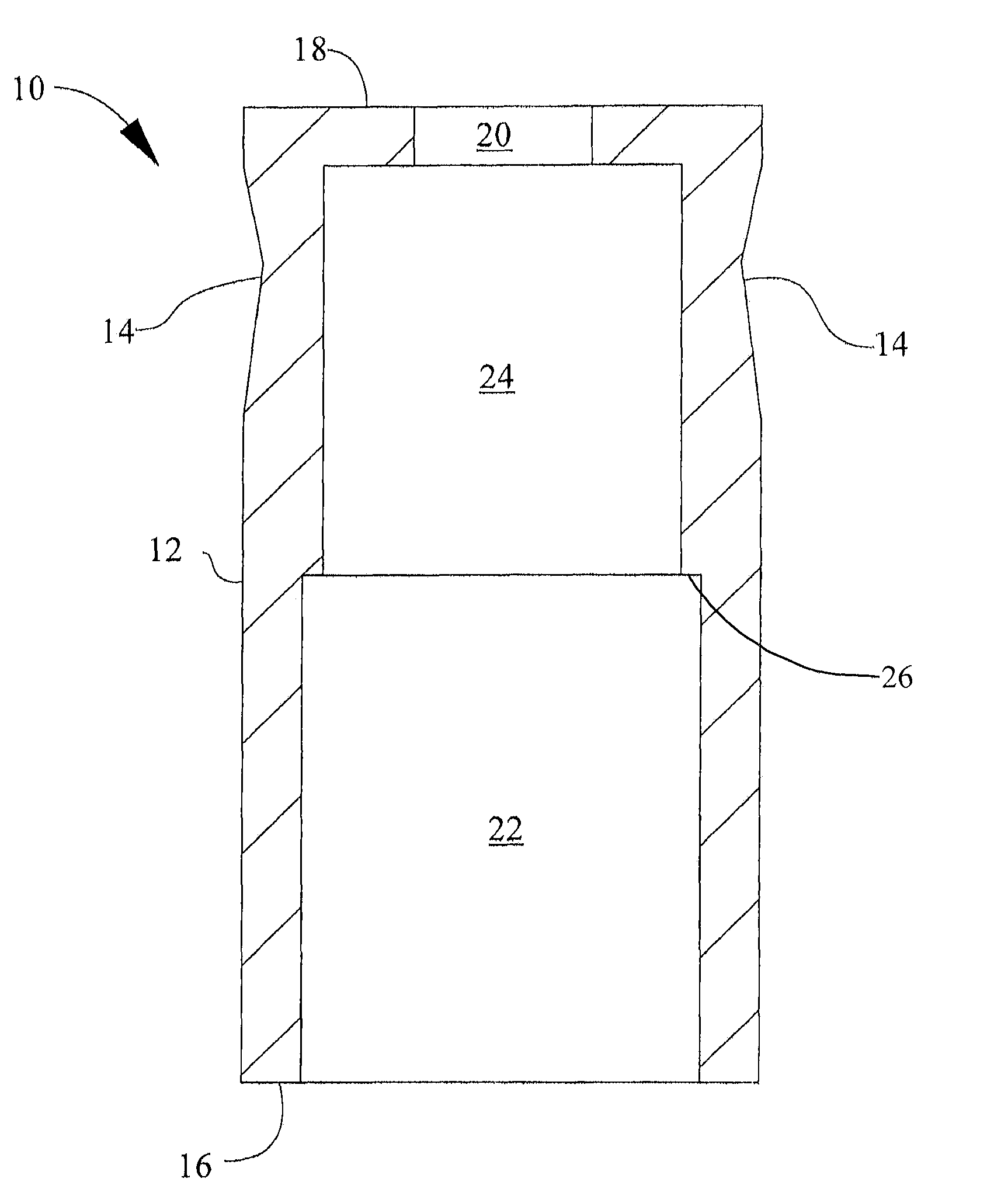

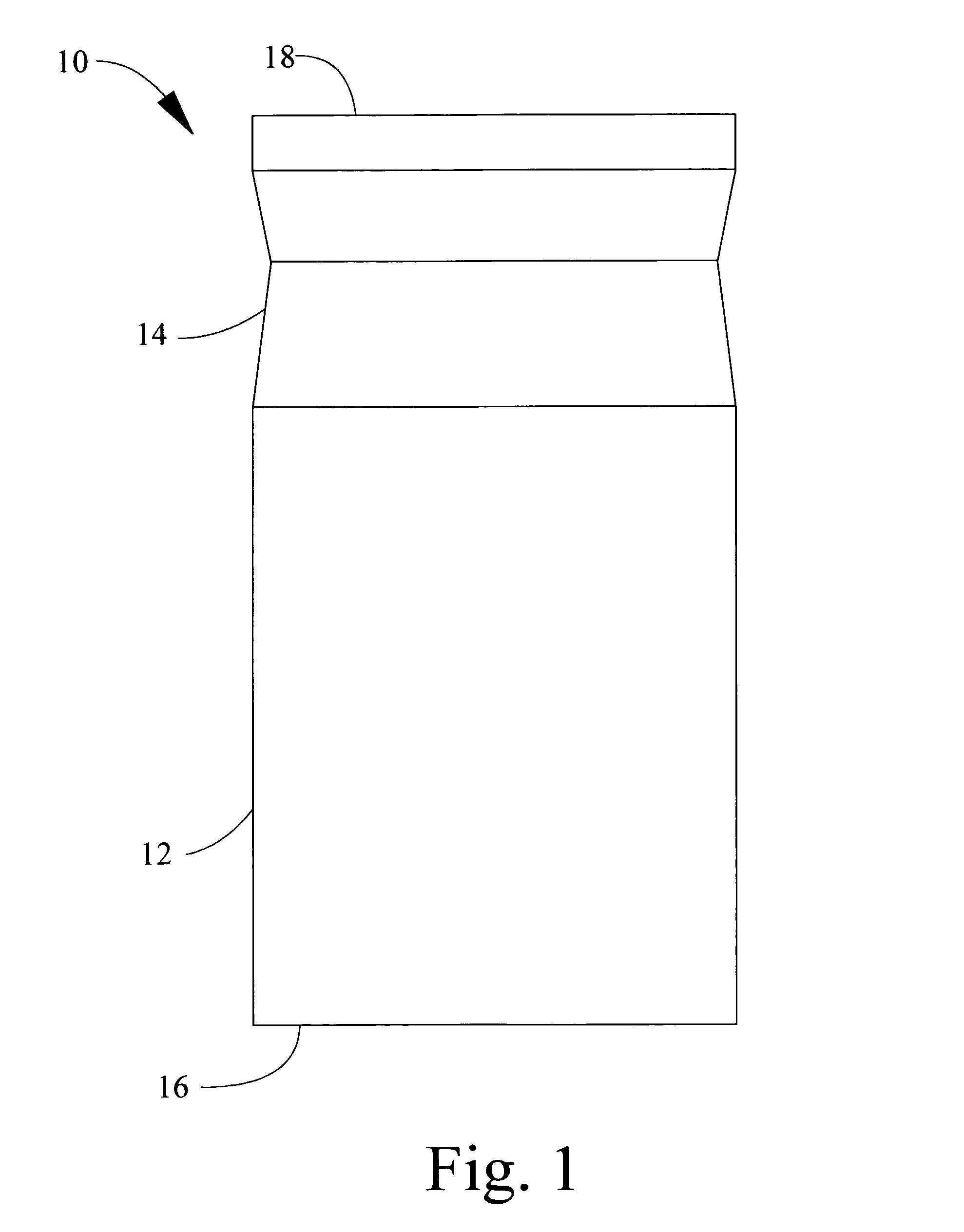

Insulated can and longneck bottle beverage container holder

ActiveUS8544678B1Suitable for useCoverings/external coatingsRigid containersInterference fitAluminum can

An insulating beverage container holder is disclosed that is adapted to receive either longneck beverage bottles or aluminum cans. The insulating beverage holder consists of a substantially cylindrical body having 3 axially aligned apertures therein. One aperture is sized for an interference fit with the cylindrical diameter of an aluminum can beverage container. A second aperture is sized for an interference fit with the neck portion of a longneck beverage container. A third aperture, situated between the first and second apertures, is sized for an interference fit with the larger diameter of a longneck beverage container. Retaining mechanisms are also disclosed that secure longneck beverage containers within the holder to prevent inadvertent removal of the beverage container from within the insulated beverage container holder.

Owner:FLIPZIE INC

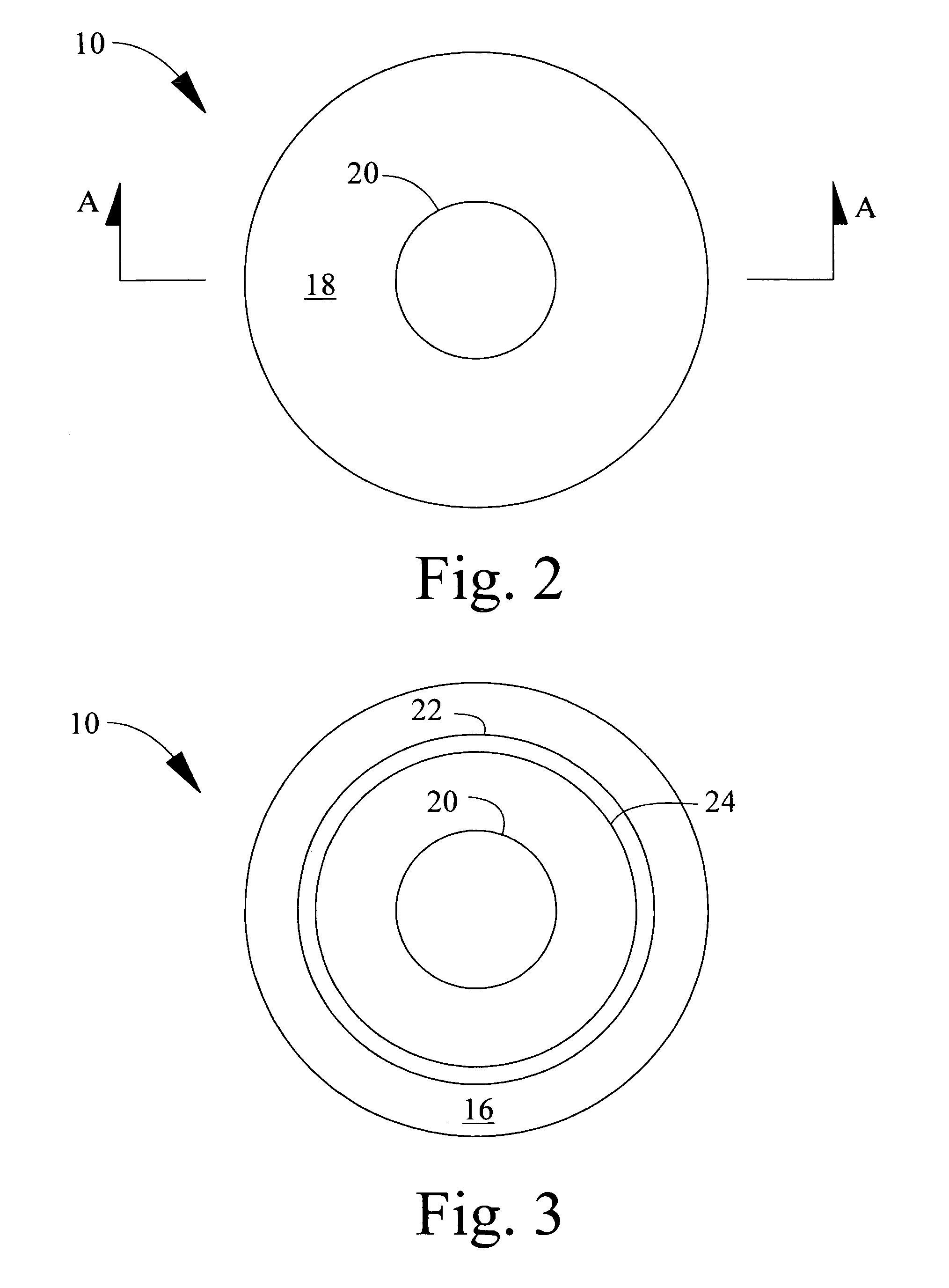

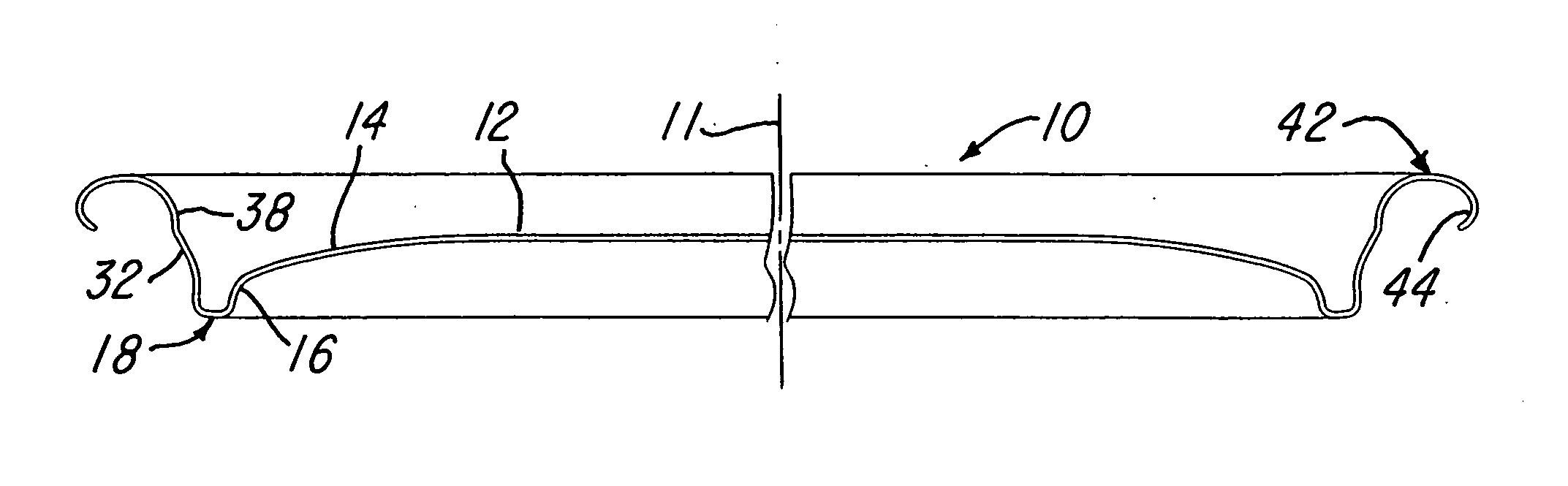

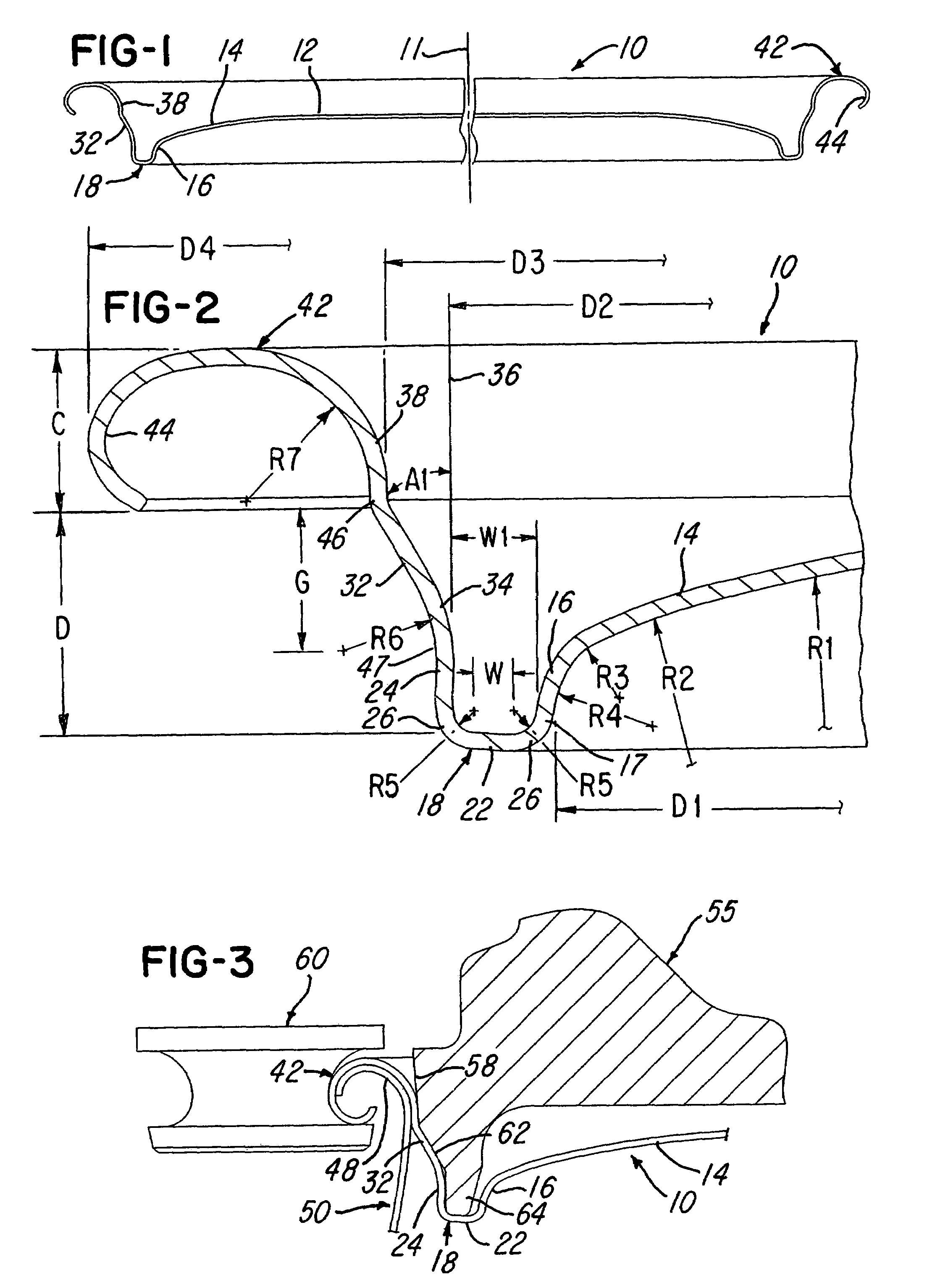

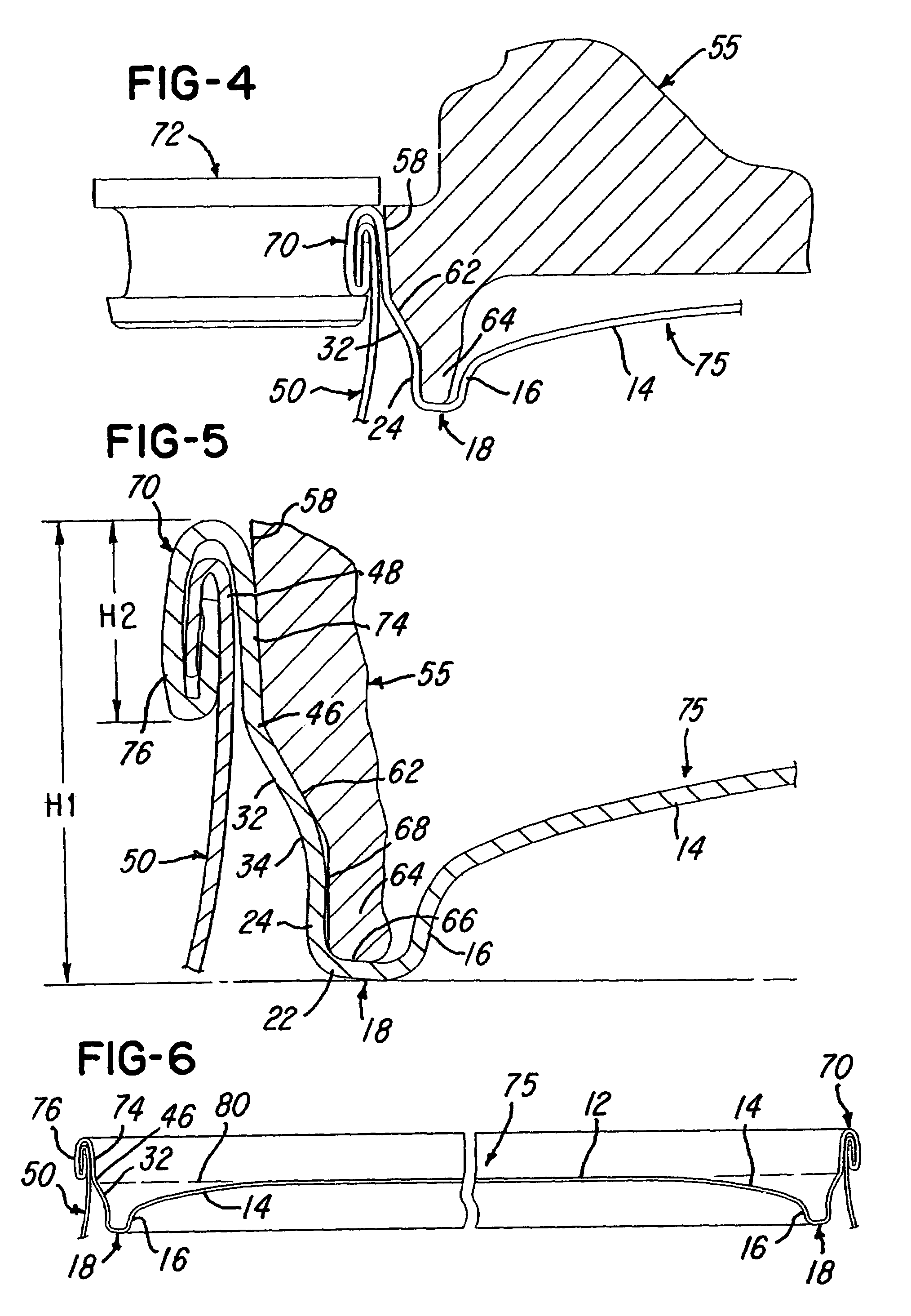

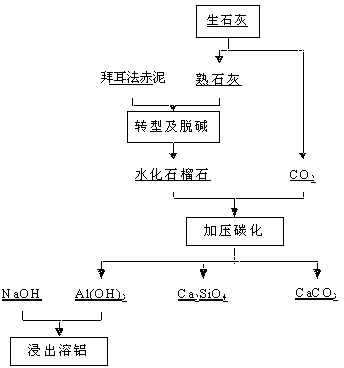

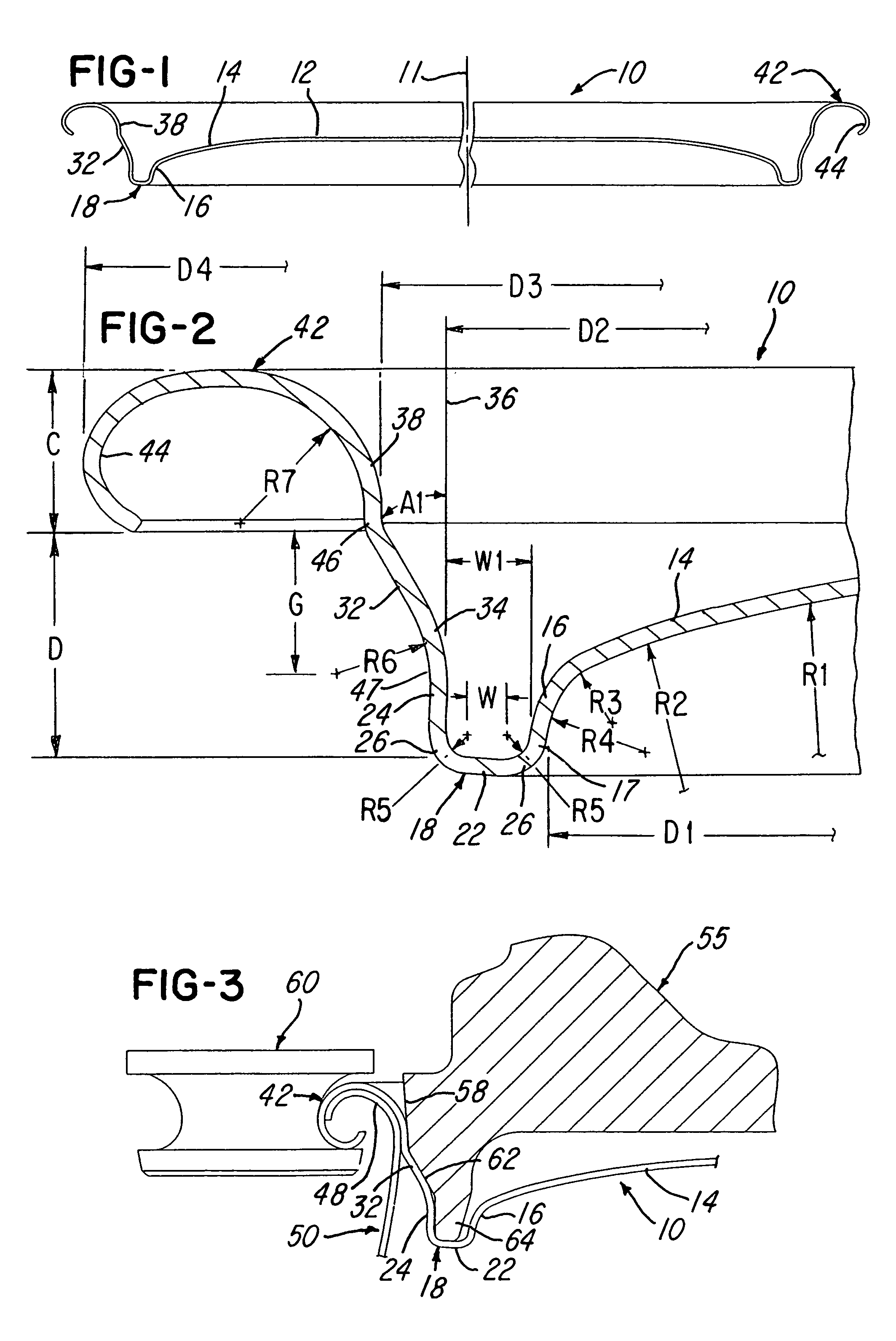

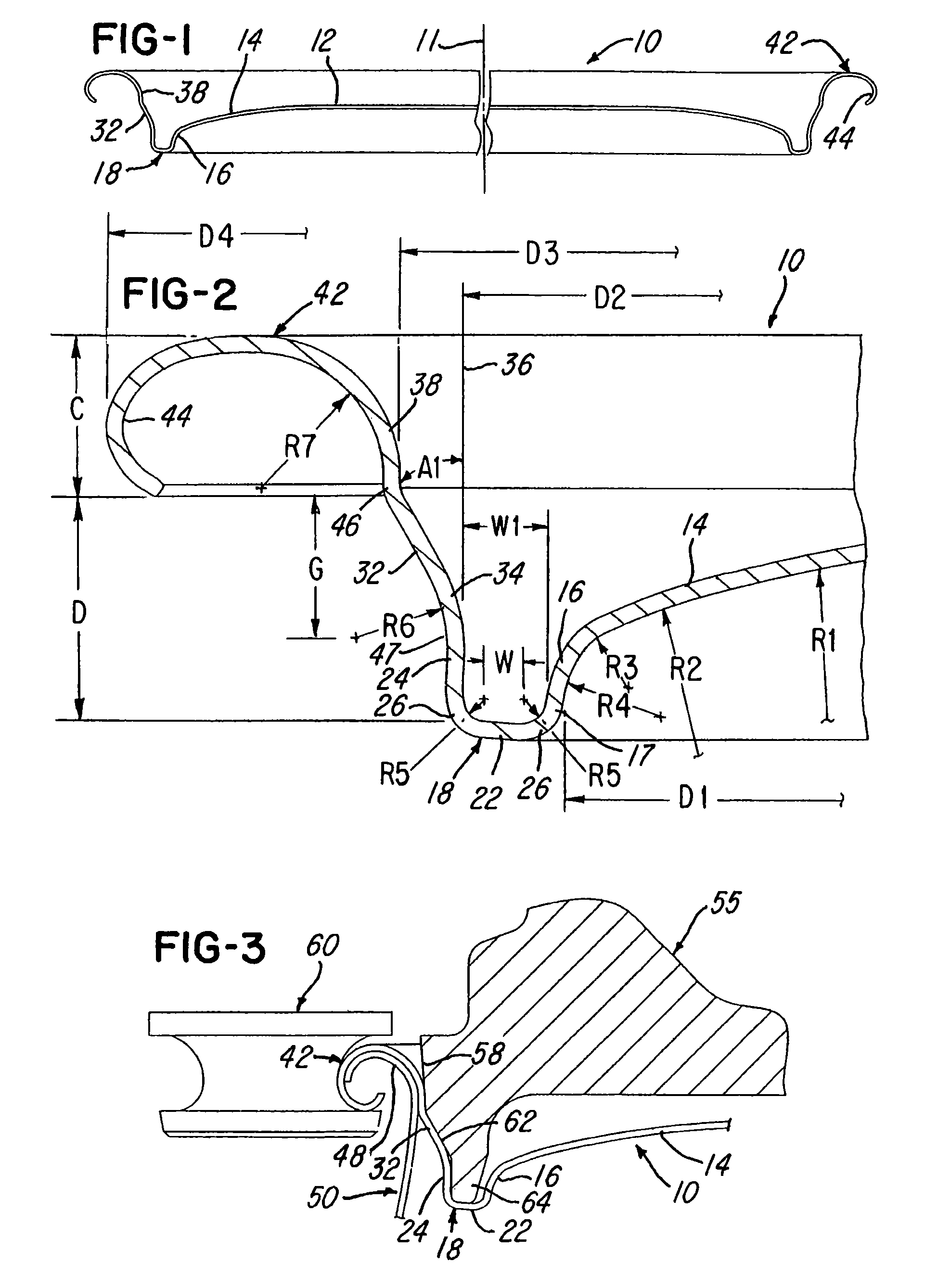

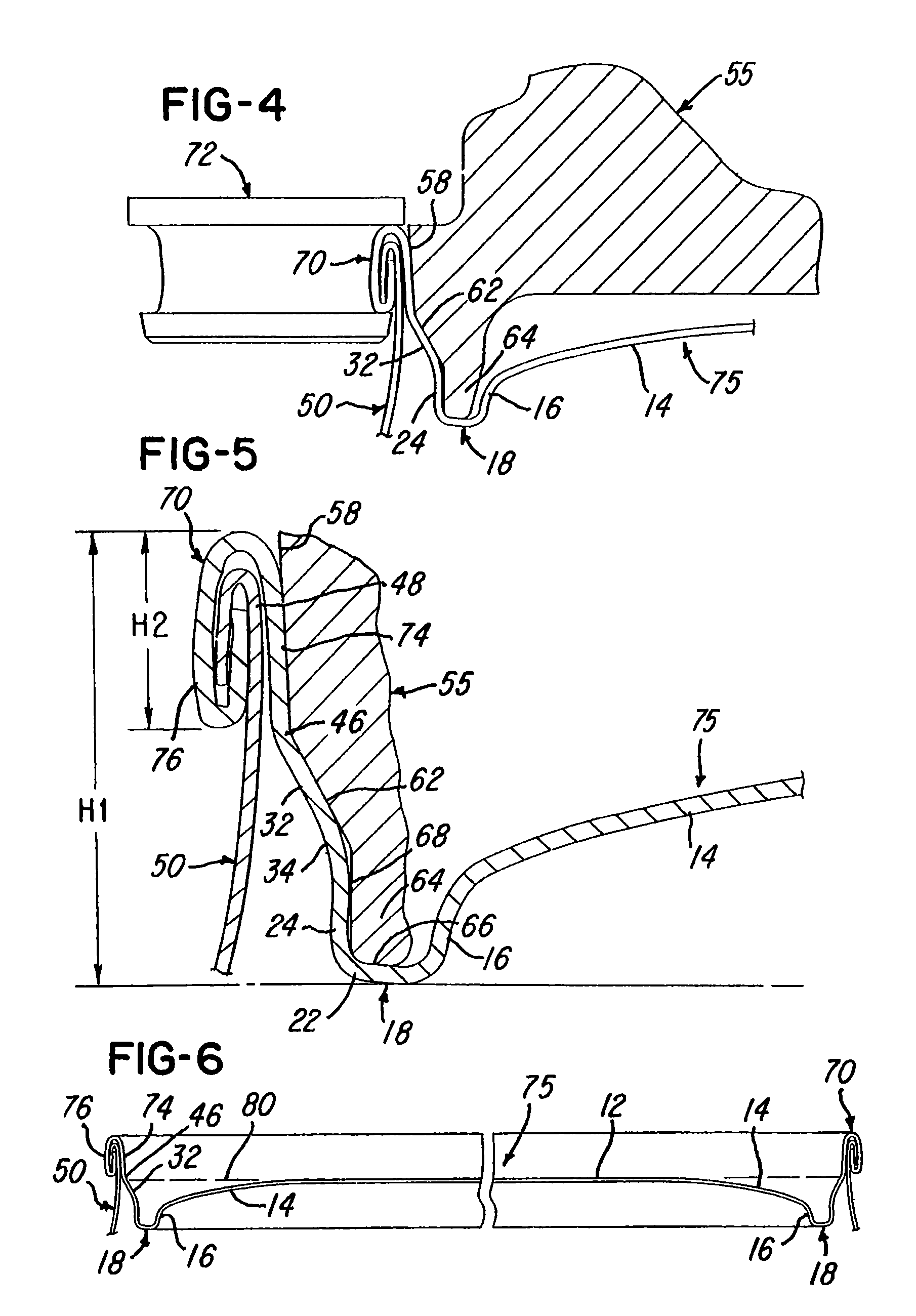

Can shell and double-seamed can end

InactiveUS20050029269A1Reduction in blank diameterIncrease strength/weight ratioRigid containersHollow articlesCountersinkAluminum can

A drawn aluminum can shell has a peripheral crown which is double-seamed with an end portion of an aluminum can body to provide a can end having a generally flat center panel connected by an inclined curved or straight panel wall to an inclined inner wall of an annular U-shaped countersink. The countersink has an outer wall which connects with an inclined lower wall portion of a chuckwall at a junction below the center panel, and the chuckwall has a curved or inclined upper wall portion which connects with an inner wall of the crown. The chuckwall also has an intermediate wall portion forming a break, and the inner bottom width of the countersink is less than the radial width of the panel wall. The inclined upper wall portion of the chuckwall extends at an angle greater than the angle of the inclined lower wall portion of the chuckwall.

Owner:BALL CORP +1

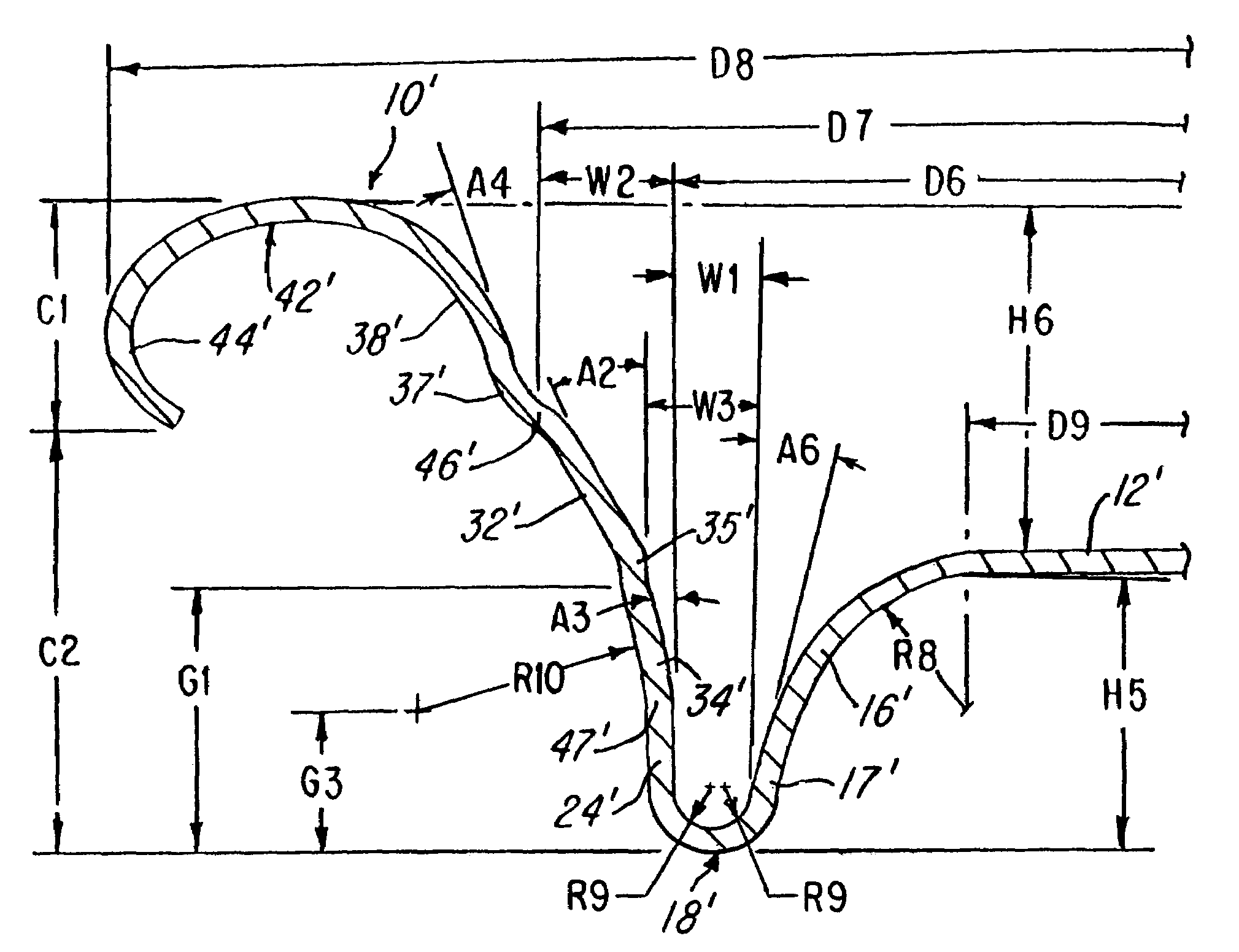

Can shell and double-seamed can end

InactiveUS7341163B2Reduction in blank diameterIncrease strength/weight ratioRigid containersHollow articlesAcute angleAluminum can

A drawn aluminum can shell has a peripheral crown which is double-seamed with an end portion of an aluminum can body to provide a can end having a generally flat center panel connected by a curved panel wall to an inner wall of an annular U-shaped countersink. The countersink has a generally cylindrical outer wall and an inner width less than the radius of the panel wall. The outer wall of the countersink connects with a frusto-conical chuckwall at a junction below the center panel, and the chuckwall extends to an inner wall of the crown at an angle of at least 16° with the center axis. The chuckwall has an S-curved intermediate configuration, the inner width of the countersink is less than the radius of the panel wall, and the inner wall of the countersink extends at an acute angle relative to the outer wall.

Owner:CONTAINER DEVELOPMENT LTD

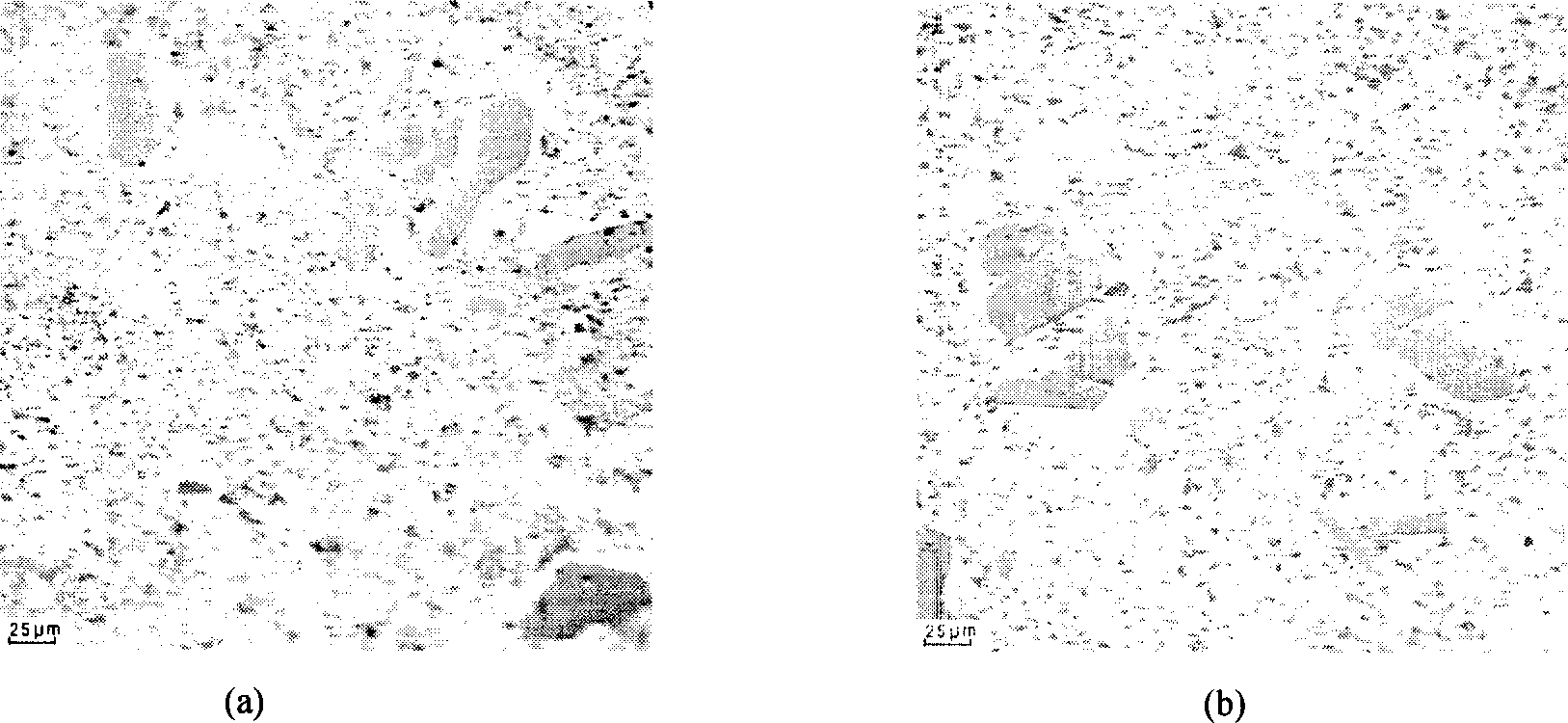

Aluminium-titanium-horon rare earth fining agent, and its preparing method

The invention relates to the thinning reagent having the aluminum, the boron and the lanthanide of the aluminum and the aluminum alloy, it belongs to the domain of the applied technique of the aluminum alloy. The said thinning reagent factors include the aluminum, the boron, the titanium and the lanthanide (mainly includes the lanthanum and the Ce), the said producing process is showed as follows: the pure aluminum ingot, the alloy ingot having the aluminum and the lanthanide, the potassium hexafluorotitanate and the potassium borofluoride are prepared according to the thinning reagent element confecting in advance; the aluminum ingot and the aluminum lanthanide ingot are heated and melted in the intermediate frequency inducing stove, then several material are added; the fusing body acts with the high temperature; the temperature keeps even and the dregs is removed after the action; then the fusing body is irrigated to the ingot or connecting cast and rolled to the line material. According to the said process condition, the high pure aluminum can be removed the pole crystal, the size of the crystal grain of the industry pure aluminum and all series of distortional aluminum alloy can be divided to under the 100um, the casting form crystal grain core can be reduced to under 2um firmly to all sorts of the aluminum used in the foil material; the size of the crystal grain of the alloy of the aluminum and the silicon can be reduced to under 150-200um. At the same time, the intension, the molding ability and the tenacity of the industry pure aluminum and all sorts of the aluminum alloy can be improved highly.

Owner:TSINGHUA UNIV

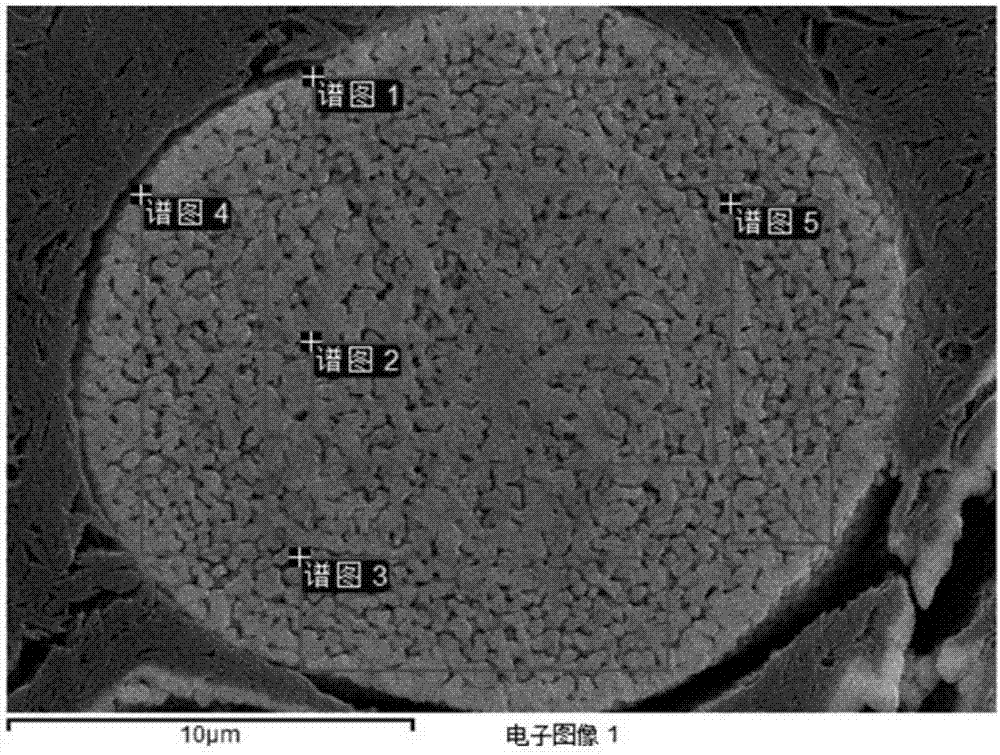

Preparation method of Co3O4 with large grain size and uniformly doped with aluminum

ActiveCN108011101AEvenly distributedUniform particle size distributionCell electrodesCobalt oxides/hydroxidesCobalt(II,III) oxideMicrometer

The invention relates to a preparation method of Co3O4 with large grain size and uniformly doped with aluminum. The invention provides the preparation method of the Co3O4 which is uniformly doped withaluminum and is large in grain size and uniform in particle distribution, and the obtained Co3O4 with the large grain size and uniformly doped with aluminum can completely conform to the requirementof preparation of 4.45V high-voltage lithium cobalt oxide. According to the method, the large-grain size and aluminum-doped cobalt carbonate is synthesized by a wet method, and the problems of difficulty in enlargement of cobalt hydroxide (or hydroxyl cobalt) system grain size and non-uniform particle distribution are solved; with the regard to the problem of uniform aluminum doping of a cobalt carbonate system, a parameter is set from principle, an aluminum compound is prevented from being independently separated out and gathered, the doped Al element can be uniformly distributed in the Co3O4, the grain size reaches 15 micrometers or above, and the particle distribution is uniform; and the lithium cobalt oxide prepared from the aluminum-doped Co3O4 has high specific capacity and excellentcycle property under 4.45V.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드

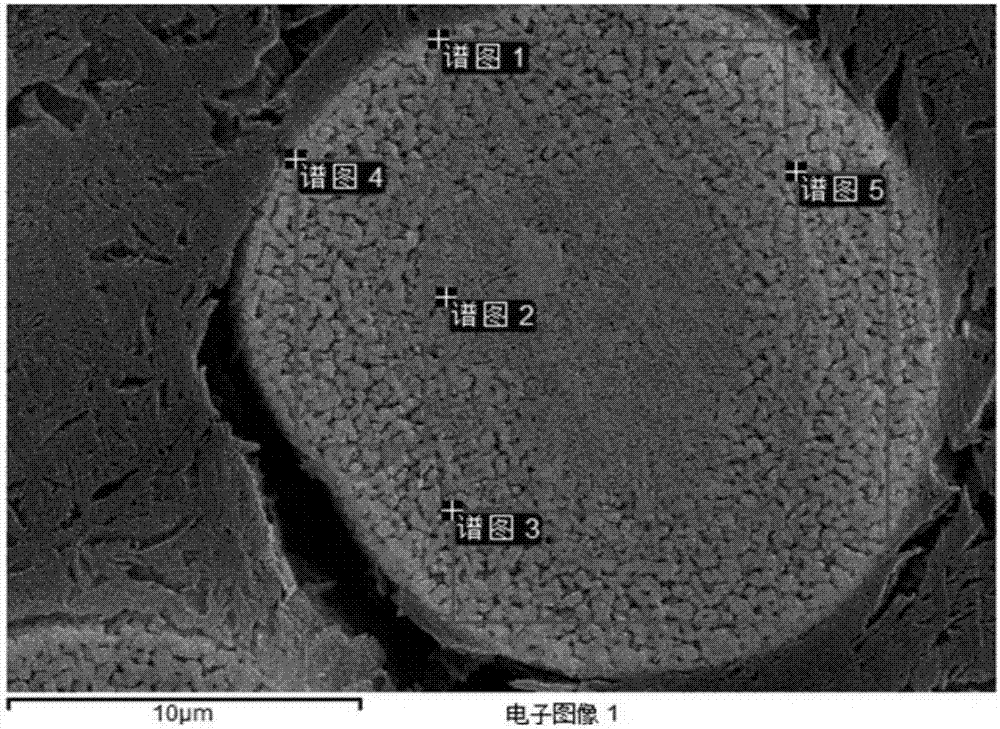

Method for dissolving Bayer process red mud

ActiveCN102757060AMeet industrial requirementsReduce sodiumCalcium/strontium/barium carbonatesSludge treatmentCalcium silicateAluminium hydroxide

The invention discloses a method for dissolving red mud. The method comprises the following specific steps of: mixing Bayer process red mud with white lime in the mass ratio of 1:(0.3-0.9); stirring at the temperature of 80-140 DEG C for reacting for 1-15 hours for calcifying, transforming and dealkalizing; mixing calcified, deformed and dealkalized Bayer process red mud with clear water or a low-concentration sodium aluminate solution in an enclosed container; introducing CO2 into the container to obtain calcified slag containing calcium silicate, calcium carbonate and aluminum hydroxide serving as main components; and extracting aluminum hydroxide from the calcified slag by using a sodium hydroxide solution or an aluminum hydroxide solution. In the method disclosed by the invention, the structure and composition of red mud are changed by adopting calcification transformation and pressurizing calcification transformation methods, so that dealkalization and extraction of aluminum can be realized; and iron is extracted properly, so that the structure and the composition of red mud can meet the requirements of cement production, and the aim of dissolving red mud on a large scale at low cost is fulfilled.

Owner:DONGDA NONFERROUS SOLID WASTE TECH RES INST LIAOLING CO LTD

Can shell and double-seamed can end

InactiveUS7819275B2Reduce the overall diameterRaise the ratioRigid containersHollow articlesAluminum canEngineering

A drawn aluminum can shell has a peripheral crown which is double-seamed with an end portion of an aluminum can body to provide a can end having a generally flat center panel connected by an inclined curved or straight panel wall to an inclined inner wall of an annular U-shaped countersink. The countersink has an outer wall which connects with an inclined lower wall portion of a chuckwall at a junction below the center panel, and the chuckwall has a curved or inclined upper wall portion which connects with an inner wall of the crown. The chuckwall also has an intermediate wall portion forming a break, and the inner bottom width of the countersink is less than the radial width of the panel wall. The inclined upper wall portion of the chuckwall extends at an angle greater than the angle of the inclined lower wall portion of the chuckwall.

Owner:BALL CORP +1

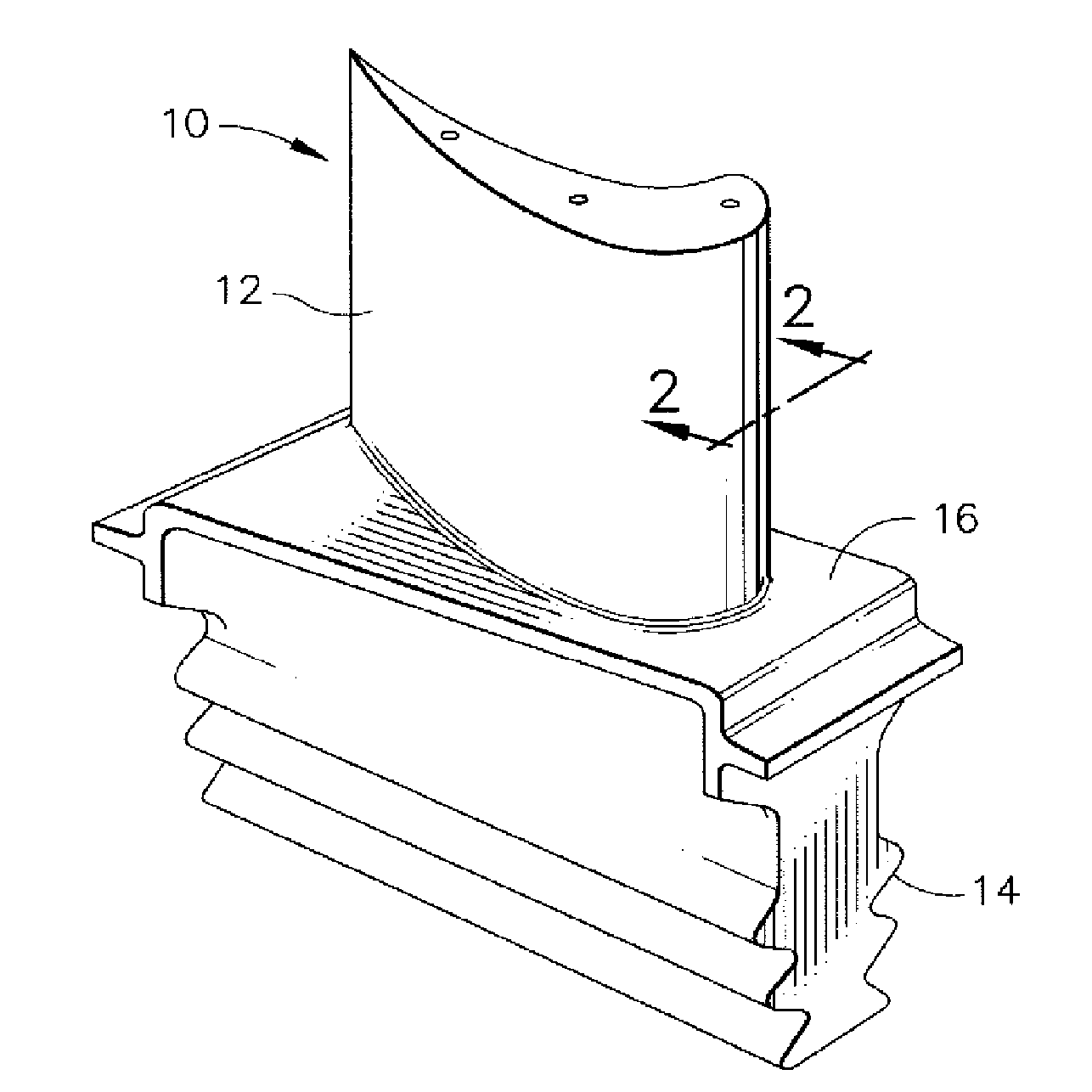

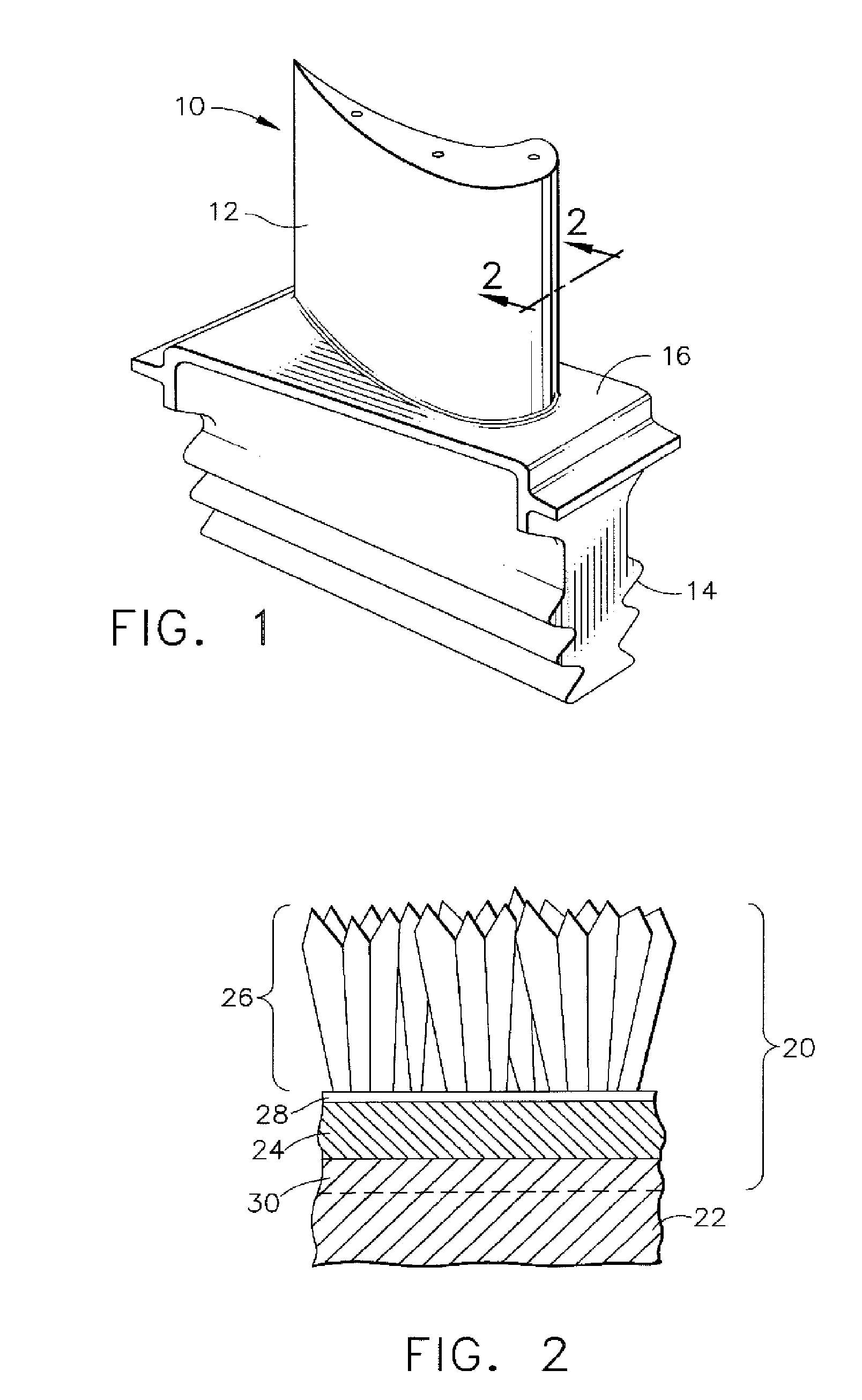

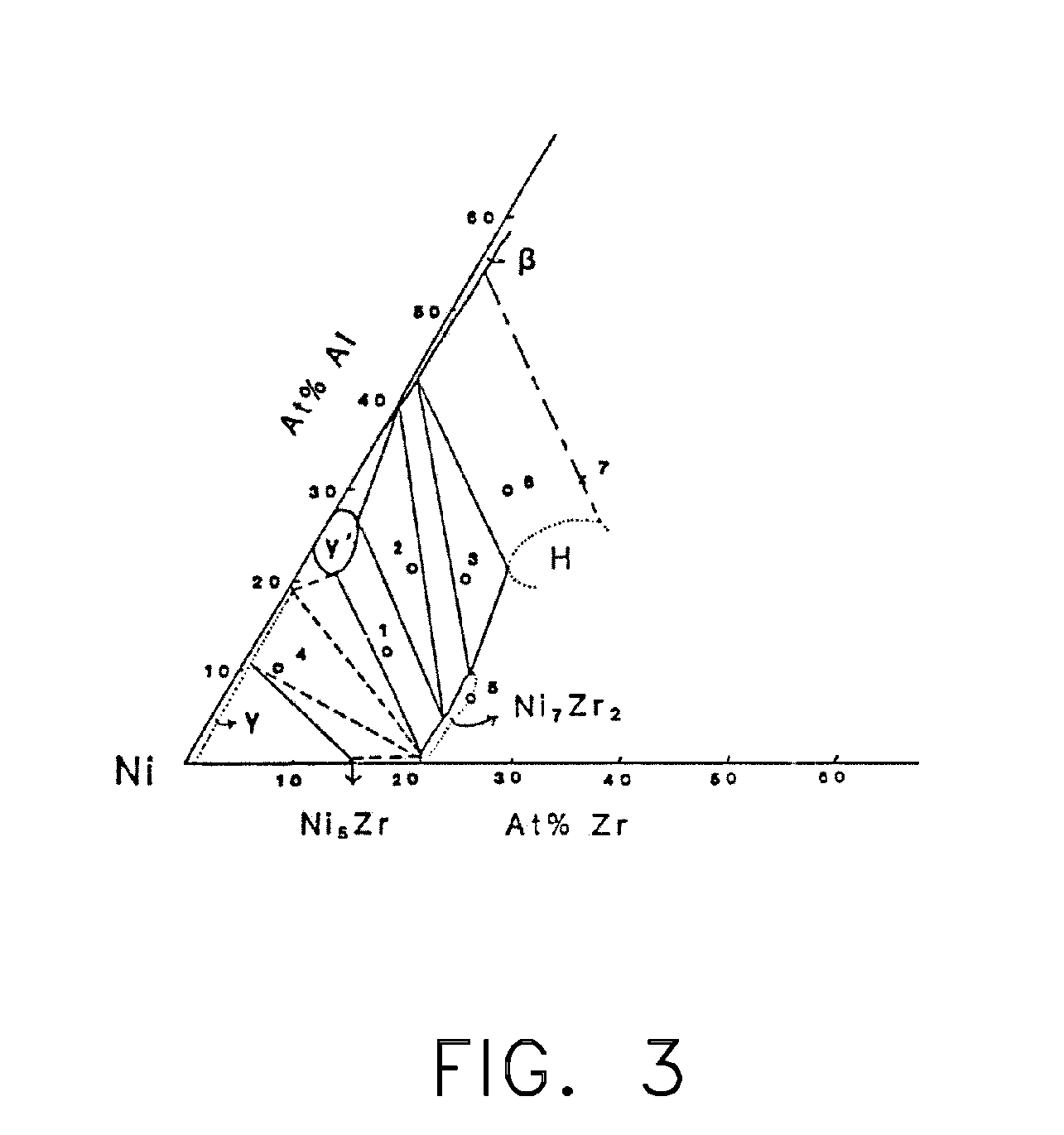

Coating systems containing beta phase and gamma-prime phase nickel aluminide

ActiveUS20060093801A1High solubility limitIncrease resistanceMolten spray coatingPropellersGreek letter betaBeta phase

A coating and process for depositing the coating on a substrate. The coating is a nickel aluminide overlay coating of predominantly the beta (NiAl) and gamma-prime (Ni3Al) intermetallic phases, and is suitable for use as an environmental coating and as a bond coat for a thermal barrier coating (TBC). The coating can be formed by depositing nickel and aluminum in appropriate amounts to yield the desired beta+gamma prime phase content. Alternatively, nickel and aluminum can be deposited so that the aluminum content of the coating exceeds the appropriate amount to yield the desired beta+gamma prime phase content, after which the coating is heat treated to diffuse the excess aluminum from the coating into the substrate to yield the desired beta+gamma prime phase content.

Owner:GENERAL ELECTRIC CO

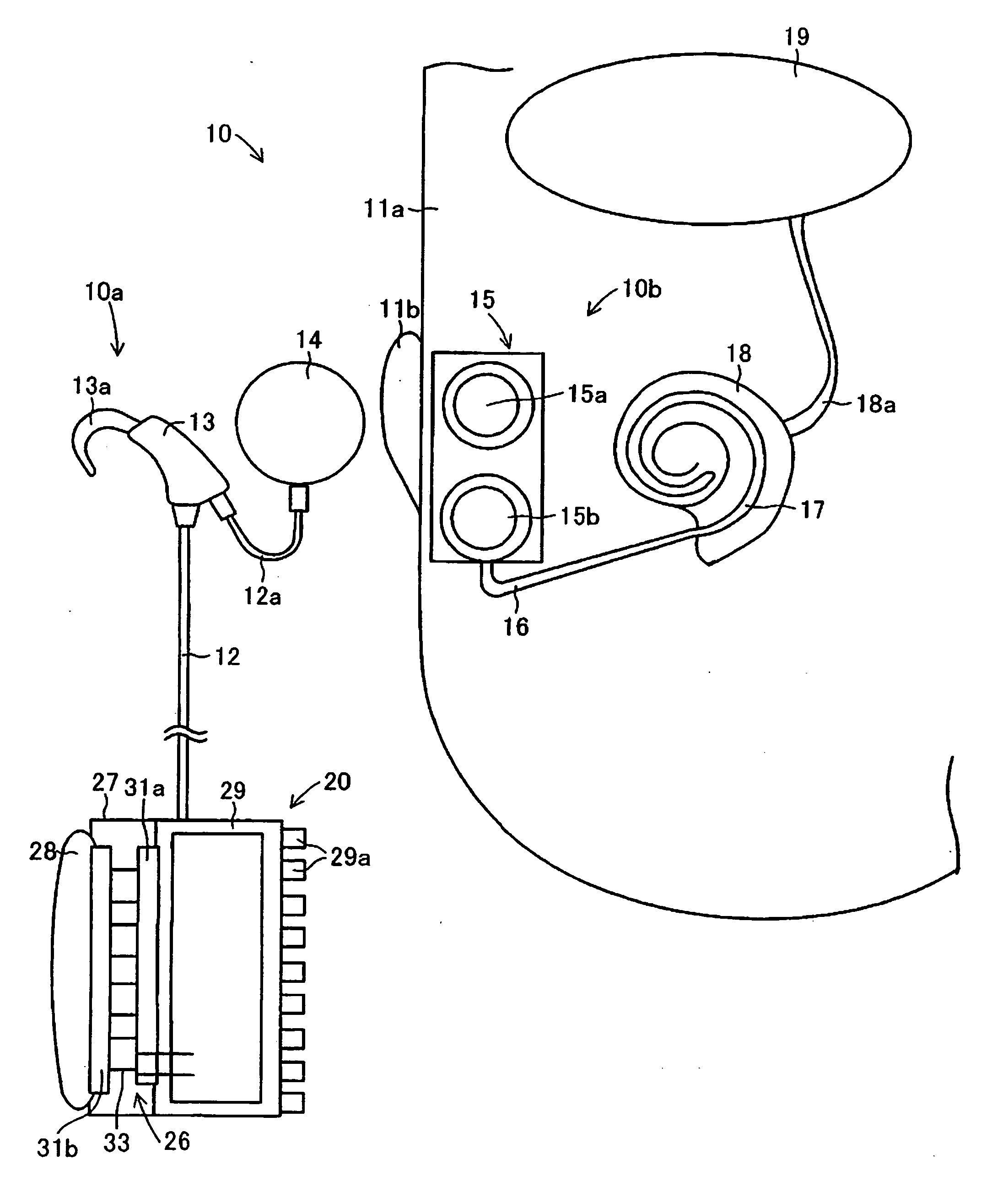

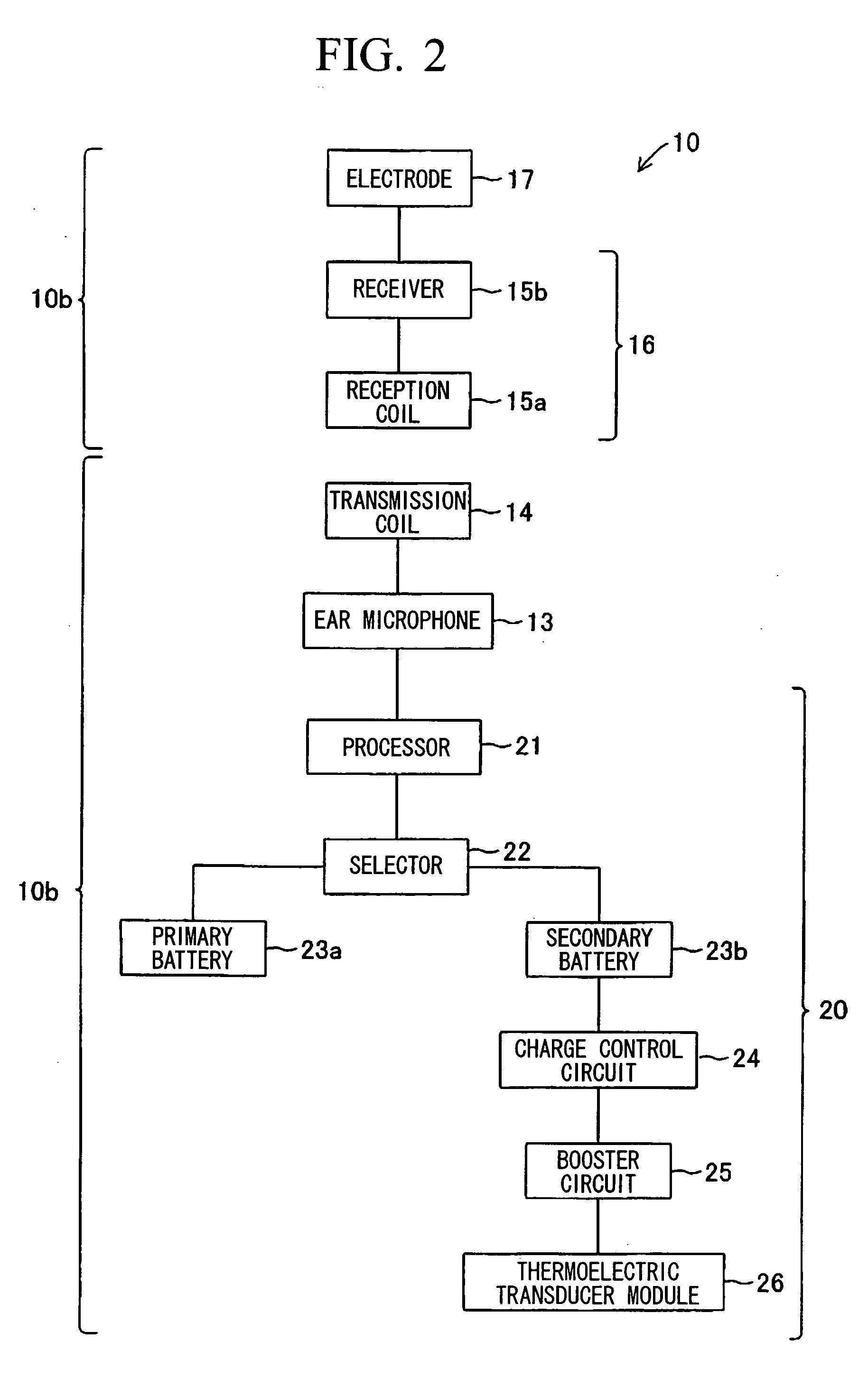

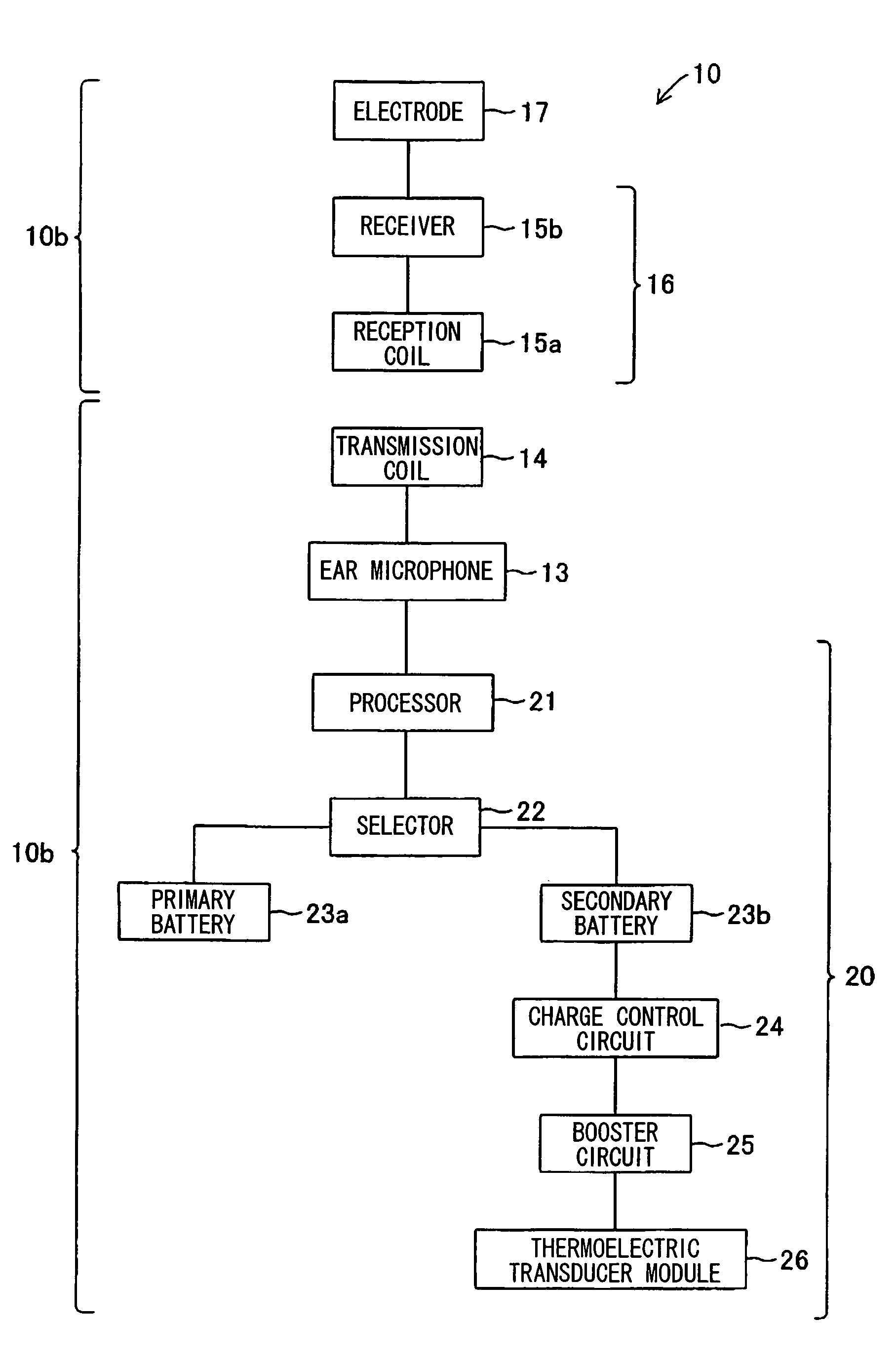

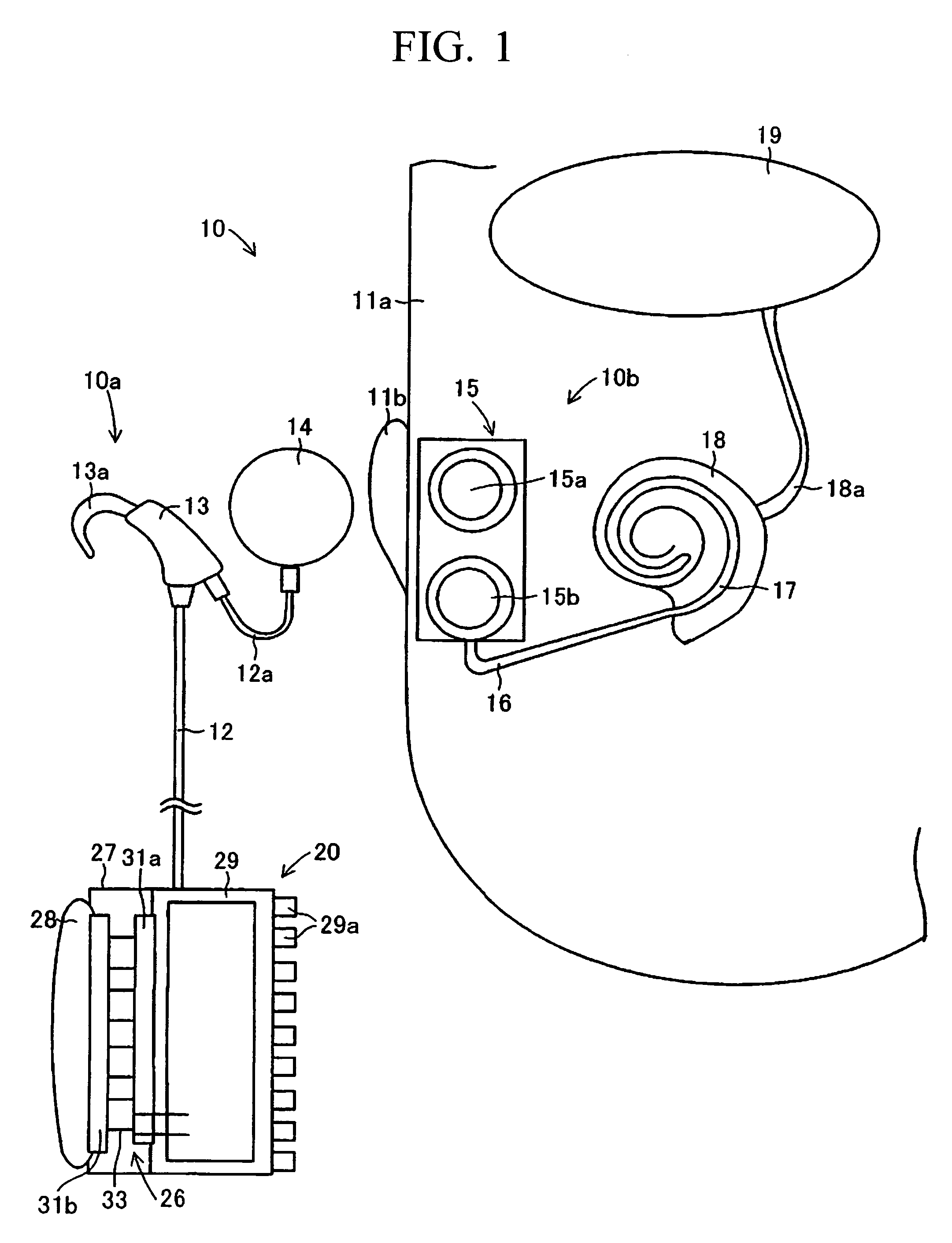

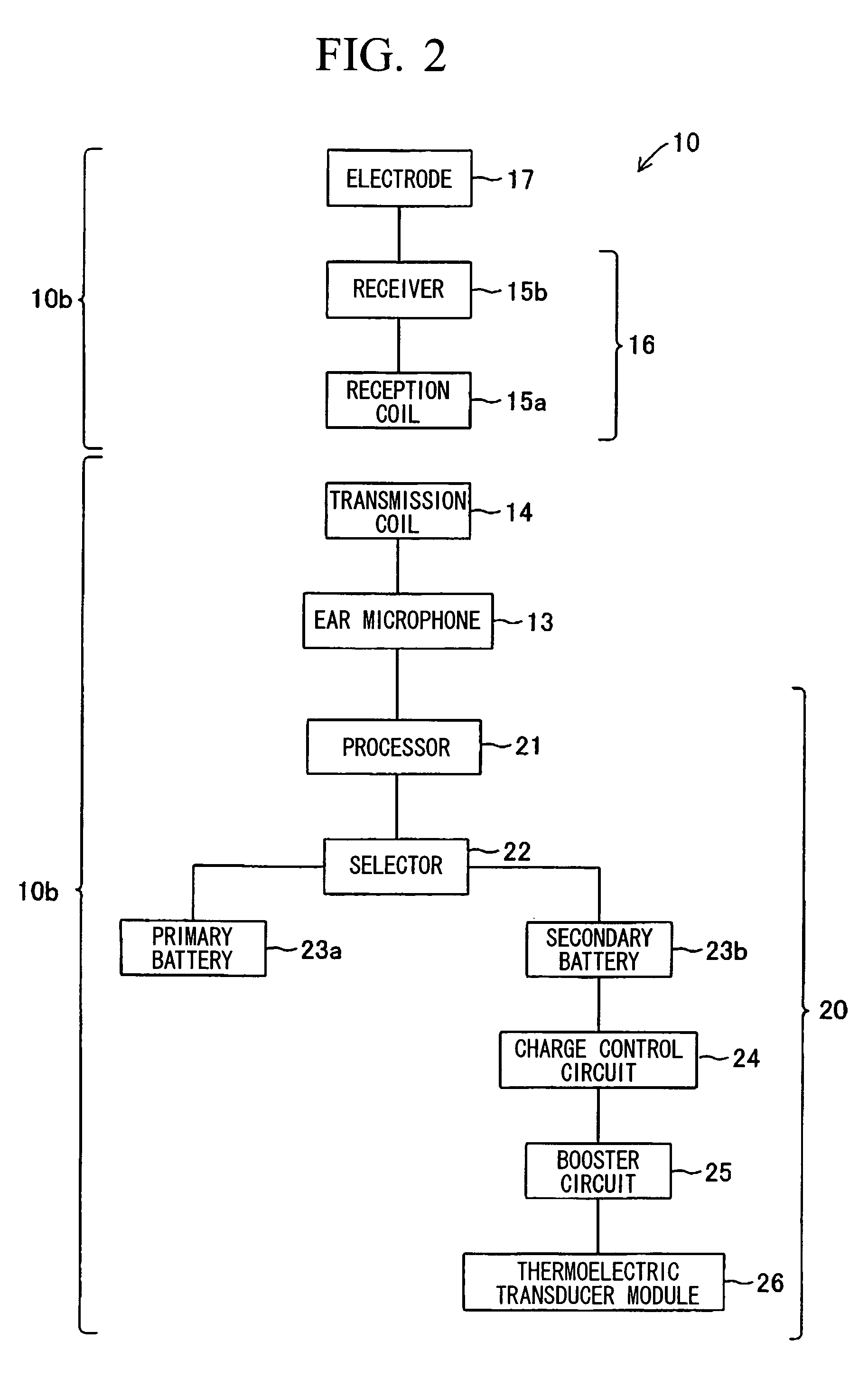

Artificial inner ear and thermoelectric generator therefor

InactiveUS20060169314A1Generate large amountImprove heat transfer efficiencyElectrotherapyBatteries circuit arrangementsElectricitySpeech Processor

An artificial inner ear includes a speech processor that operates based on electricity generated by a thermoelectric transducer module, in which numerous thermoelectric elements join between oppositely arranged upper and lower substrates each having numerous electrodes. A heat absorption layer composed of a heat conductive material such as a resin, rubber, and metal is attached to the upper substrate of the thermoelectric transducer module. The heat absorption layer has deformability in shape in conformity with a prescribed part of the human body and is heated using human body temperature so as to cause a temperature difference between the upper and lower substrates, thus generating electricity in the thermoelectric transducer module. A heat-dissipation member composed of aluminum can be attached to the lower substrate so as to increase the temperature difference.

Owner:YAMAHA CORP

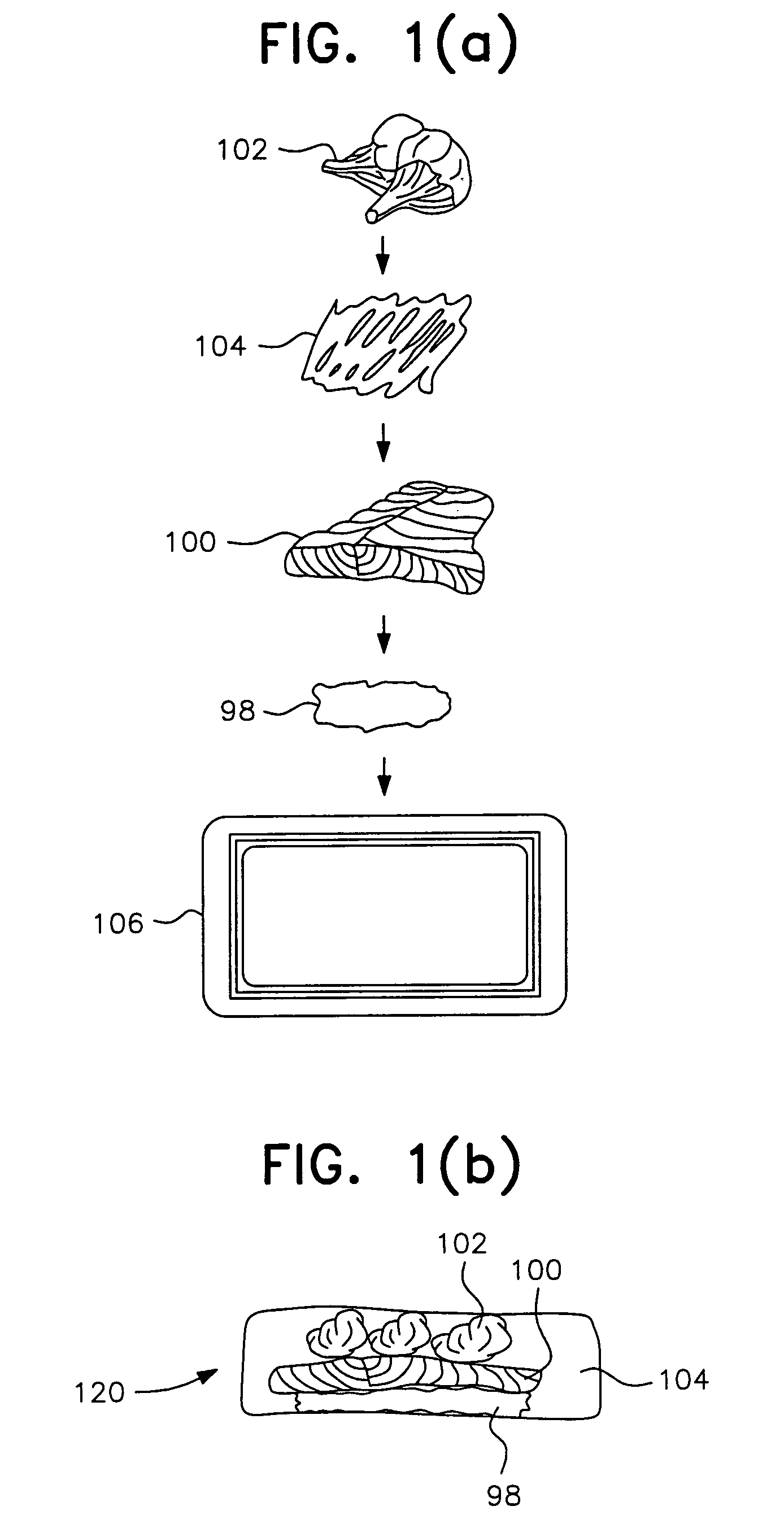

Flexible microwave cooking pouch containing a raw frozen protein portion and method of making

ActiveUS7015442B2Increase valueIncrease typeBio-packagingClimate change adaptationPolyesterWater based

A sealed cooking pouch specifically designed for microwave cooking raw frozen protein entrees containing a raw meat protein portion, preferably beef, poultry, fish, pork or veal, along with starch, sauce and vegetable portions. The packaging material is manipulated into a pouch shape, meant to receive the protein entree ingredients before sealing, during the manufacturing process. The packaging material is composed of a heat-sealable polyester layer with a thin layer of aluminum deposited on one side and a layer of water-repellant 20 lb–25 lb. structural paper stock, laminated together through the use of a water-based adhesive. The aluminum can be uniformly deposited centrally where maximum temperature concentration is desired, and deposited in patterns that allow for temperature attenuation in parts of the package where this is desirable. The structural paper outer layer is treated with a wax emulsion to repel water that forms from condensation on the outside of the cooking pouch.

Owner:SMART POUCH

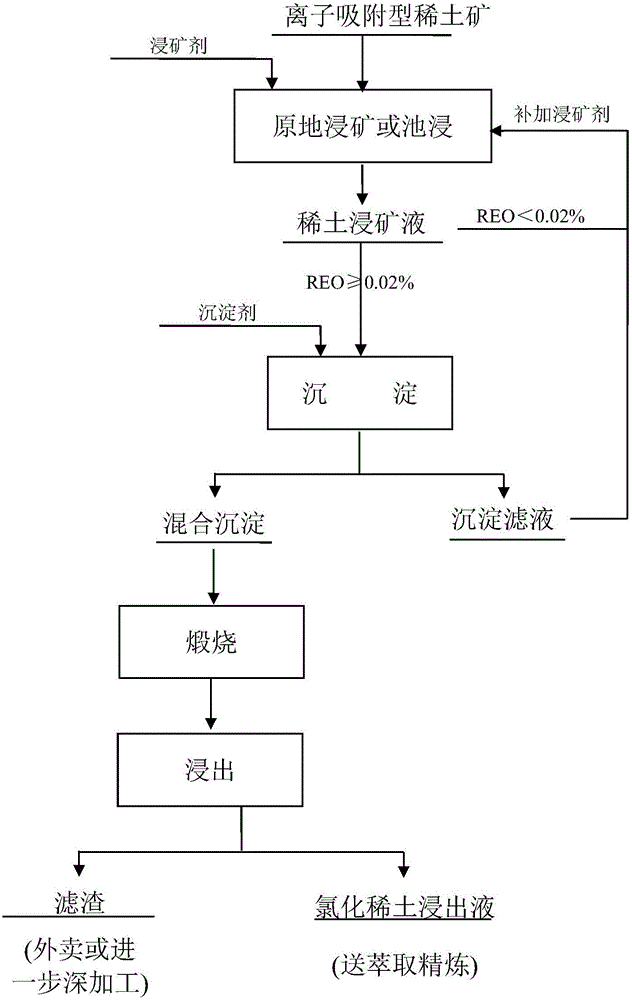

Method for extracting rare earth and aluminum from ion adsorption type rare earth ores

ActiveCN105803226AEfficient separationAchieve purificationProcess efficiency improvementAluminum canRare earth

The invention relates to a method for extracting rare earth and aluminum from ion adsorption type rare earth ores. The method includes the steps that (1), ore leaching is performed, wherein an ore leaching agent is added for in-situ ore leaching or pond leaching, and rare earth ore leaching liquid with the rare earth concentration higher than 0.02% is obtained; (2), precipitation is performed, wherein solid and liquid separation is performed after a precipitation agent is added into the rare earth ore leaching liquid for precipitation, and precipitated filter liquor and mixed precipitate containing rare earth and aluminum are obtained; (3), calcination is performed, wherein the mixed precipitate containing rare earth and aluminum is calcinated, and calcinated products containing rare earth oxide and alpha-aluminum oxide are obtained; and (4), leaching out is performed, wherein solid and liquid separation is performed after a chlorination leaching agent is added into the calcinated products containing rare earth oxide and alpha-aluminum oxide for leaching out, chlorinated rare earth leaching-out liquid and filter residues containing alpha-aluminum oxide are obtained, rare earth oxide is extracted from the chlorinated rare earth leaching-out liquid, and aluminum oxide fine products are extracted from the filter residues containing alpha-aluminum oxide. The method is simple in technology, precipitation is directly performed without impurity removal, and by means of the dissolution property difference of the calcinated products in an acid environment, the rare earth and the aluminum can be separated and recycled.

Owner:CHANGSHA RES INST OF MINING & METALLURGY +1

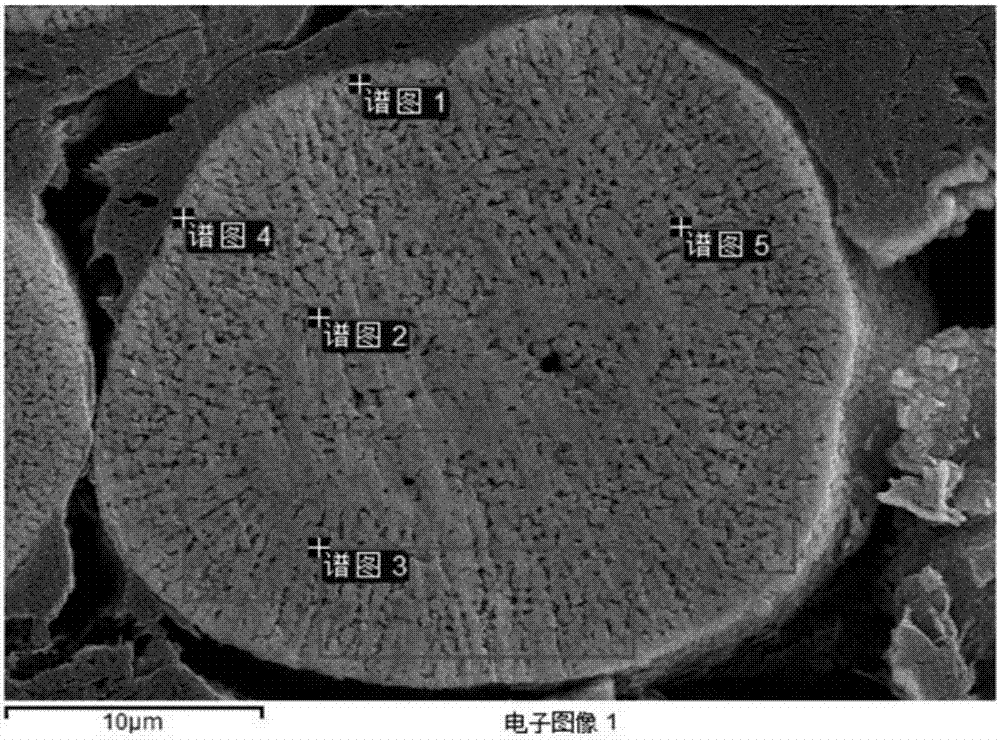

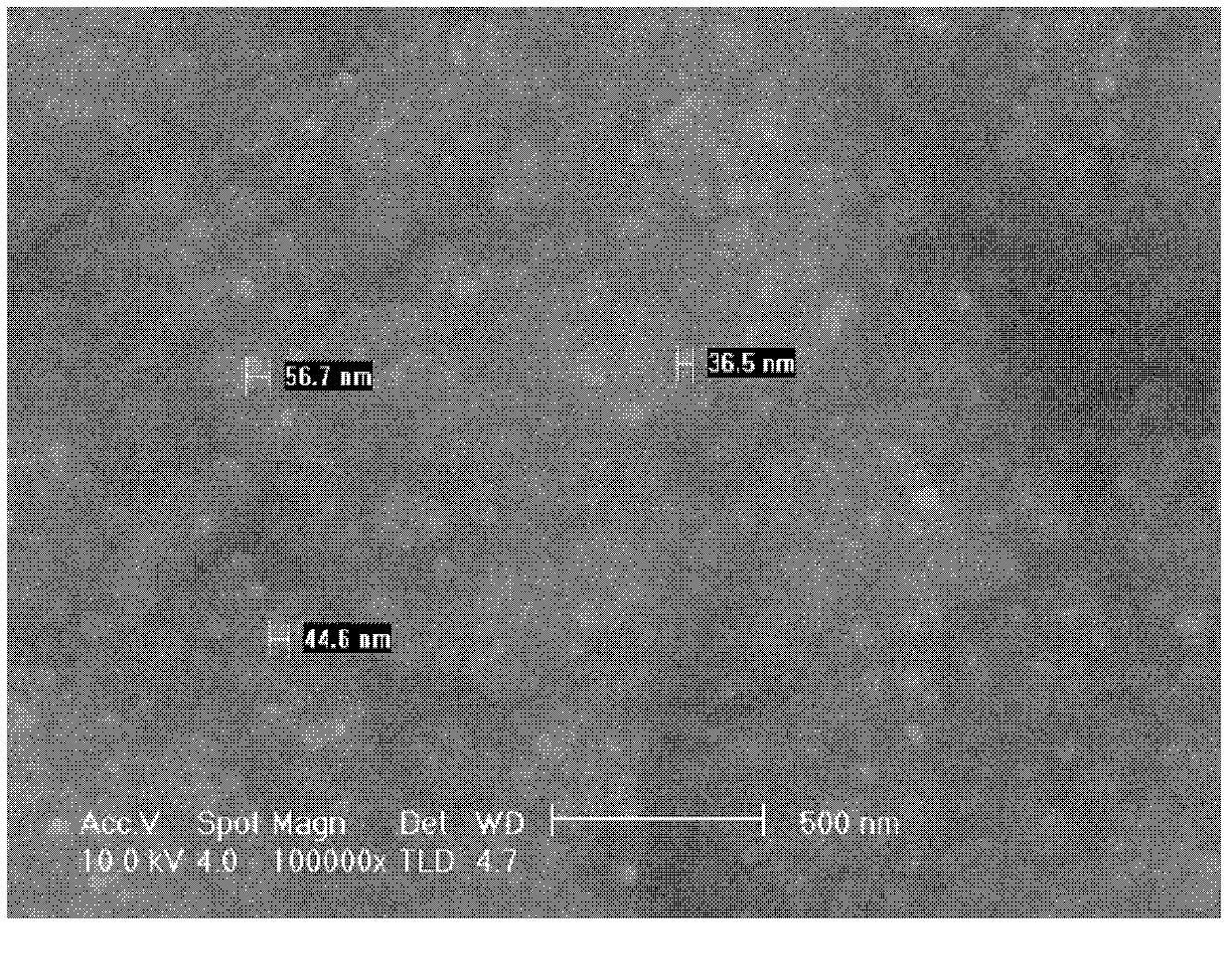

Method for preparing nanometer aluminum or nanometer aluminum coating in low-temperature electro-deposition form by using ion liquid/additive system

ActiveCN102888630AHigh purityWide variety of sourcesMaterial nanotechnologyElectrochemical windowIonic liquid

The invention designs a method for preparing nanometer aluminum or nanometer aluminum coating in an electro-deposition form by using an ion liquid / additive system. The method is characterized in that: ion liquid and anhydrous aluminum trichloride are mixed into a low-temperature electrolyte and suitable additives are added for preparing the ion liquid / additive system. A processed substrate is taken as a deposition cathode; the direct current electro-deposition is adopted for preparing the nanometer aluminum or nanometer aluminum coating; and the size of the aluminum grains is adjusted according to requirements. According to the method, the problems of high cost and small output of the present technology for producing the nanometer aluminum are solved; the adopted ion liquid is conventional ion liquid and is characterized by wide source, low cost, high conductivity, wide electrochemical window and being non-volatile and environment-friendly; the suitable additives are used, so that the high-quality nanometer aluminum or nanometer aluminum coating obtained in the conventional ion liquid is realized; the obtained aluminum deposited coating is compact, smooth and flat; a nanometer material can be obtained by using the ion liquid / additive system at lower temperature; the reaction is easy to control; the energy consumption is low; the obtained nanometer aluminum is high in quality and high in current efficiency; the size of the nanometer aluminum can be effectively controlled by adjusting the dosage and formula of the additives; the process is simple; the cost is low; and the application prospect is better.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

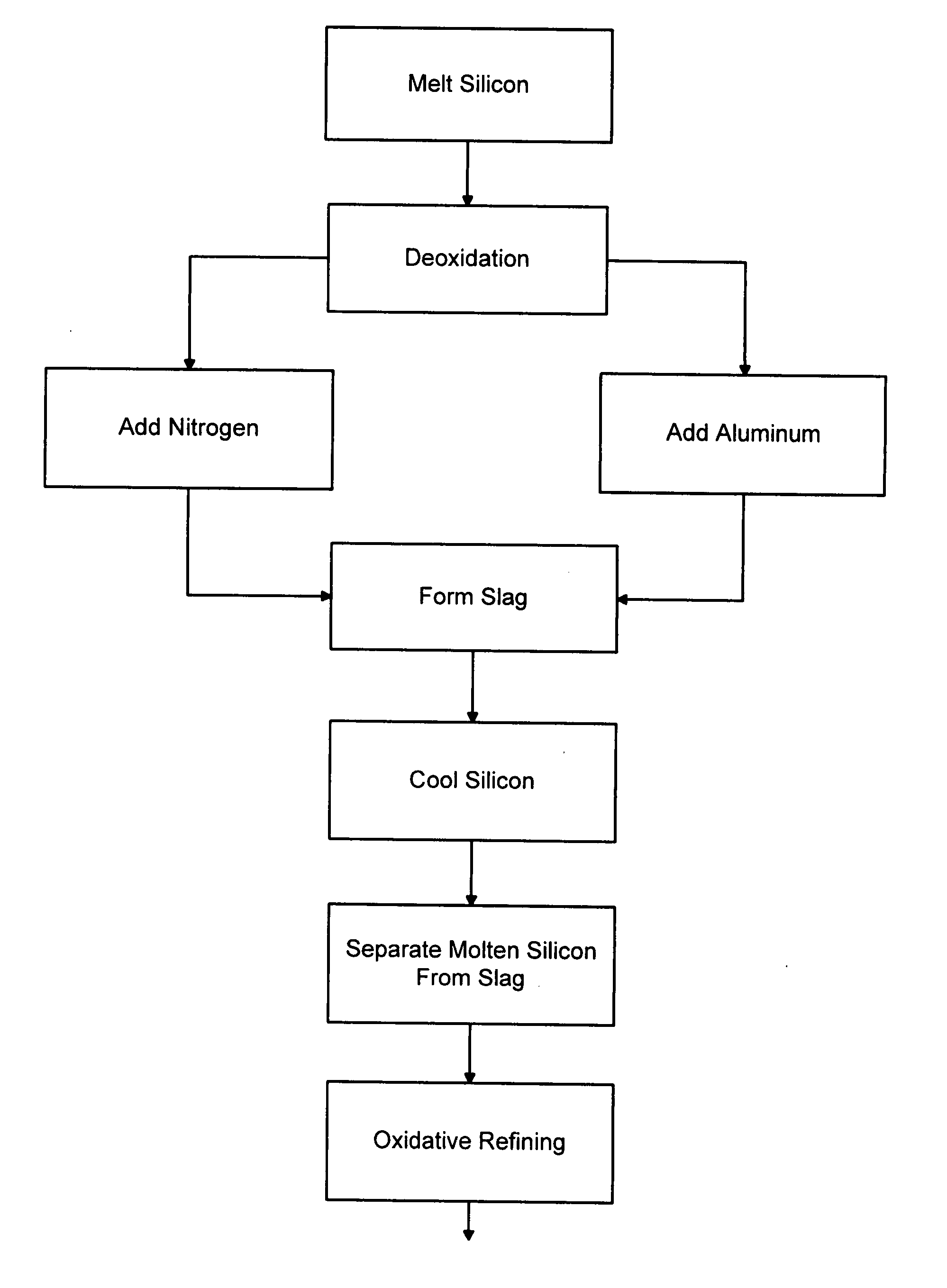

Silicon refining process

Nitrogen and aluminum and fluxing agents (Al2O3, SiO2, CaO and MgO) are added to molten silicon to create an oxy-nitride slag that acts as a sink for dissolved boron and phosphorus. The nitrogen can be added by bubbling nitrogen gas through the molten silicon; the aluminum can be added as aluminum metal or as Al2O3. Normally, the silicon must initially be deoxidized to allow the boron and phosphorus refining reactions to occur. The process may be followed by oxidative refining, SiC settling, the Silgrain process and directional solidification to remove other impurities and produce silicon suitable for use in solar cells. In an alternative version of the process, the molten silicon is passed through a particulate bed formed of a nitrogen-containing compound and an aluminum-containing compound.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

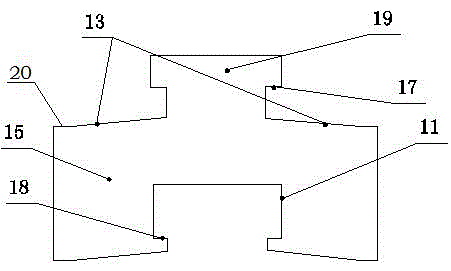

Anode carbon block structure for prebaking aluminum cell with no residue anode

The invention discloses an anode carbon block structure for a prebaking aluminum cell with no residue anode. The anode carbon block structure comprises a carbon block body (15). An upper carbon block T-shaped connection convex head (19) is arranged on the top of the carbon block body (15). The two sides of the upper carbon block T-shaped connection convex head (19) are provided with T-shaped connection convex head force-bearing shoulders (17). The bottom of the upper carbon block T-shaped connection convex head (19) is provided with a lower carbon block T-shaped connection groove (11) used in cooperation with the upper carbon block T-shaped connection convex head (19). The bottom of the lower carbon block T-shaped connection groove (11) is provided with T-shaped connection groove hook force-bearing shoulder (18). The anode carbon block structure has the advantages that no residue anode is generated after the anode carbon block structure is used in cooperation with a mechanical connection steel claw, the utilization rate of the anode carbon block is improved from traditional 70-80% to 100%, the production cost of electrolytic aluminum can be lowered, the working conditions of the electrolytic cell is stable, electrical losses are low relatively, and heat energy is saved.

Owner:贵州铝城铝业原材料研究发展有限公司

Artificial inner ear and thermoelectric generator therefor

InactiveUS7532937B2Generate large amountImprove heat transfer efficiencyBatteries circuit arrangementsThermoelectric device with peltier/seeback effectHuman bodySpeech Processor

An artificial inner ear includes a speech processor that operates based on electricity generated by a thermoelectric transducer module, in which numerous thermoelectric elements join between oppositely arranged upper and lower substrates each having numerous electrodes. A heat absorption layer composed of a heat conductive material such as a resin, rubber, and metal is attached to the upper substrate of the thermoelectric transducer module. The heat absorption layer has deformability in shape in conformity with a prescribed part of the human body and is heated using human body temperature so as to cause a temperature difference between the upper and lower substrates, thus generating electricity in the thermoelectric transducer module. A heat-dissipation member composed of aluminum can be attached to the lower substrate so as to increase the temperature difference.

Owner:YAMAHA CORP

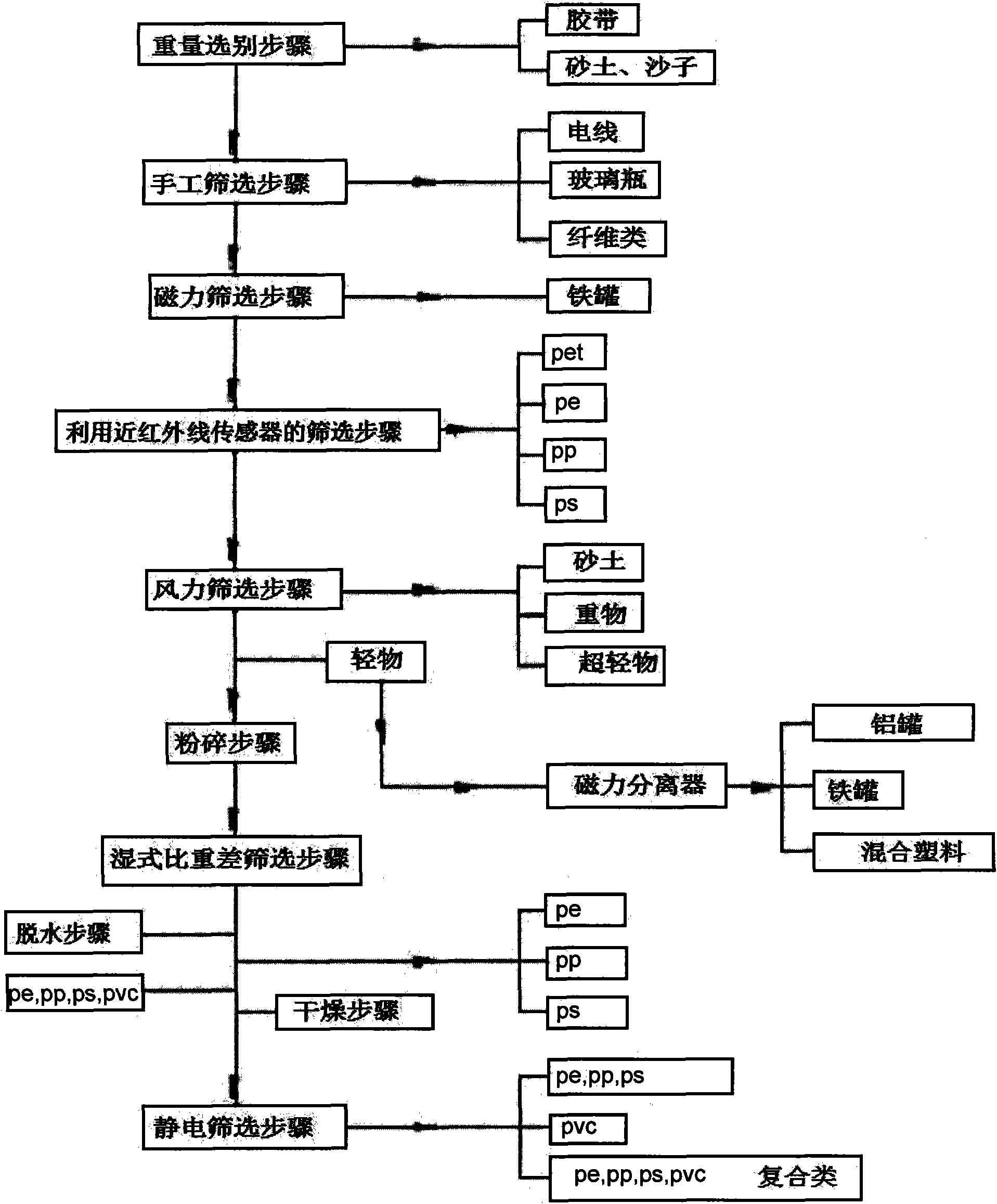

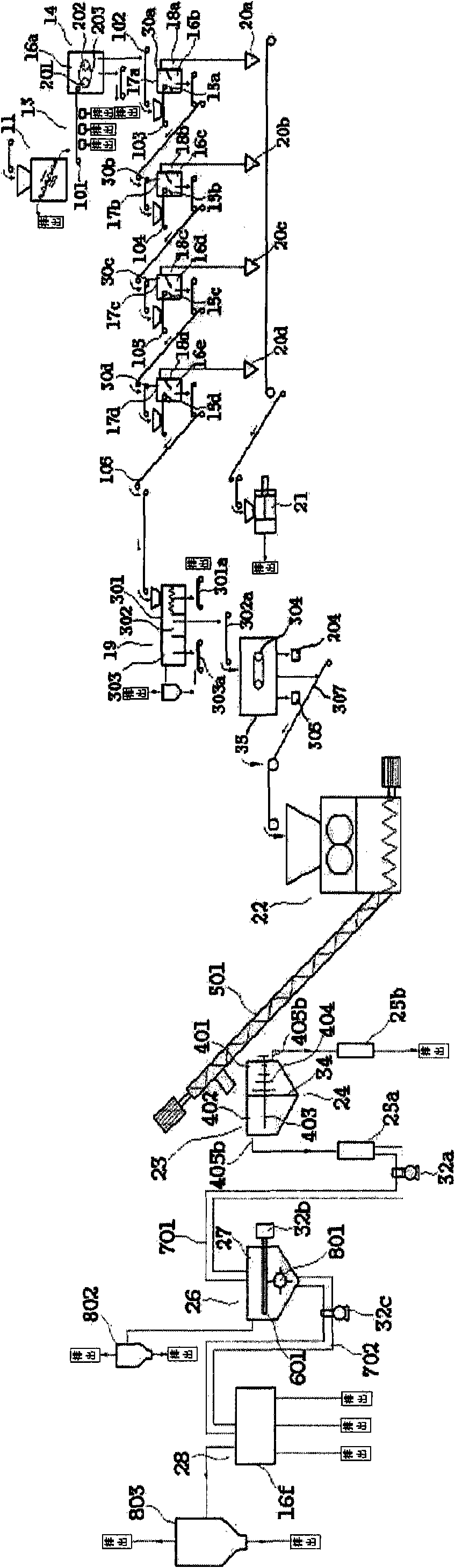

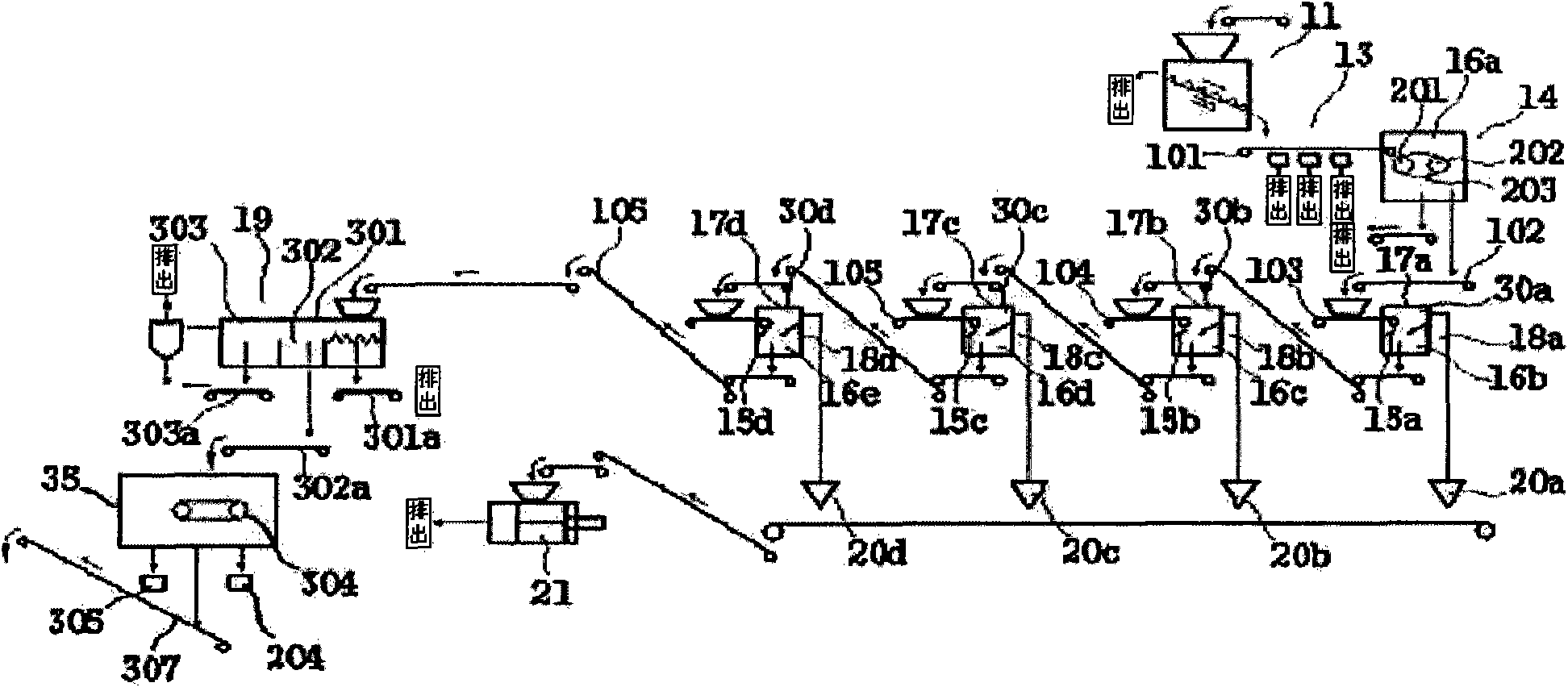

Selection method for recycling plastic

InactiveCN102079114AAvoid wastingAvoid pollutionPlastic recyclingWet separationScreening methodAluminum can

A selection method for recycling plastic is provided to reuse the plastic mixed in household waste by assorting the plastic from the household waste, and to reduce air pollution by preventing the plastic from burning with other waste. A selection method for recycling plastic comprises the following: a step of assorting water; a step of assorting steel and metals; a step of assorting plastic including PE, PP, PS, and PET by classification using near infrared ray sensor; a step of wind force selection process to assort light plastic; a step of assorting aluminum cans from the selected light plastic; a step of crushing the light plastic; a step of assorting crushed light plastic into PE, PP, PET, and PVC using gravity difference in a water tub; a step of dehydrating the selected PE, PP, PS, PET, and PVC; a step of drying the selected PE, PP, PS, PET, and PVC; and a step of minutely assorting PE, PP, PS, PET, and PVC.

Owner:SEOHUNG & TECH +1

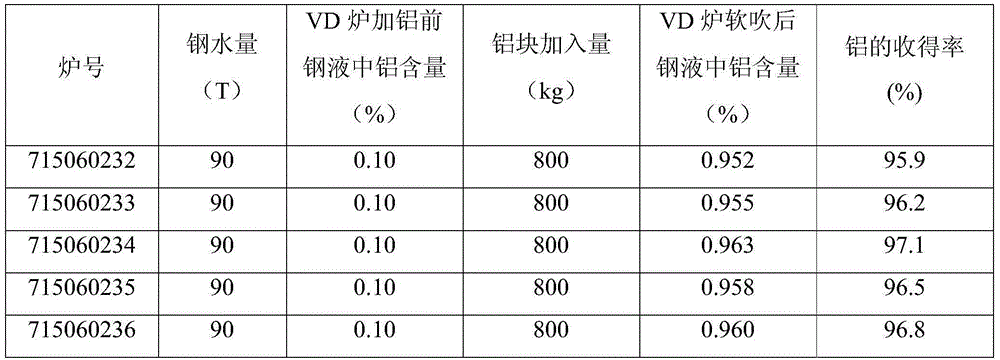

Efficient production process of high aluminum-alloy-content structure round steel

ActiveCN105177215AImprove absorption rateHigh yieldManufacturing convertersSmelting processCastability

The invention relates to a production method of round steel, in particular to an efficient production process of high aluminum-alloy-content structure round steel. Al accounts for 0.70-1.20% in the round steel by weight. The preparation method comprises the converter smelting process, the LF external refining process, the VD furnace vacuum refining process, the square bloom continuous casting process and the rolling process. The high aluminum-alloy-content structure round steel produced through the method is low in cost, high in purity and good in castability, the adsorption rate of aluminum can be higher than 95%, calcium treatment is not needed, sequence casting of 12-15 times can be achieved, the production efficiency is greatly improved, the surface quality of the round steel is high, and the technical problems of high aluminum-alloy-content structure round steel produced in the prior art that the continuous castability is poor, nodulation occurs easily, the adsorption rate of aluminum is low, the yield is unstable, the purity is low, the surface quality of the round steel is low and the quality is unstable are solved.

Owner:ZENITH STEEL GROUP CORP +1

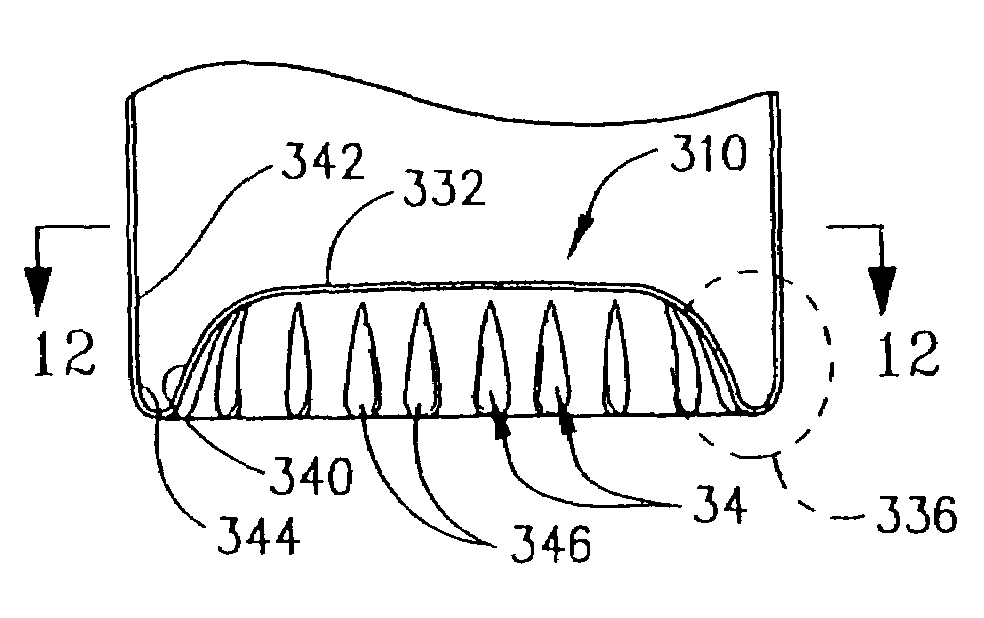

Method and container having reinforcing rib structures

InactiveUS7185525B2Amount of material usedMaintain structural integrityRigid containersHollow articlesAluminum canEngineering

A method is provided for forming an end closure for a surrounding sidewall of a container, such as an aluminum can. The method includes forming a central body panel oriented transversely to the central axis of the can and forming an outer surrounding margin portion joined to the sidewall such that the margin portion has a support section oriented longitudinally relative to the sidewall. A portion of the margin is corrugated to provide a rib structure having longitudinally extending first rib components located on the support section. This method can be accomplished during the ironing and doming of a can.

Owner:WERTH ELMER D +1

Can shell and double-seamed can end

InactiveUS8313004B2Reduce the overall diameterRaise the ratioRigid containersHollow articlesAluminum canEngineering

A drawn aluminum can shell has a peripheral crown which is double-seamed with an end portion of an aluminum can body to provide a can end having a generally flat center panel connected by an inclined curved or straight panel wall to an inclined inner wall of an annular U-shaped countersink. The countersink has an outer wall which connects with an inclined lower wall portion of a chuckwall at a junction below the center panel, and the chuckwall has a curved or inclined upper wall portion which connects with an inner wall of the crown. The chuckwall also has an intermediate wall portion forming a break, and the inner bottom width of the countersink is less than the radial width of the panel wall. The inclined upper wall portion of the chuckwall extends at an angle greater than the angle of the inclined lower wall portion of the chuckwall.

Owner:BALL CORP +1

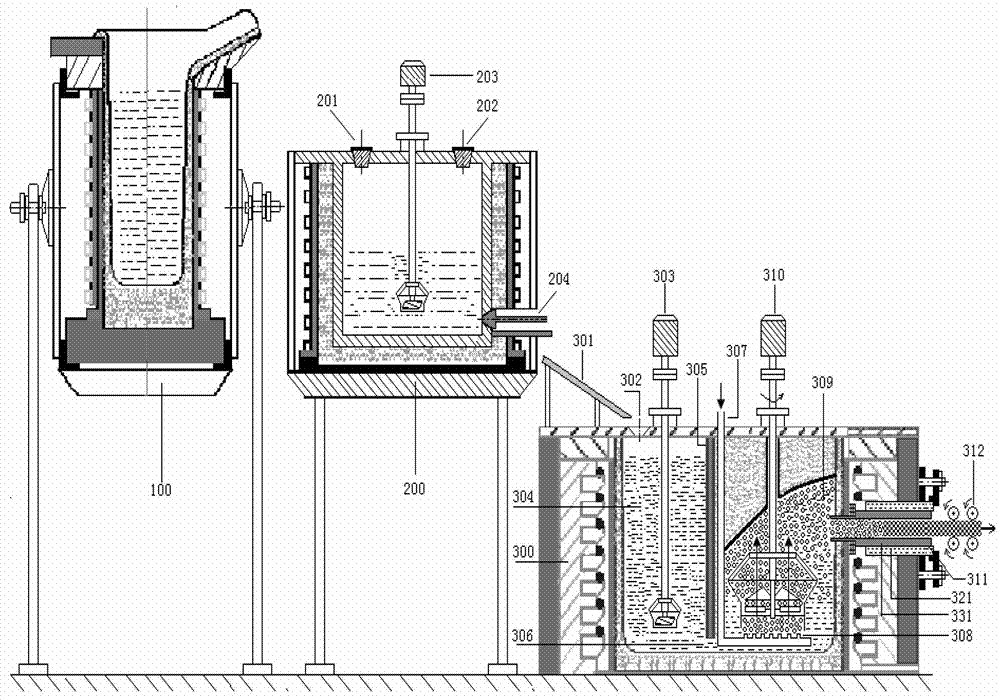

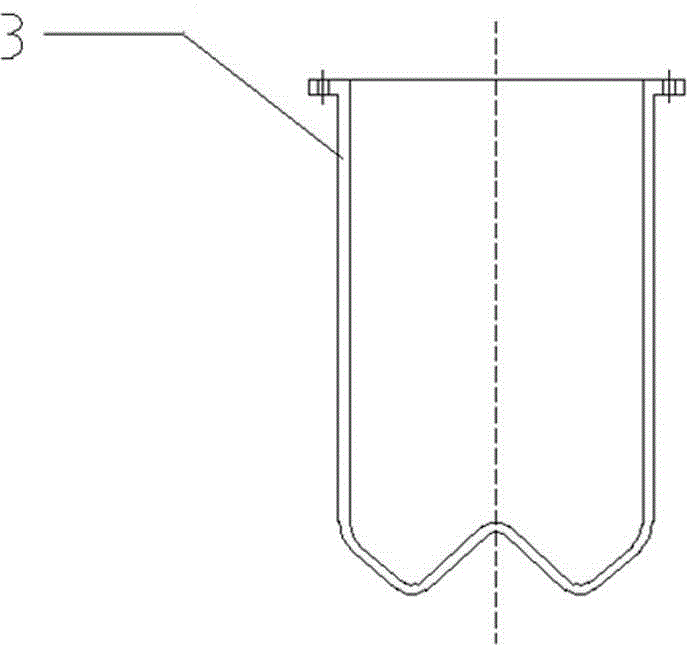

Continuous casting system capable of obtaining closed-cell foam aluminum with uniform bubble bodies

InactiveCN102962413AImprove uniformityEasy to manufactureMelt-holding vesselsStirring devicesAluminum canGraphite

The invention discloses a continuous casting system capable of obtaining closed-cell foam aluminum with uniform bubble bodies. The continuous casting system comprises a smelting furnace, a tundish, a continuous foaming furnace, a continuous casting mould and a continuous traction device, wherein the tundish is provided with a stirrer for preventing sedimentation of melt tackifying particles; the continuous foaming furnace is divided into a liquid storage chamber and a foaming chamber by a baffle; a guide hole for a melt in the liquid storage chamber to flow to the foaming chamber is formed in the lower part of the baffle; the liquid storage chamber is provided with a stirrer for maintaining the tackifying particles to be uniformly dispersed in the melt; the foaming chamber is provided with a venting pipe and an air-liquid mixing agitator capable of guaranteeing that the melt and air bubbles enter into the lower part and are fully mixed; and the continuous casting mould comprises a water cooled jacket and a graphite inner mould; and the continuous traction device is a traction roller. According to the continuous casting system, the closed-cell foam aluminum can be continuously cast, and the fluctuation of the liquid surface of the melt does not cause destruction of the uniformity of the bubble bodies.

Owner:CENT SOUTH UNIV

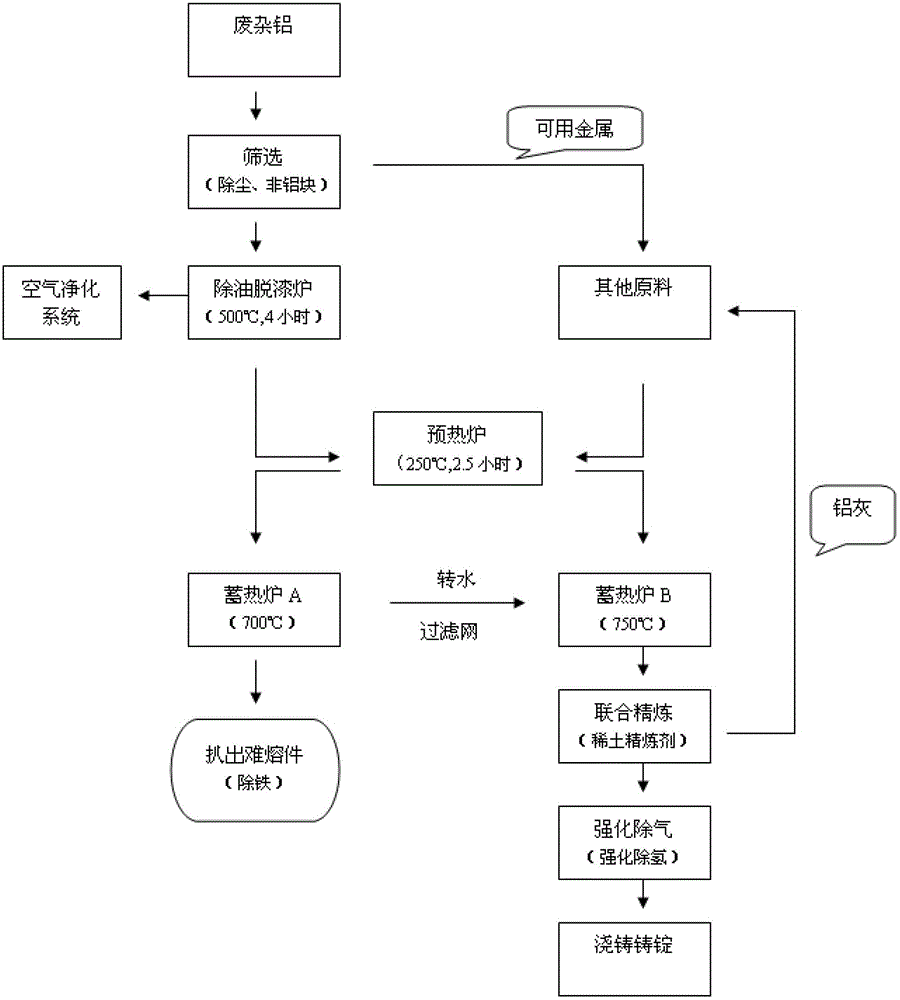

Multi-stage impurity removing and refining method in production process of secondary aluminum

ActiveCN103146924AGood effectThorough and effective impurity removal and purification processProcess efficiency improvementRare earthAluminum can

The invention relates to a multi-stage impurity removing and refining method in the production process of secondary aluminum. The method comprises the following steps of: (1) pretreating, wherein pure aluminum scraps are obtained for standby; (2) removing paint; (3) preparing material; (4) drying; (5) melting; (6) mixed melting; (7) refining, degassing and deslagging; (8) adjusting components; (9) re-degassing until pinholes are qualified, standing, and removing hydrogen in the melt thoroughly; and (10) when the temperature reaches 680-720 DEG C, casting cast ingots of the secondary aluminum product. According to the method, physical and chemical methods are integrated, from screening in the pretreating process and drying and preheating for removing dirt, corrosion and oils on the surface of the waste aluminum, to the melting process and refining process for removing inserts in the waste aluminum parts, a rare earth type modifier is used, so that not only the mechanical property of aluminum melt can be improved, but also the melt can be effectively purified; and meanwhile, a refining agent and an inert gas combined refining method are adopted to control impurities and hydrogen content, so that the waste aluminum can be gradually purified.

Owner:天津新立中合金集团有限公司

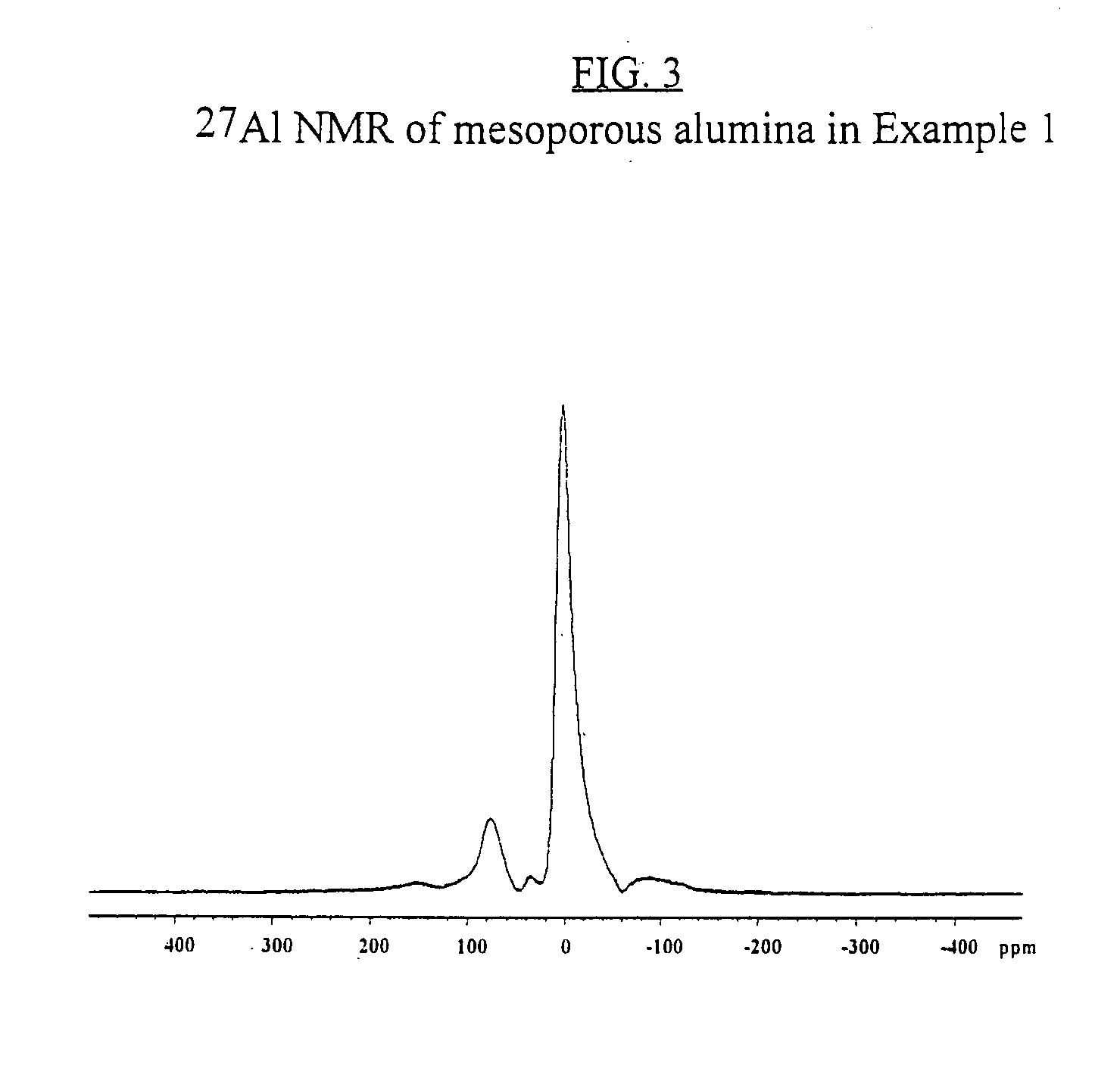

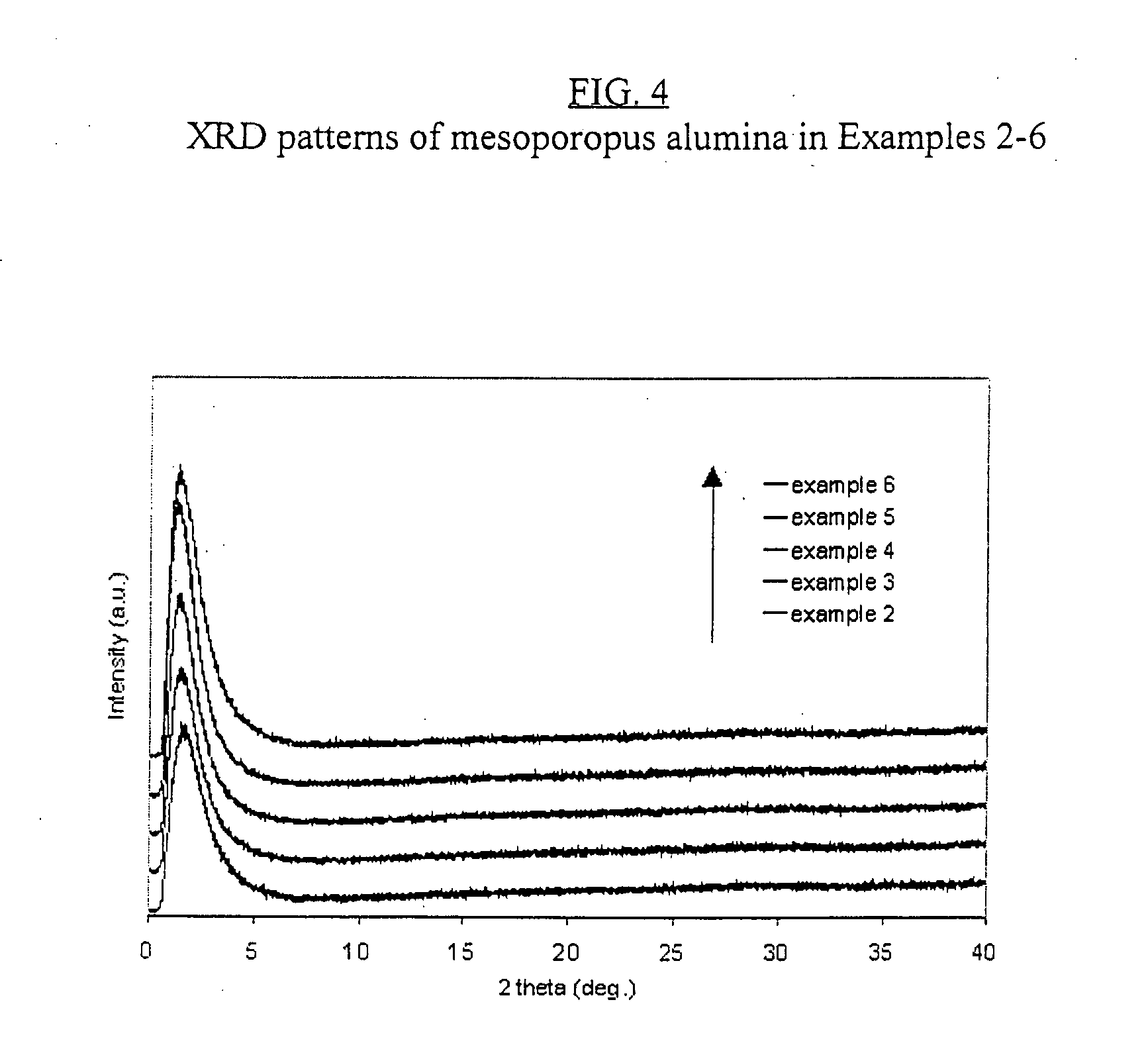

Mesoporous aluminum oxide, preparation and use thereof

InactiveUS20070170096A1Cost-effectiveEasy to operateHydrogenCatalytic naphtha reformingSteam reformingCatalytic reforming

Mesoporous aluminum oxides with high surface areas have been synthesized using inexpensive, small organic templating agents instead of surfactants. Option-ally, some of the aluminum can be framework-substituted by one or more other elements. The material has high thermal stability and possesses a three-dimensionally randomly connected mesopore network with continuously tunable pore sizes. This material can be used as catalysts for dehydration, hydrotreating, hydrogenation, catalytic reforming, steam reforming, amination, Fischer-Tropsch synthesis and Diels-Alder synthesis, etc.

Owner:LUMMUS TECH INC

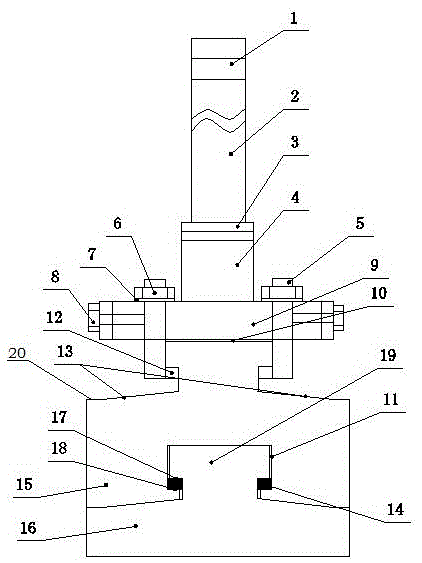

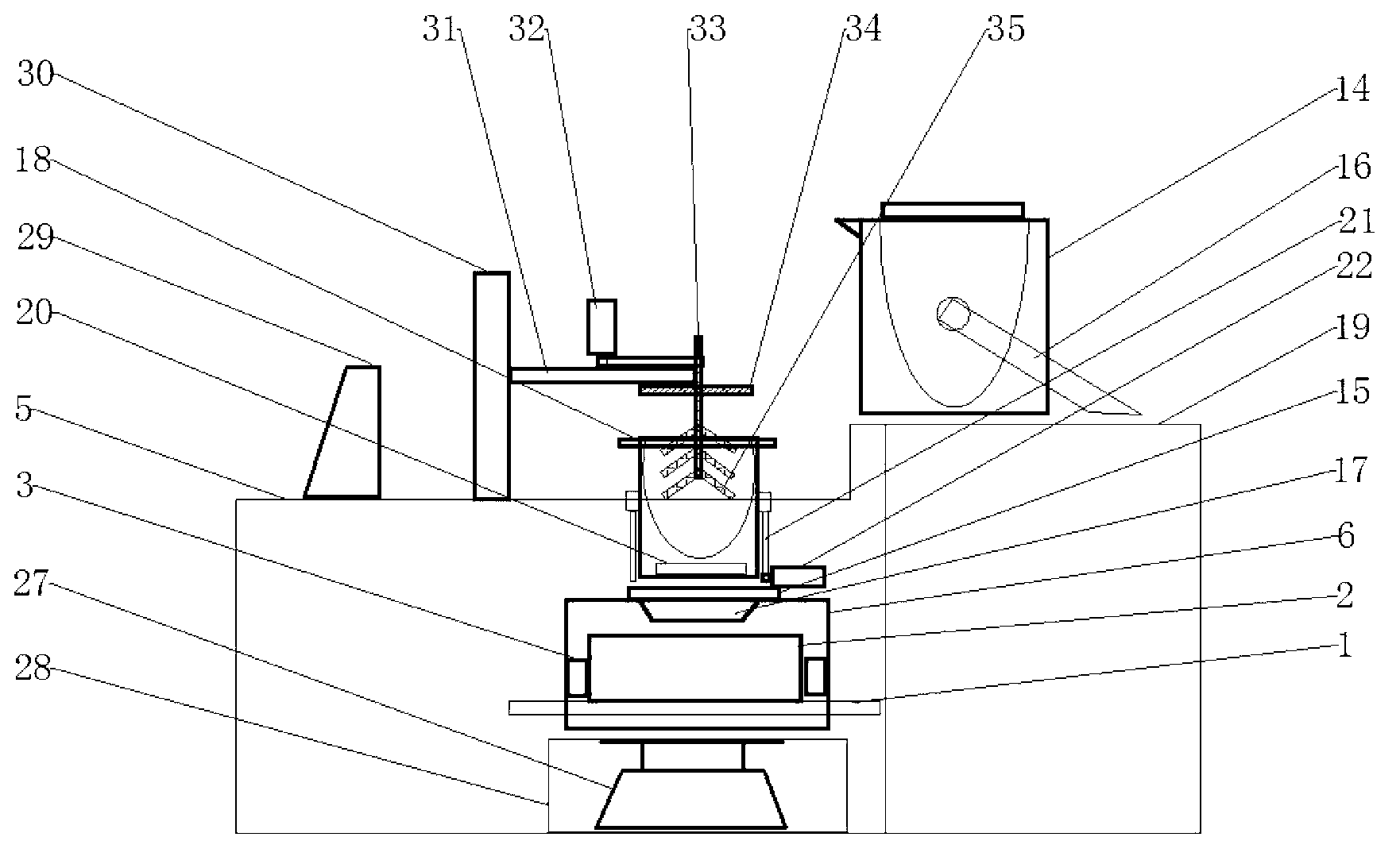

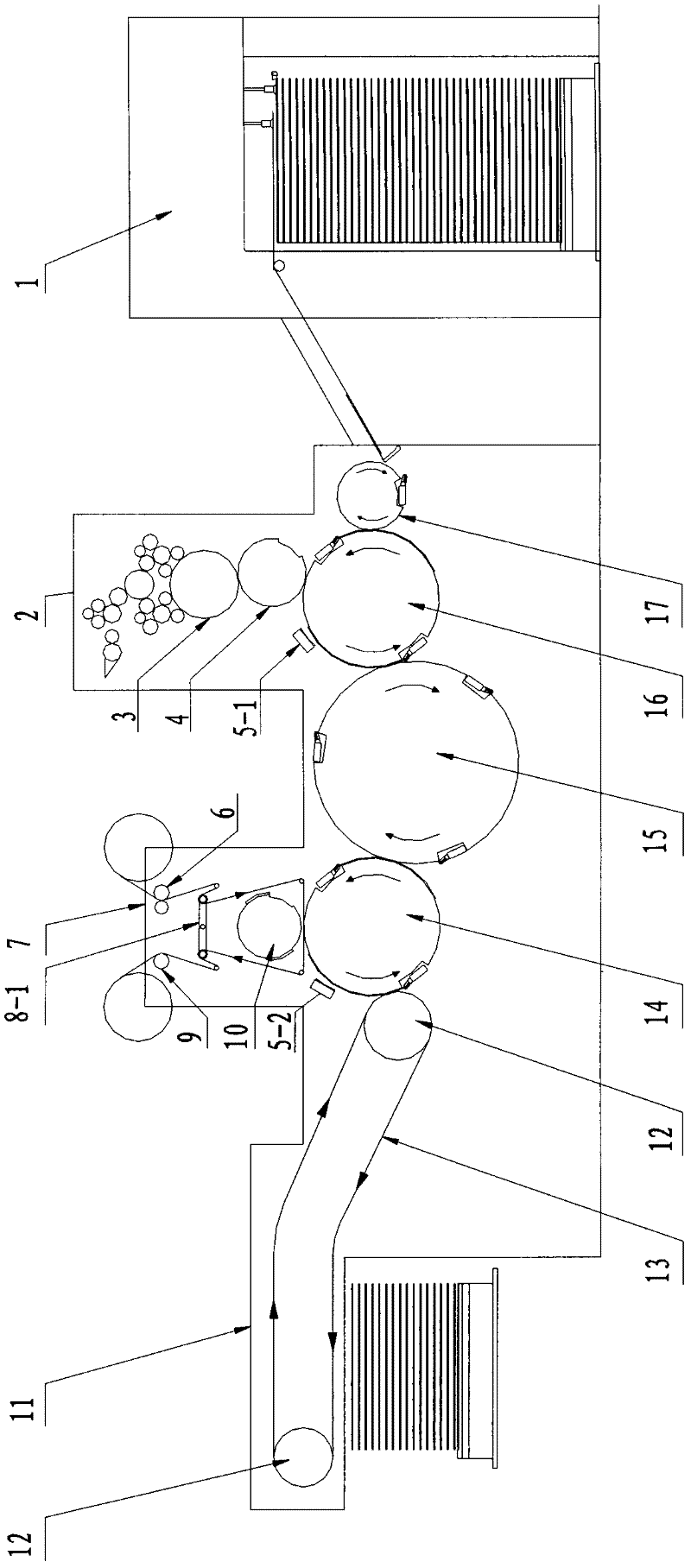

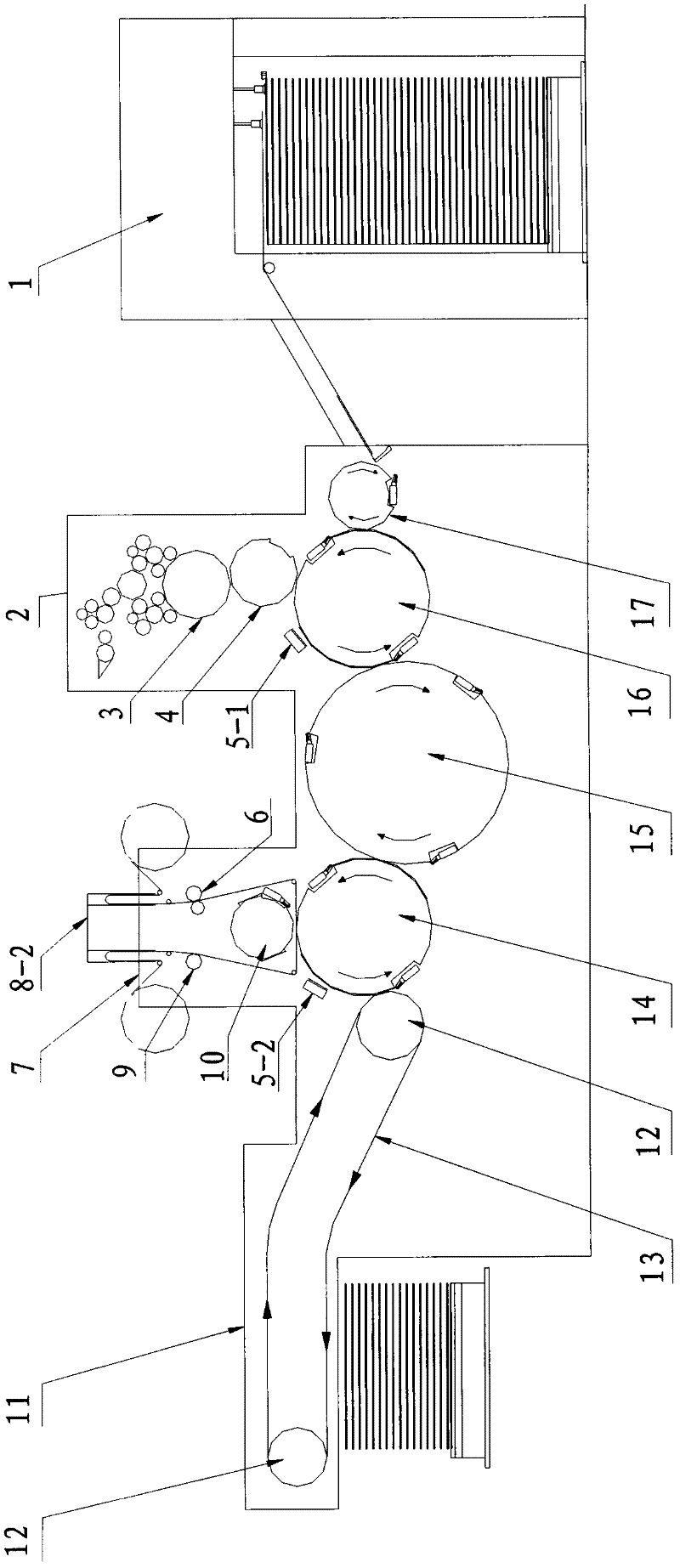

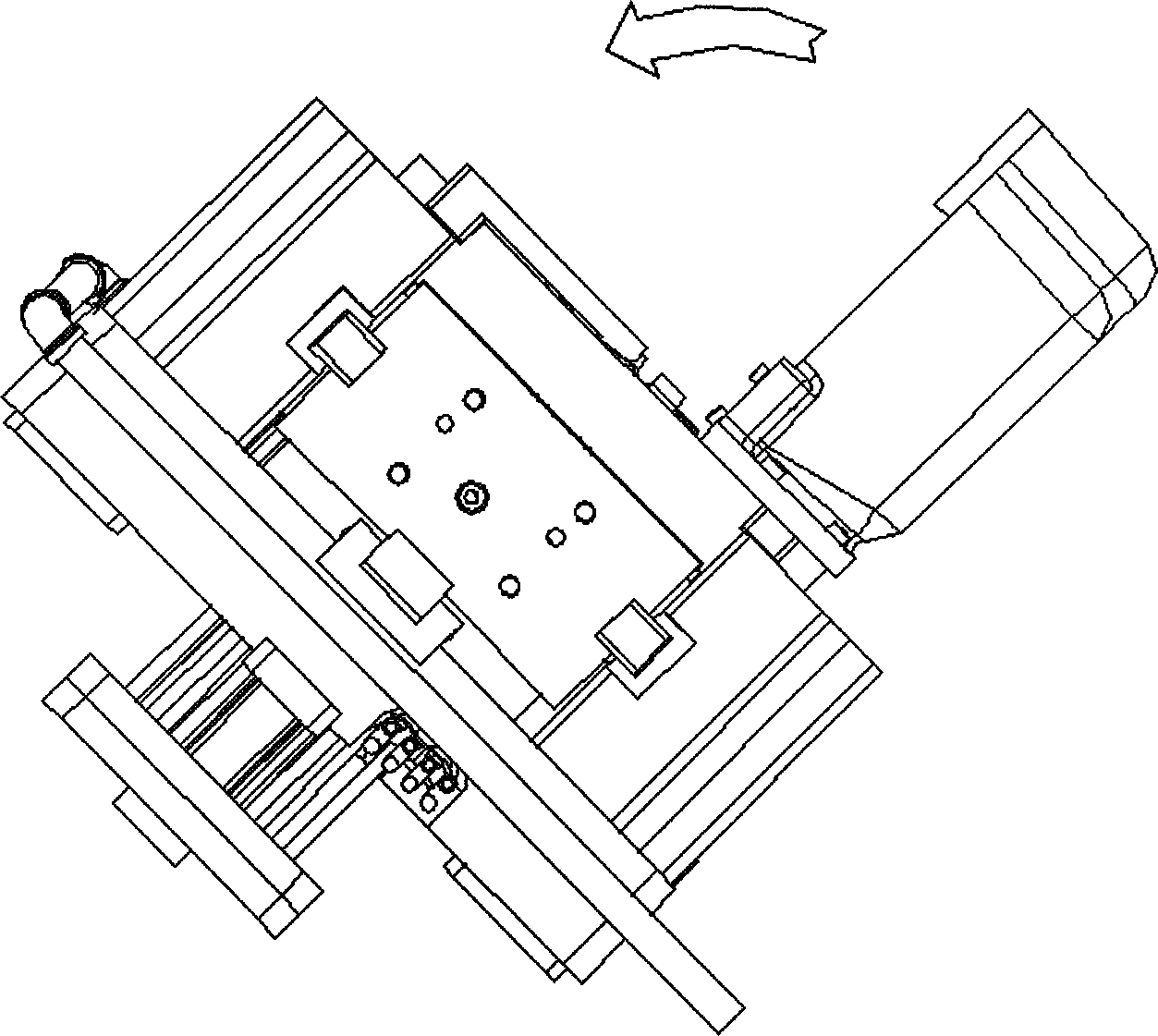

Complete equipment for producing foam aluminum

The invention relates to complete equipment for producing foam aluminum, and relates to manufacture of an alloy with an open or closed gap. The complete equipment mainly comprises a mould conveying device, a machining platform, a seal box type heat preserving furnace, two same stirring devices, two same smelting devices, a shaping device, a cooling device and a control platform, wherein the two same stirring devices can vertically lift. According to the invention, the operation of the integral equipment is controlled by the independently arranged control platform through a circuit, machining processes, namely metal smelting, pouring, mould preheating, tackifying, forming stirring, heat preservation foaming shaping and cooling, and equipment systematization are designed to the same machining platform so that the three dimensions, automation and continuity of smelting, stirring, pouring, foaming heat preservation and cooling procedures are realized, so that the defects that the full-automatic continuous production of a foam aluminum production procedure can not be realized, the automation degree is low, the production efficiency is lower, or large-size high-quality foam aluminum can not be manufactured, the process flow is complex and more procedures are needed in the prior art are overcome.

Owner:HEBEI UNIV OF TECH

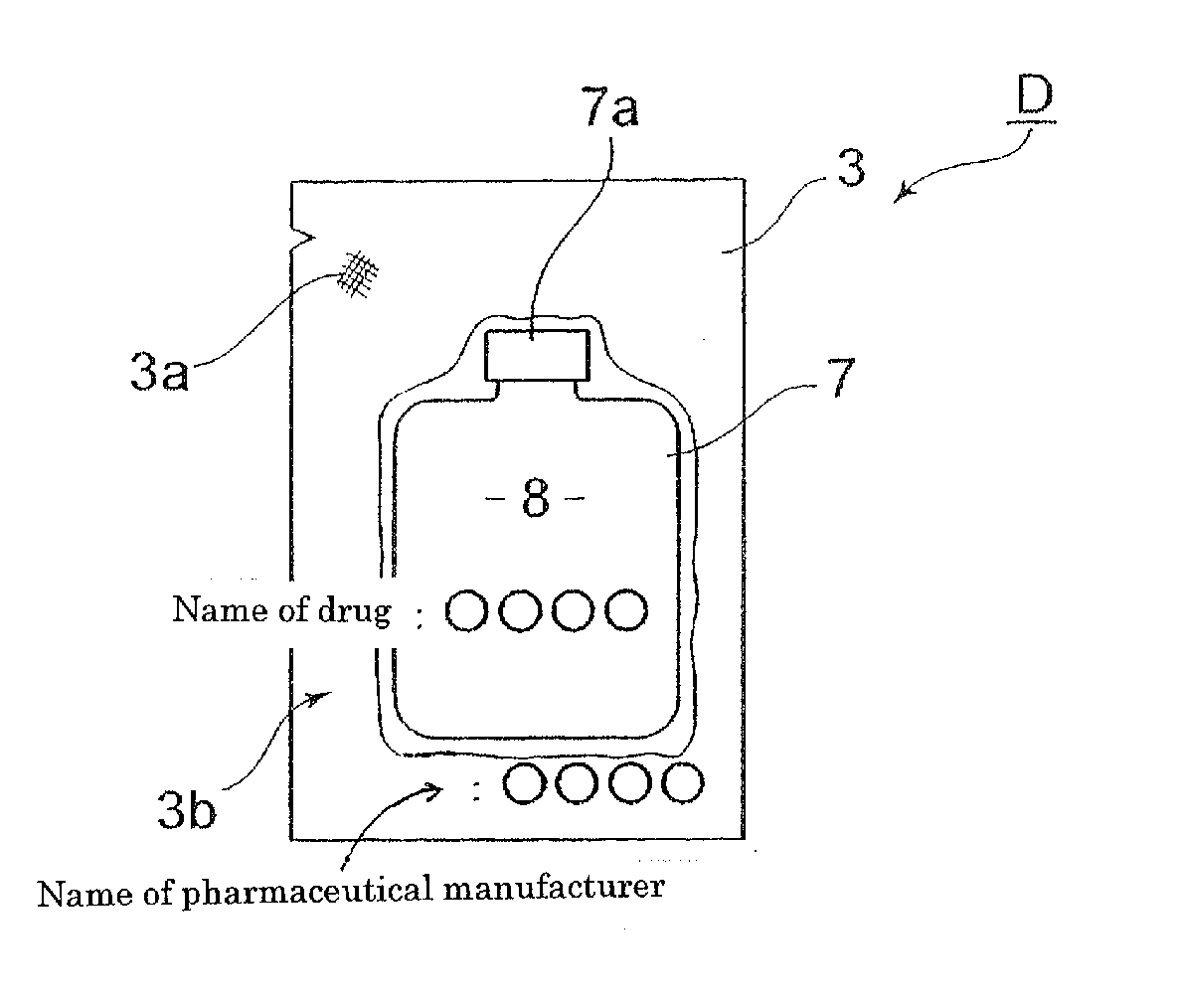

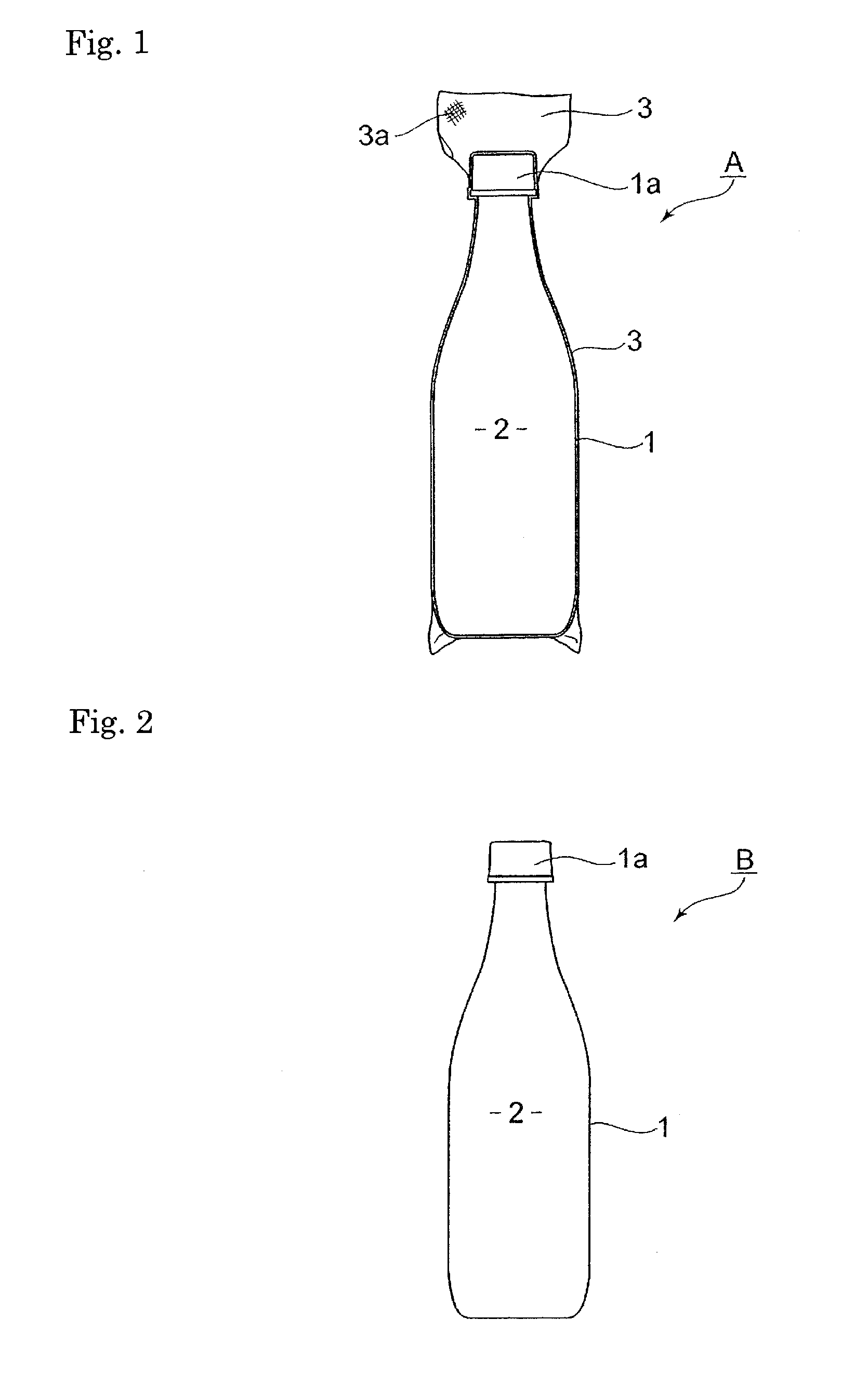

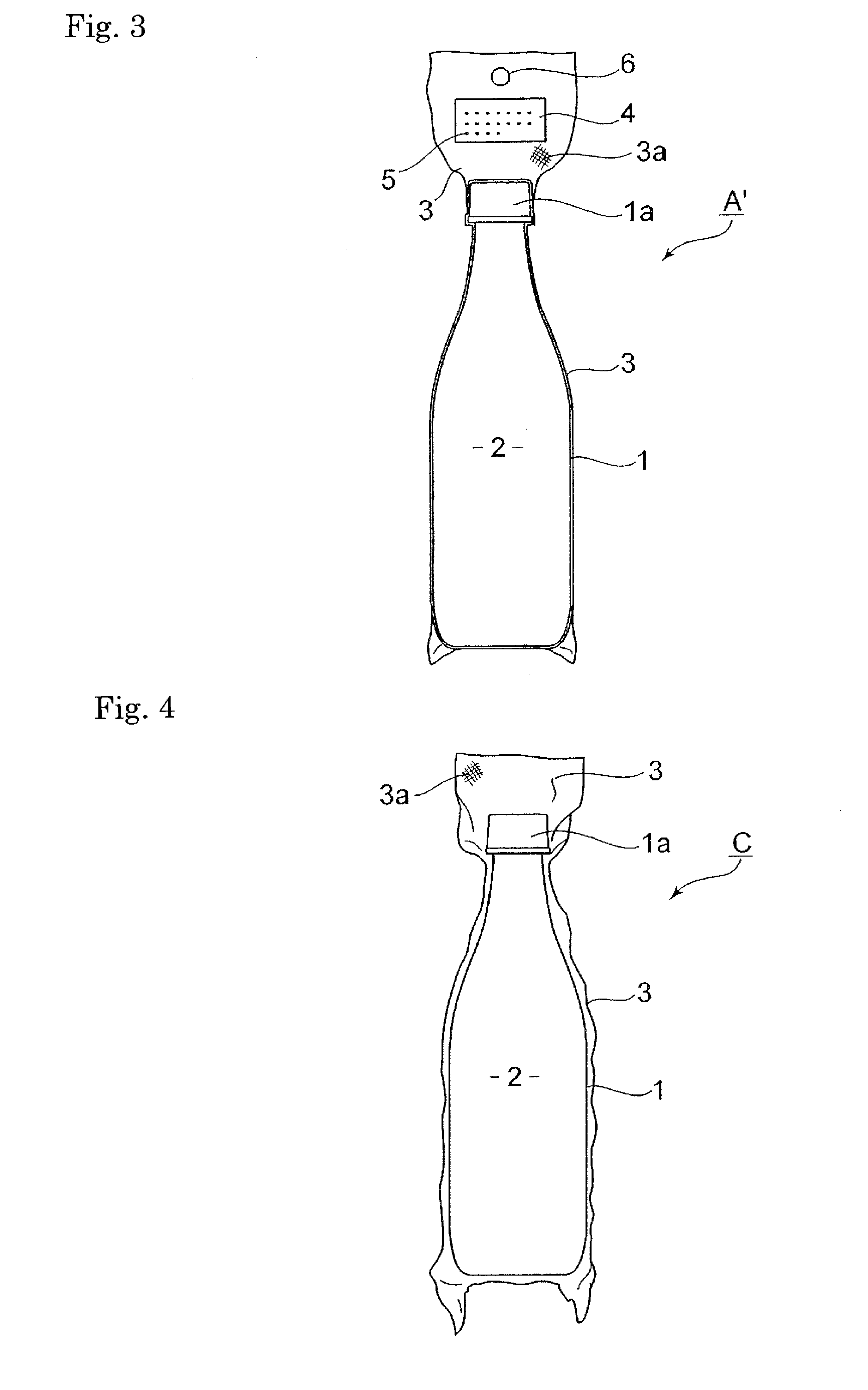

Container superior in air-tightness and a method of keeping gas molecules or volatile components in the container

InactiveUS20150069056A1Excellent gas barrier performanceMultiple wrapper applicationPackaging under vacuum/special atmospherePolyethylene terephthalate glycolVacuum pack

A bottle made of polyethylene terephthalate does likely undergo that a gas having a small molecular weight or volatile component escapes from the bottle in a short time in comparison with a glass bottle, steel can, and aluminum can. For a countermeasure, a simple operation prevents hydrogen molecules, helium gas, and volatile component from scattering and being lost. A container filled with gas, or liquid or viscous fluid in which gas is dissolved, or metal granules adsorbing gas is given a cap, and then, the whole of the container including the cap is packed with a metal foil laminated film superior in gas-barrier properties to be vacuum packaged.

Owner:NANO JET JAPAN +1

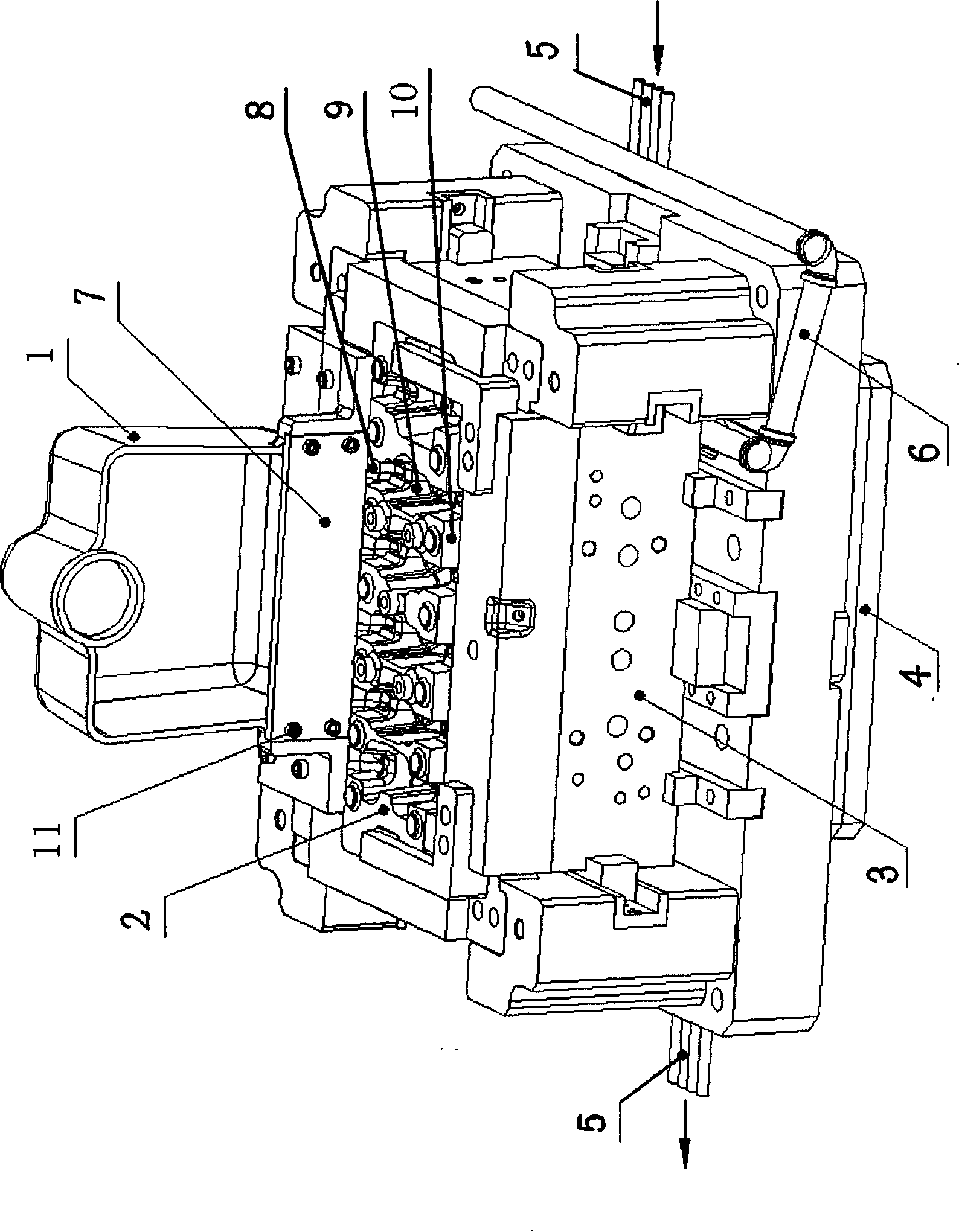

Single paper cold waving printing equipment and operation method thereof

The invention discloses single paper cold waving printing equipment. The equipment comprises a paper feeding unit, a gluing unit, a cold waving unit and a paper collection unit. An operation method of the equipment comprises the following steps of: conveying single paper to the gluing unit through the paper feeding unit; transferring an adhesive onto a part which is required to be subjected to cold waving on the paper, wherein the viscosity of the adhesive printed on the paper is improved by an ultraviolet (UV) curing device I; holding the paper by using a cripper on a cold waving printing roller; discharging electrochemical aluminum which is temporarily stored by using an aluminum storage device; recovering the electrochemical aluminum which remains after the cold waving by using a foil collection roller; pulling the electrochemical aluminum between an impression roller and the cold waving printing roller by using the aluminum storage device towards the paper feeding unit so as to realize the jumping of the electrochemical aluminum, and storing the electrochemical aluminum at the same time; curing a part which is just subjected to the cold waving by using a UV curing device II; and transferring the cured paper by using a chain towards a paper collection pile so as to realize the whole single paper cold waving process. The invention has the advantages that: due to the adoptionof an independent cold waving unit, the single paper is directly subjected to the cold waving, so that the jumping of the electrochemical aluminum can be realized and controlled, and the electrochemical aluminum can be greatly saved.

Owner:MASTERWORK GROUP CO LTD +1

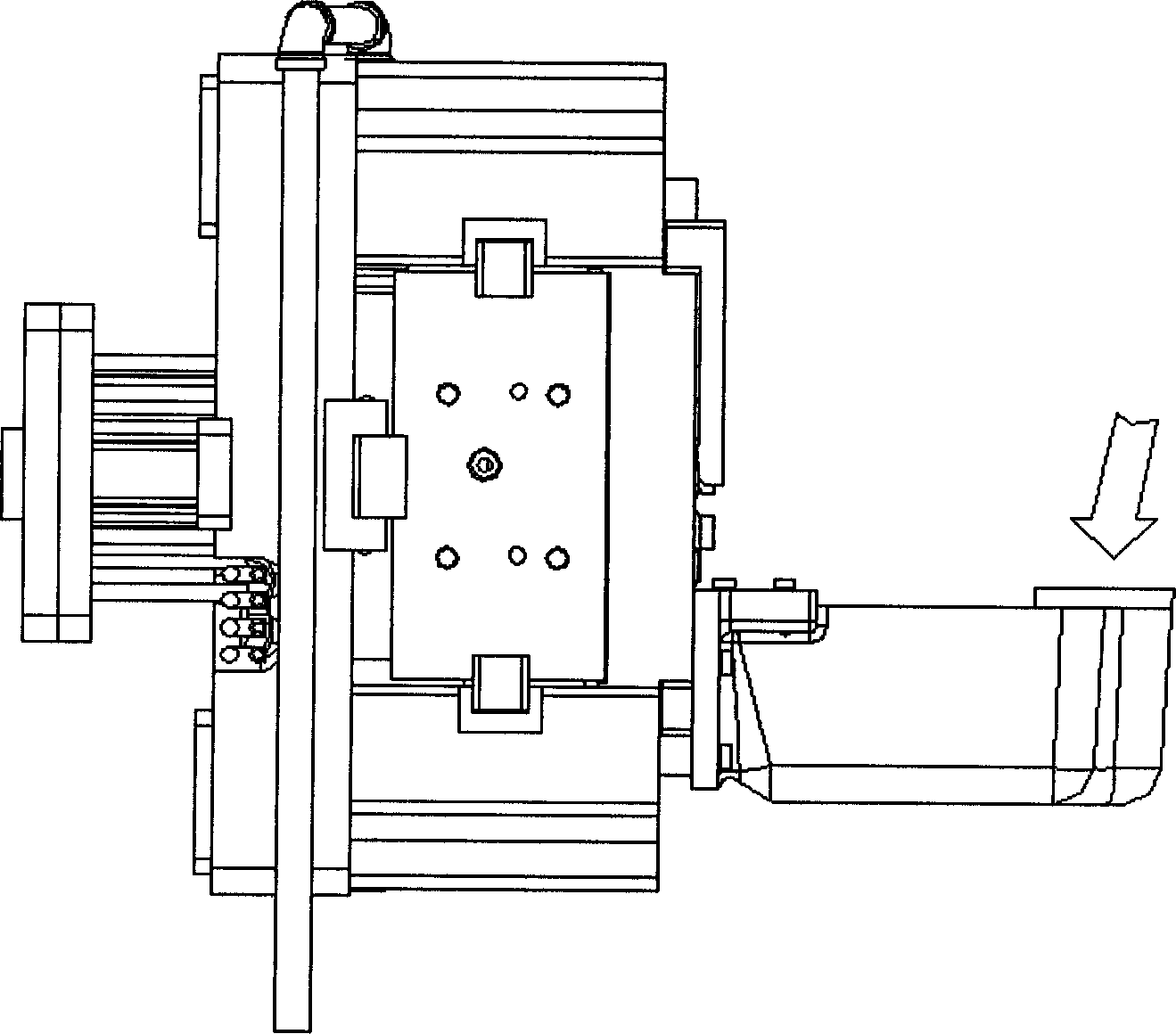

Metal section mould with controllable cross section and gravity slantingly-rotated foundry technique of aluminum alloy cylinder cover of metal section mould

The invention discloses a metal section mould with a controllable cross section and a gravity slantly-rotated foundry technique of an aluminum alloy cylinder cover of the metal section mould. The metal section mould comprises a pouring cup (1), a dead head sand core (2), a molding module (3), an ejector device (4), a water cooling device (5) and a negative pressure air extractor (6), and a control cross section retaining plate (7) is installed at the intersection position of the pouring cup and the dead head sand core on the lower portion of the pouring cup (1). Molten aluminum can only enter a casting cavity from a dead head beside an air inlet lateral cover due to retaining functions of the control cross section retaining plate in a slantingly-rotated pouring process, then the molten aluminum is discharged from a dead head at the position of a middle spark plug and a dead head beside an air discharge lateral cover, stable molten aluminum mold filling in a mold filling process is achieved, a principle of mold filling sequence and air inlet and air outlet in sequence is followed, the whole mold filling speed and time of a casting piece are controlled by controlling the minimum mold filling cross section of the pouring cup, defects such as air holes, shrinkage holes and shrinkage porosities produced by an original piece are obviously overcome, and accordingly product yield, acceptability and quality of the metal casting piece are improved.

Owner:WENZHOU RUIMING IND

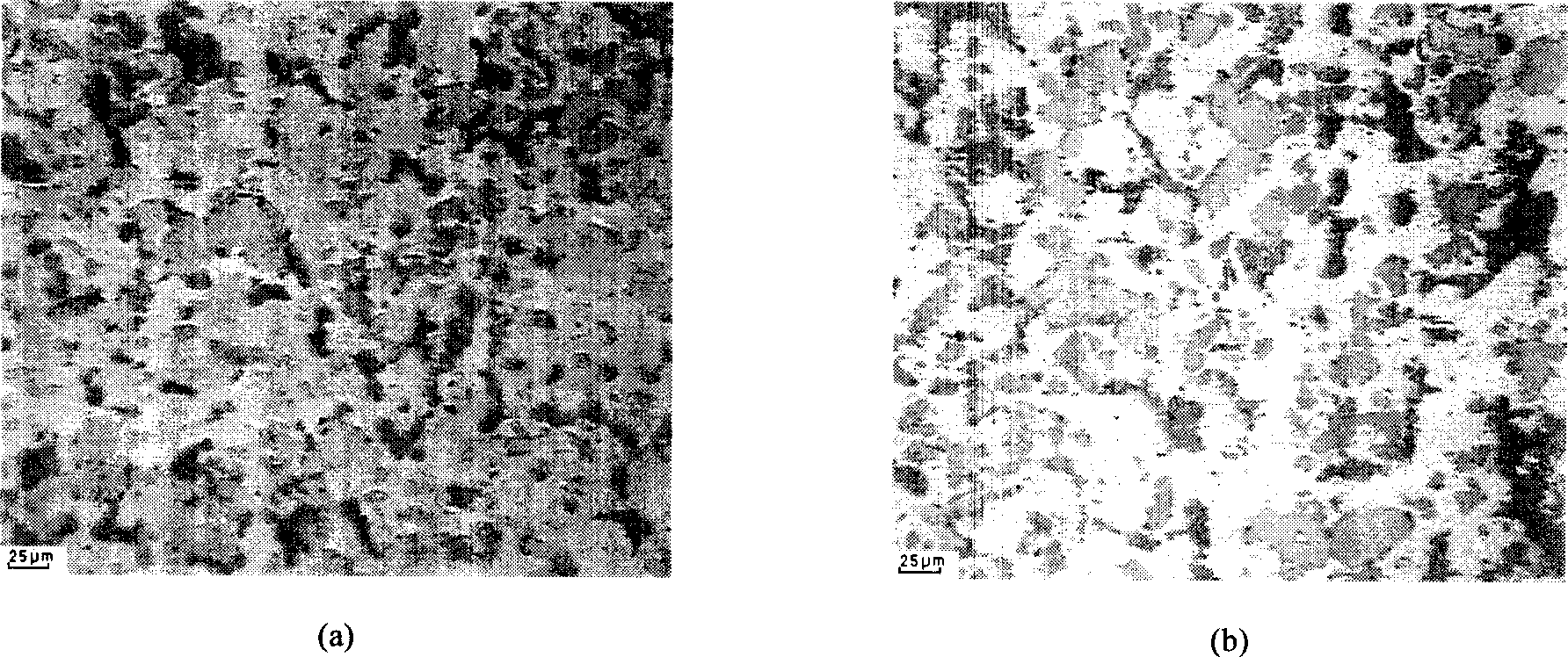

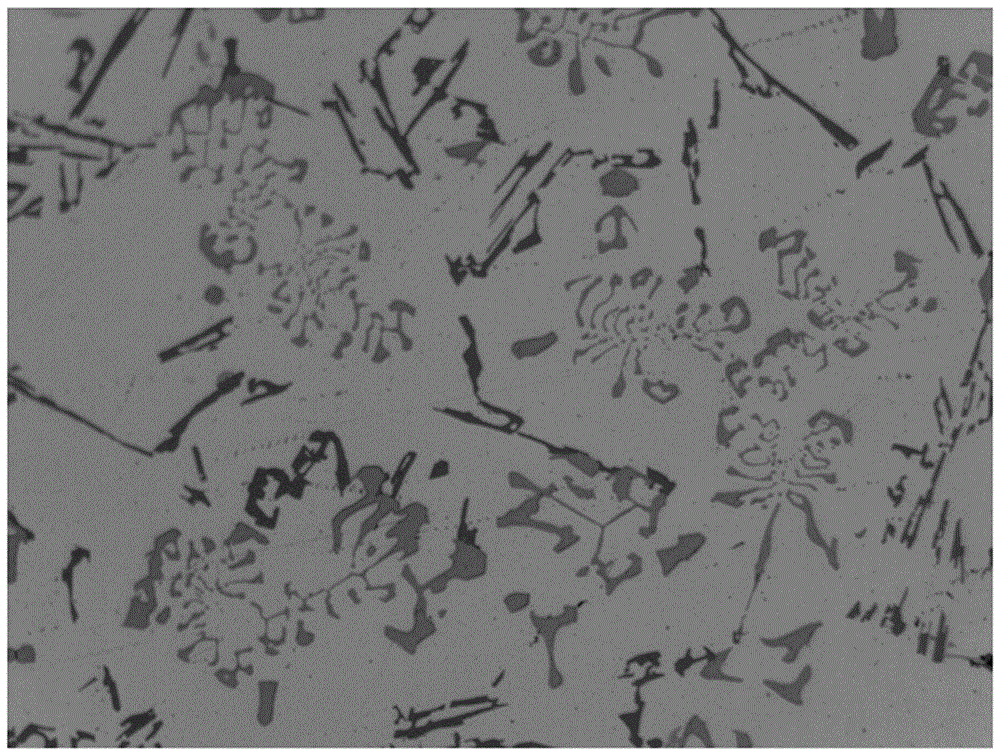

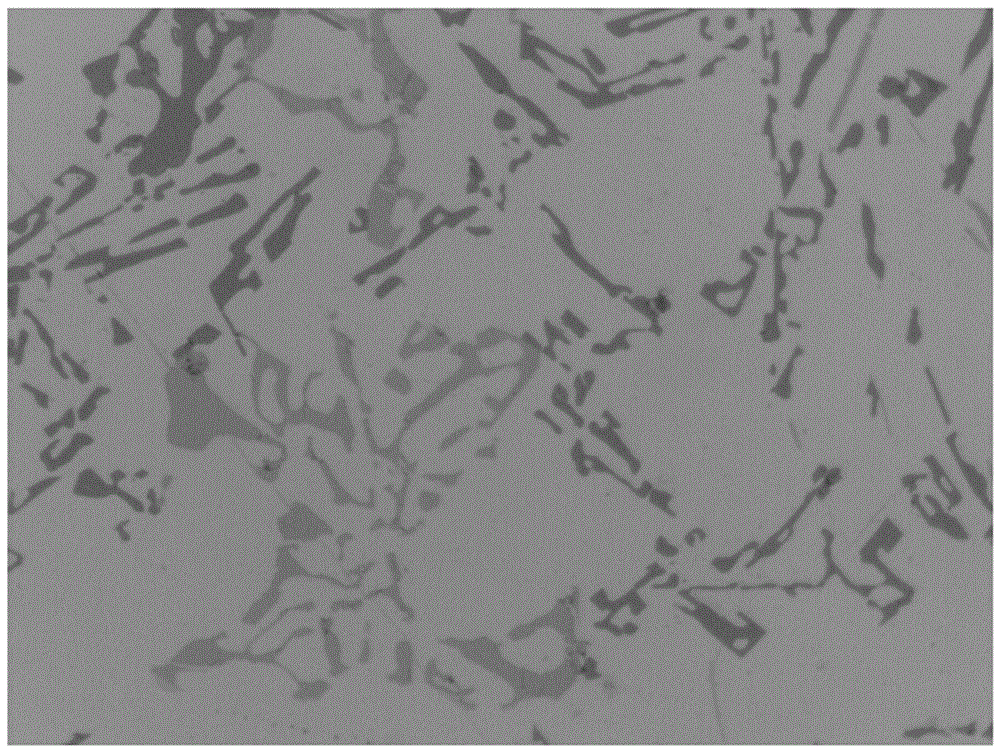

Alterant of iron-rich phase in secondary aluminum and alteration method

The invention relates to an alterant of an iron-rich phase in secondary aluminum and an alteration method. The alterant is composed of a [Mn] agent and a [B] agent. The alteration method includes the steps that part of secondary aluminum is heated to form a melt, then the [Mn] agent is added, the remaining secondary aluminum is added after the [Mn] agent melts, the [B] agent is added, refining is carried out after the [B] agent melts, pouring is carried out after standing is carried out for a period of time, and the secondary aluminum obtained after alteration treatment is obtained. According to the alterant and the alteration method, the Fe element in the iron-rich phase can be replaced through the [Mn] agent, the advantage growth orientation of the iron-rich phase is changed, and therefore a needle-like beta-Fe phase is eliminated; meanwhile, the forming temperature of the iron-rich phase can be reduced through B in the [B] agent, the growth time of a primary iron-rich phase is shortened, the growth space of the primary iron-rich phase is reduced, the B can also serve as a surface-active element, and is absorbed to the surface of the iron-rich phase in the initial phase of formation of the iron-rich phase, and growth of the iron-rich phase is restrained, so that through the combined action of the [Mn] agent and the [B] agent, existence of the needle-like iron-rich phase and the primary iron-rich phase can be completely eliminated, the uniform Chinese character type iron-rich phase is obtained; and in addition, the adding amount of the Mn can be greatly reduced, and the mechanical performance and the machining performance of the secondary aluminum can be greatly improved.

Owner:GUANGDONG INST OF NEW MATERIALS

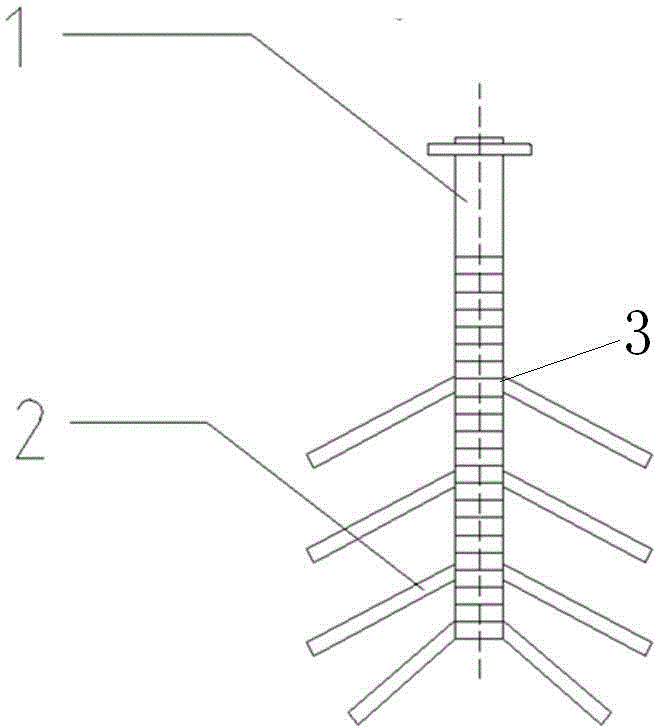

Tackifying and foaming stirring device for preparing foamed aluminum

ActiveCN104607079ASuppression of floatingStir wellRotary stirring mixersMixer accessoriesPolymer scienceAluminum can

The invention discloses a tackifying and foaming stirring device for preparing foamed aluminum, relates to a stirring device, and solves the problem that the high-quality foamed aluminum cannot be prepared by adopting the existing forming device. The tackifying and foaming stirring device for preparing the foamed aluminum comprises a cylindrical stirring furnace body, wherein a heating device is fixed outside the furnace body, a stirring paddle is arranged inside the furnace body, and the stirring paddle is installed on a furnace cover; the stirring paddle is in a four-layer folded-blade paddle form, four layers of paddle blades are arranged on a central shaft of the stirring paddle, each layer is provided with three paddle blades, the paddle blades at each layer are arranged to stagger each other for 120 degrees, a dip angle of the paddle blades at the lowermost layer is smaller than that of the paddle blades at the upper three layers, and the upper part of the central shaft is fixed on the furnace cover through a fixing disc and the central shaft driven by a motor to rotate. The tackifying and foaming stirring device is simple in structure, ingenious in design, capable of uniformly and rapidly stirring metal liquid by virtue of the four-layer paddle blades and good in foaming effect.

Owner:广东磐龙交通环境设施工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com