Aluminium-titanium-horon rare earth fining agent, and its preparing method

A refiner, aluminum titanium boron technology, applied in the field of aluminum alloy applications, can solve no obvious problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

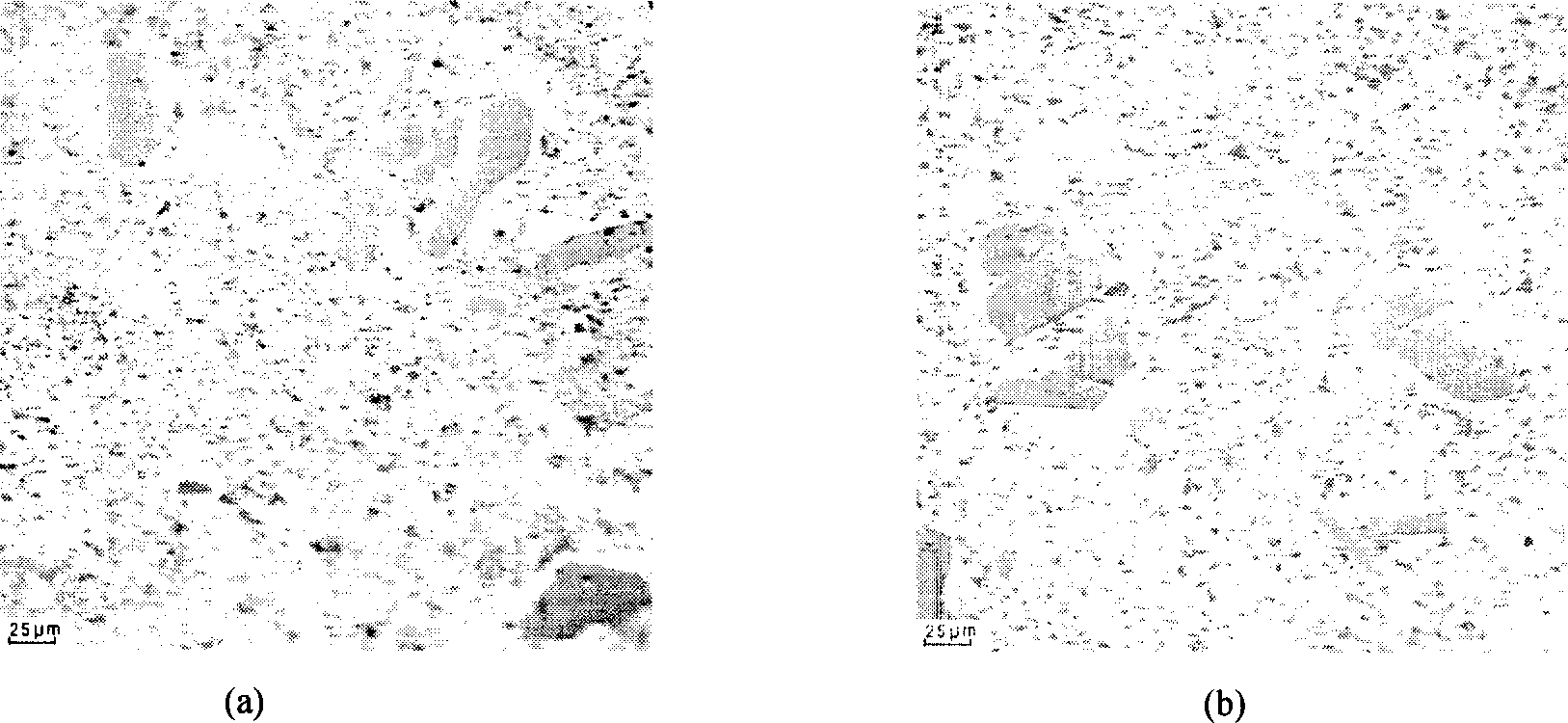

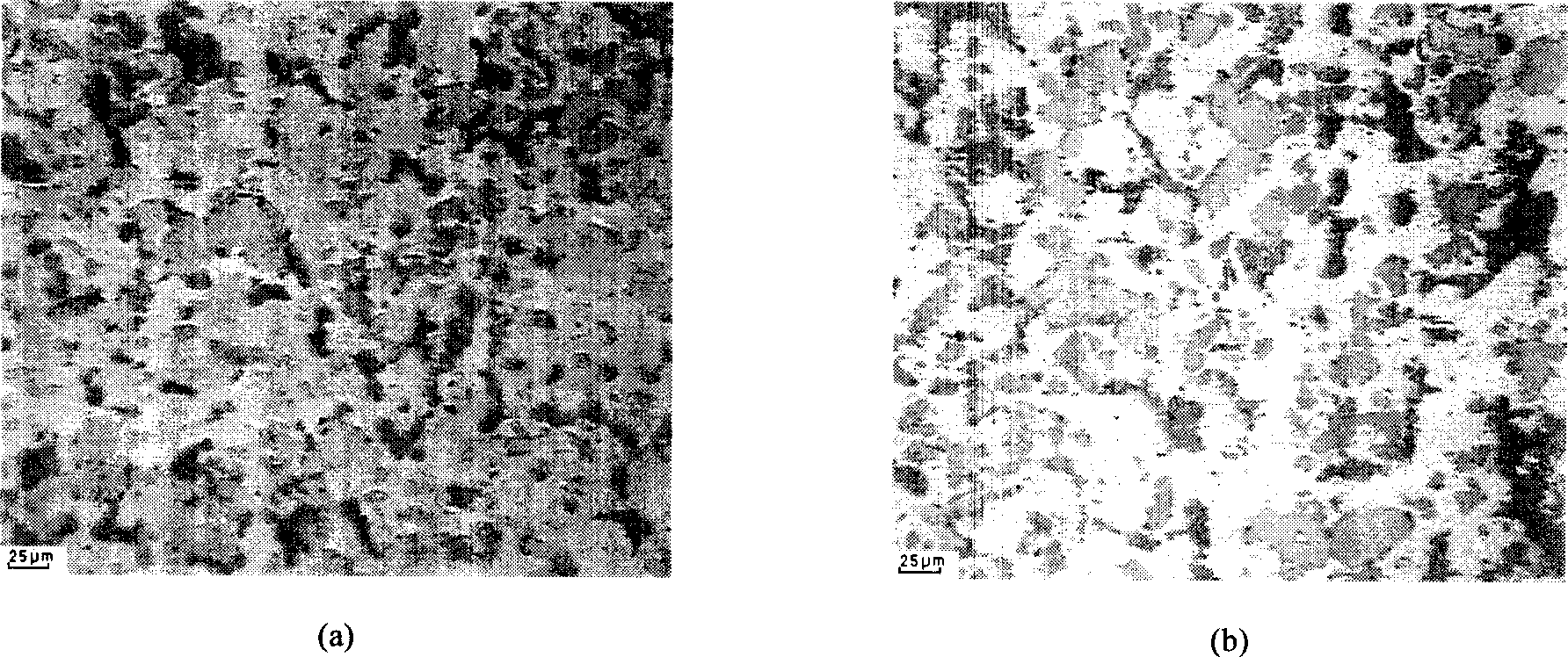

Image

Examples

Embodiment 1

[0044] When applied to high-purity aluminum, its main components are:

[0045] Ingredient content, wt%

[0046] Aluminum Al 91.5

[0047] Titanium Ti 6.5

[0048] Boron B 1.0

[0049] Misch RE 2.0

Embodiment 2

[0051] When applied to industrial pure aluminum, its main components are:

[0052] Ingredient content, wt%

[0053] Aluminum Al 86.00-92.00

[0054] Titanium Ti 5.0

[0055] Boron B 1.0

[0056] Misch RE 1.0

Embodiment 3

[0058] When applied to aluminum alloys of grades above 1100, its main components are:

[0059] Ingredient content, wt%

[0060] Aluminum Al 86.00-92.00

[0061] Titanium Ti 3.0

[0062] Boron B 1.0

[0063] Misch RE 2.0

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com