Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

400 results about "Fe element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compound soft magnetic material with operational performances of high-frequency and large power and process for preparing same

InactiveCN101694800AHigh resistivityHigh saturation magnetic inductionInorganic material magnetismIron powderDecomposition

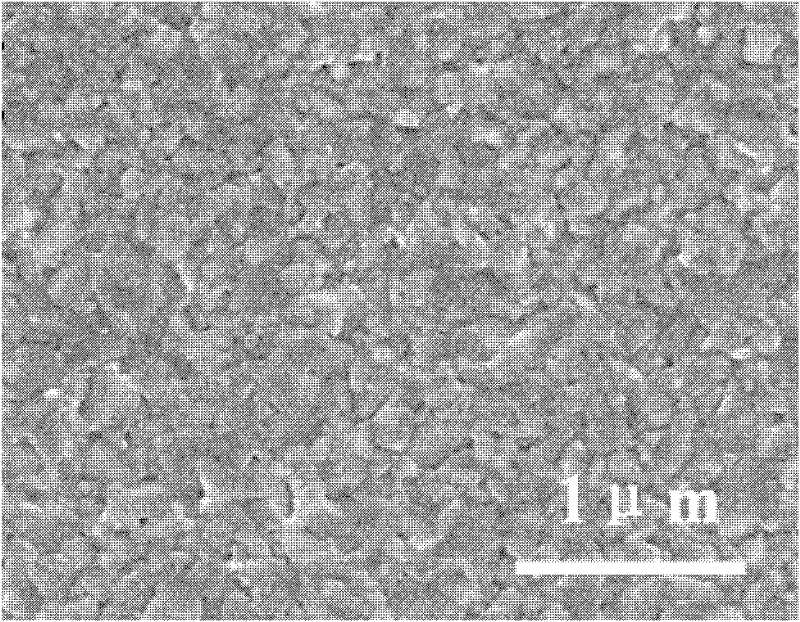

Disclosed is a compound soft magnetic material with operational performances of high-frequency and large power and process for preparing same. By adopting the technology of controlling the hydrolytic decomposition and sedimentation of ethyl orthosilicate under room temperature, the surfaces of iron powder particles with large grain diameters are evenly coated with amorphous silicon dioxide shells, thus Fe / SiO2 core-shell composite soft magnetic powder which is completely insulated with controllable shell thickness between 100 and 300 nanometers is manufactured, wherein SiO2 is 2-11 percent by mass, and Fe element is 89-98 percent by mass. The compound soft magnetic material with operational performances of high-frequency and large power and the process for preparing same are rich in raw material sources, simple in technological process, environment-friendly and suitable for industrialized production.

Owner:WUXI RES INST OF APPLIED TECH TSINGHUA UNIV +1

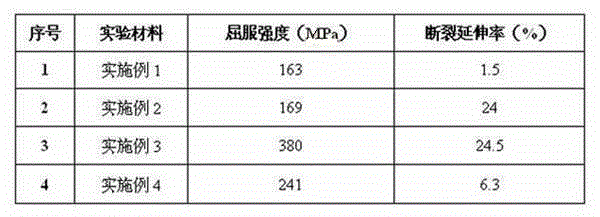

Pure titanium wire for spectacle frame and manufacturing method thereof

The invention discloses a pure titanium wire for a spectacle frame and a manufacturing method thereof. 0 to 0.20 weight percent of O element and 0 to 0.26 weight percent of Fe element are added in the pure titanium cast ingot smelting process. The amount of Fe and O elements needed to be added during reinforcement is obtained according to the strength theta 0 of original spongy titanium, and the adding amount of Fe and TiO2 in the pure titanium material smelting process is determined further. Through forging, rolling, drawing and annealing processes, the strength controllable pure titanium wire is prepared and meets requirements on titanium wire properties of different parts of the spectacle frame. In the smelting process for preparing the pure titanium material, accurate amount of Fe element and O element are added, and chemical composition content in the pure titanium wire is controlled, so that the strength of the pure titanium wire is accurately controlled, the strength deviation of TA2 pure titanium wires produced in different batches is controlled within 40MPa, and the pure titanium wires meeting specific strength requirements are produced.

Owner:XIAN AEROSPACE NEW MATERIAL

Magnetic toner

ActiveUS7544455B2Improve development performanceHigh blacknessDevelopersDielectric lossAqueous solution

A magnetic toner having magnetic toner particles each containing at least a binder resin and a magnetic iron oxide particle, in which: when a solution is prepared by dissolving the magnetic iron oxide particles in an acidic aqueous solution and an Fe element amount in a solution in which all the magnetic iron oxide particles are dissolved is defined as a total Fe element amount, a ratio X of the amount of Fe(2+) in a solution in which the magnetic iron oxide particles are dissolved to a state where 10 mass % of the total Fe element amount is present in the solution (solution having an Fe element-dissolving ratio of 10 mass %) to an Fe element amount in the solution having a specific Fe element-dissolving ratio; and the dielectric loss tangents of the magnetic toner measured at a temperature of 40° C. satisfy specific conditions.

Owner:CANON KK

Method for synthesizing ferrum-aluminium spinelle

The invention relates to a synthesis method of hercynite and has the technical proposal that aluminium compound and iron compound are mixed according to the mol ratio of Al ion to Fe ion of two to one, added with TiO2 fine powder of 1-20wt percent of the mixture obtained from the mixing of the aluminium compound and the iron compound and 1-6wt percent of binding agent to be mixed for 5 to 180 minutes for formation and then dried for 20 to 30 hours under the temperature of 90 to 120 DEG C and warmed up to 1100 to 1700DEG C with a temperature rising speed of 0.5 to 10 DEG C / min in the atmosphere of nitrogen to be kept warm for 5 to 600 minutes and next naturally cooled so as to obtain the hercynite. The invention is characterized by simple technology, low reaction temperature, low cost of raw materials and no environmental pollution; due to the low oxygen content in the atmosphere of the nitrogen, Fe elements exist in the form of Fe<2+> and all aluminium and iron are transformed to FeAl2O4 under the firing temperature; in addition, as the TiO2 is introduced, Ti<4+> can easily enter into crystal lattice of the FeAl2O4 to produce oxygen-iron vacancy concentration and ferric-ion vacancy concentration so as to promote the sintering with apparent porosity less than or equal to 2 percent after sintering.

Owner:WUHAN UNIV OF SCI & TECH

Zirconium cladding surface resistant to high temperature and oxidation ZrCrFe/AlCrFeTiZr composite gradient coating preparing technology

ActiveCN107513694AImprove the interface binding forceHigh strengthVacuum evaporation coatingSputtering coatingHigh entropy alloysAlloy coating

The invention discloses a zirconium cladding surface resistant to high temperature and oxidation ZrCrFe / AlCrFeTiZr composite gradient coating preparing technology. Ultrahigh vacuum multitarget co-sputtering technique is adopted, a ZrCrFe / AlCrFeTiZr composite gradient alloy resistant to high temperature and oxidation protecting coating is prepared on the surface of a zirconium alloy base body, and the zirconium cladding surface resistant to high temperature and oxidation ZrCrFe / AlCrFeTiZr composite gradient coating preparing technology comprises the steps of predepositional treatment, bias voltage anti-splash washing and ZrCrFe / AlCrFeTiZr composite gradient alloy coating deposition. The preparing process of the composite coating is divided into two steps, the first step is to prepare ZrCrFe gradient transition layer coating, in a deposited ZrCrFe transition layer, the atomic percentage content of Zr element is changed from the gradient of 100 at%-35 at% in the thickness direction, the atomic percentage content of Cr element is changed from the gradient of 0 at%-33 at% in the thickness direction, and the atomic percentage content of Fe element is changed from the gradient of 0 at%-33 at% in the thickness direction; the second step is to prepare a AlCrFeTiZr high-entropy alloy coating, in a deposited AlCrFeTiZr high-entropy alloy coating, the atomic percentage content of Al element is controlled in 0.5 at%-1.0at %, and the atomic percentage of other elements is between 10 at%-35 at%. Bonding force of the coating prepared by the technology is excellent, the surface is dense and uniform, and the coating has excellent performance such as high strength, resistance to high temperature and oxidation and irradiation resistance.

Owner:田雨

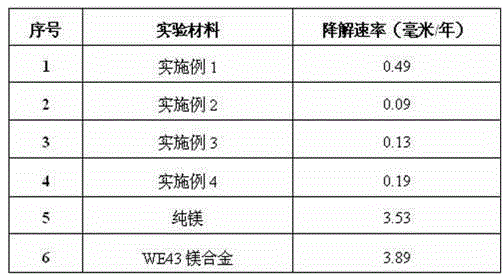

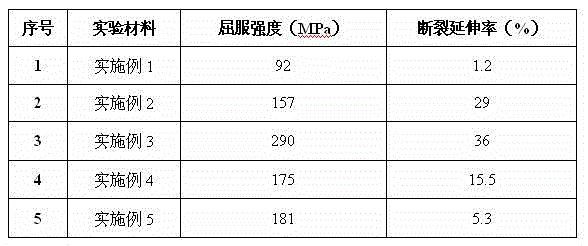

Degradable corrosion-resistant high-toughness Zn-Fe zinc alloy for human body and application thereof

ActiveCN104689369ALow costImprove corrosion resistanceSuture equipmentsProsthesisZinc alloysUltimate tensile strength

The invention provides a degradable corrosion-resistant high-toughness Zn-Fe zinc alloy for a human body and application thereof and relates to the field of medical implant materials. The corrosion-resistant high-toughness Zn-Fe zinc alloy provided by the invention is aimed at overcoming the defects in the prior art and has the advantages that the cost of adding materials is low, the strength is high, the plasticity is good, the degradation rate is controllable, and meanwhile, the Zn-Fe zinc alloy can be degraded by human bodies. The zinc alloy contains a Zn element and a Fe element, wherein the mass percent of Zn element is 90-99.998%, and the mass percent of Fe element is 0.002-10%. According to the zinc alloy provided by the invention, the cost of the added materials is low, degradation products of all ingredients of a prepared alloy material can be degraded through human body metabolism, the corrosion resistance is far higher than that of a magnesium alloy, the degradation rate is greatly lowered, a longer-time mechanical support can be provided, and the strength and toughness of the alloy material are good.

Owner:XIAN ADVANCED MEDICAL TECH

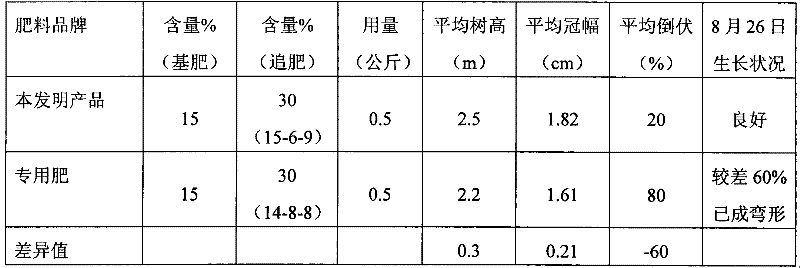

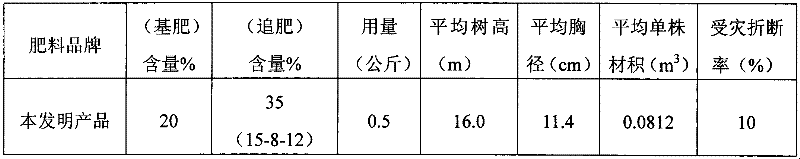

Eucalyptus ecological fertilizer containing Mn and Fe elements and fertilizing method

ActiveCN102503675AMeet nutrient needsImprove resistance to natural disasters (typhoonFertilising methodsFertilizer mixturesFrostAdditive ingredient

The invention discloses a eucalyptus ecological fertilizer containing Mn and Fe elements and a fertilizing method. The eucalyptus ecological fertilizer containing the Mn and Fe elements is prepared by mixing inorganic nutrients, organic fertilizers and a bonder, and includes following effective ingredients in mass percents of: 7-20 percent of the inorganic nutrients, 4-15 percent of P2O5, 4-20 percent of K2O4, 0.05-0.2 percent of B, 0.05-0.1 percent of Zn, 0.01-0.05 percent of Cu, 0.01-0.2 percent of Mn, 0.01-0.2 percent of Fe, 5-25 percent of organic matters and 0.15-5 percent of the bonder. According to the eucalyptus ecological fertilizer disclosed by the invention, major elements, secondary elements and trace elements are matched according to a reasonable proportion, and a property amount of the organic fertilizers are added, so that not only can the nutrient requirements of the eucalyptus growth be met, the use ratio of the fertilizer is improved, and the wastage rate of the fertilizer is decreased, but also the stress resistance and the lodging resistance of eucalyptus are enhanced, the capacity of resisting natural calamities (such as typhoon and frost), the loss is reduced and the economic benefit is improved.

Owner:GUANGXI LIYUANBAO SCI & TECH

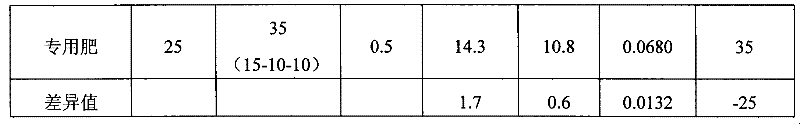

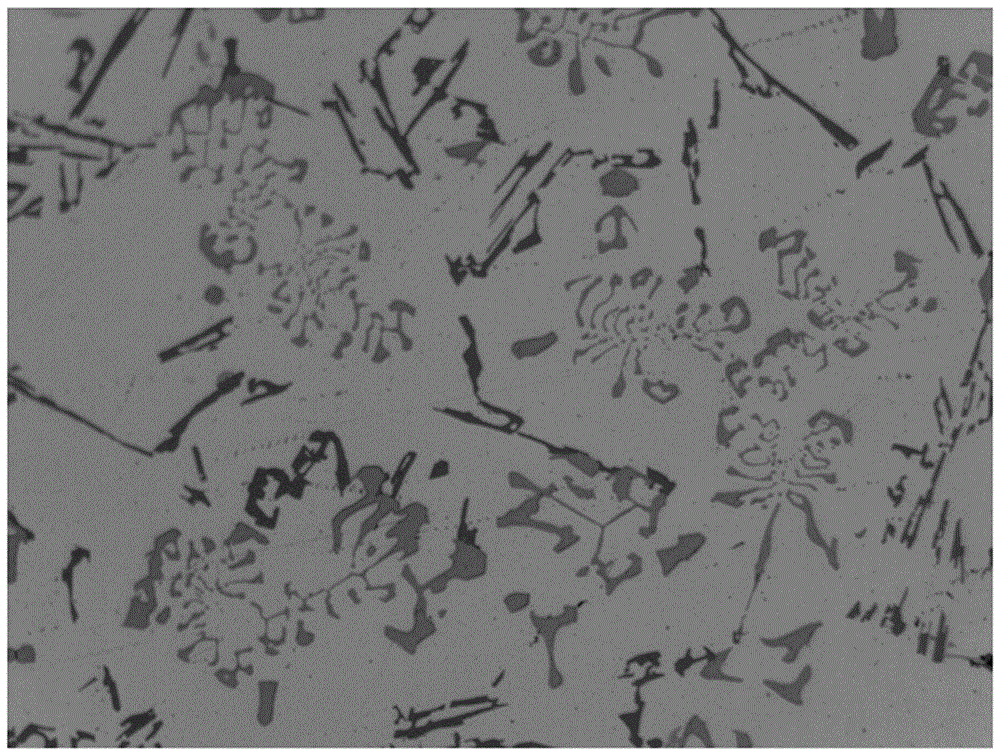

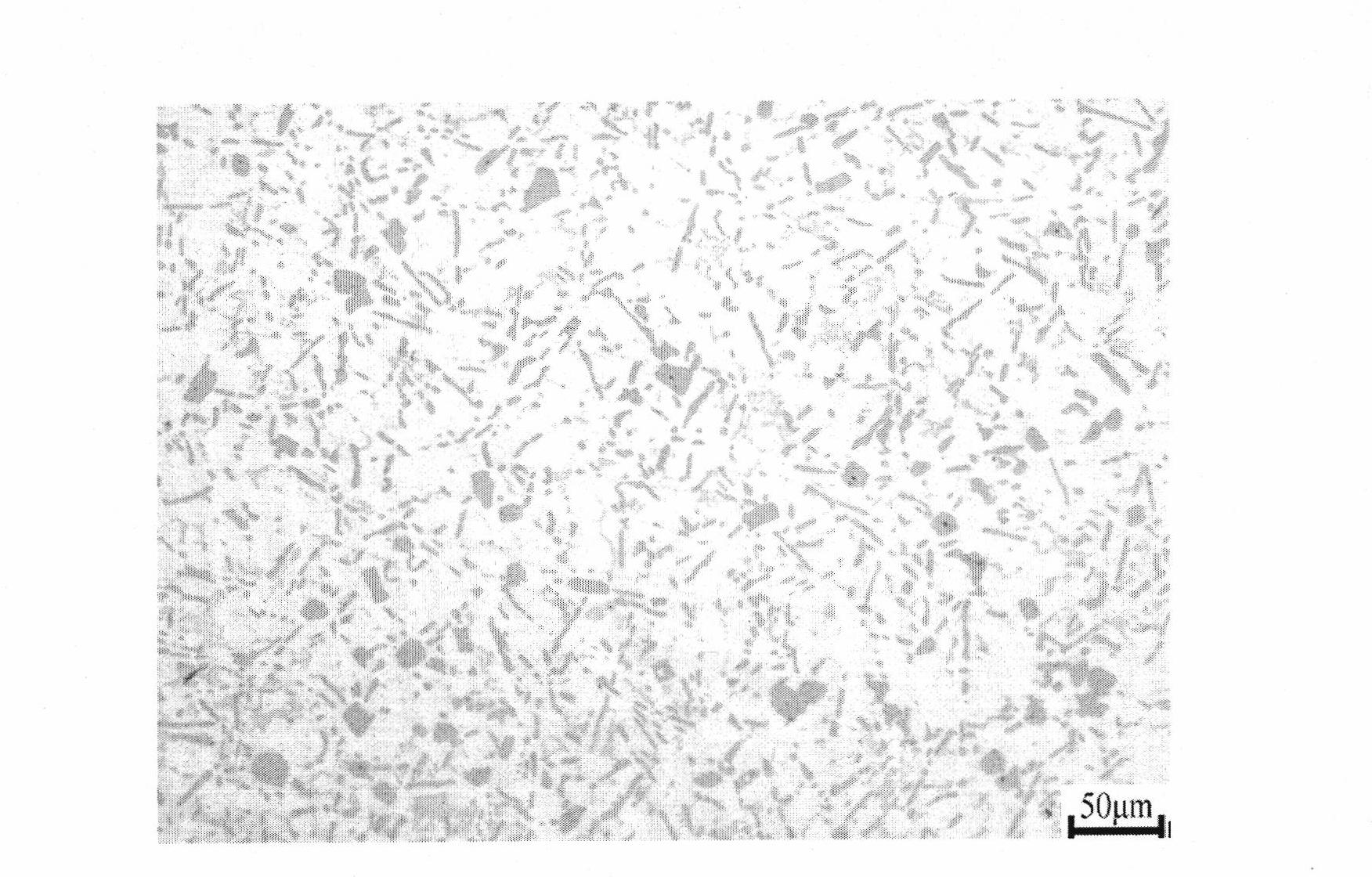

Alterant of iron-rich phase in secondary aluminum and alteration method

The invention relates to an alterant of an iron-rich phase in secondary aluminum and an alteration method. The alterant is composed of a [Mn] agent and a [B] agent. The alteration method includes the steps that part of secondary aluminum is heated to form a melt, then the [Mn] agent is added, the remaining secondary aluminum is added after the [Mn] agent melts, the [B] agent is added, refining is carried out after the [B] agent melts, pouring is carried out after standing is carried out for a period of time, and the secondary aluminum obtained after alteration treatment is obtained. According to the alterant and the alteration method, the Fe element in the iron-rich phase can be replaced through the [Mn] agent, the advantage growth orientation of the iron-rich phase is changed, and therefore a needle-like beta-Fe phase is eliminated; meanwhile, the forming temperature of the iron-rich phase can be reduced through B in the [B] agent, the growth time of a primary iron-rich phase is shortened, the growth space of the primary iron-rich phase is reduced, the B can also serve as a surface-active element, and is absorbed to the surface of the iron-rich phase in the initial phase of formation of the iron-rich phase, and growth of the iron-rich phase is restrained, so that through the combined action of the [Mn] agent and the [B] agent, existence of the needle-like iron-rich phase and the primary iron-rich phase can be completely eliminated, the uniform Chinese character type iron-rich phase is obtained; and in addition, the adding amount of the Mn can be greatly reduced, and the mechanical performance and the machining performance of the secondary aluminum can be greatly improved.

Owner:GUANGDONG INST OF NEW MATERIALS

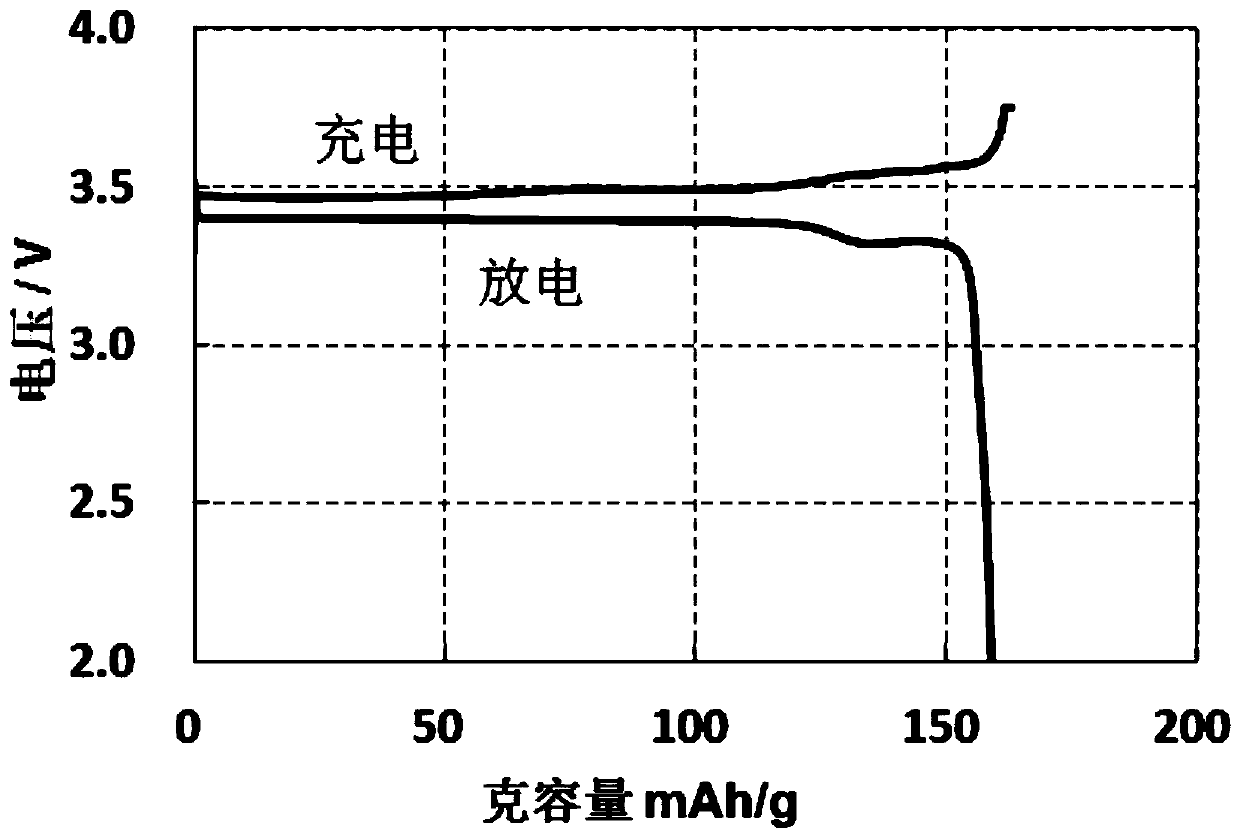

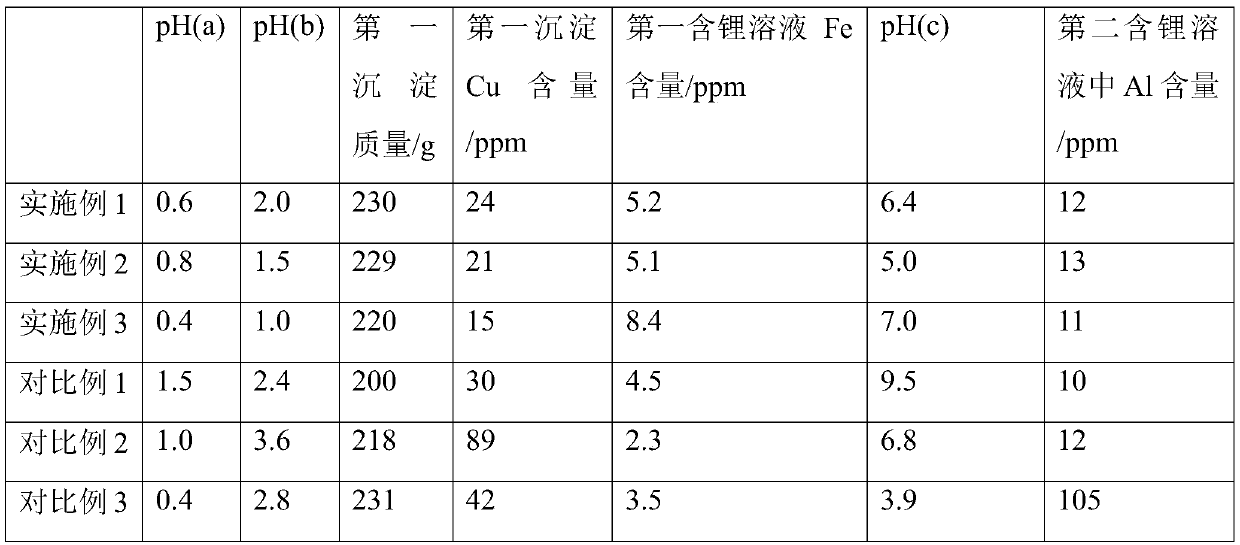

Method for recycling lithium iron phosphate positive electrode material

ActiveCN109721043AEasy to recycleImprove recycling ratesCell electrodesWaste accumulators reclaimingLithium iron phosphateSolvent

The present invention relates to the field of electrochemistry, and more particularly to a method for recycling a lithium iron phosphate positive electrode material. The method comprises the followingsteps: contacting a recycled cell material with an acid solution, and carrying out solid-liquid separation to obtain a first liquid phase and an insoluble substance; adjusting the pH value of the first liquid phase, and carrying out solid-liquid separation to obtain a first lithium-containing solution and a first precipitate; mixing the first precipitate, a second lithium-containing solution andan auxiliary agent to obtain a second liquid phase; adjusting the contents of Li element, Fe element, P element and C element in the second liquid phase to obtain a third liquid phase; removing the solvent of the third liquid phase to obtain a lithium iron phosphate precursor; and calcining the precursor in a reducing environment to obtain the lithium iron phosphate positive electrode material. The method for recycling the lithium iron phosphate positive electrode material provided by the present invention has the advantages of simple process, high recycling rate, low impurity content and thelike, and has a good industrialization prospect.

Owner:CONTEMPORARY AMPEREX TECH CO

Ultraviolet blocking-up solar energy ultra-white configurated glass and method for manufacturing the same

The present invention is one kind of white figured glass capable of blocking ultraviolet ray for solar photovoltaic cell assembly with crystalline silicon cell and non-crystalline silicon electrode plates and its production process. The white figured glass is made of material with very low Fe element content and added CeO2, and has very low ultraviolet ray transmittance. Its production process includes sorting material, compounding material, mixing, smelting, rolling, annealing and other steps.

Owner:ZHEJIANG JIAFU GLASS CO LTD

Degradable corrosion-resistant high-toughness Zn-Fe-X zinc alloy for human body and application thereof

ActiveCN104689378ALow costImprove corrosion resistanceSuture equipmentsProsthesisAdditive ingredientZinc alloys

The invention provides a degradable corrosion-resistant high-toughness Zn-Fe-X zinc alloy for a human body and application thereof and relates to the field of medical implant materials. The zinc alloy contains a Zn element, a Fe element and an X element, wherein the X element is at least one of Mg, Ca and Sr, the mass percent of Zn element is 89.92-99.997%, the mass percent of Fe element is 0.002-10%, and the mass percent of X element is 0.001-0.08%. According to the zinc alloy provided by the invention, the cost of added materials is low, degradation products of all ingredients of a prepared alloy material can be degraded through human body metabolism, the corrosion resistance is far higher than that of a magnesium alloy, the degradation rate is greatly lowered, a longer-time mechanical support can be provided, and the strength and toughness of the alloy material are good.

Owner:XIAN ADVANCED MEDICAL TECH

6A02 aluminum alloy round ingot and production process thereof

The invention discloses a 6A02 aluminum alloy round ingot. The aluminum alloy material is composed of, by weight percentage, 0.35-0.5% of Cu, 0.6-0.75% of Mg, 0.2-0.3% of Mn, > / =0.25% of Fe, 0.65-1.0% of Si, < / =0.15% of Zn, < / =0.15% of Ti, < / =0.1% of other total, and the balance Al, and the total is 100%. A production process of the 6A02 aluminum round ingot includes steps of burdening, smelting, refining, casting and cast rod examining. The technical scheme further determines component parameters of the 6A02 aluminum alloy round ingot within a national standard range, reduces content of Zn and Fe elements, and can lower brittleness of castings, improve cracking resistance and reduce tendency, produced aluminum alloy is high in plasticity and good in anticorrosion performance.

Owner:四川阳光坚端铝业有限公司

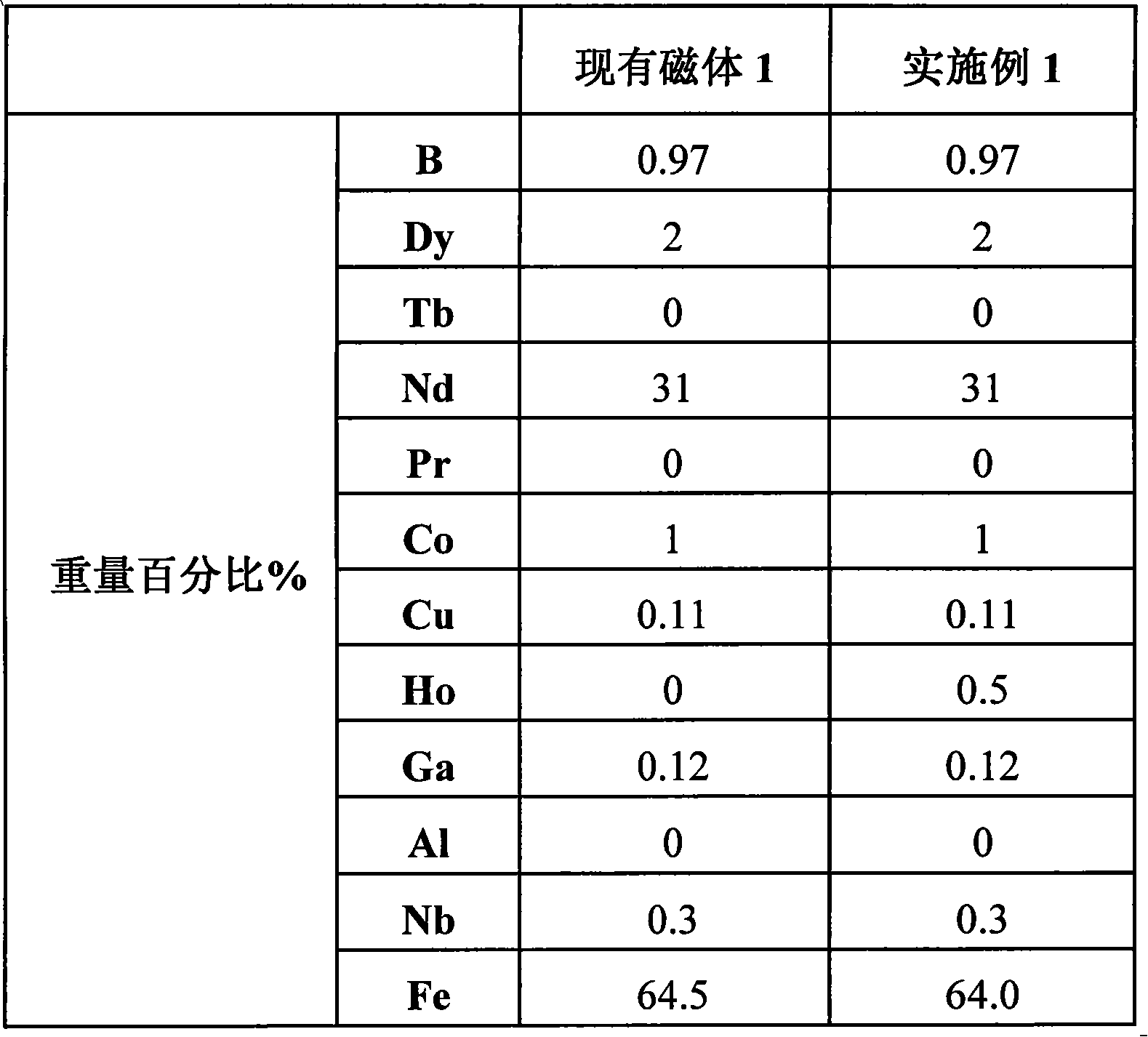

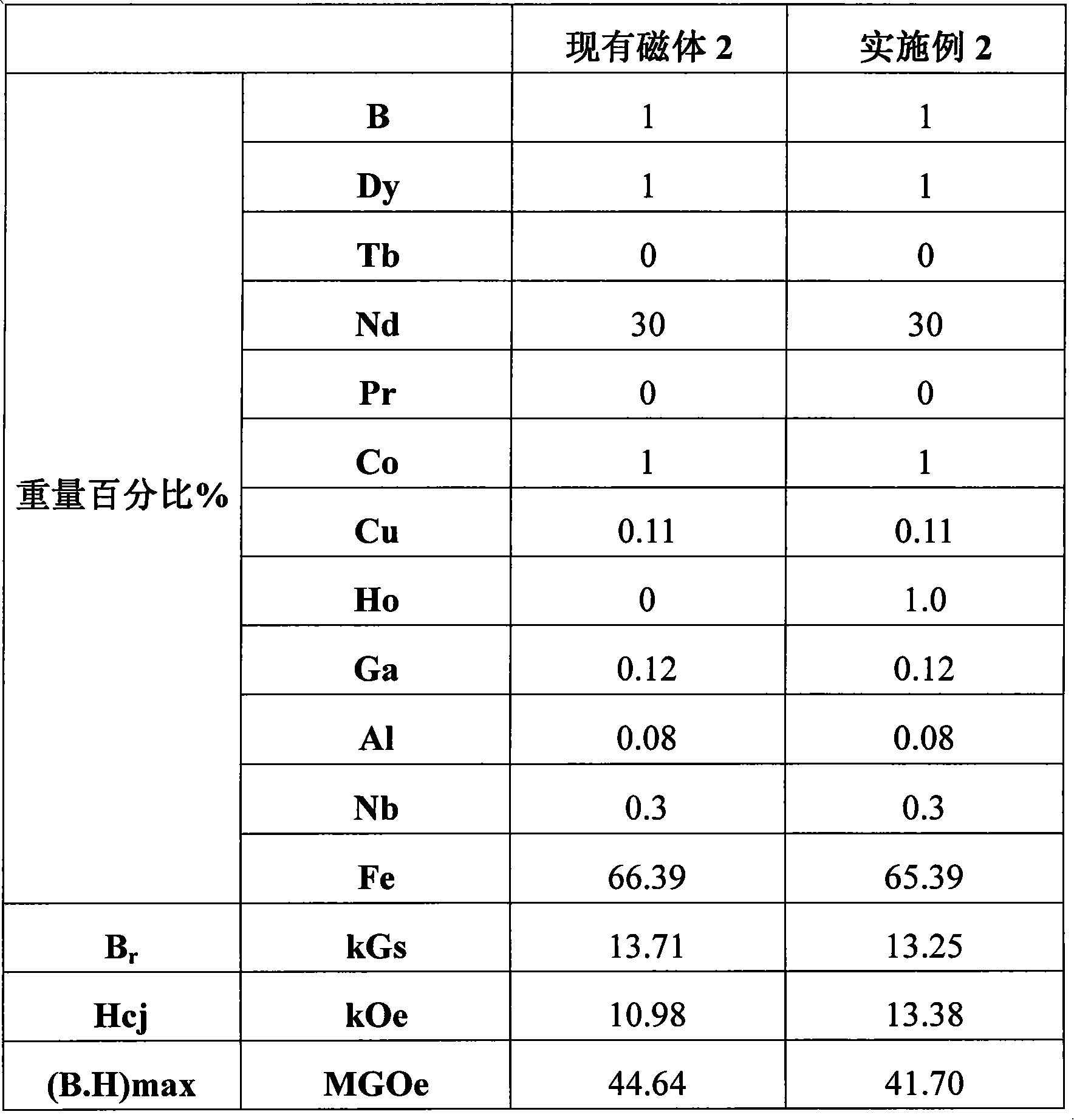

Novel sintered neodymium-iron-boron permanent-magnet material and manufacture method thereof

ActiveCN101582317ALow costSave heavy rare earth resourcesInorganic material magnetismInductances/transformers/magnets manufactureHolmiumMetallurgy

The invention provides a novel sintered neodymium-iron-boron permanent-magnet material containing holmium and a manufacture method thereof. The novel sintered neodymium-iron-boron permanent-magnet material has the structural formula as follows: LnAlphaHoBetaBGammaMxNyFe100-Alpha-Beta-Gamma-x-y, wherein Ln is lanthanon comprising Nd and one or more selected from Pr, Dy and Tb; M is an additive element comprising Co and Cu; N is an additive element comprising one or more selected from Al, Ga, Nb, Zr and Ti; Alpha, Beta, Gamma, x and y are weight percentages of each element; Fe is an Fe element or unavoidable impurities; and Alpha is mare than or equal to 29 and less than or equal to 33, Beta is more than or equal to 0.5 and less than or equal to 4, Gamma is more than or equal to 0.95 and less than or equal to 1.20, x is more than or equal to 0 and less than or equal to 3.5, and y is more than or equal to 0 and less than or equal to 1.50. In the invention, the addition of Ho has a remarkable function in improving the Hcj of a magnet.

Owner:SANVAC BEIJING MAGNETICS +1

High-strength cast aluminum-silicon alloy for engine body and preparation method thereof

The invention relates to a high-strength cast aluminum-silicon alloy for an engine body and a preparation method thereof, belonging to the field of metal materials. The alloy comprises the following components in percentage by weight: 12.0-14.0% of Si, less than 0.3% of Ni, 3.0-5.0% of Cu, 0.3-0.8% of Fe, 0.4-0.8% of Mn, less than 0.4% of Mg, 0.1-0.2% of Ti, less than 0.27wt% of Zr and balance of Al. Heat treatment parameters are as follows: the solution treatment is carried out at 510+ / -5 DEG C for 5-8h and then water quenching is carried out at room temperature; and the aging treatment is carried out at 160+ / -5 DEG C for 6-10h and then air cooling is carried out. The tensile strength and the yield strength of the alloy at room temperature after heat treatment respectively reach 316-336MPa and 245-263MPa, the elongation of the broken alloy reaches 0.72-0.83%, and the Brinell hardness reaches 155-166HBW to the maximum. Compared with the similar alloys, the alloy of the invention has the advantages of high mechanical properties, low content of Ni elements, reduction of content of noble elements in the alloy, wider allowed fluctuation range of content of Fe elements, good cast ingot quality, simple processes and strong operability.

Owner:UNIV OF SCI & TECH BEIJING

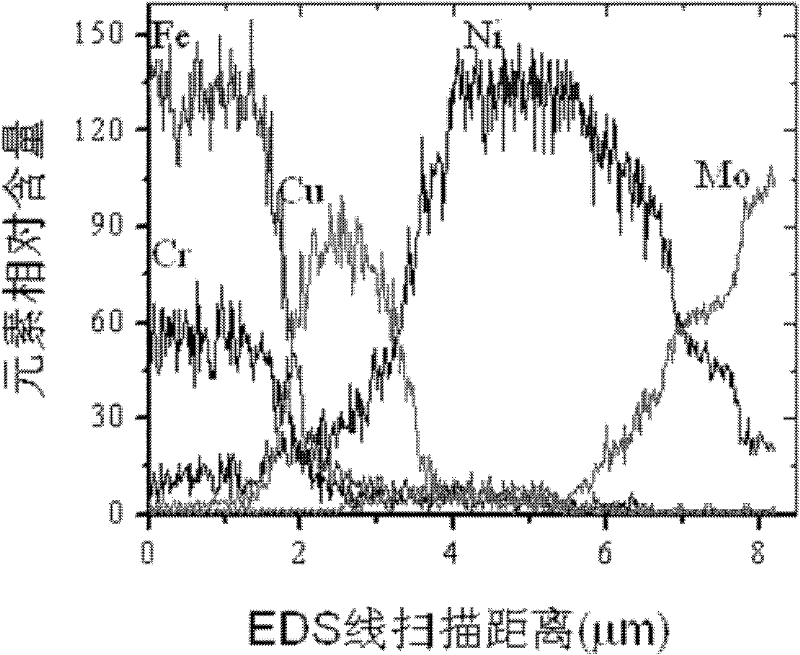

Method for preparing multi-element doping lithium iron phosphate by taking ferrous metallurgy sludge as main raw material

InactiveCN101651204AOvercoming the limitations of relying solely on multiple chemical reagentsReduce manufacturing costElectrode manufacturing processesSludgeLithium-ion battery

The invention discloses a method for preparing multi-element doping lithium iron phosphate by taking ferrous metallurgy sludge as main raw material, belonging to the preparation technical filed of cathode material of lithium ion batteries. In the method, Fe-base multi-element alloy phase containing multiple doping elements is obtained from the ferrous metallurgy sludge by a reduction and magneticseparation method, the Fe-base multi-element alloy phase is oxidized to obtain composite oxide which is Fe source and a multi-doping-element source, Li and P are added in by chemical metering, and multi-element doping lithium iron phosphate is synthesized by roasting under the protection of inert gas such as N2 or Ar. The Fe element and multiple doping elements (a plurality kinds of Zn, Cr, Ni, Mo, V, Mn, Ti or all) for preparing the multi-element doping lithium iron phosphate are from the ferrous metallurgy sludge, thereby overcoming the limitation that the raw material for preparing the multi-element doping lithium iron phosphate depends on various chemical agents singly, providing a new pathway for high value-added utilization of the ferrous metallurgy sludge while reducing the preparation cost.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Rear earth-ferrotitanium hydrogen storage alloy for wind power storage and preparation method thereof

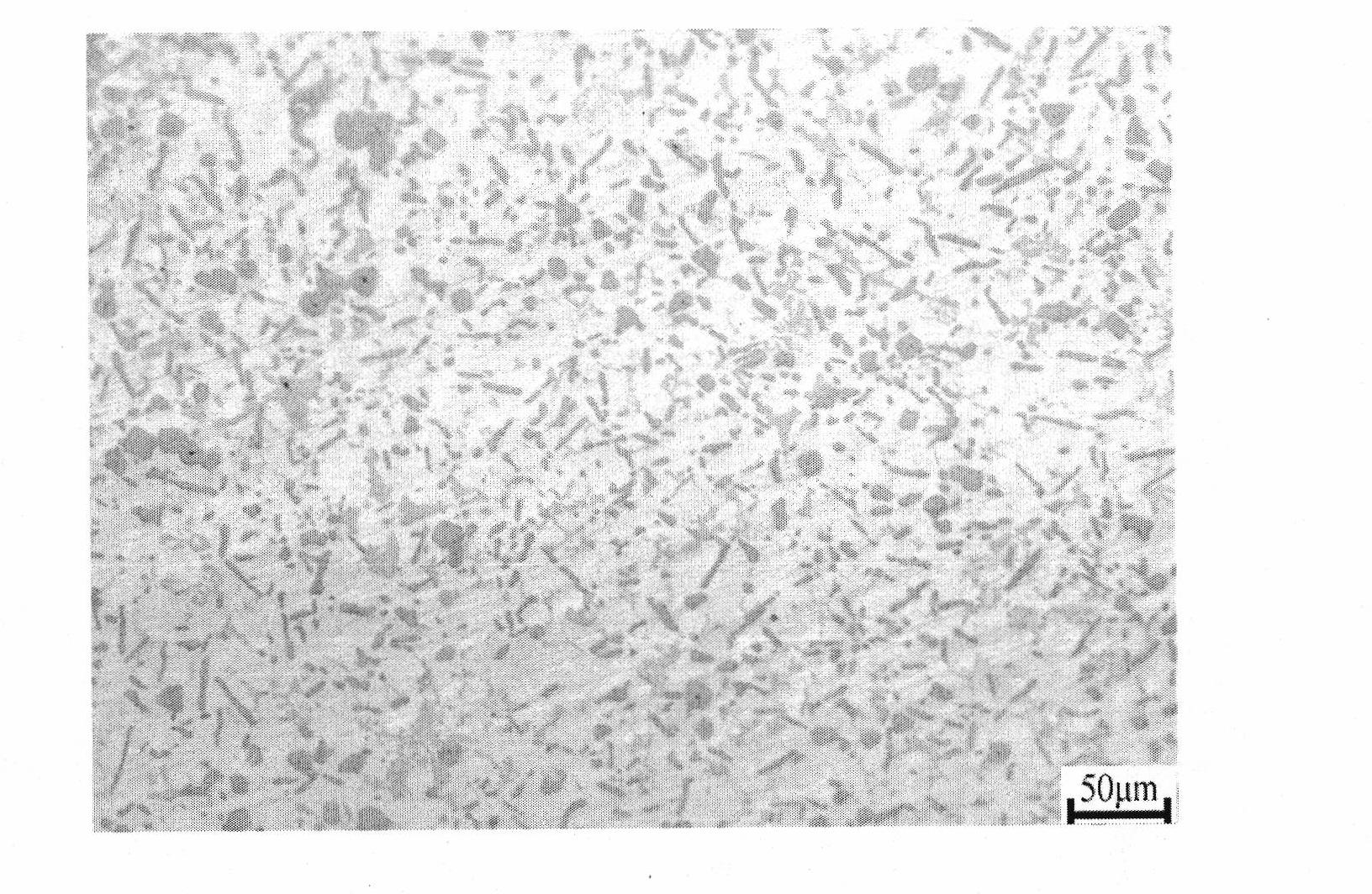

The invention belongs to the technical field of hydrogen storage alloys, and relates to a rear earth-ferrotitanium hydrogen storage alloy for wind power storage and a preparation method thereof. The rear earth-ferrotitanium hydrogen storage alloy consists of Ti, Fe, Mn, multi-component rear earth and few LaNi5 alloy, and has a chemical formula as follows: Ti1.1-xFe0.8Mn0.2Mx+yLaNi5, wherein x is an atomic ratio greater than 0 and less than or equal to 0.09, y is mass percent greater than or equal to 2% and less than or equal to 8%, and M is multi-component rear earth which further contains at least one of Ce, Y, Nd, Pr and Gd in addition to La with the atomic ratio of 0.5-0.7. The alloy is prepared by the following steps: proportioning, carrying out vacuum smelting, carrying out rapid quenching, carrying out mechanical crushing and carrying out ball-milling. The rear earth-ferrotitanium hydrogen storage alloy mainly adopts Ti and Fe elements which are rich in the natural world and cheap, so that large-scale popularization and application are facilitated. Compared with a smelting and annealing process, the alloy with high-density nanocrystalline grains is prepared through the rapid quenching process; and by virtue of mechanical ball-milling, the alloy forms high-density crystal defects. The rapid quenching process and the ball-milling process are simple and easy to grasp, so that the preparation method is suitable for large-scale production.

Owner:CENT IRON & STEEL RES INST

High-strength high heat conductivity thin-walled die casting aluminum alloy and preparation method thereof

The invention relates to a high-strength high heat conductivity thin-walled die casting aluminum alloy and a preparation method thereof. The alloy comprises the following elements in percentage by weight: 12-14wt% of Si, 0.05-3wt% of Cu, 0.40-0.80wt% of Fe, 0.00-0.05wt% of Mg, less than 0.05wt% of other impurities and the balance of Al. Compared with the prior art, by strictly controlling the total amount of Cu and Mg within 0.05-3wt% and then carrying out thermal treatment at 175 DEG C for 4h, Cu and Mg elements will not dissolved in a substrate, so that a micro dispersive CuAl2 second phaseand Mg17Al12 second phase are formed in the material. Fe element can prevent the material from being stuck to a die, so that a thin-walled product is casted more effectively. Meanwhile, the second phases can enhance the strength of the material effectively, so that the tensile strength of the material is greater than 300MPa, the yield strength is greater than 150MPa and the ductility is 8-10%.

Owner:苏州慧驰轻合金精密成型科技有限公司

Preparation method of high-performance neodymium-iron-boron magnet

ActiveCN106205924AEffective Diffusion UtilizationInhibited DiffusionInductances/transformers/magnets manufactureMagnetic materialsDysprosiumFe element

The invention discloses a preparation method of a high-performance neodymium-iron-boron magnet. The preparation method mainly comprises a step of manufacturing an auxiliary diffusion alloy, wherein auxiliary diffusion alloy powder and normal neodymium-iron-boron magnet powder are mixed and sintered, and then are subjected to dysprosium and terbium element diffusion on the crystal boundary to obtain the auxiliary diffusion alloy; and the auxiliary diffusion alloy comprises the main components of Nd-Fe-M, wherein Nd is an Nd element, Fe is an Fe element and M is one or a combination of multiple elements of Al, Cu, Ga, Mg, Ca, Zr, Ti, Co and Nb, wherein Nd is 60-80wt%, Fe is 5-15wt%, and the M is 5-35wt%. Compared with the prior art, by adoption of the technical scheme of the preparation method, dysprosium and terbium are enriched at the crystal boundary, and a crystal boundary diffusion channel is provided; diffusion of the dysprosium and terbium to the interior of main phase crystal particles is suppressed; the effective diffusion utilization rate of the dysprosium and terbium is improved; and the magnet coercivity is improved.

Owner:YANTAI ZHENGHAI MAGNETIC MATERIAL CO LTD

Flexible metal substrate connected with back electrode of solar battery and fabrication method thereof

ActiveCN102201456AImprove production yieldImprove yieldFinal product manufactureSemiconductor devicesContact layerSolar battery

The invention discloses a flexible metal substrate connected with a back electrode of a solar battery and a fabrication method thereof. The flexible metal substrate has a structure made of stainless steel strip / copper / nickel / nickel-molybdenum alloy, wherein a nickel layer and a nickel-molybdenum alloy coating layer serve as diffusion barrier layers which are both multi-layer coating layers; and the mass content of molybdenum in the nickel-molybdenum alloy coating layer in the diffusion barrier layers is gradually increased from 10% to 80% layer by layer along the growth direction of the coating layer. Therefore, the diffusion of copper and Fe element in the steel strip can be effectively prevented, no new harmful elements are introduced, and the nickel-molybdenum alloy with high molybdenum content can enhance the bonding force between the substrate and a back electrode (Mo layer). Meanwhile, a Cu layer serves as a main current conduction layer, so that the Mo layer is only used as theback contact layer capable of forming good ohmic contact with an absorption layer. The flexible metal substrate used as the substrate of a CIGS (copper indium gallium selenide) solar battery can greatly lower the requirement on the thickness of the Mo layer, and the flexible substrate described in the invention can be manufactured continuously with low cost and high efficiency on a continuous electroplating production line.

Owner:HUNAN YONGSHENG NEW MATERIALS

Chemical vapor deposition preparation method for Fe-doped monolayer MoS2

The invention belongs to the production of two-dimensional nano-materials, and concretely relates to a chemical vapor deposition preparation method for an Fe-doped monolayer MoS2. Sublimed sulfur is used as a sulfur source, molybdenum trioxide is used as a molybdenum source, an Fe compound is selected as an Fe element dopant, highly-pure argon is used as a current carrying gas to transport a precursor to a reaction area, a substrate selects SiO2 / Si, and the substrate is pretreated before a growth reaction. The whole growth process comprises a spatial gas phase reaction process and a surface growth process. Low-valence transition metal oxide, transition metal oxysulfides, transition metal sulfides and various other intermediate groups are generated in the spatial gas phase reaction process,the Fe compound reacts with all the various intermediate groups on the upper part of the substrate together with the current carrying gas, a large area of the Fe-doped monolayer MoS2 grows on the substrate through adsorption, diffusion, reaction and desorption processes, and the largest size can reach 30 [mu]m.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

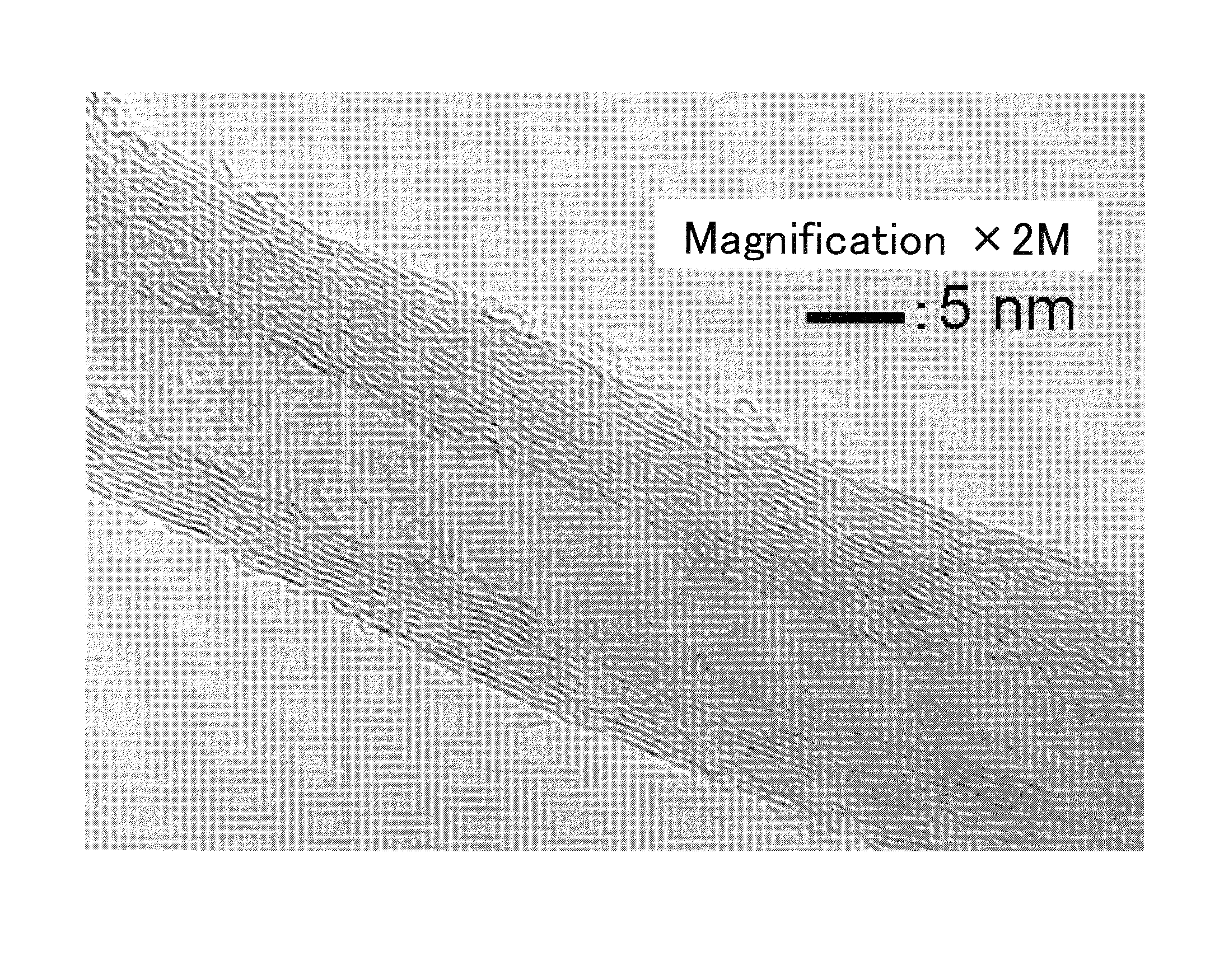

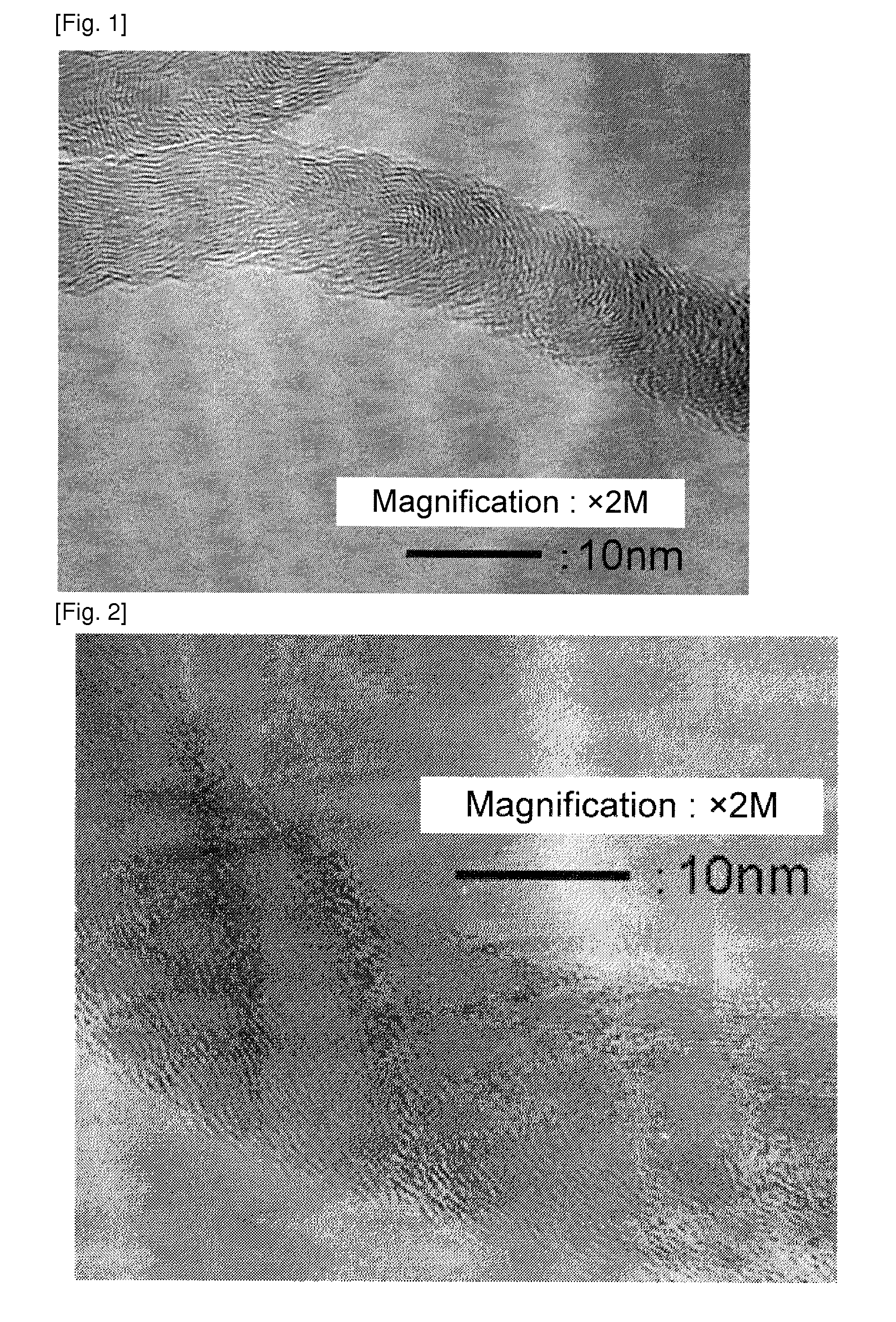

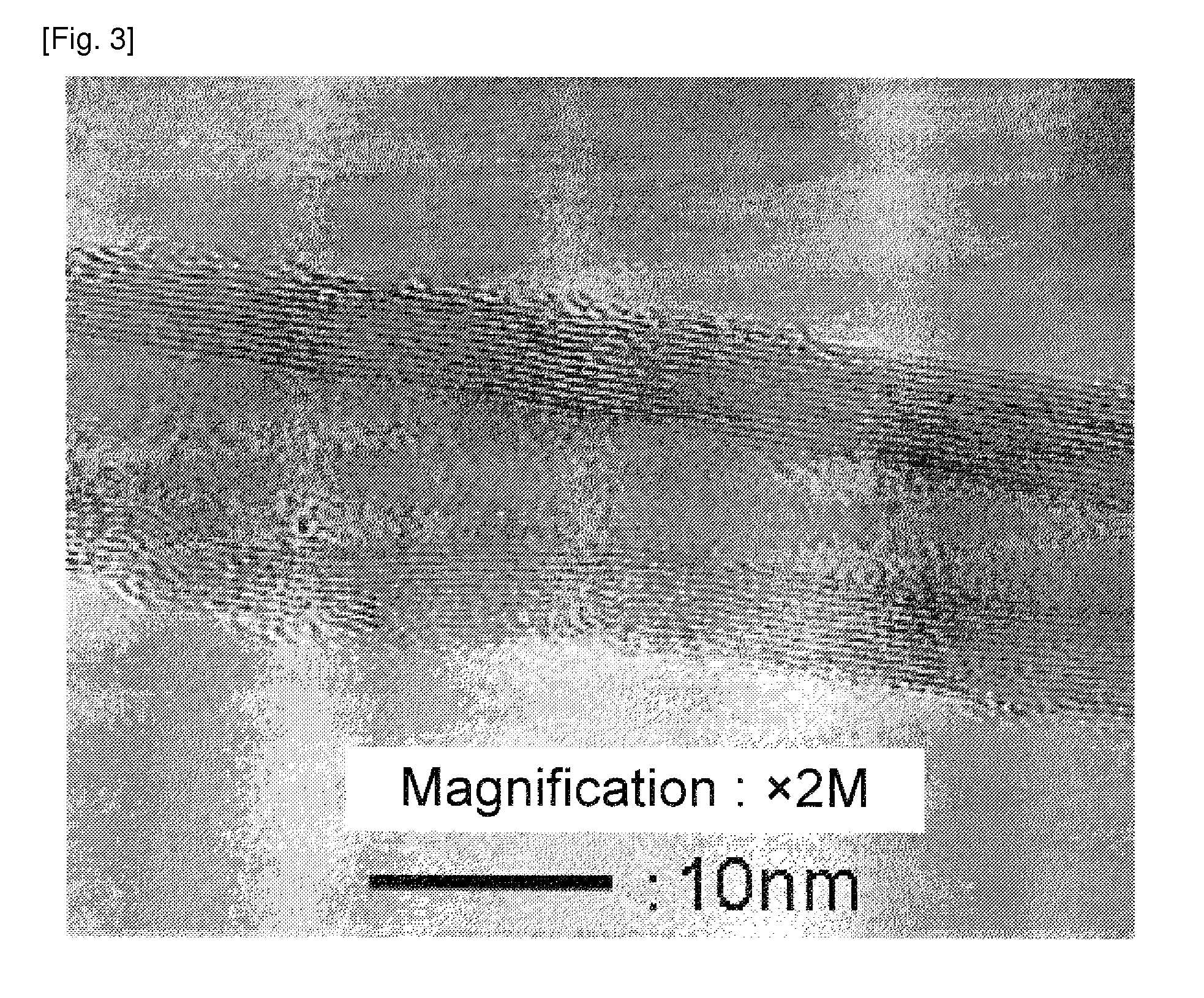

Carbon fiber and catalyst for production of carbon fiber

InactiveUS20110104490A1Simple processEffective massMaterial nanotechnologyCell electrodesFiberParticulates

A catalyst for production of a carbon fiber is obtained by dissolving or dispersing [I] a compound containing Fe element; [II] a compound containing Co element; [III] a compound containing at least one element selected from the group consisting of Ti, V, Cr, and Mn; and [IV] a compound containing at least one element selected from the group consisting of W and Mo in a solvent to obtain a solution or a fluid dispersion, and then by impregnating a particulate carrier with the solution or the fluid dispersion. By means of a step of bringing a carbon source into contact with the catalyst in a vapor phase, the carbon fiber is obtained which is tubular and in which a graphite layer is approximately parallel with the carbon fiber axis, and a shell is in a multi-walled structure.

Owner:SHOWA DENKO KK

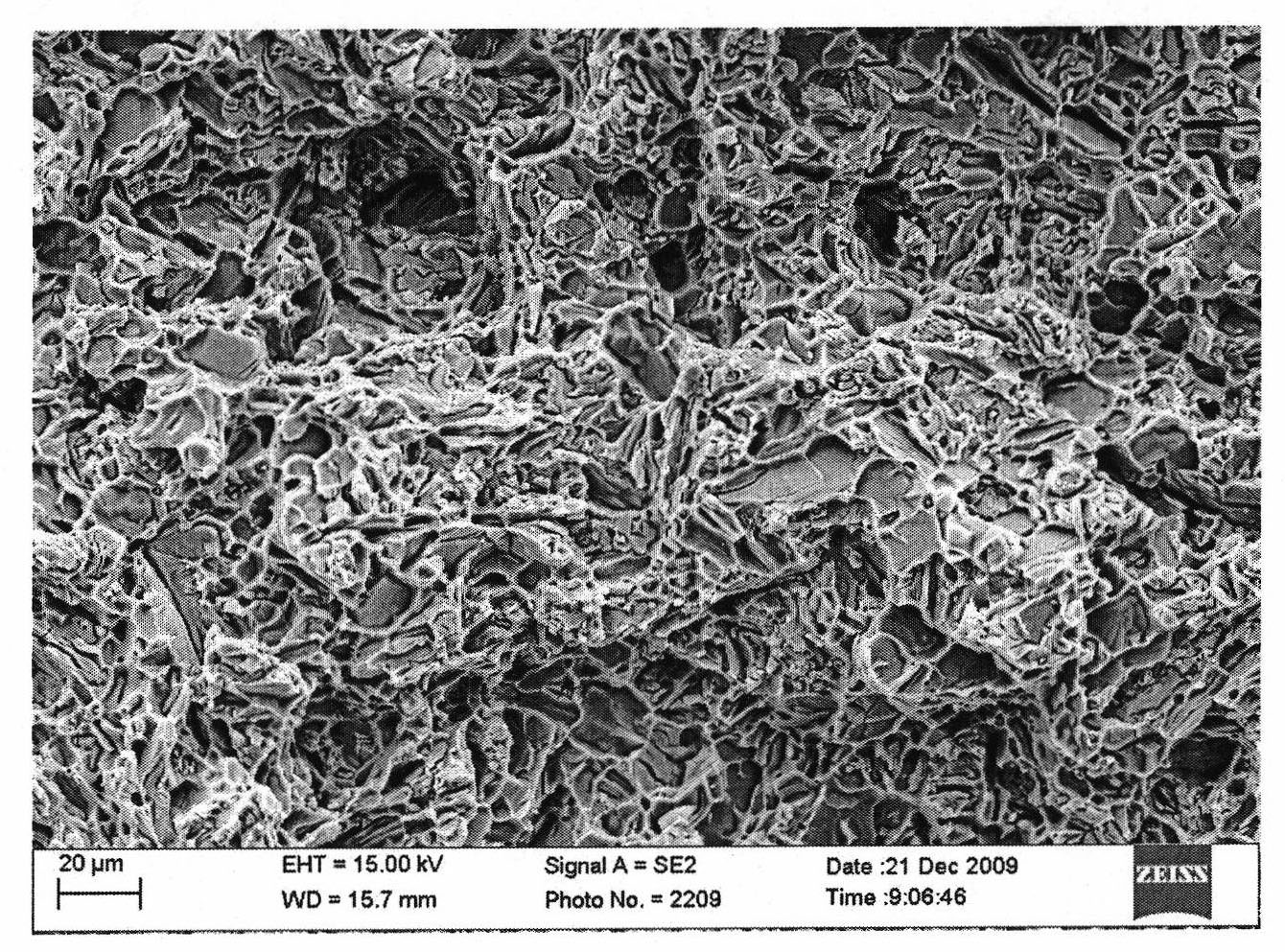

Method for preparing CuFe alloy material with different Fe contents by adopting vacuum induction smelting

ActiveCN109457167AEasy accessDense tissueFoundry mouldsFoundry coresNonferrous metalMaterials science

The invention discloses a method for preparing a CuFe alloy material with different Fe contents by adopting vacuum induction smelting, and belongs to the technical field of nonferrous metal alloys. The method mainly comprises the following steps of proportioning, charging, vacuumizing, smelting, casting and discharging from a furnace. According to the method, the CuFe alloy is prepared by adoptinga vacuum induction melting method, wherein the Fe element is added in the form of a CuFe mother alloy, the CuFe alloy prepared through the method has the advantages of compact structure, few pores and inclusion, and no macroscopic and microscopic segregation and other defects.

Owner:SIRUI ADVANCED COPPER ALLOY CO LTD

Corrosion-resistant and high-strength and toughness Zn-Fe-Li-based zinc alloy capable of being degraded in human body and application of corrosion-resistant and high-strength and toughness Zn-Fe-Li-based zinc alloy

The invention discloses a corrosion-resistant and high-strength and toughness Zn-Fe-Li-based zinc alloy capable of being degraded in a human body and an application of the corrosion-resistant and high-strength and toughness Zn-Fe-Li-based zinc alloy, relates to field of medical implantation materials, and provides the corrosion-resistant and high-strength and toughness Zn-Fe-Li-based zinc alloy which is low in cost of added materials, high in strength, good in plasticity and controllable in degradation rate, has non-expanding and non-migrating degradation products and can be simultaneously degraded in the human body against the defects in the prior art. The zinc alloy comprises Zn, Fe and Li elements, wherein the content of the Zn element in mass percentage is 80-99.997%, the content of the Fe element in mass percentage is 0.002-10%, and the content of the Li element in mass percentage is 0.001-10%. The cost of the materials added into the zinc-based alloy disclosed by the invention is low, the degradation products of various components in the prepared alloy material can be degraded in the human body by metabolism, the corrosion resistance is much higher than that of a magnesium alloy, the degradation speed is greatly reduced, the mechanical support can be provided for a longer time, and the alloy material has good strength and toughness.

Owner:XIAN ADVANCED MEDICAL TECH

High-elasticity copper-chromium-zirconium alloy and machining process thereof

The invention discloses a high-elastic copper-chromium-zirconium alloy and a processing technology thereof. By improving the strength and elasticity of the copper-chromium-zirconium alloy wire, the electrical conductivity does not decrease significantly, so that it can meet the requirements of high strength, elasticity and electrical conductivity, such as conductive springs. The copper chromium zirconium alloy, its mass percentage is: Cr 0.5~1.2%, Zr 0.05~0.5%, 0.2 <x(x为si、ti两种元素或si、ti、fe三种元素)<1.5%,余量为cu。其中,si、fe元素提高合金强度,ti元素提高合金的弹性性能。该合金经过以下工艺流程:a连铸、b固溶、c轧制、d时效、e拉拔、f成品退火、合金丝材成品。所制备合金的抗拉强度σb can reach 680~780MPa, the plastic elongation δ is 2~6%, the electrical conductivity is 68~75%IACS, and the hardness (Hv) is greater than 165.< / x(x为si、ti两种元素或si、ti、fe三种元素)<1.5%,余量为cu。其中,si、fe元素提高合金强度,ti元素提高合金的弹性性能。该合金经过以下工艺流程:a连铸、b固溶、c轧制、d时效、e拉拔、f成品退火、合金丝材成品。所制备合金的抗拉强度σ

Owner:苏州中色华人铜业有限公司

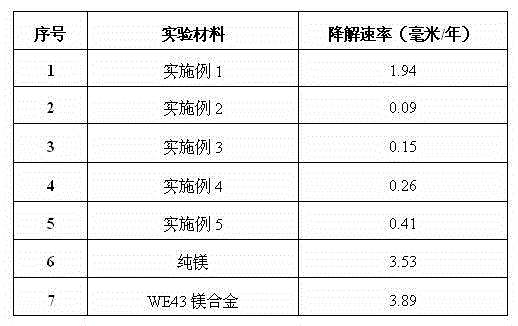

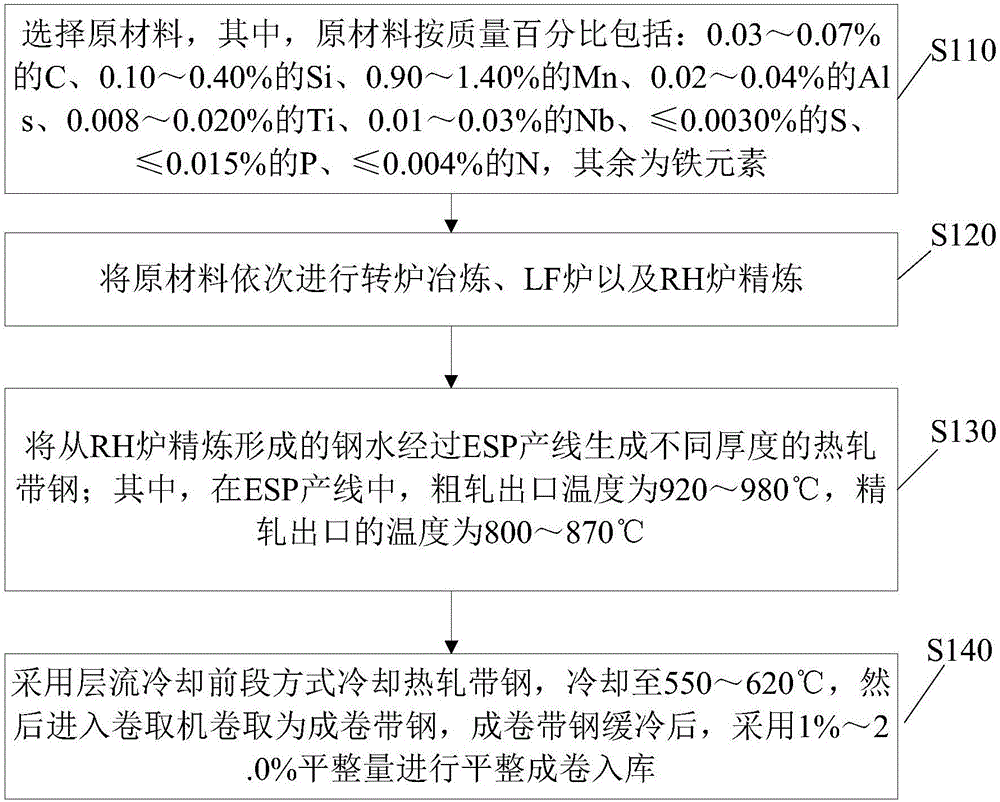

Method for producing RE510L steel of thin specification based on ESP sheet billet continuous coasting and rolling procedure

ActiveCN106834887ASolve the costSolve the problem of energy consumptionMetal rolling arrangementsProduction lineStrip steel

The invention provides a method for producing RE510L steel of a thin specification based on an ESP sheet billet continuous coasting and rolling procedure. The method includes the steps that raw materials are selected, and the raw materials comprise, in percentage by mass, 0.03-0.07% of C, 0.10-0.40% of Si, 0.90-1.40% of Mn, 0.02-0.04% of Als, 0.008-0.020% of Ti, 0.01-0.03% of Nb, less than or equal to 0.0030% of S, less than or equal to 0.015% of P, less than or equal to 0.004% of N and the balance Fe elements; the raw materials are subjected to converter smelting and LF furnace and RH furnace refining; molten steel formed through RH furnace refining generates hot rolling strip steel of different thicknesses through an ESP production line; in the ESP production line, the rough rolling outlet temperature is 920-980 DEG C, the finish rolling outlet temperature is 800-870 DEG C; the hot rolling strip steel is cooled in a front segment laminar flow cooling manner, and the hot rolling strip steel is cooled to 550-620 DEG C and then enters a recoiling machine to be coiled into coiled strip steel; and after the coiled strip steel is cooled, leveling, coiling and entering warehouse are performed by adopting the leveling quantity of 1-2.0%. By means of the method, problems that traditional hot rolling is high in cost, energy consumption is large and the like are solved.

Owner:RIZHAO STEEL HLDG GROUP

Carbon nanofiber, producing method and use of the same

InactiveUS20110101265A1Improve surface activityImprove conductivityMaterial nanotechnologyCarbon compoundsParticulatesFiber

A catalyst for producing a carbon nanofiber is obtained by dissolving or dispersing [I] a compound containing Fe element; [II] a compound containing Co element; [III] a compound containing at least one element selected from the group consisting of Ti, V, Cr, and Mn; and [IV] a compound containing at least one element selected from the group consisting of W and Mo in a solvent to obtain a solution or the fluid dispersion, and then impregnating a particulate carrier with the solution or the fluid dispersion. A carbon nanofiber is obtained by bringing a carbon element-containing compound into contact with the catalyst in a vapor phase at a temperature of 300 degrees C. to 500 degrees C.

Owner:SHOWA DENKO KK

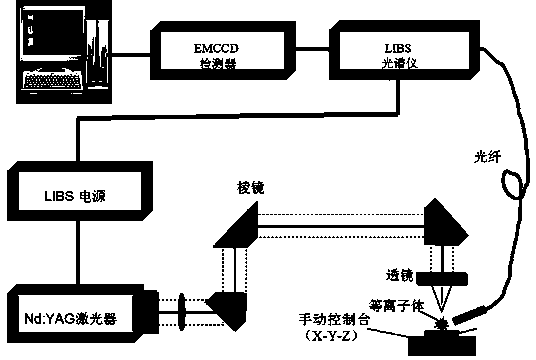

Method for detecting total iron in iron ore based on laser-induced-breakdown spectroscopy

InactiveCN103808695AEasy to operateData processing is simpleAnalysis by material excitationNist databaseData acquisition

The invention discloses a method for detecting total iron content in iron ore by using an improved internal standard method combined with laser-induced-breakdown spectroscopy. The method comprises the following steps: adding different masses of analytically pure iron trioxide to a to-be-detected iron ore sample A, cladding and tabletting to obtain a sample B by using polyethylene powder; collecting data at different positions on the sample B by using a laser-induced-breakdown spectroscopy system; carrying out qualitative analysis on the iron ore by combining with characteristic spectral line information of an Fe element in a database for national institute of standards and technology (NIST); sorting out the characteristic spectral line of the Fe element; selecting FeI438.5813nm as an analytical line, and the MnI405.5210nm as an internal standard line according to the selection criteria of the analytic line and an internal standard line; building a linear equation by taking the strength difference of two spectral lines as a Y axis and the concentration gradient of Fe in the sample B as an X axis, wherein the intercept obtained from a straight line by extension and an X axis is the mass percent of the Fe element. The method is simple to operate, environment-friendly, easy to process data, and high in accuracy.

Owner:NORTHWEST UNIV

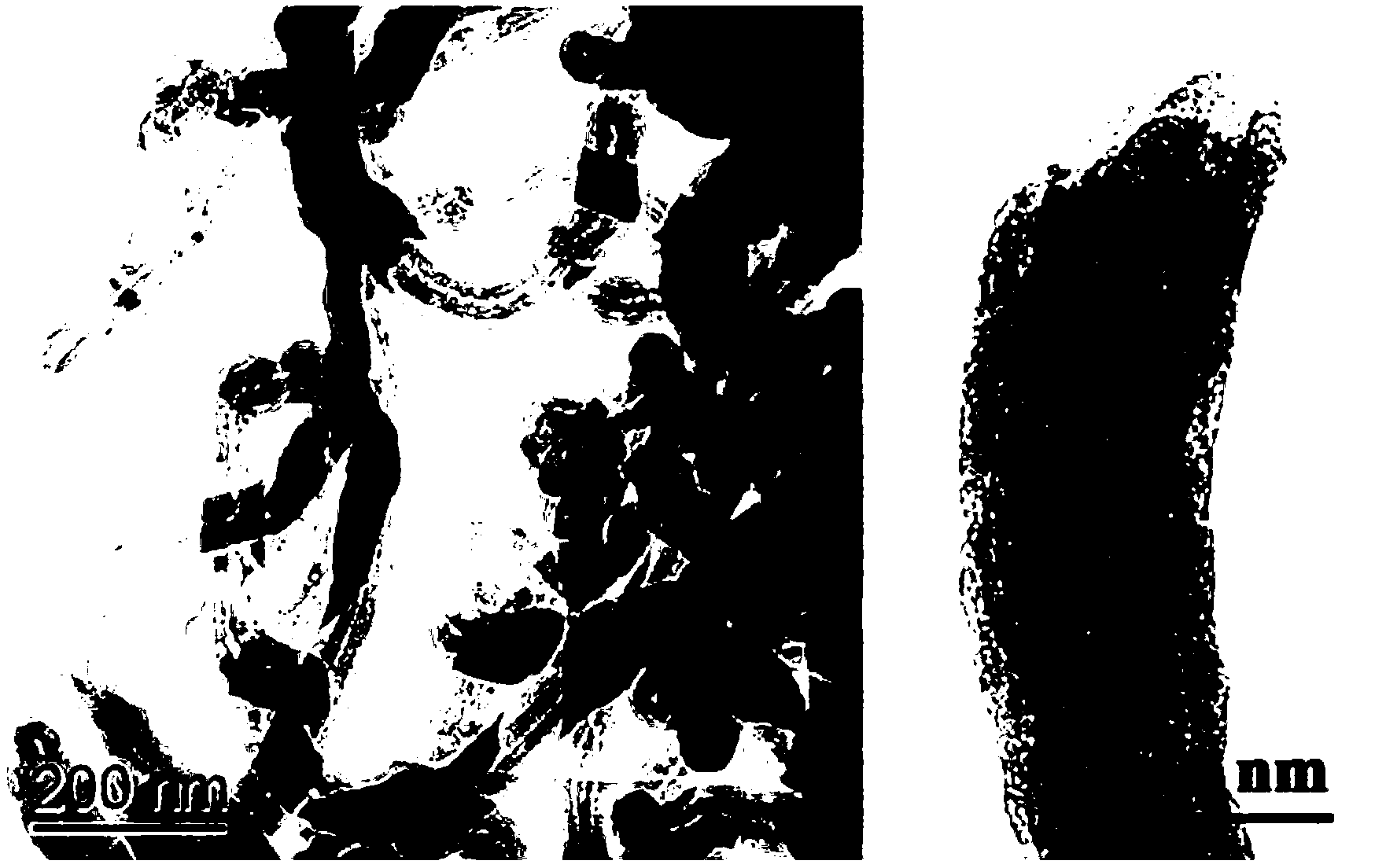

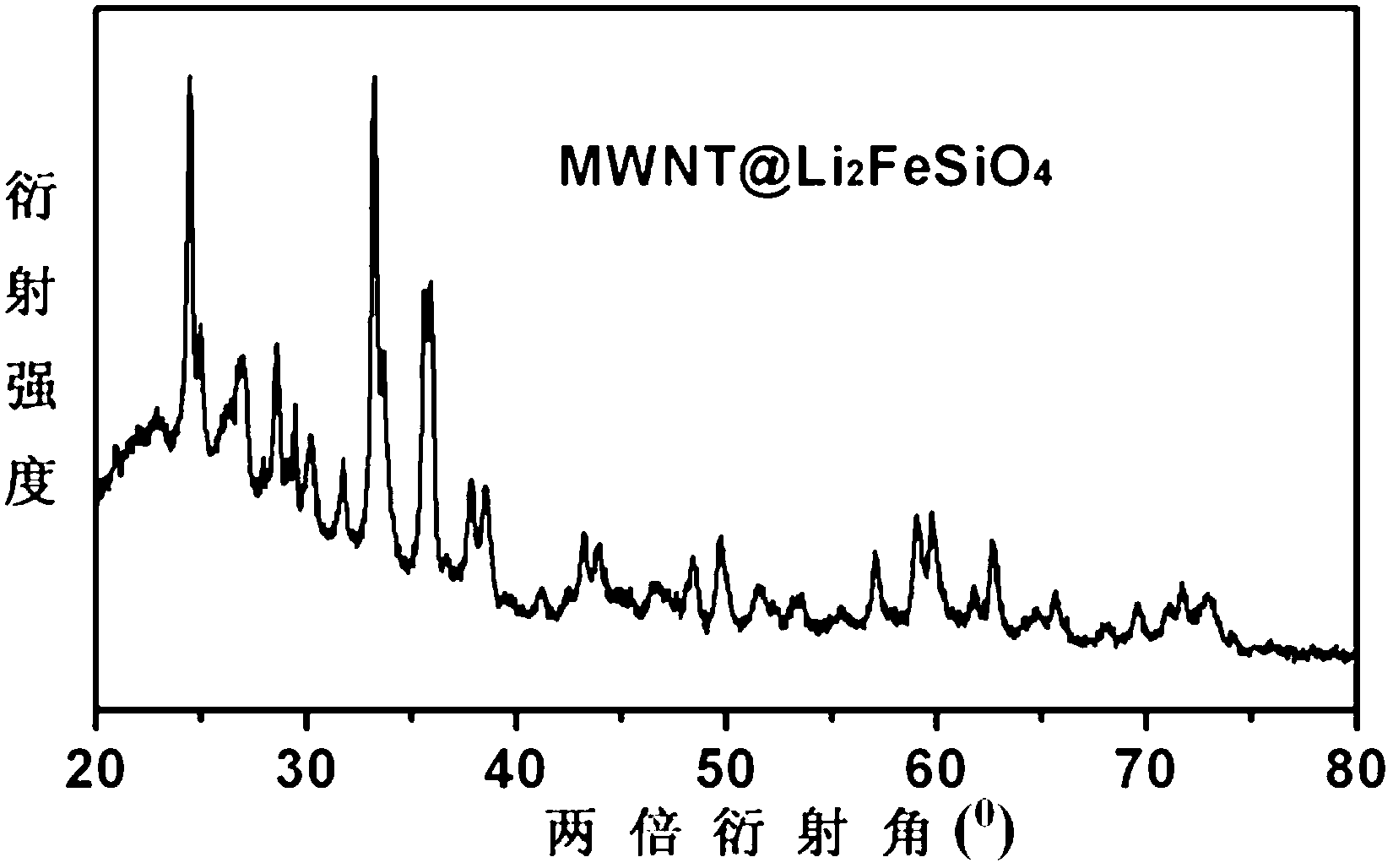

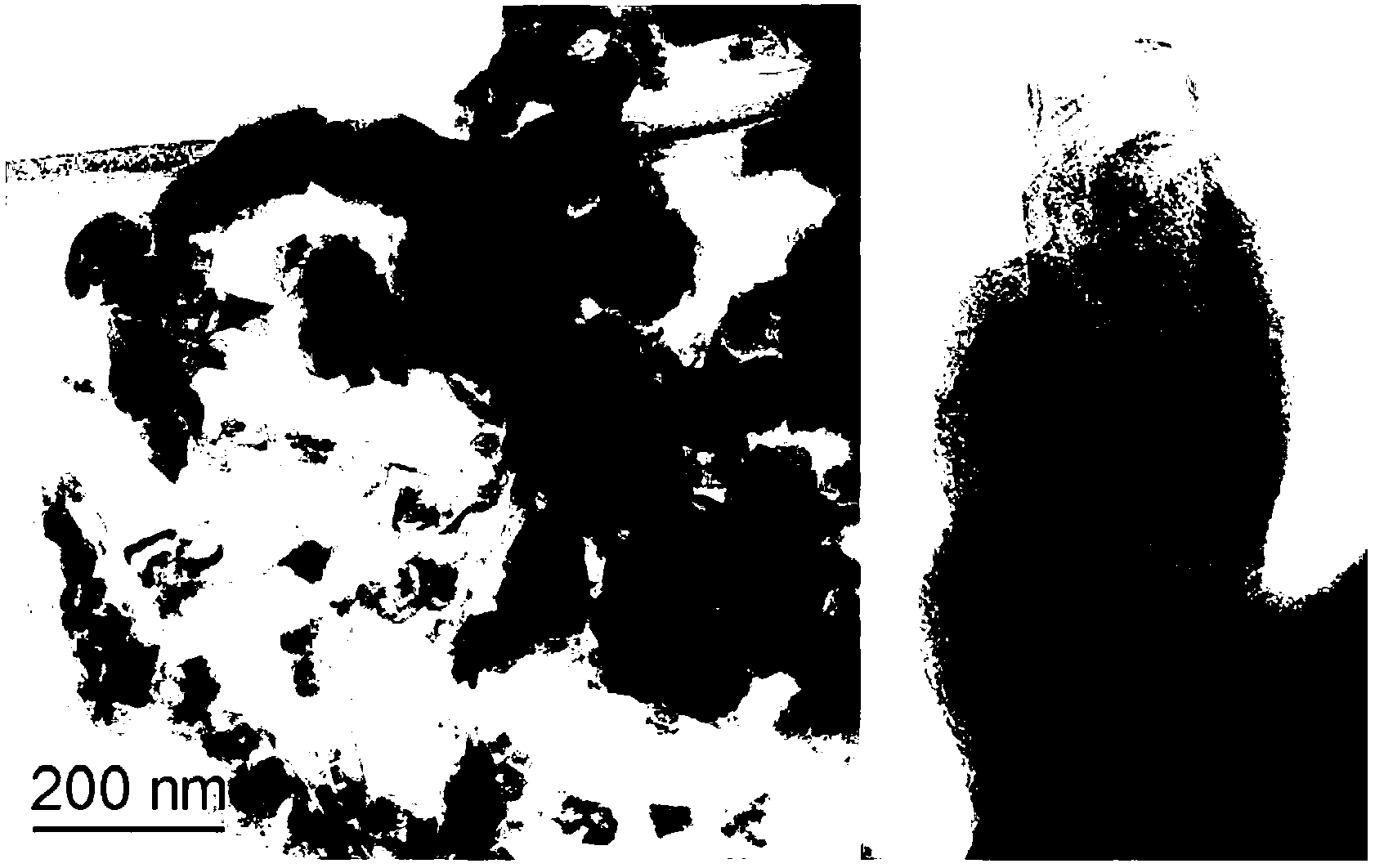

Preparation method of carbon nano-Li2FeSiO4 composite cathode material

InactiveCN102709561AImprove conductivityImprove electrochemical activityCell electrodesComposite cathodeCarbon nanomaterials

The invention provides a preparation method of a carbon nano-Li2FeSiO4 composite cathode material. The preparation method comprises the following steps of: uniformly loading different contents of silica on the surface of a carbon nanomaterial, taking a carbon nano-silica compound as a template, dissolving the carbon nano-silica compound in ethanol according to the molar ratio of Fe element to Si element to Li element of 1: 1: 2 and carrying out uniform ultrasonic mixing; stirring the mixing liquid at 60 DEG C till the ethanol is completely volatilized, uniformly grinding the obtained solid in an agate mortar, and tabletting the powder obtained after grinding; and heating the tablets in an inert atmosphere to 550-650 DEG C and calcining at constant temperature for 5-10h to obtain the carbon nano-Li2FeSiO4 composite cathode material with a core-shell structure.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

High-strength casting aluminium-silicon alloy for piston and preparation method thereof

The invention relates to a casting aluminium-silicon alloy for motor piston and a preparation method thereof, belonging to the field of metal materials. The aluminium-silicon alloy comprises 12.0-14.0 wt% of Si, less than 0.3 wt% of Ni, 1.8-3.0 wt% of Cu, 0.3-0.8 wt% of Fe, 0.3-0.6 wt% of Mn, less than 0.4 wt% of Mg, 0.1-0.2 wt% of Ti, less than 0.3 wt% of Zr and balance of Al. The heat treatment parameters are as follows: 510+ / -5 DEG C*5-8h+water quenching under room temperature for solution treatment; and 160+ / -5 DEG C*6-10h+air cooling for ageing treatment. The tensile strength and yield strength of the alloy under the room temperature reach 283-305MPa and 178-190MPa respectively and the elongtation percentage after breaking reaches 1.8-3.2%. Compared with similar alloys, the aluminium-silicon alloy of the invention has higher mechanical property, reduces Ni element content and noble metal element content of the alloy and allows Fe element to fluctuate in wider scope; the invention has good quality of ingot casting, simple process and strong operability.

Owner:UNIV OF SCI & TECH BEIJING

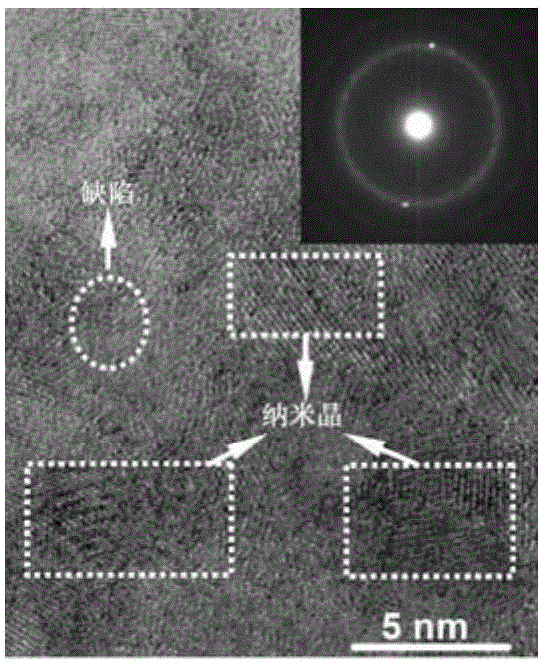

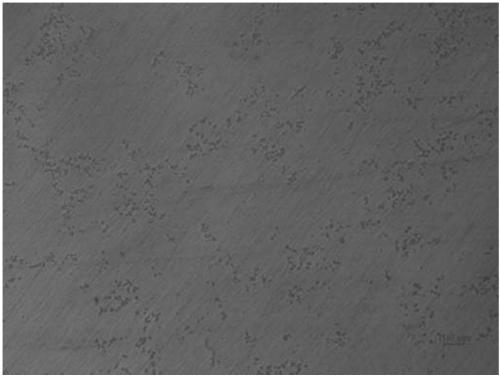

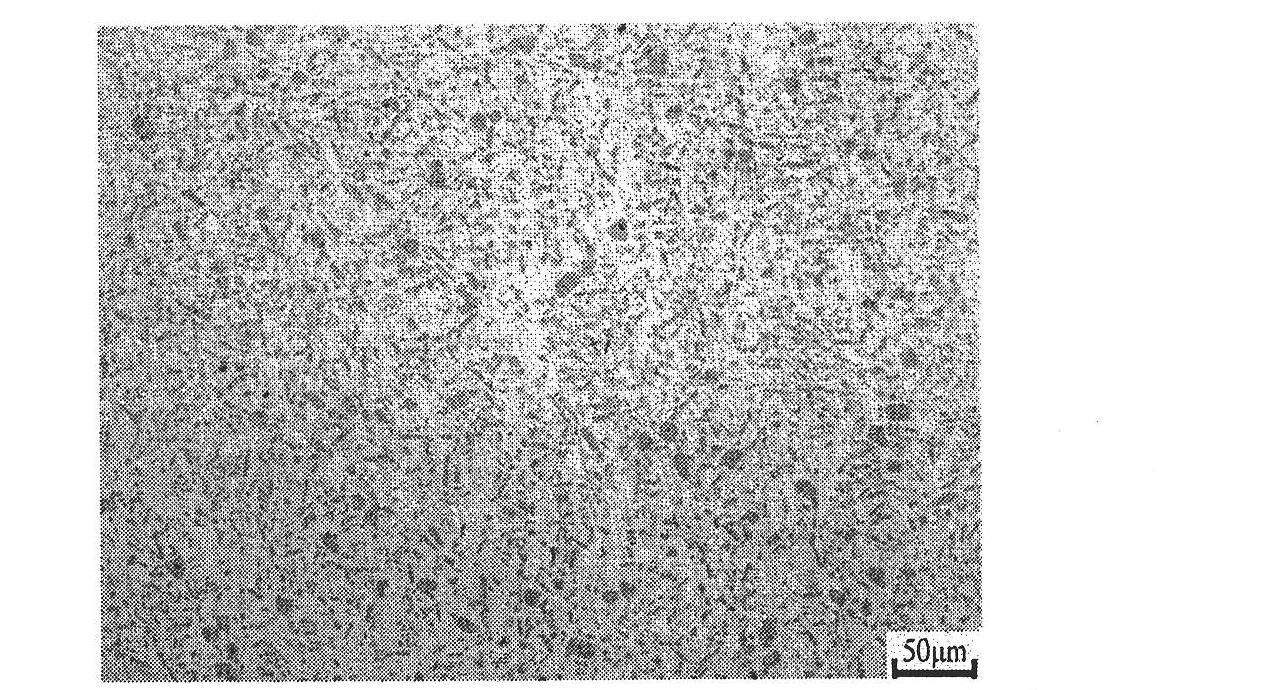

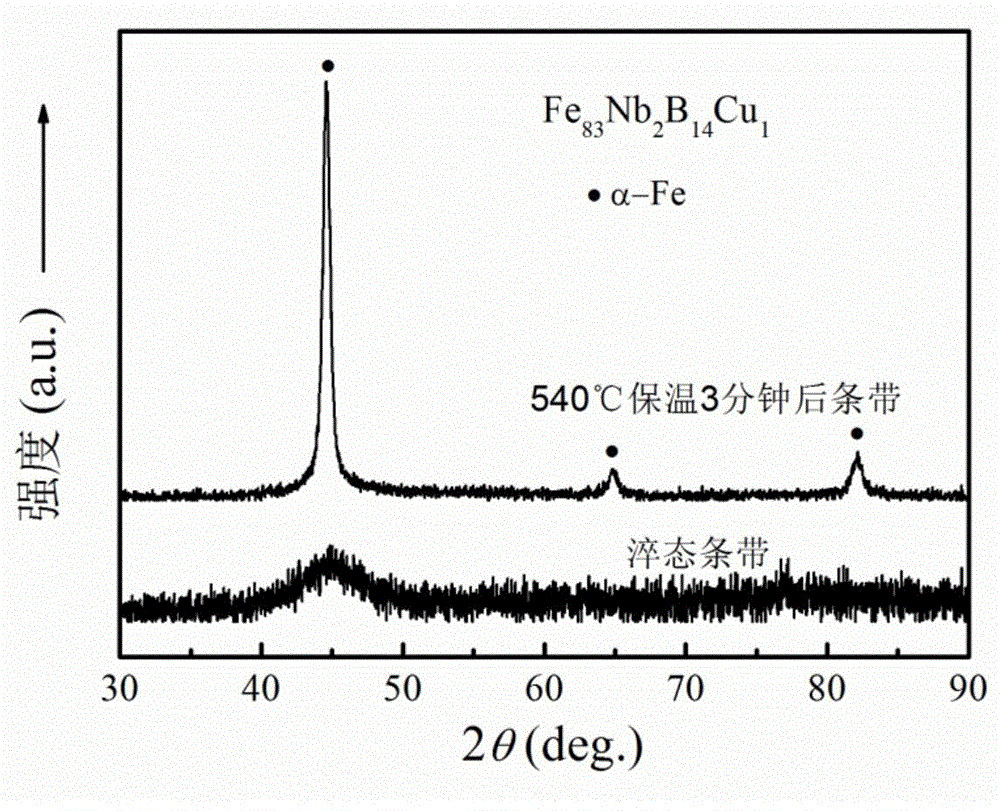

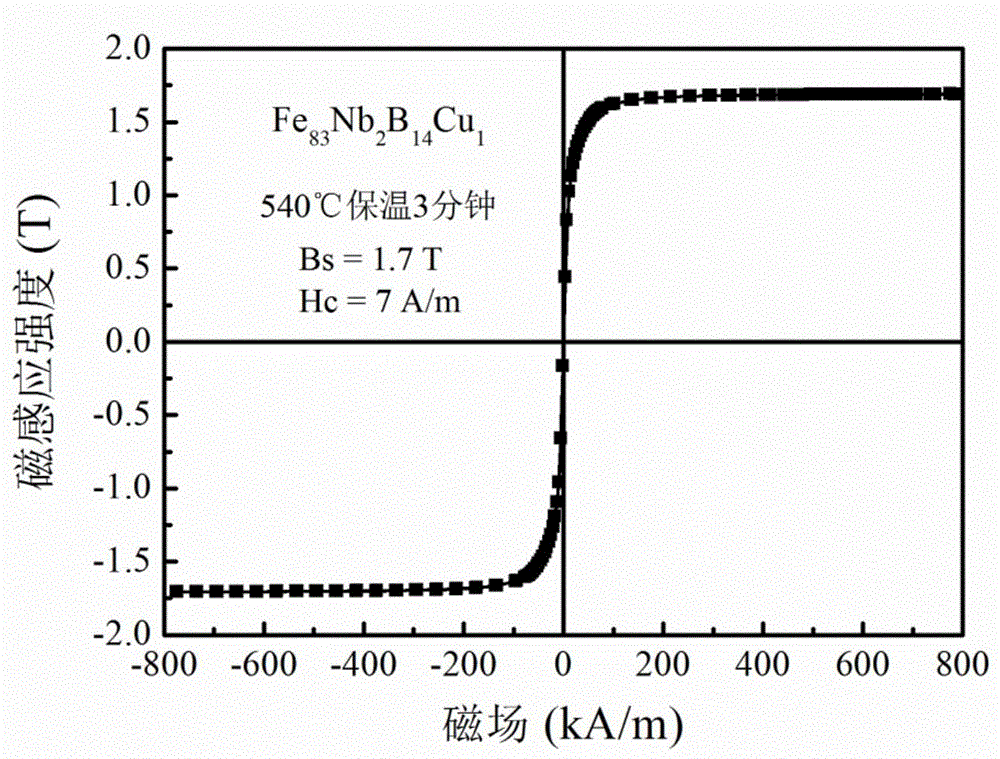

Fe-based nano crystal soft magnetic alloy material and preparation method thereof

InactiveCN104831169AStrong Amorphous Formation AbilityStrong magnetic propertiesMagnetic materialsTO-18Nanocrystal

The invention provides a Fe-based nano crystal soft magnetic alloy material and a preparation method thereof. A molecular formula of the material is FeaNbbBcCud, wherein, a, b, c and d respectively present atom percentage content of corresponding elements, a is greater than or equal to 80 and less than or equal to 85, b is greater than or equal to 1 and less than or equal to 3, c is greater than or equal to 12 and less than or equal to 18, d is greater than or equal to 0.8 and less than or equal to 1.2, wherein, sum of a, b, c and d is 100. The alloy material has high Fe element content and low Nb element content, production cost is reduced; a structure comprises an amorphous matrix and an alpha-Fe NANO crystal grain phase with average crystal grain size less than 20nm body-centered cubic, the alloy material has high saturation magnetic induction intensity and low coercive force, so that the Fe-based nano crystal soft magnetic alloy material has the advantages of low cost and good soft-magnetic performance, and has good application prospect.

Owner:LONDERFUL NEW MATERIAL NANTONG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com