Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

435 results about "Si element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

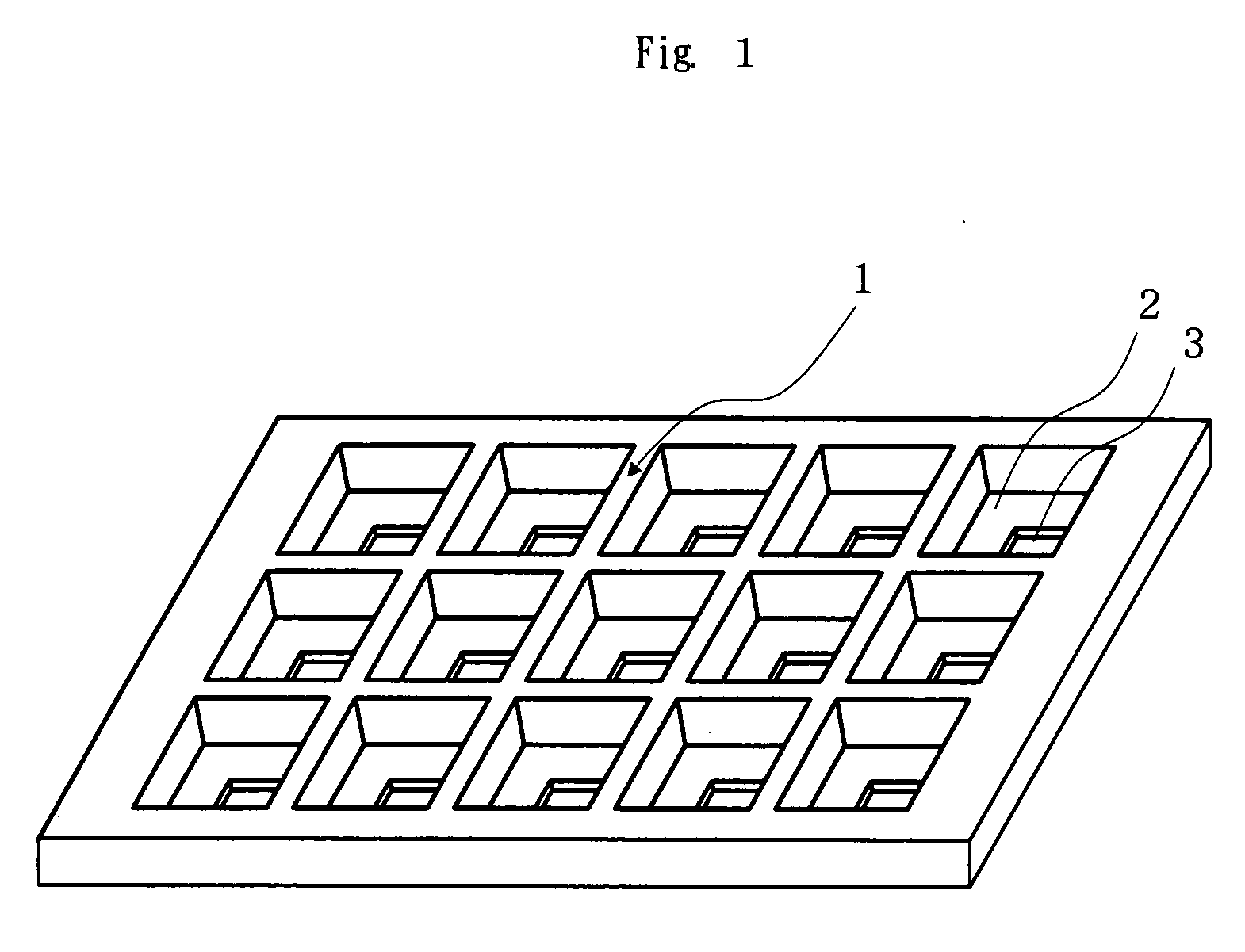

Glass member

InactiveUS20060063009A1Low heat resistanceHigh strengthCathode ray tubes/electron beam tubesGlass/slag layered productsRare-earth elementHigh intensity

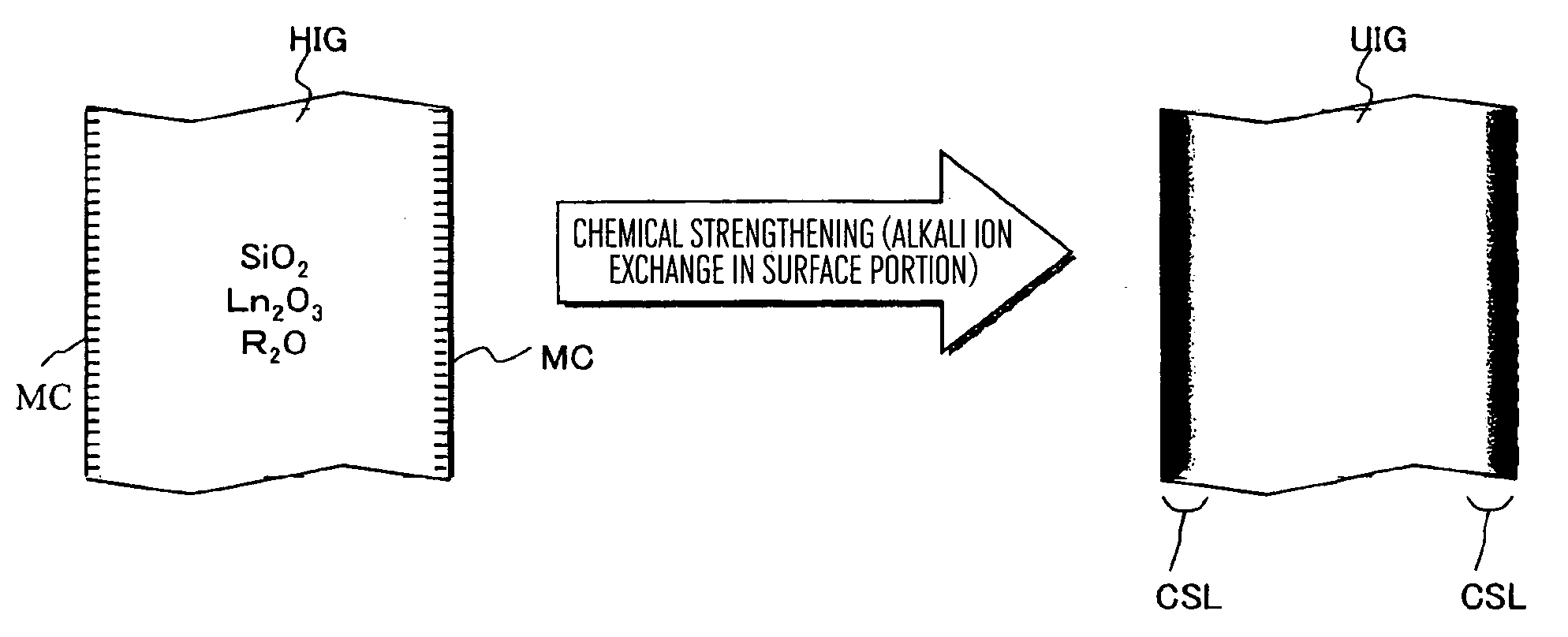

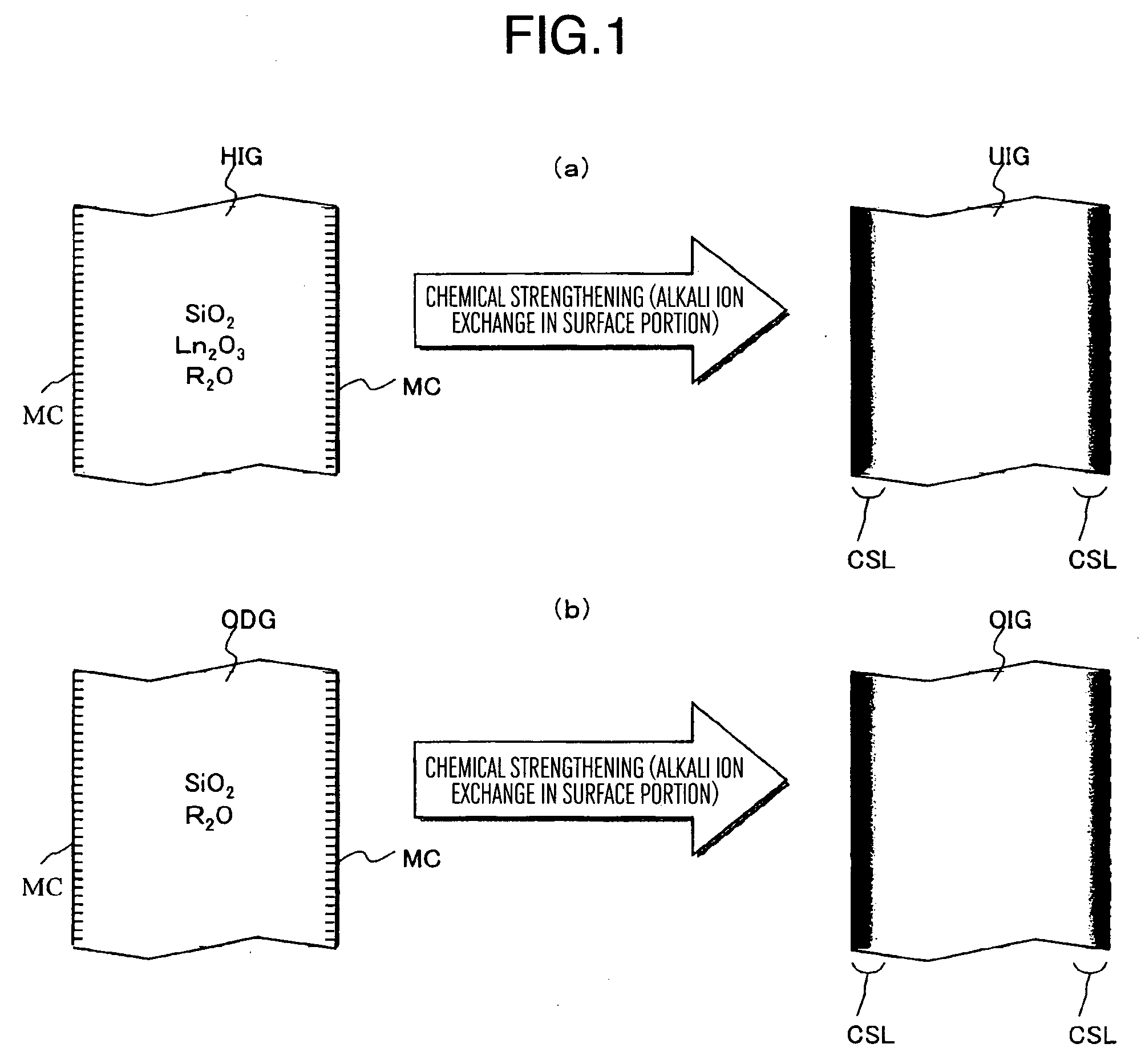

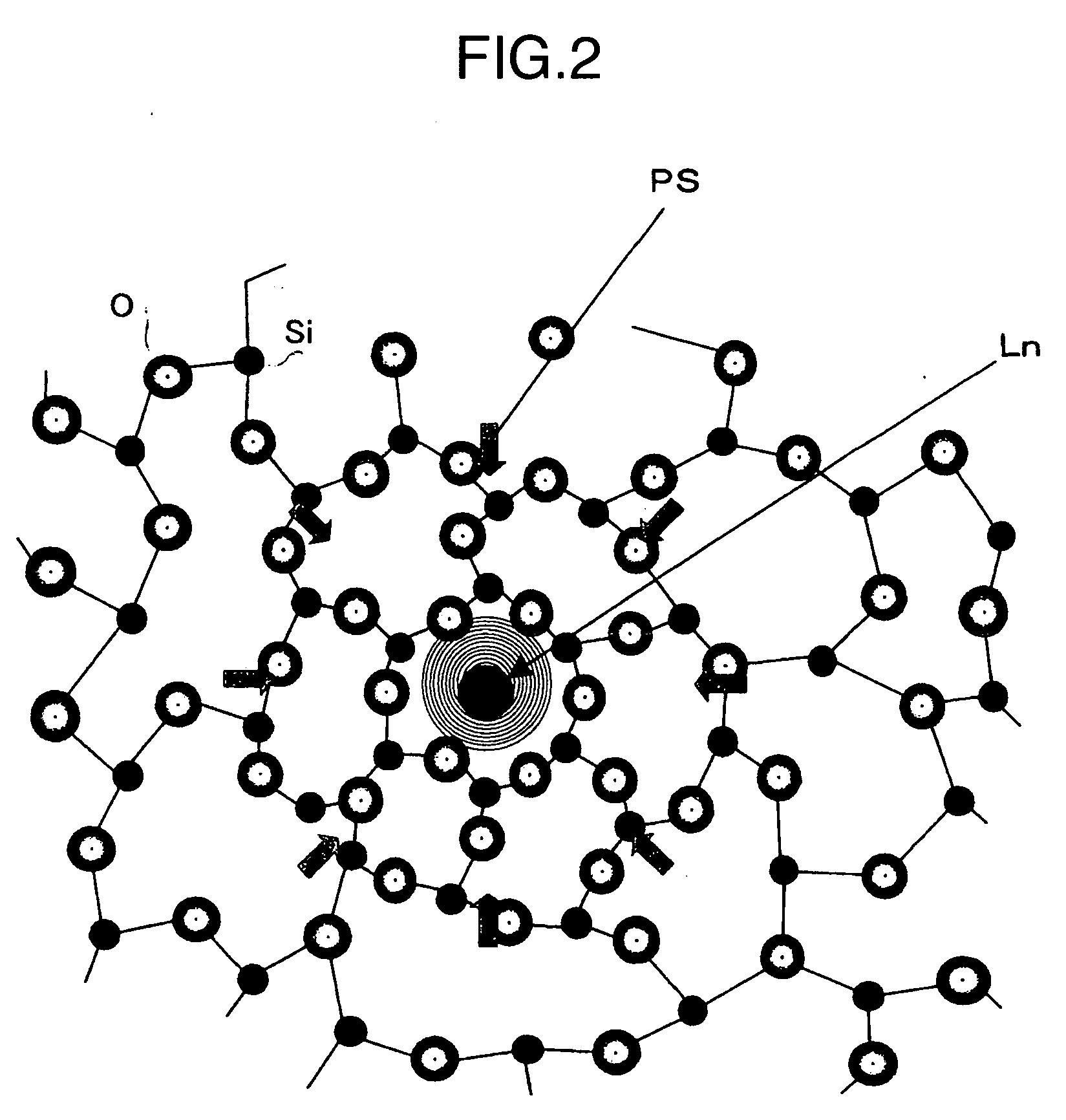

The present invention is envisioned to provide a high-strength glass which is applicable to the objective of size and weight reduction. A compression stress layer is formed in a surface portion of an oxide-based glass containing at least one rare earth element selected from the group consisting of Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu and further containing at least Si element and an alkali metal element.

Owner:HITACHI LTD

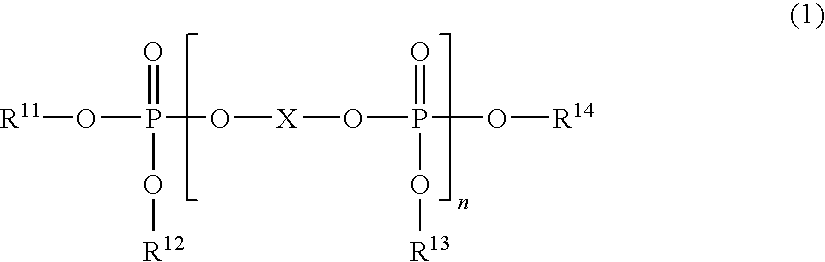

Polycarbonate resin composition

ActiveUS20090118406A1Good colorHigh light reflectivityFibre treatmentSpecial tyresThermal stabilityPolycarbonate

There is provided a resin composition that is excellent in thermal stability, light reflectivity and color, and preferably in flame retardancy.There is also provided a method for producing a resin composition which comprises mixing 60 to 99.9 parts by weight of polycarbonate resin (component A) with 0.1 to 40 parts by weight of titanium dioxide pigment (component B), the component B(i) satisfying 0.05≦(b)−(a)≦0.6, when weight reduction at 23 to 100° C. by thermogravimetric analysis (TGA) is (a) wt % and weight reduction at 23 to 300° C. by TGA is (b) wt %, and(ii) satisfying 0.001≦(d) / (c)≦0.01 and 0.001≦(e) / (c)≦0.02, when weight percentages derived from Ti, Al and Si elements in X-ray fluorescence analysis are (c) wt %, (d) wt % and (e) wt %, respectively.

Owner:TEIJIN CHEM LTD

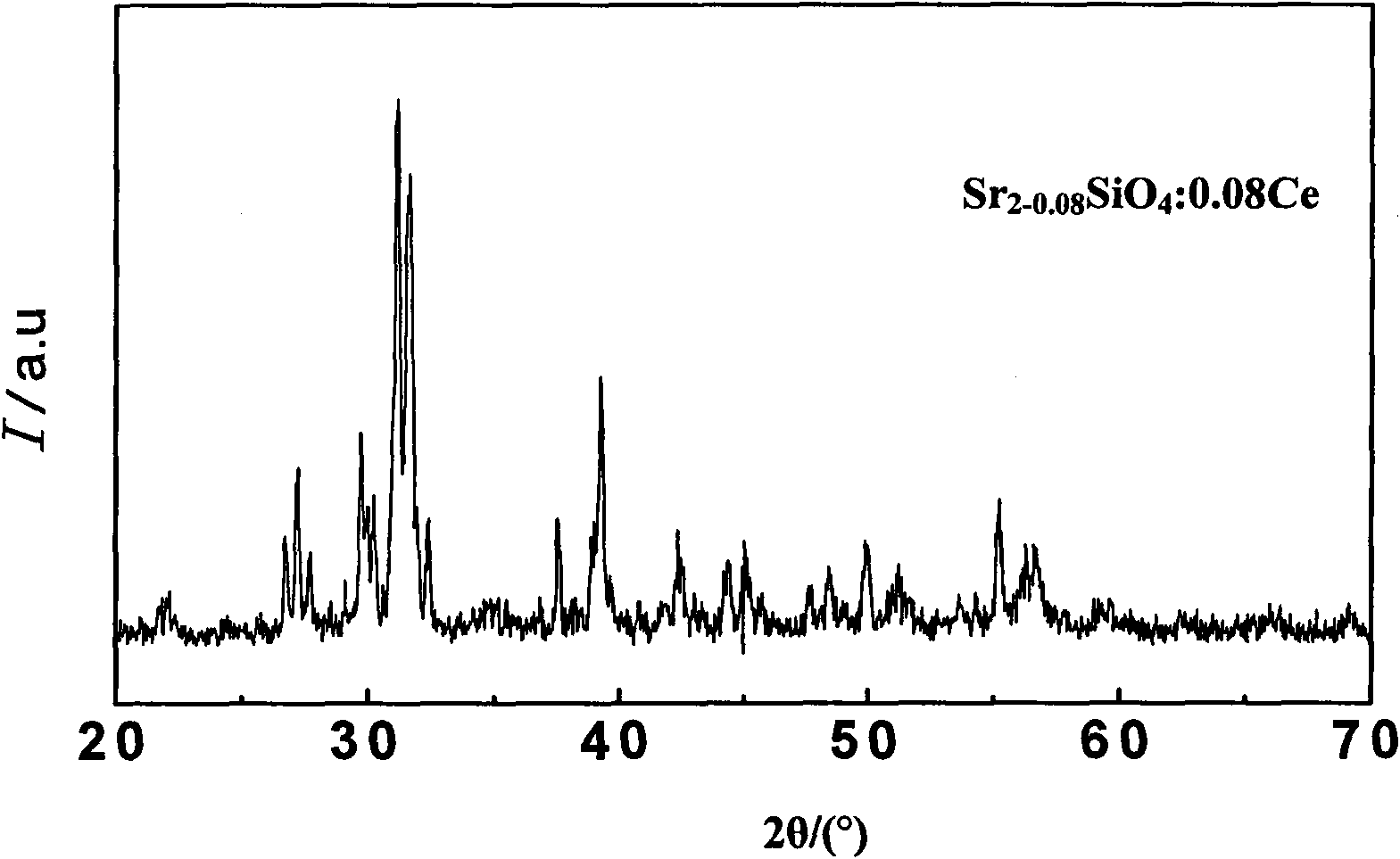

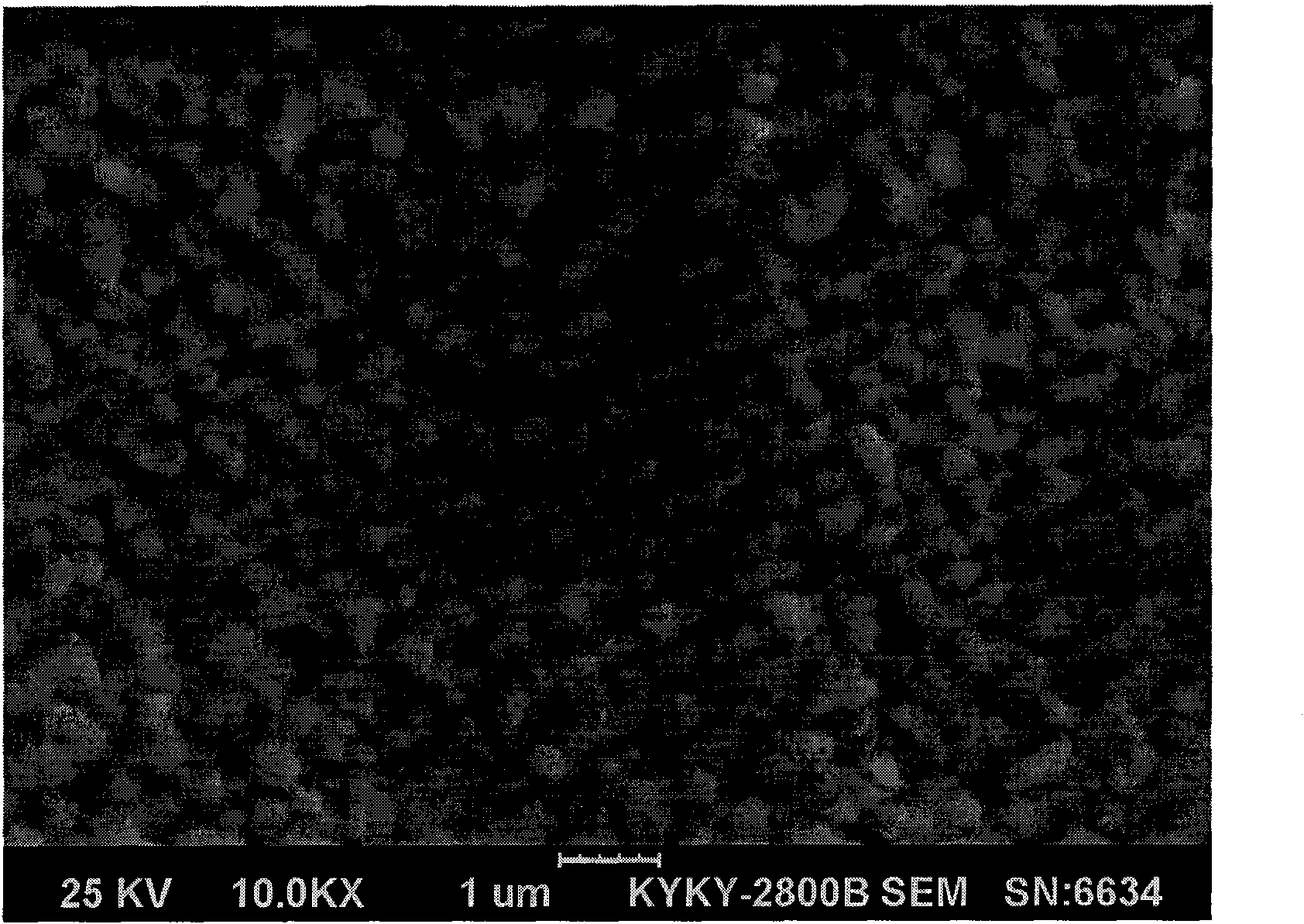

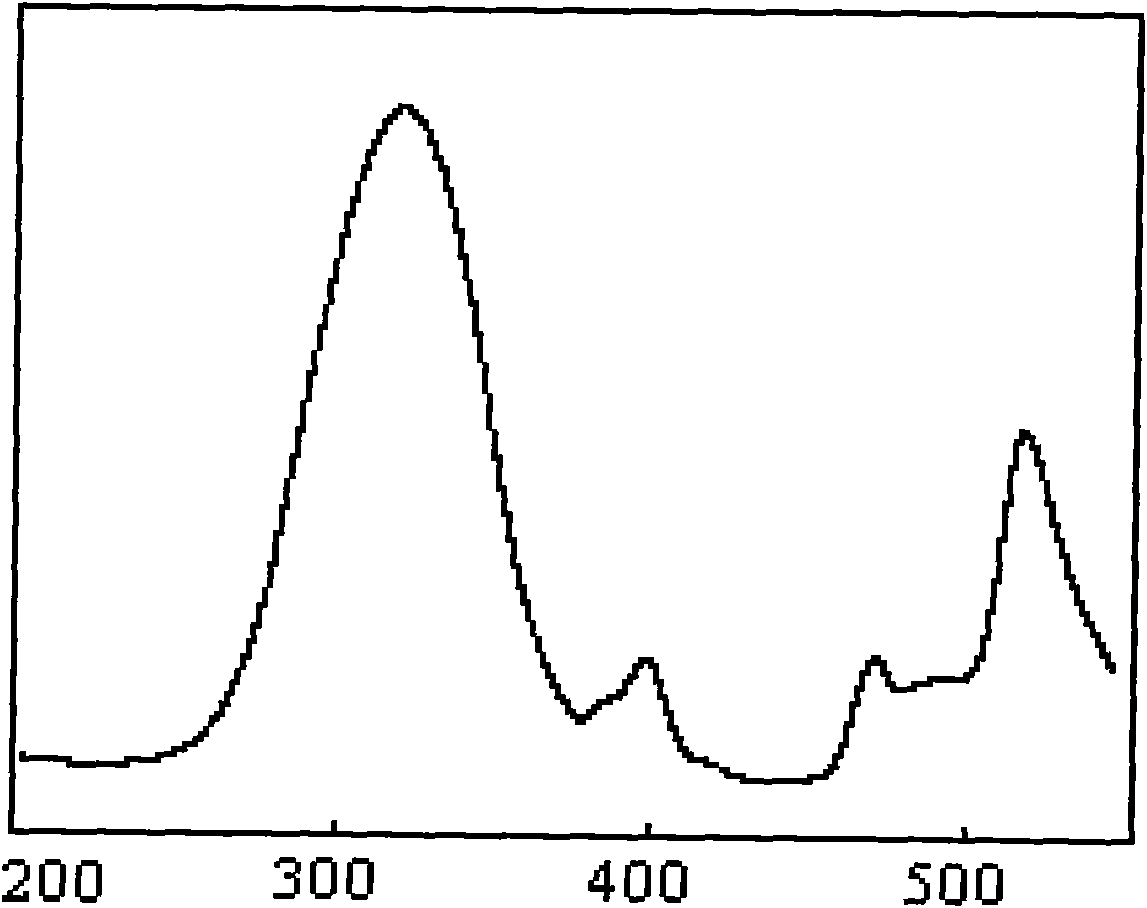

Method for preparing alkaline-earth silicate fluorescent powder activated by rare earth elements

InactiveCN101591535AShort timeShorten the production cycleLuminescent compositionsSemiconductor devicesRare-earth elementMicrowave oven

The invention discloses a method for preparing alkaline-earth silicate fluorescent powder activated by rare earth elements. The chemical expression formula of the alkaline-earth silicate fluorescent powder is M2-xSiO4:xRe, wherein M is any one or combination of Ca, Mg, Zn, Sr and Ba; Re is one or combination of Ce, Tb, Eu, Dy and Sm; and x is less than or equal to 0.4. The method comprises the following steps: weighting soluble salt of the elements according to stoichiometric proportion; introducing Si element by tetraethoxy silane (TEOS), and preparing various compositions into homogeneous solution; and introducing a microwave oven drying method in a gel preparing process to prepare an alkaline-earth silicate fluorescent material. The method disclosed by the invention has low energy consumption and short cycle; and the prepared product has good dispersibility, small grain diameter and concentrated granularity distribution, is similar to a sphere, optimizes the structural performance of the material, provides convenient condition for LED encapsulation to have even and compact coating, and has active promoting function of improving LED performance.

Owner:IRICO

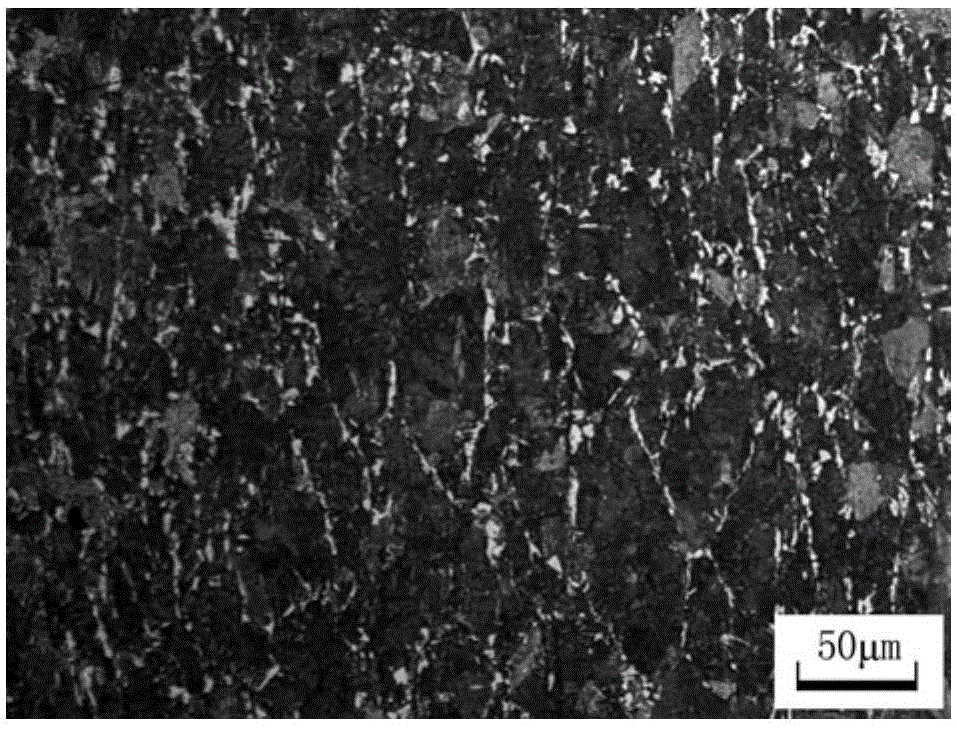

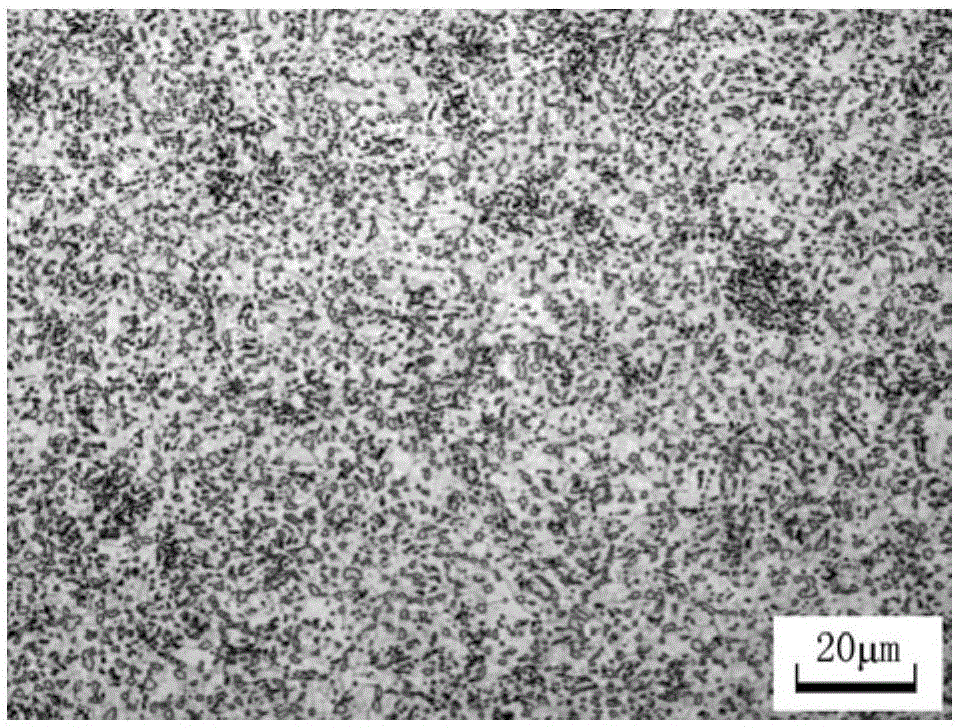

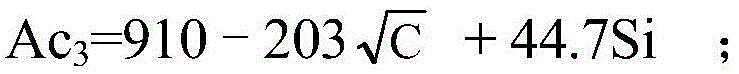

Medium-high carbon hot rolled strip steel with excellent fine blanking performance and production method

The invention discloses medium-high carbon hot rolled strip steel with excellent fine blanking performance and a production method. The strip steel comprises chemical components in percentage by weight as follows: 0.50%-0.65% of C, 0.60%-1.50% of Si, 0.50%-1.70% of Mn, 0.0030%-0.0070% of Ca, 0.0008%-0.005% of B, 0.015%-0.030% of Als, smaller than or equal to 0.015% of P, smaller than or equal to 0.008% of S and the balance of Fe and inevitable impurities. According to the principle that the activity of carbon atoms in austenite is improved by the Si element, a fast spheroidizing annealing technology is adopted, the heat preservation time is shortened to 1h-2h at the annealing temperature, the cost is reduced, the energy is saved, and the hot rolled strip steel with the excellent blanking performance is obtained finally and is suitable for producing automobile part raw materials with complex shapes and quench hardening requirements.

Owner:武汉钢铁有限公司

Semi-steel steelmaking method

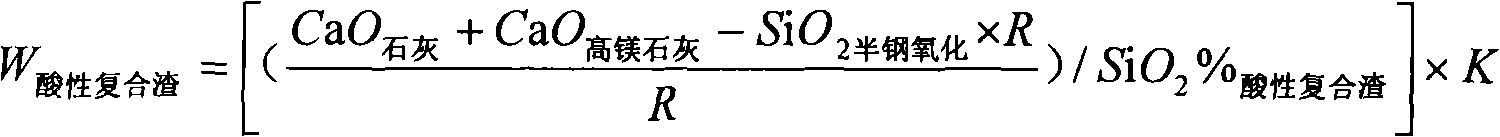

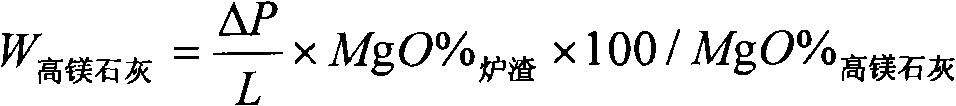

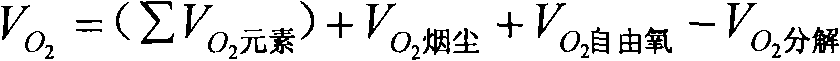

The invention discloses a semi-steel steelmaking method, wherein the method comprises the steps of: adding raw materials into a steel making furnace, blowing oxygen into the furnace to obtain molten steel and slag; the raw materials comprises raw steel, lime, high-magnesium lime and acid composite slag; the raw steel contains semi-steel after vanadium extraction; the addition of the acid composite slag meets the following formula: W (acid composite slag) is equal to (( (CaO (lime) plus CaO (high-magnesium lime) minus SiO2 (oxidized semi-steel) multiplied by R) divided by R ) divided by SiO2% (acid composite slag) ) multiplied by K, wherein W acid composite slag refers to the addition of the acid composite slag, CaO lime refers to the quantity of CaO brought in by the lime, CaO high-magnesium lime refers to quantity of CaO brought in by the high-magnesium lime, SiO2 oxidized semi-steel refers to the quantity of SiO2 converted from the quantity of Si element in the semi-steel, R refers to the alkalinity of slag, and ranges from 3 to 5, SiO2% acid composite slag refers to the weight percentage of SiO2 in the acid composite slag, and K refers to a fluctuation coefficient with a value ranging from 0.98 to 1.02. The semi-steel steelmaking method can achieve good dephophorization and desulfurization and is applicable to the automation production.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +2

Soft-magnetic high-entropy block amorphous alloy FeCoNiMB and preparation method thereof

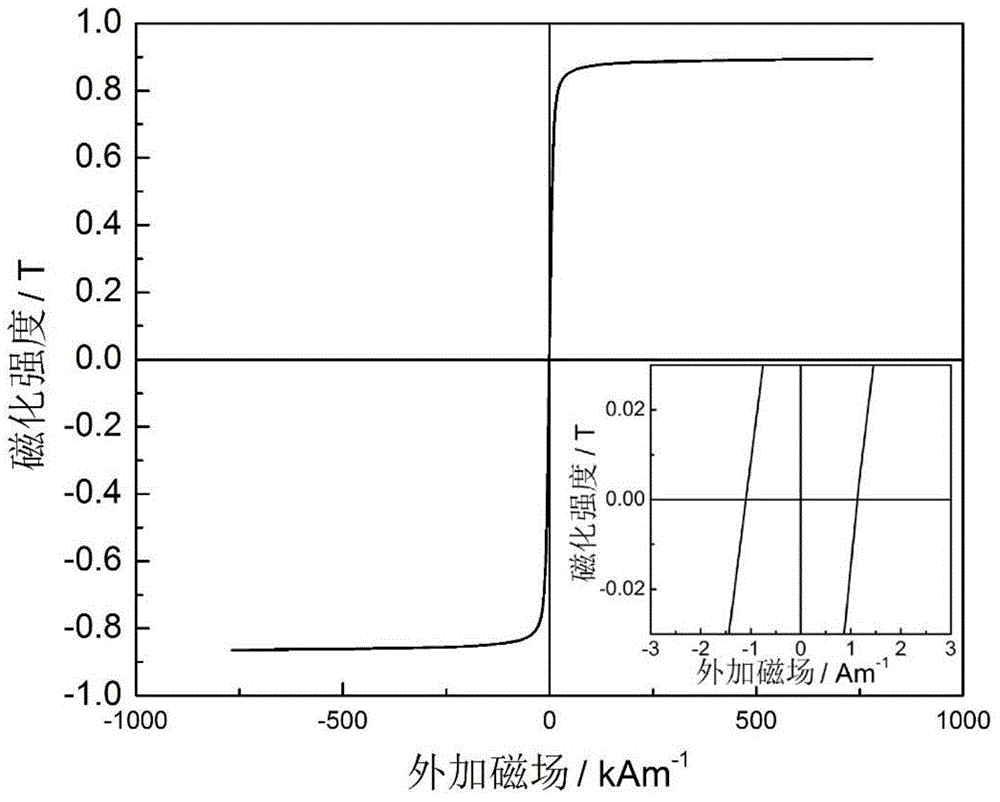

ActiveCN104878324AEnhanced Amorphous Formation AbilityImprove thermal stabilityMagnetic materialsMagnetizationIngot

The invention provides a soft-magnetic high-entropy block amorphous alloy FeCoNiMB. M represents at least one of P, C and Si elements, and typical compositions include Fe25Co25Ni25Si7.5B17.5, Fe25Co25Ni25Si10B15, Fe25Co25Ni25P5C4Si6B10, Fe25Co25Ni25P12C8B5 and Fe25Co25Ni25P10C10B5. The saturation magnetization of the alloy is 0.80-0.87T, coercivity is 1.1-3.4A / m, and effective magnetic conductivity under 1kHz is 12500-19800. The invention further provides a preparation method of the soft-magnetic high-entropy block amorphous alloy. The preparation method includes preparing a master alloy ingot through arc melting or induction melting, and preparing an amorphous band and an amorphous bar by single-roll melt-spinning and copper-mold casting respectively. The technical blank in preparation of the soft-magnetic high-entropy block amorphous alloy is filled up, and the provided alloy has an application prospect of serving as a soft-magnetic functional device.

Owner:DALIAN UNIV OF TECH

Iron-based alloy powder for laser cladding of TRT (Blast Furnace Top Pressure Recovery Turbine Unit) parts

ActiveCN102352508AImprove performanceModerate hardnessMetallic material coating processesHeat stabilityNickel alloy

The invention discloses iron-based alloy powder for the laser cladding of TRT (Blast Furnace Top Pressure Recovery Turbine Unit) parts. As for the powder, on the basis of an iron-nickel-chromium alloy, Mo, Nb, N and Si element strengthening matrixes are added, and the alloy melting point is reduced while the moderate hardness is kept, and the comprehensive properties such as high strength, abrasion resistance and the like are ensured, thus being convenient for laser cladding; and trace elements Ce and Hf are added to improve the crystal boundary quality, inhibit and prevent cracks, improve the heat stability and chemical stability of a cladding layer and endow the alloy with oxidation resistance, corrosion resistance and abrasion resistance under a higher temperature and wider application range. Failed parts made from carbon steel, structural steel, hardened and tempered steel, stainless steel, tool steel and other materials can be repaired by using the powder and combining the laser cladding technology, thus the powder has wide application prospects and obvious benefits.

Owner:河北瑞兆激光再制造技术股份有限公司

Low expansion superhigh silicon aluminum alloy and method for making same

The low expansion Si-Al alloy has very high Si mass ratio of 61.6-70.8 %. The preparation process includes loading Si into mold cavity and pressing with punch head to form pre-fabricated block; preheating the mold to 500-600 deg.c and heating aluminum material to melt; casting aluminum into the mold; pressing with punch head; maintaining the pressure of the punch head while cooling the mold; demolding; and high temperature annealing of the cast ingot. The Si-Al alloy has high Si content, low density, high compactness, low expansion and other performance. The extrusion casting process to add Si element into Al alloy to form Si-Al alloy with very high Si content uses simple preparing apparatus and has low cost.

Owner:哈尔滨天行健航天新材料有限责任公司

Aluminum alloy ingot

The invention discloses an aluminum alloy ingot. The aluminum alloy ingot comprises, by weight , 9.6%-12.0% of Si, 1.5%-3.5% of Cu, less than 0.3% of Mg, less than 1.3% of Fe, less than 1.0% of Zn, less than 0.5% of Mn, less than 0.5% of Ni, less than 0.3% of Sn, 1%.-2%. of Sr, 1%.-2%. of Ti, 1%.-2%. of B and the balance Al. The Si element is added to the aluminum alloy ingot so that strength and toughness of the aluminum alloy ingot are effectively improved, and the Ti and B elements added into the aluminum alloy ingot enables a die-casting product to generate good grain refinement, casting cracks are effectively avoided, the appearance of a casting is improved, the surface quality of the ingot is improved, particularly cold shut of the ingot is reduced, and the impact toughness of the aluminum alloy ingot is effectively improved by 15%-20% on the condition that the strength of the aluminum alloy ingot is not reduced.

Owner:WUXI GREAT TECH

Manufacturing method of steel

The invention provides a manufacturing method of steel, comprising the following steps: smelting the molten steel to ensure that the content of P in the molten steel is less than or equal to 0.035%, the content of S is less than or equal to 0.015% and the content of V is less than or equal to 0.15%; then adding Cu element and Ni element to the molten steel to ensure that the content of Cu in the molten steel is 0.20-0.60% and the content of Ni is 0.15-0.55%; tapping to a steel ladle when the content of C in the molten steel is below 0.05%; adding physical mixture of lime and fluorite and predeoxidizing agent to the steel ladle in the tapping process to ensure that the content of S in the molten steel is less than or equal to 0.012%; adding Cr element, Si element and Mn element to the molten steel to ensure that the content of Si in the molten steel is 0.25-0.60%, the content of Mn is 0.80-1.60% and the content of Cr is 0.20-0.80%; feeding Al simple substance to the molten steel to carry out final deoxidation; heating the molten steel in the condition of argon blowing to lead the steel slag to melt; then adding Al simple substance to the steel ladle to ensure that the content of S in the molten steel is less than or equal to 0.010%; and then adding C element to the molten steel to ensure that the content of C in the molten steel is 0.08-0.16%; feeding Al simple substance and alloy containing Ti, V and N to the molten steel to control that the content of acid-soluble aluminium in the molten steel is 0.025-0.040%, the content of Ti is 0.005-0.015%, the content of V is 0.08-0.15% and the content of N is 0.010-0.020%.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +3

Titanium alloy with thin sheet layer microstructure and manufacturing method thereof

The invention provides a titanium alloy with a thin sheet layer microstructure and a manufacturing method thereof. The titanium alloy is characterized in that: 1) a certain amount of Si element is added into the alloy so that Ti5Si3 or Ti2Si type silicide can be dissolved out from the alloy under a certain condition; 2) controlling the adding amount of alloying elements, namely Zr, Sn and beta stable elements, which affect the dissolving temperature of the silicide so as to guarantee that the alpha + beta / beta transformation temperature of the titanium alloy is lower than the dissolving temperature of the silicide; 3) fully deforming the alloy at the temperature of below the dissolving temperature of the silicide, and finally properly deforming the alloy in the alpha + beta phase area over 1 to 2 fire, wherein the primary beta crystallite dimension of the alloy after thermal treatment is less than 200 mu m and the alloy has a thin sheet lamellar structure. The invention also provides a titanium alloy component and a corresponding smelting, hot working and heat treatment process. The thin sheet layer titanium alloy of which the primary beta crystallite dimension of the alloy after thermal treatment is less than 200 mu m can be prepared by the process. The titanium alloy has relatively high strength and plastic toughness matching, is a high-strength, high-toughness and high-temperature resistant titanium alloy material and is expected to be well popularized and applied in the field of aerospace.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

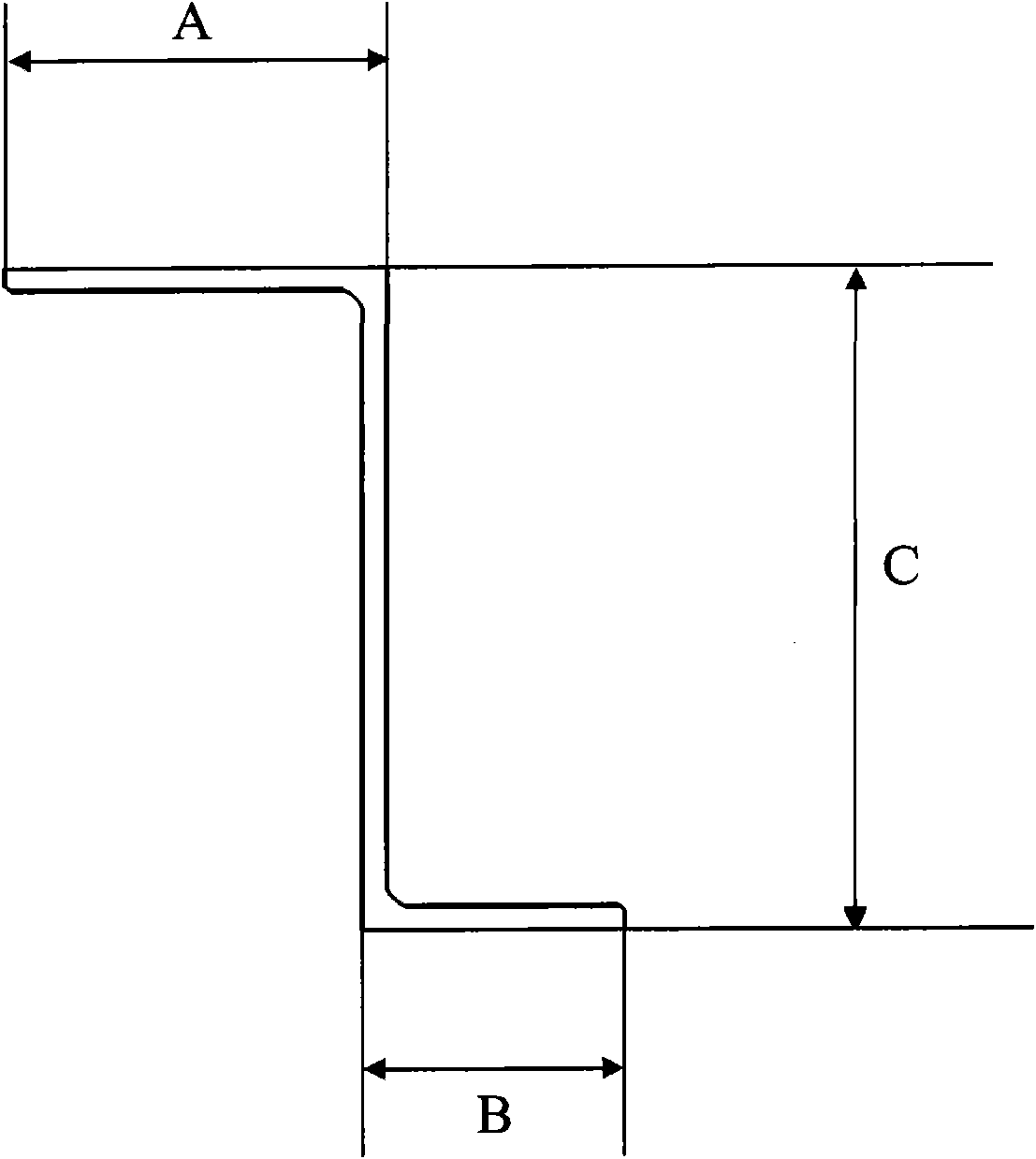

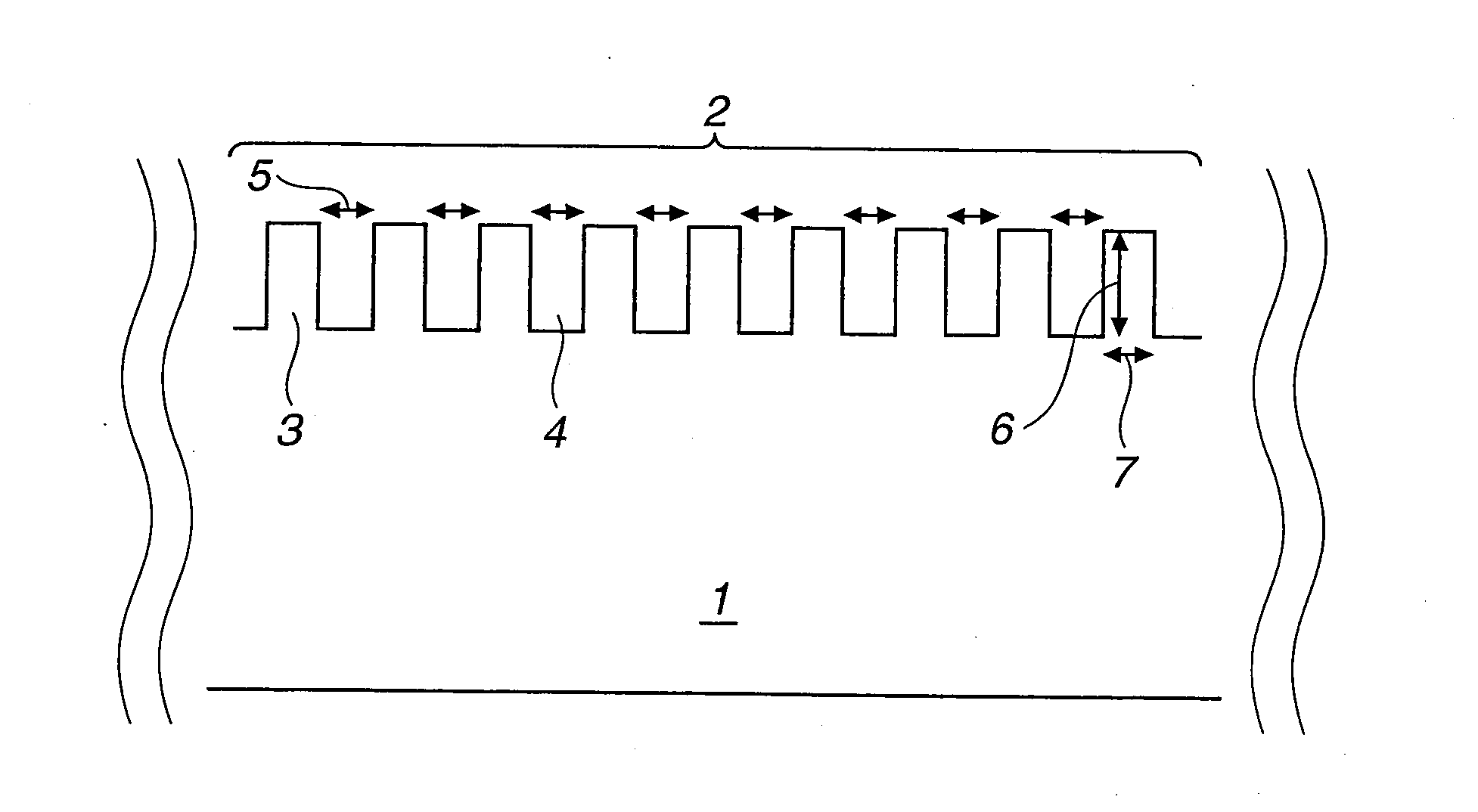

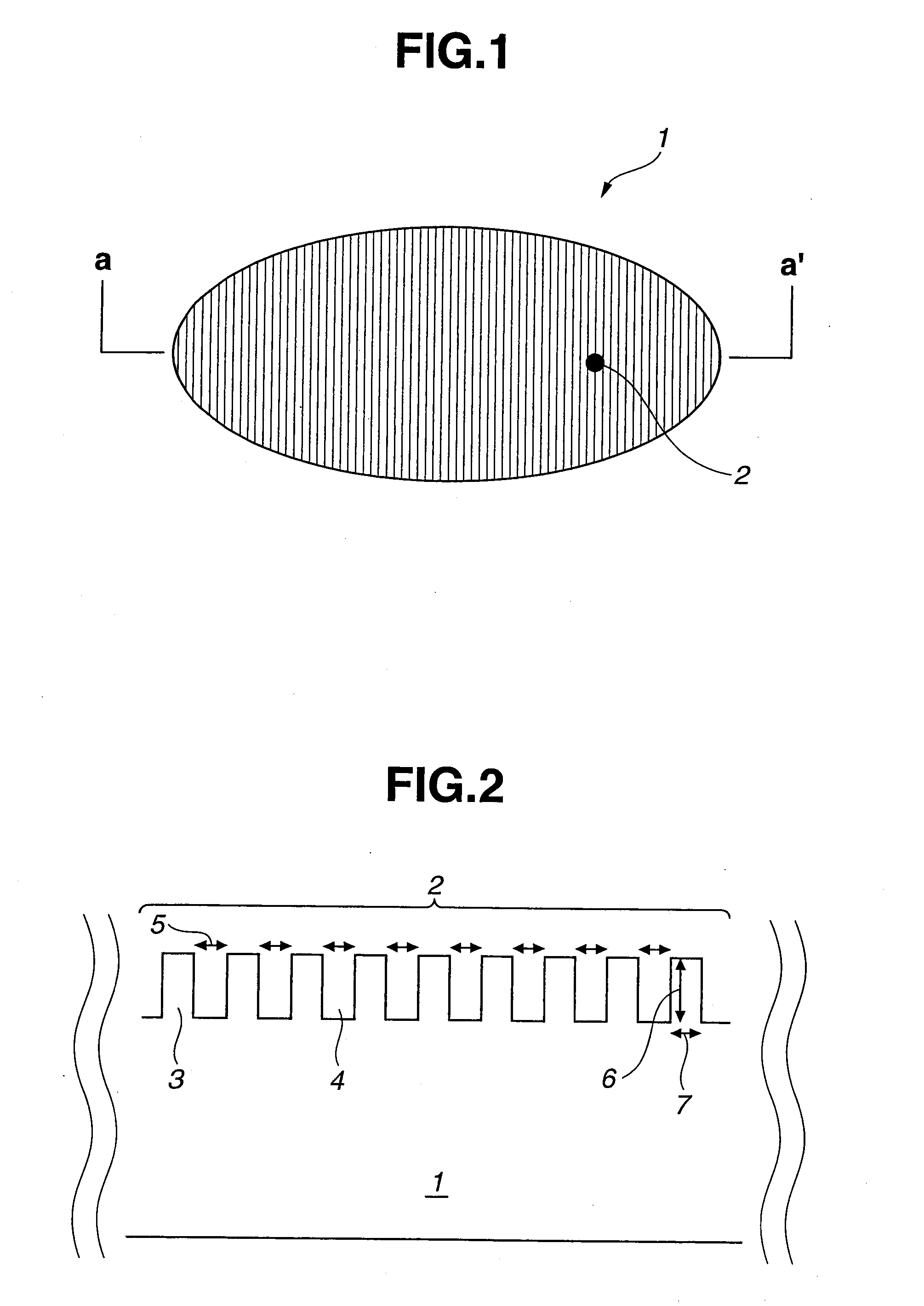

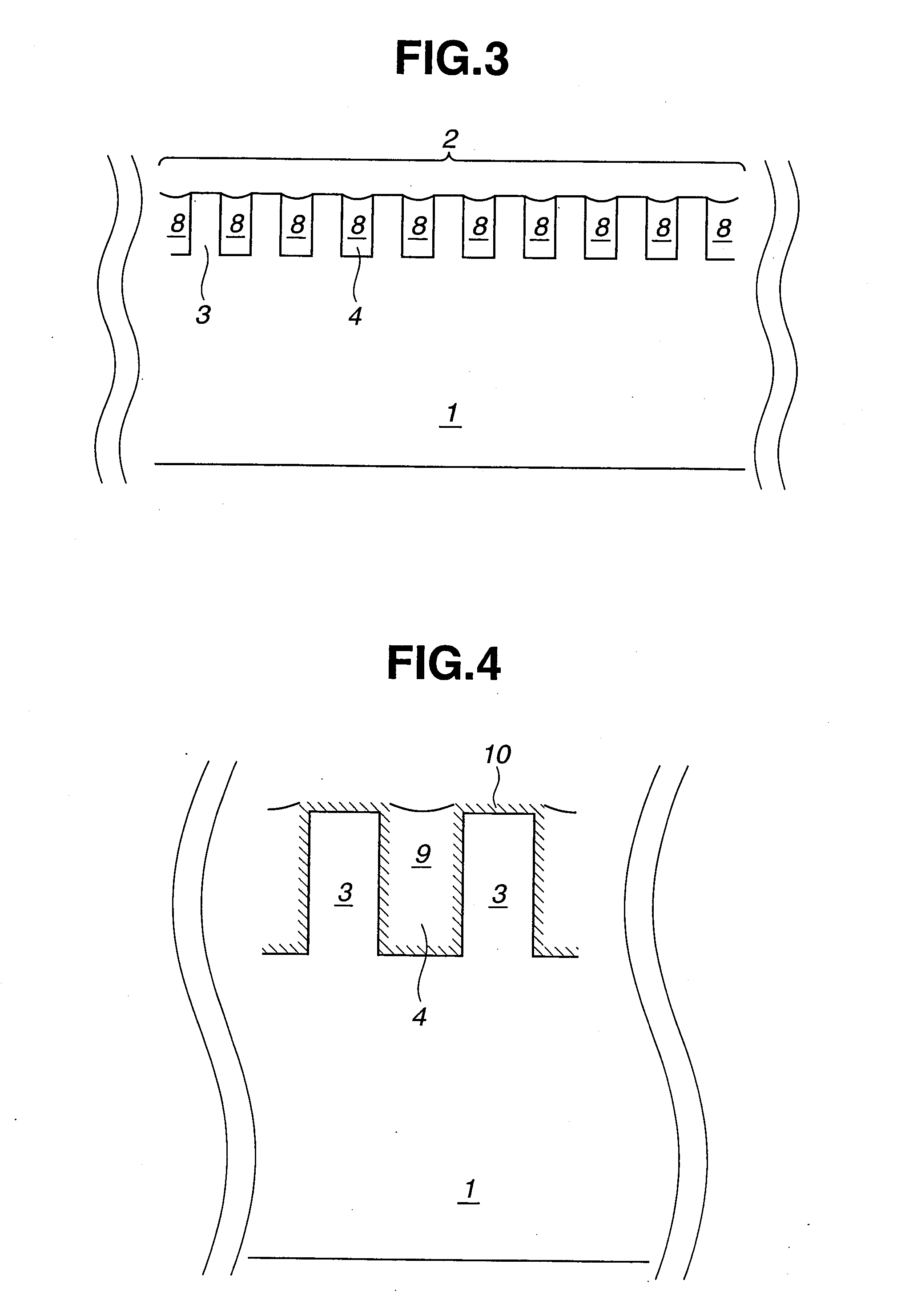

Cleaning Agent For Silicon Wafer

InactiveUS20110214685A1Reduce capillary forceShort timeNon-surface-active detergent compositionsElectrostatic cleaningWater basedOrganic solvent

A cleaning agent for a silicon wafer (a first cleaning agent) contains at least a water-based cleaning liquid and a water-repellent cleaning liquid for providing at least a recessed portion of an uneven pattern with water repellency during a cleaning process. The water-based cleaning liquid is a liquid in which a water-repellent compound having a reactive moiety chemically bondable to Si element in the silicon wafer and a hydrophobic group, and an organic solvent including at least an alcoholic solvent are mixed and contained. With this cleaning agent, the cleaning process which tends to induce a pattern collapse can be improved.

Owner:CENT GLASS CO LTD

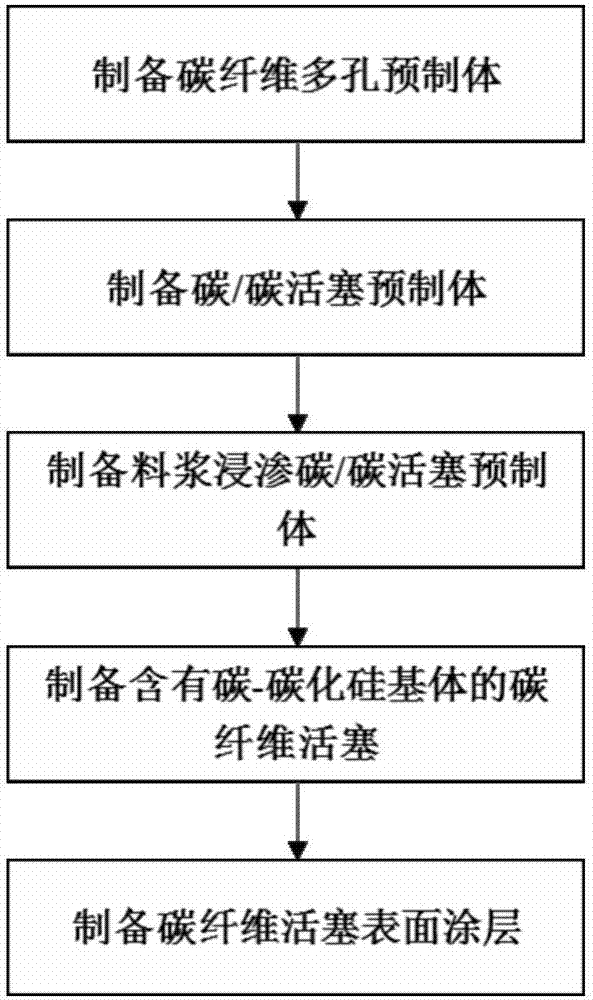

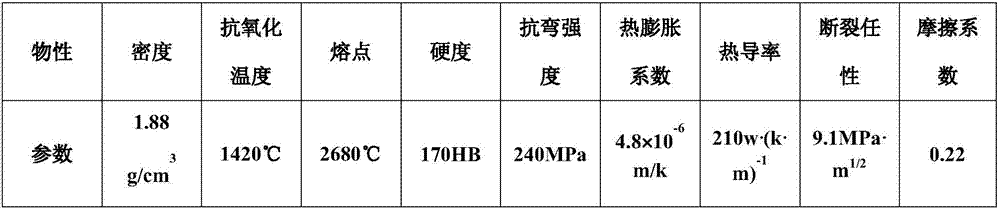

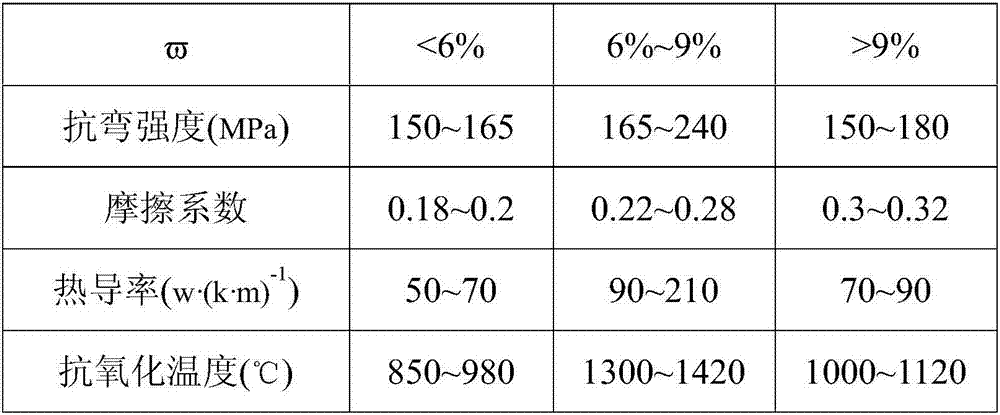

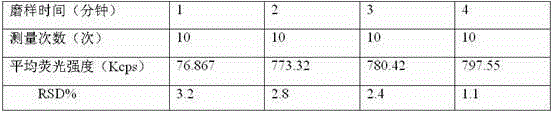

Cf/C-SiC composite material as well as preparation method and application thereof

The invention designs a composite material. The composite material comprises carbon-fiber perform, matrix carbon, filler and diamond-like carbon, wherein the matrix carbon is uniformly adhered on the carbon fiber of the perform to form the carbon-fiber perform with the matrix carbon; the filler fills the inside of the carbon-fiber perform with the matrix carbon and coats the outside of the carbon-fiber perform with the matrix carbon to form a semifinished product; the diamond-like carbon comprises a diamond-like carbon layer coated on the semifinished product; and the filler contains a Ti element, a Si element, a C element and a Mo element. The composite material has the advantages that a method of combining four processes of CVI, SI, RMI and PECVD to prepare a finished product with the advantages of high compactness, low thermal expansion coefficient and friction coefficient, high self-lubricating property, high thermal conductivity, oxidation resistance, thermal shock resistance, ablation resistance, wear resistance, high strength and toughness and the like; and simultaneously, the process is simple, the preparation period is short, the equipment requirement is low, the cost is low, net shaping can be realized and convenience is brought for large-scale industrial application.

Owner:XIANGTAN UNIV

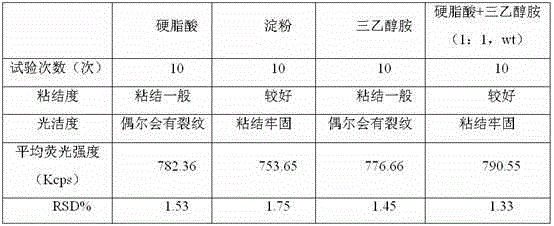

Method for rapidly measuring content of SO2 in cement clinker

InactiveCN105021641AShort analysis timeShorten the timeMaterial analysis using wave/particle radiationStearic acidUltimate tensile strength

The invention discloses a method for rapidly measuring content of SO2 in cement clinker. The method comprises the following steps: (1) a grinding aid is added into a cement clinker sample to be analyzed and grinding for 3-4 min, wherein the grinding aid is a mixture of stearic acid and triethanolamine; (2) tabletting the ground sample, loading the sample onto an X-ray fluorescence spectrometer and measuring to obtain fluorescence intensity of the Si element in the sample; and (3) obtaining mass percentage of SiO2 in the sample according to a working curve of fluorescence intensity and content. In comparison with a traditional method, the method provided by the invention has advantages as follows: analysis time is greatly shortened; detection time of a sample is reduced to 10 min from traditionally 3 h; analysis speed is raised; and labor intensity of operators is greatly reduced.

Owner:GUANGXI YUFENG CEMENT

High-temperature-oxidization-resistant coating material for hot-stamped formed steel and hot-dipping plating technology

ActiveCN103952653ARefined grain sizeGood high temperature oxidation resistanceHot-dipping/immersion processesRare-earth elementHigh density

The invention discloses a high-temperature-oxidization-resistant coating material for hot-stamped formed steel and a hot-dipping plating technology. A plating solution comprises the following components in percentage by mass: 5.0-20.0% of Si, 0.5-10.0% of Ni, 0.1-12.0% of Ce, 0.1-2.0% of La, not more than 1.0% of Fe, and the balance of Al and inevitable impurities. According to the coating material, the grain size of the texture can be effectively refined by adding rare earth and other elements in the plating solution; the coating is an Al-Si-Ni-rare earth material, Al and Si elements are main components of the coating and are combined with ferrum to generate a ferro-silicon-aluminum phase and further improve the oxidization resistance capability, the melting point of aluminum silicon can be further improved by Ni, and the grain size of the coating can be refined through the rare earth elements; therefore, the coating has the characteristics that the high-temperature oxidization resistance performance is excellent, the surface is difficult to crack after hot-stamped forming, and the coating is not adhered to a mold. Elements in the coating obtained by adopting the technology are uniformly distributed and organized with high density, are closely combined with a substrate, thus having high high-temperature oxidization resistance performance; during heating process, the high-temperature-oxidization-resistant coating material does not stick a furnace bottom roll, a steel substrate and a stamping mold can be better protected.

Owner:HEBEI IRON AND STEEL

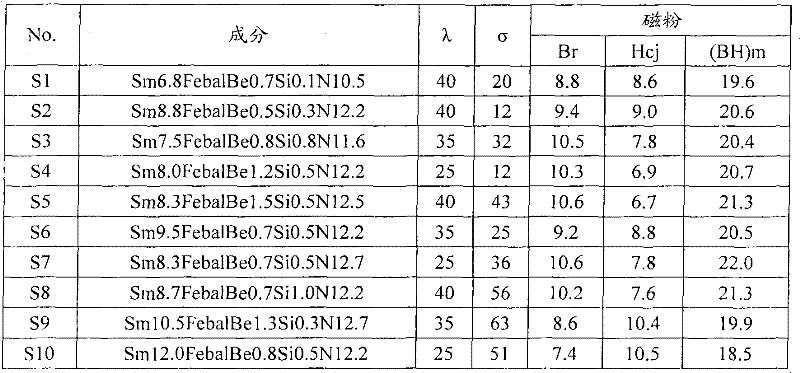

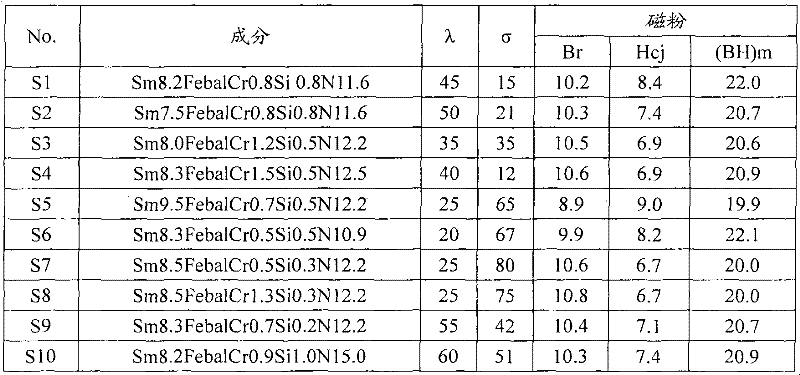

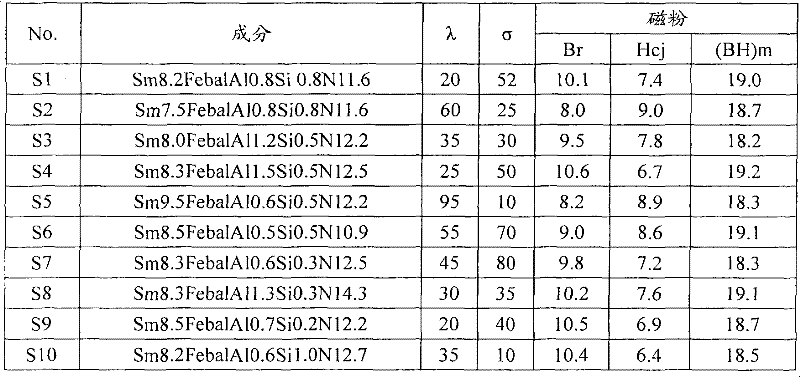

Rare earth permanent magnetic powder and bonded magnet

ActiveCN102208234AImprove liquidityHigh saturation magnetizationInorganic material magnetismThin material handlingRare earthNanocrystal

The invention discloses a rare earth permanent magnetic powder which takes Sm, Fe, M, N and Si as main components, and takes a TbCU7 structure as a main phase, the M is at least one of the Be, Cr, Al, Ti, Ga, Nb, Zr, Ta, Mo and V. The Si element is added in the rare earth permanent magnetic powder to add the glass forming ability of a samarium-ferro alloy, and the M element with a certain amount is compounded and added to increase the wetting property of an alloy solution; and therefore, the alloy solution is more convenient to be ejected from a smelting device. The samarium element content in the rare earth permanent magnetic powder is in a 1-12 at% range, the content of the M is in a 0.1-1.5 at% range, the content of N is in a 10-15 at% range, the content of Si is in a 0.1-1.5 at% range, and the rest is ferrum. An average grain size of the rare earth permanent magnetic powder is 10-100 microns; and the rare earth permanent magnetic powder is composed of a nano-crystal with an average size of 10-120 nm and amorphous structure.

Owner:GRIREM ADVANCED MATERIALS CO LTD

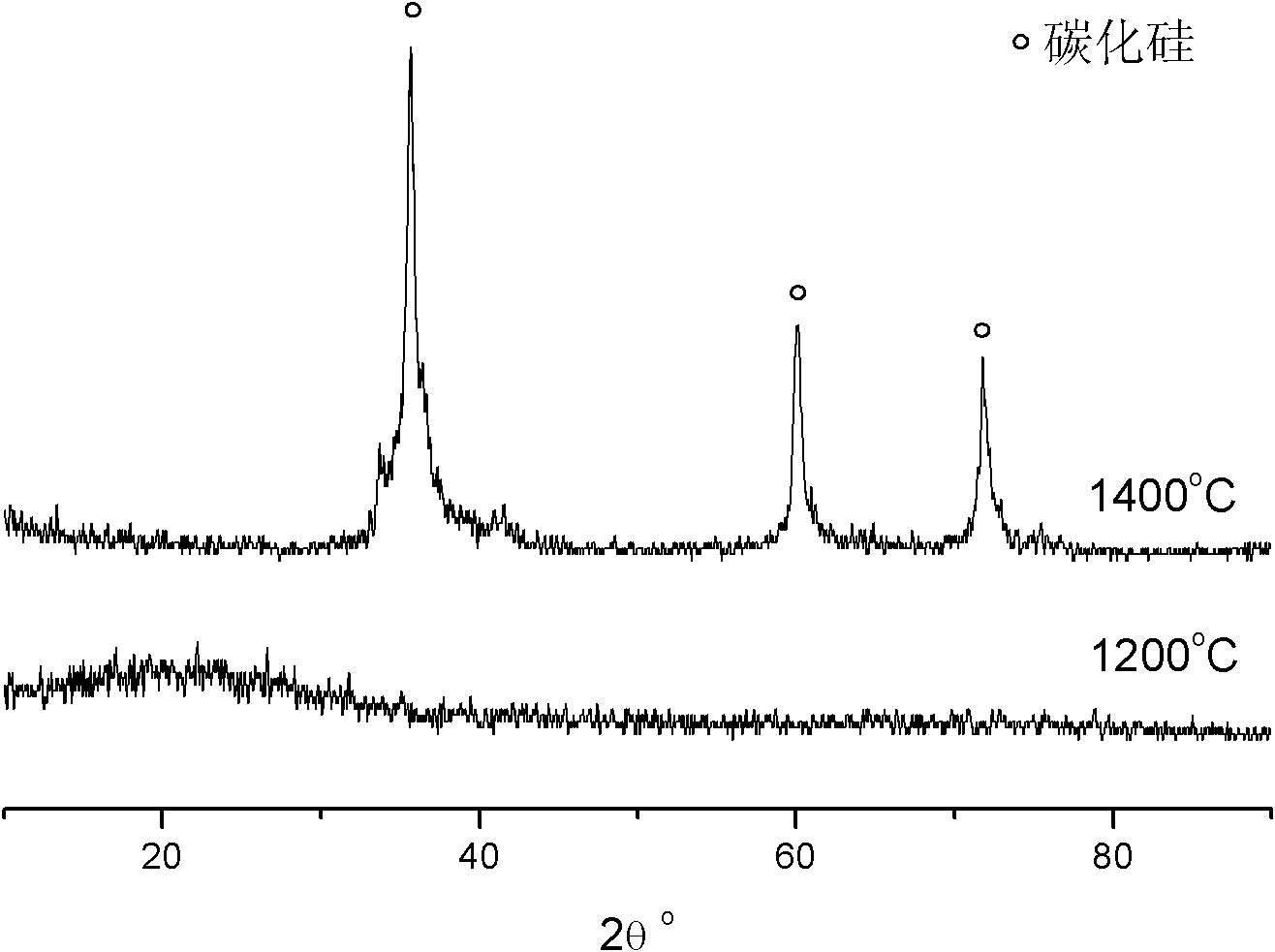

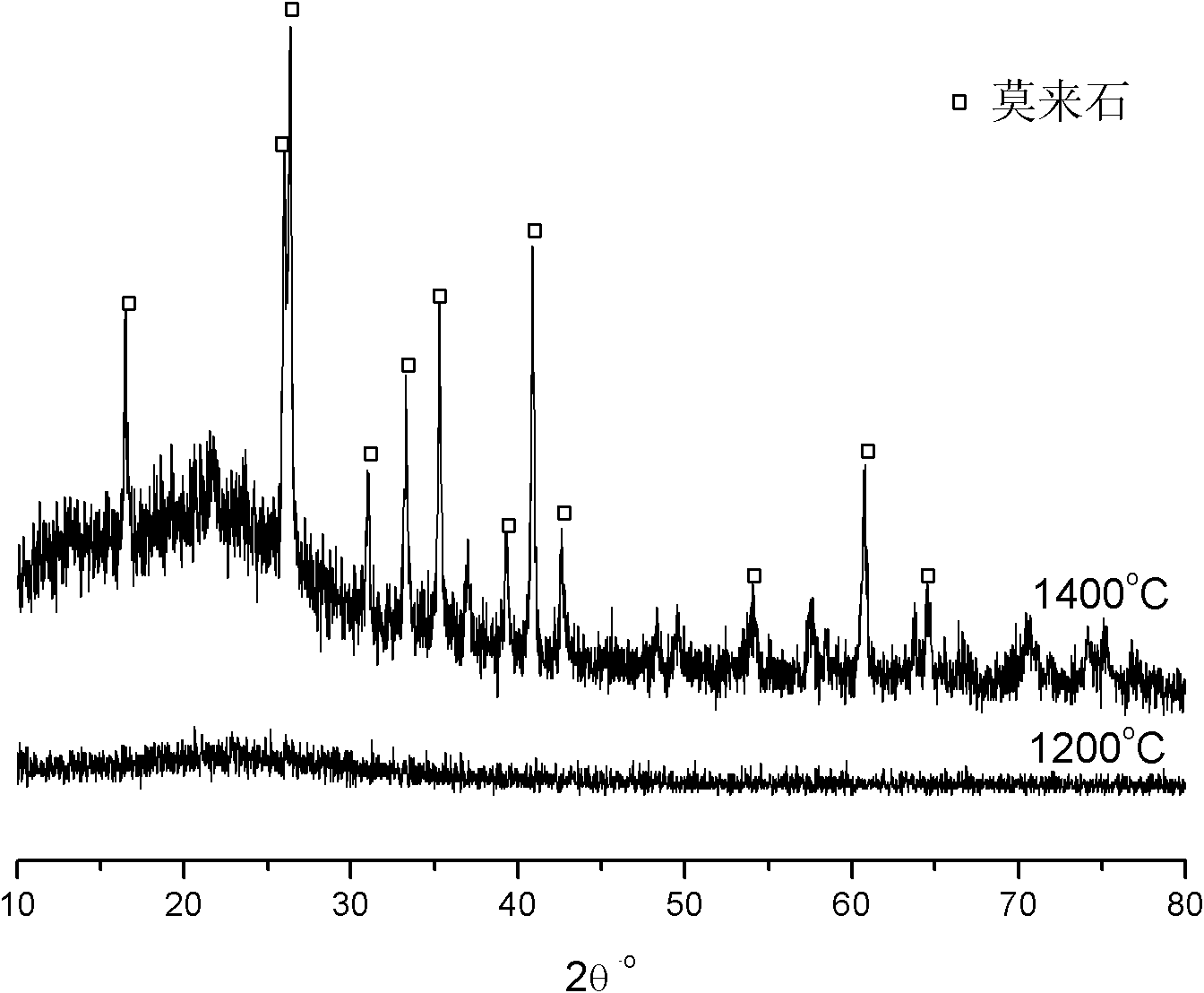

Si-Al-O-C ceramic material and preparation method thereof

The invention belongs to the field of high temperature resistant ceramic materials and preparation methods thereof and discloses an Si-Al-O-C ceramic material and a preparation method thereof. The Si-Al-O-C ceramic material contains the following elements in percentage by mass: 27-32 percent of Si element, 20-24 percent of O element, 25-30 percent of C element and 14-28 percent of Al element. The preparation method of the Si-Al-O-C ceramic material comprises the steps of aluminum sol preparation, gel preparation, precursor preparation, Si-Al-O-C ceramic material preparation and the like. The invention has the advantages of low cost, good heat stability, simple preparation process, low equipment requirements, and the like.

Owner:NAT UNIV OF DEFENSE TECH

Low-alloy high-intensity high-toughness steel and production method of low-alloy high-intensity high-toughness steel

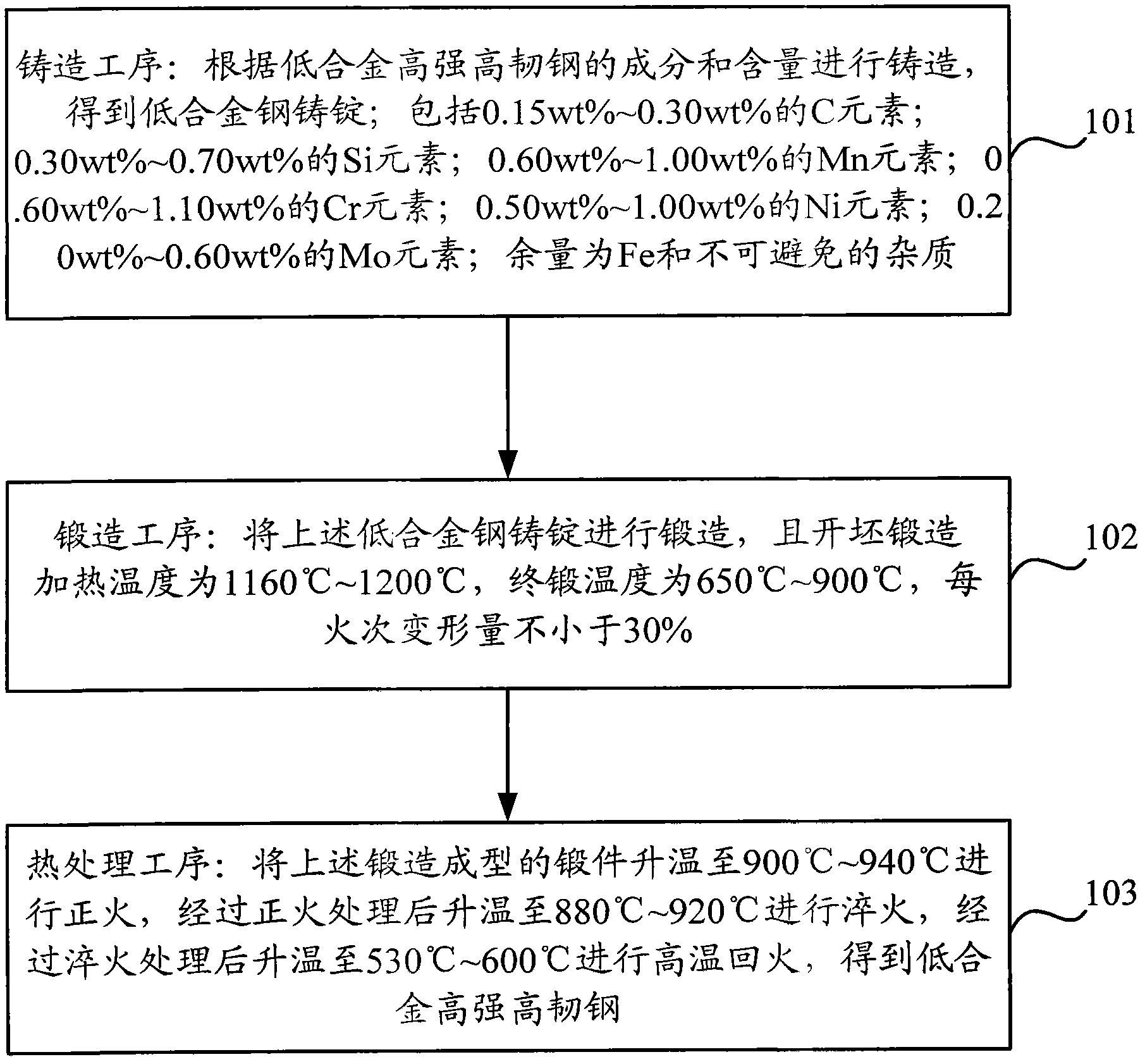

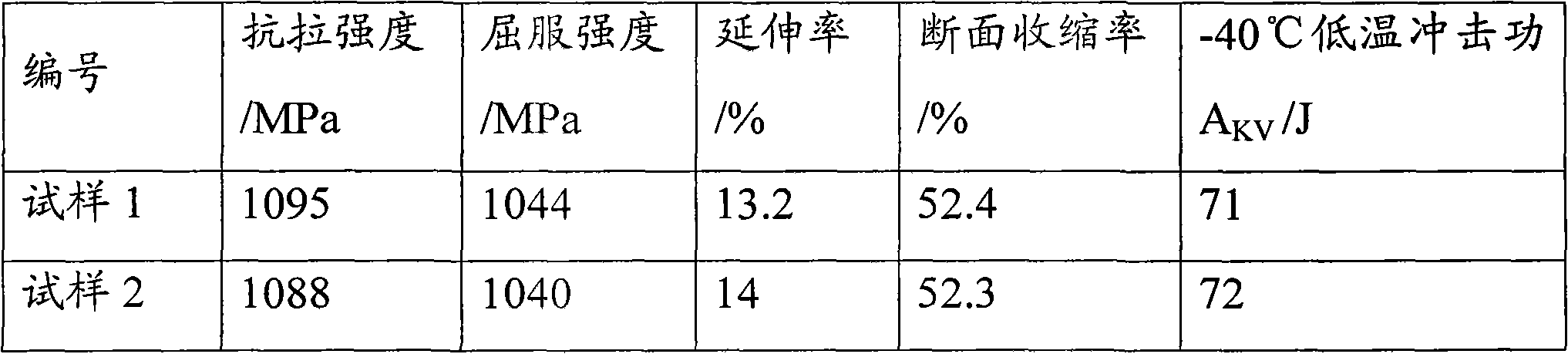

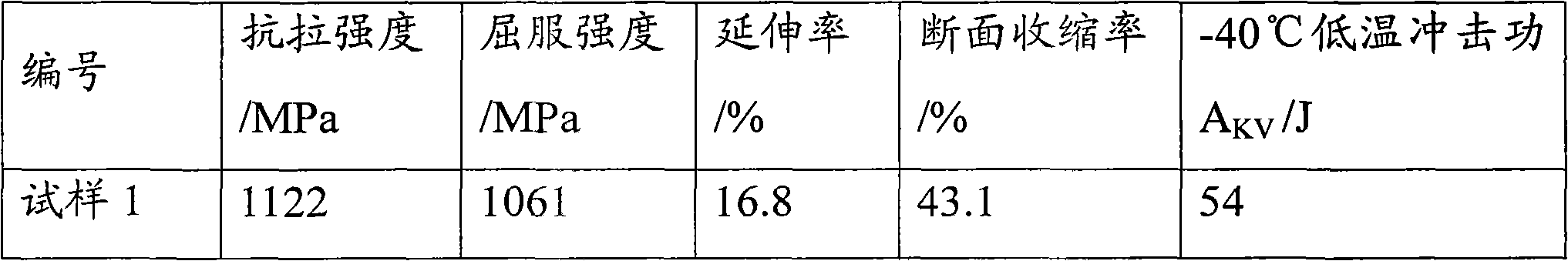

The invention discloses low-alloy high-intensity high-toughness steel and a production method of low-alloy high-intensity high-toughness steel. The method comprises the following work procedures of: the casting work procedure: the casting is carried out according to the following ingredients and contents to obtain low-alloy steel cast ingots: 0.15 to 0.30 weight percent of C elements, 0.30 to 0.70 weight percent of Si elements, 0.60 to 1.00 weight percent of Mn elements, 0.60 to 1.10 weight percent of Cr elements, 0.50 to 1.00 weight percent of Ni elements, 0.20 to 0.60 weight percent of Mo elements and the balance Fe and unavoidable impurities; the forging work procedure: the low-alloy steel cast ingots are forged, in addition, the blank opening forging heating temperature is 1160 DEG C to 1200 DEG C, the final forging temperature is 650 DEG C to 900 DEG C, and the deformation in each firing time is not smaller than 30 percent; and the heat treatment work procedure: the temperature of the forged and formed forgings is raised to 900 to 940 DEG C to be subjected to normalizing, the temperature is raised to 880 to 920 DEG C for carrying out quenching after the normalizing treatment, the temperature is raised to 530 to 600 DEG C for carrying out high-temperature tempering after the quenching treatment, and the low-alloy high-intensity high-toughness steel is obtained. In the embodiment of the invention, the low-alloy high-intensity high-toughness steel has high intensity and high toughness.

Owner:SANY GRP

Reinforced aluminum alloy with high electrical and thermal conductivity and its manufacturing process thereof

A reinforced aluminum alloy with high electric and thermal conductivity of the present invention has the weight percentage below: Mg 0.61˜0.65%, Si 0.4˜0.45%, rare earth elements 0.21˜0.3%, B 0.03˜0.10% and the balances essentially Al and unavoidable impurities. The reinforced aluminum alloy enhanced the containing of Mg and Si elements compared to the conventional aluminum alloy such as 6063, and controlled the containing of the Mg and Si in a certain relatively narrower range so as to control the desired quality of the aluminum alloy. At the same time, a Ce of the rare earth elements and B element are added into the aluminum alloy and completely solid melted the added alloys to the aluminum alloy. It is not only remaining the strength of the aluminum alloy, but also increasing the electric and thermal conductivity.

Owner:CHEN MING

Method for preparing hydrogenated silicon film by utilizing magnetron sputtering

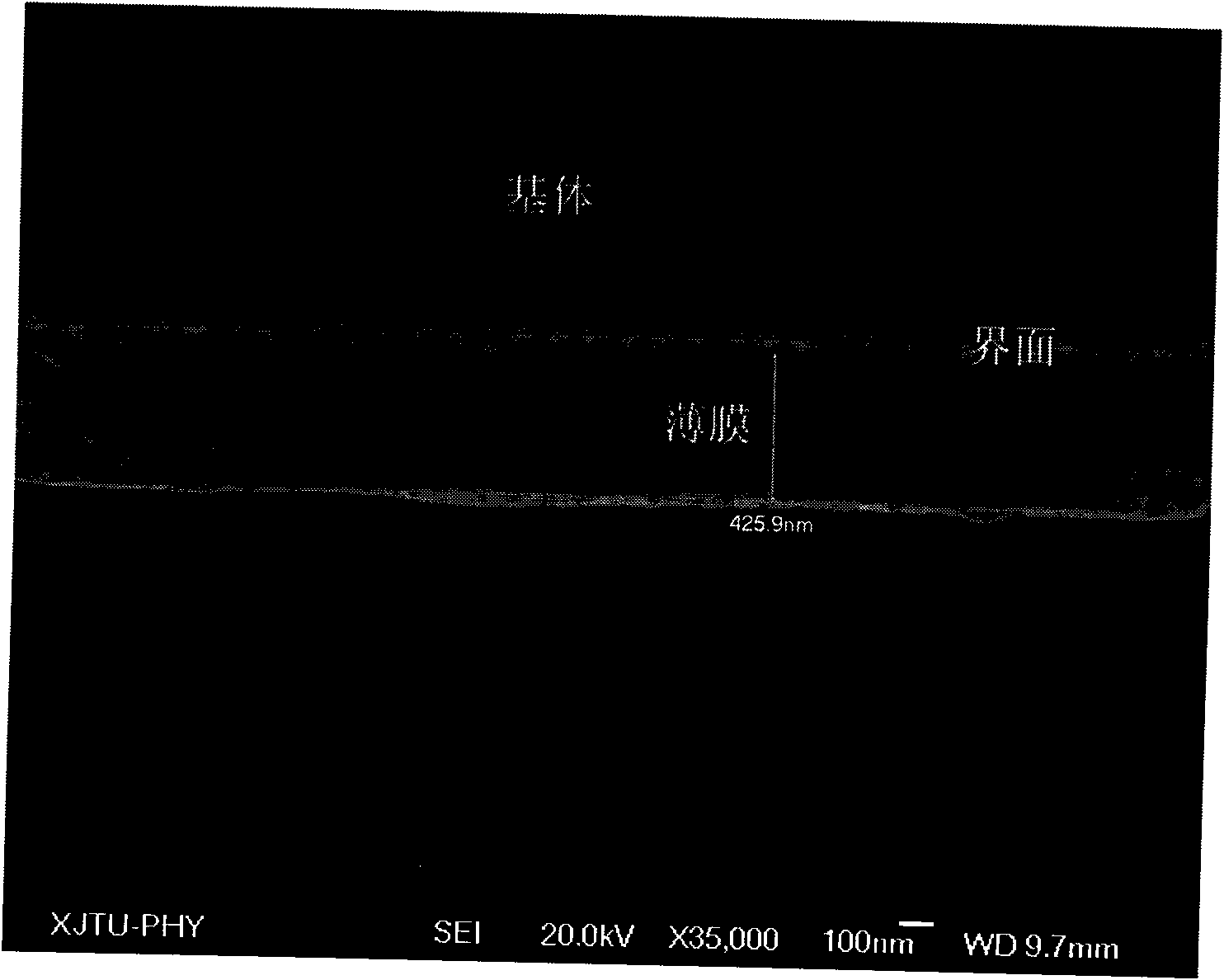

InactiveCN101660131AChange photoelectric propertiesFlat surfaceVacuum evaporation coatingSputtering coatingIntermediate frequencyOptoelectronics

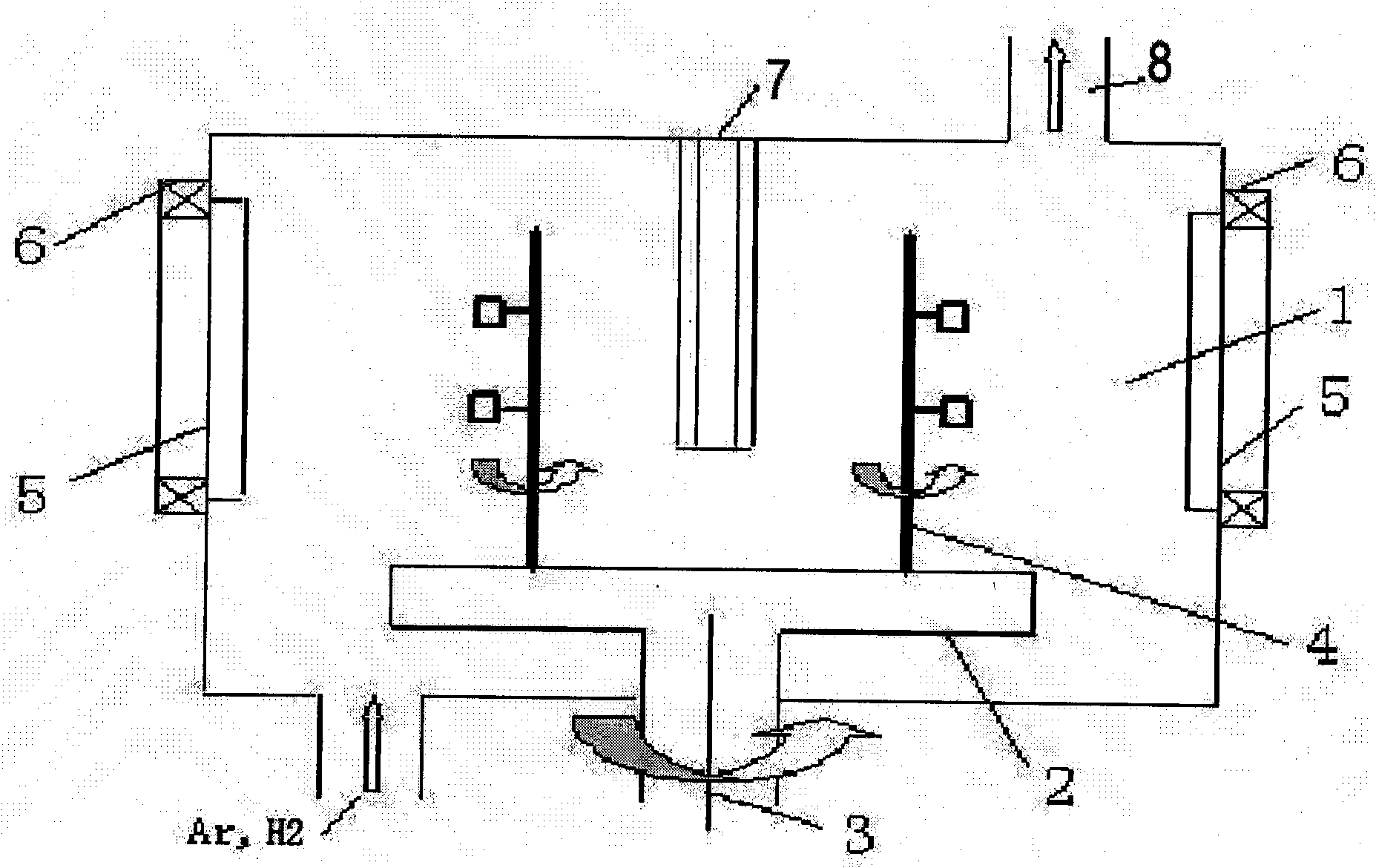

The invention discloses a method for preparing a hydrogenated silicon film by utilizing magnetron sputtering. The method comprises the following steps, pretreating a substrate and placing the substrate in a magnetron sputtering filming device; utilizing a plane Si target as a source of Si element; adjusting the power of an intermediate frequency pulse power supply to control the sputtering rate ofthe Si target; utilizing high-purity Ar gas as main ionization gas, and ensuring the effective glow discharge process; and adopting high-purity H2 gas as reaction gas, ionizing the H2, and combiningthe H2 with the Si element, forming the hydrogenated silicon film on the surface of the substrate through deposition, and annealing the film at the temperature of 550 DEG C to 950 DEG C in vacuum to obtain the nano-crystalline / non-crystalline composite structure. The invention achieves regulation and control to microstructure of the hydrogenated silicon film by changing introduction proportion ofhydrogen so as to further change the photoelectric properties of the film. The preparation method is simple and reliable, and the prepared hydrogenated silicon film is hopeful to be applied to solar batteries.

Owner:XI AN JIAOTONG UNIV

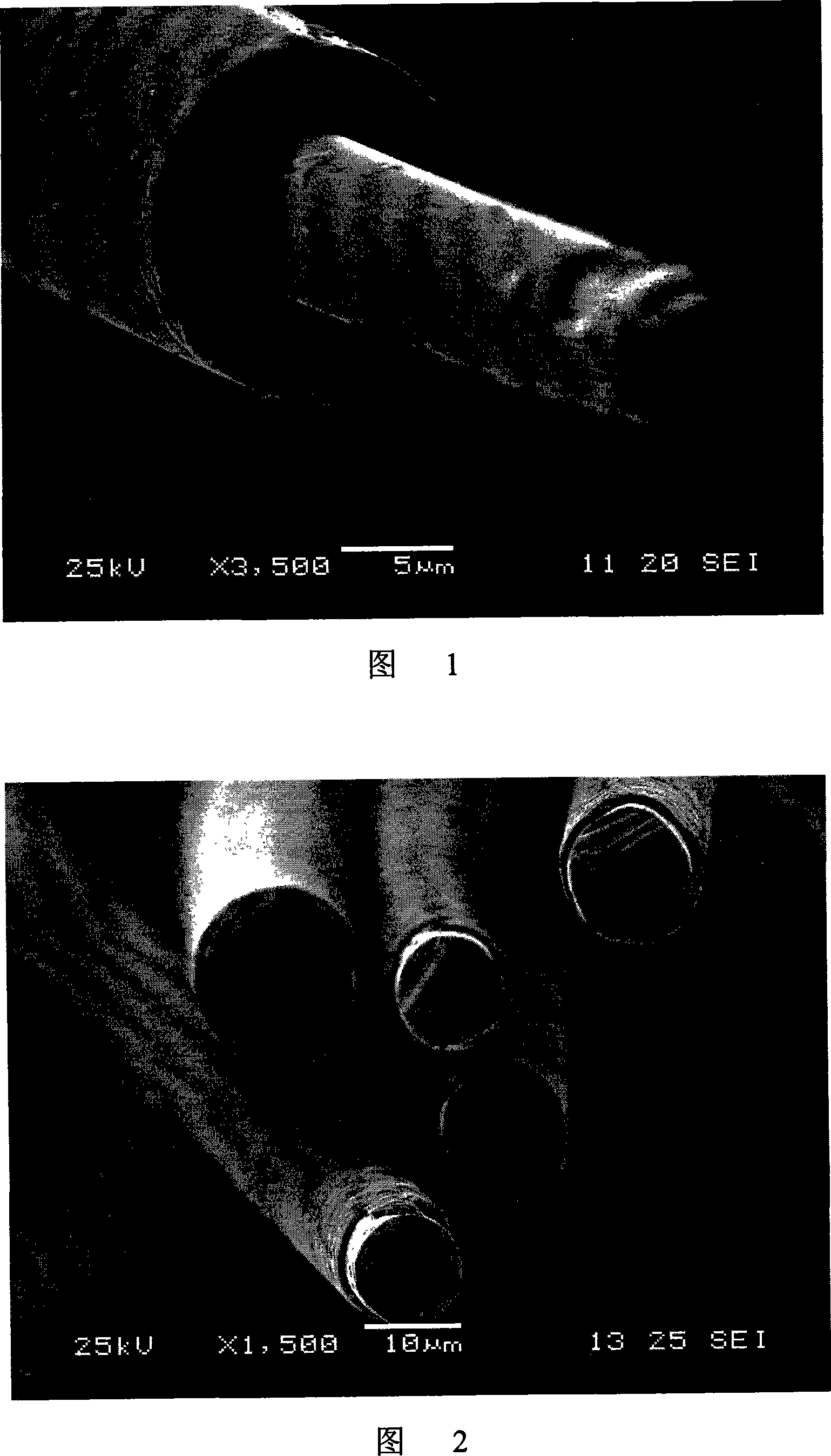

Core-skin structure micropore silicon carbide fiber and method for producing the same

InactiveCN101195938AArtificial filament heat treatmentFibre chemical featuresActivation methodChemical adsorption

The invention relates to skin-core structure micro-pore silicon carbide fiber and the preparation method, the fiber is characterized in that both the skin layer and the core part contain the micro-pore with pore diameter less than 2 nm, and the micro-pore volume content of the skin is higher than the core part; the ratio between the skin layer thickness and the radius is 0.1 to 0.9; according to the differences of the skin thickness, the specific surface area of the fiber is 400m<2> / g to 1400m<2> / g, and the average pore diameter is 1.30 to 1.60 nm; the C content of the skin layer is more than 90 wt percent, the residual is Si, or Si and O; the C content of the core part is 27 to 35 wt percent, the O content is 10 to 20 wt percent, and the residual is Si. The preparation method is characterized in that the Si element of the skin layer is etched through the KOH activation method and the skin-core structure is formed, simultaneously, the micro-pore with higher proportion is formed, the specific surface area and the conducting property of the fiber can be adjusted through the method. The skin-core structure micro-pore silicon carbide fiber of the invention can be used in the physico chemical adsorption field, catalyst carrier field, and wave-absorbed stealth field.

Owner:NAT UNIV OF DEFENSE TECH

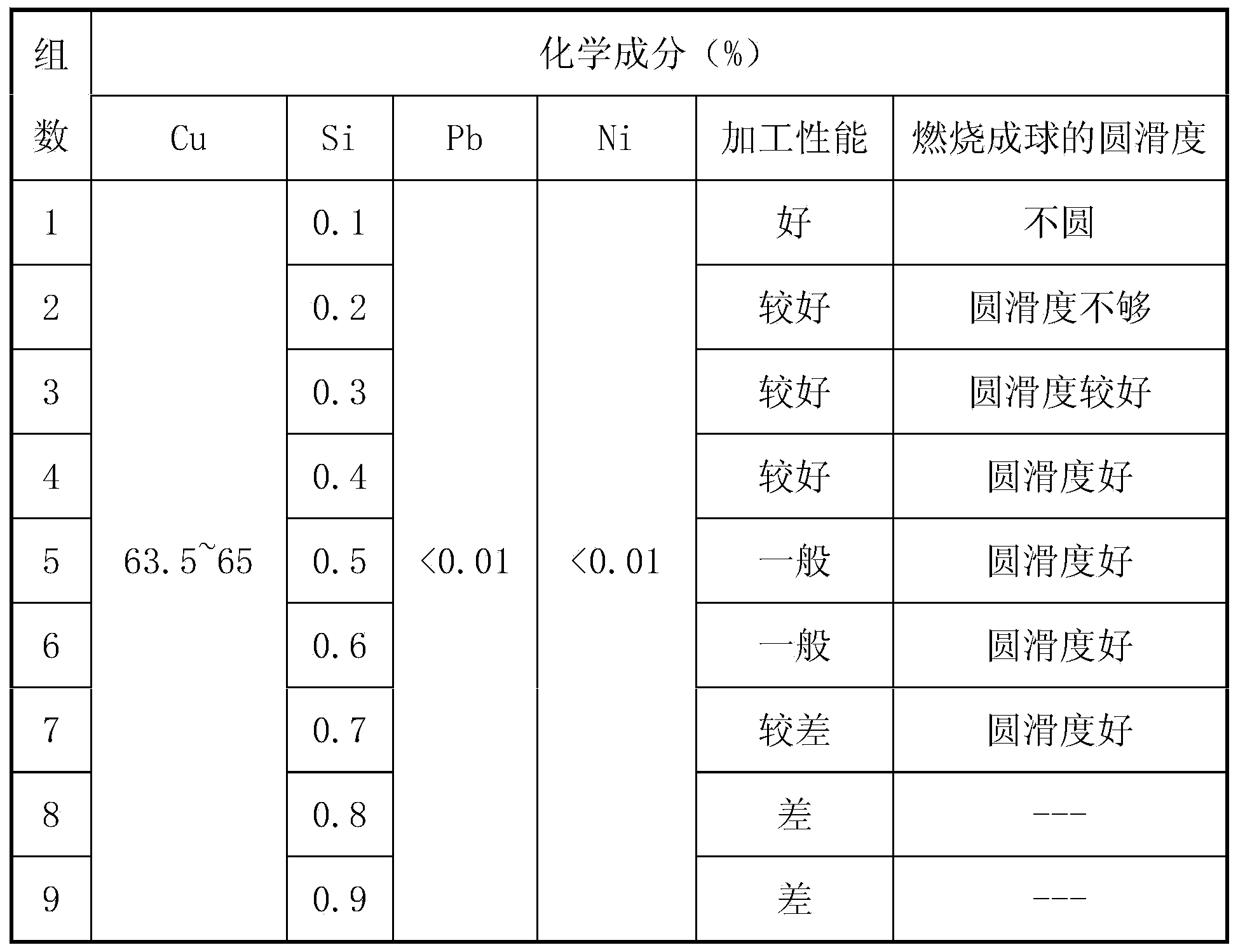

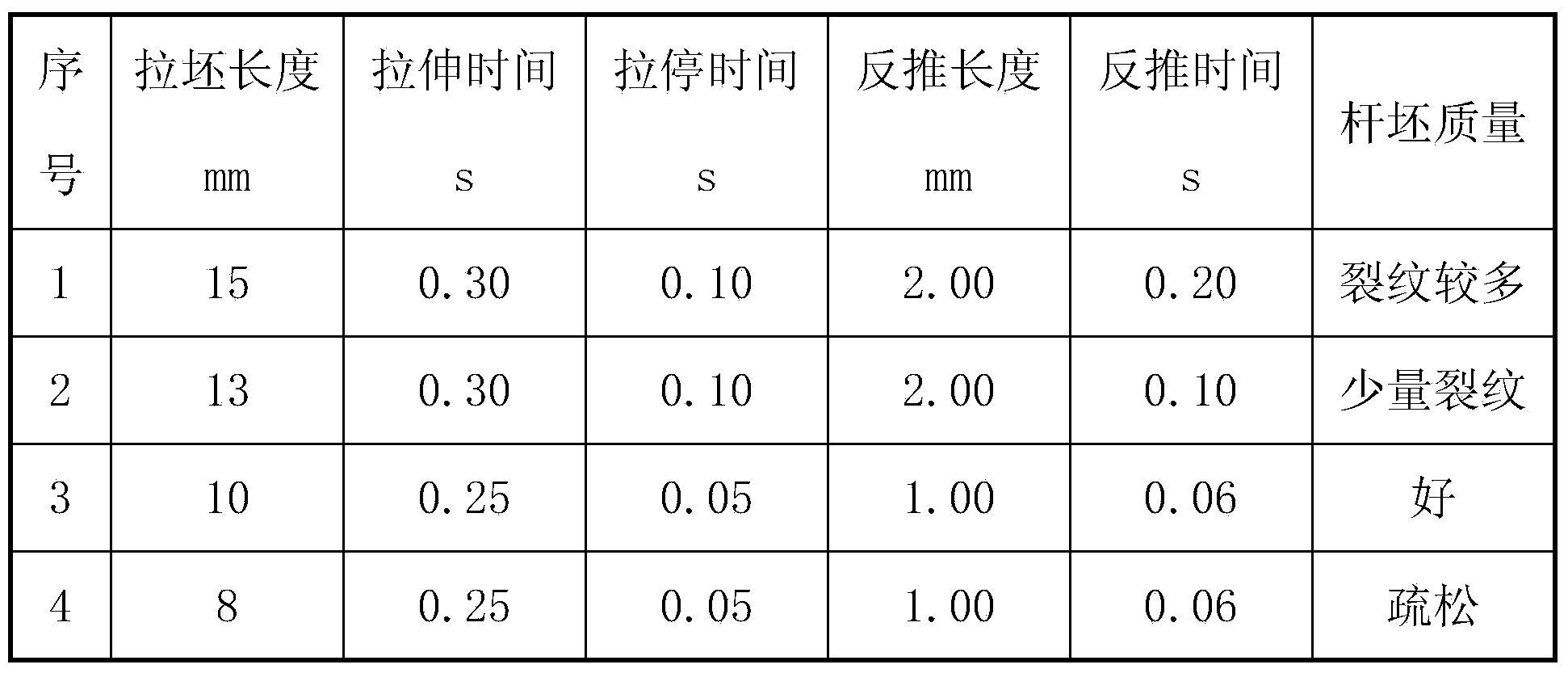

Brass wire and processing method of brass wire

The invention provides a brass wire applied to the technical field of production and processing of wires. The invention simultaneously relates to a processing method of the brass wire. The brass wire comprises the following components: Cu, Sn, Si and Zn, wherein the Cu element accounts for 63.5%-65% by weight, the Sn element accounts for 0.8-1.2% by weight, the Si element accounts for 0.10-0.50% by weight, and the balance is the Zn. In the brass wire and the processing method, provided by the invention, the mechanical performance value of the brass wire is controlled at 650-750MPa, a sphere formed by combustion is smooth and full, the problem of brittle failure caused by over-hard performance can be avoided, and the brass wire can not be processed into a ball needle due to the influence of relatively soft performance. When the brass wire is formed, a rewinding machine is adopted for taking up, and the diameter degree is good; and when the brass wire is machined by a customer, the paying-off is smooth, the wire wrapping phenomenon can be avoided, and the brass wire can completely meet the requirements of jewelry processed from the brass wires in jewelry industry.

Owner:安徽鑫科铜业有限公司

Welding wire for connection of aluminum/steel dissimilar alloy and processing process thereof

InactiveCN101745751AHigh affinityGrowth inhibitionWelding/cutting media/materialsSoldering mediaCrack resistanceCu element

The invention aims to provide a welding wire for connection of aluminum / steel dissimilar alloy and a processing process thereof. The welding wire has a good comprehensive performance, adopts a special element to substitute the Si element, ensures good flow of solder and reduces the brittleness of the compound layer on the joint interface. In the technical scheme, the welding wire is prepared through adding such elements as Ag, Mn, Mg, Ti, Zr and Zn with Al-Cu as a matrix. The processing process of the welding wire comprises stock preparation, melting, component analysis, extrusion, wire drawing and cleaning. The invention has the advantages that: due to the high content of Cu element, the invention can inhibit the growth of the compound layer on the interface, improve the performance of the Al-Fe compound layer, and particularly improves the crack resistance of the compound layer; since the Ag element, the aluminum and the steel all have high affinity, the invention can enhance the flowing property of liquid solder in the steel surface; the Mn and Ti elements can improve the performance of the compound and the flowing property of the solder; the Mg and Zn elements can promote the flowing property of the solder and improve the strength of the welding wire; and the refined grain of Zr can also enhance the strength of the welding wire.

Owner:HARBIN INST OF TECH

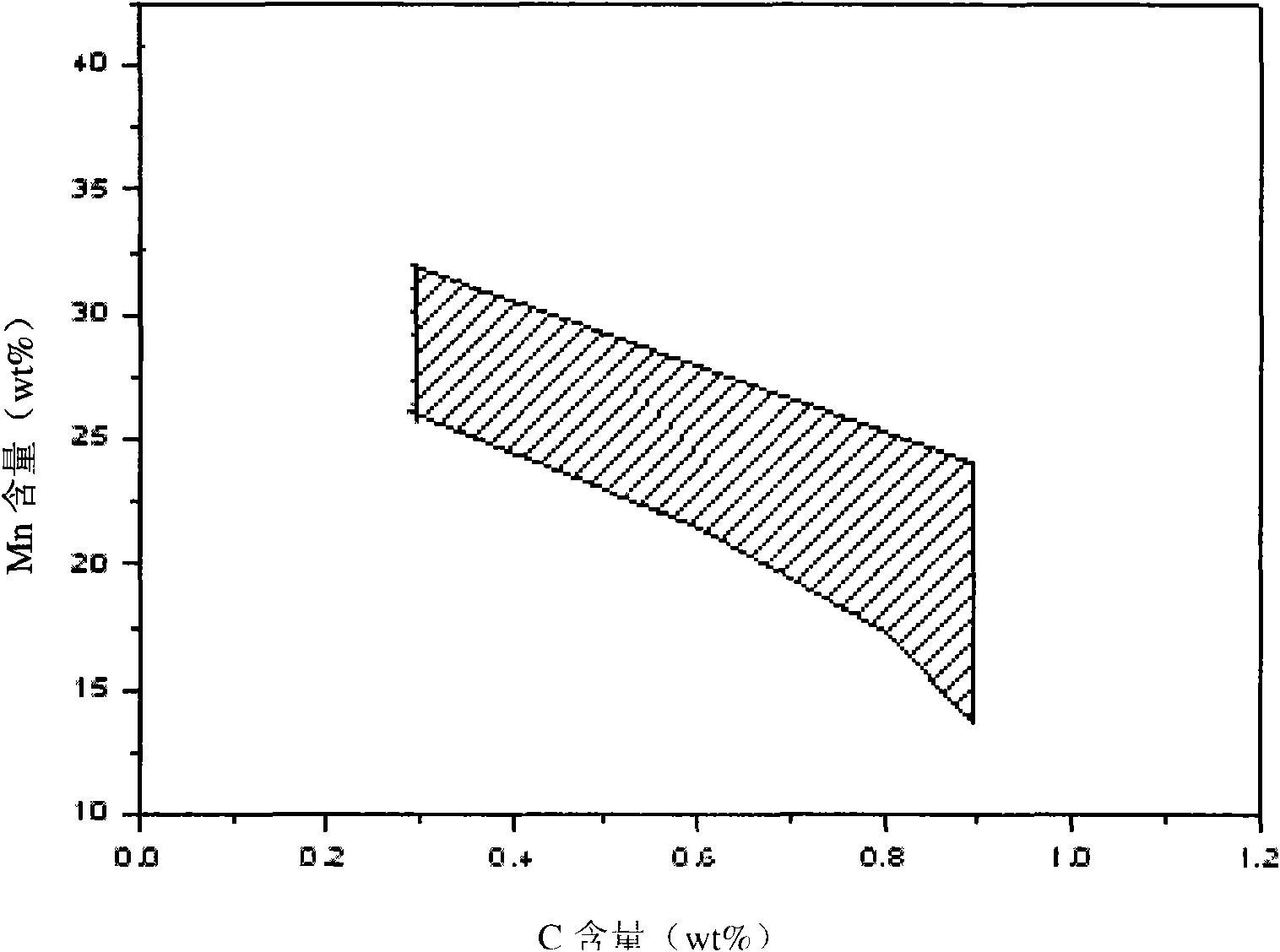

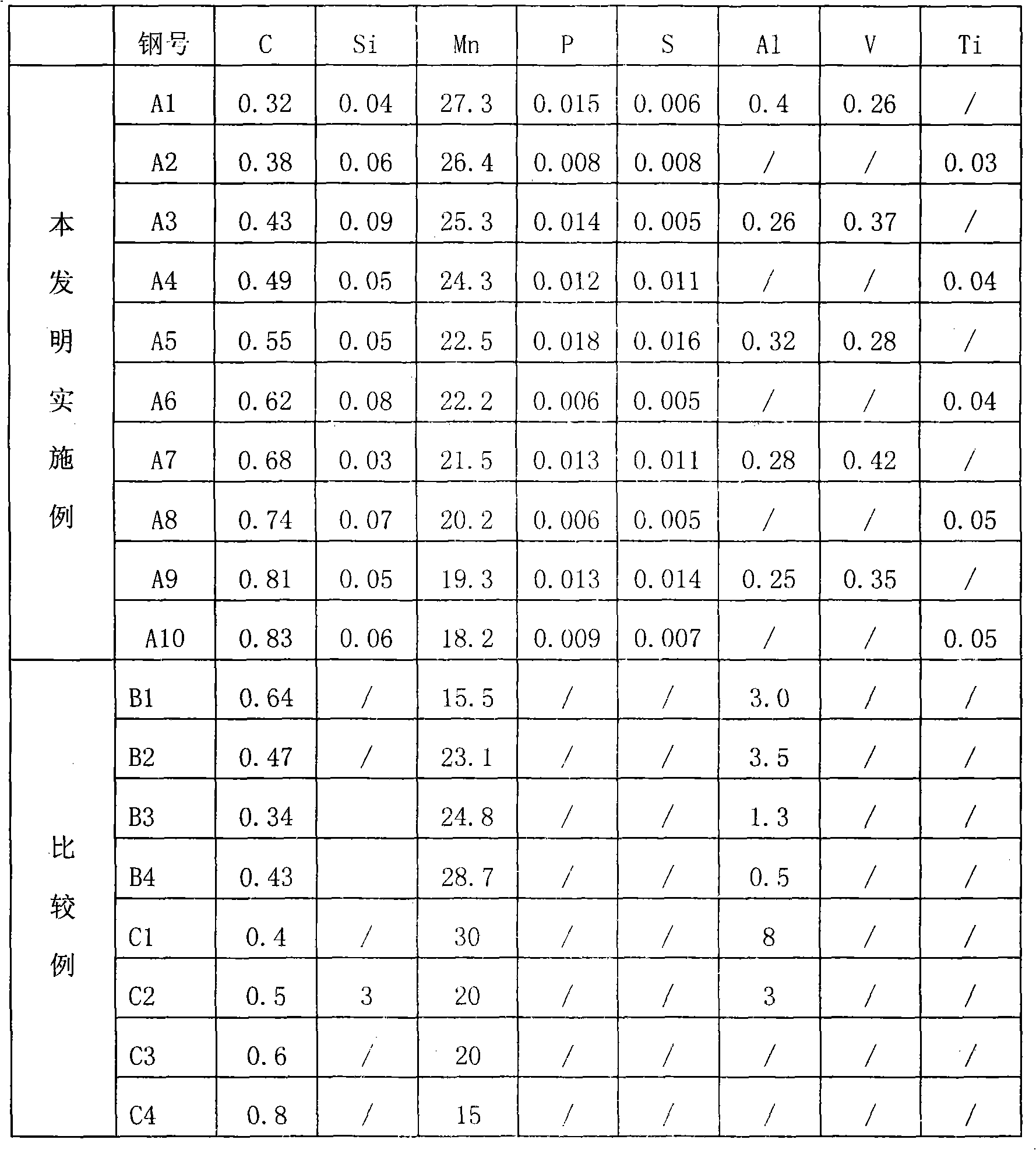

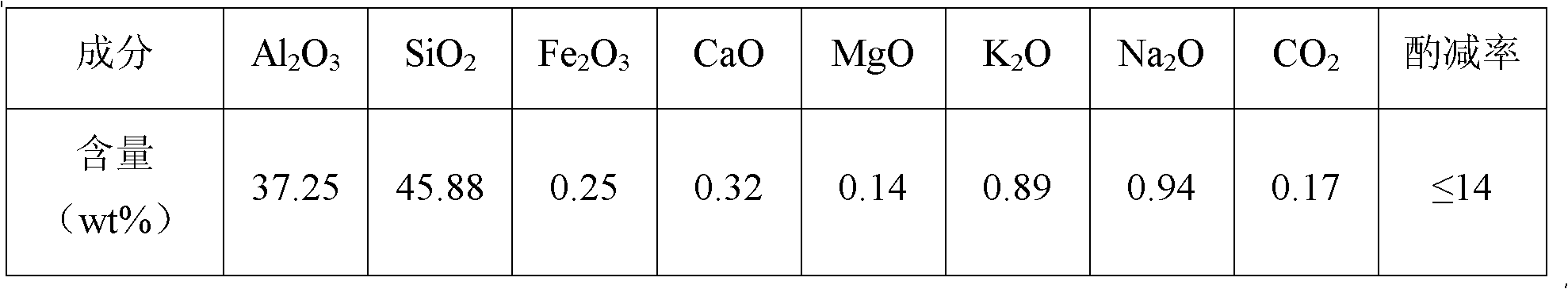

Preparation method for twinning induced plasticity (TWIP) steel for low-cost large-expansibility expansion pipe and steel pipe

InactiveCN102560259AImprove corrosion resistanceImprove cleanlinessFurnace typesHeat treatment furnacesRare-earth elementMaterials science

The invention relates to a preparation method for TWIP steel for a low-cost large-expansibility expansion pipe and a steel pipe. The TWIP steel comprises the chemical components, by weight percentage, 0.30-0.65% of C, 15-30% of Mn, 0.10-1.0% of Cr, 0.01-0.20% of Al, 0.10-1.0% of Si, 0.030-0.30% of Re, S<=0.002%, P<=0.005% and the balance ferrum. Component design is instructed through alloy stacking fault energy, vacuum smelting is conducted, rare earth ferroaluminum is deoxidized, a right amount of Cr and Si elements are added, a small amount of rare earth elements are added, and steel with low content of sulphur and phosphorus and certain grain scale for the large-expansibility expansion pipe is obtained, wherein a base body of the steel is austenite, and the steel has a twinning inducedplasticity effect. The steel is manufactured into large-expansibility large-size expandable casing pipes through hot extrusion.

Owner:SOUTHWEST PETROLEUM UNIV

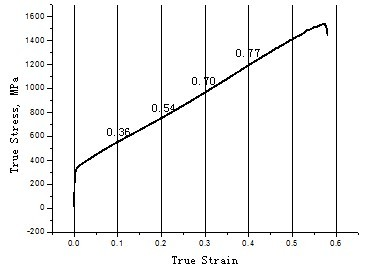

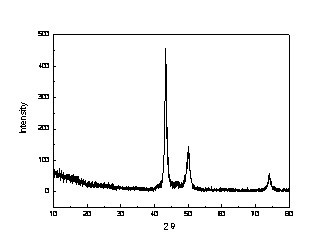

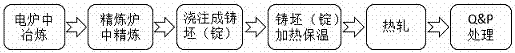

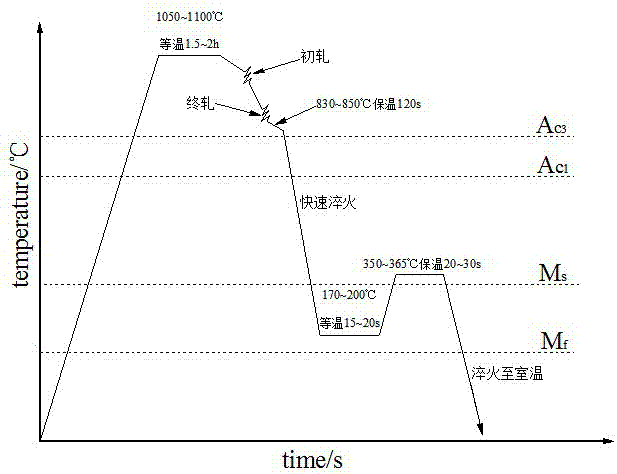

Component design and production method of 1500 MPa-grade low-carbon and medium-manganese copper-contained steel

The invention relates to component design and a production method of 1500 MPa-grade low-carbon and medium-manganese copper-contained steel. The 1500 MPa-grade low-carbon and medium-manganese copper-contained steel comprises the following chemical components in percentage by mass: 0.20-0.23% of C, 0.5-0.8% of Si, 3.5-4.0% of Mn, 1.2-2.0% of Al, 0.5-1.0% of Cr, 0.6-1.0% of Cu, 0.2-0.5% of Ni, 0.003-0.012% of N, 0.00051-0.003% of B, and the balance of Fe and inevitable impurities. One part of alloy elements are added based on traditional TRIP steel to largely increase the content of manganese to reach the medium-manganese range; when Al is used for replacing the Si elements, a proper amount of Si elements are retained, so that the Al and Si elements are matched for use; and a certain quantity of precipitation-hardened Cu elements are added to match with a proper amount of Ni elements for use to eliminate the hot brittle phenomenon caused by Cu in hot working. In addition, few Cr elements are added; a proper amount of N elements are added to match with the Al elements for use; through matching between hot rolling and hot partition processes, a martensite+residual austenite+separated second-phase particle structure with ultrahigh strength and excellent plasticity is obtained; and the tensile strength exceeds 1500 MPa.

Owner:SHANDONG JIANZHU UNIV

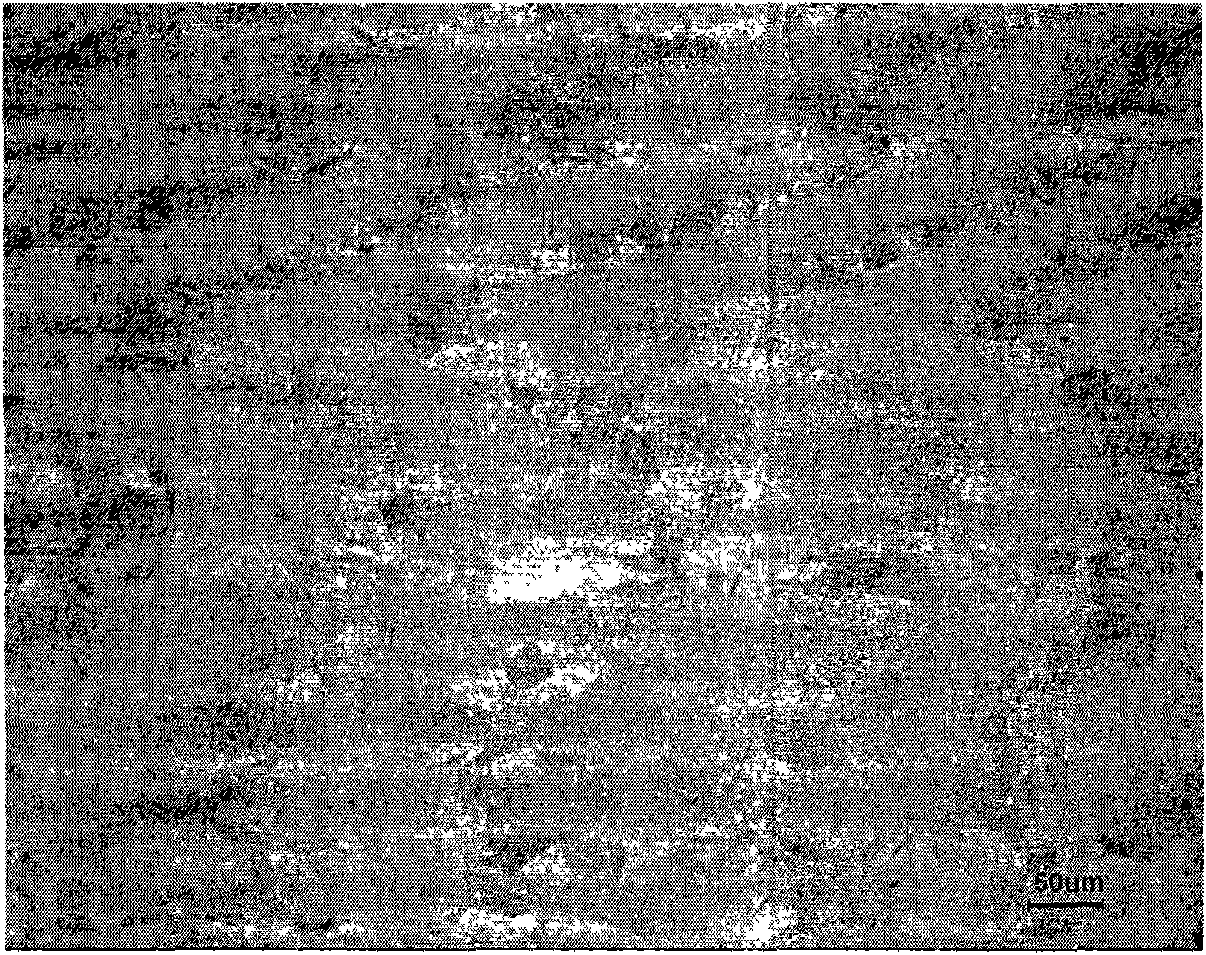

Hadifield steel with excellent mechanical property and manufacturing method thereof

The invention provides hadifield steel with excellent mechanical property, which comprises the following chemical components in percentage by weight: 0.3 to 1.0 percent of C, 15.0 to 30.0 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.025 percent of S, 0.1 to 0.4 percent of V or 0.02 to 0.06 percent of Ti, and the balance of Fe and inevitable impurities. The invention also provides a method for manufacturing the steel, which comprises the processes of pouring, casting, hot rolling, cooling and reeling. Without Ai and Si elements, the hadifield steel has good TWIP effect, high strength and high plasticity, which can be used for manufacturing automobile components with high strength, high plasticity and high impact absorption energy.

Owner:BAOSHAN IRON & STEEL CO LTD

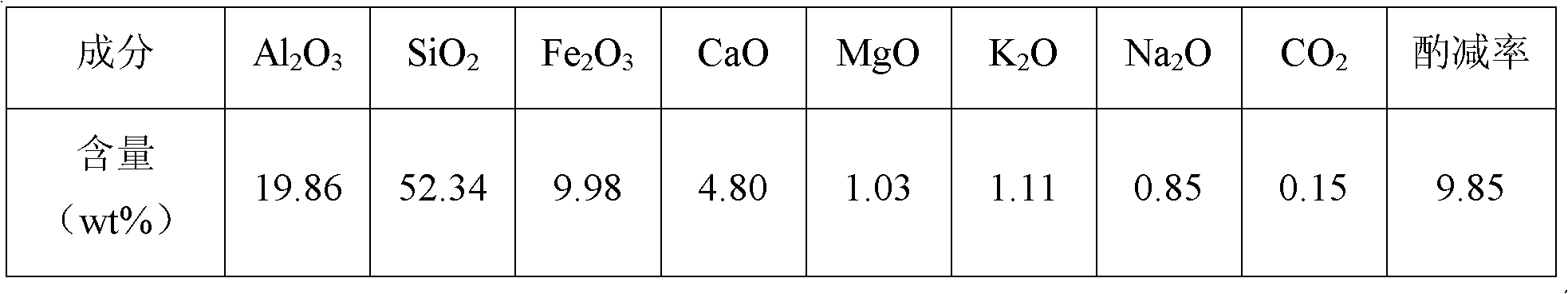

Method for producing sludge modifier by utilizing coal gangue

InactiveCN101948142ARealize resource utilizationRealize comprehensive utilizationSludge treatment by de-watering/drying/thickeningSolid waste disposalAlkalinitySludge

Owner:TIANJIN TEDA ENVIRONMENTAL PROTECTION +1

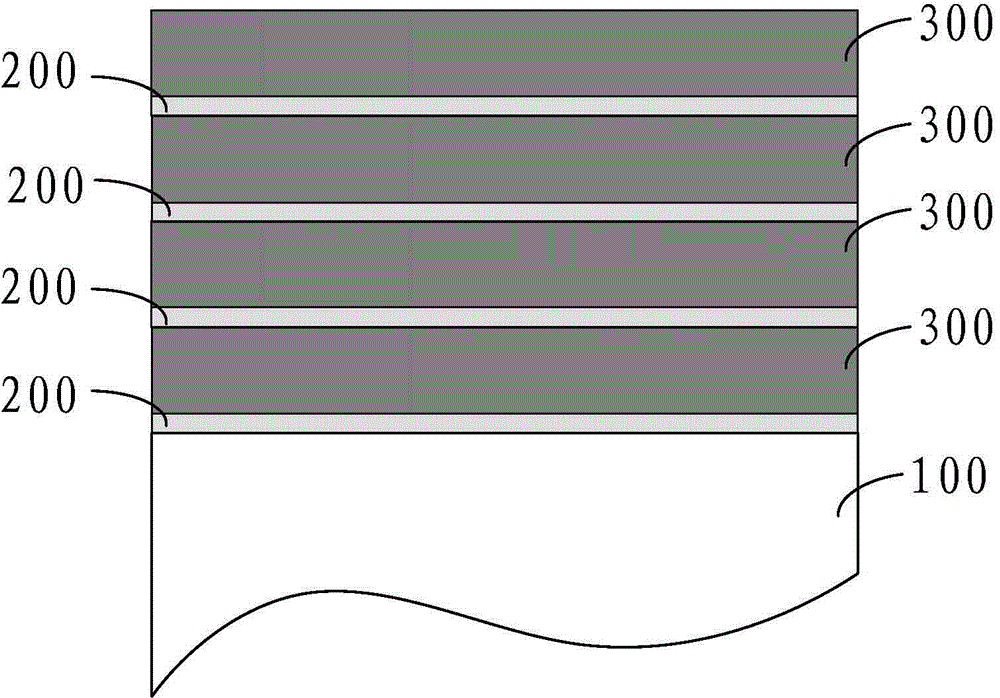

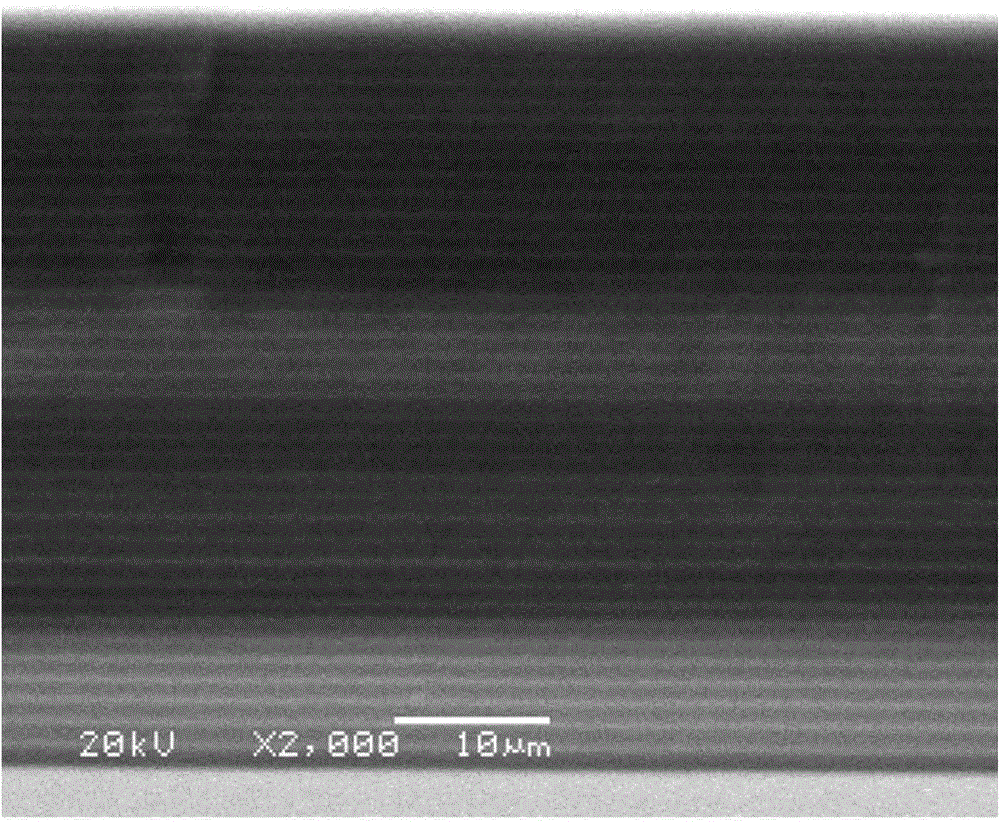

Carbon-based antifriction wear resistant coat and production method thereof

InactiveCN104694893AImproved corrosion/erosion resistanceExcellent water environment tribological propertiesVacuum evaporation coatingSputtering coatingCarbon filmWater based

The invention provides a carbon-based antifriction wear resistant coat and a production method thereof. The carbon-based antifriction wear resistant coat is a multilayer film structure formed through alternative deposition of a bonding layer and a working layer; the bonding layer is a film of simple substance or nitride or carbide of one of Ti, Cr and W elements, or a film of the Si element; and the working layer is a graphite-like amorphous carbon film, and the atom percentage content of the graphite structure in the graphite-like carbon film is not lower than 70%. The alternative deposition of the bonding layer and the working layer realizes heavy gauge production of the graphite-like amorphous carbon coat, so the water environment friction performance of the graphite-like amorphous carbon coat is stable for a long time; and the above alternative deposition multi-interface design improves the corrosion / erosion resistance of the graphite-like amorphous carbon coat in various water-based fluid environments.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

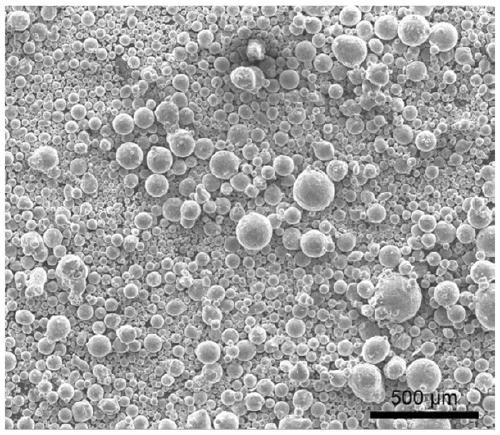

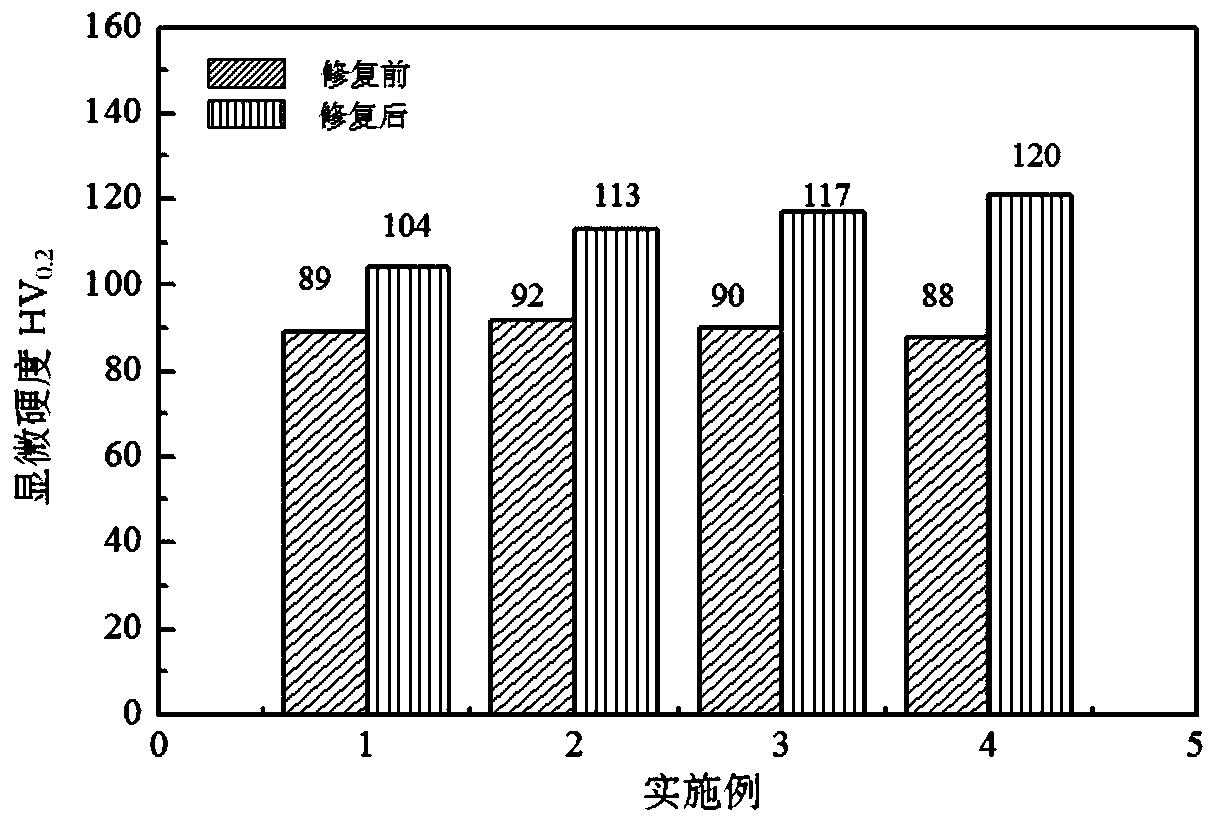

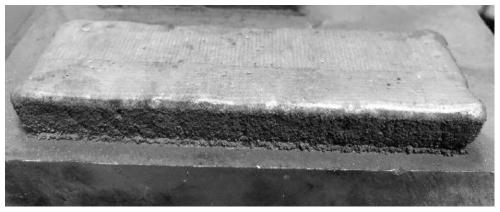

Aluminum alloy powder for laser coaxial powder feeding additive manufacturing and application of aluminum alloy powder in repairing 5-series aluminum alloy

ActiveCN111593238AEliminate anisotropyIncrease contentAdditive manufacturing apparatusMetallic material coating processesSi elementAluminium alloy

The invention discloses aluminum alloy powder for laser coaxial powder feeding additive manufacturing and application of the aluminum alloy powder in repairing 5-series aluminum alloy. The aluminum alloy powder is composed of the following components in percentage by mass: 0.4-1.5 wt% of Si, 0.5-5.0 wt% of Mg, 0.15-0.8 wt% of Cu, 0.05-0.9 wt% of Mn, 0.15-0.7 wt% of Zn, 0.01-1.0 wt% of Cr, 0.2-1.2wt% of Ti, 0.1-2.0 wt% of Fe, 0.2-2.1 wt% of Zr, 0.2-2.1 wt% of Sc, 0.15-0.65 wt% of Ni, 0.2-2.5 wt% of TiB2, 0.1-0.9 wt% of Ce, and the balance of Al. The beneficial elements including Zn, Cr, Ti, Fe, Ni, TiB2 and Ce are added on the basis of the 5-series aluminum alloy, second phases such as a long-range ordered phase and a twin crystal phase are formed to form synergistic reinforcement of the elements, so that the anisotropy of the material is eliminated, meanwhile, the content of Si element is increased, then a eutectic structure is formed in the later period of laser cladding solidification, and the eutectic structure is used for supplementing hot crack pores caused by rapid solidification.

Owner:CENT SOUTH UNIV +1

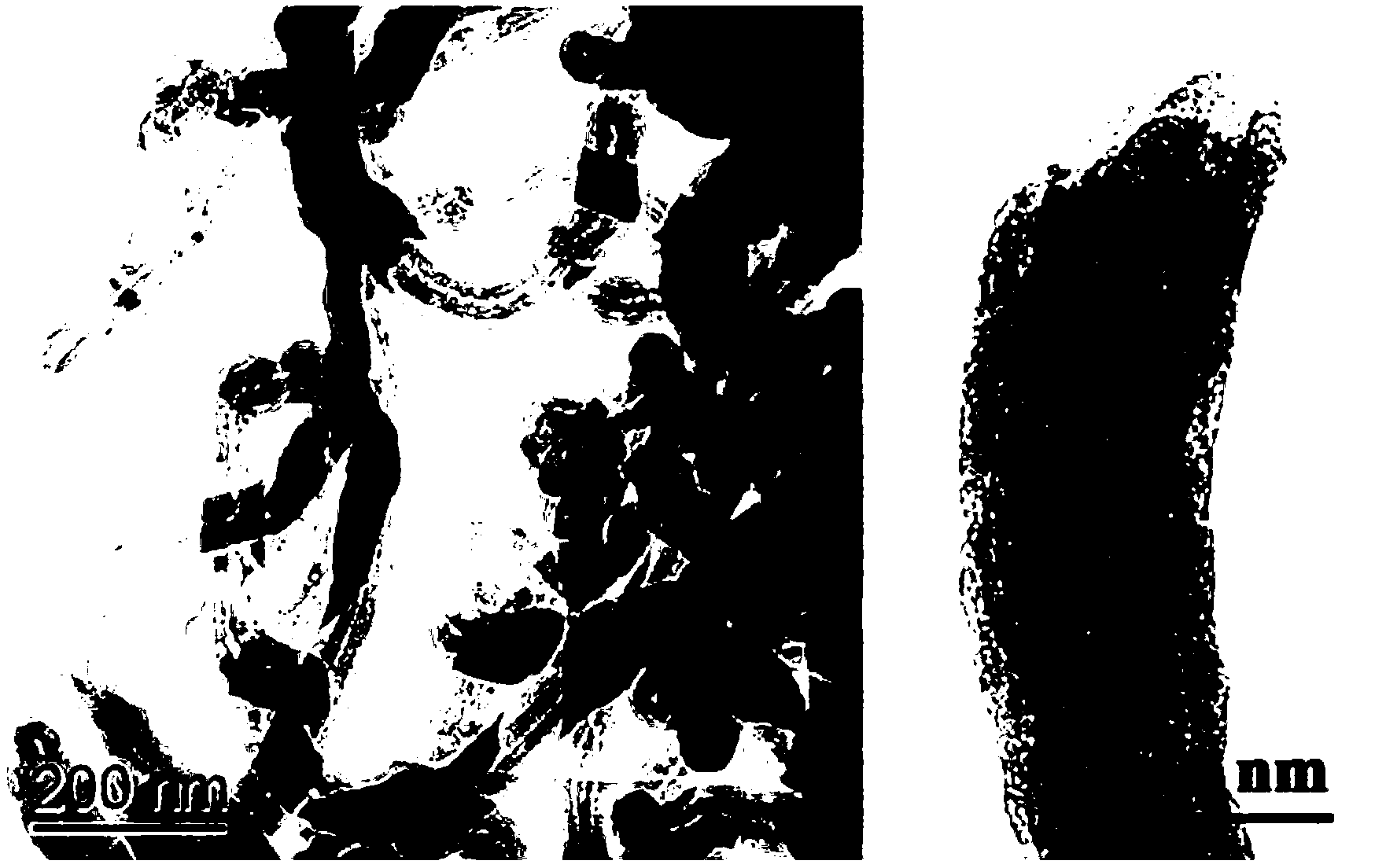

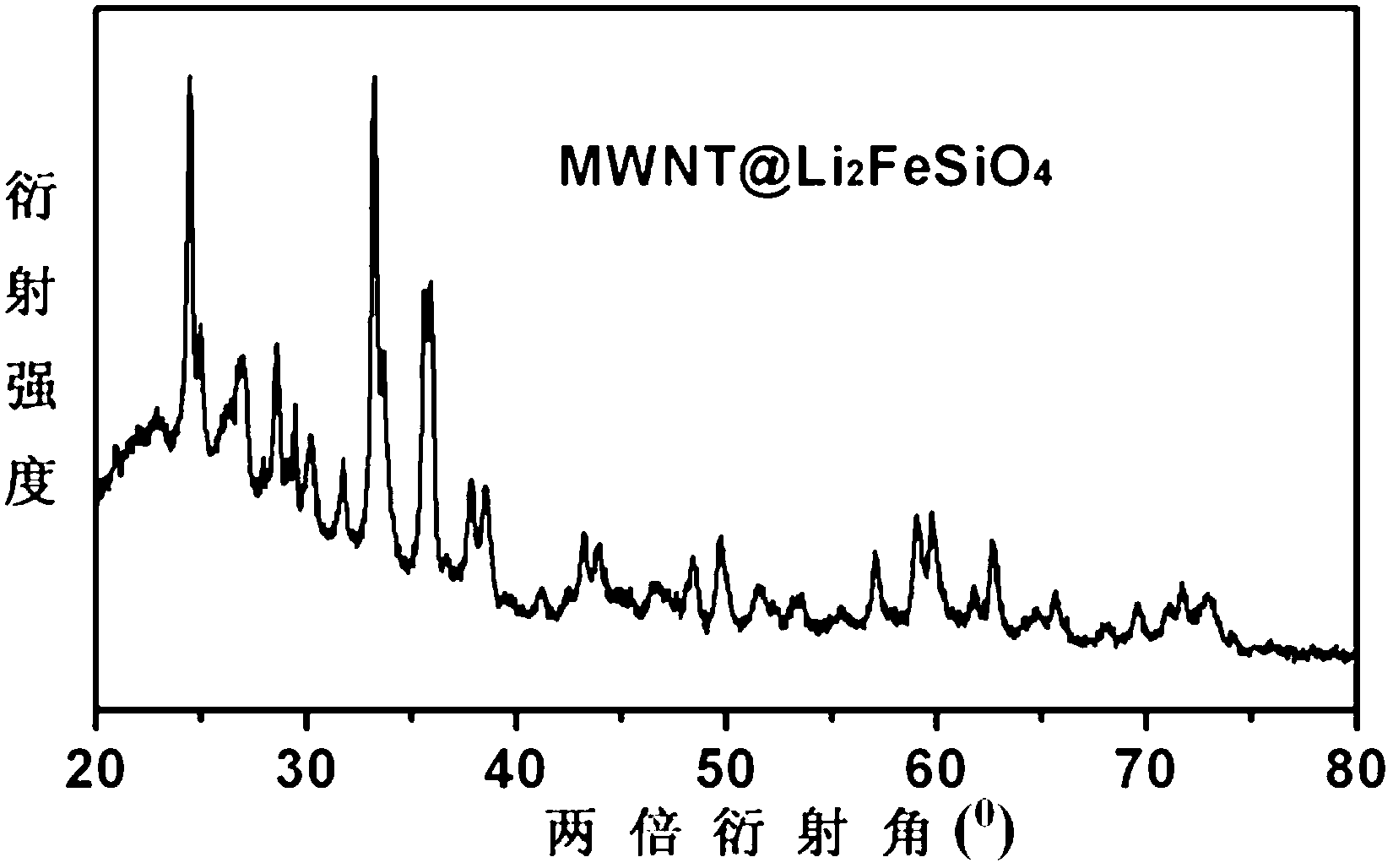

Preparation method of carbon nano-Li2FeSiO4 composite cathode material

InactiveCN102709561AImprove conductivityImprove electrochemical activityCell electrodesComposite cathodeCarbon nanomaterials

The invention provides a preparation method of a carbon nano-Li2FeSiO4 composite cathode material. The preparation method comprises the following steps of: uniformly loading different contents of silica on the surface of a carbon nanomaterial, taking a carbon nano-silica compound as a template, dissolving the carbon nano-silica compound in ethanol according to the molar ratio of Fe element to Si element to Li element of 1: 1: 2 and carrying out uniform ultrasonic mixing; stirring the mixing liquid at 60 DEG C till the ethanol is completely volatilized, uniformly grinding the obtained solid in an agate mortar, and tabletting the powder obtained after grinding; and heating the tablets in an inert atmosphere to 550-650 DEG C and calcining at constant temperature for 5-10h to obtain the carbon nano-Li2FeSiO4 composite cathode material with a core-shell structure.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com