Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

297 results about "Mn element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nickel-rich concentration gradient type lithium nickel cobalt aluminum oxide positive pole material, preparation method thereof and lithium ion battery

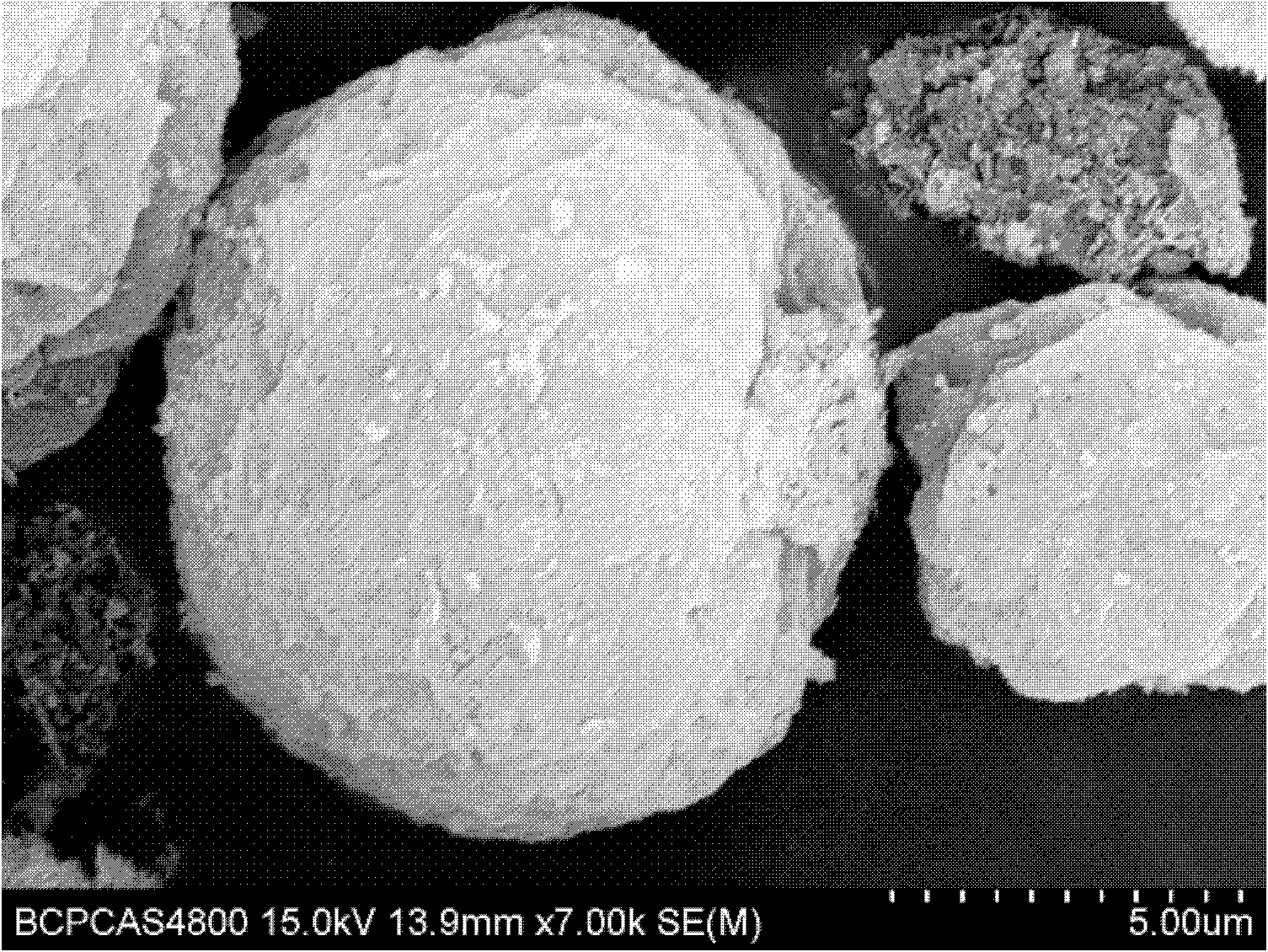

ActiveCN104300135AImprove cycle performanceLower pHCell electrodesSecondary cellsSodium-ion batteryConcentration gradient

The invention provides a nickel-rich concentration gradient type lithium nickel cobalt aluminum oxide positive pole material, a preparation method thereof and a lithium ion battery. The nickel-rich concentration gradient type lithium nickel cobalt aluminum oxide positive pole material has a near-spherical appearance and a core-shell structure, wherein the content of Ni element in an inner layer is high, the content of Mn element in an outer layer is high, bulk molybdenum element doping is performed, and the surfaces of particles are coated with aluminum oxide. The reversible discharge capacity of the nickel-rich concentration gradient type lithium nickel cobalt aluminum oxide positive pole material provided by the invention under the current density of 350mA / g is more than 172mAh / g, and the capacity retention rate after 100 times of charge and discharge cycles at the rate of 2C is more than 85%. The lithium ion battery which takes nickel-rich concentration gradient type lithium nickel cobalt aluminum oxide as the positive pole material has the prominent advantages of high capacity, good thermal stability, good cycling stability, excellent rate property and the like, and has broad application prospects in the fields of electronic equipment, communication, transportation and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

F, Mn codoped deposit nano SnO2 transparent thermal-insulation film

The invention discloses an F, Mn co-doping deposition nano-SnO2 transparent heat insulating thin film, wherein the F, Mn element co-doping effect is utilized to increase the number charge carriers in the thin film material, thus increasing the index of thin film reflection to infrared rays. The invention can prevent the excess doping of one single element, it can be applied to chemical CVD or supersonic spraying thermal dissociation deposition.

Owner:雷智 +1

Method for producing manganese nitride

InactiveCN101172586AImprove thermal efficiencyProcess stabilityNitrogen-metal/silicon/boron binary compoundsManganese compoundsHydrogenNitrogen

The invention provides a preparation method of nitrogenized manganese. The nitrogenized manganese is prepared by continuously nitriding the material containing manganese in the atmosphere containing nitrogen and reducible hydrogen gas with 0.01 to 10 MPa absolute pressure through a nitriding reactor at 350 to 1200 DEG C, the nitrogen content in the obtained nitrogenized manganese is 3 to 25 percent, and the Mn element content is higher than 50 percent.

Owner:冯良荣

Method for preparing nano-scale lithium ion battery anode material

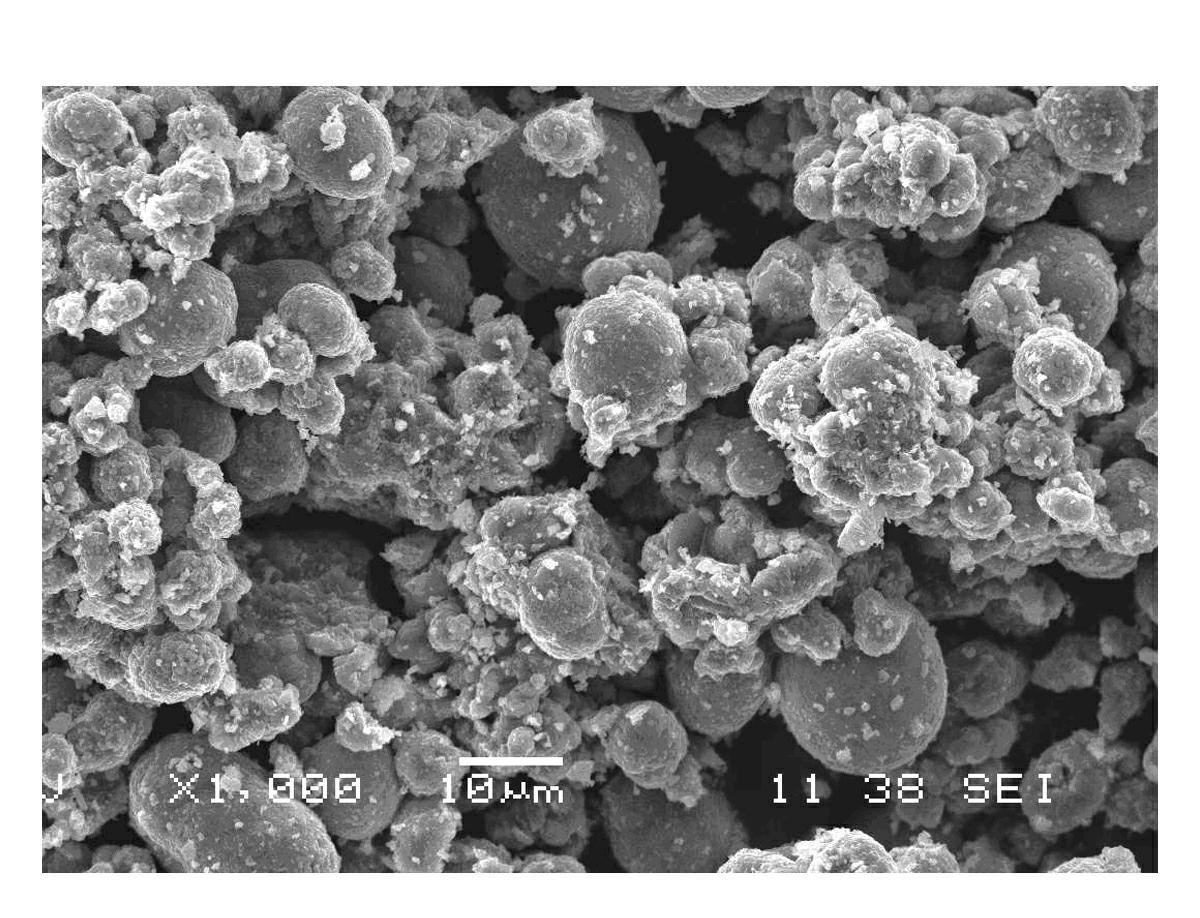

InactiveCN101867039AWell mixedUniform particle size distributionCell electrodesReaction temperatureBULK ACTIVE INGREDIENT

The invention discloses a method for preparing a nano-scale lithium ion battery anode material. The anode material is LiNixCoyMnzO2(x+y+z=1). The method comprises: dissolving compounds which contain Li, Ni, Co and Mn elements in deionized water, fully mixing the mixture to obtain uniform mixed solution, adding solution of precipitator into the mixed solution, transferring the mixed solution into a water / oil bath pot to heat the mixed solution to perform a reaction fully to obtain a LiNixCoyMnzO2(x+y+z=1) precipitate, filtering the reaction solution, washing the precipitate, drying the precipitate by spraying, and sintering the precipitate in the air at a high temperature to obtain the LiNixCoyMnzO2(x+y+z=1) anode material of which the primary particle size is of nano scale. In the invention, the LiNixCoyMnzO2(x+y+z=1) anode material for alpha-NaFeO2 type lithium ion batteries, of which the primary particles have a nano spherical polymer structure, is prepared by combining co-precipitation and spray drying, the active ingredients are mixed uniformly, the activities of the reactants are high, the reaction time and reaction temperature are reduced, the obtained product is of the nano scale and the particle size distribution of the product is uniform.

Owner:IRICO

High tensile strength low carbon bainite thick steel plate and its production method

InactiveCN1786245AReduce carbon contentLow carbon content, low temperature toughnessOther manufacturing equipments/toolsChemical compositionHigh intensity

The invention offers a high tensile strength low carbon bainite coarse plate and its manufacturing method. Its compositions (Wt%) are C 0.052%-0.08%, Si 0.1%-0.5%, Mn1.65%-1.90%, Nb 0.015%-0.060%, Ti 0.005%-0.03%, B 0.0005%-0.003%, Mo 0.25%-0.50%, Cu 0.62%-0.85%, Ni 0.42%-0.80%, Al 0.015%-0.05%, and rest Fe and other inevitable impurity. The invention adopts low cost Mn element as the main additional element, fully applies the changing action of Cu, Mo, Ni, Nb, B to the bainite. The steel has low carbon, good low temperature toughness, welding performance, and forming performance. Its Nb and Ti element is low. And it is fit for large-scale industrialization continuous casting production. The TMCP+ RPC+T technique is adopted to make tensile strength over 900N / mm2 high intensity and tenacity steel. Adopting lower steel blank heating temperature can economize energy and improve steel low temperature toughness. The product can apply in engineering machinery, digging machinery, heavy-duty car, and marine facilities field, and etc.

Owner:UNIV OF SCI & TECH BEIJING +1

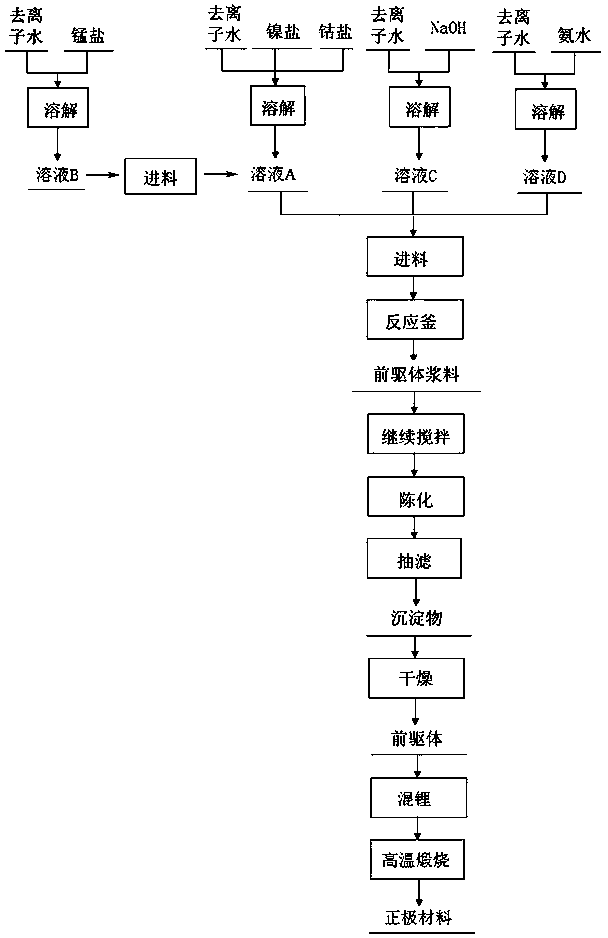

Preparation method of nickel-cobalt-manganese ternary material enabling element content in gradient distribution

InactiveCN108598466AImprove co-precipitation synthesis processImprove stabilitySecondary cellsPositive electrodesManganeseLithium-ion battery

The invention belongs to the technical field of the lithium ion battery material preparation, and specifically relates to a preparation method of a nickel-cobalt-manganese ternary material enabling element content in gradient distribution. The chemical formula of the positive material is LiNixCoyMnzO2, x is not less than 0.5 and not more than 0.9, and the sum of x, y and z is equal to 1. The preparation process disclosed by the invention is based on co-precipitation method principle, the concentration of the metal ion entering the reaction kettle is continuously changed by changing the feedingway, the Mn element concentration is gradually increased, the concentration of each of the Ni element and the Co element is gradually reduced, thereby synthesizing the nickel-enriched positive material precursor particle with gradiently increased Mn element content and gradiently reduced Ni element content from center to the surface, and finally the nickel-enriched positive material with elementsin gradient distribution is formed by calcining the nickel-enriched positive material precursor particle with the lithium source in a mixed way. The full-gradient material is obviously different fromthe material with uniformly distributed elements from inside to outside and synthesized through the common co-precipitation method, and the higher specific capacity and good circulating performance and heat stability are provided.

Owner:HARBIN INST OF TECH AT WEIHAI

Anticorrosion coating for neodymium-iron-boron rare earth permanent magnet and manufacturing method thereof

ActiveCN102191464AUndamagedReduce scratchesVacuum evaporation coatingSputtering coatingRare earthHardness

The invention relates to a coating for a neodymium-iron-boron aluminum-based alloy and a manufacturing method thereof, wherein the coating has excellent anticorrosion properties and higher hardness. The coating for the aluminum-based alloy comprises an inner layer and an outermost layer, wherein the inner layer consists of an aluminum-based alloy coating A or B which comprises the component of Al100-x-Mx; and the outermost layer consists of an oxide layer alloy which comprises the component of (Al100-x-Mx)2O3, wherein M is one or more of Cr, Co, Mo, W, Zr, Ti, Nb and Mn elements, and x is more than or equal to 0.05 and is less than or equal to 10, and is average atomic percent. The coating is obtained through treatment by a vapor deposition process or a sputtering process, has the characteristics of higher hardness, strong bonding force, high compactness and the like, and can better protect neodymium-iron-boron magnets from being corroded to the maximum extent.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH

Application of high-entropy alloy powder to laser cladding

InactiveCN105401042AImprove wettabilityHigh hardnessMetallic material coating processesHigh entropy alloysHardness

Owner:TIANJIN UNIV

Manufacturing method of steel

The invention provides a manufacturing method of steel, comprising the following steps: smelting the molten steel to ensure that the content of P in the molten steel is less than or equal to 0.035%, the content of S is less than or equal to 0.015% and the content of V is less than or equal to 0.15%; then adding Cu element and Ni element to the molten steel to ensure that the content of Cu in the molten steel is 0.20-0.60% and the content of Ni is 0.15-0.55%; tapping to a steel ladle when the content of C in the molten steel is below 0.05%; adding physical mixture of lime and fluorite and predeoxidizing agent to the steel ladle in the tapping process to ensure that the content of S in the molten steel is less than or equal to 0.012%; adding Cr element, Si element and Mn element to the molten steel to ensure that the content of Si in the molten steel is 0.25-0.60%, the content of Mn is 0.80-1.60% and the content of Cr is 0.20-0.80%; feeding Al simple substance to the molten steel to carry out final deoxidation; heating the molten steel in the condition of argon blowing to lead the steel slag to melt; then adding Al simple substance to the steel ladle to ensure that the content of S in the molten steel is less than or equal to 0.010%; and then adding C element to the molten steel to ensure that the content of C in the molten steel is 0.08-0.16%; feeding Al simple substance and alloy containing Ti, V and N to the molten steel to control that the content of acid-soluble aluminium in the molten steel is 0.025-0.040%, the content of Ti is 0.005-0.015%, the content of V is 0.08-0.15% and the content of N is 0.010-0.020%.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +3

Single crystal ternary cathode material having gradient concentration distribution and primary particle oriented growth, preparation method thereof and lithium ion battery

ActiveCN109560276AImproved magnification performanceImprove cycle stabilityCell electrodesSecondary cellsCyclic processSingle crystal

The invention provides a single crystal ternary cathode material having gradient concentration distribution and primary particle oriented growth. The single crystal ternary cathode material having gradient concentration distribution and primary particle oriented growth microstructure does not easily produce stress to destroy the structure during charge and discharge compared to ternary cathode materials having a core-shell structure of a two-phase interface and a non-directional growth structure; the surface Mn content is the same as the bulk Mn content, which effectively alleviates the dissolution of Mn element during the cycle; the structure of primary particle oriented growth can greatly shorten the Li+ migration distance and increase the migration rate of Li+, thereby improving the rate performance and cycle stability of the material; the surface of single crystal particles is smooth, can be in good contact with a conductive agent, and is greatly compact, which is beneficial to increasing the volumetric energy density of the material.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

High-nickel lithium ion positive electrode material and preparation method thereof

InactiveCN110034297AReduce the mixing degree of lithium and nickelHigh discharge specific capacitySecondary cellsPositive electrodesLithiumCrystal structure

The invention discloses a high-nickel lithium ion positive electrode material. The molecular formula is LiNi<x>Co<y>Mn<1-x-y-z>M<z>O2, wherein M is a doping element, the lithium ion positive electrodematerial is spherical secondary particle formed by gathering primary particle, and the structure of the lithium ion positive electrode material is a homogeneous-phase structure, a core-shell structure and a concentration gradient structure. The preparation method of the lithium ion positive electrode material comprises the steps of preparing a high-nickel positive electrode material precursor andpreparing the lithium ion secondary battery positive electrode. The precursor of the high-nickel positive electrode material is synthesized by a co-precipitation method, uniform mixing of elements can be facilitated, reaction can be more sufficient by adding the aging process, and morphology control is facilitated; and with the adoption of multi-element co-doping, the stability of a material crystal structure can be improved, the content of a Mn element is reduced, other doping elements are introduced, the lithium and nickel mixed arrangement degree of the high-nickel positive electrode material can be reduced, the orderliness of a layered material is ensured, the structure of the material is stabilized, the discharging specific capacity is improved, so that the energy density of the battery is improved.

Owner:SUNWODA ELECTRIC VEHICLE BATTERY CO LTD

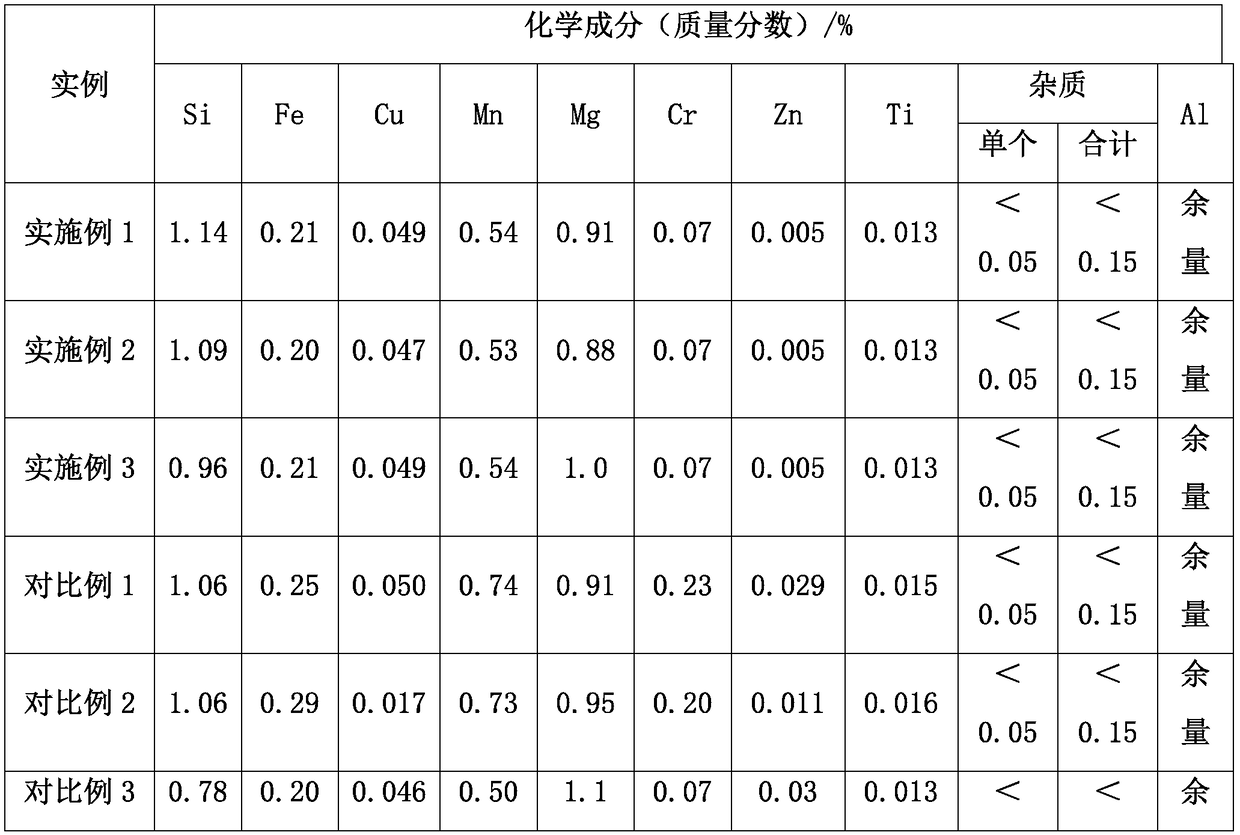

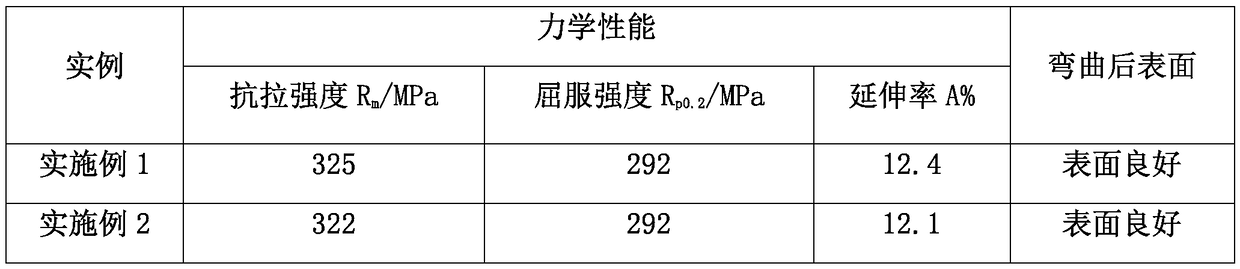

6082S aluminum alloy sheet for stamping and processing technology thereof

The invention belongs to the technical field of aluminum alloy processing, and relates to a 6082S aluminum alloy sheet for stamping and a processing technology thereof. The 6082S aluminum alloy sheetis prepared from the following elements of, in percentage by weight, 0.9-1.2% of Si, 0.1-0.25% of Fe, less than or equal to 0.1% of Cu, 0. 5-0.6% of Mn, 0.8-1.1% of Mg, less than or equal to 0.1%of Cr, less than or equal to 0.1% of Zn, 0.01-0.02% of Ti, less than or equal to 0.05% of a single impurity, less than or equal to 0.15% of total impurities, and the balance Al. The defect that the existing 6082 aluminum alloy is wide in range is solved, due to the existence of Fe and Mn elements in the alloy, micron-scale AlFeSi, AlMnSiFe and Al6Mn phases are often separated out in the solidificationprocess, the coarse one-time solidification phases is hard and brittle, is difficult to dissolve in an aluminum matrix in subsequent homogenization and solid solution treatment, in the stamping process, a crack source can be easily formed, so that stamping cracking is caused; by controlling the component range of 6082 aluminum alloy, a thin plate with good stamping performance is obtained.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

Method for preparing nano lithium manganese phosphate material with uniform size

InactiveCN103996853AUniform sizeReduce energy consumptionMaterial nanotechnologyCell electrodesOrganic solventRoom temperature

The invention provides a method for preparing a nano lithium manganese phosphate material with uniform size. The method comprises the steps of adding H3PO4 into a mixed solvent consisting of an organic solvent and water, wherein the organic solvent and the water are in volume ratio of (0.2-1) to 1; adding LiOH, and adjusting the pH value to be 9.5 to 13; adding oleic acid and uniformly stirring, wherein the concentration of oleic acid is 0.02 to 0.2mol / L; adding MnSO4, and maintaining the molar ratio of Mn elements and P elements to be 1 to 1; transferring the solution into a hydrothermal reaction kettle and reacting for 5h to 30h under the temperature of 90 to 210 DEG C; cooling at room temperature, then opening the hydrothermal reaction kettle, filtering the solution, separating the mixture, and drying a product at the temperature of 50 to 90 DEG C to obtain the nano lithium manganese phosphate material with uniform size. The size of the material is uniform and is smaller than 40nm, the device is simple, and the energy consumption is low; the method has the characteristics that raw materials are easily available and environmentally friendly.

Owner:TIANJIN UNIV

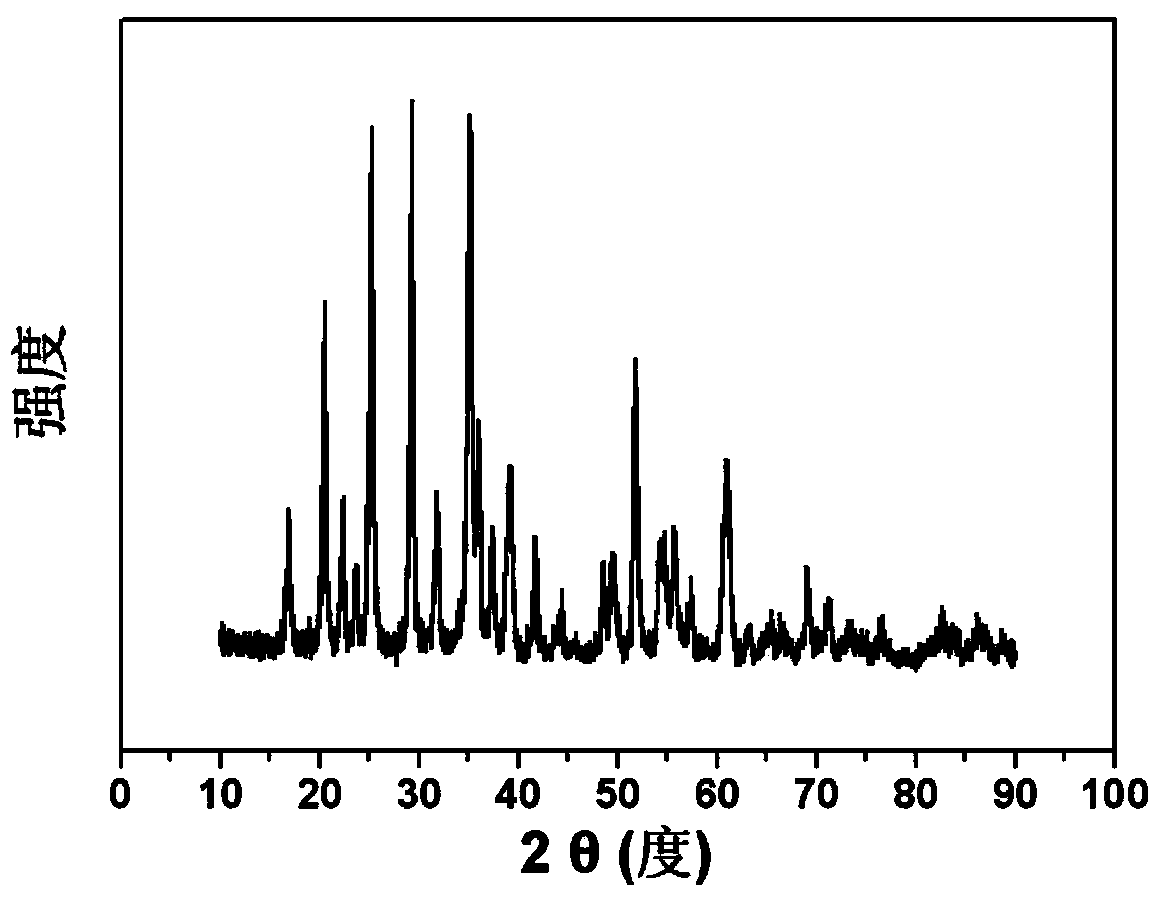

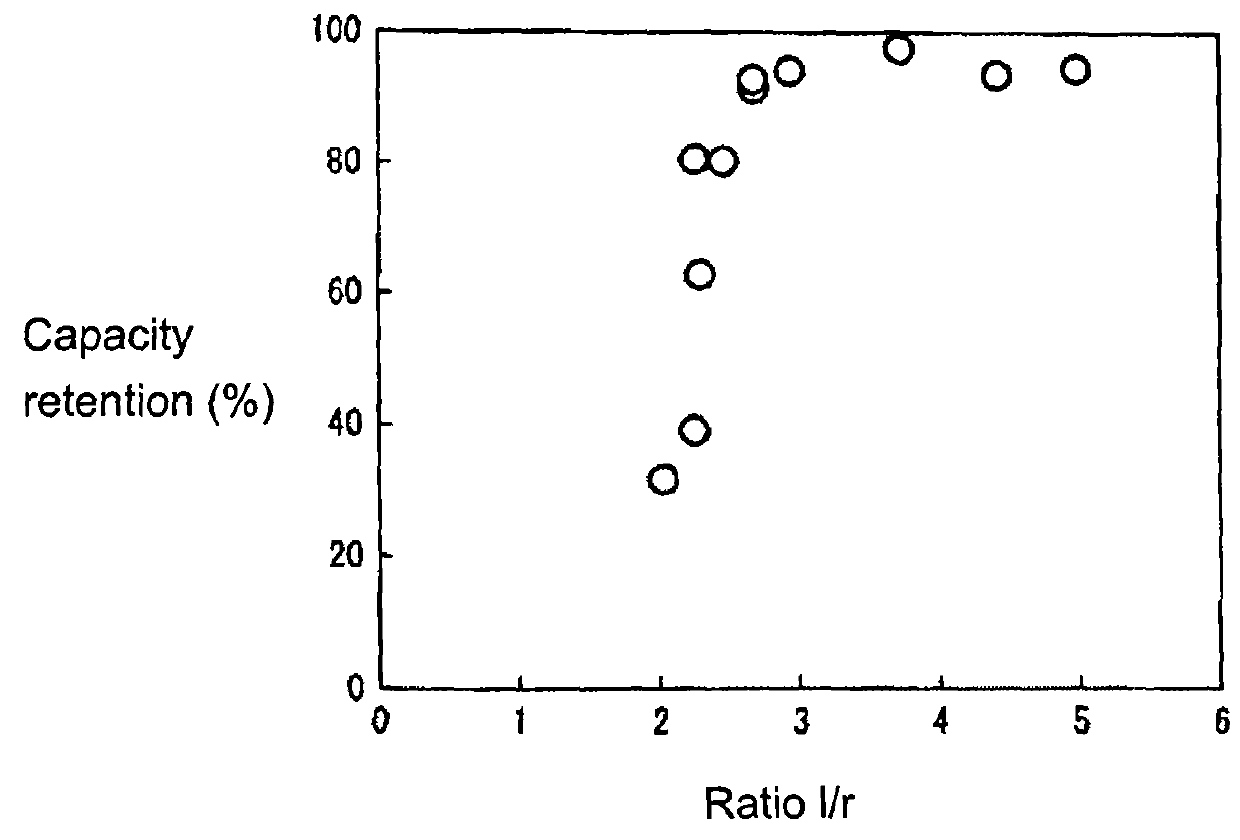

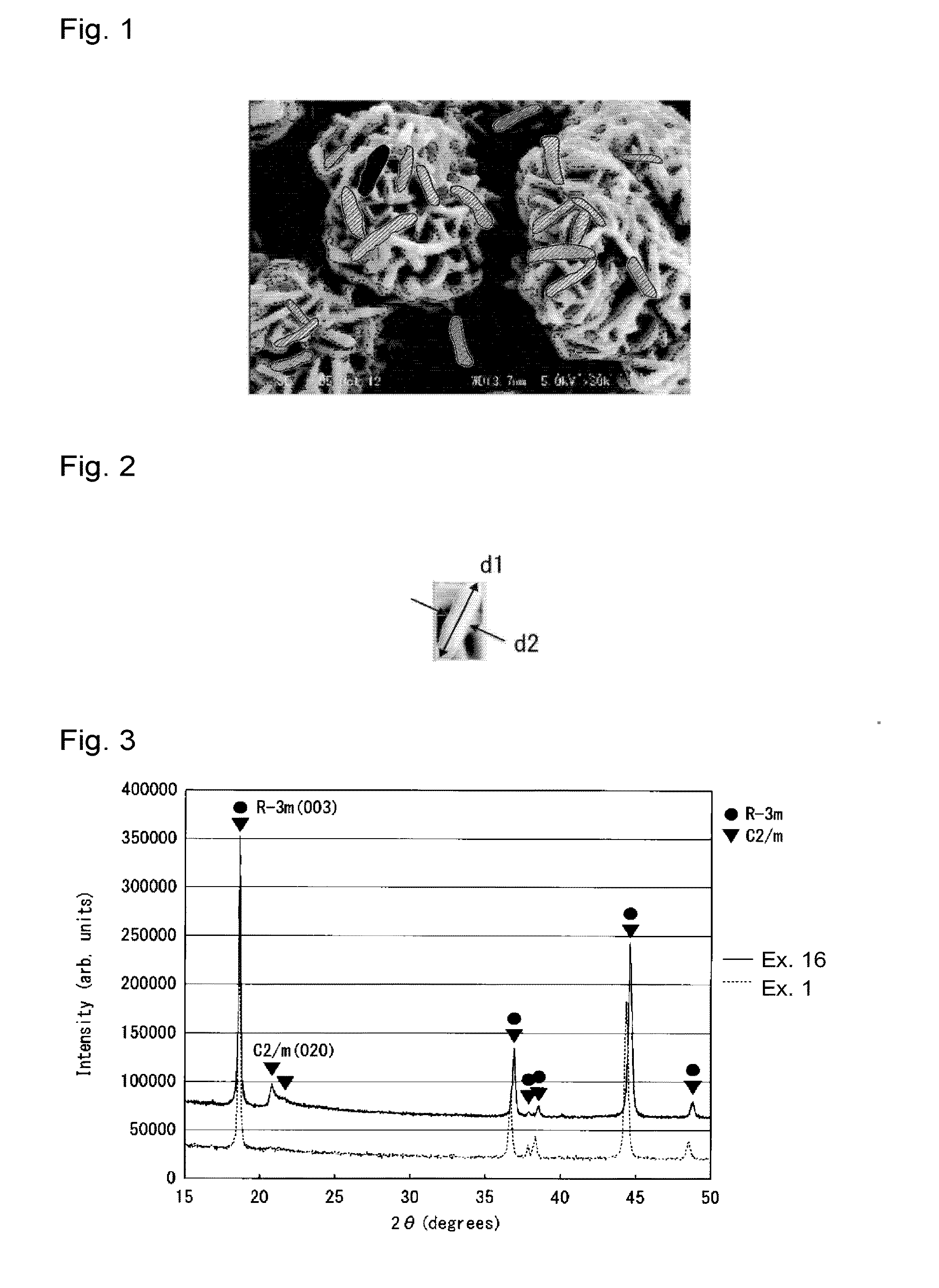

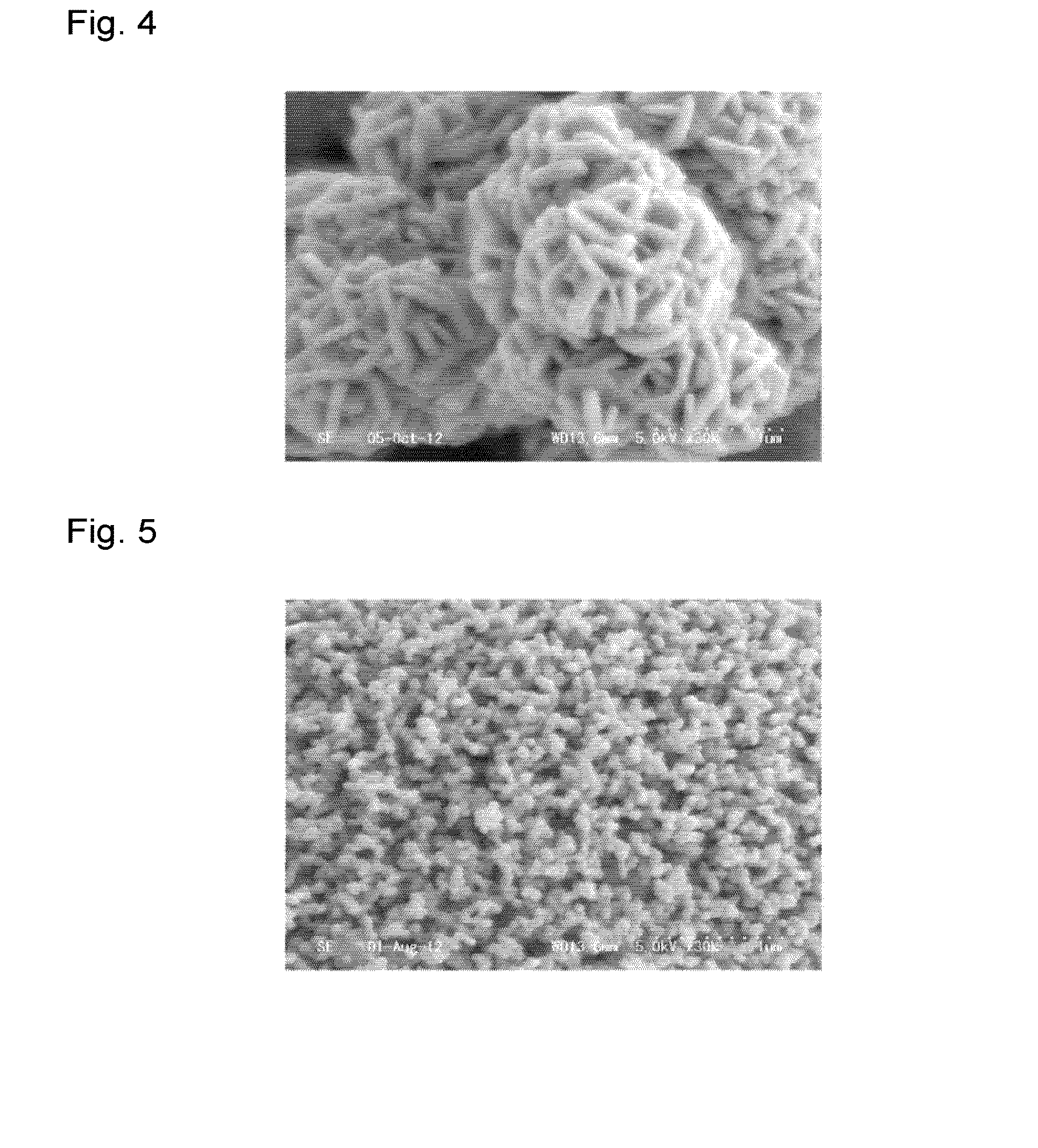

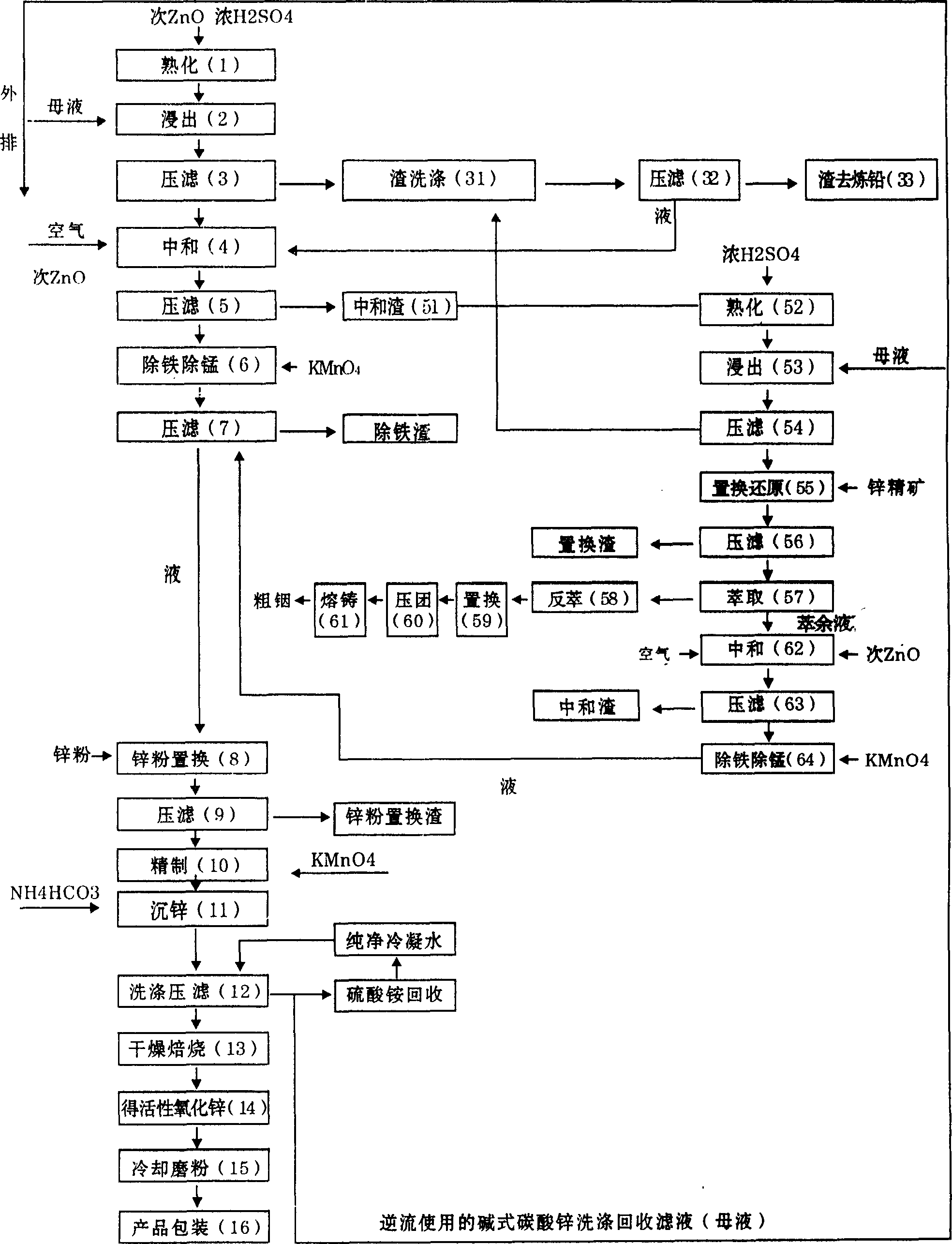

Cathode active material

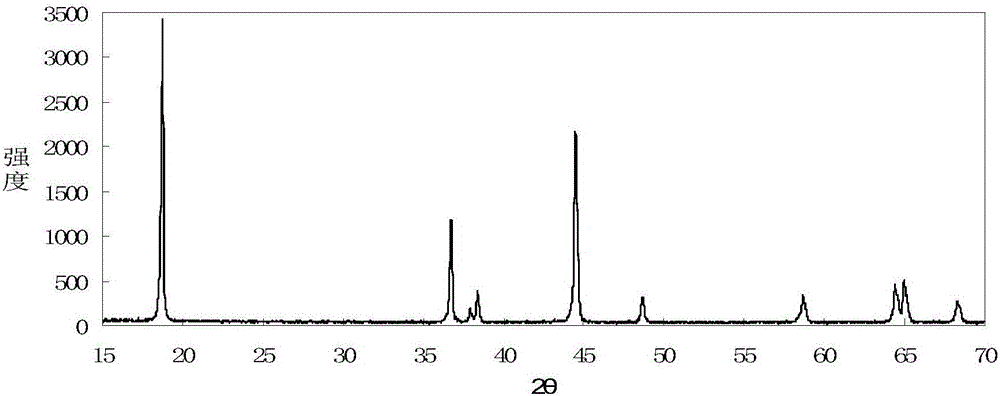

InactiveUS20160056462A1Improve discharge performanceHigh cycle durabilityPositive electrodesNon-aqueous electrolyte accumulator electrodesSpace groupX-ray

To provide a cathode active material which achieves a high discharge capacity and excellent cycle durability.A cathode active material represented by LiaMOx (wherein M is an element including at least one member selected from Ni element, Co element and Mn element (other than Li element and O element), “a” is from 1.1 to 1.7, and x is the number of moles of O element required to satisfy the valences of Li element and M),wherein in an X-ray diffraction pattern, the ratio (I / r) of the crystallite size (I) of (003) plane to the crystallite size (r) of (110) plane assigned to a crystal structure with space group R-3m is at least 2.6.

Owner:SUMITOMO CHEM CO LTD

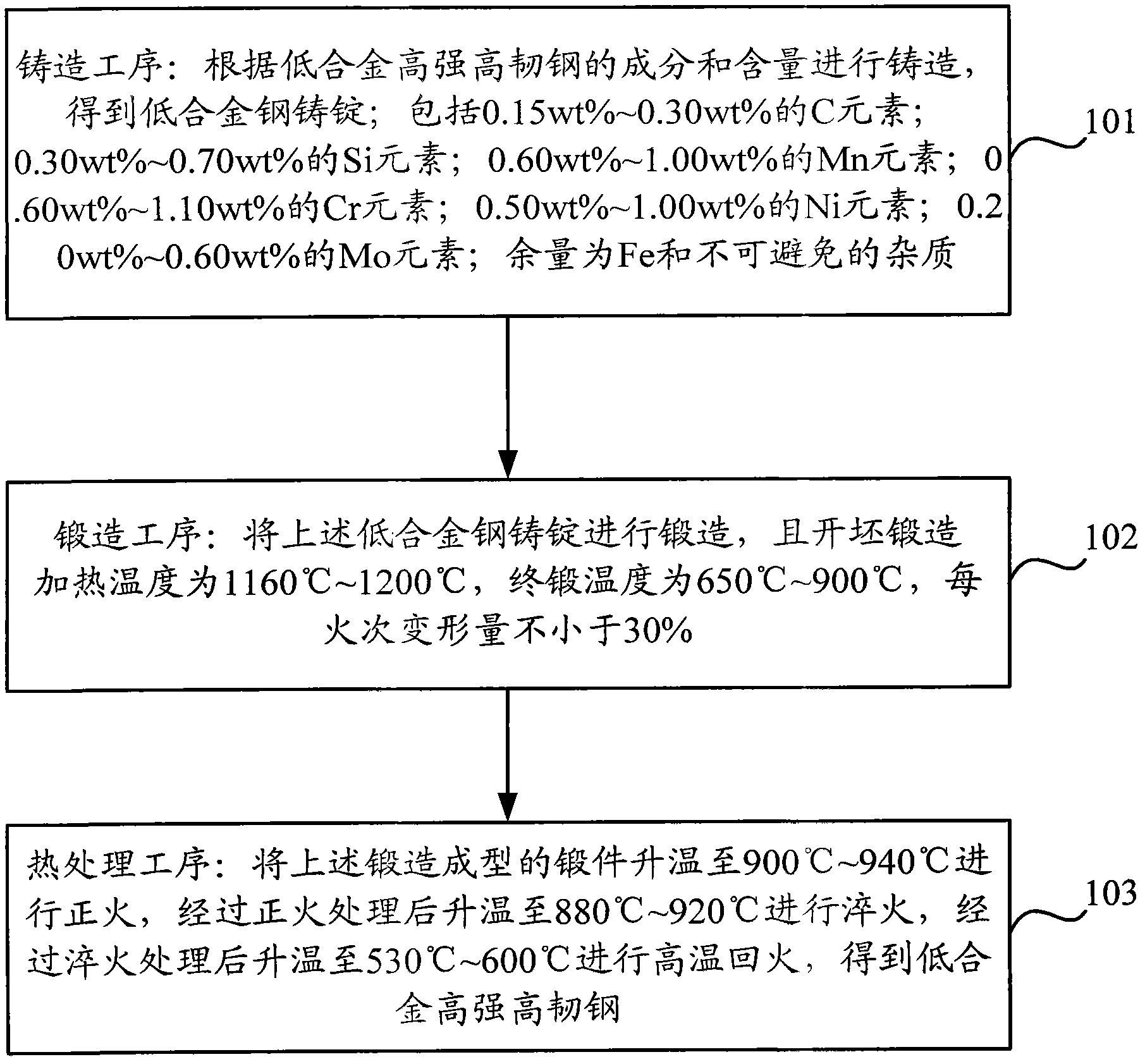

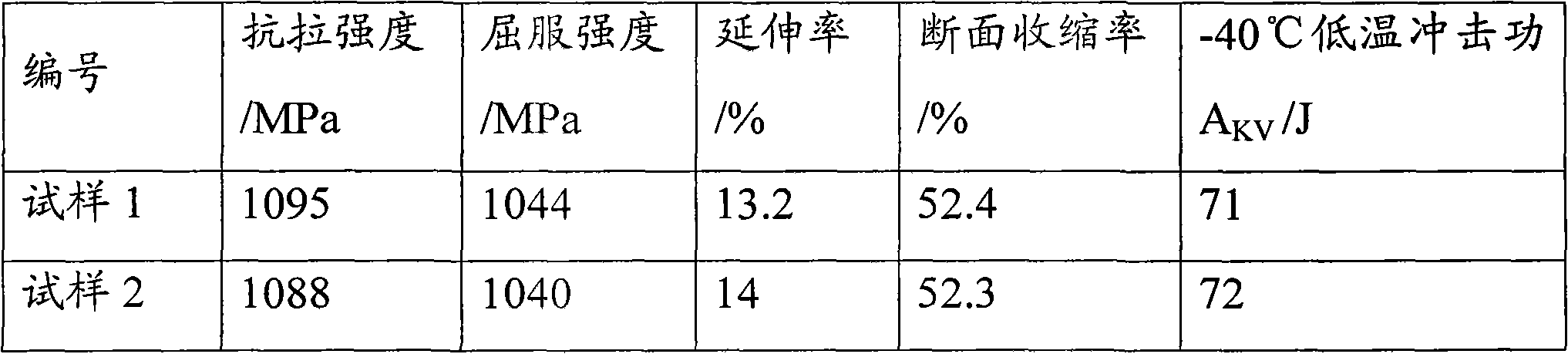

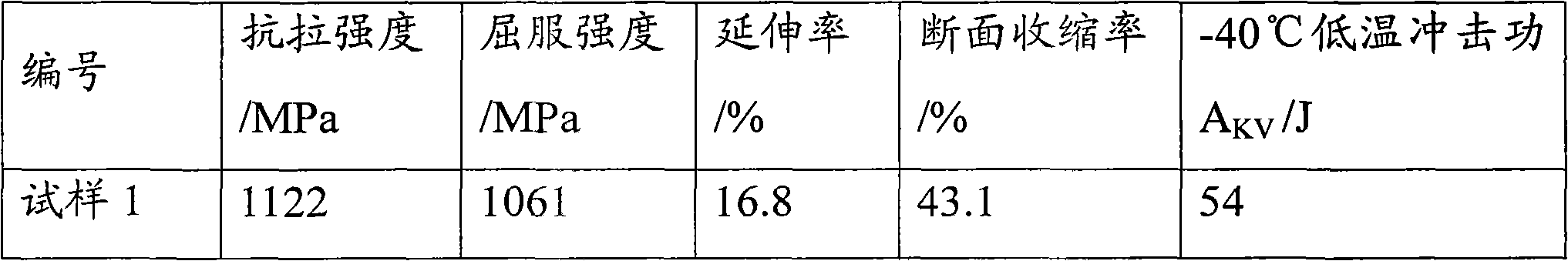

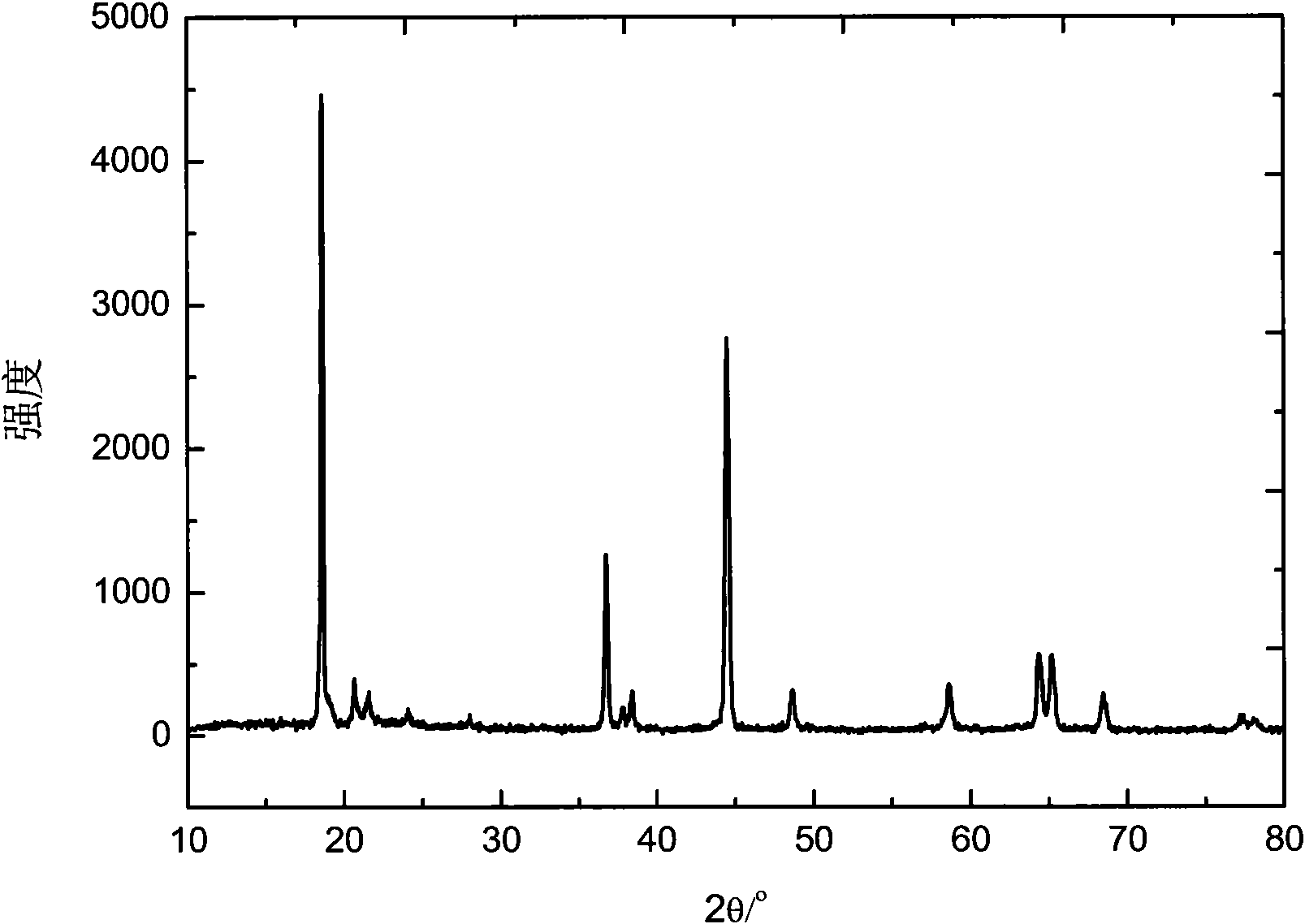

Low-alloy high-intensity high-toughness steel and production method of low-alloy high-intensity high-toughness steel

The invention discloses low-alloy high-intensity high-toughness steel and a production method of low-alloy high-intensity high-toughness steel. The method comprises the following work procedures of: the casting work procedure: the casting is carried out according to the following ingredients and contents to obtain low-alloy steel cast ingots: 0.15 to 0.30 weight percent of C elements, 0.30 to 0.70 weight percent of Si elements, 0.60 to 1.00 weight percent of Mn elements, 0.60 to 1.10 weight percent of Cr elements, 0.50 to 1.00 weight percent of Ni elements, 0.20 to 0.60 weight percent of Mo elements and the balance Fe and unavoidable impurities; the forging work procedure: the low-alloy steel cast ingots are forged, in addition, the blank opening forging heating temperature is 1160 DEG C to 1200 DEG C, the final forging temperature is 650 DEG C to 900 DEG C, and the deformation in each firing time is not smaller than 30 percent; and the heat treatment work procedure: the temperature of the forged and formed forgings is raised to 900 to 940 DEG C to be subjected to normalizing, the temperature is raised to 880 to 920 DEG C for carrying out quenching after the normalizing treatment, the temperature is raised to 530 to 600 DEG C for carrying out high-temperature tempering after the quenching treatment, and the low-alloy high-intensity high-toughness steel is obtained. In the embodiment of the invention, the low-alloy high-intensity high-toughness steel has high intensity and high toughness.

Owner:SANY GRP

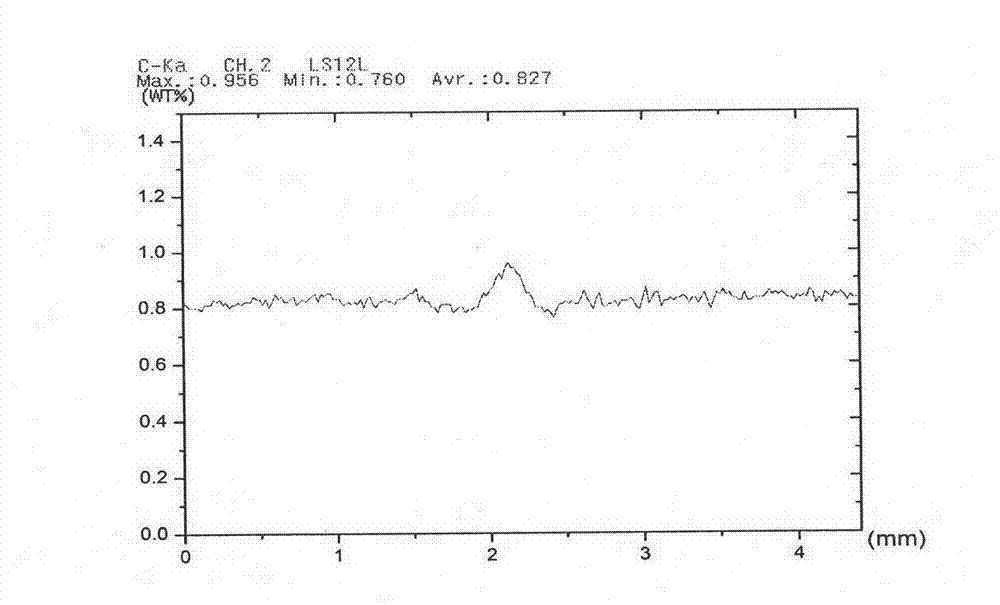

High-purity copper-manganese-alloy sputtering target

InactiveUS20140158532A1Avoid pollutionGood effectCellsElectric discharge tubesSputteringSelf-diffusion

Provided is a high-purity copper-manganese-alloy sputtering target comprising 0.05 to 20 wt. % of Mn, 2 wt ppm or less of C, and the remainder being Cu and inevitable impurities, wherein in formation of a film on a wafer by sputtering the target, the number of particles composed of C, at least one element selected from Mn, Si, and Mg, or a compound composed of C and at least one element selected from Mn, Si, and Mg and having a diameter of 0.20 μm or more is 30 or less on average. Particle generation during sputtering can be effectively suppressed by thus adding an appropriate amount of Mn element to copper and controlling the amount of carbon. In particular, a high-purity copper-manganese-alloy sputtering target that is useful for forming semiconductor copper alloy line having a self-diffusion suppression function is provided.

Owner:JX NIPPON MINING& METALS CORP

Activating method of cathode material

InactiveCN102169979AAvoid attenuationAvoid problems with degraded cycle performanceCell electrodesUltrasound attenuationPhysical chemistry

The invention belongs to the technical field of lithium ion cells, and in particular discloses an activating method of a cathode material, which comprises the step of: under a water and oxygen-free environment, soaking the cathode material in an activating solution to activate the cathode material, wherein the general formula of the cathode material is xLi2MnO3.yLiMO3, x is more than 0 or less than 1, y is equal to 1-x, M is a metal element, both Li2MnO3 and LiMO3 have a laminated structure, the activating solution is an organic solution of an activating agent, and the activating agent is NO2BF4 or NO2PF4. The method provided by the invention can not cause loss of the Mn element in the cathode material and introduction of impurities in the generated cathode material. Meanwhile, because the activation is not acid activation, a cubic structure for damaging an oxygen layer is avoided being brought by the acid activation, problems of high capacity attenuation and reduced cycle performance of the cathode material prepared in the invention are avoided.

Owner:BYD CO LTD

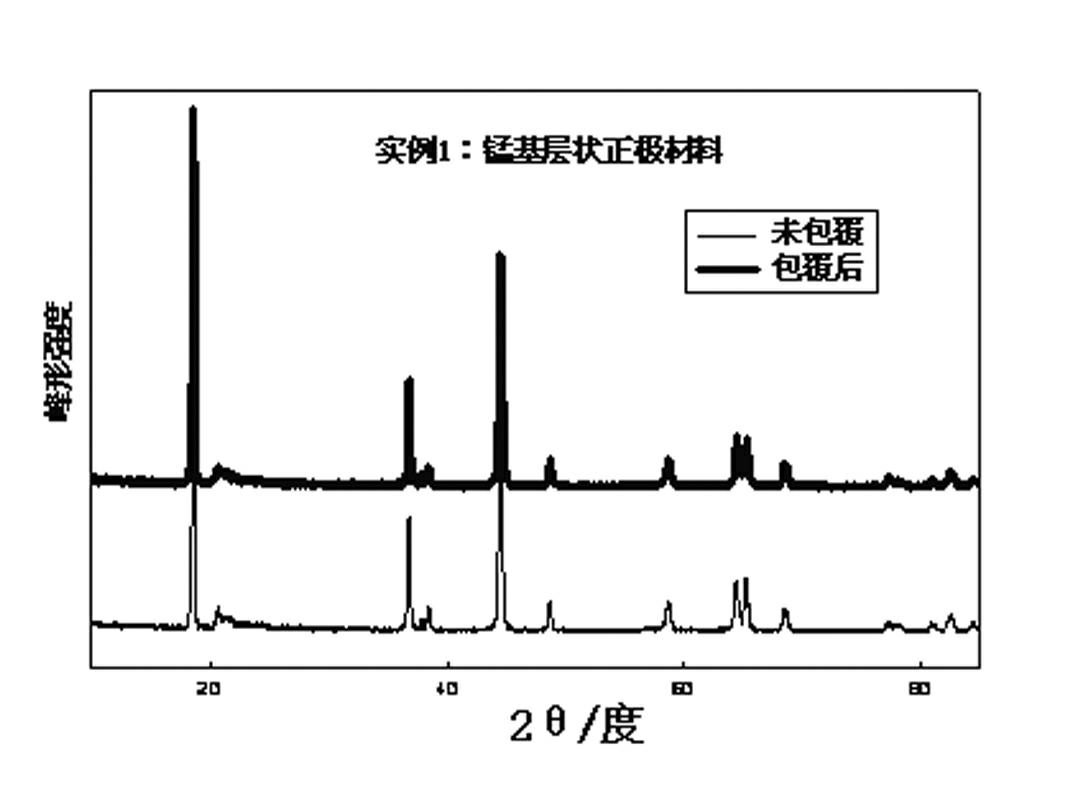

High-safety power lithium ion secondary battery composite positive material and preparation method thereof

InactiveCN106602004AInhibitory responseAvoid performance degradationSecondary cellsPositive electrodesElectrical batteryLithium hydroxide

The invention relates to a high-safety power lithium ion secondary battery composite positive material and a preparation method thereof, the chemical formula of the high-safety power lithium ion secondary battery composite positive material is LixNiyCozMn1-y-zO2, 0.9 < x < 1.3, 0 <y< 1, 0 < z< 1, y+ z< =1, tapping density is greater than or equal to 1.5g / cm<3>, the preparation method is as follows: first, sodium hydroxide / potassium hydroxide mixed with ammonia is added into a solution of a soluble salt containing Ni-Co-Mn elements to obtain a Ni-Co-Mn hydroxide precursor, the dried precursor is mixed evenly with a lithium source or lithium hydroxide or lithium carbonate for high temperature sintering to obtain the LixNiyCozMn1-y-zO2, the LixNiyCozMn1-y-zO2 is added into a well-dissolved aluminum solution for drying by vacuum drying and heat treatment at 400-700 DEG C to obtain Al-coated LixNiyCozMn1-y-zO2. The coated positive electrode material has good safety performance and circulation performances, and can be used for long circulation and high safety lithium ion power batteries.

Owner:HENAN KELONG NEW ENERGY CO LTD

Production technology of 7-series aluminum alloy tubular products

ActiveCN109554561AReduce air cooling speedLower the deoxidation temperatureManufacturing technologyDeoxygenation

The invention belongs to the technical field of aluminum alloy production and manufacture, and relates to a production technology of 7-series aluminum alloy tubular products. Aluminum alloy ingot casting is prepared from the following components in percentage by mass: 4.0-7.0% of Zn, 0.6-1.5% of Mg, 0.1-0.5% of Cu, less than or equal to 0.1-0.5% of Cr, less than or equal to 0.15-0.25% of Zr, lessthan or equal to 0.1% of Ti, less than or equal to 0.05% of single impurity, less than or equal to 0.15% of total impurities and the balance of Al. Sulfate and graphite are adopted to be added into molten aluminum liquid according to the mass fraction ratio of 1 to 9-3 to7 in the process of aluminum liquid refining, magnesium oxide and aluminum oxide in the aluminum liquid are removed, the deoxygenation temperature is 720+ / -5 DEG C, therefore, the air cooling speed of aluminum alloy profiles after extruded forming is 100 DEG C / min, and the problems that in the prior art, the production technology of 7-series aluminum alloy with no Mn element added has excessive cooling speed and is not easy to control are solved.

Owner:CHINA ZHONGWANG

High toughness low carbon bainite thick steel plate and its production method

InactiveCN1786247AReduce carbon contentImprove low temperature toughnessOther manufacturing equipments/toolsChemical compositionUltimate tensile strength

The invention offers a high tensile strength low carbon bainite coarse plate and its manufacturing method. Its compositions (Wt%) are C 0.04%-0.08%, Si 0.1%-0.5%, Mn 1.4%-1.85%, Nb 0.015%-0.060%, Ti 0.005%-0.03%, B 0.0005%-0.0030%, Cu 0.10%-0.60%, Ni 0.05%-0.6%, Al 0.015%-0.05%, rest Fe and other inevitable impurity. The invention adopts low cost Mn element as the main additional element, fully applies the changing action of Cu, Ni, Nb, B to the bainite. The steel has low carbon content, good low temperature toughness. The turning temperature is under ¿C80 centigrade degree. Welding performance is good and simple. Forming is good. TMCP+RPC technique is adopted to improve steel tensile strength, reduced cost. The product can widely apply in engineering machinery, digging machinery, heavy-duty car, and marine facilities field, and etc.

Owner:UNIV OF SCI & TECH BEIJING +1

6-series railway vehicle suspension arm aluminum profile and preparation method thereof

ActiveCN104073698AFine Stable MicrostructureHomogeneous dispersion stateChemical compositionMaterials science

The invention discloses a 6-series railway vehicle suspension arm aluminum profile which contains the following metal substances in percentage by mass: 0.6-0.7% of Si, less than 0.15% of Fe, 0.5-0.7% of Mg, 0.02-0.25% of Mn, less than 0.01% of Cu, 0.1-0.25% of Cr, less than 0.05% of Zn, 0.03-0.06% of Ti and the balance of Al. The invention also discloses a preparation method of the 6-series railway vehicle suspension arm aluminum profile. The 6-series railway vehicle suspension arm aluminum profile has optimized chemical components as compared with the aluminum profile in the prior art, the Mn element content is enhanced to 0.2%, and the Cr element content is enhanced to 0.12%; the Mn can be utilized to enhance the recrystallization temperature characteristic and inhibit the crystal grains from growing, thereby refining the crystal grains of the profile and enhancing the microstructure of the material (grain refinement); and the optimized aluminum profile has the advantages of high tensile strength, high yield strength and high elongation percentage.

Owner:龙口市丛林铝材有限公司

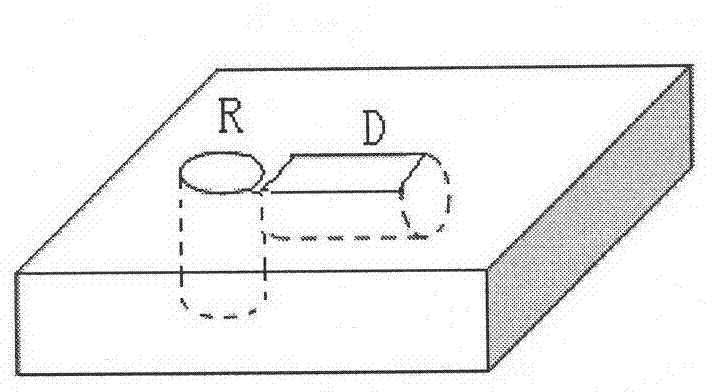

Method for quantitatively examining center segregations of wire rod

InactiveCN102954976AGuaranteed StrengthPrecise positioningMaterial analysis using wave/particle radiationElectron probe microanalysisX-ray

The invention discloses a method for quantitatively examining the center segregation of a wire rod. The method comprises the following steps: taking two wire rod samples, rubbing down the cross section of one of the wire rod samples, splitting the other sample at the 2 / 3 position along the vertical direction of the wire rod sample, rubbing down the profile of the lager sample, putting the two rubbed surfaces next to each other in a same plane, inlaying through using a conductive resin, grinding the samples, polishing the plane when the width of the vertical profile of the wire rod sample is equal to the diameter of the other wire rod sample, and corroding the samples through using an alcohol solution of nitric acid; marking through drawing a line at the severest segregation position, and polishing the samples; and putting the samples in an electronic probe analyzer, finding the made mark through using a secondary electron image, carrying out C and Mn element X-ray intensity line analysis measurement of the full width of the samples through utilizing element characteristic X-ray spectrum analysis under an acceleration voltage of 10-20kV, an electron beam current of above 100nA and a beam spot dimension of 20-50mum, recording through using curves, testing the X-ray intensities of a standard sample of the analytic elements under same test conditions, converting the X-ray intensities in the curves into concentration contents, obtaining maximum concentrations and average concentrations from the curves, and obtaining the center segregation rates through calculating according to a formula of the center segregation rate=(the maximum value / the average value)*100%.

Owner:ANGANG STEEL CO LTD

Evaporative pattern casting magnesium alloy and smelting method thereof

The present invention relates to a evaporative pattern casting special-purpose magnesium alloy and its smelting method. It is characterized by that in the formula of magnesium alloy the content of zinc is reduced, the contents of Al and Mn elements are properly regulated, and the mixed rare earth RE richly containing Ce and elements of Ti and C are added so as to fine the crystal grains of evaporative pattern casting magnesium alloy, reduce its dispersed shrinkage defect and improve its casting property and mechanical property.

Owner:SHANGHAI AIERSI LIGHT ALLOY

Aluminum clad manganese-base laminated composite lithium ion battery cathode material and preparation method thereof

ActiveCN102593445AEliminate oxygen deficiencyStable structureCell electrodesAutomotive batteryManganese

The invention discloses an aluminum clad manganese-base laminated composite lithium ion battery cathode material and a preparation method thereof. According to the anode material, aluminum salt is coated on an outer surface of a manganese-base cathode material with a laminated structure in a chemical formula of Li(LixMn1-y-zM1yM2z)O2. The preparation method comprises the following steps of: (1) preparing a mixture; (2) sintering and treating powder; (3) preparing a corresponding amount of soluble aluminum salt, adding the soluble aluminum salt into the manganese-base laminated cathode material, and uniformly stirring; (4) preparing a NH3.H2O solution, a NH4F solution or a NH4H2PO4 solution, adding the solution into slurry of aluminum nitrate and the manganese-base laminated cathode material, and uniformly stirring; and (5) drying the slurry obtained in the step (4), and sintering at the temperature of between 400 and 800 DEG C for 5 to 15 hours. The aluminum clad manganese-base laminated composite lithium ion battery cathode material has high capacity, low first charging voltage platform and excellent long cycle performance, takes an Mn element as a basis, and is low in raw material cost and particularly suitable for preparing large batteries such as batteries of electric vehicles.

Owner:HUNAN SHANSHAN ENERGY TECH CO LTD

Container foil material and method for manufacturing container foil

InactiveCN102409200AHigh strengthSatisfy productionMetal rolling arrangementsPunchingUltimate tensile strength

The invention relates to a manufacture method of an aluminum alloy material, concretely relates to a container foil material and a method for manufacturing a container foil. The alloy of the container foil material comprises the following compositions by weight percentage: 0.20-0.26% of Si, 0.42-0.50% of Fe, 0.05% of Cu, 0.15-0.20% of Mn, 0.01% of Mg, 0.1% of Zn, 0.04% of Ti and the balance of Al. According to the invention, the content of Fe and Si are re-allocated by the material on the basis of a 8011 alloy, and certain Mn element is added, so that the material intensity can be raised, and the material has good processing performance and is easy to roll. The detection of the material shows that the when aluminum foil thickness is 0.05-0.06mm, the tensile strength is 120-160MPa, the elongation percentage is greater than or equal to 12% and the cupping value is greater than or equal to 5.0. The material of the invention has good punching performance, and can be used for producing various aviation tableware.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

Preparation method of high-entropy alloy powder and cladding layer and application

InactiveCN104141127AImprove wettabilityHigh hardnessMetallic material coating processesHigh entropy alloysWear resistance

The invention discloses a preparation method of high-entropy alloy powder and a cladding layer and application. The high-entropy alloy powder is composed of Fe, Ni, Cr, Al, Cu and Mn element powder, the composition is represented as FeNiCrAlCuMnx, wherein x is the mole ratio of Mn and its value range is 0-1. Matching calculation is carried out according to the mole ratio of each element, the mass of each component is accurately weighed, then the components are fully mixed to obtain the high-entropy alloy powder, and the high-entropy alloy powder is mixed with ethanol, then the mixture is used for coating the surface of a substrate material evenly, and after drying, laser cladding is carried out, thus obtaining the cladding layer. The invention provides the high-entropy alloy powder entirely composed of metal elements to conduct material surface modification, and through laser cladding, the cladding layer with a good shape can be obtained, thus improving the material hardness and wear resistance.

Owner:TIANJIN UNIV

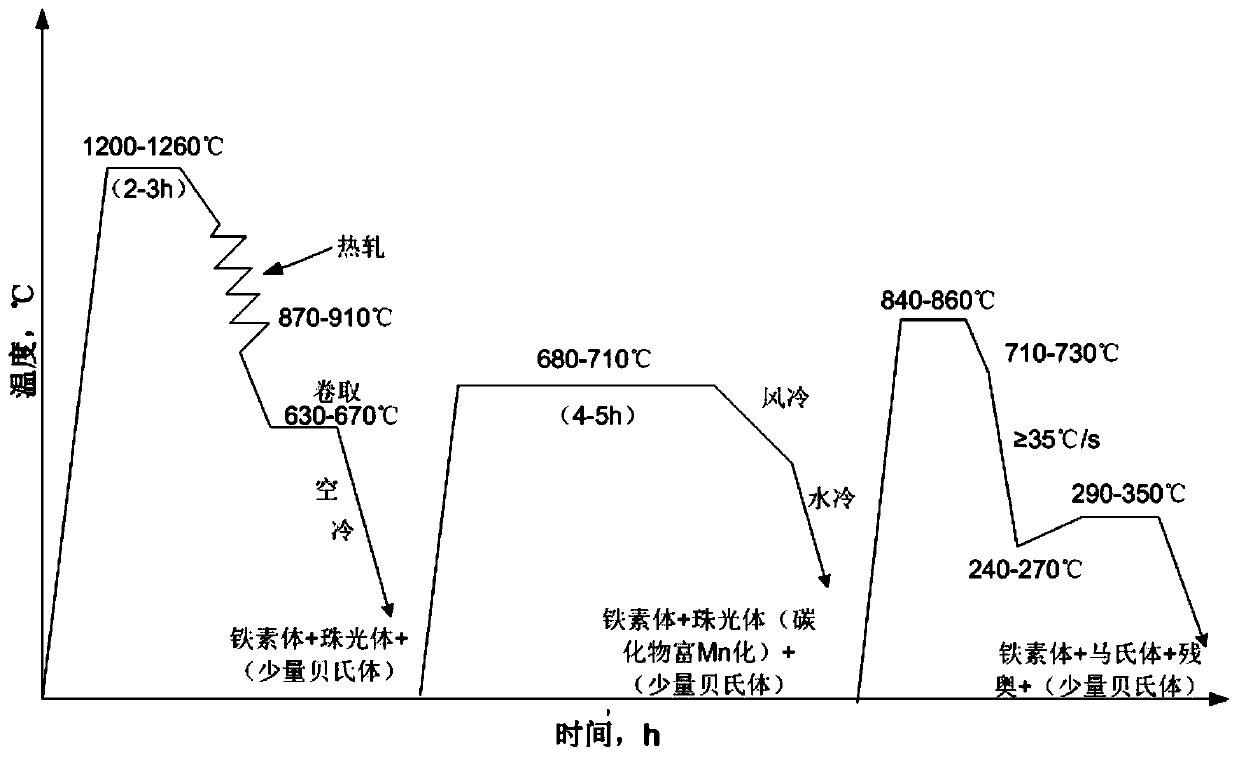

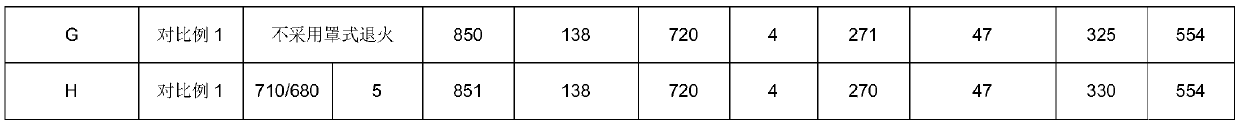

980MPa-grade cold-rolled Q&P steel with excellent plasticity and manufacturing method thereof

The invention provides 980MPa-grade cold-rolled Q&P steel with excellent plasticity and a manufacturing method thereof. The 980MPa-grade cold-rolled Q&P steel comprises the following components of 0.18%-0.21% of C, 1.4%-1.6% of Si, 1.8%-2.1% of Mn, 0.04%-0.06% of Nb, 0.02%-0.05% of Al, less than or equal to 0.01% of P, less than or equal to 0.01% of S and the balance Fe. According to the 980MPa-grade cold-rolled Q&P steel with the excellent plasticity, compared with the prior art, noble metal elements such as Al, Ni and Mo are not added, the content of Mn is relatively low, the Mn element is mainly used for enriching and stabilizing austenite in the austenite, the plasticity of the material is obviously improved, and the product of strength and elongation can reach 25 GPa%; two-phase region annealing is adopted, the annealing temperature is low, and quenching partition treatment can be implemented on an existing continuous annealing production line through adopting an approximate one-step method; and on the other hand, through annealing treatment of the hot-rolled coil, the influence of the alloy element Mn on the material performance is improved, and equipment does not need to betransformed and invested.

Owner:MAANSHAN IRON & STEEL CO LTD

Cathode active material

InactiveUS20160043396A1Improve discharge performanceHigh cycle durabilityPositive electrodesCobalt compoundsSpace groupX-ray

To provide a cathode active material to be used for a positive electrode of a lithium ion secondary battery having a high discharge capacity and favorable cycle durability.A cathode active material, which comprises a lithium-containing composite oxide containing at least one transition metal element (X) selected from the group consisting of Ni element, Co element and Mn element, and Li element (provided that the molar ratio (Li / X) of the Li element based on the total amount of the transition metal element (X) is from 1.1 to 1.7),wherein the aspect ratio of primary particles is from 2.5 to 10, andin an X-ray diffraction pattern, the ratio (I020 / I003) of the integrated intensity (I020) of a peak of (020) plane assigned to a crystal structure with space group C2 / m to the integrated intensity (I003) of a peak of (003) plane assigned to a crystal structure with space group R-3m is from 0.02 to 0.3.

Owner:SUMITOMO CHEM CO LTD

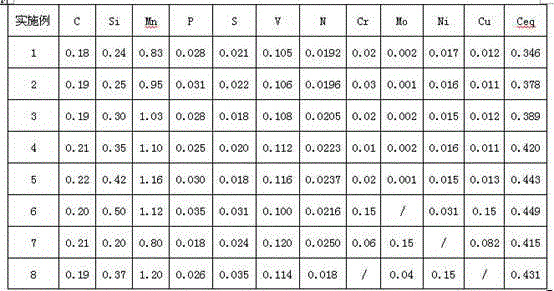

Crude indium and active zinc oxide co-production process

The coproduction technique for coarse indium and active ZnO comprises: (1) curing In-contained hypo-ZnO or material contained both Zn and In; (2) leaching out with mother liquor; (3) filter pressing; (4) neutralizing; (5) filter pressing; (51) extracting neutralized slag; (52) cuing; (53) leaching out; (54) filter pressing; (55) displacing and reducing with Zinc concentrate; (56) filter pressing; (57) extracting; (58) back extracting; (59) displacing; (60) agglomerating; (61) fusing and casting; then, obtaining the coarse IN element; meanwhile, (4) neutralizing; (5) filter pressing; (6) removing Fe and Mn elements with KMnO4; (64) mixing reffinate; (7) filter pressing; (8) displacing with Zn powder; (9) filter pressing; (10) refining with KMnO4; (11) depositing with NH4HCO3; (12) cleaning, filter pressing; (13) drying and baking; (14) obtaining the active ZnO. Compared with the independent prior art, this invention produces little pollution, has small loss to valuable metal, makes full use to the source with low request, and needs low cost and investment.

Owner:黄有余

British standard B500B ribbed thread steel bar and production method thereof

The invention discloses a British standard B500B ribbed thread steel bar and a production method thereof. The British standard B500B ribbed thread steel bar comprises, by mass, 0.18%-0.22% of C, 0.20%-0.50% of Si, 0.80%-1.20% of Mn, 0%-0.035% of P and S, 0.10%-0.12% of V, 0.018%-0.025% of N, 0%-0.15% of Cr, Mo, Ni and Cu, and the balance Fe and inevitable impurities, wherein the carbon equivalent Ceq is smaller than or equal to 0.50%. According to the British standard B500B ribbed thread steel bar, the precipitation temperature and the brittle transition temperature of carbonitride can be lowered by optimizing and adjusting the content of the C element, the Si element and the Mn element and adding microalloy elements V, so that tensile strength, toughness and yield strength of coiled reinforced bars are effectively improved, and thus the British standard B500B ribbed thread steel bar meeting the tensile strength and yield strength requirements is obtained. According to the method, low-manganese and high-vanadium alloying is adopted, the control-rolling temperature and the control-cooling technology are matched to be reasonably designed, and the British standard B500B ribbed thread steel bar which is qualified in low-cost production performance and excellent in weldability is obtained. Economical benefits and social benefits are achieved.

Owner:HEBEI IRON AND STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com